Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4259results about How to "Improve fire resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

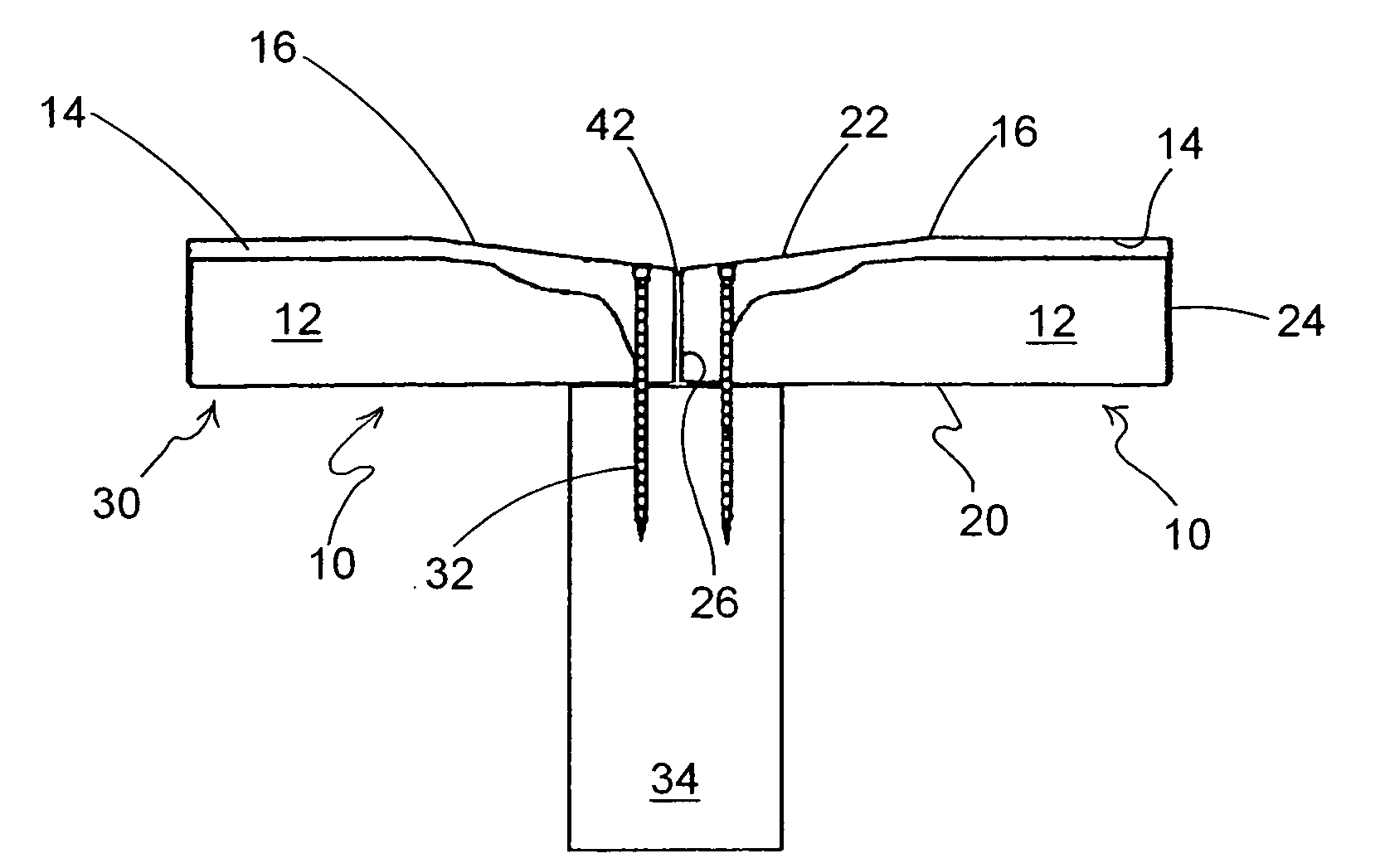

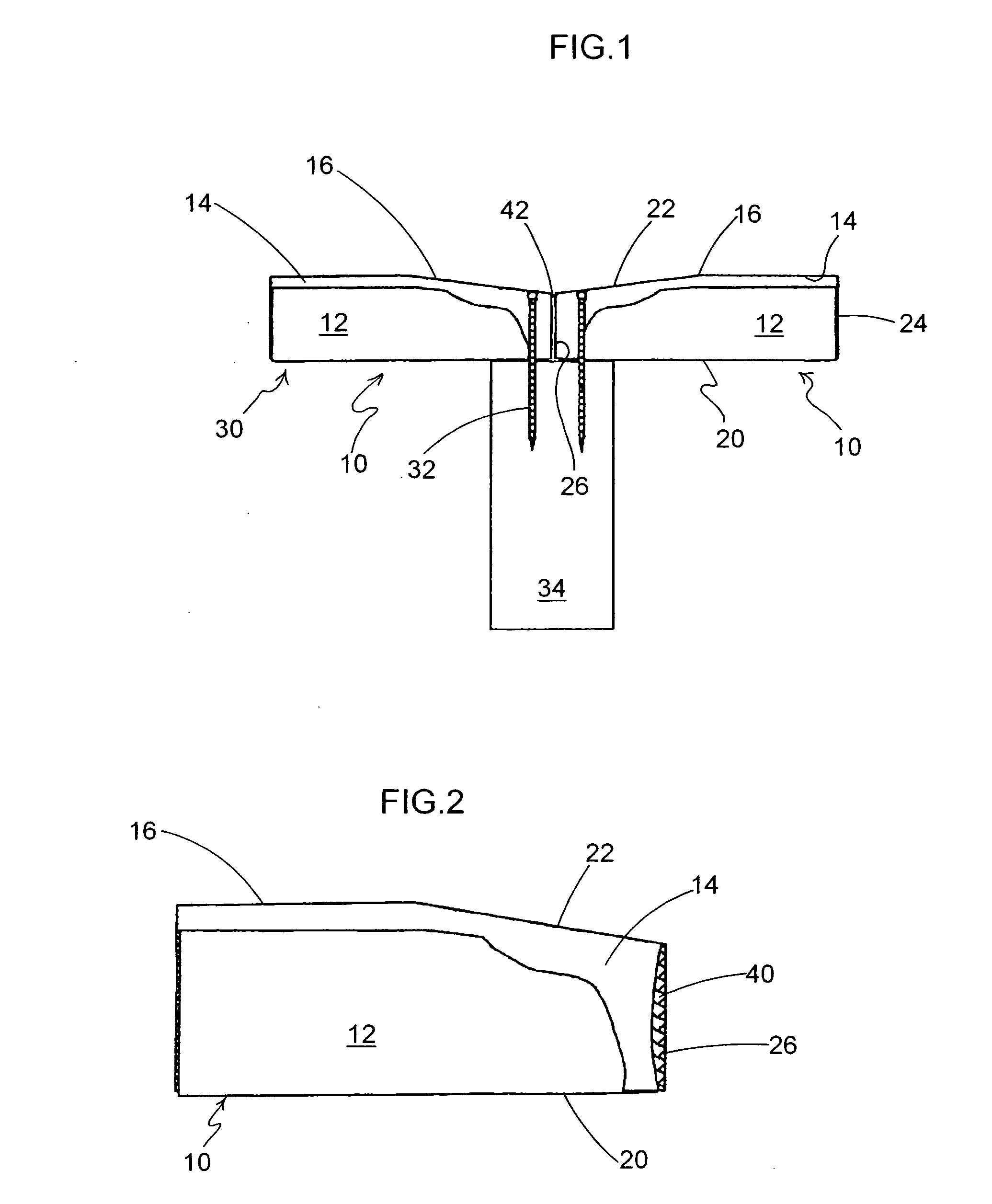

Fire-resistant gypsum panel

InactiveUS20080087366A1Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

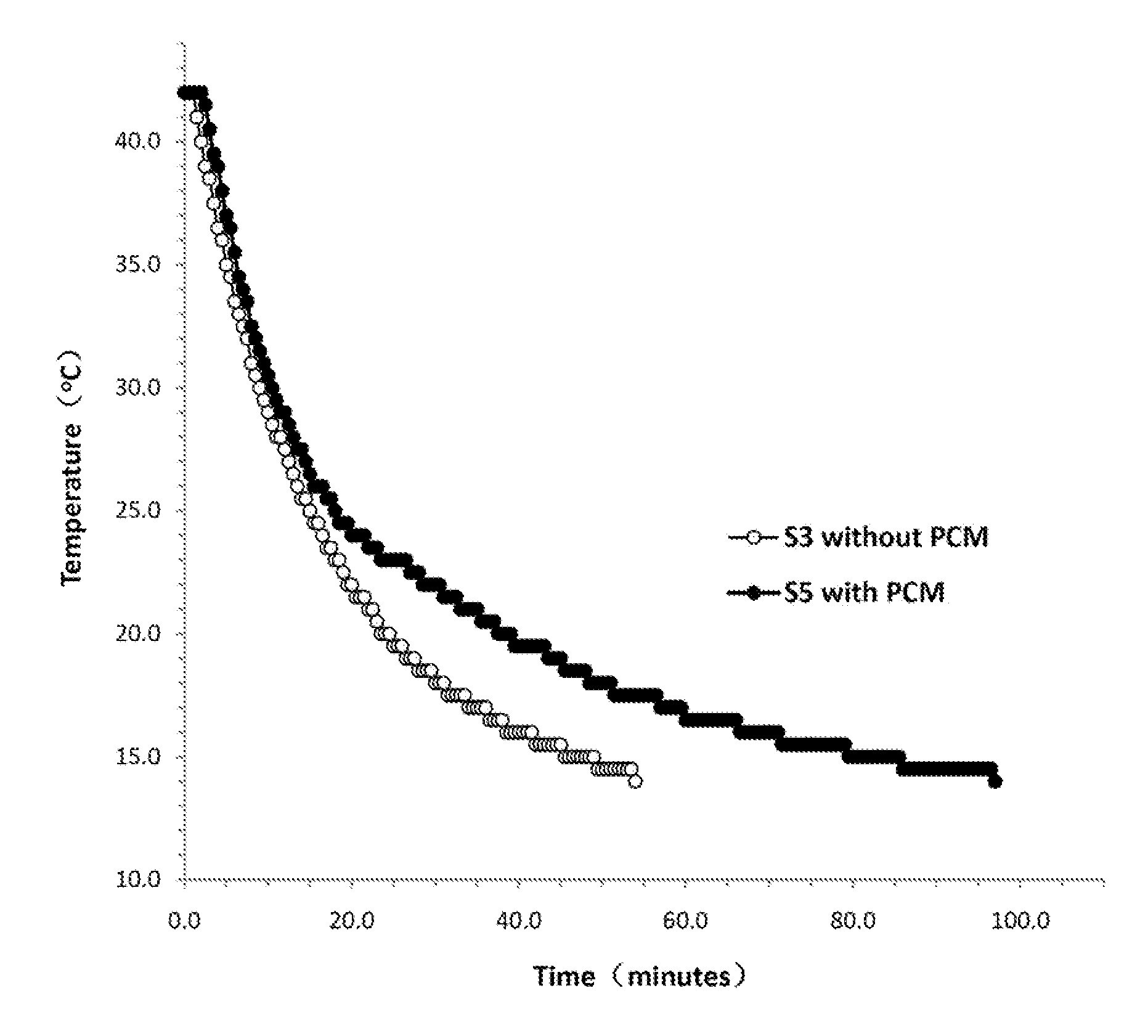

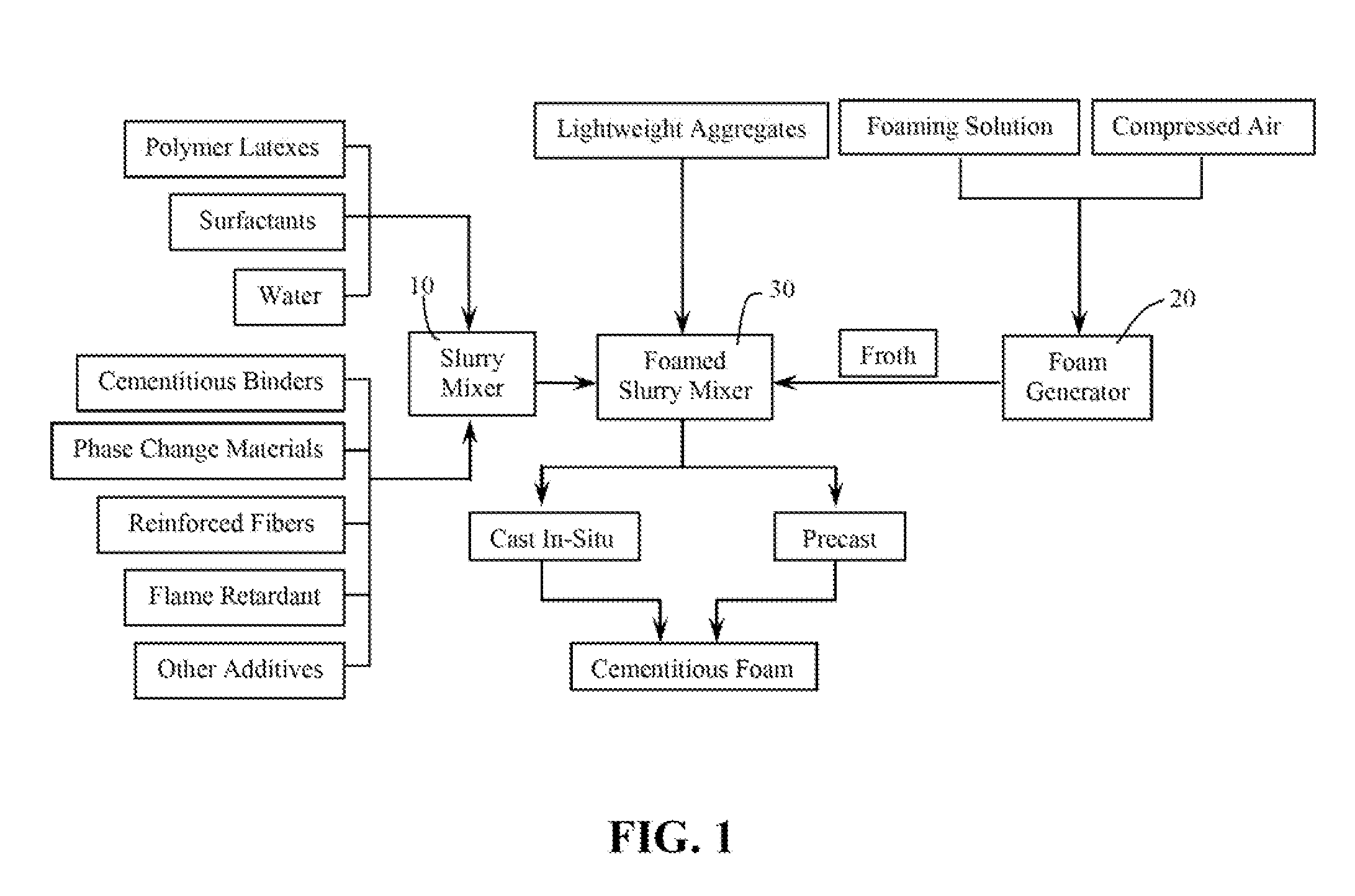

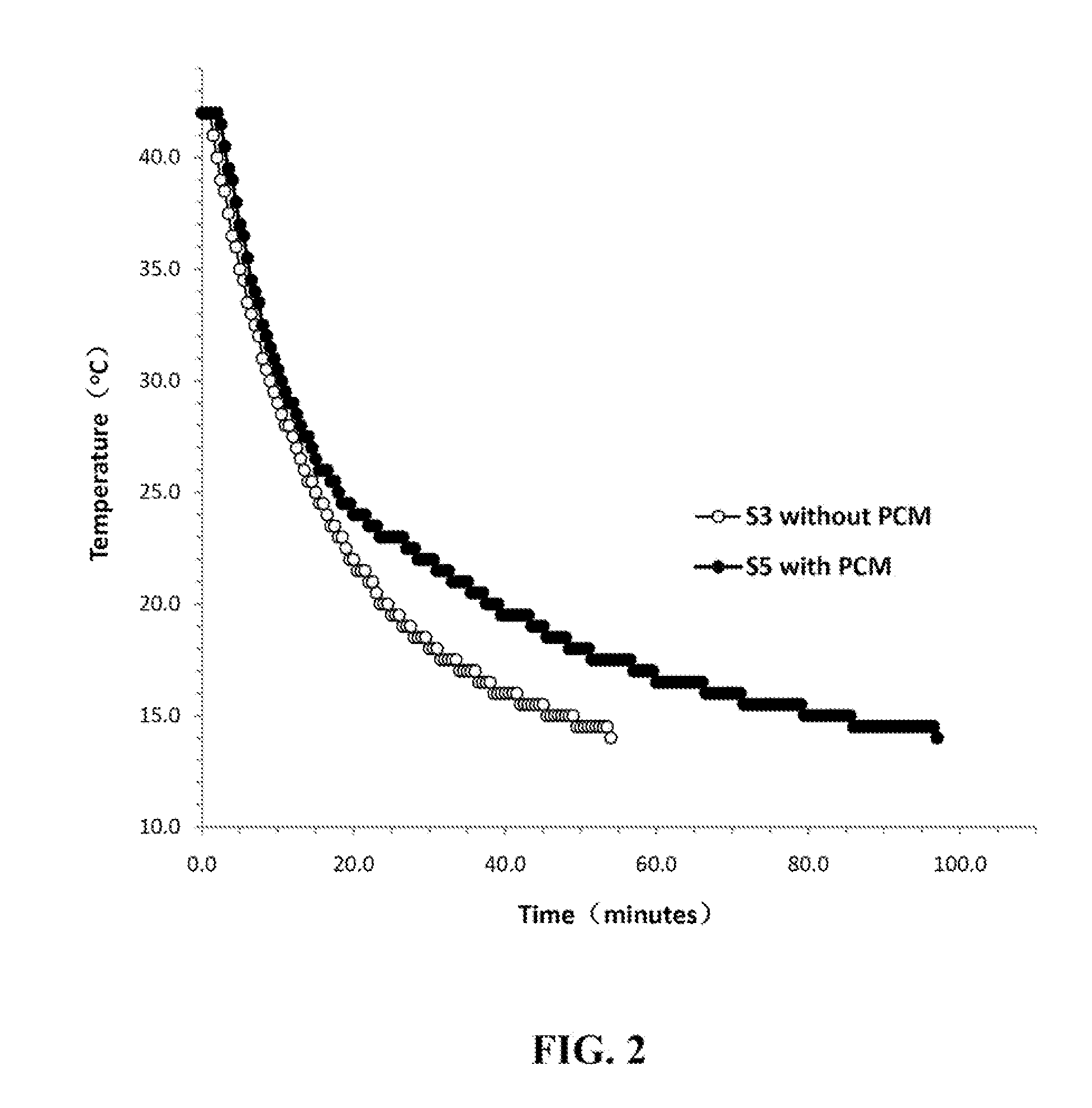

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

Fire-resistant gypsum

InactiveUS20050263925A1Point becomes highImprove fire resistanceConstruction materialWood working apparatusGlass fiberFiber

An improved, fire-resistant, set gypsum composition contains set calcium sulfate dihydrate as the major ingredient and a reinforcing ingredient of resilient, flexible, boron-free glass fibers. Continuous filament forming glass compositions with a softening point preferably greater than about 1580° F. (about 860° C.) and more preferably greater than about 1681° F. (about 916° C.) may be used. The fibers typically are distributed as their separate constituent individual glass filaments uniformly throughout the set calcium sulfate dihydrate.

Owner:OWENS CORNING FIBERGLAS TECH INC

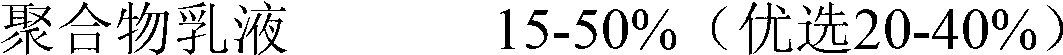

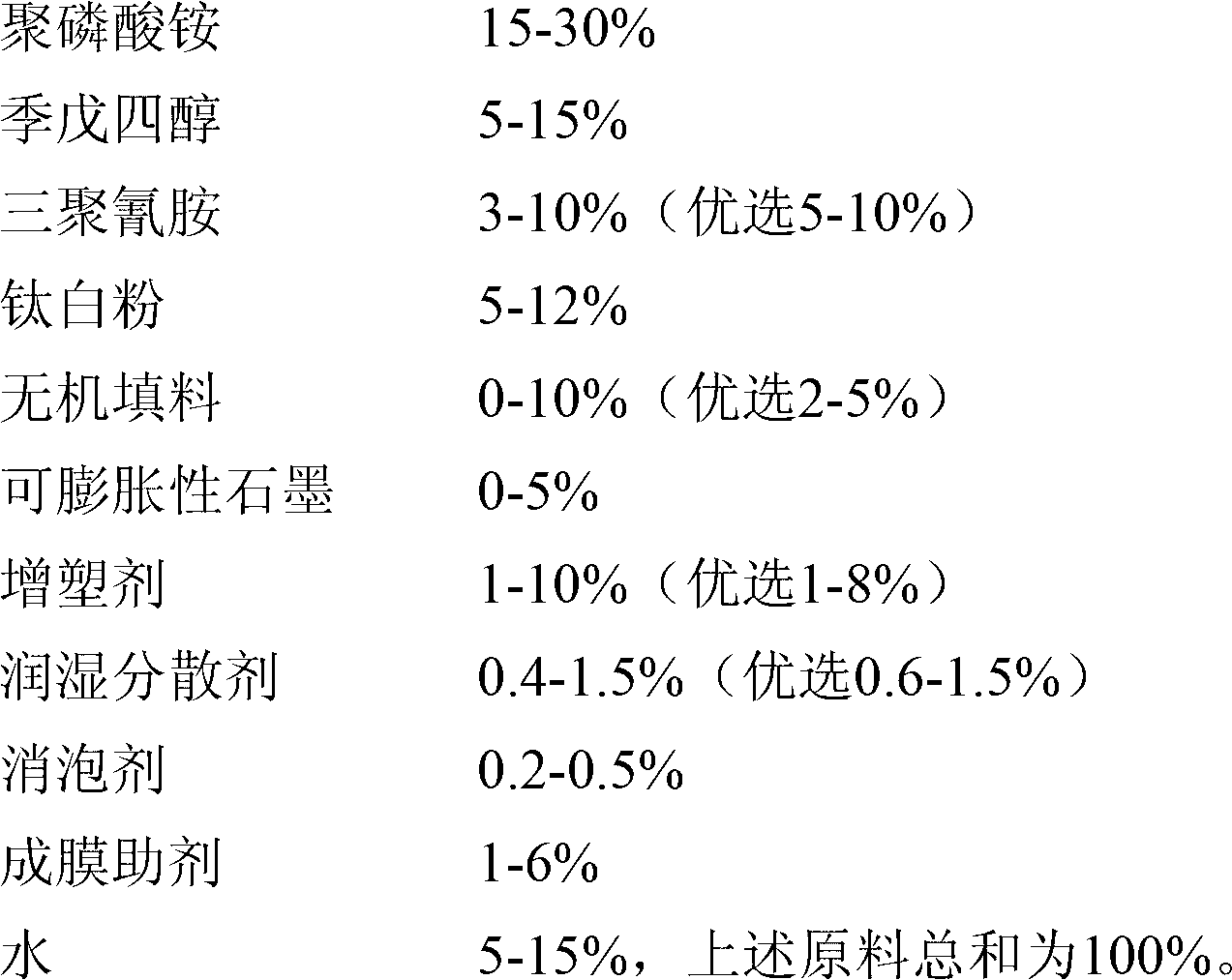

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

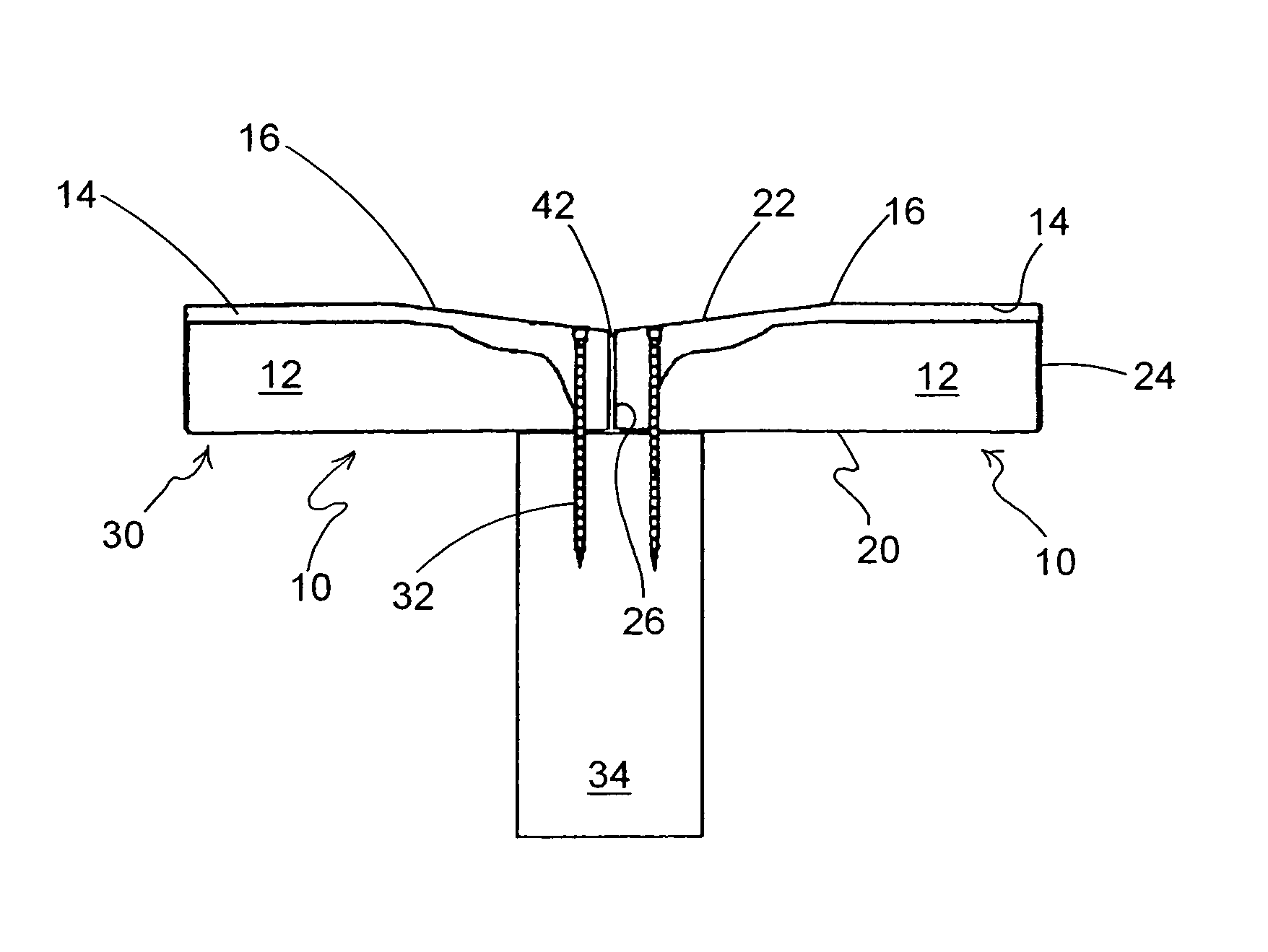

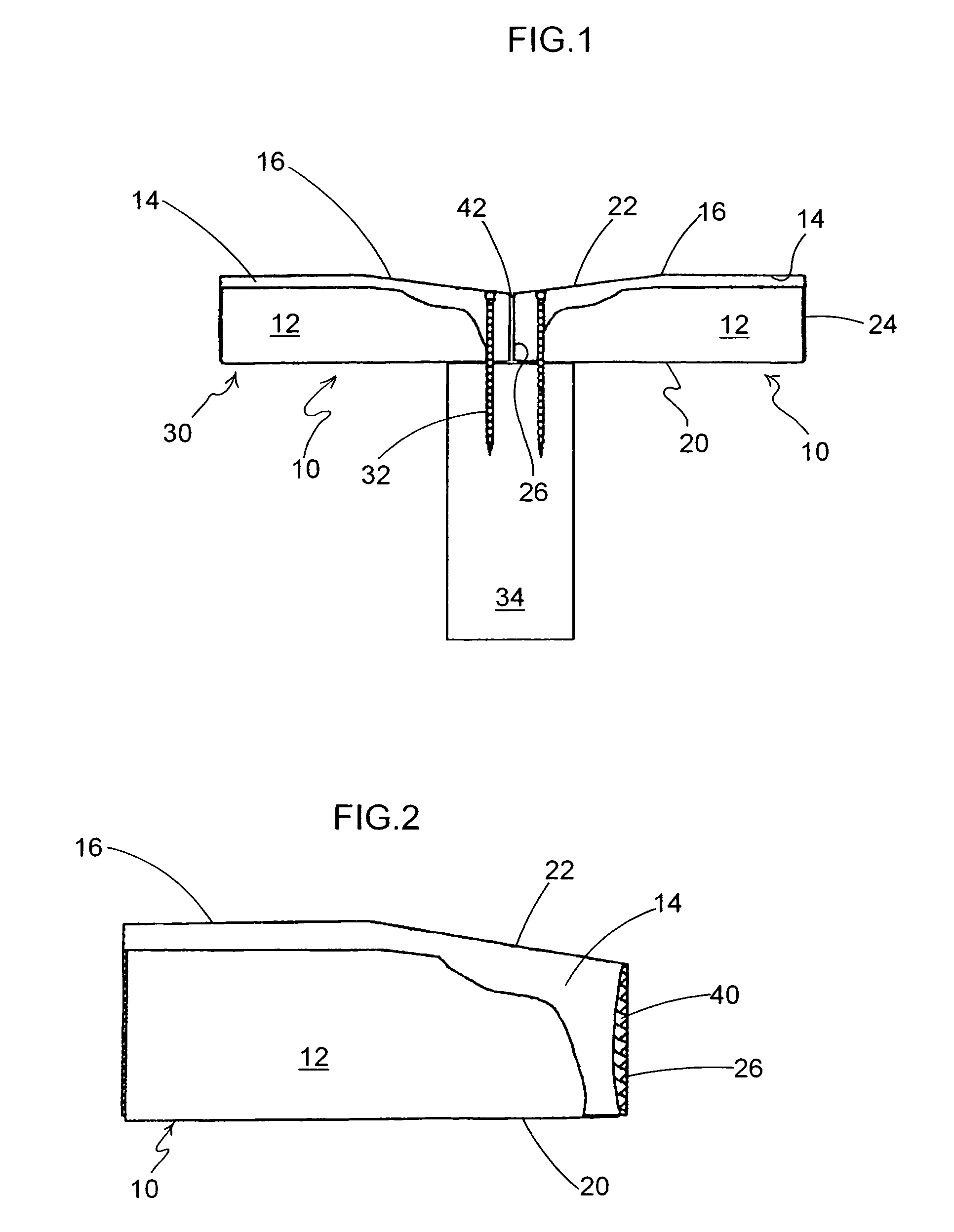

Fire-resistant gypsum panel

InactiveUS7776170B2Improve fire resistanceImprove fire performanceConstruction materialCovering/liningsFire protectionSlurry

A method of continuously forming a multilayer panel includes making a gypsum slurry, then dividing the gypsum slurry into at least a primary gypsum slurry and a secondary gypsum slurry. An additive slurry having water and an intumescent material is created, then added to the secondary gypsum slurry to make an expandable layer slurry that is spread over at least a portion of a facing material. The primary gypsum slurry is distributed over the secondary gypsum slurry over the facing material and the expanding layer slurry to form a core. Optionally, another layer, an edge coating, is applied to the expanding layer for additional fire protection. The edge coating includes a second intumescent material. During a fire, the expanding layer expands to increase the thickness of the fire exposed gypsum panel and the edge coating expands to seal the gap between adjoining gypsum panels.

Owner:UNITED STATES GYPSUM CO

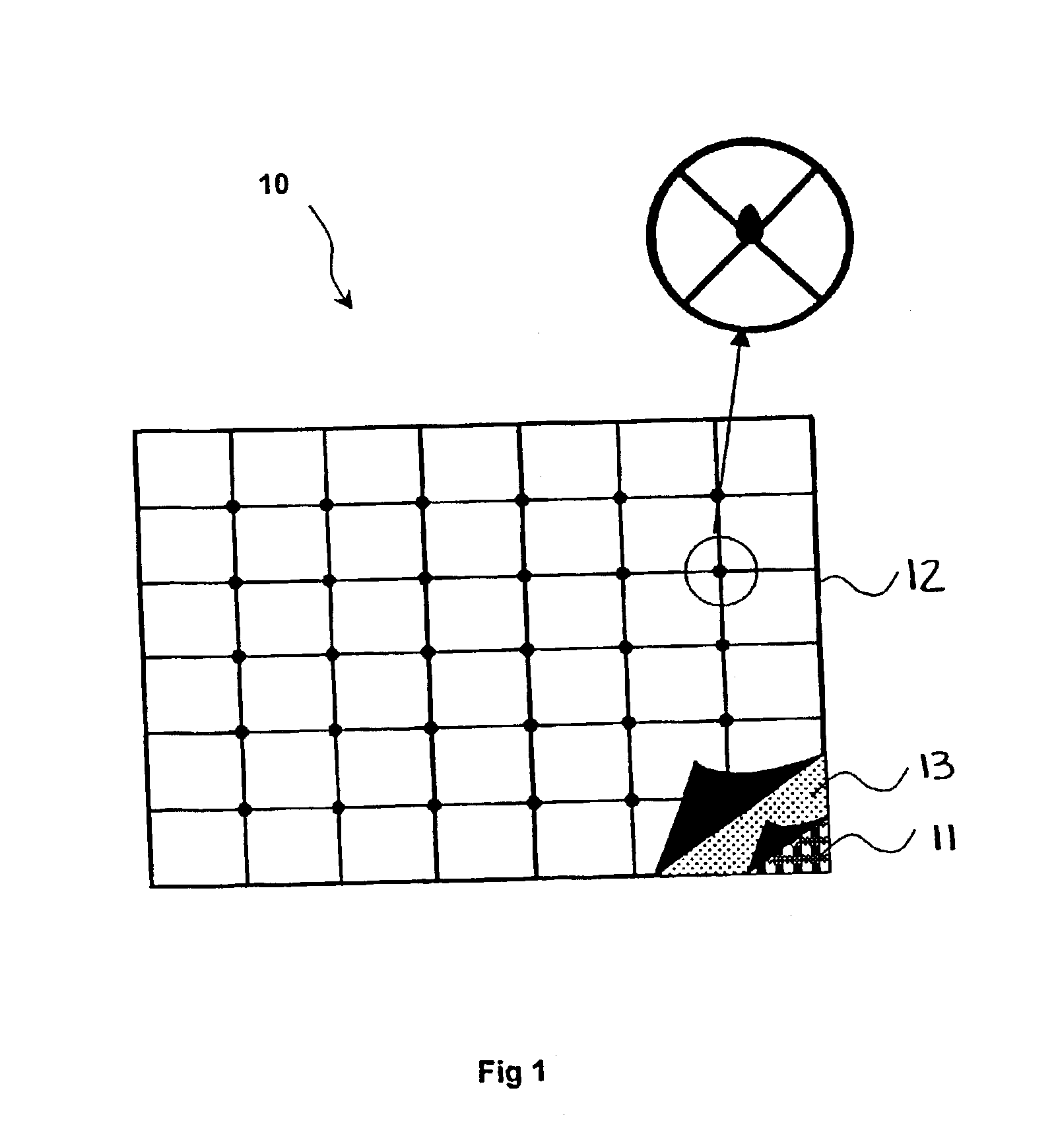

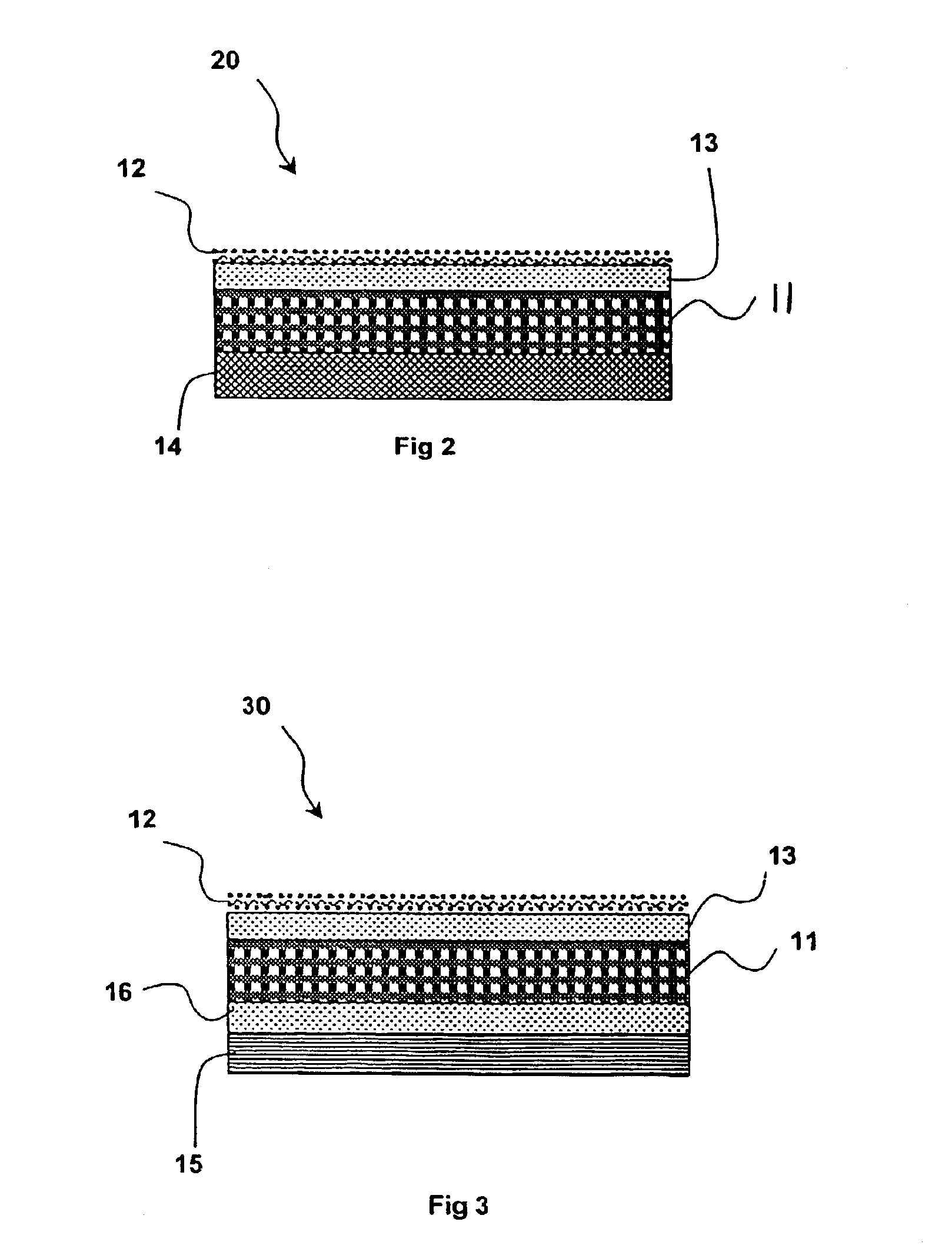

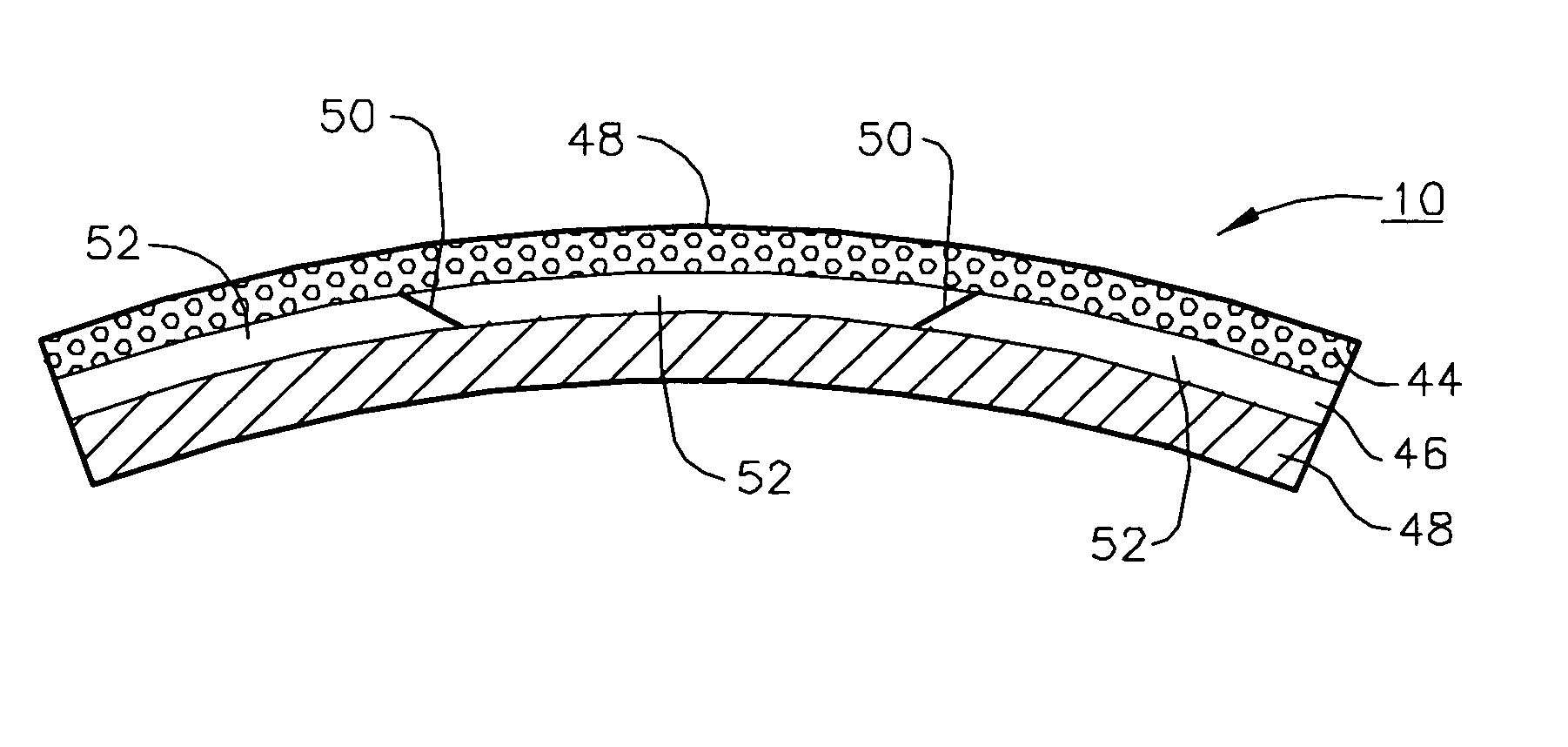

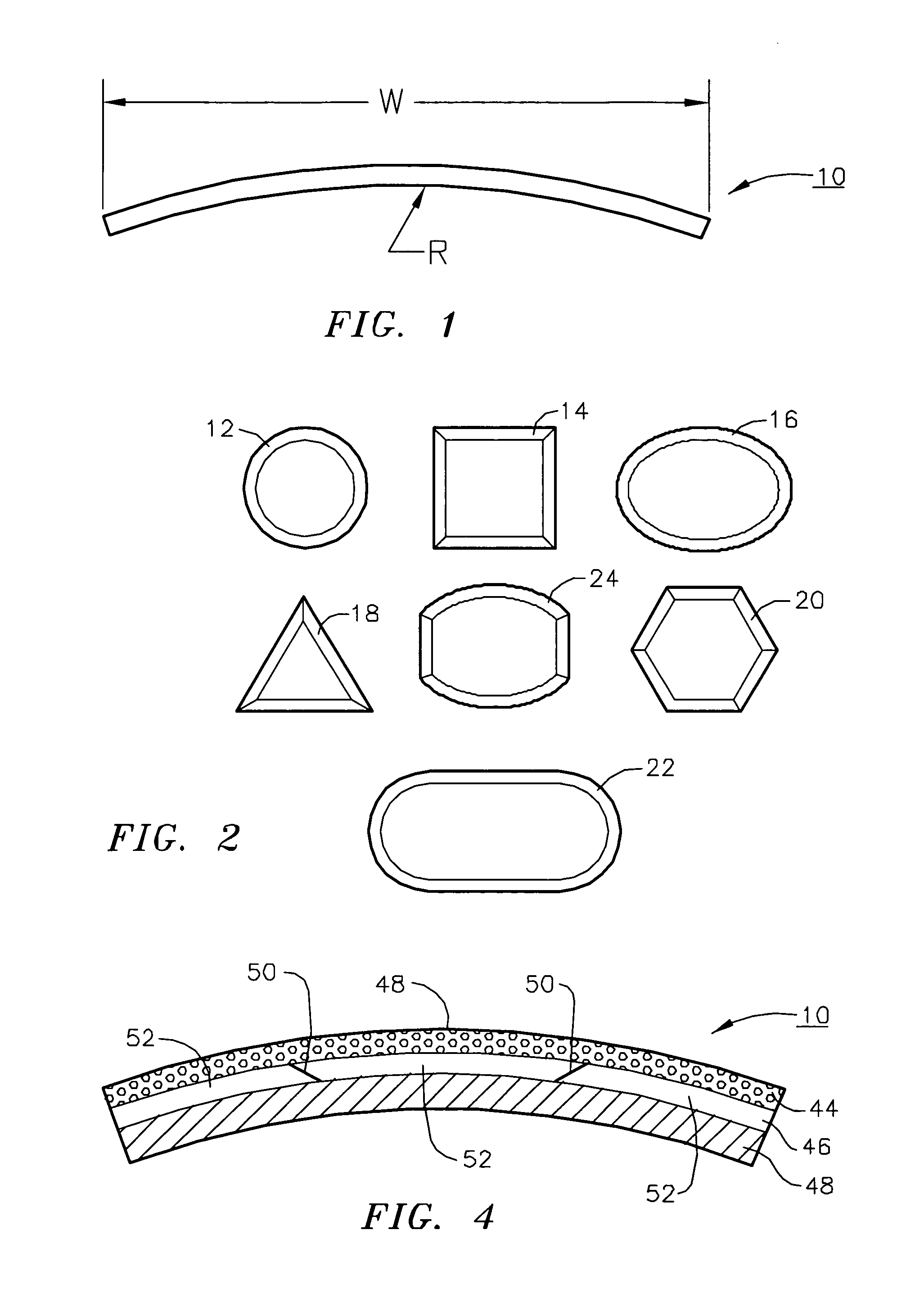

Multilayer slip resistant sheet material

InactiveUS6925766B2Increase coefficient of frictionGood walkabilityRoof covering using tiles/slatesTreadsEngineeringSlip resistance

There is provided a sheet material having a walking surface with high slip resistance. The sheet material has a flexible structural layer laminated to a mesh layer which has interconnected reinforced strands and protruding nodes to impart a high coefficient of friction. The high coefficient of friction of the sheet material provides a roofing underlayment which is safe to walk upon in dry, wet or dusty conditions, and on steeply sloped surfaces. The sheet material may also be used as an industrial wrapping material or a fabric.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

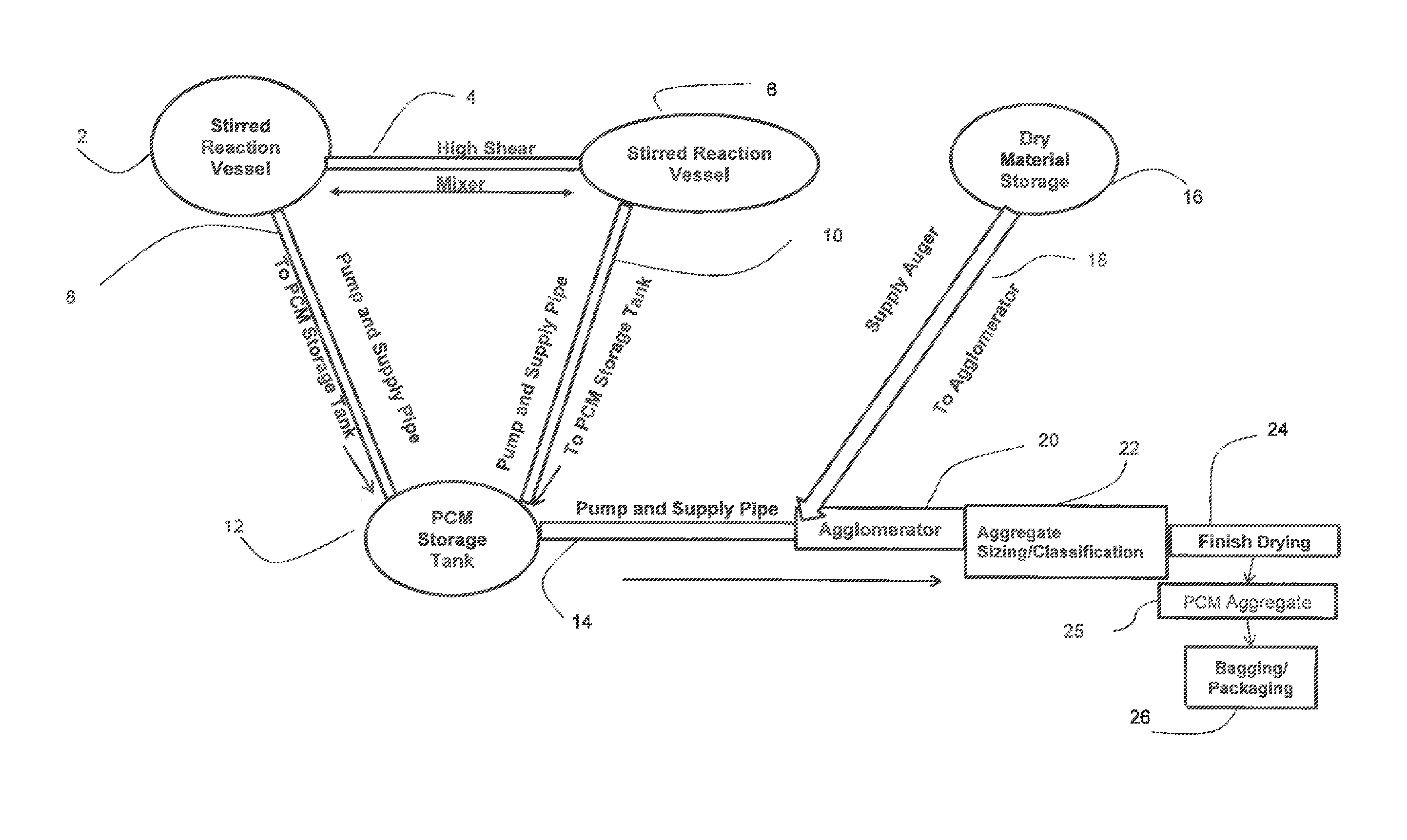

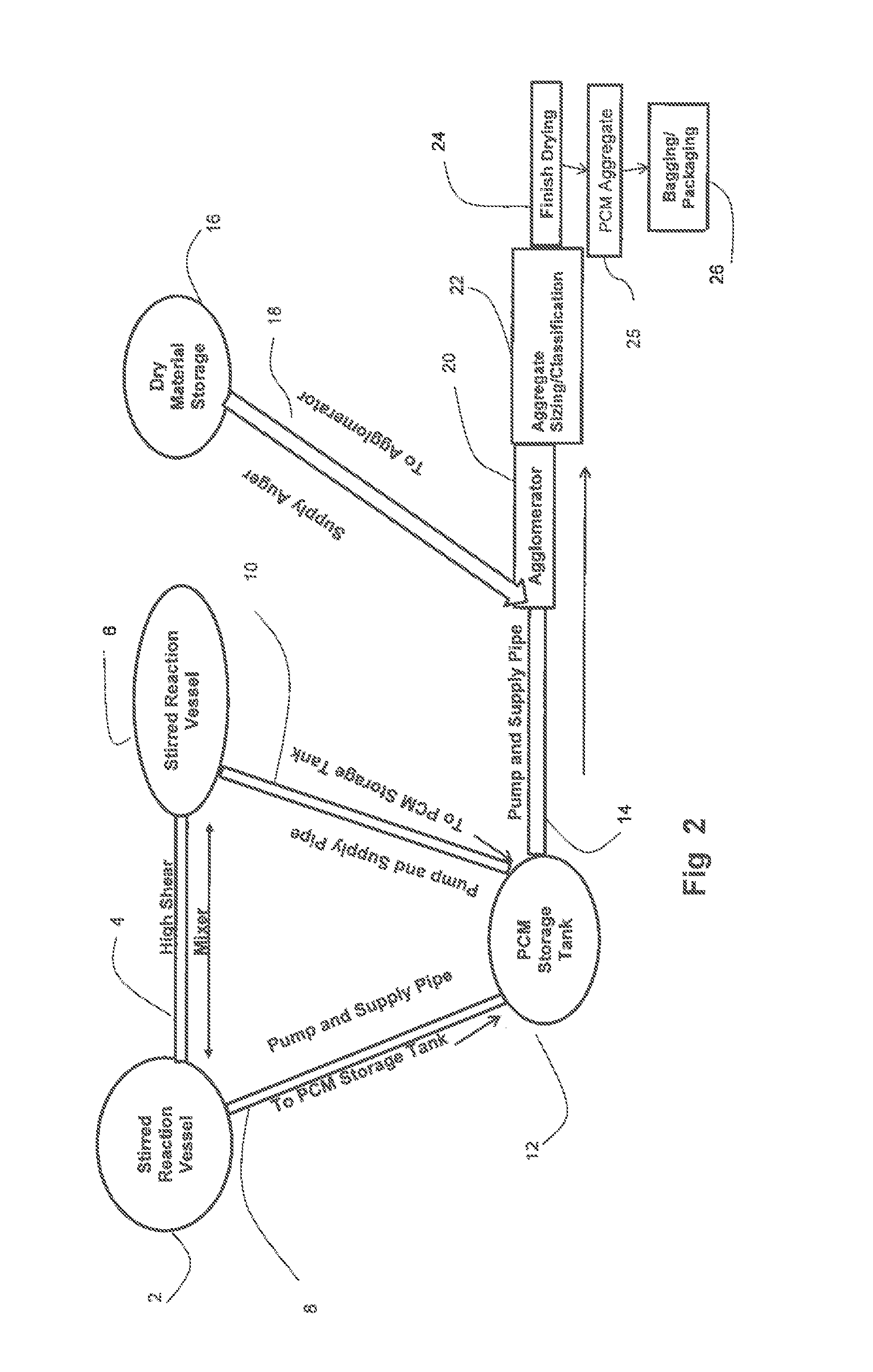

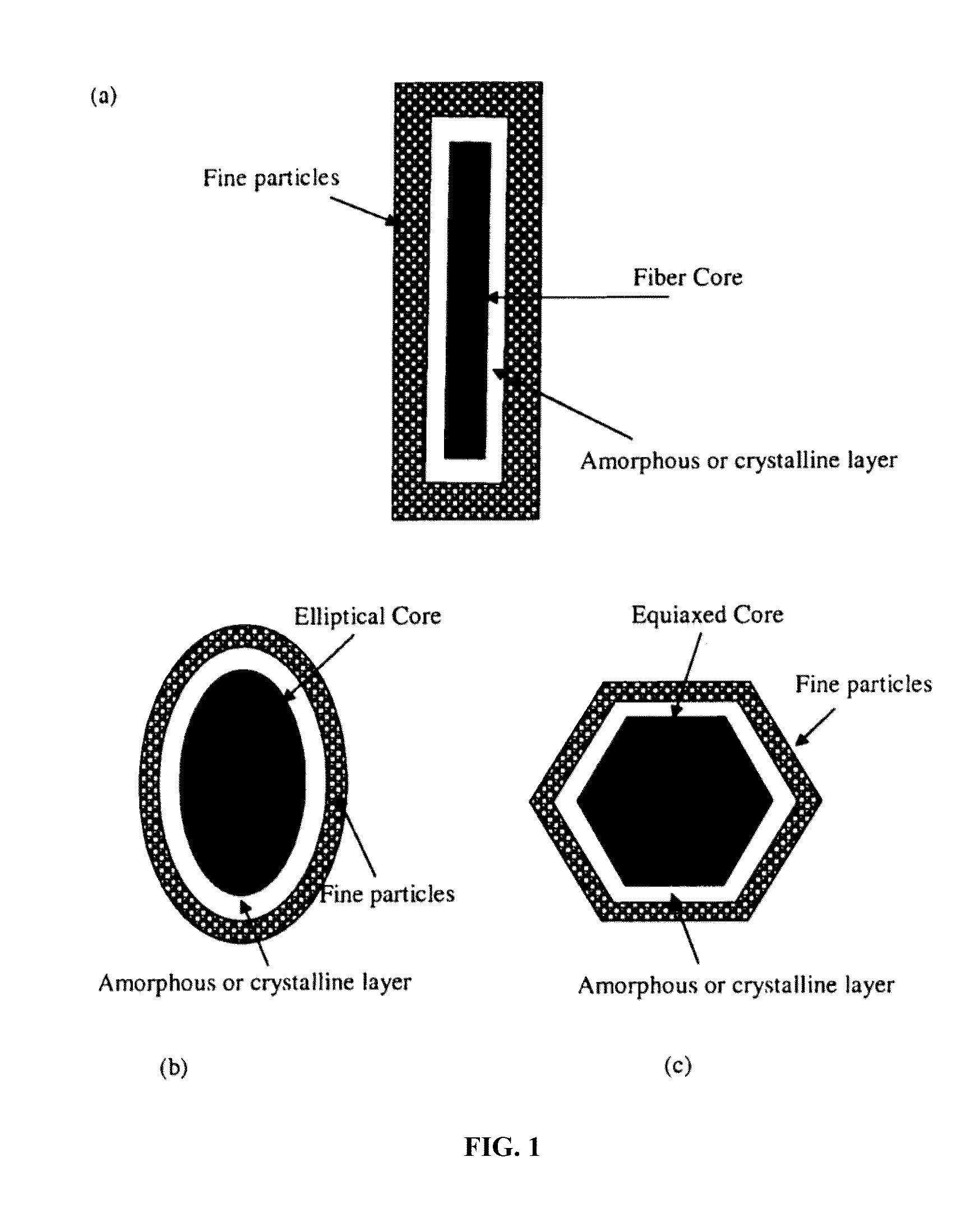

Phase change aggregates including particulate phase change material

InactiveUS20130298991A1Highly fire-resistantEnhanced heat transferSolid waste managementSynthetic resin layered productsEmulsionPhase-change material

The present invention provides methods of producing manufactured aggregates and other compositions from a particulate PCM slurry, suspension or emulsion by combining a cementitious binder and a adsorbent and / or absorbent with the PCM slurry. The PCM-containing composition can be produced in an agglomeration process. The ingredients can also be mixed to form a viscous mass which can be extruded or otherwise formed to produce useful products.

Owner:SMART PCM PATENT HOLDCO

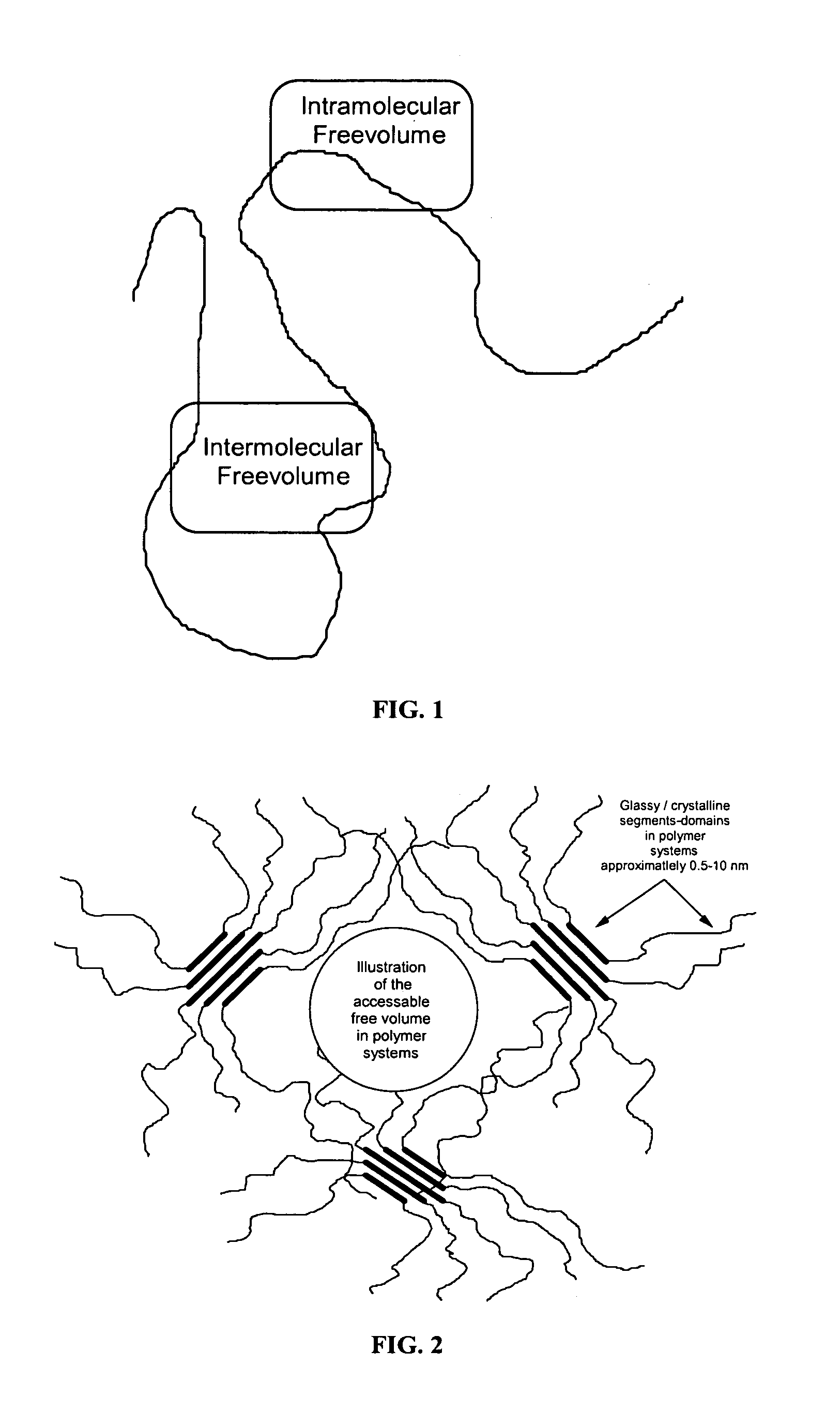

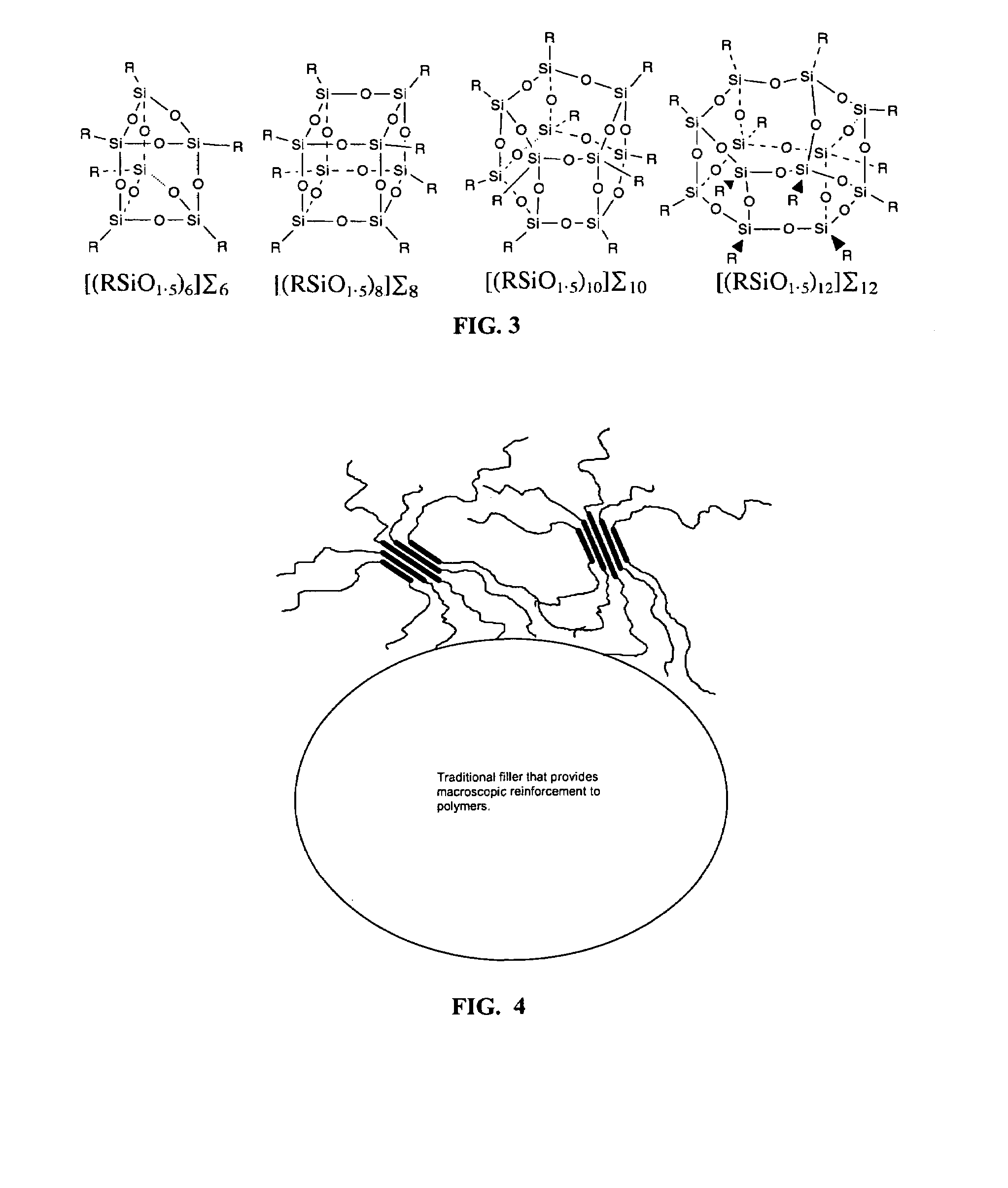

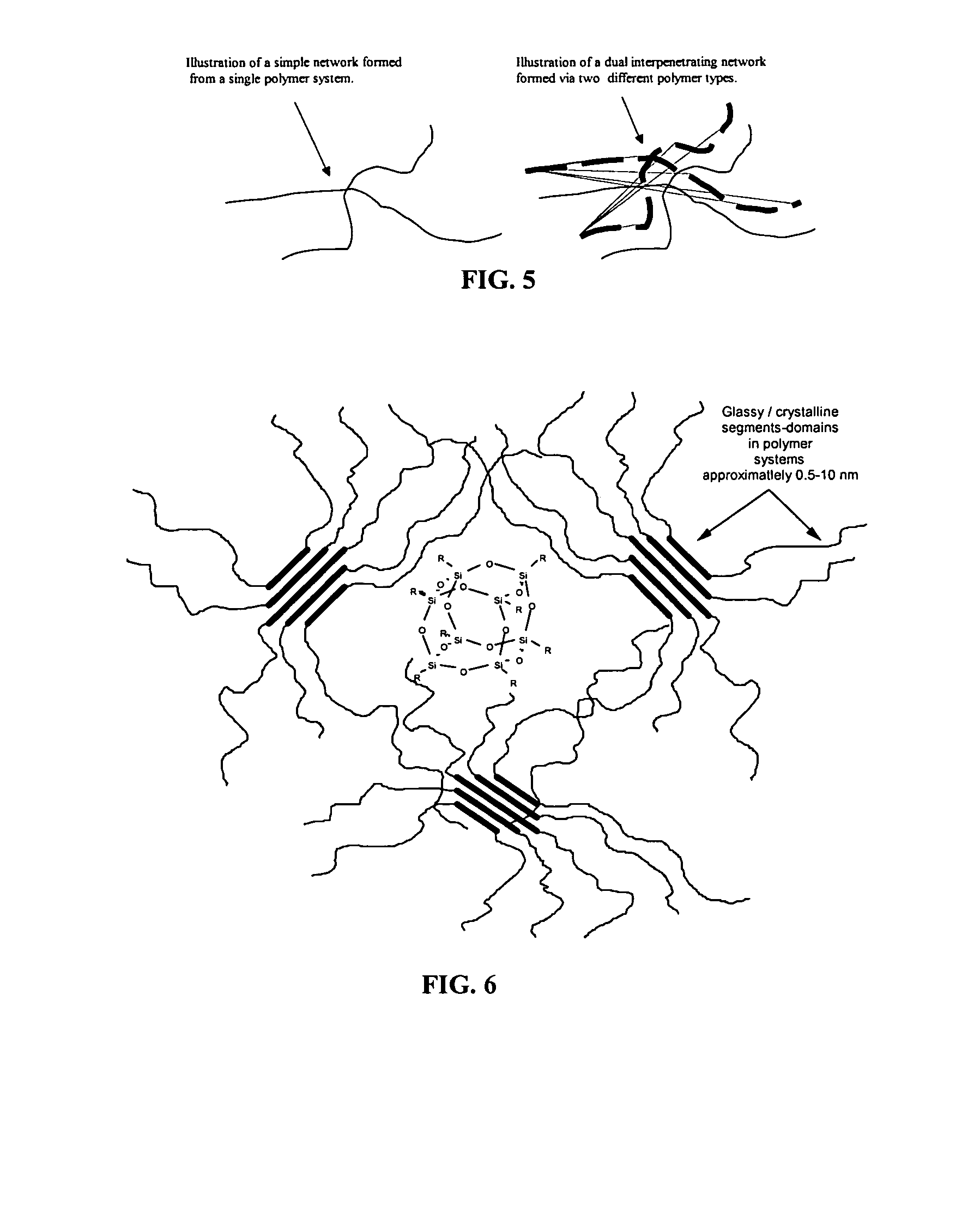

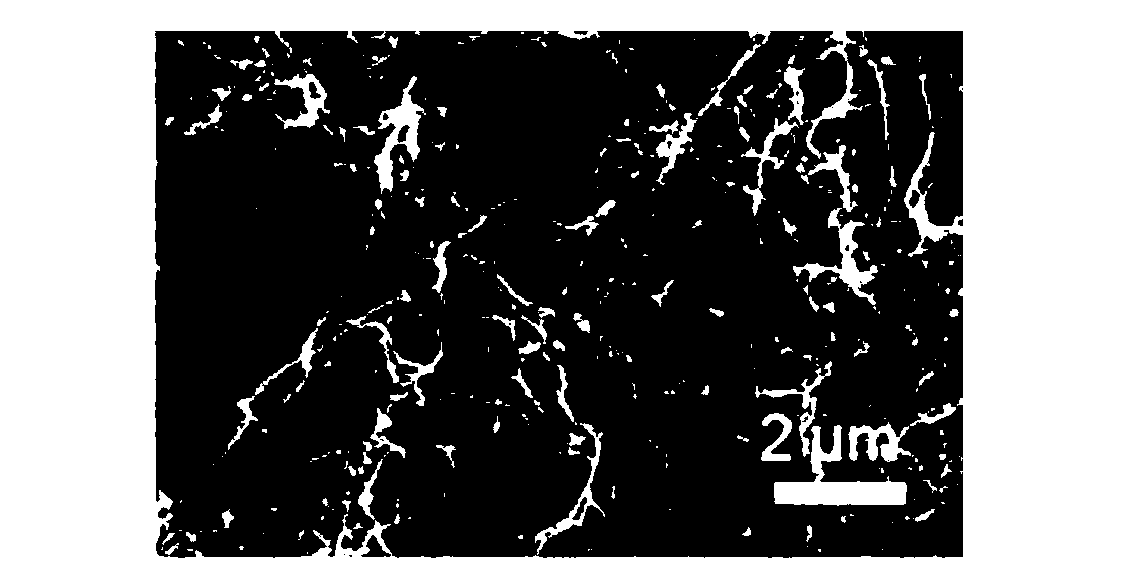

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

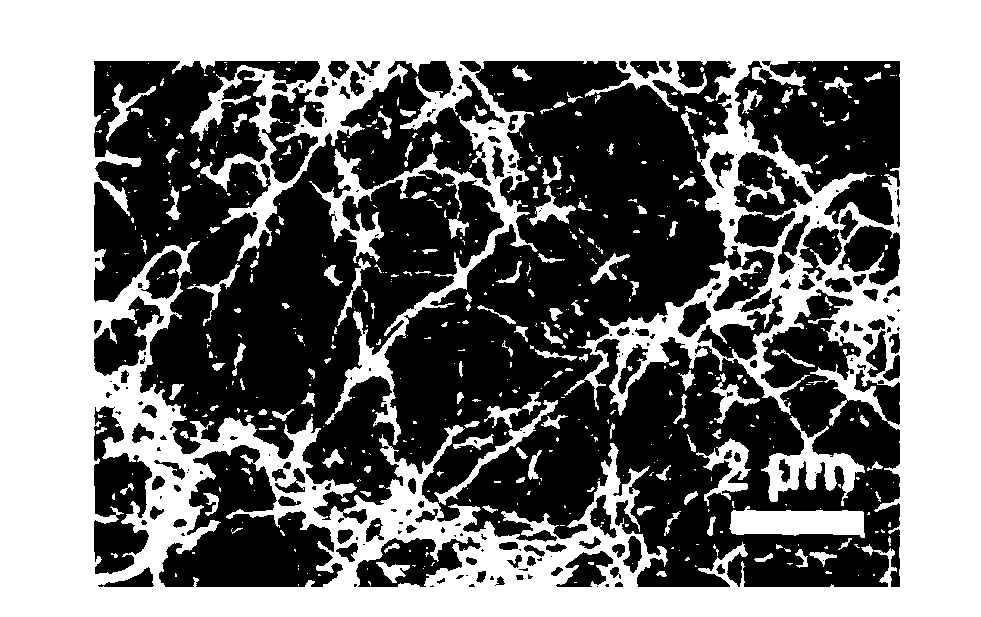

Carbon nanofiber aerogel as well as preparation method and application thereof

The invention provides a carbon nanofiber aerogel as well as a preparation method and the application of the carbon nanofiber aerogel. The method comprises the following steps: a), obtaining neutral bacterial cellulose blocks by soaking bacterial cellulose blocks into deionized water for deacidification; b), using liquid nitrogen to refrigerate the neutral bacterial cellulose blocks and drying in a freeze dryer to obtain a bacterial cellulose aerogel; and c), warming the bacterial cellulose aerogel and performing high-temperature pyrolysis to obtain the carbon nanofiber aerogel. The preparation method for the carbon nanofiber aerogel, provided by the invention, is simple, feasible and good in repeatability, and the raw material is cheap and easy to obtain, so that large-scale preparation can be realized easily; the carbon nanofiber aerogel prepared by the invention has good lipophilicity and facilitates adsorbing raw oil and chemical reagent during raw oil pollution and chemical reagent leakage; and in addition, as the carbon nanofiber aerogel has electrical conductivity and elasticity, the carbon nanofiber aerogel can be further used for preparing a pressure sensor.

Owner:UNIV OF SCI & TECH OF CHINA

Flame-retardant sheet and formed article therefrom

InactiveUS20070009723A1Improve fire resistanceNo toxicityFibre treatmentSynthetic resin layered productsFiberGraphite

The object of the present invention is to provide a highly fire resistant fiber sheet and a molded fiber sheet thereof. The fibers of the fire resistant sheet of the present invention contain expandable graphite. When said expandable graphite is exposed to high temperatures, it will expand, giving self-extinguishing properties to said fiber sheet. Since said fire resistant molded fiber sheet is highly fire resistant and nontoxic to humans and animals, it is useful for car or building interiors, and the like.

Owner:NAGOYA OIL CHEM CO LTD

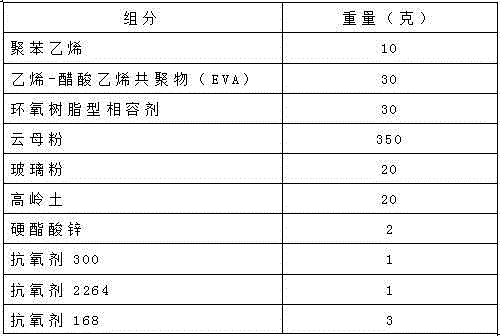

Flame-retardant fire-resistant rubber composition and preparation method thereof, and flame-retardant fire-resistant rubber wrapping tape

InactiveCN103819758AImprove fire resistanceIncrease elasticityInsulated cablesRubber layered productsPolymer scienceFire retardant

The invention provides a flame-retardant fire-resistant rubber composition and a preparation method thereof, and a flame-retardant fire-resistant rubber wrapping tape. The flame-retardant fire-resistant rubber composition is prepared from the following components in parts by mass: 50-120 parts of an organic polymer, 10-100 parts of a reinforcing filler, 20-80 parts of a non-reinforcing filler, 5-120 parts of a flame-retardant agent, 0.1-5 parts of a coupling agent, 1-30 parts of a liquid operation oil, and 1-10 parts of a curing agent. The flame-retardant fire-resistant rubber composition and the preparation method thereof and the flame-retardant fire-resistant rubber wrapping tape have the advantages of excellent flame-retardant fire-resistant performance, good elasticity, good flexibility, simple and safe use and lower cost.

Owner:秦荣勤

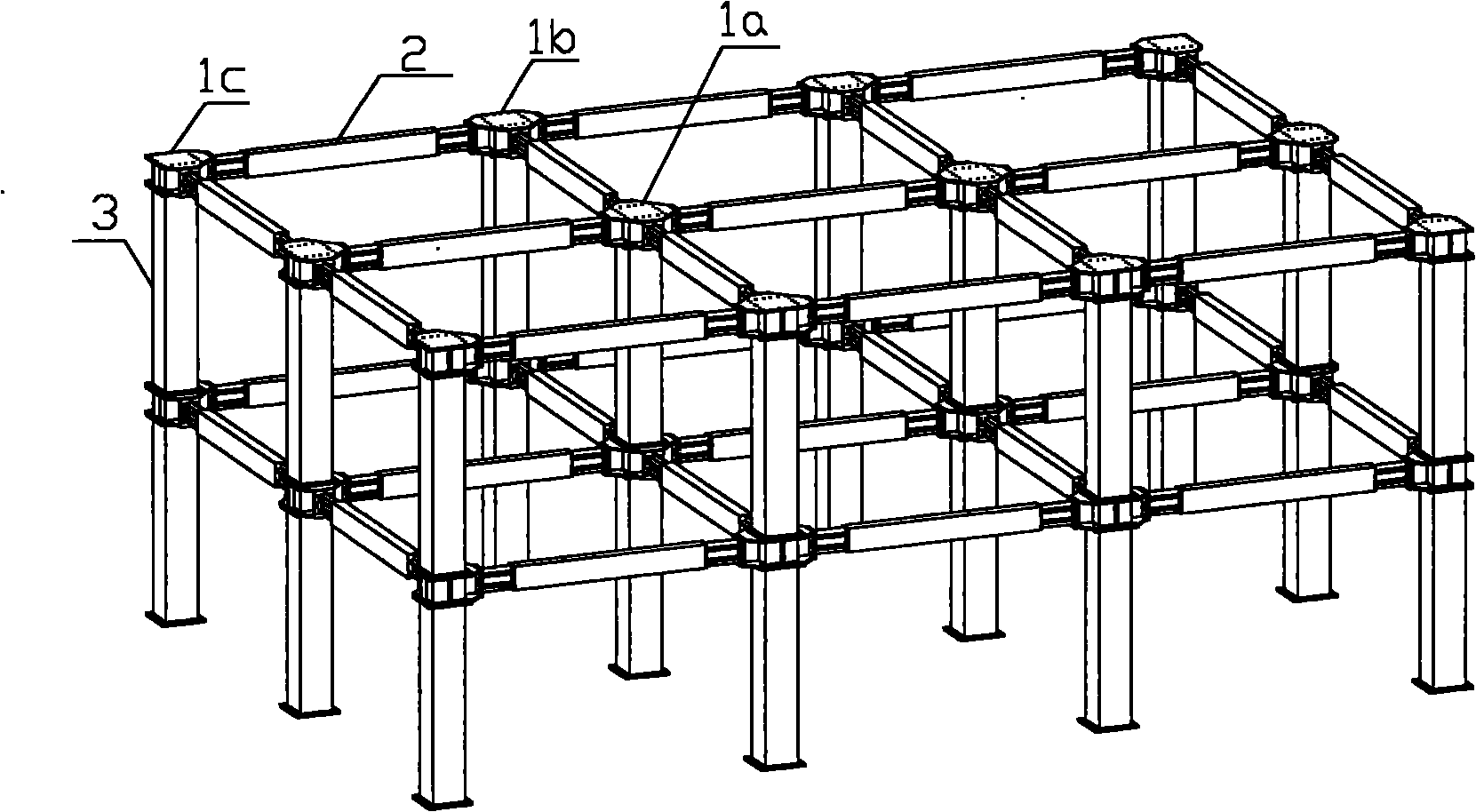

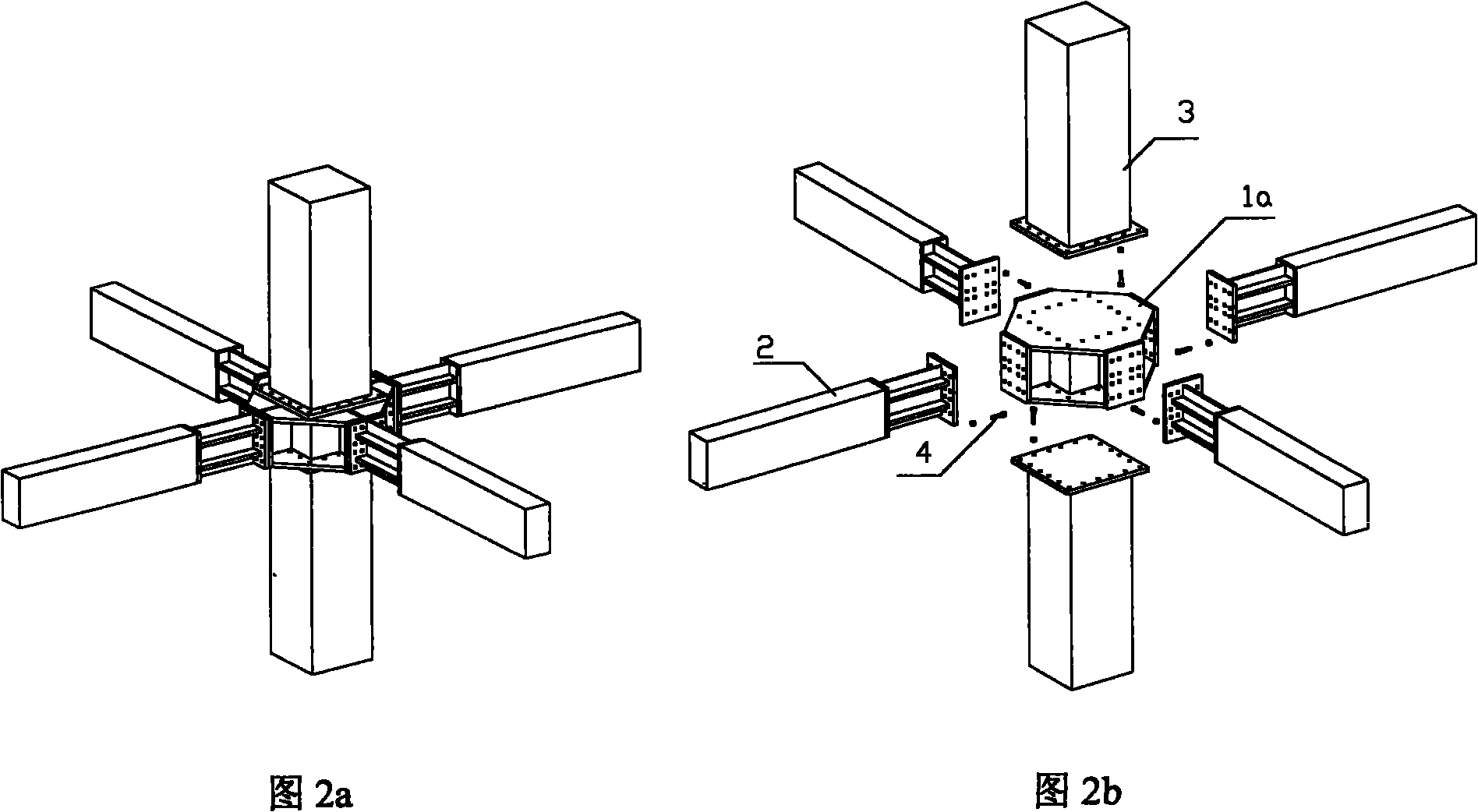

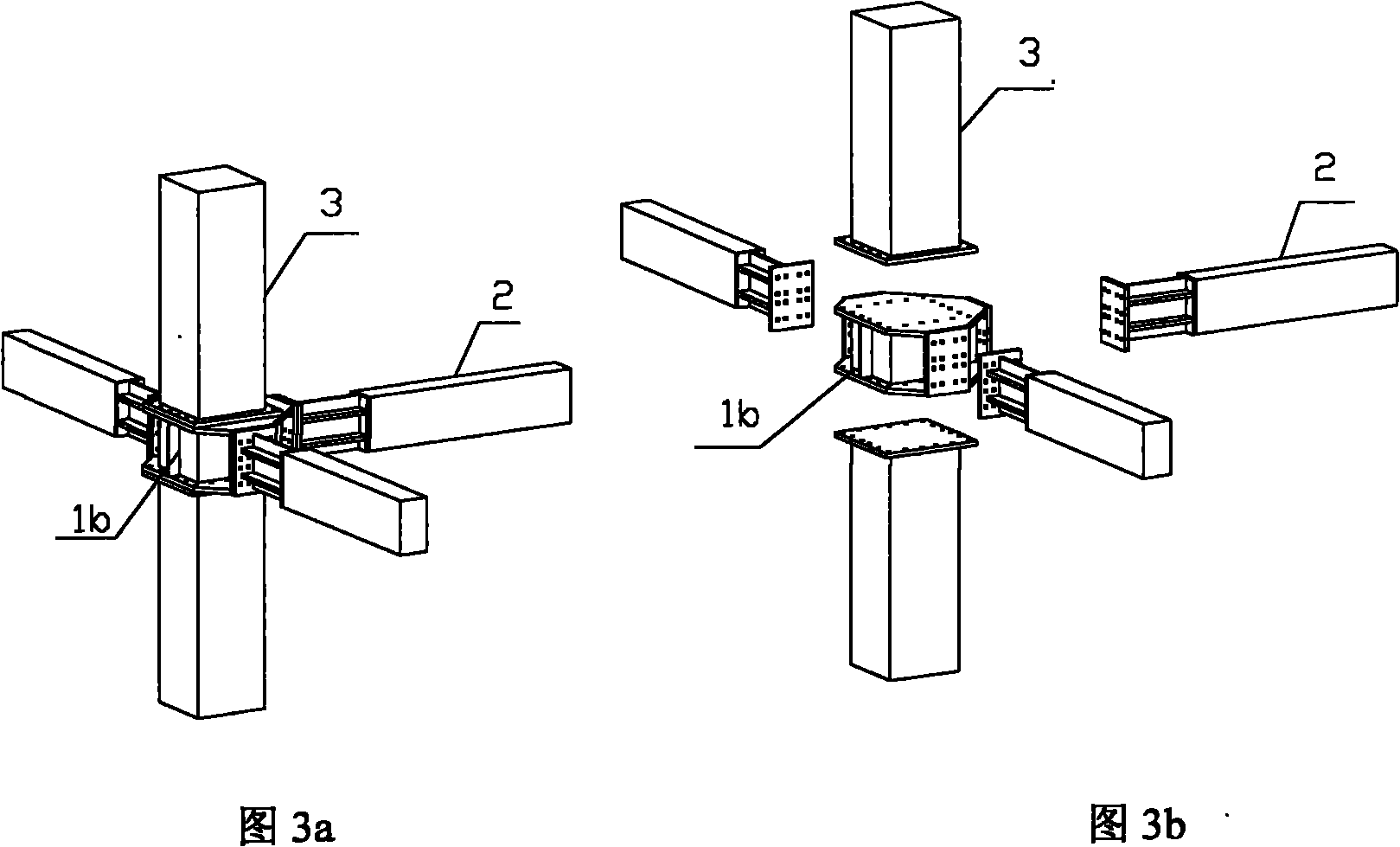

Steel joint precast and assembled reinforced concrete frame structure

InactiveCN101818521AEasy to replace and maintainEasy to replaceBuilding constructionsReinforced concrete columnRebar

The invention discloses a steel joint precast and assembled reinforced concrete frame structure, which comprises precast beam members, precast column members and joints, wherein each of the nodes comprises a steel plate box in which annular horizontal reinforced rib plates and vertical reinforced rib plates are arranged; the upper and lower surfaces of the steel plate box are respectively provided with an upper force bearing plate and a lower force bearing plate; the outer surface of the steel plate box is provided with rib plates which are respectively connected with the upper and lower force bearing plates; the rib plates are connected with vertical force bearing plates which are respectively connected with the upper and lower force bearing plates; each precast beam member comprises a precast reinforced concrete beam; a beam-end precast steel plate is precast on the end part of the precast reinforced concrete beam, and is connected with a shaped steel beam which is connected with a beam-end force bearing plate; each precast column member comprises a precast reinforced concrete column; a steel plate enclosure box is arranged on the lateral surface of the end part of the precast reinforced concrete column; studs are arranged on the inner lateral surface of the closure box; the end part of the steel plate closure box is provided with a column-end steel force bearing plate; the upper and lower force bearing plates of each joint are respectively with the adjacent columns; and the vertical force bearing plates are connected with adjacent beams.

Owner:SOUTHEAST UNIV

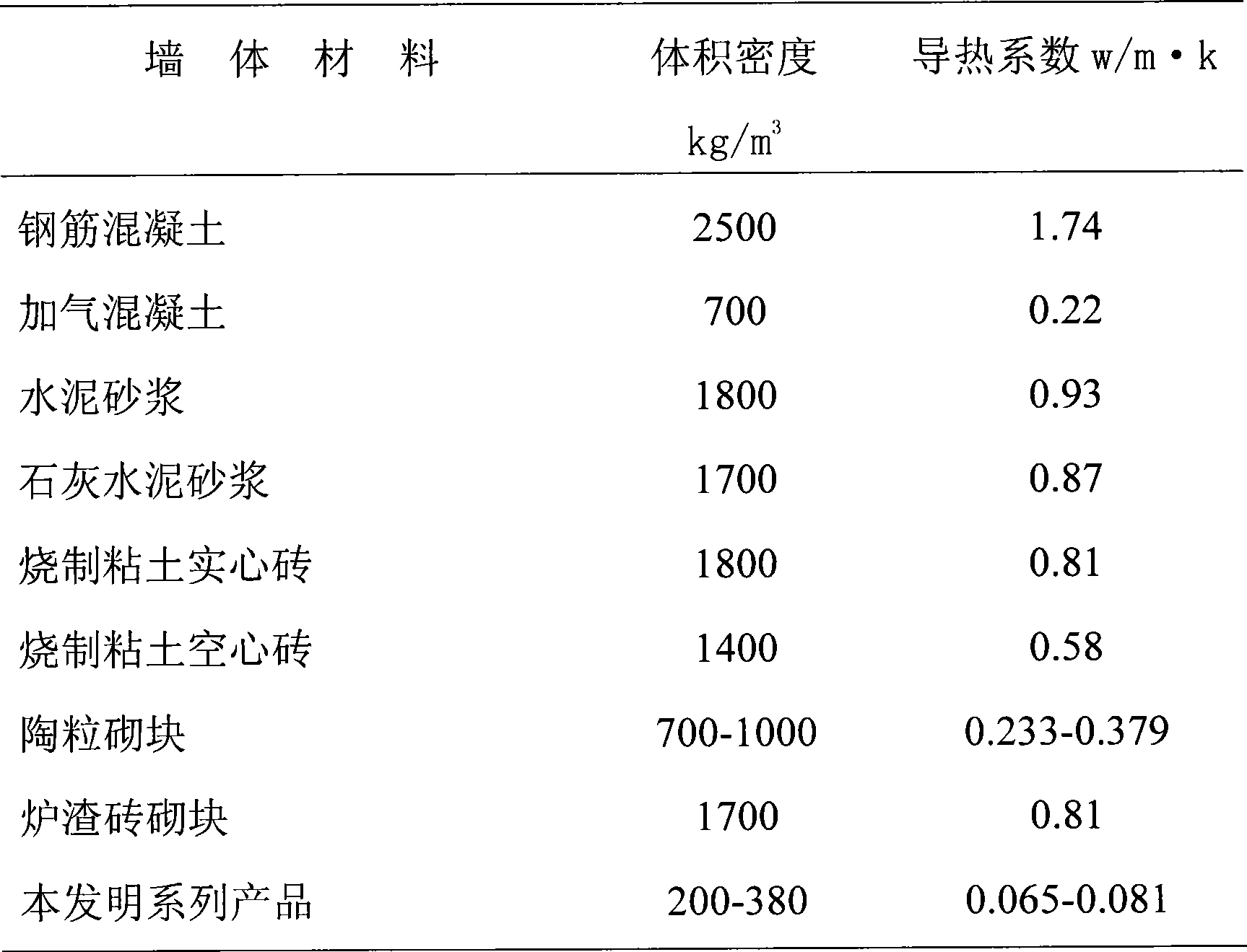

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Compound of Wood and Synthetic Material

InactiveUS20080029926A1Advantageous thermal propertyStrong materialCovering/liningsSynthetic resin layered productsPolyesterCompound s

The invention relates to a compound of a thermoplastic synthetic material and a strengthening components whereby the technical problem of indicating a high-grade compound work material at low production cost, in particular for outdoor application has been solved in that the thermoplastic synthetic material is a synthetic polyester, preferably a polyethylene terephthalate (PET), and the strengthening components is an organic filler, preferably fine-particle wood or wood fibers. The invention also relates to the production of structural parts from the component as well as the structural parts themselves.

Owner:FRITZ EGGER GMBH & CO OG

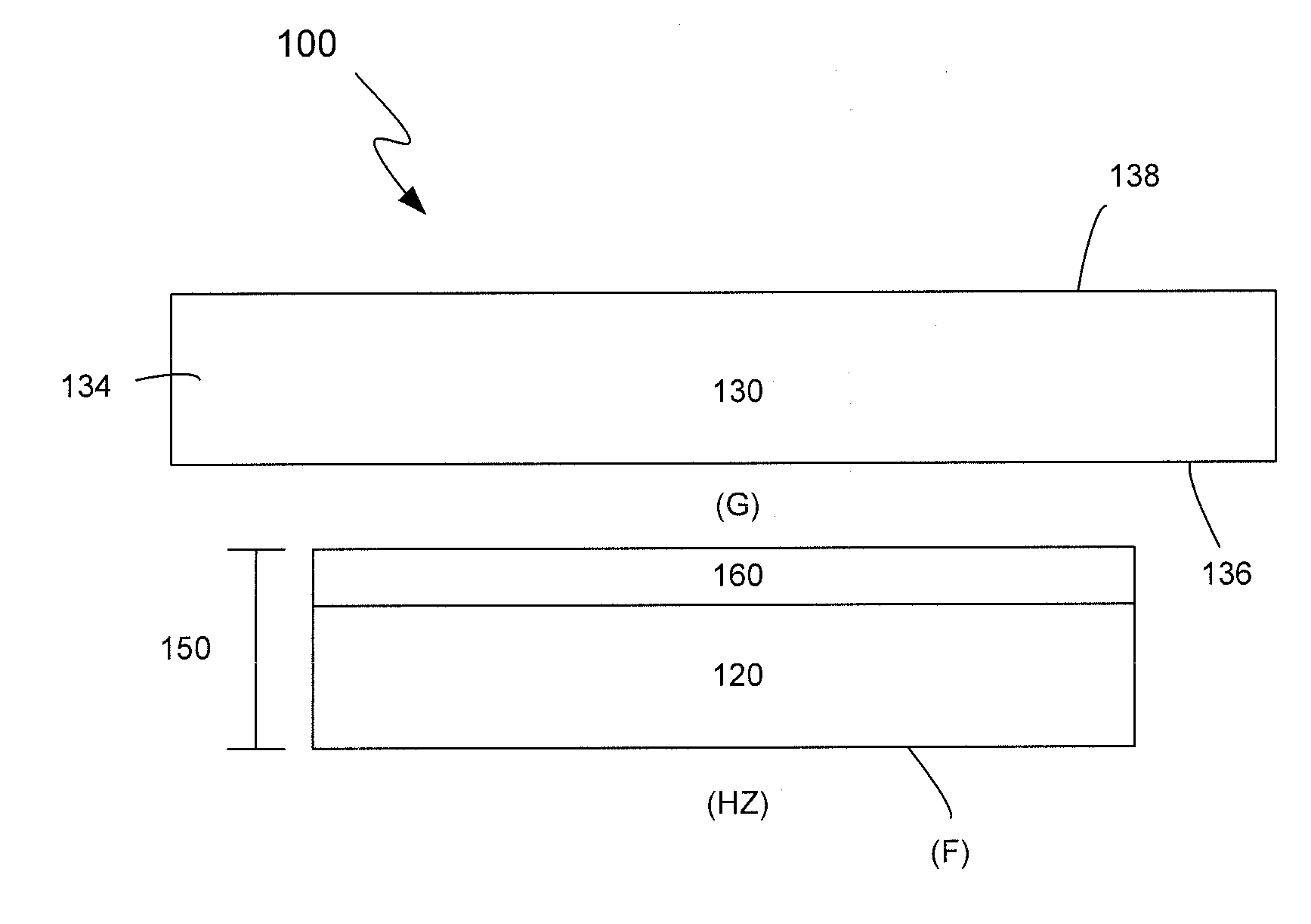

Fire resistant systems, methods and apparatus

InactiveUS20100304078A1Facilitate high fire resistanceConducive to lightweightNatural mineral layered productsAdhesivesInorganic materialsPhase-change material

The present disclosure relates to fire-resistant systems, methods, and apparatus. In one embodiment, a fire-resistant system includes a fire-resistant panel and a protected material coupled to the fire-resistant panel. The fire-resistant panel includes a passive layer and a back layer. The passive layer comprises a phyllosilicate material. The back layer comprises an inorganic material and may be coupled to the passive layer. Optionally, the fire-resistant panel may include a secondary layer comprising a functional material, where the functional material comprises one of a phase change material or an endothermic material.

Owner:ARCONIC INC

Ballistic shield

A ballistic shield for protection against up to 7.62×63 mm AP rounds (NIJ Level IV). The ballistic shield is multiple layered and includes polymer foam, ceramic tiles, and a support structure fabricated from ballistic resistant fabric. Individual layers are bonded with adhesives and preferably wrapped with fabric. Under the fabric cover of the exterior surface of the shield is a polymer foam layer that exhibits excellent blast impact resistance and blast attenuation properties as well as a hard ceramic or the like layer. The foam layer is preferably made from liquid crystal or semi-crystalline polymer to enhance fire resistance and provide enhanced ductility. According to various preferred embodiments, the man-portable ballistic shield also incorporates a compact video system for viewing the front side of the ballistic shield to eliminate the transparent view port of current ballistic shields and protective foam about the periphery and on the rear surface thereof.

Owner:WRIGHT MATERIALS RES

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

Water thin type expanding steel structure fire-resisting paint and its preparation method

The present invention relates to a water thin expanding steel structure fire-resisting coating material and its preparation method. Said ivnention adopts a self-synthesized high melting temp. acrylate emulsion as main film-forming substance, adding proper quantity of chlorometaemulsion to raise fibre resistance of film-forming substance self-body, and on the basis of convertional ammonium polyphosphate fire-resistant adjuvant an expandable graphite as foaming material is added so as to form the invented fire-resisting coating material. Said invention can greatly raise forming rate to coating layer, the thickness of foamed layer can be up to 30-50 times that of original coating layer, and its fire-resisting limit can be up to 75 min (thickness of coating layer is 3 mm).

Owner:TONGJI UNIV

Low-density composite foaming cement and preparation method thereof

The invention discloses low-density composite foaming cement and a preparation method thereof, relating to a light building material. The foaming cement is prepared by adopting a normal-temperature foaming technology, and comprises the following components in parts by weight: 100 parts of cement, 10-50 parts of active admixture, 1-5 parts of redispersible emulsion powder, 1-4 parts of water repellent, 0.5-1.5 parts of cellulose ether, 0.3-0.7 parts of reinforced fiber, 0.2-0.5 parts of foam stabilizer, 3-8 parts of foaming agent and 50-80 parts of water. The method comprises the following preparation steps of: proportionally mixing and stirring the cement, active admixture, redispersible emulsion powder, water repellent, cellulose ether, reinforced fiber, foam stabilizer, and water into cement slurry; adding the foaming agent; and stirring, molding by casting and naturally curing. The foaming cement disclosed by the invention has the advantages of low volume weight, small heat conducting coefficient, small shrinkage ratio, high intensity, integration of heat preservation, sound insulation, fire prevention and low carbon, simple and convenient production preparation process and easiness in controlling.

Owner:JIANGSU JINMAO TECH DEV

Carpet Fiber Polymeric Blend

ActiveUS20080157425A1Improve fire resistanceImprove spinnabilityFlame-proof filament manufactureCeramic shaping apparatusYarnPolymer chemistry

The invention provides carpet fibers prepared from a blend of polymeric components, said fiber exhibiting improved properties, such as improved spinnability and improved fire resistance. The carpet fibers particularly comprise a majority of polytrimethylene terephthalate (PTT) and a minority of polyethylene terephthalate (PET). The invention further provides yarns and carpets prepared from the inventive fibers, said yarns and carpets likewise exhibiting improved properties. The invention also provides methods of improving various physical properties (such as fire resistance, spinnability, and elongation) of a polymeric composition.

Owner:ALADDIN MFG CORP

Expanded type aqueous facing fireproof coating and preparation method thereof

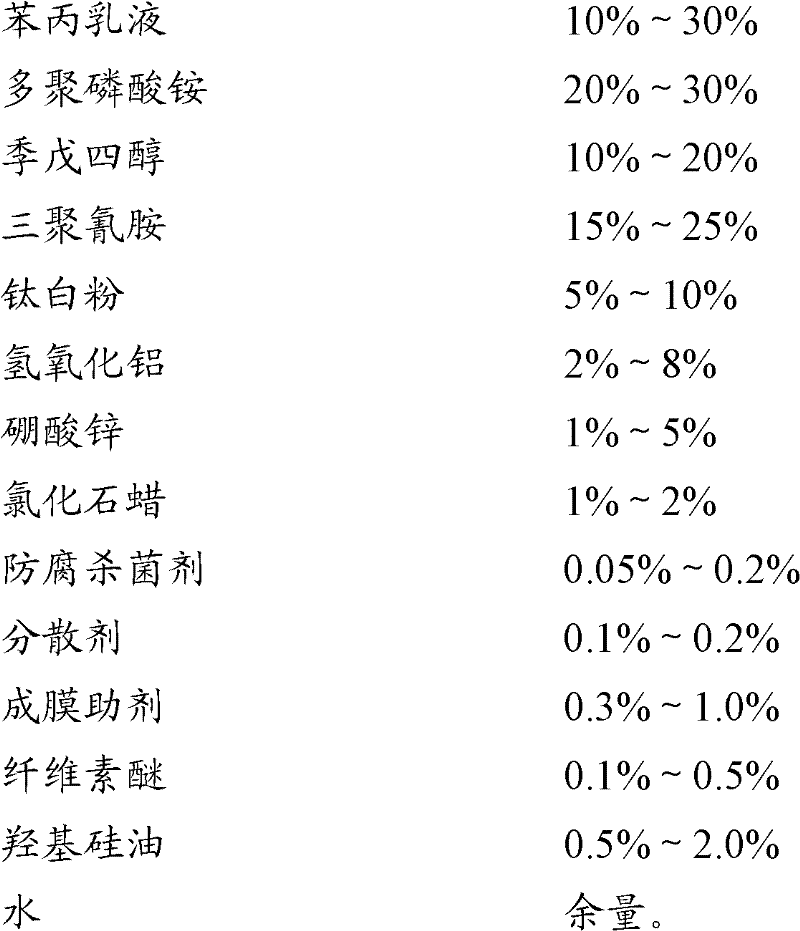

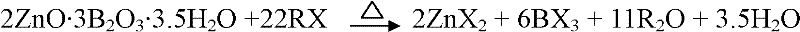

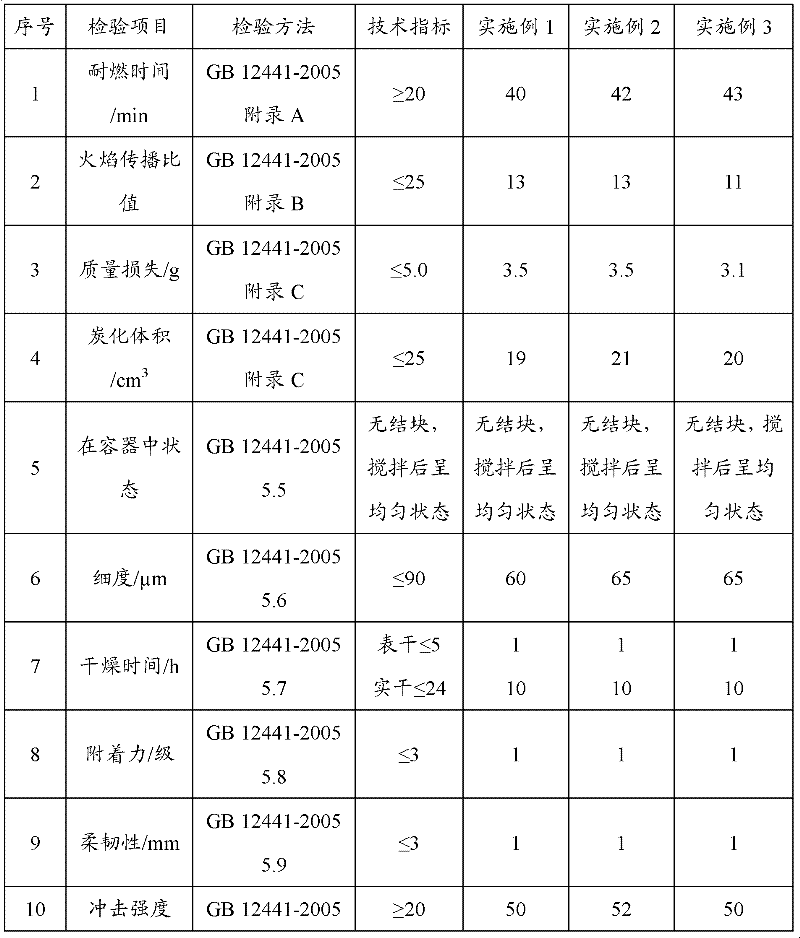

ActiveCN102675992AImprove fire resistanceImprove water resistanceFireproof paintsCelluloseChlorinated paraffins

The invention provides an expanded type aqueous facing fireproof coating, which comprises the following components by weight: 10% to 30% of styrene-acrylic emulsion, 20% to 30% of ammonium polyphosphate, 10% to 20% of pentaerythritol, 15% to 25% of melamine, 5% to 10% of titanium dioxide, 2% to 8% of aluminum hydroxide, 1% to 5% of zinc borate, 1% to 2% of chlorinated paraffin, 0.05% to 0.2% of antiseptic, 0.1% to 0.2% of dispersing agent, 0.3% to 1.0% of film-forming auxiliary, 0.1% to 0.5% of cellulose ether, 0.5% to 2.0% of hydroxy silicone oil and the balance of water. The expanded type aqueous facing fireproof coating, provided by the invention, has the advantages of excellent water resistance and salt mist resistance, excellent adhesion and flexibility, good storage stability, no layering, no fineness change and no packing phenomenon, excellent waterproof resistance, smooth and fine coating film, no toxicity and pollution, and environment-friendliness.

Owner:CARPOLY CHEM GRP

Wood-like composite materials and methods of preparation thereof

InactiveUS20140342124A1High compressive strengthLow water absorptionConstruction materialNatural patternsCalcium silicateFlexural strength

The invention provides novel wood-like composite materials and methods for preparation thereof. The wood-like composite materials can be readily produced from widely available, low cost precursor materials by a production process that involves casting in a mold that is suitable for large-scale production. The precursor materials include calcium silicate, for example, wollastonite, and particulate filler materials which comprise silicon dioxide-rich materials such as quartz, mica, feldspar, sand and glass. Additives can include calcium carbonate-rich and magnesium carbonate-rich materials. Various additives can be used to fine-tune the physical appearance and mechanical properties of the composite material, such as colorants such as particles of colored materials, such as, and pigments (e.g., black iron oxide, cobalt oxide and chromium oxide). These wood-like composite materials exhibit visual patterns unique to wood as well as display compressive strength, flexural strength and water absorption superior to that of wood.

Owner:ZAMBRZYCKI DAWID +4

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

Ceramic fiber building fireproof plate

The present invention is fireproof building board of ceramic fiber, and belongs to the field of ceramic fiber material technology. The fireproof building board of ceramic fiber is produced with aluminum silicate fiber or light refractory stuffing as base material, and through adding one or several kinds of enhancing fiber; adding proper amount of organic binding agent or inorganic binding agent, stuffing and additive; pulping; forming; drying and other steps. The fireproof building board of ceramic fiber is used as the heat insulating board in building, and has high fire rating, high fire resistance, high heat isolating performance, high strength, low density and low cost.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

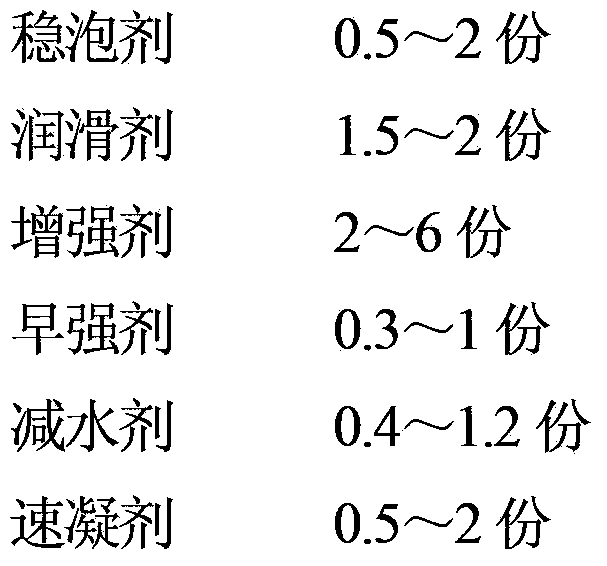

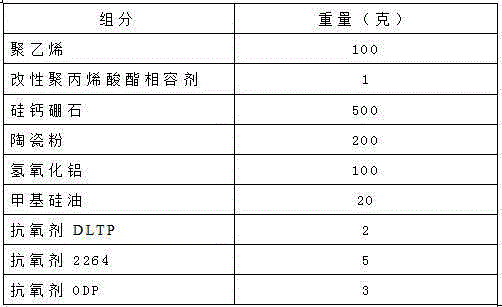

Ceramifying polyolefin fireproof cable material

InactiveCN105348627ALow priceSimple processing technologyPlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention provides a ceramifying polyolefin fireproof cable material. The material is prepared by the following components in parts by weight: 40-100 parts of polyolefin; 1-30 parts of a compatilizer; 350-450 parts of ceramifying powder; 20-200 parts of a flux; 20-90 parts of a fire retardant; 2-20 parts of a lubricant; and 1-10 parts of an anti-oxidant. Polyolefin is selected from one or more of an ethane-vinyl acetate copolymer, polypropylene, polystyrene, polyethylene and a polyolefin elastomer. The ceramifying powder is selected from one or more of pottery clay, powdered steatile, mica powder, pyrophillite, ascharite, datolite, calcite, limestone, spodumene and clay. The ceramifying polyolefin fireproof cable material has the advantages of good fireproof performance, environmental protection, low cost, easy processing and good application prospect.

Owner:SUZHOU CPLUS NEW MATERIAL

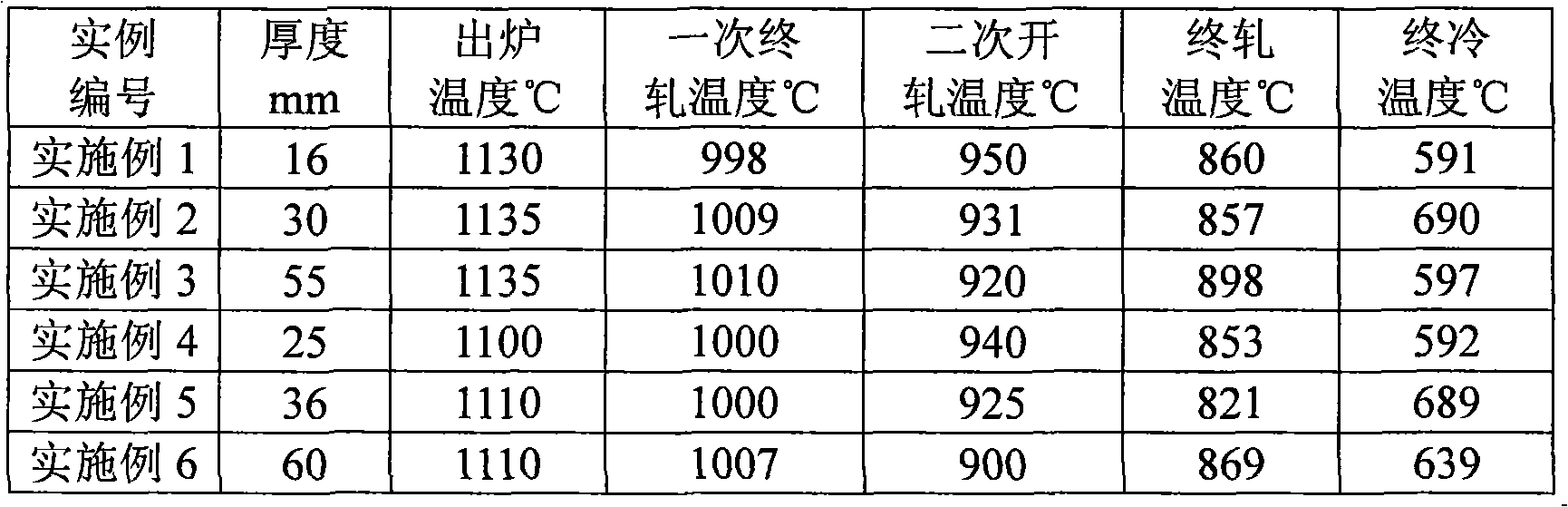

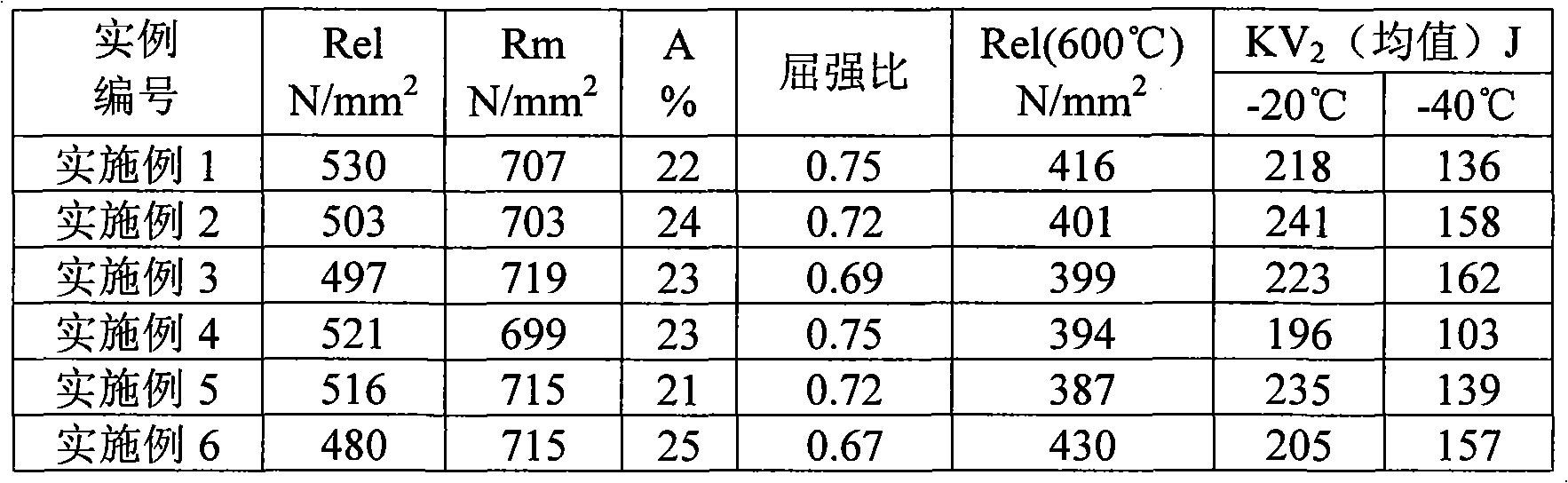

High-performance building structure refractory steel plates and manufacturing method thereof

ActiveCN101906585AMeet design needsMeet construction needsTemperature control deviceChemical compositionHeating time

The invention discloses high-performance building structure refractory steel plates and a manufacturing method thereof. The high-performance building structure refractory steel plate comprises the following chemical components in percentage by weight: 0.02 to 0.12 percent of C, 0.05 to 0.50 percent of Si, 0.08 to 1.50 percent of Mn, 0.010 to 0.050 percent of Nb, 0.010 to 0.040 percent of Ti, 0.010 to 0.050 percent of Als, 0.20 to 0.60 percent of Cr, 0.20 to 0.40 percent of Mo, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.0040 percent of N, less than or equal to 0.0020 percent of O and the balance of Fe and inevitable impurities. The production process of the high-performance building structure refractory steel plates is characterized in that: the steel blank heating temperature is 1,100 to 1,250 DEG C; the heating time is 60 to 110s / cm; two-stage controlled rolling is adopted; the final rolling temperature is kept between 800 and 900 DEG C; cooling is started 30 to 120 seconds later after final rolling; the final cooling temperature is kept between 500 and 750 DEG C; the steel plates are stacked quickly, cooled slowly and kept at a constant temperature; the stacking temperature is kept between 650 and 300 DEG C; and the temperature is kept for 10 to 24 hours. The plates have the characteristics of simple chemical components, low cost, and high refractability.

Owner:ANGANG STEEL CO LTD

Method of making a highly fire resistant construction board

InactiveUS6054088AHeat dissipationStrengthen and prevent fragmentationArmourPaper/cardboard articlesParticulatesGypsum

A highly fire resistant construction board is produced by embedding a sheet of expanded metal net in a building board made from a water settable inorganic binder. In a preferred embodiment, the wallboard is made from a combination of gypsum, cement, and a particulate mineral filler such as perlite or vermiculite, and contains an embedded layer of expanded metal net made from a magnesium alloy.

Owner:ALHAMAD SHAIKH GHALEB MOHAMMAD YASSIN

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to a castable for preparing a high-temperature ceramic wear-resistant lining, which contains 10-25% of fused mullite with a particle size of 3-5mm, and 20-45% of fused mullite with a particle size of 1-3mm. 3-7% of andalusite with a particle size of 0.1mm-1mm, 8-25% of platy corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum, and pure calcium aluminate with a particle size of <0.074mm 2-10% of cement, 2-6% of silicon micropowder, and 2-10% of alumina micropowder. The castable can be applied to the intersection of blast furnace hot air pipe and air supply branch pipe, etc. where thermal shock stability is high. The lining made of it has good thermal stability, high temperature air erosion resistance, good thermal shock resistance, It has the advantages of long life cycle, simple manufacturing method, short construction period, environmental protection and pollution-free, low cost, and easy industrial production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com