Washing-resistant flame-retardant polyester cotton blended fabric and preparation method thereof

A polyester-cotton blended, flame-retardant cotton technology, used in textiles, fabrics, flame-retardant fibers, etc., can solve the problems of poor compatibility, loss of flame-retardant effect, poor washing resistance, and easy loss of flame-retardants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

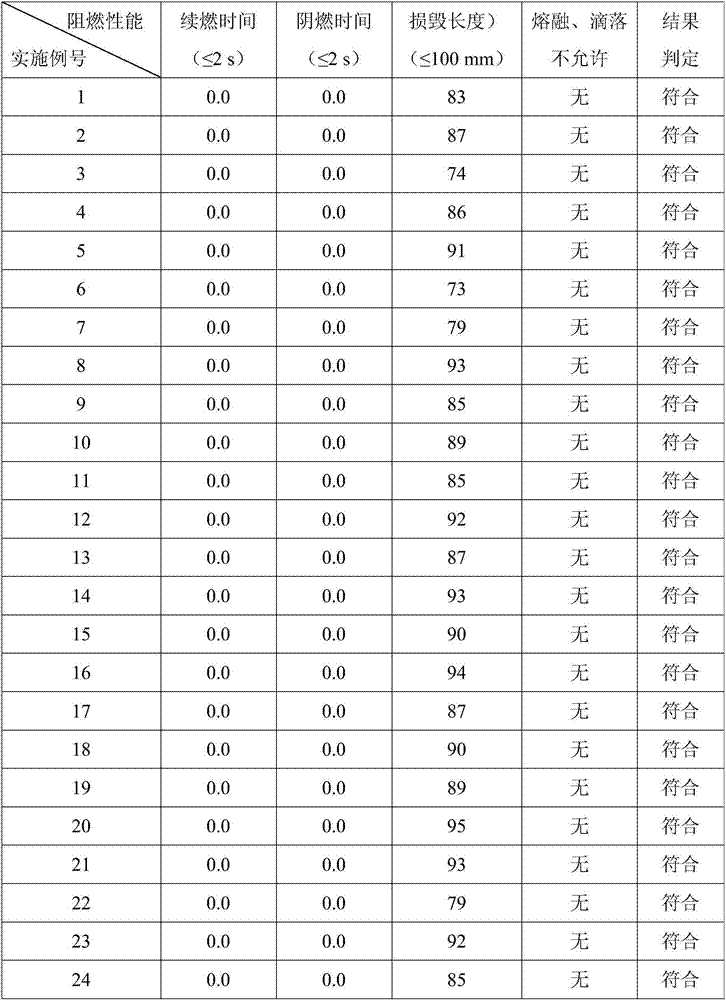

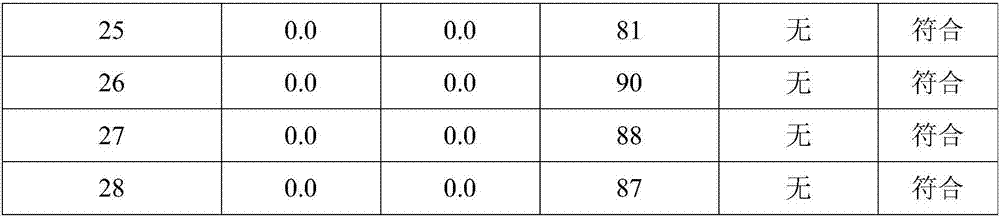

Examples

preparation example Construction

[0049] 1. Preparation of polyester-cotton blended fabric

[0050] Take the polyester-cotton blended fabric used as raw material for preparing flame-retardant copolyester chips with a phosphorus content of 7000ppm as an example:

[0051] Put the flame-retardant copolyester chips into a vacuum drying chamber and dry at 120°C for 12-14 hours to make the water content lower than 0.02wt%. Melt-spinning is carried out according to the conventional polyester fiber melt-spinning method to obtain flame-retardant polyester Fiber; Cotton fiber is carried out flame retardant treatment by any prior art method, such as can carry out flame retardant finishing according to routine Proban (Proban) method, namely at room temperature by padding by four hydroxymethyl phosphorus chloride and amide Flame-retardant finishing liquid composed of low-molecular pre-shrinkage body → pre-drying on heat setting machine (100-120°C) → ammonia fumigation → oxidation washing → drying (130-140°C) → pre-shrinkin...

Embodiment 1

[0055] Under normal temperature, 950 grams of phosphorus-containing cyanuric acid epoxy acrylate (structural formula B is 500 grams, structural formula C is 450 grams) and 50 grams of N, N-methylenebisacrylamide are mixed with mass percent concentration with ethanol 30% glue, mixed evenly, placed in the glue tank of the padding machine, the polyester-cotton blended fabric F8500 (50 / 50) passed through the glue in the glue tank, and passed through the padding machine under the roll pressure of 0.15MPa. Second dipping and second rolling, and then drying in a blast oven at 100°C to obtain the dipped polyester-cotton blended fabric;

[0056] Under normal temperature and nitrogen protection, the above-mentioned dipped polyester-cotton blended fabric was irradiated in a 1MeV electron beam equipment, and the irradiation dose was 150KGy. The fabric was soaped and rinsed, then dried and weighed, and the mass percentage of the fabric increased by 24%. , to obtain a washable flame-retarda...

Embodiment 2

[0058] With water, 800 grams of vinyl phosphoric acid and 200 grams of N-methylolacrylamide are prepared into a glue solution with a mass percentage concentration of 45%, mix well, place in the glue solution tank of the padding machine, and put the polyester-cotton blended fabric F6500 (92 / 8) pass through the glue in the glue tank, under the roll pressure of 0.3MPa, go through the second dipping and second rolling of the padding machine, and then dry in a blast oven at 120°C to obtain the dipped polyester-cotton blended fabric;

[0059] Under normal temperature and nitrogen protection, the above-mentioned dipped polyester-cotton blended fabric was irradiated with an electron beam with an irradiation dose of 100KGy, then soaped, rinsed with water, weighed after drying, and the fabric increased by 16% by mass to obtain washable Flame-retardant polyester-cotton blended fabric 2; Others are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com