Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

553 results about "Weld pool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weld pool commonly refers to the dime-sized workable portion of a weld where the base metal has reached its melting point and is ready to be infused with filler material. The weld pool is central to the success of the welding process. It was first observed in oxy-fuel welding by Fouché & Picard in 1903, after the discovery of acetylene by Edmund Davy in 1836.

Method of welding titanium and titanium based alloys to ferrous metals

InactiveUS6875949B2Welding/cutting media/materialsWelding/soldering/cutting articlesFull recoveryPoor quality

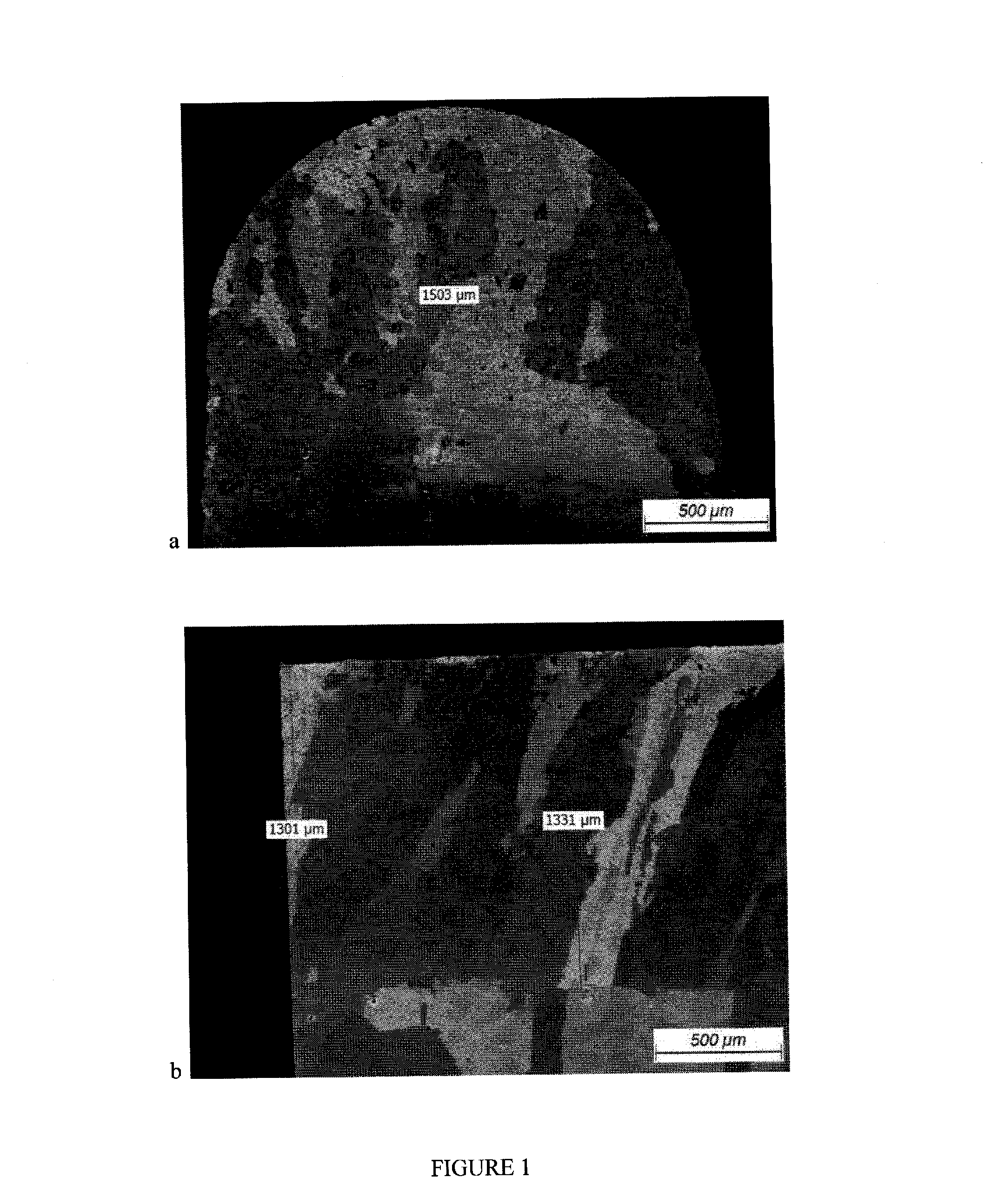

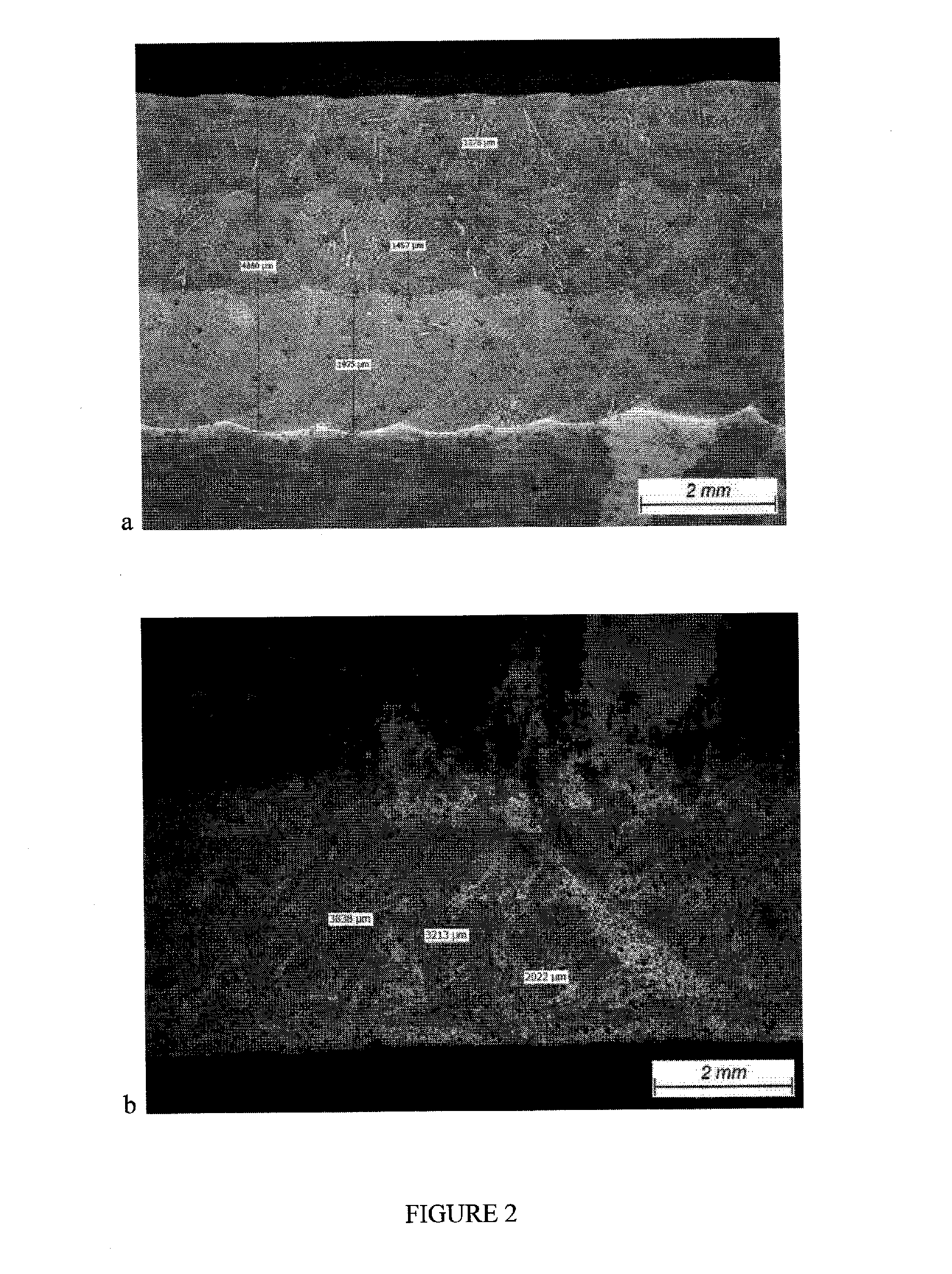

A method of welding titanium, and titanium based alloys, to ferrous metals is described. Welding of titanium, and titanium based alloys, is plagued with poor quality and highly brittle welds, substantially due to formation of Ti—Fe intermetallics in the weld pool. The instant invention provides supplementary filler material to alter the proportions of various elements in the weld pool. Certain fillers, such as nickel or iron, added to the weld pool enable high quality welds to be fabricated utilizing a wide variety of fusion welding techniques, including laser welding, between titanium, or titanium based alloys, and ferrous metals, including but not limited to the welding of nickel-titanium and stainless steel. Filler material may be supplied in various forms, including foil, wire, powders, preformed gaskets, and numerous others. Optionally, the titanium or titanium based alloy may be stress relieved to achieve full recovery of the shape memory strain prior to welding.

Owner:EDISON WELDING INSTITUTE INC

Method of cladding, additive manufacturing and fusion welding of superalloys and materialf or the same

The present concept is a method of substantially crack-free cladding, fusion welding and additive manufacturing of superalloys. The method involves the application of a high temperature pre-alloyed filler powder that includes melting point depressants, to a superalloy base material. The base material and pre-alloyed filler powder are heated to a temperature that will fully melt the pre-alloyed filler powder and also melt a surface layer of the base material, thereby forming a weld pool. Upon solidification and cooling of the weld pool, there is coalescence between a weld bead and the base material thereby forming the weld bead which is substantially crack-free. The high temperature pre-alloyed filler powder consists in wt % of the following chemical elements: Co 9-15%; Al 3-6.5%; C 0.1-0.2%; Ti, Zr and Hf with a total content from 1 to 8.5%; Ta and Nb with a total content from 0.5 to 8.5%; W and Mo with a total content from 7 to 20%; Cr and Re with a total content from 6.5 to 18.5%; Fe and Mn with a total content from 0.1 to 1%; B 0.1-0.6% with Ni and impurities to balance.

Owner:LIBURDI ENG

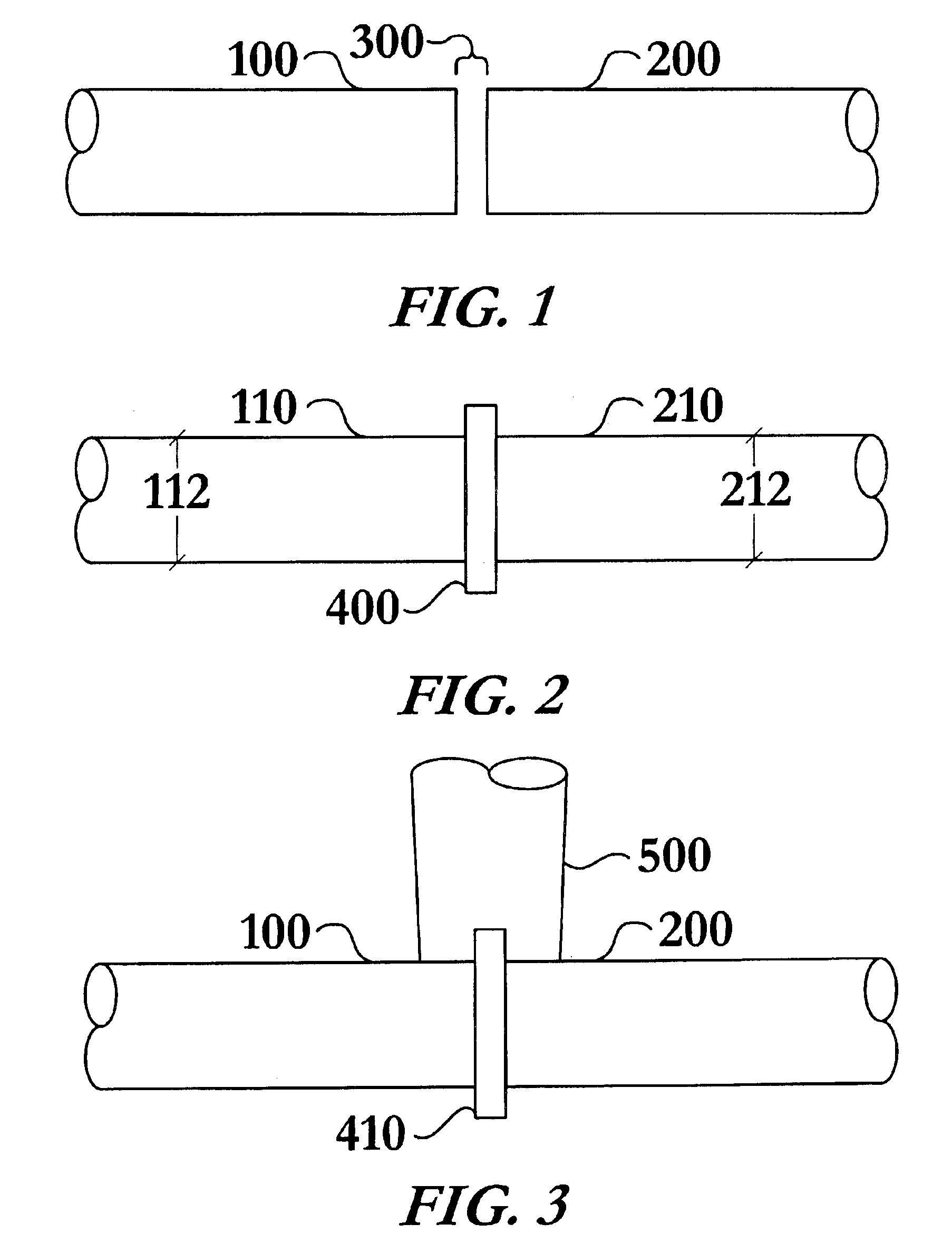

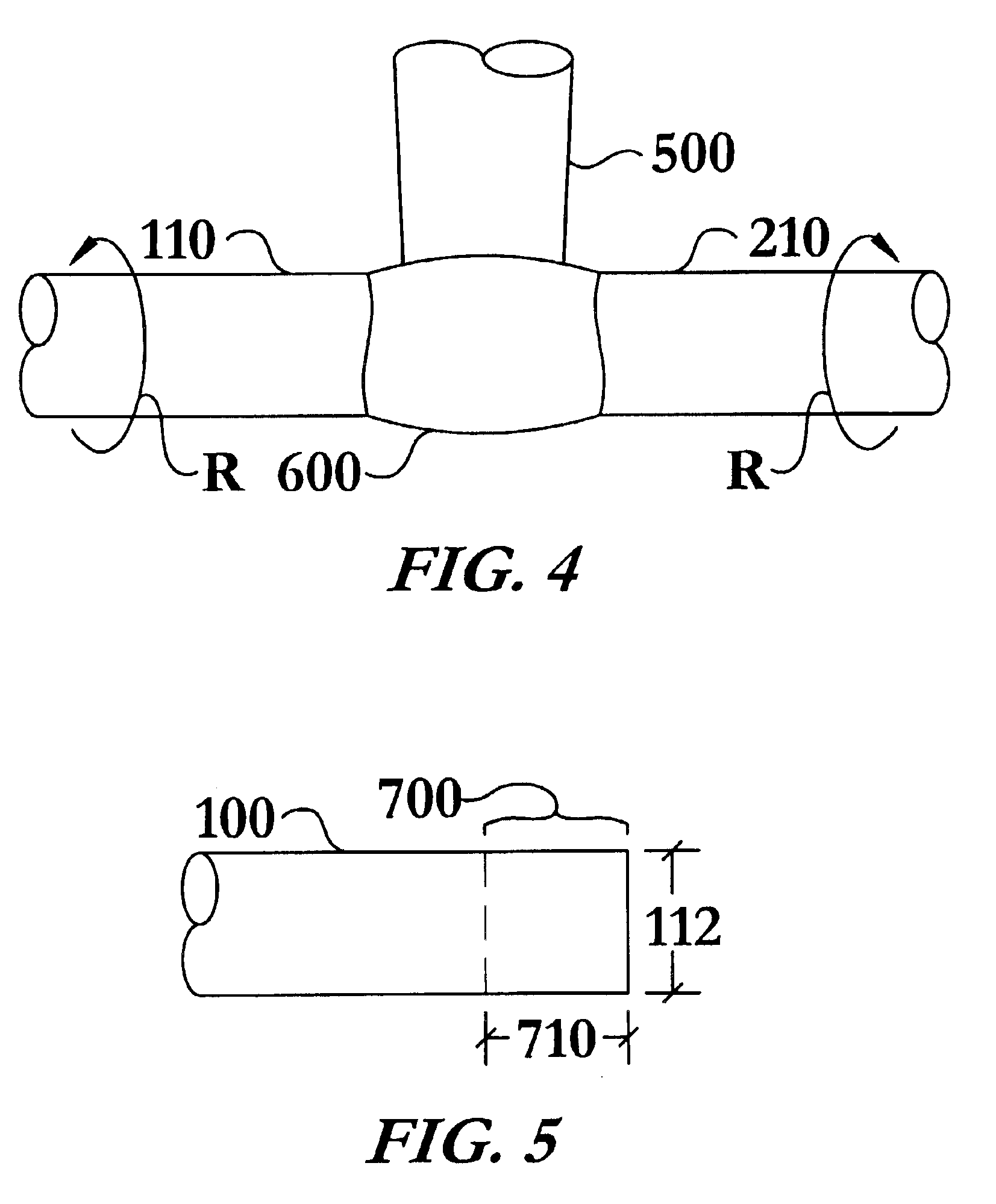

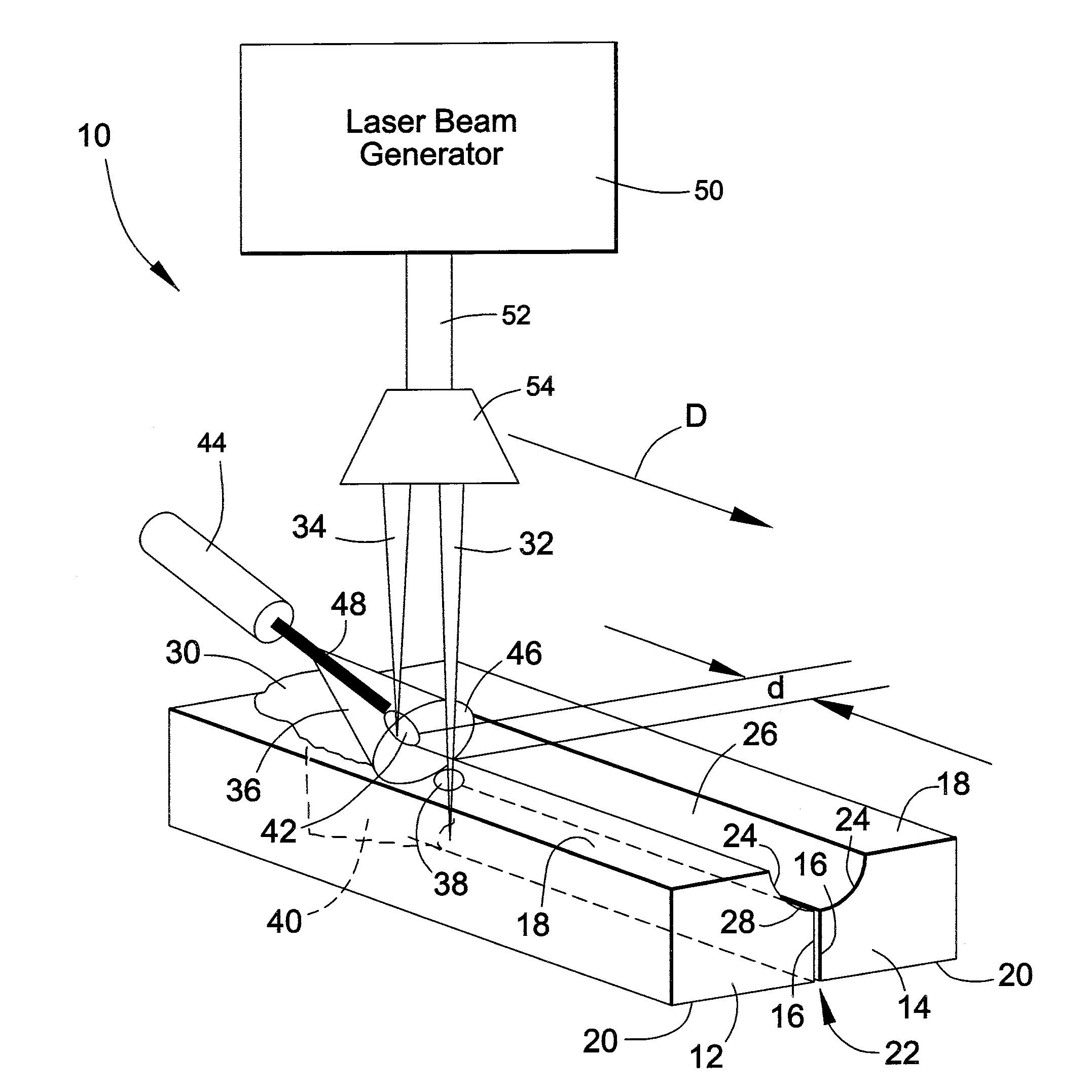

Coated material welding with multiple energy beams

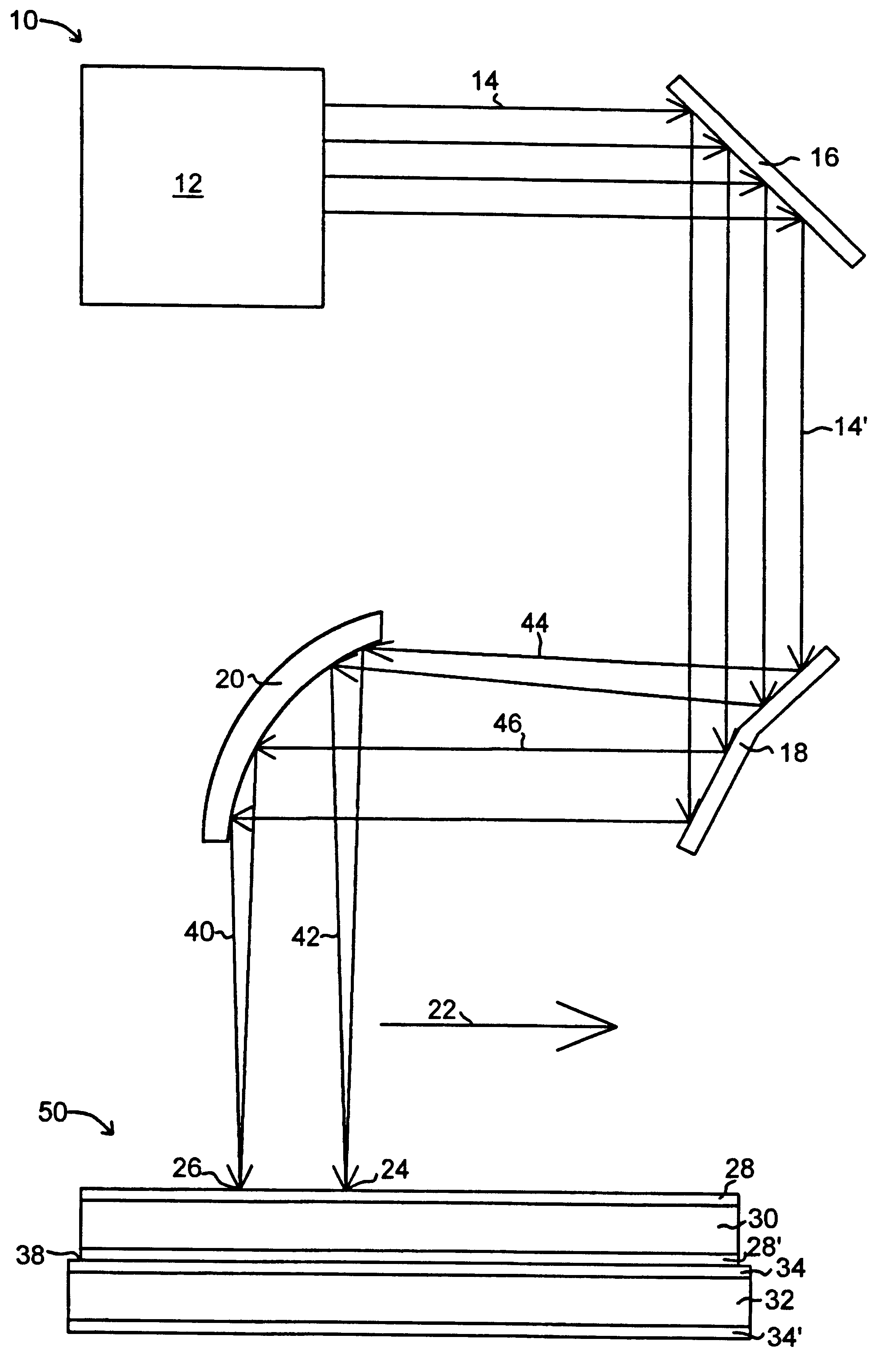

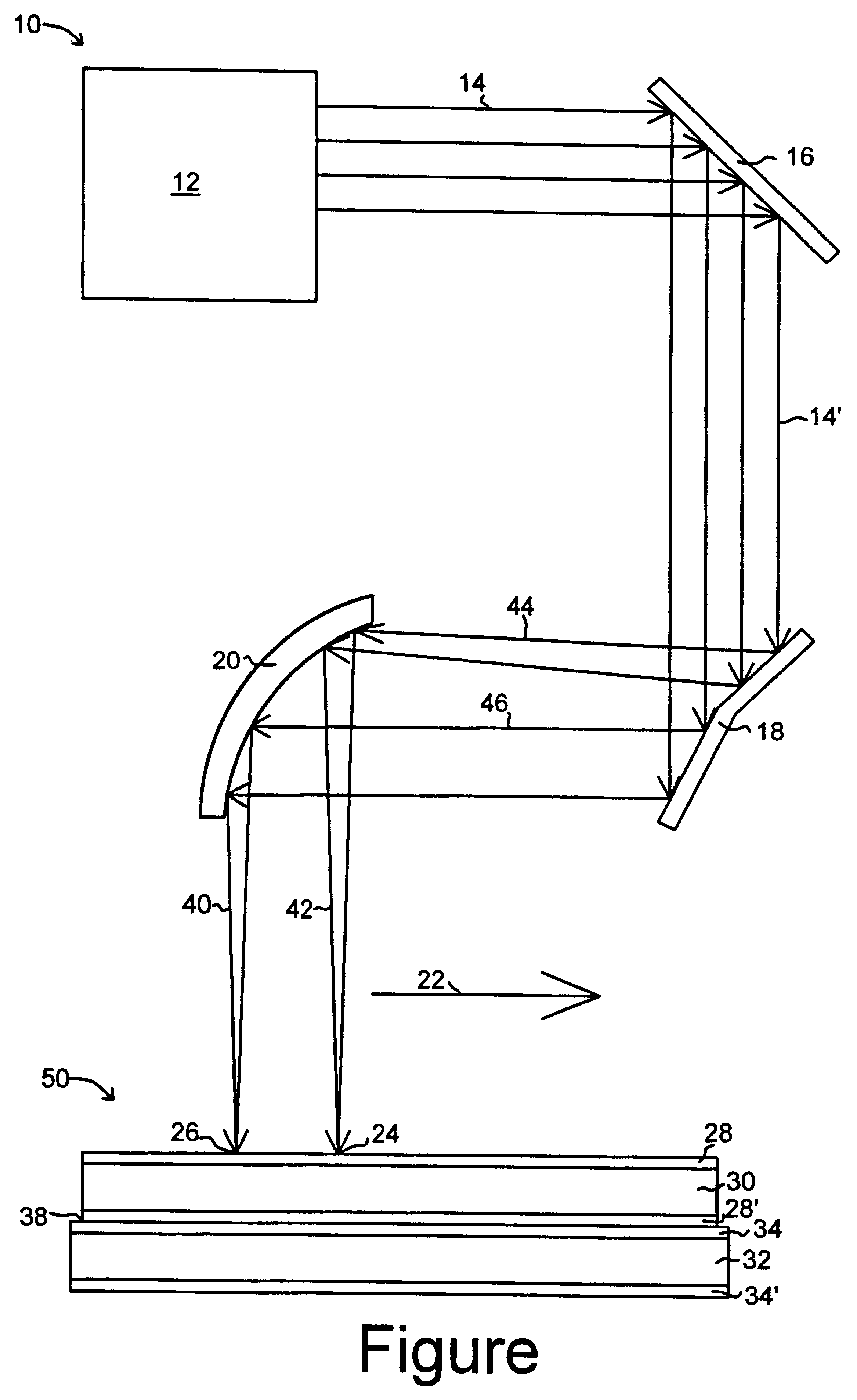

InactiveUS6608278B1High level of porosityQuality improvementVehicle componentsWelding/soldering/cutting articlesPorosityBeam source

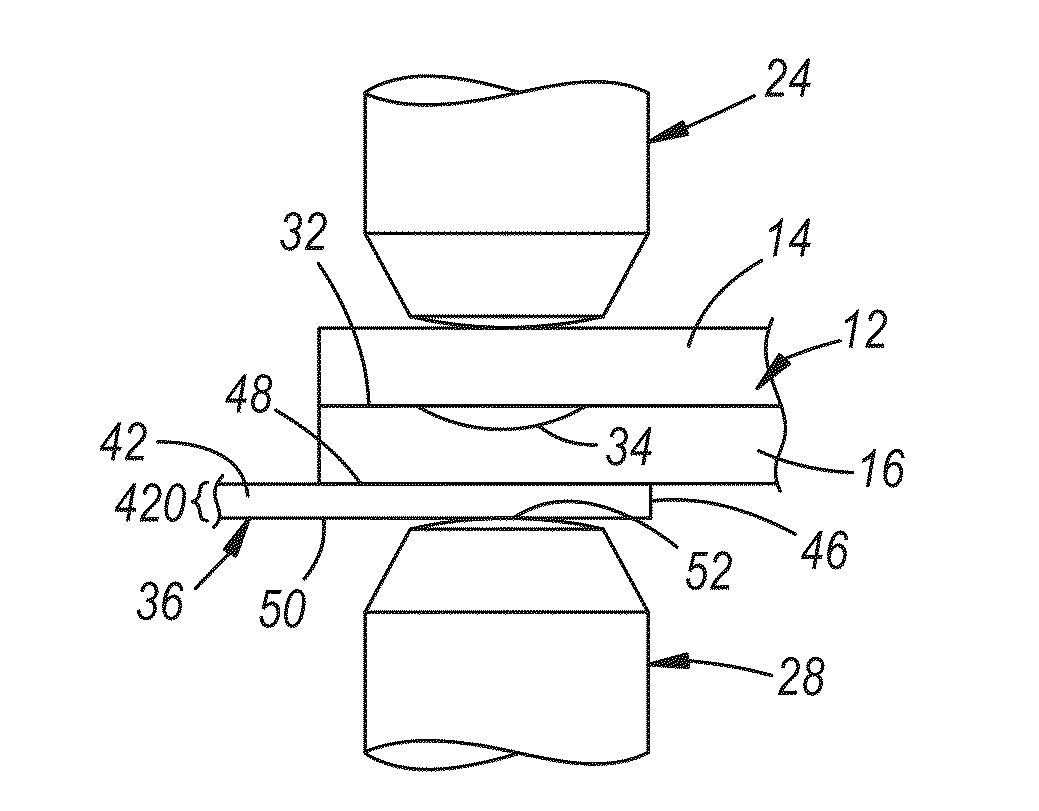

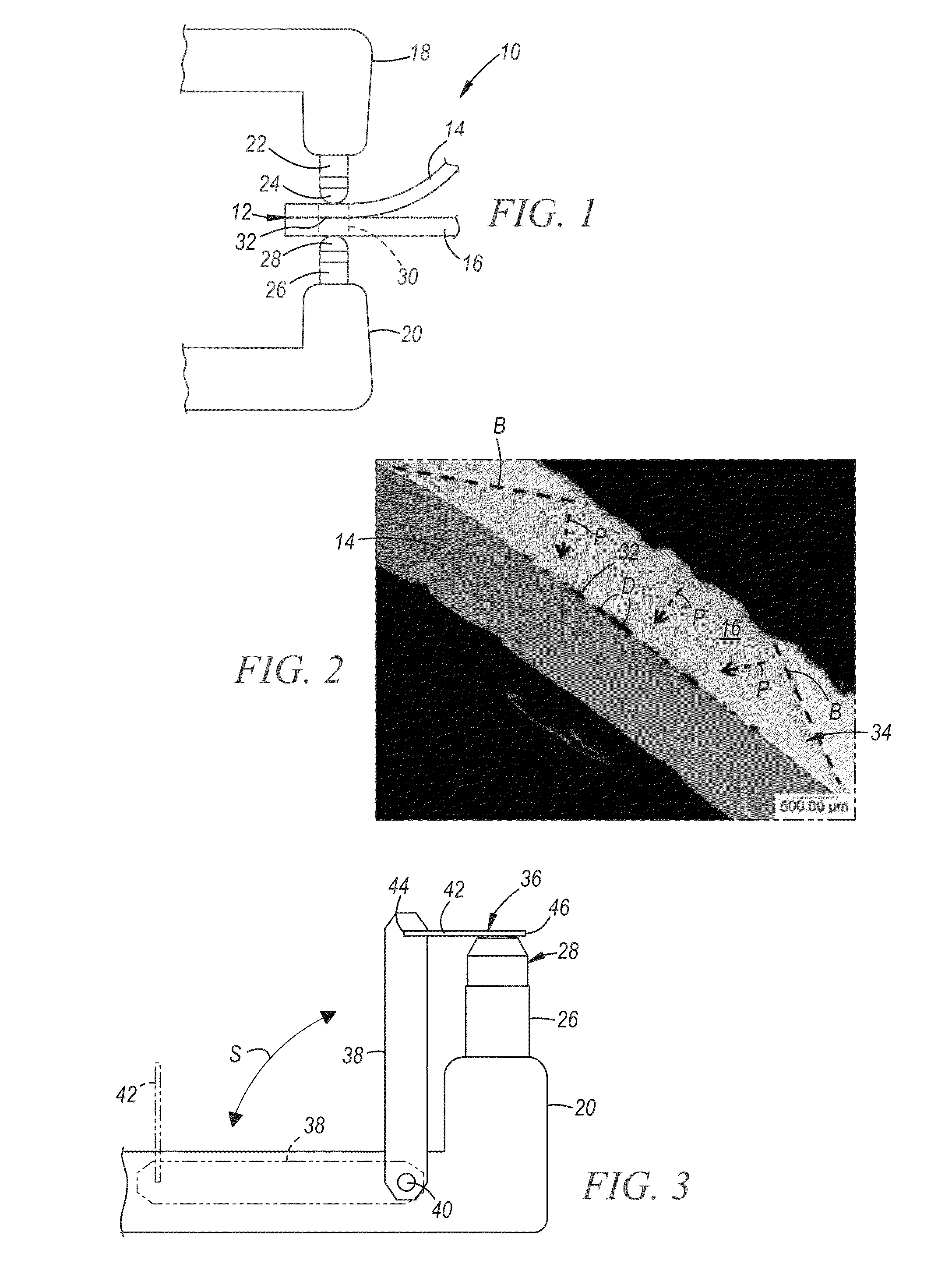

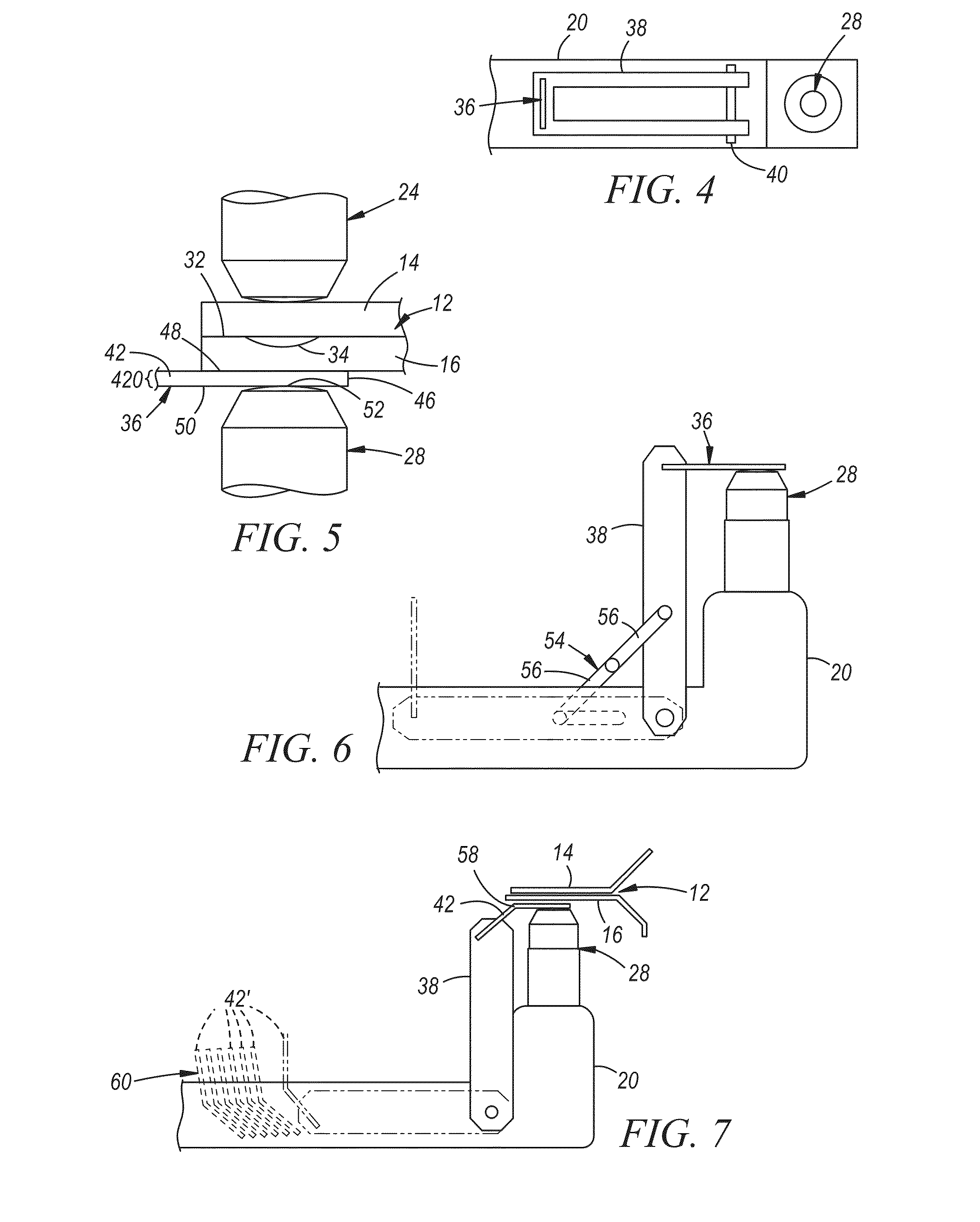

To overcome 1) the high levels of porosity due to coating material vaporization and entrapment into the weld, 2) spewing of molten base metal from the weld leaving holes and pits in the weld, and 3) humping effects when oblong beam configurations are used at higher weld speeds to weld coated materials, the present invention features an energy source (10) with multiple separated energy beams (24, 26) (formed by using multiple separate beam sources or manipulation of a single beam (14) into separated multiple energy beams (44, 46) using wedge mirror (18) and parabolic focusing mirror (20)) that produces high quality (porosity free) lap welds in a weld stack (50) of layered materials (30, 32) coated with coating material (28, 28', 34, 34') with zero gap at interface (38) during the welding process. An energy source (12) with multiple, separated energy beams (24, 26) extends the beam keyhole and increases the time and conditions available for vapor / gas to diffuse less violently through the molten weld pool.

Owner:EDISON WELDING INSTITUTE INC

Multi-step direct welding of an aluminum-based workpiece to a steel workpiece

ActiveUS20150053655A1Welding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductancePower flow

A workpiece stack-up that includes at least a steel workpiece and an aluminum-based workpiece can be resistance spot welded by employing a multi-stage spot welding method in which the passage of electrical current is controlled to perform multiple stages of weld joint development. The multiple stages include: (1) a molten weld pool growth stage in which a molten weld pool is initiated and grown within the aluminum-based workpiece; (2) a molten weld pool solidification stage in which the molten weld pool is allowed to cool and solidify into a weld nugget that forms all or part of a weld joint; (3) a weld nugget re-melting stage in which at least a portion of the weld nugget is re-melted; and (4) a re-melted weld nugget solidification stage in which the re-melted portion of the weld nugget is allowed to cool and solidify.

Owner:GM GLOBAL TECH OPERATIONS LLC

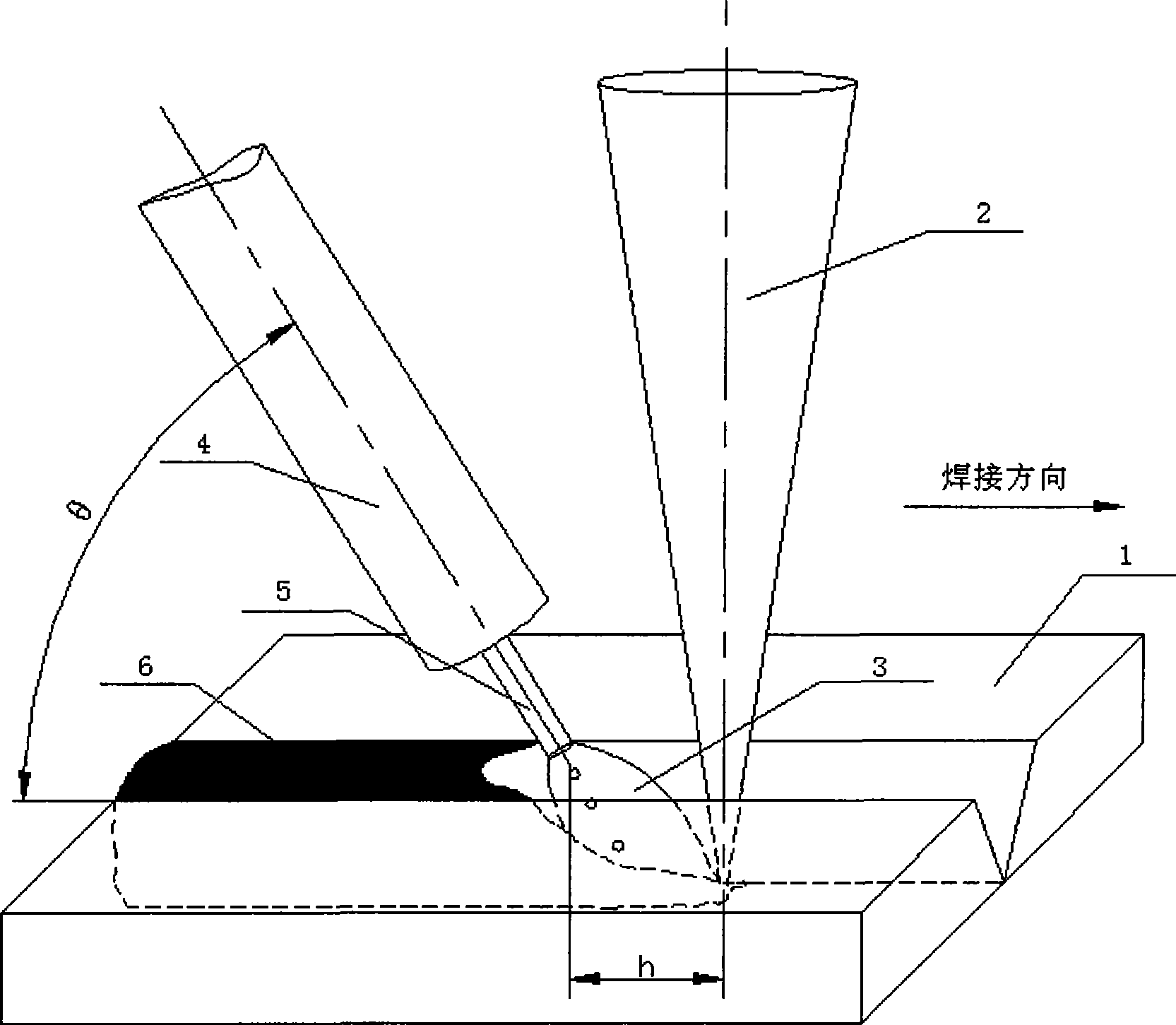

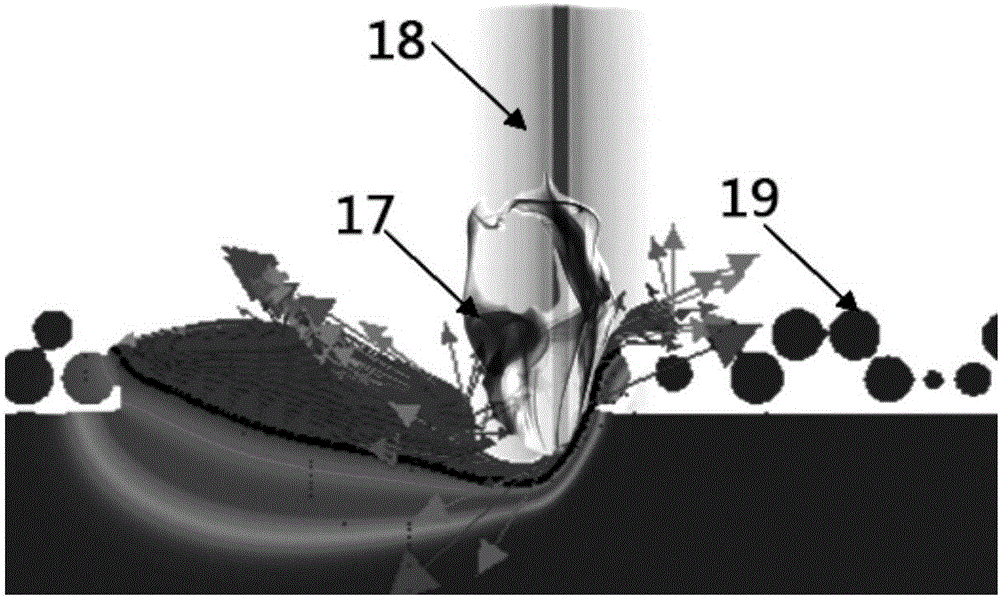

High-strength or ultra-high strong steel laser-electrical arc composite heat source welding method

InactiveCN101367157AImprove performanceLow preheat weldingLaser beam welding apparatusMetalSoldering process

The invention provides a novel high-strength or ultrahigh-strength steel laser-arc composite heat source welding method, which belongs to the technical field of the welding of high-strength or ultrahigh-strength steel. The method aims to solve the technical problem that the higher temperature needs to be adopted for preheating in order to prevent cold cracks during the welding of the high-strength or ultrahigh-strength steel. The welding method mainly comprises the following steps: the laser power is higher than 800 watts, a composite form that laser (2) is ahead and electric arc (3) follows is adopted along the welding direction, the filament spacing h is controlled to between 3 and 7 millimeters, and an included angle theta between an electric arc welding gun (4) and the horizontal plane is between 45 and 60 DEG. When the method is used to weld, a composite heat source welding pool is elongated and the oscillation of the pool is sharpened, so that the solidification rate of pool metal is reduced and grains are refined, thereby reducing the cold crack sensitivity during the welding process of the high-strength or ultrahigh-strength steel. The welding method can reduce the preheating temperature of the welding of the high-strength or ultrahigh-strength steel, and even can realize high-strength non-preheating welding.

Owner:HARBIN WELDING INST LTD

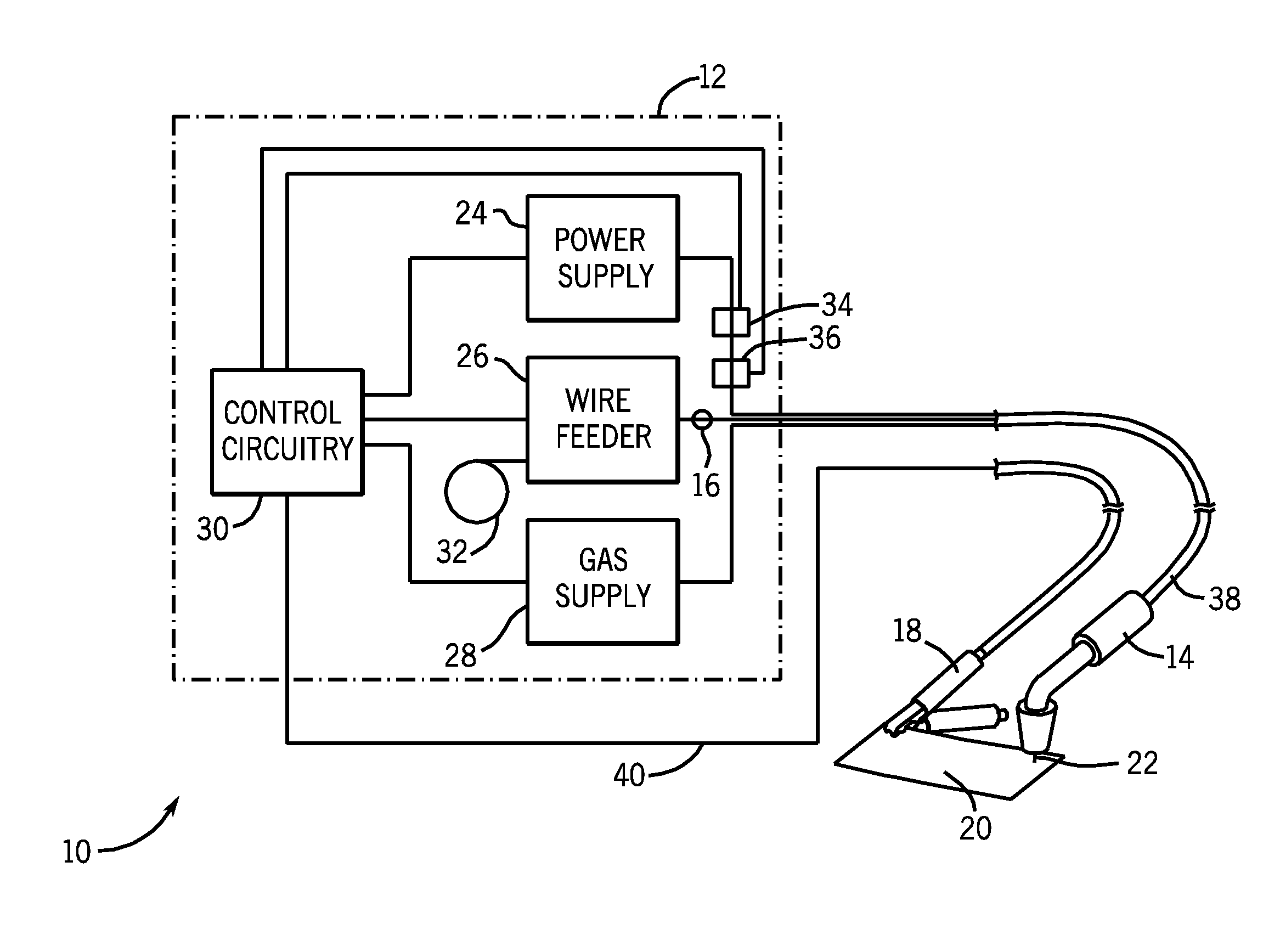

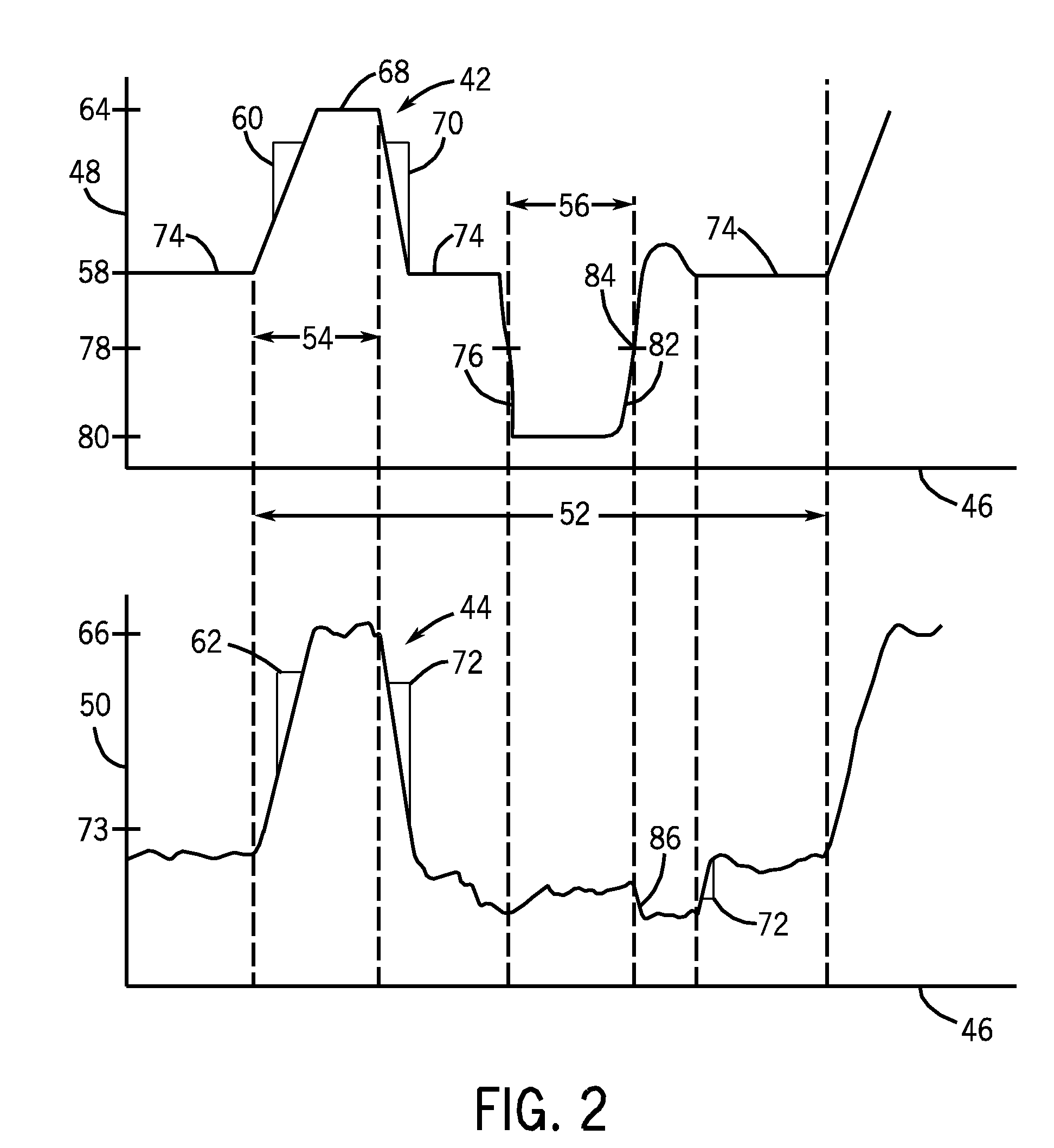

Metal core welding wire pulsed welding system and method

InactiveUS20080264917A1Avoid damageImprove waveformArc welding apparatusWelding/cutting media/materialsThin metalNuclear engineering

Provided is a welding system and method for controlling a welding system with an improved pulsed waveform suitable for use with metal core welding wires. The waveform includes peak pulses (of voltage, current, power, energy or a combination thereof) that aid in transfer of molten metal from the wire to the weld pool. The pulse duration is sufficiently short to avoid damage to the metal core welding wire. The waveform enables welding of thin metals and reduces spatter.

Owner:ILLINOIS TOOL WORKS INC

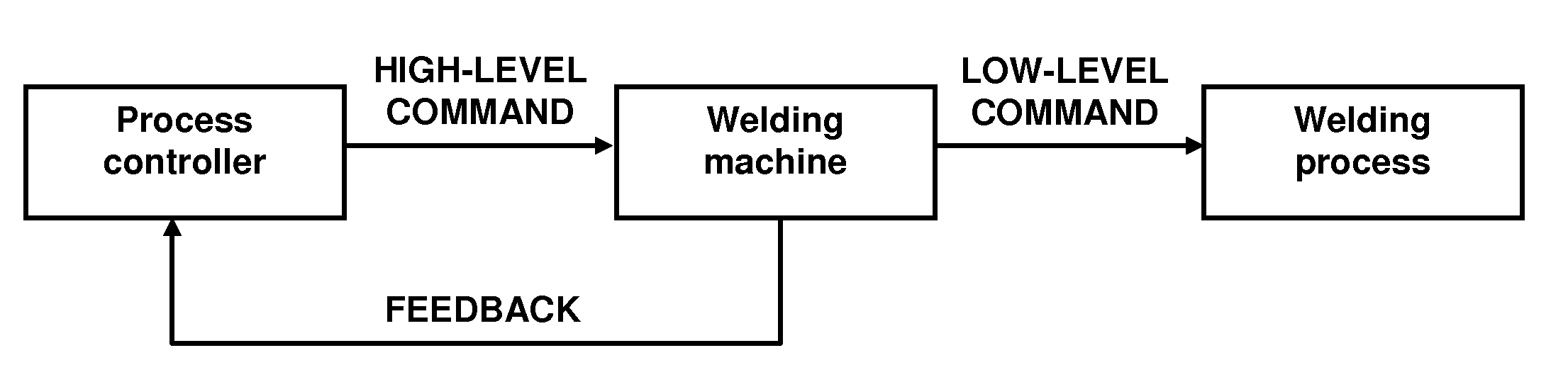

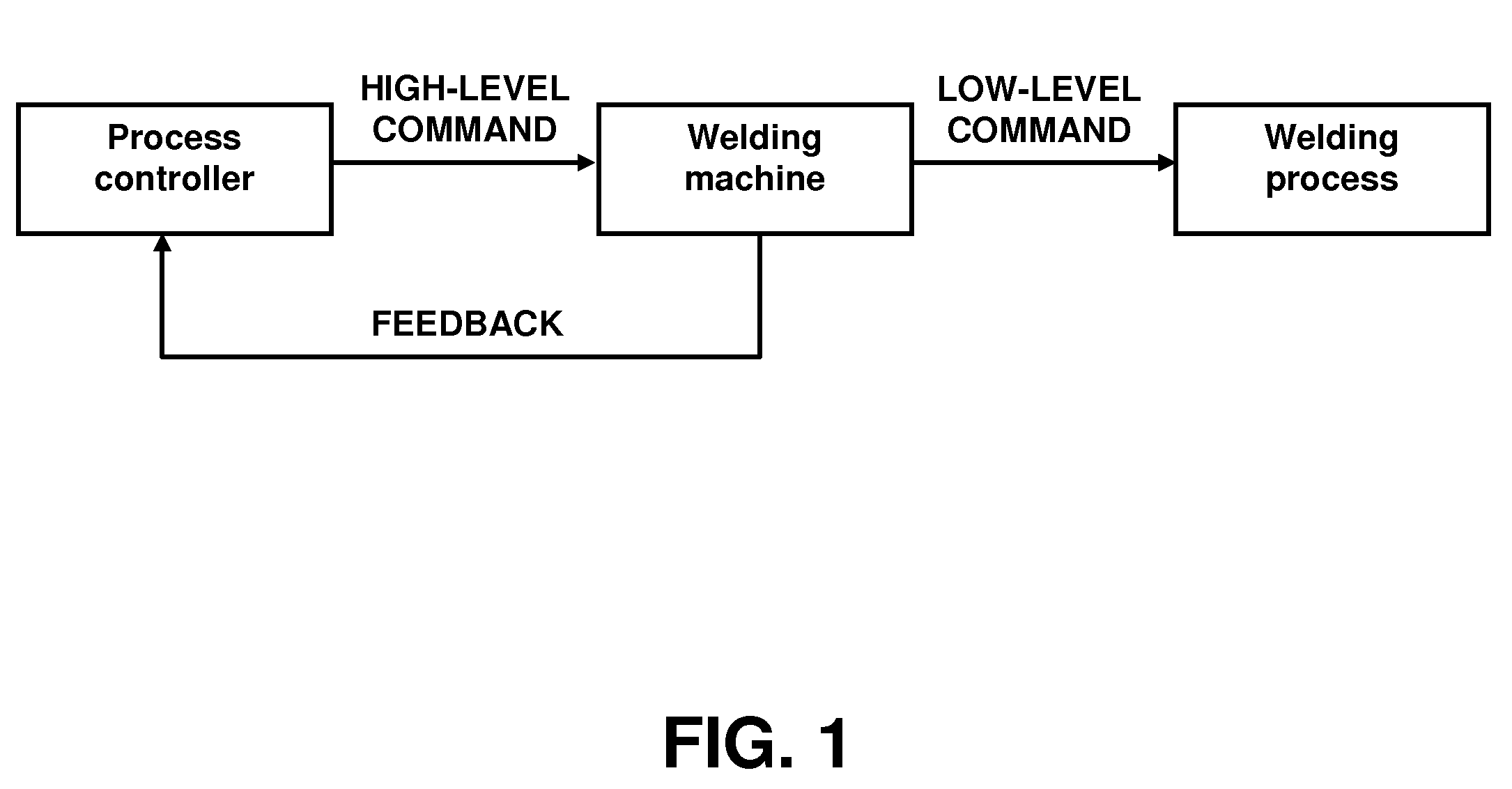

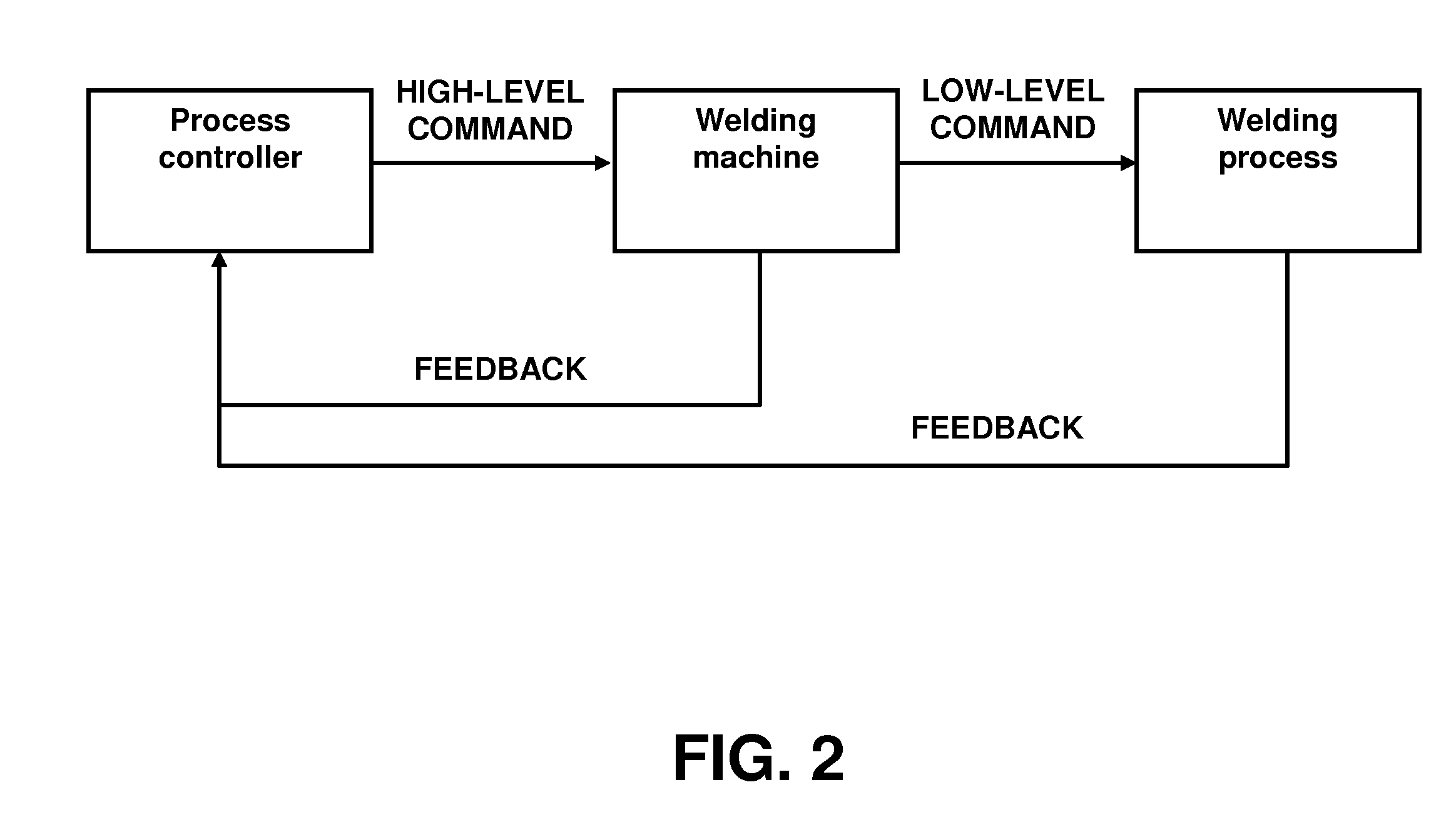

Controlled weld pool volume control of welding processes

ActiveUS20100288734A1Easy to controlAccurate volumeTemperatue controlElectron beam welding apparatusReal-time dataEngineering

A new method of process control for fusion welding maintains a controlled weld pool size or volume, for example in some applications a substantially constant weld pool size or volume. The invention comprises a method of linking machine and process variables to the weld pool size or volume in real time, thereby enabling constant weld pool volume control. The invention further comprises a method of using thermal inverse models to rapidly process real-time data and enable models-based control of welding processes so as to implement constant weld pool volume control.

Owner:SIGMA LAB OF ARIZONA

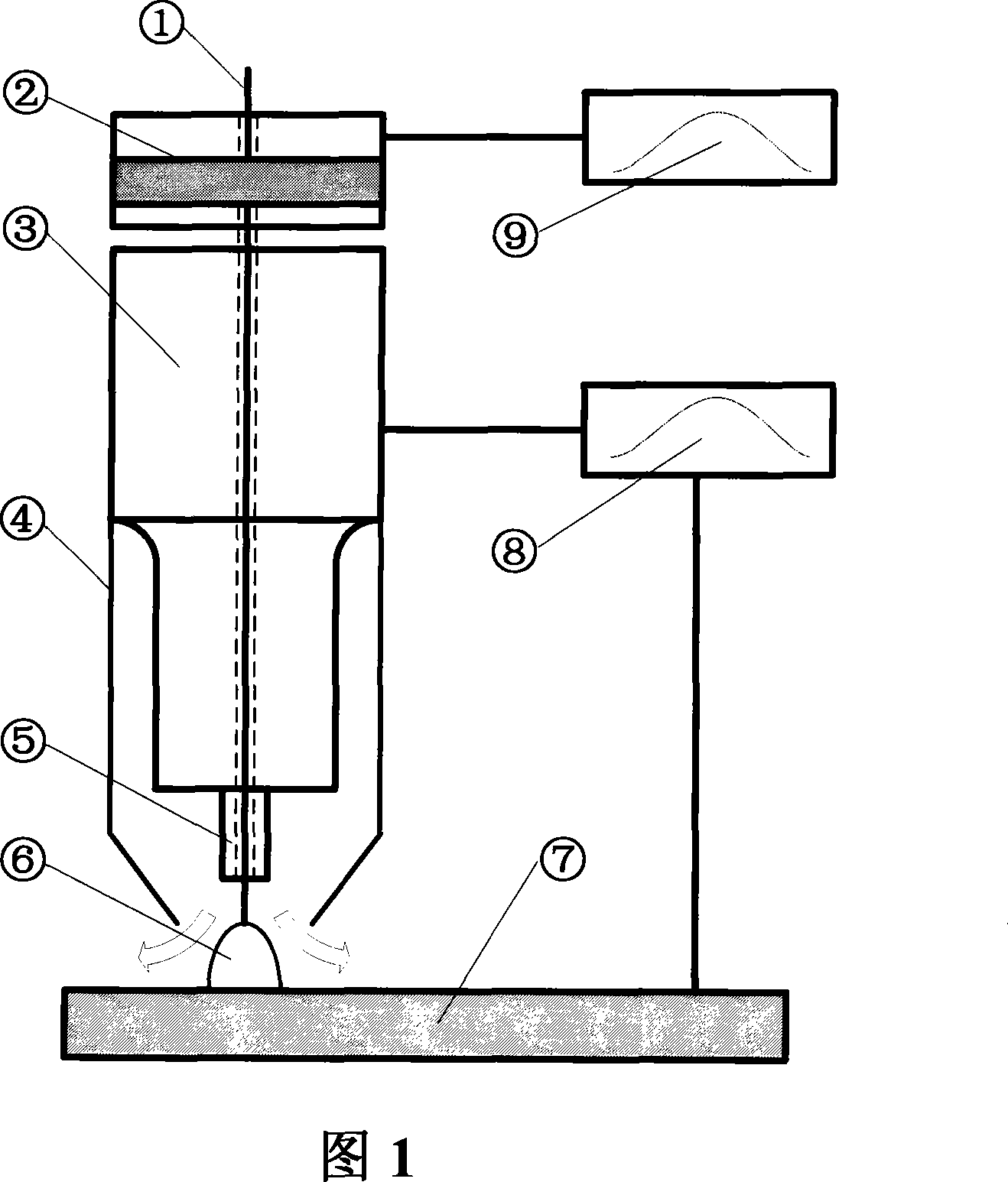

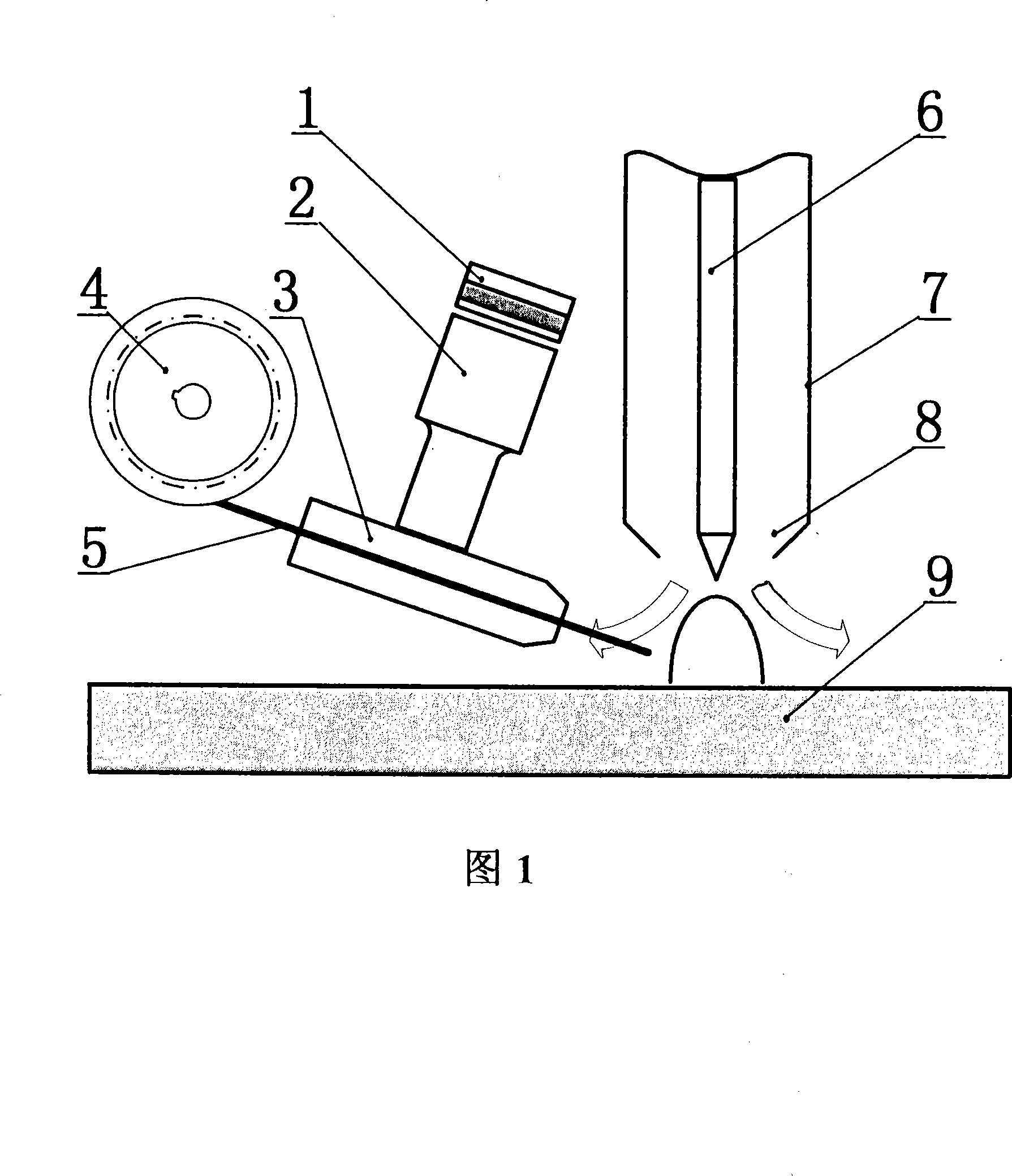

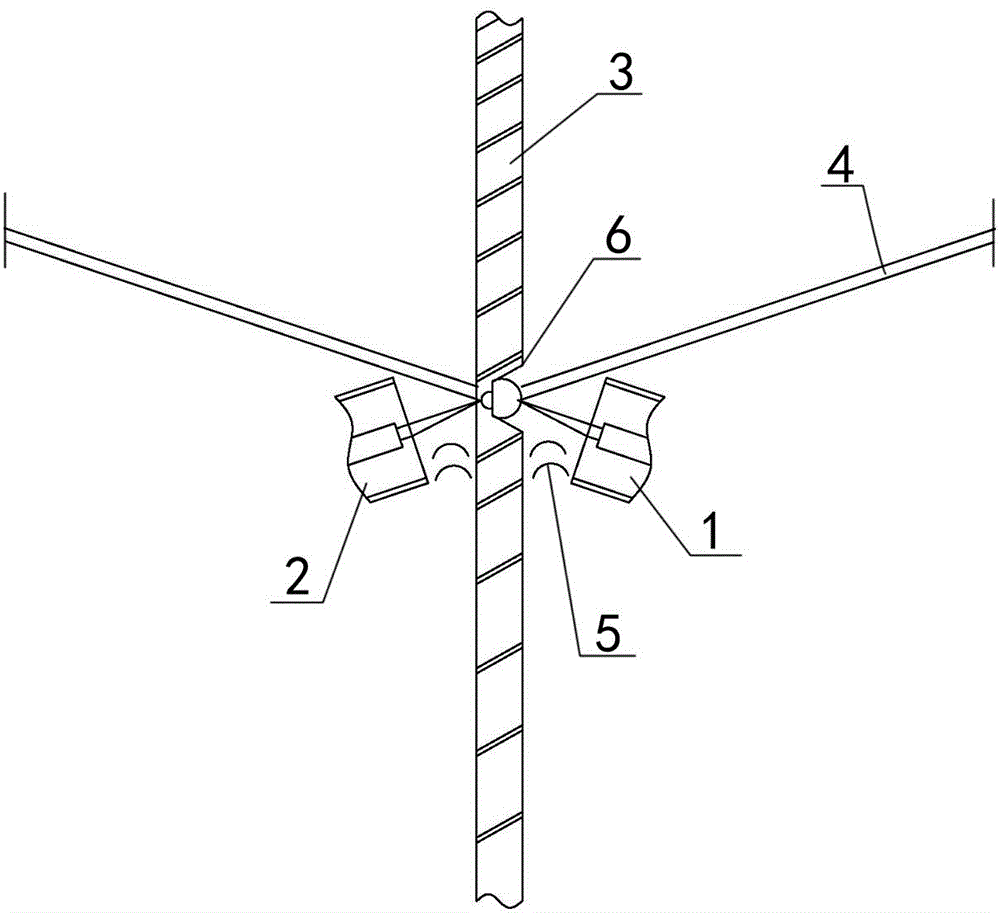

Ultrasound wave and melt pole electrical arc compound welding method

The invention provides a weld method compounding an ultrasonic and a gas metal arc welding so as to make use of the cavitation effect and the vibration effect of the ultrasonic to lead welding drops generated by the gas metal arc welding to be smoothly transmitted to a welding pool when the drops are still small. And when in welding, an electric arc shrinks under the effect of the ultrasonic and then the stiffness of the electric arc can be enhanced, which has a significant application value for welding of special positions such as a full-position welding, an overhead position welding, a flat position welding and a horizontal position welding, etc.. The invention includes the following steps: an ultrasonic generator is connected with an ultrasonic transducer 2 to convert ultrasonic energy into mechanical vibration; an ultrasonic transformer 3 enlarges amplitude; a conductive tip 5 is combined with the ultrasonic transformer; a protective gas nozzle 4 is fixed on the vibration node of the transformer; a welding wire 1 is connected with the conductive tip 5 to start a welding power supply 9 and then start an ultrasonic power supply after the electric arc becomes stable, then the transducer converts electrical energy into vibration and the ultrasonic transformer enlarges the ultrasonic amplitude which is transmitted to a melting electrode.

Owner:HARBIN INST OF TECH

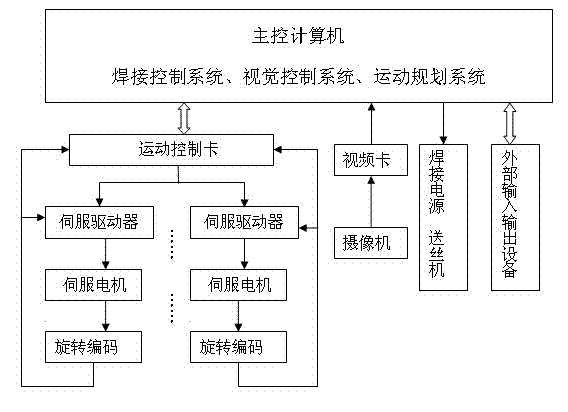

Arc welding robot jointing monitoring system based vision sensing

InactiveCN101224519AMeet local intelligence requirementsFlexible controlArc welding apparatusProgramme total factory controlSimulationVision sensor

The invention provides an arc welding robot welding monitoring system which is based on visual sensing in the arc welding robot technical field. The invention comprises a welding robot, a robot controller, a visual sensing system, an interface circuit device, a main control computer, and a dual inverter arc welding power source; wherein, the visual sensing system dynamically collects the images of a welding pool and transmits the images to the main control computer which receives the image information which is provided by the visual sensor and achieves the image processing; furthermore, the main control computer adjusts the dual inverter arc welding power source and controls the welding robot through the interface circuit device according to the processing results; the interface circuit device consists of a simulation signal output sub-module, a welding switch and process state detection sub-module and a robot controller general I / O sub-module; the welding robot receives a moving instruction signal which is emitted by the main control computer, and the welding is achieved by moving a welding gun. The invention improves the monitoring capability of the user to the welding process of the arc welding robot, and widens the application range of the robots in the welding automation field.

Owner:SHANGHAI JIAO TONG UNIV +1

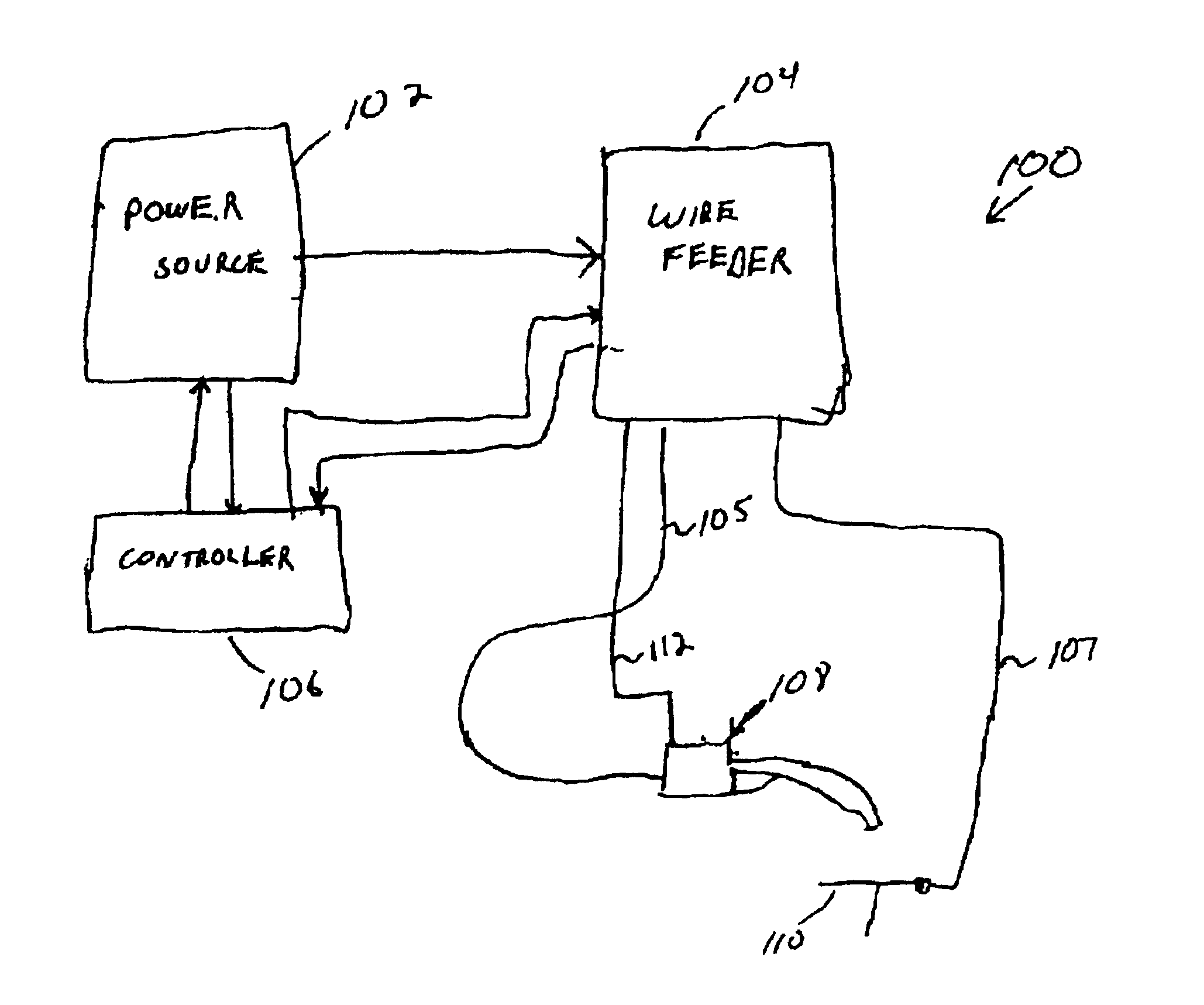

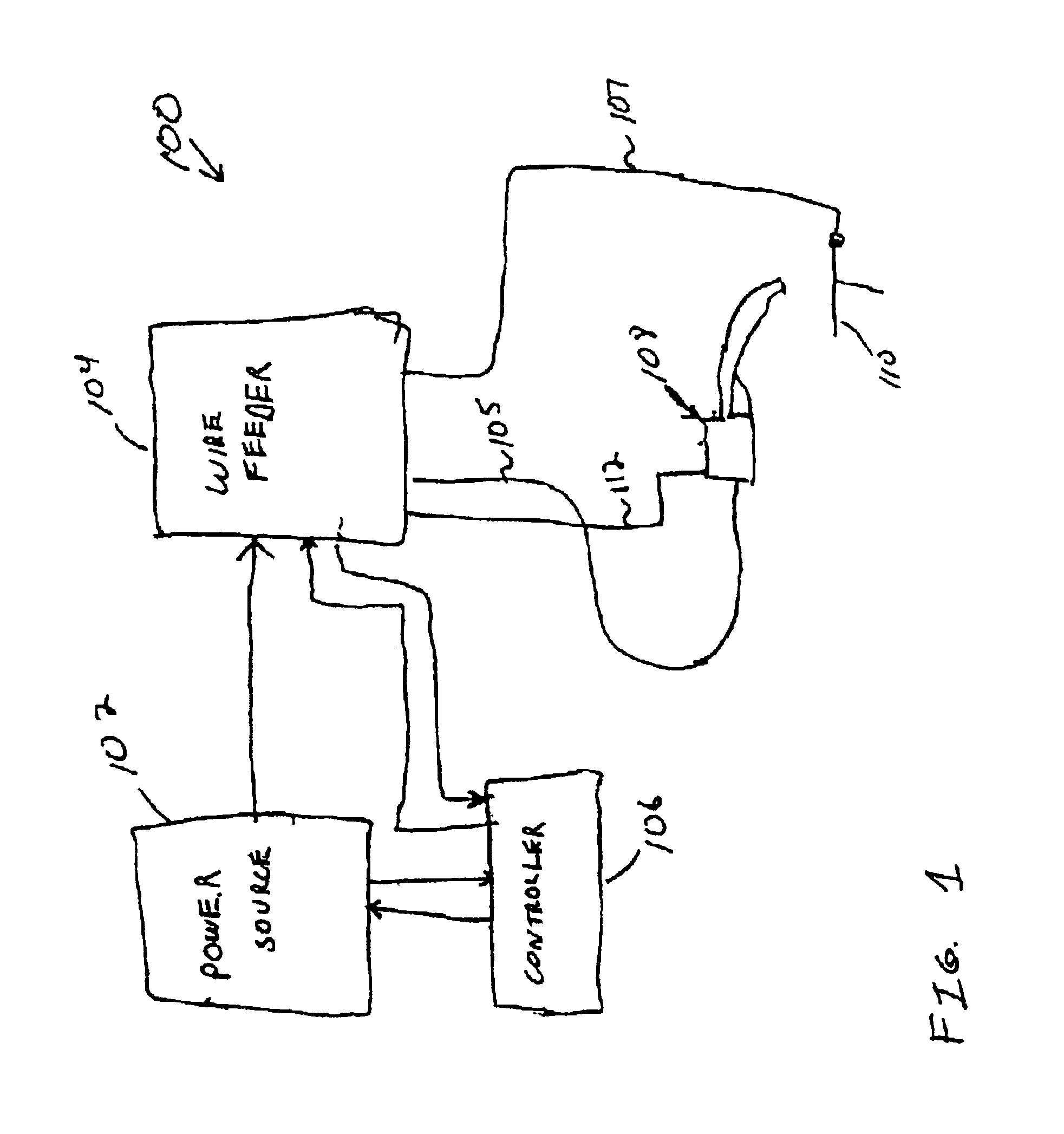

Method and apparatus for controlling a welding system

A method and apparatus for controlling a welding-type power supply includes providing a current wave form having an arc current portion and a short circuit current portion. An arc state is entered by retracting a welding wire, and a short circuit state is entered by advancing the wire. The current enters the arc current portion prior to the creation of the arc and the current enters the short circuit current portion prior to the creation of the short, by coordinating the wave form with the wire retraction. This may be preformed on a wire having a diameter of 2.4 mm or more to a weld and applying a welding current of less than 100 amps, or of less than 35 amps. One current waveform during the arc state includes at least three segments, and the last segment is entered into prior to the short circuit state being entered, and is the same current magnitude as the current magnitude at the start of the short circuit state. Penetration and / or bead formation may be controlled by controlling the advancement of the wire into the weld pool. The balance may be user set.

Owner:ILLINOIS TOOL WORKS INC

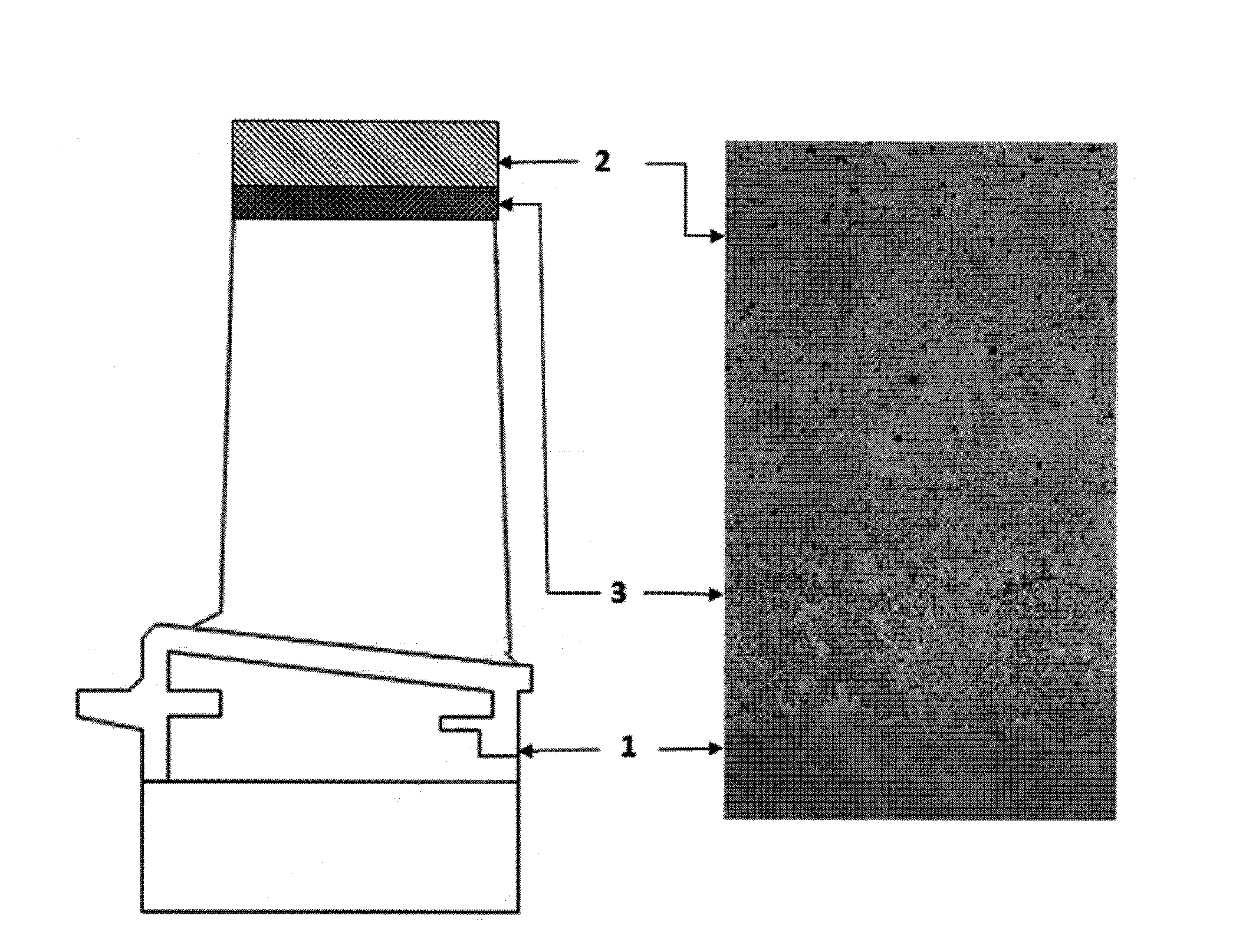

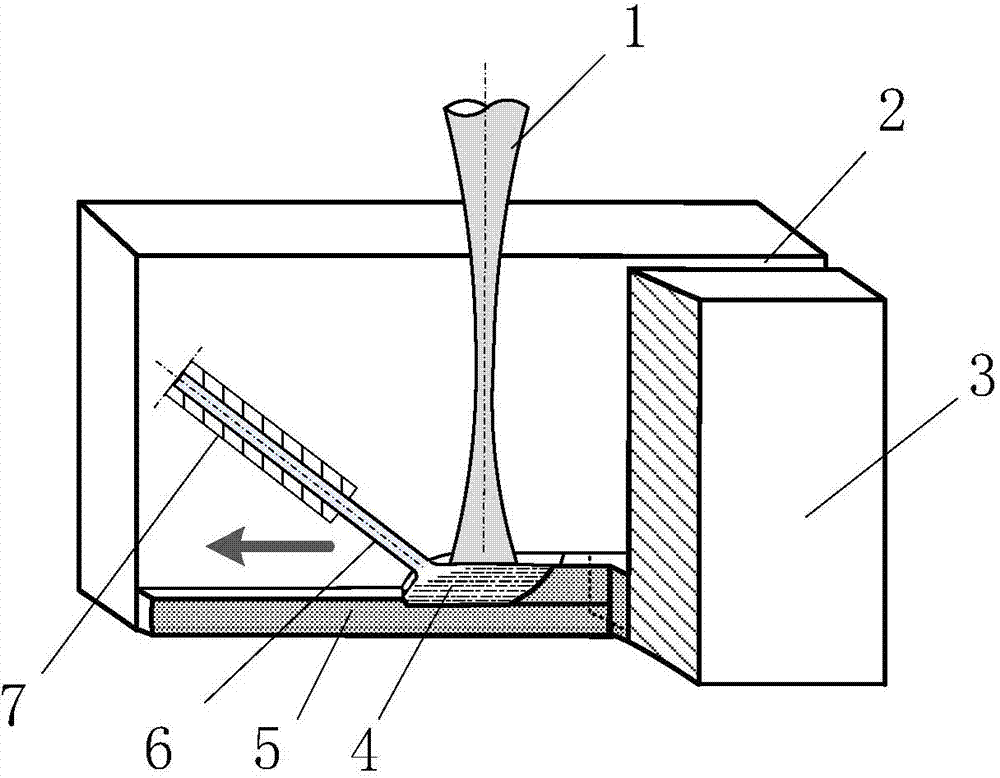

Part-geometry independent real time closed loop weld pool temperature control system for multi-layer dmd process

ActiveUS20060032840A1Additive manufacturing apparatusIncreasing energy efficiencyMelting tankTemperature control

In a direct metal deposition system which builds up a metallic overlay on a substrate by moving the substrate relative to a laser in a metallic powder feed, the laser power is adjusted for successive layers by sensing the weld pool in a plurality of selected points in each layer and adjusting the power during successive layers to maintain a weld pool that corresponds to those achieved during deposition of a lower optimal layer. This compensates for heating of the substrate resulting from the deposition which tends to increase the pool size or temperature in the higher layers.

Owner:DM3D TECH

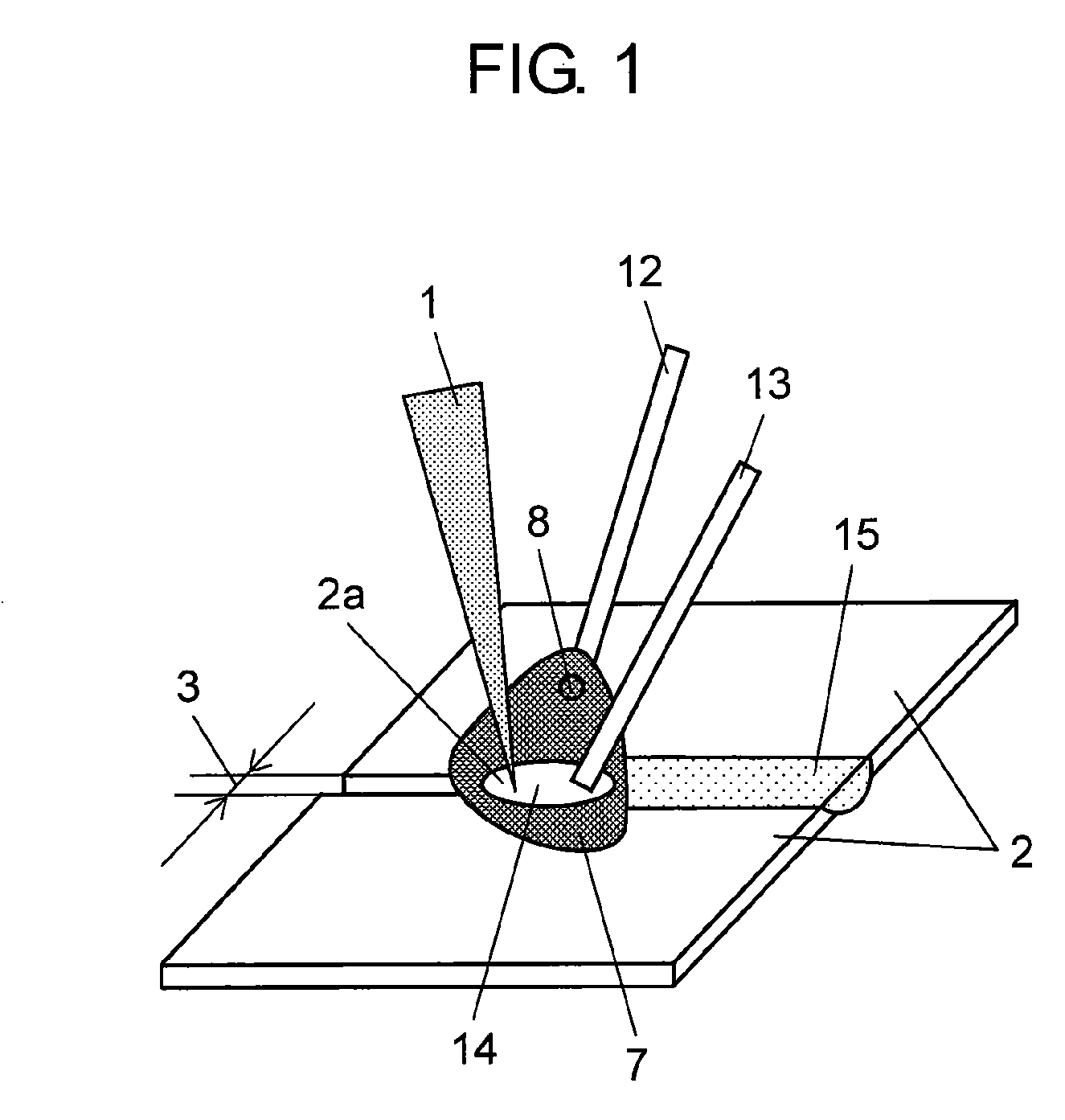

Hybrid welding method and hybrid welding apparatus

ActiveUS20110132878A1Total current dropIncrease deposition rateArc welding apparatusWelding/cutting media/materialsEngineeringLaser beams

Disclosed is a method for hybrid welding in which a laser beam is applied to the welding position of objects to be welded, and at the same time, a first wire is fed to the welding position so as to perform arc welding using an arc generated between the objects to be welded and the first wire. In this method, one or more second wires are fed to a molten weld pool formed by the laser beam and arc welding, thereby increasing the amount of welding without increasing the arc current.

Owner:PANASONIC CORP

Synchronized rotating arc welding method and system

ActiveUS20150076119A1Increase success rateSpeed up preparationArc welding apparatusWelding/cutting media/materialsEngineeringMovement control

A welding method includes feeding a welding electrode axially from a welding torch, moving the welding electrode radially in a desired pattern with respect to a central axis of the welding torch by a motion control assembly within the welding torch, transmitting from control circuitry a signal corresponding to a position of the welding electrode relative to a weld joint or weld pool, advancing the welding torch or a workpiece to establish a weld, and transferring material from the welding electrode to a first location in an area of the weld pool. The welding electrode moves radially while feeding the welding electrode from the welding torch, the material from the welding electrode is transferred to the first location during a first cycle of the desired pattern, and the first location is controlled based at least in part on the signal.

Owner:ILLINOIS TOOL WORKS INC

Aluminum sheet product and method of welding structural components

InactiveUS6153854AMaintain structural integrityLoss of mechanical propertyWelding/cutting media/materialsSoldering mediaFilling materialsUltimate tensile strength

PCT No. PCT / EP97 / 07274 Sec. 371 Date Dec. 1, 1999 Sec. 102(e) Date Dec. 1, 1999 PCT Filed Dec. 19, 1997 PCT Pub. No. WO98 / 28130 PCT Pub. Date Jul. 2, 1998In the welding of aluminum alloy, structural components, e.g. in the aerospace industry, one of the welded components is a sheet product having a core and a clad layer of filler material. During welding, the clad layer provided filler for the welding pool, and the core remains substantially unmelted. Consequently, adhesion between the core and the clad layer maintains its strength, e.g. keeps at least 80% of its pre-welding strength.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

Ultrasonic vibration and welding stick feeding system compound welding method and device thereof

InactiveCN101239415AControl transitionAchieve welding productionArc welding apparatusMelting tankCavitation

The invention discloses an ultrasonic vibration and welding wire feed system composite welding method and a device thereof which are provided with a stable welding process, high quality of welding seams, controllable welding pool grain growth phenomenon after welding, and high welding quality in normal welding surroundings. The objective is achieved by following steps: transmitting cavitation effect and vibration effect to the welding pool during the welding wire and welding pool contacting process by broadcasting the ultrasonic in the welding wire feed system. The melt drop size at the terminal of the welding wire is controlled effectively by ultrasonic action during welding process, transition from melt drop to welding pool is more stable, and welding seam quality is further improved. Since ultrasonic is applied in the welding feed system during welding process, welding wire melt drop transition condition is affected, energy distribution status during welding process is improved, thereby refinement and homogenization degree of the joint, and mechanical property such as intensity are further enhanced.

Owner:HARBIN INST OF TECH

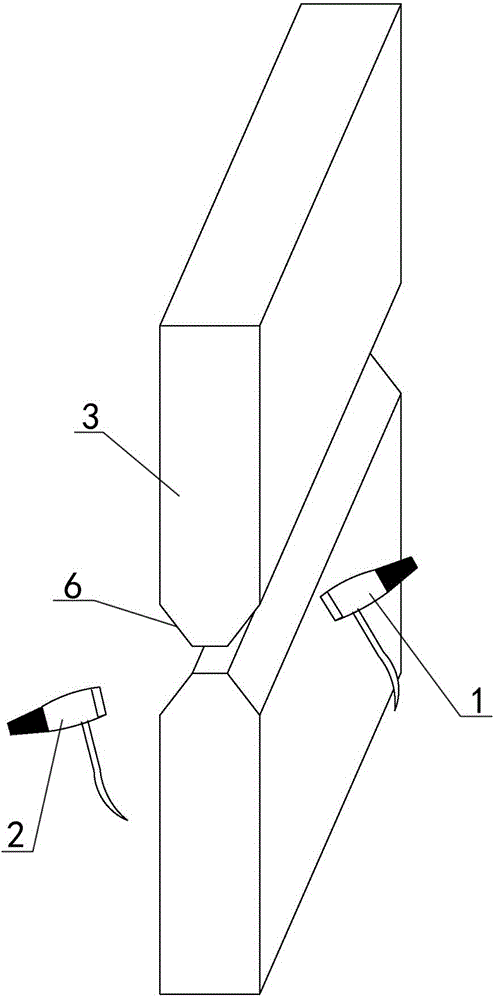

Laser electrical arc complex welding method for intensifying current magnetohydrodynamics effect

InactiveCN101176954AEasy to shapeImprove energy coupling efficiencyArc welding apparatusLaser beam welding apparatusARC complexEnergy coupling

The invention relates to a laser-arc hybrid welding method which reinforces dynamic effect of current and magnetic fluid, belonging to technical field of laser material processing. The invention is characterized in that: a synergistic arrangement of laser and electric arc is adopted and a filler wire is added simultaneously; wherein, the electric arc and the wire are arranged at both sides of a laser beam; the wire is arranged in the front and is contacted with a workpiece, and the electric arc is arranged at the back; the two polarities of the welding power are connected with a tungsten electrode and the wire respectively; the welding power forms a current loop by flowing through a weld pool and the electric arc by the wire, and most of the welding power flows through the weld pool and produces electromagnetic force. The invention has the advantages that the energy coupling efficiency and the stability in the welding process are both highly improved by fully utilizing influence of dynamic effect of arc current and magnetic fluid on the heat exchange situation and the flowing state of the weld pool, and the surface forming state of a weld joint is greatly improved because of the significantly improved tolerance of the electric arc arranging at the back of the weld pool to the wire fluctuation.

Owner:BEIJING UNIV OF TECH

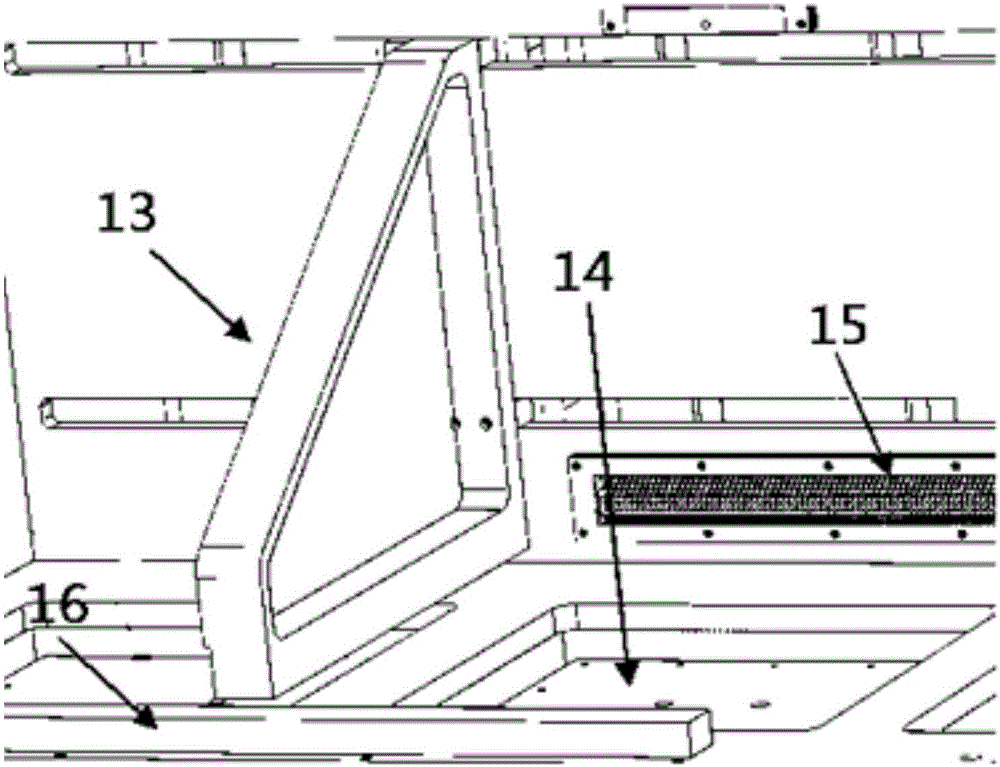

Device for entering and exiting of shielding gas on two sides of forming bin of metal 3D printing equipment

ActiveCN106623928AIncrease profitAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankShielding gas

The invention provides a device for entering and exiting of shielding gas on two sides of a forming bin of metal 3D printing equipment. Gas exiting and entering devices for working bins in metal selective forming equipment are generally simple pore channel devices or rectangular devices, have common problems that gas flow produced at a gas inlet in a laser sintering process for powder cannot blow away black smoke and metal vapor plasma produced under mutual action of laser and powder, and then larger power loss of laser and irregular shape of a weld pool are caused and result in severe influence on forming quality and forming precision of formed parts, or have the problem that powder sintering black smoke close to the gas inlet and is blown to be scattered on a powder layer close to a gas outlet and printing work is affected. The specific device is mainly designed to enable gas flow to form stable laminar flow and effectively blow away the black smoke and metal vapor plasma produced during laser sintering of the powder, the laser energy utilization rate can be increased by about 10%-15%, the quality and the precision of the formed parts can be improved effectively, and the density of the formed parts approaches 100%.

Owner:BEIJING UNIV OF TECH

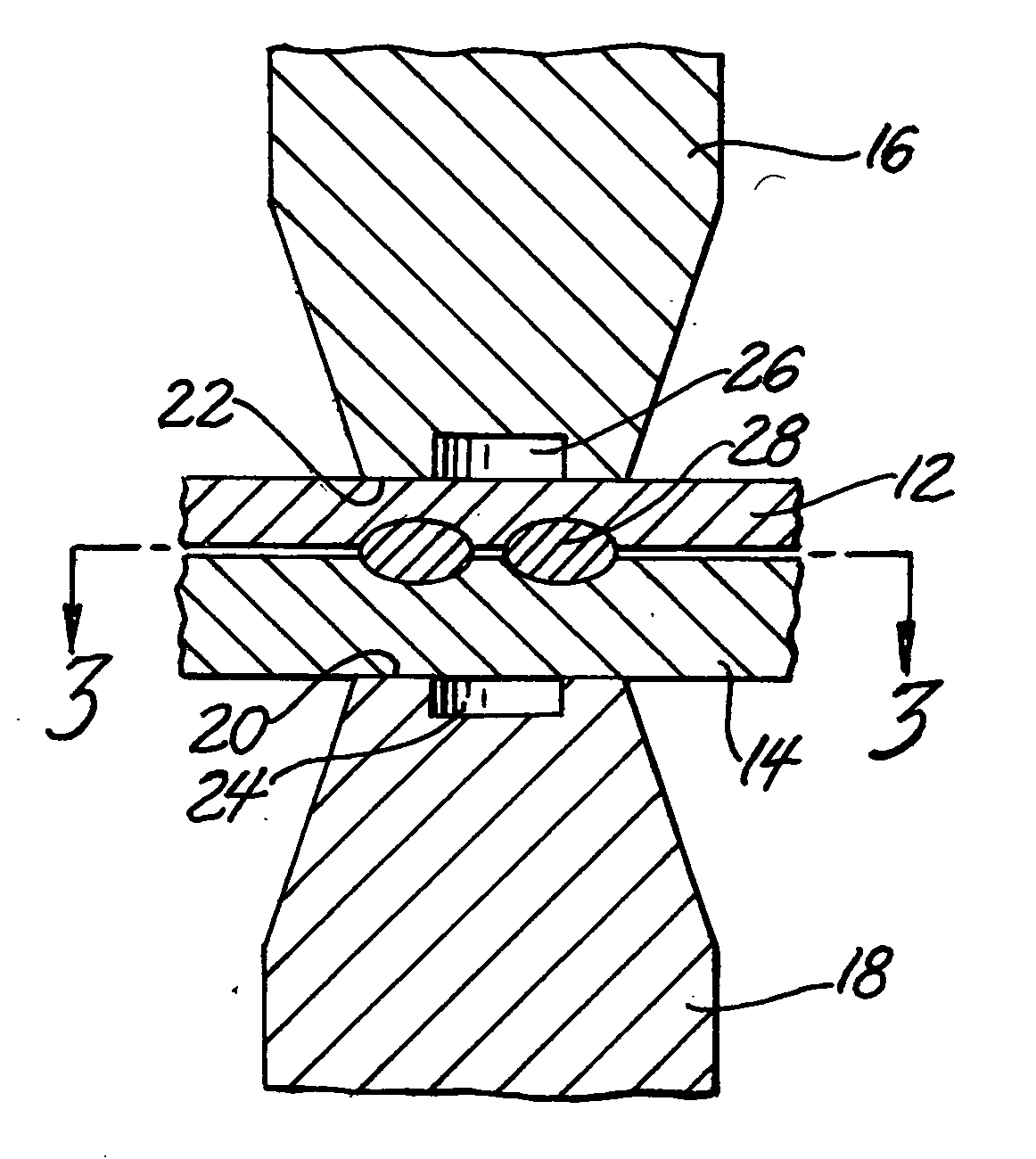

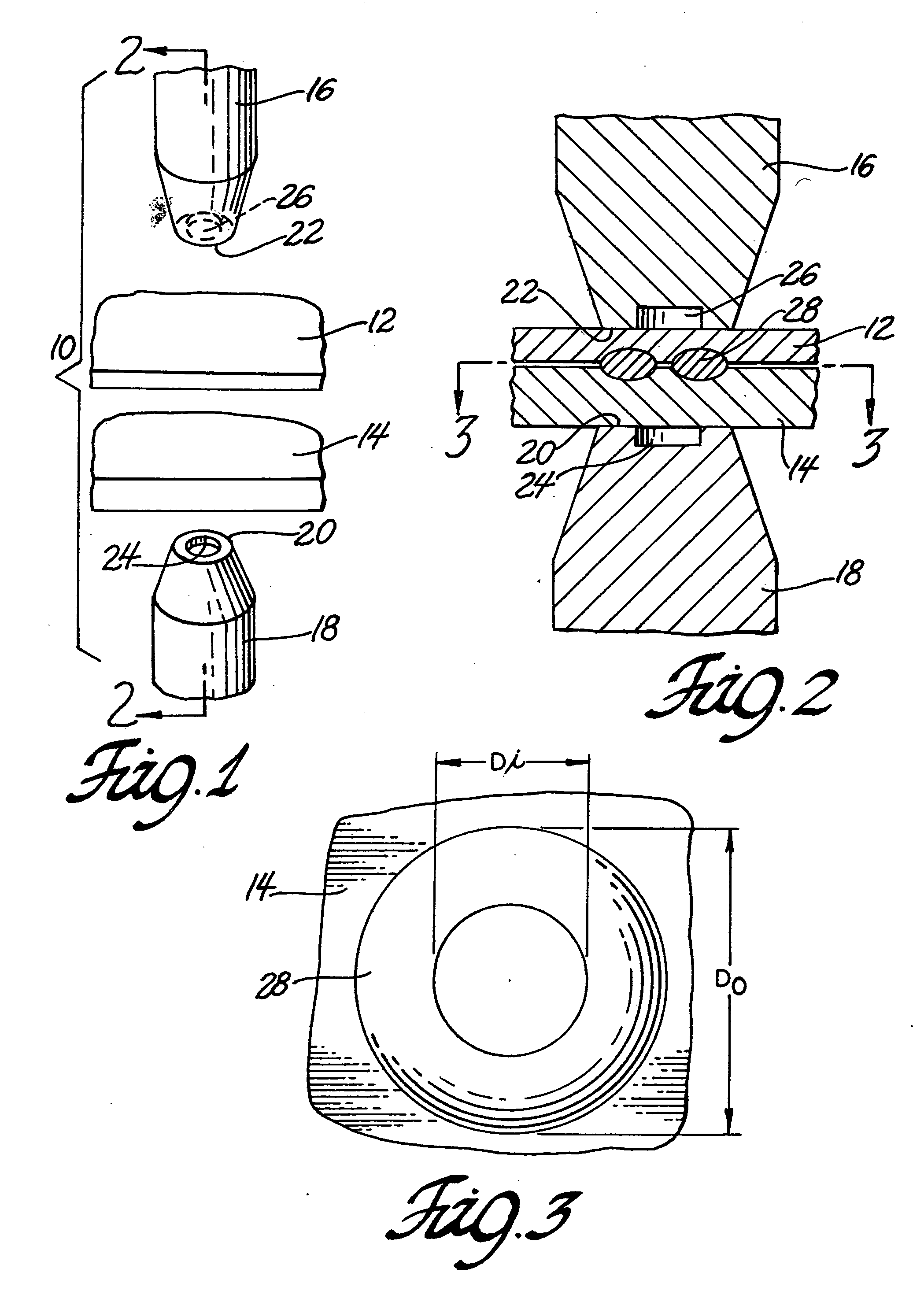

Resistance welding of high strength steels

InactiveUS20050247679A1Improve propertiesHigh strengthOhmic-resistance electrodesVehicle componentsElectrical resistance and conductanceHigh intensity

The formation of spot welds in high strength steel workpieces is improved by using welding electrodes with annular, or donut shaped welding tips for the formation of the molten metal weld pool at the weld site. The annular poll solidifies to form an annular weld nugget. Preferably the donut shaped nugget has an internal diameter that is no more than three-quarters of the outside diameter. The method is applicable to carbon steel workpieces with allowing elements for strengthening, and to thick sheets of mild carbon steels.

Owner:GM GLOBAL TECH OPERATIONS LLC

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

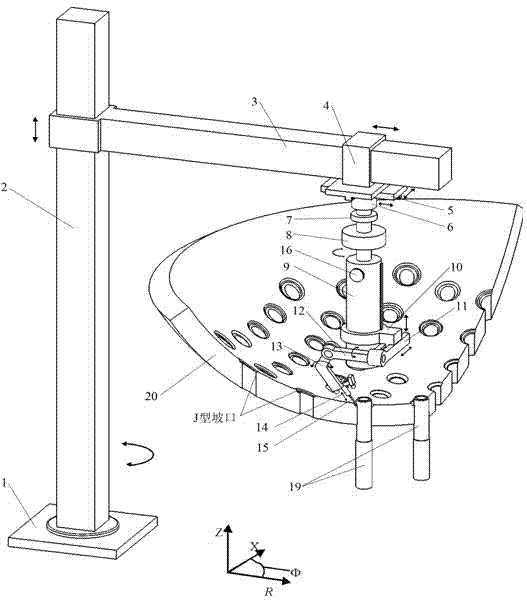

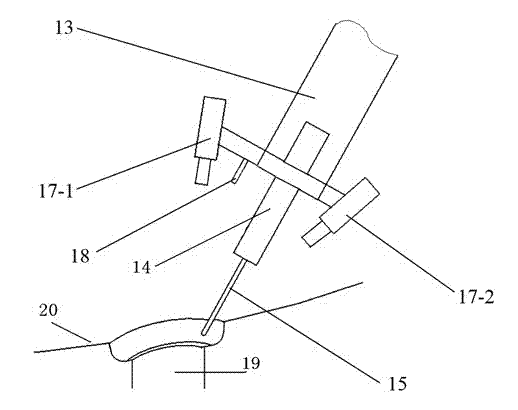

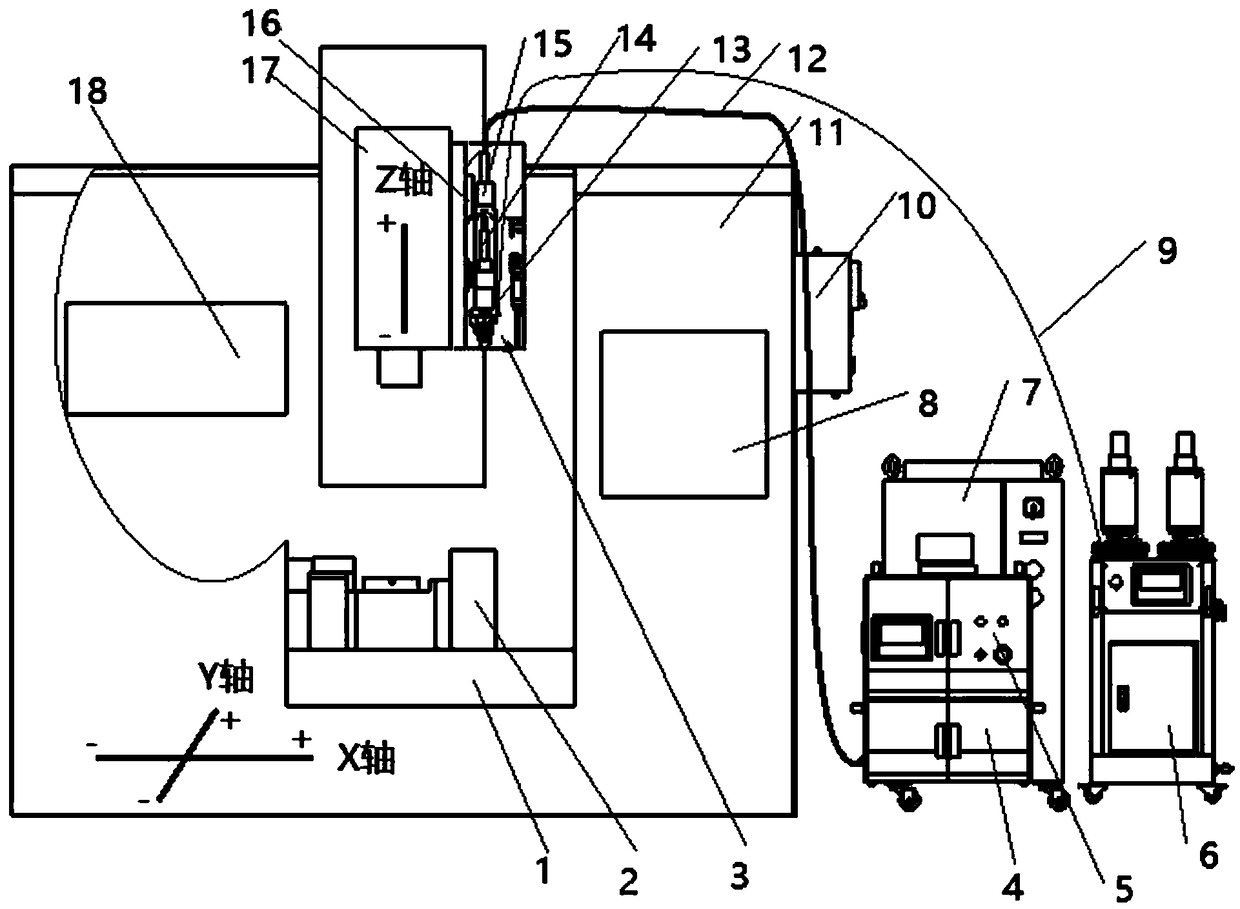

Circular seam welding robot device

ActiveCN102049638AWith visual functionFacilitates motion controlProgramme-controlled manipulatorWelding/cutting auxillary devicesMachineVision sensor

The invention discloses a robot device for the circular seam welding of large spherical crown workpieces and pipes. A robot main body comprises a machine head and a machine frame. The machine head consists of a cross sliding table mechanism, a six-freedom-degree motion system, a sliding ring system and a welding gun. The machine frame consists of a fixed base, upright columns, a cross beam and a slider. The machine frame of the robot makes large range motion and moves the robot main body to a position to be welded, the accuracy of micro motion is compensated by the cross sliding table mechanism of the machine head, and six-freedom-degree circular seam welding is realized. Welding process is monitored by a visual sensing technology, and a video camera fits a laser generator and serves as an optical visual sensor for laser structures. Another video camera fits the welding gun, serves as a visual sensor for a welding pool, and carries out real-time visual detection for the welding process. The robot device is particularly suitable for accurate locating motion required for welding large spherical crown workpieces and pipes, and can finish specific track welding in narrow space and control welding hot deformation.

Owner:TIANJIN YANGTIAN TECH CO LTD

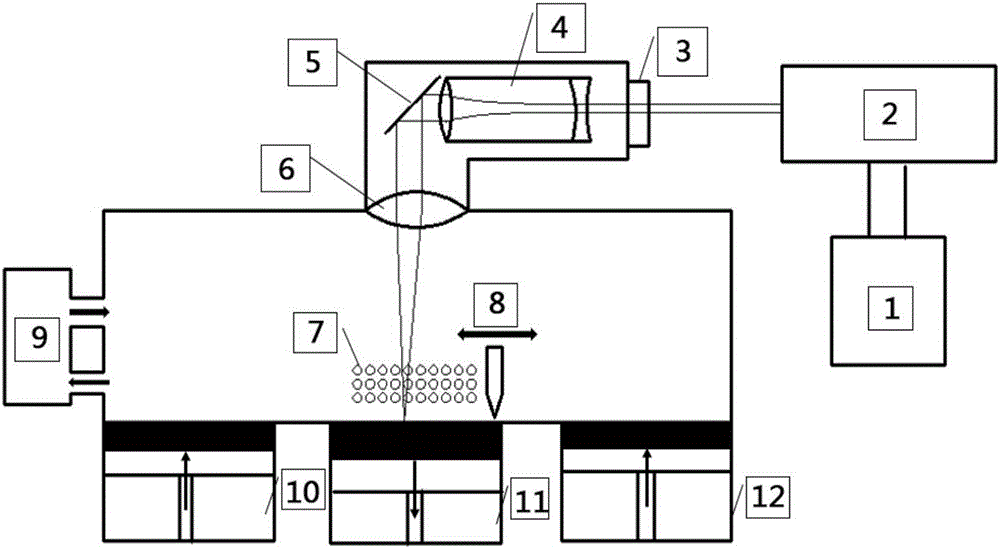

Laser additive and subtractive composite manufacturing device and method

InactiveCN108213423AImprove Additive QualityImprove product qualityAdditive manufacturing apparatusIncreasing energy efficiencyControl systemMonitoring system

The invention discloses a laser additive and subtractive composite manufacturing device and method. The device comprises a subtractive system, a laser additive system, a control system and a monitoring system, wherein the subtractive system is a five-axis linkage machine tool, the laser additive system comprises a laser device, a water cooling device and a pulverizing device, the control system isconnected with the subtractive system and the laser additive system through signals, and the monitoring system is connected with the control system through signals and used for acquiring a weld poolimage and workpiece dimension parameters and transmitting the weld pool image and the workpiece dimension parameters to the control system. The manufacturing method is characterized in that additive and subtractive operations are performed by the aid of the device and repeated until processing is qualified. The method has the advantages of high yield, low running cost and the like.

Owner:NANJING HUIRUI PHOTOELECTRIC TECH CO LTD

Electric arc wire filling additive manufacturing method for inclined thin-walled structural part

InactiveCN105921852AAchieve high-quality moldingOvercome costsArc welding apparatusMelting tankElectric arc furnace

The invention provides an electric arc wire filling additive manufacturing method for an inclined thin-walled structural part. The electric arc wire filling additive manufacturing method is used for manufacturing the inclined thin-walled structural part forming a certain included angle with a substrate. When multiple layers of single-pass inclined thin-walled parts are stacked, a first layer is formed by lapping two stacked weld beads, so that the problem of weld pool flowing due to excessive offset during stacking of a second layer is effectively solved; and when the second layer and subsequent layers are stacked, a welding gun horizontally shifts for a certain distance in a direction perpendicular to the height, thereby forming an inclined structure. According to the electric arc wire filling additive manufacturing method disclosed by the invention, the problems of high equipment cost, complex system, low forming precision of stacked parts and the like of an existing inclined thin-walled structural part are solved; the forming of the inclined thin-walled structural part can be finished in a mode of not turning over the substrate by a positioner; high-quality forming of the inclined thin-walled structural part is realized; and in addition, the method is easy in automation of forming process.

Owner:SOUTHWEST JIAOTONG UNIV

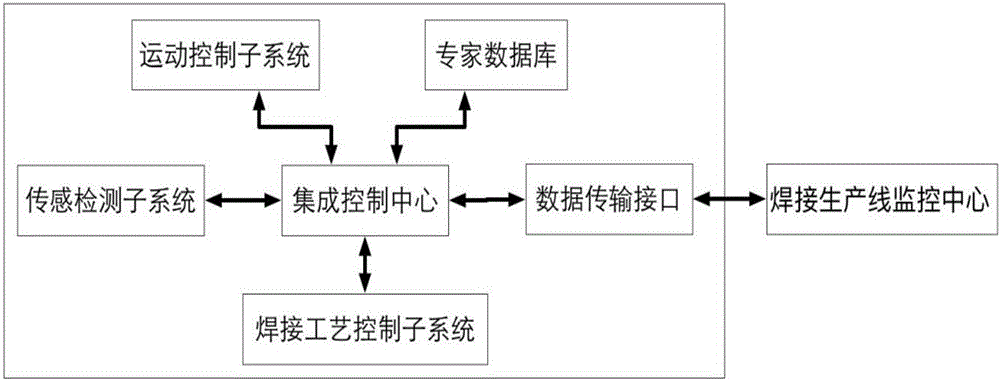

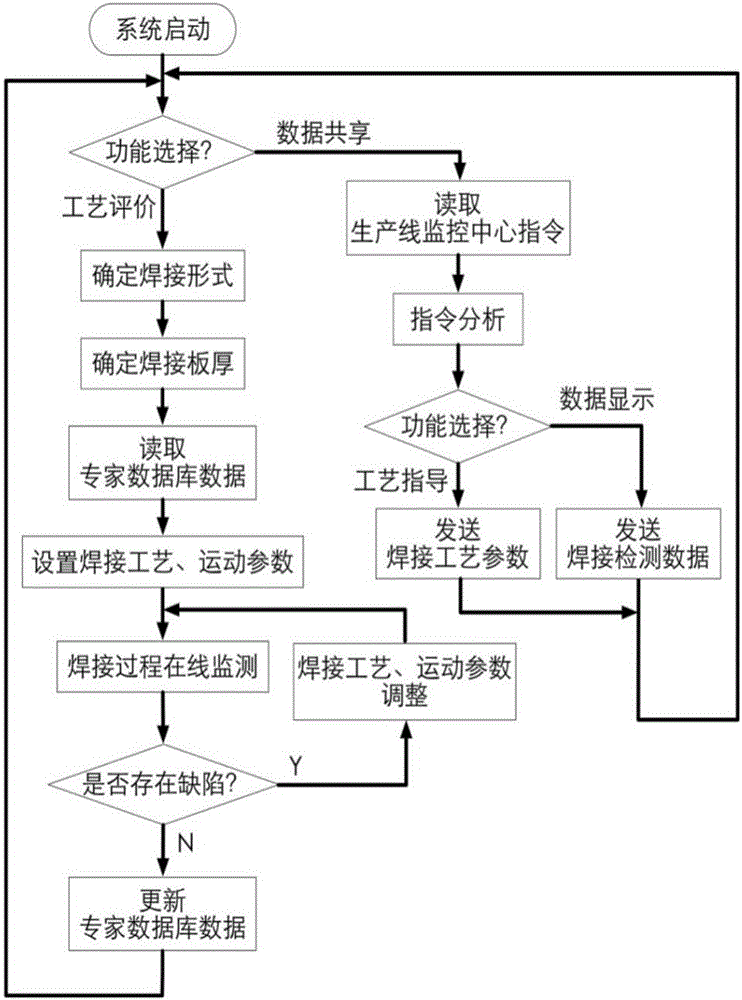

On-line monitoring system and method for weld pool dynamic process

ActiveCN105855743ARealize optimal adjustmentImplement automatic trackingWelding apparatusData informationWeld seam

The invention discloses an on-line monitoring system and method for a weld pool dynamic process. The on-line monitoring system for the weld pool dynamic process comprises an integrated control center, a sensing detection subsystem, a motion control subsystem, an expert database, a welding process control subsystem and a data transmission interface. The integrated control center is used for receiving data information, sending motion control instructions, welding process control instructions and data and reading instructions. The sensing detection subsystem is used for acquiring weld pool image information, process information, acoustical signals and temperature. The motion control subsystem is used for accomplishing weld seam tracking, welding gun height adjustment and speed control. The expert database is used for storing welding process control parameters, motion control parameters and sensing detection information. The welding process control subsystem is used for achieving control on welding current, arc voltage and speed. The data transmission interface is used for achieving data communication. The on-line monitoring method adopts the monitoring system to carry out on-line monitoring. The on-line monitoring system and the on-line monitoring method for the weld pool dynamic process have the advantages of being high in reliability, highly integrated in function and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Hybrid laser arc welding process and apparatus

ActiveUS20120000892A1Increase welding depthEliminate stomataEngine manufactureArc welding apparatusEngineeringWeld seam

A welding method and apparatus for welding workpieces together by conducting a laser beam welding process on a joint region that includes a weld seam defined by and between faying surfaces of the workpieces, and then conducting a hybrid laser arc welding process on the joint region. The laser beam welding process entails causing a first laser beam to travel along the joint region, penetrate the weld seam and form a weldment. The hybrid laser arc welding process remelts the weldment by simultaneously causing an electric arc and a second laser beam to overlap and travel along the joint region and form a weld pool in the weldment. On cooling, a weld joint is formed within the joint region and its weld seam.

Owner:GENERAL ELECTRIC CO

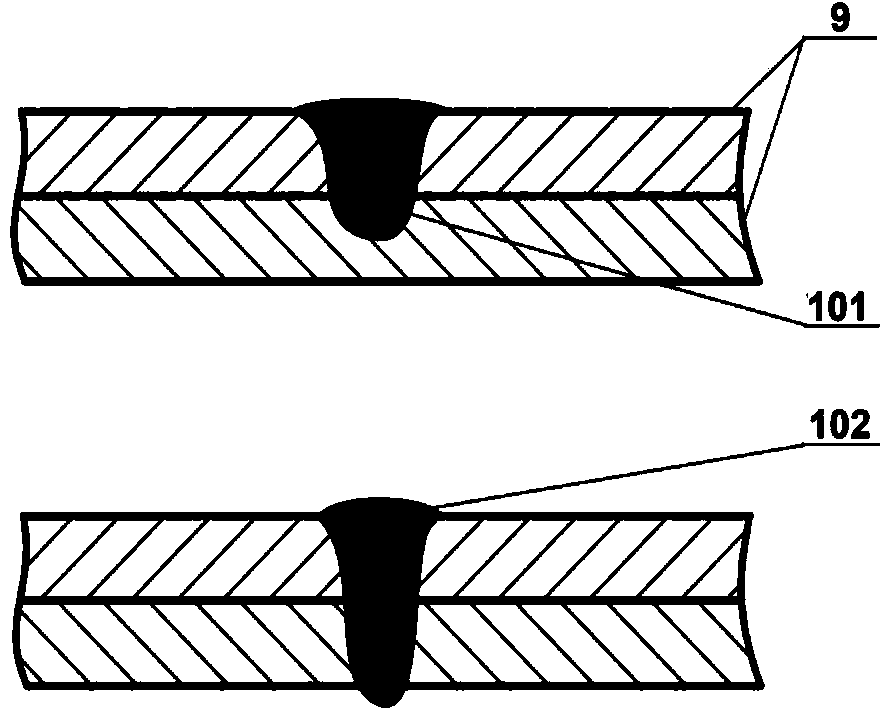

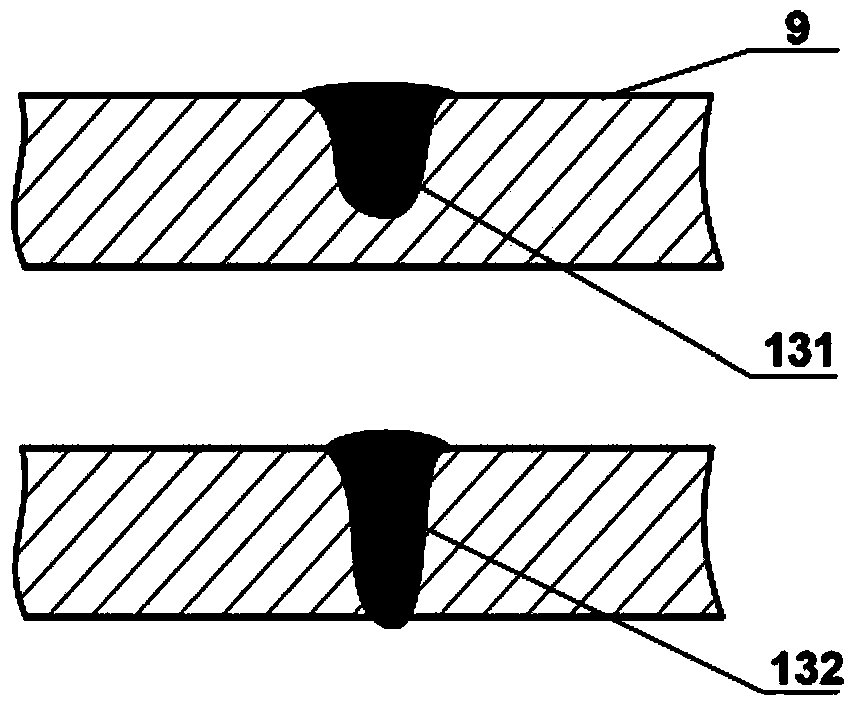

Double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method

InactiveCN104096954AAvoid drippingImprove liquidityArc welding apparatusDomestic vesselsButt weldingEngineering

A double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method is implemented by the following steps: cleaning up sundry, carrying out groove processing on the welding position of a wall plate of a stainless steel storage tank, welding position welding, choosing welding torch equipment, aligning a same weld pool by a main welding torch and an auxiliary welding torch from the inside and outside of a weld joint respectively synchronously, arcing synchronously by the main welding torch and the auxiliary welding torch, enabling the auxiliary welding torch to be moved synchronous to the main welding torch, welding along the same direction at the same speed, and stopping arcing by the main welding torch and the auxiliary welding torch synchronously. By adopting the double two-sided synchronous tungsten electrode high-frequency pulse argon arc welding butt welding method, the inner side forming of the weld joint is protected and penetrated, the defects of oxidation, overlap, lack of penetration and the like of the weld joint are avoided, the processes of root clearing, grinding and re-welding on the inner side are omitted, compared with the prior art, the method has the advantages of simple method and easy implementation, the production efficiency is greatly improved, and the labor intensity of workers is lowered.

Owner:中建一局集团安装工程有限公司 +1

Laser beam welding

ActiveUS20130270233A1Overcome disadvantagesWelding/soldering/cutting articlesMetal working apparatusLeading edgeMelting tank

A process is provided for laser beam welding of surface treated steel components. Two steel components, at least one of which is a surface treated steel component, are relatively arranged to form a joint that is to be welded. Using a laser beam, the two steel components are irradiated along the joint so as to heat materials within each of the two steel components to a welding temperature, and thereby form a weld pool. During welding a metallic constituent is introduced into a leading edge of the weld pool, in front of the laser beam along a welding direction. The introduced metallic constituent combines with a species, which is released into the weld pool from the surface treated steel component, to form a compound that is stable within the weld pool at the welding temperature.

Owner:MAGNA INTERNATIONAL INC

Workpiece welding process

InactiveUS7015417B2Weld a workpiece efficiently and securelyEfficient use ofArc welding apparatusElectron beam welding apparatusOptoelectronicsLaser light

A laser light L is emitted from a laser light source 6 to workpieces 1, 2, to form a laser molten weld pool 3, and immediately thereafter, an arc molten weld pool 4 is formed using an arc welding machine 7; thereby plates 1, 2 are welded. The arc welding machine 7 is provided with a filler wire to form a bead 5 on the plate 1. With the welding process according to the present invention, workpieces can be efficiently and securely welded regardless of shape and material of the workpieces.

Owner:HONDA MOTOR CO LTD

Laser filler wire welding method for thick plate narrow gap

ActiveCN103801833AAvoid it happening againReduce generationWelding/soldering/cutting articlesMetal working apparatusThick plateWeld seam

The invention relates to a laser filler wire welding method for a thick plate narrow gap, and belongs to the technical field of laser material processing. The laser filler wire welding method for the thick plate narrow gap is characterized by comprising the steps that positive out-of-focus laser beams are adopted, the laser beams enter a narrow gap groove of a workpiece to be welded and act on the bottom and the side wall of the groove, and a welding pool is formed in a thermal conducting welding mode; a filler wire enters the welding pool in a wire forward feeding mode and is heated through the welding pool to be molten, the gap is filled with the molten wire to form a weld joint, and a thick plate is connected in a single-path multi-layer welding mode. According to the laser filler wire welding method for the thick plate narrow gap, the thermal conducting welding mode and the mode that the filler wire is heated through the welding pool to be molten are adopted, and the welding process is stable; meanwhile, the laser beams act on the side wall of the groove so that the welding defects such as the defect that the side wall is incompletely fused can be effectively avoided.

Owner:BEIJING UNIV OF TECH

Non-contact acoustic inspection method for additive manufacturing processes

ActiveUS20170146489A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAdditive manufacturing apparatusEngineeringAcoustic wave

A method for inspecting an additive manufacturing process in which a directed energy source is used to create a weld pool at an exposed build surface of a mass of powdered material, and selectively fuse the powdered material to form a workpiece. The inspection method includes: using a noncontact method to generate an acoustic wave in the build surface; using a noncontact method to measure displacement of the build surface in response to the acoustic wave; and determining at least one sub-surface material property of the workpiece by analyzing the displacement of the build surface.

Owner:GENERAL ELECTRIC CO

Resistance spot welding steel and aluminum workpieces using insertable cover

ActiveUS20150096961A1Reduce current densityLow densityElectrode supporting devicesWelding/soldering/cutting articlesElectrical resistance and conductanceSpot welding

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy workpiece together includes several steps. One step involves inserting a cover between the aluminum or aluminum alloy workpiece and an adjacent welding electrode. In another step, the adjacent welding electrode is pressed against cover, and another opposed welding electrode is pressed against the steel workpiece at a weld site. In yet another step, electrical current is passed between the welding electrodes, passed through the cover, and passed through the workpieces in order to initiate and grow a molten weld pool within the aluminum or aluminum alloy workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com