Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4655results about How to "Flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite natural polymer gel material

ActiveCN105837861ALarge specific surface areaImprove mechanical propertiesAerogel preparationColloidal chemistry detailsNon solventWater based

The invention discloses a composite natural polymer gel material with a cross-linking agent. The material comprises hydrogel, organogel, aerogel and bioplastics and mainly overcomes the problem of low mechanical strength of conventional natural polymer gel materials. According to the invention, a certain amount of the cross-linking agent is added into a natural polymer water-based solution or dispersion liquid, then stirring is carried out, the obtained mixture is placed in a non-solvent for physical cross-linking, and then washing is carried out so as to obtain composite natural polymer hydrogel; water in the composite natural polymer hydrogel is replaced with an organic solution so as to prepare composite natural polymer organogel; the composite natural polymer hydrogel or organogel is dried so as to prepare composite natural polymer aerogel; the composite natural polymer aerogel is subjected to hydrophobic treatment so as to obtain hydrophobic aerogel; the composite natural polymer aerogel is subjected to heat treatment so as to obtain carbon aerogel; and one or more selected from the above-mentioned gel materials are subjected to high-temperature pressing so as to prepare composite natural polymer bioplastics. The composite natural polymer gel material prepared in the invention has the advantages of excellent mechanical properties, a high specific surface area, high elongation at break, etc., and can be easily processed into molded products of a plurality of forms.

Owner:浙江绍兴万德福生物技术有限公司 +1

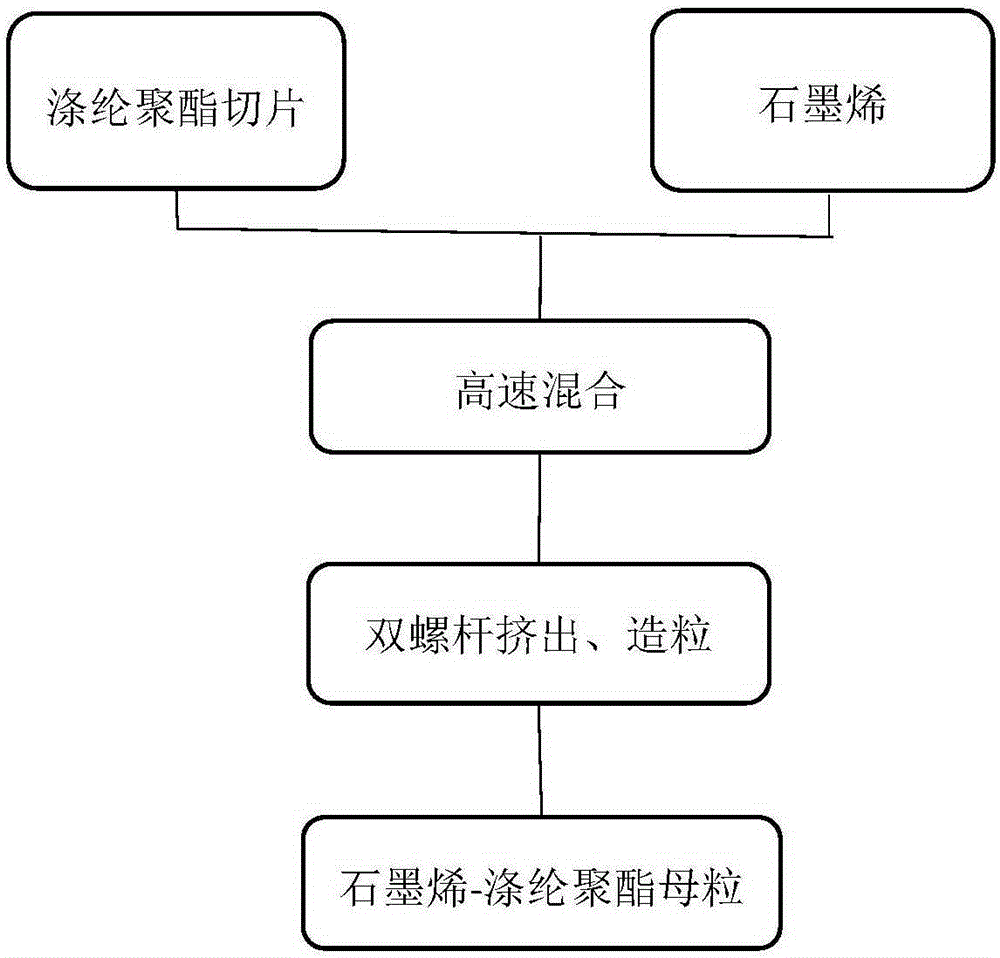

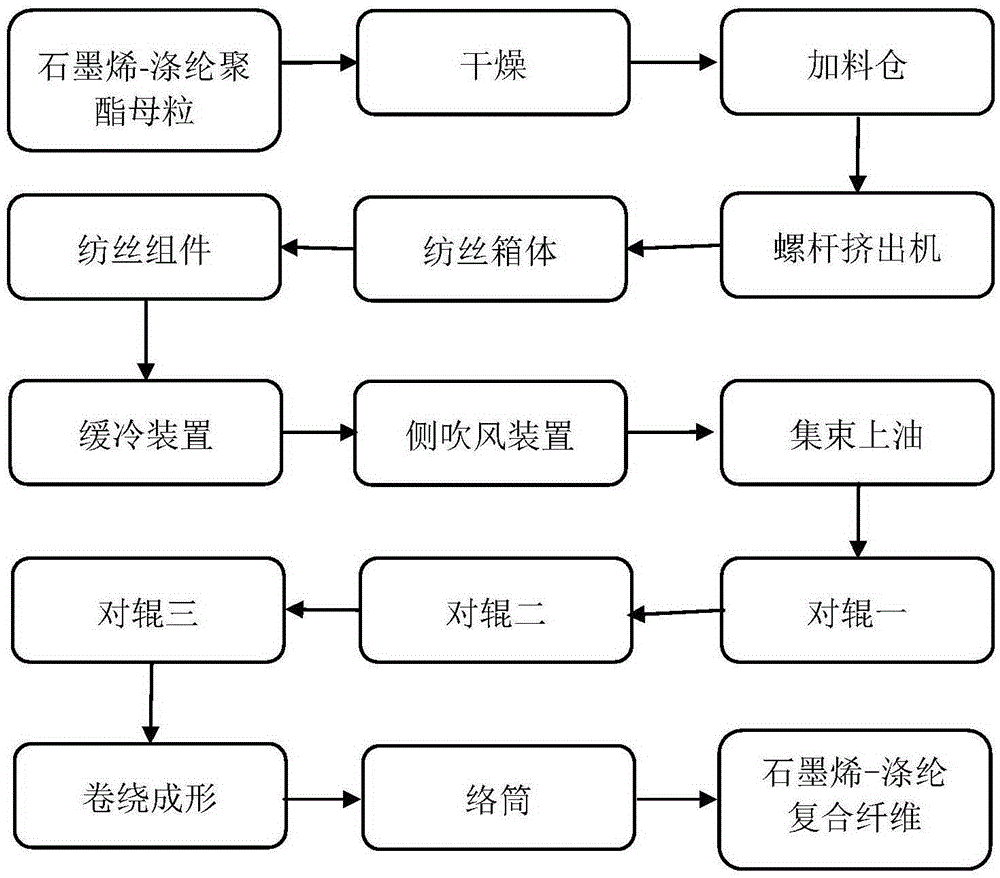

Preparation method of graphene-polyester nano-composite fiber

ActiveCN105200547AHigh breaking strengthEasy to prepareElectroconductive/antistatic filament manufactureFilament/thread formingNanometreSurface modification

The invention discloses a preparation method of graphene-polyester nano-composite fiber. The preparation method comprises the step of preparing graphene-terylene polyester composite master batch and the step of preparing the graphene-polyester nano-composite fiber from the composite master batch. Compared with other conventional methods, the preparation method has the advantages that the technology is extremely simple, the reinforcing material is excellent in performance and low in cost; besides, excellent mechanical property and functional characteristics of graphene self endow the nano-composite fiber with functionalities like high strength and antistatic property, surface-modified and modified graphene has good dispersity and perfect interfacial compatibility in terylene polyester polymer matrix, which enables graphene to be effectively and uniformly compounded with a terylene polyester chip base material.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Lithium ion-conducting garnet-like compounds

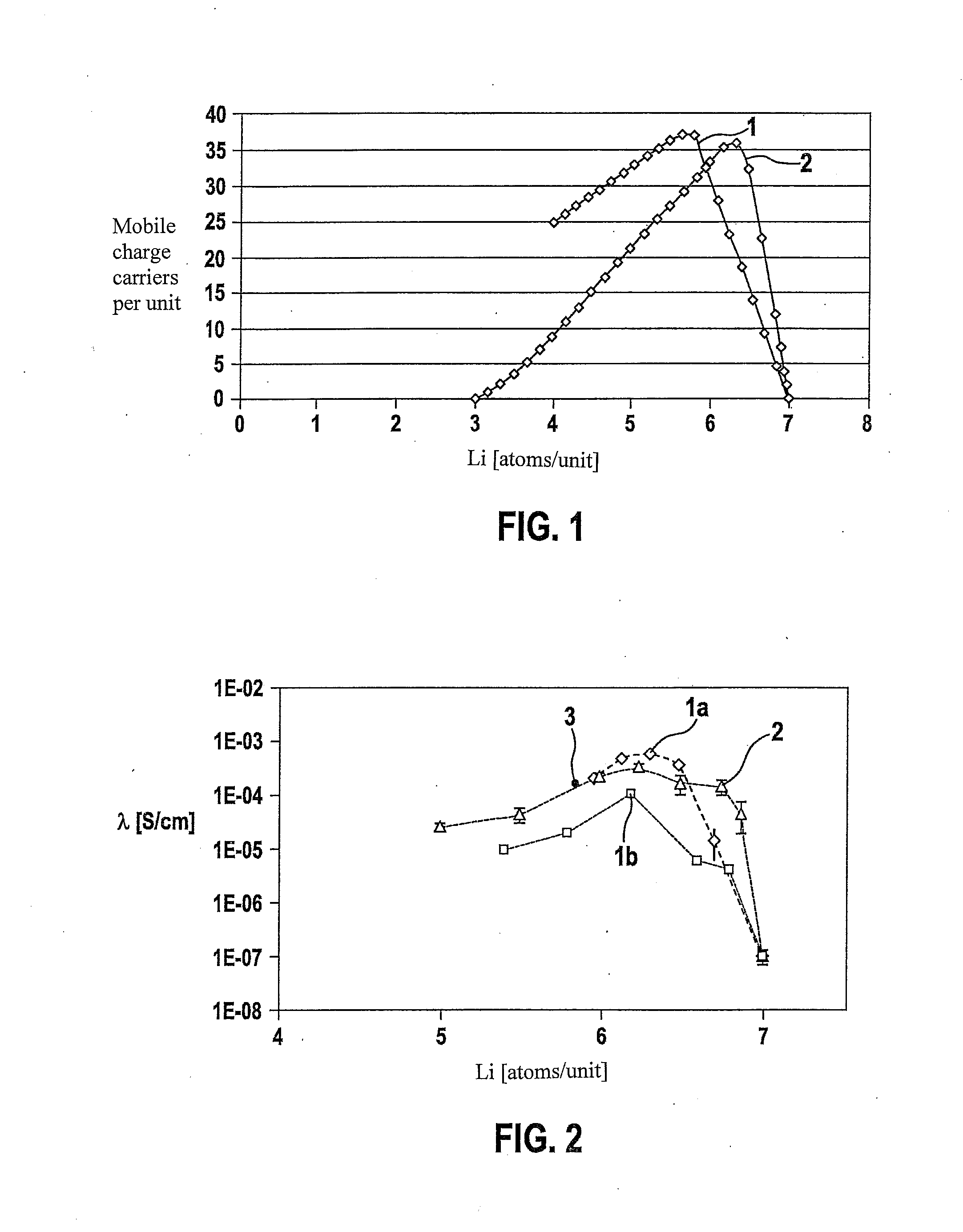

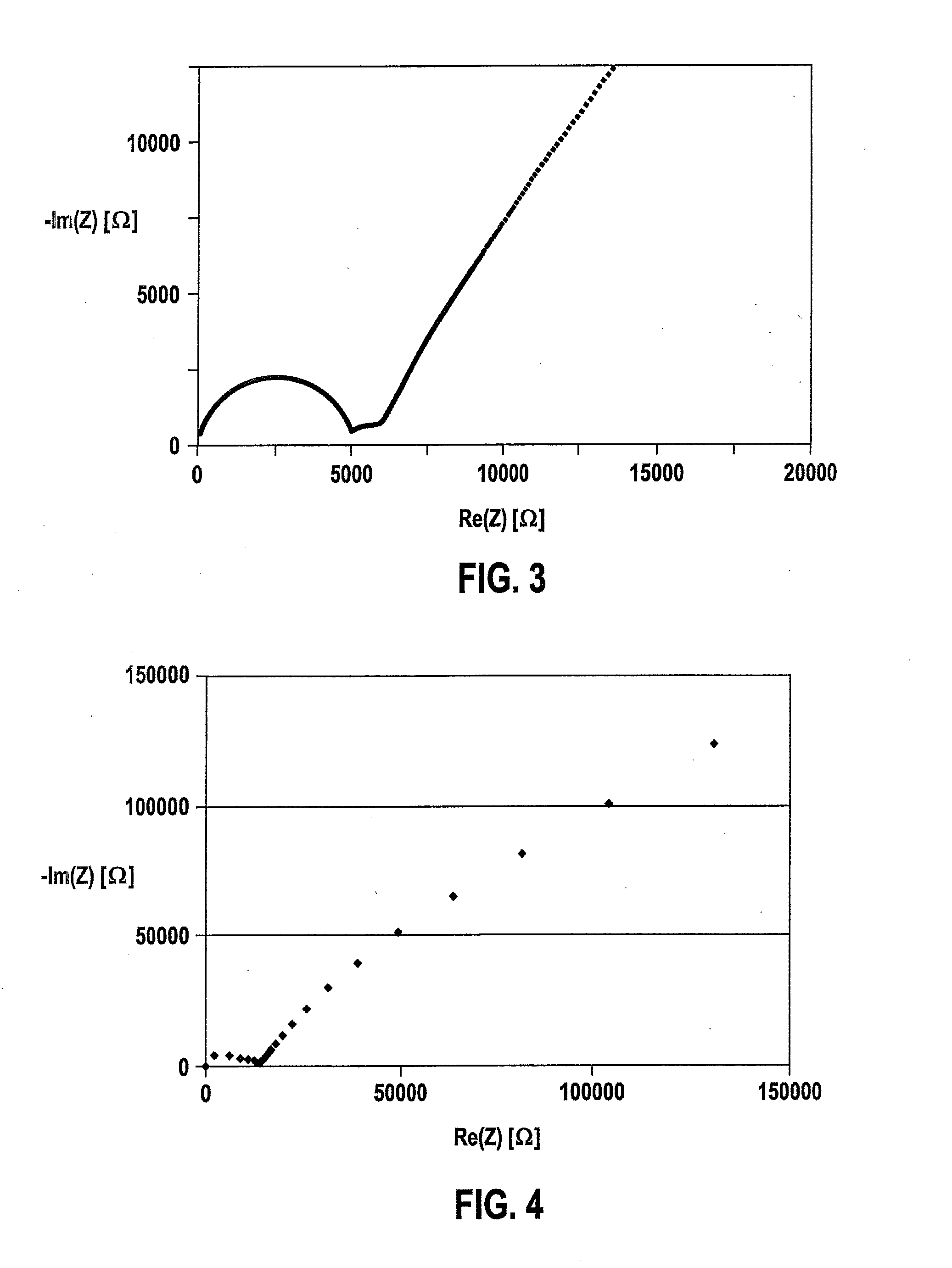

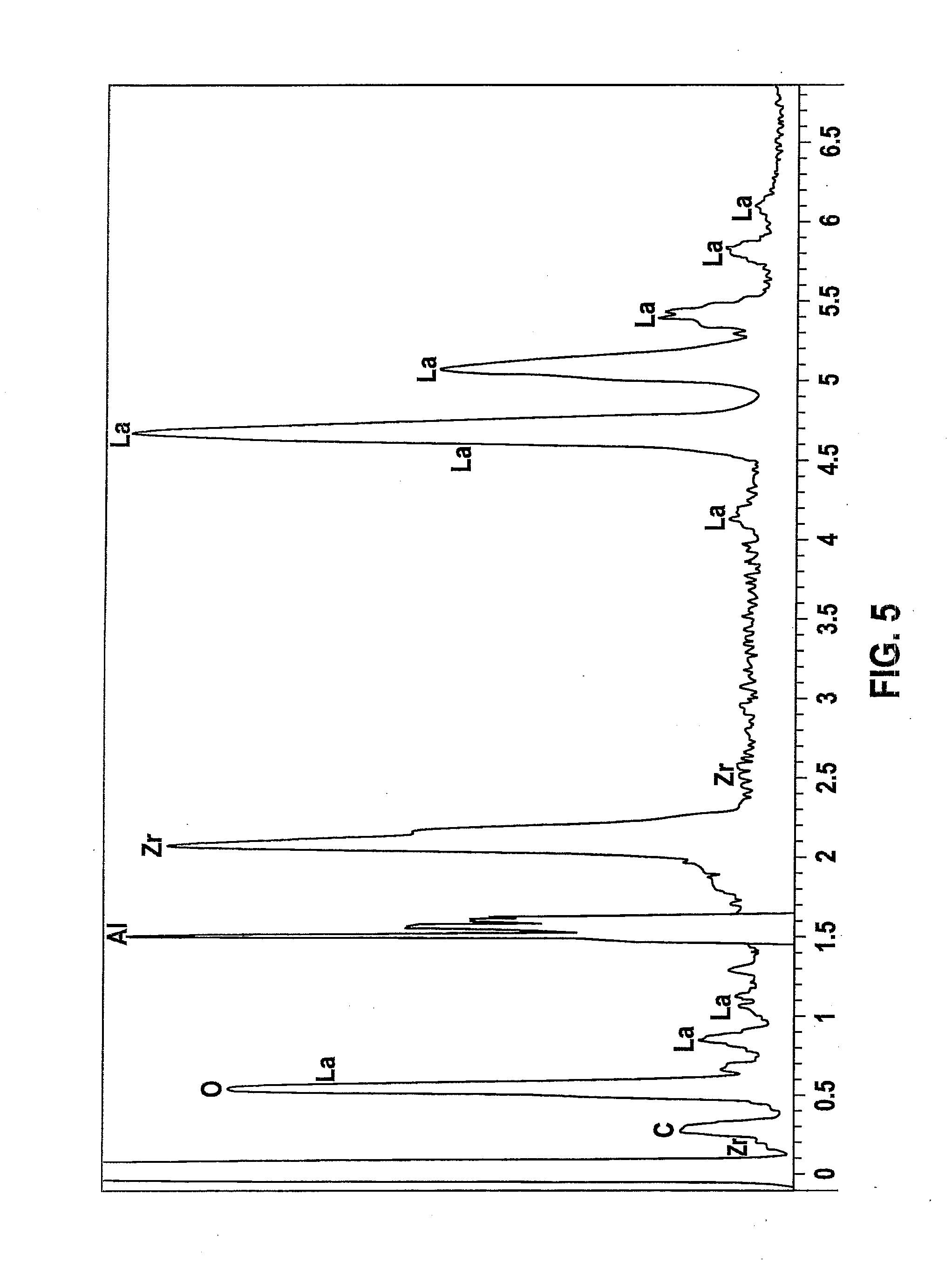

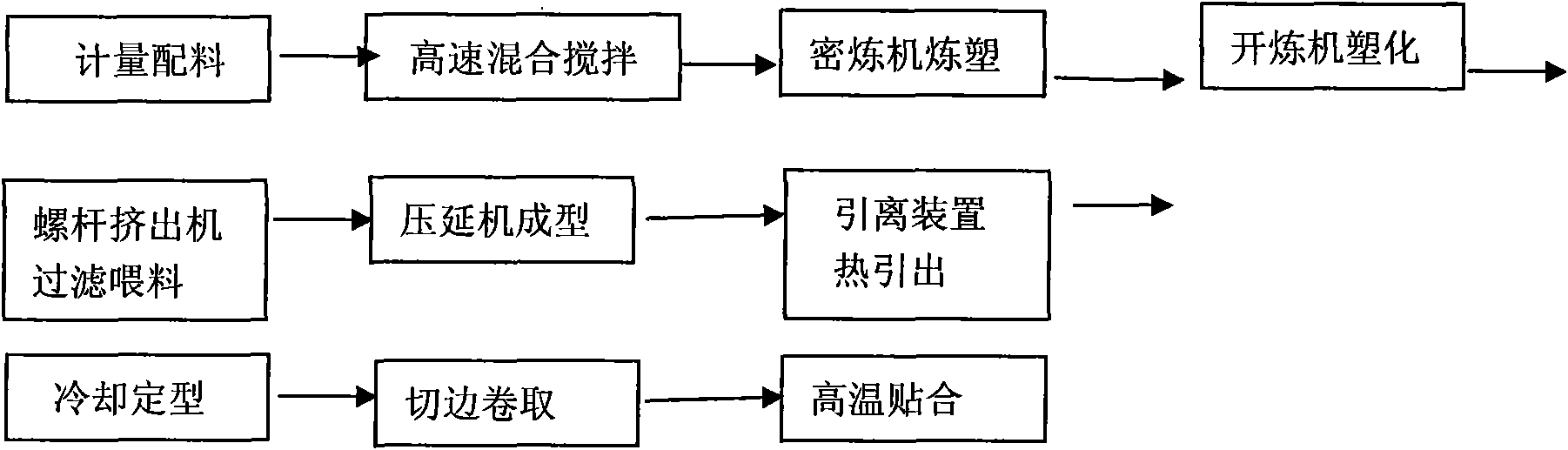

ActiveUS20140295287A1Loss can be compensatedImprove stabilityTantalum compoundsZirconium compoundsLithiumCompound a

A lithium ion-conducting compound, having a garnet-like crystal structure, and having the general formula: Lin[A(3-a′-a″)A′(a′)A″(a″)][B(2-b′-b″)B′(b′)B″(b″)][C′(c′)C″(c″)]O12, where A, A′, A″ stand for a dodecahedral position of the crystal structure, where A stands for La, Y, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm and / or Yb, A′ stands for Ca, Sr and / or Ba, A″ stands for Na and / or K, 0<a′<2 and 0<a″<1, where B, B′, B″ stand for an octahedral position of the crystal structure, where B stands for Zr, Hf and / or Sn, B′ stands for Ta, Nb, Sb and / or Bi, B″ stands for at least one element selected from the group including Te, W and Mo, 0<b′<2 and 0<b″<2, where C and C″ stand for a tetrahedral position of the crystal structure, where C stands for Al and Ga, C″ stands for Si and / or Ge, 0<c′<0.5 and 0<c″<0.4, and where n=7+a′+2·a″−b′−2·b″−3·c′−4·c″ and 5.5<n<6.875.

Owner:ROBERT BOSCH GMBH

High-elastic wearproof athletic floor material and preparation method thereof

ActiveCN101538393AIncrease elasticityGood surface wear resistanceResiliently-mounted floorsPlasticizerPolyresin

The invention discloses a high-elastic wearproof athletic floor material, which is prepared by raw materials with the following proportioning by weight: 100 portions of PVC high-polymerization degree resin, 40-60 portions of plasticizer, 5-10 portions of TPU polyurethane elastomer, 2.5-4.0 portions of composite heat stabilizer, 0.05-0.1 portion of mildew inhibitor, and 30-50 portions of filler modifier. The method adopts the technology of laminating high-strength ultralow-shrinkage fibre glass mesh cloth in the high-performance rolling embryonic membrane, and the athletic floor produced by the method completely meets the service performance requirements, and simultaneously has high elasticity, good surface abrasion resistance and small shrinkage factor of product size.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

High toughness packing reinforced polyphenyl thioether composite material and its preparation method

Owner:KINGFA SCI & TECH CO LTD +1

high-filling-content micro-nano powder/polymer composite material for 3D printing and preparation method and product thereof

ActiveCN103980592AEnhanced interactionImprove performance3D object support structuresCross-linkAntioxidant

The invention relates to a high-filling-content micro-nano powder / polymer composite material for 3D printing and a preparation method and a product thereof. The material contains the following raw materials, by weight, 10-30 parts of a polymer, 90-70 parts of a micro-nano powder, 0.05-0.2 part of an irradiation sensitizer and 0.01-0.02 part of an antioxidant. The micro nano powder is used as a main material and polymer resin is used as a binding agent, and moulding is finished by a 3D printing mode. Simultaneously, the irradiation sensitizer is added, and the polymer resin forms a three-dimensional cross-linked network after electron beam irradiation. Then, strength, heat resistance and chemical corrosion resistance are raised after resin bonding. The high-filling-content micro-nano powder endows the moulding material with excellent mechanical properties. In addition, according to changes of product usage environment and demand, types of the micro-nano powder are changed so as to obtain a material with special functionality, such as excellent conductivity, thermal conductivity, flame resistance, impact resistance and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Environment protecting wood wax oil

InactiveCN101550316ANo pollution in the processMeet environmental protection requirementsCoatingsWood impregnation detailsWaxVegetable oil

The present invention relates to an environment protecting wood wax oil which comprises the following main components by weight: 75-85 parts of vegetable oil, 0.1-1 part of vegetable wax or animal wax, 11-22 parts of rosin resin, 1-2 parts of drier and 0.1-1 part of cosolvent. The preparing method of the wood wax oil comprises the following steps: heating and melting the vegetable oil and wax mixing system, reducing the temperature and adding other materials, and mixing to uniform for obtaining the wood wax oil. The wood wax oil related to the invention can totally penetrate into the wood. The wood wax oil of the invention is remarkably different with the traditional paint with the existence of paint skin. The surface of wood wax oil has an open texture effect. The different woods can represent different real tactile sensation. Furthermore the wood with the environment protecting wood wax oil can be partially restored and retrofitted without mark. The wood wax oil can preserve various excellent performances of wood and effectively prevent the seasoning cracking of wood. The wood is caused to possess the excellent performances of ventilation, drying, corrosion resistance, worm resistance, flame resistance, etc. The using quality of wood can be increased comprehensively.

Owner:TIANJIN XIANDAIREN RE EMPLOYMENT SERVICE

Composition of insulating mold coating in use for glass, and preparation method

InactiveCN101050065ACurb riseImprove insulation effectPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyFatty alcohol

This invention relates to a method for preparing heat-insulating paint composition for glass. The heat-insulating paint composition comprises: micro-emulsified resin 20-60 wt. %, nanopowder (20-150 nm) 15-40 wt. %, and paint additive as balance. The micro-emulsified resin comprises: at least one of organosilicon resin, inorganic silicon resin, alkyd resin, epoxy resin, acrylate and polyurethane 50-80 wt.%, inorganic salt 0.001-5 wt.%, at least one of anionic, cationic and nonionic surfactants 0.001-8 wt.%, C1-C5 lower fatty alcohol 1-20 wt.%, and water as balance. The heat-insulating paint composition has such advantages as high heat insulation performance, high transparency, and high hardness, and can be used on building glass and automobile glass.

Owner:朱建强

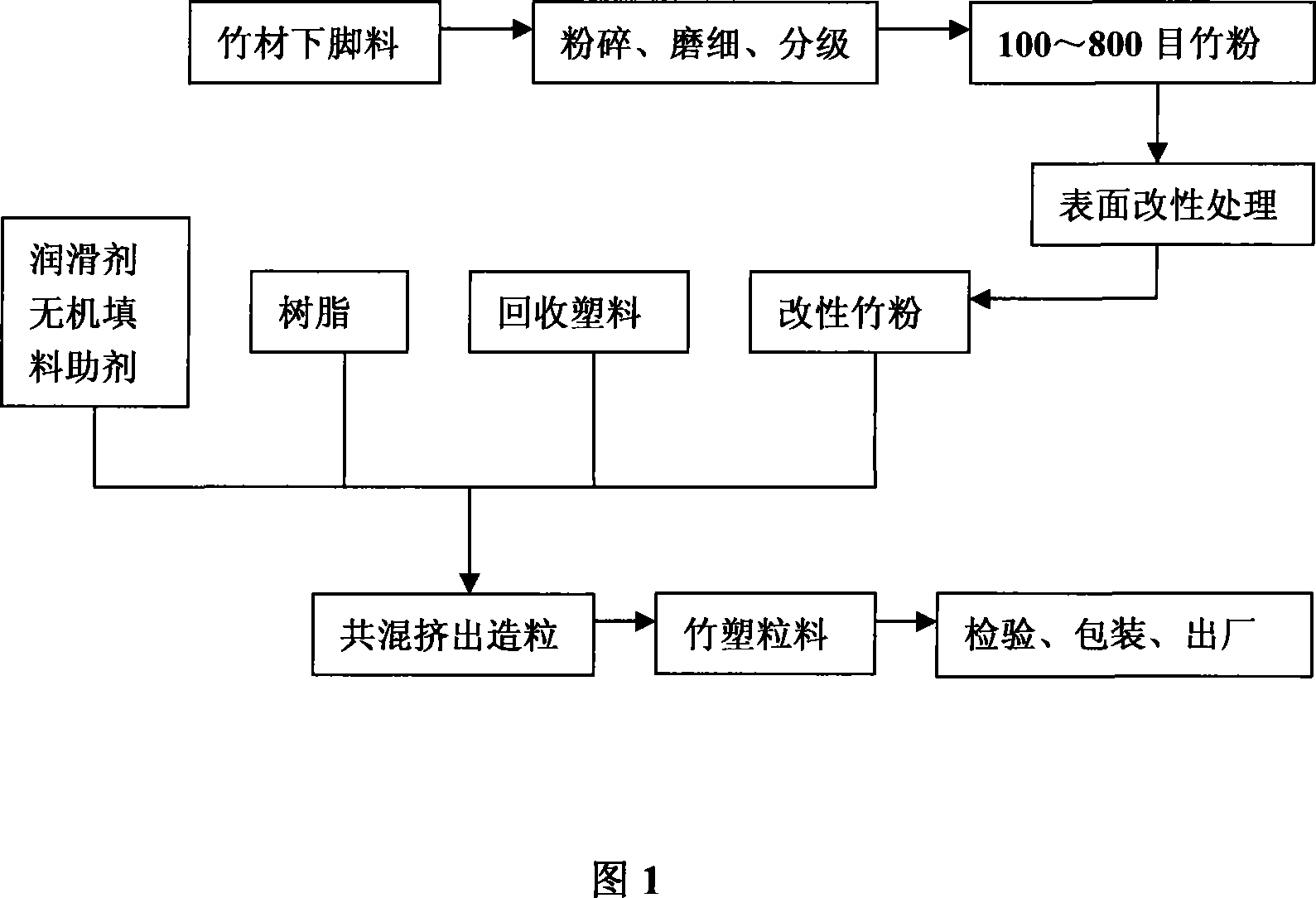

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

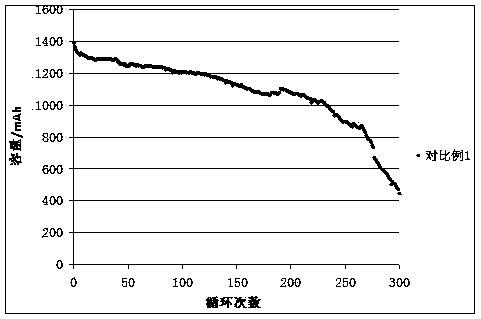

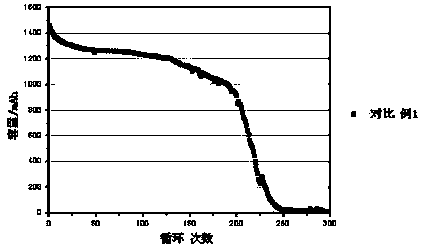

High-voltage lithium ion battery electrolyte

ActiveCN103401020AIncrease oxidation potentialSolve severe flatulenceSecondary cellsElectrolytic agentInternal resistance

The invention specifically relates to a high-voltage lithium ion battery electrolyte, which belongs to the technical field of lithium ion battery electrolytes. The high-voltage lithium ion battery electrolyte provided by the invention comprises a non-aqueous solvent, a lithium salt and an additive, wherein the additive comprises a mixture of a fluoro-ether additive and an alkyl dinitrile additive. A lithium ion battery using the high-voltage lithium ion battery electrolyte has stable cycle performance at normal temperature, no gas generation at a high temperature condition and small changes of internal resistance. A preparation process for the high-voltage lithium ion battery electrolyte is simple and easy to implement and has good market prospects.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

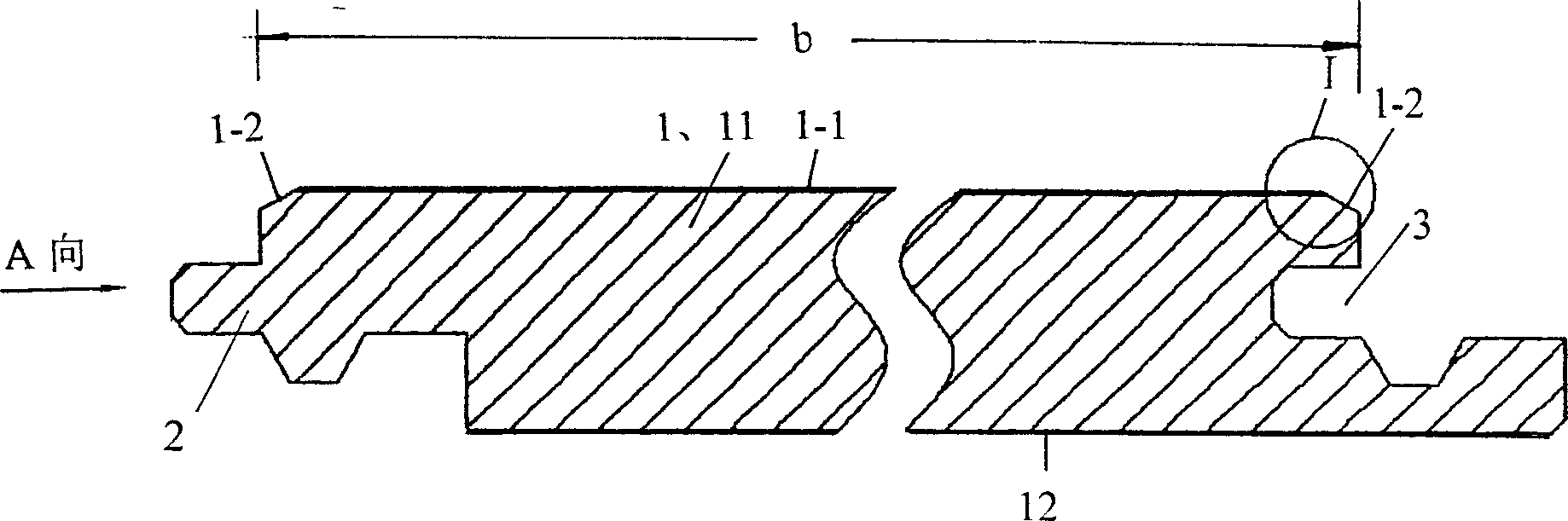

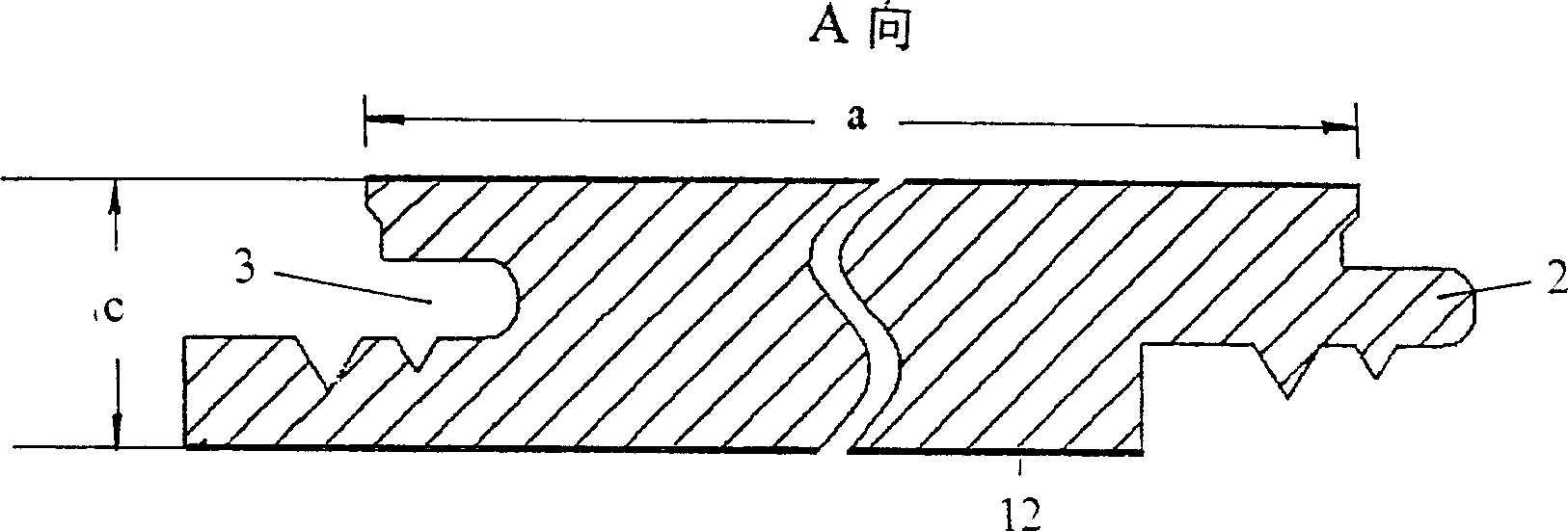

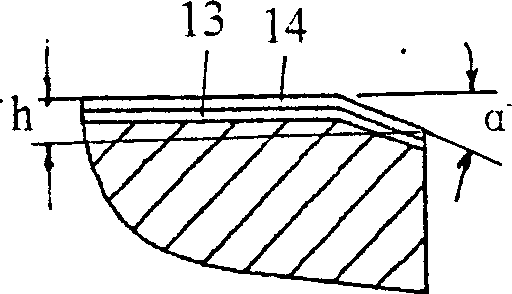

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

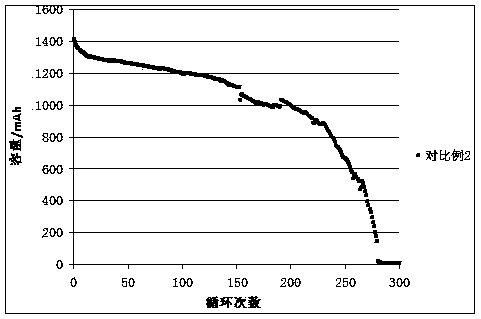

High-voltage lithium-ion battery electrolyte

InactiveCN103456993AImprove cycle lifeIncrease oxidation potentialSecondary cellsElectrolytic agentInternal resistance

The invention belongs to the technical field of lithium-ion battery electrolytes, and particularly relates to a high-voltage lithium-ion battery electrolyte. The high-voltage lithium-ion battery electrolyte comprises non-aqueous solvents, lithium salt and additives, wherein the additives comprise the mixture of fluoro phosphonitrile, fluoro-ether and unsaturated olefinic sultone. A lithium-ion battery using the high-voltage lithium-ion battery electrolyte is long in cycle life under the high voltage and small in internal resistance change. The high-voltage lithium-ion battery electrolyte is simple in preparing technique, easy to realize, and broad in market prospect.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

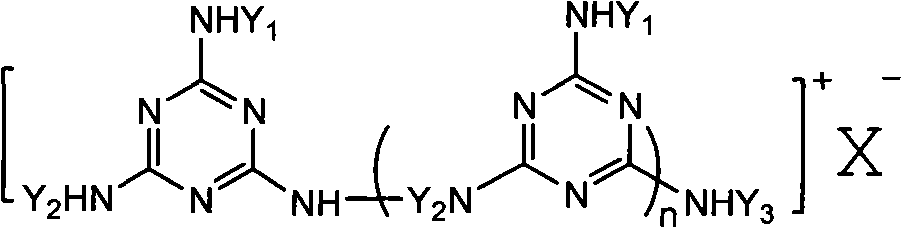

Materials of high flame-retardancy organic intercalation layered clay and preparation method thereof

InactiveCN101786637ASimple preparation technologyImprove solubilitySilicon compoundsOrganic acidChemistry

The invention relates to materials and a method for preparing high flame-retardancy organic intercalation layered clay. The method is performed by inserting melamine or derivatives of melamine into layered clay, especially montmorillonite layers, and the invention is characterized in that the inserted material is at least one compound of salt formed by melamine or derivatives of melamine and an organic acid and is inserted in the clay by cation exchange. The invention also relates to a method for preparing the materials. In the method, the materials are prepared from melamine, derivatives of the melamine and the layered clay by the steps of material mixing, dispersing, cation exchange, grinding and the like. The organic layered clay prepared by the invention can disperse in polymers, has excellent expansion performance and flame retardancy, and can be used as an expansion type fire prevention additive, or used as an expansion type flame retardant component for preparing additives of flame retardant plastic, rubber, thin films, coating, foam plastic and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

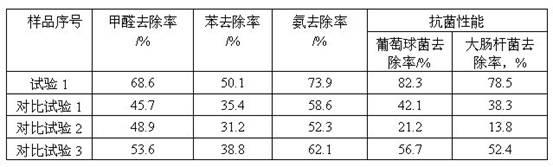

Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

The invention belongs to the technical field of inorganic materials and in particular relates to a kieselguhr-based environmentally-friendly glaze material for an inner wall brick and the inner wall brick prepared by using the same as well as a preparation method. The kieselguhr-based environmentally-friendly glaze material for the inner wall brick comprises kieselguhr, a nano TiO2 / tourmaline composite material, a sintering adjuvant, ceramic pigment, a dispersing agent and water, wherein the weight ratio of kieselguhr to nano TiO2 / tourmaline composite material to sintering adjuvant to ceramic pigment to dispersing agent to water is (40-92):(6-40):(2-15):(0-8):(0.1-4):(60-250). According to the invention, a functional raw material nano TiO2 / tourmaline composite material is introduced in the environmentally-friendly glaze material for the inner wall brick, and the functional raw material has multiple functions of obviously dispelling poisonous and harmful gases such as formaldehyde, ammonia, benzene, volatile organic compound (VOC) and the like which are released by various decoration and finishing materials, furniture and the like, releasing negative ions, resisting bacterium and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

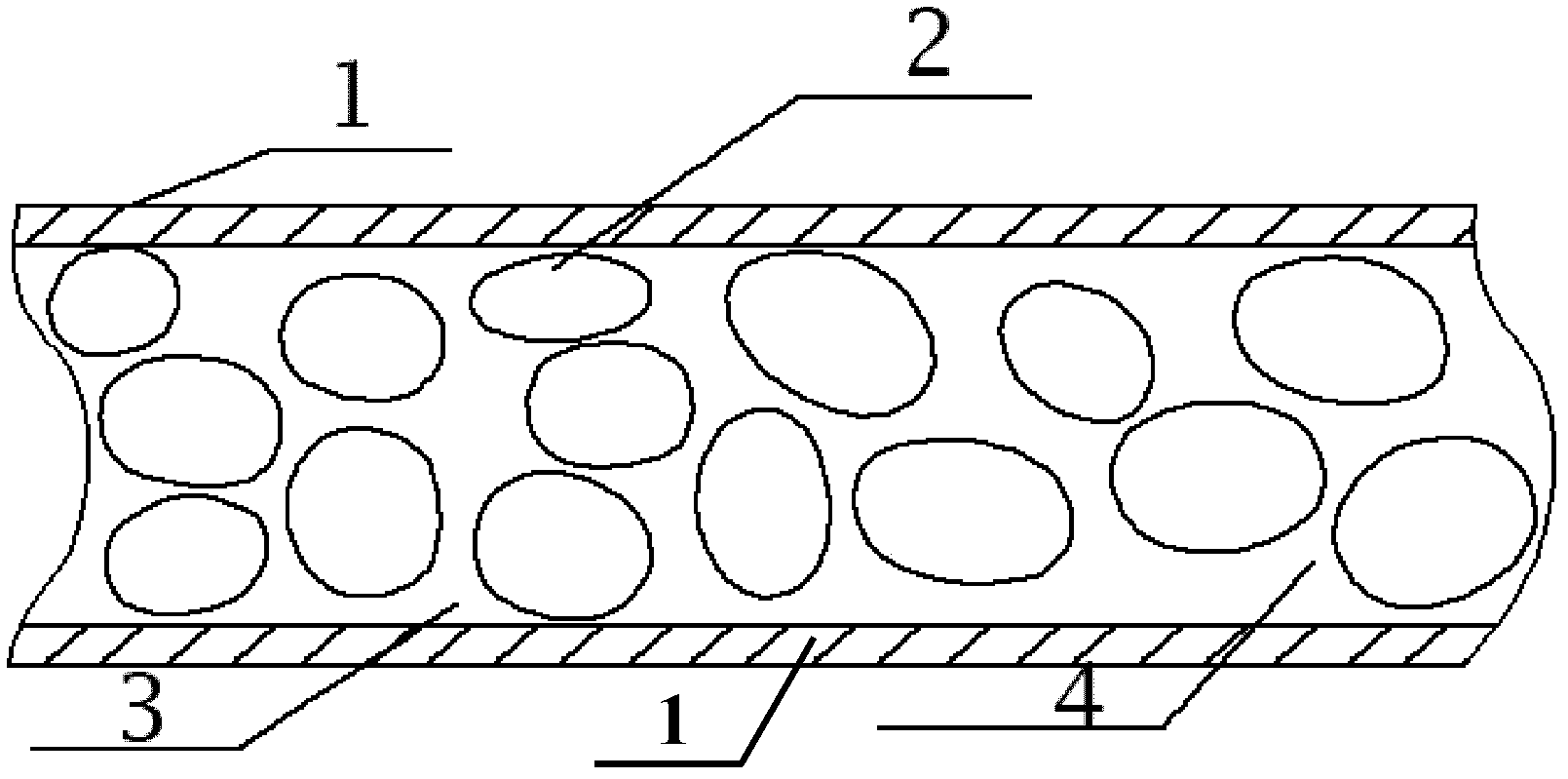

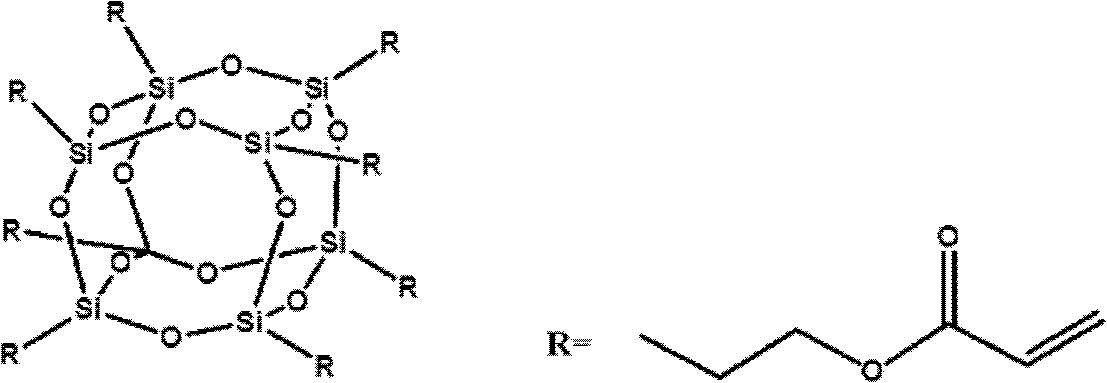

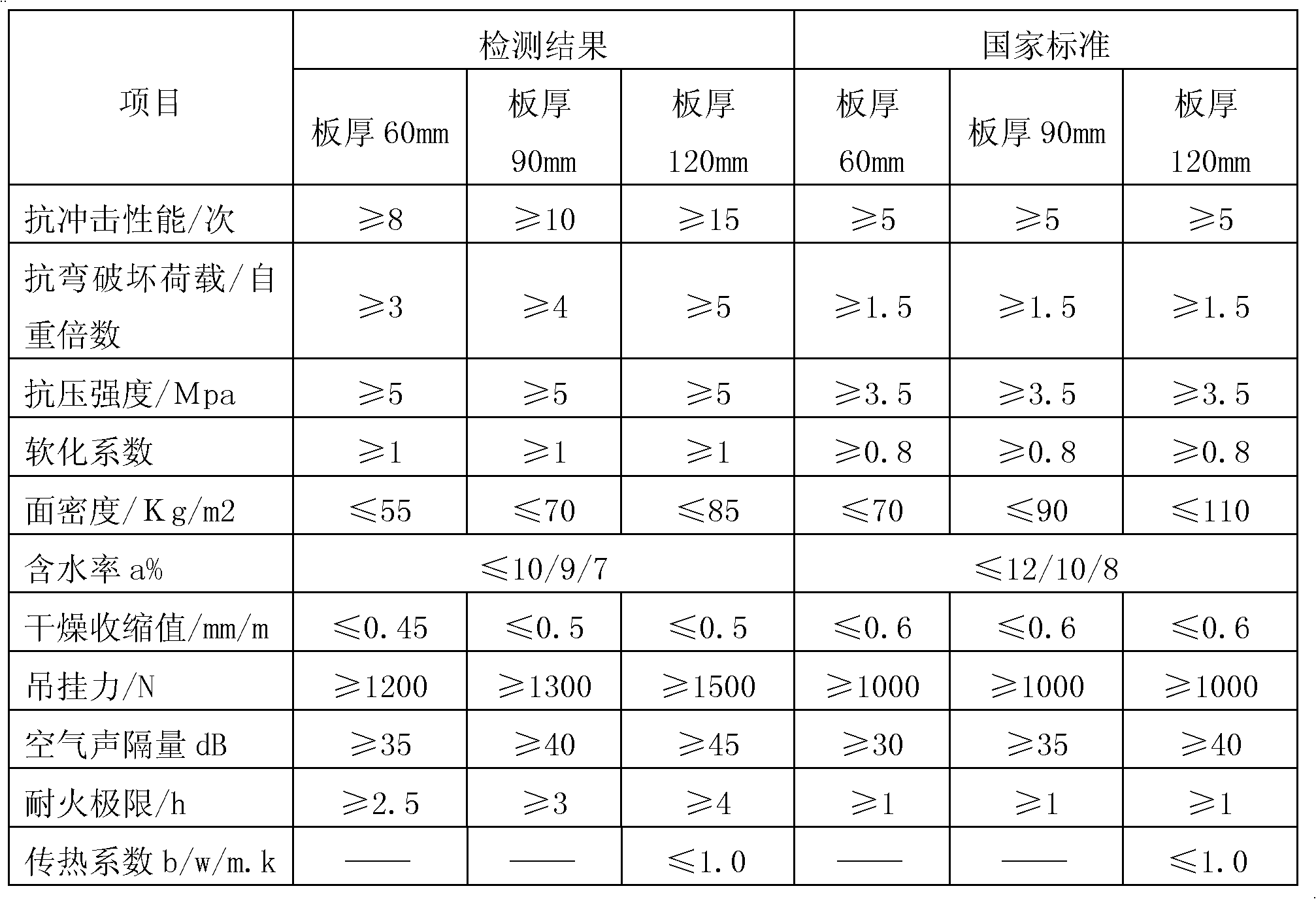

Light energy-saving and heat-insulating composite wallboard and preparation method thereof

InactiveCN102505799AHigh bonding strengthPlay a role in reducing waterClimate change adaptationCeramic shaping apparatusCalcium silicateLight energy

The invention provides a light energy-saving and heat-insulating composite wallboard which is on the basis of organic / inorganic hybridized nano-enhanced modification technology and a preparation method thereof, and relates to a heat-insulating wallboard. According to the heat-insulating wallboard, a calcium silicate plate serves as a surface layer of the wallboard and ceramsite concrete serves as a core material. The ceramsite concrete is prepared from ceramsite, cement, coal ash, gypsum, AcryloPOSS, redispersible emulsion powder, cellulose, a water reducing agent, a foaming agent and an early strength agent. The strength, the durability, the flame resistance and the working performances of the light energy-saving and heat-insulating composite wallboard are improved by adding organic / inorganic hybridized nano particles into the ceramsite concrete and using the nano size enhancement effect and the flame resistance of the POSS, so the composite wallboard is energy-saving and environment-friendly, is easy to assemble and disassemble and can be hung through a nail.

Owner:XIAMEN UNIV

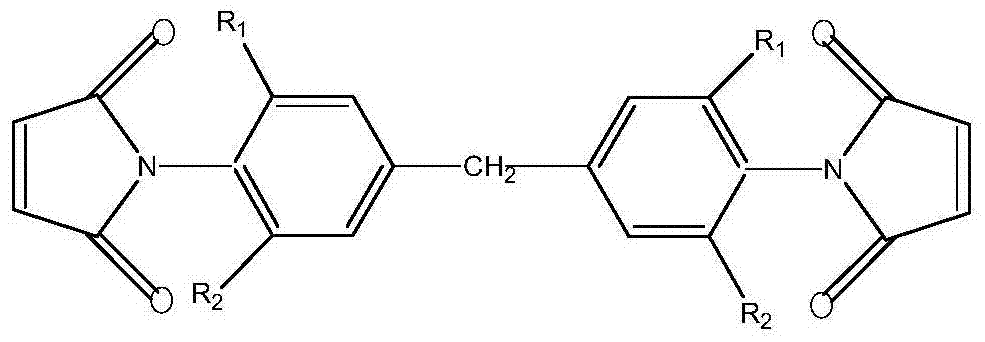

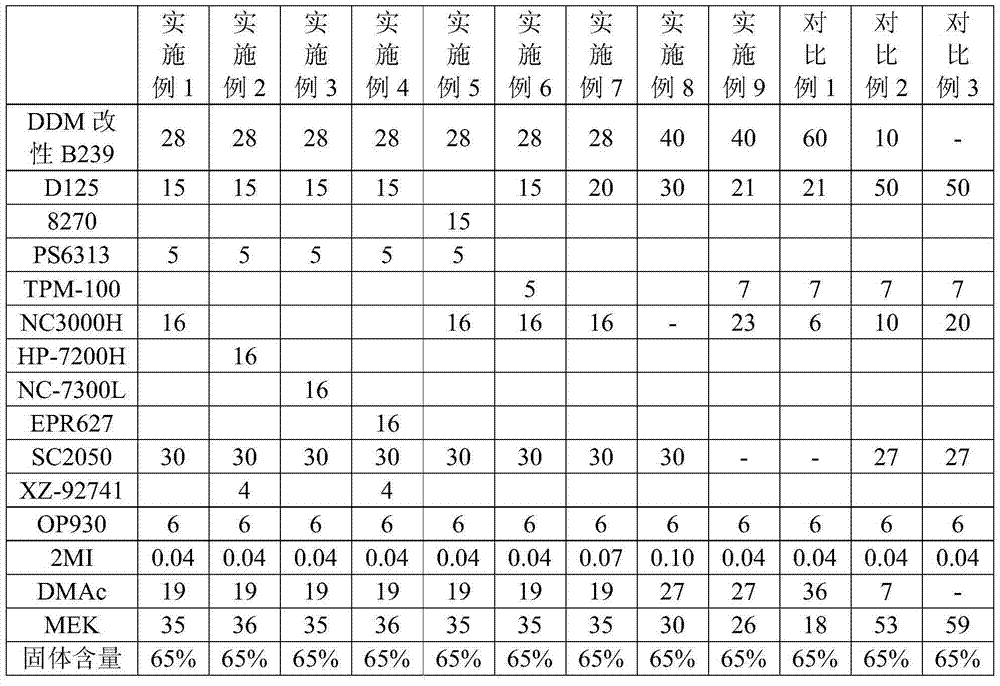

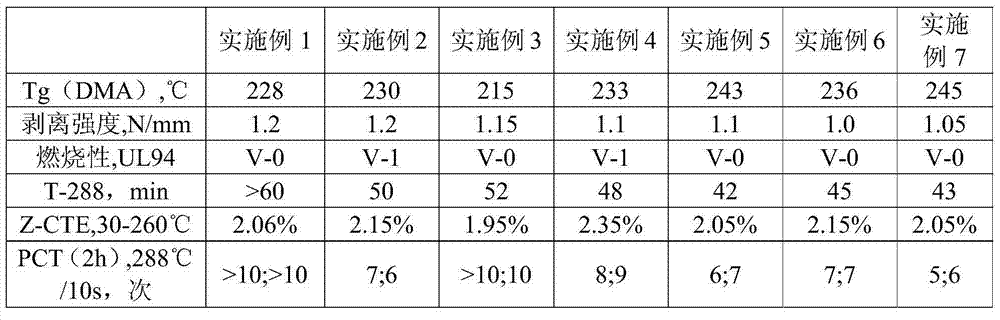

Resin composition, prepreg using resin composition and laminate

ActiveCN104725781AHigh TgLow CTESynthetic resin layered productsCircuit susbtrate materialsDielectric lossElastic modulus

The invention belongs to the technical field of copper clad laminates and particularly relates to a resin composition, prepreg using the resin composition and a laminate. The resin composition contains the ingredients in percentage by weight: 15-55% of amine modified bismaleimide (BMI), 10-45% of benzoxazine resin and 0-75% of epoxy resin. According to the resin composition, through further reaction of benzoxazine (BOZ) and amine modified bismaleimide (BMI), performance advantages of two kinds of high-performance resin, namely BMI and BOZ, are excellently exerted, so that the prepreg and the copper clad laminates, manufactured from the resin composition, have the properties of high Tg, relatively high peeling strength, relatively low CTE, relatively low water absorbing capacity, relatively low dielectric loss, relatively high elastic modulus high-temperature retention rate, relatively good resistance to hot and damp and the like, and reach a flame-retardant level UL94-V0.

Owner:GUANGDONG SHENGYI SCI TECH

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

Ethylene propylene rubber cable insulating material for ship and ocean use and manufacturing method thereof

ActiveCN102344612ASmall outer diameterReduce weightPlastic/resin/waxes insulatorsMicrocrystalline waxPolymer science

The invention discloses an ethylene propylene rubber cable insulating material for ship and ocean use and a manufacturing method thereof. The insulating material comprises by weight: 11 parts of ethylene propylene rubber 2470; 9 parts of ethylene propylene rubber 4044; 1.0-1.5 parts of high pressure polyethylene; 0.5-1.0 part of dicumyl peroxide; 0.3-0.4 part of triallyl isocyanurate; 0.5-0.8 part of 2-mercaptobenzimidazole; 1-1.5 parts of titanium dioxide; 1.0-1.5 parts of paraffin oil; 1.0-1.5 parts of zinc oxide; 0.6-1.0 part of microcrystalline wax; 0.2-0.5 part of stearic acid; 1-2 partsof white carbon black; 10-15 parts of superfine talc powder; and 12-16 parts of modified calcined argil. The method consists of the steps of: conducting uniform banbury mixing to ethylene propylene rubber and high pressure polyethylene; then adding titanium dioxide and the like in order for uniform mixing; carrying out triangle bag packaging with an open mill for 7 times, then filtering rubber, and putting the filtered rubber in a banbury mixer and adding an antioxidant for mixing well; finally conducting triangle bag packaging in an open mill for 5 times and extruding rubber sheets. The insulating material has the advantages of low smoke, free of halogen, flame retardation, high mechanical strength and high insulation resistance.

Owner:嘉兴顾翔制冷设备有限公司

Modified amino resin expansion type water flame-proof paint

InactiveCN101117510AImprove flame retardant performanceIncreased resistance to ignitionFireproof paintsEmulsion paintsPliabilityMelamine

The present invention relates to amino resin intumescent aqueous flame retardant coating, in particular to an intumescent aqueous flame retardant coating. The present invention eliminates the release of harmful organic volatile compounds of the inflaming-retardant coating in use, improving poor fire resistant performance of dewatering catalyst due to a high disassembling temperature, solving the problems of long manufacturing period, low efficiency and high cost of the inflaming-retardant wood materials. The materials for the present invention comprises amino resin, polyvinyl acetal resin, dewatering catalyst, melamine, charring agents, dope assistant, antifoaming agent, palette filling and water. The present invention has storage for a long time, good cohesion, slow and low emission of heat and low emission of smoke, enjoying good flexibility and good strike-resistant performance; furthermore, the present invention can be manufactured easily and used conveniently and can be easily popularized without emission of harmful organic volatile in use. Compared with a prior wooden inflaming-retardant liquid, the present invention has the advantages of simple process, convenient operation, low cost and high efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

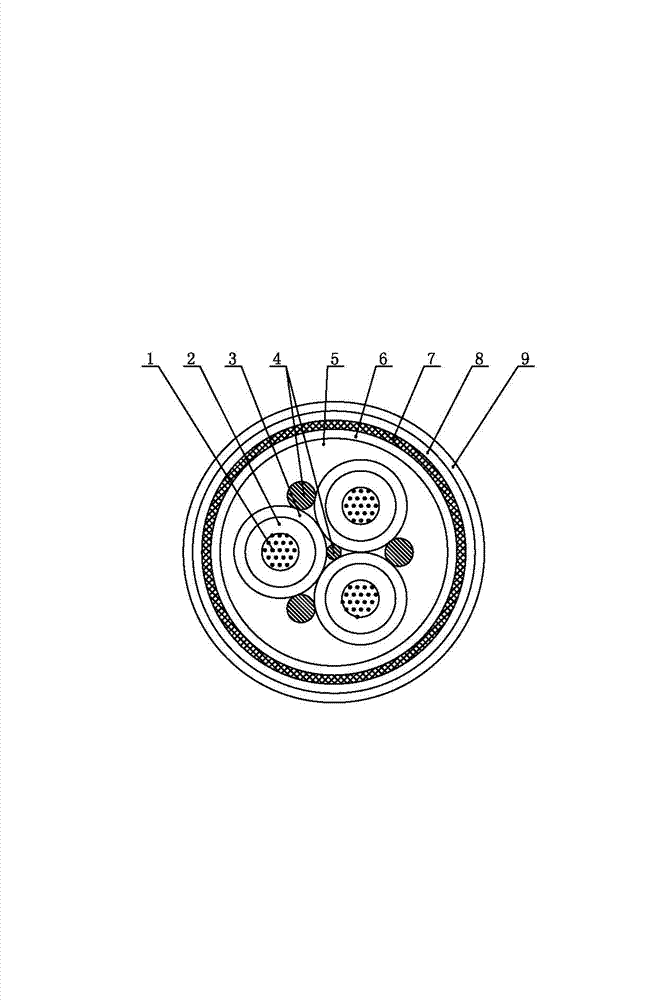

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

Composite interior material for motor car and preparation method thereof

InactiveCN102619022AGood compatibilityImprove functionalityNon-woven fabricsAdhesivesWork in processHot pressing

The invention relates to a composite interior material for a motor car and a preparation method thereof. The composite interior material comprises 60-80% of high performance fibers, 10-20% of flame retardant fibers and 10-20% of hot-melt fibers; and the preparation method comprises the following specific steps of: 1) opening the high performance fibers, the flame retardant fibers and the hot-melt fibers by a bale opener; reopening the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a rough opener; and then mixing the high performance fibers, the flame retardant fibers and the hot-melt fibers by using a cotton blending machine; finely opening the mixture by using a fine opener; and combing the mixture by using a carding machine; 2) by using a nonwoven needle-punched machining technology, lapping the combed fibers in a cross way by a lapping machine; and then carrying out needle punching on the fibers by using a needle machine; and processing the fibers by using a singeing machine and a glazing calendar; and 3) carrying out composite hot pressing on a fiber felt which is a needle-punched, singed and calendared semi-finished product; and finally, forming the composite interior material together with a thermoplastic resin.

Owner:NANTONG UNIVERSITY +1

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

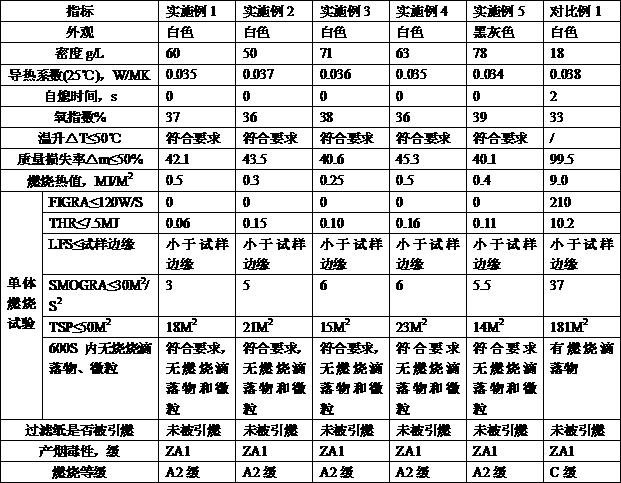

High-flame-retardance composite heat-insulating foam material and preparation method thereof

The invention relates to the technical field of polystyrene foam materials, in particular to a high-flame-retardance composite heat-insulating foam material and a preparation method thereof. The high-flame-retardance composite heat-insulating foam material comprises polystyrene foaming particles with the density of 18 to 20 g / L and a flame-retardant composite layer wrapped on the surface of the polystyrene foaming particles, wherein the flame-retardant composite layer consists of a flame-retardant binder of 5 to 50 g / L and an inorganic flame retardant of 5 to 75 g / L. Compared with the prior art, the invention optimizes the formula of the flame retardant and adopts environment-friendly, non-toxic and low-price organic and inorganic flame retardants. The prepared composite heat-insulating material has low production cost. After the product is combusted, the product has the advantages of alveolate skeleton structure, no melted drop, low smoke output quantity, no combustion dripping substance and no particle, so the flame-retardant performance and the flame-retardant grade of the product are obviously improved and the product has wide development prospect in the heat insulation field of buildings such as roofs and walls.

Owner:宁波龙利钜能新材料有限公司 +1

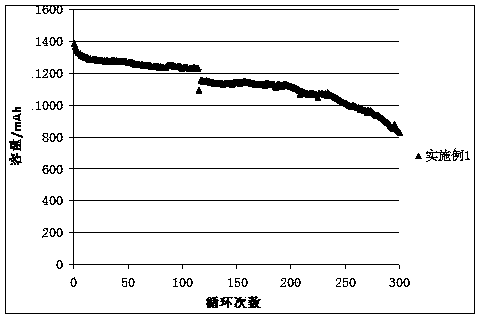

Lithium ion battery electrolyte and lithium ion battery containing the same

ActiveCN101471454AWide liquid temperature rangeFlame retardantSecondary cellsElectrolytic agentCombustion

A Li-ion battery electrolyte contains lithium salt, ionic liquid and a non-aqueous solvent, wherein the anion contained in the ionic liquid is showed by formula (1). A Li-ion battery comprises an electrical core and the above electrolyte, which can retard combustion of organic solvents. The Li-ion battery using the electrolyte can suppress capacity fade at low temperature, and can reduce the amount of gas generated by the electrolyte at high temperature, thereby effectively preventing battery expansion and improving the high-temperature performance of the battery.

Owner:BYD CO LTD

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

Polymer composite function fibers containing partial graphene, and preparation method thereof

ActiveCN105002595AIncrease productivityHigh strengthElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolyesterPolymer science

The present invention discloses a polymer composite function fibers containing partial graphene, and a preparation method thereof. The fibers comprise a component A and a component B, wherein the component A and the component B are combined in a partial exposing manner, side-by-side manner or skin-core manner, and 20-100% of the outer area of each fiber is the component B. The method comprises: crystallizing a polyester containing 0.1-1 wt% of partial reducing graphene and a polyester containing 4-20 wt% of a nanometer composite filler containing partial reducing graphene and TiO2, drying, carrying out melt composite spinning, and carrying out drawing and relaxation heat setting at a temperature of 80-160 DEG C, and reducing the partial graphene in the fibers to achieve the carbon / oxygen atom ratio of 9 / 1-15 / 1 through the reducing treatment. According to the present invention, the prepared fibers can be produced at the high spinning speed, and the production efficiency is high; and the fibers have characteristics of low single fineness, high strength and lower resistivity, meets the antistatic requirement, and further has characteristics of anti-bacterial property and flame retardant property so as to provide good application prospects.

Owner:NINGBO MYBABY BABY & CHILDREN PROD MFG

Poly acrylate composite emulsion for pressure' sensitive adhesive and its preparing and using method

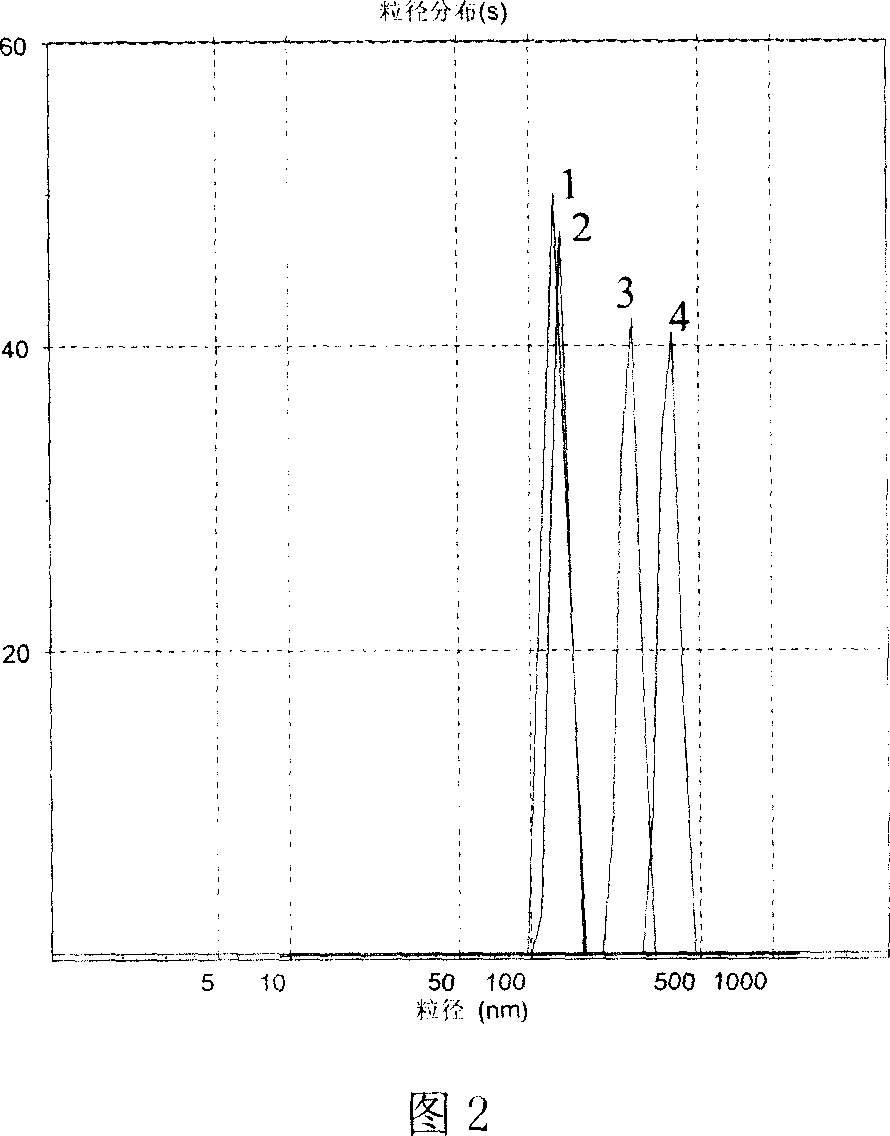

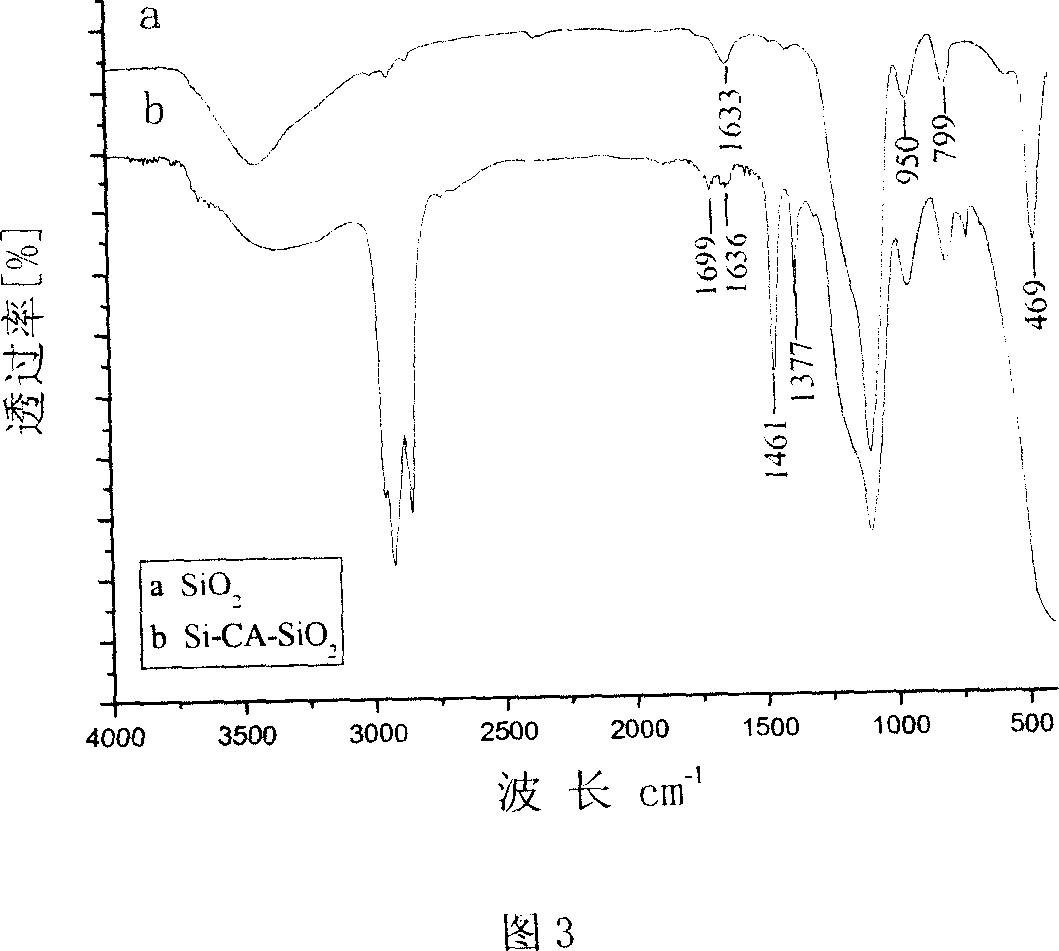

InactiveCN1944479AImprove interface compatibilityUniform particle sizeFilm/foil adhesivesEster polymer adhesivesEmulsionAcrylic acid

The present invention is composite polyacrylate emulsion for pressure sensitive adhesive and its preparation process and application, and relates to polyacrylate based adhesive. The composite emulsion is one core-shell structure with silane cross-linking agent surface modified nanometer silica as the core and the copolymer of acrylate and acrylic acid as the shell, and has solid content of 30-40 %, viscosity of 1-6 mPa.s, composite emulsion particle size of 250-700 nm and particle size dispersing index of 0.005-0.15. The composite polyacrylate emulsion is prepared through preparing nanometer silica alcohol sol, surface modification of nanometer silica and preparing nanometer silica-polyacrylate composite emulsion. The composite polyacrylate emulsion coating is dried to obtain the pressure sensitive adhesive with high initial adhering performance and cohesive property.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com