Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148results about "Brickwork leakage repair/prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

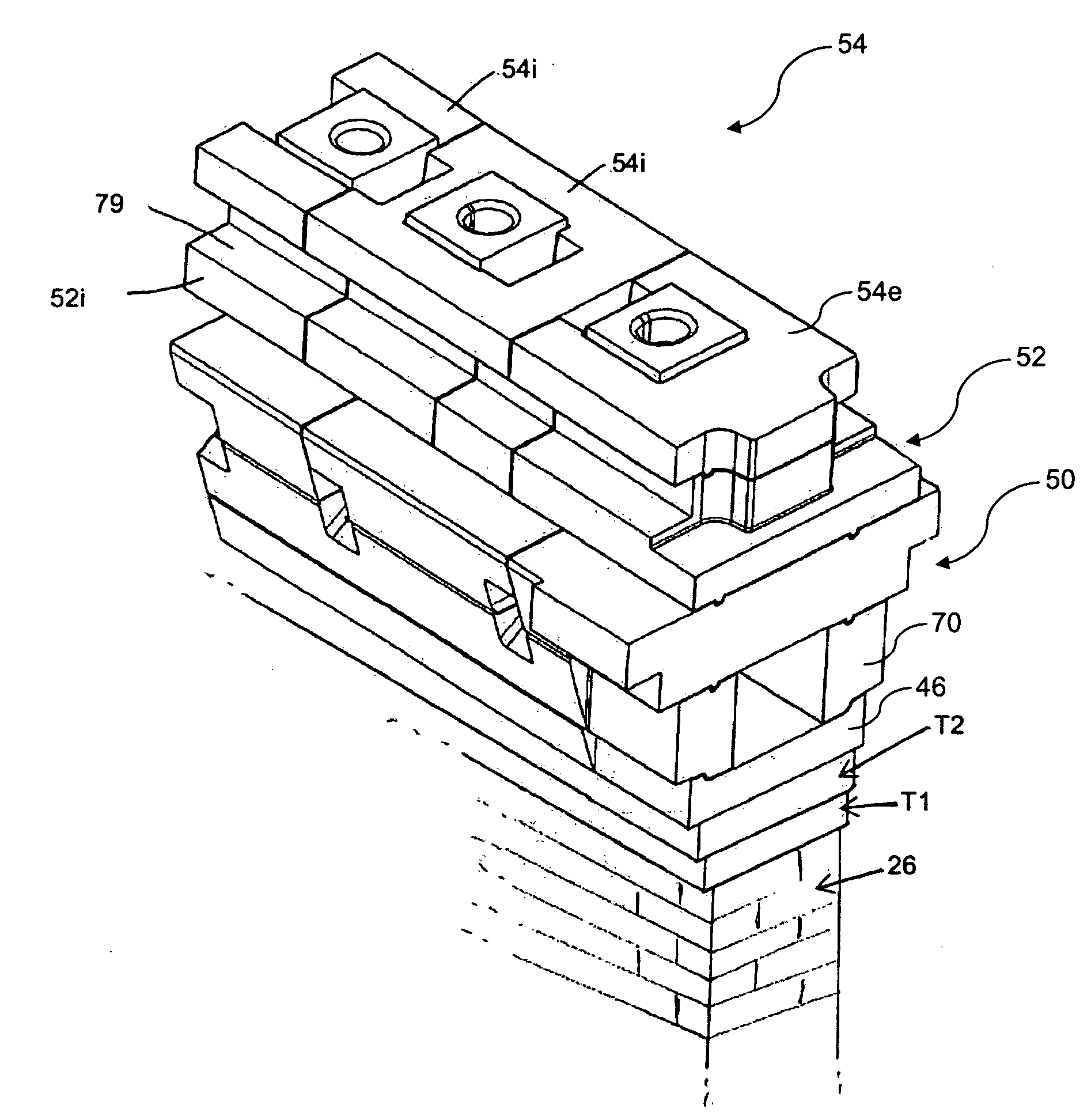

Corbel repairs of coke ovens

ActiveUS8266853B2Cost-effective constructionSave significant amountFurnace componentsFloorsEngineeringCoke oven

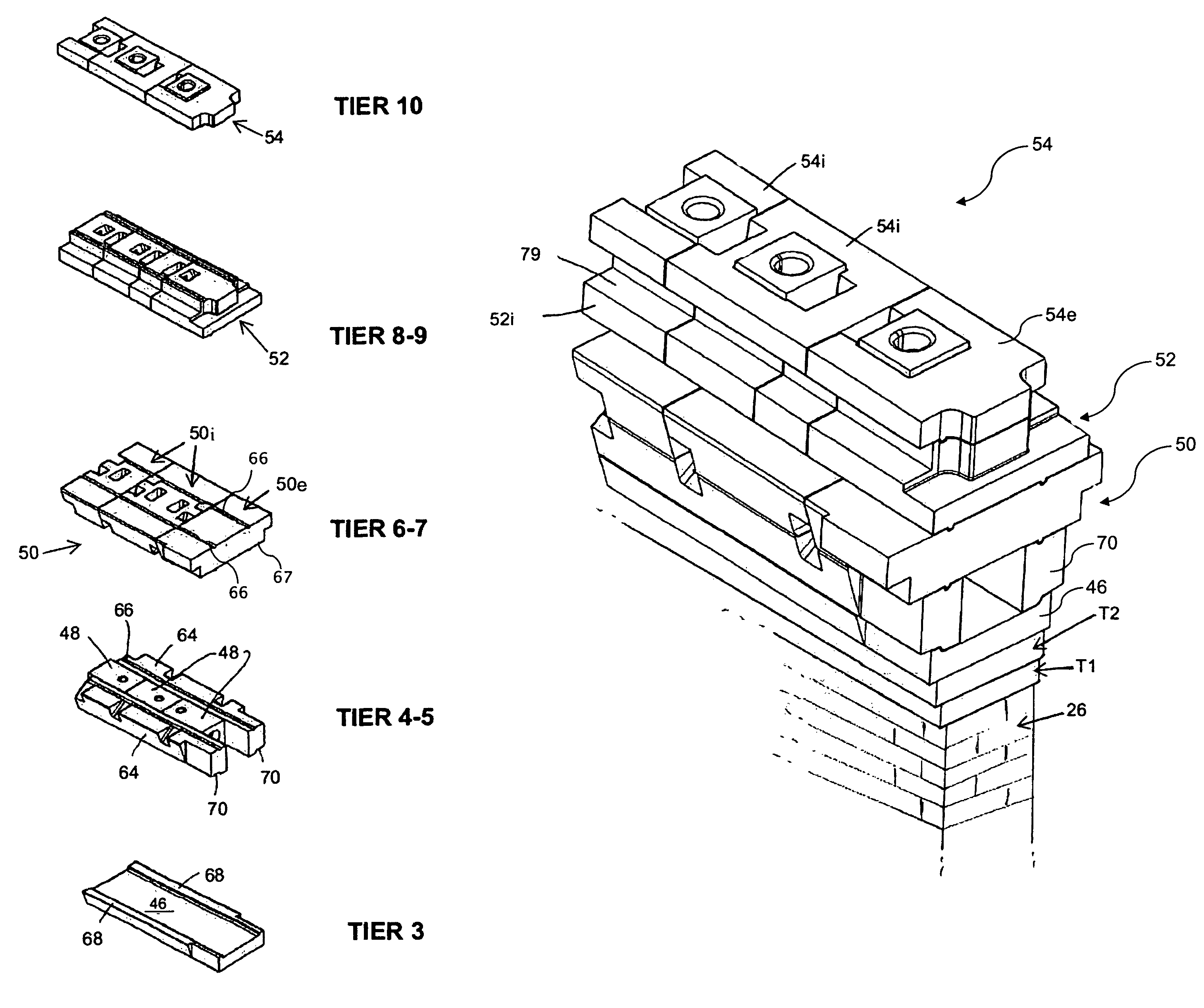

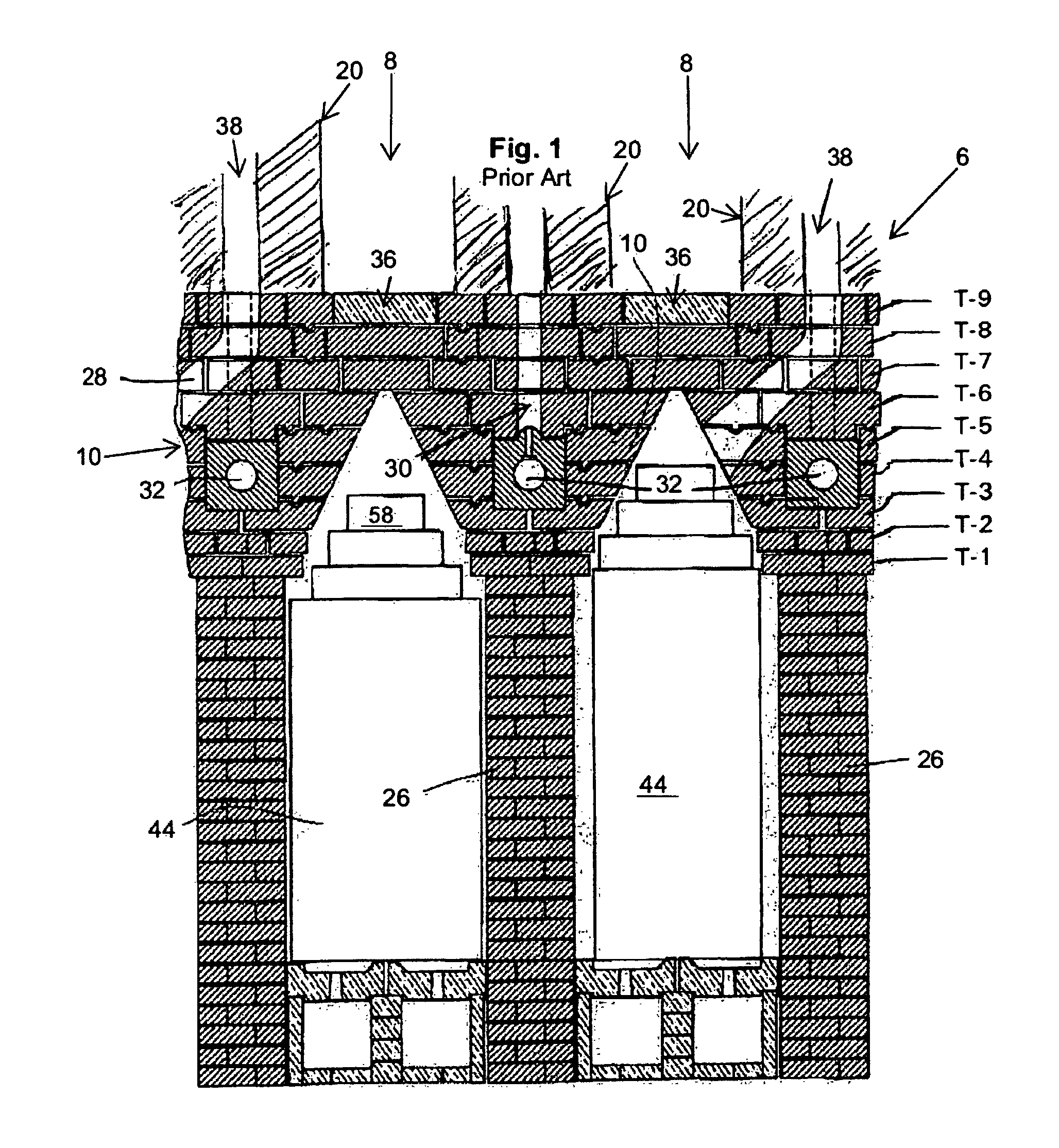

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

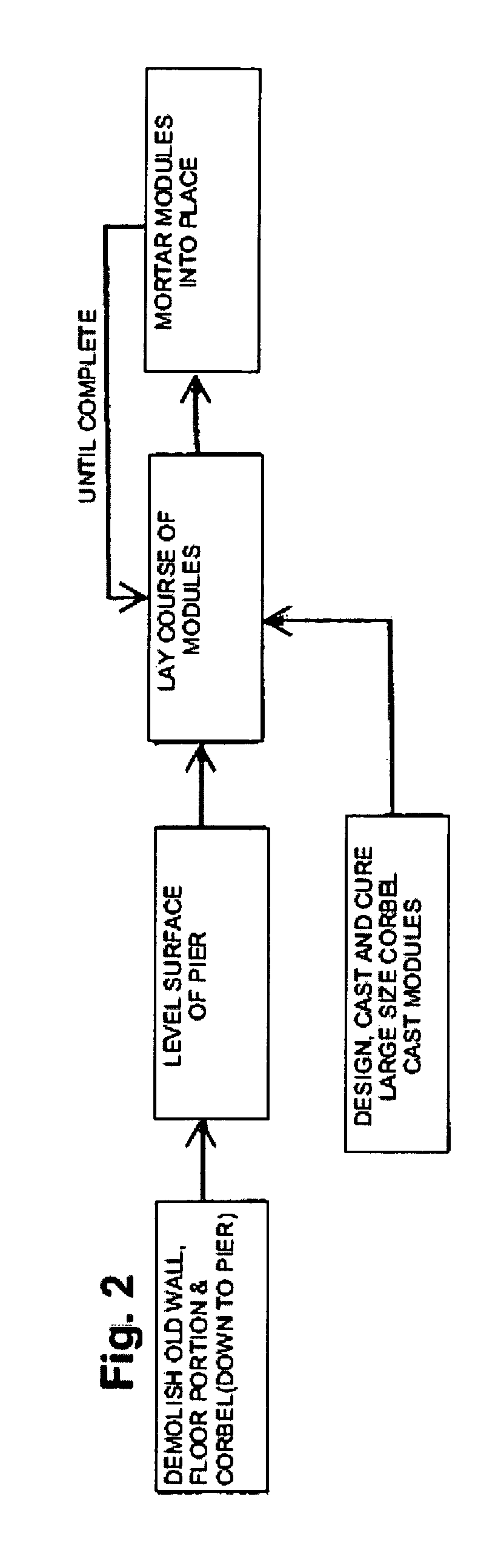

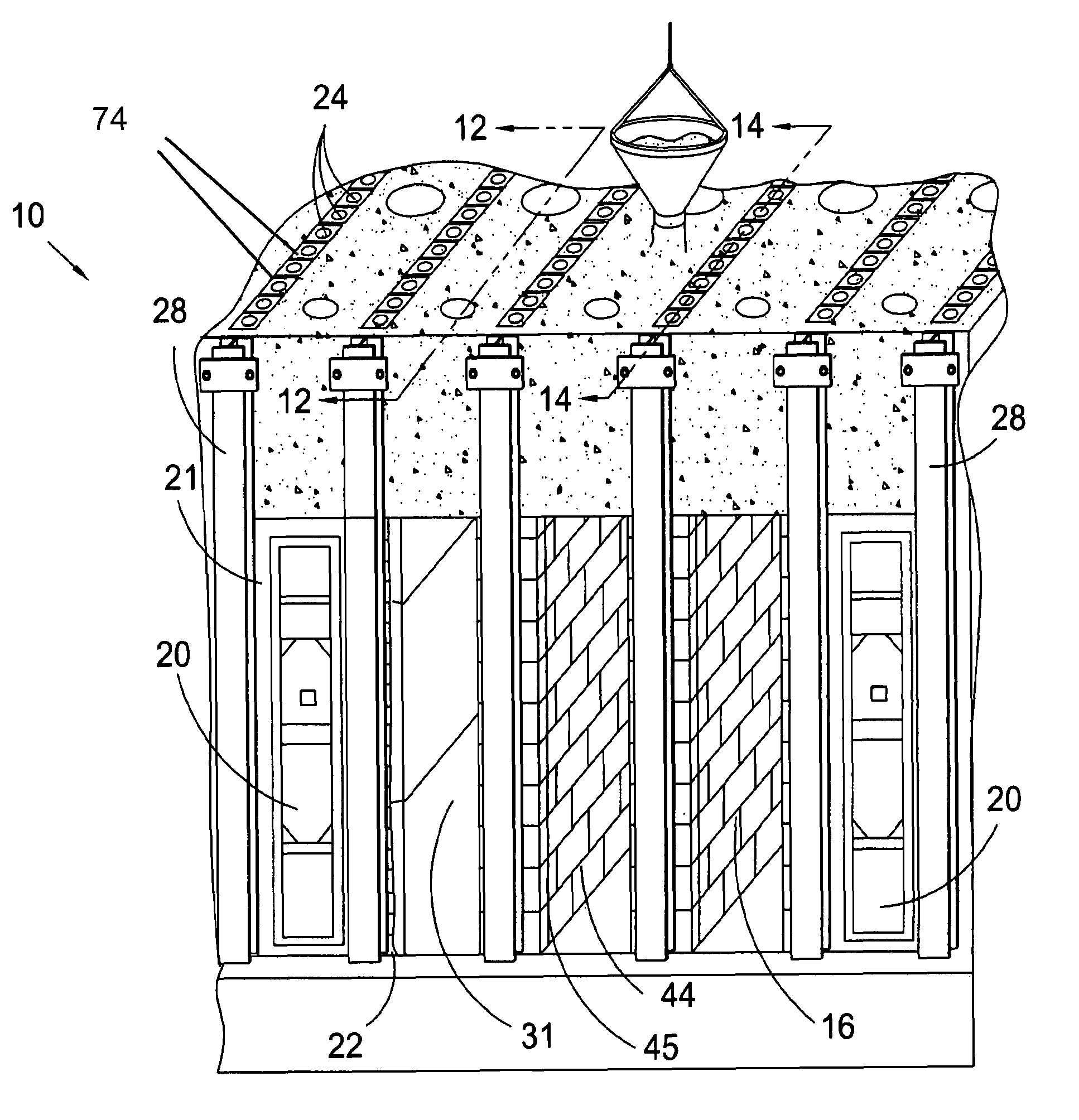

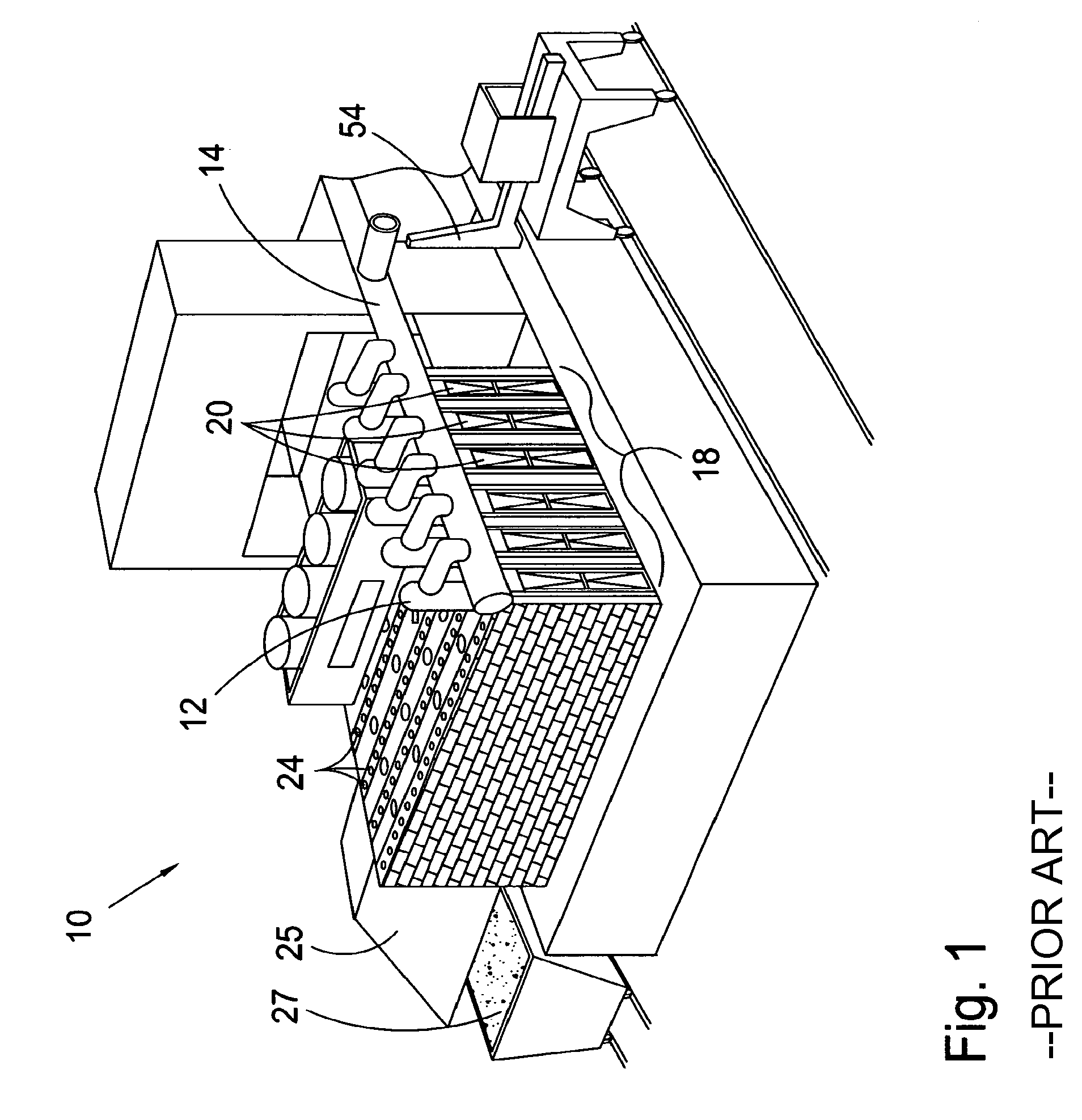

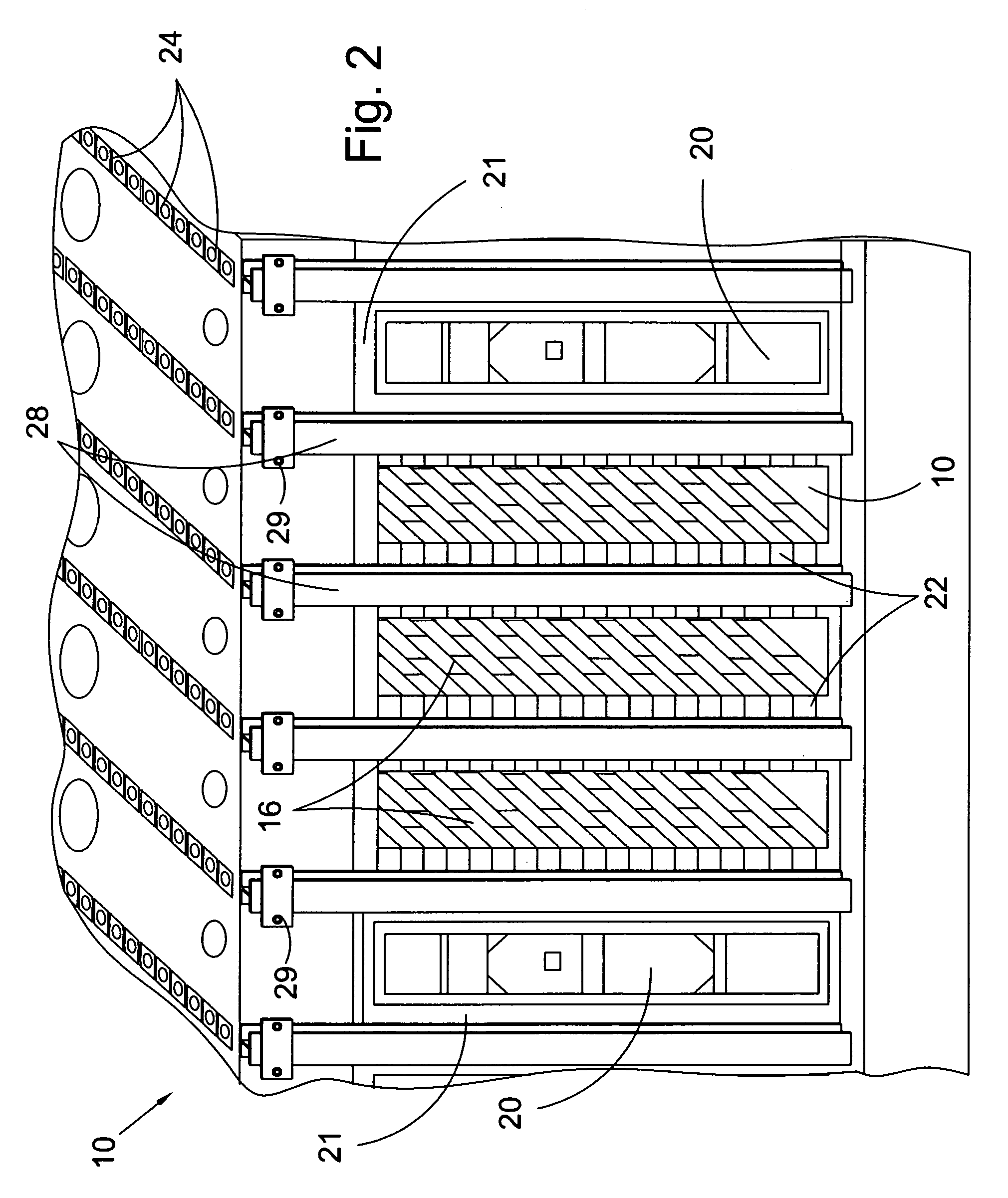

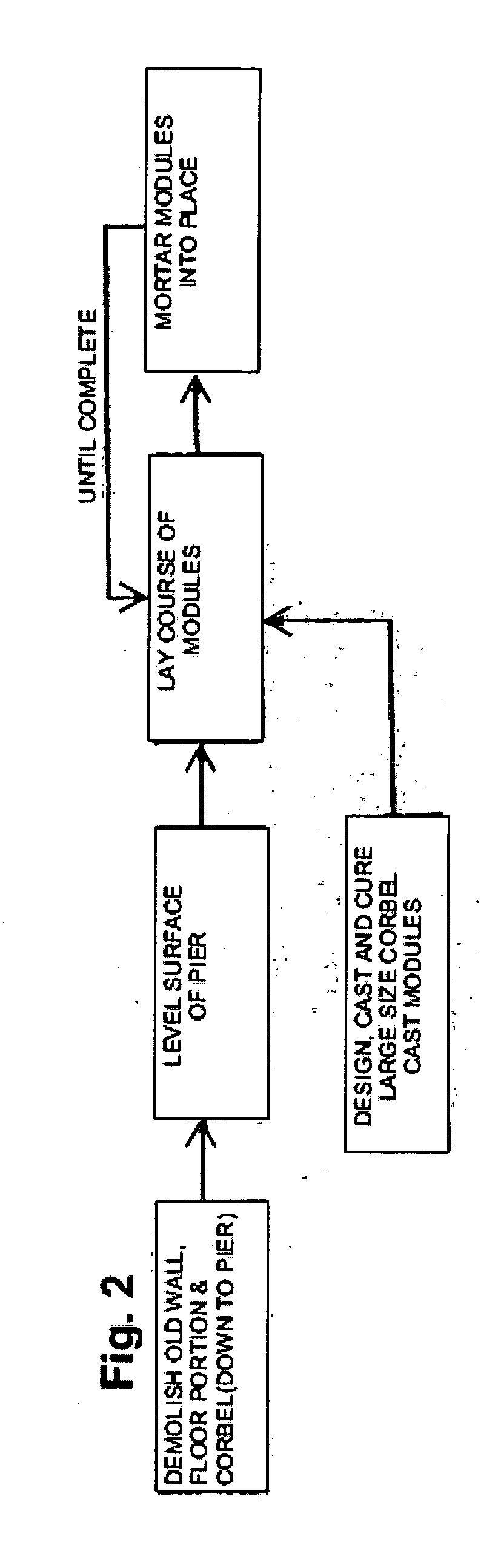

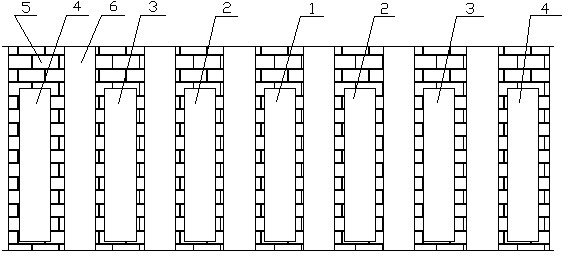

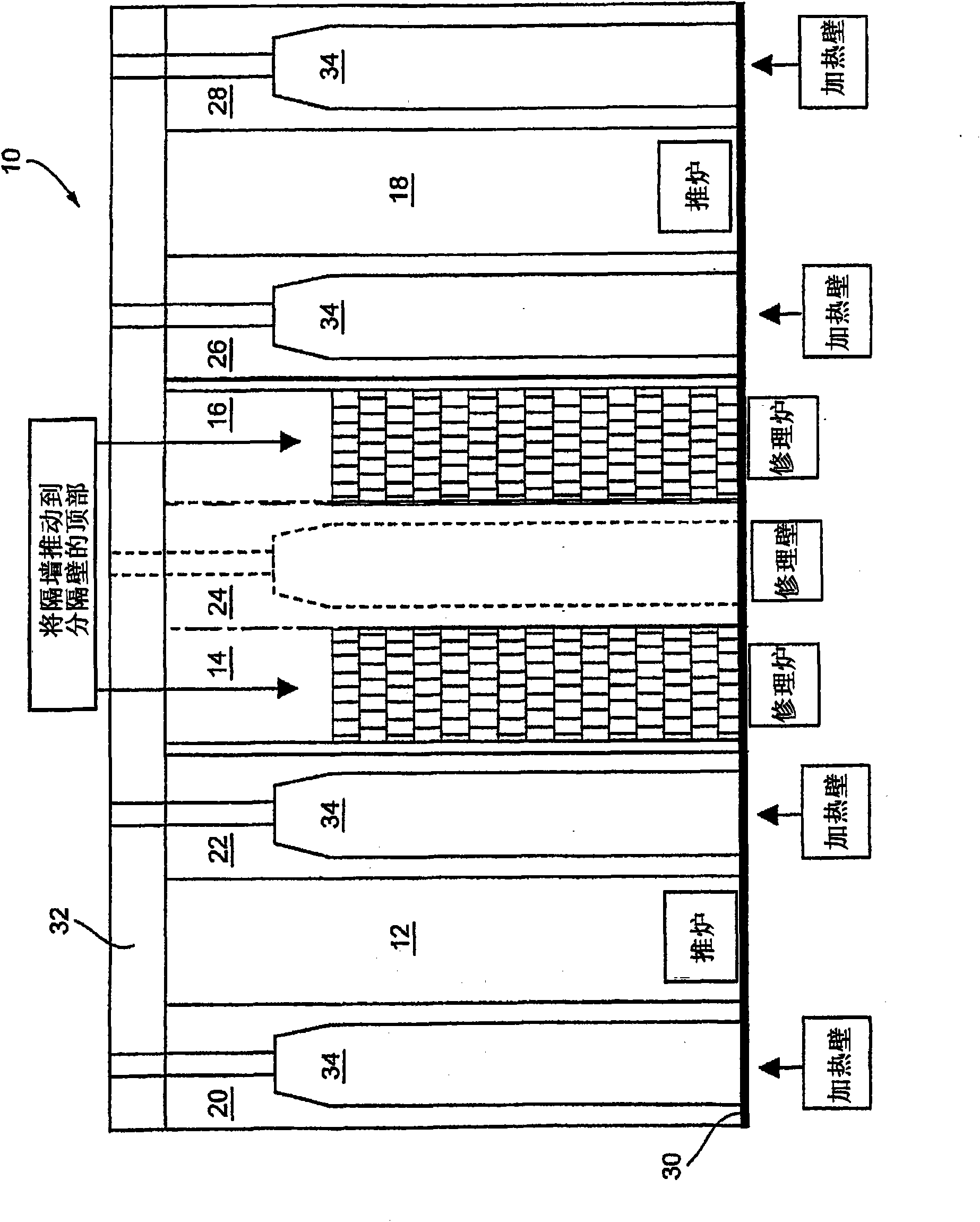

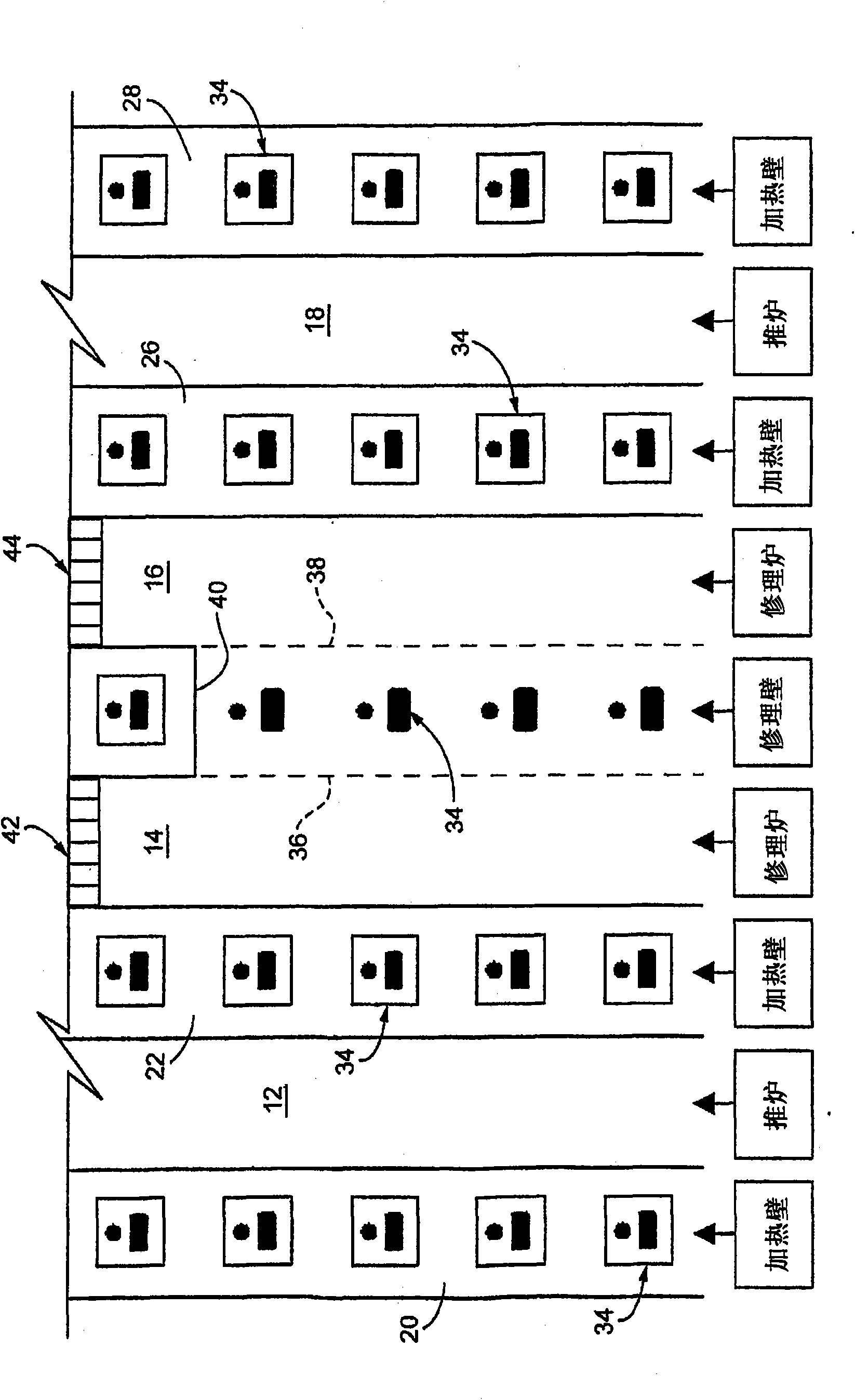

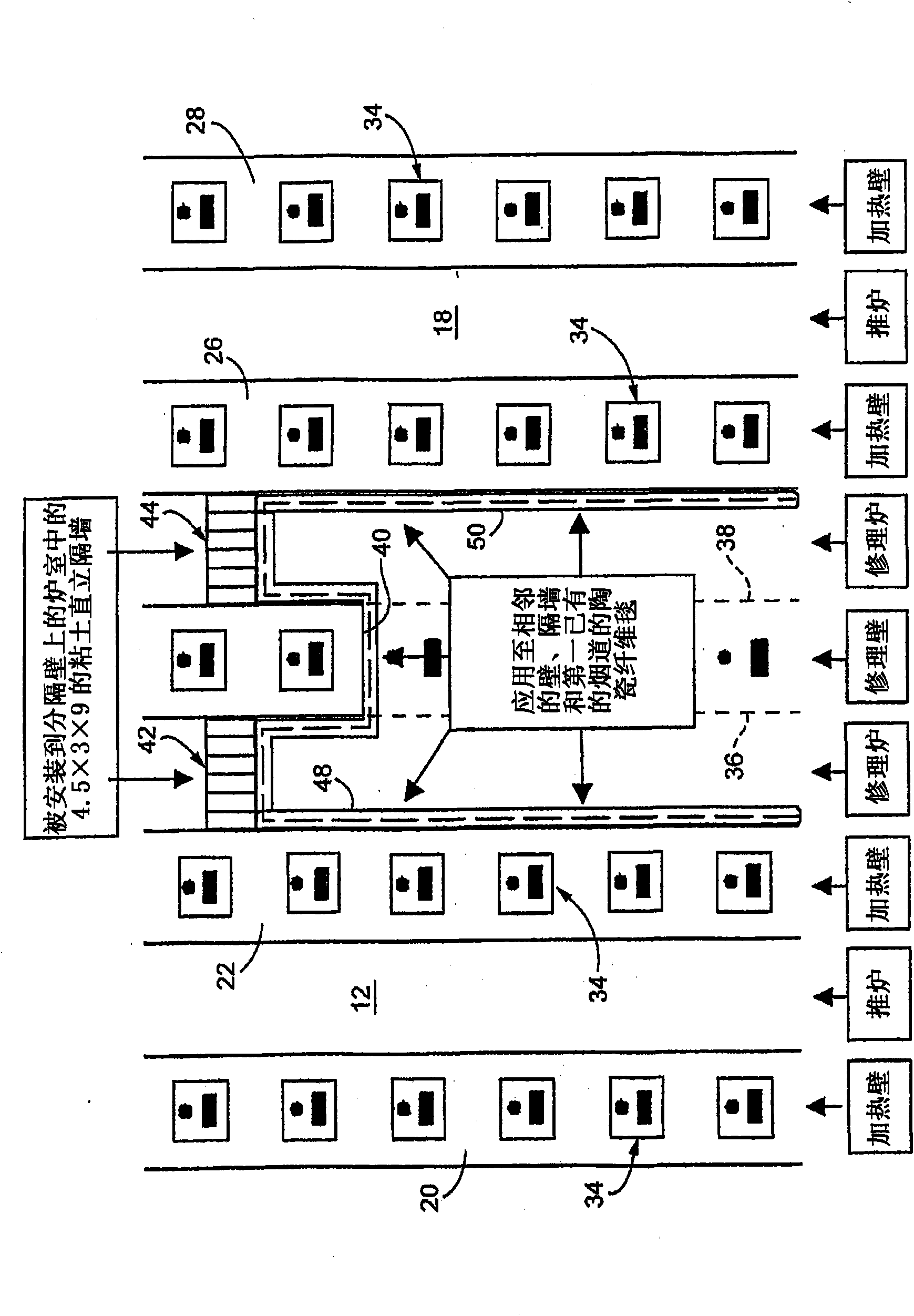

Coke oven reconstruction

ActiveUS7827689B2Good dimensional stabilityNegligible heatingConstruction materialCoke oven brickworkComputer moduleEngineering

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

Corbel repairs of coke ovens

ActiveUS20100287871A1Cost-effective constructionSave significant amountFurnace componentsWallsEngineeringCoke oven

An improved corbel includes a first tier having first blocks and a second tier having second blocks. Each of the first blocks includes a first aperture extending through the block from a first surface to a back surface and a second aperture formed through a top surface of the block, extending into the first aperture. The first blocks are arranged on a substantially planar surface to align the respective first apertures to define a first passageway. Each of the second blocks includes a third aperture extending through the second block from a top surface to a bottom surface. The second blocks are disposed above the first tier to align the third aperture of each of the second blocks with the second aperture of the first blocks to form a second passageway.

Owner:VANOCUR REFRACTORIES LLC

Liquid grouting material used for coke oven furnace wall crack hot repairing, and preparation method and application method thereof

ActiveCN107445633ANormal working conditionsSolve the problem of poor liquidityBrickwork leakage repair/preventionEnvironmental resistanceRefractory

The invention discloses a liquid grouting material used for coke oven furnace wall crack hot repairing, and a preparation method thereof. The liquid grouting material used for coke oven furnace wall crack hot repairing is composed of, by mass, 100 parts of water glass, 100 to 250 parts of a solid filling material, and 9 to 16 parts of an additive. The solid filling material is composed of, by mass, 50 to 70% of mullite, 20 to 30% of refractory clay, and 10 to 20% of quartz sand. The additive is composed of a dispersant, a penetrant, and an antifoaming agent. According to the preparation method, the additive and the solid filling material are added into a water glass solution successively for uniform mixing so as to obtain the liquid grouting material used for coke oven furnace wall crack hot repairing. The liquid grouting material used for coke oven furnace wall crack hot repairing is convenient for pumping, possesses excellent cohesiveness with refractory material to be repaired, is wide in curing sintering temperature range, and is convenient for construction; the raw materials are cheap and easily available; no harm on human body is caused; the preparation period is short; the preparation method is simple; production cost is low; the production process is friendly to the environment; no pollution is caused; and large scale production can be realized.

Owner:SHANGHAI INST OF TECH

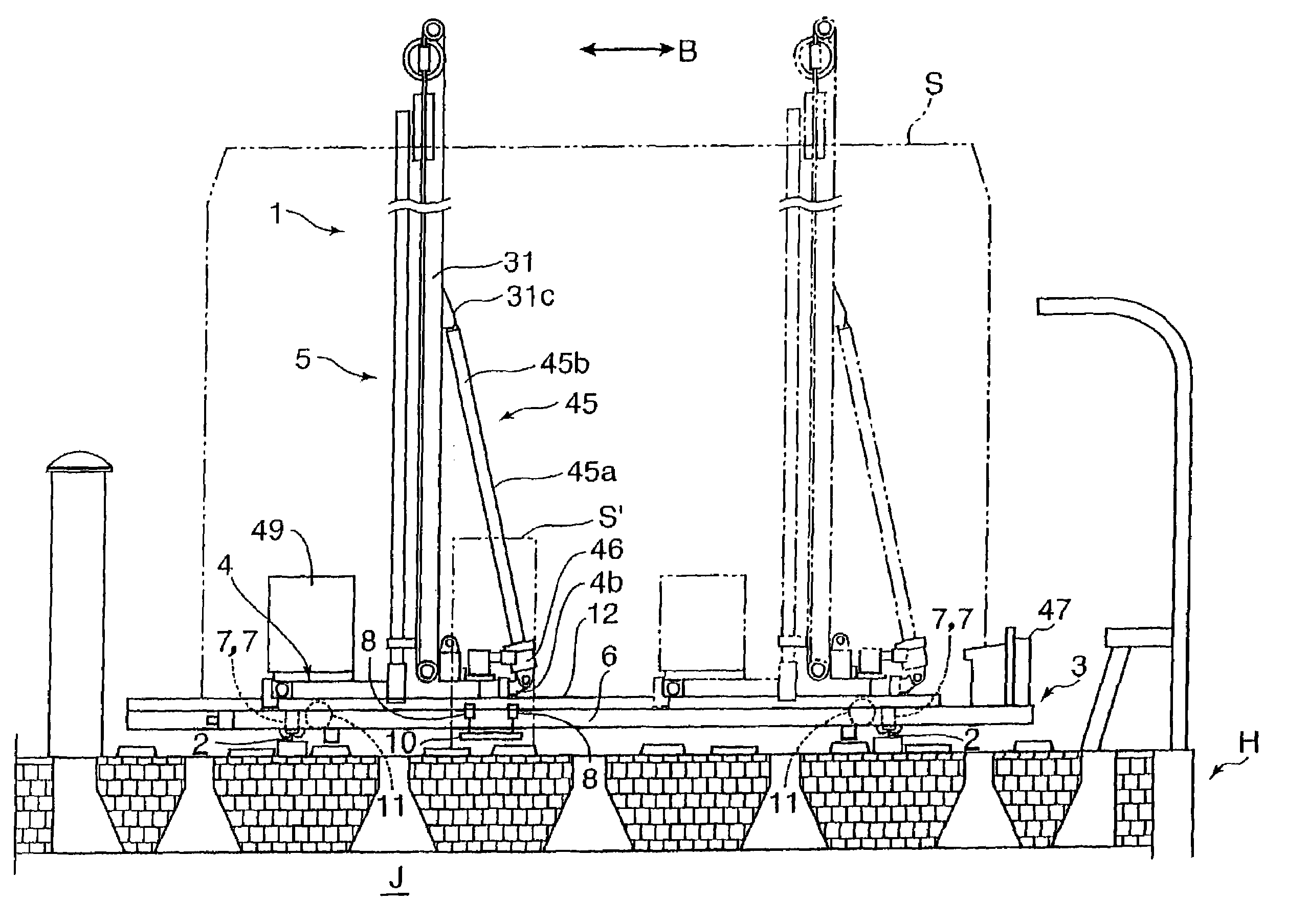

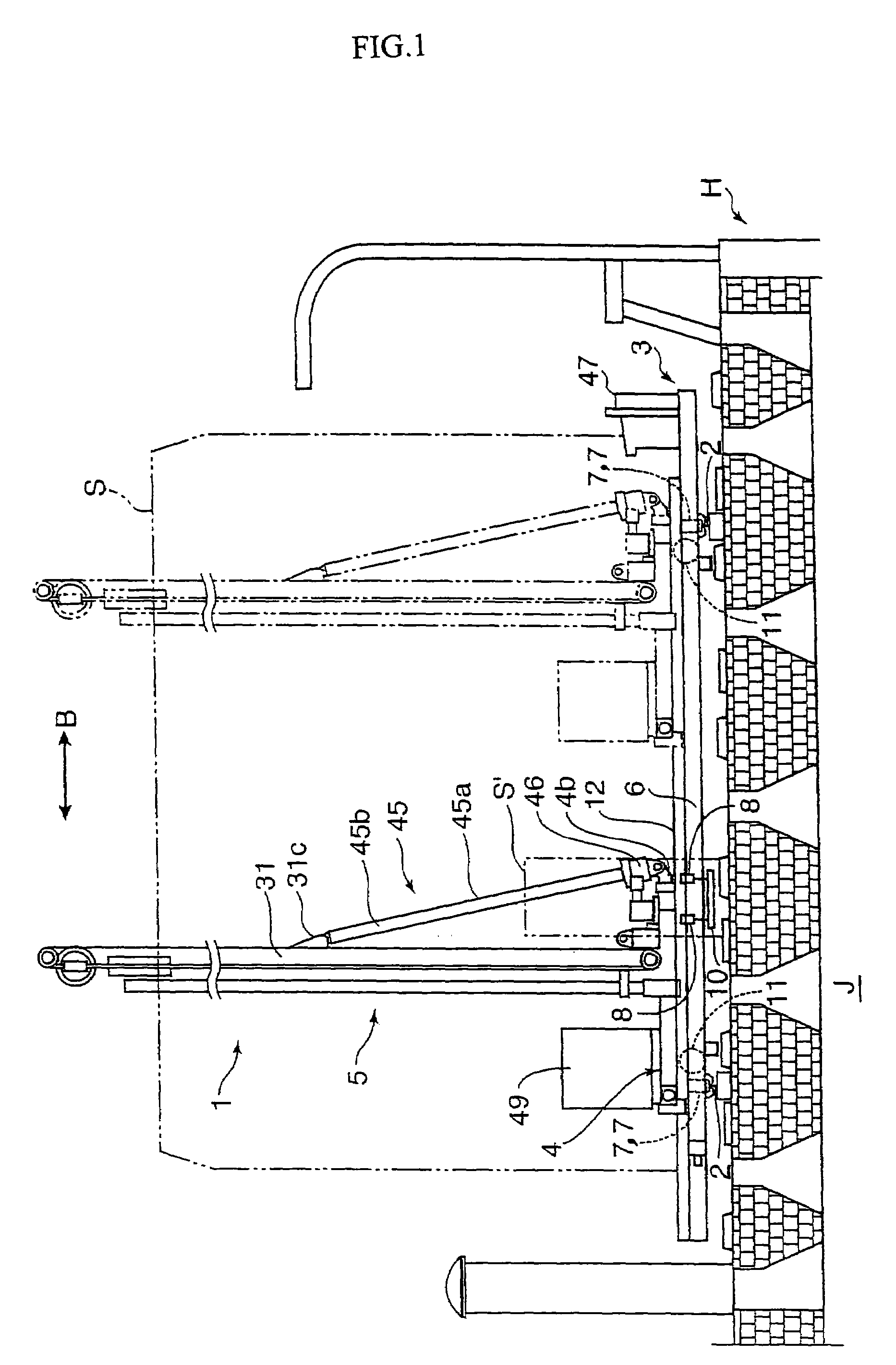

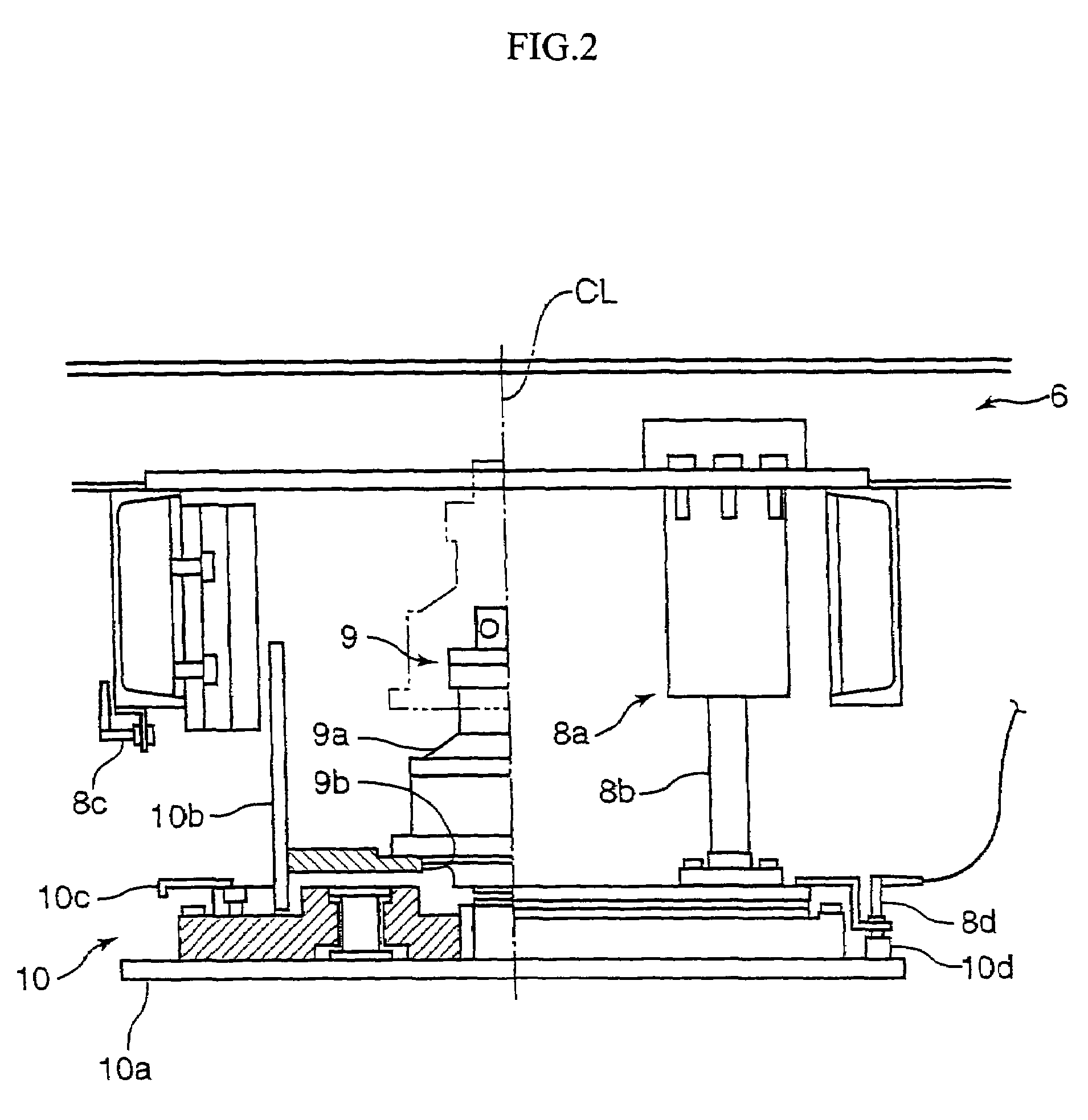

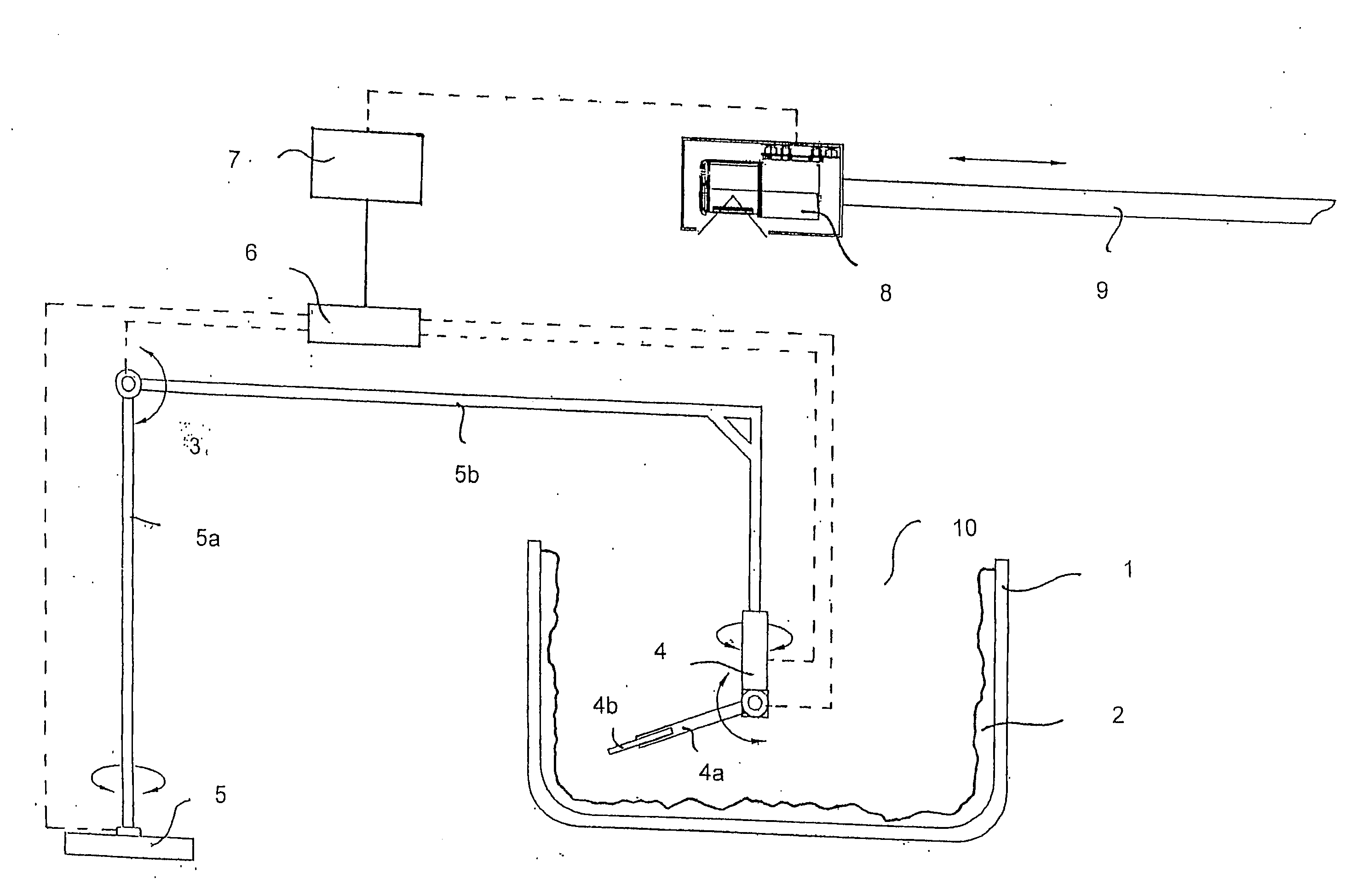

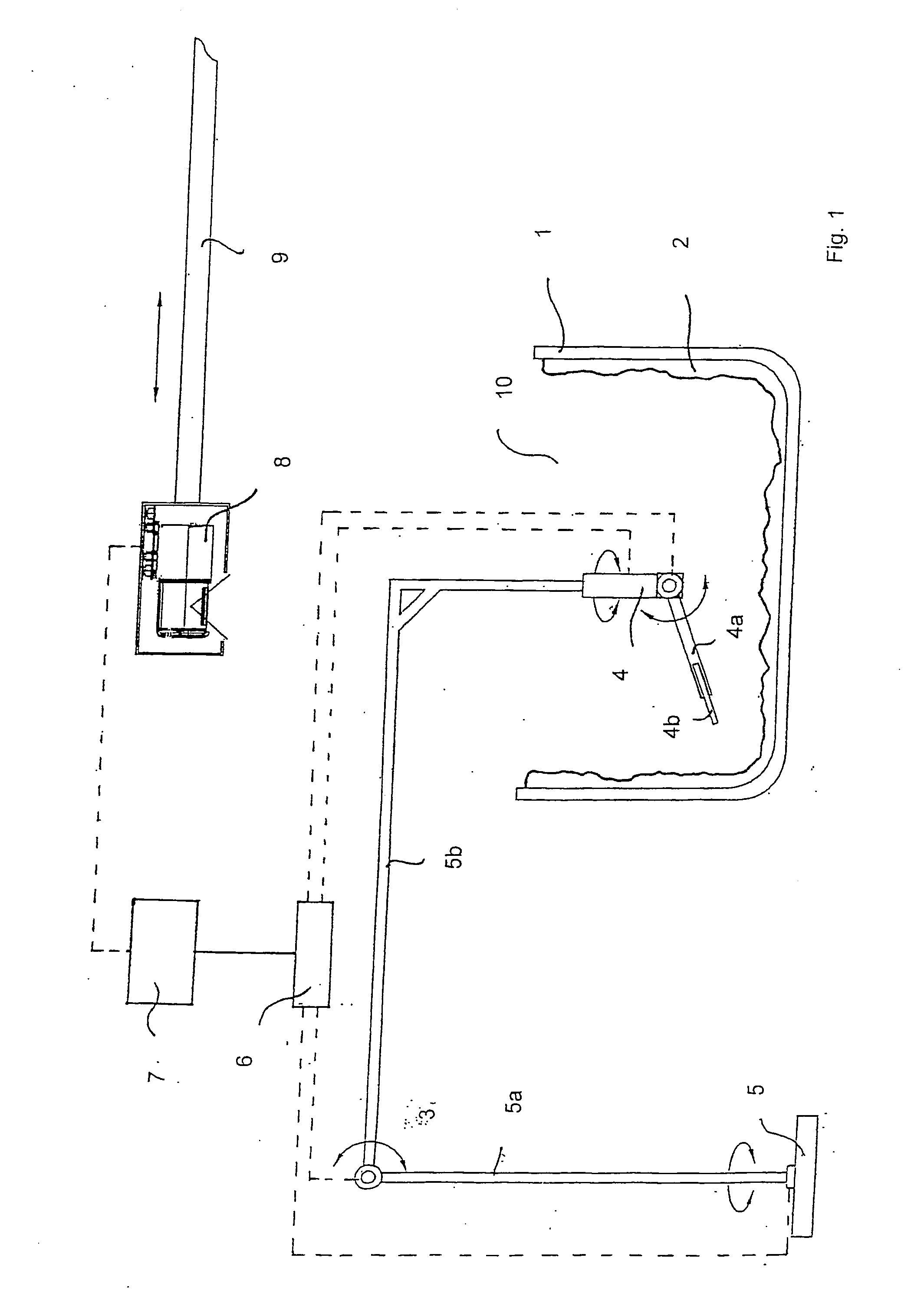

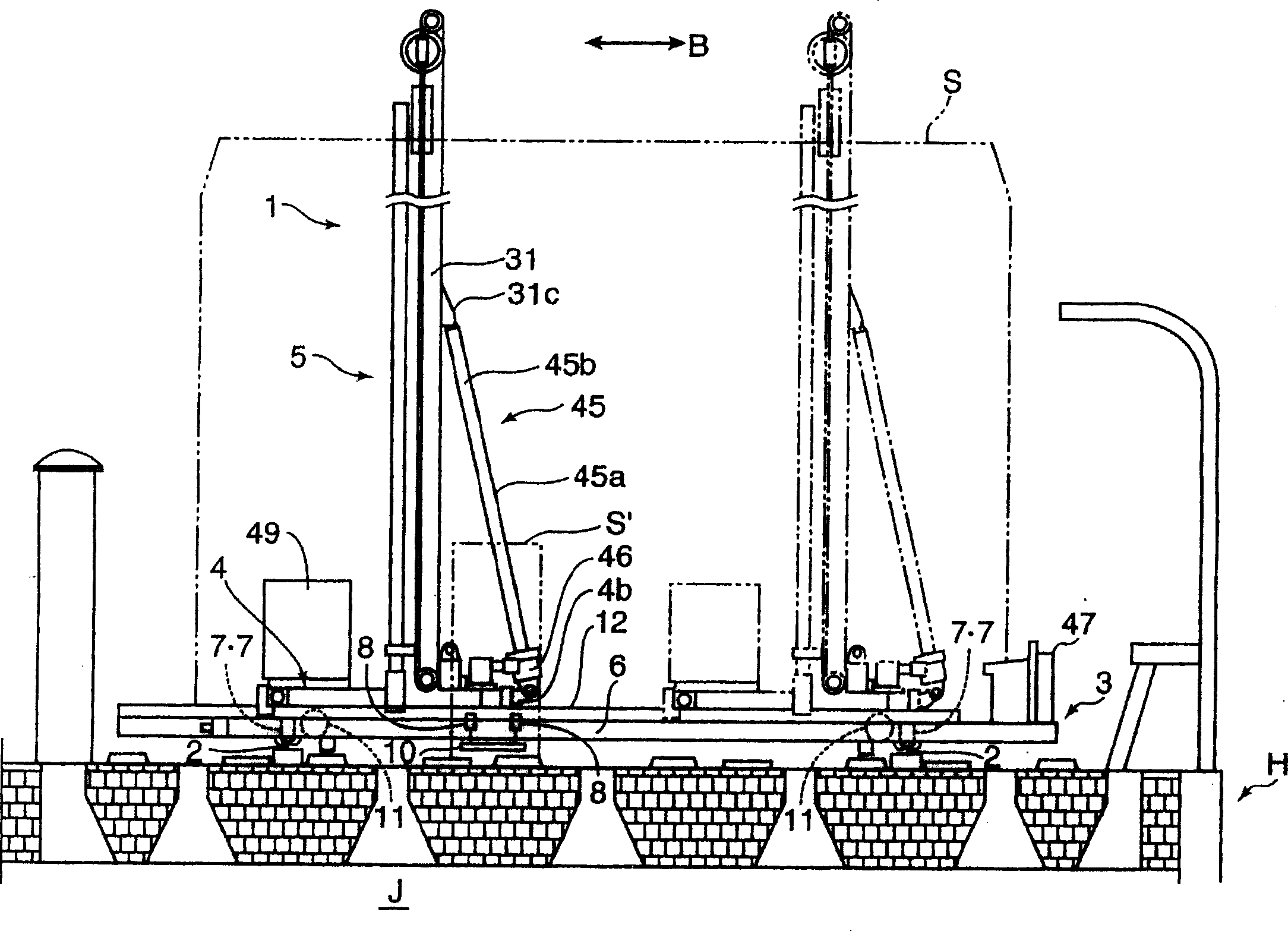

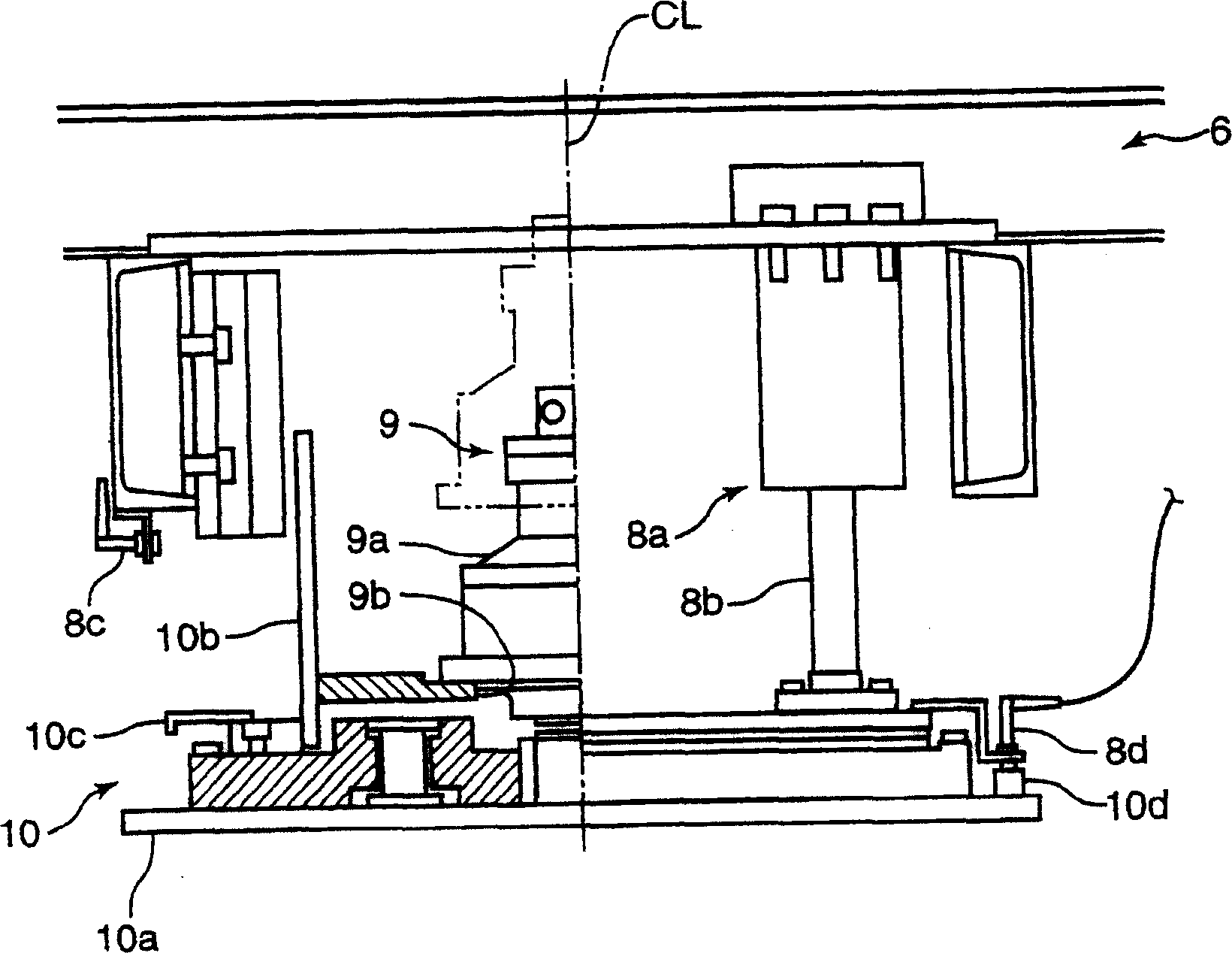

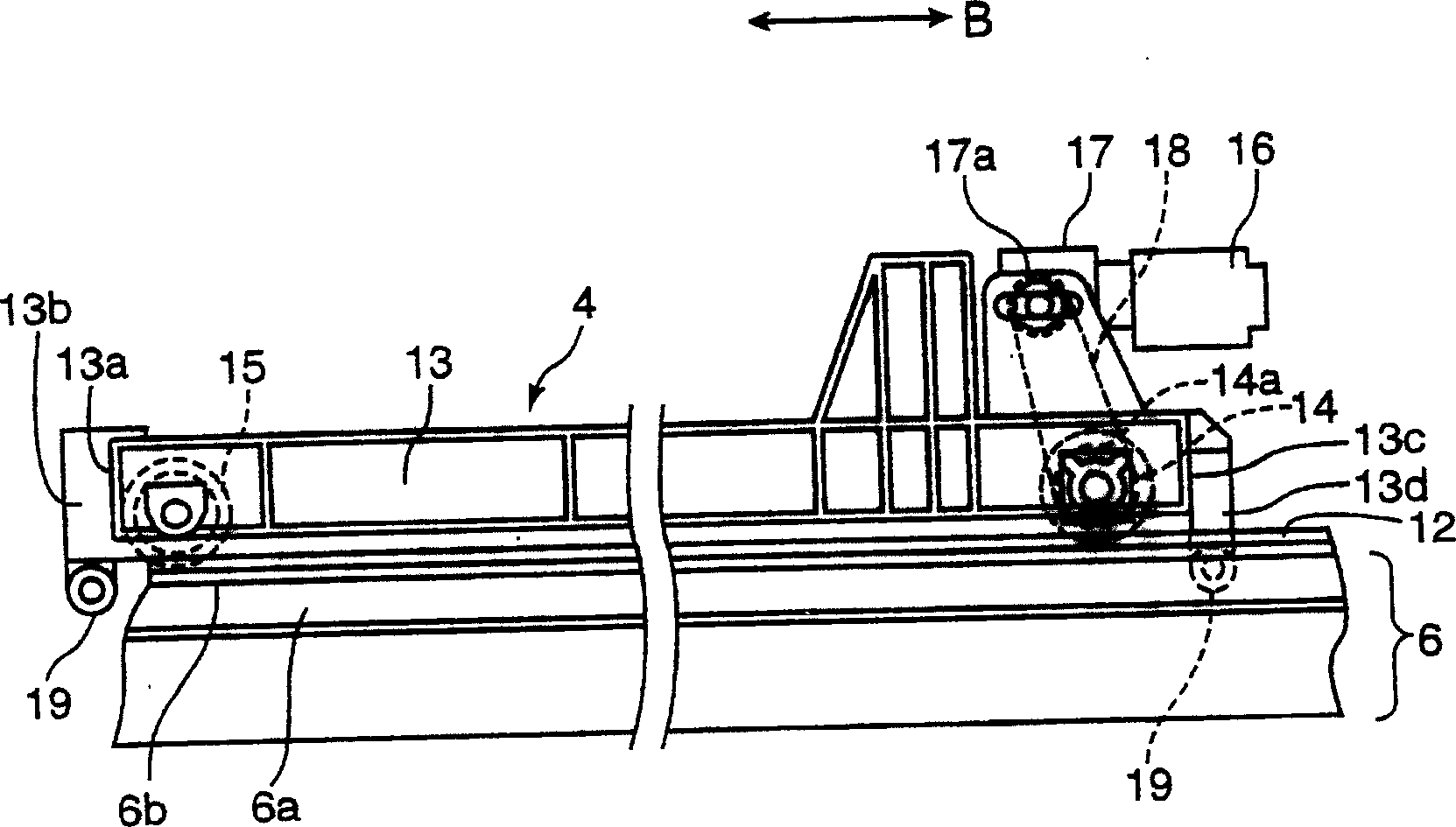

Coke oven repairing apparatus

ActiveUS7547377B2Repairable rangeLinings repairBrickwork leakage repair/preventionCoke ovenEngineering

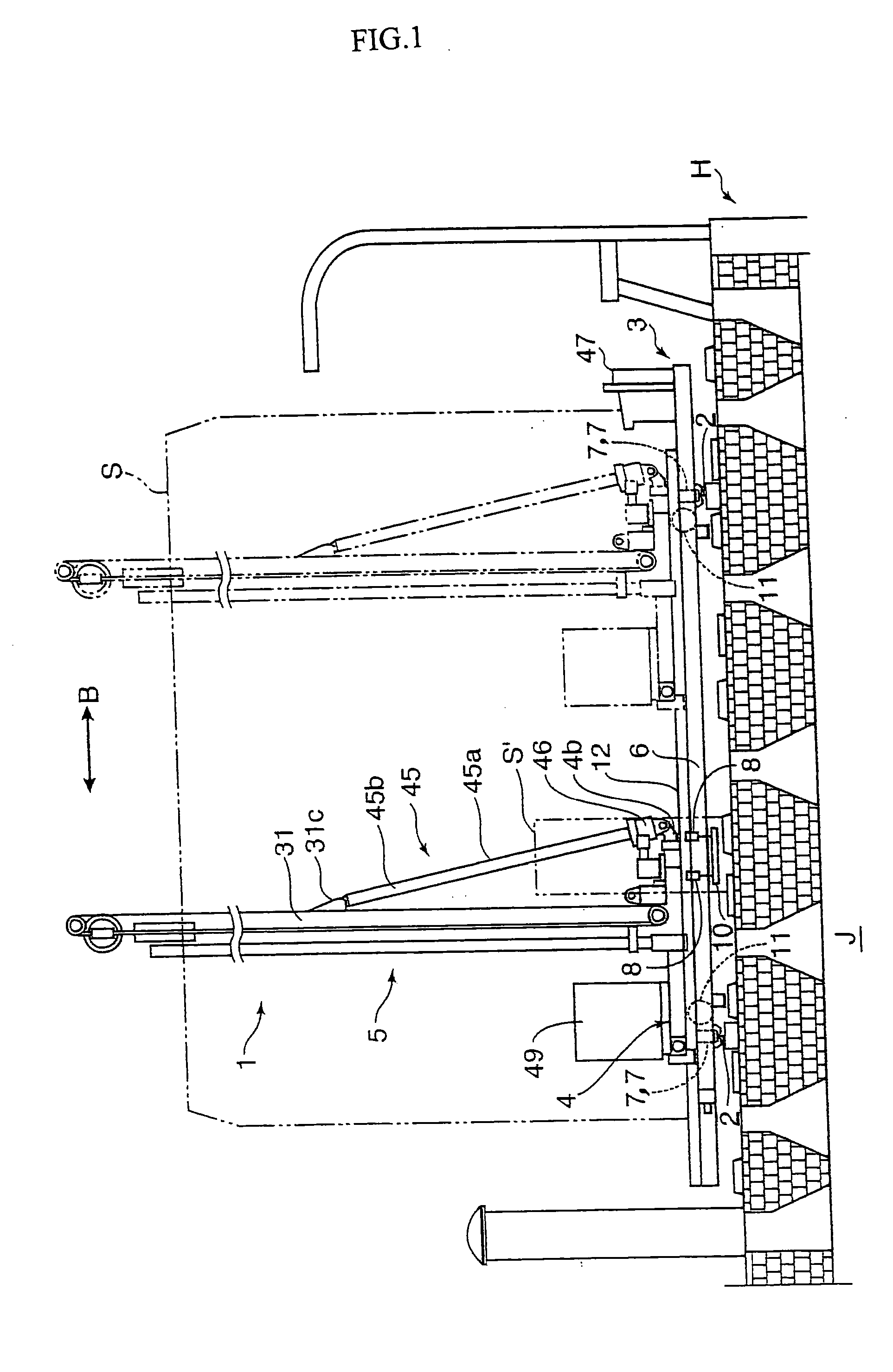

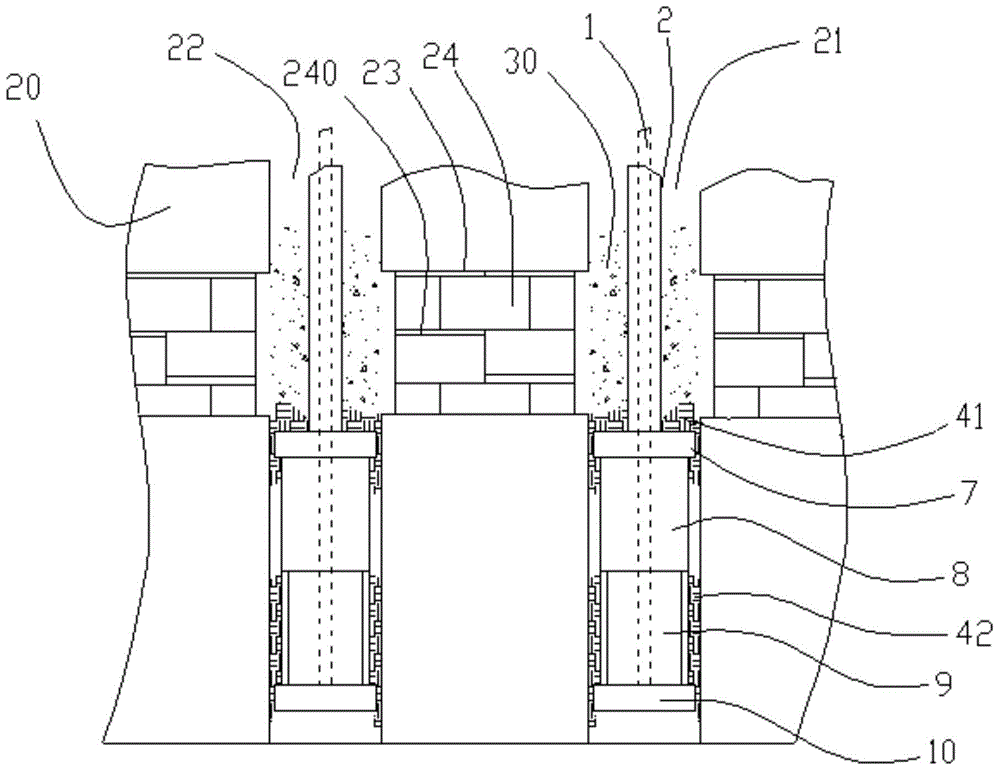

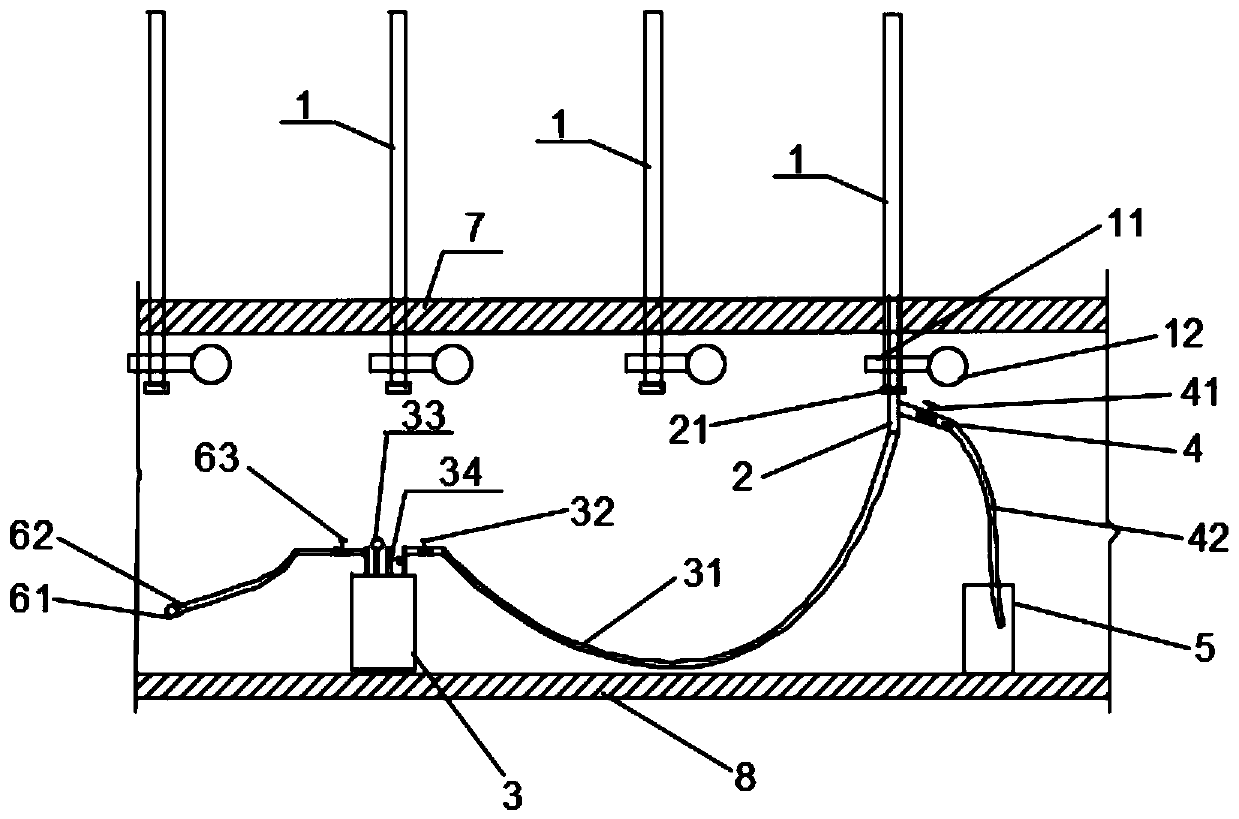

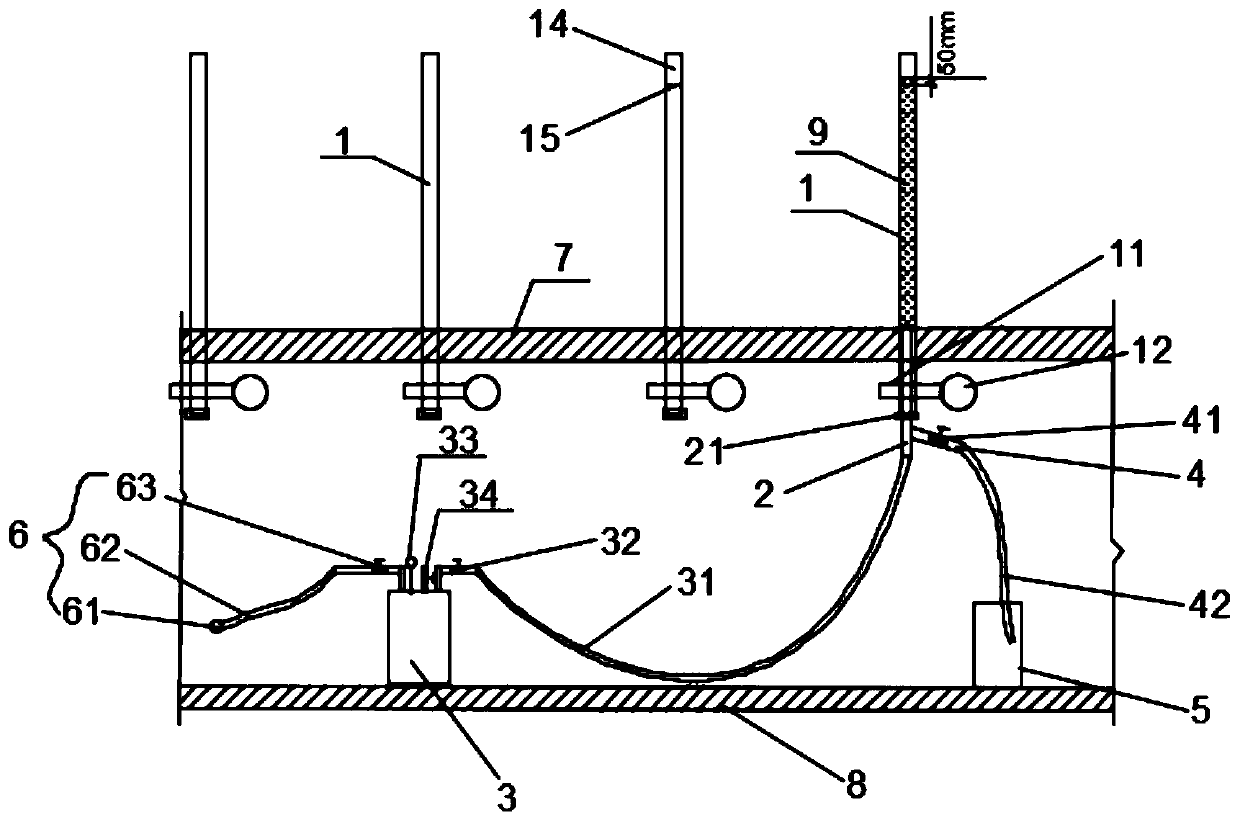

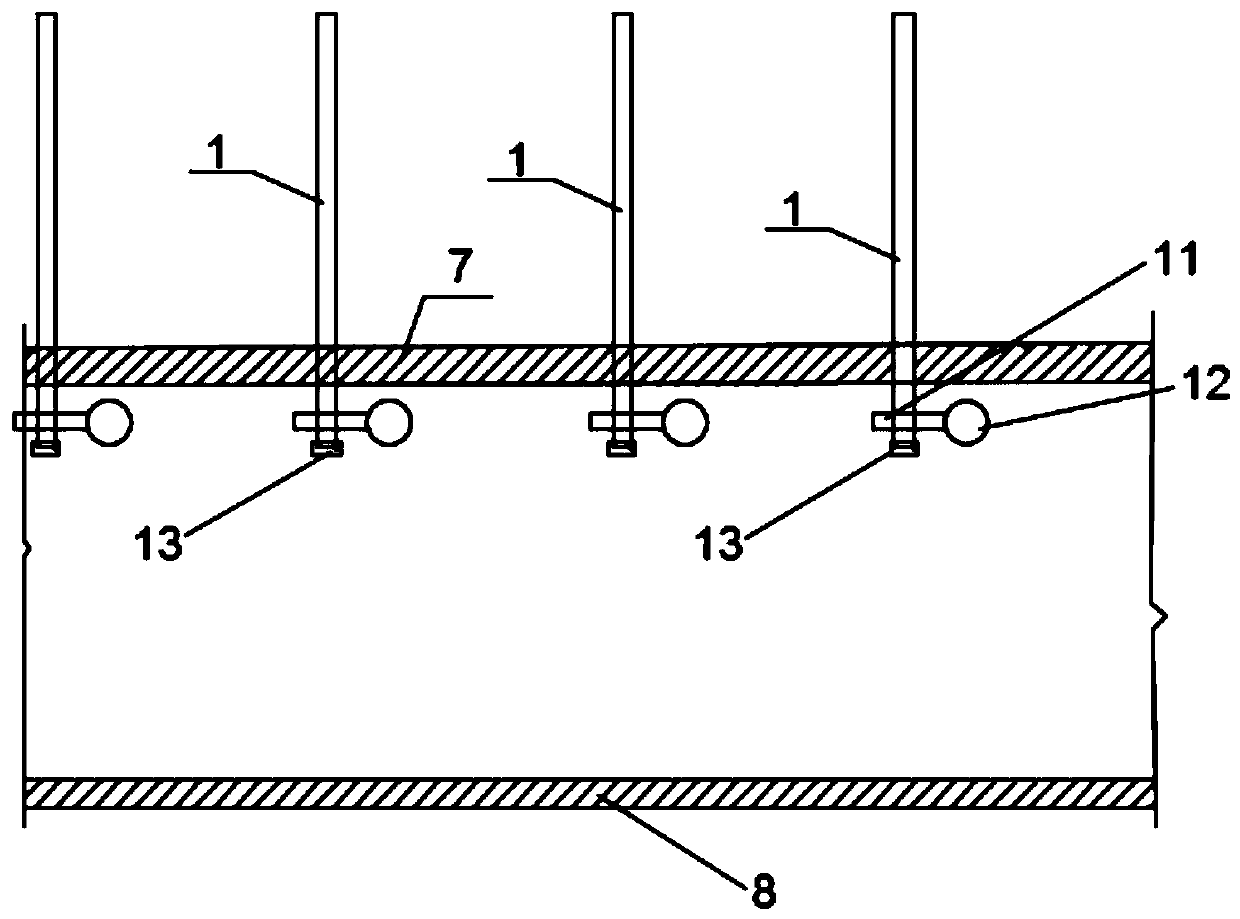

A coke-oven repairing apparatus comprising: a traveling carriage 3 which travels in the direction of coke oven battery with the carriage straddled on the rails placed on the top of a coke oven; a traversing carriage 4 provided on said traveling carriage 3, which moves in the direction orthogonal to the direction of coke oven battery; and a working device 5 for making repairs on the oven walls within the coke oven which is mounted on said traversing carriage 4, wherein the working device 5 includes: a guide post 31 which stands on the traversing carriage 4, and is also coupled, at its lower end portion, to a supporting portion provided on the traversing carriage through a pivot shaft 42; a lance 32 which ascends or descends along the guide post 31; and a derricking device 45 which tilts the guide post 31 between a forward-tilted posture and a backward-tilted posture using the pivot shaft 42 as the fulcrum to oscillate the lance 32 inserted in a coke-oven carbonizing chamber through a charging-hole, within the carbonizing chamber.

Owner:KANSAI COKE & CHEM

Repairing method of coking chamber of coke oven by using silica bricks

ActiveCN101974339AAvoid damageReduce outputCoke oven brickworkBrickwork leakage repair/preventionFiberBrick

The invention discloses a repairing method of a coking chamber of a coke oven by using silica bricks, comprising the following steps of: burning silica bricks or coking silica bricks according to the size of a coke oven silica brick; preparing the specific fireclay by adopting a coke oven hot-patch specific high-temperature binder, wherein added materials comprise high alumina powder and fireclay; manufacturing a thermal insulation material by adopting an aluminium silicate fiber felt with a certain thickness, evenly coating glass liquid on the aluminium silicate fiber felt and pasting the aluminium silicate fiber felt to a high-temperature silica brick wall surface for insulating; insulating heat by adopting an asbestos cloth as a fire curtain; manufacturing an insulating cage and squeezing the insulating cage into the coking chamber to form an insulating seal wall; and arranging buffer ovens with 1-2 holes on both sides of the coking chamber to be repaired and discontinuously heating burning chambers of both sides of the coking chamber to be repaired to control the temperature of the silica bricks. Due to the adoption of the technical scheme, the invention realizes oven wall restoration under a heat-state condition, greatly reduces the destroy to the coke oven silica bricks in a repairing process and the influence on coke over output and overcomes the defects of short use period, frequent repair, destroy of new oven wall bricks, and the like of the traditional repairing method.

Owner:WUHU XINXING DUCTILE IRON PIPES

Hot-state repair method of bottom refractory brick for coke furnace carbonization chamber

InactiveCN1978590AAvoid strain cracksExtend your lifeBrickwork leakage repair/preventionCarbonizationFire brick

The invention discloses a heating repair method of the firebrick in bottom of the coke-oven charring room. The process includes: preparing the repair material, cleaning the charring room and repairing the masonry. The firebrick is selective and heated. The repairing pug is matched and kept the temperature after cleaning the charring room, last to repair the masonry above 800DEG C. The invention can avoid the firebrick crack to prolong the coke-oven life comparing to the cooling repair. The life of the repairing part can reach above 60 months by selecting the alumina brick, so it can save the cooling time and the energy.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

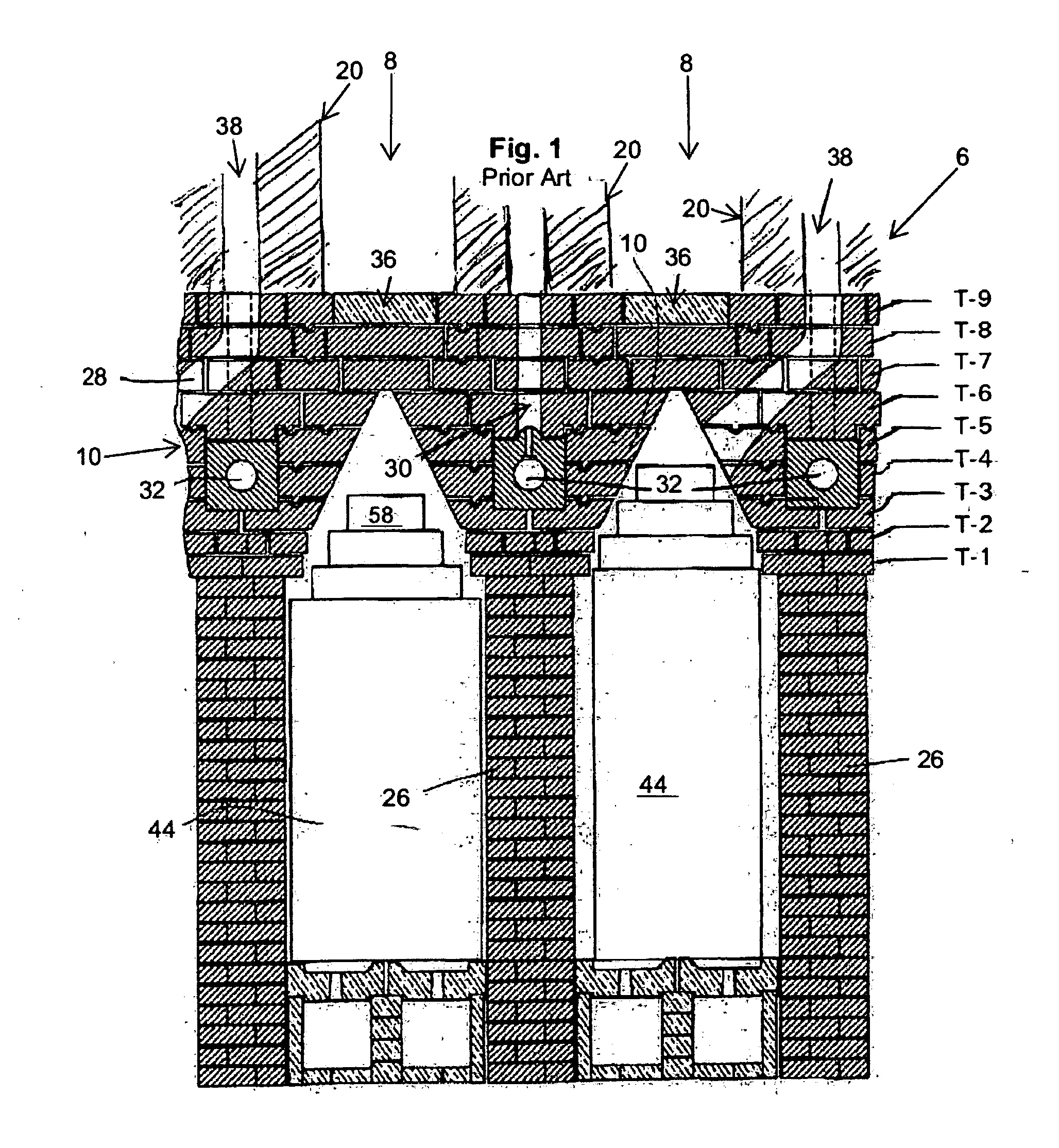

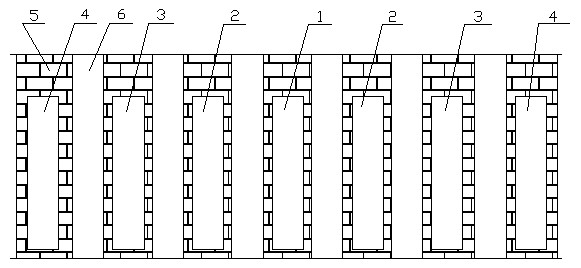

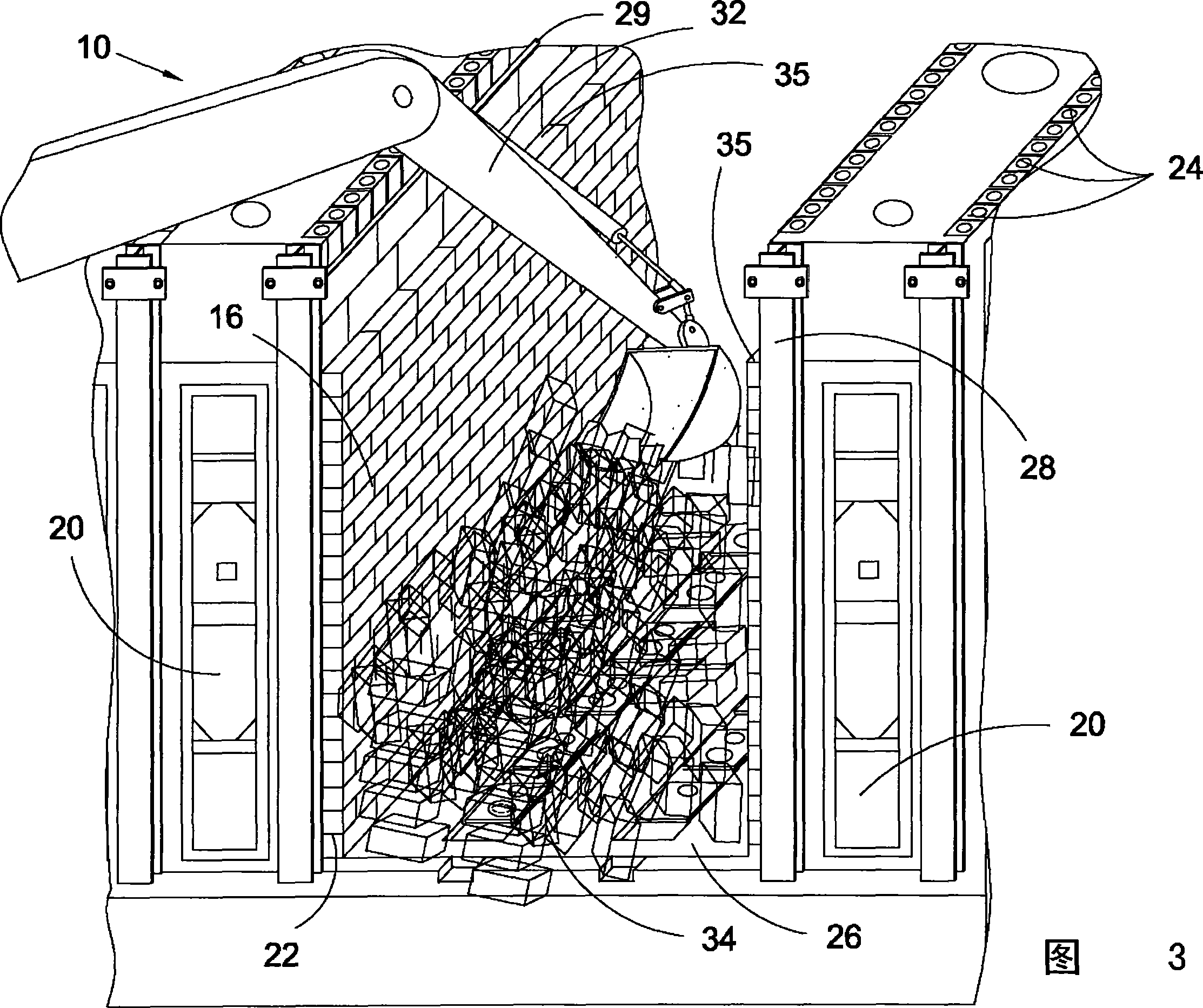

Method for coke oven repair

ActiveUS20170313943A1Quicker procedureSimple and rapid replacementCoke oven brickworkCoke oven expansion/contraction preventionBrickCoke oven

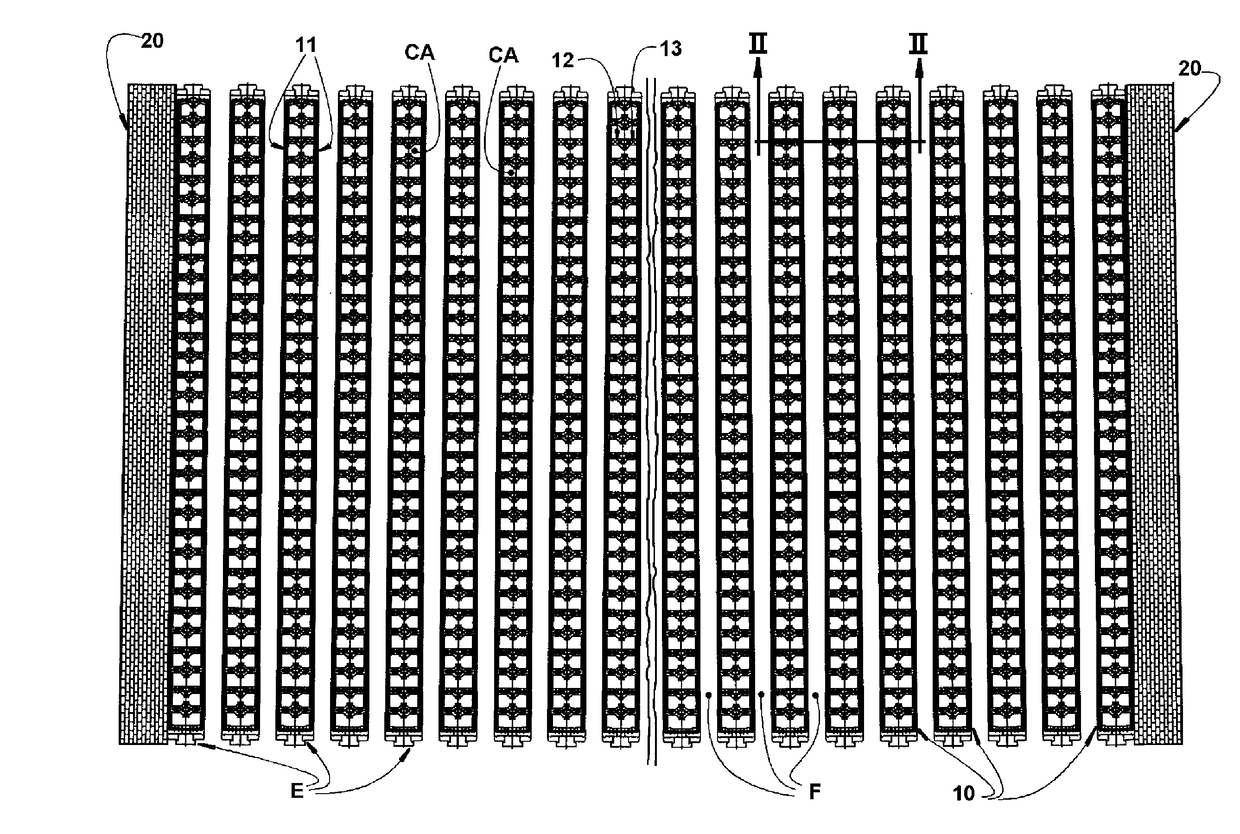

The ovens (F) are arranged side by side in a battery and are each delimited by two sidewalls (10) formed by side bricks (11) and joined by transverse bricks (12, 13). The method comprises: cutting each sidewall (10) to be repaired in accordance with a cutting plane (PC) defining a respective end flat face (14) in the middle portion of the wall (10a) to be maintained and coinciding with the face of a row of transverse bricks (12, 13) facing an adjacent end wall portion (10b) which is being removed; providing in each flat end face (14), a pair of cutouts (15), each having in a basic transverse face, a longitudinal middle channel (15c) in which a tongue (11c) of new bricks from a new end wall portion (10b) is fitted; fitting in each cutout (15) a corresponding portion of a vertical row of side bricks (11a, 11b) for the new end wall portion (10b) until the formation is complete.

Owner:PAUL WURTH DO BRASIL TECHA E SOLUCOES INDIS LTDA +1

Synchronous cutting-off and unroofing repair method for coke side oven head of large-scale coke oven machine

ActiveCN102504837ASolve denudationSolve the holeCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberMaterial consumption

The invention relates to a synchronous cutting-off and unroofing repair method for a coke side oven head of a large-scale coke oven machine, which belongs to a coke oven and particularly relates to a repair method for the coke oven. The synchronous cutting-off and unroofing repair method comprises the following steps of: cooling a repair area-reinforcing an oven column, correspondingly arranging a banking number and a buffer oven number, building a retaining wall, disassembling an ascending tube and cooling a repair number and relevant oven numbers; disassembling the ovens-disassembling a masonry body, installing a support and carrying out temperature monitoring on the repair number and the relevant oven numbers; repairing the building-determining a building centerline and a wall surface datum line and building according to the key points; and warming after repair-carrying out temperature rise speed control and disassembling the support and digging up the retaining wall. The repair method has the advantages that all the damaged parts of the oven head are disassembled and newly built; the wall surfaces of damaged coking chambers can be repaired within a large area so as to completely solve the abrasion and the hole through on the wall surfaces of the coking chambers and the inter-leakage of partition walls of a combustion chamber; after one-time repair, the damaged parts can beused for 5-8 years, so that the oven repair frequency, the time and the material consumption are reduced; the wall surfaces of the repaired parts are level, are small in coke pushing resistance, are beneficial to protecting a coke pusher and an oven body and producing the coke oven and also facilitates energy conservation and consumption reduction; and the high-temperature burn accident of maintenance personnel is also avoided.

Owner:MAGANG (GROUP) HOLDING CO LTD

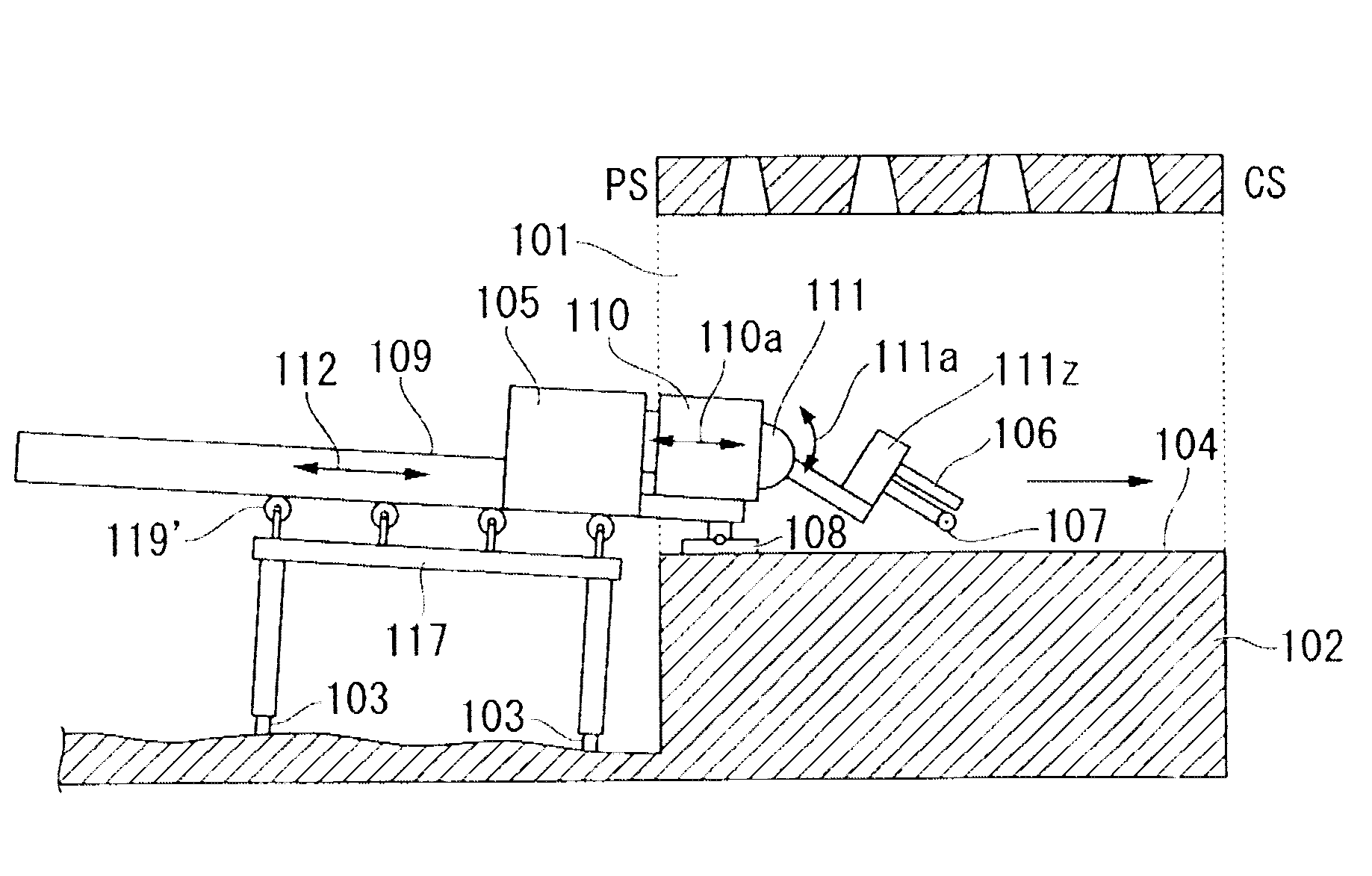

Cook oven repairing apparatus

ActiveUS20070102278A1Continuous operationWide rangeLinings repairBrickwork leakage repair/preventionCoke ovenEngineering

A coke-oven repairing apparatus comprising: a traveling carriage 3 which travels in the direction of coke oven battery with the carriage straddled on the rails placed on the top of a coke oven; a traversing carriage4 provided on said traveling carriage 3, which moves in the direction orthogonal to the direction of coke oven battery; and a working device 5 for making repairs on the oven walls within the coke oven which is mounted on said traversing carriage 4, wherein the working device 5 includes: a guide post 31 which stands on the traversing carriage 4, and is also coupled, at its lower end portion, to a supporting portion provided on the traversing carriage through a pivot shaft 42; a lance 32 which ascends or descends along the guide post 31; and a derricking device 45 which tilts the guide post 31 between a forward-tilted posture and a backward-tilted posture using the pivot shaft 42 as the fulcrum to oscillate the lance 32 inserted in a coke-oven carbonizing chamber through a charging-hole, within the carbonizing chamber.

Owner:KANSAI COKE & CHEM

Method for increasing air tightness of coke oven top and oven top structure

InactiveCN102146294AFix damageAvoid mutual leakageCoke oven expansion/contraction preventionBrickwork leakage repair/preventionThermodynamicsWhole body

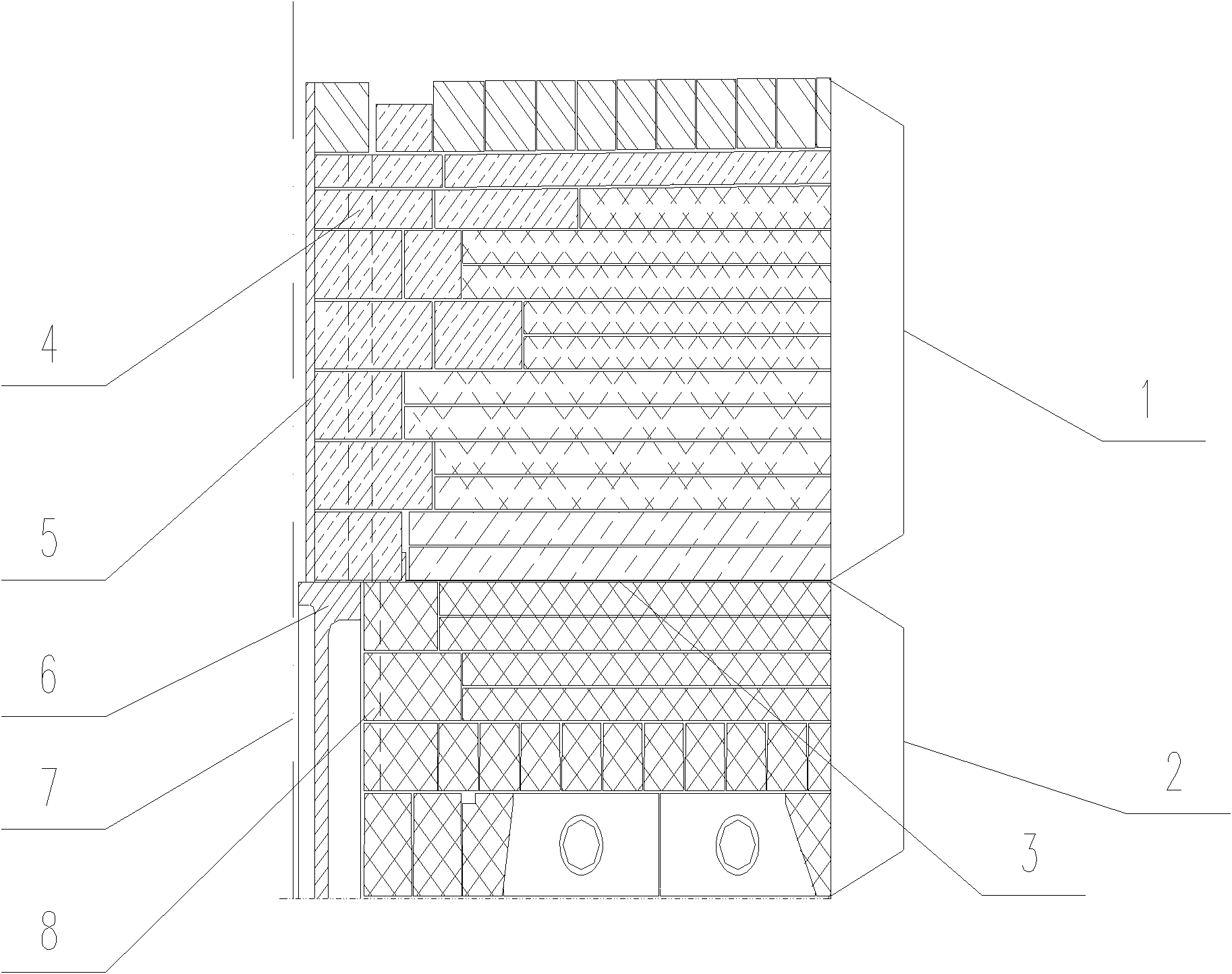

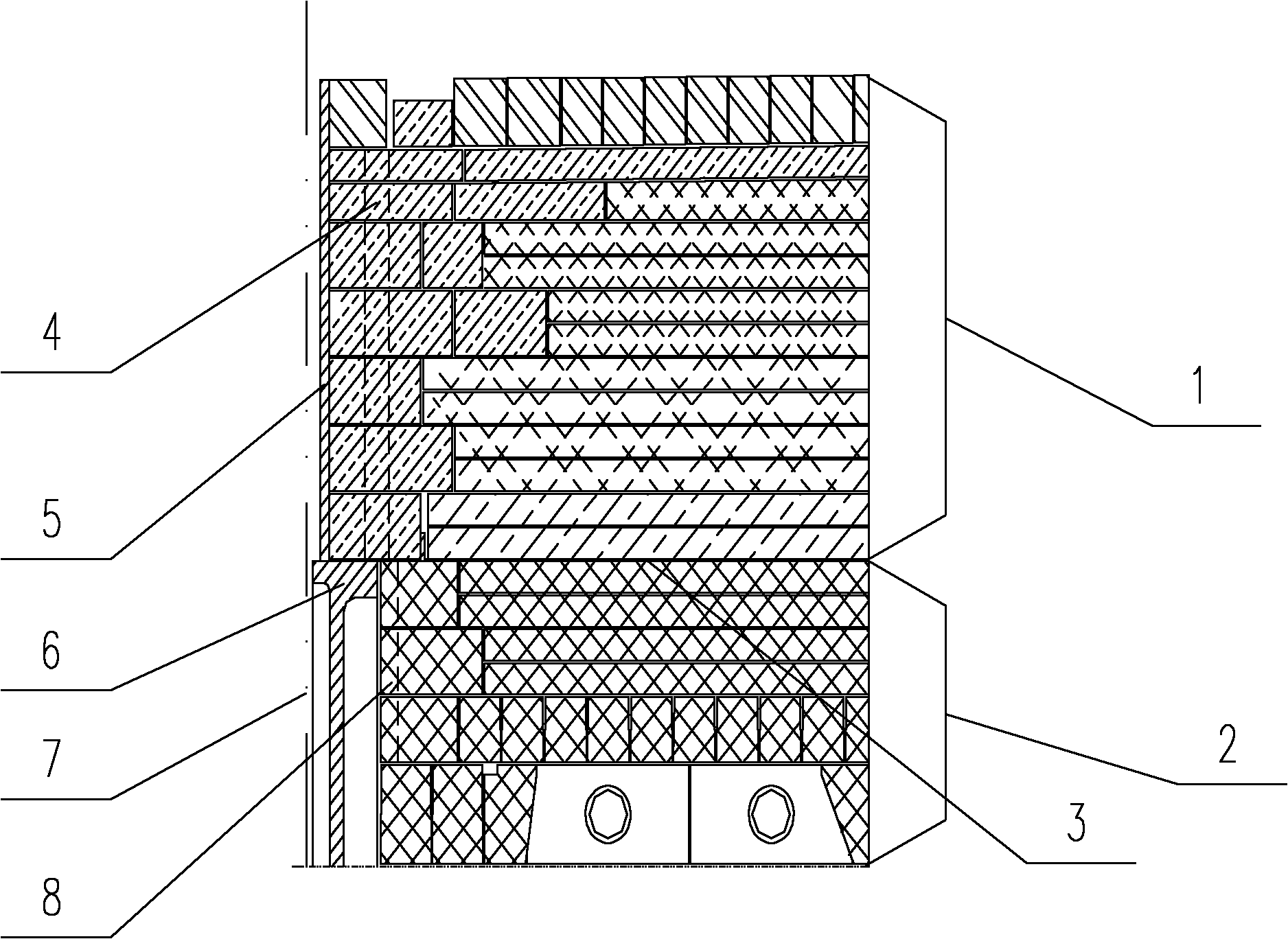

The invention relates to a method for increasing air tightness of a coke oven top and an oven top structure. The coke oven top is divided into two structures of an oven top upper portion and an oven top lower portion, wherein the oven top upper portion and the oven top lower portion are respectively built as independent whole bodies, and a sliding layer is arranged between the oven top upper portion and the oven top lower portion; when an oven is dried, after the over top upper portion and the oven top lower portion are respectively swelled, mortars are grouted via a grouting hole on the oven top upper portion to fill a top gap on the oven top upper portion and a gap between the oven top lower portion and a big protective plate so as to prevent mutual leakage between adjacent carbonization chambers and assure the leakproofness of the coke oven. The invention has the advantages that the situation that the oven top upper portion is swelled together with the oven top lower portion to cause damages due to non-uniform swelling at the oven top upper portion and the oven top lower portion of the coke oven can be effectively solved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Method for repairing bricks at bottom of carbonization chamber of large coke oven

ActiveCN102424753AShorten cooling timeImprove thermal stabilityBrickwork leakage repair/preventionBrickCarbonization

The invention discloses a method for repairing bricks at the bottom of a carbonization chamber of a large coke oven. The method comprises the following steps of: setting empty furnace number and blanking number, reinforcing furnace stays, controlling temperature of a vertical flue in a repairing area, performing gradual temperature reduction and forced temperature reduction on repairing number, setting a temperature keeping area and the repairing area in the carbonization chamber, repairing the bricks at the bottom of the carbonization chamber, heating the carbonization chamber, and detachingfurnace stay reinforcing facilities. The method has the advantages that: the bricks on a machine side and a coke side are repaired respectively, heat insulation is performed on the other side in the repairing period, repairing number adjacent carbonization chambers are subjected to empty furnace treatment, the stable temperature reduction can be realized, a repairing range is wide, and a problem that the bricks at the bottom of the carbonization chamber are cannot be repaired in a large area or a whole channel in the production process is radically solved; the repaired carbonization chamber has high thermal stability, can effectively resist thermal stress generated through temperature rise, and is safe and reliable, the service life is prolonged, furnace repairing frequency and time are reduced, the maintenance cost is reduced, and the smooth production of the coke oven is ensured; and severe environment of furnace repairing operation is improved, the construction is safe, and a burn accident is avoided.

Owner:MAGANG (GROUP) HOLDING CO LTD

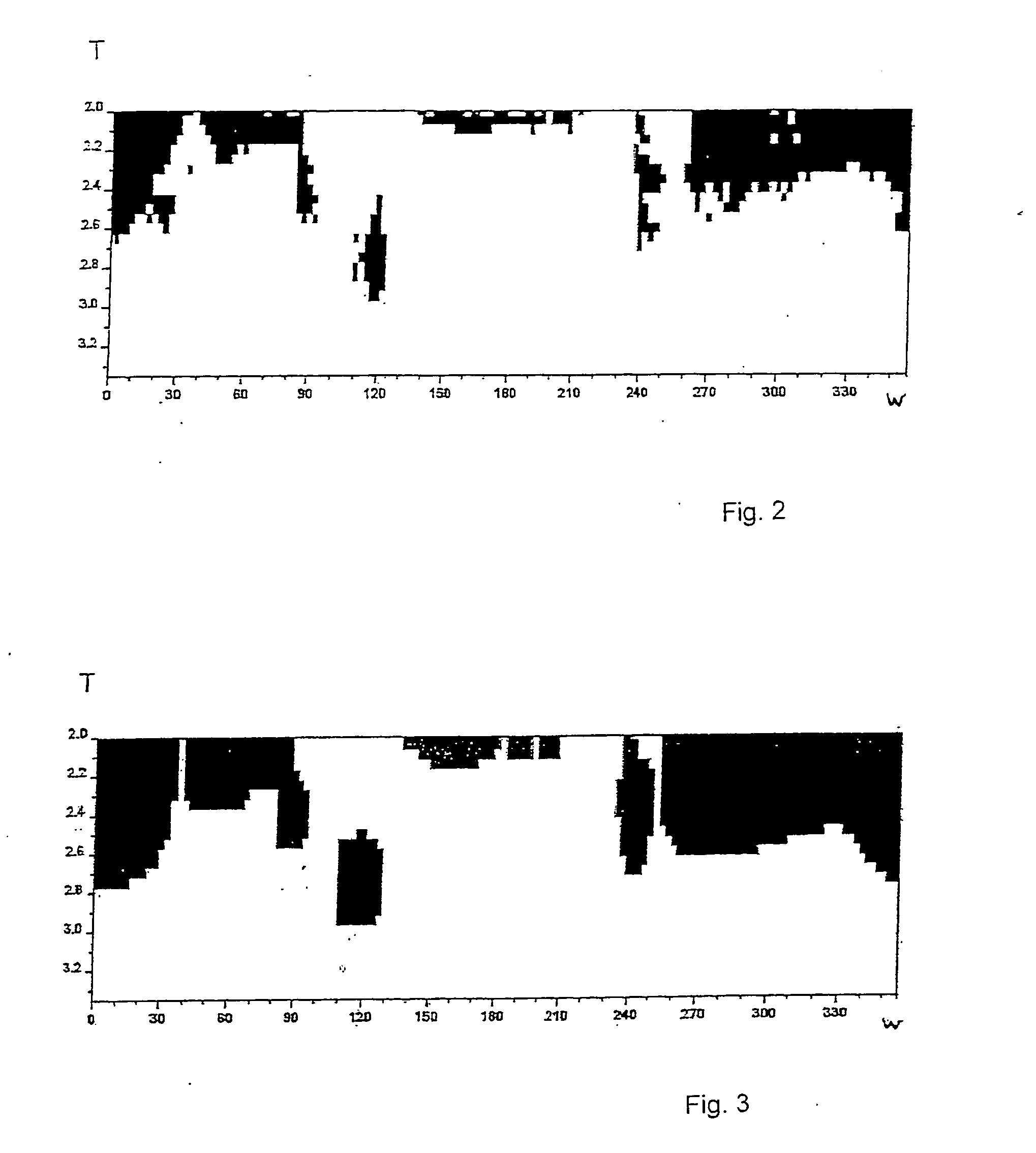

Method for repairing a protective lining of an industrial reaction or transport vessel

ActiveUS20050263945A1Increase speedImprove accuracyLinings repairBrickwork leakage repair/preventionData transmissionData conversion

The present invention relates to a method for repairing a protective lining of an industrial reaction or transport vessel, such as a converter vessel, electric arc furnace, or ladle. The method comprises identifying combined areas of the lining having a thickness below a predetermined threshold value by means of a measuring device, which measuring device measures the residual thickness of the lining and a processing unit, which processing unit in a first step transforms the residual thickness data into binary data, by comparing the measured residual thickness data with the predetermined threshold value for the thickness of the lining, and assigning the binary value “1” to areas of the lining having a thickness below the pre-determined threshold value, and the binary value “0” to areas of the lining having a thickness equal or higher than the pre-determined threshold value, or vice versa, in a second step combines isolated areas of the lining having a thickness below the predetermined threshold value into combined areas of the lining to which the binary value for areas of the lining having a thickness below the pre-determined threshold value is assigned, and in a third step computes the position and repair sequence of each of the combined areas and transfers these data to a repair device, and applying monolithic lining material onto the combined areas computed by the processing unit by means of a repair device.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

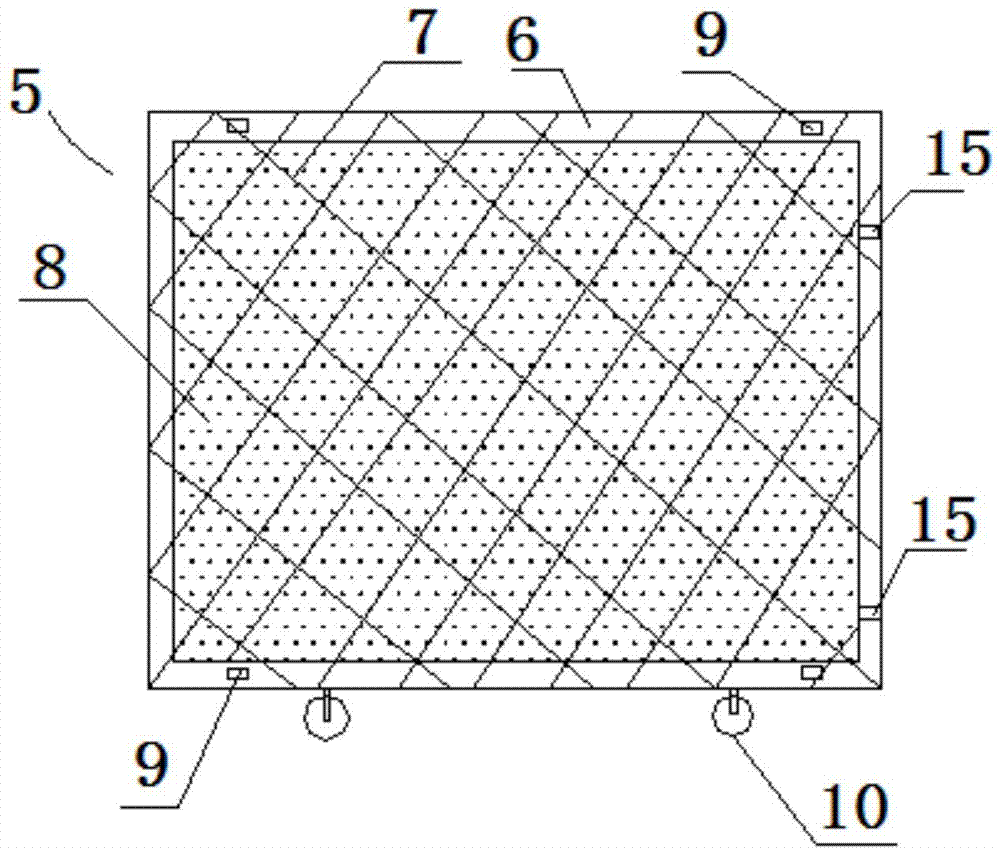

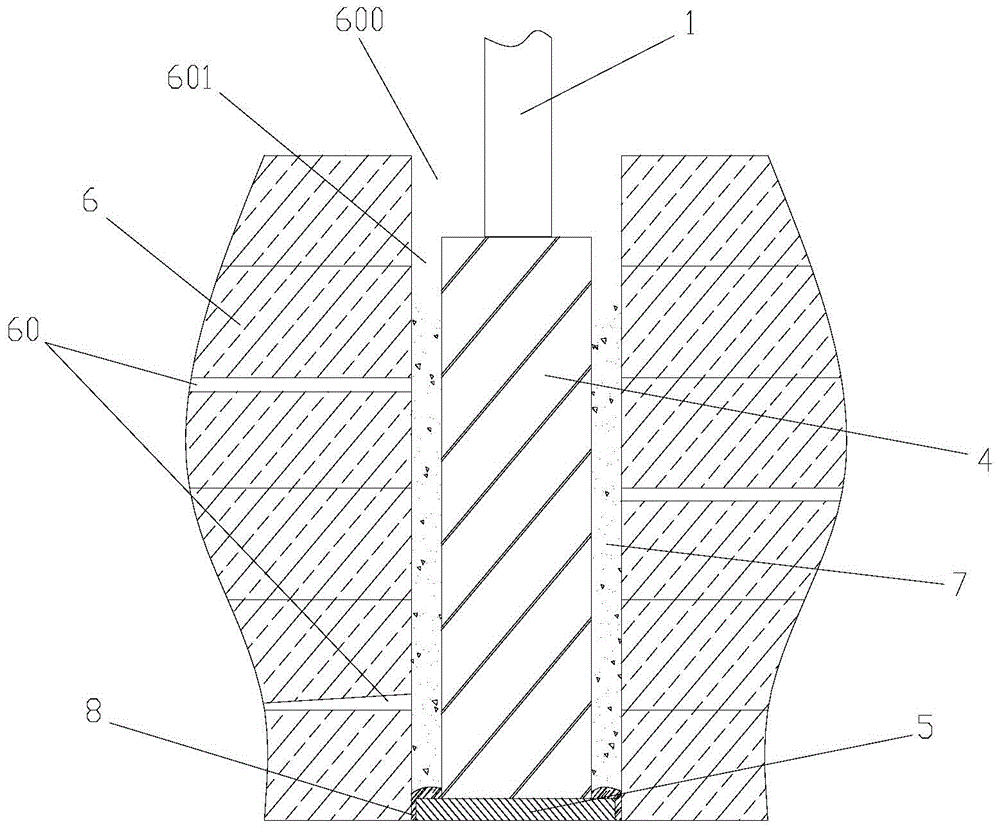

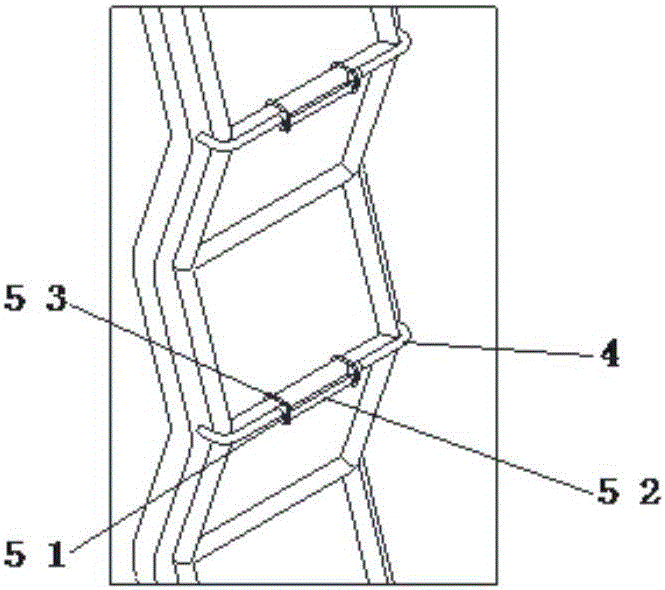

Repairing protection apparatus of coke oven charing chamber, production method thereof and repairing method of charing chamber

ActiveCN104498059AExtended service lifeGuaranteed outputBrickwork leakage repair/preventionCombustion chamberThermal insulation

The invention discloses a repairing protection apparatus of a coke oven charing chamber, a production method thereof and a repairing method of the charing chamber, the repairing protection apparatus comprises an inner side thermal insulation board arranged in the charing chamber and comprises furnace wall heat insulation combination plates arranged on the furnace wall at two sides of the charing chamber, the furnace wall heat insulation combination plates on the furnace wall at two sides are respectively connected to two ends of the inner side thermal insulation board; a gap with size bigger than that of metope of furnace wall and used for repairing is arranged on the furnace wall heat insulation combination plate positioned at furnace wall side to be repaired; and the repairing protection apparatus also comprises a top heat insulation combination plate arranged over the heat insulation combination plate and a bottom heat insulation structure paved at bottom of the charing chamber. According to the invention, the furnace wall repairing can be carried out under high temperature of 700-800 DEG C which is kept in a combustion chamber, damage of repairing at low temperature on a furnace can be avoided, repairing time can be shortened, repairing efficiency is increased; repairing effect can be ensured, service life of coke oven is increased, and coke output and quality can be ensured.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

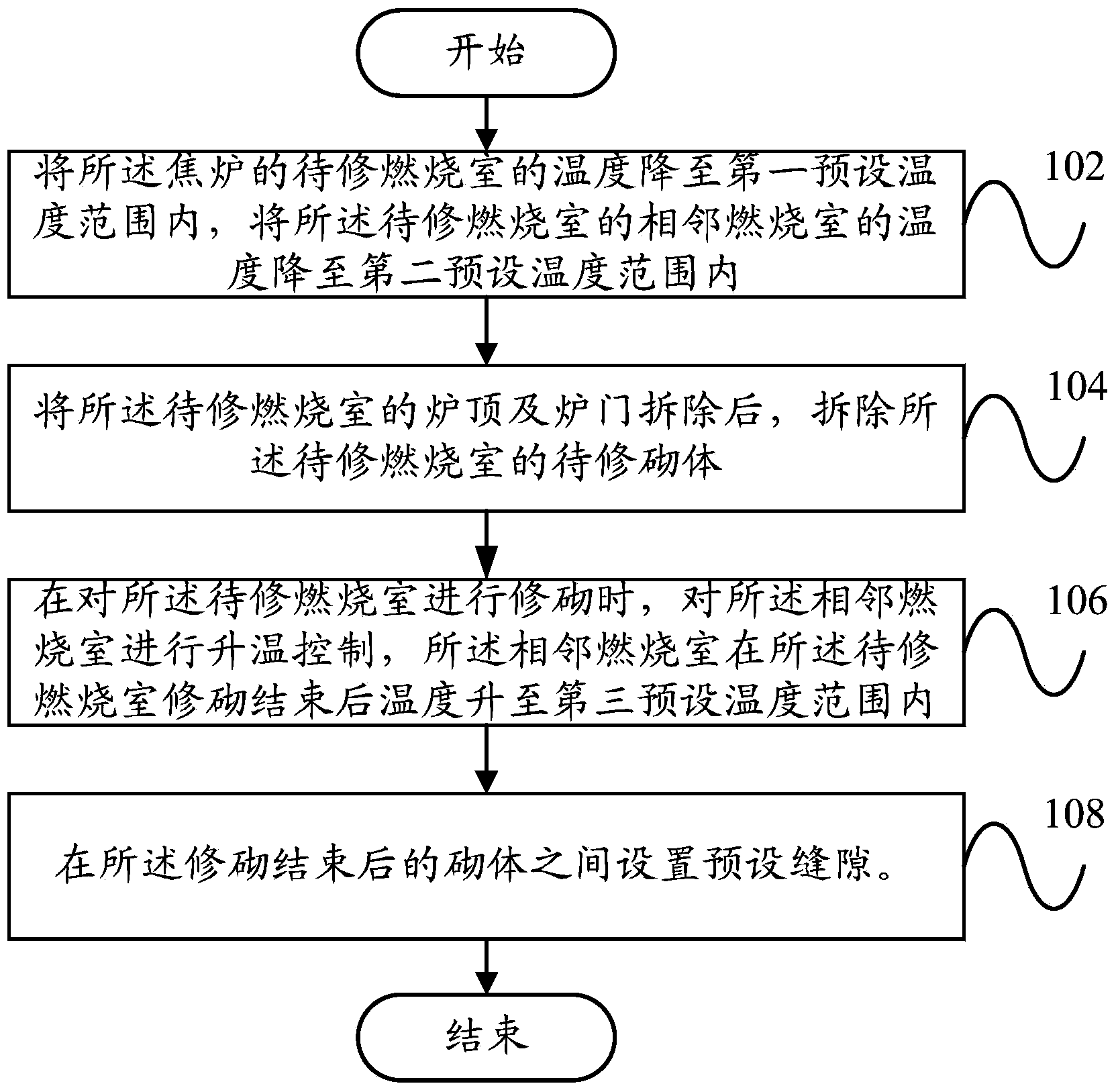

Coke oven maintenance method

ActiveCN104357067AIncrease productionShorten heating timeCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberCoke oven

The invention provides a coke oven maintenance method which comprises steps as follows: the temperature of a to-be-maintained combustion chamber of a coke oven is reduced to a range of a first preset temperature, and the temperature of a combustion chamber adjacent to the to-be-maintained combustion chamber is reduced to a range of a second preset temperature; after an oven roof and an oven door of the to-be-maintained combustion chamber are dismounted, to-be-maintained brickworks of the to-be-maintained combustion chamber are dismounted; when the to-be-maintained combustion chamber is maintained, the adjacent combustion chamber is subjected to temperature rise control, and the temperature of the adjacent combustion chamber is increased to a range of a third preset temperature after maintenance of the to-be-maintained combustion chamber are finished; and preset gaps are formed between adjacent brickworks after maintenance ends. With the adoption of the technical scheme, the problem of secondary damage of an oven wall due to the fact that the brickwork temperature and the sizes of the preset gaps in the joint positions of new and old brickworks cannot be controlled effectively is solved, so that the size of the maintained combustion chamber is standard, the brickworks are neat, the loss and the cost are reduced, and the yield of the coke oven is increased.

Owner:LIAONING Z H &X METALLURGICAL TECH

Coke oven door lining brick repairing process

ActiveCN102676181ALow costReduce labor intensityBrickwork leakage repair/preventionCoke oven doors/closuresAluminateBrick

The invention relates to a coke oven door lining brick repairing process, comprising the following steps of: cleaning a damaged surface; preparing the damaged part to be repaired into a pitted surface with steel chisel for connection with a repaired material; preparing an oven door lining brick repairing material; evenly pouring a layer of sparse mortar prepared from aluminate cement and water on the damaged surface and filling repairing materials; spraying a layer of aluminate cement on the surface; and immediately trowelling the repairing surface with a cutter to ensure a smoothed repairing surface. By using a corbel special repairing material remained after dry quenching during annual overhaul, new oven door lining bricks are not required, thereby avoiding wasting resources and reducing the cost; the damaged oven door lining brick does not need to be removed, thereby reducing the labour intensity and shortening the operation time; the whole repairing process only consumes 1-1.5h; and by using the oven door repaired by the invention, the service life is prolonged.

Owner:SGIS SONGSHAN CO LTD

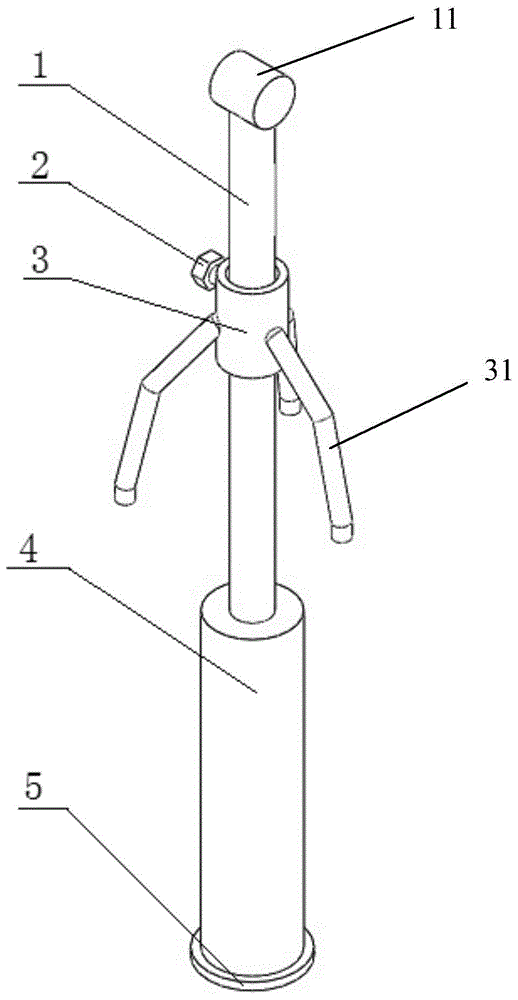

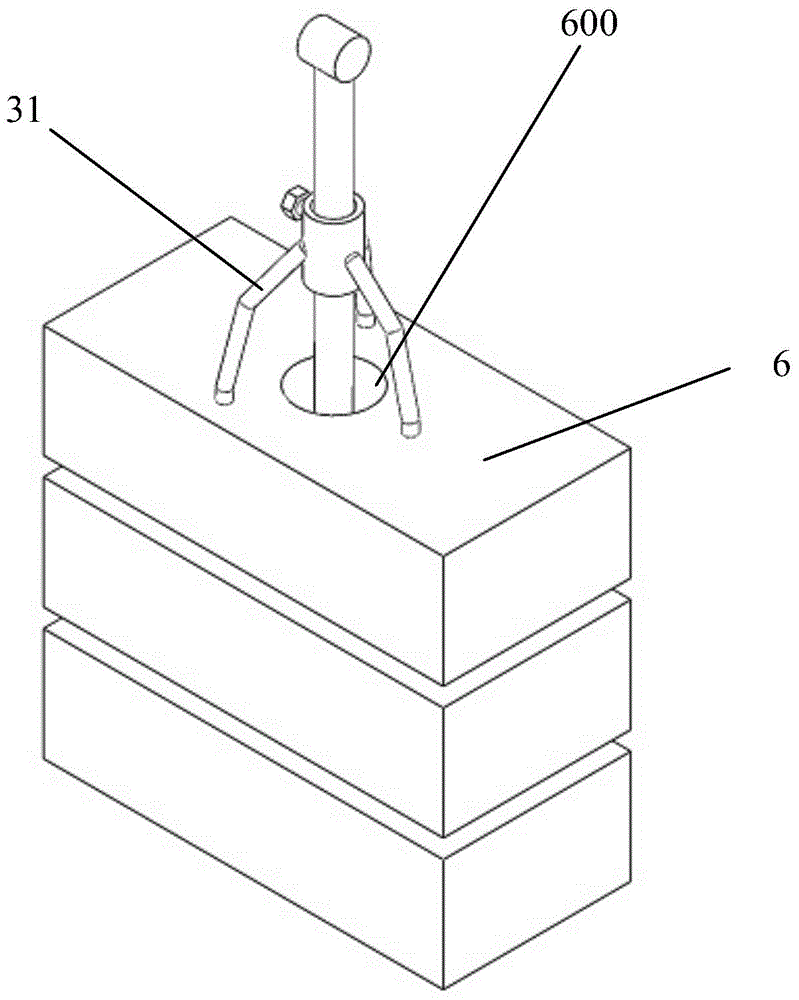

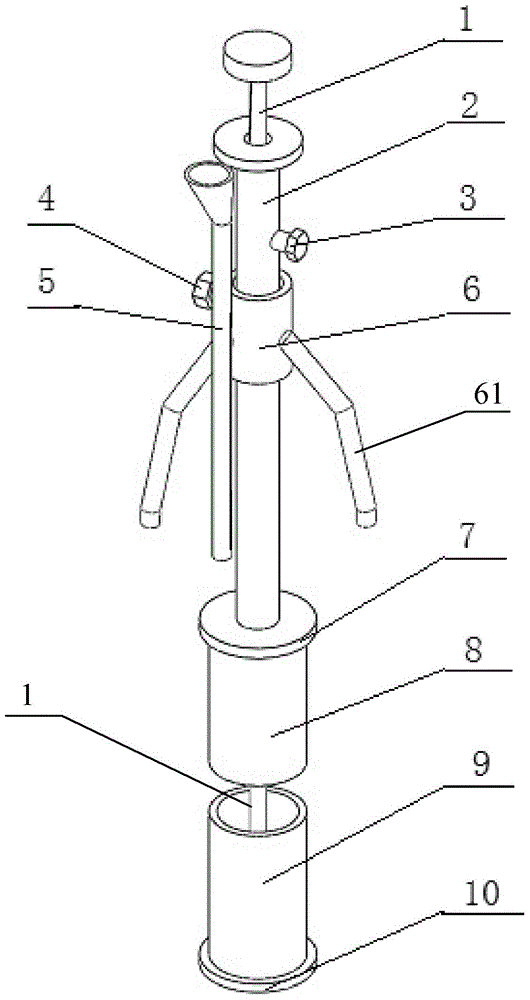

Sealing device and method for fire observation hole of coke oven

The invention provides a sealing device and method for a fire observation hole of a coke oven. The sealing device comprises a wipe repairing device, a base and a fixed mechanism, wherein the wipe repairing device is of a column shape, the side surface of the wipe repairing device is smooth, the outer diameter of the wipe repairing device is smaller than the inner diameter of the fire observation hole, the wipe repairing device is used for stretching into the fire observation hole, and when the wipe repairing device stretches into the fire observation hole, a gap for being filled with grouting materials is formed between the wipe repairing device and the side wall of the fire observation hole to enable the grouting materials to permeate into a brickwork joint of the fire observation hole; the base is fixed at the lower end of the wipe repairing device, the outer diameter of the base is smaller than the inner diameter of the fire observation hole and is larger than that of the wipe repairing device, and the base is used for obstructing the grouting materials so as to avoid the falling of the grouting materials when the grouting materials are poured into the periphery of the side surface of the wipe repairing device; and the fixed mechanism is connected with the upper end of the wipe repairing device and is used for stably positioning the wipe repairing device into the fire observation hole of the coke oven. According to the sealing device and the sealing method, the grouting materials can be rapidly and conveniently poured into the brickwork joint of the fire observation hole, are firmly positioned and do not fall, and furthermore, the coal feeding operation is not influenced.

Owner:SHANDONG IRON & STEEL CO LTD

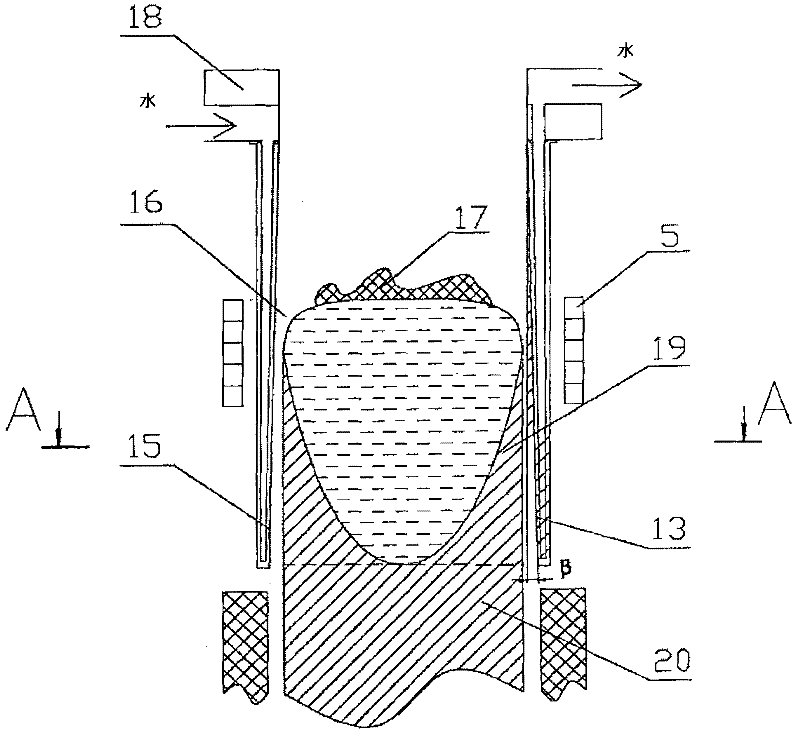

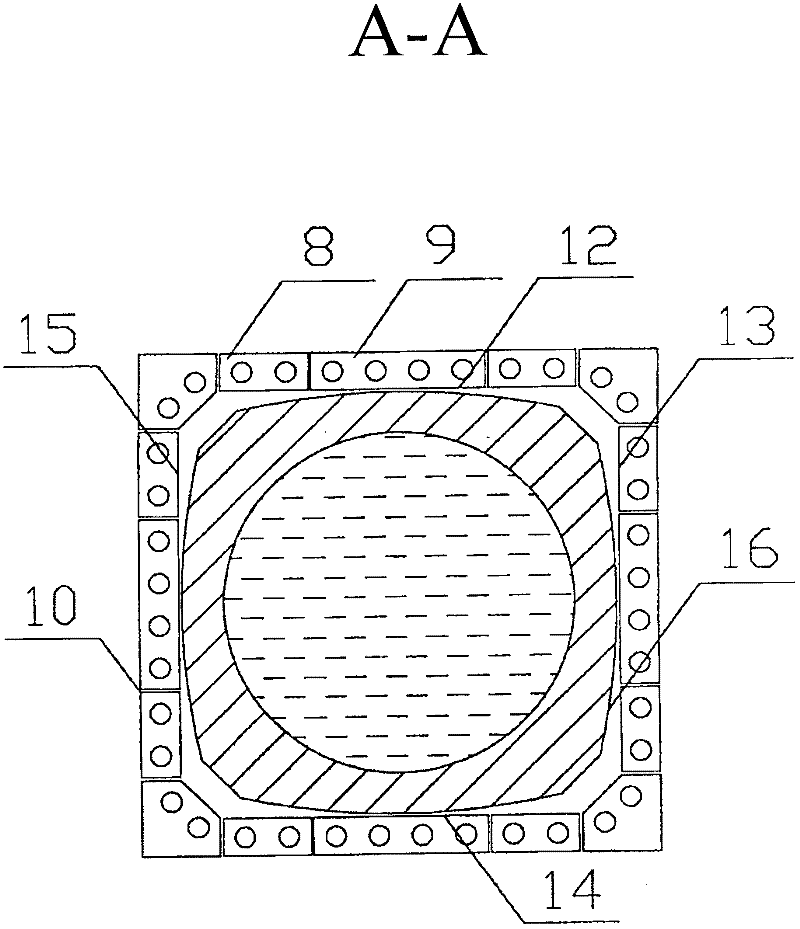

Apparatus for producing multicrystalline silicon ingots by induction method

InactiveCN102471924APolycrystalline material growthBrickwork leakage repair/preventionSquare cross sectionCrucible

An apparatus for producing multicrystalline silicon ingots by the induction method comprises an enclosure, which includes means for start-up heating of silicon and a cooled crucible enveloped by an inductor. The crucible has a movable bottom and four walls consisting of sections spaced apart by vertically extending slots, means for moving the movable bottom, and a controlled cooling compartment arranged under the cooled crucible. The inside face of the crucible defines a melting chamber of a rectangular or square cross-section. The walls of the cooled crucible extend outwards at least from the inductor toward the lowest portion of the cooled crucible to thereby expand the melting chamber, and the angle ss of expanding the melting chamber is defined by the equation ss = arctg [2 (k - 1.35 10 3 b ) / d], where d is the dimension of the smaller side of the rectangle or of the side of the square of the cross-section of the melting chamber at the inducer level, b is the dimension of the adjoining side of the cross-section of the melting chamber at the inducer level, k is an empirical coefficient, which is 1.5 to 2. The apparatus makes it possible to decrease silicon melt spills and to increase the quality of multicrystalline silicon thus produced.

Owner:SOLIN DEV

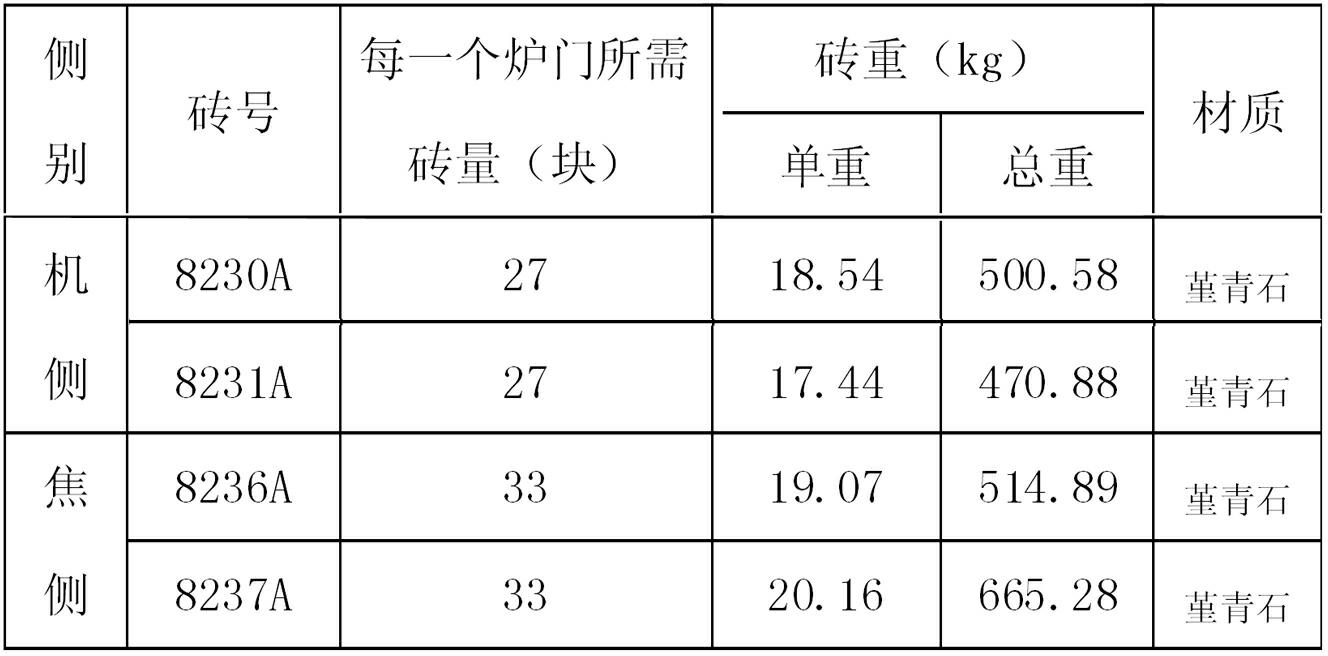

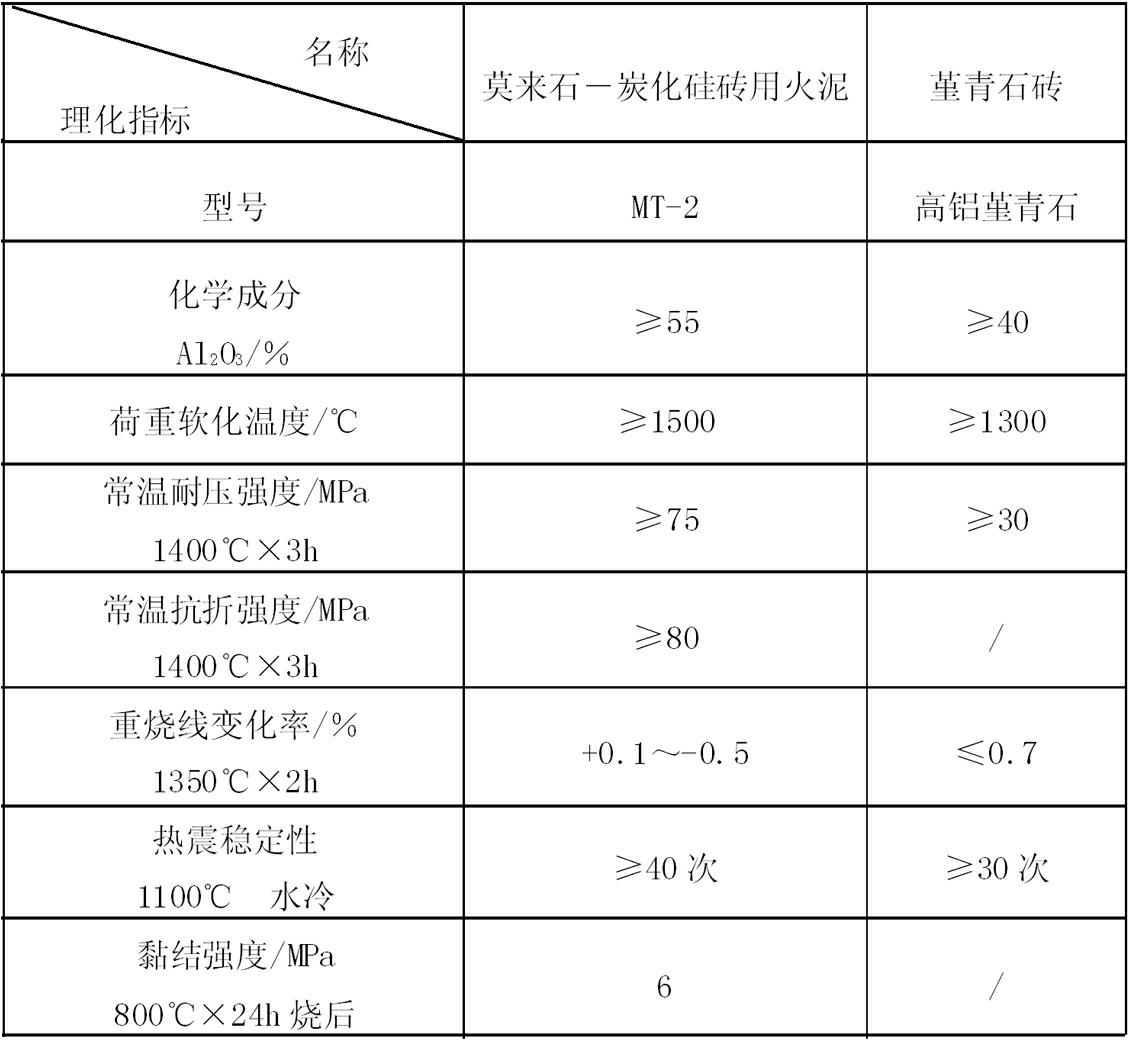

Hot patching process for bottom brick of carbonization chamber of coke oven

InactiveCN101805622APrevent burstGuaranteed Furnace LifeCoke oven brickworkBrickwork leakage repair/preventionCarbonizationMullite

The invention belongs to the technical field of improvement on a refractory process for a coke oven body, and discloses a hot patching process for a bottom brick of a carbonization chamber of a coke oven. The process comprises the following steps: cooling the repaired oven in advance to reach a target oven temperature of 1,120 DEG C on the machine side and 1,180 DEG C on the coke side; controlling the temperature of an oven head to between 950 and 1,000 DEG C; after the coke is completely pushed to the repaired oven, cooling the oven temperature to between 850 and 900 DEG C, and controlling the temperature of the oven head to between 800 and 850 DEG C; when cooling, putting an insulating brick retaining wall in the coke side direction on the coke side 1m away a repair section from a large cover port of the oven top; when the repaired oven is cooled to between 800 and 850 DEG C, ensuring that the temperature of the wall is above 700 DEG C; cleaning the damaged surface; replacing a silicon brick by using a mullite high-aluminum clay brick; and arranging an oven door on the machine side, and opening the oven door on the machine side when the temperature is raised to 1,100 DEG C to observe the repair effect. The process can fully avoid the problem of cracking during repairing the brick, realizes the maintenance of coke oven production under an abnormal working condition, and prolongs the service life of the coke oven.

Owner:NANJING IRON & STEEL CO LTD

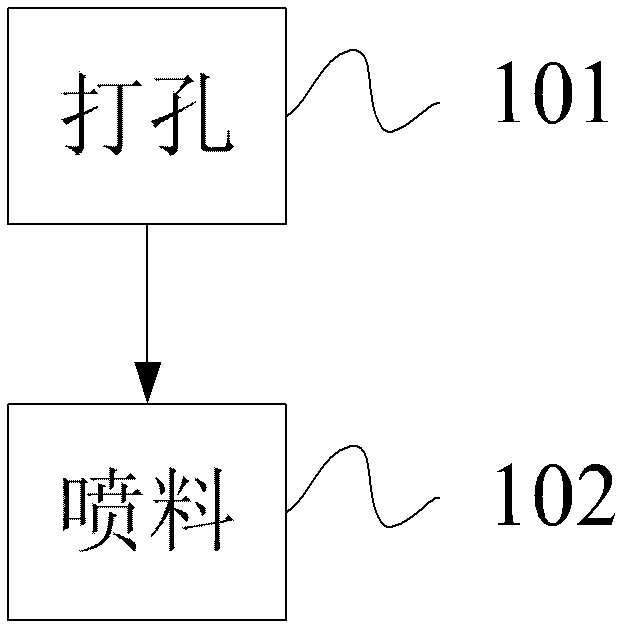

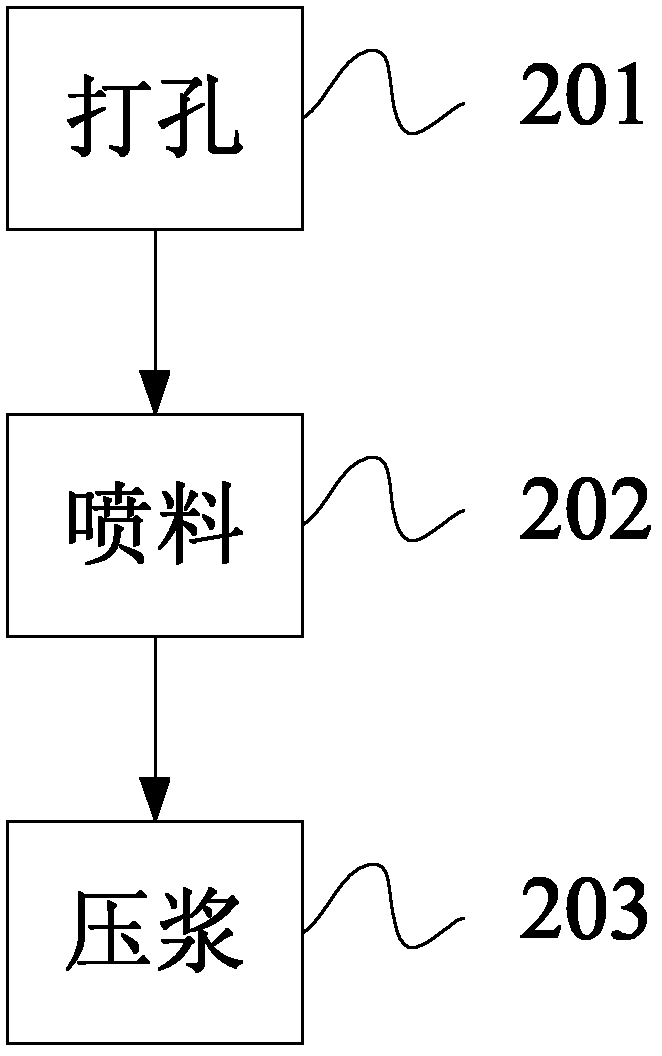

Coke oven body mending process

ActiveCN102304367AReduce human and material resources inputImprove repair effectBrickwork leakage repair/preventionBrickMaterial resources

The invention discloses a coke oven body mending process which comprises the following steps: puncturing, namely, drilling a grout hole which is communicated with a brick work joint at the brick work joint position; and jetting, namely, jetting refractory mortar into the grout hole through using a shotcreting machine. According to the invention, in the coke oven body mending process, the brick work joint which generates a string-leakage hole source is opened through the puncturing step so that the refractory mortar can be directly jetted in the brick work joint, and the mended coke oven can not be mended again within a long time, thereby greatly reducing the mending time of the coke oven body. Thus, the coke oven body mending process provided by the invention has good mending effect and is capable of reducing the manpower and material resources for mending.

Owner:LAIWU IRON & STEEL GRP

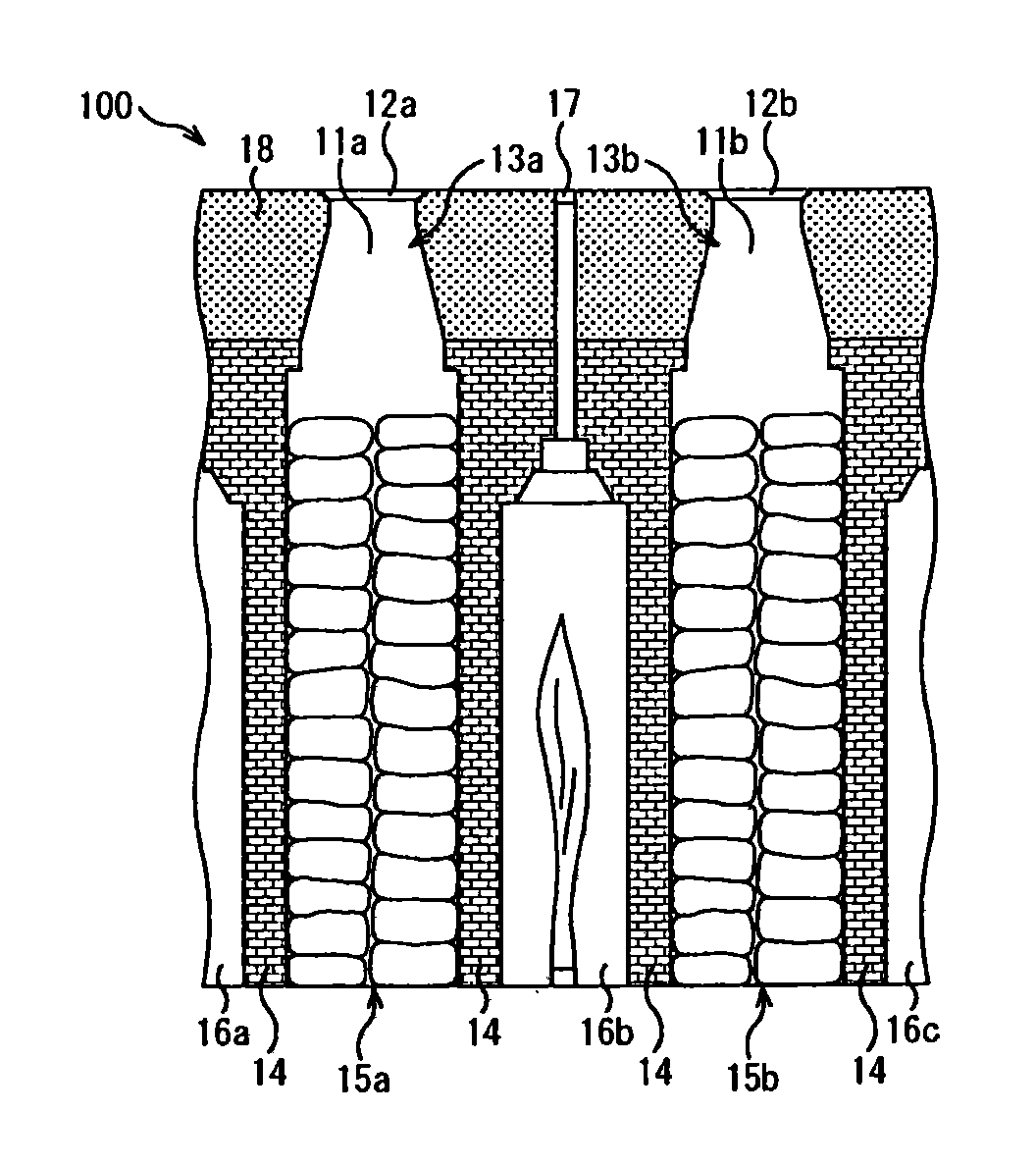

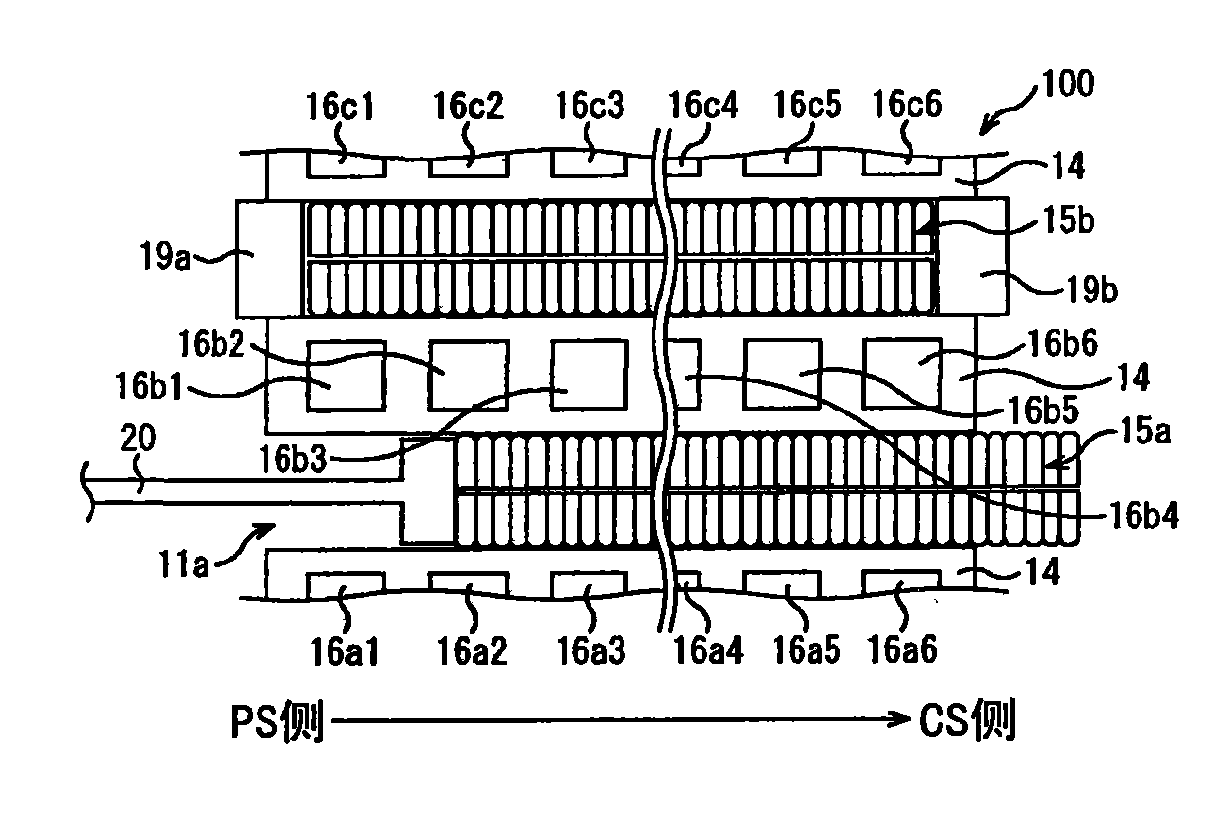

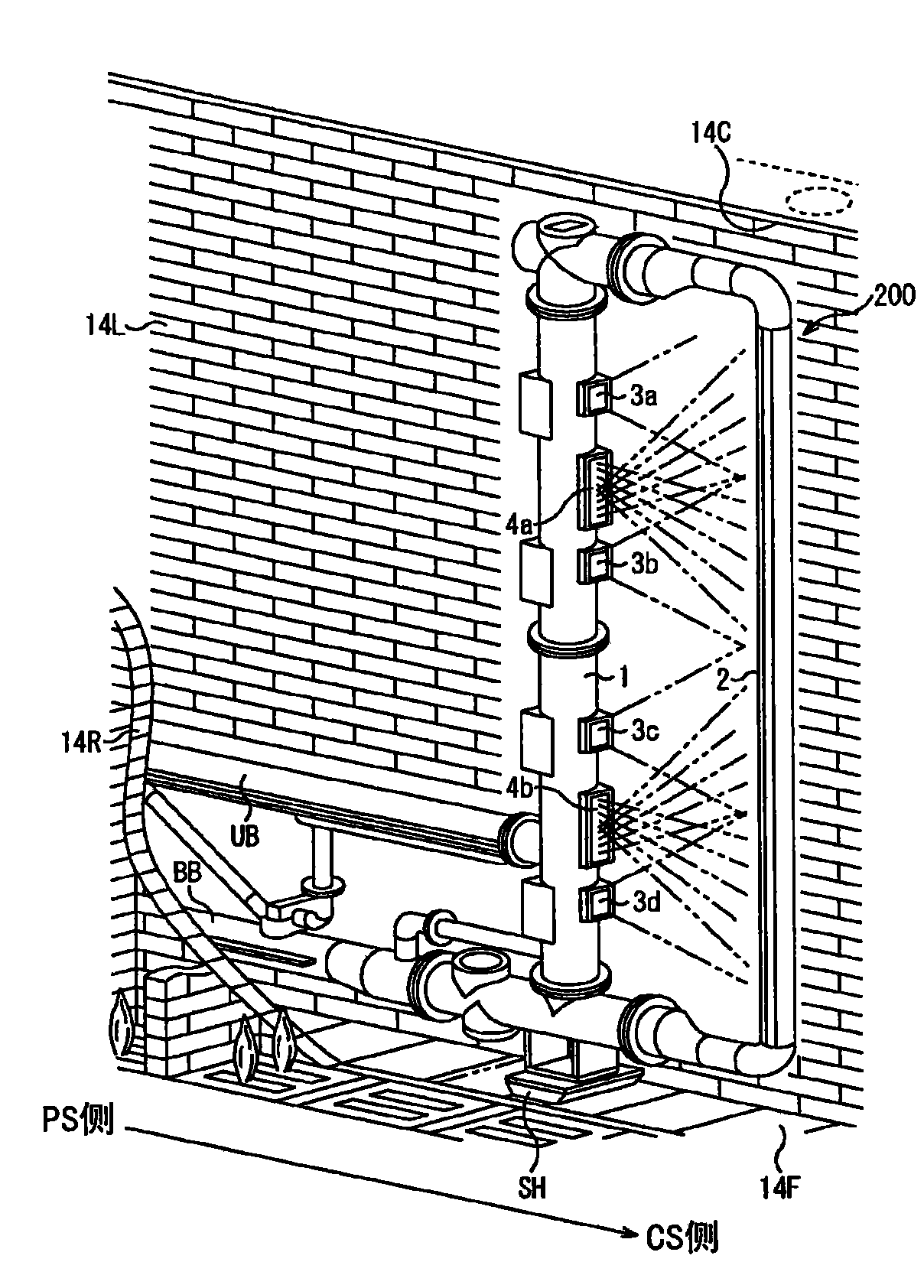

Coke-oven wall-surface evaluating apparatus, coke-oven wall-surface repair supporting apparatus, coke-oven wall-surface evaluating method, coke-oven wall-surface repair supporting method, and computer

An oven wall three-dimensional profile data (701) representing concave and convex amounts on all over oven walls (14R, 14L) at a right side and left side of a coking chamber (11) is generated by using image signals obtained by a wall surface observation apparatus (200). A resistance index 'k' in which a resistance received by pushed coke (15) resulting from a rising gradient existing on the oven wall (14) is indexed is asked by using the oven wall three-dimensional profile data (701). It can be verified that there is a correlation between this resistance index 'k' and a pushing load. Accordingly, it is possible to quantitatively evaluate a state of the oven wall (14) affecting on the pushing load.

Owner:NIPPON STEEL CORP

Method for repairing main gas collecting tube of clean heat recovery coke-oven

InactiveCN101659871AReduce trafficAvoid passingBrickwork leakage repair/preventionGas collecting tubeButt joint

The invention relates to a method for preparing a main gas collecting tube of a clean heat recovery coke-oven, and the method comprises the following steps: a temporary connecting pipe is butt-jointed, welded and sealed with a coke side gas collecting tube and a machine side gas collecting tube respectively; the front top end of a burnout part of the main gas collecting tube is provided with an outlet of a protection wall, a binding molded bag which is filled with refractory material is put into the main gas collecting tube from the outlet of the protection wall, and the protection wall is built layer by layer; the middle-lower end of a side of the protection wall is provided with a repair entrance and exit, which is plugged when the repair of the main gas collecting tube is finished, andthen the outer surface of the repair entrance and exit after being plugged is welded and sealed with the main gas collecting tube; and the protection wall is disassembled, the outlet of the protection wall is plugged after the inside of the main gas collecting tube is cleaned up, and then the outer surface of the outlet of the protection wall after being plugged is welded and sealed with the maingas collecting tube. The burnout main gas collecting tube can be repaired without stopping the production of the coke-oven, the repairing cost is low, the coke-oven can be put into operation and the production can be restored in a short time, and the economic loss is low.

Owner:山西兴高能源集团股份有限公司

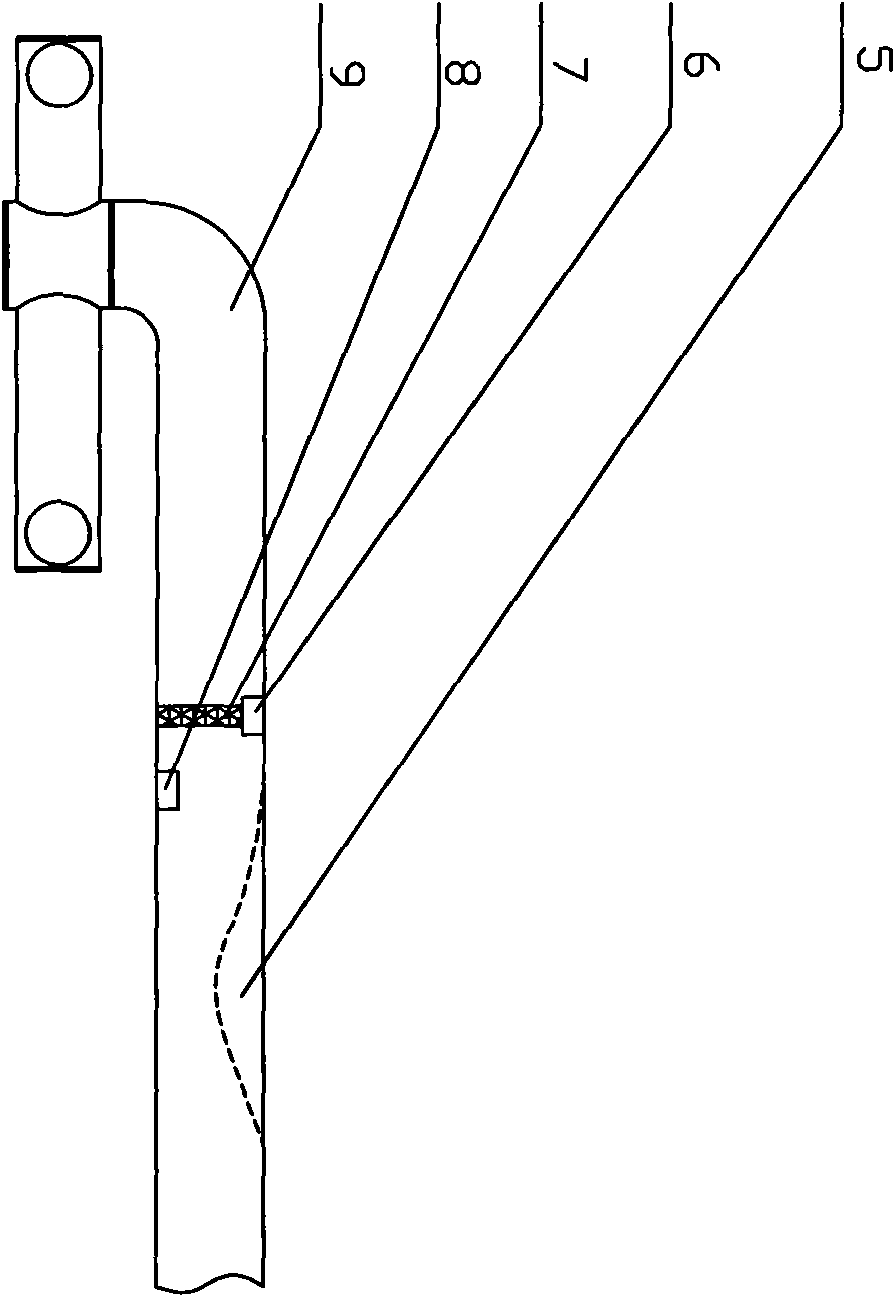

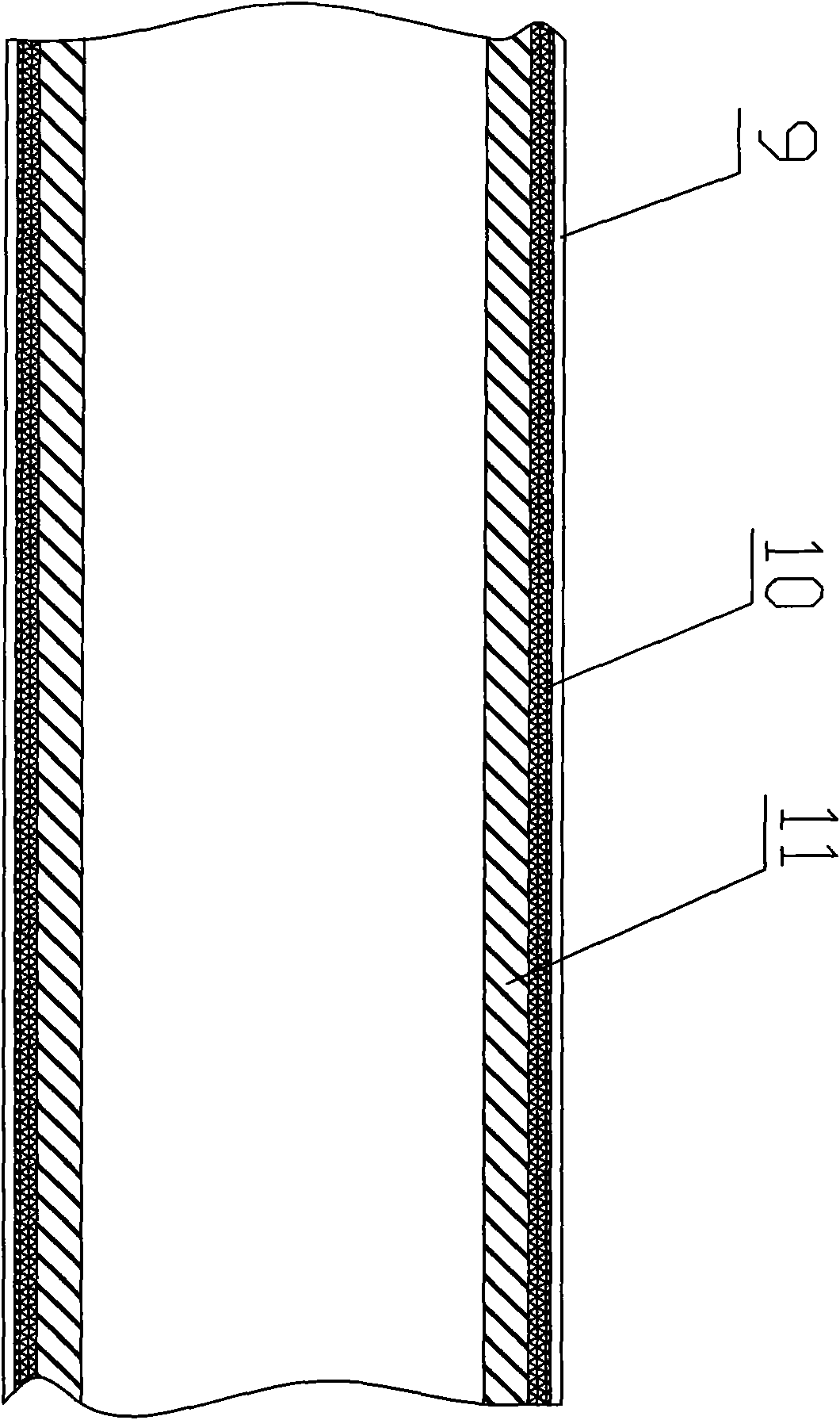

Repair method and repair device for wall surface of coke oven chamber at bottom edge thereof

ActiveCN102171311AAvoid damageAvoid measuringFurnace componentsBrickwork leakage repair/preventionThermal sprayingShortest distance

A repair method for the wall surface of a coke oven chamber at the bottom edge thereof is a method for repairing a damaged part on the wall surface of the coke oven chamber close to the bottom thereof, and comprises an oven bottom profile measuring step for determining a oven bottom approximation curve which approximates the oven bottom by measuring the distance between an oven bottom profile measuring device and the oven bottom in the vertical direction while moving the oven bottom profile measuring device along the length of the oven in the coke oven chamber to thereby determine the irregular shape of the oven bottom, an oven wall profile measuring step for determining the irregular shape of the oven wall while moving an oven wall profile measuring device in parallel with the oven bottom approximation curve so that the shortest distance between the shell of the oven wall profile measuring device and the oven bottom approximation curve is at least a first predetermined distance, and a repair step for spraying a repair material from thermal spraying equipment to the damaged part while moving the thermal spraying equipment in parallel with the oven bottom approximation curve so that the shortest distance between the shell of the thermal spraying equipment and the oven bottom approximation curve is at least a second predetermined distance.

Owner:NIPPON STEEL CORP

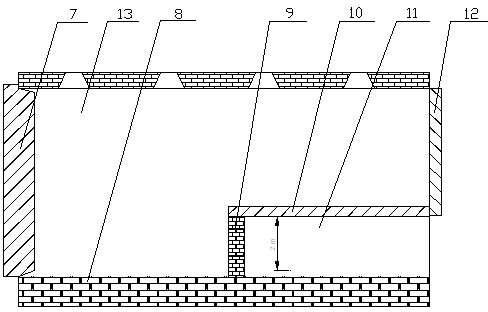

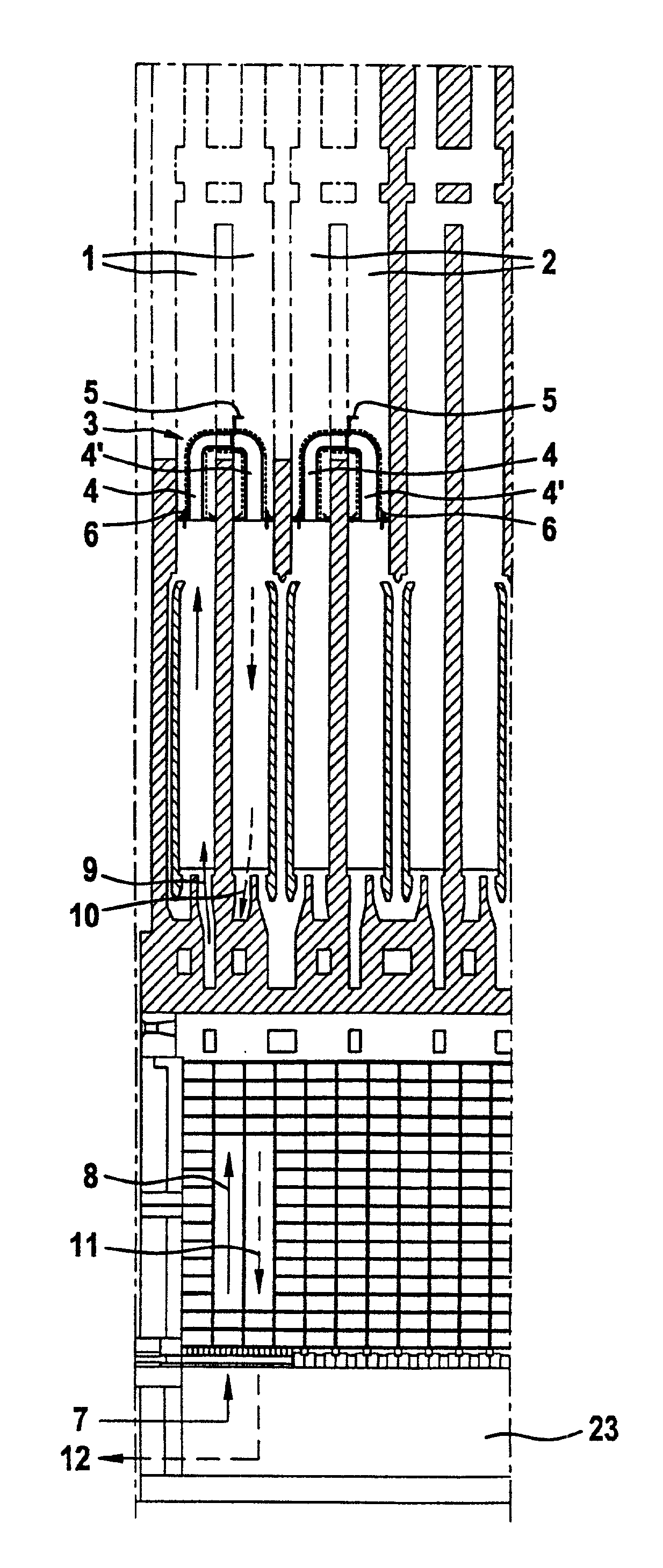

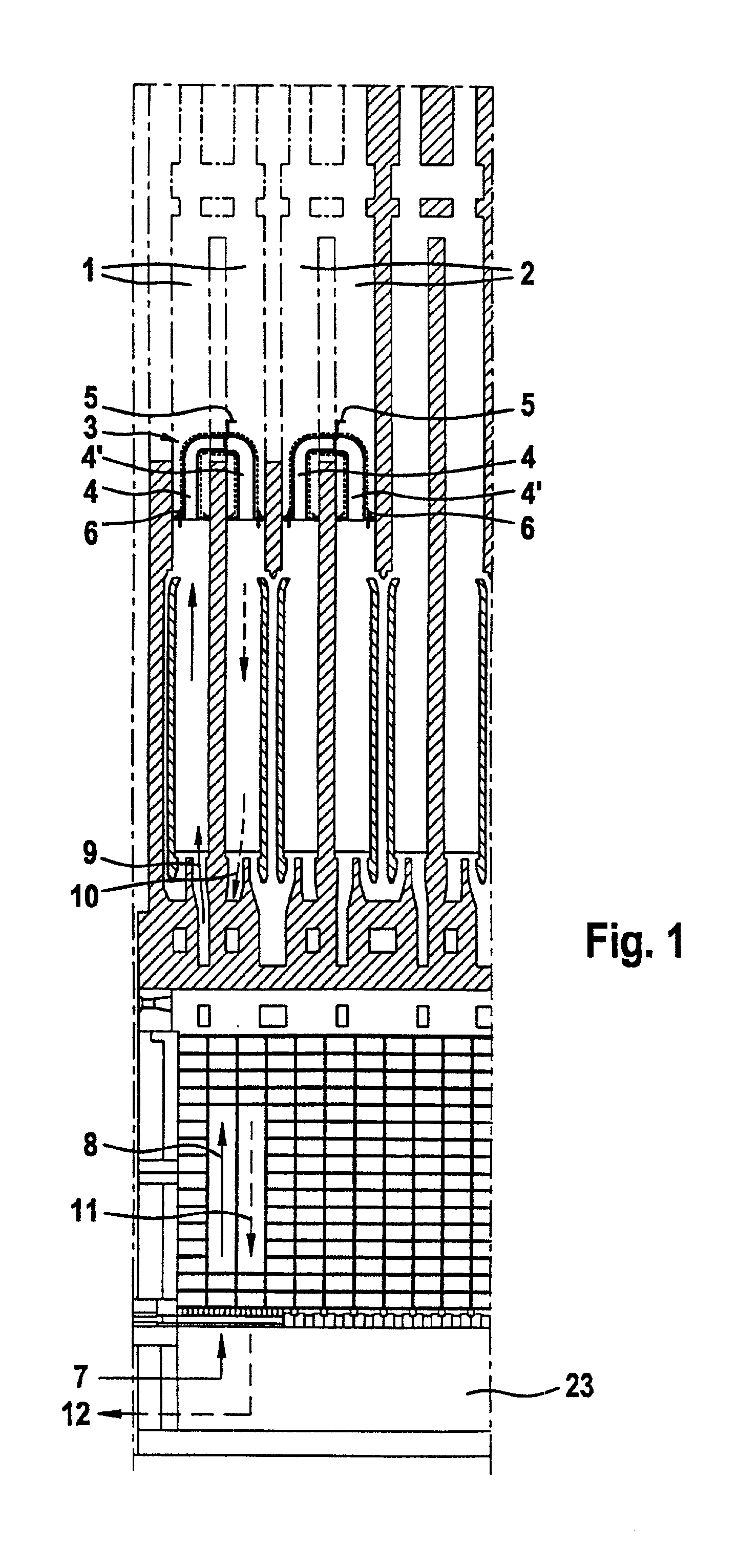

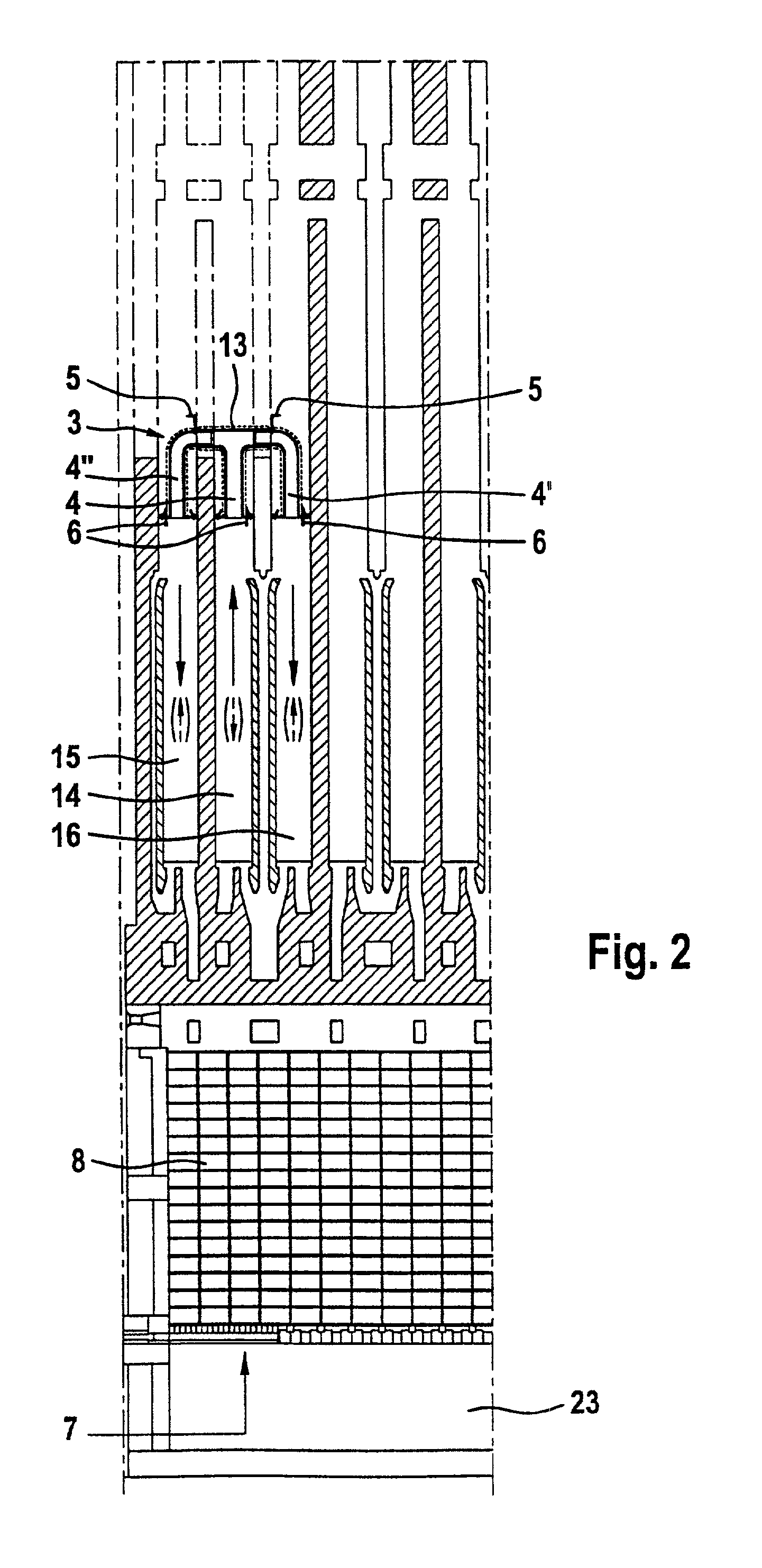

Method of hot-repairing the heating flues of a coke-oven battery and device for carrying out said method

InactiveUS7037409B1Simple and energy-efficient heatingLow costCombustible gas coke oven heatingLinings repairCombustionExhaust fumes

A method and a device for the hot-repairing of the heating flues of a coke-oven battery according to which the completed sections of a heating flue still under construction are heated by means of a heated gas. The heated gas comprises the air usually provided for combustion in the heating flues during coking operations. The air is guided through the flow paths provided for in the coke-oven battery for combustion air and waste gases as well as through the regenerator, heated as it passes through the flow paths and then guided through the heating flues to be repaired. The completed section of the heating flue is separated from the non-completed portion by an air-reversion device that also directs the heated air.

Owner:UHDE GMBH

Coke oven reconstruction

InactiveCN101225312AGood dimensional stabilityNegligible thermal expansionFurnace componentsCoke oven brickworkEngineeringCoke oven

A new, faster and more efficient process to replace heating walls and ceilings in coke oven batteries. Thus, when replaced, at least one heating wall is constructed of thermally stable non-expanding large size modular cast modules from end to end and the ceiling adjacent the heating wall is constructed of thermally stable non-expanding large modular cast blocks.

Owner:VANOCUR REFRACTORIES LLC

Repair of heating walls in a refractory furnace

A method of repairing a refractory brick wall in a furnace that includes: (a) identifying a refractory brick wall or portion thereof that requires repair / reconstruction, pre engineering construction dimensions and accommodating various battery oven designs and oven heating systems; (b) demolishing the refractory brick wall or wall portion thereof identified in step (a); (c) installing outer reusable forms in situ, defining a new wall or portion thereof; (d) installing inner consumable forms defining one or more passageways within the new wall or portion thereof; and (e) pouring castable material into one or more areas bounded by the outer forms; (f) curing said castable material; and (g) removing the outer reuseable forms.

Owner:FOSBEL INTELLECTUAL LTD (GB)

Brickwork joint sealing device and brickwork joint sealing method for horizontal channel of dryoff oven of coke oven

ActiveCN104531175AAffect normal heatingImprove sealingBrickwork leakage repair/preventionSlurryCoke oven

The invention relates to a brickwork joint sealing device and a brickwork joint sealing method for a horizontal channel of a dryoff oven of a coke oven. The device comprises a sealing element, a first operating rod, a recovery barrel, a second operating rod, a bracket, a first fixed element and a second fixed element, wherein the sealing element is placed in a vertical flue and forms seal with the side wall of the vertical flue, so that slurry for sealing the brickwork joint can be injected to the upper side of the sealing element and permeate into the brickwork joint; the first operating rod is connected to the sealing element for operating the sealing element; the recovery barrel is arranged below the sealing element and is opened upward for recovering residual slurry permeating into the brickwork joint; the second operating rod passes through the sealing element or the first operating rod movably up and down and is connected with the recovery barrel for moving the recovery barrel up and down; the bracket is arranged on the top of the coke oven for at least supporting the first operating rod or the second operating rod; the first fixed element is connected to the first operating rod for fixing the position of the first operating rod; the second fixed element is connected to the second operating rod for fixing the position of the second operating rod. The device and method provided by the invention can be used for simply and conveniently sealing the horizontal channel of the dryoff oven of the coke oven.

Owner:SHANDONG IRON & STEEL CO LTD

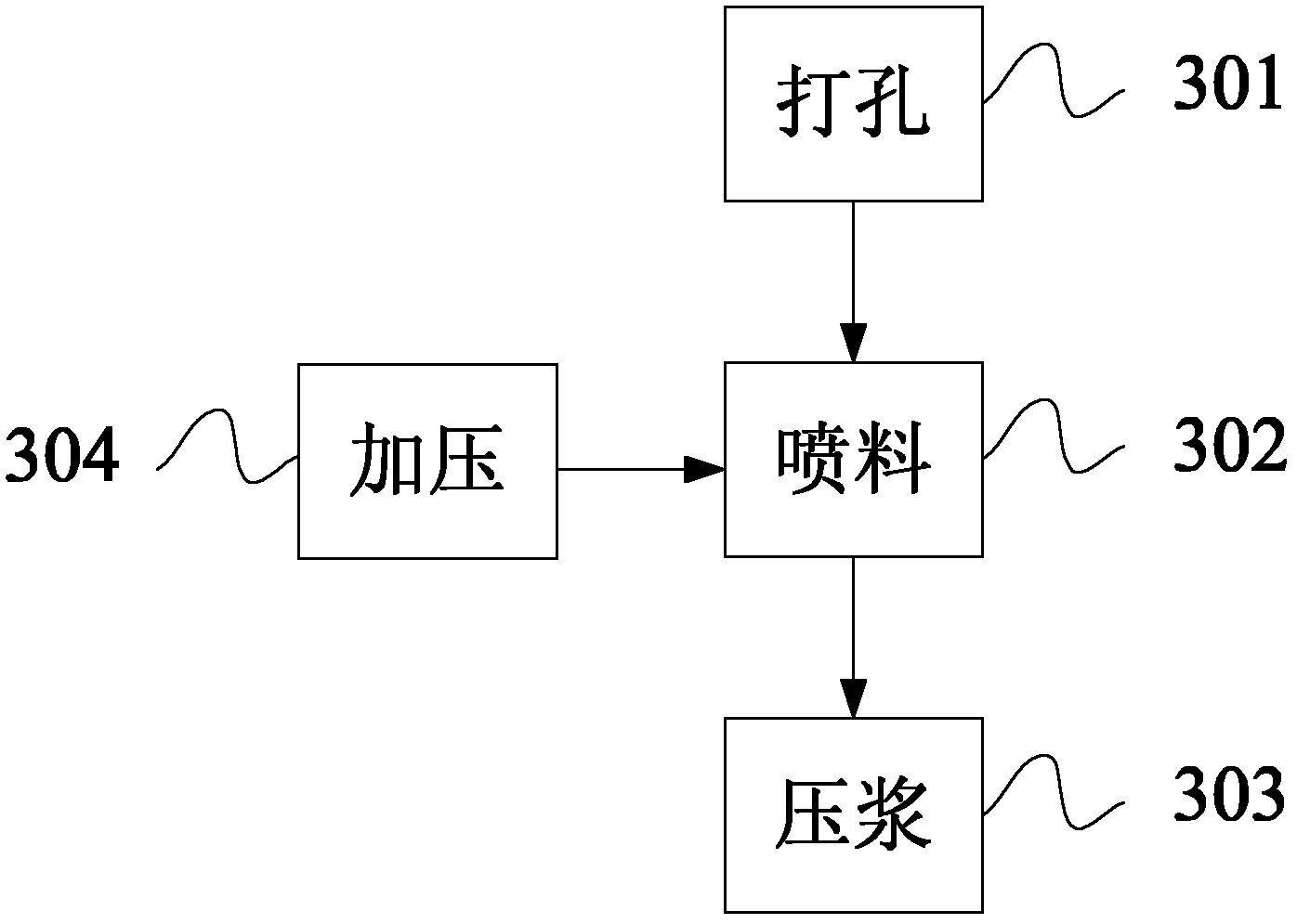

Coke oven gas lower spray pipe brick gas duct full-slurry grouting sealing system and method

PendingCN111363563AImprove grout seal qualityReduced sealing processBrickwork leakage repair/preventionAir compressionBrick

The invention discloses a coke oven gas lower spray pipe brick gas duct full-slurry grouting sealing system and method, and relates to the technical field of coke oven thermal state engineering. The system comprises a slurry spraying pipe, a slurry spraying tank, a slurry return tank and an air compression system, the slurry spraying pipe is arranged at the lower end of a brick gas channel, the slurry spraying pipe extends upwards into the brick gas channel and is in sealing connection with a lower spraying pipe four-way joint through a quick sealing joint, slurry in the slurry spraying tank is poured into the brick gas channel through an air compression system, and the amount of the slurry in the slurry spraying tank is configured to enable the height of the slurry poured into the brick gas channel to be 50 mm higher than the upward position of a horizontal brick joint of a top-layer gas channel pipe brick in the brick gas channel. By means of the technical scheme, the one-time full-height integral grouting sealing effect can be achieved by controlling the slurry amount, the grouting sealing quality of the coke oven gas down-spraying pipe brick gas channel is improved, the construction period is shortened, the construction cost is reduced, the subsequent repairing procedures of the brick gas channel can be effectively reduced, the construction cost is reduced, and a high use and promotion value is achieved.

Owner:CHINA MCC5 GROUP CORP

Repair apparatus for coke oven

ActiveCN1898359AEasy to operateImprove repair accuracyLinings repairBrickwork leakage repair/preventionCarbonizationEngineering

A repair apparatus for a coke oven, comprising a traveling carriage (3) put across rails laid down on the coke oven and traveling in the direction of the furnace group of the coke oven. A transverse carriage (4) moving in a direction orthogonal to the traveling direction is installed on the traveling carriage (3). A work device (5) for repairing a furnace wall on the inside of the coke oven is mounted on the transverse carriage (4). The work device (5) is characterized by comprising a guide post (31) vertically installed on the transverse carriage (4) and having a lower end part connected, through a pivot shaft (42), to a support part formed on the transverse carriage, a lance (32) lifting along the guide post (31), and a derricking device (45) swinging the lance (32) inserted through an insert hole into a coke oven carbonization chamber in a furnace length direction by swinging the guide post (31) about the pivot shaft (42) between a forward tilted attitude and a backward tilted attitude.

Owner:KANSAI COKE & CHEM

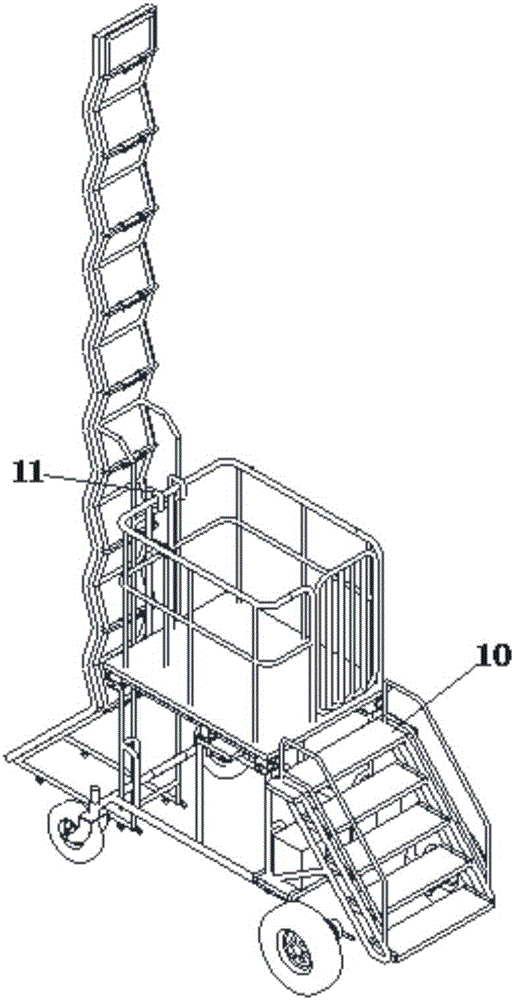

Heat-insulating method used during hot maintenance of coke oven carbonization room

ActiveCN106350081AQuickly block high temperatureShorten maintenance cycleBrickwork leakage repair/preventionFiberMetallurgy

The invention discloses a heat-insulating method used during hot maintenance of a coke oven carbonization room. The heat-insulating method comprises the following steps: 1) laying the whole volume of ceramic fiber felt onto a waved framework of a heat-insulating protective shield used during hot maintenance of the coke oven carbonization room, and tying wave peaks of the waved structure by using ceramic fiber ropes 4, so that a ceramic fiber felt 3 is segmentally stressed, wherein the outer surface of the heat-insulating protective shield used during the hot maintenance of the coke oven carbonization room is coated with a heat-insulating material; 2) after tying completion of the ceramic fiber ropes, transporting the heat-insulating protective shield used during hot maintenance of the coke oven carbonization room to a maintenance site by using manpower or a movable lifting platform; 3) after removing a carbonization chamber oven door required to be maintained, aligning the heat-insulating protective shield used during hot maintenance of the coke oven carbonization room to the a carbonization room, and pushing forward till a position needs to be insulated. In the heat-insulating method, the self-made heat-insulating protective shield used during the hot maintenance of the coke oven carbonization room is used, and during using, the heat-insulating protective shield used during the hot maintenance of the coke oven carbonization room can rapidly insulate high heat of the carbonization chamber, so that the maintenance cycle is shortened; the protective shield can be used for several times in a turnover manner, so that the maintenance cost is lowered.

Owner:CHINA FIRST METALLURGICAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com