Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1613results about How to "With insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

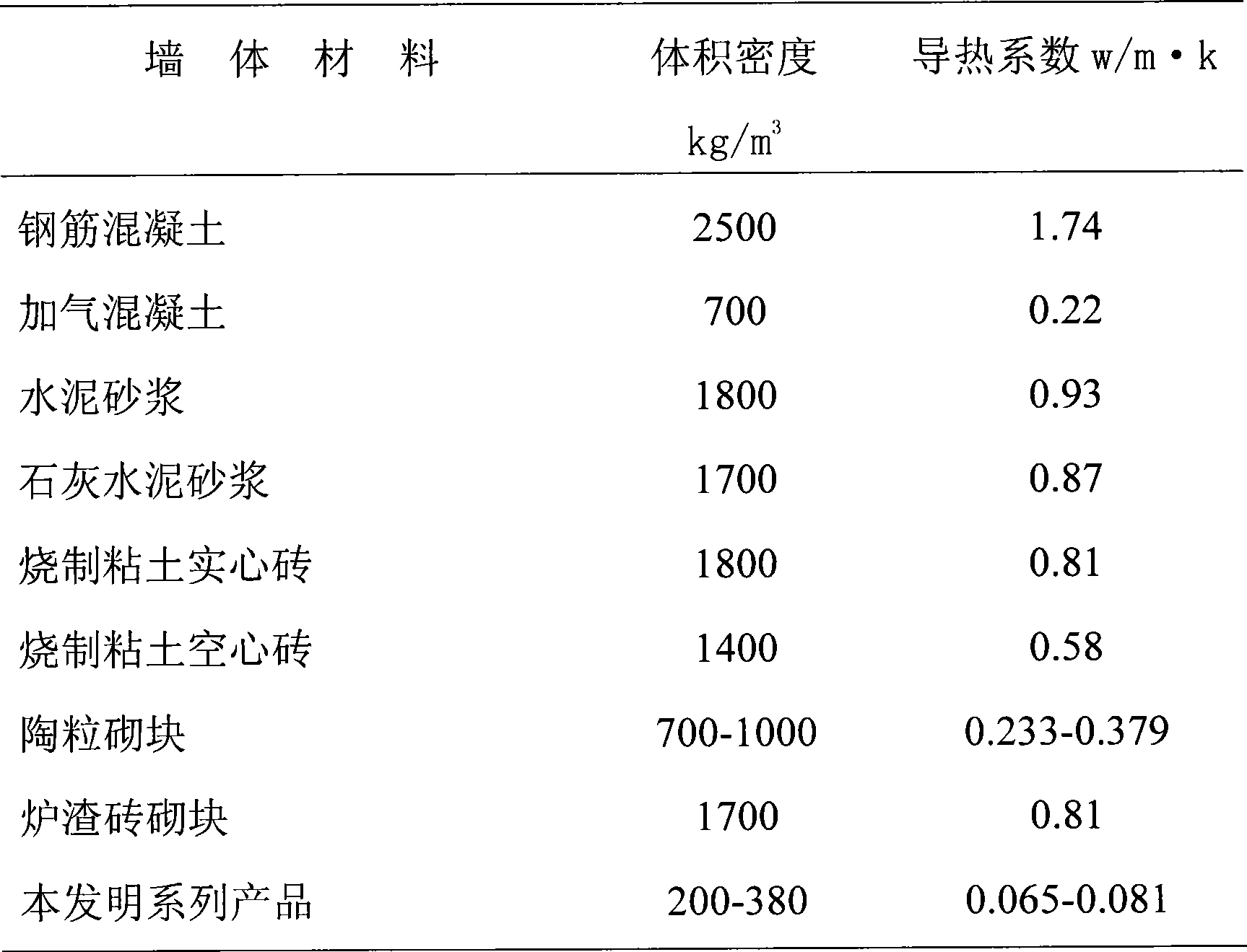

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Composite material with anti-bacterial and purifying functions and preparation method of composite material

ActiveCN104607039AImprove adsorption capacityImprove decomposition rateWater/sewage treatment by irradiationDispersed particle separationDecompositionRare earth

The invention relates to a composite material with anti-bacterial and purifying functions and a preparation method of the composite material, and belongs to the technical field of environmental-friendly materials. The composite material with the anti-bacterial and purifying functions comprises raw materials in parts by weight as follows: 70-95 parts of a mineral composite adsorption material, 3-25 parts of a photocatalytic degradation material, 2-15 parts of a rare earth inorganic anti-bacterial material and 1-10 parts of an additive, wherein the mineral composite adsorption material is prepared from sepiolite, diatomite, medical stone and attapulgite; the photocatalytic degradation material is prepared from titanium oxide, tourmaline and far infrared ceramic powder; the rare earth inorganic anti-bacterial material is prepared from zinc oxide, cerium oxide and silver oxide; the additive is a mixture of activated carbon, carboxymethylcellulose and pumice powder. The composite material with anti-bacterial and purifying functions has high adsorption and decomposition rate, can be resistant to water and damp and has excellent anti-bacterial effect. Meanwhile, the invention provides the preparation method. According to the preparation method, the cost is low, the amount of produced wastewater is low, and powder is simple and convenient to apply.

Owner:淄博木齐新材料科技有限公司

Cellular concrete product

InactiveCN101353265AHigh strengthImprove thermal insulation performanceSolid waste managementCeramicwareMetakaolinAdjuvant

A foamed concrete product is characterized in that Portland cement or ordinary Portland cement is taken as gelling material; zeolite powder, metakaolin powder, limestone powder, fly ash or silicon ash powder are taken as admixtures; protein hydrolysate of hoof and horn of animals is taken as a foaming agent; an acrylate coagulator or a polycarboxylic acid type water reducing agent is taken as an adjuvant, and water is active water. In order to improve the early strength, the later compressive strength, the bending strength and the anti-tensile splitting strength of the low-density foamed concrete, a plurality of admixtures comprising the zeolite powder, the metakaolin powder, the silicon ash powder or the limestone powder are chosen, by mutual collocation of the components and contents of the admixtures, the comprehensive improvement of various strengths is achieved, and the multifunctional effects of insulating heat, adjusting moisture, preserving heat, and the like, are obtained. In the foamed concrete blocks of the ordinary Portland cement, the density is 500-800kg / m<3>, the compressive strength is 6-8MPa and the water absorption rate is 5-10%, the heat preserving property and the heat insulating property are obviously improved, the water absorption performance and the moisture adjusting index are remarkably improved, and the better cost performance ratio is obtained.

Owner:周照柱

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

Foaming powder coating

InactiveCN101205425AImprove the decorative effectHigh mechanical strengthPolyurea/polyurethane coatingsPowdery paintsNon toxicityElectrostatic coating

Then invention discloses a foaming powder coating, belonging to the electrostatic coating powder coatings technical field. The coating is prepared by melting extrusion hybrid method from the following materials in weight portions: resin of 40 to 60 portions, curing agent of 0 to 24 portions, pigment and filler of 40 to 60 portions, foaming agent of 1 to 15 portions, flame retardant of 1 to 5 portions, and flow agent of 1 to 5 portions. The invention has the advantages of non-toxicity and harmlessness, no solvent contained, green and environmental protection; the coating can be directly coated on metal plates and easily operated; the foaming expansion layer has good decorative effect and high mechanic strength; the foaming powder coating of the invention can be used to produce building material products with heat insulation, heat preservation, fire proof, and sound proof effects; the building material products are economic, environmental protective, poisonless, harmless and flame retardant.

Owner:XUZHOU ZENITH COATING

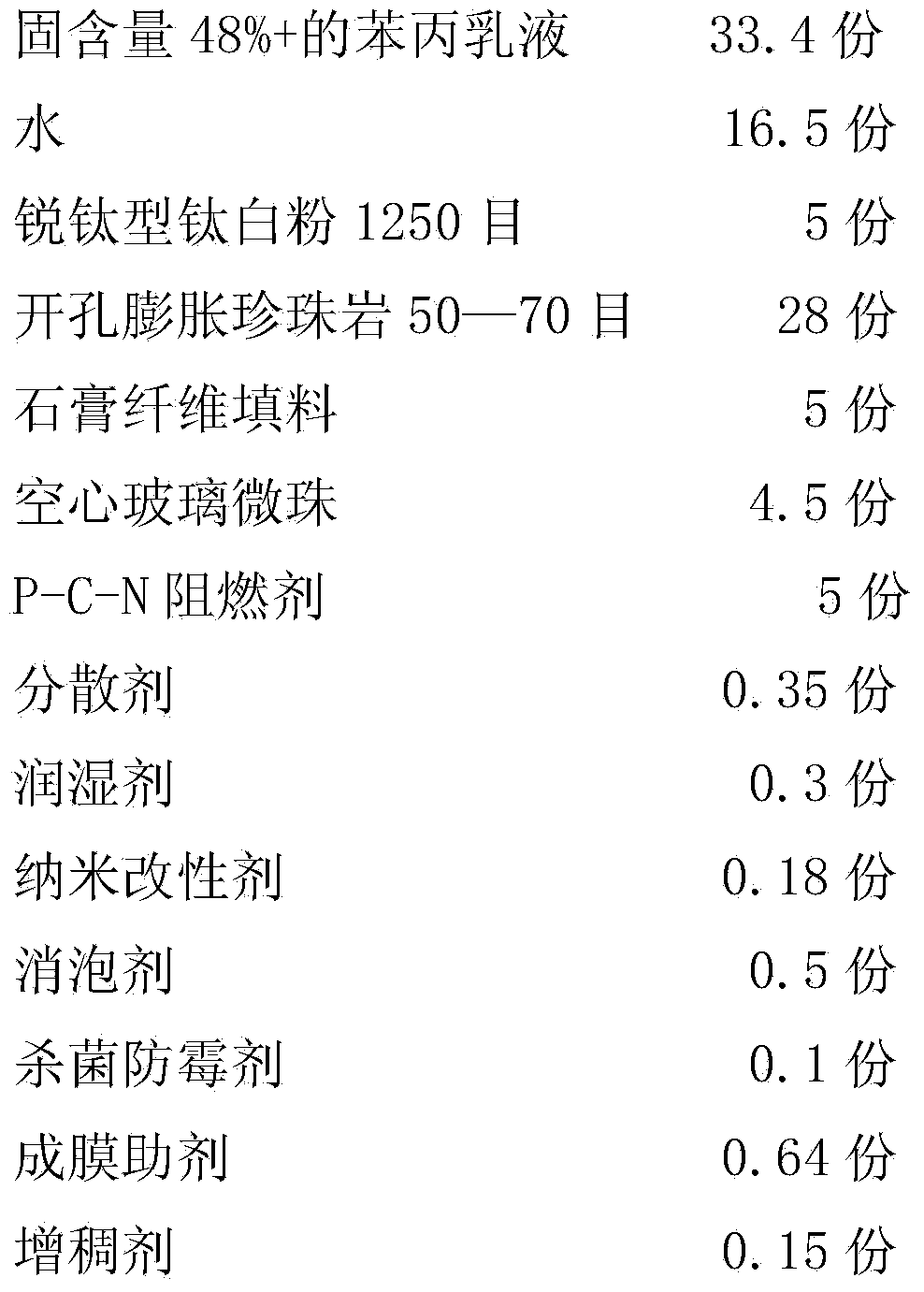

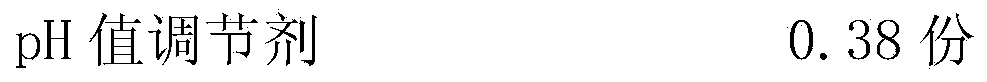

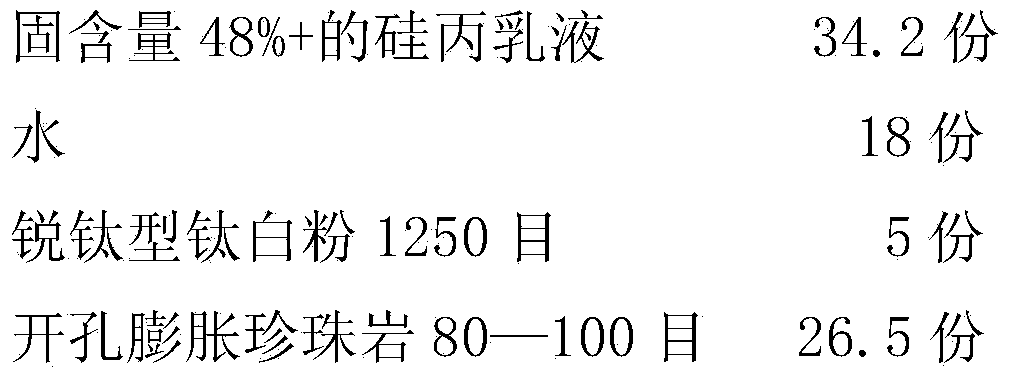

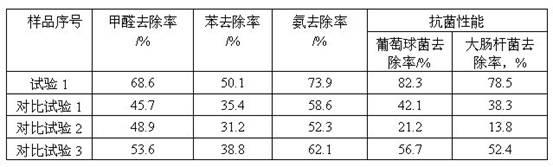

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

Diatomite-based environmentally friendly glaze for interior wall tiles and interior wall tiles prepared using the glaze

The invention belongs to the technical field of inorganic materials and in particular relates to a kieselguhr-based environmentally-friendly glaze material for an inner wall brick and the inner wall brick prepared by using the same as well as a preparation method. The kieselguhr-based environmentally-friendly glaze material for the inner wall brick comprises kieselguhr, a nano TiO2 / tourmaline composite material, a sintering adjuvant, ceramic pigment, a dispersing agent and water, wherein the weight ratio of kieselguhr to nano TiO2 / tourmaline composite material to sintering adjuvant to ceramic pigment to dispersing agent to water is (40-92):(6-40):(2-15):(0-8):(0.1-4):(60-250). According to the invention, a functional raw material nano TiO2 / tourmaline composite material is introduced in the environmentally-friendly glaze material for the inner wall brick, and the functional raw material has multiple functions of obviously dispelling poisonous and harmful gases such as formaldehyde, ammonia, benzene, volatile organic compound (VOC) and the like which are released by various decoration and finishing materials, furniture and the like, releasing negative ions, resisting bacterium and the like.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

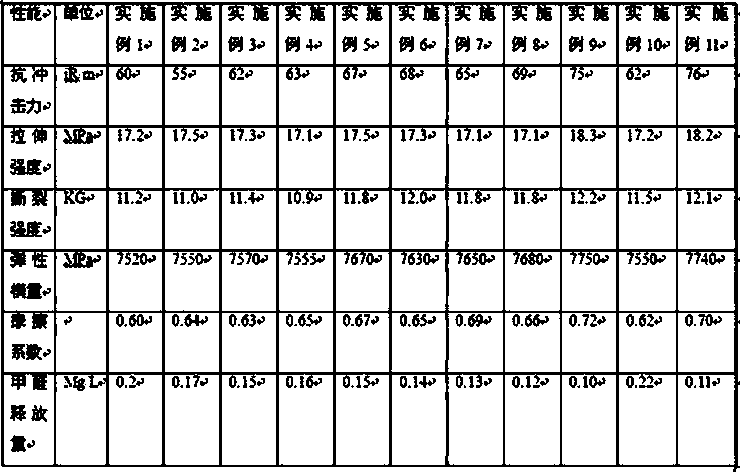

PVC (polyvinyl chloride) micro-foam floor and preparation method thereof

Owner:安徽济峰节能材料有限公司

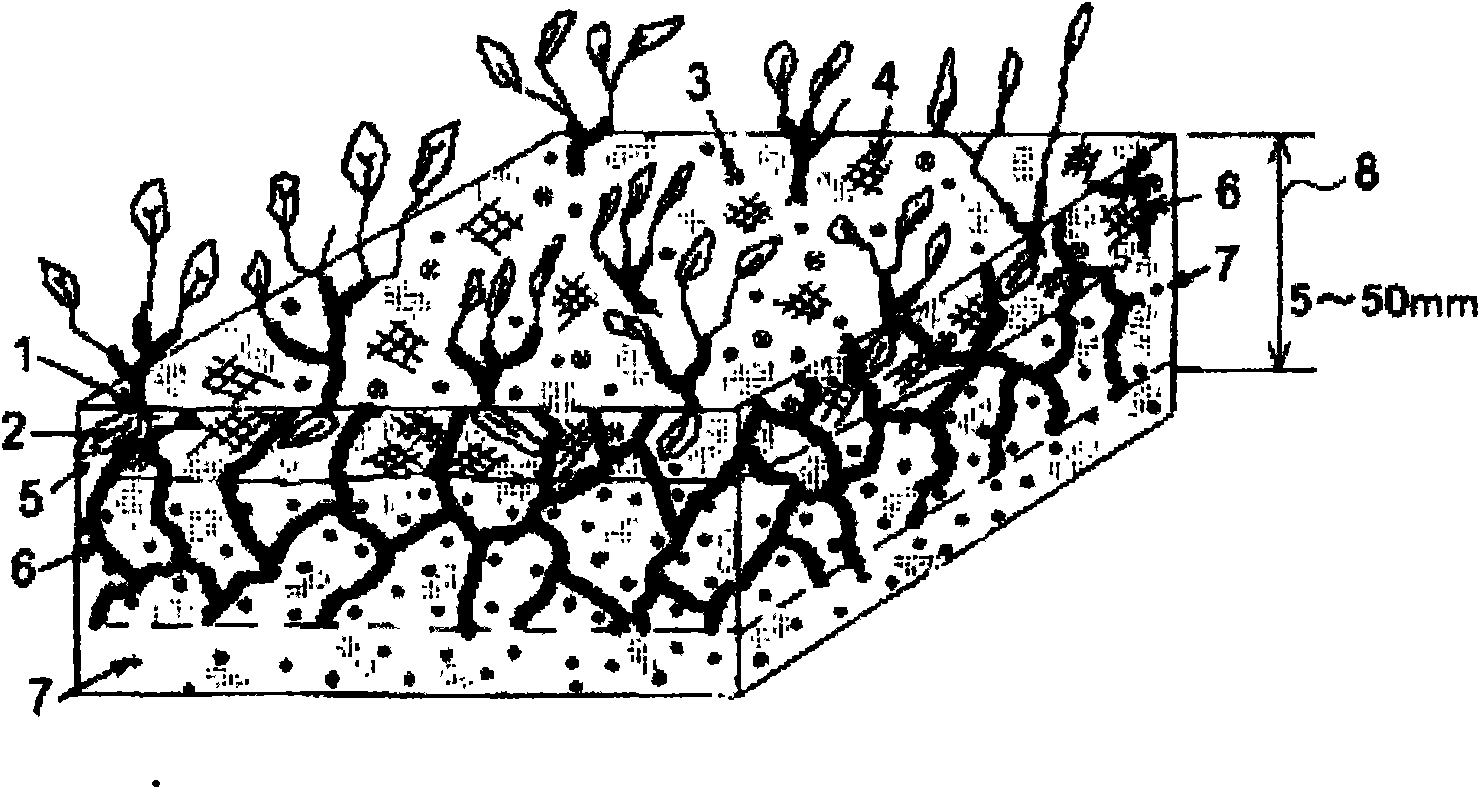

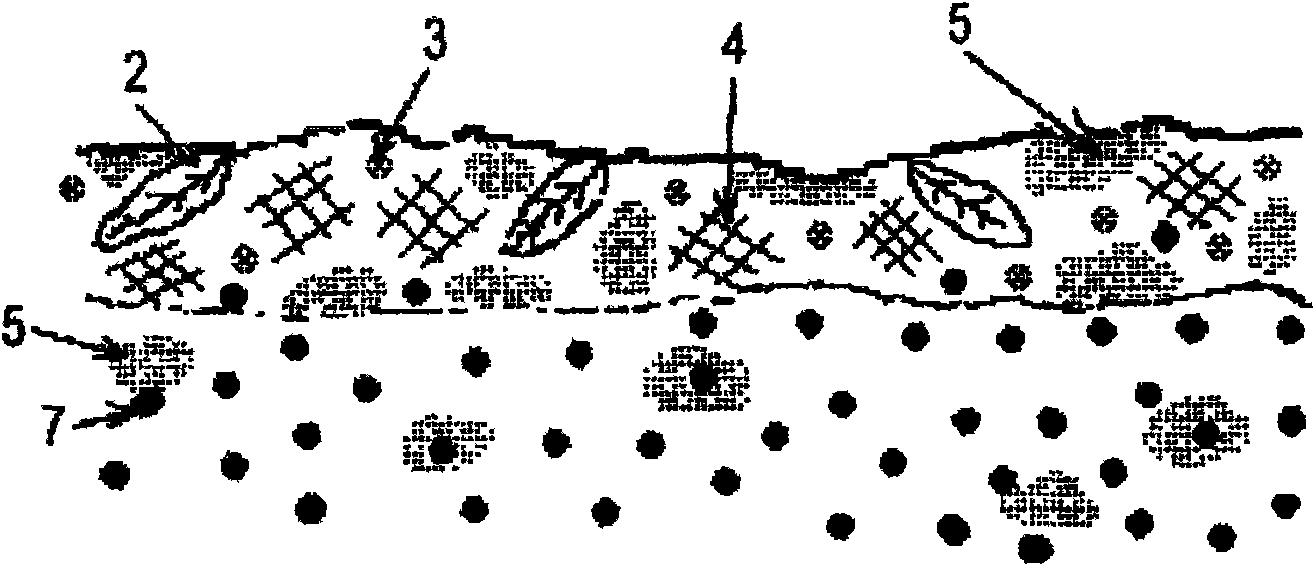

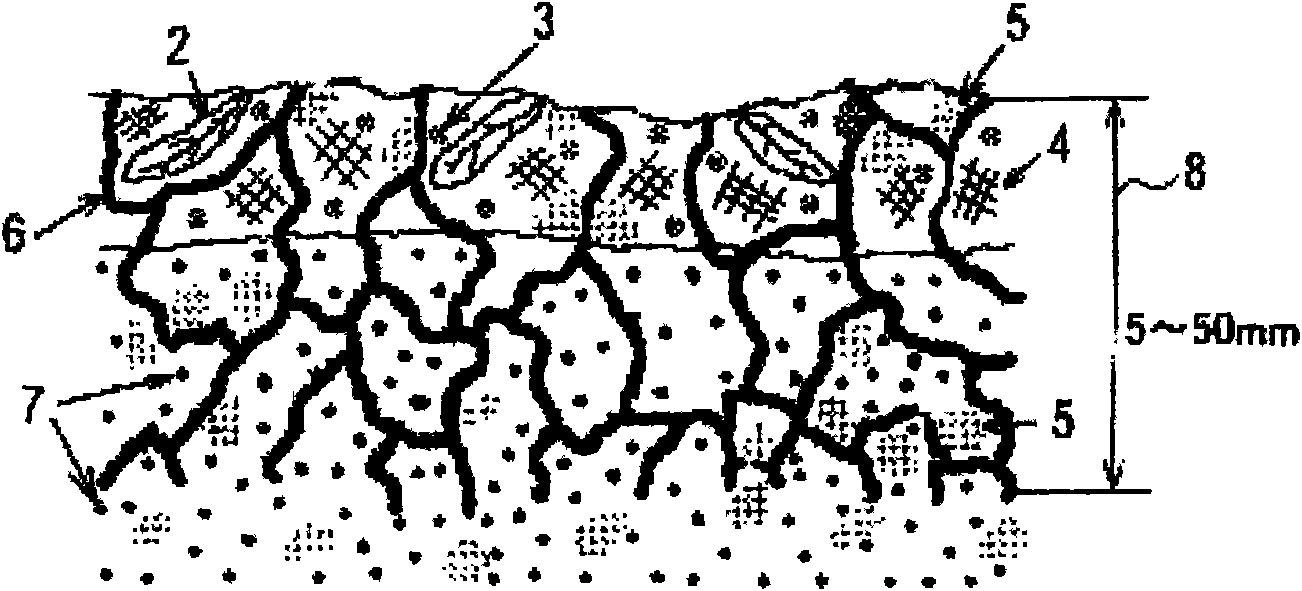

Desert control method of chemical sand-fixing greening technology based on organic composite materials

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

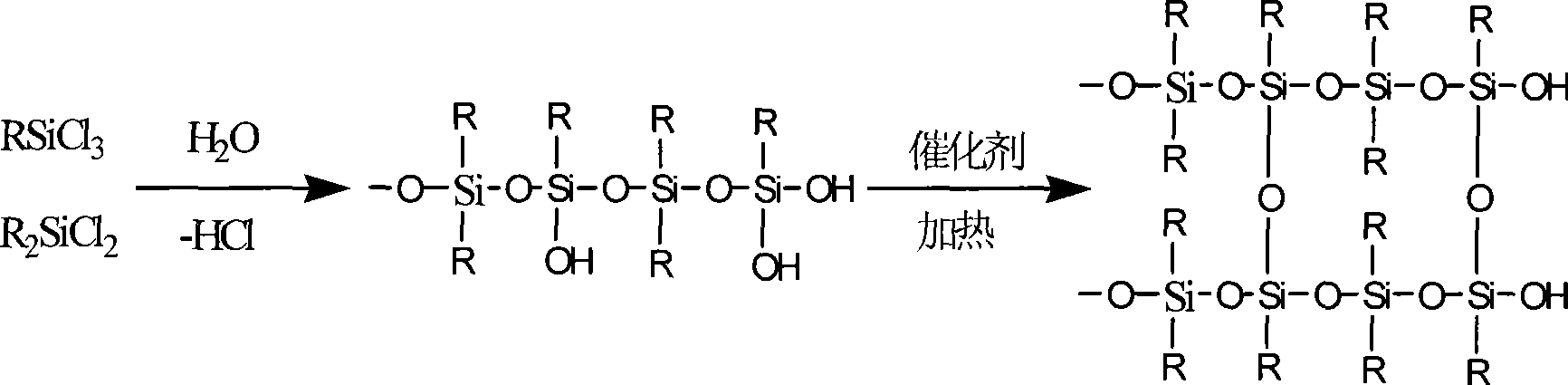

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

Solid wall paper and its production method and use

InactiveCN101100832APromote environmental protectionFireproofSpecial paperPaper/cardboardWoolSurface finishing

The invention discloses a new type solid wall paper, its manufacturing method and application. Its feature is that pulpwood formed three-dimensional bass-relief pattern and colorful plate type is used to form the solid wall paper which has various design and color, geometry by monomer jointing, assembling, and arranging. The method includes the following steps: adding solid filling and additive, or any one of wood pulp, bamboo pulp, or their mixture into paper making pure wool pulp; using pulp molding plant and die to product; pulping; forming; drying; shaping; ginning; scratching; brush coating or surface overlaying film to obtain the solid wall paper. It can be used in the decoration for bedroom, drawing room, and public occasion.

Owner:BEIJING TONGLANHAI TECH CO LTD

Method for producing ceramic tile using polished waste material

The waste material collected from polish waste water and waste slag via deposition, press filtering and ageing is mixed with high temperature sand, kaolin and low temperature sand. The mixture is wet milled in a ball mill, 250-mesh sieved, iron eliminated and spray dried to form powdered material; the powdered material is dry formed into ceramic tile adobe in a ceramic press; and the ceramic tile adobe is baked in a roller hearth kiln at 1140-1200 deg.c in 40-75 min. The said method utilizes the waste reasonably and the product has excellent performance.

Owner:FOSHAN OCEANO CERAMICS

Honeycomb concrete

InactiveCN101239837ASolve the problem of "cold bridge"Extended service lifeCeramicwarePortland cementFilling materials

The present invention relates to a honeycomb concrete belong to a building material. The honeycomb concrete comprises the mother material and supplementary material with the following weight proportion: quick hardening sulfaluminous cement or ultrastrength cement: 30-70 parts; filling material: 25-60 parts; ordinary Portland cement: 5-10 parts; waterproofing agent: 1-1.5 parts; bleeding agent: 2.0-3.0 parts; suspension agent: 2.0-5.0 parts; foam stabilizer: 0.1-0.5 parts; and honeycomb agent: 38-60 parts. The invention has the following advantages and beneficial effects: light weight, high strength, long service lifetime, heat preserving with high efficiency, heat insulation, sound insulation, self-water-proofing, non combustibility, impact resistance, small contraction percentage, convenient construction and installation, reducing the weight of the building, increasing the using area, convenient product preparation and construction, the concrete not only can be made in factory but also can be made at the construction site.

Owner:徐东亮 +2

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

Polyvinyl chloride (PVC) wood-plastic foaming wood grain section and preparation method thereof

The invention discloses a polyvinyl chloride (PVC) wood-plastic foaming wood grain section and a preparation method thereof. The wood-plastic foaming wood grain section is prepared from the following raw materials: plastics, an organic filler, an aid, a modifier, a foaming agent, a wood grain masterbatch and the like. The preparation method comprises the following steps of: mixing a foaming mixed material and the wood grain masterbatch and co-extruding from an extruder in a conical twin screw extrusion production line according to a one-step process route; foaming and molding by using a foaming mold; and cooling and shaping by using a shaping mold to obtain the PVC wood-plastic foaming wood grain section. The PVC wood-plastic foaming wood grain section has the advantages of light weight, high specific strength, waterproofness, corrosion resistance and heat preservation, and has the processing characteristic that wood can be nailed, sawed and planed; in addition, the PVC wood-plastic foaming wood grain section has highly simulated solid wood appearance, natural and clear textures, and bright surface color, is an ideal wood-simulated wood-plastic product, and can be widely applied to building, transportation, packaging, home decoration and daily product markets.

Owner:北京欧尼克环保技术有限公司

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

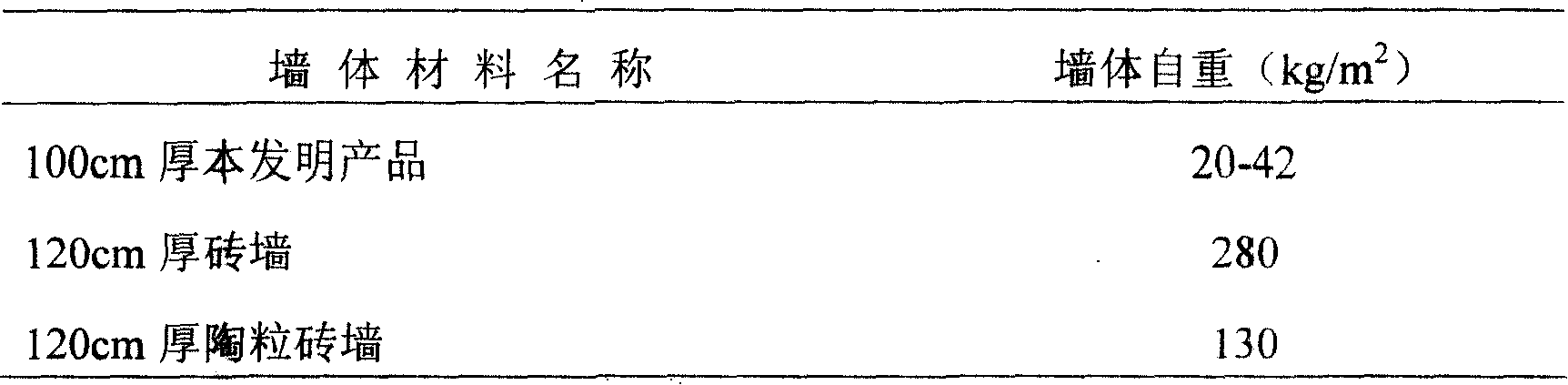

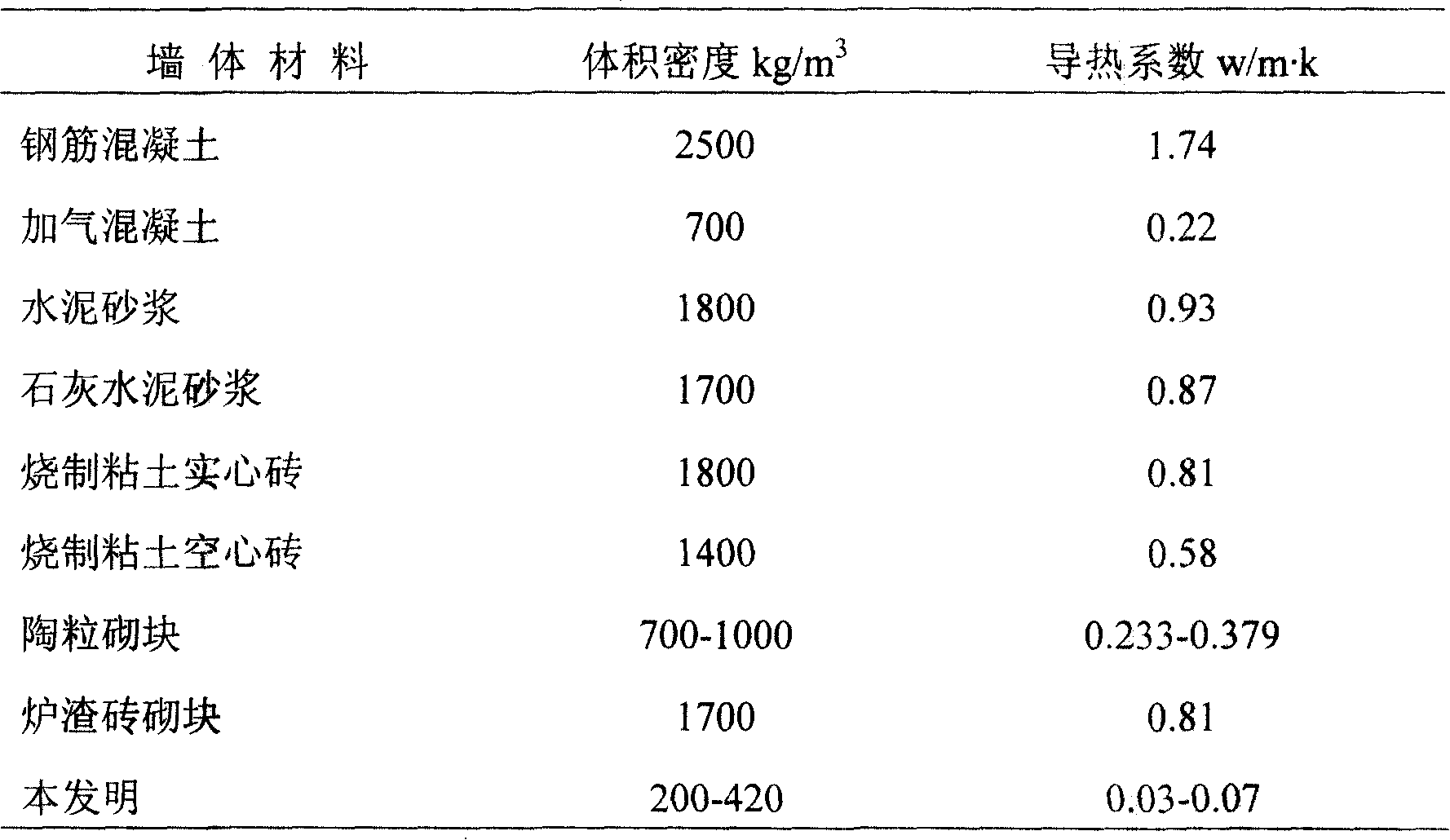

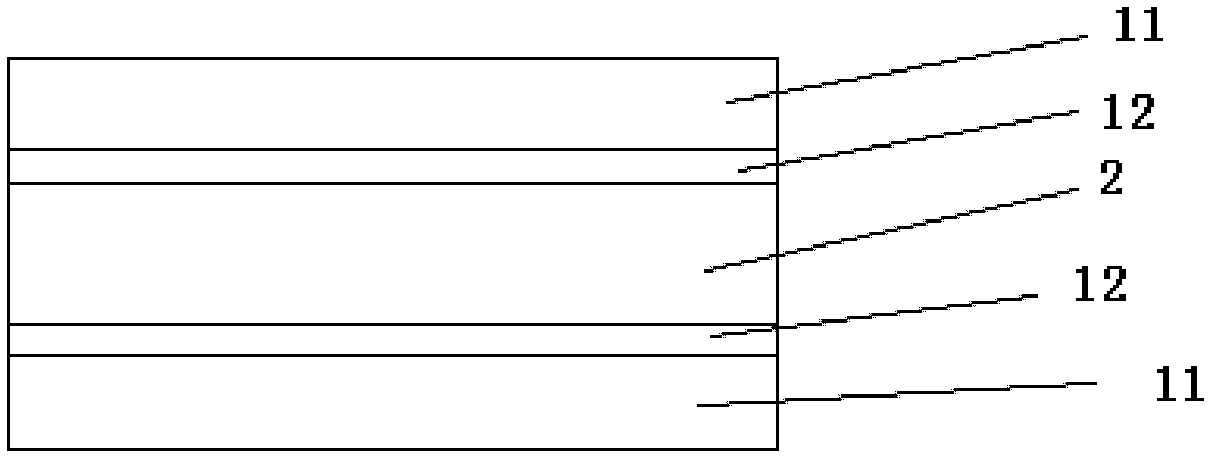

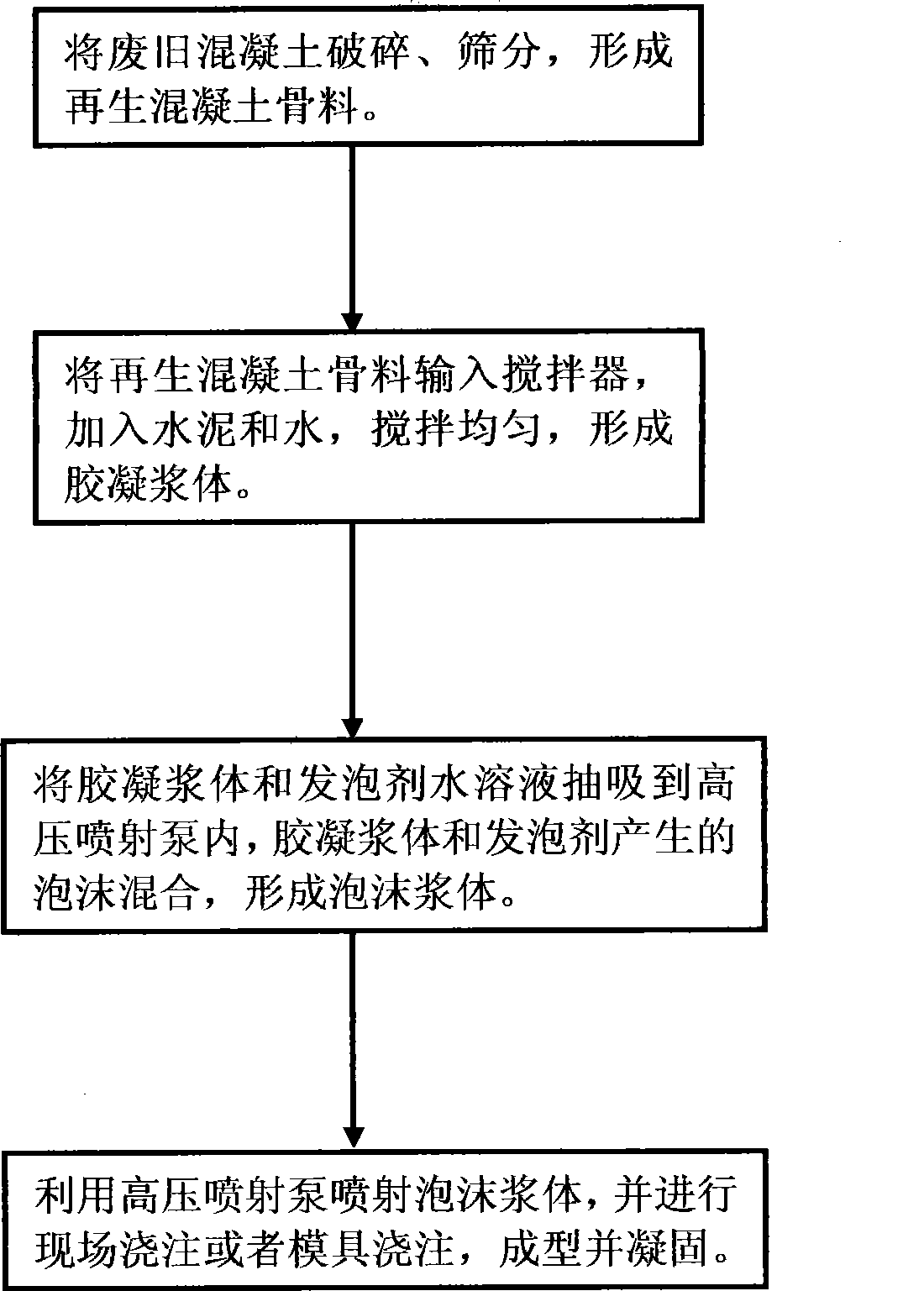

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

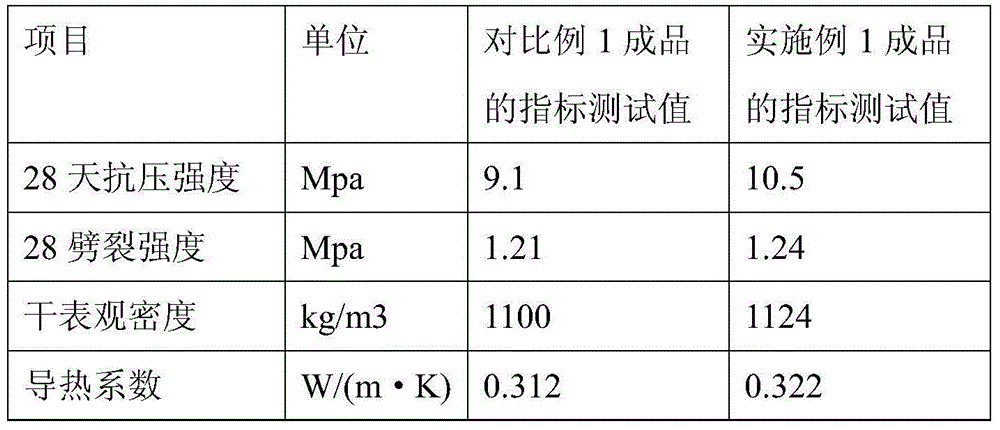

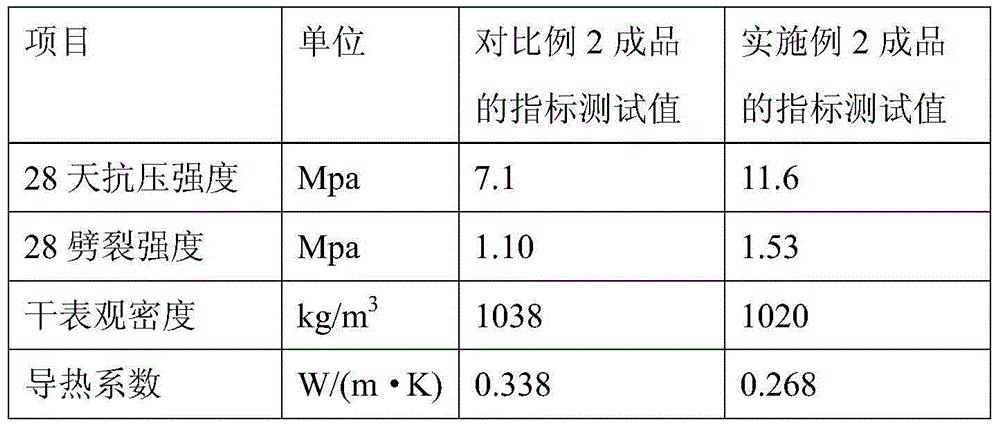

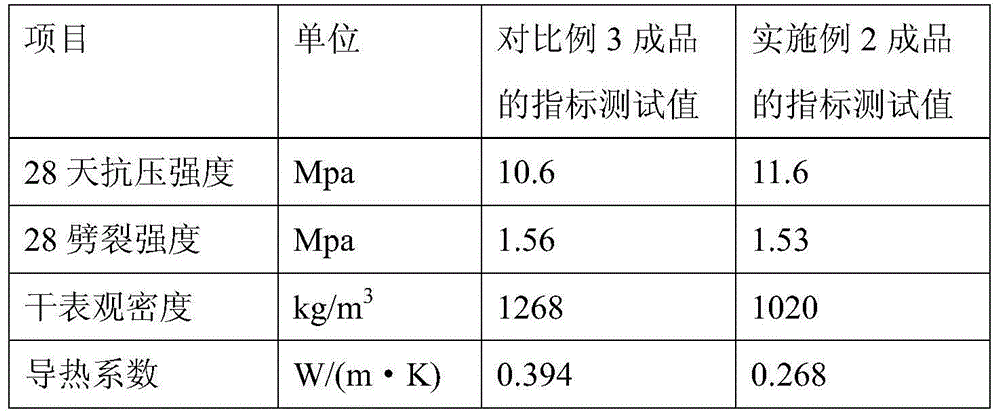

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

Method for producing self-insulation baked brick by using pure coal gangue

InactiveCN101672083ASmall granularityImprove plasticity indexBuilding componentsCeramicwareCoal wasteCoal gangue

The invention relates to a method for producing self-insulation baked bricks by using pure coal gangue, comprising the following components in weight percent: 65-85 coal gangue, 2-10 coal dust, 10-25coal residue or fly ash and 3-15 pore forming agent. The method comprises the following processing steps: firstly crushing raw materials in particles with particle size being less than 3mm, wherein particles less than 0.5mm accounts for more than 60%; adding water of hole forming agents such as sawdust, rice hulls or straw and the like and evenly stirring; and obtaining finished products by aging,rolling and refining, extrusion molding, drying and roasting. The invention has the advantages of comprehensively using raw materials such as coal gangue, fly ash, sawdust and the like which are absolute waste in industry and agriculture, thus having important realistic significance in protecting environment and plowland, using the processes of jaw crushing, hammer crushing and screening to further lower the particle size of the coal gangue raw material, thus being favor of improving the plasticity indexes of raw materials and controlling lime bloating phenomenon, and has the effects of lightweight, heat preservation, heat insulation and sound insulation, thus completely satisfying the requirement of saving 50% of energy for buildings.

Owner:沈正

Foam concrete function gradient composite board and preparing method thereof

ActiveCN105604239ALight weightWith heat insulationClimate change adaptationBuilding componentsFoam concreteThermal insulation

The invention discloses a foam concrete function gradient composite board and a preparing method thereof. The foam concrete function gradient composite board is a board body, comprising an upper protection layer and a lower protection layer as well as a thermal insulation layer between the two protection layers; two transverse ends of the board body are respectively provided with a groove and a tenon for connecting and positioning; a frame layer is paved in the thermal insulation layer and longitudinally penetrates through the thermal insulation layer and extends into the upper and lower protection layers to connect the upper and lower protection layers and the middle thermal insulation layer into a whole; the thermal insulation layer and the protection layers are formed by adopting continuous pouring; decoration layers are arranged at outer surfaces of the two protection layers; the frame layer is woven by FRB ribs. The foam concrete function gradient composite board prepared by the preparing method can be used for construct a novel building wall body and a roof surface system integrating multiple functions of fire prevention, thermal insulation, decoration and durability and has very wide popularization and application values.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

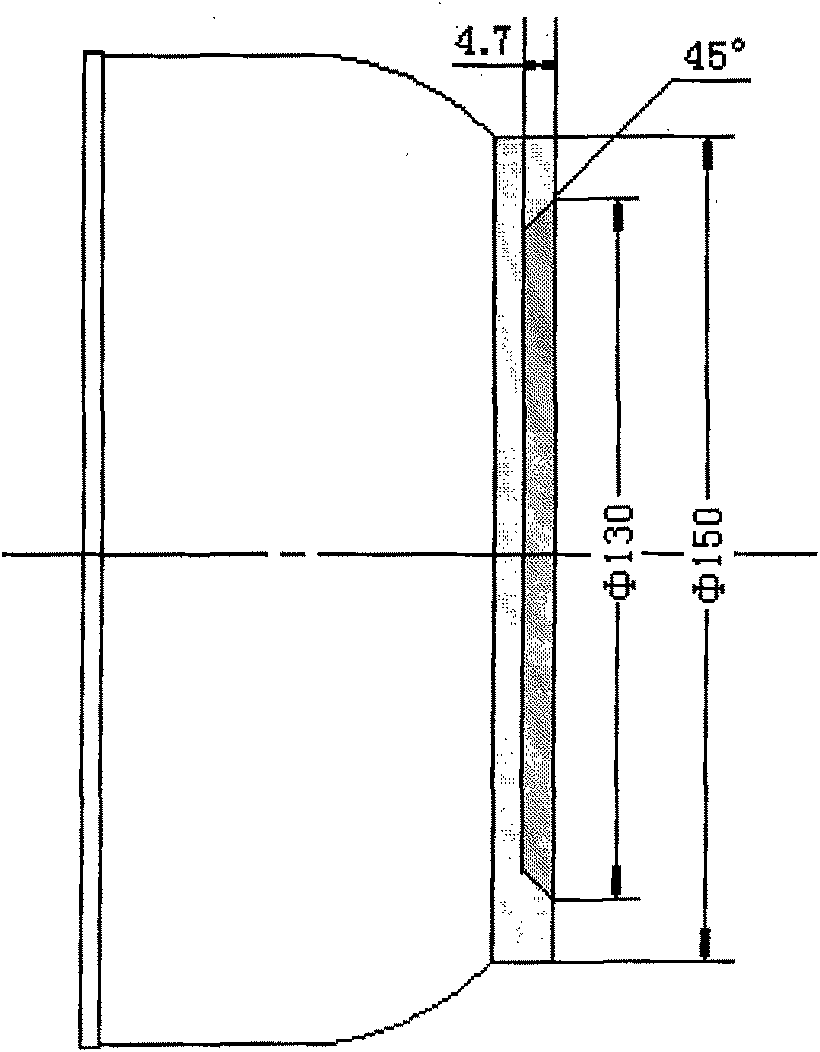

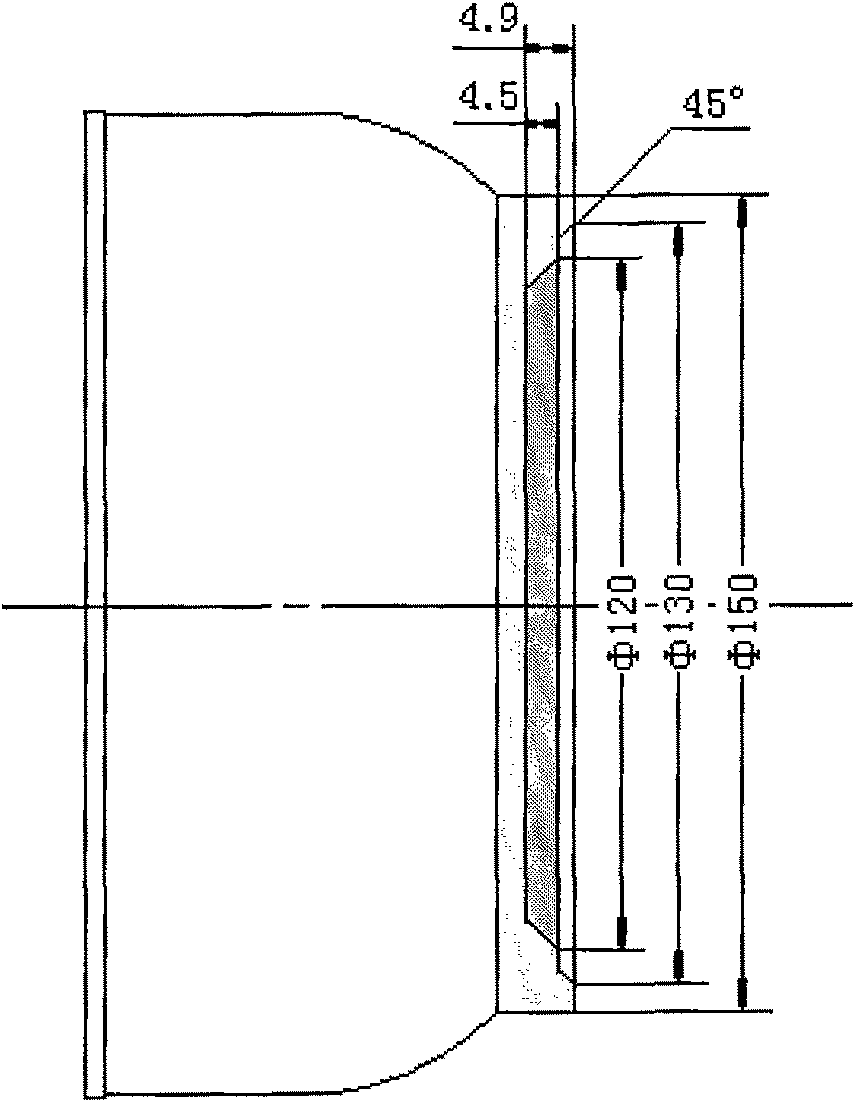

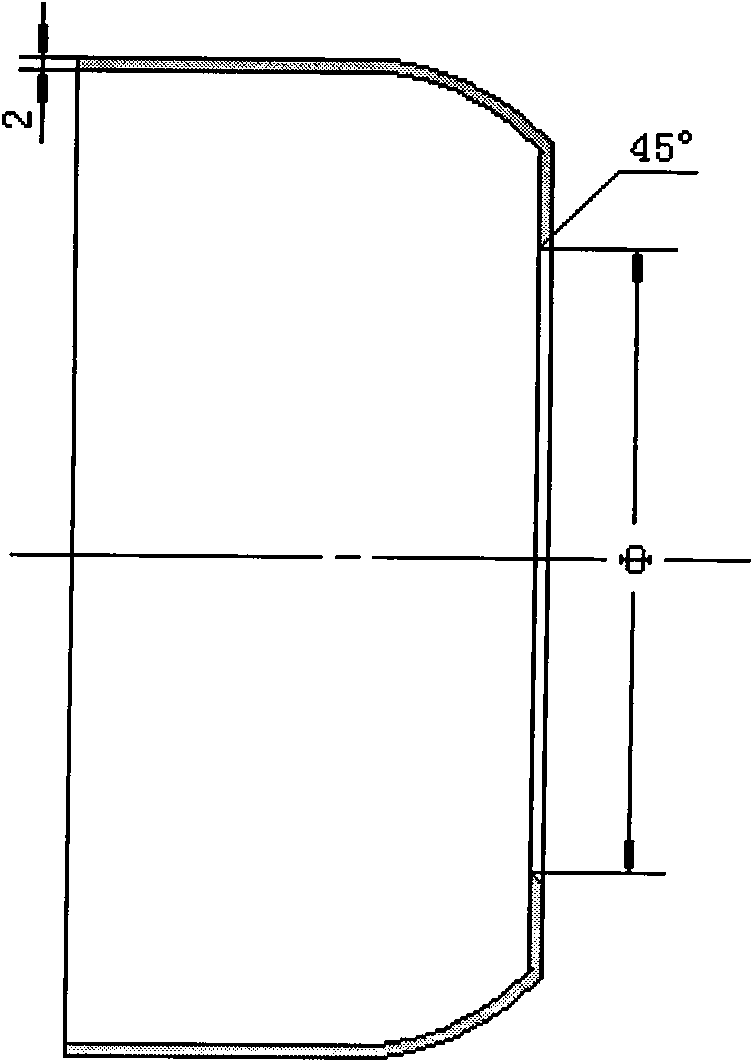

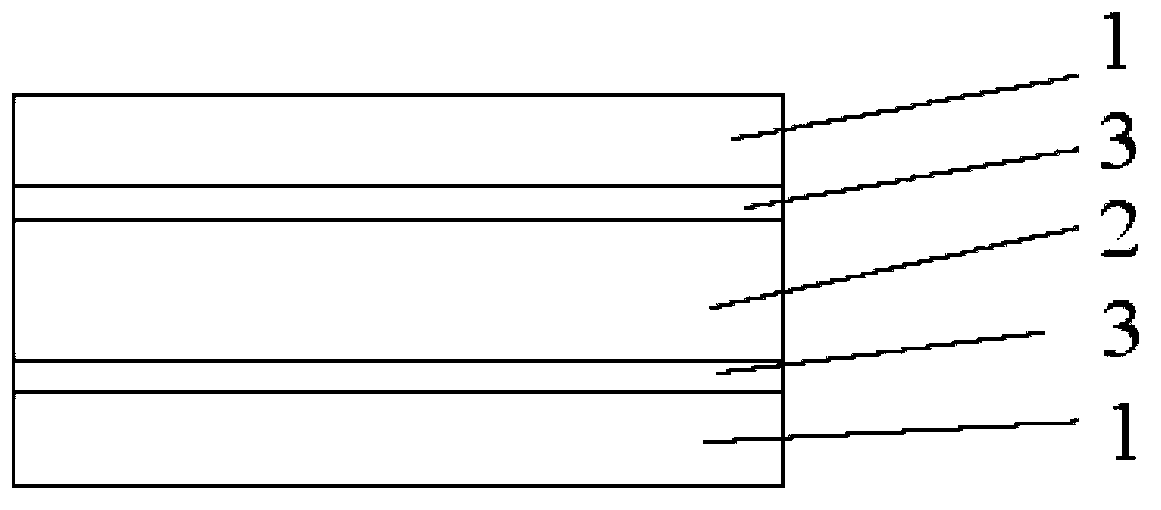

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

Lightweight ceramic material and process for manufacturing same

The present invention is one kind of light ceramic material and its production process, and belongs to building material technology. The ceramic material is produced with waste slag from polishing ceramic product, ceramic clay, high temperature sand and low temperature sand and through material compounding, crushing, forming, drying, sintering in kiln and packing. The produced ceramic material has the features of light weight, high strength, heat insulation, sound insulation, fireproofing, waterproofing and long service life. The present invention raises the utilization of ceramic raw material, reduces environmental pollution, and the produced ceramic material may be used in decorating outer and inner walls of building, as tunnel sound insulating material, house ceiling decoration, etc.

Owner:聂曼云

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

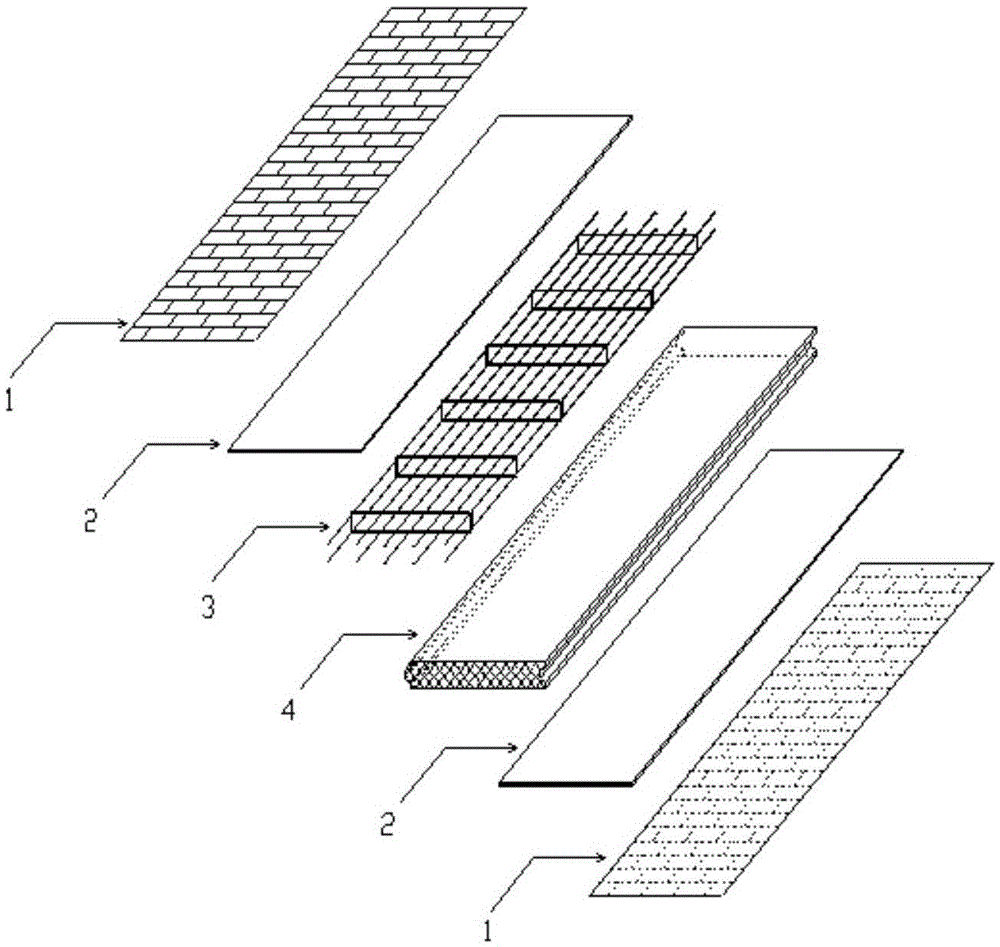

Light-weight and high-strength thermoplastic composite material sandwich board and production method thereof

InactiveCN103568396ALight in massLightweight and high-strength qualitySynthetic resin layered productsLaminationSandwich boardHoneycomb

The invention relates to a light-weight and high-strength thermoplastic composite material sandwich board and a production method thereof. The light-weight and high-strength thermoplastic composite material sandwich board comprises two panels and a sandwich layer, wherein the sandwich layer is fixedly arranged between the two panels. The preparation method comprises the following steps: putting the sandwich layer between the two panels; and sticking the two panels on the front and rear faces of the sandwich layer by a thermoplastic glue film through a hot pressing process and a cold pressing process to produce the thermoplastic composite material sandwich board. The panels are continuous fiber enhanced thermoplastic composite material boards and the sandwich layer is made of a honeycomb aluminum material. Compared with the prior art, the thermoplastic composite material sandwich board has the advantages of light weight, high strength, heat preservation, fireproof prevention, moisture prevention, corrosion prevention and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Wall fireproof insulating material and preparation method thereof

InactiveCN107162519ASimple recipeEasy to prepareClimate change adaptationHeat proofingPerliteMagnesium

The invention discloses a wall fireproof insulating material, comprising, by weight, 40-60 parts of cement, 30-40 parts of closed-cell expanded perlite, 20-30 parts of vitrified glass beads, 10-30 parts of glass fiber, 10-20 parts of sepiolite powder, 5-15 parts of a fiber, 15-25 parts of a silicate, 5-10 parts of mica powder, 2-8 parts of lightweight ceramsite, 5-15 parts of quartz sand, 3-8 parts of magnesium oxide, 5-15 parts of asbestos, 4-10 parts of heavy calcium carbonate, 3-10 parts of latex powder, 2-6 parts of a flame retardant, 1-5 parts of a mildew preventive, 3-8 parts of a foaming agent, and 60-80 parts of deionized water. The wall fireproof insulating material has simple formulation and is convenient to prepare, and has good fireproof and insulating properties.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Preparation of Foam Concrete by a Chemical Foaming Method

The invention discloses a chemical foaming method for preparing foamed concrete, which belongs to the technical field of building thermal insulation materials. The raw material composition and weight percentage of foam concrete are: cement 20-80wt%, ore powder 1-5wt%, fly ash 5-30wt%, foaming agent 1-6wt%, water 10-70wt%, modifier 0.2- 1.5wt%, fiber 0.2-1wt%, auxiliary material 1-8wt%. Its preparation method is to pour water into the container first, then put a certain amount of cement, ore powder, fly ash, and additives into the water, stir evenly with a stirrer, pour in foaming agent to mix and stir, and then quickly transfer After leaving the mixer, the foaming is completed within 30 minutes, and the strength is reached after 24 hours, and the formed foam concrete is obtained after 28 days of curing. The foamed concrete obtained by the invention has good water resistance, low thermal conductivity, low dry density, high strength, strong durability, simple formula and convenient construction; it can partially replace polystyrene board, extruded plastic board and rubber powder in the external wall insulation system Polystyrene particles and other organic insulation materials.

Owner:北京翰高兄弟科技发展有限公司

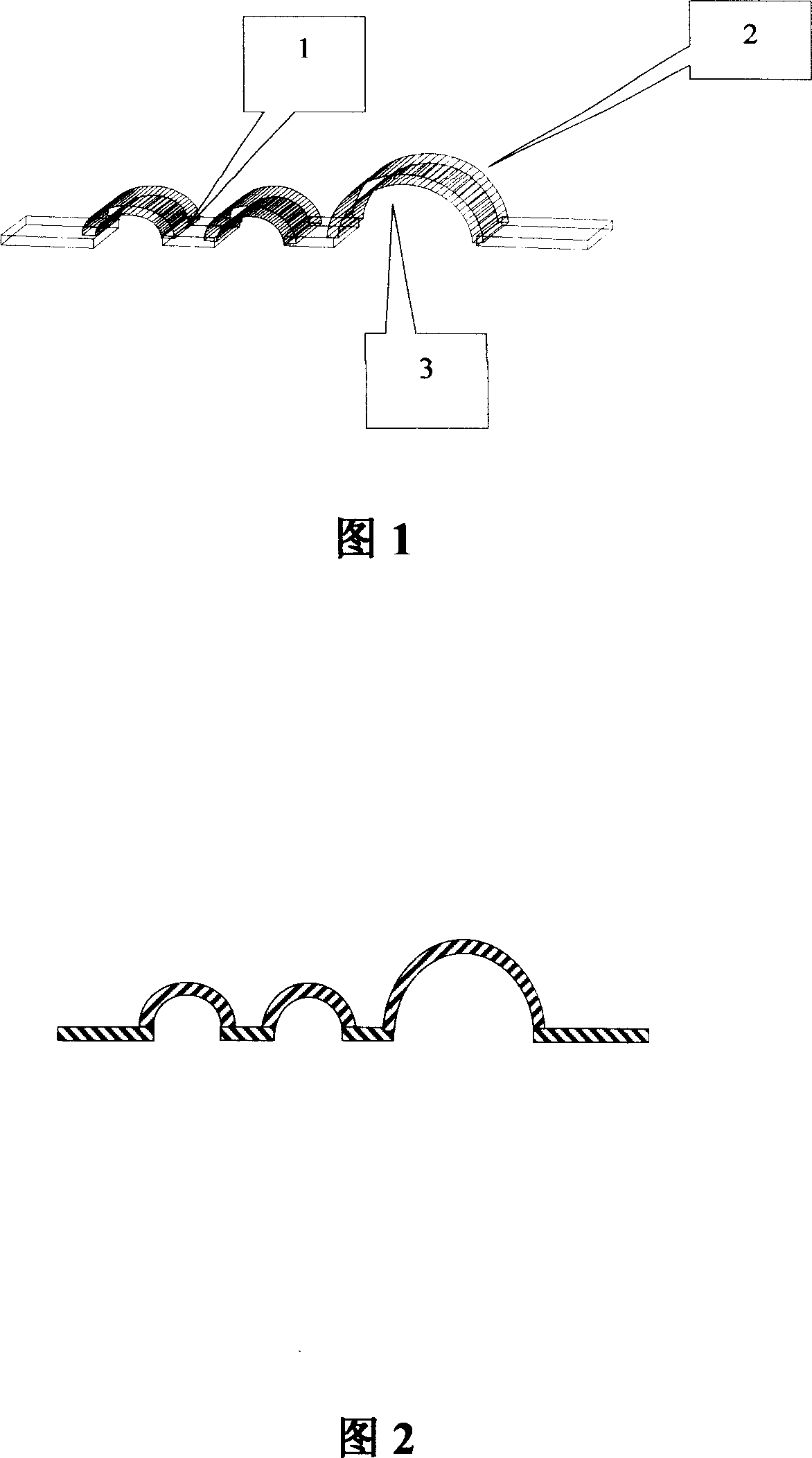

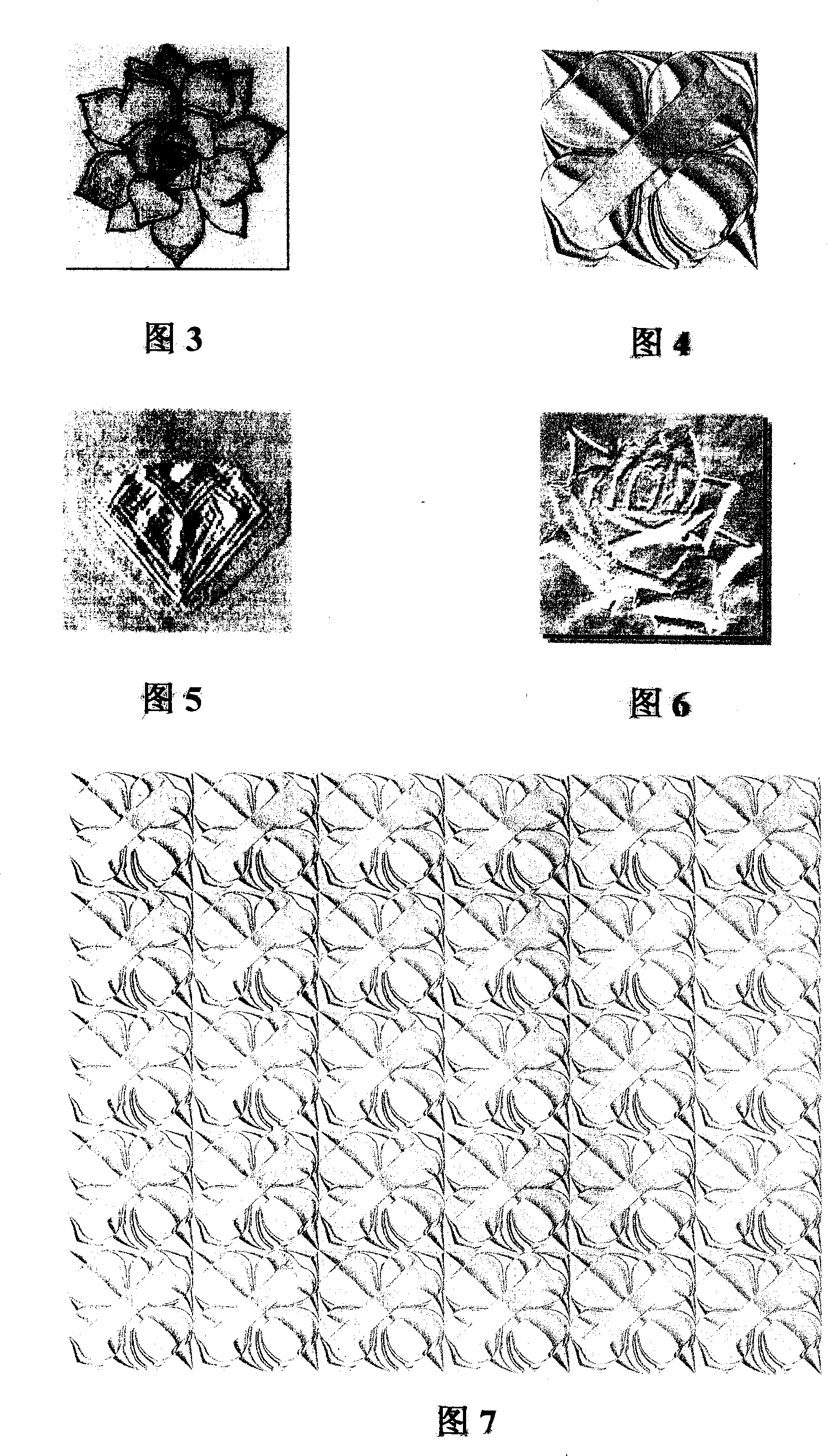

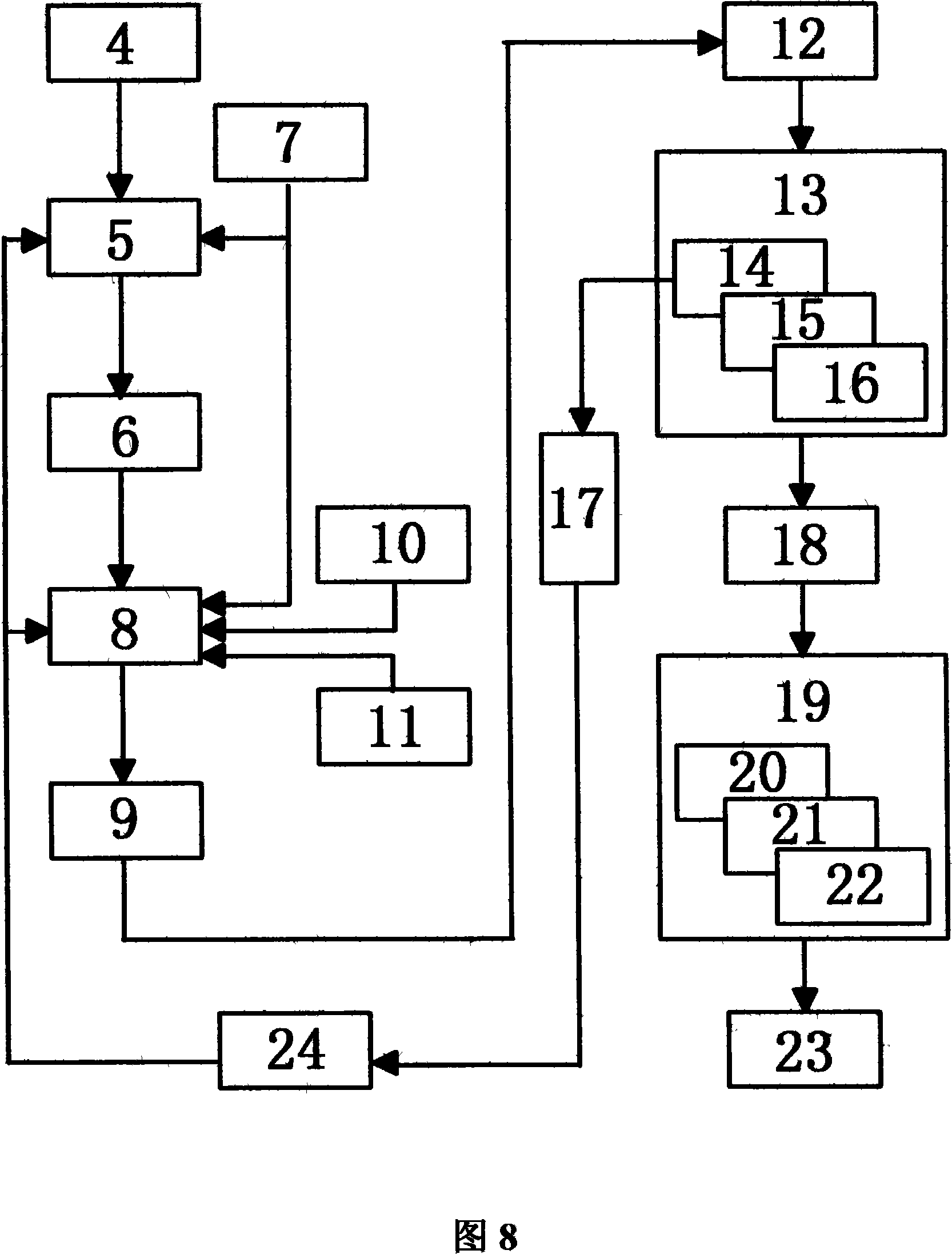

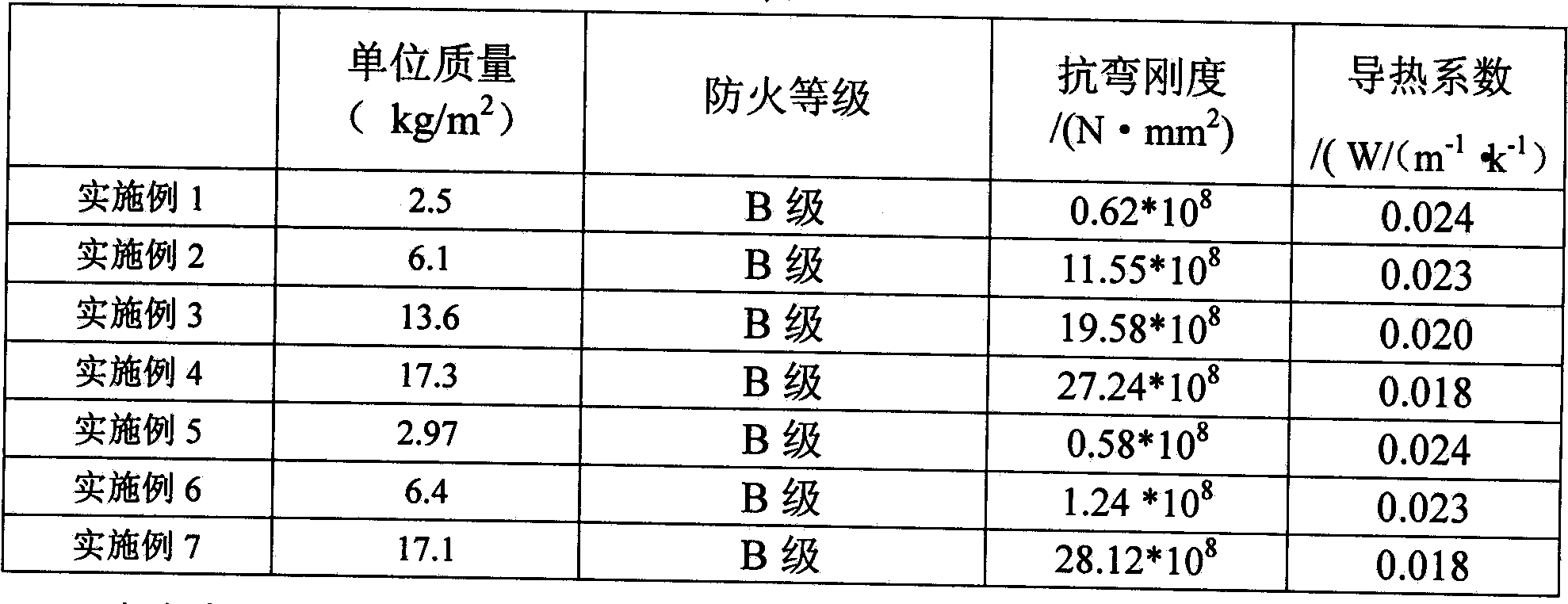

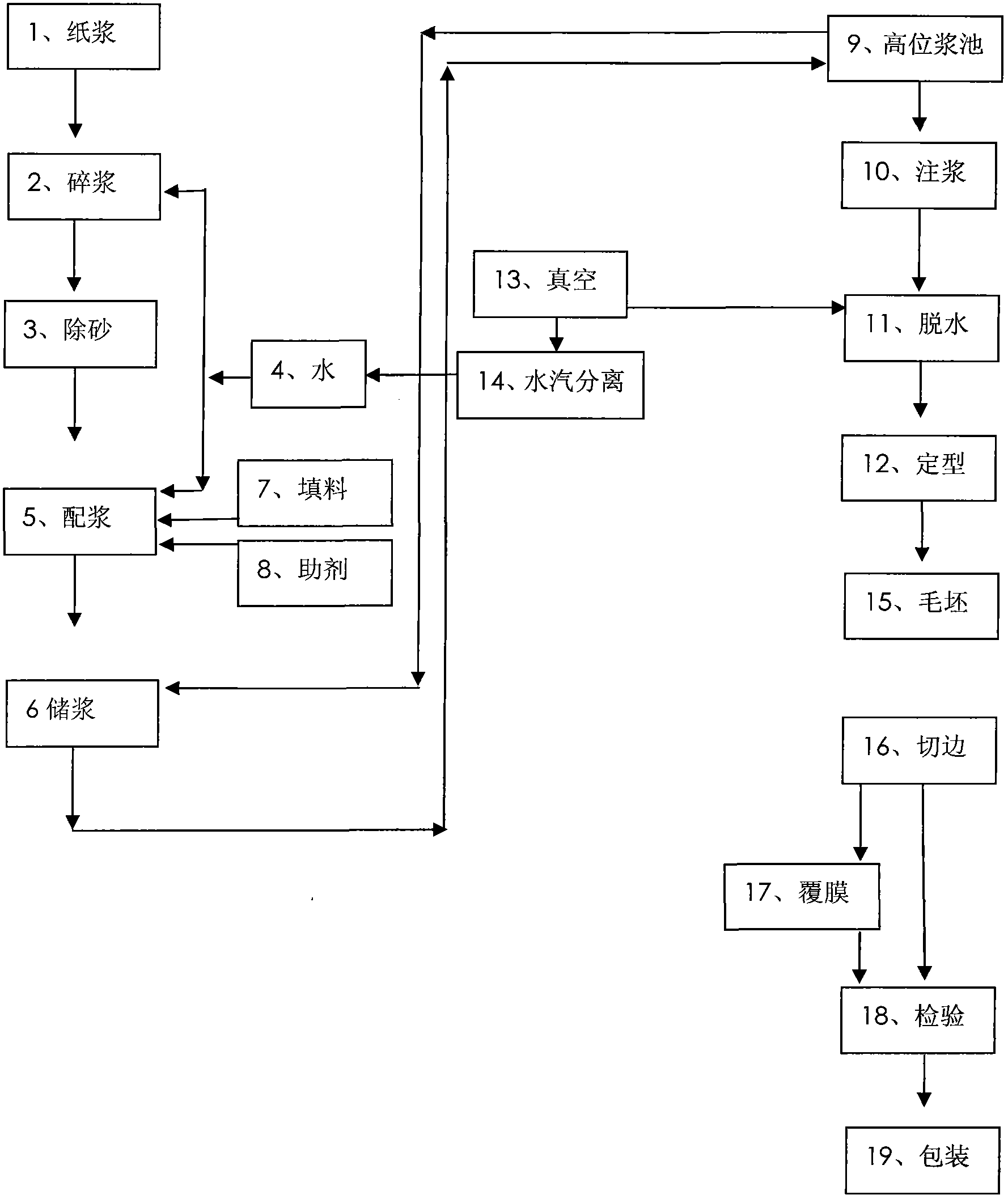

Three-dimensional pulp moulding decorating plate as well as manufacturing method and application thereof

ActiveCN102691388APromote environmental protectionFlame retardantCovering/liningsThree-dimensional effectsPulp and paper industryMolded pulp

The invention relates to a three-dimensional pulp moulding decorating plate as well as a manufacturing method thereof by using a common pulp moulding device and a practical application thereof in the field of decoration. The height of the three-dimensional protruding part of the three-dimensional pulp moulding decorating plate ranges from 5mm to 150mm and the ordinary wallpaper is not as high as the protruding part. The three-dimensional pulp moulding decorating plate can be spliced and cut, and the wallpaper with the same specification and different patterns can be spliced into more patterns.

Owner:BEIJING TONGLANHAI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com