Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194 results about "Brick kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brick kilns are designed to finish bricks and produce charcoal or other heat-treated materials. A brick kiln should be constructed to withstand high heat temperatures and have a strong resistance to outdoor elements.

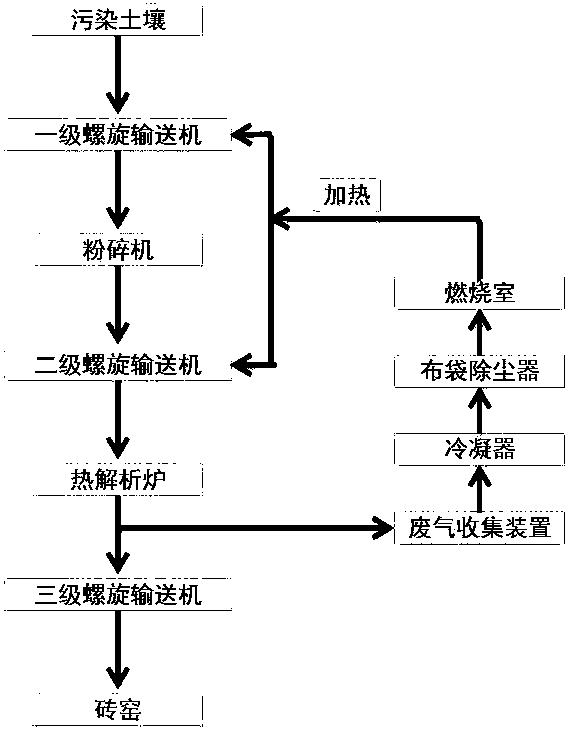

Remediation method of organic contaminated soil

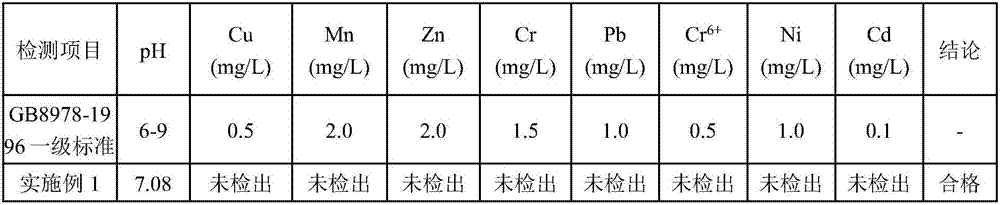

InactiveCN104307864ASave energyIncrease the efficiency of thermal desorptionContaminated soil reclamationIncinerator apparatusPollution soilSoil remediation

The invention relates to the field of soil remediation, in particular to a remediation method of organic contaminated soil. The remediation method comprises the following steps: 1) crushing and screening soil to be remedied; 2) carrying out thermal desorption treatment on the soil remedied after being screened in the first step; 3) conveying the soil subjected to thermal desorption treatment in the second step to a brick kiln under the condition that the soil is not cooled, and burning into bricks; 4) burning waste gas generated in thermal desorption in the second step, and using heat generated by burning for heating the soil to be treated. With the adoption of the remediation method of the organic contaminated soil, the soil subjected to thermal desorption is high in temperature and can be used for making bricks, and thus a great deal of energy is saved; the waste gas is burnt after being purified, energy generated by burning is used for heating a conveyer belt, the heated conveyer belt is capable of carrying out primary heating on the soil, so that thermal desorption efficiency is greatly improved when the soil with higher temperature enters a thermal desorption furnace.

Owner:常州宝利环保科技有限公司

Production process for sesame rice composite fragrance type white spirit

ActiveCN102399663APersonality fashionElegant and elegant aromaAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a production process for sesame rice composite fragrance type white spirit and belongs to the technical field of brewing. The production process comprises the following steps of: crushing 270 to 300 weight parts of broomcorn, 120 to 130 weight parts of millet, 110 to 120 weight parts of wheat and 60 to 70 weight parts of corn; mixing the crushed materials as well as 40 to50 weight parts of wheat bran and 30 to 40 weight parts of steamed rice husk; wetting the materials by adding water; steaming by a retort method; cooling the cooked fermented grains; adding 180 to 210 weight parts of mouldy bran and 180 to 210 weight parts of yeast for making hard liquor; supplementing water; stirring uniformly; stacking and fermenting; soaking 650 to 670 weight parts of rice in hot water; cooking; spreading and cooling; adding yeast for cultivating fungi and saccharifying; mixing the saccharified fermented grains and the stacked and fermented distilled grains; cooling; allowing the mixture to enter a muddy bottom brick kiln pit and fermenting; taking the fermented grains out of the pit; adding the fermented grains into 140 to 160 weight parts of steamed rice husk; addinginto a rice steamer and distilling to prepare sesame rice composite fragrance type raw wine; storing the raw wine for more than 3 years; and blending to prepare the finished product wine. The sesame rice composite fragrance type white spirit has the advantages, namely 'tastefulness and exquisiteness', of the sesame fragrance type spirit and the advantages, namely 'flexibility and clearness', of the rice fragrance type spirit, and has unique flavor.

Owner:好客友品(山东)电子商务有限公司

Brick making method

InactiveCN104086158AAvoid destructionImprove plasticityCeramic materials productionClaywaresLand resourcesWarm water

The invention discloses a brick making method which adopts coal gangue, building waste residues and building clay as raw materials and comprises the following steps: (1) grinding the raw materials into particles with particle sizes of less than 1mm; (2) uniformly mixing the raw material particles, adding warm water, a naphthalene water reducer and silica fume, stirring to prepare a mud material, and ageing for more than 24 hours; (3) stirring a mixture obtained after the ageing for 0.5-1 hour, and extruding the re-stirred mixture by adopting a vacuum brick extrusion machine to prepare green bricks; (4) putting the green bricks into a brick kiln, and intensively eliminating moisture and drying; (5) roasting by adopting a process of main internal combustion and auxiliary external combustion; (6) cooling to obtain finished bricks. According to the brick making method, the coal gangue, the building waste residues and the building clay are fully utilized as the brick making raw materials, farmland and land resources can be saved, plant covers and river environments are prevented from being destroyed, and produced floor tiles are good in plasticity and water permeability, relatively good in pressure bearing property, energy-saving and environmentally friendly.

Owner:重庆市永川区立富机砖厂

Cement rotary kiln mouth refractory construction method

The invention discloses a cement rotary kiln mouth refractory construction method, and belongs to the technical field of refractory materials. Firstly, an anchoring part is welded; then, a side surface template is mounted and constructed, and a refractory is provided; then, the refractory is cast in a mold in the six o'clock direction, and an exhaust hole is formed in the refractory; finally, a brick kiln performs baking, and the side surface template is dismounted; and the steps from casting of the refractory to dismounting of the side surface template are repeated until the whole circle of a kiln mouth is constructed. The cement rotary kiln mouth refractory construction method has the advantages of reducing the low water adding quantity of the refractory in the kiln mouth, improving the compactness and the erosion resistance of the refractory and reducing the damage risk of the refractory.

Owner:TONGDA REFRACTORY TECH CO LTD +1

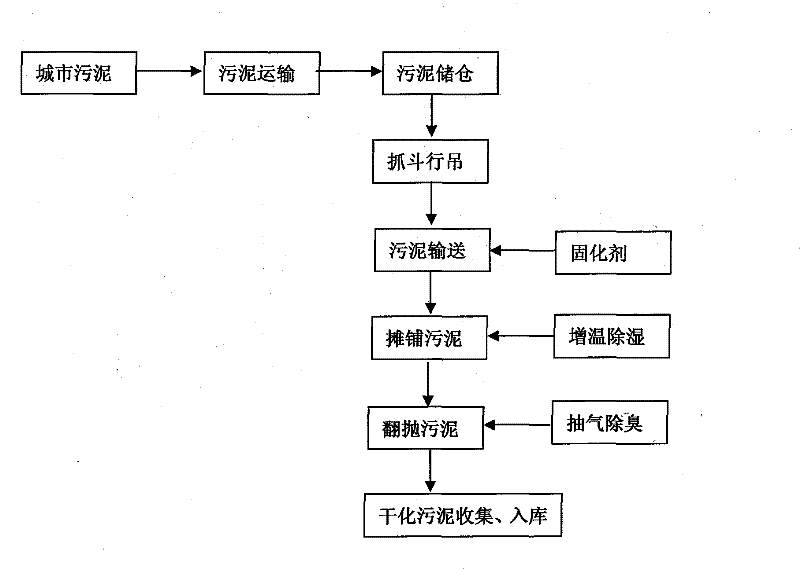

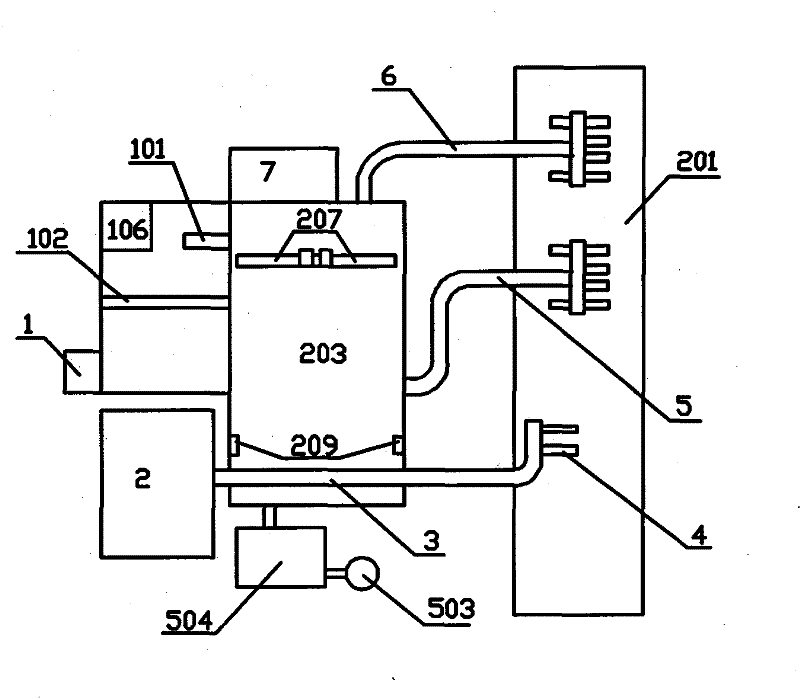

Sludge drying system

ActiveCN102531317AReduce moisture contentProtection securitySludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentSolar dryingSludge

The invention discloses a sludge drying system, which comprises a sealed sludge storage cabin and a drying device. Sludge in the sealed sludge storage cabin is fed into the drying device for drying the sludge through a material feeding mode. The sealed sludge storage cabin comprises a sludge feeding device, a grab bucket crane, a grab bucket crane track, a sludge tank barrier, a feeding port and a control chamber. The grab bucket crane grabs the sludge in the sealed sludge storage cabin and sends the sludge to a feeding hopper of the sludge feeding device which transmits the sludge to the drying device. The drying device comprises a roof, a wall body, a material table and a sludge paver. The sludge paver paves and throws the sludge, and then the sludge is performed with warming for dehumidification and drying by waste heat from a flue and solar energy, and the dried sludge is conveyed outside the drying chamber through a material conveying machine. By means of the sludge drying system, the sludge is placed in a sealed environment, polluted gas generated by the sludge is prevented from being directly discharged into the air, waste heat of a brick kiln and the solar energy are used for drying the sludge, and physical heat on the tail portions of fired bricks in a tunnel brick kiln can be used fully, so that a large amount of energy can be saved.

Owner:南京鑫翔环保产业有限公司

Method for preparing novel sintered brick from construction waste

InactiveCN111484263AQuality assuranceReduce processing stepsTransportation and packagingRotary stirring mixersBrick kilnRaw material

The invention discloses a method for preparing a novel sintered brick from construction waste, which comprises the following steps: 1. collecting construction waste, and removing impurities from the construction waste for later use; 2, the construction waste is thrown into a crushing mechanism to be crushed, and the construction waste obtained after extrusion crushing falls into a conveying mechanism through a discharging hopper; the crushed construction waste is conveyed into a mixing mechanism through the conveying mechanism; 3, water is added into the sintered brick mixed raw material, stirring is carried out to form brick body pug, and the brick body pug is prepared into a sintered brick blank; and step 4, the sintered brick blank is put into a brick kiln for roasting, drying and shaping are carried out, according to the novel sintered brick preparation device, construction waste and sintered brick raw materials are stirred and mixed through a second mixing frame, meanwhile, a first mixing frame rotates while rotating around a rotary disc, the sintered brick preparation raw materials can be fully mixed and stirred to be uniform, and therefore the quality is better when the rawmaterials are used for preparing sintered bricks.

Owner:深圳市俊隆环保科技有限公司

Method for preparing sintered brick by utilizing water base well drilling cuttings

ActiveCN107459336AReduce wasteRealize resource utilizationCeramic materials productionClaywaresWater basedContinuous reactor

The invention discloses a method for preparing a sintered brick by utilizing water base well drilling cuttings. The method comprises a step (1) of automatically adding the water base well drilling cuttings into a sunken continuous reactor, and adding a modifier into the reactor for reaction; a step (2) of conveying modified solid waste to a brick factory, mixing the solid waste with internal combustion materials and shale soil, and performing crushing and sieving; a step (3) of transferring the mixture into a brick manufacturing mixing system, adding water, stirring and shaping to make a green brick; a step (4) of drying the green brick and then sending the green brick into a brick kiln, sintering for 10-15 h and then cooling, taking the product out of the kiln, and obtaining the finished sintered brick. Waste mud is adopted for modification, so that the waste mud meets the component requirements for preparing the sintered shale brick, and harmful substances in the drilling cuttings are removed; when the modified drill cuttings are used for preparing the sintered brick, the process is simplified, and aging is not required. Waste water can also be used as mixing water, and not only is the solid waste recycling implemented, but also the waste water recycling is implemented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

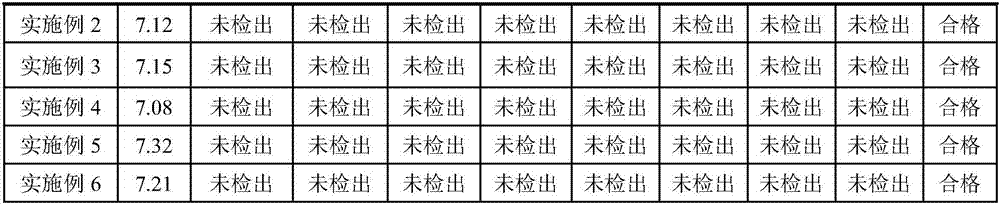

Light-level foamed internal wall brick and its manufacturing method

InactiveCN1676808ATake advantage ofRelieve stressConstruction materialSolid waste managementC constantAgricultural engineering

The invention refers to a method of making the new-type architecture wall-body material, especially the light froth inner-wall brick which used to the inner wall material. The character of the method is that in the brick there are many air holes formed by the sinter froth anomalistic distributed. The manufacture method is that in the industry waste cinder the block grain which is burned to crystal vitreous body shape accounts for 64%-74% after the smashing according to weight ratio, the waste earth accounts for 15-25%, cock grain accounts for 10%, add-adhesive accounts for 1%, mixes evenly, and then pressed to the flan at the special-purpose machine, open fire burns it in the ordinary agglutinates brick kiln, froth to cock grain when controlling the temperature in the agglutinate 1000-1200 deg. C constant temperature for 10-20 hours in the agglutinate, cut the bricks to the just size to the needs of the inner-wall after the natural cooling. The brick is a new-type wall-body material; its weight is only 1 / 5 of the ordinary agglutinate brick. It recycles waste, and lower the cost is also suitable to do building material of the wall, it has the characters that the transporting reduces effort, the construction is convenient, and protects the cultivated land resources, favorable country advantage people.

Owner:毛光辉

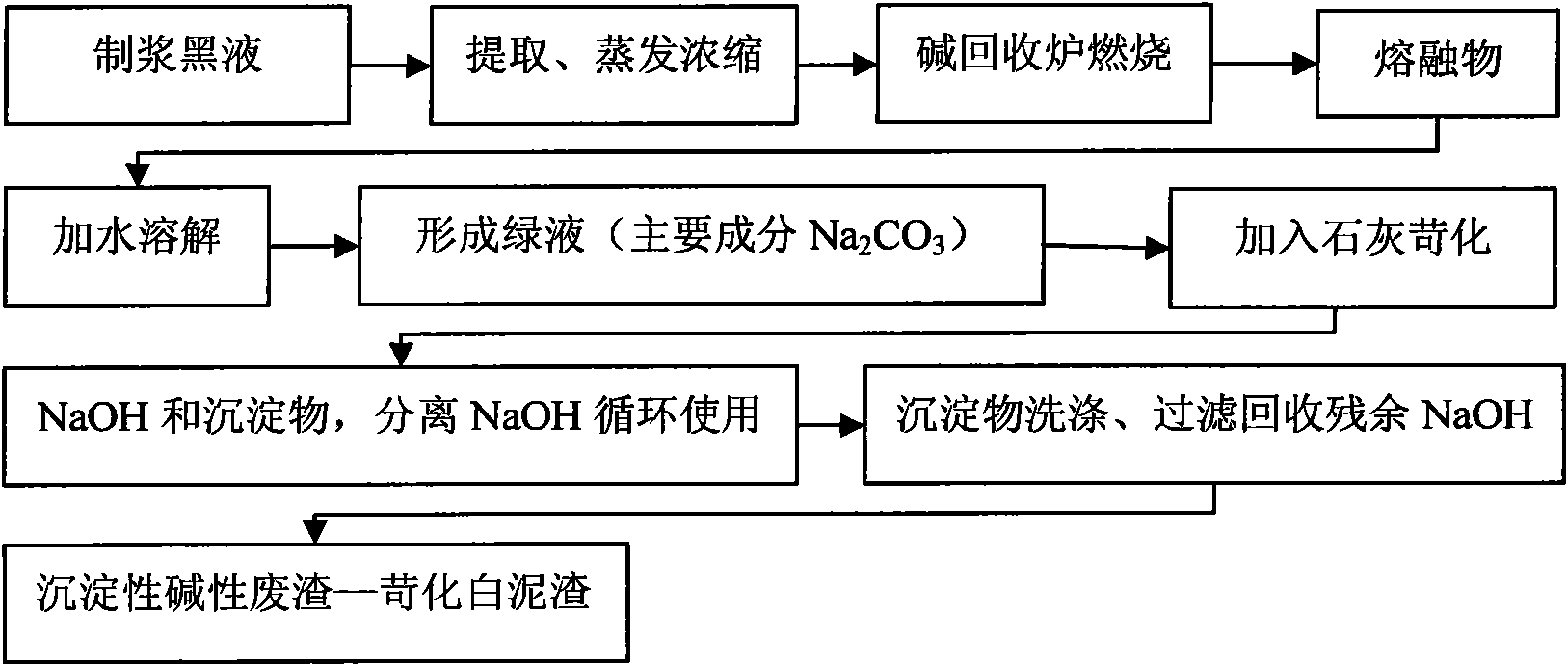

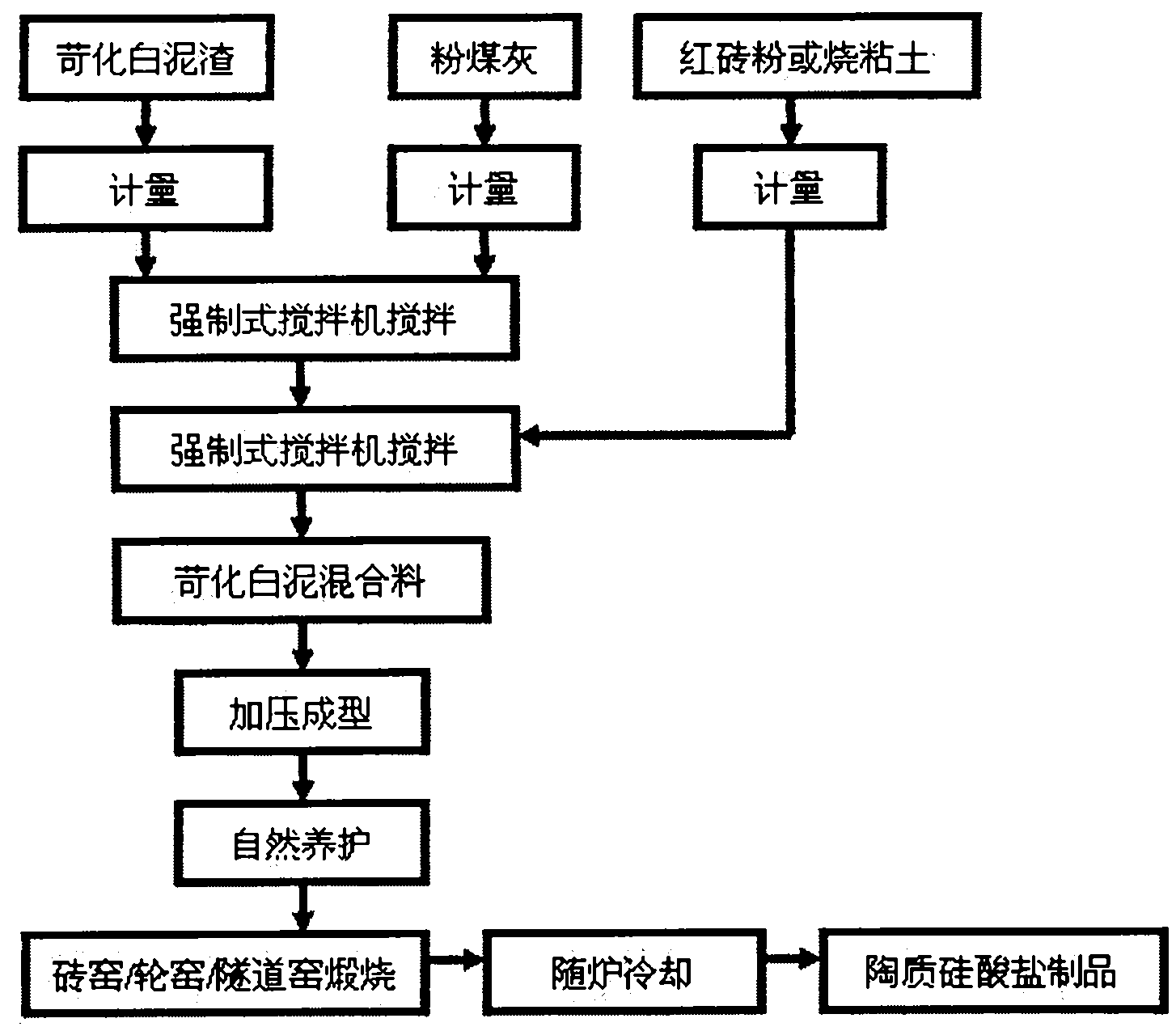

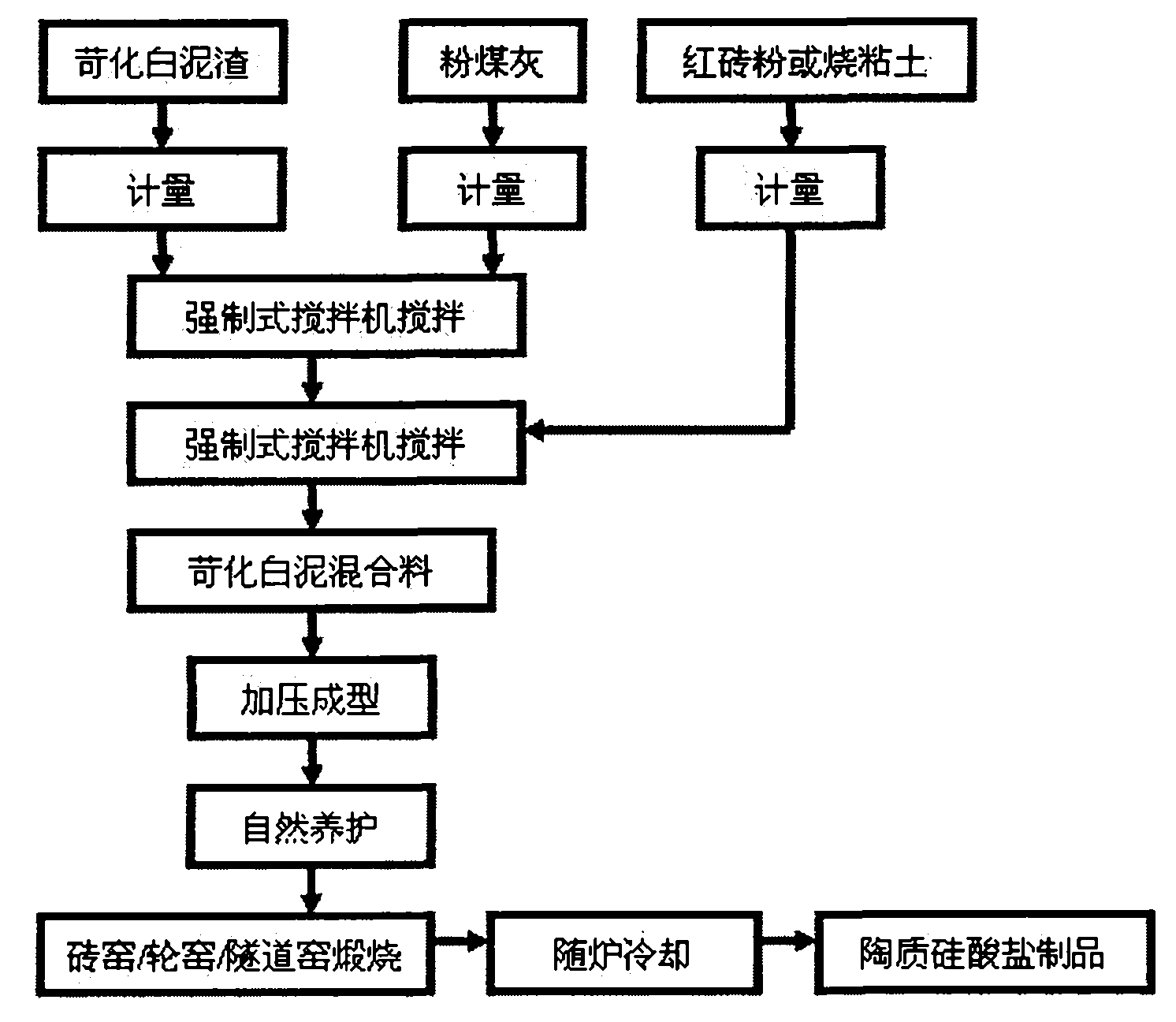

Method for preparing high-strength ceramic wall material from papermaking causticized white mud residues

InactiveCN102070322AReduce moisture contentHigh strengthCeramic materials productionClaywaresPapermakingCalcination

The invention discloses a method for preparing a high-strength ceramic wall material from papermaking causticized white mud residues. The method comprises the following steps of: (1) adding papermaking causticized white mud residues and fly ash to a forced mixer, stirring, after the papermaking causticized white mud residues and fly ash are uniformly mixed, adding red brick powder or fired clay to the forced mixer, and uniformly stirring to obtain a mixture; (2) by selecting a brick former, adding the mixture obtained in the step (1) to a former die to obtain formed brick blanks; (3) piling the formed brick blanks in a stock yard with favorable ventilation conditions for dewatering and solidification until the brick blanks have constant quality and initial compression strength over 1 MPa;and (4) and conveying the dewatered and solidified brick blanks into a brick kiln for calcining, keeping the temperature and cooling in the kiln to a room temperature so as to obtain the high-strength ceramic wall material. The method provided by the invention is favorable for greatly decreasing the water content of the causticized white mud residues before calcination and decreasing the burning heat consumption and the production cost, a formed test piece can be easily and practically calcined in a low-cost common brick kiln, and a ceramic wall material which has high higher compression strength and can substitute clay bricks can be obtained through selecting suitable parameters for the calcination process.

Owner:NANJING UNIV OF SCI & TECH

Method for producing brick using garbage and waste dreg as raw materials

The invention relates to a method for producing bricks with rubbishes and waste residues, comprising: sorting rubbishes and waste residues, adding in water in 8%-15%, fly ash in 10%-20% and clay in 20%-25% and blending, pressing mixture into brick blanks by vacuum extruder and drying the brick blanks and feeding them into a brickkiln for sintering at high temperature (1000 deg.C-1150 deg.C) for 4-6 hours, and then naturally cooling and making the bricks. It better solves environmental protection problem and can recycle waste resources. And the produced bricks can replace the existing clay bricks.

Owner:童玉明

Sludge drying process

ActiveCN102557378AReduce moisture contentTake advantage ofSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentTunnel kilnSolar drying

The invention discloses a sludge drying process. The sludge drying process comprises the following steps of firstly transporting urban sludge with the water content of 80-85% into a sludge storage bin for sealed storage, controlling a grab crane to grab the sludge in the sludge storage bin and send into a feed hopper of a sludge feed device through a PLC (programmable logic controller) system, simultaneously adding a curing agent into the hopper, fully stirring, then transporting the sludge to a drying room of a drying device, utilizing residual heat from a flue and a ceiling of the drying room to absorb solar energy for a PC (polycarbonate) sun board in the drying room to perform heating, dehumidification and drying on the sludge in the drying room, and further conveying the dried sludgeto the outside of the drying room through a material conveying machine. According to the sludge drying process disclosed by the invention, the sludge is operated in a closed environment and is not directly exposed in air, and toxic and harmful gas carried in the sludge can be prevented from polluting the environment; the residual heat of a brick kiln and the solar energy are utilized for drying, so that physical heat at the tail part of burned bricks in a tunnel kiln can be fully utilized, the heat of the sludge is increased and energy can be greatly saved; and a test proves that the water content in the dried sludge is low and can achieve 10-25%.

Owner:南京鑫翔环保产业有限公司

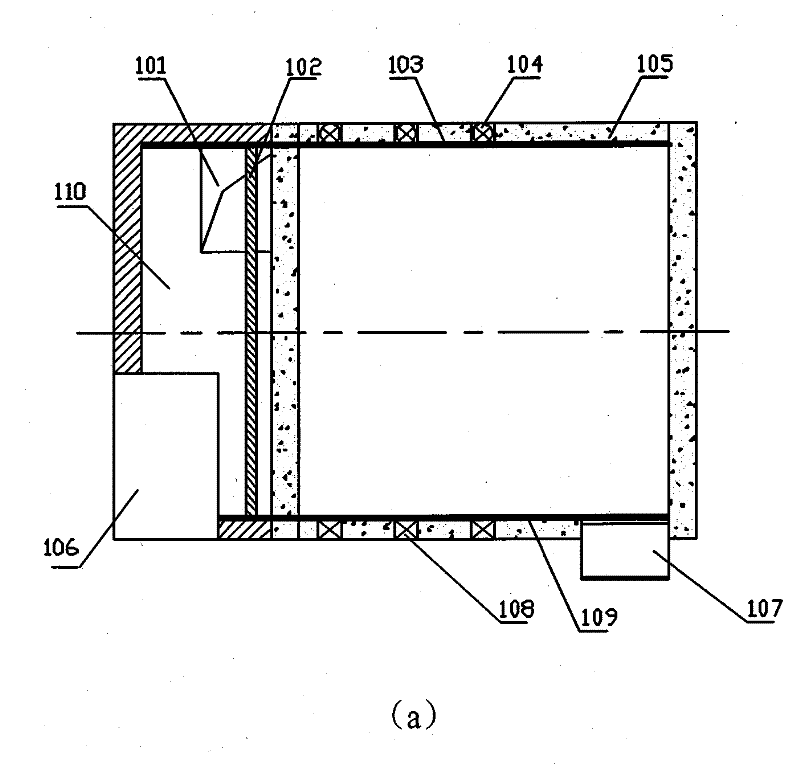

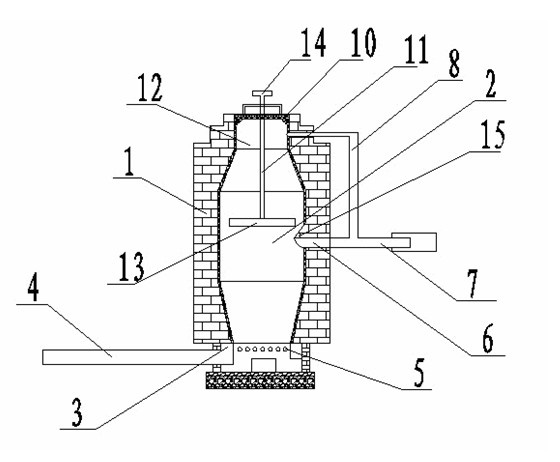

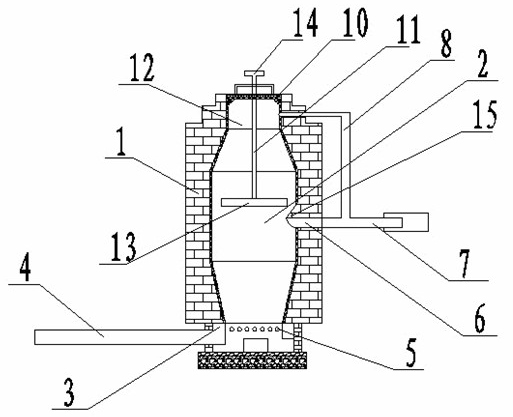

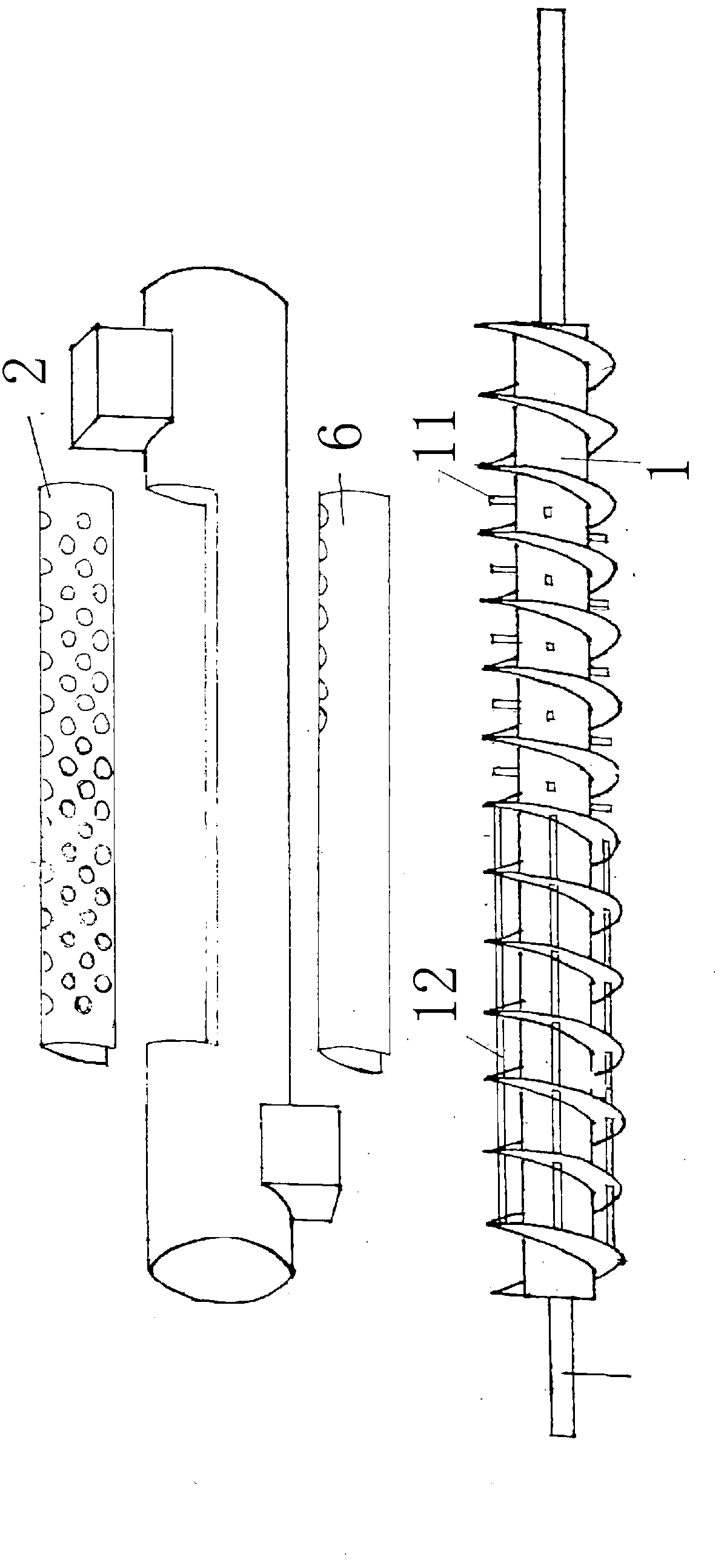

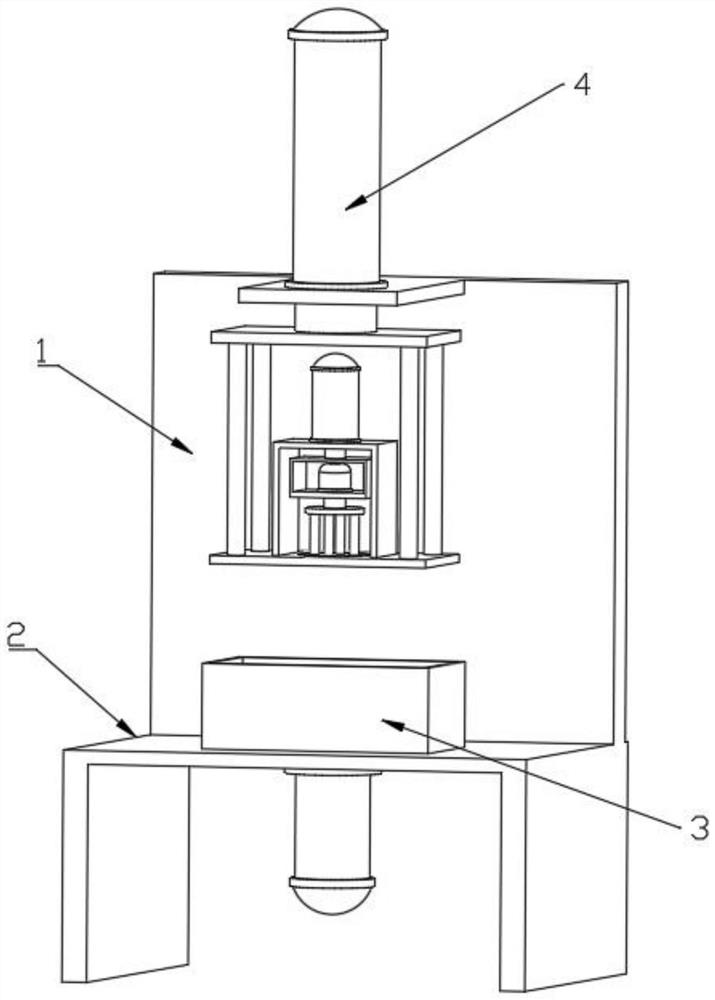

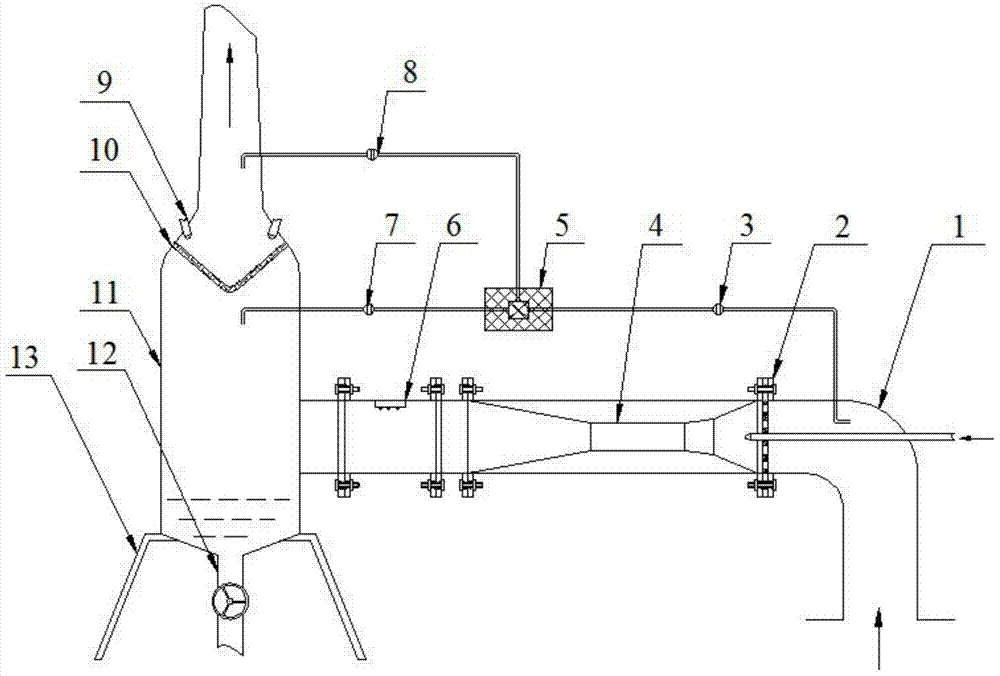

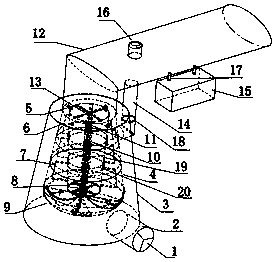

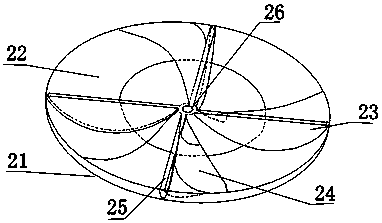

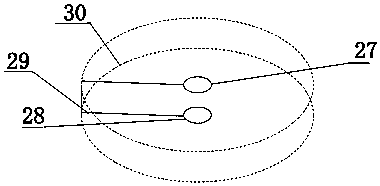

Brick kiln type biomass gas production furnace

InactiveCN102585904APromote conversionIncrease the number ofTobacco preparationCombustible gas productionProduction rateProcess engineering

The invention discloses a brick kiln type biomass gas production furnace. A furnace body (1) of the brick kiln type biomass gas production furnace has a brick structure; a hearth (2) has an olive shape with a large middle part and small upper and lower parts; a gas outlet channel (6) is formed close to the middle part of the hearth (2); and the upper part of the hearth (2) is provided with a water return pipe (8) which is communicated with the gas outlet channel (6). The capacity of the hearth is increased, the conversion of biomass gas is facilitated, and the brick kiln type biomass gas production furnace has the characteristics of low manufacturing cost, large hearth capacity, long gas production time, high gas production rate, high quality of gas, long service life and the like and is particularly suitable for mountain areas for producing flue-cured tobaccos.

Owner:彭化国

Production method for firing environment-friendly sintered bricks with sludge from domestic sewage plant

InactiveCN107814553AImprove plasticityPrevent solidificationCeramic materials productionClaywaresLand resourcesSludge

The invention relates to the technical field of environment-friendly sintered bricks and particularly relates to a production method for firing environment-friendly sintered bricks with sludge from adomestic sewage plant. According to the production method, coal ash, domestic sludge and construction waste are used as main materials for making bricks, and land resources are greatly saved by wasterecovery and by changing waste materials into things of value. The production method comprises the following steps: mixed materials are firstly stirred, and then aged for a long time, so that water isuniformly mixed with the mixed materials, and during ageing, water is added to a material ageing pool at regular time every three hours so as to prevent the mixed materials from solidifying and facilitate stirring for the second time; and during stirring for the second time, clay and cement are added, so that the plasticity of the mixed materials is greatly improved, brick making and forming of abrick machine are facilitated, and the strength of bricks is improved; green bricks undergo three steps of preheating, calcining and cooling in a brick firing kiln, so as to prevent shock chilling ofthe green bricks or deformation of the green bricks due to shock chilling, and thus greatly improving the attractiveness of the bricks.

Owner:石狮市鸿辉环保建材有限公司

Gangue-containing fired brick and manufacturing method thereof

InactiveCN108516793ARealize recycling of resourcesImprove mechanical propertiesCeramic materials productionClaywaresFire brickBrick kiln

The invention discloses a gangue-containing fired brick and a manufacturing method thereof. The fired brick comprises the following raw materials (by weight): 15-20 parts of fly ash, 15-20 parts of gangue, 2-5 parts of glass powder, 50-60 parts of shale, 2-5 parts of diatomite, 2-5 parts of titanium diboride, and 3-5 parts of magnesium oxide. The technology comprises the following steps: respectively crushing and screening shale and gangue as standby materials; fully stirring and mixing the standby materials and the other raw materials to obtain a mixture; adding water (water addition amount is 14-16% of total weight of the mixture) into the mixture and mixing and stirring, placing in a sealed container for 6-8 days after uniform stirring so as to obtain an aged material; carrying out secondary stirring and mixing on the aged material, extruding by the use of a vacuum extruder, and preparing a blank body through a slitter, a blank cutter and a blank turning machine; airing the blank ofa solid brick or cored brick until water content is 3-5%, and sintering in a brickkiln. The invention has the following advantages: resources cyclic utilization of fly ash and gangue can be achieved,and the finished product has good mechanical properties and mechanical properties.

Owner:赤水市瑞泰建材有限公司

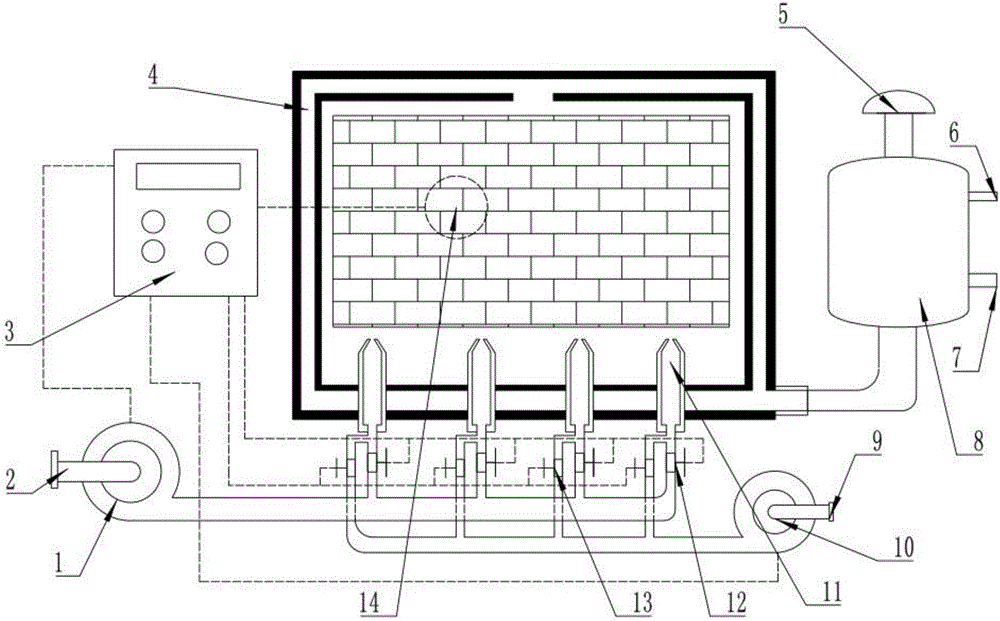

Brick kiln for firing coal gangue bricks

InactiveCN106482521AIncrease profitPrecise temperature controlFurnace typesControl devices for furnacesControl systemEconomic benefits

The invention discloses a brick kiln for firing coal gangue bricks, mainly comprising a fuel gas booster (1), a fuel gas inlet (2), a control system (3), a kiln (4), an exhaust opening (5), a water inlet (6), a water outlet (7), an afterheat collector (8), an air inlet (9), a fan (10), a nozzle (11), a gas valve (12), an air valve (13) and a temperature sensor (14). Through arranging a heat circulation channel in the kiln wall, the coal gangue bricks can be rapidly processed, the energy source is fully utilized and the economic benefit is improved. Through arranging the brick kiln, temperature of the kiln can be accurately controlled, the product quality is improved, and product quality stability is guaranteed; besides, the afterheat can be fully used and the economic benefit is improved.

Owner:重庆市万盛区万兴建筑材料有限公司

Carbonized husk thermal insulation and heat reserving brick

ActiveCN103922693AAchieve consumptionAchieve reasonable utilizationSolid waste managementAdhesiveThermal insulation

The invention relates to a carbonized husk thermal insulation and heat reserving brick which is characterized by being processed by taking a black husk prototype material husk carbon as a raw material, mixing 1 part of magnesium chloride with 2 parts of water to obtain a magnesium chloride diluent, mixing 2-2 parts of magnesium chloride diluent with 1 part of magnesium oxide to obtain an adhesive, mixing 3-5 parts of husk carbon with 1 part of chlorine and magnesium oxide adhesive to prepare brick blank, compressing in a die and the like. According to the invention, a brick kiln is not needed to be built, soil is not used instead of waste husk carbon, so that production cost is low, the pollution of husk on environment is governed because a large amount of husk wastes are consumed, and the prepared brick is porous, low in density and rough in texture, has the advantages of light weight, thermal insulation, heat reservation, sound insulation, shock absorption and the like, and is a novel environment-friendly indoor partition wall material.

Owner:嘉兴久珥科技有限公司

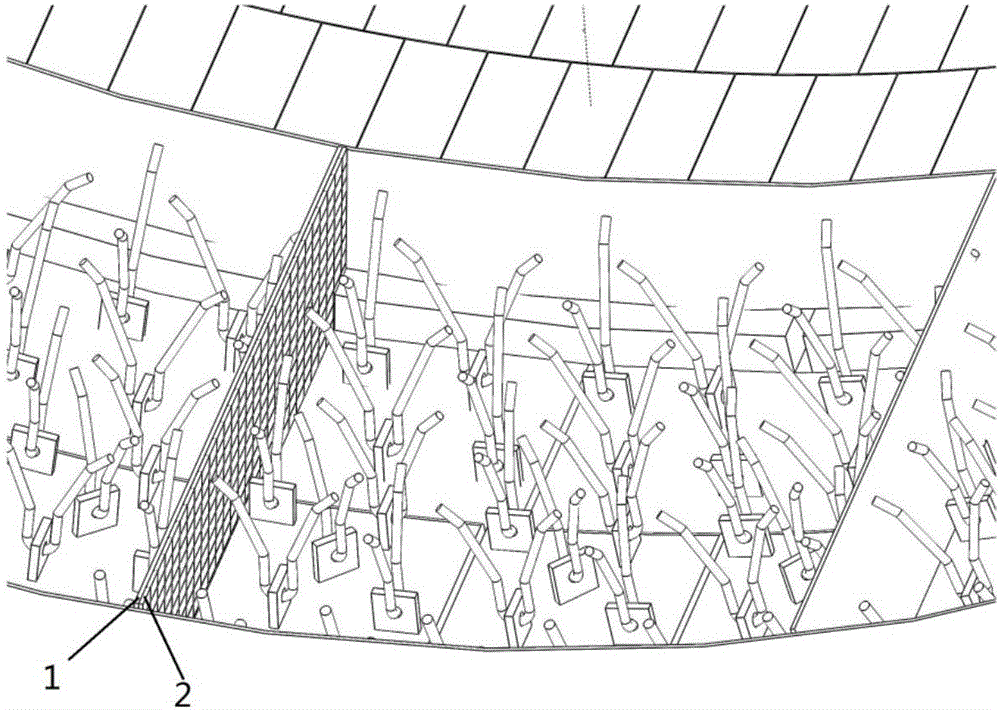

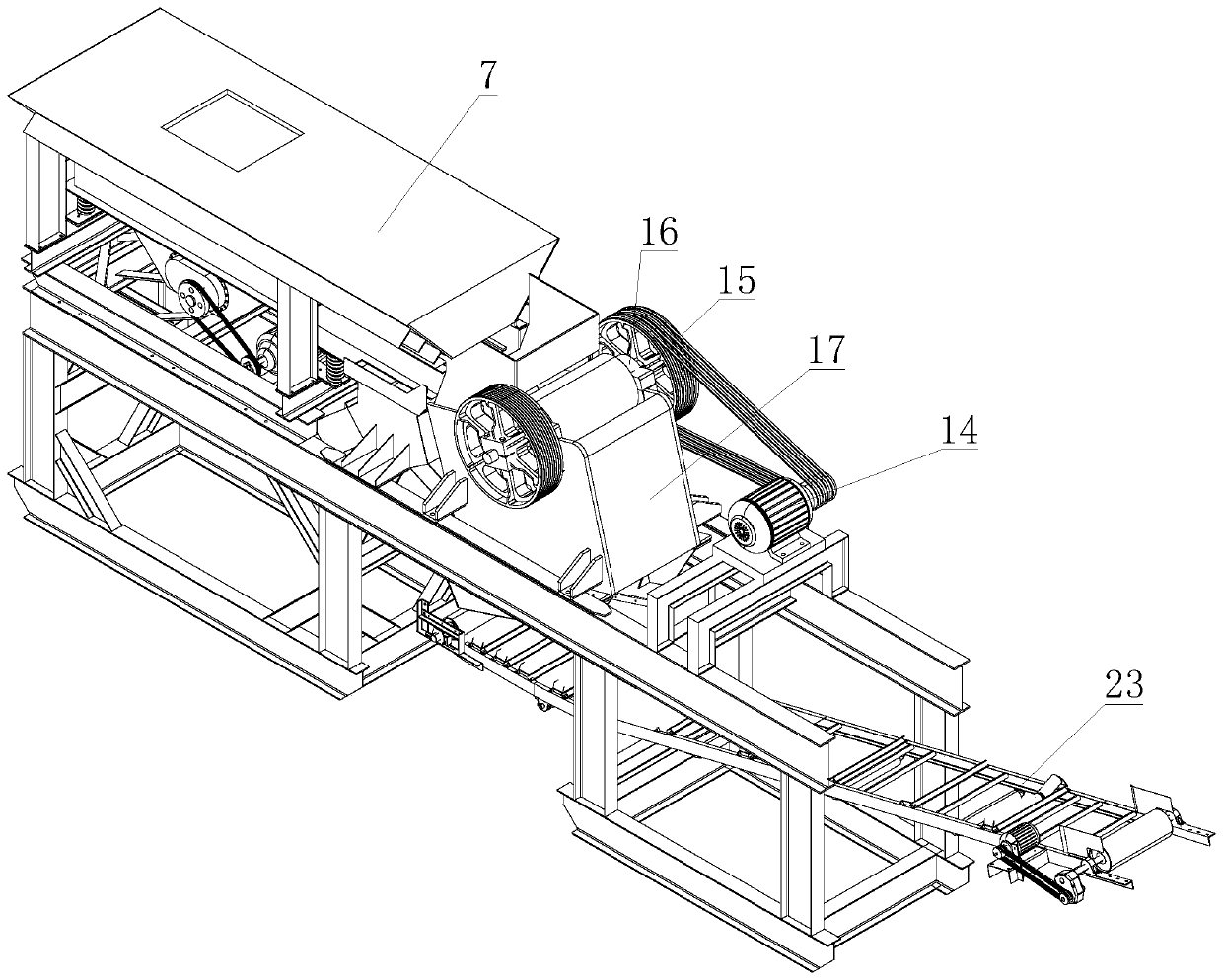

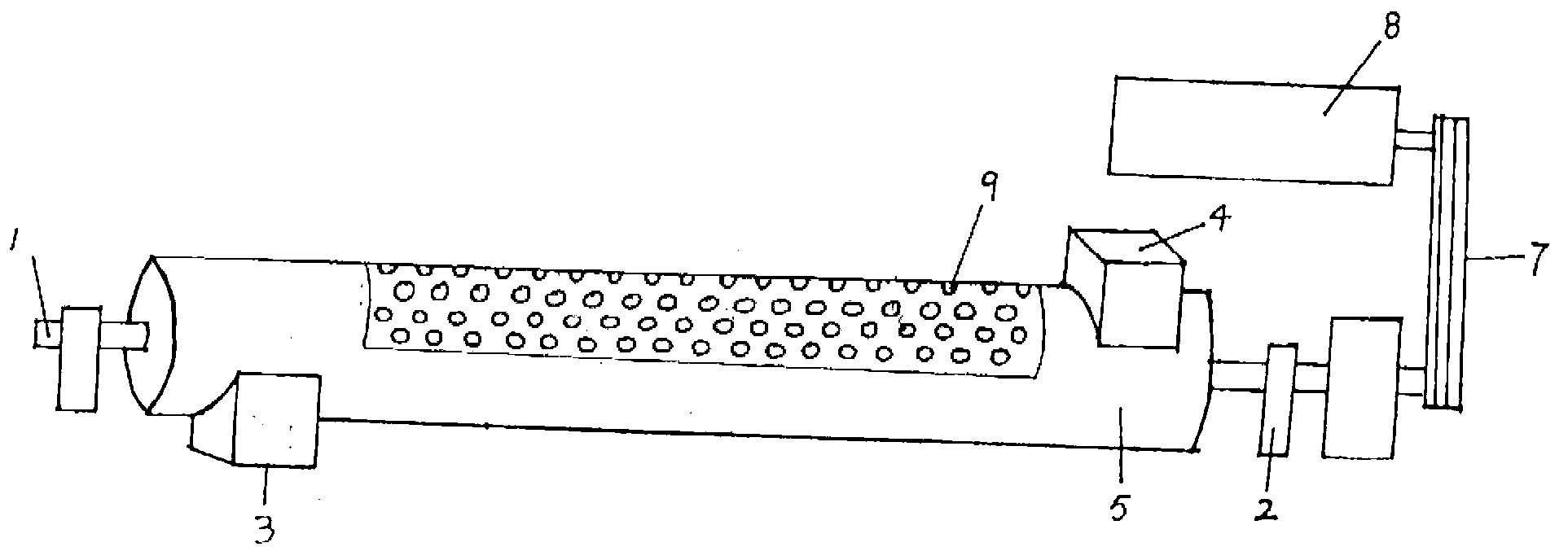

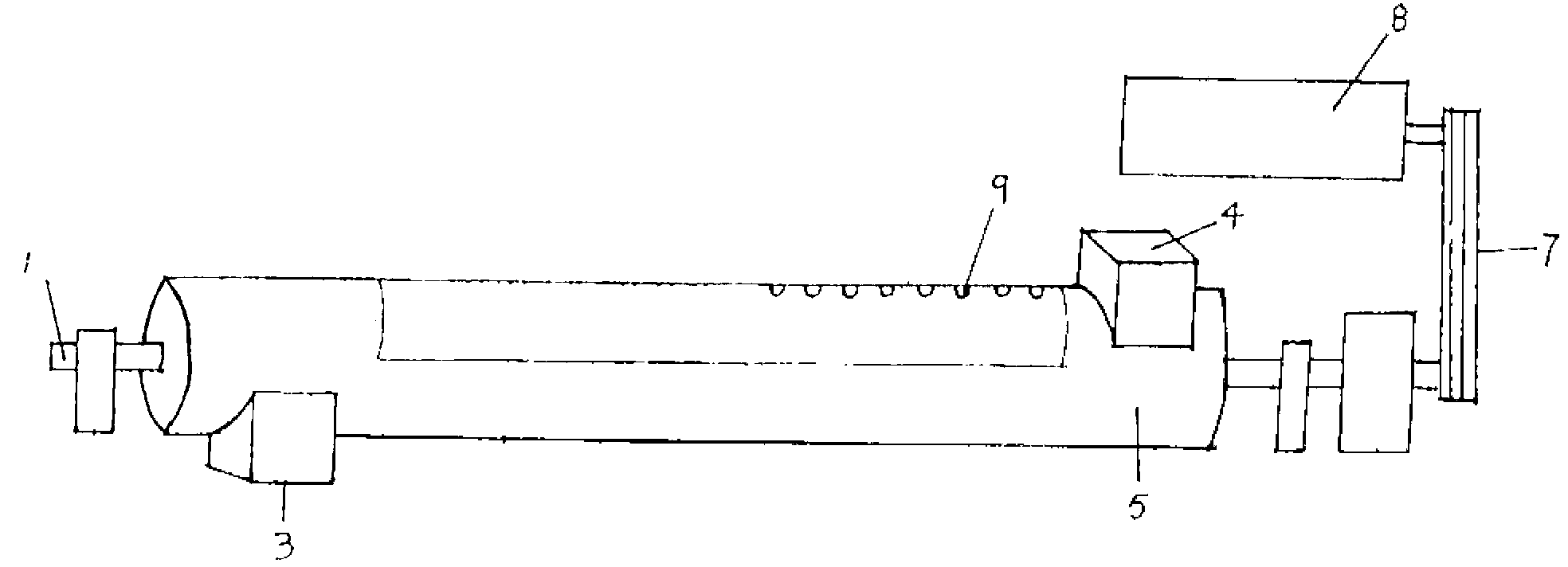

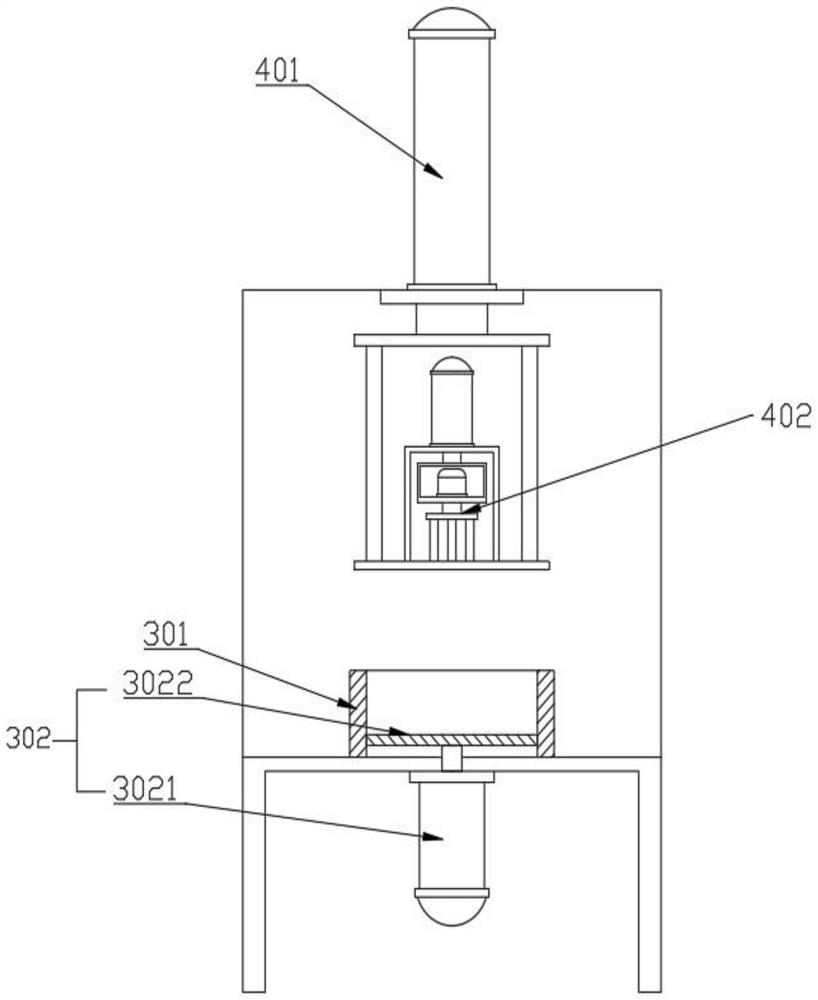

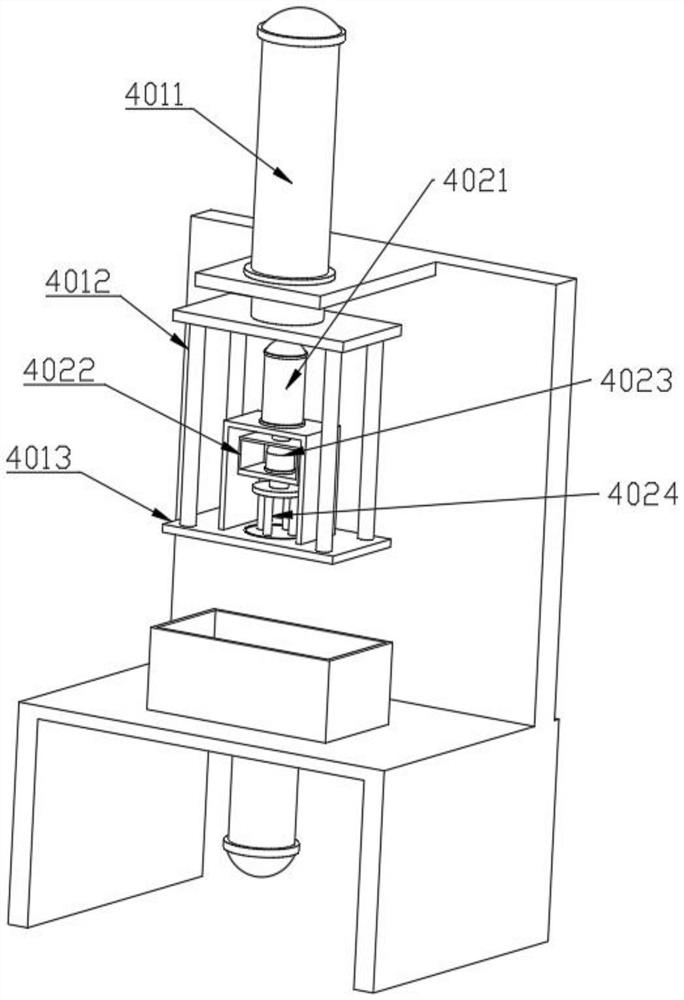

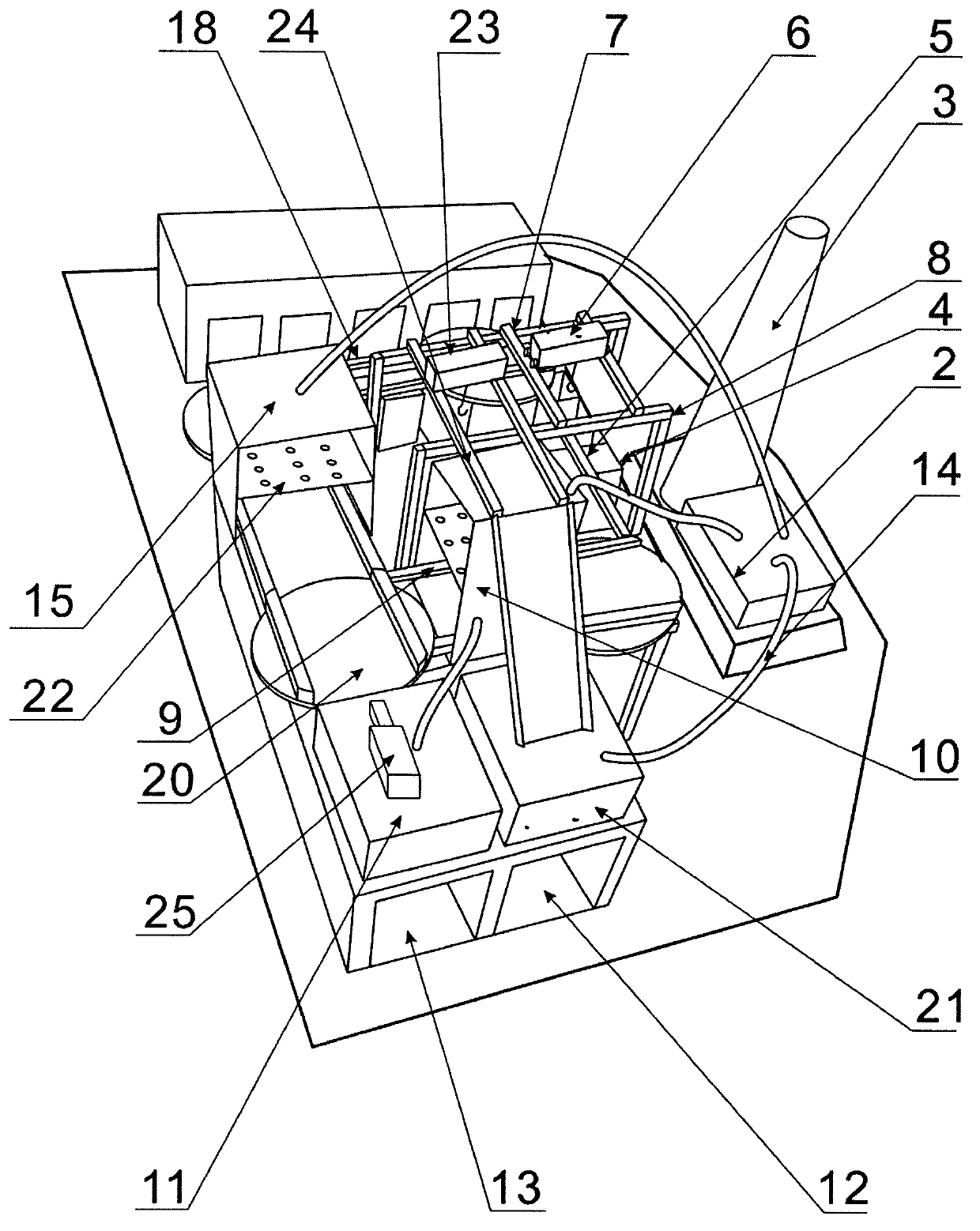

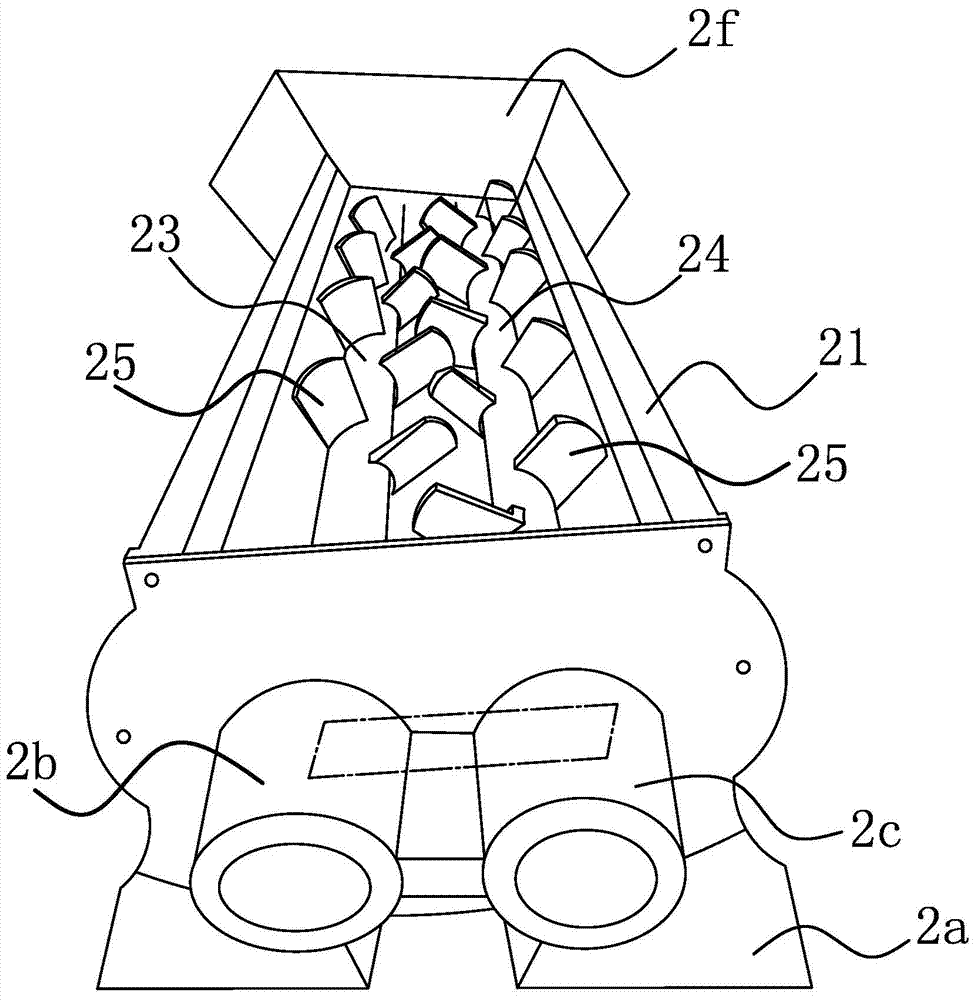

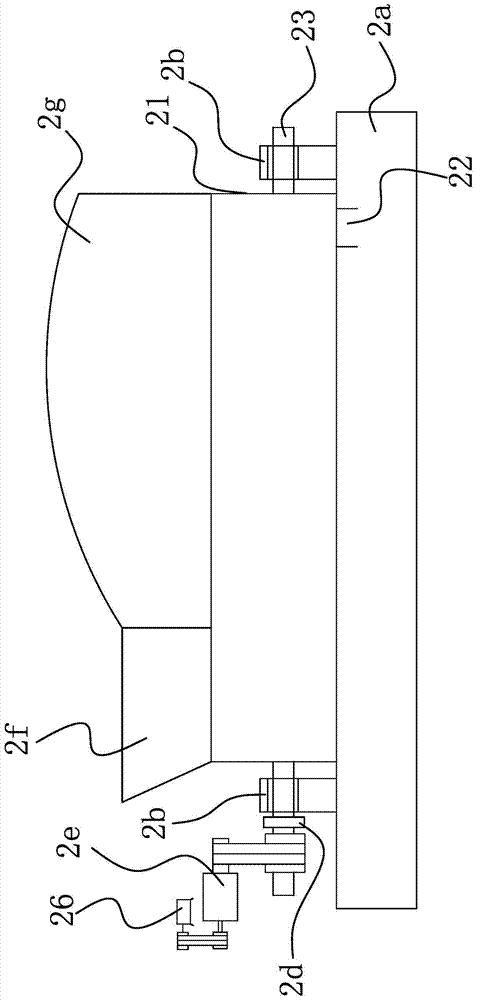

Solid waste treatment equipment and application thereof in brick kiln

ActiveCN103075873ASpeed up looseningKeep dryDrying solid materialsDrying machinesBarrel ShapedWaste treatment

The invention relates to chemical machinery, in particular to solid waste treatment equipment and an application. The solid waste treatment equipment comprises a long barrel-shaped shell which is horizontally arranged, wherein an inlet is formed in one end of the long barrel-shaped shell, and an outlet is formed in the other end of the long barrel-shaped shell; a spiral rotating shaft is arranged along the axial direction of the long barrel-shaped shell, more than one longitudinal stirring rods which are perpendicular to the spiral rotating shaft are arranged on one side, which is near the inlet, of the spiral rotating shaft, and more than one transverse stirring rods which are parallel to the spiral rotating shaft are arranged on one side, which is near the outlet, of the spiral rotating shaft; and an upper shell which can be opened is arranged on the upper part of the long barrel-shaped shell, and more than one through holes are formed in the upper shell. The solid waste treatment equipment is put in a flat-top tunnel brick kiln, high temperature in the flat-top tunnel brick kiln is utilized to treat solid waste in the solid waste treatment equipment, the spiral rotating shaft is rotated, the solid waste is stirred by the longitudinal stirring rods, so as to evaporate moisture, and the solid waste is stirred by the transverse stirring rods, so as to loosen the solid waste. According to the solid waste treatment equipment, the treatment of the solid waste can be promoted, and gas can be effectively exported.

Owner:白志广

Waste incinerator slag processing technology

The invention discloses a waste incinerator slag processing technology. The technology comprises the following steps: removing metal impurities from slag; sending the obtained slag to a vibration mesh screen, screening, and allowing particles containing nitrogen and potassium elements and having a granularity being smaller than 5mm to be used as an agricultural fertilizer; mixing 40-50wt% of particles with the granularity being greater than 5mm and 25-35wt% of clay with 25-30wt% of an adhesive; adding a glycerin and phenolic resin solution accounting for 10% of the weight of the above obtained mixture, sending the obtained material to a stirrer, and stirring until uniformity; sending the stirred material to a high-pressure chamber, and carrying out high-pressure pressing; and carrying out molding block formation on the compressed material, disposing obtained blocks in a brick kiln, and carrying out high temperature sintering to obtain finished bricks. Waste incinerator slag screening allows fly ash containing N and K elements to be used as the agricultural fertilizer, and the bricks formed after mixing the particles with the granularity being greater than 5mm, clay and the adhesive, pressing and sintering can be used as a building material.

Owner:安徽中泰创展环境科技有限公司

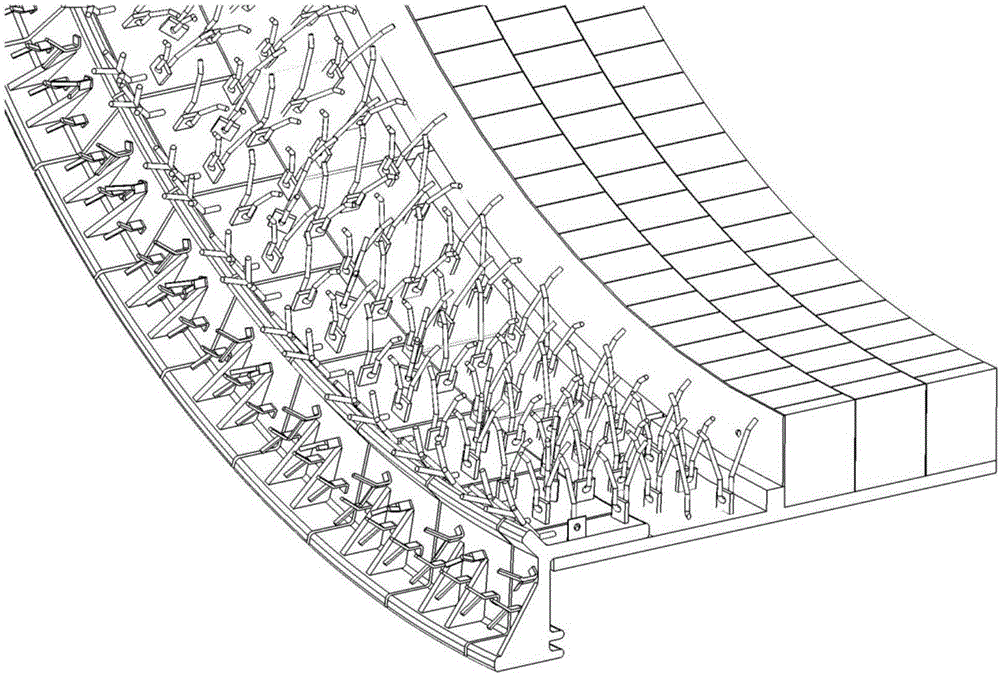

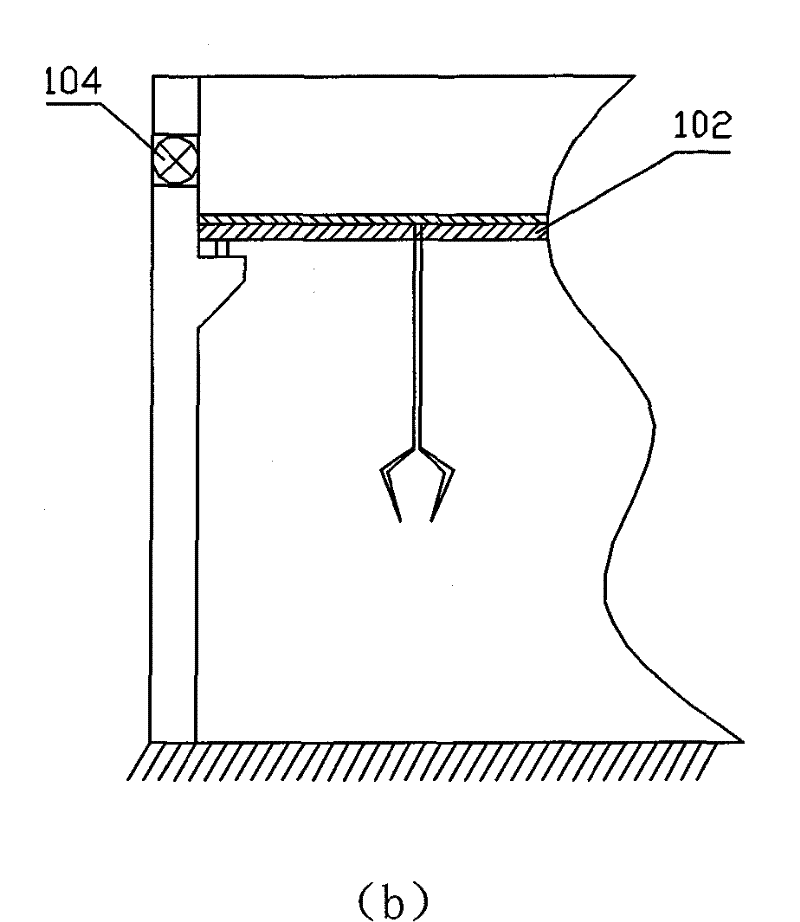

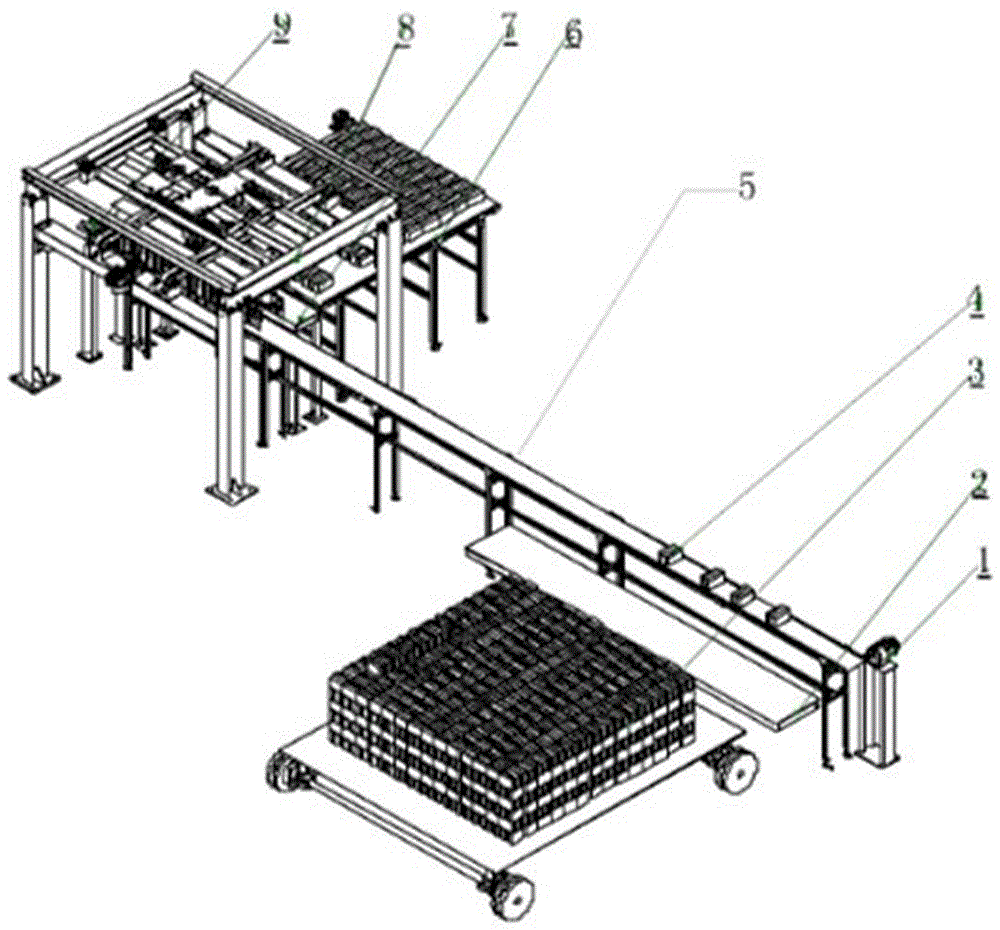

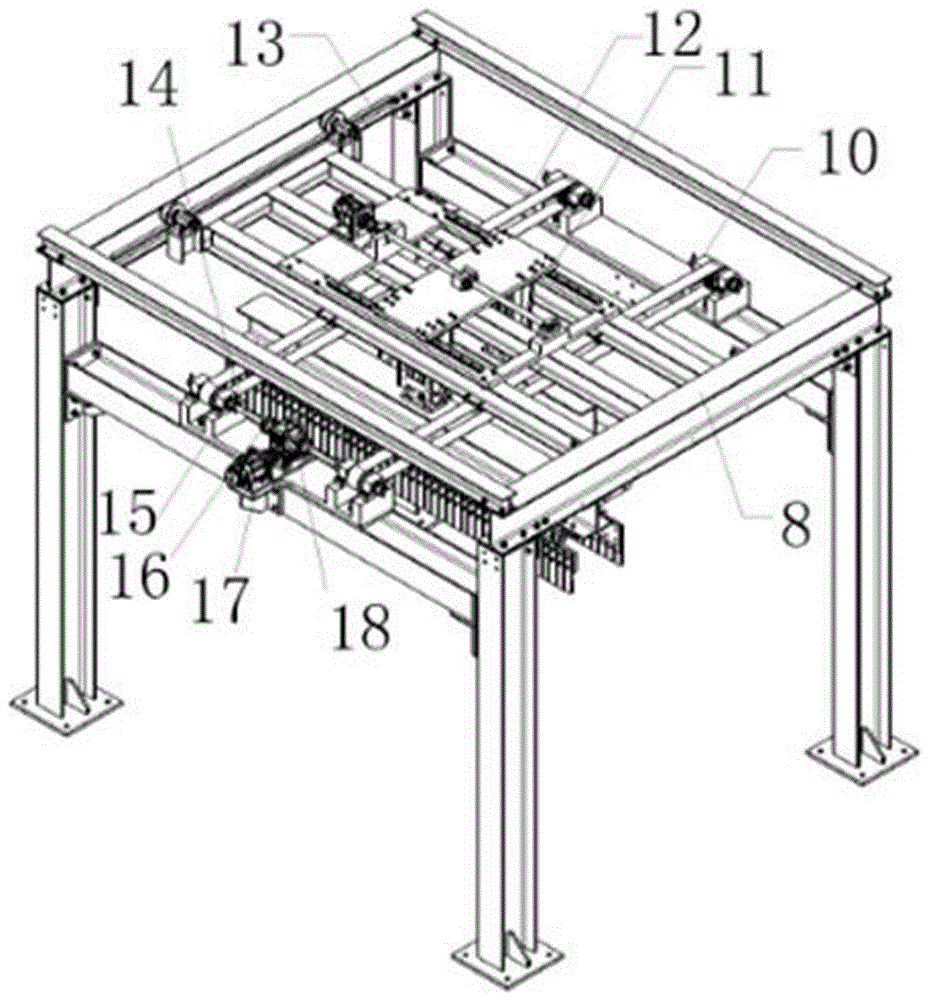

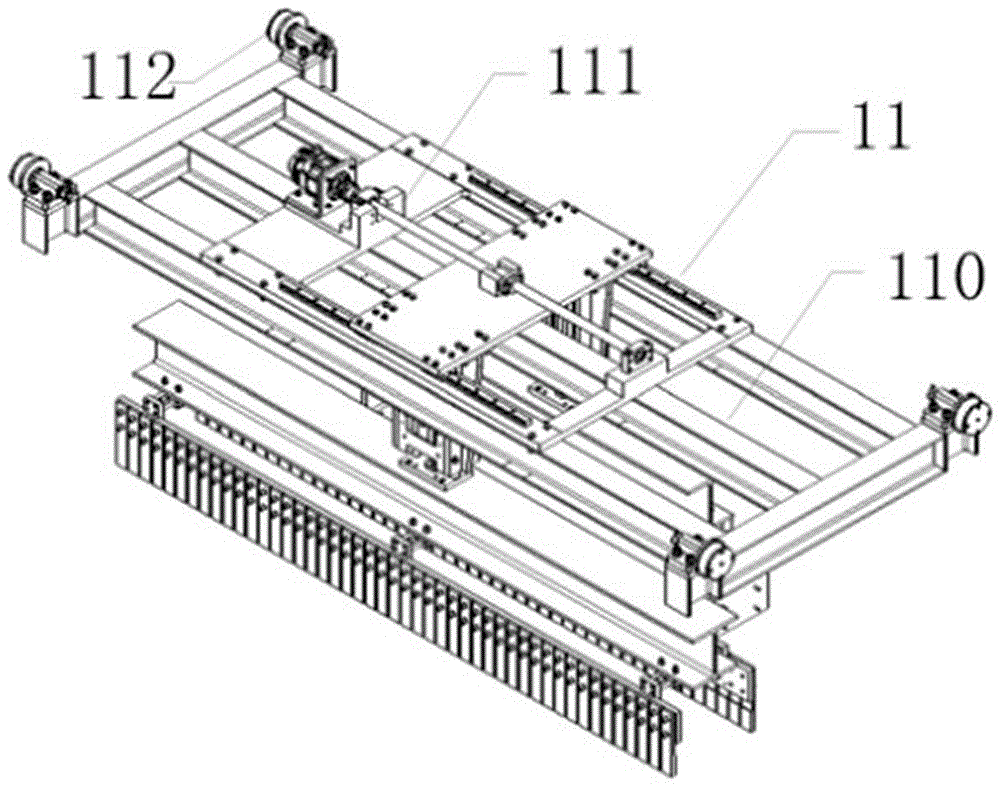

Brick conveying and arranging mechanism

ActiveCN105819197AImplement transfer movementRealize conveying finishingConveyor partsEngineeringSlide plate

The invention discloses a brick conveying and arranging mechanism which comprises a variable frequency motor, a working platform and a brick kiln car. A conveyer belt positioning adjustment mechanism, which is fixedly mounted on an intermediate transferring platform, is arranged at the left end of a brick linkage transferring mechanism. A whole variable frequency conveyer belt and a servo motor conveyer belt are linked with each other by the brick linkage transferring mechanism and a brick carrying linkage mechanism. Under the combined action of a second servo motor arranged on the brick linkage transferring mechanism and a turbine reducer, the condition that the brick carrying linkage mechanism moves back and forth along lateral support brackets is realized. A first servo motor arranged on the brick carrying linkage mechanism is used for realizing the moving back and forth of a sliding plate on a screw rod. Bricks can be clamped by lifting cylinders arranged at the lower end of the sliding plate and finger cylinders. The transferring of the bricks is realized well when the bricks are clamped in brick clamping spring leaves. The transferring precision is ensured well through the positioning action of the conveyer belt positioning adjustment mechanism and a brick transferring adjustment mechanism.

Owner:广西柳州市莱恩自动化设备有限公司

Method for preparing high-strength silicon mullite bricks

ActiveCN113954209AAvoid the presence of holesHigh strengthDischarging arrangementFeeding arrangmentsCompression moldingMullite

The invention discloses a method for preparing high-strength silicon mullite bricks, and belongs to the technical field of silicon mullite brick manufacturing. The method for preparing the high-strength silicon mullite bricks comprises the following steps: S1, raw material mixing: injecting raw materials required for manufacturing the silicon mullite bricks into a stirring barrel, and uniformly stirring and mixing; S2, compression molding: injecting the mixed silicon mullite brick raw materials into a brick blank molding device, removing bubbles in the silicon mullite brick raw materials by the brick blank molding device, and pressing the silicon mullite brick raw materials into brick blanks; and S3, sintering to form bricks: putting the brick blanks subjected to compression molding into a brick kiln, and carrying out sintering to form the bricks. Through the arrangement of a bubble removing assembly in the brick blank forming device, mixed raw materials in a forming mold can be stirred, so that bubbles in the mixed raw materials can be removed, the situation that holes exist in sintered and formed bricks can be avoided, and the purpose of improving the strength of the silicon mullite bricks is achieved.

Owner:浙江骏海新材料有限公司

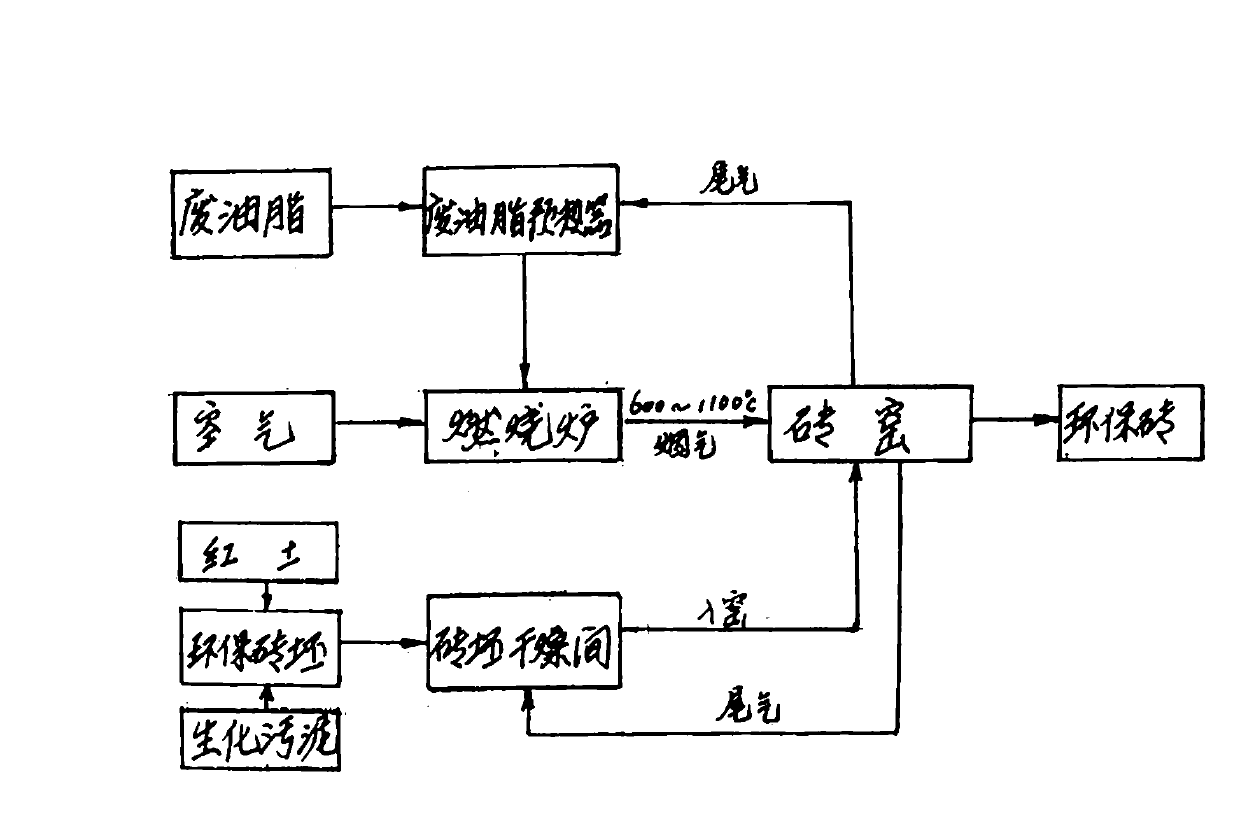

Method for preparing environment-friendly bricks by using mixture of biochemical sludge and red clay and by using waste oil as fuel

InactiveCN103130491AWidely distributedImprove insulation performanceCeramic materials productionClaywaresOil and greaseCombustion

The invention relates to a method for preparing environment-friendly bricks by using a mixture of biochemical sludge and red clay and by using waste oil as a fuel. According to the invention, biochemical sludge produced during urban sewage treatment process is mixed and stirred with red clay and coal cinder powder according to a certain ratio, such that a plastic mixed brick pug is prepared; the pug is pressed in a brick press, such that environment-friendly brick blanks are prepared; the brick blanks are dried, and are fired in a kiln, such that the environment-friendly brick products are obtained. During firing, a firing heat source of high-temperature flue gas produced by combustion of a fuel of waste oil is delivered into the brick kiln through a pipe. According to the invention, the environment-friendly bricks are fired by using a mixture of biochemical sludge and red clay and by using waste oil as the fuel, such that wastes are turned into valuable matters, and energy is saved. The red clay is widely distributed, such that the material is easy to obtain and is cheap. Also, no farmland is occupied. The method has good social and economical benefits.

Owner:陈丰

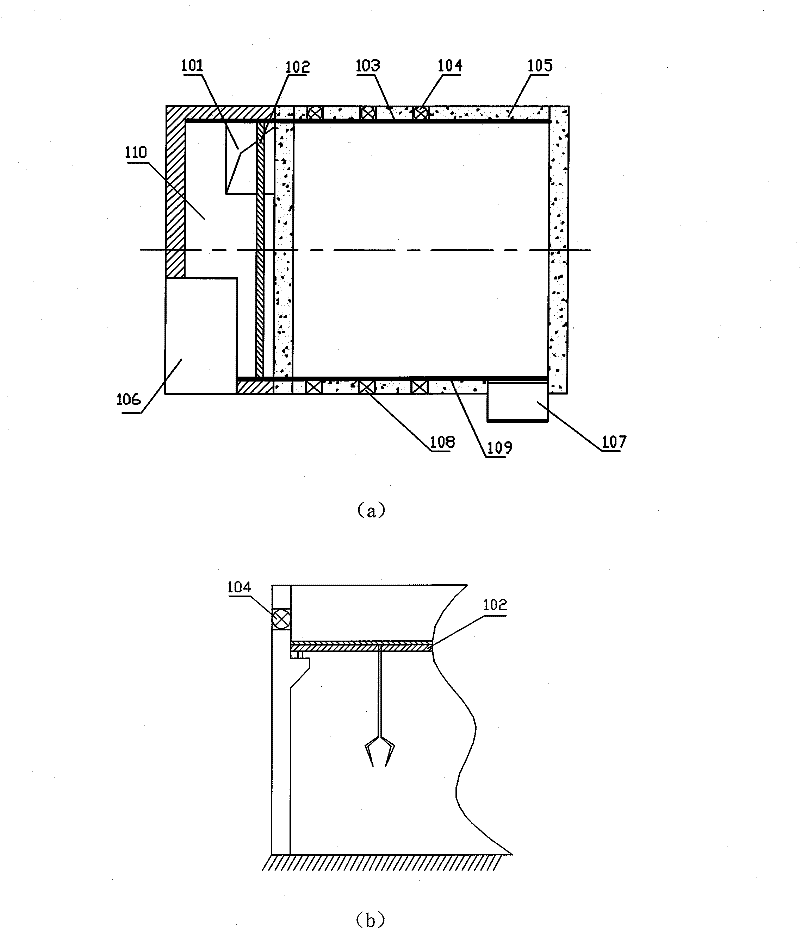

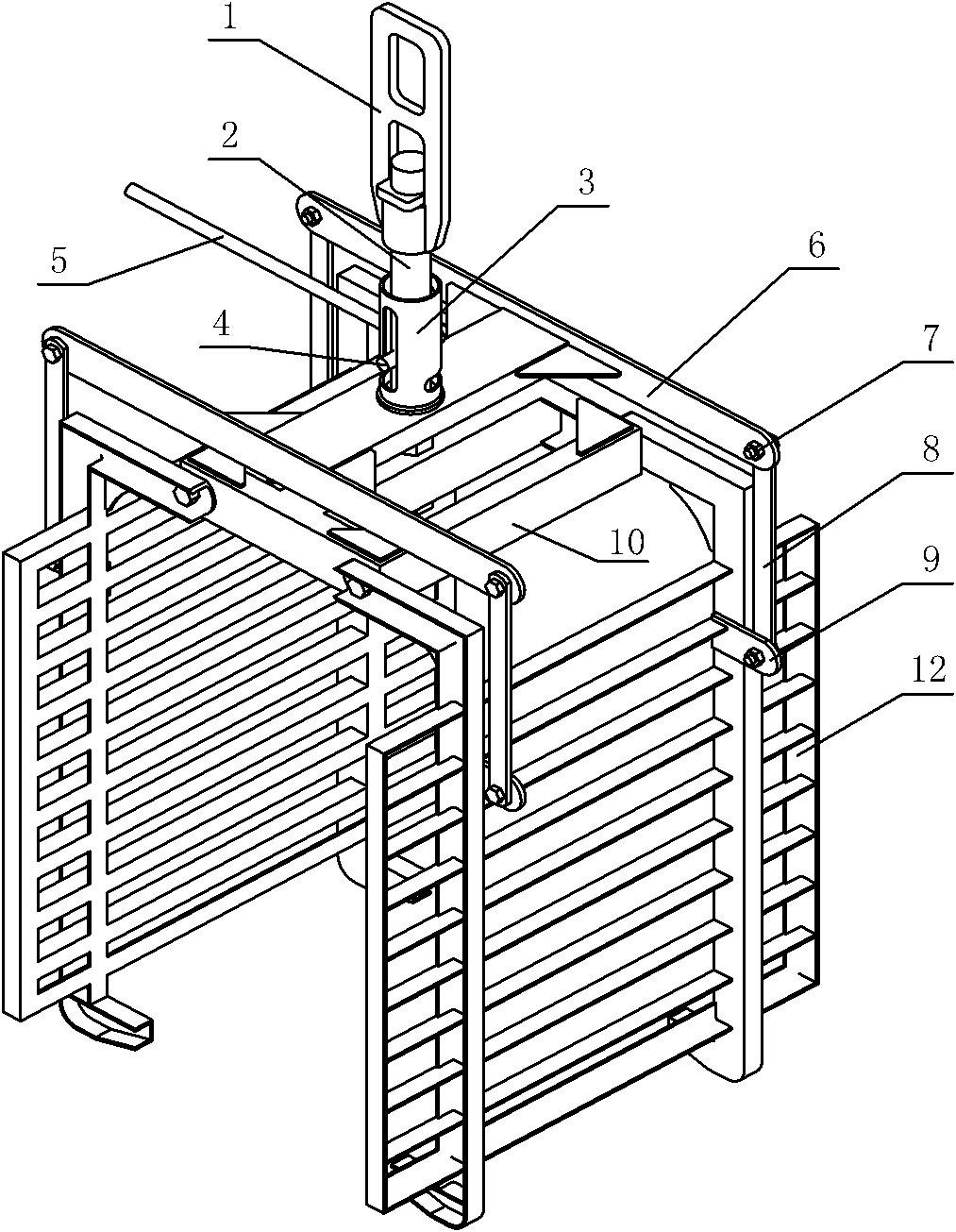

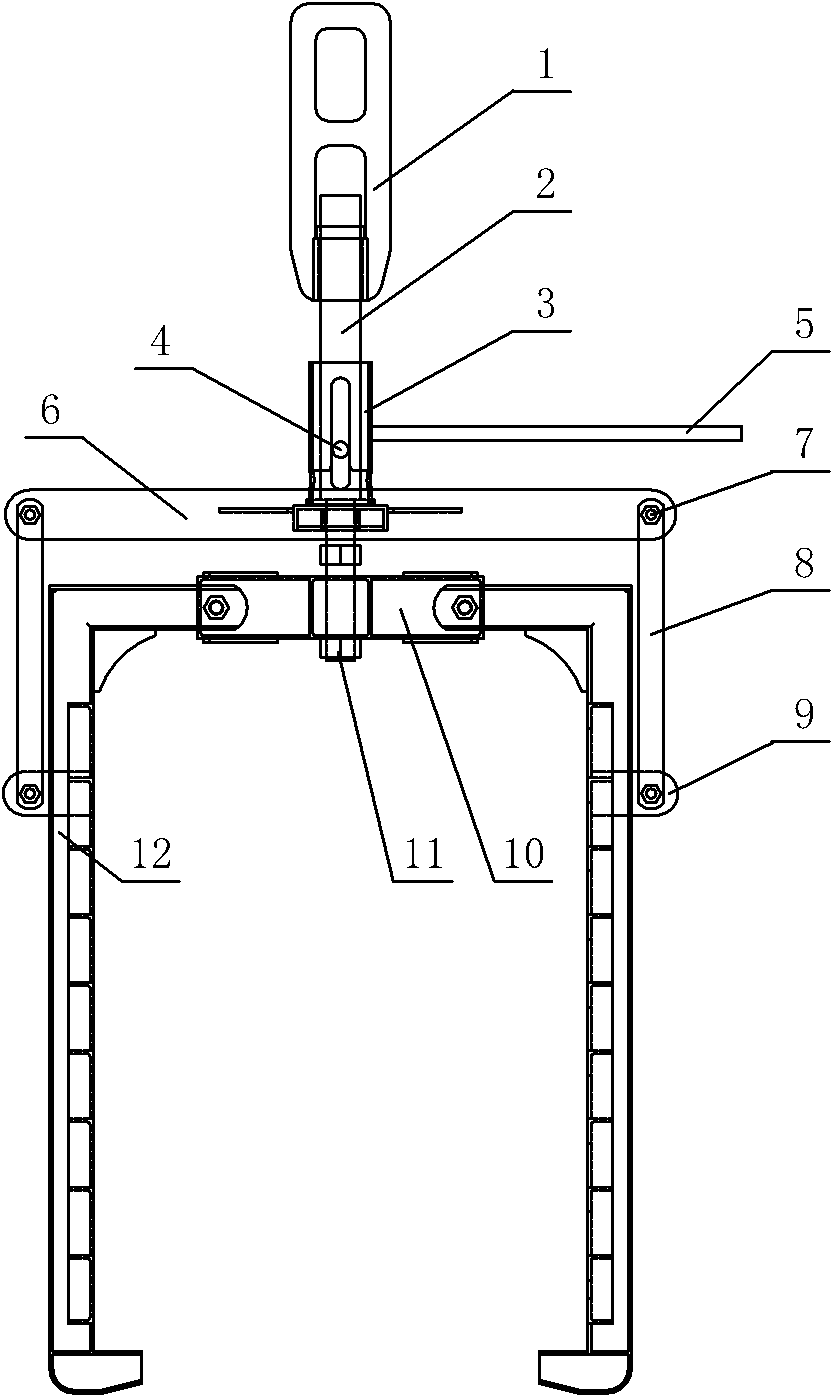

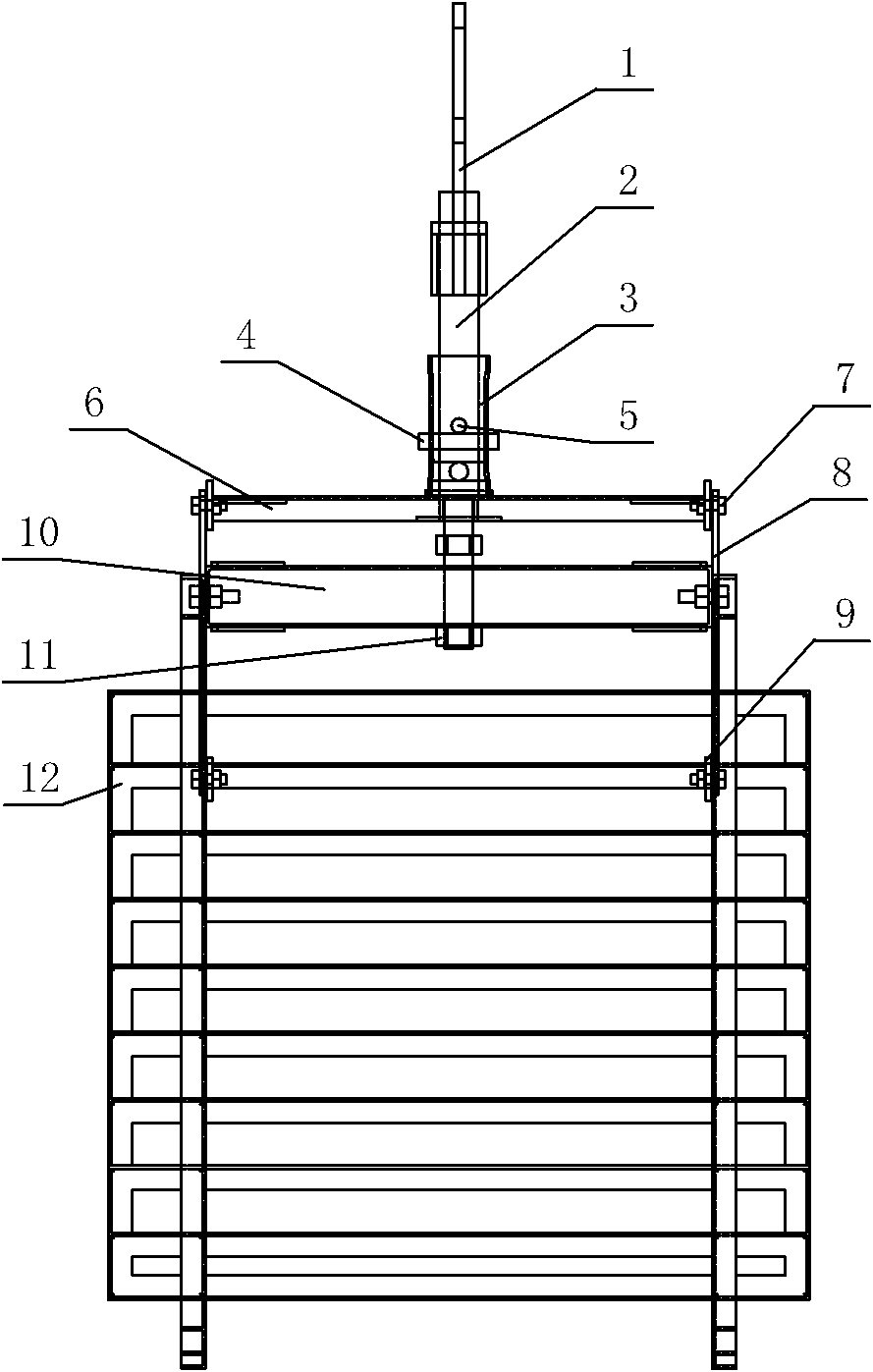

Semi-automatic brick hanging fixture

InactiveCN102001583ASimple structureEasy to manufactureLoad-engaging elementsSemi automaticBrick kiln

The invention provides a semi-automatic brick hanging fixture, and belongs to a vertical transportation tool of a brick supporter for brick kiln construction. The semi-automatic brick hanging fixture mainly comprises a hook (1), an operating handle (5), a support (10), jaws (12) and a door-type hanger, wherein the hook (1) is connected with the support (10) through a hanger rod (2), and a hanger sleeve (3) is arranged on the hanger rod (2); and one end of the operating handle (5) is fixedly connected with the side of the hanger sleeve (3), and the door-type hanger bestrides the two jaws (12) and are connected with the two jaws (12). The semi-automatic brick hanging fixture has the advantages of simple structure and low manufacturing cost, and is easy to manufacture, and the jaws are opened and closed instantaneously by rotating the hanger sleeve and changing the lifting action point in the construction of vertical transportation of materials, accordingly, the construction process is simple and fast.

Owner:CHINA FIRST METALLURGICAL GROUP

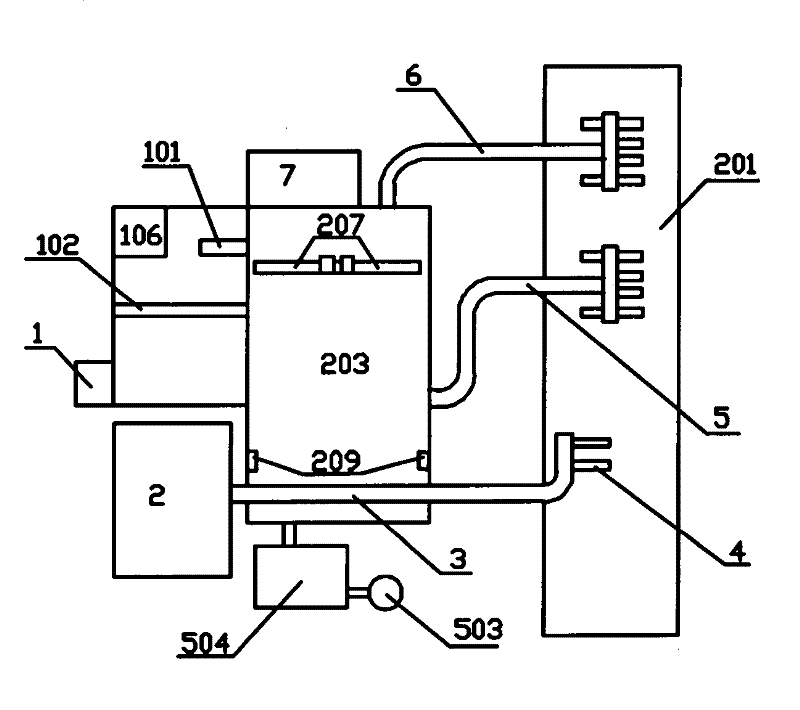

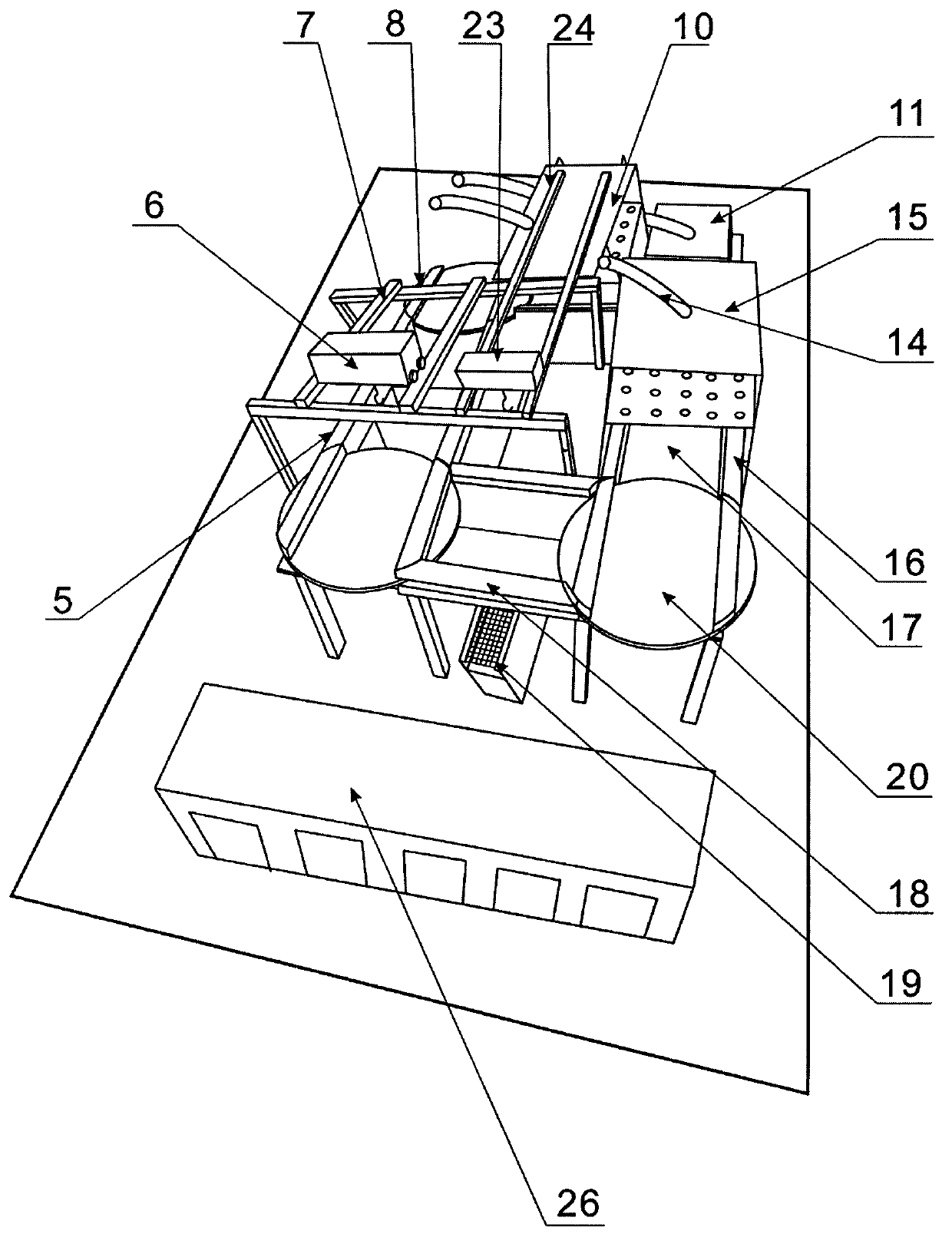

Method and system for carrying out thermal treatment on household garbage by using brick kiln

InactiveCN103100552AReduce pollutionImprove working environmentWaste processingSolid waste disposalAir blowerThermal treatment

The invention discloses a method for carrying out thermal treatment on household garbage by using a brick kiln. The method provided by the invention comprises the five steps of: primarily sorting, cleaning and dehydrating, primarily baking, drying and classifying-recovering, wherein a heat source for primary baking is derived from hot air at the top of a tunnel type brick baking chamber; and a heat source for the drying is derived from high-temperature air in a cooling channel of the brick kiln. The invention further discloses a garbage treatment system based on waste heat of the brick kiln; and the garbage treatment system comprises an eluting water device, a primary baking device, a drying device, a splitting device, a cycloid machine and a negative-pressure chamber, wherein the negative-pressure chamber is provided with an air blower and is connected with a chimney. The method provided by the invention uses the structure of the brick kiln and the garbage treatment system in a combined manner, and uses waste heat of the brick kiln in the garbage treatment process, so that energy and resources can be saved; and the garbage pollution is reduced, and the working condition of staff can be improved.

Owner:蒲仁建

Ultrasonic-assisted spraying drainage and atomization dust removal device

InactiveCN103611384AImprove dust removal effectCompact structureCombination devicesAuxillary pretreatmentUltrasonic assistedEngineering

The invention relates to an ultrasonic-assisted spraying drainage and atomization dust removal device which is applied to the dust removal field of small- and medium-size coal-fired boilers or brick kilns. The ultrasonic-assisted spraying drainage and atomization dust removal device mainly comprises a smoke elbow, a flange plate group, a spraying drainage instrument, an ultrasonic generator, a sampling analyzer, a timing cleaner, a conical filter net, a condensation and separation chamber, a sewage drainage pipe and a bracket, wherein during working, the spraying drainage instrument sucks smoke into a cleaning solution for fully mixing and washing the smoke, so that most smoke dust can be cleaned away; meanwhile, an alkaline solution and acidic gas are subjected to neutral reaction to remove harmful gas; residual fine particles are condensed to be enlarged under the action of ultrasonics and then are washed and filtered again; finally qualified smoke is discharged; the sampling analyzer can send a signal according to the measured smoke concentration to control pressure of spraying liquid and the sound intensity and the frequency of the ultrasonics, so that the optimal cleaning effect can be achieved. The dust removal device disclosed by the invention is particularly good in effect in removing the harmful gas and the fine particles from the smoke.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Autoclaved sand-lime brick prepared from superfine copper tailings

The invention discloses an autoclaved sand-lime brick prepared from superfine copper tailings. The autoclaved sand-lime brick is prepared from the following raw materials: the superfine copper tailings, fly ash, cement, river sand, metakaolin, a water reducing agent and slag. The autoclaved sand-lime brick is prepared by using the superfine copper tailings as a mixture source of the autoclaved sand-lime brick, and a novel environment-friendly building material is prepared by utilizing the characteristics of low energy consumption, no clay, wide production raw materials and the like in the production process of the autoclaved sand-lime brick. Meanwhile, the autoclaved sand-lime brick is produced by adopting industrial waste tailings, so that the use of other mineral raw materials is reduced, consumables can be saved, wastes are turned into wealth, the treatment and utilization process of the superfine copper tailings is greatly simplified, the economic, safe and environmental burden of brick kiln brick firing enterprises is relieved, the economic value of the superfine copper tailings is improved, and the economic benefit is increased. Practical prospects and values of the autoclaved sand-lime brick are exerted, national environmental protection policy requirements are met, and the application prospects are huge.

Owner:ANHUI UNIV OF SCI & TECH

High-temperature hot air device suitable for waste gas circulation heating of brick kiln

PendingCN109539815AImprove adaptabilityReduce consumptionControl devices for furnacesWaste heat treatmentHeat flowEngineering

The invention relates to the technical field of waste gas circulating heating devices, in particular to a high-temperature hot air device suitable for waste gas circulation heating of a brick kiln. The high-temperature hot air device comprises a hot air flow channel and a heater arranged in the hot air flow channel; the hot air flow channel comprises an air blower, an air inlet pipe, an outer cylinder body, an inner cylinder body and a rotating body, wherein the inner cylinder body is arranged in the outer cylinder body, an outer flow channel is formed between the outer cylinder body and the inner cylinder body, nozzles are evenly distributed on the top of the inner cylinder body, and the rotating body is arranged in the inner cylinder body. According to the high-temperature hot air devicesuitable for waste gas circulation heating of the brick kiln, the principle of fluid mechanics and aerodynamics is fully utilized, and an 80-degree inclined plane, a diffuser pipe heat flow channel,an impeller inner bottom plate flow mixing device, a four-leg supporting device and the like are adopted in the structure, so that not only is water contained in waste gas further removed, but also the waste gas is fully mixed in the heating area and keeps the long stagnation time, the waste gas is sufficiently heated, the heating efficiency is improved, and the energy consumption is reduced.

Owner:NANCHANG INST OF TECH

Fabricating method of pure colliery waste brick

InactiveCN101570428AHigh strengthEvenly heatedCeramic materials productionClaywaresMolding machineBrick kiln

The invention relates to a fabricating method of a pure colliery waste brick, which comprises the following steps: mixing driving recrement with coal refuse evenly, wherein the driving recrement occupies 25-35 of the weight percent, and the balance is the coal refuse; crushing the driving recrement and the coal refuse; adding 5-7 percent of water into the crushed coal refuse and the crushed driving recrement mixture; aging the mixture in an ageing chamber for 22-26h, molding the mixture into the brick by a brick molding machine and directly placing the brick into a brick kiln to be fired for 10-20h for fabricating the finished product. All the bricks are overlapped with each other at one end in the brick kiln. The method has the characteristics of simple process without adding clay, short firing time, no coal consumption during the firing, small space occupation and time and labor saving without drying the brick, energy saving, multipurpose use of waste, agricultural land protection, less land occupation, little investment, and the like, thereby having better popularization and practicability values.

Owner:刘镇

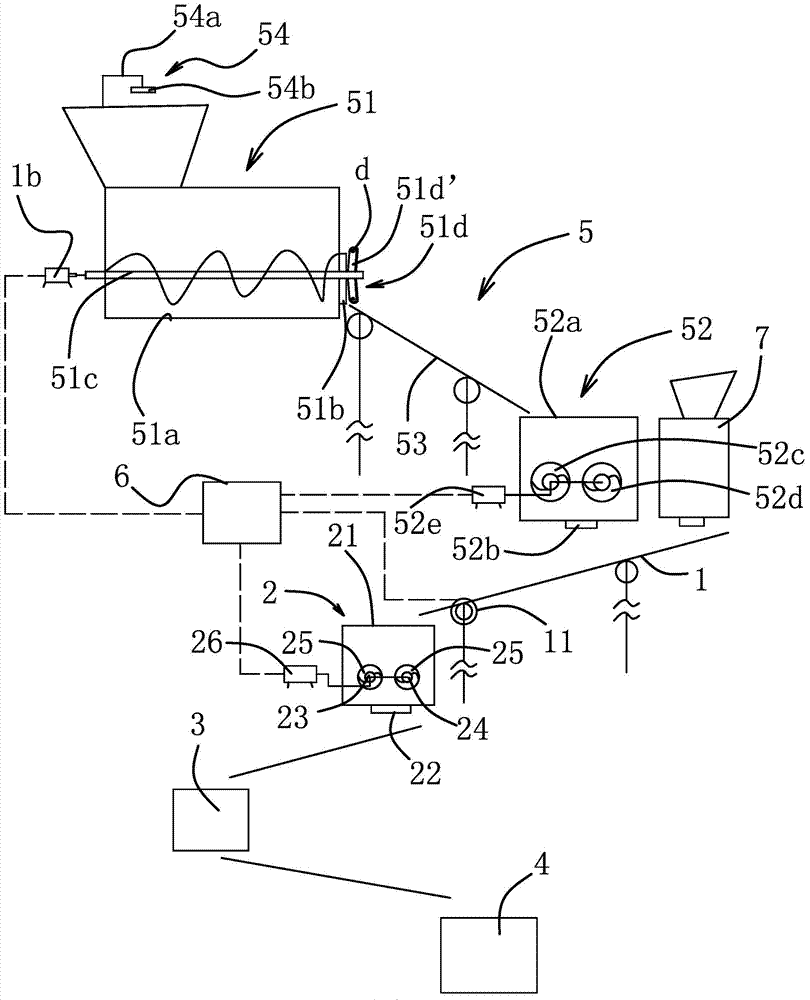

Production system and production process for producing bricks by utilizing paper pulp sludge

InactiveCN103771898AImprove structural strengthReasonable designCeramicwareSludgePulp and paper industry

The invention belongs to the technical field of construction materials, in particular relates to a production system and a production process for producing bricks by utilizing paper pulp sludge, and aims to solve the technical problems of unreasonable design, complicated production process and the like in the prior art. The system sequentially comprises a brick making material conveying device used for conveying a brick making material, an agitation device used for agitating the brick making material, a molding device used for processing the brick making material into an adobe and a brick kiln used for firing the adobe into a brick finished product, as well as a paper pulp sludge adding mechanism used for adding paper pulp sludge into the brick making material, wherein the blanking end of the paper pulp sludge adding mechanism is positioned above the brick making material conveying device. The production process comprises the following steps: A, preparing raw materials; B, fermenting; C, molding an adobe; and D, firing a brick. The production system and the production process have the advantages of more reasonable design, simpler structure and simple process, and is easy to operate and produce.

Owner:黄 建华

Method for manufacturing sintered bricks by using kitchen waste and sintered brick material composition

InactiveCN103204671ATake advantage ofSimple processCeramic materials productionClaywaresWastewaterOil water

The invention discloses a method for manufacturing sintered bricks by using kitchen waste and a sintered brick material composition. The method for manufacturing sintered bricks by using kitchen waste specifically comprises the following steps of: 1, pouring the kitchen waste in a solid-liquid separator for solid-liquid separation to obtain solid waste and oil water mixture; 2, carrying out oil-water separation on the oil water mixture obtained in step 1 in a separator to separate waste water and waste oil; 3, placing the solid waste obtained in step 1 in a pulping machine, adding the waste water separated in step 2 for pulping, adding clay, coal gangue and shale in the waste starch, and stirring uniformly to obtain the sintered brick material composition; and 4, feeding the sintered brick material composition obtained in step 3 in a brick machine and extruding into green bricks, and drying or stoving the green bricks, then feeding into a brick kiln and sintering into the finished product of bricks. The kitchen waste is fully utilized, and energy conservation and environmental protection are achieved.

Owner:任荣

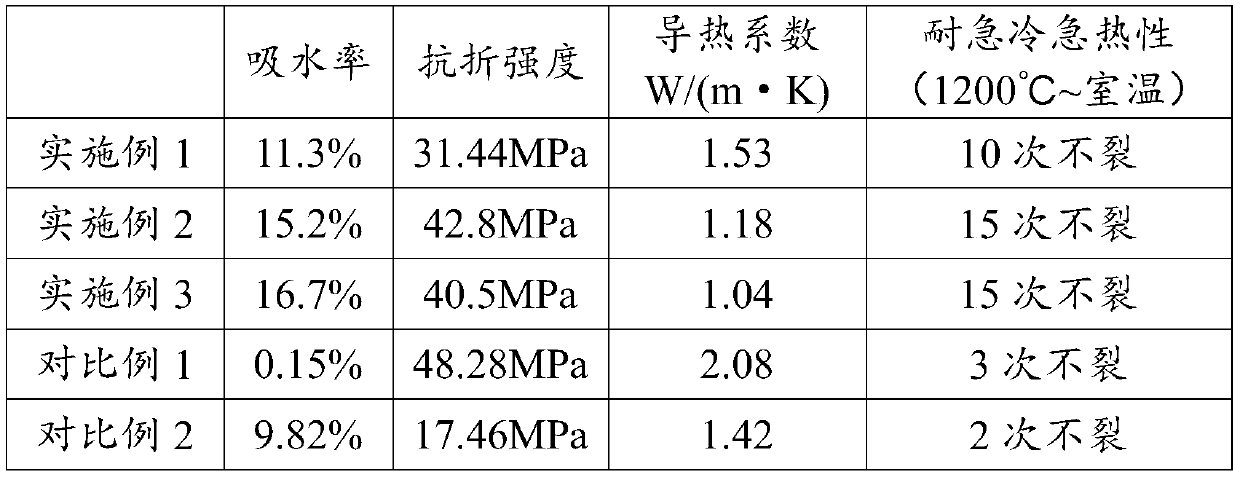

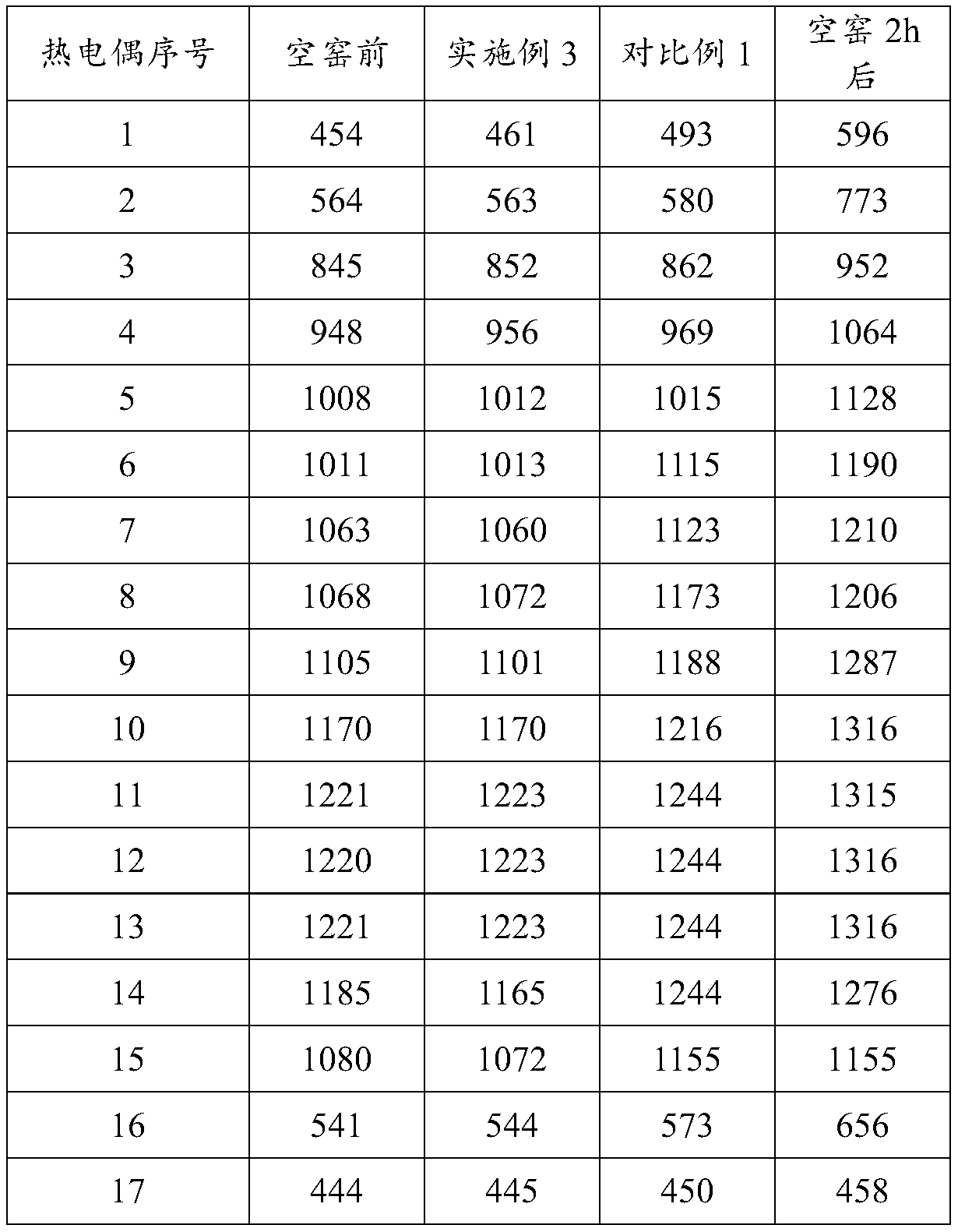

Brick with temperature for porcelain brick kiln, and preparation method and application thereof

ActiveCN111138165AStable temperature profileImprove thermal shock resistanceCeramic materials productionClaywaresAdhesiveMullite

The invention discloses a brick with a temperature for a porcelain brick kiln. The brick is prepared from roller waste, magnesia, bentonite, polished tile waste residues, fly ash, potassium-sodium sand and an adhesive. Correspondingly, the invention also discloses a preparation method for the brick with the temperature and an application of the brick with the temperature in the porcelain tile firing process. The brick with the temperature provided by the invention has the following advantages: acicular mullite and cordierite are generated through reasonable formula structure and high-temperature firing, so the breaking strength and thermal shock resistance of the brick with temperature are improved, and the service life of the brick with temperature is prolonged. Meanwhile, the brick withthe temperature is high in porosity, low in heat conductivity coefficient and high in heat capacity, heat of the kiln can be fully taken away, and the temperature curve of the kiln is kept stable.

Owner:肇庆乐华陶瓷洁具有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com