Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Improve partial wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

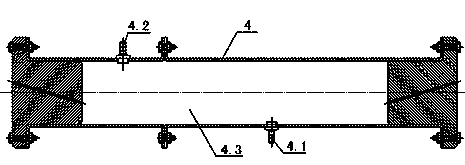

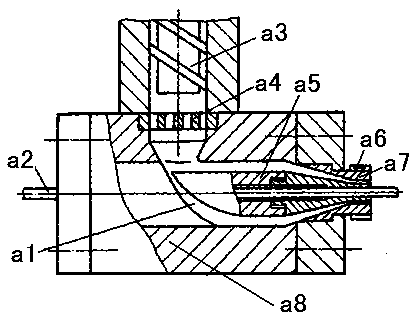

Multilayer compound eccentric-wear-preventing continuous sucker rod and manufacturing device and method thereof

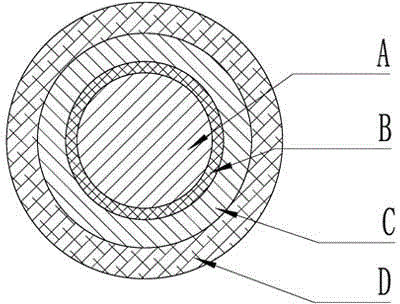

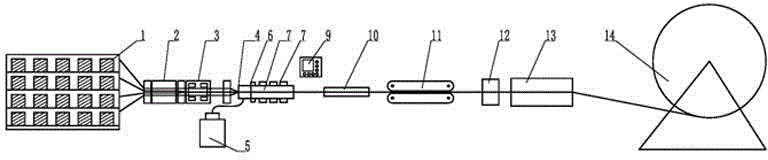

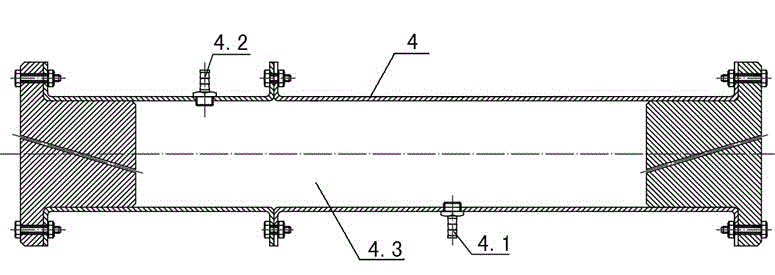

ActiveCN104060944AAccelerated corrosionImprove partial wear resistanceDrilling rodsLayered productsEpoxyManufacturing technology

The invention relates to a multilayer compound eccentric-wear-preventing continuous sucker rod and a manufacturing device and a manufacturing method thereof. The sucker rod is characterized in that one section or several sections of the external surface of a fiber reinforced resin matrix composite rod body are respectively covered with a thermosetting wear layer; each thermosetting wear layer is made from one of polyurethane, a fluorocarbon coating, modified epoxide resin, vinylester resin, unsaturated polyester and phenolic resin; by adopting a manufacturing technology of multilayer composite winding and pultrusion or weaving and pultrusion, an internal layer of longitudinal fibers, an intertwining layer or a weaving layer and an external layer of longitudinal fibers are formed from interior to exterior in sequence; the manufactured rod body has a continuous length of 0-5000m. The sucker rod has the beneficial effects that the radial strength and the axial compressive strength are enhanced; the corrosion resistance and the eccentric wear resistance of the thermosetting wear layers are improved by 30%; the maximum temperature tolerance of the thermosetting wear layers is up to 190 DEG C; meanwhile, the bonding between an sucker rod body and each thermosetting wear layer is greater in length and quite high in strength, so that the slippage and the layering of an eccentric-wear-preventing layer from the surface of the sucker rod in the normal operation of an oil well are avoided.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

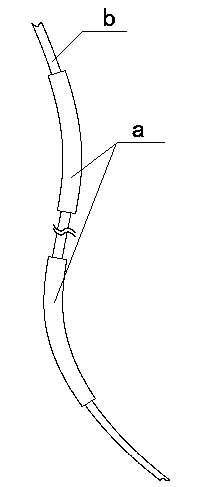

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

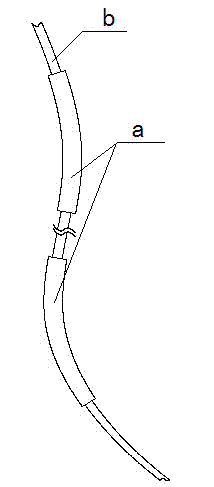

ActiveCN103075112AAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

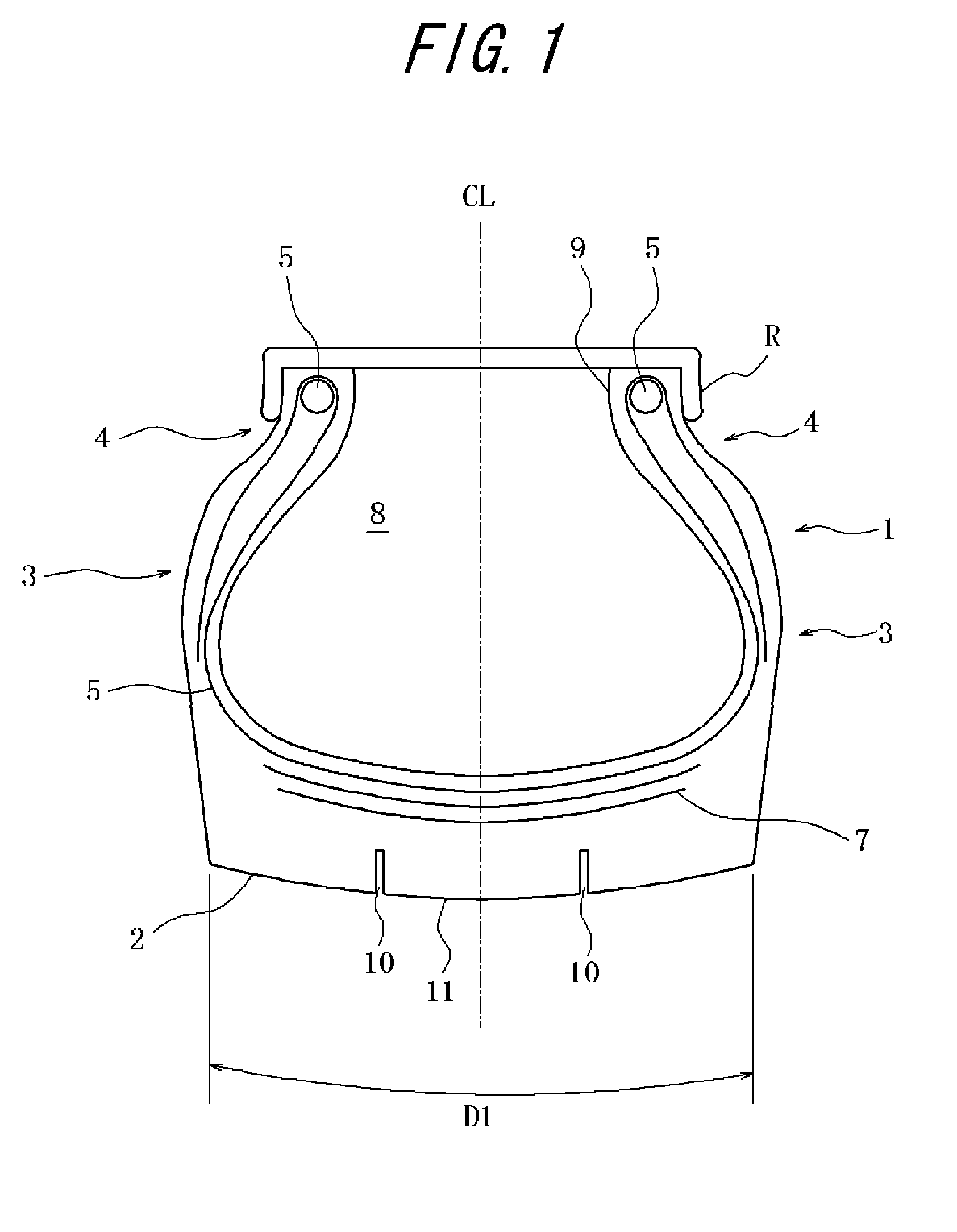

Pneumatic tire

InactiveUS20050211354A1Improve partial wear resistanceRaise security concernsTyre tread bands/patternsNon-skid devicesMechanical engineeringEngineering

Owner:SUMITOMO RUBBER IND LTD

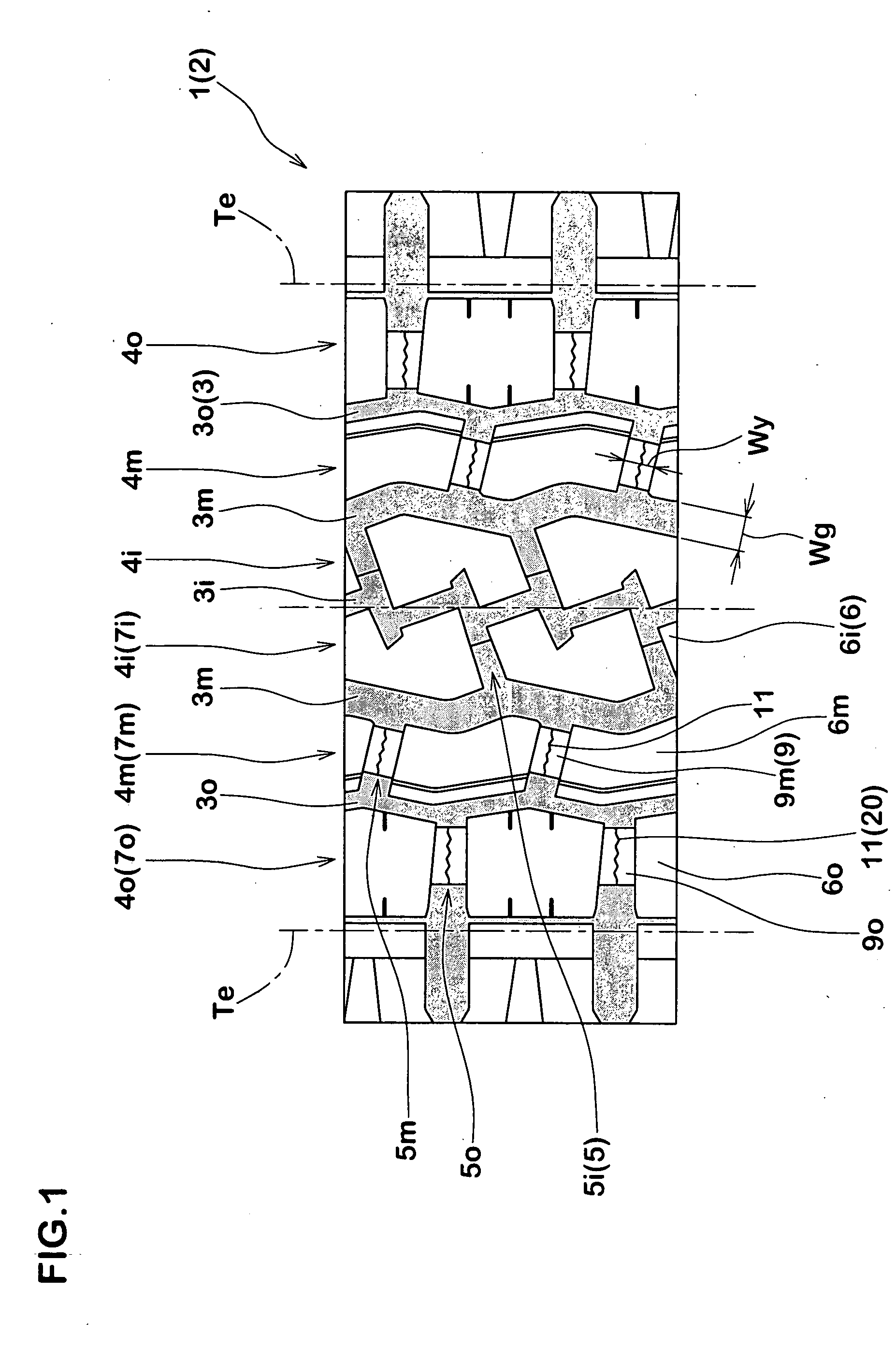

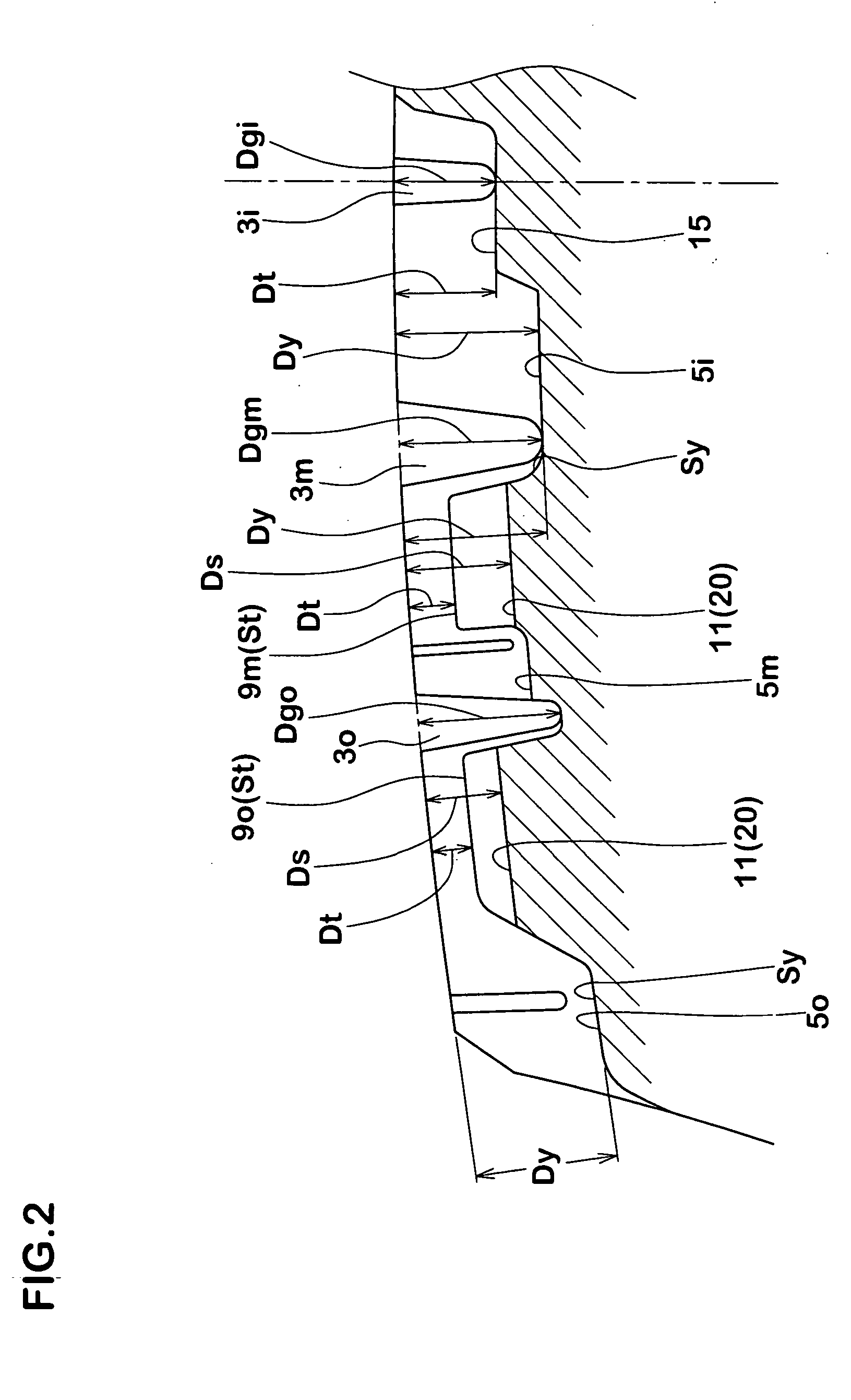

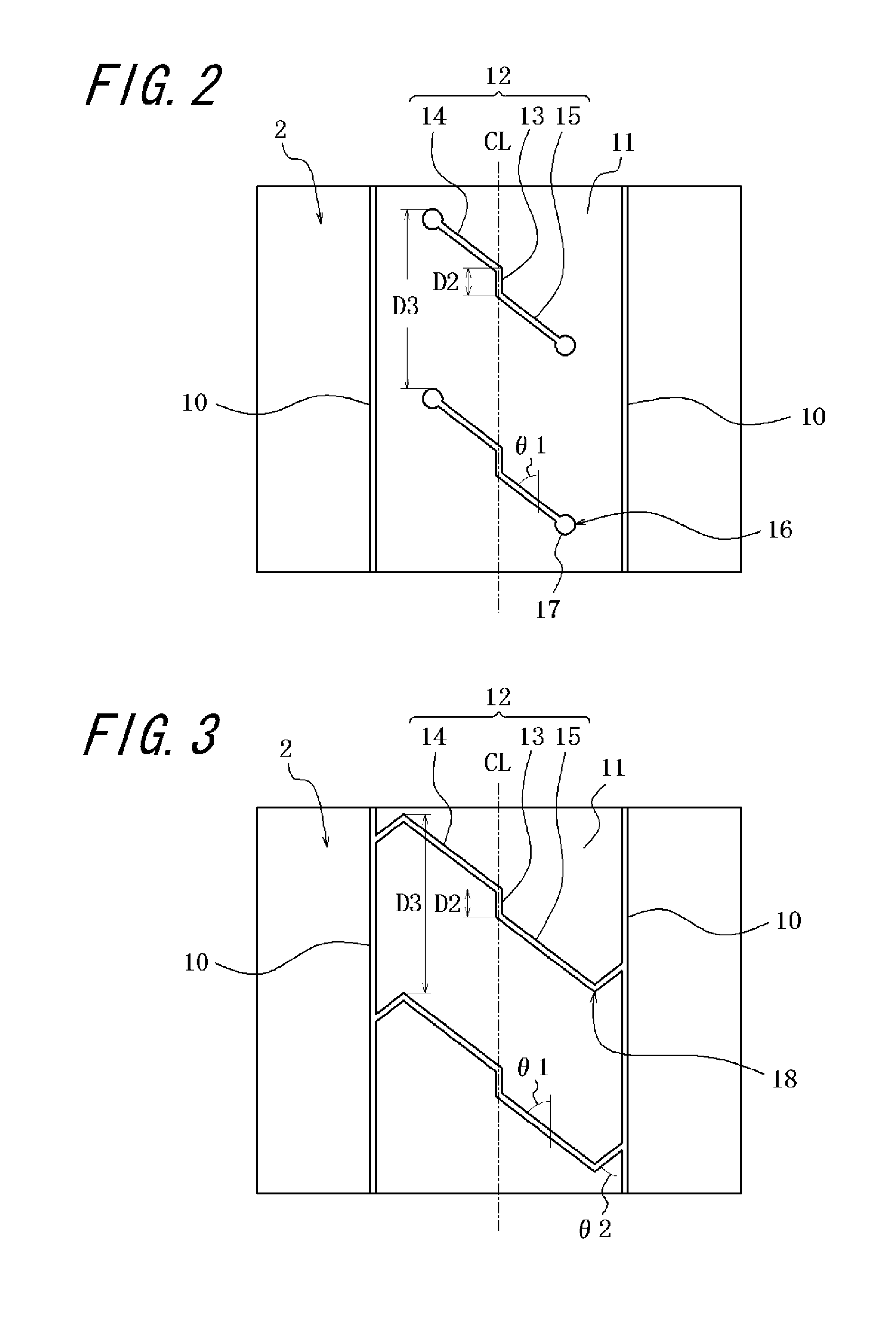

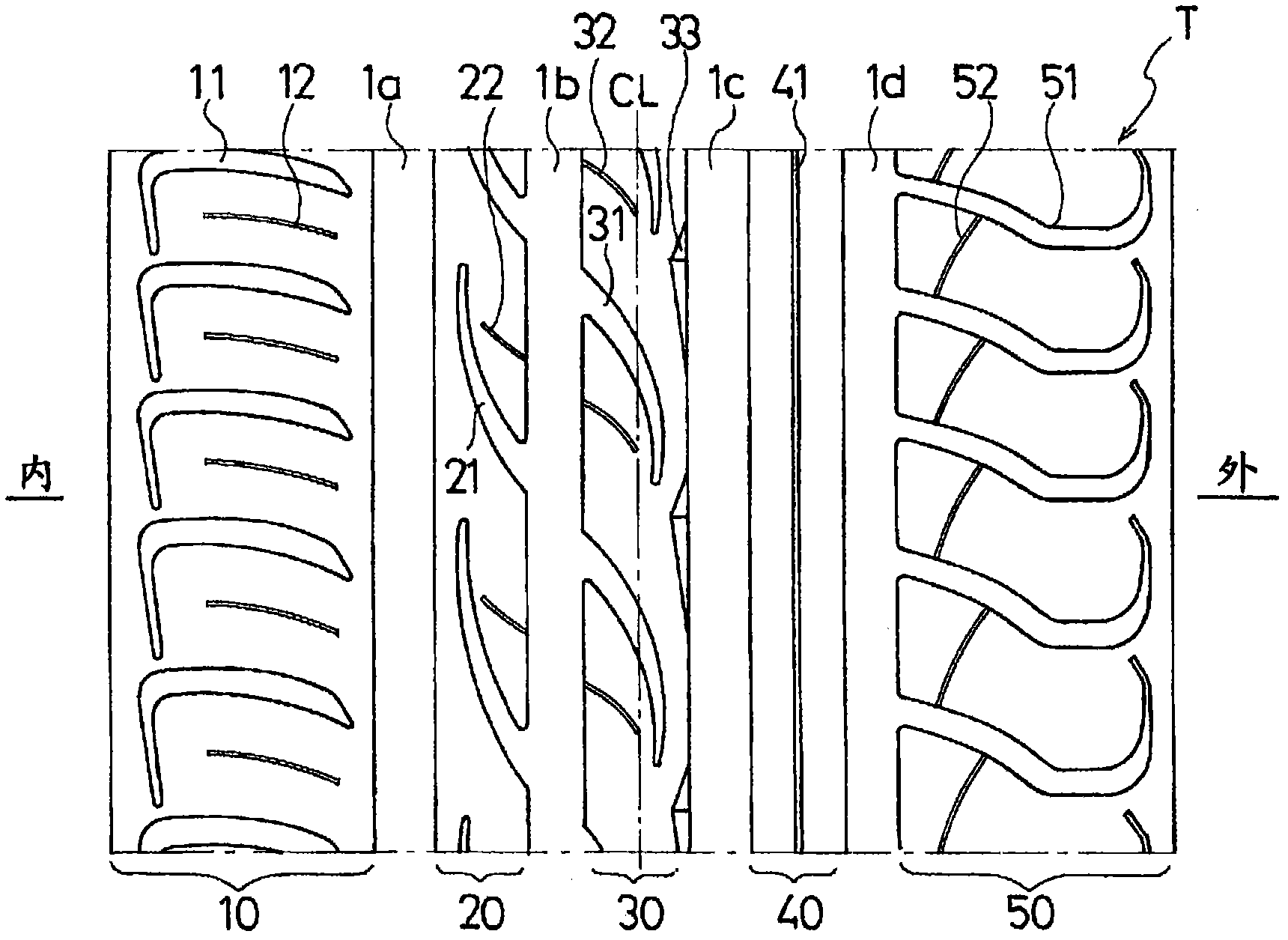

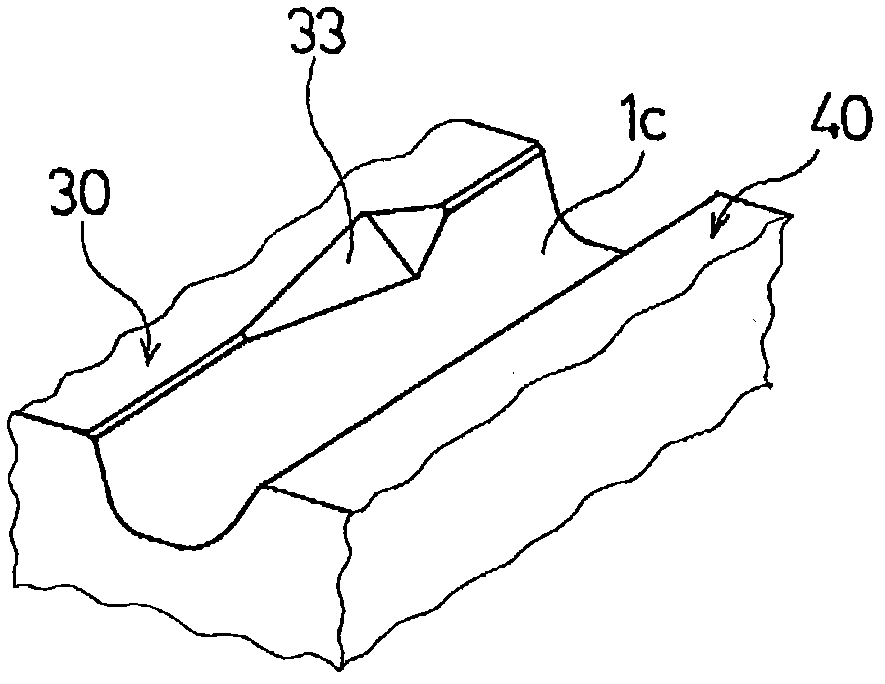

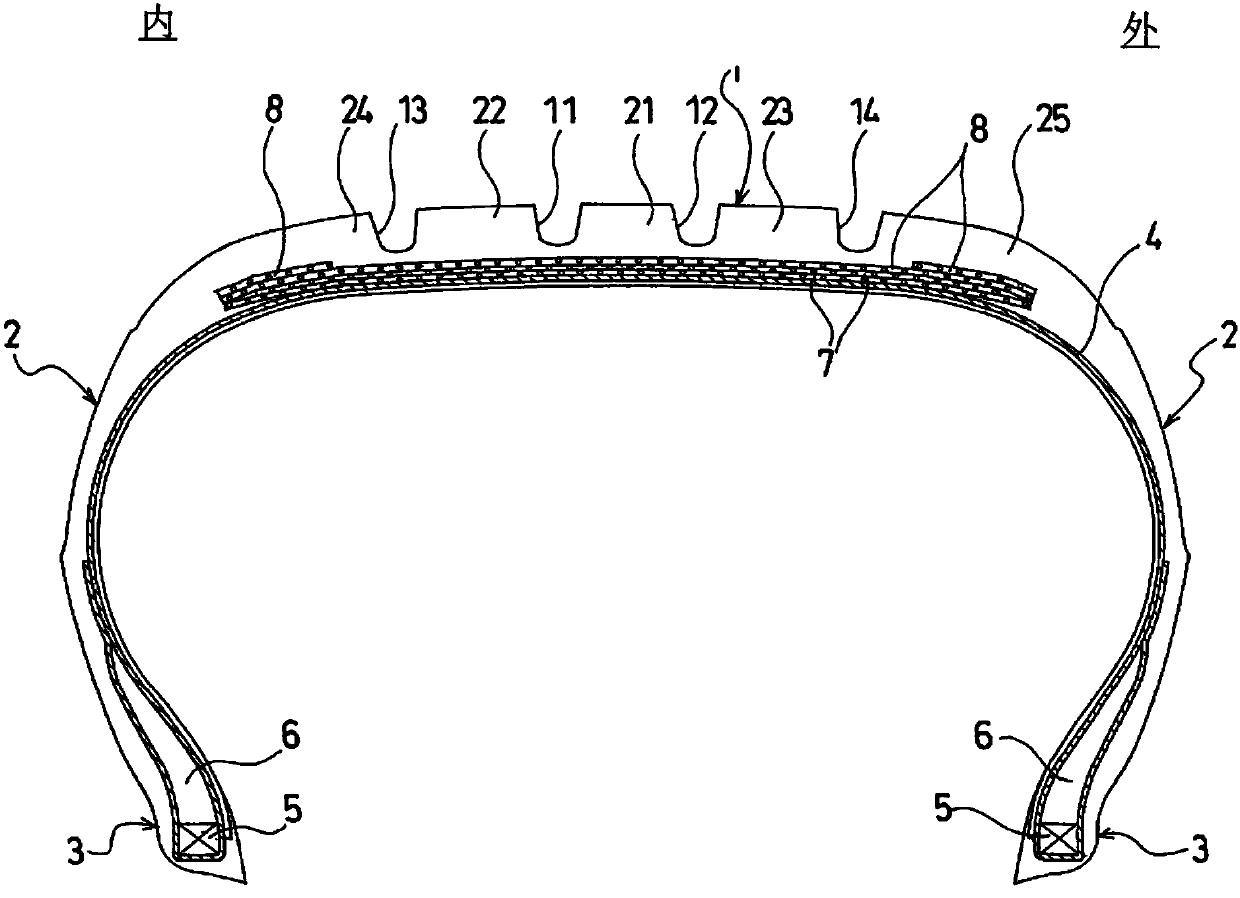

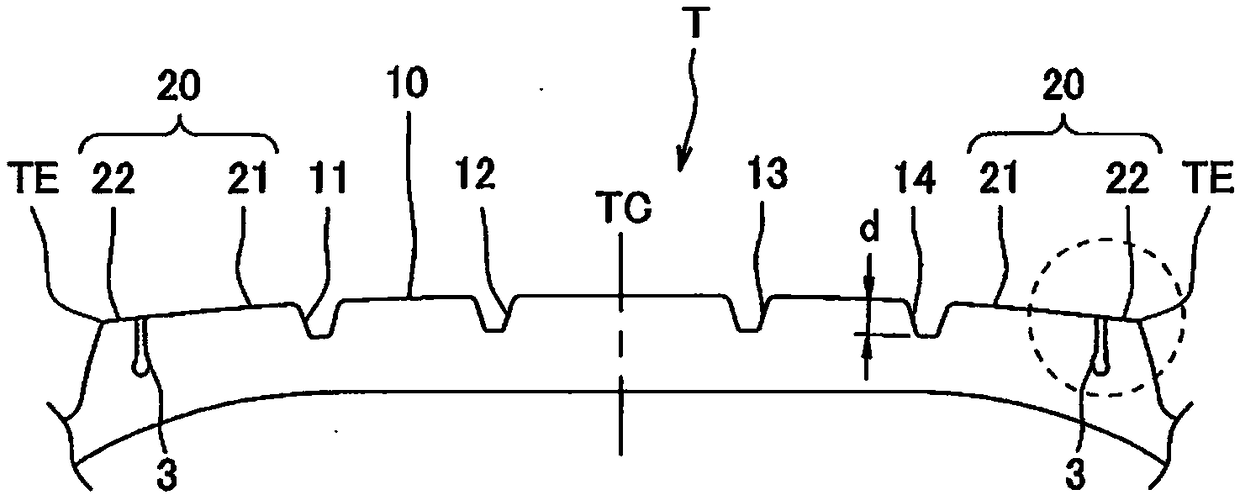

Pneumatic tire

ActiveUS20110005652A1Improve partial wear resistanceIncrease resistanceHeavy duty tyresHeavy duty vehicleEngineeringWear resistance

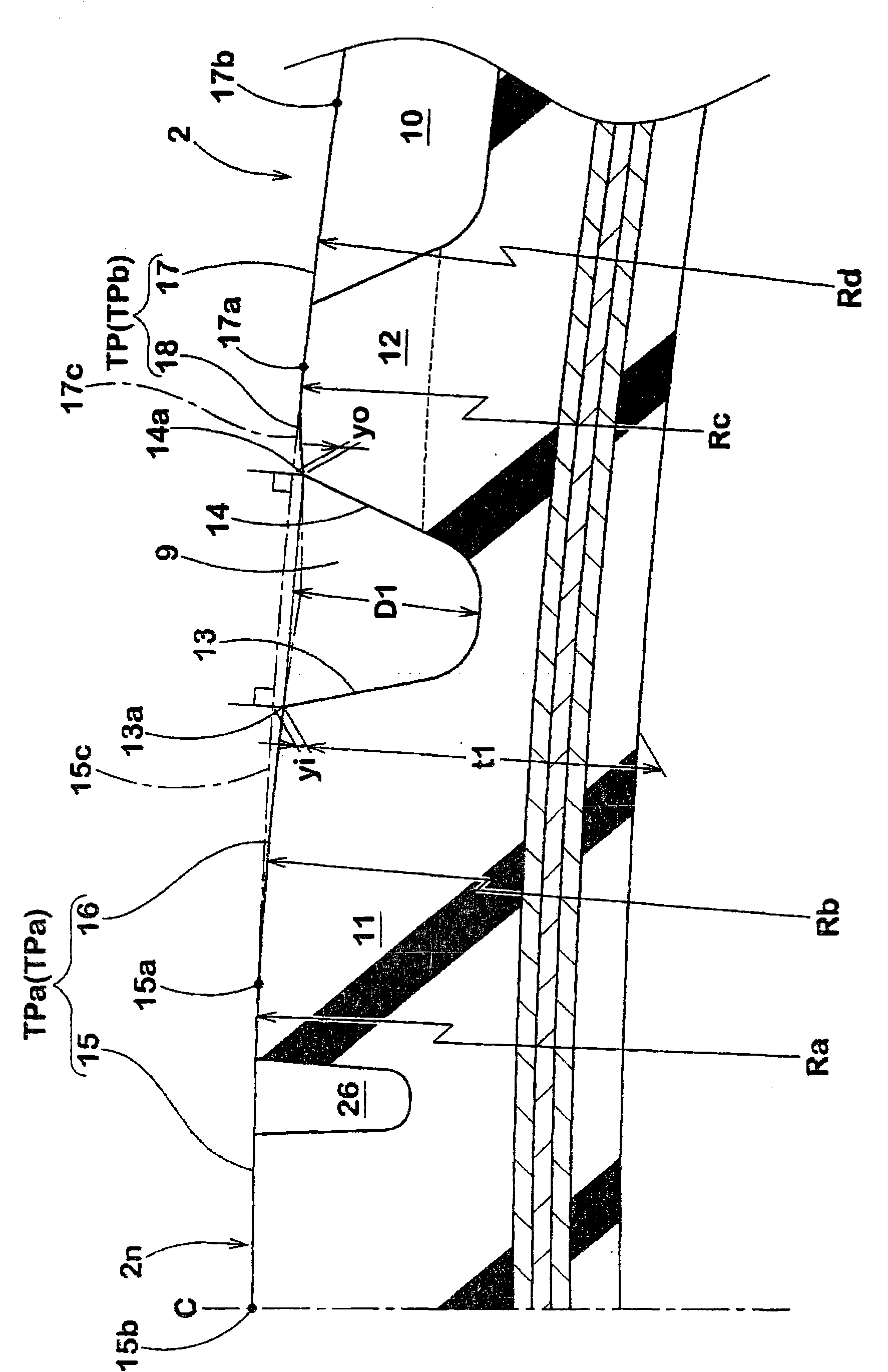

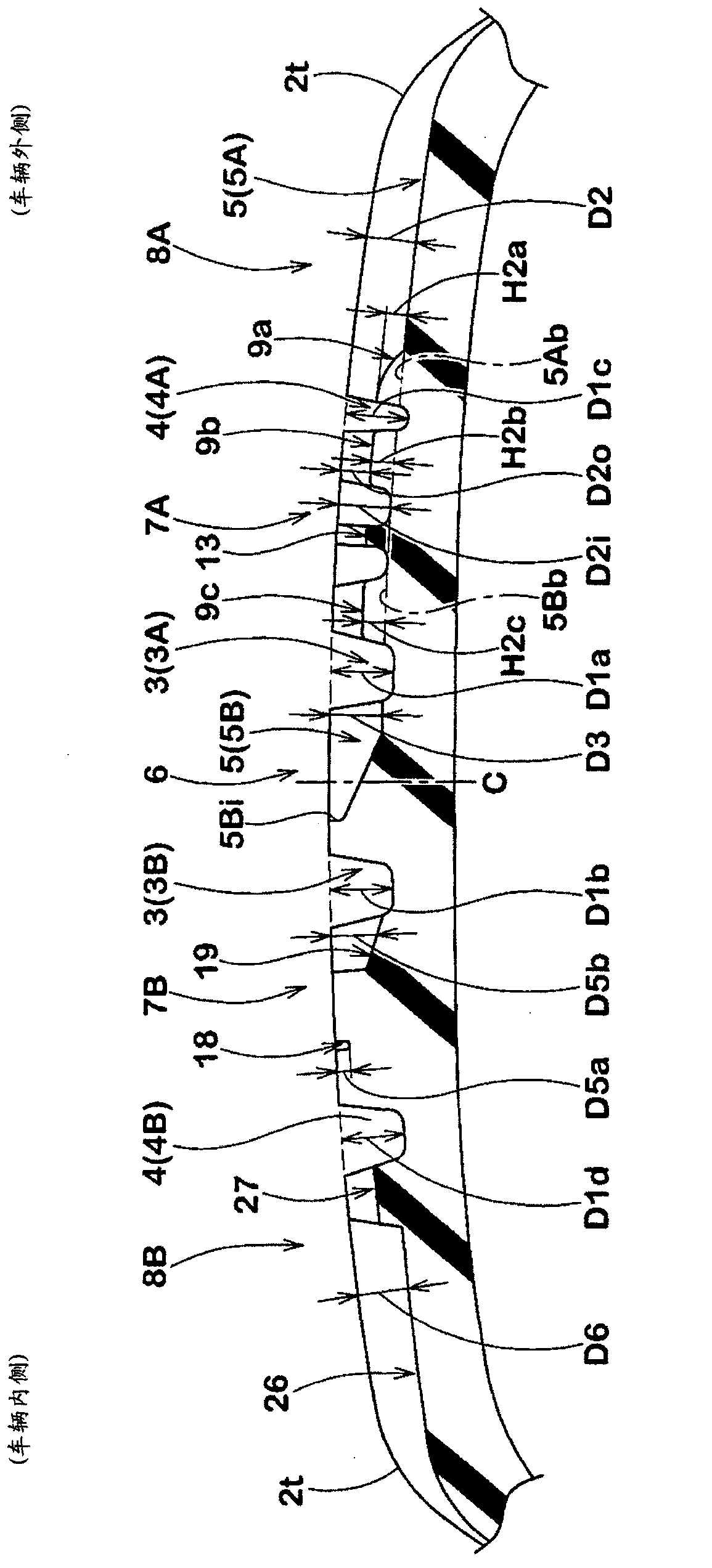

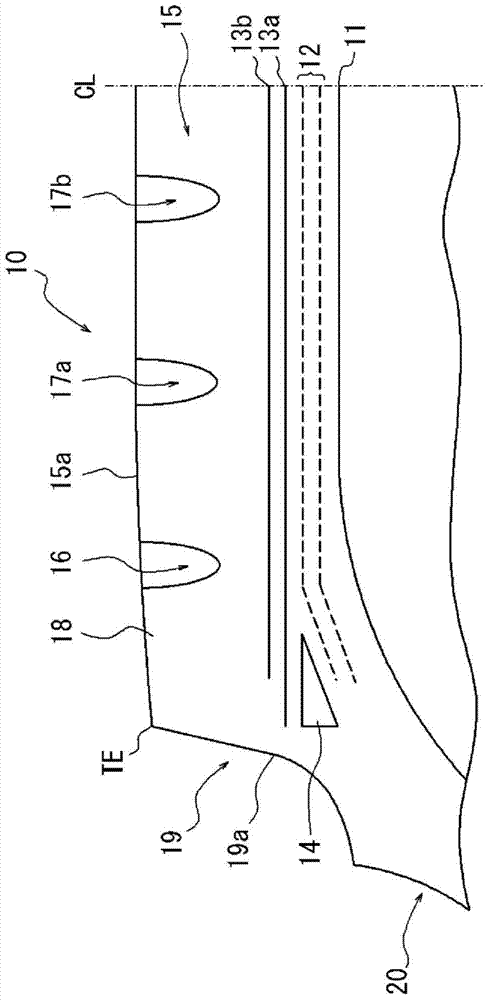

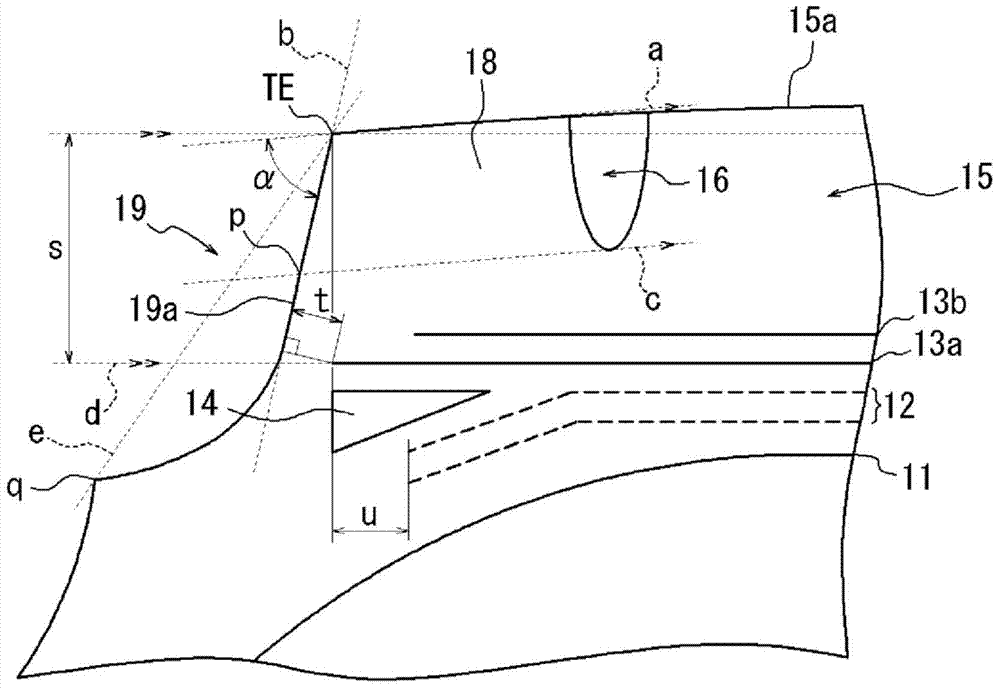

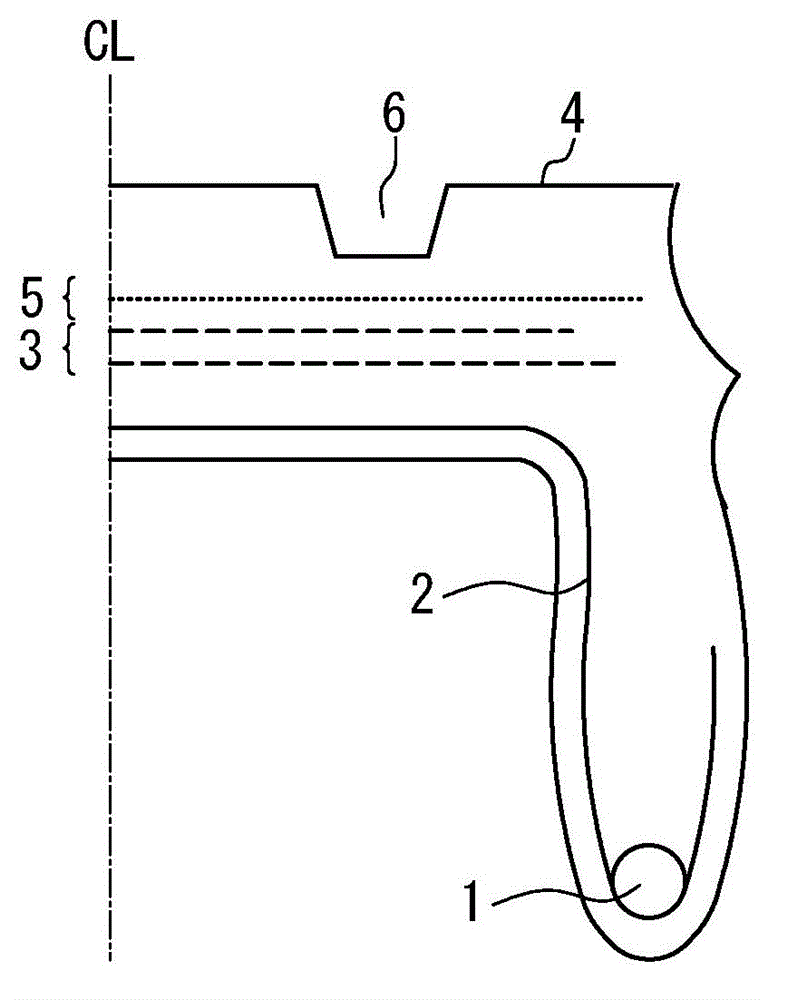

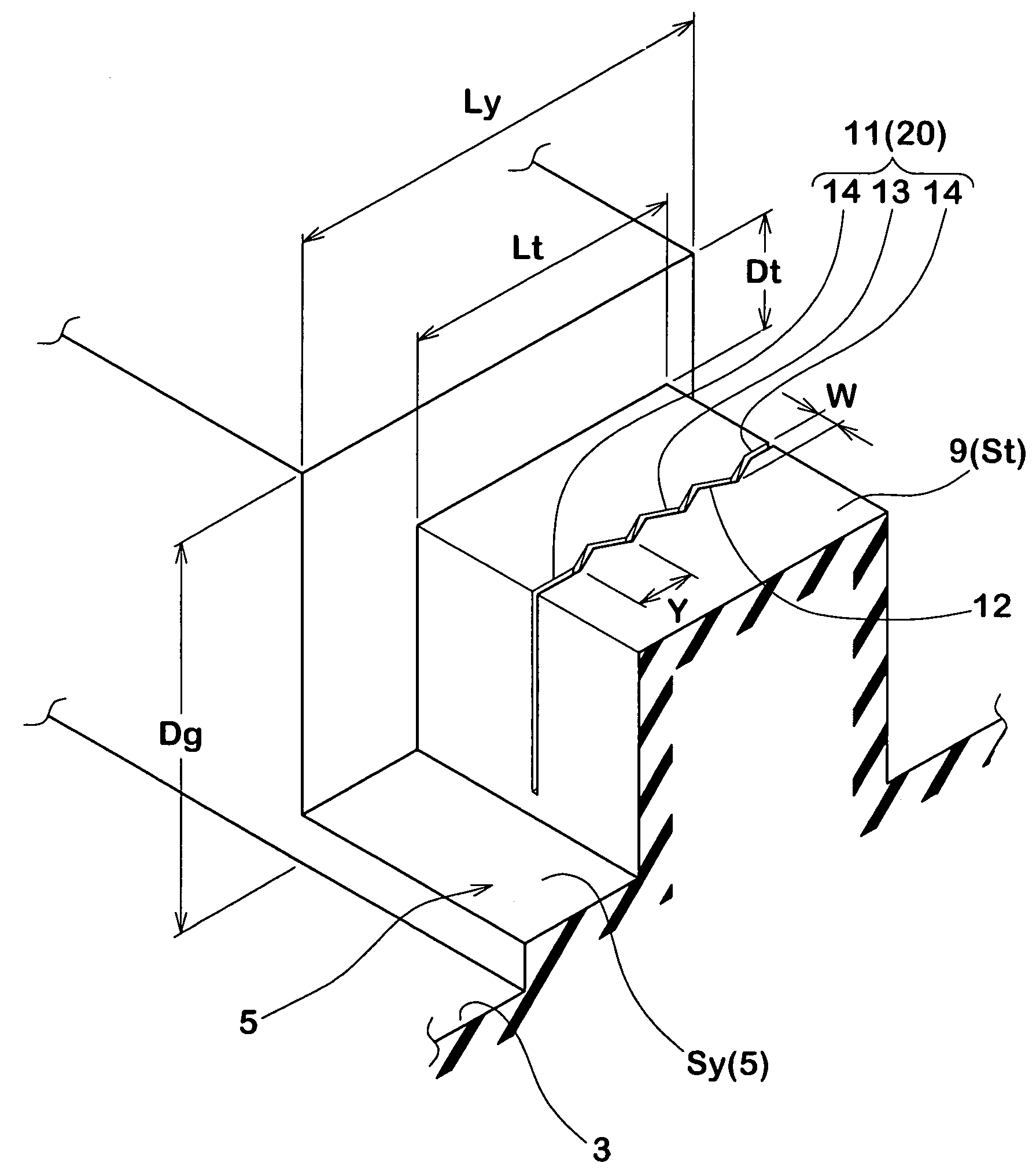

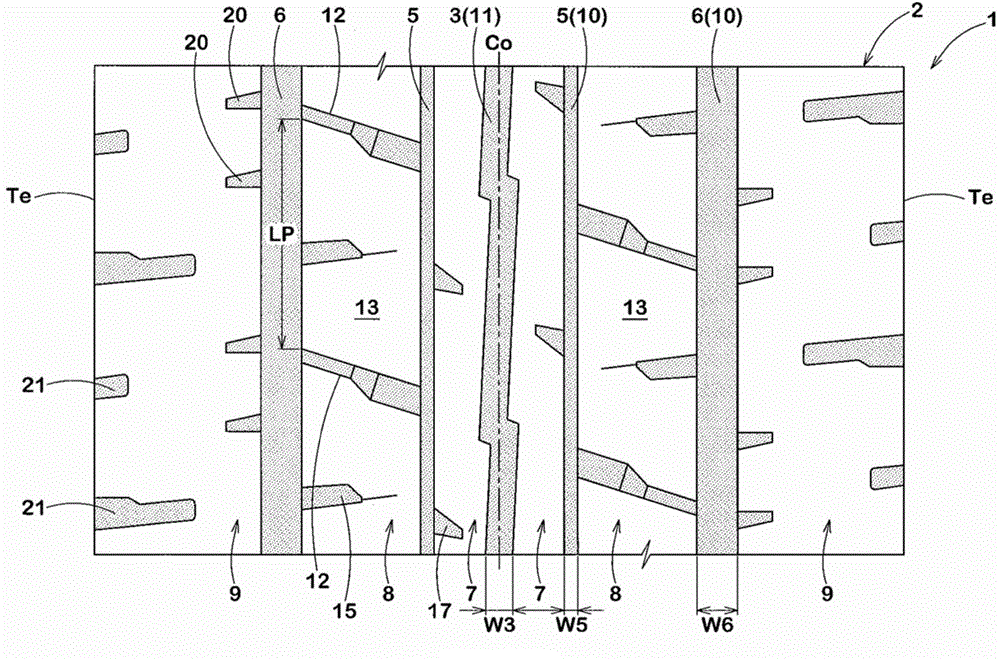

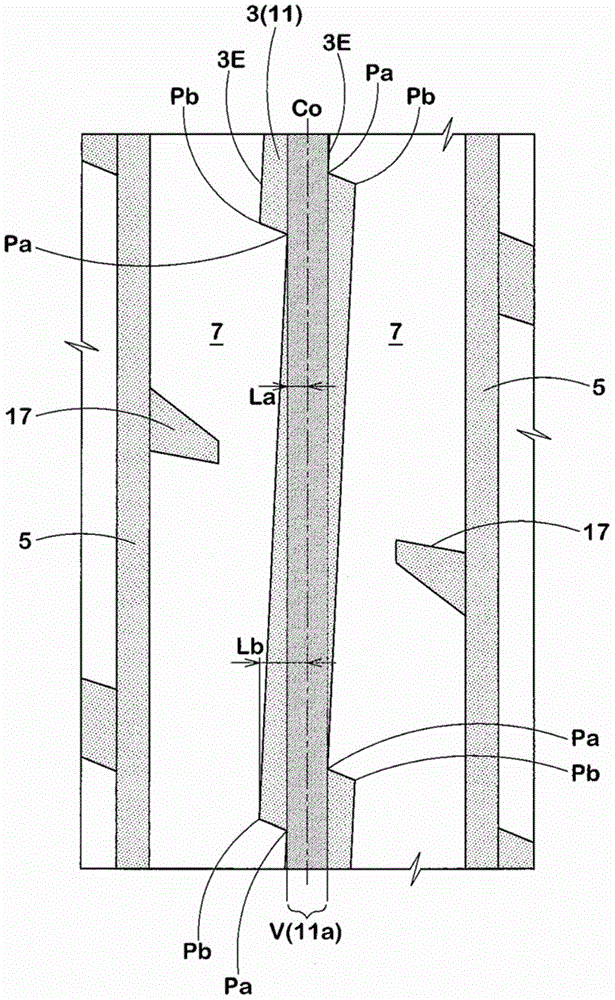

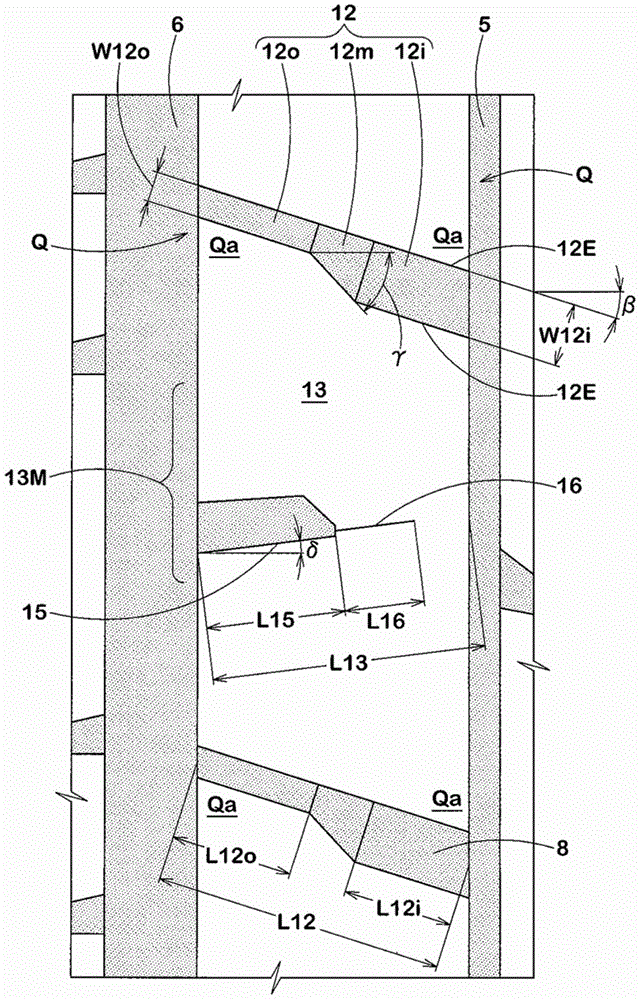

A pneumatic tire has a tread pattern designed to provide improved heat dissipation properties, wear resistance, and uneven wear resistance. The tire has arranged in a tread (2) two circumferential fine grooves (10) disposed on opposite sides of the equatorial surface (CL) of the tire and extending in the circumferential direction of the tire, and the circumferential fine grooves (10) define a center land section (11). In the center land section (11) are formed oblique fine grooves (12) each having a first small groove (13) extending in the tire's circumferential direction, a second small groove (14) extending obliquely relative to the circumferential direction from one end of the first small groove (13) toward one circumferential fine groove, and a third small groove (15) extending obliquely relative to the circumferential direction from the other end of the first small groove (13) toward the other circumferential fine groove.

Owner:BRIDGESTONE CORP

Pneumatic tyre

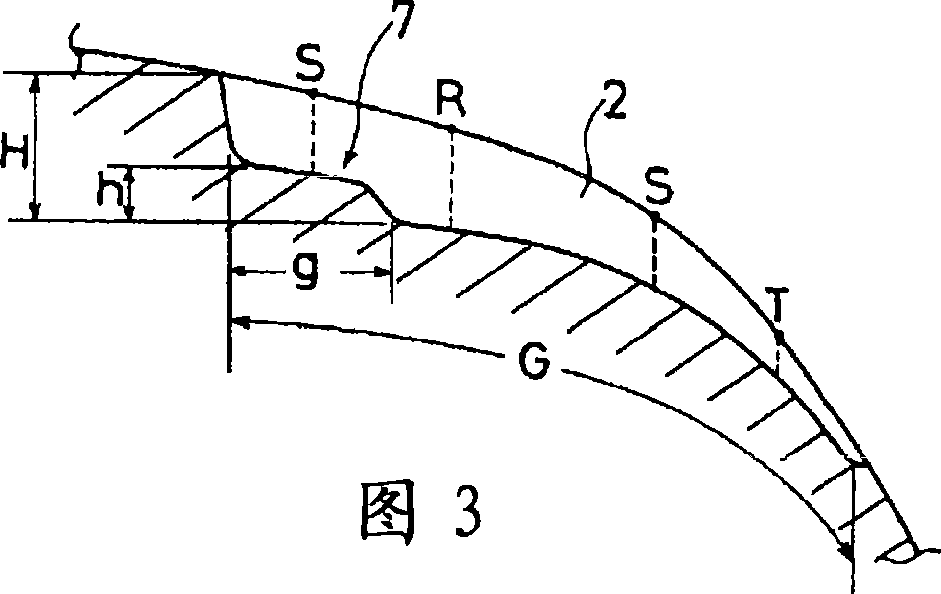

ActiveCN102218976AReliable drainageImprove drainage capacitySpecial tyresTyre tread bands/patternsEngineeringMechanical engineering

The invention relates to a pneumatic tyre, which has the characteristics of drainage decrease prevention, operating stability improvement, noise performance and good anti-wearing performances. The tread contour of the pneumatic tyre in the invention comprises an inner side part and an outer side part. The inner side part comprises an inner side tyre surface reference face formed by circular arcs with a radius of curvature and an inner side chamfered circular arc face formed by circular arcs with a smaller radius of curvature. The outer side part comprises an outer side tyre surface reference face formed by circular arcs with a radius of curvature and an outer side chamfered circular arc face formed by circular arcs with a smaller radius of curvature. The outer side chamfered depth is larger than the inner side chamfered depth. The outer side chamfered depth is a normal-direction distance between an outer side imagined circular arc extending from outer side tyre surface reference face towards the axial inner side and the outer side chamfered circular arc face. The inner side chamfered depth is a normal-direction distance between an inner side imagined circular arc extending from the inner side tyre surface reference face towards the axial outer side and the inner side chamfered circular arc face.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN103182903AImprove rigidityImprove handling stabilityTyre tread bands/patternsGroove widthPulp and paper industry

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

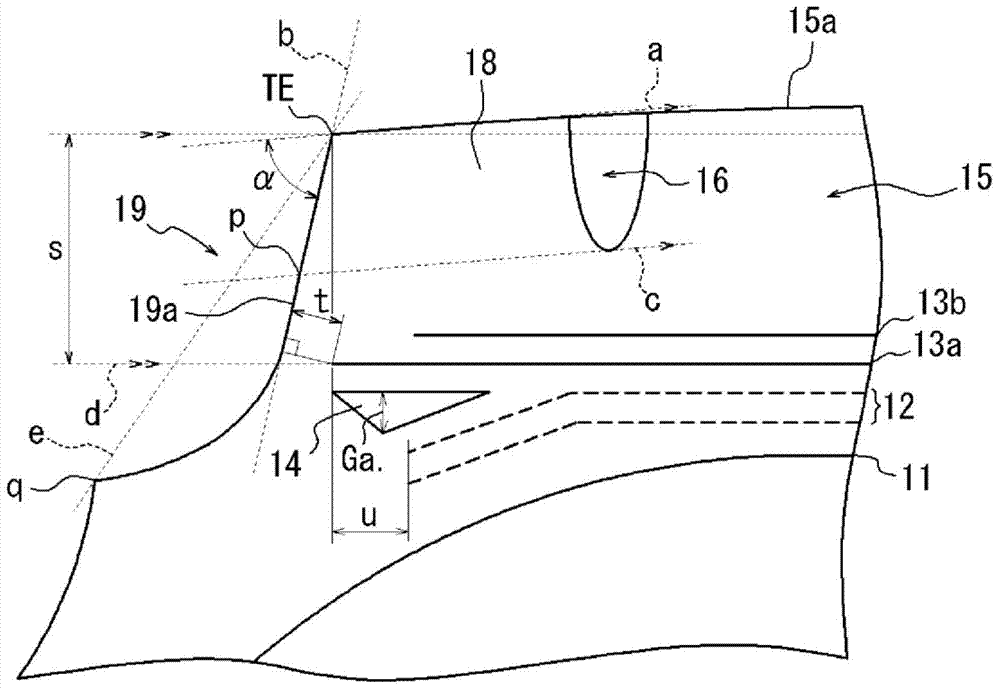

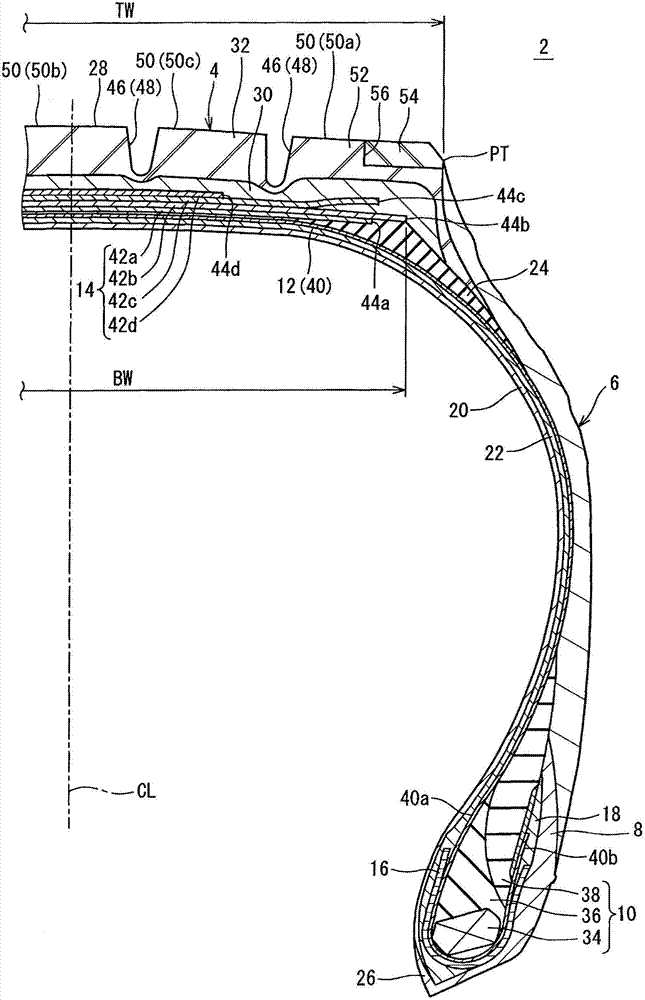

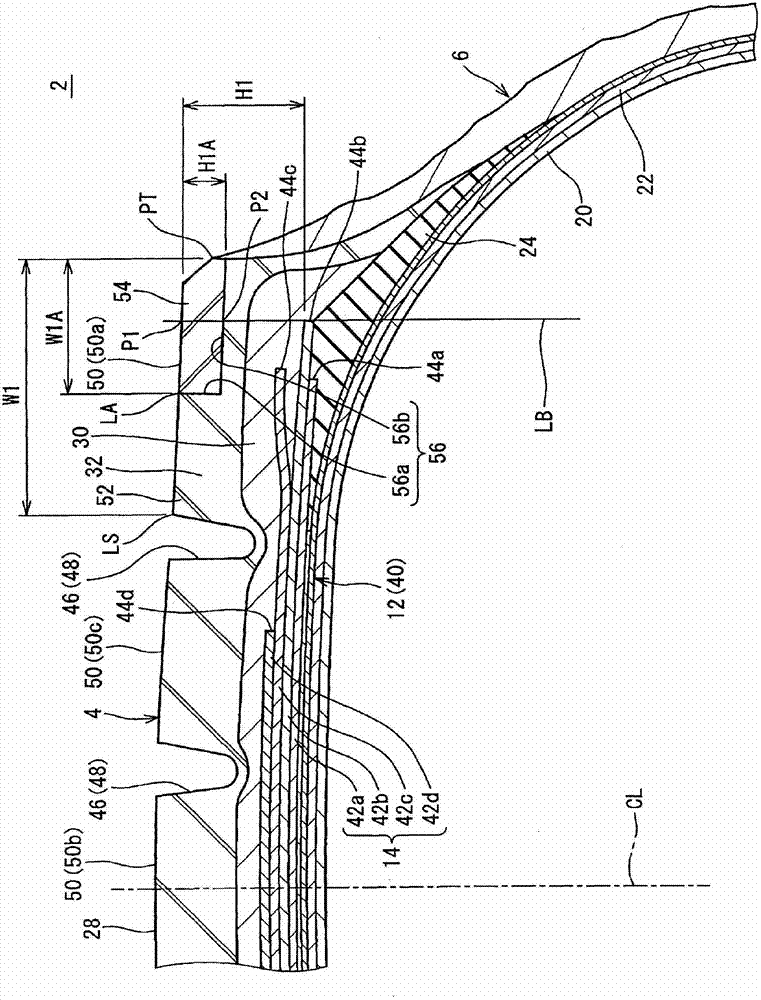

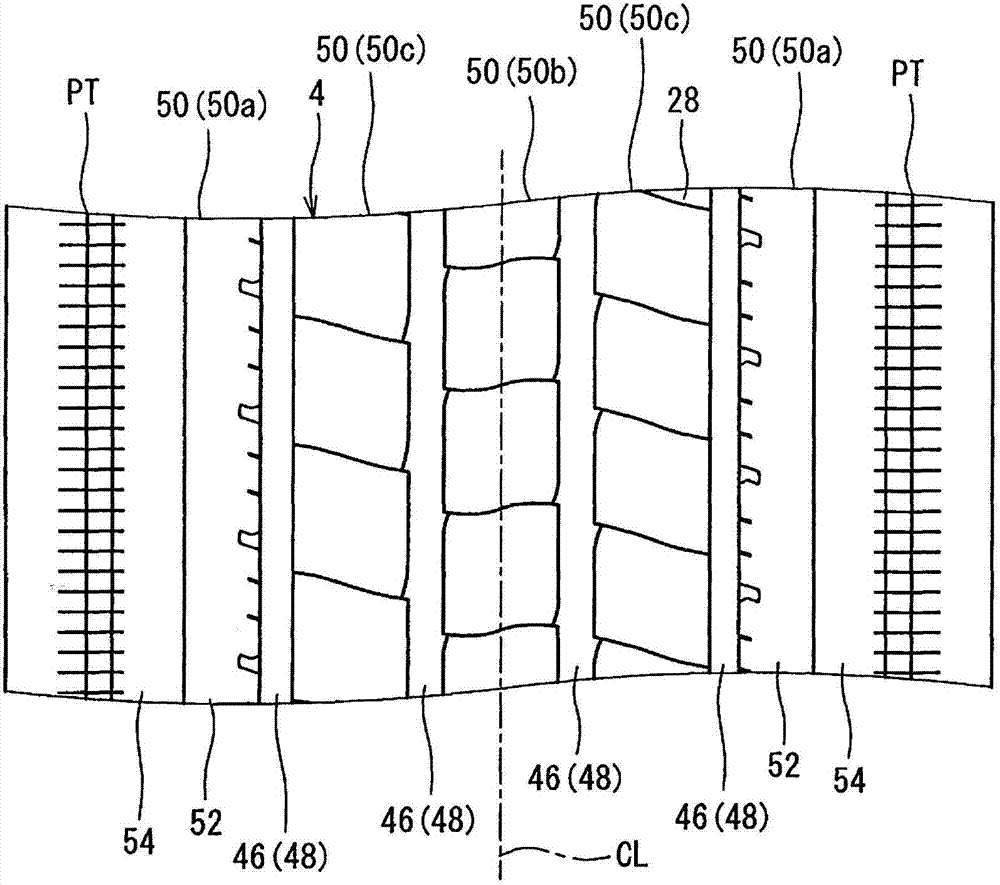

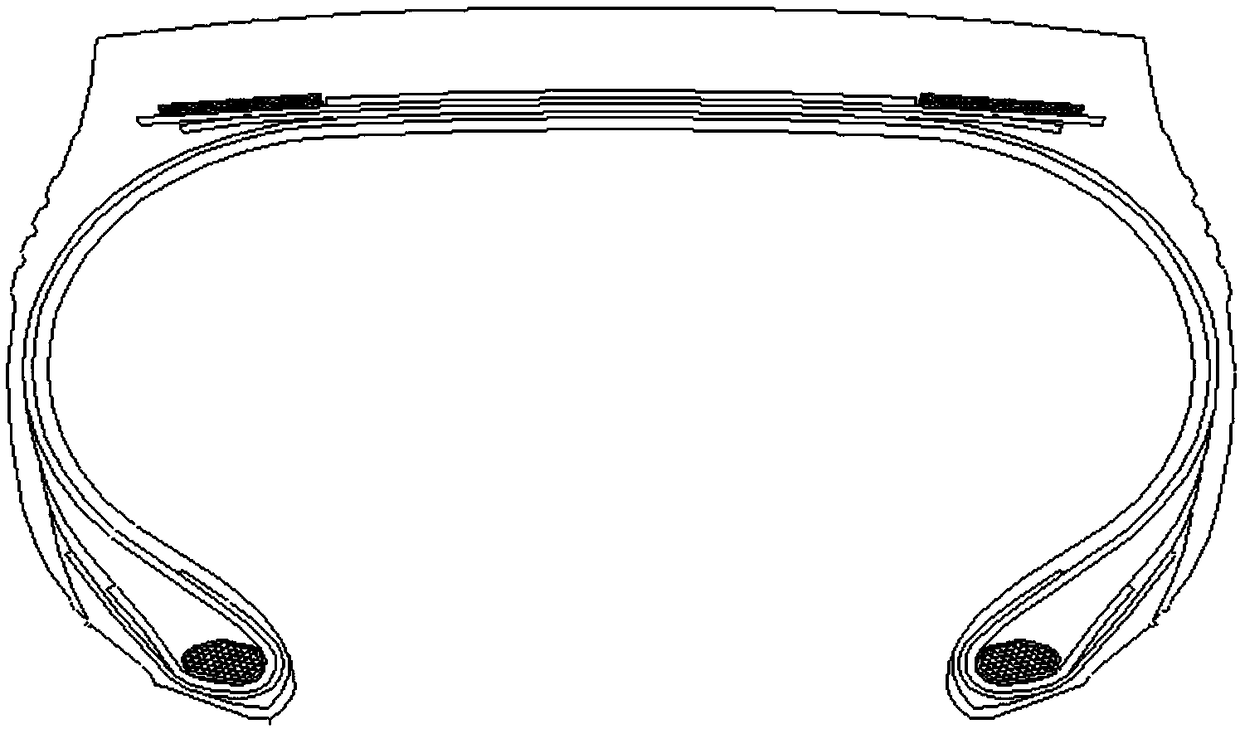

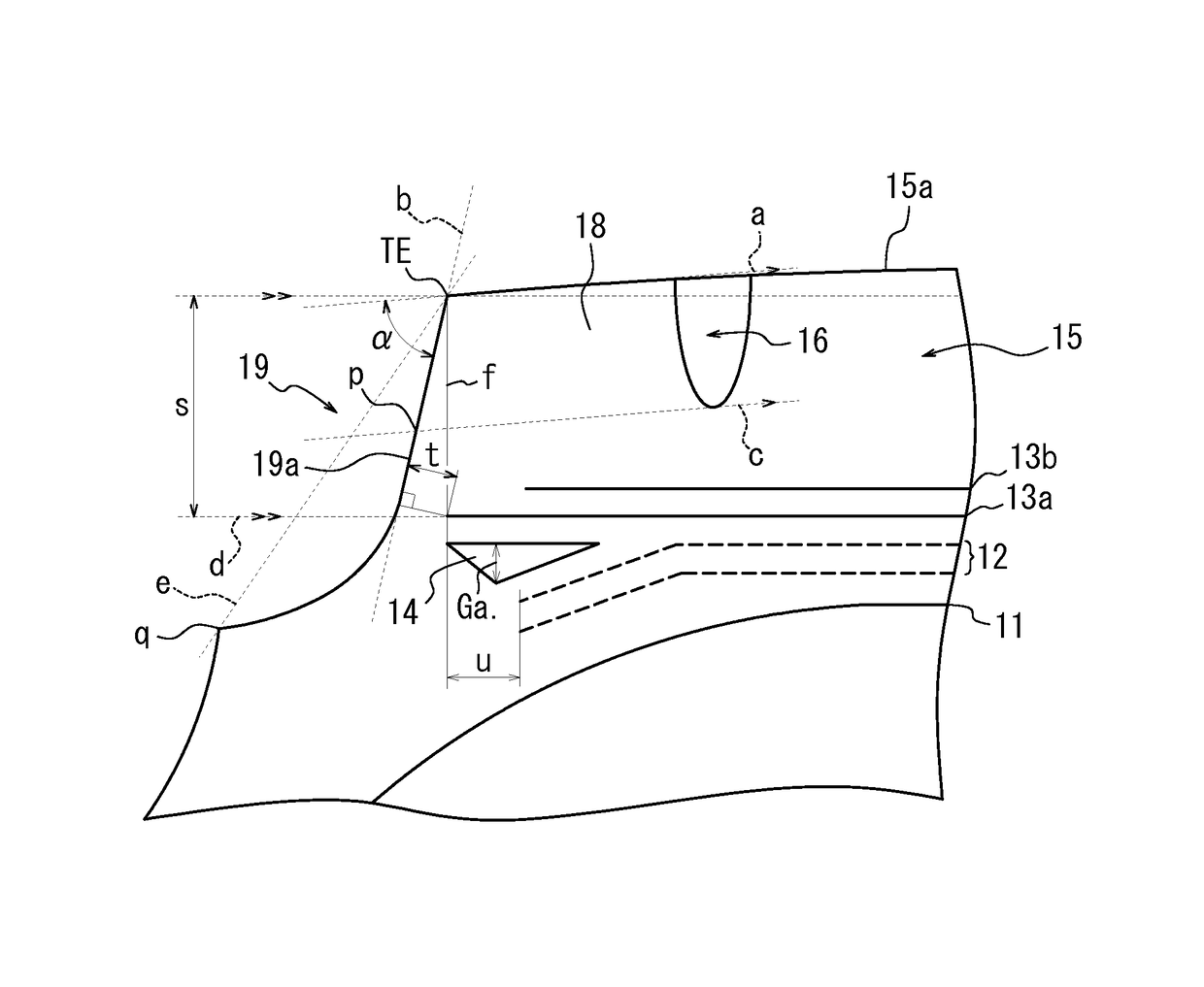

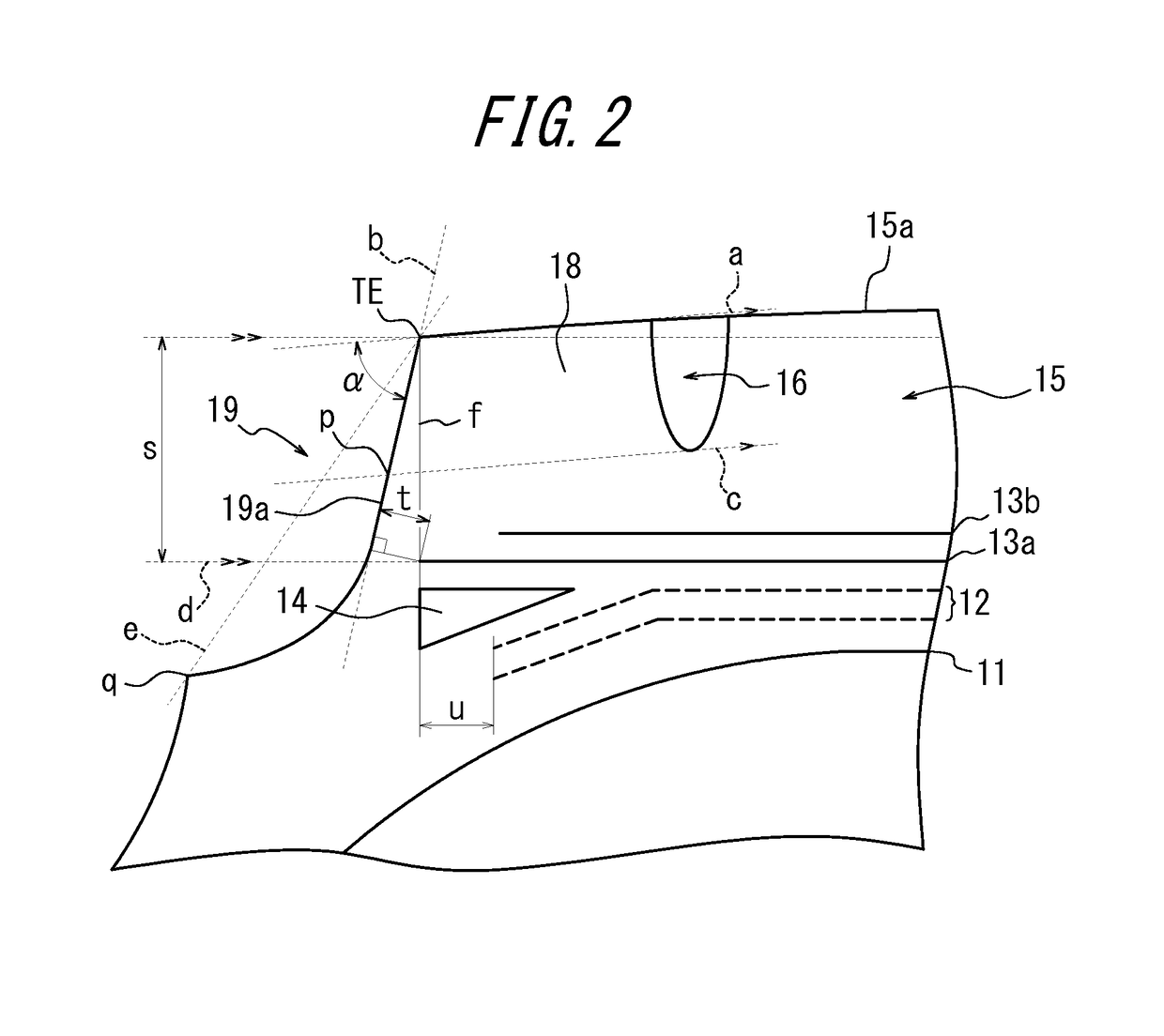

InactiveCN103370211ANot easy to partial wearImprove partial wear resistanceHeavy duty tyresHeavy duty vehicleButtressEngineering

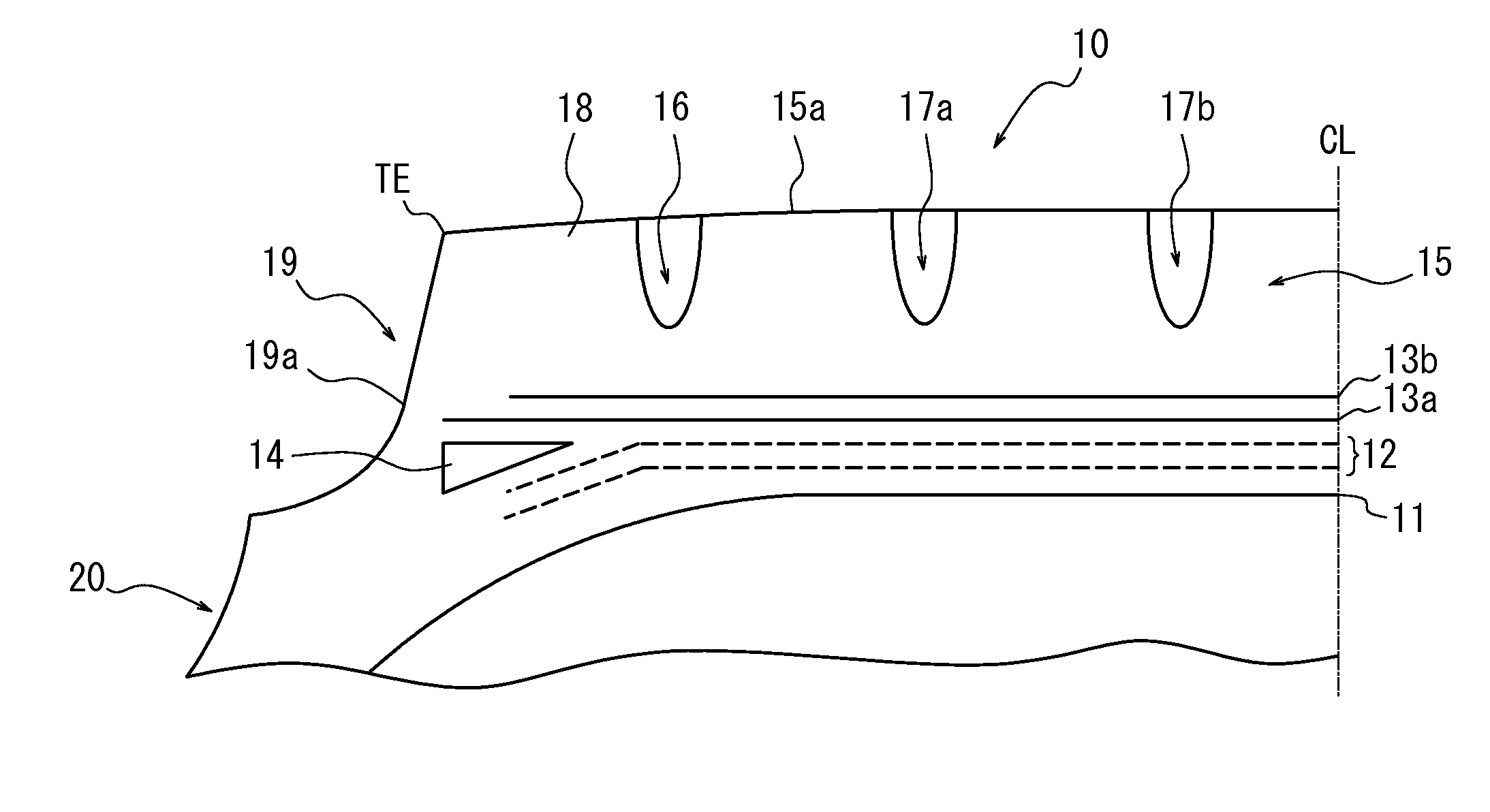

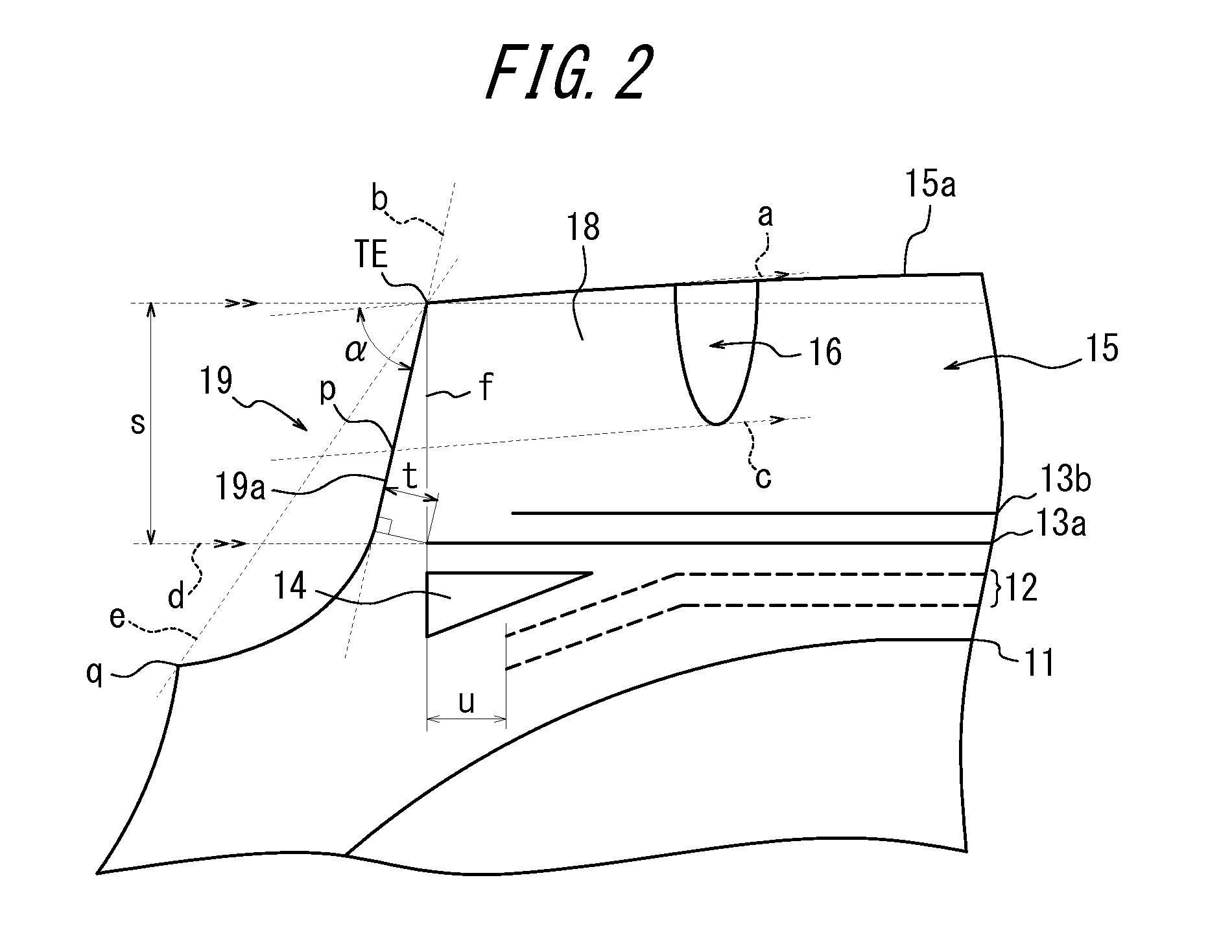

A pneumatic tire configured in such a manner that the outer ends of a belt reinforcement layer (12) are located on the outer sides of the outermost grooves (16) in the width direction of the tire, the outermost grooves (16) extending in the circumferential direction of the tire. Buttress portions (19) located on the outer sides of the tread (15) in the width direction of the tire and connecting the surface (15a) of the tread (15) to the sidewalls (20) have outer surfaces which are, in a cross-section of the tire taken in the width direction thereof, recessed so as not to protrude further inward in the width direction of the tire than the outer ends of the surface (15a) of the tread (15) in the width direction of the tire.

Owner:BRIDGESTONE CORP

pneumatic tire

InactiveCN102264561AReduce crash noiseImprove rigidityTyre tread bands/patternsLeading edgeGroove width

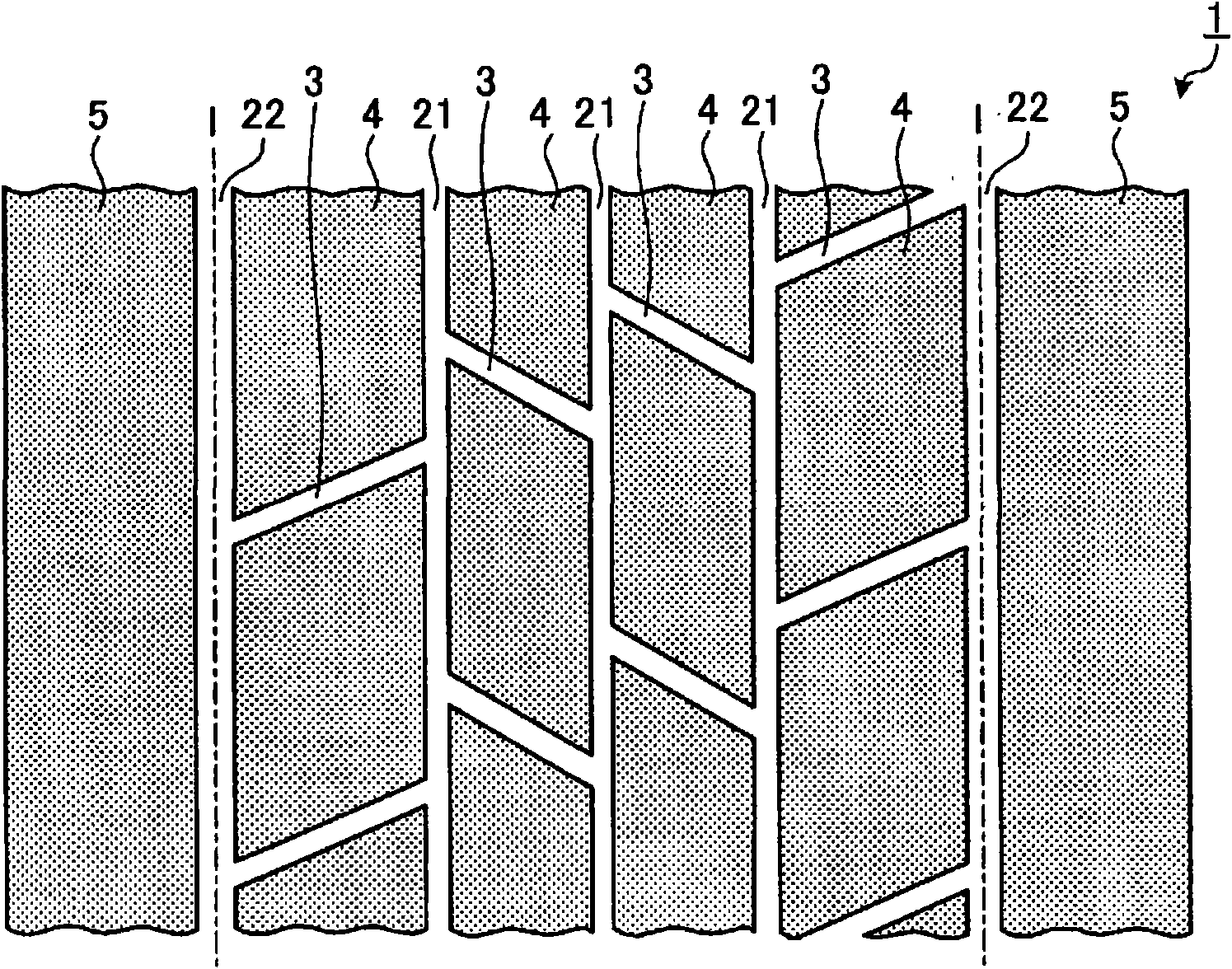

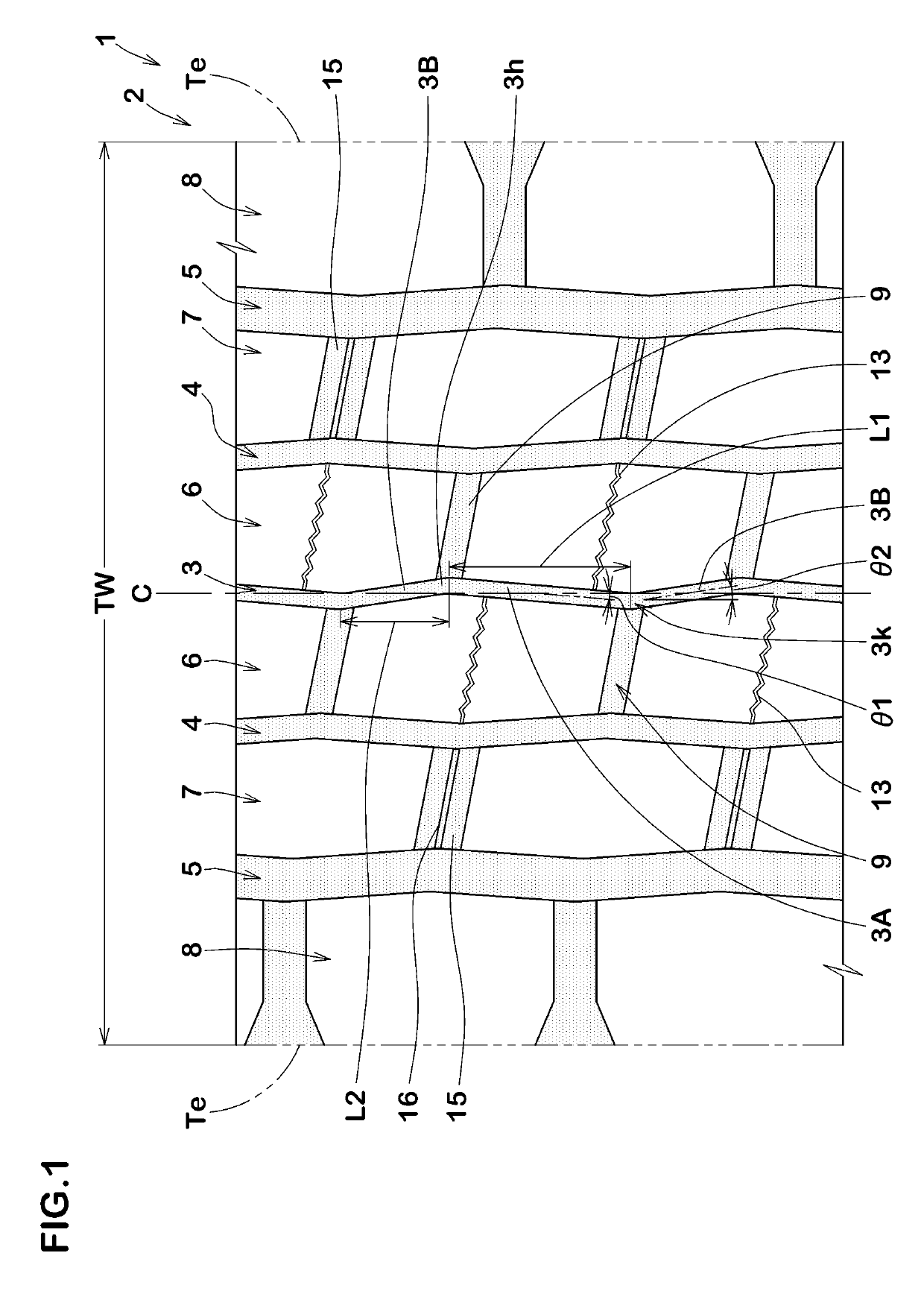

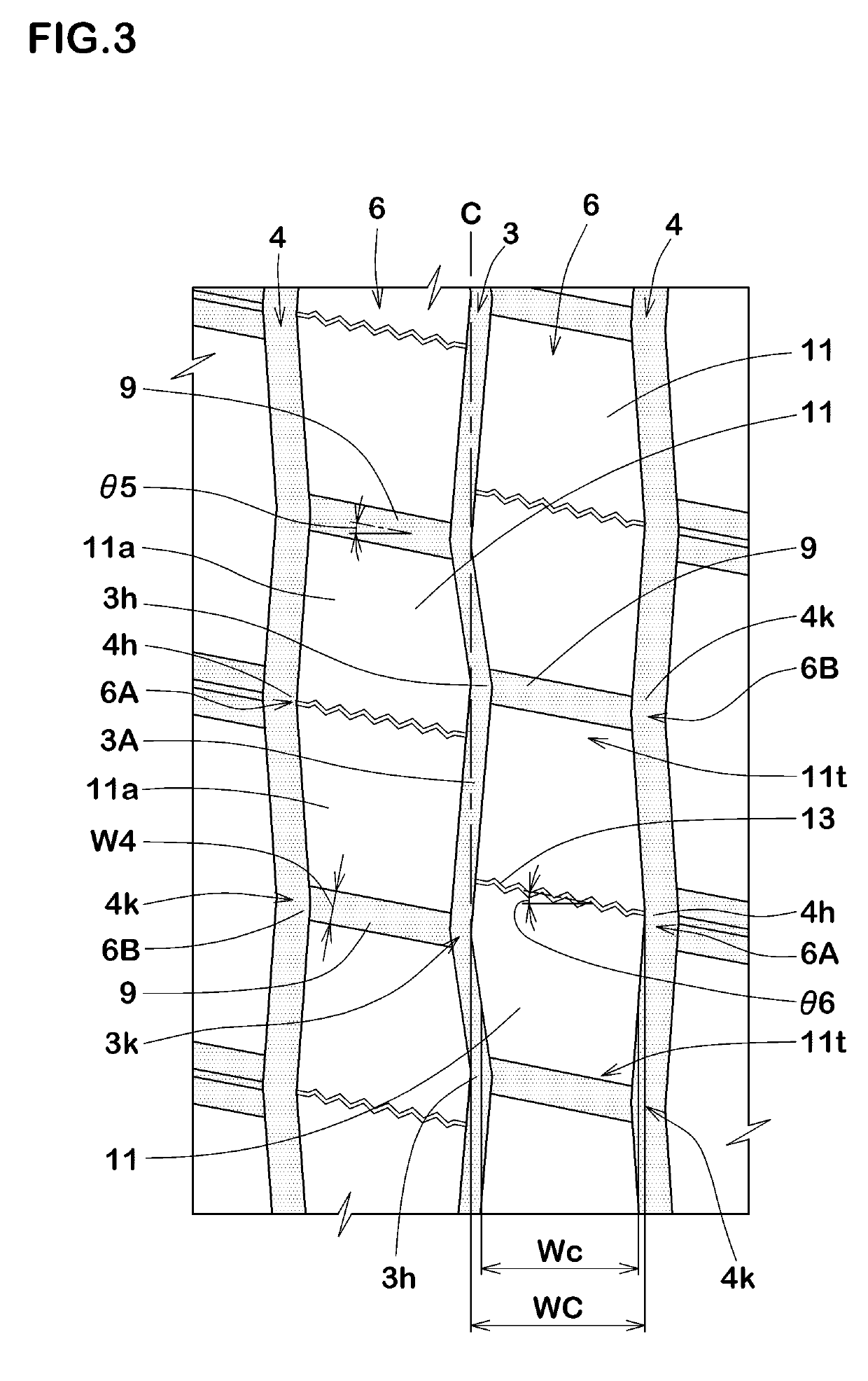

The present invention aims to provide a pneumatic tire capable of effectively preventing a large collision noise caused by simultaneous collision of a plurality of blocks of each row with a road surface. The six block rows (9, 10, 13) on the tread contact surface (1) consist of five circumferential grooves (2, 3, 4) extending continuously in a zigzag manner in the circumferential direction of the tread. A plurality of transverse grooves (5, 6, 11) extending in the tread width direction are defined between adjacent circumferential grooves and between the outermost circumferential groove (4) and the corresponding tread side edge (e). The five circumferential grooves (2, 3, 4) include circumferential narrow grooves (2, 4) and a pair of circumferential wide grooves 3, and a pair of circumferential wide grooves (3) are arranged on both sides of the tire equator line and are narrower than the circumferential direction The width of the slots (2, 4) is wide. The transverse grooves (5, 6) are inclined relative to the tread width direction. Each pattern block (7, 8, 12) of the pattern block row (9, 10, 13) has a polygonal plane profile shape with more than six sides, and at the same time, the minimum length of the pattern block in the tread width direction is located at the The length in the tread width direction of the central portion of the block in the tread circumferential direction is longer than the length in the tread width direction of the end portion in the tread circumferential direction. The tread edges (7a, 8a, 12a) of the blocks (7, 8, 12) of each block row (9, 10, 13) are spaced apart from each other in the circumferential direction of the tread when the tire rolls under load.

Owner:BRIDGESTONE CORP

Fibre reinforced composite anti-eccentric coiled rod as well as preparation device and preparation method thereof

ActiveCN103075112BAccelerated corrosionImprove partial wear resistanceDrilling rodsDrilling casingsEpoxyThermoplastic

The invention relates to a fibre reinforced composite anti-eccentric coiled rod and a preparation device thereof. The technical scheme adopted by the invention is as follows: one or more sections of the external surface of a fibre-reinforced resin matrix composite rod body is coated with a thermoplastic wear layer; the rod body is made of one of fibreglass, carbon fibre and basalt fibre; and a resin matrix is one of epoxy resin, urethane resin and vinyl ester resin. A plastic extruder and a cooling device are arranged between a draw gear and a winding device, the plastic extruder is used for coating one thermoplastic wear layer on one or more sections of the surface of a molded sucker rod, and then the cooling device is used for performing cooling treatment, so that the fibre reinforced composite anti-eccentric coiled rod is formed. The invention has the following beneficial effects: the coiled rod has excellent anticorrosion and anti-eccentric performances; the quantity of joints is greatly reduced; the breakage probability and the piston effect are reduced; and in addition, the production efficiency is high, and the operation is simple and convenient.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Heavy duty pneumatic tire

InactiveCN103287214AExcellent partial wear resistanceImproved low fuel consumption and uneven wear resistanceHeavy duty tyresHeavy duty vehicleElastic modulusGround contact

The invention provides a heavy duty pneumatic tire with low oil consumption and excellent uneven wear resistance. The tire has a belt and a tread such that ratio of width of the belt to width of the tread is greater than or equal to 0.95 and is not greater than 1.0. The tread has shoulder land portions on outer sides in axial direction, each shoulder portion has a cap layer including a body portion and a pad, the pad has complex elastic modulus greater than complex elastic modulus of the body portion, the body portion has loss tangent less than loss tangent of the pad, and each shoulder portion has ground-contact surface which has outer and inner ground-contact surfaces separated by boundary between the body portion and pad such that ratio of average ground-contact pressure of the outer ground-contact surface relative to average ground-contact pressure of the inner ground contact surface is greater than or equal to 0.85 and is not greater than 0.95.

Owner:SUMITOMO RUBBER IND LTD

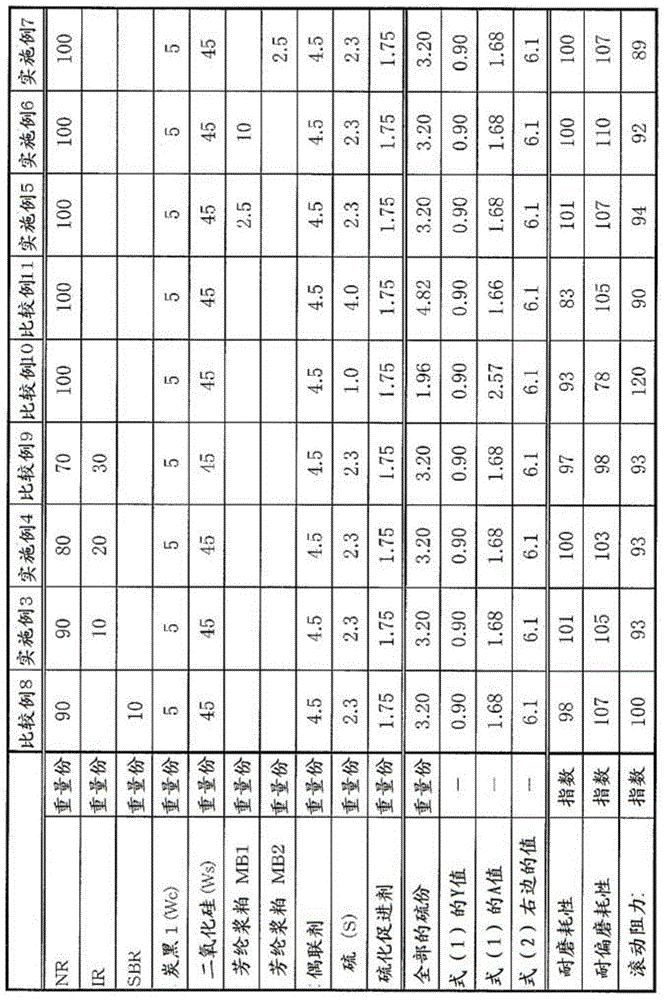

Rubber composition for heavy load pneumatic tire

ActiveCN105073871AReduce rolling resistanceImprove wear resistanceHeavy duty tyresHeavy duty vehicleRolling resistanceVulcanization

Provided is a rubber composition for heavy load pneumatic tires, the rubber composition being configured so as to improve low rolling resistance, wear resistance and uneven wear resistance above prior levels. The rubber composition is characterized in that: 35-50 parts by weight of silica, 1.5-3.5 parts by weight of sulfur, and carbon black, sulfenamide vulcanization accelerator and sulfur-containing silane coupling agent are blended with respect to 100 parts by weight of a diene rubber containing 80-100 weight% of natural rubber; the total of the sulfur and the sulfur in the sulfur-containing silane coupling agent is 1.85-6.0 parts by weight; and the amount of the sulfenamide vulcanization accelerator blended is (A) parts by weight, which is determined from a specific formula (1), to 2.6 parts by weight.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveUS20130299052A1Accurate processingImprove partial wear resistanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

Provided is a pneumatic tire including: a belt reinforcing layer (12) having an outside end portion in the tire width direction disposed outside in the tire width direction than a tire circumferential groove (16) disposed at the outermost side in the tire width direction, in which a buttress portion (19) being positioned on the outside of a tread (15) in the tire width direction and connecting a surface (15a) of the tread (15) to a sidewall (20) is formed to have, in section in the tire width direction, an outer surface in a concave shape with a depth shallow enough not to be set into the inside in the tire width direction from the outside end of the surface (15a) of the tread (15) in the tire width direction.

Owner:BRIDGESTONE CORP

Pneumatic radial tire for automobiles

ActiveCN103068594AReduce consumptionImprove comfortSpecial tyresPneumatic tyre reinforcementsEngineeringMechanical engineering

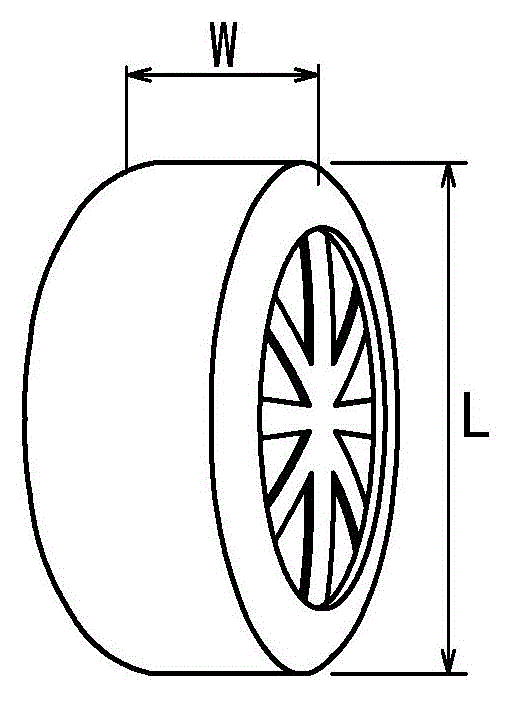

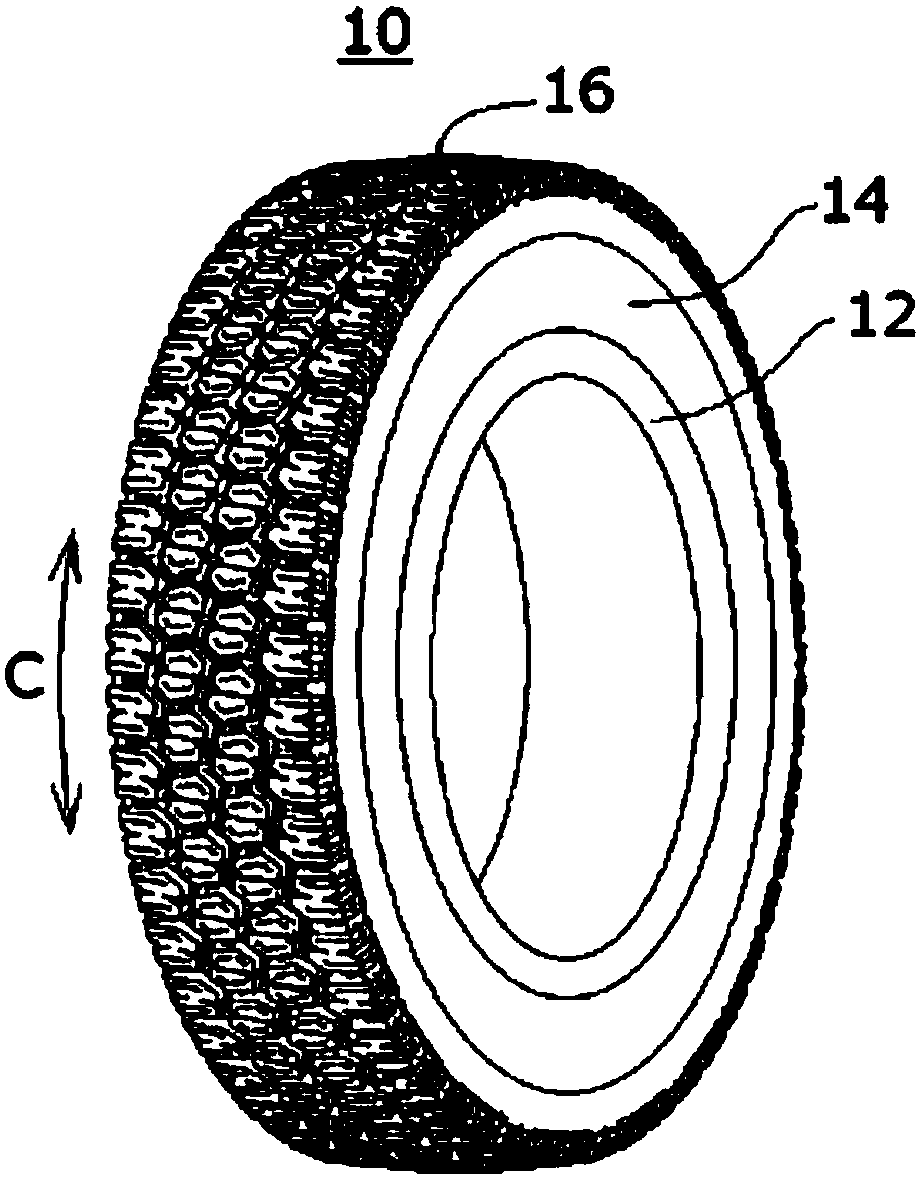

A pneumatic radial tire for a passenger vehicle has a ratio W / L where W is a cross-sectional width and L is an outer diameter. The tire also has a belt-reinforcing layer having a high rigidity and disposed between a belt and a tread.

Owner:BRIDGESTONE CORP

Pneumatic tire

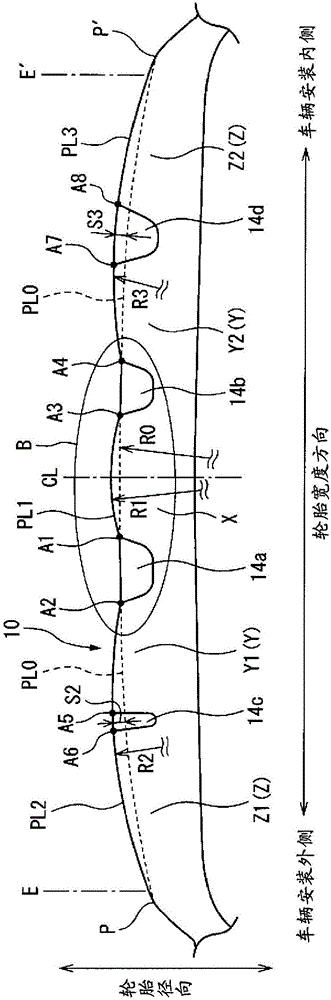

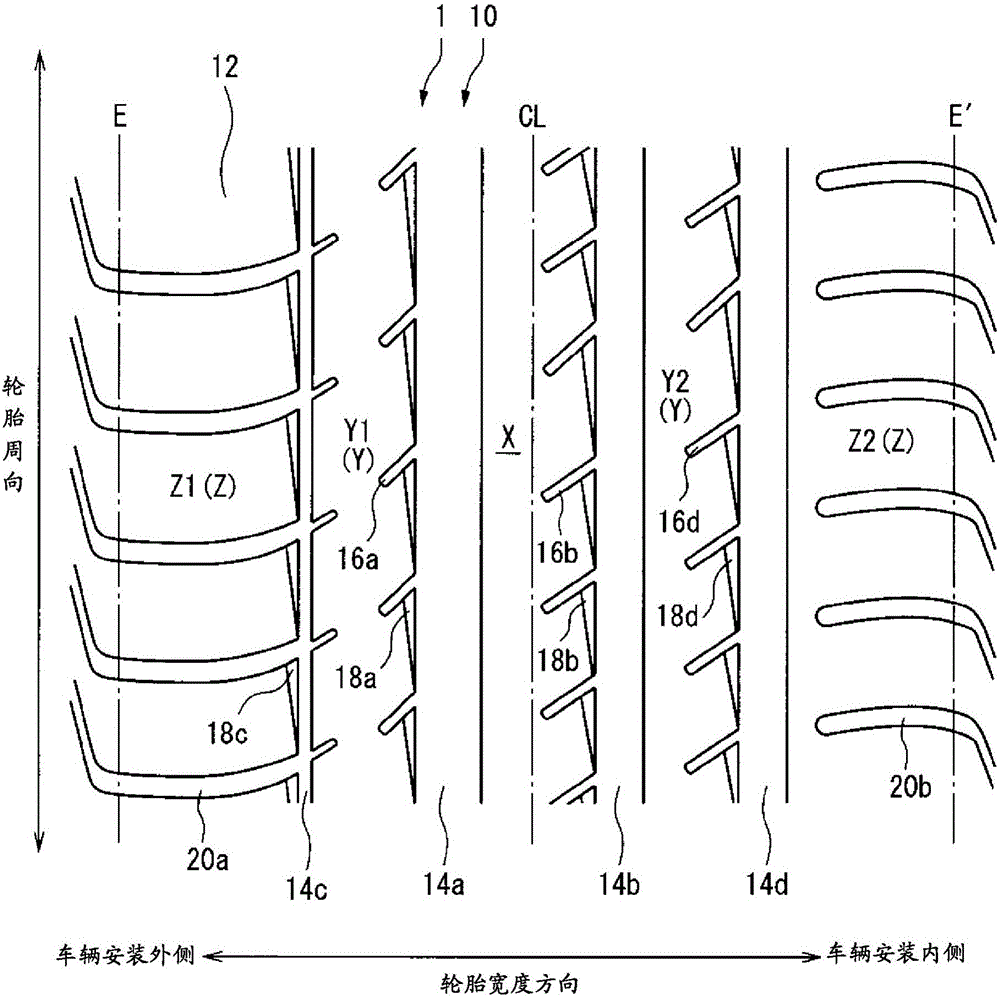

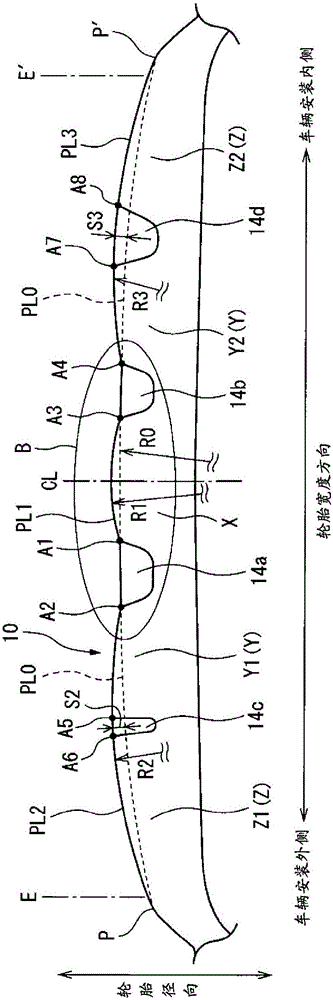

ActiveCN106573506ASlot Area Ratio ImprovementImprove handling stabilitySpecial tyresInflatable tyresArea ratioAutomotive engineering

Provided is a pneumatic tire that improves, in a balanced way, maneuvering stability performance, hydroplaning resistance performance, and uneven-abrasion resistance performance. A profile line (PL1) of a center land section (X) projects further outward in the tire radial direction than a standard profile line (PL0). Including the tire width-direction outermost points (A2, A4) of center principal grooves (14a, 14b) and the tire width-direction end points (A5, A6, A7, A8) of shoulder primary grooves (14c, 14d), profile lines (PL2, PL3), of subcenter land sections (Y1, Y2) and shoulder land sections (Z1, Z2) which are partition-formed in sequence further outward in the tire width direction than the two center principal grooves (14a, 14b), project further outward in the tire radial direction than the standard profile line (PL0). The groove area ratio (Go) of a vehicle mount outside region and the groove area ratio (Gi) of a vehicle mount inside region satisfy the relationship Gi > Go.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

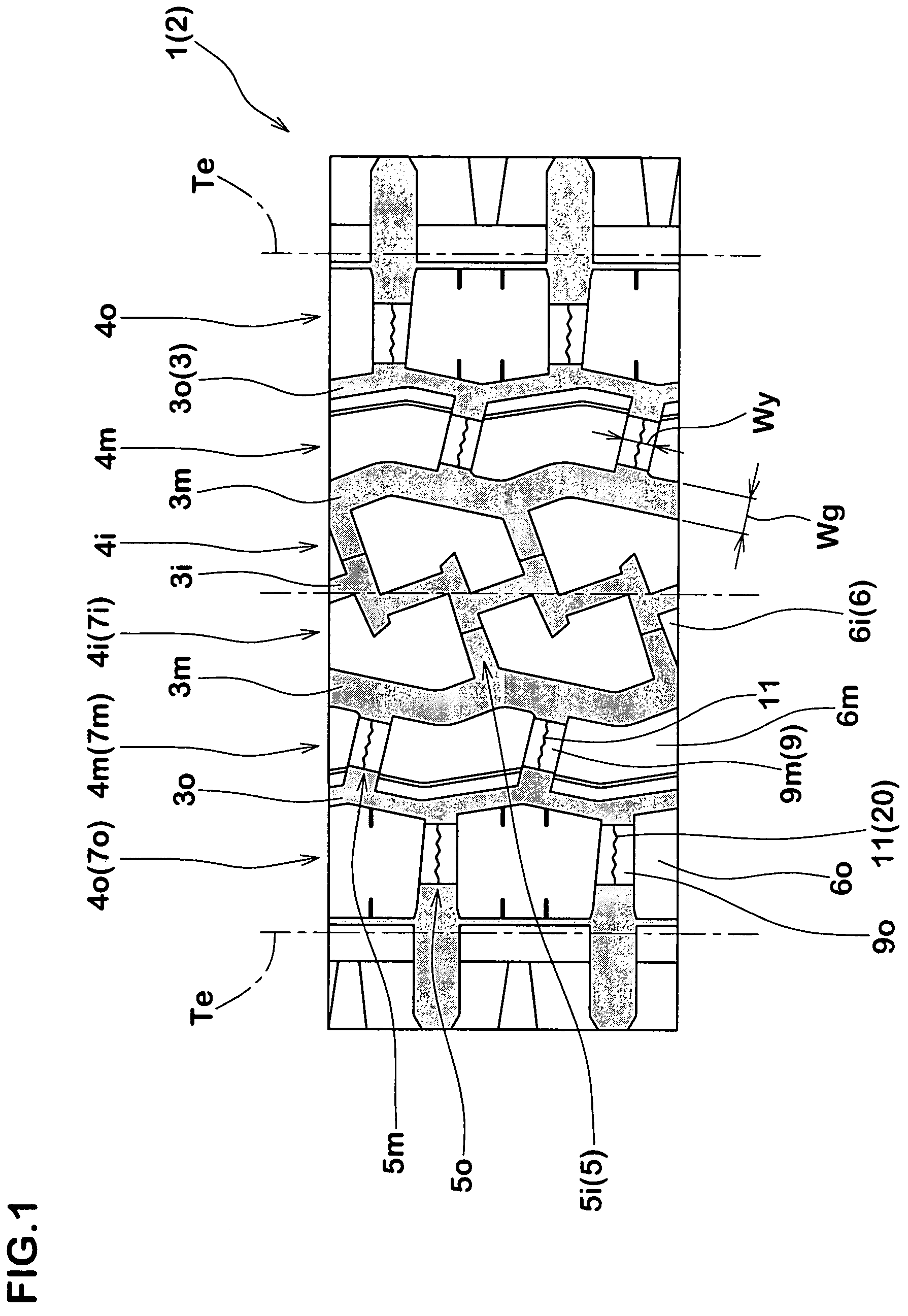

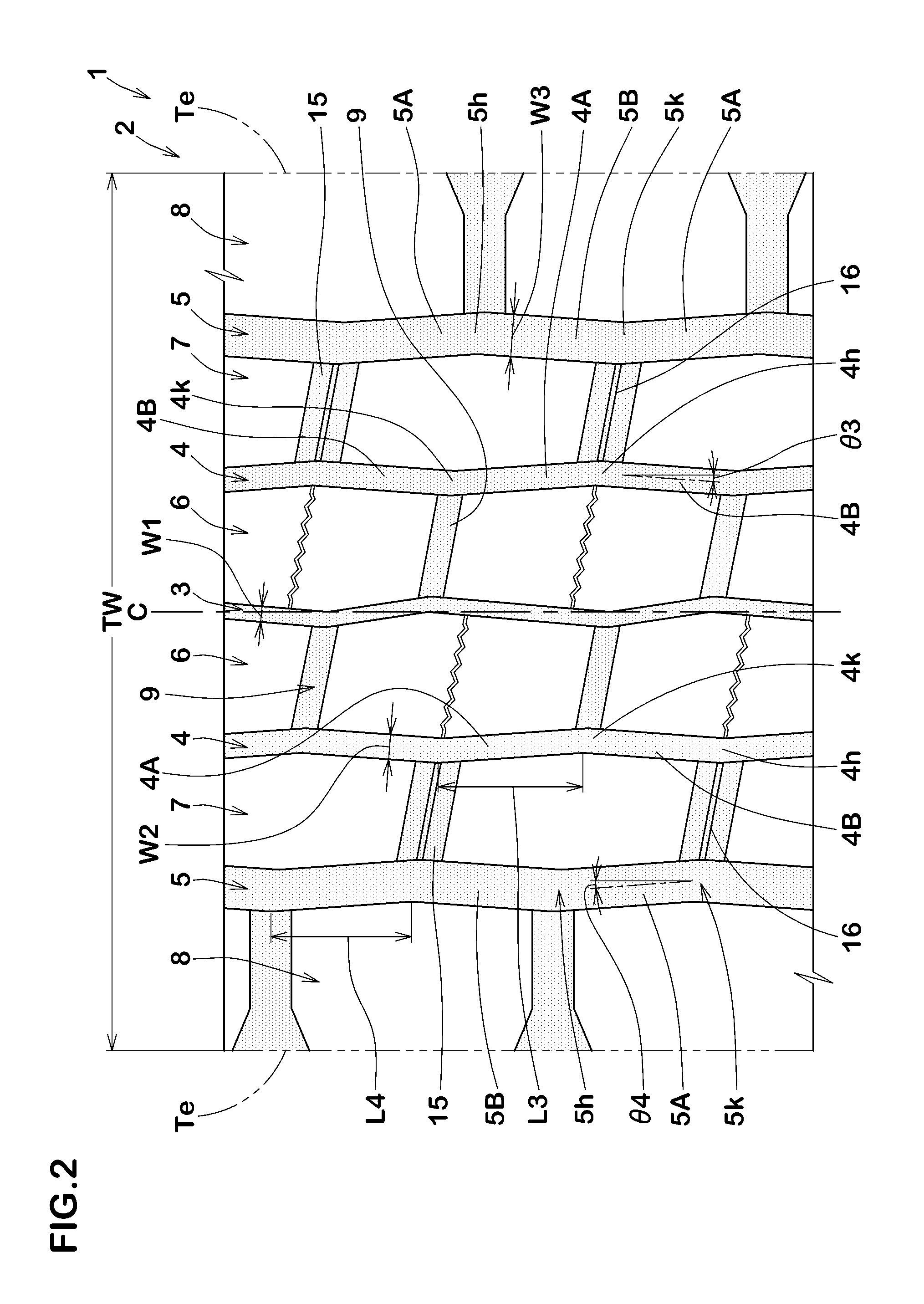

ActiveCN102036839AGood maintenance of partial wear resistanceImprove drainage capacityTyre tread bands/patternsStructural engineeringTread

A pneumatic tire having enhanced water discharge performance achieved with resistance to uneven wear maintained at a high level. In the pneumatic tire, at least three main grooves extending in the tire's circumferential direction are formed in a tread section, and rows of land sections are formed by the main grooves. Referring to a pair of land sections located on both sides of any one of the main grooves other than the main groove on the outermost side of the tire in the lateral direction thereof, first tilt grooves tilting relative to the tire's circumferential direction are formed in either of the pair of land sections, second tilt grooves tilting in the same direction as the first tilt grooves are formed in the other of the pair, one end of each of the first tilt grooves is opened to the main groove located between the pair of land sections with the other end terminating in said land section of the pair, and one end of each of the second tilt grooves is opened to the main groove located between the pair of land sections with the other end terminating in the other of the pair.

Owner:THE YOKOHAMA RUBBER CO LTD

Flat pneumatic radial tire for heavy duty and method of manufacturing the same

InactiveCN101203391AIncreased durabilityImprove partial wear resistanceTyresPneumatic tyre reinforcementsRoom temperatureEngineering

The invention relates to a flat pneumatic radial tire for heavy loads having a 0-degree belt composed of steel cords, and the durability of the tire is improved. The pneumatic radial tire is equipped with a multi-layer steel cord belt layer (6) on the outer periphery of the carcass layer (4), wherein the steel cord belt layer (6) is composed of at least one 0 degree belt layer (7) and at least two inclined belt layers (8), the cord angle of the 0 degree belt layer relative to the tire circumferential direction is substantially 0 degree, and the cord angle of the inclined belt layer relative to the tire circumferential direction It is a substantially balanced angle in the range of 45 to 65 degrees. A tire vulcanized and molded in a metal mold is released from the mold, assembled to a rim at a high temperature, inflated, and cooled to normal temperature in the inflated state to produce the tire.

Owner:THE YOKOHAMA RUBBER CO LTD

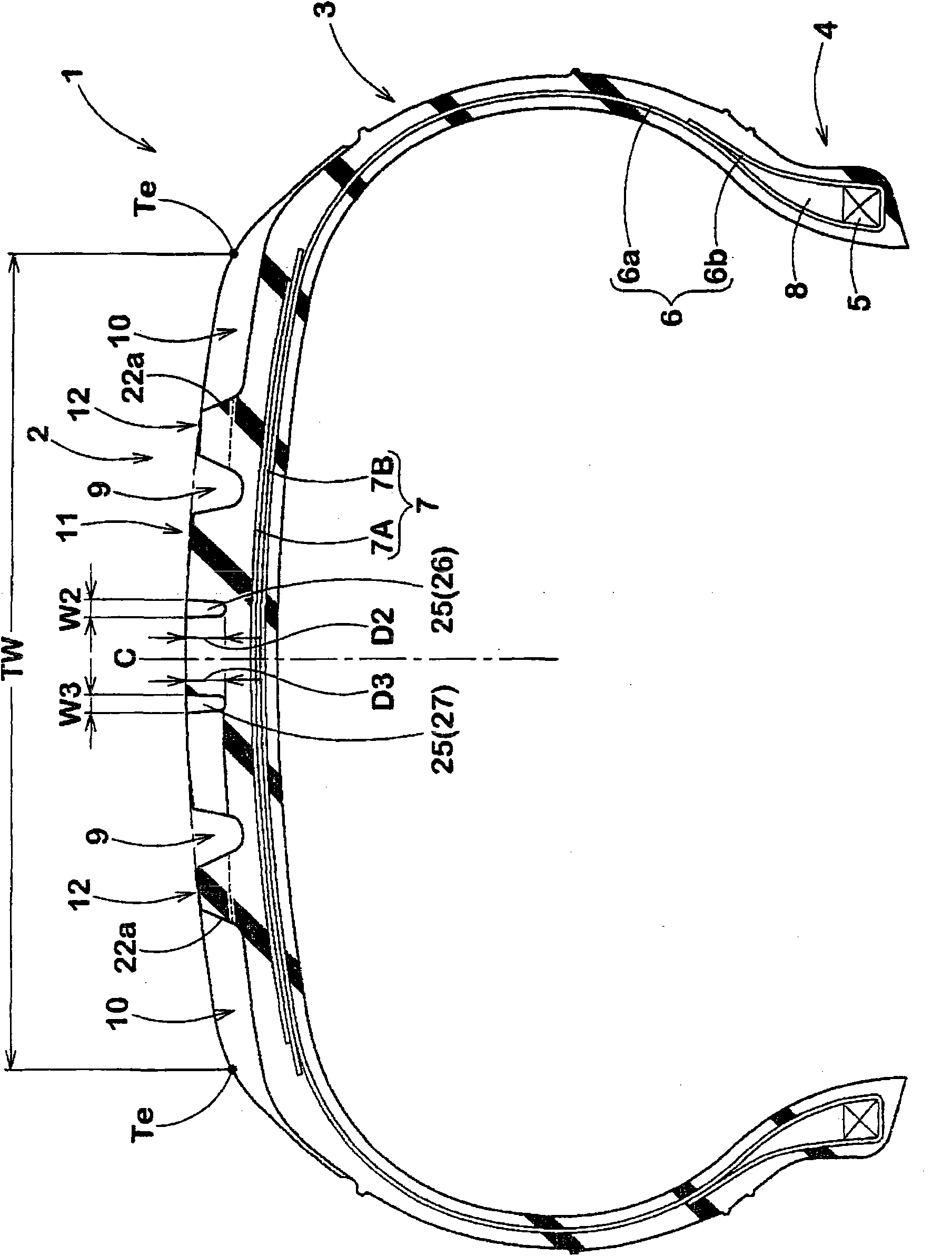

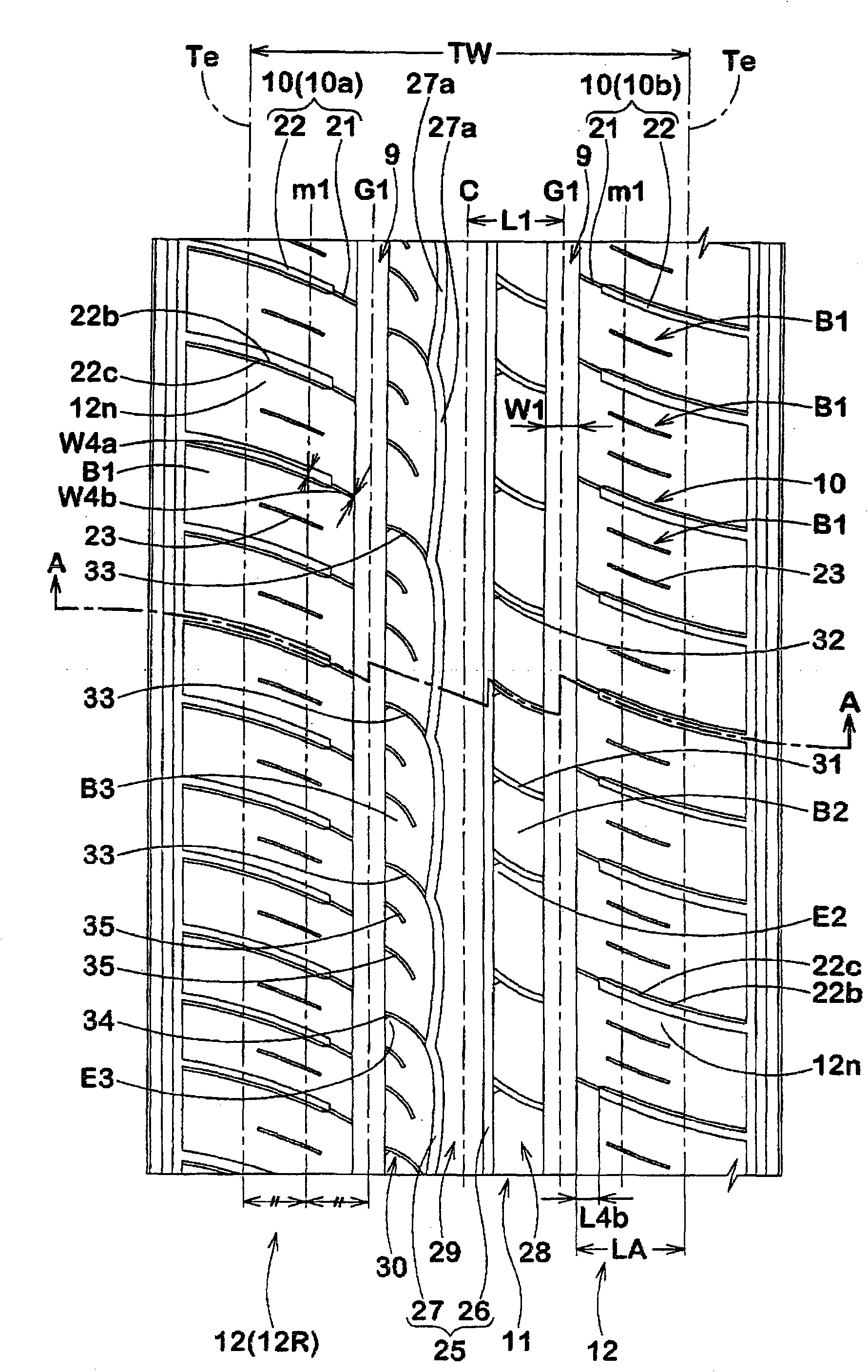

Pneumatic tire

InactiveCN101626907AReduce rolling resistanceRolling Resistance RetentionHeavy duty tyresHeavy duty vehicleGround contactRolling resistance

A pneumatic tire having reduced rolling resistance with its high snow traction performance maintained. The pneumatic tire (1) has a tread center region and tread shoulder regions divided by the center lines (I) of circumferential main grooves (22) located on the outermost sides in the lateral direction of the tire. Further, the ratio G = (A + B) / X which is the ratio of the sum (A + B) of the groove area A of circumferential grooves (21, 22) and the groove area B of lateral grooves (3) to the area X of ground contact of the tread is G = 0.25, the ratio S = B / (A + B) which is the ratio of the groove area B of the lateral grooves (3) to the sum (A + B) of the groove area A of the circumferential grooves (21, 22) and the groove area B of the lateral grooves (3) is 0.25 < S < 0.45, and the ratio Gs = C / Y which is the ratio of the groove area C of the tread shoulder regions to the area Y of ground contact of the tread shoulder regions is Gs < 0.20, and the ratio G and the ratio Gs has the relationship of Gs < G.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

InactiveCN107074034AEffective drainageEnsure normal drainageTyre tread bands/patternsTyre sidewallsGround contactEngineering

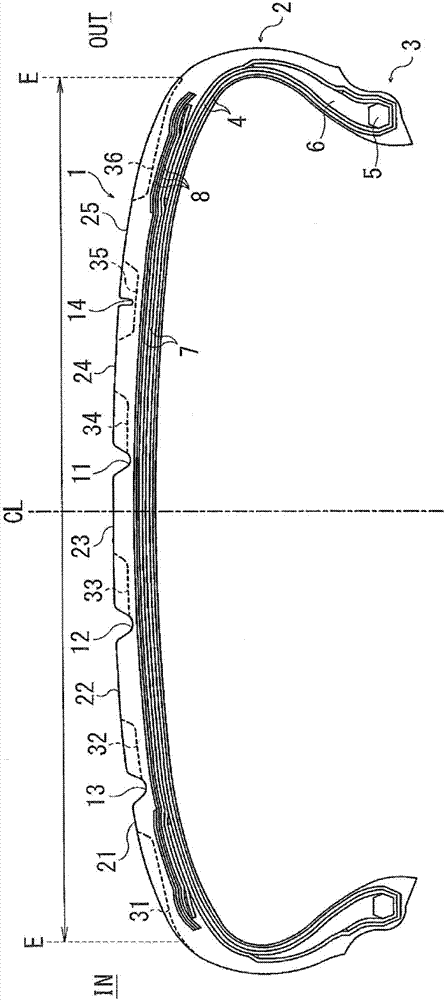

Provided is a pneumatic tire that makes it possible to improve abrasion resistance performance and wet performance as well as improve tire appearance in a later period of wear. The distances GL1-GL4 from first to third main grooves 11, 12, 13 and a narrow groove 14 to a tire equator CL are configured to be 5-20%, 20-35%, 55-70%, and 40-60% of a tire ground contact half width TL / 2, respectively. The invention is provided with: a first lug groove 31 having one end that reaches a vehicle inner-side ground contact end E and another end that is closed inside a first rib 21; a second lug groove 32 having one end that is connected to the third main groove 13 and another end that is closed inside a second rib 22; a third lug groove 33 having one end that is connected to the second main groove 12 and another end that is closed inside a third rib 23; a fourth lug groove 34 having one end that is connected to the first main groove 11 and another end that is closed inside a fourth rib 24; a fifth lug groove 35 that intersects with the narrow groove 14 and has ends that are closed inside the fourth rib 24 and a fifth rib 25; and a sixth lug groove 36 having one end that reaches a vehicle outer-side ground contact end E and another end that is closed inside the fifth rib 25.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN107554202ASuppresses the decline in soil dischargeInhibition of decreased tractionTyre tread bands/patternsGround contactEngineering

Provided is a pneumatic tire. In a shoulder block row in which a plurality of shoulder blocks are disposed in a tire circumferential direction, a lateral groove between adjacent shoulder blocks in thetire circumferential direction has a first shallow groove portion that is positioned on a side close to a main groove and has a depth shallower than that of the main groove, a third shallow groove portion that is positioned on a side close to a tire ground contact end and has a depth shallower than that of the main groove, and a second shallow groove portion that is positioned between the first shallow groove portion and the third shallow groove portion, and has a depth shallower than those of the first shallow groove portion and the third shallow groove portion.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire with tread having sipe in tie bar

InactiveUS7490645B2Improve partial wear resistanceAvoid crackingTyre tread bands/patternsNon-skid devicesMechanical engineeringTread

Owner:SUMITOMO RUBBER IND LTD

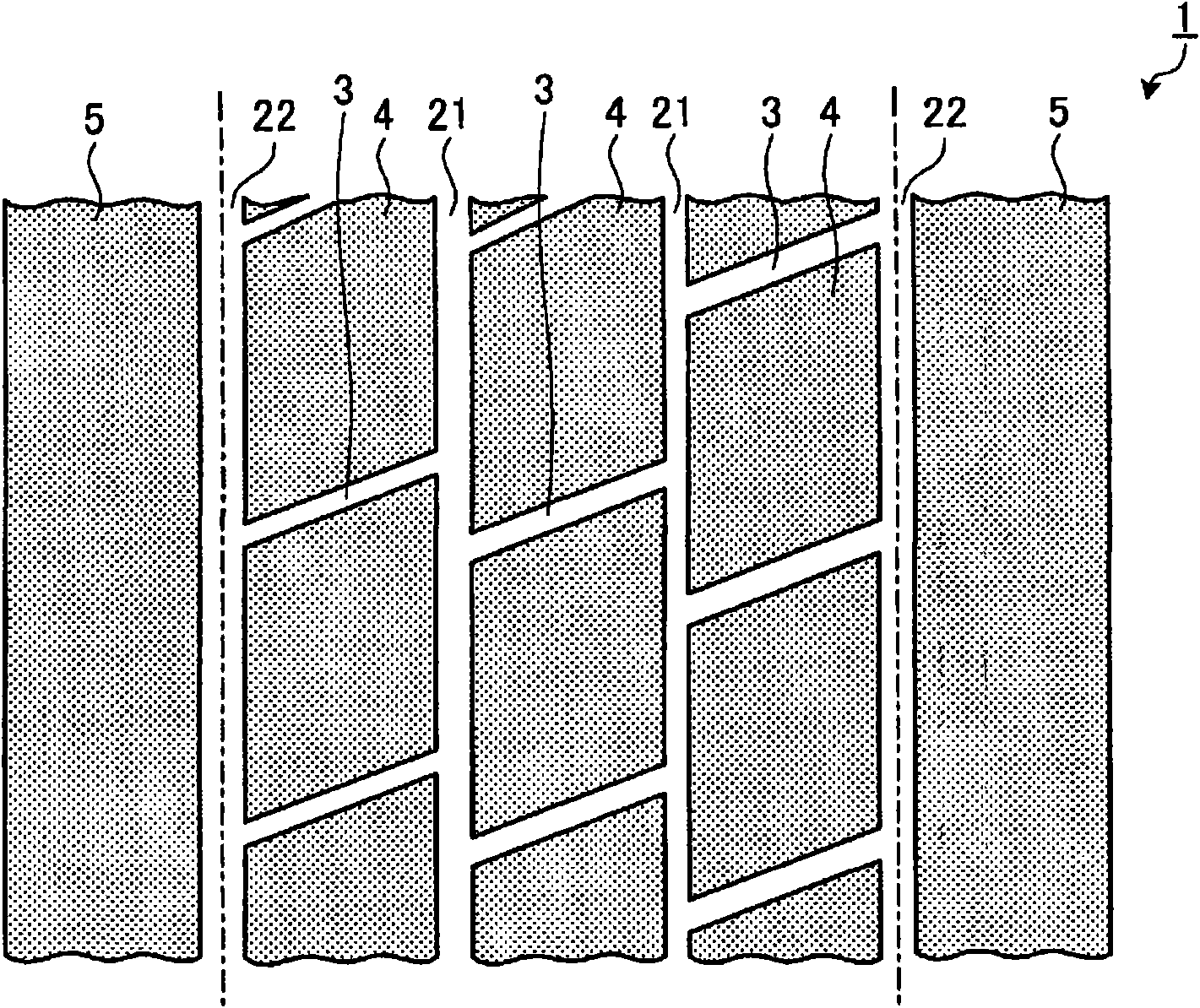

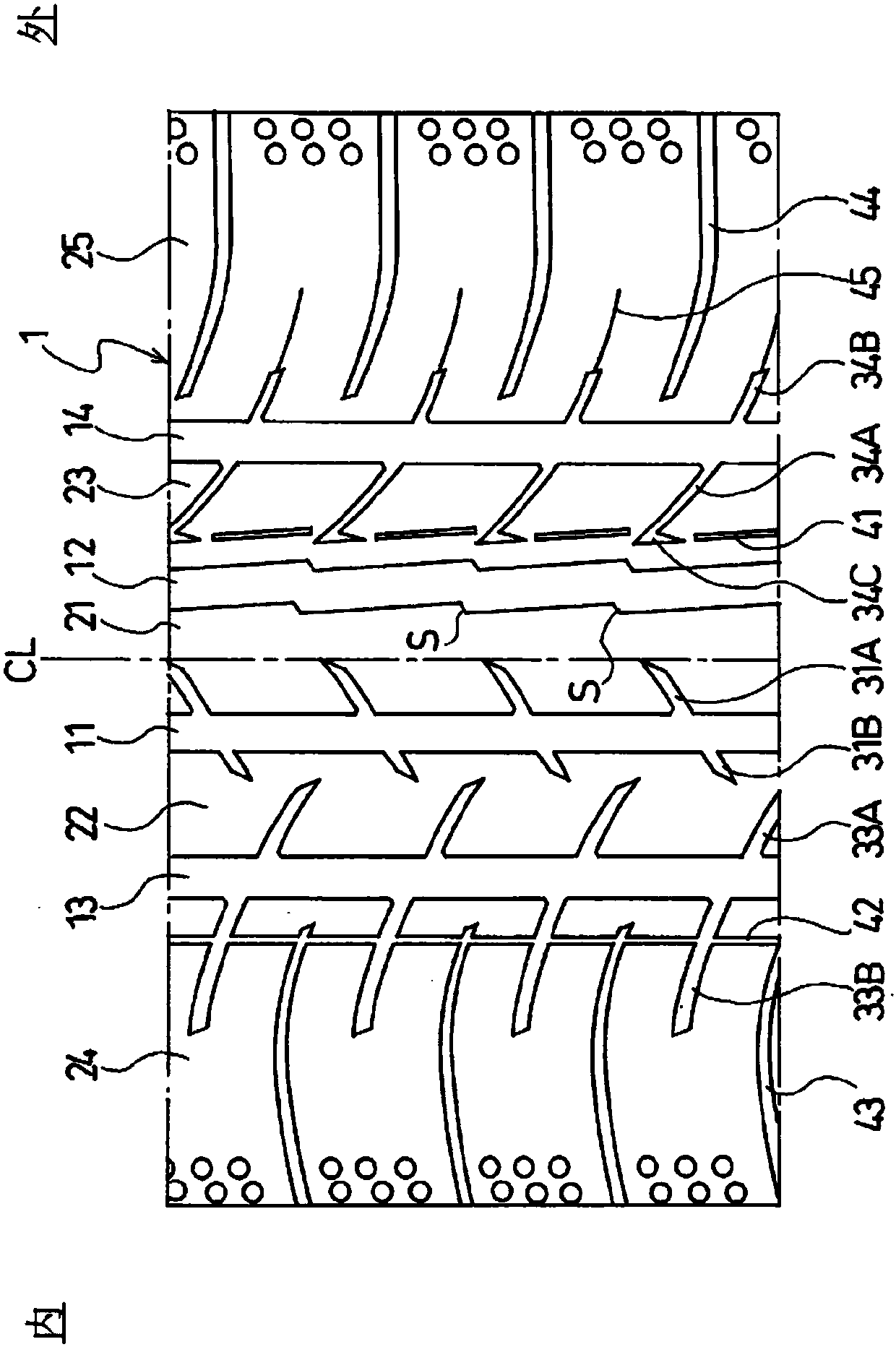

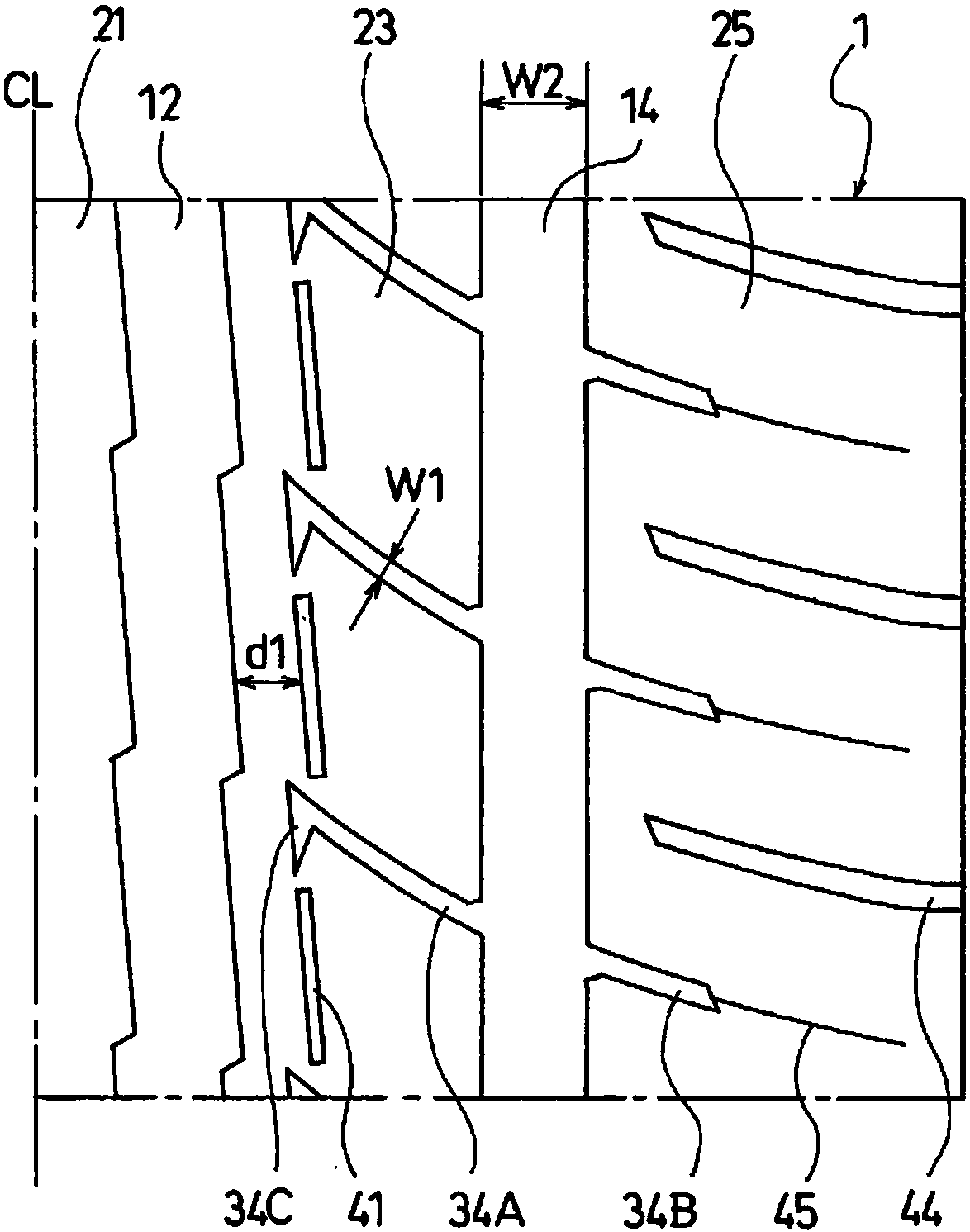

Heavy duty pneumatic tire

ActiveUS20160137005A1Improve partial wear resistanceEnsuring Wet PerformanceTyre tread bands/patternsNon-skid devicesEngineeringHeavy duty

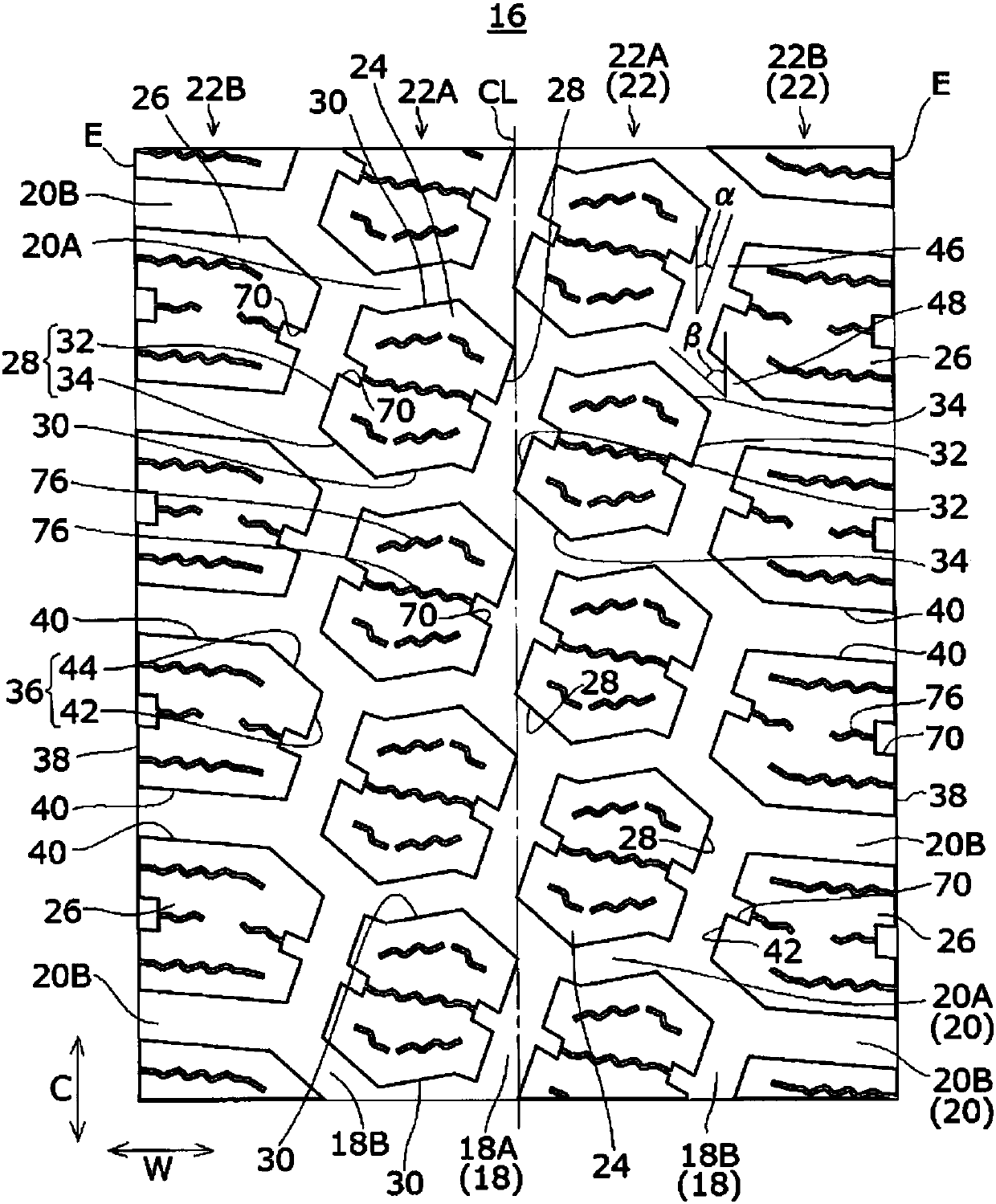

A heavy duty pneumatic tire includes a tread including a pair of central portions, a pair of middle portions and a pair of shoulder portions, wherein each of the portions has an axial width varying periodically while increasing and decreasing in a circumferential direction of the tire. Each of the central portions includes a central block with a hexagonal shaped top face and a central sipe. A total that is the sum of each maximum axial width of the central portions, each maximum axial width of the middle portions, each maximum axial width of the shoulder portions, a maximum axial length of the central sipe provided on one of the central portions, and a maximum axial length of the central sipe provided on the other one of the central portions is in a range of from 1.05 to 1.31 times a tread width.

Owner:SUMITOMO RUBBER IND LTD

Pneumatic tire

ActiveCN107709047AGuaranteed rigidityImprove driving stabilityInflatable tyresTyre tread bands/patternsRoad surfaceTread

A pneumatic tire is provided which makes it possible to achieve both steering stability on dry road surfaces and steering stability on wet road surfaces. This pneumatic tire is provided with a tread portion, a sidewall, and a bead, and has a mounting direction specified with respect to the vehicle, wherein: four main grooves are provided, which include a pair of center main grooves which extend inthe tread portion in the tire circumferential direction and a pair of shoulder main grooves which are outside of the center main grooves and extend in the tire circumferential direction; five land portions are defined by said main grooves, and the center main groove to the outside of the vehicle has a zigzag shape along the tire circumferential direction; multiple lug grooves are provided in theland portions and extend from the main grooves other than the center main groove that has a zigzag shape, towards both sides in the width direction of the tire, and terminate within the respective land portion.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneunatic tyre

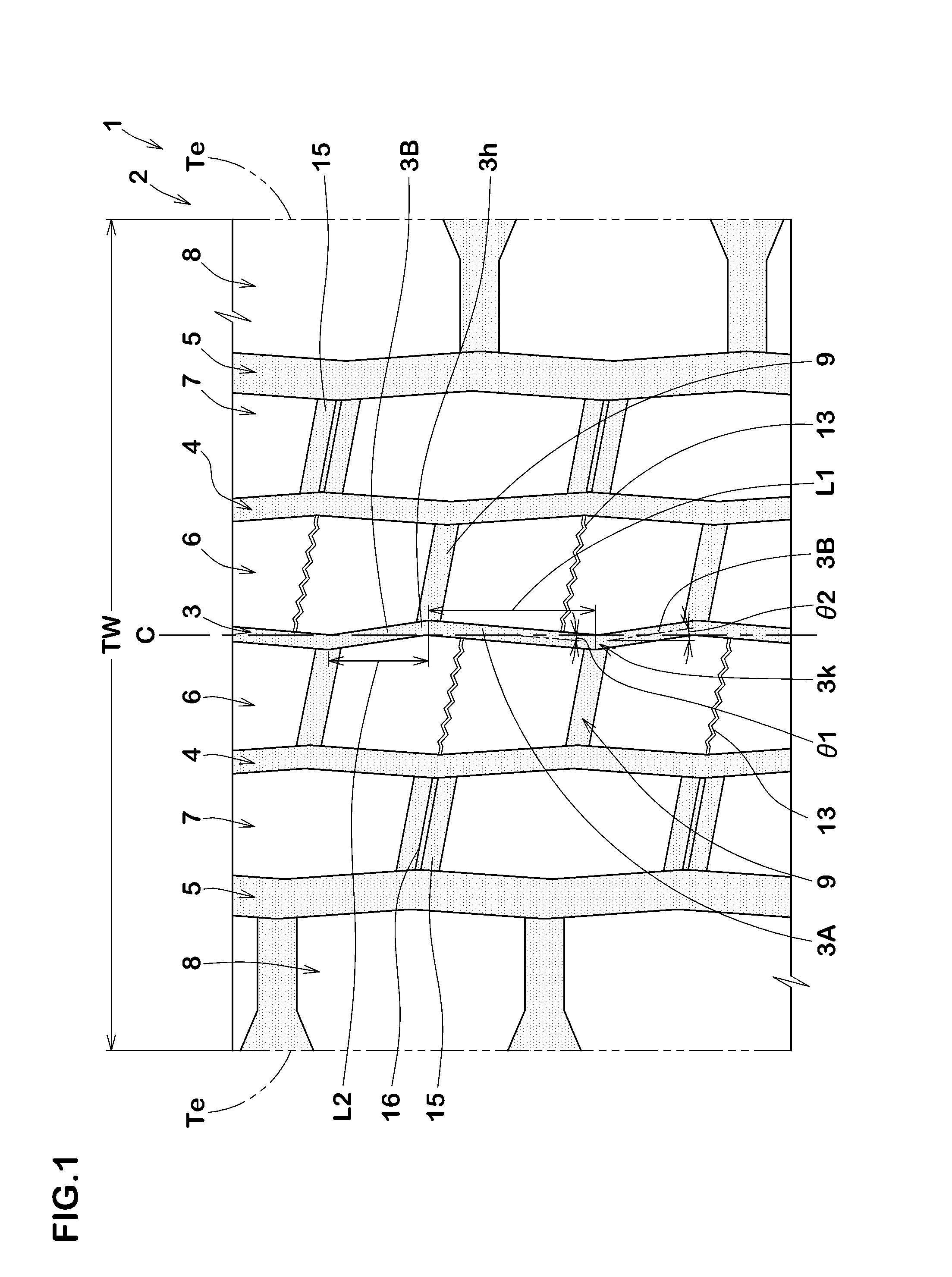

ActiveCN105270097AImprove partial wear resistanceEasy to moveTyre tread bands/patternsTransverse grooveEngineering

The invention provides a pneunatic tyre which prevents water discharging performance and improves uneven wear resistance and noise performance. The tire tread is provided with a central main groove in an equatorial plane of the tire, a pair of central auxiliary grooves at two sides of the central main groove, and a pair of tire shoulder main grooves at two sides, thereby forming central landing parts, middle landing parts and tire shoulder landing parts. Each middle landing part is provided with middle transverse grooves which are separately arranged in a circumferential direction and respectively extend from the central auxiliary groove to the tire shoulder main groove in an angle beta in 10-20 DEG. Each middle transverse groove is composed of a large-width part which is connected with the central auxiliary groove, a small-width part which is connected with the tire shoulder main groove, and a transition part which connects the large-width part with the small-width part. The angle beta of the middle transverse groove is larger than the angle alpha of the grounding front edge part of the middle landing part in the shape of a grounding surface.

Owner:SUMITOMO RUBBER IND LTD

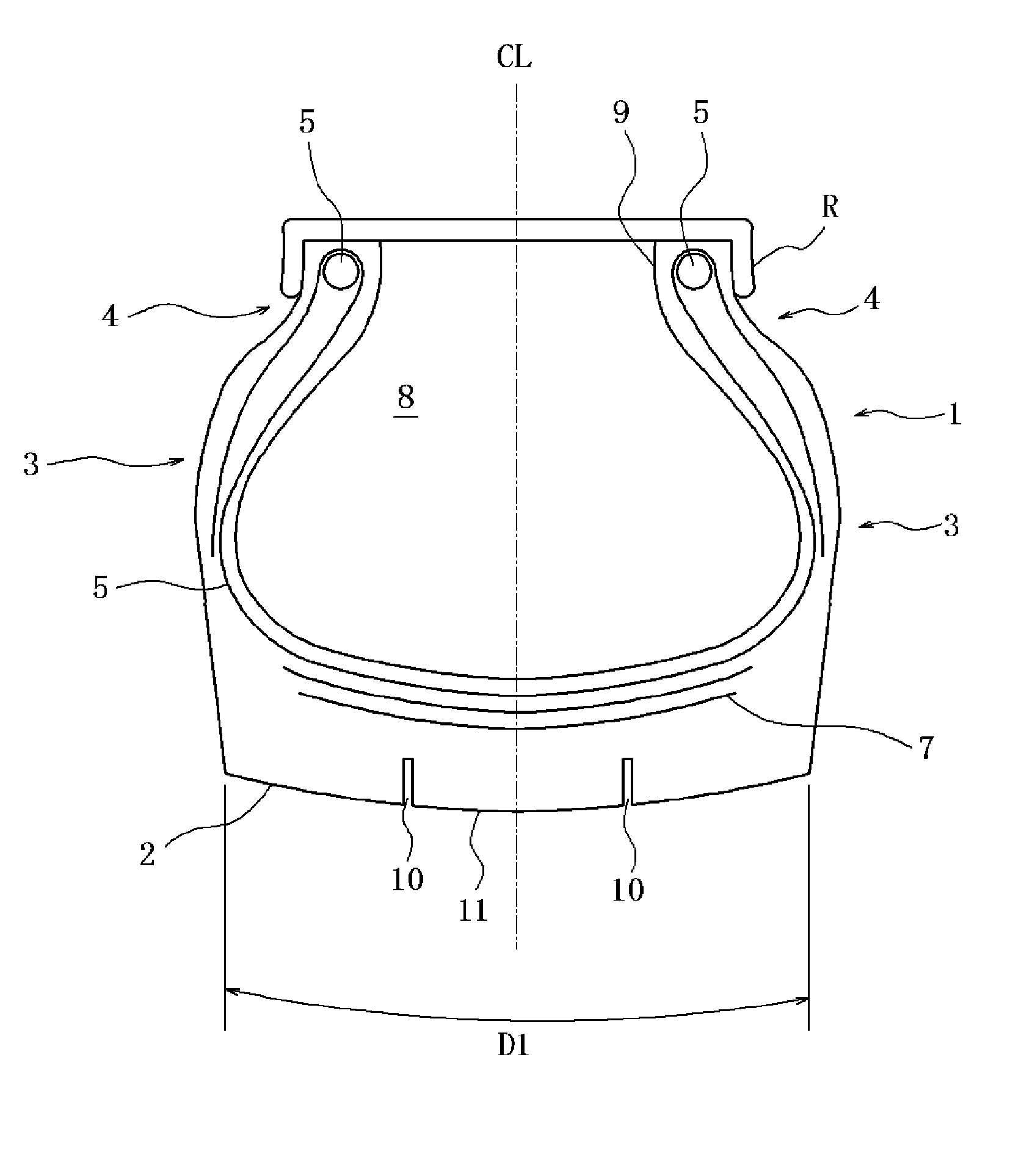

Load-bearing inflatable radial tire

PendingCN109109574AImprove partial wear resistanceImprove handling stabilityPneumatic tyre reinforcementsEngineeringWear resistance

The invention provides a load-bearing inflatable radial tire according to the problems of the existing belt ply structure that the formed and vulcanized tire cannot be balanced on the same tire in theaspects of durability, eccentric wearing resistance and operation stability. An expansion rate of a central area of the belt ply on the innermost side is 1.2 to 1.9 percent, a tension-elongation curve of a zero-degree belt ply steel wire has a mutation point of the curve trend when the elongation rate is in a range of 0.8 percent to 1.4 percent, and a mutation point area is located in a range ofthe 40 to 110 N of the tension; and by adopting the load-bearing inflatable radial tire, the performances can be well balanced.

Owner:ZHONGCE RUBBER GRP CO LTD

Pneumatic tire

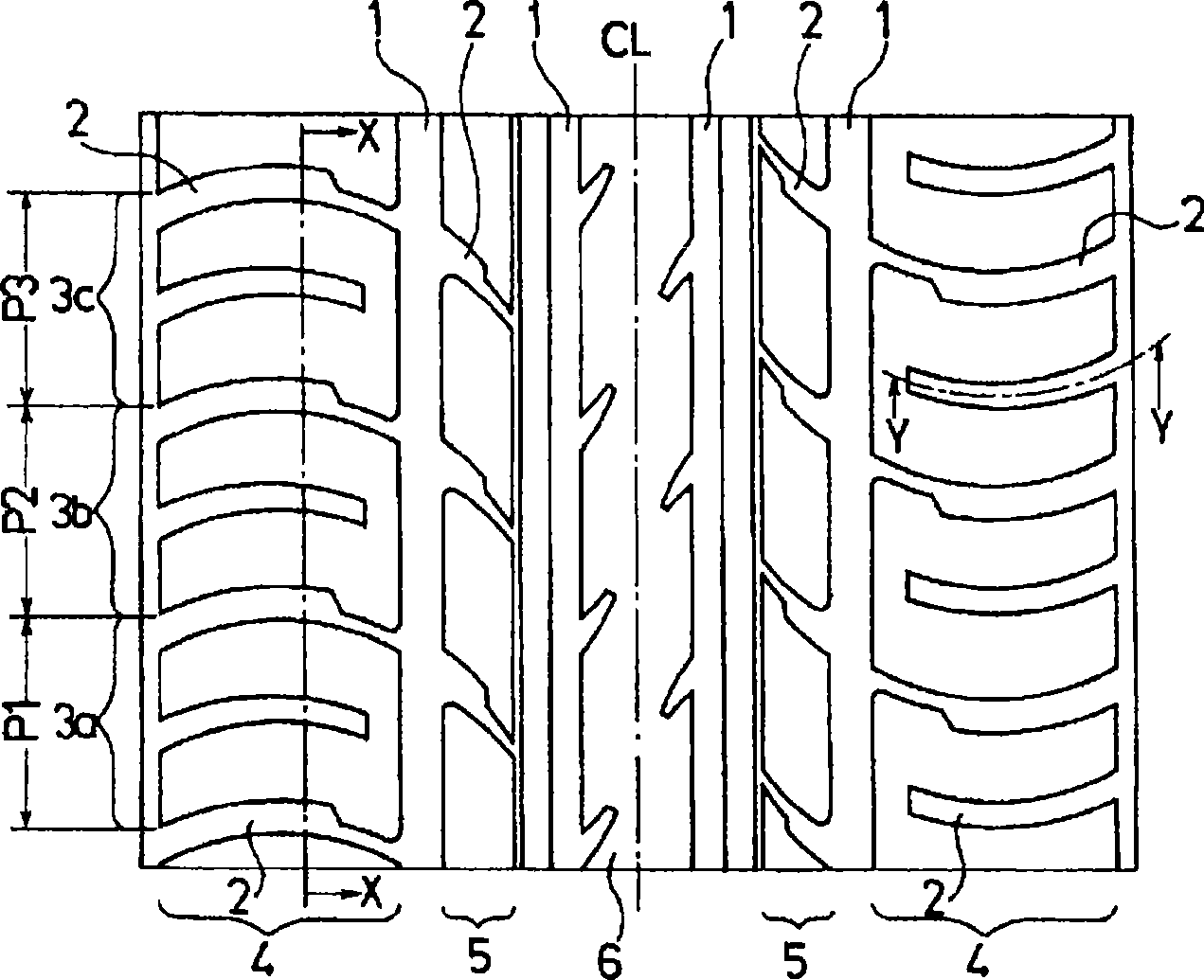

InactiveCN101454167AEliminate poor rigidityMeasuring Thickness HomogenizationTyre tread bands/patternsPitch variationEngineering

To provide a pneumatic tire with an improved uniformity, in which pitch variation is adopted for suppressing pattern noise. The ratios of groove area in pitches (3a, 3b, 3c) with different pitch lengths are set to be smaller in pitches with longerr pitch lengths. Groove wall angles a on the obtuse angle side that is formed by the groove walls of lateral grooves (2) and the tangential direction of the tread surface are larger in the pitches with longer pitch lengths.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

ActiveCN108099504ALow ground pressureReduce rigidityTyre tread bands/patternsCrack resistanceTear resistance

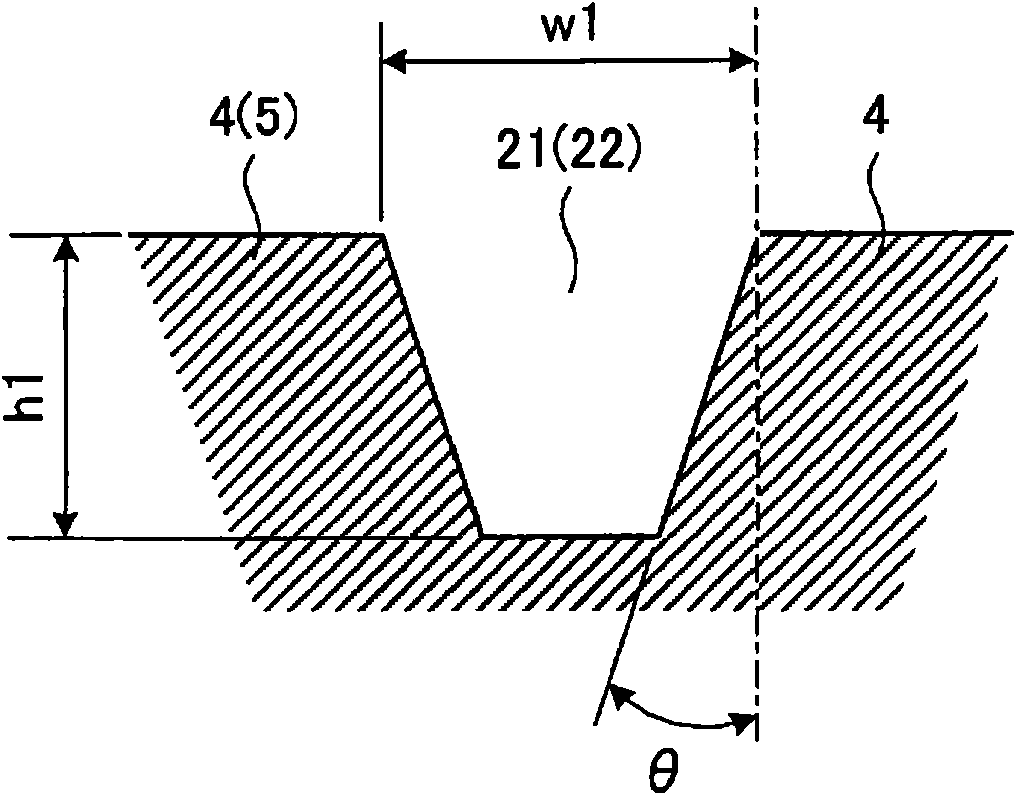

The present invention provides a pneumatic tire in which a narrow groove extending in a tire circumferential direction is formed in a shoulder land portion, and the pneumatic tire is excellent in a groove bottom crack resistance, an irregular wear resistance and a tear resistance. A pneumatic tire comprising a narrow groove (3) extending in a tire circumferential direction, the narrow groove (3) being formed in a shoulder land portion of a tread, wherein an inside concave curved surface (41) and an outside concave curved surface (42) are formed in a groove bottom portion of the narrow groove (3), the inside concave curved surface (41) being obtained by depressing a groove wall in a tread center side and the outside concave curved surface (42) being obtained by depressing a groove wall in atread end side, and the groove bottom portion of the narrow groove (3) is provided as a shape which is wider than an opening portion of the narrow groove (3) and is rounded, and wherein a height (H1)of the inside concave curved surface (41) measured along a depth direction of the narrow groove (3) is greater than a height (H2) of the outside concave curved surface (42).

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

ActiveCN106573500ASpacing Number ImprovementImprove handling stabilityTyre tread bands/patternsEngineeringOperational stability

The purpose of the present invention is to provide a pneumatic tire having improved operational stability performance, anti-noise / vibration performance, and anti-uneven wear performance in a well-balanced manner. In a tire meridional cross-sectional view, a profile line (PL1) of a center land portion (X) defined and formed by two center main grooves (14a, 14b) protrudes outside a reference profile line (PL0) in a tire radius direction. Profile lines (PL2, PL3) of sub-center land portions (Y1, Y2) and shoulder land portions (Z1, Z2) defined and formed in order outside the two center main grooves (14a, 14b) in the tire width direction protrude outside the reference profile line (PL0) in the tire radius direction. A pitch number (Po) of a vehicle-mount outside region and a pitch number (Pi) of a vehicle-mount inside region satisfy the relationship Po < Pi.

Owner:THE YOKOHAMA RUBBER CO LTD

Pneumatic tire

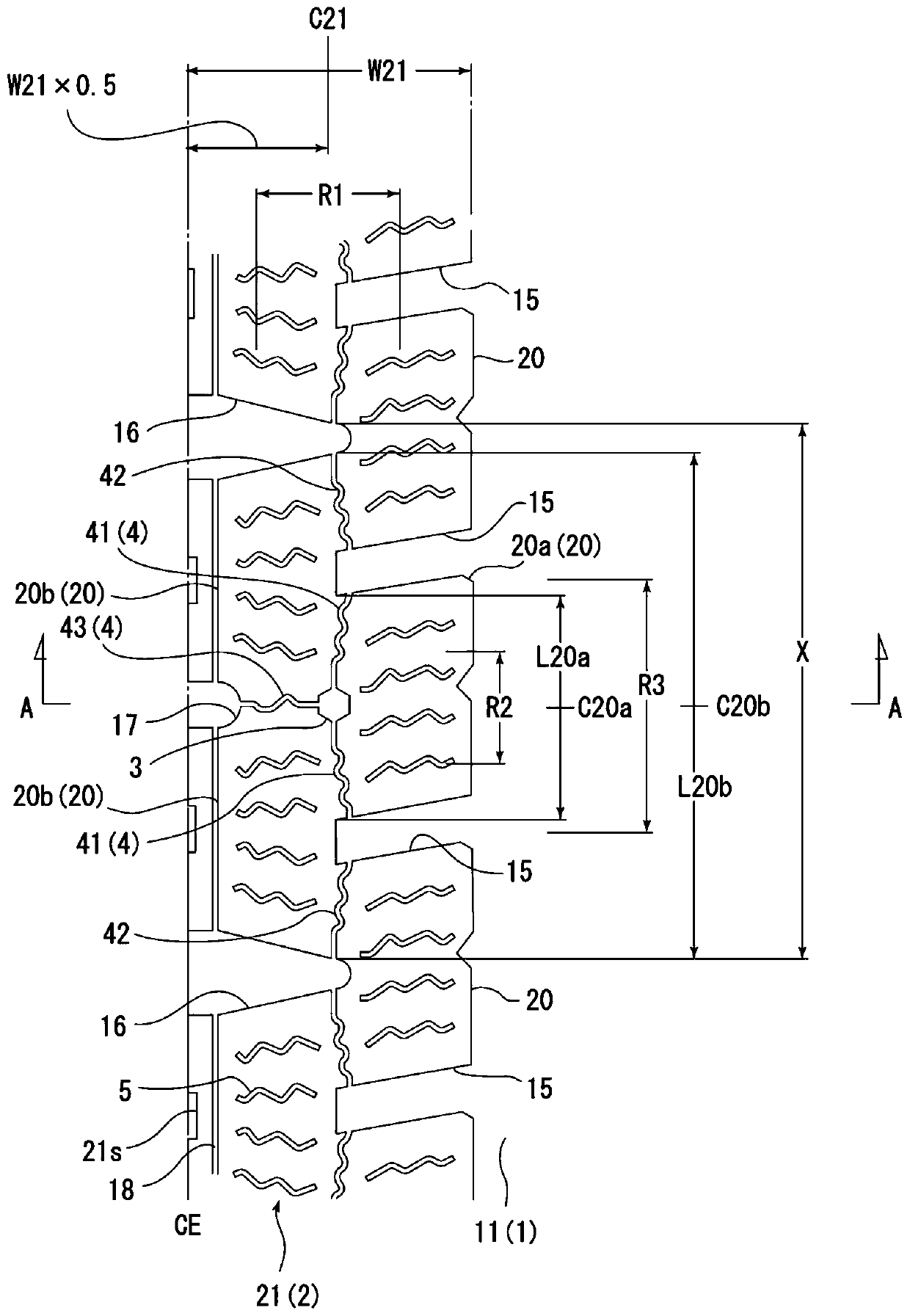

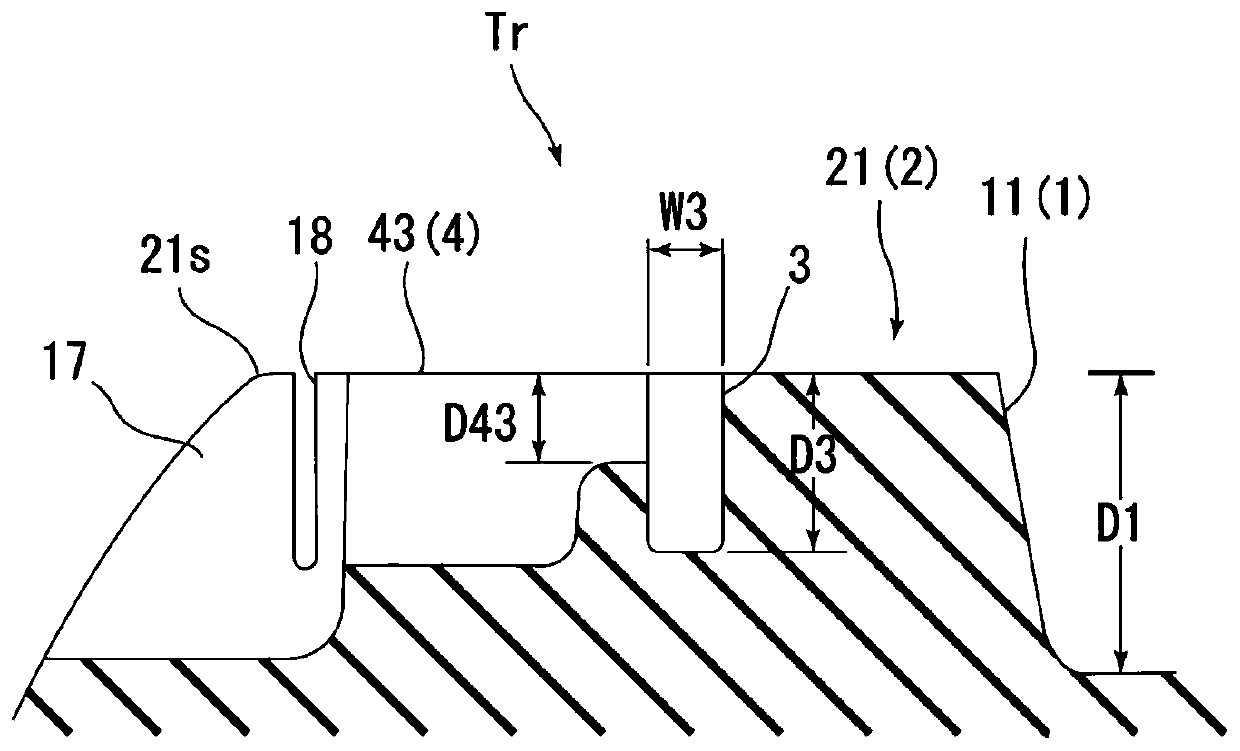

ActiveCN109910510AImprove rigidityIncrease shear forceTyre tread bands/patternsGround contactAgricultural engineering

The invention provides a pneumatic tire capable of improving snow performance. A tread (Tr) is provided with a plurality of main grooves (1) continuously extending in the tire circumferential direction, and a plurality of land rows (2) divided by the plurality of main grooves (1). The land row (2) is provided with a snow hole (3) formed in the center of the land row (2) in the width direction, andsipes (4) for connecting the main groove (1), the ground contact end (CE) or the lateral groove to the snow hole (3). Therefore, the shearing force of the snow column during the driving on the ice and snow covered road surface can be improved, the occurrence of snow inclusion can be inhibited, and the snow performance is improved.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

ActiveUS9630452B2Accurate processingImprove partial wear resistanceHeavy duty tyresHeavy duty vehicleMechanical engineeringTread

Owner:BRIDGESTONE CORP

Heavy duty pneumatic tire

ActiveUS10343461B2Improve partial wear resistanceEnsuring Wet PerformanceTyre tread bands/patternsEngineeringHeavy duty

A heavy duty pneumatic tire includes a tread including a pair of central portions, a pair of middle portions and a pair of shoulder portions, wherein each of the portions has an axial width varying periodically while increasing and decreasing in a circumferential direction of the tire. Each of the central portions includes a central block with a hexagonal shaped top face and a central sipe. A total that is the sum of each maximum axial width of the central portions, each maximum axial width of the middle portions, each maximum axial width of the shoulder portions, a maximum axial length of the central sipe provided on one of the central portions, and a maximum axial length of the central sipe provided on the other one of the central portions is in a range of from 1.05 to 1.31 times a tread width.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com