Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

692 results about "Hydrophobic silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic silica is a form of silicon dioxide (commonly known as silica) that has hydrophobic groups chemically bonded to the surface. The hydrophobic groups are normally alkyl or polydimethylsiloxane chains. Hydrophobic silica can be processed in different ways; such as fumed silica, precipitated silica, and aerosol assisted self assembly, all existing in the form of nanoparticles.

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

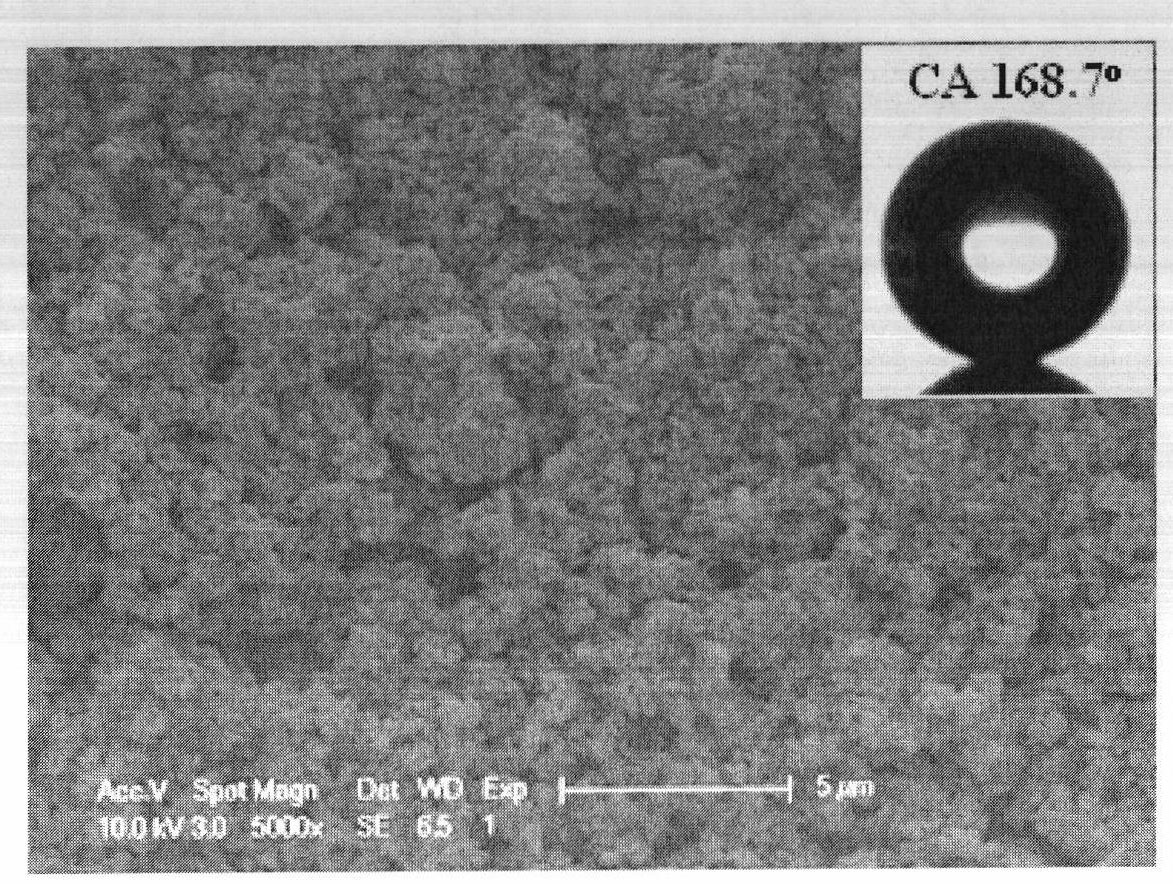

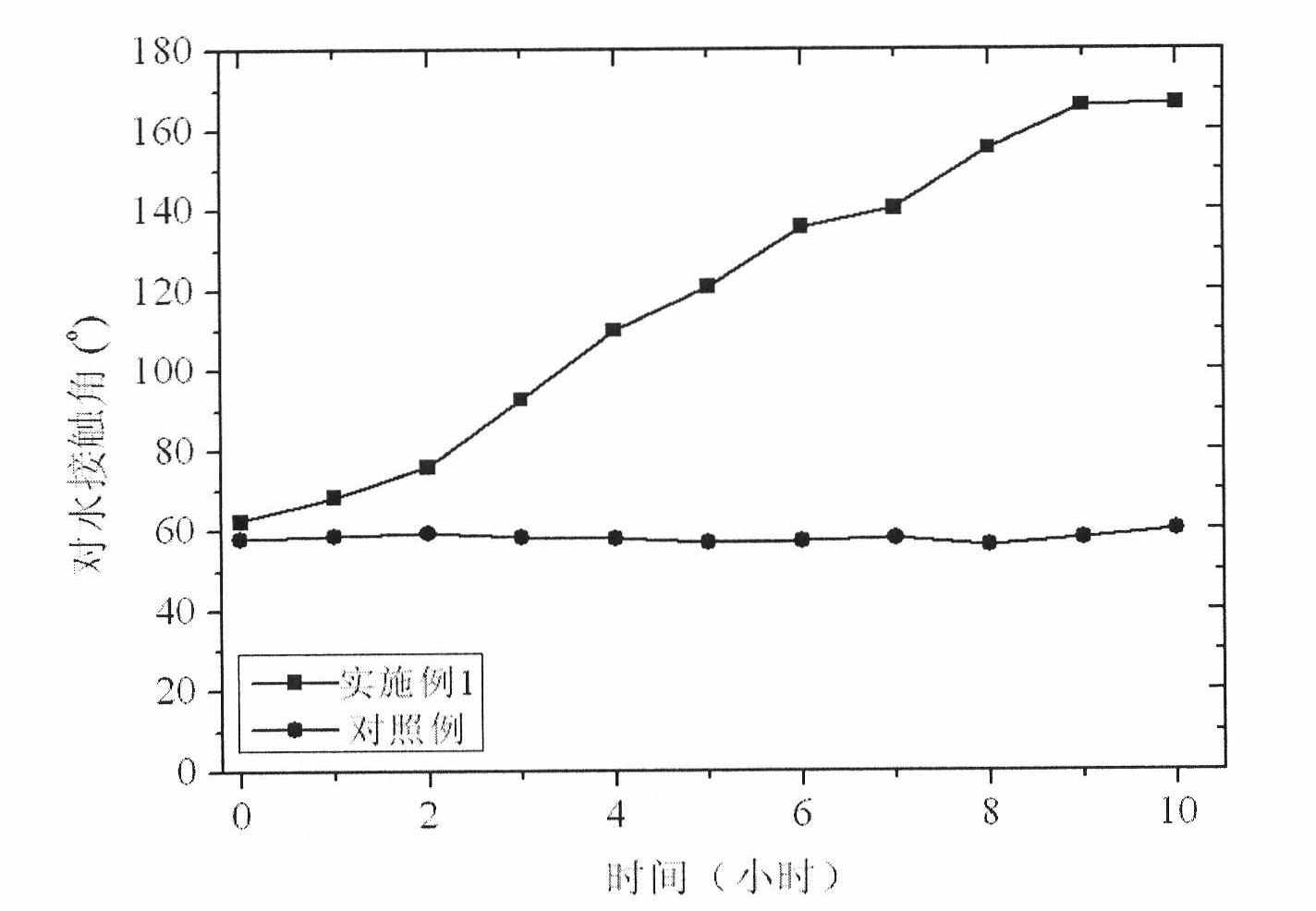

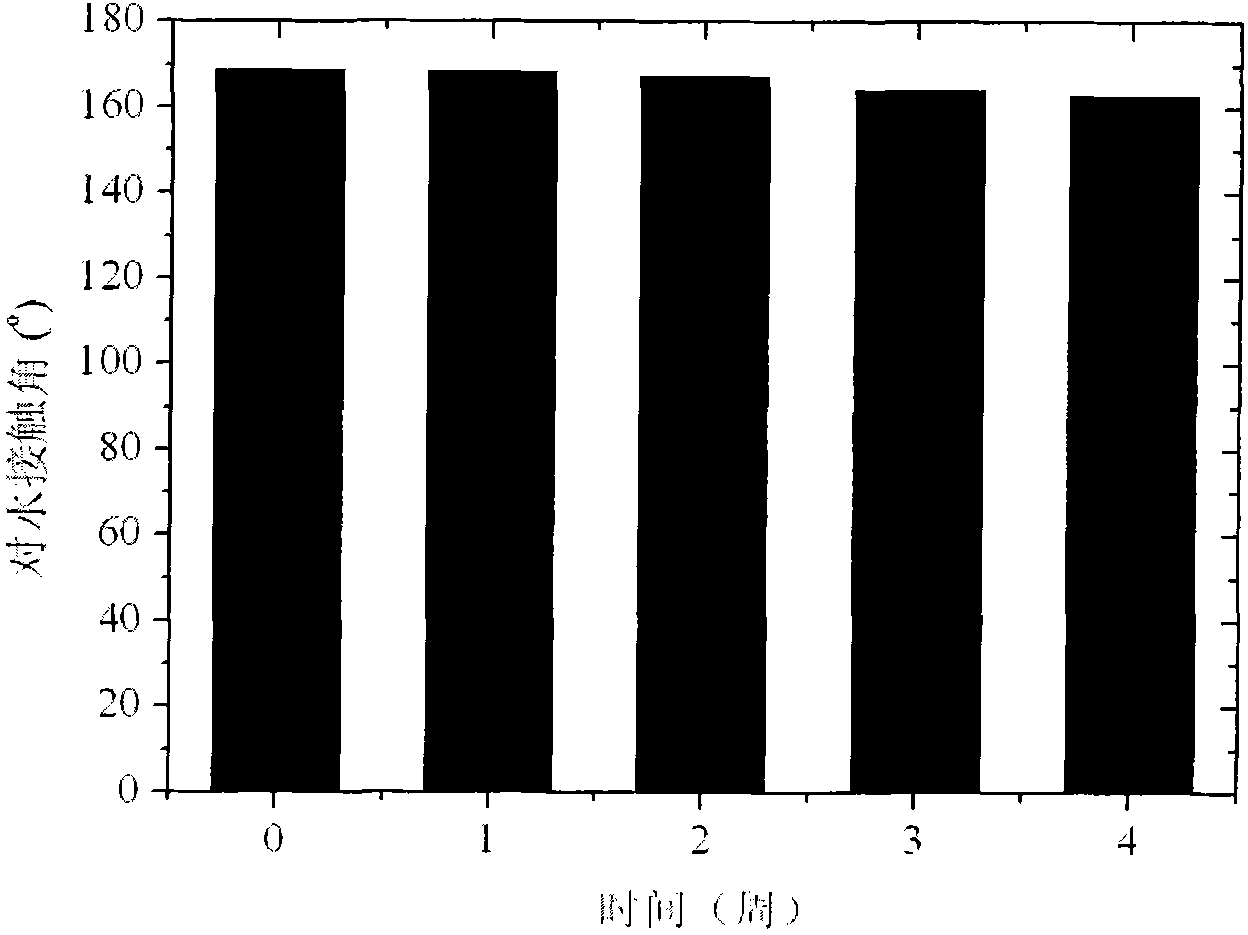

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

Tire with low hydrocarbon emission rubber combination of tread and sidewall components with compositional limitations

InactiveUS7214731B2Eliminate emissionsEmission reductionSpecial tyresInflatable tyresElastomerHydrophobic silica

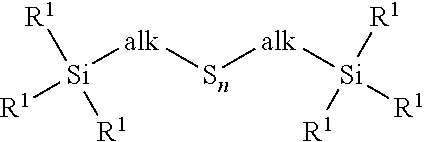

The invention relates to a tire of a structural combination of tire tread and sidewall components with compositional limitations containing minimal, if any, of in situ formed alcohol and methyl isobutyl ketone byproducts. The tread component rubber composition contains pre-hydrophobated silica reinforcement. The sidewall component contains low unsaturation EPDM or brominated copolymer of isobutylene and p-methylstyrene and may contain pre-hydrophobated silica reinforcement. The silica reinforcement for said tread and sidewall components is a pre-hydrophobated precipitated silica. The pre-hydrophobated silica is prepared, prior to mixing with the elastomer(s), by reacting hydroxyl groups (e.g. silanol groups) contained on the surface of a precipitated silica with an alkoxyorganomercaptosilane or a combination of an alkoxyorganomercaptosilane and a substituted alkylsilane or with a bis-3(trialkoxysilylalkyl) polysulfide which contains an average of from 2 to 4 connecting sulfur atoms in its polysulfidic bridge to form a composite thereof. The alcohol byproduct therefrom is removed from the composite prior to its introduction into the rubber composition(s). In another aspect of the invention, the connecting sidewall rubber composition, and optionally the tread composition is free of N-(1,3-dimethylbutyl)-N′-phenyl-p-phenylenediamine antidegradant (referred herein to as 6PPD) in order to prevent in situ formation of methyl isobutyl ketone byproduct from the reaction of 6PPD with atmospheric oxygen and / or ozone.

Owner:THE GOODYEAR TIRE & RUBBER CO

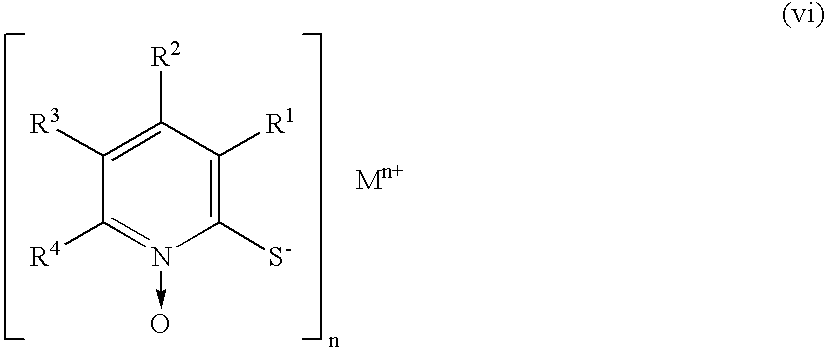

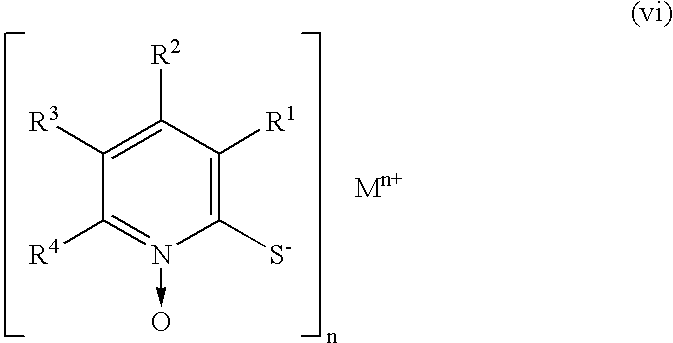

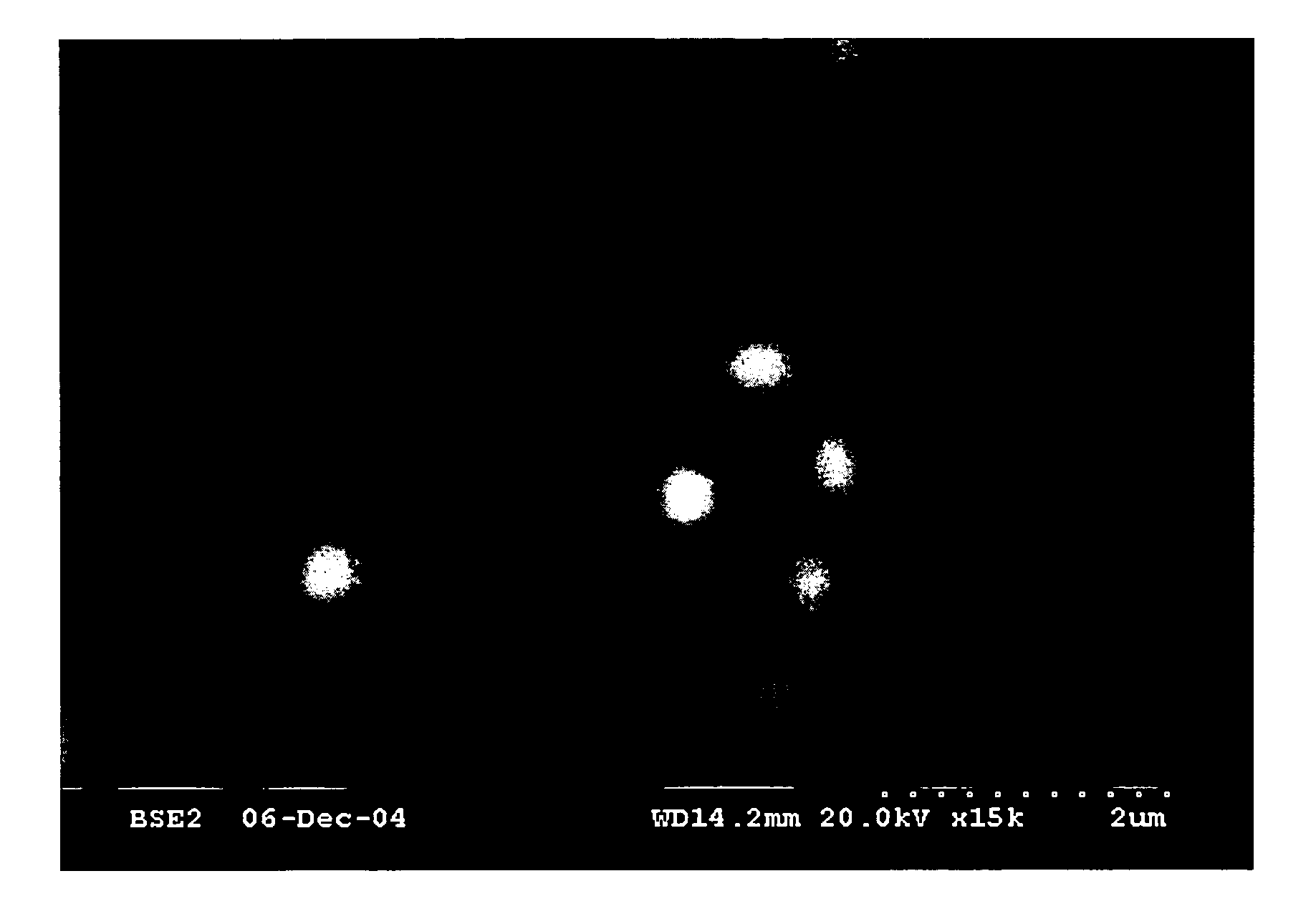

Water soluble metal and semiconductor nanoparticle complexes

The invention provides a water soluble complex comprising an inner core of a metal or semi-conductor nanoparticle. The nanoparticle is coated with a hydrophobic ligand, which is encapsulated in a micelle. In an aqueous medium, the micelle comprises a hydrophilic shell and a hydrophobic core, the hydrophilic shell comprising a plurality of hydrophilic moieties, the hydrophobic core comprising a plurality of hydrophobic moieties, each hydrophobic moiety comprising at least one chain, each chain comprising a minimum of 8 atoms; wherein the total number of atoms in all chains for each moiety comprises at least 24 atoms. The micelle has a minimum average diameter of approximately 5 nm and a maximum average diameter of approximately 45 nm.

Owner:THE ROCKEFELLER UNIV

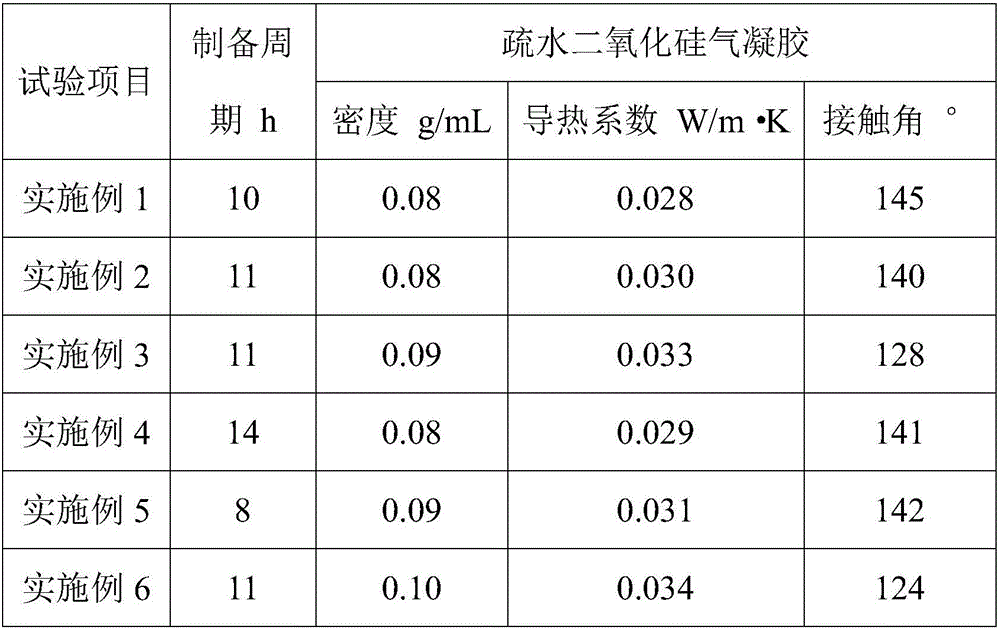

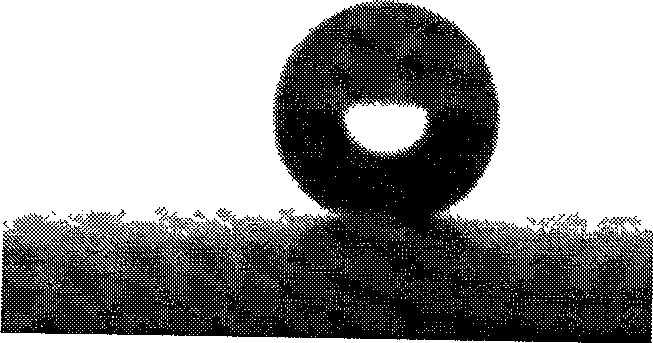

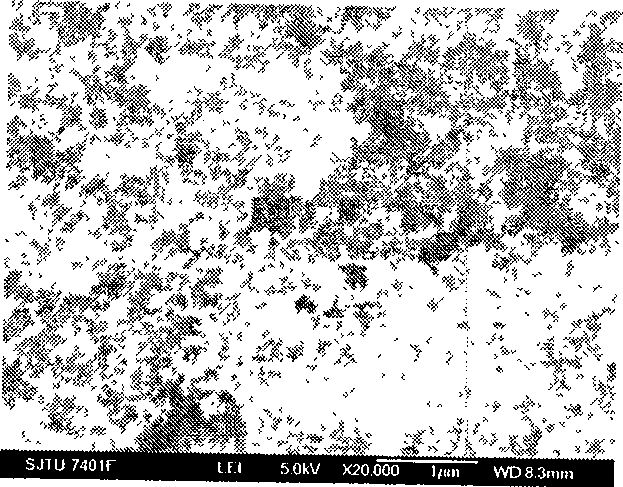

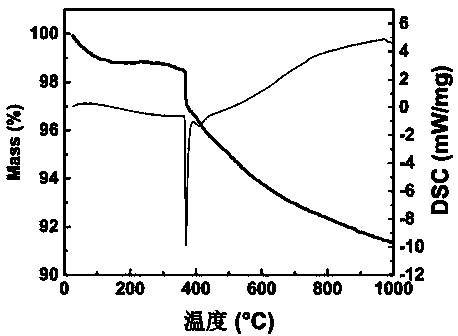

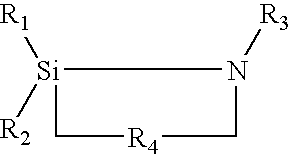

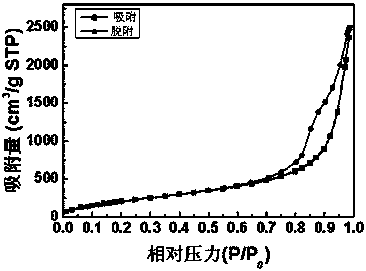

Preparation method for hydrophobic silica aerogel

The present invention discloses a preparation method for hydrophobic silica aerogel with industrial waterglass as a raw material, which comprises the following steps: diluting the industrial waterglass with water; neutralizing with an acid to obtain hydrosol; allowing the hydrosol to stand and age for 8-48 hours at normal temperature so as to form hydrogel; replacing the water in the hydrogel with anhydrous ethanol; allowing the hydrogel to react with organosilane compounds; performing surface modification and simultaneous solvent exchange with n-hexane; suction-filtering; washing; allowing to stand at normal temperature to obtain white hydrophobic silica aerogel powder. The preparation method has simple process and low cost, and the prepared aerogel has porous network-like structure which features a low density and a high specific surface area.

Owner:SHENZHEN UNIV

Coating compositions incorporating nanotechnology and methods for making same

InactiveUS20070027232A1Resisting deteriorationSpecial tyresPolyester coatingsWater basedSilica particle

The present invention relates to coating compositions, particularly water-based coating compositions, which incorporate nanotechnology. More specifically, the water-based coating compositions may include: a binder; a plurality of hydrophobic silica particles; and a solvent. The coating compositions may be applied to a variety of different surfaces, such as, for example, metals, plastics and signs, among others to impart resistance to corrosion and / or deterioration over time, as well as good adhesion thereto.

Owner:CHEMCOAT

Water based hydrophobic self-cleaning coating compositions

InactiveUS20090064894A1Efficient use ofWater-repelling agents additionSemiconductor/solid-state device manufacturingWater basedHydrophobic silica

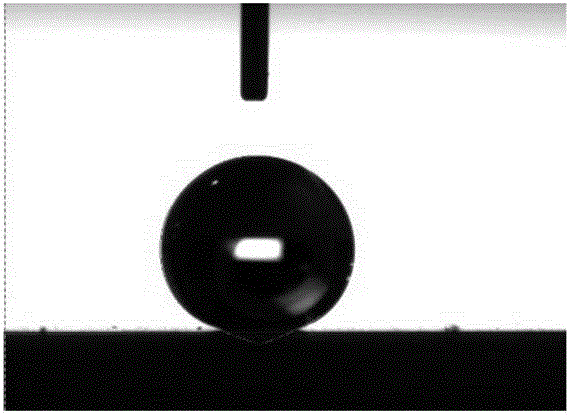

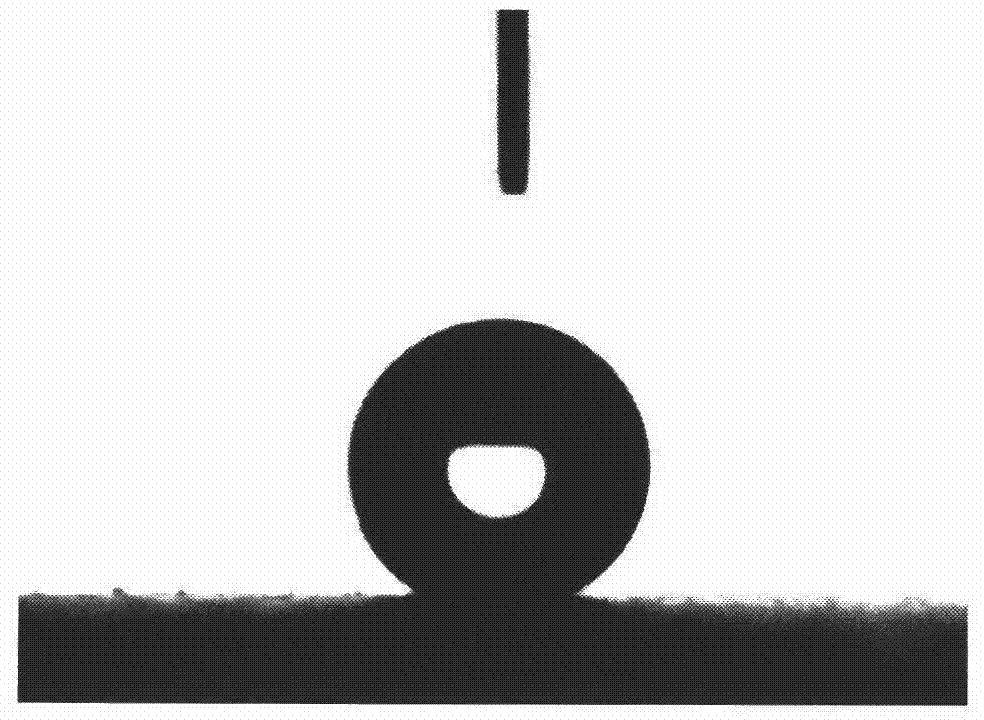

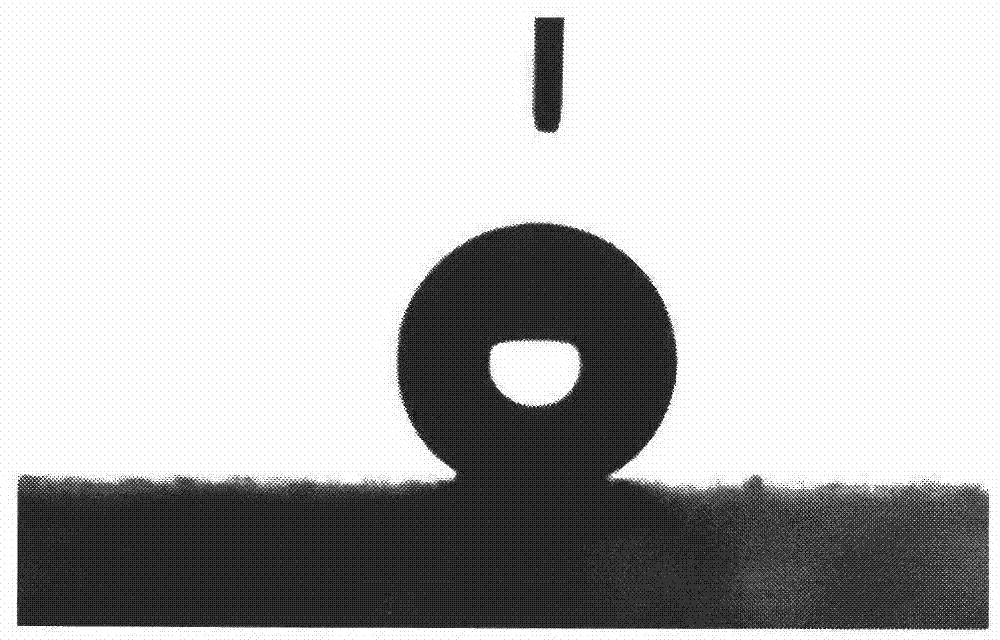

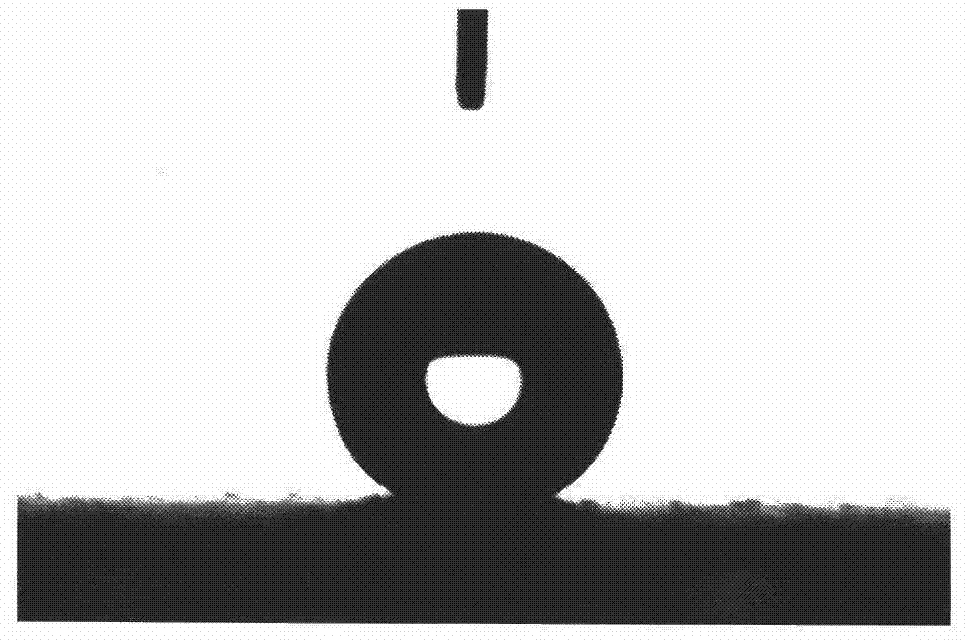

A coating composition comprising hydrophobic particles having an average size of between 7 nm and 4,000 nm and a wetting agent for promoting dispersion of the hydrophobic particles in water. The hydrophobic particles may be oxides, such as silica, titania, or zinc oxide. In one embodiment, the hydrophobic particles comprise fumed silica. The coating composition may be brushed, spin coated, or dipped onto a surface. In one embodiment, once the coating composition dries, the coating formed thereby is characterized by a contact angle formed with a water droplet in excess of 165 degrees. A method of making a coating composition comprising providing hydrophobic particles having an average size of between 7 nm and 4,000 nm, mixing a wetting agent with the hydrophobic particles to form a paste, and dispersing the paste in water by mixing to form a mixture.

Owner:VALVOLINE LICENSING & INTPROP LLC

Processes for making silane, hydrophobated silica, silica masterbatch and rubber products

ActiveUS20100022684A1Excellent scorch safetyNo lossPigmenting treatmentSilicon organic compoundsPolymer scienceHydrophobic silica

The present invention provides a process for making silica-filled rubber masterbatch using silica hydrophobated with a trimethoxy silane coupling agent that is soluble in an alcohol-water solution containing at least about 70 wt % water. One embodiment uses a mixture of trimethoxy silanes, one or more of which react with rubber to bond the silica to the rubber, and one or more of which do not react with rubber, but do hydrophobate the silica. Hydrophobated silica is mixed with latex polymer and incorporated into rubber during coagulation of the latex, which is preferably coagulated with calcium chloride. The present invention further provides a process for making the trimethoxy silane coupling agents. Preferred trimethoxy silane coupling agents include bis-(3-trimethoxysilylpropyl)-disulfide and bis-(3-trimethoxysilylpropyl)-tetrasulfide. Rubber products, particularly tires, compounded with the inventive silica masterbatch can be processed for a long time before scorching because the silica masterbatch provides a long scorch time.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS20020197490A1Shorten the running cycleExcellent in uniformity of coating film surfaceAntifouling/underwater paintsLayered productsHydrophobic silicaHardness

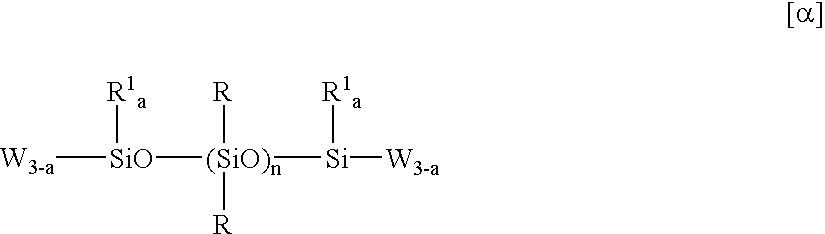

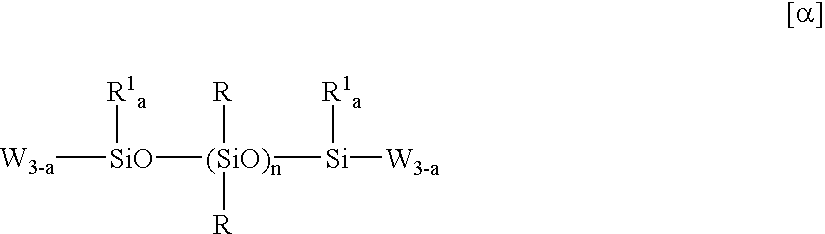

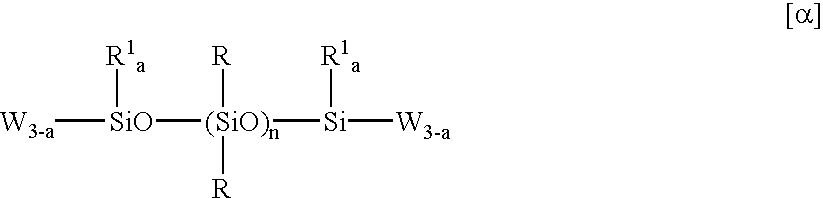

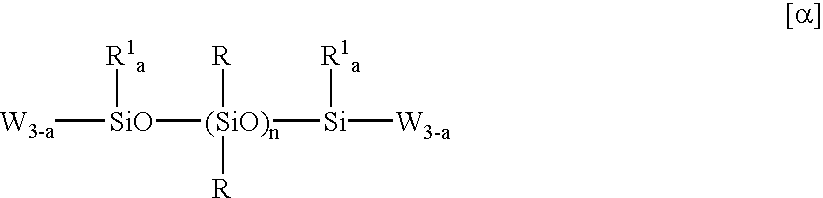

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A). The organopolysiloxane (A) is preferably represented by the formula: W3-a(R1a)Si(R2)O-(Si(R2)O)n-Si(R1a)W3-a [alpha] (wherein W represents a hydroxyl group or a hydrolyzable group; each of R1 and R independently represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 12 carbon atoms, provided that the hydrocarbon groups R1 as well as the hydrocarbon groups R may be identical with or different from each other; n is an integer of 5 or greater; and a is 0, 1 or 2). When, in the formula [alpha], W represents a hydroxyl group and a is 2, the curable composition preferably comprises, in addition to the components (A) and either (B-1) or (B-2), (C) an organosilane represented by the formula: R1bSiX4-b [I] (wherein R1 represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 8 carbon atoms; X represents a hydrolyzable group; and b is 0 or 1), or a partial hydrolyzate of the organosilane. Thus, a curable composition, especially a curable paint composition and an antifouling paint composition, and an antifouling coating film of the following characteristics can be provided. The curable composition, in particular when used as a coating material or a paint, is excellent in sprayability and enables forming a thick coating film by one-time application. The curable composition enables shortening the operating period for coating, and a coating film of uniform thickness can be obtained by the application thereof. The obtained coating film is excellent in film strength and film hardness and, when used for antifouling purposes, exerts excellent antifouling capability for a prolonged period of time. Further, the curable composition ensures excellent storage stability before application thereof.

Owner:CHUGOKU MARINE PAINTS +1

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS6451437B1Improve balanceShorten the running cycleAntifouling/underwater paintsLayered productsPolymer scienceHydrophobic silica

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A).

Owner:CHUGOKU MARINE PAINTS +1

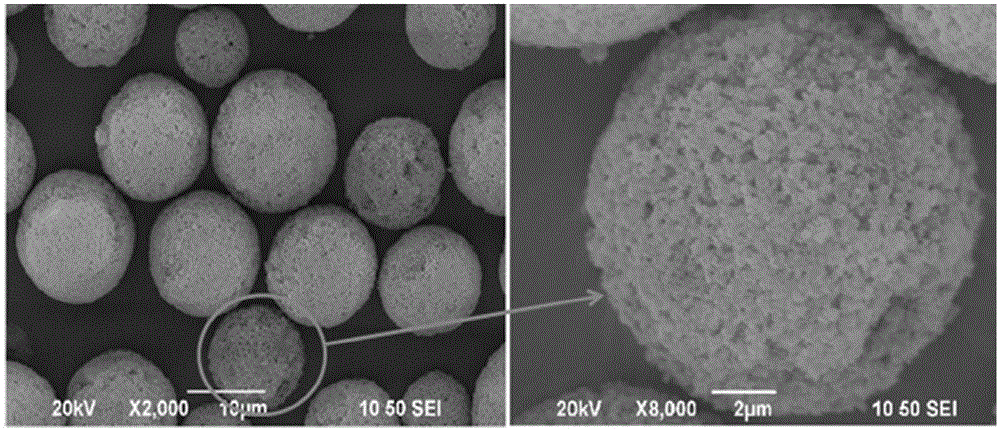

Preparation method for super-hydrophobic silica particle and super-hydrophobic coating

InactiveCN106587075ASimple manufacturing processExcellent superhydrophobic propertiesSilicaPolyurea/polyurethane coatingsHydrophobic silicaUltrasonic nebulization

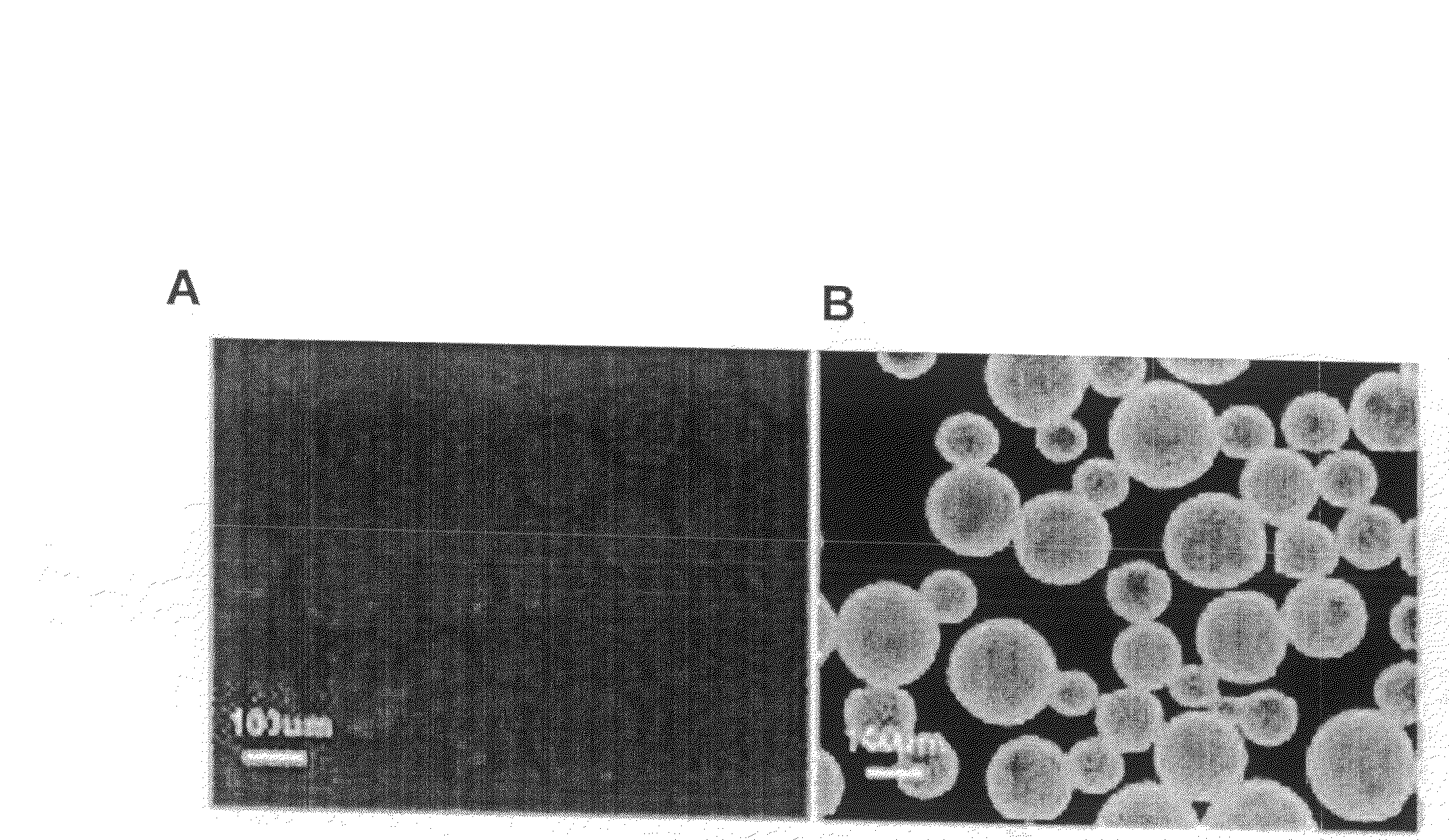

The invention provides a preparation method for super-hydrophobic silica particles and super-hydrophobic coatings. The method includes the following steps that in step S1, nanometer silica particles and silane modifiers are dispersed in a solvent to form a mixed solution, wherein weight ratio for nanometer silica particles and silane modifiers and the solvent is 1:0.05-0.5:3-20; the PH value of the mixed solution is adjusted to 2.0-5.0 by hydrochloric acid, and then the mixed solution is stirred for 2 to 24 hours at the temperature from 0 DEG C to 50 DEG C; the PH value of the mixed solution is adjusted to 6.0-7.5 by ammonia water, and then the mixed solution is stirred for 0.5 to 3 hours; a dispersion solution of modified nanometer silica particles is achieved; in step S2 the dispersion solution is dispersed into droplets by an ultrasonic nebulization technology and is dried at the temperature from 80 DEG C to 120 DEG C; the super-hydrophobic silica particles are achieved. With the preparation method for super-hydrophobic silica particles and super-hydrophobic coatings, the super-hydrophobic silica particles and the super-hydrophobic coatings are achieved, and have the advantages of being good in super-hydrophobic effect and simple in manufacturing process.

Owner:THE HONG KONG POLYTECHNIC UNIV

Preparation method of hydrophobic silica aerogel heat-insulation composite material

ActiveCN104556969AReduce replacement timeReduce the number of replacementsSilicon compoundsFiberPtru catalyst

The invention relates to a preparation method of a hydrophobic silica aerogel heat-insulation composite material. The method comprises steps as follows: (1) preparation of silica sol: siloxane is used as a precursor, an organic solvent, water and an acid catalyst are added, and the silica sol is obtained; (2) preparation of composite gel: a flame retardant and an infrared blocking agent are added to the silica sol, the mixture is evenly mixed, a base catalyst is added, an inorganic fiber product is immersed in the silica sol, and the mixture is left to stand; (3) solvent replacement: the composite gel is replaced by the organic solvent; (4) drying: the composite gel is dried. With the adoption of the method, the process is simple, the production cycle is short, the cost is lower, the equipment requirement is low, reaction conditions are controllable, product performance is excellent, and the prepared silica aerogel composite material has the overall waterproof performance, the extremely low heat conductivity coefficient and the excellent high-temperature heat-insulation performance, can pass an incombustibility test under the condition that the material is ensured to be hydrophobic as a whole and reaches level A1 according to the incombustibility test.

Owner:纳诺科技有限公司

Hydrophobic silica particles and methods of making same

InactiveUS20070196656A1Overcome problemsPigmenting treatmentParticle separator tubesSilica nanoparticlesSilica particle

A method of preparing hydrophobic silica particles includes the step of reacting together in a single step a mixture of silane ether monomers and organically modified silane ether monomers with a hydrolyzing agent. The method also includes producing hydrophobic silica microparticles and nanoparticles that can include dyes and / or magnetizable components. The silica nanoparticles can be used in the detection, visualization and / or analysis of latent fingerprints.

Owner:UNIVERSITY OF SUNDERLAND

Method of preparing hydrophobic silica

The invention provides hydrophobic surface-treated silica particles having (1) a ratio T2:T3 of about 0.4 or more, wherein T2 is the intensity of a peak having a chemical shift in the CP / MAS 29Si NMR spectrum centered within the range of −56 ppm to −59 ppm, and wherein T3 is the intensity of a peak having a chemical shift in the CP / MAS 29Si NMR spectrum centered within the range of −65 ppm to −69 ppm, and (2) a ratio (T2+T3) / (T2+T3+M) of greater than about 0.05, wherein M is the intensity of a peak having a chemical shift in the CP / MAS 29Si NMR spectrum centered within the range of +7 ppm to +18 ppm. The invention also provides a method of preparing hydrophobic surface-treated silica particles.

Owner:CABOT CORP

Modified silicon dioxide aerogel microsphere thermal-insulation coating

ActiveCN104231798AGood dispersionGood heat insulationEpoxy resin coatingsPigment treatment with organosilicon compoundsPolymer scienceSilanes

The invention discloses a thermal-insulation coating by taking hydrophobic silicon dioxide aerogel microspheres as thermal-insulation packing. The coating is prepared by the following main steps: preparing the hydrophobic silicon dioxide aerogel microspheres; and mixing the prepared hydrophobic silicon dioxide aerogel microspheres and a polymer emulsion to prepare the thermal-insulation coating. Hydrophobic modification of the silicon dioxide aerogel microspheres includes the following two modes: in one mode, silicon dioxide wet-gel microspheres are modified by adopting halogenated hydrocarbon and in the other mode, alkoxy silane, silazane or siloxane is added into a mixed solution in a sol preparing stage. When the coating is prepared, a surfactant is added, so that the compatibility between the hydrophobic silicon dioxide aerogel microspheres and the polymer emulsion can be improved, the dispersibility of the microspheres in the coating can be improved, the coating quality can be improved, and the thermal-insulation performance of the coating can be improved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Rapid preparation process of aerogel

Disclosed herein is a rapid preparation process of aerogel. More specifically, the present invention relates to a rapid preparation process of aerogel which enables a considerable reduction in preparation time and preparation costs via simultaneous treatment of solvent exchange and surface-modification of hydrophilic-to-hydrophobic transition.The rapid preparation process comprises mixing a cation exchange resin with sodium silicate (water glass) as a starting material, and removing the sodium ion from the sodium silicate, to subject the sodium silicate to ion exchange; adding a base catalyst and an organosilane compound to the sodium silicate to subject the sodium silicate to gelation; aging the gellized silica gel at room temperature for 2 to 4 hours to discharge water from the silica gel and to modify the surface of the silica gel into hydrophobicity; and drying the hydrophobic silica gel at atmospheric pressure for 18 to 27 hours.

Owner:KOREA INST OF ENERGY RES

Hydrophobic silica aerogel heat-insulation composite material and preparation method thereof

The invention discloses a hydrophobic silica aerogel heat-insulation composite material and a preparation method thereof. The composite material consists of silica aerogel and an inorganic fiber product, wherein the silica aerogel is doped with a flame retardant and an infrared blocking agent. During preparation of sol, siloxane containing hydrophobic groups is introduced, and the content and the distribution state of the hydrophobic groups in a system are controlled by controlling the reactant content and reaction conditions, so that the composite material can pass the test of GB8624-2012 Classification for Burning Behavior of Building Materials and Products (A1-level). The preparation method of the composite material comprises steps as follows: (1) preparation of the silica sol; (2) preparation of composite gel; (3) solvent replacement; (4) drying. With the adoption of the method, the process is simple, the production cycle is short, the cost is lower, the equipment requirement is low, and the prepared silica aerogel composite material has the overall waterproof performance, the extremely low heat conductivity coefficient and the excellent high-temperature heat-insulation performance.

Owner:纳诺科技有限公司

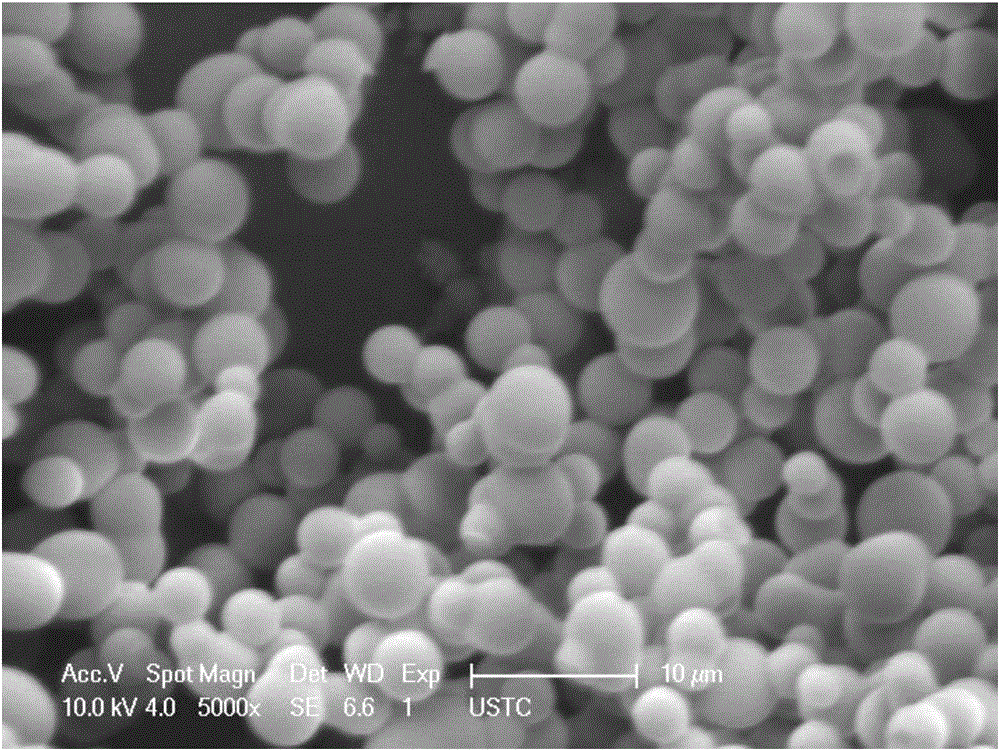

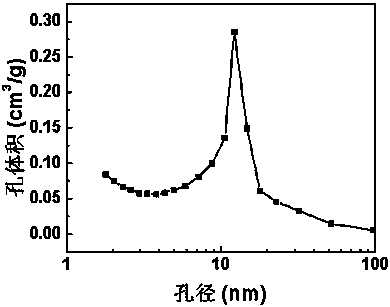

Preparation method of nanometer aerogel heat-insulation coating

InactiveCN102079949AReduce heat transferReduce contact areaSilicaPolyurea/polyurethane coatingsSupercritical dryingSolid particle

The invention relates to a preparation method of nanometer aerogel heat-insulation coating, which comprises the following steps: dissolving aerogel, solidifying the aerogel, aging, replacing by a surface modification solvent, drying at normal pressure and preparing lyophobic silicon dioxide aerogel; or supercritically drying and preparing hydrophilic silicon dioxide aerogel. The preparation method provided by the invention has the beneficial effects that the aperture of the silicon dioxide aerogel prepared by adopting the method provided by the invention is in nanometer-level distribution, and the main aperture of the silicon dioxide aerogel is10nm and is less than the free path of an air molecular movement, thereby greatly reducing the heat transfer generated by a gas molecular heat movement; the aerogel in the invention is in a network structure formed by overlapping the spherical granules of nanometer silicon dioxide, thereby reducing the contact area of solid granules, increasing the heat transfer path and further achieving the effects of heat maintenance and heat insulation; and lyophobic and hydrophilic type silicon dioxide aerogel can be prepared according to different drying processes to be used by matching organic or inorganic coatings.

Owner:李志

Method for quickly preparing hydrophobic silicon dioxide aerogel at low cost

InactiveCN106745004AAvoid pollutionReduce surface tensionSilicaNanotechnologyPhysical chemistryAmbient pressure

The invention discloses a method for quickly preparing hydrophobic silicon dioxide aerogel at low cost. The method comprises the following steps of (S1) mixing a silicon source, water and a surfactant evenly to obtain a precursor solution, adding an acid catalyst to the precursor solution, adjusting the pH value to be 3-4, and then hydrolyzing to obtain sol; and (S2) dropwise adding an alkali catalyst to the sol obtained in the step (S1), continuously stirring in the dropwise adding process, adjusting the pH value to be 6-7, and carrying out gel standing, ageing and ambient pressure drying to obtain the hydrophobic silicon dioxide aerogel. The method is low in cost, free of solvent exchange, short in production cycle and free of environmental pollution; and the prepared hydrophobic silicon dioxide aerogel has good heat preservation and heat insulation properties, hydrophobicity and flexibility.

Owner:ECONANO TECH LTD BEIJING

Preparation method of polymer hydrophobic surface

InactiveCN101456016AExcellent superhydrophobic propertiesUniform surface colorPretreated surfacesPolyester coatingsCoated surfacePolymer science

The invention provides a method for preparing a polymer hydrophobic surface and belongs to the technical field of polymer chemical material. The method comprises: preparing a polymer desperation and hydrophobic silica desperation; uniformly mixing the polymer desperation and the hydrophobic silica desperation for preparing a hydrophobic coating; spraying the hydrophobic coating onto a completely cleaned base surface uniformly with a spray gun; and finally, subjecting the sprayed base surface to heat treatment and cooling the base surface to obtain the polymer hydrophobic surface. The surface of a coating processed by the method is obvious in super-hydrophobic performance, uniform in luster and stable in performance, free from damage caused by scrubbing to the super-hydrophobic performance, simple in preparation process, low in preparation process implementation cost and applicable surfaces made from various materials without damaging the original materials by corrosive materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of hydrophobic silica aerogel composite fiber felt material

The invention relates to a preparation method of a hydrophobic silica aerogel composite fiber felt material. The preparation method comprises the following steps: mixing tetraethyl orthosilicate, ethanol, water and an acid catalyst to obtain silica sol; adding an alkali catalyst to the silica sol, uniformly stirring, pouring the mixture into a fiber felt (ceramic or glass fiber felt), immersing, and standing, so as to obtain a gel composite material; ageing the gel composite material in the fiber felt in mother liquor for a certain period of time, and then carrying out solvent exchange, so asto obtain a composite material; immersing the composite material in a solution containing certain concentration of a surface modifier for standing modification, and then drying the composite materialunder atmospheric pressure to obtain the hydrophobic silica aerogel composite fiber felt material. The preparation method has the advantages of simple process, short production cycle, lower cost, lowequipment requirement and excellent product performance, and the hydrophobic silica aerogel composite fiber felt material has superhydrophobic property, strong adsorption property and low thermal conductivity.

Owner:ZHEJIANG UNIV OF TECH

Process for producing hydrophobic silica powder

InactiveUS20060112860A1Good dispersionSimple equipmentMaterial nanotechnologyPigmenting treatmentColloidal silicaAzane

A process for producing a hydrophobic silica powder, comprises the steps for hydrophobic treatment of: adding to an aqueous silica sol containing hydrophilic colloidal silica having a specific surface area of 5.5 to 550 m2 / g, a disilazane compound represented by formula (1) (R13Si)2NH (1) wherein each R1 is C1-6alkyl group or phenyl group that is selected independently of one another, in an amount of 0.1 to 10 mmol per surface area 100 m2 of the hydrophilic colloidal silica, to obtain a first mixture of the aqueous silica sol and the disilazane compound; and heating the mixture at a temperature of 50 to 100° C. for aging it to obtain a slurry as dispersion of hydrophobic treated colloidal silica. The process provides a hydrophobic silica powder through a simple hydrophobic treatment step.

Owner:NISSAN CHEM IND LTD

Method of preparing hydrophobic silica directly from an aqueous colloidal silica dispersion

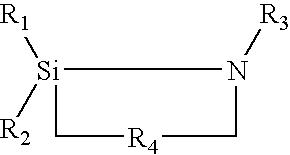

The invention provides a method of preparing hydrophobic silica particles comprising (a) providing an aqueous colloidal silica dispersion comprising about 5-70 wt. % of silica particles having an average overall particle size of about 10-1000 nm, wherein the silica particles comprise surface silanol groups, (b) combining the silica dispersion with about 3-75 μmole / m2 (based on the BET surface area of the silica) of a silyl amine treating agent and optionally with other ingredients to provide a reaction mixture, wherein the reaction mixture has a pH of about 7 or more, and comprises no more than about 50 wt. % of an organic solvent, and (c) drying the dispersion to provide hydrophobic silica particles. The invention further provides a method of preparing a toner composition comprising combining the hydrophobic silica particles as recited above with toner particles to provide a toner composition.

Owner:CABOT CORP

Brushable cosmetic preparation having a high water content

Brushable cosmetic preparation having a creamy or paste-like consistency, containing 50 to 95 wt. % of water, hydrophobed silicon dioxide powder, at least one cosmetically relevant active ingredient or auxiliary substance that is water-soluble or is dispersible or emulsifiable in an aqueous medium, and a viscosity regulator. It is produced by adding at least one cosmetically relevant active ingredient and / or auxiliary substance and optionally at least one pigment in water to a solution or dispersion adding hydrophobed silicon powder in portions or continuously whilst mixing and continuing mixing until the mixture, which is originally in powder form after addition of hydrophobed silicon dioxide powder, takes on a pasty consistency, and then adding a viscosity regulator and optionally at least one oil body, optionally before, together with or after addition of the viscosity regulator, with mixing. It can be used in pastes, creams, gels, pencils, foams, emulsions, dispersions, roll-ons, lotions.

Owner:DEGUSSA AG

Preparation method of super hydrophobic coating based on super hydrophobic silica and resin

InactiveCN103587185ASuperhydrophobicRestoring the superhydrophobic functionSynthetic resin layered productsSurface layerHydrophobic silica

The invention discloses a preparation method of a super hydrophobic coating based on super hydrophobic silica and resin. The resin as a substrate is coated on a glass slide; the super hydrophobic silica is bonded to the resin; and the resin is cured to prepare the super hydrophobic coating. The super hydrophobic coating prepared by the invention is composed of a base resin and a super hydrophobic silica surface layer. The body of the super hydrophobic silica layer is a super hydrophobic material, and if the surface is worn, the coating still has the same super hydrophobic property. When the super hydrophobic coating is polluted, the super hydrophobic function can be recovered by scraping off the surface layer. The super hydrophobic coating provided by the invention also can achieve waterproof effect due to the base resin.

Owner:WUXI SHUNYE TECH

High-Temperature Non-Skid Coating Composition

One embodiment relates to a coating composition, comprising a novolac epoxy resin comprising silicon carbide powder; an amine curing agent, said agent comprising at least a cycloaliphatic amine; a hydrophobic silica thixotrope agent; and an aluminum oxide powder having the following mesh retention characteristics, based on the weight of the aluminum oxide powder: about 0 wt. % size 10 mesh, ≧ about 5 wt. % size 16 mesh, ≧ about 20 wt. % size 18 mesh, ≧ about 10 wt. % size 20 mesh, and ≦ about 5 wt. % size 30 mesh. Other embodiments relate to making and using the coating composition, and coatings made from the coating composition.

Owner:RICHARD PARKS CORROSION TECH

Method of preparing hydrophobic silica directly from an aqueous colloidal silica dispersion

The invention provides a method of preparing hydrophobic silica particles comprising (a) providing an aqueous colloidal silica dispersion comprising about 5-70 wt. % of silica particles having an average overall particle size of about 10-1000 nm, wherein the silica particles comprise surface silanol groups, (b) combining the silica dispersion with about 3-75 μmole / m2 (based on the BET surface area of the silica) of a silyl amine treating agent and optionally with other ingredients to provide a reaction mixture, wherein the reaction mixture has a pH of about 7 or more, and comprises no more than about 50 wt. % of an organic solvent, and (c) drying the dispersion to provide hydrophobic silica particles. The invention further provides a method of preparing a toner composition comprising combining the hydrophobic silica particles as recited above with toner particles to provide a toner composition.

Owner:CABOT CORP

Preparation method of silica aerogel under atmospheric pressure

InactiveCN108423685ASimple and fast operationSimple processSilicon compoundsPolymer scienceHydrophobic silica

The invention discloses a method for preparing super-hydrophobic silica aerogel by atmospheric pressure drying. The method comprises the following steps: 1) preparing sol; 2) gelatinizing the sol; 3)aging gel; 4) exchanging a gel solvent; 5) carrying out surface hydrophobic modification; and 6) carrying out drying under atmospheric pressure. According to the preparation method of the silica aerogel, provided by the invention, tetraethoxysilane is used as a silicon source, ethanol is used as a solvent, acid and alkali are used as catalysts, and trimethylchlorosilane is used as a surface modifier, so that super-hydrophobic silica aerogel is prepared by atmospheric pressure drying. The prepared SiO2 aerogel with a super-hydrophobic three-dimensional network structure is tested to have a highspecific surface area, low density and good hydrophobicity at a room temperature. Therefore, the silica aerogel prepared through the method provided by the invention has excellent adsorption performance and has a good application prospect in the field of energy conservation. The preparation method of the silica aerogel under atmospheric pressure, provided by the invention, is simple in procedureand low in equipment requirements, can also shorten the process flow and reduce the cost, and is easy to industrialize.

Owner:ZHEJIANG UNIV OF TECH

Backing Sheet For Photovoltaic Modules

InactiveUS20090078314A1Improve adhesionGood color retentionSynthetic resin layered productsElectrical equipmentFluoropolymerHydrophobic silica

The present invention provides a protective backing sheet for photovoltaic modules. The backing sheet has a layer including fluoropolymer which is cured on a substrate, and the layer includes a hydrophobic silica. The amount of hydrophobic silica contained in the layer is within the range of 2.5 to 15.0% by weight, and preferably in the range of 7.5 to 12.5%. Also, the layer including fluoropolymer may further include a titanium dioxide.

Owner:MADICO INC

Method of preparing hydrophobic silica

The invention provides hydrophobic surface-treated silica particles having (1) a ratio T2:T3 of about 0.4 or more, wherein T2 is the intensity of a peak having a chemical shift in the CP / MAS<29>Si NMR spectrum centered within the range of -56 ppm to -59 ppm, and wherein T3 is the intensity of a peak having a chemical shift in the CP / MAS <29>Si NMR spectrum centered within the range of -65 ppm to -69 ppm, and (2) a ratio (T2 +T3) / (T2 +T3 +M) of greater than about 0.05, wherein M is the intensity of a peak having a chemical shift in the CP / MAS <29>Si NMR spectrum centered within the range of +7 ppm to +18 ppm. The invention also provides a method of preparing hydrophobic surface-treated silica particles.

Owner:CABOT CORP

Adhesive composition

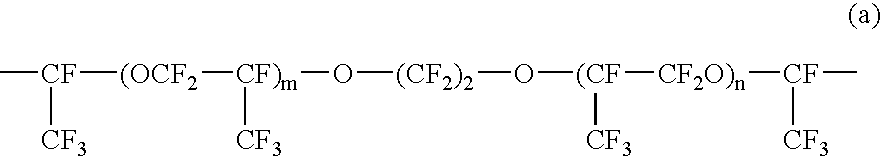

An adhesive composition comprises (A) a linear polyfluoro compound containing alkenyl groups and having a perfluoropolyether structure backbone, (B) a fluorine-bearing organohydrogensiloxane, (C) a platinum compound, (D) a hydrophobic silica powder, (E) an isocyanurate having an epoxy and / or trialkoxysilyl group, (F) an organosiloxane containing an SiH group and an epoxy and / or trialkoxysilyl group, and (G) a carboxylic anhydride. The composition cures into a fluoroelastomer having excellent characteristics and achieves a firm adhesion to a broad range of metal and plastic substrates by brief heating at relatively low temperatures.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com