Textile finishing agent with thermal protecting, antibacterial and moisture-keeping functions, and health socks using the same

A technology of functional finishing agent and antibacterial agent, which is applied in the field of multifunctional textile finishing agent and multifunctional health care socks, and can solve the problems of damaged equipment, poor washing resistance, and poor spinnability of synthetic fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

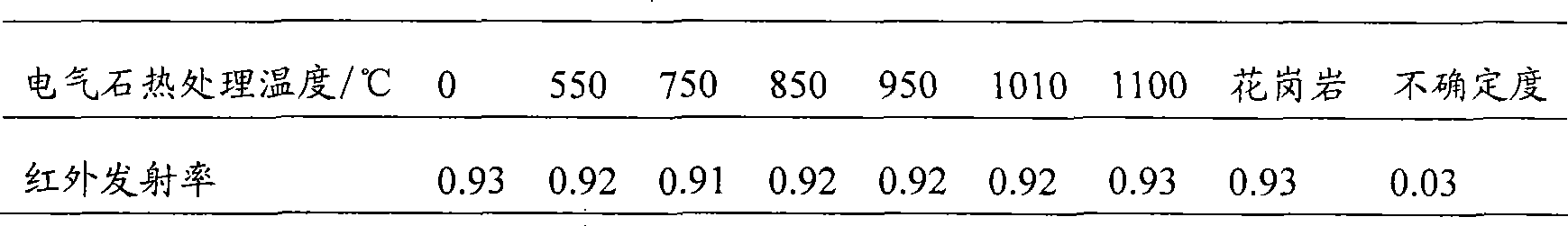

[0062] Example 1 Preparation of Textile Functional Finishing Agent

[0063] Prepare the following components (by weight):

[0064] Tourmaline powder (particle size is 300 nanometers - 5 microns) 10 parts

[0065] Silver ion antibacterial agent (purchased from Japan Bell Spinning Co., Ltd.) 5 parts

[0066] Glycerin (microcapsule emulsion) 5 parts

[0067] Dispersant 8 parts

[0068] Cross-linking agent 5 parts

[0069] Rheology modifier 9 parts

[0070] 58 parts of water

[0071] Mix the above tourmaline powder, silver ion antibacterial agent and glycerin evenly, then add dispersant and stir at room temperature for 2 hours, then add crosslinking agent, rheology modifier and water, stir and mix at room temperature until uniform.

[0072] After the above-mentioned finishing agent was prepared, samples were taken according to Chinese standard FZ / T 01021-92, with reference to AATCC 100-1999, and its antibacterial effect was tested with Staphylococcus aureus and Klebsiella ...

Embodiment 2

[0075] Example 2 Preparation of socks

[0076] Finishing agent obtained by embodiment 1 is diluted to 50ml / l working solution. Soak pure cotton socks in the working solution for 2 hours at room temperature. Dry it at 80°C after centrifugal dehydration, and then pack it with ironing.

[0077] The samples were sent to the Chemical Fiber Product Testing Center of China Chemical Fiber Industry Association for inspection. The inspection basis is the IC-100 tester.

[0078] table 3

[0079]

Embodiment 3

[0080] Example 3 Preparation of Textile Functional Finishing Agent with Foaming Properties

[0081] Prepare the following components (by weight):

[0082] Hexacyclite slurry (average particle size is 3 microns) 30 parts

[0083] 1,1'-Hexamethylenebis[5-4(-chlorophenyl)biguanide]gluconate 4 parts

[0084] Aloe Vera Extract (Microcapsule Emulsion) 5 parts

[0085] Dispersant 5 parts

[0086] 3 parts of cross-linking agent

[0087] Foaming agent 25 parts

[0088] Rheology modifier 10 parts

[0089] 18 parts of water

[0090]Wherein, in the hexacyclite slurry, the content of hexacyclite powder is 35%.

[0091] Mix the above hexacyclite slurry, biguanide antibacterial agent and humectant evenly, then add dispersant and stir at room temperature for 2 hours, then add crosslinking agent, foaming agent, rheology modifier and water, stir and mix at room temperature until even.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com