Preparation method and application of super-hydrophobic and adhesion-adjustable surface with micro-nano composite structure

A technology of micro-nano composite structure and composite microstructure, which is applied in the direction of coating, etc., can solve the problems of limited control of the surface adhesion characteristics of polymer products, and achieve the effects of excellent super-hydrophobic performance, expanded application range, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

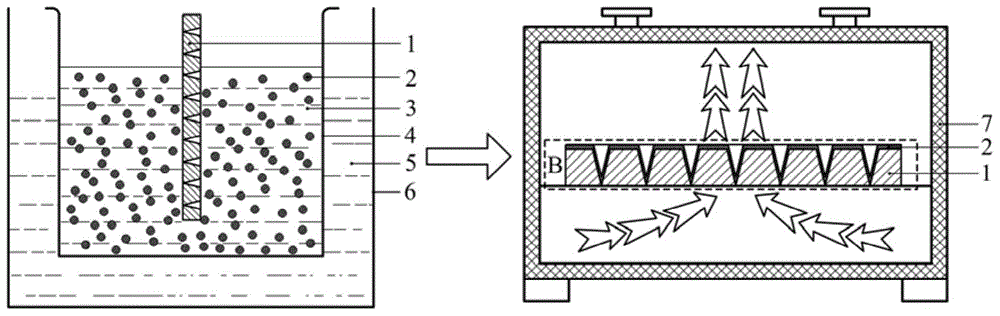

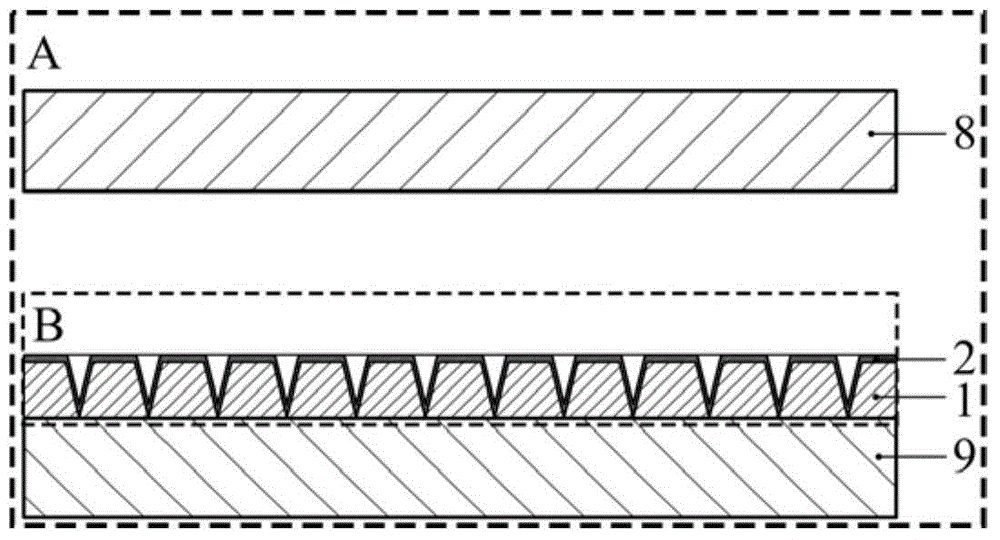

[0040] figure 1 with Figure 2a-2c The specific implementation process for preparing a super-hydrophobic and high-adhesion surface using the present invention is shown. The equipment required for the implementation process of the present invention includes an injection molding machine (not shown in the figure), an injection mold A with a micro-nano composite structure template, an ultrasonic vibrator 6 and an oven 7. An injection mold A with a micro-nano composite structure template is connected to the injection molding machine. The injection mold A with a micro-nano composite structure template includes a fixed mold 8, a movable mold 9, and a hydrophilic nano-SiO 2 The solution-coated screen template B is provided with heating, cooling and demolding devices (not shown in the figure). Hydrophilic Nano SiO 2 The solution-coated screen template B includes screen template 1 with a mesh number of 1800 and hydrophilic nano-SiO attached to it. 2 Particle 2.

[0041] The implementation...

Embodiment 2

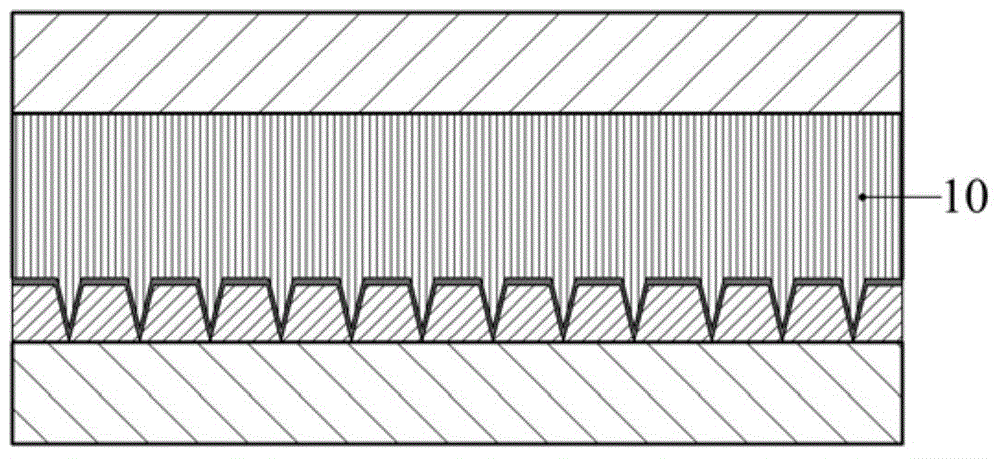

[0044] The implementation process of the PP product 11 with a super-hydrophobic and low-adhesion injection surface of the present invention is as follows. 0.6g of hydrophobic nano SiO 2 Particles 2 and 20ml of absolute ethanol 3 are formulated into a solution. After stirring evenly, immerse the sieve template 1 with a mesh number of 3000 into the solution. After 20 minutes of ultrasonic dispersion, the solution is slowly taken out and dried by dipping and pulling. Hydrophobic Nano SiO 2 Solution coated screen template. The obtained template is adhered to the cavity surface of the fixed mold 9 to form an injection mold A with a micro-nano composite structure template. Heat the injection mold A with the micro-nano composite structure template to 120°C, and inject the PP melt 10 into the closed cavity of the injection mold A with the micro-nano composite structure template through the injection molding machine to push the screw axis forward By means of shifting, apply a pressure ...

Embodiment 3

[0048] The implementation process of using the PP product 11 with a super-hydrophobic and medium-adherent injection surface of the present invention is as follows. 0.04g hydrophilic nano SiO 2 Particles 2 and 20ml of absolute ethanol 3 are prepared into a solution. After stirring, the two-stage composite microstructure template 13 is immersed in the solution. After 20 minutes of ultrasonic dispersion, it is slowly taken out and dried by dipping and pulling, so as to obtain the Water Nano SiO 2 Solution-coated two-stage composite microstructure template D. Hydrophilic Nano SiO 2 The solution-coated two-stage composite microstructure template D is adhered to the cavity surface of the fixed mold 9 to form an injection mold A with a micro-nano composite structure template. Heat the injection mold A with the micro-nano composite structure template to 120°C, and use the injection molding machine to inject the PP melt 10 into the closed injection mold A with the micro-nano composite s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com