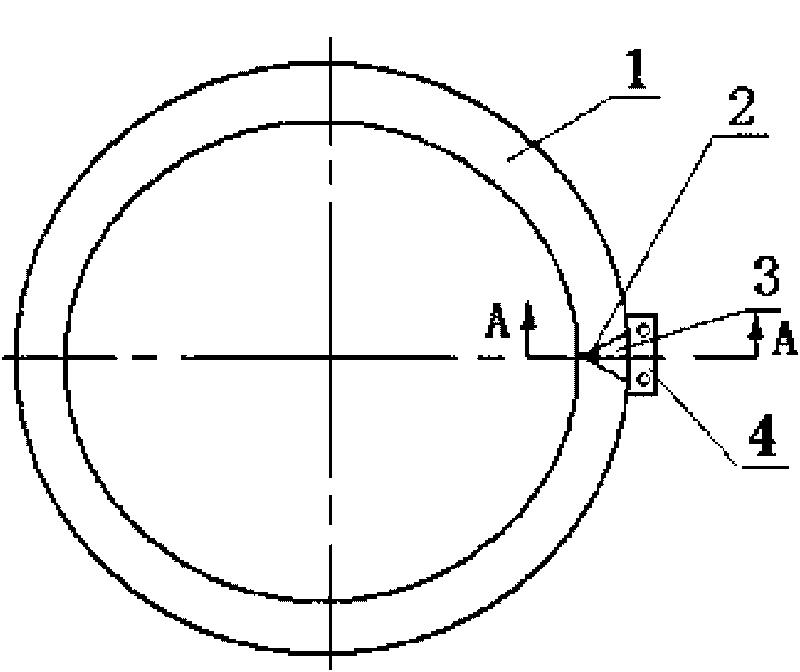

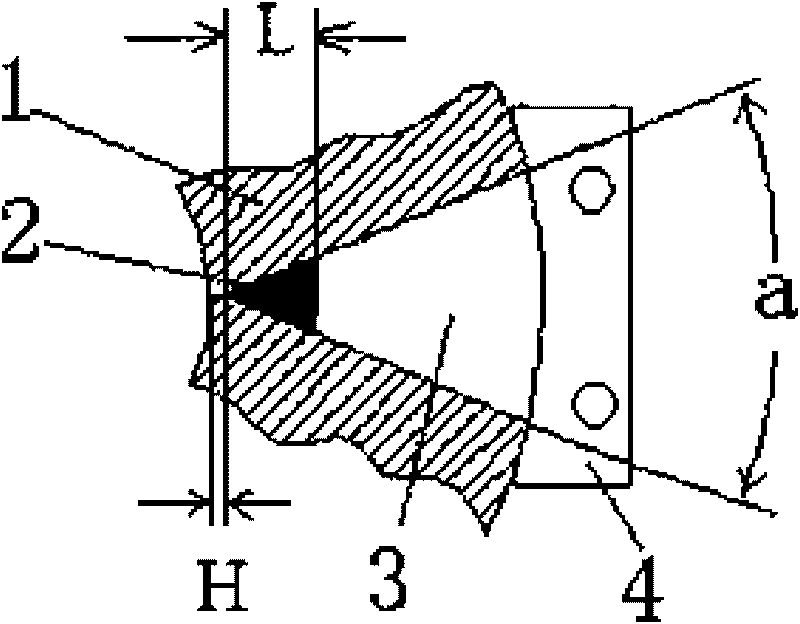

Electroslag welding method for cylindrical longitudinal seam V groove

An electroslag welding, cylindrical technology, applied in the field of electroslag welding of the V-shaped groove of the cylindrical longitudinal seam, can solve the problems such as the difficulty of clamping the cylindrical groove, the high requirement of welder skills, and the impossibility of welding. , to achieve the effect of reducing defects, good welding quality and reducing mechanical processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

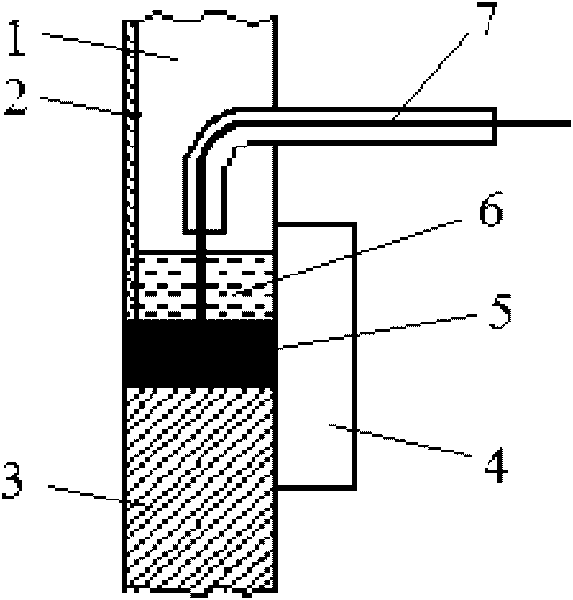

[0028] Electroslag welding is performed on a cylindrical longitudinal seam with a thickness of 50mm. The specific process parameters are:

[0029] Welding material: H10Mn2, HJ431; welding wire does not swing

[0030] Wire diameter: ¢3; wire extension length: 70mm

[0031] Depth of slag pool: 50mm; wire feeding speed: 200m / h

[0032] Welding voltage: 38-40V; Welding current: 400A

[0033] The method of the present invention breaks through the technical prejudice that electroslag welding can only weld type II grooves, uses electroslag welding to remelt, reduces the defects existing in bottoming welding, and adopts backside water cooling during welding to speed up the welding seam area The cooling speed prevents the back of the weld from being broken down, and at the same time, limits the growth of grains. V-groove electroslag welding is used for welding, which has good welding quality and high welding efficiency, reduces the mechanical processing before welding, saves welding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com