Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "No melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

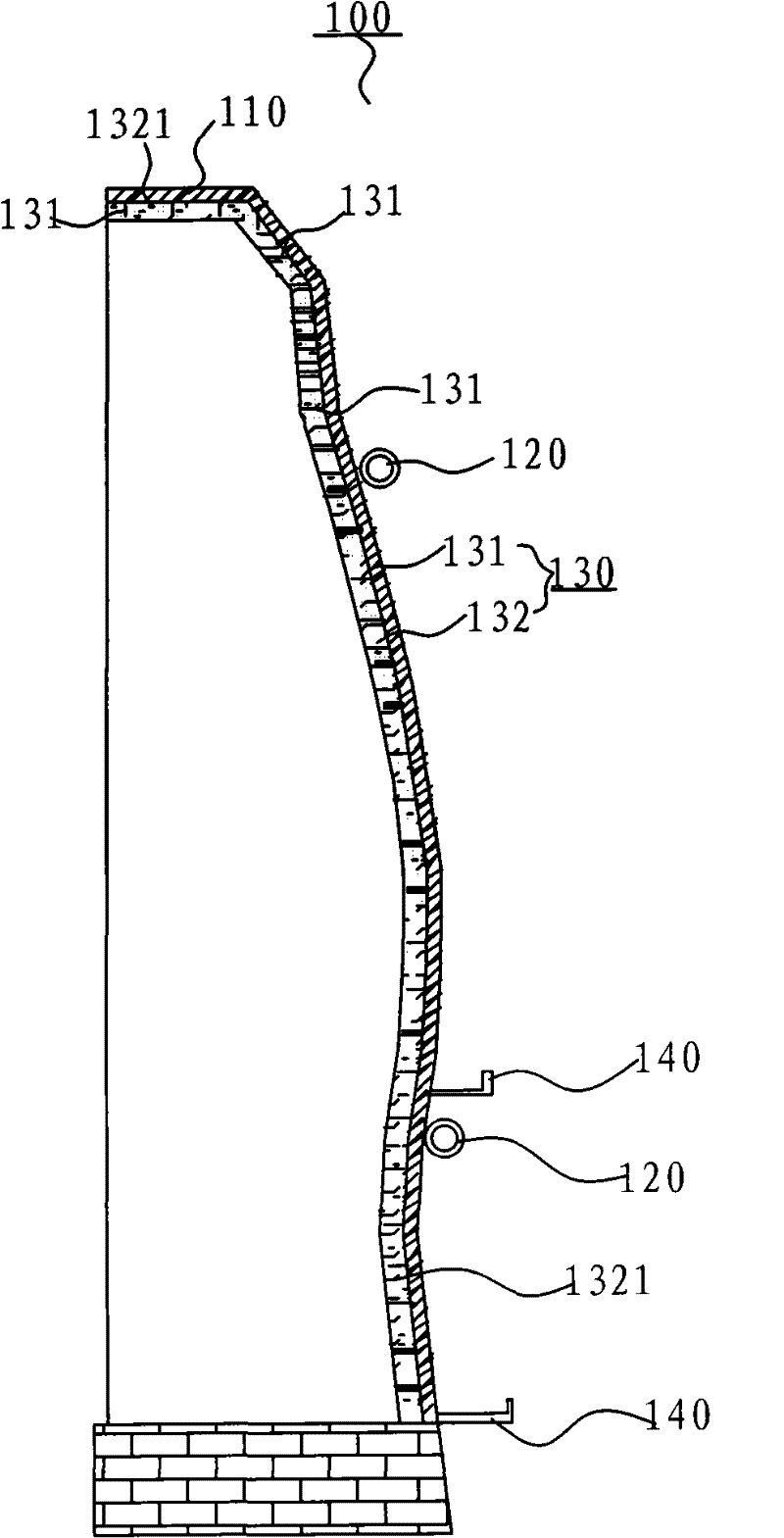

Electricity isolator, manufacturing method and use thereof

The invention relates to an electrical spacer and a manufacturing method thereof. The electrical spacer is used for batteries and other devices. Electrodes are separated mutually to keep ionic conductivity. The spacer is preferably made of thin and porous insulating material, has high iron conductivity, good mechanical strength, and can withstand chemical substances and solvents used in a system (such as in the electrolyte of the battery) for a long time. The spacer completely separates a cathode and an anode in the battery. In addition, the spacer has continuous elasticity and moves in accordance with the system, such as the movement in an electrode array during the charging and the discharging processes. The problem can be solved by the spacer; the spacer comprises a plurality of holes; flat and flexible base material for a coating layer is arranged on the base material and in the base material; meanwhile, the base material is made of self-weaving or non-weaving non conductive glass or ceramic fiber or the combination of the conductive glass and the ceramic fiber; and the coating layer is a porous electrical isolation ceramic coating layer. The spacer is characterized in that the thickness of the spacer is less than 100 microns.

Owner:EVONIK DEGUSSA GMBH

Decellularization cornea preparation method

The invention relates to a decellularization cornea preparation method, which adopts steps of corneal epithelium layer removing, ultraviolet cross-linking, viral inactivation, decellularization treatment, gradient dehydration, radiation protection and sterilization. According to the present invention, the prepared decellularization cornea has characteristics of complete antigen removing, no excitation of host acquired immunity reaction, good biocompatibility, low damage on nature corneal stroma, maintaining of structure characteristics of the nature corneal, and maintaining of effective components of the nature corneal so as to provide physical and chemical properties similar to the nature corneal; and after the prepared decellularization cornea is transplanted, animal experiment results show that characteristics of transparent transplanted cornea, no scar formation, no melting generation and no neovascularization are provided, the transplanted cornea and the recipient bed are completely integrated after transplanting a month, the transplanted cornea is subjected to complete epithelization after three months, corneal stroma cells migrate toward the decellularization cornea graft so as to prove that the tissue just takes place slow reconstruction, and the transplanted cornea after 6 months does not show significant difference in histology and appearance detection compared with the nature cornea.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

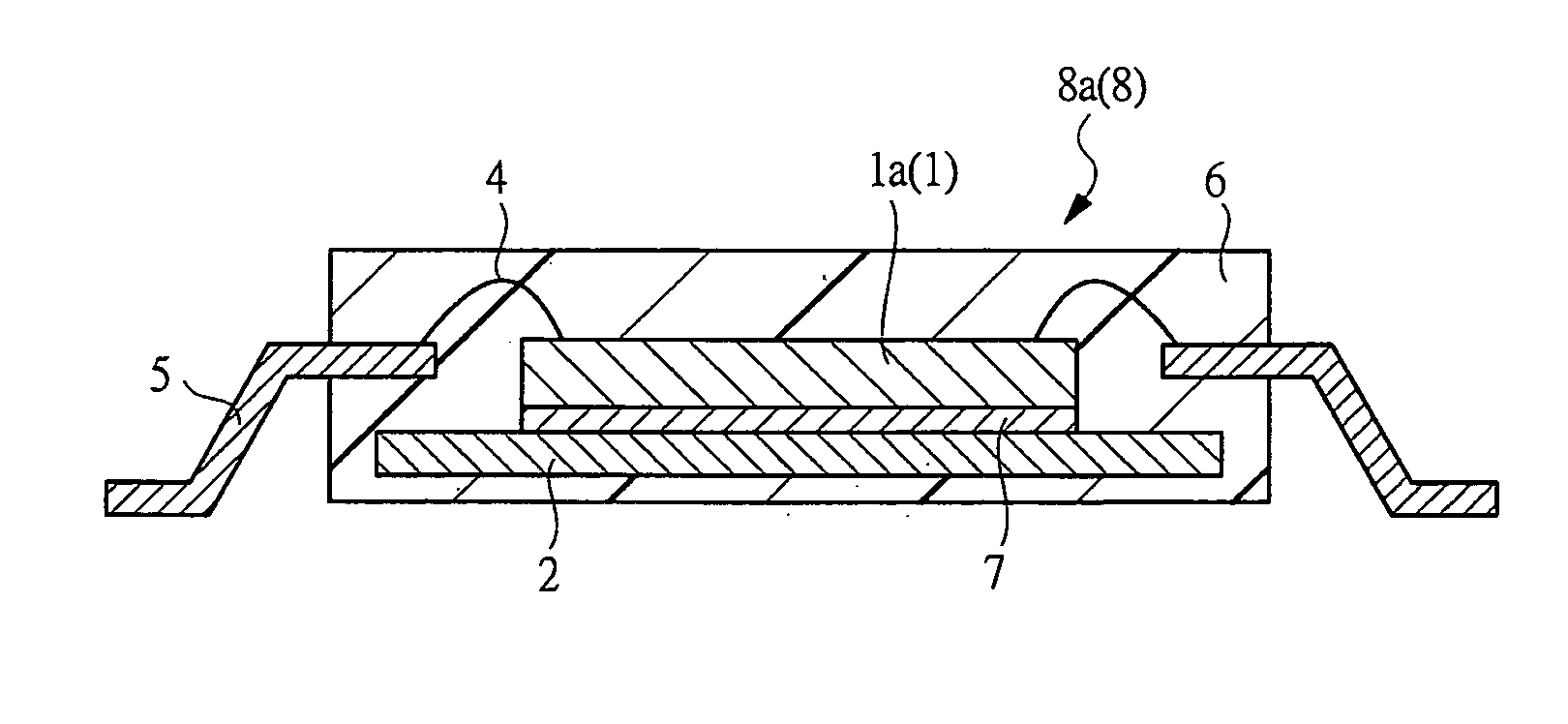

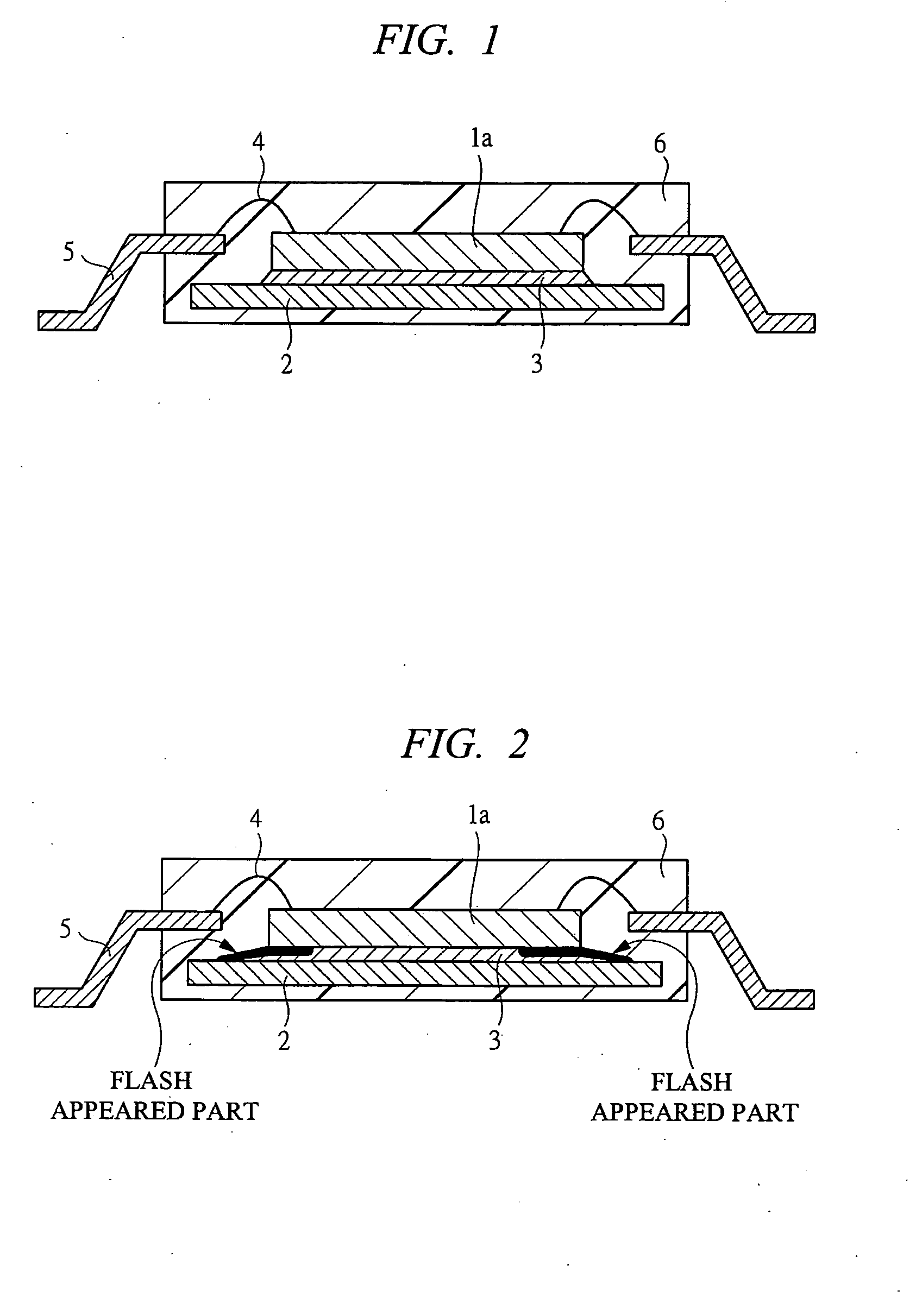

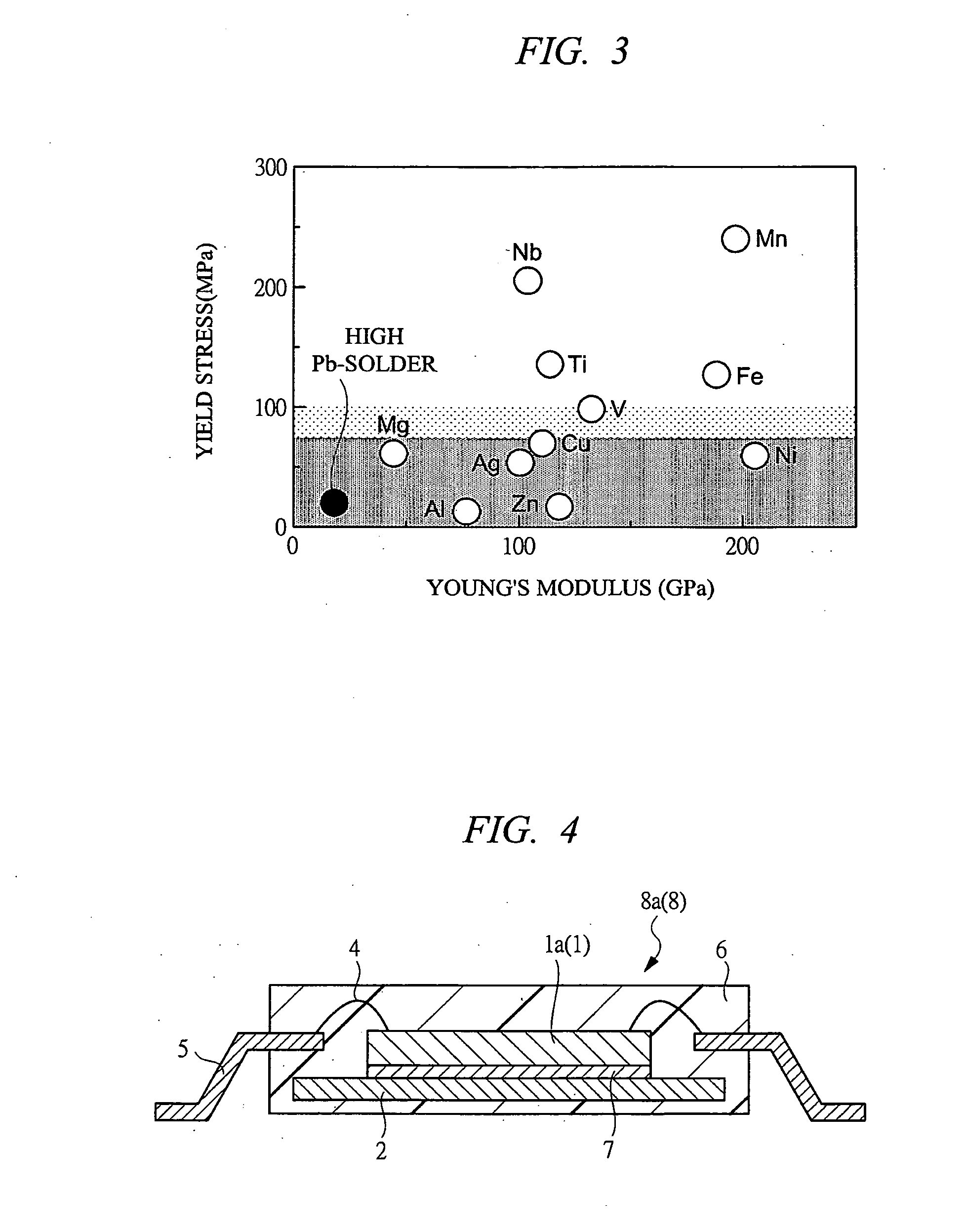

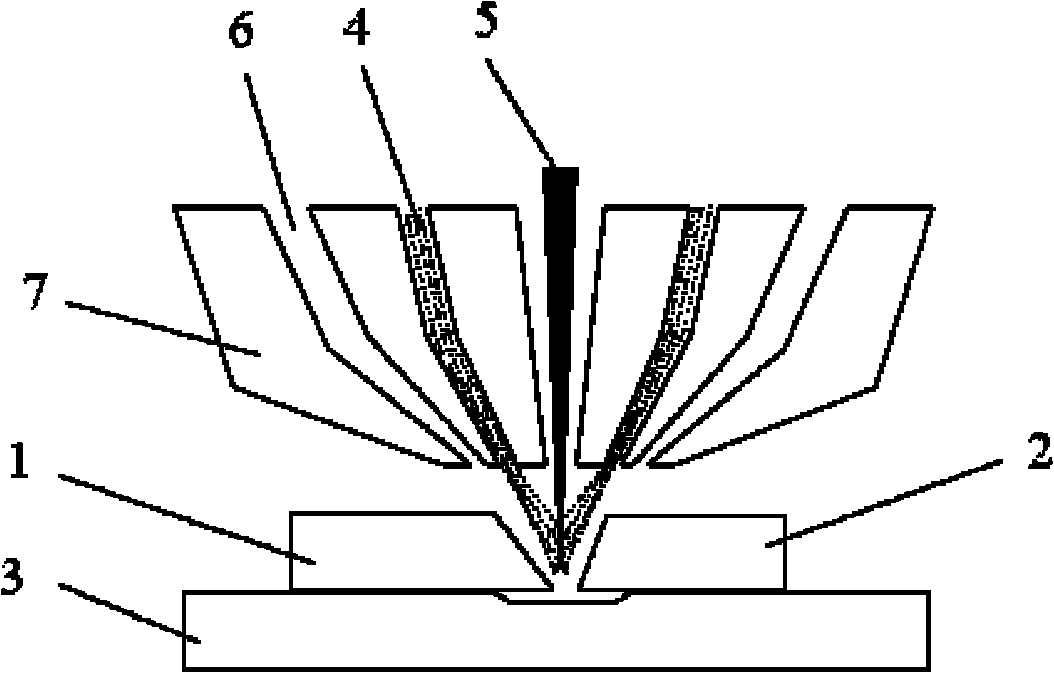

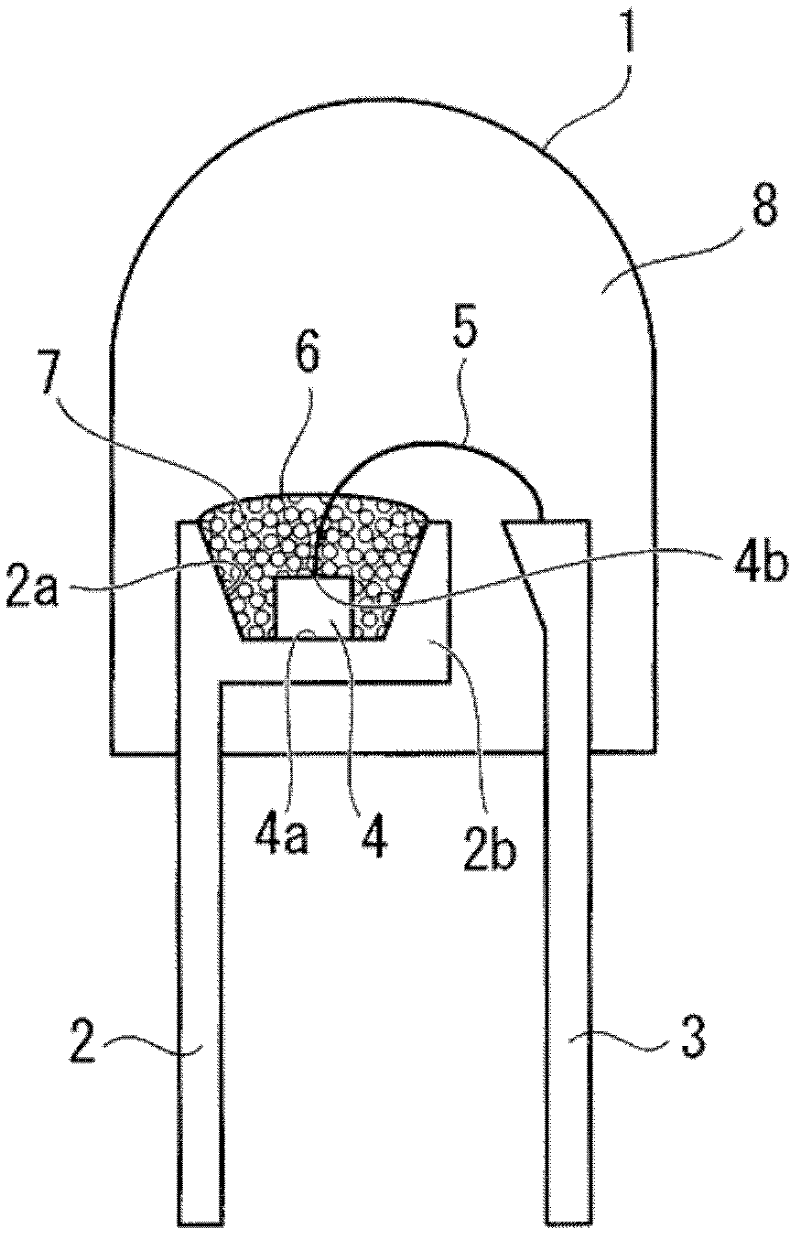

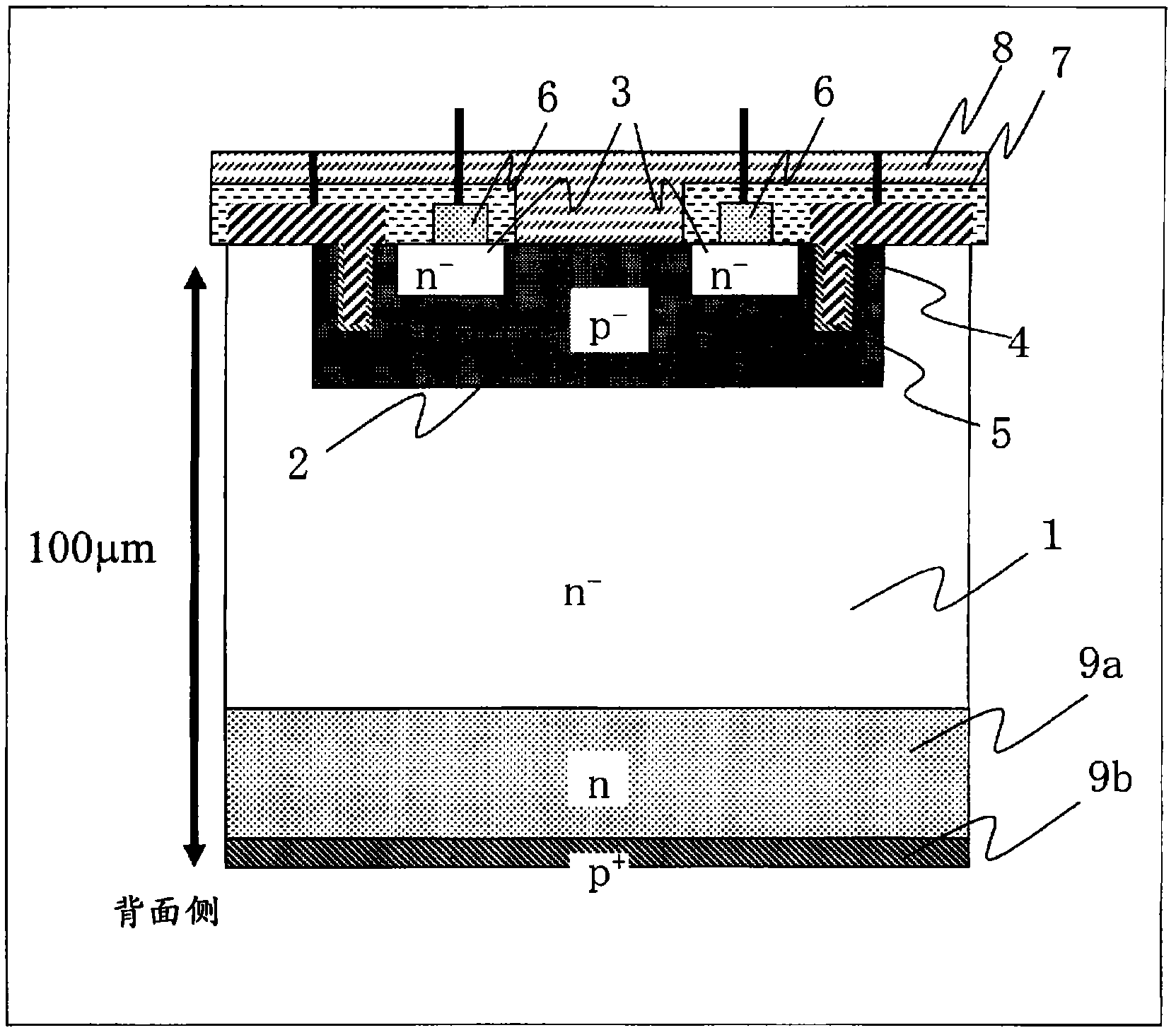

Semiconductor Device And Production Method For Semiconductor Device

InactiveUS20080122050A1Improve connection reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceThermal expansion

A power semiconductor device in which a semiconductor element is die-mount-connected onto a lead frame in a Pb-free manner. In a die-mount-connection with a large difference of thermal expansion coefficient between a semiconductor element 1 and a lead frame 2, the connection is made with an intermetallic compound 200 having a melting point of 260° C. or higher or a Pb-free solder having a melting point of 260° C. or higher to 400° C. or lower, at the same time, the thermal stress produced in temperature cycles is buffered by a metal layer 100 having a melting point of 260° C. or higher. A Pb-free die-mount-connection which does not melt at the time of reflowing but have no chip crack to occur according to thermal stress can be achieved.

Owner:RENESAS TECH CORP

Balling method using medium- and low-grade phosphate rocks or ground phosphate rocks

ActiveCN103663396AHigh strengthHigh phosphorus contentPhosphorus compoundsPhosphoric acidCalciums magnesium

The invention relates to a balling method using medium- and low-grade phosphate rocks or ground phosphate rocks. The method comprises the following steps: S1, preparing materials, namely A, 85-100 parts of 60-120-mesh medium-grade and low-grade phosphate rocks or ground phosphate rocks, B, 1-10 parts of water or aqueous liquor of phosphoric acid, C, 2-8 parts of coke powder with the granularity of 60-120 meshes and D, 1-8 parts of one or more of phosphate fire clay, kaolin, sodium silicate, sodium carbonate, calcium carbonate and serpentine; S2, stirring, namely after uniformly mixing the raw materials, pressing the mixture into balls by use of a dry powder ball press machine, after pre-drying, delivering the mixture to a vertical calcining kiln, using purified yellow phosphorus tail gas, heating to 850-950 DEG C; starting roasting to obtain a finished product. The method is free from binders and low in cost, and the medium-grade and low-grade phosphate rocks are not hardened. The value of the medium-grade and low-grade phosphate rocks can be improved, and the ground phosphate rock of a mine can be fully utilized. The phosphate rock balls prepared are suitable for production of yellow phosphorus or calcium magnesium phosphate fertilizers.

Owner:刘静忠 +1

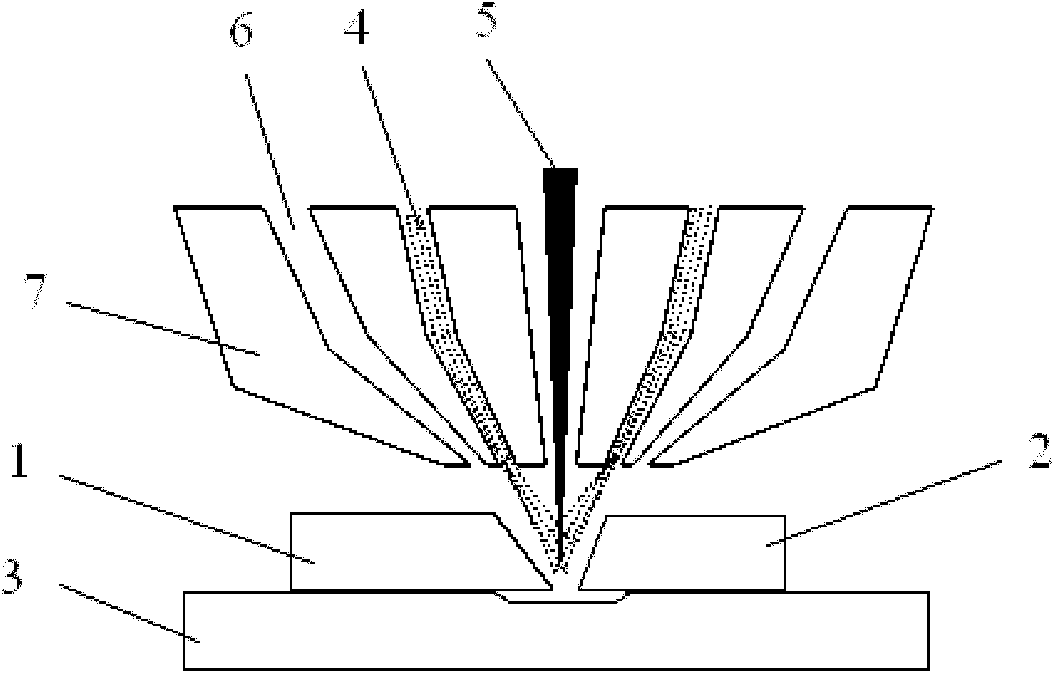

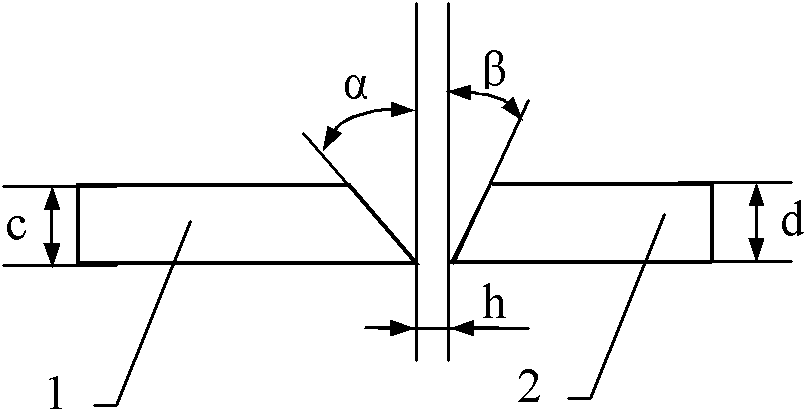

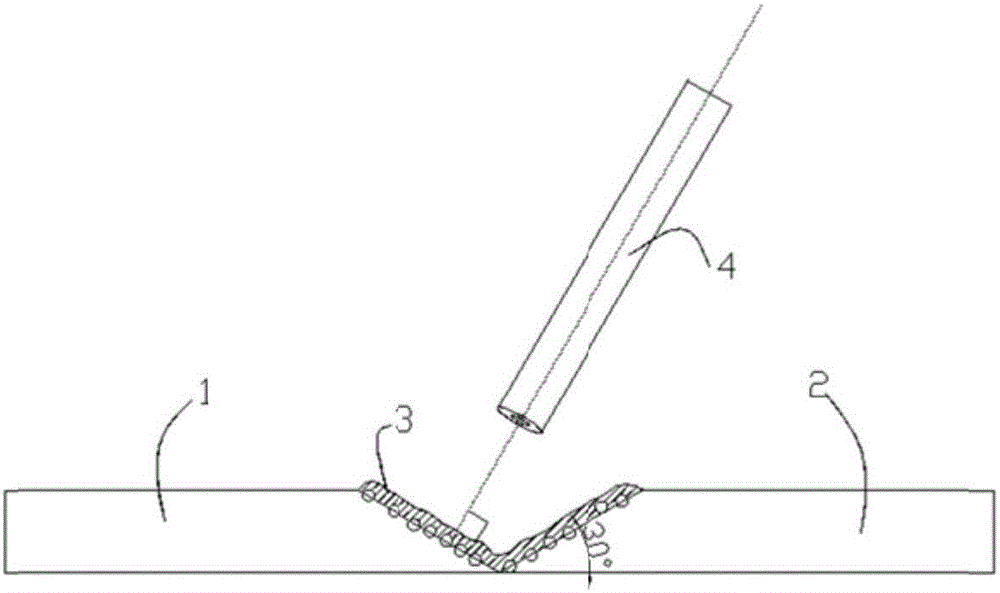

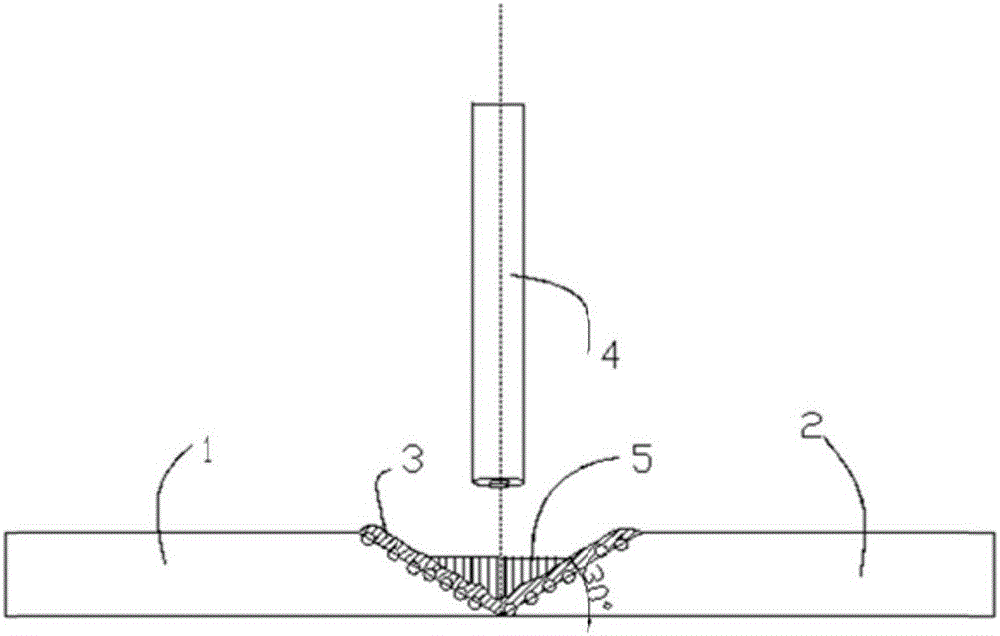

Method for performing laser welding by filling powder between aluminum sheet and steel sheet

InactiveCN102091873AAvoid overheatingHigh processing flexibilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthMaterials science

The invention discloses a method for performing laser welding by filling powder between an aluminum sheet and a steel sheet and belongs to the technical field of laser welding. Electric arc energy in the prior art is difficult to control, if too much heat is input into one side of aluminum, the temperature is too high, and the temper brittleness phenomenon is generated and intensity of a welding joint is reduced. Moreover, the phenomenon of welding wire blocking is generated during welding. The technical problems are more serious for sheets with thickness of less than 4mm. A welding workpiece is an aluminum panel and a steel panel which are butted on the same plane with gaps; beveled edges are formed at seams; Al-Si solder is adopted, alloying elements Cu, Mn, and Zn are added, and the aluminum panel and the steel panel are respectively the aluminum sheet and the steel sheet of which the thicknesses are both 1 to 4mm; and the Al-Si solder is made into powder, powdery Al-Si solder is added into a groove formed by clamping the beveled edges of the aluminum sheet and the steel sheet respectively, and the aluminum sheet and the steel sheet travel together and welding is performed by taking laser as a welding heat source.

Owner:CHANGCHUN UNIV OF SCI & TECH

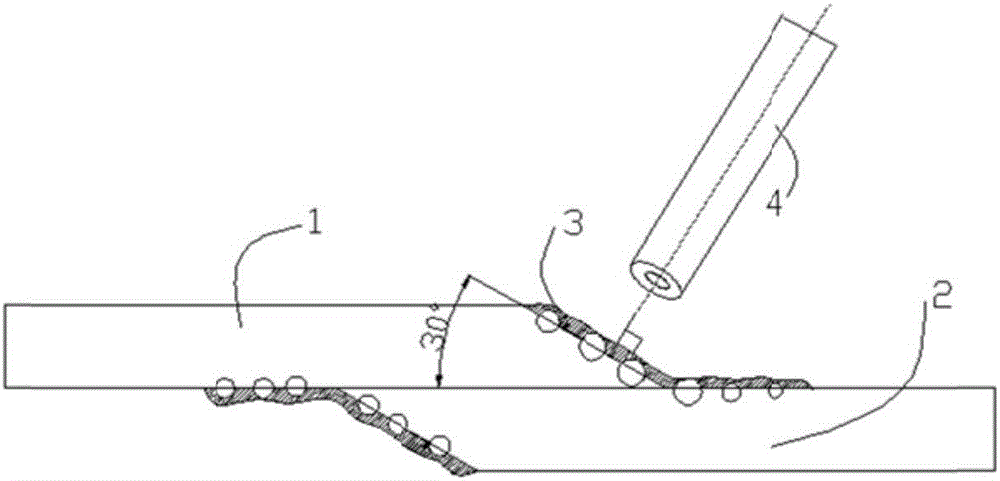

Steel/aluminum dissimilar metal part laser deposition additive manufacturing method

ActiveCN105665709ANo meltingWell formedAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturingMetal

The invention discloses a steel / aluminum dissimilar metal element laser deposition additive manufacturing method, and aims to achieve integral additive manufacturing of a steel / aluminum dissimilar metal element from steel / aluminum dissimilar metal by using an additive manufacturing aluminum alloy process progressively in a one-step continuous formation manner or on a steel molded base body. According to the steel / aluminum dissimilar metal element laser deposition additive manufacturing method, the molded element has different components and properties at different parts by changing components, speeds and manufacturing process parameter conditions of conveying materials, furthermore integral design and manufacturing of material-structure-function can be achieved, and the steel / aluminum dissimilar metal element laser deposition additive manufacturing method has unique advantages of high efficiency, low cost, high performance quality and the like in the aspect of manufacturing dissimilar metal elements.

Owner:JILIN UNIV

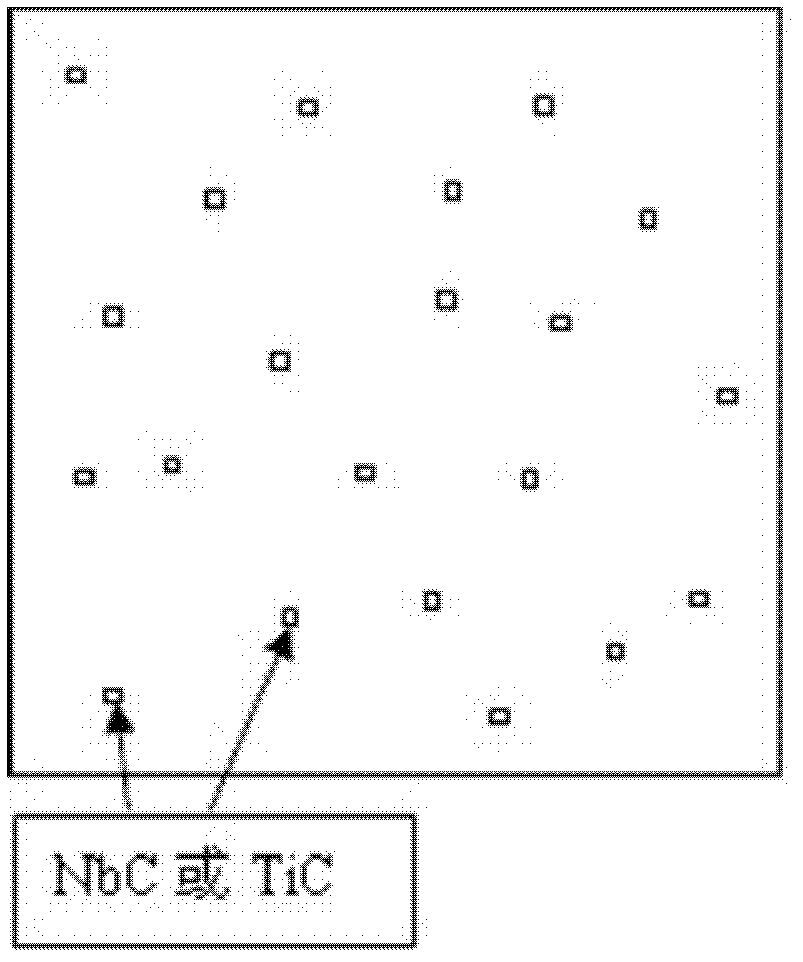

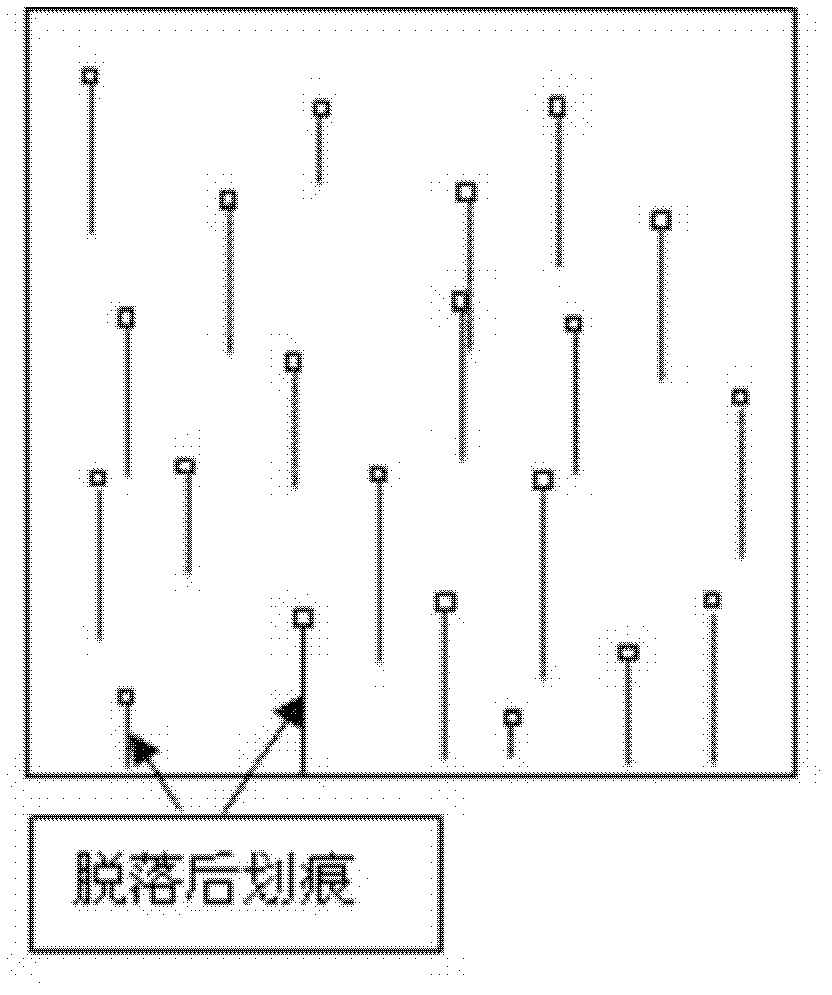

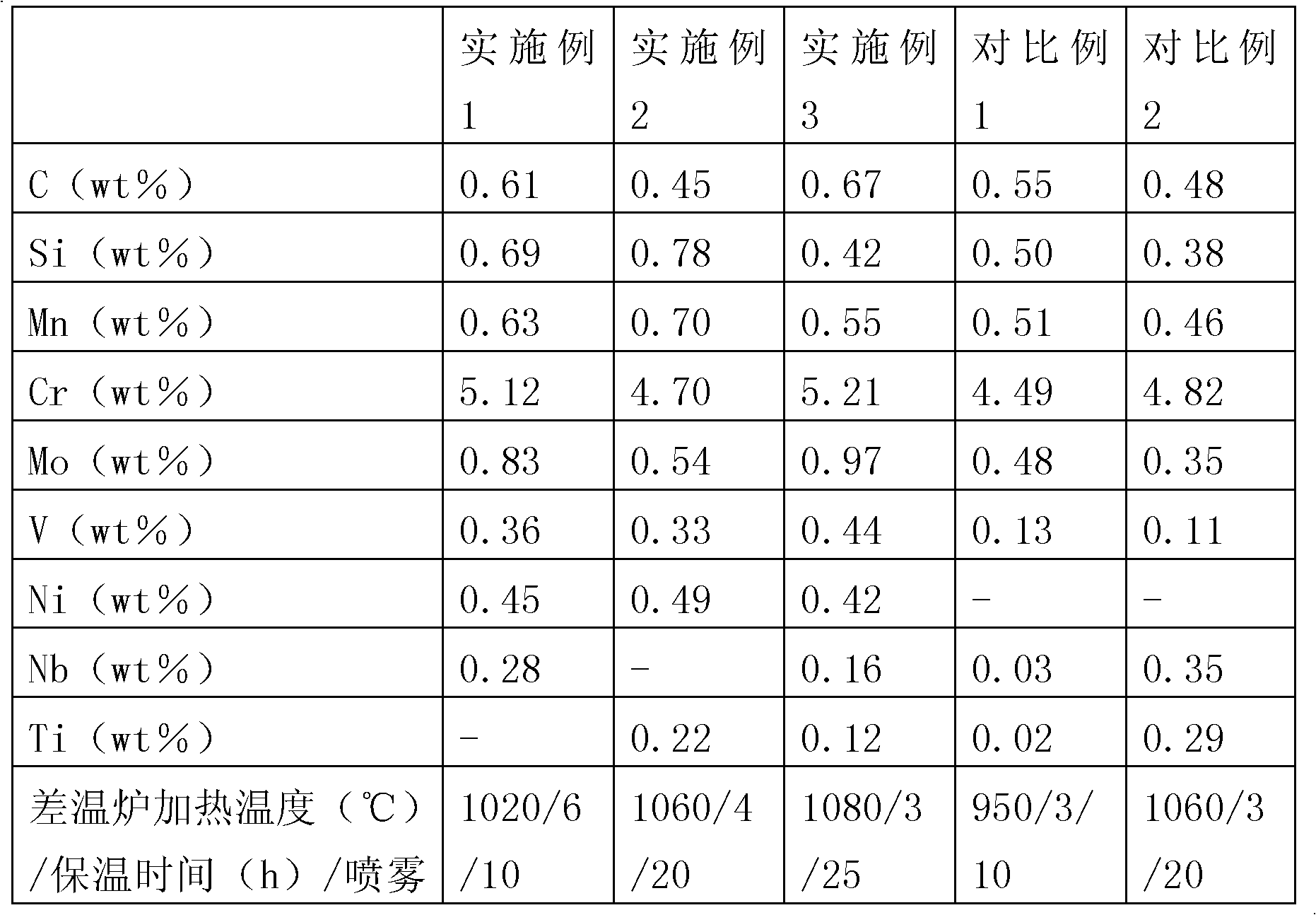

Supporting roller with roughness keeping capability and manufacturing method thereof

ActiveCN102634738AHigh roughness retentionIncrease productivityCounter-pressure devicesFurnace typesMetallurgy

The invention discloses a supporting roller with a roughness keeping capability, comprising the following chemical components in mass percentage: 0.40-0.70% of C, 0.40-0.80% of Si, 0.50-0.80% of Mn, 4.5-5.5% of Cr, 0.40-1.00% of Mo, 0.30-0.50% of V, 0.40-0.60% of Ni. The supporting roller further comprises one or two of 0.05-0.30% of Nb and 0.05-0.30% of Ti, and residual amounts of Fe and unavoidable impurities. The invention further discloses a manufacturing method of the supporting roller; and the roughness keeping capability of the manufactured supporting roller is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

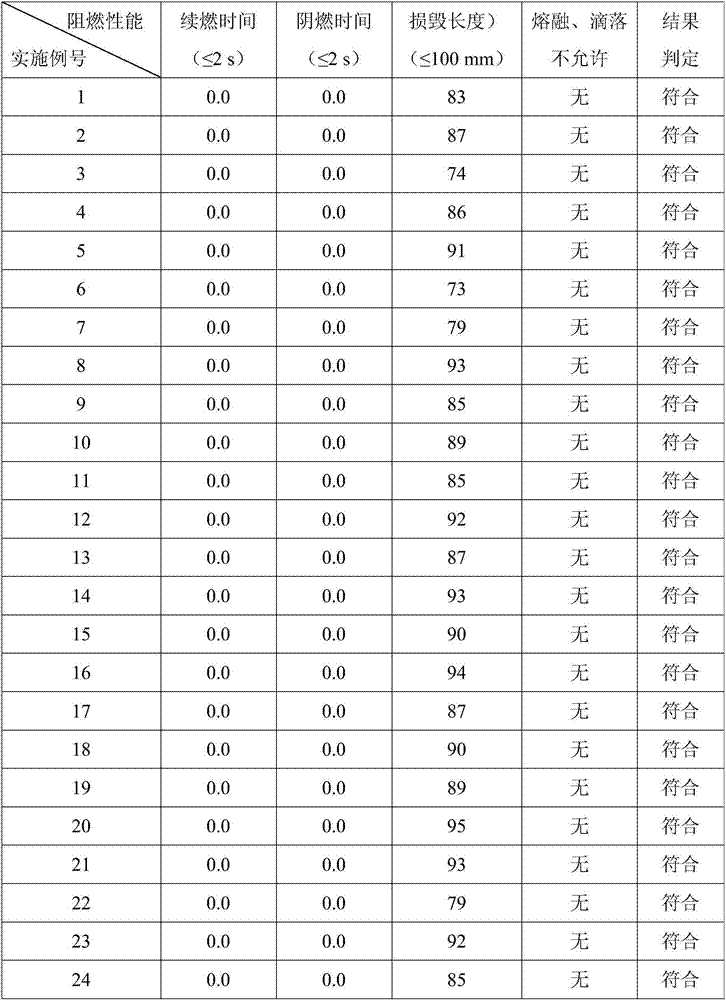

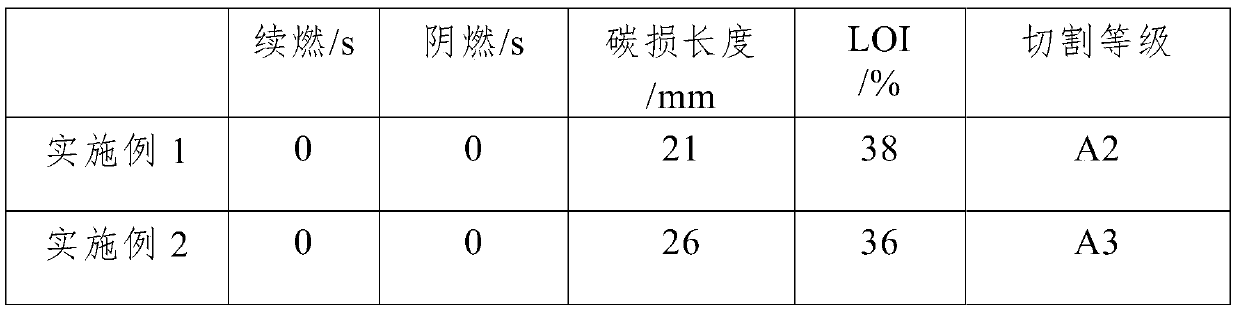

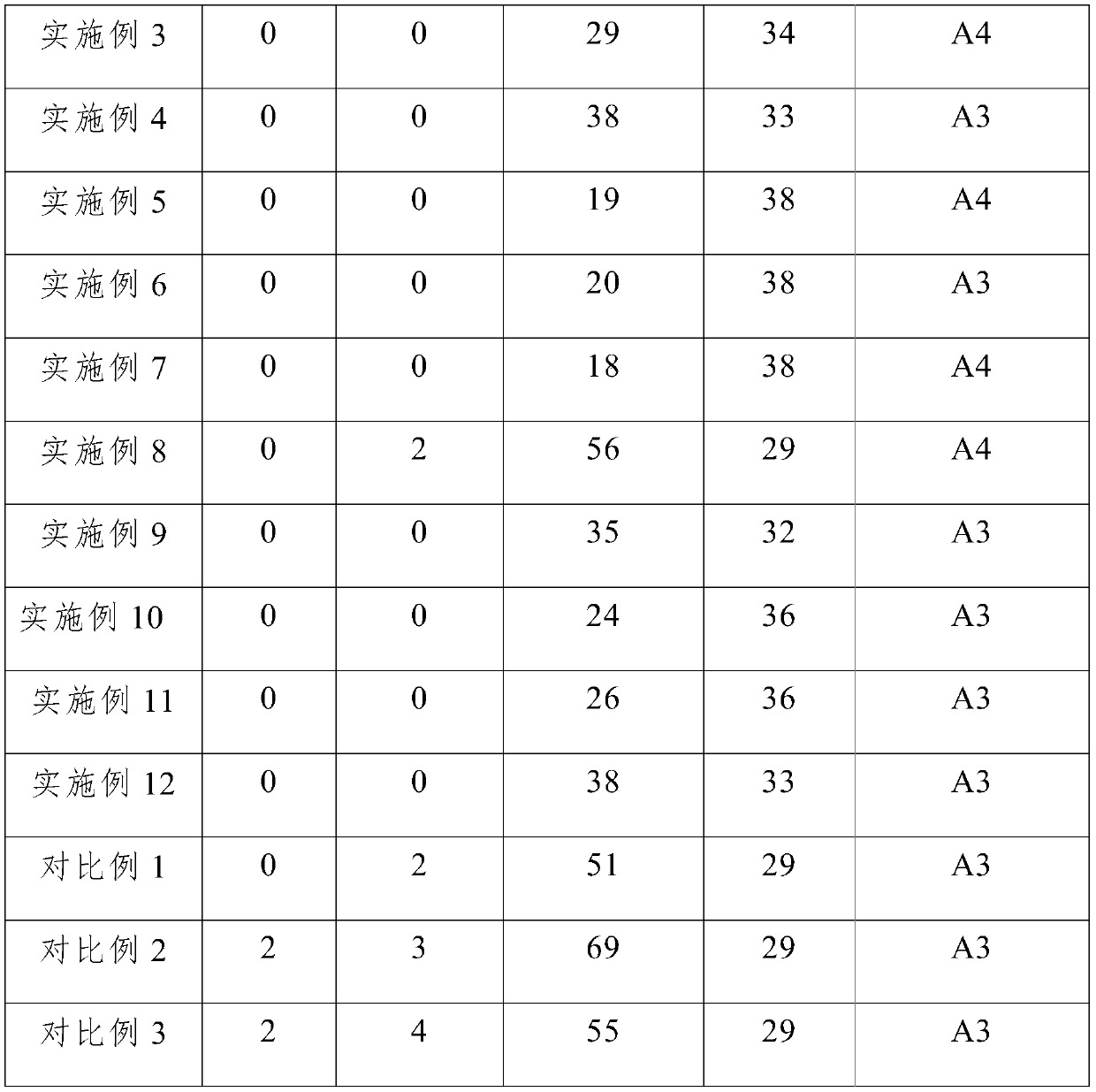

Method for preparing light, thin, heat-insulating flame-retardant plush fabric

InactiveCN106192176AComfortable to wearGood warmth retentionFabric breaking/softeningWeft knittingYarnPolyester

The invention relates to a method for preparing a light, thin, heat-insulating and flame-retardant plush fabric. The method comprises the steps of weaving a fabric, wherein terry yarn is 98% of 32S / 1 aramid fiber 1313 / 2% of conductive filament, and connecting yarn is 100D / 36F polyester flame-retardant double-sided plush; causing the fabric to undergo dyeing, drying, soft forming, galling, intermediate shaping, combing, shearing and final shaping, and obtaining the light, thin, heat-insulating and flame-retardant plush fabric. The method is short in process and good in stability, the obtained plush fabric insulates heat, is light and thin, has an outstanding flame-retardant effect, does not melt, has no melting drip and does not generate smoke, the afterflame time is 0 s, the smoldering time is 0 s, the plush fabric is permanently resistant to flame and is comfortable to wear and soft in touch, the final finished knitted fabric gram weight is 271 g / m2, the heat-insulating value CLO is 0.5-1.0, and the plush fabric has good application prospects.

Owner:SHANGHAI CHALLENGE TEXTILE

Double-layer compound biological filter material for aerated biological filter and method for preparing same

InactiveCN101759281AComponent film performance is goodLess componentsSustainable biological treatmentCeramic materials productionRough surfaceVoid ratio

The invention discloses a double-layer compound biological filter material for an aerated biological filter. The double-layer compound biological filter material is formed by combining an inner layer and an outer layer, wherein the inner layer consists of attapulgite clay and fly ash in a weight ratio of 4:6; and the outer layer consists of attapulgite clay, kieselguhr and coal dust in a weight ratio of 7-10:9-12:1. The preparation method comprises the following steps of: uniformly mixing the attapulgite clay and the fly ash, and forming inner cores of solid spheres in a granulator; uniformly mixing the attapulgite clay, the kieselguhr and the coal dust to obtain mixed powder, continuously and slowly adding the mixed powder into the granulator to coat the surfaces of the inner cores of the solid spheres for granulation to obtain the finished product spheres; and drying the finished spheres naturally for 24 hours and in a constant-temperature fan drying box at the temperature of 120 DEG C for 2 hours, taking the finished spheres out of the drying box, directly putting the finished spheres in a box-typed resistance furnace to sinter the finished spheres at the temperature of between 950 and 1.050 DEG C for 20 minutes, and naturally cooling the finished spheres to obtain the double-layer compound biological filter material. The double-layer compound biological filter material obtained by the preparation method has the advantages of rough surface, high void ratio, good wearing resistance, high strength, easy film formation and high economy and practicability.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

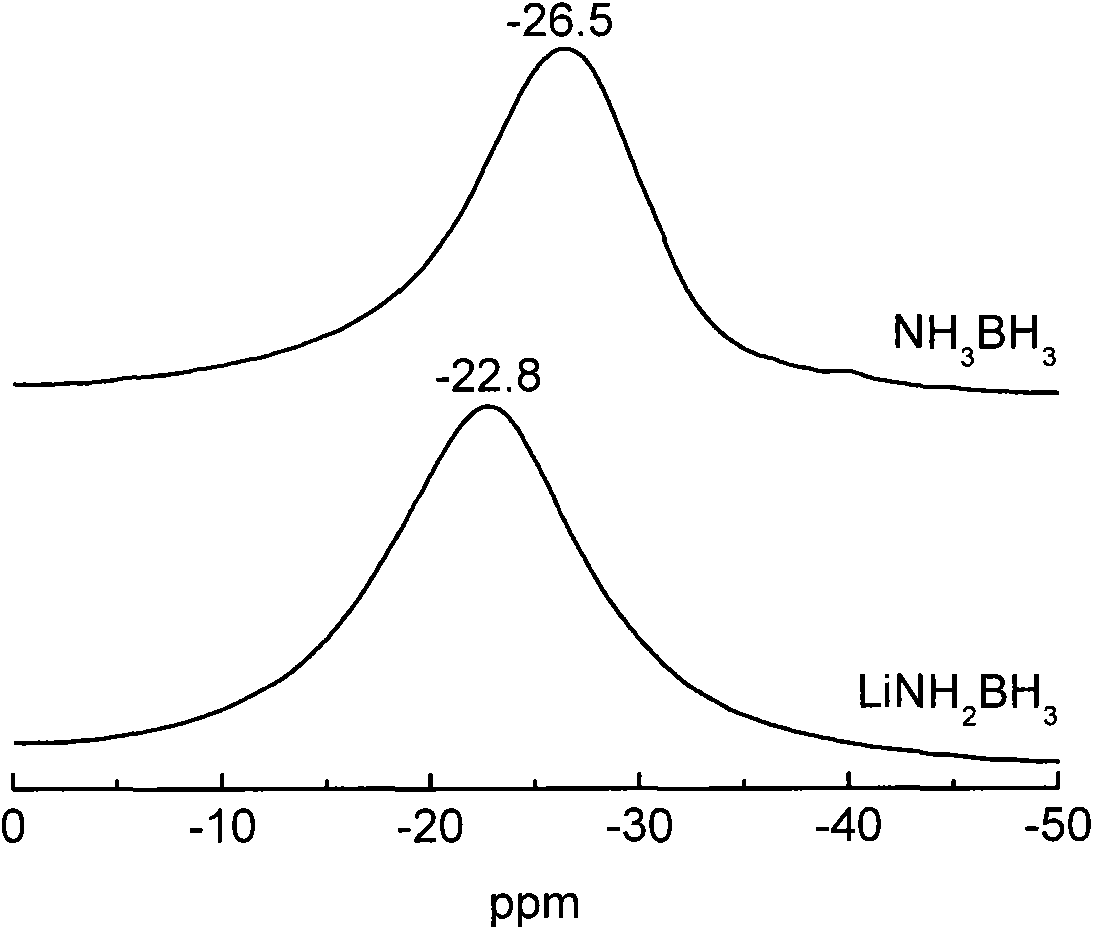

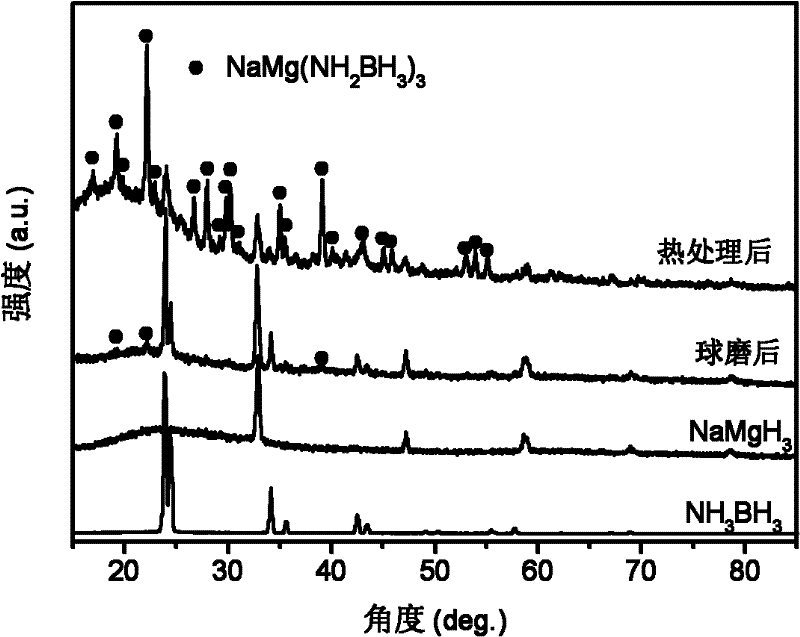

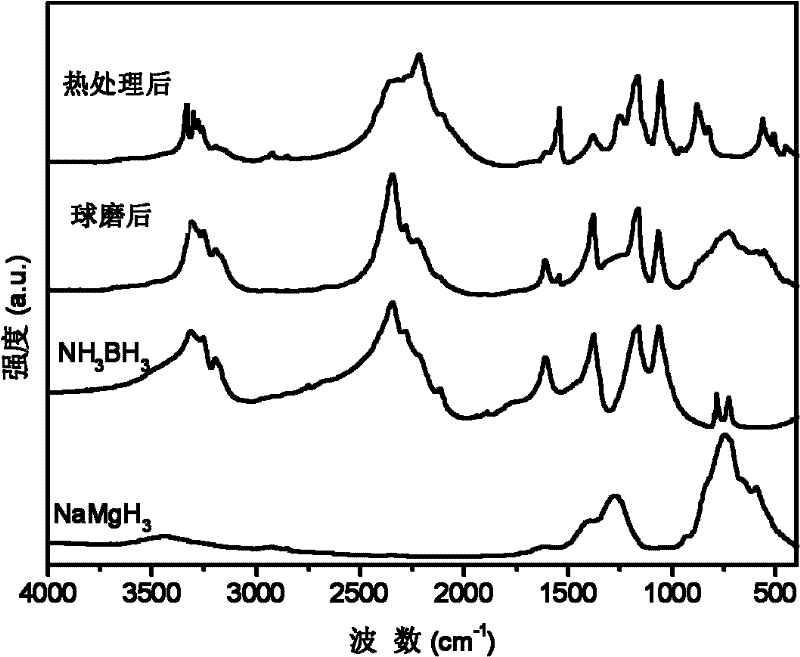

Metal ammonia borane compound hydrogen storage material and preparation method thereof

InactiveCN101613083AImproved hydrogen release performanceStrong donating abilityHydrogen productionMetal hydridesHydrogen atmosphereImpurity

The invention relates to a material and technology for storing hydrogen, in particular to a novel metal ammonia borane compound hydrogen storage material and a preparation method thereof. The novel metal ammonia borane compound hydrogen storage material is prepared by taking the mixture of ammonia borane NH3BH3 and metal M or metal hydride NHy as an initial raw material and performing ball milling on the raw material in an inert protective atmosphere or a reactive hydrogen atmosphere. The molecular formula of the novel metal ammonia borane compound hydrogen storage material is MxNH(3-nx)BH3, wherein x is more than 0 and less than or equal to 1, and n is more than or equal to 1 and less than or equal to 3. The mole ratio of NH3BH3 to M or NHy in the phase composition of the raw material is 1-50:1. The preparation method provided by the invention has high efficiency and simple and easy operation. The novel metal ammonia borane compound hydrogen storage material provided by the invention has the advantages of high hydrogen storage capacity, low hydrogen production temperature, fast hydrogen production dynamics, no impurities, no gaseous pollutants and the like and has the application prospective of automobile-mounted hydrogen storage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

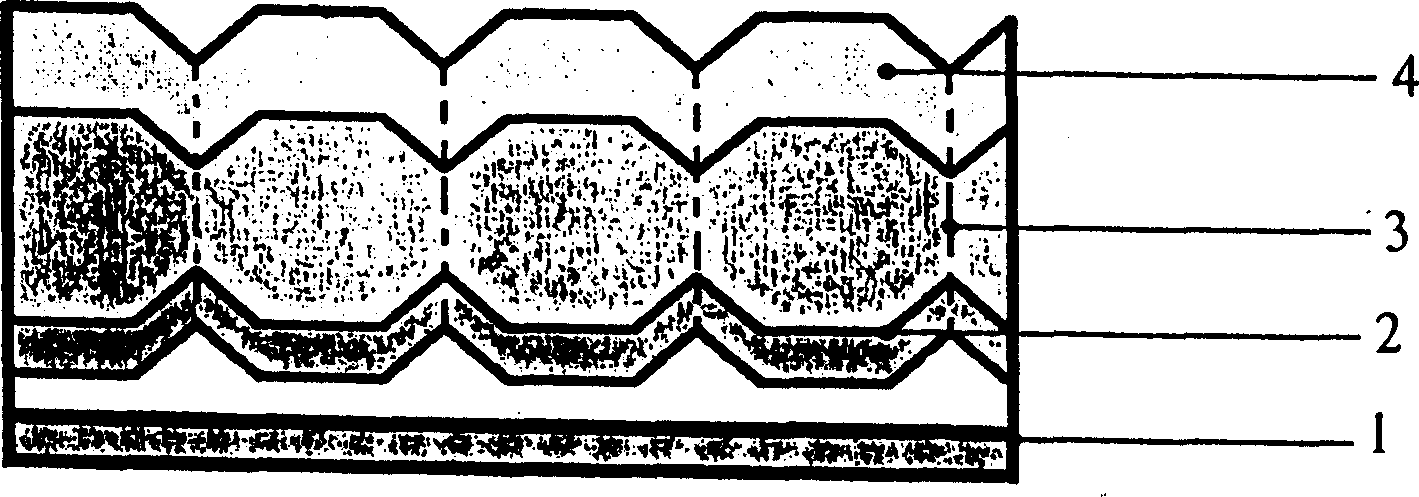

Fire-retardant, heat-isolating, waterproof and breathing comfortable fireman suit material

InactiveCN1548291AImprove fire extinguishing effectNo meltingSynthetic resin layered productsThermal stabilityFire retardant

The fire-retardant, heat-isolating, waterproof and breathing comfortable fireman suit material includes from outside to inside fireproof layer, waterproof and breathing layer, heat-isolating layer and comfortable layer. Owing to the reinforced fire-retardant and heat-isolating performance, the present invention can reduce the fire distinguishing distance to raise the fire distinguishing effect. The material has overall protecting performance of 30.7 cal / sq cm as well as high fire-retardant performance, high strength, water resisting resistance, etc.

Owner:SHANGHAI GARMENT GRP IMP & EXP

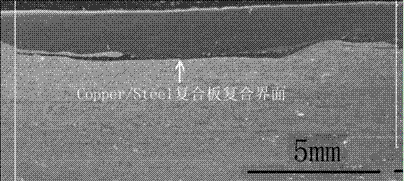

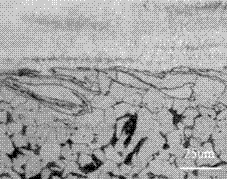

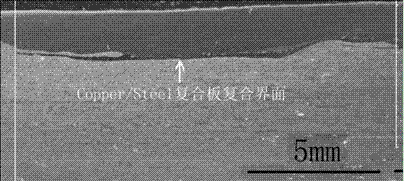

A kind of preparation method of copper-steel composite board

InactiveCN102284784ANo meltingMelting does not produceNon-electric welding apparatusMachine controlCopper

A method for preparing a copper-steel composite plate, the method steps are: placing the steel plate on the bottom, placing the copper plate on it, fastening the two metal plates on the workbench, selecting a stirring head whose length is slightly greater than the thickness of the copper plate Clamped on the friction stir welding machine. The technical effect of the invention is that the quality of the joint is good and stable, the preparation process is controlled by a machine, the parameter setting is easy to monitor, and the repeatability is good.

Owner:NANCHANG HANGKONG UNIVERSITY

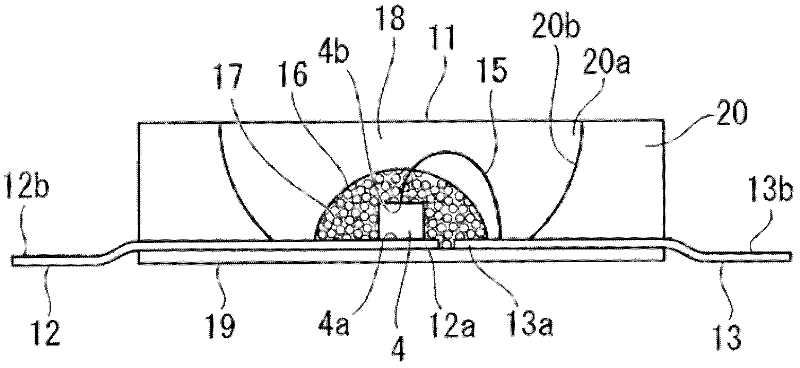

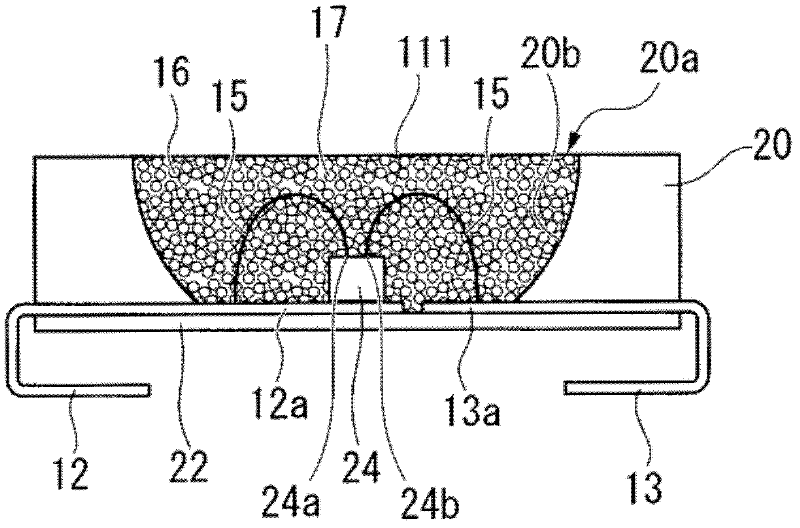

Fluorescent substance, process for producing same, and luminescent device including same

ActiveCN102575161AHigh luminous intensityNo meltingSolid-state devicesLuminescent compositionsNitrogenOxygen

Provided are a fluorescent substance represented by the general formula (A1-xRxM2X)m(M2X4)n, a process for producing the fluorescent substance, and a luminescent device including the fluorescent substance. (In the formula, element A is one or more elements selected from Li, Na, Be, Mg, Ca, Sr, Ba, Sc, Y, La, Gd, and Lu; element R is one or more elements selected from Mn, Ce, Pr, Nd, Sm, Eu, Tb, Dy, Ho, Er, Tm, and Yb; element M is one or more elements selected from Si, Ge, Sn, Ti, Hf, Zr, Be, B, Al, Ga, In, Tl, and Zn; element X is oxygen and / or nitrogen; n and m each is an integer of 1 or larger; and x is a real number of 0 < x <1.)

Owner:NAT INST FOR MATERIALS SCI

High-transparency high-heat-stability TPU (thermoplastic polyurethane) film and preparation method thereof

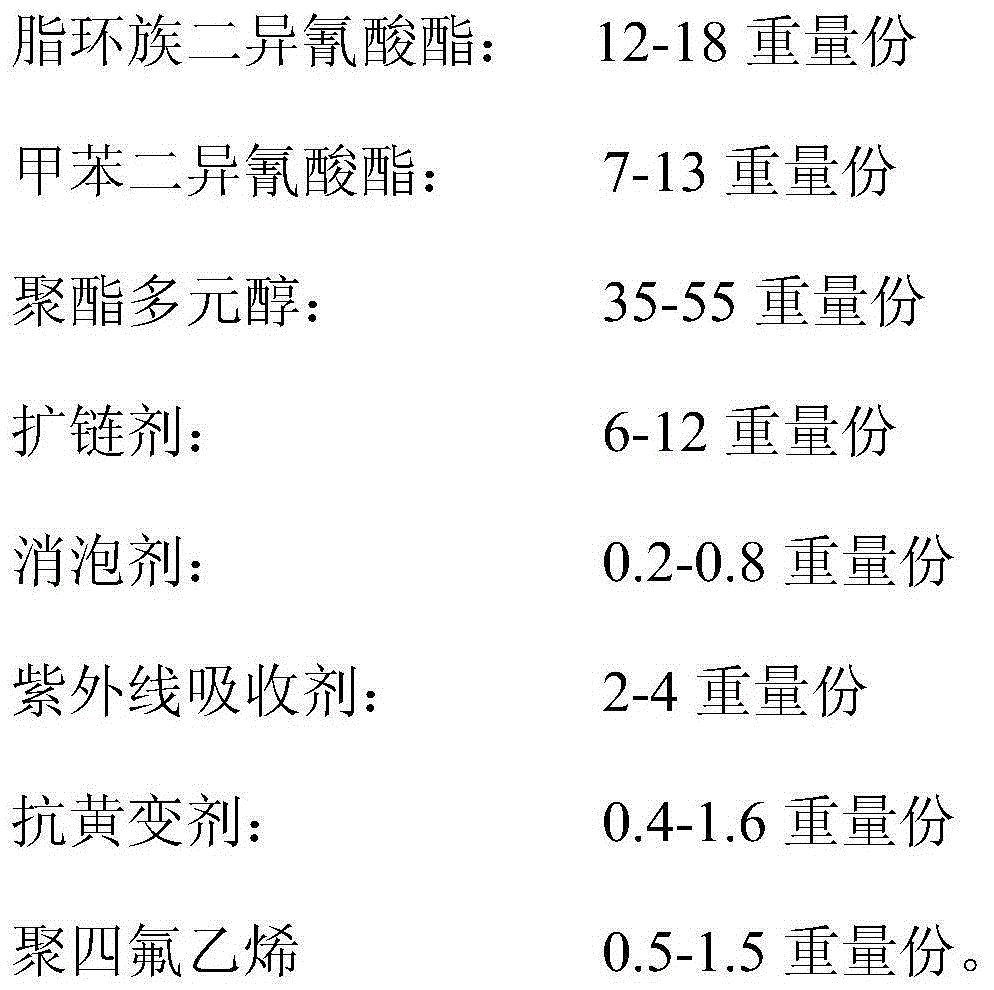

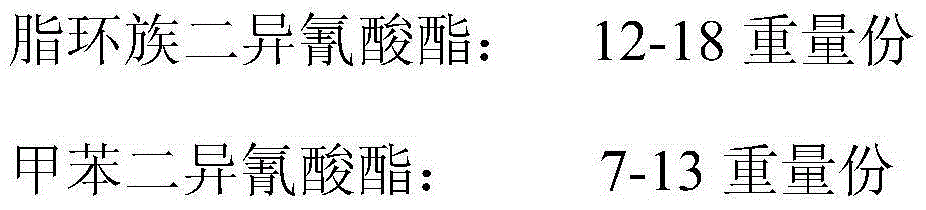

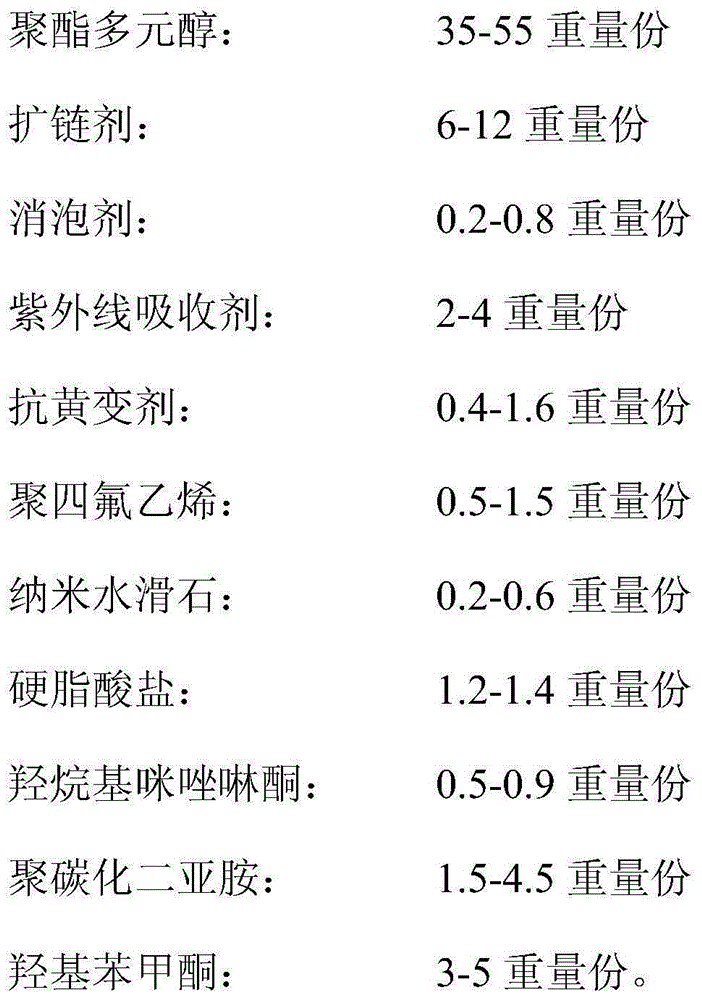

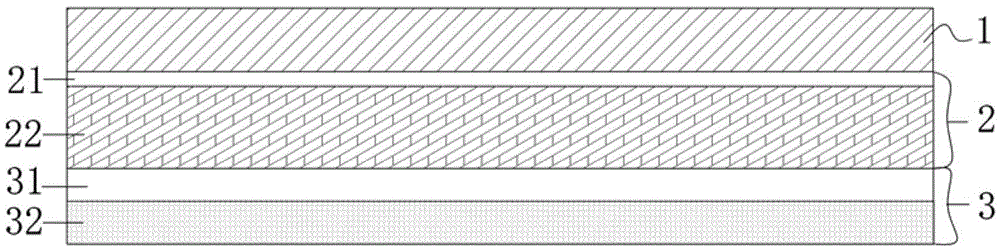

The invention relates to a high-transparency high-heat-stability TPU (thermoplastic polyurethane) film and a preparation method thereof. The TPU film is mainly prepared from the following raw materials in parts by weight: 12-18 parts of alicyclic diisocyanate, 7-13 parts of toluene diisocyanate, 35-55 parts of polyester polyol, 6-12 parts of chain extender, 0.2-0.8 part of defoaming agent, 2-4 parts of ultraviolet absorbent, 0.4-1.6 parts of anti-yellowing agent and 0.5-1.5 parts of polytetrafluoroethylene. The preparation method of the TPU film comprises the following steps: predrying the components according to the formula, mixing, and extruding by an extruder. The TPU film has the advantages of high transparency, excellent heat stability and excellent mechanical properties. The light transmittance is greater than 95%, and the yellowing resistance is Grade 5 above.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD

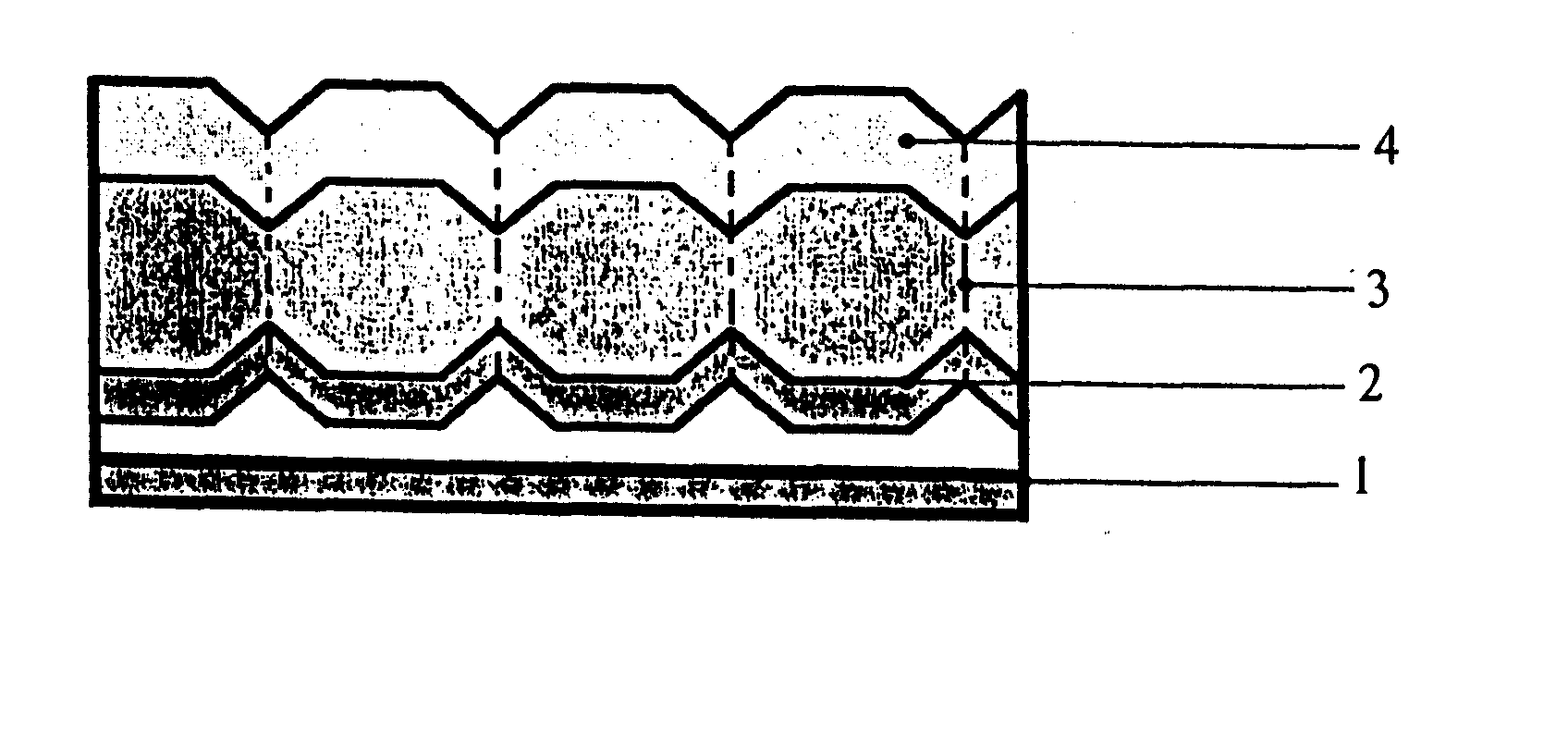

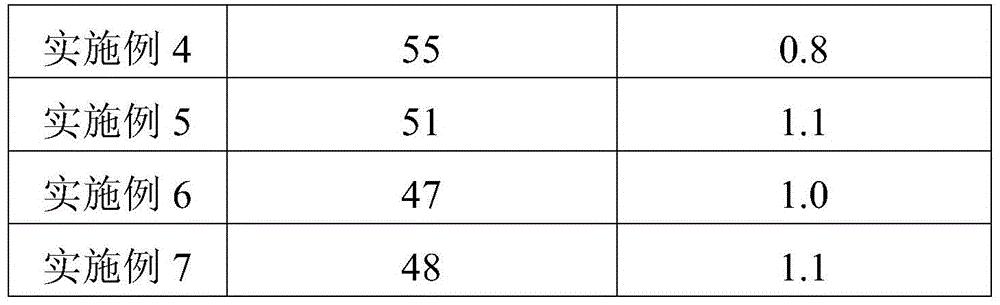

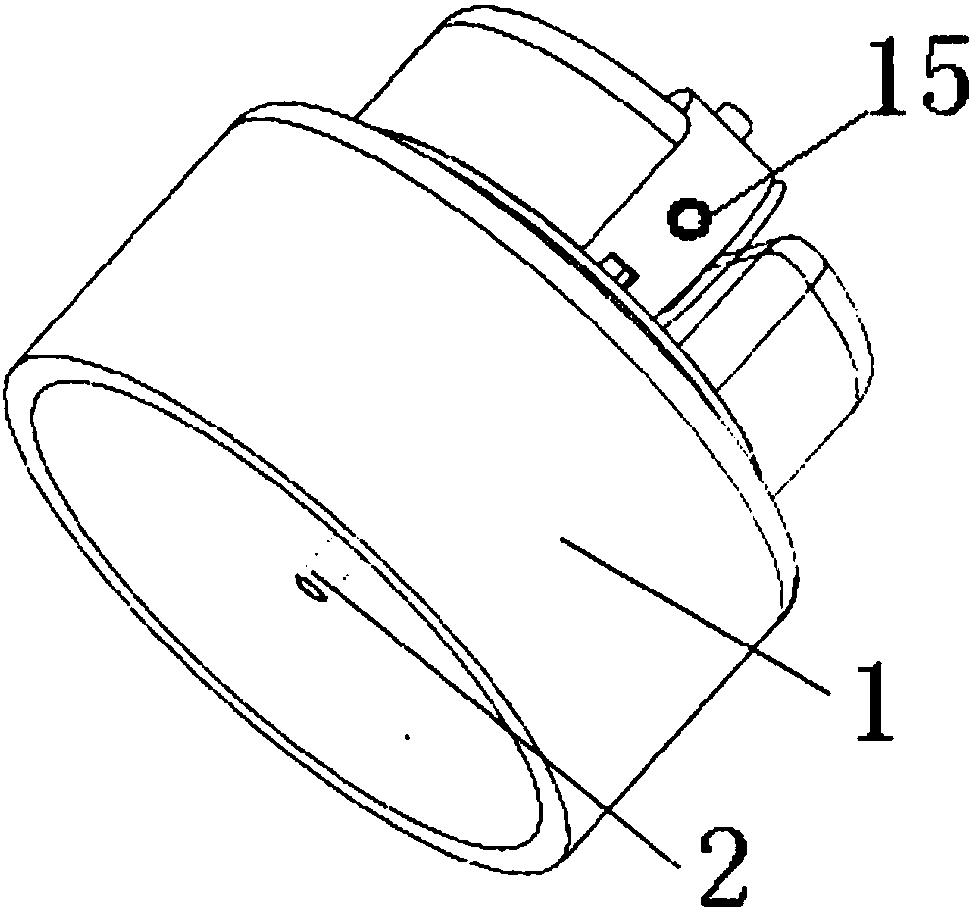

High-comfort protective garment fabric, protective garment and manufacturing method of high-comfort protective garment fabric

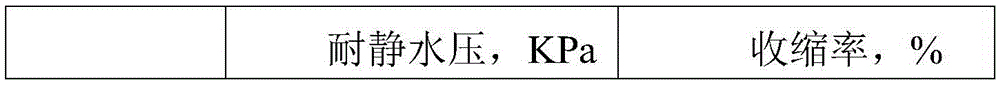

InactiveCN105581409AHigh heat protection valueHinders and slows down heat transferWeft knittingSynthetic resin layered productsShrinkage rateCarbonization

The invention discloses a high-comfort protective garment fabric and a protective garment. The high-comfort protective garment fabric is composed of an outer layer, a waterproof and breathable layer and a heat-insulating comfortable layer in sequence. According to the high-comfort protective garment fabric and the protective garment, two or more materials with different carbonization hot-shrinkage rates are combined, meanwhile, layering and inlaying are combined, and novel dual-layer woven structures, knitted structures and the like are formed. During a thermal test, a surface hunching form is formed, and therefore the heat transfer rate of heat radiation and heat conduction is hindered and reduced, and a higher heat protection value is obtained at the same gram weight. Therefore, in a product scheme with the same heat protection value, the effect of weight-reducing optimization is achieved, and meanwhile the safety, comfort and attractiveness of a garment in an existing scheme are effectively improved.

Owner:SHANGHAI TANLON FIBER CO LTD

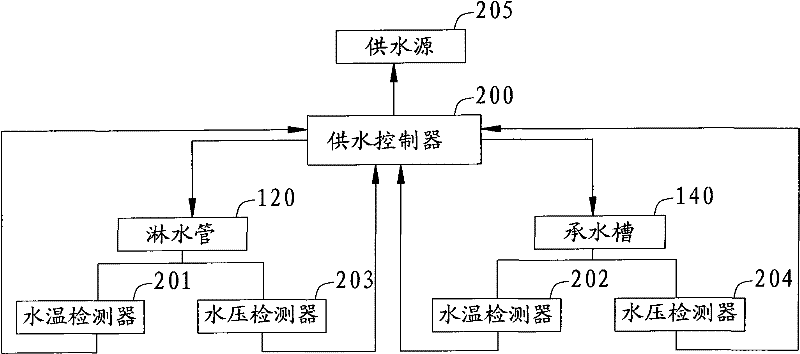

Automatic control feedback cabin and method based on temperature field three-dimensional imaging

ActiveCN107839581AMeet refrigeration requirementsNo meltingAir-treating devicesRefrigerated goods vehicleCold airAutomatic control

The invention relates to the field of logistics, in particular to an automatic control feedback cabin and method based on temperature field three-dimensional imaging. A three-dimensional visualizationtemperature field of the whole vehicle is acquired by temperature sensors arranged in the whole vehicle to construct a three-dimensional image, an identification is conducted by means of an RGB colorsystem recognition, a reddish color is selected and the position in the vehicle compartment is marked; the priority is set as one; the dangerous temperature is set as T, and the temperature difference between the temperature at the latest point in time and the dangerous temperature is determined; the smaller value is selected and the position in the vehicle compartment is marked; the priority isset as two; the temperatures are obtained by the temperature sensors periodically, the temperature trend and temperature change within the same time point are determined, and the highest temperature is selected and the position in the vehicle compartment is marked; the priority is set as three; wind division and guiding are conducted through an air inlet pipe by universal air outlets, the air inlet pipe is connected with a cold air source, and the universal air outlets sequentially aim at and blow winds to the positions determined as prior one, prior two and prior three to perform precise cooling.

Owner:LUDONG UNIVERSITY

eva/pc composite adhesive film for low shrinkage solar cell encapsulation

InactiveCN102275363ALow shrinkageGood physical and mechanical propertiesSynthetic resin layered productsPhotovoltaic energy generationComposite filmShrinkage rate

The invention discloses an EVA / PC composite adhesive film for encapsulating solar cells with a low shrinkage rate, which is sequentially composed of an upper layer of EVA film, a core layer of PC film and a lower layer of EVA film. Due to the high melting point, high strength and modulus of the core PC film, the composite EVA / PC film not only has better physical and mechanical properties than ordinary EVA film, but also has a shrinkage rate reduced to less than 0.5%, which is much lower than At present, the shrinkage rate of the EVA adhesive film is 3%, and its transparency and aging resistance fully meet the requirements of the solar cell packaging adhesive film. The layered composite EVA / PC adhesive film of the invention can improve the production efficiency of solar cells, improve product quality, reduce defective rate and cost.

Owner:NINGBO HUAFENG PACKAGE

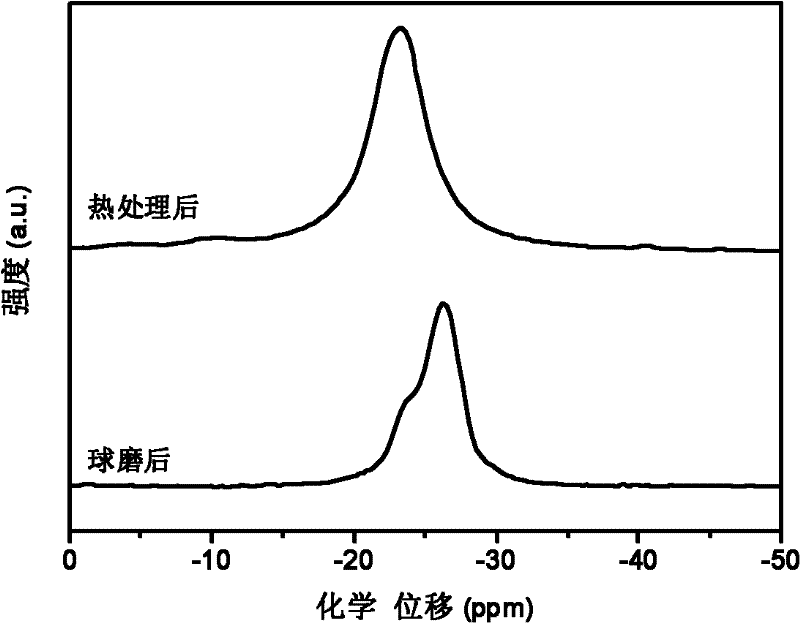

Multi-metal ammonia borane compound hydrogen storage material and preparation and composite hydrogen release method thereof

InactiveCN102530872AIncrease energy densityAdjustable ionic propertiesMonoborane/diborane hydridesHydrogen productionHydrogen atmosphereHydrogen storage system

The invention relates to the field of hydrogen storage material and hydrogen production, in particular to a multi-level ammonia borane compound hydrogen storage material and preparation and composite hydrogen release method thereof. The mixture of ammonia borane NH3BH3 and multi-metal hydride M1Mm2nHx is used as the starting material, and the multi-level ammonia borane compound hydrogen storage material is prepared by ball milling or auxiliary heat treatment in an inertia protection atmosphere or reactive hydrogen atmosphere, wherein the molecular formula of the multi-level ammonia borane compound hydrogen storage material is M1mM2n(NH2BH3)x, wherein 0<m<=4, 0<n<=4 and 1<=x<=10; the starting material comprises the phases of NH3BH3 and M1mM2nHx at a molar ratio of (1-10):1. The multi-level ammonia borane hydrogen storage material provided by the invention has obvious advantages of relatively high hydrogen storage capacity, low hydrogen release temperature, no impurity gas pollutant and the like. The composite hydrogen release technology provided by the invention effectively integrates the synthesis reaction and decomposition reaction of the multi-level ammonia borane so that the hydrogen storage system can realize high-capacity and fast hydrogen release in a proper temperature, and has application prospect in vehicular hydrogen storage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Tunnel lightweight inorganic fireproof composite material

ActiveCN101200380AMeet construction requirementsSignificantly reduce drynessLayered productsFiberFireproofing

The invention provides a light inorganic fireproofing composite material for tunnel, which is compounded by three layers of materials from inside to outside; the first layer is spray inorganic fireproofing material, the components of which comprise inorganic fireproofing fiber, expanded vermiculite powder, expanded graphite powder and ordinary Portland cement; the second layer is surface fireproofing material, the components comprises ordinary Portland cement, mica powder, gypsum and talcum powder; the third layer is fireproofing decorative material, which is a fire-retardant single-side composite aluminum foil. The composite material has the advantages that: the fire endurance is high; the thermal conductivity in hydrocarbon fire scene is extremely low; the fireproofing result is excellent; the self quality loss in fire is less without melting and dropping; the weight is light; the weathering is good; the sound-absorbing is good and the high-frequency drying reduction is obvious; the cost is low; the construction strength is less and the charge is low; furthermore, the ornament is good and the surface is smooth and beautiful surface, thereby the invention can mainly be used in the fire protection for the tunnel wall.

Owner:应急管理部四川消防研究所

Sole material for high temperature resistant labor protection shoes

The invention relates to a material for manufacturing a labor protection article, in particular to a sole material for high temperature resistant labor protection shoes used in a high temperature environment. The material comprises the following components in portion by weight: 38.5 to 40.5 portions of butyronitrile, 7.6 to 8.2 portions of sulfur, 2.51 to 3.05 portions of accelerating agent DM, 11.3 to 13.1 portions of accelerating agent TMTD, 4.3 to 4.9 portions of zinc oxide, 1.8 to 2.2 portions of carbon black, 4.9 to 5.5 portions of calcium carbonate, 7.6 to 8.2 portions of stearic acid, 0.107 to 0.1198 portion of dibutyl phthalate, 0.38 to 0.60 portion of zinc stearate, 4.53 to 5.02 portions of coumarone resin, and 8.9 to 9.5 portions of magnesium oxide. The components of the materialare mixed reasonably; and actual detections show that a sole product manufactured by adopting a component formula of the material has good high temperature resisting capacity and can meet high temperature resistant use requirements.

Owner:JIANGSU PROVINCE PAIDENG SHOES IND

Washing-resistant flame-retardant polyester cotton blended fabric and preparation method thereof

InactiveCN107201654AUniform and stable flame retardant qualityFlame retardant permanentWeft knittingWarp knittingFiberPolyester

The invention discloses a washing-resistant flame-retardant polyester cotton blended fabric and a preparation method thereof. The fabric contains flame-retardant terylene fiber and flame-retardant cotton fiber, and is characterized in that the outer surface of the formed fiber of the polyester cotton blended fabric is soaked by glue liquid containing fire retardants and crosslinking agents; then, the flame-retardant terylene fiber and flame-retardant cotton fiber with the outer surface soaked with the fire retardants and the crosslinking agents are subjected to grafting reaction to form a surface layer material; then, soaping, rinsing and drying are performed; the washing-resistant flame-retardant polyester cotton blended fabric is obtained. The washing-resistant flame-retardant polyester cotton blended fabric has the characteristics of flame-retardant performance, water washing resistance and the like; the production process is simple; the efficiency is high; wide application prospects are realized in the fields of decoration materials, individual protection garments and the like for industrial and traffic buildings with fireproof requirements in electric power, petroleum and the like; the practicability is high.

Owner:四川东方绝缘材料股份有限公司

Modified polyphenylene sulfide based flame-retardant anti-cutting yarn, preparation method and gloves

The present invention relates to a modified polyphenylene sulfide based flame-retardant anti-cutting yarn. The yarn comprises the following components in percentage by mass: 20-80% of modified polyphenylene sulfide fibers, 5-40% of flame-retardant fibers and 5-40% of cutting reinforced filaments; and the modified polyphenylene sulfide fibers are polyphenylene sulfide fibers subjected to oxidationmodification, part or all of sulfur atoms in a polyphenylene sulfide structure are oxidized into sulfonyls or sulfoxide groups by oxidation modification, and the modified polyphenylene sulfide fibershave the characteristics of no melting under the high temperature, no melting shrinkage, instant quenching away from fire and the like. Protective gloves prepared from the yarn have ideal cut resistance and flame-retardant protection performance, the wearing comfort of the flame-retardant anti-cutting gloves is improved, and the cost is lower. In the field of labor protection gloves, compared witharamid fibers, the flame-retardant anti-cutting yarn has a certain advantage of substitutability.

Owner:SHANDONG XINGYU GLOVES

Cold spraying welding method used for improving strength of dissimilar metal joints and based on interface pinning effect

InactiveCN106756979ADeposit dense and low porosityHigh bonding strengthHeat inorganic powder coatingPre treatmentDissimilar metal

The invention discloses a cold spraying welding method used for improving the strength of dissimilar metal joints and based on the interface pinning effect, and the cold spraying welding method is used for connecting of a first metal and a second metal, wherein the first metal is fine copper, and the second metal is fine aluminum. The cold spraying welding method specifically comprises the following steps that (1), the groove surfaces of the first metal and the second metal are subjected to pre-treatment; (2), cold spraying is conducted through composite powder B, and a composite coating layer is formed in each of the groove surfaces of the first metal and the second metal; and (3), cold spraying is conducted through composite powder A, grooves of the first metal and the second metal are filled to form sedimentary bodies, and thus connecting of the first metal and the second metal is achieved. According to the cold spraying welding method used for improving the strength of the dissimilar metal joints and based on the interface pinning effect, through spraying of the composite layers which have a certain thickness, the pinning effect and the interface reinforcing effect, then the sedimentary bodies are formed through cold spraying and connected with the dissimilar metal joints with a certain groove, and finally a connecting body with high combined strength is obtained; connecting of the aluminum and the copper which are complex in structure can be achieved, the interface combined strength is high, the temperature in the connecting process is low, and oxidation and a new phase are not fundamentally generated.

Owner:XI AN JIAOTONG UNIV

High temperature resistant release adhesive tape as well as preparation method and use of adhesive tape

ActiveCN104629640ANo meltingNo embrittlementLamination ancillary operationsFilm/foil adhesivesThin membraneSilicone tape

The invention discloses a high temperature resistant release adhesive tape as well as a preparation method and the use of the adhesive tape. The high temperature resistant release adhesive tape is composed of a release layer, a substrate and an adhesive layer, wherein the release layer and the adhesive layer are formed on the substrate in a coating or spray-coating manner; the substrate is a thin film prepared from the mixed material of PA6 and PA66, or PA6, or PA66 as a major material. The preparation method comprises the following steps: firstly, preparing the substrate from the mixed material of PA6 and PA66, or PA6, or PA66 as the major material; secondly, treating the thin film by use of a corona treater to reduce the surface energy; thirdly, forming the release layer and the adhesive layer on the corresponding release surface and adhesive surface of the thin film in a coating or spray-coating manner respectively; and finally, slitting and curling, and packaging to obtain a finished product. The high temperature resistant release adhesive tape is low in cost, and capable of bearing the use temperature within the range of 150 to 220 DEG C without melting, embrittlement, breakage and the like. The high temperature resistant release adhesive tape can be widely applied to composite materials, and to the fields of bicycle frame five-way part wrapping, the difficult corner mold stripping parts of other pipe fittings, vacuum-pumping process sealing adhesive tapes in the electronic industry and the like.

Owner:厦门新旺新材料科技有限公司

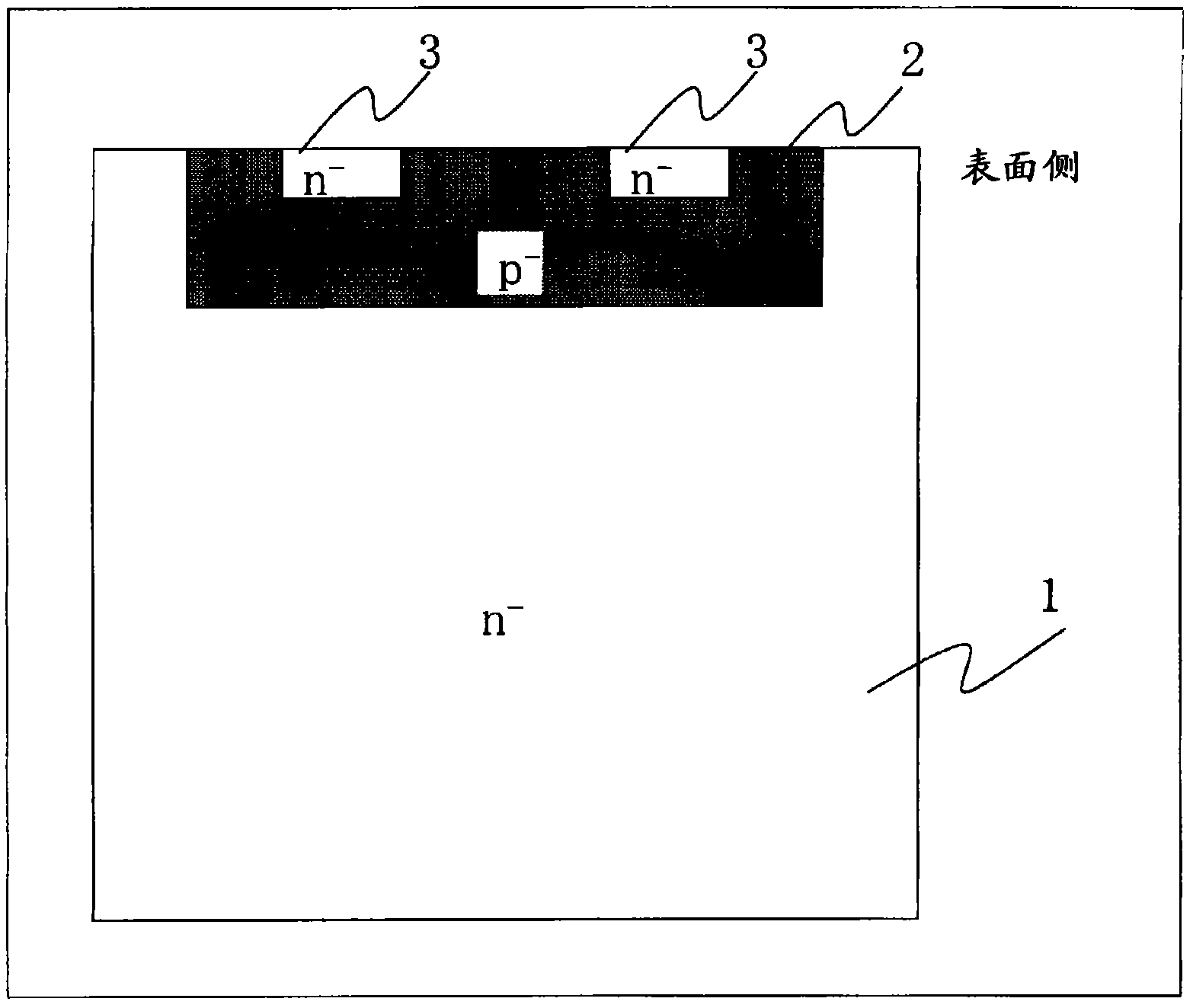

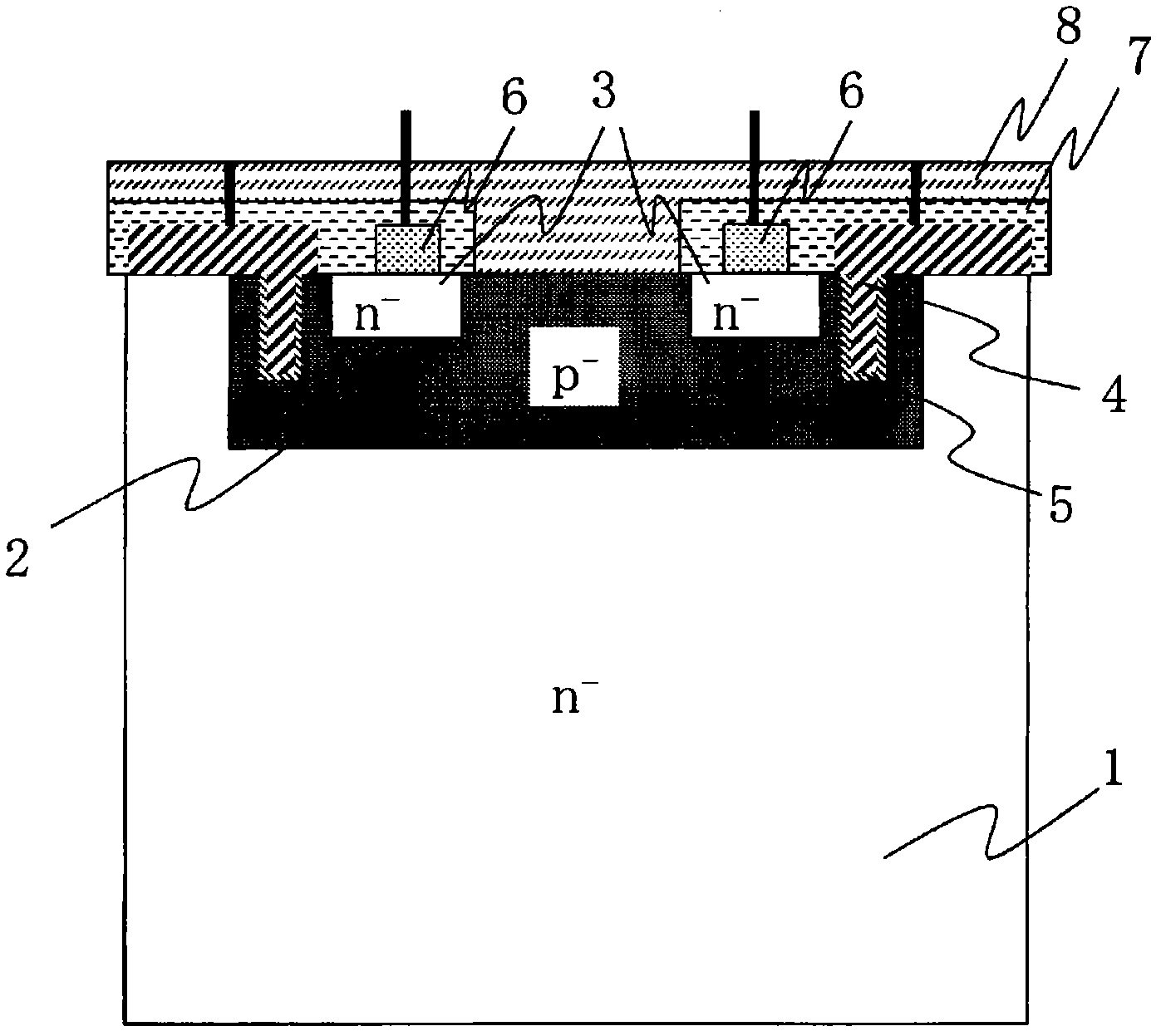

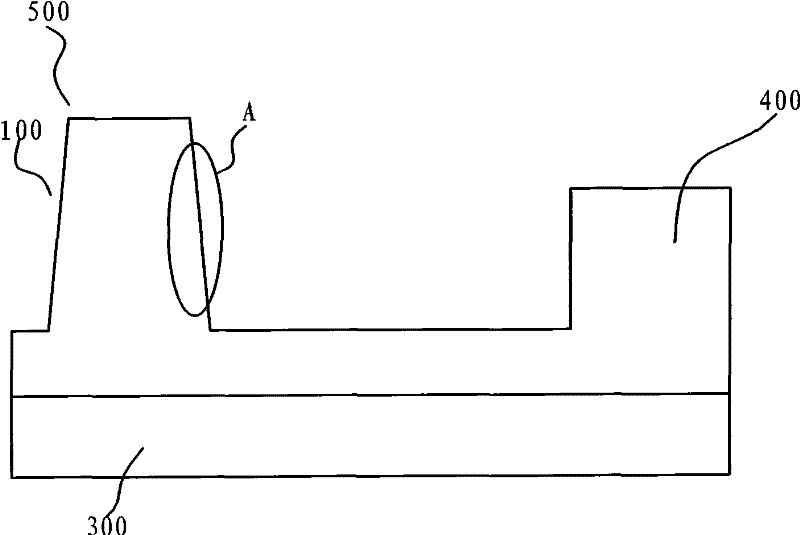

Method for manufacturing semiconductor device

InactiveCN102668037AFully activatedNo meltingSemiconductor/solid-state device manufacturingSemiconductor devicesIrradiationSemiconductor

Disclosed is a method for manufacturing a semiconductor device, wherein a semiconductor Si substrate, which is thinned down to 300 [mu]m or less, is heated such that the temperature at a position deeper than 1 [mu]m from the back surface of the semiconductor Si substrate is within a temperature range of 950-1412 DEG C (inclusive) without melting Si during a laser annealing process. Specifically disclosed is a method for manufacturing a semiconductor device, wherein a semiconductor region is formed by introducing an impurity from the front surface of a semiconductor substrate, the substrate is fixed to a supporting substrate using an electrostatic chuck, and then the impurity is activated by heating the front surface of the substrate by irradiation of a laser having a long wavelength of 3 [mu]m or more, while heating the entire substrate at 250 DEG C or more.

Owner:HITACHI LTD

Refractory material and its preparation method

The invention discloses a refractory material, which contains thermally conductive fiber. The refractory material has good thermal conductivity. In addition, the invention also provides a preparation method of the refractory material, a stove kiln with the refractory material, a flash smelting furnace and a smelting system.

Owner:CHINA NERIN ENG

Acid and alkali resistant automobile glass ink and preparation method thereof

InactiveCN110607091APromote meltingImprove compactnessGlass making apparatusInksGlass fiberFumed silica

The invention relates to the technical field of automobile glass ink, and discloses acid and alkali resistant automobile glass ink and a preparation method thereof. The automobile glass ink comprisesthe following components in parts by weight: glass powder, varnish, chrome iron brown, composite glass fibers, zinc stearate, a leveling agent and fumed silica. The preparation method comprises the following steps: stirring the glass powder, the varnish, the zinc stearate and the fumed silica at a rotating speed of 500-800 r / min for 10-15 min, then adding the composite glass fibers, the chrome iron brown and the leveling agent, and stirring the mixture at a rotating speed of 1000-1500 r / min for 20-30 min to obtain the acid and alkali resistant automobile glass ink. The glass ink prepared by the method has good acid and alkali resistance.

Owner:石柳青

Method of separating vanadium and titanium efficiently from vanadium slag mixed material

ActiveCN110055417AEfficient separationLow firing temperatureProcess efficiency improvementSlagSulfate

The invention provides a method of separating vanadium and titanium efficiently from a vanadium slag mixed material. The method is characterized by comprising the following steps: (1) crushing and screening; (2) water quenching vanadium slag; (3) crushing and screening; (4) mixing; (5) tabletting; (6) roasting and activating; (7) roasting selectively; (8) cooling and uniformly mixing; (9) leaching; and (10) preparing vanadium pentoxide. Raw materials in the roasting process are prevented from being fused and decomposed by adding a silicon dioxide mixed material to tablet. Vanadium and titaniumare sulfated by ammonium sulfate roasting, and sulfate of titanium is decomposed by means of selective roasting, so that vanadium and titanium in the vanadium slag are separated. The method reduces the energy consumption needed by a conventional vanadium slag roasting and vanadium extracting process, and a tablet is roasted invariable in shape in the reaction process, and the condition that the service life is affected as the tablet is adhered to a reactor is avoided. The method is a typical low-carbon, green and environment-friendly vanadium slag utilization technique.

Owner:SICHUAN UNIV

Synthetic fiber paper for highly heat-resistant circuit board with negative thermal expansion coefficient and preparation method and application

InactiveCN104674594AExpansion coefficient can be controlledGuaranteed uniformityNon-fibrous pulp additionPaper/cardboardPapermakingPrinted circuit board

The invention relates to synthetic fiber paper for a highly heat-resistant circuit board with negative thermal expansion coefficient and a preparation method and application. The synthetic fiber paper is prepared from the following components in percentage by weight: 10-90% of structural fiber and the balance of viscose fibers, wherein the viscose fibers are fibers with negative thermal expansion coefficient and are selected from poly-p-phenylene terephthamide precipitation fibers and / or poly (p-phenylene terephthalamide) pulp. The preparation method comprises the following steps: preparing the structural fibers and viscose fibers into papermaking pulp; papermaking and moulding by a wet process; and hot-rolling and calendering to prepare the synthetic fiber paper. X-Y axis thermal expansion coefficient (CTE) in a plane of the synthetic fiber paper is negative and can offset CTE of thermosetting resin in a substrate of a printed circuit board, so that the printed circuit board is relatively stable and reliable, and the synthetic fiber paper can be applied to preparing a reinforcing material of the substrate of the printed circuit board.

Owner:深圳昊天龙邦复合材料有限公司

Length control packaging process of metal in quartz glass capillary tube and auxiliary tool thereof

ActiveCN106112261AImprove absorption rateReduce the chance of meltingWelding/soldering/cutting articlesLaser beam welding apparatusEngineeringFailure causes

The invention discloses a length control packaging process of metal in a quartz glass capillary tube and an auxiliary tool thereof, which solve the problem of packaging failure caused by easy melting of the end of an inner metal wire because a flame point is close to the end of the inner metal wire in a traditional flame packaging process. The packaging process comprises the step of packaging the quartz glass capillary tube by adopting a CO2 laser welding machine, wherein specific welding parameters of the CO2 laser welding machine include: laser power: 600 W to 900 W, focusing form: defocusing, focal distance: 5 mm to 10 mm, relative rotation speed: 15 rpm to 25 rpm. The length control packaging process has the characteristics that the packaging length of a detector can be greatly shortened, the size after packaging can be effectively controlled within 20 mm, and the repeatability of the packaging method and process is high.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com