Foam concrete function gradient composite board and preparing method thereof

A technology of foam concrete and functional gradient, applied in building components, climate change adaptation, construction, etc., can solve the problems of complex construction, large ice expansion stress, slag drop, etc., and achieve wide application value, good waterproof performance, and save construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

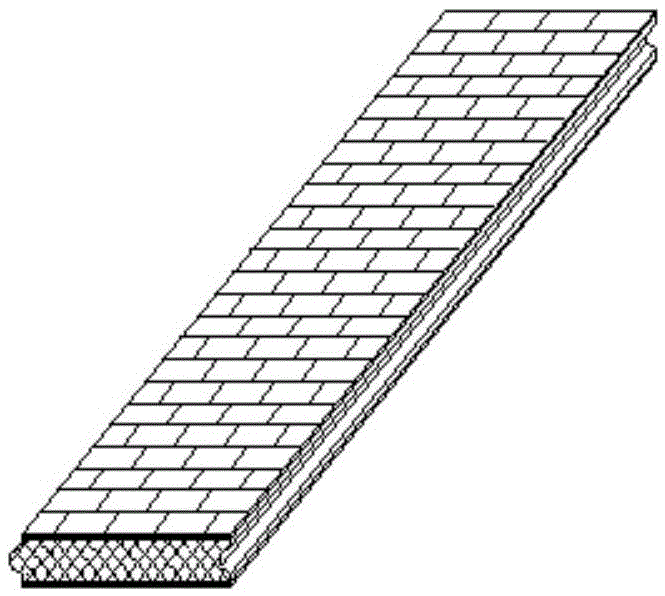

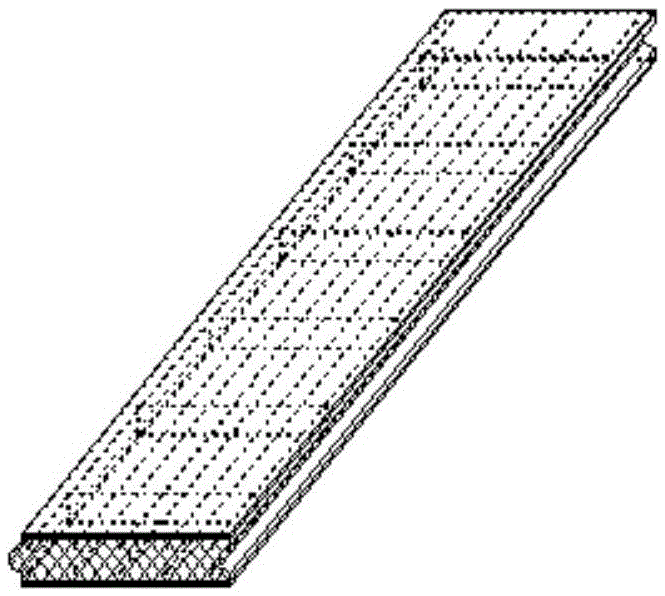

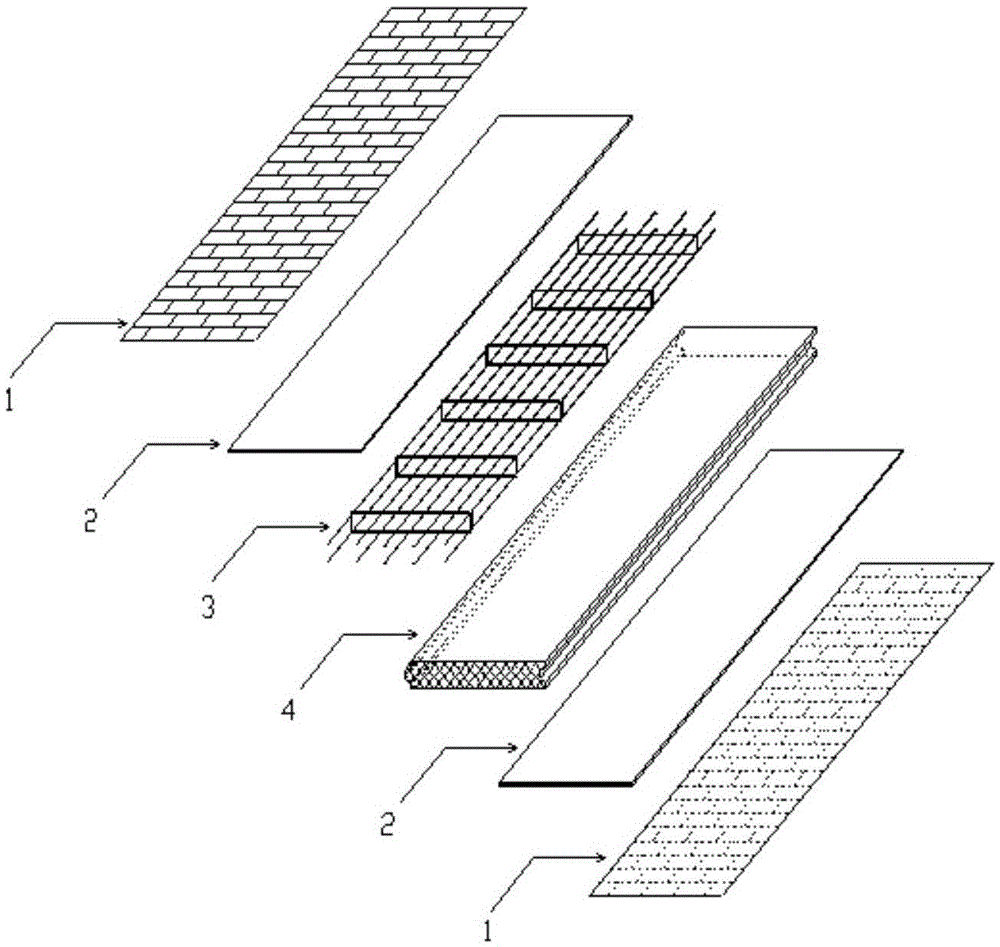

[0093] Referring to the accompanying drawings, a foam concrete functionally graded composite board is a board body, the board body includes two upper and lower protective layers 2 and an insulating layer 4 arranged between the two protective layers 2, and the horizontal two sides of the board body The ends are respectively provided with grooves and tenons for connection and positioning;

[0094] A skeleton layer 3 is laid inside the thermal insulation layer 4, and the skeleton layer 3 runs through the thermal insulation layer 4 longitudinally and extends into the upper and lower protective layers 2, so as to connect the upper and lower protective layers 2 with the middle thermal insulation layer 4 as a whole. ;

[0095] The outer surfaces of the two protective layers 2 are provided with a decorative layer 1 .

[0096] The protective layer is made of waterproof anti-crack mortar, and the waterproof anti-crack mortar includes 45g of Portland cement, 55g of tuff rock powder, 30g...

Embodiment 2

[0116] The thickness of the plate is 90mm, the thickness of the protective layer is 10mm, the thickness of the thermal insulation layer is 70mm, and the thickness of the skeleton layer is 80mm.

[0117] The protective layer is made of waterproof and anti-crack mortar, which includes 65g of Portland cement, 25g of tuff rock powder, and 36g of quartz sand (mixed from 18g of 24-50 mesh and 18g of 50-100 mesh quartz sand) ), 2g waterproof anti-cracking agent (made by mixing 1g6mm long polyvinyl alcohol fiber with 1g silane hydrophobic powder), 0.1g hydroxypropyl methylcellulose ether, 2g polycarboxylate water reducer and 27g water .

[0118] The insulation layer is made of foam concrete, and the foam concrete is made of 85g Portland cement, 15g tuff rock powder, 0.3g two-way coagulation regulator (made by mixing 0.2g tartaric acid and 0.1g sodium silicate), 1g polycarboxylic acid It is water reducer, 30g water and 0.2g HTW-I composite blowing agent.

[0119] The preparation meth...

Embodiment 3

[0138] The thickness of the plate is 120mm, the thickness of the protective layer is 25mm, the thickness of the thermal insulation layer is 70mm, and the thickness of the skeleton layer is 80mm.

[0139] The protective layer is made of waterproof and anti-crack mortar, which includes 90g of Portland cement, 10g of tuff rock powder, and 46g of quartz sand (mixed from 23g of 24-50 mesh and 23g of 50-100 mesh quartz sand) ), 3g waterproof anti-cracking agent (made by mixing 1.5g 6mm polyvinyl alcohol fiber with 1.5g silane hydrophobic powder), 0.02g hydroxypropyl methylcellulose ether, 3g polycarboxylate water reducer and 35g water composition.

[0140] The insulation layer is made of foam concrete, and the foam concrete is made of 100g Portland cement, 0.1g tuff rock powder, 0.3g two-way coagulation regulator (made by mixing 0.2g tartaric acid and 0.1g sodium silicate), 3g polycarboxylate reducing agent Water agent, 60g water and 0.8gHTW-I type composite blowing agent.

[0141...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com