Method for repairing bricks at bottom of carbonization chamber of large coke oven

A repair method and technology for a carbonization chamber, applied in the field of coke ovens, can solve the problems of frequent furnace repairs, long time, harsh operating environment, etc., and achieve the effects of reducing the number of furnace repairs, prolonging the service life, and improving the harsh environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

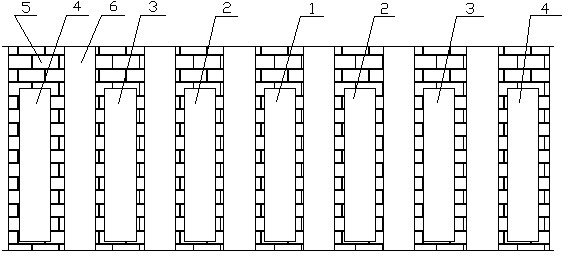

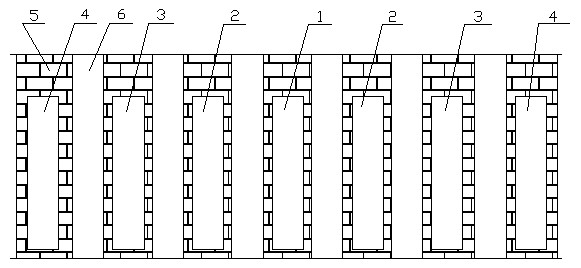

[0038] The company's 50-hole JN60-82 double-connected fire channel, waste gas circulation, reheating coke oven with coke oven gas spraying down, and the average width of the carbonization chamber is 4500mm and the height is 6m. During the production process, the refractory brick at the bottom of the No. 60 carbonization chamber was damaged in a large area, which affected the production of the coke oven. In June, 2010, repaired according to the method of the present invention, the specific steps are as follows:

[0039] 1. Setting of empty furnace number and braising furnace number: Repair the empty furnace numbers of No. 59 and No. 61 of the two adjacent carbonization chambers of the furnace number, and keep the empty furnace state; No. 58 and No. 62 of the two adjacent carbonization chambers of the empty furnace number are the braising furnace numbers , keep the state of the oven.

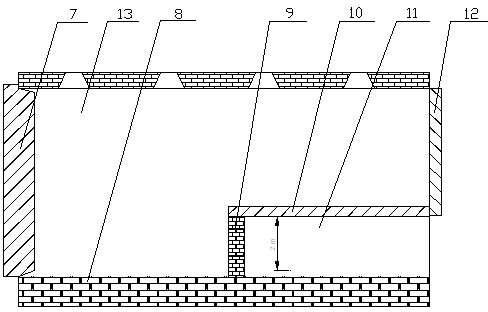

[0040] 2. Reinforcement of furnace columns: 12# channel steel is used to connect furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com