Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

931 results about "Thermal printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

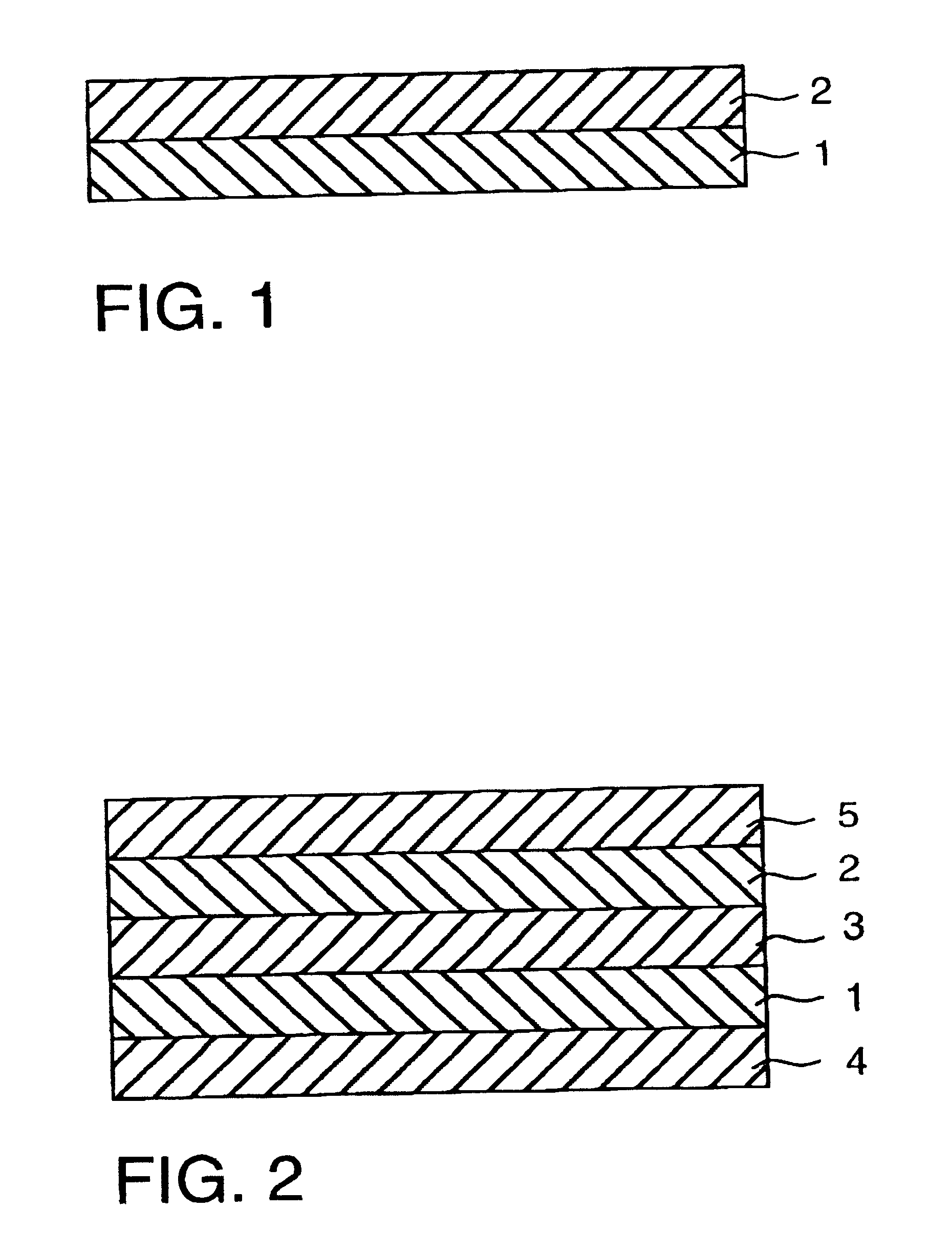

Thermal printing (or direct thermal printing) is a digital printing process which produces a printed image by selectively heating coated thermochromic paper, or thermal paper as it is commonly known, when the paper passes over the thermal print head. The coating turns black in the areas where it is heated, producing an image. Two-color direct thermal printers can print both black and an additional color (often red) by applying heat at two different temperatures.

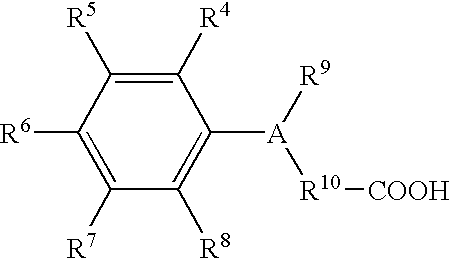

High speed negative-working thermal printing plates

Negative working thermally imageable elements useful as lithographic printing plate precursors and methods for their use are disclosed. The elements have a substrate, a layer of imageable composition over the substrate, and, optionally, an overcoat layer over the layer of imageable composition. The imageable composition has an allyl-functional polymeric binder. Optimum resolution and on-press performance can be attained without a post-exposure bake. The elements do not require a post-exposure bake and can be used in on-press development applications.

Owner:KODAK POLYCHROME GRAPHICS

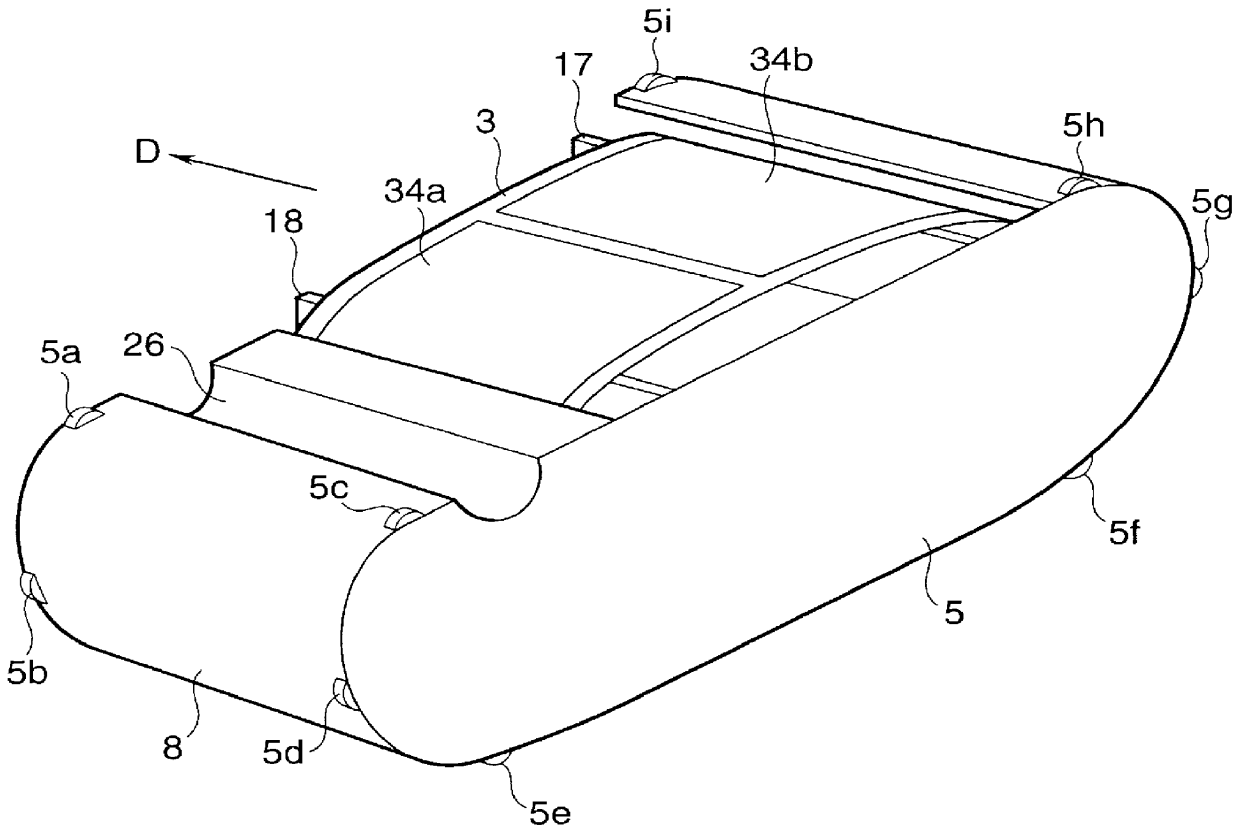

Cassette for holding ink ribbon and print paper therein and printer incorporating the cassette therein

An ink ribbon-print paper cassette is used in a thermal printer. A paper tray accommodates a stack of single sheets of print paper. The paper tray has an opening through which the print paper is fed into a paper path on a sheet-by-sheet basis. An ink ribbon for thermal printing runs over a thermal head located adjacent the paper tray. A housing accommodates the paper tray, thermal head, and ink ribbon therein. When the cassette is loaded into the thermal printer, the outer surface of the cassette and an inner wall of the thermal printer cooperate to form a paper path therebetween through which each of the sheets of print paper is advanced from the paper tray to the thermal head.

Owner:OKI DATA CORP

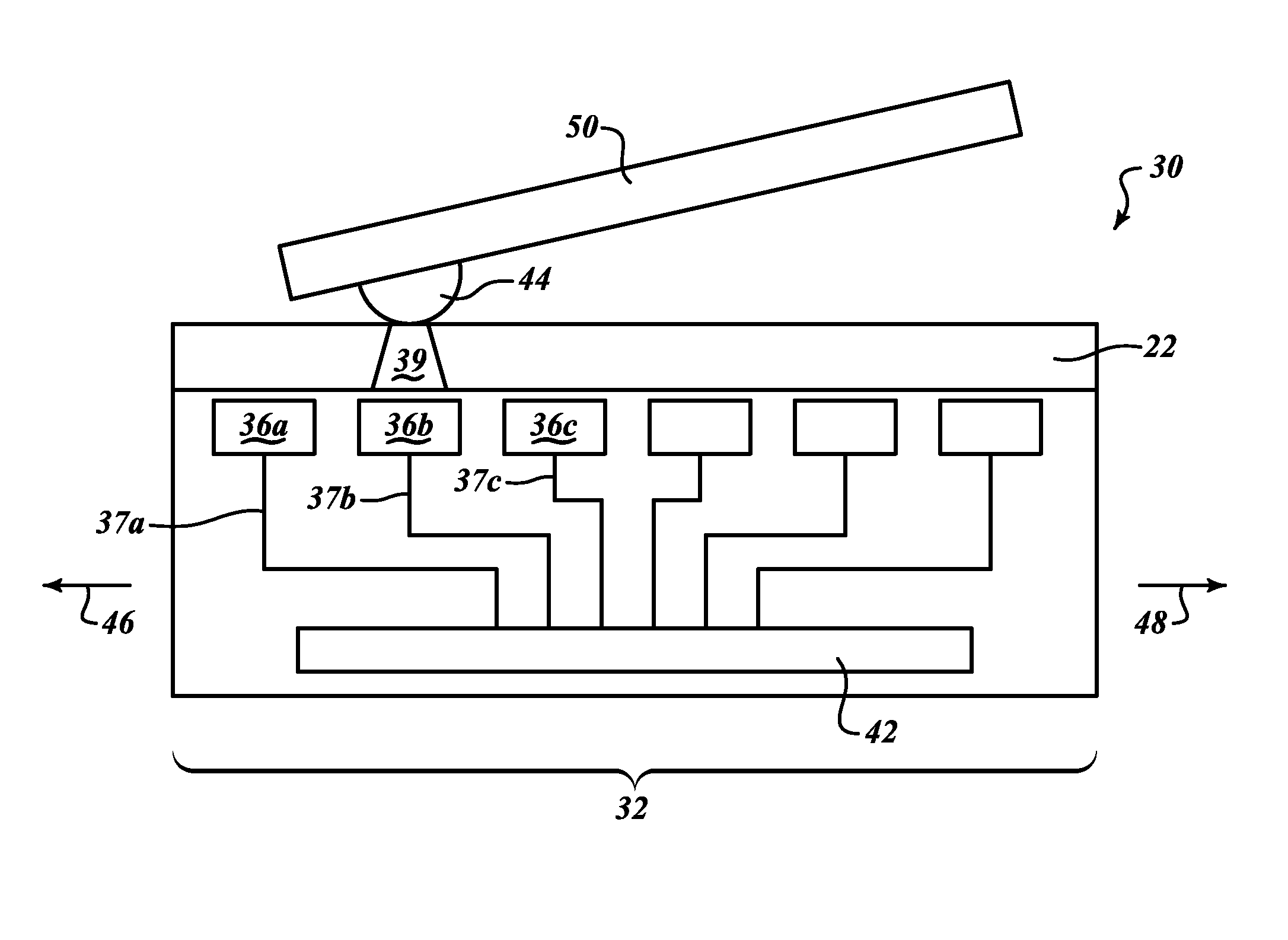

Phase change memory devices, method for encoding, and methods for storing data

ActiveUS9093141B2Electrical apparatusVariable resistance carrier recordingThermal energyPhase-change memory

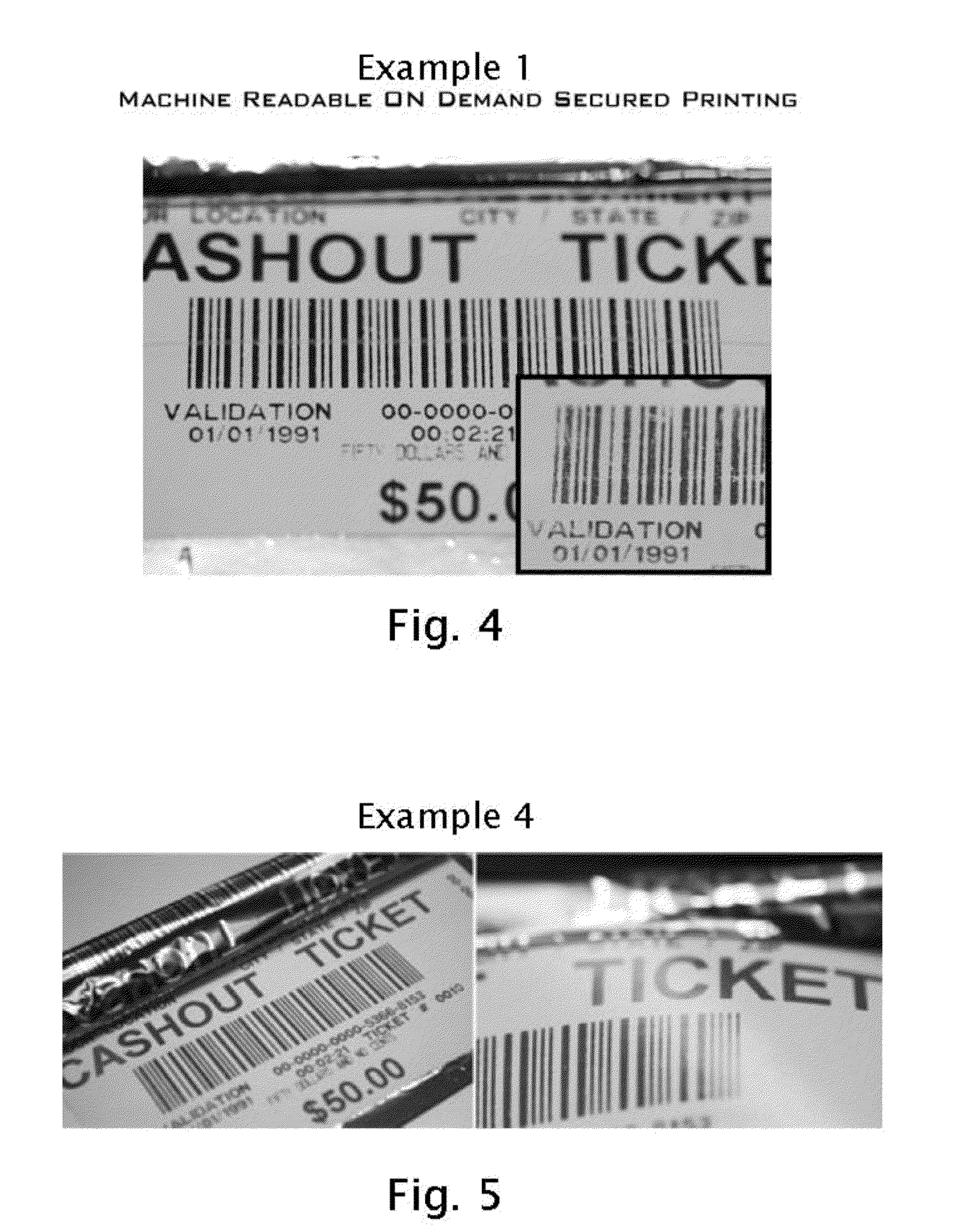

Phase change memory cells including a phase change media can be encoded using a source of energy that is not integral with the memory cell. External sources of energy include thermal heads, such as those used in direct thermal printing or thermal transfer printing and sources of electromagnetic radiation, such as lasers. Such types of phase change memory devices can be associated with substrates that include thermochromic materials or are suitable for thermal transfer printing so that the memory cells can be encoded and print media applied to the substrate using the same source of thermal energy.

Owner:INTERMEC IP CORP

Rare-earth oxide thermal spray coated articles and powders for thermal spraying

InactiveUS6852433B2Improve uniformityMinimal warpingMolten spray coatingNatural mineral layered productsThermal sprayingRare earth

A rare-earth oxide thermal spray coated article comprising a substrate and a coating layer formed by thermally spraying a rare-earth oxide thermal spraying powder onto a surface of the substrate, said coating layer being of a gray or black color having, in the L*a*b* color space, an L* value of up to 50, an a value of −3.0 to +3.0, and a b* value of −3.0 to +3.0.

Owner:SHIN ETSU CHEM IND CO LTD

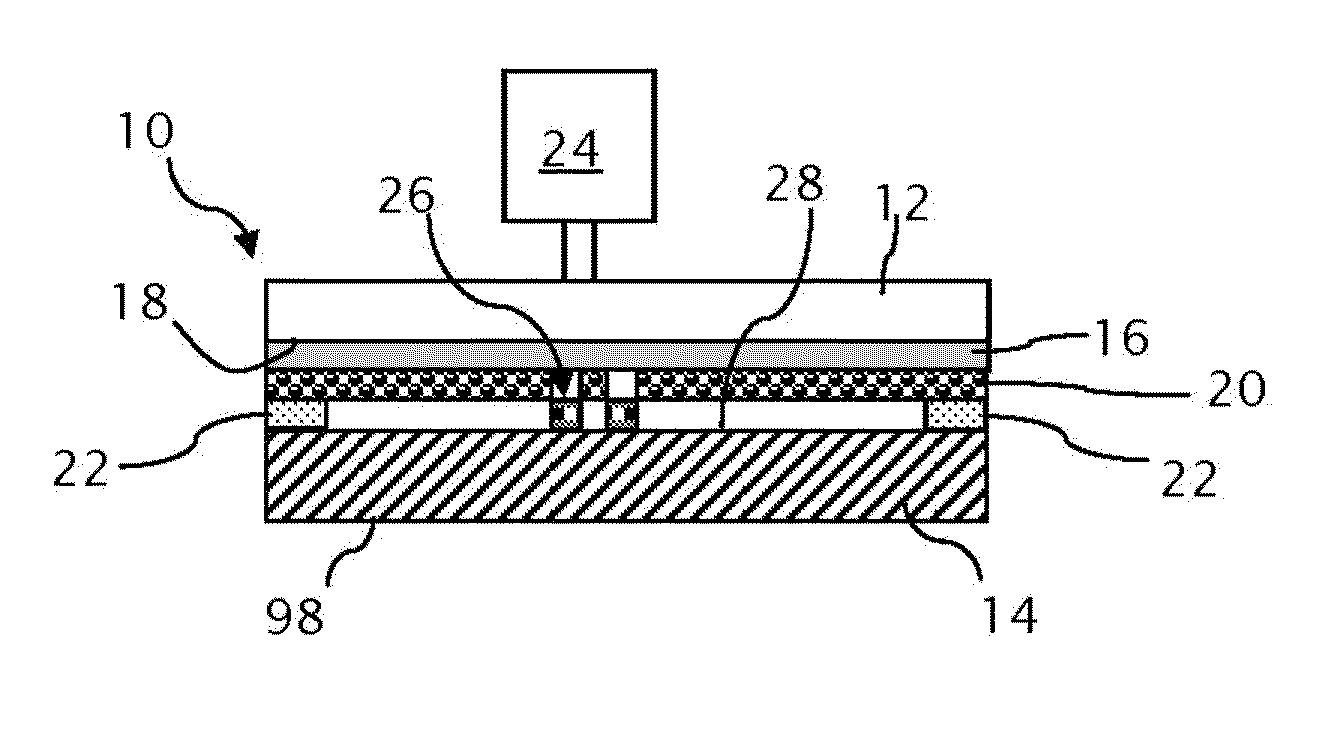

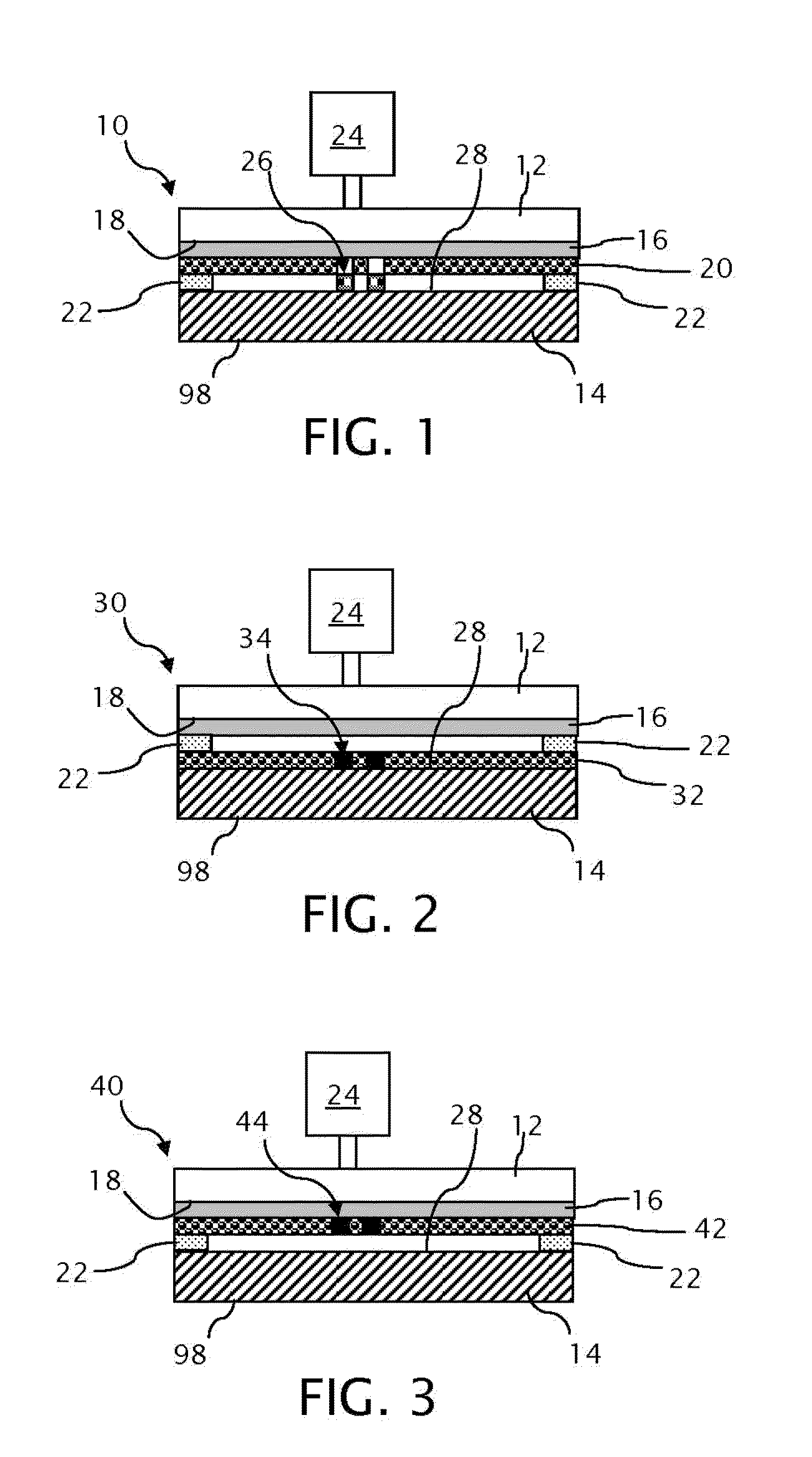

On-demand printable construct

ActiveUS20120149561A1Enhanced interactive responseAvoid contactBoard gamesPattern printingEngineeringThermal printing

Owner:WS PACKAGING GROUP

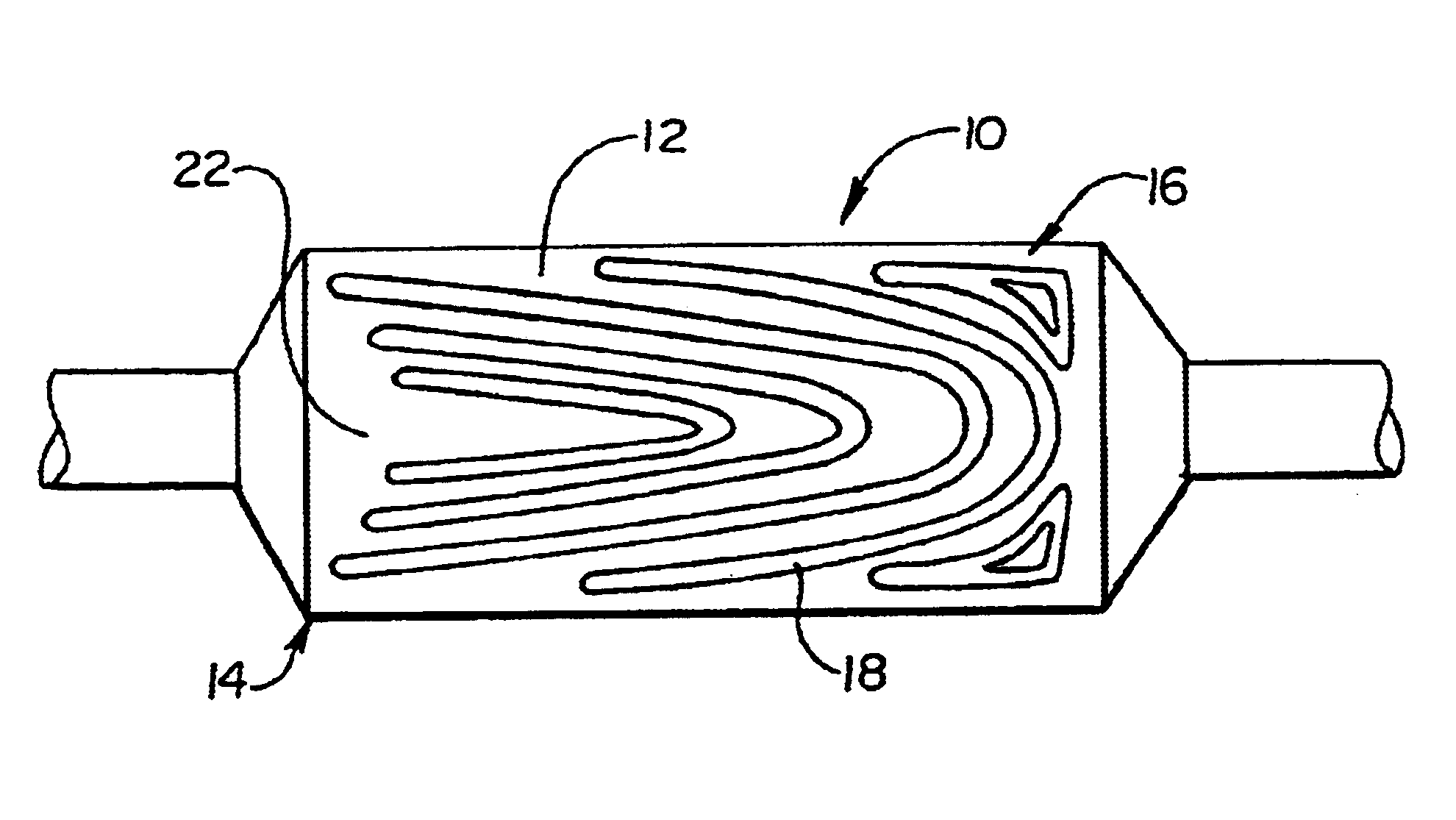

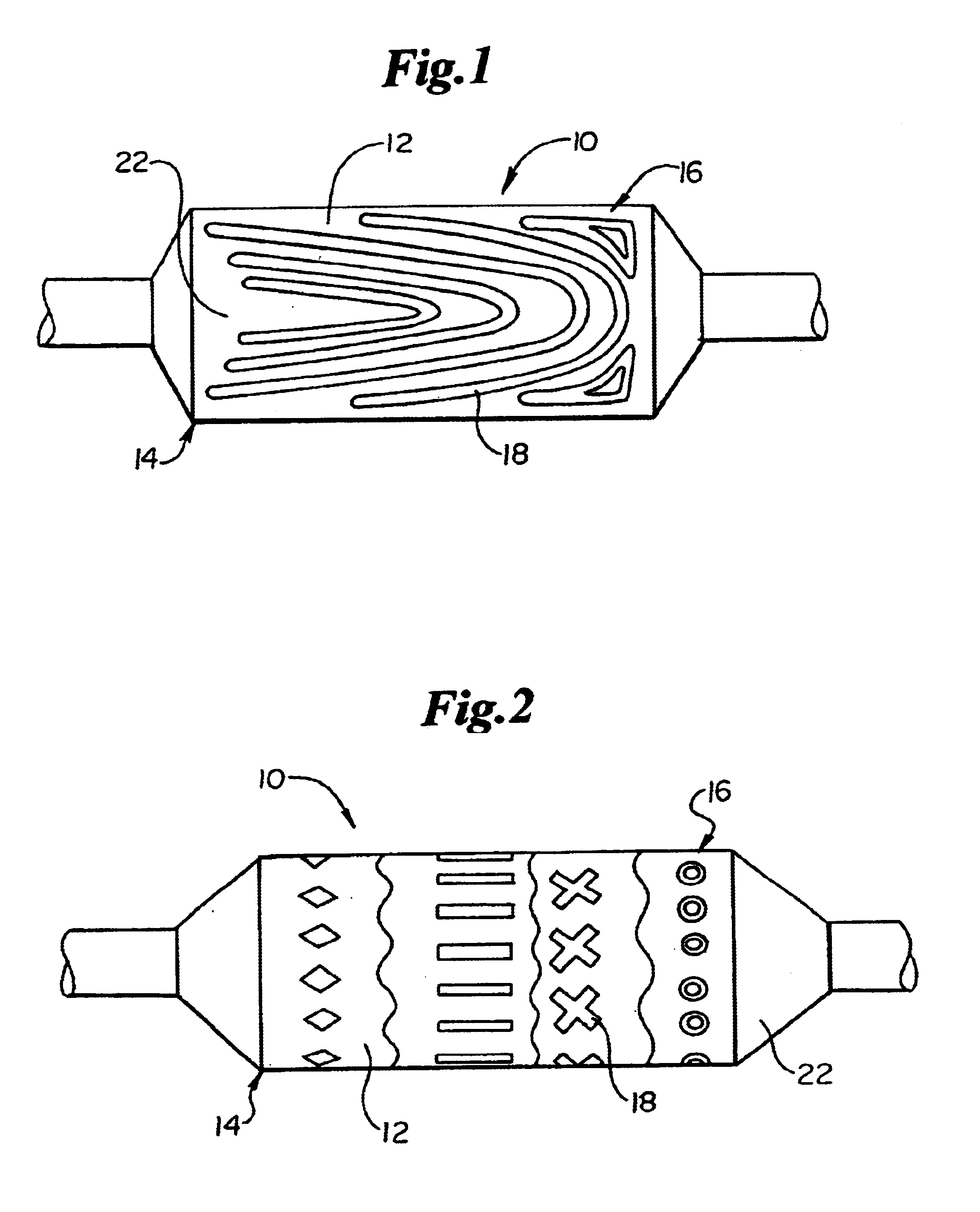

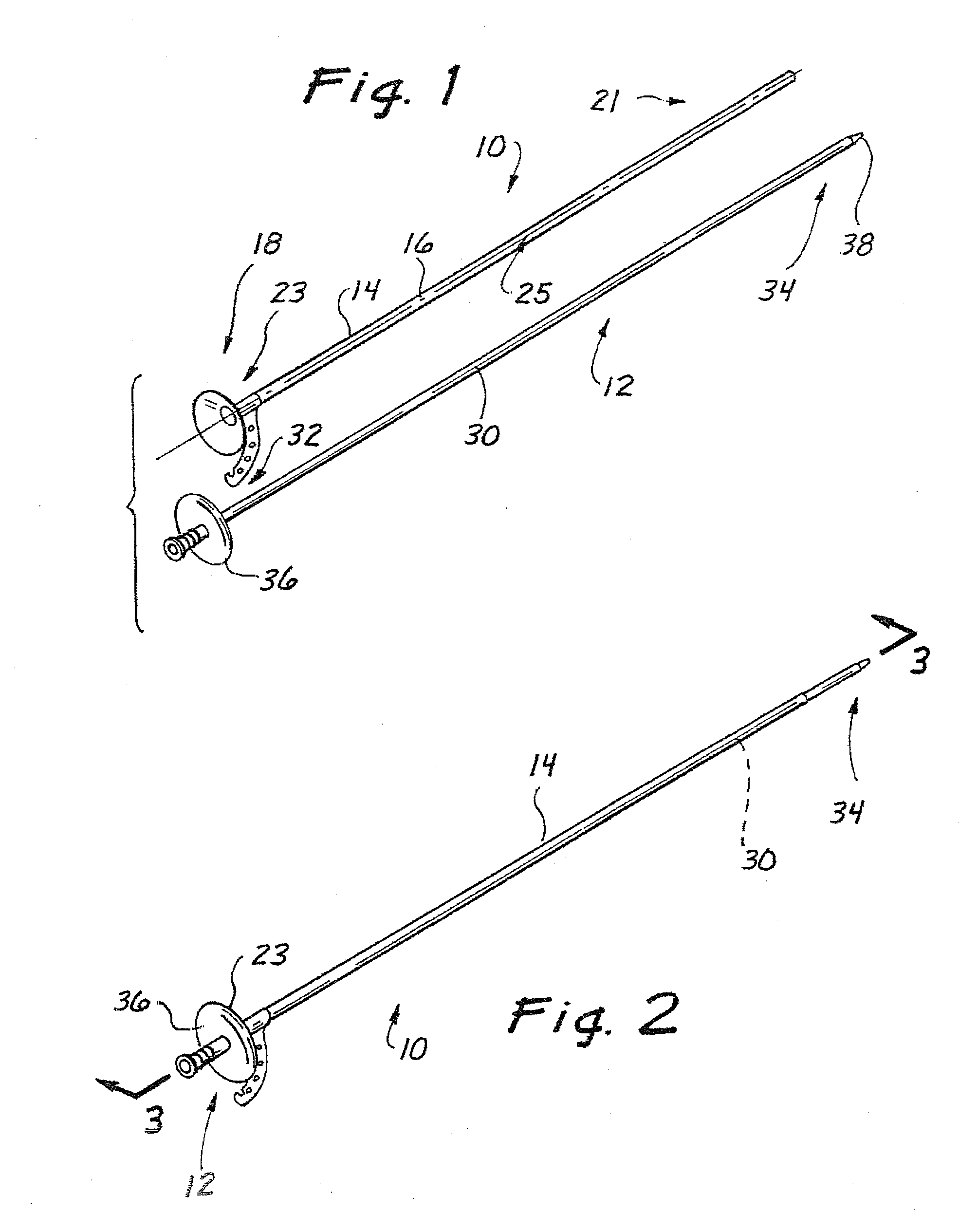

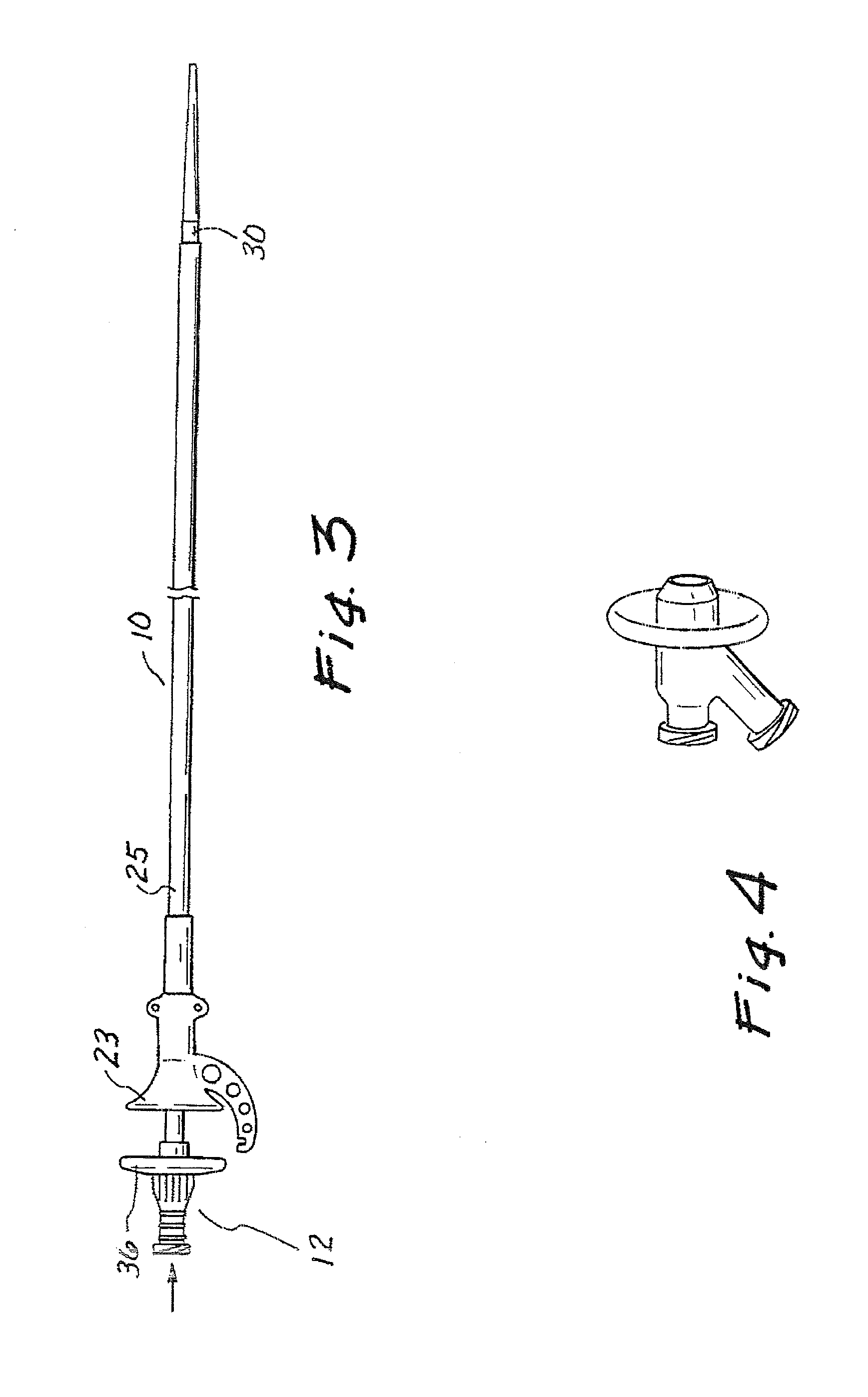

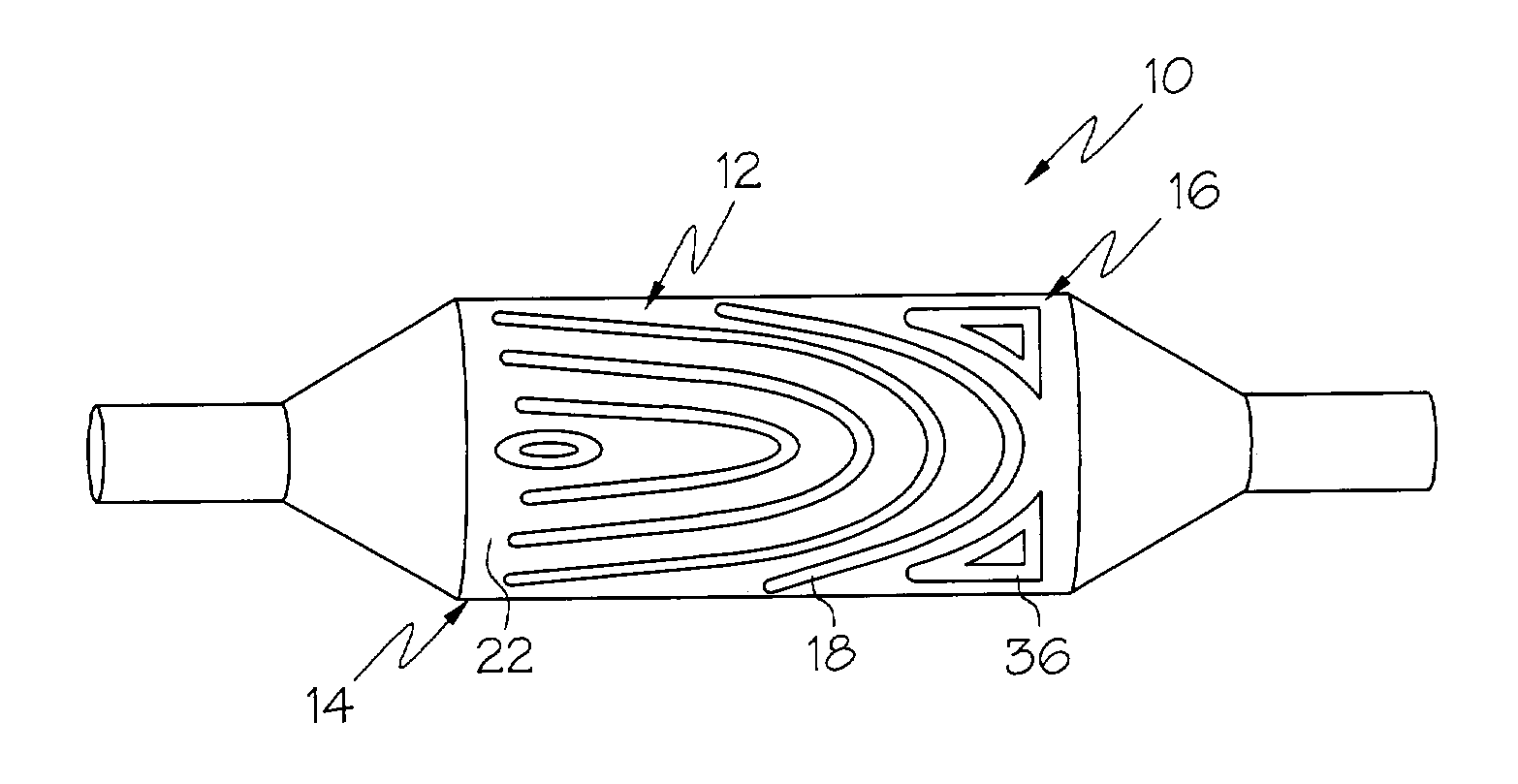

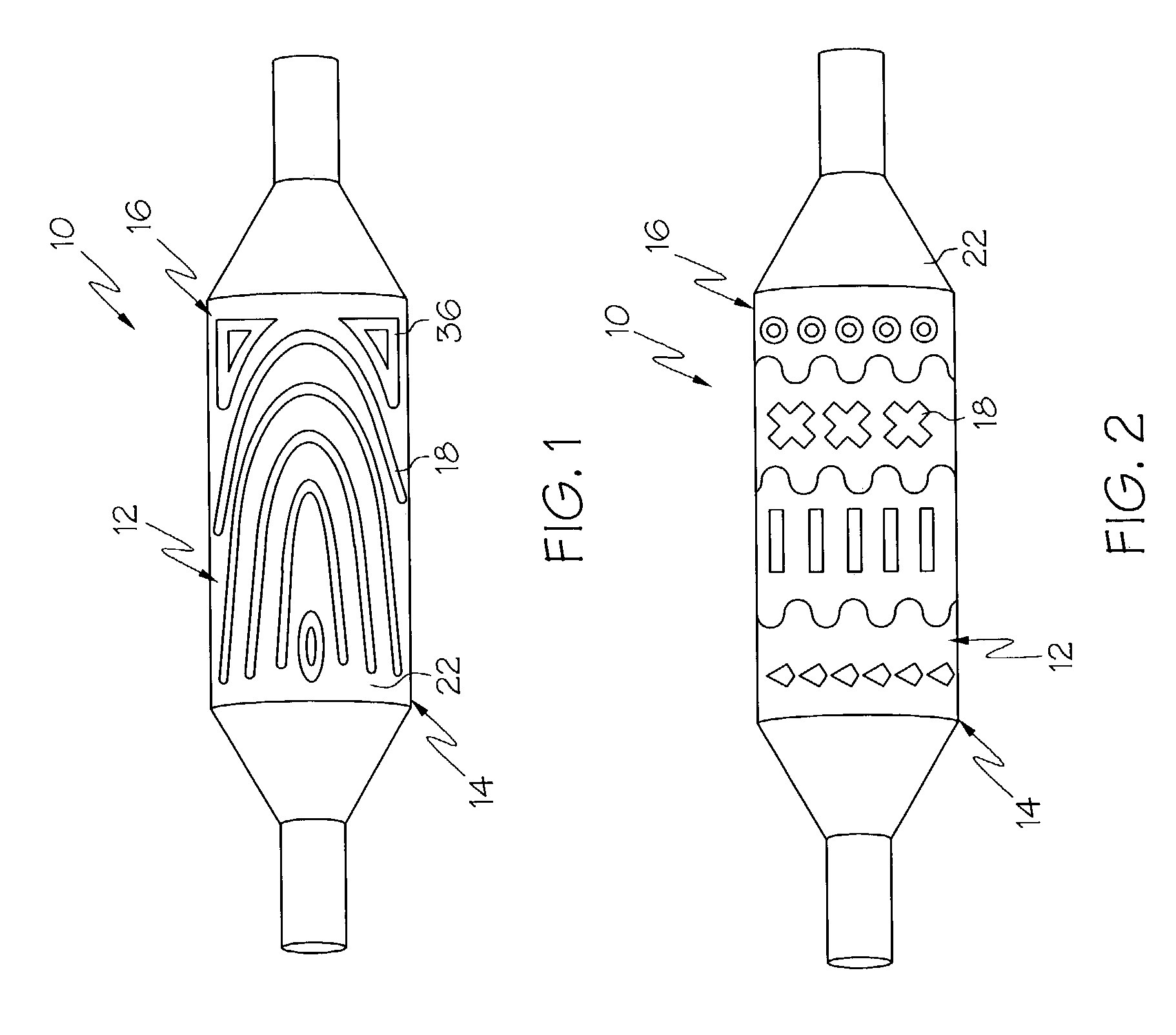

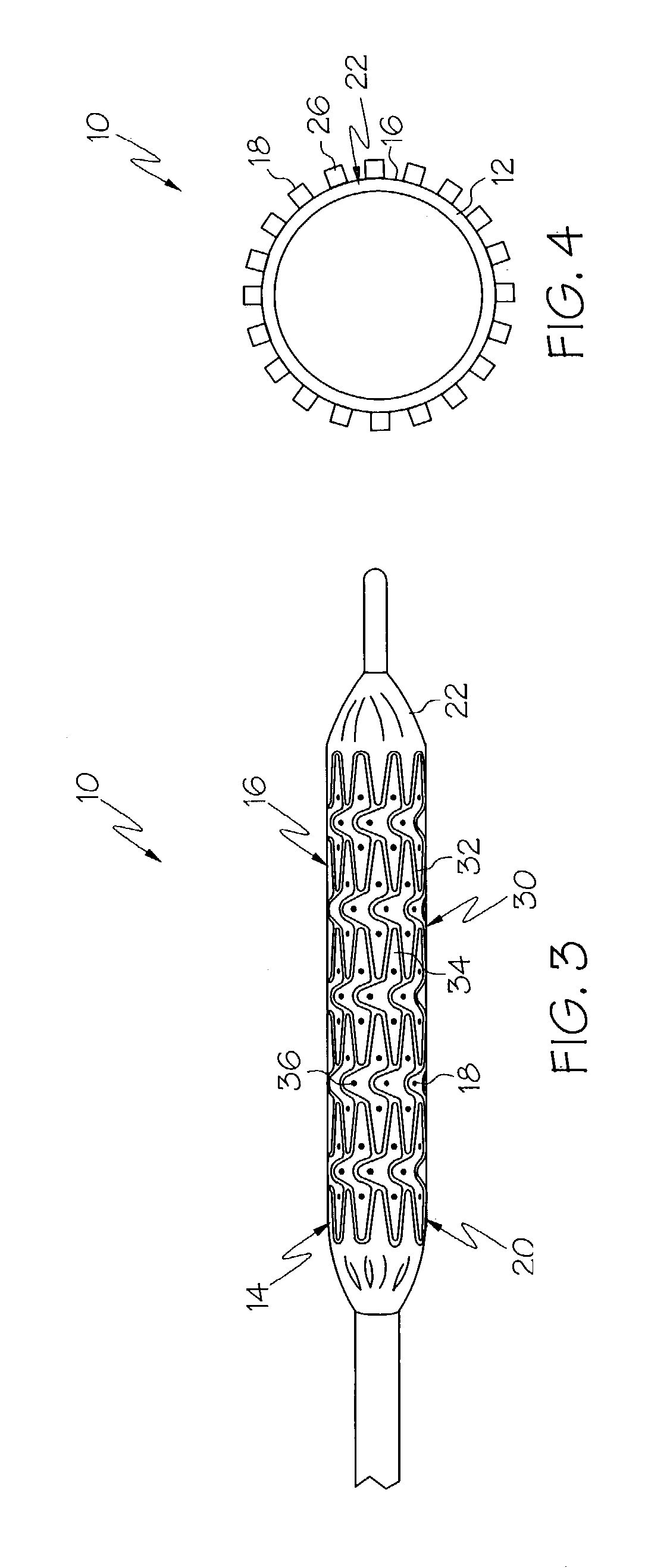

Fiber pattern printing

InactiveUS6841213B2Improved stent retaining characteristicHelp positioningSurgeryPretreated surfacesFiberSpray coating

A substantially tubular member comprises a body. The body is constructed from a first material and has an external surface. At least a portion of the external surface has a predetermined pattern of a second material deposited thereon. The predetermined pattern of the second material is deposited on the at least a portion of the external surface by one or more printing processes such as solution coating, spray coating, thermal printing, piezo jet printing, contact printing and any combination thereof.

Owner:BOSTON SCI SCIMED INC

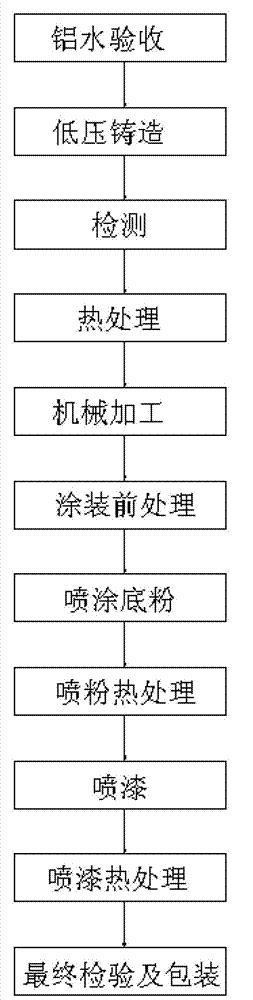

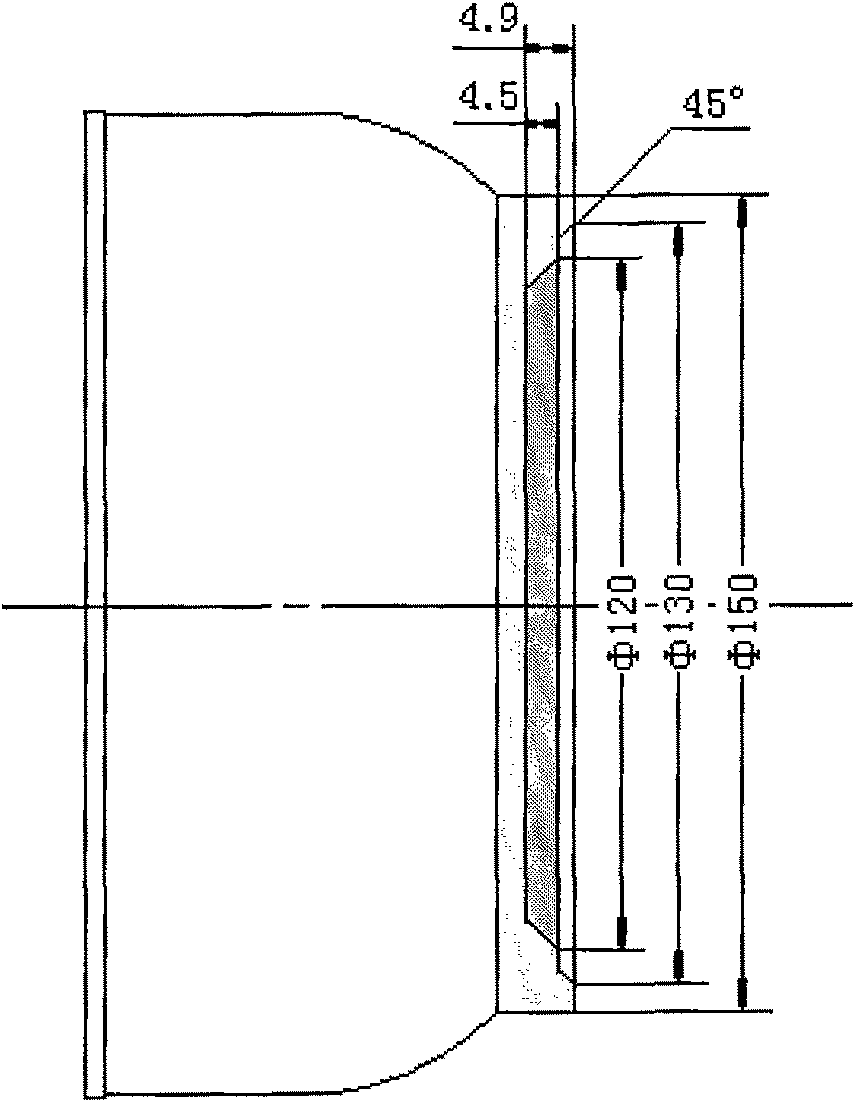

Manufacturing method for aluminum alloy automobile hub

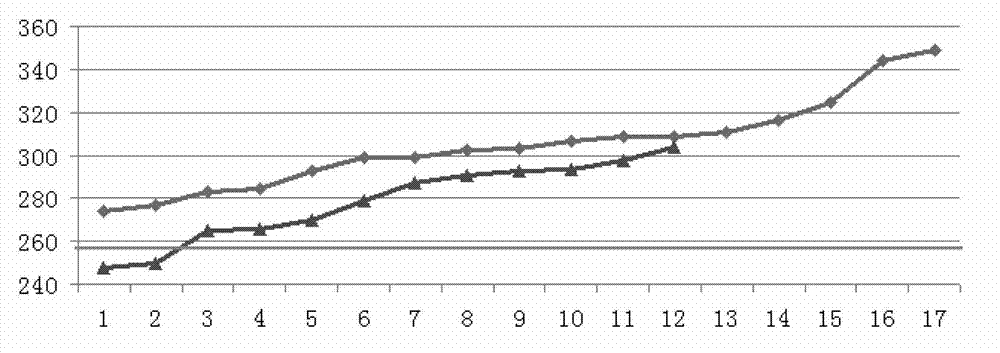

InactiveCN103008202AIncrease productivityReduce processing timeHubsPretreated surfacesProperty valueThermal printing

The invention relates to a manufacturing method for an aluminum alloy automobile hub, which comprises the following steps: (1) checking and accepting molten aluminum; (2) casting at low pressure; (3) detecting; (4) performing thermal treatment; (5) machining; (6) performing coating pretreatment; (7) spraying body powder; (8) performing thermal treating for spraying the body powder; (9) painting; and (10) performing thermal treating for painting. According to the manufacturing method provided by the invention, a feeding chain speed is reduced from 27 min / rack to 20 min / rack; the processing time is shortened; the production efficiency of a hub product is greatly increased; the capacity of thermal treating process is increased by near 1 / 4; equal property values of the product all meet a standard; and the ductility property of the product is promoted.

Owner:TIANJIN DAIKA WHEEL HUB MFG

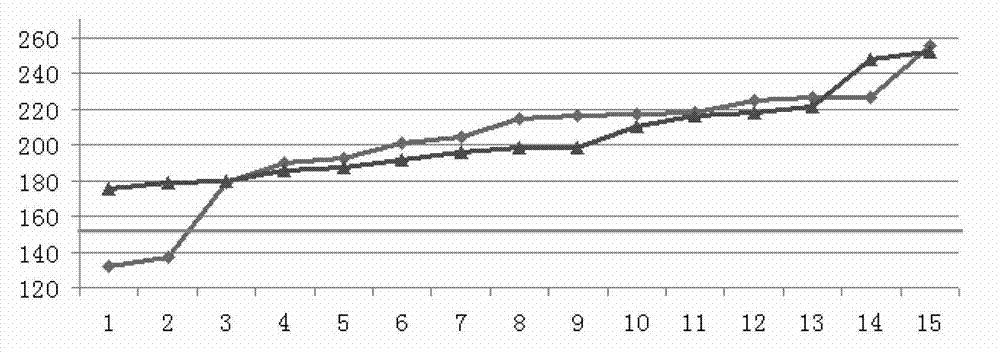

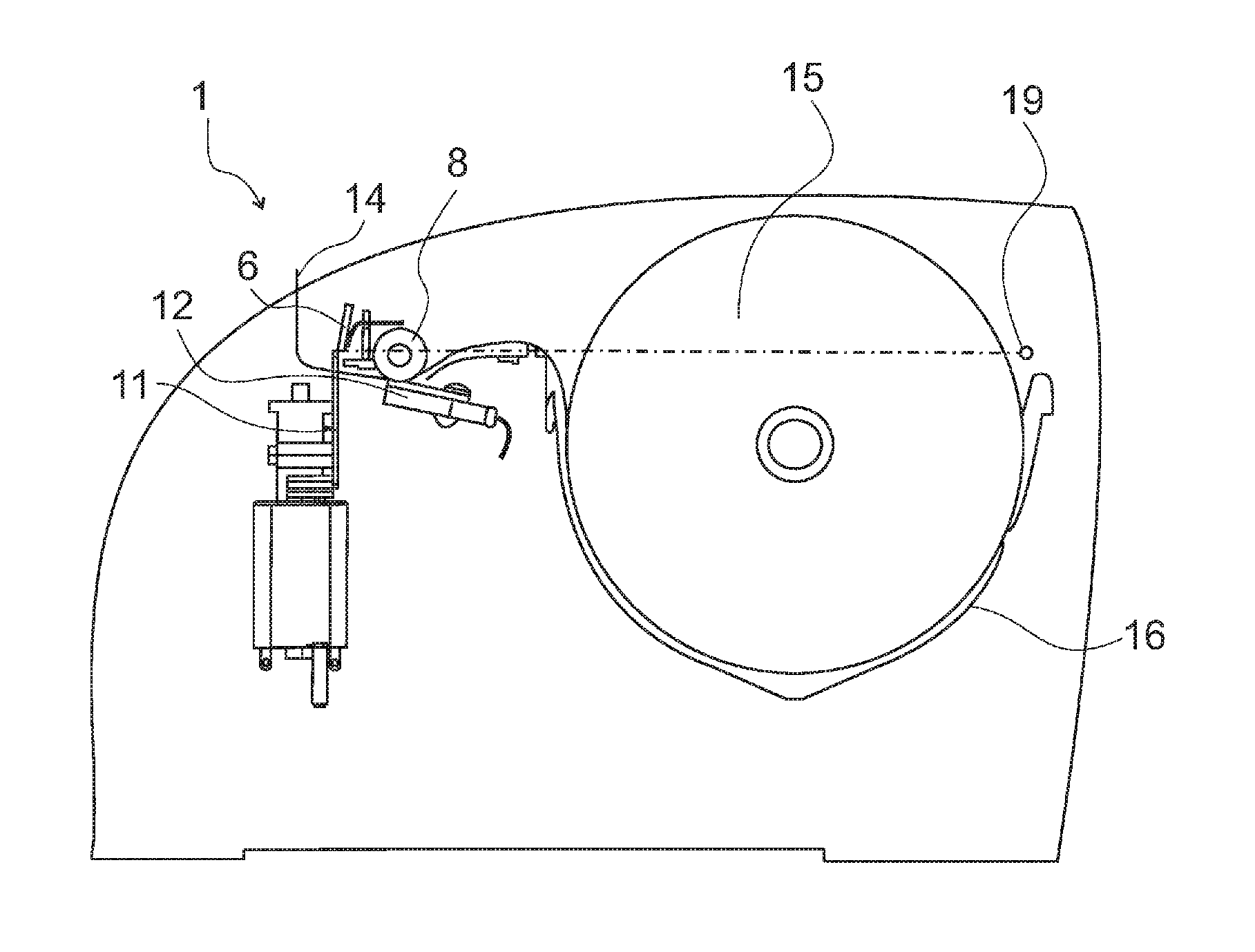

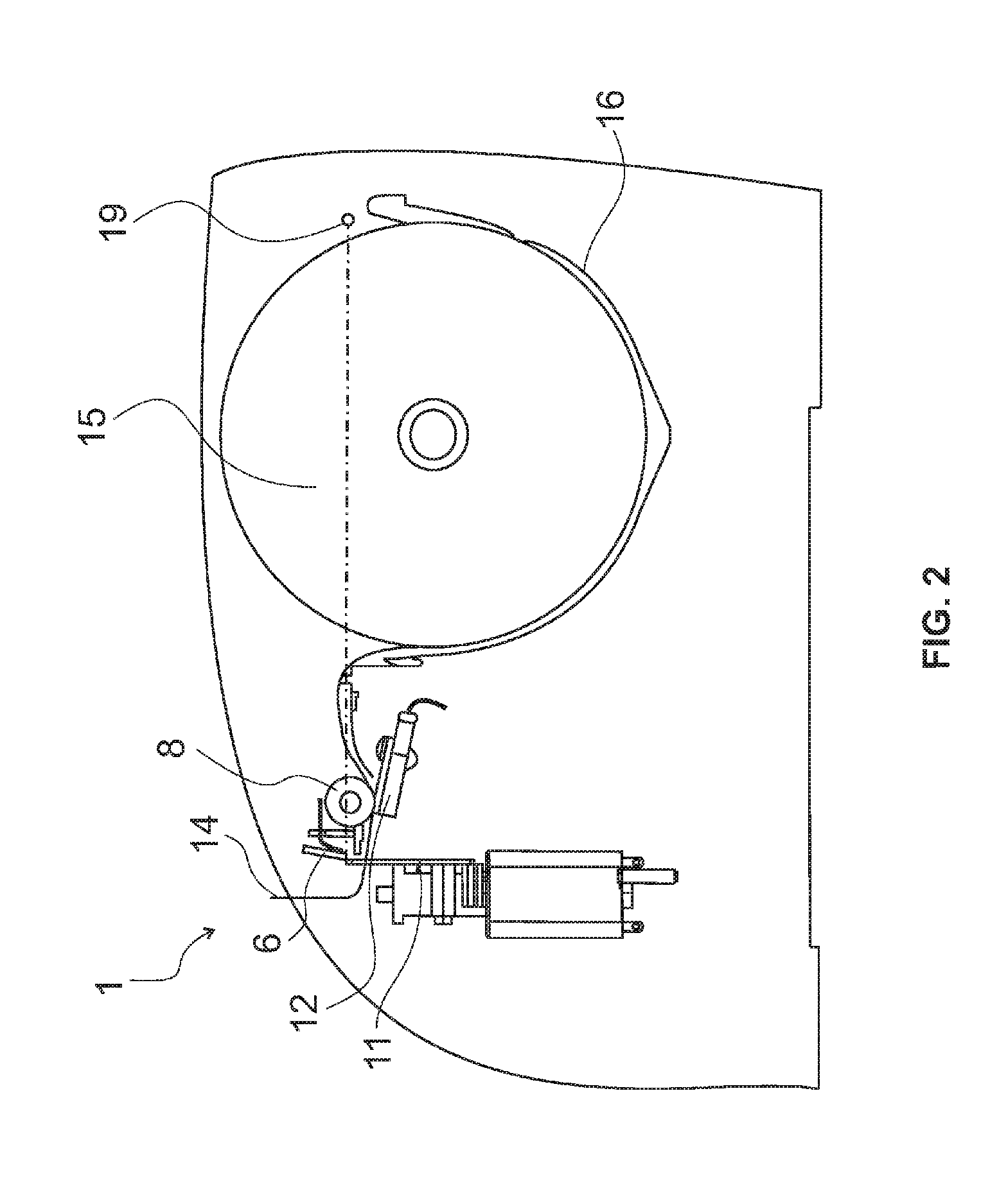

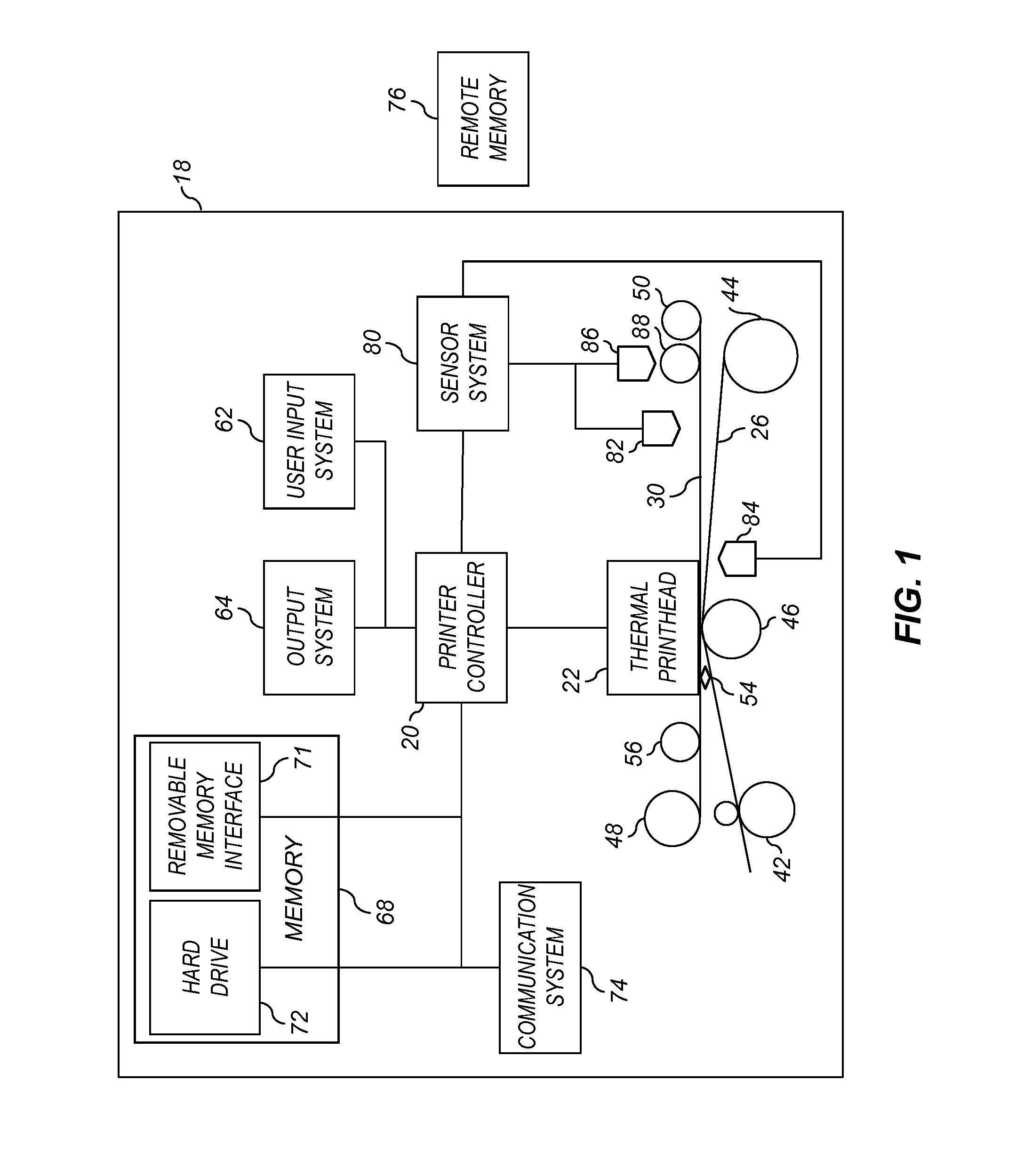

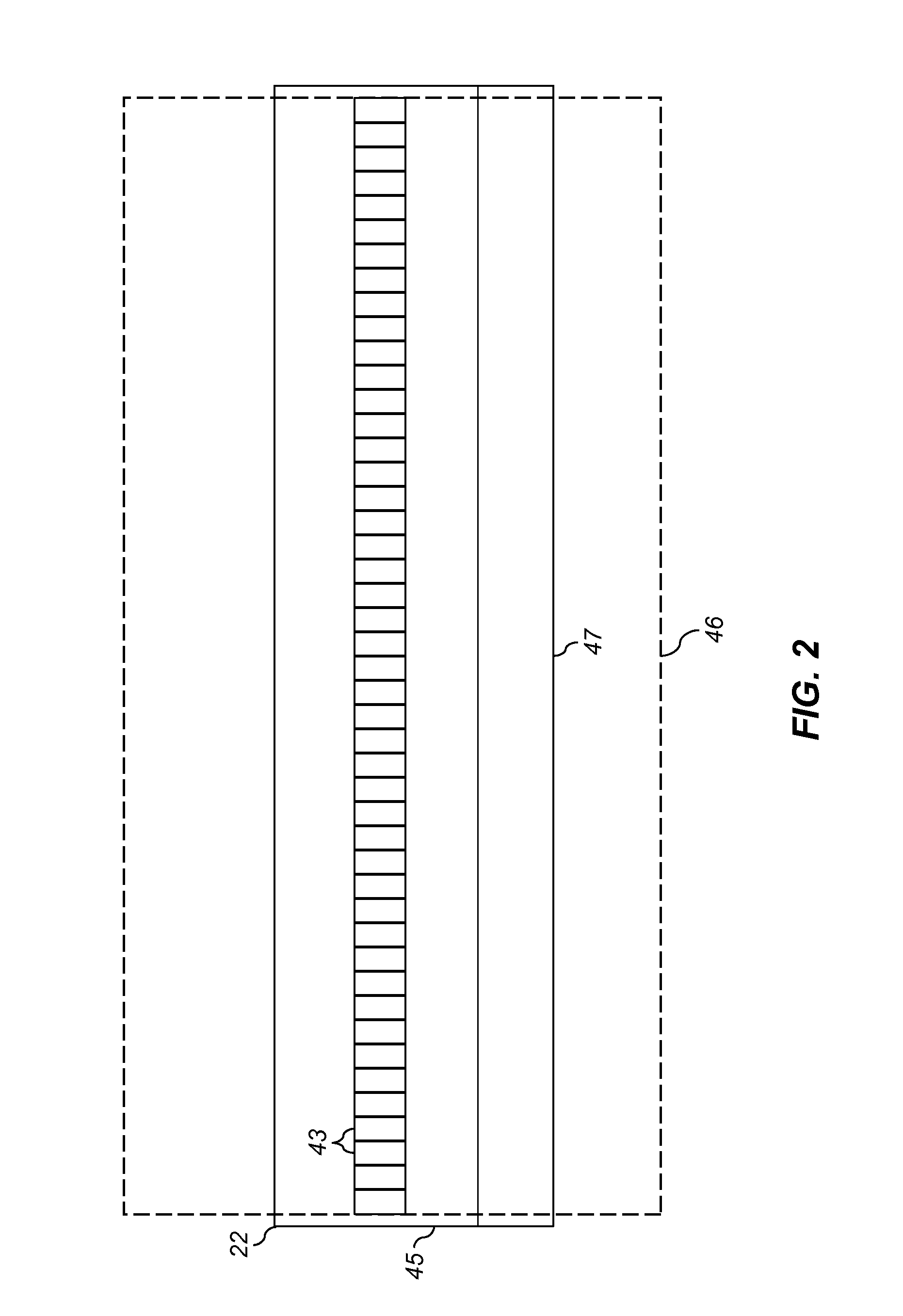

Thermal printing

A conventional thermal printer has had a structure in which a platen roller cannot be removed from a frame. Therefore, it has been necessary to insert a printing paper between a thermal head and the platen roller. Thus, it has been hard to load the printing paper. In order to solve the problem, there has been devised means for engaging the platen roller with the frame by the biasing force of the thermal head pressing the platen roller to forcibly lift up the platen roller, thereby removing the platen roller. However, there have been problems in that great operating force is required for the removal and the precision in a platen roller support position is low. A frame is provided with a slit (1c) having such a shape as to guide a bearing of a platen roller (2), and the bearing of a platen roller (2) is pushed against the slit by a lock arm using the biasing force of a pressure spring (8) for causing a thermal head (5) to come in press-contact with the platen roller (2). Consequently, the platen roller (2) is supported.

Owner:SEIKO INSTR INC

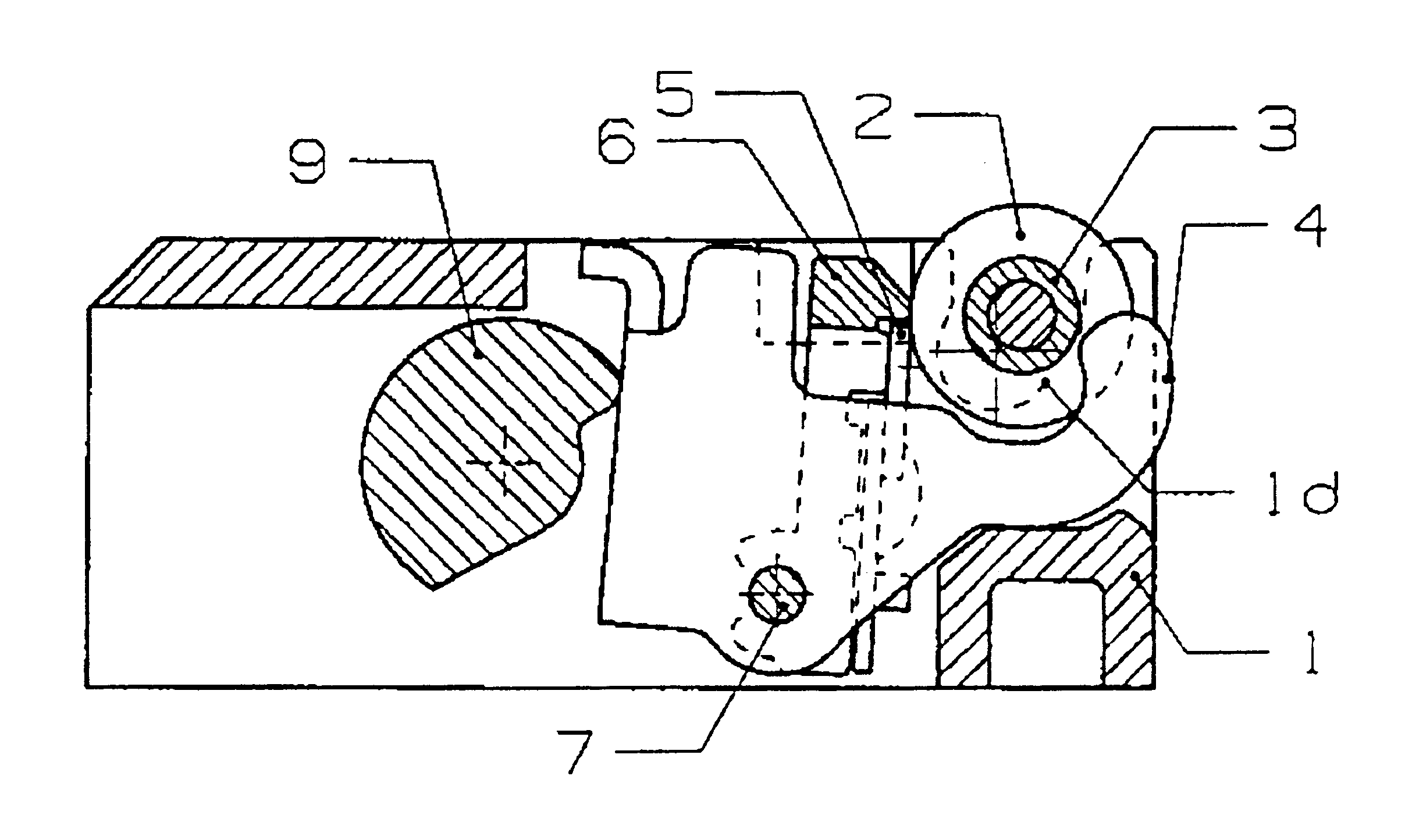

Textile finishing agent with thermal protecting, antibacterial and moisture-keeping functions, and health socks using the same

InactiveCN101476240AStay hydratedAvoid crackingFibre treatmentPanty-hoseTextile technologyHuman body

The invention provides a weaving finishing agent with the functions of emitting far infrared ray, generating air negative ion, resisting bacterium and retaining moisture, which has positive roles to human body health, belonging to the functional textile technology field. The invention further provides the socks applying the weaving finishing agent, which achieves the functions of warming, killing and resisting bacterium, retaining skin moisture, preventing skin seasoning check, promoting blood circulation, promoting metabolism and alleviating fatigue and ache.

Owner:SHENZHEN BAOLI VOGUE TECH

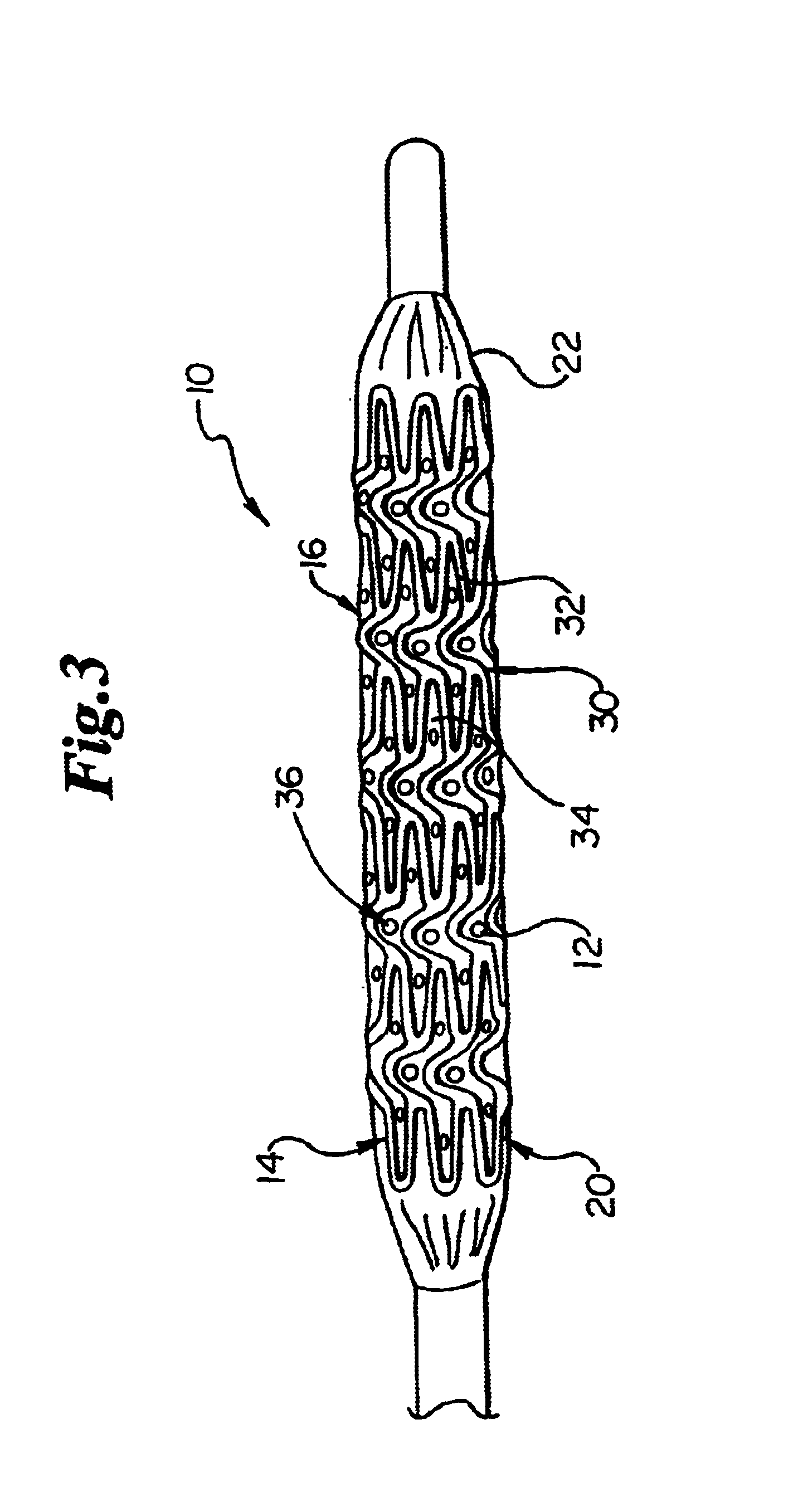

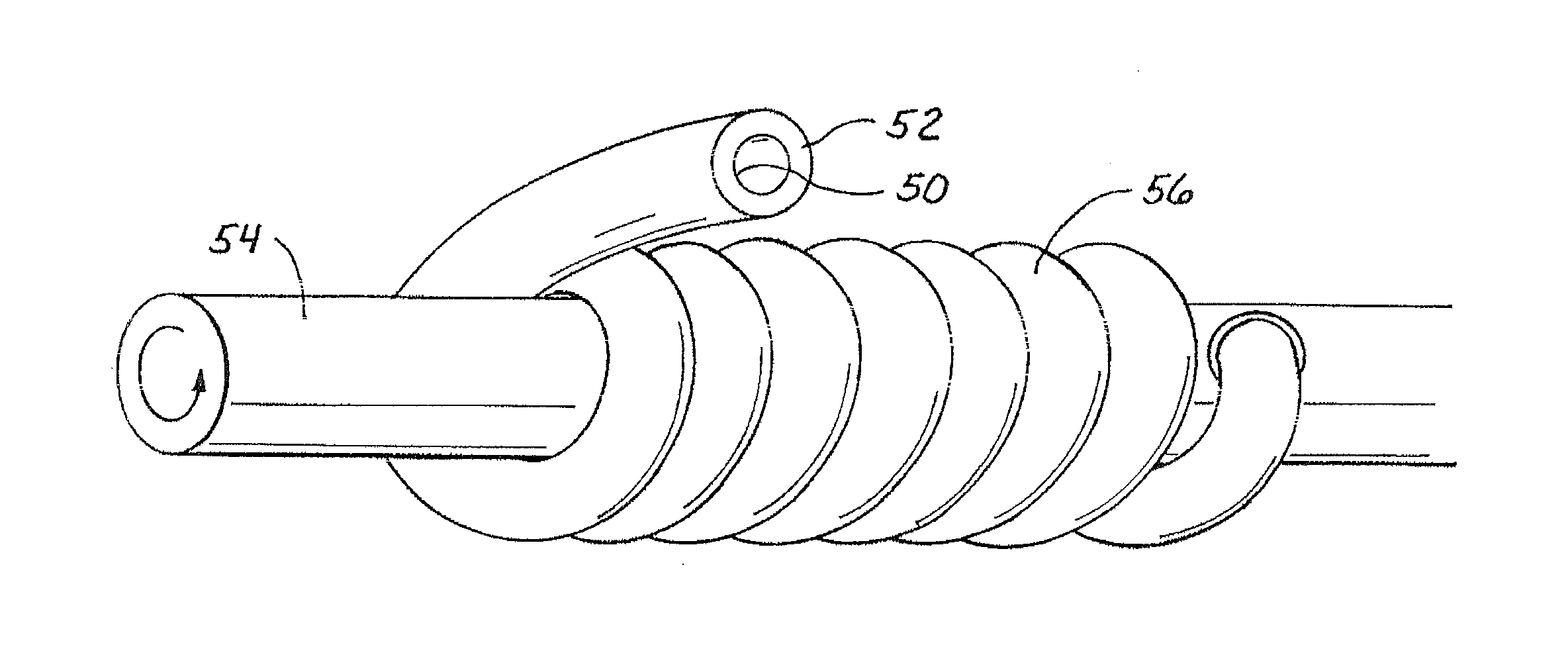

Method of making medical tubing having variable characteristics using thermal winding

InactiveUS20130327469A1Flexible processCatheterFlexible pipesVariable CharacteristicThermal printing

An efficient and cost-effective method of manufacturing a kink-resistant tube, wherein a coated wire is wound around a mandrel while simultaneously being heated to melt the coating, is provided.

Owner:APPL MEDICAL RESOURCES CORP

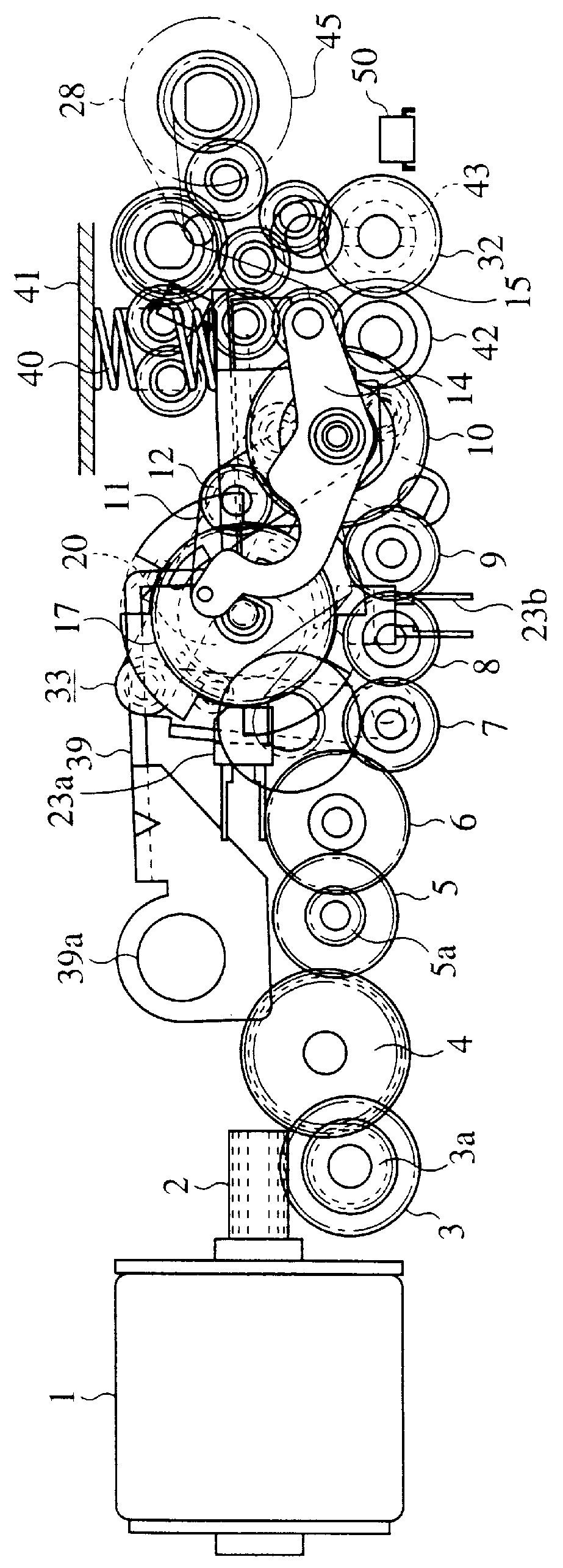

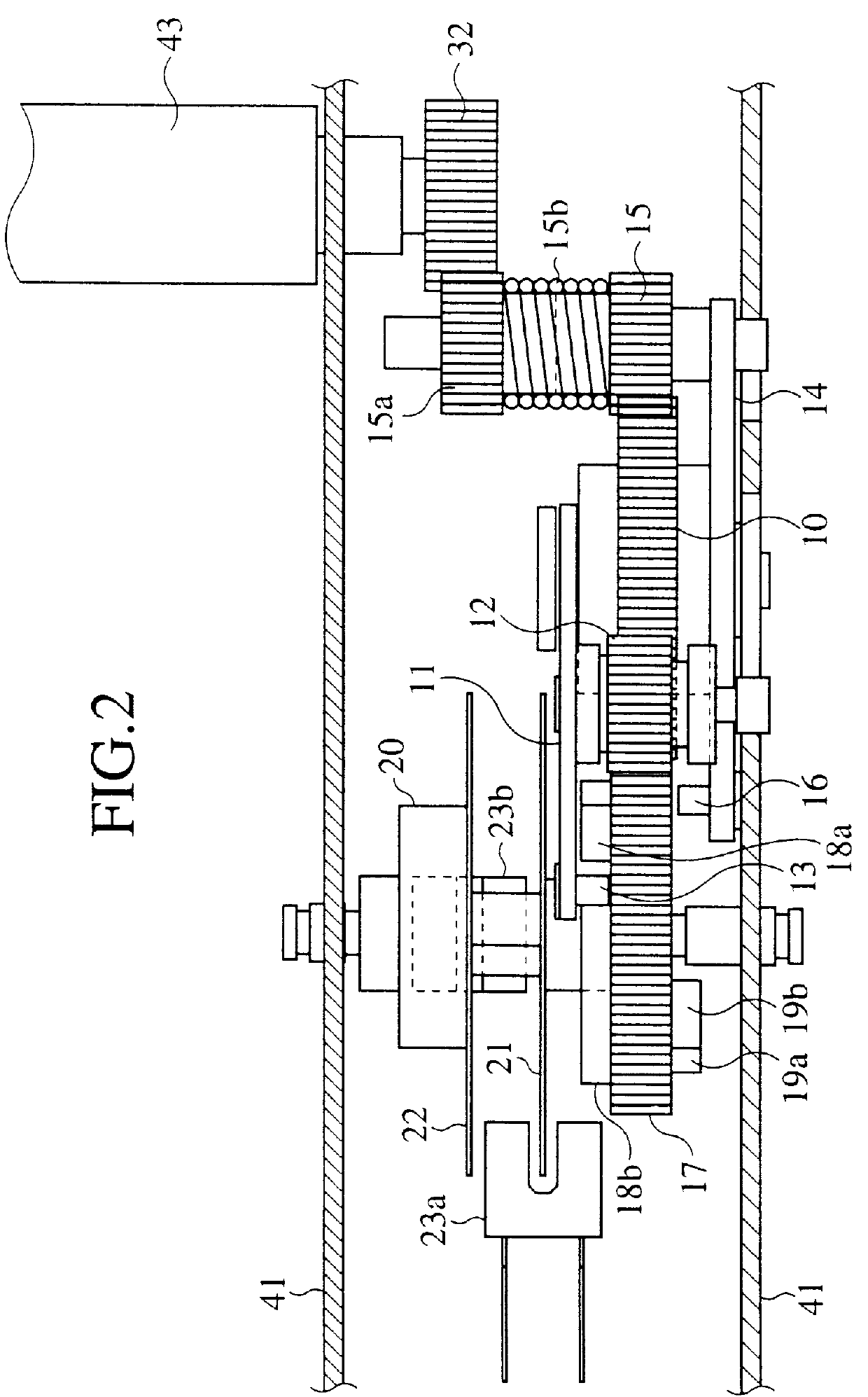

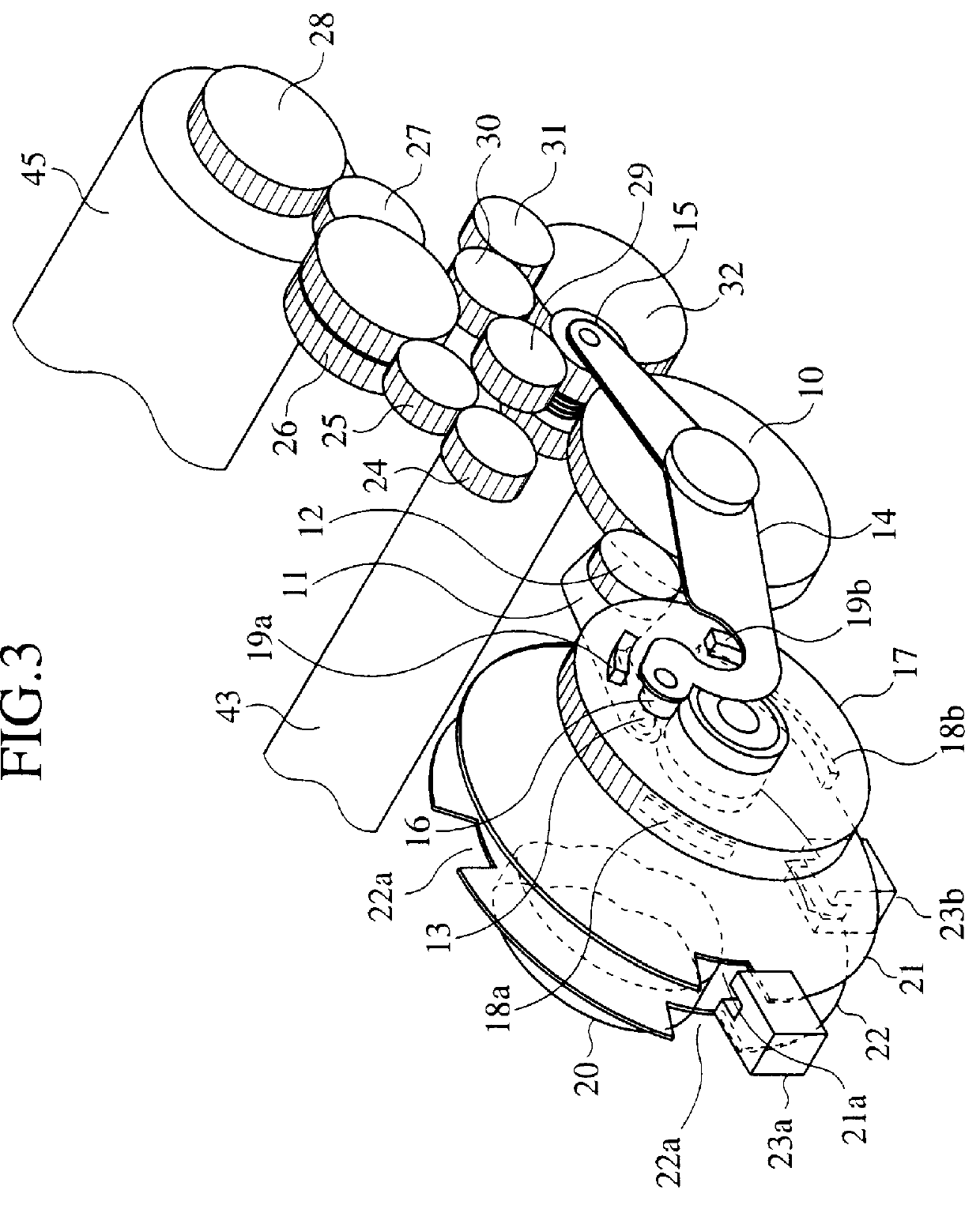

Thermal printer with a mode changing gear

A thermal transfer type printer comprising a sun gear 10 connected (indirectly) with a motor 1, exchanging arms 11, 14 having a pin 13,16 respectively, planet gears 12,15, an exchanging gear having bosses 18,19 and engaging with the planet gear 12, a cam 20, a link mechanism 33, and gears 24-32 which engage with the planet gear 15 when the planet gear 15 comes to a predetermined angle position so as to drive a printing paper feeding mechanism 43,44 and to drive an ink ribbon feeding mechanism 45,46. The procedures of the pressing and separation of the thermal printing head, the feeding of the ink ribbon, and the feeding of the paper, can be carried out using only one motor, though not only web type paper but also sheet type paper are usable.

Owner:MITSUBISHI ELECTRIC CORP

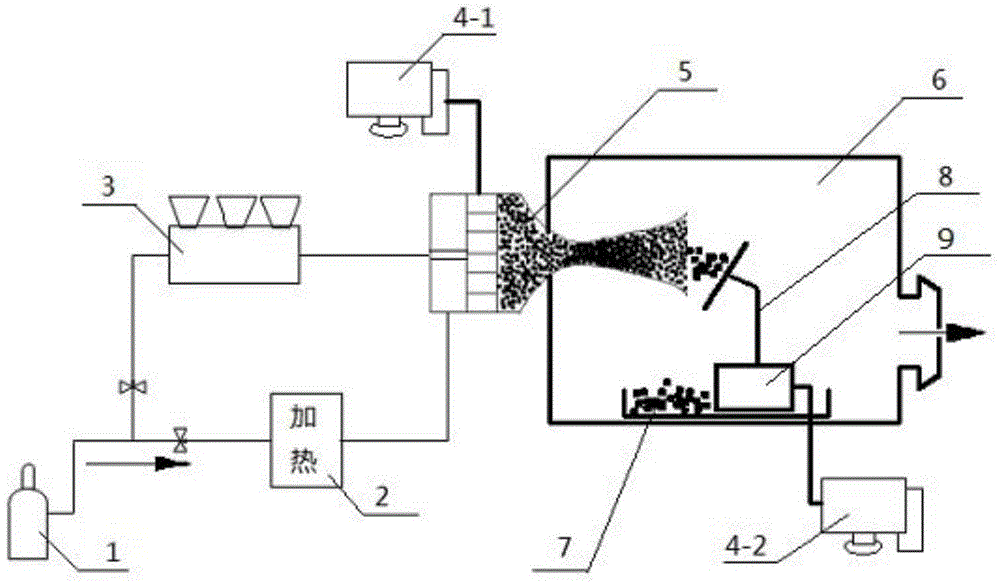

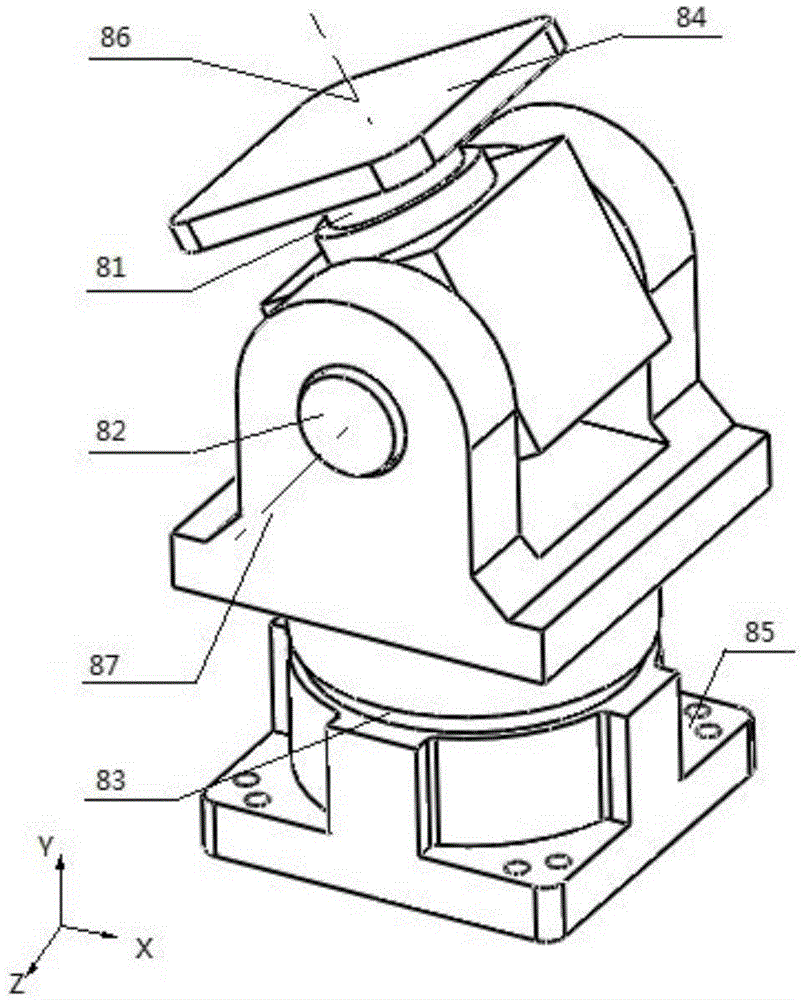

3D printing method and system based on cold spraying

InactiveCN104985813AImprove production efficiencyImprove bindingAdditive manufacturing apparatusIncreasing energy efficiencyThermal printingHigh pressure

The invention discloses a 3D printing method and system based on cold spraying. High-pressure gas carrying powder granular materials needing to be printed through low-temperature preheating generates supersonic speed gas-solid bidirectional flow after passing through a scaling laval nozzle, high-speed particle flow is sprayed from the nozzle in a solid state condition, the high-speed particle flow impacts a substrate, and meanwhile the high-speed particles generate plastic deformation and are cold-welded and bonded onto the substrate; a fact matched with the process exists is that in a vacuum sealing room, a printing platform can be controlled by a computer, and stretching and contracting in the height direction and rotation around three rotating shafts are conducted according to needs; according to actual characteristics of a three-dimensional model needing to be printed, the printing section with better effects is calculated and analyzed automatically through the computer, at the time, the printing platform capable of rotating and lifting freely adjusts self-height and the needed angle to form a relative work position beneficial to an optimal printing section with the printing nozzle, meanwhile, the position of the printing platform is adjusted in real time, and the rapid and efficient printing process is achieved.

Owner:TONGJI UNIV

Thermal ink jet ink composition

A thermal ink jet ink composition include a volatile organic solvent, a binder resin, a dye, a humectant in an amount less than 40% by weight of the thermal ink jet ink composition, and an additive for extending the decap time. The additive is present in an amount greater than 0.1% by weight of the thermal ink jet ink composition. The additive is selected from plasticizers, surfactants, aliphatic hydrocarbons, drying oils and mixtures thereof. The additive does not phase separate from the ink jet composition during application of the ink to a substrate in thermal ink jet printing.

Owner:VIDEOJET TECH INC

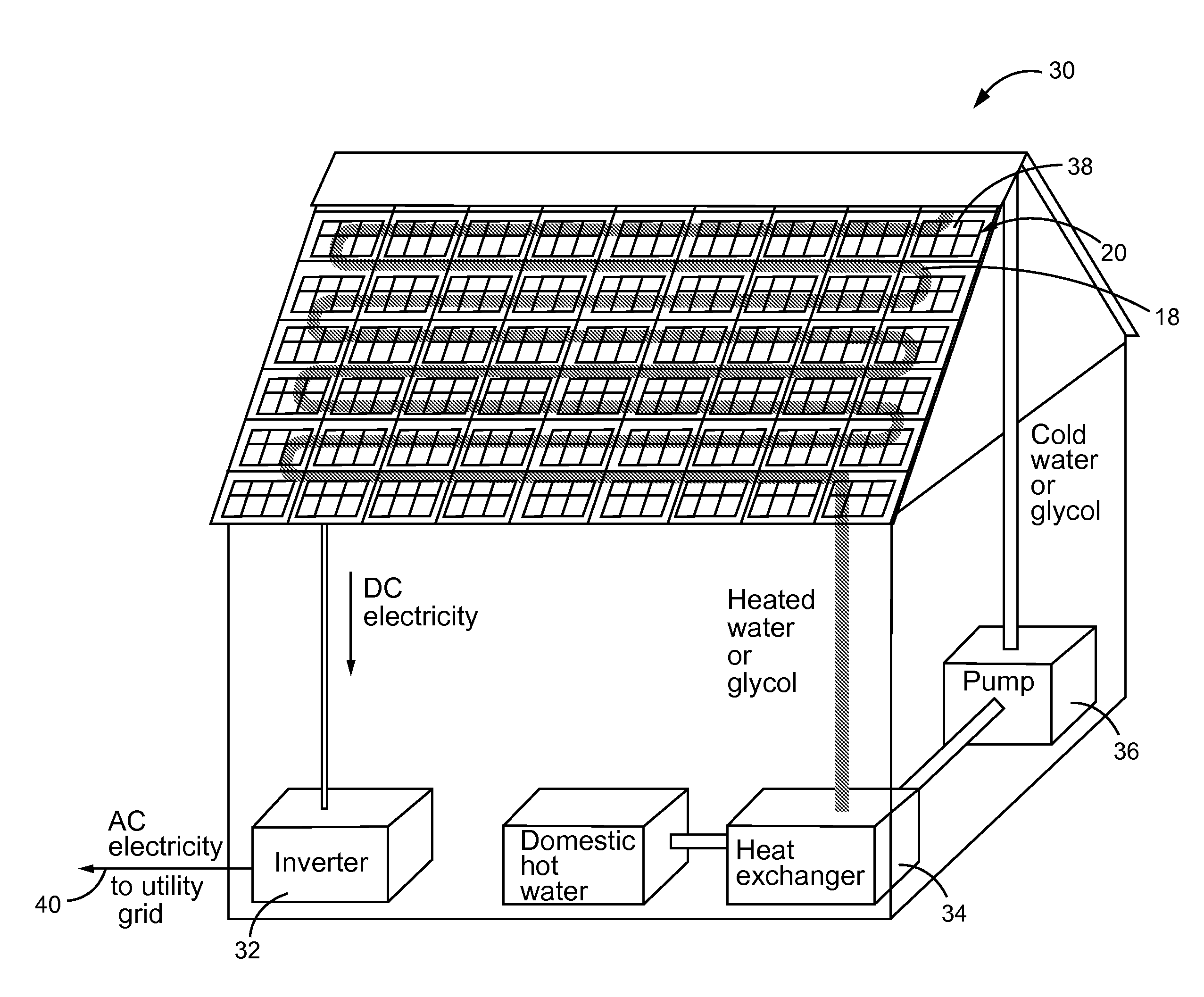

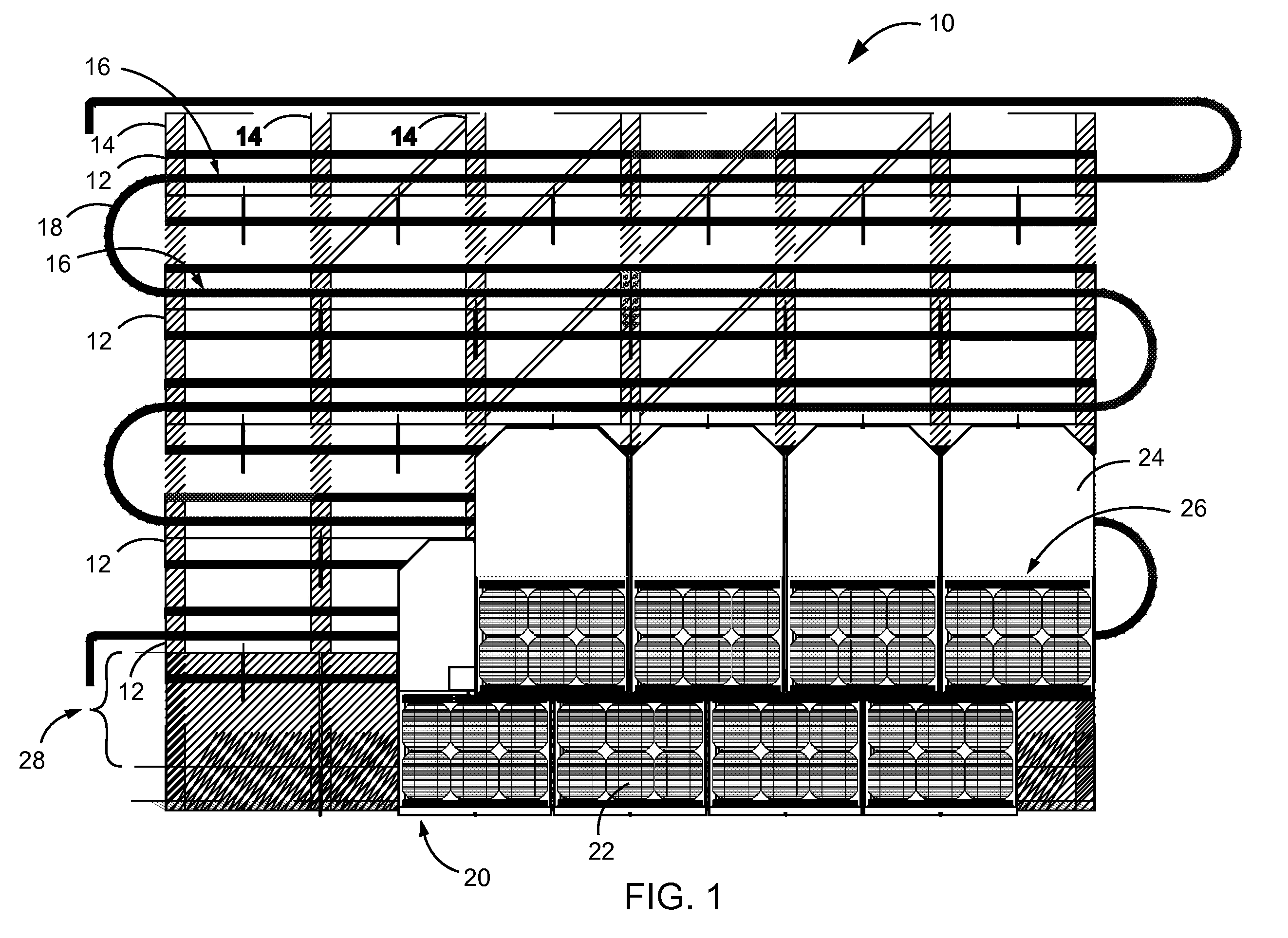

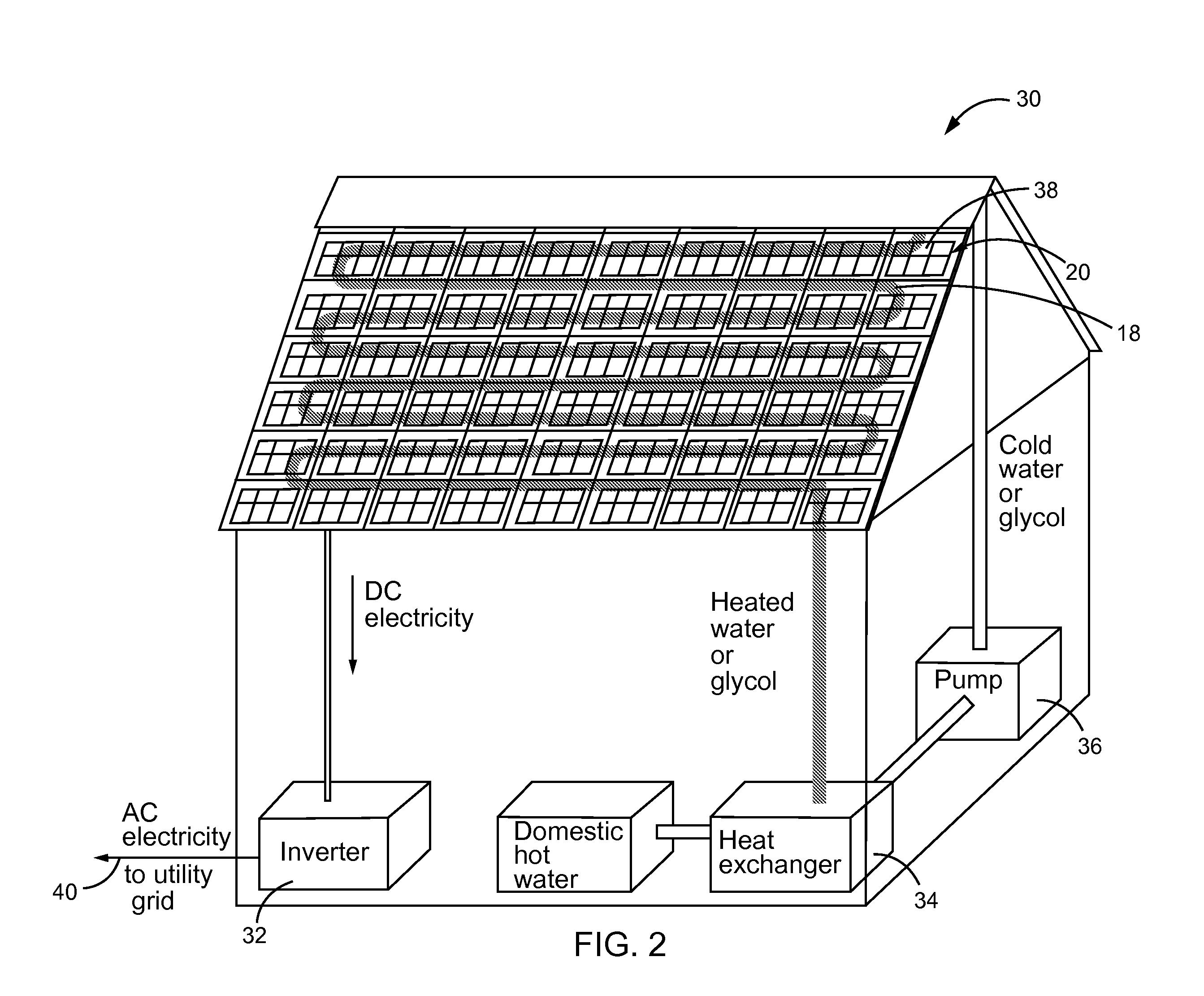

Building integrated thermal electric hybrid roofing system

ActiveUS20110179726A1Energy efficiencyPhotovoltaic supportsSolar heating energyElectricityThermal energy

A building integrated thermal electric hybrid roofing system is disclosed. The system comprises a plurality of metal battens having a longitudinal channel mounted horizontally onto a plurality of wooden battens, a thermal tubing containing liquid mounted on the longitudinal channels, a plurality of solar electric roof tiles mounted on the plurality of metal battens and connected in series to form a string, an inverter connected to each of the strings, a heat exchanger connected to the thermal tubing, and a pump connected between the thermal tubing and the heat exchanger. The plurality of solar electric roof tiles generates DC electricity from solar energy and the inverter converts the DC electricity to AC electricity to feed to a utility grid. The plurality of metal battens collects the solar energy and converts into thermal energy through running the liquid which is extracted to the heat exchanger resulting in producing domestic hot water.

Owner:PAO FRANK +1

Fiber pattern printing

InactiveUS20040126526A1Improved stent retaining characteristicHelp positioningSurgeryPretreated surfacesFiberSpray coating

A substantially tubular member comprises a body. The body is constructed from a first material and has an external surface. At least a portion of the external surface has a predetermined pattern of a second material deposited thereon. The predetermined pattern of the second material is deposited on the at least a portion of the external surface by one or more printing processes such as solution coating, spray coating, thermal printing, piezo jet printing, contact printing and any combination thereof.

Owner:BOSTON SCI SCIMED INC

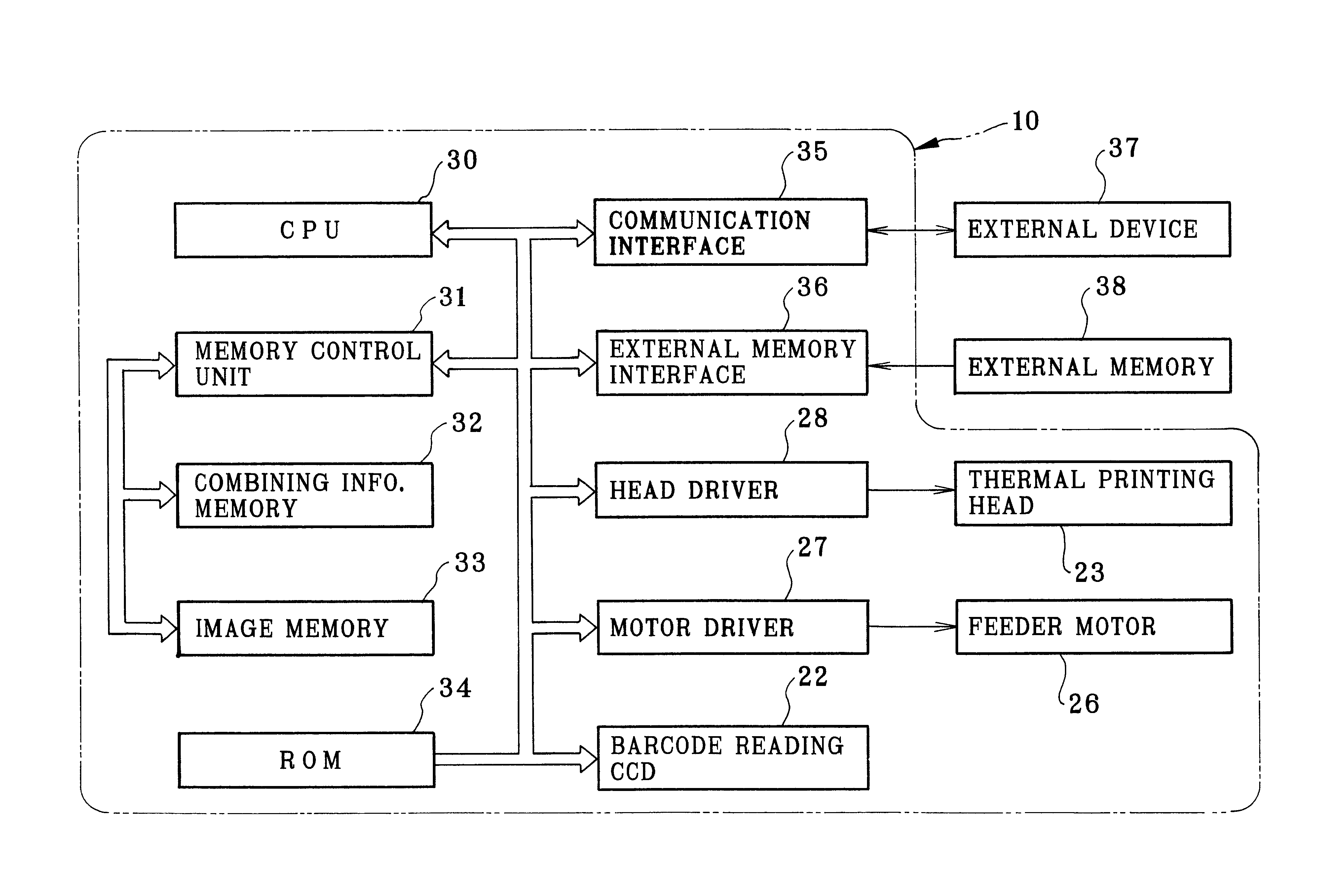

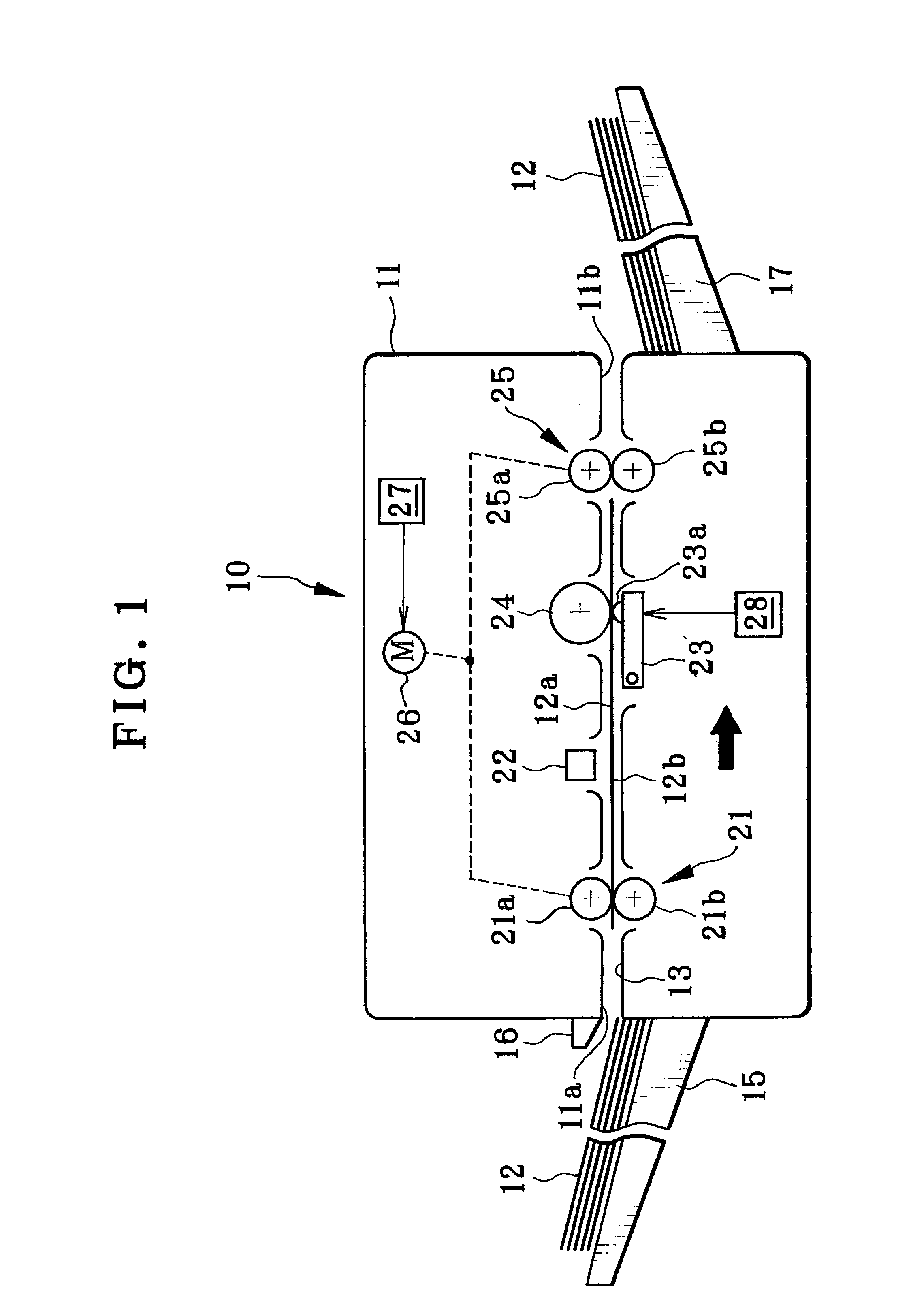

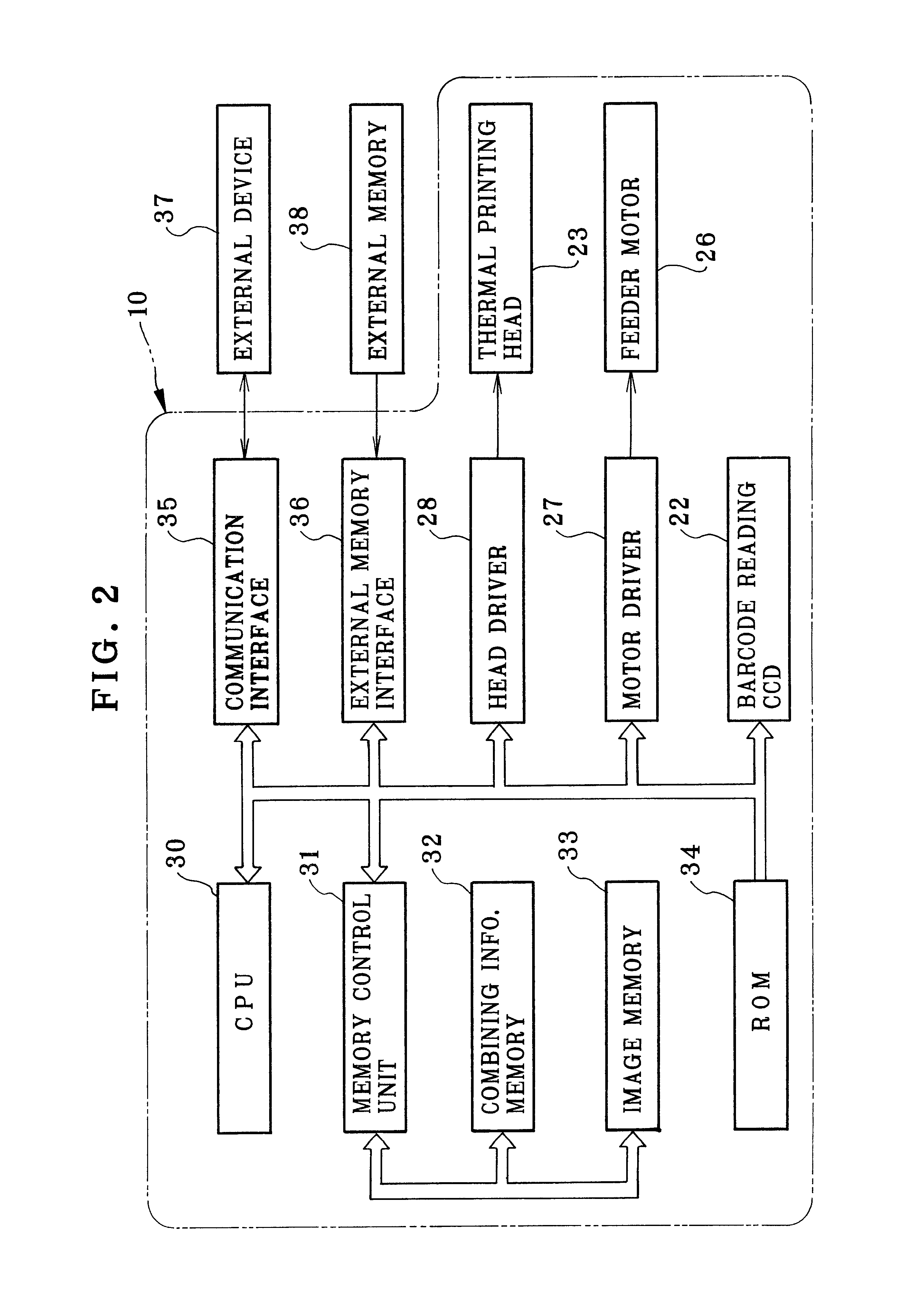

Printer and printing method capable of double-sided printing

A thermal printer includes a thermal printing head in an image forming section, which prints an image on one of first and second surfaces of a recording sheet oriented downwards. Feeder rollers feed the recording sheet to the image forming section after the recording sheet is set in a sheet supply slot. The printer includes at least one first memory for storing first image data of an image for being printed on the first surface, and second image data of an image for being printed on the second surface. The first or second image data are read from the first memory, and input to the image forming section. A second memory stores information of discrimination bar code adapted for designating the second image data associated with the first image data according to common assignment to the recording sheet. The information of the discrimination bar code is read from the second memory at a time of printing with the first image data to the first surface, and is printed on the first surface by the image forming section. A reading CCD reads the discrimination bar code from the first surface at a time of printing to the second surface. The second image data is specified according to the discrimination bar code, read from the first memory, and input to the image forming section.

Owner:FUJIFILM CORP +1

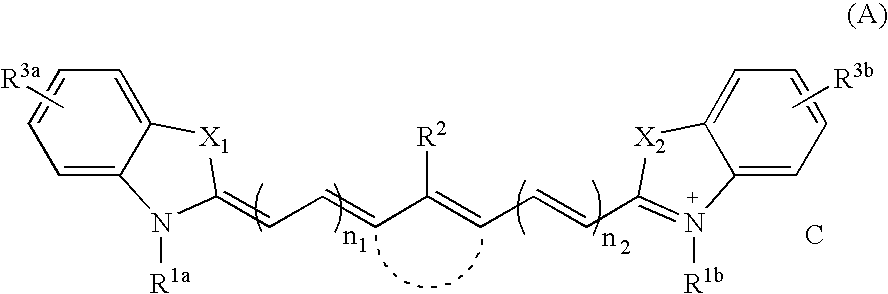

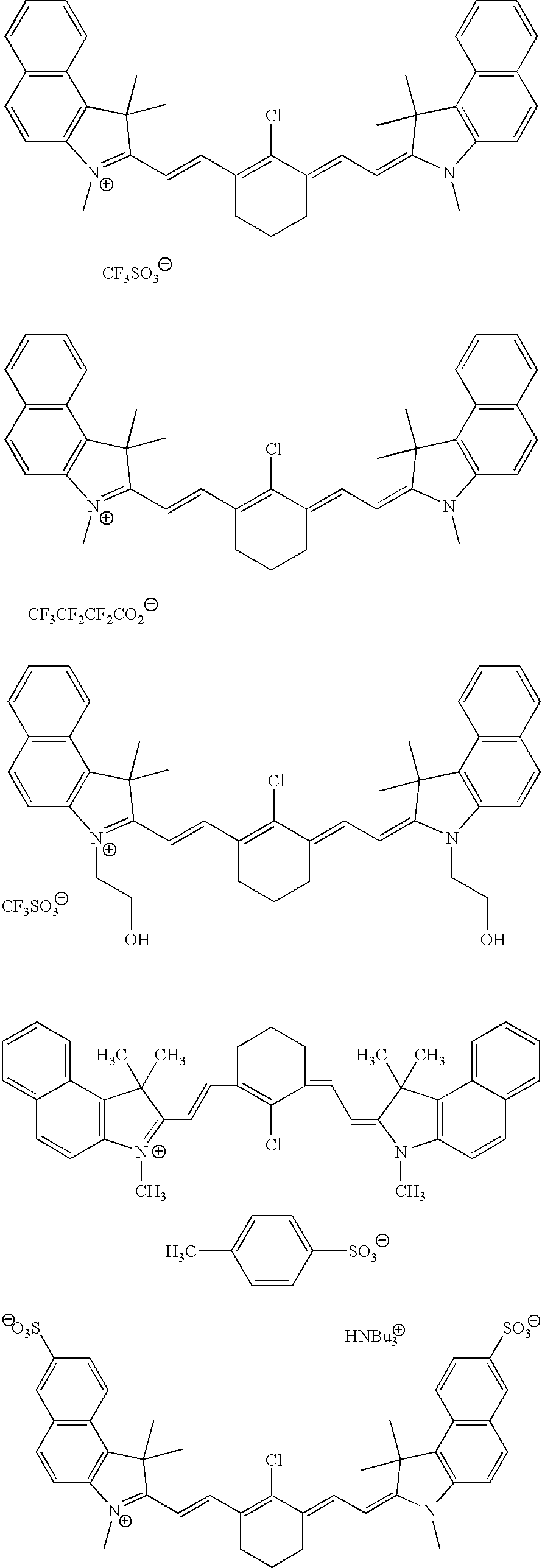

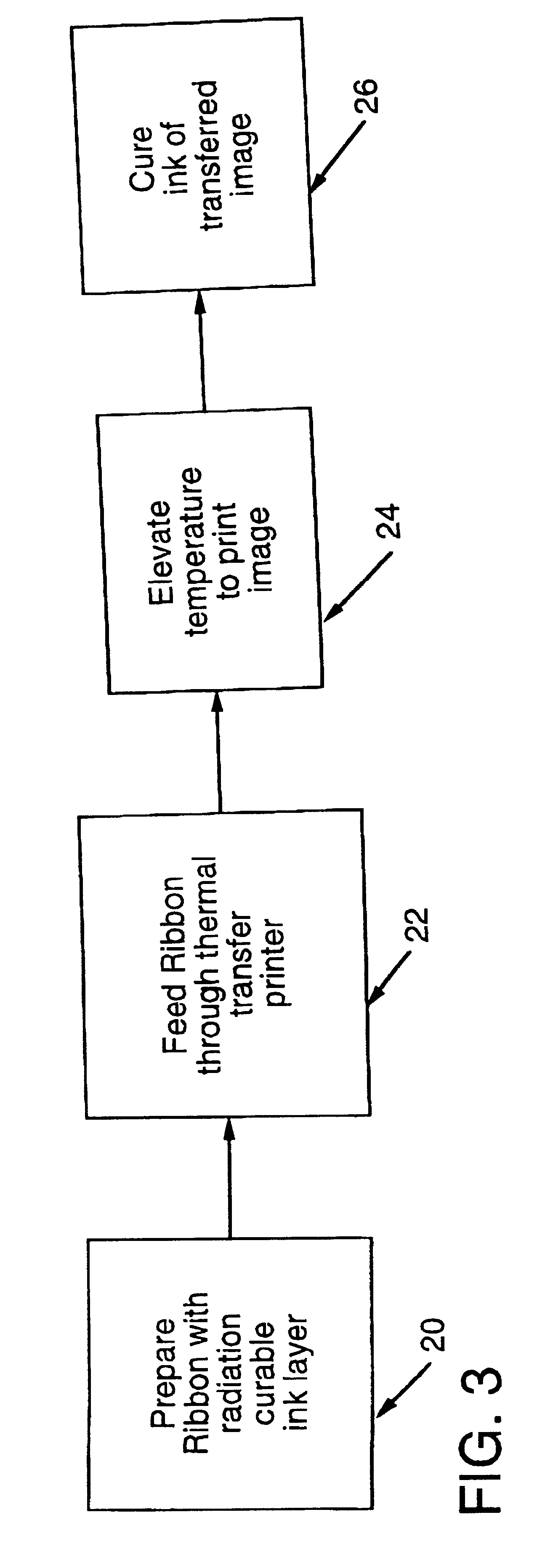

Radiation-curable thermal printing ink and ink ribbons and methods of making, using and printing using the same

A radiation-curable ink, a method of making the ink, a thermal transfer printer ribbon having a radiation-curable ink layer, and a thermal transfer printer with an actinic energy source are provided. A method of thermal transfer printing using an ink ribbon having radiation-curable components is also provided. The radiation curable components of the ink can be thermally dried and are cured after printing of an image on a receiving article.

Owner:SONY CHEM OF AMERICA

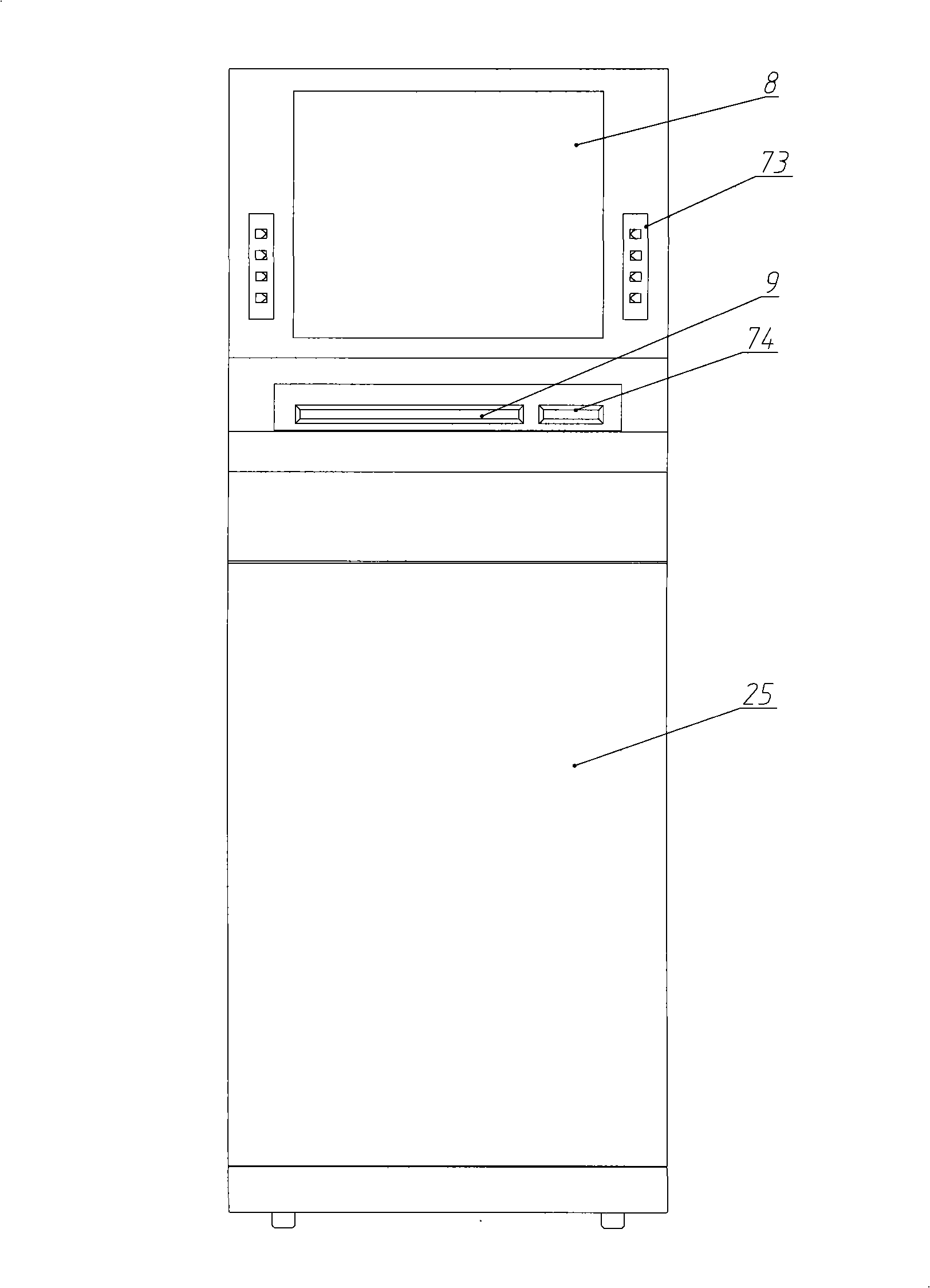

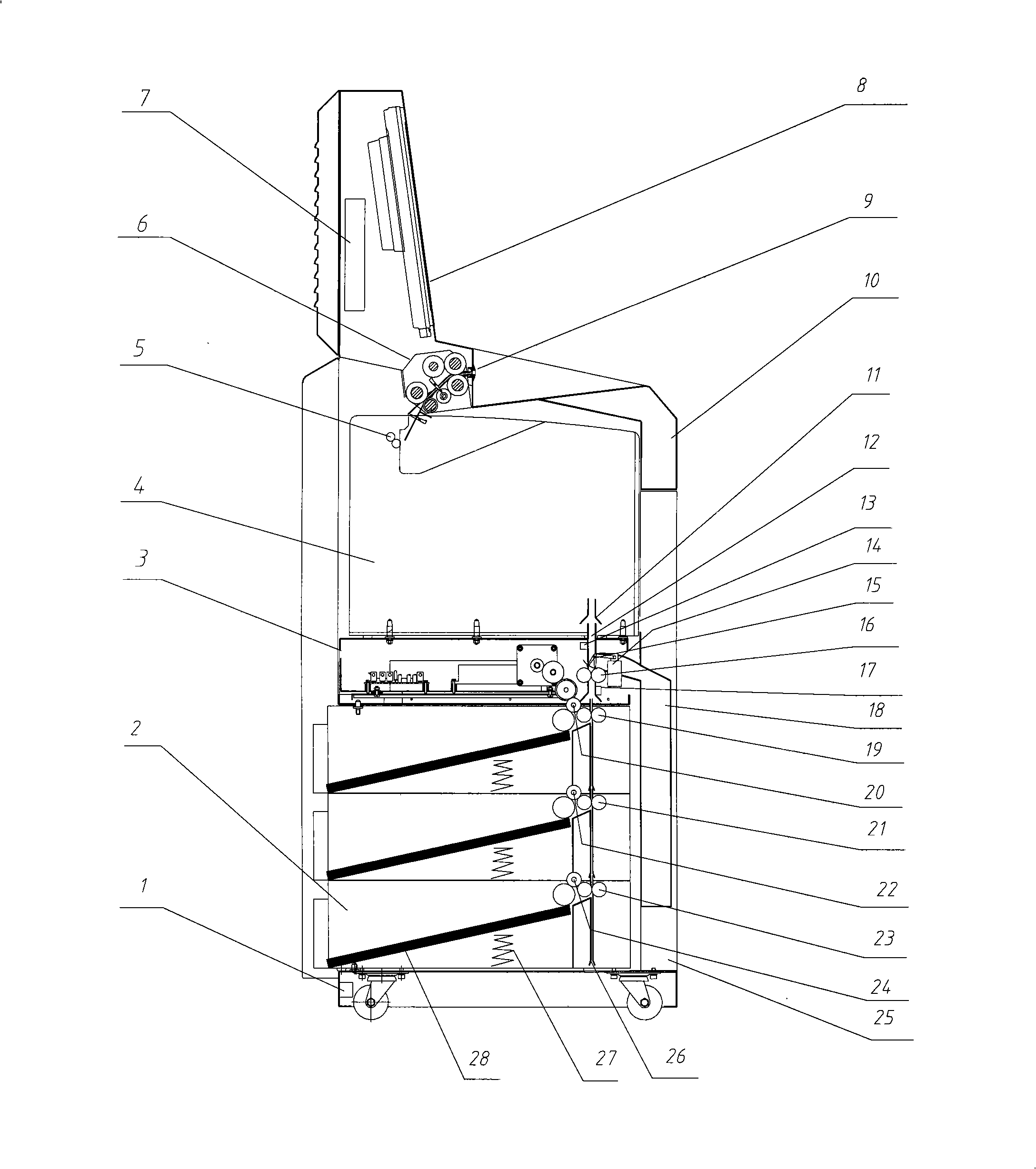

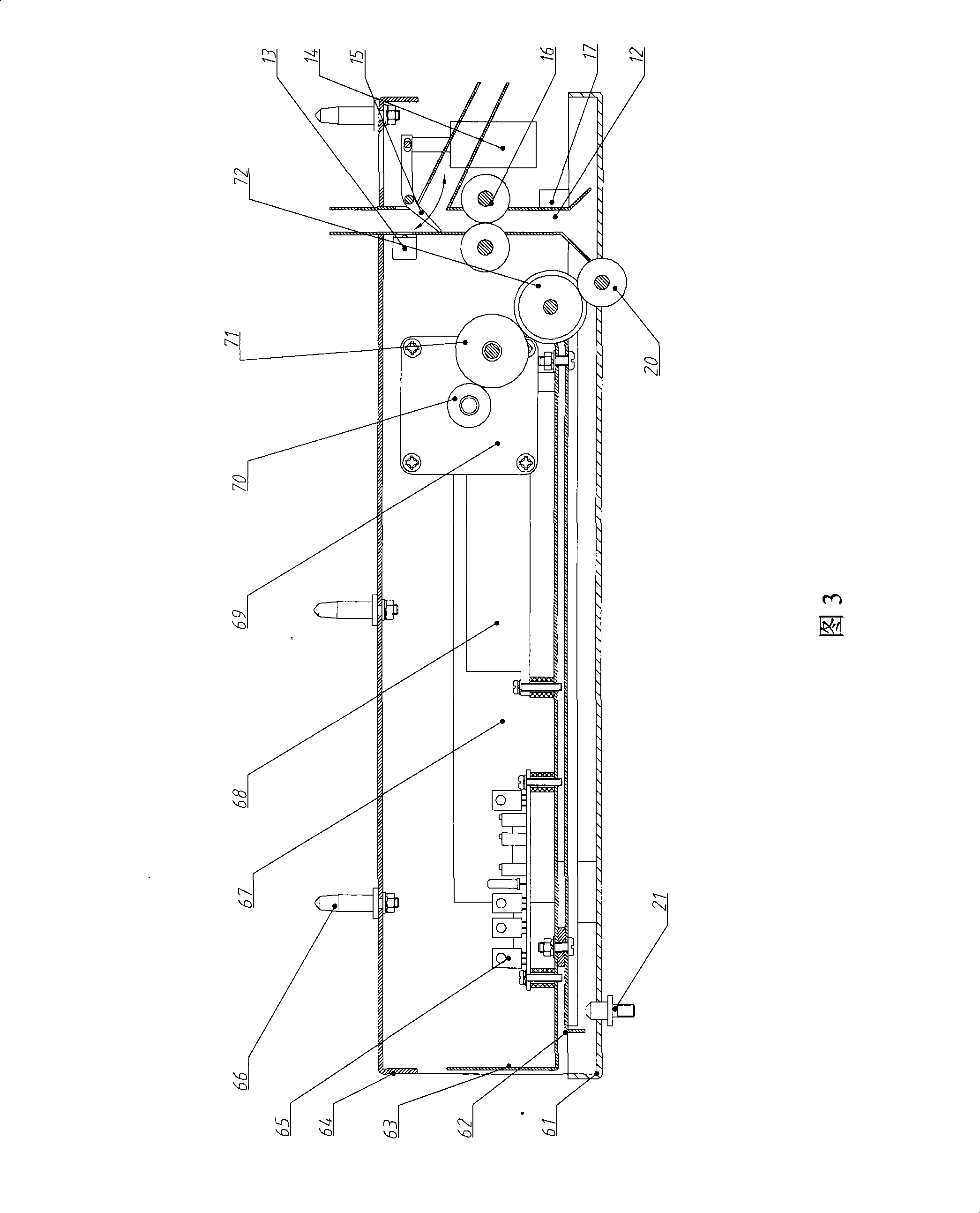

Self-help printing stamping terminal

A self-help printing stamp terminal comprises a computer PC system, a printer, an automatic stamp mechanism, a paper box control device, a plurality of input paper boxes, a card reader and a case and the like. The paper box control device is eqiupped between the printer and a plurality of input paper boxes, and the feed roll outlet of the printer is connected with the automatic stamp mechanism inlet; the communication port of the paper box control device is connected with the computer PC system, and communication port of the input paper box. The client passes by the terminal panel self-help operation, and the machine computer system and the background system perform the information exchange through the net mouth; the box control device realizes the automatic paper feeding of the corresponding paper box in the machine according to the system requirement, and puts into the printer for printing; and the output bill enters the automatic stamp mechanism to output. The terminal can be used for processing the self-help fee bill printing, the bank public receipt self-help printing and other self-help service fields needing the bill stamp.

Owner:杭州东信银星金融设备有限公司

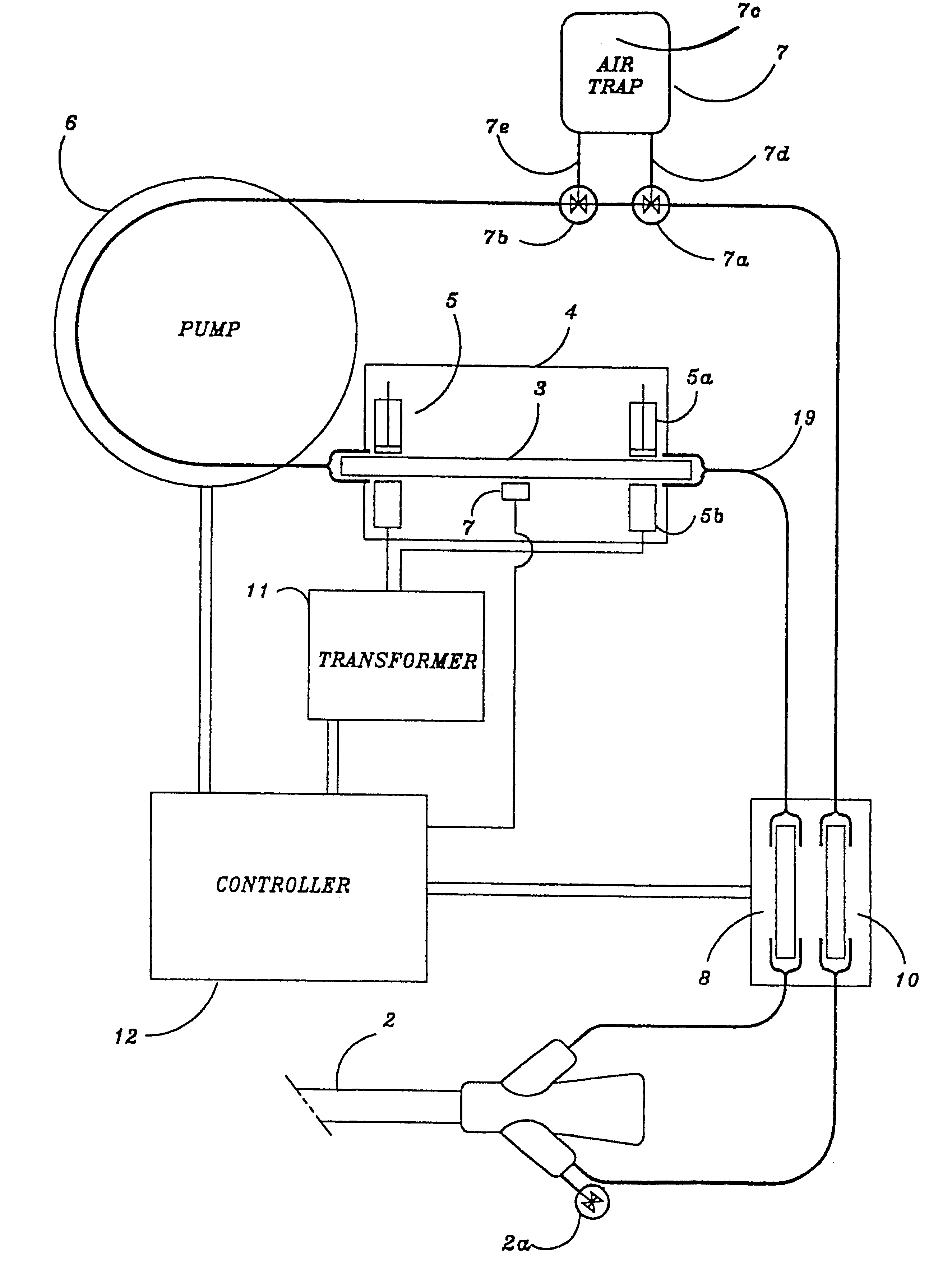

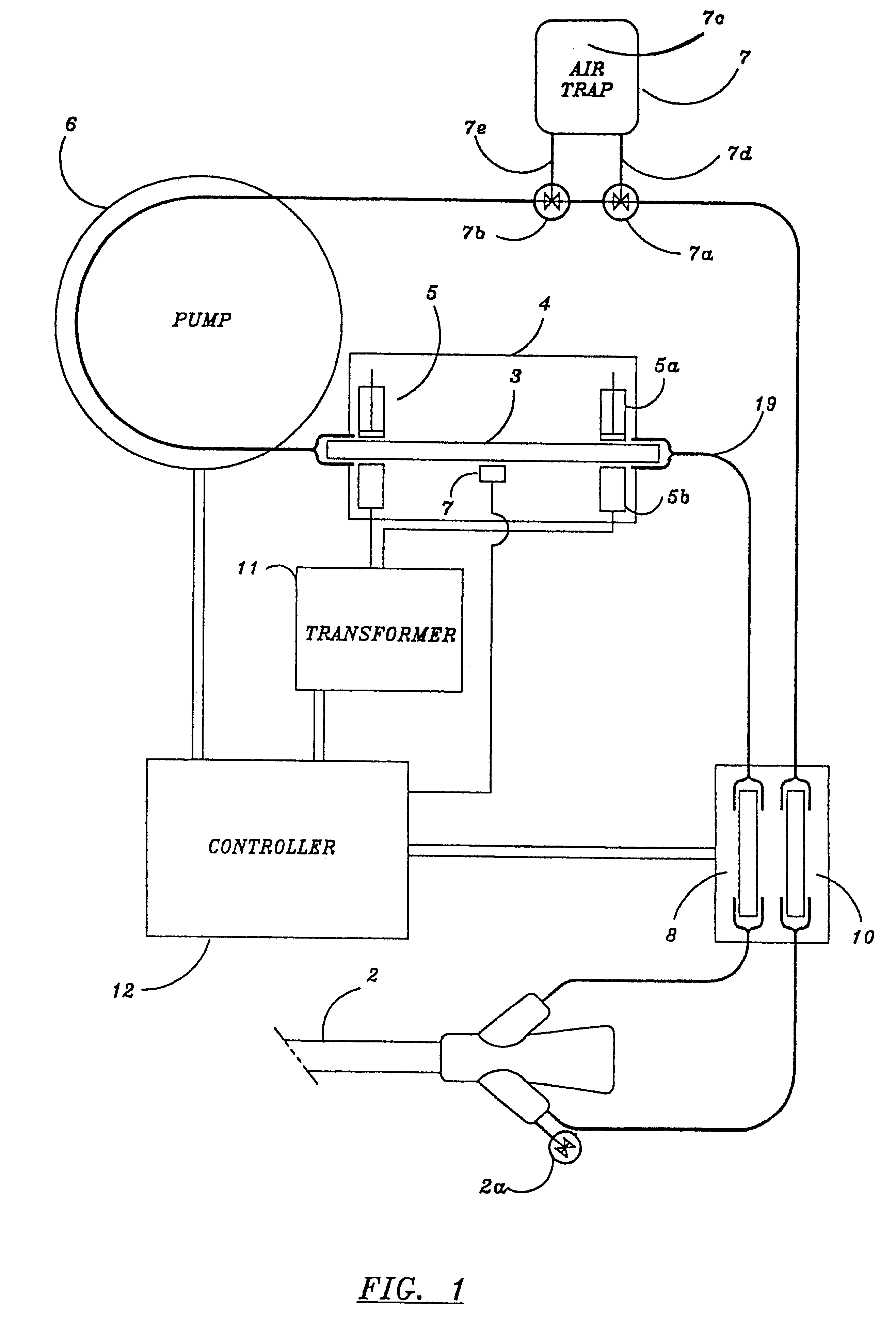

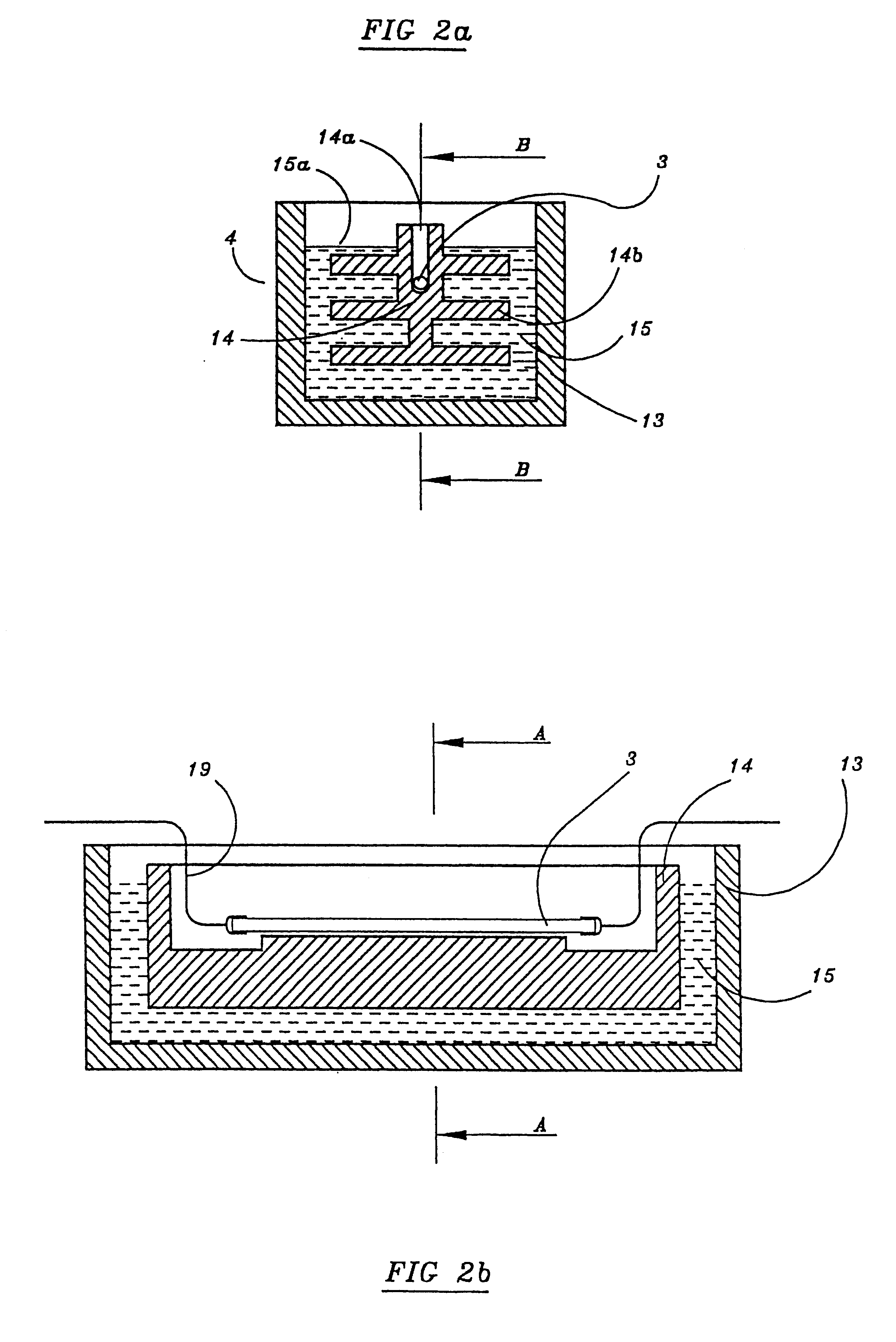

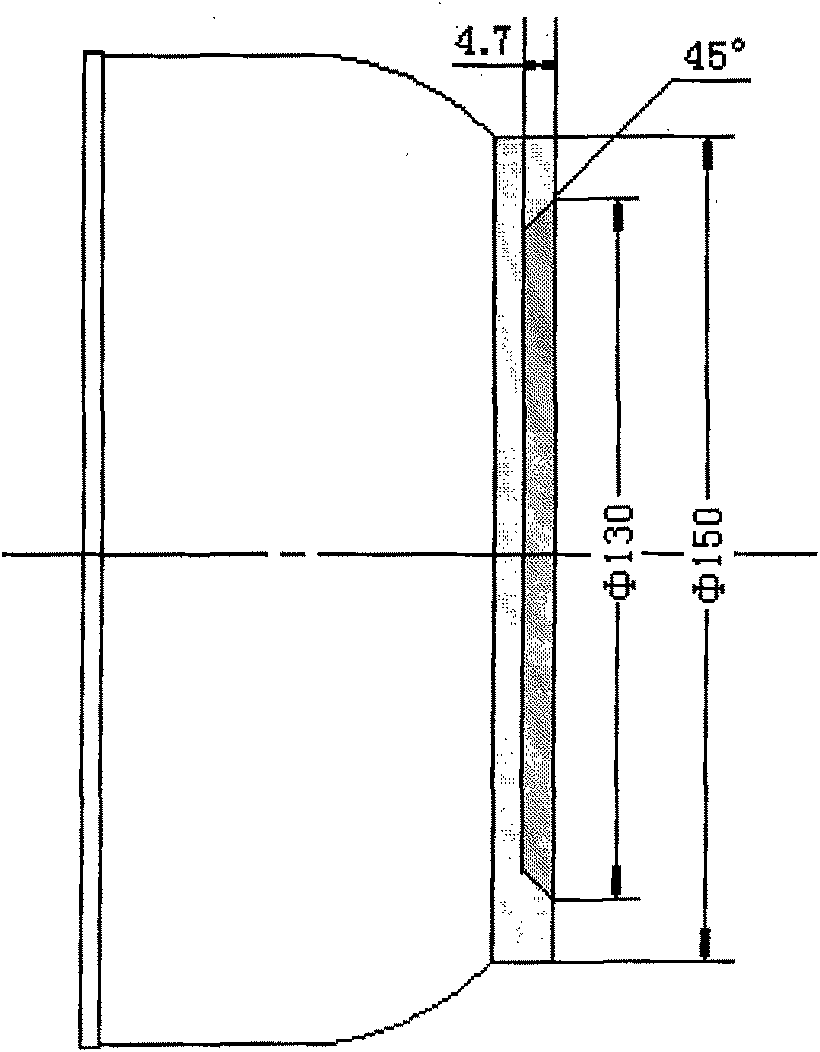

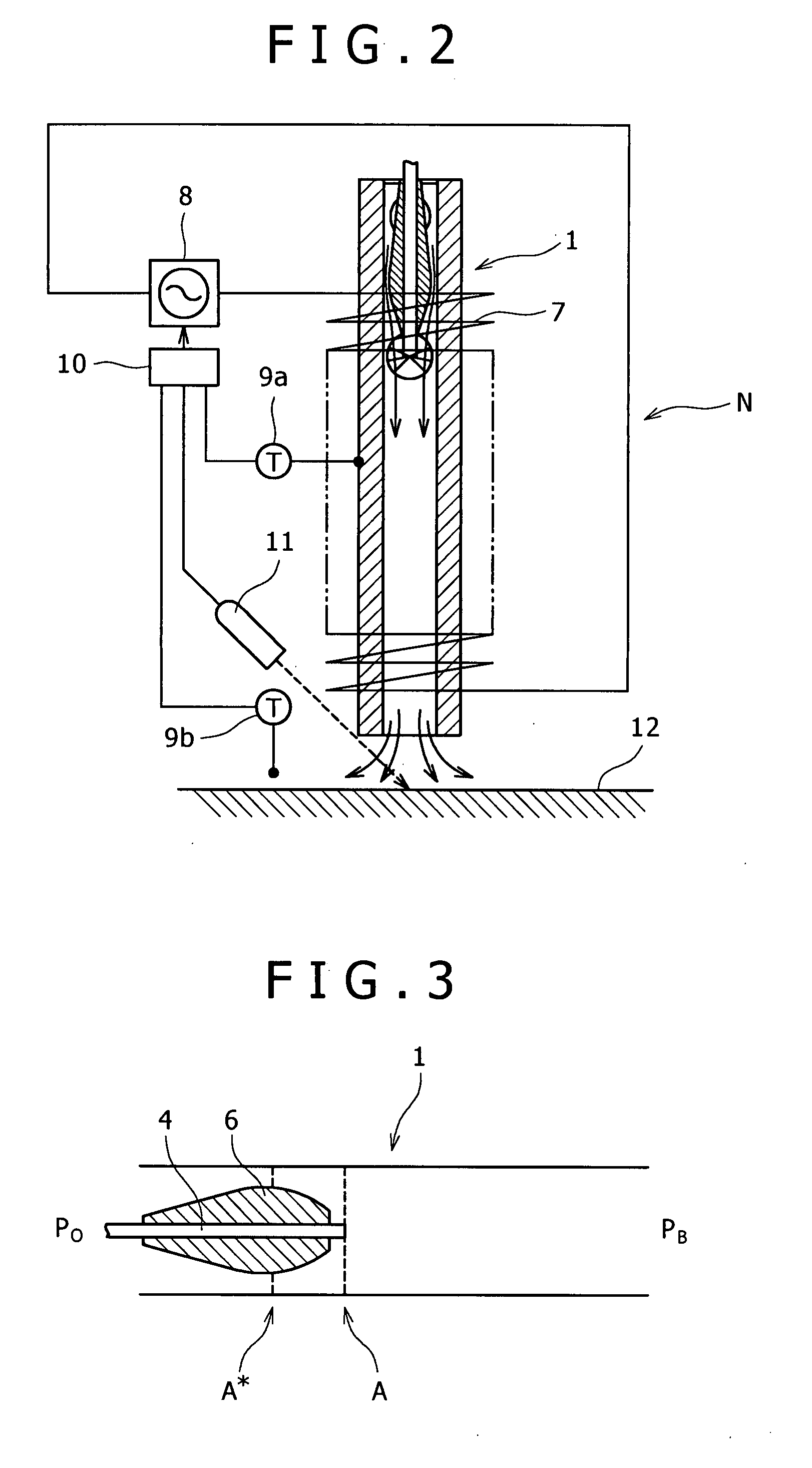

Thermal treatment apparatus

InactiveUS6849063B1Good thermal couplingIncrease contact areaFlexible member pumpsSurgical instrument detailsElectricityAir trapping

A temperature-setting device for providing a predetermined temperature to a quantity of fluid circulating therethrough, a thermal treatment apparatus including such device for selectively treating a targeted tissue adjacent a subject's body cavity, and techniques using such thermal treatment apparatus are provided. The temperature-setting device comprises: an electrically conducting tubular element, a housing element for receiving the tubular element; and a transformer electrically connectable to the housing element. The tubular element functions as a resistor and heats the fluid circulating therethrough. Alternatively, the housing element comprises a thermal conducting member disposed within a bath of a cooling substance, the thermal conducting member having a recess for receiving the tubular element. The tubular element may alternately be placed in a housing element functioning as a heater and a housing element functioning as a cooler, thereby alternately heating or cooling the fluid circulating therethrough. The thermal treatment apparatus comprises: a temperature-setting device according to the present invention; a catheter insertable into a subject's body cavity, the catheter including a thermal treating section for thermally treating a targeted tissue; a pump; thermal sensor assemblies; and an air trapping element.

Owner:JPMORGAN CHASE BANK AS ADMINISTATIVE AGENT

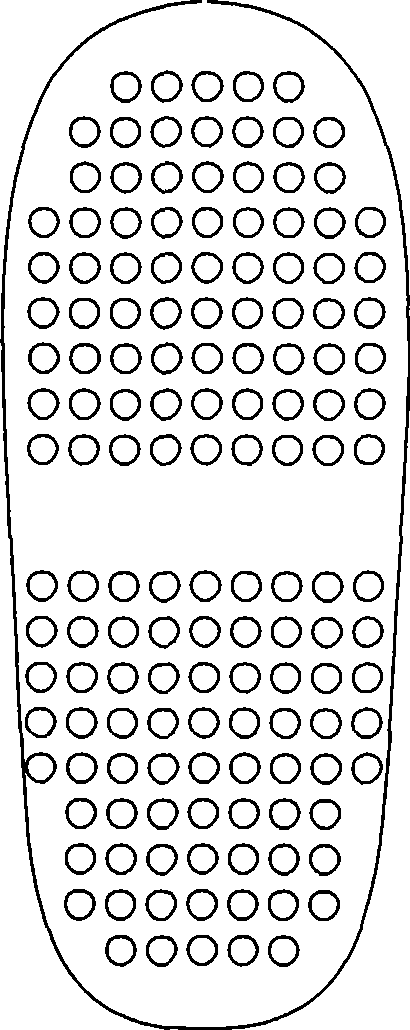

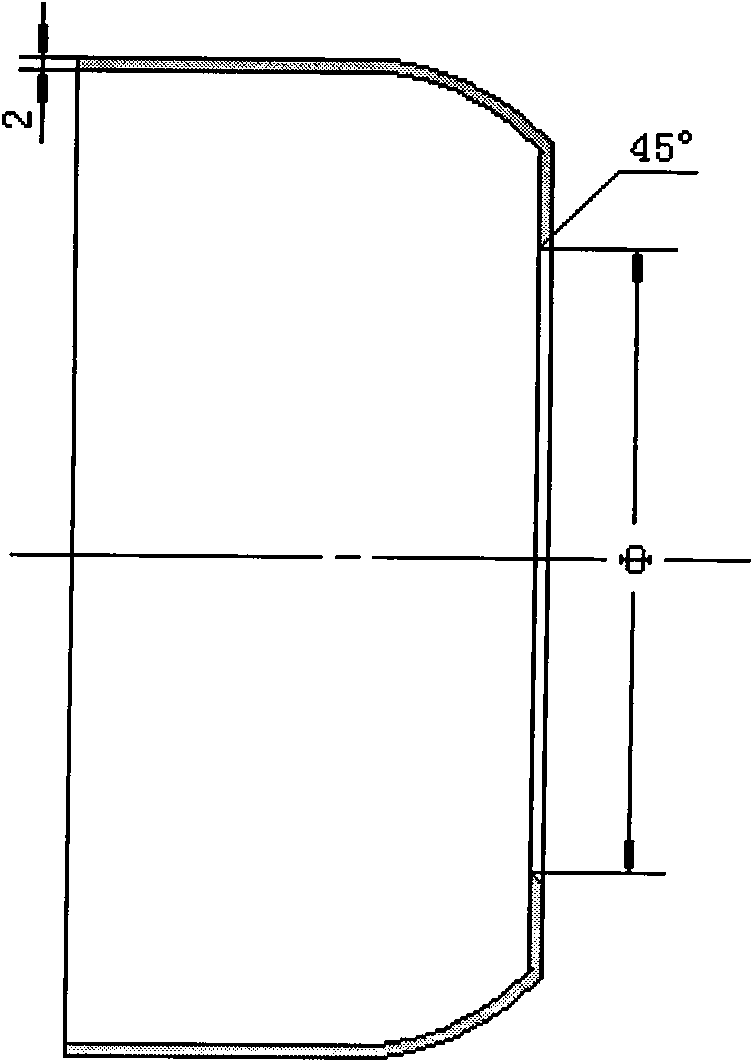

Method for thermal spraying of composite bottom layer of aluminum pan of electromagnetic oven

InactiveCN101880850AWide range of choicesImprove product qualityCooking-vessel materialsDomestic stoves or rangesThermal sprayingThermal printing

The invention discloses a method for thermal spraying of a composite bottom layer of an aluminum pan of an electromagnetic oven, which is used in the manufacturing industry of food cookers and is as shown by a drawing appended to the abstract. A magnetic composite layer with a certain thickness is formed by using an automatic spraying method, designing the joint of a coating and the pan bottom into a concave mosaic structure and spraying a magnetic material (pure iron, iron alloy or 430 stainless steel) to the bottom of the aluminum pan so as to meet the operating requirements of the electromagnetic oven. According to the requirements of a product, one or more material (copper, stainless steel, aluminum, nickel, chromium or ceramic) coatings with different thicknesses or functions can be sprayed to realize aesthetic property, practicability and functionality of the electromagnetic oven pan to ensure that the pans for the electromagnetic oven become various middle-grade and high-grade series products.

Owner:慈溪光华金属复合材料有限公司

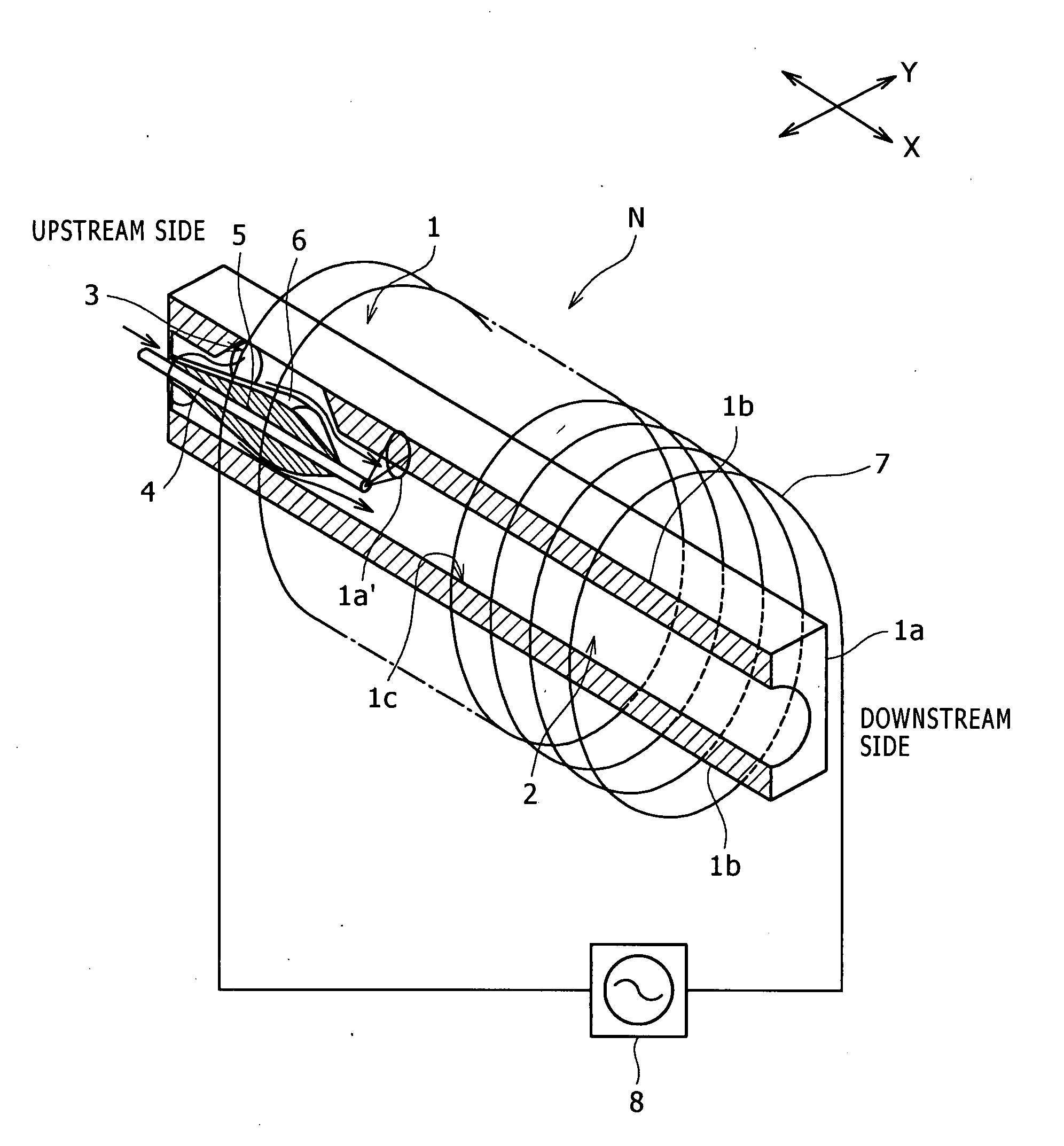

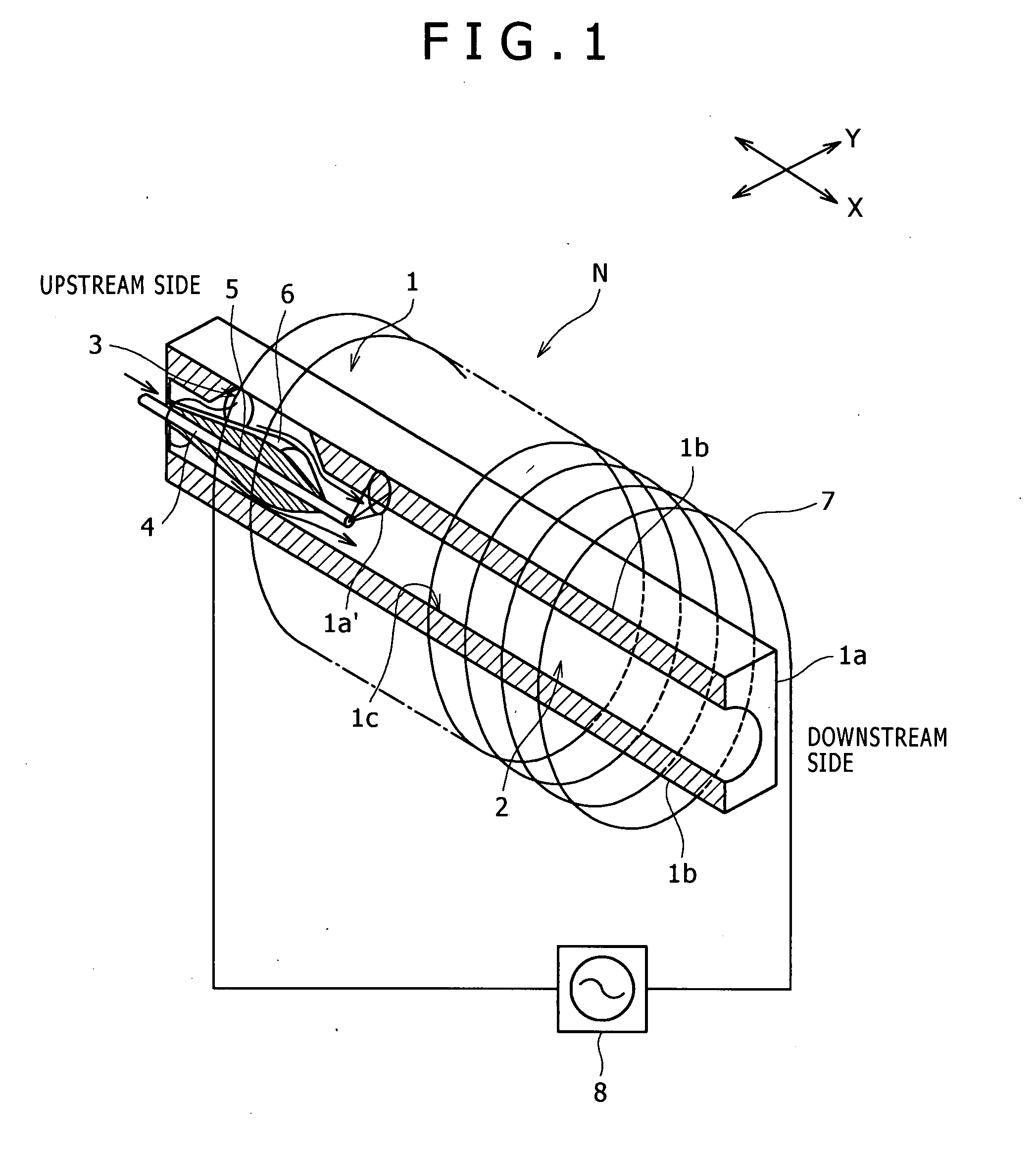

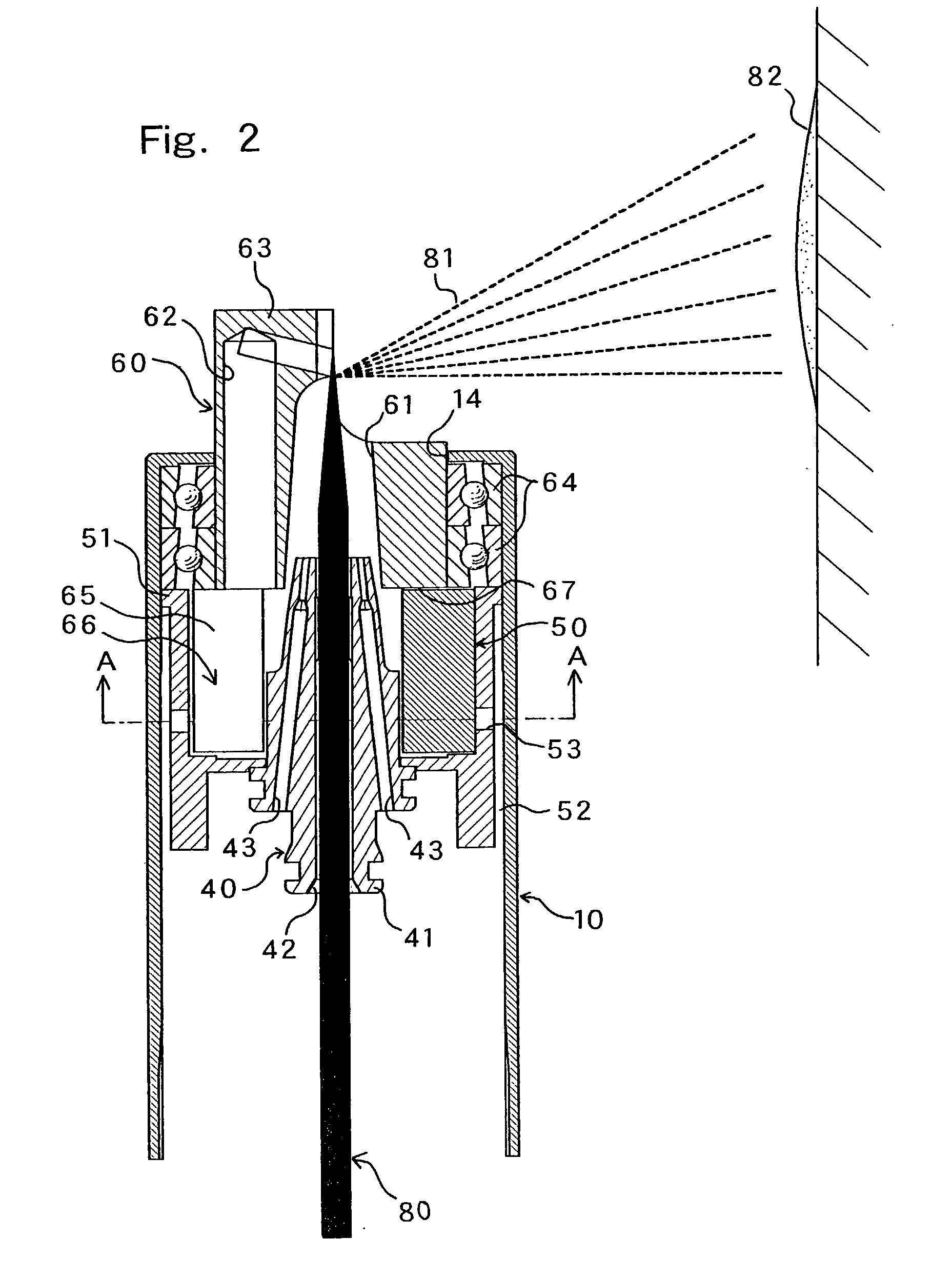

Thermal spraying nozzle device and thermal spraying system using the same

InactiveUS20090056620A1Reduce componentsEasy to controlLiquid surface applicatorsMolten spray coatingThermal sprayingProduct gas

[Subject]A thermal spraying nozzle device capable of accurately forming a uniform and compact metal laminate, as well as a thermal spraying system using the thermal spraying nozzle device, are to be provided.[Solution]A thermal spraying nozzle device wherein carrier gas is introduced into an inlet side of a nozzle (1) to form a supersonic gas flow in the entire region inside the nozzle and a thermal spraying material is atomized and ejected by the gas flow, the thermal spraying nozzle device comprising a thermal spraying material inserting section (5) for insertion therethrough of the thermal spraying material (4) formed in a linear shape into the nozzle (1) from the inlet side substantially in parallel with the gas flow and a laser device for heating and melting the thermal spraying material projected from the thermal spraying material inserting section in the vicinity of a front end of the thermal spraying material inserting section, particles of the thermal spraying material melted and atomized by the laser device being cooled quickly by the supersonic gas flow in the nozzle (1) and ejected in a solidified or semi-solidified state.

Owner:KOBE STEEL LTD

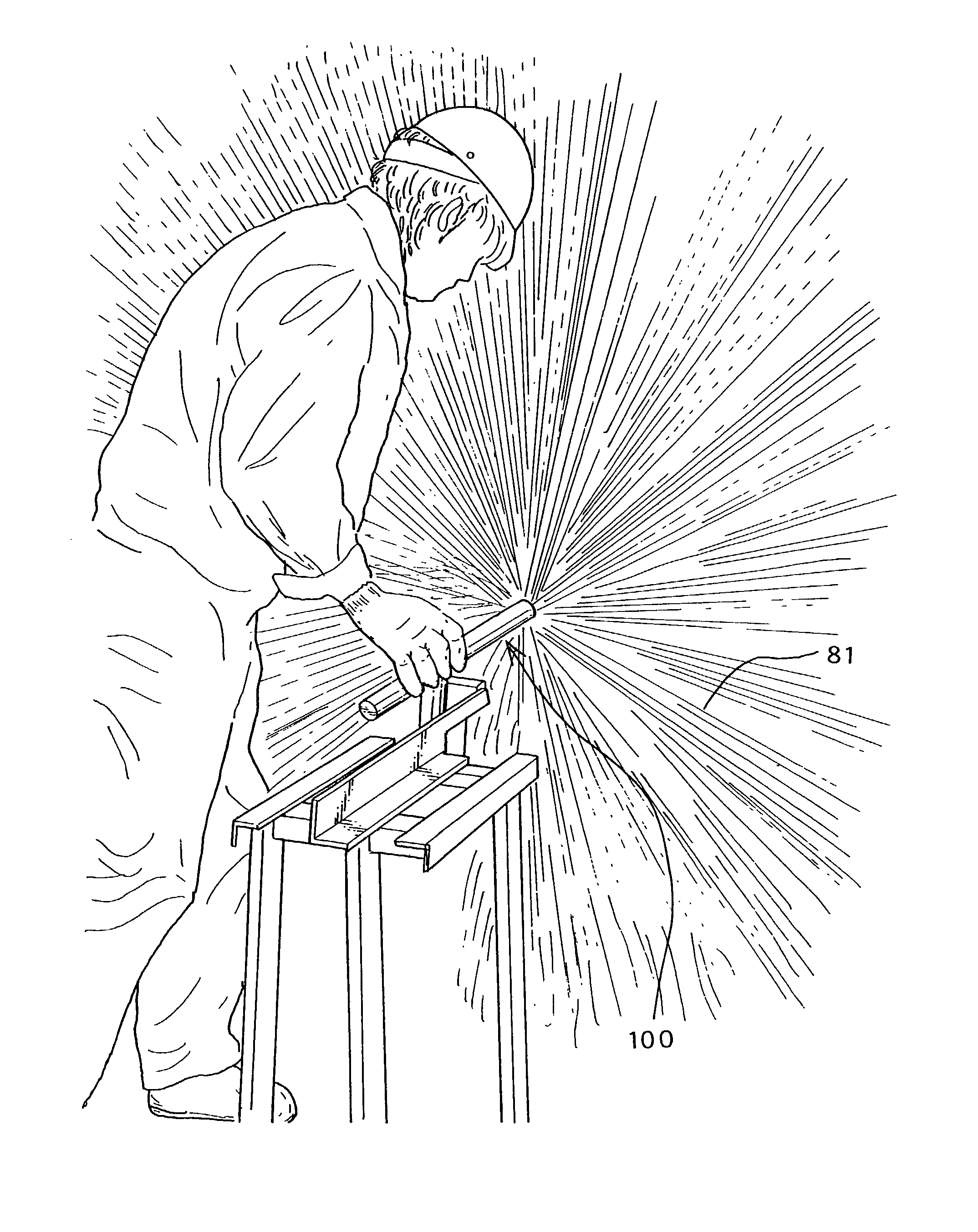

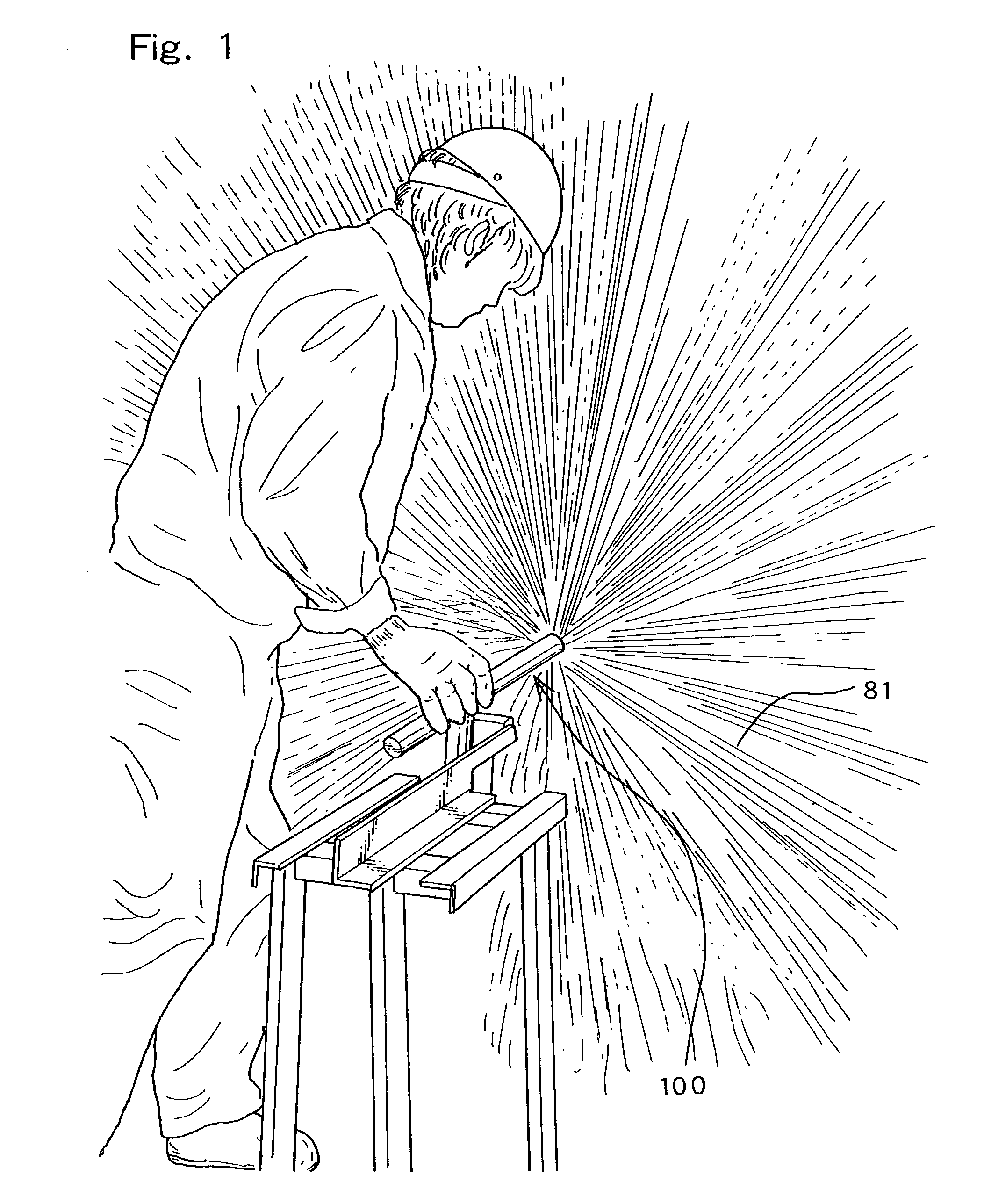

Torch for thermal spraying

InactiveUS20030075618A1Increased durabilityAvoid damageLiquid surface applicatorsMovable spraying apparatusForming gasThermal spraying

The thermal spraying torch 100 is capable of successively supplying a thermal spray material 80 heated and fused by a plasma forming gas in an arc generated between electrodes contained in an outer cylinder 10, or by a combustion gas supplied passing through the outer cylinder 10 and burned under high temperature conditions. The torch can spray the thermal spray material 80 via a nozzle 40 by the plasma forming gas or the combustion gas so that droplet(s) 81 can be formed, and a rotatable discharge member 60 is contained in a forward portion of the nozzle 40 and has a droplet passage 61 for the droplet(s) 81 at the center so that the droplet(s) 81 can be jetted together with the forming gas or the combustion gas. The discharge member 60 is formed with a projection 63, which changes a discharge direction of a droplet(s) 81 at the center of the distal end portion, and is formed integrally with a plurality of arm members 65, which project from the discharge member 60 and arranged in an air jet cylinder 50 that is contained in the outer cylinder 10 at the rear end, whereby an air jet space 66 for jetting a rotation air is formed, and rotational force is given to the discharge member 60 by air jetted from an air jet port 53 of the air jet cylinder 50 arranged outside the air jet space 66. Therefore, in the thermal spraying torch 100, the rotational speed of the discharge member 60 for radially discharging the droplet 81 can be set to a range from 800 to 6,000 rpm. Further, thermal spraying is carried out with respect to the inner surface of the pipes and the cylinder 91 so that the optimum sprayed coating film 82 can be formed. A process for thermal spraying with such a device is also disclosed.

Owner:SHIMAZU KOGYO YUGENKAISHA

Method and system for automatical antifreezing and thermal insulating of tunnel lining in high and cold areas

InactiveCN102953738ARealize automatic antifreeze and heat preservationReduce operating and maintenance costsUnderground chambersTunnel liningThermal insulationLiquid state

The invention relates to a method and system for the automatical antifreezing and thermal insulating of a tunnel lining in high and cold areas. The method comprises the following steps that (1) a tunnel is provided with a surrounding rock, a primary lining, a waterproof plate, a secondary lining and a thermal preservation and thermal insulation layer sequentially from the outside to the inside; (2) a plurality of heating tubes are arranged, and refrigerant is sealed in the heating tubes; (3) the heating tubes are arranged between the secondary lining and the thermal preservation and thermal insulation layer along the length direction of the tunnel, the lower parts of the two ends of the heating tubes are buried in the surrounding rock below a tunnel pavement, so that the refrigerant is uniformly distributed on the lower parts of the two ends of the heating tubes; and the refrigerant continuously transfers heat from the surrounding rock below the pavement to the surface of the secondary lining through the circulation of ascending in a spontaneous vaporized gaseous state and descending in a condensation liquid state, and furthermore, the tunnel lining can be automatically prevented from being frozen and thermally insulated. Compared with the existing antifreezing and thermal insulating technology, the method has the advantages that the operating process does not consume any energy, the spontaneous vaporizing and condensing circulation of the refrigerant is utilized only, so that the tunnel lining can be automatically prevented from being frozen and thermally insulated; and moreover, the method is flexible in design, is convenient to construct and is low in cost.

Owner:FUZHOU UNIV

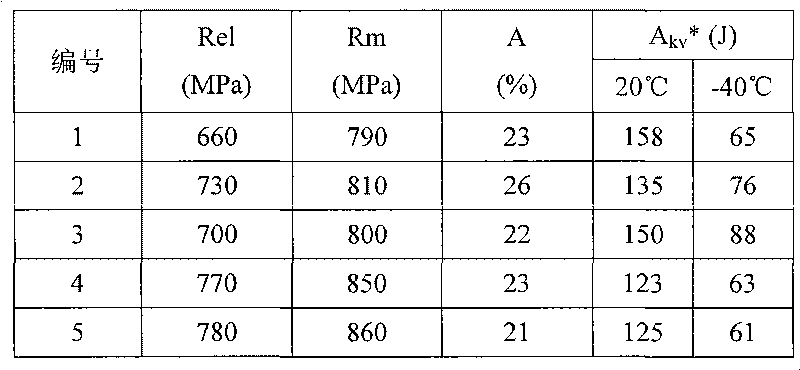

High-strength welding wires of gas shielded welding needing thermal refining after welding

InactiveCN101722382AGood mechanical propertiesImprove low temperature toughnessFurnace typesWelding/cutting media/materialsAbsorbed energyHigh intensity

The invention relates to welding wires, in particular to high-strength welding wires needing hardening and tempering after welding, comprising the following chemical components by weight percent: 0.03-0.12 wt% of C, 0.30-0.80 wt% of Si, 1.2-2.2 wt% of Mn, 1.0-2.0 wt% of Ni, 0.05-0.30 wt% of Cu, 0.10-0.50 wt% of Cr, 0.20-0.80 wt% of Mo, 0.03-0.20 wt% of Ti, equal to or less than 0.015 wt% of S, less than or equal to 0.020 wt% of P, and the balance Fe and inevitable impurity elements. As for the welding wires after rich Ar gas shielded welding, under the thermal refining state, the mechanical property of the obtained welded metal is follows: yield strength ReL is equal to or greater than 630MPa, tensile strength Rm is equal to or greater than 780MPa, elongation A is equal to or greater than 20%, and absorbed energy Akv is equal to or greater than 60J under the temperature of -40 DEG C. The welded metal of the welding wires has high strength, good low-temperature toughness and favorable welding technological property after hardening and tempering.

Owner:BAOSHAN IRON & STEEL CO LTD

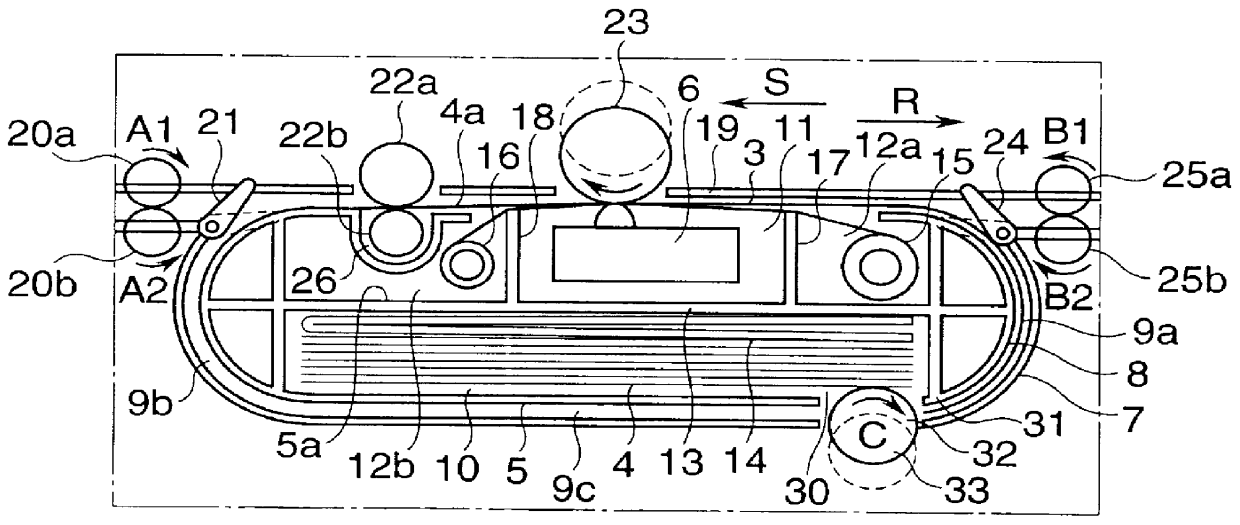

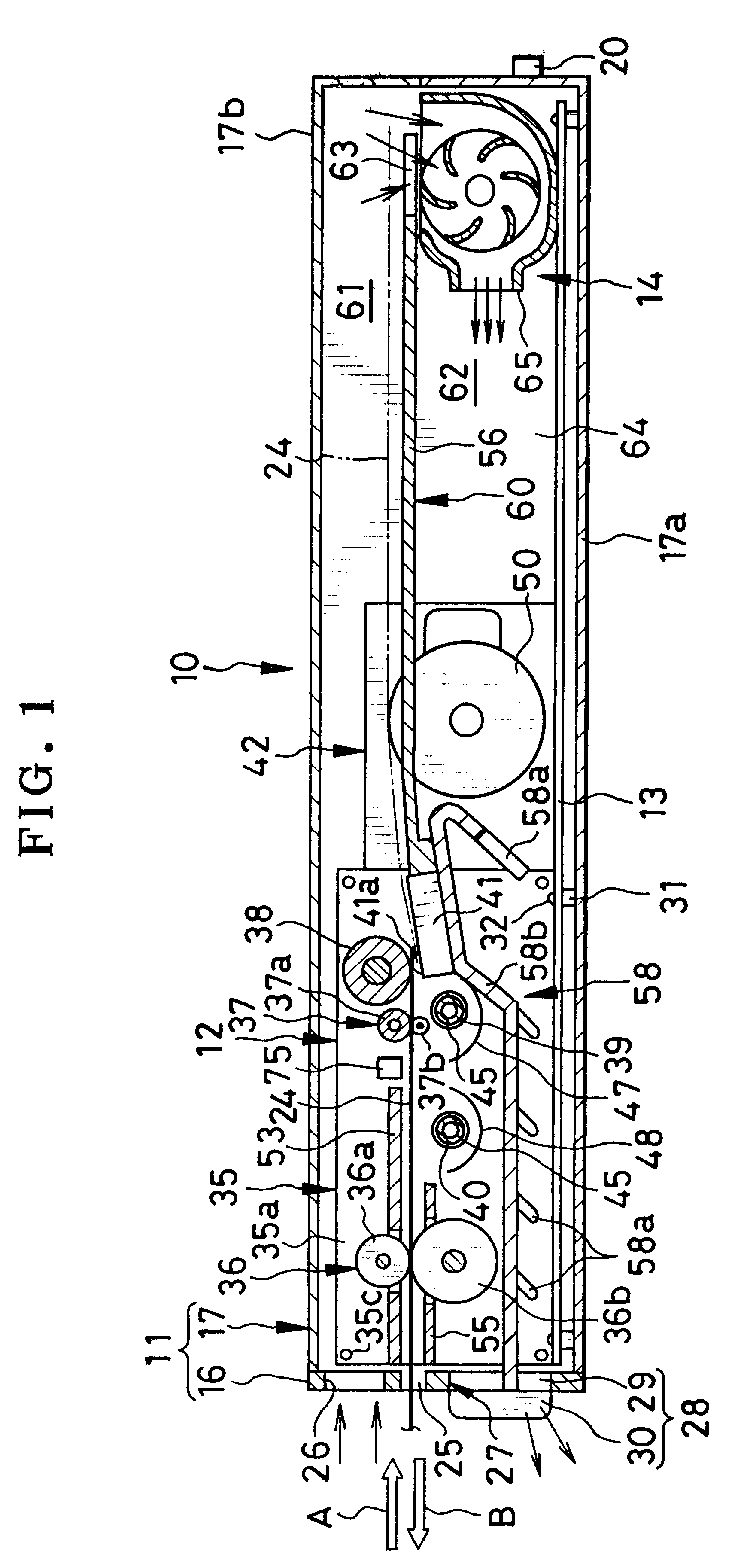

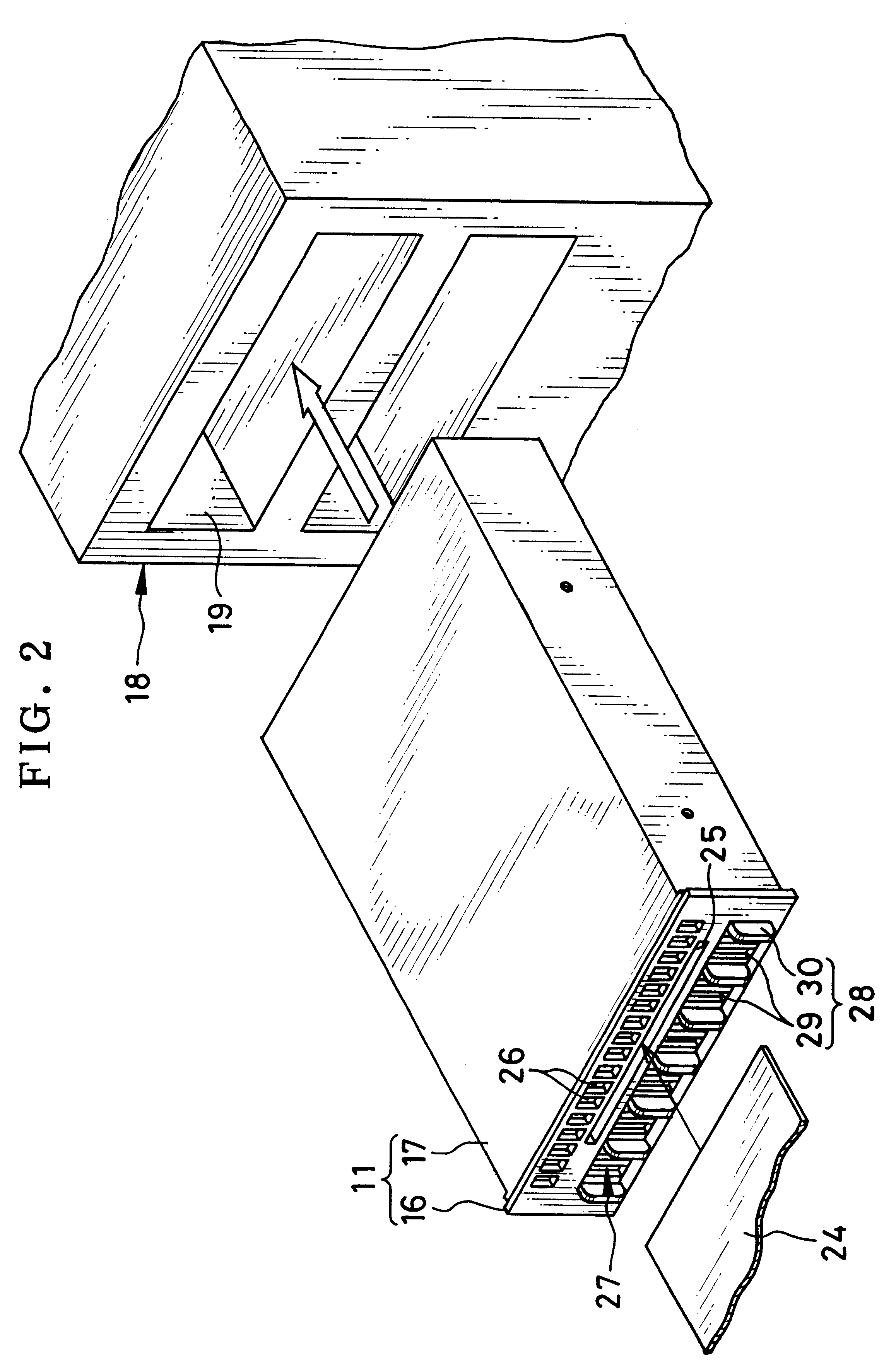

Thermal printer, thermal printing method and conveyor for recording material

A color thermal printer a conveyor for conveying a color thermosensitive recording sheet along a conveying path. A thermal head thermally records a full-color image to the recording sheet being conveyed. A fixer lamp applies ultraviolet rays of a predetermined range of wavelength to the recording sheet being conveyed, for optically fixing the recording sheet. In the thermal printer, a printer casing has a small height, and includes a front panel oriented vertically. An insertion opening in the front panel is adapted to insertion of the recording sheet before the recording, and ejection of the recording sheet after the recording. An air inlet and an air outlet are formed in the front panel. The insertion opening is disposed between the air inlet and the air outlet. An air passageway is disposed in the printer casing, and communicates from the air inlet to the air outlet via at least a portion of the conveying path. A fan unit is disposed in the air passageway, and causes air from the air inlet to flow along the air passageway, to cause heat generated in the printer casing to exit from the air outlet.

Owner:FUJIFILM CORP

Thermal printer

InactiveUS20090219375A1Easy for use printerReduce the possibility of damageRecording apparatusPower drive mechanismsHeat sensitiveThermal printing

THERMAL PRINTER comprised by two chassis, first chassis (3) having movable blade (11) from cutting mechanism (7), thermal head (12) from thermal printing mechanism (9), automatic activation mechanism from movable blade and tracking mechanism from platen roller (8), and second chassis (4) wherein fixed blade of the cutting mechanism, and platen roller of the thermal printing mechanism are positioned. Thermal head is horizontally placed allowing paper direction to frontal part from printer, and platen roller is placed right above thermal head. On frontal part, there is a vertical cutting mechanism with slightly inclination so that mobile blade movement direction in perpendicular to line formed between cover rotation axis and the contract point between both blades.

Owner:ELGIN SA

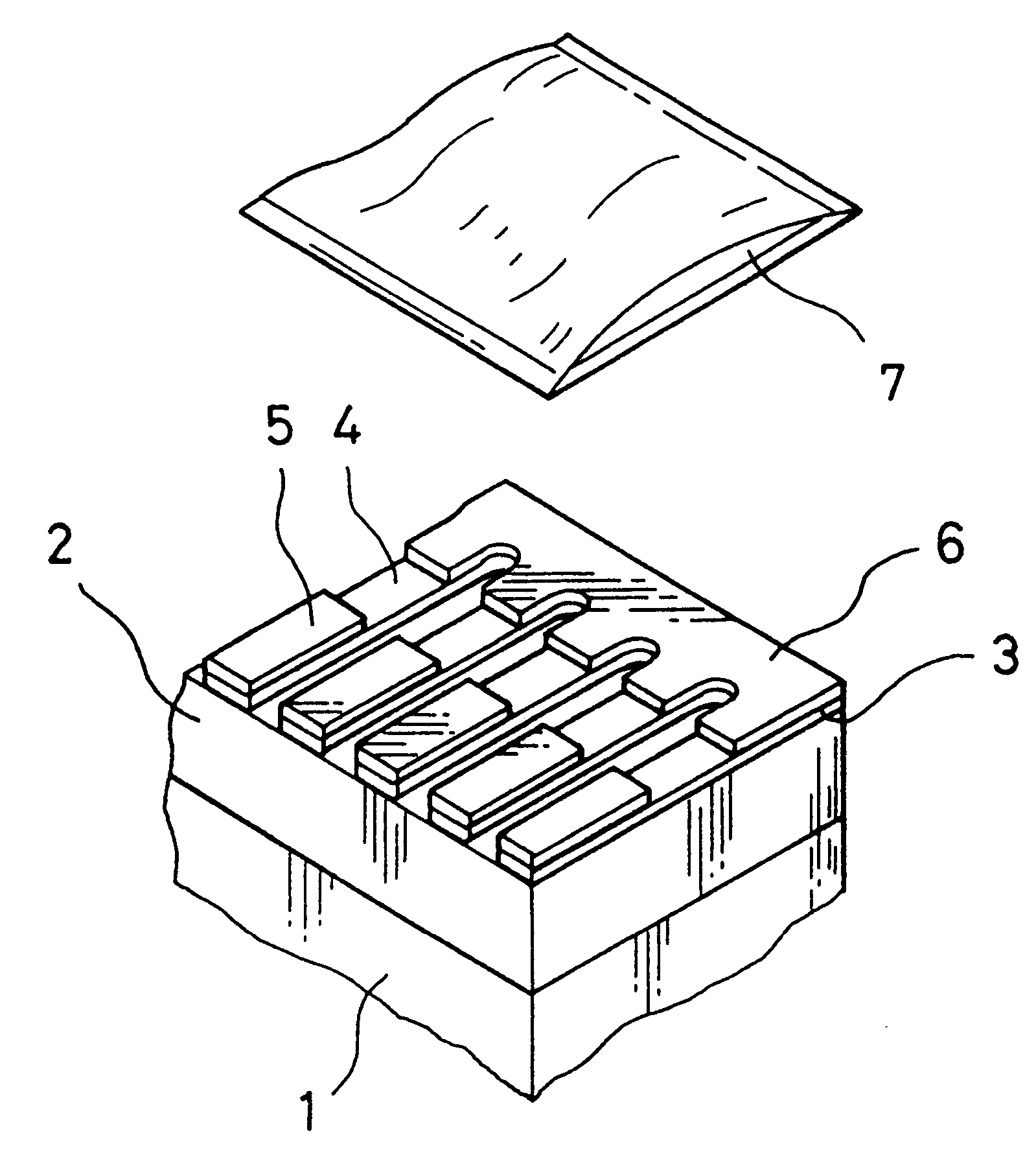

Thermal printing head, process for producing thermal printing head, recorder, sinter and target

InactiveUS6201557B1High densityLow densityVacuum evaporation coatingSputtering coatingSputteringThermal printing

A process for producing a protective layer or a primer layer for a heat-generating resistor for a thermal head by sputtering using a target comprising a sinter of a silicon nitride / silicon dioxide / magnesium oxide powder. By regulating the particle diameter of the powder, the target is prevented from suffering partial peeling during the sputtering.

Owner:KK TOSHIBA

Preparation method of titanium carbide-based cermet powder material for thermal spraying

InactiveCN102166652AImprove wear resistanceReduce coefficient of frictionMolten spray coatingSelf-propagating high-temperature synthesisThermal spraying

The invention provides a preparation method of a titanium carbide-based cermet powder material for thermal spraying, which belongs to the field of powder materials for thermal spraying. The method comprises the following steps of: firstly, weighting titanium powder, graphite powder / soot carbon, and other metal components in a proportion to prepare raw material powder; putting the raw material powder into a ball mill pot for ball milling, briquetting the mixture to form a block after the mixing is finished, placing in a self-propagating high-temperature synthesis reactor, igniting the block after the air in the reactor is removed so that the whole block is ignited to undergo a self-propagating reaction; starting a mechanical pump to vacuumize after the reaction is finished, and cooling reaction products to room temperature with the reactor so as to obtain a loose porous titanium carbide-based cermet block; and finally, after the cermet block is taken out, removing contaminants on the surface of the cermet block, and then crushing and screening residual products to obtain titanium carbide-based cermet powder for thermal spraying in different grain sizes. The preparation method in the invention has the characteristics of short synthesis time, energy saving, environmental protection, low price, and the like, and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

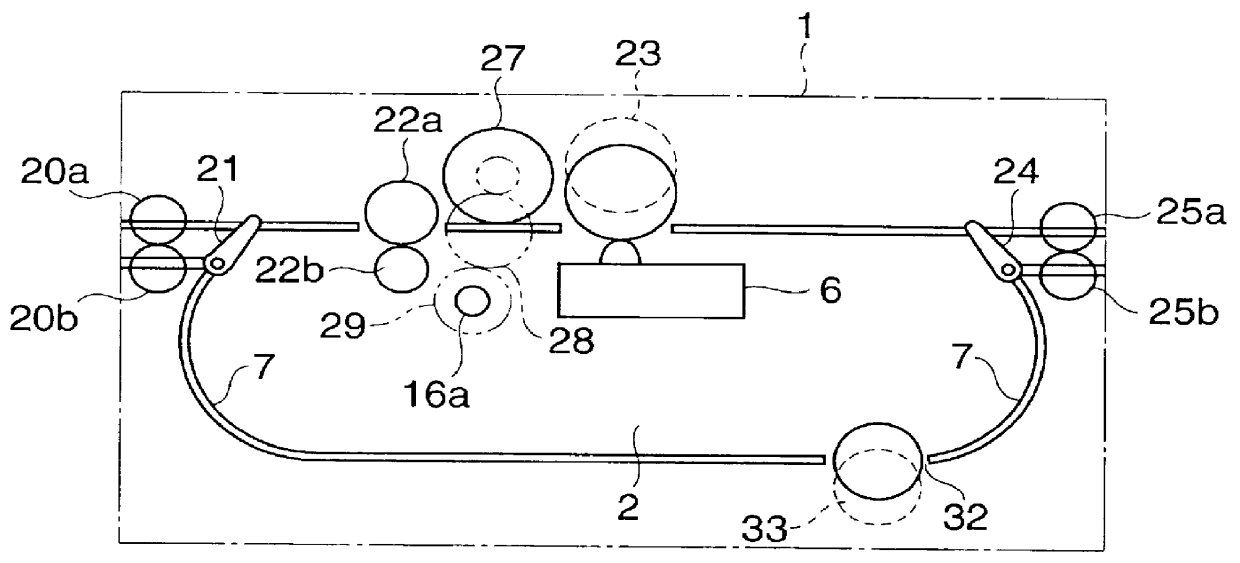

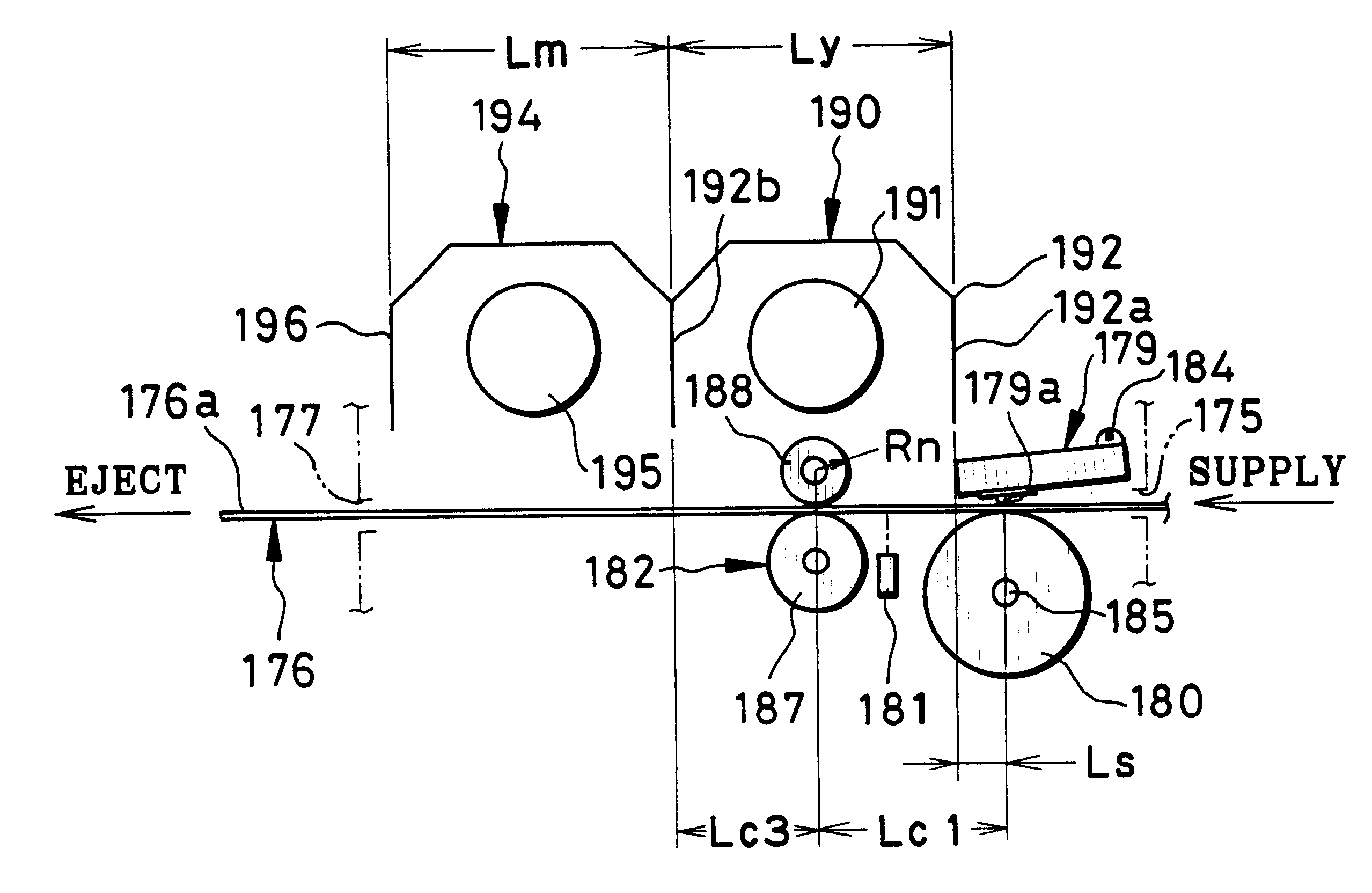

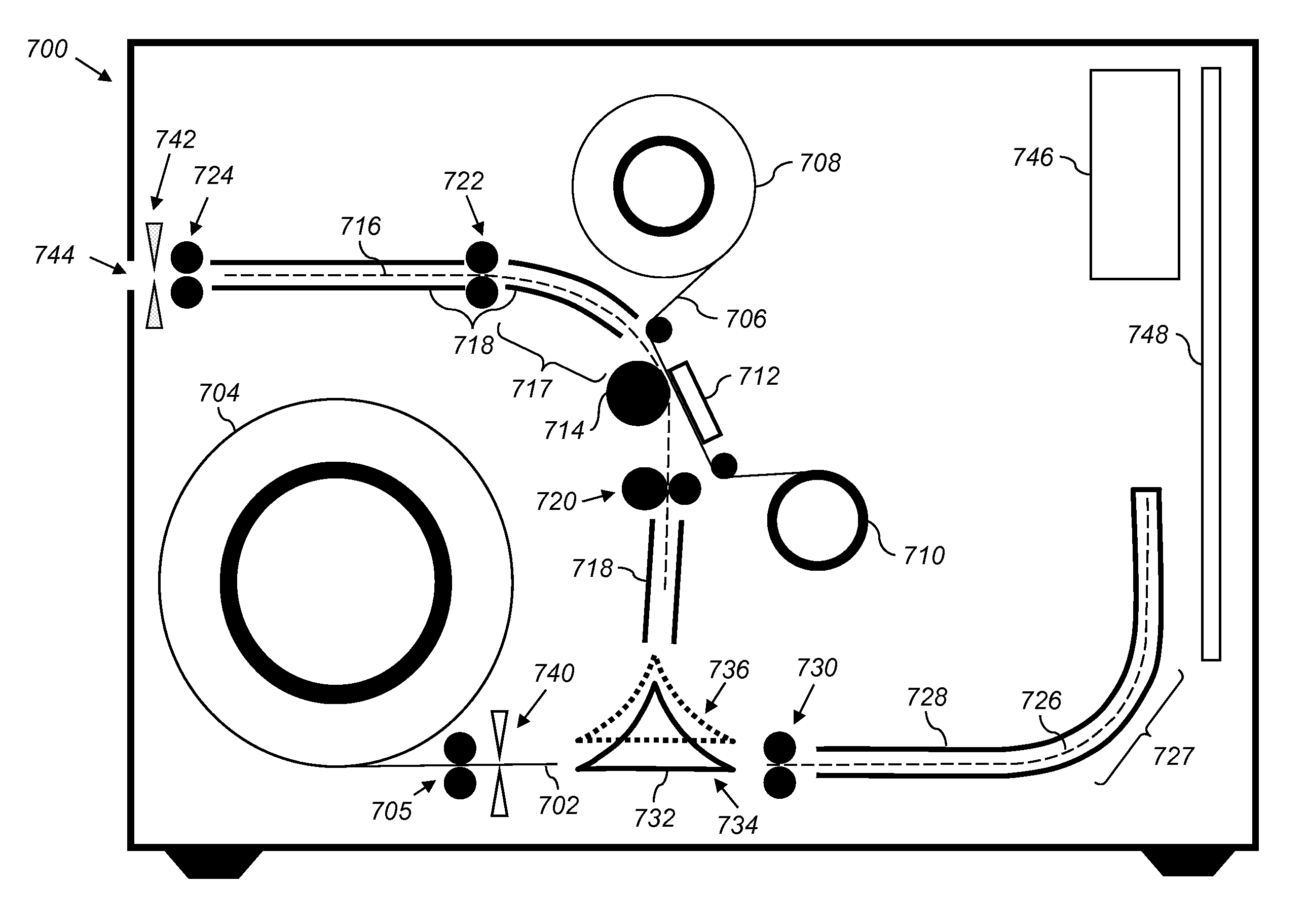

Roll-fed duplex thermal printing system

ActiveUS8599229B1Low costReduced printer sizeRecording apparatusPrinting mechanismsThermal printingEngineering

A roll-fed duplex thermal printing system, comprising a supply roll of receiver media, a printing path, a reversing path, a diverter and a cutter positioned between the supply roll and the reversing path. When the diverter is in a first position the receiver media is directed from the supply roll or the reversing path into the printing path. When the diverter is in a second position the receiver media is directed from the supply roll into the reversing path. During a printing operation, the diverter is positioned in the first position and the receiver media is fed into the printing path where a first side image is printed. The diverter is then repositioned the receiver media is fed into the reversing path where it is cut. The diverter is then repositioned again and the receiver media is fed into the printing path where a second side image is printed.

Owner:KODAK ALARIS INC

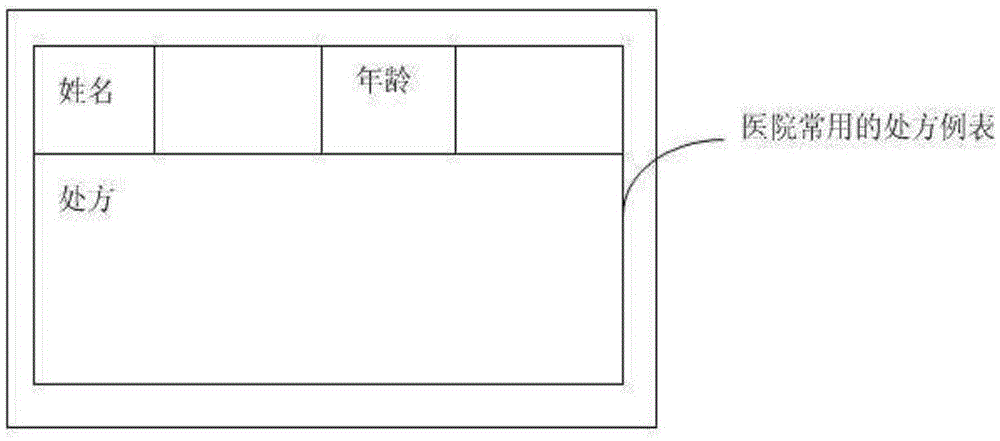

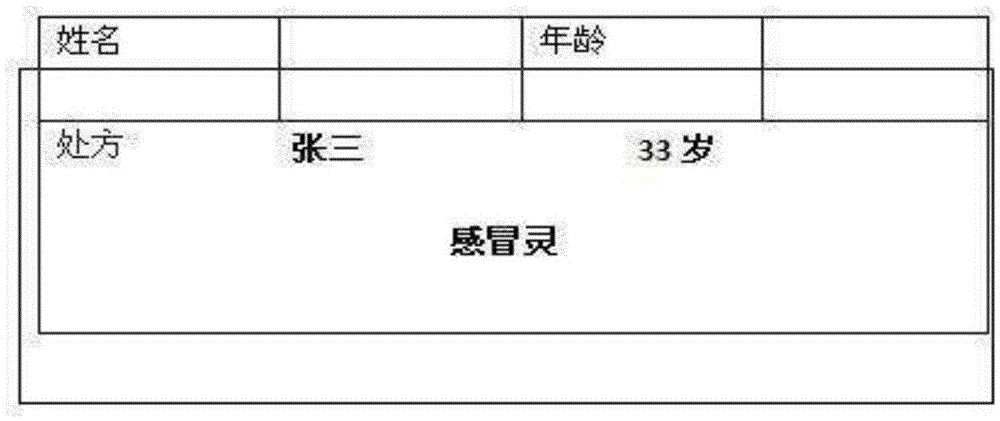

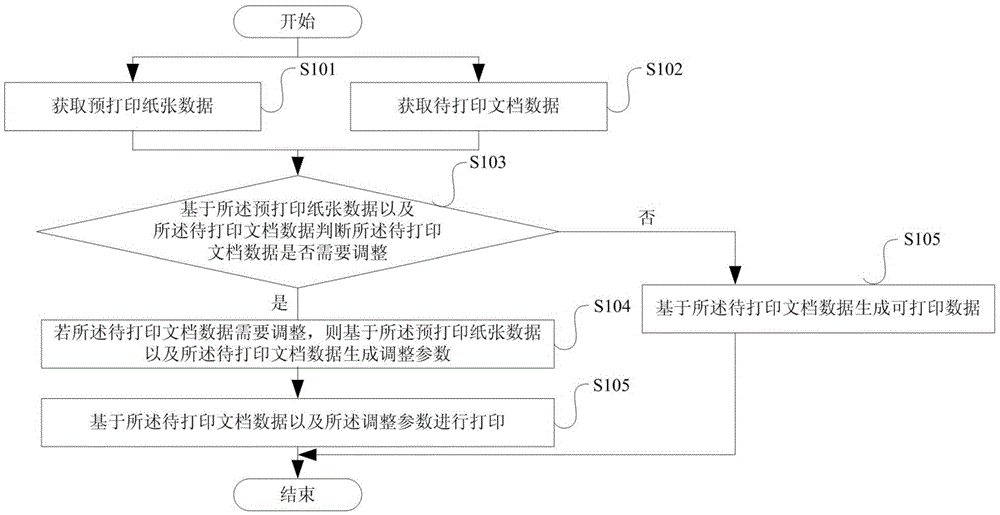

Portrait adjustment control method and apparatus suitable for preprinted paper

InactiveCN105607879ASolve the technical problem that the position of the portrait that will be printed on the preprinted paper cannot be adjusted before the official printingImprove experienceDigital output to print unitsDocumentation procedureData needs

The invention provides a portrait adjustment control method suitable for preprinted paper. The method comprises the following steps: a, obtaining preprinted paper data; b, obtaining to-be-printed document data; c, based on the preprinted paper data and the to-be-printed document data, judging whether the to-be-printed document data needs to be adjusted or not; d, if the to-be-printed document data needs to be adjusted, generating adjustment parameters based on the preprinted paper data and the to-be-printed document data; and e, performing printing based on the to-be-printed document data and the adjustment parameters. The invention furthermore provides a corresponding portrait adjustment control apparatus. According to the portrait adjustment control method and apparatus, whether the to-be-printed document data can be printed in a proper position of the preprinted paper or not is observed or identified through a preview interface or a computer identification function before formal printing, and the position of the to-be-printed document data is adjusted based on a judgment result to adjust the printing position, so that good experience is brought for a user, the working efficiency is improved, and a more environmentally-friendly printing technology is provided.

Owner:ZHUHAI PANTUM ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com