High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

A technology of self-cleaning coatings and coating materials, applied in antifouling/underwater coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor superhydrophobic durability, poor controllability, and chemical modification of coatings, etc. Achieve outstanding self-cleaning properties, mild conditions, and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

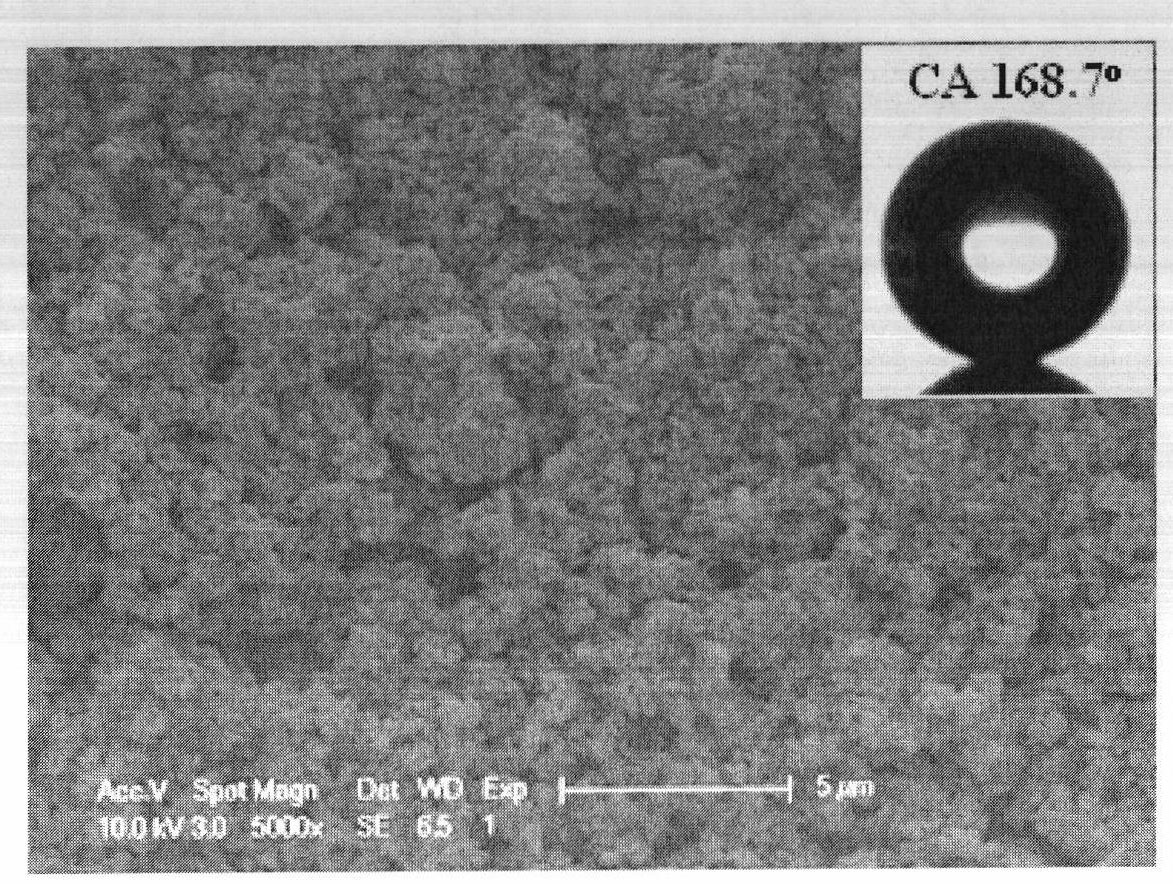

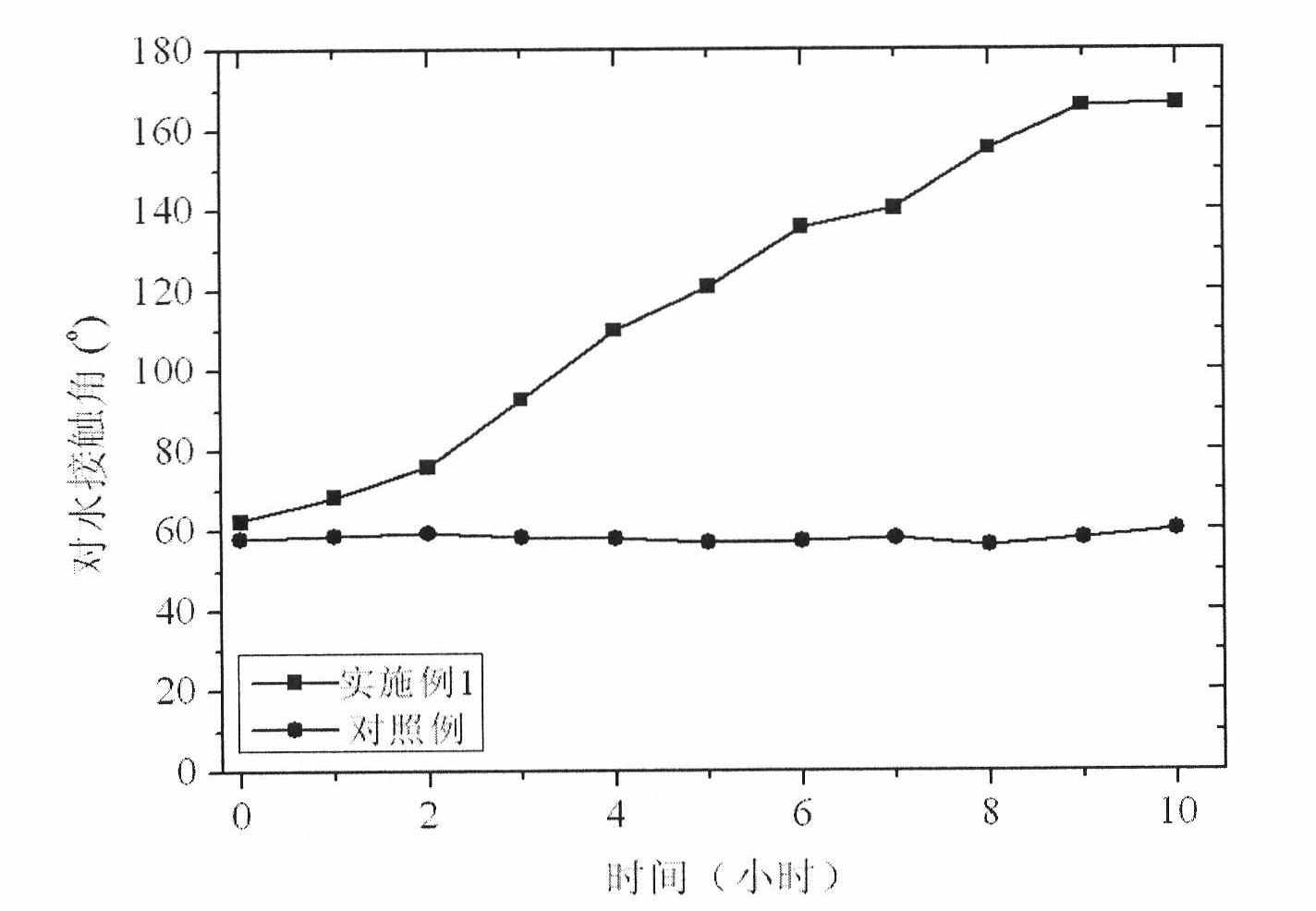

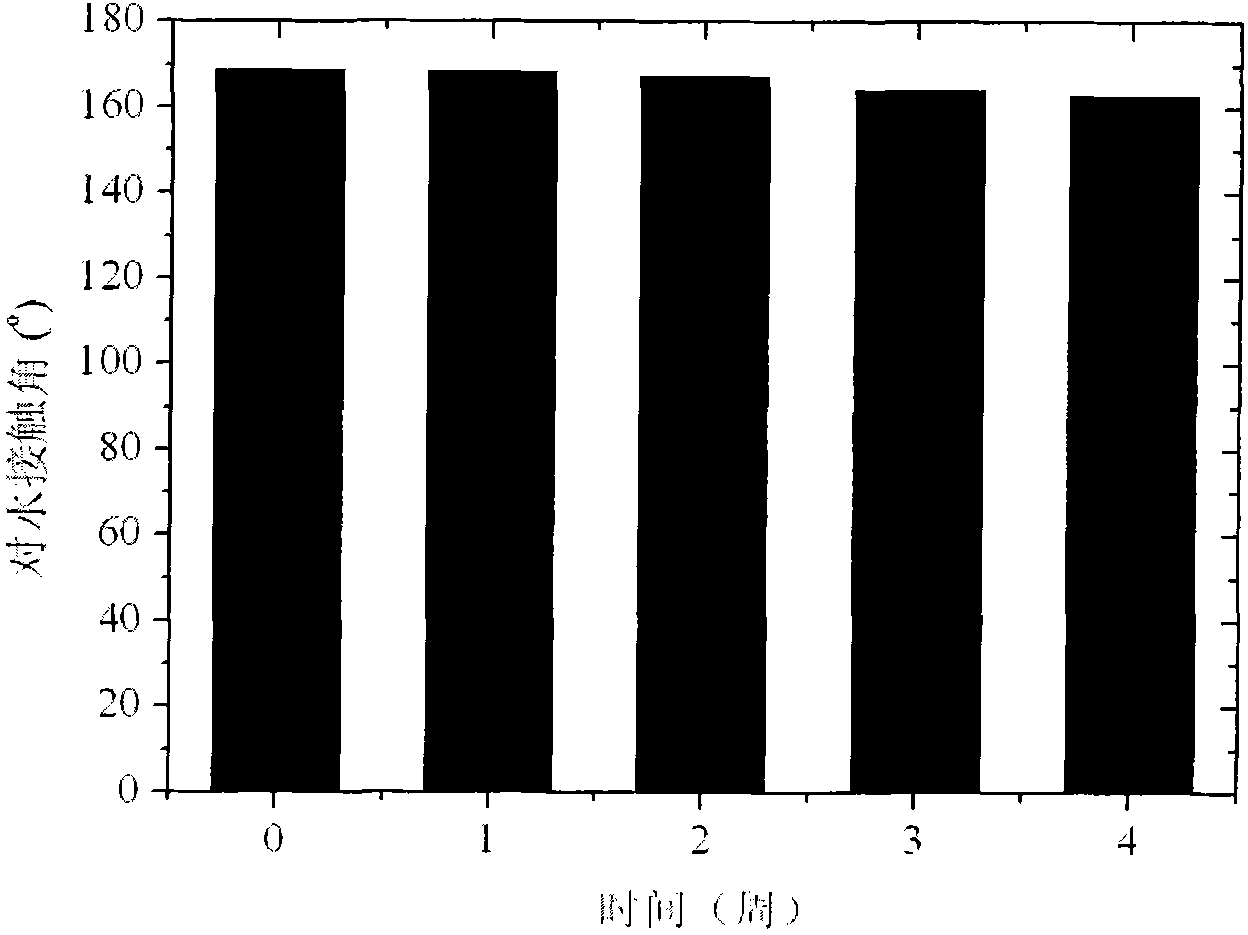

[0027] Add 0.52 parts of dispersant BYK180, 0.0035 parts of leveling agent BYK-333 and 0.0035 parts of defoamer A-141 into 250 parts of butyl acetate, shear and stir for 10 minutes to disperse; 56.5 parts of fluorine-containing hydroxypropyl silicone oil (molecular weight 8000g / mol, double-ended hydroxypropyl) and 35 parts of TiO 2 Nanoparticles (P25) were added to the above dispersion, stirred and dispersed at a speed of 1000r / min for 2 hours to obtain a nanocomposite coating; before coating, 8.5 parts of hydrogen-containing silicone oil (molecular weight 1200g / mol, double-ended hydrogen-containing ) and a small amount of platinum complex catalyst, stirred evenly, and coated on the tinplate by spraying, after curing and drying at room temperature, a super-hydrophobic coating was obtained, and the thickness of the coating was 10 μm. SEM observation shows that the coating surface has a micro-nano composite structure (see attached figure 1 ), the coating has a water contact ang...

Embodiment 2

[0029] Add 0.5 parts of dispersant BYK182, 0.002 parts of leveling agent BYK-300 and 0.002 parts of defoamer A-530 to 200 parts of xylene, shear and stir for 10 minutes to disperse; 69.2 parts of fluorinated vinyl silicone oil (molecular weight 6000g / mol, double-terminal vinyl) and 20 parts of ZnS nanoparticles were added to the above dispersion liquid, stirred and dispersed at a speed of 1000r / min for 2 hours to obtain a nanocomposite coating; before coating, 10.8 parts of hydrogen-containing fluorine were added Silicone oil (molecular weight 1800g / mol, double-terminal hydrogen-containing) and a small amount of methylvinylsiloxane coordination platinum catalyst are used to paint the film on the wood board by brushing, and after curing and drying at room temperature, a super-hydrophobic coating is obtained. The coating thickness is 95 μm, the coating water contact angle is 159.3°, and the rolling angle is 1.1°.

Embodiment 3

[0031] Add 0.4 parts of dispersant BYK145, 0.001 parts of leveling agent BYK-306 and 0.001 parts of defoamer A-065 to 200 parts of xylene, shear and stir for 10 minutes to disperse; / mol, double-ended vinyl) and 20 parts of SnO 2 Nanoparticles were added to the above dispersion, stirred and dispersed at a speed of 1000r / min for 2 hours to obtain a nanocomposite coating; Methylvinyl siloxane coordination platinum catalyst is used to coat the film on the glass plate by dip coating. After curing and drying at room temperature, a superhydrophobic coating is obtained. The thickness of the coating is 1 μm, and the water contact angle of the coating is 169.3°. Roll angle 0.5°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com