Sludge drying system

A sludge drying and sludge technology, which is applied in dehydration/drying/concentration sludge treatment, energy wastewater treatment, etc., can solve the problems of high moisture content in sludge, high energy consumption, and a large amount of toxic gas, etc., to increase its own Heat, low moisture content of sludge, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

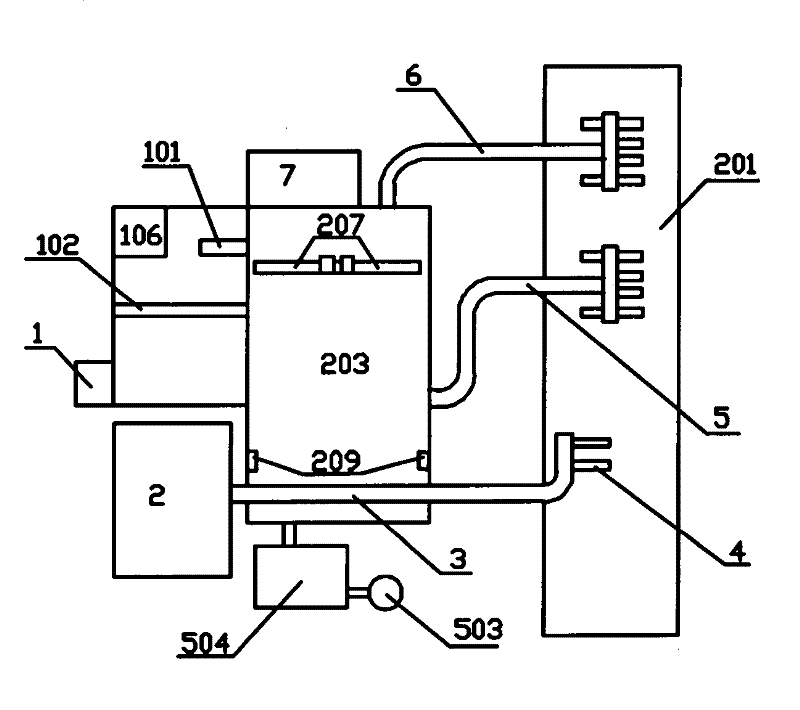

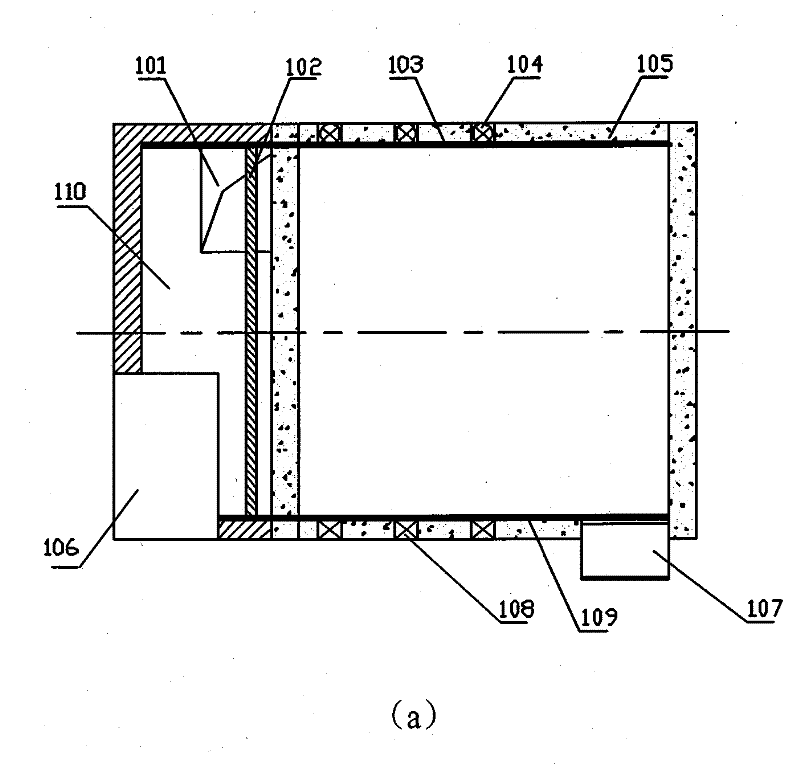

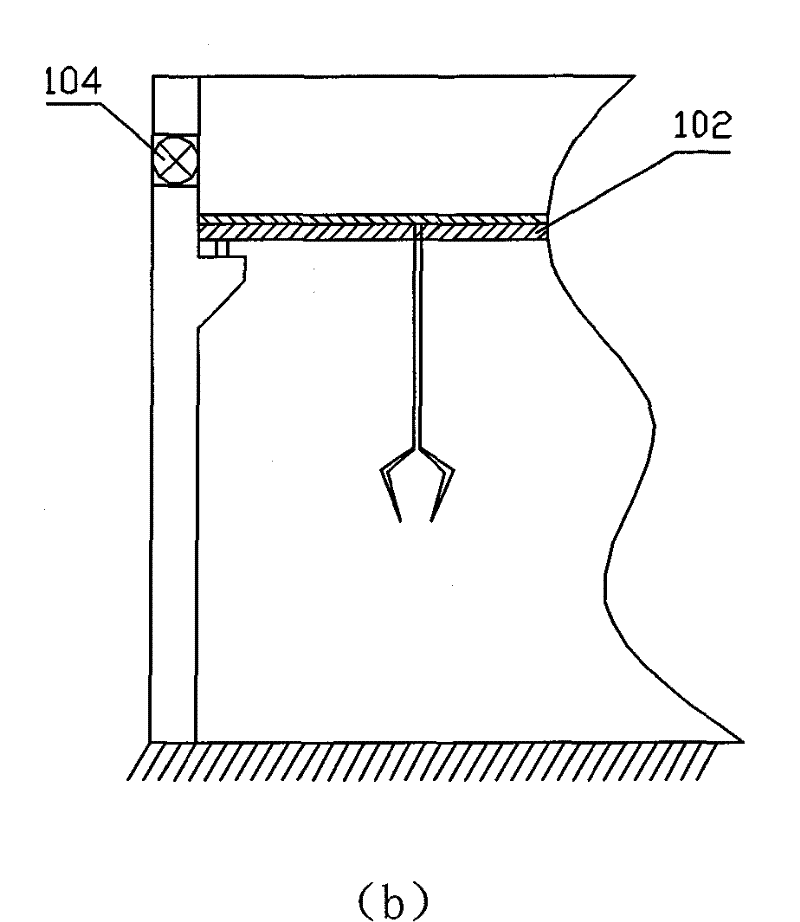

[0023] Such as figure 1 As shown, the sludge drying system of the present invention includes a sealed sludge storage bin and drying equipment, and the sludge in the sealed sludge storage bin is fed into the drying equipment for drying the sludge through a feeding method, wherein the sealed The sludge storage bin includes a sludge feeding device 101, a grab bucket crane 102, a first grab bucket crane rail 103, a second grab bucket crane rail 109, a sludge pool stem 105, a feed port 107, and a control room 106 , the first grabbing bucket hanging track 103 and the second grabbing bucket hanging track 109 are arranged in parallel on two opposite side walls of the sludge tank stalk 105, and the heights of the positions are the same, such as the first grabbing bucket hanging track 103 The height of the second grab bucket hanging rail 109 from the bottom wall of the sludge tank stem 105 is 60% to 80% of the height of the side wall, that is, two opposite sludge tank stems 105 side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com