Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120 results about "Electroslag welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroslag welding (ESW) is a highly productive, single pass welding process for thick (greater than 25 mm up to about 300 mm) materials in a vertical or close to vertical position. (ESW) is similar to electrogas welding, but the main difference is the arc starts in a different location. An electric arc is initially struck by wire that is fed into the desired weld location and then flux is added. Additional flux is added until the molten slag, reaching the tip of the electrode, extinguishes the arc. The wire is then continually fed through a consumable guide tube (can oscillate if desired) into the surfaces of the metal workpieces and the filler metal are then melted using the electrical resistance of the molten slag to cause coalescence. The wire and tube then move up along the workpiece while a copper retaining shoe that was put into place before starting (can be water-cooled if desired) is used to keep the weld between the plates that are being welded. Electroslag welding is used mainly to join low carbon steel plates and/or sections that are very thick. It can also be used on structural steel if certain precautions are observed, and for large cross-section aluminium busbars. This process uses a direct current (DC) voltage usually ranging from about 600 A and 40-50 V, higher currents are needed for thicker materials. Because the arc is extinguished, this is not an arc process.

High-performance refractory weather-resisting building steel and its production method

InactiveCN1354273AImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

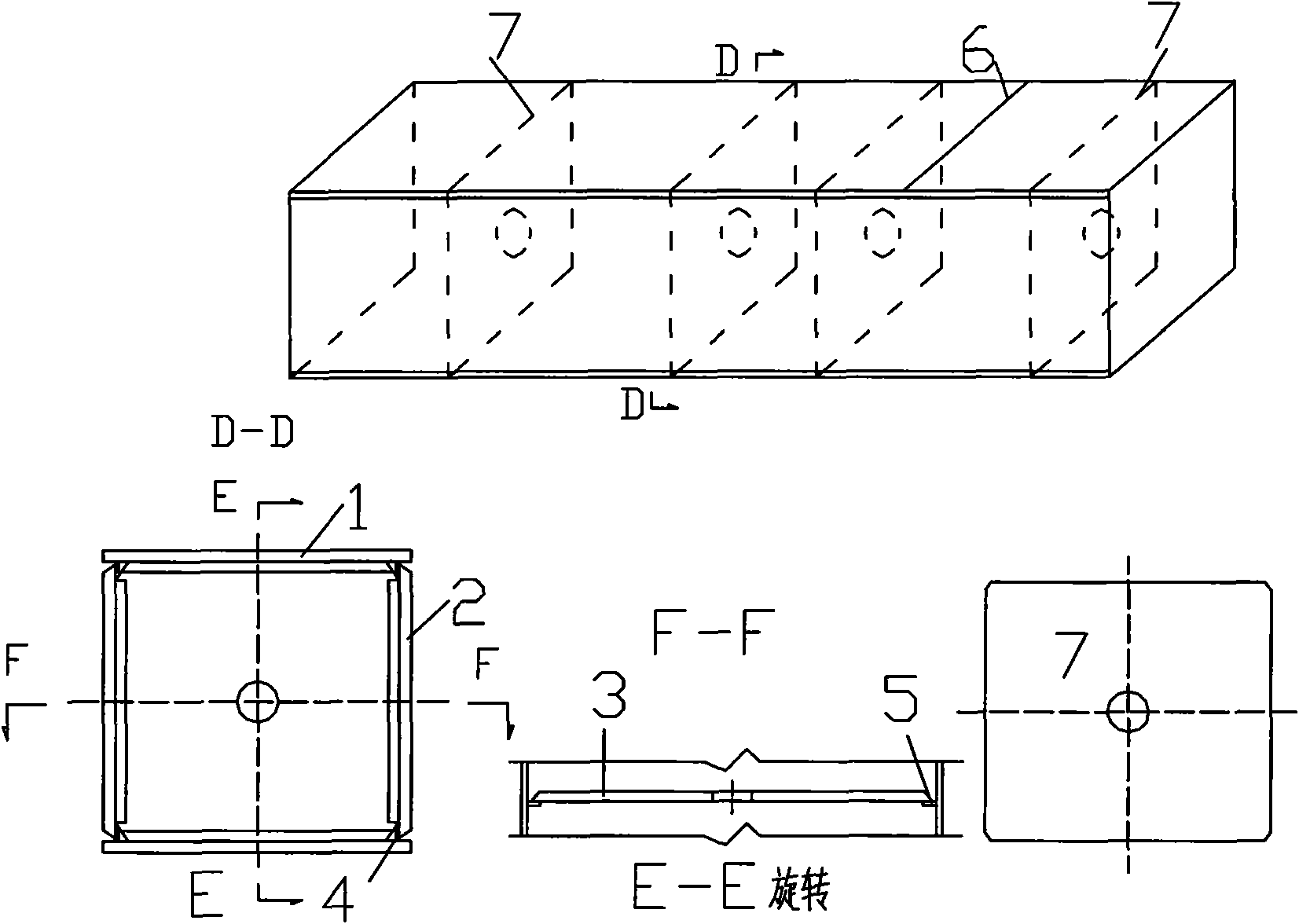

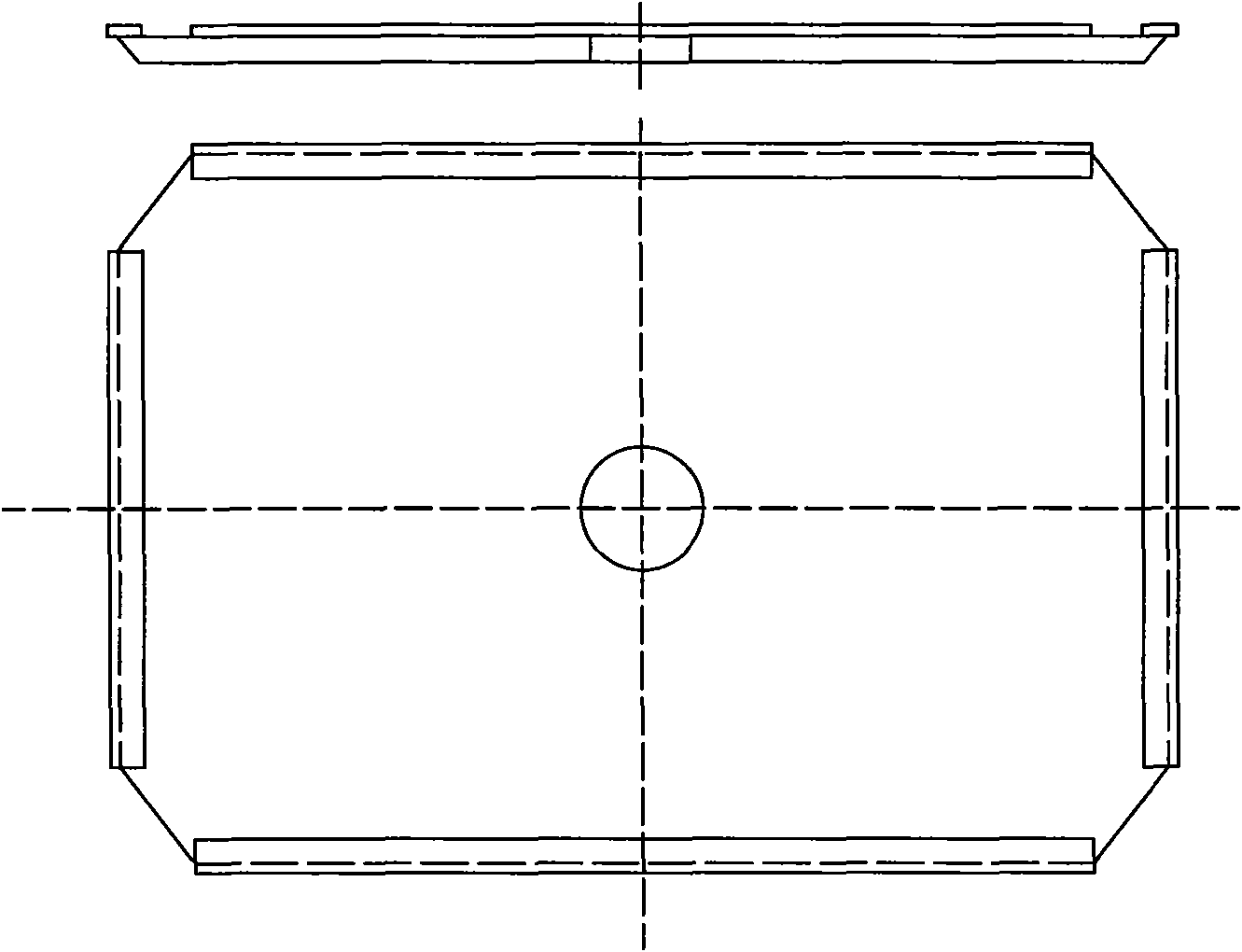

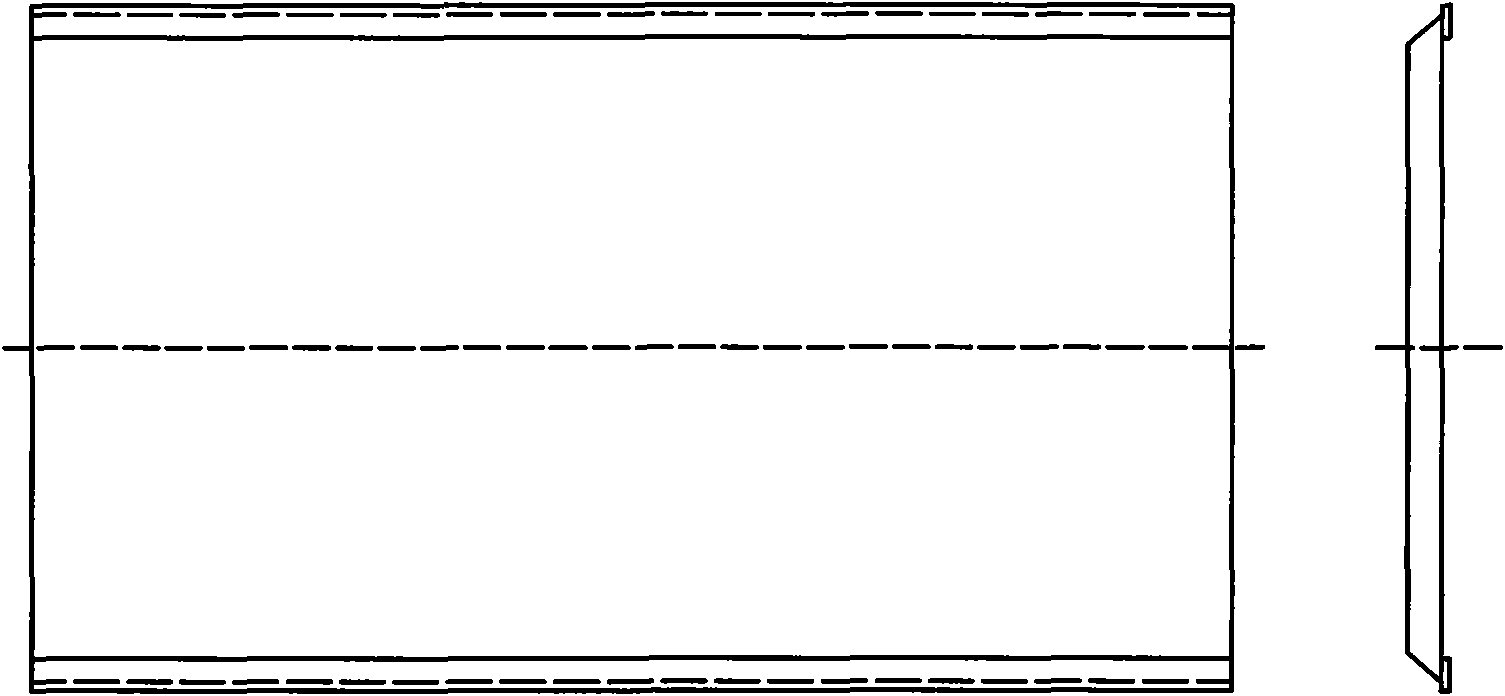

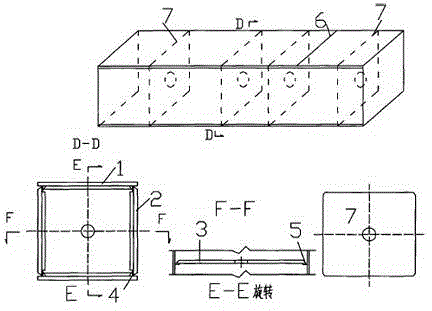

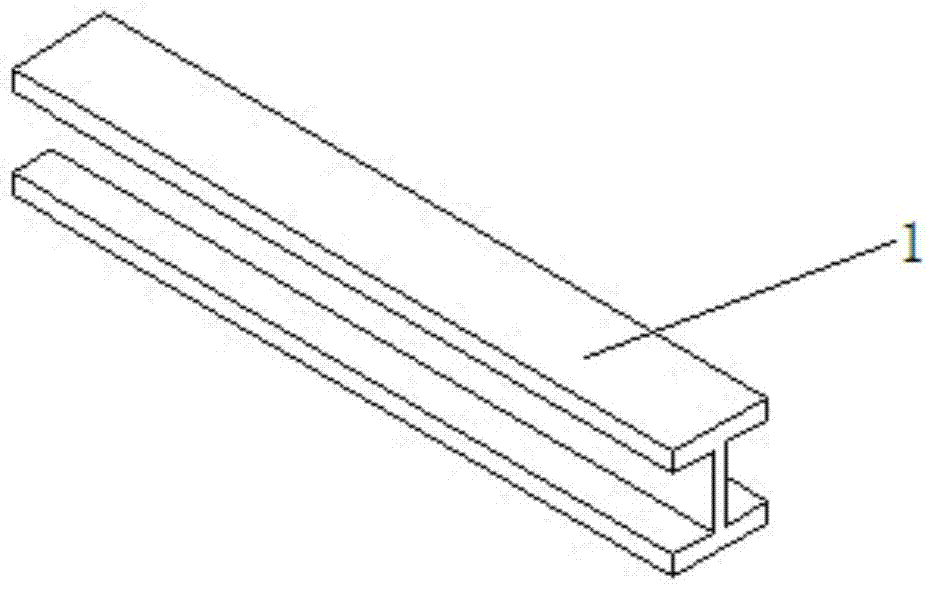

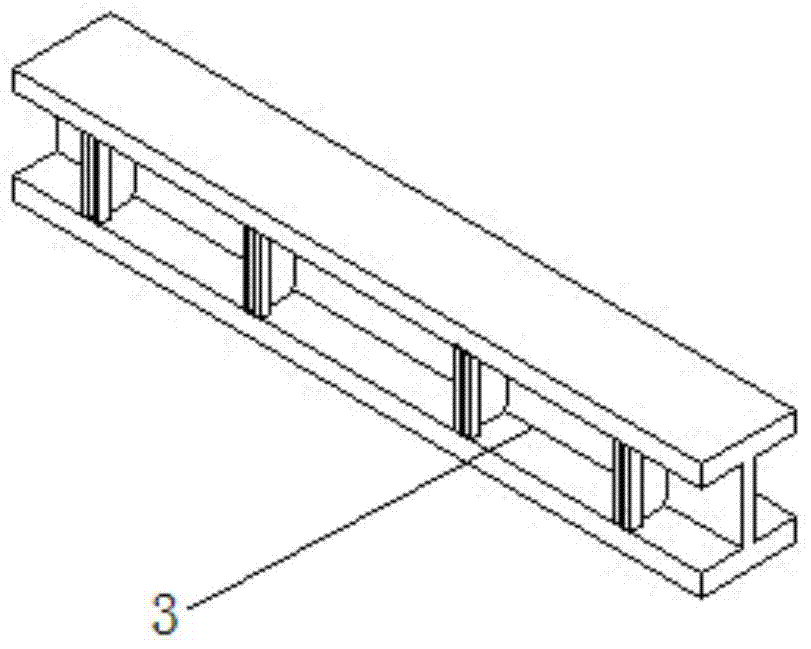

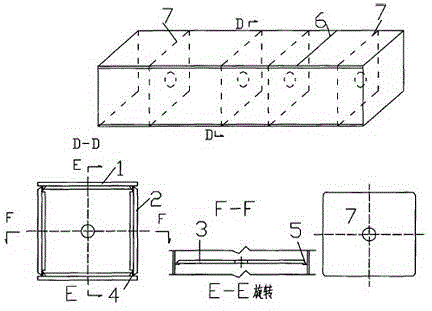

Manufacturing method for box type pillar beam

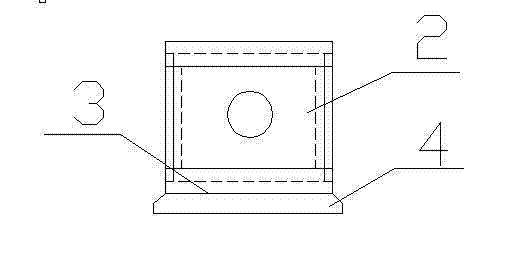

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

Normalizing type high-strength pressure vessel steel and manufacturing method thereof

The invention provides normalizing type high-strength pressure vessel steel, which comprises the following chemical components in percentage by weight: 0.12 to 0.18 percent of C, 0.15 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 0.10 to 0.40 percent of Ni, 0.01 to 0.05 percent of Nb and 0.01 to 0.03 percent of Ti, 0.015 to 0.050 percent of Als, one or both of less than or equal to 0.20 percent of V and less than or equal to 0.70 percent of Cu and the balance of Fe and inevitable impurities. In the normalizing type high-strength pressure vessel steel, the specification of the steel is controlled by utilizing a single-rolling process of a steel plate, and the uniform tissue of ferrite and pearlite is obtained by adopting normalizing heat treatment; and in the process of rolling and heat treatment, the sufficient strength and good impact properties are obtained by utilizing the effects of fine-grain strengthening, precipitation strengthening and solid solution strengthening of micro-alloying elements such as the Nb, the V, the Ti and the like. In addition, the normalizing type high-strength pressure vessel steel achieves the excellent welding performance by controlling carbon equivalent and can be welded by adopting methods of manual arc welding, hidden arc welding, gas shielded welding, electroslag welding or tungsten electrode inert gas shielded-arc welding and the like; and the normalizing type high-strength pressure vessel steel has the advantages of little used precious metals, easy control of the component of each element, simple process, low production cost and high efficiency.

Owner:武钢集团有限公司

Method for producing box beam/column with steel structure

InactiveCN101664847AEasy to produceImprove quality and efficiencyArc welding apparatusWelding/soldering/cutting articlesElectroslag weldingEngineering

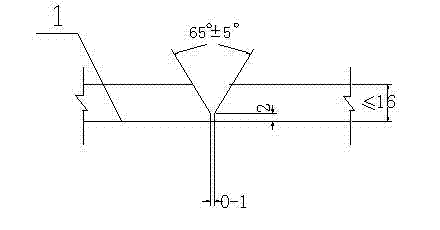

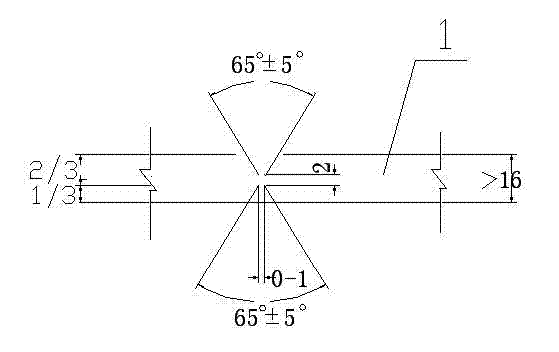

The invention relates to a method for producing a box beam / column with a steel structure, comprising the following steps: (1) numerically controlling web plates, blanking based on the size of a partition plate and processing to form a bevel outlet; (2) assembling spot welding lining plates on the backs of the web plates and the partition plate; (3) assembling cover plates and two of the web platesto form a U-shape groove on a box assembling machine; (4) placing the partition plate in the formed U-shaped groove and welding three sides of the partition plate; and (5) assembling the cover platesand welding attachment welds between every two cover plates. The method solves the problem that the box beam / column cannot produce when no special electroslag welding equipment is provided, what is more important, the method solves the problem that welding is difficult by adopting the electroslag welding when the thickness of a wall panel of the beam / column is below 18 mm during multi-layer buildings are built. By adopting the method, the processing process is simplified, the component quality and the manufacture efficiency are greatly improved, favorable economic and societal values are achieved, and polarization and application are easy.

Owner:河南天丰钢结构有限公司

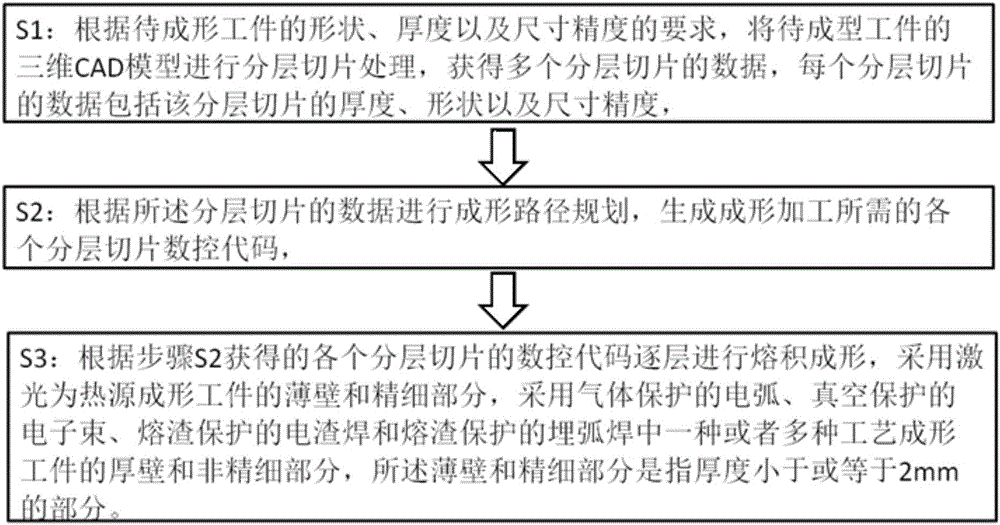

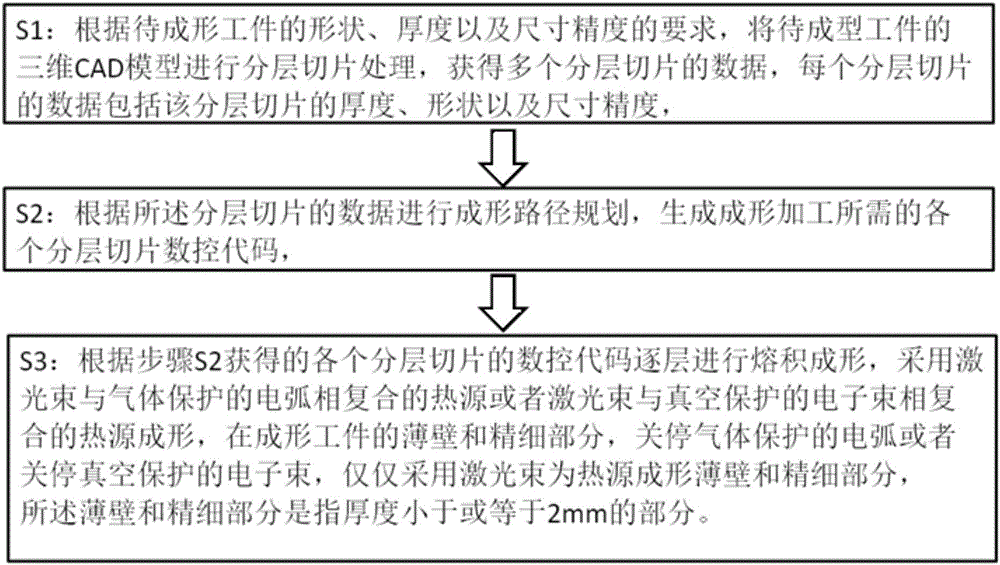

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

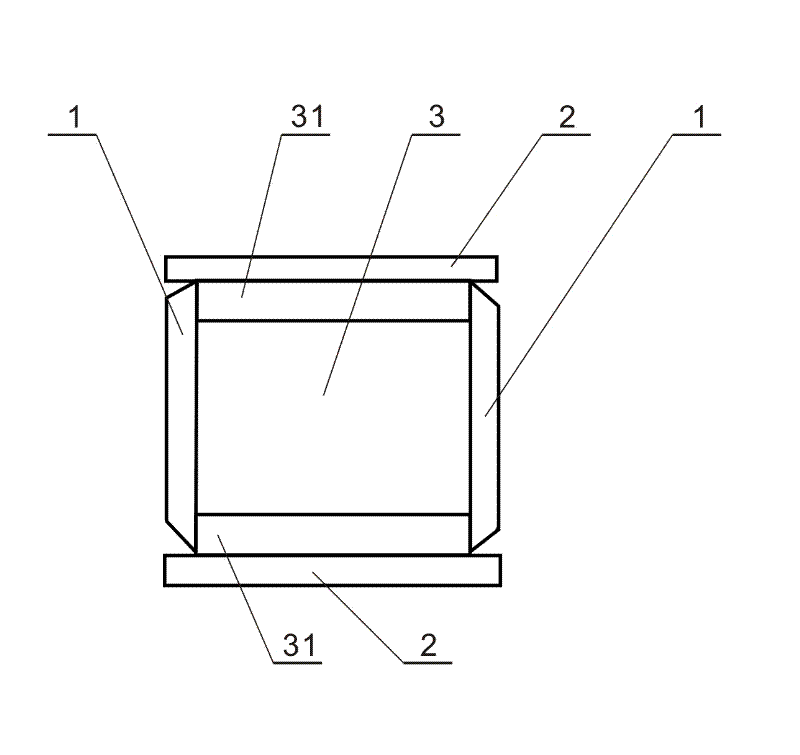

Method for welding box-shaped column

ActiveCN102240863ASimple process routeThe process route is accurateWelding apparatusSlag (welding)Electroslag welding

The invention discloses a method for welding a box-shaped column, which comprises a process for welding the box-shaped column and a method for welding a weld joint between a partition plate and a wing plate by electric slag welding. The box-shaped column comprises a web plate, the wing plate and the partition plate. The weld joint between the partition plate and the wing plate of the box-shaped column is welded by the electric slag welding method, and the overall welding process of the box-shaped column is analyzed and optimized based on the method. Thus, the process route is simple and accurate; and the method has the advantages of reducing manufacturing difficulty, improving processing precision, improving production efficiency and improving the quality of members.

Owner:BAOSTEEL CONSTR +1

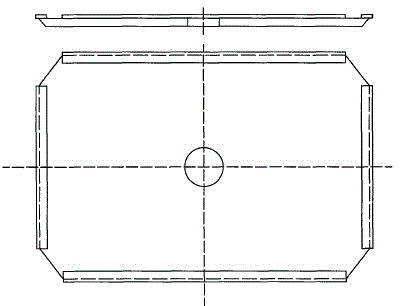

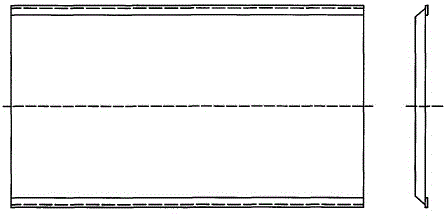

Welding machine for box beam

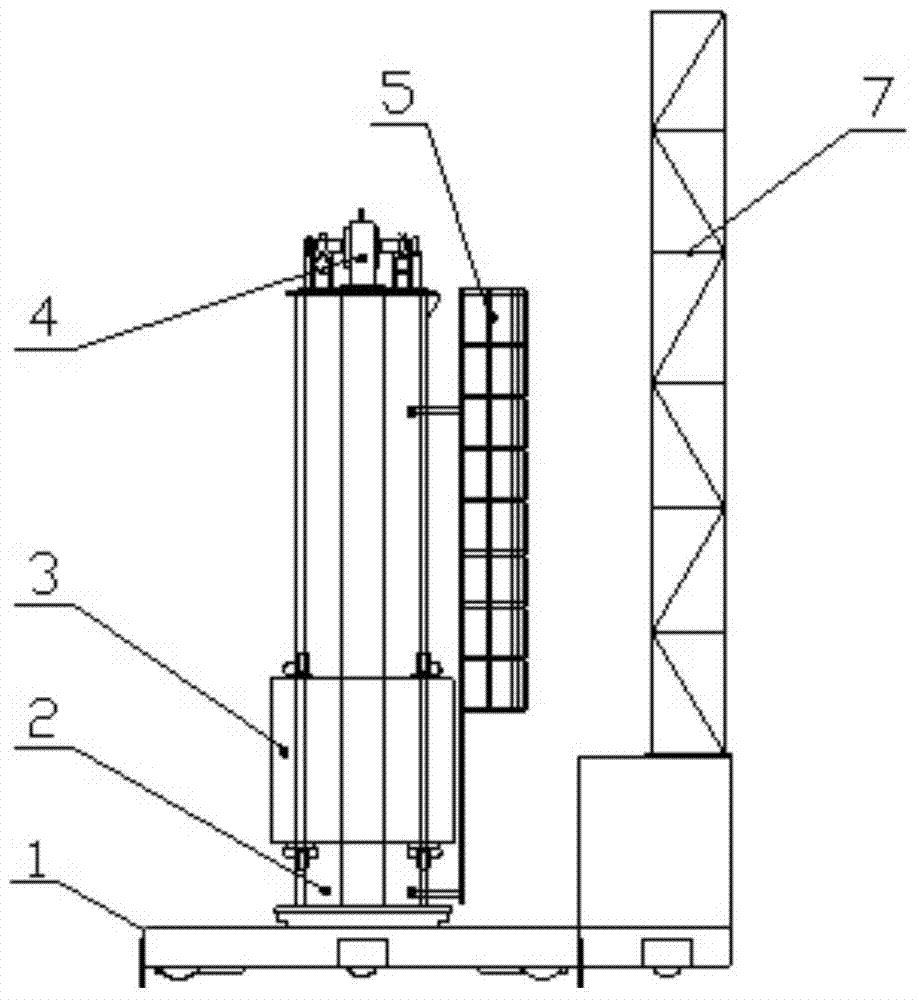

ActiveCN103567651AGuaranteed accuracyGuaranteed smoothMetal working apparatusWelding apparatusSlag (welding)Electroslag welding

The invention discloses a welding machine for a box beam. The welding machine mainly comprises a trolley part, a column mechanism, a lifting mechanism and a cantilever part, wherein the column mechanism is mounted at the trolley part; the lifting mechanism is mounted at the top end of a column; the cantilever part is mounted on one side of the column; and a crawling ladder and a line hanging device are arranged further. According to the welding machine, corresponding structural parts are reasonably combined, actions such as trolley walking, column rotation, platform lifting, machine head walking and the like can be realized, and two welding techniques of electro-slag welding and submerged-arc welding can be completed on one welding machine. According to the welding machine for the box beam, two machine heads can be adjusted right and left, up and down and front and back, the flatness of a weld joint can be guaranteed, the welding quality is improved, and the cost is lower.

Owner:南京奥特智慧数字科技有限公司

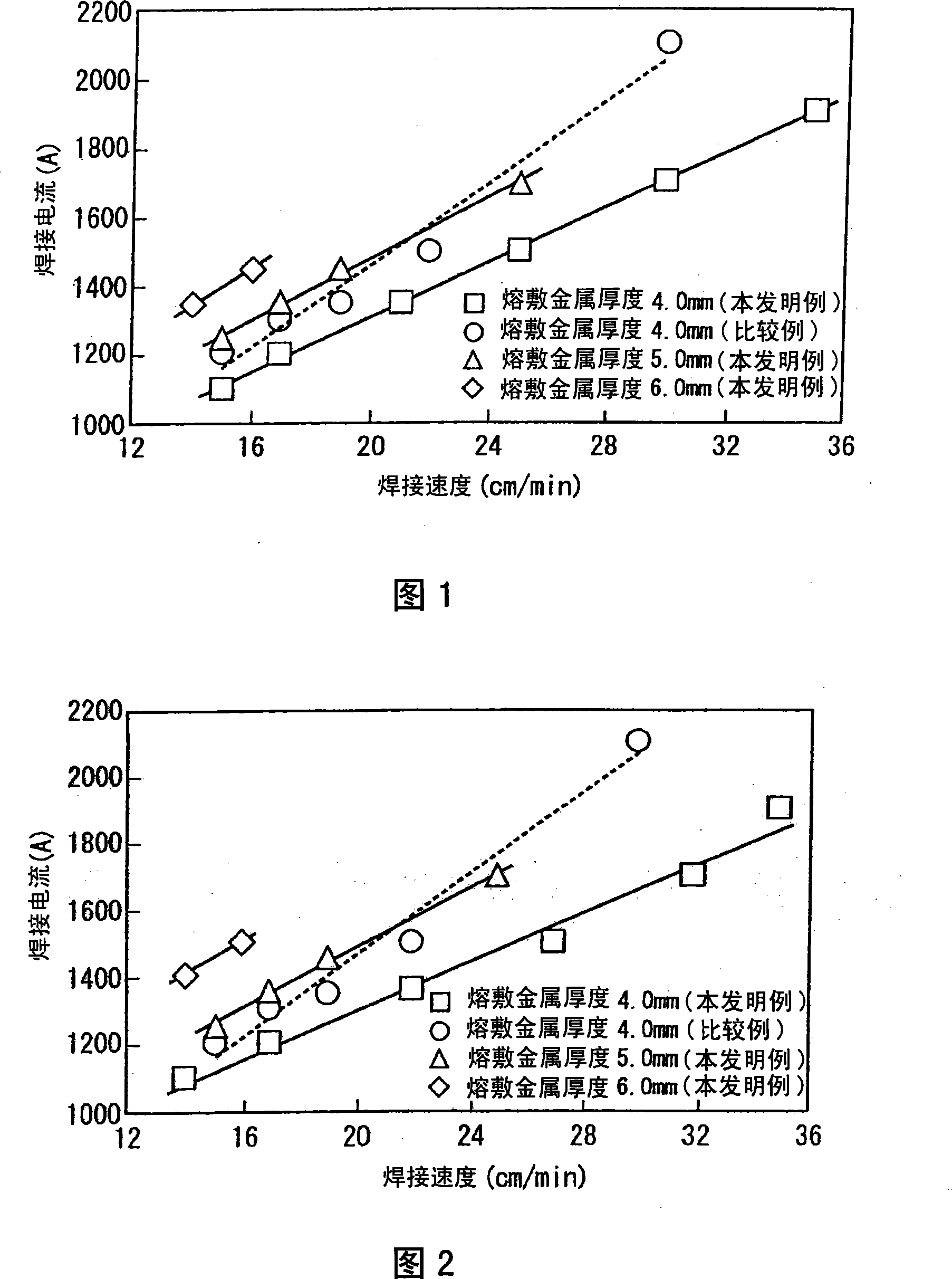

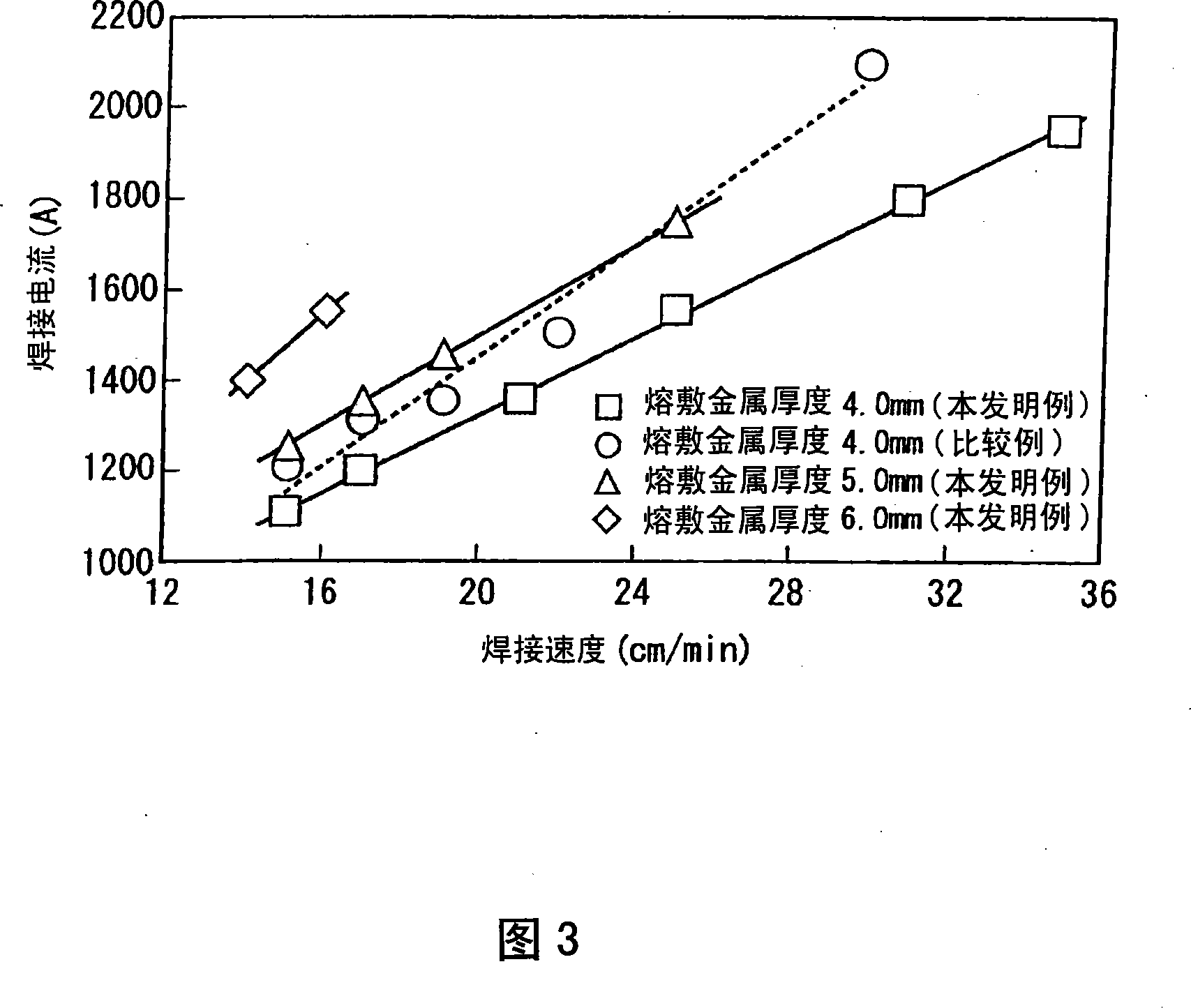

Welding flux for electroslag surfacing

Provided is an electroslag welding flux for welding. With the use of a band electrode, the electroslag welding flux can make bead welding process with a 5mm or 6mm deposited metal thickness, different form the existing welding flux with a 4mm upper deposited metal thickness. The welding flux provided in the invention contains the following components, by weight, CaF2:35 to 50 %, SiO2: 15 to 20 % without 15% involved, Al2O3: 10 to 20%, CaO: no more than 10%, the sum of MgF2 and AlF3: 5 to 10%, MgO: 5 to 15%.

Owner:KOBE STEEL LTD

Manufacturing method for steel-structure box beam/box column

InactiveCN105269253AEasy to produceImprove quality and efficiencyArc welding apparatusNumerical controlElectricity

The invention relates to a steel-structure box beam / box column. A manufacturing method for the steel-structure box beam / box column comprises the following steps that (1) numerical-control blanking of webs and a partition board is conducted according to size requirements, and grooves are machined in the webs and the partition board; (2) spot-welded lining plates are assembled to the back sides of the grooves of the webs and the partition board; (3) a U shape is formed by a cover plate and the two webs on a box-shaped assembly machine; (4) the partition board is placed in the formed U-shaped groove, and three edges of the partition board are welded; and (5) cover plates are installed, and a connecting weld joint between the cover plates is welded. According to the manufacturing method, the difficult problem that the box beam / box column cannot be produced when no special electroslag welding equipment is available is solved, and more importantly, the difficult problem that when a multi-storey house is built, a wall board, with the thickness being smaller than 18 mm, of the beam / column cannot be welded easily through electroslag welding is solved. By the adoption of the manufacturing method, machining procedures are simplified, and the quality and manufacturing efficiency of components are greatly improved; the manufacturing method has extremely high economic value and social value and is easy to apply and popularize.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

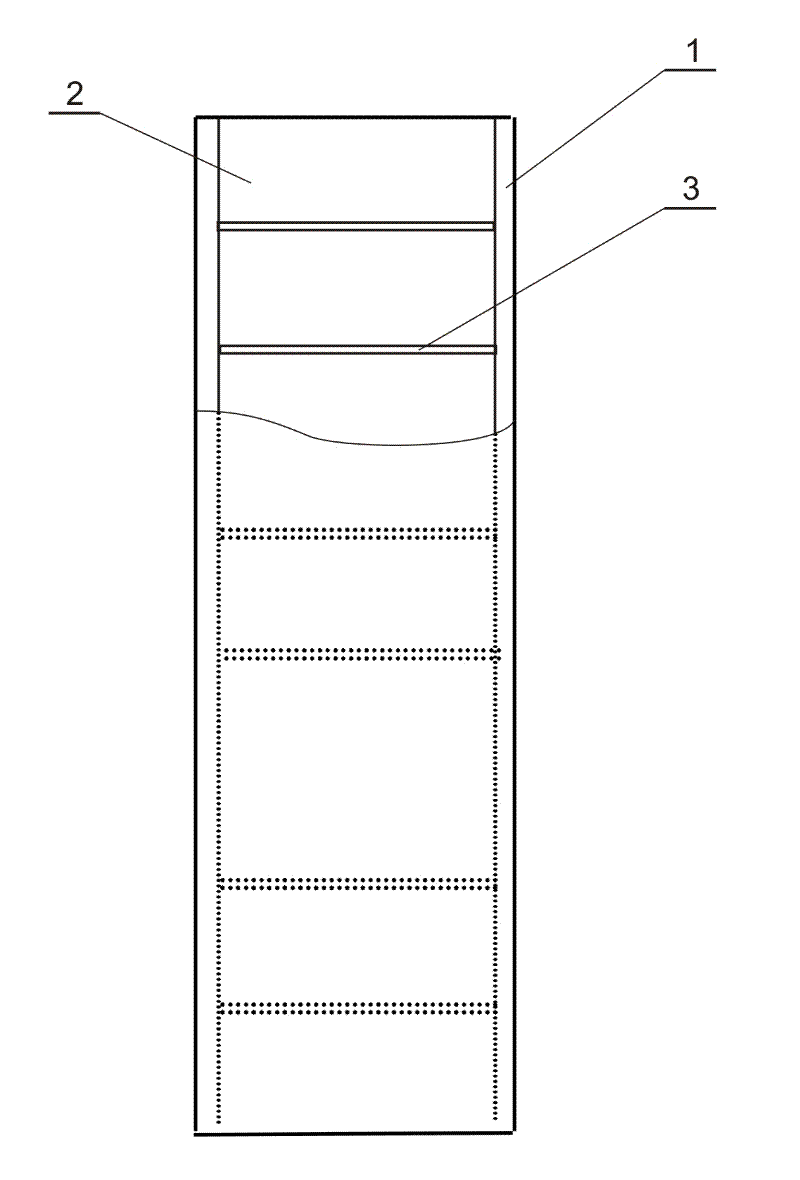

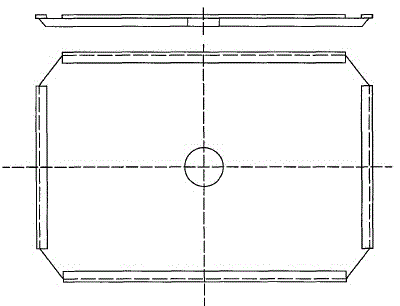

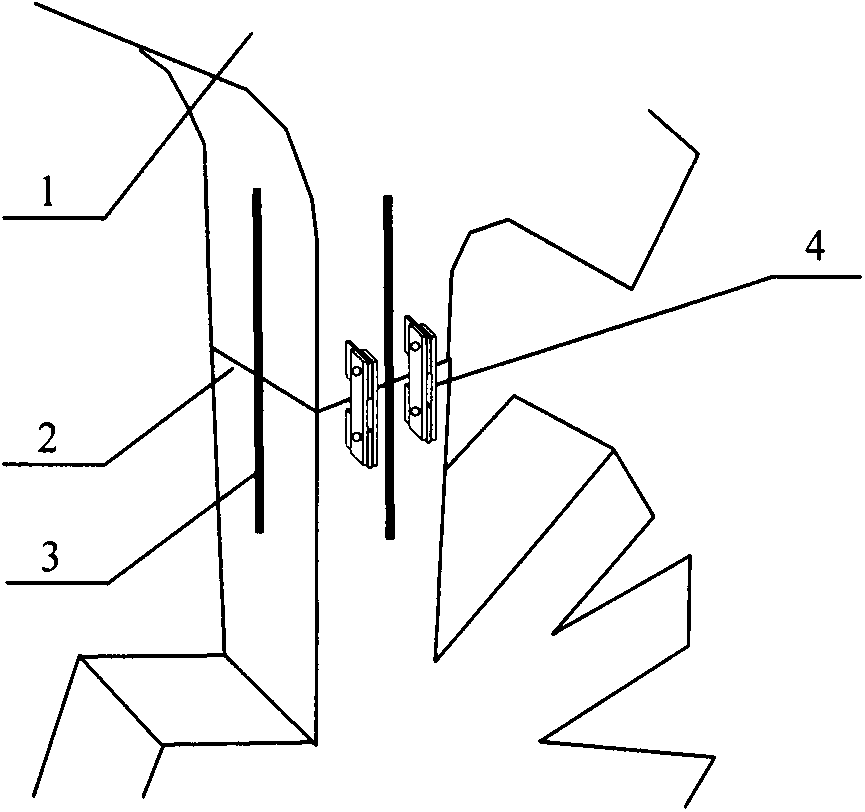

Manufacturing method of inclined electroslag welding component shaped like Chinese character 'ri'

The invention relates to a manufacturing method of an inclined electroslag welding component shaped like a Chinese character 'ri'. The process of the manufacturing method comprises the step of lofting and marking-off, the step of assembly and welding, the step of assembling H-shaped steel, the step of assembling inner diaphragm lining strips and inclined electroslag lining strips and milling edges, the step of installing and welding an inner diaphragm, the step of assembling box body covering plates at two sides, the step of correction and end milling of the component shaped like the Chinese character 'ri', the step of assembling corresponding brackets, and the step of rust removal and coating. Compared with the prior art, the manufacturing method of the inclined electroslag welding component shaped like the Chinese character 'ri' has the advantages of effectively guaranteeing the manufacturing quality of the small-section and thick-plate inclined electroslag welding component shaped like the Chinese character 'ri', not only achieving large-batch edge milling operations of the inclined electroslag lining strips, but also resolving the problems of difficult welding, difficult assembly and large deformation of the structure, obviously improving the production efficiency of workshops, and saving production cost.

Owner:成军

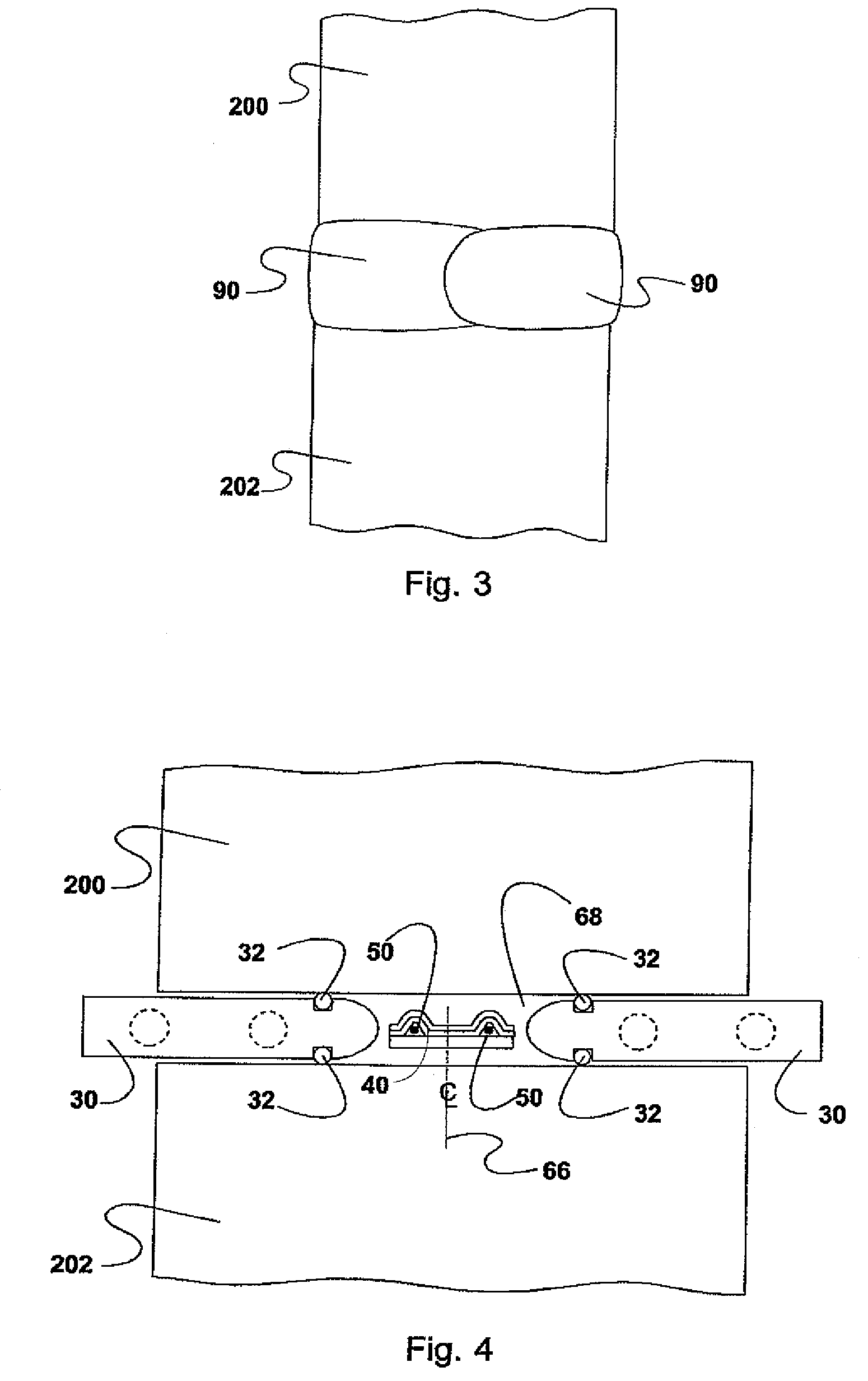

Single cylinder dual-action type spot welding machine welding head

InactiveCN101143403AReduce processing costsQuality improvementResistance electrode holdersElectrical resistance and conductanceElectroslag welding

The invention discloses a welding head for a double-acting spot welder with a single-cylinder, comprising a rails tie plate, a cylinder, an electrode tip holder, an electrode pole connected with the electrode tip holder, and electrode arranged at the electrode tip holder and a pressure replacement setting. The pressure replacement setting consists of a leader rocker die and a pinion-and-rack mechanism. A locating screw and the displacement control apparatus of a vernier regulation nut are arranged on the leader rocker die mechanism. The invention is able to correctly locate the distance of the electrodes and drive two electrodes at the same time. With the low cost needed, the invention is able to realize the precise location and the chucking power adjustment of the double-electrode of a resistance welder welding joint, which presents the coupling of variable electroslag welding with the welding joint of high cost performance, thereby leading a welding point to stable quality and preventing a work piece from deformation. The invention has simple structure. And the cost of processing components is low, which is easy to be operated.

Owner:浙江巨力电机成套设备有限公司

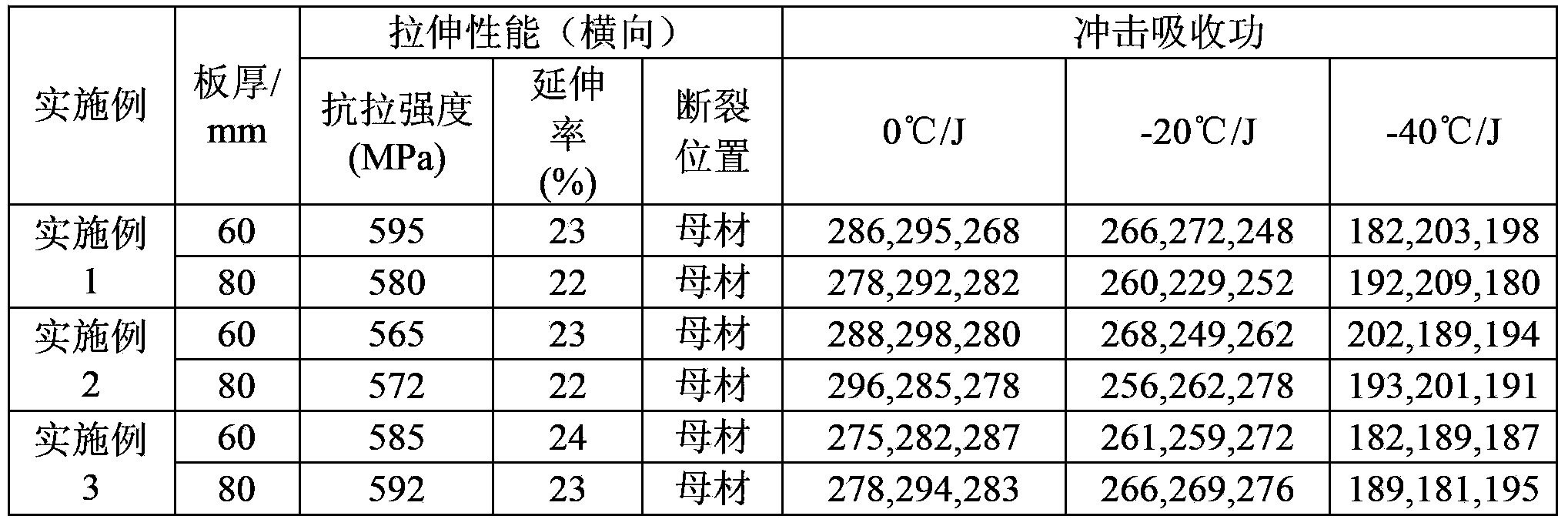

Flux for electroslag overlay welding

ActiveCN102990251AExcellent peelabilityImprove melting abilityArc welding apparatusWelding/cutting media/materialsElectroslag weldingBead shape

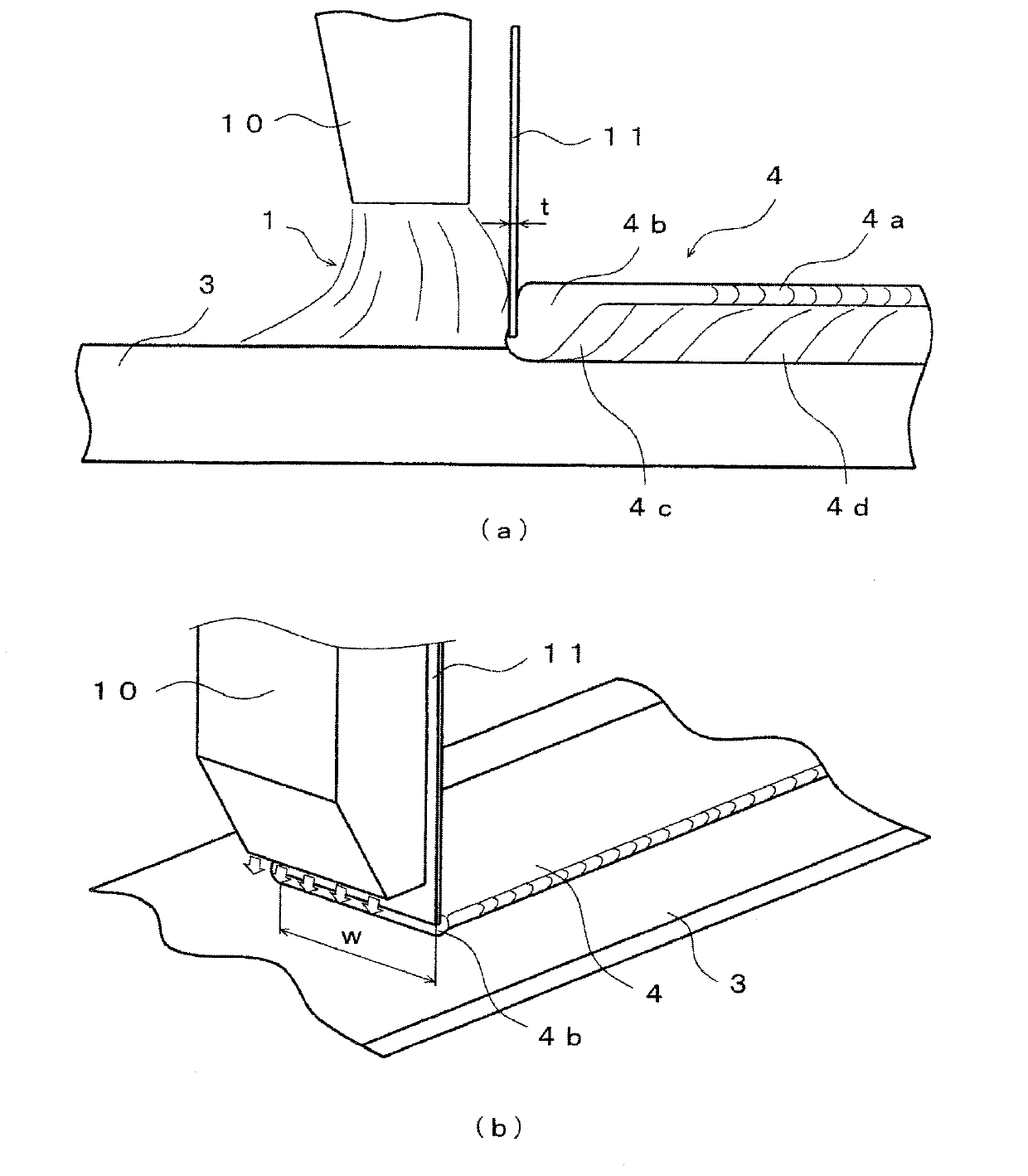

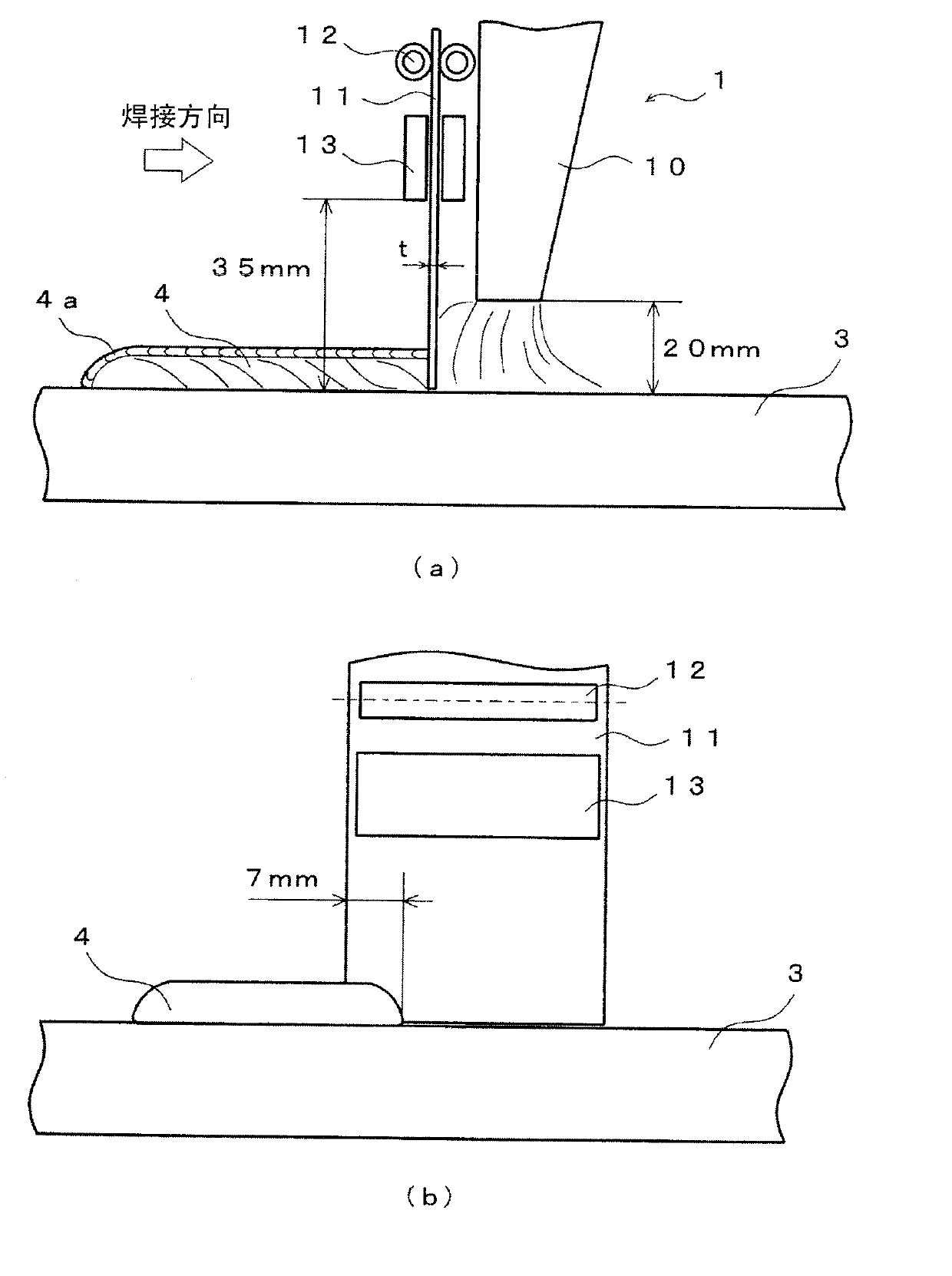

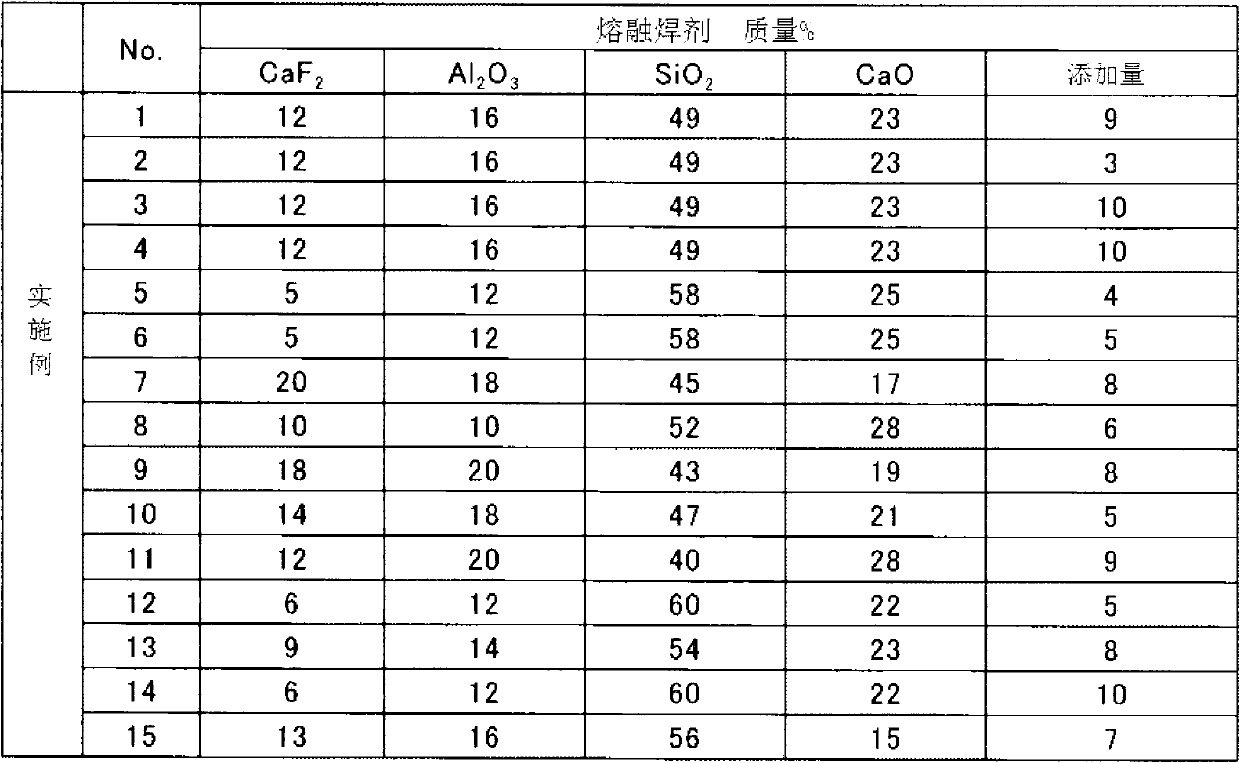

The invention provides a flux for electroslag overlay welding. The flux is advantageous in that, in electroslag overlay welding for which band steel formed by a Ni-based alloy is used, even under the condition of small heat input amount in welding, stability of welding is excellent, and good welding bead shape and welding bead appearance can be obtained. The flux (1) is used for the electroslag overlay welding for which the band steel formed by the Ni-based alloy is used. The flux (1) is a sintered flux obtained by mixing and sintering, in total mass percent of the flux, 3-10 mass% of a molten flux as a part of raw materials for the sintered flux, wherein the molten flux comprises CaF2: 5-20 mass%, Al2O3: 10-20 mass%, SiO2: 40-60 mass%, and CaO: 15-30 mass%. In addition, whole composition of the flux is optimized.

Owner:KOBE STEEL LTD

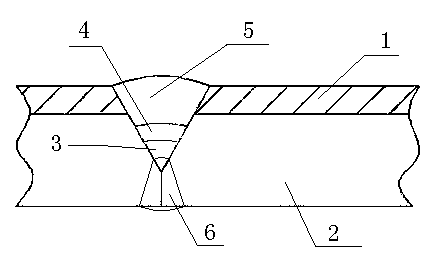

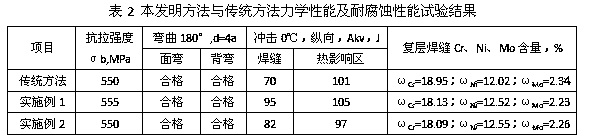

High-efficiency welding method of stainless steel composite board

InactiveCN103862183AWeld depth is smallIncrease weld widthArc welding apparatusMetal working apparatusElectricitySlag

The invention relates to the field of composite board welding methods, in particular to a high-efficiency welding method of a stainless steel composite board. The high-efficiency welding method of the stainless steel composite board comprises the following steps: processing grooves; cleaning and pairing the grooves; welding a base layer on the side of a composite layer; welding the composite layer; welding a base layer on a back surface. The high-efficiency welding method of the stainless steel composite board has the beneficial effects that since electroslag welding with wire electrodes is adopted for welding the composite layer and electrode wires with content of Cr and Ni which is close to the content of Cr and Ni of composite materials, low-carbon weld metal with excellent corrosion resistance is guaranteed to be obtained; since the electroslag welding with wire electrodes has the characteristics of small weld depth and large weld width, welding passes can be effectively reduced, the reduction of the welding passes means the simplification of the welding process, the welding efficiency is improved and the probability of occurrence of defects such as incomplete fusion and slag inclusion is also greatly reduced; since the base layer of the back surface is welded by adopting 450A-500A large-current submerged-arc welding, the weld penetration of base metal can be effectively guaranteed, the defect of incomplete fusion is precluded from occurring and the welding efficiency can be greatly improved.

Owner:JIGANG GRP

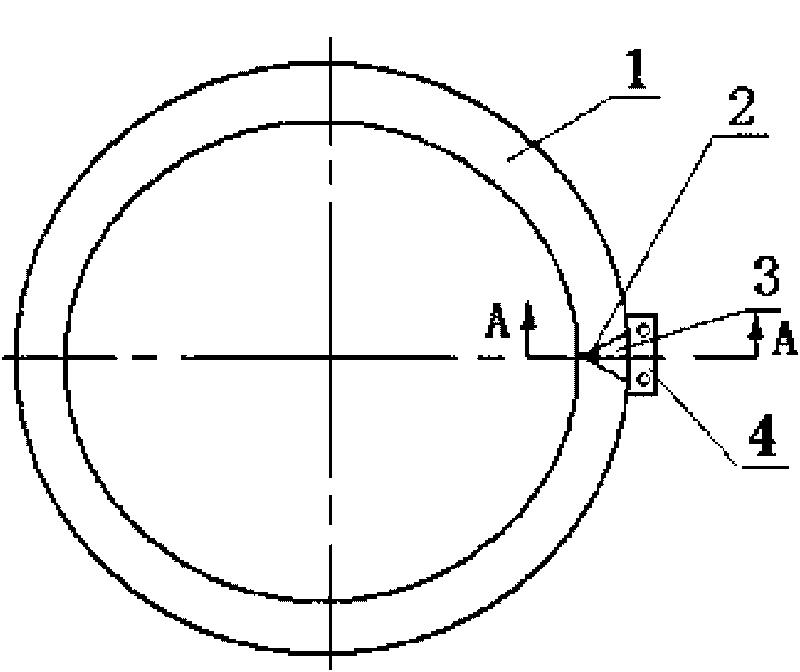

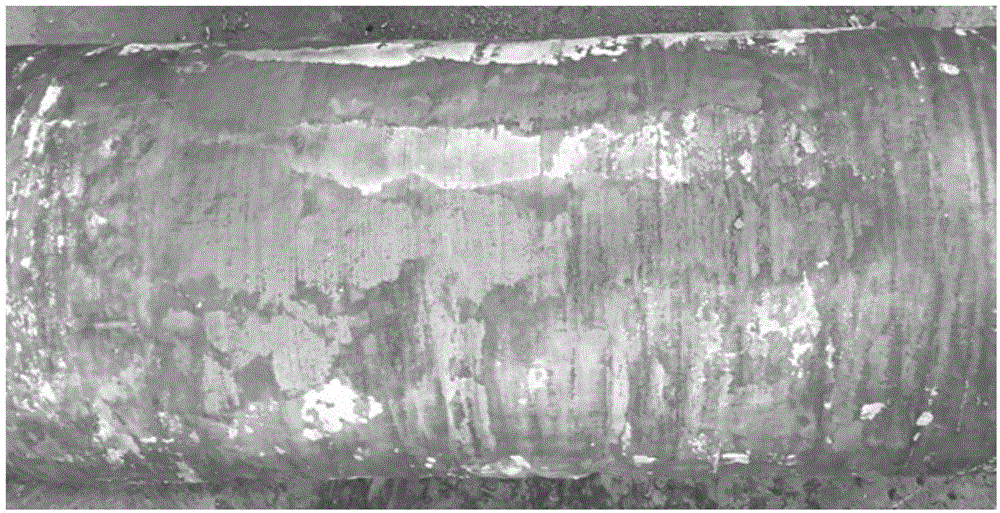

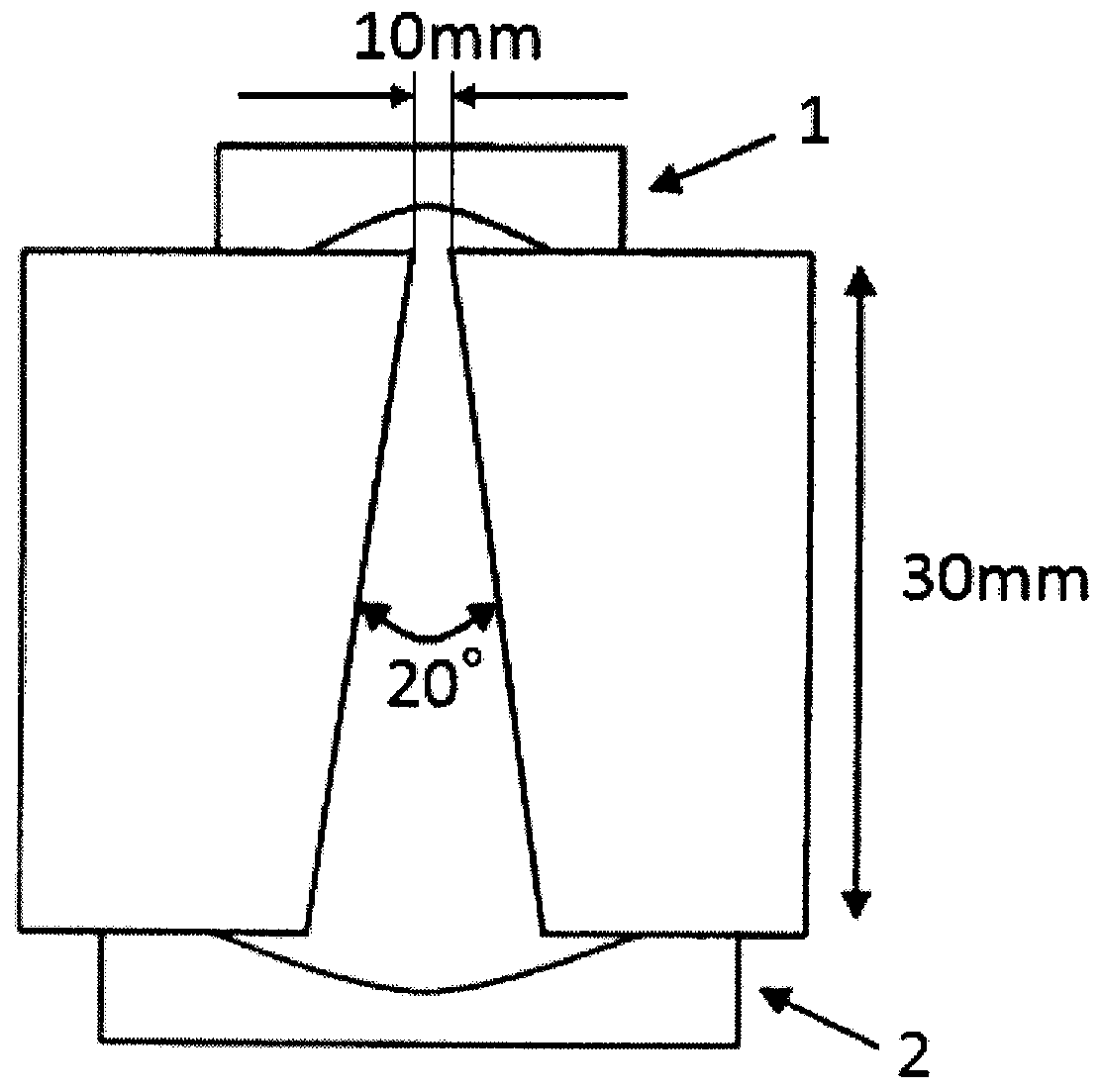

Electroslag welding method for cylindrical longitudinal seam V groove

The invention discloses an electroslag welding method for a cylindrical longitudinal seam V groove, which is implemented by the following steps: gas-cutting a butted part of workpieces into a single groove, curling a workpiece into a cylindrical shape, making the single groove combined into a double V groove, and priming the bottom of the V groove to form a priming weld seam; and erecting the cylindrical workpiece on an electroslag welding fixed beam, attaching cooling copper sliding blocks to the excircle of a cylinder body on the outside of an opening of the double V groove, electrifying a filament to smelt a welding stick and metal on the V surface of the groove of the workpiece to form a weld pool, continuously sending filaments into the weld pool, introducing cooling water to the cooling copper sliding blocks outside the weld pool, spraying water to the inner wall of the priming weld seam, in the welding process, making the cooling copper sliding blocks synchronously raised along with a welding head, and making electroslag weld seam reliably welded with the double V groove and the priming weld seam to complete the welding. The method has the advantages of high welding quality and high welding efficiency.

Owner:MCC SFRE HEAVY IND EQUIP

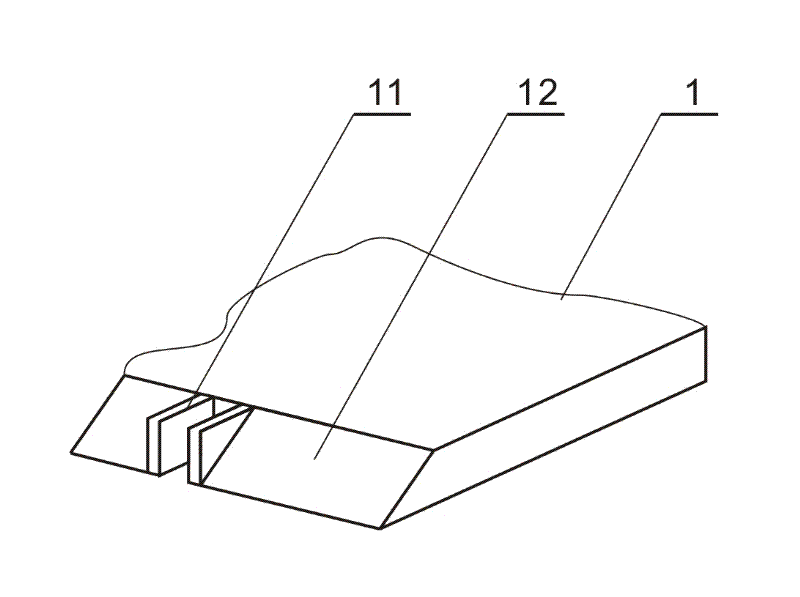

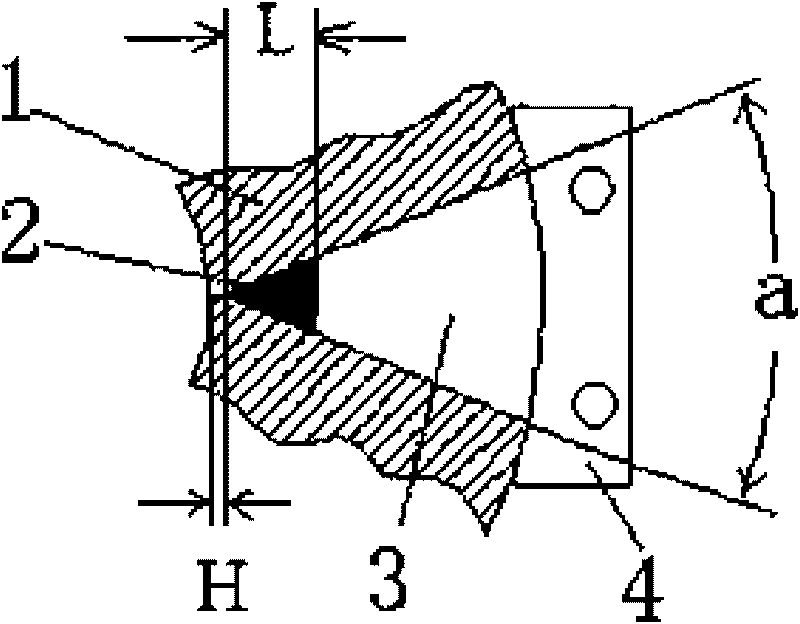

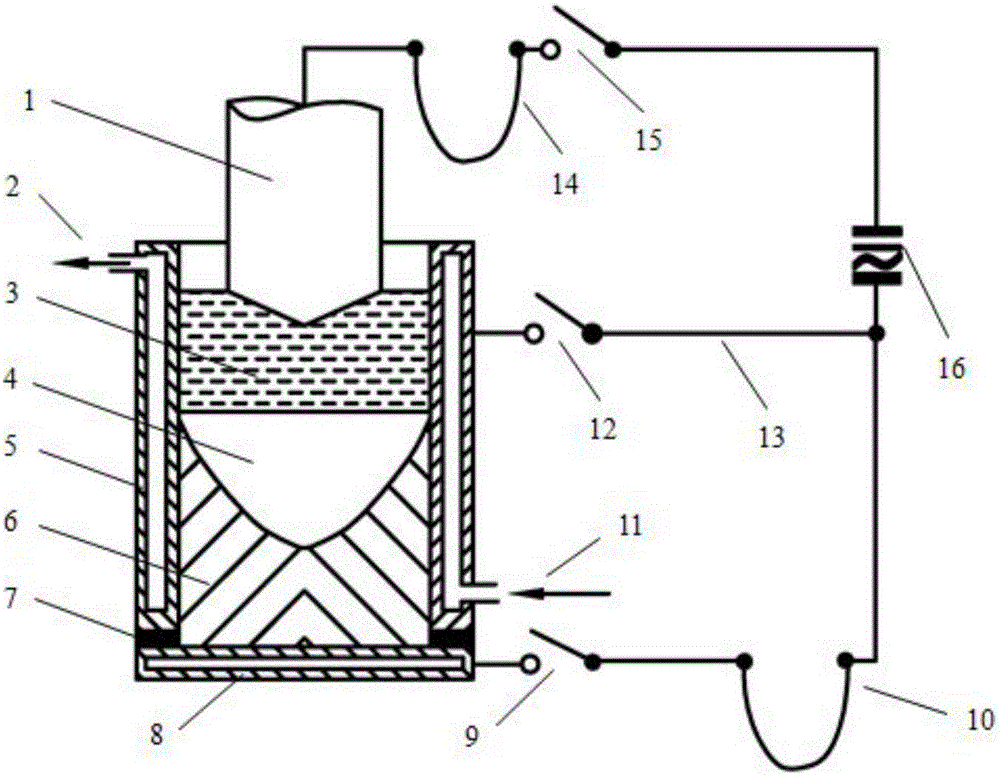

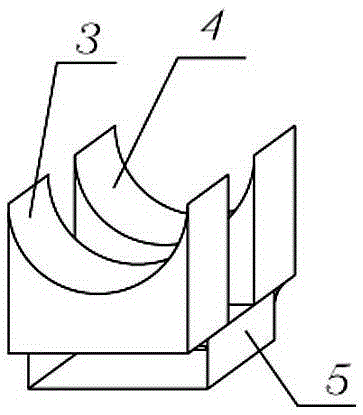

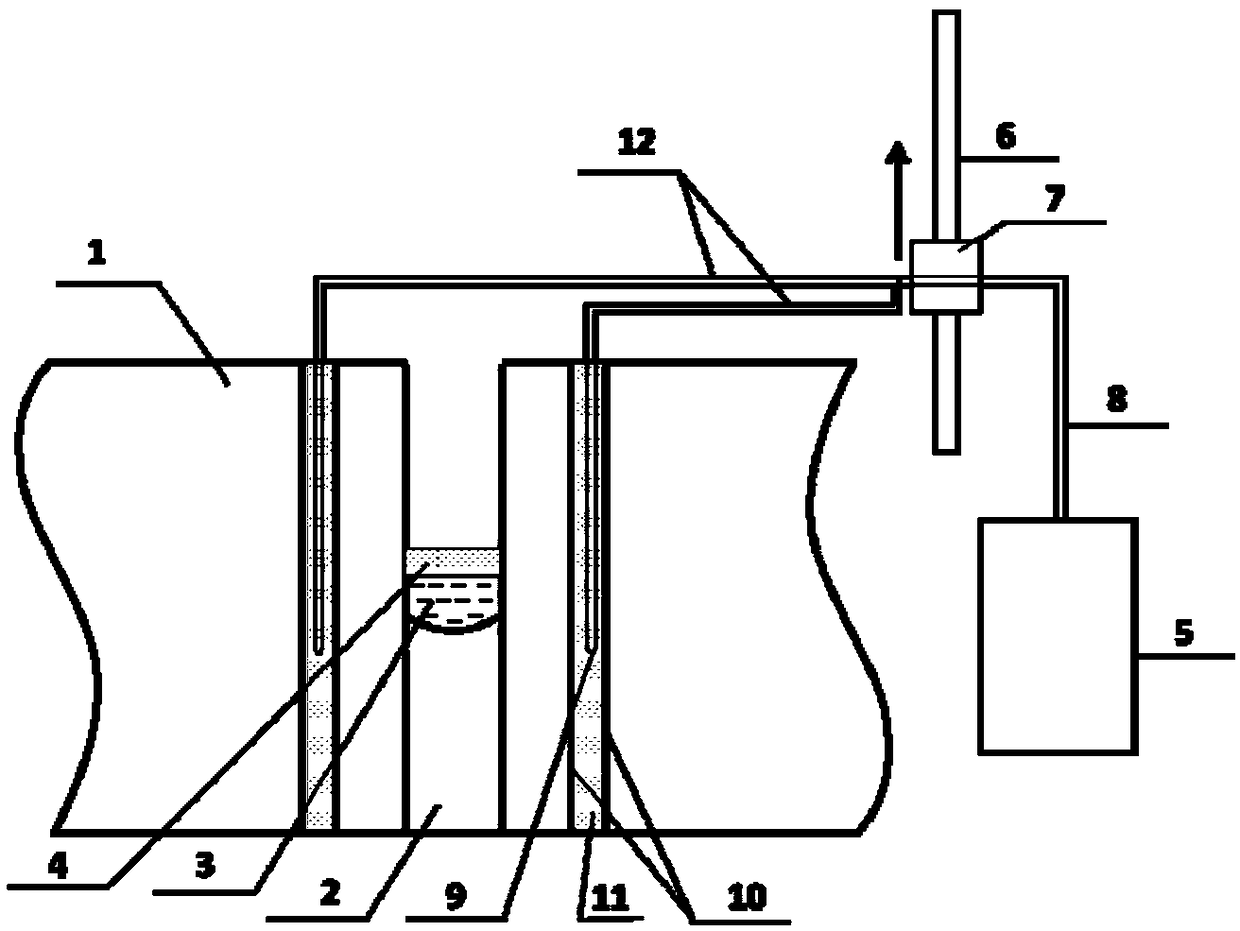

Inner water circulation copper block forced cooling device for steel structure box-type column electroslag welding

InactiveCN104785979AAccelerate the lossShort residence time at high temperatureWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneRetention time

The invention provides an inner water circulation copper block forced cooling device for steel structure box-type column electroslag welding. The device comprises two water collection tanks, a water pump, a water valve, a water pressure gauge, a water pipe, a copper block and a U-shaped pipeline. The copper block is tightly attached to the outer surface of an electroslag welding member joint; two drainage channels are formed inside the copper block along the thickness direction; and a water inlet channel is formed close to the electroslag welding member side, and a water outlet channel is formed on the other side. The water inlet channel and the water outlet channel are communicated at one end of the copper block by virtue of the U-shaped pipeline; the water inlet channel at the other end of the copper block is connected with the water collection tank I; the water outlet channel is connected with the water collection tank II; inner water circulation of the copper block is realized under the action of the water pump, and forced cooling in the electroslag welding is realized. According to the device, a too wide heat affected zone, extremely long time Deltat 8 / 5 and high-temperature retention time generated by the electroslag welding joint can be avoided, so that the mechanical property, particularly breaking tenacity, of the electroslag welding joint is improved, the device can be used for improving the microstructure and mechanical property of the building steel structure box-type column electroslag welding joint, and the shock resistance of the structure is improved.

Owner:CHONGQING UNIV

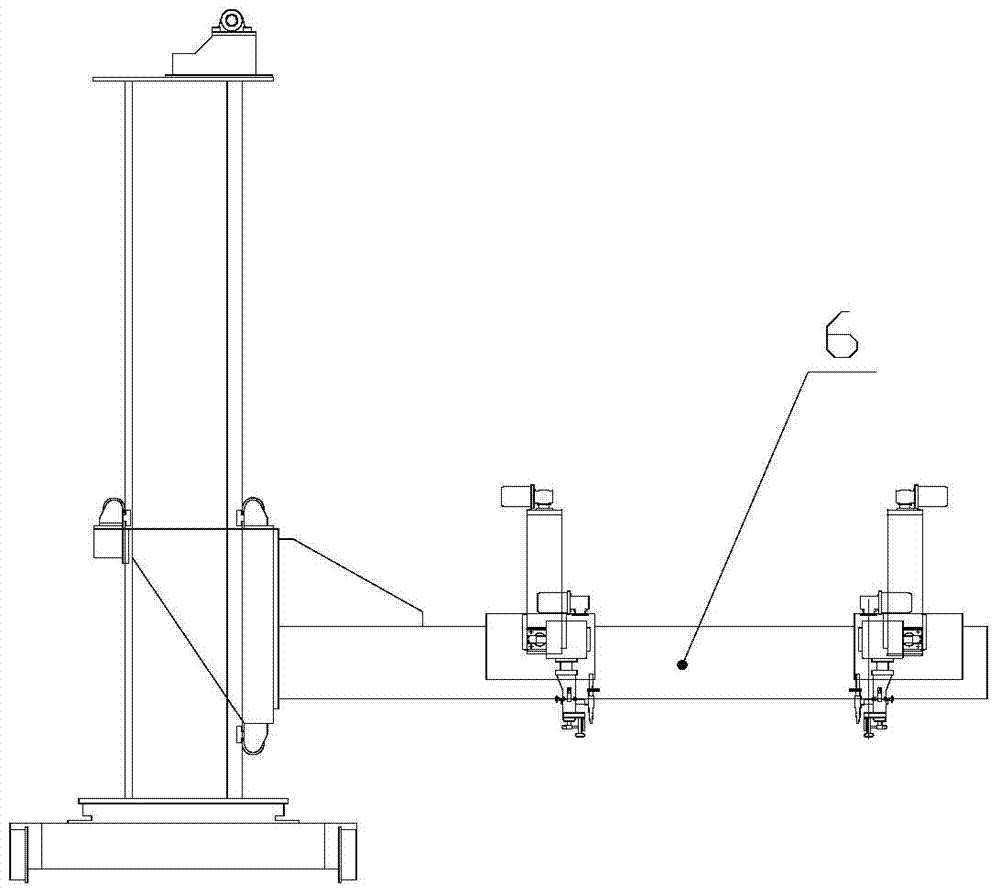

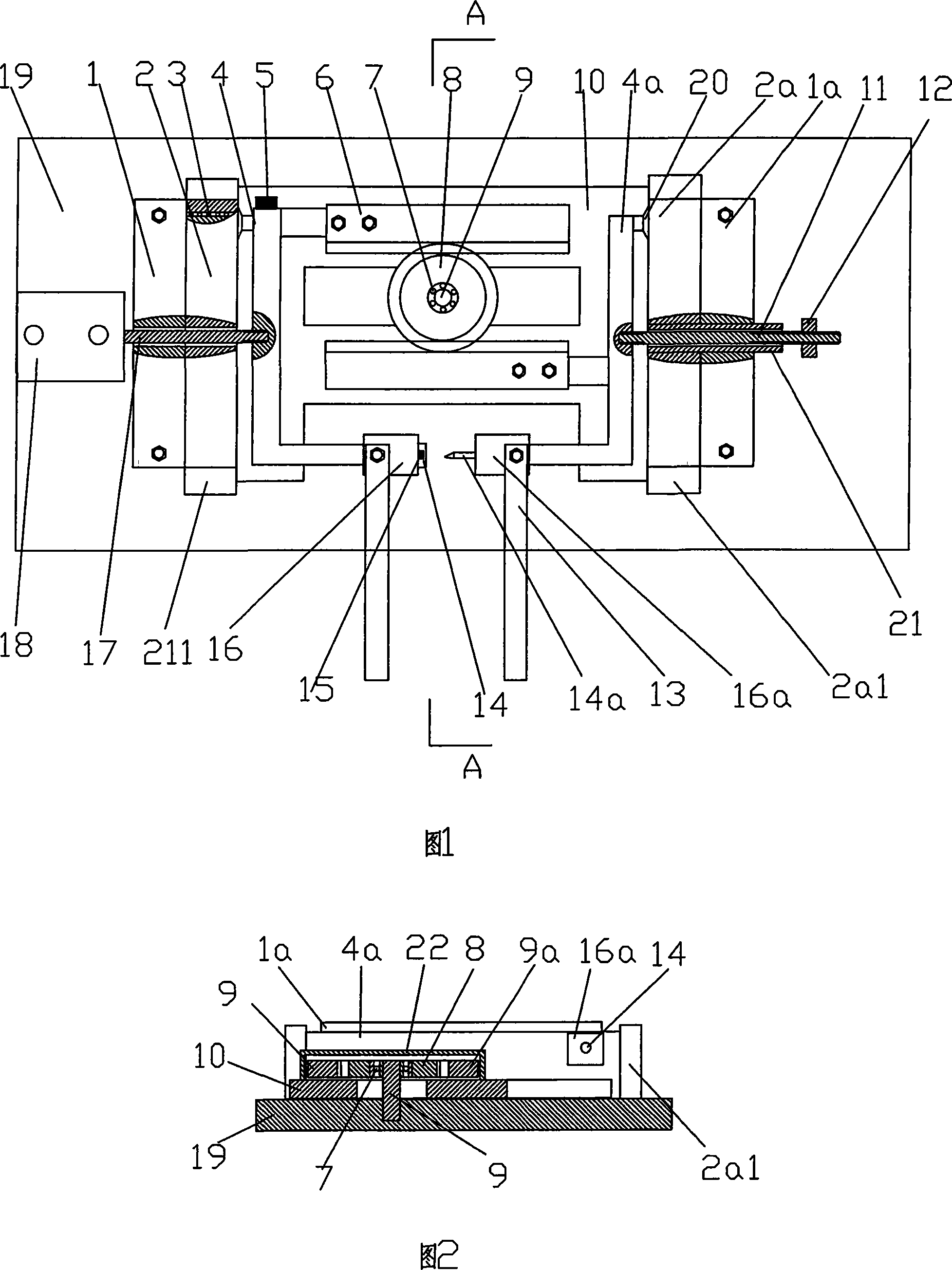

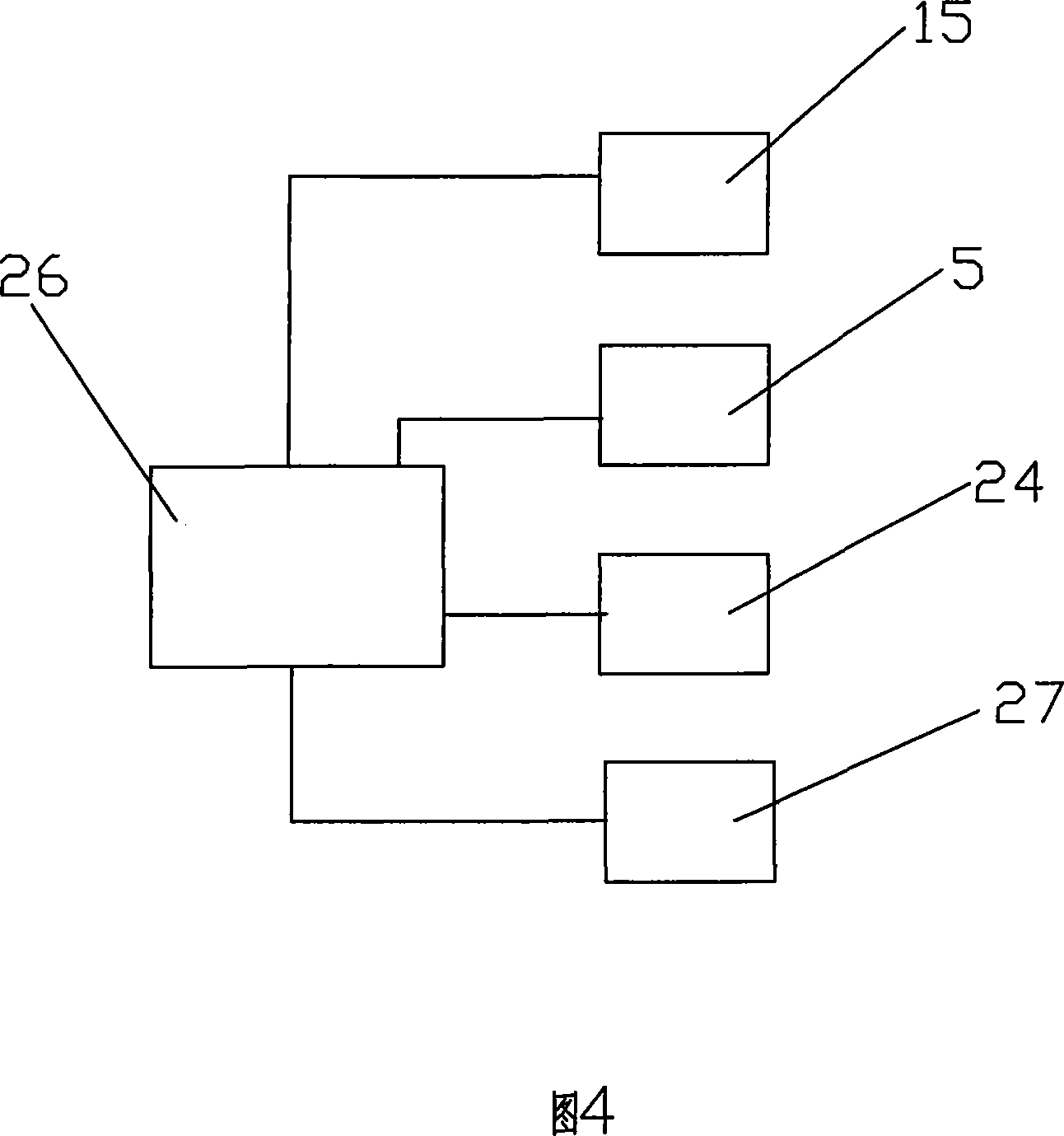

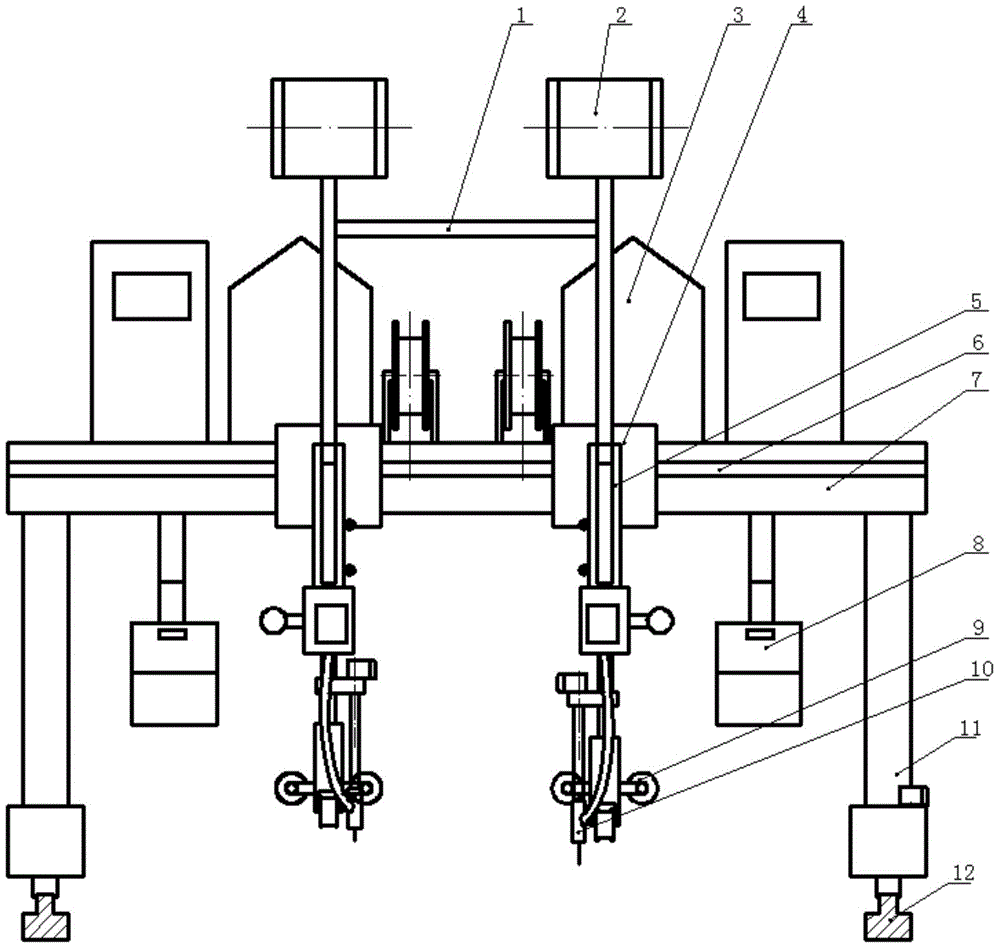

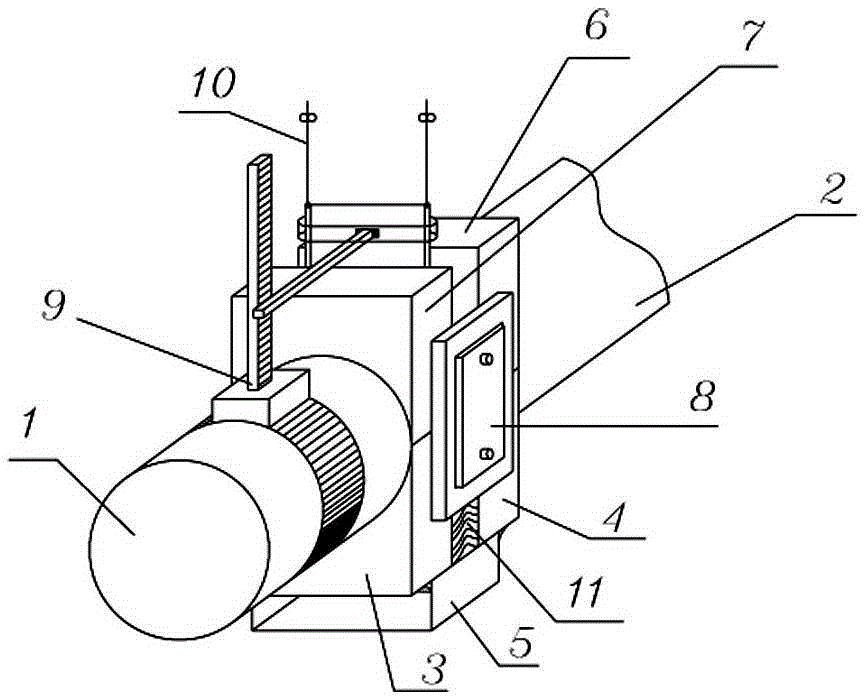

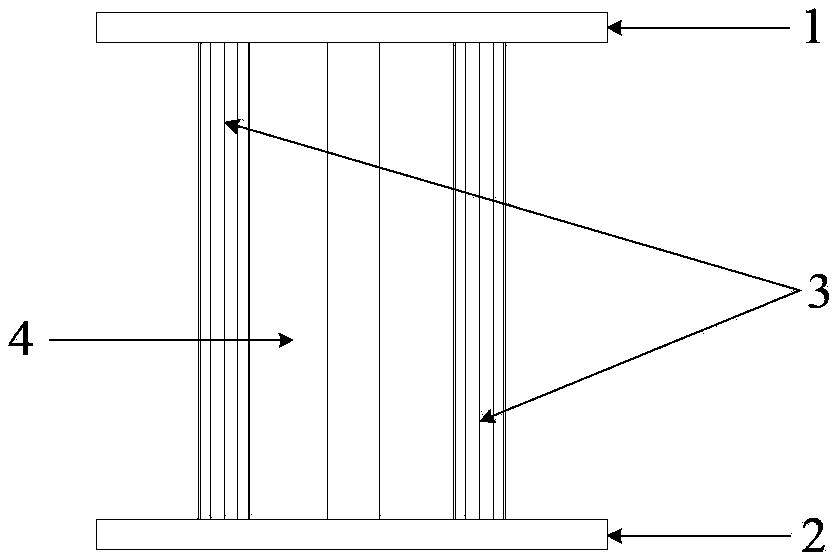

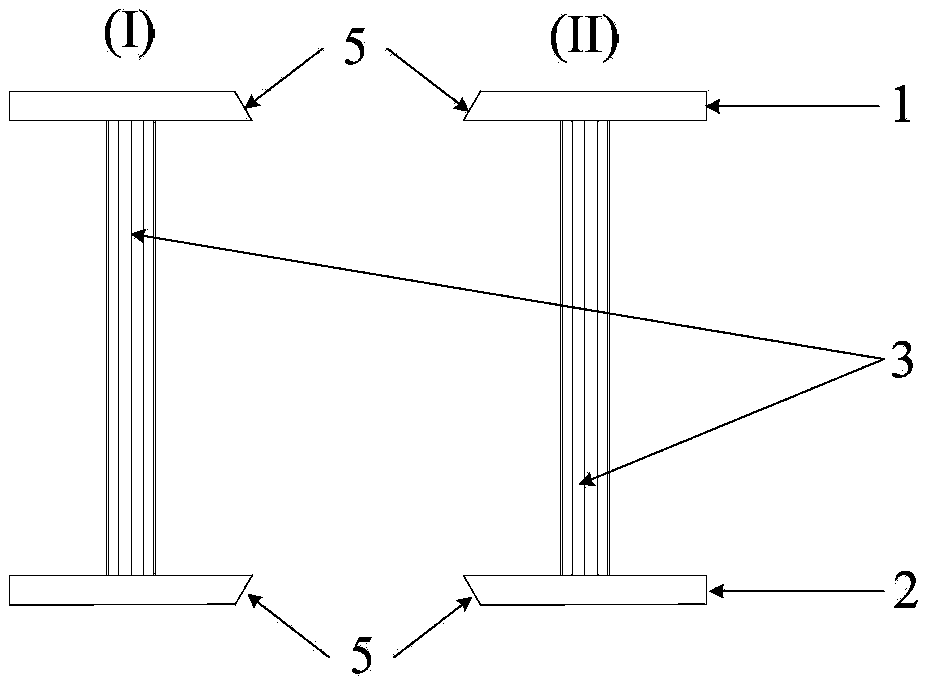

Bilateral numerical control electroslag welding device

InactiveCN104416282AGood short feedback performanceQuick responseWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlElectroslag welding

The invention relates to a bilateral numerical control electroslag welding device. A wire feeding frame which is of a quadrangle frame structure is fixedly arranged at the middle part of the upper end of a portal; wire feeding controllers are fixedly arranged at the upper ends of both sides of the wire feeding frame; the wire feeding speed is controlled by the wire feeding controllers by virtue of an electric cabinet; welding wire bins are fixedly arranged at an interval at the middle part of the upper end of the portal behind the wire feeding frame; the lower parts of welding arms are provided with telescopic sleeves in a coaxial regulating manner; the telescopic sleeves regulate welding guns to move up and down; steering devices are arranged at the lower parts of the telescopic sleeves; the welding guns are fixedly arranged on the steering devices. The bilateral numerical control electroslag welding device has a simple structure, is scientifically designed, is convenient to operate, has high welding accuracy, is convenient and reliable to operate, is convenient to regulate and is accurate to position; production efficiency can be effectively promoted; welding quality is ensured.

Owner:TIANJIN JINPU STEEL STRUCTURE

Manufacturing method of steel structure box girder/column

InactiveCN105328400AEasy to produceImprove quality and efficiencyArc welding apparatusNumerical controlElectroslag welding

The invention relates to a steel structure box girder / column. A method comprises the following steps that firstly, numerical control webs and partition plates are blanked according to the size, and grooves are machined; secondly, liner plates are assembled on the back faces of the grooves of the webs and the back faces of the grooves of the partition plates in a spot welding manner; thirdly, a U shape is formed by one cover plate and two webs on a box assembling machine; fourthly, the partition plates are placed in the formed U-shaped groove, and the three edges of the partition plates are welded; and fifthly, the cover plate is arranged, and connecting welding lines of the cover plate are welded. According to the method, the problem that the box girder and column cannot be produced due to the fact that no special electroslag welding device exists is solved, and more importantly, the problem that when a multi-layer house is built, the thickness of wall plates of the girder and the column is lower than 18 mm, and welding is not easy through electroslag welding is solved. By means of the method, the machining procedure is simplified, the quality of components and the manufacturing efficiency are greatly improved, and the steel structure box girder / column has very high economic value and social value, and is easy to apply and popularize.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

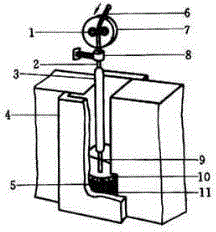

Tubular dissolved nozzle electroslag welding device of steel structural high-rise building construction

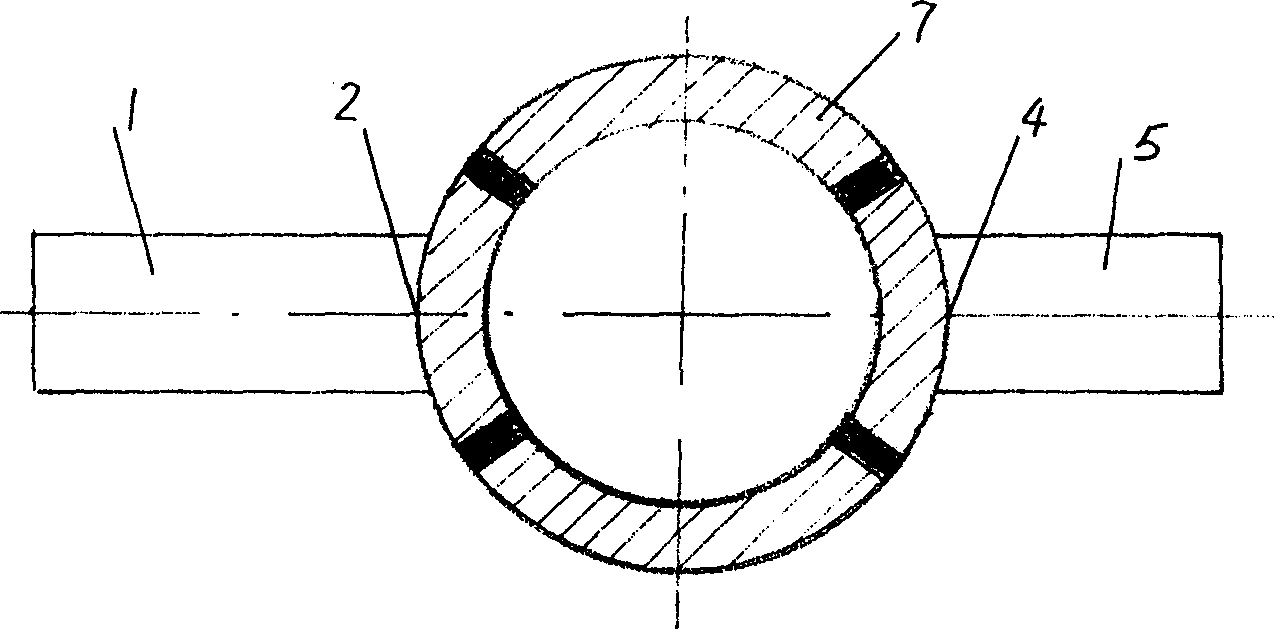

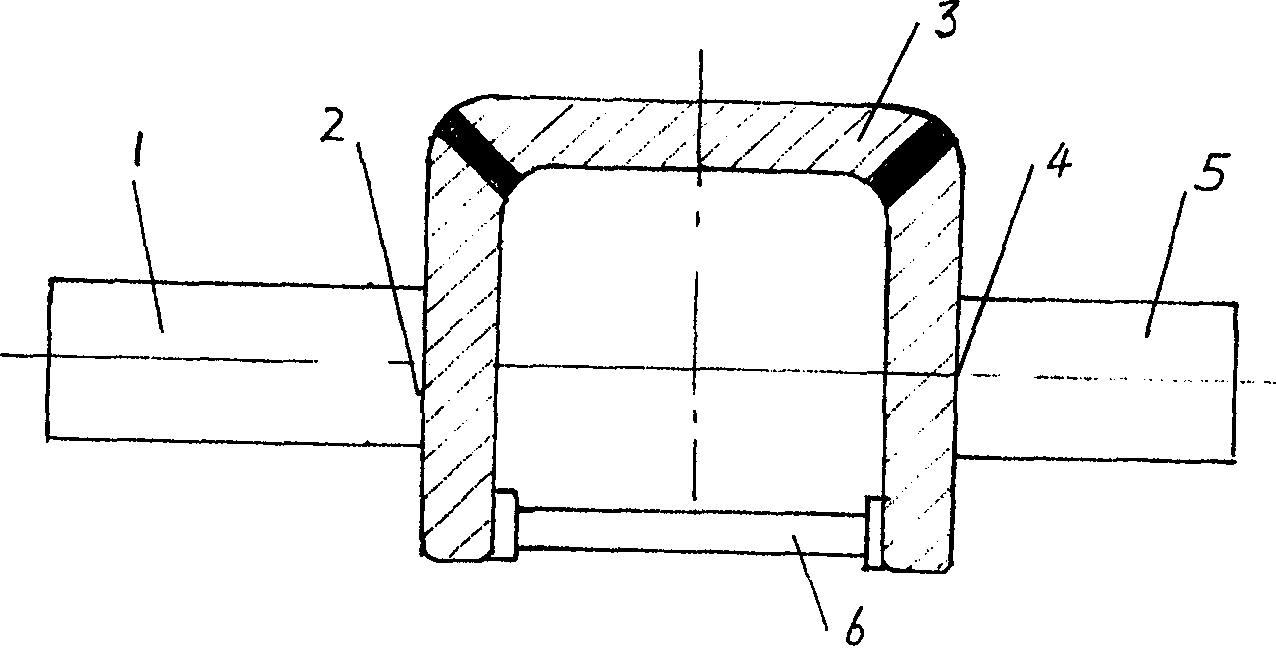

The invention discloses a tubular dissolved nozzle electroslag welding device of a steel structural high-rise building construction. The tubular dissolved nozzle electroslag welding device is composed of a feed-in pressing wheel, a tubular dissolved nozzle, a drug skin, a water cold copper block, a welding seam surface slag shell, a welding wire, an electric motor, a tubular dissolving nozzle holder, a slag pool, a melting metal and a welding seam.

Owner:HEILONGJIANG RONGDE BUILDING TECH DEV

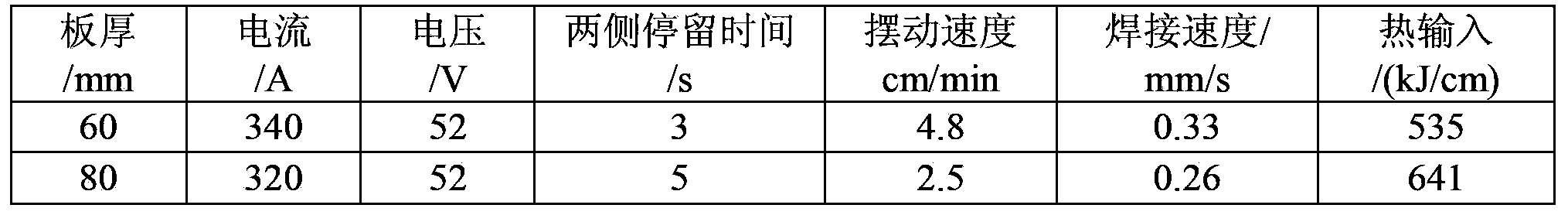

Electroslag welding solid wire for low-temperature steel plate

ActiveCN103350290AImprove performanceGuarantee surface scarring and other quality problemsWelding/cutting media/materialsSoldering mediaElectroslag weldingAbsorbed energy

The invention discloses an electroslag welding solid wire for a low-temperature steel plate. The solid wire comprises the chemical components in percentage by weight as follows: 0.04%-0.08% of C, 0.20%-0.60% of Si, 0.5%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.015% of S, 0.20%-0.60% of Mo, 3.5%-5.5% of Ni, 0.10%-0.30% of Ti, 0.005%-0.02% of B, less than or equal to 0.005% of N, 0.005%-0.2% of Zr and the balance of Fe and inevitable impurities. The solid wire is used for welding the steel plate with the thickness of less than or equal to 80 mm; the minus 40 DEG C impact absorbing energy of a weld metal of a welded joint is larger than or equal to 180 J; the tensile strength of the welded joint is larger than or equal to 565 MPa; when the strength is guaranteed, the weld metal has excellent low-temperature toughness; and the solid wire can be widely applied to electroslag welding processing of steel plates in the fields such as ships, oceaneering, buildings and bridges in cold areas and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

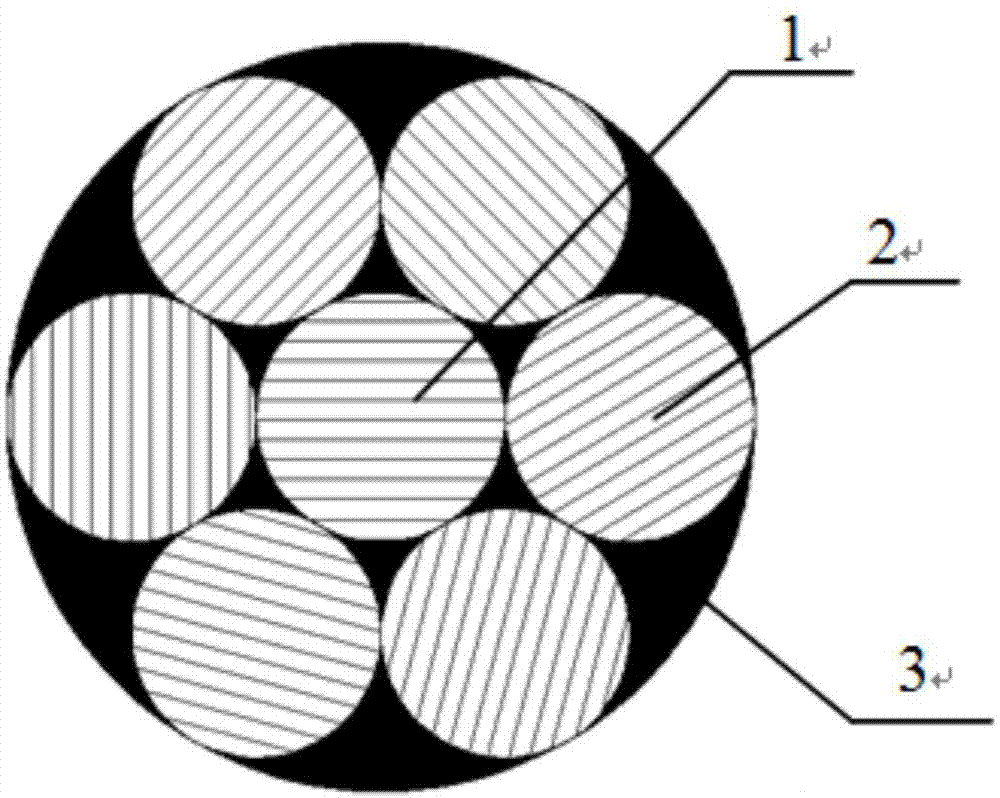

Activated stranded wire welding wire for increasing penetration depth

InactiveCN104227270ASmall sizeImprove securityWelding/cutting media/materialsSoldering mediaSodium stearateElectroslag welding

The invention discloses an activated stranded wire welding wire for increasing the penetration depth. The activated stranded wire welding wire is composed of an integrally-stranded multi-strand solid welding wire body, and an active agent with which the gaps of the stranded welding wire body are filled through extrusion. The cross section of the welding wire body is circular, and the diameter of the welding wire body ranges from 1.5 mm to 12.0 mm. The integrally-stranded multi-strand solid welding wire body is formed by stranding the solid welding wire in the middle axis, namely, the central wire, and 4 to 12 strands of solid welding wires around the central wire, namely, the peripheral wires. The active agent is composed of, by mass, 50% to 60% of SiO2, 10% to 20% of TiO2, 10% to 20% of Cr2O3, 0% to 12% of NaF, 0% to 11% of LiF, 0% to 8% of potassium fluozirconate, 0.1% to 1.0% of sodium stearate and 0.1% to 1% of yttrium oxide. The welding wire is large in welding penetration depth, an electric arc is stable, a weld joint is well formed, and the welding wire can have any length, is suitable for continuous automatic welding and can be used for electric arc welding, submerged-arc welding and electroslag welding of gas protection.

Owner:SHANDONG UNIV

Welding technique for steel structure box column

InactiveCN105458536AStrong welding operabilityThe weld is heated evenlyWelding/soldering/cutting articlesMetal working apparatusElectroslag weldingSlag

The invention discloses a welding technique for a steel structure box column. The welding technique comprises the following steps that rust, oxidizing slag and oil stains on connectors to be welded and areas which are 50-millimeter within the two sides of a welding portion are polished to be clean; partition plates of an inner cavity of the steel structure box column are welded through electroslag welding, and weld beads on the two sides of the partition plates are welded at the same time through HJ360 welding flux and silicon-contained welding wires; two main weld joints are welded at the same time, then the box column is turned by 180 degrees, and the other two main weld joints are welded at the same time; and heat preservation is conducted on the weld joints after welding is finished, ultrasonic flaw detection is conducted on the weld joints 38 hours later after welding, and the welding quality is guaranteed. According to the welding technique for the steel structure box column, the operability is high, the weld joints are heated uniformly, fusion penetration is uniform, the welding stress is small, the welding contraction deformation is small, the welding quality is high, and the welding speed is increased.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Method for preparing H13 steel by electroslag remelting of electric conducting crystallizer

The invention discloses a method for preparing H13 steel by electroslag remelting of an electric conducting crystallizer. The method comprises the following steps: 1) fluorite, lime, aluminum oxide and fused magnesite are used as raw materials, and are mixed to obtain slag; 2) the slag is baked; 3) an arc striking ring, an arc striking agent and the slag are put; 4) through switching-on and switching-off, a current path adopts power supply-consumable electrode-slag-bottom water tank-power supply; and the arc striking is slagged under protection of inert gas; 5) when the slag is totally fused, through switching-on and switching-off, the current path adopts power supply-consumable electrode-slag pool-electric conducting crystallizer-power supply; under protection of the inert gas, the electric conducting crystallizer is started for electroslag remelting; and aluminum particles are added for deoxidation; and 6) when the electroslag remelting feeding is finished, a gas valve is closed; a steel ingot is obtained by demolding; and the steel ingot is annealed and cooled along with a furnace to obtain the H13 steel. The method solves the problem of poor surface quality due to low-melting-speed smelting in a traditional electroslag remelting technology, and adopts the electric conducting crystallizer and changes the current path to obtain an electroslag ingot with excellent surface and internal quality.

Owner:NORTHEASTERN UNIV

Improved construction method for hoisting and welding large-tonnage cast steel component complex joints

InactiveCN103495793AReduce workloadHarm reductionArc welding apparatusWelding/soldering/cutting articlesCarrying capacityElectroslag welding

The invention provides an improved construction method for hoisting and welding large-tonnage cast steel component complex joints. Through studying the welding technology of cast steel joints and section steel dissimilar steel, cracks are not prone to being generated by welding in a low-temperature state, welding quality is good, and using requirements are satisfied; the welding quality of electroslag welding is guaranteed without weakening carrying capacity, and a theoretical basis is provided for welding of cast steel and section steel dissimilar materials; the improved construction method has important theoretical value and application value and provides a basis for welding of similar structures of engineering or the same industry; integrality is good, force transmission is smooth, anti-fatigue performance is good, force application to a steel structure is more reasonable, the overall structure is more stable, the workload of aerial operation is reduced, the quality of the overall engineering is improved, construction cost is lowered, and hazards of the aerial operation to constructors are lowered; besides, the technological process of the improved construction method is simple, and operating is convenient.

Owner:YONGSHENG CONSTR GRP

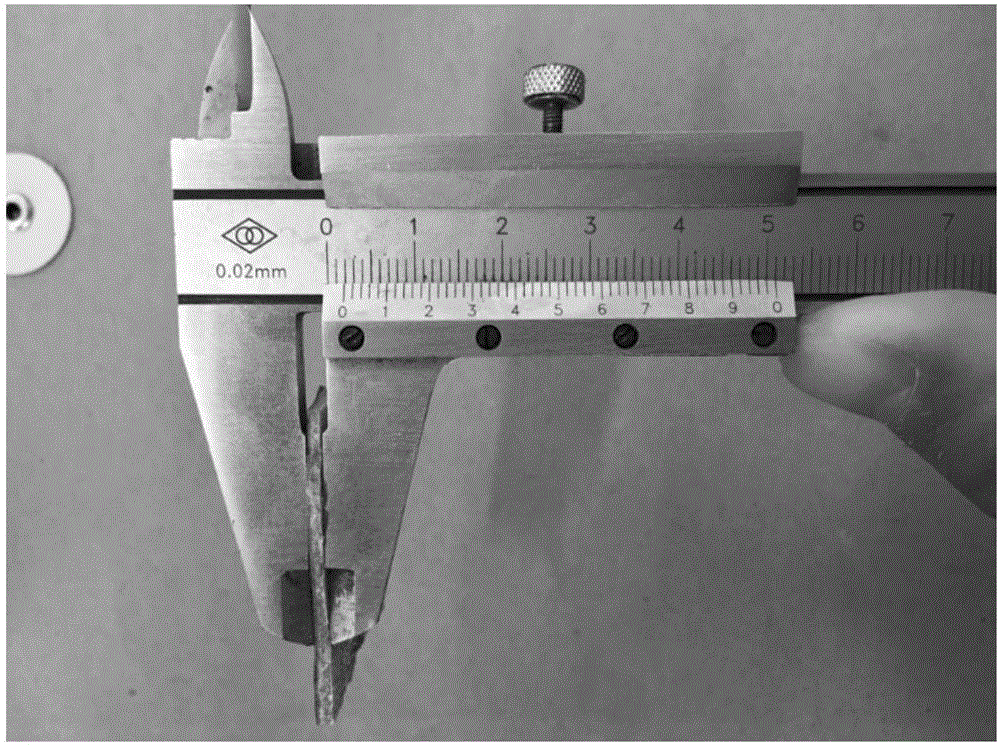

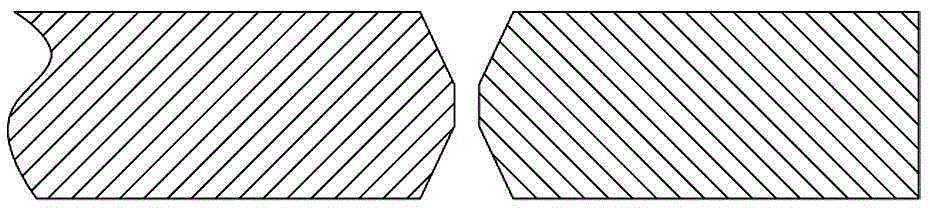

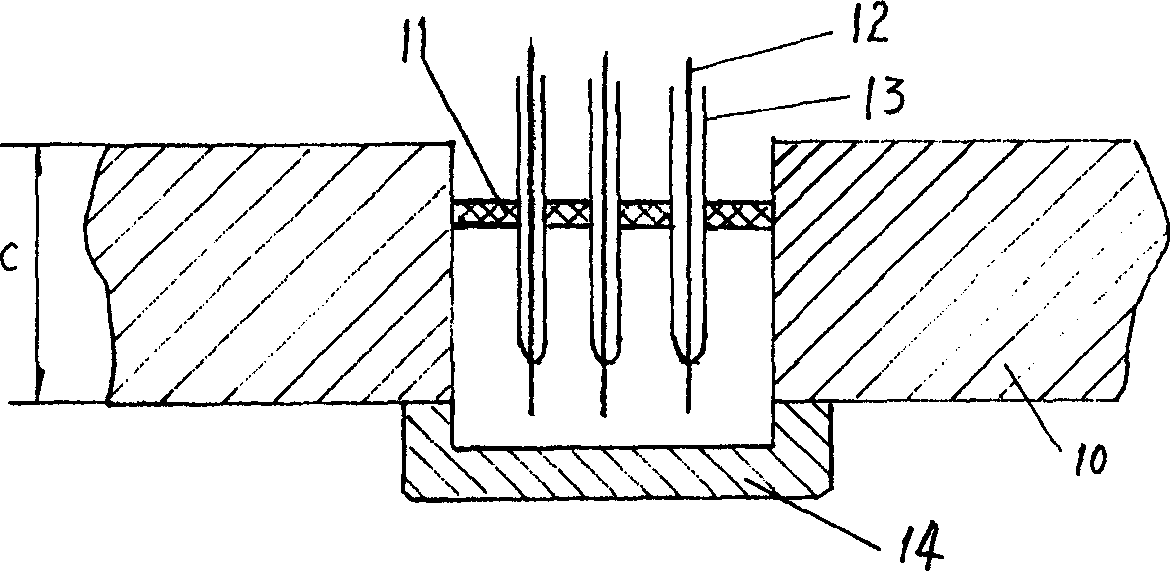

Electroslag welding repairing method for anode steel stud head

ActiveCN105382408AHigh strengthLow resistivityWelding/soldering/cutting articlesSheet steelElectroslag welding

The invention discloses an electroslag welding repairing method for an anode steel stud head. Firstly, a burnt section of the steel stud head is cut off, and a round steel bar which is identical with the steel stud head in material and diameter is selected; then, four rectangular steel plates are adopted, two rectangular steel plates are machined and then welded with a bottom plate to form a welding groove, the steel stud head and the round steel bar are placed on the welding groove, the other two steel plates are pressed on the welding groove in a covering mode to form runoff weld tabs, and the runoff weld tabs are welded on the upper portion and the lower portion of the steel stud head and the round steel bar; then, water-cooling sliding blocks are fixed to the other two side faces of the runoff weld tabs and the welding groove, and a consumable nozzle is fixed at the front end of a holding mechanism and adjusted to be located in the center of the welding groove; afterwards, welding is carried out after power-on through proper electroslag welding materials and processes; and finally, the runoff weld tabs and the welding groove are cut off, weld metal is ground to achieve smooth transition between the weld metal and the steel stud head and the round steel bar, and therefore the steel stud head is repaired. According to the electroslag welding repairing method, the steel stud head and the round steel bar are welded at a time, total cross-section metallurgical bonding is achieved, the connector strength is high, the specific resistance is low, the welding efficiency is high, and the composite repairing cost is greatly lowered.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

High-performance refractory weather-resisting building steel and its production method

InactiveCN1132958CImprove fire resistanceHigh yield strengthManufacturing cost reductionHeat-affected zone

The present invention relates to a high-performance fire-resistant weather-resisting building steel and its production method. Said invention steel contains C, Si, Mn, P, S, Mo, Ti, Al, N, O, Cr, Ni, Cu, Ca, B and one or more than one kind of Nb, V and RE and the rest is Fe. After having been undergone the processes of smelting, rolling and heat treatment, said building steel possesses high strenght, high toughness and excellent fire-resisting and weather-resisting properties. The building steel can be used for providing various steel structural members whose thickness is 4-100 mm in the fields of building, civil engineering and marine structure. Under the large linear energy (50-100 kJ / cm) welding condition of gas-arc welding, electroslag welding and high-frequency resistance welding, its heat affected zone (HAZ) still possesses excellent toughness so as to greatly raise welding efficiency of engineering structure and reduce its manufacture cost.

Owner:武钢集团有限公司

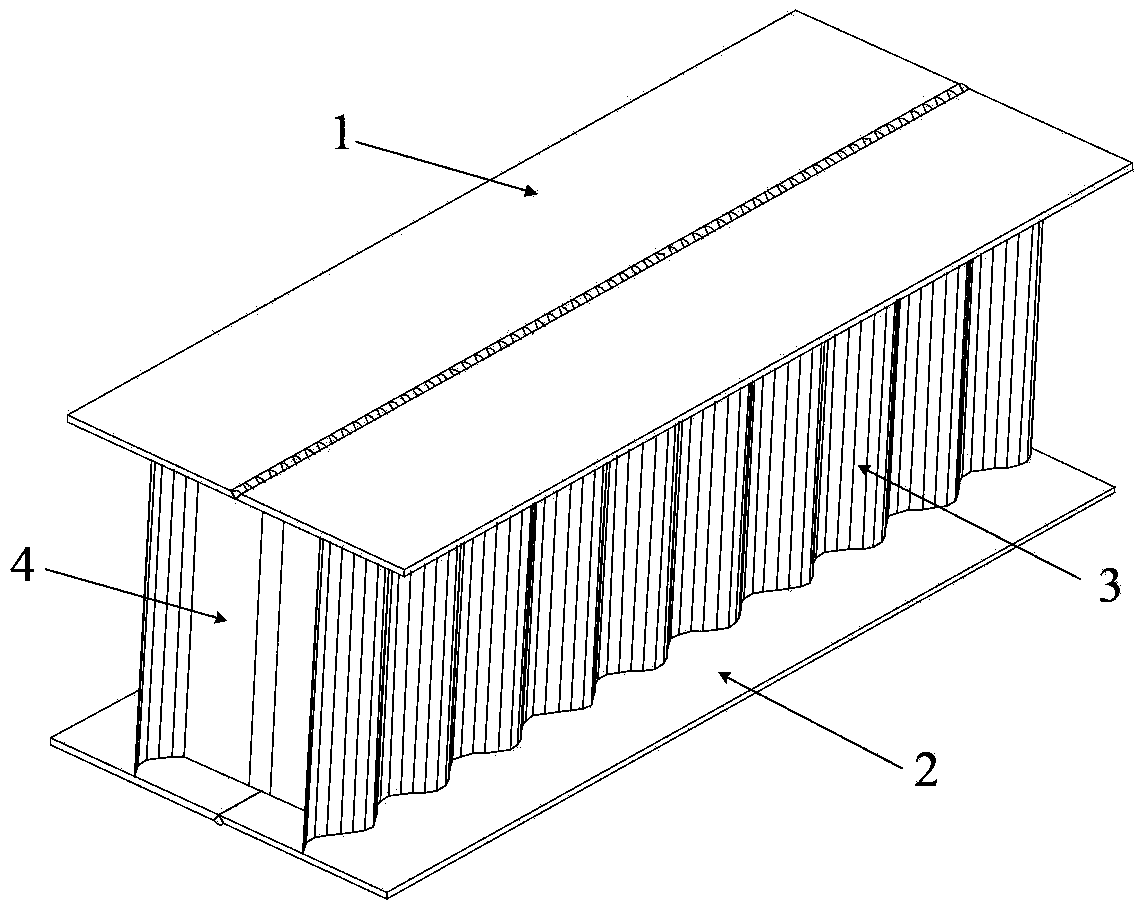

Method for manufacturing and welding wave web box type section beam and diaphragms

InactiveCN103406674AIncreased shear strengthRich section formWelding apparatusButt weldingElectroslag welding

The invention provides a method for manufacturing and welding a wave web box type section beam and diaphragms. According to the method, existing I-shaped wave web manufacture process and production equipment thereof are adopted, firstly, two I-shaped wave webs are formed through machining, and are connected through bevel butt welding of flat flange plates to form the wave web box type section beam; through a melting mouth electroslag welding method, stiffening ribs pre-welded on the I-shaped wave webs are connected to form the transverse diaphragms. The method is simple and convenient in technology, and strong in operability; as the existing I-shaped wave web manufacture method is integrated, the production cost is greatly reduced; for a web, the double wave can increase area of the web, so that the problem of insufficient shearing strength of the I-shaped wave webs caused by limited rolling capacities of wave webs is solved, and the section forms of the wave webs are enriched, an application range of the wave webs is expanded, and steel materials can be remarkably saved after the method is popularized and applied to beam structures with larger load.

Owner:TSINGHUA UNIV

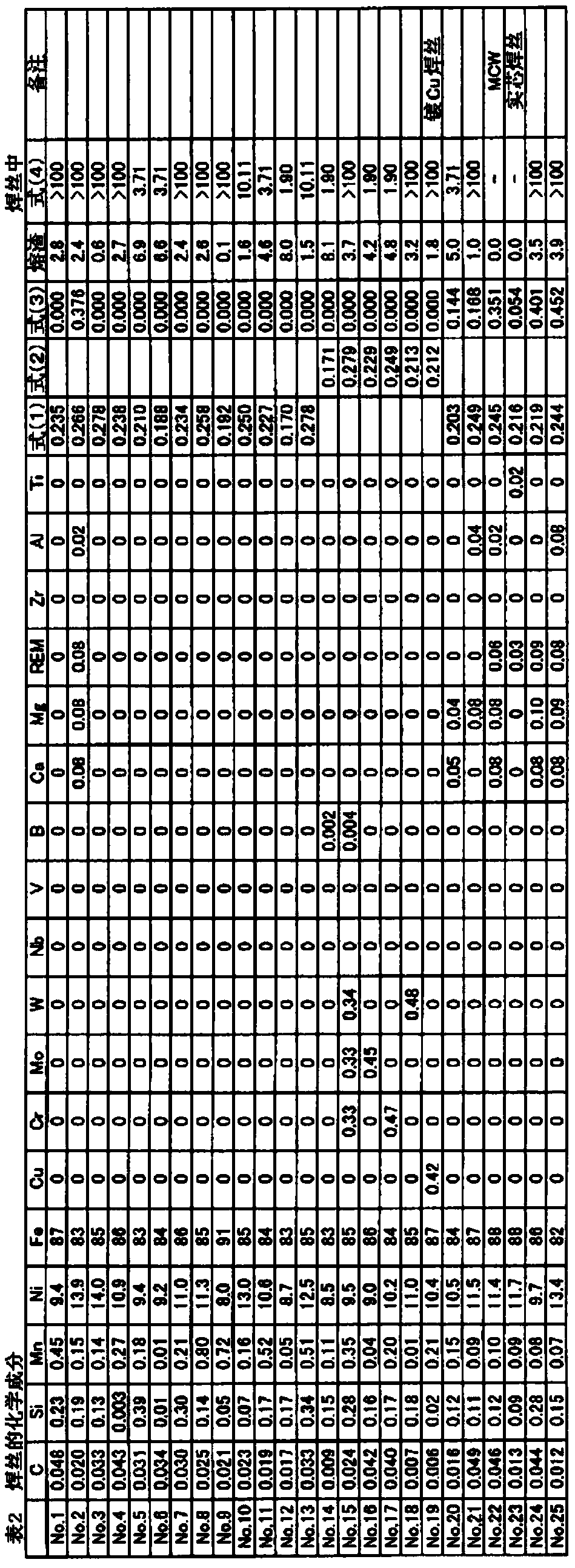

Wire for electroslag welding, flux for electroslag welding and welded joint

ActiveCN109789519AHigh strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsMetallurgyElectroslag welding

The present invention relates to a wire for electroslag welding, which is characterized by containing, in mass% relative to the total mass of the wire, more than 0% but 0.07% or less of C, more than 0% but 0.50% or less of Si, more than 0% but 1.0% or less of Mn, from 6.0% to 15.0% of Ni and 79% or more of Fe, while satisfying formula (1). The present invention also relates to: a flux for electroslag welding, which is used in electroslag welding together with the wire for electroslag welding; and a welded joint which is produced by electroslag welding that uses the wire for electroslag weldingand the flux for electroslag welding. 0.150<=C+Si / 30+Mn / 20+Ni / 60<=0.300 (1).

Owner:KOBE STEEL LTD

Welding method for backing ring trunnion of large converter

InactiveCN1657218AImprove welding efficiencyEliminate internal stressWelding/cutting auxillary devicesArc welding apparatusHydrogenElectroslag welding

A method for welding the trunnion of backing ring for large converter features the tubular-electrode electroslag welding with 3-4 tubular electrodes are used, and the dehydrogenation plus tempering is used for its post-heat-treatment. Its advantages are high efficiency and low temp of heat treating.

Owner:SHANGHAI HEAVY MACHINERY PLANT

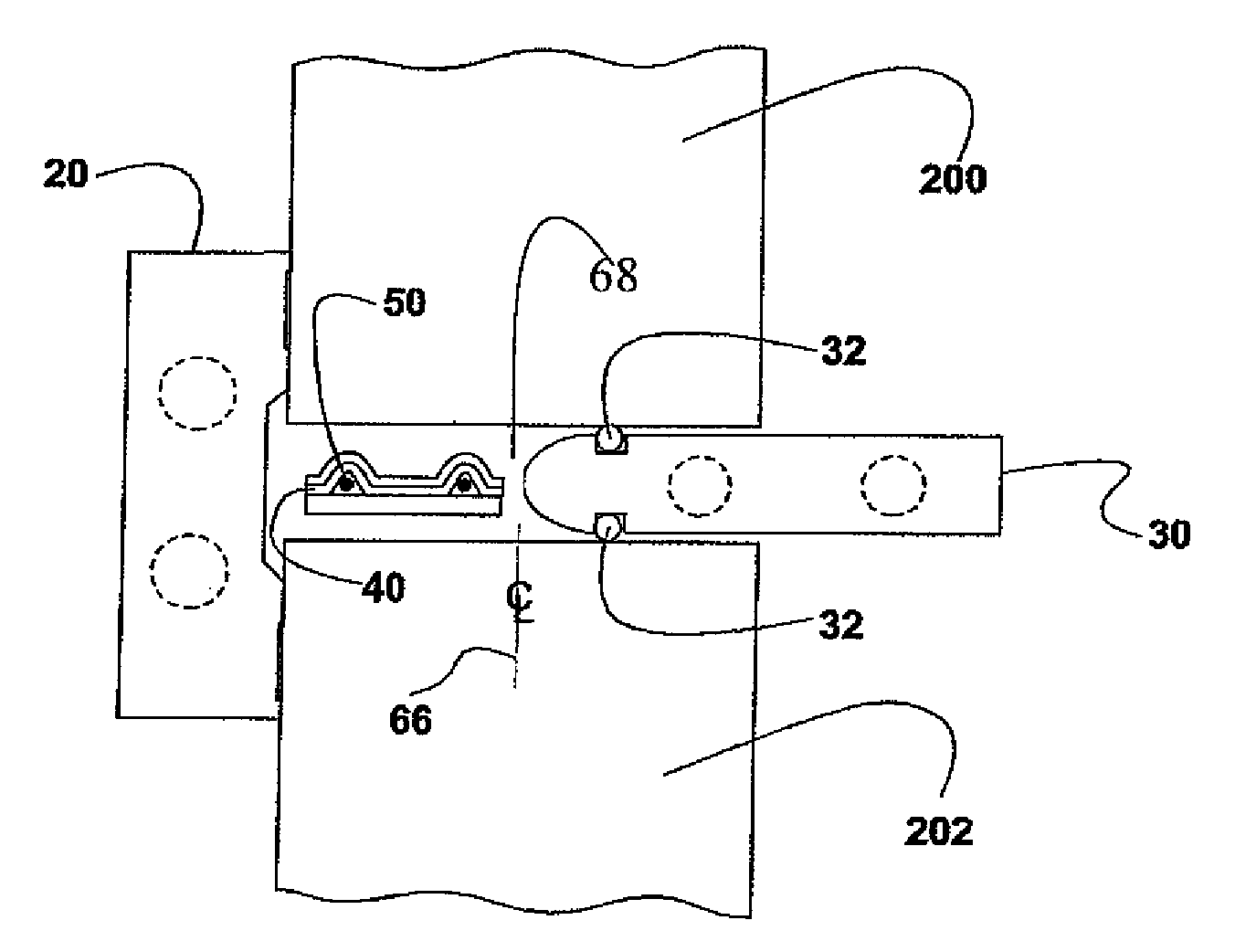

System and method for multi-pass computer controlled narrow-gap electroslag welding applications

A system and method of multi-pass computer controlled narrow-gap Electroslag welding allowing a faster vertical rate of rise at a much lower voltage, and that includes welding selected narrow-gaps within segments of a weld cavity between heavy plate steel workpieces and attendant control of the heat transfer depth penetration from the weld puddle to the workpieces according to a pre-determined profile resulting in a smaller heat affected zone and smaller grain structure in the weld metal.

Owner:ESKANDARI AMIR

Method and device for resisting softening of electroslag welding joint

ActiveCN108637532ASolve the stubborn problem of softeningShorten the high temperature residence time after weldingWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneElectroslag welding

The invention discloses a device for resisting softening of an electroslag welding joint. An air compressor, a lifting mechanism, a gas feeding pipe, a spray nozzle and baffles placed in certain areasof the two sides of a welding line are included. According to a method for resisting softening of an electroslag welding joint, mainly, the air compressor jets compressed gas into the baffles placedin the certain areas of the two sides of the welding line through the gas feeding pipe fixed to the lifting mechanism and communicating with the air compressor and the spray nozzle, so that the cooling speed after welding of an original welding softening area is increased, and the purpose of improving the tensile strength of the area is achieved. According to the method and device for resisting softening of the electroslag welding joint, by performing directional cooling on a portion, prone to be softened, in a welding heat affected zone, the high temperature keeping time after welding of theportion, prone to be softened, in the welding heat affected zone is shortened, and the chronic disease of softening of the electroslag welding welding joint is solved.

Owner:浙江江奥机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com