Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1154results about "Linings repair" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

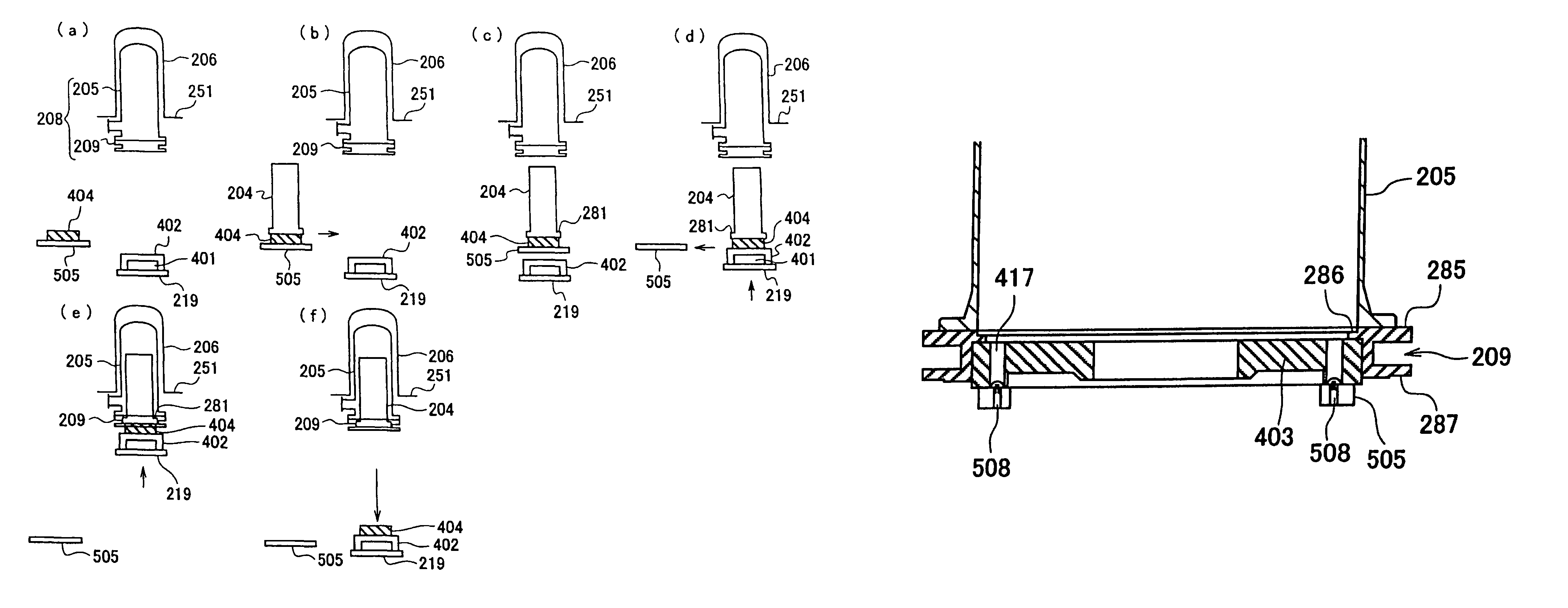

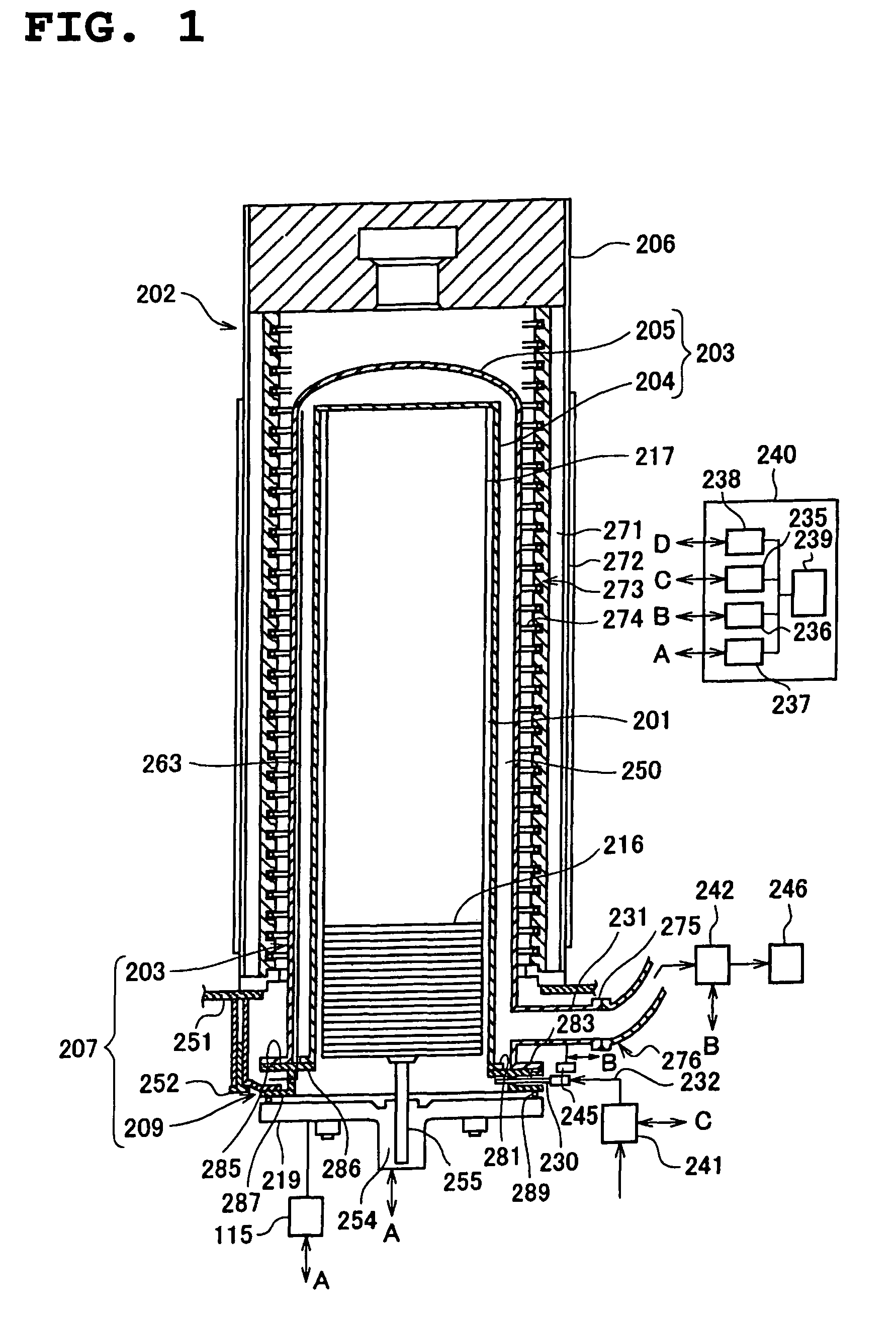

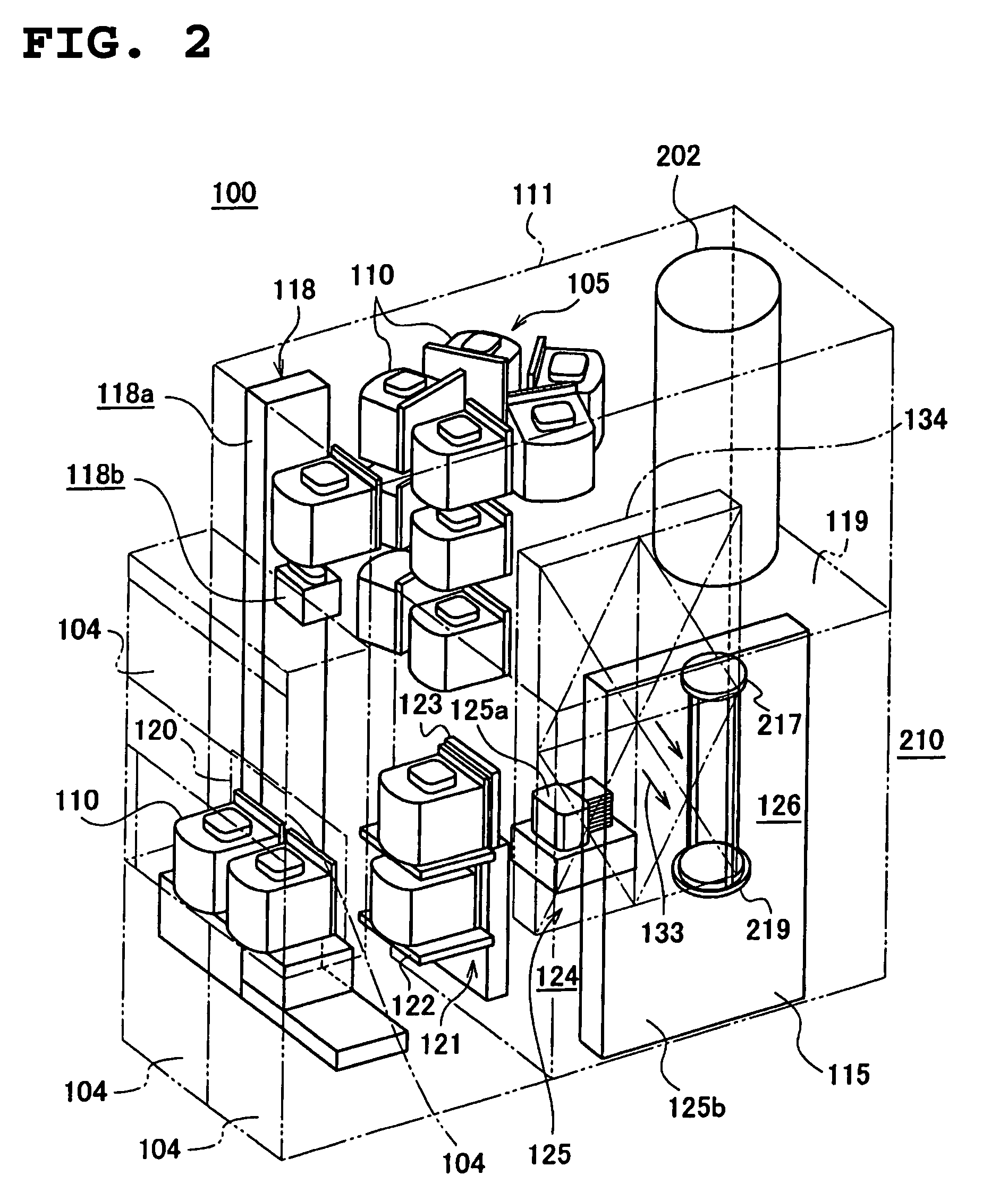

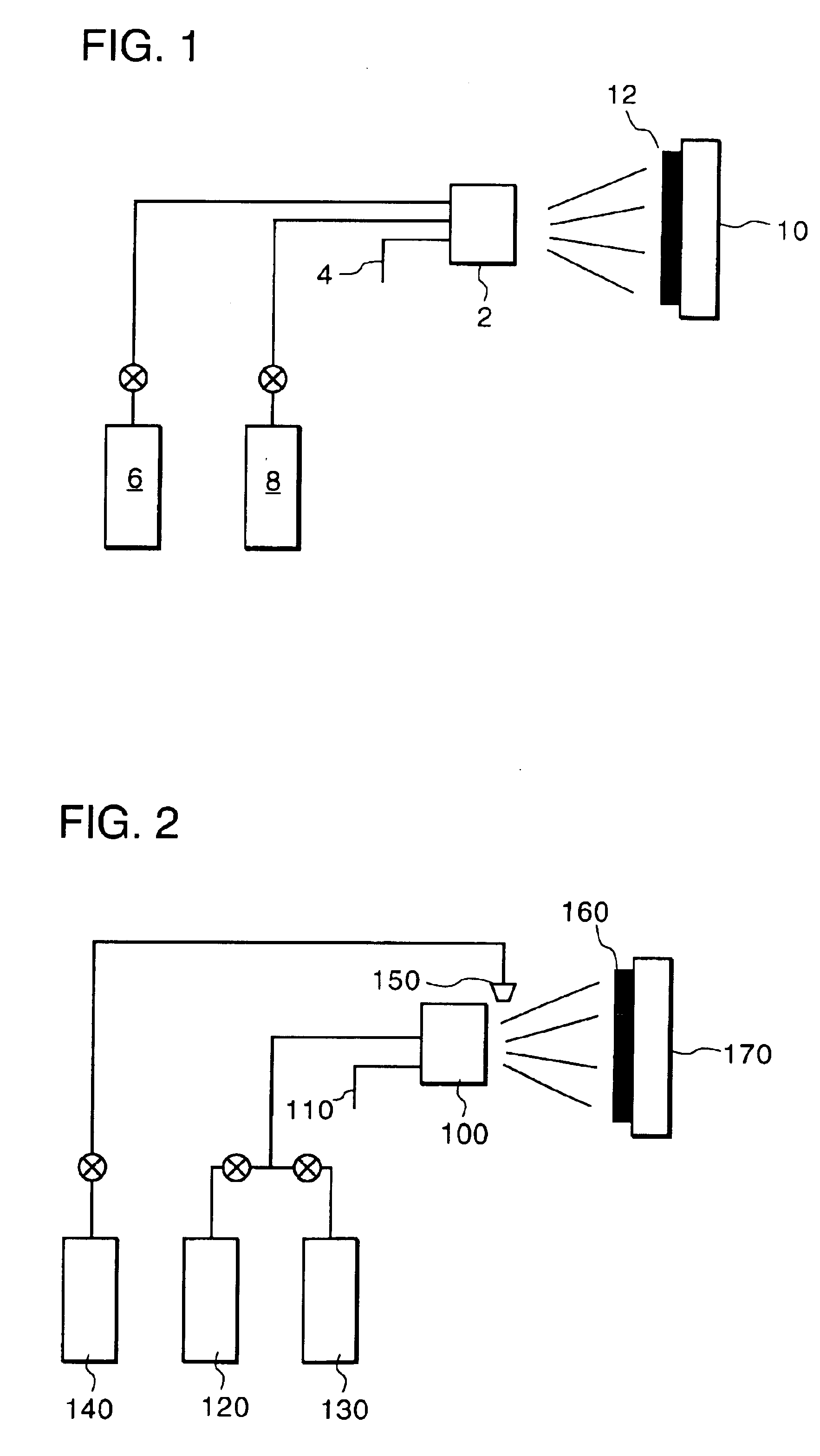

Substrate processing apparatus and attaching/detaching method of reaction vessel

ActiveUS8172947B2Linings repairSemiconductor/solid-state device manufacturingEngineeringMental detachment

Owner:KOKUSA ELECTRIC CO LTD

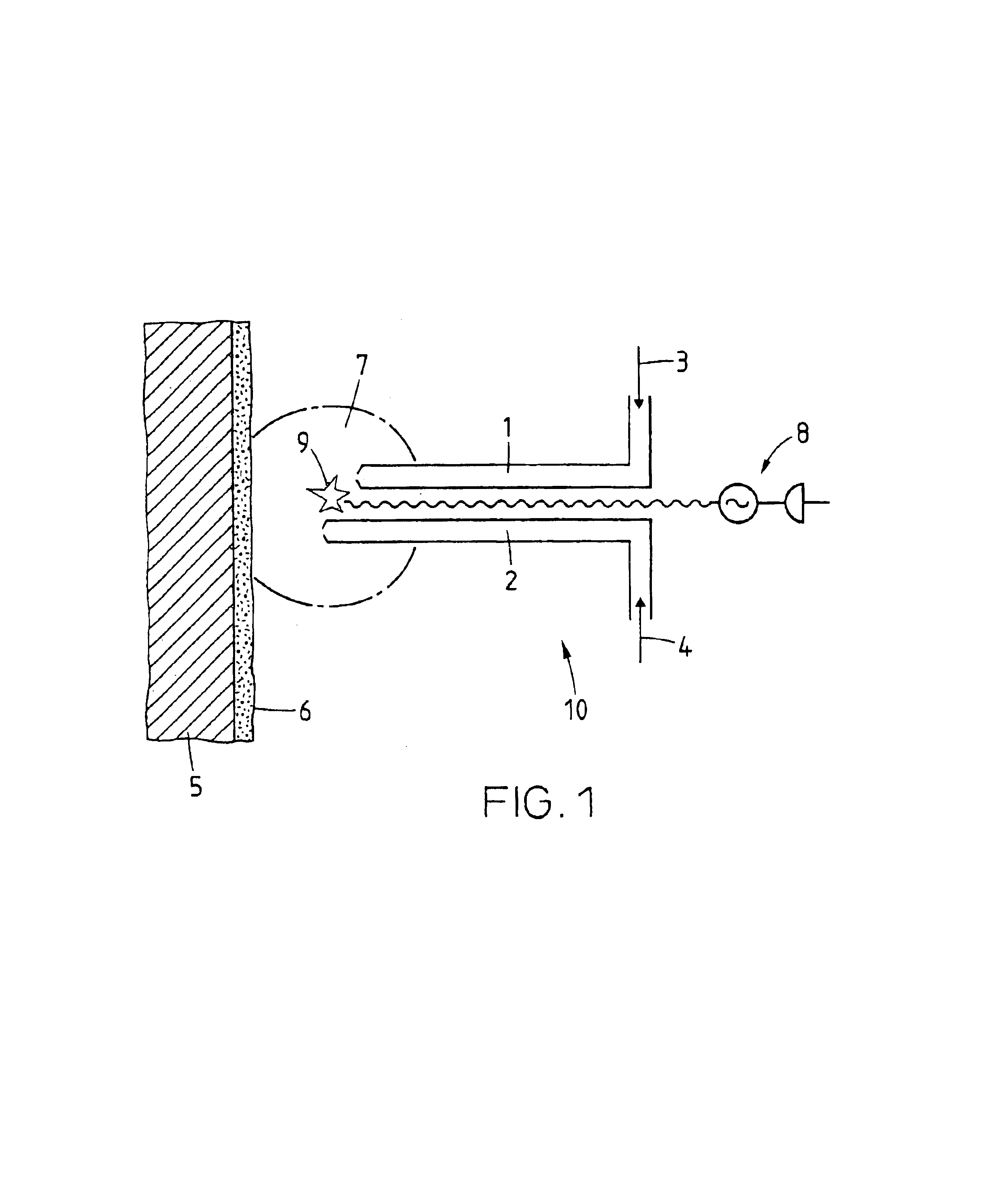

Method and apparatus for fabrication and sintering composite inserts

InactiveUS6011248AInhibit migrationNot adversely propertyMechanical apparatusLinings repairWear resistantWear resistance

The present disclosure is directed to the fabrication of a highly wear layer either directly upon an article or tool support structure or body, or as a wear resistant insert or element which is subsequently attached to the tool body. The wear material is formed by sintering particulate material using the absorption of microwave energy as a means of heating. The disclosure also encompasses post manufacture annealing, using heating by microwave radiation, of both highly wear resistant inserts and composite articles which consist of a wear resistant layer and a body. The wear resistant material, whether fabricated directly upon an article or fabricated separately and subsequently affixed to an article, provides an abrasive wear surface and greatly increases the life of the article. Microwave sintered wear resistant surfaces for mills, drills, grinders, brakes, bearings, saw blades and other articles and assemblies are disclosed.

Owner:PENN STATE RES FOUND +1

Coke oven reconstruction

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

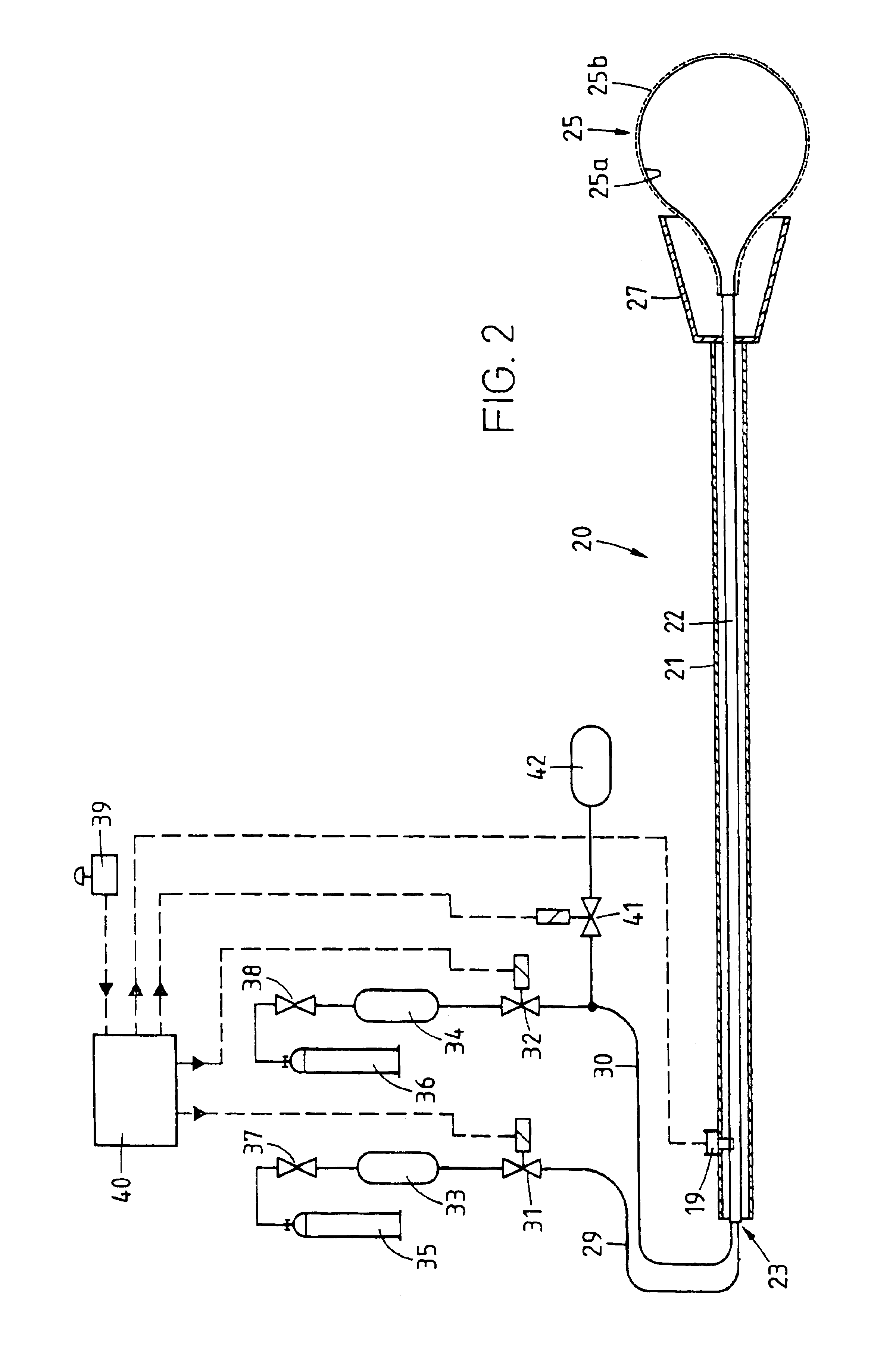

Resistive heaters and uses thereof

InactiveUS6919543B2Thermally matched wellAvoid bendingMolten spray coatingLinings repairBorideCarbide

A metallic resistive heater and a method of production are described. The resistive heater has a metallic component that is electrically conductive (i.e. has low resistivity) and an oxide, nitride, carbide, and or boride derivative of the metallic component that is electrically insulating (i.e., has high resistivity). The resistivity is controlled by controlling the amount of oxide, nitride, carbide, and boride formation during the deposition of the metallic component and the derivative.

Owner:REGAL WARE

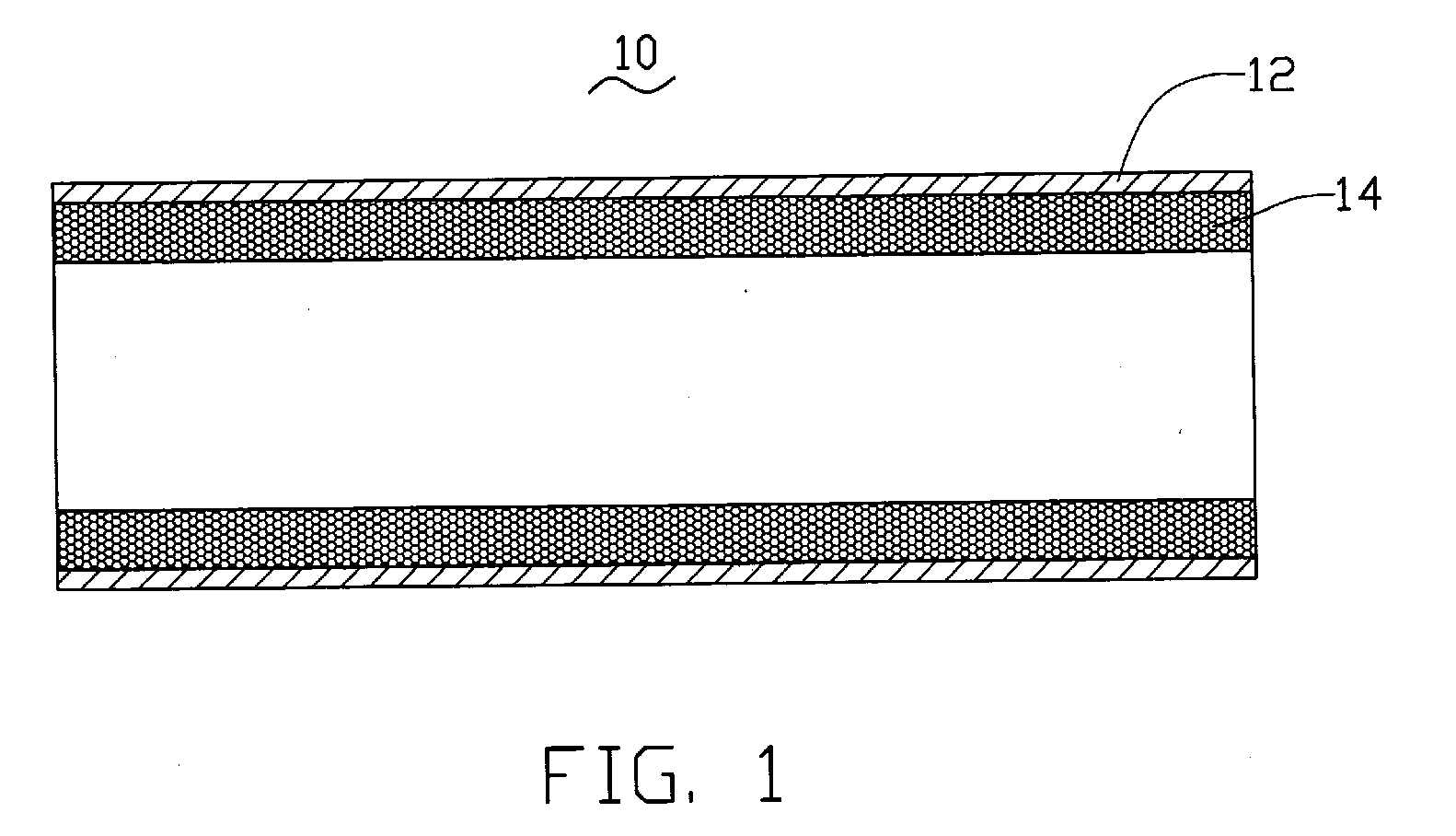

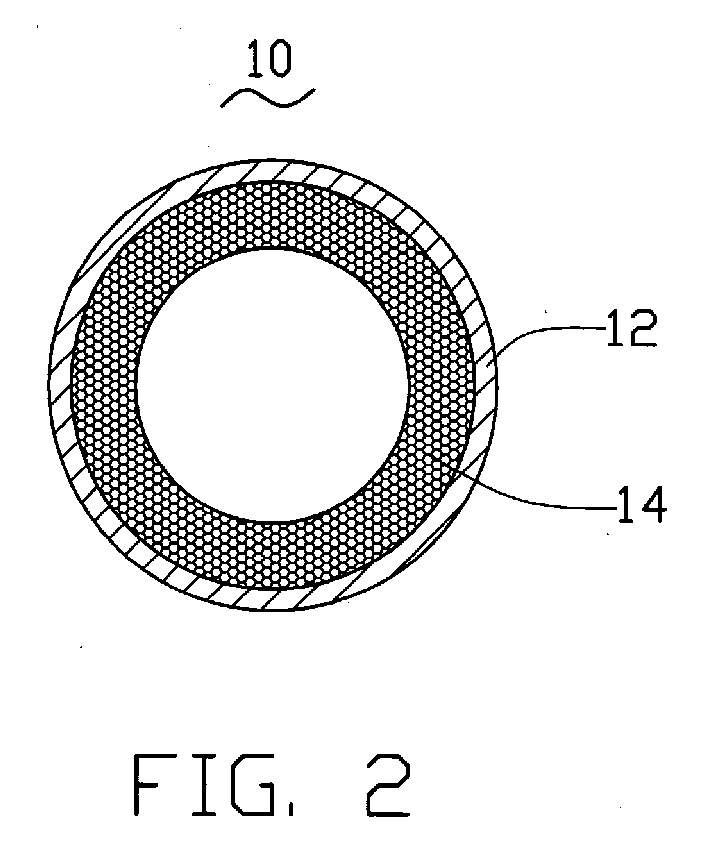

Method of manufacturing heat pipe having sintered powder wick

InactiveUS20060197245A1Improve heat transfer performanceImprove the preparation effectLinings repairLaminationGreen tapeMetallurgy

A method is disclosed to produce a heat pipe with a sintered powder wick formed inside the heat pipe. The method employs tape-casting technology to firstly produce thin sheets of powder and then these sheets are sintered to form the wick. In the tape casting procedure, a slurry of the powders necessary to construct said wick is cast onto a moving surface to form a slurry layer and then the slurry layer is dried to form a green tape. The green tape is rolled onto a mandrel and then is inserted into a hollow casing and sintered to cause the powders in the green tape to diffusion-bond together. Thus, the sintered powder wick is constructed.

Owner:HON HAI PRECISION IND CO LTD

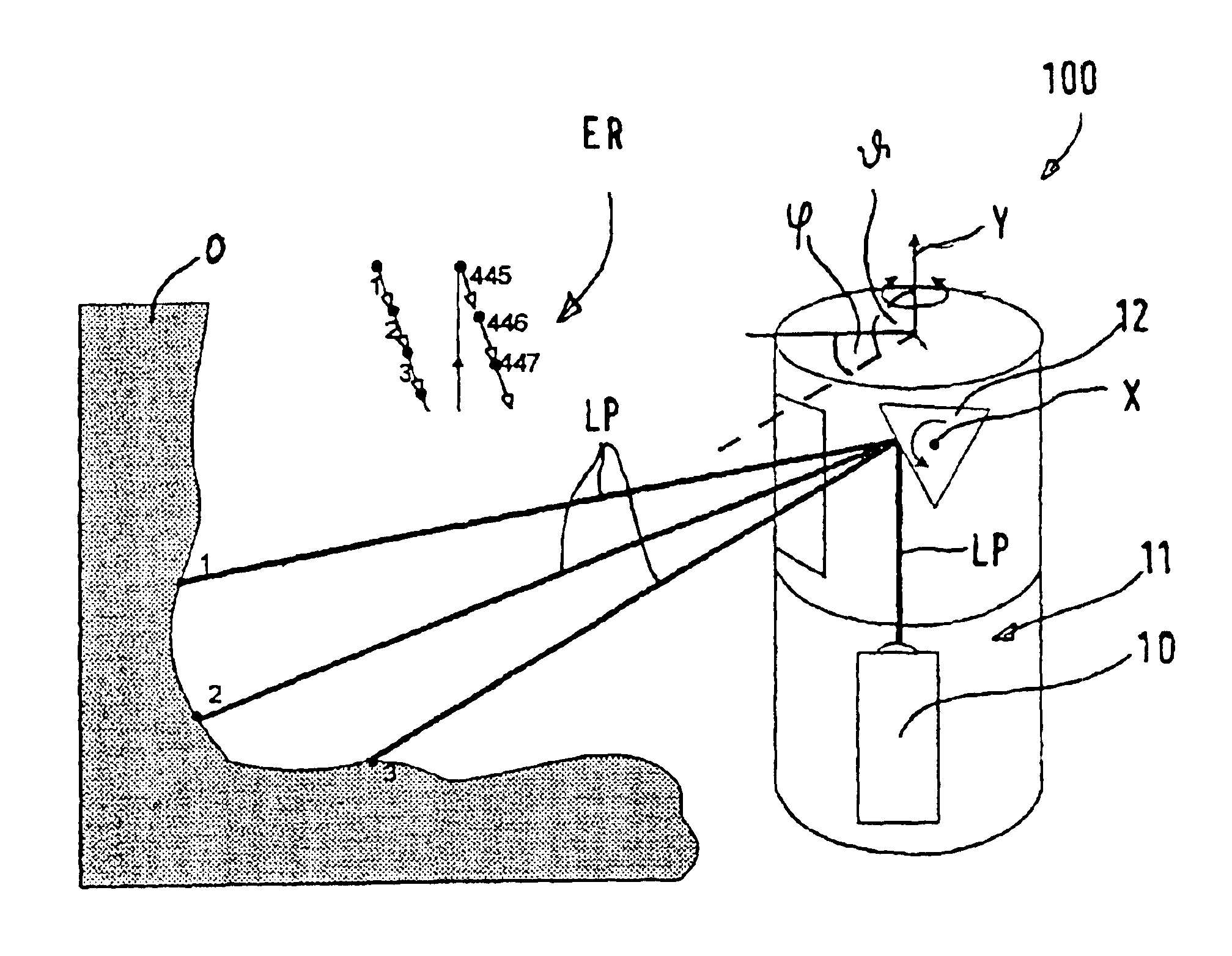

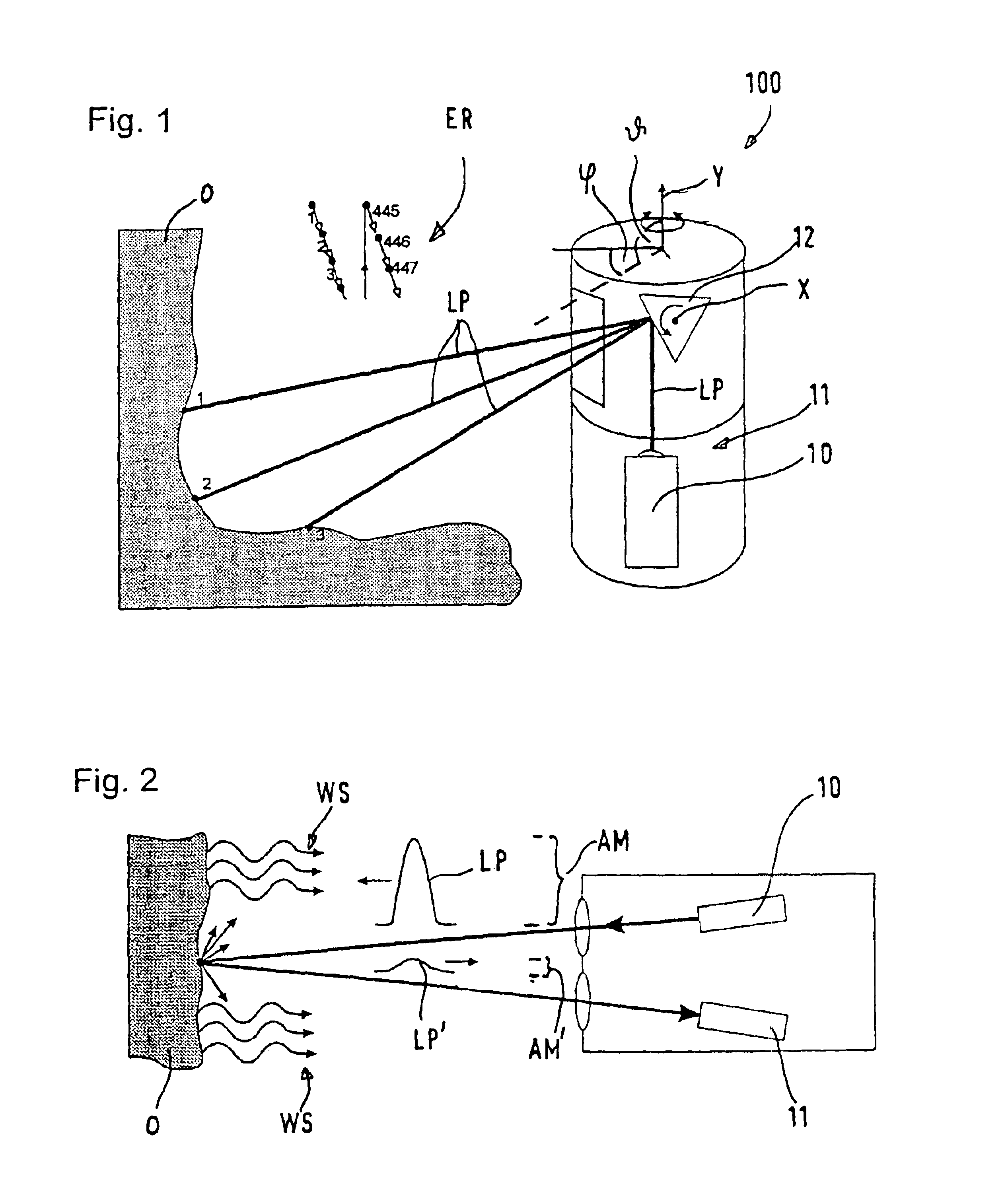

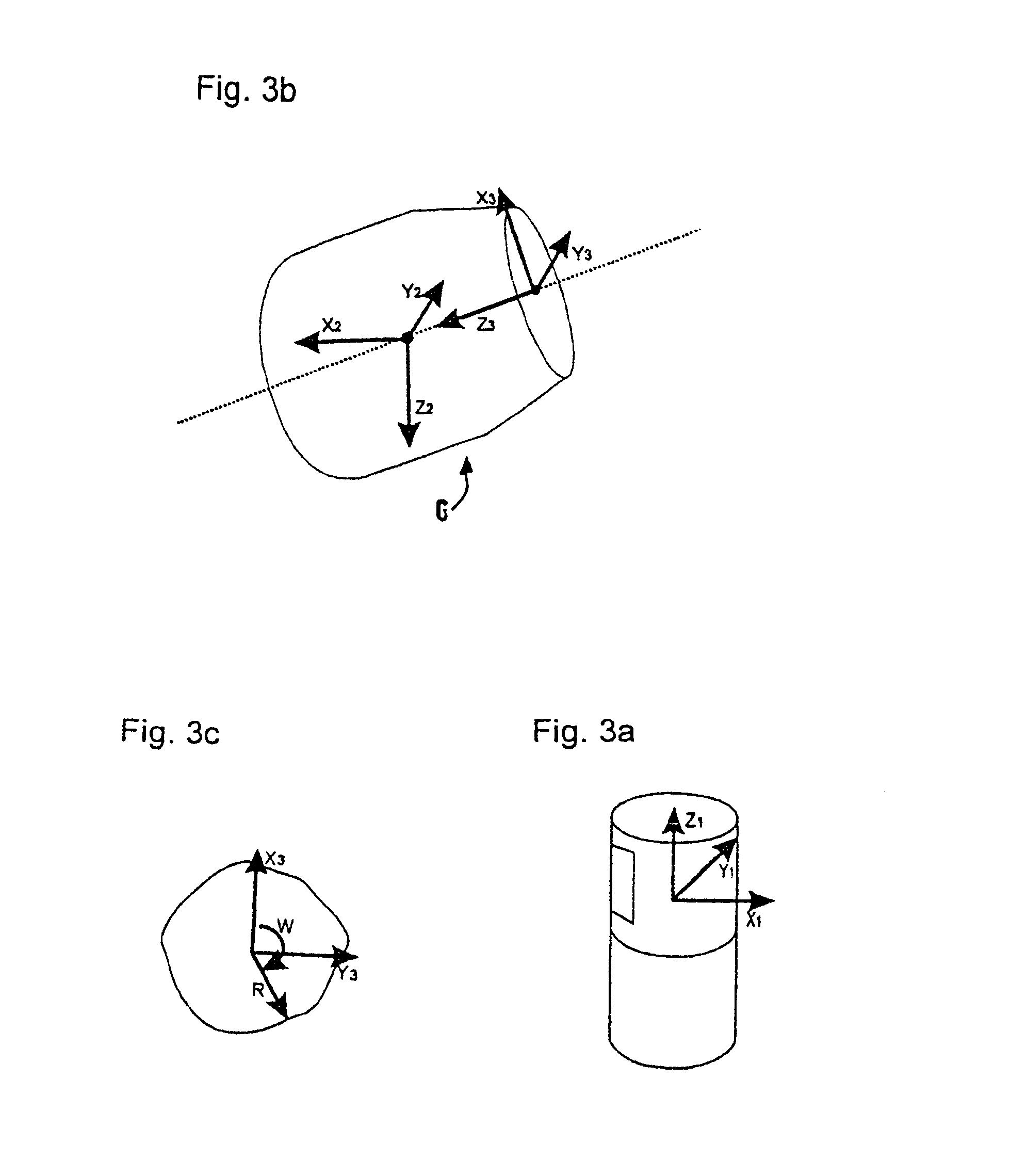

Measurement of the wear of the fireproof lining of a metallurgical vessel

According to the invention, a method for identifying and determining die position of a metallurgical vessel for measuring its fireproof lining using electromagnetic radiation, an operator is defined in relation to a two or three dimensional structure with a known shape and size. Distance values and corresponding measuring angles are determined in the area of the structure and measured distance value and corresponding measuring angles are used to scale the operator. The dimension and resolution of the operator in the pixel coordinates system and the anticipated values of the operator are adapted to the measured polar coordinates. A result value is then formed from the differences between the anticipated values of the operator and the measured values and the location of the structure that is sought is determined from the position of the minimum result value.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

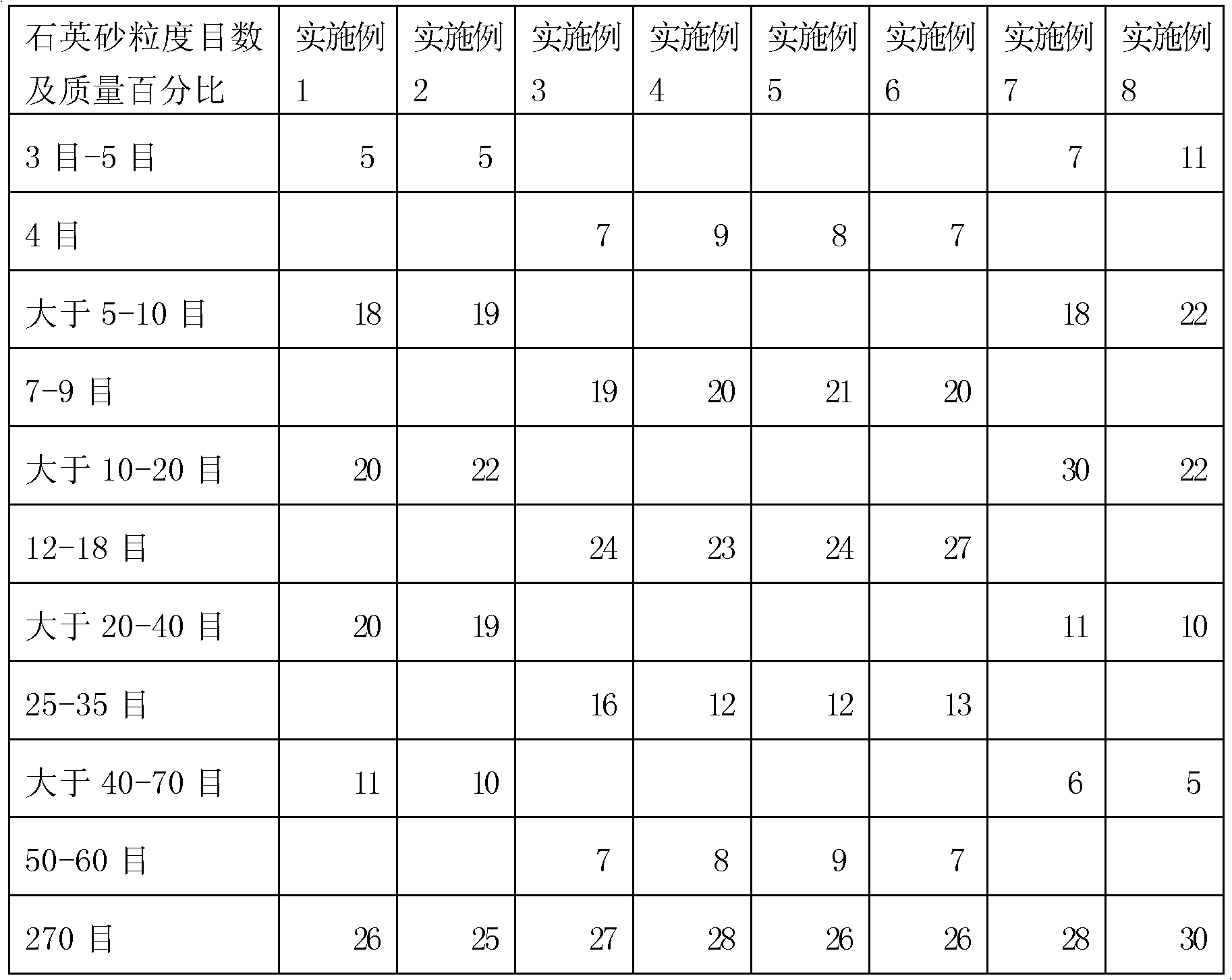

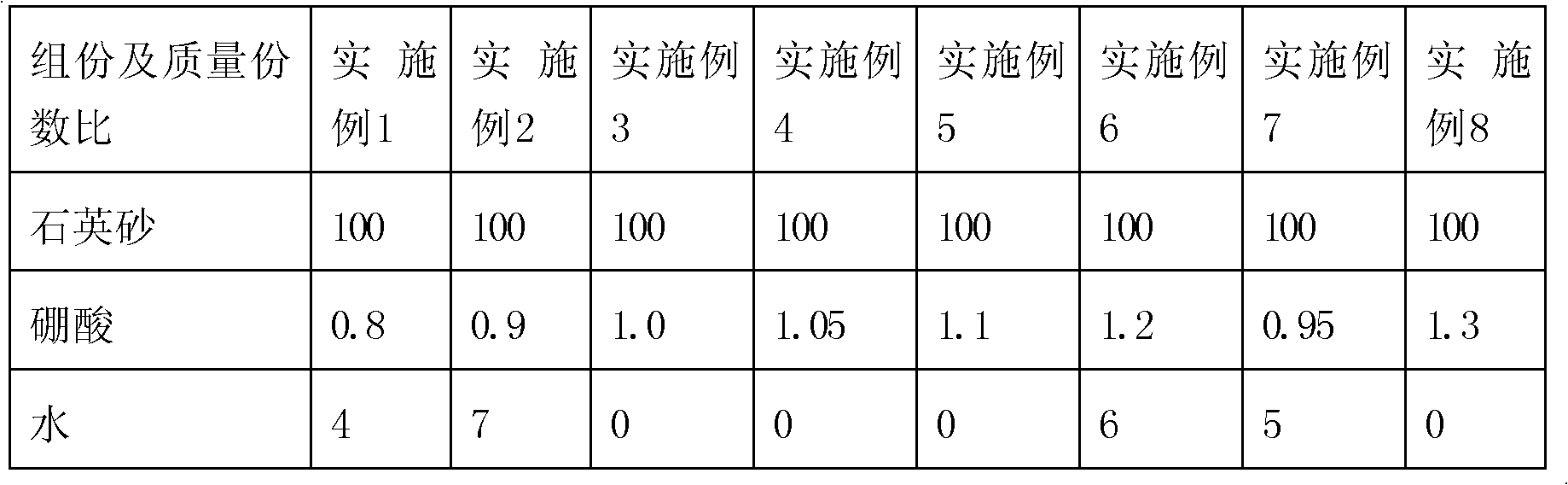

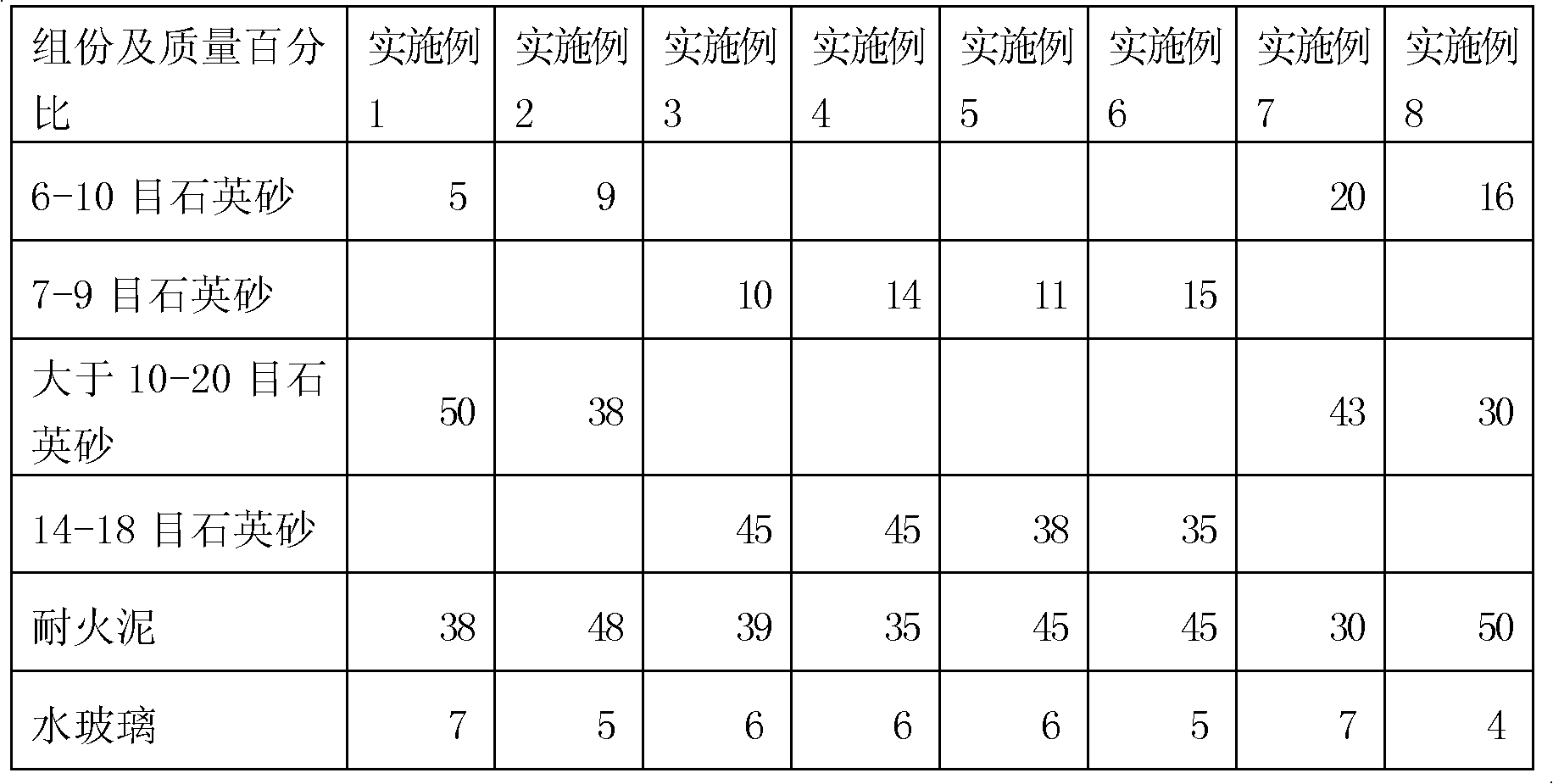

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

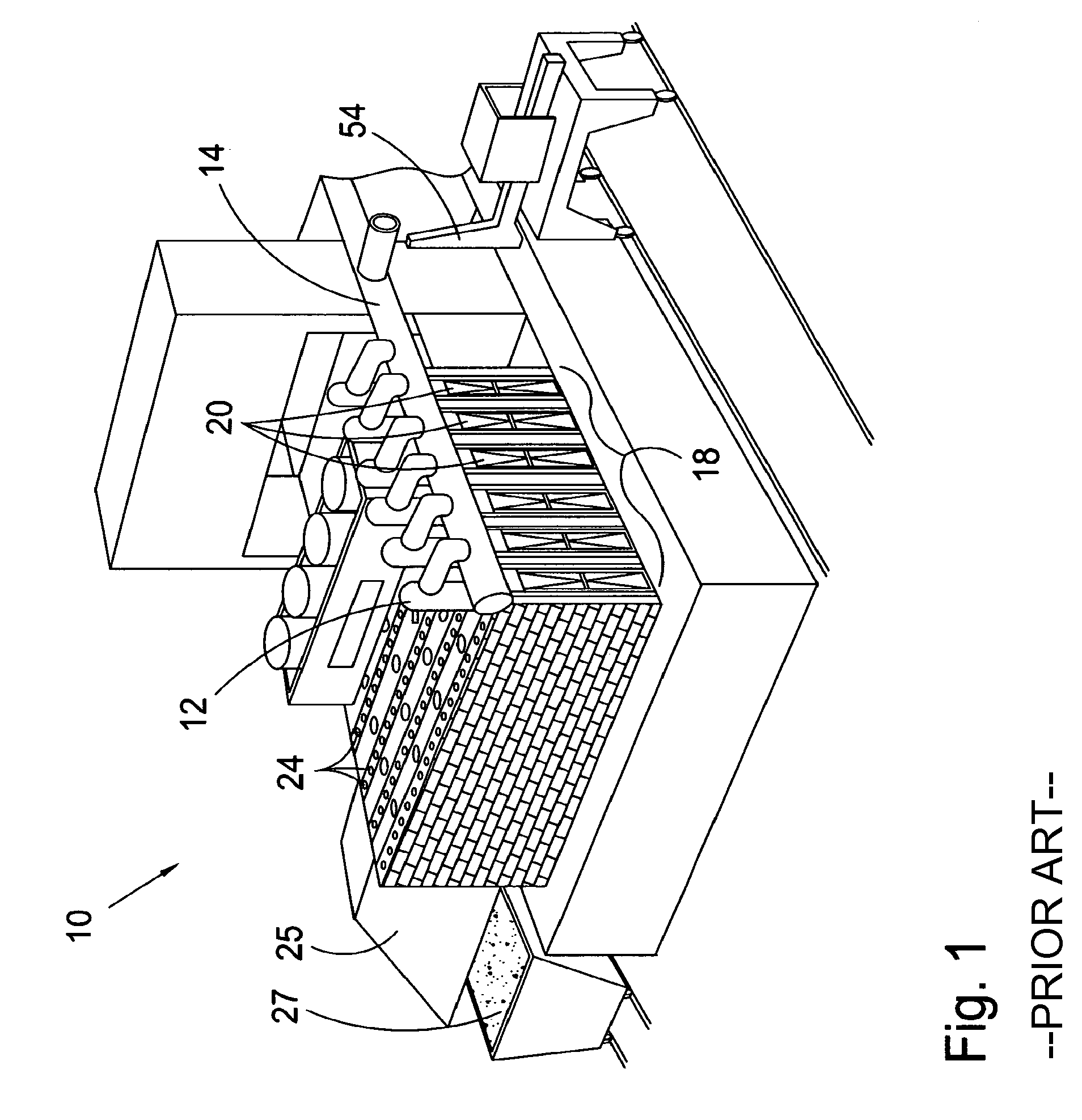

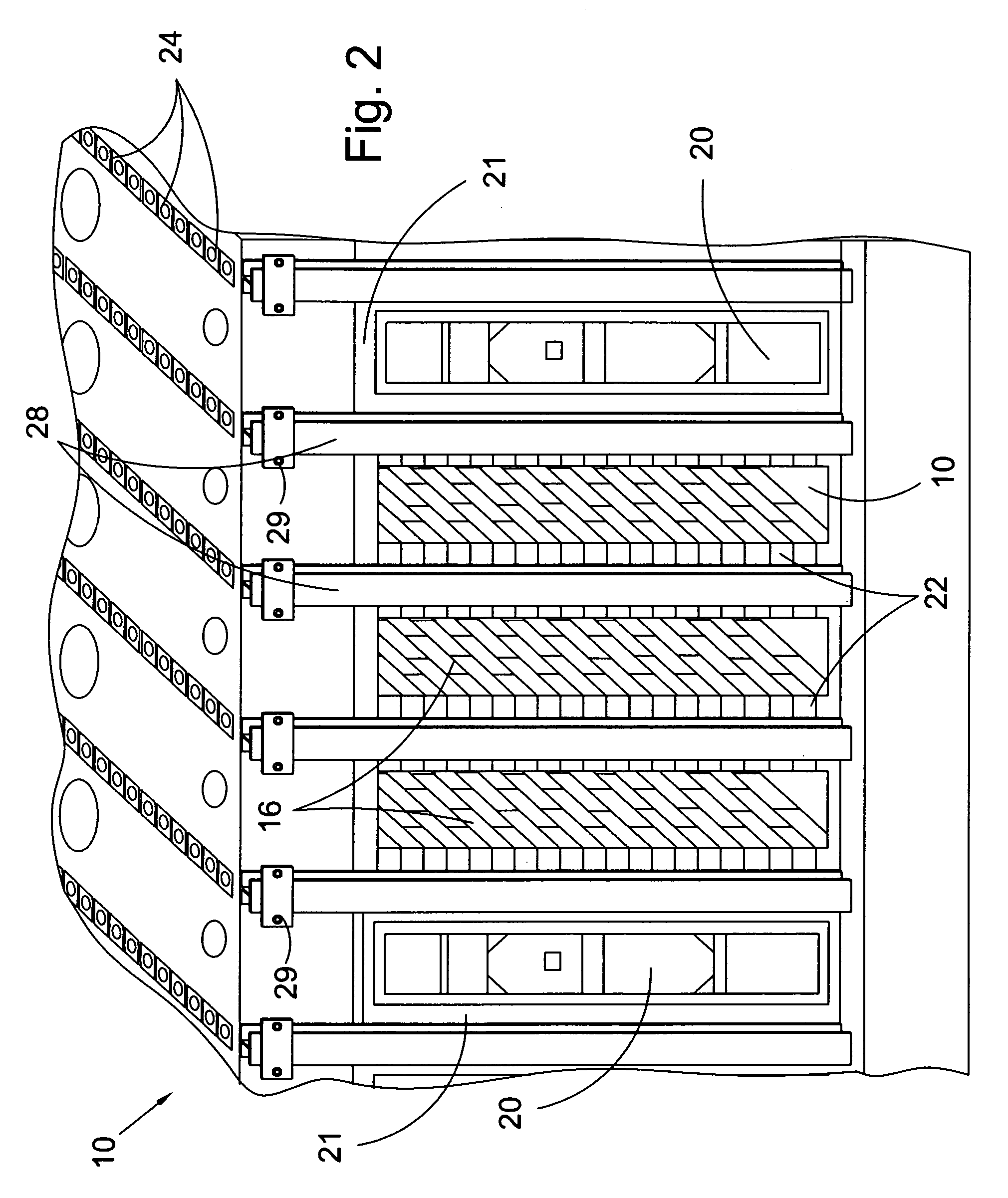

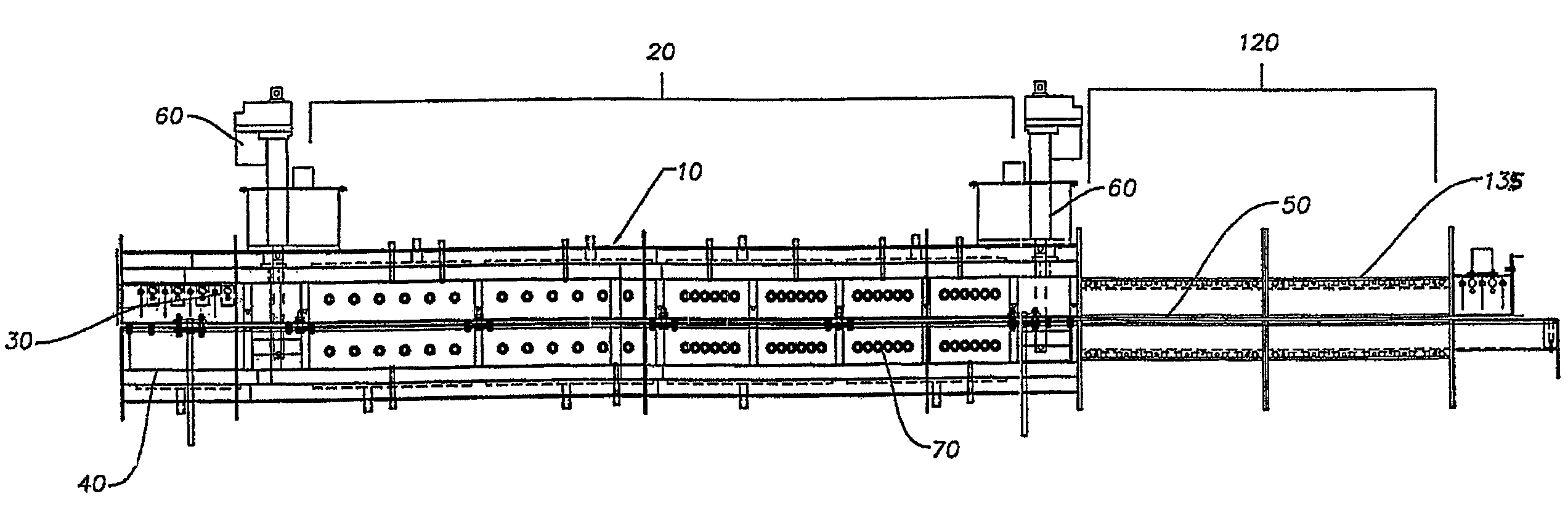

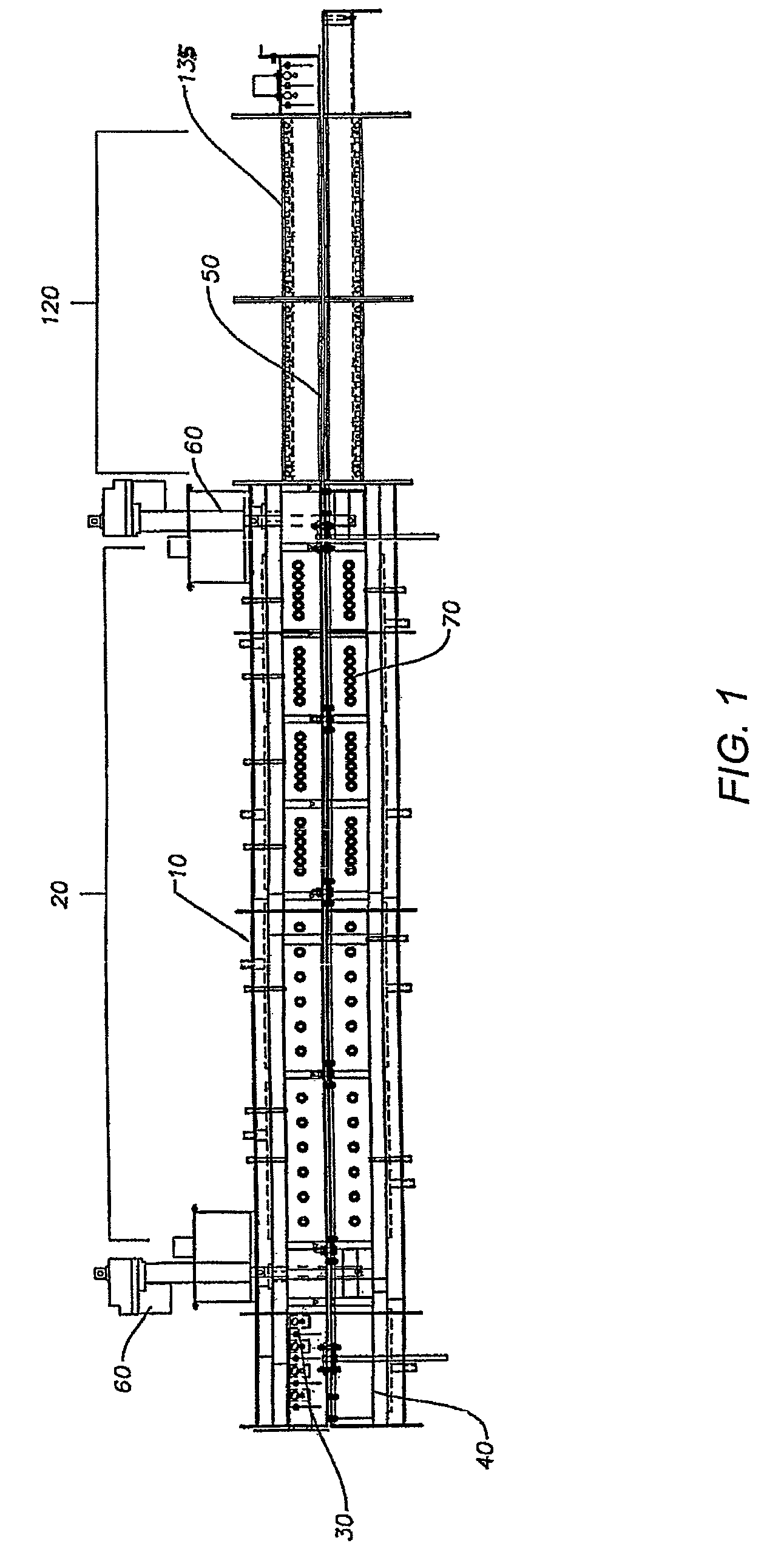

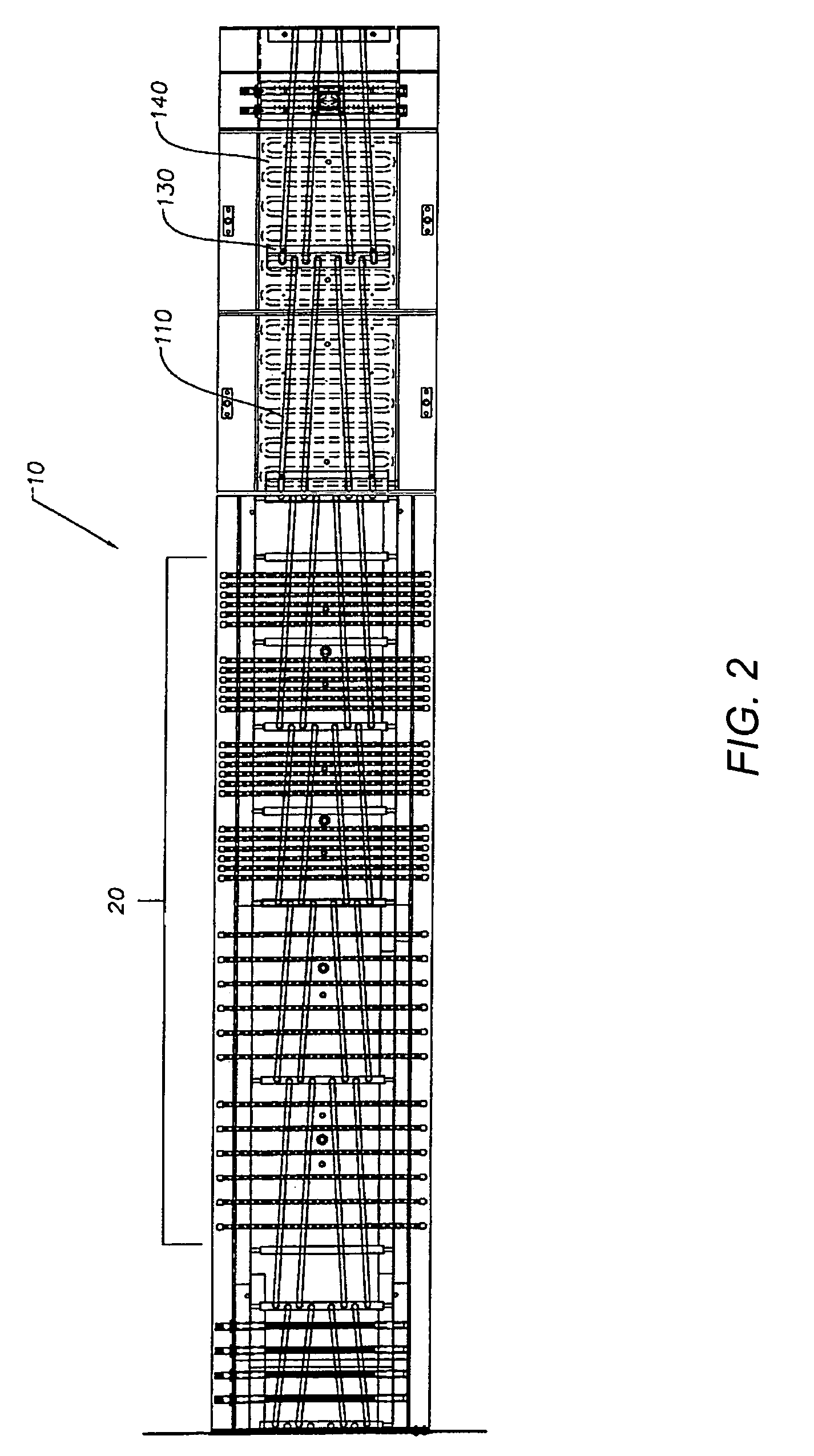

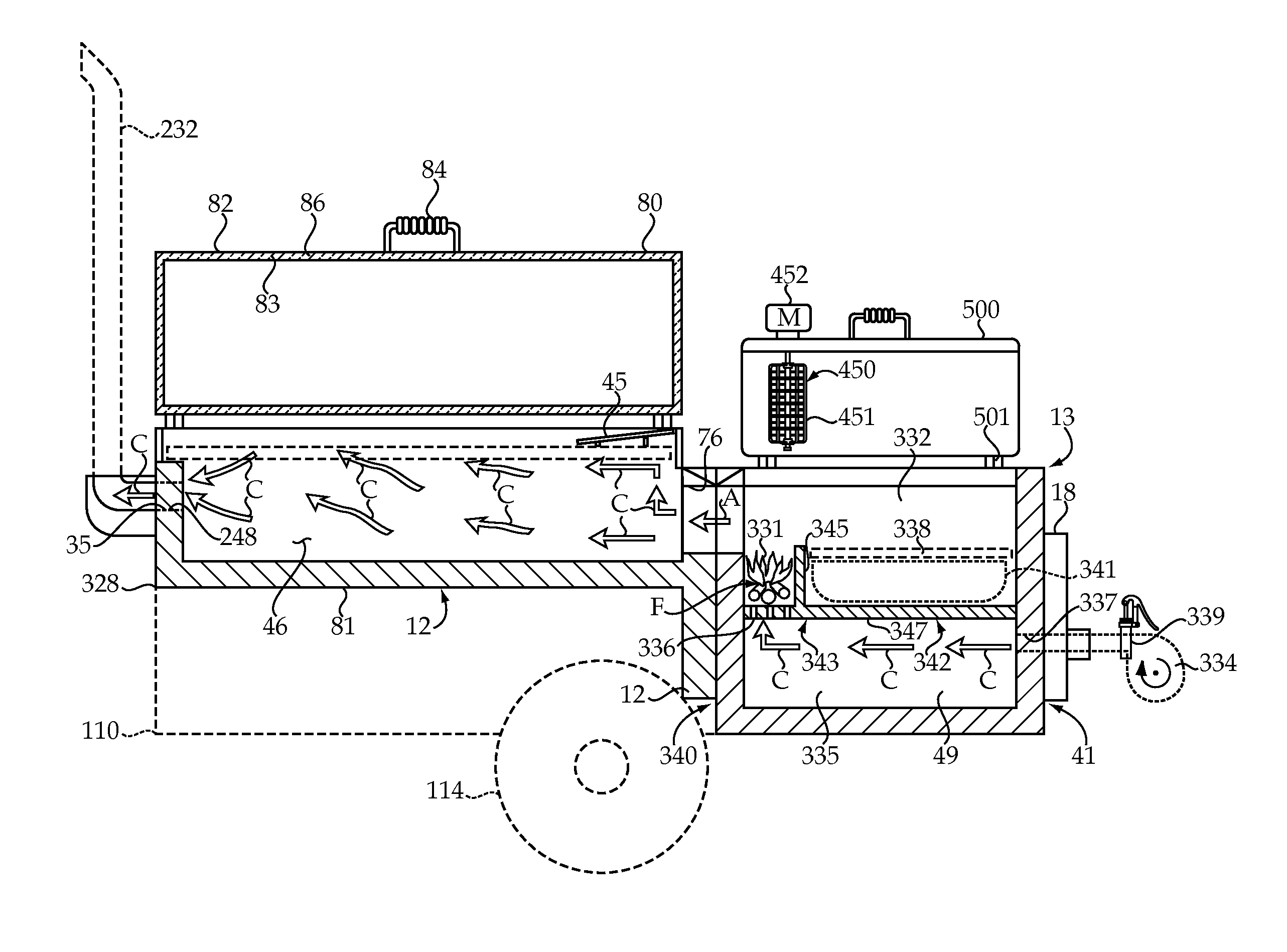

Continuous infrared furnace

A furnace of controlled heating and treatment of material using infrared radiation. The furnace is capable of continuous infrared treating of material with consistent radiation being applied to the material, ease of access to the furnace for maintenance cleaning and repair, excellent control of radiant cooling of the material to be treated, and ease of maintenance of a volatile component condenser.

Owner:ILLINOIS TOOL WORKS INC

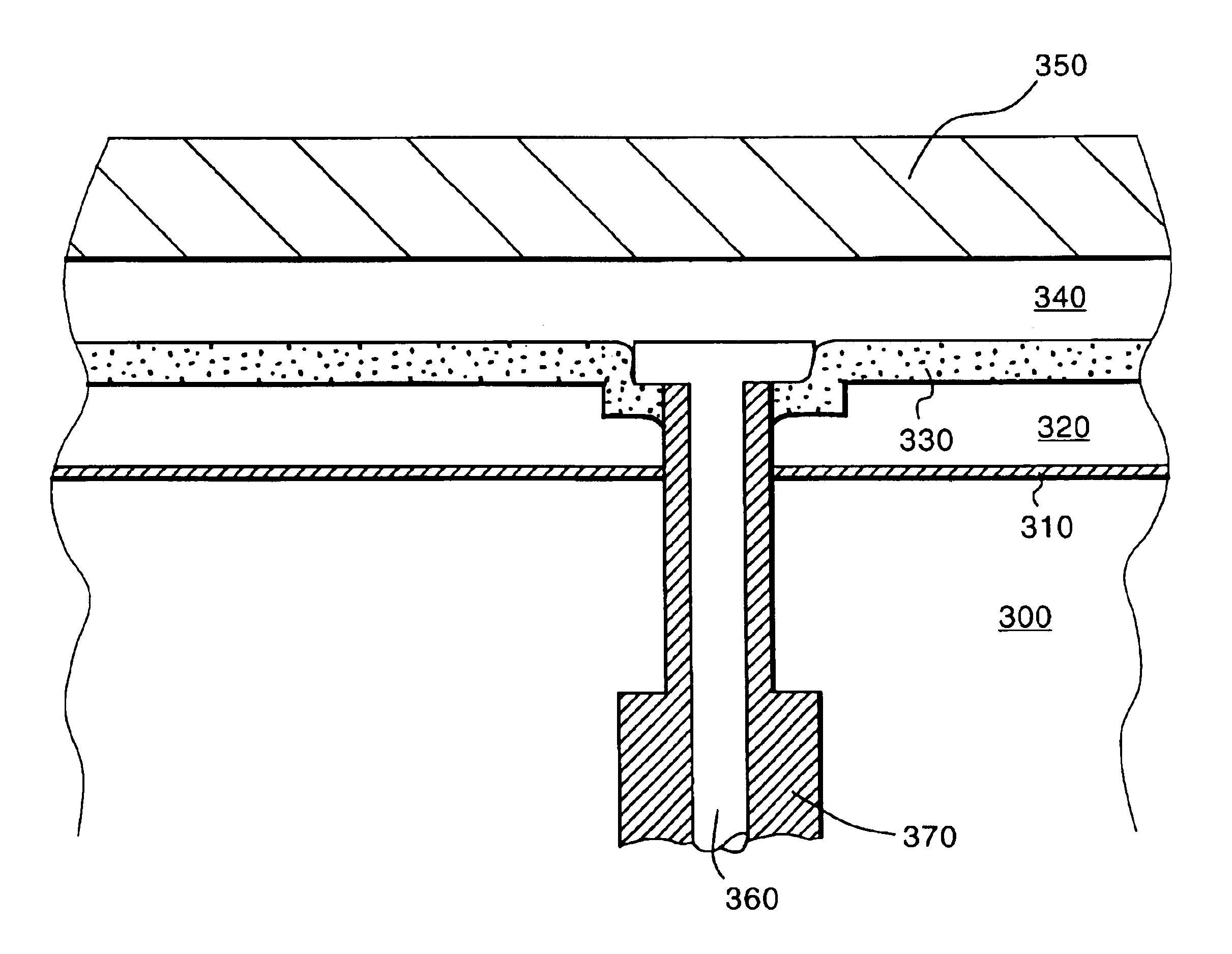

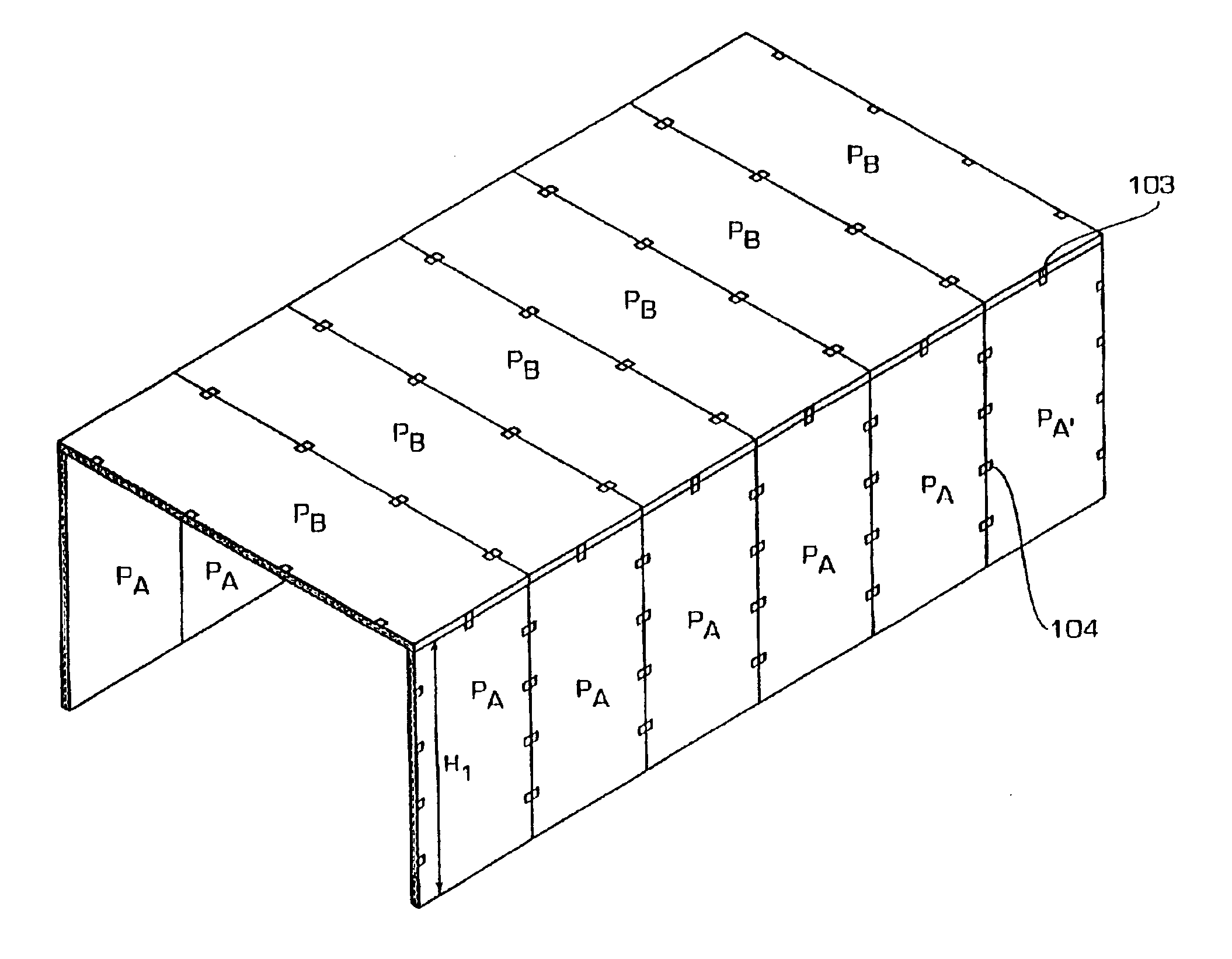

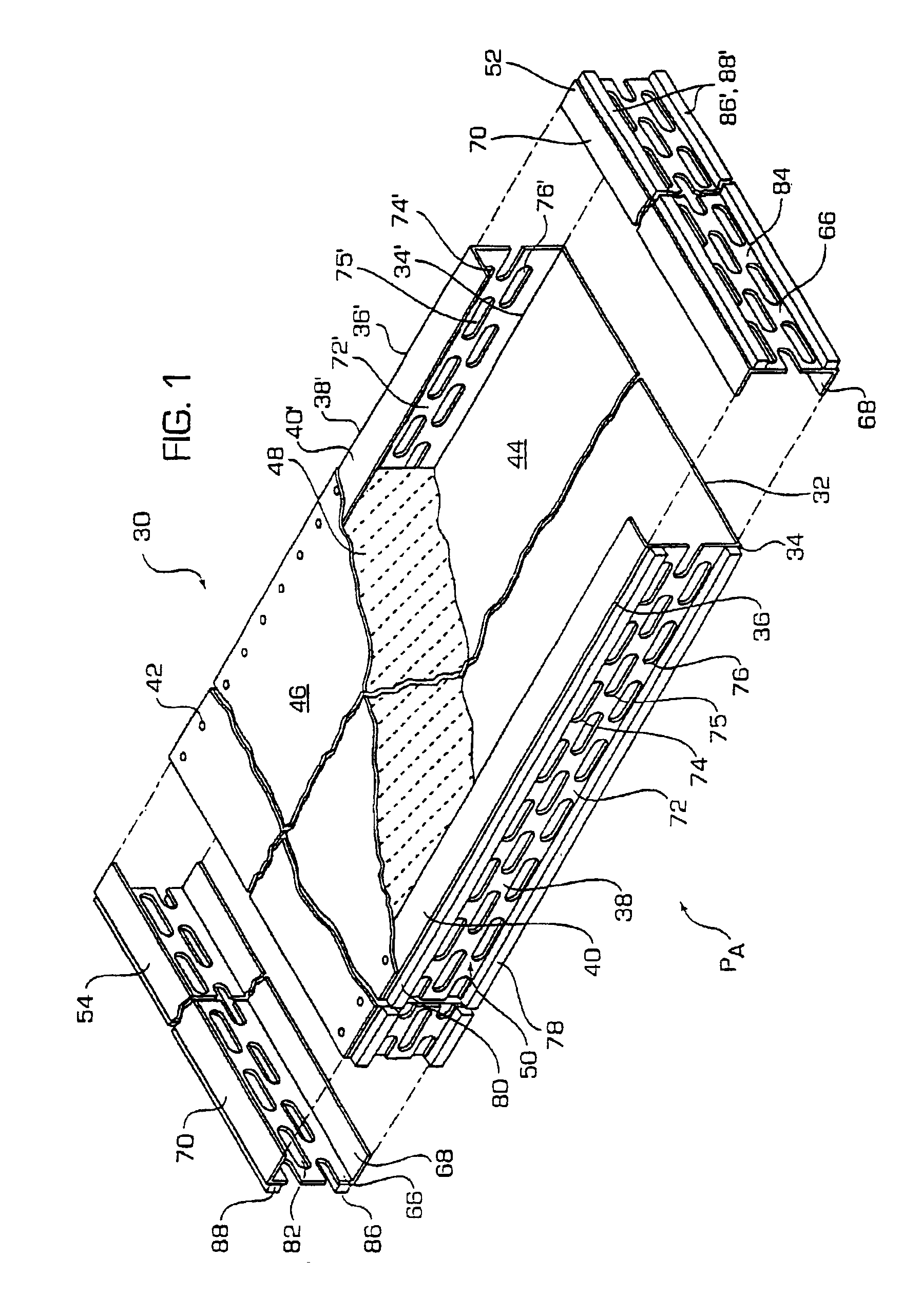

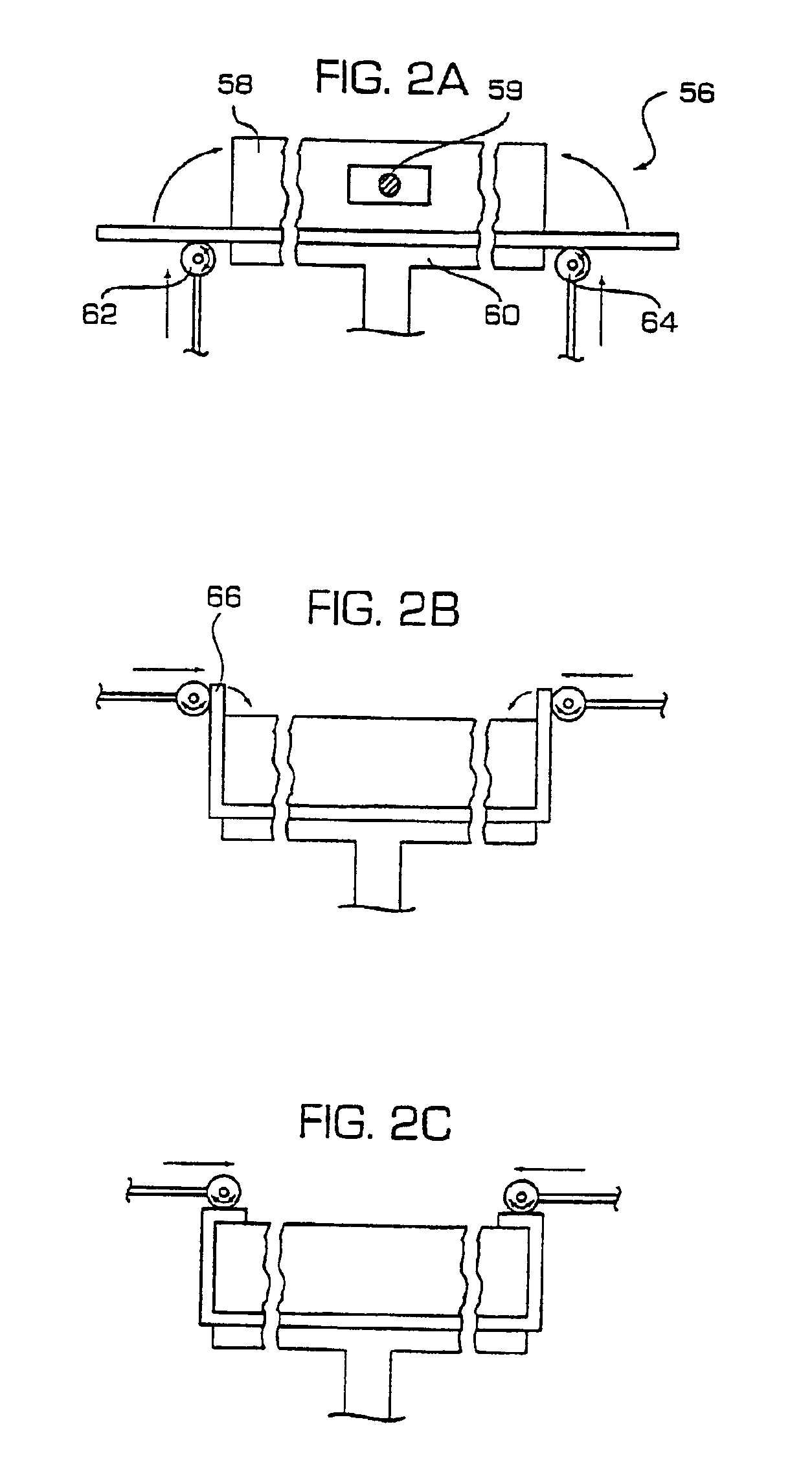

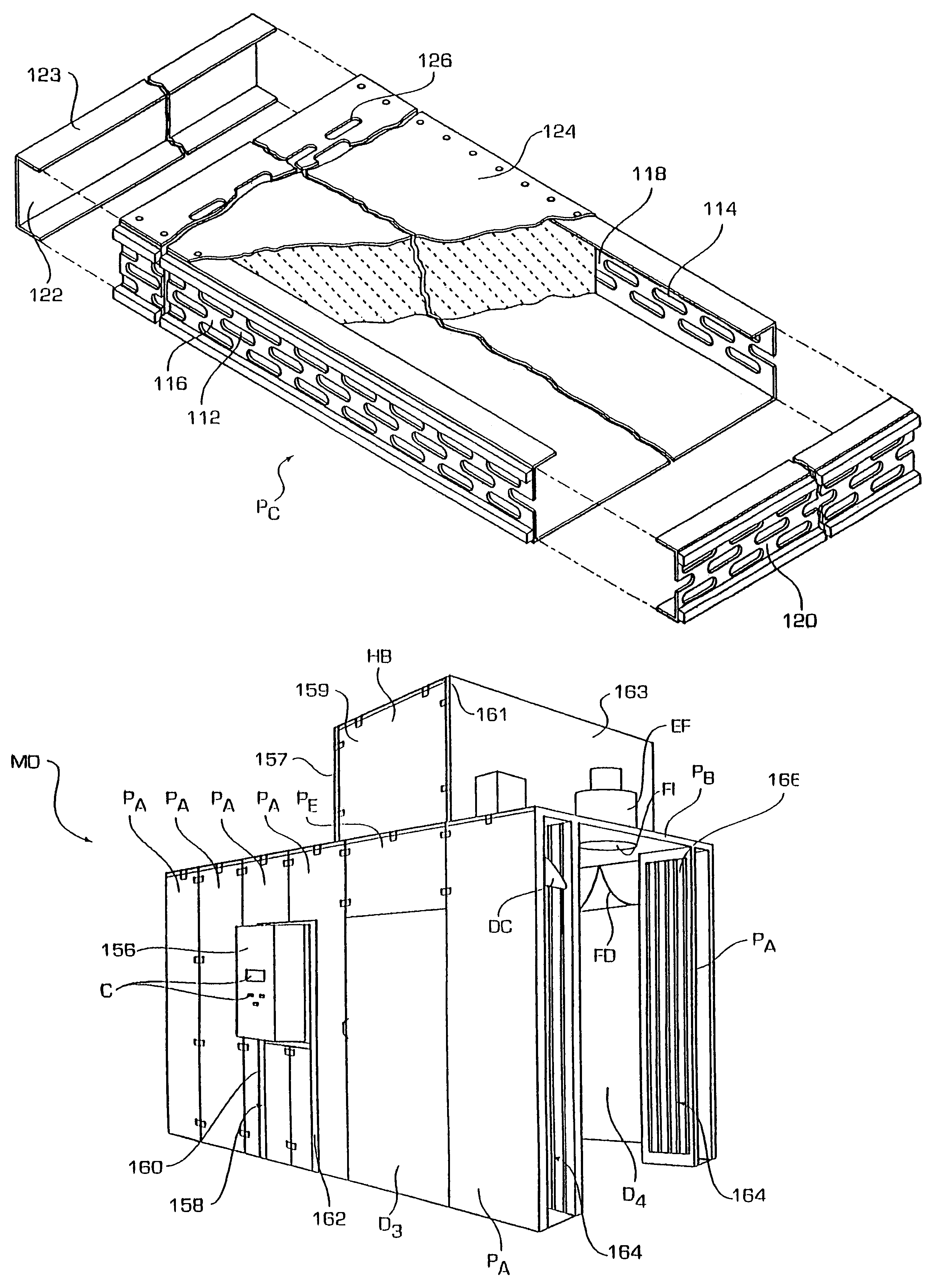

Modular oven, panel assembly and method of assembling the same

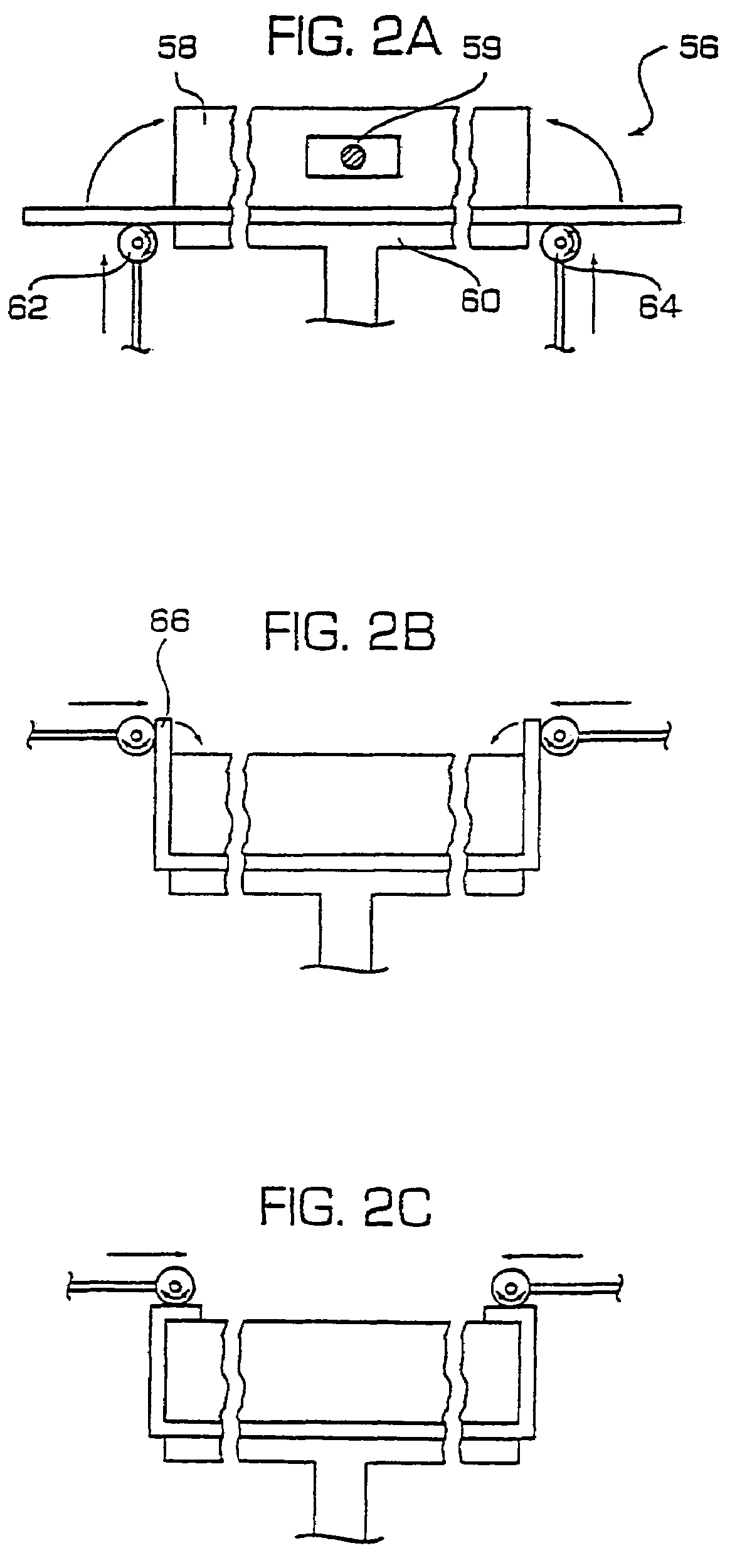

InactiveUS6905332B1Efficient productionQuick disassemblyMuffle furnacesLinings repairModularitySurface plate

A modular oven, such as a batch process oven, having a standardized set of self supporting, interconnectable panels which, when assembled, from a self-supporting heat containment shell, free of added structural support members. Also described are the self-supporting modular oven panels themselves having common roof, sidewall and end wall shell configuration and a method of assembling the panels such as in the expansion or conversion of a first modular oven assembly to a second assembly more conducive to current production requirements.

Owner:RAYPAUL INDS

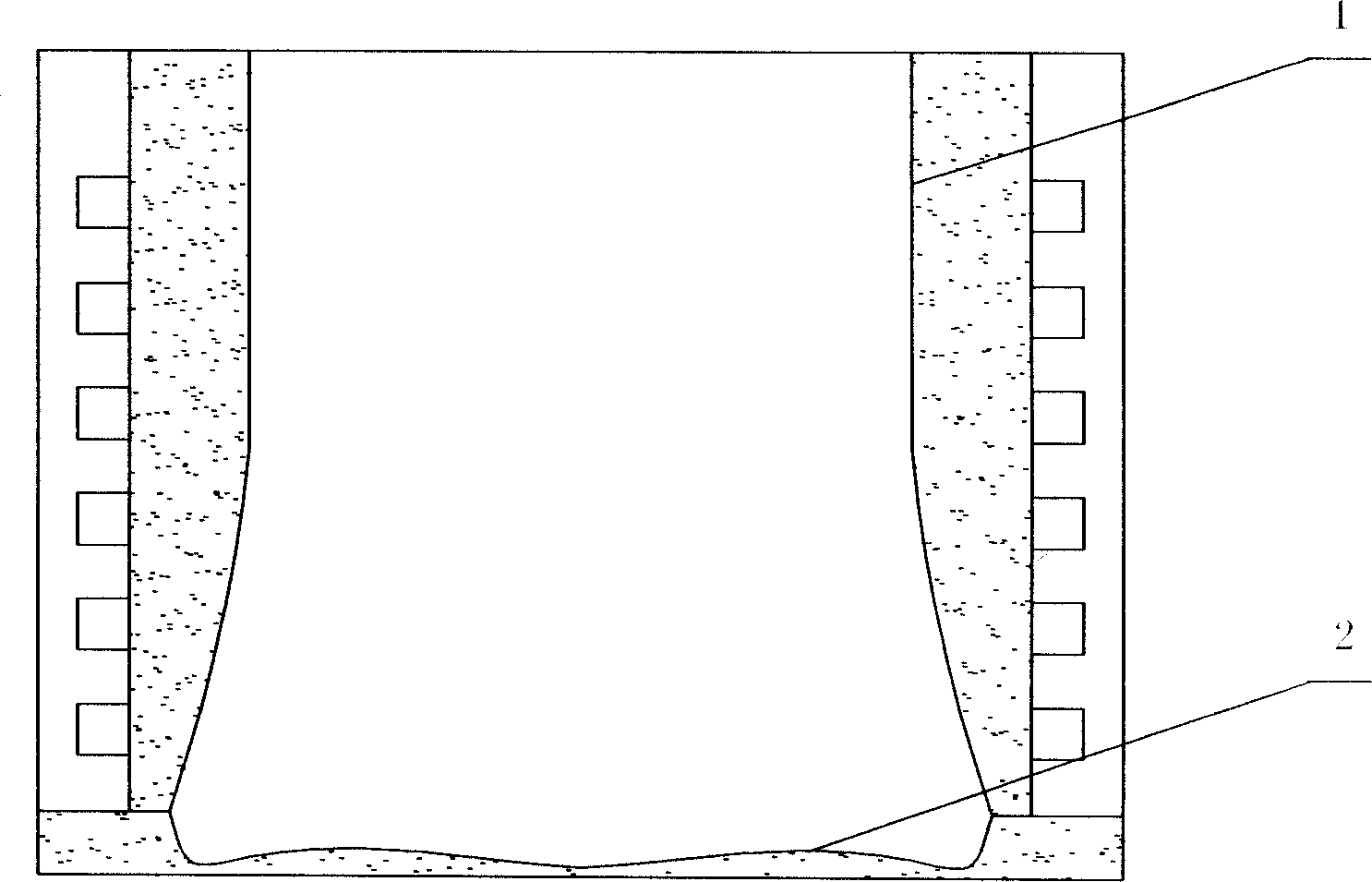

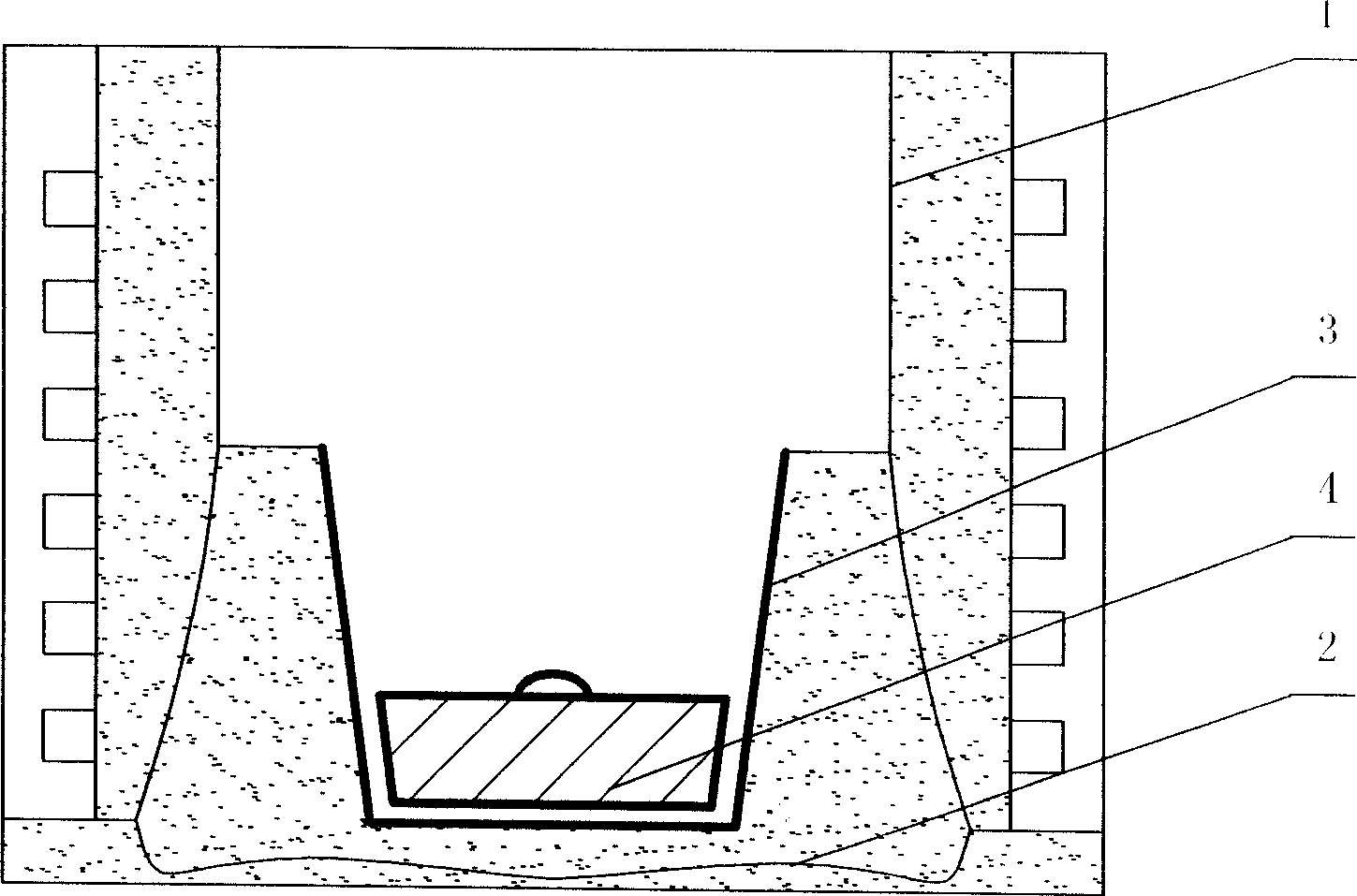

Method for repairing furnace lining of intermediate frequency furnace for steelmaking

InactiveCN1731061ARepair method is simpleQuick and effective patchingLinings repairProcess efficiency improvementSteelmakingIntermediate frequency

The present invention is furnace lining repairing process, and is especially the furnace lining repairing process for steelmaking IF furnace. The furnace lining repairing process includes the following steps: determining repairing time, clearing furnace inside, applying adhesive and furnace building material, setting forming steel mold and starting mold block, applying furnace building material, and sintering furnace building material. The furnace lining repairing process is relatively simple, and has effective repair of furnace lining, organic combination of the repair material and original furnace building material, flat furnace bottom, homogeneous heating of the hearth, good sintering effect and long service life of the repaired furnace lining.

Owner:QINGTONGXIA ALUMINUM IND GROUP

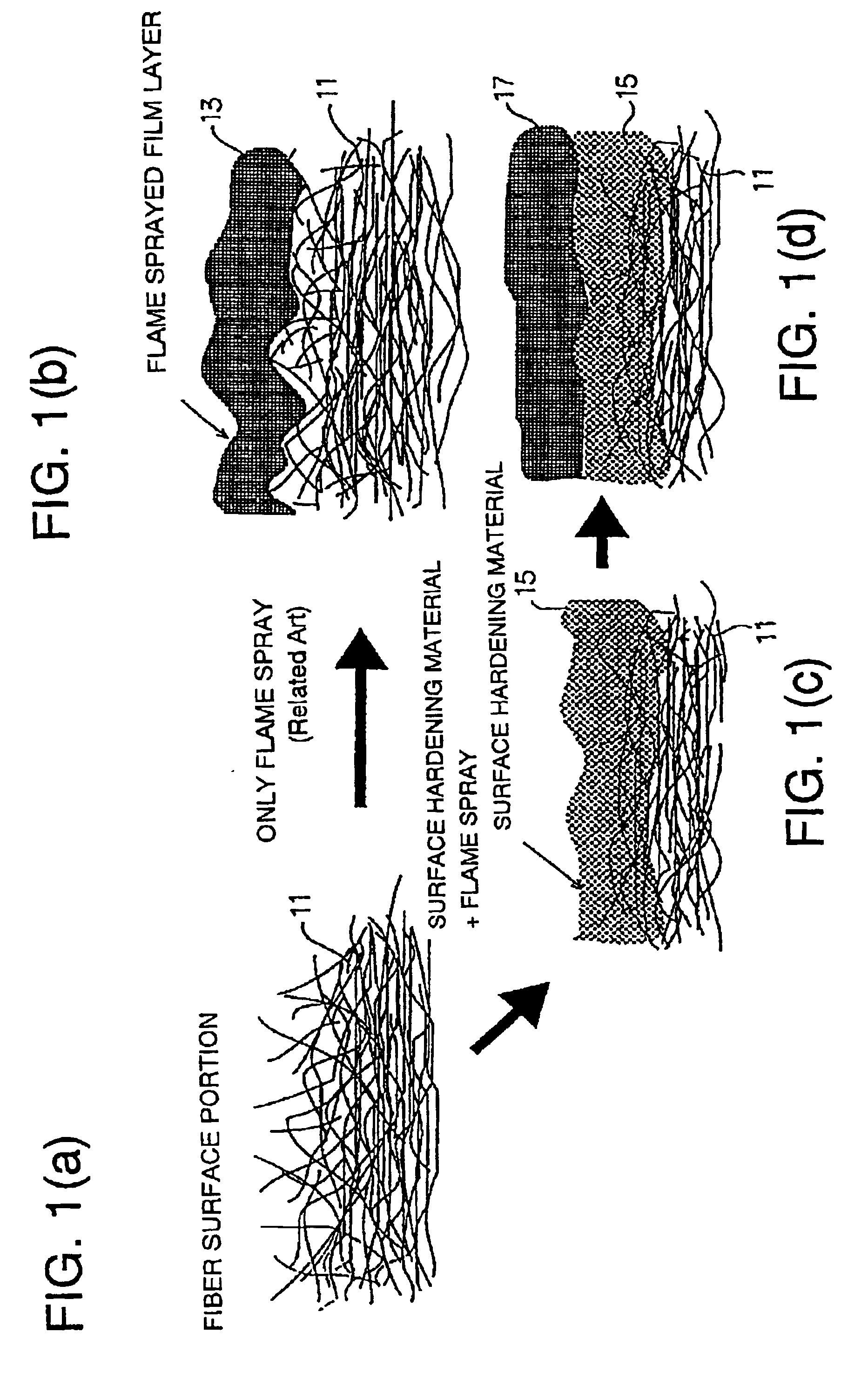

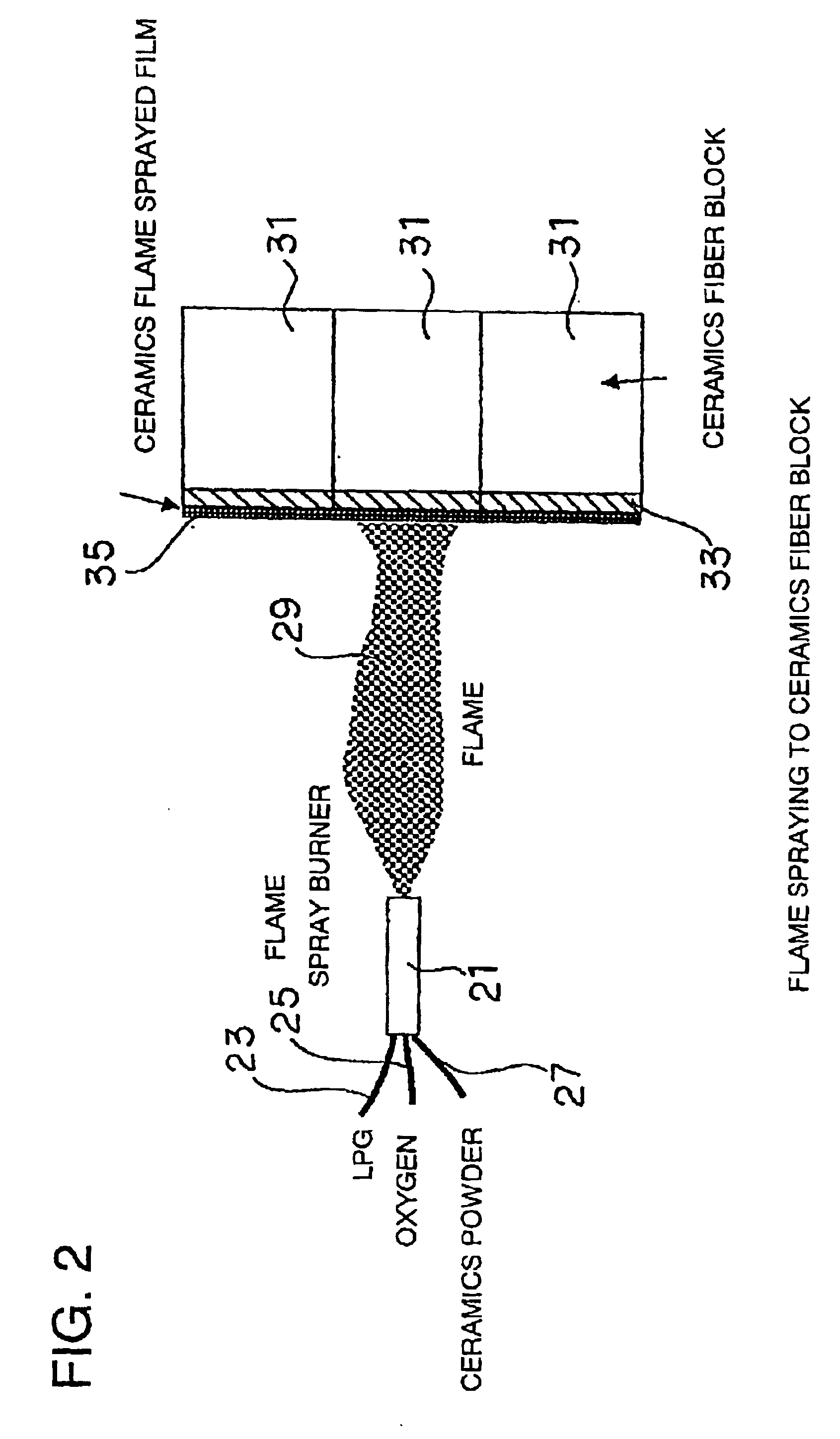

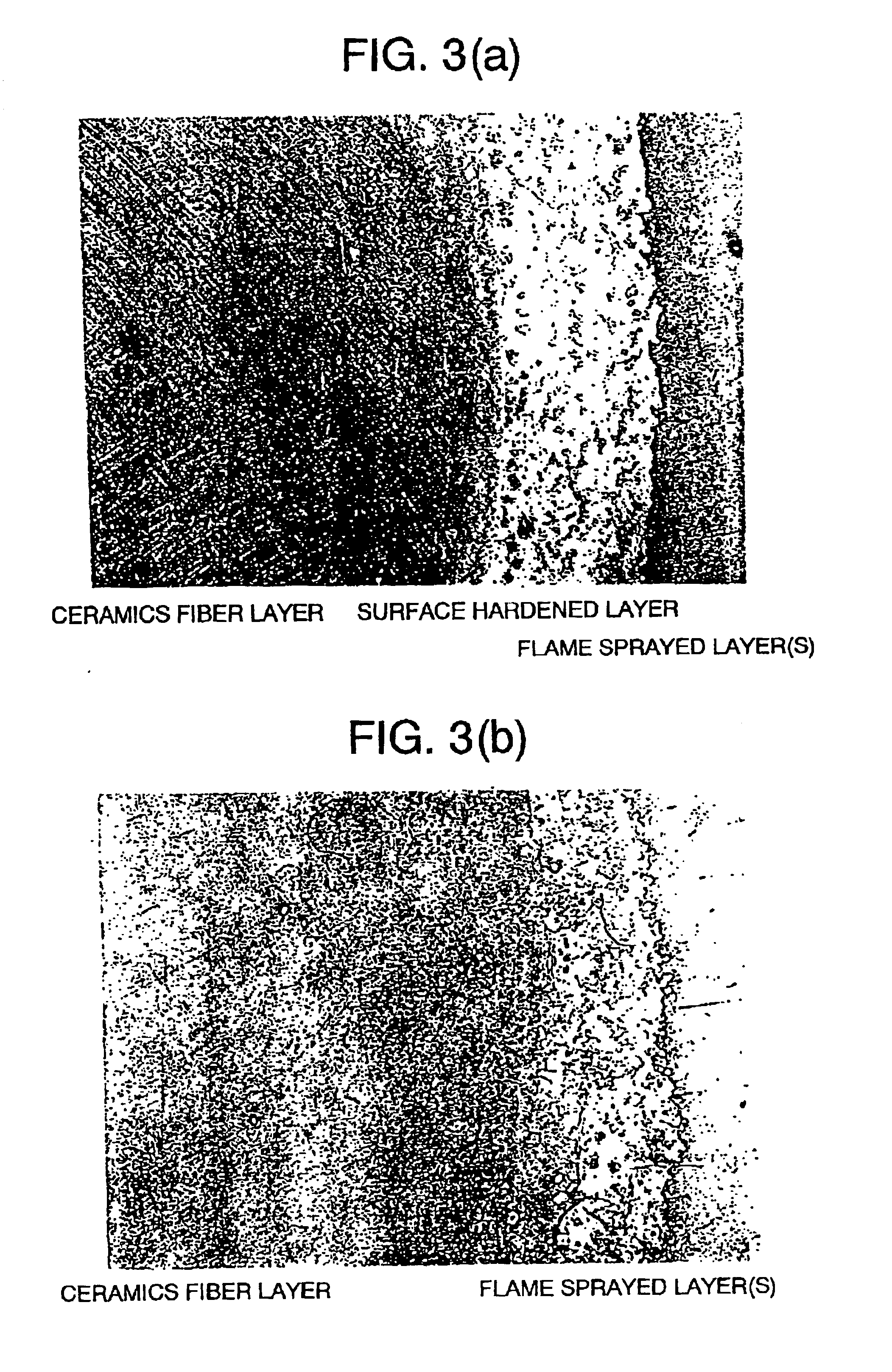

Highly endurable heat insulating material, method for production thereof, uses thereof, and working method therefor

A fire-resistant heat insulating material excellent in resistance to heat, resistance to slag, resistance to molten iron, resistance to wear, and resistance to mechanical impulse is provided. A highly endurable heat insulating material characterized by being provided on the surface of a layer of inorganic heat insulating fibers through the medium of a coating film of surface hardening material with a flame sprayed film of a fire-resistant ceramic substance.

Owner:NIPPON STEEL CORP

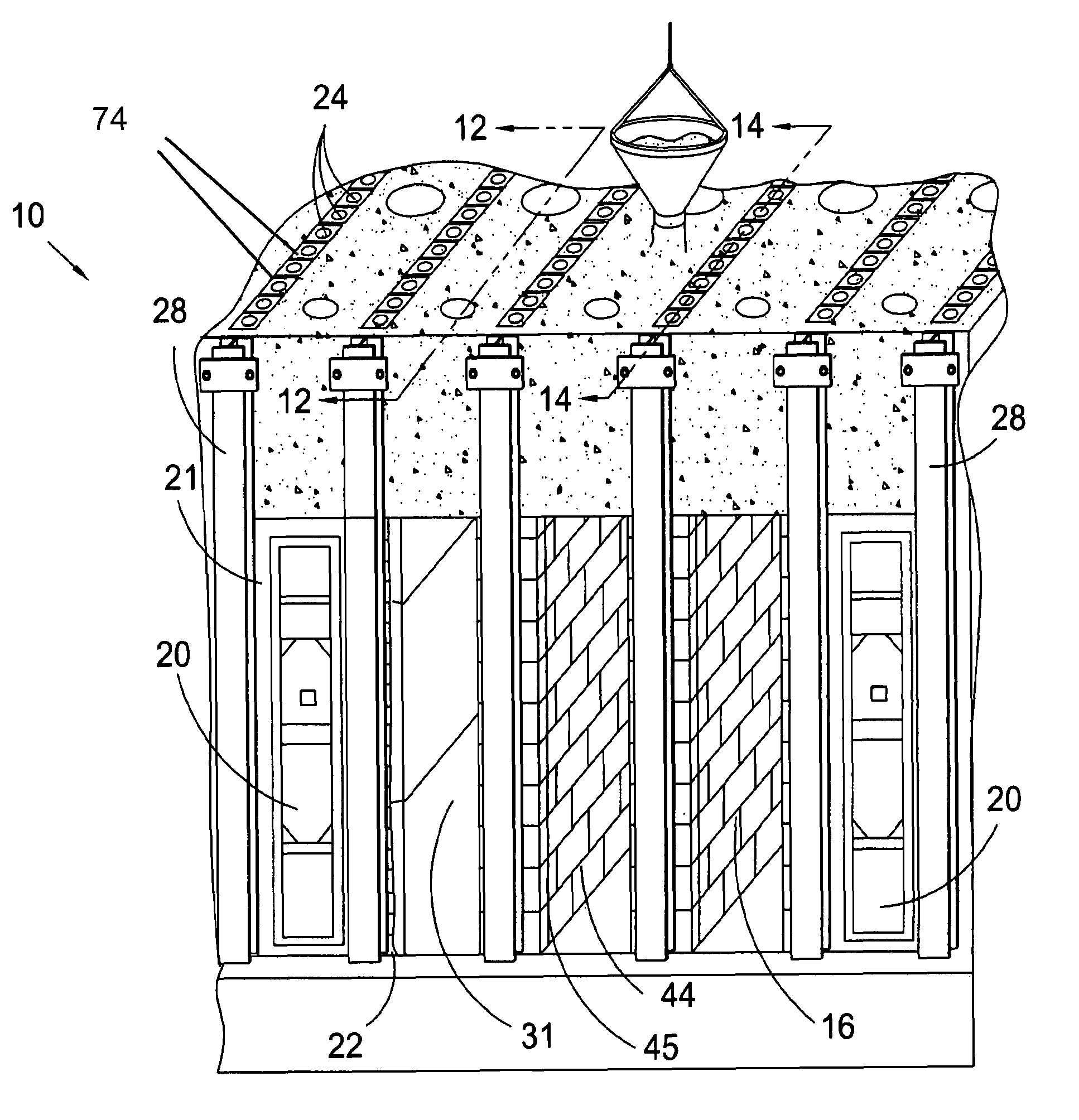

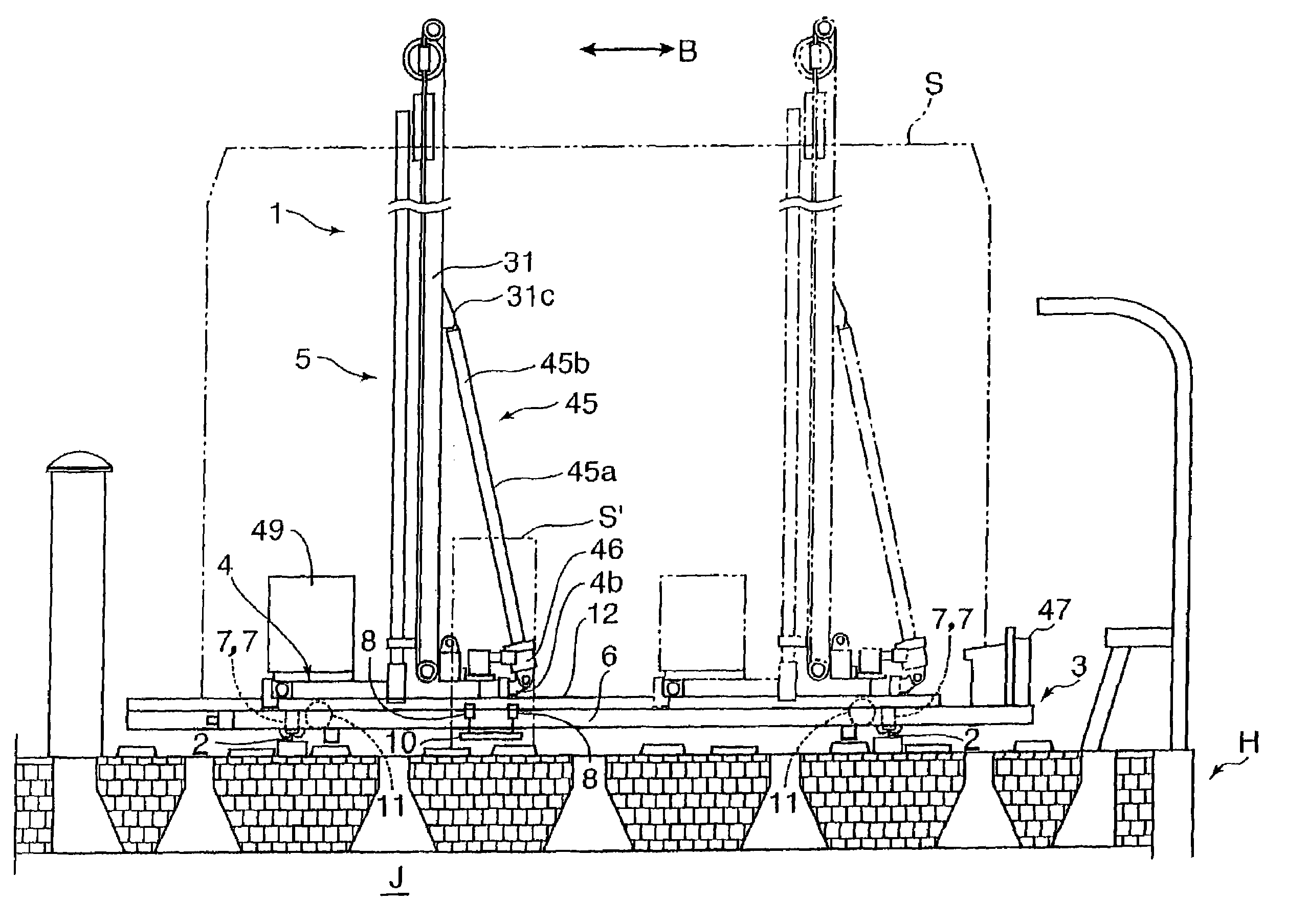

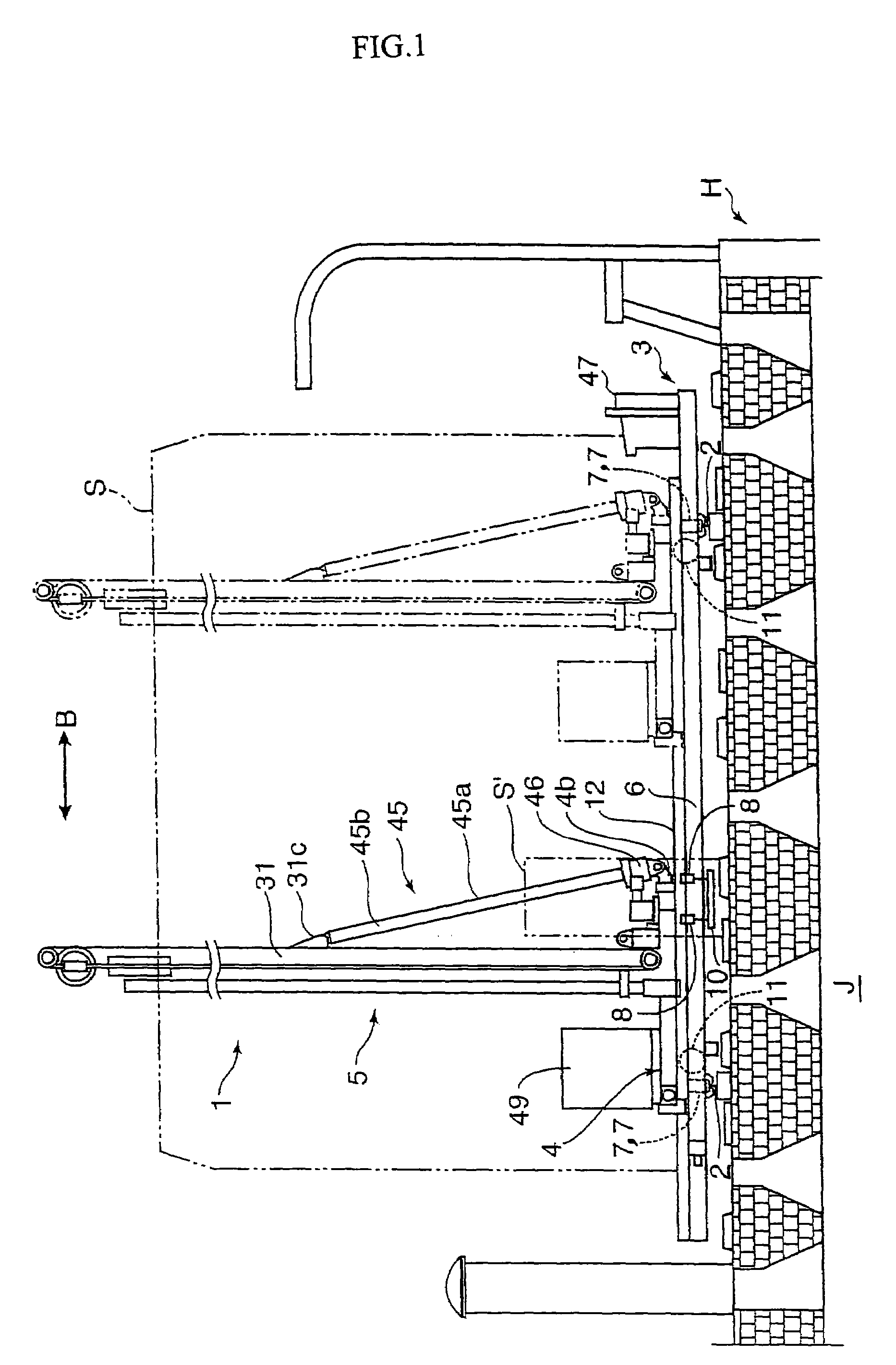

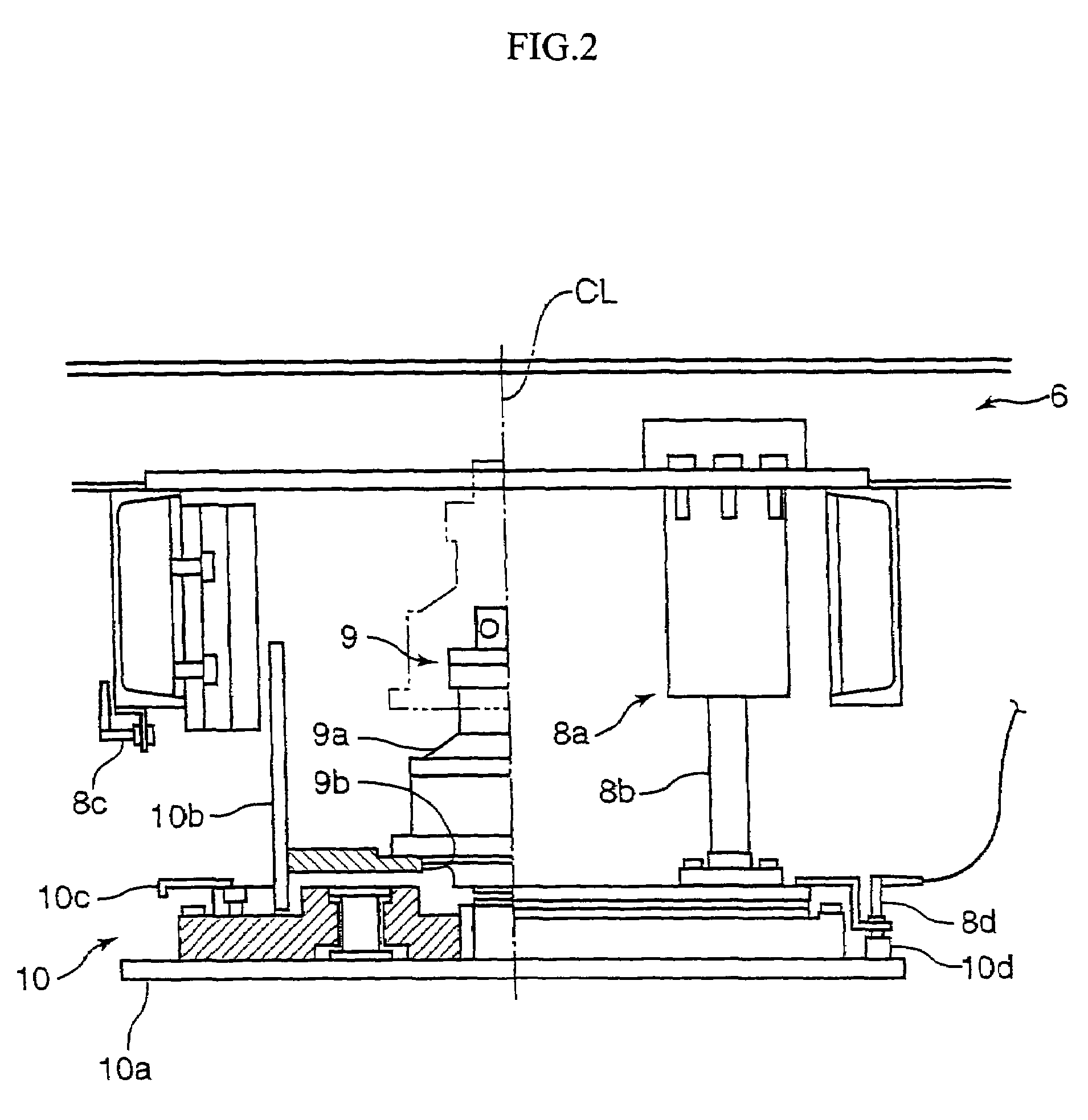

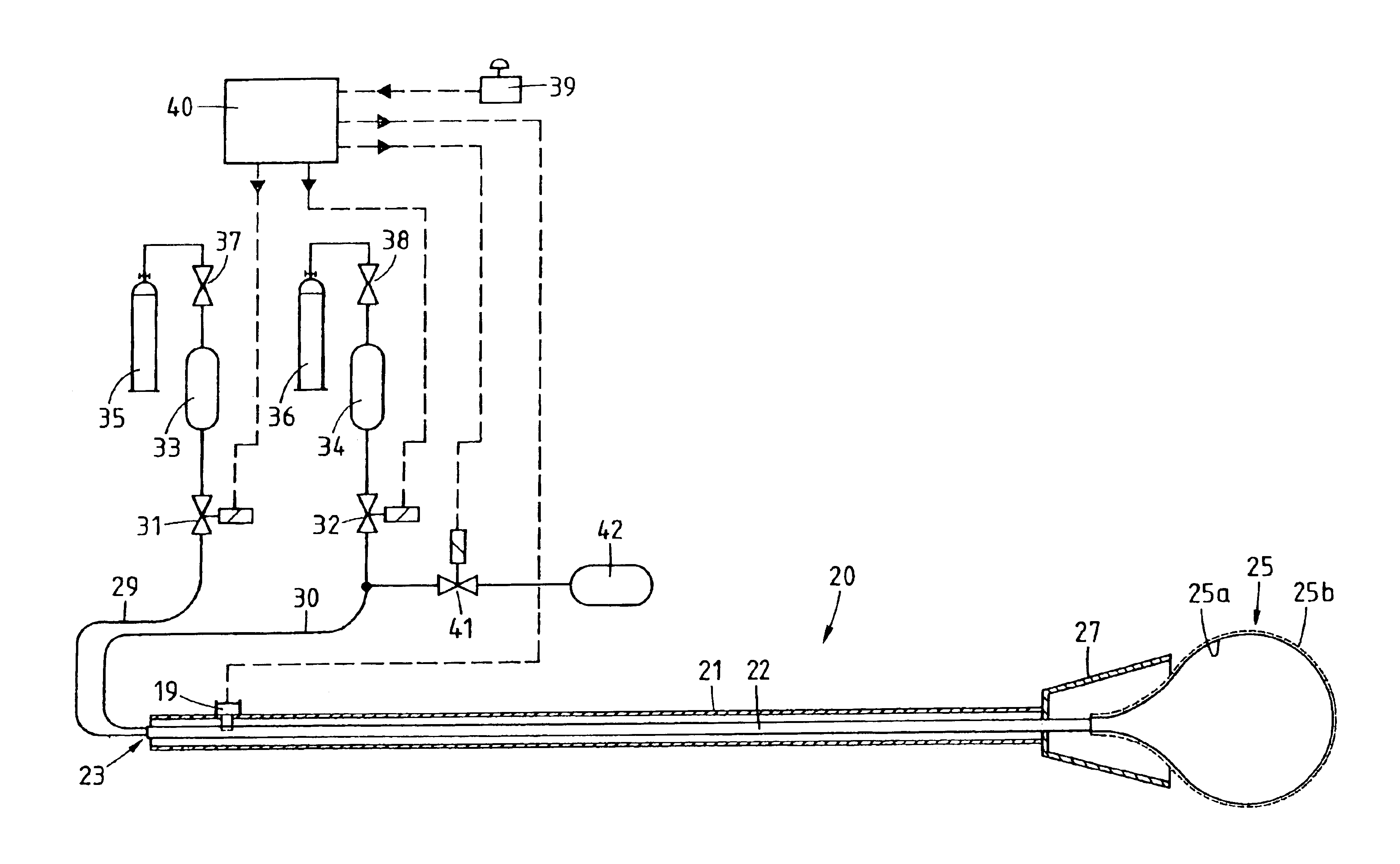

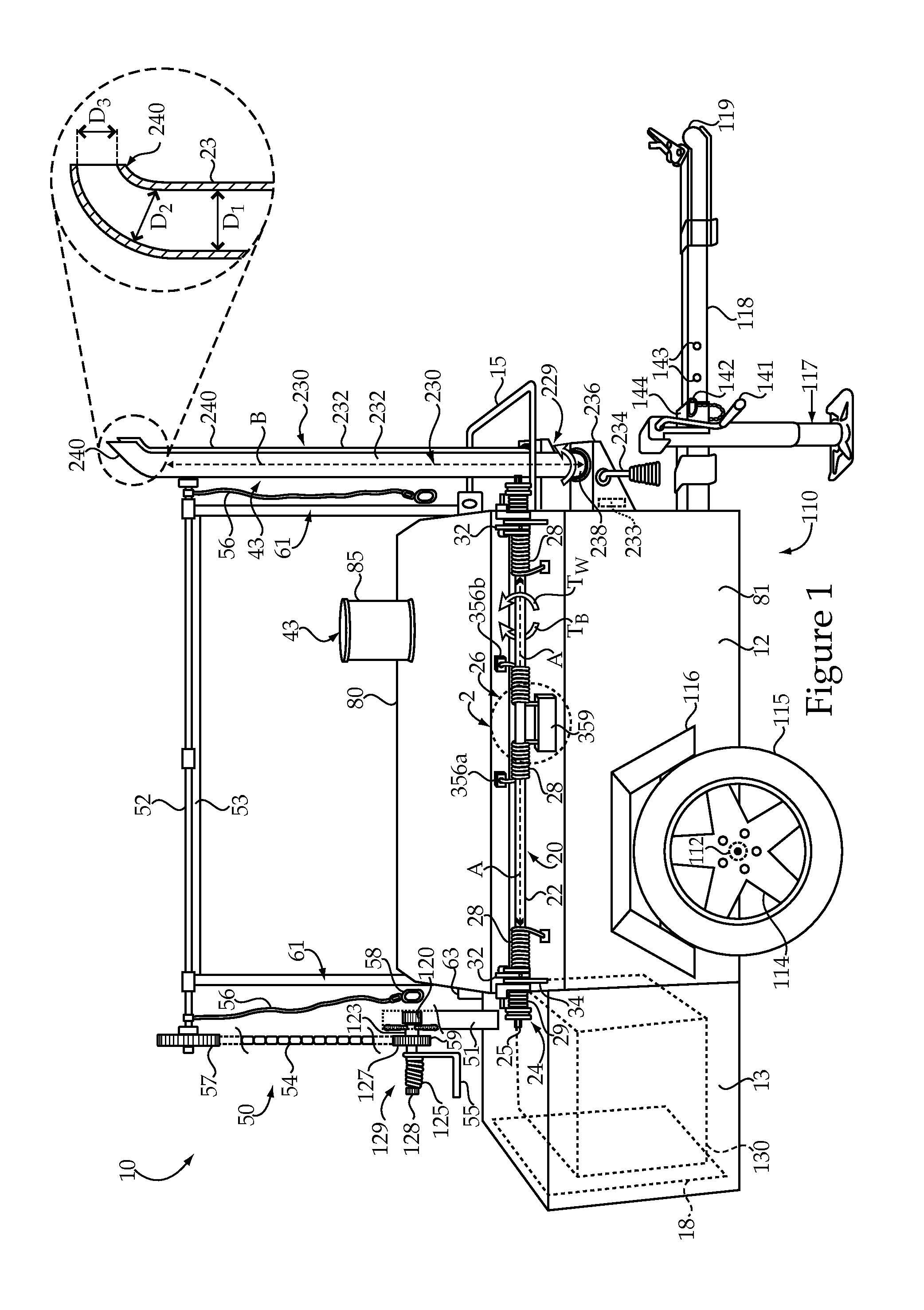

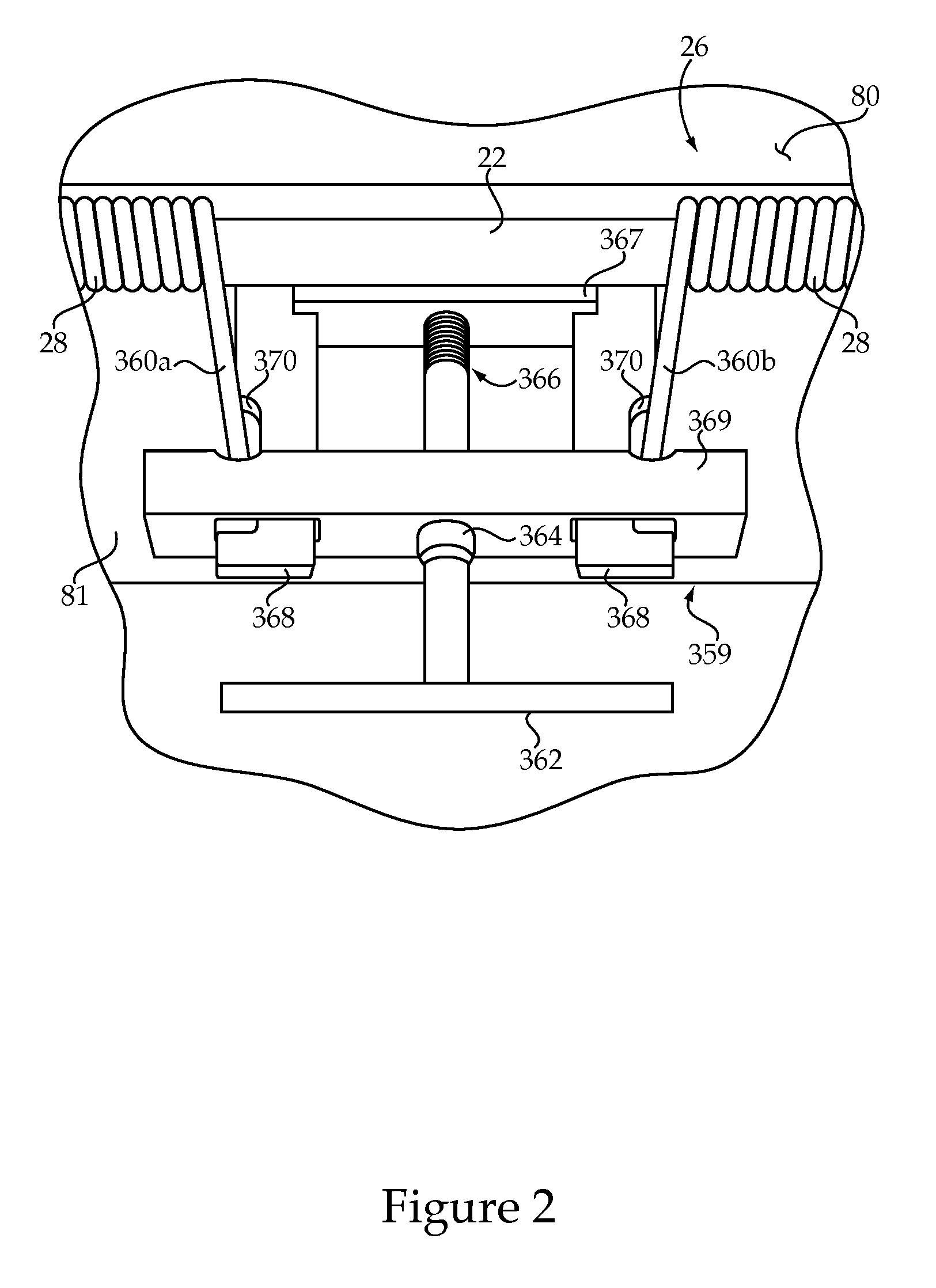

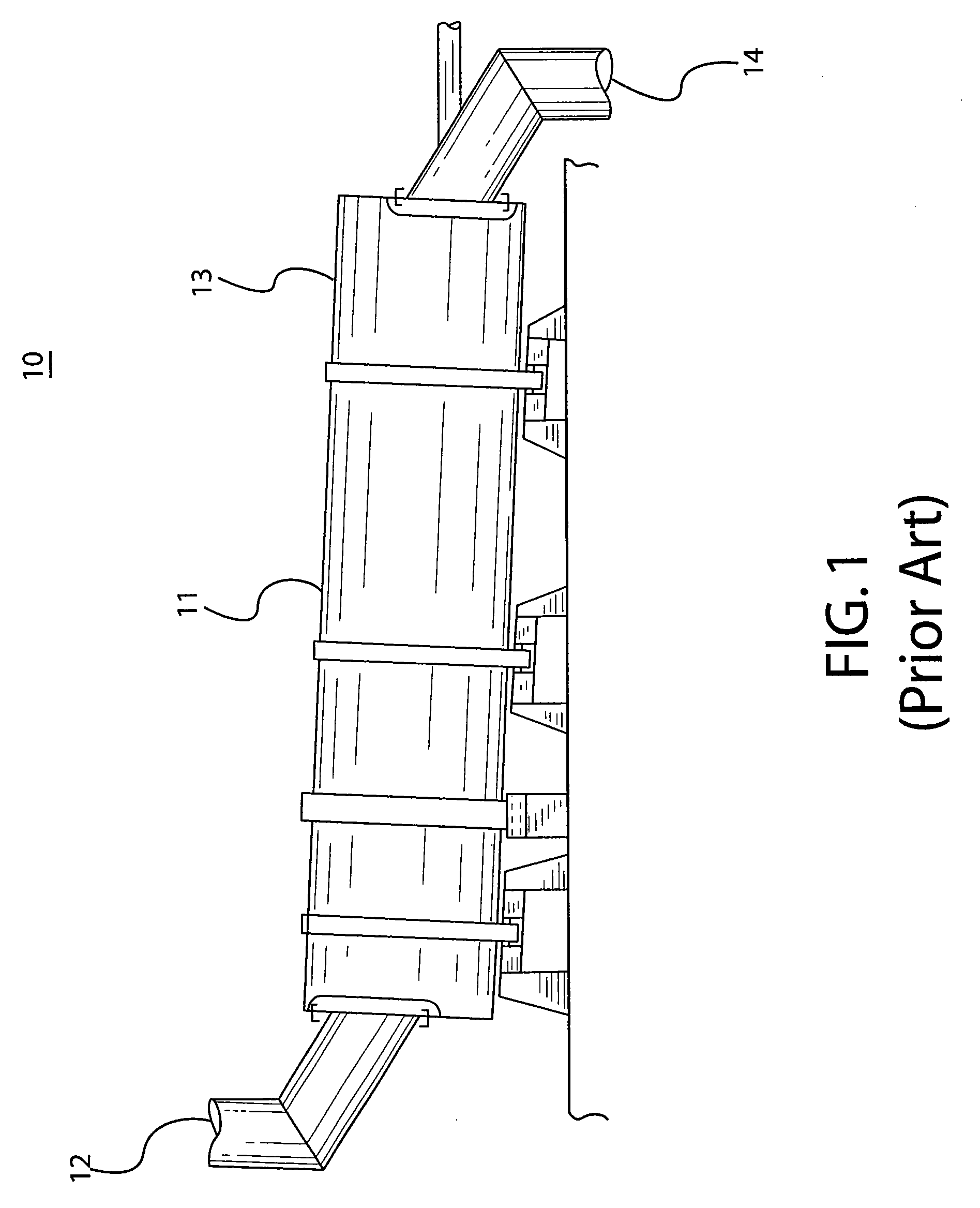

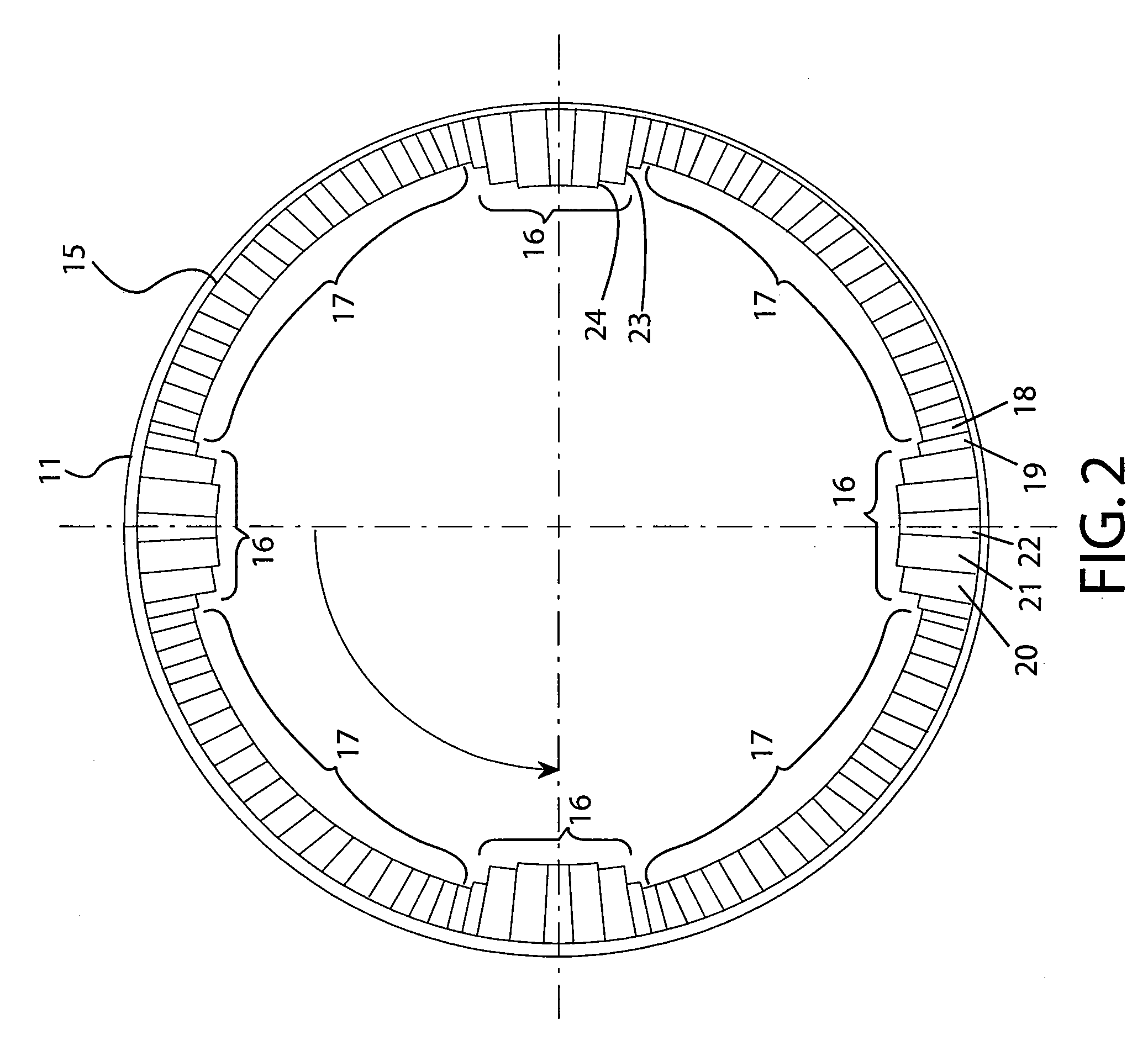

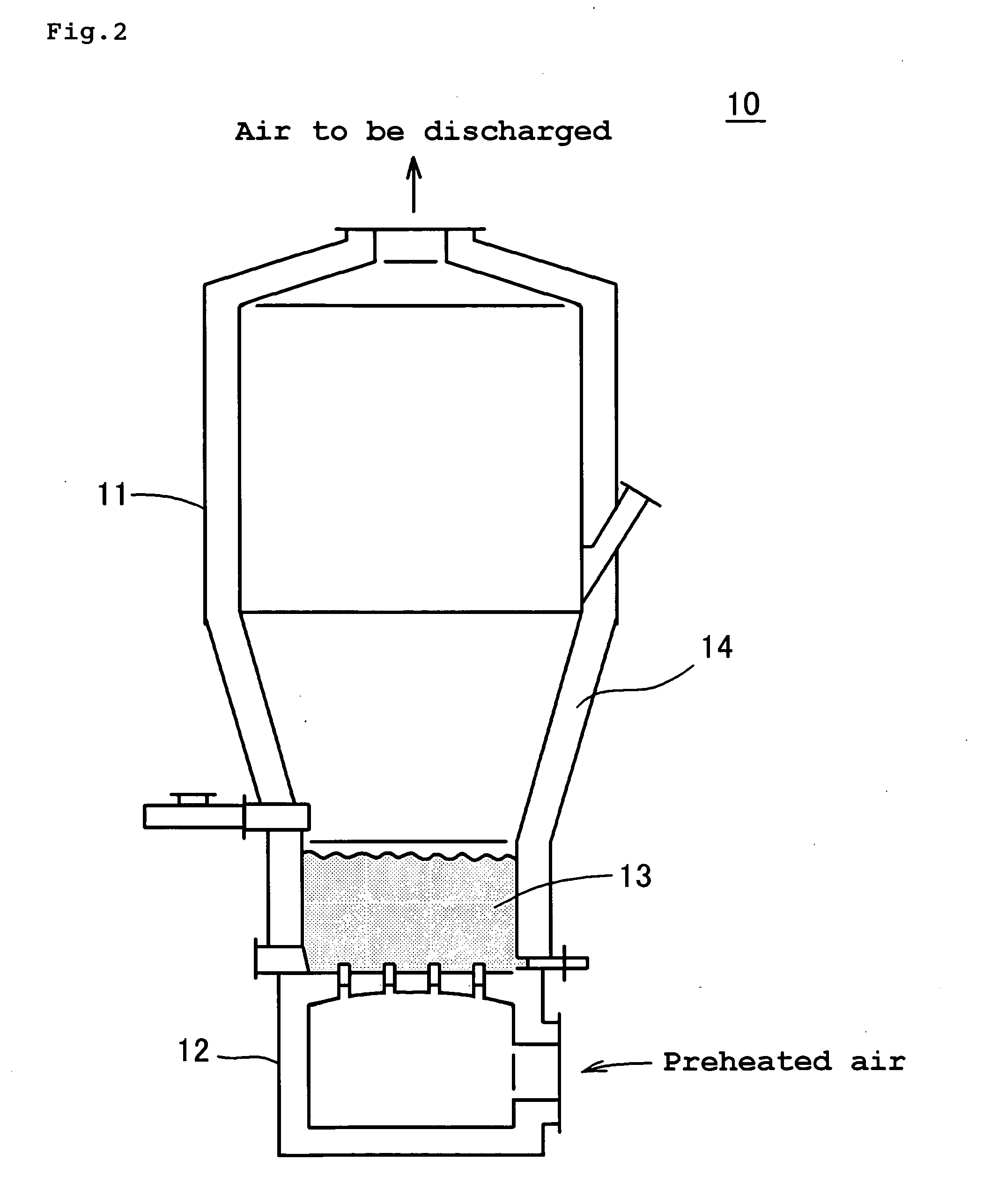

Coke oven repairing apparatus

ActiveUS7547377B2Repairable rangeLinings repairBrickwork leakage repair/preventionCoke ovenEngineering

A coke-oven repairing apparatus comprising: a traveling carriage 3 which travels in the direction of coke oven battery with the carriage straddled on the rails placed on the top of a coke oven; a traversing carriage 4 provided on said traveling carriage 3, which moves in the direction orthogonal to the direction of coke oven battery; and a working device 5 for making repairs on the oven walls within the coke oven which is mounted on said traversing carriage 4, wherein the working device 5 includes: a guide post 31 which stands on the traversing carriage 4, and is also coupled, at its lower end portion, to a supporting portion provided on the traversing carriage through a pivot shaft 42; a lance 32 which ascends or descends along the guide post 31; and a derricking device 45 which tilts the guide post 31 between a forward-tilted posture and a backward-tilted posture using the pivot shaft 42 as the fulcrum to oscillate the lance 32 inserted in a coke-oven carbonizing chamber through a charging-hole, within the carbonizing chamber.

Owner:KANSAI COKE & CHEM

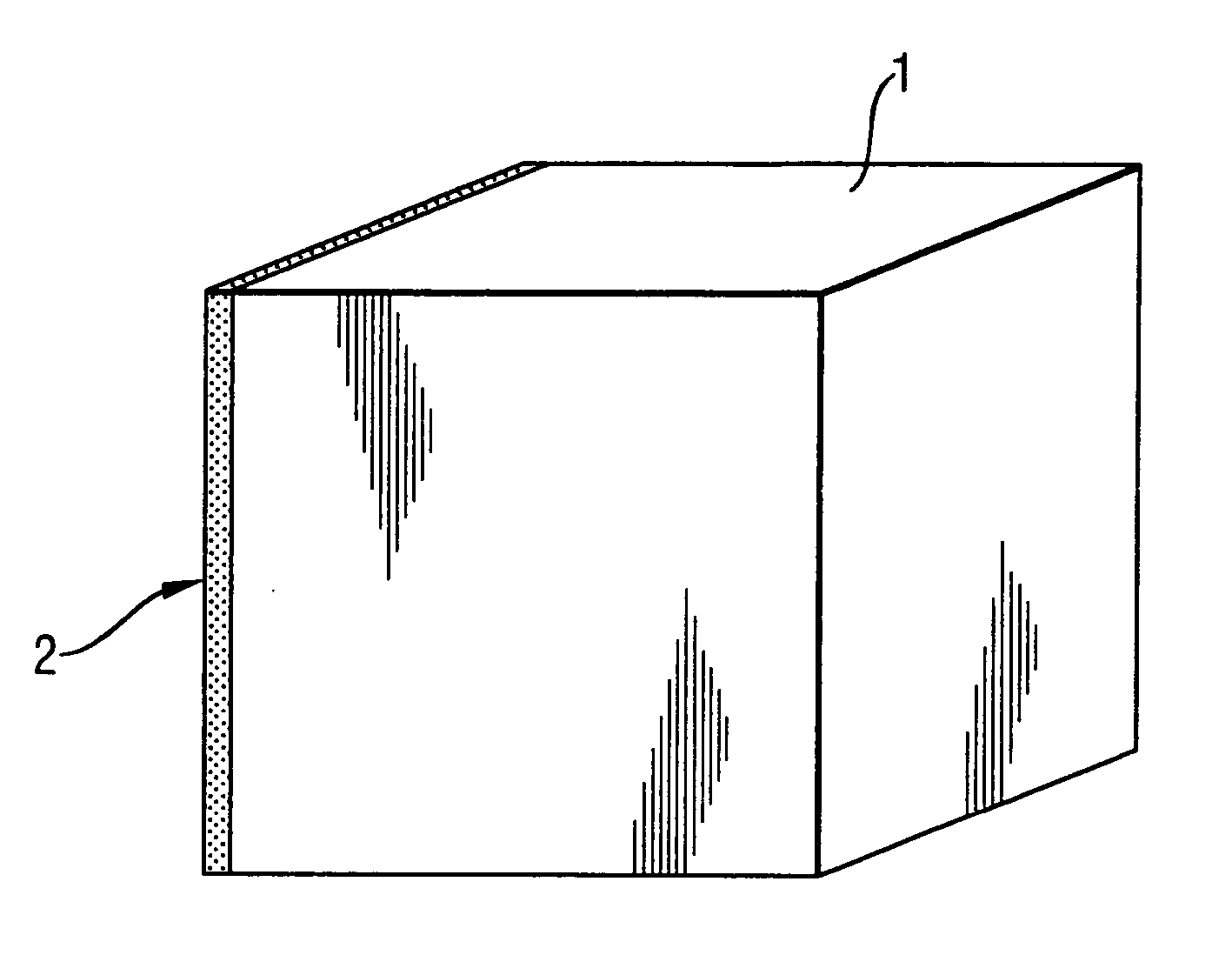

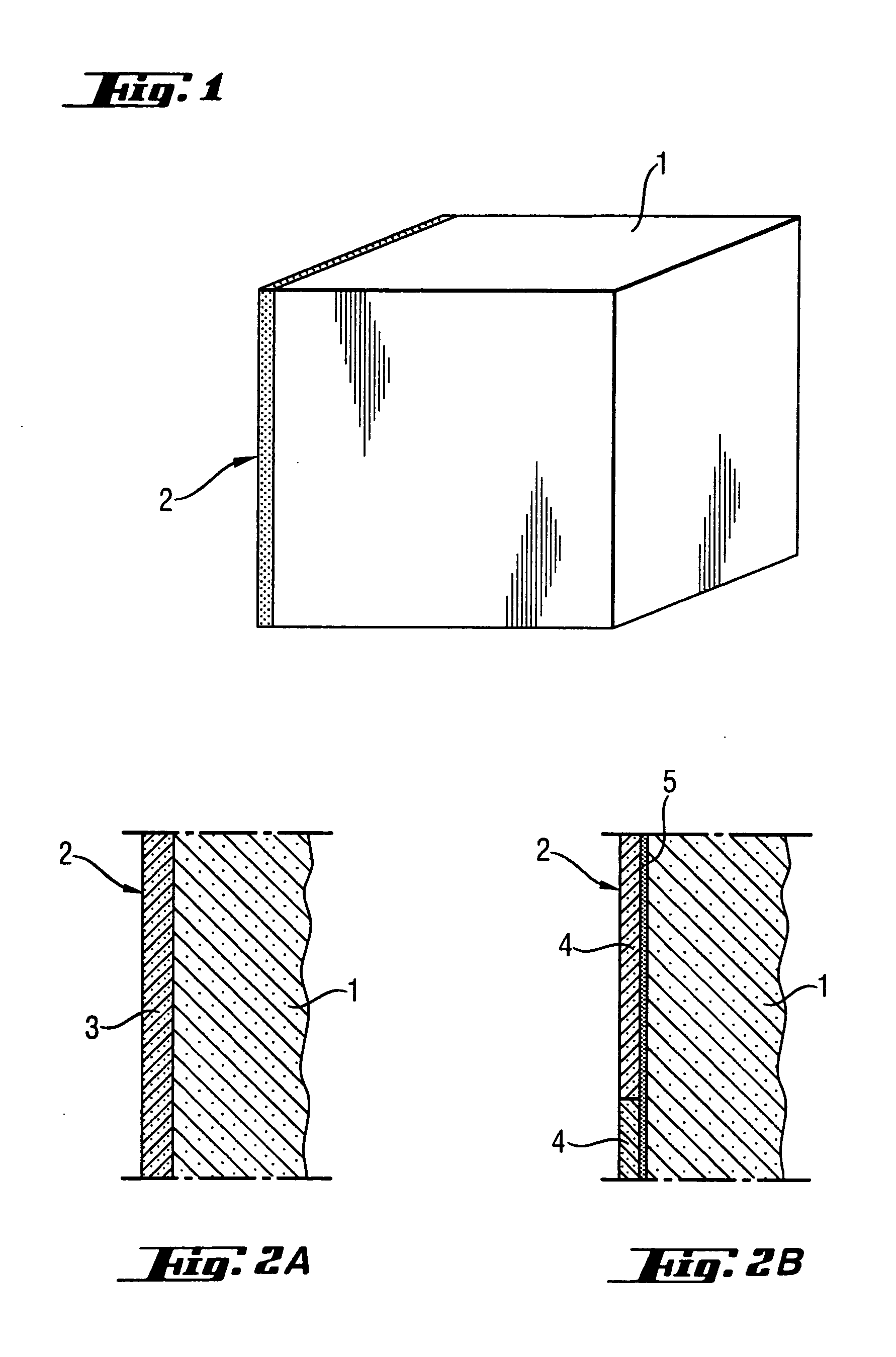

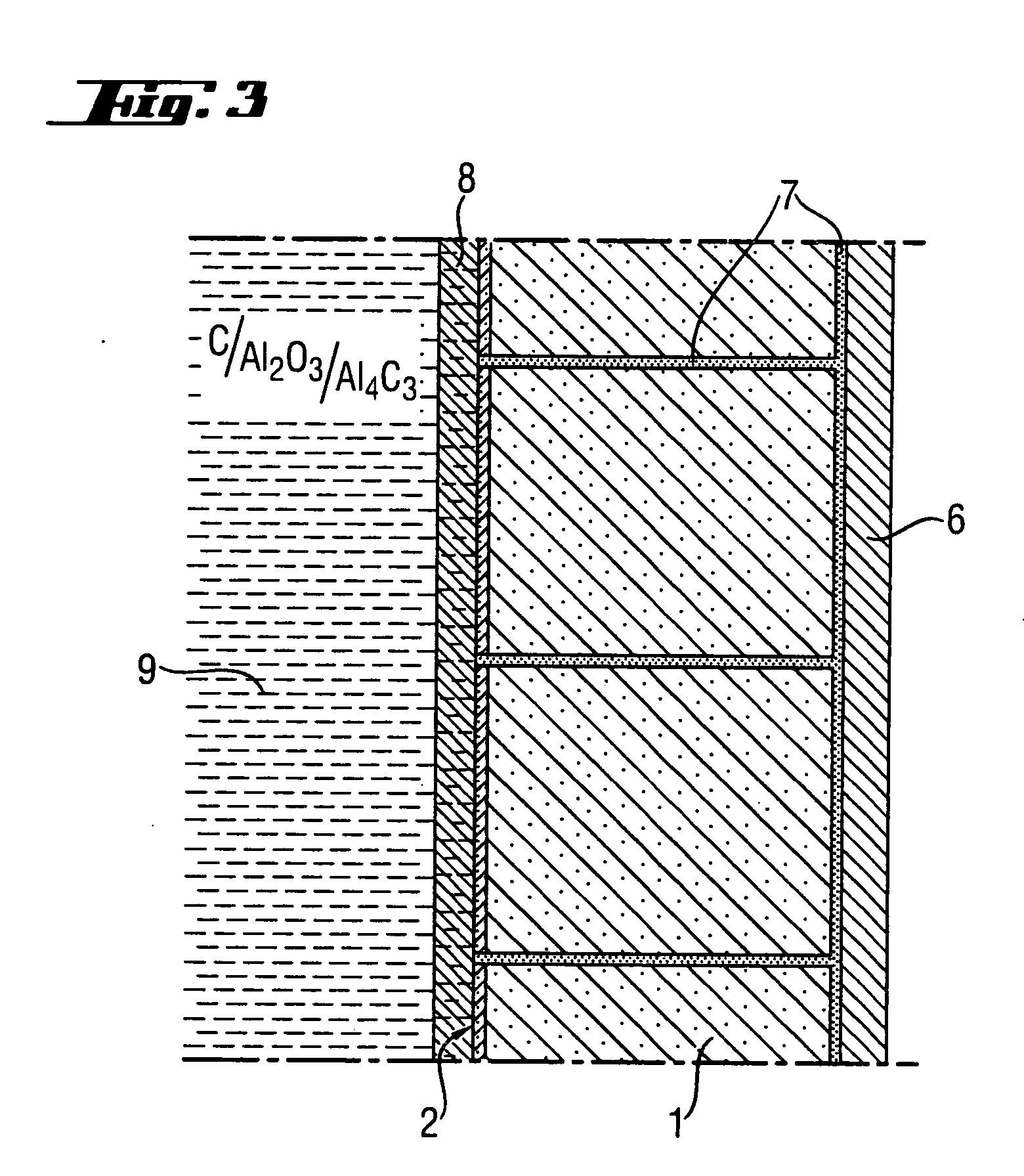

Lining for carbothermic reduction furnace

InactiveUS20050254543A1Effective heat dissipation systemOvercome disadvantagesElectric discharge heatingLinings repairRefractoryGraphite

An inner lining for the steel shell of a carbothermic reduction furnace for the production of alumina has a base layer of graphite and a coating layer of refractory material. The refractory material is corundum (Al2O3) bound by Sialon (Si.Al.O.N). The lining structure provides protection against the molten slag and it is not attacked by the CO-rich melt furnace atmosphere. Further, the lining does not contaminate the melt and it provides an effective heat dissipation system in case of a power shut-off.

Owner:SGL CARBON SE

Method for cleaning combustion devices

InactiveUS6935281B2Short timeProcess can be minimizedLinings repairBoiler cleaning apparatusCombustionSlag

An on-line method and a device for cleaning of contamination such as caking or slag deposits from surfaces in vessels and combustion installations by means of blasting technology. An explosive gas mixture is made to detonate in the proximity of the deposits and thereby clean the deposits from the surfaces.

Owner:BANG & CLEAN

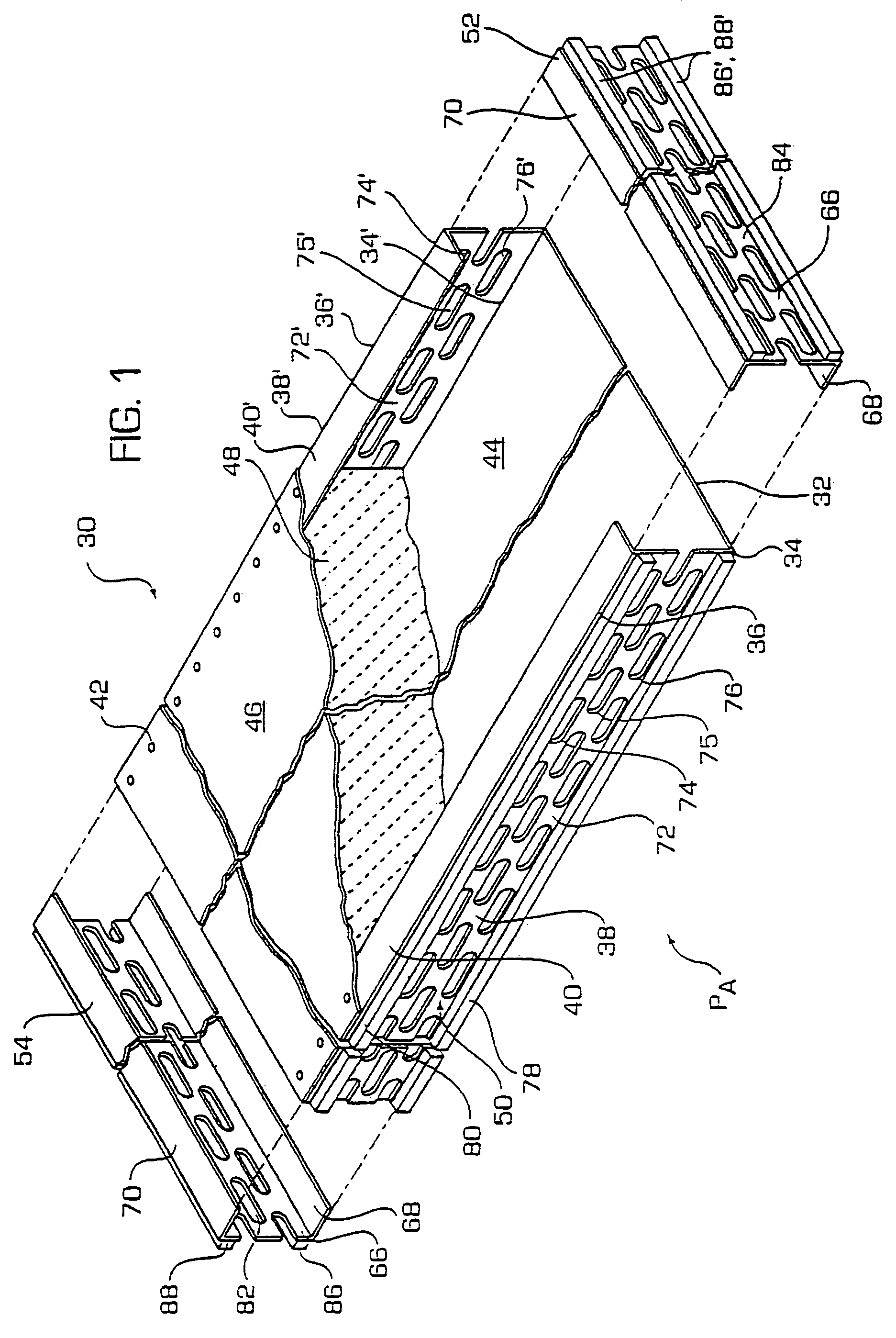

Modular oven wall panel assembly

InactiveUS7216464B2Efficient productionRapidly assembled and disassembledStoves/ranges foundationsSelf-cleaning stoves/rangesModularityManufacturing engineering

A modular oven, such as a batch process oven, includes a standardized set of self supporting, interconnectable panels which, when assembled, from a self-supporting heat containment shell, free of added structural support members. The present invention is also directed at self-supporting modular oven panels and a method of assembling the panels such as in the expansion or conversion of a first modular oven assembly to a second assembly more conducive to current production requirements.

Owner:RAYPAUL INDS

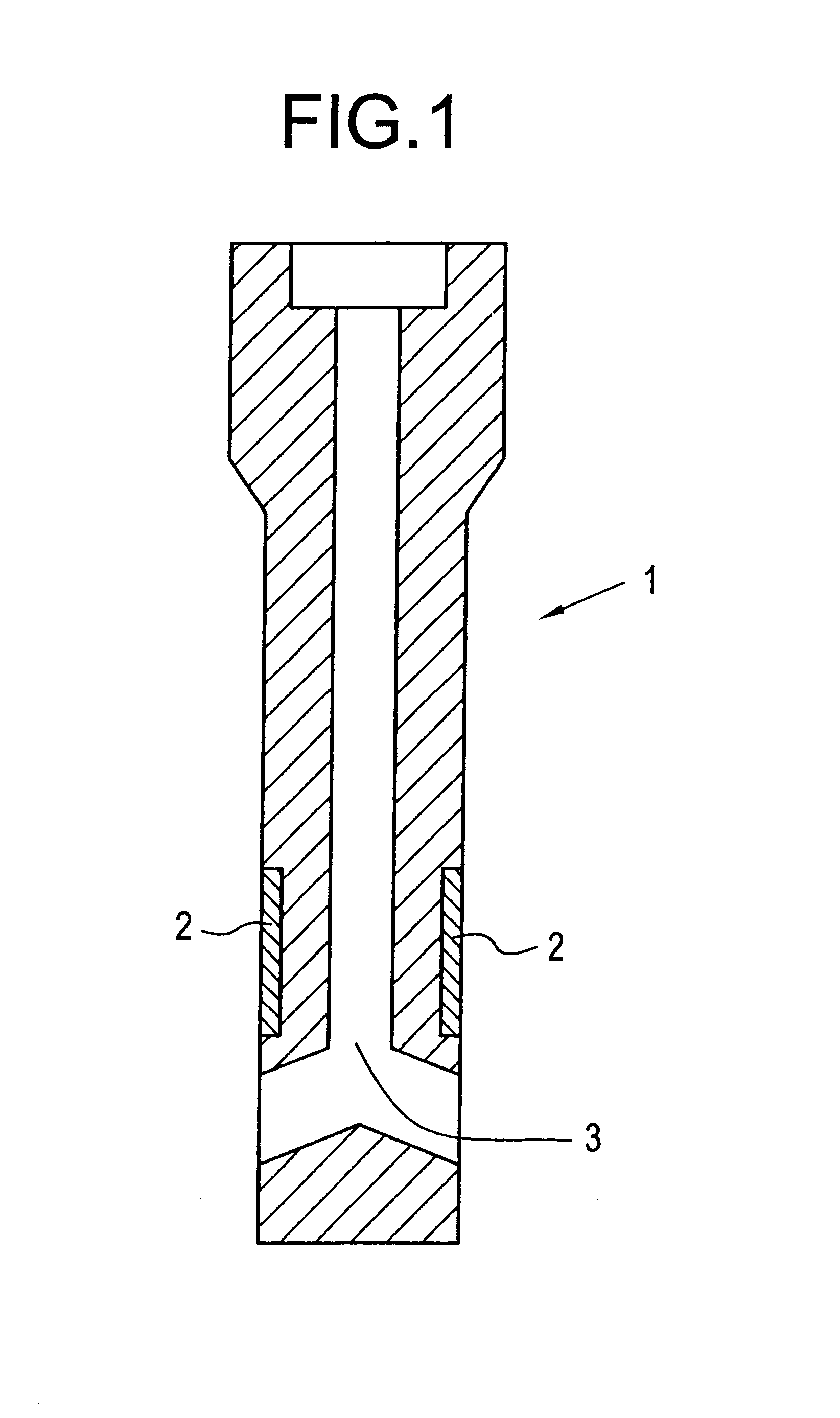

Slagline sleeve for submerged entry nozzle composition therefore

InactiveUS6586355B2Reduced contractile tendencyMelt-holding vesselsLinings repairGraphiteMolten steel

An improved submerged entry nozzle is provided which is useful in the casting of aluminum killed molten steel. The nozzle has an improved slagline sleeve or collar which surrounds the outer portion of the nozzle to protect it from corrosion during the casting process. The slagline sleeve is made from resin bonded zirconia / graphite which has been formulated so that upon curing of the resin to form resite, there is a reduction in the contractile tendency which results in a reduction in stress fracturing. The reduction of the contractile tendency and the resulting resistance to stress fracturing is achieved by adding an effective amount of calcium oxide to the resin-zirconia-graphite mixture which is used to form the sleeve.

Owner:BAKER REFRACTORIE

Venturi Vent Assembly For Outdoor Cookers

A venturi vent assembly for an outdoor cooker includes a cooker mounting flange attached to, and surrounding, one end of an outer tube. An inner tube extends through the outer tube and has an blower inlet at one end and an outlet. A plurality of ribs attach an exterior surface of an inner tube to an interior surface of the outer tube to define a plurality of venturi passages that surround a center passage of the inner tube. A valve plate is mounted on the inner tube and is movable between a closed position in contact with the outer tube to close the venturi passages, and an open position out of contact with the outer tube to open the venturi passages. The outlet tube of an electric blower may be mated to the inlet of the inner tube, and the venturi of assembly may be attached to a firebox of an outdoor cooker via the mounting flange.

Owner:CUSACK WILLIAM E

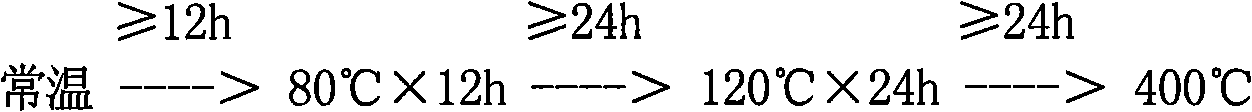

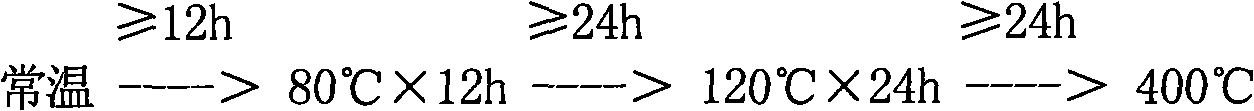

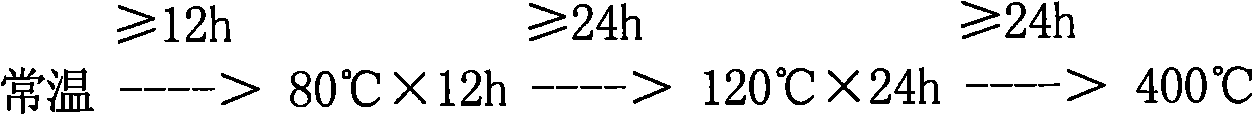

Internal lining casting material of industrial reaction furnace and lining-up method

A casting material for the internal working liner of industrial reduction furnace is prepared from aluminium oxide for insulating layer, high-Al material for intermediate layer and the compact corundum, zirconium mullite, chromium oxide, superfine zircon powder, Al2O3 powder and calcium aluminate cement through weighing raw materials except calcium aluminate cement, stirring, loading in bag for future use, casting external insulating layer, casting mediate layer and casting working liner, which includes proportionally mixing said mixture with calcium aluminate cement, adding water, stirring, moulding, vibrating, demoulding, natural curing and baking.

Owner:西安秦翔科技股份有限公司

Monothilic refractory composition

InactiveUS20050255986A1Satisfactory dispersibilityReadily availableLinings repairHeat resistanceSpinel

A subject for the invention is to provide an unshaped refractory composition having not only high thermal resistance but also improved corrosion resistance and improved unsusceptibility to slag infiltration. The invention is “an unshaped refractory composition comprising: (1) 20 to 70% by weight raw spinel material comprising an MgO—Al2O3 spinel phase and containing 2 to 20% by weight magnesia and / or raw spinel / corundum material comprising an MgO—Al2O3 spinel phase and a corundum phase and containing 2 to 20% by weight magnesia; (2) 3 to 12% by weight raw magnesia material having a particle diameter of 0.3 mm or smaller, containing particle sizes of 75 μm or smaller in an amount of 55 to 85% by weight, and having a magnesia purity of 90% by weight or higher; (3) 3 to 10% by weight alumina cement having a calcia content lower than 20% by weight; (4) 0.3 to 1.5% by weight ultrafine powder consisting mainly of silica; and (5) a raw alumina material as the remainder”.

Owner:SHINAGAWA REFRACTORIES CO LTD

Spray repair method for lining of kiln firebrick

ActiveCN101660869AExtended service lifeGood cavitation environmentLinings repairChemical industryHigh pressure

The invention mainly relates to a spray repair method for the lining of a kiln firebrick in smelting and chemical industries and the like, comprising technical processes such as scene pretreatment, spray repair, maintaining and scene heat treatment. Aiming at the damaged firebrick linings of inner walls of a roasting kiln, a sulfur kiln and a waste heat boiler in smelting and chemical industries and the like, powder-shaped high temperature fireproof material is sent to a spray pipe by directly utilizing an air compressor and an injector and then sprayed on the firebrick or a steel board needing repairing by high pressure after mixed with a certain proportion of water in a transfer piping. The method is a recovery repair technology, and is characterized in that thorough repair treatment canbe carried out on line as long as the spraying pipe can be stretched to the position needing repairing in the premise of no need for removing or bricking again; and the method has simple and effective procedure, short construction time and low repair cost, thereby effectively repairing the firebrick lining dropping from the inner part of the kiln, prolonging the service life of the kiln and guaranteeing long-term normal operation of equipment.

Owner:甘肃中顺石化工程装备有限公司

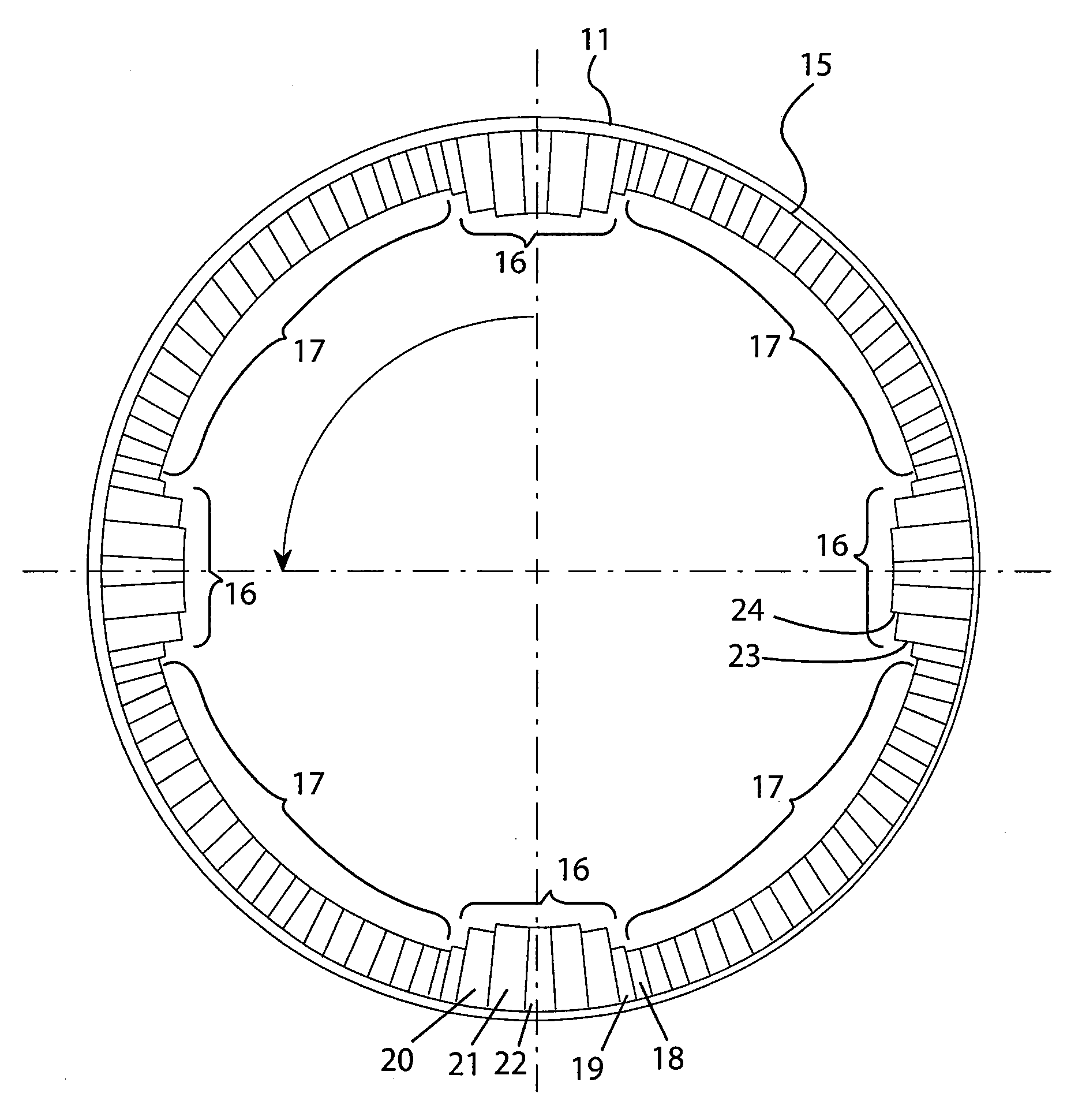

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

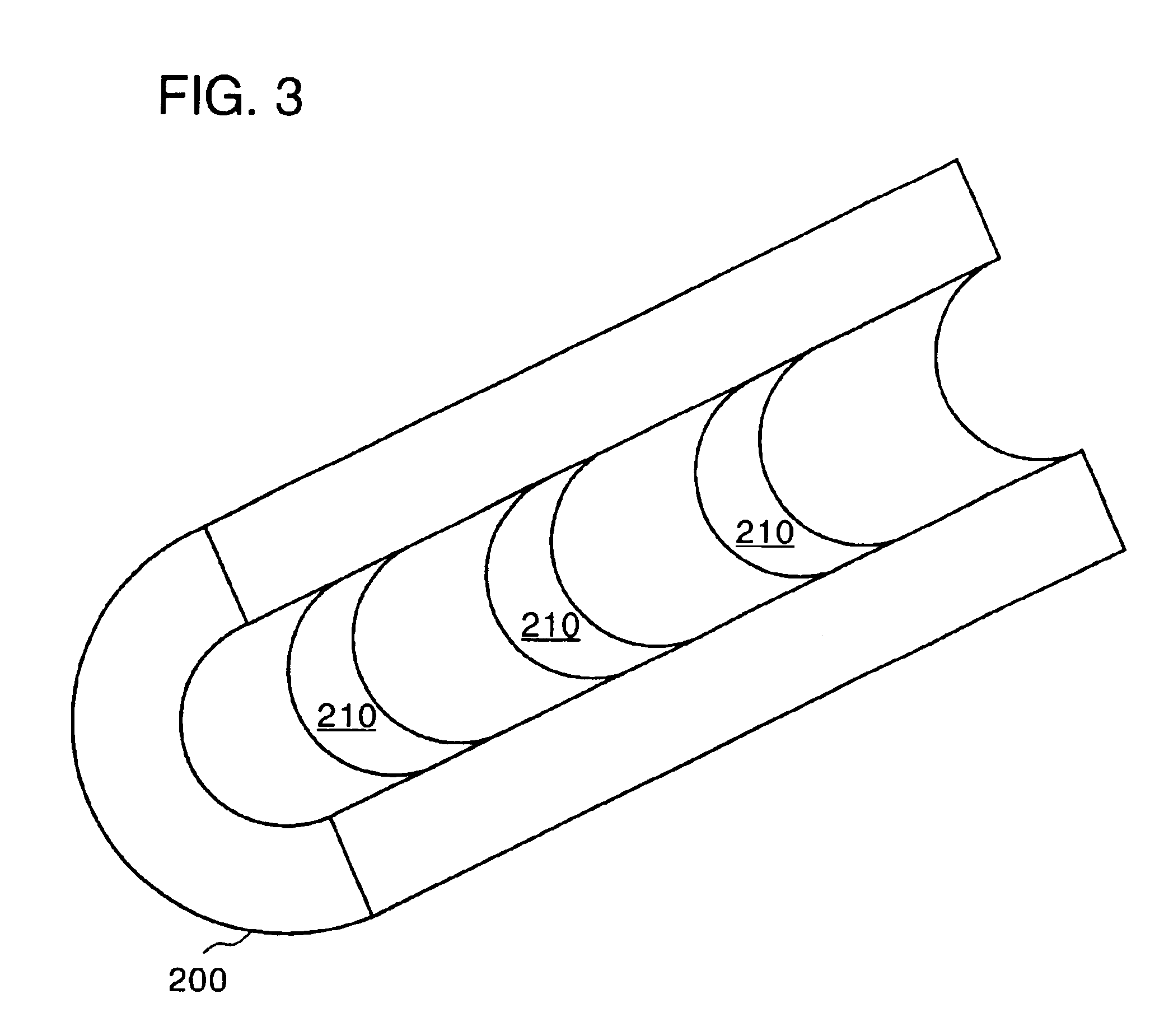

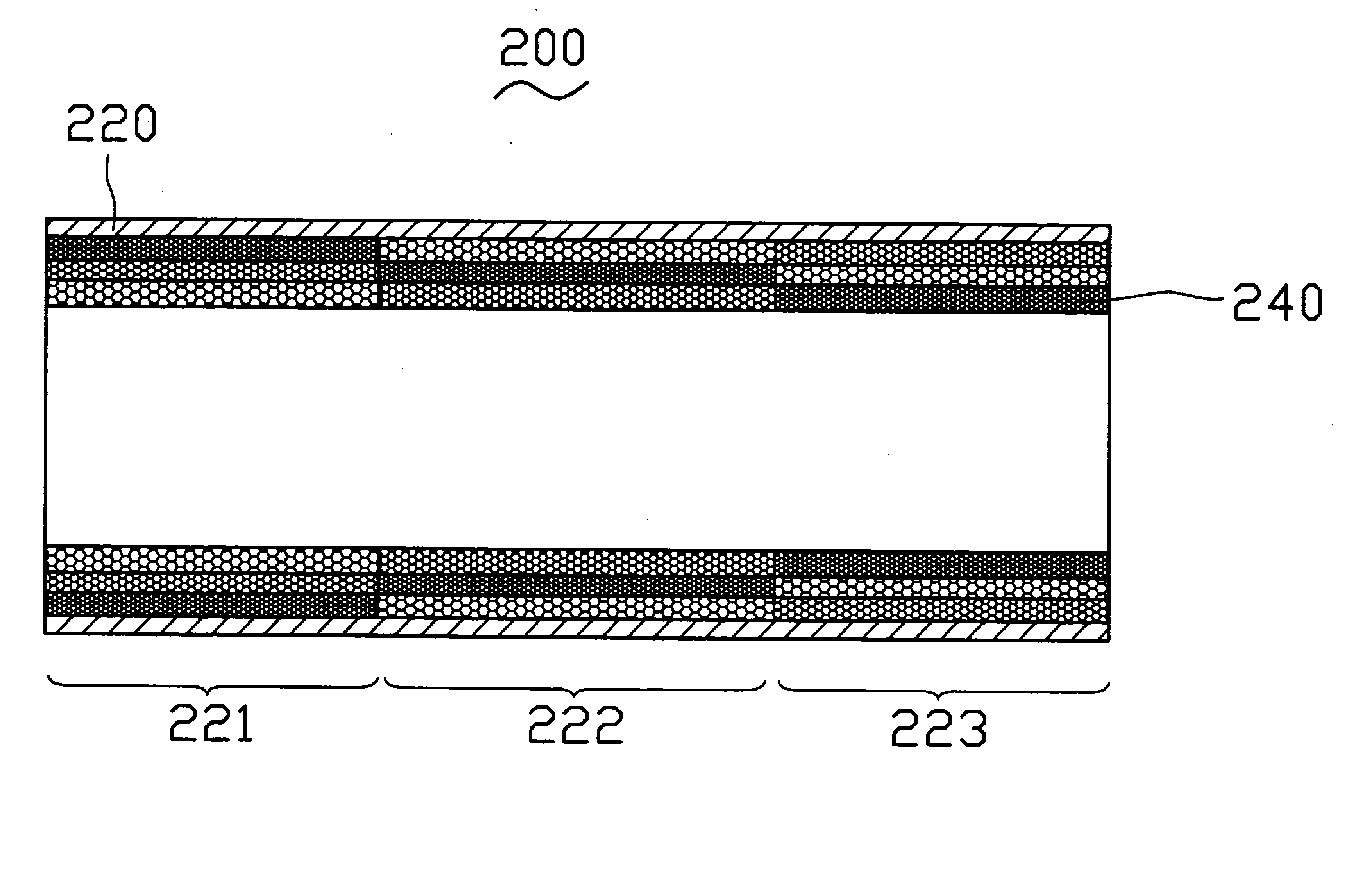

Rotary kiln lining and method

InactiveUS20120282563A1Difficult to repairCost efficientLinings repairRotary drum furnacesRefractoryEngineering

Provided is a rotary kiln having a cylindrical shell having an inner cylindrical surface and a longitudinal axis and a kiln lining disposed on the inner cylindrical surface of the shell. The kiln lining includes one or more radial portions of a first size of shaped refractory material disposed on the inner cylindrical surface of the shell along the longitudinal axis for at least a portion of the shell and one or more lifter sections comprising a second size of shaped refractory material that extend along the longitudinal axis for at least a portion of the shell and are between radial portions of the first size of shaped refractory material, wherein the second size of shaped refractory material is greater than the first size of shaped refractory material, such that the second size of shaped refractory material extends orthogonally from the inner cylindrical surface for a greater portion of the diameter of the shell than the first size of shaped refractory material, the second size of shaped refractory materials thereby forming a series of blunt faces. Also included are methods of processing materials using the inventive kiln lining, and methods of assembling the inventive kiln lining.

Owner:MAGNESITA REFRACTORIES

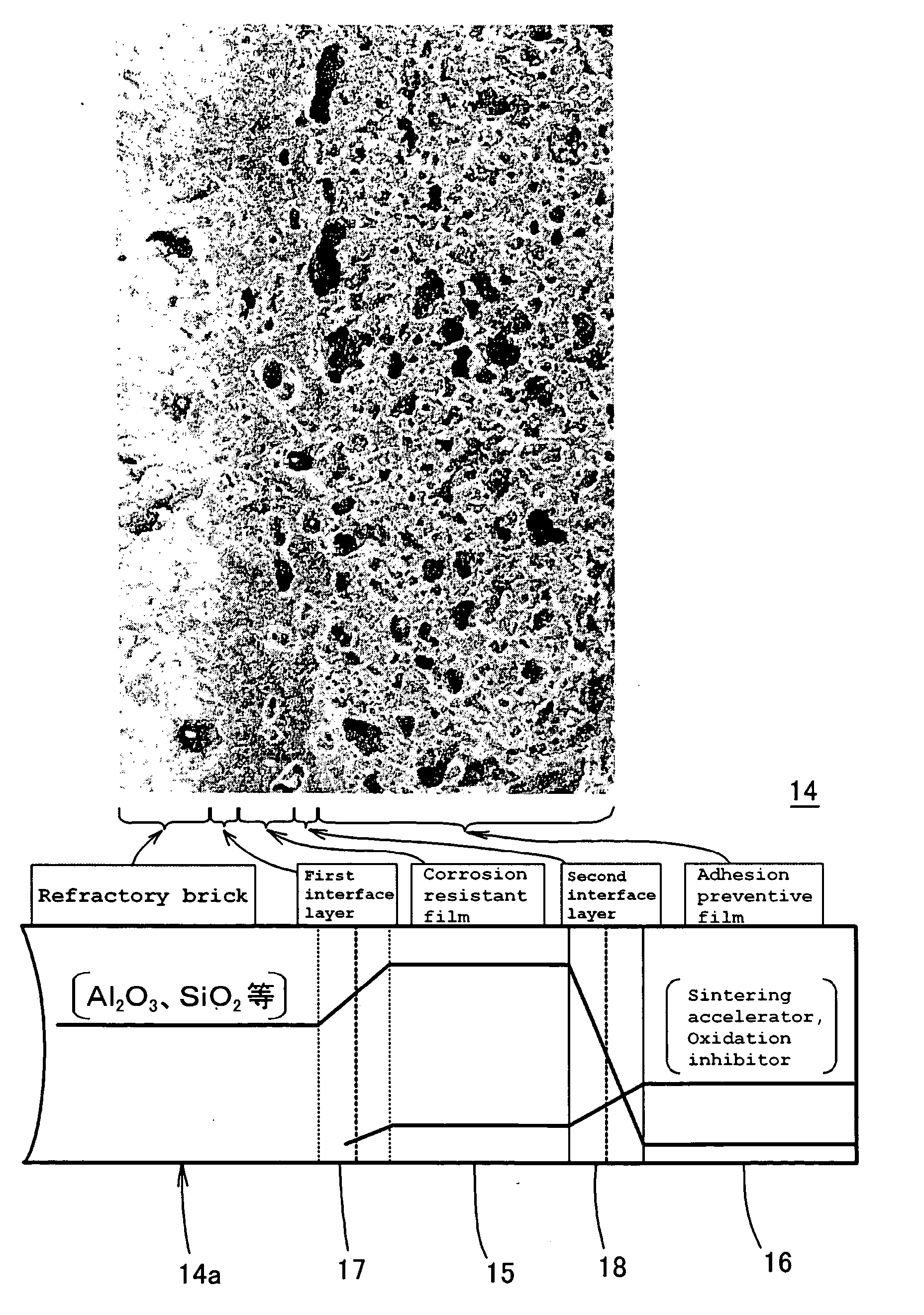

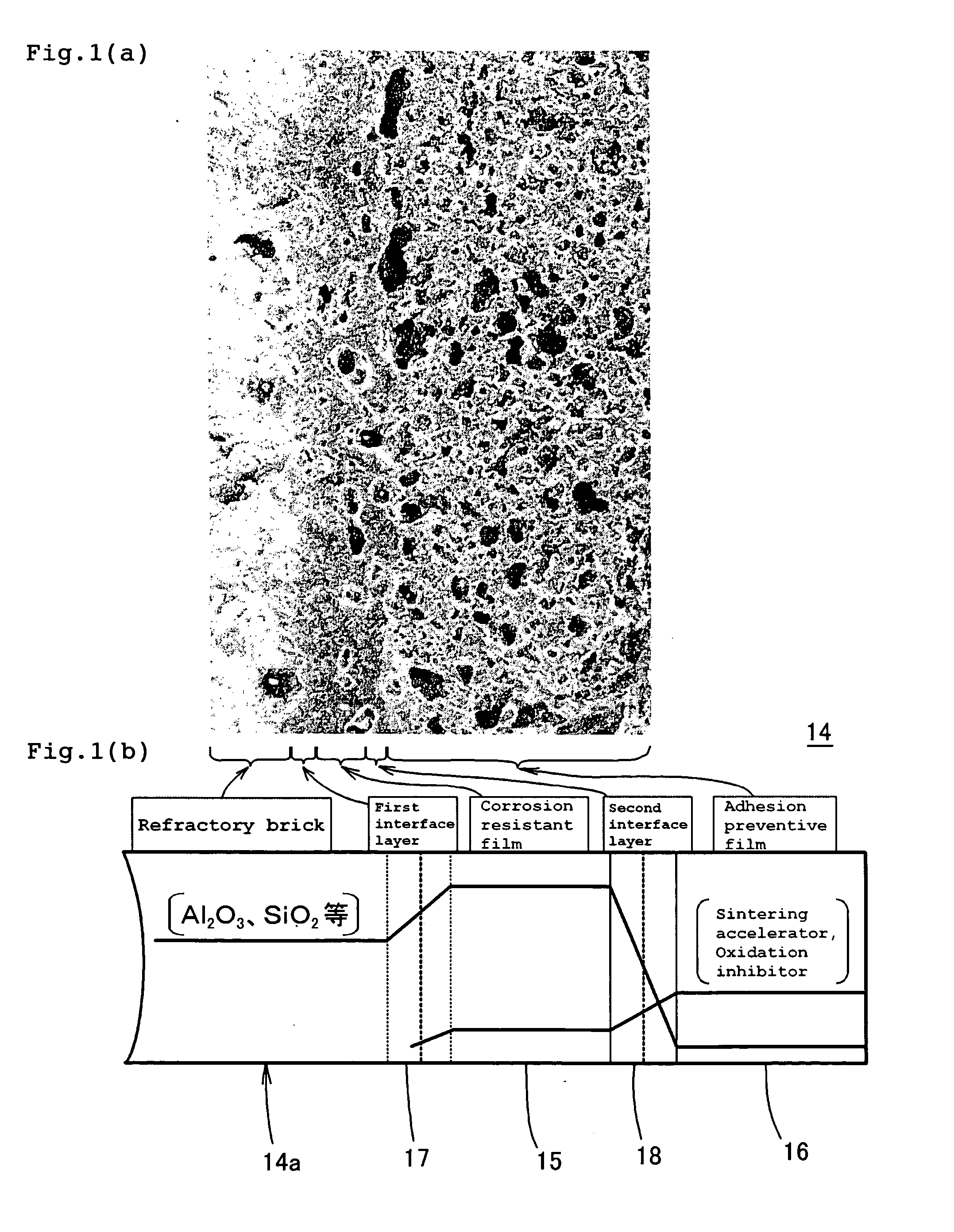

Refractory for furnace and furnace and method for surface treating furnace wall

InactiveUS20050053892A1Long service periodLow costLinings repairCasings/liningsSurface layerRefractory

A film for preventing a refractory deterioration is formed on the surface of refractory for a refuse incinerator. Since the preventive film exhibits high adhesion resistance to clinker generated in the incinerator, clinker does not adhere to the film easily. Since the preventive film is composed of fine and dence inorganic oxide based ceramics, surface layer of a brick body is covered with a film harder than the body. Consequently, wear resistance of refractory brick is enhanced. Since a corrosion resistant film exists on the surface of the body, intrusion of chloride gas is suppressed effectively, even if the body is exposed to chloride gas. Even an inexpensive fireclay brick is protected against adhesion of clinker and spalling, and use period of refractory brick is prolonged.

Owner:KITAKYUSHU FOUND FOR THE ADVANCEMENT OF IND

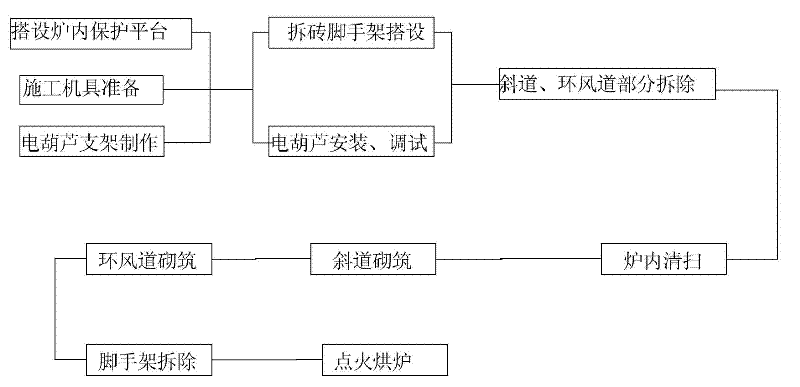

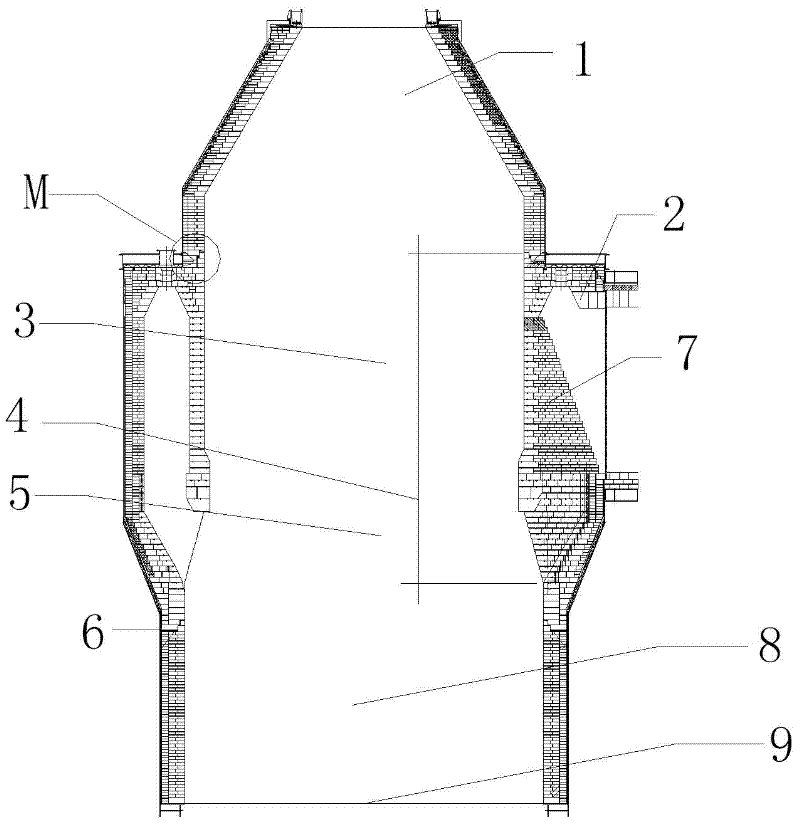

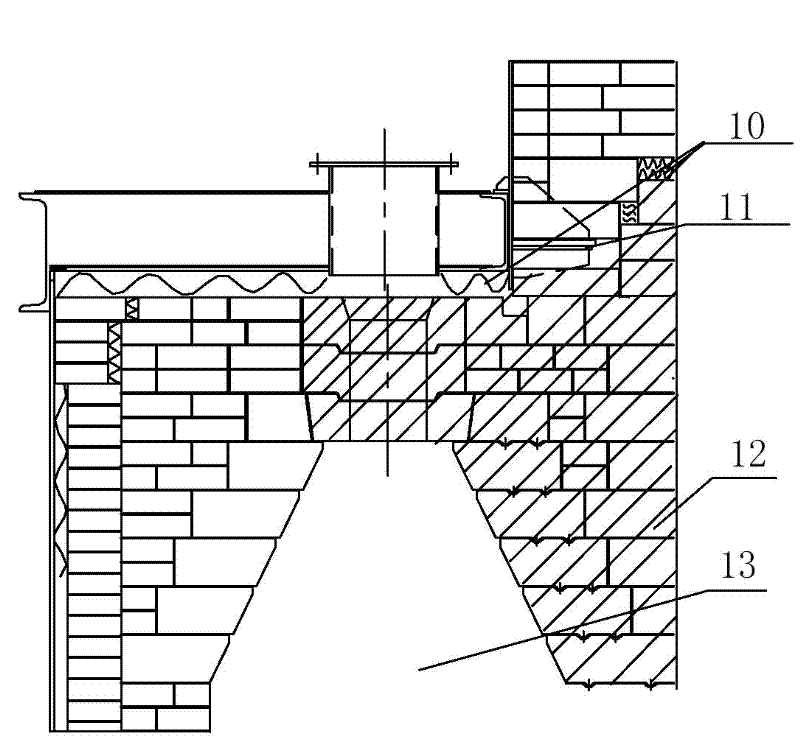

Method for overhauling fire-resistant material for annular air duct and chute in coke dry quenching furnace

The invention provides a method for overhauling a fire-resistant material for an annular air duct and a chute in a coke dry quenching furnace. A furnace body is divided into a pre-storage chamber, the annular air duct, a chute area and a cooling chamber; and brick supporting rib plates and expansion seams are arranged on a pre-storage section and the annular air duct. The method is characterized by comprising the following steps of: a, erecting a protection platform in the furnace and preparing construction equipment; b, erecting a scaffold for taking apart bricks; c, dismounting a part of the chute and the annular air duct; d, cleaning the furnace; e, constructing the chute; f, constructing the annular air duct; and g, dismounting the scaffold and igniting to bake the furnace. The method for overhauling the fire-resistant material for the annular air duct and the chute in the coke dry quenching furnace provided by the invention has the advantages of reasonable design of construction step, simplicity in operation, safe and reliable engineering quality, and reduction of the engineering construction cost.

Owner:CHINA MCC5 GROUP CORP

Production method for foam carbon extraordinarily high temperature macrotype hard heat-insulating room

InactiveCN101173839AGood heat insulationSatisfy geometry requirementsLinings repairCarbon compositesAntioxidant

The invention discloses a manufacture method of an ultrahigh temperature large hard heat insulation chamber made of foam carbon, which is characterized in that: the foam carbon is used to make the prefabricated blank of a heat insulation chamber; then the prefabricated blank of the heat insulation chamber is bound to a type modulus, which is solidified and demoulded; then a permeation proof film is laid and a corrosion-proof antioxidant is coated; finally the heat insulation chamber is completed after the integral sintering. The invention has the advantages of aiming at solving the problems of the prior domestic high temperature furnaces caused by the adoption of the soft carbon felt life tenure sewing heat insulation chamber, and producing integral, hard, abnormity and large heat insulation chamber in order to meet the needs of the high-tech industries such as alloy, moncrystalline silicon and carbon or carbon composite material and replace the imported heat insulation chamber; in addition, the invention has low cost and simple and practical production method.

Owner:烟台鲁航炭材料科技有限公司

Welding repair material for repairing coking furnace and method for repairing coking furnace

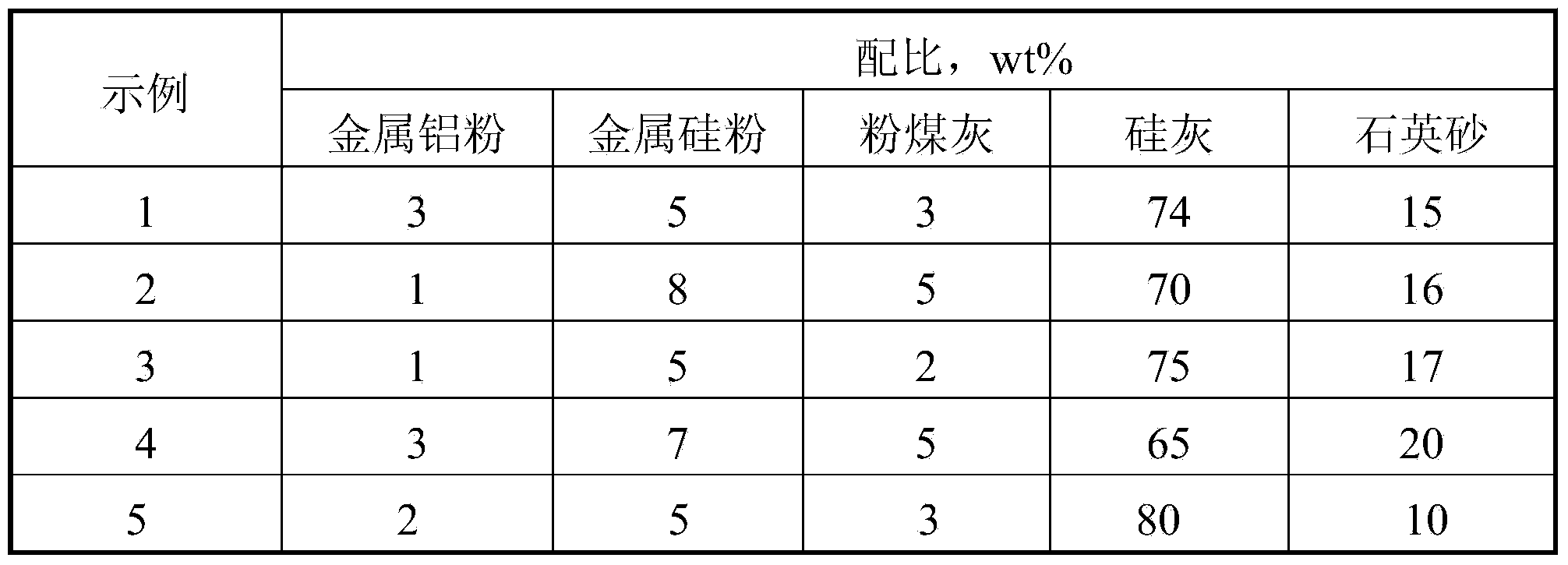

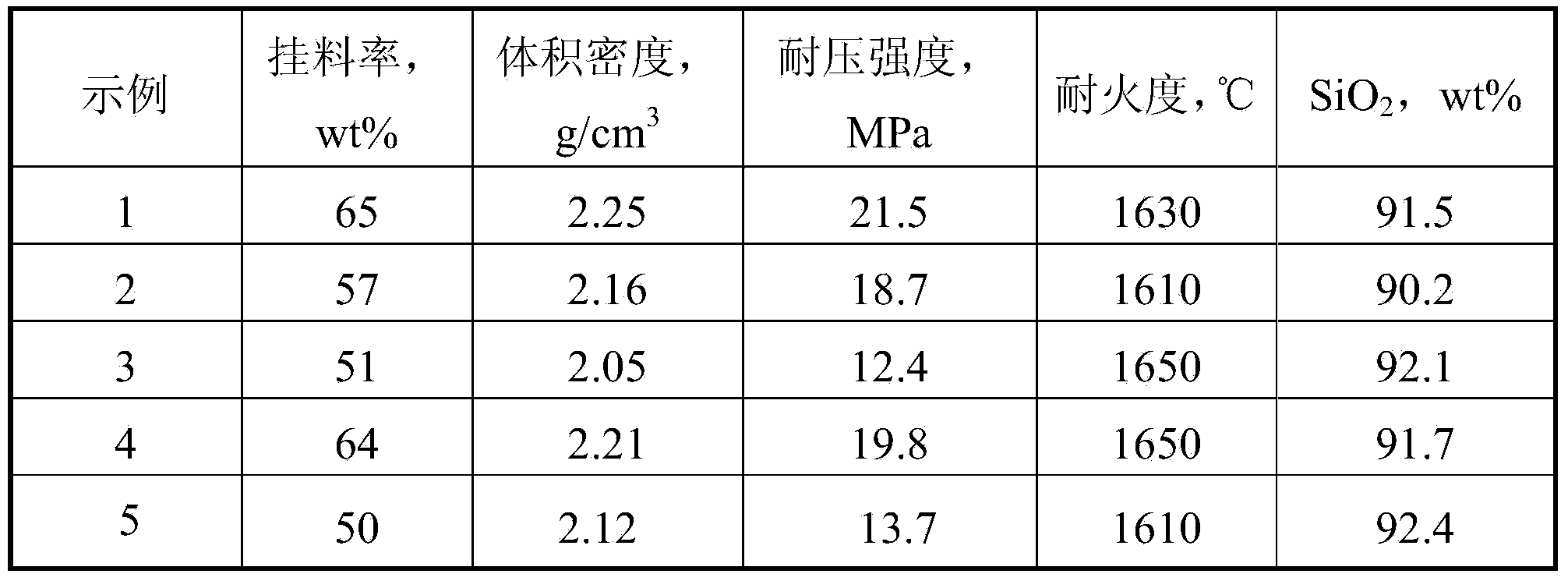

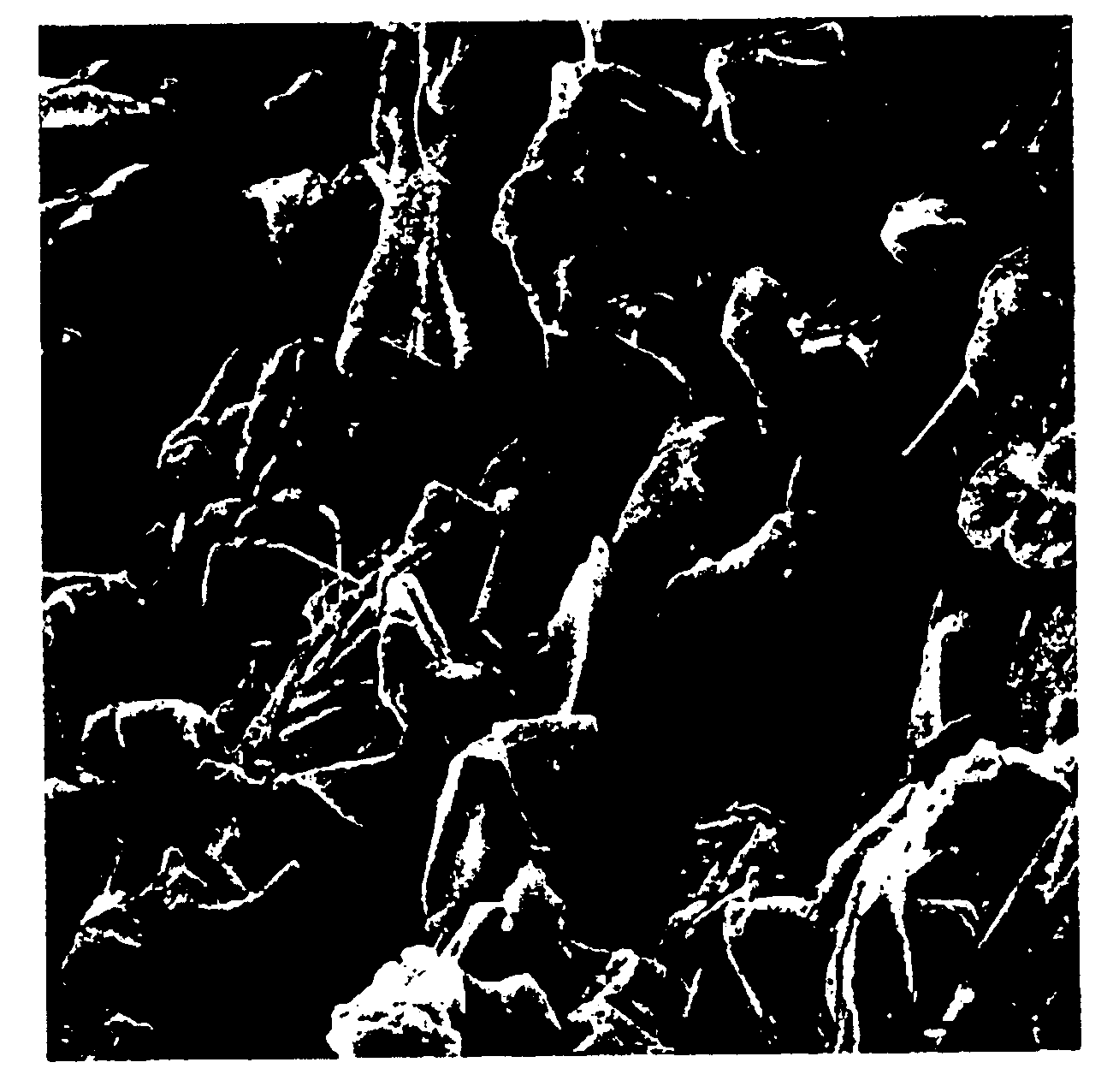

The invention provides a welding repair material for repairing a coking furnace and a method for repairing the coking furnace. The welding repair material comprises the following components in percentage by weight: 1-3% of metal aluminium powder, 5-8% of metallic silicon powder, 2-5% of mineralizing agent, 65-85% of silica fume or quartz powder and 10-20% of quartz sand. The method for repairing the coking furnace comprises the steps of spraying the welding repair material for repairing the coking furnace onto a wall brick surface of a high temperature furnace to be repaired along with an oxygen-enriched gas and carrying out an oxidation reaction, so that the welding repair material is partially molten and adhered on the wall brick surface of the coking furnace to be repaired, and a ceramic repairing layer is formed. The welding repair material for repairing the coking furnace has the advantages that secondary resources such as coal ash and silica fume are taken as raw materials, high-efficiency comprehensive utilization of the secondary resources is realized, and production cost of the welding repair material is reduced; besides, aluminium and silicon metals are added, so that spontaneous heating sintering is realized, and no high temperature high pressure gas is adopted when the welding repair material for repairing the coking furnace is adopted for repairing the coking furnace; content of silica in the welding repair material for repairing the coking furnace is more than 90%, so that the welding repair material for repairing the coking furnace is a highly silicious welding repair material and has a good silica brick breaking effect when being used for repairing the coking furnace.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method of making silicon nitride-bonded silicon carbide honeycomb filters

InactiveUS6699429B2High mechanical strengthDesirable thermal propertyLinings repairExhaust apparatusSufficient timeMicrometer

A process for forming a silicon nitride-bonded silicon carbide honeycomb monolith by a) forming a plasticizable mixture which includes (1) about 60% to 85% by weight, powdered silicon carbide with a median particle size of about 10-40 micrometers; (2) about 15% to 40% by weight, powdered silicon metal with a median particle size of about 5-20 micrometers; and, (3) organic components; b) extruding the plasticizable mixture to form a green honeycomb monolith; c) drying the green honeycomb monolith; and, d) heating the honeycomb monolith to 1450.degree. C. with a hold of 1 hour in an atmosphere of argon; and, e) nitriding the honeycomb monolith between 1450.degree. C. to 1600.degree. C. for a time sufficient to obtain a silicon nitride-bonded silicon carbide body.

Owner:CORNING INC

Slagline sleeve for submerged entry nozzle and composition therefor

InactiveUS6410469B1Reduced contractile tendencyLarge volumeMelt-holding vesselsLinings repairStress boneGraphite

An improved submerged entry nozzle is provided which is useful in the casting of aluminum killed molten steel. The nozzle has an improved slagline sleeve or collar which surrounds the outer portion of the nozzle to protect it from corrosion during the casting process. The slagline sleeve is made from resin bonded zirconia / graphite which has been formulated so that upon curing of the resin to form resite, there is a reduction in the contractile tendency which results in a reduction in stress fracturing. The reduction of the contractile tendency and the resulting resistance to stress fracturing is achieved by adding an effective amount of calcium oxide to the resin-zirconia-graphite mixture which is used to form the sleeve.

Owner:BAKER REFRACTORIE

0.5-1 ton intermediate frequency furnace wet construction process

ActiveCN102278888AExcellent adhesionImprove firmnessLinings repairIntermediate frequencyEconomic benefits

The invention relates to a 0.5-1 ton intermediate frequency furnace building technology based on a wet method. The technology is characterized by comprising the following steps: a. cutting asbestos cloth according to the dimension of an electric furnace, and preparing a quartz sand mixing material according to the size of an intermediate frequency furnace; b. distributing the asbestos cloth which is cut in advance from top to bottom on a coil in a furnace-body-type cavity to be built; c. knotting for the bottom of the furnace; d. mounting a steel pot model; e. knotting for a furnace wall; f. knotting for the top of the furnace; g. knotting for a water outlet groove; and h. drying the furnace. According to the invention, the flow is reasonable, the operation is simple, and the production cost is low; after the quarts sand is stirred and mixed by use of an appropriate amount of water, the adhesivity is stronger, feeding and knotting are convenient and simple, the furnace liner has high degree of compacting, the service life of the furnace is improved, the service life of a 1 ton intermediate frequency furnace is prolonged to 15-25 days, the service life of a 0.5 ton intermediate frequency furnace is prolonged to 80-90 days, the steel pot can also be extracted in the process of drying the furnace and can be used again, and the economic benefit is obvious.

Owner:HUAMIN NANPING AUTOMOBILE FITTINGS GROUP

Improved convertor quick-sintering heat self-flow compensation material, preparing technology and use

InactiveCN101025337AShort sintering timeImprove the efficiency of the converterLinings repairManufacturing technologyDetonation

The invention discloses a kind of improved converter fast-burning heat-junction free-running patching material, its manufacture technology and application. Its features are: the patching percent by weight is one of the two followed: (1) MgO 75-85 Al2O3 1.0-2.0, whole carbon 4.0-12.0 Fe2O3 0.5-1.5 CaO 1.0-2.5, the remnant is SiO2; (2) Mg0 60-70 Al2O3 0.5-2.0, whole carbon 4.0-12.0 Fe2O3 0.3-1.0 CaO 10.0-20.0, the remnant is SiO2. Its manufacture technology is: firstly, to weigh according the above mixture ratio and then to put it in high-temperature bonding agent, high-temperature lacquer solvent, detonation suppression and anti-oxygen, then to intermix it homogeneously by the efficient mixing machine and to deliver it to junk machine by the band carrier to press compact, after all, press it to balls by the ball forming mill. The life span of the heat-junction free-running patching material this invention offers is the time for 30-50 furnaces, and the time for sintering is lowed to 10-25 minutes. It has the merits of good heat flow, high bond strength, high erosion-resisting characteristics and anti osmosis and good sintering under low and middle temperature, and we have gotten good result in the 300-ton converter in Baogang steel works.

Owner:上海柯瑞冶金炉料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com