Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

603results about How to "Excellent superhydrophobic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

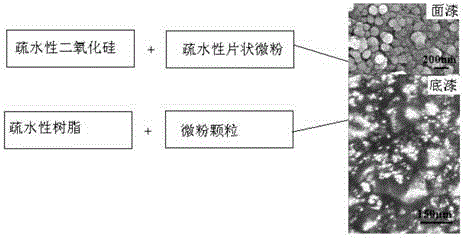

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

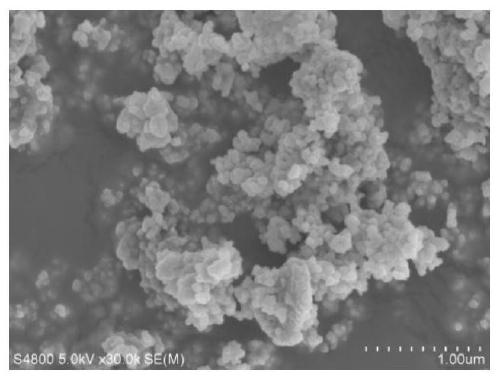

Super-hydrophobic nanometer transparent coating and preparation method thereof

ActiveCN104987520AExcellent superhydrophobic propertiesHigh transparencyCoatings with pigmentsFibre treatmentOrganic solventUltrasonic dispersion

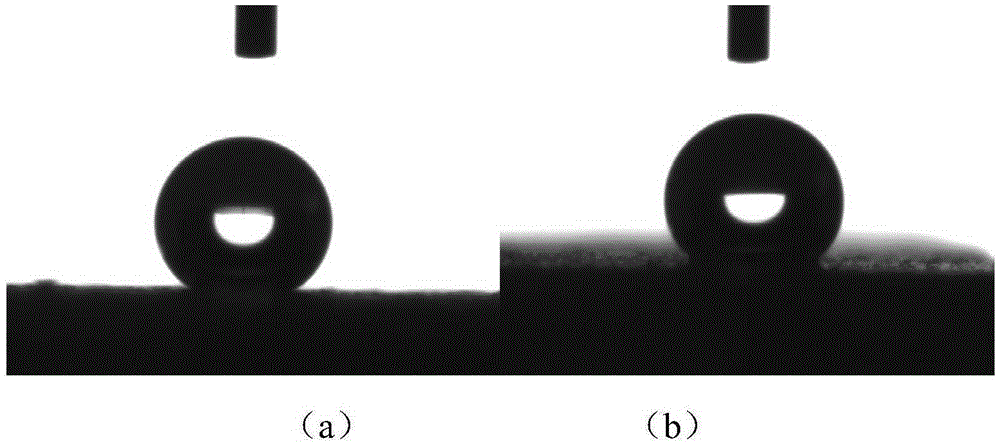

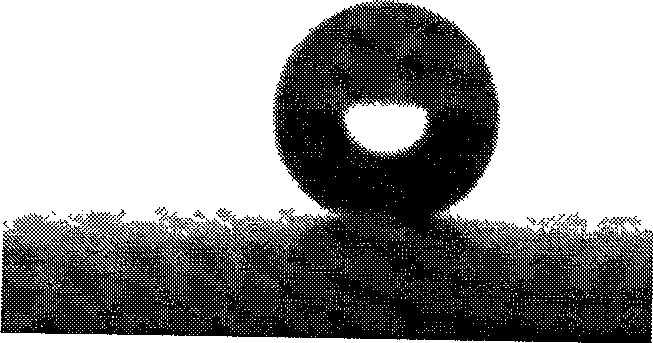

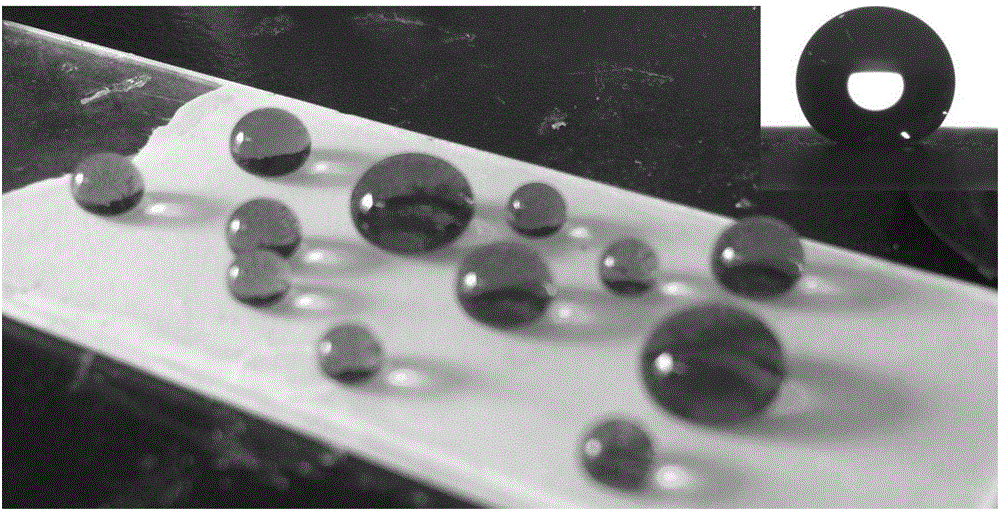

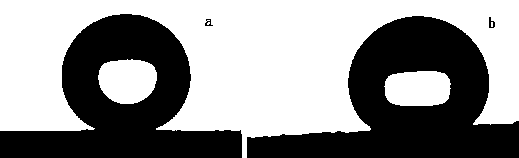

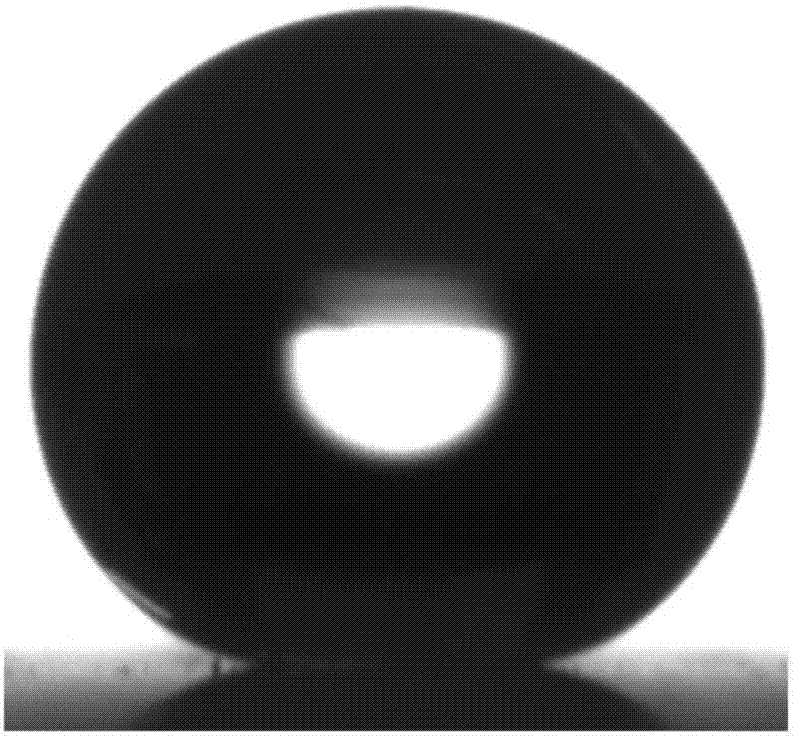

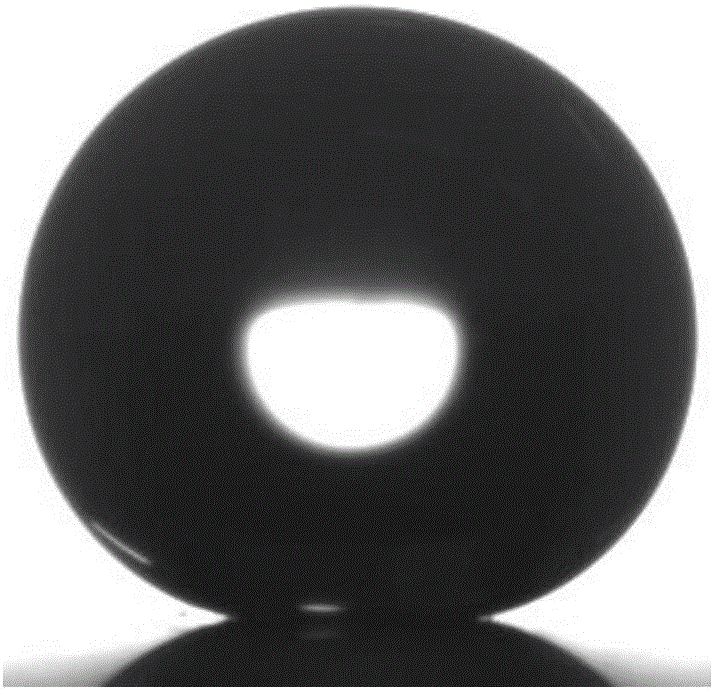

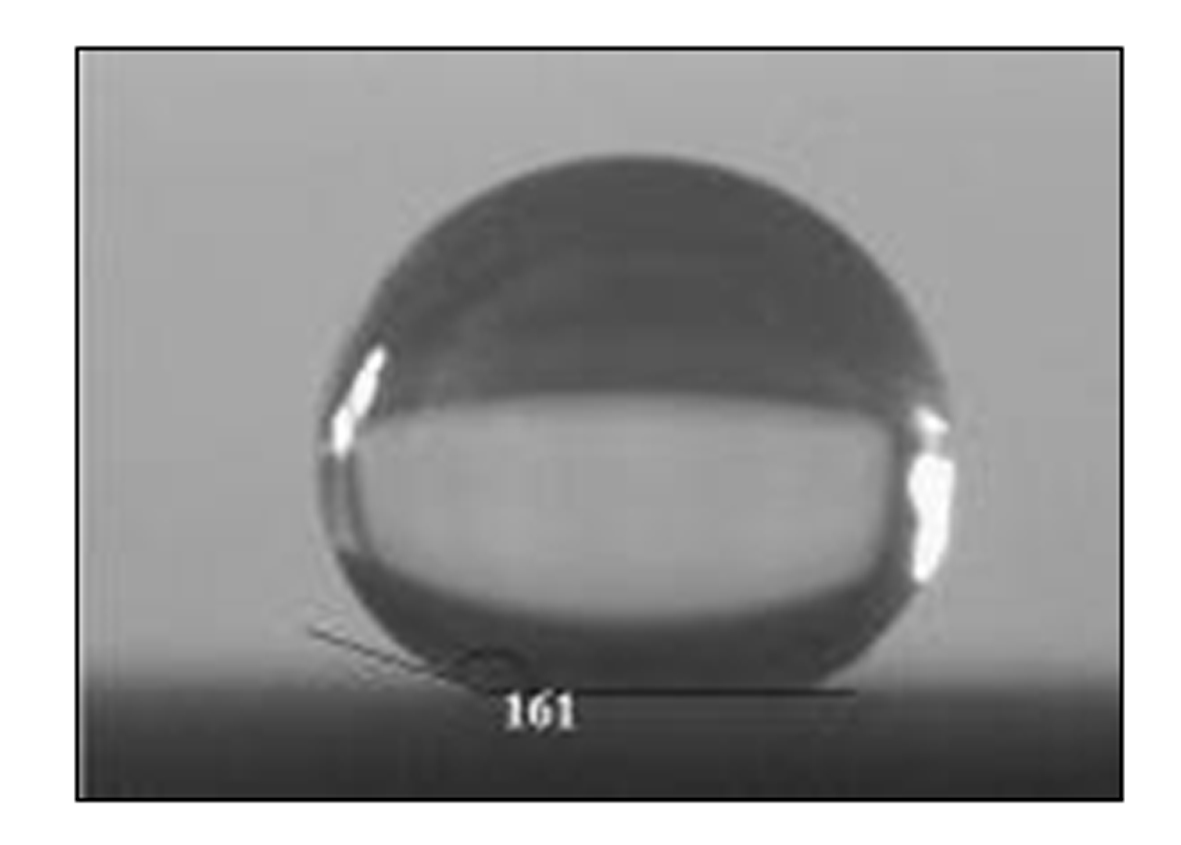

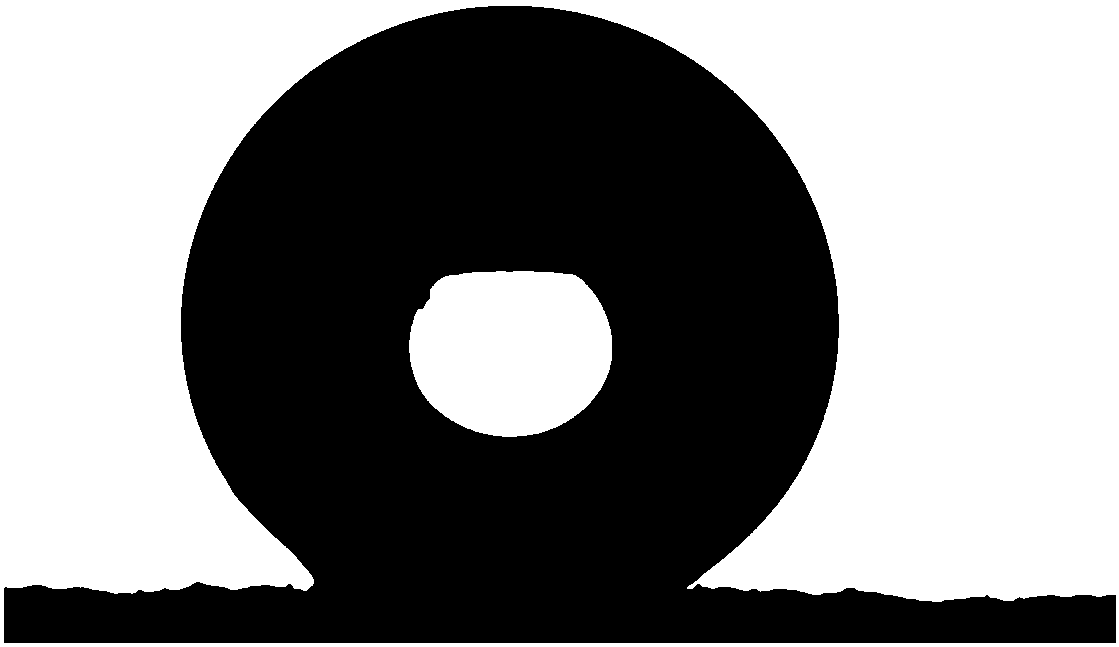

The invention provides a super-hydrophobic nanometer transparent coating and a preparation method thereof and belongs to the technical field of super-hydrophobic paint. The method includes the steps that firstly, a first category of inorganic nanometer particles are added into an organic solution, and ultrasonic dispersion is performed; secondly, dispersing agents and a second category of inorganic nanometer particles are added, and ultrasonic dispersion is performed so that a dispersion solution can be obtained; crosslinking agents and additives are added in the dispersion solution, ultrasonic dispersion is performed, finally, low-surface energy polymers are added, mixtures are evenly mixed, and transparent and clear super-hydrophobic paint is obtained; the surface of a solid base materials is coated with the transparent and clear super-hydrophobic paint, and the super-hydrophobic nanometer transparent coating is obtained through low-temperature thermal drying and curing. The super-hydrophobic performance of the super-hydrophobic nanometer transparent coating prepared through the method is excellent, the contact angle can be 160 degrees, the rolling angle is 1-7 degrees, the super-hydrophobic nanometer transparent coating can be sprayed to the surfaces of most of common materials, the morphology of the surfaces of the materials are not changed, and the application prospects and the application potency are very wide.

Owner:BEIHANG UNIV

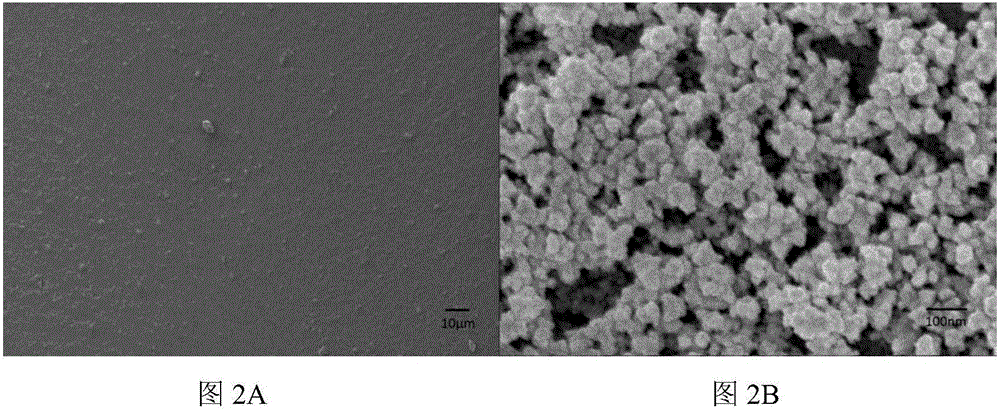

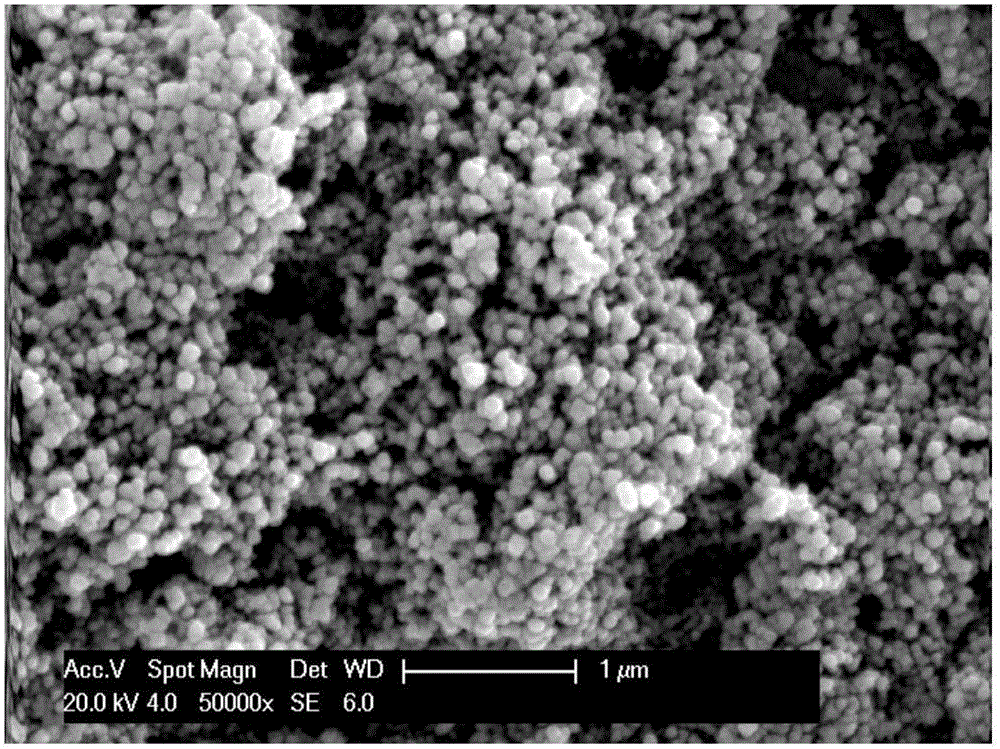

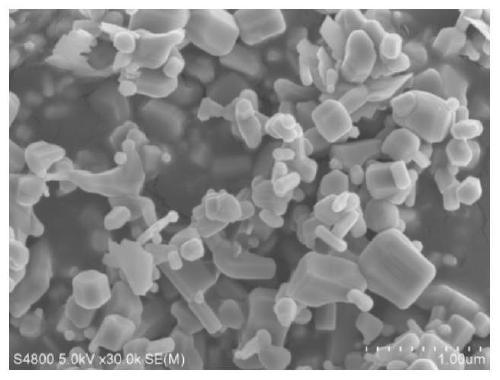

Preparation method for super-hydrophobic silica particle and super-hydrophobic coating

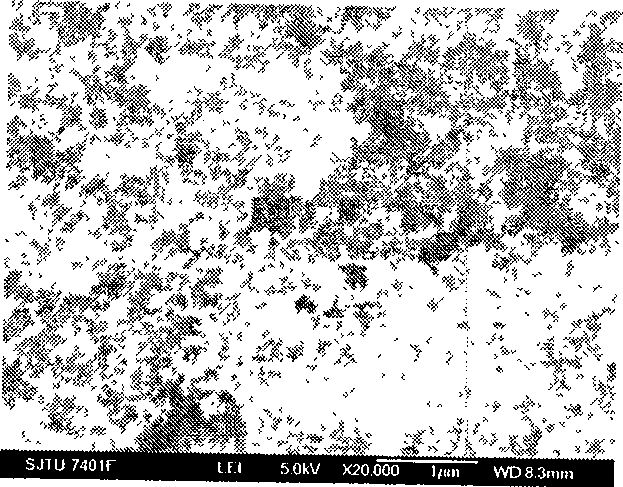

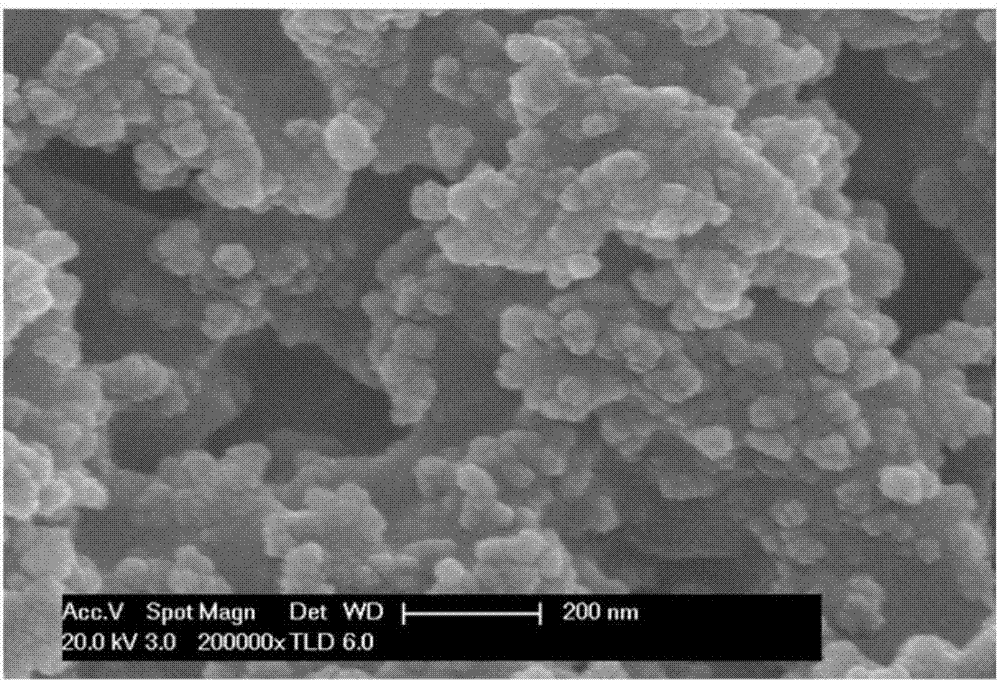

InactiveCN106587075ASimple manufacturing processExcellent superhydrophobic propertiesSilicaPolyurea/polyurethane coatingsHydrophobic silicaUltrasonic nebulization

The invention provides a preparation method for super-hydrophobic silica particles and super-hydrophobic coatings. The method includes the following steps that in step S1, nanometer silica particles and silane modifiers are dispersed in a solvent to form a mixed solution, wherein weight ratio for nanometer silica particles and silane modifiers and the solvent is 1:0.05-0.5:3-20; the PH value of the mixed solution is adjusted to 2.0-5.0 by hydrochloric acid, and then the mixed solution is stirred for 2 to 24 hours at the temperature from 0 DEG C to 50 DEG C; the PH value of the mixed solution is adjusted to 6.0-7.5 by ammonia water, and then the mixed solution is stirred for 0.5 to 3 hours; a dispersion solution of modified nanometer silica particles is achieved; in step S2 the dispersion solution is dispersed into droplets by an ultrasonic nebulization technology and is dried at the temperature from 80 DEG C to 120 DEG C; the super-hydrophobic silica particles are achieved. With the preparation method for super-hydrophobic silica particles and super-hydrophobic coatings, the super-hydrophobic silica particles and the super-hydrophobic coatings are achieved, and have the advantages of being good in super-hydrophobic effect and simple in manufacturing process.

Owner:THE HONG KONG POLYTECHNIC UNIV

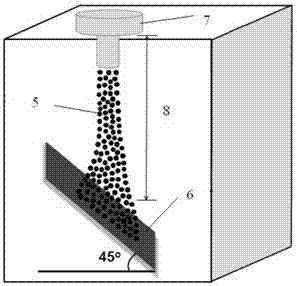

Method for preparing wear-resisting super-hydrophobic coating through cold spraying technology and product of method

ActiveCN105386032APreserve physicochemical propertiesFast depositionPressure inorganic powder coatingWear resistanceRolling angle

The invention discloses a method for preparing a wear-resisting super-hydrophobic coating through a cold spraying technology and a product of the method. The method comprises the following steps that firstly, the surface of a base body is roughened; secondly, sprayed powder is modified with low-surface-energy matter; and thirdly, the wear-resisting super-hydrophobic coating is prepared on the surface of the base body through the cold spraying technology. The static contact angle of the coating prepared through the method can be 150-180 degrees, the rolling angle of the coating is smaller than 10 degrees, and good super-hydrophobicity is achieved. According to the method, the product of a non-stick pan is prepared and has good wear resistance and non-stick performance, and compared with non-stick pans in the market, the product is more resistant to wear and has the great competitive potential in the field. In addition, the method can be used for preparing different wear-resisting super-hydrophobic coatings based on different base materials (such as metal, ceramic, glass and plastic), and the application range is wide.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

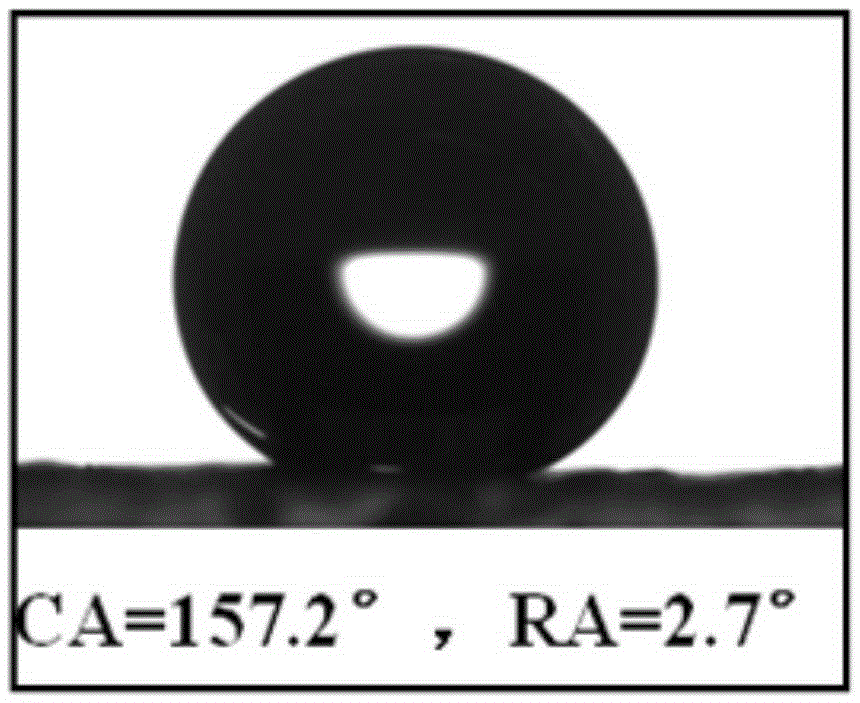

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

Method for preparing durable cellulose fiber fabric with super-hydrophobic surface

InactiveCN104594028AExcellent Durability Super Hydrophobic PropertiesMeet functional requirementsVegetal fibresCross-linkState of art

The invention relates to a method for preparing a durable cellulose fiber fabric with a super-hydrophobic surface. The method comprises the following three steps: preparing modified SiO2 composite sol, preparing a modified fabric and performing super-hydrophobic finishing on the fabric. The active groups are introduced into nanometer SiO2 and fiber surface, the fabric is finished by adopting a simple one-step method, the binding force between the fabric and the inorganic nanometer SiO2 is enhanced by virtue of the active groups on the fiber surface and the cross-linking effect on the modified SiO2 surface, the covalent bonding firmness between the modified sol and the surface of the modified cellulose fiber fabric is improved, and the super-hydrophobic interface of a fluoride-free cellulose fiber fabric with certain washing fastness is finally obtained. Compared with the prior art, the preparation method disclosed by the invention is economical and environmentally friendly, and the industrial production is promoted.

Owner:SHANGHAI UNIV OF ENG SCI

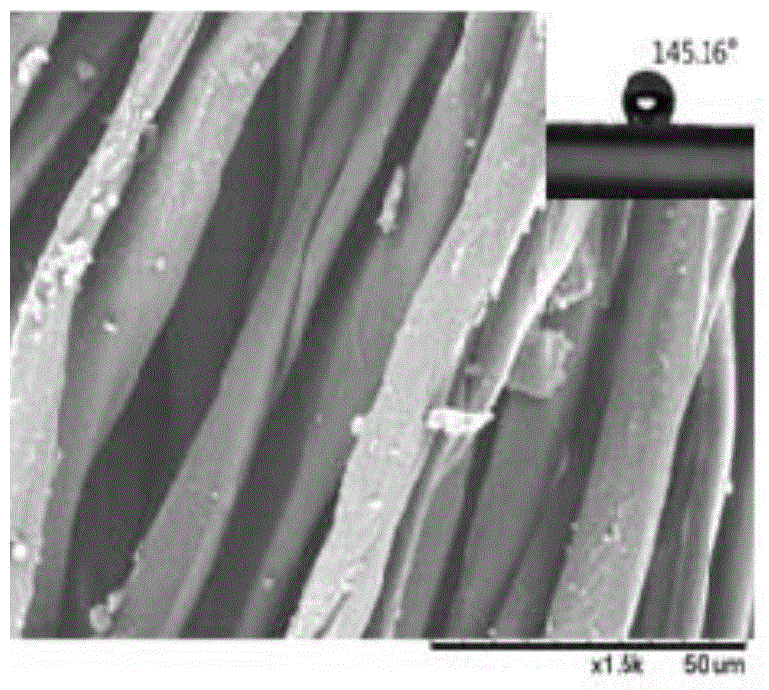

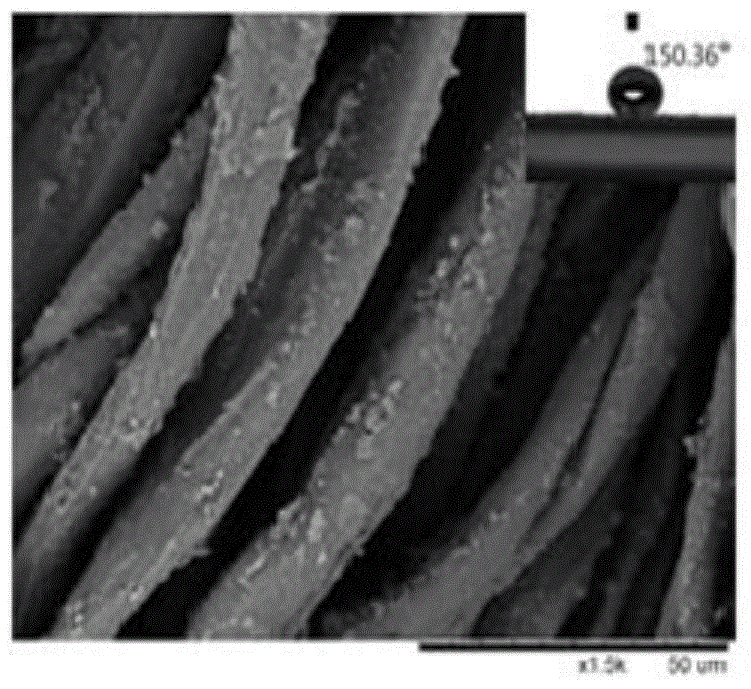

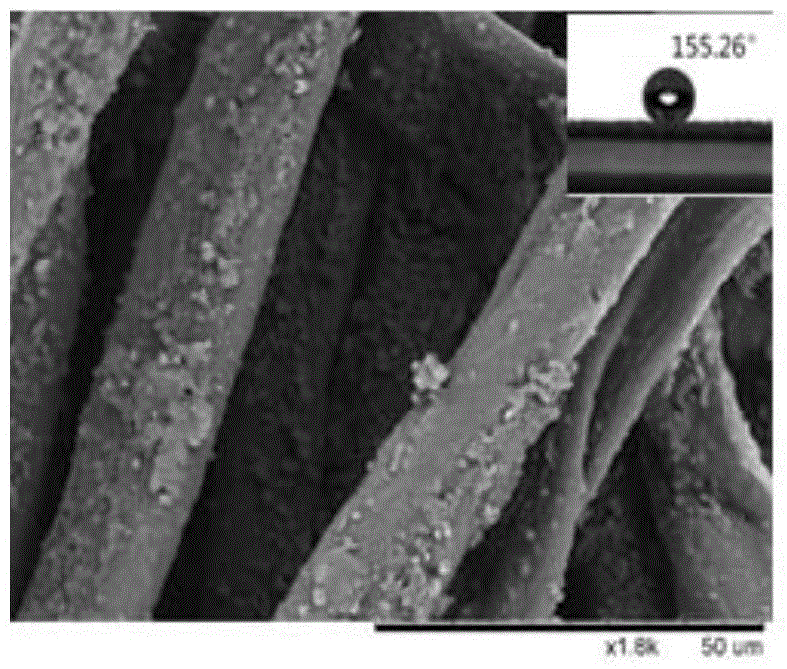

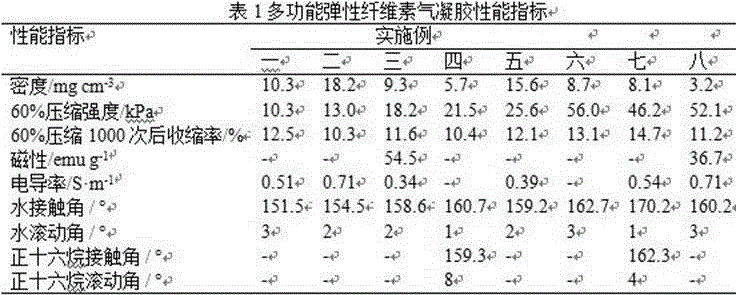

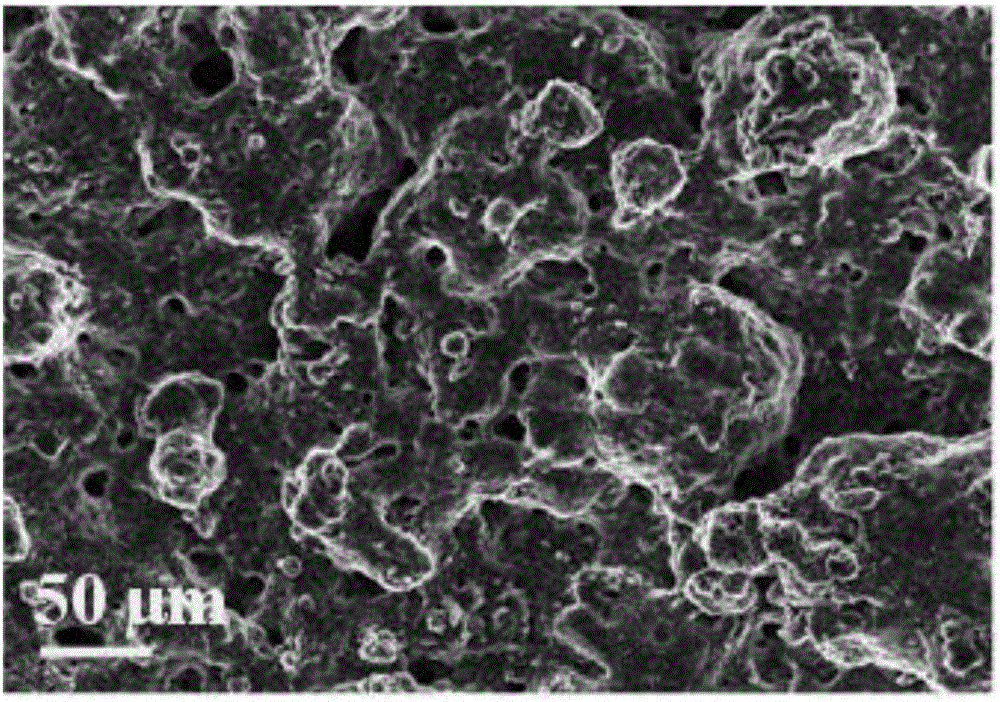

Preparation method of multifunctional cellulose elastic aerogel

The invention discloses a preparation method of a multifunctional cellulose elastic aerogel, belonging to the field of aerogel materials. The preparation method comprises the following steps: dispersing cellulose in water, carrying out pretreatment by adding sodium chlorite or / and in a solvothermal way, and cleaning with deionized water to obtain a purified cellulose dispersion solution; adding a modifier to perform chemical modification, thereby obtaining a modified cellulose suspension; dispersing the modified cellulose suspension in an organic solvent, forming, drying to form a modified cellulose gel, and finally, carrying out heat treatment on the modified cellulose gel to obtain the multifunctional cellulose elastic aerogel. The cellulose is subjected to pretreatment and chemical modification, thereby lowering the density of the aerogel, greatly enhancing the elasticity and mechanical strength of the aerogel, endowing the aerogel with excellent magnetism, electric conductivity, superhydrophobicity, superoleophobicity and many other functions, and widening the application range of the traditional cellulose aerogel.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of polymer hydrophobic surface

InactiveCN101456016AExcellent superhydrophobic propertiesUniform surface colorPretreated surfacesPolyester coatingsCoated surfacePolymer science

The invention provides a method for preparing a polymer hydrophobic surface and belongs to the technical field of polymer chemical material. The method comprises: preparing a polymer desperation and hydrophobic silica desperation; uniformly mixing the polymer desperation and the hydrophobic silica desperation for preparing a hydrophobic coating; spraying the hydrophobic coating onto a completely cleaned base surface uniformly with a spray gun; and finally, subjecting the sprayed base surface to heat treatment and cooling the base surface to obtain the polymer hydrophobic surface. The surface of a coating processed by the method is obvious in super-hydrophobic performance, uniform in luster and stable in performance, free from damage caused by scrubbing to the super-hydrophobic performance, simple in preparation process, low in preparation process implementation cost and applicable surfaces made from various materials without damaging the original materials by corrosive materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of persistent icing-resistant superhydrophobic coating

ActiveCN106883650AImproved long-lasting anti-icing performanceLong-lasting anti-icing performanceAntifouling/underwater paintsPaper coatingSuperhydrophobePolymer science

The invention relates to the field of preparation of superhydrophobic coatings, in particular to a preparation method of a persistent icing-resistant superhydrophobic coating. The preparation method comprises the following steps: firstly, carrying out cleaning and sand-blasting roughen treatment on the surface of a substrate; secondly, blending epoxy resin, a curing agent and a first solvent to obtain an epoxy resin solution; thirdly, dispersing submicron particles and nanoparticles into a second solvent, and then adding a silane coupling agent to obtain particle composite suspension; fourthly, spraying the epoxy resin solution obtained in the second step on the surface of the substrate treated in the first step, and partially curing epoxy resin adhesive; fifthly, spraying the particle composite suspension obtained in the third step on the surface of the substrate obtained in the fourth step and completely curing; sixthly, obtaining the persistent icing-resistant superhydrophobic coating. The persistent icing-resistant superhydrophobic coating disclosed by the invention has the beneficial effects that the superhydrophobic coatings prepared on the surfaces of all the substrates have good durability and firmness and persistent icing-resistant property.

Owner:哈尔滨毓干科技有限公司

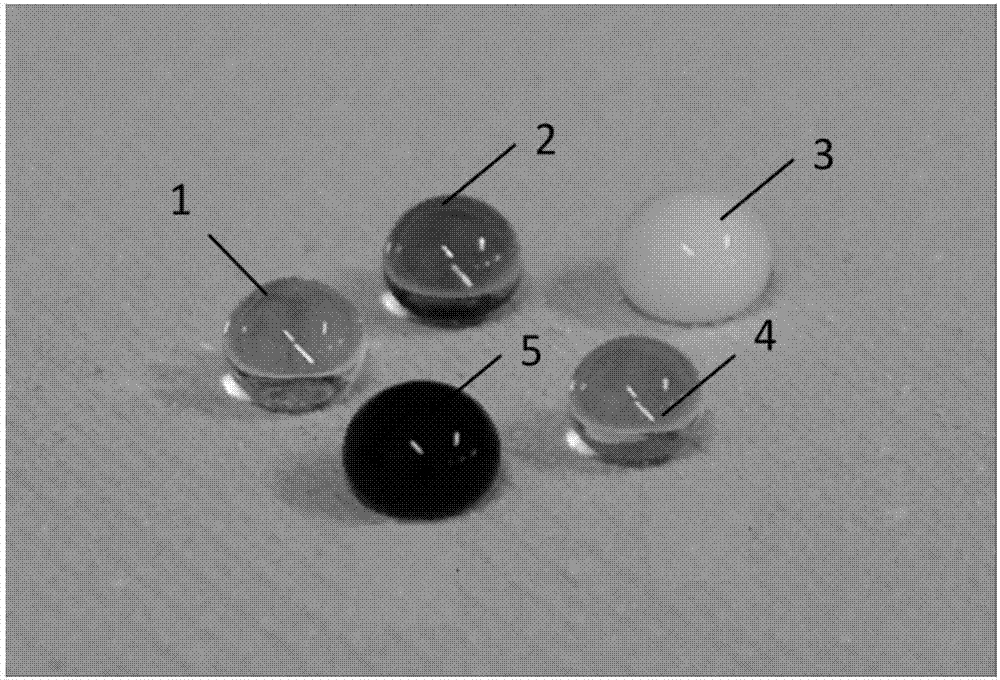

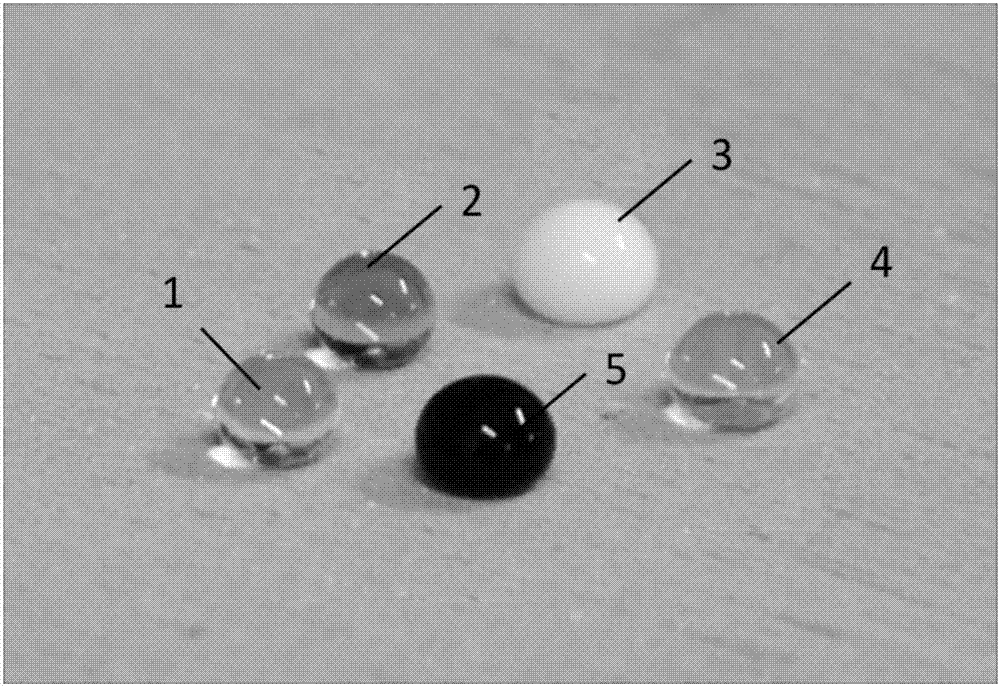

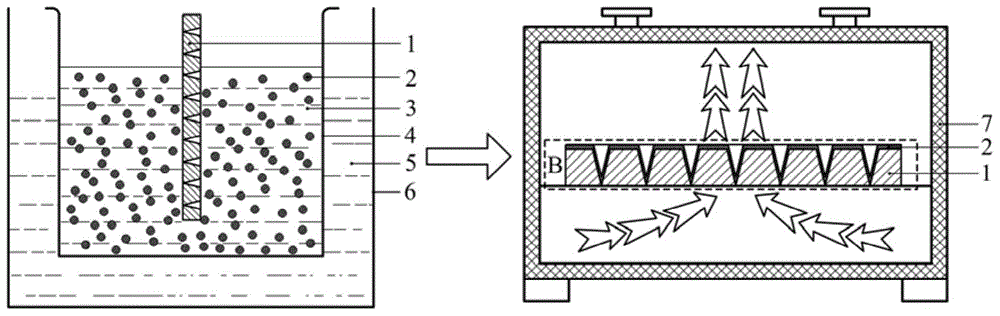

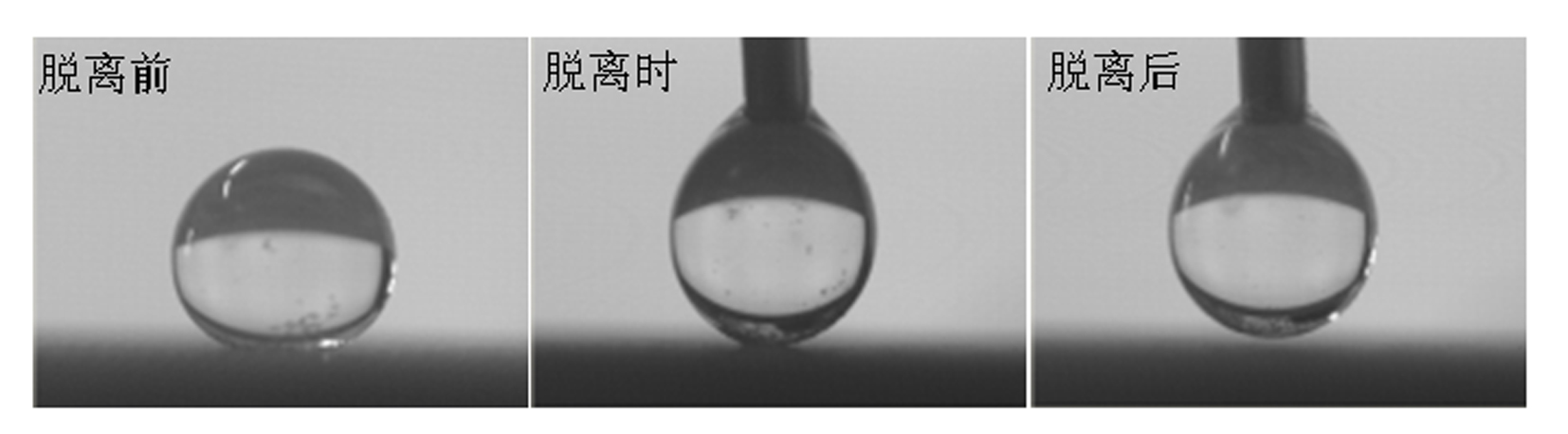

Preparation method and application of super-hydrophobic and adhesion-adjustable surface with micro-nano composite structure

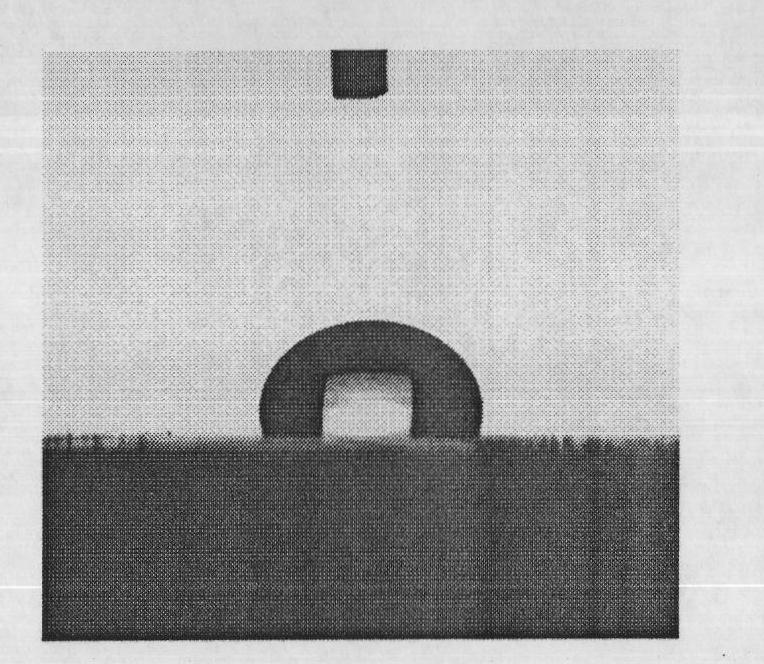

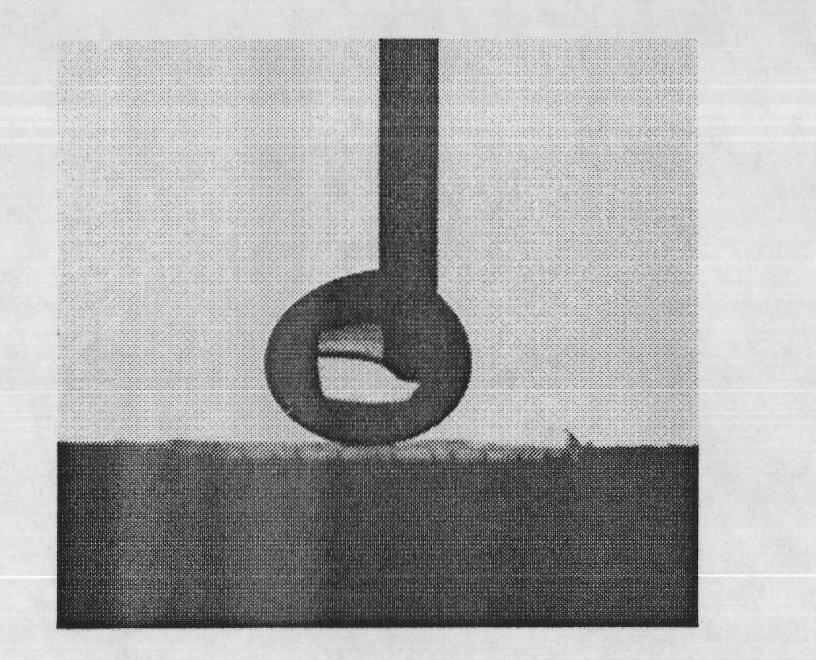

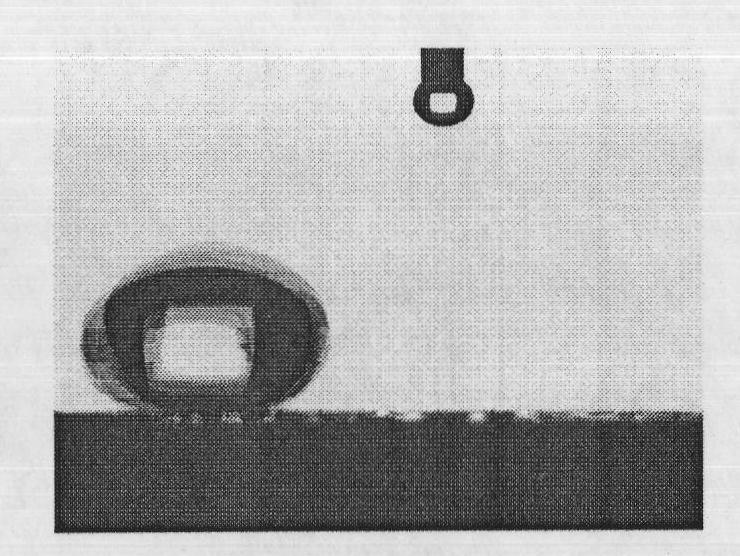

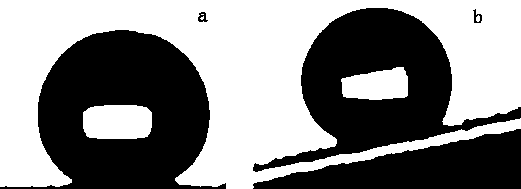

The invention relates to a preparation method for a super-hydrophobic and adhesion-adjustable surface with a micro-nano composite structure. The preparation method comprises the following steps: a, preparing a dual-level composite microstructure template according to wetting characteristics needed by a product surface; b, preparing a solution from a hydrophilic / hydrophobic nanoparticle and absolute ethyl alcohol according to adhesion characteristics needed by the product surface, immersing the dual-level composite microstructure template into the solution, carrying out ultrasonic dispersion, then taking the treated microstructure template out and drying the treated microstructure template so as to obtain a three-level micro-nano composite structure template; c, fixing the obtained template on the surface of a die cavity, injecting high-molecular melt into the cavity by using an injection machine, carrying out pressure maintaining and then carrying out cooling and molding; and d, separating a molded high-molecular product from an injection die by using a demolding apparatus. The hydrophilic / hydrophobic nanoparticle is adhered on the surface or embedded into the surface layer of the dual-level composite microstructure on the surface of the molded high-molecular product, and the molded high-molecular product surface has the characteristics of super-hydrophobicity and adjustable adhesion and can realize flexible switching between a lotus leaf effect and a petal effect.

Owner:SOUTH CHINA UNIV OF TECH

Durable superhydrophobic coatings

Durable superhydrophobic coating composition having a composition ranging from about 10 to about 80 w.t. % of an acrylic polymer resin, from about 5 to about 40 w.t. % of a polysiloxane oil, from about 1 to about 50 w.t. % of hydrophobic particles, from about 0.1 to about 10 w.t. % metal oxides, and the remainder being one or more solvents and optionally other additives. Methods of making the coating, as well as coated substrates, are also provided.

Owner:UNIVERSITY OF PITTSBURGH

Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

The invention relates to a super-hydrophilic particle hybridized super-hydrophobic coating and a preparation method thereof. A substrate is ultrasonically cleaned through acetone, absolute ethyl alcohol and deionized water in sequence for 15 min, and oil stain and dust on the surface are removed; then, absolute ethyl alcohol is used for elution, and cold-blast air is used for drying for use. Nanometer SiO2 sol is subjected to fluoroalkyl silane modification, a super-hydrophobic coating spraying solution is obtained, a super-hydrophilic monodisperse sphere type nanometer SiO2 solution, silica powder and glass beads are added into the super-hydrophobic coating spraying solution, stirred to be uniform and sprayed on the substrate, and after solidification, the super-hydrophilic particle hybridized super-hydrophobic coating is obtained. The coating has the low adhesion and super-hydrophobicity, and the condensation and dewfall efficiency and the dewdrop adsorption amount are remarkably high compared with a super-hydrophobic coating. The preparation technology is simple, no pollution is caused, operation is easy, the apparent mass is good, the cost is low, and wide application prospect and huge market benefits are achieved on the aspects of heat exchangers, water collection, seawater desalination and the like.

Owner:SOUTHEAST UNIV

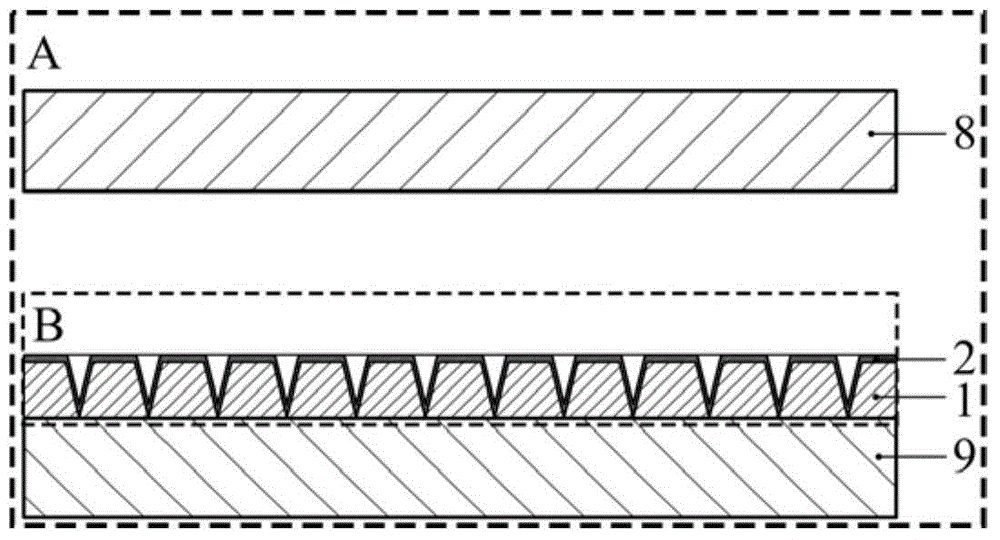

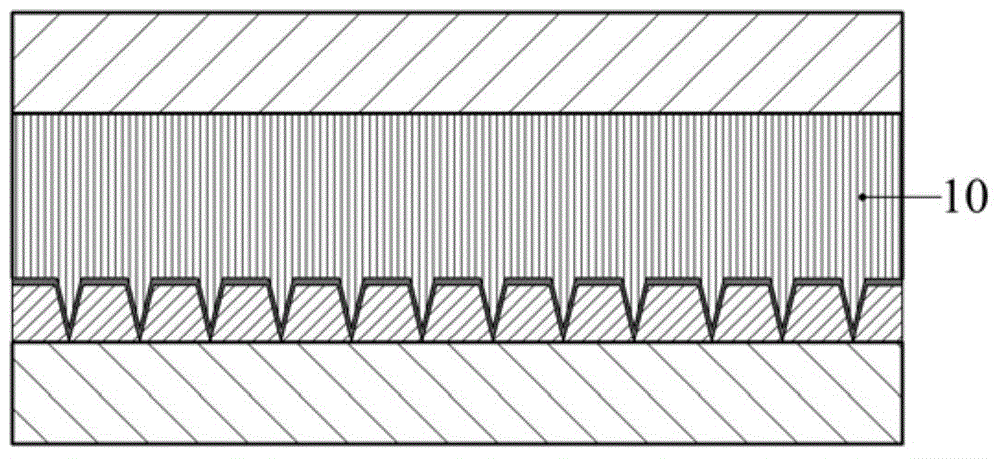

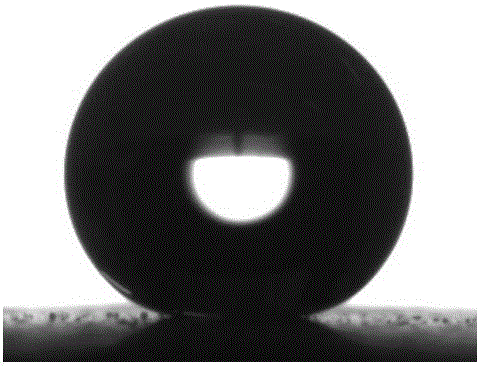

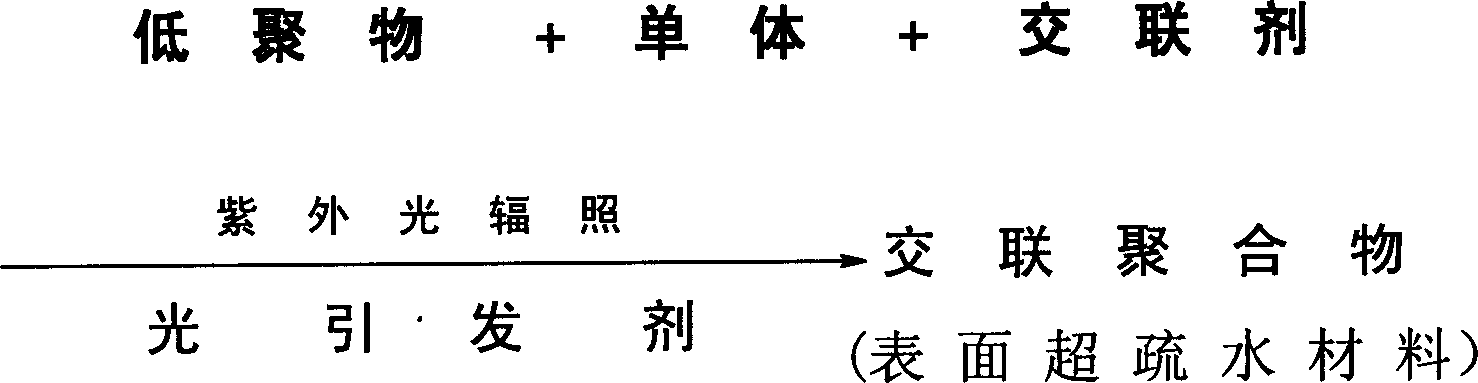

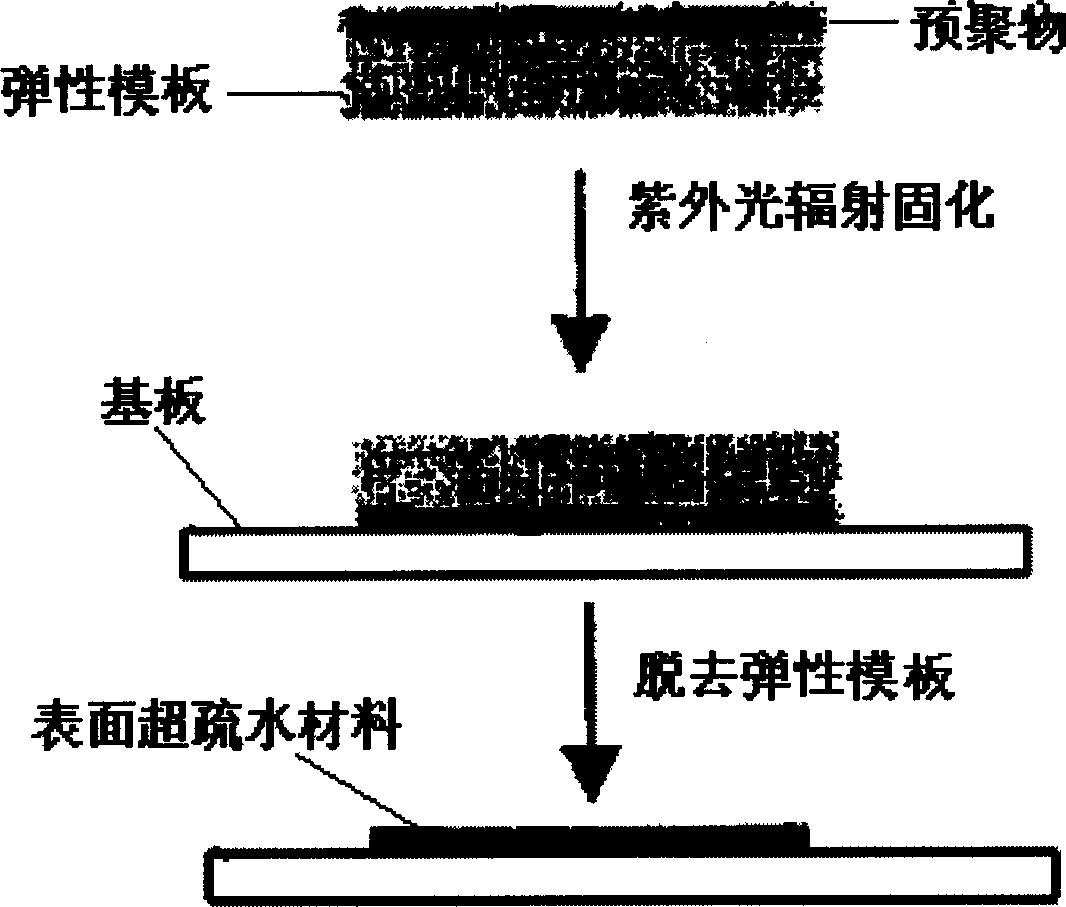

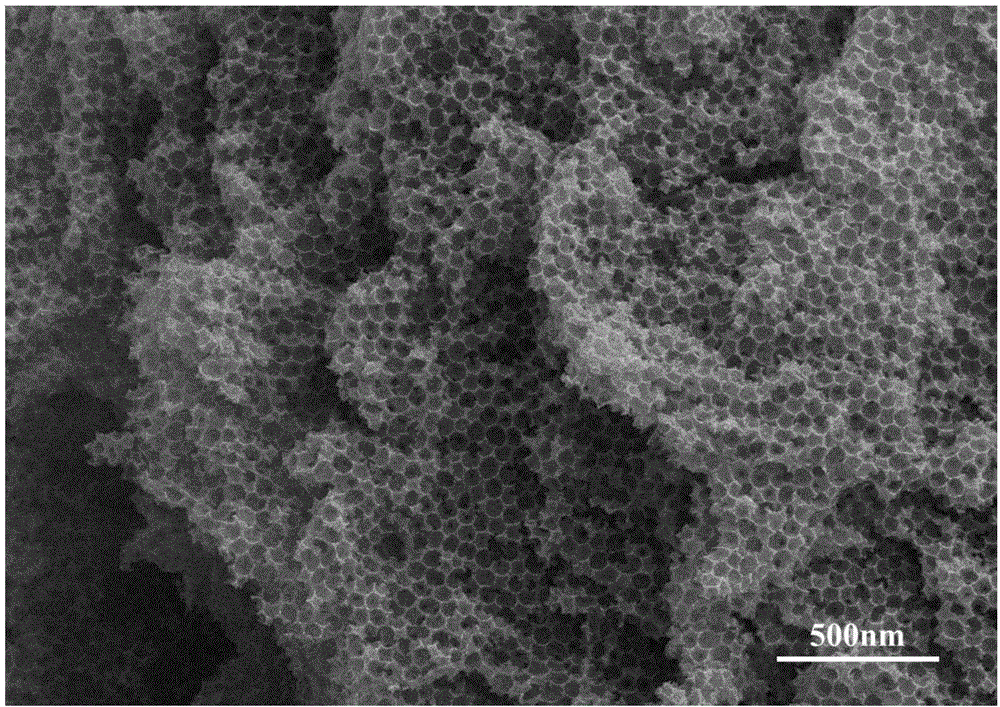

Soft template and ultraviolet curing process to prepare surface super hydrophobic material

InactiveCN1810912AExcellent superhydrophobic propertiesStrong adhesionOther chemical processesCross-linkRoom temperature

The present invention is soft template an ultraviolet curing process to prepare surface super hydrophobic material, and belongs to the field of solid material surface modifying technology. The surface super hydrophobic material is prepared through preparation of elastic soft template, setting the pre-polymer between the elastic template and the base board, ultraviolet irradiation to cure and eliminate the elastic template to obtain surface super hydrophobic material. The surface super hydrophobic material of cross-linked polymer is adhered onto the base board and is easy to separate from the elastic template. The surface super hydrophobic material has pattern copied from the elastic template, excellent super hydrophobic performance and surface water contact angle at room temperature greater than 150 deg. The surface super hydrophobic material has simple preparation process, high polymerization efficiency, less pollution, low cost and environment friendship.

Owner:TSINGHUA UNIV

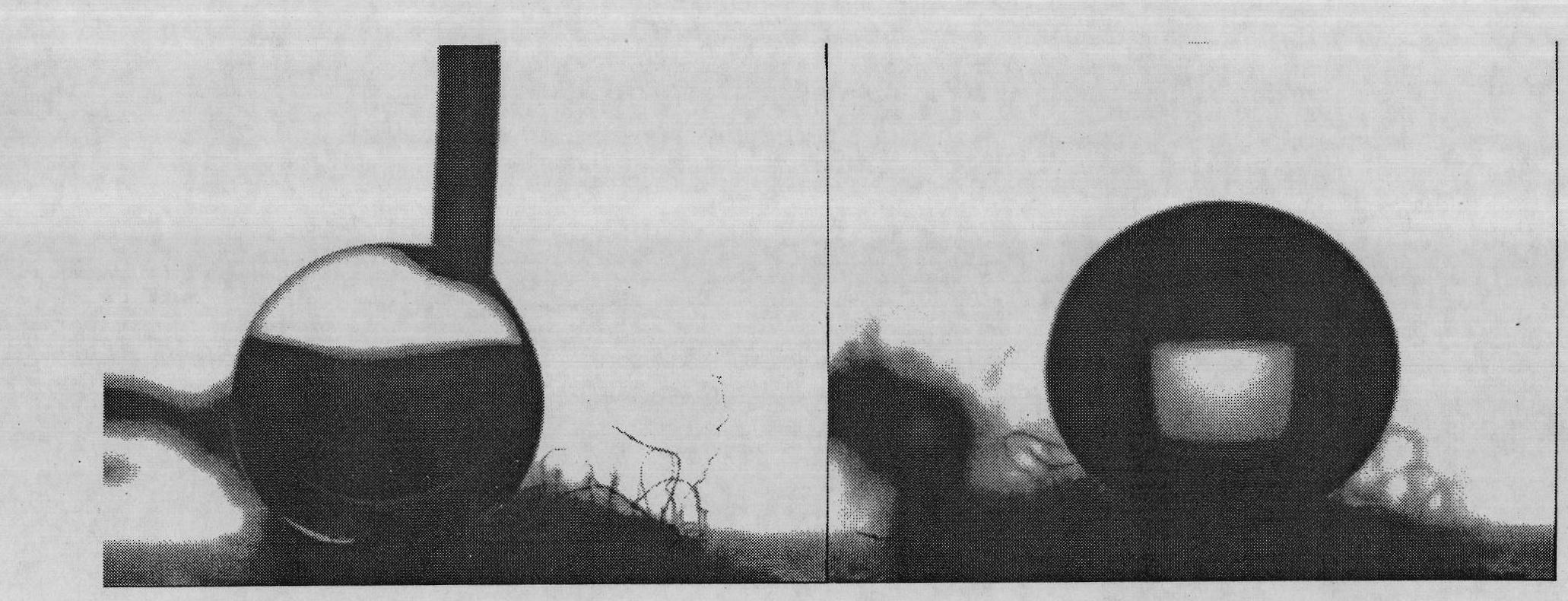

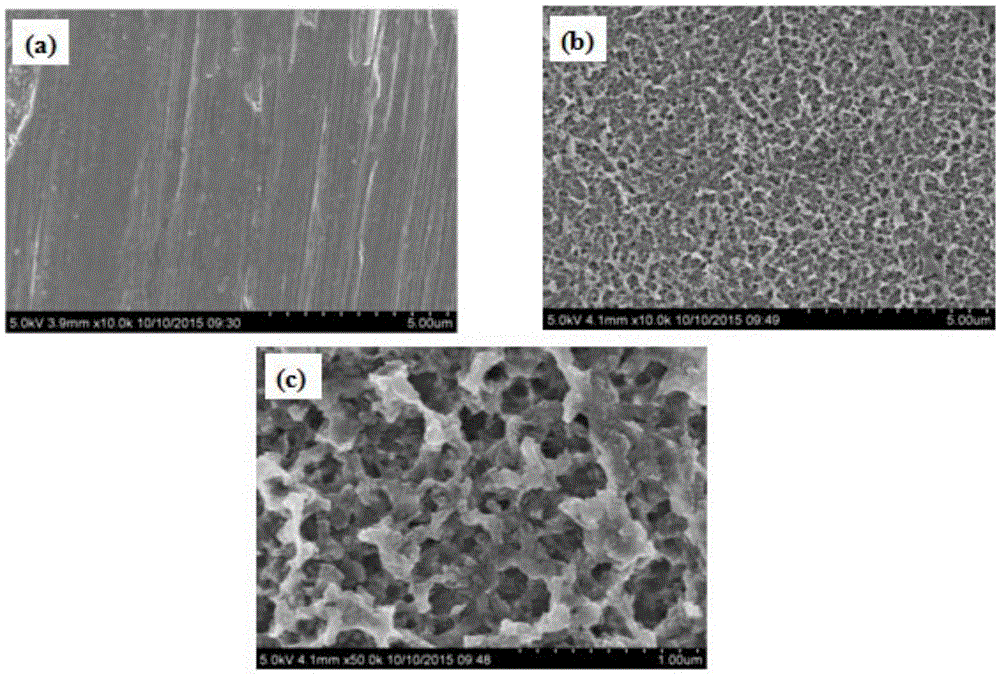

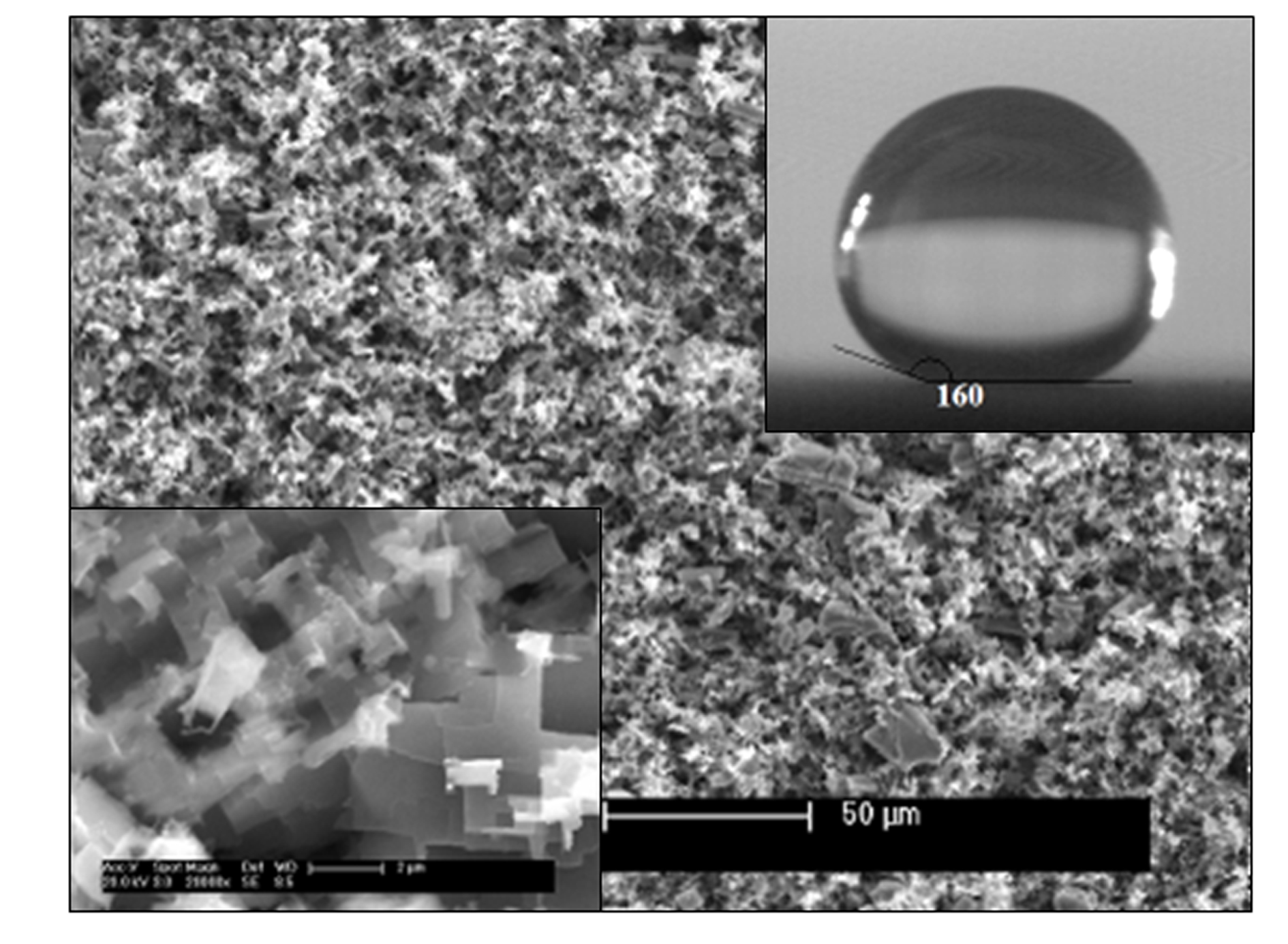

Surface treatment method for obtaining super hydrophobic aluminum or aluminum alloy surface

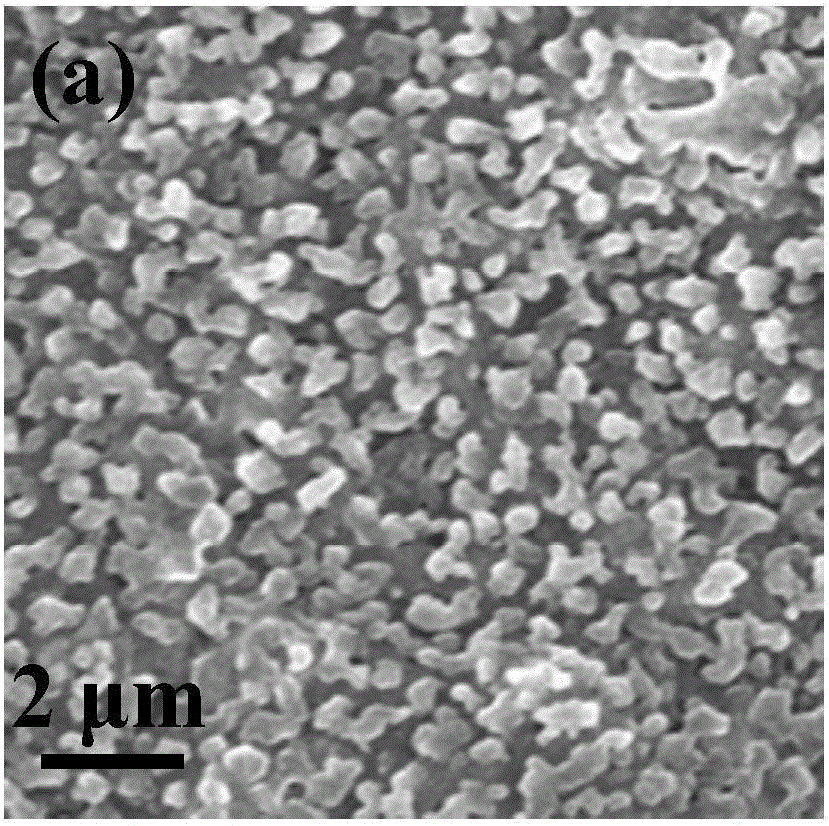

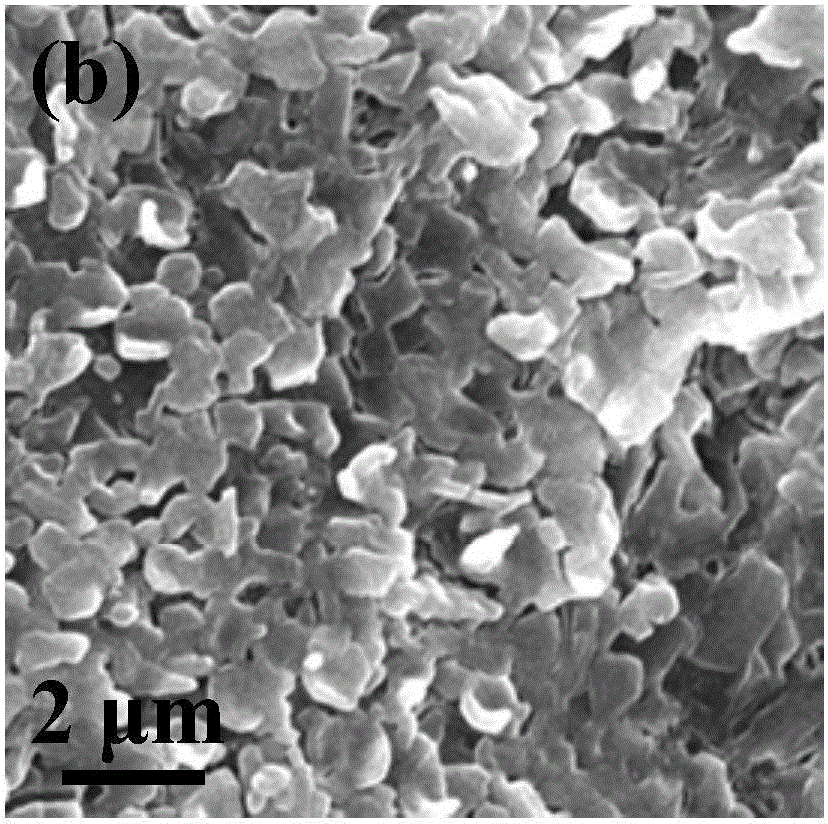

ActiveCN103993320AExcellent superhydrophobic propertiesVacuum evaporation coatingSputtering coatingMicron scaleHysteresis

The invention discloses a surface treatment method for obtaining a super hydrophobic aluminum or an aluminum alloy surface. The surface treatment method comprises the following steps: carrying out cleaning treatment on an aluminum or aluminum alloy surface by using deionized water, acetone, ethanol and deionized water sequentially, so as to obtain clean aluminum or aluminum alloy surface; and forming coarse micron scale surface topography, nanoscale surface topography or micron-nano composite scale surface topography on the clean aluminum or aluminum alloy surface. The aluminum or aluminum alloy surface treated by the method disclosed by the invention has excellent super-hydrophobicity; the static contact angle of water droplets can be up to be over 150 degrees; the contact angle hysteresis is below 10 degrees. The surface treatment method is applicable to super hydrophobic treatment of aluminum or aluminum alloy parts of an evaporator, aluminum alloy doors and windows, aluminum alloy parts of a transport aircraft, and surfaces of other aluminum or aluminum alloy components in equipment such as refrigeration equipments, air source heat pumps and the like, and especially applicable to super hydrophobic treatment of aluminum or aluminum alloy surfaces of which condensed water droplets even condensed micro droplets are super-hydrophobic.

Owner:NINGBO NOVO NEW MATER TECH

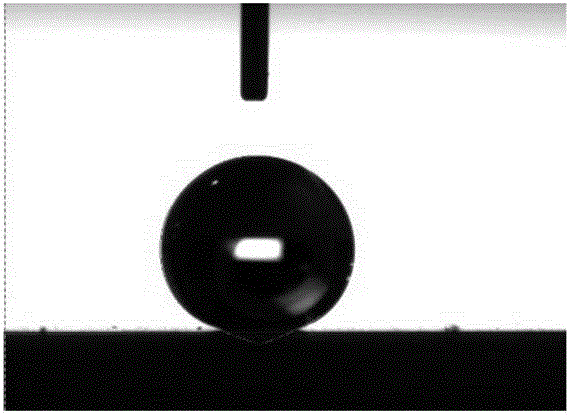

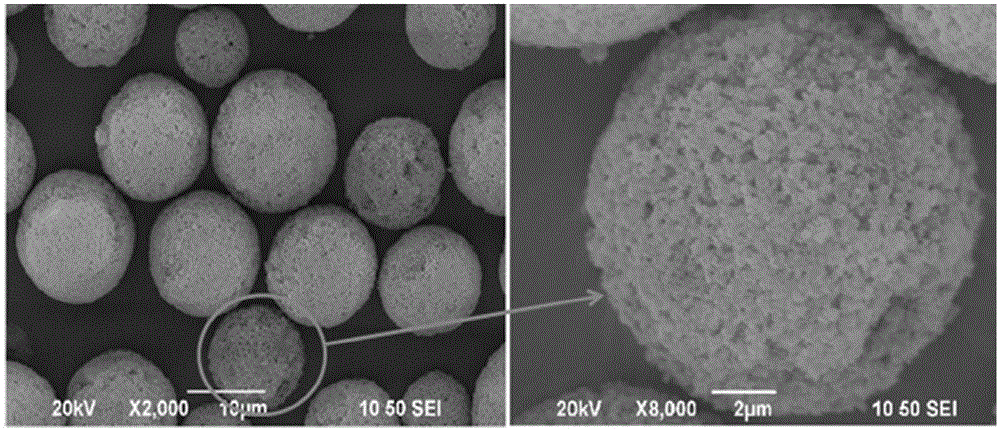

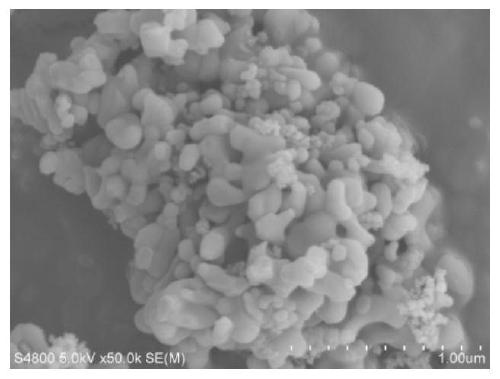

Inorganic substance super-hydrophobic paint and application thereof

ActiveCN104672962ASimple manufacturing methodImprove stabilityAntifouling/underwater paintsLayered productsMicro nanoMicrosphere

The invention relates to inorganic substance super-hydrophobic paint and application thereof. The paint is prepared in the following method: silica sol is injected into a reactor with a nano microsphere template under a negative pressure condition, the template is immersed in the silica sol for 2h, then the reactor is sealed and stored in a thermostat, the silica sol and the template react at the temperature of 60 DEG C for 12h, the template is removed by virtue of heating or water immersion, a solid blocked micro-nano composite polygon is obtained, and after the blocked micro-nano composite polygon is dried, the blocked micro-nano composite polygon is ground into powder; the powder is poured into another reactor, dispersion liquid acetone is mixed with the powder, a low-surface-energy silane coupling agent is used for modifying the powder at a temperature of 25 to 50 DEG C, the powder reacts for 10h to 15h, the micro-nano composite polygon powder accounts for 0.5 to 20 percent of the mass of the paint, and the super-hydrophobic paint is prepared. The inorganic substance super-hydrophobic paint can be smeared on the surfaces of various conventional materials, the preparation method of the paint is simple, and the obtained super-hydrophobic surface is excellent in stability.

Owner:天津超疏水纳米科技有限公司

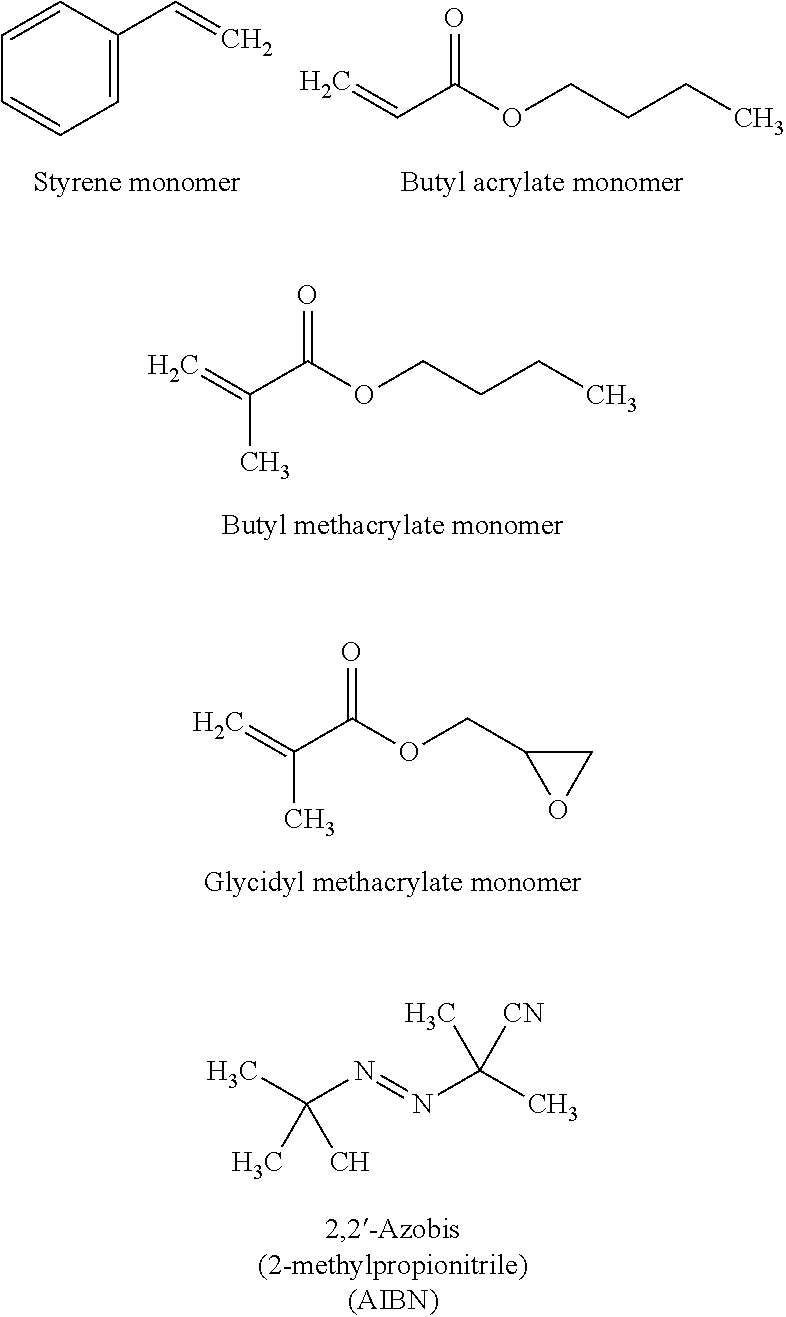

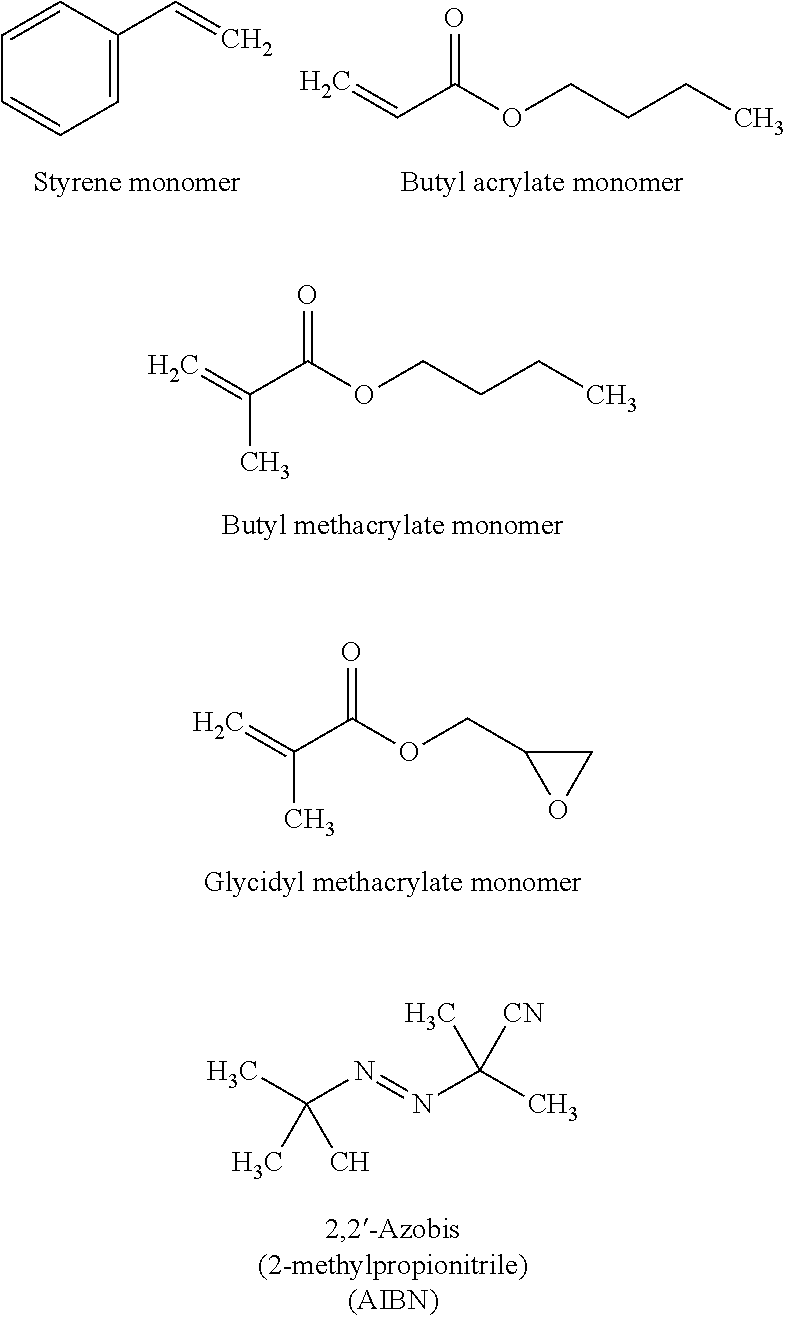

Preparation method of modified fluorine-containing acrylic superhydrophobic resin emulsion

InactiveCN104877089APut an end to the key technical problem of low modification rateExcellent superhydrophobic propertiesCoatingsEmulsionAcrylic resin

The invention discloses a preparation method of a modified fluorine-containing acrylic superhydrophobic resin emulsion, which comprises the following steps: preparing an organic hydrophobic modified SiO2 sol by a sol-gel process, and carrying out free-radical polymerization reaction under emulsifying conditions to graft SiO2 onto the fluorine-containing acrylic copolymer resin, thereby obtaining the SiO2 in-situ modified fluorine-containing acrylic superhydrophobic resin emulsion. While free radical emulsion polymerization is utilized to prepare the organic fluorine modified polyacrylate resin, the SiO2 nanoparticles are grafted by the copolymerization reaction, thereby successfully preparing the SiO2 nanoparticle in-situ modified fluorine-containing acrylic resin emulsion, and avoiding the key technical problem of very low modification ratio in the mechanical blending process. After the emulsion is completely dried, the composite coating can have excellent superhydrophobicity, and thus, the emulsion can be abundantly applied to many industrial fields. The reaction technique has the advantages of higher success rate and lower cost, and is simple to operate.

Owner:ZHONGSHAN POLYTECHNIC

Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

InactiveCN103965673AExcellent superhydrophobic propertiesFrost resistantCoatingsCoated membraneSolar battery

The invention discloses a preparation method of a super-hydrophobic, super-oleophobic and high transparency triple-function coating film, belongs to the field of novel materials, and particularly belongs to the field of self-cleaning optical materials. The method comprises the steps of firstly assembling large-grained SiO2 nano particles on a glass substrate, so as to form the lower layer of the fine structure of a functional coating layer, simultaneously adding pore-foaming agent, so as to adjust and control space filling factors, then assembling upper layer fluoride SiO2 nano fine particles, and constructing a two-stage uneven surface coating layer with a suspension structure and super-hydrophobic, super-oleophobic high and transparency functions. The functional film has frost prevention, fog prevention, pollution prevention, bacteriostasis and self-cleaning properties, also has excellent translucency, can effectively prevent properties of optical elements, photoelectron elements, solar batteries and laser systems from being influenced by environment in severe environment, greatly expands the application range of the equipment, guarantees the operational reliability, and prolongs the service life, thereby greatly improving the practical values of the equipment.

Owner:JIANGNAN UNIV +1

Simple and easy preparation method for super-hydrophobic fiber and textile and application thereof

InactiveCN102154834AExcellent superhydrophobic propertiesWide range of choicesFibre treatmentFiberRolling angle

The invention relates to a simple and easy preparation method for super-hydrophobic fiber and textile with high contact angle and low rolling angle and application thereof. Surface chemical modification is directly carried out on intrinsic coarse structures on the surface of the fiber and textile so as to prepare a fiber product with super-hydrophobic performance; the method comprises the following steps of: firstly, cleanly washing materials, then carrying out isocyanate modification on the material, and finally modifying low surface energy material. The raw material is cheap and is easily available; reaction conditions are relatively mild; the operation is simple; and the requirement on the device is low. The obtain product has good super-hydrophobic performance; the contact angle of 10microliter of water is 156 degrees; and the product has wide application in fields of self-cleaning fibers and textiles.

Owner:HUNAN UNIV

Method for preparing lasting super-hydrophobic modified polypropylene hollow fiber membrane

InactiveCN102688704AHigh water pressure resistanceImprove breathabilitySemi-permeable membranesPolypropylenePhotoinitiator

The invention relates to a method for implementing super-hydrophobic modification on a polypropylene hollow fiber membrane material, in particular to a method for preparing a lasting super-hydrophobic modified polypropylene hollow fiber membrane. The method comprises the following steps of: respectively dissolving fluorine ester containing unsaturated double bonds, acrylate containing a long alkyl chain, dithiol and a photo-initiator into an acetone solution to prepare a modification solution, soaking a polypropylene membrane treated by normal pressure plasmas into the modification solution, performing ultraviolet irradiation, washing, airing, and thus obtaining a fluorine-containing and long alkyl chain grafted modified polypropylene membrane material. A uniform, lasting and stable super-hydrophobic layer containing fluothane and the long alkyl chain is formed on the surface of the polypropylene membrane material, so that the hydrophobic polymer membrane is endowed with excellent super-hydrophobic property, high water pressure resistance and high air permeability; and the method is simple, good in treatment effect and low in cost, does not produce environment pollution, and is efficient and energy-saving.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

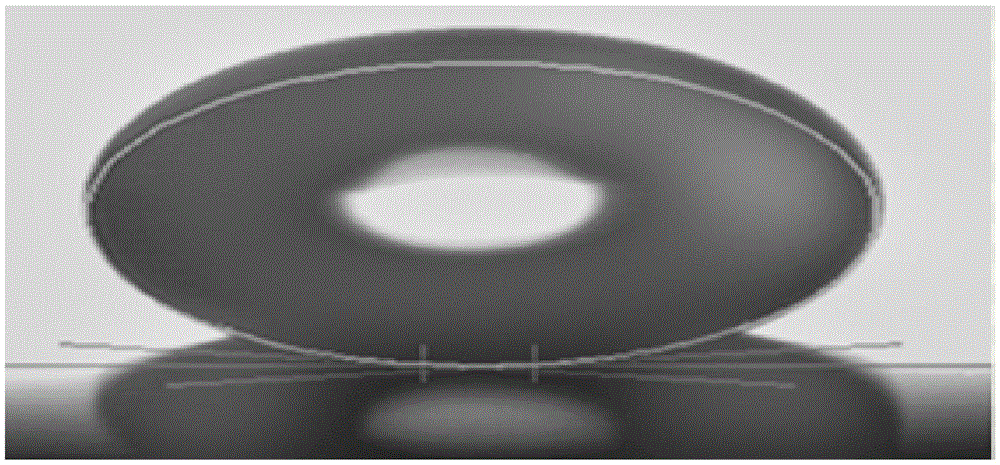

Preparing method of three-dimensional network super-hydrophobic surface

InactiveCN105463461AReduce dosageEasy to operateMetallic material coating processesSurface treatment compositionsElectrochemical responseEtching

The invention discloses a preparing method of a three-dimensional network super-hydrophobic surface. Chemical etching and surface modification are combined to be finished at one step. The preparing process of the super-hydrophobic surface comprises coarse structure preparation and surface modification. A substrate is arranged in an etchant-surface modification substance mixed solution, a coarse structure is constructed through substrate etching via the chemical or electrochemical reaction, and the surface modification is carried out through low-surface-energy substances to reduce the surface free energy. The size of the super-hydrophobic structure is controlled through reaction time, reaction temperature and concentration. The contact angle test shows that the contact angle of water drops on the surface of the super-hydrophobic structure reaches 175 degrees, and the rolling angle is smaller than 5 degrees. The electrochemical testing result shows that the corrosion resistance of super-hydrophobic stainless steel pieces is improved to about 16 times the corrosion resistance of ordinary stainless steel. The provided method is easy to operate, low in cost, good in stability, superior in super-hydrophobic performance, good in corrosion resistance, capable of facilitating industrialization and large-area popularization and capable of being applied to metal corrosion protection.

Owner:DALIAN UNIV OF TECH

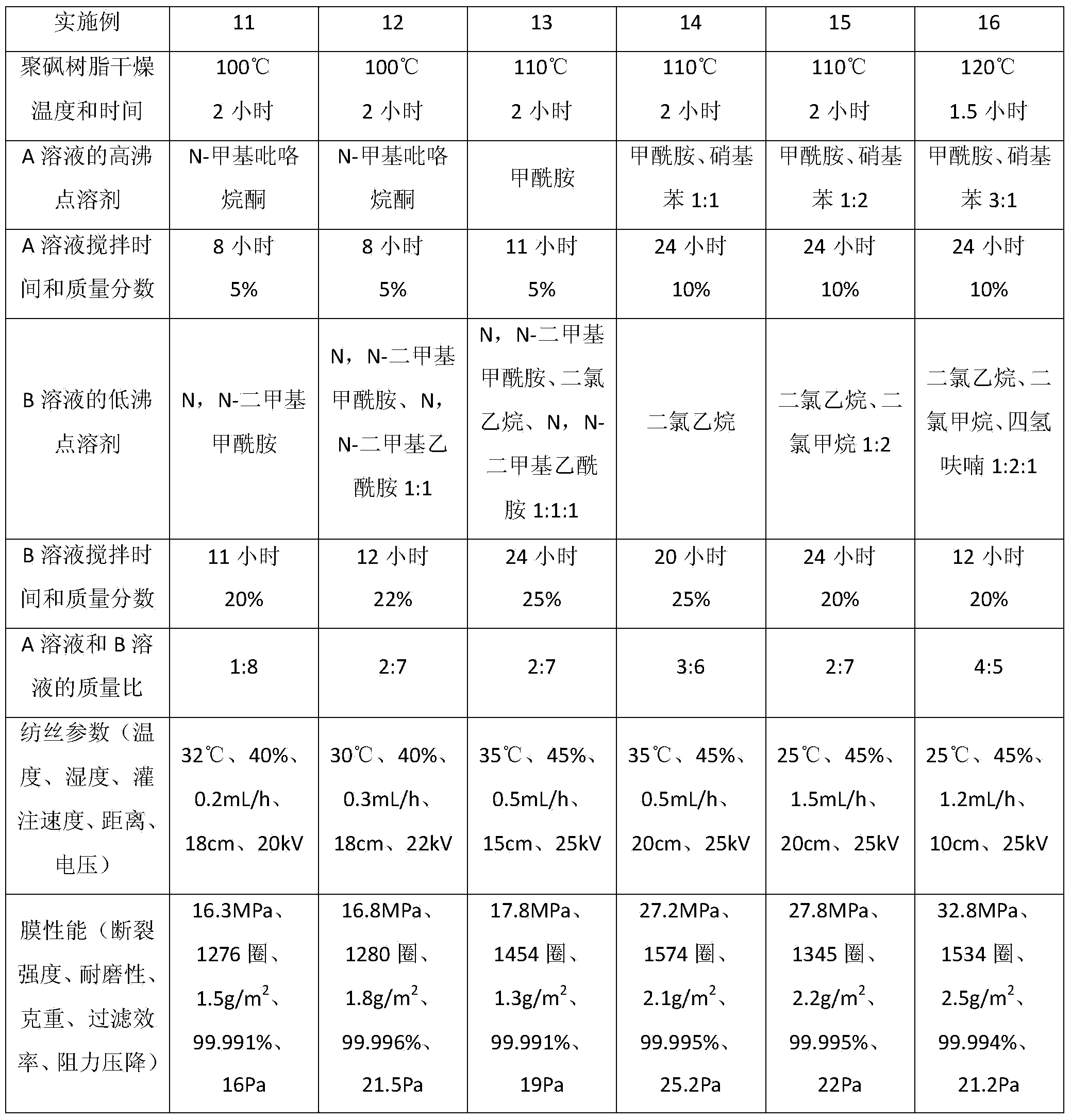

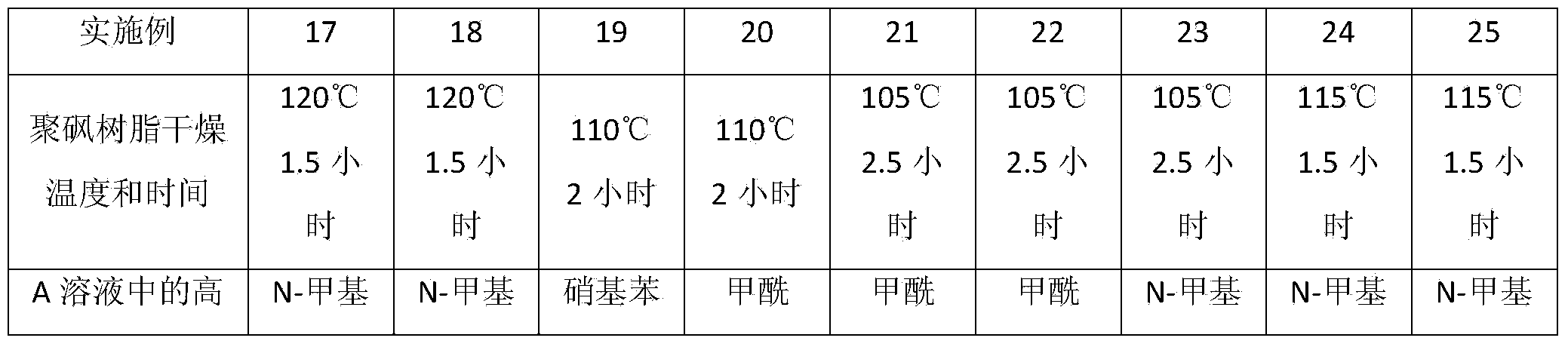

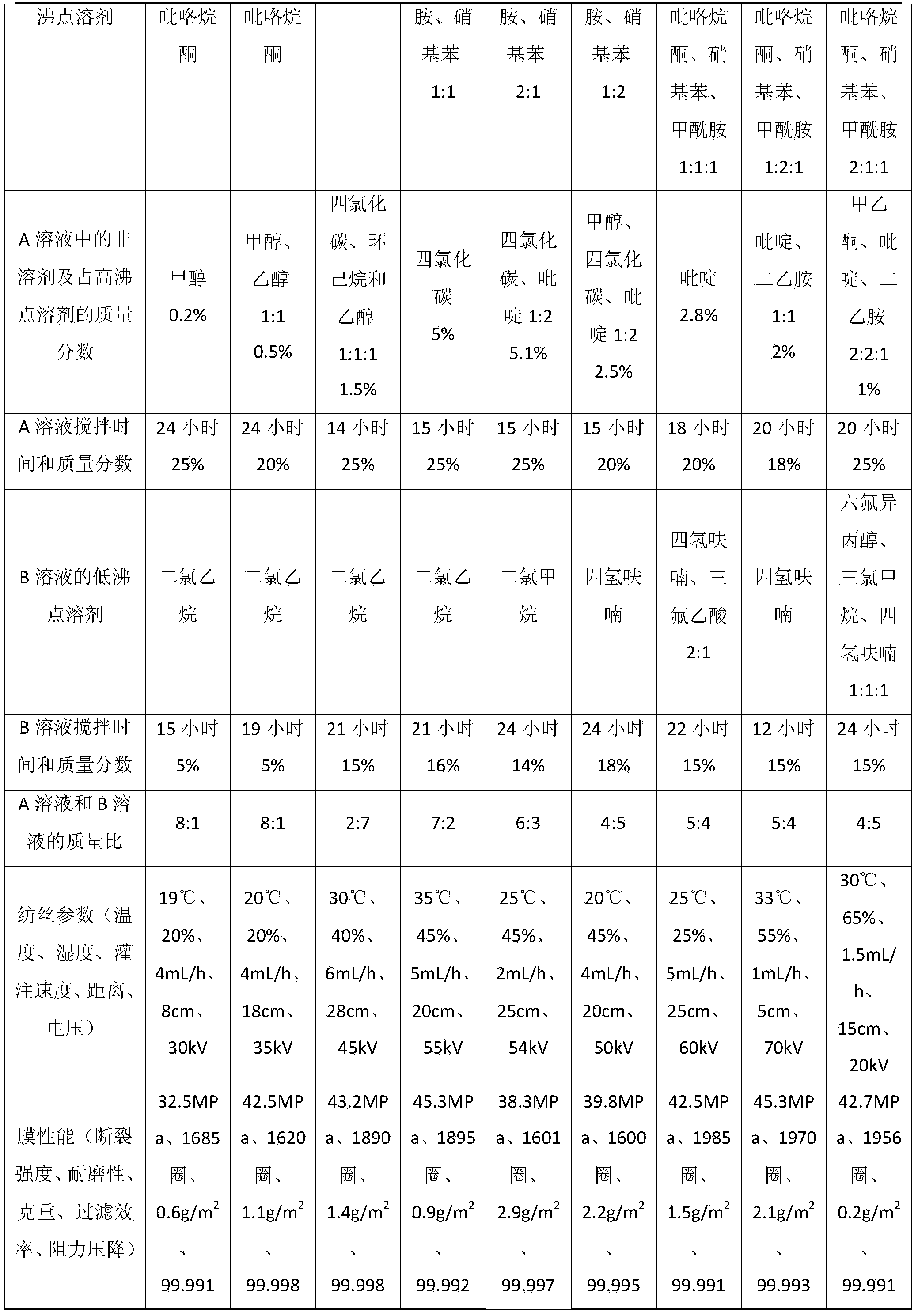

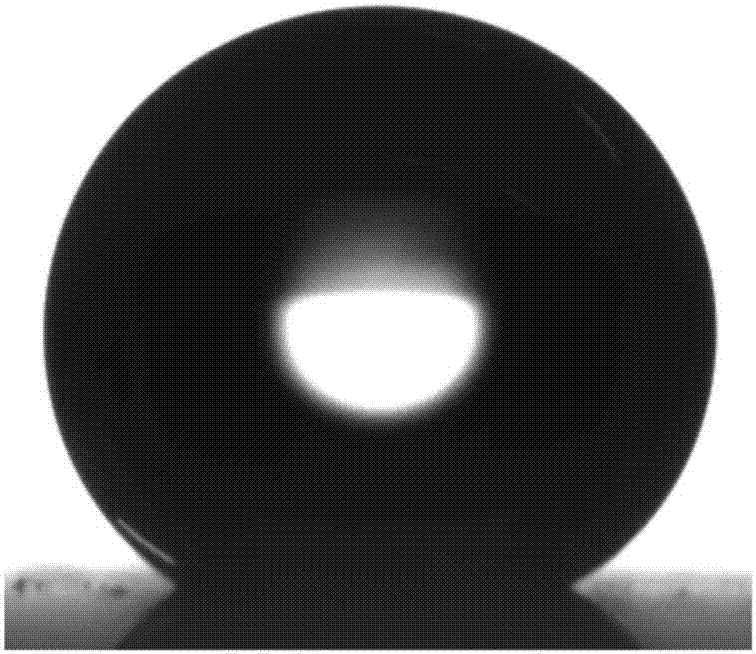

Strengthened polysulfone nano-fiber air filter membrane and electrostatic spinning preparation method thereof

InactiveCN103480285AGood flexibilityGood multi-channel connectivitySemi-permeable membranesDispersed particle separationFiberSolubility

The invention relates to a strengthened polysulfone nano-fiber air filter membrane and an electrostatic spinning preparation method thereof. The preparation method comprises the following steps of firstly, dissolving polysulfone in solvents with different melting points and different solubility parameters to form uniform liquor; and then, carrying out electrostatic spinning on the liquor by a plurality of spray heads to obtain a crossing-point adherent-nonadherent three-dimensional interpenetrating network structure polysulfone membrane. The product is a three-dimensional network shaped material which is formed by interpenetrating and alternating adherent-nonadherent fibers, wherein crossing points in the fibers are interconnected in an adherent manner by virtue of effective non-hydrogen bond bonding effects, wherein gram weight is 0.01g / m<2>-25.5g / m<2>, breaking strength is 16.1 MPa-48.6 MPa, abrasive resistance is 500 rings-2100 rings, filter efficiency for particles of 0.01 micron-5 microns reaches over 99.99%, and resistance drop is below 30Pa. According to the invention, the preparation process is simple, the cost is low, and a fiber membrane product has wide application prospect in the hyperfine filter filed.

Owner:DONGHUA UNIV

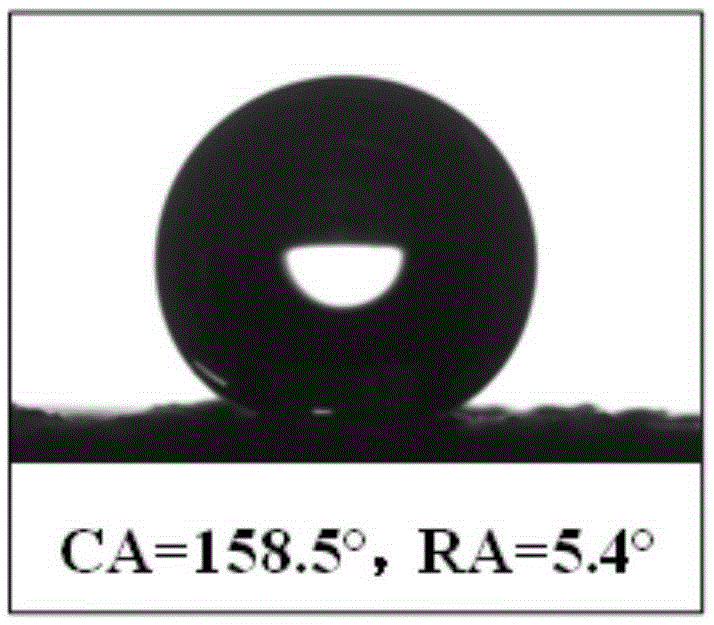

Durable super-hydrophobic coating and preparation method thereof

ActiveCN107384055AAvoid reunionGuaranteed numberAntifouling/underwater paintsPretreated surfacesMicro nanoOrganic solvent

The invention relates to a durable super-hydrophobic coating and a preparation method thereof. The preparation method comprises the following steps: 1) hybrid paint preparation: under low-speed mechanical stirring condition, adding micro nano particles, hydrophobic resin and a curing agent in a volatile organic solvent successively, performing high speed stirring and then ultrasonic dispersion to obtain the hybrid paint; 2) coating semi-solidification: coating the surface of a base material with the hybrid paint and performing semi-solidification; and 3) complete solidification: immersing the semi-solidified coating in a mixed immersion solution of the curing agent and the volatile organic solvent, taking the coating out, and drying the coating to obtain the durable super-hydrophobic coating having good wear resistance. The preparation method has no special requirement for a substrate material and its shape, the coating is suitable for various common base material surfaces such as metal, glass, timber and concrete, the equipment is simple, operation is easy, the cost is low, large-area construction is realized, and the coating has large application value on super-hydrophobic fields of self-cleaning, anticorrosion, mildew resistance, ice and frost resistance, and oil-water separation.

Owner:SOUTHEAST UNIV

Durable superhydrophobic coatings

ActiveUS20110111656A1Easy curingImprove adhesionConductive materialSynthetic resin layered productsPolymer resinSuperhydrophobic coating

Durable superhydrophobic coating composition having a composition ranging from about 10 to about 80 w.t. % of an acrylic polymer resin, from about 5 to about 40 w.t. % of a polysiloxane oil, from about 1 to about 50 w.t. % of hydrophobic particles, from about 0.1 to about 10 w.t. % metal oxides, and the remainder being one or more solvents and optionally other additives. Methods of making the coating, as well as coated substrates, are also provided.

Owner:UNIVERSITY OF PITTSBURGH

Long-time super-hydrophobic wear resistant ceramic coating

The invention discloses a long-time super-hydrophobic wear resistant ceramic coating, which solves the problems of poor durability and the like of a super-hydrophobic ceramic coating. Specifically, ceramic emulsions, nanofiber fillers, water and surface active agents are prepared into bottom emulsions, low-surface energy high-molecular polymer emulsions are used as surface emulsions, the bottom emulsions are quickly sprayed layer by layer at high temperature, the water is used as pore forming materials at the moment so as to quickly volatilize, so that uniform pore structures are constructed at the bottom, and a structural support with good mechanical strength is provided for preparing the durable super-hydrophobic coating; the surface emulsions are sprayed at high pressure and then are injected into the pore structures, so that the adhesion of low-surface energy materials and base materials is greatly increased; and the fibrosis effect of low-surface energy high-molecular polymer is achieved by virtue of high-temperature calcination, so that a fiber net structure is constructed on the surface of the ceramic coating, the super hydrophobicity of the coating is increased, the brittleness of the ceramic coating is improved, and the wear resistance of the coating is increased.

Owner:NORTHEAST GASOLINEEUM UNIV

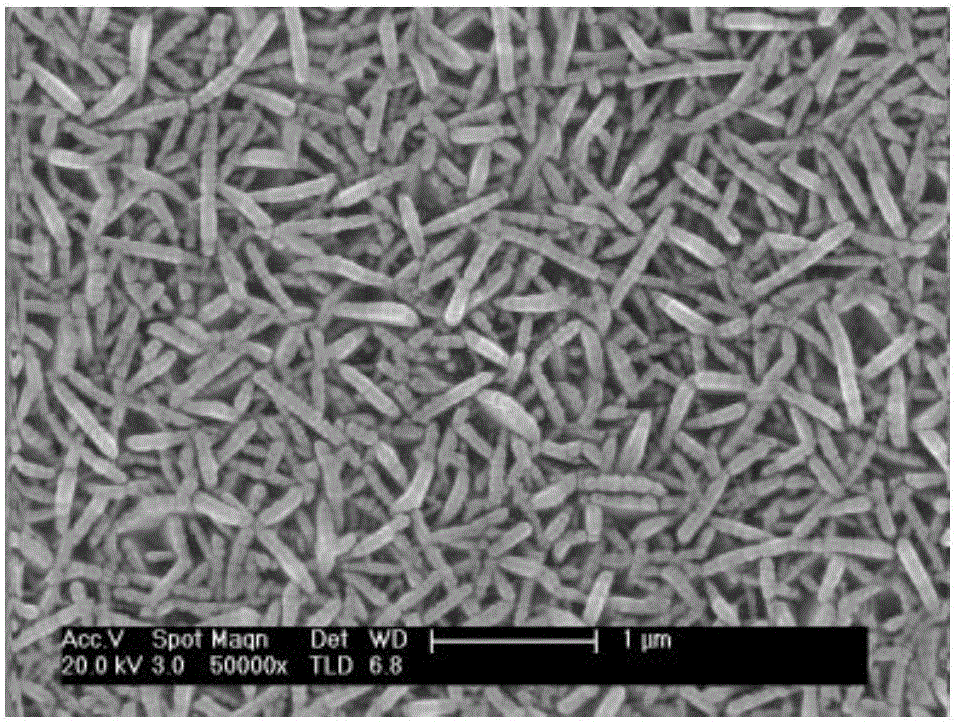

Transparent super-hydrophobic nano-array and preparation method thereof

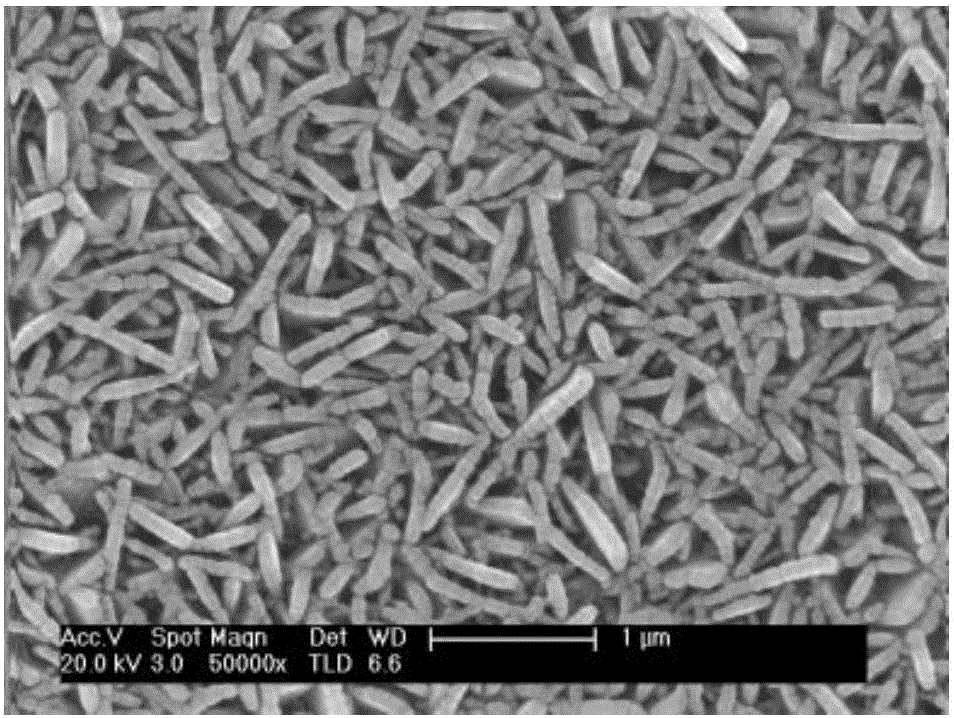

ActiveCN105776317AReduce concentrationControl growth rateZinc oxides/hydroxidesNanotechnologyDesorptionSpray coating

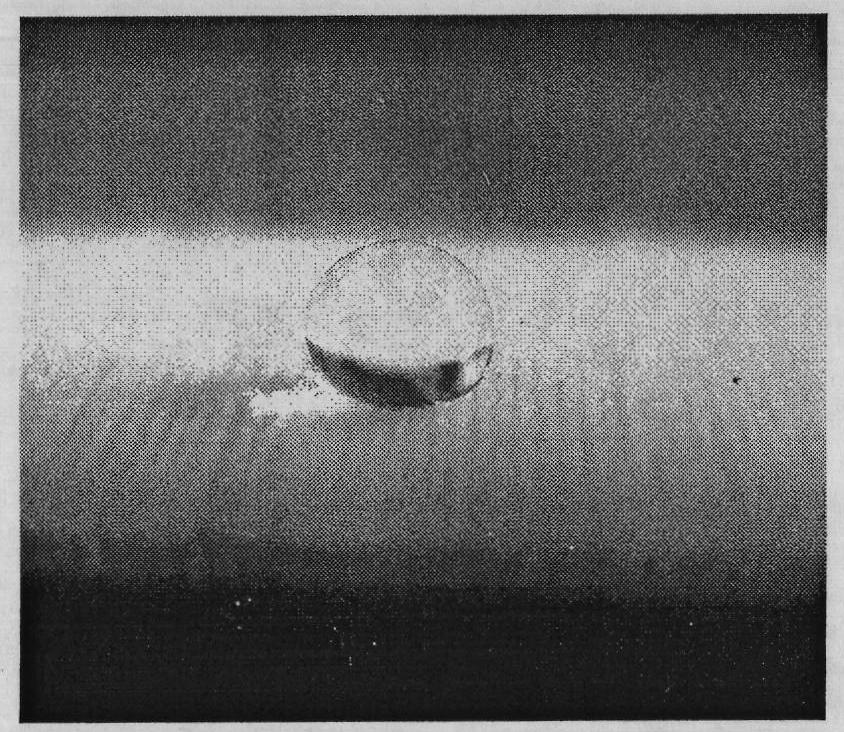

The invention discloses a transparent super-hydrophobic nano-array and a preparation method thereof. The preparation method comprises the following steps: firstly coating the surface of a substrate with zinc oxide seed crystal sol by virtue of a spin coating method or a spray coating method, so as to obtain a uniform nano-seed crystal layer; then controlling the hanging altitude and the position in a low-concentration growth solution prepared from KOH and Zn(NO3)2 by virtue of a vertical cotton thread hanging technique, so as to obtain a transparent zinc oxide nano-array, and carrying out fluorination to construct excellent super-hydrophobicity; and carrying out double-surface coating, sintering and growth on the substrate, so as to obtain the transparent super-hydrophobic nano-array on two surfaces of the substrate. Liquid drops with condensed and frosted surfaces are of a sphere shape, small in sizes, extremely easy to combine and bounce, high in desorption rate and low in coverage rate, present excellent frosting resistance and have important application prospects in products of building exterior glass, solar cells, automotive glass and the like, and furthermore, concepts can be provided for application of dropwise condensation, frosting resisting, freezing resisting and the like.

Owner:SOUTHEAST UNIV

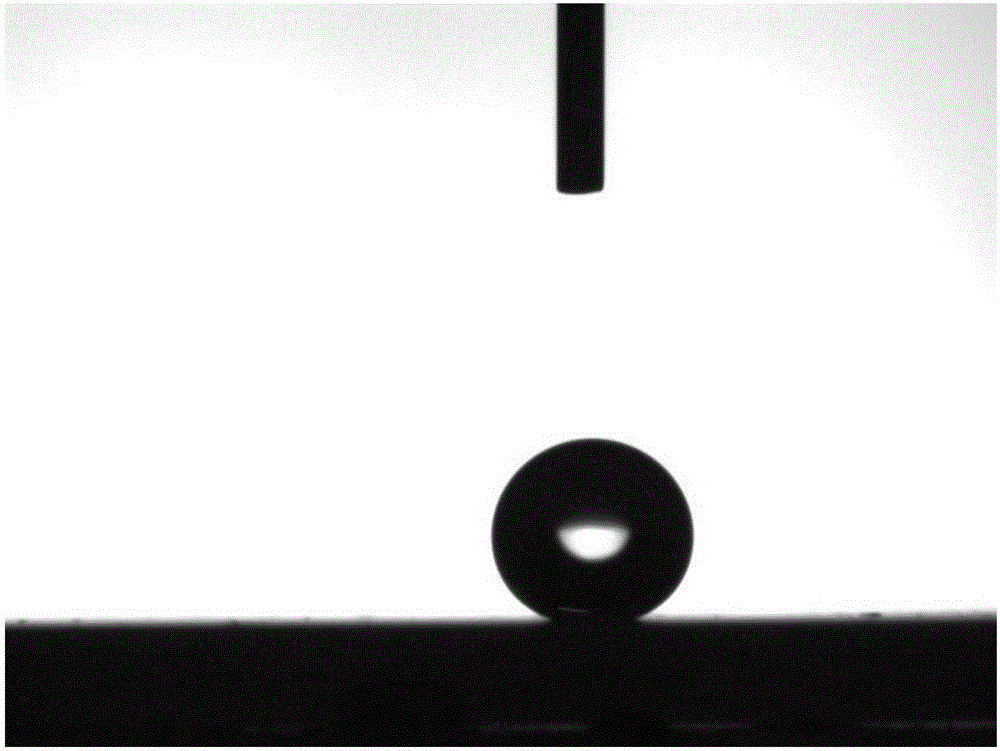

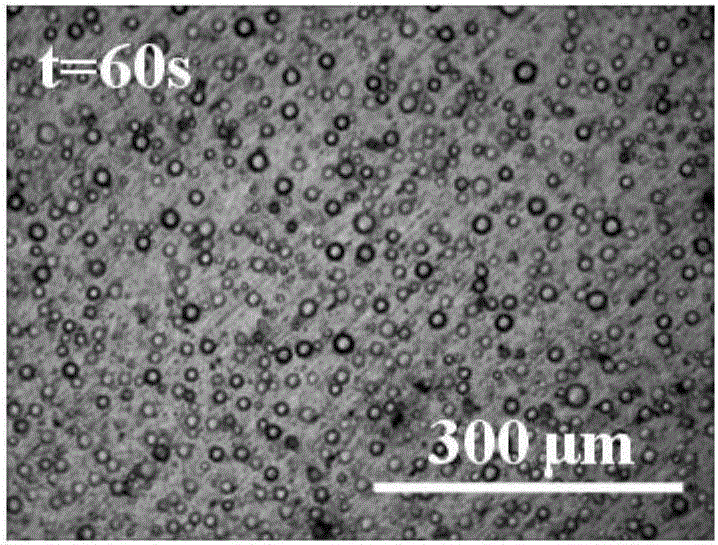

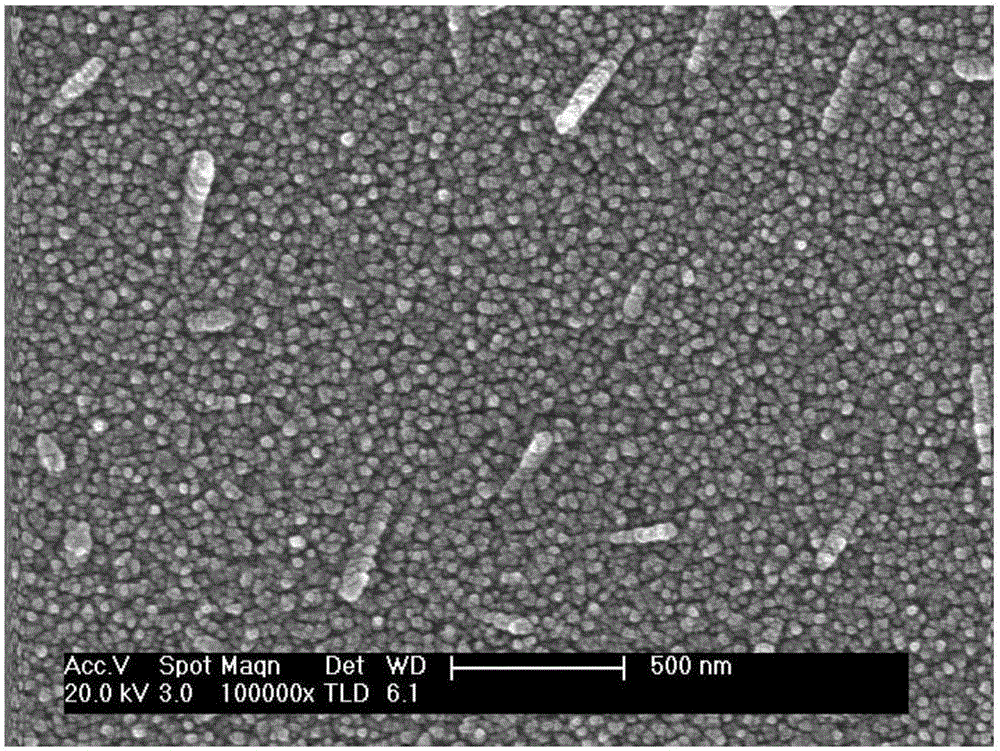

Preparation method for superhydrophobic coating with condensation microdroplet self-bouncing properties

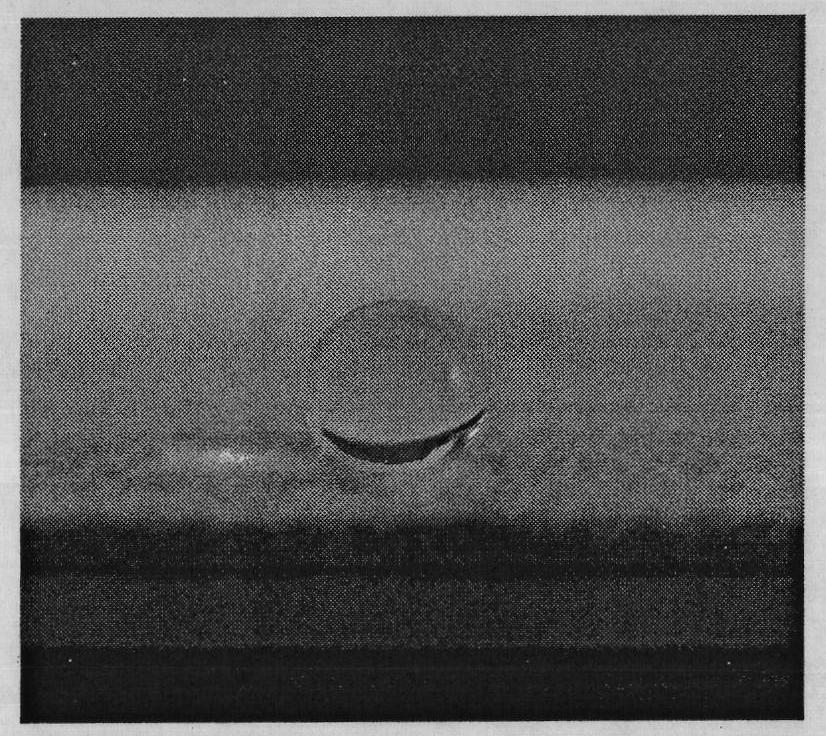

ActiveCN106634067APrevent gelAvoid reunionAntifouling/underwater paintsPaints with biocidesSilanesSuperhydrophobic coating

The invention relates to a preparation method for a superhydrophobic coating with condensation microdroplet self-bouncing properties. The preparation method comprises the following steps: with a waterborne chain type silica sol as a raw material, carrying out dilution and dispersion with an alkaline aqueous solution so as to effectively prevent the waterborne silica sol from agglomeration, then carrying out dispersing in a volatile organic solution, adding tetraethyl orthosilicate, fluoroalkyl silane and the like into the obtained dispersion liquid, then subjecting silica sol particles to surface modification, and carrying out continuous mechanical stirring so as to obtain the superhydrophobic coating. The coating can be applied to a variety of soft and hard substrates through manners of spraying, dipping, pulling, rolling or brushing, thereby obtaining the superhydrophobic surface with a porous nanometer structure, wherein the porous nanometer structure also enables condensation microdroplets to obtain self-bouncing properties. The coating has extensive application in the aspects of surface self-cleaning and corrosion and mildew prevention, especially in the aspects of condensation heat transfer, water collection, frost prevention, ice resisting, etc. The preparation method provided by the invention has the characteristics of simple preparation process and equipment, easiness in operation, low cost, etc., and is applicable to large-scale preparation and industrial production.

Owner:SOUTHEAST UNIV

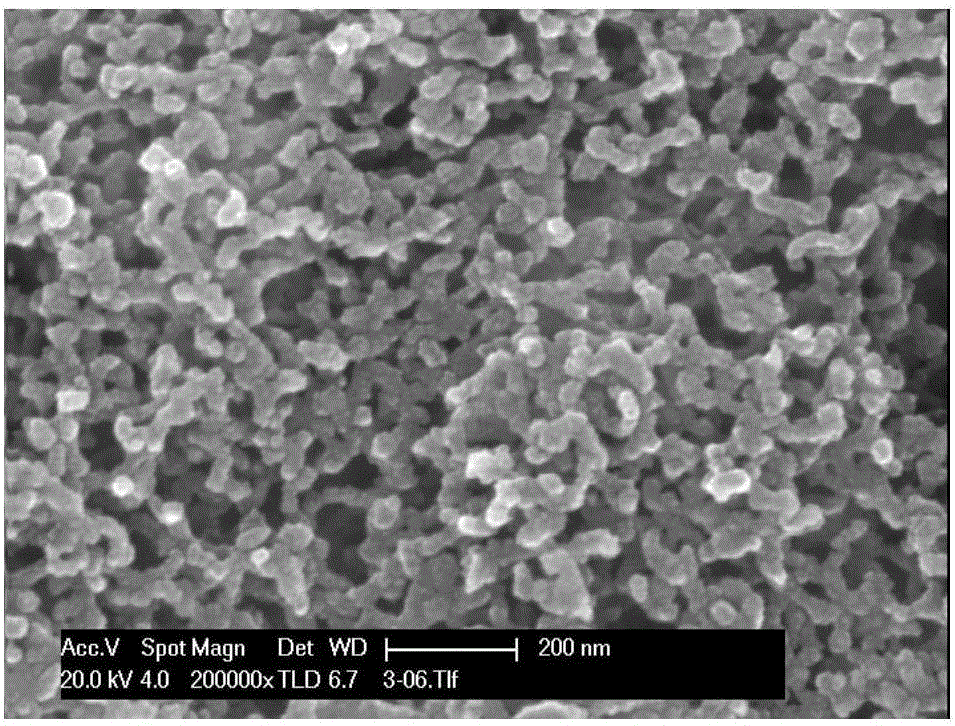

Super-hydrophobic composite coating and preparation method thereof

ActiveCN111299104AImprove hydrophobicityImprove wear resistanceSpecial surfacesTextiles and paperPolymer scienceOrganosolv

The invention provides a super-hydrophobic composite coating and a preparation method thereof. The preparation method comprises the following steps: step 1, ultrasonically dispersing epoxy resin and acuring agent of the epoxy resin in an organic solvent so as to form a uniform epoxy resin solution, spraying the epoxy resin solution onto the substrate surface, and carrying out drying; step 2, ultrasonically dispersing the epoxy resin and the curing agent of the epoxy resin in the organic solvent so as to form the uniform epoxy resin solution, adding an inorganic nanofiller into the epoxy resinsolution, carrying out uniform stirring and dispersing so as to obtain a mixed solution, and then spraying the mixed solution onto the substrate surface obtained in step 1; and step 3, ultrasonicallydispersing polydimethylsiloxane and a curing agent of polydimethylsiloxane in an organic solvent so as to form a uniform polydimethylsiloxane solution, spraying the polydimethylsiloxane solution ontothe substrate surface obtained in step 2, carrying out drying, and acquiring the super-hydrophobic composite coating after complete curing. The preparation method has the beneficial effects that no special equipment is needed; and not only is the operation simple and the application range wide, but also the super-hydrophobic performance of the coating can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of superhydrophobic surface of metal zirconium

ActiveCN101941000AExcellent superhydrophobic propertiesMeet actual needsSurface reaction electrolytic coatingPretreated surfacesAnodizingEtching

The invention provides a preparation method of a superhydrophobic surface of a metal zirconium. The method is as follows: firstly, in site building a nano / micro coarse structure on the surface of the metal zirconium through chemical etching, anodizing and ultraphonic strip membranes; and subsequently, carrying out hydrophobic treatment on the surface through low surface energy substances such as self-assembling siloxane and the like, thereby obtaining the superhydrophobic metal zirconium surface. The metal zirconium surface treated by using the method of the invention has good superhydrophobic property, a contact angle with water-drop reaches 157-163 degrees, and a roll angle is less than 3 degrees, thereby meeting the demand of industry fields on the superhydrophobic surface of the metal zirconium. The method of the invention has the characteristics of simple process, convenient operation, low production cost, easy large-scale preparation, industrial production and the like.

Owner:苏州盛泽科技创业园发展有限公司

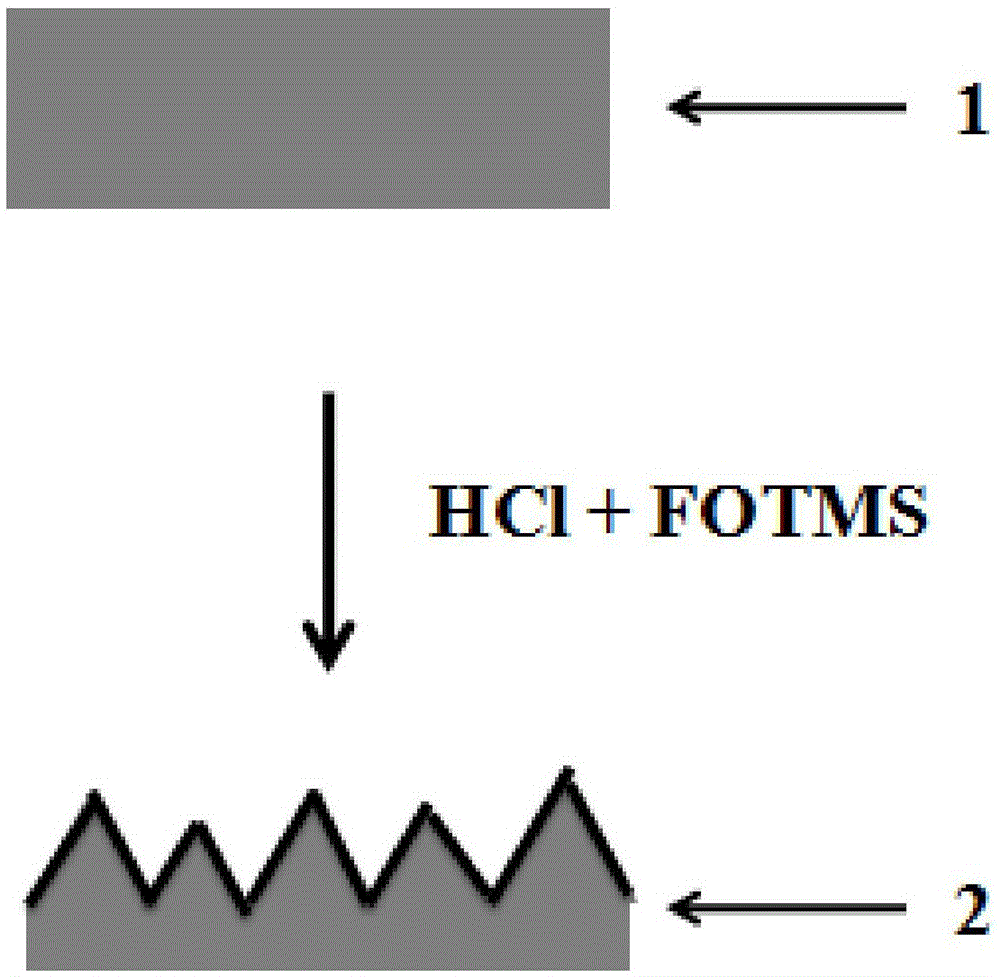

Low-cost superhydrophobic surface treatment method of aluminum alloy

InactiveCN101982560AEasy to operateSimple manufacturing processSolid state diffusion coatingStearic acidHydrophobic surfaces

The invention provides a low-cost superhydrophobic surface treatment method of aluminum alloy, which comprises the following steps: (1) carrying out chemical etching on the surface of the aluminum alloy by utilizing hydrochloric acid aqueous solution with the mass-volume concentration of 70g / L-95g / L in water bath at the temperature of 30-50 DEG C for 3-6min; and (2) carrying out evaporation modification on the surface of the aluminum alloy by utilizing long chain fatty acid solution by an evaporation method, wherein, the long chain fatty acid comprises at least one of lauric acid and stearic acid, and the long chain fatty acid solution is prepared by dissolving fatty acid into an ethanol solvent based on the mass percent of 3wt.%-15wt.%. The evaporation method comprises the following steps: placing the long chain fatty acid solution and the aluminum alloy subject to chemical etching treatment in a sealed container; putting the sealed container in a chamber electric furnace, heating until the temperature of the mixture is up to 100-200 DEG C, and performing heat preservation for 1-3h; and taking out the aluminum alloy and placing the aluminum alloy in the chamber electric furnace again, curing at the temperature of 50-90 DEG C for 0.5-1.5h, and finally taking out the aluminum alloy, and carrying out air cooling on the aluminum alloy to obtain the aluminum alloy surface which has the advantages of good superhydrophobic characteristic and less possibility of being adhered to water drops.

Owner:SOUTHEAST UNIV

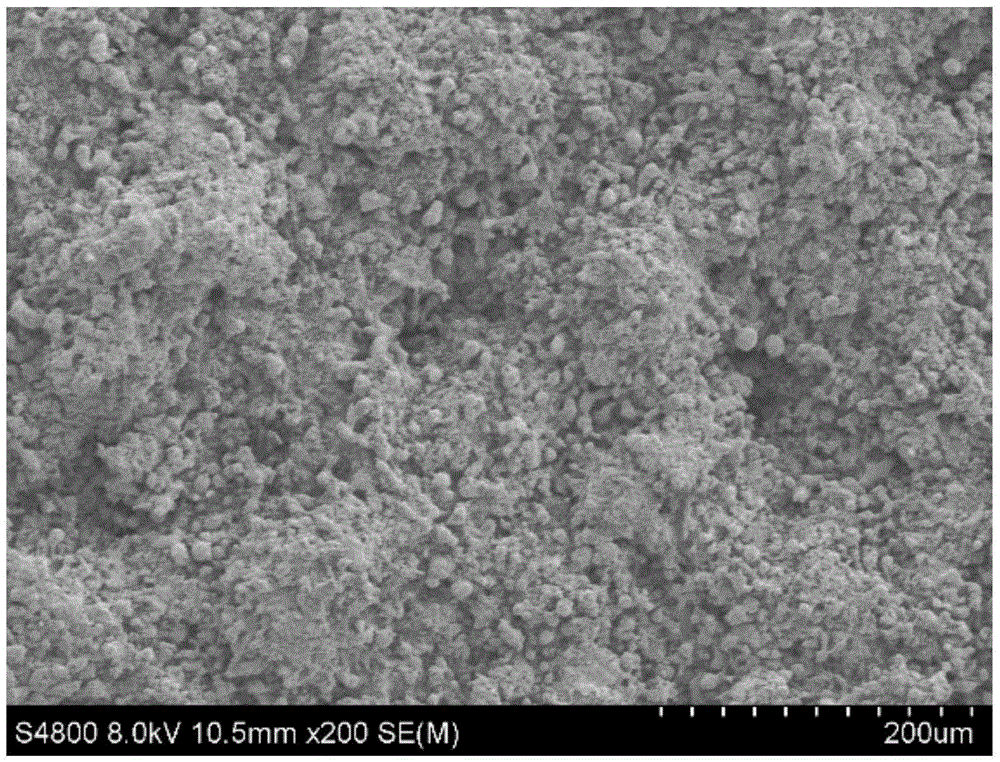

Super-hydrophobic cement and preparing method and application thereof

ActiveCN108341635AImprove hydrophobic uniformityExcellent superhydrophobicityLow speedSURFACTANT BLEND

The invention provides super-hydrophobic cement and a preparing method and application thereof. The preparing method comprises the steps that cement powder, fine sand and hydrophobic modifier are added into ethyl alcohol in sequence under low-speed mechanical stirring conditions, and then high-speed stirring is conducted to obtain a modified cement fine sand solution; the modified cement fine sandsolution is filtered, dried and smashed to obtain super-hydrophobic cement fine sand mixed powder; under low speed mechanical stirring conditions, the super-hydrophobic cement fine sand mixed powderis put into an aqueous solution containing surfactant, dispersing agent and fluoroalkyl silane, and then mechanical stirring is conducted to form the super-hydrophobic cement. According to the method,a coating does not need to be prepared additionally, the technology is simple, the operation is simple, the super-hydrophobic cement is suitable for large-scale preparation and production, the overall super-hydrophobic property of obtained concrete is good, the inside is still not super-hydrophobic after abrasion, the super-hydrophobic property is not easily damaged, and the super-hydrophobic cement is applicable to various concrete application places and has a good prospect.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com