Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

470results about How to "Inhibit the generation of cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

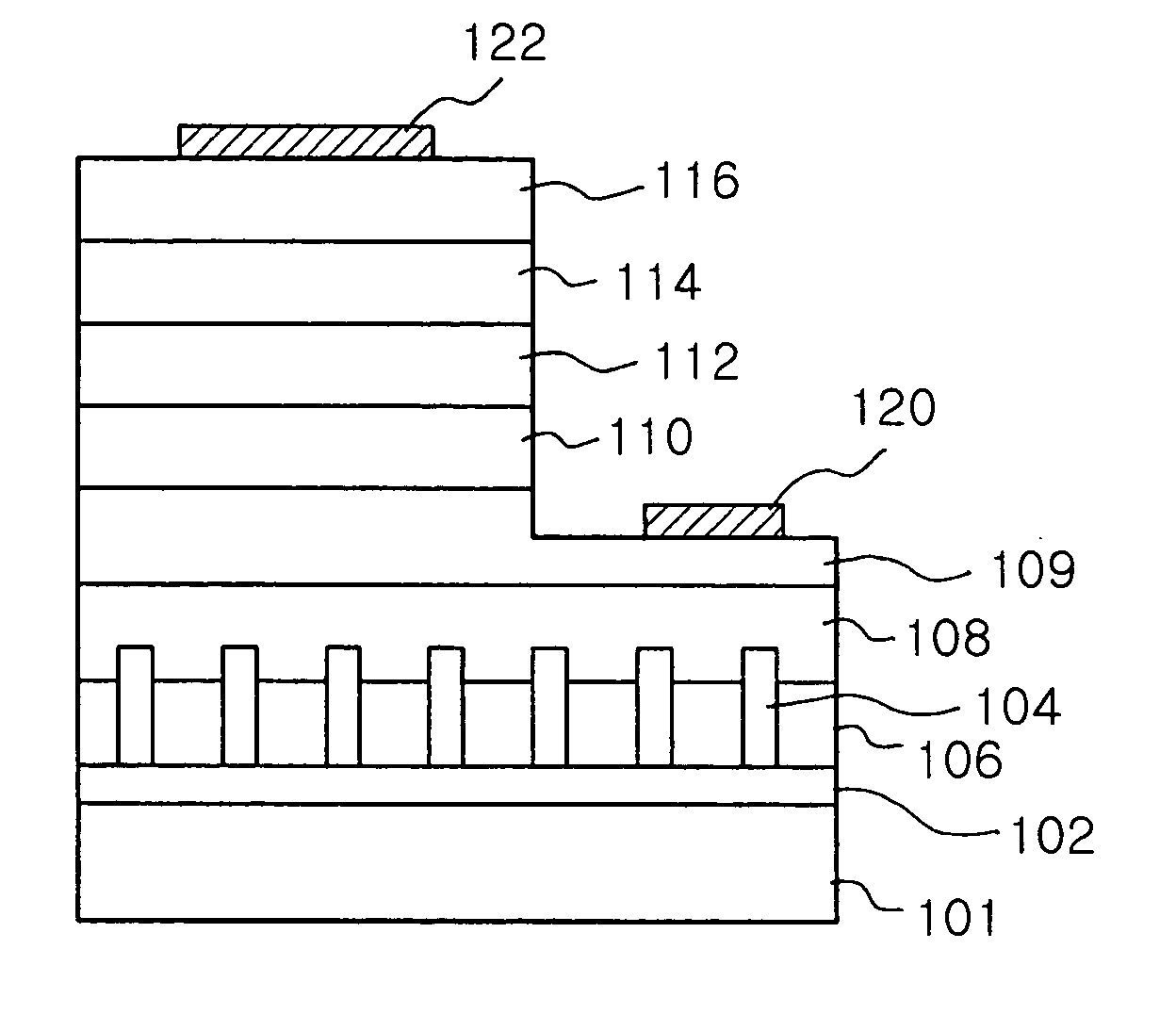

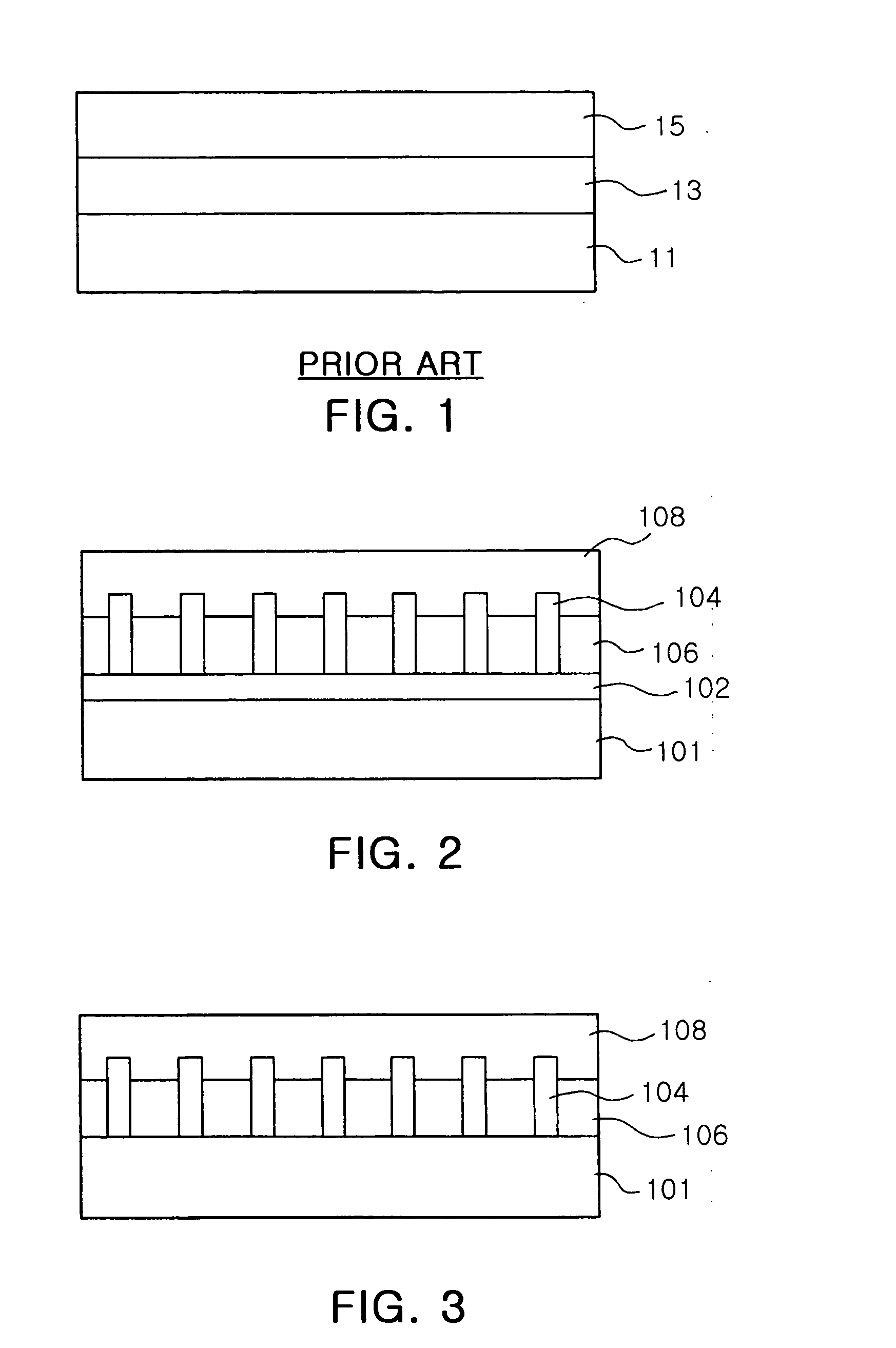

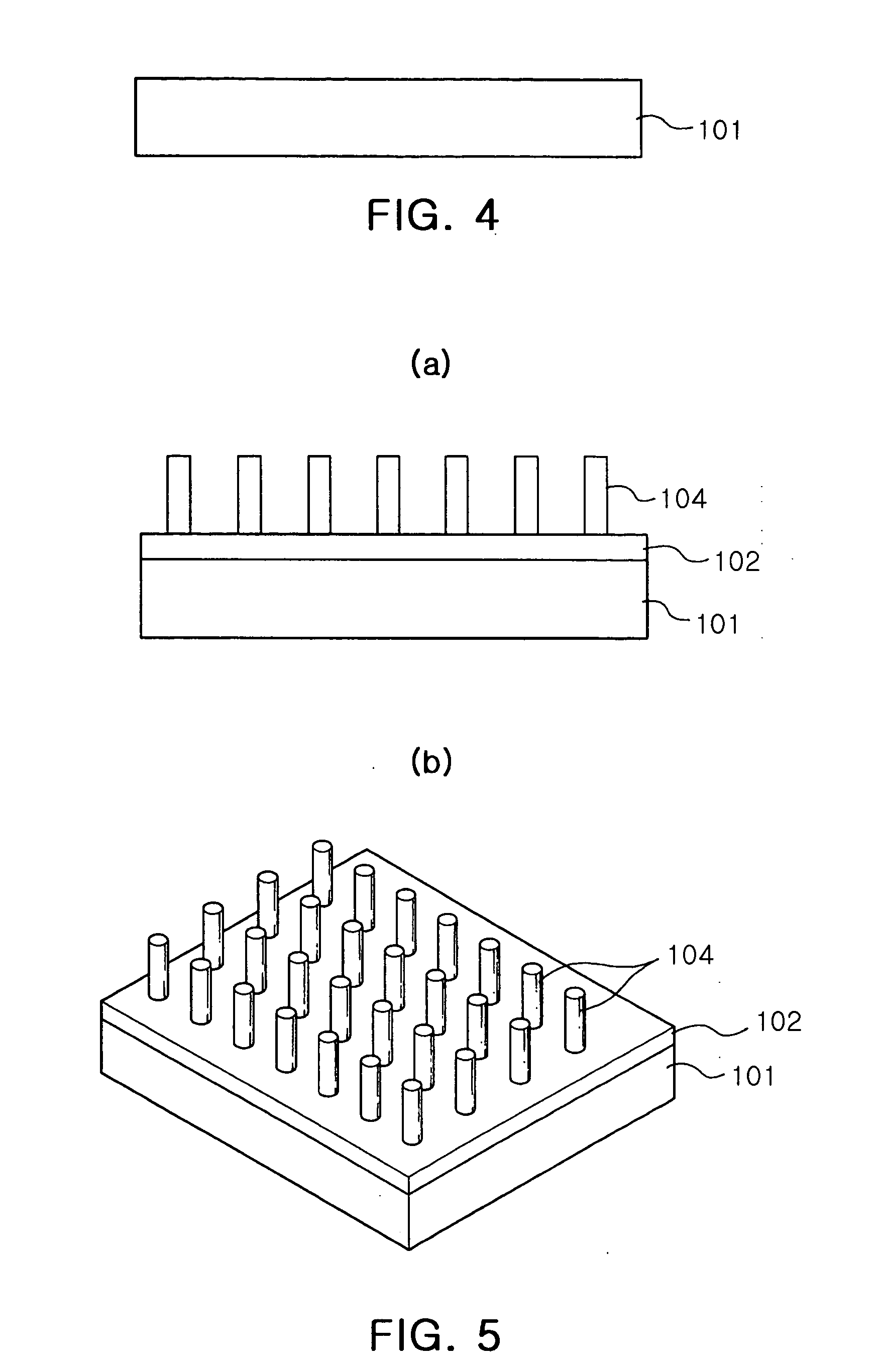

Nitride based semiconductor device using nanorods and process for preparing the same

ActiveUS20060091408A1Reduce thermal stressInhibit the generation of cracksSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialAmorphous matrix

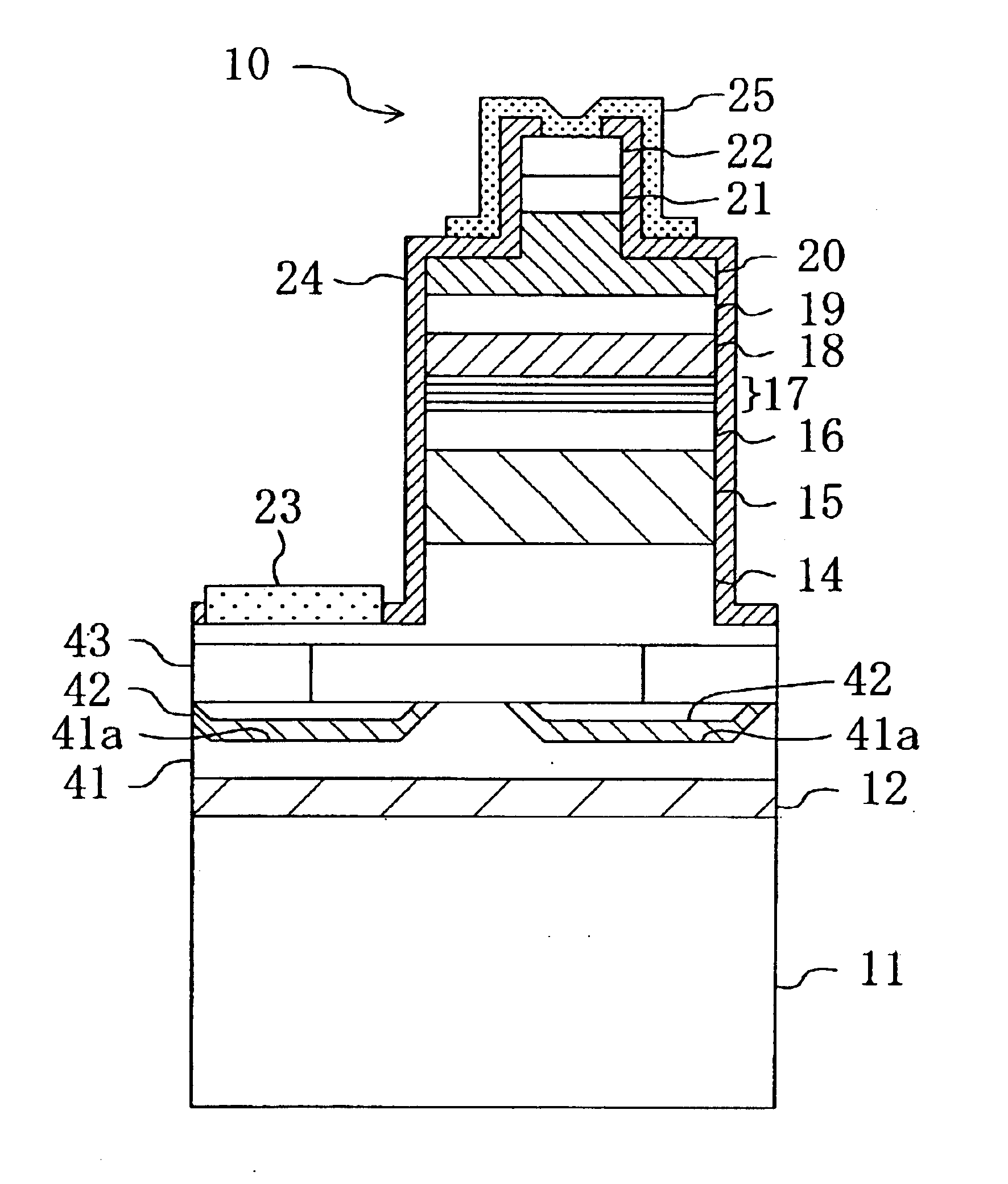

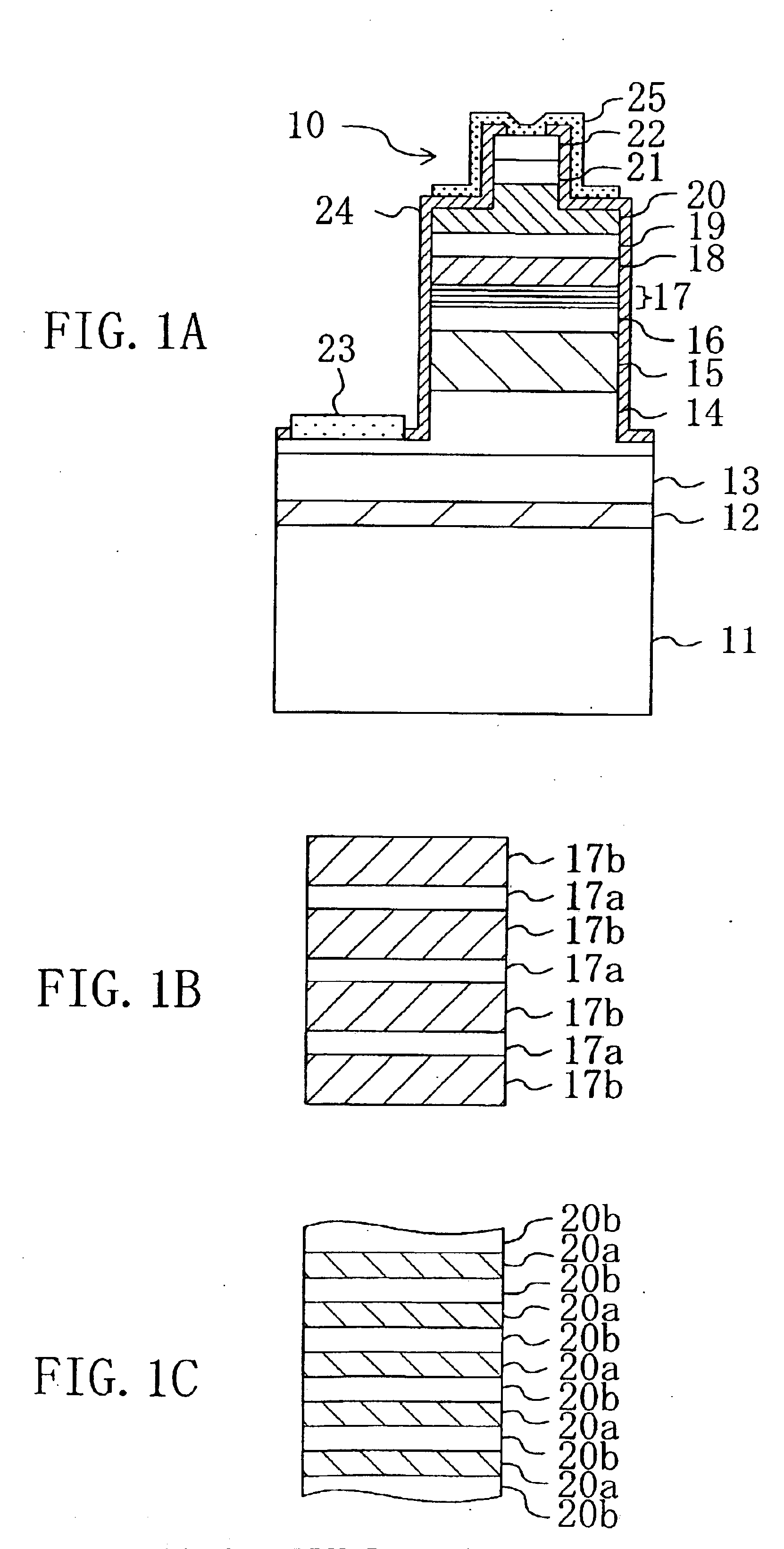

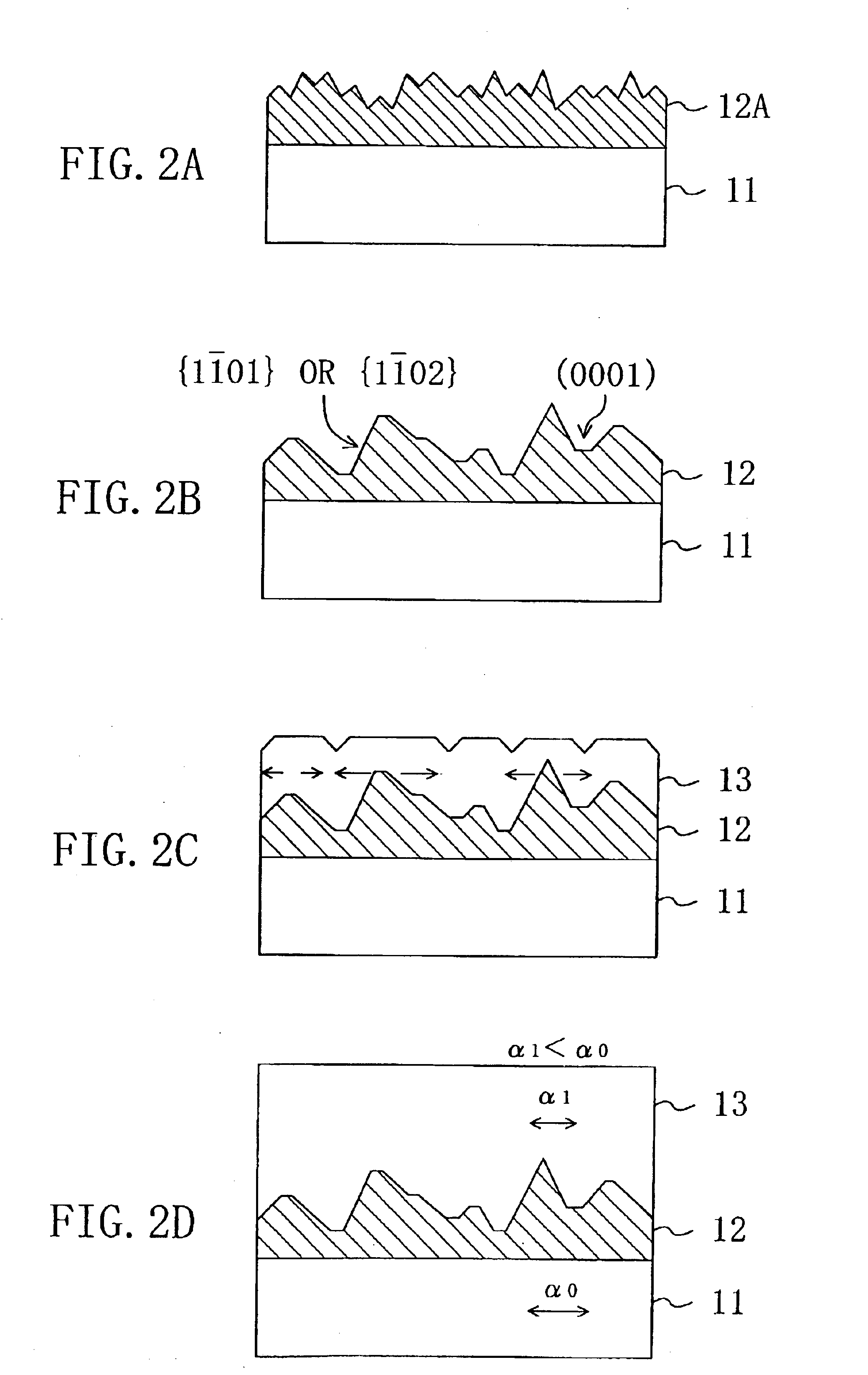

Disclosed are a nitride based semiconductor device, including a high-quality GaN layer formed on a silicone substrate, and a process for preparing the same. A nitride based semiconductor device in accordance with the present invention comprises a plurality of nanorods aligned and formed on the silicone substrate in the vertical direction; an amorphous matrix layer filling spaces between nanorods so as to protrude some upper portion of the nanorods; and a GaN layer formed on the matrix layer.

Owner:SAMSUNG ELECTRONICS CO LTD

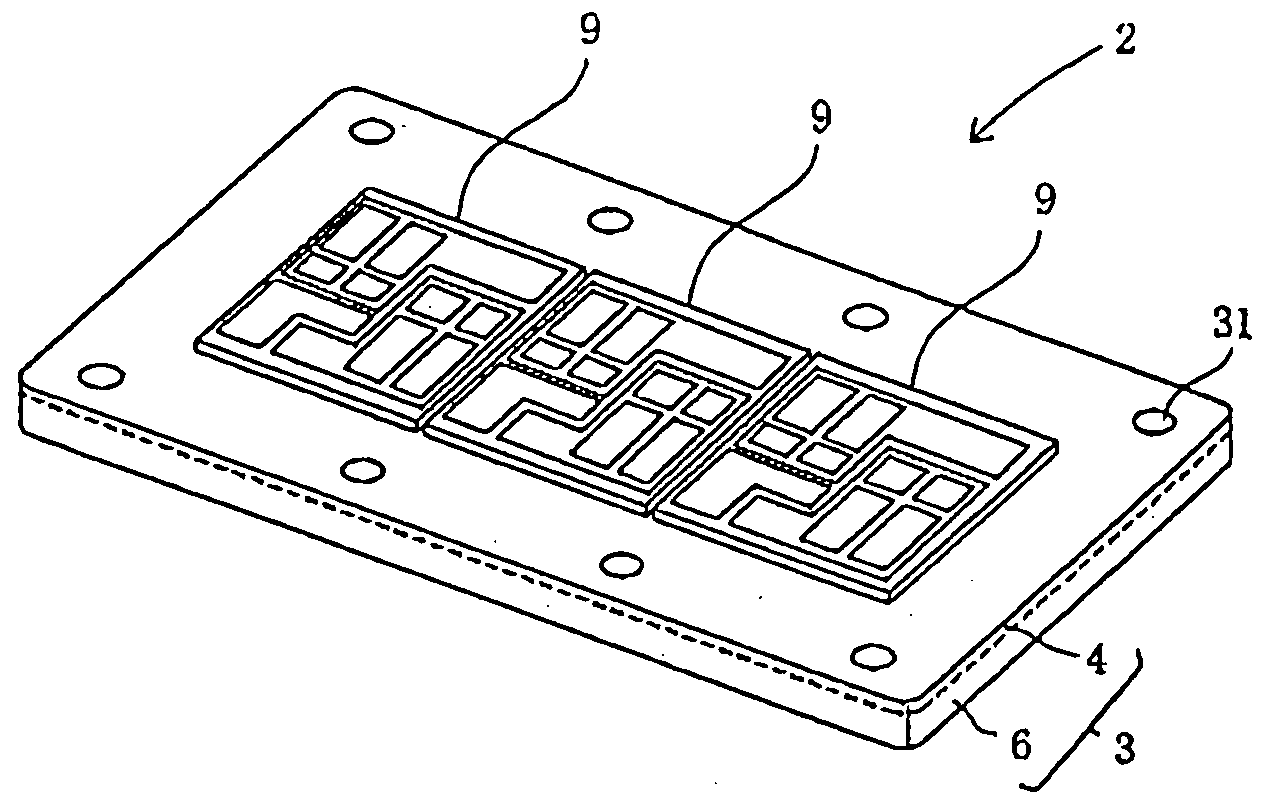

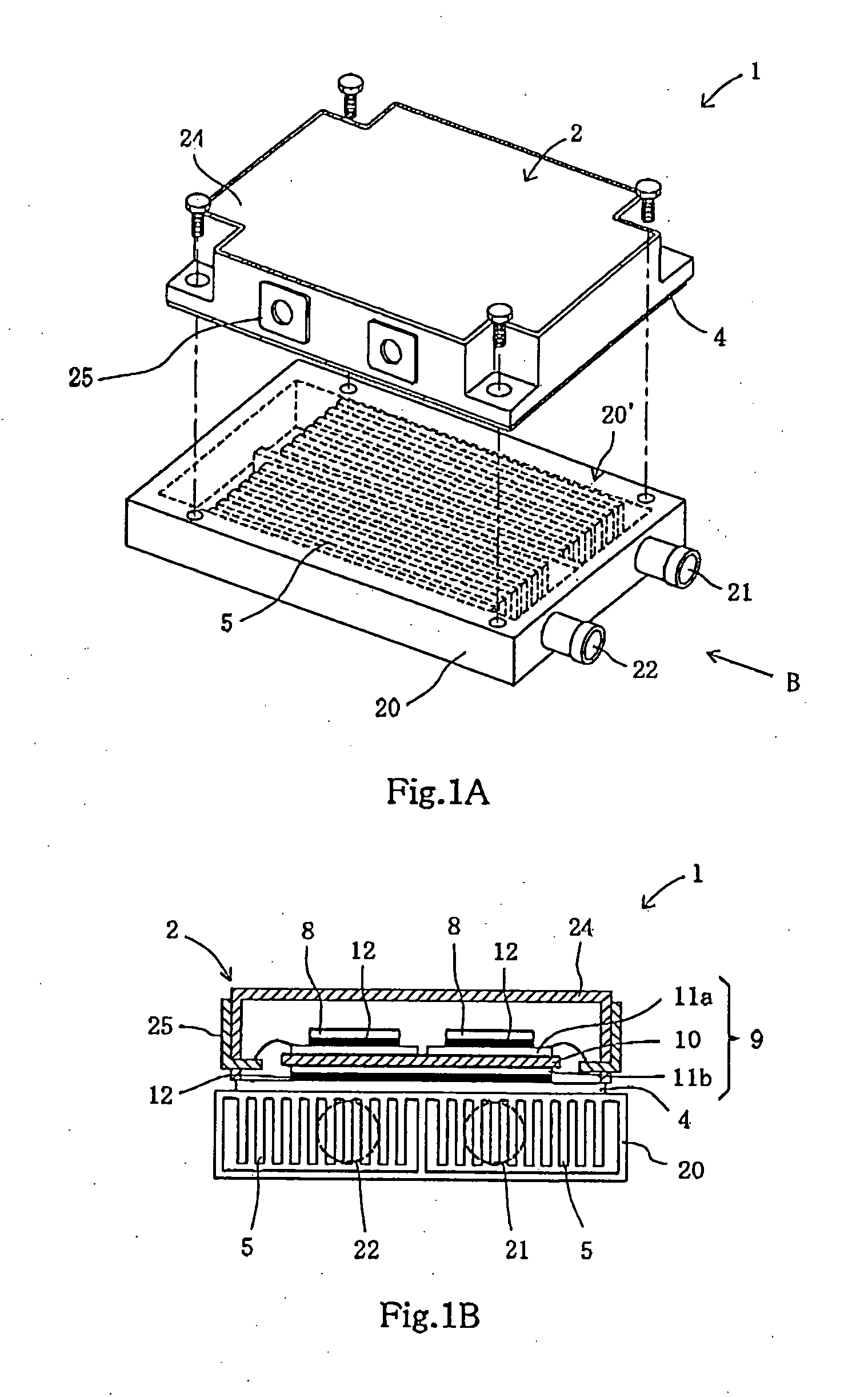

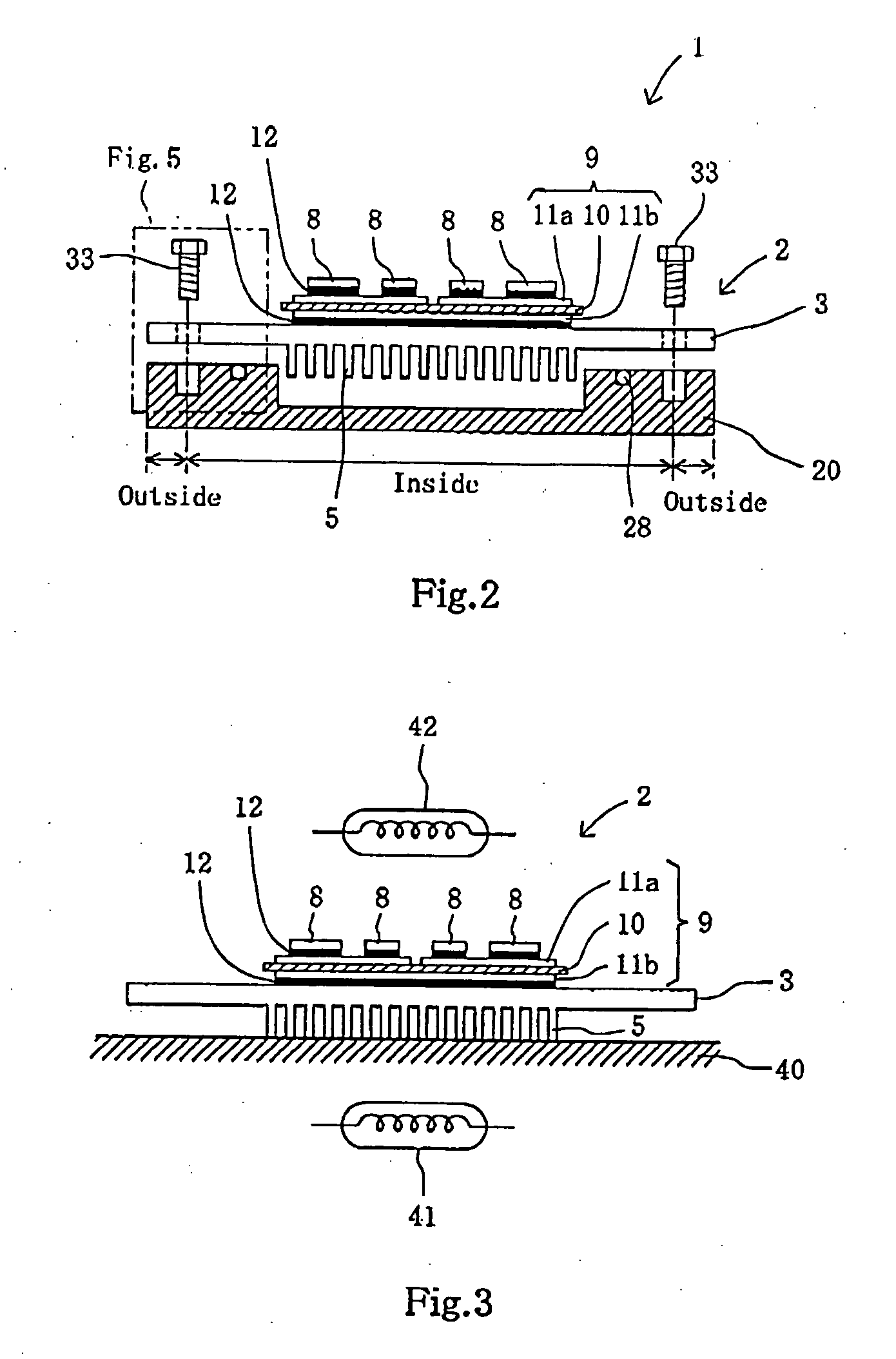

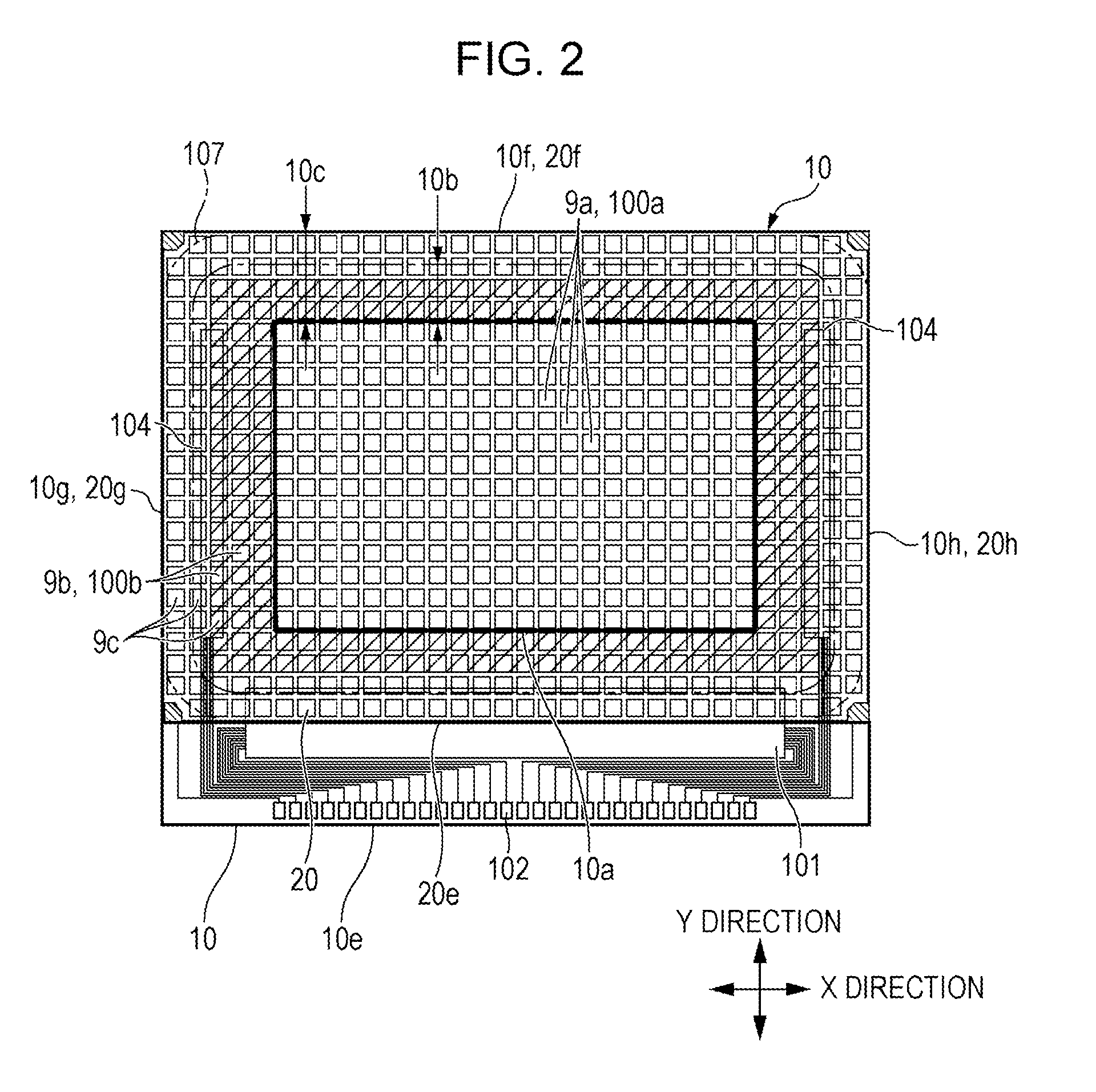

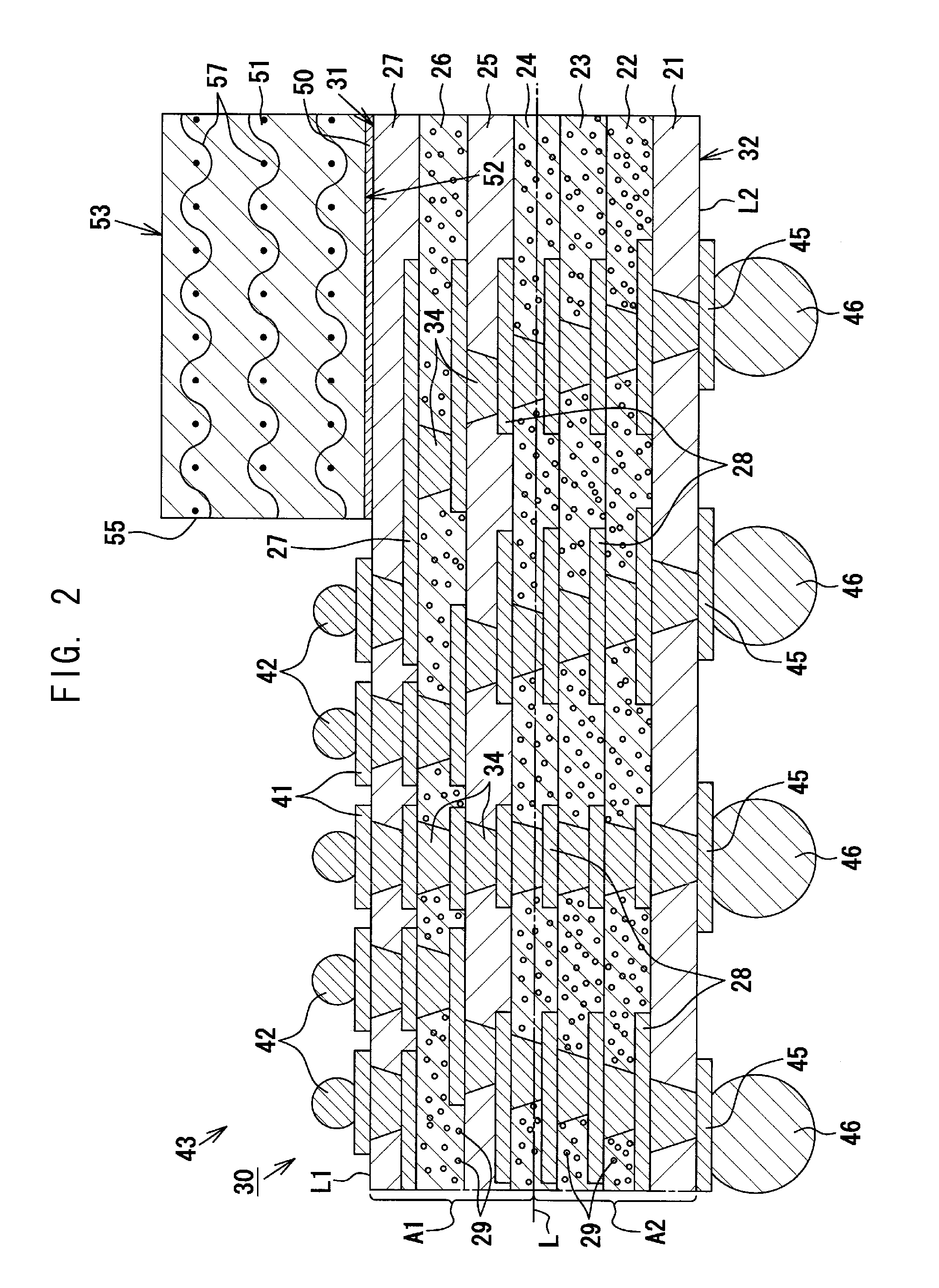

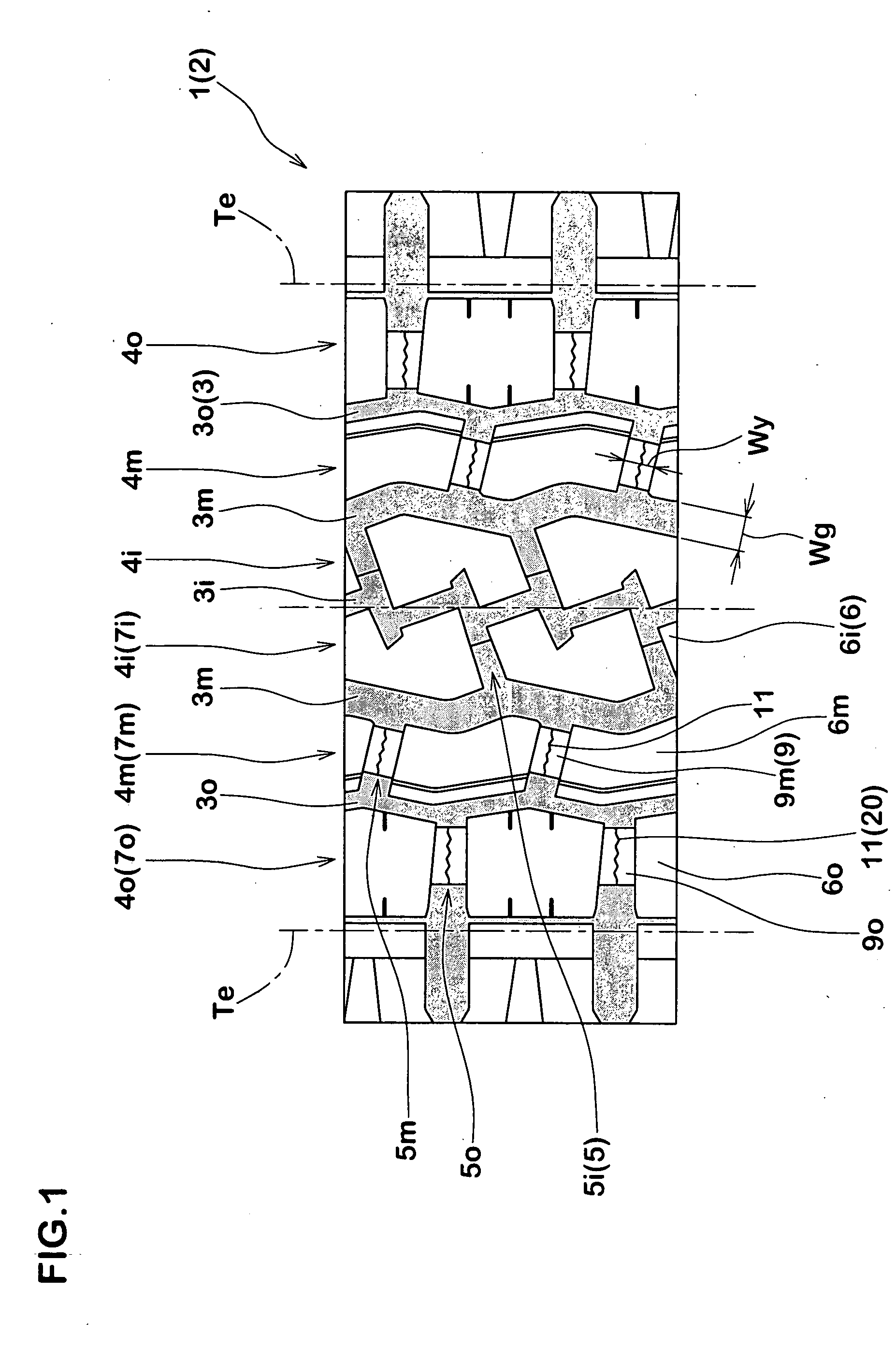

Power semiconductor module, and power semiconductor device having the module mounted therein

InactiveUS20080237847A1Avoid it happening againDegree of reductionSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHeat sink

A power semiconductor module according to the present invention includes: a planar base plate having a plurality of insulated substrates soldered on the top surface, the insulated substrates each having power semiconductor elements to be cooled mounted thereon; a plurality of radiation fins projecting from the bottom surface side of the base plate; and a peripheral wall projecting from the bottom surface side of the base plate so as to surround the radiation fins, the projecting length of the radiation fins is less than or equal to that of the peripheral wall, and the peripheral wall has end surfaces present in the same plane. In addition, a power semiconductor device having the power semiconductor module mounted therein includes: at least one reinforcing plate disposed on the top surface side of the base plate via a first buffering member; and a cooling jacket fixed to the bottom surface side of the base plate via a second buffering member with a plurality of tightening fixtures passing through the reinforcing plate and the base plate, the cooling jacket having a flow passage for a cooling medium formed to intervene in a position with respect to the base plate, and the first buffering member and the second buffering member are respectively disposed at least inside and outside with respect to the tightening fixtures.

Owner:NICHICON CORP

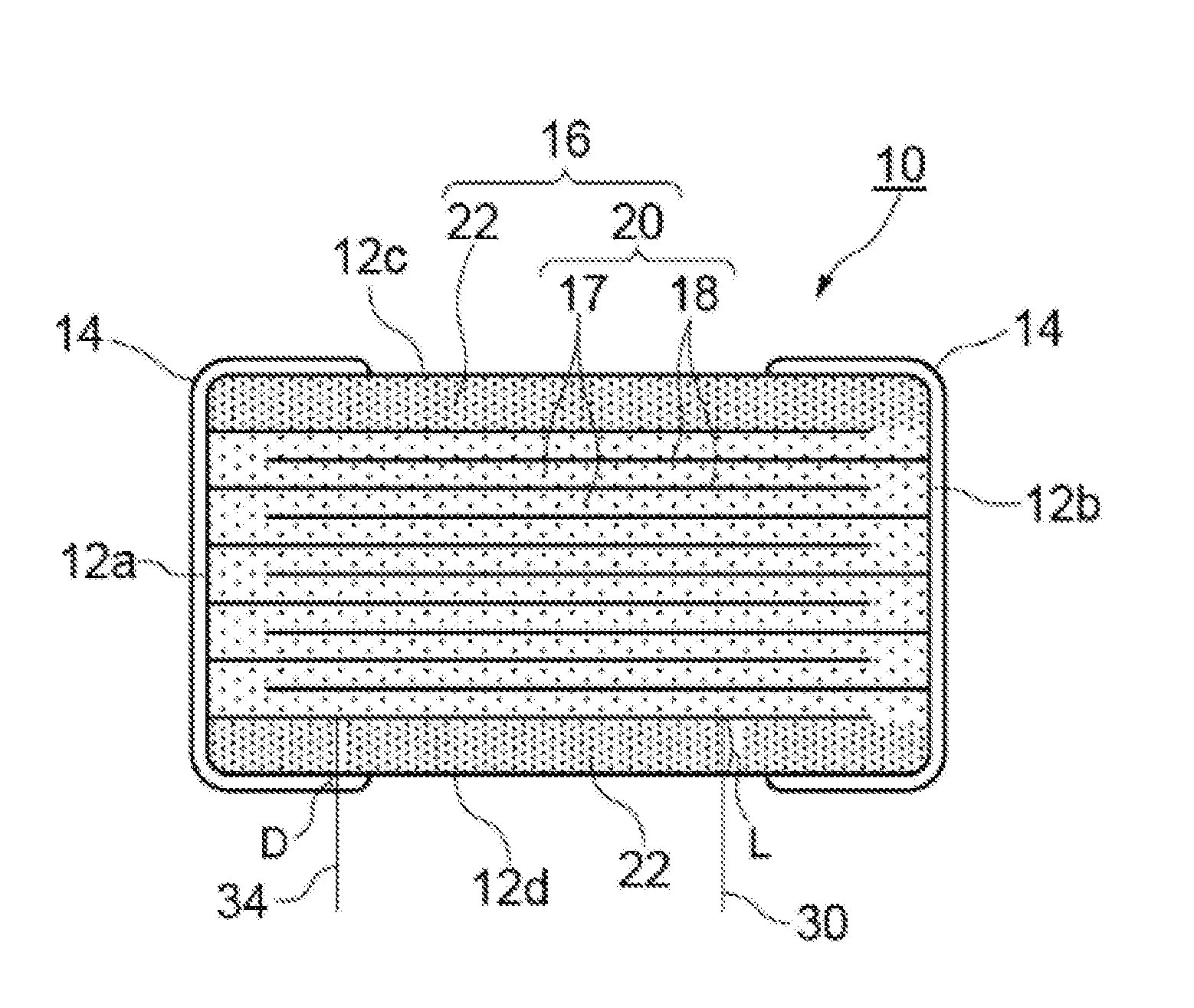

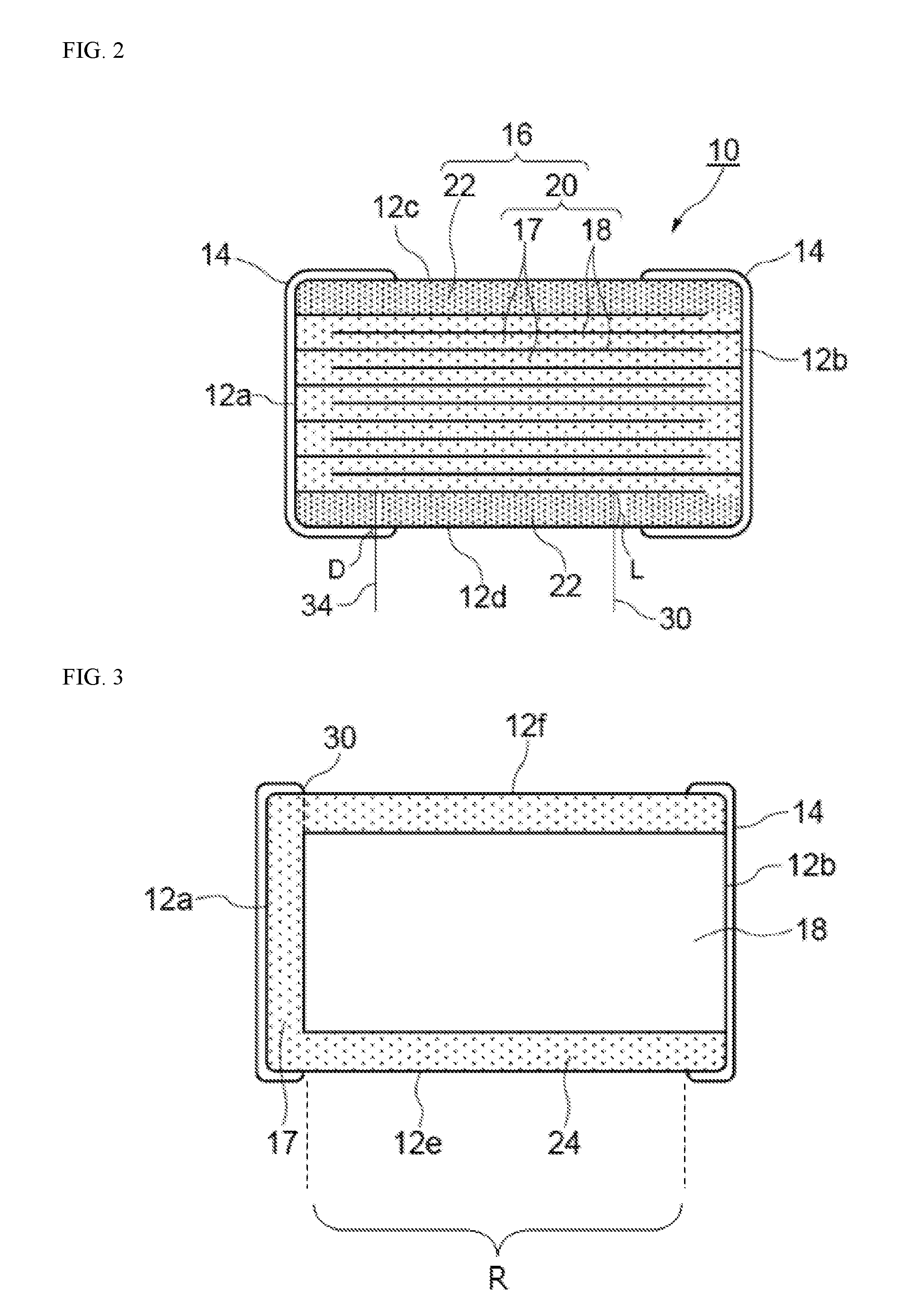

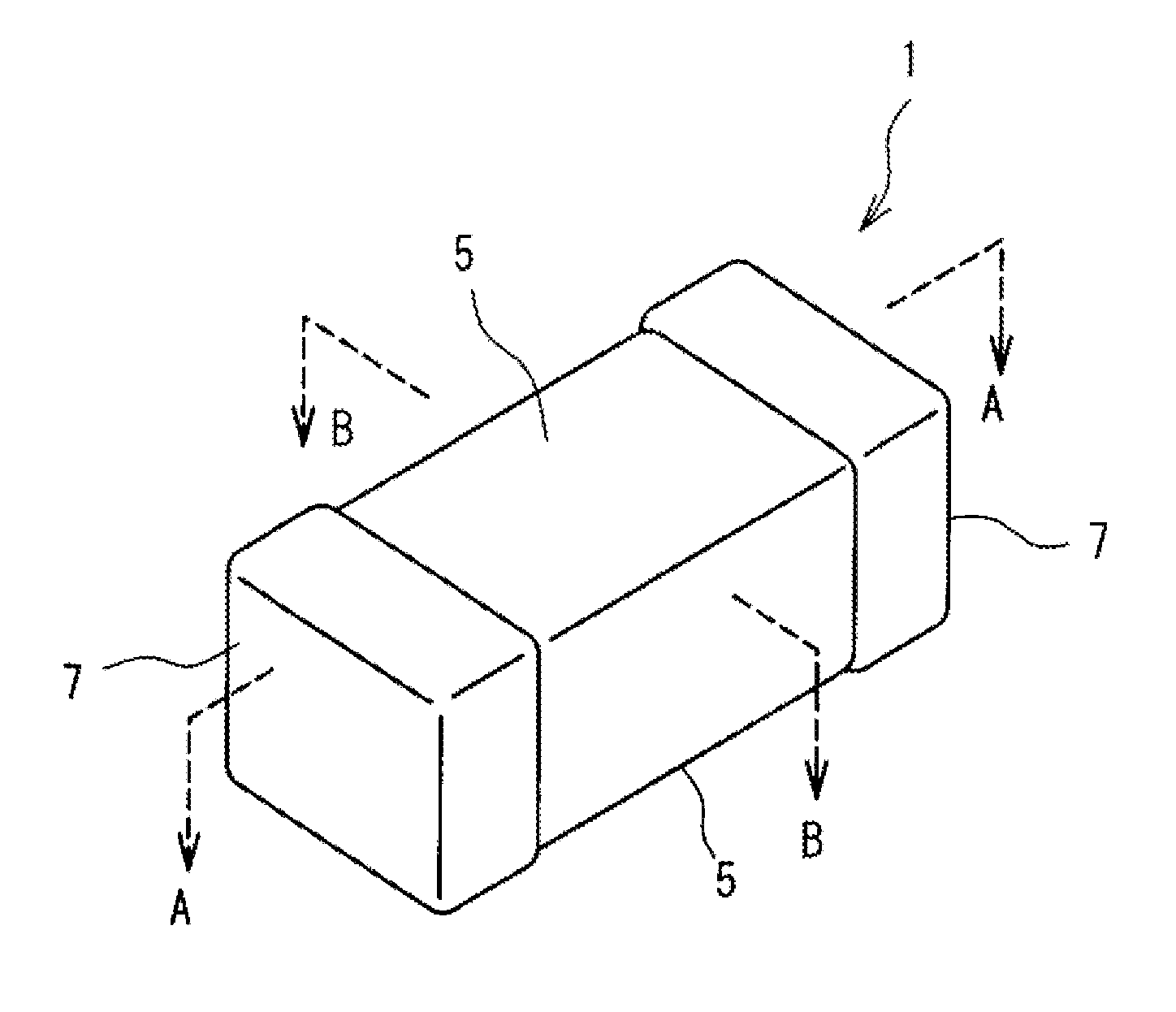

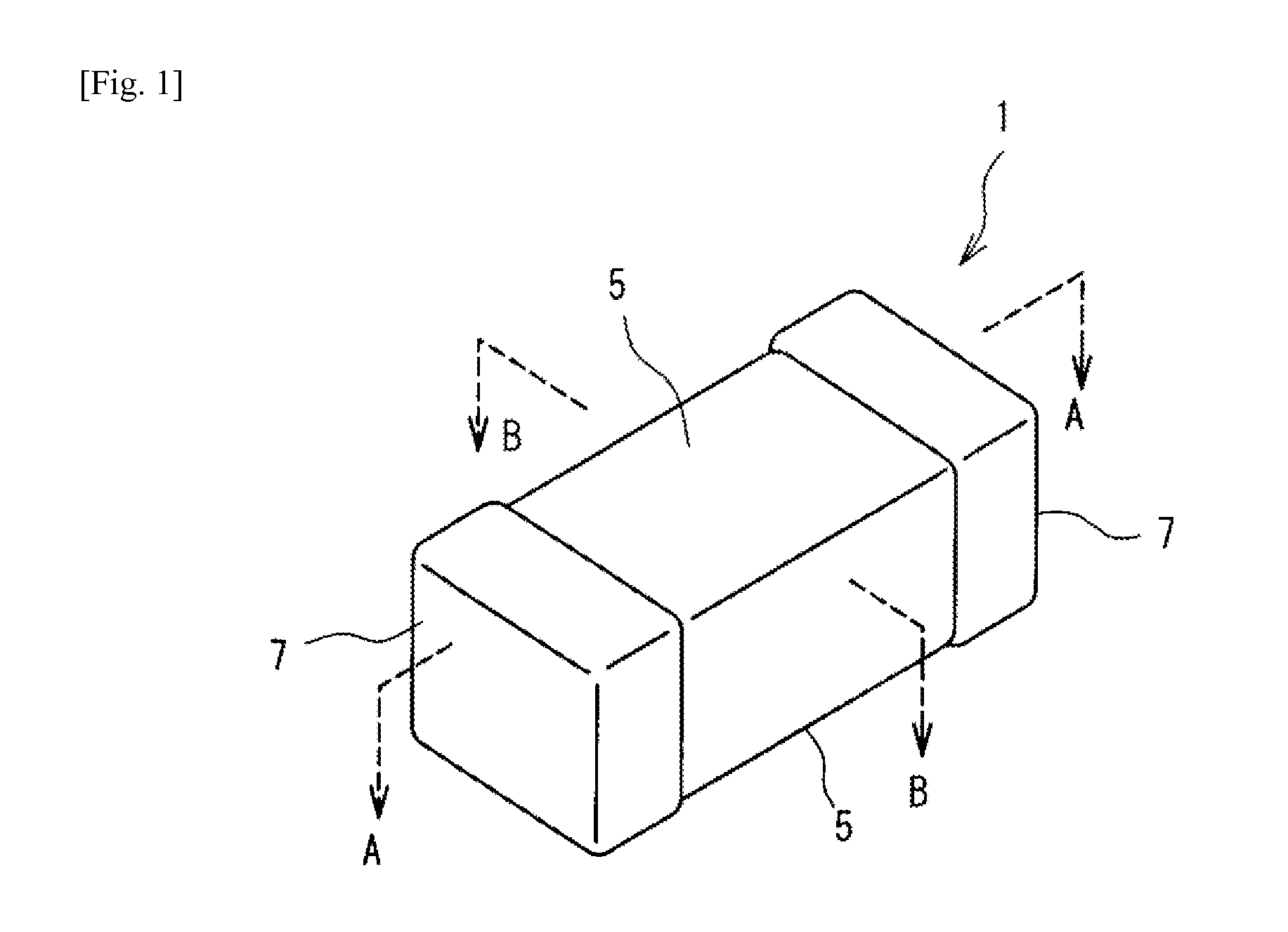

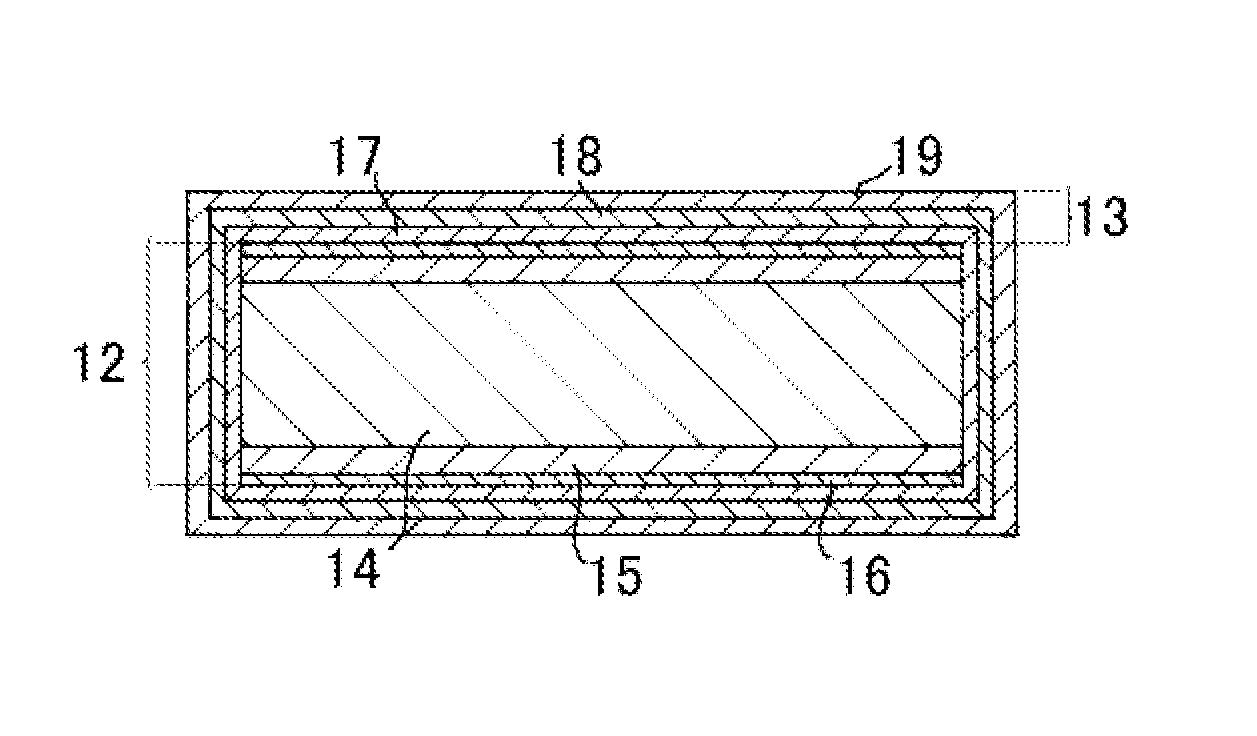

Multilayer ceramic capacitor

InactiveUS20160293331A1Reduce the effective areaReduce capacitanceFixed capacitor dielectricStacked capacitorsCapacitanceCeramic capacitor

A multilayer ceramic capacitor includes an element body of roughly rectangular solid shape which is constituted by dielectric layers alternately stacked with internal electrode layers having different polarities, with a pair of cover layers formed on it to cover the top and bottom faces in the direction of lamination of the foregoing, and which has a pair of principal faces, a pair of end faces, and a pair of side faces, wherein external electrodes are formed on the pair of end faces and at least one of the pair of principal faces of the element body, and Tt representing the thickness of the external electrode and Tc representing the thickness of the cover layer satisfy the relationship of Tt≦Tc. The multilayer ceramic capacitor has large capacitance and also exhibits excellent thermal shock resistance while sufficiently suppressing generation of cracks.

Owner:TAIYO YUDEN KK

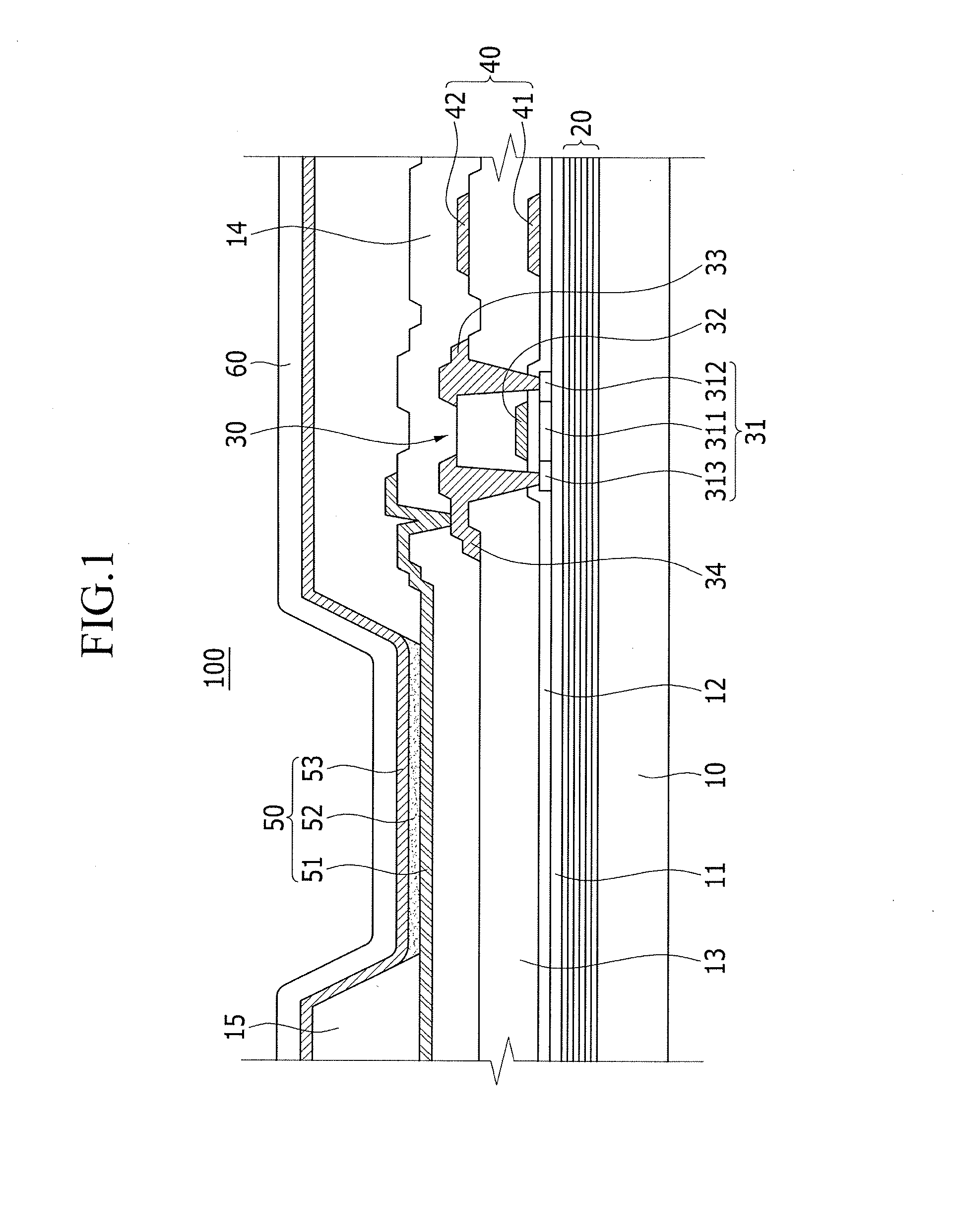

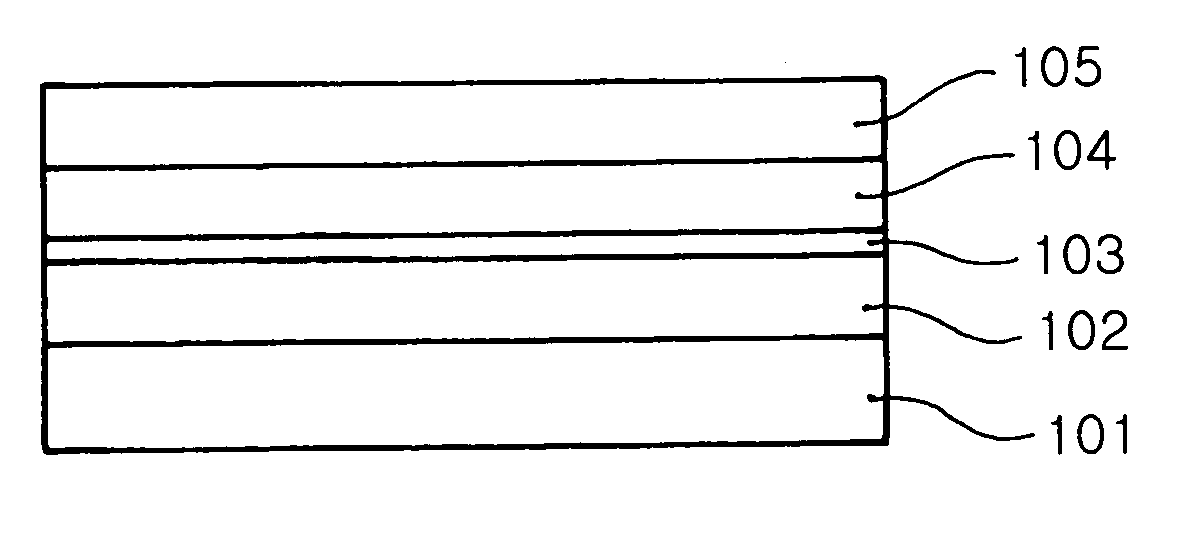

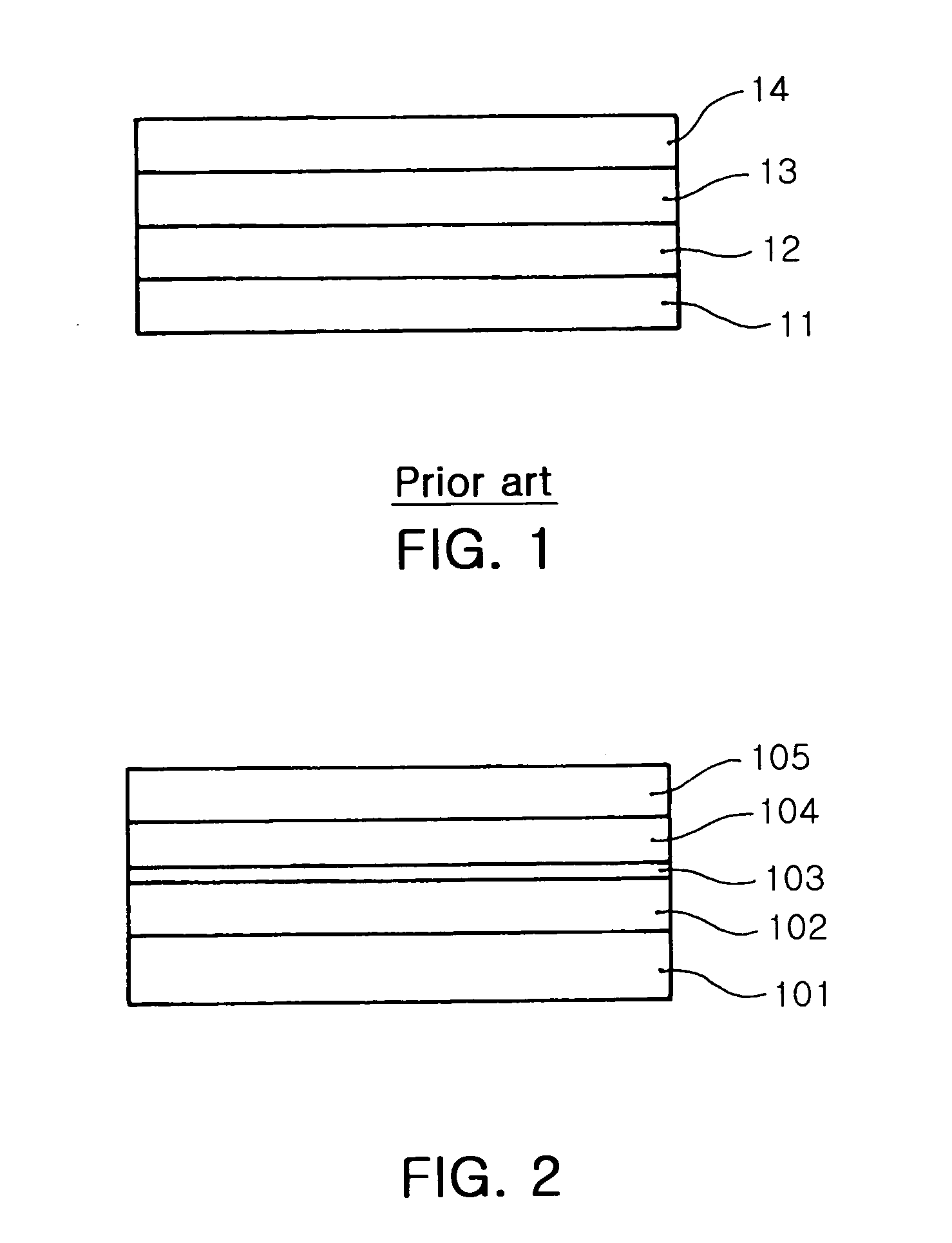

Organic light emitting diode display

ActiveUS20150102324A1Increase flexibilityHigh transparencyElectroluminescent light sourcesSolid-state devicesInsulation layerDisplay device

An organic light emitting diode (OLED) display includes a flexible substrate, a barrier layer disposed on the flexible substrate, and an organic light emitting diode disposed on the barrier layer. The barrier layer includes a plurality of metal layers and a plurality of insulation layers in which the metal layers and the insulation layers are alternatively stacked with each other on the flexible substrate.

Owner:SAMSUNG DISPLAY CO LTD

Electrostatic chuck

InactiveUS20130026720A1Inhibit the generation of cracksFast heatingSleeve/socket jointsSemiconductor/solid-state device manufacturingMetallurgyInorganic materials

An electrostatic chuck comprises: a ceramic plate provided with recesses on a major surface and provided with an electrode in an inner part of the ceramic plate; a temperature regulating plate bonded to the major surface of the ceramic plate; a first bonding agent provided between the ceramic plate and the temperature regulating plate; and a heater provided in the each of the recesses of the ceramic plate. The first bonding agent has a first major agent including an organic material, a first amorphous filler including an inorganic material, and a first spherical filler including an inorganic material. The first amorphous filler and the first spherical filler are dispersion-compounded into the first major agent. The first major agent, the first amorphous filler, and the first spherical filler are made of an electrically insulating material. An average diameter of the first spherical filler is greater than a maximum value of a minor axis of the first amorphous filler. A thickness of the first bonding agent is greater than or equal to the average diameter of the first spherical filler. A width of the each of the recesses is greater than a width of the heater, and a depth of the each of the recesses is greater than a thickness of the heater. The heater is adhered within the each of the recesses by a second bonding agent. A first distance between a major surface of the heater on the side of the temperature regulating plate and a major surface of the temperature regulating plate is greater than a second distance between the major surface between the recesses of the ceramic plate and the major surface of the temperature regulating plate.

Owner:TOTO LTD

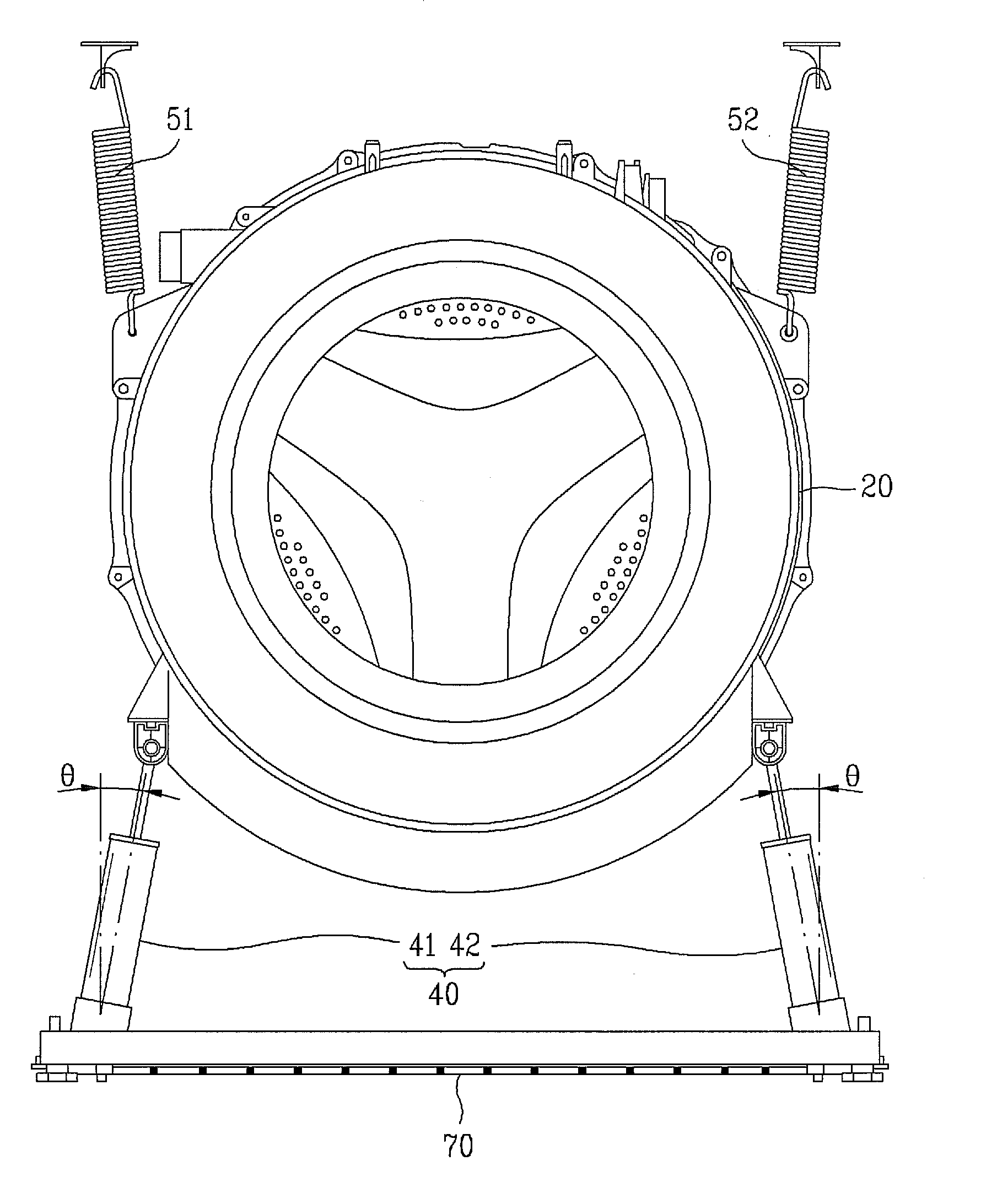

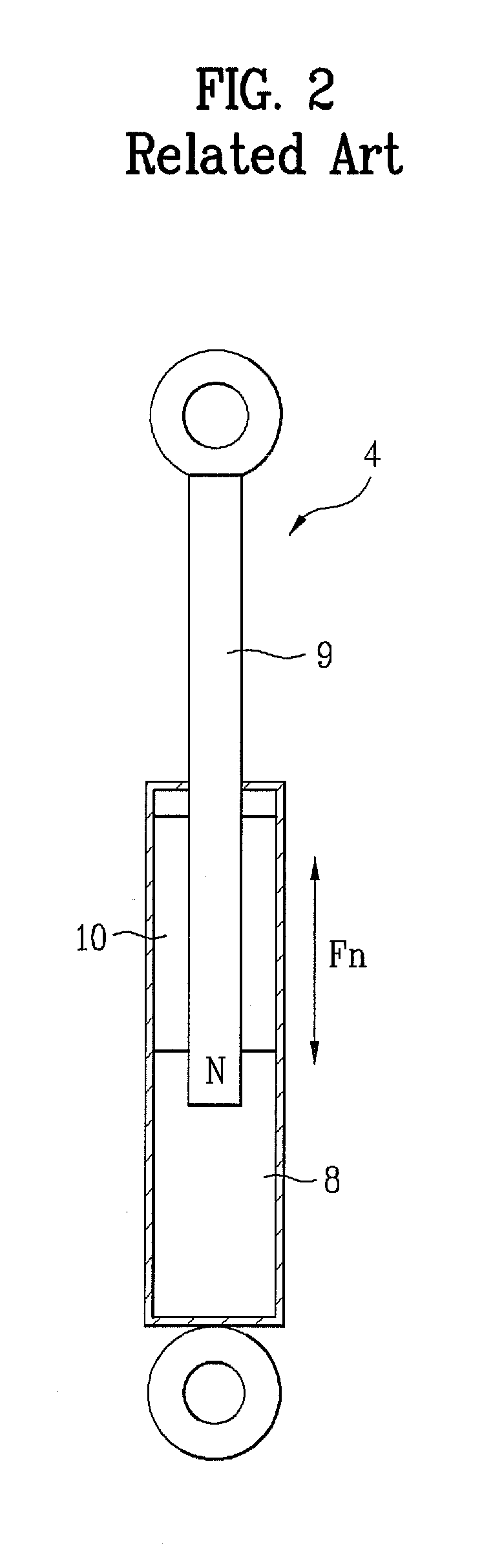

Mechanical apparatus for washing/drying

InactiveUS20070289339A1Inhibit the generation of cracksExtended availabilityOther washing machinesWashing machine with receptaclesHinge angleEngineering

A mechanical apparatus for washing / drying is disclosed. Accordingly, the present invention provides a structure for damping and absorbing vibration of a tub in a washer or dryer. The present invention includes a tub accommodating water therein, a drum rotatably provided within the tub, a spring provided to elastically support the tub, and a damping means having one end rotatably connected to the tub by a hinge assembly and the other end connected to a shock-absorbing member fixed to a cabinet.

Owner:LG ELECTRONICS INC

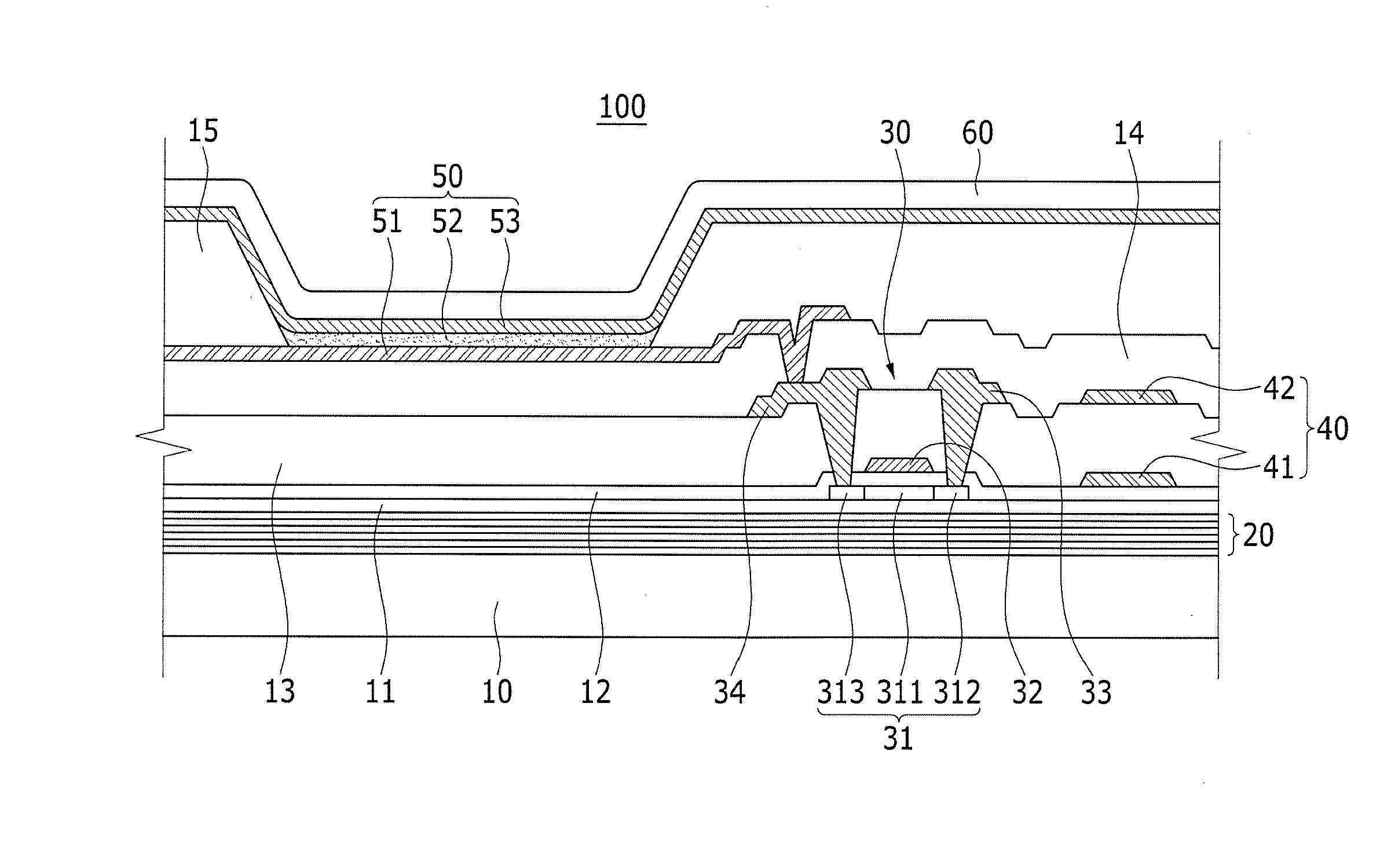

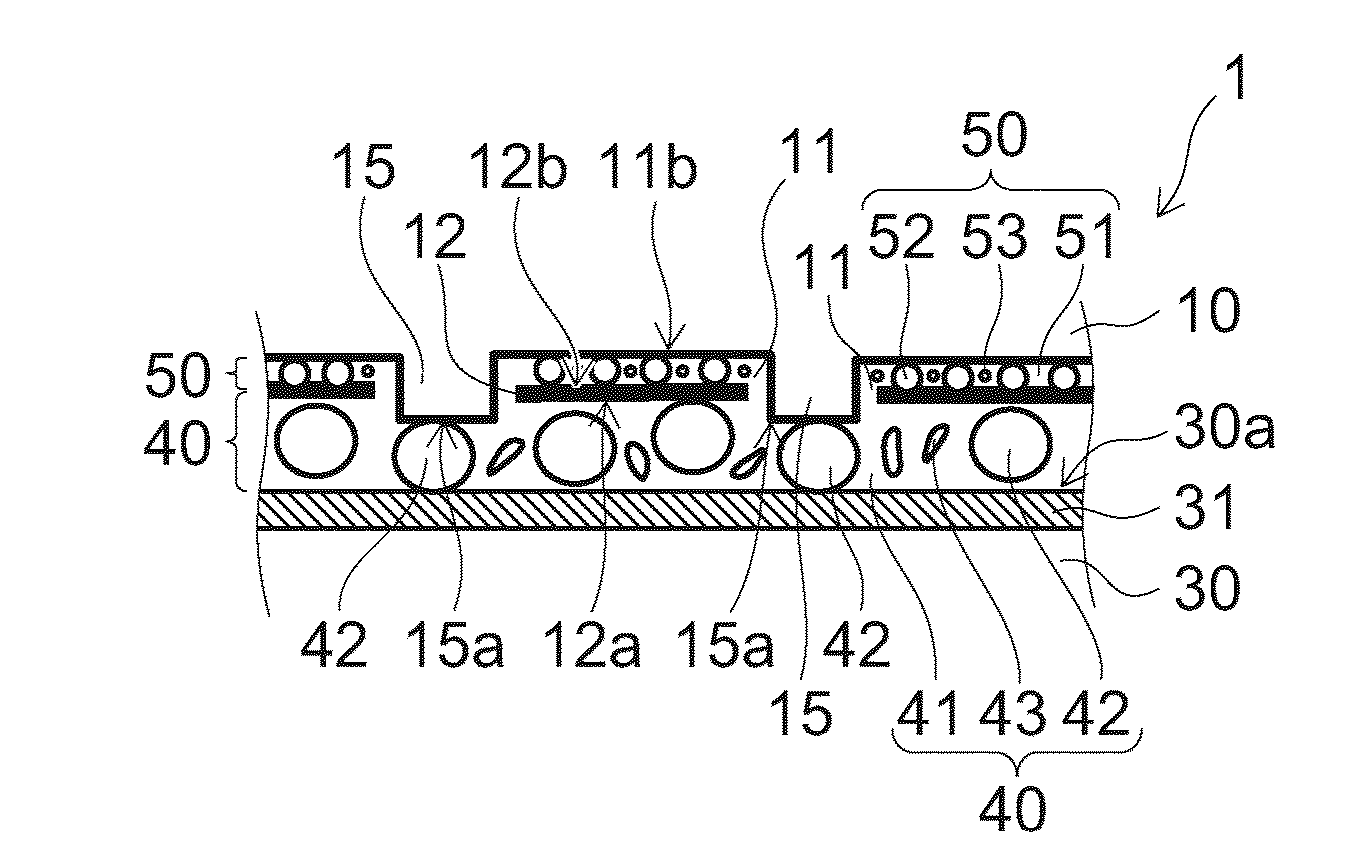

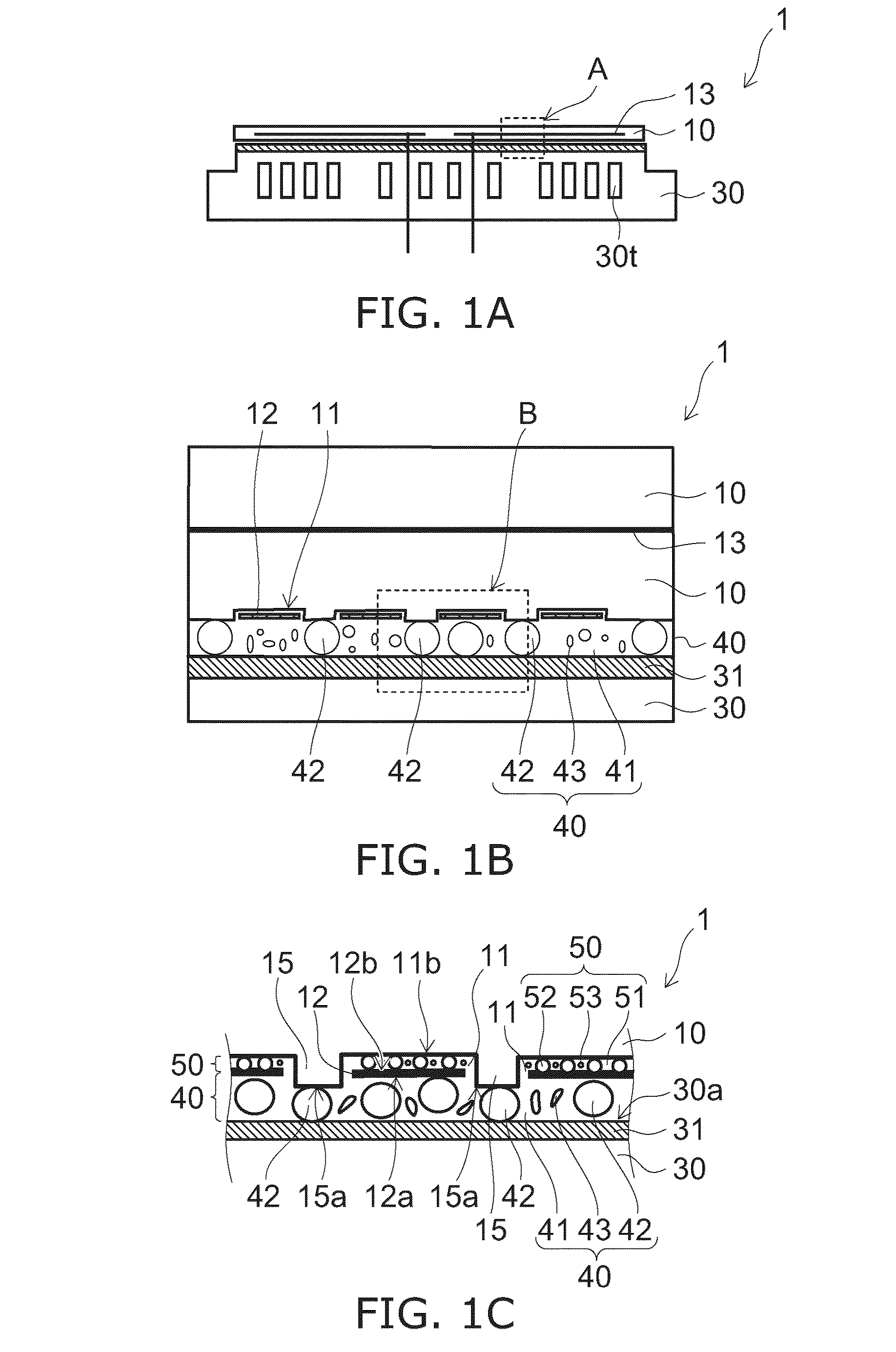

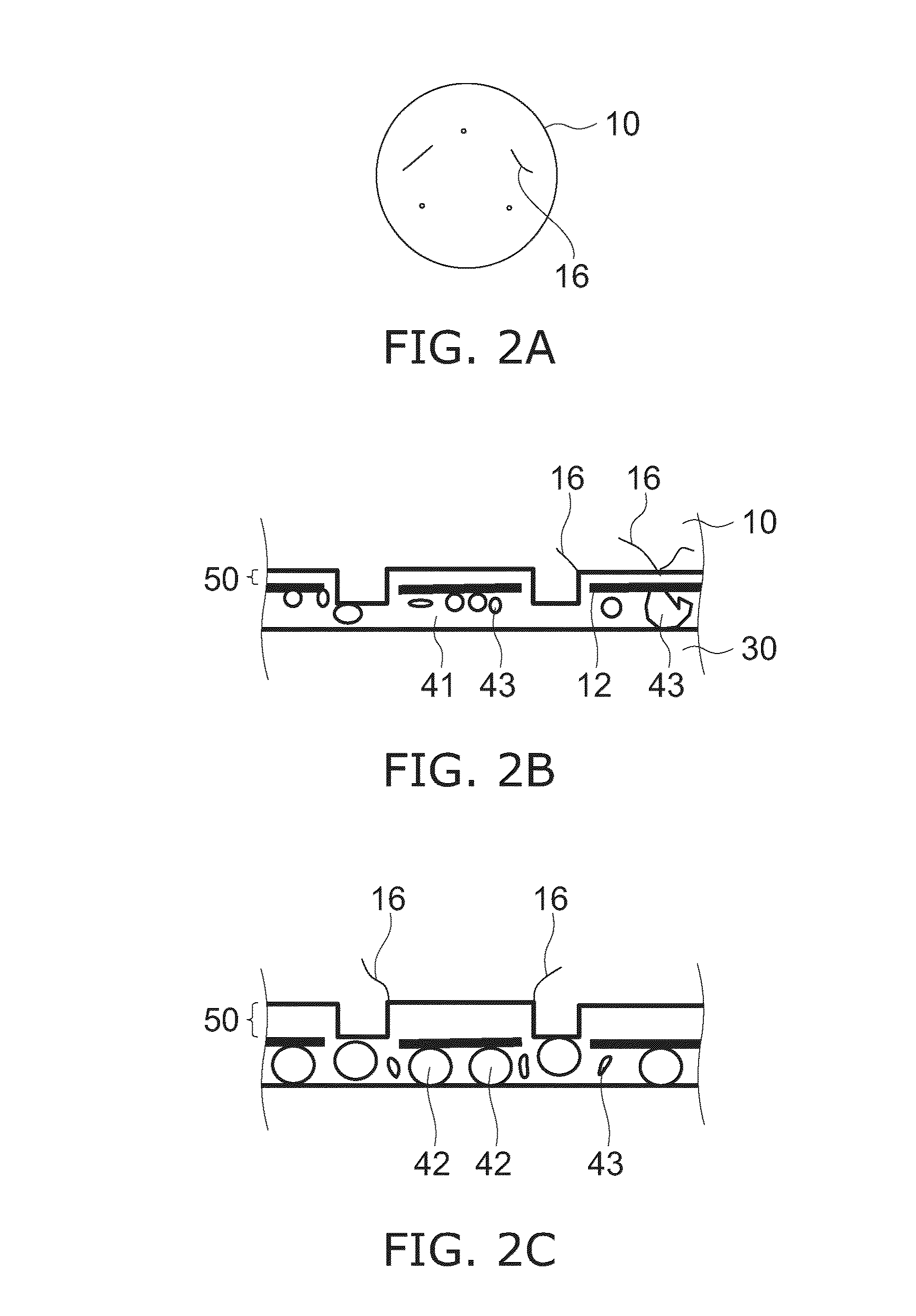

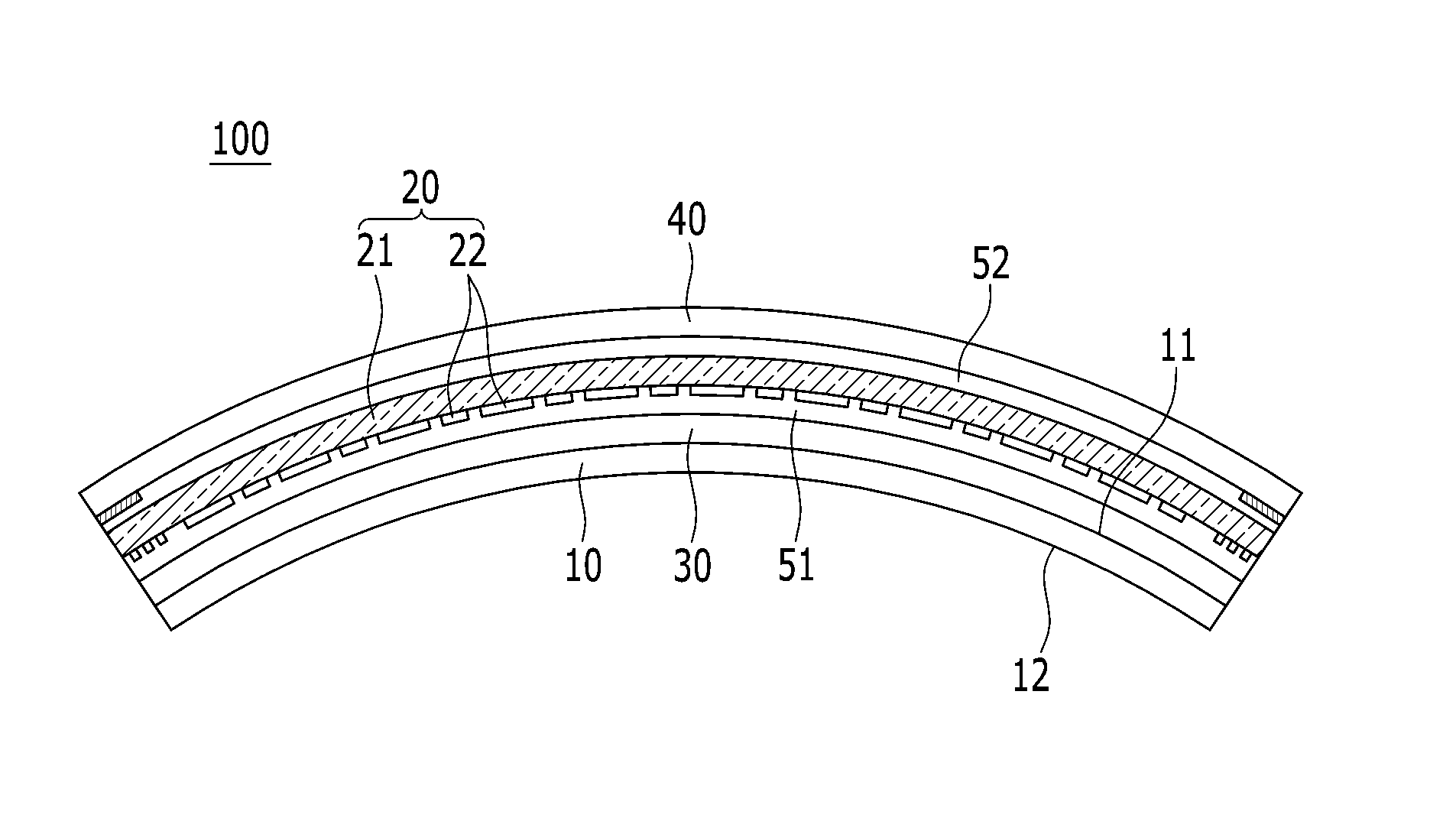

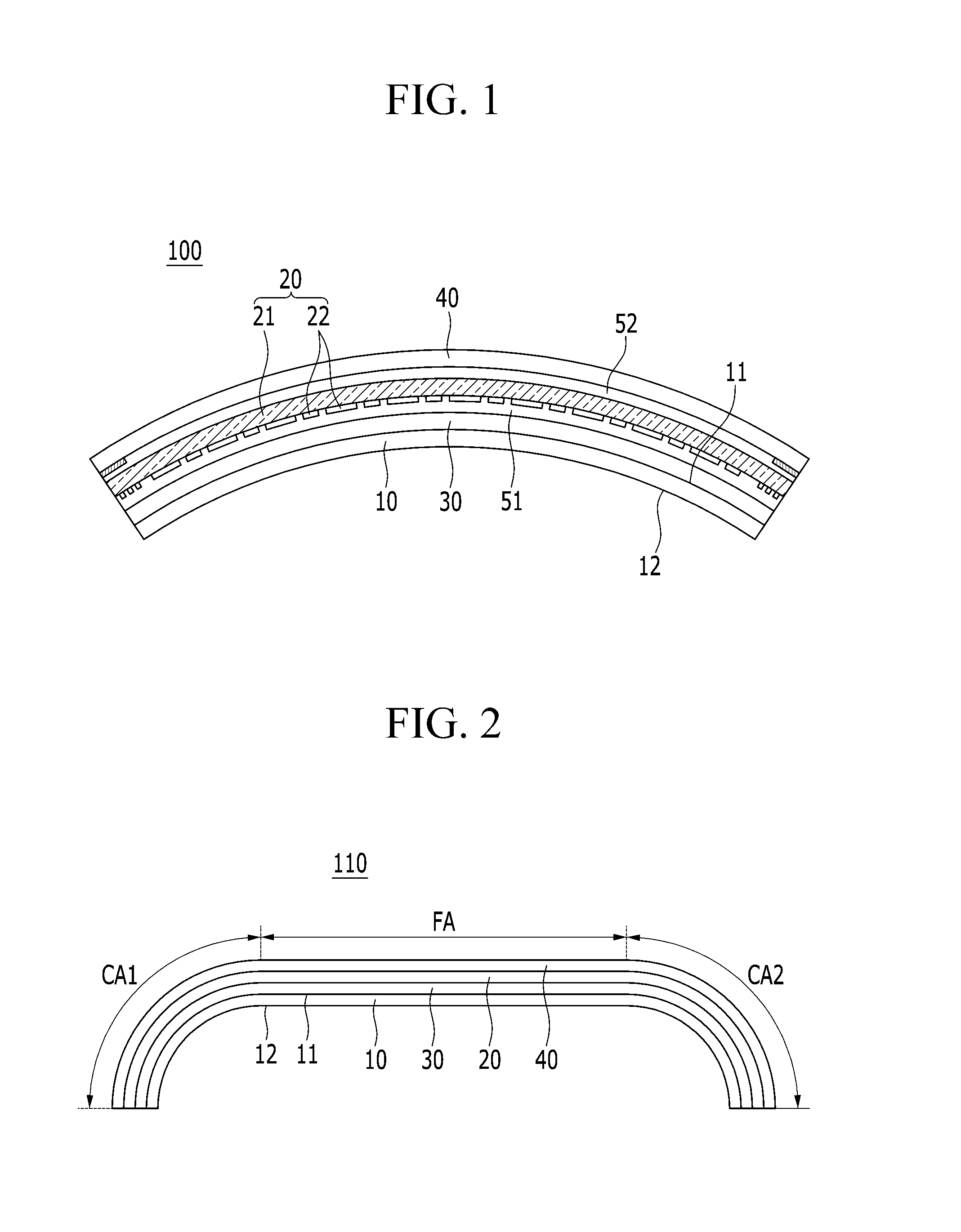

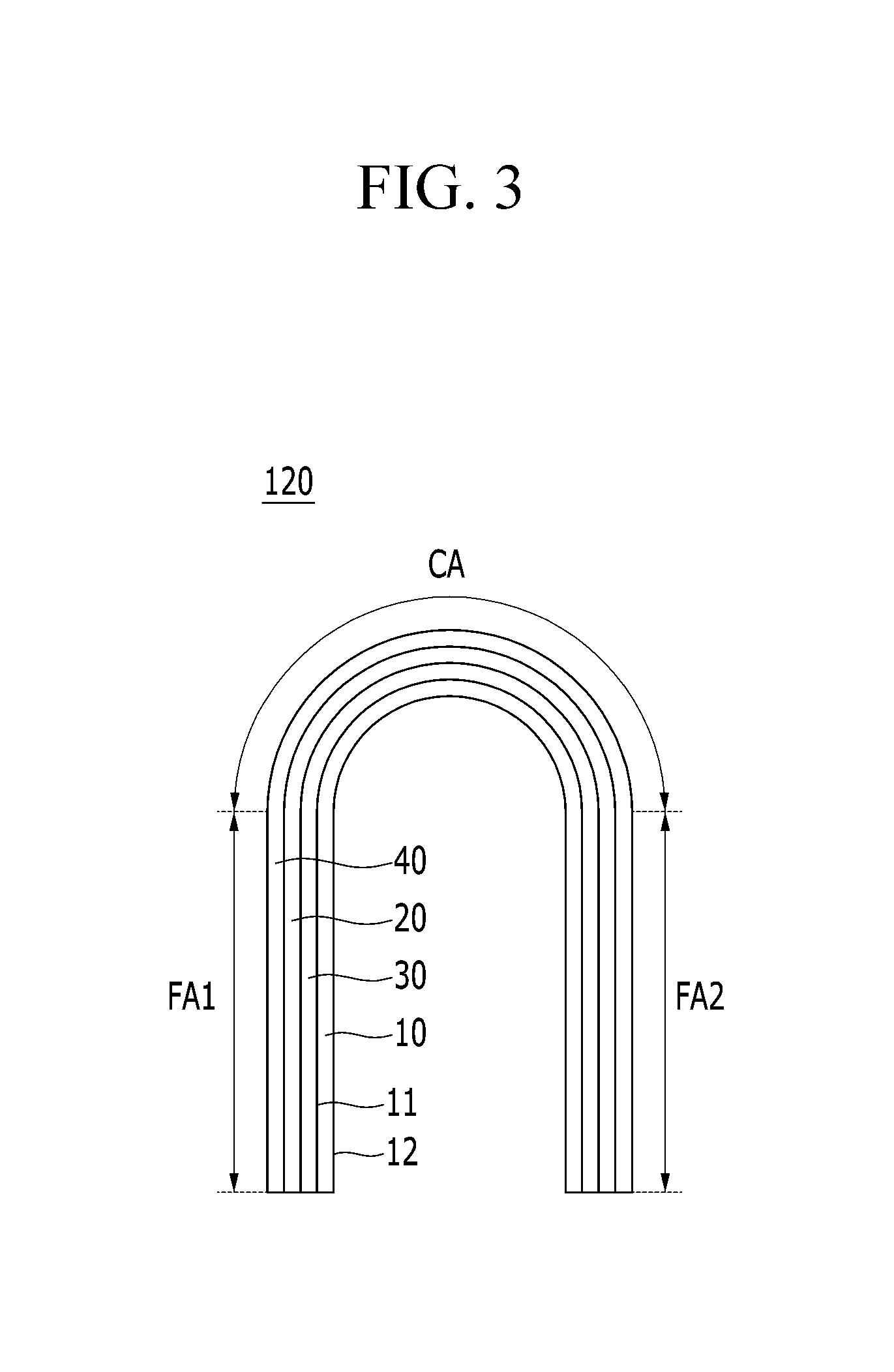

Flexible display device with touch panel

ActiveUS20160011689A1Crack suppressionInhibit the generation of cracksDigital data processing detailsInput/output processes for data processingFlexible displayComputer science

A flexible display device includes a display panel including a first surface including a display area configured to display an image, and a second surface disposed on the opposite side of the display panel from the first surface, and a touch panel disposed on the first surface, the touch panel including a base film and a transparent conductive layer disposed on a surface of the base film facing the display panel, in which at least a portion of each of the display panel and the touch panel is bendable such that centers of curvature of the display panel and the touch panel are positioned outside the second surface.

Owner:SAMSUNG DISPLAY CO LTD

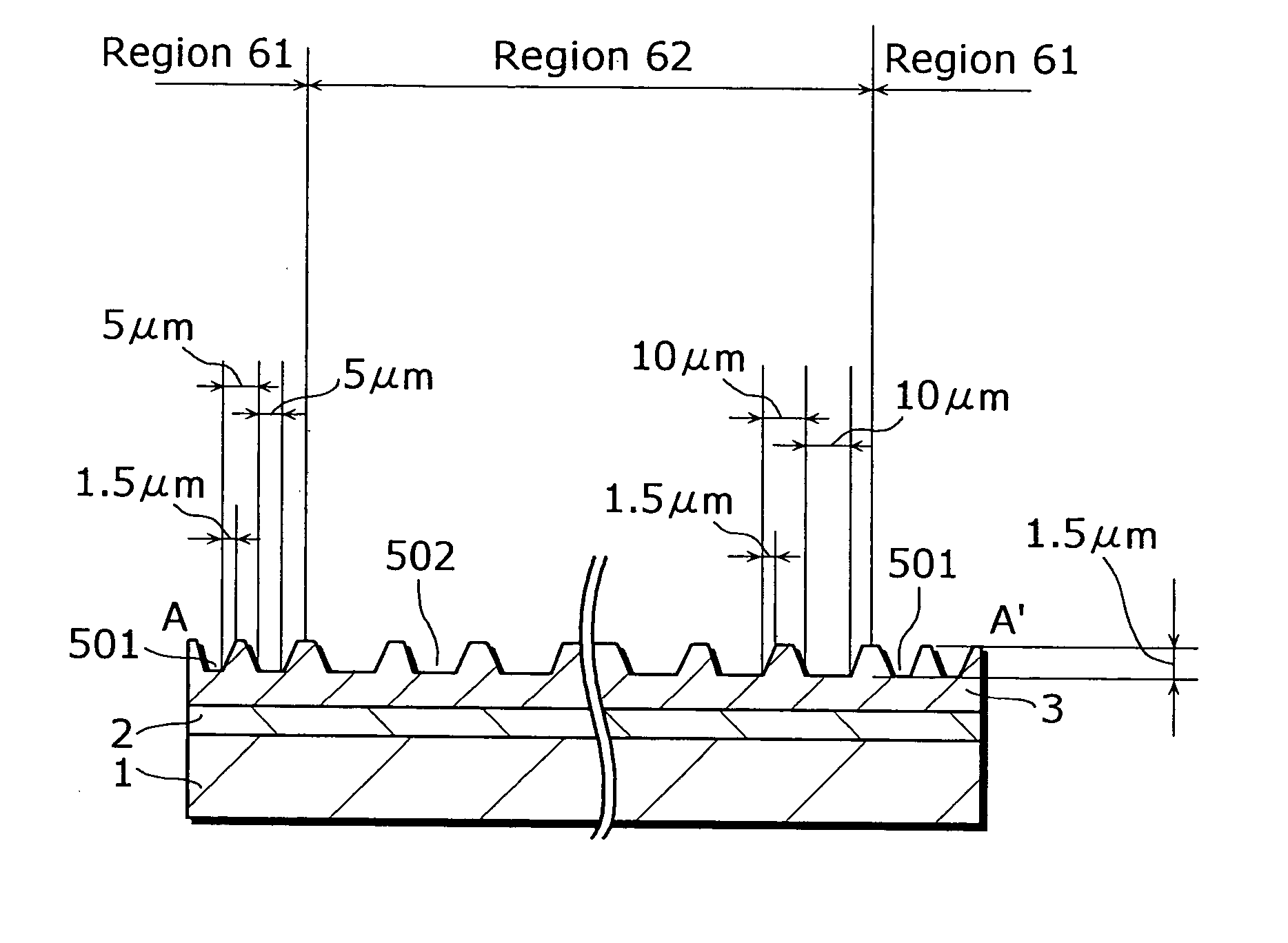

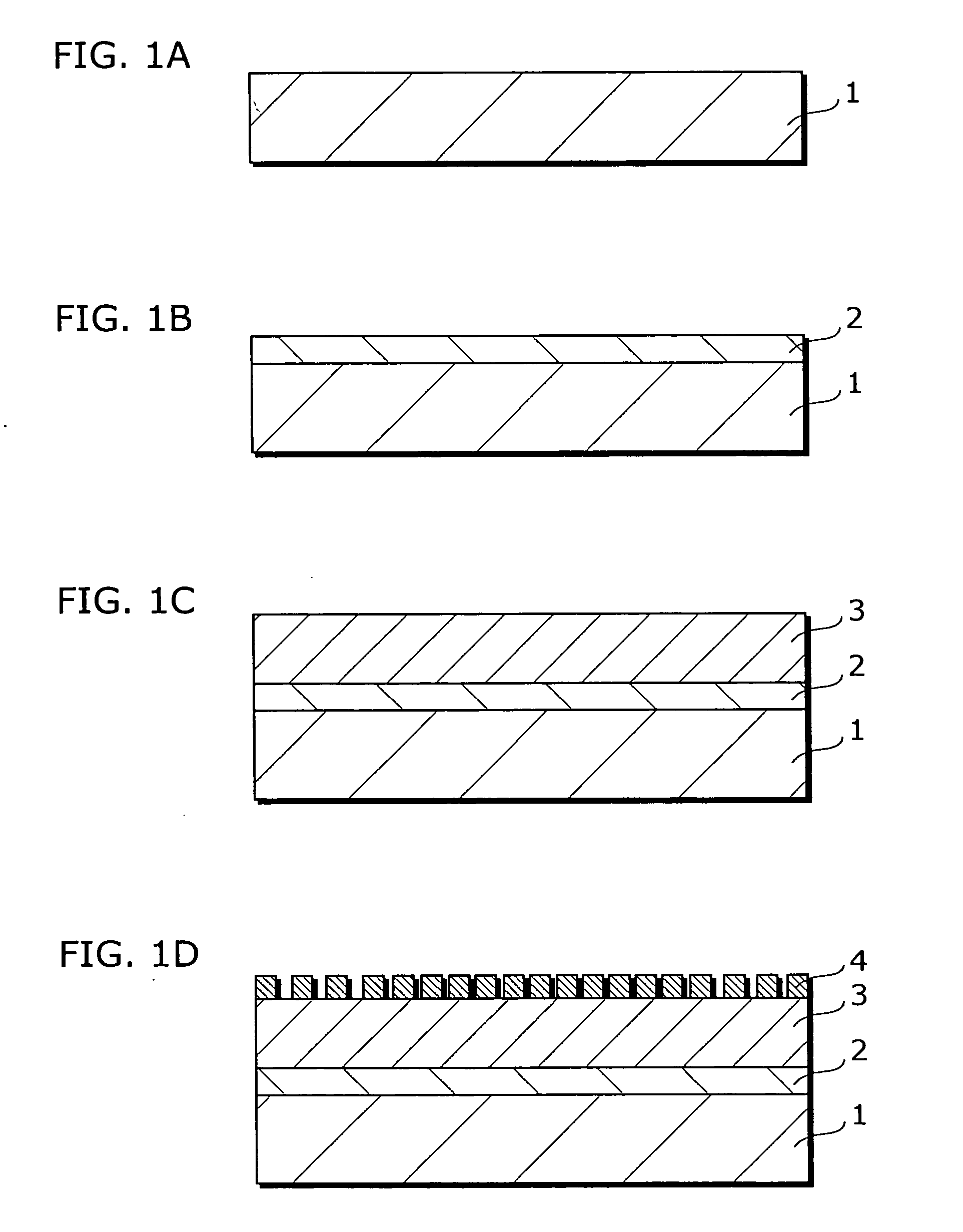

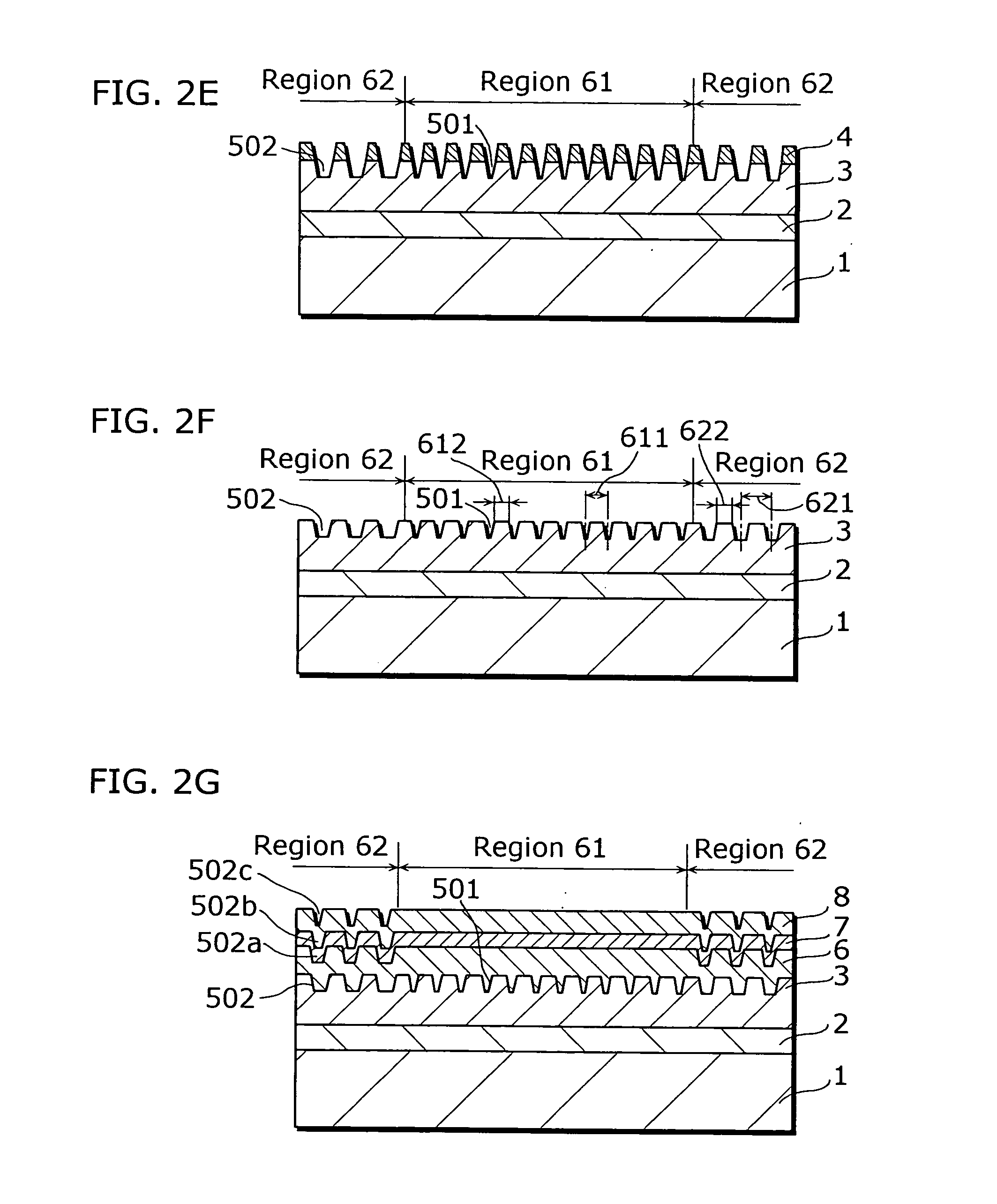

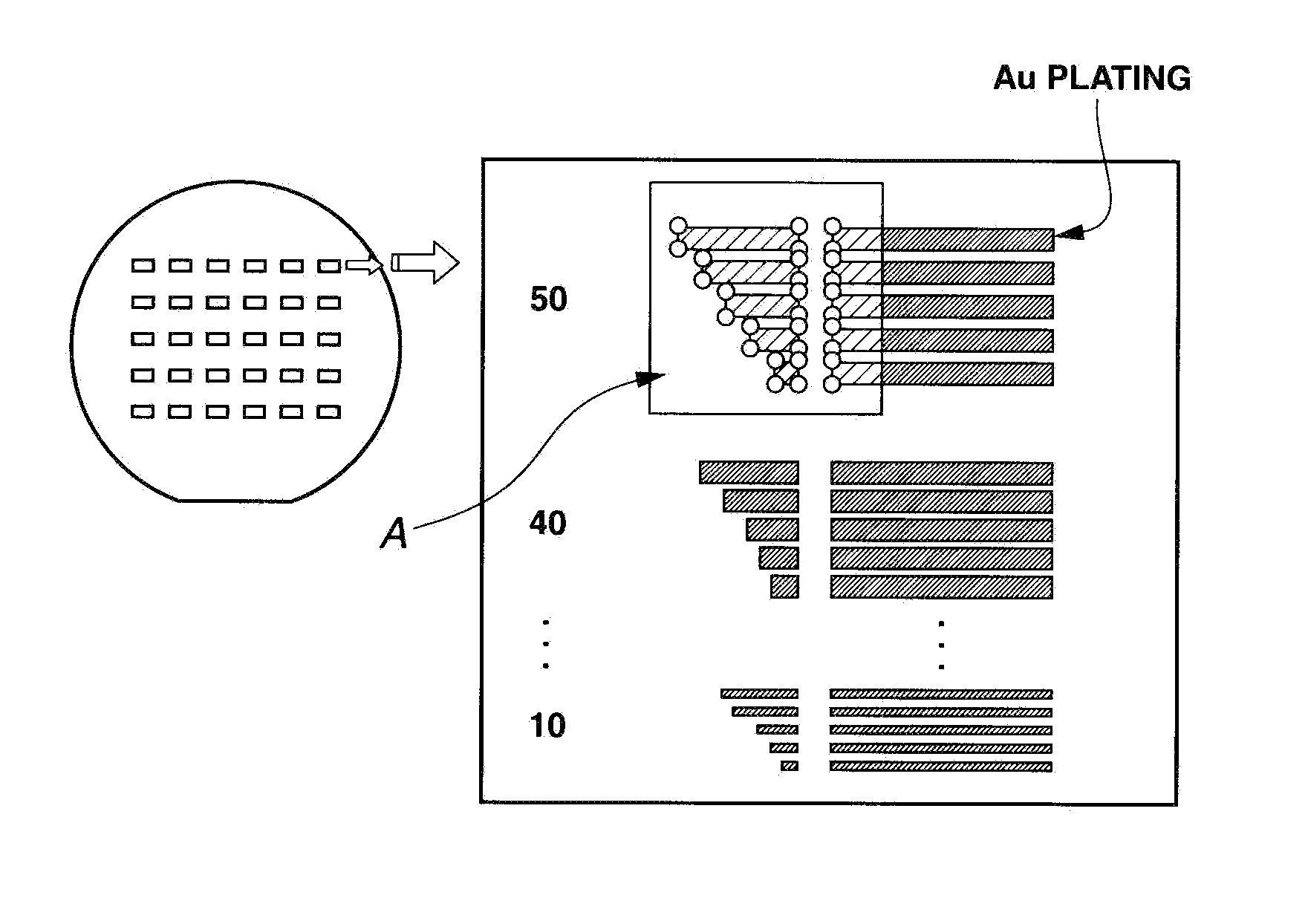

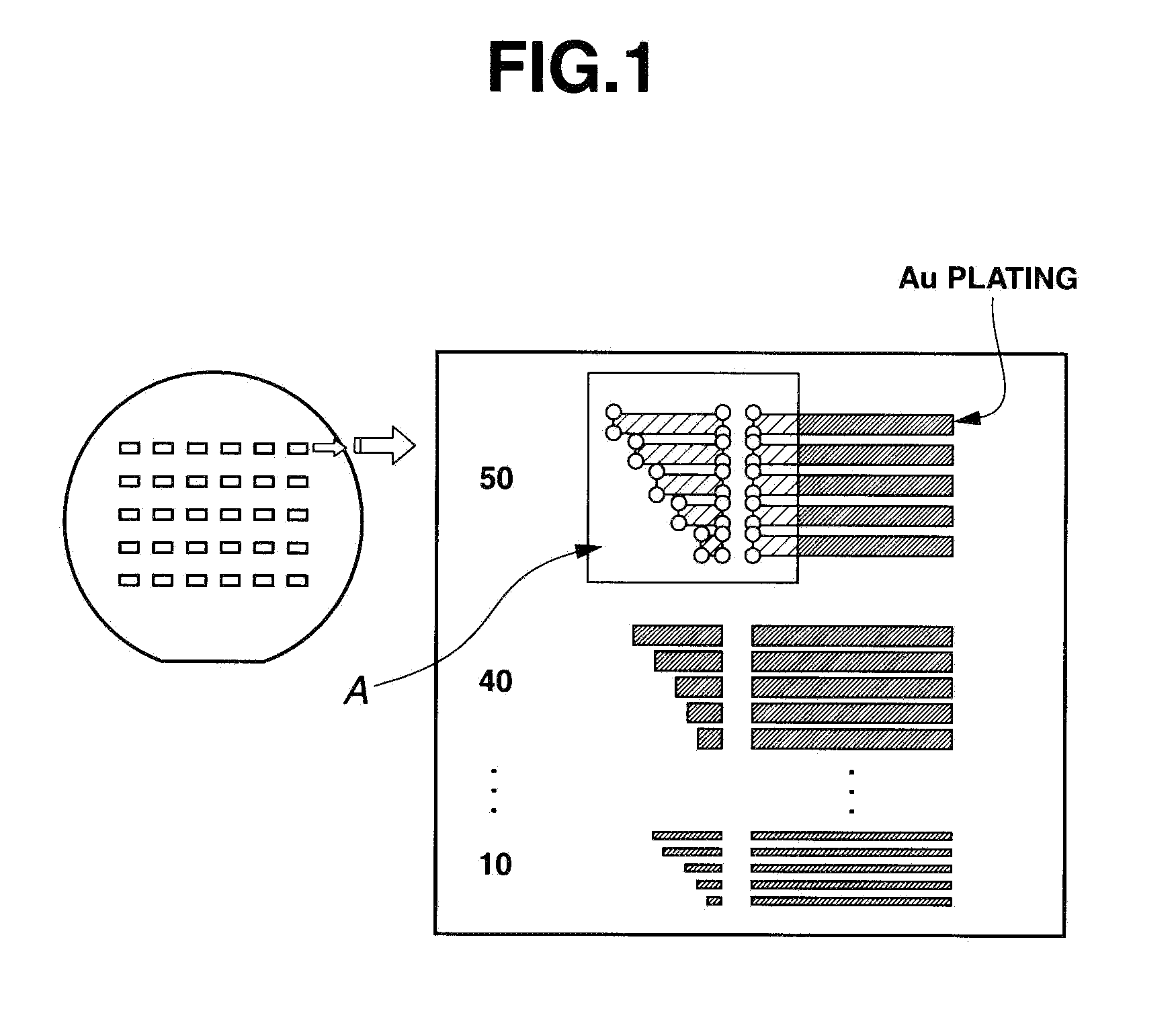

Manufacturing method for semiconductor device, semiconductor device and semiconductor wafer

ActiveUS20050039673A1High yieldInhibit the generation of cracksPolycrystalline material growthFrom solid stateEngineeringSemiconductor

A manufacturing method for a semiconductor device formed in a device region composed of a plurality of semiconductor layers on a substrate, the method including a trench forming step of forming a trench on the substrate around the device region and a semiconductor growth step of growing the semiconductor layer in the device region.

Owner:PANASONIC CORP

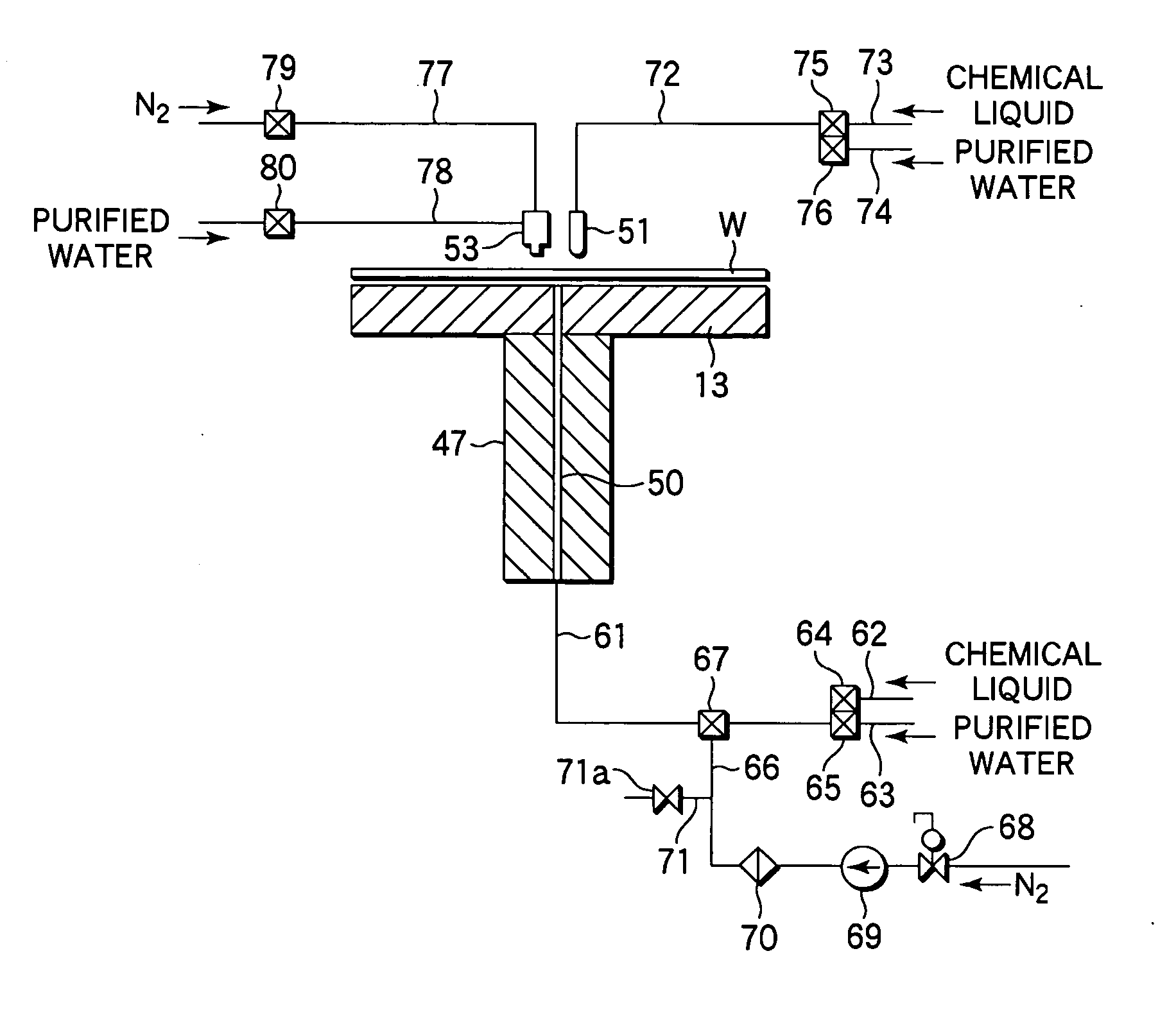

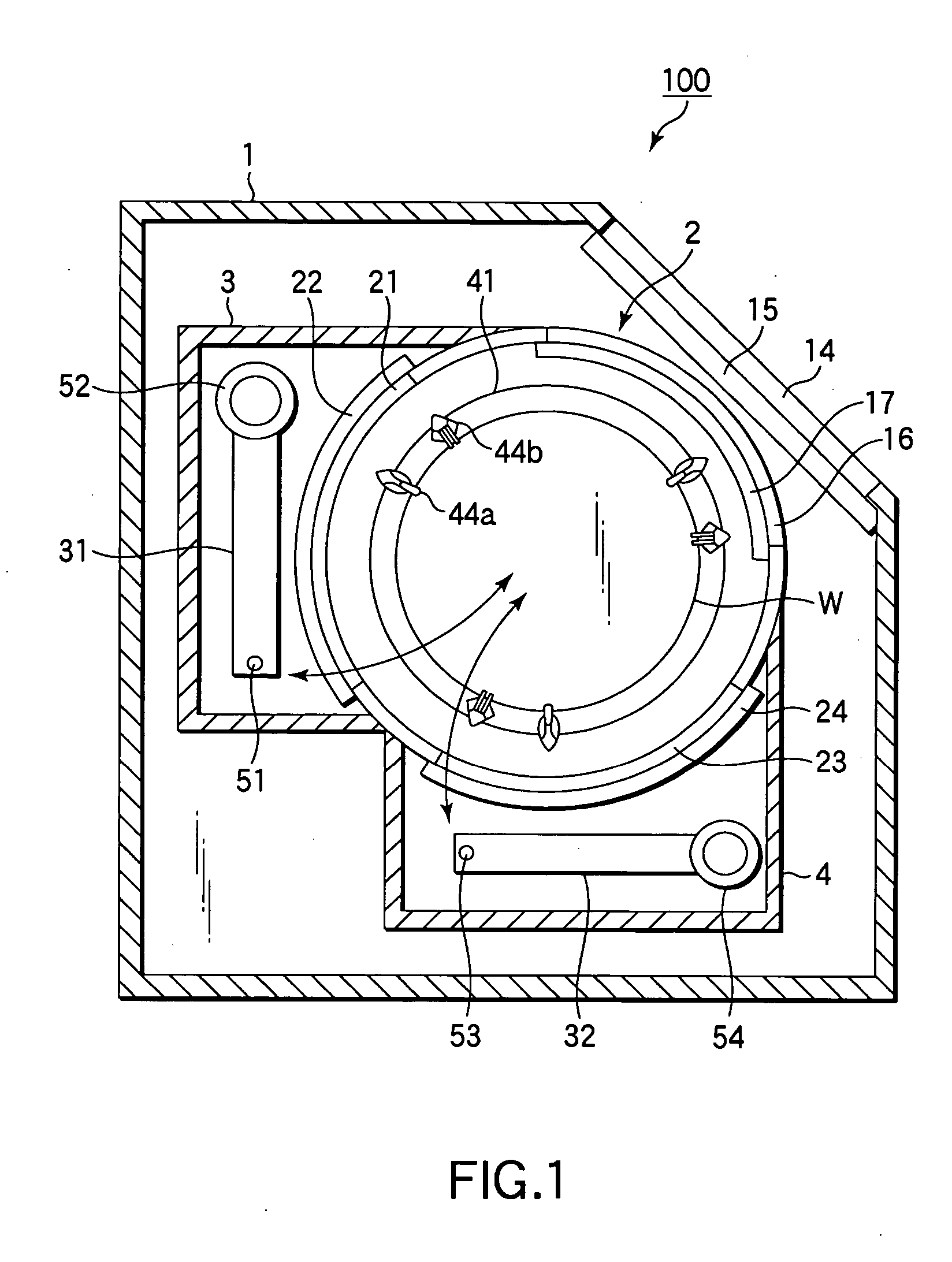

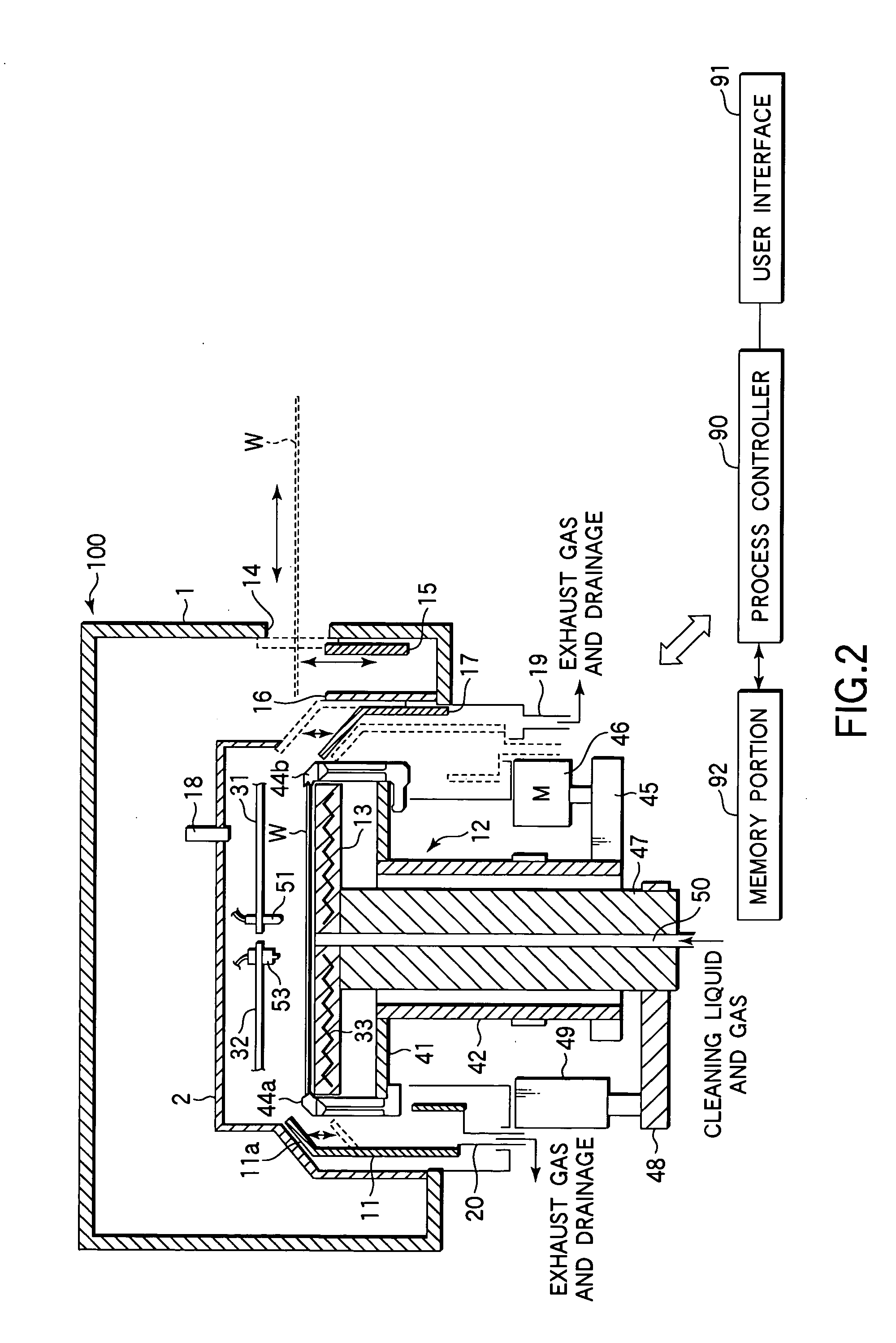

Liquid processing method and liquid processing apparatus

ActiveUS20070113872A1Inhibit the generation of cracksIncreased number of spinsSemiconductor/solid-state device manufacturingCleaning using toolsEngineering

A liquid processing method includes: placing a plate adjacently to at least one of surfaces of a target substrate, and supplying a process liquid into a gap between the plate and the target substrate, thereby forming a liquid film of the process liquid; subjecting the target substrate to a process using a state with the liquid film of the process liquid thus formed; and supplying a gas to the liquid film, thereby breaking the liquid film, after finishing the process.

Owner:TOKYO ELECTRON LTD

Soldering flux and solder paste composition

InactiveUS20080053572A1High reliabilityExcellent solderabilityWelding/cutting media/materialsSoldering mediaSolder pastePolymer chemistry

A soldering flux contains a base resin and an activating agent. The base resin contains a thermoplastic acrylic resin having a glass transition temperature of below −50° C. This enables to sufficiently suppress the occurrence of cracks in the flux residue after soldering, under the severe environment where the temperature difference is extremely large. The soldering flux has high reliability and excellent solderability, and is conventional with respect to the load against manufacturing cost and environment.

Owner:DENSO CORP +1

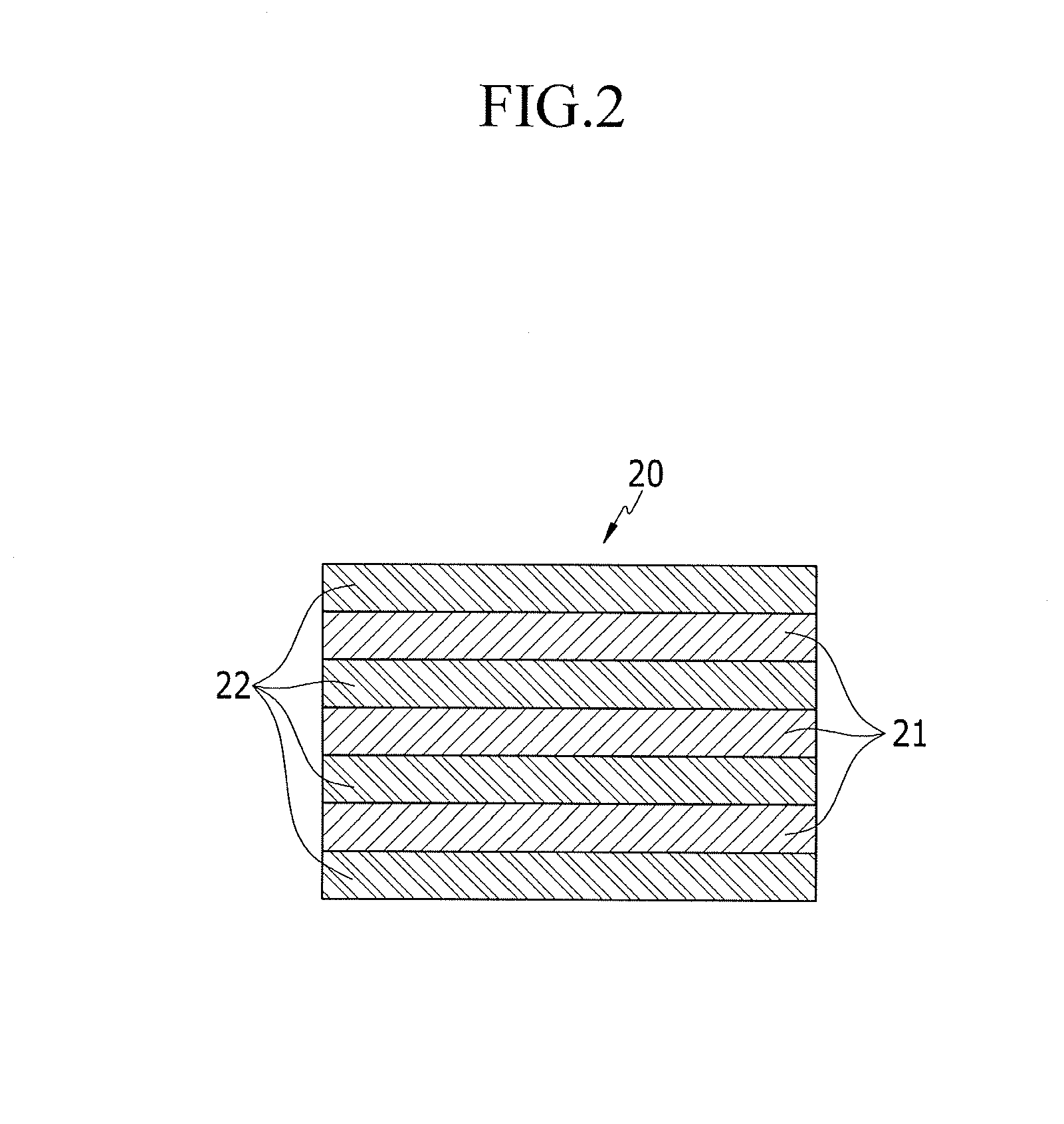

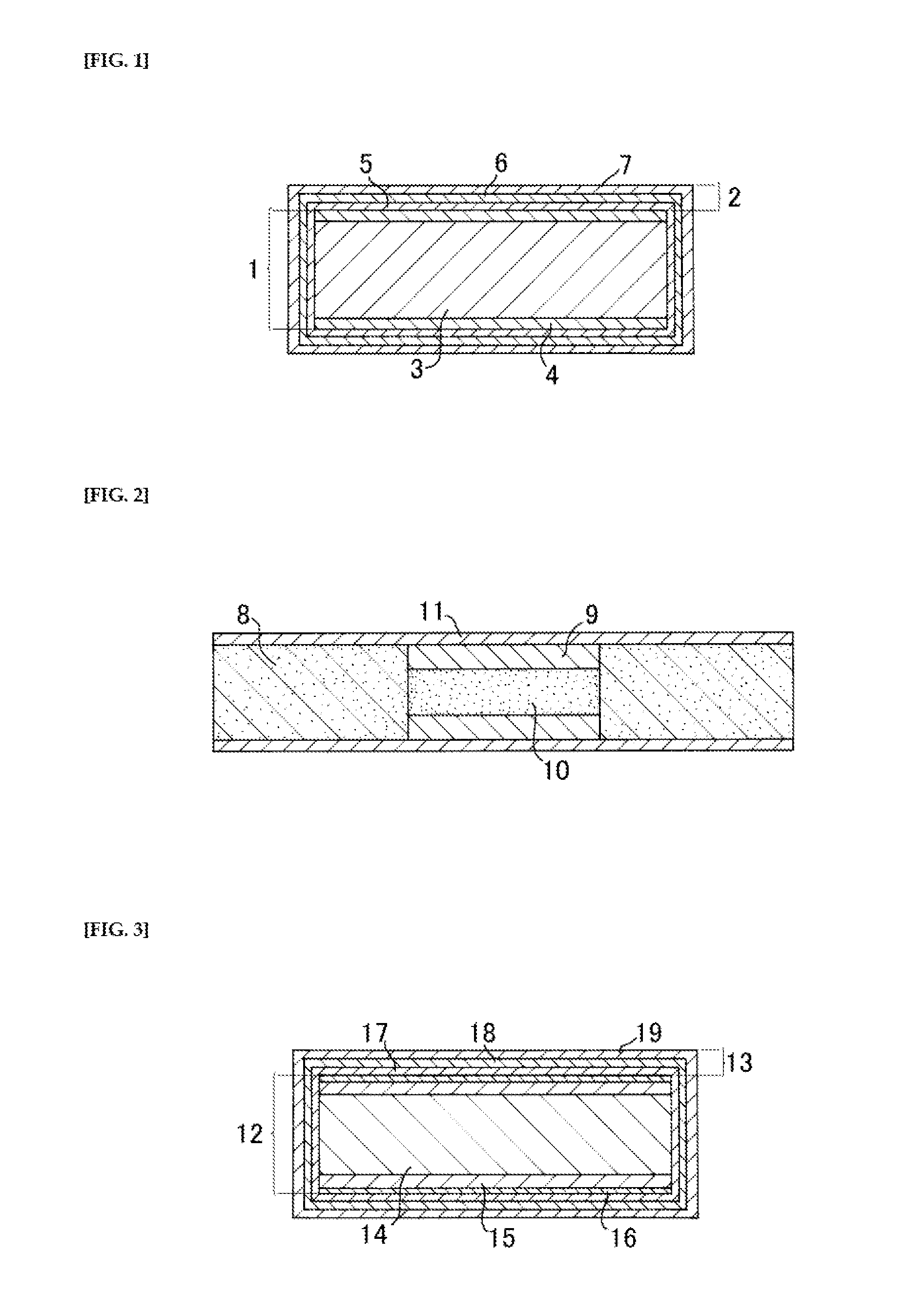

Laminated ceramic capacitor

ActiveUS20120262840A1Improved moisture resistancePrevent generation of crackFixed capacitor dielectricStacked capacitorsCrystalliteDielectric layer

The laminated ceramic capacitor has a laminate block made of alternately laminated ceramic dielectric layers and internal electrodes, a pair of cover layers, laminated on top and bottom of the laminate block, ceramic bodies formed on both side faces of the laminate block, and a pair of external electrodes that are electrically connected to the internal electrodes, wherein the average grain size of the ceramic dielectric grains constituting the ceramic body is smaller than the average grain size of the ceramic dielectric grains constituting the ceramic dielectric layer in the laminate block.

Owner:TAIYO YUDEN KK

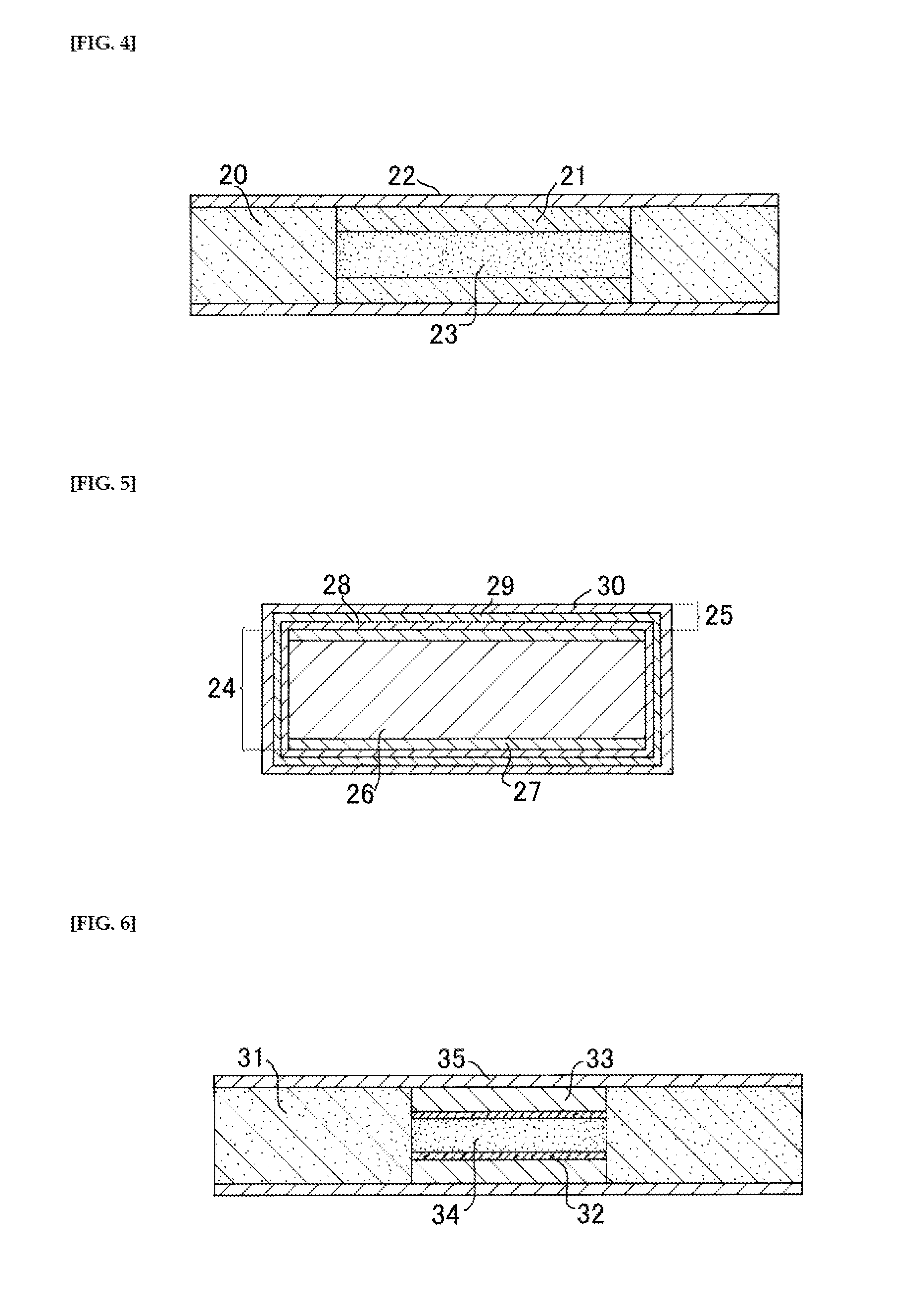

Secondary battery and electronic device including the same

ActiveUS20160013469A1Improve reliabilityInhibit the generation of cracksElectrode rolling/calenderingSmall-sized cells cases/jacketsLaser lightCurrent collector

An electronic device having a novel structure, specifically, an electronic device having a novel structure that can be changed into various appearances is provided. Specifically, after an active material layer is formed on one or both surfaces of a current collector, the active material layer in a bent region is partly removed. The removed region of the active material layer can be in a linear shape, a dot shape, or a matrix shape, for example. After the active material layer is formed on one or both surfaces of the current collector, laser processing for removing part of the active material layer in an irradiation region is performed using laser light or the like. On the region where the surface of the current collector is exposed, the active material layer is not provided, and this region is a region that does not function as a battery. Owing to this region, a secondary battery with a wide movable region can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

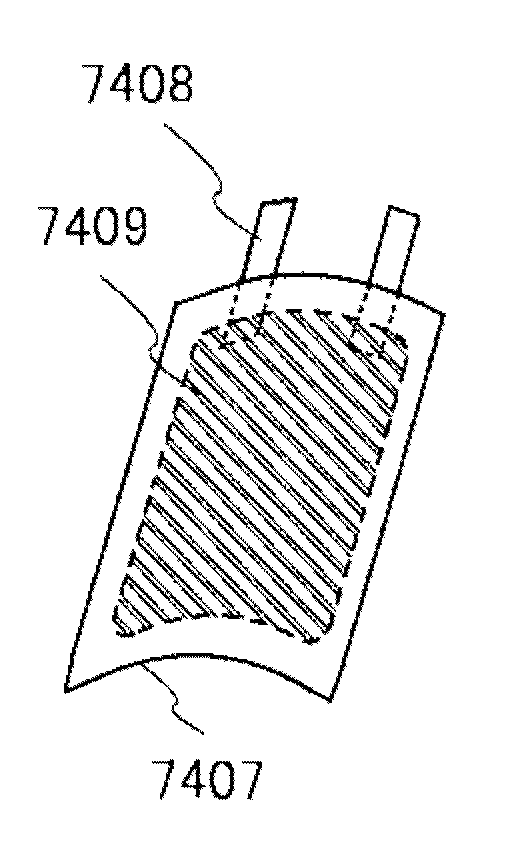

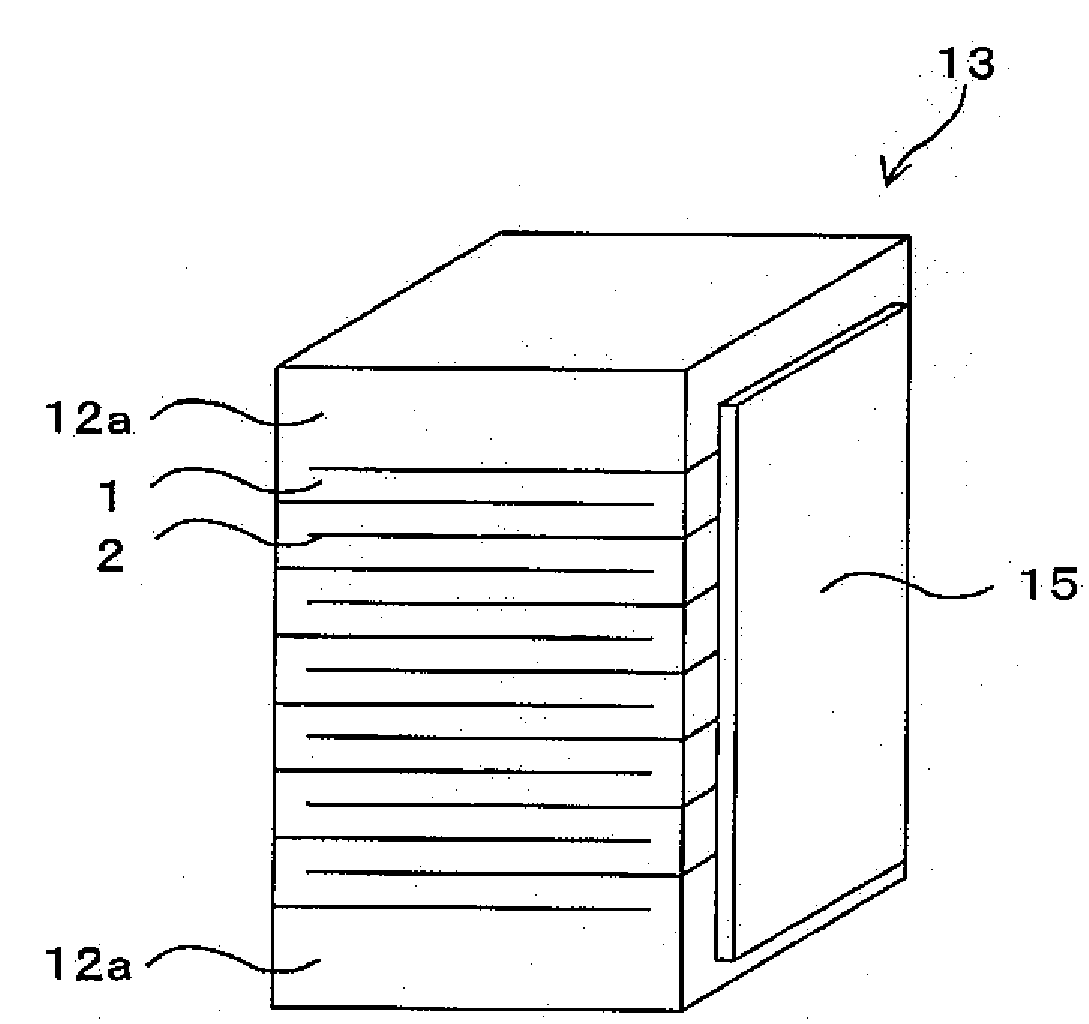

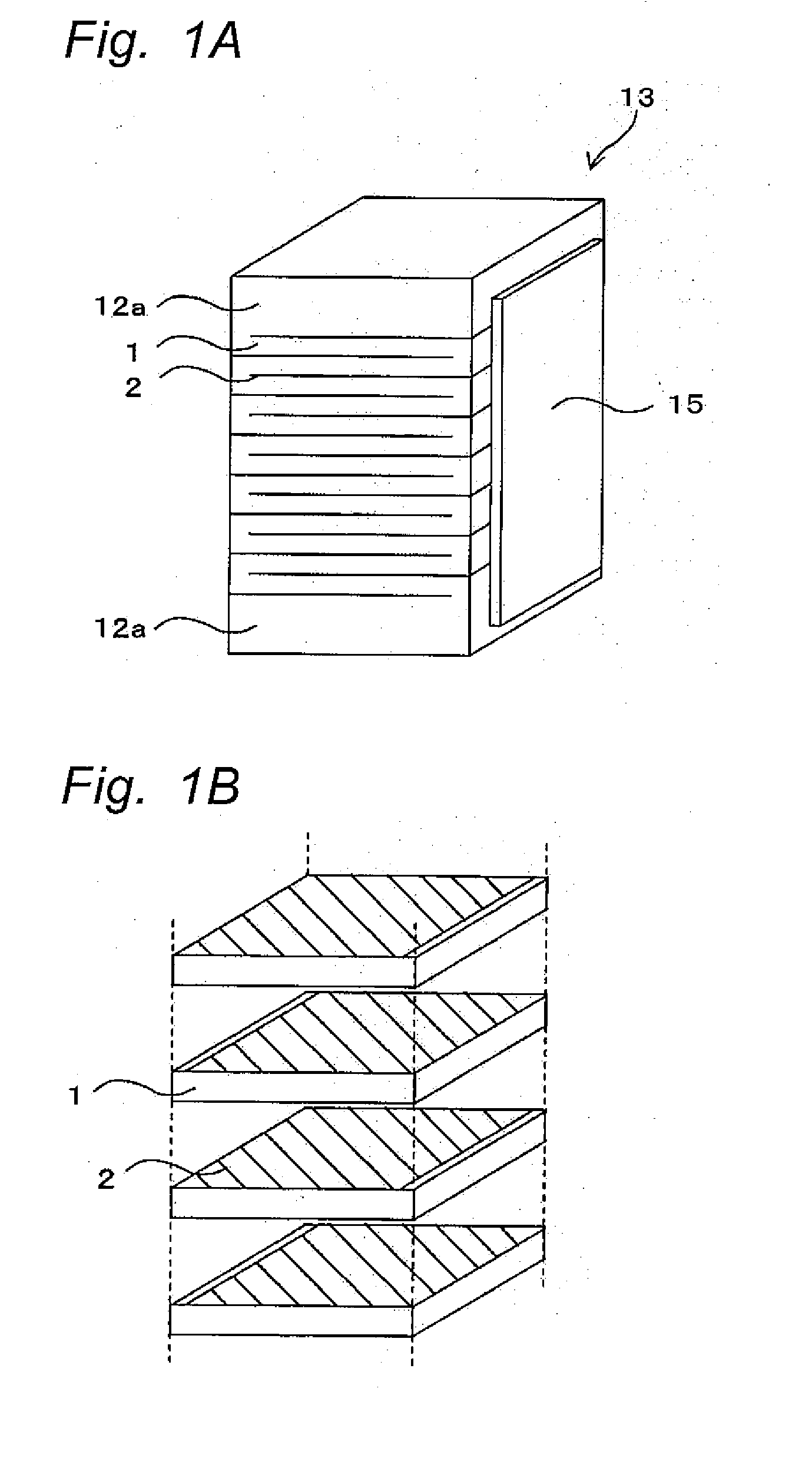

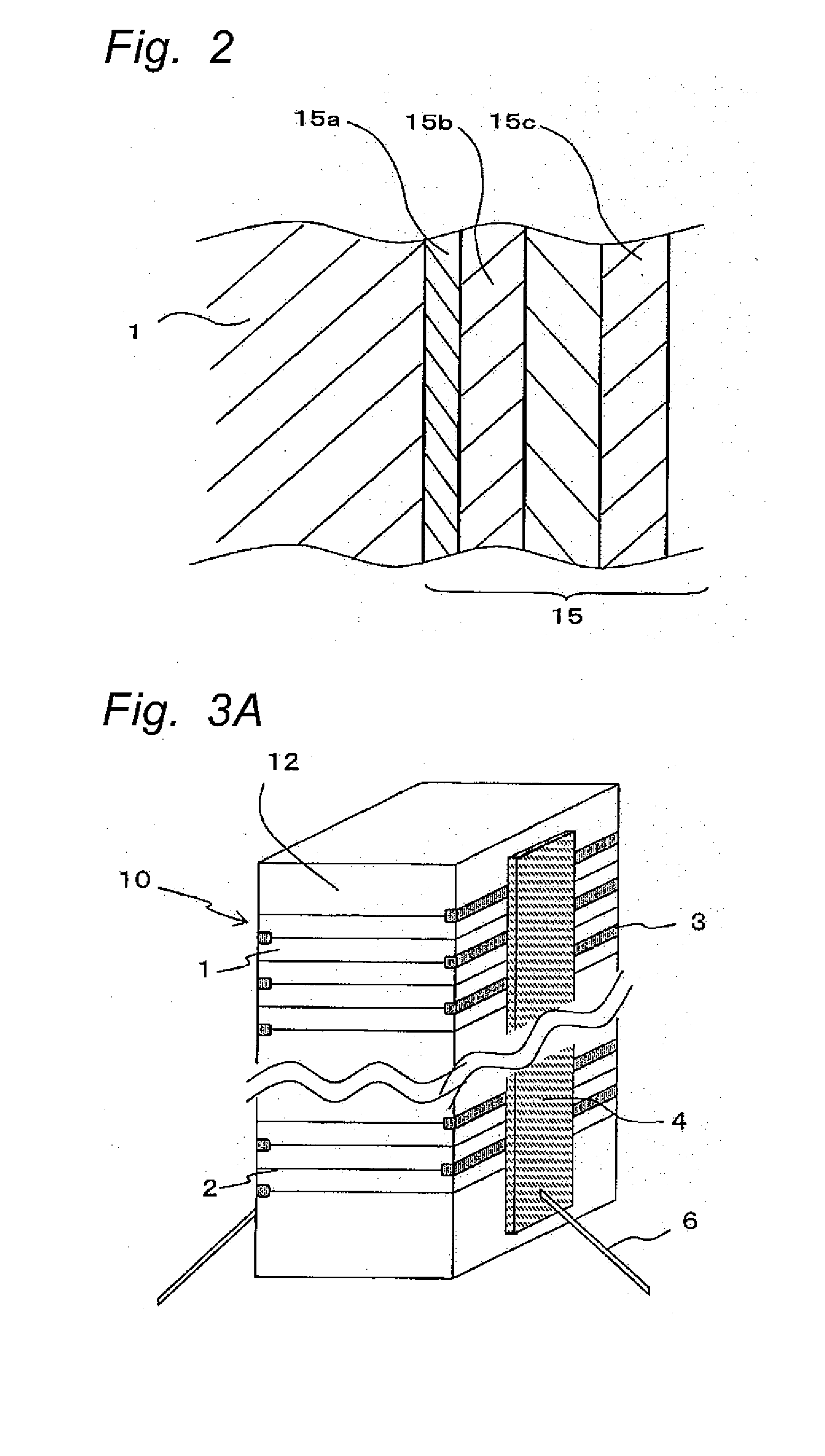

Multi-Layer Piezoelectric Element and Method for Manufacturing the Same

ActiveUS20080238264A1Inhibit the generation of cracksAvoid it happening againPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringVoltage

The multi-layer piezoelectric element comprises a stack having an active portion constituted from at least one piezoelectric layer and a plurality of internal electrodes consisting of first and second internal electrodes placed one on another, the active portion being subjected to expansion and contraction in response to a voltage applied across the first internal electrode and the second internal electrode, and external electrodes formed on two side faces of the stack with one thereof being connected to the first internal electrode and the other connected to the second internal electrode, wherein each of the external electrodes is constituted from three or more layers including a first layer formed in contact with the side face of the stack and a second layer formed on the first layer, to provide a multi-layer piezoelectric element having high durability.

Owner:KYOCERA CORP

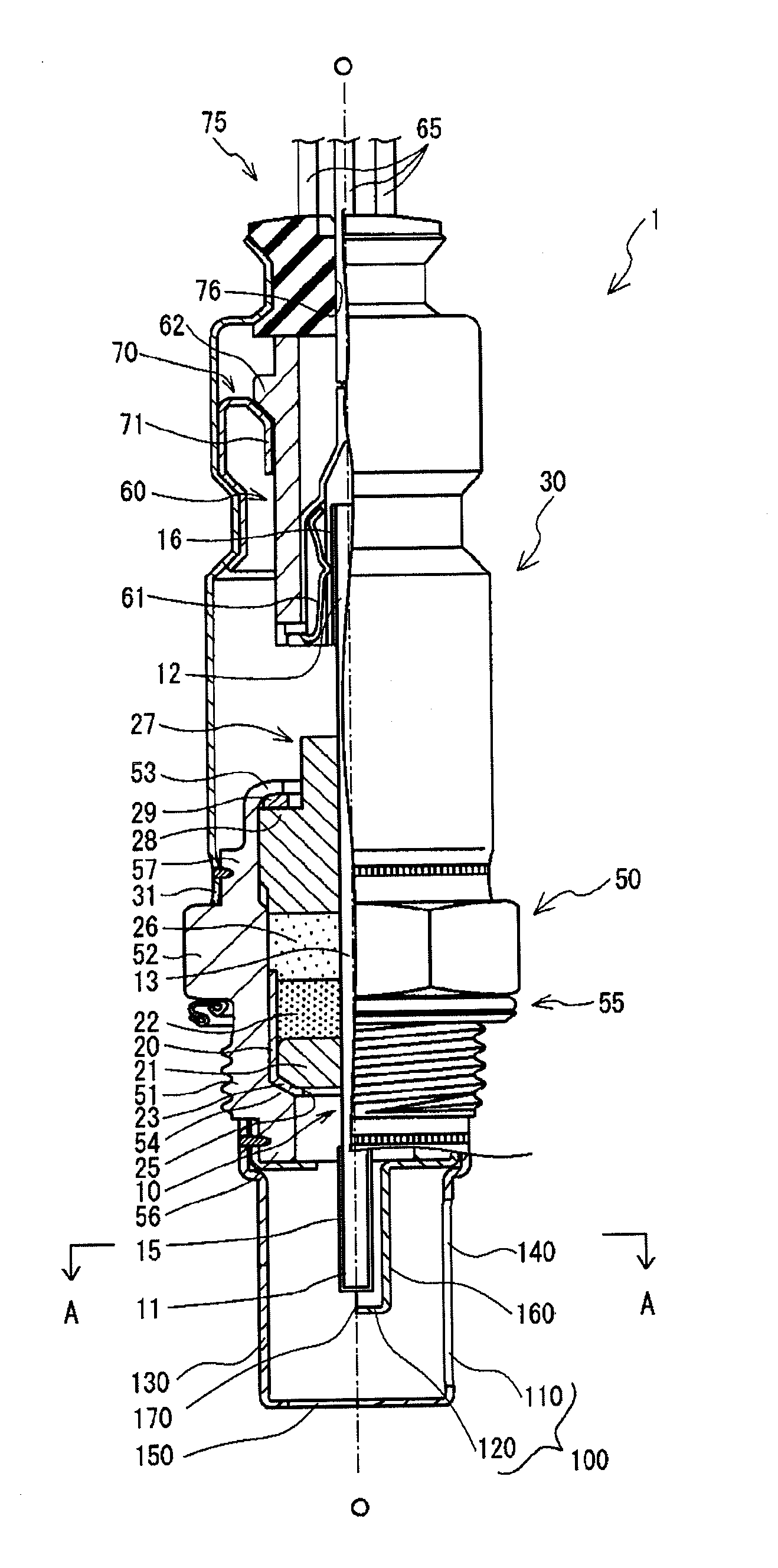

Gas sensor

InactiveUS20110209523A1Inhibit the generation of cracksDeterioration in detection can be restrainedInternal-combustion engine testingMaterial analysis by electric/magnetic meansEngineering

Owner:NGK SPARK PLUG CO LTD

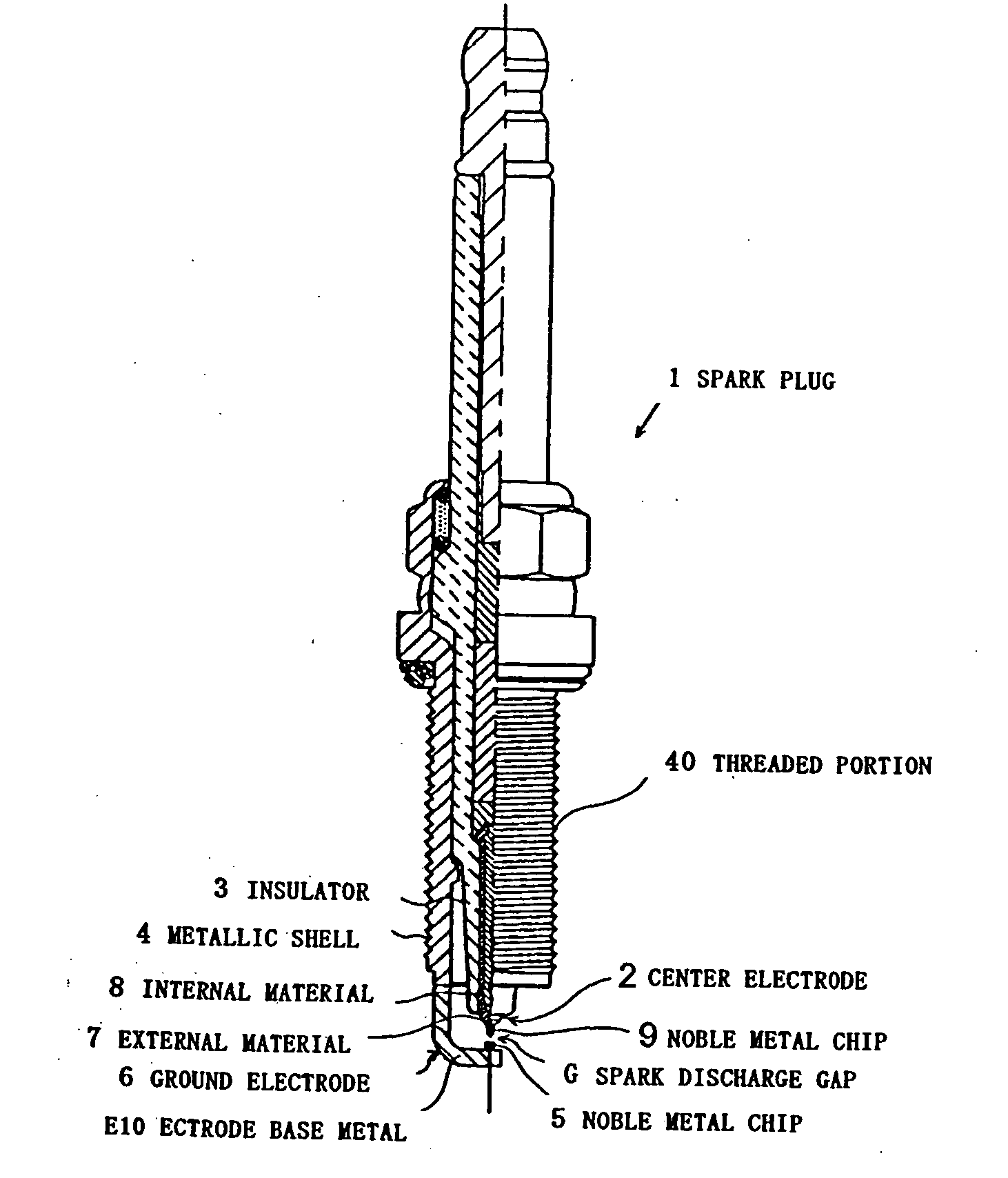

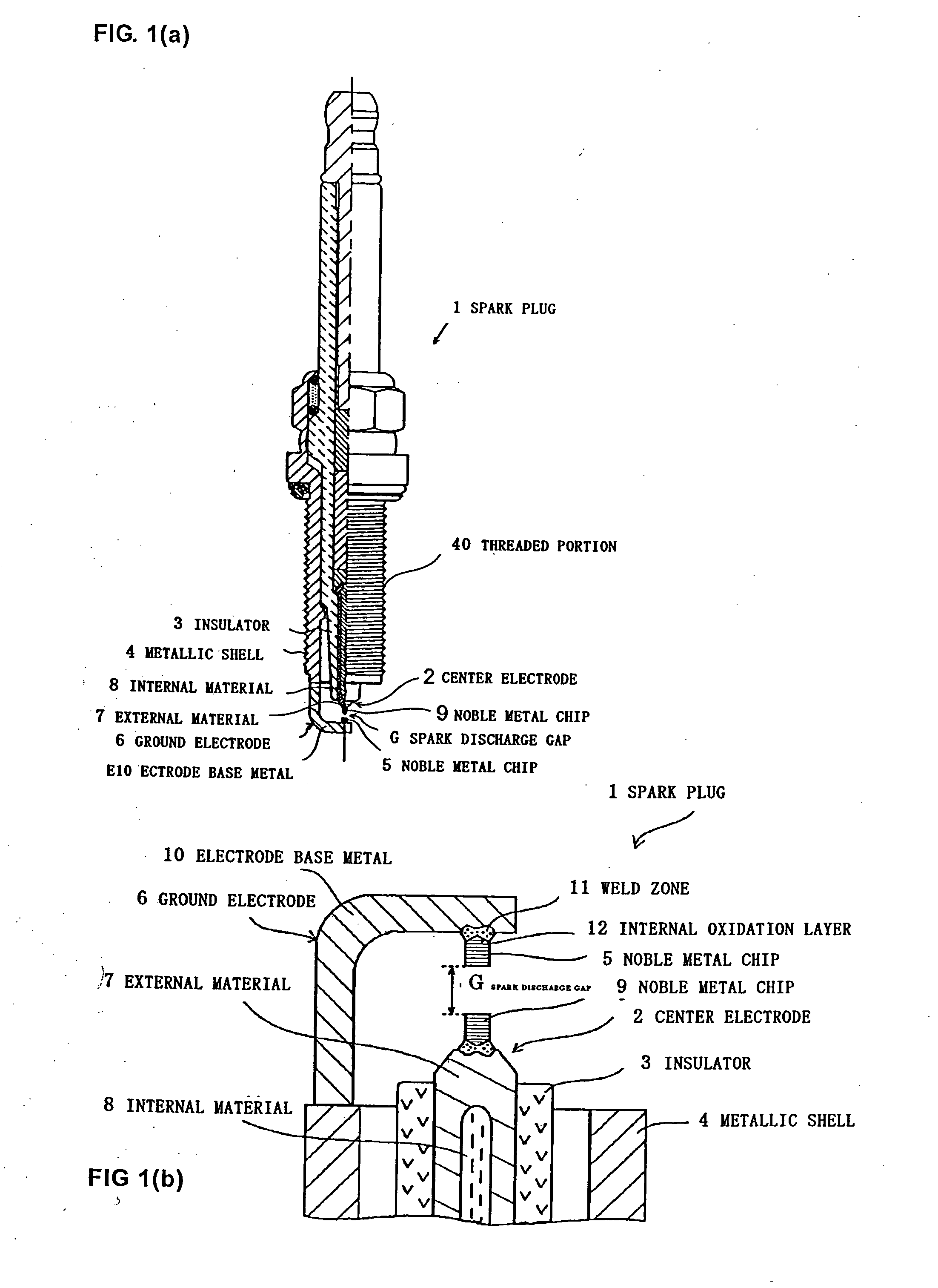

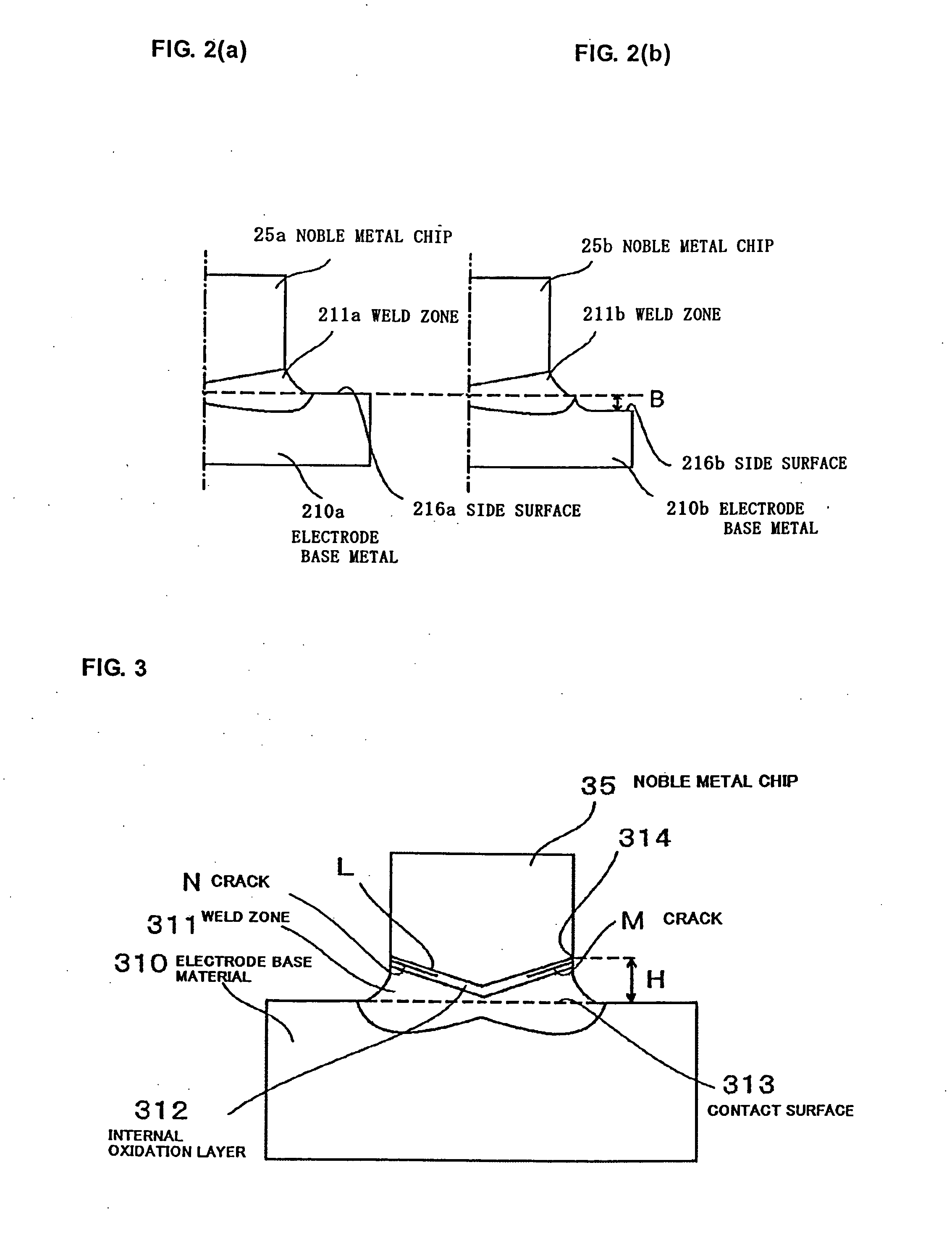

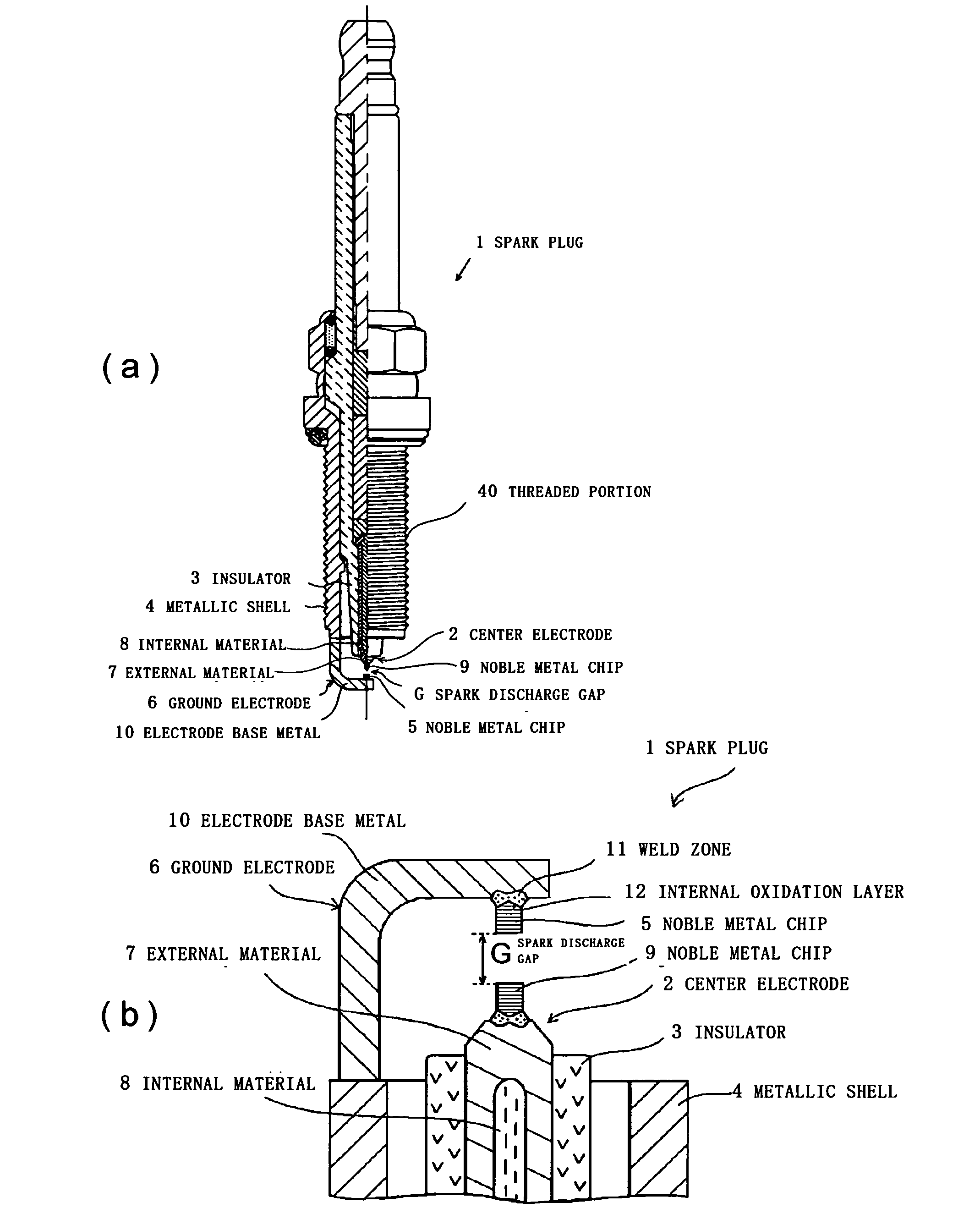

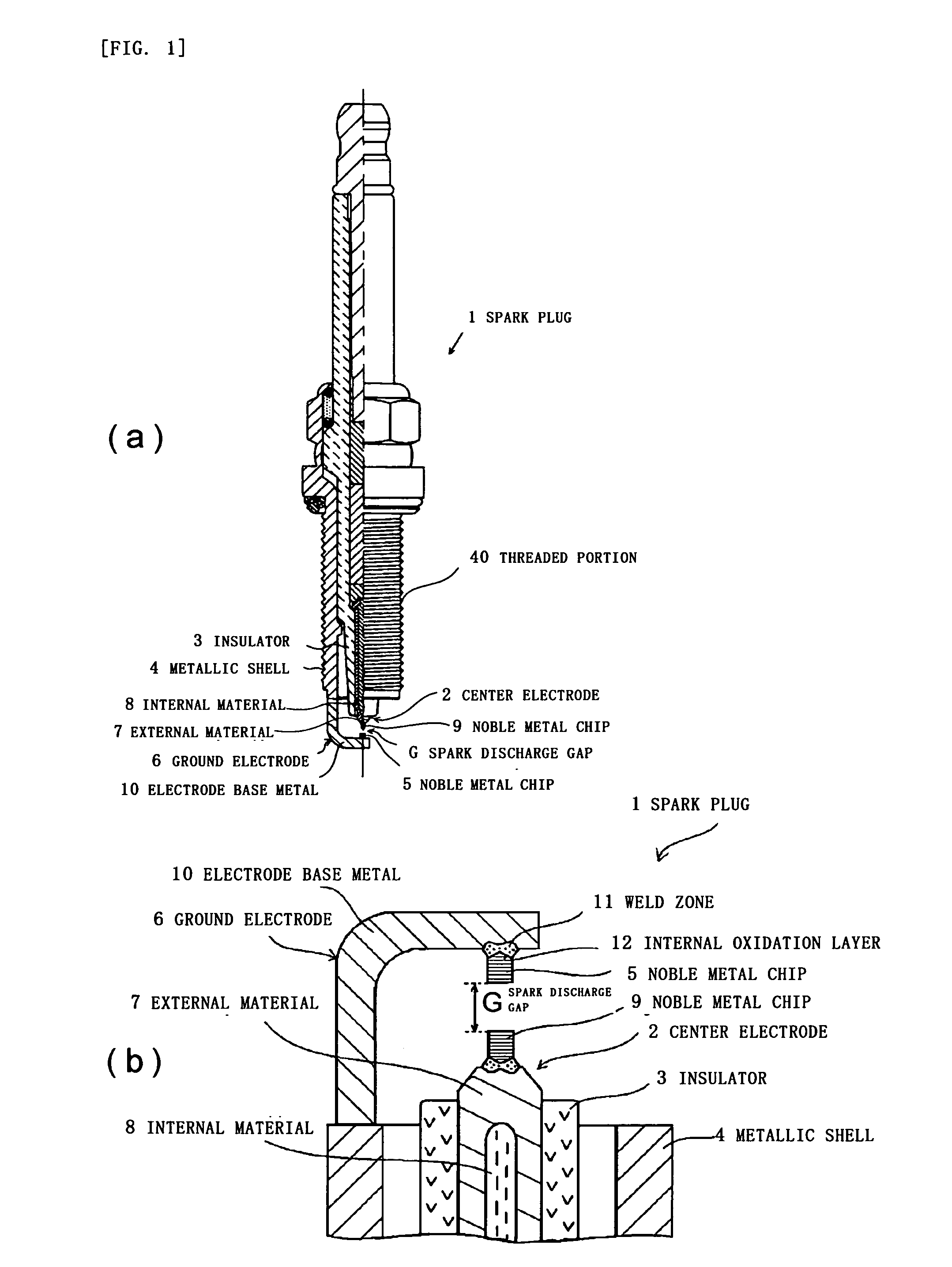

Spark plug and process for producing the spark plug

ActiveUS20100264802A1Prevent oxidationPrevent separation and detachmentSpark gapsSparking plugs manufactureEngineeringSpark plug

A spark plug in which an ignition portion of a ground electrode formed through joining of a noble metal chip to the ground electrode has high durability, and a method of manufacturing the spark plug.

Owner:NGK SPARK PLUG CO LTD

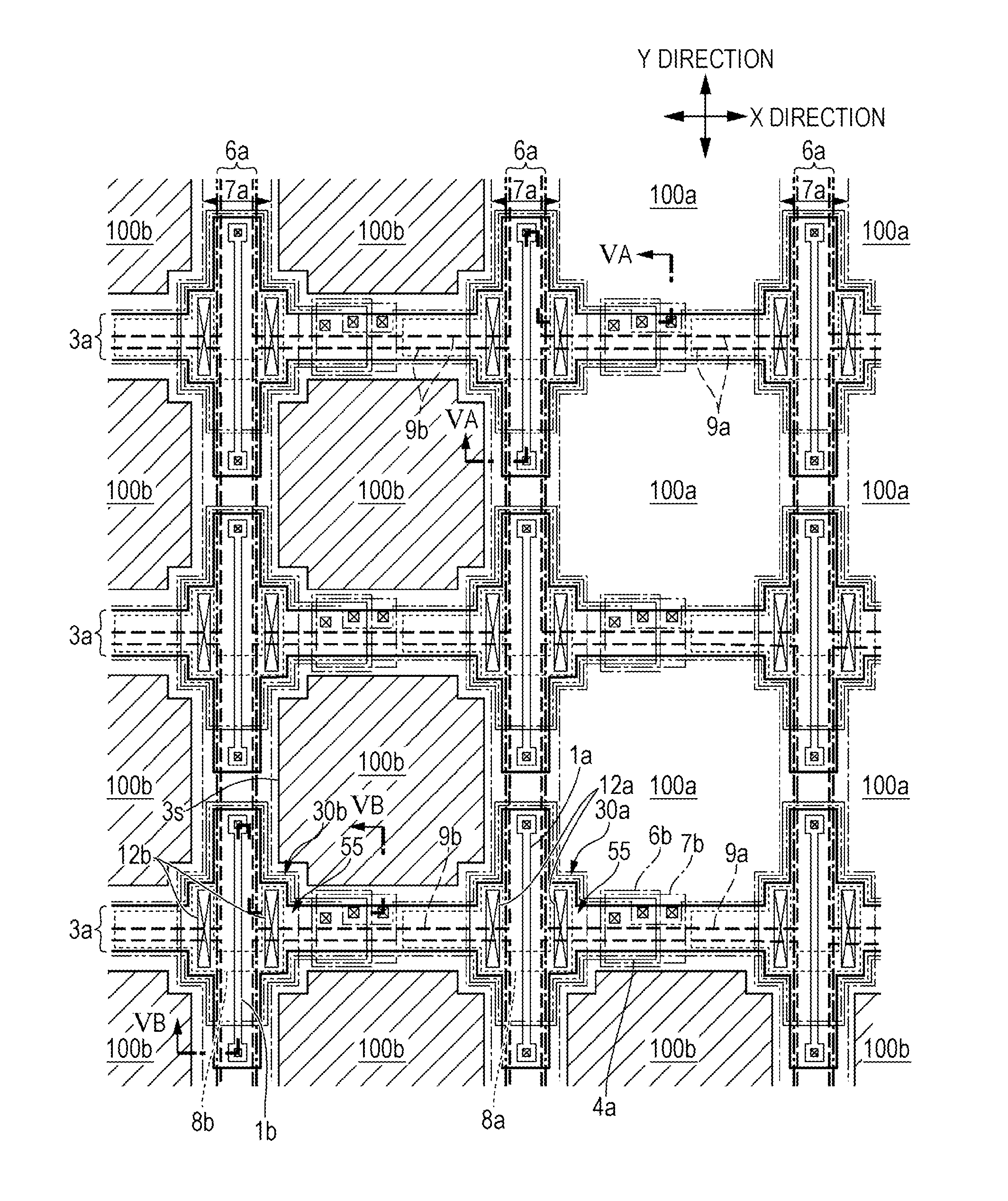

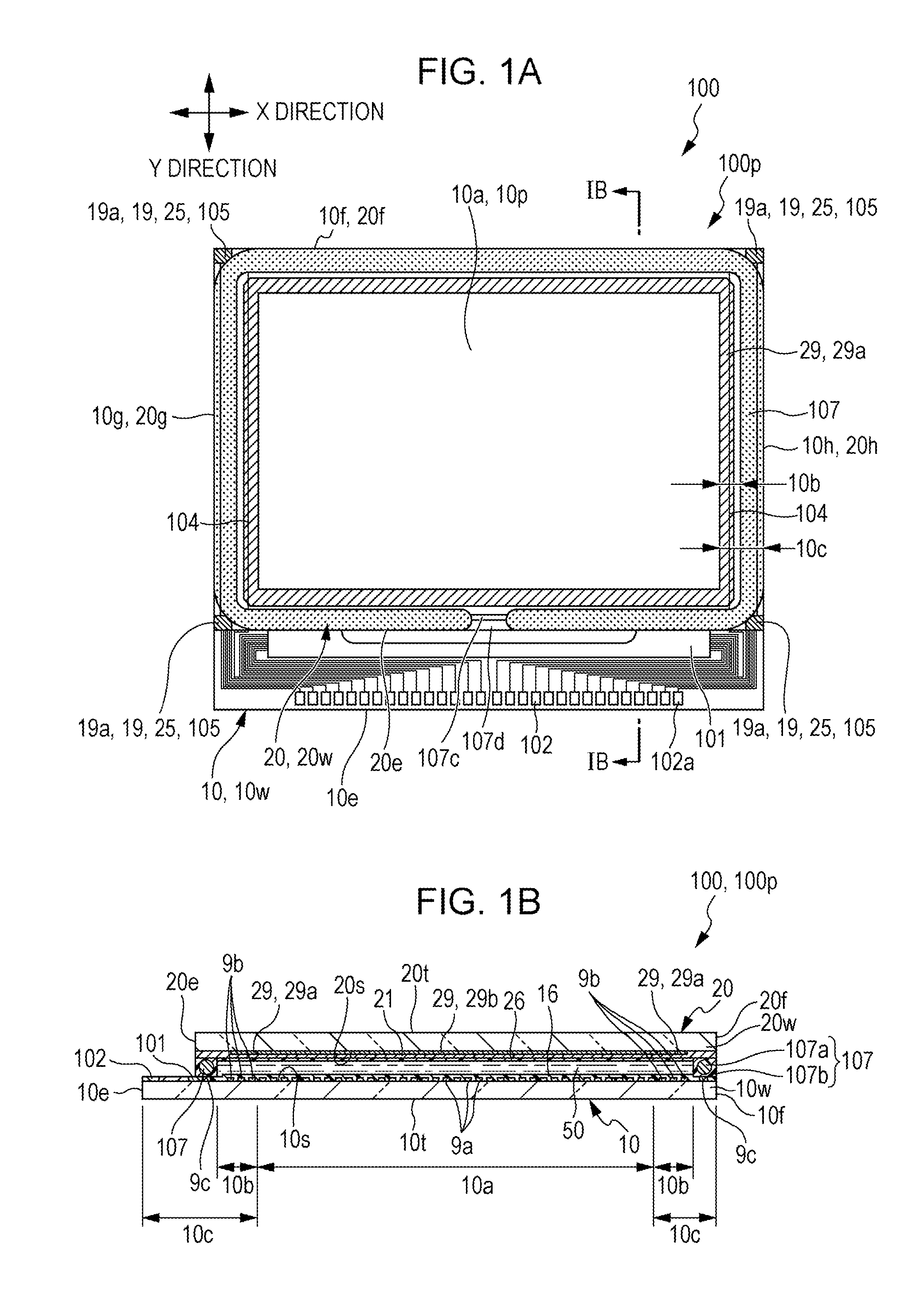

Electro-optical device and electronic apparatus

ActiveUS20150103284A1InhibitionInhibit the generation of cracksSolid-state devicesNon-linear opticsElectricityElectric devices

In a display pixel of an element substrate of an electro-optical device, a first gate electrode of a first transistor is electrically connected to a scanning line via a first contact hole of an insulating film. In a dummy pixel, a light blocking layer of the same layer as the scanning line is formed, and a second gate electrode of a second transistor is electrically connected to a scanning line via a second contact hole. A gap between the end portion of the second contact hole and the end portion of the scanning line is wider than the gap between the end portion of the first contact hole and the end portion of the scanning line.

Owner:SEIKO EPSON CORP

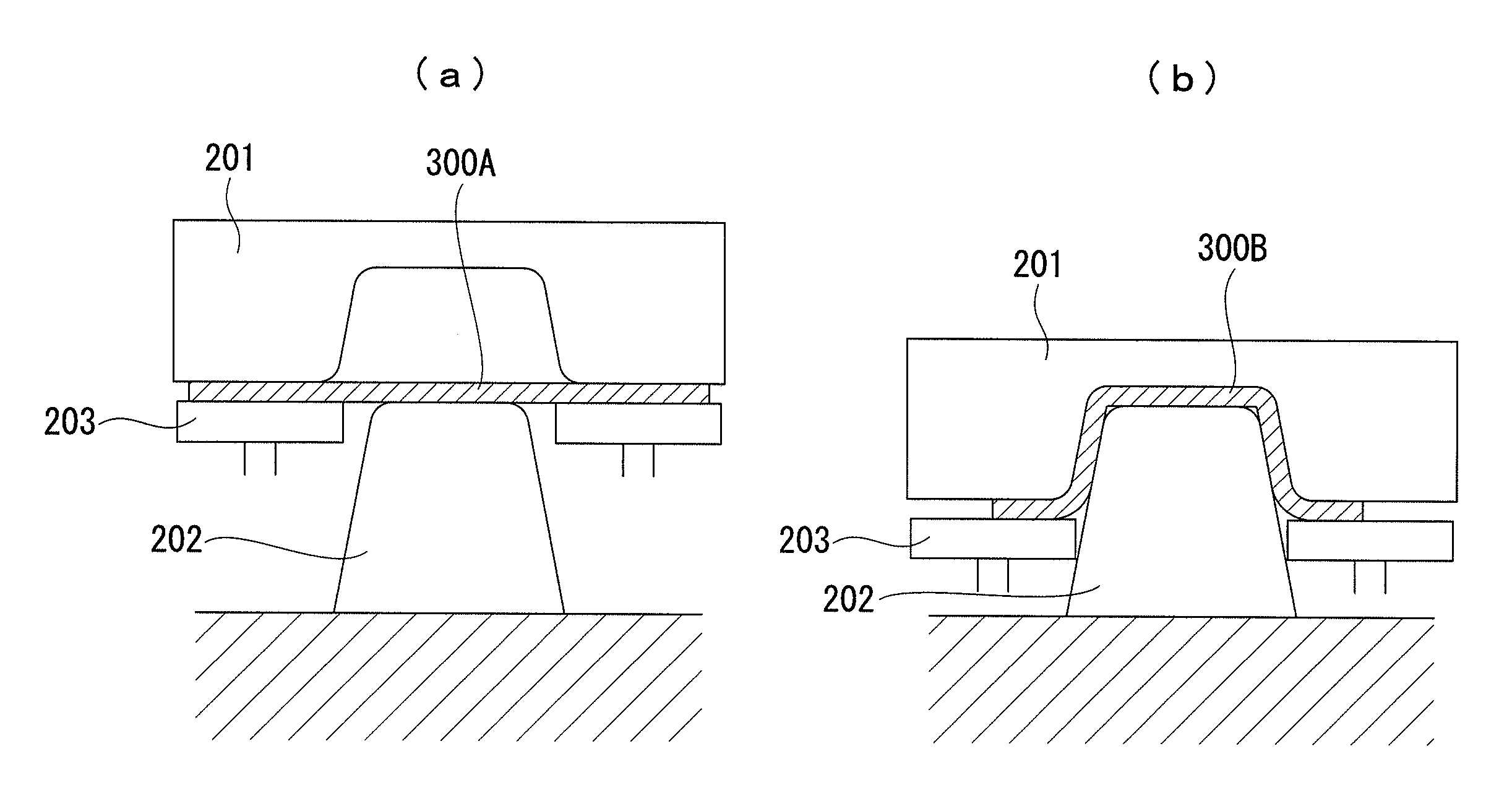

Press-forming method of component with l shape

ActiveUS20120297853A1Inhibit the generation of cracksSuppress generationVehicle componentsEngineeringMetal sheet

The present invention provides a forming method that forms a press component with an L shape from a blank metal sheet, the press component having a top sheet section and a vertical wall section which is connected to the top sheet section via a bent section having a part curved in an arc shape and which has a flange section on an opposite side to the bent section, the top sheet section being arranged on an outside of the arc of the vertical wall section, the method including: disposing the blank metal sheet between a die and both of a pad and a bending die; and forming the vertical wall section and the flange section while at least a part of the blank metal sheet is caused to slide on a part of the die corresponding to the top sheet section, the forming of the vertical wall section and the flange section being performed in a state where the pad is made close to or brought into contact with the blank metal sheet.

Owner:NIPPON STEEL CORP

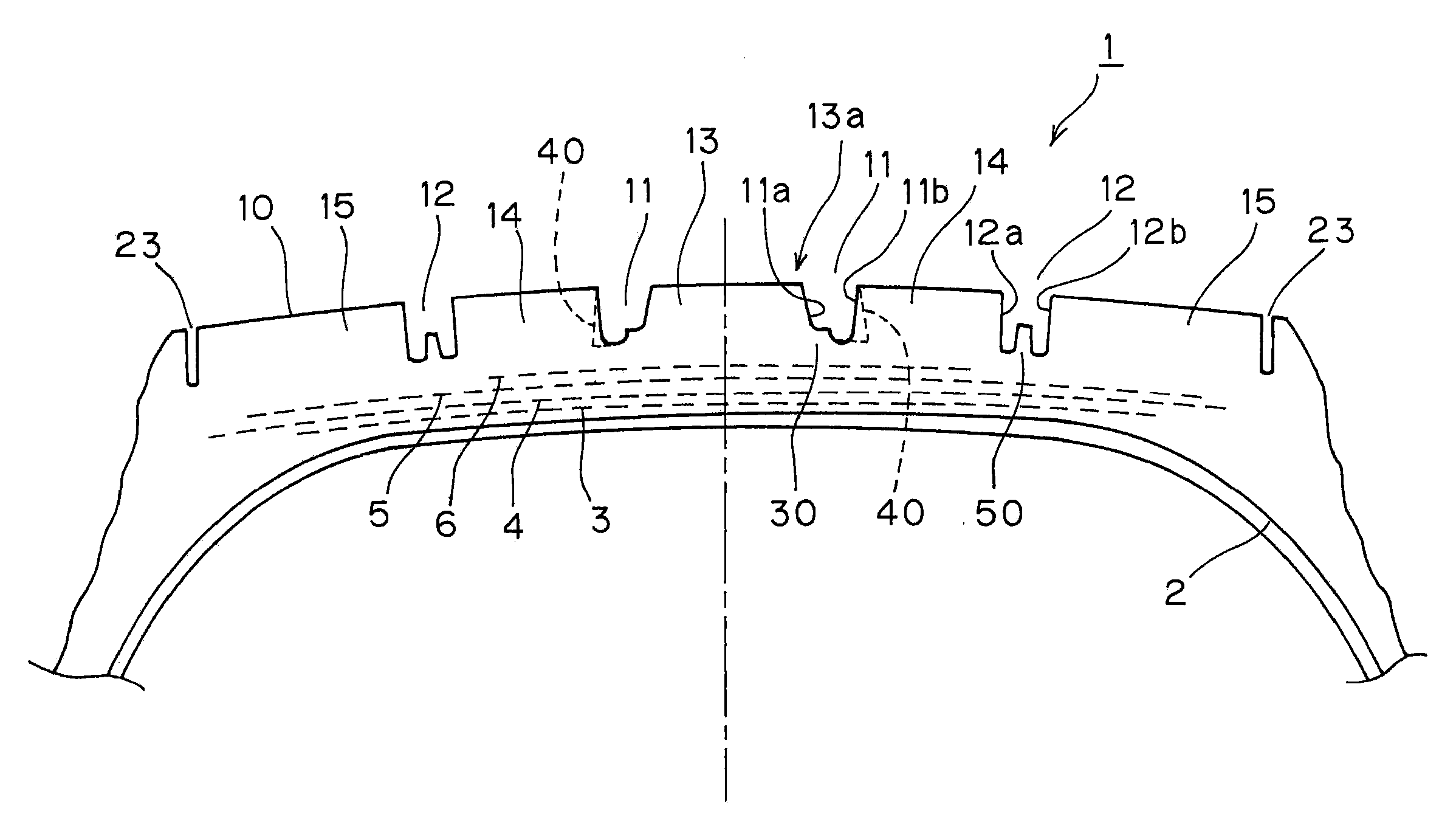

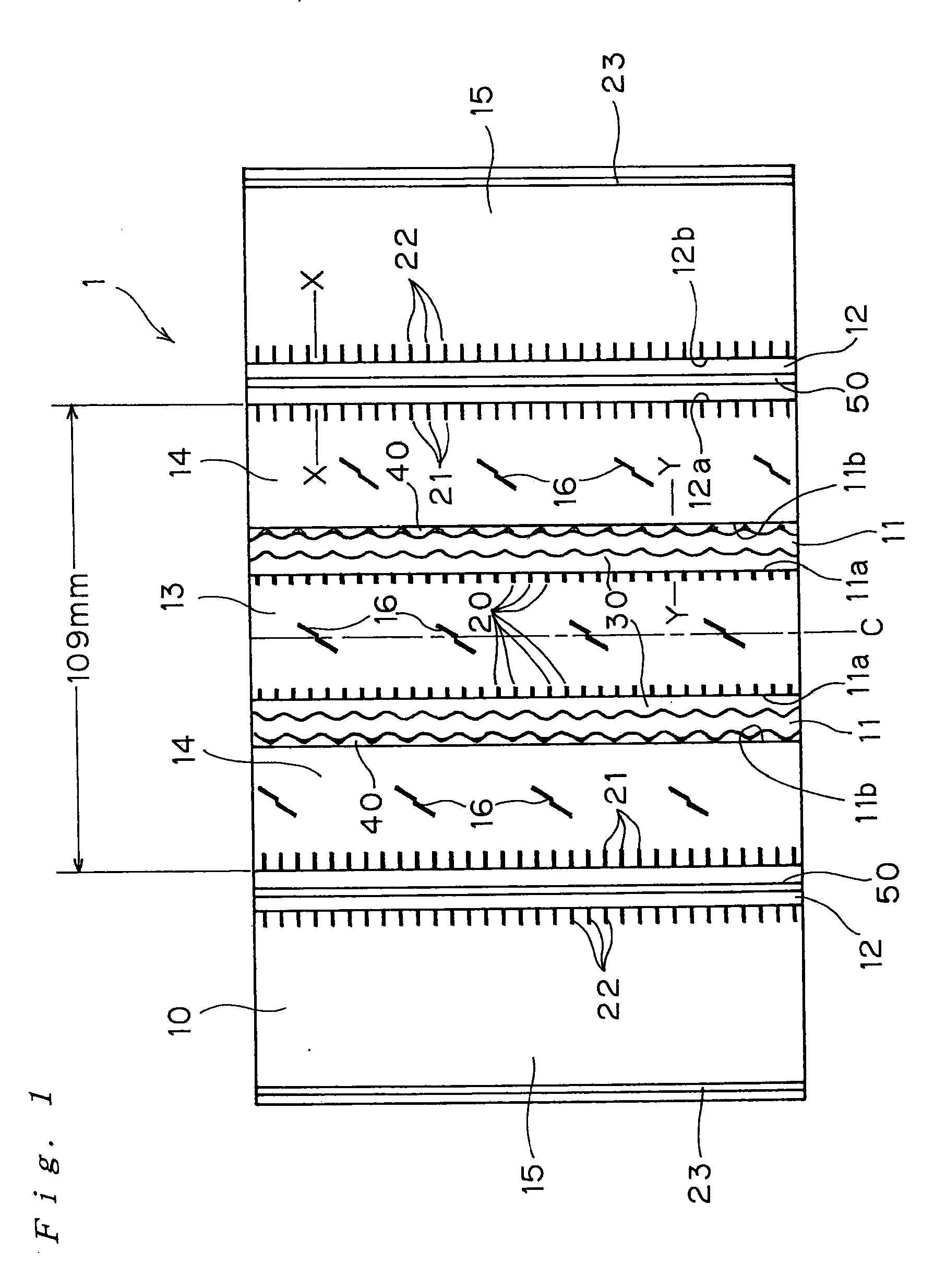

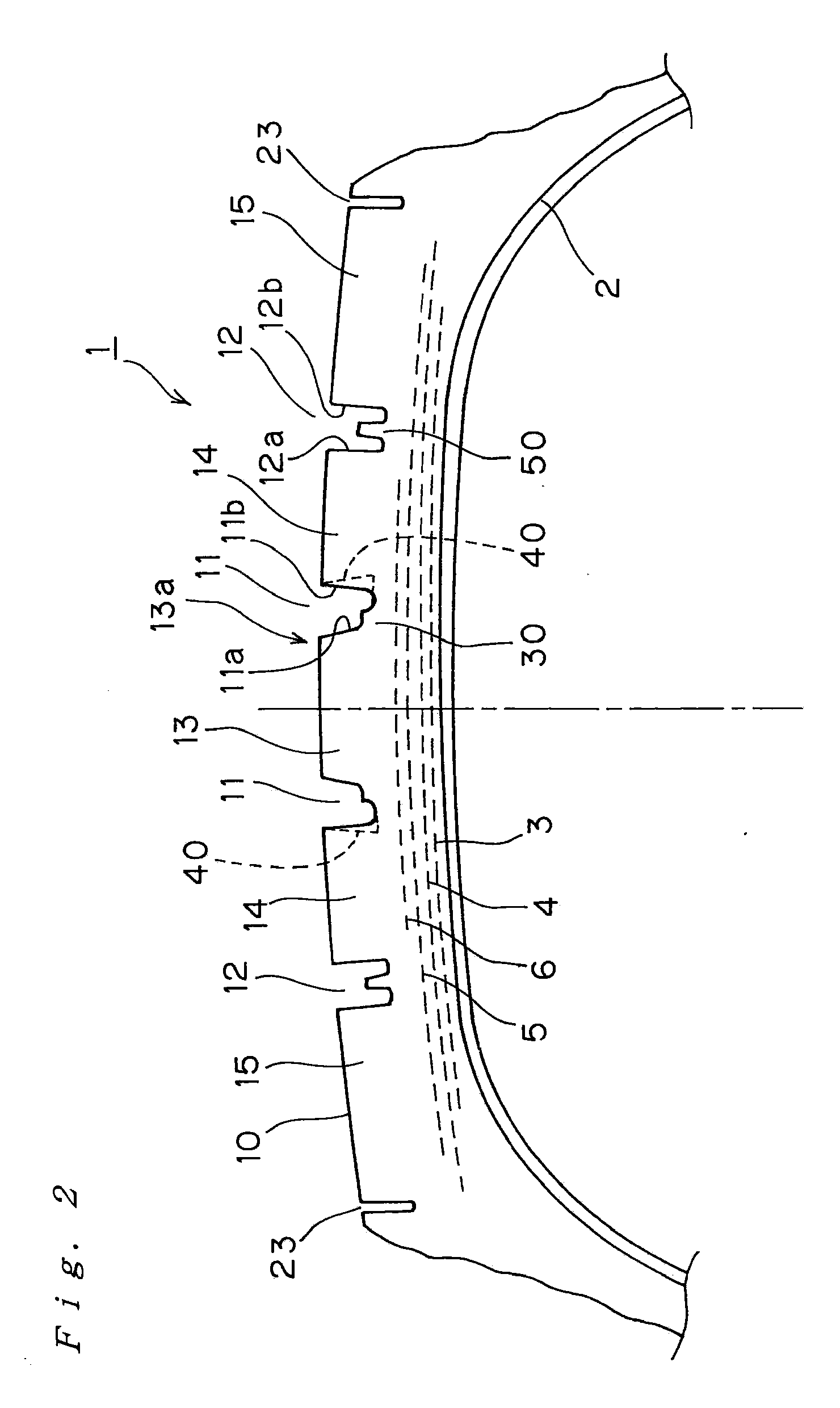

Pneumatic tire

InactiveUS20080121326A1Improve wear resistanceImprove the immunityTyre tread bands/patternsNon-skid devicesEngineeringTread

A pneumatic tire of the invention includes: a stepped-shaped raised area provided in the main groove positioned at a center area of the tire so as to be continued circumferentially of the tire, connected to either the main groove walls, and raised from the groove bottom; and a ridge lower than a tread surface of the tire in each of the main grooves on both outsides of the main groove at the center area of the tire so as to be raised from the center of the groove bottom continuously along the length thereof without being joined with the groove walls, and the angle of inclination of the main groove walls with respect to the normal line of the tangential line on the tread surface of the main groove portion is parallel to each other or is 5° or smaller.

Owner:TOYO TIRE & RUBBER CO LTD

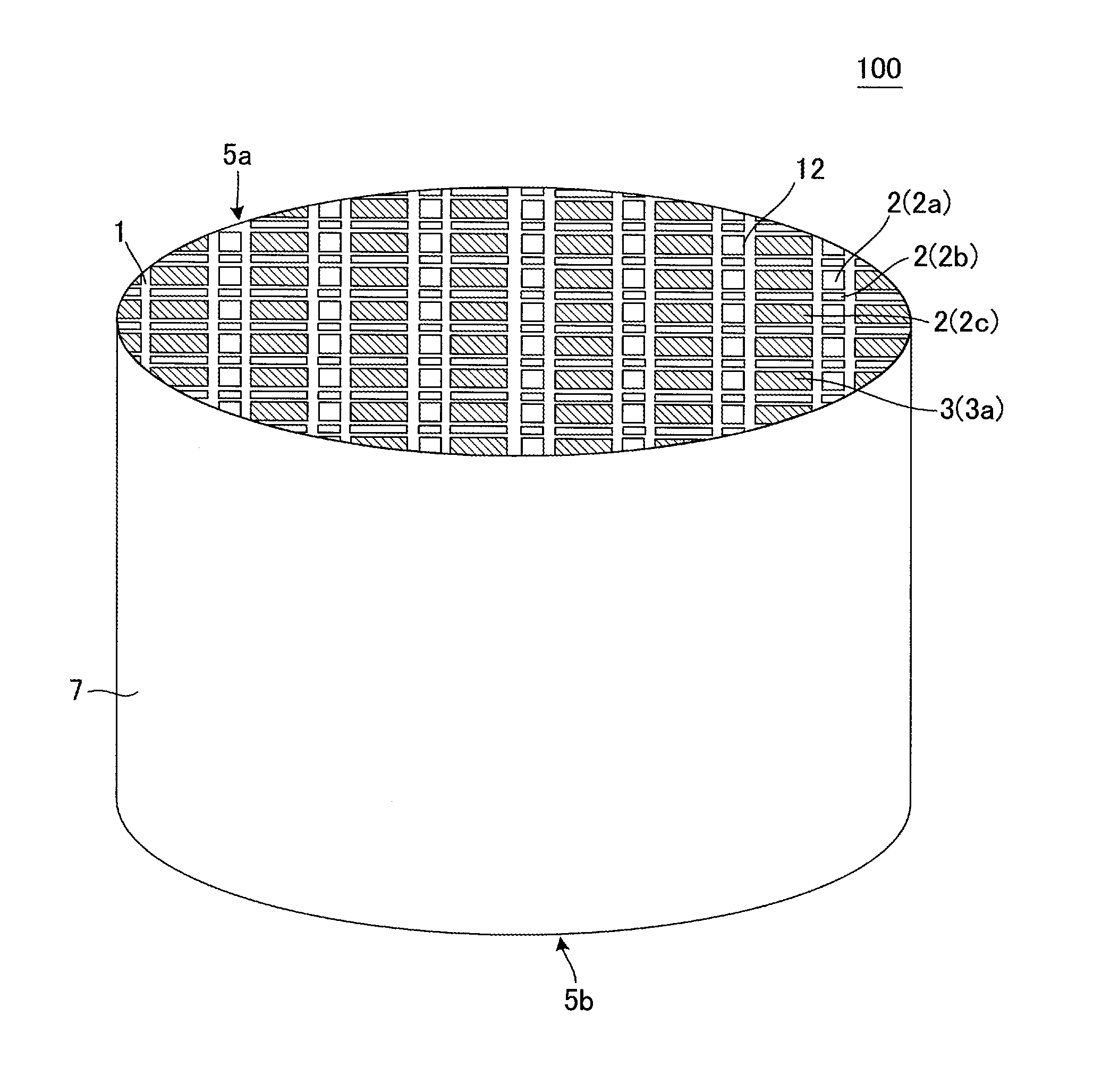

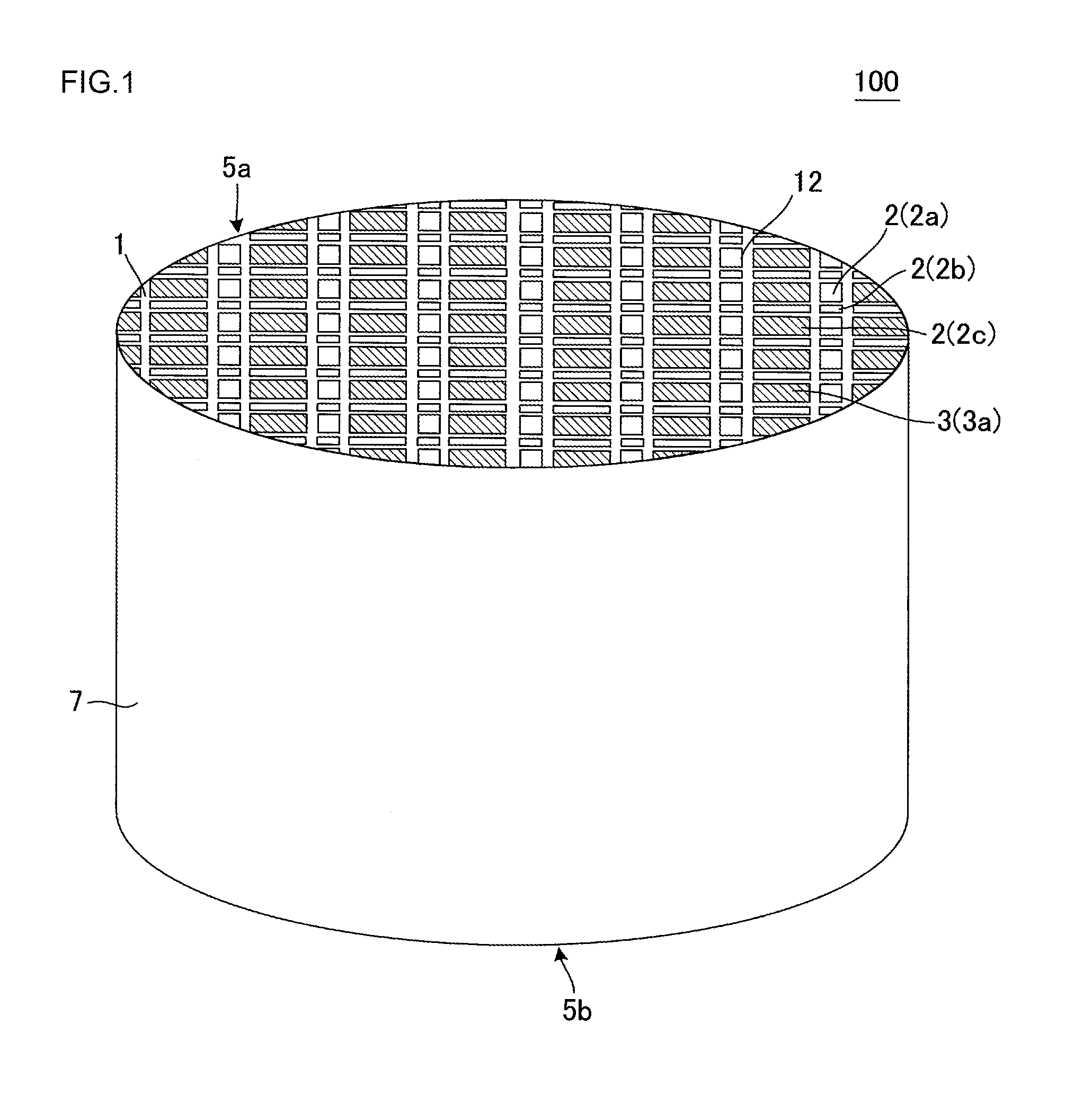

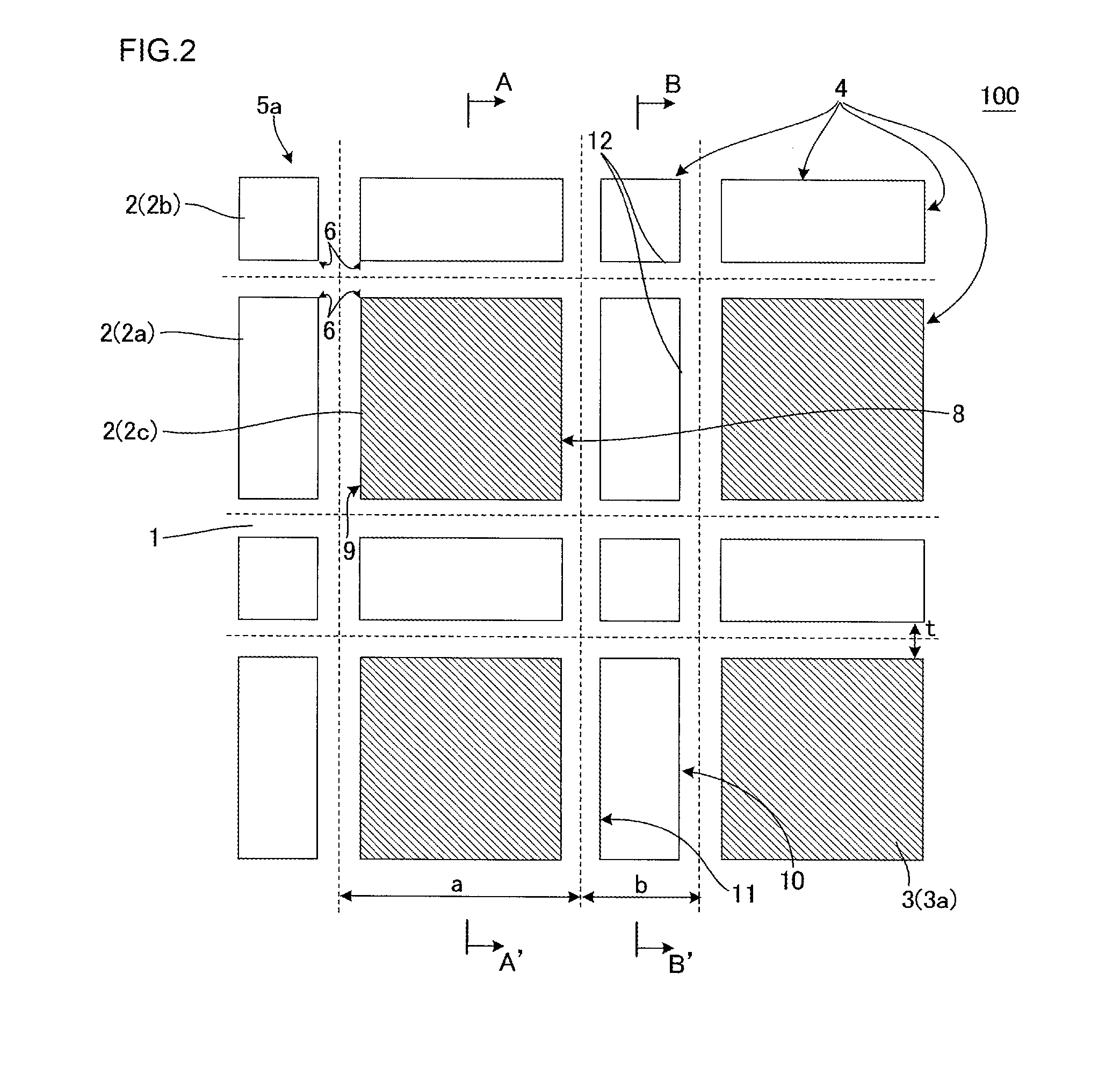

Honeycomb filter

ActiveUS20160067653A1Efficiently regenerateImprove ignitabilityCombination devicesGas treatmentHoneycombUnit volume

In a cross section perpendicular to a central axis direction of the honeycomb substrate, cells are arranged so that a periphery of an inlet plugged cell is surrounded with four rectangular outlet plugged cells and four square outlet plugged cells, and in the cross section, a partition wall center distance a, a partition wall center distance b and a partition wall thickness t satisfy the following equation (1). Additionally, an amount of a catalyst per unit volume of partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the inlet plugged cells is larger than an amount of a catalyst per unit volume of the partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the square outlet plugged cells.0.95<b / at<1.90 (1)

Owner:NGK INSULATORS LTD

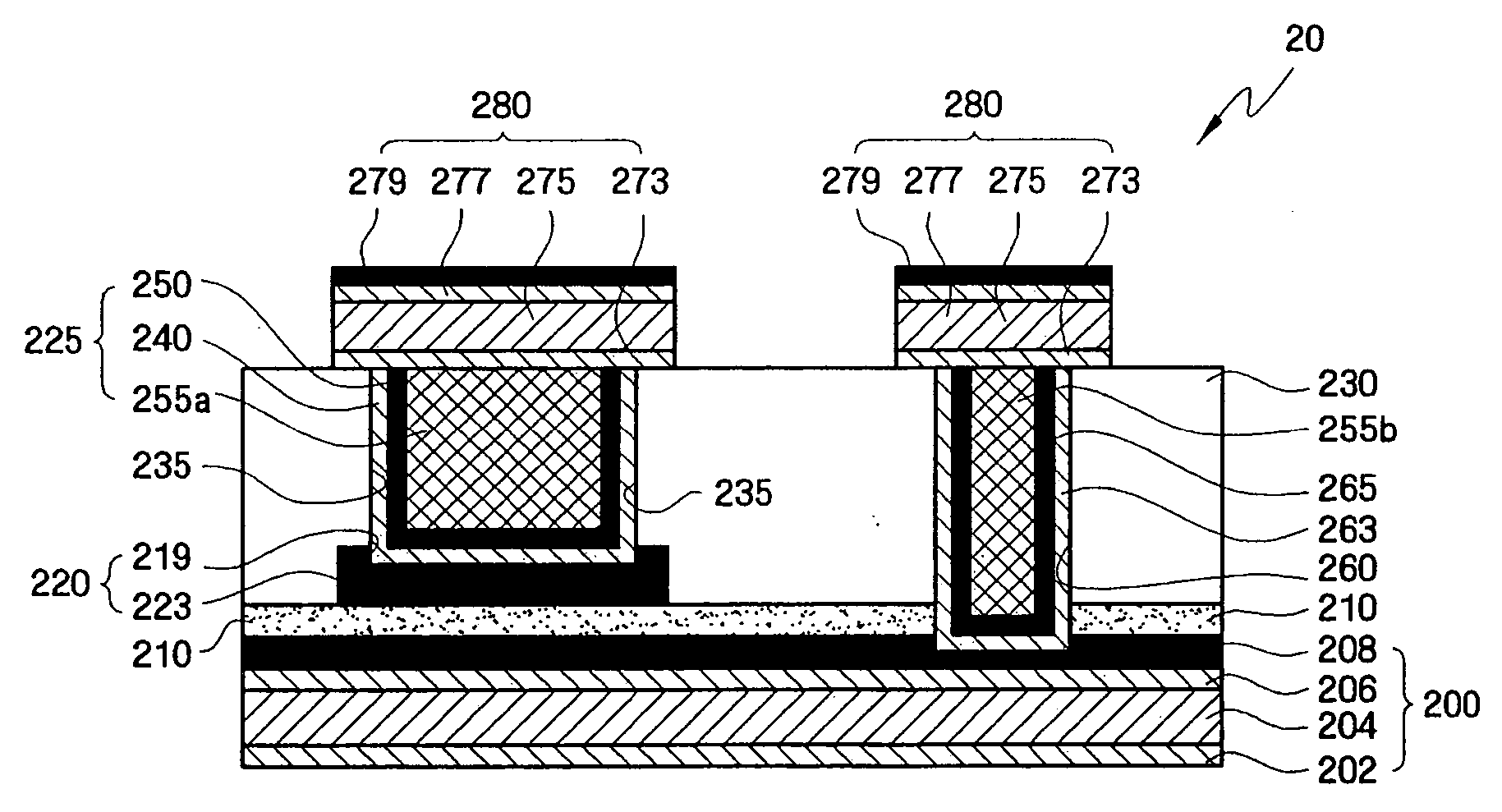

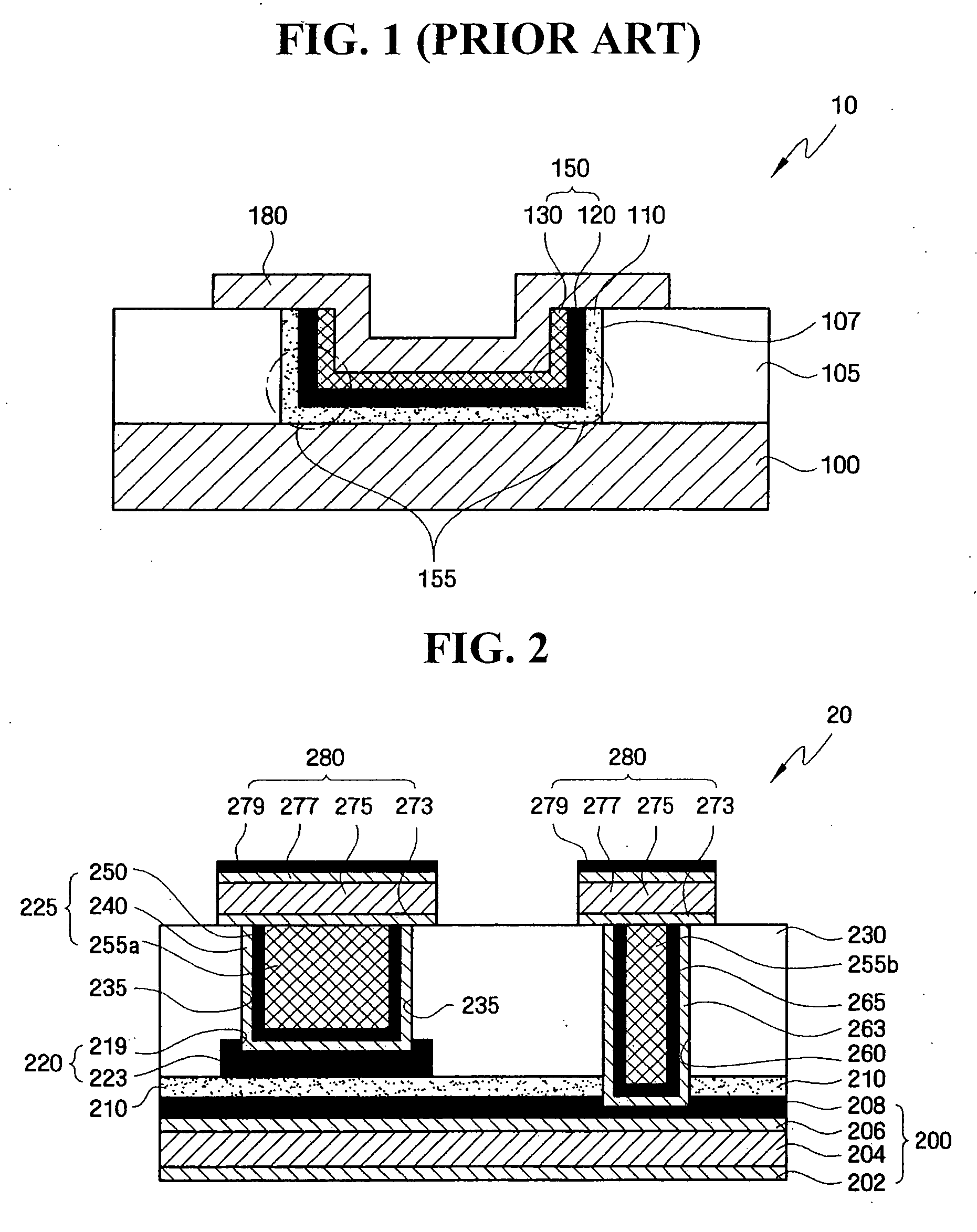

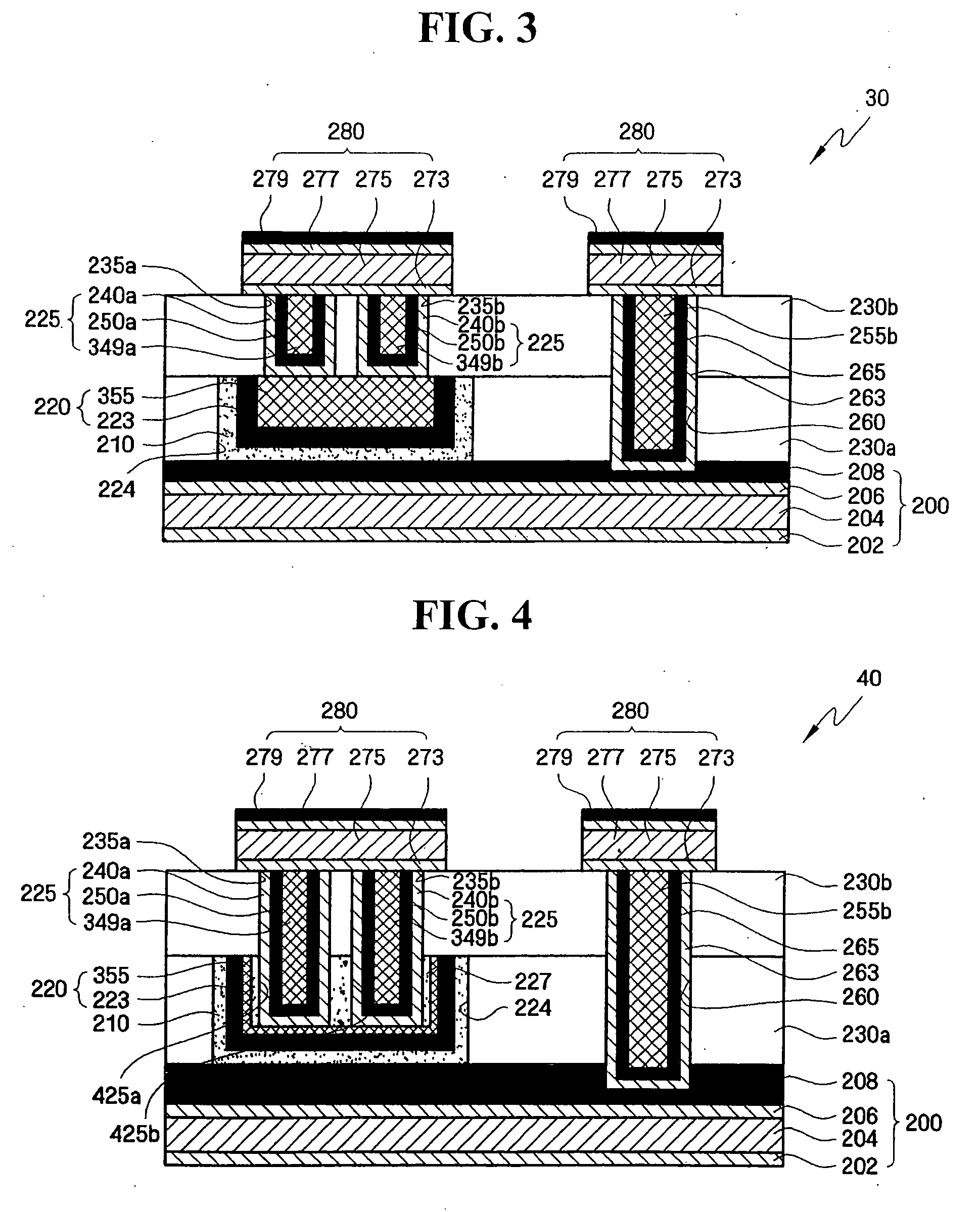

Metal-insulator-metal capacitor and method of fabricating the same

InactiveUS20060157766A1Avoid crackingInhibit the generation of cracksTransistorSolid-state devicesMetal-insulator-metalOptoelectronics

In a metal-insulator-metal (MIM) capacitor and a method of fabricating the MIM capacitor, a metal-insulator-metal (MIM) capacitor comprises: a lower electrode pattern which is formed on a substrate and includes a conductive layer having a portion as a lower interconnect; a dielectric layer on the lower electrode pattern; a first upper electrode pattern on the dielectric layer; an interlayer insulating layer which covers the first upper electrode pattern, the dielectric layer, and the lower electrode pattern and has a planarized upper surface; a second upper electrode opening pattern formed in the interlayer insulating layer to expose the first upper electrode pattern; a second upper electrode which fills the opening pattern and has an upper surface that is substantially level with an upper surface of the interlayer insulating layer; and an upper interconnect on the interlayer insulating layer and contacts the second upper electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

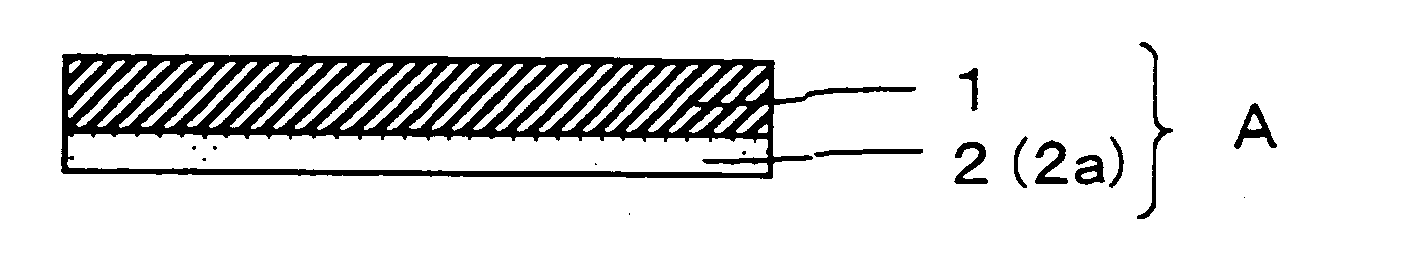

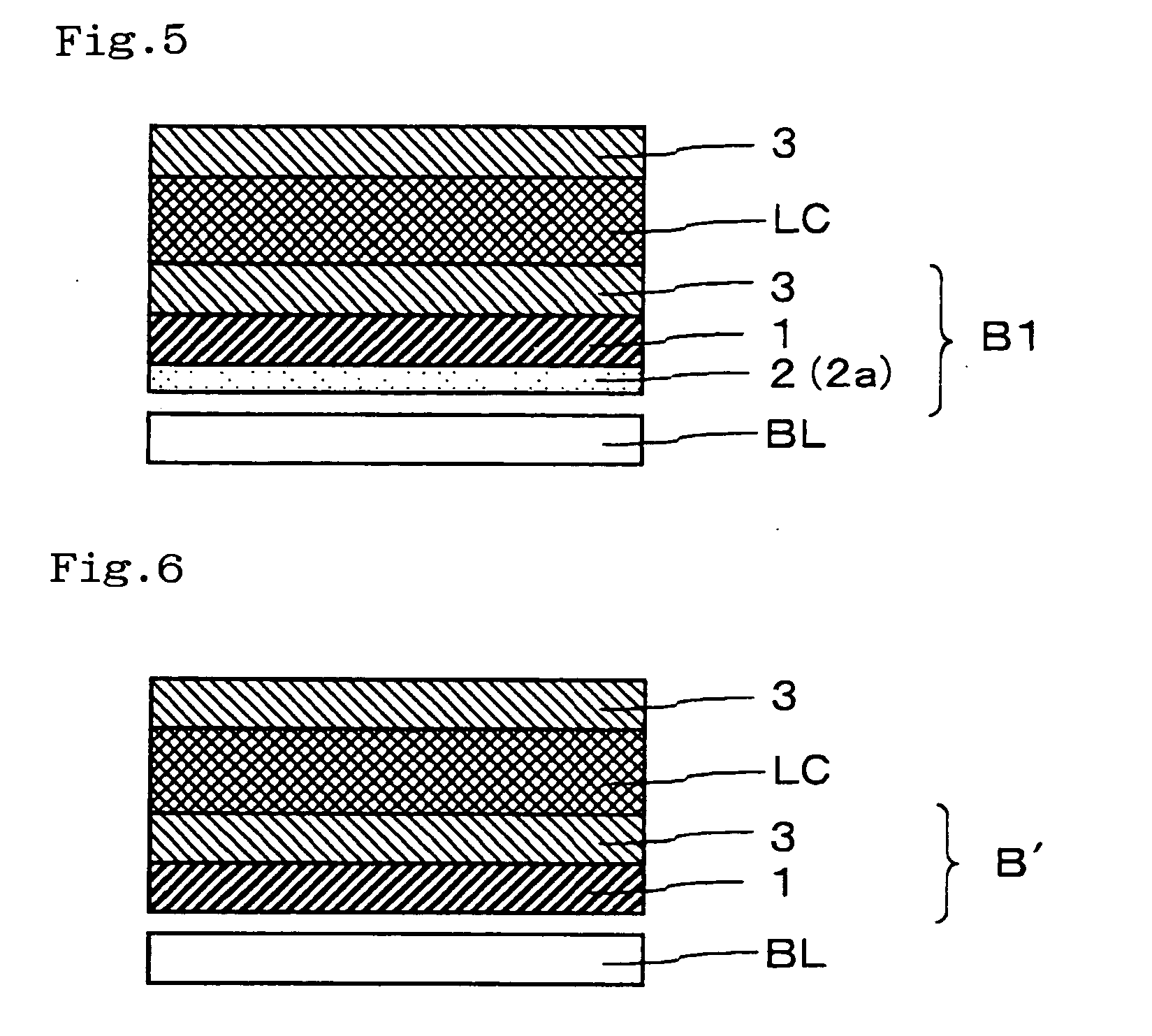

Lineraly polarized light separating film, linearly polarized light separating laminate film, backlight system and liquid crystal display

InactiveUS20050083450A1Improve scratch resistanceEasy to operateProjectorsPolarising elementsLiquid-crystal displayResin coating

A linearly polarized light separating film comprising a linearly polarized light separating film and a hard coat layer, which is preferably a thickness in the range of from 1 to 6 μm, which is preferably formed with a resin coat layer having conductivity in which metal oxide fine particles are dispersed, on one side thereof, is good in scratch resistance, and in handleability.

Owner:NITTO DENKO CORP

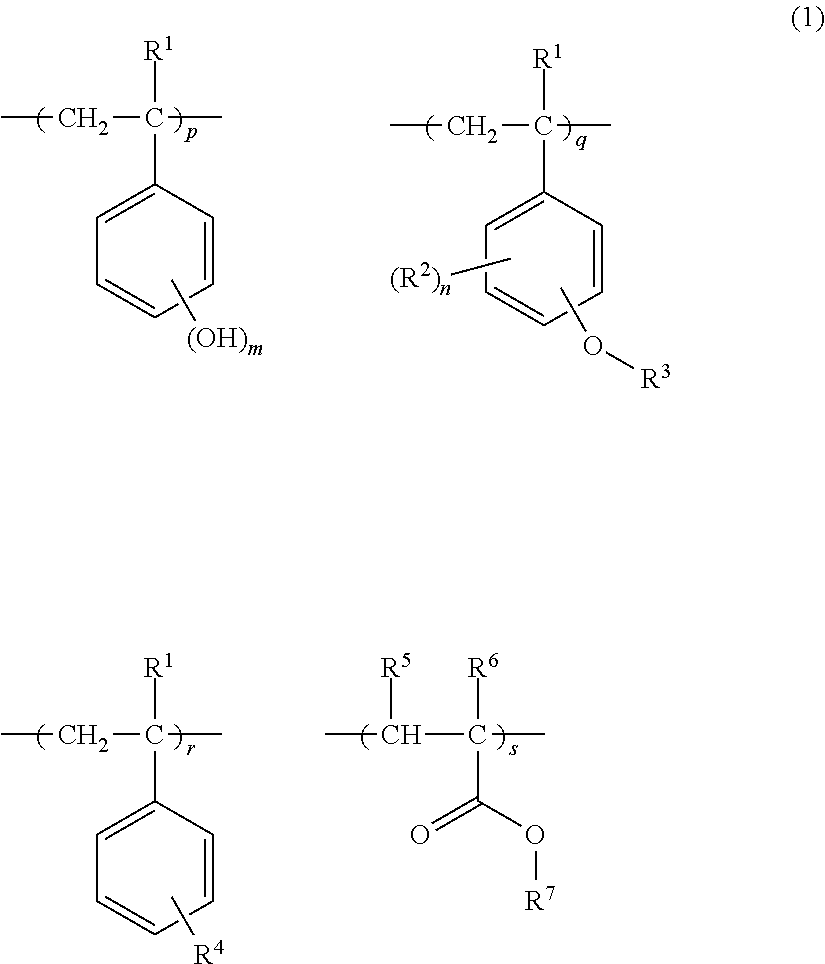

Chemically amplified positive resist composition and patterning process

ActiveUS20120184101A1High sensitivityInhibit the generation of cracksPhotosensitive materialsSemiconductor/solid-state device manufacturingVinyl etherPolymer science

In a chemically amplified positive resist composition comprising a base resin and an acid generator in a solvent, the base resin contains both an alkali-insoluble or substantially alkali-insoluble polymer having an acid labile group-protected acidic functional group having a Mw of 1,000-500,000 and an alkyl vinyl ether polymer having a Mw of 10,000-500,000. The composition forms on a substrate a resist film of 5-100 μm thick which can be briefly developed to form a pattern at a high sensitivity and a high degree of removal or dissolution to bottom.

Owner:SHIN ETSU CHEM IND CO LTD

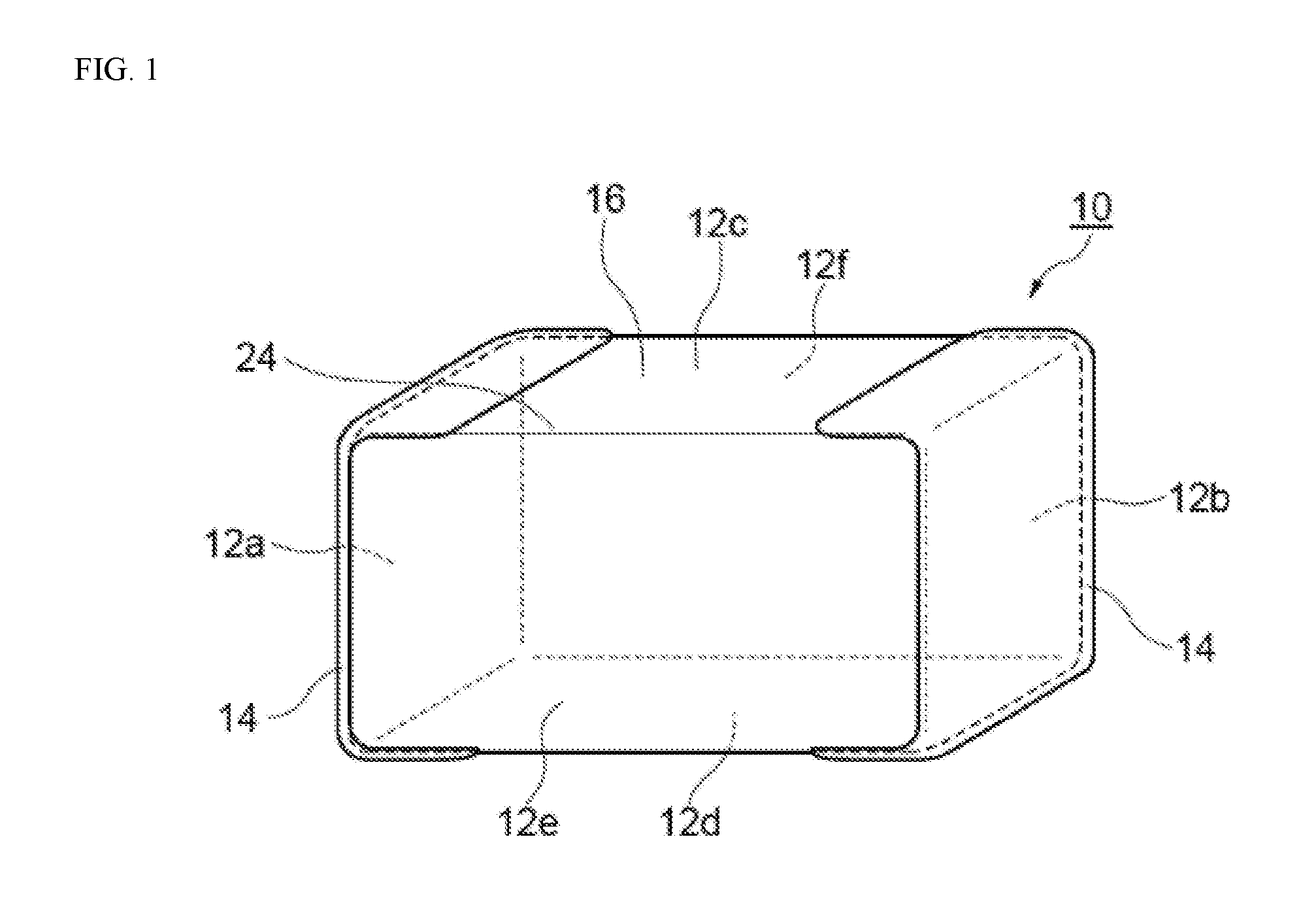

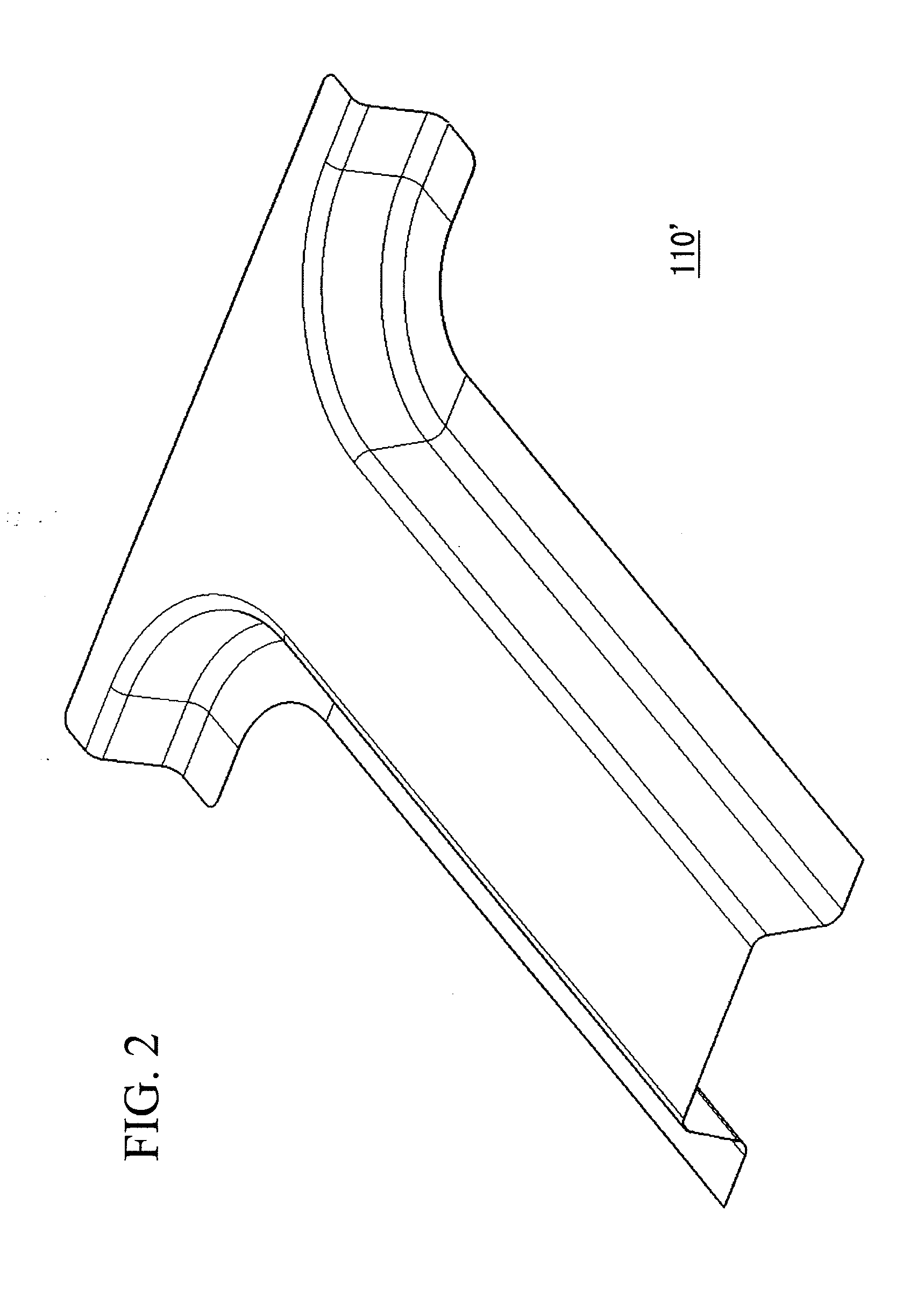

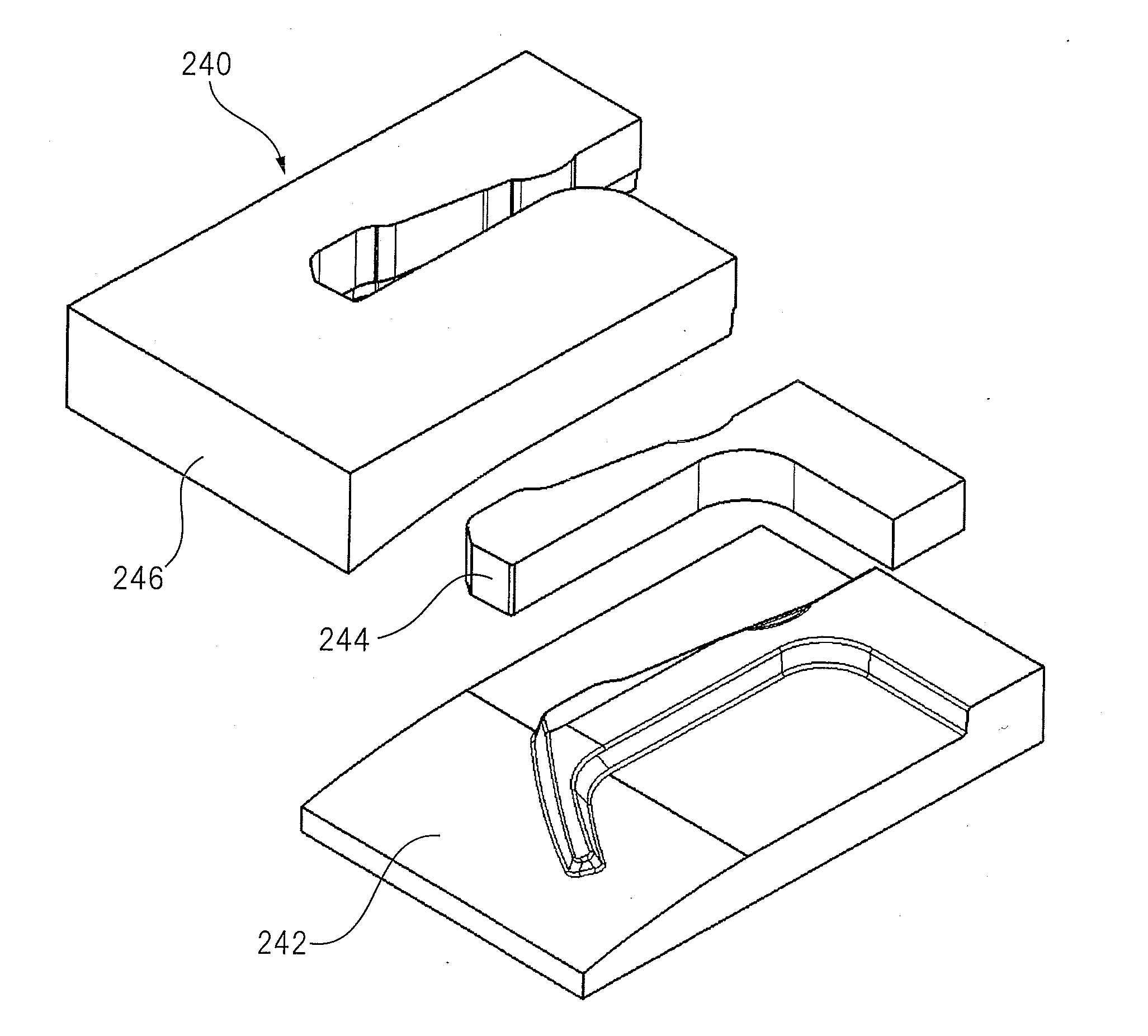

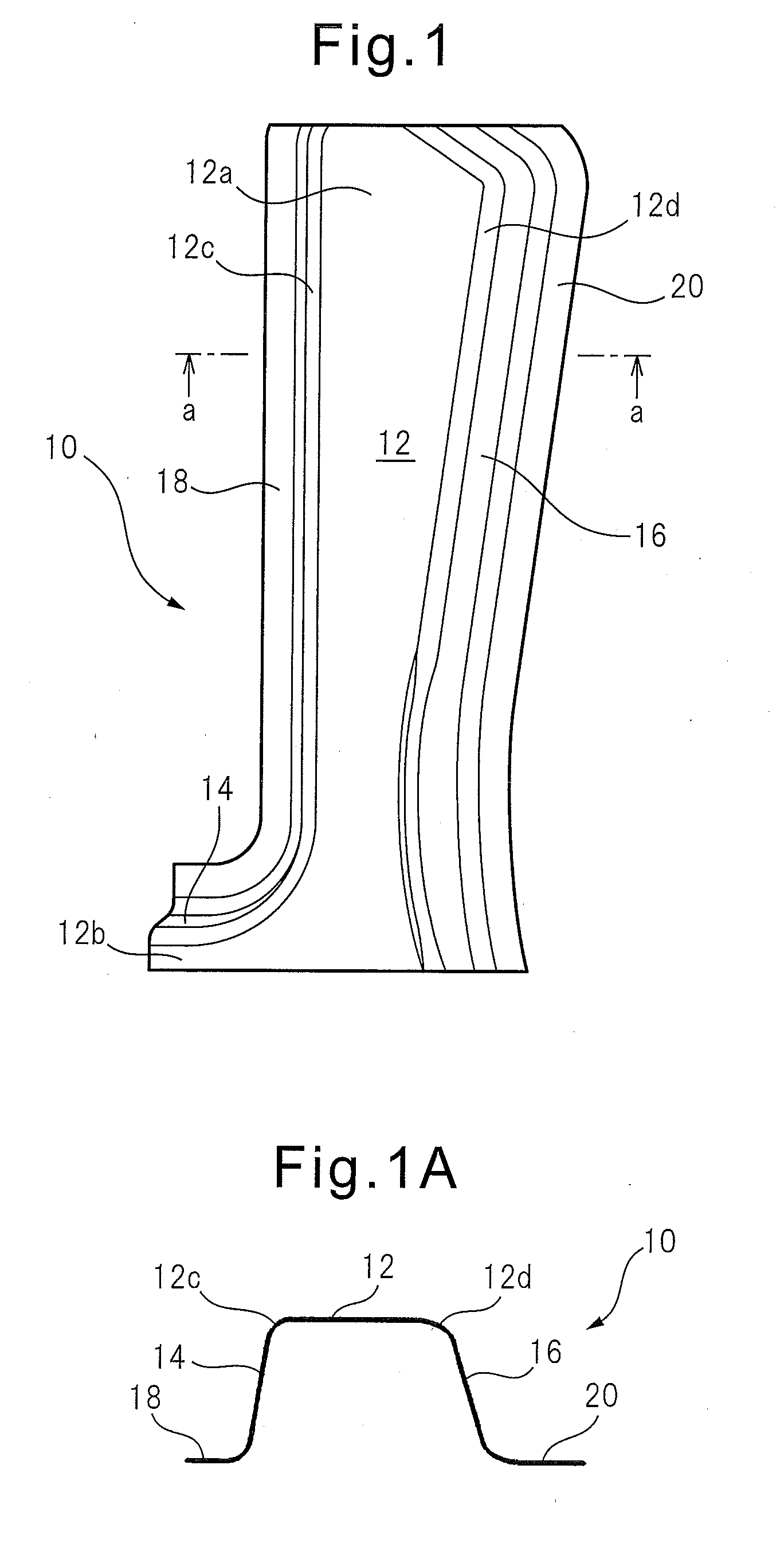

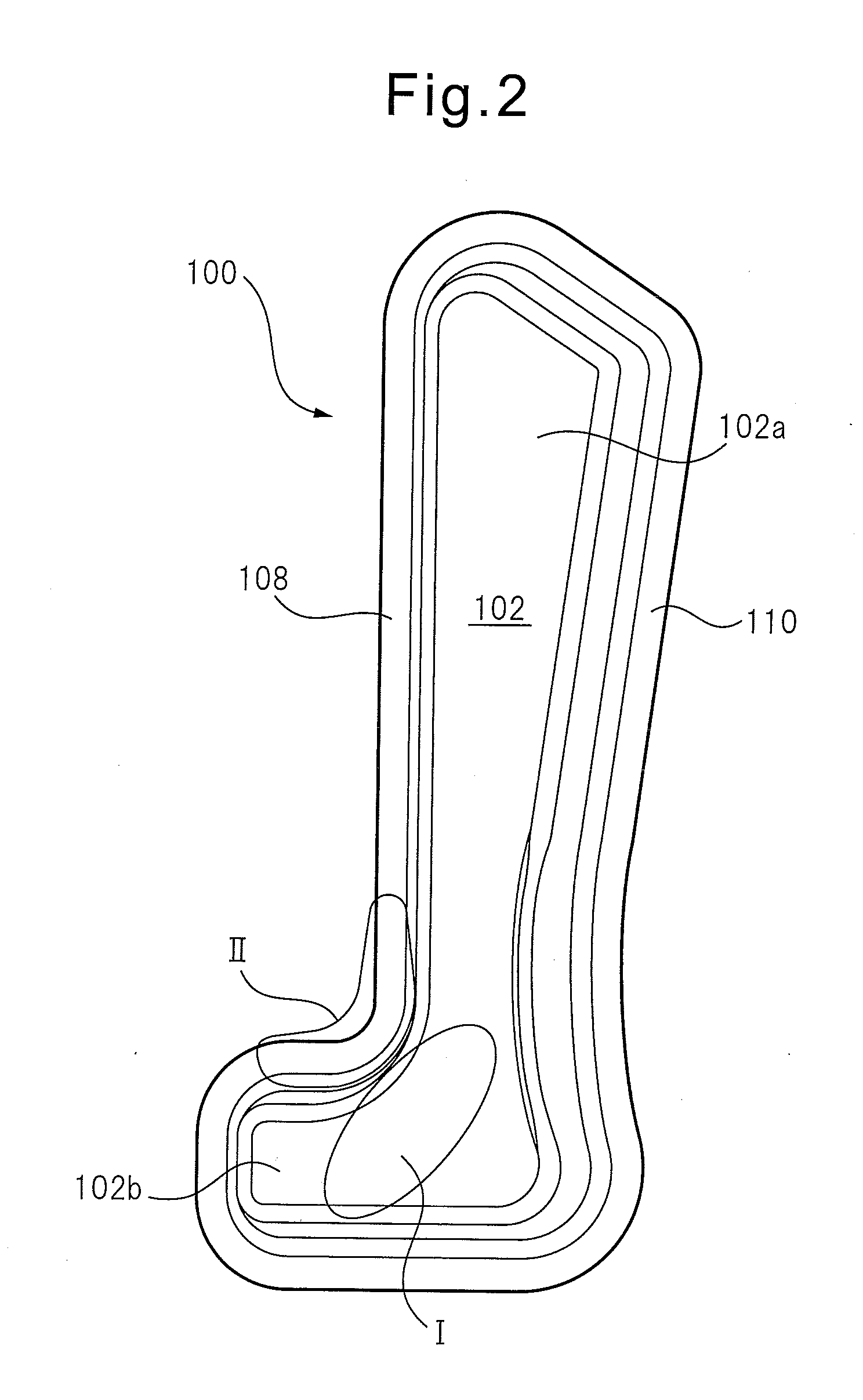

Method of producing l-shaped product

ActiveUS20130239645A1Generation of wrinkle can be suppressedReduce wall thicknessVehicle componentsStructural engineeringMechanical engineering

A method of producing an L-shaped product (10) which includes an L-shaped flat top wall (12), an inside wall (14) extending and connected along an inside edge (12c) of the top wall, and an outside wall (16) extending and connected along an outside edge (12d) of the top wall, each of the inside and outside walls being terminated by flange (18, 20) substantially parallel to the top wall, is disclosed. The method comprises the steps of: providing sheet metal material; providing a drawing die assembly; and stamping the sheet metal material by the drawing die assembly to produce an intermediate product. The method further comprises the steps of: providing a bending die assembly; and stamping the intermediate product by the bending die assembly to produce an L-shaped product completed.

Owner:NIPPON STEEL CORP +1

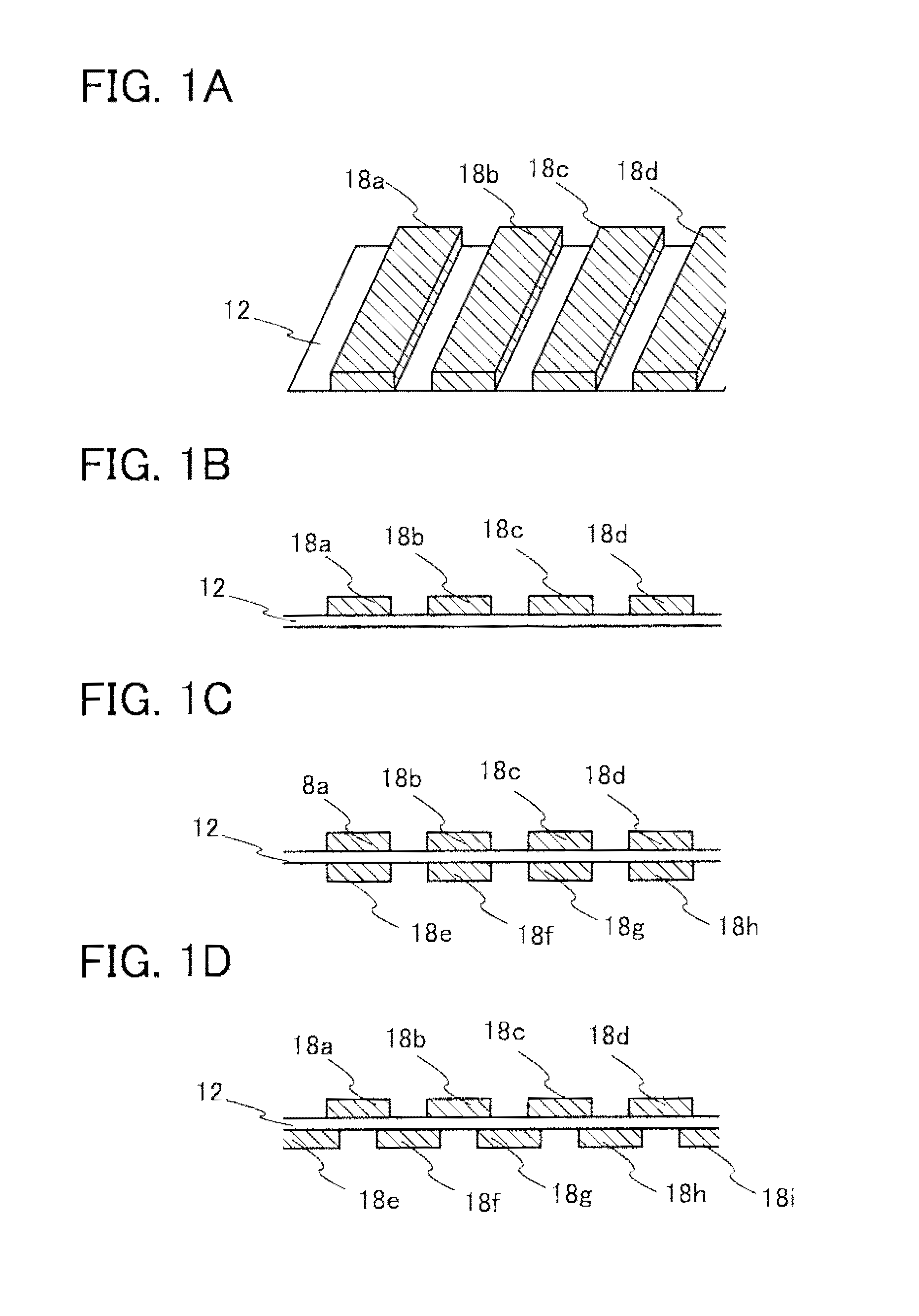

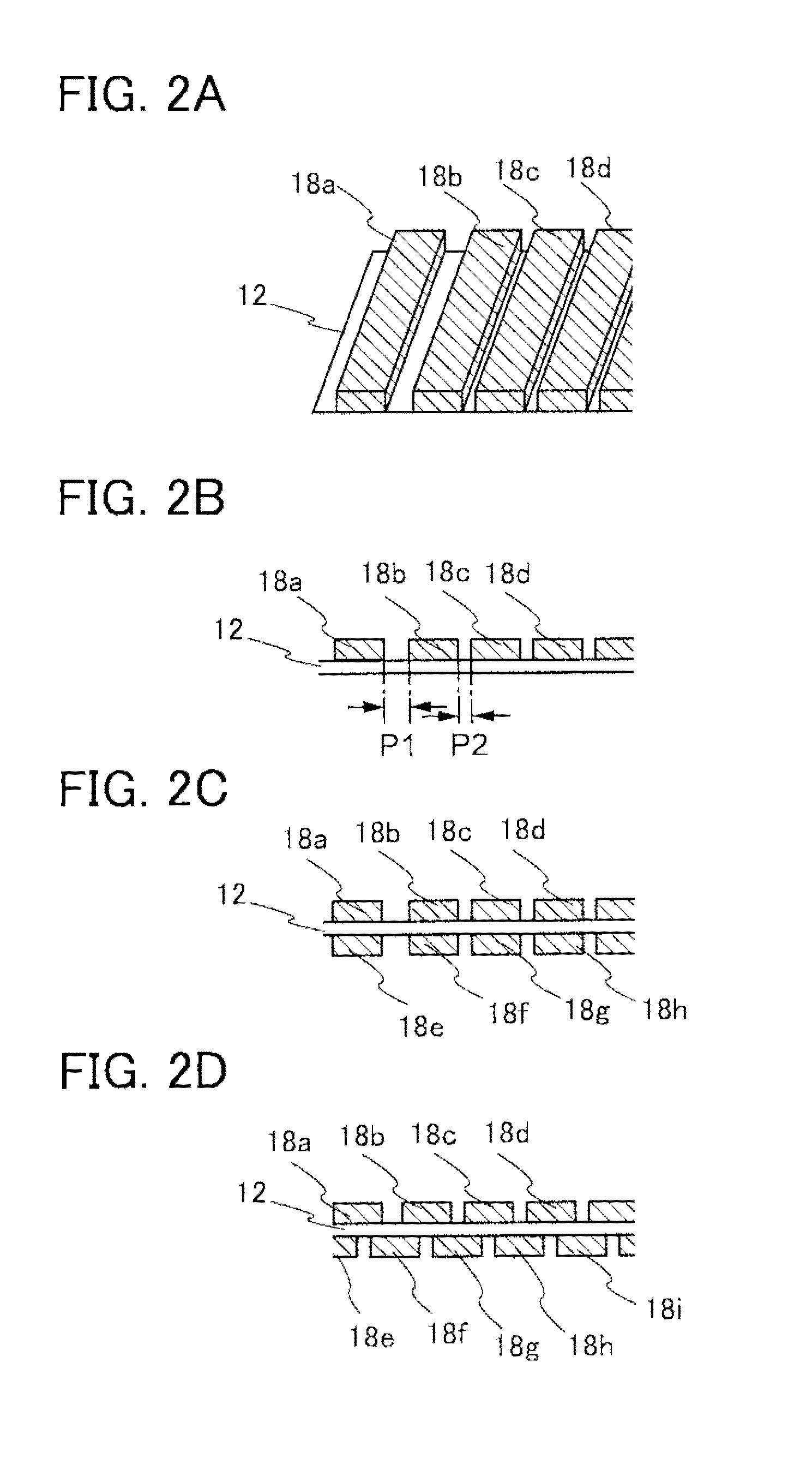

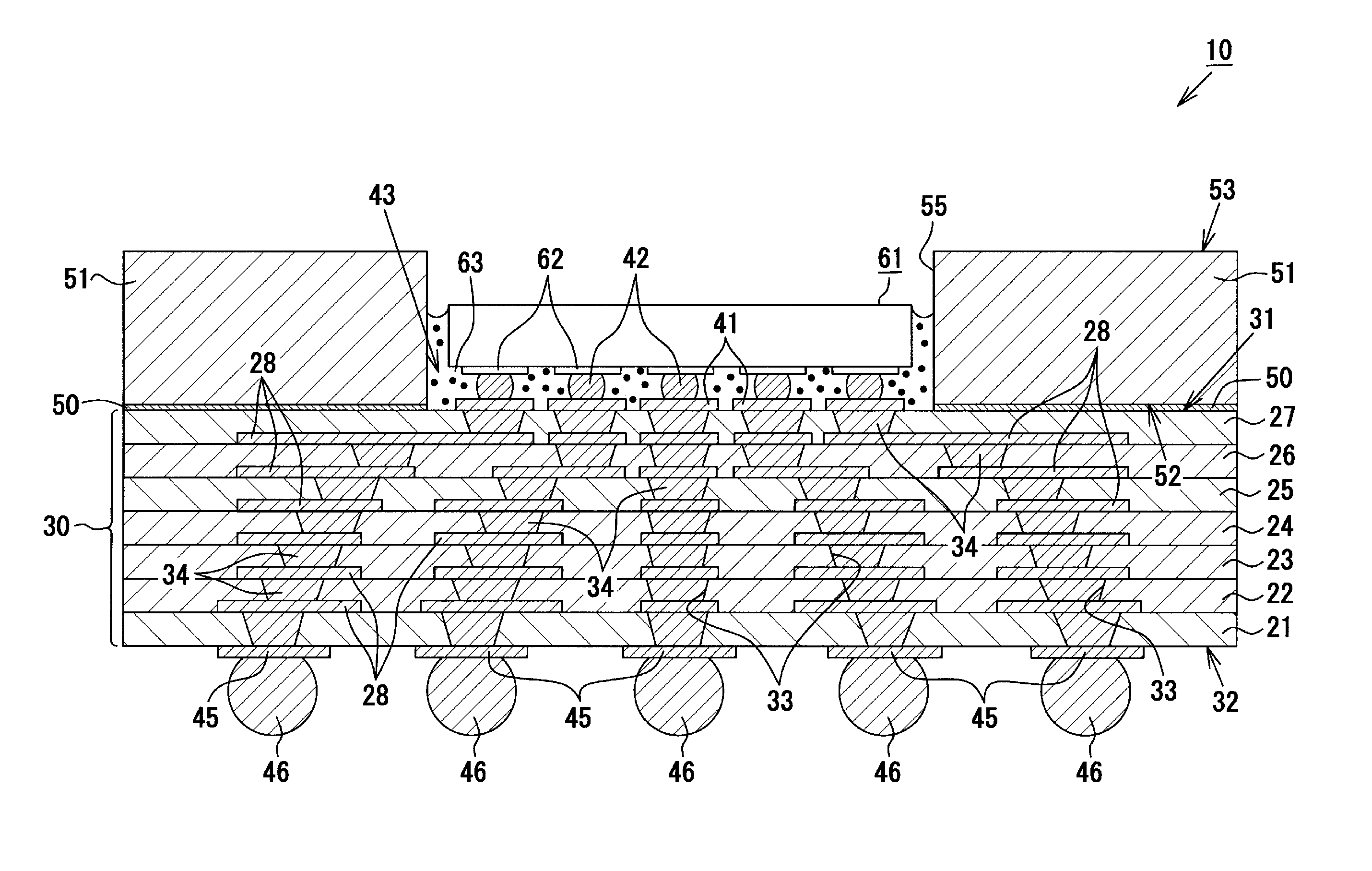

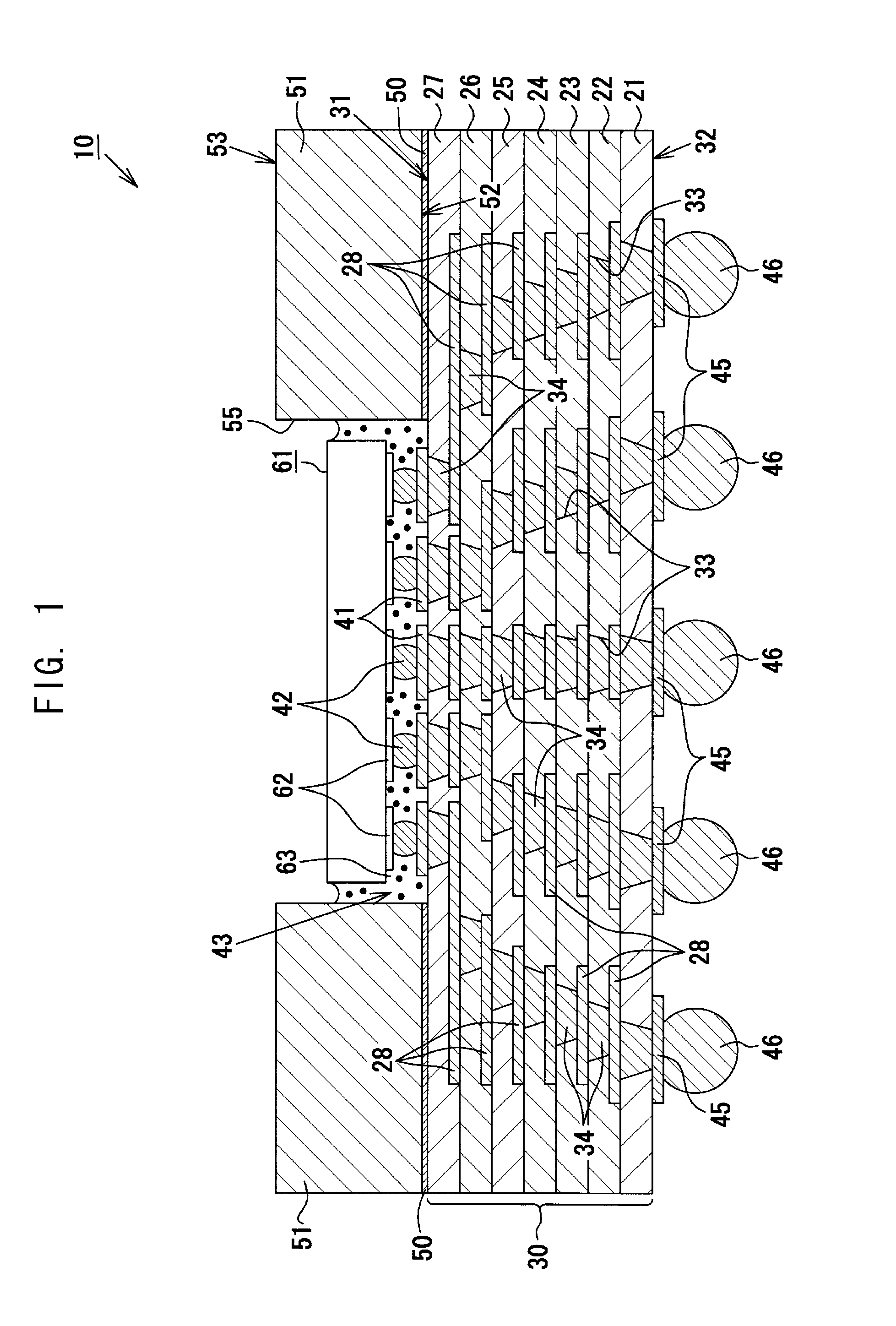

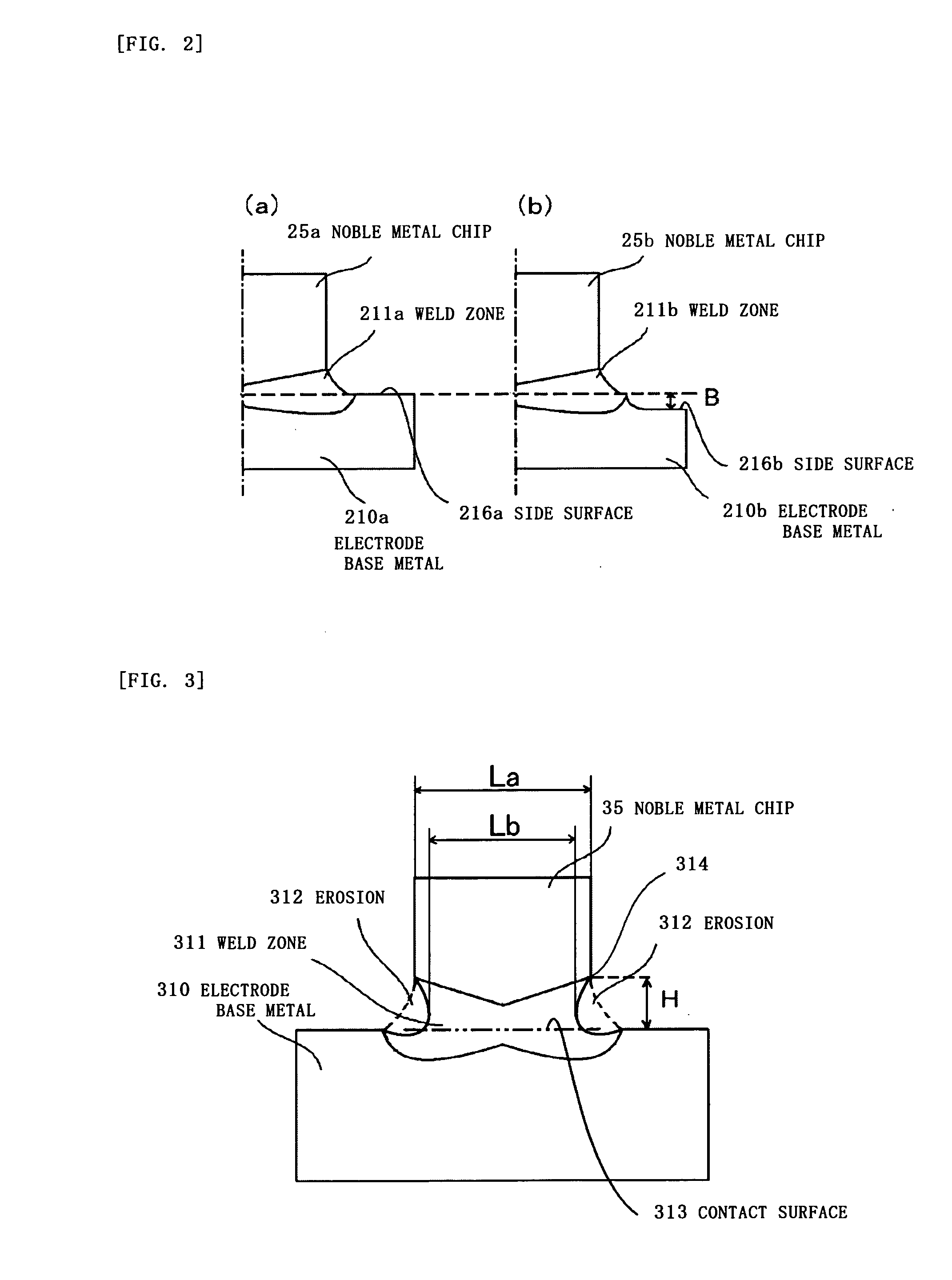

Multilayer wiring substrate

InactiveUS20120024582A1Improve reliabilityInhibit the generation of cracksSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerThermal expansion

A multilayer wiring substrate includes a laminate structure in which resin insulation layers and conductor layers are alternately laminated. The resin insulation layers include first-type resin insulation layers, and second-type resin insulation layers, each of which contains an inorganic material in a larger amount and is smaller in thermal expansion coefficient as compared with first-type resin insulation layers. On a cross section of the laminate structure taken along a thickness direction thereof, the ratio of a total thickness of the second-type resin insulation layers located in an area A2 to a thickness corresponding to the area A2 is greater than the ratio of a total thickness of the second-type resin insulation layers located in an area A1 to a thickness corresponding to the area A1. The laminate structure is warped such that the laminate structure is convex toward the side where the second main face is present.

Owner:NGK SPARK PLUG CO LTD

Spark plug and process for producing the spark plug

InactiveUS20100264801A1Prevent oxidationElectrode thickness can be decreasedSpark gapsSparking plugs manufactureEngineeringGrounding electrodes

A spark plug in which an ignition portion of a ground electrode formed through joining of a noble metal chip to the ground electrode has high durability, and a method of manufacturing the spark plug.

Owner:NGK SPARK PLUG CO LTD

Pneumatic Tire

InactiveUS20090137701A1Improve balanceReduce fuel consumptionSpecial tyresTyre tread bands/patternsSilane couplingButadiene-styrene rubber

A pneumatic tire having excellent balance between low fuel consumption and grip property and capability of suppressing crack generation in a tread groove bottom while maintaining abrasion resistance is provided. The pneumatic tire has a tread formed from a rubber composition includes per 100 parts by weight of a diene rubber containing a styrene-butadiene rubber, from 30 to 150 parts by weight of a reinforcing filler containing from 20 to 100 parts by weight of silica, and from 5 to 40 parts by weight of a carboxyl-terminally modified liquid polybutadiene, and further includes a silane coupling agent in an amount of from to 25 parts by weight per 100 parts by weight of the silica.

Owner:TOYO TIRE & RUBBER CO LTD

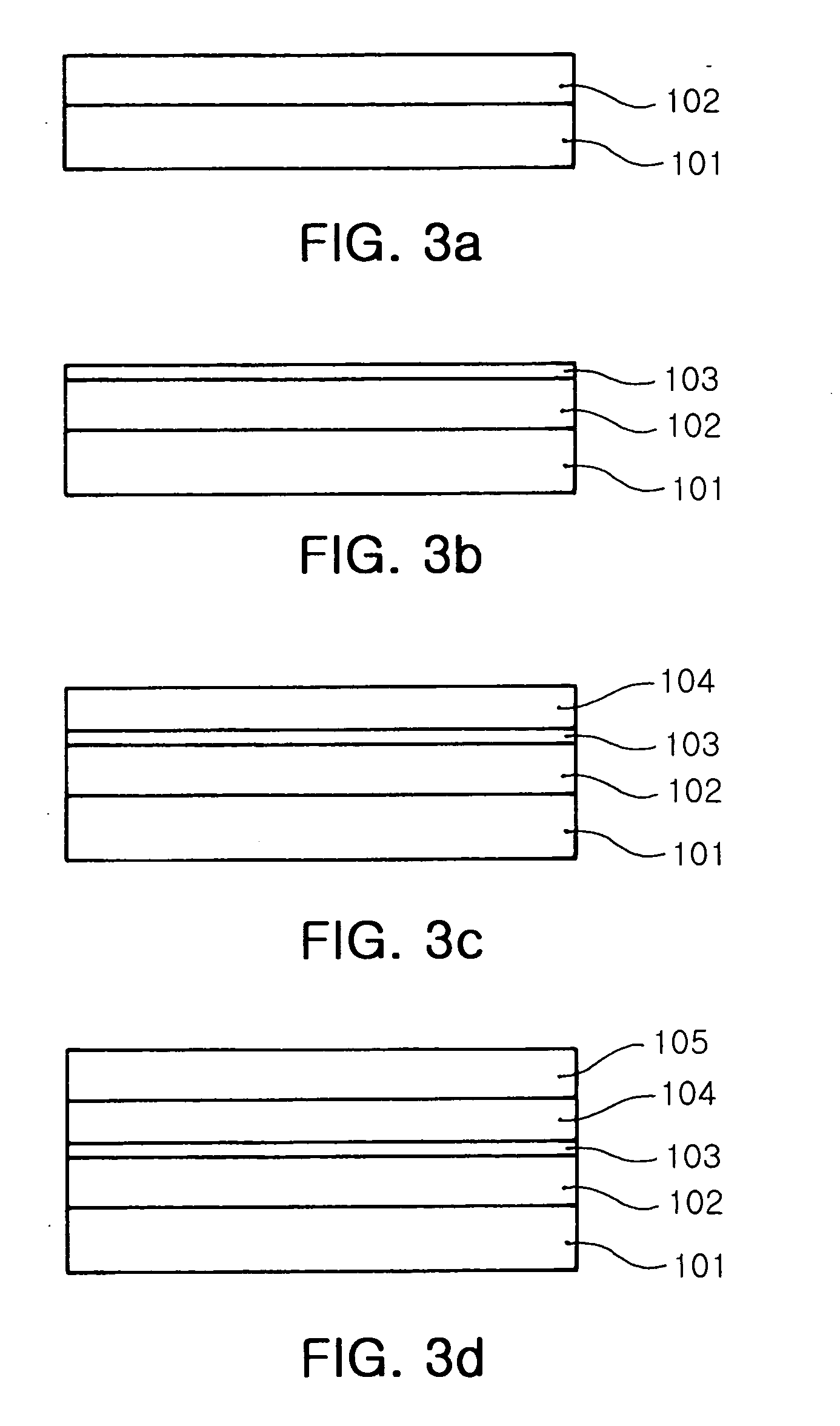

Nitride based semiconductor device and process for preparing the same

ActiveUS20060091500A1Facilitate two-dimensional growthIncrease pressurePolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialSingle crystal

A process for preparing a nitride based semiconductor device in accordance with the present invention comprises growing a high temperature AlN single crystal layer on a substrate; growing a first GaN layer on the high temperature AlN single crystal layer in a first V / III ratio, under a first pressure of 300 Torr or more, such that the predominant direction of growth is the lateral direction; and growing a second GaN layer on the first GaN layer in a second V / III ratio lower than the first V / III ratio, under a second pressure lower than the first pressure such that the predominant direction of growth is the lateral direction.

Owner:SAMSUNG ELECTRONICS CO LTD

Pneumatic tire

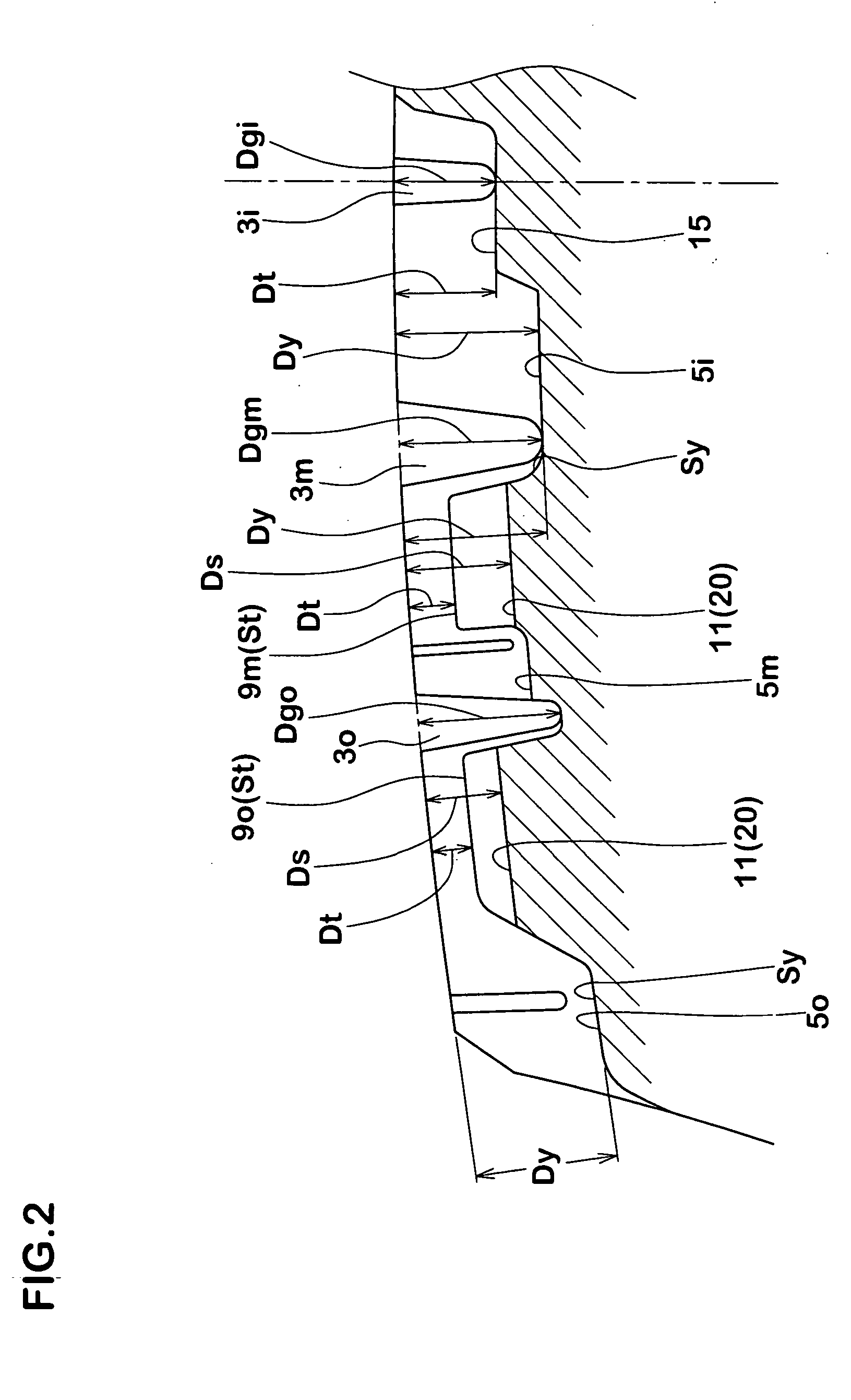

InactiveUS20050211354A1Improve partial wear resistanceRaise security concernsTyre tread bands/patternsNon-skid devicesMechanical engineeringEngineering

Owner:SUMITOMO RUBBER IND LTD

Nitride semiconductor, method for manufacturing the same and nitride semiconductor device

InactiveUS6858877B2Inhibit the generation of cracksLaser detailsSolid-state devicesGallium nitrideCrystal growth

Owner:PANASONIC CORP

Heat dissipating component for semiconductor element

ActiveUS20140182824A1Improve thermal conductivityInhibit the generation of cracksSemiconductor/solid-state device detailsSolid-state devicesAlloyLayer thickness

Disclosed is a heat dissipating component for a semiconductor element, having a tabular body 0.4-6 mm in thickness containing 40-70 volume % of diamond particles, with the balance comprising metal of which the principal component is aluminum, and coated on both surfaces by a coating layer comprising metal of which the principal component is aluminum, or an aluminum-ceramic based composite material, to form an aluminum-diamond based composite body. On at least the two major surfaces thereof are formed, in order from the major surface side, (1) an amorphous Ni alloy layer 0.1-1 μm in film thickness, (2) an Ni layer 1-5 μm in film thickness, and (3) an Au layer 0.05-4 μm in film thickness, the ratio of the Ni alloy layer and the Ni layer (Ni alloy layer thickness / Ni layer thickness) being 0.3 or less.

Owner:DENKA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com