Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2431results about "Non-skid devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

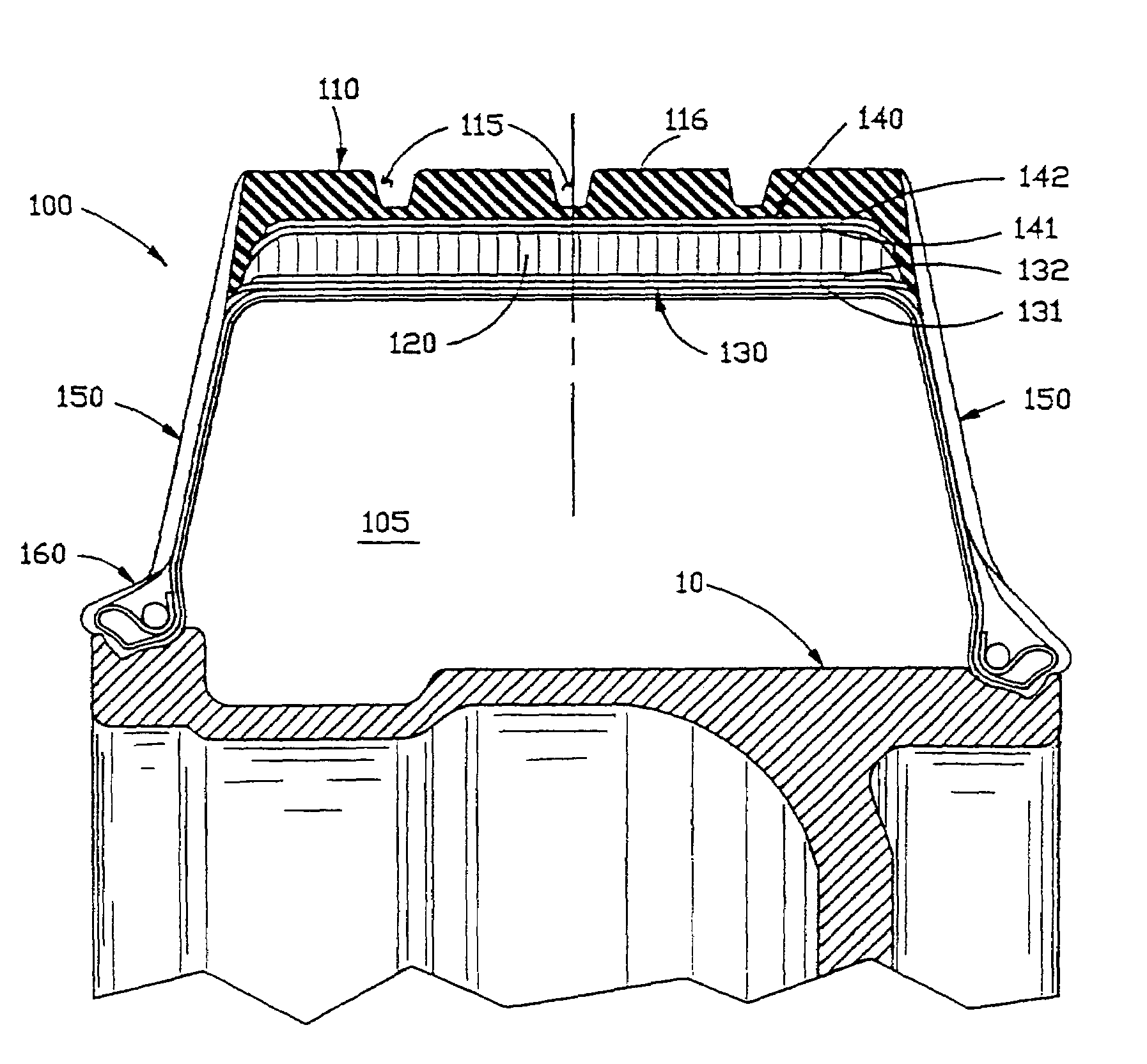

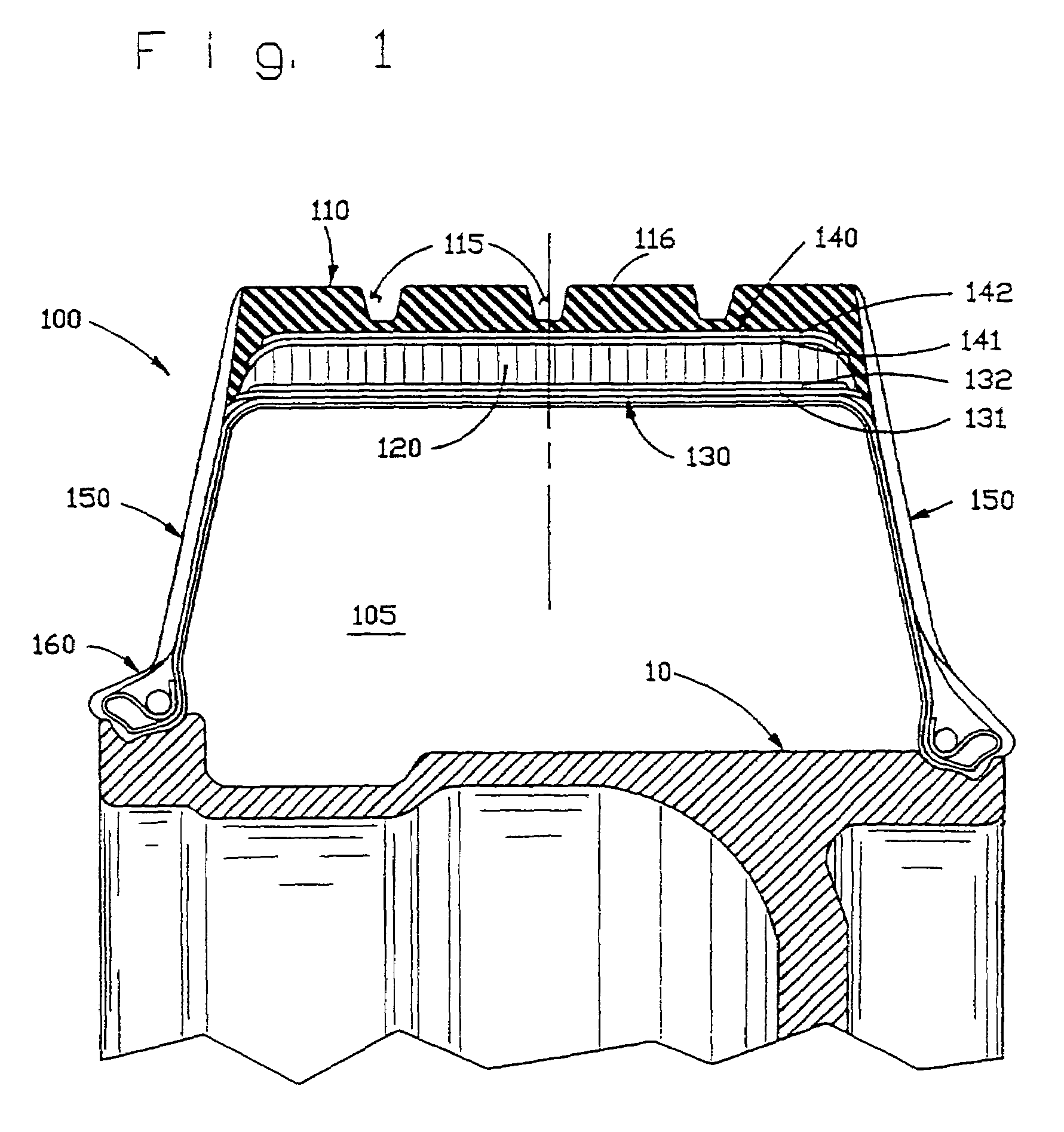

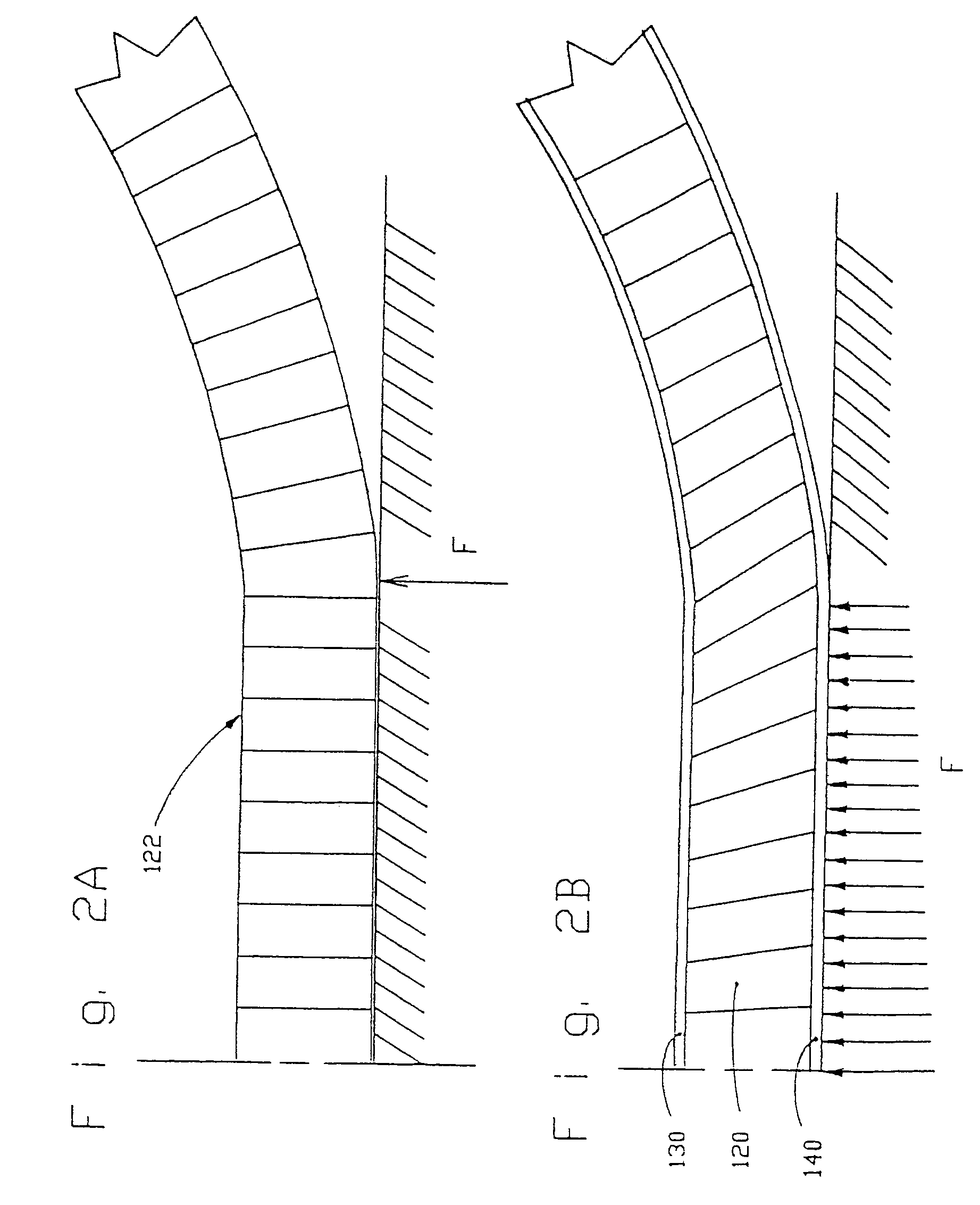

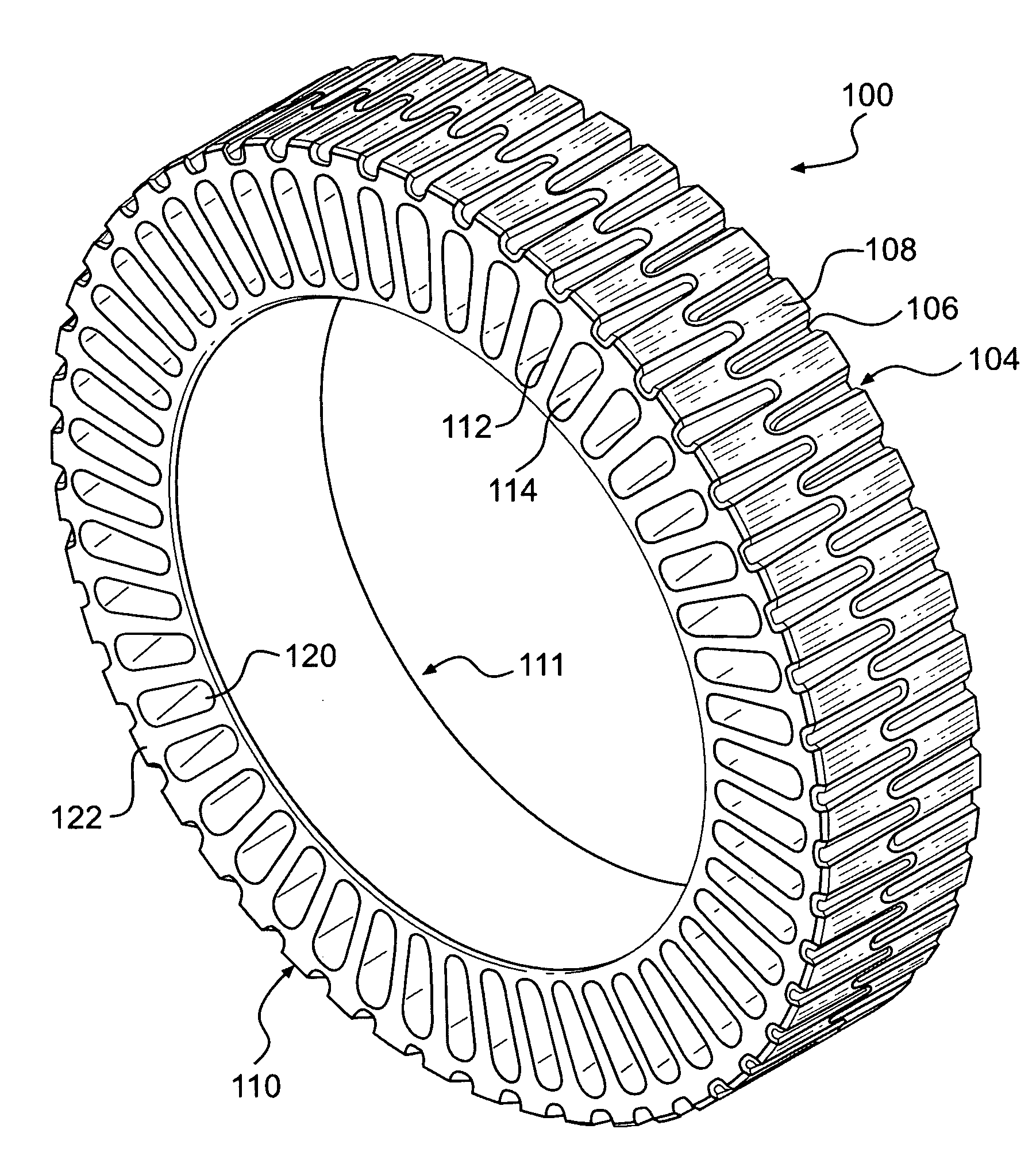

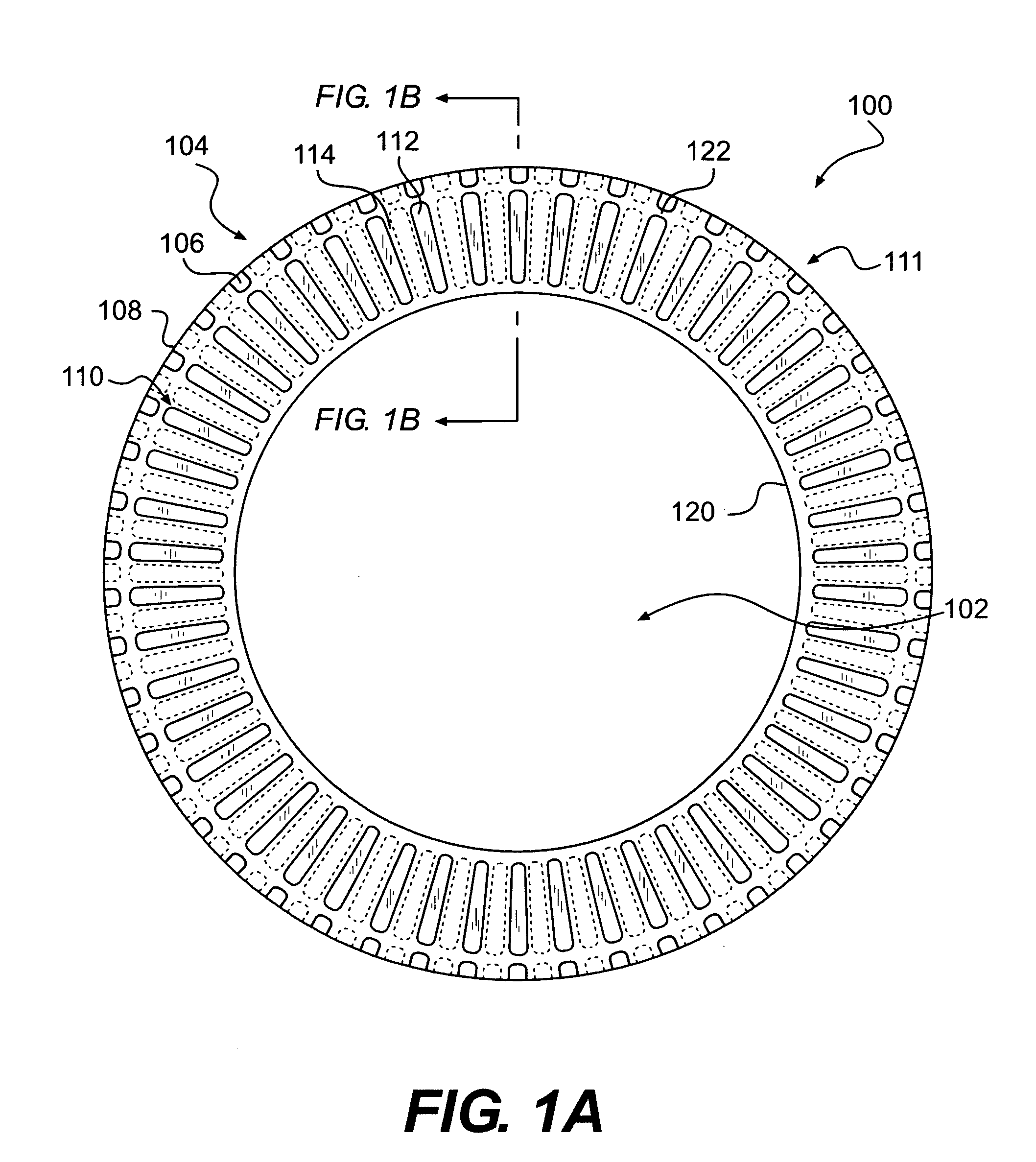

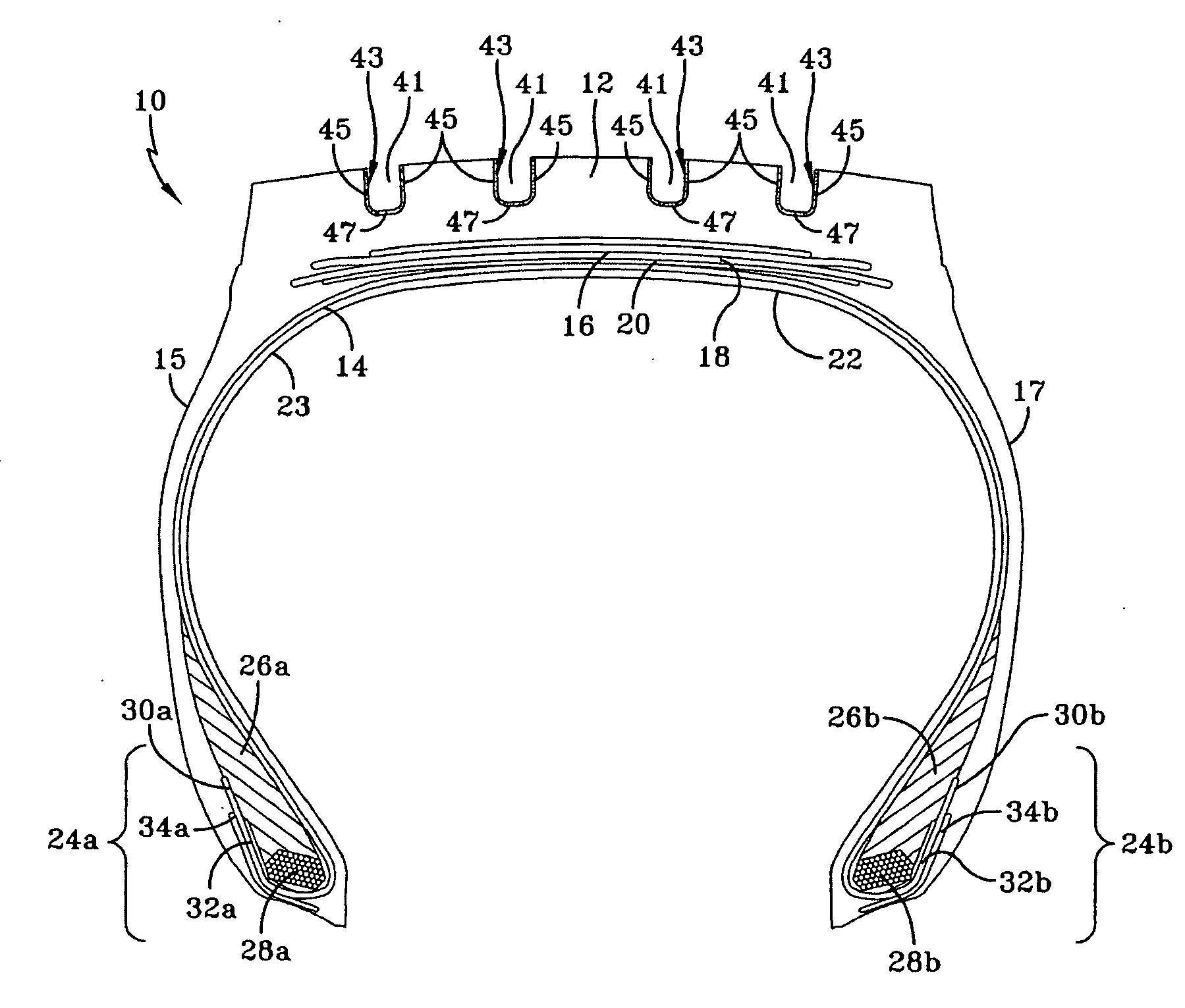

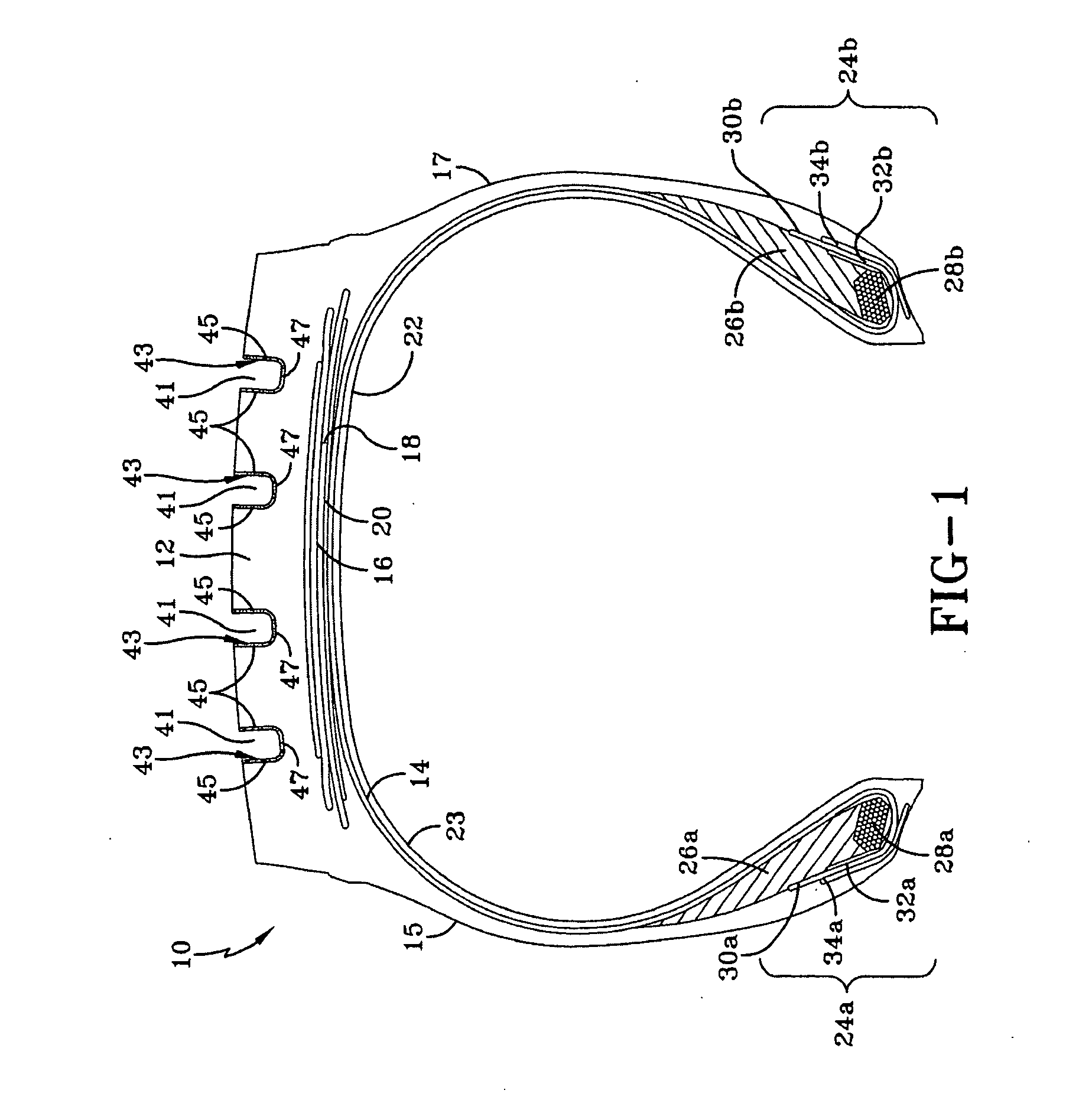

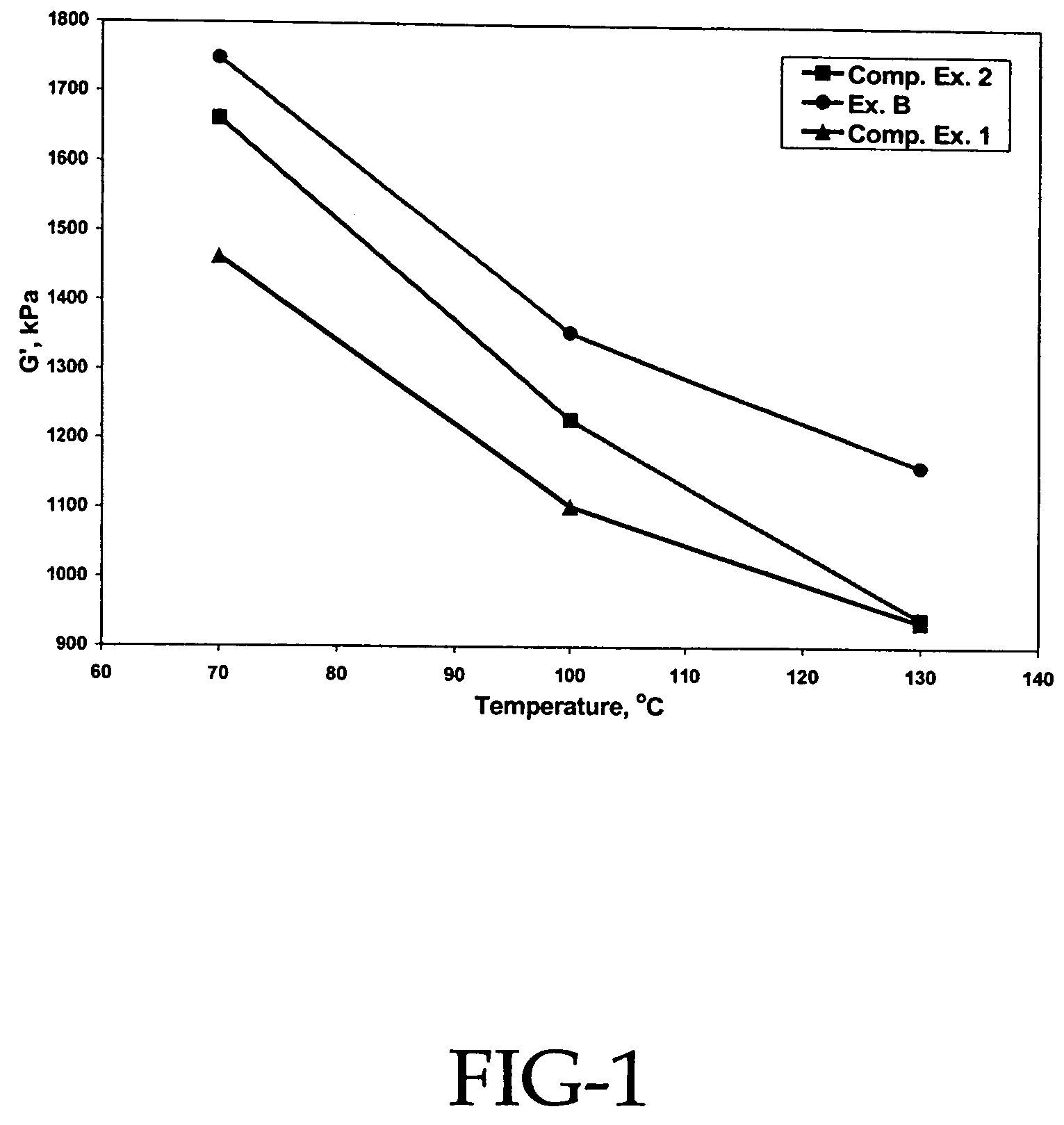

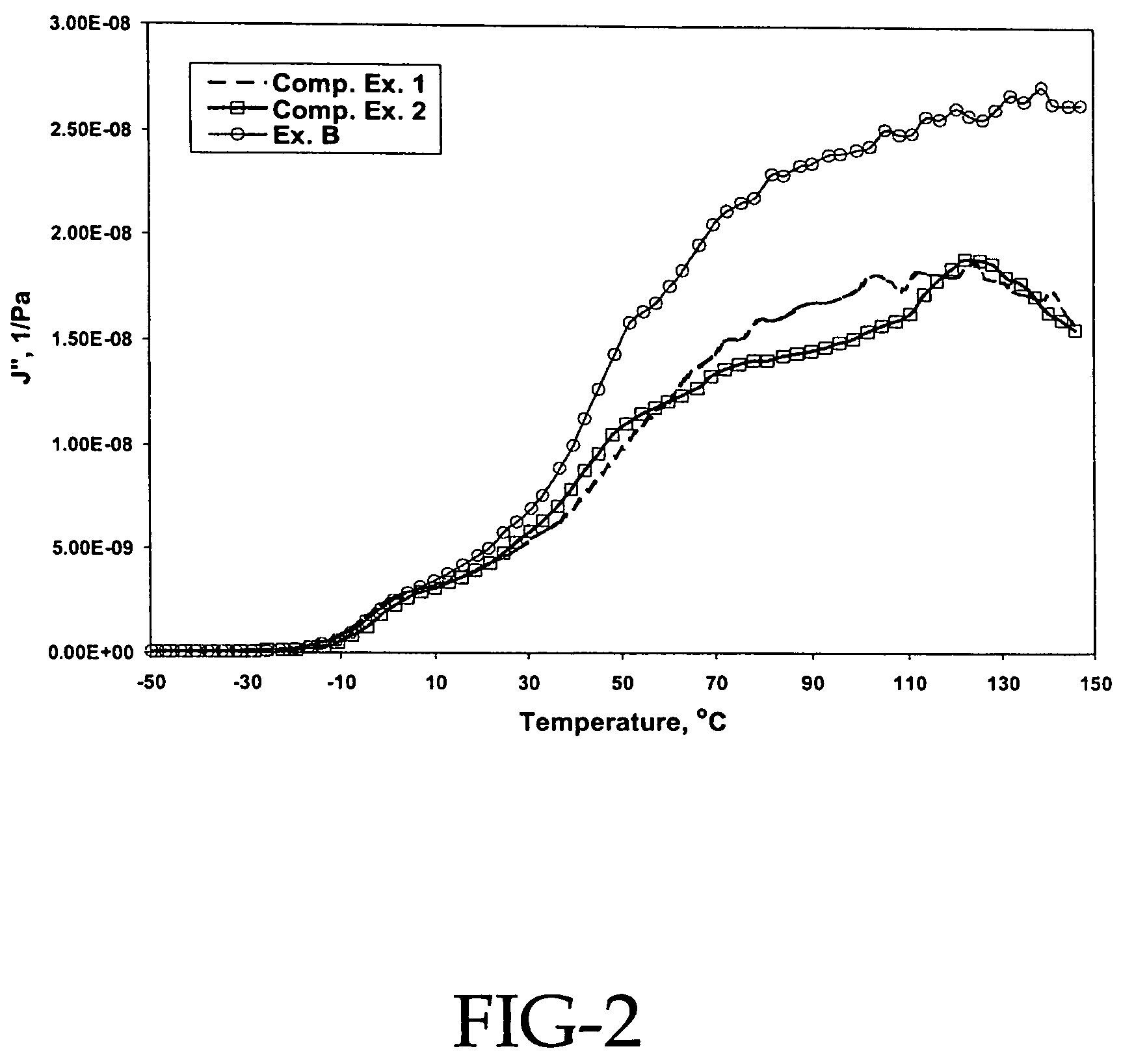

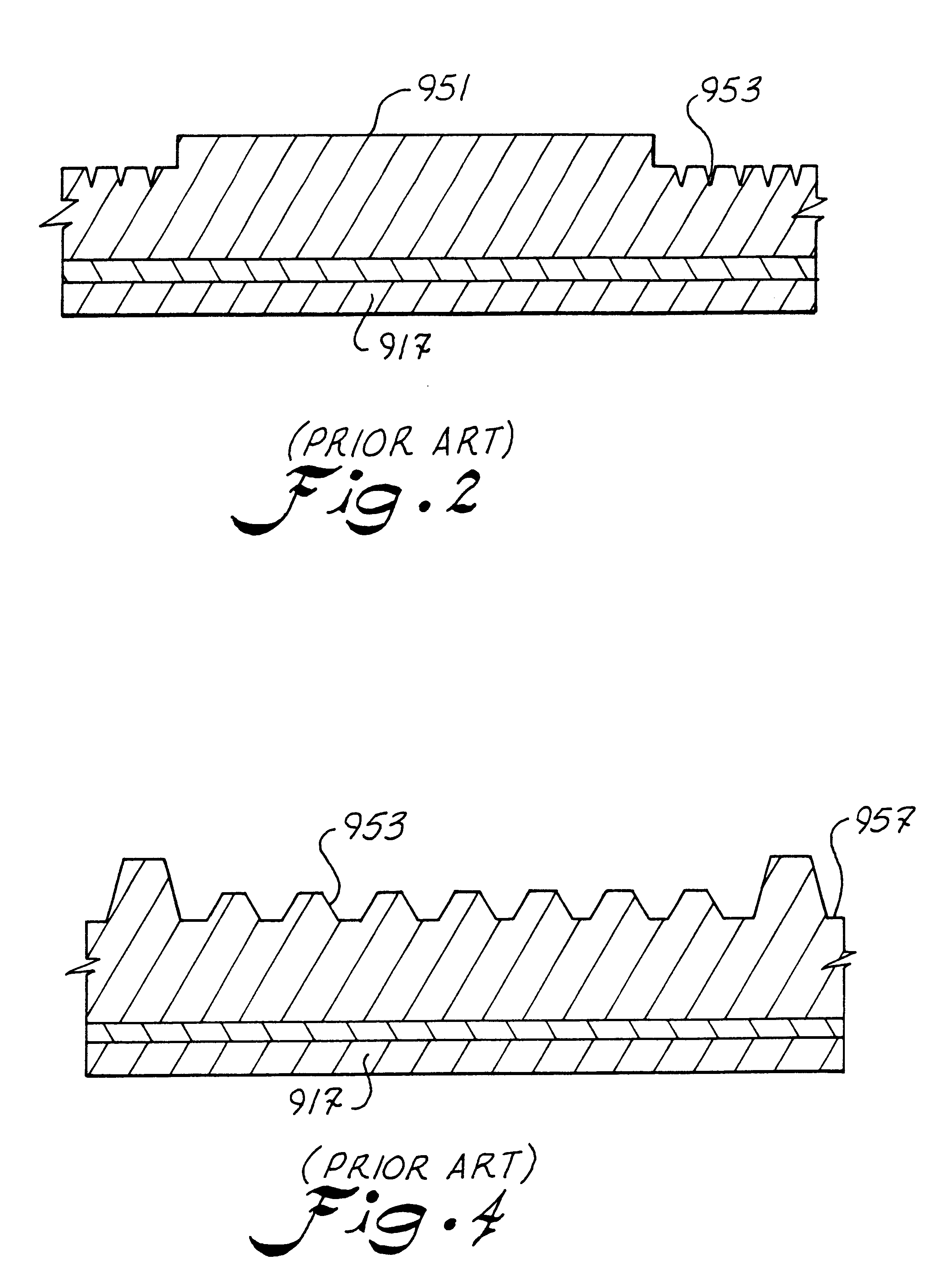

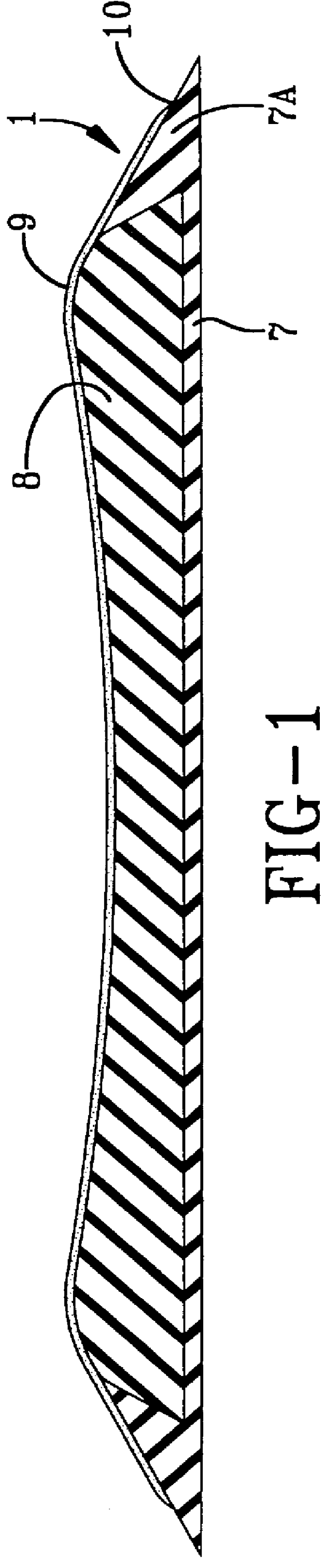

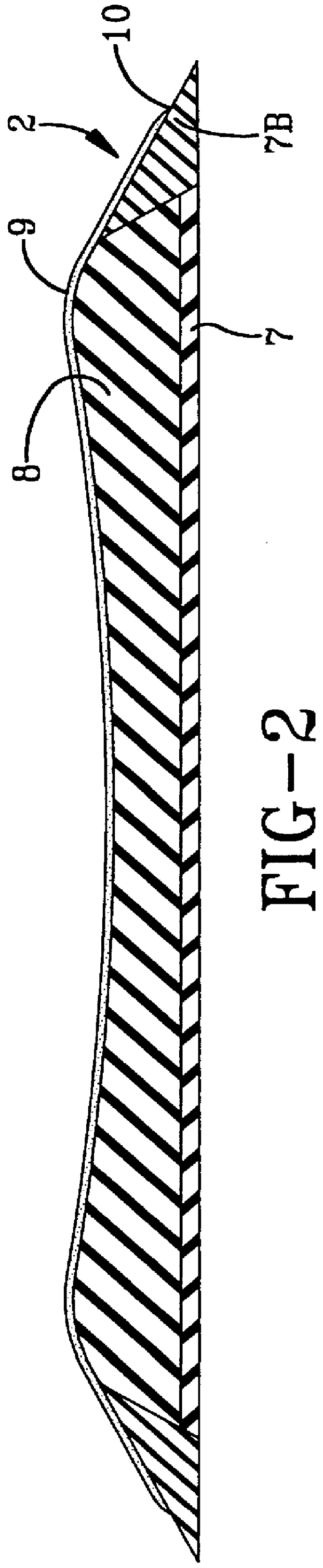

Structurally supported resilient tire and materials

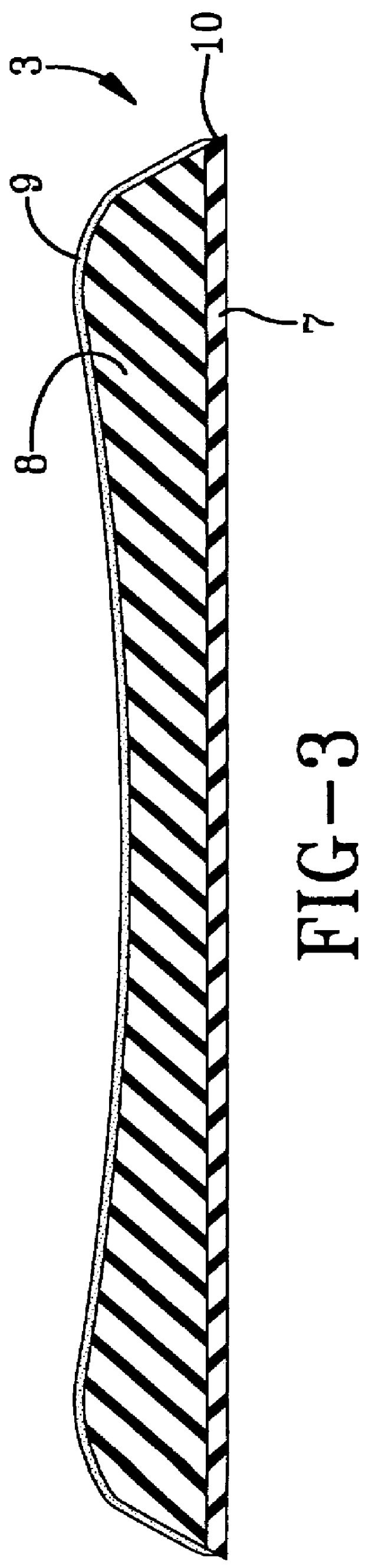

The invention comprises an improved non-pneumatic tire, and particularly a shear layer for a non-pneumatic tire wherein the shear layer comprises an elastomeric composition that includes a metal salt of a carboxylic acid. The shear layer preferably comprises a dienic elastomeric composition that includes a metal salt of a carboxylic acid. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate. In one embodiment of the invention, the metal salt of the carboxylic acid is zinc diacrylate or zinc dimethacrylate, and a peroxide curative agent is employed.

Owner:MICHELIN RECH & TECH SA

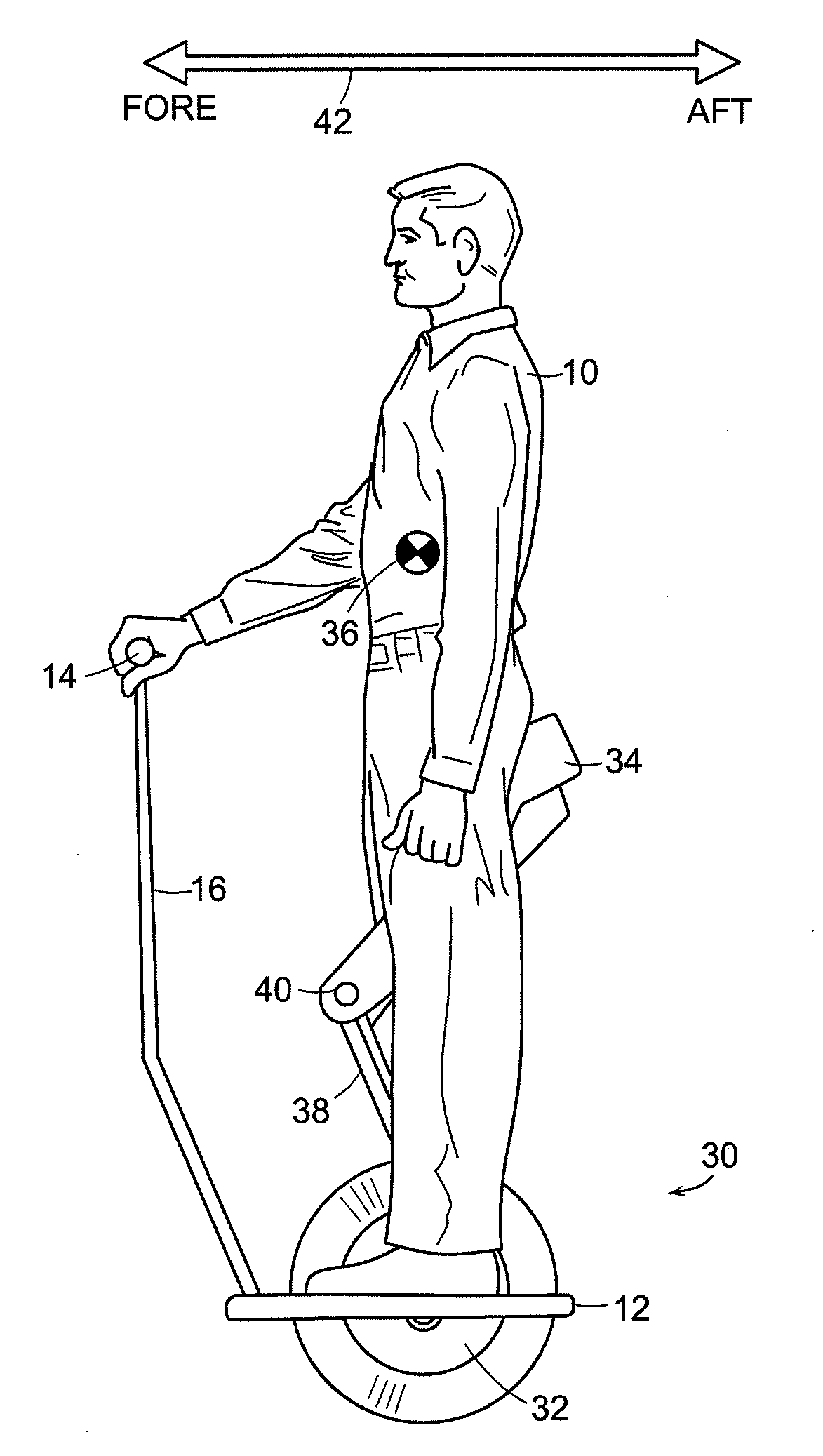

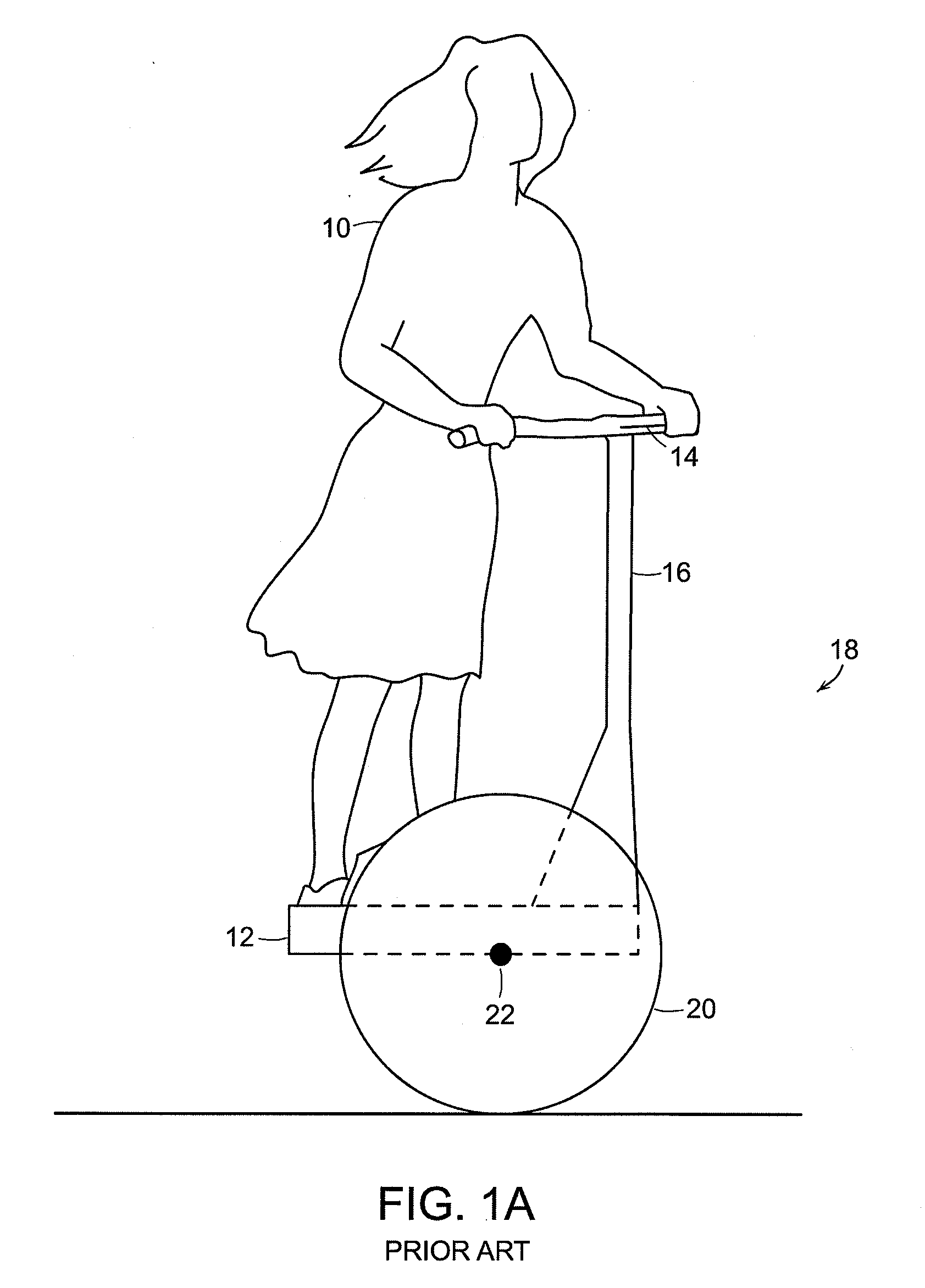

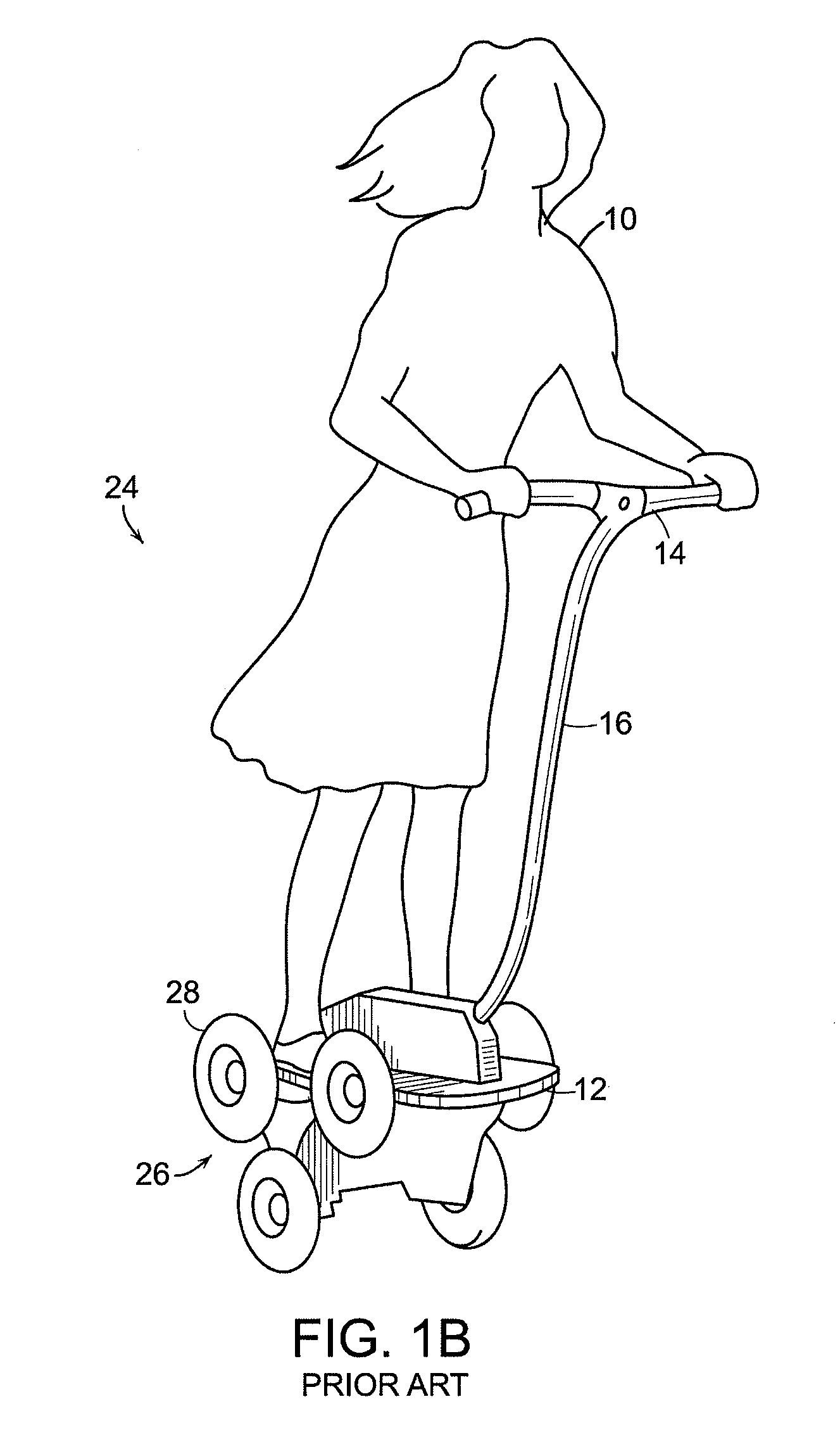

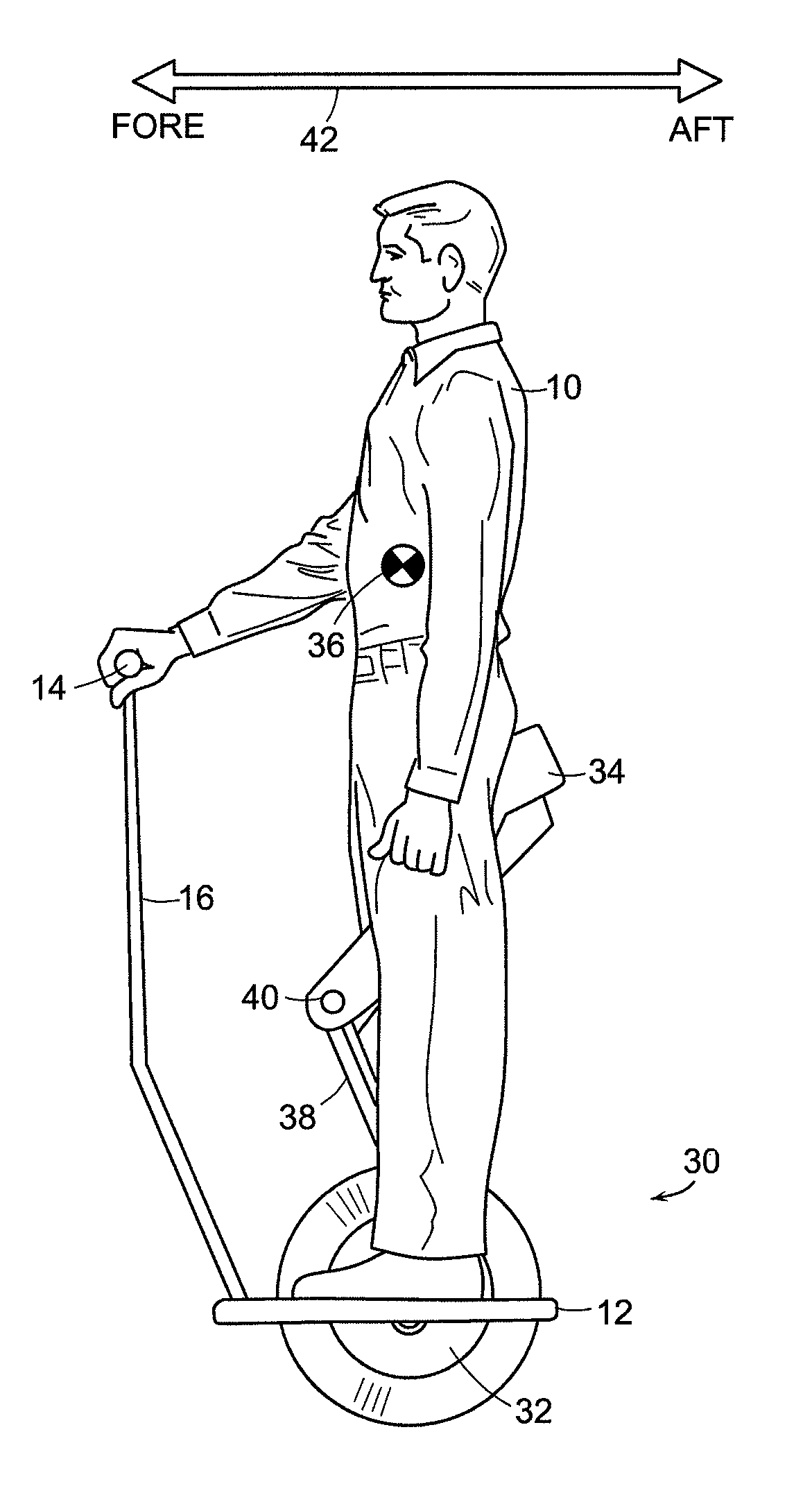

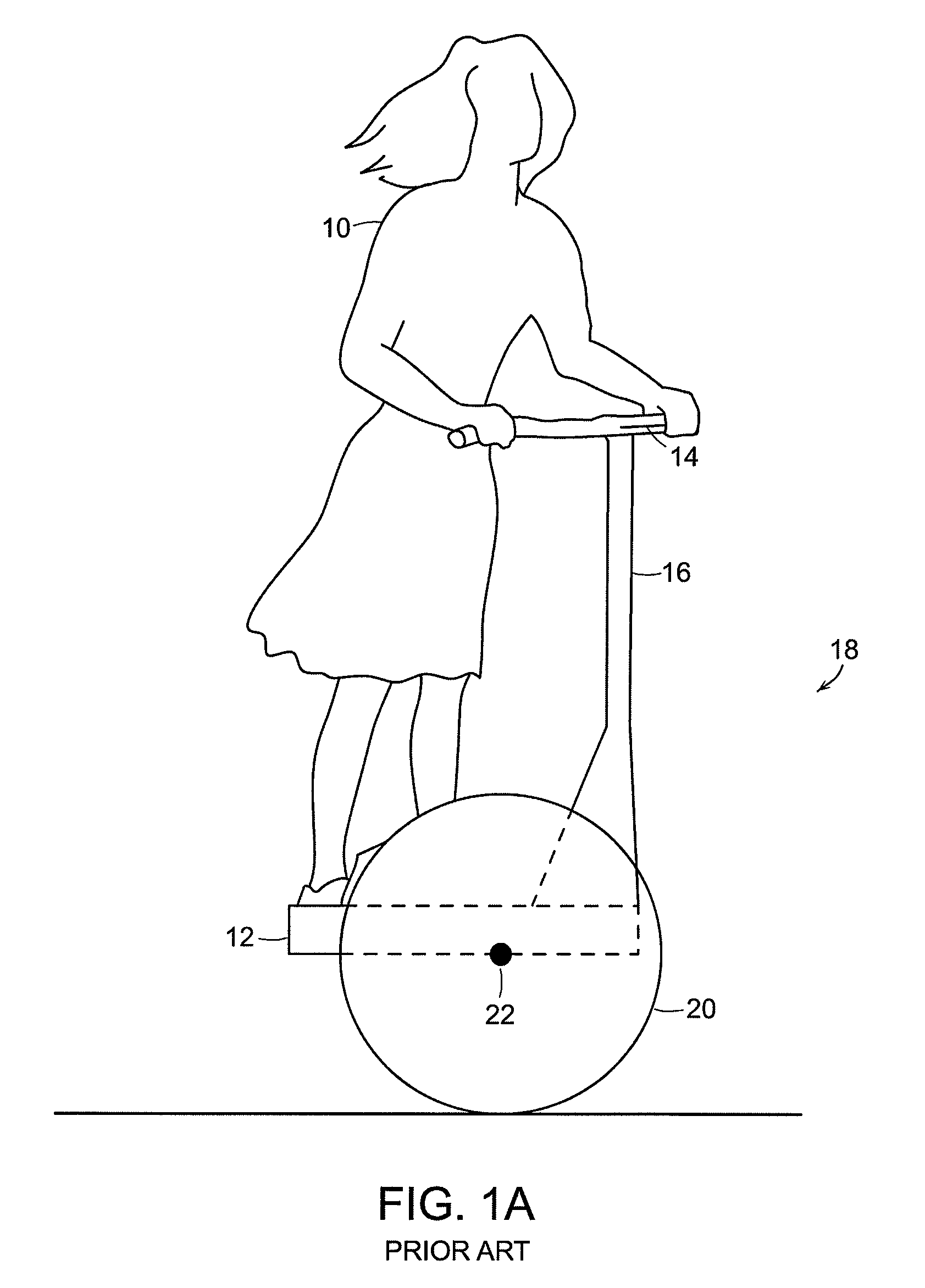

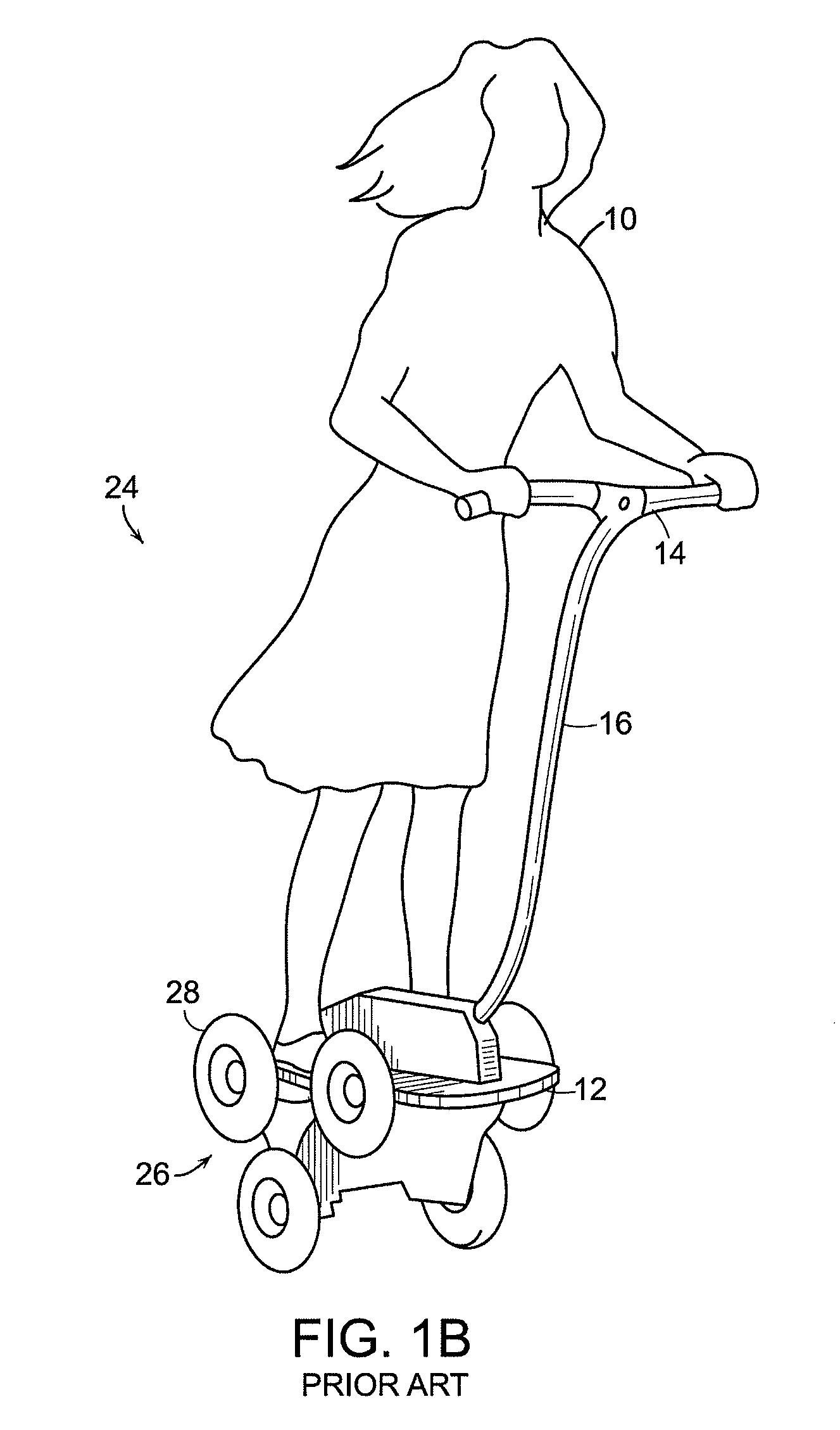

Apparatus and method for control of a vehicle

An apparatus and method for transporting a payload over a surface is provided. A vehicle supports a payload with a support partially enclosed by an enclosure. Two laterally disposed ground-contacting elements are coupled to at least one of the enclosure or support. A motorized drive is coupled to the ground-contacting elements. A controller coupled to the drive governs the operation of the drive at least in response to the position of the center of gravity of the vehicle to dynamically control balancing of the vehicle.

Owner:SEGWAY INC

Apparatus and method for control of a vehicle

Owner:SEGWAY INC

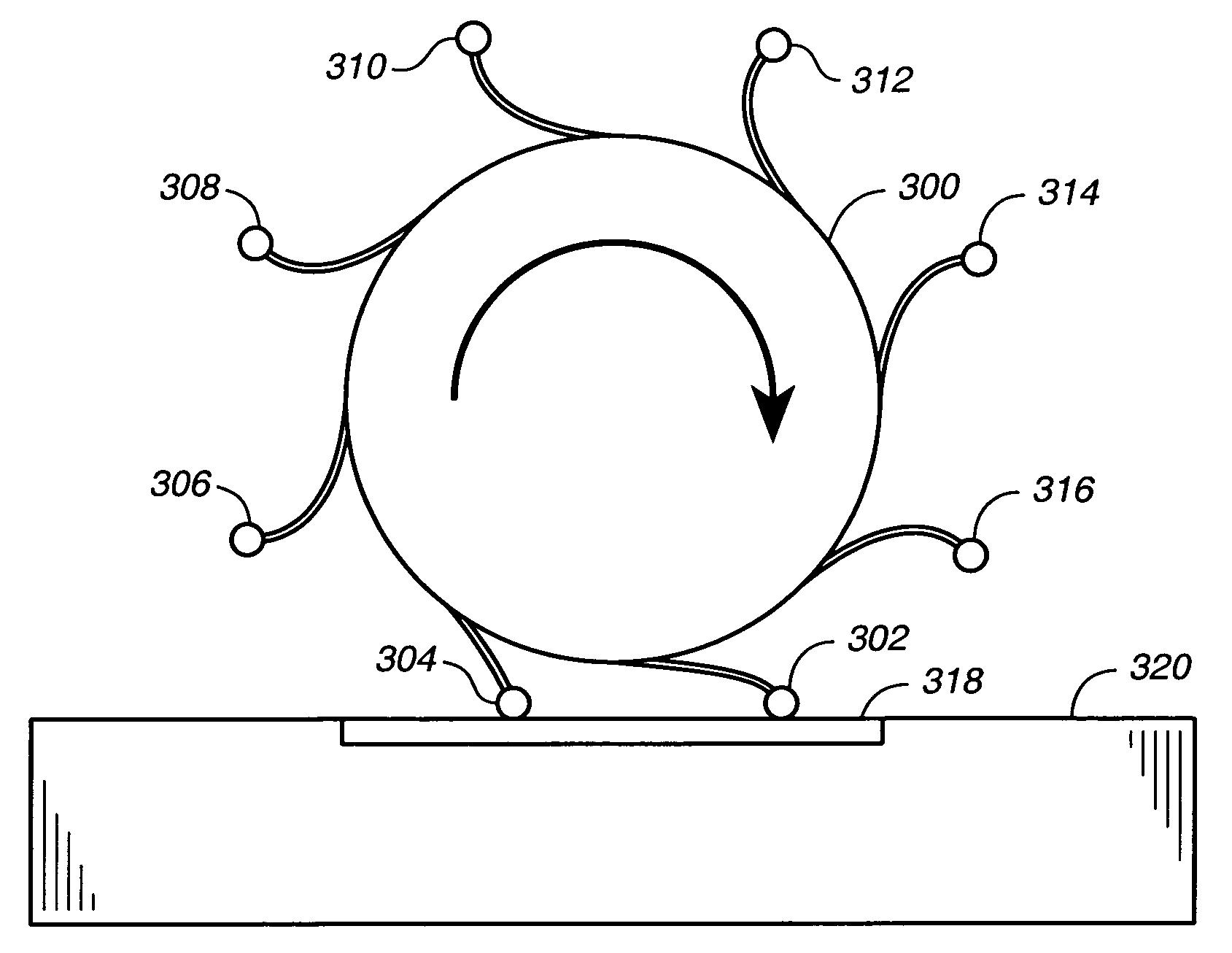

Structure having nano-fibers on annular curved surface, method of making same and method of using same to adhere to a surface

Owner:RGT UNIV OF CALIFORNIA

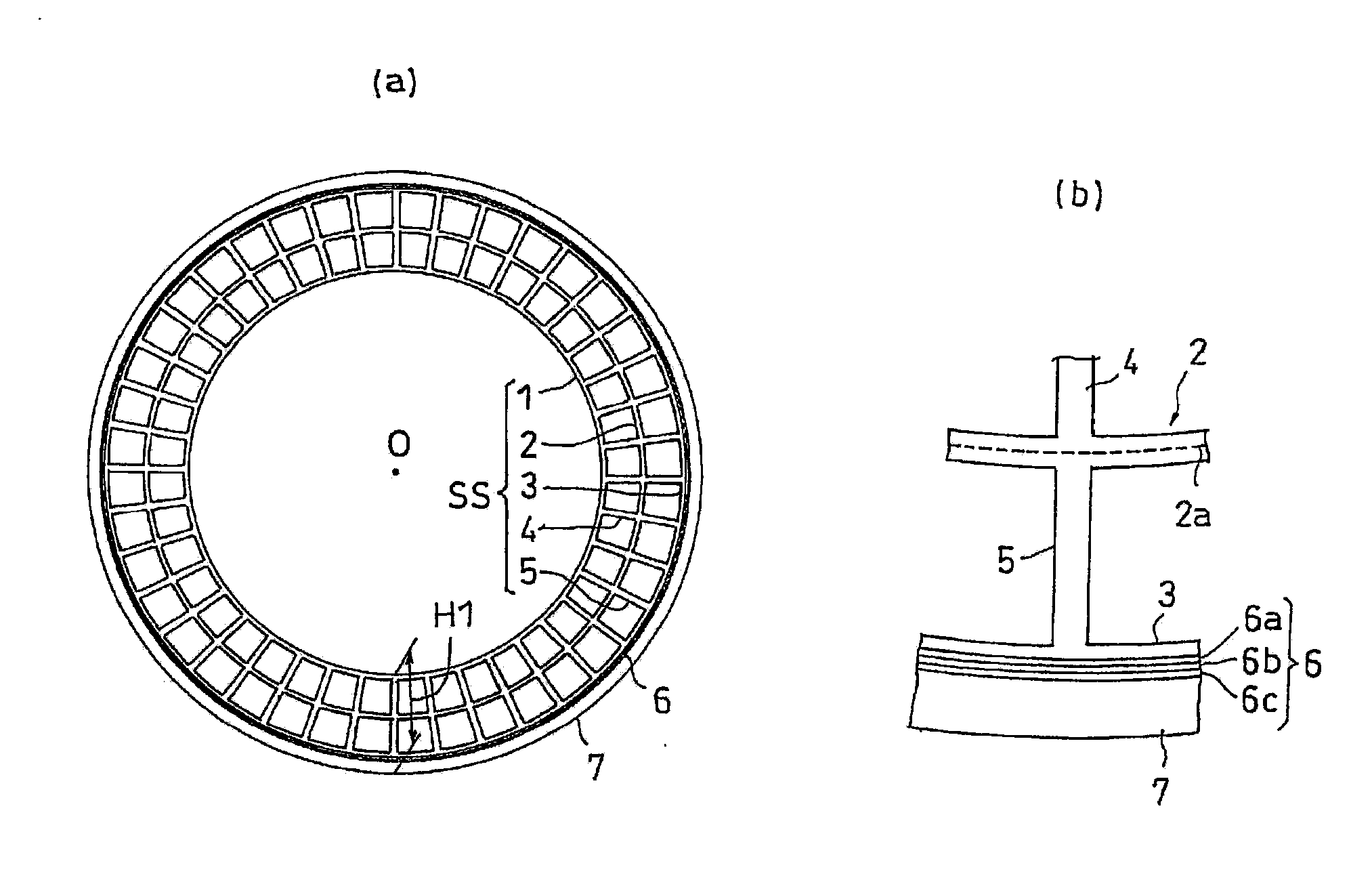

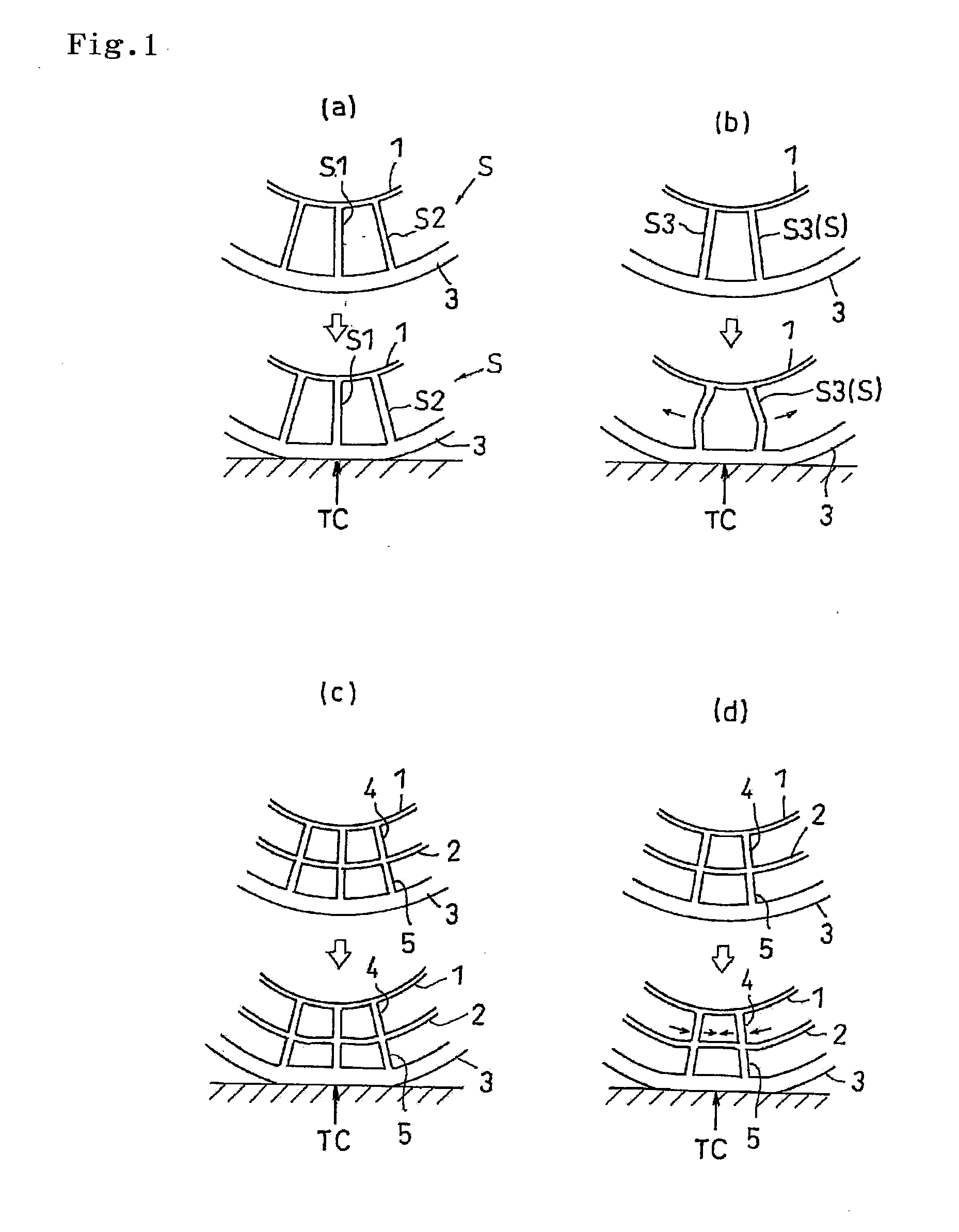

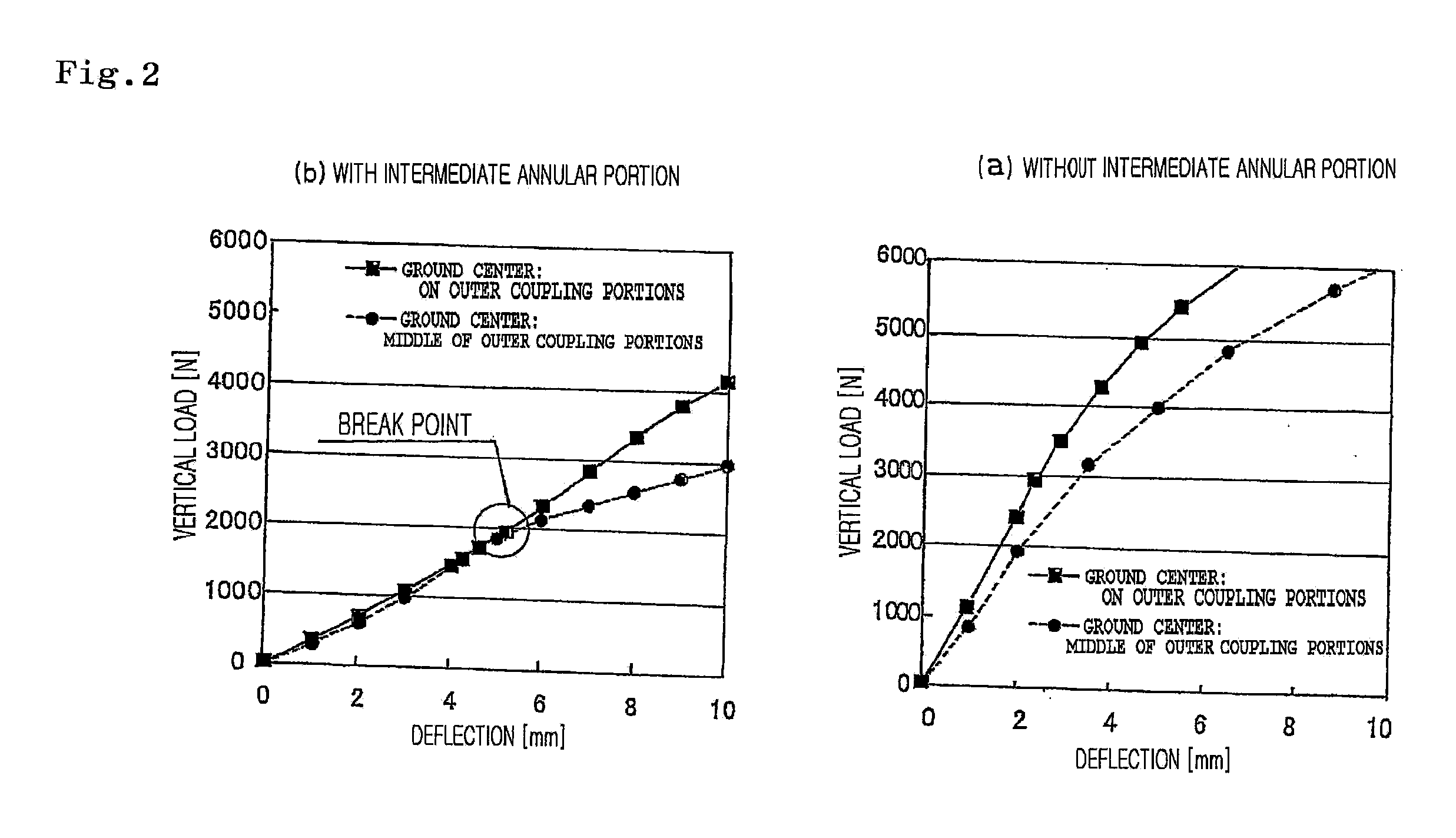

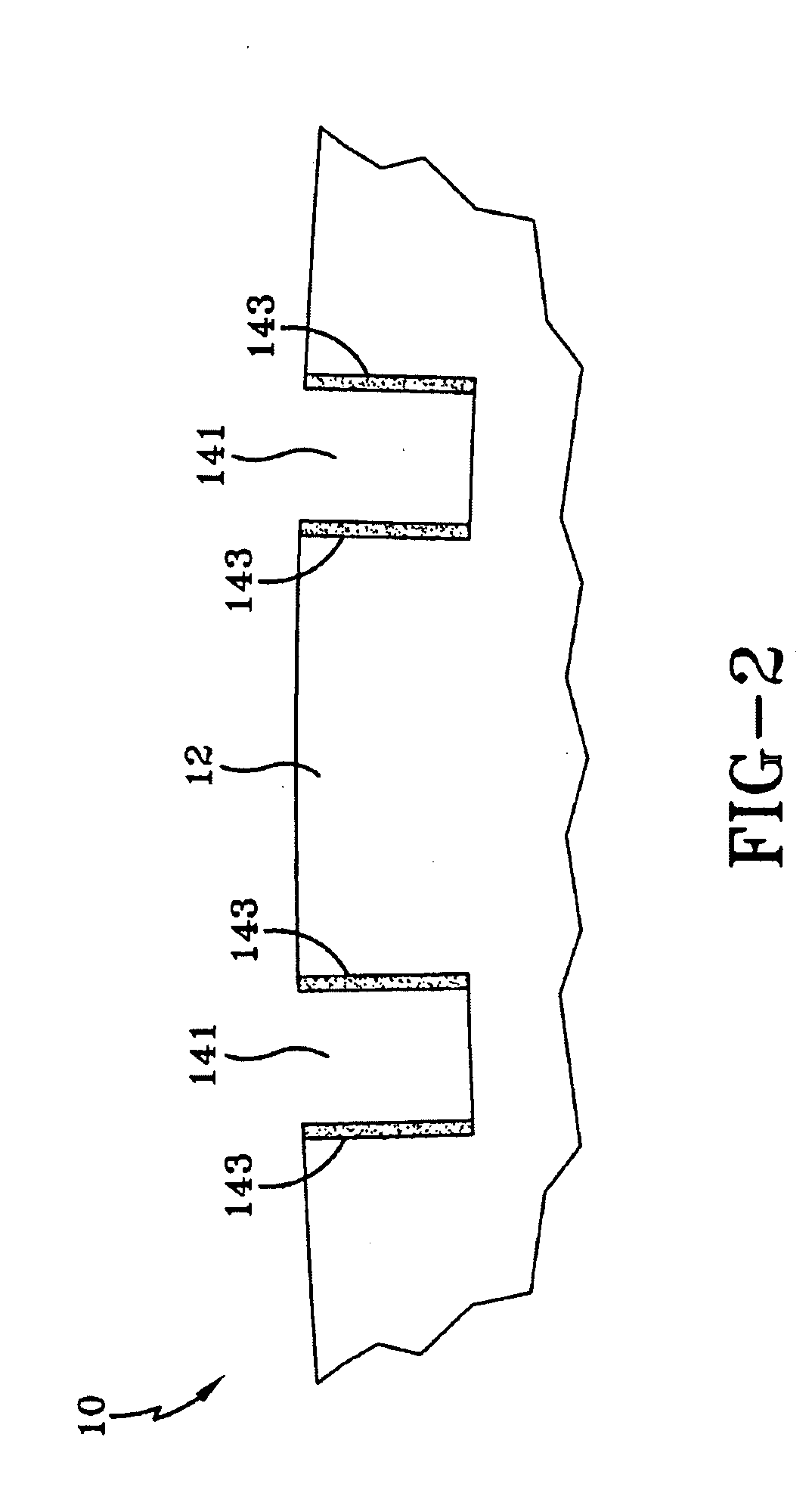

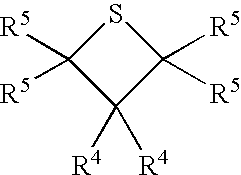

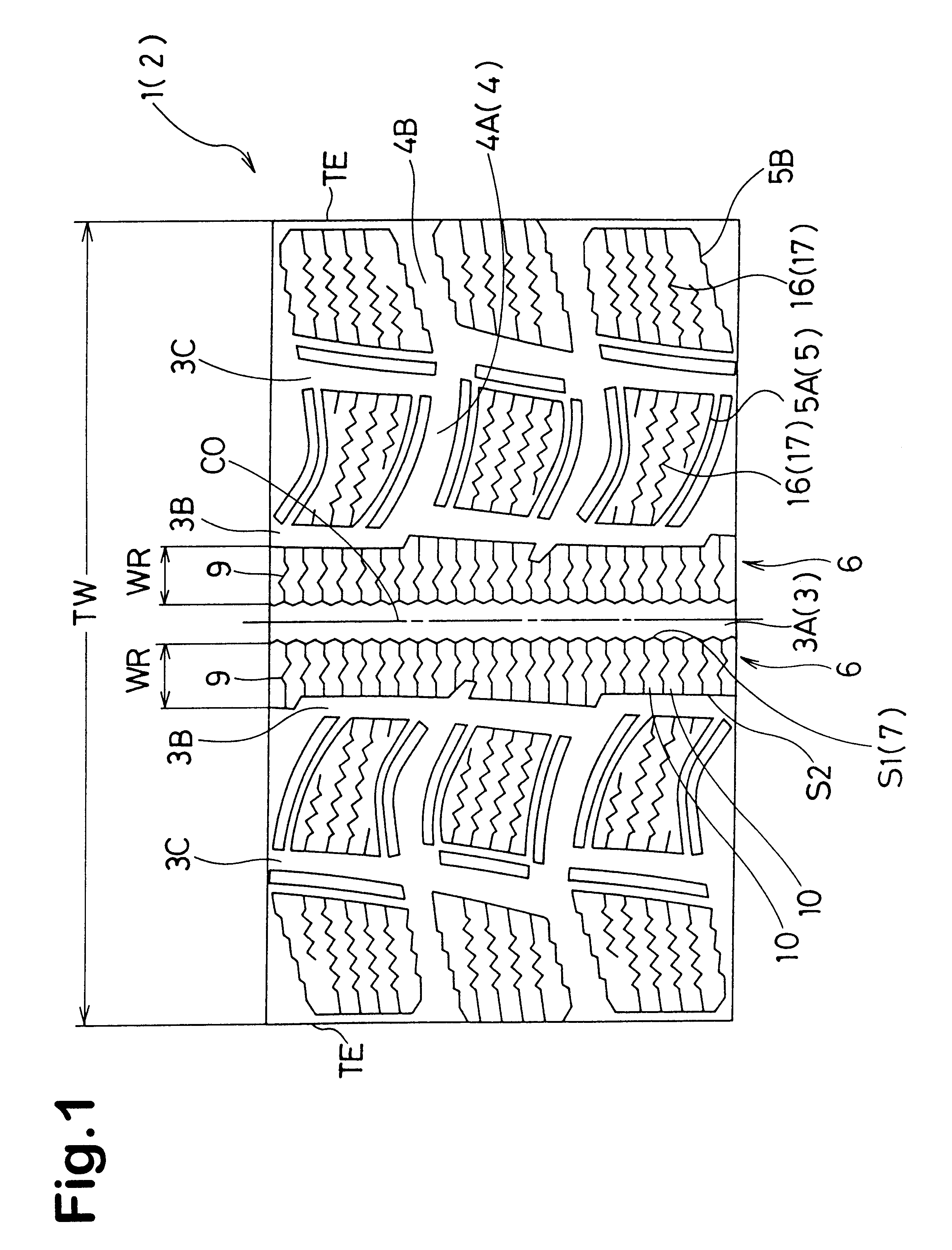

Non-pneumatic tire and its manufacturing method

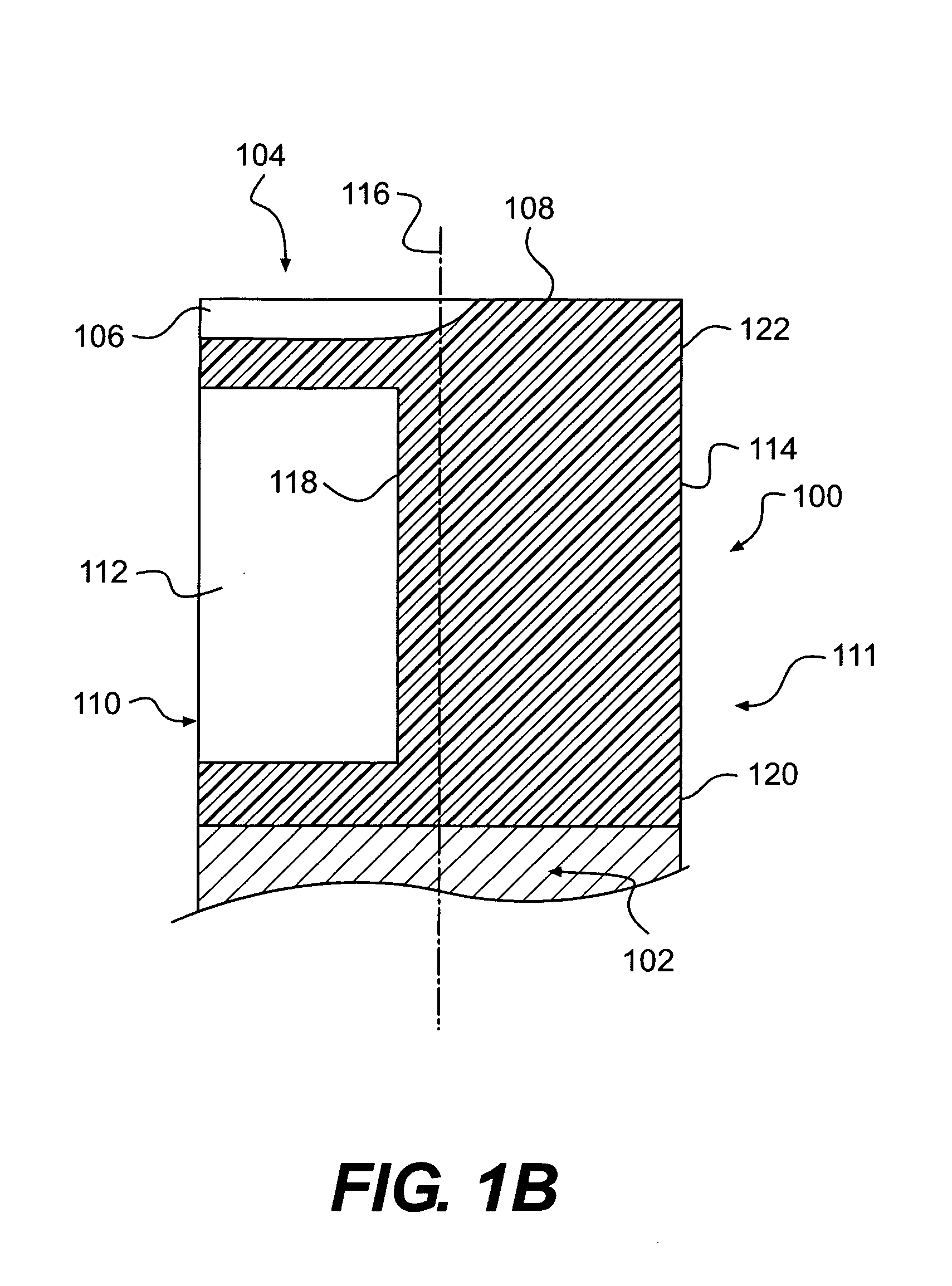

InactiveUS20100200131A1Increased durabilityRigidity fluctuation is hardNon-inflatable tyresTyresCouplingEngineering

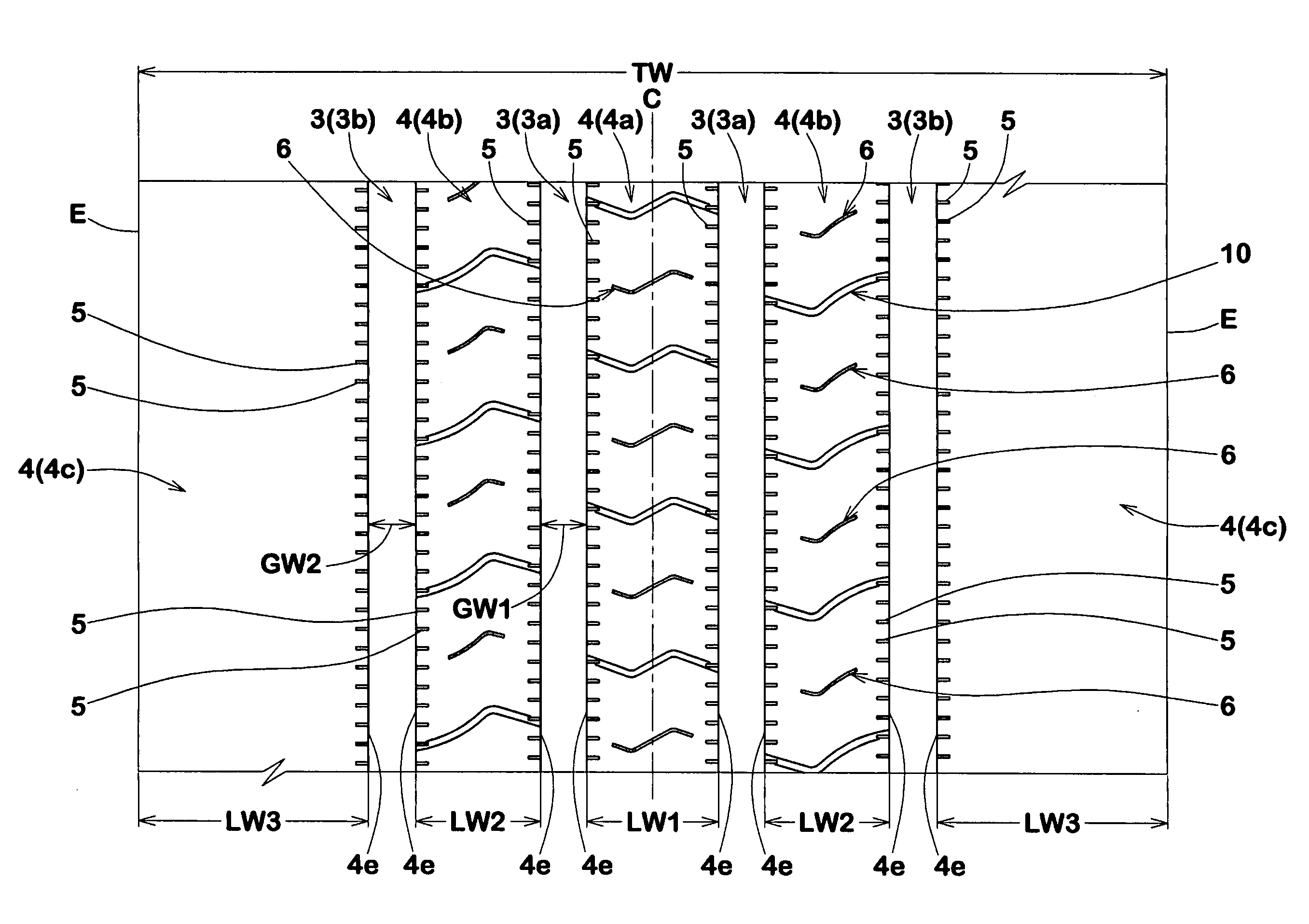

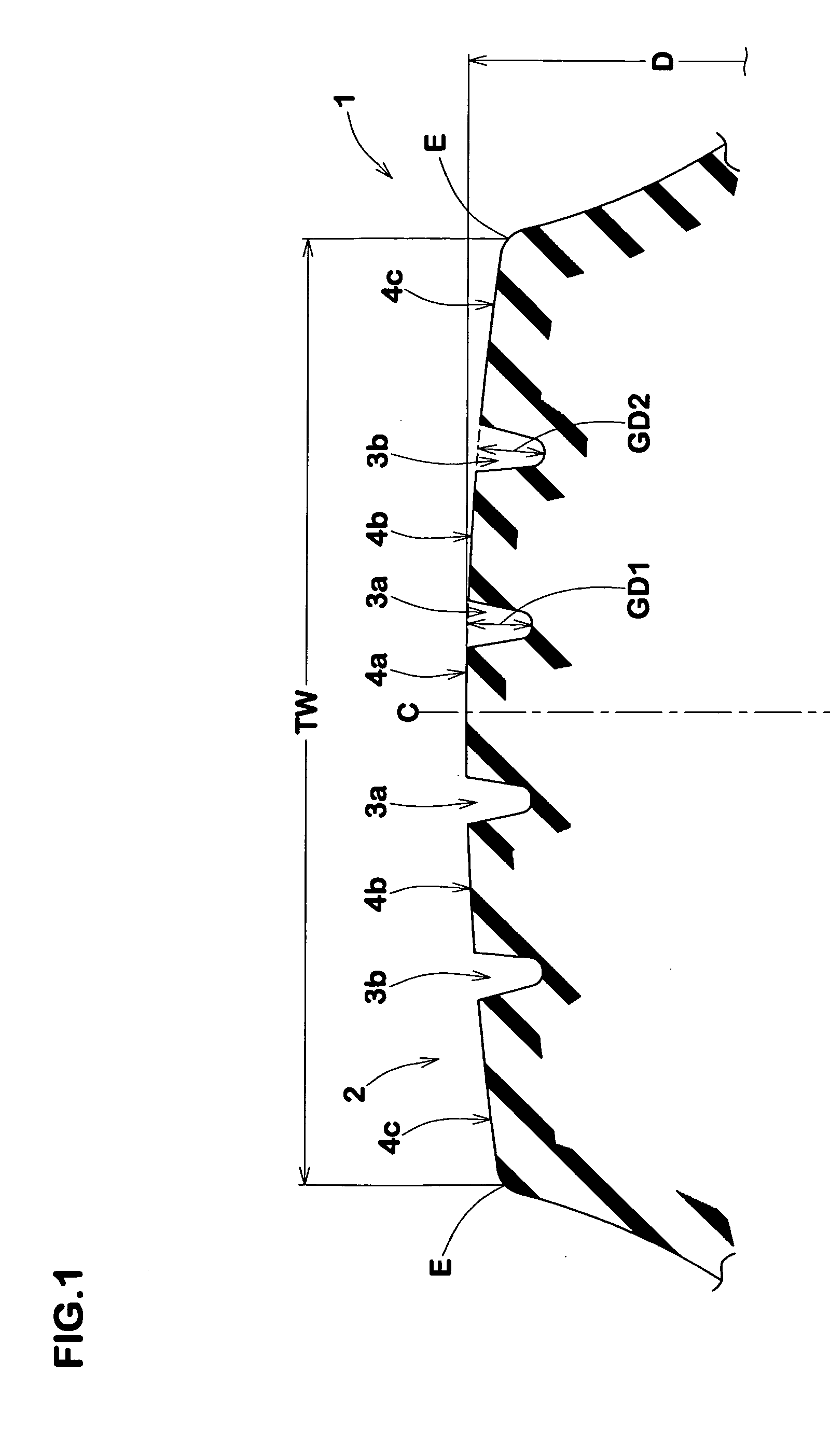

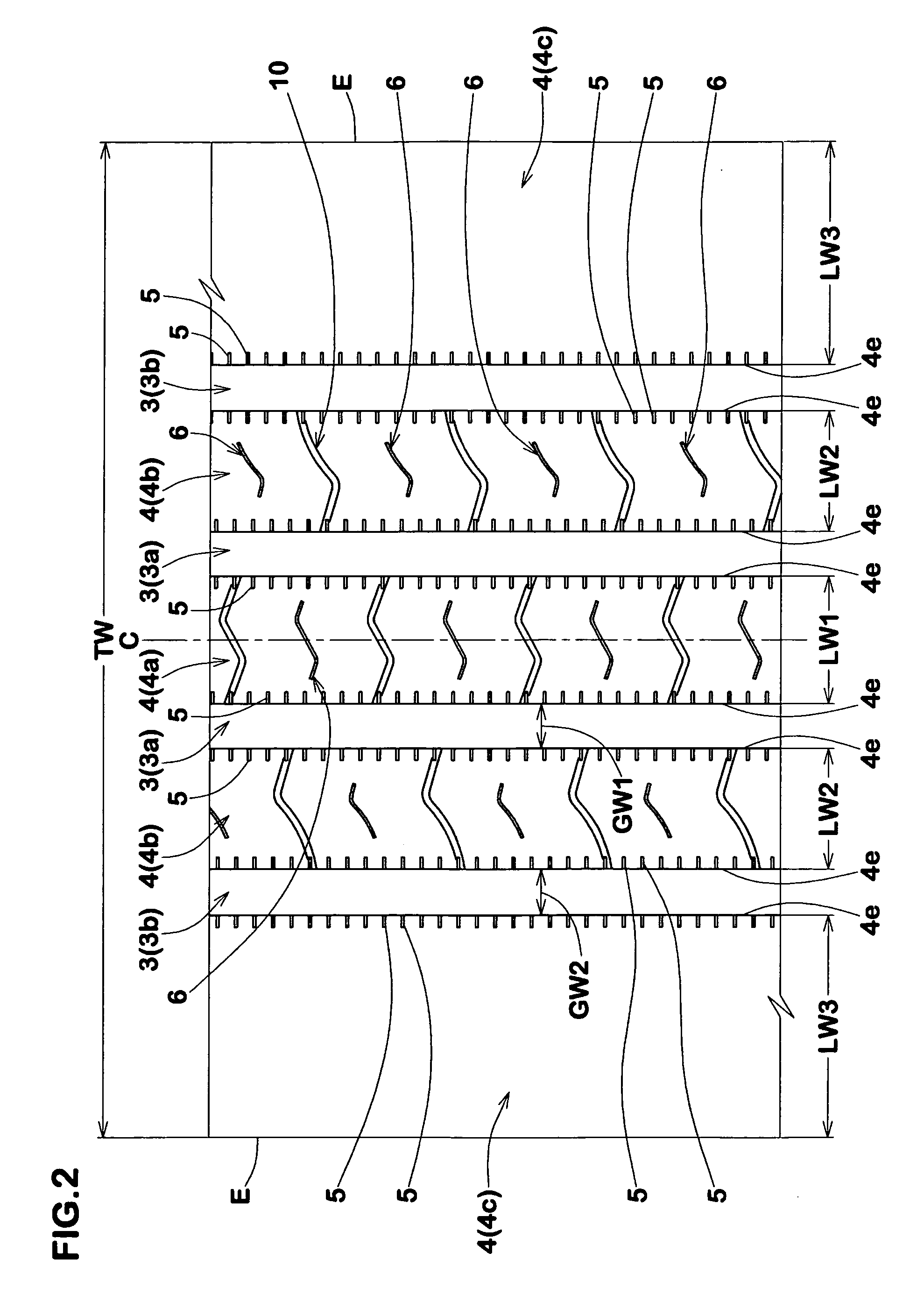

In a non-pneumatic tire having a support structure body supporting a load from a vehicle, the support structure body (SS) comprises an inner annular portion (1) an intermediate annular portion (2) provided concentrically in an outer side of the inner annular portion (1), an outer annular portion (3) provided concentrically in an outer side of the intermediate annular portion (2), a plurality of inner coupling portions (4) coupling the inner annular portion (1) and the intermediate annular portion (2) and being independent in a circumferential direction, and a plurality of outer coupling portions (5) coupling the outer annular portion (3) and the intermediate annular portion (2) and being independent in a circumferential direction.

Owner:TOYO TIRE & RUBBER CO LTD

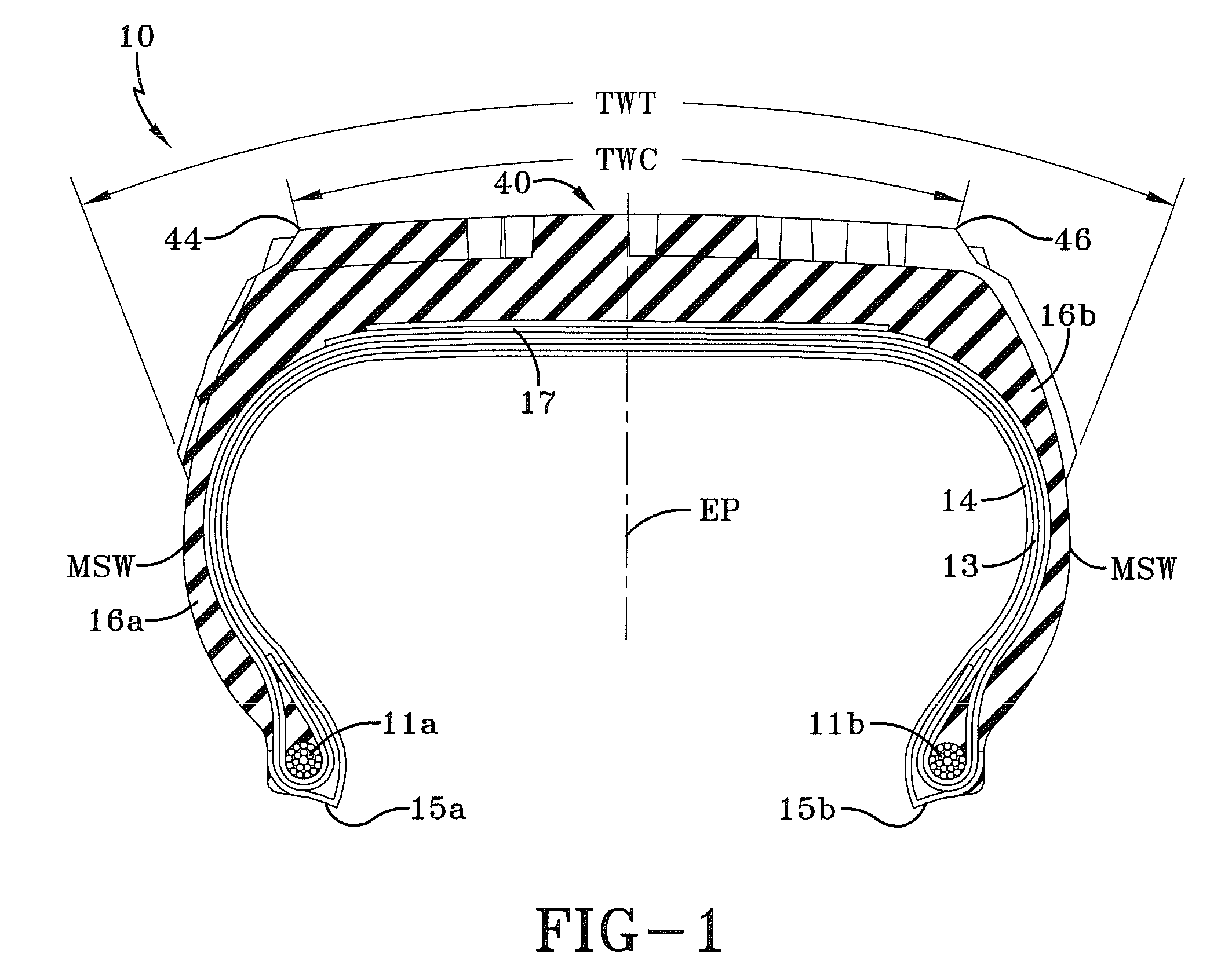

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

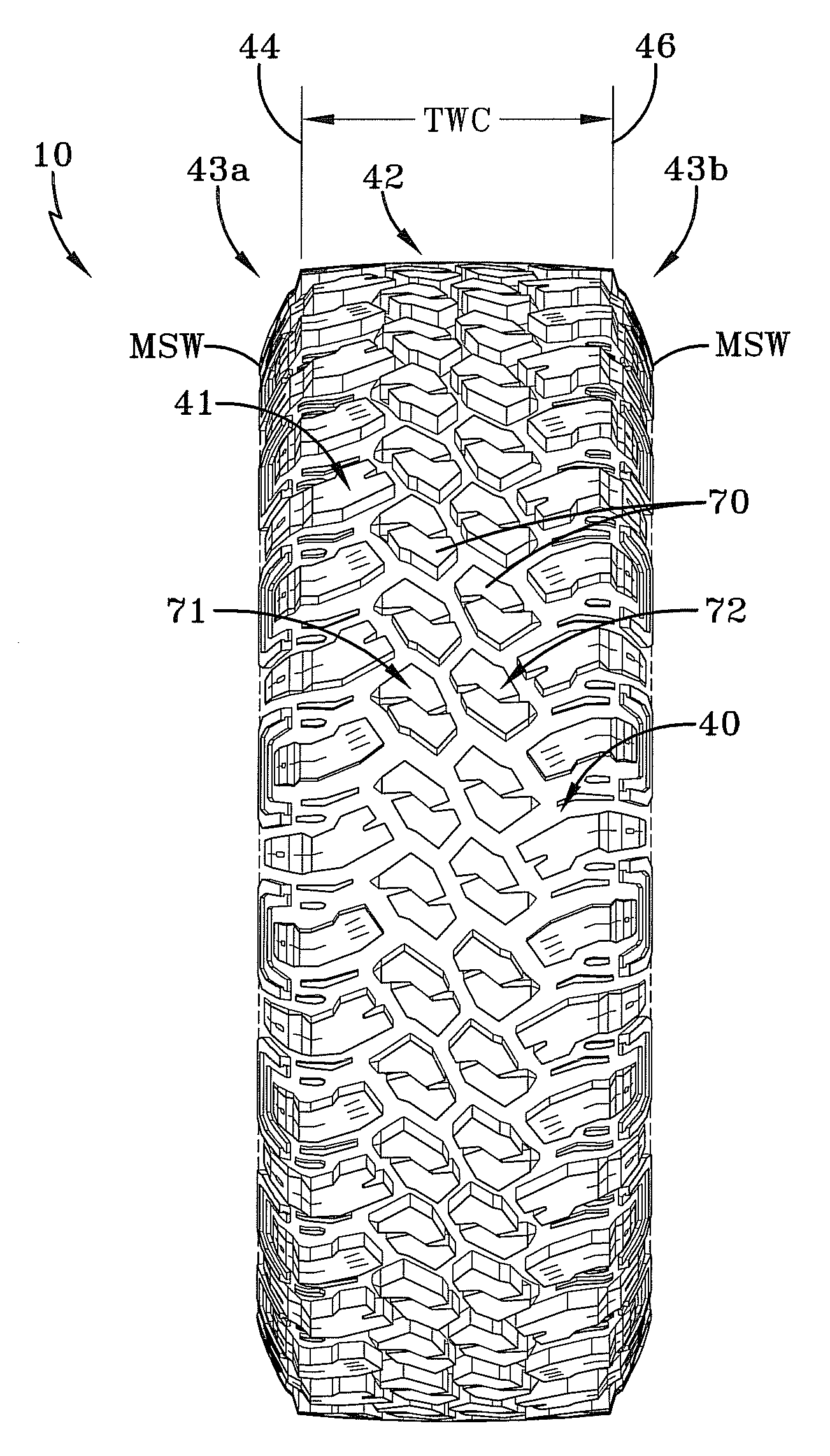

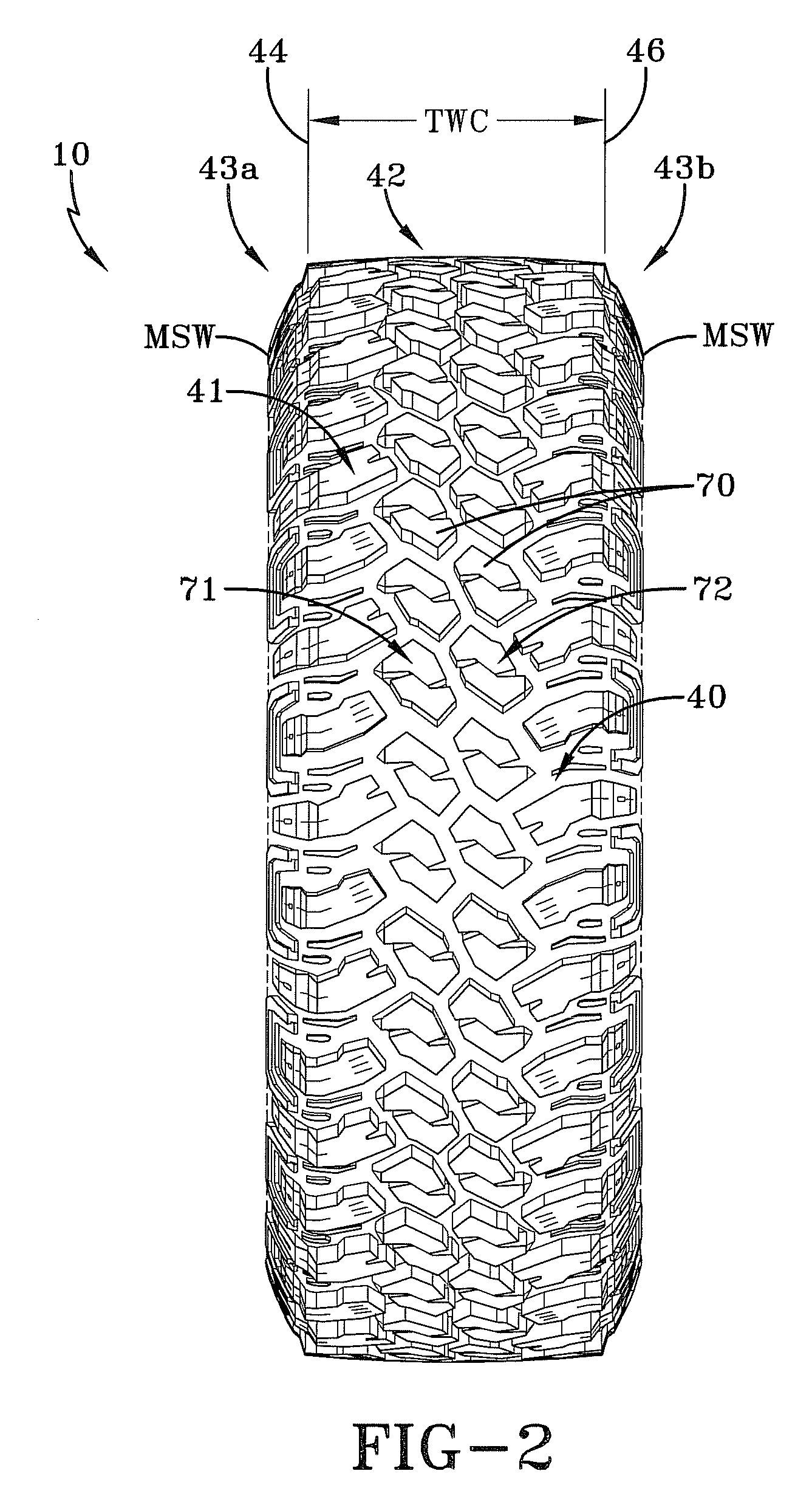

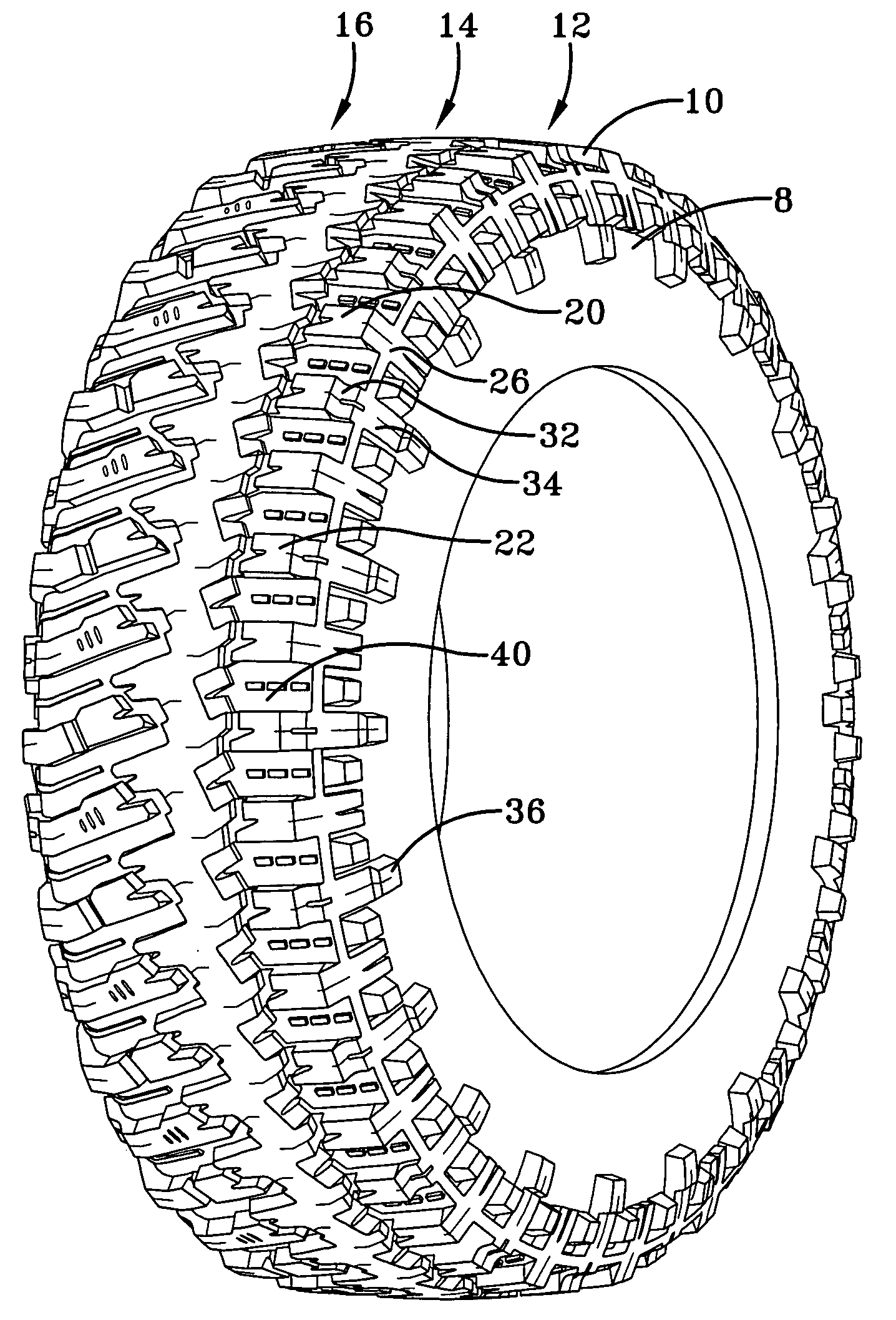

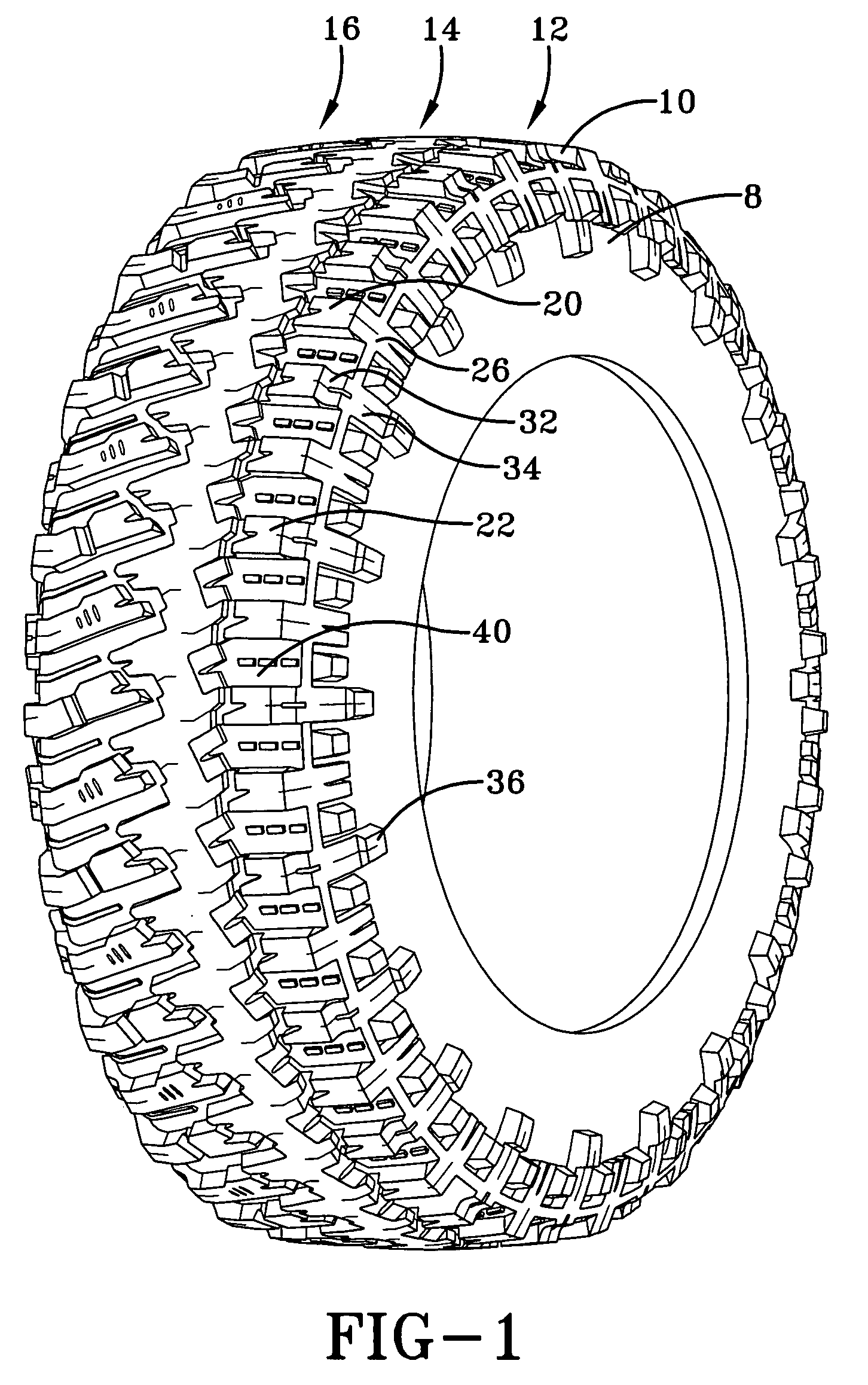

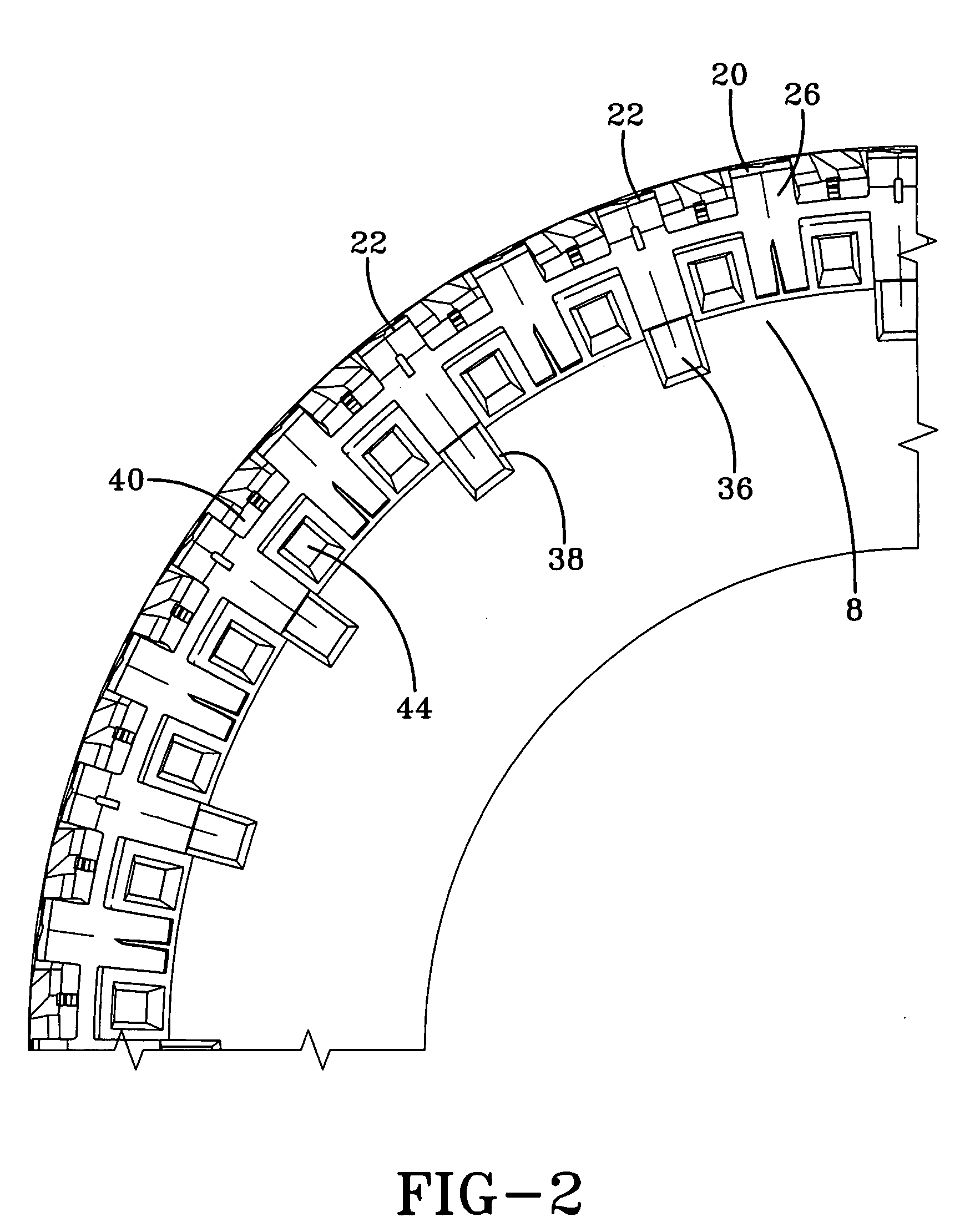

Grip tire with added puncture protection

InactiveUS20090107600A1Improve protectionWeight increaseInflatable tyresTyre tread bands/patternsTruckTread

A lightweight truck and passenger vehicle tire having an improved tread design that provides numerous biting edges for increased grip in mud, snow, loose debris, and when climbing rocks as well as providing increased protection from punctures and cuts to the tire's shoulder and upper sidewall regions.

Owner:THE GOODYEAR TIRE & RUBBER CO

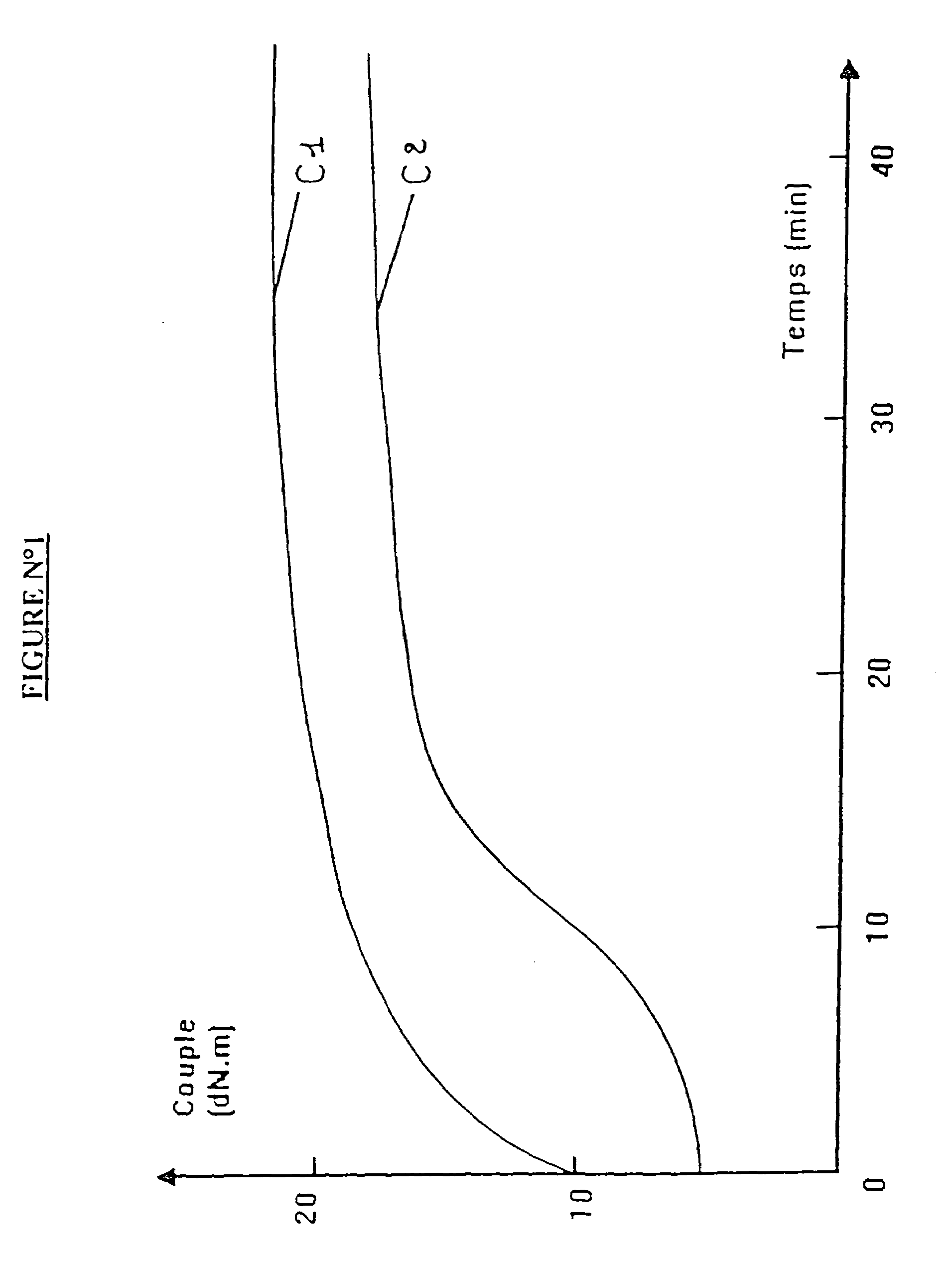

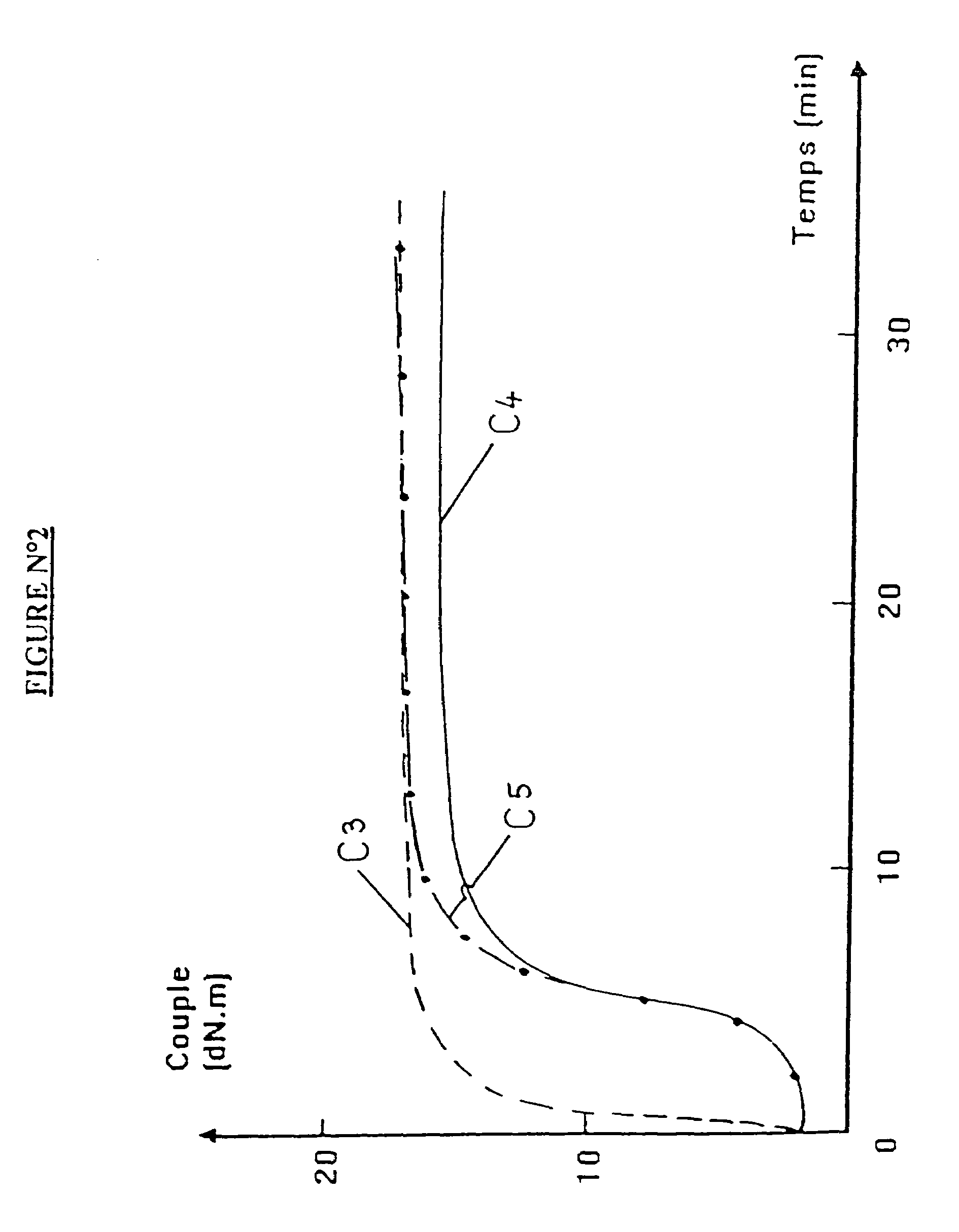

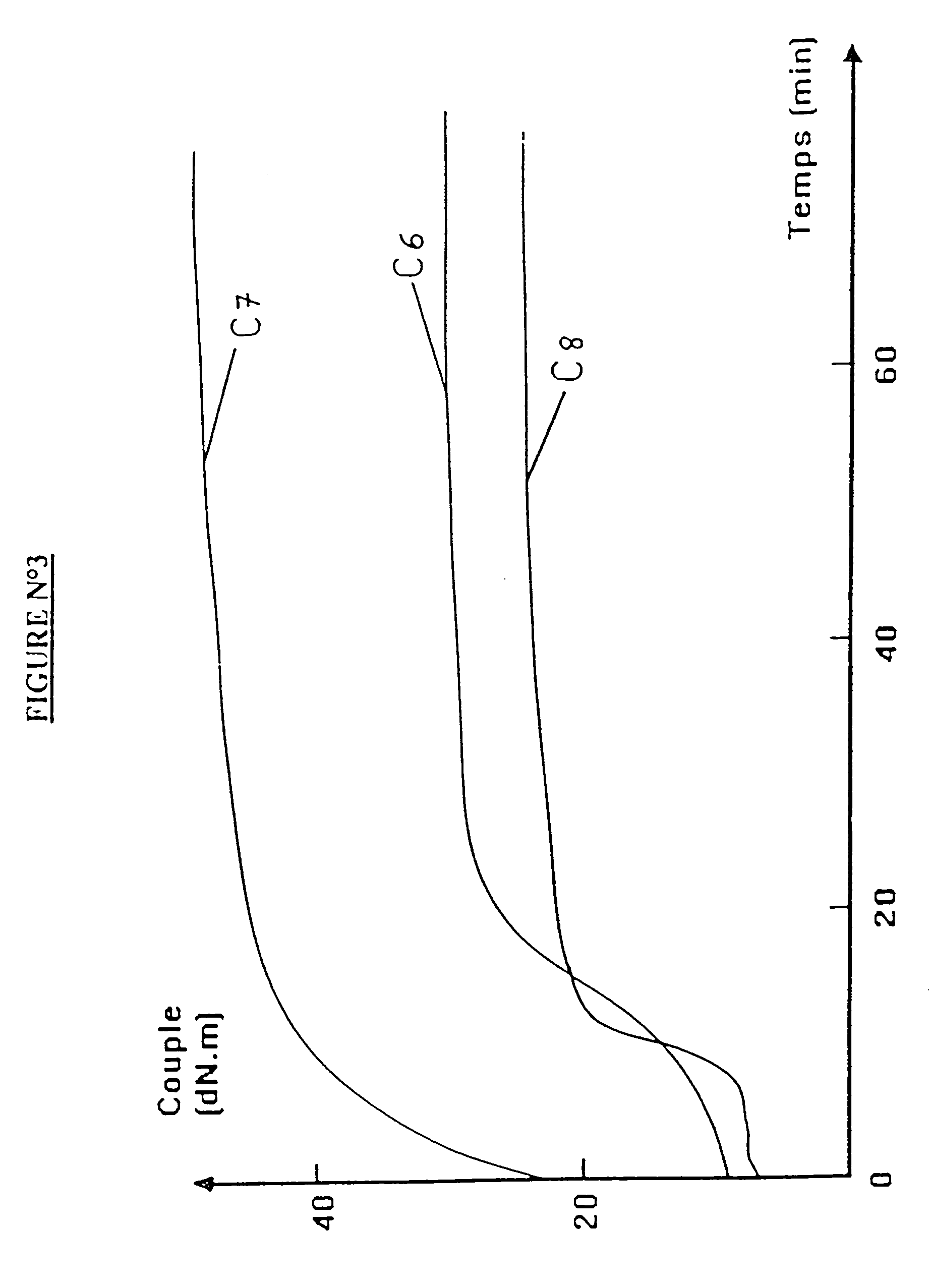

Tread for a tire having a rigidity gradient

InactiveUS7199175B2Obtained simply and economicallyAccurate gradientSpecial tyresTyre tread bands/patternsElastomerEngineering

A tire tread comprising a rubber composition based on (phr: parts by weight per hundred parts of elastomer):(i) a diene elastomer;(ii) more than 50 phr of an inorganic filler as reinforcing filler;(iii) between 2 and 15 phr of an (inorganic filler / diene elastomer) coupling agent;(iv) between 1 and 10 phr of a methylene acceptor, and(v) between 0.5 and 5 phr of a methylene donor.This tread has, after mechanical running-in of the tire for which it is intended (“auto-accommodation”), a rigidity gradient which increases radially from the surface towards the inside of the tread. Use of such a tread for the manufacturing or recapping of tires. Tires comprising a tread according to the invention, in particular of the snow or ice type (“winter” tires).

Owner:MICHELIN RECH & TECH SA

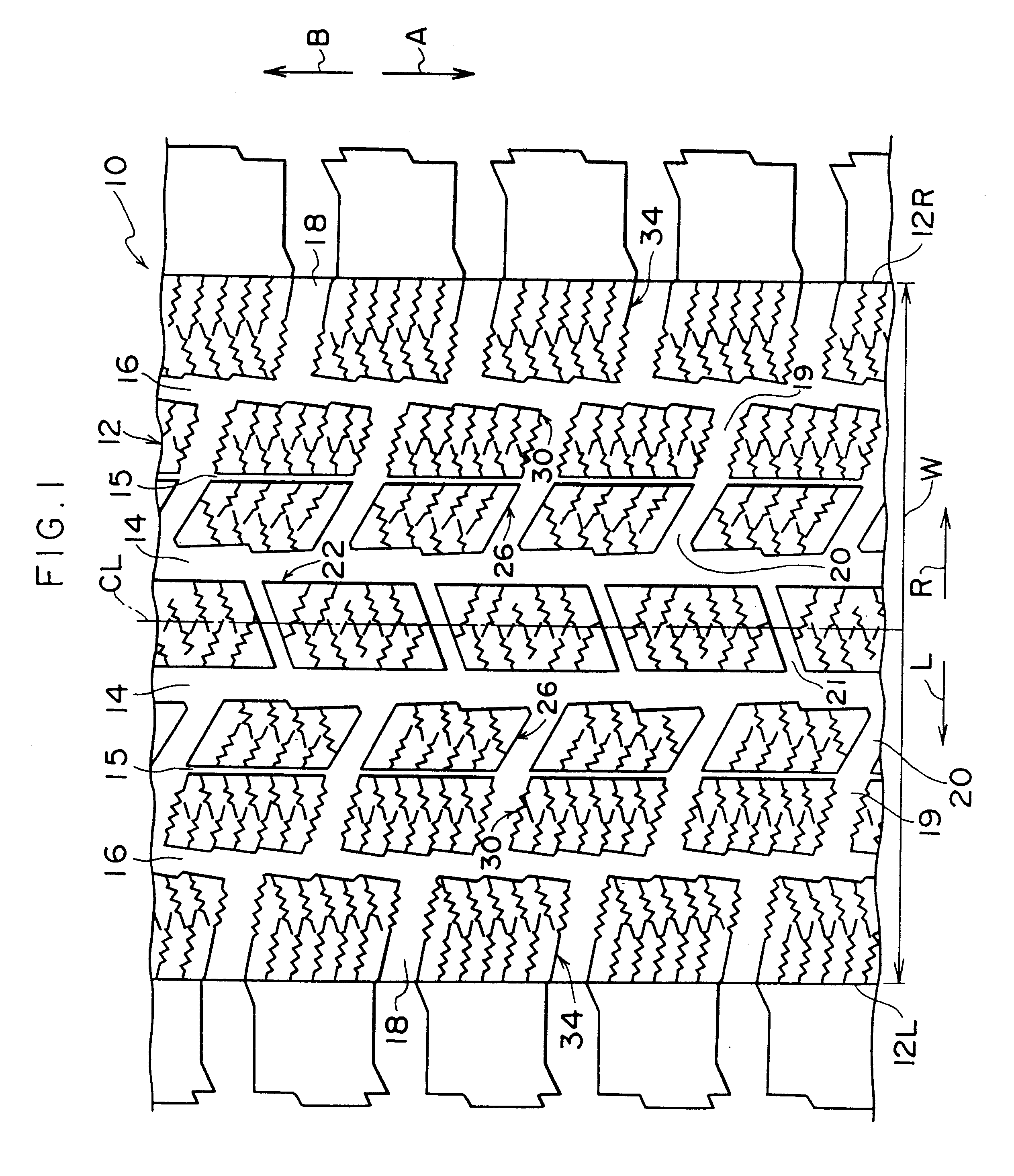

Non-pneumatic tire

A non-pneumatic tire comprising side cavities that are staggered with respect to laterally opposing side cavities, and laterally extending tread grooves that are in substantial radial alignment with the cavities. In another embodiment, the invention is to a tire comprising side ribs that are staggered with respect to laterally opposing side ribs, and laterally extending tread grooves that are substantially offset relative to the side ribs. Also provided are processes for making such tires and to off-the-road (OTR) vehicles employing such tires.

Owner:LANXESS SOLUTIONS US INC

Pneumatic tire

The invention is directed to a pneumatic tire having a tread including a vulcanizable rubber composition including, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 60 to 95 phr of solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 30 percent by weight, a vinyl 1,2 content of from 50 to 70 percent by weight based on the butadiene content, and a Tg of from about −40° C. to about −20° C.;(B) 5 to 15 phr of cis-1,4 polybutadiene having a Tg of from −95° C. to −105° C.;(C) 10 to 20 phr of 3,4-polyisoprene;(D) 30 to 70 phr of processing oil;(E) 10 to 30 phr of carbon black having an Iodine absorption ranging from 192 to 212 g / kg according to ASTM D-1510 and an oil absorption ranging from 126 to 142 cc / 100 g according to ASTM D-2414;(F) 90 to 110 phr of silica;(G) 0.5 to 20 phr of a sulfur containing organosilicon compound; and(H) 10 to 20 phr of resin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Tire tread with groove reinforcement

A tire has an axis of rotation. The tire includes two sidewalls extending radially outward and a tread disposed radially outward of the two sidewalls and interconnecting the two sidewalls. The tread includes a main portion comprising a first compound and a reinforcing structure comprising a second compound having reinforcing short fibers oriented between −20 degrees to +20 degrees to a circumferential direction of the tread. The main portion of the tread includes at least one circumferential groove separating circumferential ribs. Each circumferential groove has two sides and a base therebetween. The reinforcing structure includes a layer of the second compound secured to the sides of each circumferential groove.

Owner:THE GOODYEAR TIRE & RUBBER CO

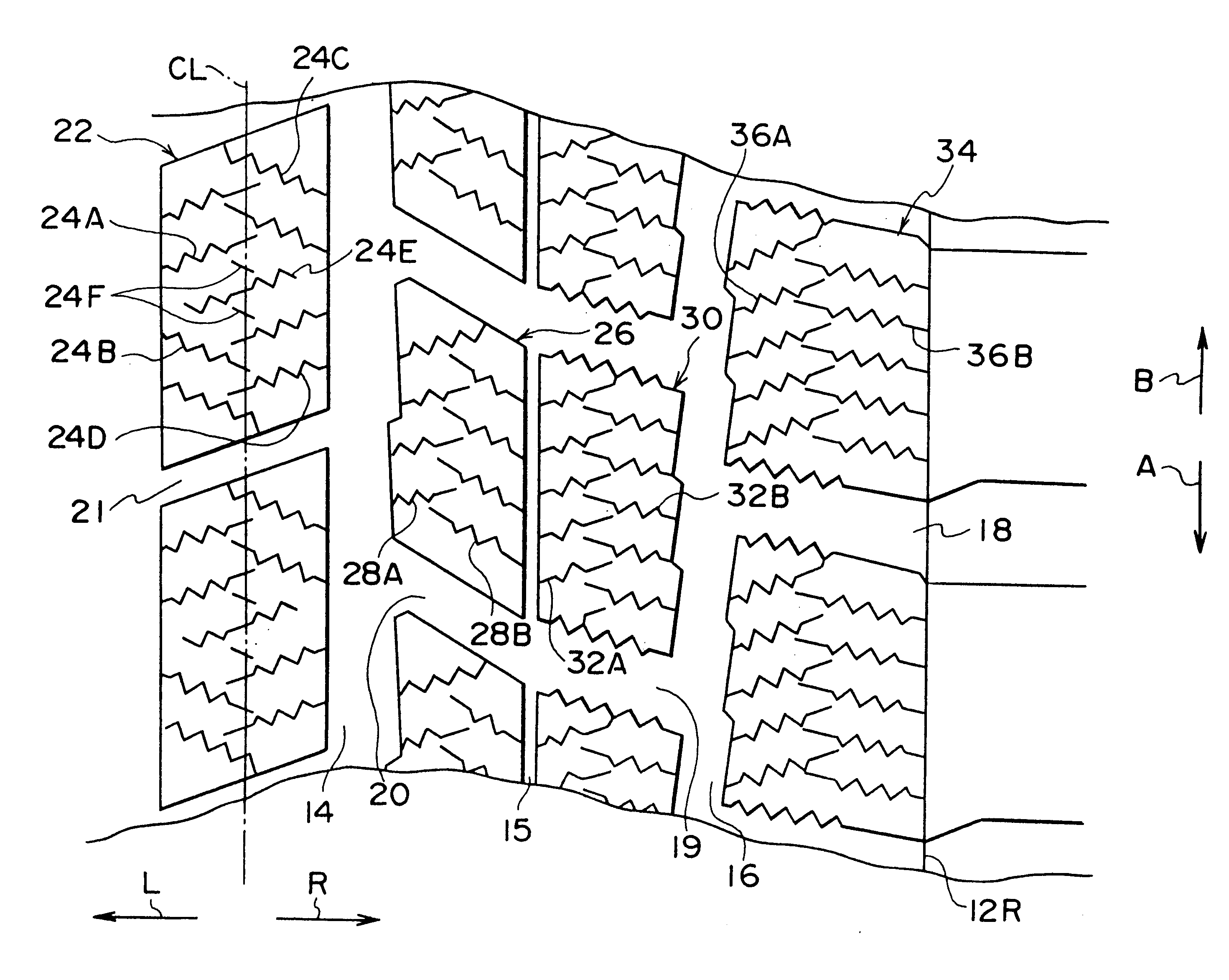

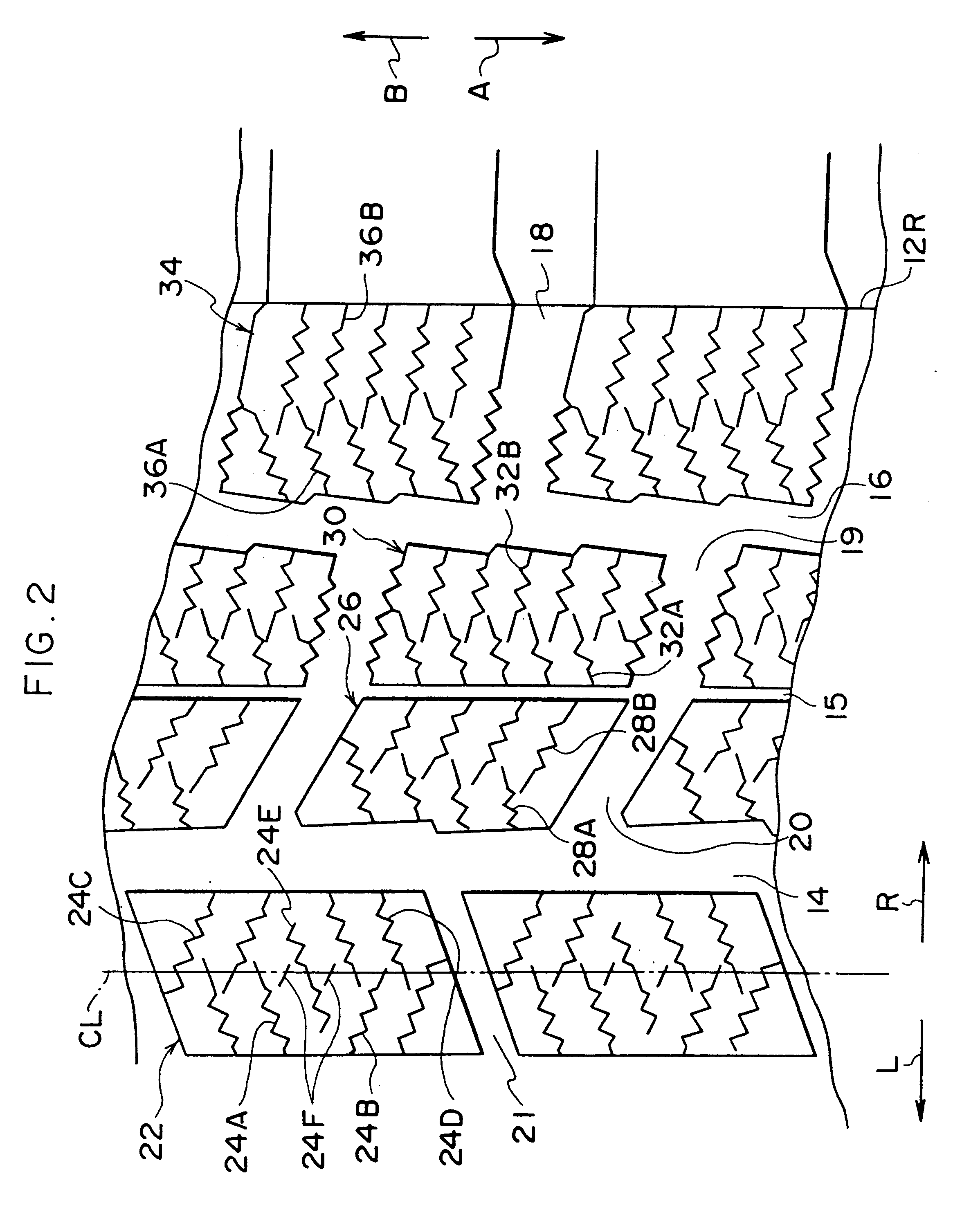

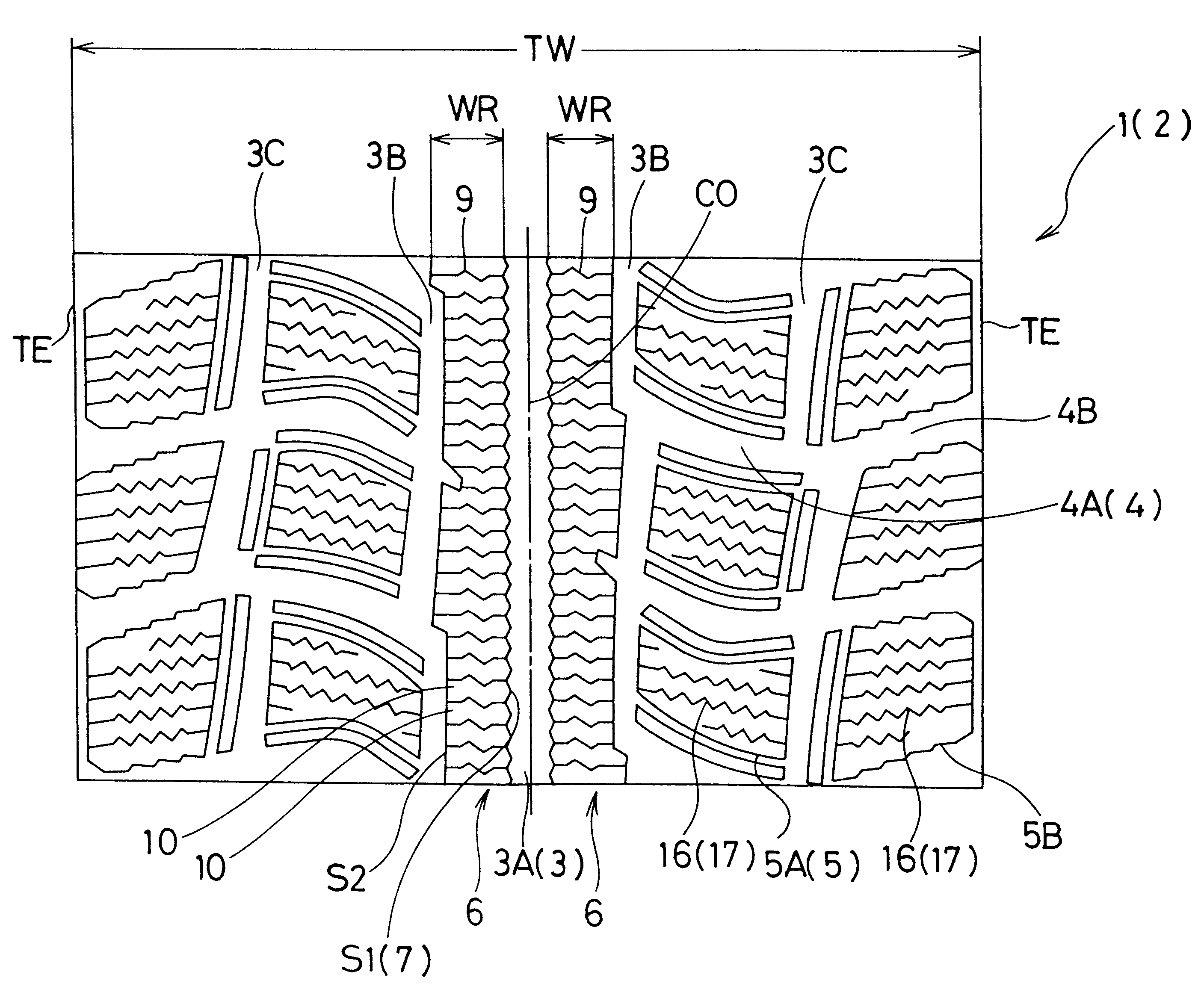

Pneumatic tire having tread including pairs of sipes

InactiveUS6571844B1Rigid enoughImprove propertiesTyre tread bands/patternsNon-skid devicesEngineeringCommon line

Sipes extending from one end of a block to the central area of the block and sipes extending from the other end of the block to the central area of the block (sipes 24, 28, 32 and 36) are inclined in directions opposite to each other. The sipes extending from one end of the block and the sipes extending from the other end of the block intersect a common line extending along the circumferential direction of the tire. Due to this structure, the number of portions of the sipes, which portions are located in the central area of the block, is made greater than that in the peripheral area of the block. The density of sipes is thus increased in the central area of a block where water tends to form when driving on ice, for improving braking and traction properties on ice.

Owner:BRIDGESTONE CORP

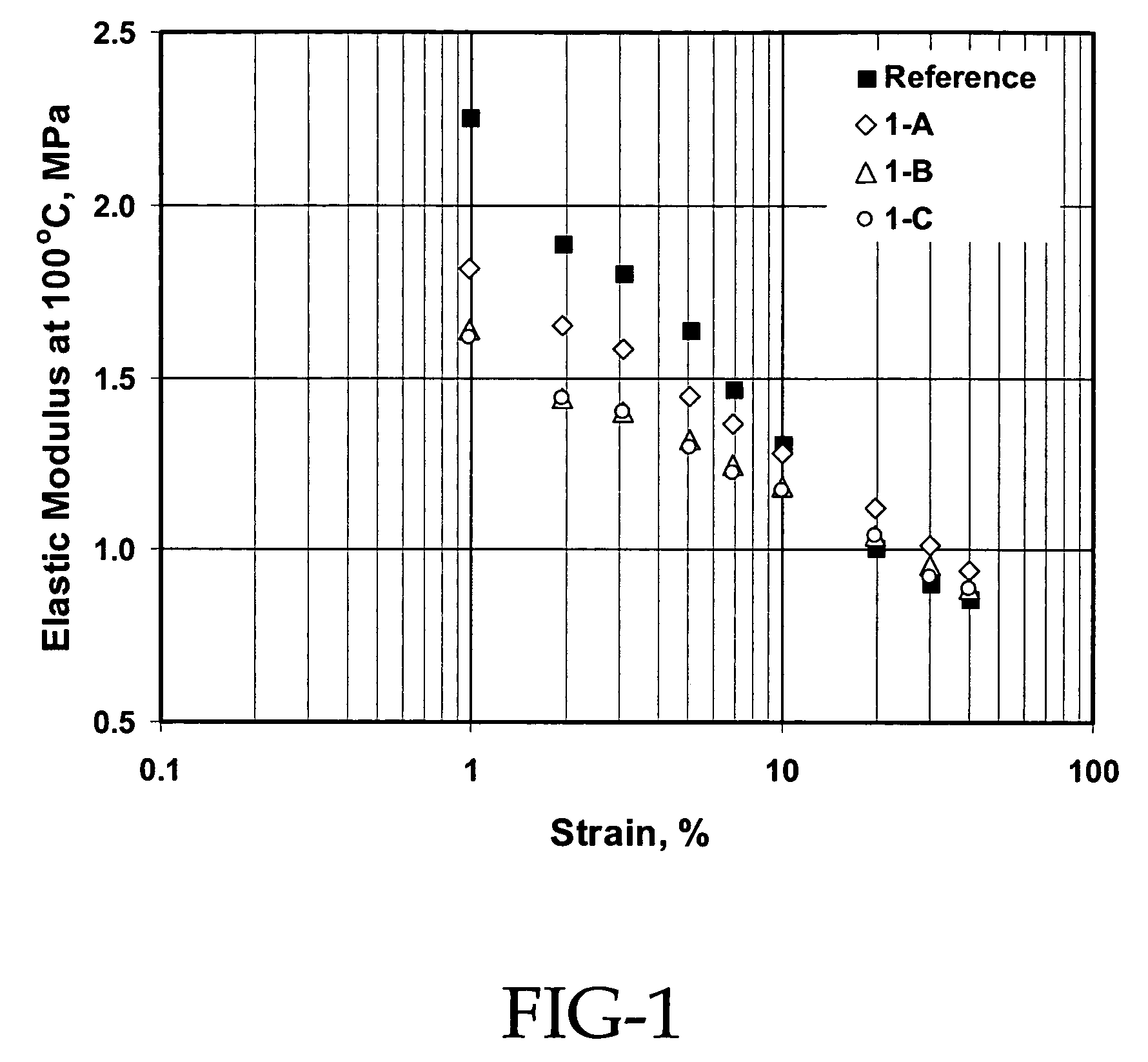

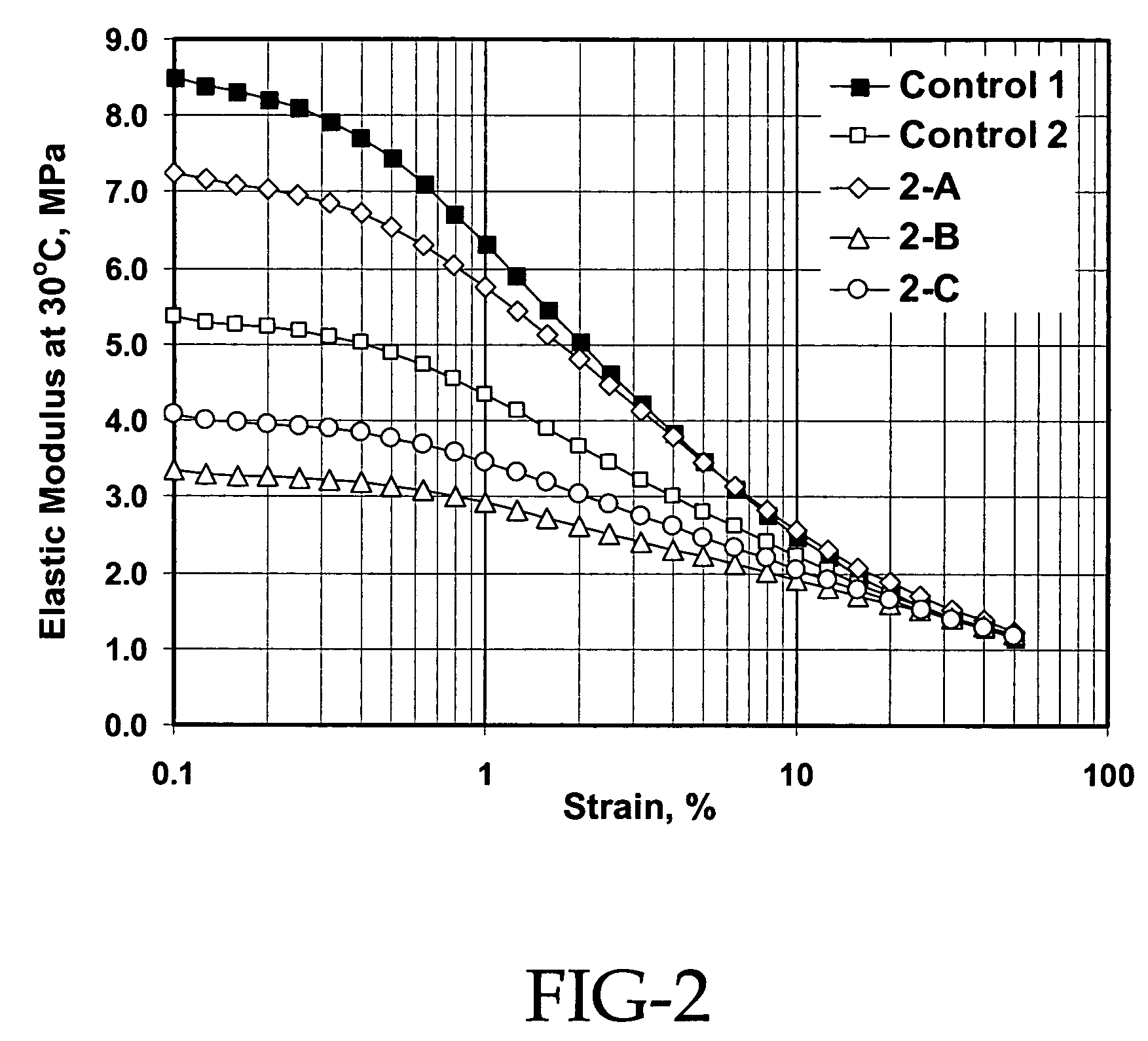

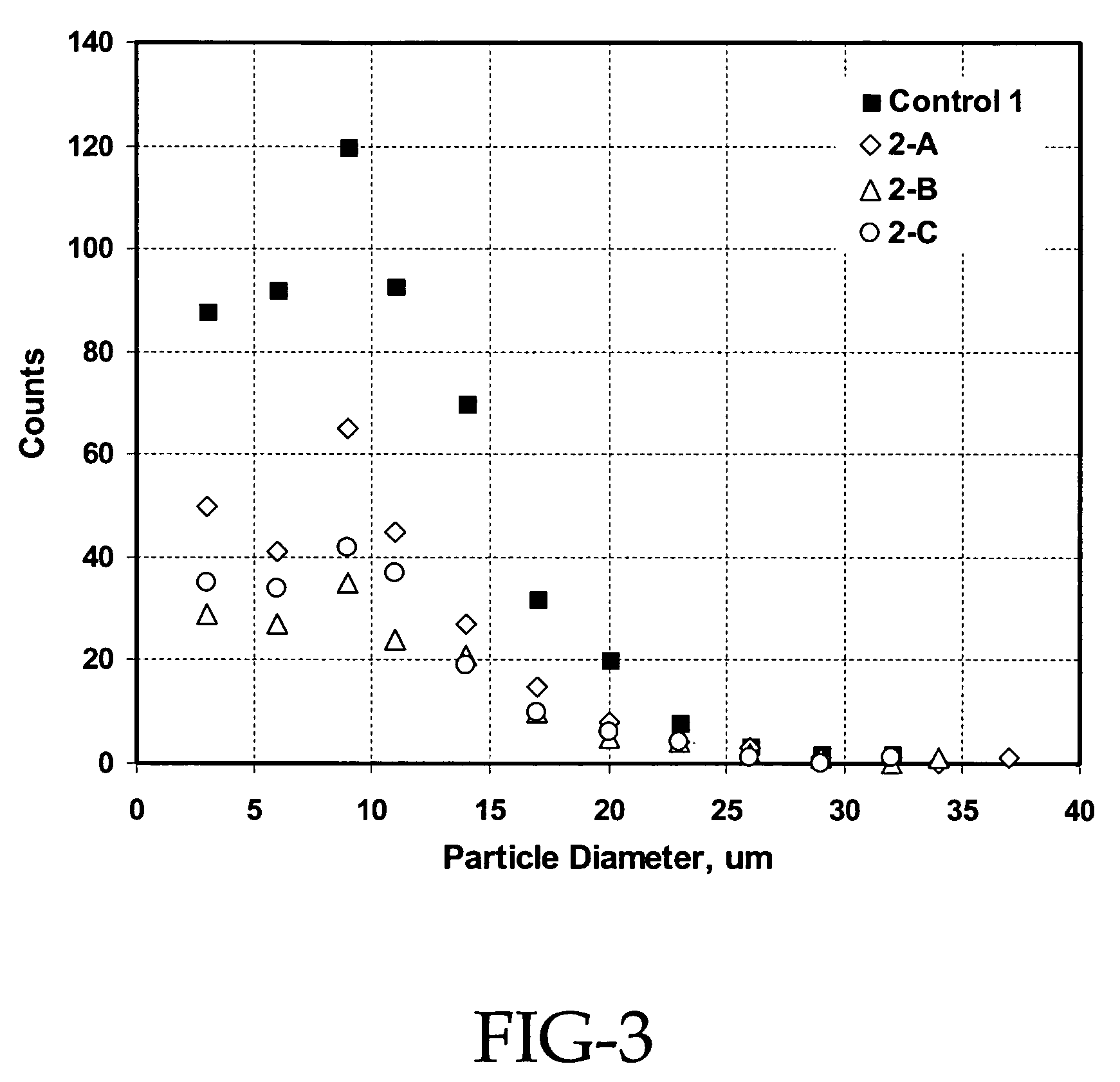

Rubber composition containing resinous nanoparticle

InactiveUS7347237B2Deteriorate controllabilityDeteriorate stabilitySpecial tyresInflatable tyresElastomerEngineering

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber composition with silica reinforcement obtained with an amino acid or amino acid-containing protein based activator and use thereof in tires

InactiveUS20030135006A1Enhance various physical propertyImprove curingSpecial tyresTyre tread bands/patternsElastomerPolymer science

The invention relates to the preparation of a silica reinforced rubber composition where alkoxysilane and / or sulfur cure reactions within the elastomer host are controlled by the use of a selected amino acid, or amino acid-containing protein based, activator. The invention also relates to such composite and to a tire having at least one component of such composite

Owner:THE GOODYEAR TIRE & RUBBER CO

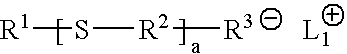

Functional polymers prepared with sulfur-containing initiators

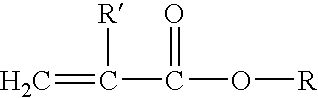

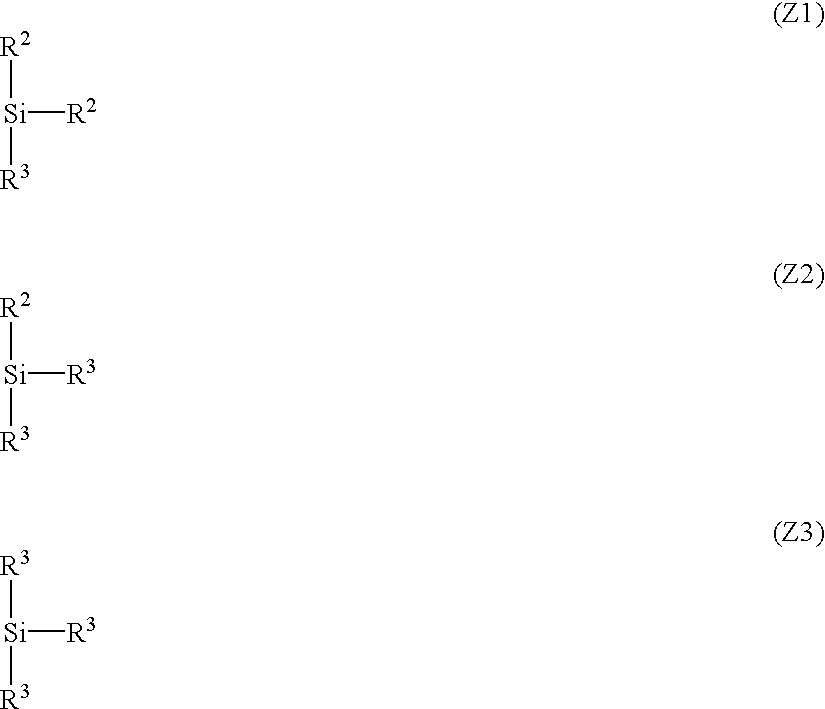

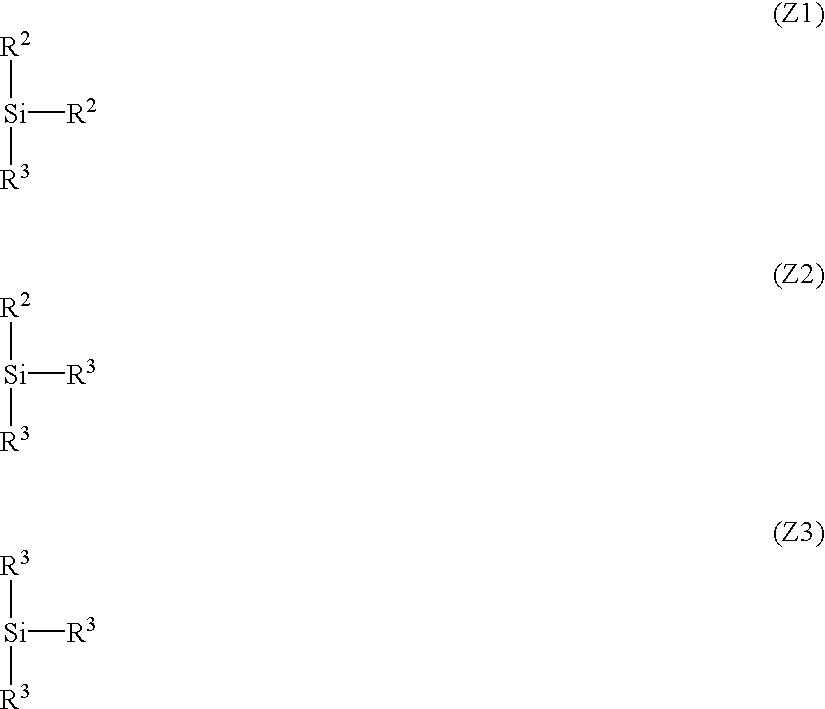

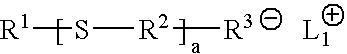

A method for forming a polymer including a sulfur-containing functional group, the method comprising introducing a sulfur-containing initiator defined by the formulawith conjugated diene monomer and optionally copolymerizable monomer within a polymerization medium and allowing the sulfur-containing initiator to initiate the polymerization of the conjugated diene monomer and the optional copolymerizable monomer, where R1 is a monovalent organic group, R2 is a divalent organic group, R3 is a divalent organic group or a bond, and a is an integer from 1 to about 5.

Owner:BRIDGESTONE CORP

Rubber composition for tire tread having high performance on ice and pneumatic tire using the same

InactiveUS6550508B1Good physical propertiesReduce hardnessNon-inflatable tyresSpecial tyresFiberVulcanization

Owner:YOKOHAMA RUBBER CO LTD

Heavy-duty tire

InactiveUS20070151646A1Increase stiffnessReduce ground pressureHeavy duty tyresHeavy duty vehicleEngineeringHeavy duty

Owner:SUMITOMO RUBBER IND LTD

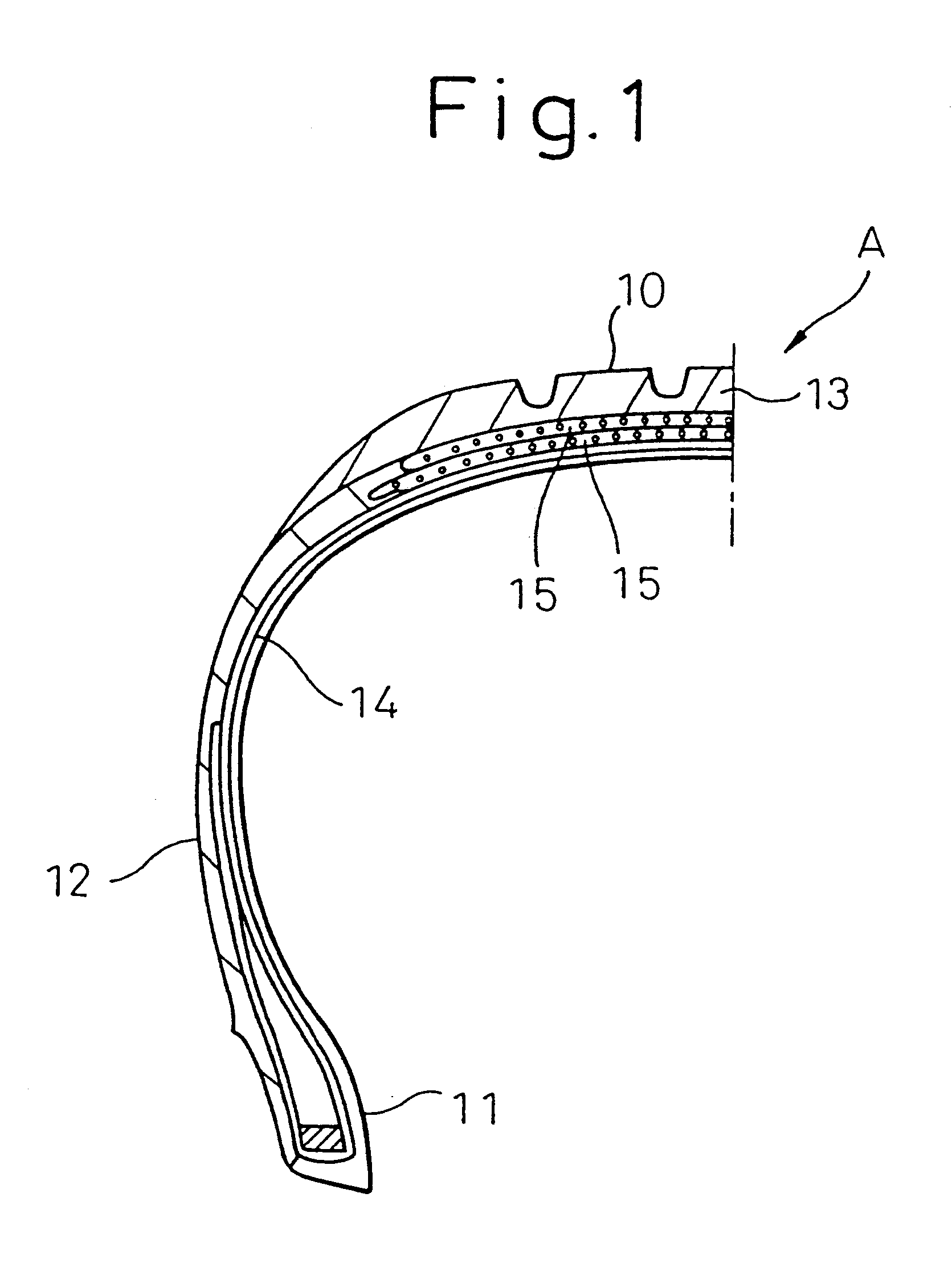

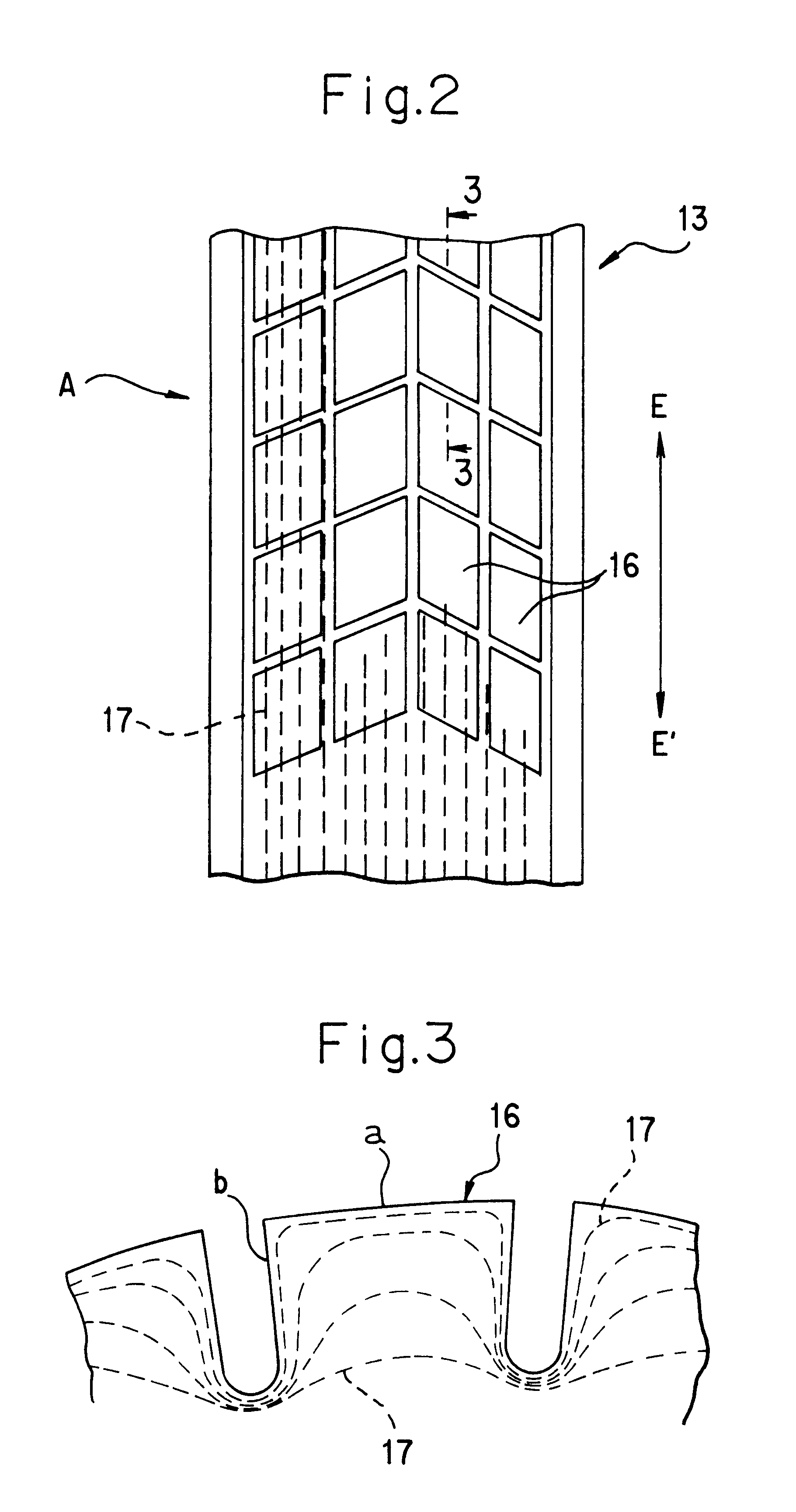

Pneumatic Tire

InactiveUS20070199633A1Reduce rigidityImprove cooling effectHeavy duty tyresTyre tread bands/patternsEngineeringMechanical engineering

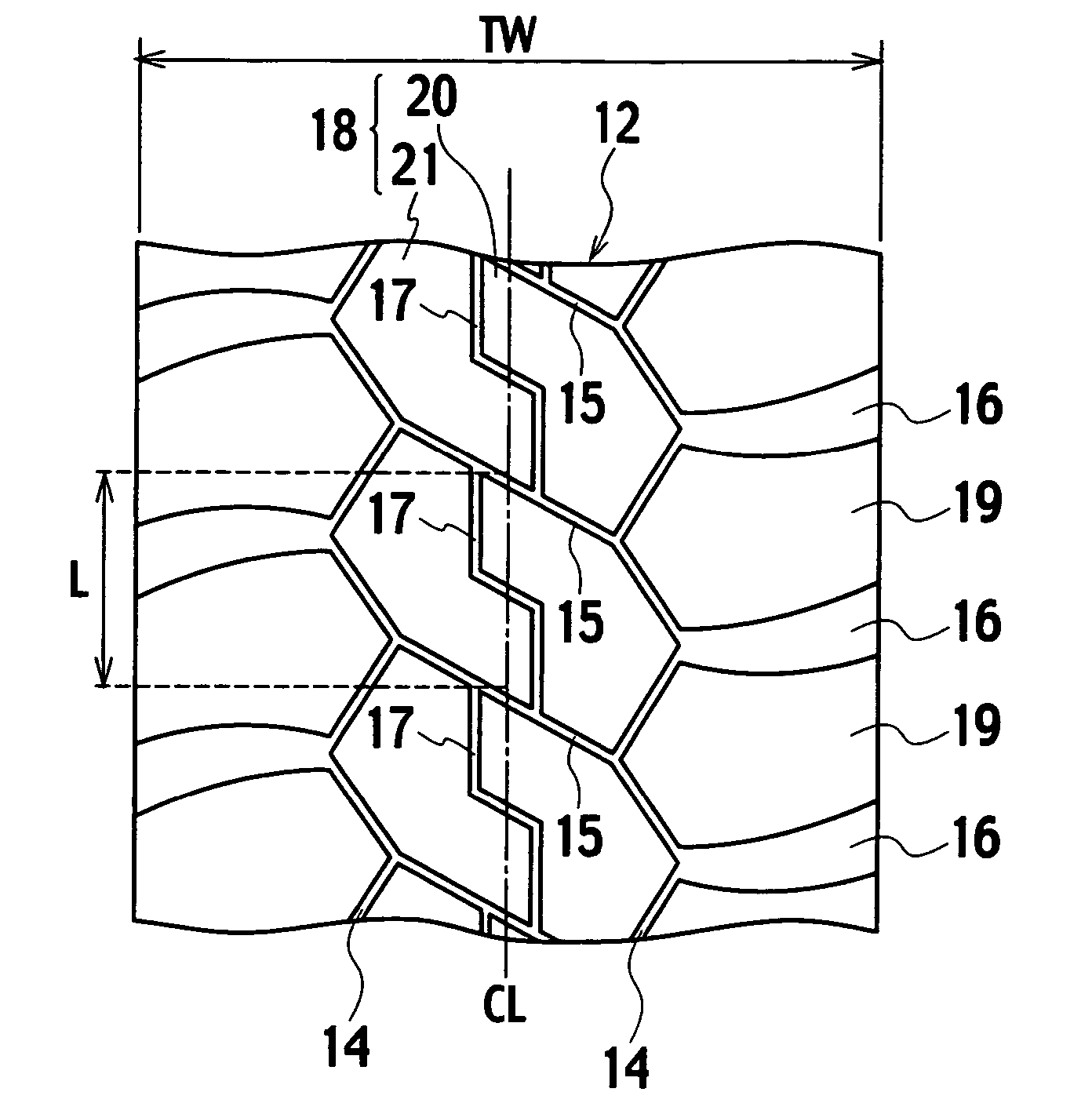

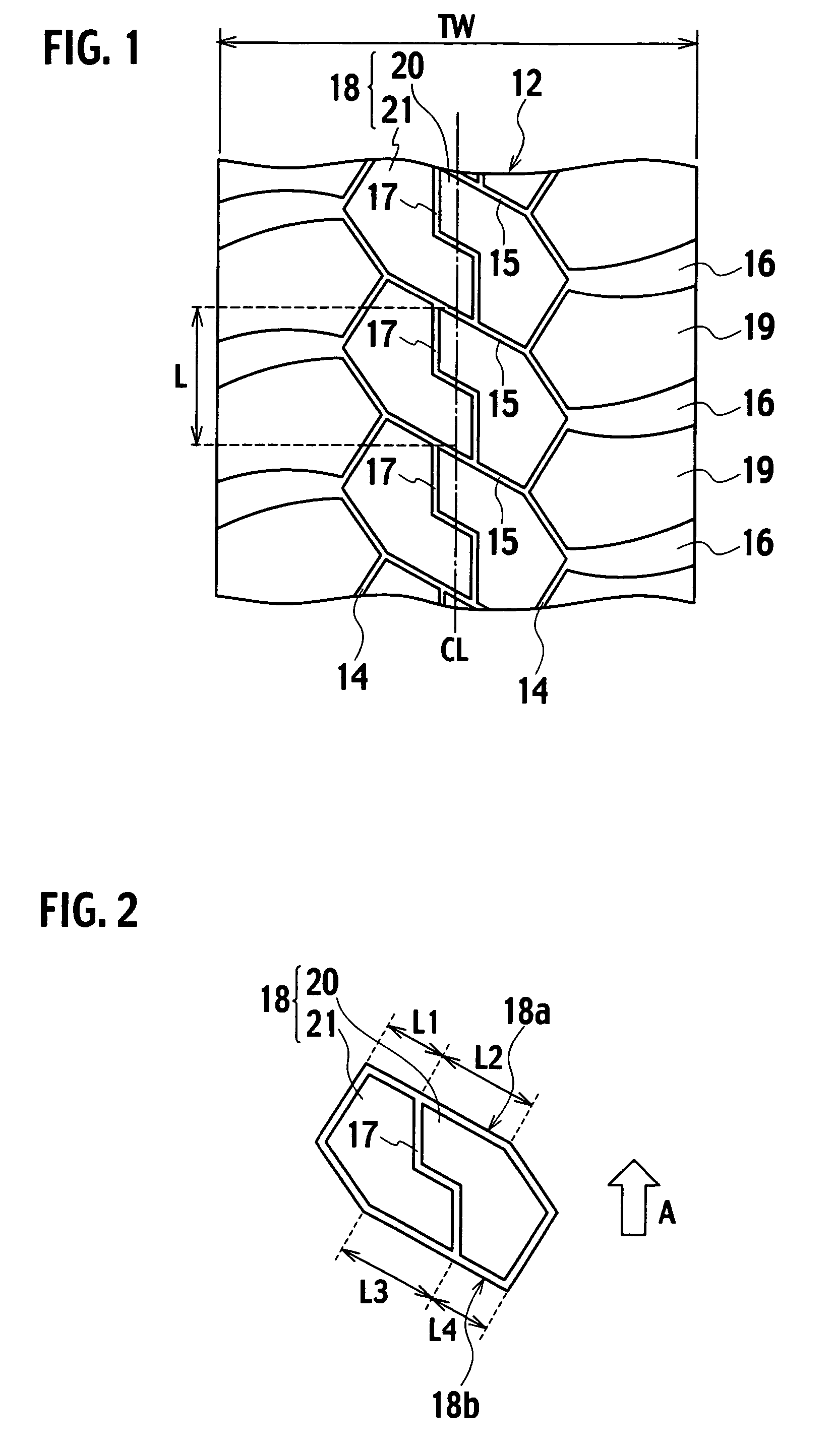

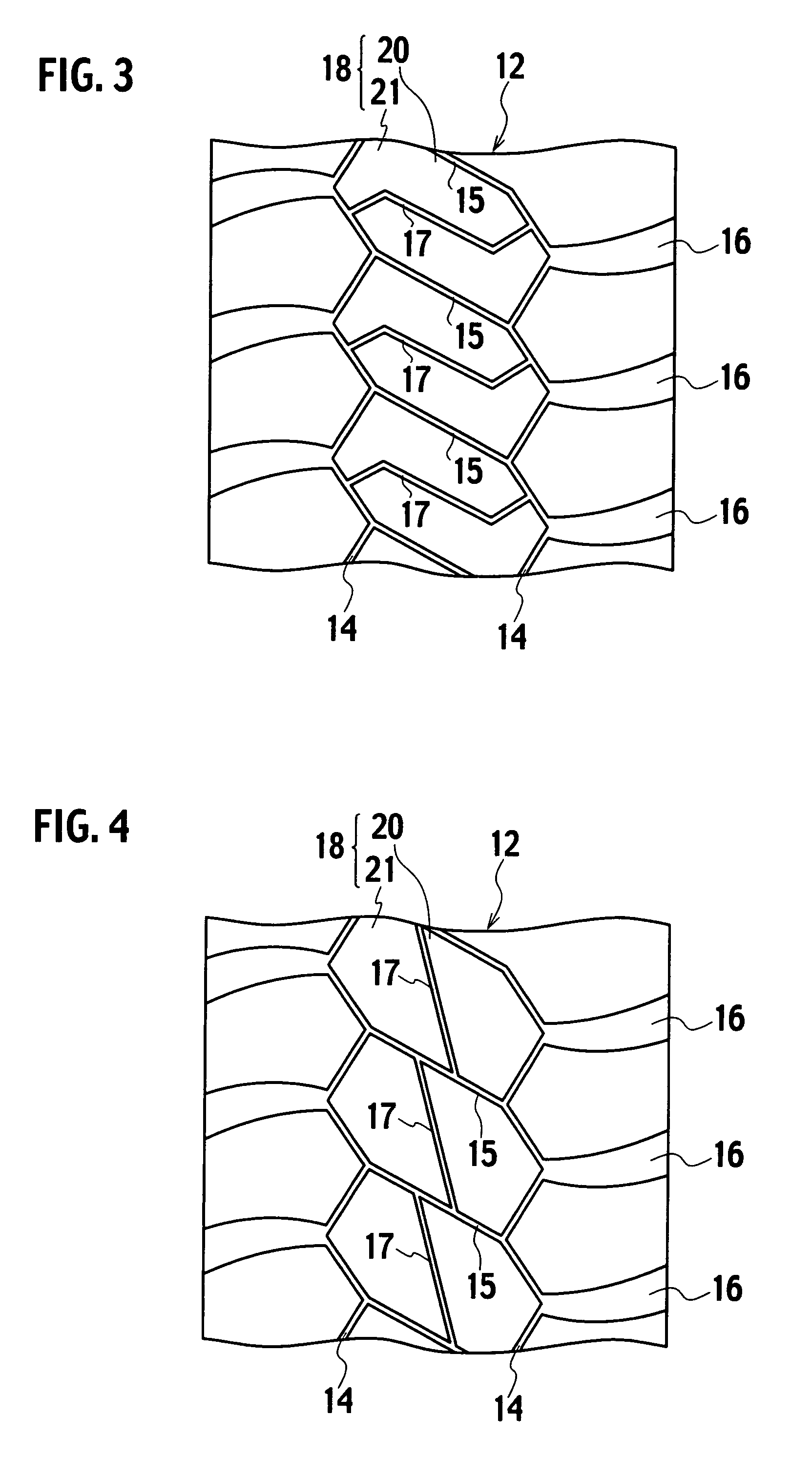

A pneumatic tire includes a column of center blocks (18) partitioned, on a tread center region, by circumferential thin grooves (14) formed along a tire circumferential direction and crosswise thin grooves (15) formed along a tire width direction, and columns of shoulder blocks (19) partitioned by the circumferential thin grooves (14) and main rag grooves (16) on shoulder portions. Each of the center blocks (18) includes one or more sub-thin grooves (17); each of which has a length of 100 to 180% of a circumferential length of the center block (18)

Owner:BRIDGESTONE CORP

Rubber mixtures

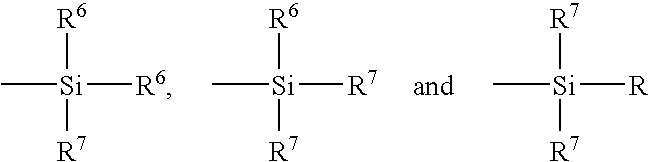

Rubber mixtures which contain an organosilane of the general structure 1R2R3Si—R4—Z (I), wherein R1, R2 and R3 independently of one another are H, (C1-C4)alkyl, (C1-C4)alkoxy or halogen and the number of alkyl groups is ≧1; R4 is a linear or branched (C1-C18)alkylidene group; and Z=H, halogen, SCN, SH or Sx—R4—SiR1R2R3, where x is 2 to 10. The rubber mixtures are useful in molding compositions particularly for tires and tire treads.

Owner:EVONIK DEGUSSA GMBH

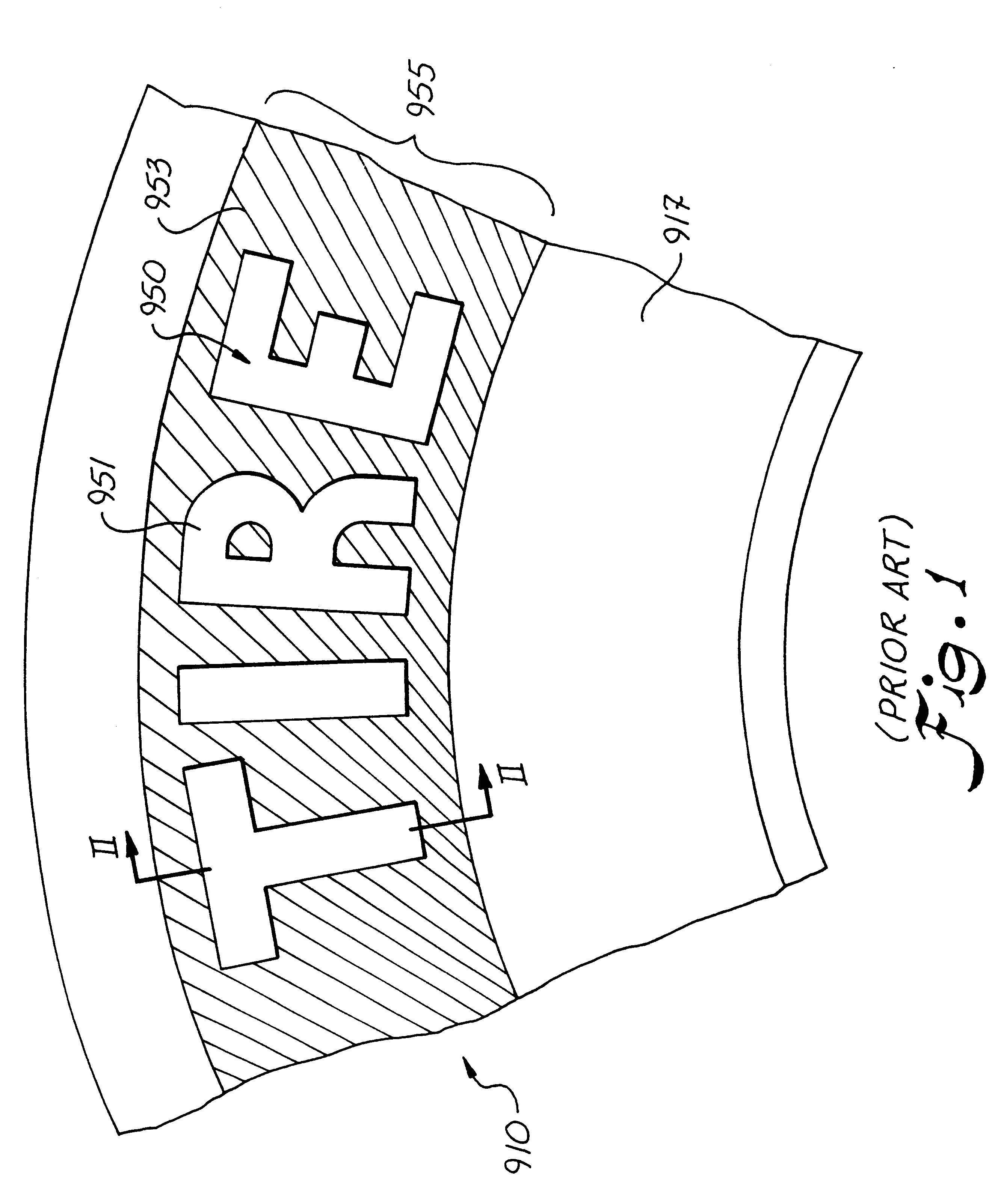

Design pattern for a tire

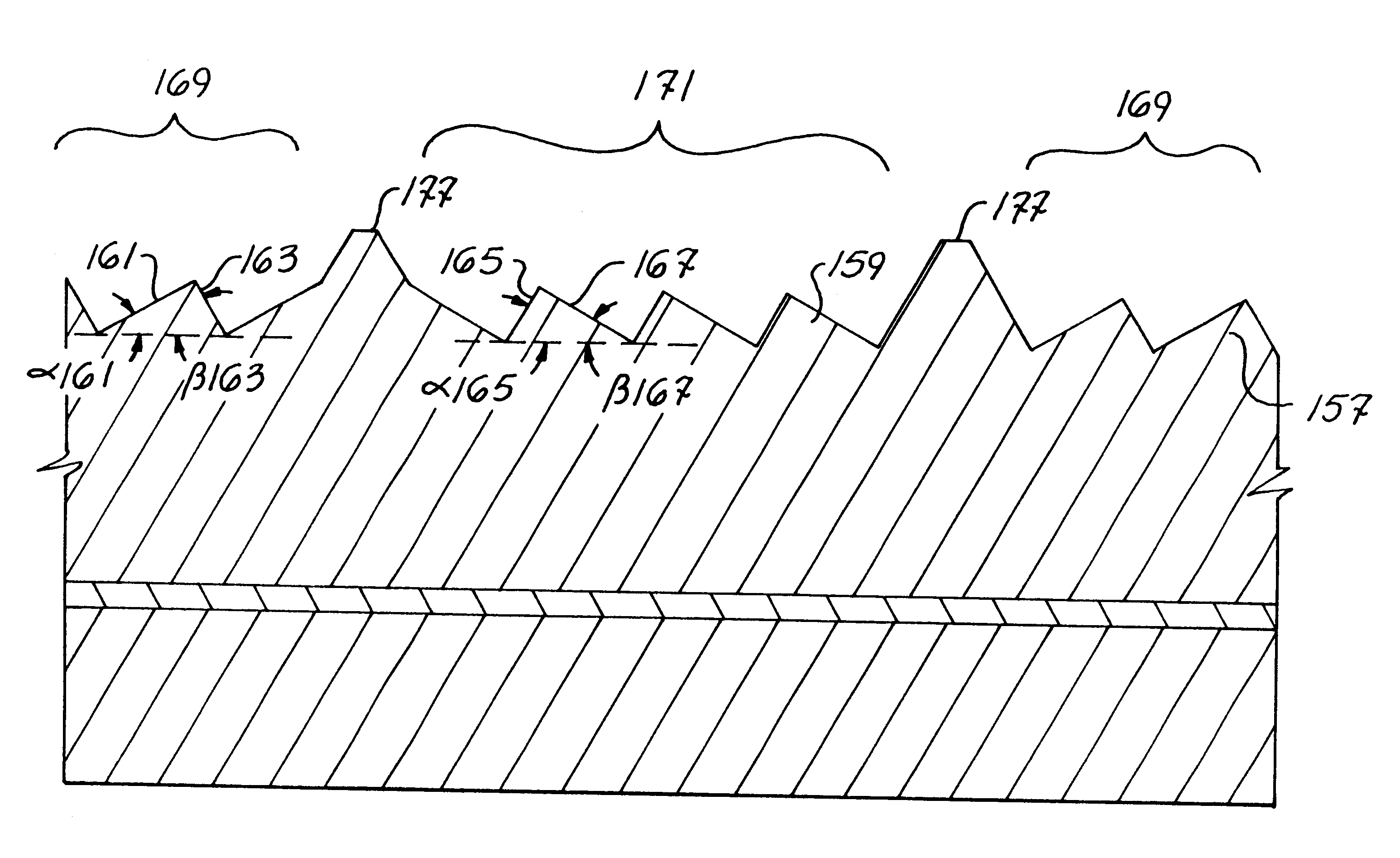

InactiveUS6253815B1Wider illumination angleLight effect designsInflatable tyresEngineeringOptical contrast

An opaque article having a surface and substantially asymmetric striae extending along the surface. A portion of the striae reside in a first area and have an orientation. Another portion of the striae reside in a second area and have an orientation substantially opposite the striae in the first area. The first area striae and the second area striae create an optical contrast therebetween at a wide range of viewing angles and illumination angles. The opaque article can be a tire. The striae can reside at numerous locations on the tire, including, for example, the sidewall, tread ribs or blocks, and stone ejectors.

Owner:MICHELIN RECH & TECH SA

Pneumatic tire

A tire has a tread and a pair of opposing shoulders. In the first sidewall, a series of extension blocks creates a pair of concentric rings. In the second sidewall, a different configuration of extension blocks may be present. The second sidewall has alternating extension blocks where one of the blocks has a portion that is located radially inward of the other block.

Owner:THE GOODYEAR TIRE & RUBBER CO

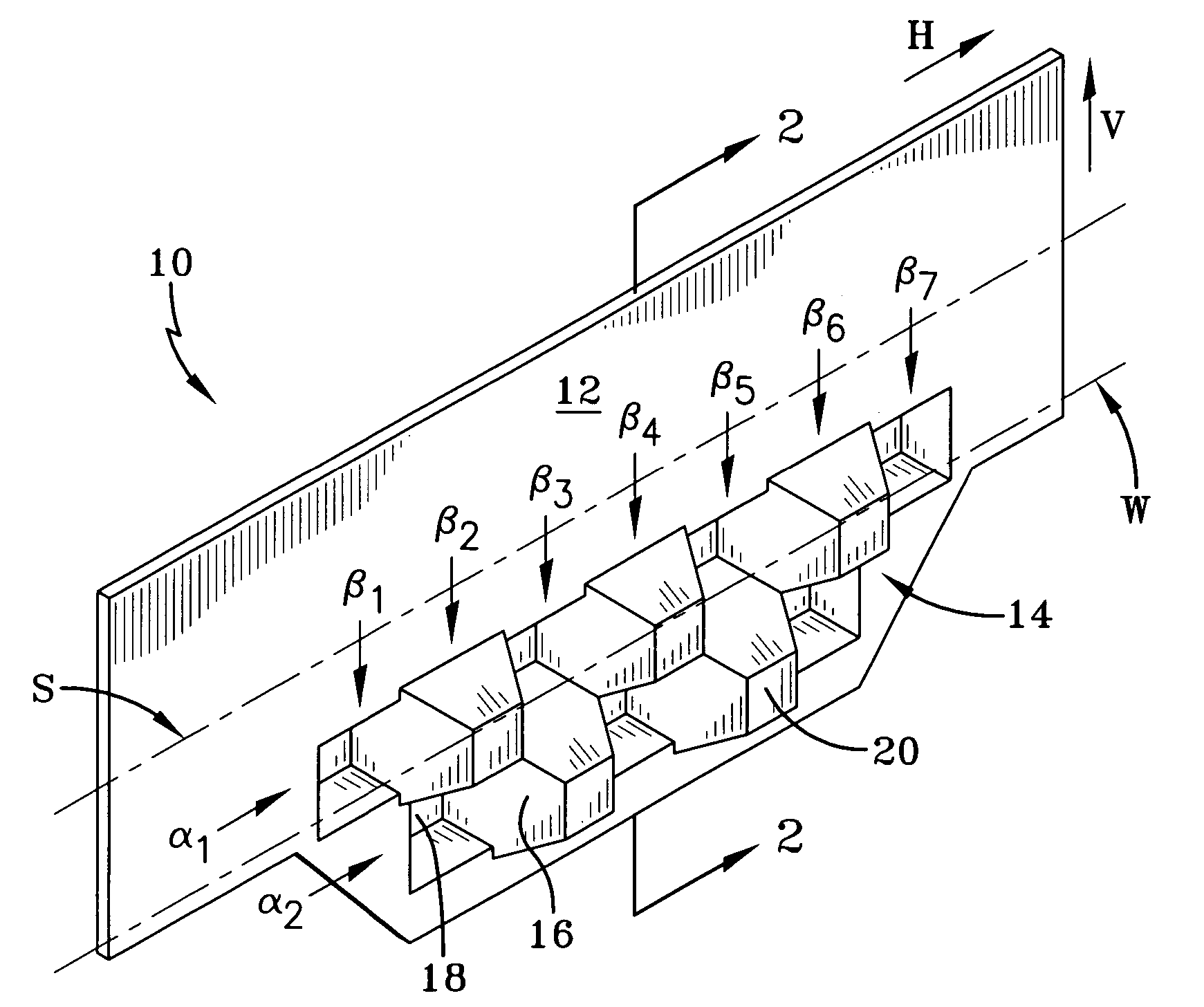

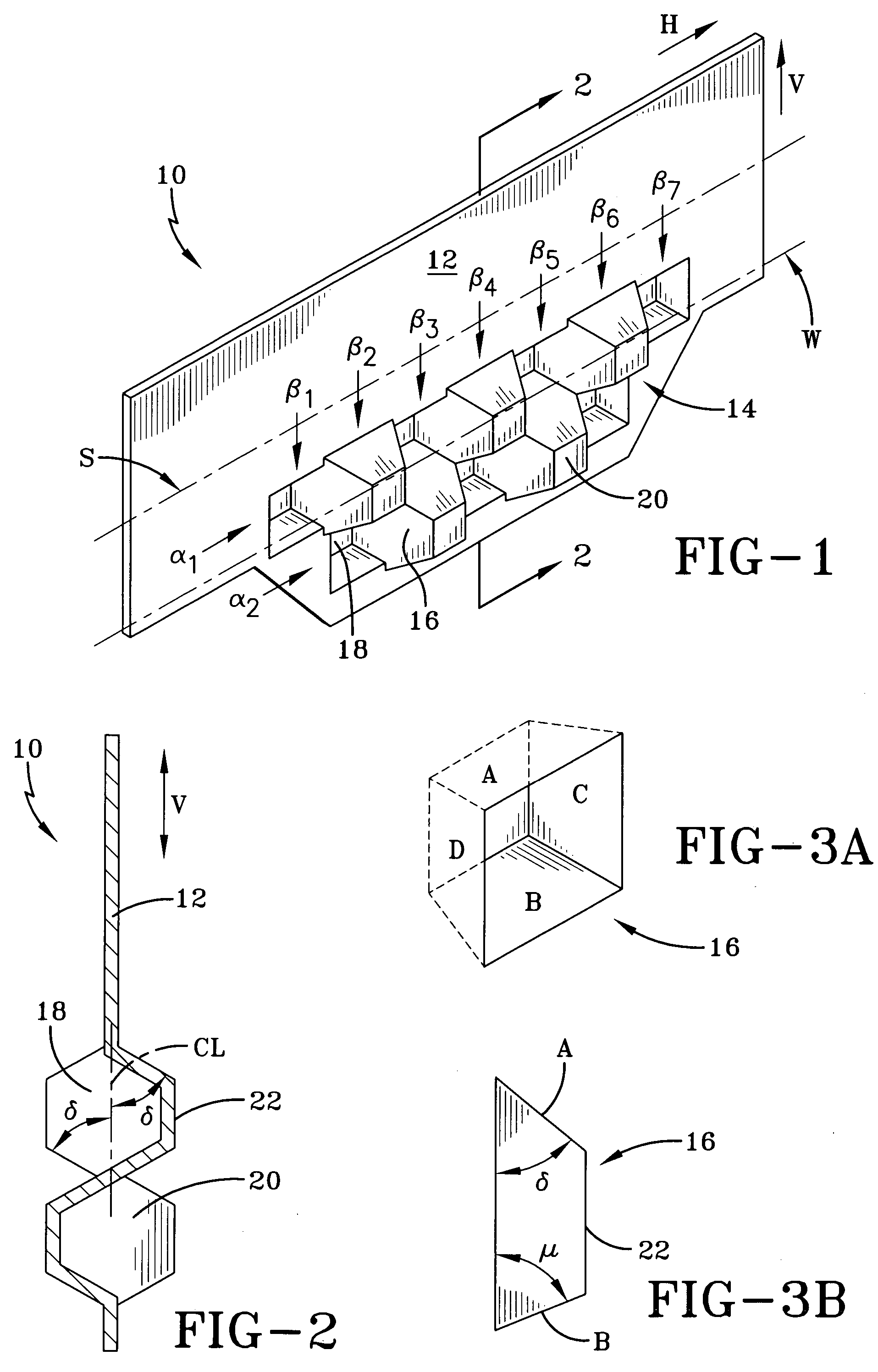

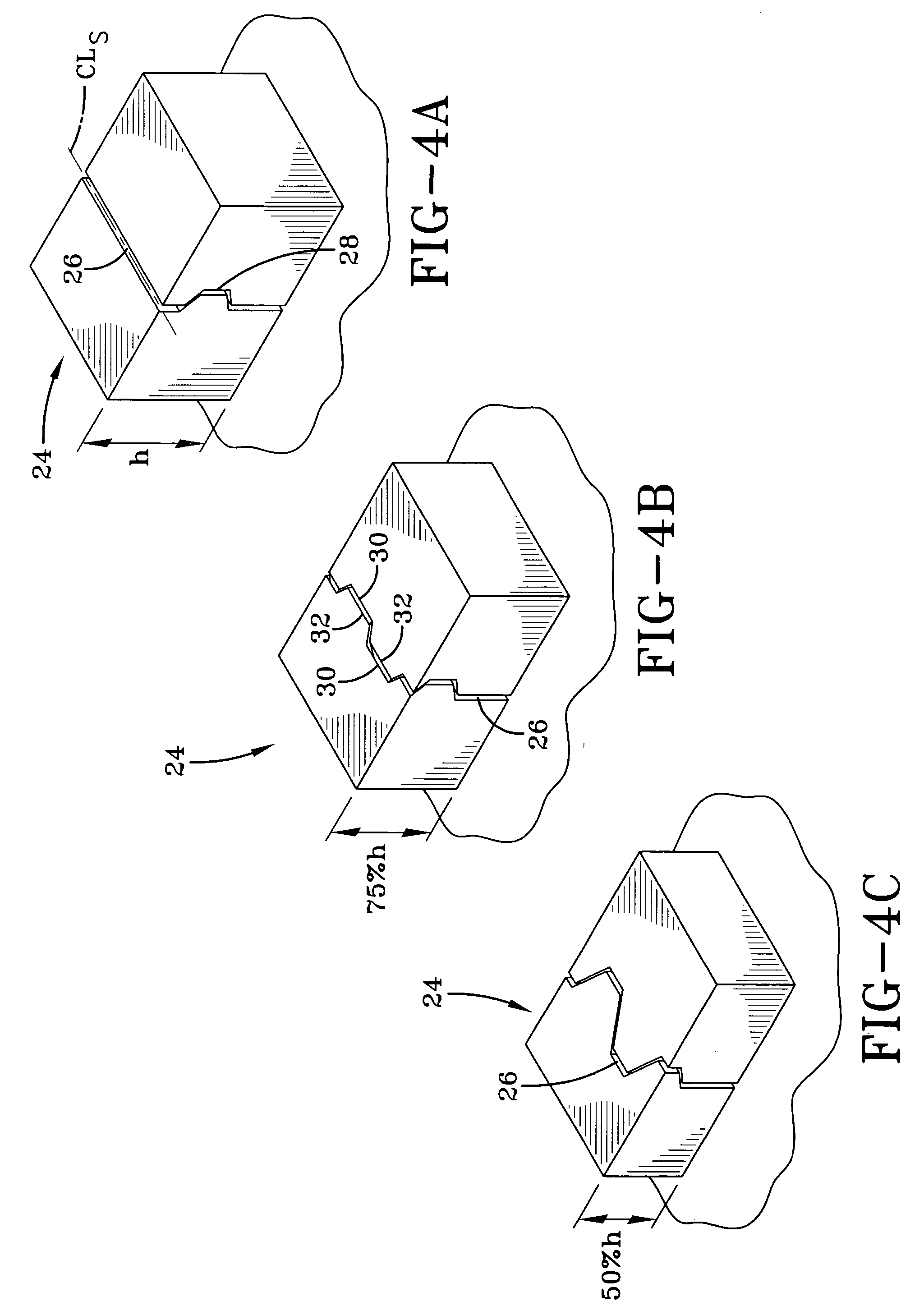

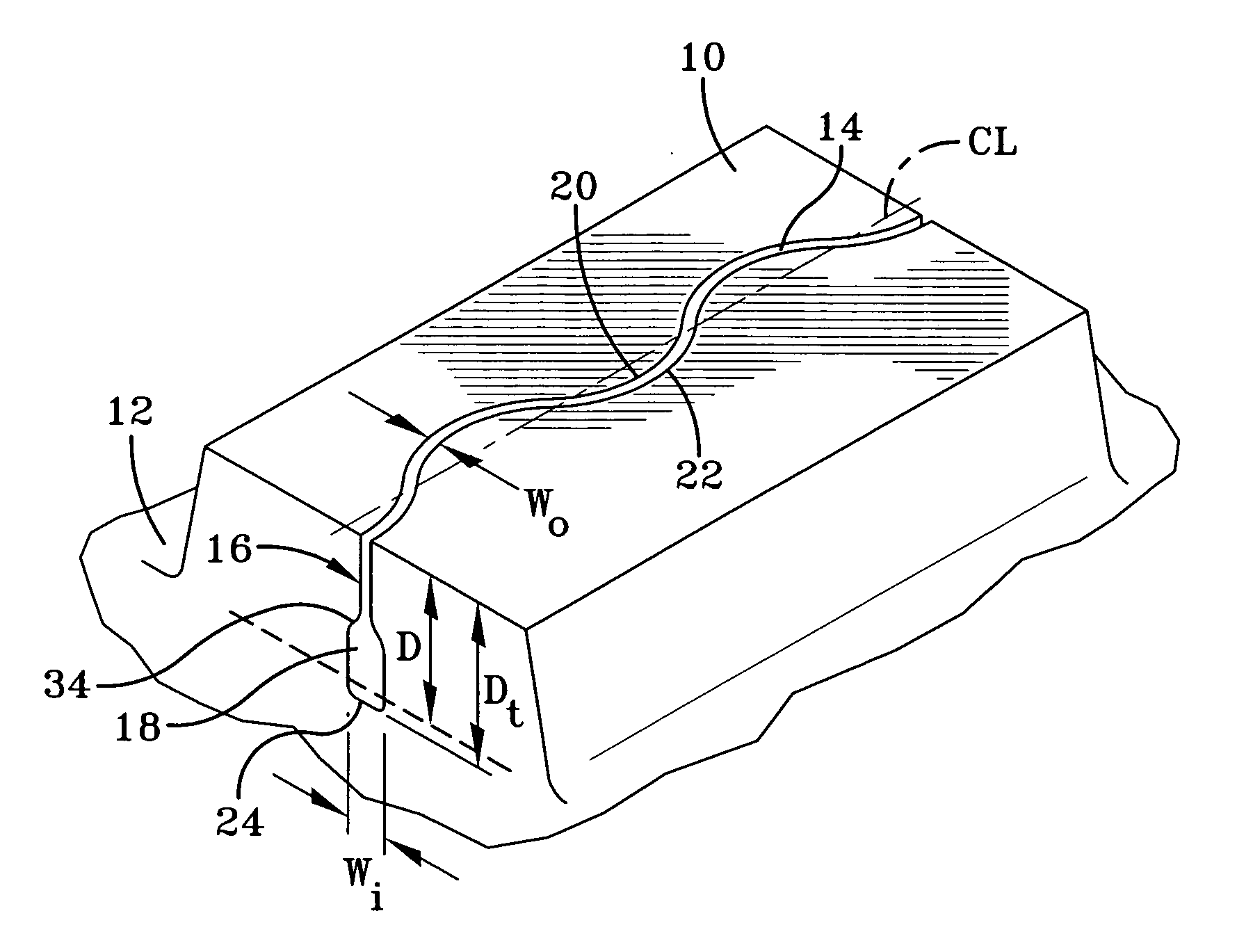

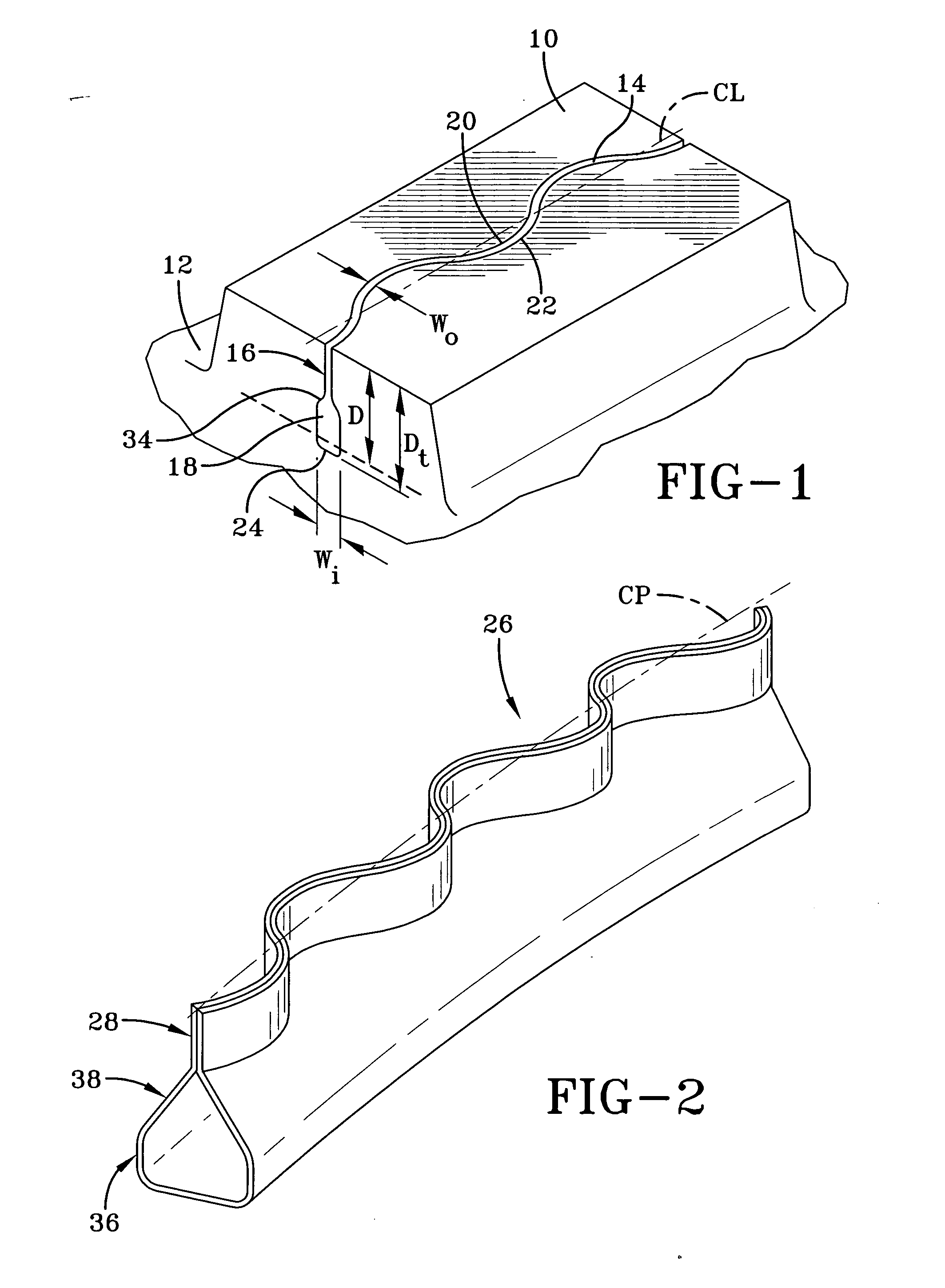

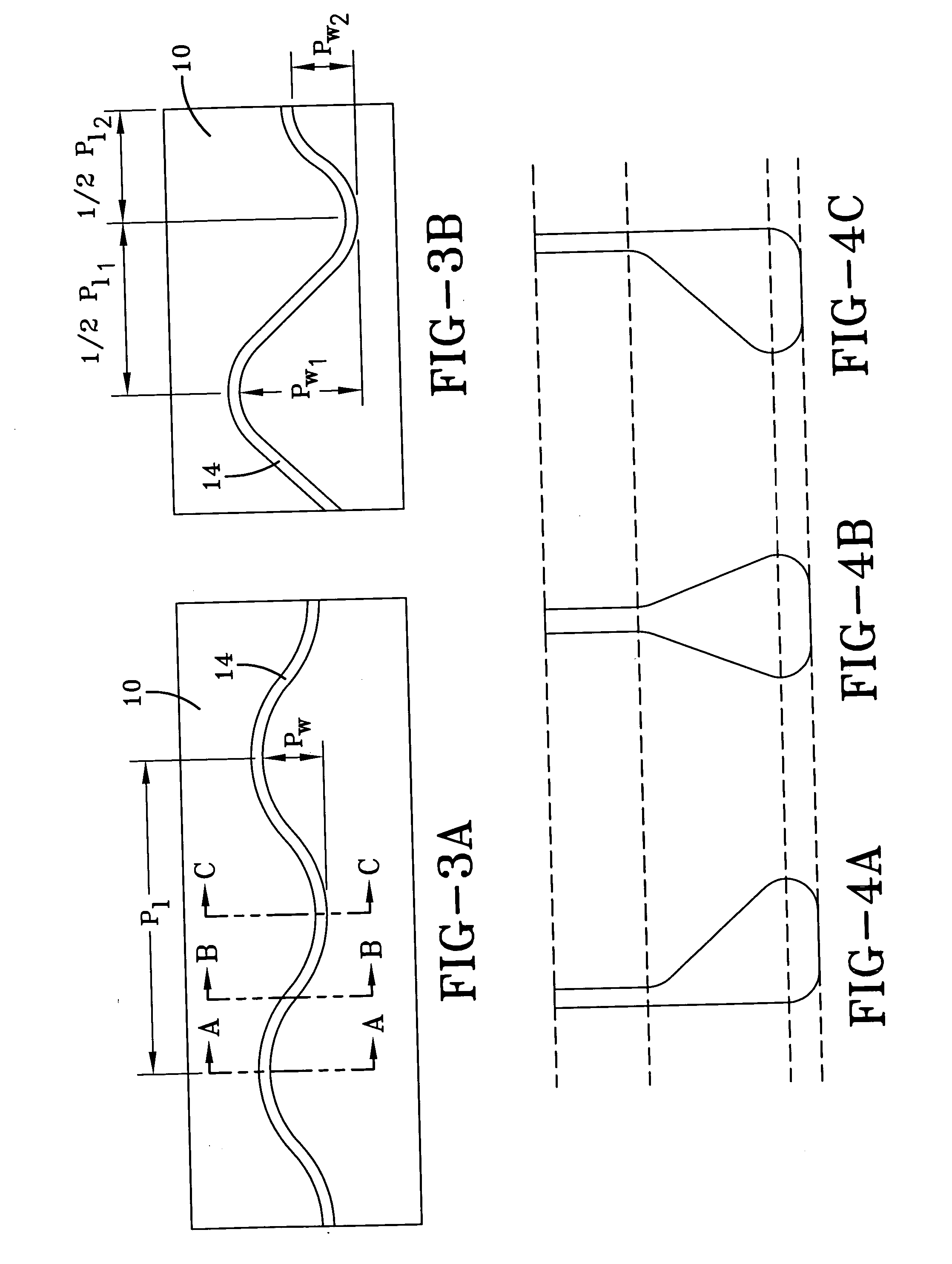

Three-dimensional sipes for treads

ActiveUS20050109438A1Good traction characteristicsPrevent slippingTyresTyre tread bands/patternsEngineeringKnife blades

Both a mold blade for forming sipes and the sipe so formed in a tire tread element have three dimensional portions. In the formed sipe, the three dimensional portion creates a constant interlocking of the opposing sipe faces. The blade and the sipe have at least one row of alternating polygonal shaped recesses and protrusions. The recesses and protrusions terminate in a vertex; the vertex has a planar, or two-dimensional, configuration that is parallel to either-the blade centerline or the sipe centerline.

Owner:THE GOODYEAR TIRE & RUBBER CO

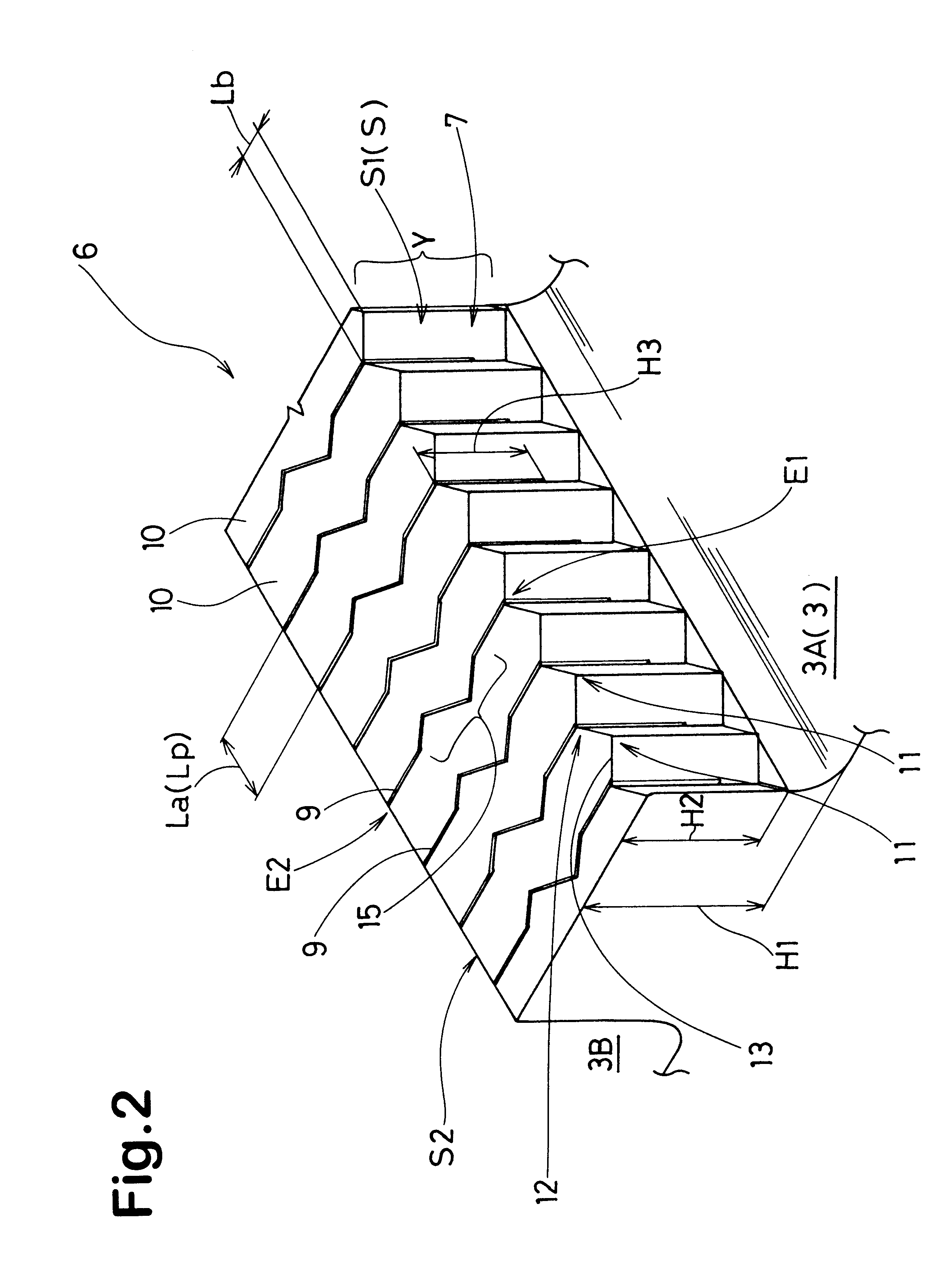

Vehicle tire including sipes extending across rib

InactiveUS6250354B1Reduce appearance problemsIncrease the traction without deteriorating the durabilityTyre tread bands/patternsNon-skid devicesEngineeringTread

A vehicle tire includes a tread portion provided with a plurality of blocks and at least one circumferential rib, the circumferential rib having a first side face facing a circumferential groove and a second side face, and first side face being corrugated to form furrows and ridges which are arranged alternatively in the circumferential direction and extend radially of the tire, the corrugation having an amplitude Lb in the range of 0.5 to 2.0 mm, the circumferential rib being provided with sipes extending thereacross so that each sipe has an end opened in one of the furrows on the first side face and an end opened in said second side face, and the spacings La of the sipes being in the range of 2.0 to 5.0 mm. Each of the sipe has a zigzag middle part.

Owner:SUMITOMO RUBBER IND LTD

Tire having silica reinforced rubber tread with outer cap containing carbon black

InactiveUS6044882AImprove propertiesAdvantageously producedSpecial tyresTyresTire beadPolymer science

The invention relates to a rubber tire composed of carbon black reinforced rubber carcass and having a rubber tread which is quantitatively reinforced with silica and which, in turn, has a thin, integral, rubber outer cap on its outer surface which contains a quantitative amount of carbon black. In one aspect, said outer cap, sometimes referred to herein as an outer top cap, extends across the outer surface of the tread which is normally intended to be ground contacting and in an alternative aspect, the outer top cap extends only over the outer portion, namely the peripheral edges, of said tread surface intended to be ground contacting. The outer, carbon black reinforced, rubber tread top cap connects with at least one other carbon black reinforced rubber component of the tire in a manner to provide a path of reduced electrical resistance from said outer tread top cap to the bead portion of the tire carcass and, therefore, such a path from the vehicle to the road surface.

Owner:THE GOODYEAR TIRE & RUBBER CO

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

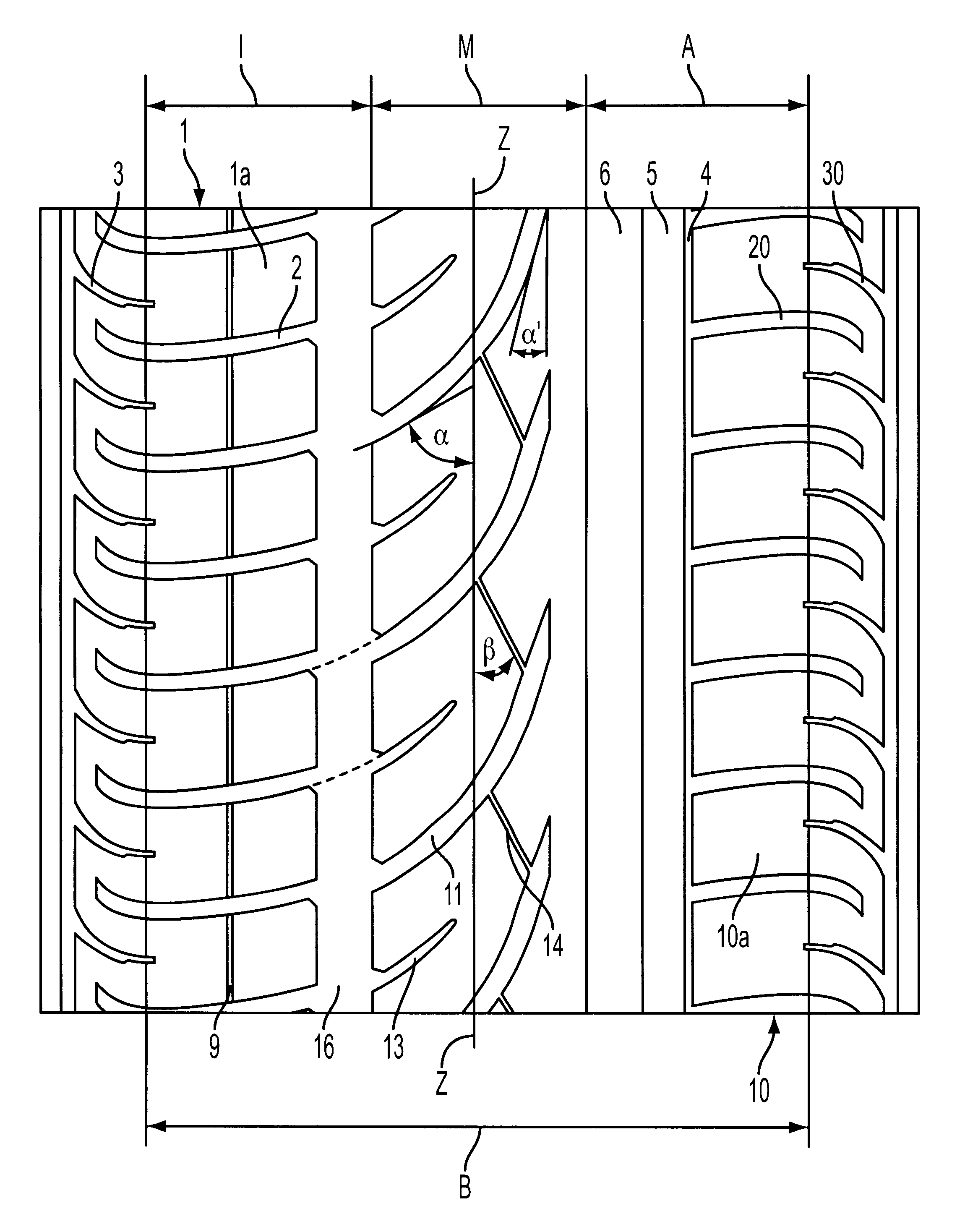

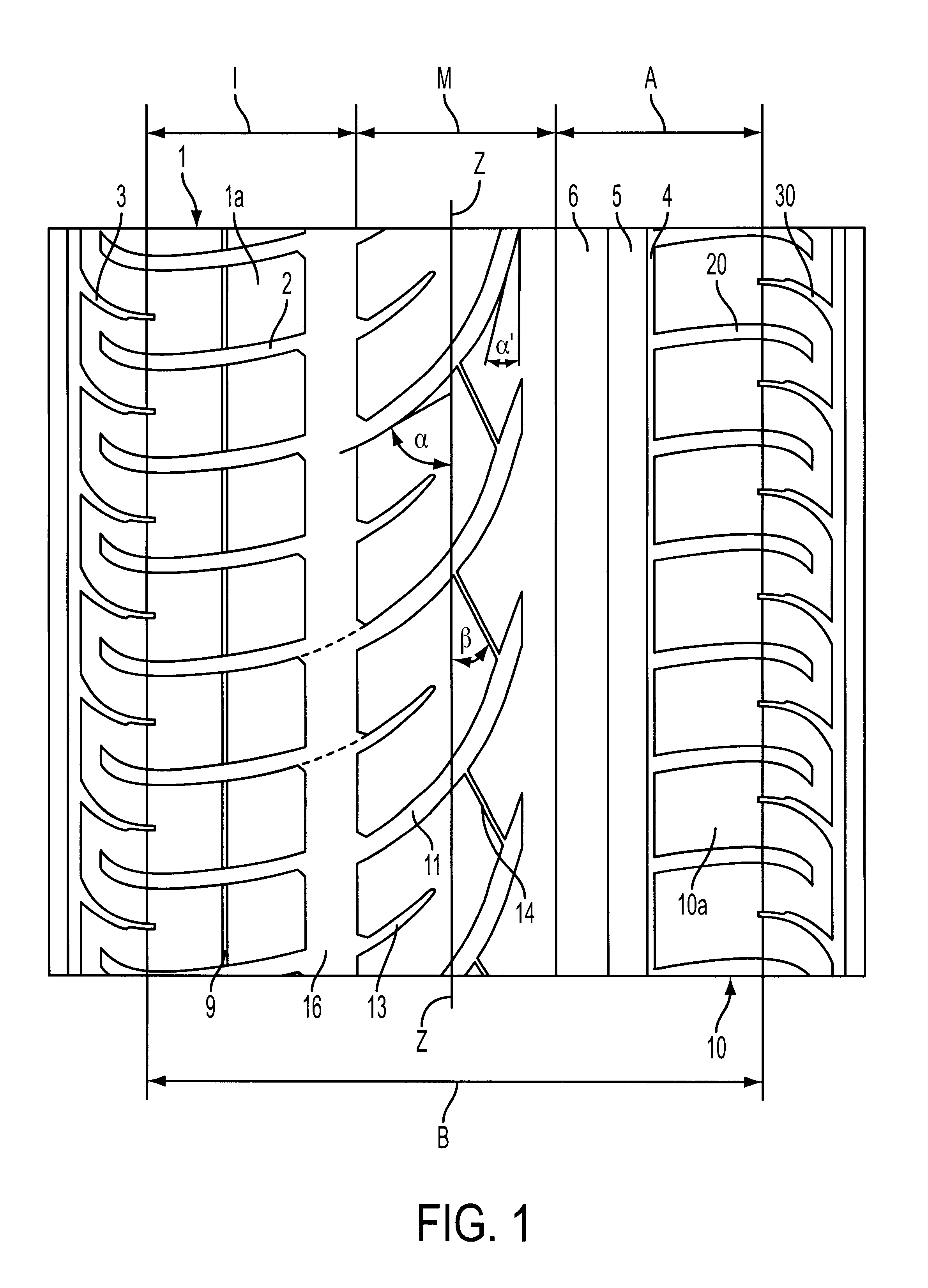

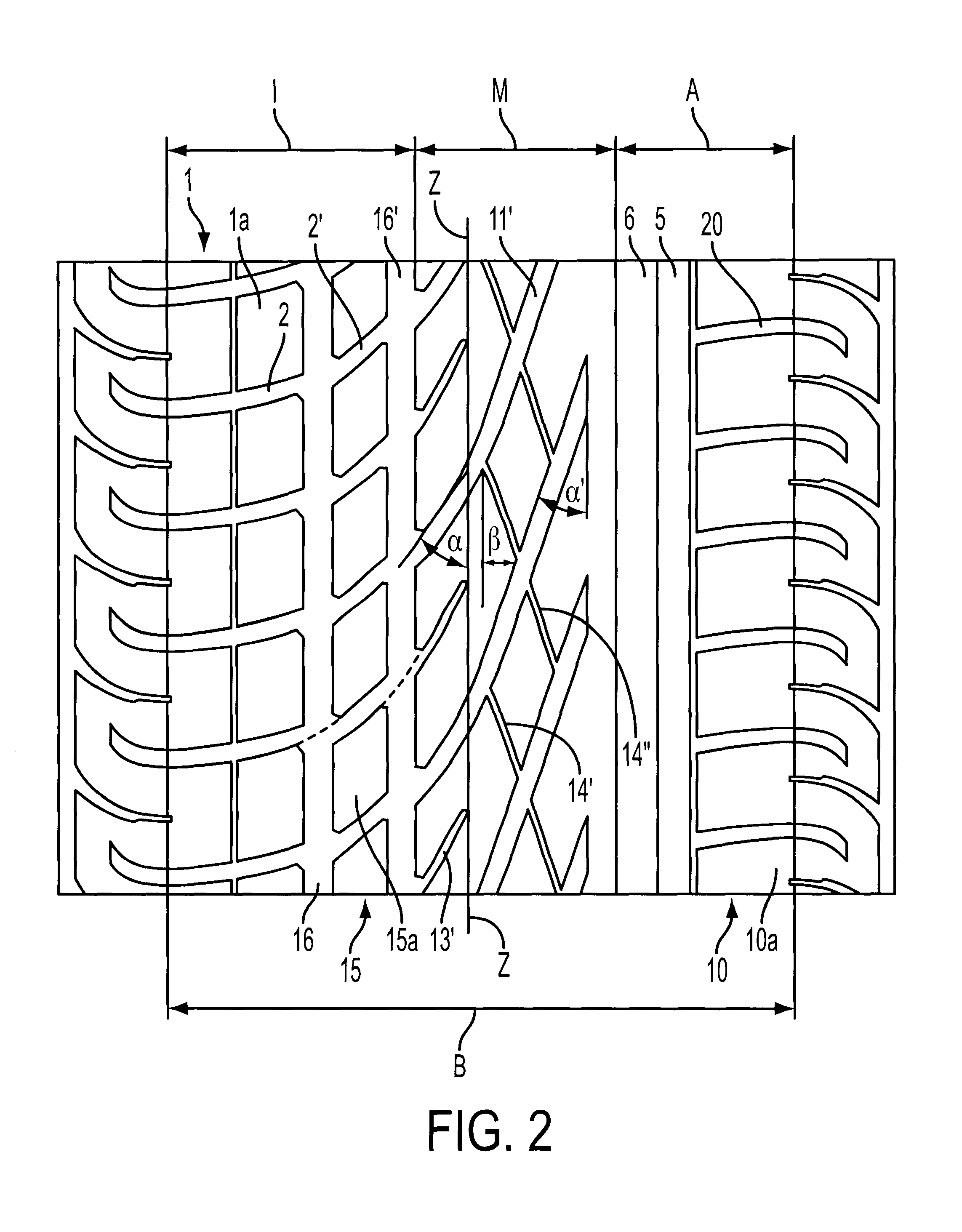

Vehicular pneumatic tire and process of making vehicular pneumatic tire

InactiveUS6439286B1Narrow profileAvoid impactTyresTyre tread bands/patternsTransverse grooveEngineering

Vehicular pneumatic tire having an asymmetric tread formed in relation to a circumference of a running surface and process of making vehicular pneumatic tire. The vehicular pneumatic tire includes an outside region that includes an outside shoulder block row and an outside circumferential groove, an inside region that includes an inside shoulder block row and an inside circumferential groove, and a center region that is laterally delimited by the outside circumferential groove and the inside circumferential groove. A plurality of transverse grooves are arranged within the inside shoulder block row, and the plurality of transverse grooves further are arranged to extend into the center region. No more than about one-half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions. The process includes forming an outside region to include an outside shoulder block row and an outside circumferential groove, forming an inside region to include an inside shoulder block row and an inside circumferential groove, and laterally delimiting a center region with the outside circumferential groove and the inside circumferential groove. The process further includes arranging a plurality of transverse grooves within the inside shoulder block row and to extend into the center region. No more than one half of the plurality of transverse grooves are arranged to at least nearly entirely traverse the center region and are oriented to form an angle to a circumferential equator line of no more than approximately 30° over at least one-third of their longitudinal extensions.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

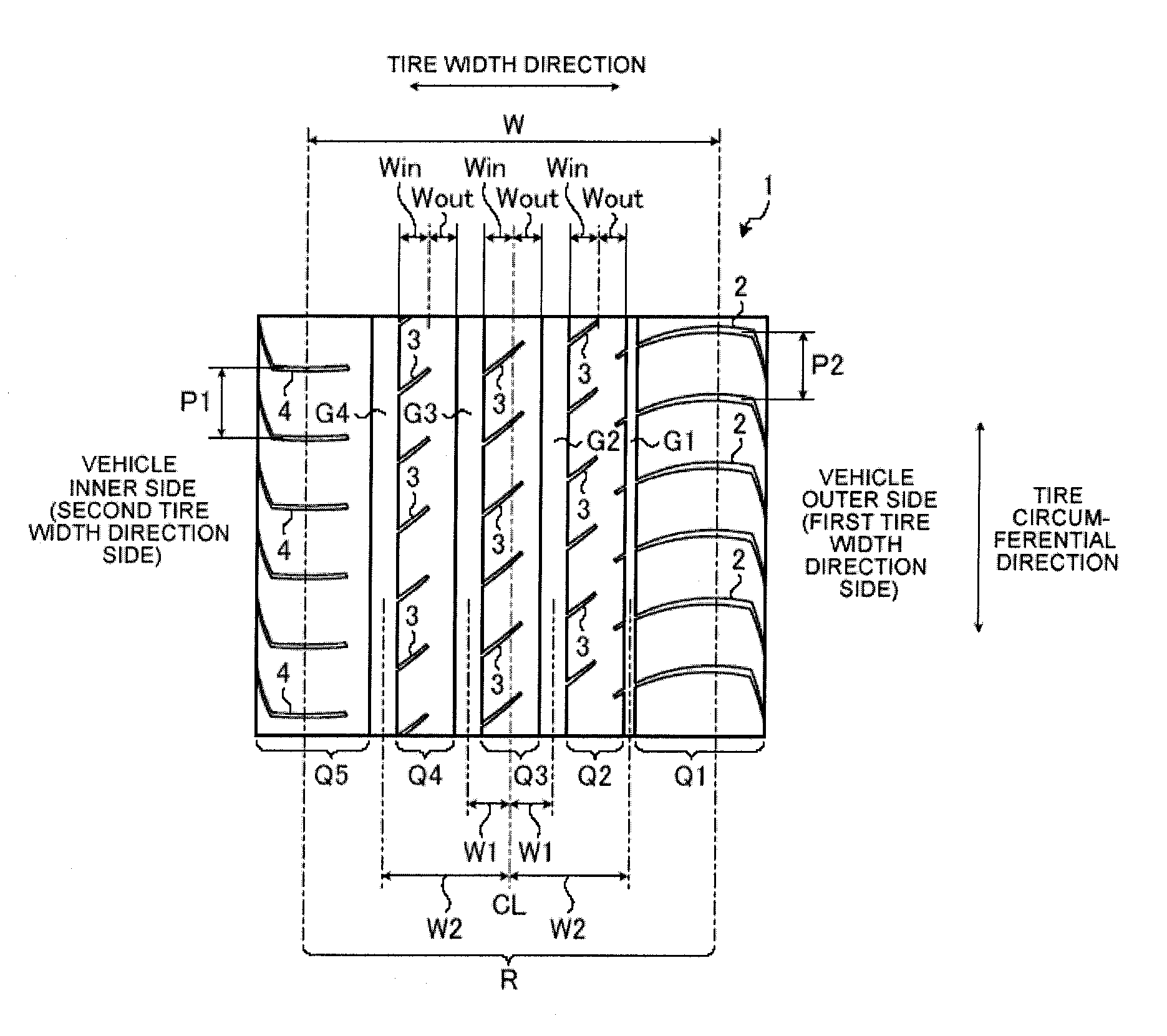

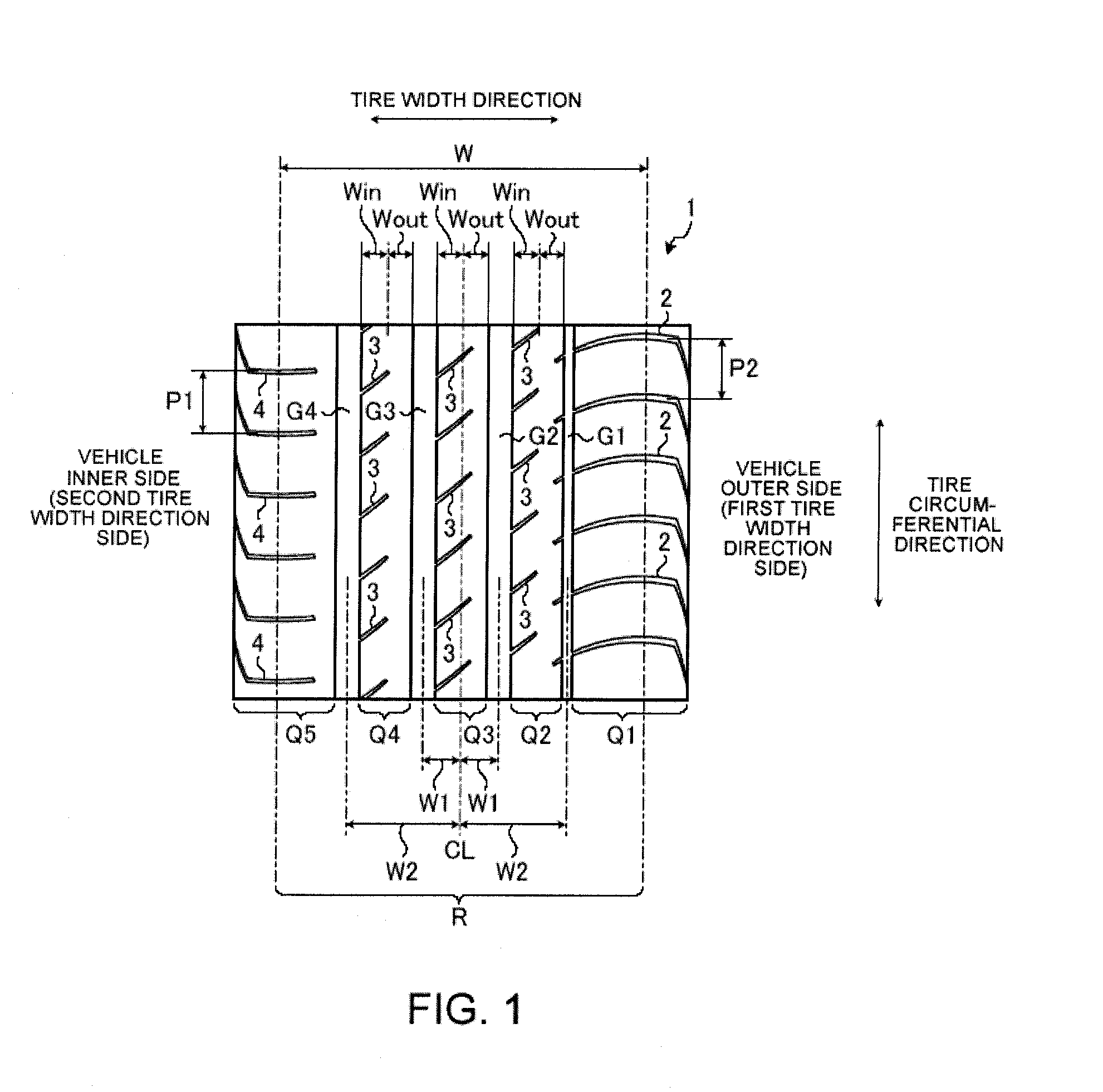

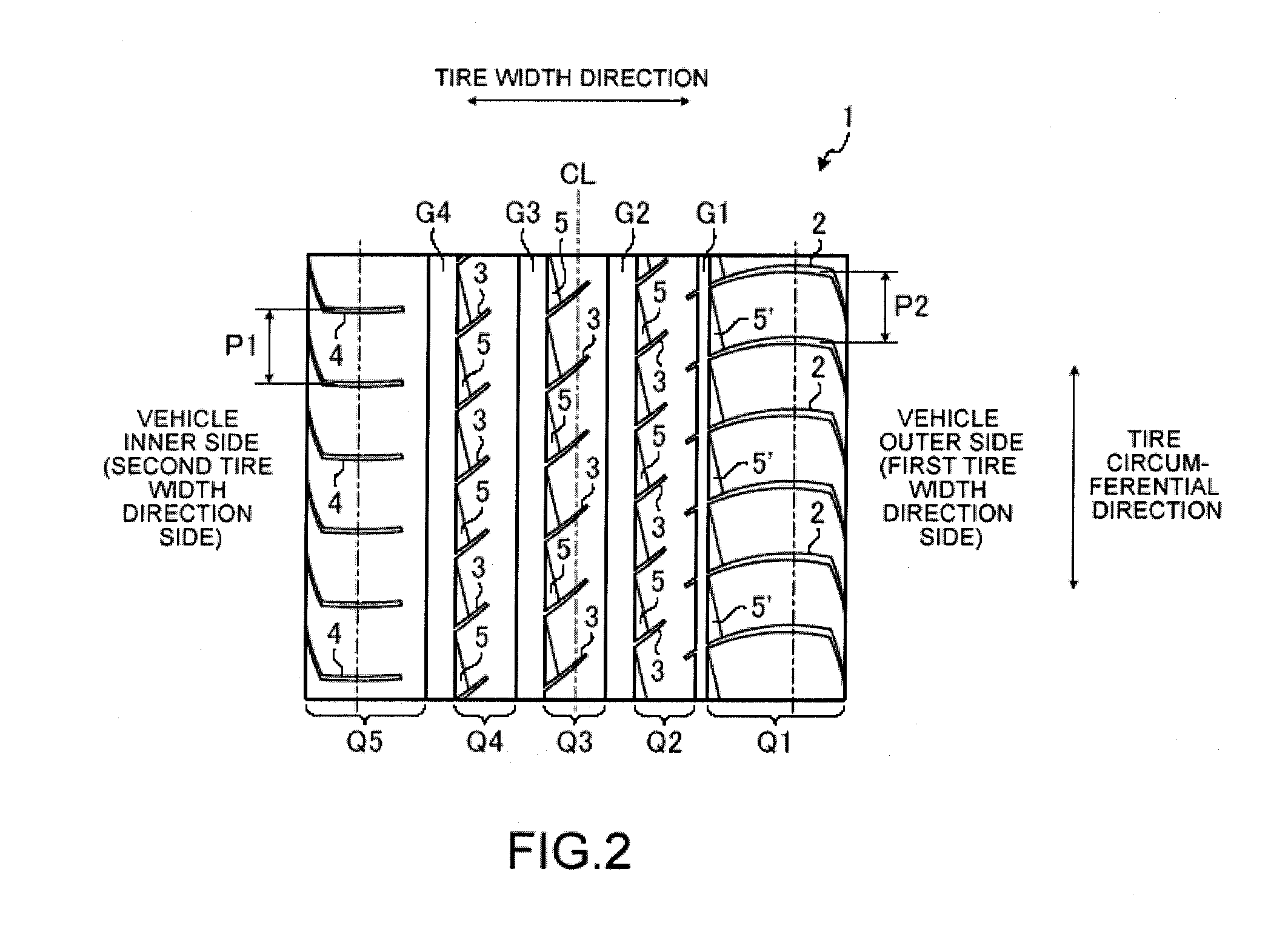

Pneumatic tire

ActiveUS20100212792A1Improve steering stabilityGuaranteed rigidityTyre tread bands/patternsNon-skid devicesGround contactGroove width

A pneumatic tire including five land portions Q1, Q2, Q3, Q4, Q5 in a tread surface 1 by providing four main grooves G1, G2, G3, and G4 in a ground contact region R of the tread surface 1, wherein positions and groove widths of the main grooves G1, G2, G3, and G4 are specified together with only the land portion Q1 positioned outermost on a vehicle outer side when mounted on a vehicle being formed into a block row, and the other land portions Q2, Q3, Q4, and Q5 being formed into ribs, and a groove area proportion of the tread surface 1 is larger on a vehicle inner side than the vehicle outer side with a tire equator CL and center lines of the land portions Q2, Q3, Q4 as boundaries.

Owner:YOKOHAMA RUBBER CO LTD

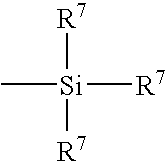

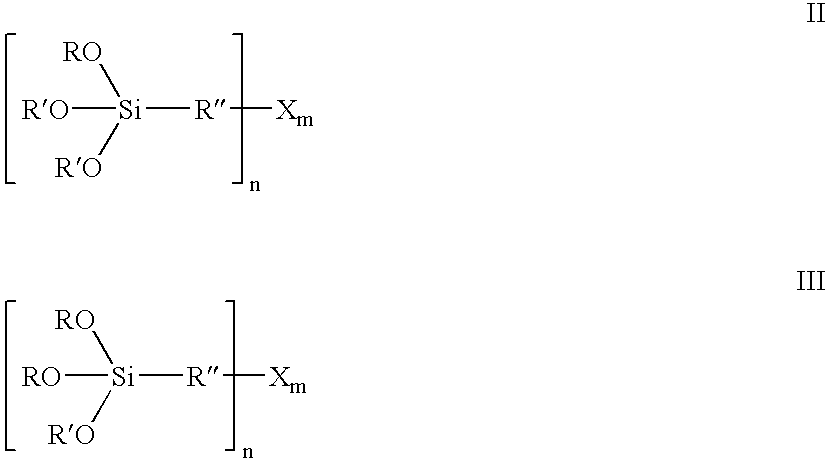

Blocked mercaptosilane hydrolyzates as coupling agents for mineral-filled elastomer compositions

InactiveUS7301042B2Low VOC emissionReduce load levelSilicon organic compoundsGroup 5/15 element organic compoundsElastomerSilica particle

Rubber composition intended for the manufacture of tire casings which have improved hysteretic properties and scorch safety, based on at least one elastomer and silica by way of reinforcing filler enclosing a reinforcing additive consisting of the mixture and / or the product of in situ reaction of at least one functionalized polyorganosiloxane compound containing, per molecule, at least one functional siloxy unit capable of bonding chemically and / or physically to the surface hydroxyl sites of the silica particles and at least one functionalized organosilane compound containing, per molecule, at least one functional group capable of bonding chemically and / or physically to the polyorganosiloxane and / or the hydroxyl sites of the silica particles and at least one other functional group capable of bonding chemically and / or physically to the polymer chains.

Owner:GENERAL ELECTRIC CO

Pneumatic tire tread

A pneumatic tire tread has tread elements formed by circumferential and / or lateral grooves. At least one tread element has a sipe that devolves from a constant width sipe having a three dimensional aspect in at least a portion of the radially outer portion of the sipe to a wider width groove at the base of the tread feature.

Owner:THE GOODYEAR TIRE & RUBBER CO

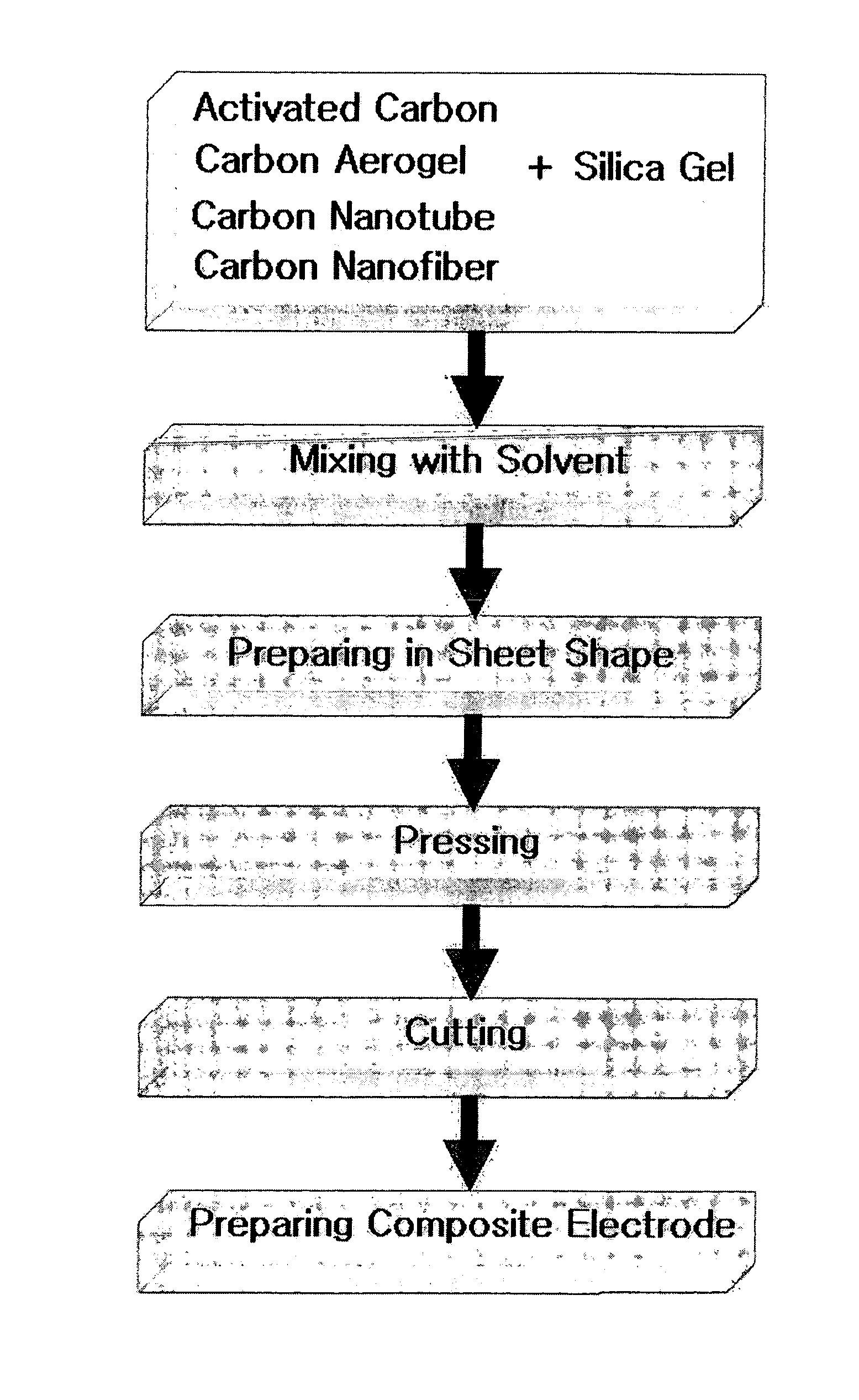

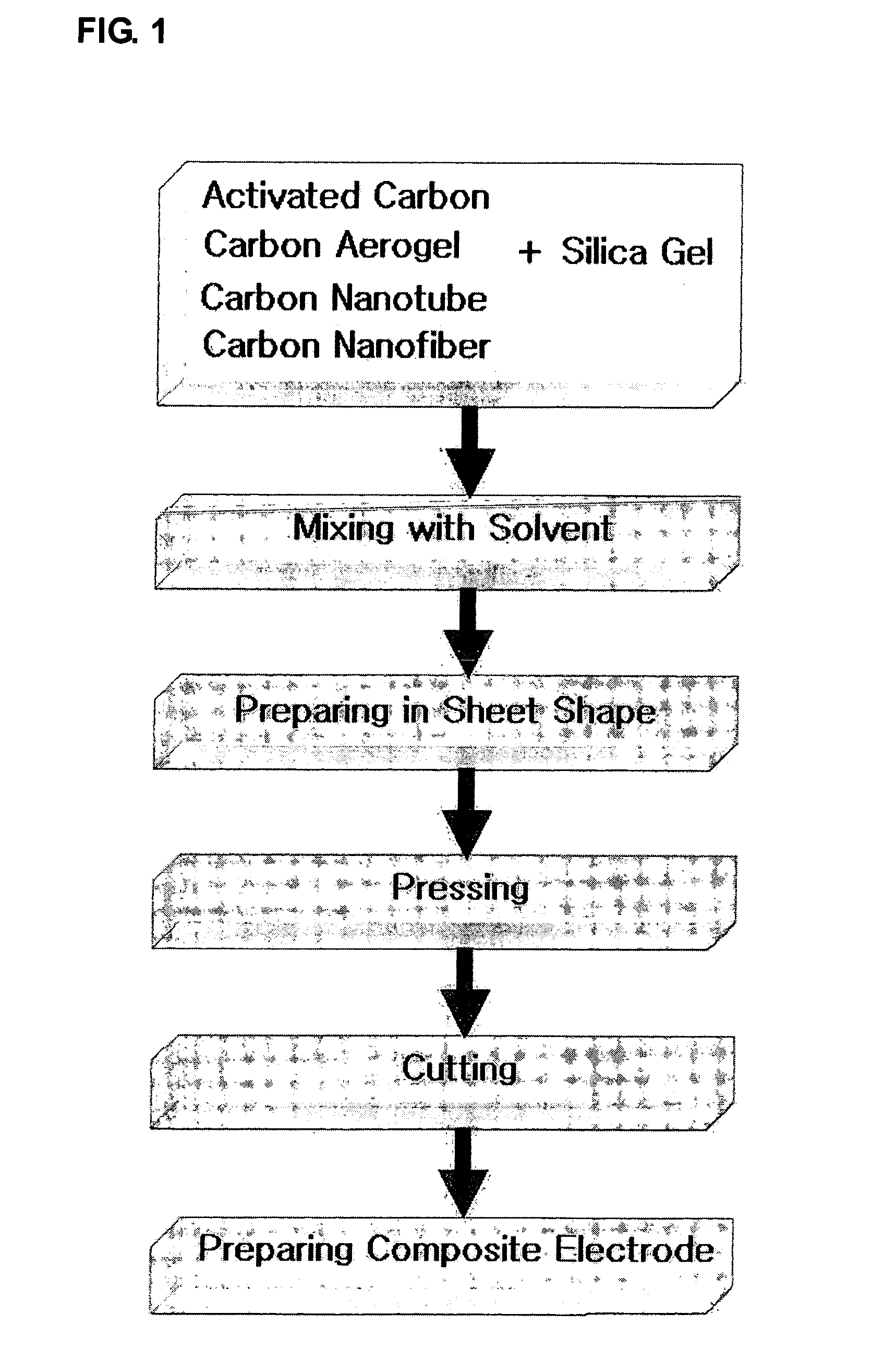

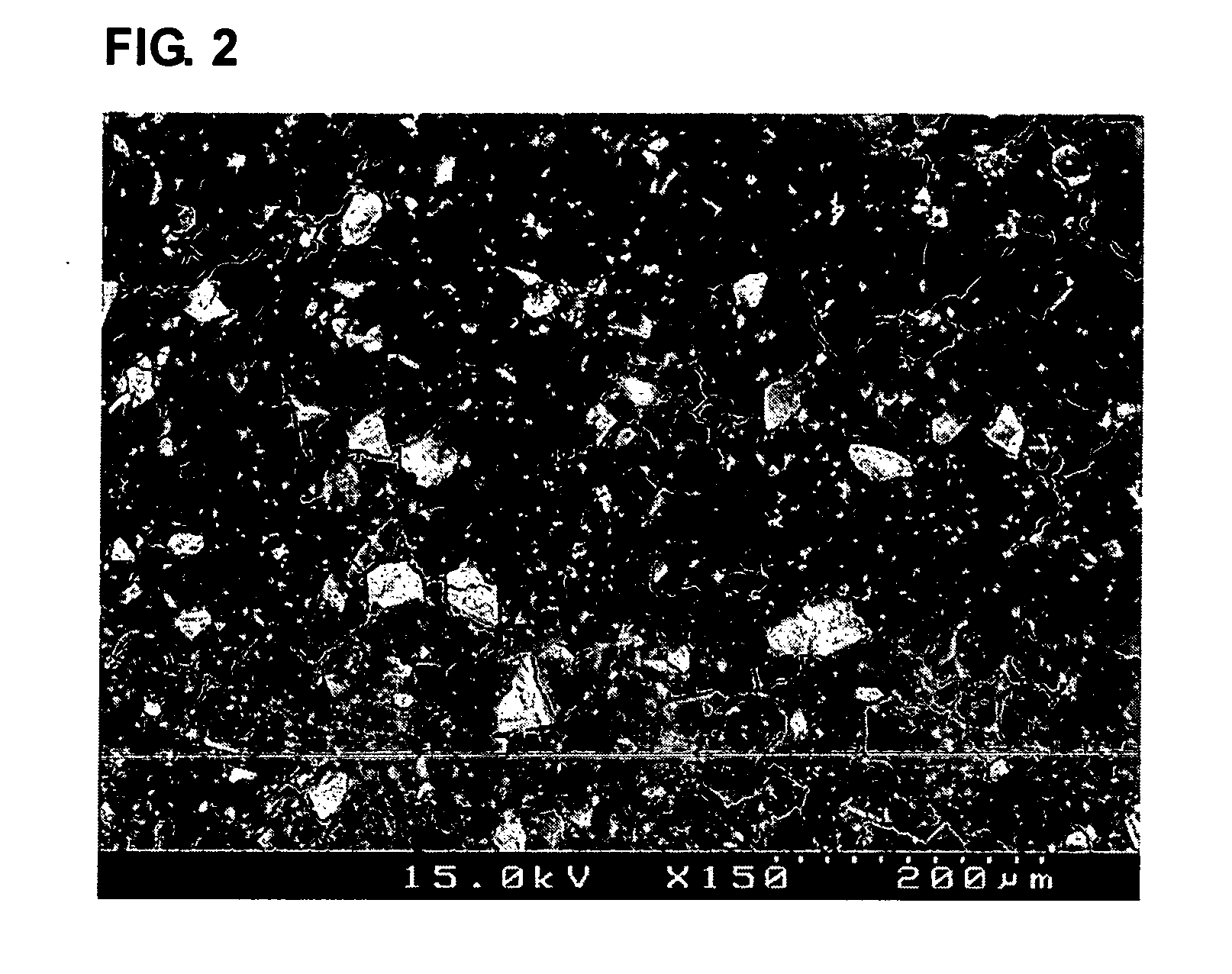

Carbon-porous media composite electrode and preparation method thereof

InactiveUS20050155216A1Improve hydrophilicitySimple processMaterial nanotechnologyElectrolytic capacitorsWater useCapacitance

The present invention discloses a carbon-porous media composite electrode material, a composite electrode using the same and a preparation method thereof. The carbon-porous media composite electrode can be applied for a device such as a secondary battery, a capacitor or the like, or for preparing ultra pure water using a capacitive deionization process, purifying salty water or the like.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com