Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

233results about How to "Eliminate stomata" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method and current collector

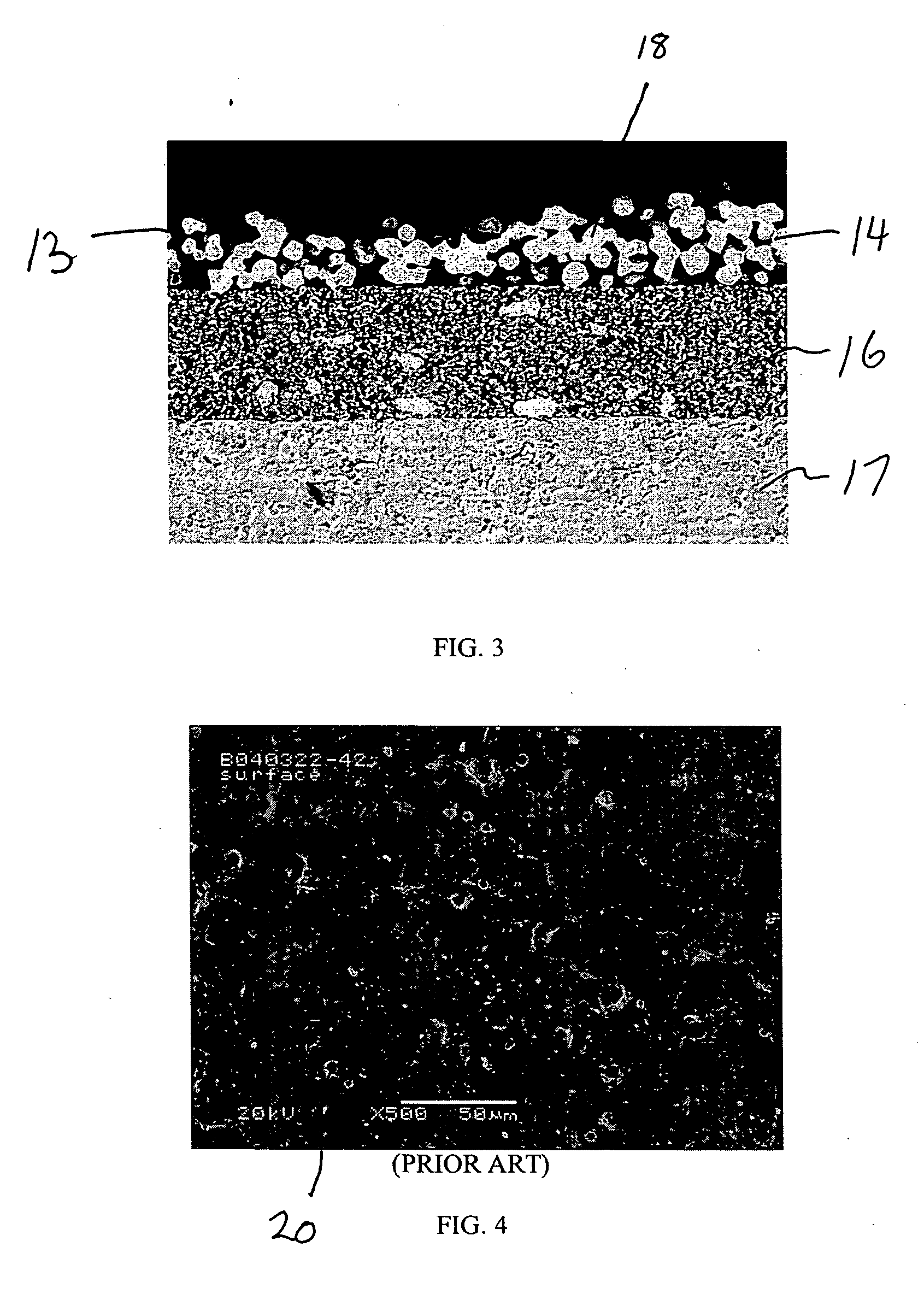

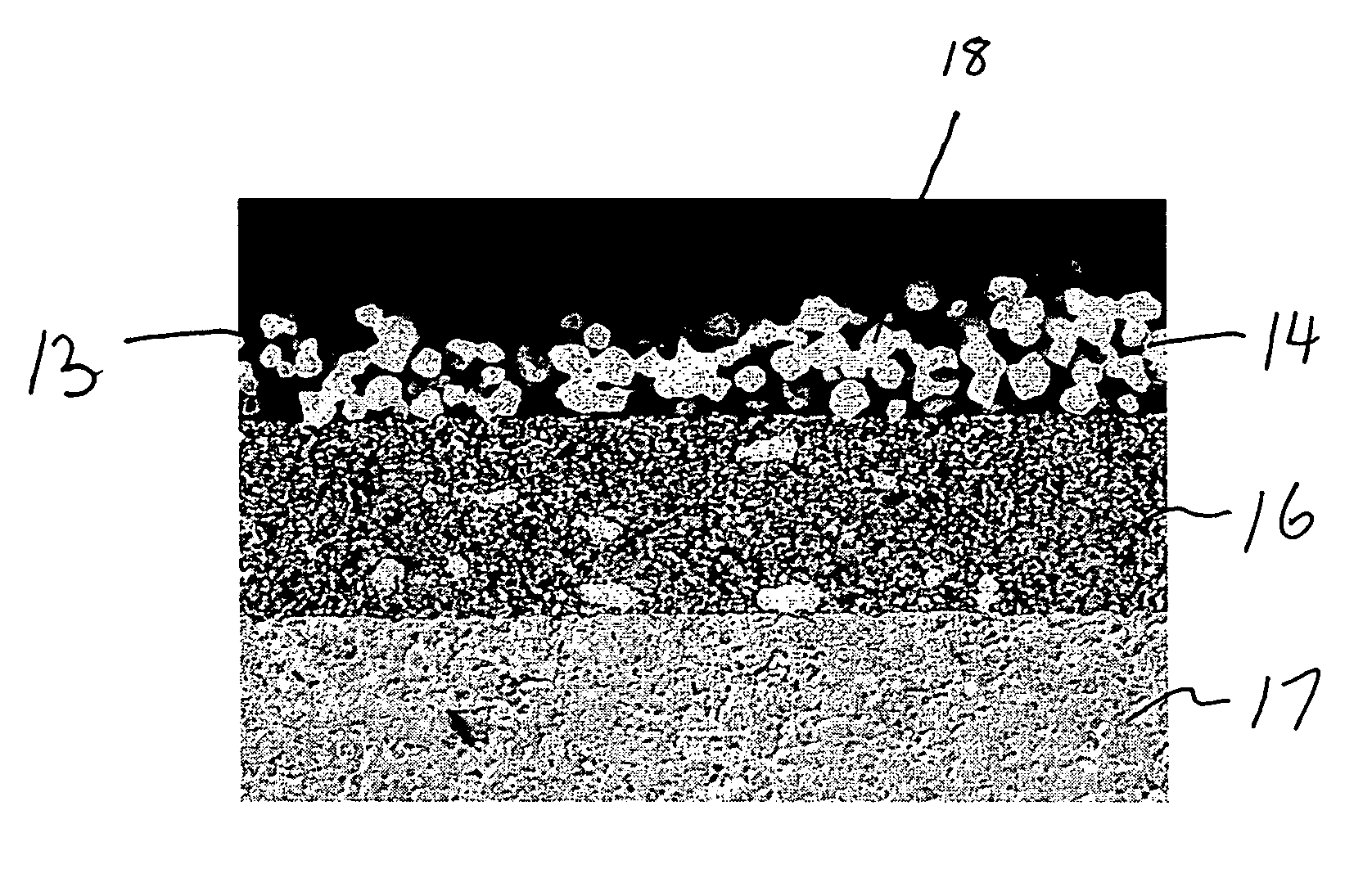

InactiveUS20060127749A1Improve adhesionGood mechanical integrityTransportation and packagingCell electrodesPorosityElectrical conductor

A method of forming a current collector layer on electrode layers of an electrochemical air separation element and a current collector. A slurry is prepared that contains electrically conductive particles having surface deposits of a metallic oxide on a metal or metal alloy conductor. The metallic oxide surface deposit constitutes a lower weight percentage of the electrically conductive particles than the metal or metal alloy. The slurry is applied to a structure that contains an electrolyte and electrode layers. The slurry can be applied by dip coating techniques. The resultant coated form is then fired to partly sinter the electrically conductive particles and thereby to obtain porous current collector layers affixed to the electrode layers. The current collector of the present invention is between about 5 microns and about 100 microns thick and preferably has a porosity of between about 10 percent and about 70 percent with pores having a pore size of between about 0.1 microns and about 20 microns.

Owner:PRAXAIR TECH INC

Laser seal welding technique for 3A21 aluminum alloy casing

ActiveCN105081573ASmall heat affected zoneSmall thermal deformationWelding/soldering/cutting articlesMetal working apparatusWeld seamSpot welding

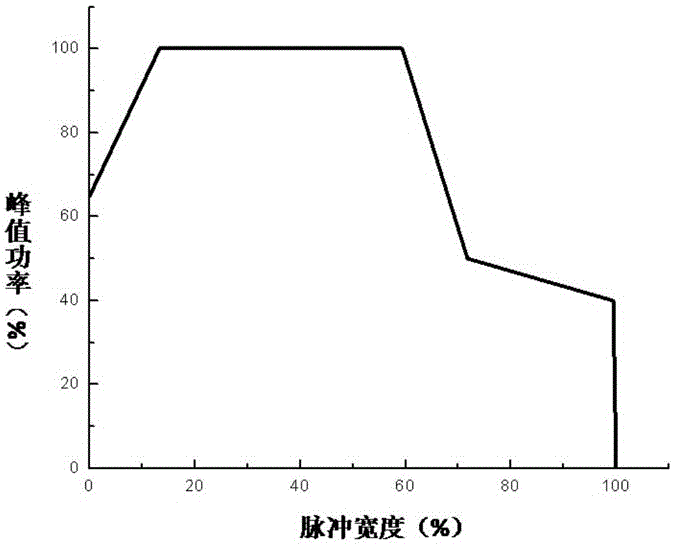

The invention discloses a laser seal welding technique for a 3A21 aluminum alloy casing. The laser seal welding technique comprises the following steps of visual alignment, laser spot welding location and laser seal welding. The technological parameters of the laser seal welding are that the laser pulse peak power is 3000W-3500W, the impulse waveform is preheating thermal-insulation wave, the pulse width is 4ms-8ms, the pulse repetition frequency is 10Hz-20Hz, the welding speed is 108mm / min-180mm / min, and the defocusing amount is -1mm to -2mm. The laser seal welding technique for the 3A21 aluminum alloy casing can effectively remove cracks and air holes on welding seams of laser welding of the 3A21 aluminum alloy casing. The sealed 3A21 aluminum alloy casing has the beneficial effects of being attractive in welding seam appearance, high in air tightness, high in reliability, high in efficiency and low in cost.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

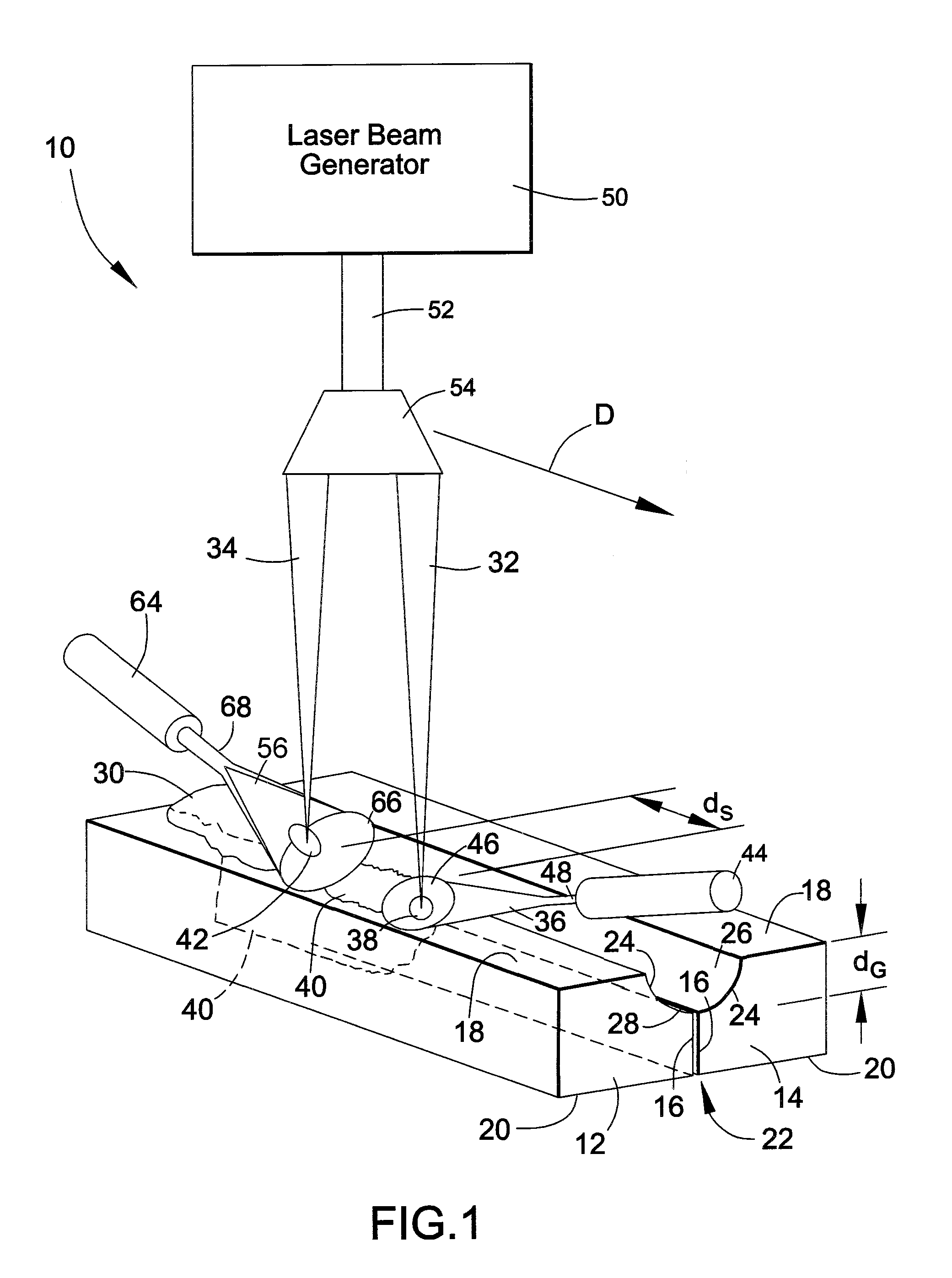

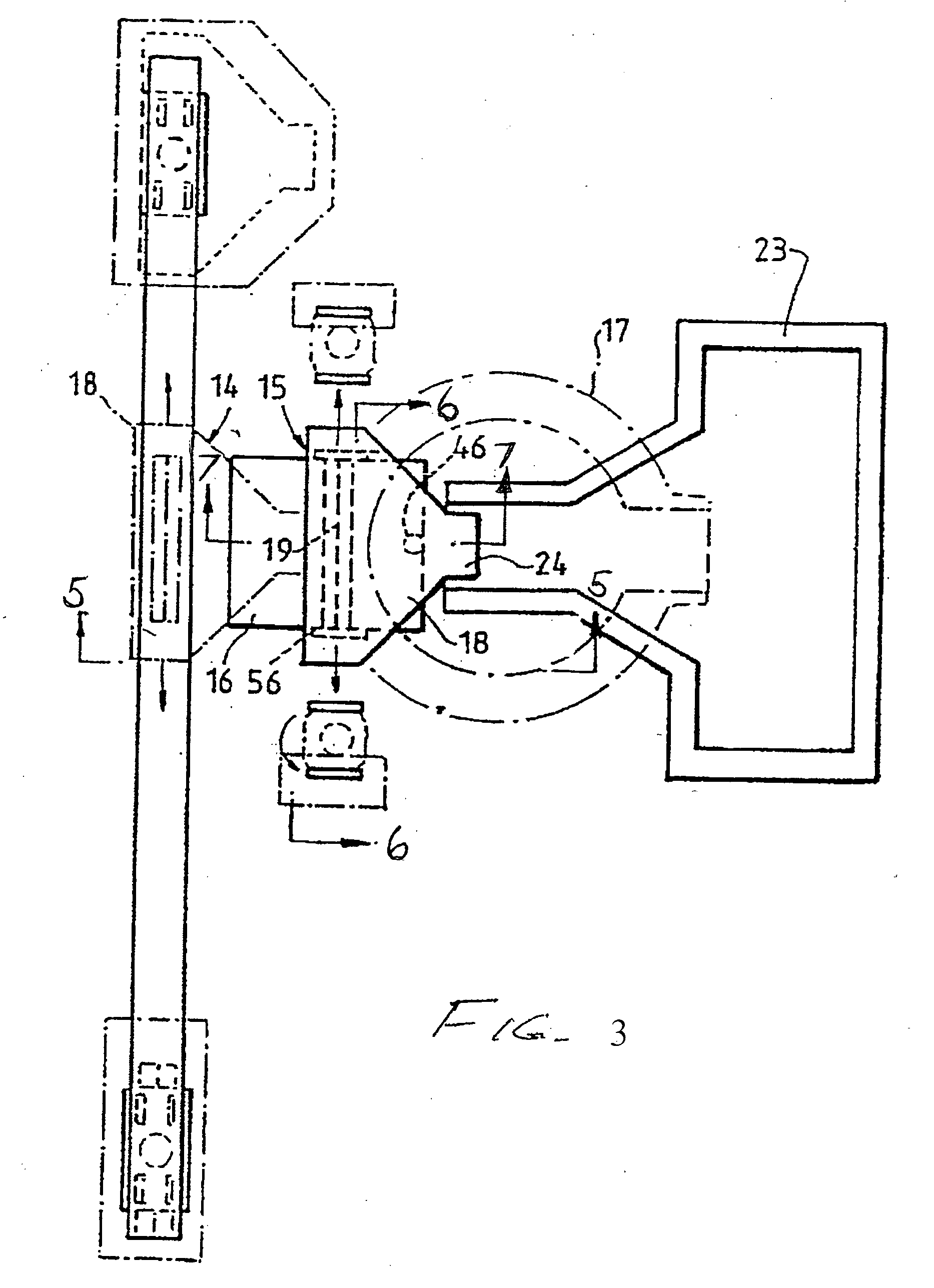

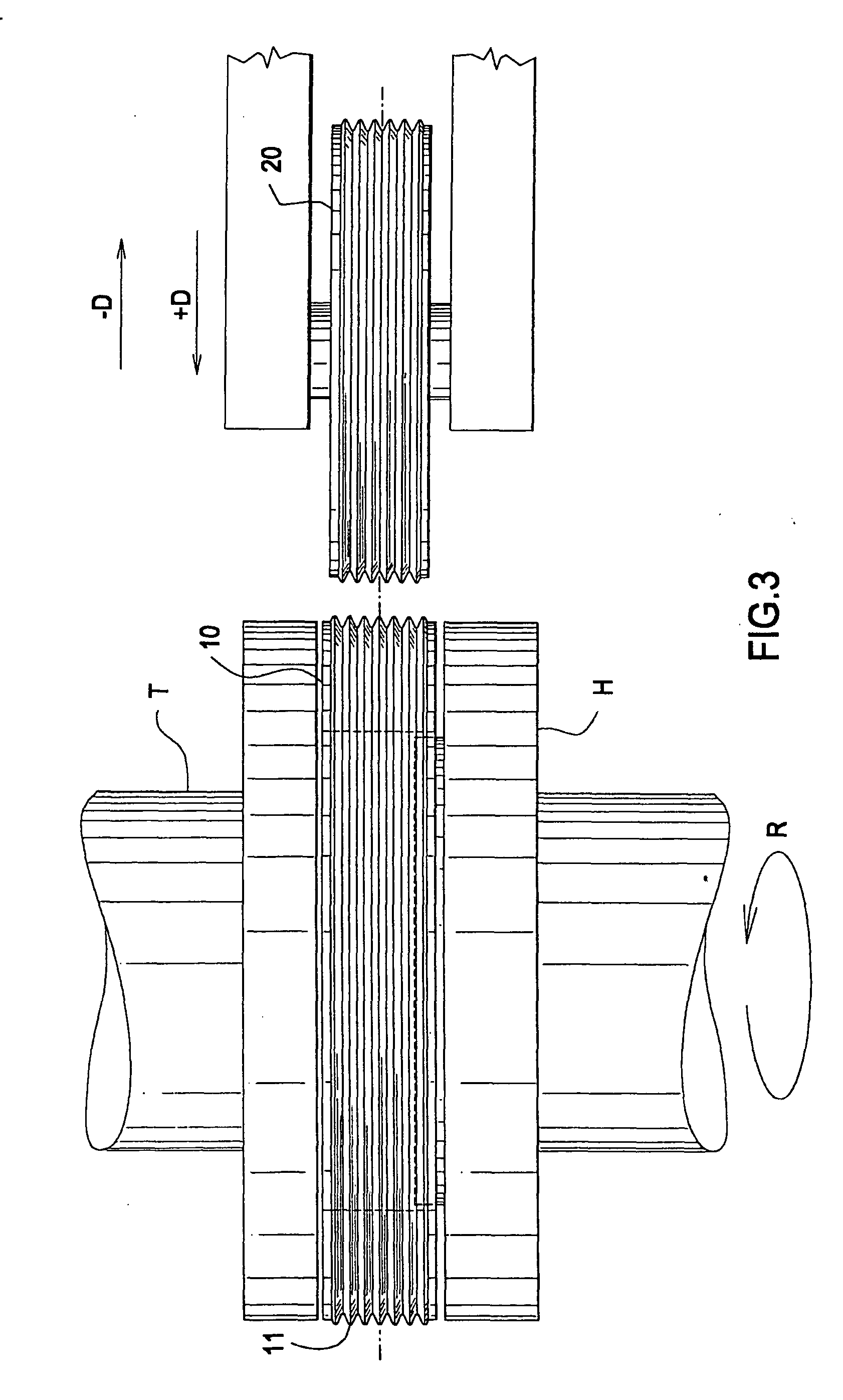

Hybrid laser arc welding process and apparatus

ActiveUS20120006795A1Promote eliminationEasy to eliminateTurbinesEngine manufactureWeld seamElectric arc

A welding method and apparatus for welding workpieces together by conducting a forward hybrid welding process on a joint region that includes a weld seam defined by and between faying surfaces of the workpieces, and then conducting an aft hybrid welding process on the joint region. The forward hybrid welding process simultaneously causes a forward laser beam and a forward electric arc to travel along the joint region, which in combination penetrates the weld seam and forms a weld pool that solidifies to form a weldment. The aft hybrid welding process utilizes an aft electric arc and an aft laser beam to produce a second weld pool that remelts and mixes with the weldment. On cooling, a weld joint is formed that is capable of deeply penetrating the weld seam of the joint region.

Owner:GENERAL ELECTRIC CO

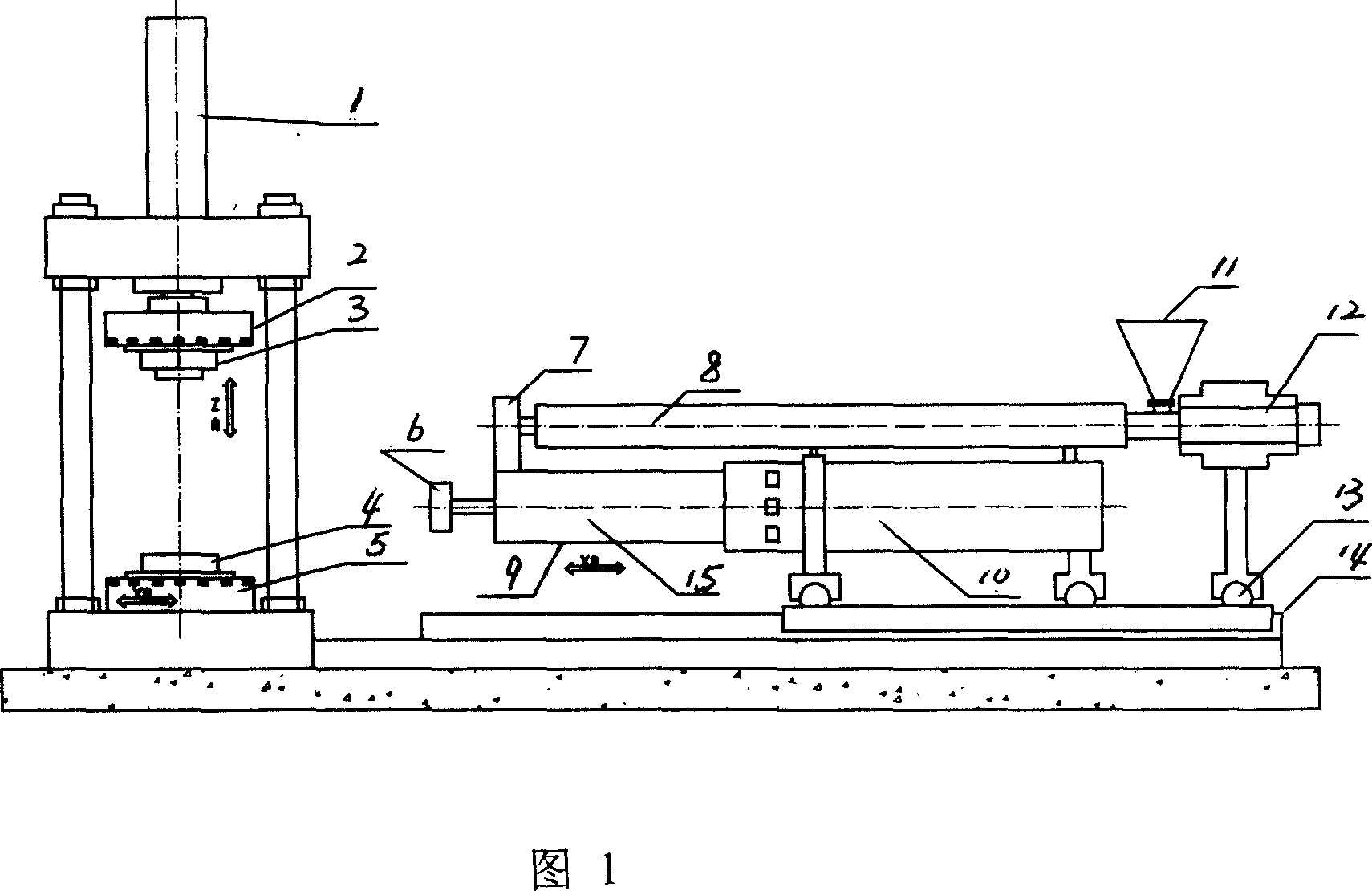

Wide-band laser-induced hybrid cladding restoration and surface strengthening method for dies

InactiveCN102373468AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesRepair timeLaser scanning

A wide-band laser-induced hybrid cladding repairing and surface strengthening method for dies is characterized in that a Ni based alloy powder for wide-band laser-induced hybrid cladding is used to repair damaged areas of dies or strengthen the surface of dies. By the adoption of a wide-band scanning system, different dies such as plastic die, hot work die, cold work die and the like can be repaired and undergo surface strengthening. The width of a single track laser-induced hybrid cladding layer reaches 20-30mm; the thickness of each track cladding can reaches 3mm; laser scan speed reaches 10m / min; the powder flow reaches 15kg / h; the powder utilization rate is 90%; the efficiency is raised by 5-10 times in comparison with simple laser cladding; repairing time is shortened by 30%; energy is saved by 10-40%; defects such as pores and crack in the coating are eliminated; wear resistance, corrosion resistance, antioxidation performance and fatigue resistance of dies are greatly raised; and the service life of dies can be increased by 3-10 times.

Owner:XIAOGAN KELONG INDAL

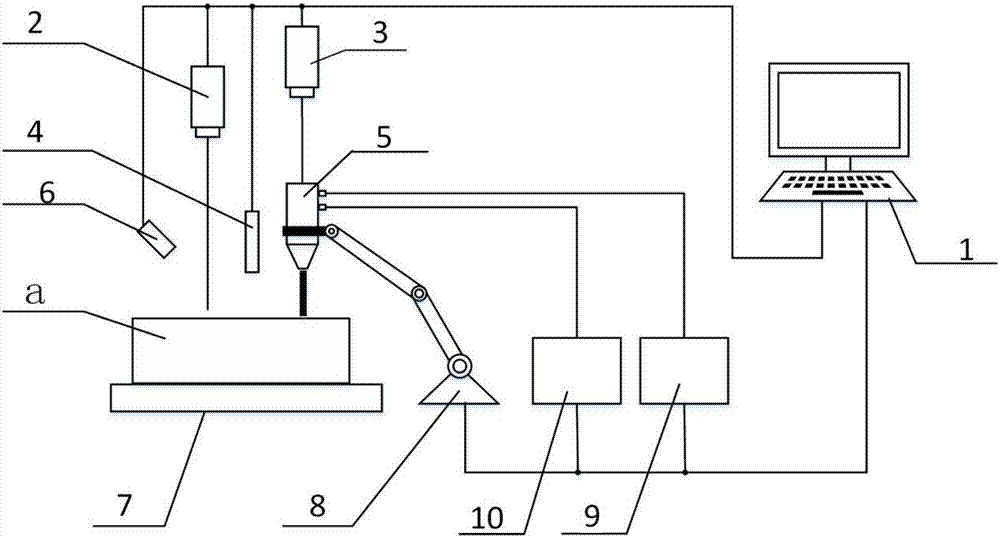

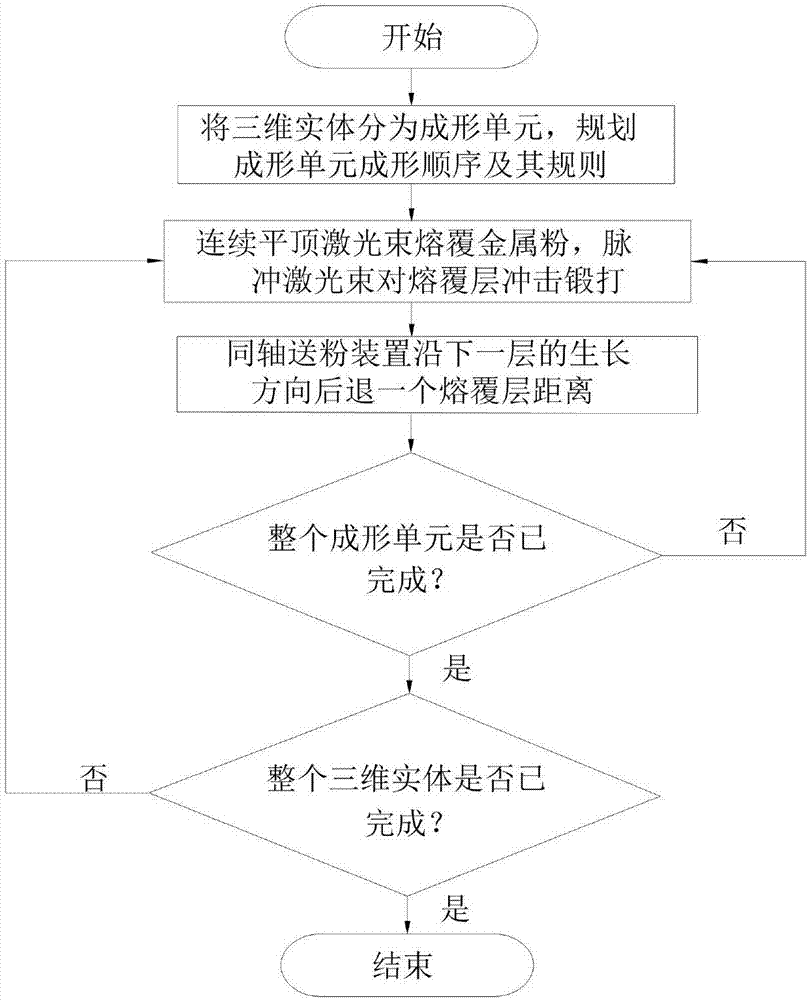

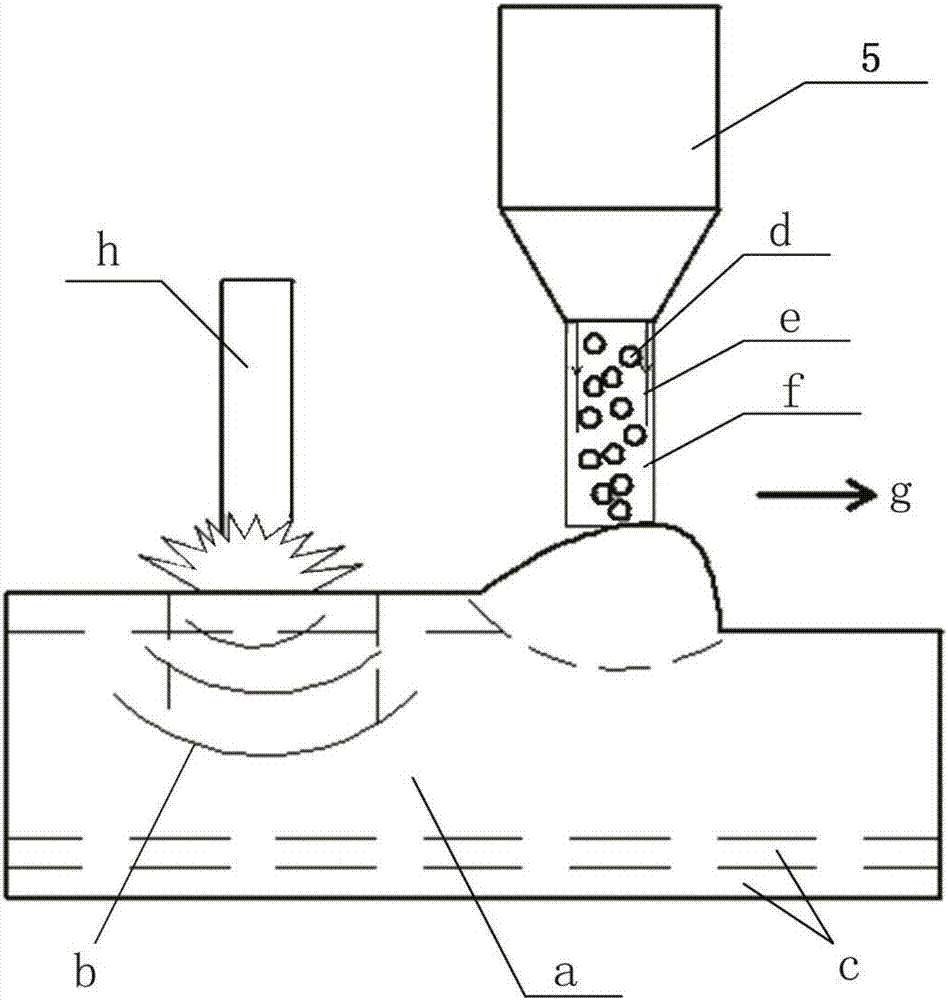

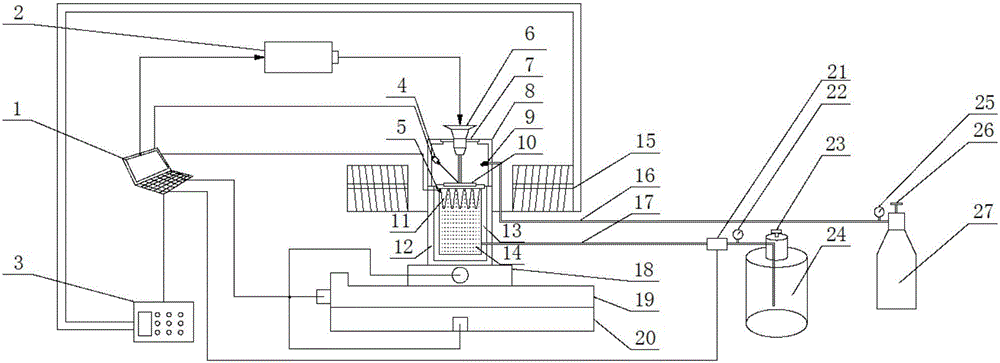

Inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method

ActiveCN107262713ASolve undermeltSolve the problem of impenetrabilityAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsInductor

The invention relates to an inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method. The device comprises a master controller, a pulse laser device, a continuous laser device, a temperature inductor, a coaxial powder feeding device, a visual tracking system, a workbench, a mechanical arm, a metal powder container and a gas container. The pulse laser device, the continuous laser device, the temperature inductor and the visual tracking system are all arranged above the workbench. The mechanical arm tightly clamps the coaxial powder feeding device, so that the coaxial powder feeding device is located between the continuous laser device and the workbench, and is coaxial with the continuous laser device. The coaxial powder feeding device communicates with the metal powder container and the gas container. The pulse laser device, the continuous laser device, the temperature inductor, the visual tracking system, the mechanical arm, the metal powder container and the gas container are all connected with the master controller. The inside-laser coaxial powder feeding laser impacting and forging composite machining forming device and method can solve the problems of insufficient fusion and incomplete fusion of the Gaussian light spot edges, inner defects of gas holes, incomplete fusion, cracks and shrinkage are effectively eliminated, and the inner stress state of a formed part is greatly improved.

Owner:GUANGDONG UNIV OF TECH

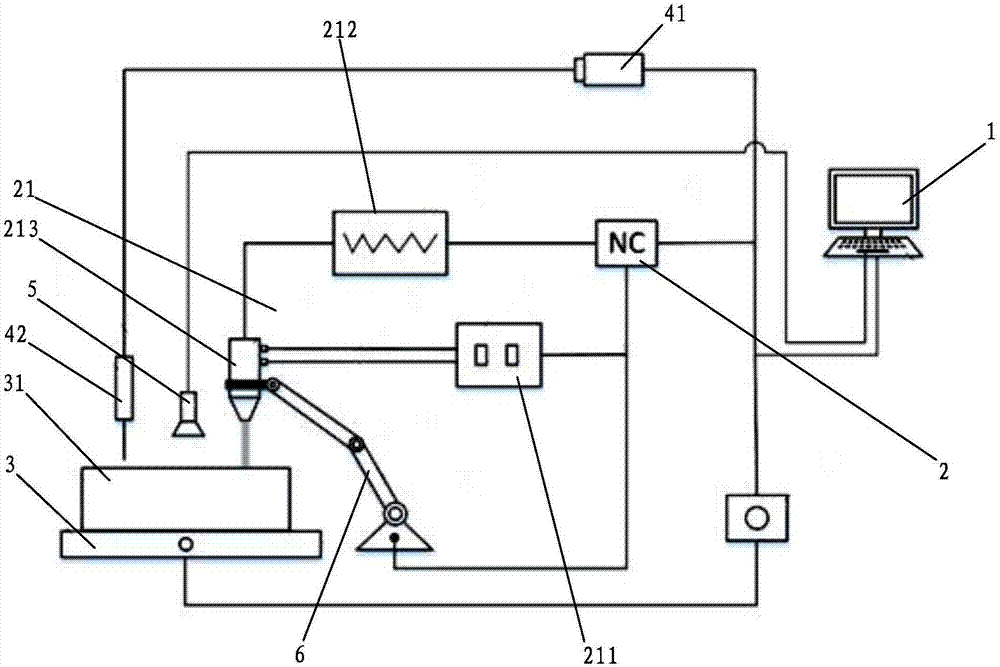

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

Aluminum alloy for high power radiator and purification method of melt of aluminum alloy

ActiveCN104233020AMeet quality requirementsImprove degassing effectPurification methodsHydrogen content

The invention relates to an aluminum alloy for a high power radiator. The aluminum alloy is characterized by being prepared from the following chemical components in percentage by weight: 0.50-0.55% of Mg, 0.40-0.45% of Si, less than 0.19% of Fe, less than or equal to 0.05% of Ti, less than or equal to 0.02% of Cr, less than or equal to 0.02% of Mn, less than or equal to 0.02% of Zn, less than or equal to 0.02% of Cu, less than or equal to 0.02% of a single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. According to a purification method of the melt of the aluminum alloy for the high power radiator, the hydrogen content in the aluminum alloy melt is reduced to below 0.07ml / 100g and the dregginess of the melt is reduced to below 0.01% by virtue of process control of aluminum alloy smelting, refining, degassing, deslagging and the like, so that the processing quality requirement on the aluminum alloy for the high power radiator is satisfied.

Owner:ALNAN ALUMINIUM CO LTD

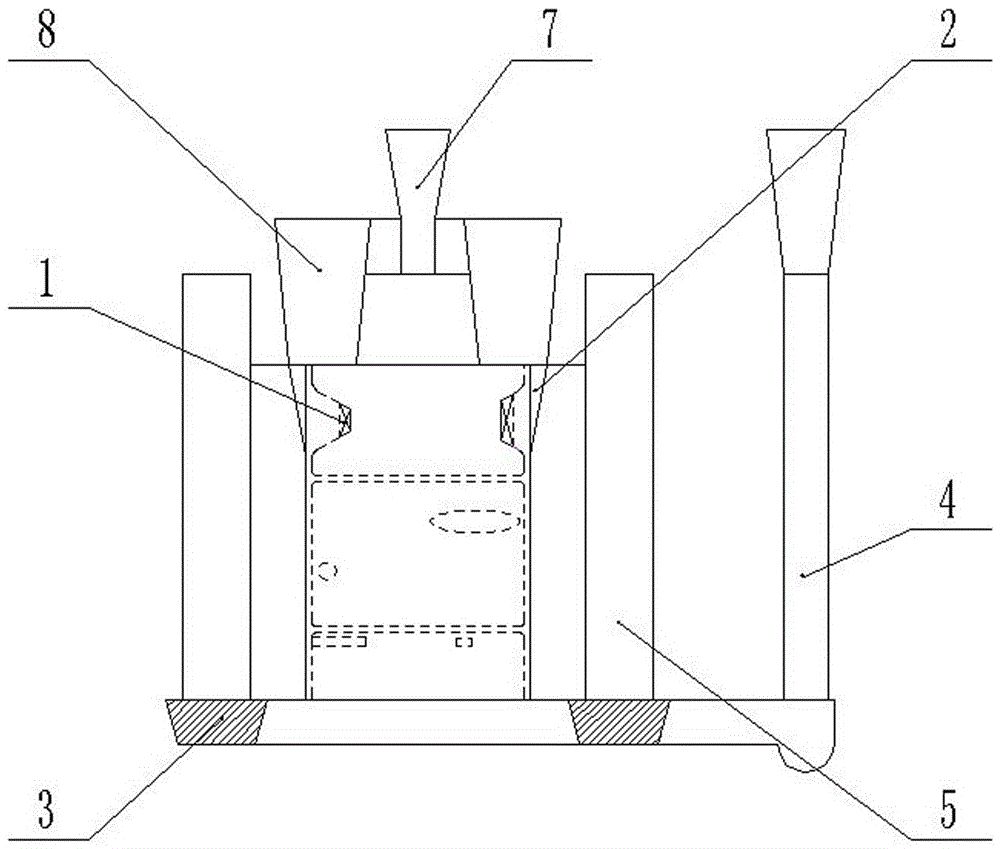

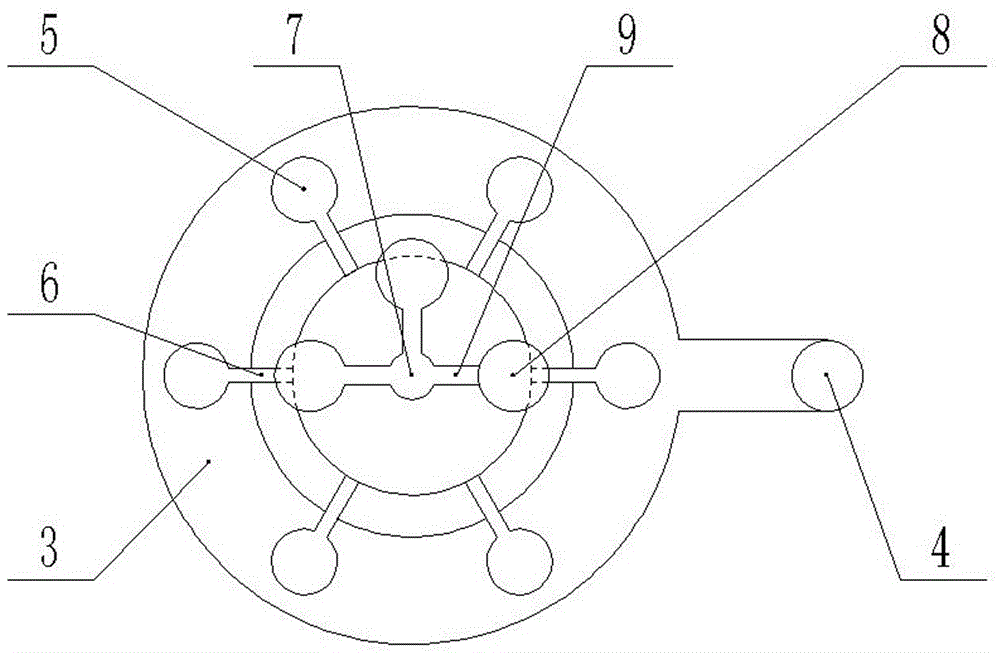

Solidification and feeding method for complicated annular thin-wall shell steel casting

The invention discloses a solidification and feeding method for a complicated annular thin-wall shell steel casting. By means of the solidification and feeding method, the problem that in the casting process of existing complicated annular thin-wall steel castings, shrinkage porosity, shrinkage cavities and crack defects are prone to occur is resolved. The solidification and feeding method comprises the following steps that a, steel casting sand mold cavity is made; b, annular transverse runners and a straight runner are made on the steel casting sand mold cavity, slag collecting cylinders are arranged on the upper surfaces of the annular transverse runners, gap inner runners are arranged between the slag collecting cylinders and the outer wall of the steel casting sand mold cavity, a feeding auxiliary sprue and top risers are arranged on the upper portion of the steel casting sand mold cavity, and a gap auxiliary runner is arranged between each top riser and the feeding auxiliary sprue; c, during pouring, the film forming pouring temperature of molten metal is 1500 DEG C-1520 DEG C; and d, when the molten metal level reaches the upper portions of the top risers, melt metal pouring is stopped on the straight runner, and the molten metal enters the steel casting sand mold cavity through the feeding auxiliary sprue until pouring is completed. The whole mold filling process is stable, no disturbance exists, and the phenomena of pores and dreg inclusion defects are avoided.

Owner:SHANXI PINGYANG IND MACHINERY

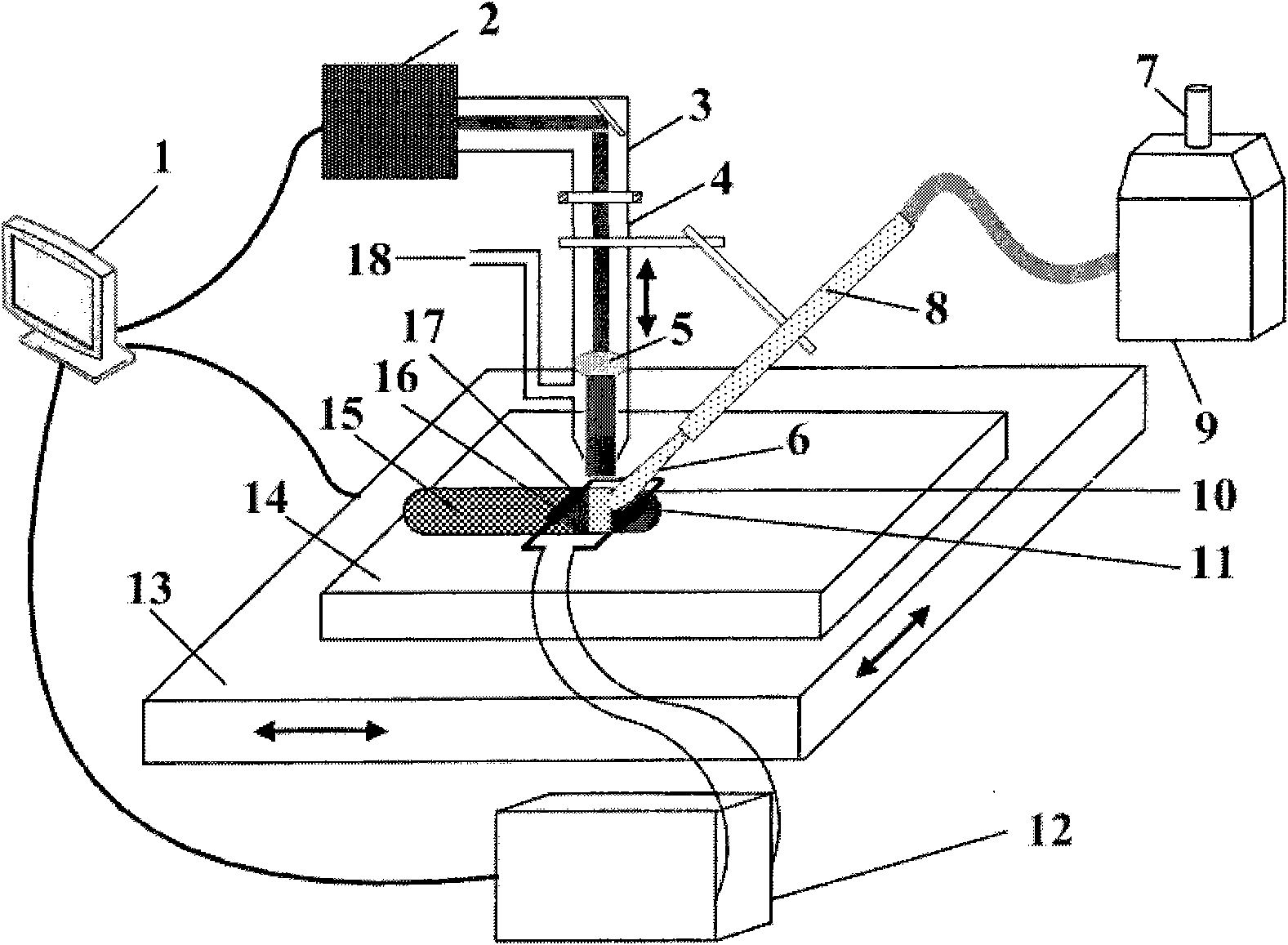

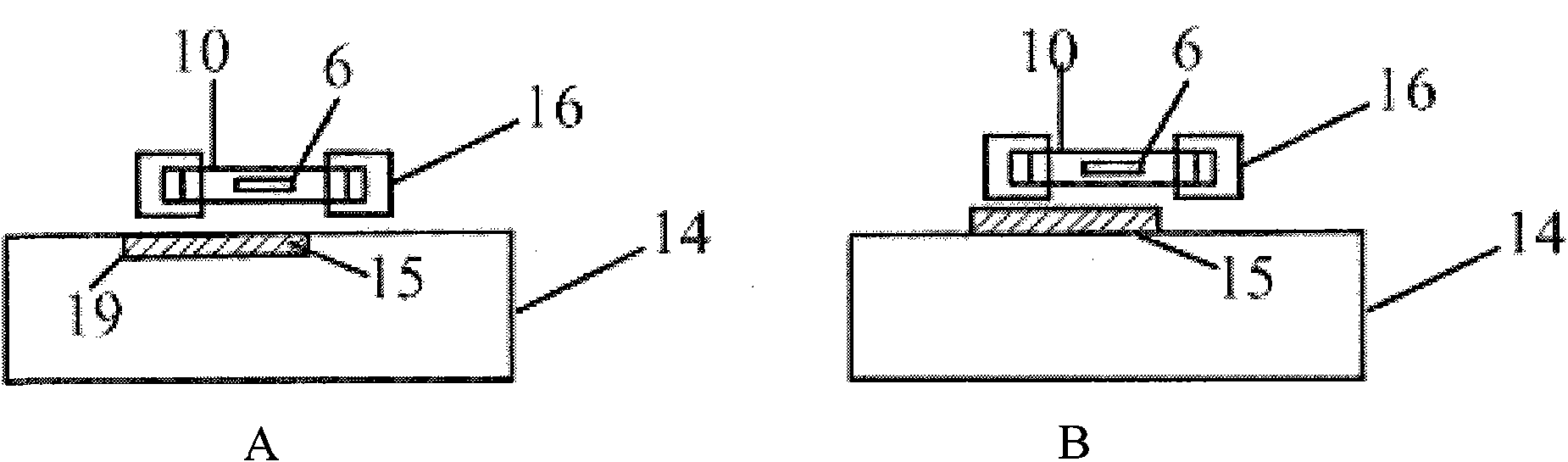

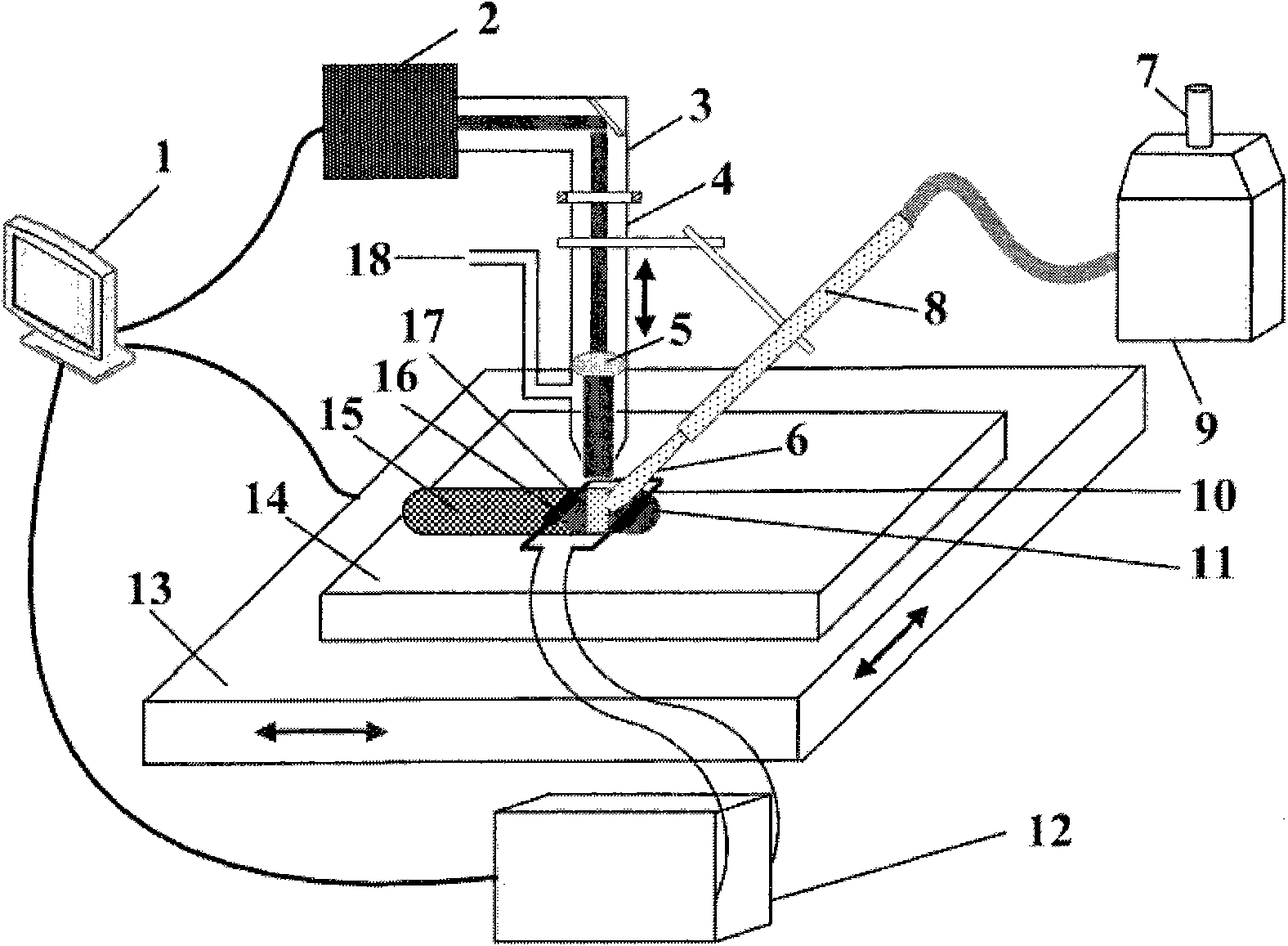

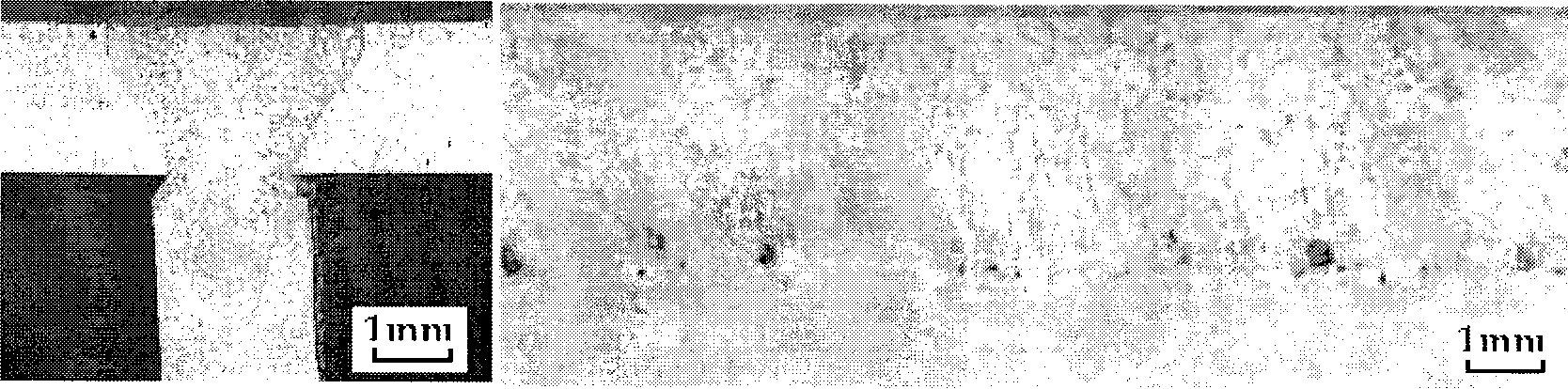

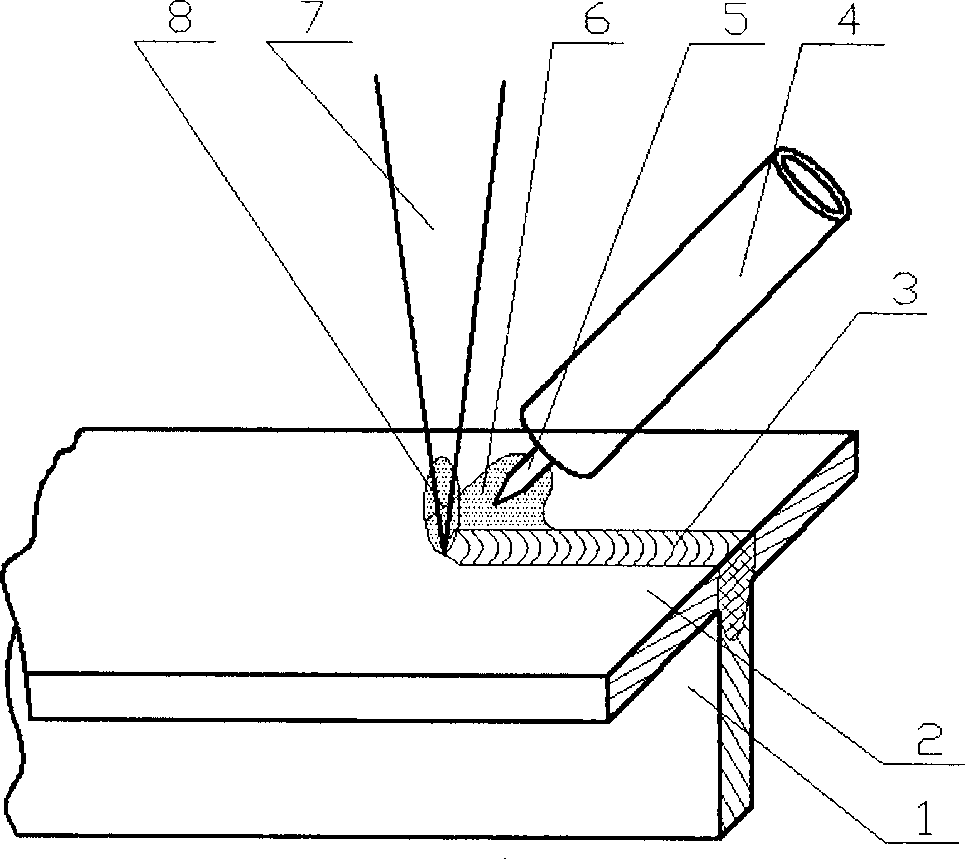

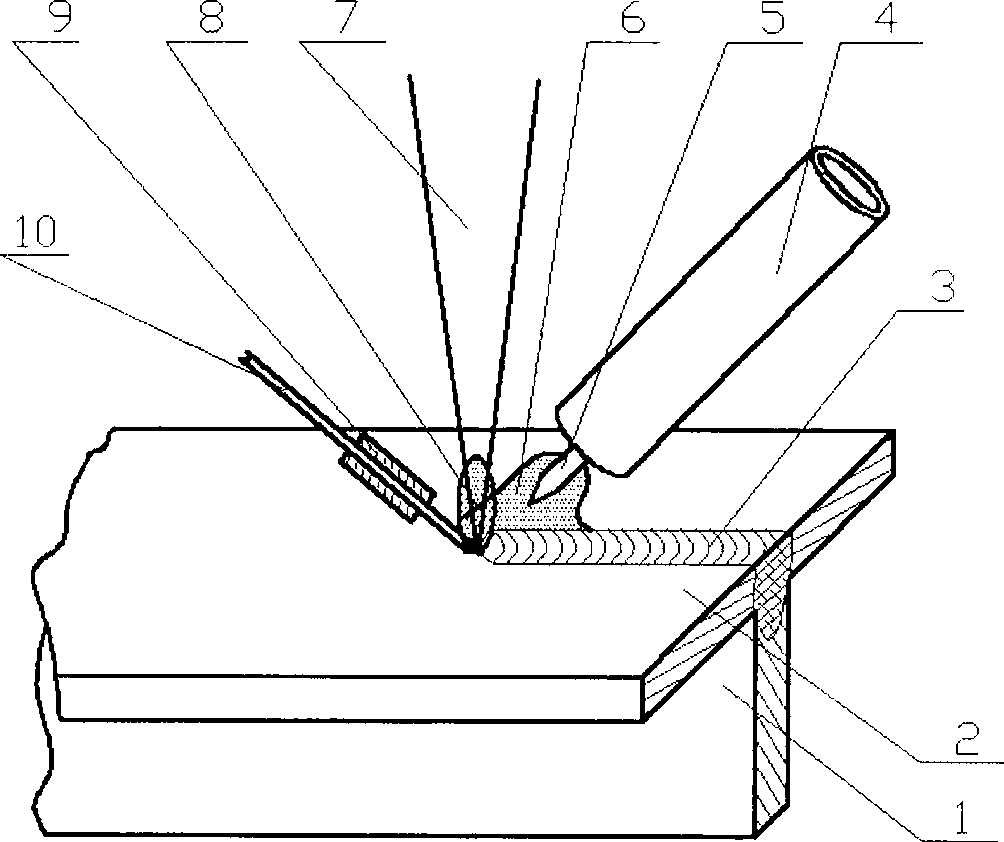

Laser-arc hybrid welding method of light sheet T type joint

InactiveCN101474727AEasy to shapeImproved weld toe transitionLaser beam welding apparatusLight beamEngineering

The invention relates to a laser-arc composite welding method for a T-shaped joint of a thin plate, belonging to the technical field of laser materials processing. The method adopts a laser-arc composite thermal source to complete the welding of the T-shaped joint on the lateral face of a bottom plate, a laser bean enters from the top face of the bottom plate, an electric arc is in paraxial arrangement at the front part or the rear of the laser bean, and the composite thermal source accomplishes the penetration fusion welding from the lateral face of the bottom plate of the T-shaped joint. The welding seam of the joint welded by the method is favorably shaped, a weld toe of the connection part of a rib plate and the bottom plate is uniformly and smoothly transited, and air holes, cracks and other defects are not presented after the welding seam is anatomized. The method fully utilizes the characteristics of the composite thermal source; and under the mutual actions of laser and arc, the stability of a welding process is obviously improved, the welding efficiency is increased, and the welding deformation can be lessened.

Owner:BEIJING UNIV OF TECH

Method and device for conducting laser cladding with assistance of electromagnetic stirring in forced cooling environment

ActiveCN106757001AAvoid destructionImprove qualityMetallic material coating processesEngineeringCopper

The invention provides a method and device for conducting laser cladding with the assistance of electromagnetic stirring in a forced cooling environment. The device comprises a fiber laser, a liquid nitrogen forced cooling platform, an electromagnetic stirring platform, a temperature detection and feedback system and a computer control system. The method comprises the steps that a sample is placed on a special clamp made of red copper, the red copper clamp is forcibly cooled through liquid nitrogen, then cold is indirectly transmitted to the sample, and thus forced cooling of the sample in the laser cladding process is achieved. Meanwhile, the magnetic field intensity of the electromagnetic stirring platform is adjusted and controlled through a computer, and thus the laser cladding process with the assistance of electromagnetic stirring under forced cooling is achieved. According to the method and device for conducting laser cladding with the assistance of electromagnetic stirring in the forced cooling environment, laser cladding is conducted with the assistance of forced cooling and electromagnetic stirring to prepare a composite coating so that the good metallurgical bonding capacity of the composite coating with a matrix can be remarkably improved, a hard phase and uniform tissue distribution in the clad coating are achieved, grains are refined, and stress concentration is avoided; and defects such as cracks and pores of the laser clad coating are eliminated, and the quality of the clad coating is improved.

Owner:JIANGSU UNIV

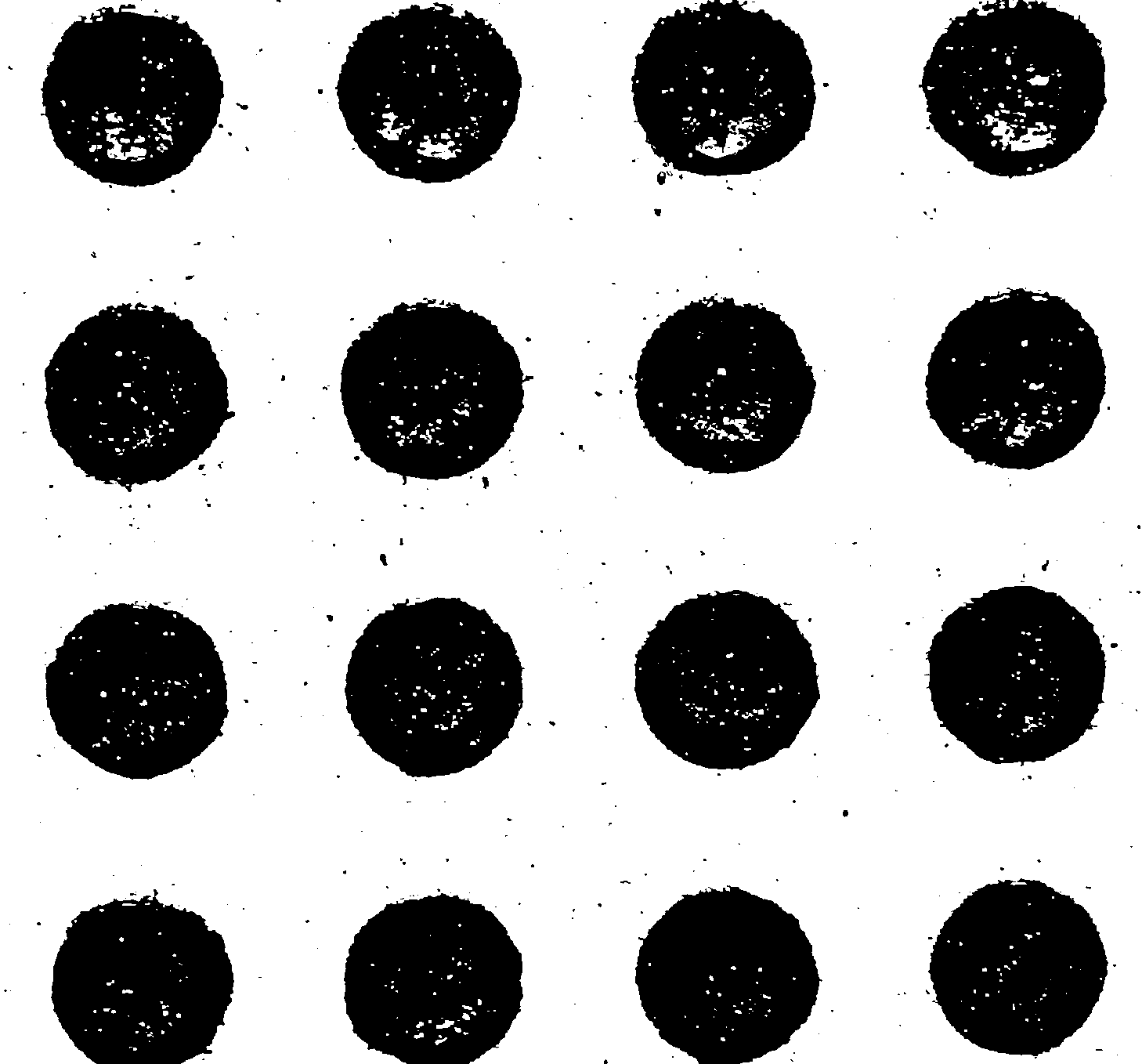

Medical device having a surface including a biologically active agent therein, and methods

ActiveUS20050271696A1Controlled release rateSmall sizePeptide/protein ingredientsGenetic material ingredientsActive agentInsertion stent

The present invention provides a medical device, and methods of preparing and using a medical device. The medical device has a surface including a biologically active agent therein. The methods are particularly useful for preparing, for example, coated stents having a biologically active agent within the coating.

Owner:MEDTRONIC INC

As-cast pearlite ductile iron material for crankshaft, and preparation method of the same

The invention relates to an as-cast pearlite ductile iron material for crankshaft, and a preparation method of the same. The material is composed of the following elements by mass percent: C: 3.40-3.75%, Si: 2.25-2.60%, Mn: 0.15-0.35%, S: less than 0.015%, P: less than 0.04%, Cu: 0.9-1.1%, Sn: 0.01-0.03%, Mg: 0.03-0.05%, and the balance of Fe. The material is prepared by the steps of using Q10 cast iron, scrap returns and steel scrap as the raw materials for smelting, performing spheroidizing and ladle inoculation, performing metal-stream inoculation while casting, and then, cooling naturally. The obtained material is steady in texture; for the material, the impact value is not less than 40J / cm2, the strength of extension is not less than 850MPa, the yield strength is not less than 480MPa, the ductility is not less than 5.5%, the hardness is HB250-310, the rate of spheroidization is not less than 85% and the pearlite content is not less than 90%; the material can be used for manufacturing gasoline engine turbocharging high-effect crankshafts for cars.

Owner:上海圣德曼铸造海安有限公司

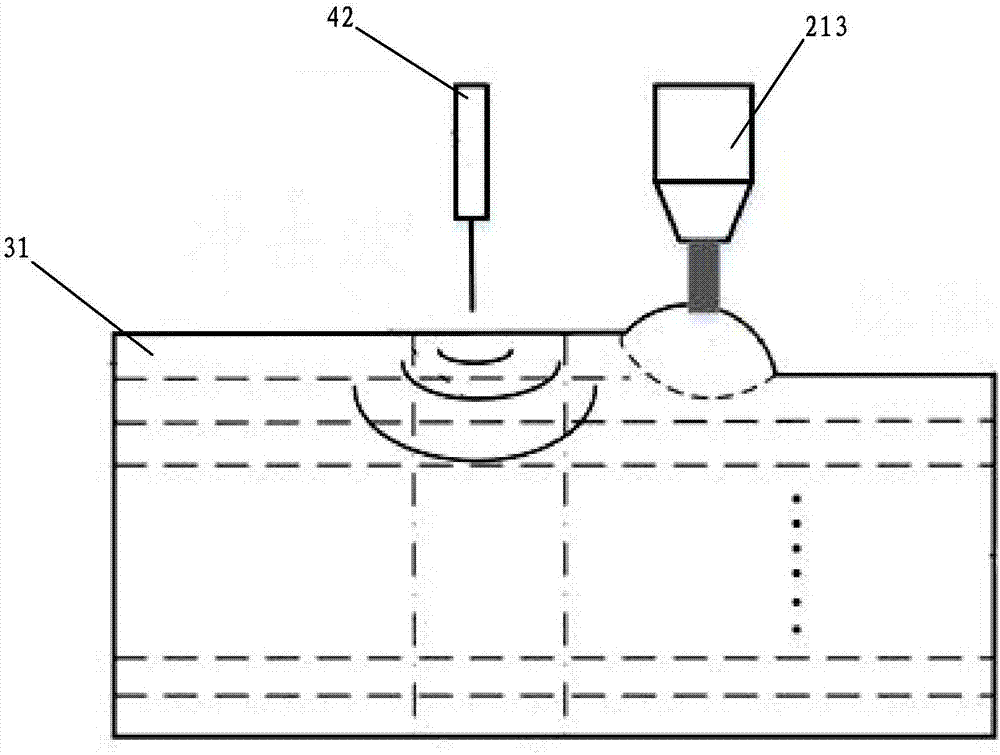

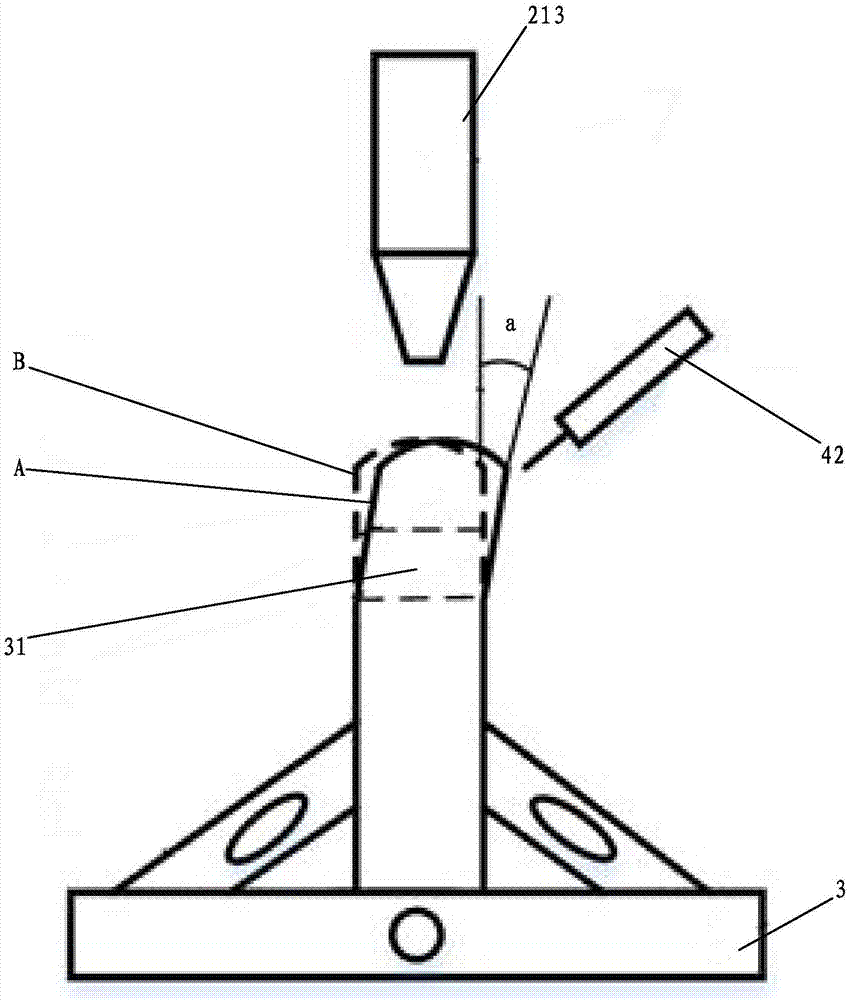

Molten coating forming device and method of metal material gradient components

InactiveCN105817626AEnabling Additive ManufacturingLow costAdditive manufacturing apparatusAtmospheric pressureAdditive layer manufacturing

The invention discloses a molten coating forming device and a method of metal material gradient components. The device comprises at least two metal smelting units, and further comprises an air pressure driving device, a molten coating head, a laser surface auxiliary remelting device, a powder feeder, a three-dimensional forming platform and an atmosphere protecting device; the air pressure driving device is connected with the metal smelting units through pipelines; the molten coating head is connected to the lower ends of the metal smelting units; the three-dimensional forming platform is arranged below the molten coating head; the laser surface auxiliary remelting device is arranged on one side of the three-dimensional forming platform; the powder feeder is arranged on the other side of the three-dimensional forming platform; and the metal smelting units, the molten coating head, the laser surface auxiliary remelting device, the powder feeder and the three-dimensional forming platform are all arranged in the atmosphere protecting device. The device can realize the added material manufacturing of part and gradient components with metal materials with high efficiency, high quality and low cost.

Owner:XI AN JIAOTONG UNIV

Anti-dezincification free-cutting brass rod and production method thereof

The invention provides an anti-dezincification free-cutting brass rod being excellent in mechanical property, high in density and good in cutting property and a production method thereof. The brass rod comprises the following raw materials in percentage by mass: 60-66 of Cu, 0.1-06% of Bi, 0.1-0.5% of Sn, 0.02-0.07% of Fe, 0.2-0.8% of Al, less than 0.0038% of a modificator, 0.2-0.3% of Si, less than 0.15% of Ni, less than 0.15% of Pb, 0.08-0.18% of an As-Cu alloy, and the balance of Zn as well as impurities of which the total mass is less than 0.5%. The production method comprises the following steps: carrying out casting and extruding on a solid brass ingot; and extruding the treated brass ingot into the brass rod.

Owner:龙岩市鸿航金属科技有限公司

Manufacturing method for casting metal lithium target

InactiveCN105349952AEliminate stomataEliminate shrinkageVacuum evaporation coatingSputtering coatingLithiumLiquid metal

Provided is a manufacturing method for casting a metal lithium target. A casting die for metal lithium is prepared according to the needed size, a stainless steel liner tube is located in the middle of the die, and cooling liquid can be injected into the stainless steel liner tube; liquid metal lithium is injected into a sandwich layer between the die and the stainless steel liner tube, and after the liquid metal lithium is solidified and formed, a metal lithium rotating target of the target size is formed through outline processing. The bottom-to-top directional solidification manner is adopted, the process is simple and convenient, and the high-purity metal lithium target which is small in grain size and high in compactness can be manufactured by eliminating air holes and shrinkage cavities in the metal lithium target. Casting conditions are optimized in the casting process, the flaw detection yield of the metal lithium target can be increased, and therefore the metal lithium target can be better applied to electrochromic glass.

Owner:GEMCH MATERIAL TECH SUZHOU

Casting steel strip with low surface roughness and low porosity

InactiveUS20040177944A1High alumina contentAvoid increased oxygen levelsThin material handlingSquare MillimeterSurface roughness

A method of producing cast steel strip having low surface roughness and low porosity by casting with molten steel having a total oxygen content of at least about 70 ppm and a free oxygen content between 20 and 60 ppm, and a temperature that allows a majority of any oxide inclusions to be in a liquidus state. The total oxygen content may be at least 100 ppm and the the free oxygen content between 30 and 50 ppm. The steel strip produced by the method may have a per unit area density of at least about 120 oxide inclusions per square millimeter to a depth of about 2 microns from the strip surface.

Owner:NUCOR CORP

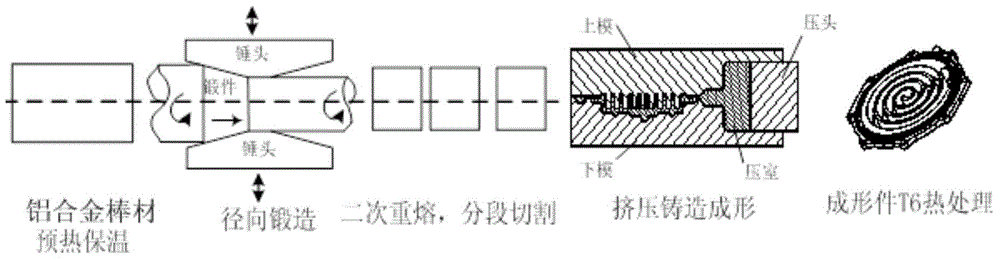

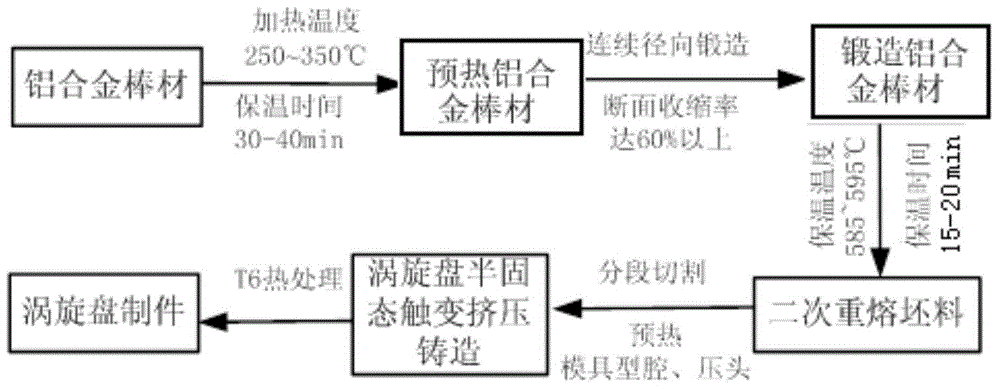

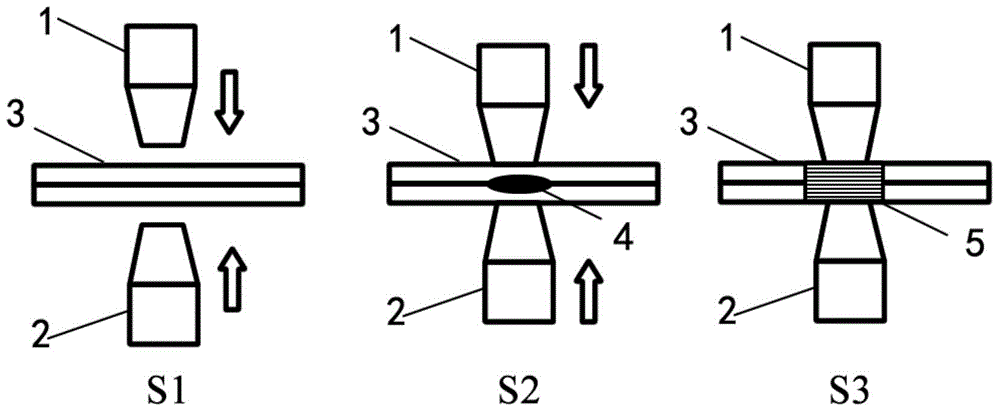

Process for preparing semi-solid state aluminum alloy scroll plate by radial forging strain induction method

InactiveCN104561852AAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencySemi solidInduction method

The invention discloses a process for preparing a semi-solid state aluminum alloy scroll plate by a radial forging strain induction method. The method comprises the following steps: pre-heating an aluminum alloy rods at first; performing radial forging on the aluminum alloy rods; performing secondary remelting on blanks subjected to radial forging; performing extrusion casting on the aluminum alloy scroll plate; performing T6 heat treatment on the aluminum alloy scroll plate acquired by extrusion casting in a semi-solid state to increase the mechanical property. According to the process, the aluminum alloy semi-solid state blanks which are uniform and free of microdefect are prepared and are subjected to extrusion casting to form a scroll plate workpiece with less microdefects and high mechanical performance, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

Ultrasonic wave-electrical resistance composite welding method

InactiveCN104907715AImprove welding qualityIncrease solder joint sizeWelding/soldering/cutting articlesMetal working apparatusMolten stateLiquid metal

The invention discloses an ultrasonic wave-electrical resistance composite welding method, wherein the method comprises that, at the pre-pressing stage, a welding contact face of a workpiece to be welded is maintained to be contacted; upper and lower electrode welding heads are respectively set at two sides of the workpiece to be welded and the electrode welding heads are maintained at the same shaft; the electrode welding heads are shared by the electrical resistance welding and the ultrasonic wave welding for use; at the welding stage, current is communicated between the electrode welding heads while applying ultrasonic wave; the vibration and friction heat produced by the electrical resistance heat and ultrasonic wave are utilized to heat the workpiece to be welded to reach at a molten state to form a molten core; at the cooling crystallization stage, after the size of the molten core of the workpiece to be welded reaches at a preset size, the pressure of the electrode welding heads are maintained constantly; the electrical resistance welding current and the ultrasonic wave are stopped; or the electrical resistance welding current is cut off, after the ultrasonic wave works until the preset time; and until the liquid state metal is cooled to form a welding spot / a welding joint. According to the invention, the contact between workpieces to be welded is increased by utilizing the high frequency vibration produced by the ultrasonic wave; and the indentation welding defects are reduced, thus the mechanical property of a welding joint is improved.

Owner:DALIAN UNIV OF TECH

Rare earth Sc micro-alloyed Al-Mg-Si-Cu alloy and preparation method thereof

The invention discloses a rare earth Sc micro-alloyed Al-Mg-Si-Cu alloy and a preparation method thereof. The rare earth Sc micro-alloyed Al-Mg-Si-Cu alloy is characterized in that the Al-Mg-Si-Cu alloy contains rare earth Sc in the mass percentage of 0.15%-0.45% and an Al-Sc intermediate alloy which is melted in vacuum is added in the melting process of the Al-Mg-Si-Cu alloy according to the preparation method of the novel rare earth aluminum alloy. The Al-Mg-Si-Cu alloy disclosed by the invention has the advantages of simple processing technology and reasonable proportioning of components; through the micro-alloying action of rare earth Sc, Al-Mg-Si-Cu alloy grains are significantly refined, the strength of the alloy is improved and the plasticity of the alloy is improved; simultaneously, due to addition of Sc, Al3Sc mass points are formed, these mass points can take the effects of impeding dislocation motion and pinning a subboundary, the recrystallization of the Al-Mg-Si-Cu alloy is inhibited, the thermal stability of the Al-Mg-Si-Cu alloy is further improved and the range of forging temperature of the Al-Mg-Si-Cu alloy is broadened.

Owner:HEFEI UNIV OF TECH

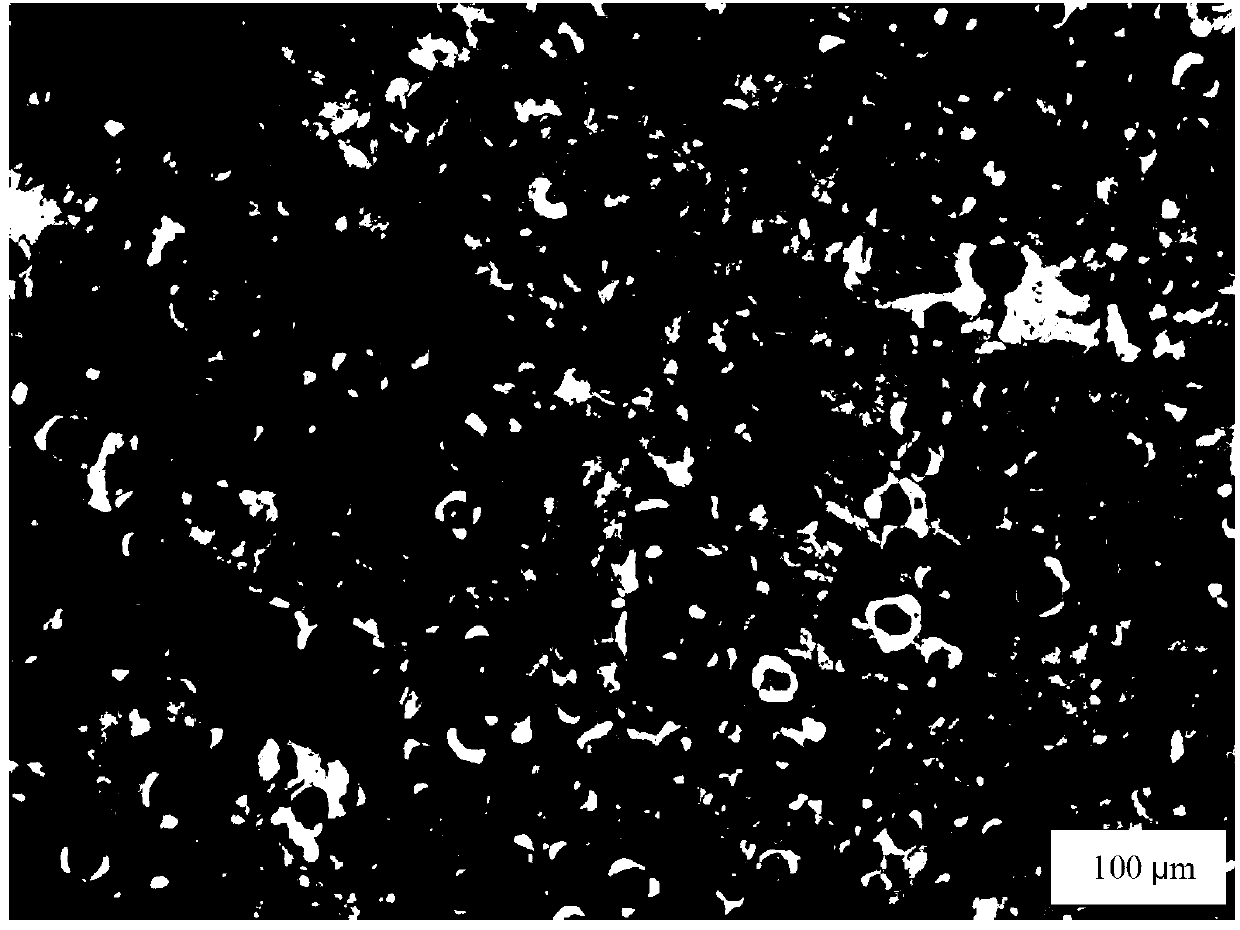

Current collector to conduct an electrical current to or from an electrode layer

InactiveUS7449262B2Poorly adhered to the electrodeSolve bulkyFinal product manufactureTransportation and packagingPorosityElectrical conductor

A current collector and method of forming the same in which a slurry is prepared that contains electrically conductive particles having surface deposits of a metallic oxide on a metal or metal alloy conductor that has a lower weight percentage of the electrically conductive particles than the metal or metal alloy. The slurry is applied to a structure that contains an electrolyte and electrode layers. The resultant coated form is then fired to partly sinter the electrically conductive particles and thereby to obtain porous current collector layers affixed to the electrode layers. The current collector of the present invention is between about 5 microns and about 100 microns thick and preferably has a porosity of between about 10 percent and about 70 percent with pores having a pore size of between about 0.1 microns and about 20 microns.

Owner:PRAXAIR TECH INC

Hybrid laser arc welding process and apparatus

A welding method and apparatus for welding workpieces together by conducting a forward hybrid welding process on a joint region that includes a weld seam defined by and between faying surfaces of the workpieces, and then conducting an aft hybrid welding process on the joint region. The forward hybrid welding process simultaneously causes a forward laser beam and a forward electric arc to travel along the joint region, which in combination penetrates the weld seam and forms a weld pool that solidifies to form a weldment. The aft hybrid welding process utilizes an aft electric arc and an aft laser beam to produce a second weld pool that remelts and mixes with the weldment. On cooling, a weld joint is formed that is capable of deeply penetrating the weld seam of the joint region.

Owner:GENERAL ELECTRIC CO

Fine equiaxed grain Al-Zn-Mg series aluminum alloy and preparation method thereof

The invention discloses a fine equiaxed grain Al-Zn-Mg series aluminum alloy and a preparation method thereof. The aluminum alloy comprises elements Zn, Mg, Cu, Ti, B, and the balance Al and inevitable impurity elements. The preparation method comprises the steps of preparing materials, smelting aluminum alloy, spray blowing refining in a furnace, online grain refining, online degassing filtering,semicontinuous casting, ingot casting homogenizing, heating and extruding, online quenching and manual ageing treatment. According to the fine equiaxed grain Al-Zn-Mg series aluminum alloy and the preparation method thereof, the components of the alloy and the preparation technology parameters are optimally designed, so that an Al-Zn-Mg series aluminum alloy extruding material gains a completely-recrystallized fine and uniform equiaxed grain structure; the structure stripes and color difference of an oxide film are removed, and thus the quality of the oxide film of the Al-Zn-Mg series aluminum alloy can be improved; the oxide film is uniform in color, fine in texture, high in glossiness, outstanding in coloring effect, and applicable to manufacturing of various aluminum alloy sheets or tube-bar sections with high requirements on intensity and surface decoration, such as housings, intermediate frames and side frames of various large-screen electronic products.

Owner:GUANGDONG INST OF NEW MATERIALS

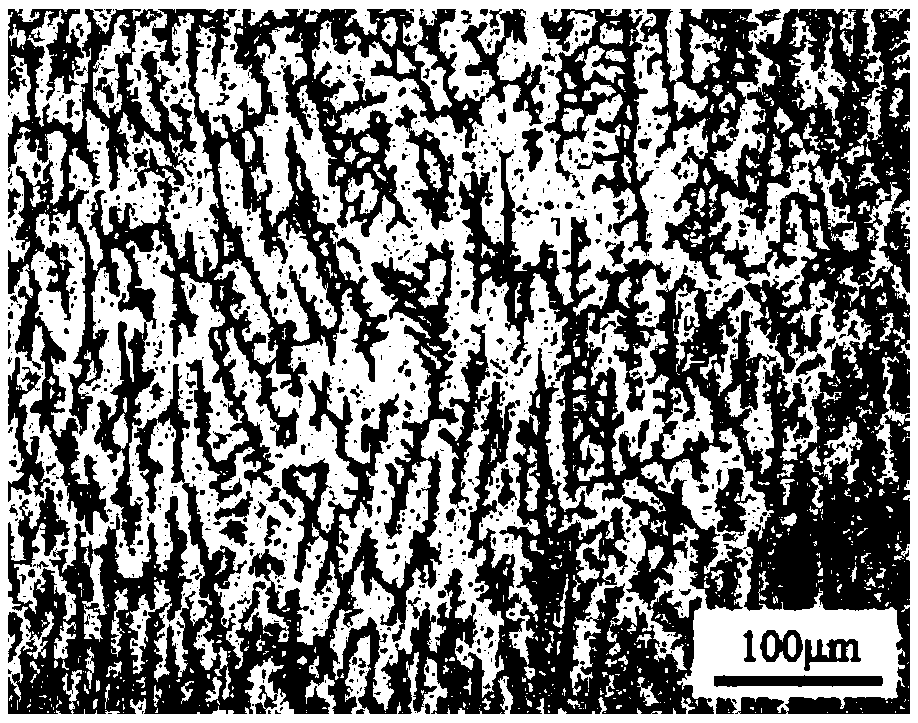

Laser surfacing modification method for thermal barrier coating

ActiveCN103266295AHigh bonding strengthImprove thermal fatigue lifeMolten spray coatingEfficient propulsion technologiesStress concentrationThermal fatigue

The invention relates to a laser surfacing modification method for a thermal barrier coating. The method comprises the following steps of: firstly, carrying out washing and sand blasting on the surface of a base body; then, preparing the thermal barrier coating in a thermal spraying state on the surface of the base body; then, designing shape, size, arrangement rule and distribution density of laser modification unit bodies in a pile nail structure to be prepared in the thermal barrier coating; then, adjusting the process parameters of a laser according to a design model; then, performing laser modification to the thermal barrier coating; and finally, performing the stress relief annealing treatment to the laser modified thermal barrier coating. With the adoption of the method for arranging discontinuous and dispersed intensifying unit bodies in the pile nail structure in the thermal barrier coating, the thermal barrier coating can not only generate characteristic of soft and hard alternate change, but also generate the 'pinning effect', thus not only relieving stress concentration at the crack tip of the coating and reducing the crack rate of the coating, but also extremely improving the bonding strength of the coatings, prolonging the thermal fatigue service life of the thermal barrier coating, improving the tissue structure of the coating and improving the compactness of the coating.

Owner:FOSHAN TAOYUAN INST OF ADVANCED MFG

Production process of ultrathin-wall and leakage-free aviation aluminium alloy castings

The invention relates to a production process of ultrathin-wall and leakage-free aviation aluminium alloy castings. The production process is characterized by comprising the following steps of: manufacturing a pressure-casting mould, machining a double circular ingate, a pressure-casting inlet and a distribution pouring gate on a right mould of the pressure-casting mould; machining a T-shaped exhaust groove on a left mould of the pressure-casting mould, pouring, lightly pressing, strongly pressing and demoulding; and finally carrying out infiltration process treatment. The special pressure-casting mould of the ultrathin-wall and leakage-free aviation aluminium alloy castings adopts a double circular feeding structure and a T-shaped exhaust groove structure, wherein the double circular feeding structure ensures that aluminium liquid fast enters a cavity in the pressure casting process and the thin wall of a part is partially filled; and the T-shaped exhaust groove structure ensures the exhaust of the cavity during the fast filling of the aluminium liquid and prevents the castings from carrying gas. The infiltration process of the invention improves the air impermeability of the product and enables the part to have an inflaming retarding function in addition, and the infiltration is finished through carrying out the work procedures of cleaning with hot water, drying, infiltrating and baking on the castings.

Owner:CHANGZHOU RANTO METALWORK

Apparatus and process for forming low-pressure and large-capacity digital-controlled extruding pouring plastic

The invention is concerned with the low-voltage big-capacity numerical control packing plastics equipment and the technics, it is: the plastic enters the screw from hopper, enters the storage jar by the rotation of the screw after plasticizing by the plasticizing screw, moves the nozzle valve of the storage extruding jar to the top mould cavity of the lower mould in the standing clapper die spotting press, the oil cylinder dosing pushes the piston to crushes in the mould cavity by passing the nozzle valve according to the order of the digital control system, exits the storage extruding jar, the top and bottom mould in standing clapper spotting press clapper die and keeping press, at the same time enters the next period, opens the mould after keeping press, the manipulator takes out the production from the mould cavity.

Owner:HANGZHOU XINGYUAN FILTER TECH

Austenitic stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

InactiveCN108637529ASpeed up the flowFlow deepensArc welding apparatusWelding/cutting media/materialsActive agentDendrite

The invention provides an austenitic stainless steel argon tungsten-arc welding active agent and relates to the field of activators for welding. The active agent provided by the invention is composedof oxides and is poisonless and harmless. After the active agent is added, the quantity of metallic vapor generated on the surface of a molten pool is restrained, under the circumstance of little metal vapor, only metal within a small range near an anode spot rises, is gasified and ionized, thus an arc electric conduction channel is tightened, arc pressure is increased, flowing of metal liquid inthe molten pool is quickened, enlarged and deepened, fusion depth is increased substantially, and 16-mm single face welding and double face shaping can be achieved. In addition, SiO2 enables the content of Si in a weld joint to be increased slightly through metallurgic reaction, Si has a direct influence on a solidification mode, Si can increase w(Cr)eq / w(Ni)eq, the development of FA solidification mode is facilitated, the ferritiszation effect is facilitated, generation of a delta phase can be facilitated, the development of austenitic dendrites is hindered, and mechanical properties of a weld joint structure are improved.

Owner:HUAHENG WELDING +1

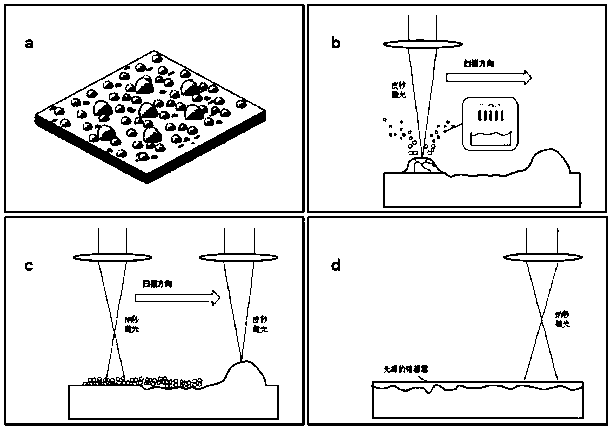

Technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser

ActiveCN109514076AAchieve initial flatteningEliminate microcracksWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond laserMicro nano

The invention discloses a technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser. The technological method comprises the steps of firstly, irradiatingthe ceramic surface to be machined through picosecond laser along a certain scanning trace, and removing micro protrusions of the ceramic surface, so that the preliminary flattening is achieved; meanwhile, generating a large number of micro-nano particles by using a removal mechanism for the electronic state of ceramic materials through picosecond laser, wherein the micro-nano particles exist at adjacent space areas of the irradiated ceramic surface; starting a low power nanosecond laser according to the preset time for tracing the scanning path of the picosecond laser, and irradiating and fusing the micro-nano particles uniformly distributed on the ceramic surface; and finally forming a compact and smooth fine-grain melted layer so that the polishing effect is achieved. According to the technological method, original pore cracks of the ceramic materials are repaired, and the shortcomings that a heat affected zone generated by traditional laser polishing is large and the material surface is liable to generate micro-cracks and pores are overcome; and low removal amount, high efficiency and accuracy and submicron-level fine polishing of the ceramic materials is achieved.

Owner:BEIJING UNIV OF TECH

Aluminum alloy medium-thickness plate laser welding device and method

ActiveCN110170742AGuaranteed welding penetrationEliminate stomataLaser beam welding apparatusLight beamOptoelectronics

The invention discloses an aluminum alloy medium-thickness plate laser welding device. The laser welding device comprises a first laser, a second laser, a first collimating mirror, a refraction mirror, a rotating platform, a reflecting mirror, a focusing lens and a second collimating mirror are arranged in sequence, the first laser device can emit a first light beam, the second laser device can emit a second light beam, the top surface of the refraction mirror is a plane and is arranged towards the first collimating mirror, the bottom surface of the refraction mirror is an inclined plane, therefraction mirror is connected with the rotary platform, the reflecting mirror can reflect the second light beam, the first light beam can penetrate through the reflecting mirror, and the focusing mirror can be used for focusing the first light beam and the second light beam. The device further provides a laser welding method for the aluminum alloy medium-thickness plate, the second light beam moves along the welding line direction of the workpiece to be welded, the focused second light beam moves along the welding line direction of the workpiece to be welded, the second light beam rotates around the focused first light beam, the first light beam can ensure the welding penetration depth, the second light beam rotates around the first light beam, and the stirring molten pool can eliminate air holes.

Owner:HUAZHONG UNIV OF SCI & TECH

Application of nanometer aluminum oxide-based composite ceramic coating

InactiveCN102443753AImprove insulation performanceReduce intrinsic internal stressMolten spray coatingNano structuringCeramic coating

The invention relates to a nanometer aluminum oxide-based coating technology, in particular to a nanometer aluminum oxide-based composite ceramic coating for resisting corrosion of plasma gas in a high-voltage environment. The nanometer aluminum oxide-based composite ceramic coating is prepared by a hot spraying method and has the thickness being 50mum to 2mm; and the nanometer aluminum oxide-based composite ceramic coating comprises the following components of 20-75 percent by weight of aluminum oxide, 10-40 percent by weight of zirconium oxide and 10-60 percent by weight of rare earth oxide, wherein the rare earth oxide is any one or a combination of more than two of yttrium oxide, lanthanum oxide, gadolinium oxide, cerium oxide, dysprosium oxide, neodymium oxide and europium oxide. Thenanometer aluminum oxide-based composite ceramic coating has a compact nanometer structure, the capability of resisting electric breakdown of 24-29KV / MM and the function of resisting corrosion of fluorine-containing plasma. In various plasma devices, the ceramic coating is used on the surfaces of related parts, so that the conditions of frequent maintenance, cleaning and replacement can be avoided.

Owner:安徽禹恒材料技术有限公司

Method of flow forming a metal part

InactiveUS20050019201A1Low costIncrease inertiaMetal-working apparatusPortable liftingPorositySurface layer

A method of flow forming sintered metal parts. The first step is forming a round disk by conventional powder metal process. The disk can be a donut shape part with or without a flange on one side of its outer diameter. The disk can then be copper impregnated or used as is, depending on the requirements. The disk is placed in a spinner held in proper tooling and grooves are spun in its outer diameter. The spinning can be done with a finishing roller or by a pre-finishing roller, followed by a finishing roller. This process not only creates a part with great accuracy, it also densifies and eliminates the powder metal porosities on the surface layer by the pressures inserted in spinning.

Owner:THE GATES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com