Manufacturing method for aluminum alloy automobile hub

A technology for automobile wheels and manufacturing methods, which is applied in the direction of wheels, manufacturing tools, vehicle parts, etc., can solve the problems of long manufacturing time, high manufacturing cost, and low production efficiency of wheel hubs, and achieve shortened processing time, improved elongation performance, and production The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

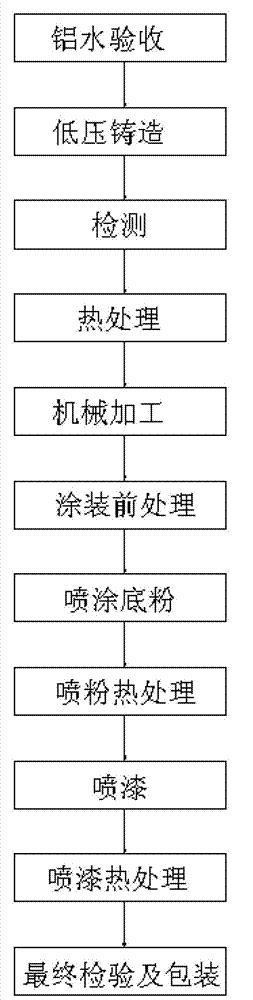

[0032] A manufacturing method of an aluminum alloy automobile wheel hub adopts the following process steps:

[0033] (1) Acceptance of aluminum water: to ensure that the quality of aluminum alloy solution is qualified, and the ratio index of aluminum liquid is as follows: A356.2 alloy ingot: aluminum scrap: geometric waste = 6:3:1, so that the percentage of Si in the important chemical composition of aluminum liquid is The content reaches 6.5%~7.5%, the percentage of Mg is 0.28%~0.32%, and the percentage of Fe is less than or equal to 0.15%.

[0034] (2) Low-pressure casting: inject the qualified aluminum alloy solution into the low-pressure casting mold, and cast it into a wheel hub blank.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com