Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve thermal fatigue life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HIGH-Cr HIGH-Ni, HEAT-RESISTANT, AUSTENITIC CAST STEEL AND EXHAUST EQUIPMENT MEMBERS FORMED THEREBY

Owner:HITACHI METALS LTD

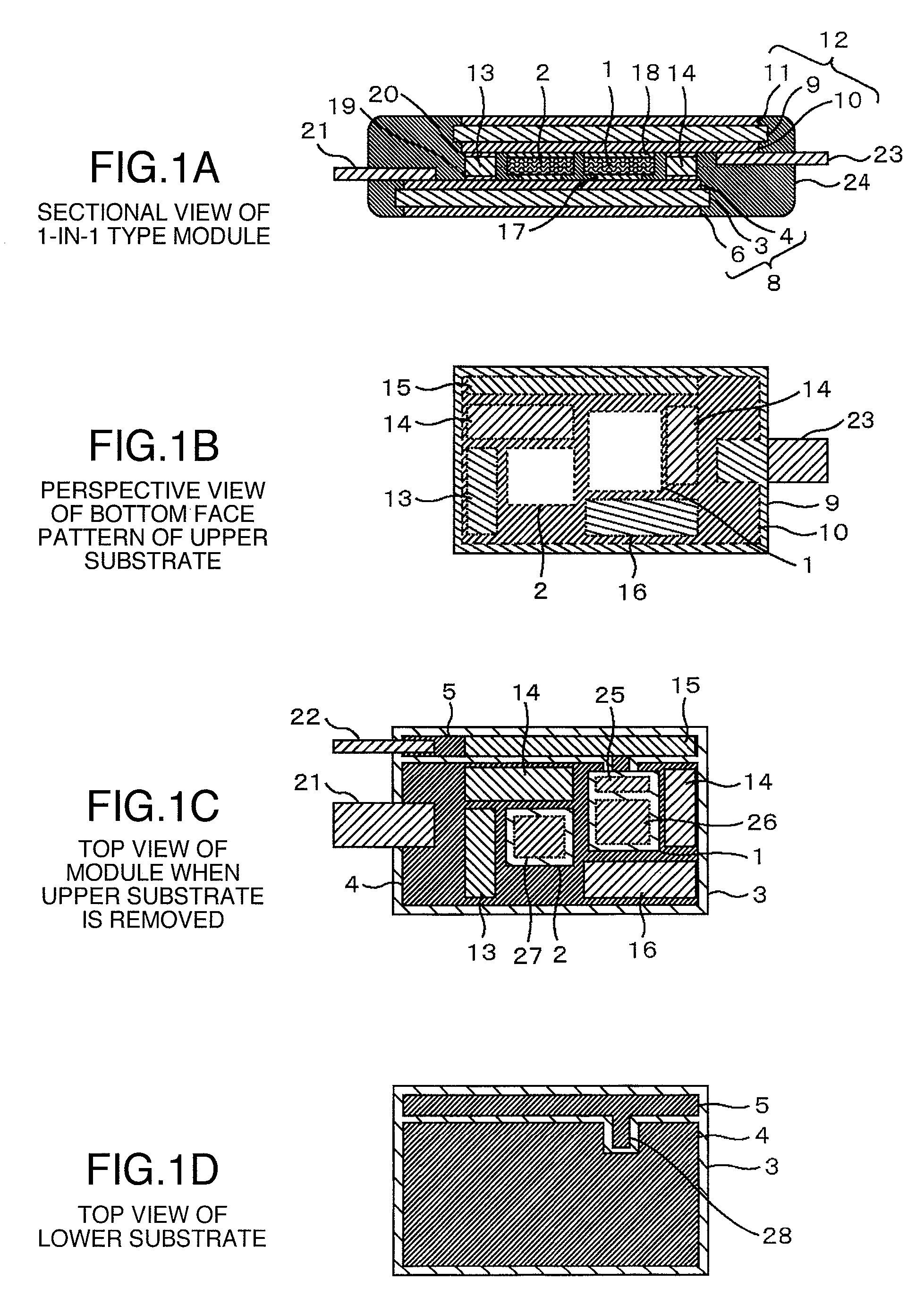

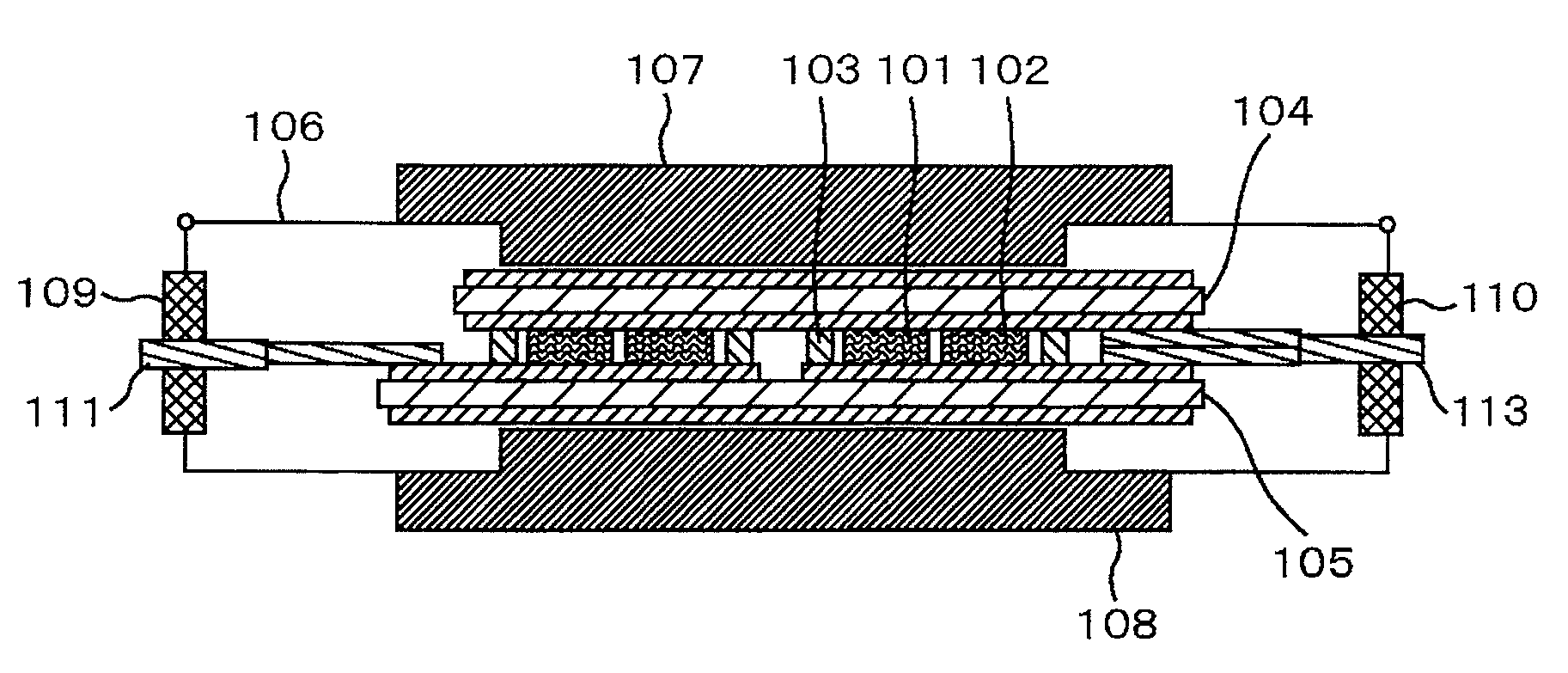

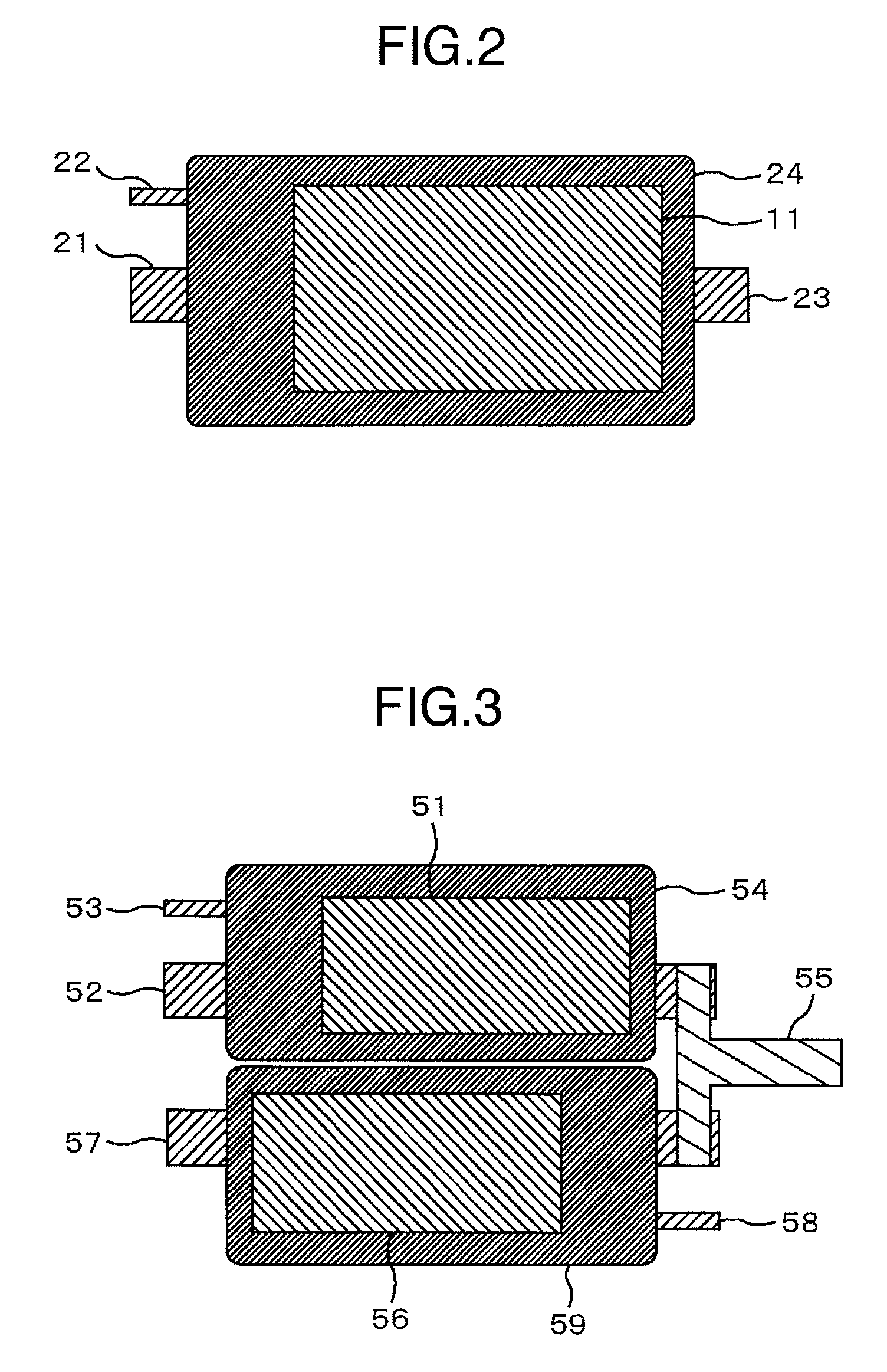

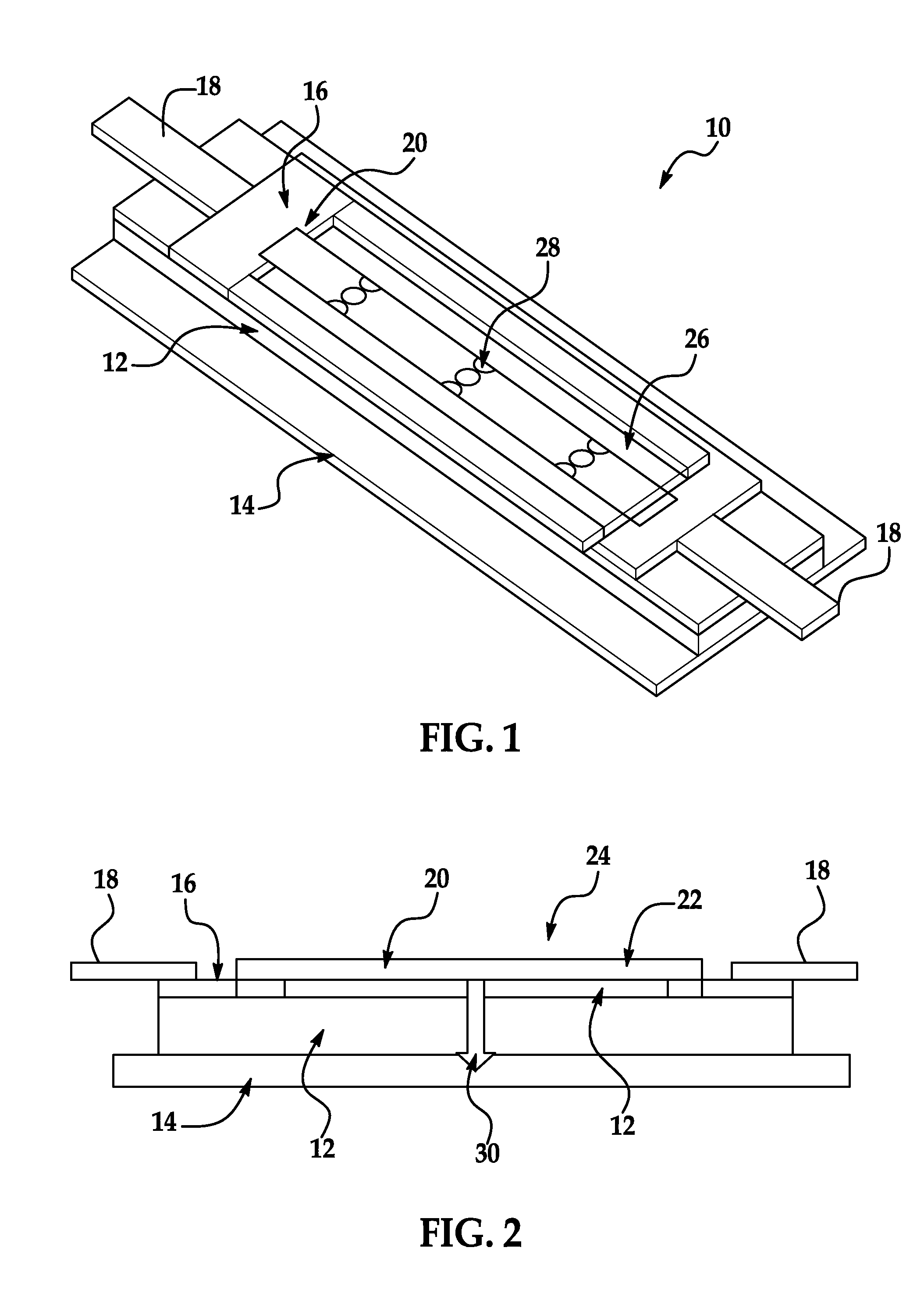

Power Semiconductor Module

InactiveUS20070267739A1Possibility of damageAvoid fracturesSemiconductor/solid-state device detailsLaminating printed circuit boardsThermal expansionInorganic materials

A power semiconductor module and an inverter apparatus in which a device or a joining part is not mechanically damaged even when the temperature in use becomes a high temperature in the range of 175 to 250° C., resulting in excellent reliability at high temperature retaining test and thermal cycling test. Low thermal expansion ceramic substrates are disposed above and below the device. A material having a coefficient of thermal expansion of 10 ppm / K or less is disposed between the ceramic substrates. In addition, an inorganic material having a coefficient of thermal expansion in the range of 2 to 6 ppm / K or less is disposed around the device.

Owner:HITACHI LTD

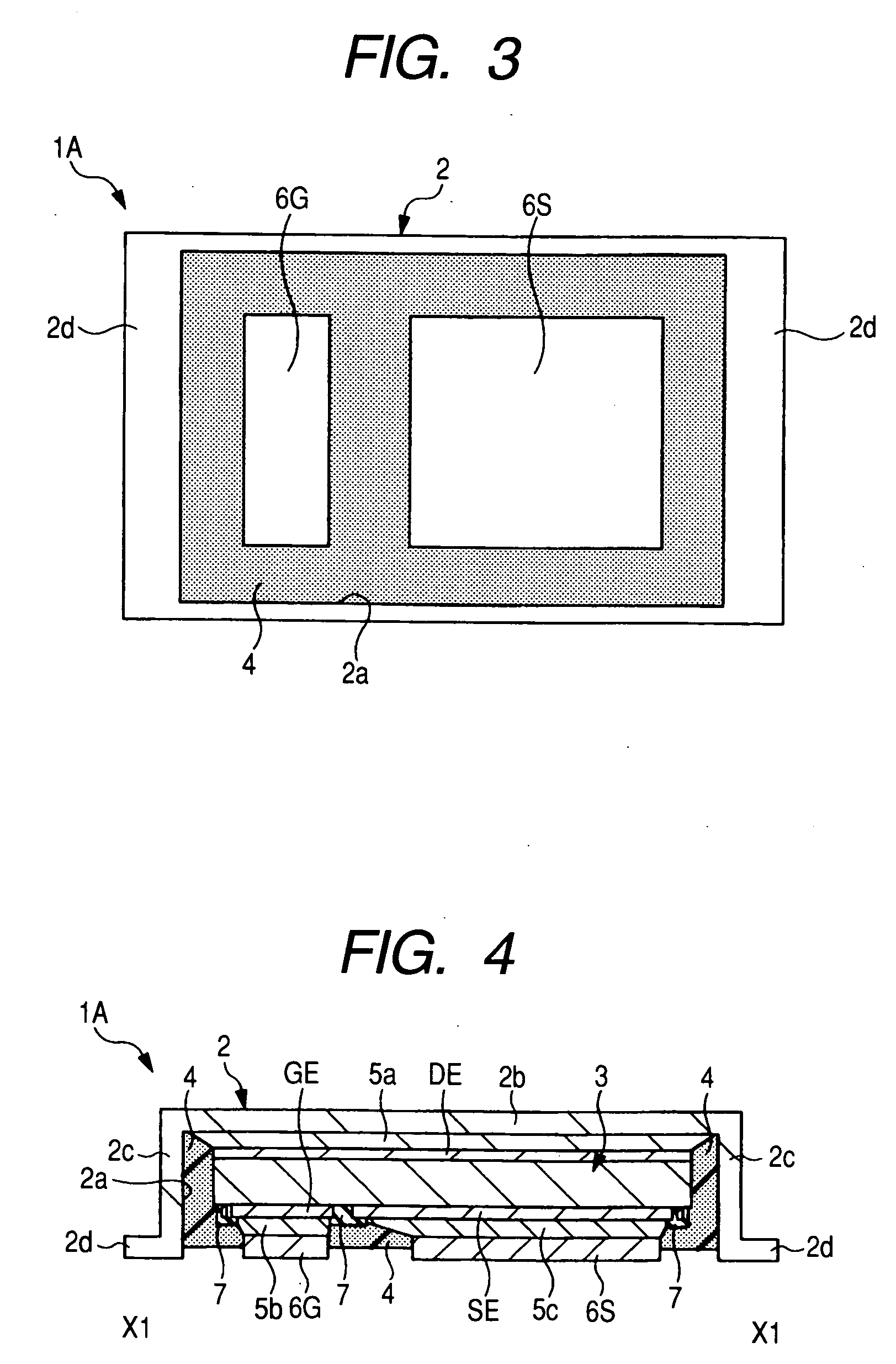

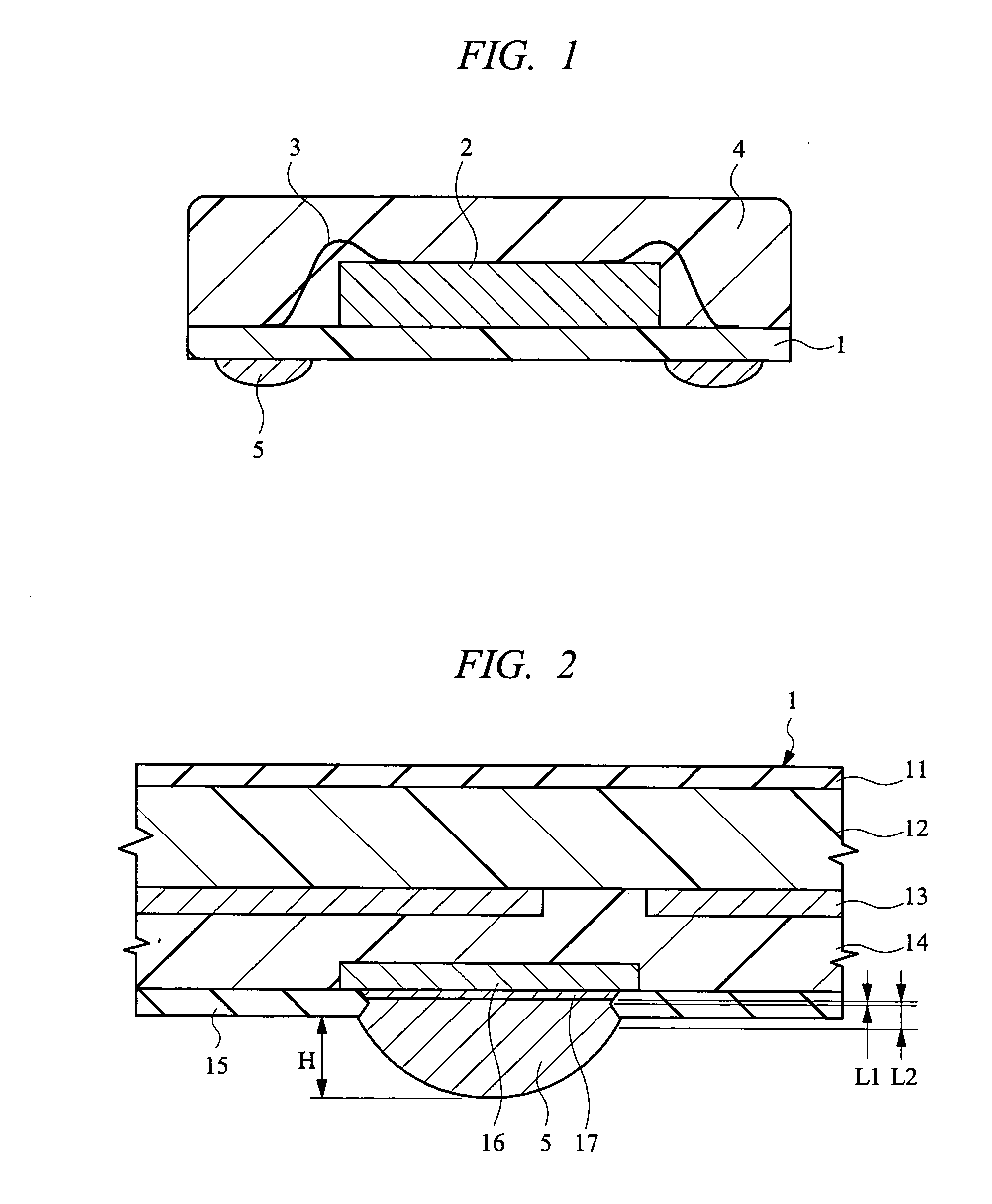

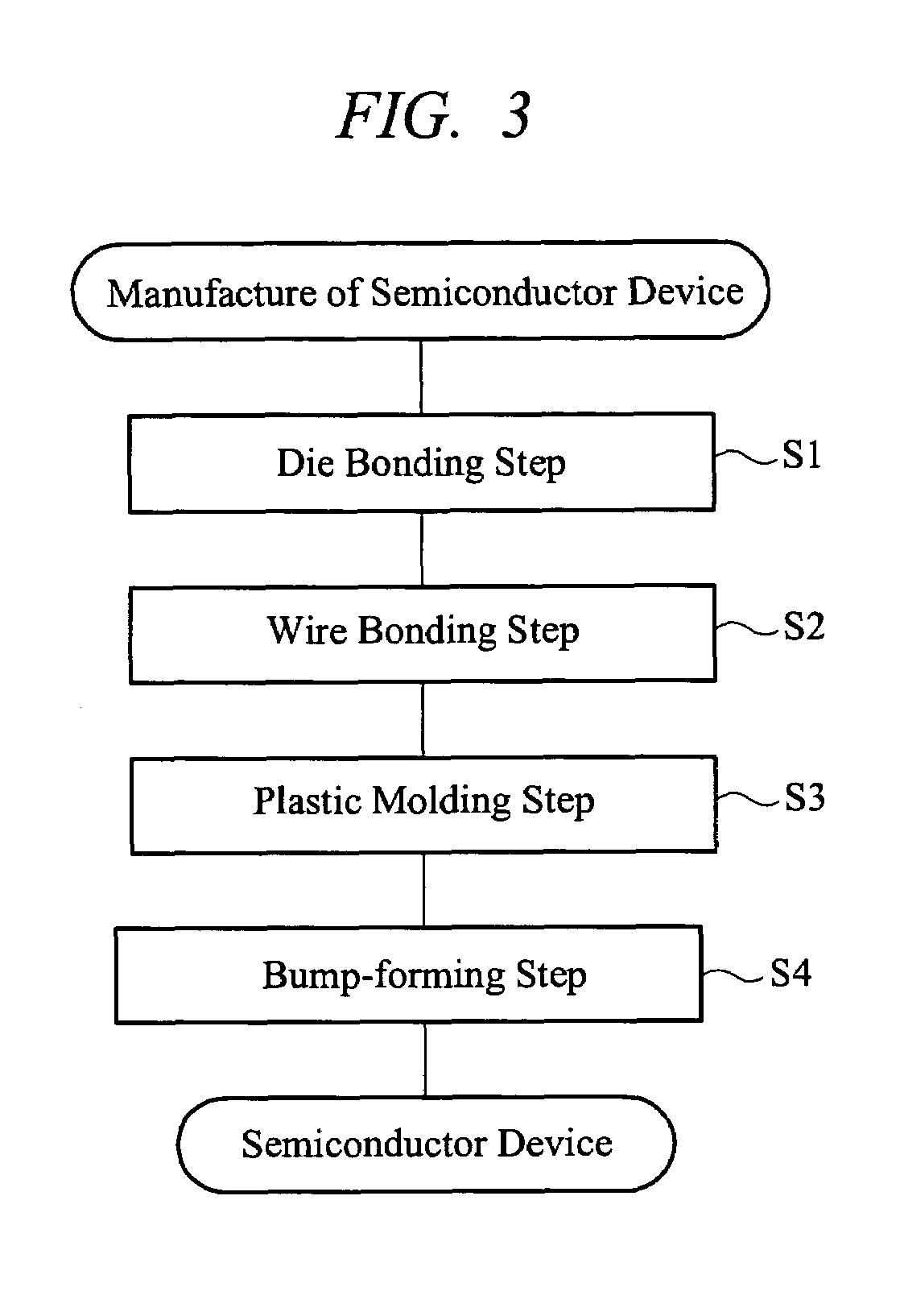

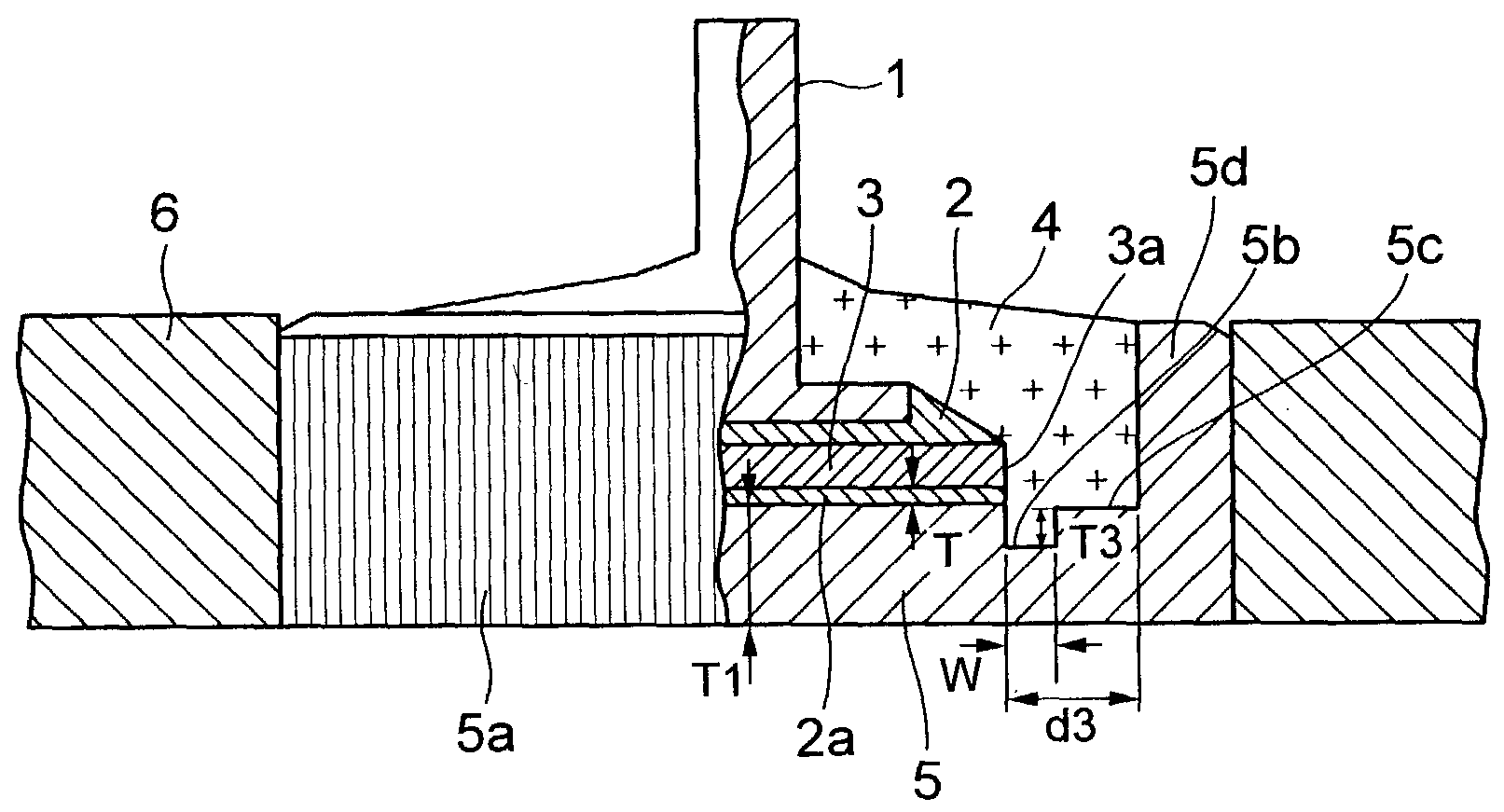

Semiconductor device and method of manufacturing the same

InactiveUS20070210430A1Improve thermal fatigue lifeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipMetal

A semiconductor chip is sealed by resin without covering an outer terminal of a semiconductor device having a power transistor. A semiconductor chip having a power transistor is housed within a recess of a metal cap while a drain electrode on a first surface of the semiconductor chip is bonded to a bottom of the recess via a connection material. A gate electrode and a source electrode are formed on a second surface opposite to the first surface of the semiconductor chip, and the gate electrode and the source electrode are bonded with metal plate terminals 6G, 6S via connection materials 5b, 5c. In addition, the semiconductor chip is sealed by a resin sealing body with mounting-surfaces of the metal plate terminals 6G, 6S being exposed. Mounting surfaces of the metal plate terminals 6G, 6S and a third part of the metal cap are bonded to electrodes on a mounting board 10 via connection materials 5e, 5f and 5g.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device and method of manufacturing the same

InactiveUS20060175700A1Improve thermal fatigue lifeSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor chip is sealed by resin without covering an outer terminal of a semiconductor device having a power transistor. A semiconductor chip having a power transistor is housed within a recess of a metal cap while a drain electrode on a first surface of the semiconductor chip is bonded to a bottom of the recess via a connection material. A gate electrode and a source electrode are formed on a second surface opposite to the first surface of the semiconductor chip, and the gate electrode and the source electrode are bonded with metal plate terminals In addition, the semiconductor chip is sealed by a resin sealing body with mounting-surfaces of the metal plate terminals being exposed. Mounting surfaces of the metal plate terminals and a third part of the metal cap are bonded to electrodes on a mounting board.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device and method of manufacturing the same

InactiveUS7220617B2Improve thermal fatigue lifeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipMetal

A semiconductor chip is sealed by resin without covering an outer terminal of a semiconductor device having a power transistor. A semiconductor chip having a power transistor is housed within a recess of a metal cap while a drain electrode on a first surface of the semiconductor chip is bonded to a bottom of the recess via a connection material. A gate electrode and a source electrode are formed on a second surface opposite to the first surface of the semiconductor chip, and the gate electrode and the source electrode are bonded with metal plate terminals. In addition, the semiconductor chip is sealed by a resin sealing body with mounting-surfaces of the metal plate terminals being exposed. Mounting surfaces of the metal plate terminals and a third part of the metal cap are bonded to electrodes on a mounting board.

Owner:RENESAS ELECTRONICS CORP

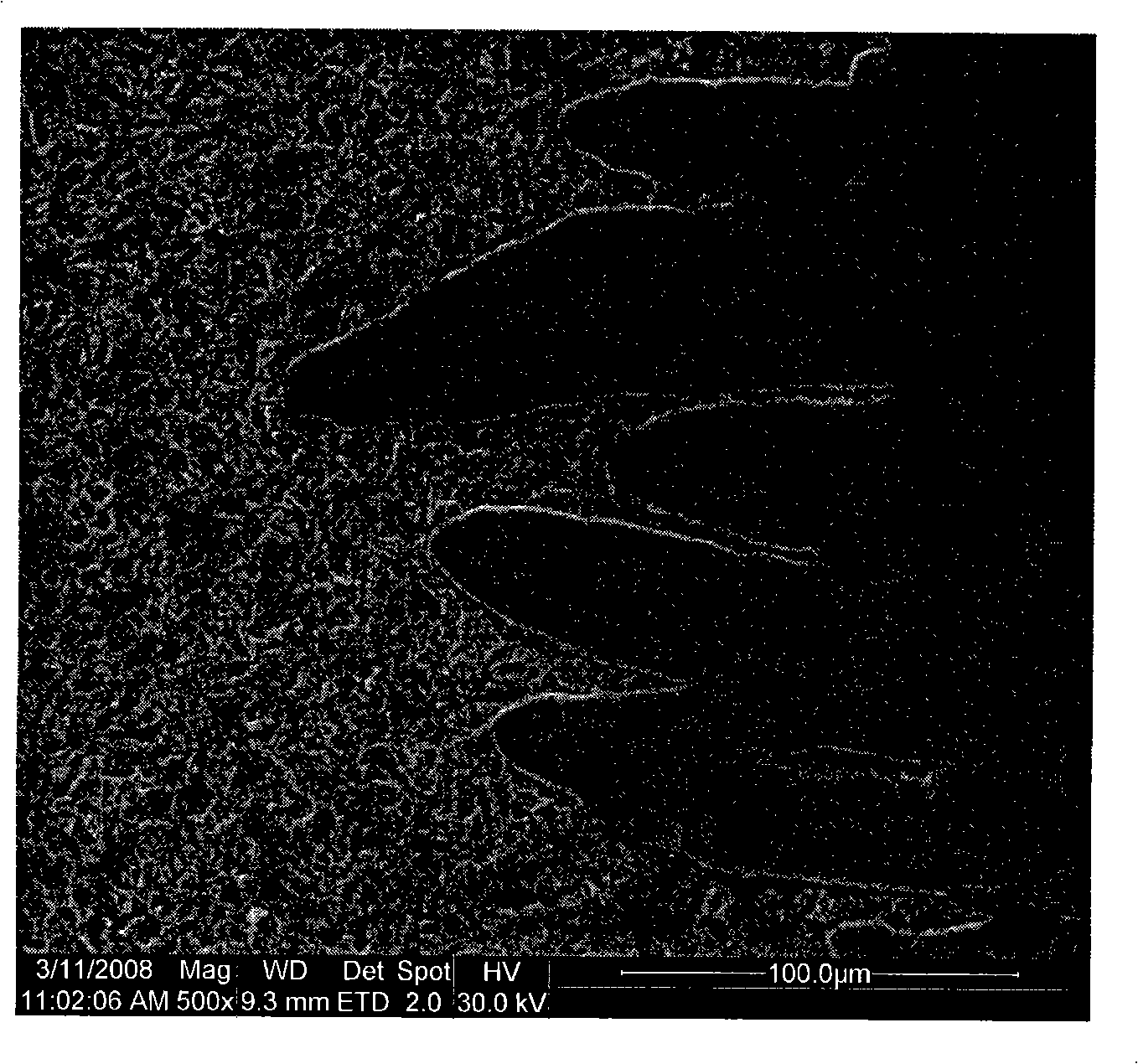

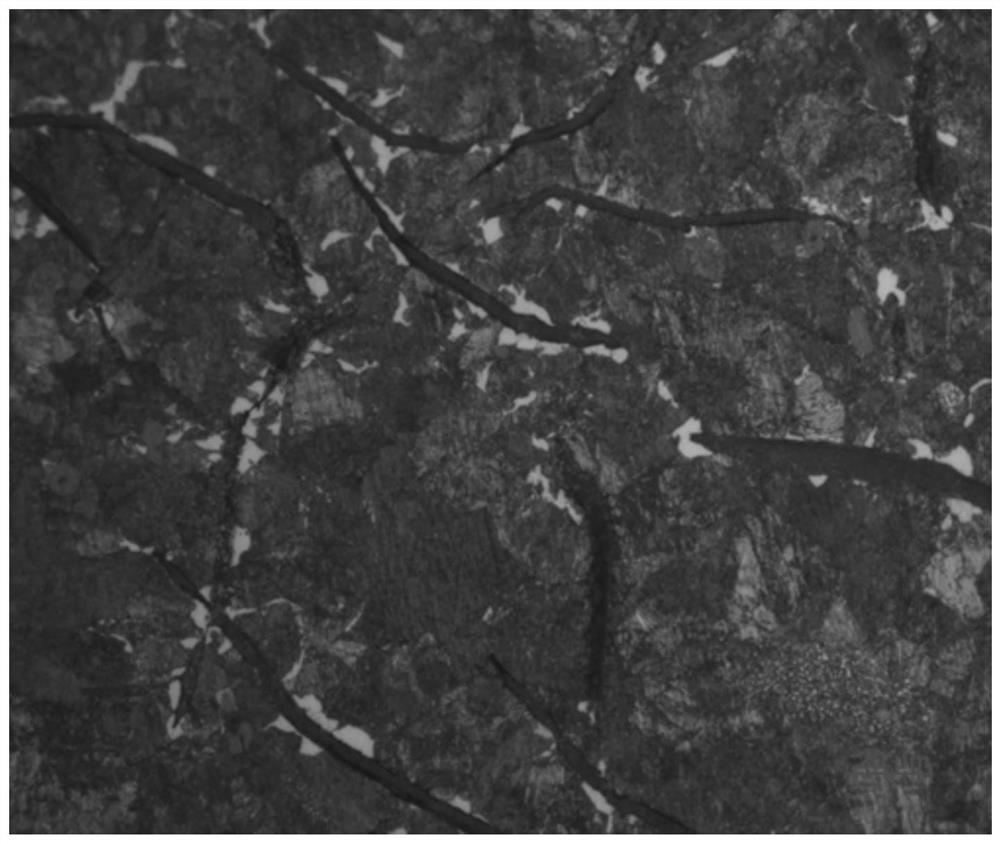

Fe-Al intermetallic compound/AL2O3ceramic composite coating and method of producing the same

InactiveCN101269562AImprove thermal fatigue lifeAnodisationMolten spray coatingThermal sprayingMicro arc oxidation

The invention relates to a Fe-Al inter-metallic compound Al2O3 ceramic complex coating and the preparation method thereof, which is characterized in that the Fe-Al inter-metallic compound Al2O3 ceramic complex coating is arranged on a steel base material surface, the total thickness of the coating is between 0.1 mm to 2 mm, the thickness of a micro-arc oxidation Al2O3 ceramic coating is between 50 to 200 Mum. A hot spray method is adopted, an aluminized coating is obtained in the steel base material (electrode) surface, FeAl2 and FeAl phases are formed by reacting in the interface between the aluminized coating and a die cavity surface as well as in the aluminized coating after heat treatment, and a metallurgical bonding is generated between the coating and the die cavity; after the micro-arc oxidation treatment, a Al2O3 ceramic film layer is obtained on the coating surface. The hardness of the ceramic complex coating can reach more than 1200 HV, and the bonding strength between the complex coating and the die cavity reaches more than 250 MPa, and the abrasive resistance is three times of the W18 Cr 4 V steel (64 HRC), and the heat fatigue life is raised more than twice than H 13 steel (47 HRC). The Fe-Al inter-metallic compound Al2O3 ceramic complex coating and the preparation method thereof can be widely used for the surface treatment of die cast dies and the restoration of failure moulds in the die cavity because of abrasive oversize, and can prolong the service life of the die cast dies.

Owner:HUBEI UNIV OF TECH

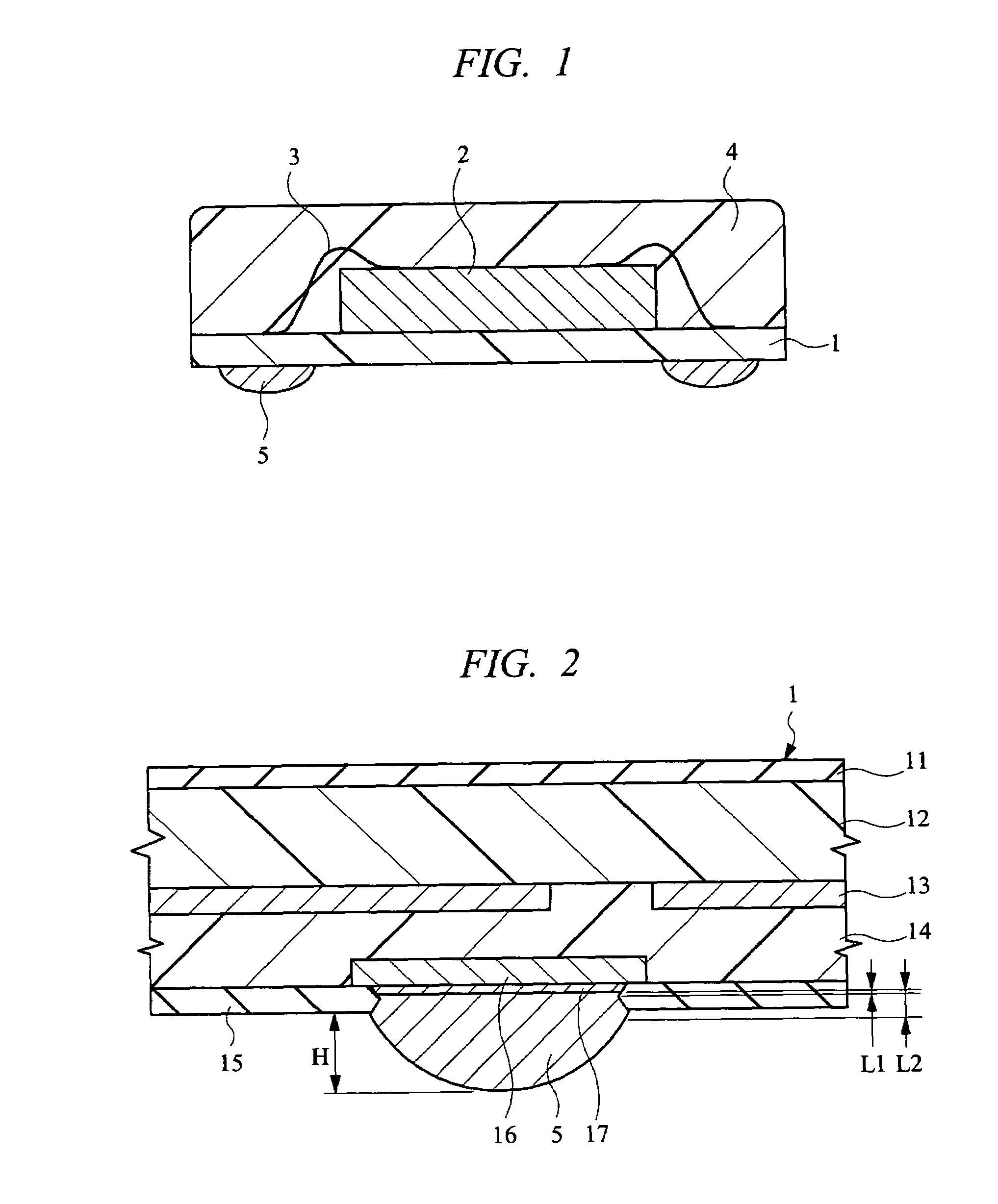

Semiconductor device and manufacturing method thereof

InactiveUS20060151877A1Inhibit reduction of strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsDevice materialCombined use

In order to inhibit the connection failure due to the degradation of the connection interface strength of the electrode pad and the warp thereof in the semiconductor device having an electrode pad, a metal layer formed on the electrode pad, and a metal bump formed on the metal layer, in the present invention, gold (Au) is contained in the metal layer, the metal bump is made of solder mainly made of Sn and designed to have an average height H of 100 μm or less per unit area in the electrode pad, and the concentration of Au of the metal layer dissolved in the solder is set to 1.3×10−3 (Vol %) or less. More preferably, the metal bump contains palladium (Pd), and the solder coating for forming the metal bump on the electrode pad is performed by using the dipping and the paste printing in combination.

Owner:RENESAS ELECTRONICS CORP

Laser surfacing modification method for thermal barrier coating

ActiveCN103266295AHigh bonding strengthImprove thermal fatigue lifeMolten spray coatingEfficient propulsion technologiesStress concentrationThermal fatigue

The invention relates to a laser surfacing modification method for a thermal barrier coating. The method comprises the following steps of: firstly, carrying out washing and sand blasting on the surface of a base body; then, preparing the thermal barrier coating in a thermal spraying state on the surface of the base body; then, designing shape, size, arrangement rule and distribution density of laser modification unit bodies in a pile nail structure to be prepared in the thermal barrier coating; then, adjusting the process parameters of a laser according to a design model; then, performing laser modification to the thermal barrier coating; and finally, performing the stress relief annealing treatment to the laser modified thermal barrier coating. With the adoption of the method for arranging discontinuous and dispersed intensifying unit bodies in the pile nail structure in the thermal barrier coating, the thermal barrier coating can not only generate characteristic of soft and hard alternate change, but also generate the 'pinning effect', thus not only relieving stress concentration at the crack tip of the coating and reducing the crack rate of the coating, but also extremely improving the bonding strength of the coatings, prolonging the thermal fatigue service life of the thermal barrier coating, improving the tissue structure of the coating and improving the compactness of the coating.

Owner:FOSHAN TAOYUAN INST OF ADVANCED MFG

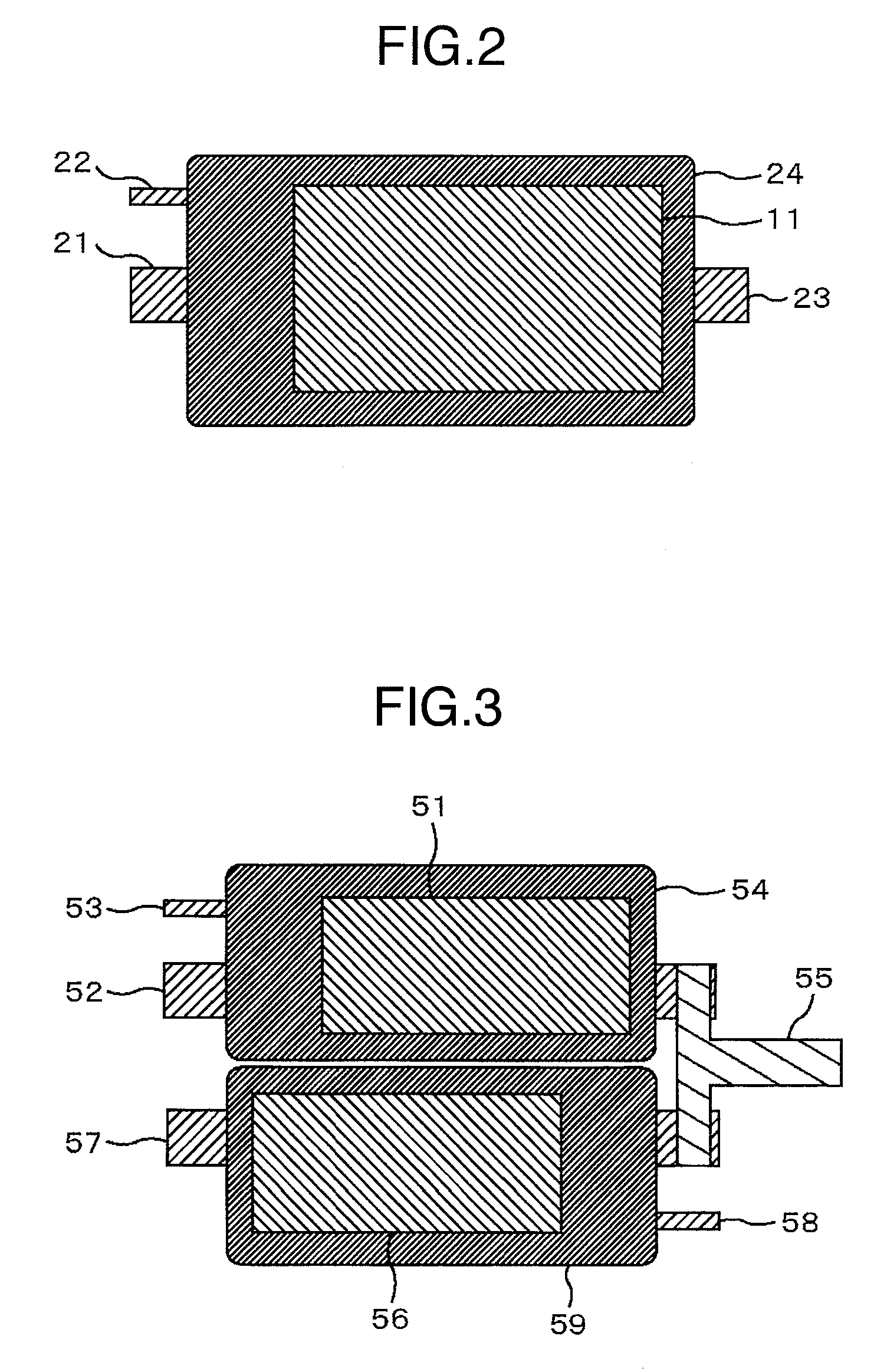

Power semiconductor module

InactiveUS7608917B2Avoid warpingReduce thermal strainSemiconductor/solid-state device detailsLaminating printed circuit boardsThermal expansionInorganic materials

A power semiconductor module and an inverter apparatus in which a device or a joining part is not mechanically damaged even when the temperature in use becomes a high temperature in the range of 175 to 250° C., resulting in excellent reliability at high temperature retaining test and thermal cycling test. Low thermal expansion ceramic substrates are disposed above and below the device. A material having a coefficient of thermal expansion of 10 ppm / K or less is disposed between the ceramic substrates. In addition, an inorganic material having a coefficient of thermal expansion in the range of 2 to 6 ppm / K or less is disposed around the device.

Owner:HITACHI LTD

High-Cr, high-Ni, heat-resistant, austenitic cast steel and exhaust equipment members formed thereby

ActiveUS8241558B2Prolong lifeHigh elongationSilencing apparatusMachines/enginesImpurityHeat resistant

Owner:HITACHI METALS LTD

Reusable lightweight braking disc and preparation method thereof

InactiveCN107723645AImprove thermal fatigue lifeReduce thermal stressMolten spray coatingBraking discsCobaltSurface coating

The invention belongs to the technical field of automobile / high speed rail fittings, and particularly relates to a reusable lightweight braking disc and a preparation method thereof. The braking disccomprises a base body and a surface coating. The surface coating is made of zirconium oxide, aluminium oxide and chromium carbide or tungsten carbide-12% cobalt. A transition layer is arranged betweenthe base body and the surface coating. The transition layer selects and uses an alloy layer made of one or more of Al, Ni, Cr and Y and / or a mixed layer made of mixture of materials used for the surface coating and metal. The preparation method of the braking disc comprises the steps that the base body of the braking disc is obtained through casting; then washing and coarsening are conducted on the base body; and then the transition layer and the surface coating are prepared in sequence. According to the reusable lightweight braking disc and the preparation method thereof, the braking disc base body is not prone to being deformed, the bonding strength between the coating and the base body is high, and the coating is not prone to falling off.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Method for building SMT welding spot IMC thermal fatigue probability failure physical model

ActiveCN103984835AAverage working hoursShorten the timeSpecial data processing applicationsNormal densityThermal fatigue

The invention provides a method for building an SMT welding spot IMC thermal fatigue probability failure physical model. The method includes the following steps of determining an IMC growth physical model, (2) determining a physical model of the relation between SMT welding spot thermal fatigue service life and IMC thicknesses, and (3) determining IMC thickness distribution probability density function mu (delta). After the preceding three steps are carried out, by means of intermetallic components, namely the bond IMC, the function relation between SMT welding spot reliability and the SMT welding spot machining process and between SMT welding spot reliability and work conditions is directly built; considering dispersion of the IMC thicknesses, discretization is carried out on different products or identical products of different batches, and the SMT welding spot IMC thermal fatigue probability failure physical model is built. According to the method, the relation between the SMT welding spot reliability and process conditions is directly built, and bases are provided for improving the production welding process, the SMT welding spot work environment, prolonging SMT welding spot thermal fatigue service life and improving reliability of welding electronic products.

Owner:BEIHANG UNIV

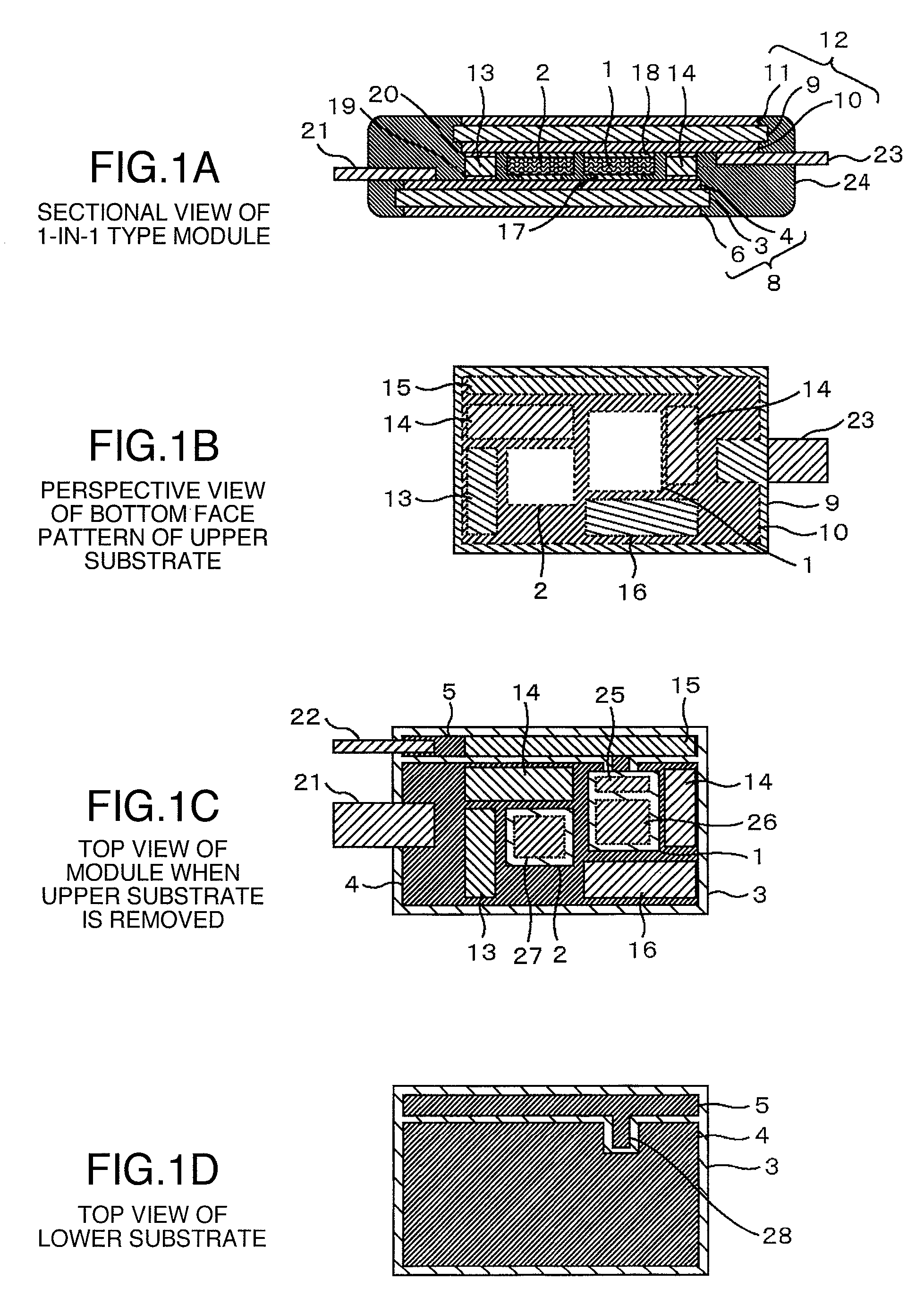

Semiconductor device having lead free solders between semiconductor chip and frame and gabrication method thereof

InactiveUS20100181666A1Inhibit the generation of cracksRelieve pressureSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device includes a semiconductor chip having a current path between a first principal surface and a second principal surface opposite from the first principal surface, a first conductive frame having an opposite region to the first principal surface, and a second conductive frame electrically connected via electrical connection member to a pad formed on the second principal surface. In a gap between the first principal surface and the first conductive frame, there are arranged multiple column-shaped lead-free solders which are arranged within a circle drawn around a center of the opposite region and having a diameter corresponding to a narrow side of the opposite region, and which electrically connects the first conductive frame with the semiconductor chip, and a filler which is filled between the multiple column-shaped lead-free solders.

Owner:RENESAS ELECTRONICS CORP

Semiconductor device having a particular electrode structure

InactiveUS7211892B2Reduced inhibitory strengthImprove thermal fatigue lifePrinted circuit assemblingSemiconductor/solid-state device detailsMetallurgyPalladium

Owner:RENESAS ELECTRONICS CORP

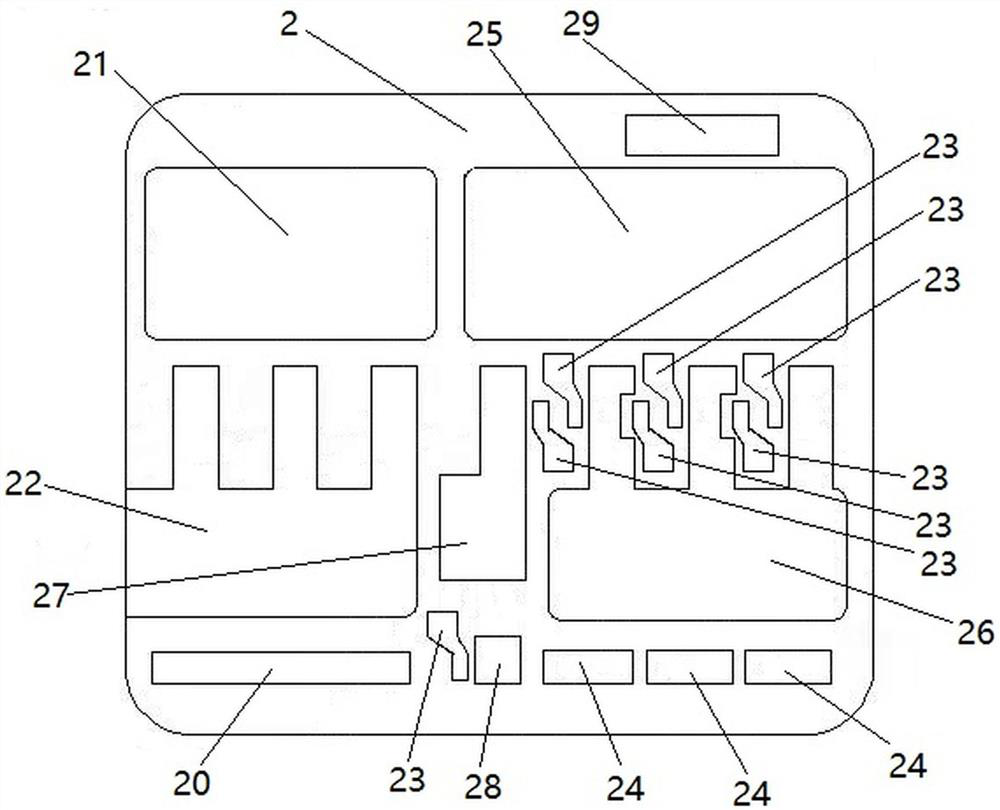

Fuse assembly

InactiveUS20150357144A1Decrease riseImprove thermal fatigue lifeEmergency protective device manufactureTemperature cyclingOperating temperature

A fuse assembly of a motor controller is provided. The fuse assembly includes a base, a base plate to which the base is attached, a lead frame that is attached to the base, at least one lead that is attached to the lead frame, and a fuse element attached to the base and covered with a fusible material. Heat is generated in the fuse element by a high flow of current carried by the assembly. The heat is operatively transferred through the assembly by direct conduction to the base and then base plate. The assembly sufficiently transfers heat to reduce rise in temperature of and properly cool the assembly. An operating temperature of the assembly is reduced to minimize or prevent damage thereto. The assembly has increased thermal-fatigue life and minimizes thermal-fatigue damage to the assembly during temperature cycling in an aircraft. Thermal stress of the assembly is minimized.

Owner:HAMILTON SUNDSTRAND CORP

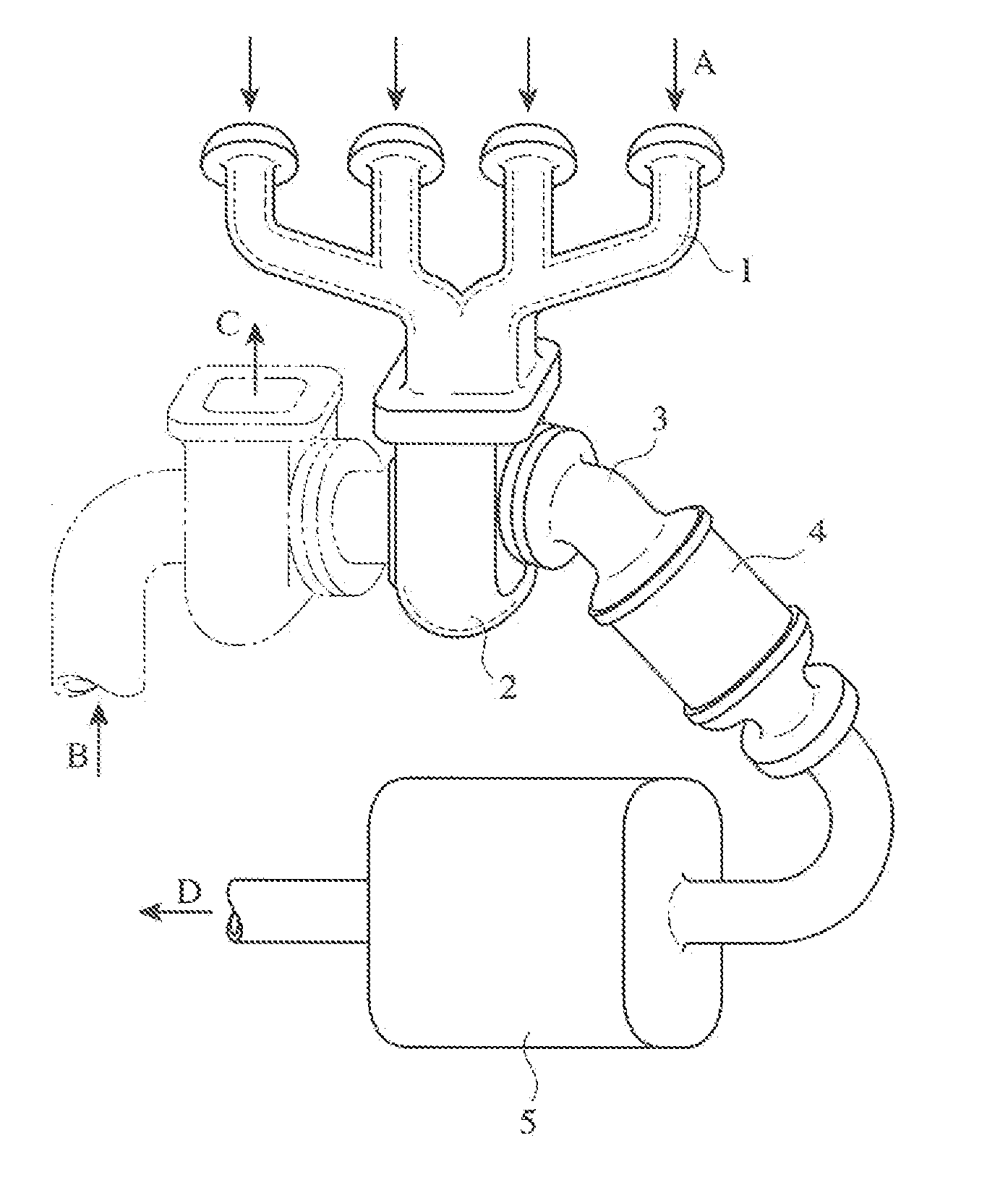

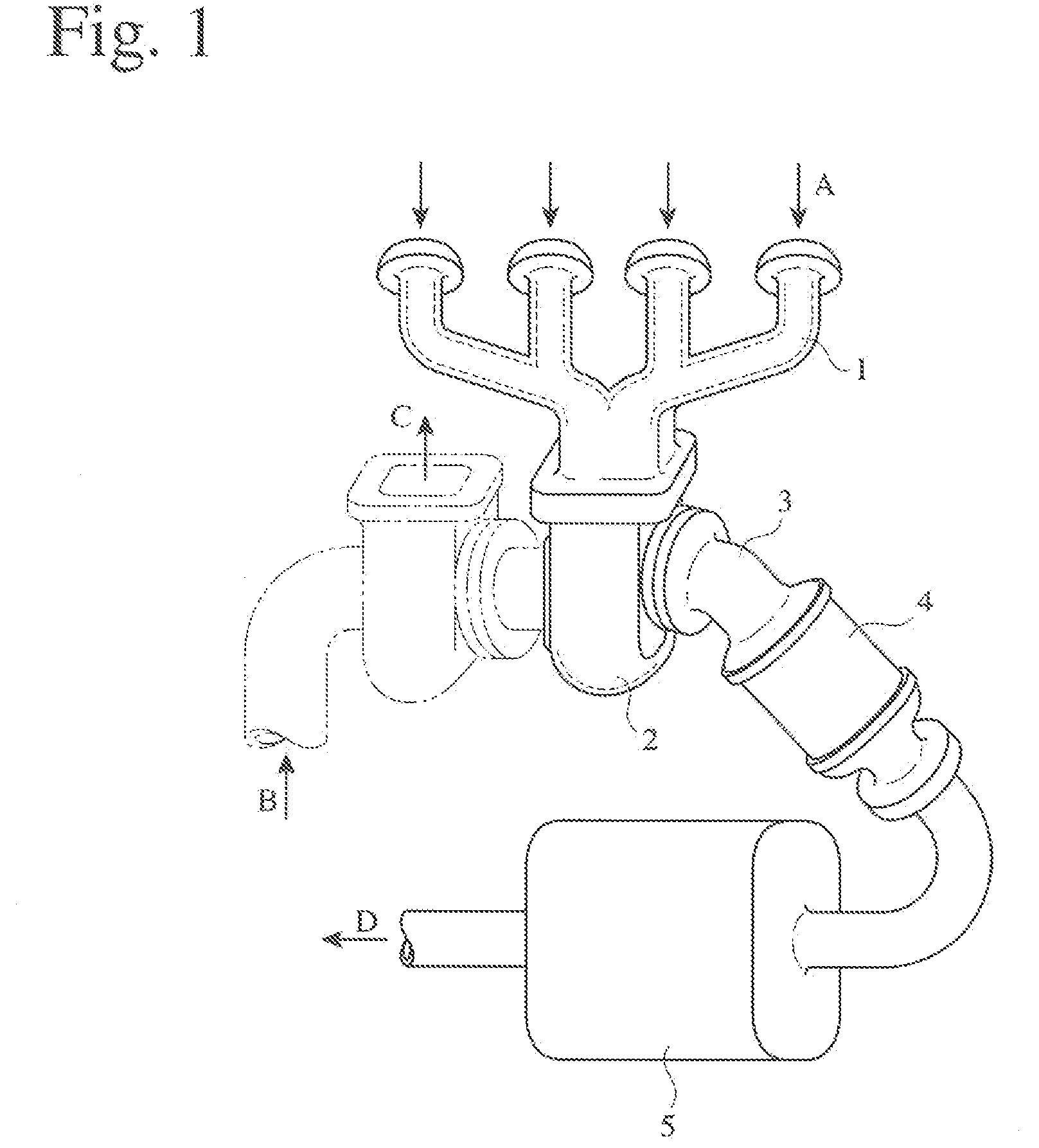

Heat-resistant, austenitic cast steel and exhaust member made thereof

ActiveUS20110000200A1Improve heat resistanceImprove solderabilitySilencing apparatusMachines/enginesMetallurgyAustenite

Heat-resistant, austenitic cast steel comprising by mass 0.3-0.6% of C, 1.1-2% of Si, 1.5% or less of Mn, 17.5-22.5% of Cr, 8-13% of Ni, 1.5-4% as (W+2Mo) of at least one of W and Mo, 1-4% of Nb, 0.01-0.3% of N, 0.01-0.5% of S, the balance being Fe and inevitable impurities, and meeting the following formulae (1), (2), (3) and (4):0.05≦(C—Nb / 8)≦0.6 (1),17.5≦17.5Si—(W+2Mo) (2),5.6Si+(W+2Mo)≦13.7 (3), and0.08Si+(C—Nb / 8)+0.015Cr+0.011Ni+0.03W+0.02Mo<0.96 (4),wherein the symbol of each element corresponds to the amount (% by mass) of each element in the cast steel.

Owner:HITACHI METALS LTD

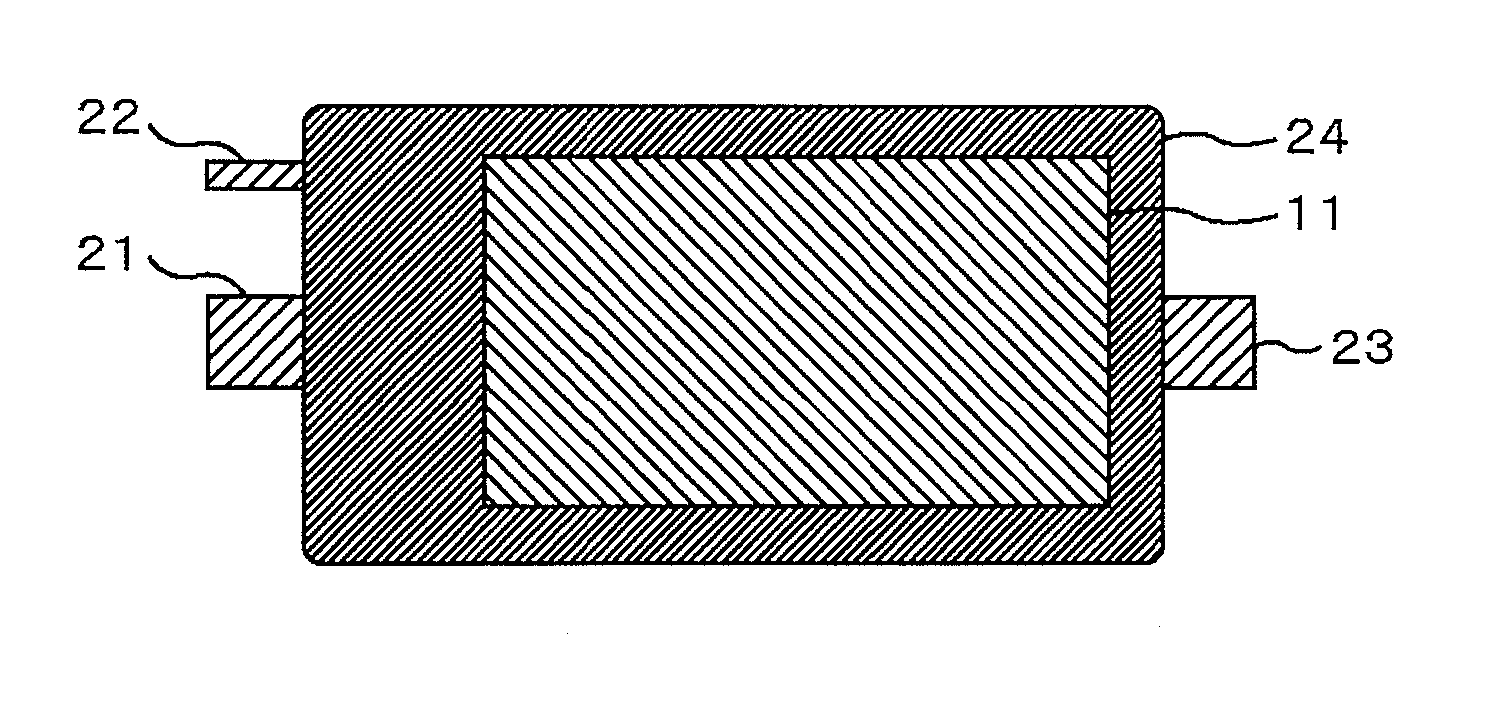

Semiconductor device

InactiveUS7061090B2Reduce thermal deformationImprove thermal fatigue lifeSemiconductor/solid-state device detailsSolid-state devicesThermal fatigueSemiconductor chip

A semiconductor device comprises a semi-conductor chip bonded on a top surface inside a case electrode by a bonding material and a lead electrode bonded on a top surface of the semiconductor chip by a bonding material with a space of the case electrode filled with an insulating material for sealing the bonded sections, wherein a groove is provided on a top surface of the case electrode from an edge of the semiconductor chip, to thereby reduce heat distortion which is generated on a large scale at an end of the bonding material on account of a difference in coefficients of linear thermal expansion between the semiconductor chip and the case electrode and improve the thermal fatigue life.

Owner:HITACHI LTD

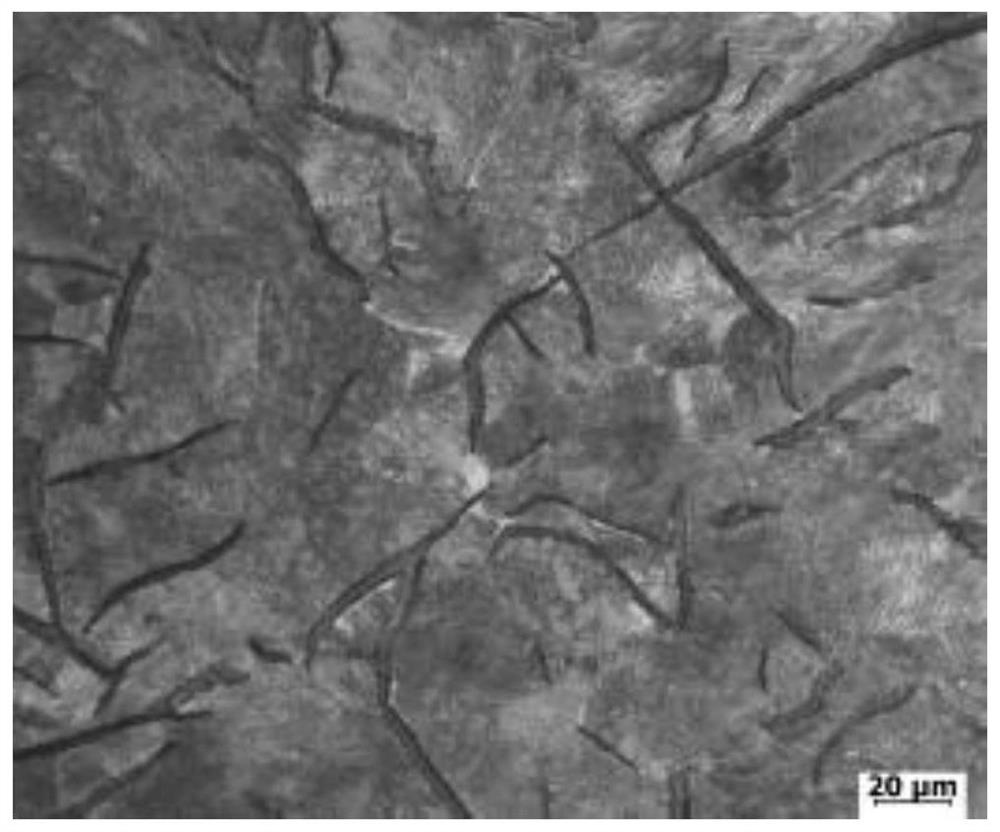

Cerium-contained steel for centrifugal ductile ink cast tube die and preparation method of cerium-contained steel

The invention relates to cerium-contained steel for a centrifugal ductile ink cast tube die and a preparation method of the cerium-contained steel and belongs to the field of steel and iron materials.The cerium element is added to 21CrMo10 steel, and ingredient optimization is performed. The activity of the molybdenum in the steel is improved through the addition of the cerium, the effect of themolybdenum is enhanced, and the effect of combination alloying is achieved; the cerium can improve the high-temperature mechanical performance and corrosion resistance of the steel, and meanwhile thecerium can also improve the high-temperature oxidation resistance performance of the steel; and the cerium can refine grains, the toughness of the steel is further improved, and thus the thermal fatigue life of the steel is prolonged. The content of the cerium element added to the steel is not large, the content of the molybdenum is lowered through ingredient optimization, and the production costis slightly lowered.

Owner:JIANGSU UNIV

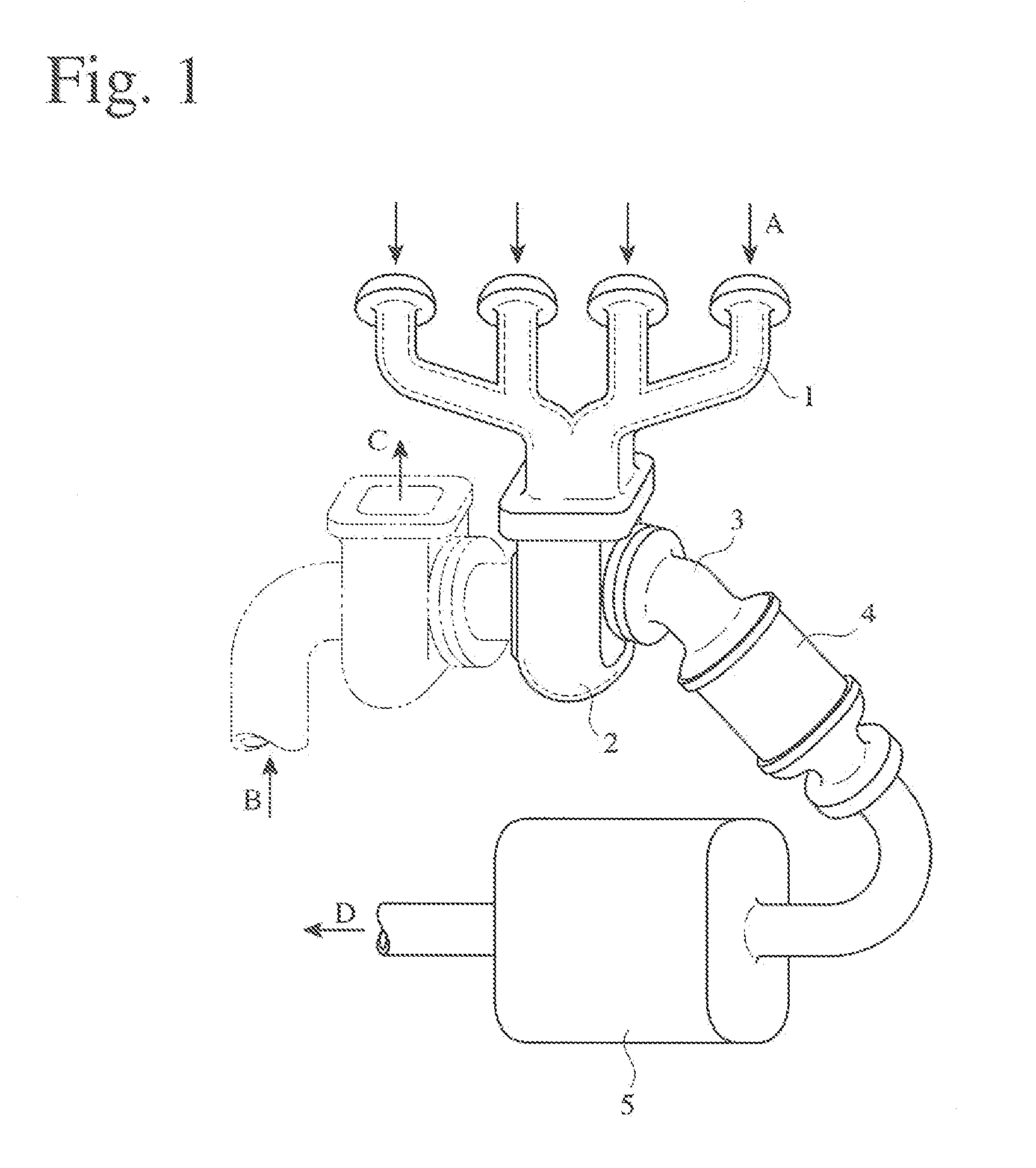

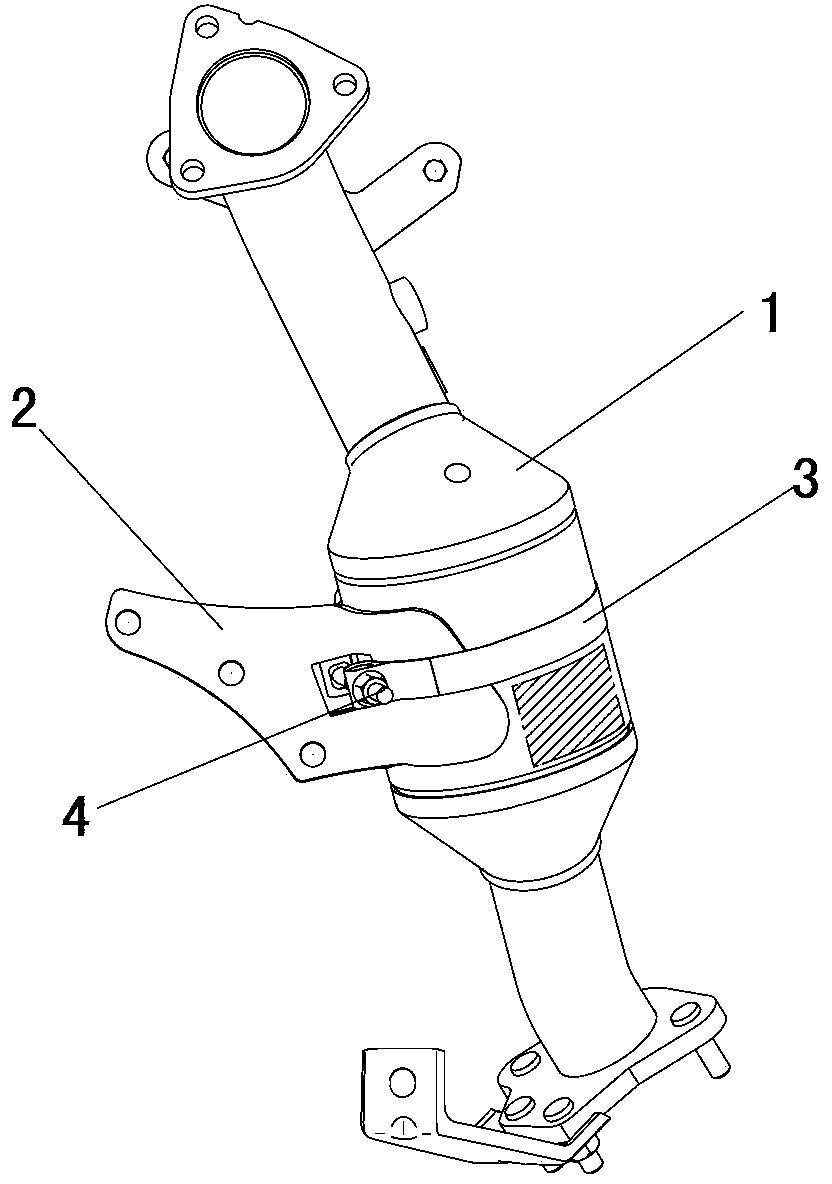

Automobile exhaust system hot end support

ActiveCN104279045AReduce installation prestressImprove fatigue lifeExhaust apparatusSilencing apparatusResonanceCylinder block

An automobile exhaust system hot end support is used for being connected with a three-way catalyst shell. The automobile exhaust system hot end support comprises a support body, a strap and a fastening bolt, wherein the strap surrounds the three-way catalyst shell to be connected with the fastening bolt into a hoop, and the fastening bolt penetrates through the support body to be connected with the two ends of the strap so that the support body can be fixed to the three-way catalyst shell. Due to the fact that the support is directly connected with the three-way catalyst shell, the problem that the space in an engine cabin is small is effectively avoided. Due to the fact that the support is directly connected to the three-way catalyst shell and is very close to an engine cylinder block, the rigidity of the whole system is effectively improved, the first-order frequency of the system is increased to be higher than 200 Hz, resonance of an engine within 6000 RPM is avoided, and the fatigue life of the whole system is effectively prolonged.

Owner:SHANGHAI TENNECO EXHAUST SYST

PIM device and manufacturing method thereof

ActiveCN113556026AGood thermal cycleShape stableAC motor controlSemiconductor/solid-state device detailsPhysicsEngineering

The invention relates to the technical field of semiconductor devices, in particular to a PIM device and a manufacturing method thereof, and the PIM device comprises a copper-clad ceramic substrate, and a three-phase rectification unit, a three-phase inversion unit, a braking unit and a temperature control detection NTC device which are arranged on the copper-clad ceramic substrate; the three-phase rectification unit comprises six diode chips arranged on the copper-clad ceramic substrate and clip copper sheets corresponding to the six diode chips one by one; the three-phase inversion unit comprises six IGBT chips, six clip emitter copper sheets in one-to-one correspondence with the six IGBT chips, and six clip control electrode copper sheets in one-to-one correspondence with the six IGBT chips. The braking unit comprises a diode chip VII, an IGBT chip VII, a clip copper sheet, a clip emitter copper sheet and a clip control electrode copper sheet. According to the technical scheme, the PIM device is small and exquisite in structure and convenient to use, when the PIM device is applied to a related circuit, the circuit structure can be simplified, the PIM device is stable in performance based on the clip technology adopted by the PIM device, and the circuit using the PIM device is further safe and reliable.

Owner:乐山希尔电子股份有限公司 +1

Re-melted and hardened natural gas engine aluminum alloy piston

InactiveCN104514646AHigh strengthReliably bear mechanicalMachines/enginesPistonsCombustion chamberThermal fatigue

A re-melted and hardened natural gas engine aluminum alloy piston comprises a piston body and a top combustion chamber. An annular re-melted and hardened layer is arranged at an arc corner of the bottom of the combustion chamber, the cross section of the re-melted and hardened layer is a circular arc, the particle size of a metallographic structure primary silicon phase and an intermetallic phase of a reinforced annular area is 1 / 4-1 / 10 that of a non-re-melted portion of a matrix after the arc corner of the bottom of the combustion chamber of the piston is re-melted, so that the thermal fatigue resistance of the piston is improved, mechanical load and thermal load generated in operation of an engine are more reliably borne, thermal fatigue resistance experiment results indicate that the thermal fatigue resistance life of the reinforced annular area can be prolonged by about 2-5 times, and the service life of the piston is greatly prolonged in practical use.

Owner:DONGFENG PISTON & BEARING

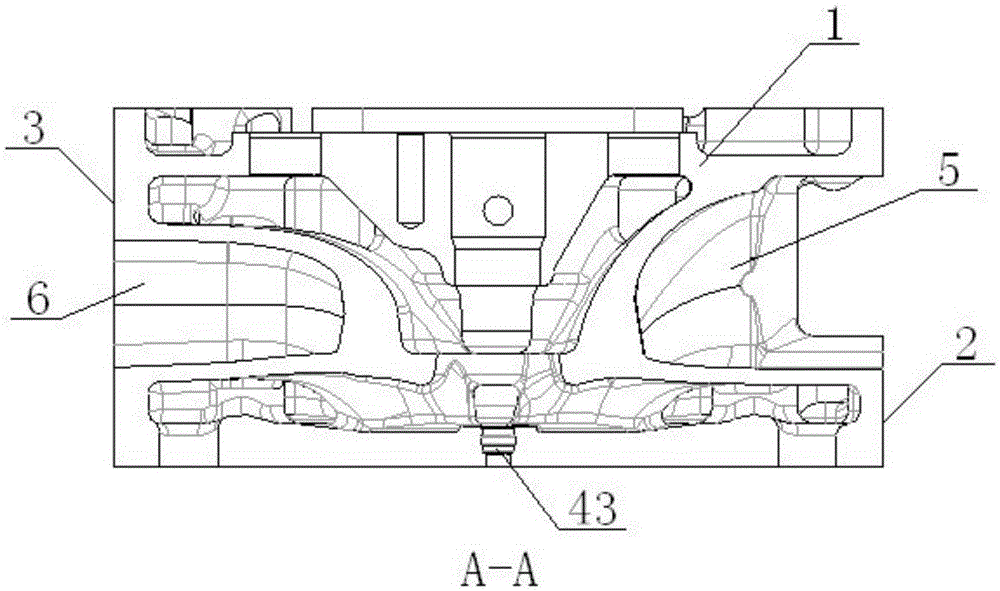

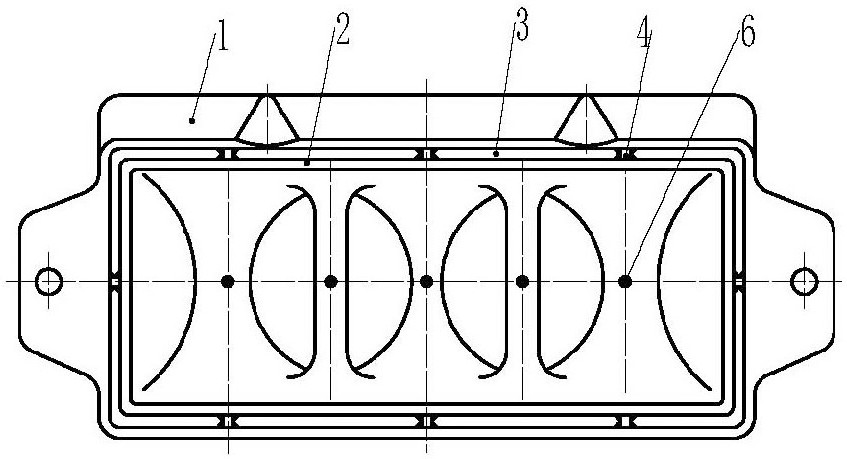

Diesel engine integral cylinder cover with air valves arranged in parallel

ActiveCN105275657AControl swirl ratioShorten the lengthCylinder headsCylindersInlet channelThermal fatigue

A diesel engine integral cylinder cover with air valves arranged in parallel comprises a cylinder cover body, an air inlet channel and an air exhaust channel, and the air inlet channel and the air exhaust channel are arranged in the cylinder cover body. One side of the cylinder cover body is an air inlet side end face with an air inlet channel opening, and the other side of the cylinder cover body is an air exhaust side end face with an air exhaust channel opening. The cylinder cover body is of a multi-cylinder and one-cover integral structure. The part, corresponding to each cylinder, of a cylinder cover bottom surface is provided with two air inlet valve holes, two air exhaust valve holes and an oil injector hole. The air inlet valve holes are close to the air inlet side end face, and the center connection line of every two air inlet valve holes is parallel to the air inlet side end face. The air exhaust valve holes are close to the air exhaust side end face, and the center connection line of every two air exhaust valve holes is parallel to the air exhaust side end face. Two bolt holes are formed in the position, between flame face sealing tapes of every two adjacent cylinders, of the cylinder cover bottom surface, and an unload groove is formed between every two bolt holes. According to the diesel engine integral cylinder cover with the air valves arranged in parallel, the flow capacity of the air channels is high, and the thermal fatigue resistance is good.

Owner:DONGFENG COMML VEHICLE CO LTD

Wafer-level packaging reliability optimization method

PendingCN113128171ABest designImprove thermal fatigue lifeSemiconductor/solid-state device detailsSolid-state devicesThermal fatigueStructural engineering

Owner:NANTONG UNIVERSITY

A kind of pim device and manufacturing method thereof

ActiveCN113556026BGood thermal cycle performanceShape stableAC motor controlSemiconductor/solid-state device detailsDevice materialHemt circuits

Owner:乐山希尔电子股份有限公司 +1

Cast iron mold with gap interlayer

A cast iron mold with a gap interlayer comprises a bottom layer, a working layer and a gap layer arranged between the bottom layer and the working layer, the bottom layer and the bottom of the working layer are welded and connected through cotter pins, supporting blocks are located on the peripheral edge of the cast iron mold and are adopted for welding and supporting, cotter pin welding is that the cotter pins penetrate through the bottom layer and the working layer, and the two ends of the cotter pins are welded through plug welding seams. The thickness of the working layer is 1 / 2 of that of the bottom layer. The gap layer is arranged between the working layer and the bottom layer, a large amount of cooling water sprayed on an iron block can enter the gap layer between the working layer and the bottom layer during cast iron production, meanwhile, the working layer and the bottom layer are cooled, the thermal load of the working layer and the bottom layer is reduced, therefore the thermal fatigue life of the cast iron mold is prolonged, and the replacement frequency of the cast iron mold is reduced.

Owner:SHILIN LUOHE METALLURGY EQUIP

Circuit board with digital signal isolation circuit chip and packaging method

InactiveCN105206591AEasy to useImprove withstand voltage characteristicsSemiconductor/solid-state device detailsSolid-state devicesInterconnectionDigital signal

The invention discloses a circuit board with a digital signal isolation circuit chip and a packaging method. The circuit board includes a substrate and one or a plurality of digital signal isolation circuit chips, wherein the digital signal isolation circuit chip is packaged on the substrate through a flip-chip bonding mode. The flip-chip bonding packaging technology is adopted in a digital signal isolation circuit, and therefore, problems caused by bonding and interconnection can be greatly reduced, and the reliability of the chip can be improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

A kind of engine cylinder head and preparation method thereof

ActiveCN113337686BImprove thermal fatigue lifeFurnace typesHeat treatment furnacesTemperingCylinder head

The present application relates to an engine cylinder head and a preparation method thereof. The preparation method includes the following steps: (1) normalizing treatment: heating an engine cylinder head blank cast from an alloy material to 850°C to 950°C, and keeping the temperature for 1.5h ~2.5h; then air-cooled, cooled to ≤230°C, stopped air-cooled, and finally cooled to room temperature; (2) Tempering treatment: put the normalized engine cylinder head blank into the furnace for tempering treatment , the tempering temperature is 550℃~650℃, and the tempering time is 2~3h; (3) after the tempering treatment is completed, shot peening and machining treatment are carried out in sequence to obtain the engine cylinder head. The present application can improve the strength of the engine cylinder head cast with the alloy material, thereby improving the thermal fatigue life.

Owner:DONGFENG COMML VEHICLE CO LTD

Bayesian inference-based brake disc and optimization design method

PendingCN114218681AImprove cooling effectIncrease surface areaGeometric CADMathematical modelsThermal fatigueControl theory

The invention discloses a brake disc based on Bayesian inference and an optimization design method.The brake disc comprises a brake disc inner disc face, the brake disc inner disc face is of a scraggly gradually-changing curved surface structure in the radial direction, and the gradually-changing curved surface structure comprises a middle arc-shaped outer convex face protruding outwards; the method comprises the following steps: taking R1, R2, R3, L1 and L2 as design variables, selecting a satisfactory average Mises stress of the brake disc surface as an observation value, and calculating the average Mises stress of the brake disc surface according to the average Mises stress of the brake disc surface, the average Mises stress of the brake disc surface, the average Mises stress of the brake disc surface, the average Mises stress of the brake disc surface and the average Mises stress of the brake disc surface, and the average Mises stress of the brake disc surface and the average Mises stress of the brake disc surface. The design variables are reversely optimized based on the Bayesian inference theory, information updating of the design variables is achieved, and finally the optimal solution of the design variables is determined; the internal heat dissipation area is increased, the heat dissipation capacity of the brake disc is improved, the brake disc structure has good heat crack resistance, the thermal fatigue life of the brake disc can be prolonged, and the brake safety of a vehicle is improved.

Owner:SINO TRUK JINAN POWER

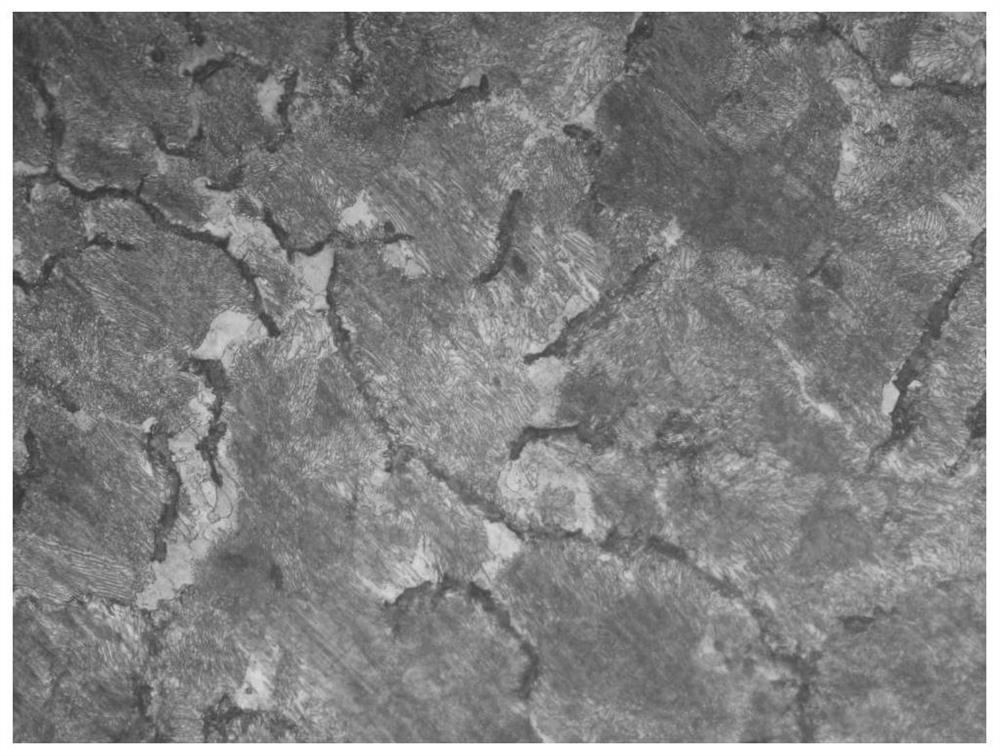

Quenched and tempered gray cast iron, gray cast iron quenched and tempered method and its application

The invention discloses a quenched and tempered gray cast iron, a gray cast iron quenching and tempering method and application thereof. The gray cast iron quenching and tempering method includes the following steps: placing a gray cast iron blank in a quenching furnace at 850-950° C. for 0.5-2 h, Immediately after coming out of the furnace, put it into quenching oil at 65~85℃ for 3~6min, control the cooling rate to be 65~85℃ / s, and air-cool to no higher than 200℃ after the oil is discharged; put the grey cast iron blank at 550℃~650℃ The temperature is kept in a tempering furnace at ℃ for 1 to 4 hours, and air-cooled to room temperature after being released from the furnace to obtain quenched and tempered gray cast iron. The invention develops a quenching and tempering process suitable for gray cast iron, which avoids quenching and cracking of gray cast iron, the structure of quenched and tempered gray cast iron is uniform, the shape and size of graphite do not change, and the matrix structure is dominated by fine sorbite (more than 90%). ), the internal stress is the smallest, which can effectively prevent the expansion of thermal fatigue cracks, and improve the mechanical strength and thermal fatigue resistance of the material while ensuring the thermal conductivity.

Owner:DONGFENG COMML VEHICLE CO LTD

High thermal fatigue resistant commercial vehicle brake disc material and preparation method thereof

PendingCN114855068AImprove thermal fatigue lifeProcess efficiency improvementCarbide siliconThermal fatigue

The invention relates to the technical field of automobiles, in particular to a high-thermal-fatigue-resistant commercial vehicle brake disc material and a preparation method thereof. The invention discloses a commercial vehicle brake disc material resistant to high thermal fatigue. The material is prepared from, by weight, 61%-78% of waste steel, 17%-33% of foundry returns, 0.25%-0.7% of ferromolybdenum alloy, 1.4%-2.0% of silicon carbide, 1.7%-2.5% of carburant, 0.24%-0.5% of copper, 0.10%-0.25% of ferromanganese, 0.17%-0.45% of ferrochromium and 0.15%-0.2% of ferrous sulfide. The preparation method of the commercial vehicle brake disc material resistant to high thermal fatigue comprises the following steps: step 1, preparing materials; 2, feeding and melting; thirdly, molten iron components are smelted; 4, discharging and inoculation treatment; and fifthly, pouring is conducted. The effect of prolonging the thermal fatigue resisting life of the brake disc can be achieved, and the problem that the service life of a brake disc of an existing disc brake is short under the high heat load is solved.

Owner:CHINA FIRST AUTOMOBILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com