Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

207 results about "Screw axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A screw axis (helical axis or twist axis) is a line that is simultaneously the axis of rotation and the line along which translation of a body occurs. Chasles' theorem shows that each Euclidean displacement in three-dimensional space has a screw axis, and the displacement can be decomposed into a rotation about and a slide along this screw axis.

Orthopaedic screws

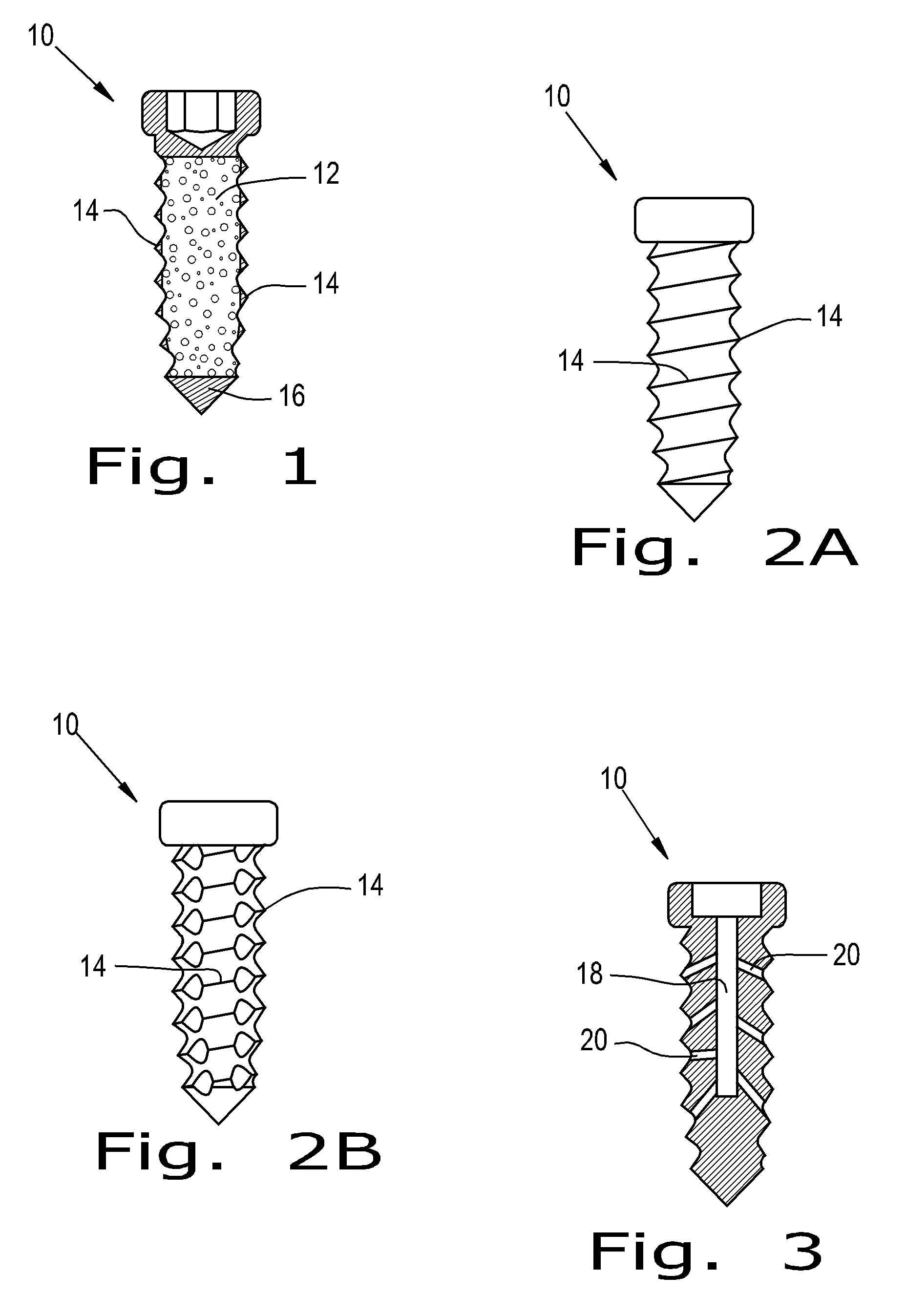

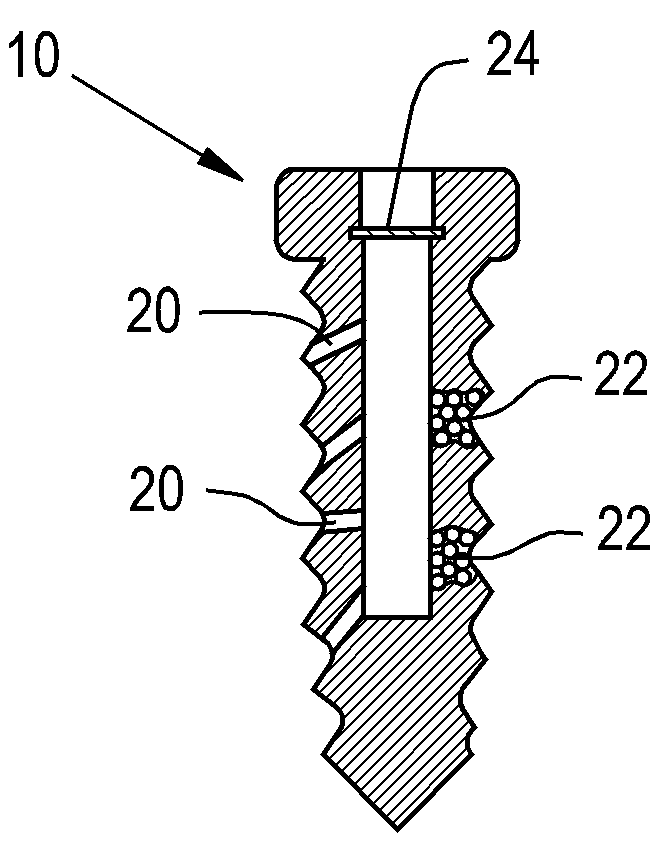

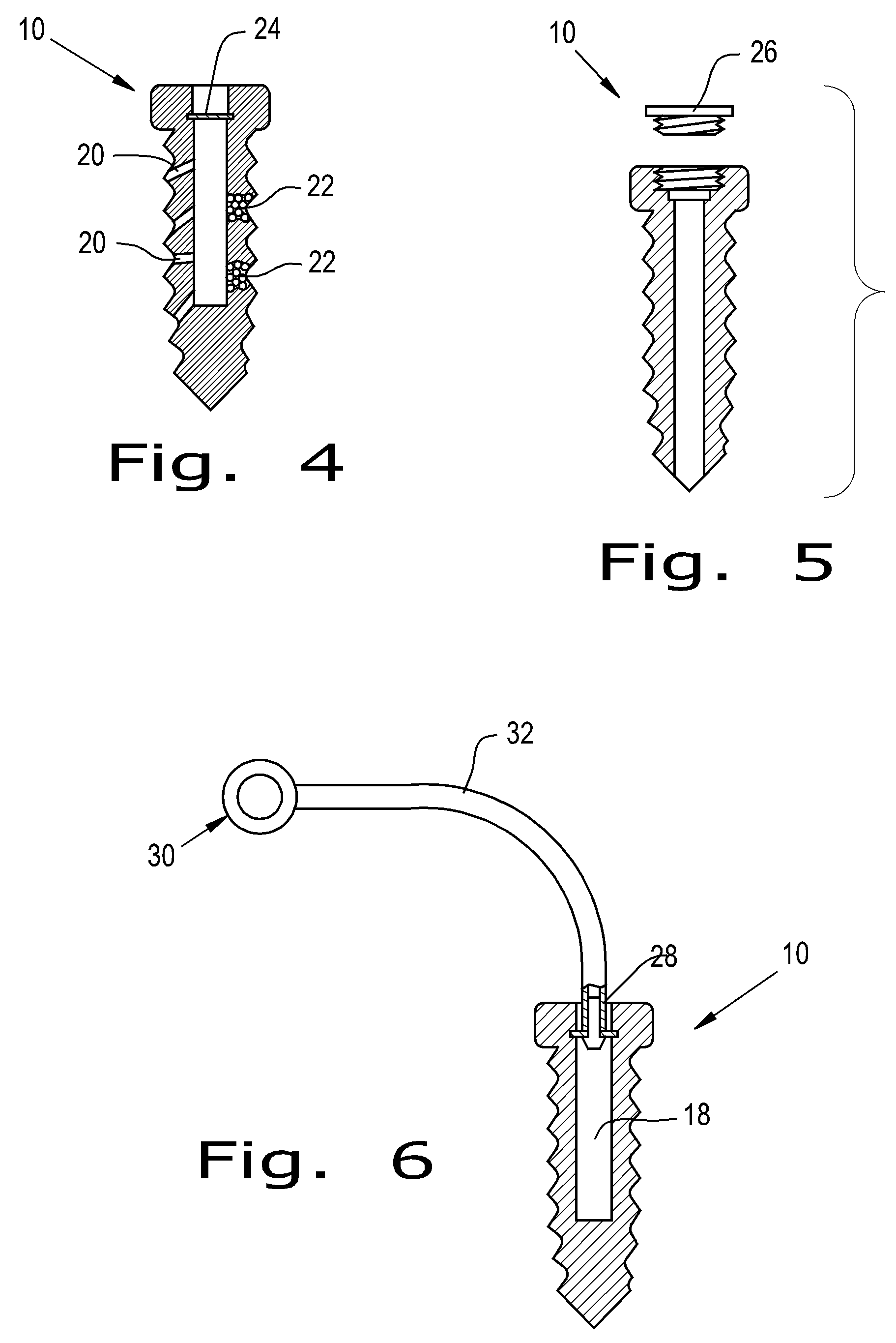

ActiveUS20100042167A1Successful tissue integrationImprove adhesion strengthSuture equipmentsAdditive manufacturing apparatusPorositySolid region

An orthopaedic screw having a plurality of regions, at least one of which may be porous. The orthopaedic screw includes a head, a tip and at least one thread. The porosity of the screw of the present invention can vary within the part or region, including changes in pore shape, size and density. These characteristics can vary along the length of the screw axis and / or radially (from the outer diameter to the axis). The orthopaedic screw may further include at least one solid region formed of any implantable polymer, reinforced polymer or metal.

Owner:SMED TATD

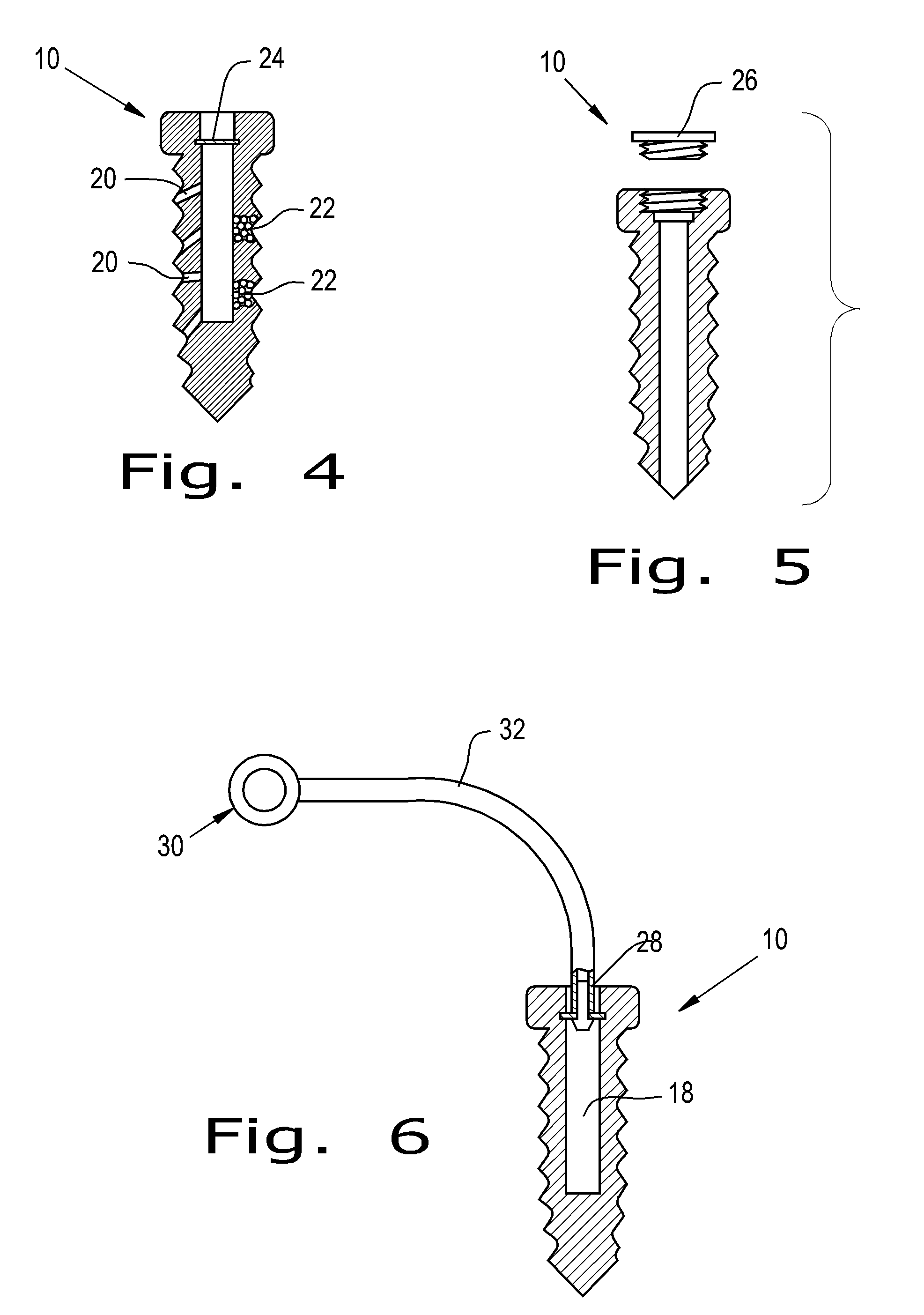

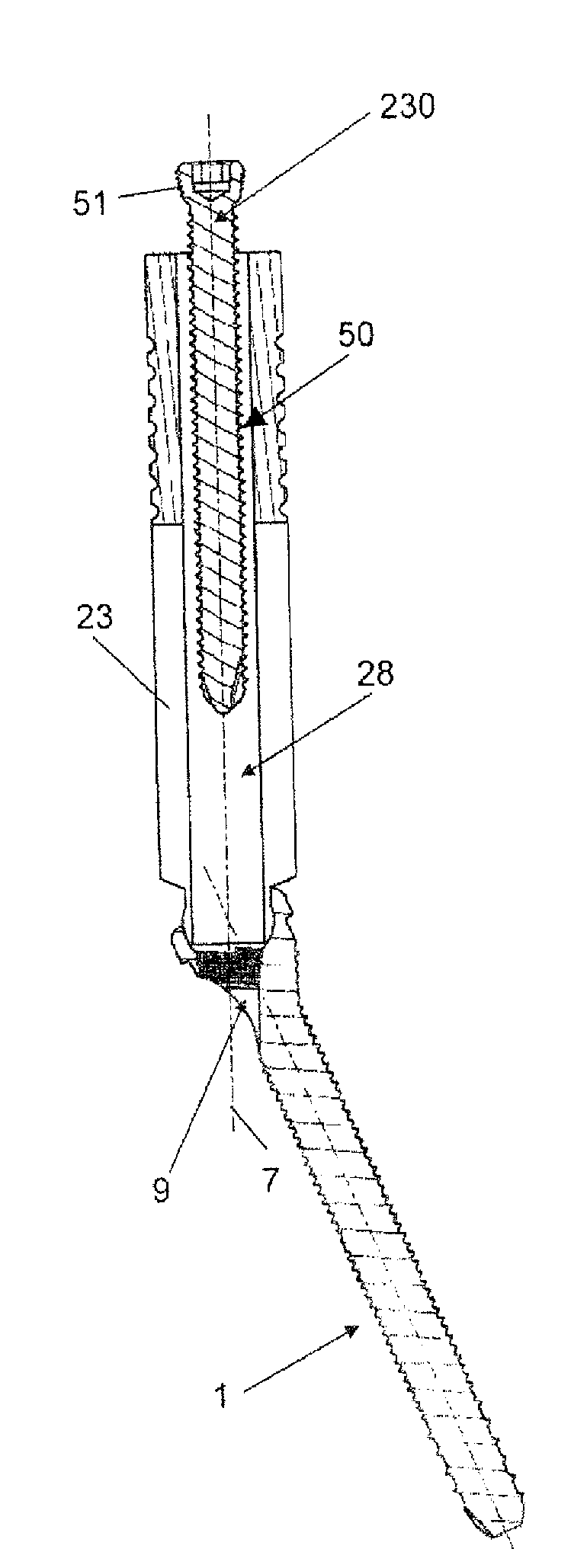

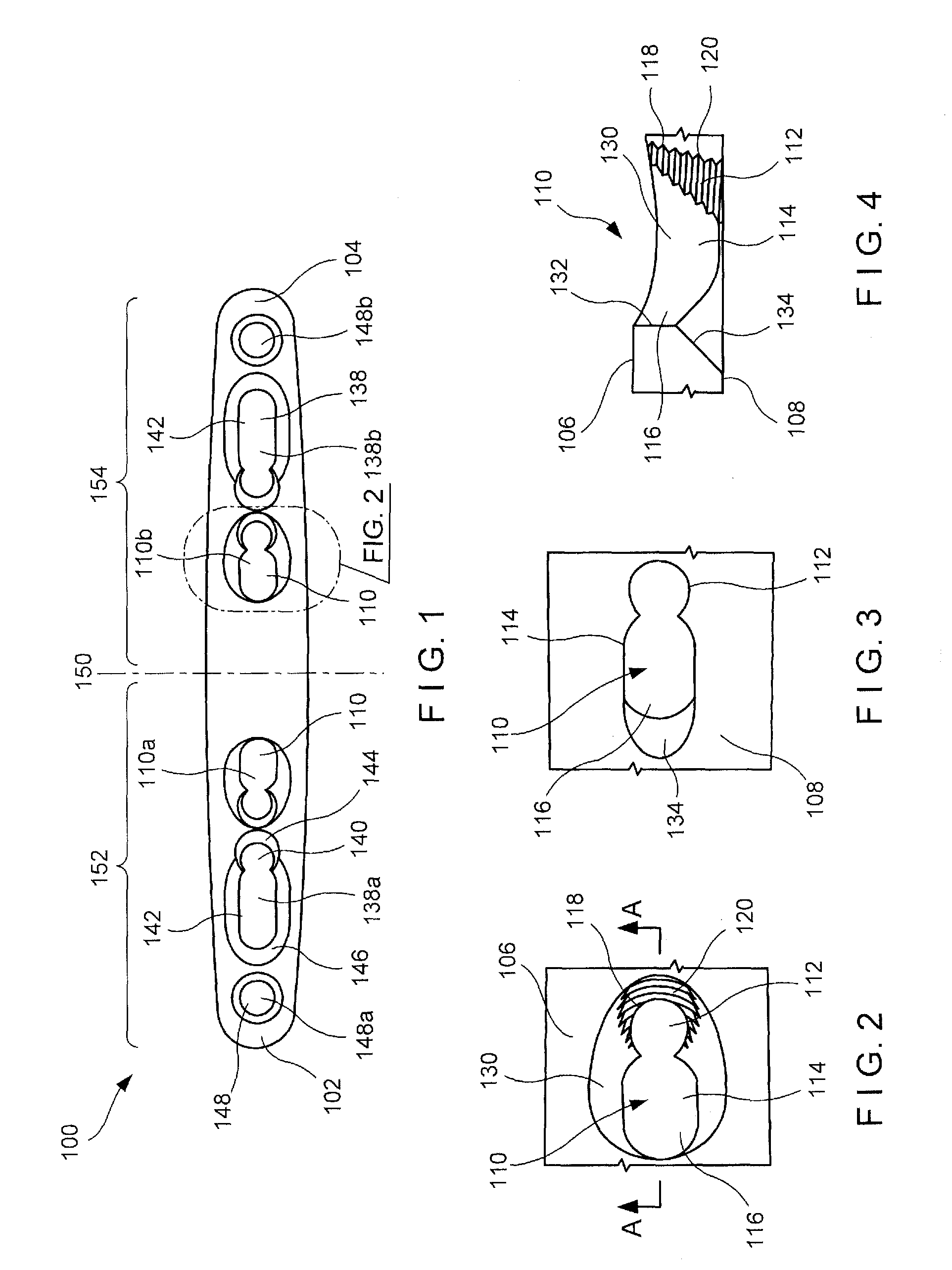

Bone Screw Assembly and Instruments for Implantation of the Same

InactiveUS20110282398A1Prevent crashReduce the cross-sectional areaSuture equipmentsInternal osteosythesisAcute angleEngineering

A bone screw includes a screw shaft extending longitudinally along a screw axis and a screw head extending from a proximal end of the screw shaft and configured to be releasably coupled to a surgical tool. The bone screw also includes a through hole defining a through hole axis and extending through the screw head, the through hole axis intersecting the screw axis at an acute angle α, the through hole being adapted to receive therein a second screw and tapering from a first end at a proximal end of the screw head to a second end opening to an outer surface of the screw head.

Owner:DEPUY SYNTHES PROD INC

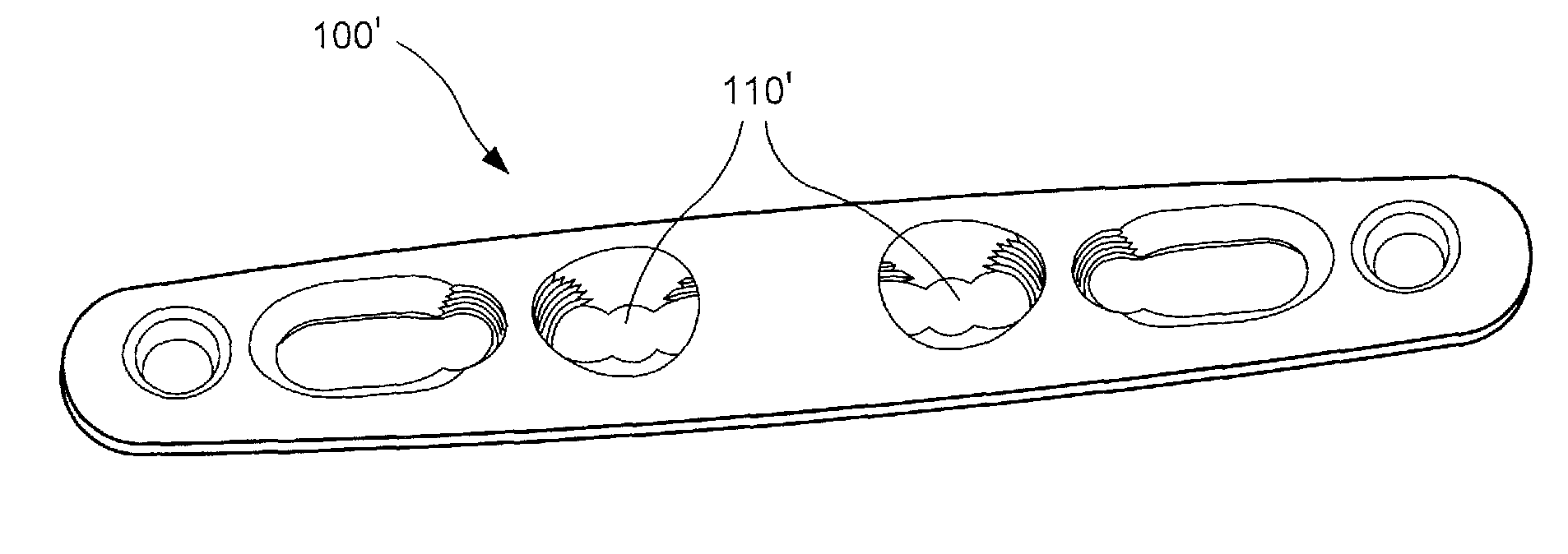

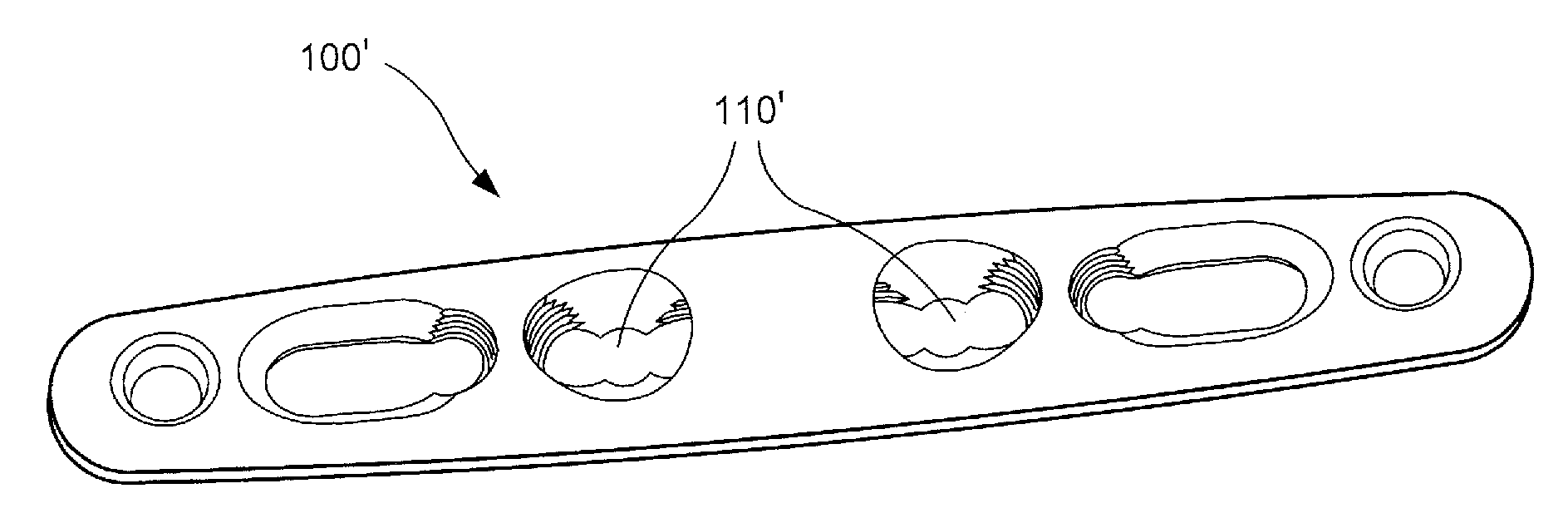

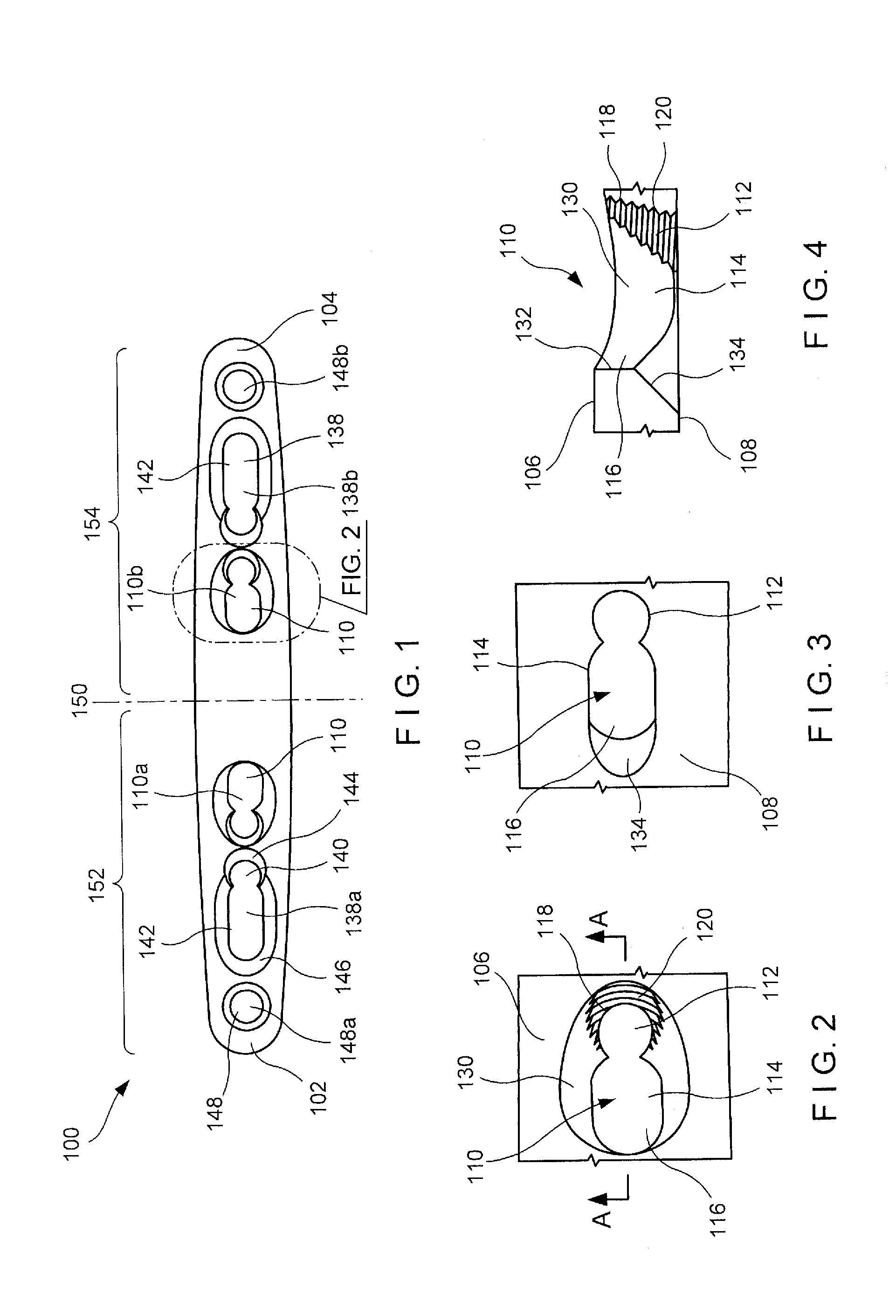

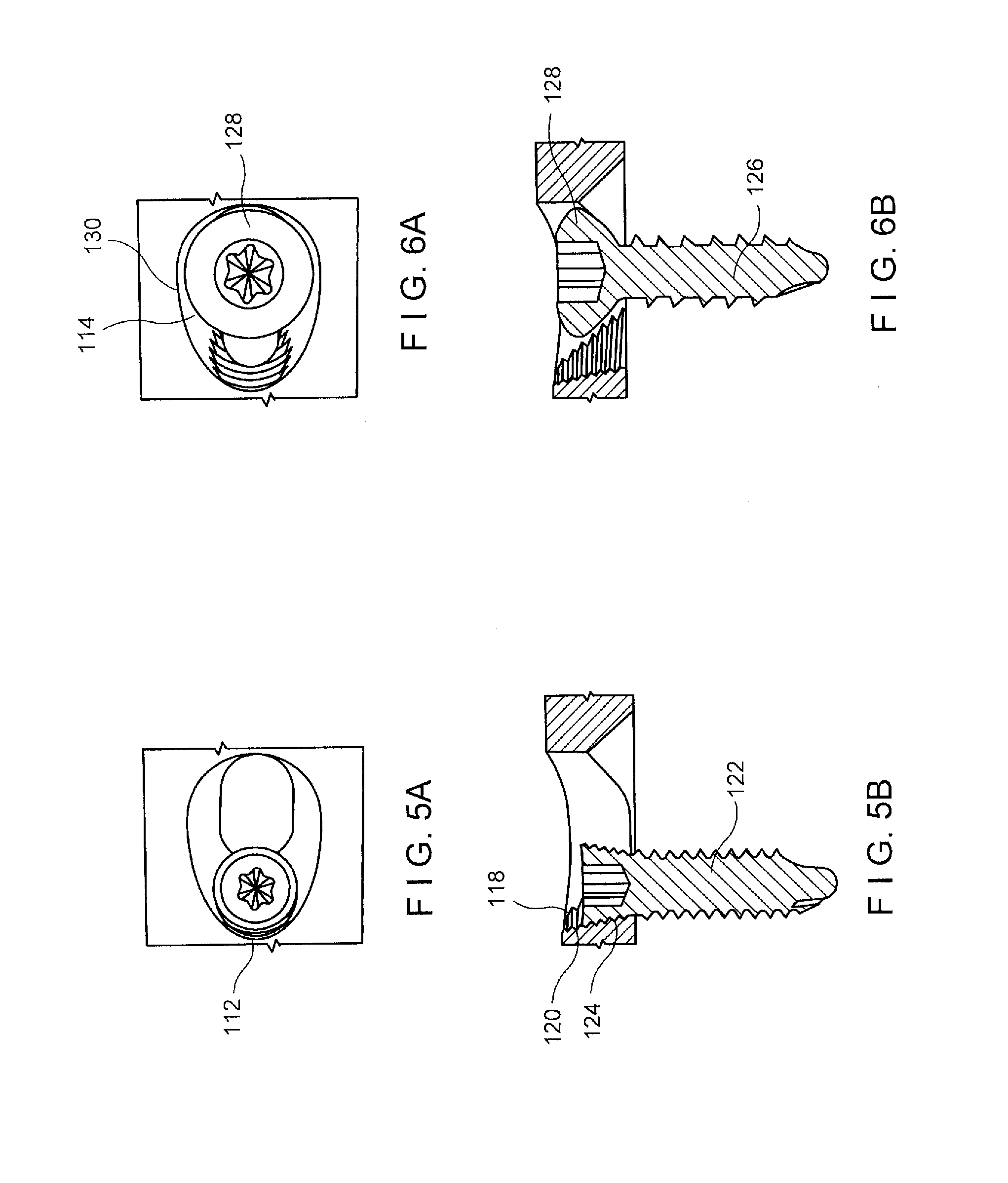

Ulna osteotomy system

ActiveUS9023052B2Non-surgical orthopedic devicesSurgical sawsUlnar shortening osteotomyBone fixation

A bone plate includes a first three-part combination hole extending through a proximal portion of the plate, a first portion configured to engage a threaded head portion of a bone fixation element, a second portion configured to receive a bone fixation element along an axis substantially perpendicular to a longitudinal axis of the bone and a third portion defining a screw axis extending toward the distal end of the elongated body at a non-perpendicular angle relative to the longitudinal axis in combination with a first two-part combination hole extending through the proximal portion, a first threaded portion configured to engage a threaded head portion of a bone fixation element and a second portion defining an elongated slot extending along a longitudinal axis of the plate for receiving a bone fixation element so that the plate may slide along its longitudinal axis relative to the bone fixation element.

Owner:DEPUY SYNTHES PROD INC

Ulna Osteotomy System

A bone plate includes a first three-part combination hole extending through a proximal portion of the plate, a first portion configured to engage a threaded head portion of a bone fixation element, a second portion configured to receive a bone fixation element along an axis substantially perpendicular to a longitudinal axis of the bone and a third portion defining a screw axis extending toward the distal end of the elongated body at a non-perpendicular angle relative to the longitudinal axis in combination with a first two-part combination hole extending through the proximal portion, a first threaded portion configured to engage a threaded head portion of a bone fixation element and a second portion defining an elongated slot extending along a longitudinal axis of the plate for receiving a bone fixation element so that the plate may slide along its longitudinal axis relative to the bone fixation element.

Owner:DEPUY SYNTHES PROD INC

Orthopaedic screws

ActiveUS8475505B2Improve adhesion strengthStrong bonesSuture equipmentsAdditive manufacturing apparatusPorositySolid region

Owner:SMED TATD

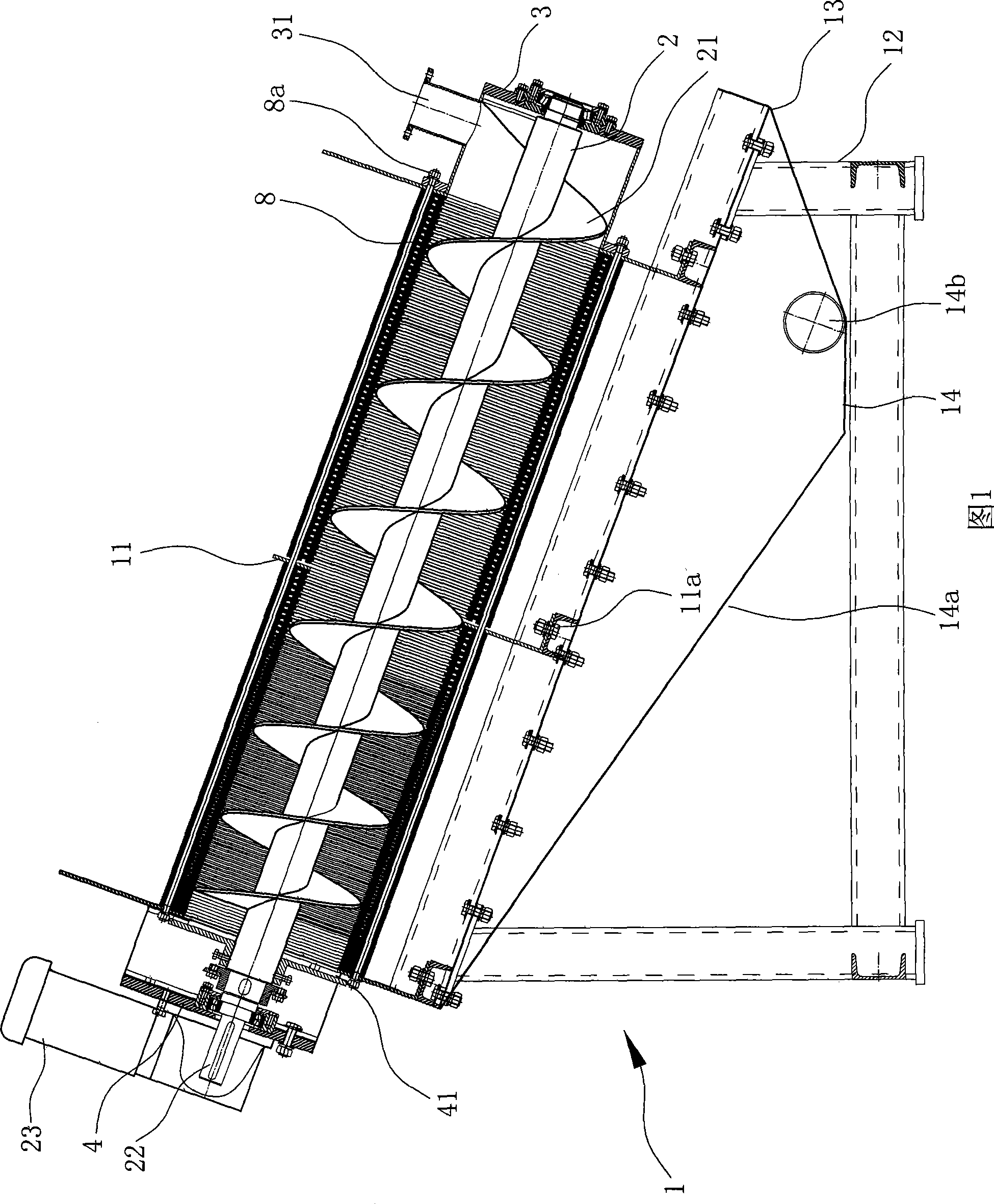

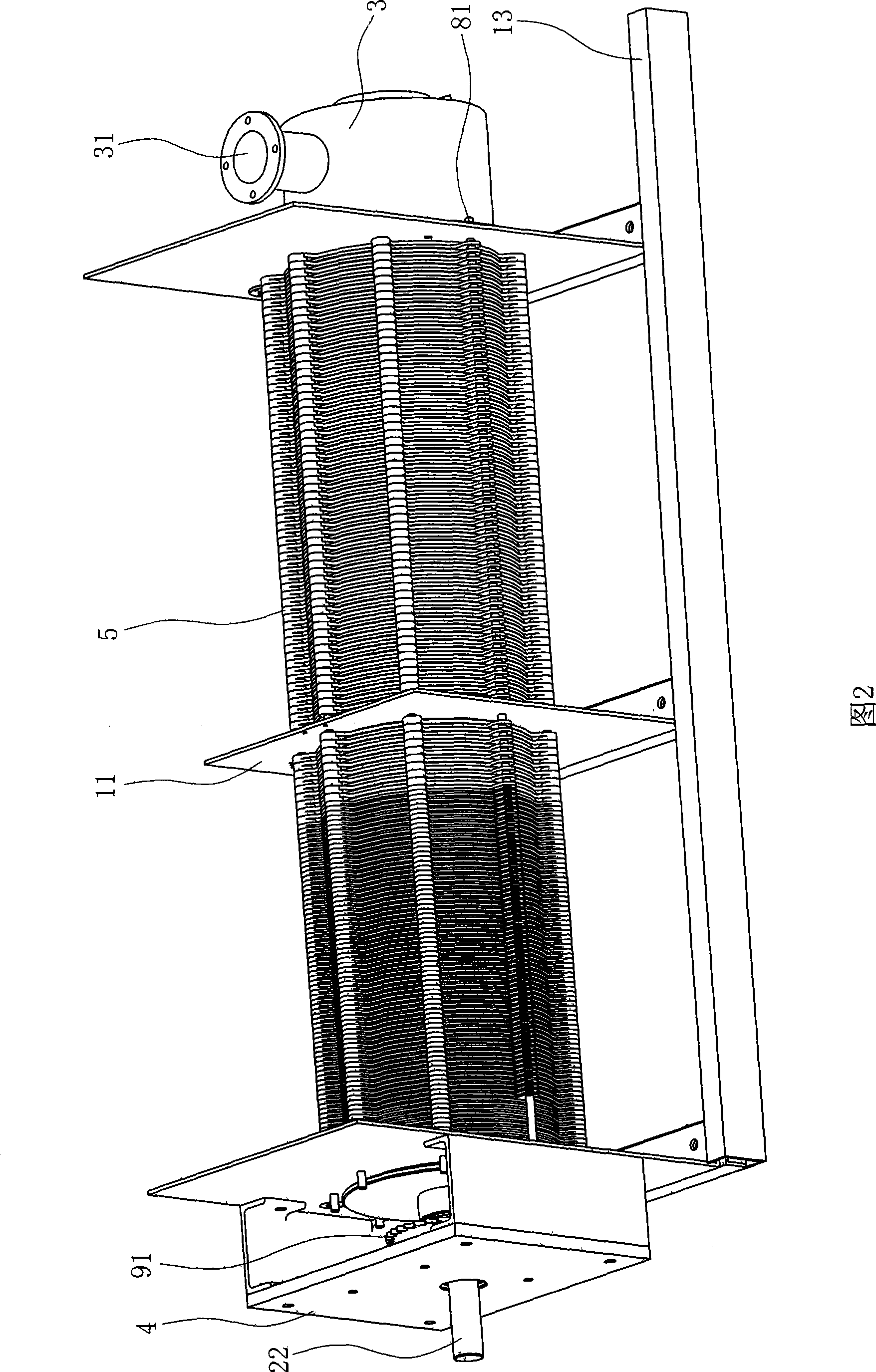

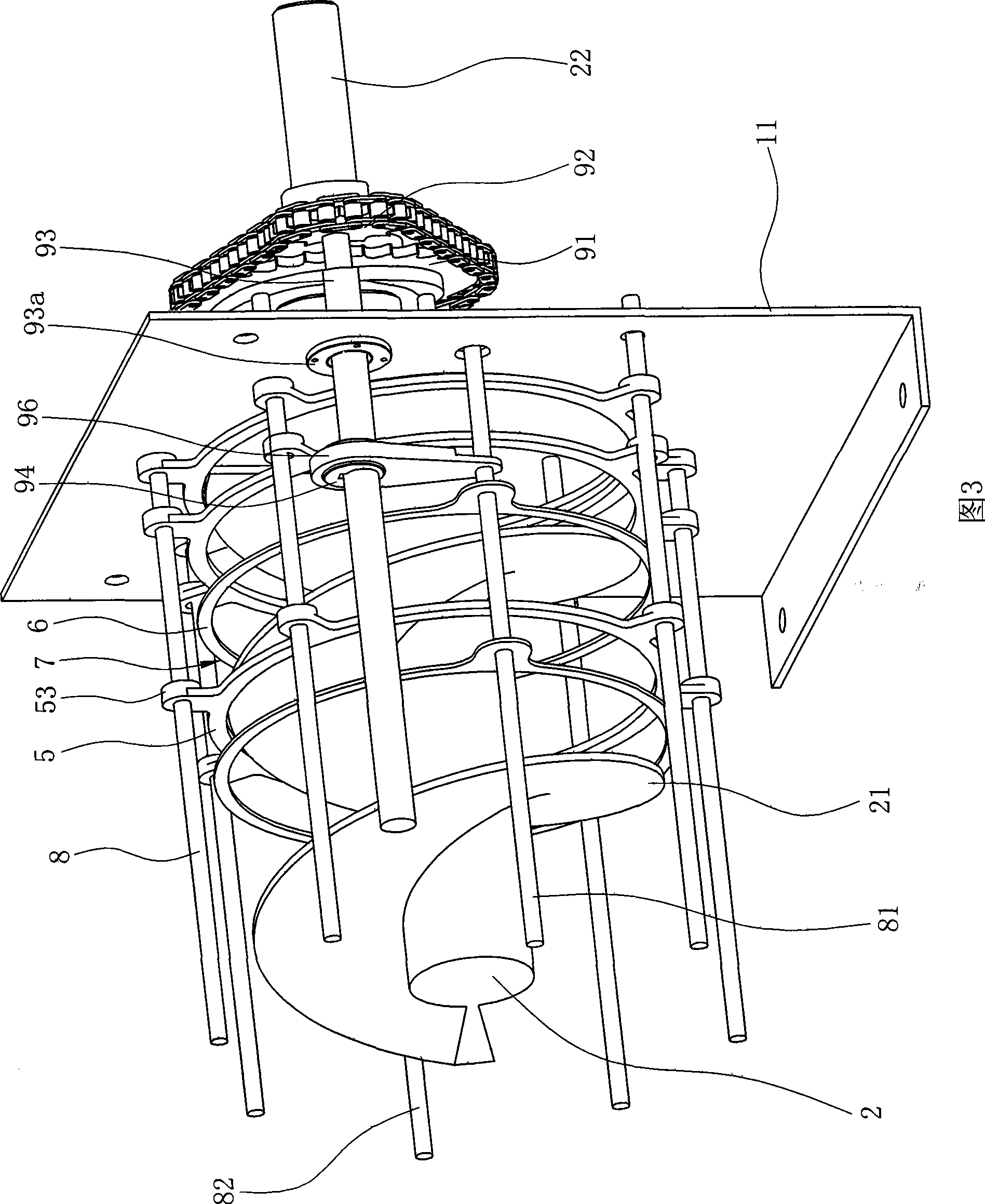

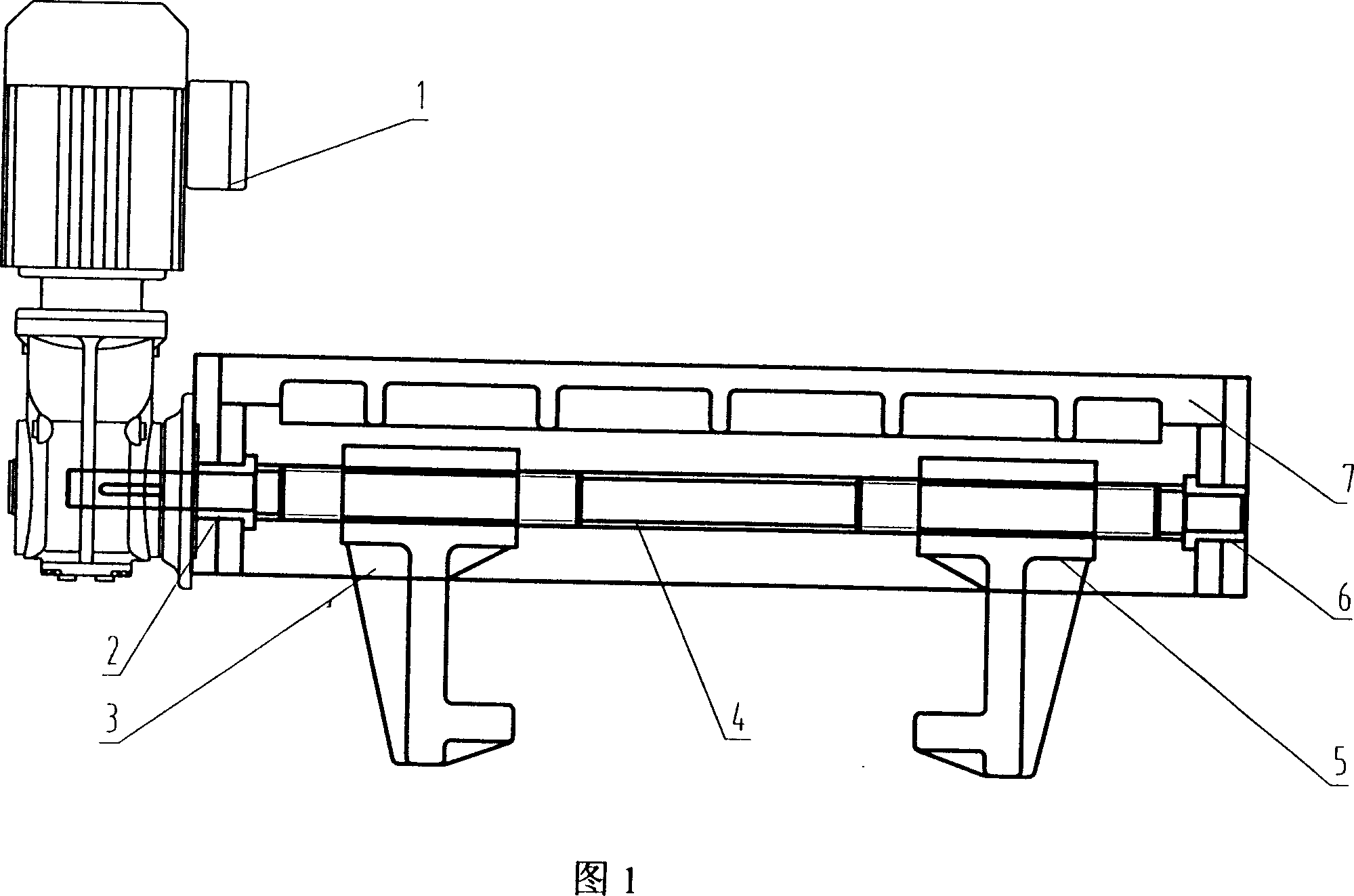

Spiral squeezing type sludge dewatering equipment

InactiveCN101417854APass smoothlyAvoid wear and tearSludge treatment by de-watering/drying/thickeningEngineeringDynamic filtering

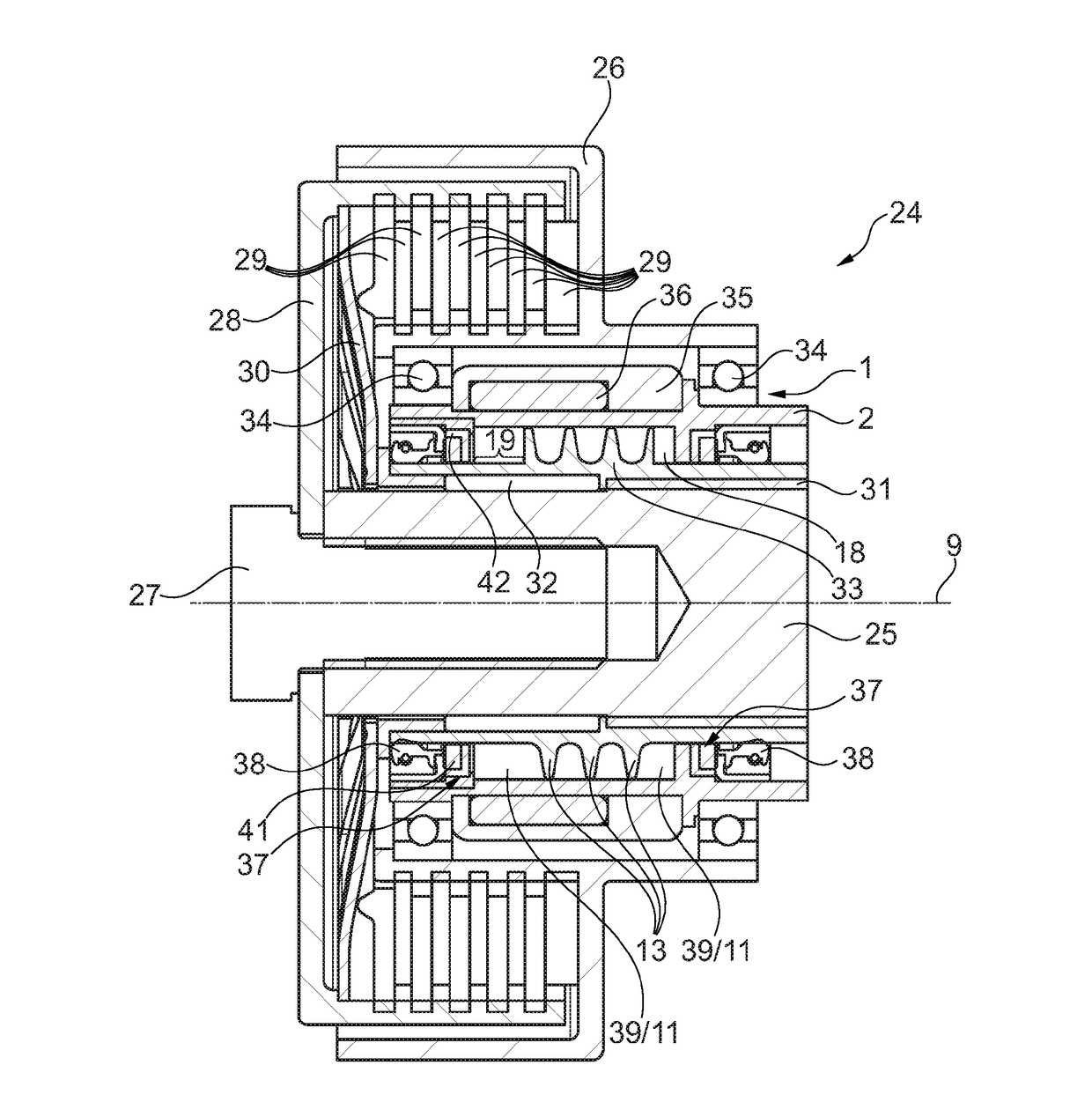

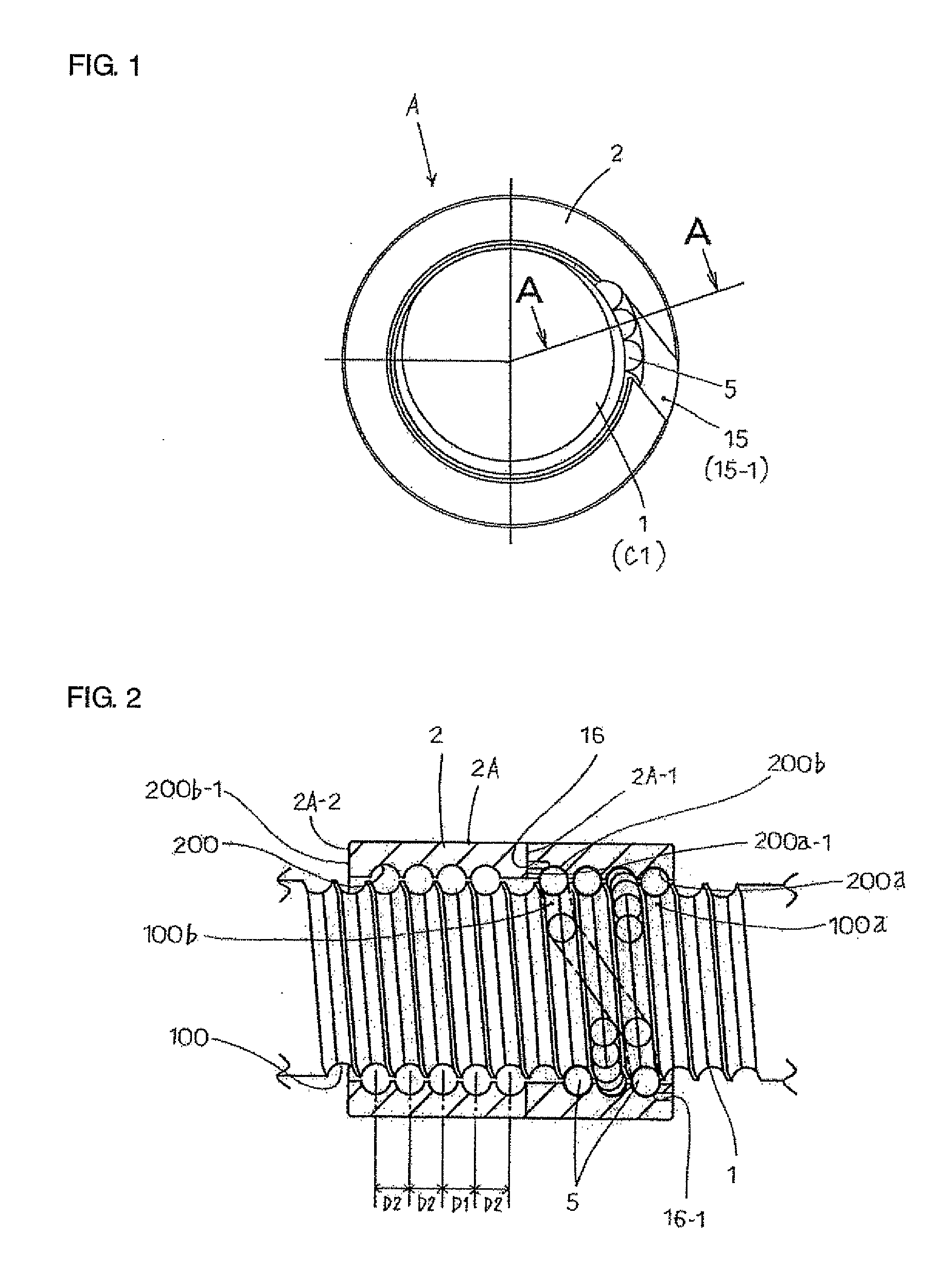

The invention discloses a spiral extrusion type sludge dewaterer comprising a frame (1), a water inlet part, an sludge outlet part (41), an water outlet part, a screw axis (2) and filter disc groups formed by the crossover interval arrangement of a plurality of annular static filter discs (5) and annular dynamic filter discs (6), wherein, each static filter disc (5) is fixed relatively to the frame (1), each dynamic filter disc (6) can form upper and lower spacing swinging movement relative to the frame (1) following the screw axis (2) under the driving of a transmission mechanism, and besides, the distance between the adjacent two static filter discs (5) is a little bigger than the thickness of the dynamic filter disc (6) so as to form a clearance (7) for water to flow through between the static filter discs (5) and dynamic filter discs (6). Compared with the prior art, the effluent water directly flows out from the clearances between filter disc groups, thus avoiding the abrasive action of sludge to the static filter discs and dynamic filter discs; and the device is long in service time, can realize solid-liquid separation by using only one power supply, and is low in energy consumption, and the parts is convenient to arrange, simple in structure and easy to practically implement.

Owner:浙江德安新技术发展有限公司

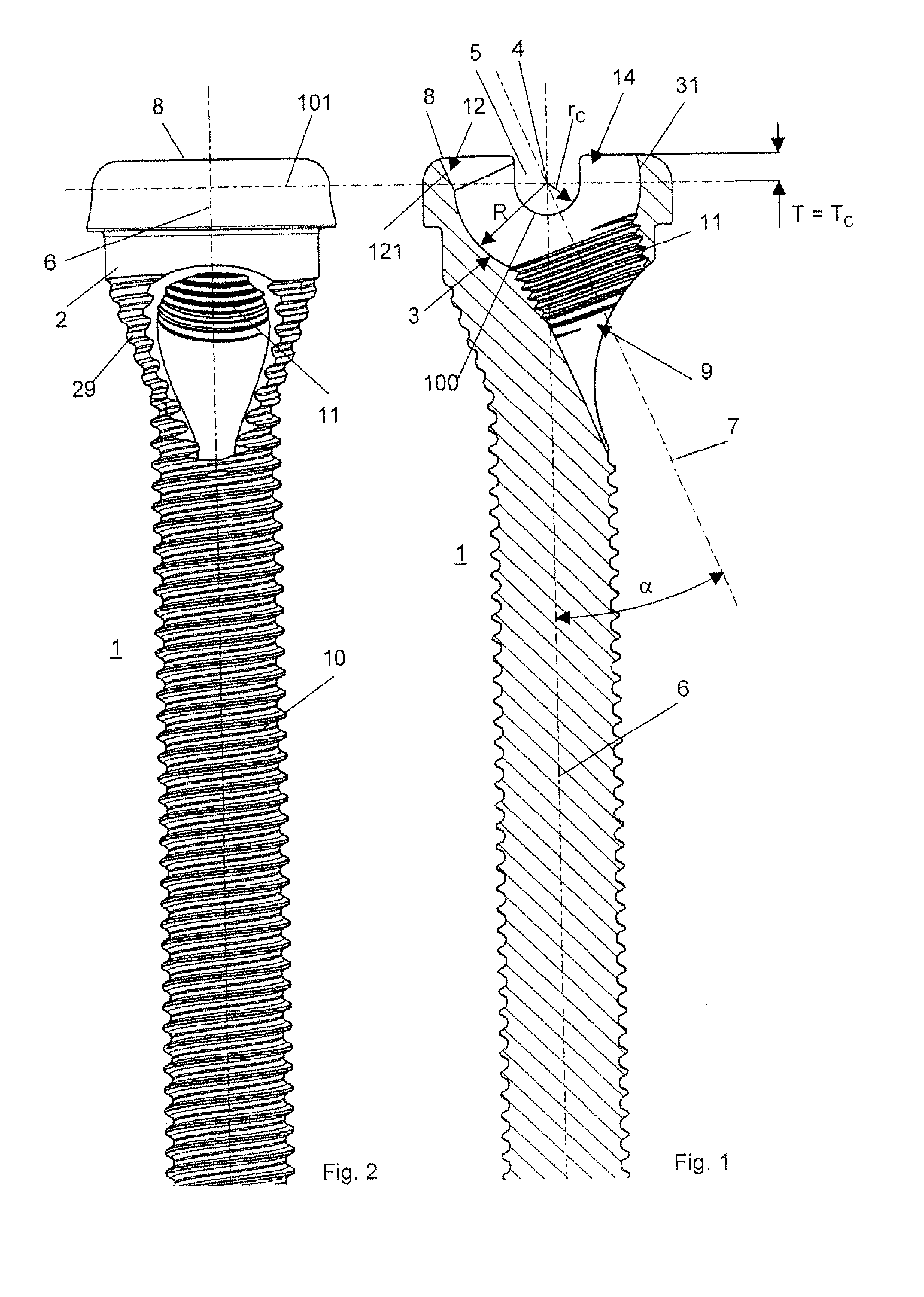

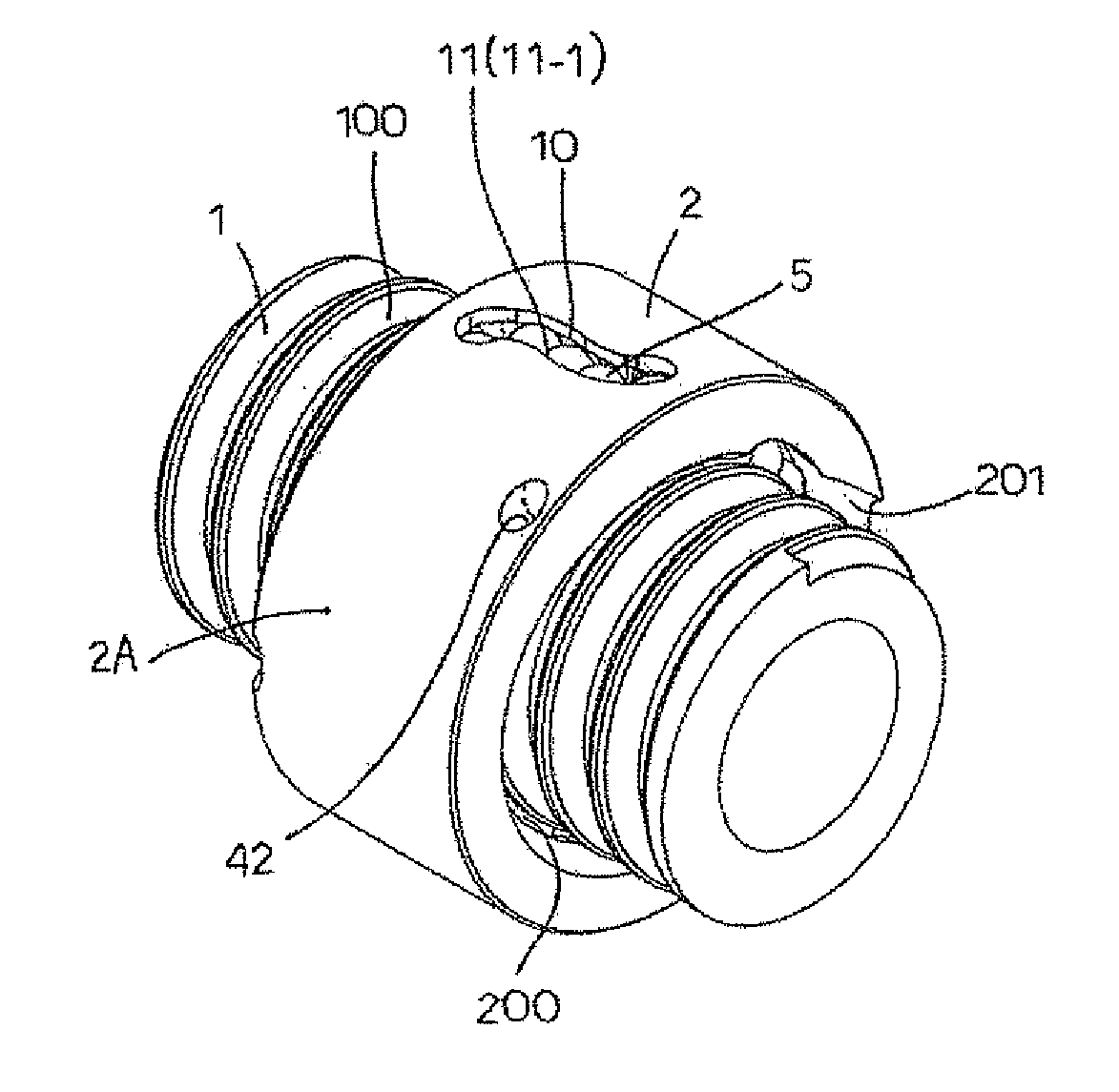

Element with a shank and a holding element connected to it for connecting to a rod

ActiveUS8828060B2Easy to produceLow production costSuture equipmentsInternal osteosythesisScrew axisEngineering

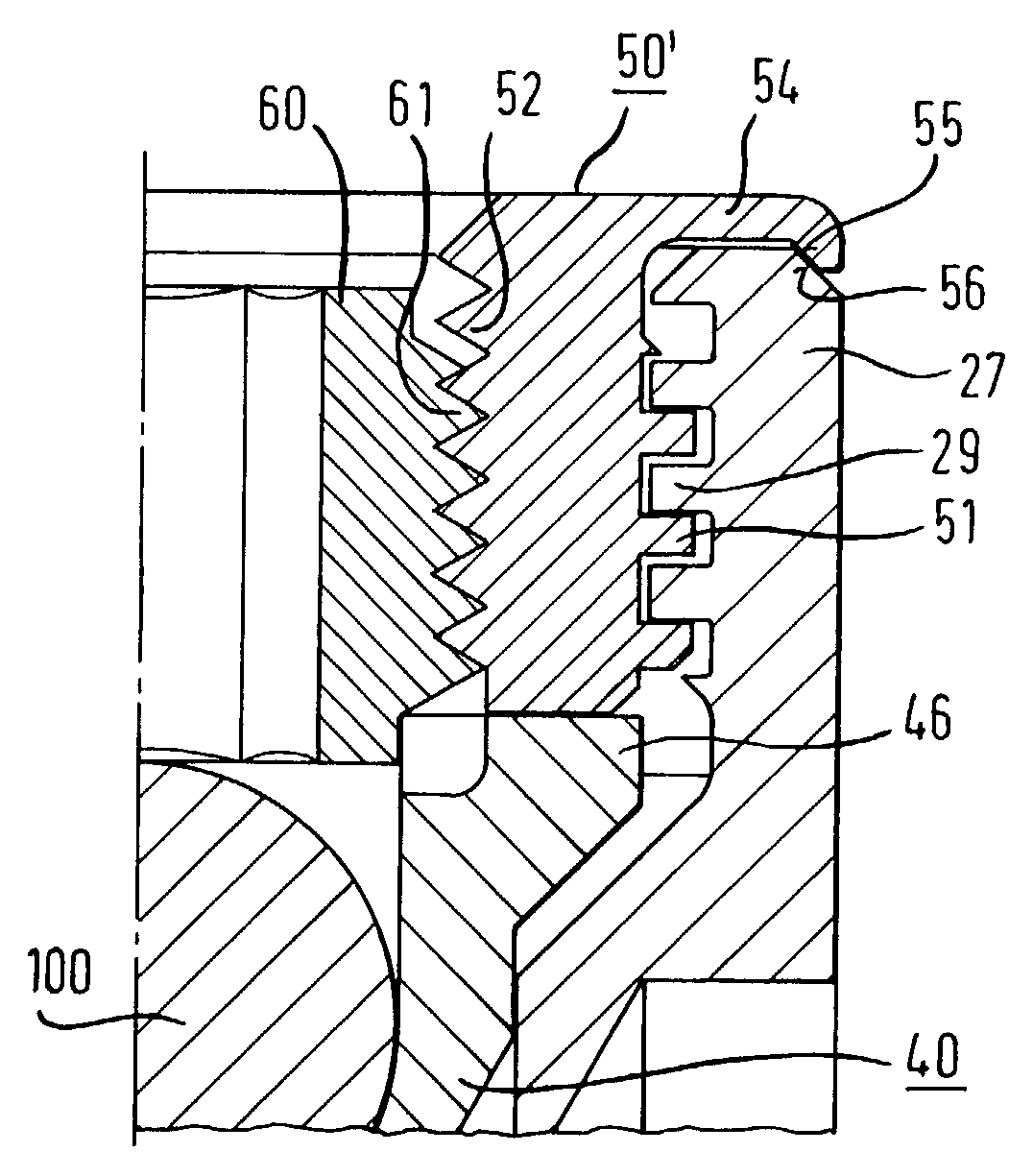

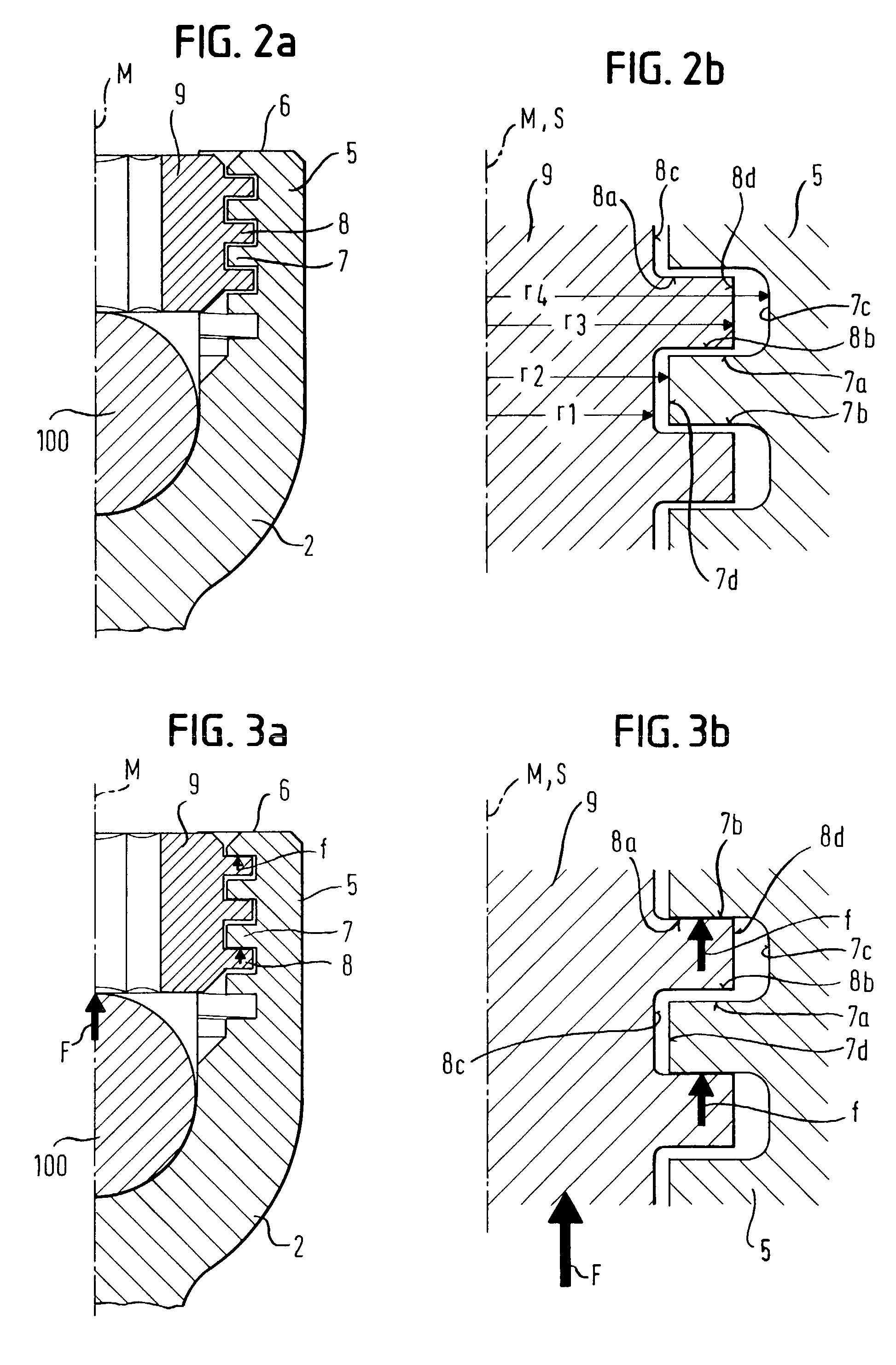

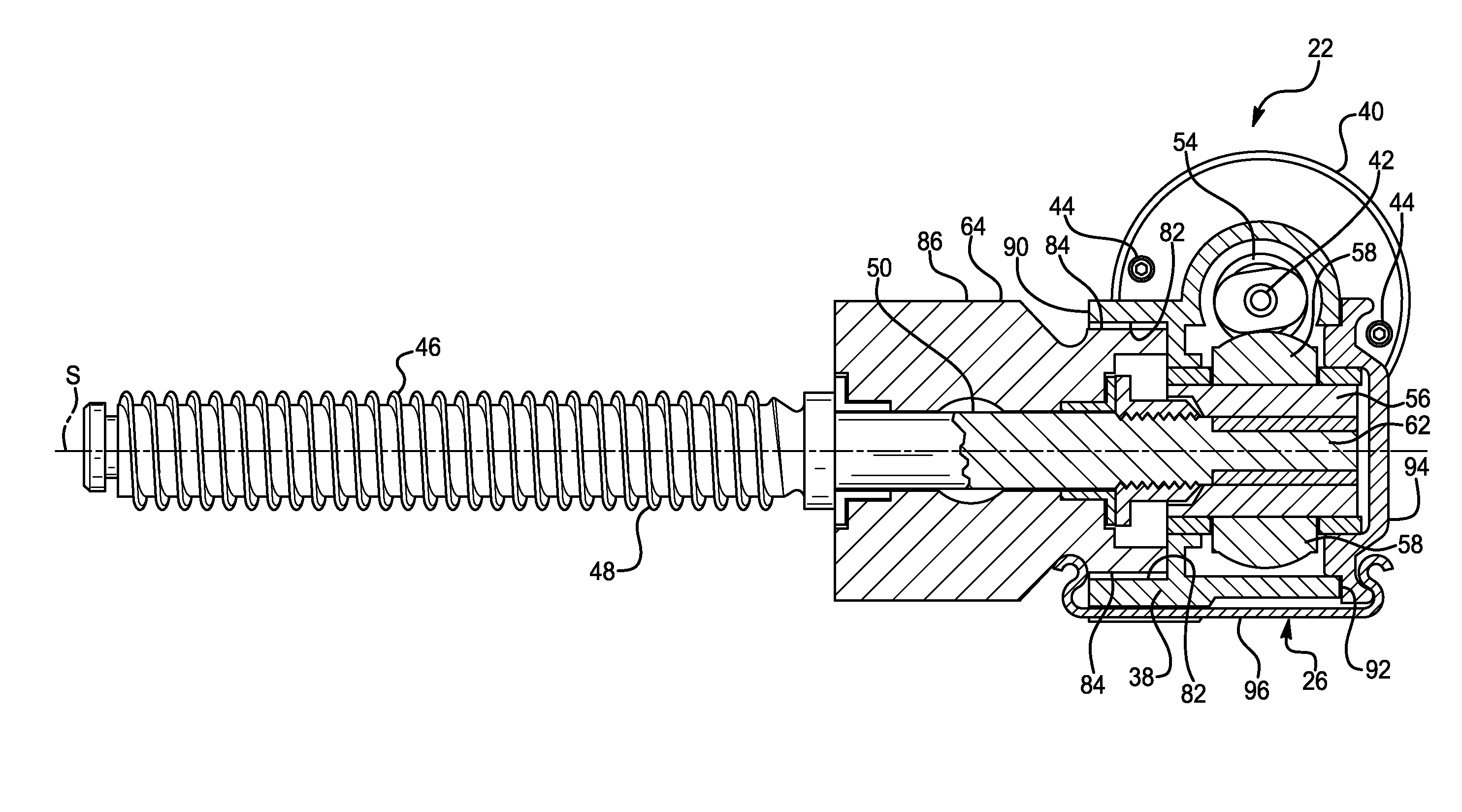

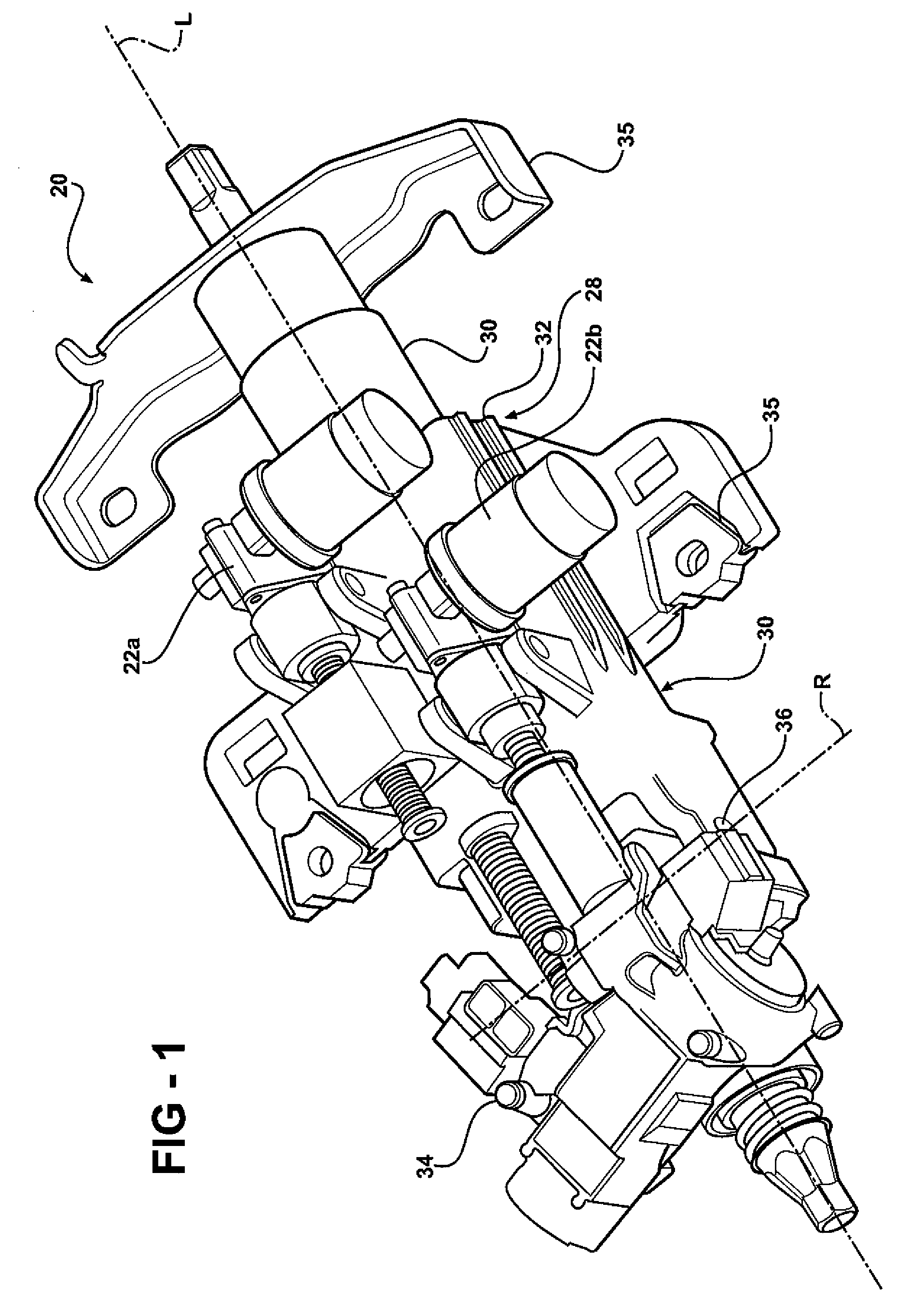

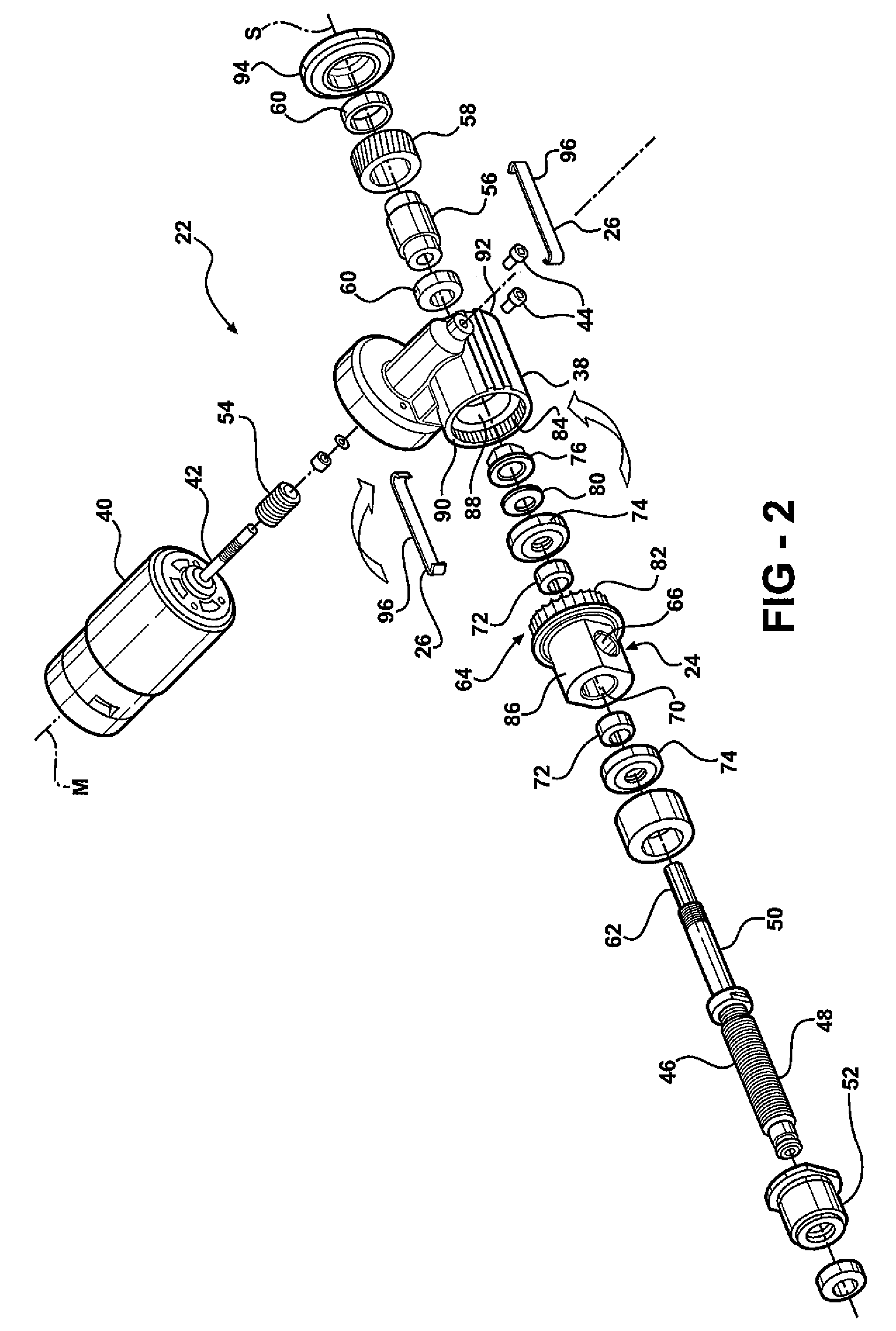

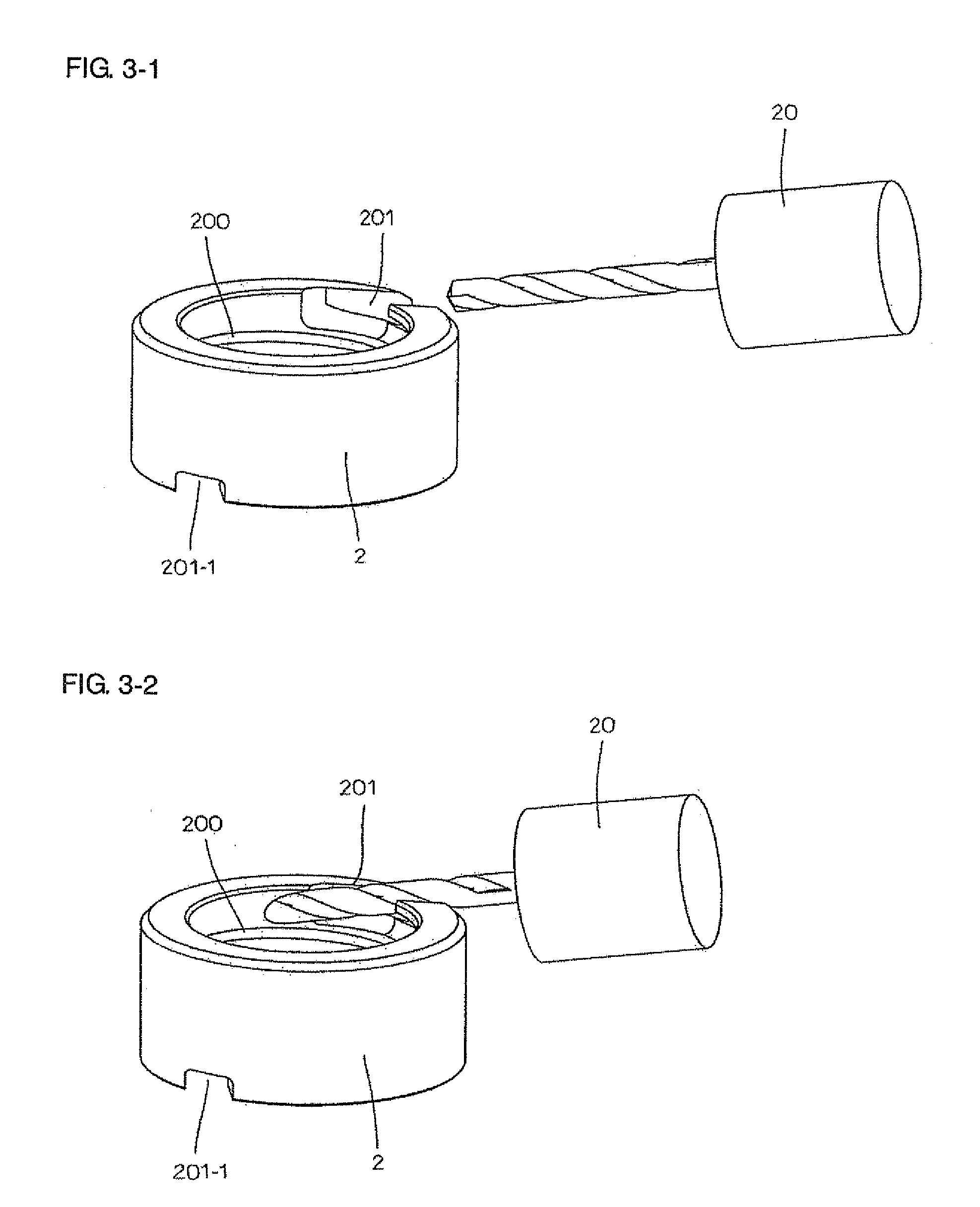

An element with a shank (1) and a holding element (2) connected to it for connecting to a rod (100) is provided. The holding element (2) has a recess (3) having a U-shaped cross-section for receiving the rod (100) with two legs (4, 5) open at one end (6) and an inner thread (7) on the open legs (4, 5) and a locking element (9) with an outer thread (8) which cooperates with the inner thread of the legs, wherein the inner thread (7) of the legs and the outer thread (8) of the locking element are constructed with a flat thread in which the two flanks (7a, 7b; 8a, 8b)) enclose an angle of 90° in each case with the screw axis (S, M). This prevents splaying of the open legs when the locking element is screwed in. The flat thread is easy to produce.

Owner:BIEDERMANN TECH GMBH & CO KG

Robot hand and robot device

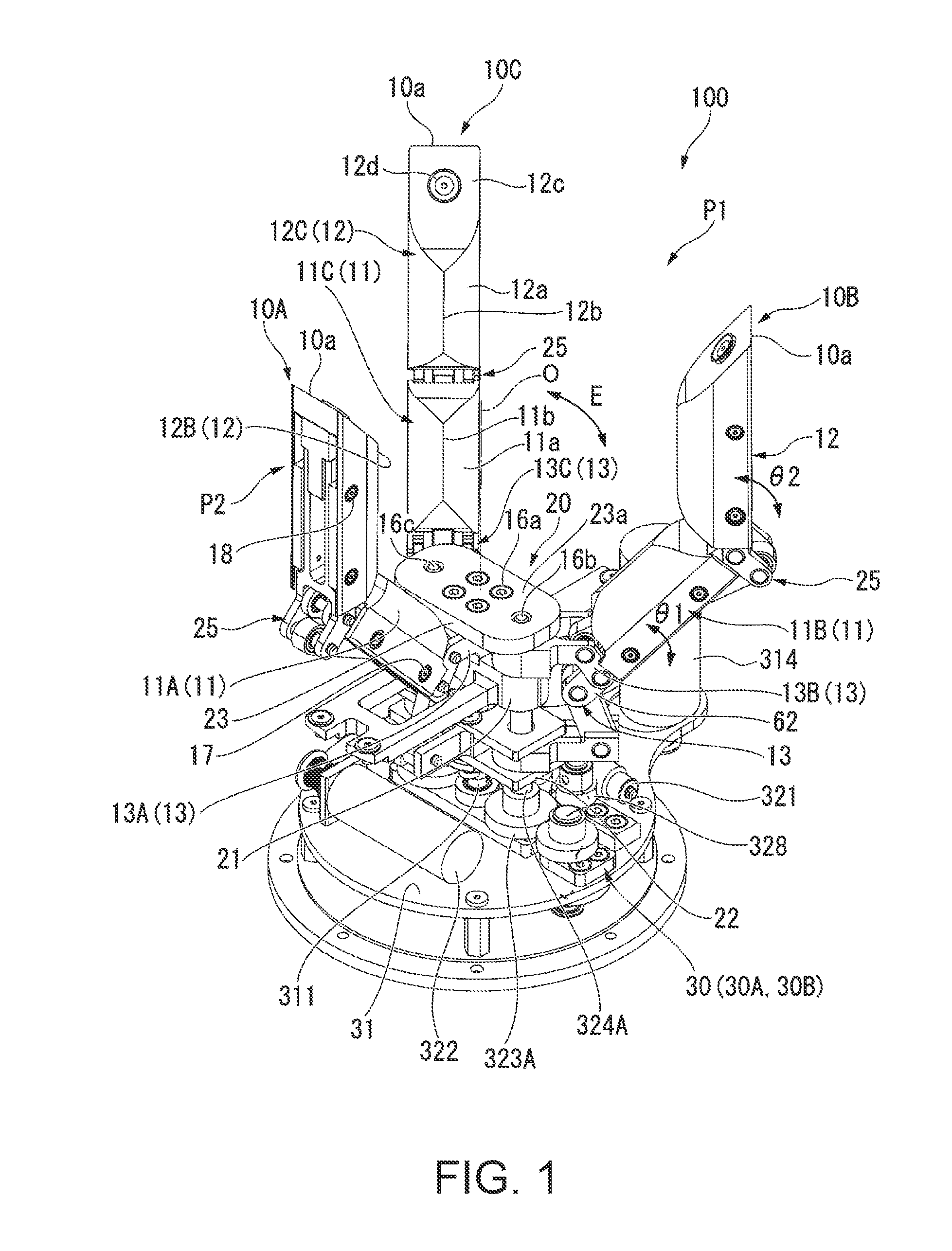

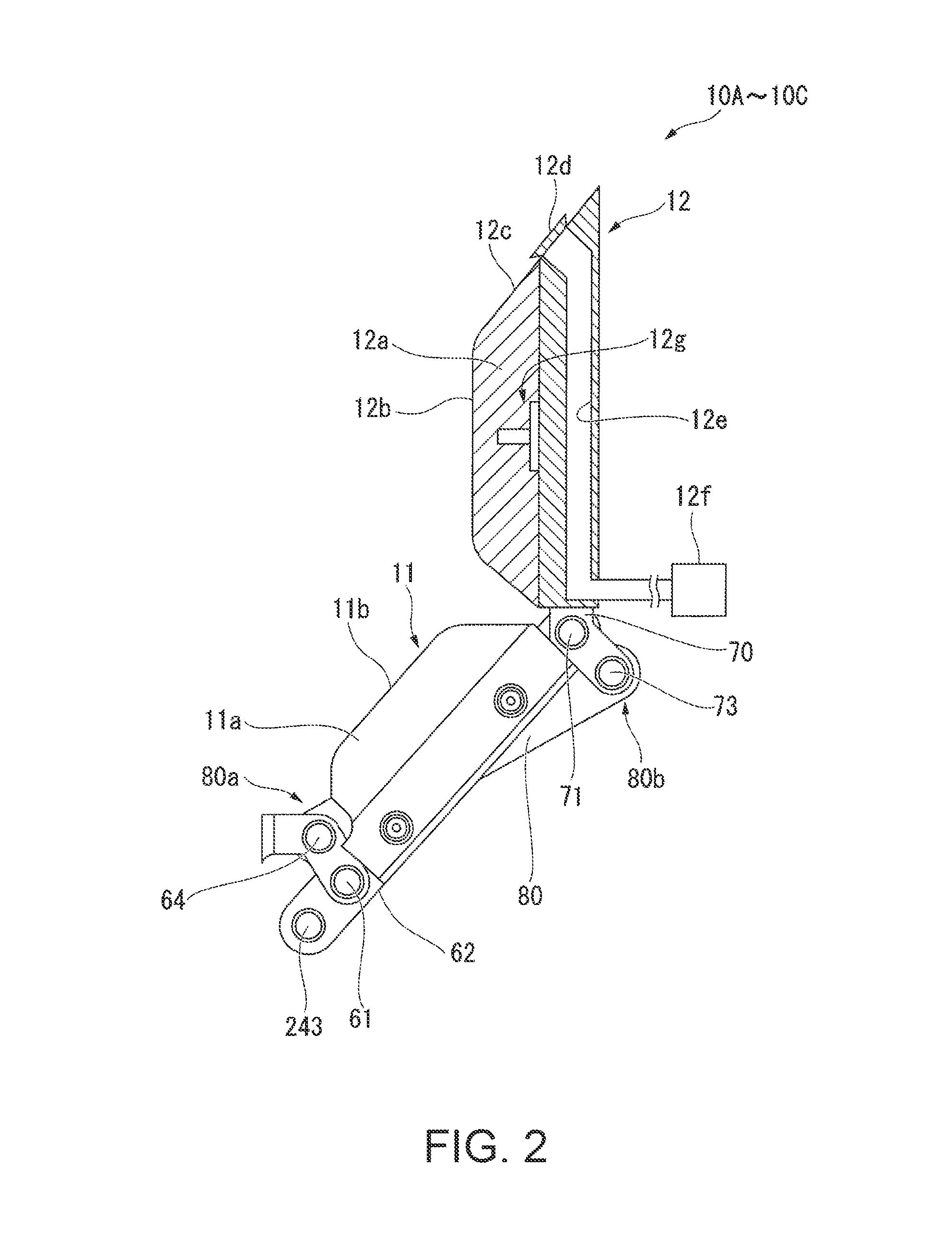

A robot hand includes a finger unit that includes a first knuckle section that is supported to a predetermined base section and a second knuckle section that is supported to the first knuckle section; a drive section that includes a male screw that is rotatable around a predetermined screw axis by a predetermined drive source and a female screw that is screw-coupled with the male screw and moves in an axial direction of the screw axis according to rotation of the male screw, in which the female screw and the first knuckle section are connected to each other so that the first knuckle section moves in association with movement of the female screw; and a link section that connects the first knuckle section and the second knuckle section so that the second knuckle section moves in association with movement of the first knuckle section.

Owner:SEIKO EPSON CORP

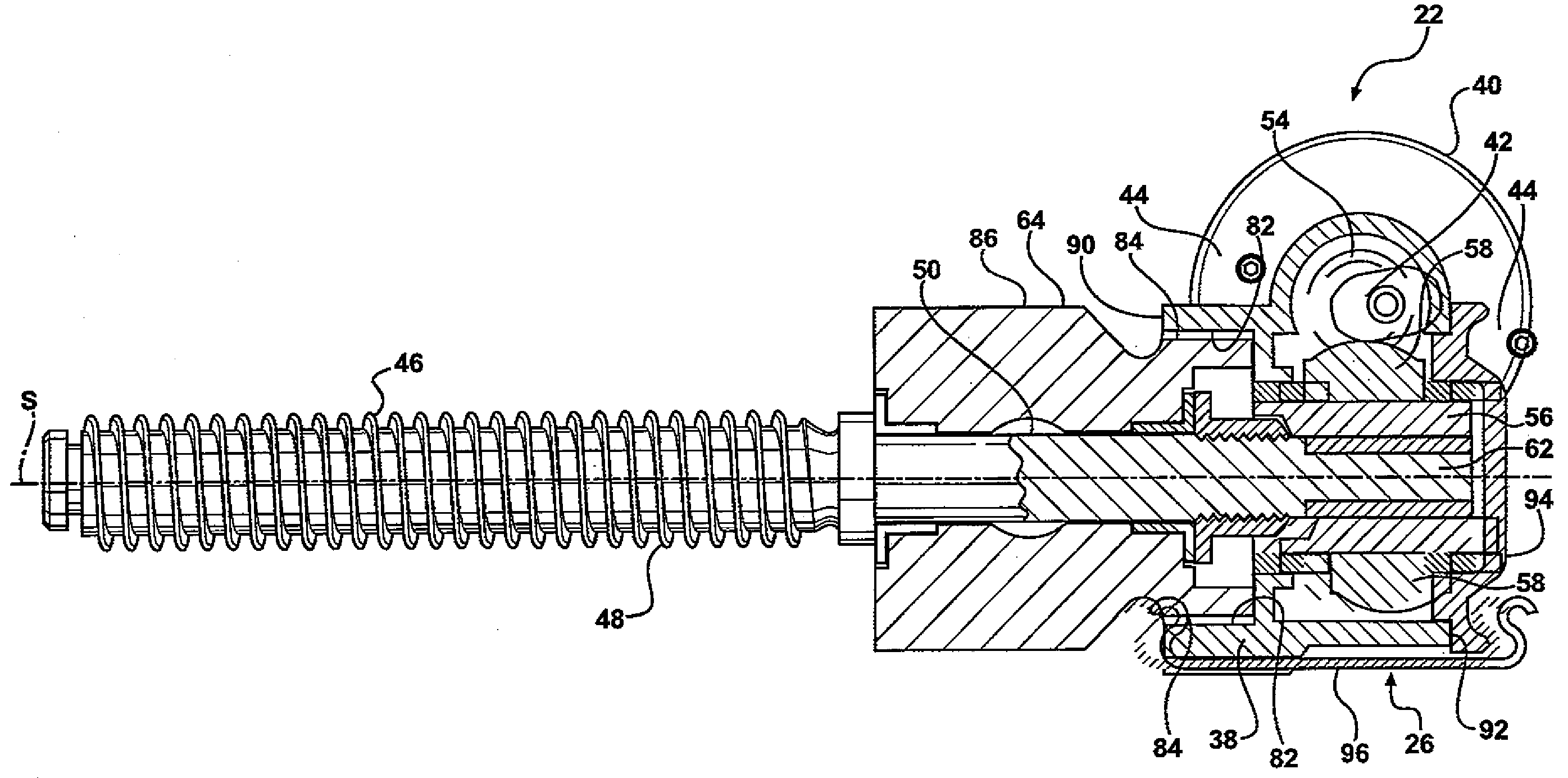

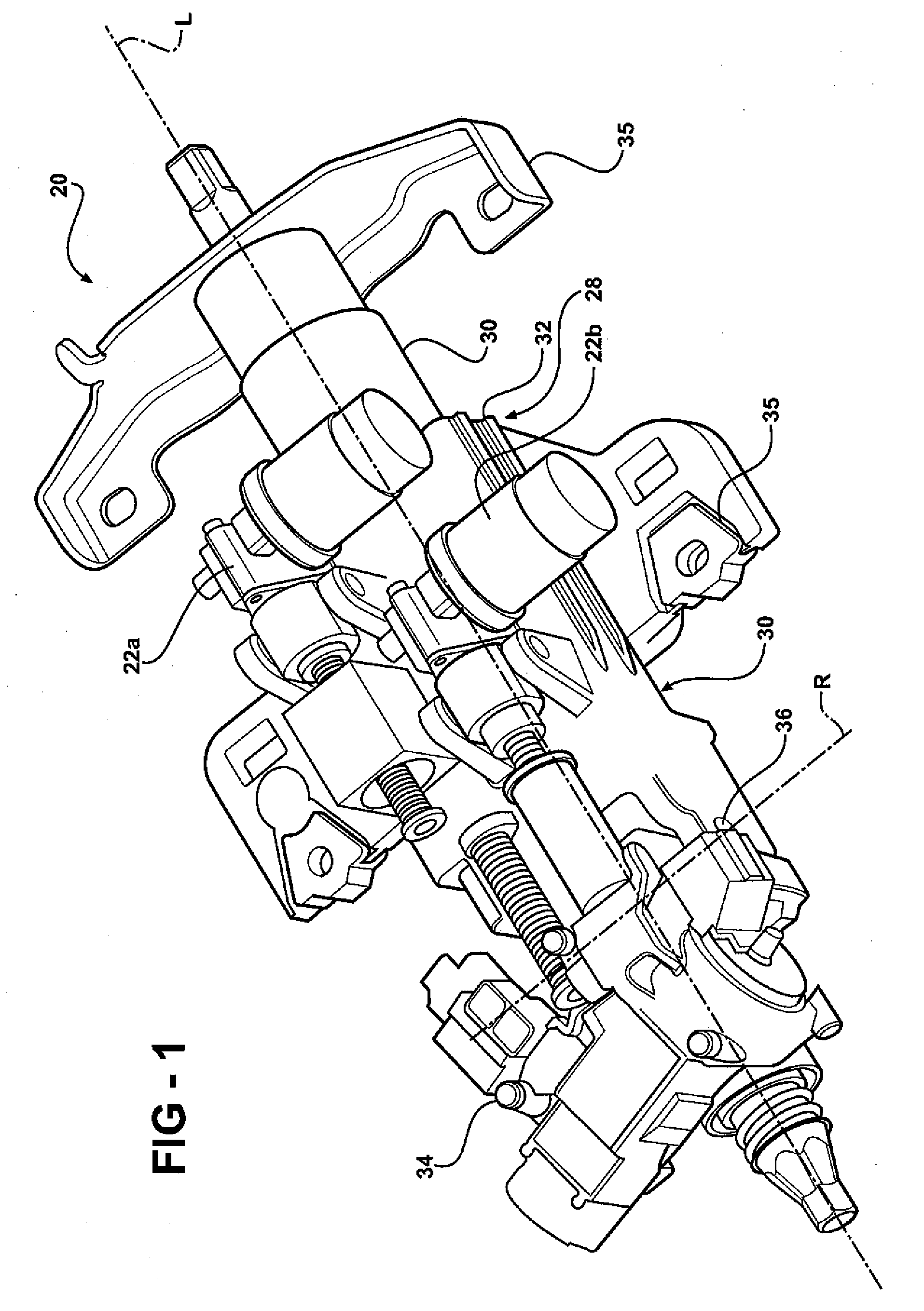

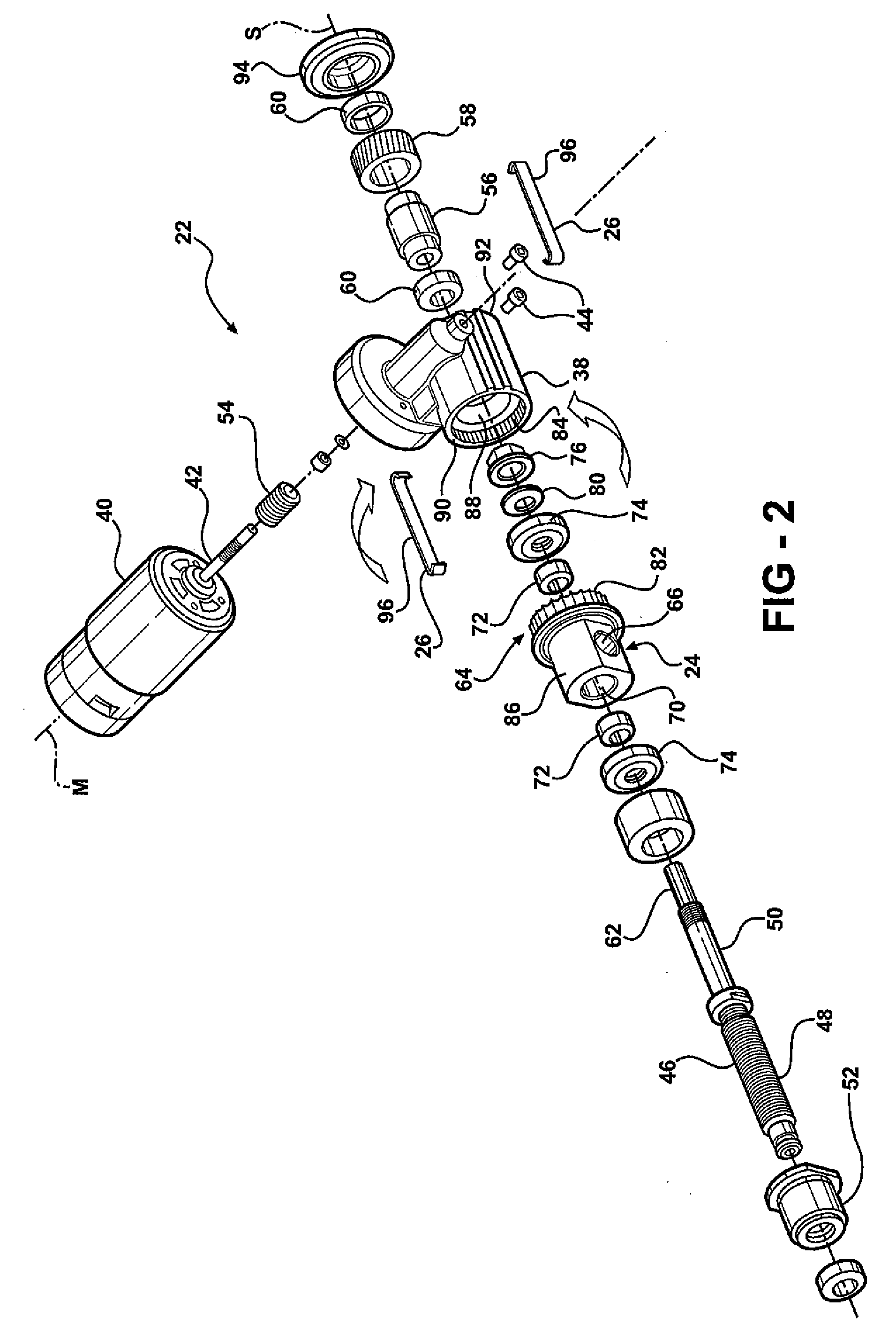

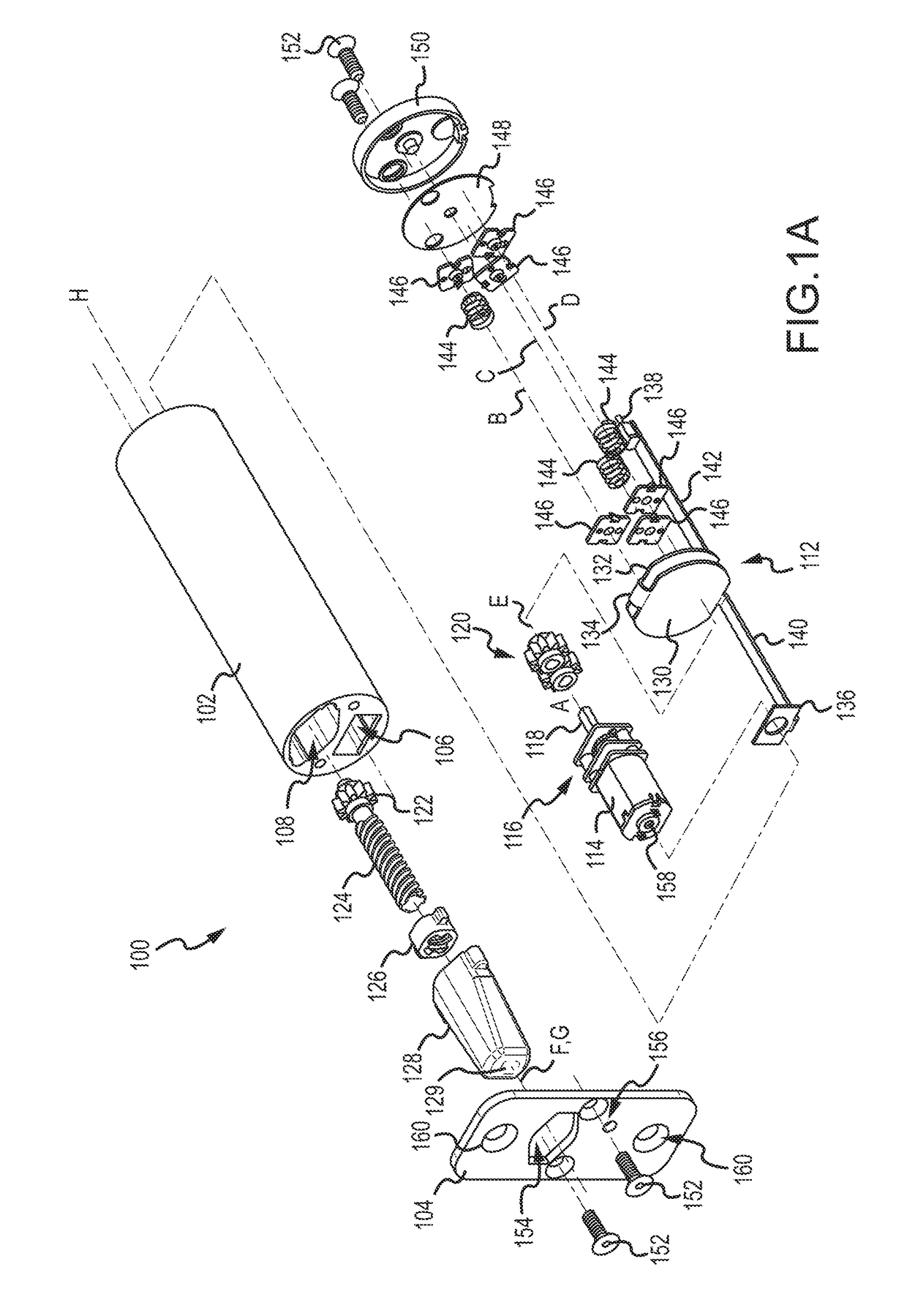

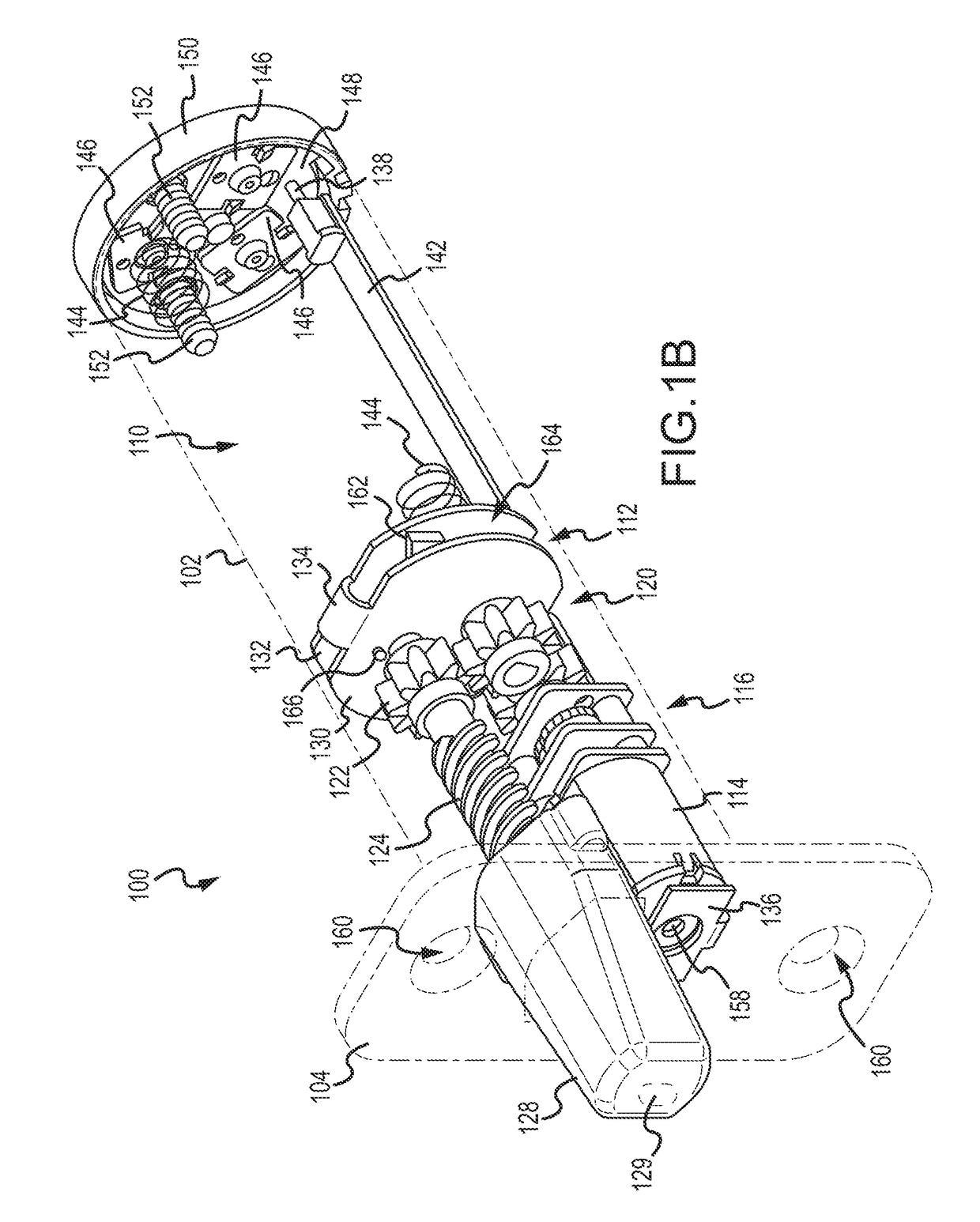

Modular power actuator

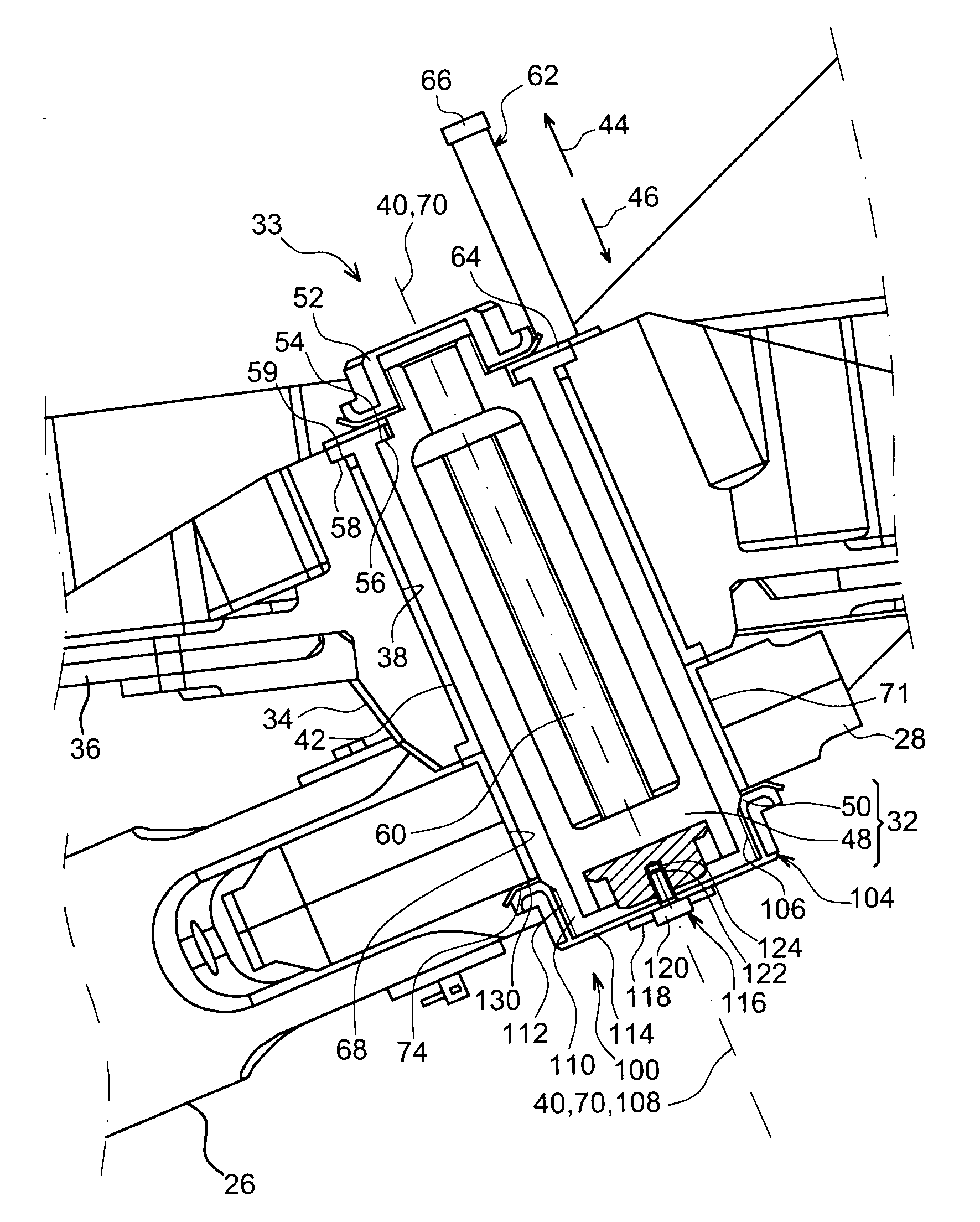

A power actuator assembly includes a torque transmission device, a motor mounted to the torque transmission device extending along a motor axis, and a screw coupled to the torque transmission device and extending along a screw axis. An adjustment mechanism interconnects the screw and the torque transmission device and permits selective rotational adjustment between the adjustment mechanism and the torque transmission device to rotate the motor relative to the torque transmission device. A connecting device releasably interconnects the adjustment mechanism to the torque transmission device to permit repeated re-positioning of the motor relative to the torque transmission device.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Actuator

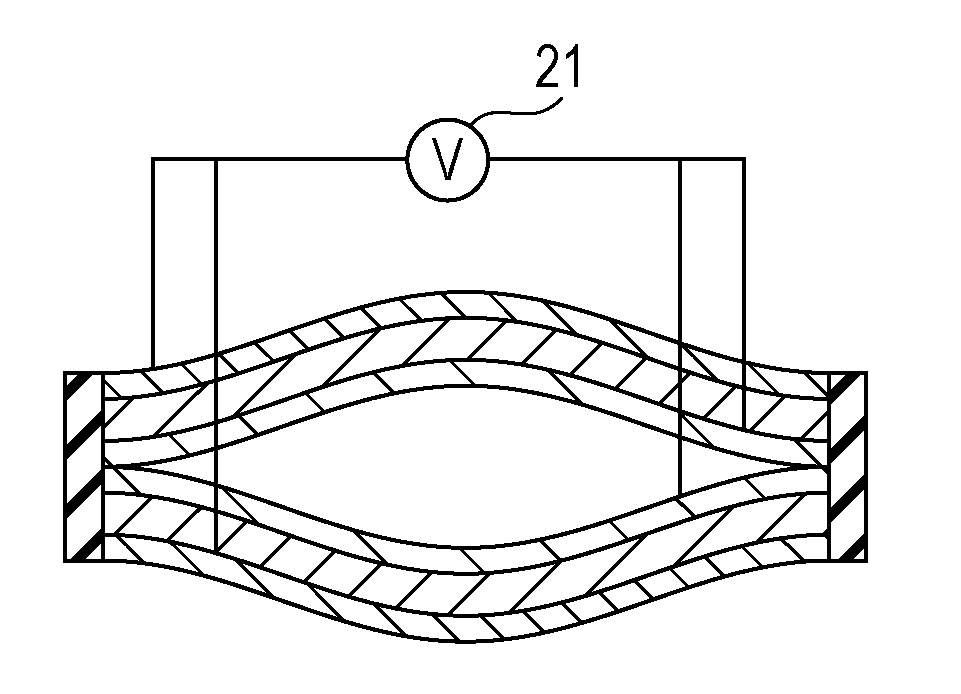

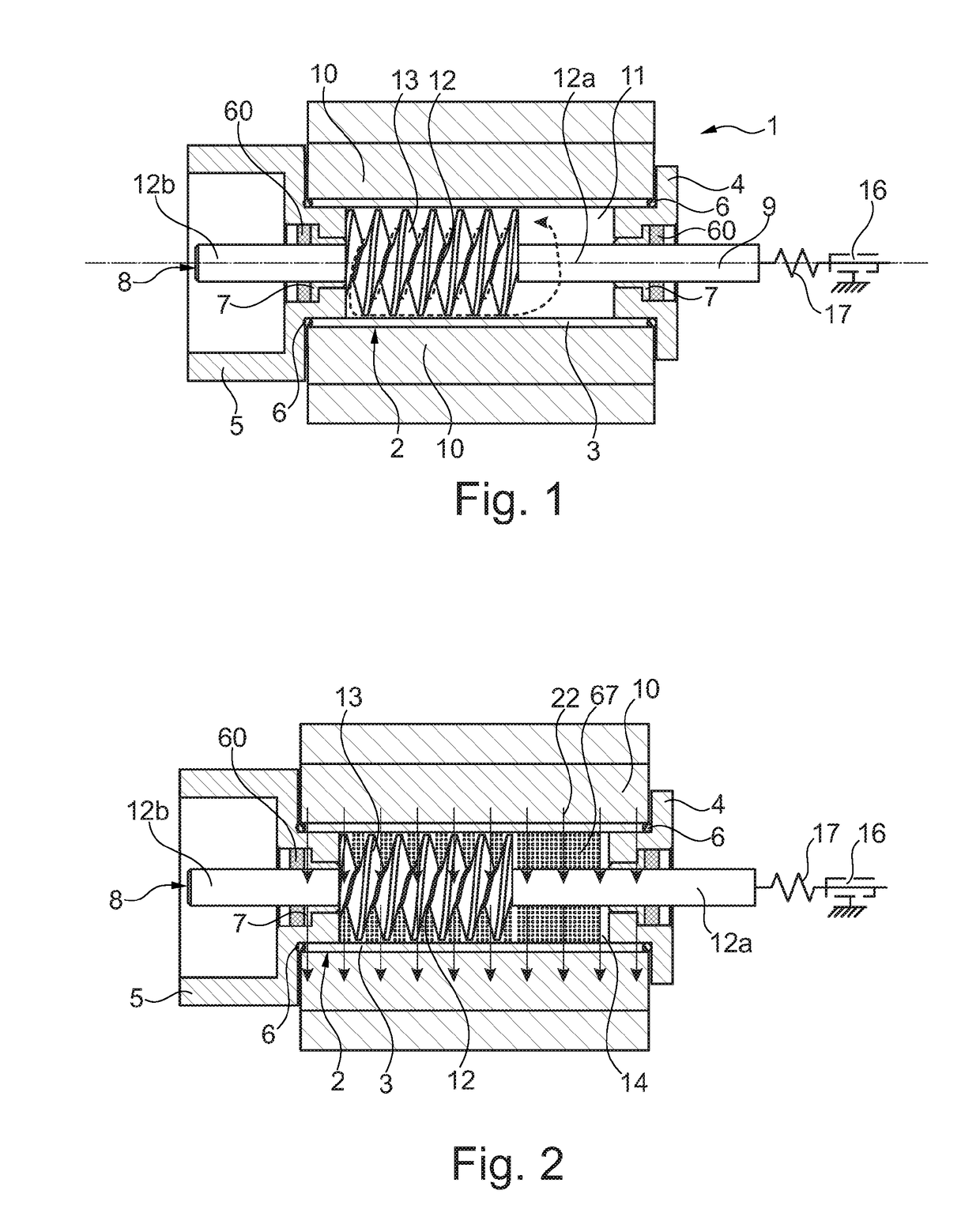

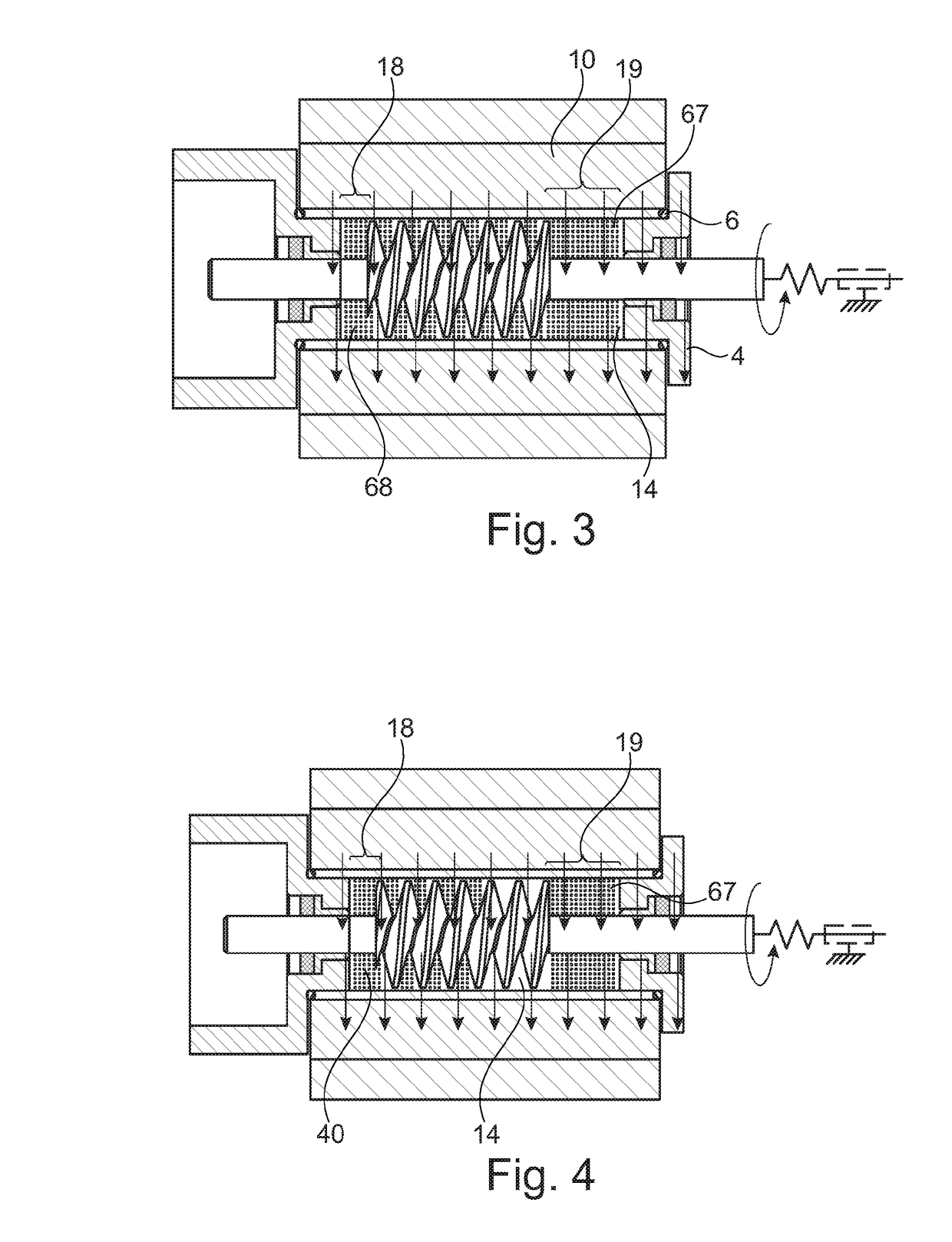

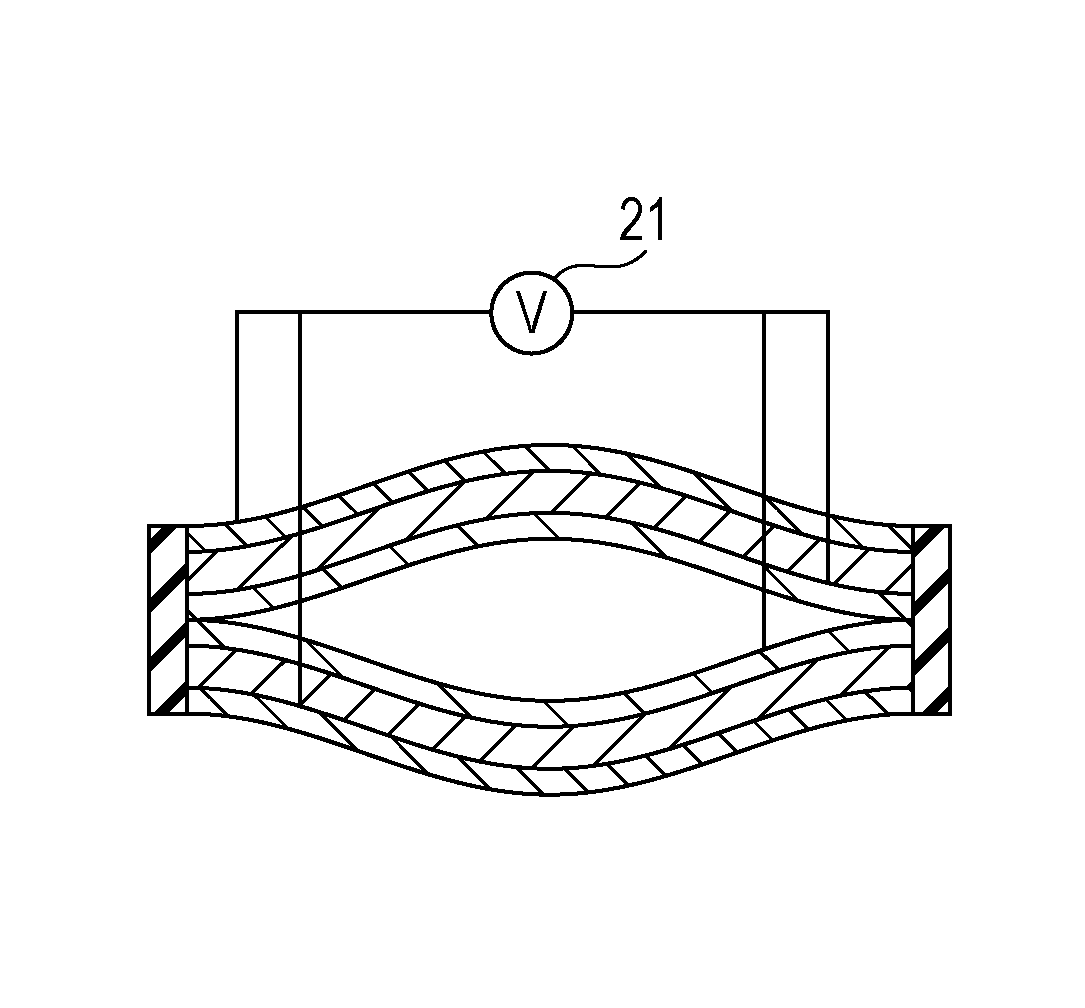

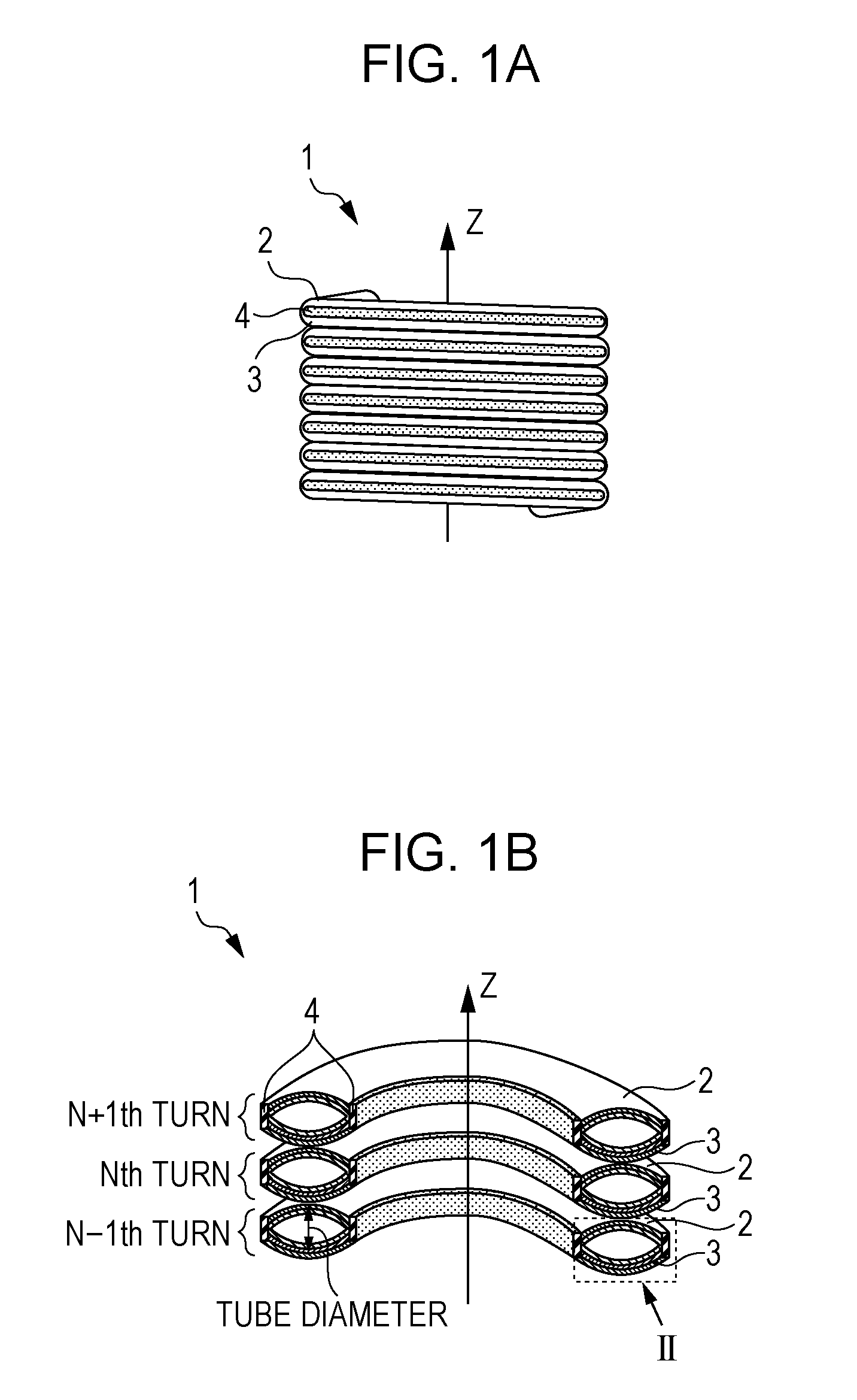

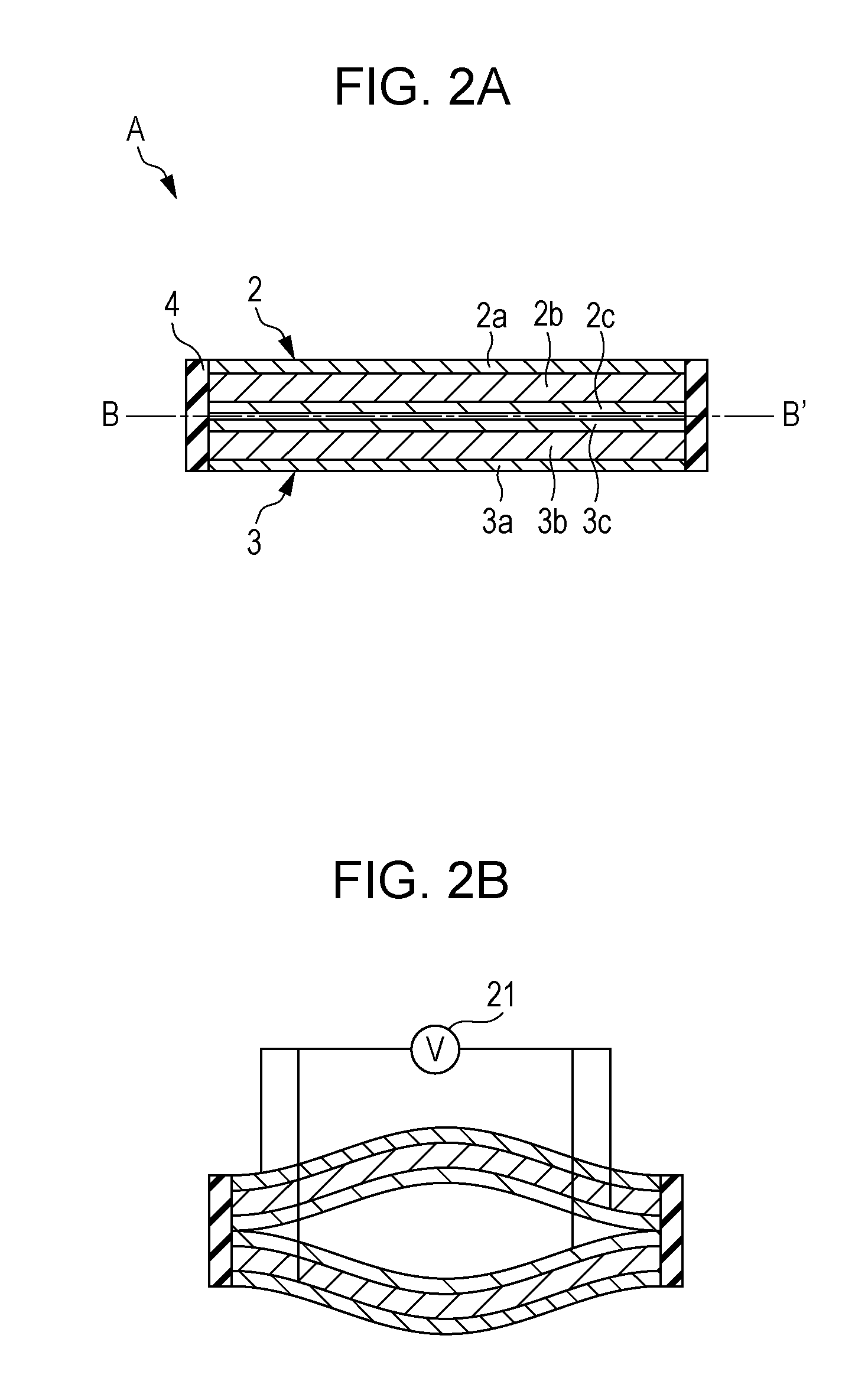

InactiveUS20120032553A1Reduce weight and sizeIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesActuatorControl theory

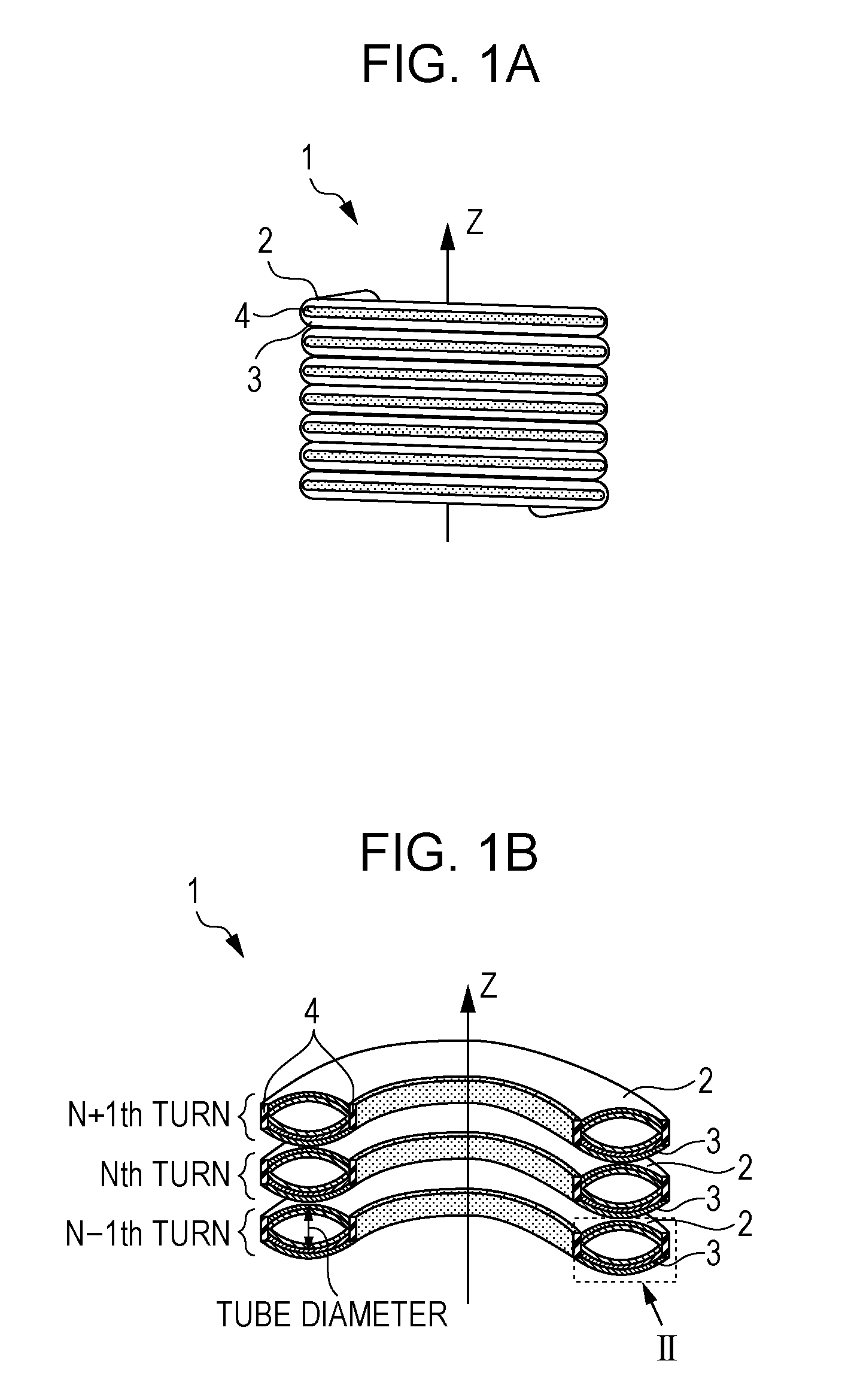

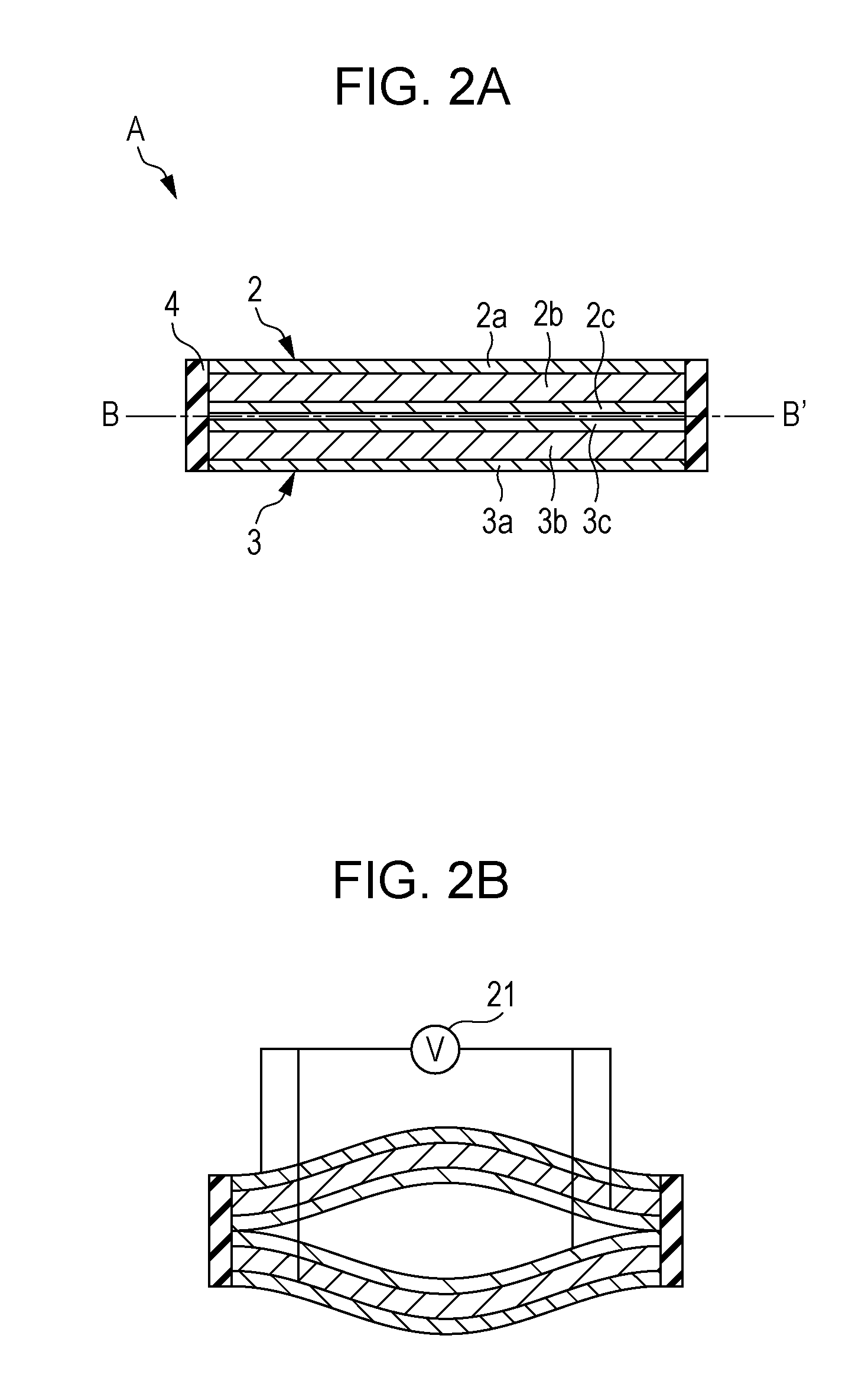

An expansion and contraction actuator has a first long actuator portion and a second long actuator portion that face each other and connection members that connect the long sides of each of the first long actuator portion and the second long actuator portion to each other, in which a part of the first long actuator portion and a part of the second long actuator portion are apart from each other to thereby form a hollow structure, the first long actuator portion and the second long actuator portion each have a pair of long electrodes and a long electrolyte layer having an electrolyte, long internal electrodes thereof are the same cathode or anode electrodes, long external electrodes thereof are counter electrodes thereto, and the actuator expands and contracts in the direction of the screw axis by voltage application.

Owner:CANON KK

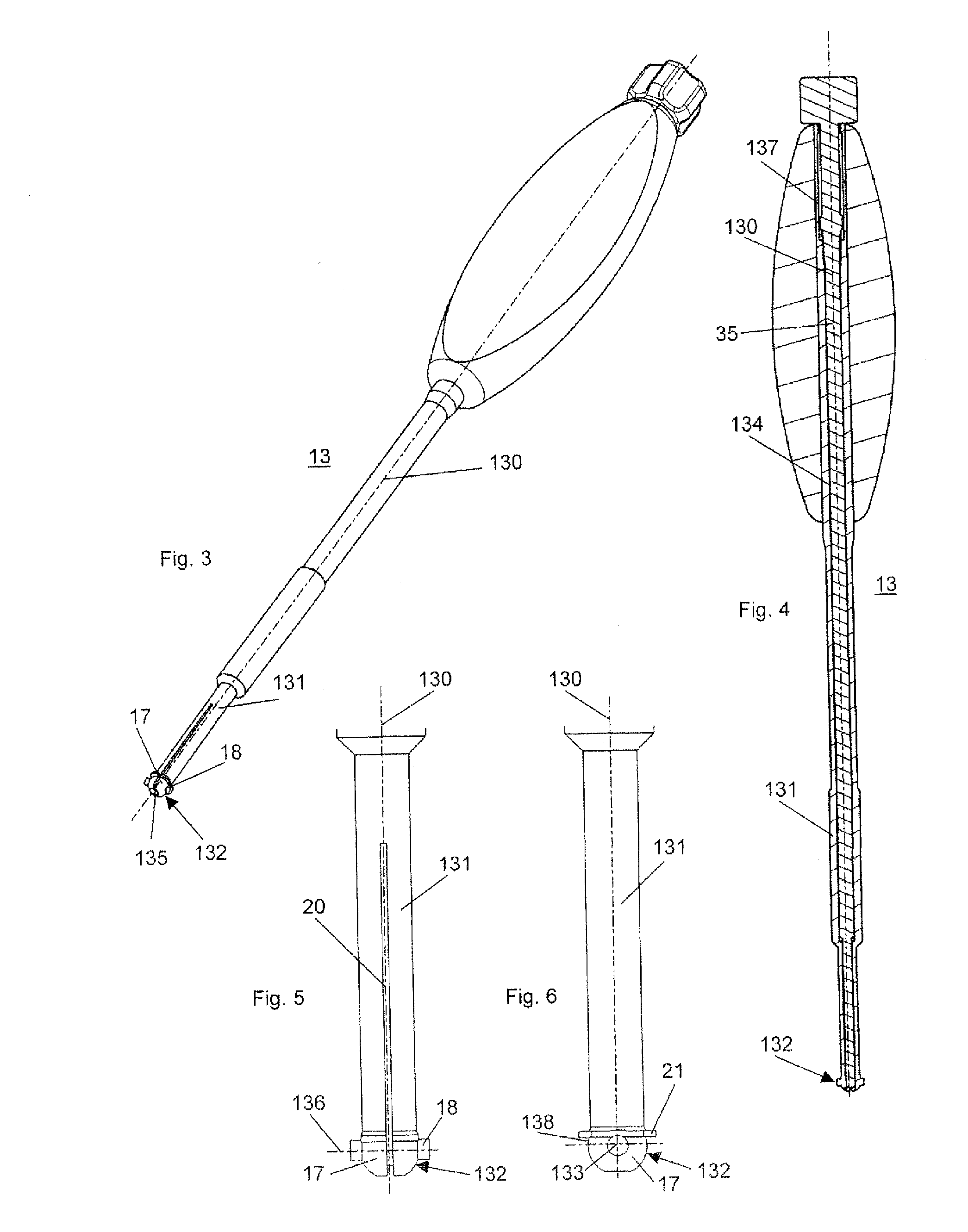

Ground Anchor

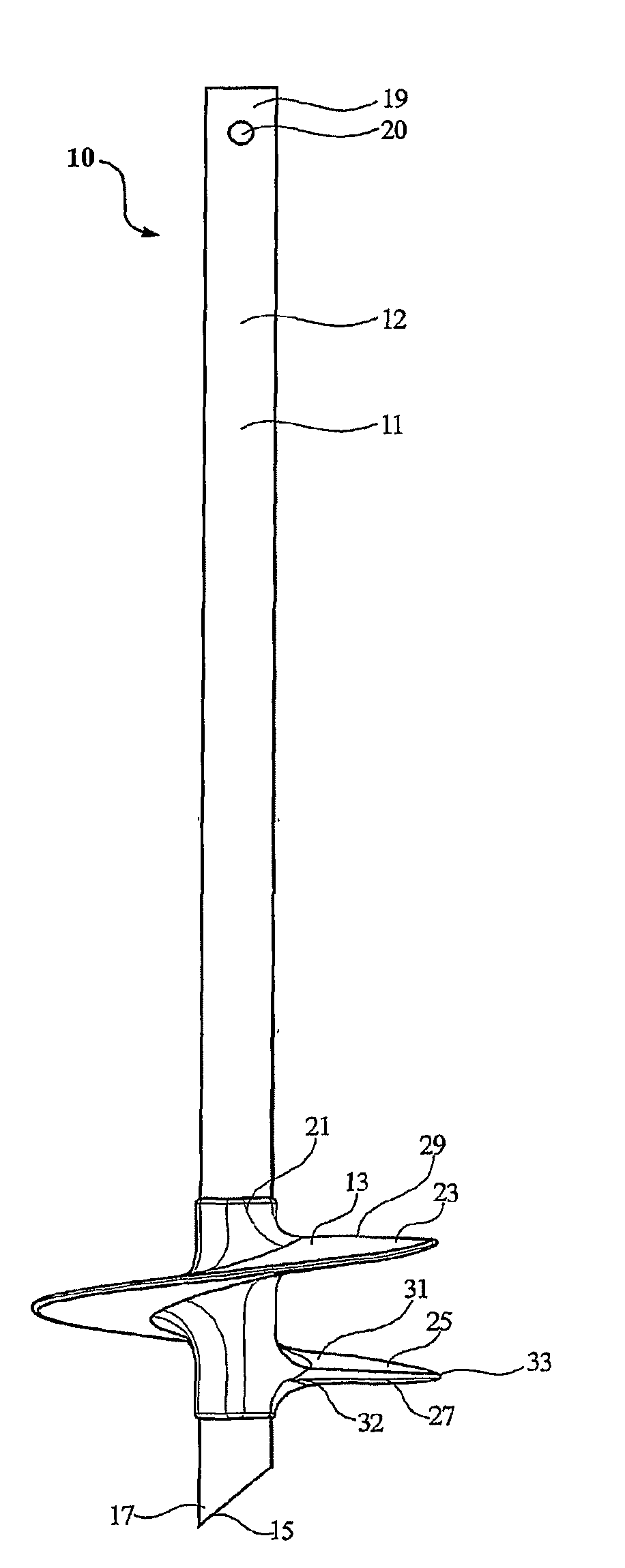

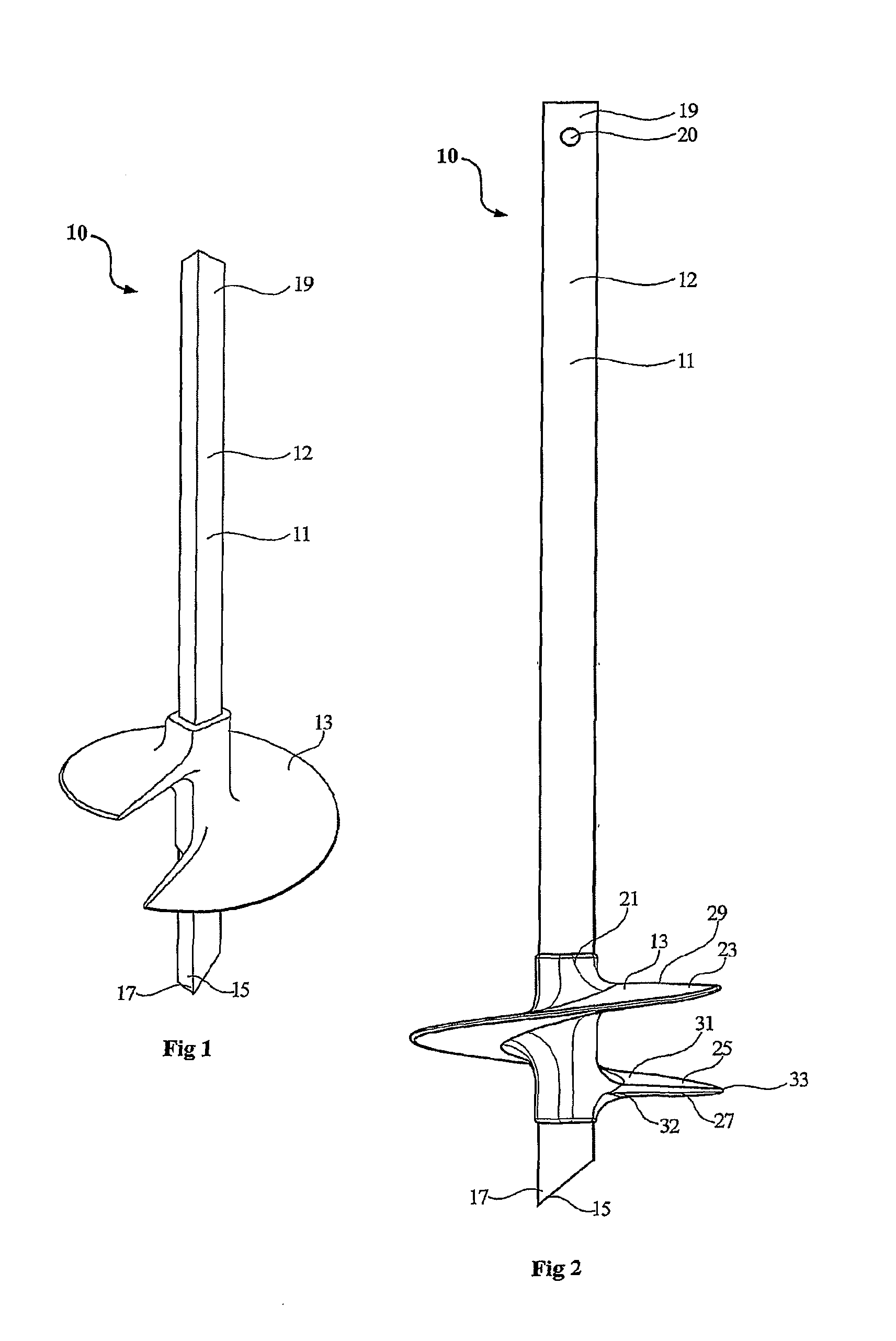

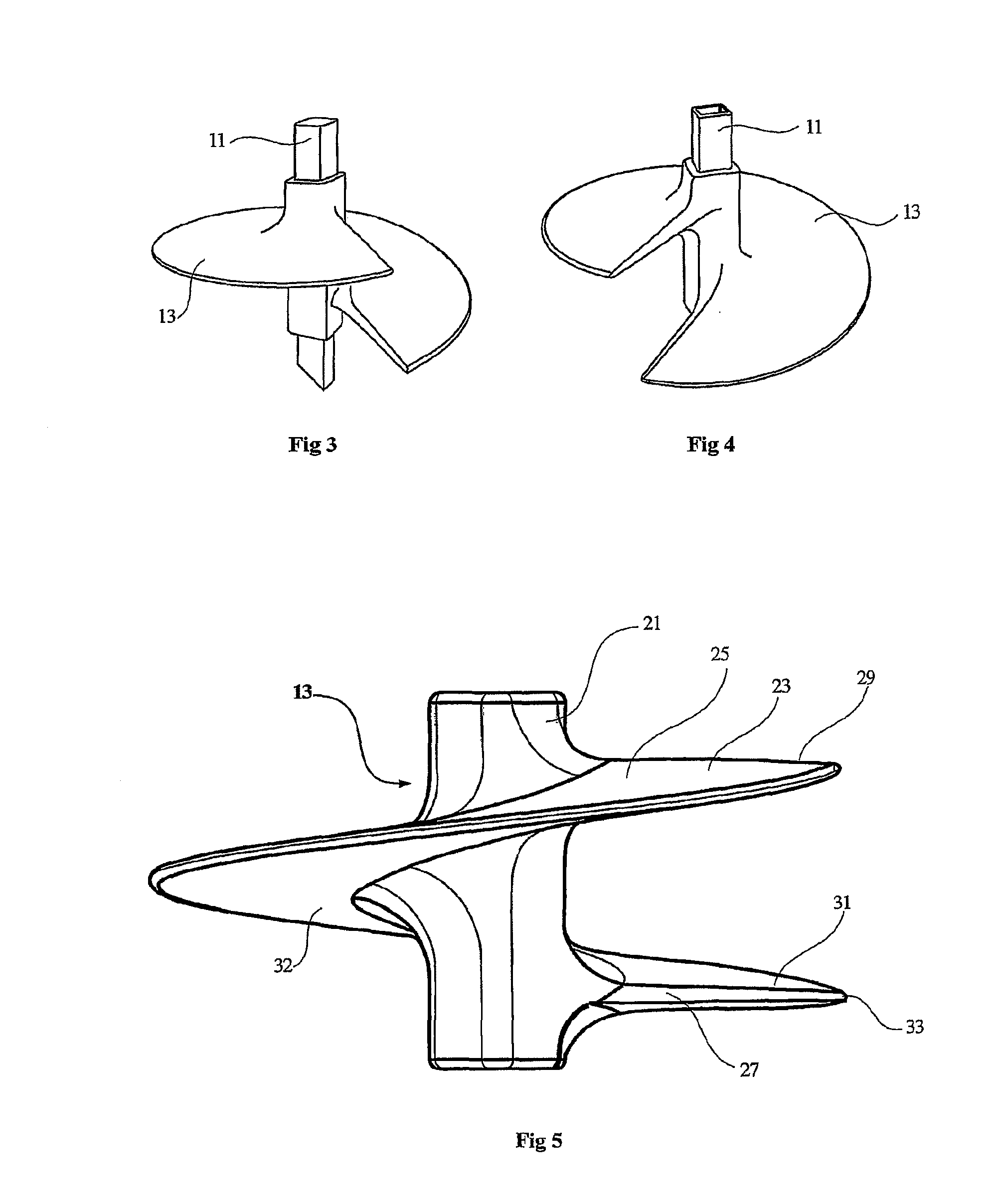

InactiveUS20080302028A1Improved holding abilityIncrease the effective diameterTowersBuilding constructionsNormal loadPropeller

A ground anchor (10) comprising an anchor shaft (11) and an anchoring screw (13) moulded onto the anchoring shaft adjacent the lower end thereof. The anchoring shaft (11) is of a rectangular cross-section with four side walls (12). The anchoring shaft (11) is configured at its bottom end (15) for ground penetration. The upper end (19) of the anchor shaft (11) is configured to receive torque applied thereto. The anchoring screw (13) comprises a hub (21) and a screw flight (23) on the hub. The anchoring screw (13) is moulded onto the anchor shaft (11), and the hub (21) is keyed to the anchor shaft. The anchoring screw (13) is so constructed that the spiral flight (23) is rigid yet has some resilient flexibility which allows the flight to deflect laterally in the direction of the screw axis. Specifically, the screw flight (23) has sufficient rigidity to allow it to penetrate the ground in which it is intended to be used when torque is applied to the anchor shaft (11). Further, the screw flight (23) has sufficient rigidity in order to retain the ground anchor (10) embedded in the ground when subjected to the normal load conditions for which it is intended, as is the case with conventional ground anchors. The resilient flexibility provides the screw flight (23) with a degree of ‘springiness’, so allowing the screw flight (23) to deflect laterally in the direction of the screw axis when subjected to the loadings to which it is exposed when winding into the ground. With this arrangement, the pitch of the helical screw (25) is permitted to alter during ground embedment as ground pressure increases.

Owner:LEWENHOFF STEPHEN MARK

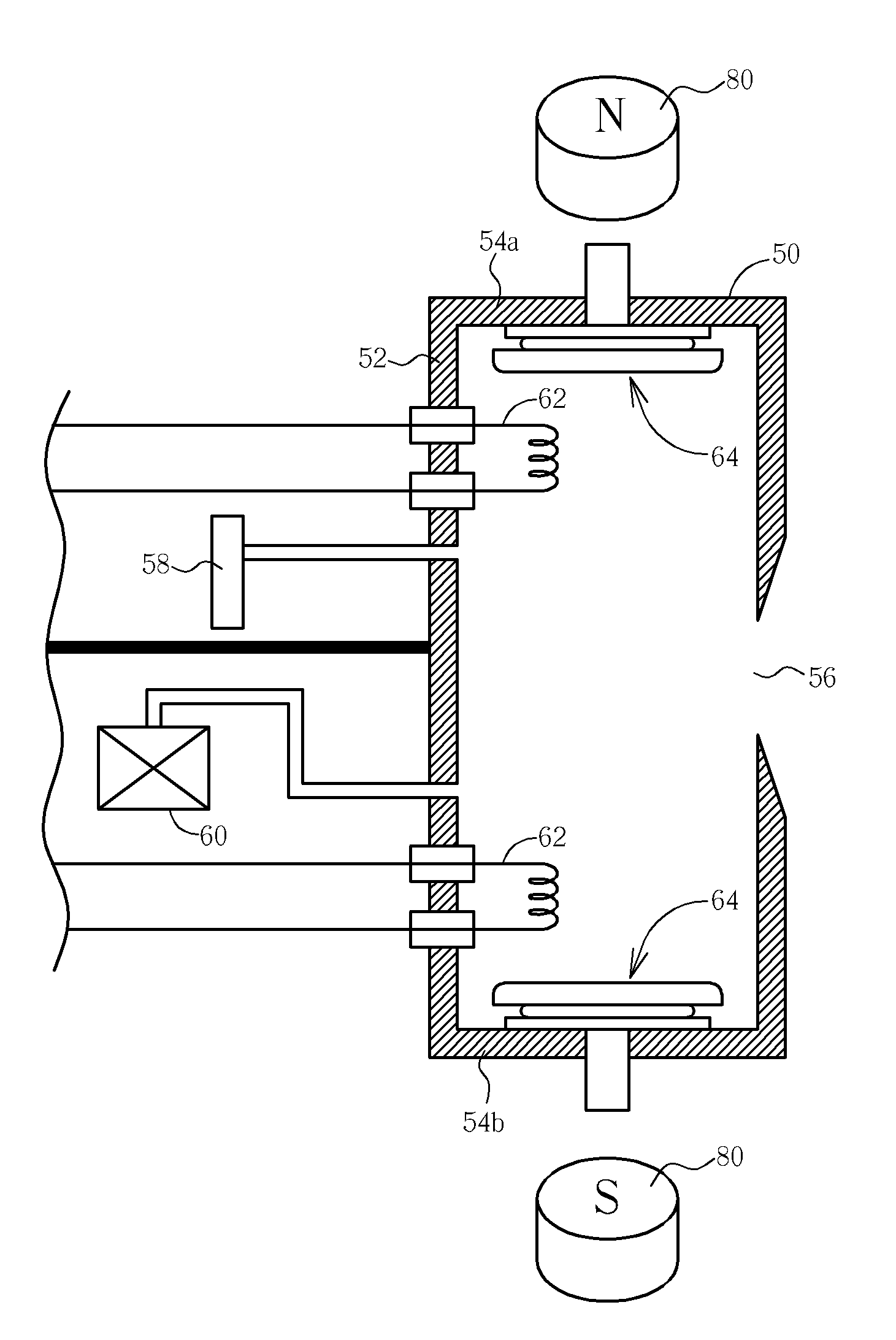

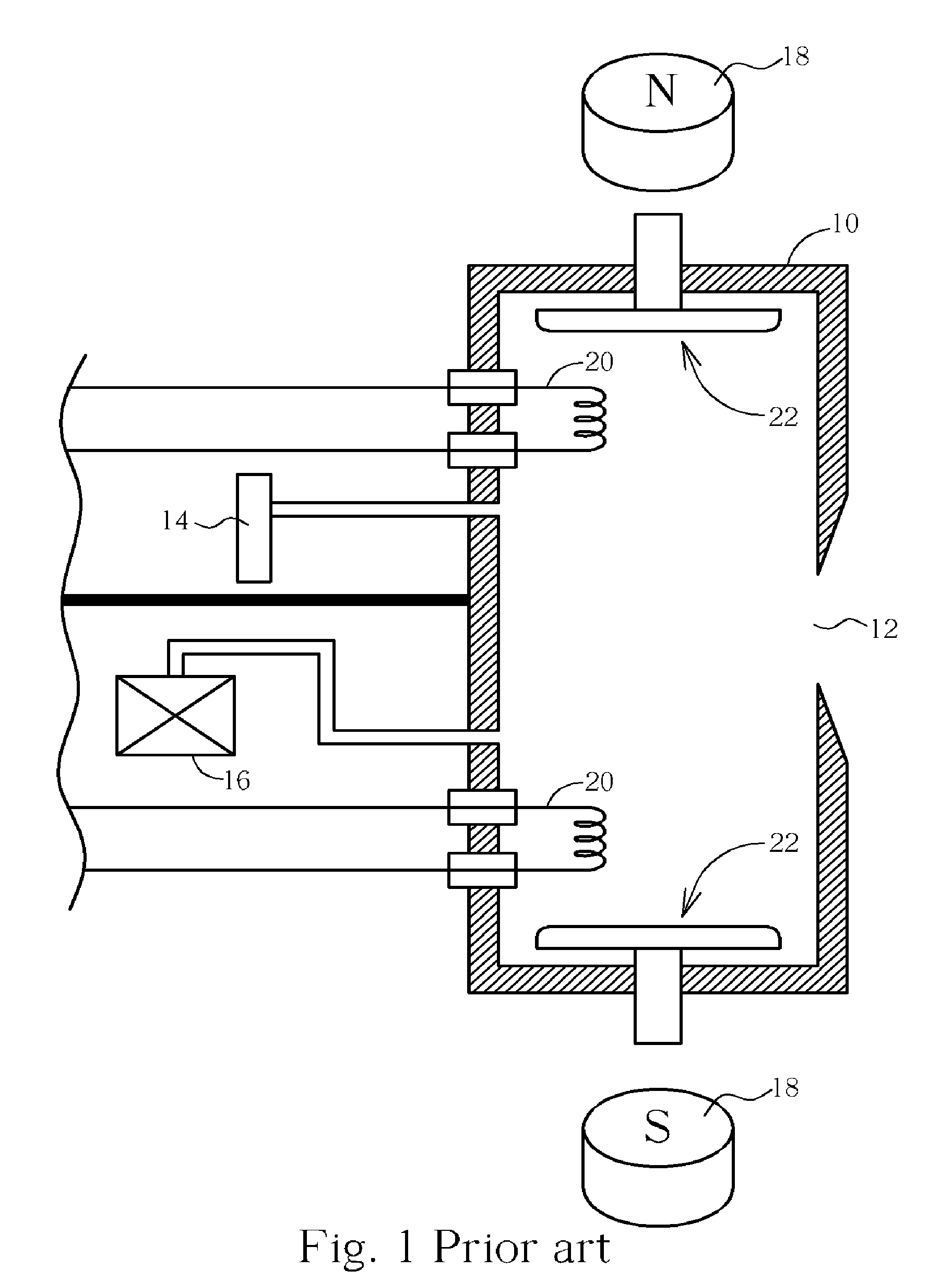

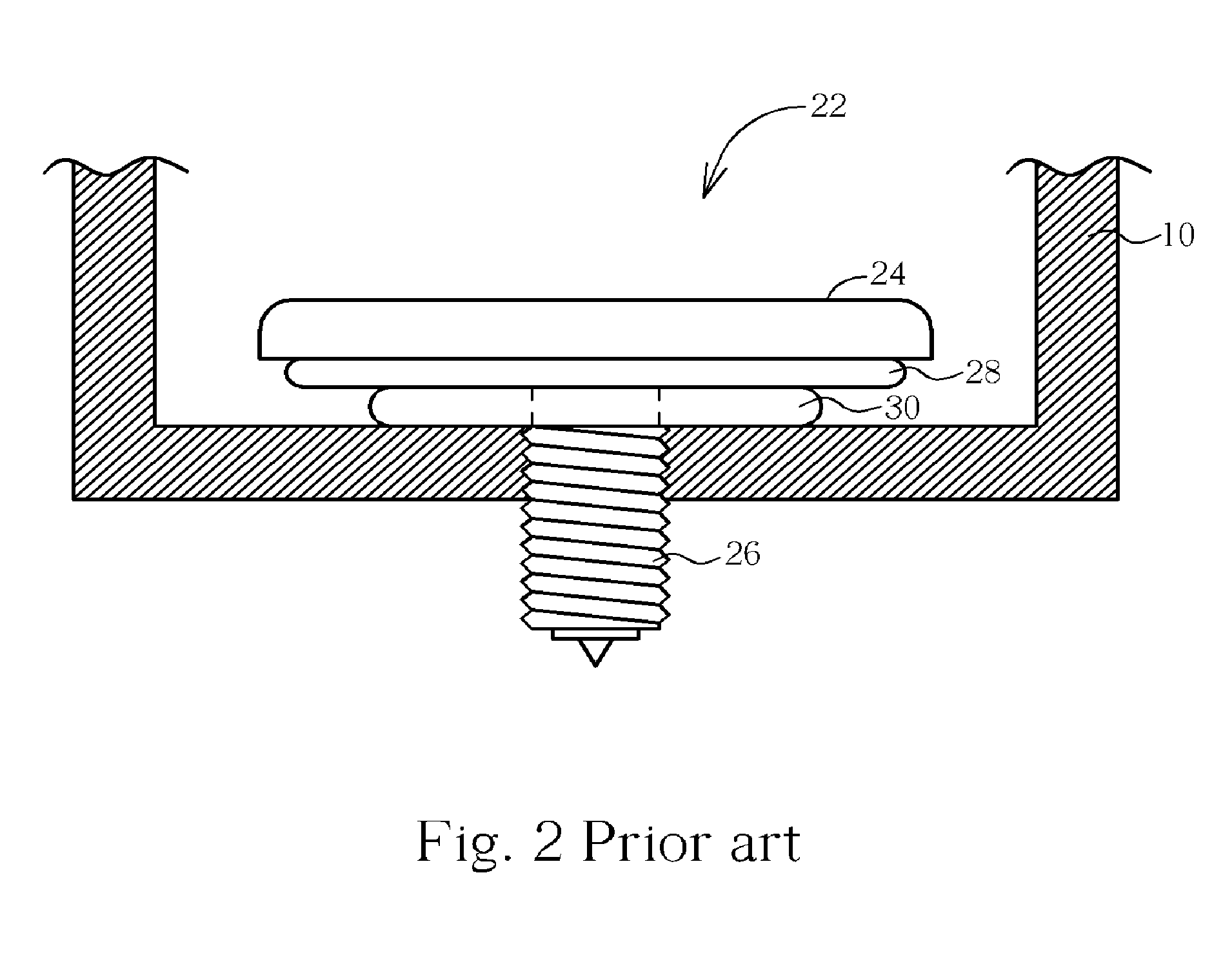

Arc chamber for an ion implantation system

ActiveUS20090008570A1Reduce flakingExtended service lifeMaterial analysis by optical meansElectric arc lampsIon implantationScrew axis

An arc chamber for an ion implantation system includes an exit aperture positioned at a wall of the arc chamber, filaments respectively positioned at two opposing sides within the arc chamber, and repeller structures respectively positioned at two opposing walls within the arc chamber between the filaments and the arc chamber. The repeller structure includes a repeller substrate with a screw axis for fitting the repeller structure to the arc chamber, an insulator positioned underneath the repeller substrate providing an electrical isolation between the repeller substrate and the arc chamber, and a conductive spacer covering a portion of the insulator positioned in between the insulator and the arc chamber.

Owner:UNITED MICROELECTRONICS CORP

Modular power actuator

A power actuator assembly includes a torque transmission device, a motor mounted to the torque transmission device extending along a motor axis, and a screw coupled to the torque transmission device and extending along a screw axis. An adjustment mechanism interconnects the screw and the torque transmission device and permits selective rotational adjustment between the adjustment mechanism and the torque transmission device to rotate the motor relative to the torque transmission device. A connecting device releasably interconnects the adjustment mechanism to the torque transmission device to permit repeated re-positioning of the motor relative to the torque transmission device.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Thermal displacement correcting method of a machine tool and a termal displace ment correcting device

ActiveCN101530974AHigh precisionHigh correctionAutomatic control devicesComputer controlBall screwEngineering

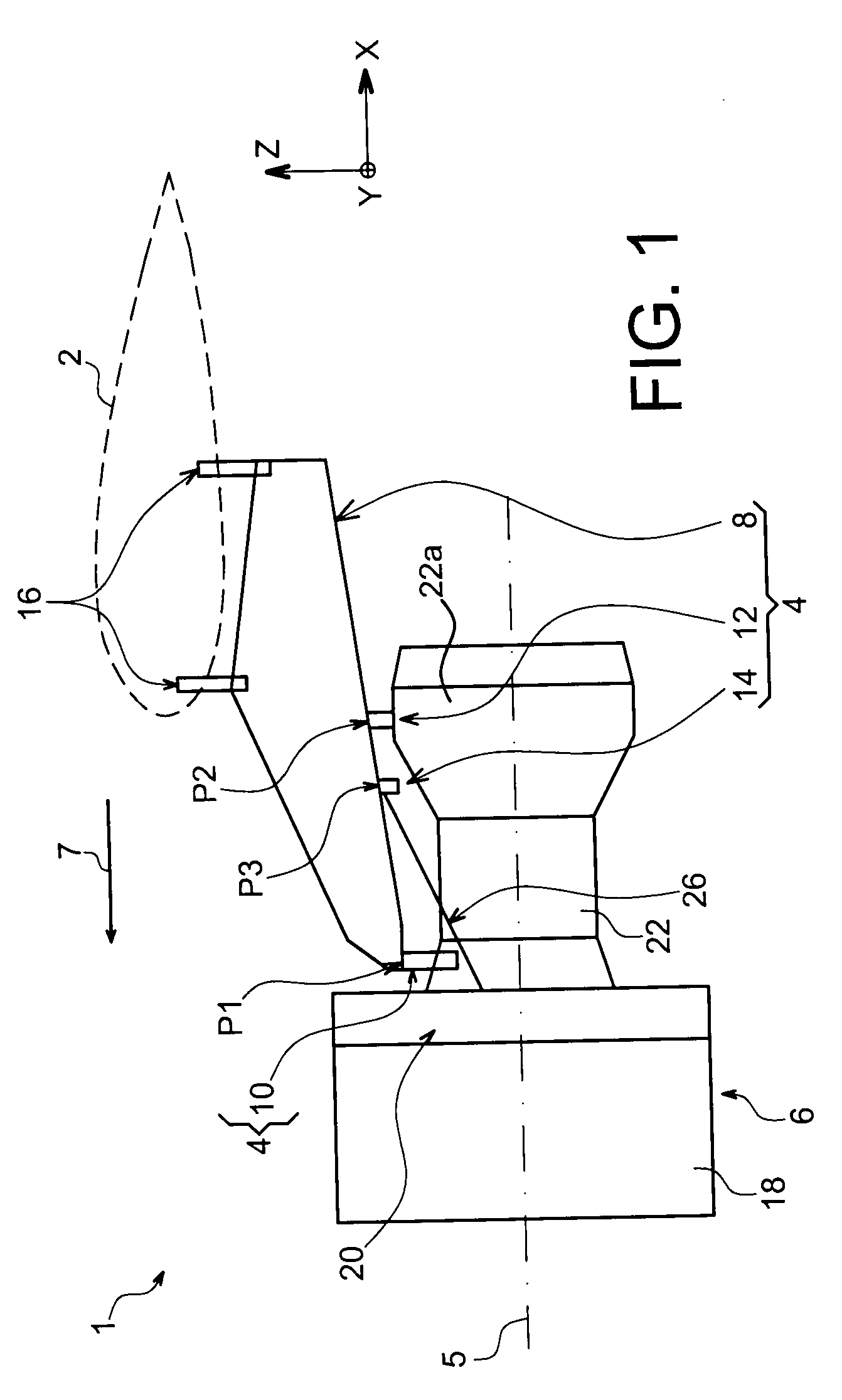

The present invention provides a thermal displacement correcting method of a machine tool and a thermal displacement correcting device, which is used to correct error caused by thermal displacement of a ball screw mechanism generated in operation of a machine tool. A first heat productivity computing division calculates a first heat productivity generated by a nut on a screw axis according to a rotary speed detected by a speed detector; a second heat productivity computing division calculates a second heat productivity generated by a servo motor on a screw axis according to a temperature increase detected by a temperature detecting division. A temperature distribution computing division calculates the temperature distribution that separated into a plurality of zones in length direction of the screw axis. A thermal displacement quantity computing division calculates thermal displacement quantity of each zone according to temperature distribution calculated by the temperature distribution computing division. A correction computing division calculates a correction of machining data for nut feed calculation according to the thermal displacement quantity calculated by the thermal displacement quantity computing division.

Owner:BROTHER KOGYO KK

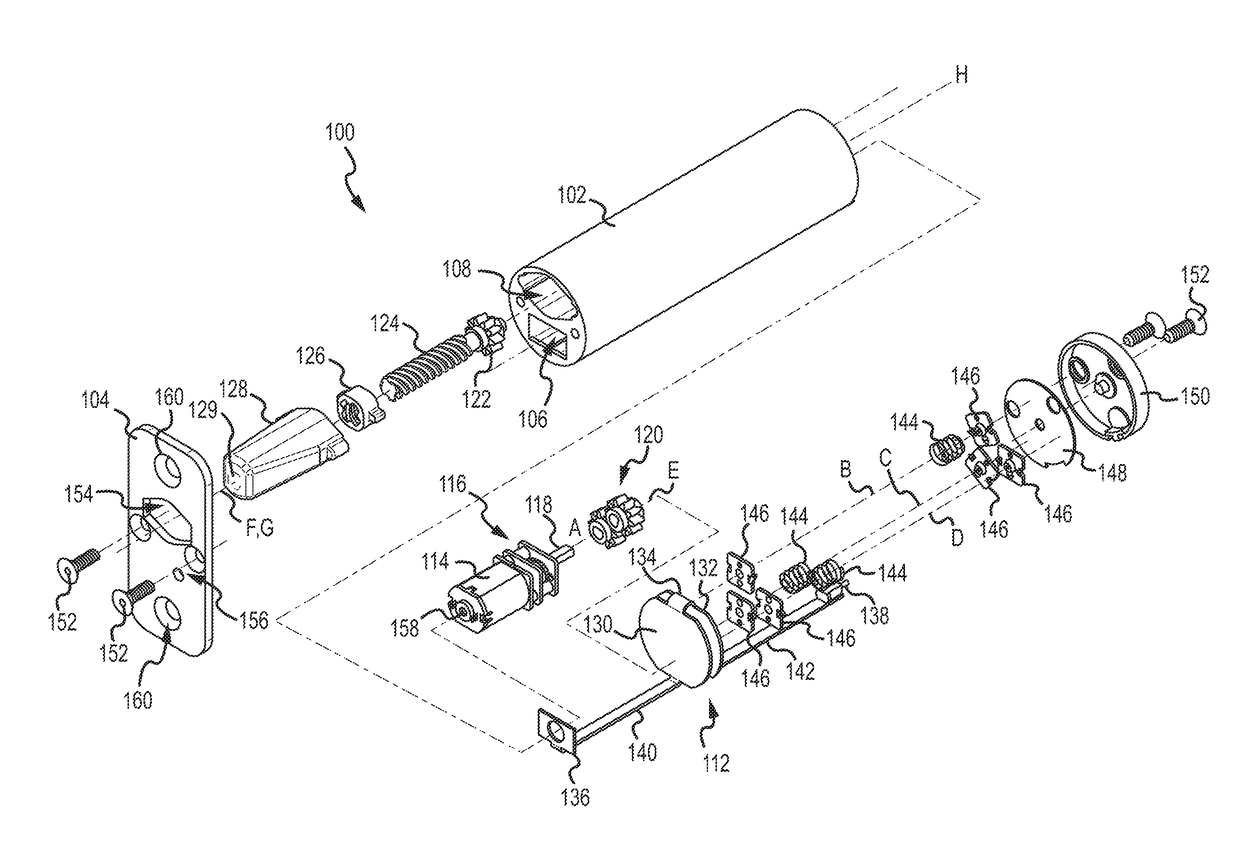

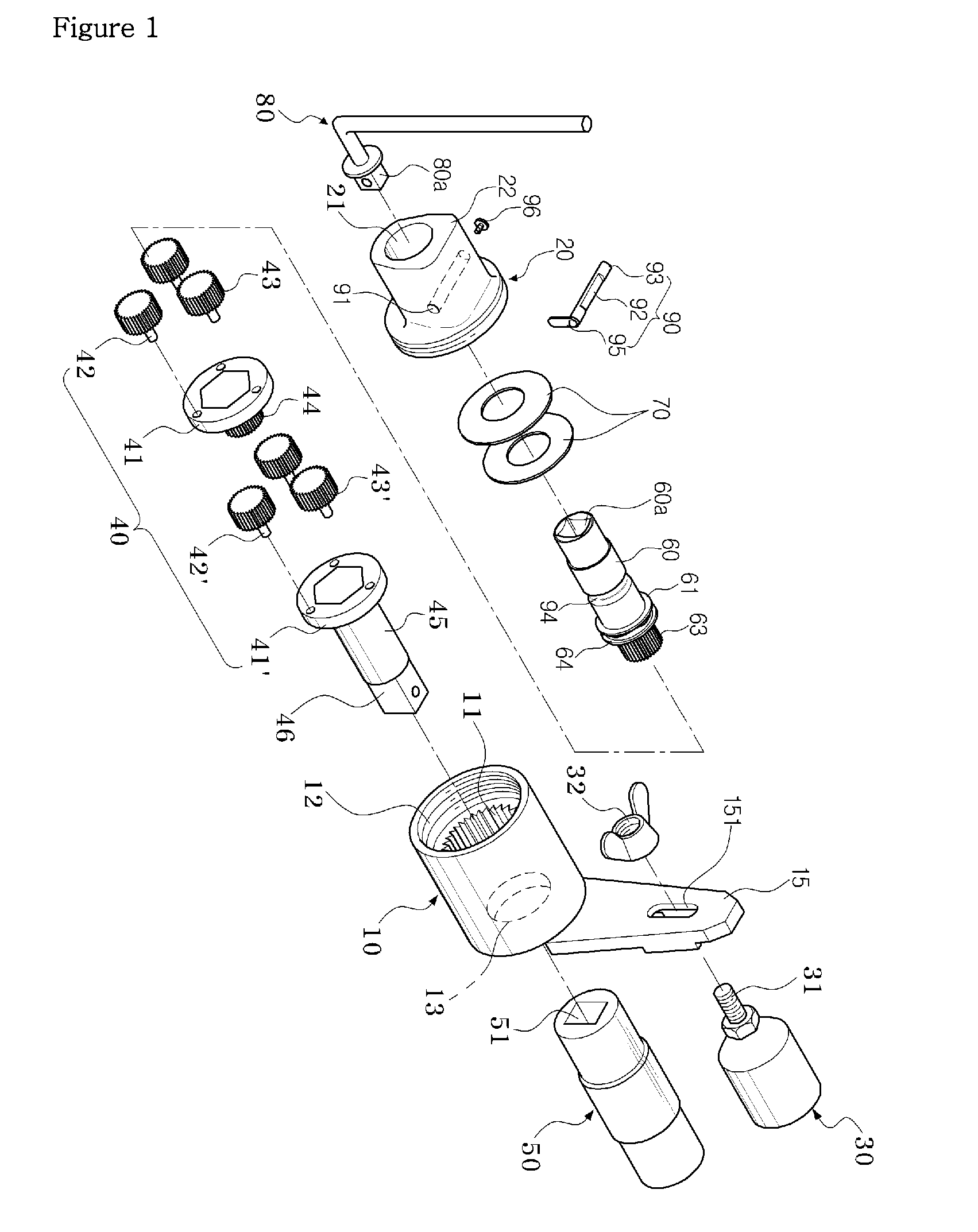

Locking system having an electronic deadbolt

A motor with a shaft and a shaft axis is disposed within a housing. A lead screw has an axis and is rotatably mounted in the housing. A deadbolt linearly extends from the housing based on rotation of the lead screw. A gear set with a plurality of gears, each having an axis, is disposed in the housing and operably connects the motor and the lead screw. A circuit board is disposed within the housing and has a plurality of portions communicatively connected by a ribbon. Each portion is disposed substantially orthogonal to the motor shaft axis, the lead screw axis, and the plurality of gear axes.

Owner:AMESBURY GROUP

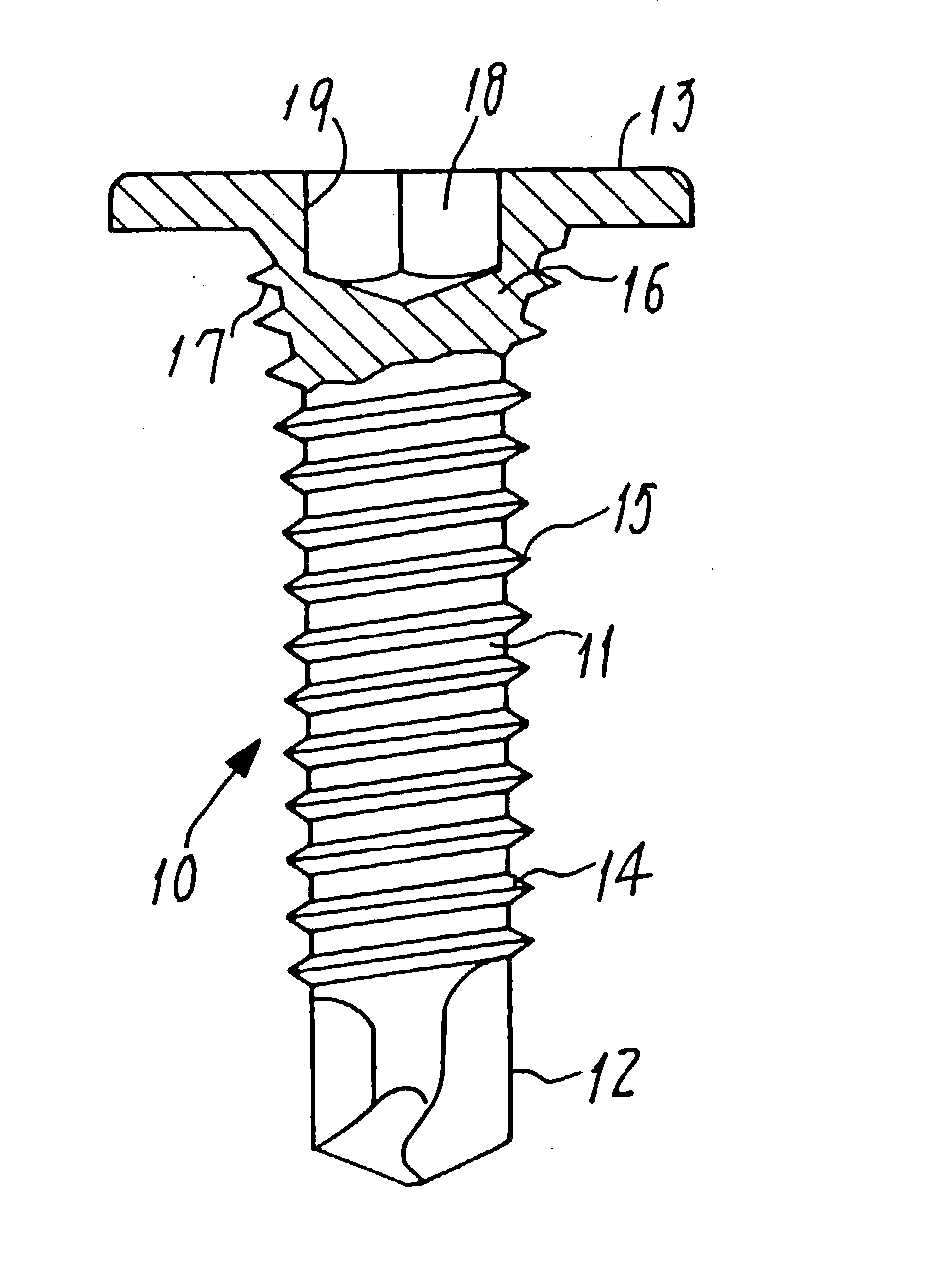

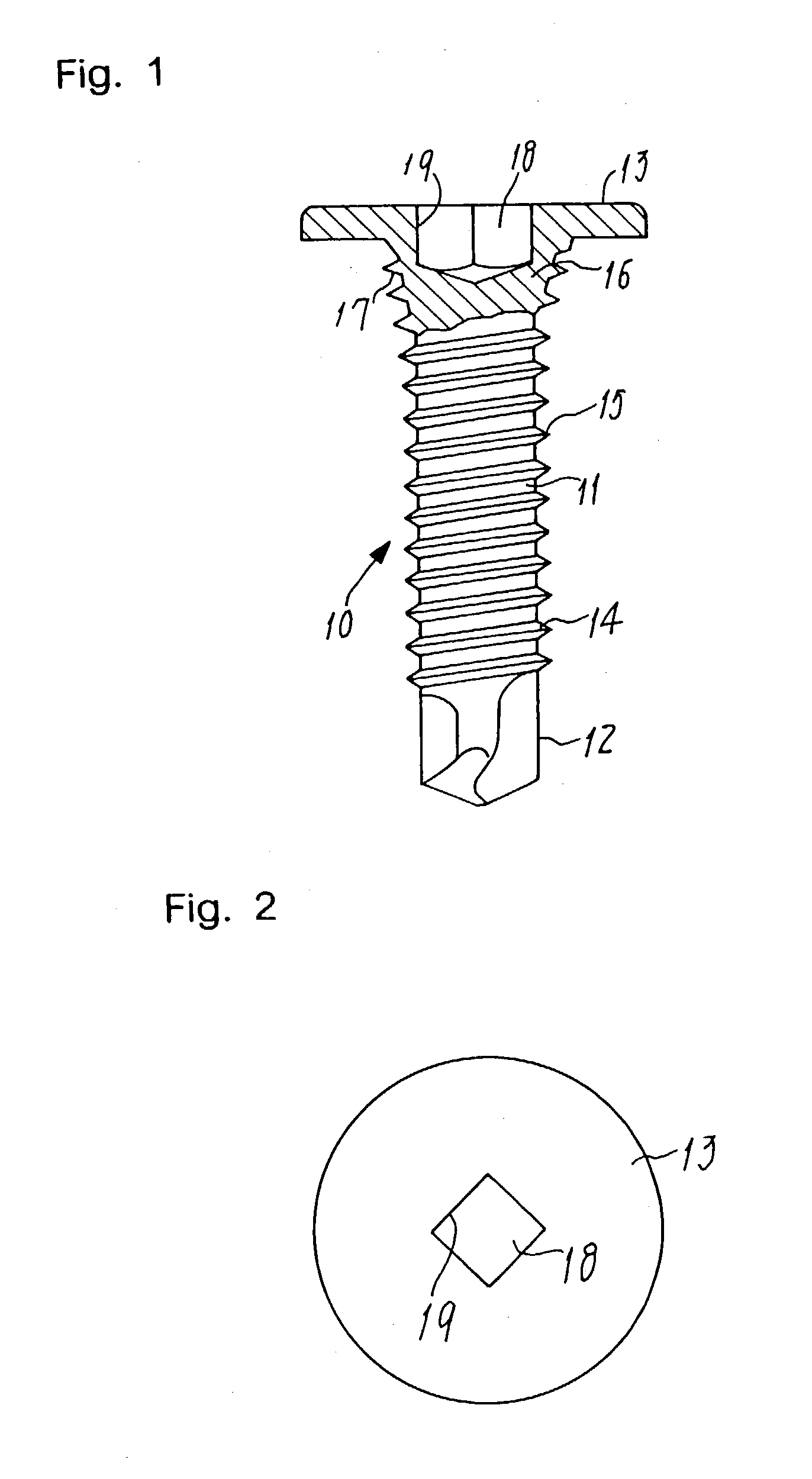

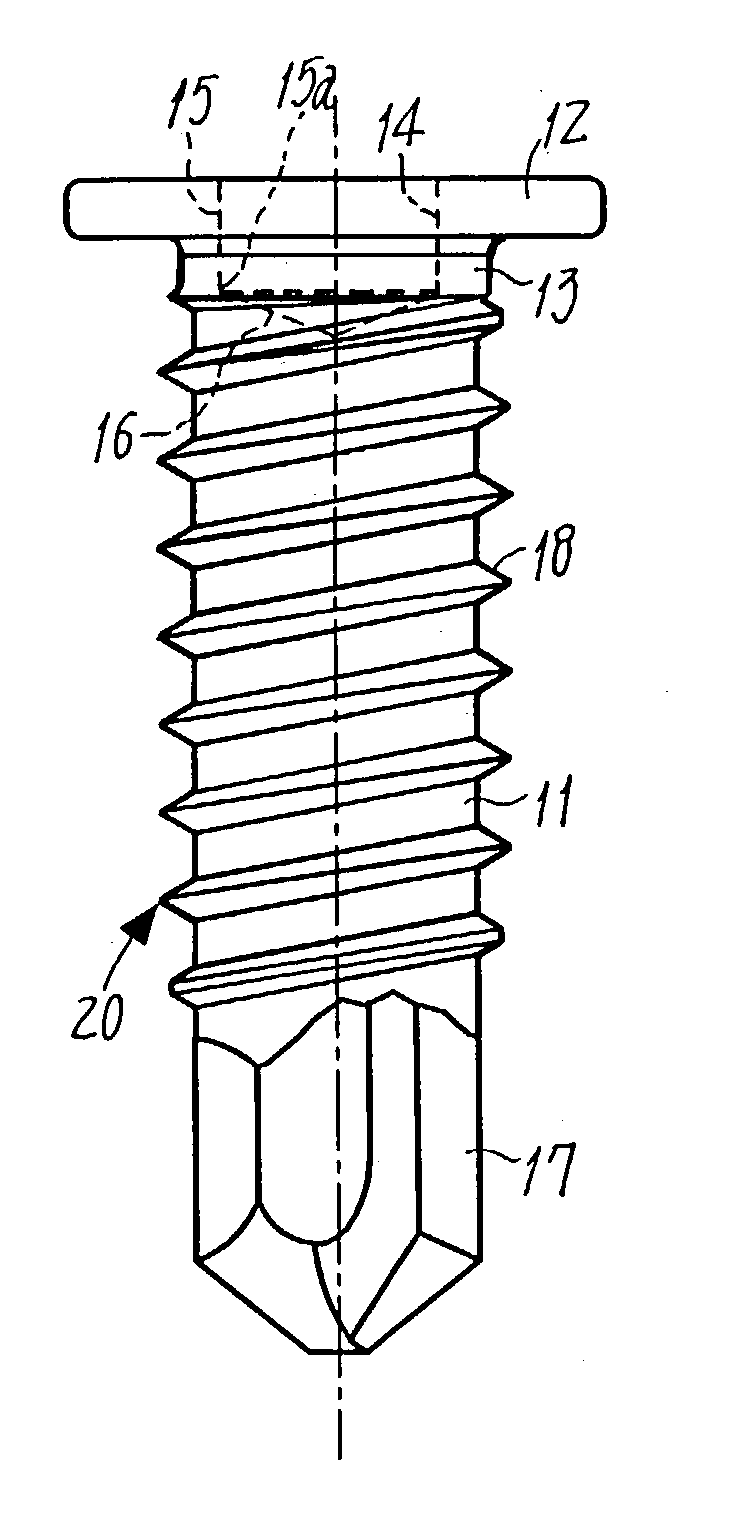

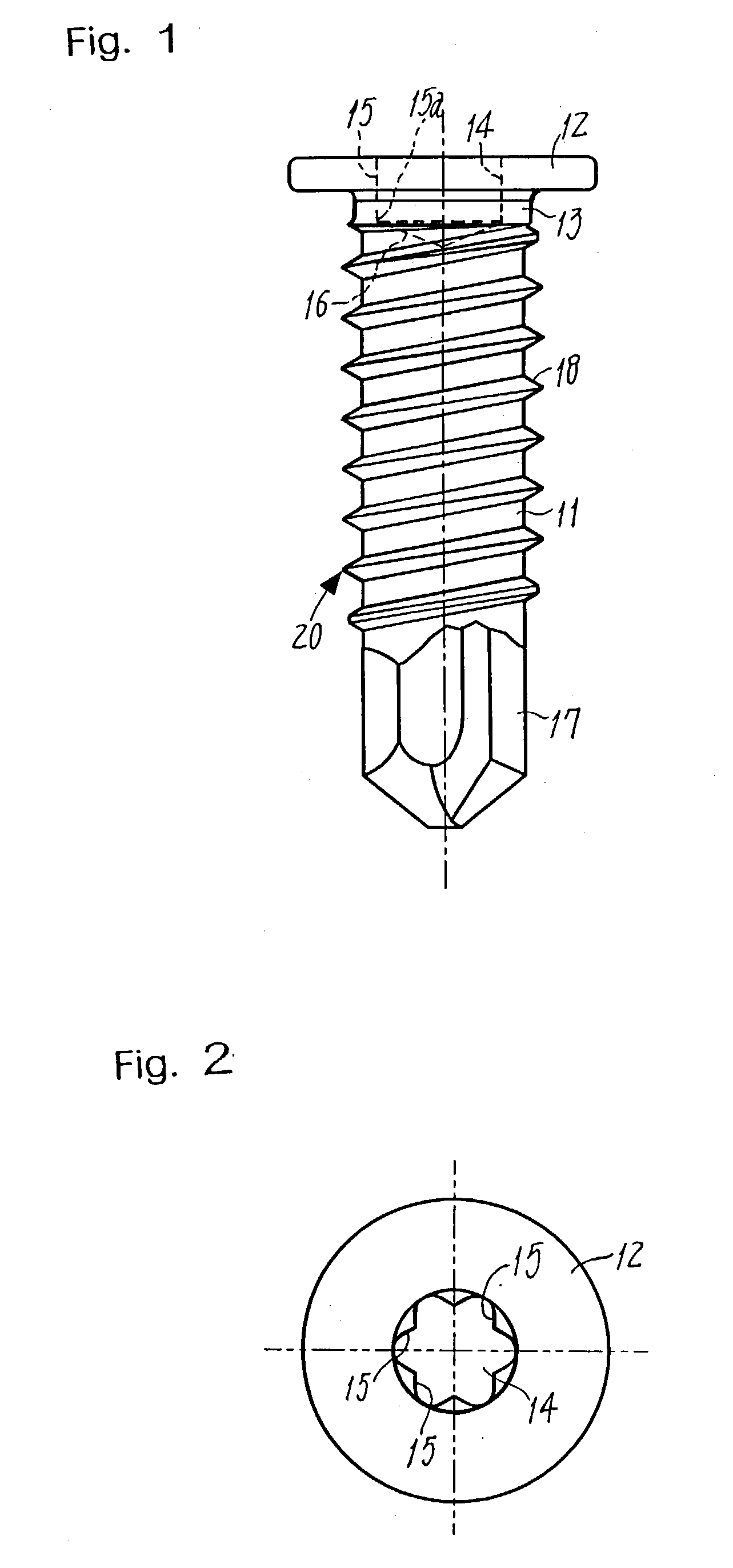

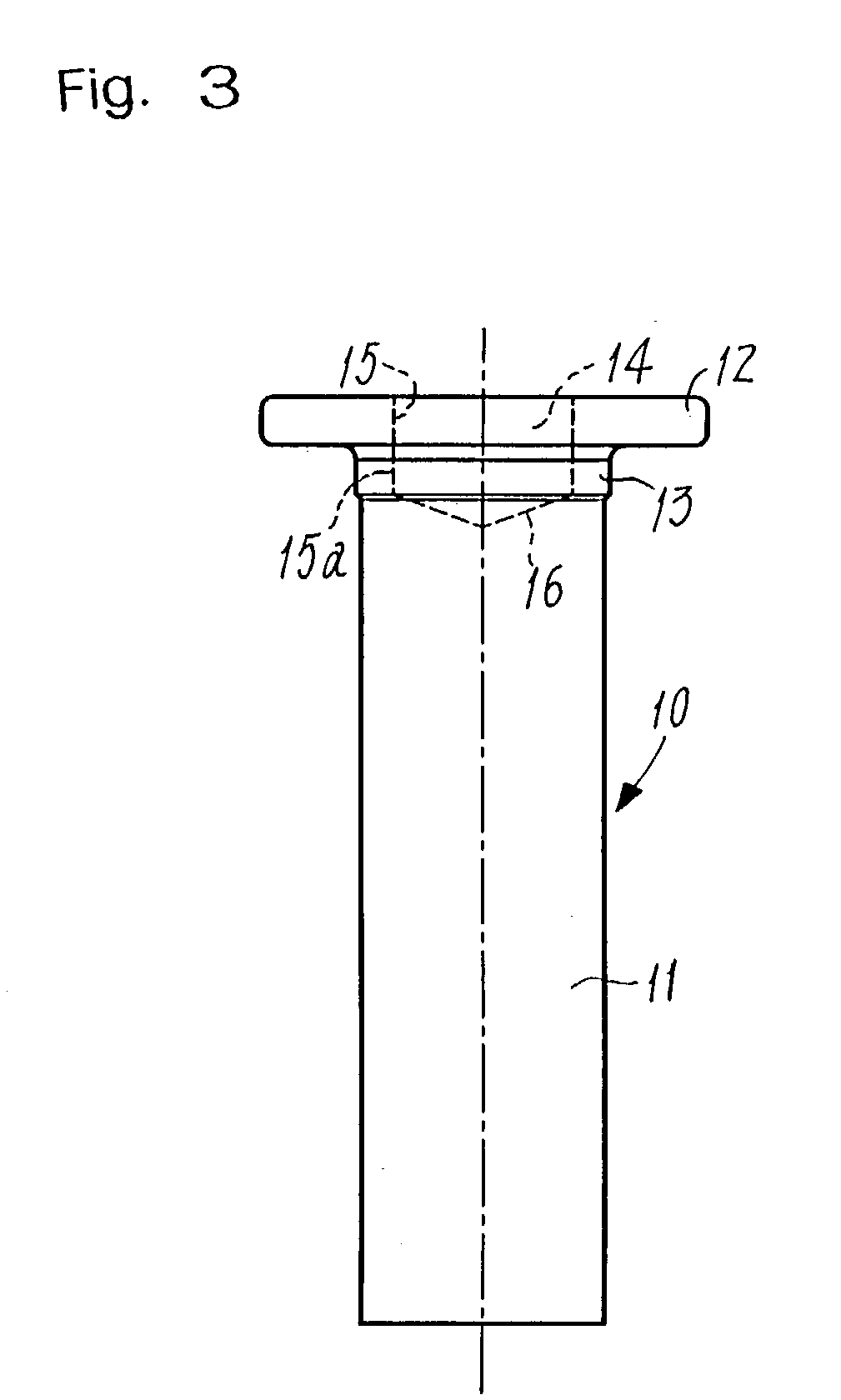

Self-drilling screw for use in steel houses

A self-drilling screw (10) for use in steel houses has a leg (11), one end of the leg being formed as a drilling portion (12), the other end continuing to a flathead (13) through a neck (16) disposed close to the flathead (13). A tapping thread (14) formed around the leg continue from drilling portion, with a guiding thread (15) continuing from the tapping thread. A fastening thread (17) formed around the neck has a larger diameter than tapping and guiding threads (14, 15), the neck (16) being a thickened portion of the leg (11). A recess (18) formed in flathead (13) to engage with a driving tool is defined by and between torque-receiving walls (19) extending in parallel with the screw axis and beyond a boundary between the flathead (13) and neck (16), so that a driver can fit in the recess of such a thinned flathead to transmit a strong torque to tighten the screw into a steel panel, without any fear of caming-out problem.

Owner:SHINJO MFG CO LTD

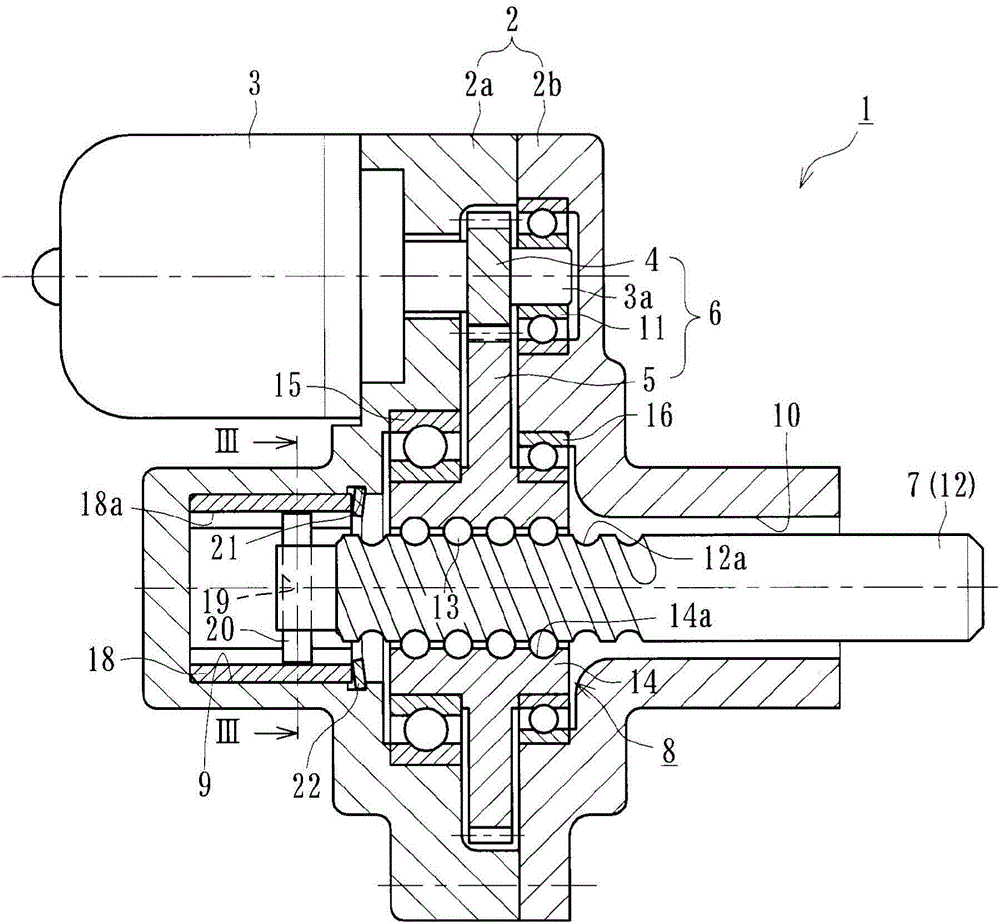

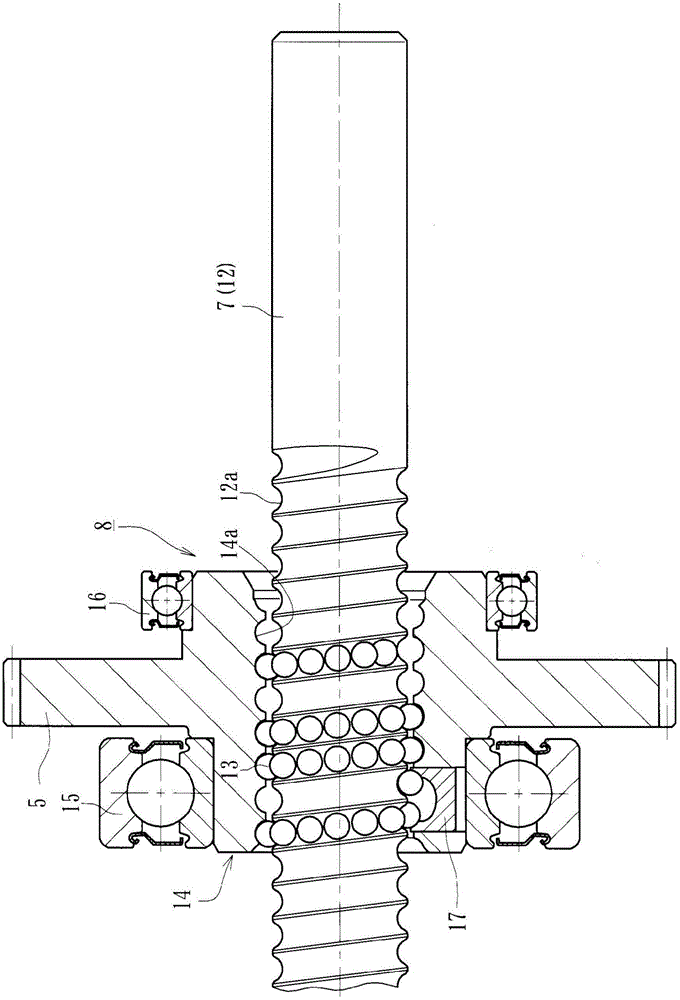

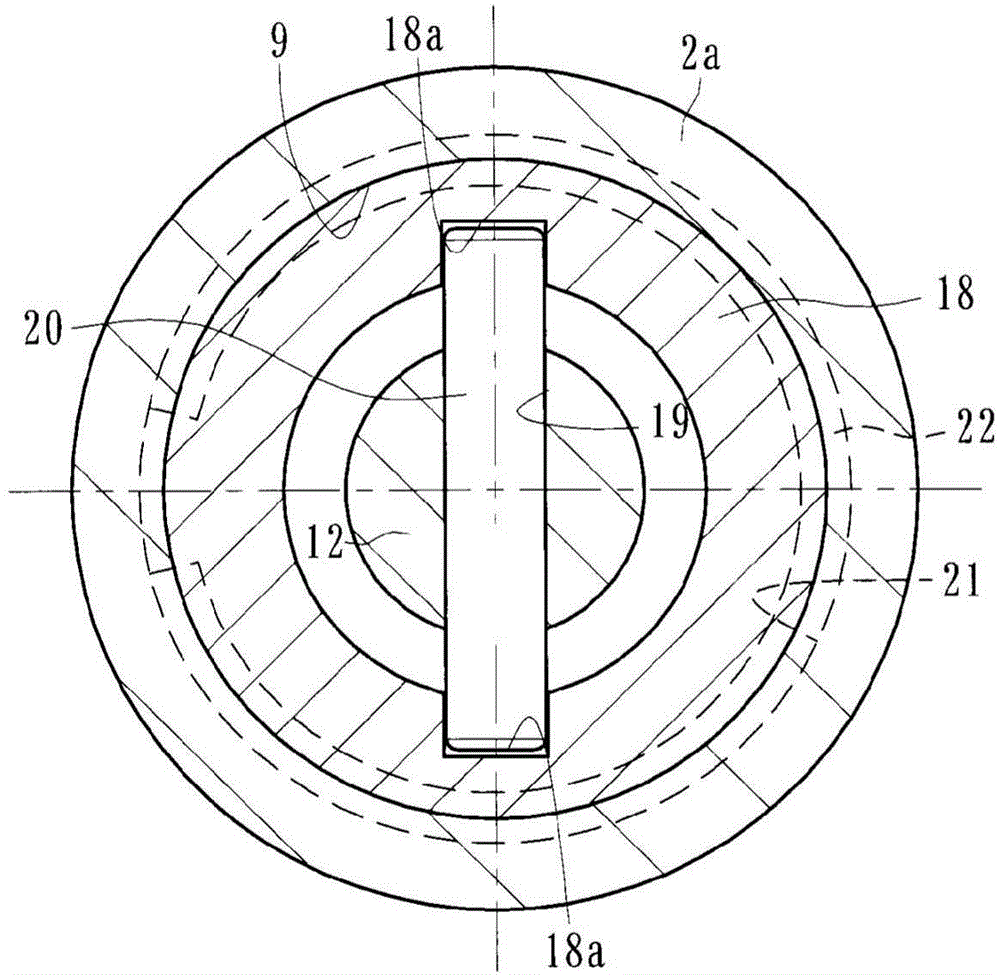

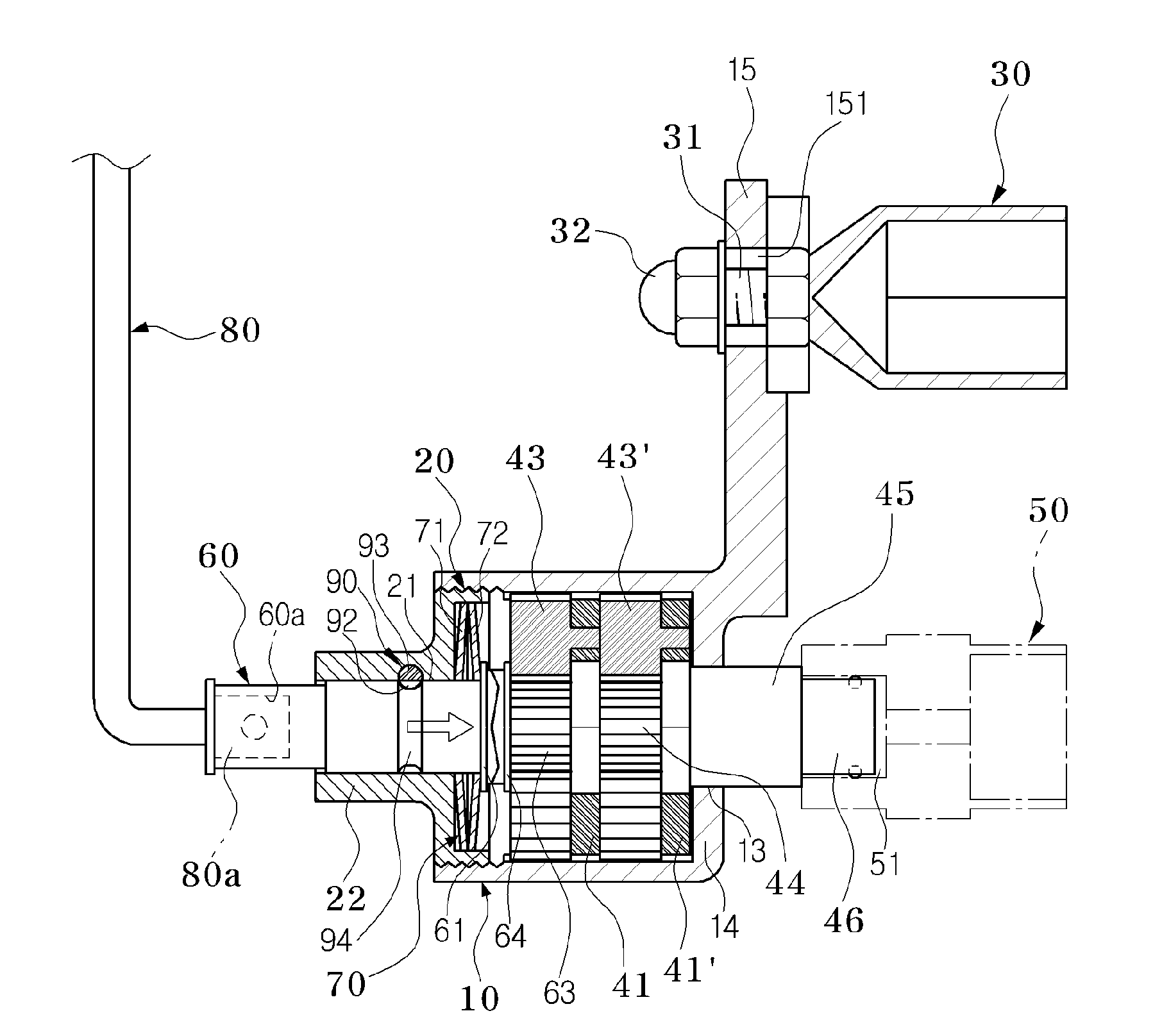

Electric linear actuator

ActiveCN104160176AReduce sliding frictionReduce wearGearingMechanical energy handlingLinear motionDrive shaft

[Aim] Provided is an electric linear actuator that is capable of reducing sliding friction and wear and that has a simple structure for cost reduction. [Solution] In an electric linear actuator that includes a ball screw mechanism (8) which converts a rotational motion of an electric motor (3) into a linear motion in an axial direction of a driving shaft (7) via a speed reduction mechanism (6), a cylindrical sleeve (18) is fitted into a housing hole (9) of a housing (2a), and a pair of recessed grooves (18a) are formed at opposing positions extending in an axial direction in an inner periphery of the sleeve (18) so that a guide pin (20) implanted in a tip portion of a screw axis (12) is engaged. An annular groove (21) is formed in an opening portion of the housing hole (9) of the housing (2a), and the sleeve (18) is retained in a pressed state by a hole retaining ring (22) that is mounted on the annular groove (21) and provided with a curved portion which has peaks at positions that are symmetrical to a cut-out portion.

Owner:NTN CORP

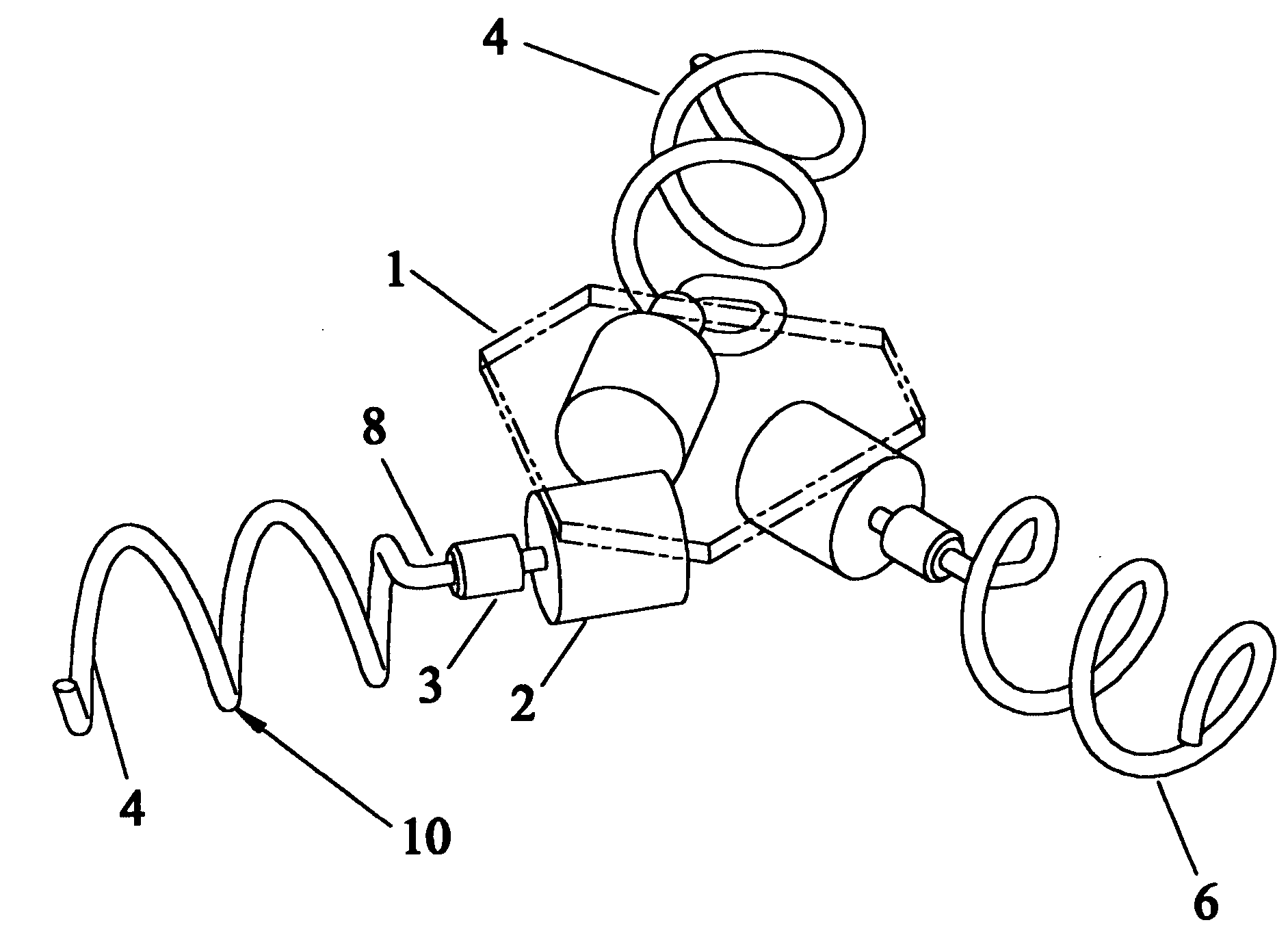

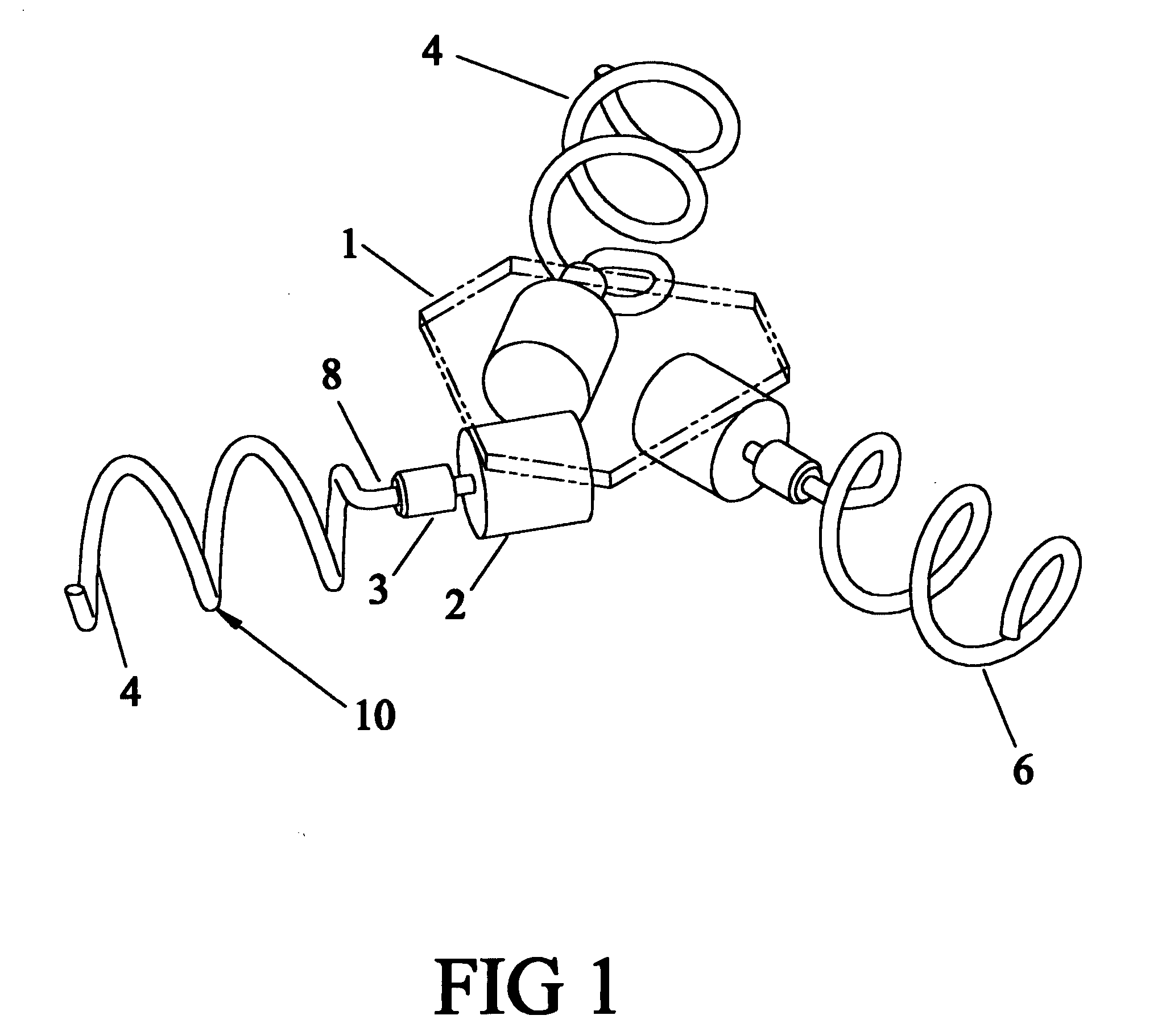

Screw driven mobile base

The present invention is a screw driven, mobile base for traversing a wide range of outdoor soft or rough surfaces and terrains. The device has three degrees of freedom in a plane and, thus, is highly maneuverable, able to travel in any horizontal direction relative to its orientation and able to orient itself independently of the direction of travel. Each screw comprises a structural core with an outer helical edge profile of curved cross-section, having an abrasion resistant, low friction material on the outer surface. The device rides on the low friction profiles and relies on the combined effects of the multiple drive screws against the ground surface. The drive screw axes are non-parallel in most of the configurations.

Owner:LEXEN TIMOTHY CARL

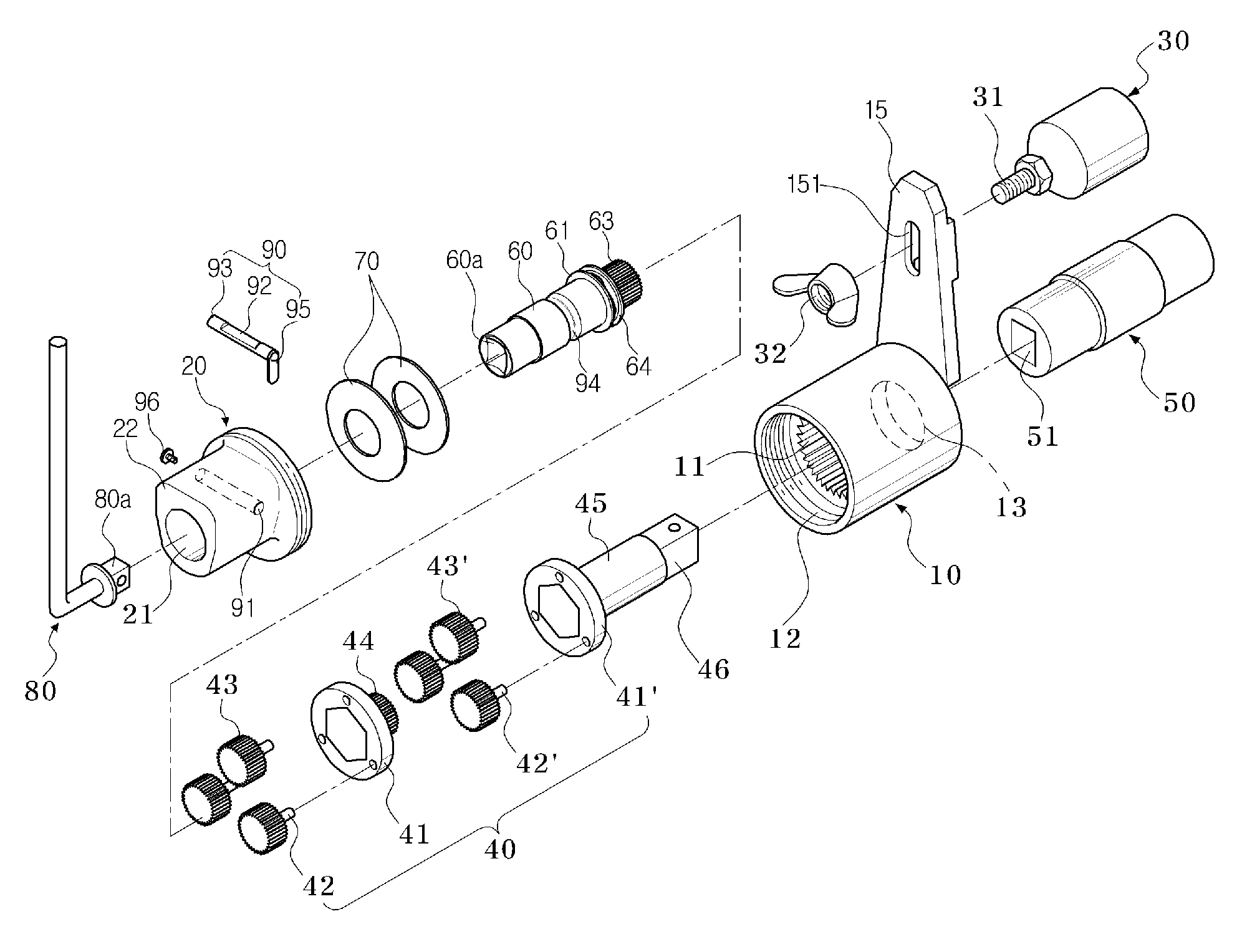

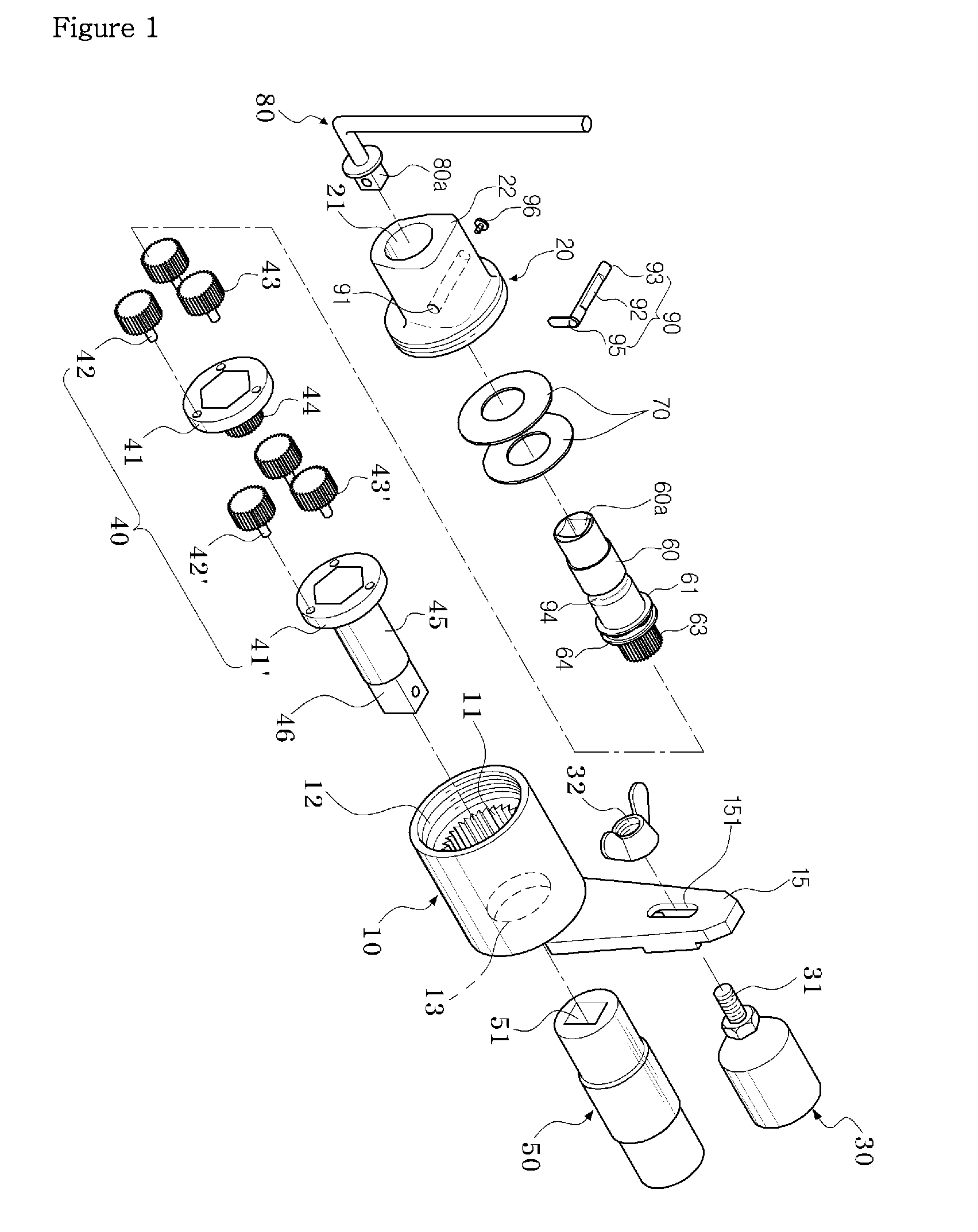

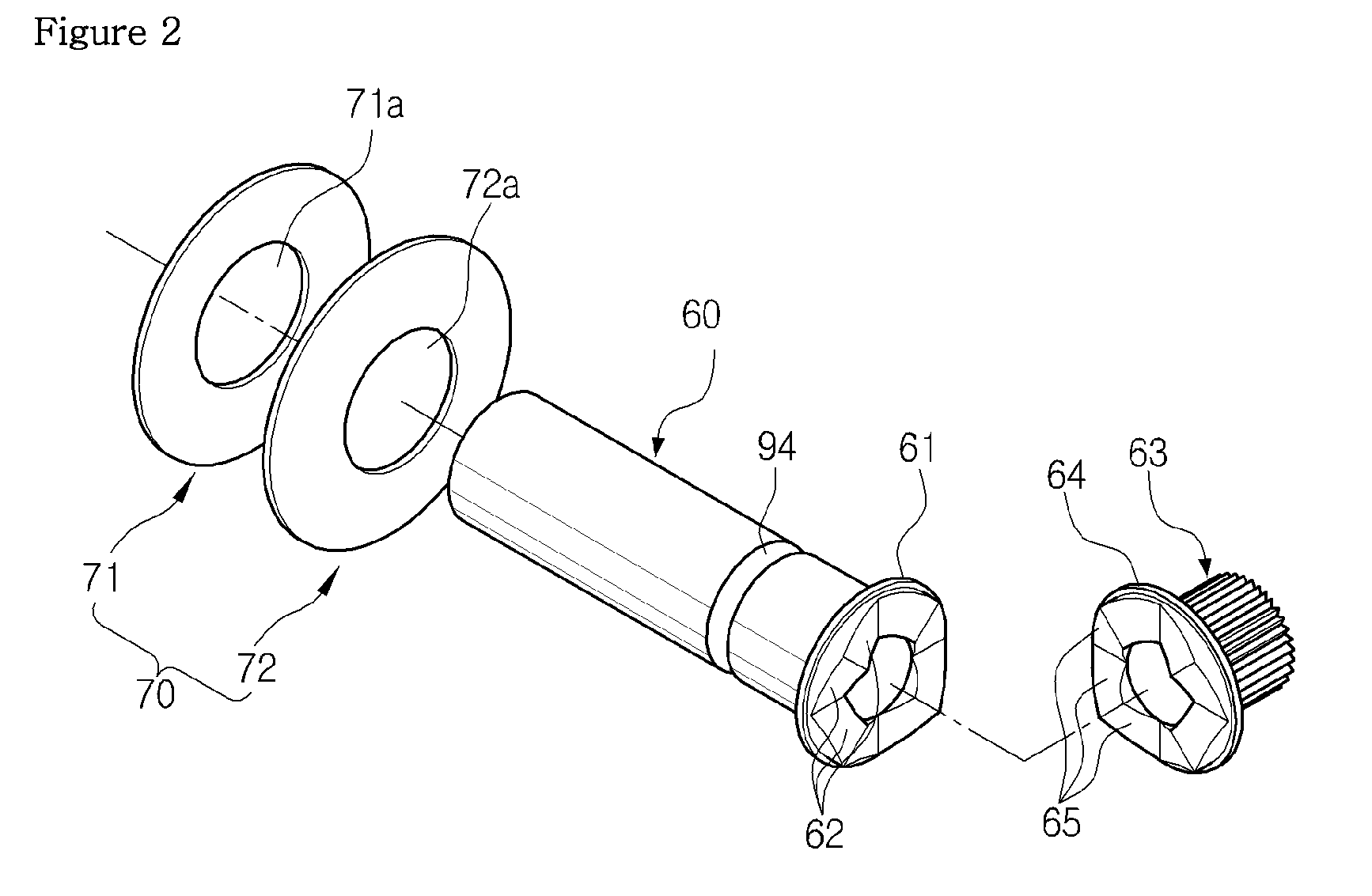

Wrench

InactiveUS20080098856A1Maximize convenienceEasy to installWheel mounting apparatusSpannersGear wheelEngineering

This invention is about a device used for installing a fixing nut on the targeted objects-multiple fixing screw axes protruded from the hub or for separating them from the targeted object or the fixing screw axis in order to fix vehicle's tire wheel to the hub when installing or separating a fixing nut from targeted objects. Based on the idle operation of the operating gear, not based on the visual examination, the invention immediately recognizes the complete installation of a fixing nut. Likewise, this invention is to provide a wrench that maximizes user convenience.

Owner:KIM NAM SUK

Magnetorheological actuator having a rotationally driven threaded spindle and clutch having an actuator

InactiveUS20170089408A1High strengthIncrease pressureMagnetic circuit rotating partsGearingMagnetic currentMagnetorheological fluid

A magnetorheological actuator including a chamber, in particular a chamber at least sections of which are shaped like a hollow cylinder, containing a magnetorheological fluid, and further including a control element disposed in the chamber, wherein the control element suitable for applying the operating force of the actuator, wherein the control element is a threaded spindle or screw or threaded rod driven to rotate about its longitudinal axis, in particular about the screw axis, and including a spindle core and a thread disposed thereon, the thread surrounded by the magnetorheological fluid, is provided. A clutch having such an actuator is also provided.

Owner:SCHAEFFLER TECH AG & CO KG

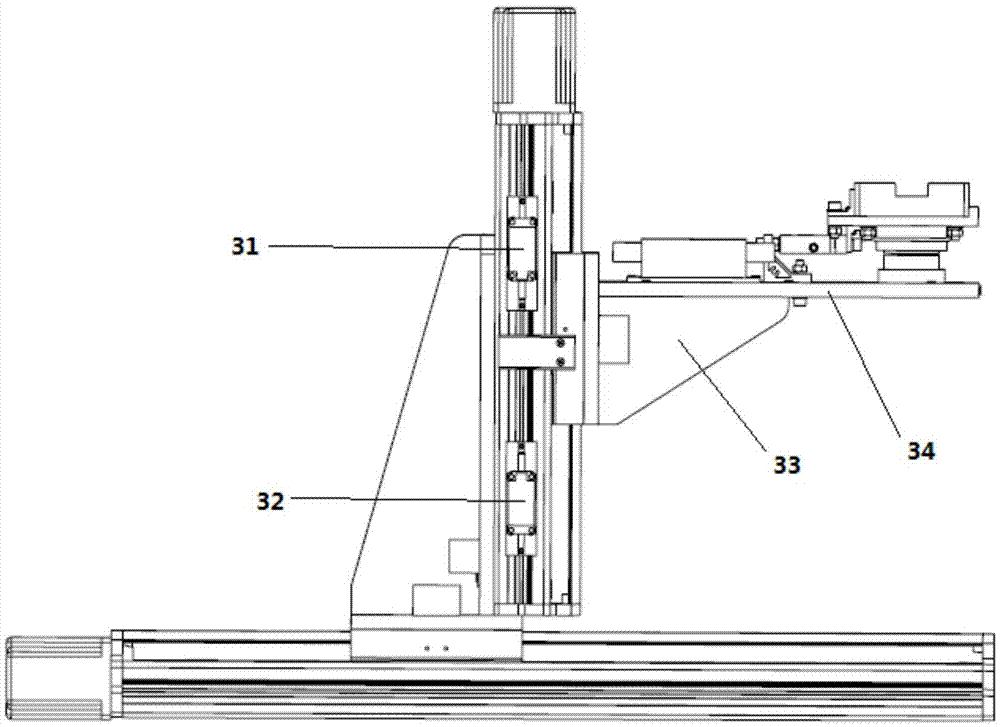

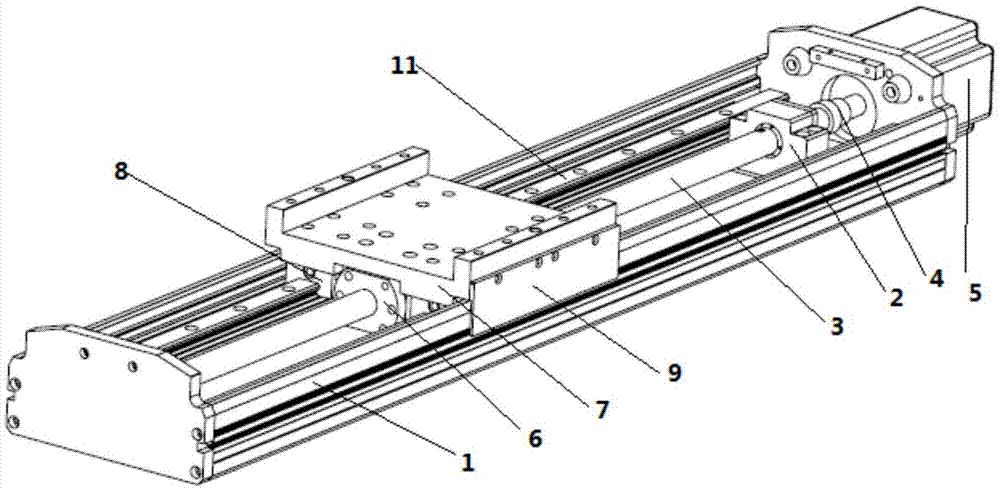

Automatic detection device for releasing force of hand automobile seat lock and sliding force of slide rail

InactiveCN105445013AHigh transmission precisionPrecise positioningMachine part testingApparatus for force/torque/work measurementCar seatAudio power amplifier

The invention relates to an automatic detection device for releasing force of a hand automobile seat lock and sliding force of a slide rail. The automatic detection device comprises a pedestal A, a bearing pedestal A, a leading screw axis A, a plum coupling A, a horizontal driving motor, a nut mounting sleeve A, a horizontal slide unit, a slide block A, a horizontal induction plate, a pedestal B, a bearing pedestal B, a leading screw axis B, a plum coupling B, a vertical driving motor, a nut mounting sleeve B, a vertical slide unit, a slide block B, a release lever amplifier, a release lever tester, and a support plate for the release lever tester. The automatic detection device for releasing force of a hand automobile seat lock and sliding force of a slide rail is wide in the range of application, and can detect a plurality of models of hand automobile seats. The automatic detection device takes a ballscrew with high precision as a transmission system, and is high in transmission precision and accurate in positioning. The automatic detection device uses a direct measurement method to avoid various errors generated by indirect measurement. The automatic detection device can perform automatic detection, and is low in human intervention, high in efficiency and significant in economic benefit. For the automatic detection device, a nylon block which directly contacts the release lever can prevent damaging the seat.

Owner:YANSHAN UNIV

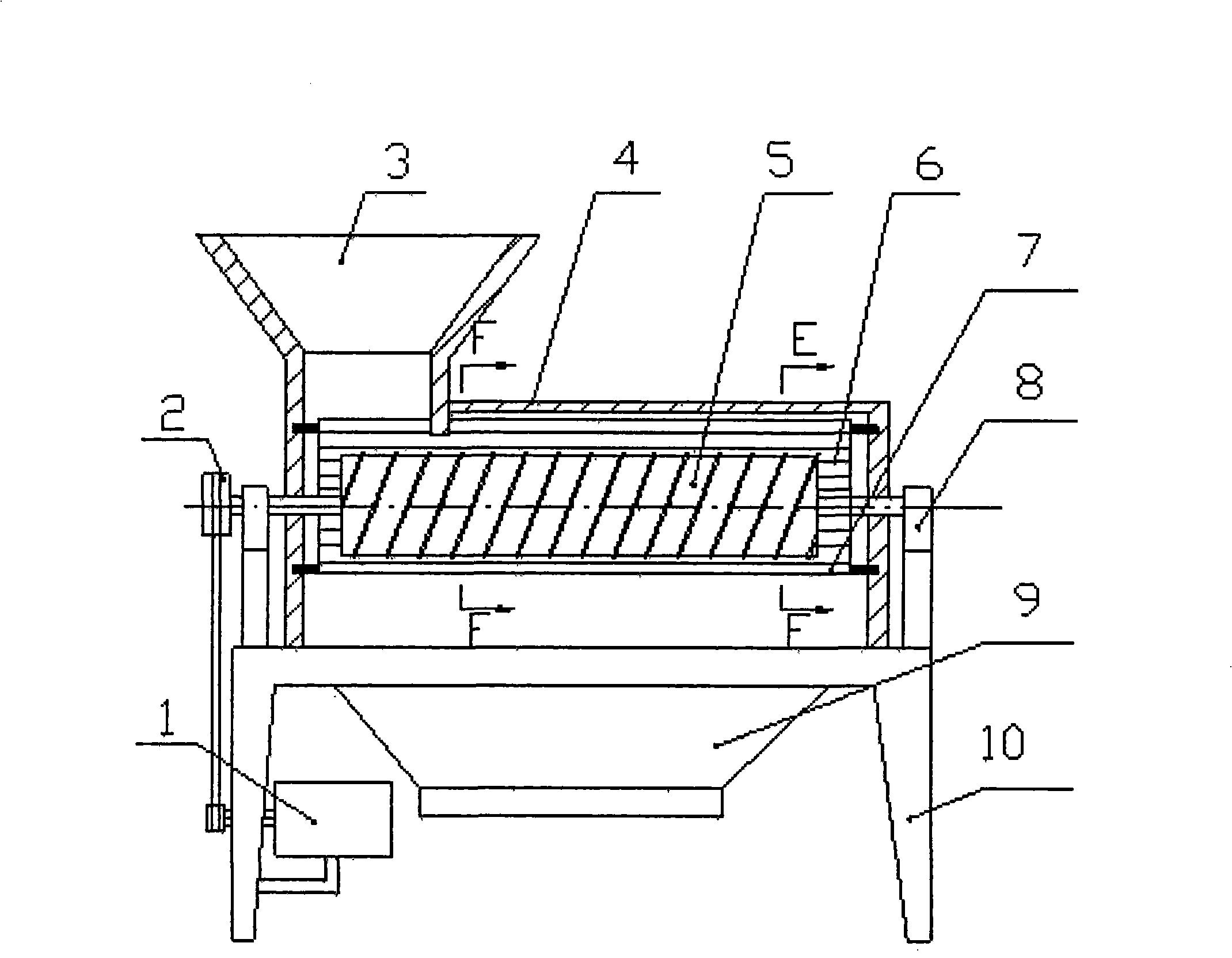

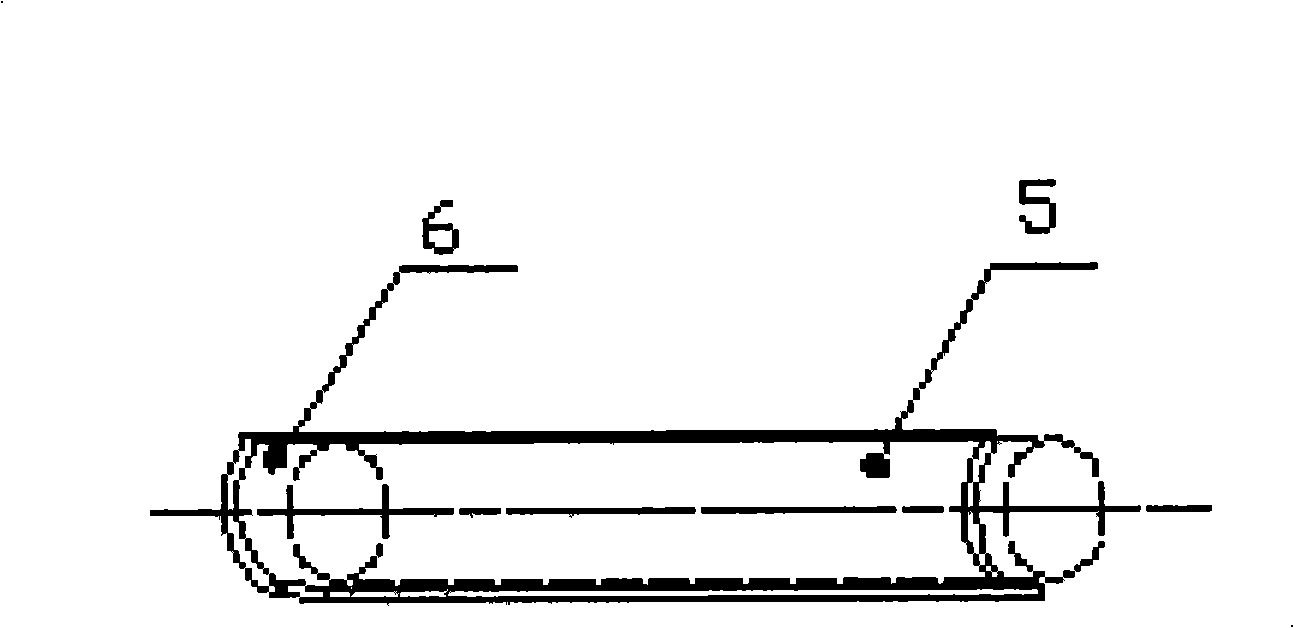

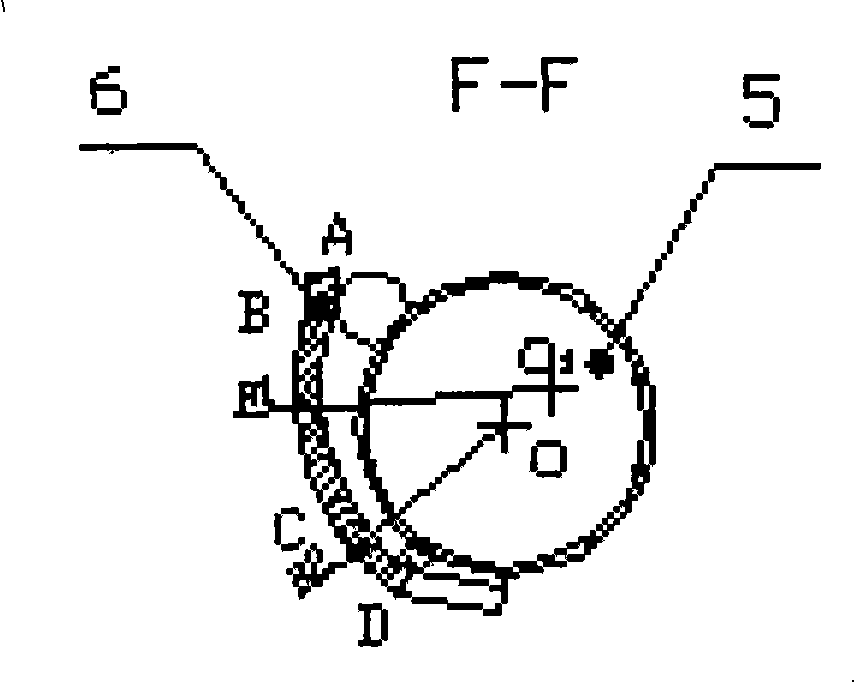

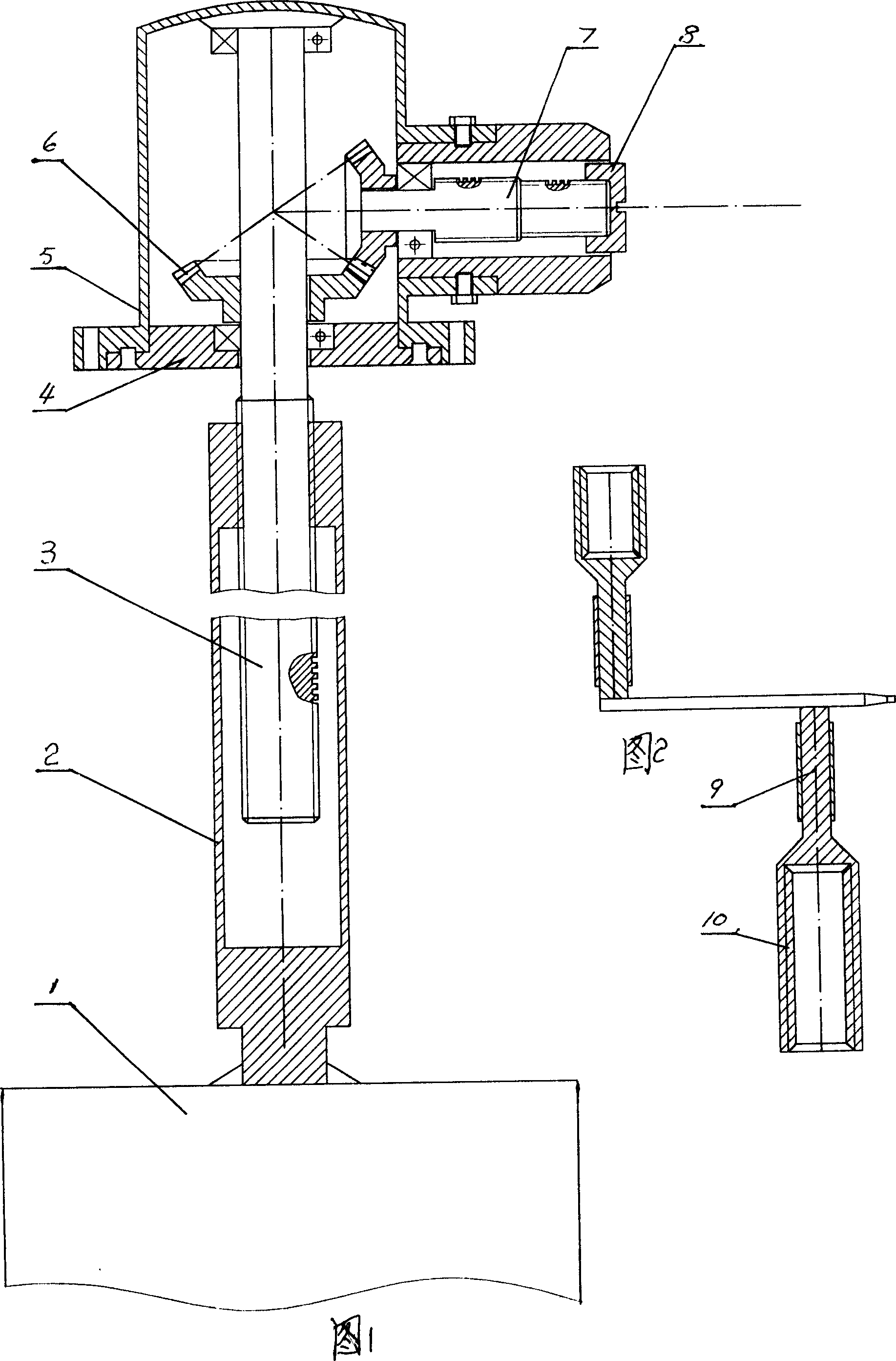

Plate type peeling machine for macadamia nut

The invention relates to a plate-type huller for Australian nuts, comprising a motor or a diesel engine, a transmission mechanism, a feed hopper, a screw axis, a hulling plate, a peel-shell leading-out plate, a discharge hopper, a machine frame, etc. The huller is characterized in that: the screw axis is driven to rotate by the motor or the diesel engine through the transmission mechanism; the hulling plate is fixed on the machine frame; after entering from the feed hopper, nuts are squeezed and twisted by the screw axis and the hulling plate so as to crack nut peel and separate seeds out; the screw axis is equidistantly wound and welded on a hollow shaft; the hulling plate adopts a gradual change distance type structure; the distance between a working surface of the hulling plate and the screw axis partially becomes shorter from a working front end to a tail end and partially becomes longer; a maximum distance and a minimum distance are respectively a maximum nut diameter and a minimum nut diameter, and the distance between a working surface of the tail end of the hulling plate and the screw axis is a maximum seed diameter. The huller is simple in structure and low in manufacturing cost, can work fixedly or movably and process 800-1,600 kg of nuts per hour, does not need to have fruits graded, and is good in the quality of processed seeds.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST

Self-drilling screw for use in steel houses

A self-drilling screw (20) for use in steel houses has: a leg (11) with opposite end regions and having a screw thread (18) formed by the rolling method, one of the leg end regions being formed as a drilling portion (17), the other end region continuing to a flathead (12) through a neck (13) disposed close to the flathead. A recess (14) formed in the flathead (12) can engage a wrenching bit of a screw driver, and the recess has torque-receiving vanes (15) extending generally in parallel with an axis of the screw. The neck (13) is a thickened portion of the leg (11) to have a diameter larger than a diameter of valleys of the thread (18) and smaller than its outer diameter. The neck (13) extends between the top of flathead (12) and the inner ends (15a) of vanes (15), with the recess (14) having a conical bottom (16) disposed in the leg, so that the thinned head of self-drilling screw withstands a strong torque for tightening it and also protects the driver bit from "caming-out".

Owner:YUGENKAISHA SHINJO SEISAKUSHO

Operating device for theftproof water gate

InactiveCN1563598AWith anti-theft waterWith anti-theft water functionConstructionsIrrigation ditchesDrive shaftEngineering

This invention is a switch use to open or close the theft proof floodgate. It features are: The support position of transmission, drive screw rod is in the holes on the bottom of the transmission box and in the hole of the box cover. The support position of drive axis is in the horizontal hole on the side of the box cover. In the box the bevel gear on the screw rod in gear to the bevel gear on the drive axis. On the drive axis there are two different axes, they have different diameter and inverse screw, the step axes are geared with handle female screw separately, the screw axis on the outer is the smaller one. In the hole on the box cover's side have female screw be geared with the box cover. The end of handle is connected with turning handle, and other end of handle is formed screw cylinder, on its surface there are screws, they are geared with the screw axis on drive axis.

Owner:贾树宝

Bogie lifting device

InactiveCN1927689ASolve lifting problemsStable and efficient liftingLoad-engaging elementsBogieEngineering

The invention relates to a lifting device of sway bogie using in the production and maintenance process of railway vehicles when the sway bogie transports. It is characterized by: rotating motor is linked with the drive leading screw axis by keys and fixed on the suspending frame through bolts, the drive leading screw axis is matched and linked with the suspending frame through the left and right rotate packages, and it also is linked with the left and right jackcatch screwthread. Its advantages are: making the manufacture and maintenance of sway bogie more efficient, meeting the needs of technique skillfully, achieving the pipelining repair and manufacture, solving the problem of lifting of the sway bogie, it is a reliable lifting device of sway bogie with multi-adaptability and lays the groundwork for faster transportation of bogie. Its application is wide, it makes claws closed or open using of the drive of screw and adapts to different bogie and different width swing bolster in the mixed multi-line transportation or the multi- products transportation; the structure is simple and convenient, the screw drive ensures the positioning accurate and claws clamps exact and lifting smooth and efficient.

Owner:郑卫星

Actuator

InactiveUS8405277B2Reduce weight and sizeIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesActuatorControl theory

An expansion and contraction actuator has a first long actuator portion and a second long actuator portion that face each other and connection members that connect the long sides of each of the first long actuator portion and the second long actuator portion to each other, in which a part of the first long actuator portion and a part of the second long actuator portion are apart from each other to thereby form a hollow structure, the first long actuator portion and the second long actuator portion each have a pair of long electrodes and a long electrolyte layer having an electrolyte, long internal electrodes thereof are the same cathode or anode electrodes, long external electrodes thereof are counter electrodes thereto, and the actuator expands and contracts in the direction of the screw axis by voltage application.

Owner:CANON KK

Wrench

InactiveUS7490535B2Easy to installEasy detachmentWheel mounting apparatusSpannersEngineeringVisual examination

This invention is about a device used for installing a fixing nut on the targeted objects-multiple fixing screw axes protruded from the hub or for separating them from the targeted object or the fixing screw axis in order to fix vehicle's tire wheel to the hub when installing or separating a fixing nut from targeted objects. Based on the idle operation of the operating gear, not based on the visual examination, the invention immediately recognizes the complete installation of a fixing nut. Likewise, this invention is to provide a wrench that maximizes user convenience.

Owner:KIM NAM SUK

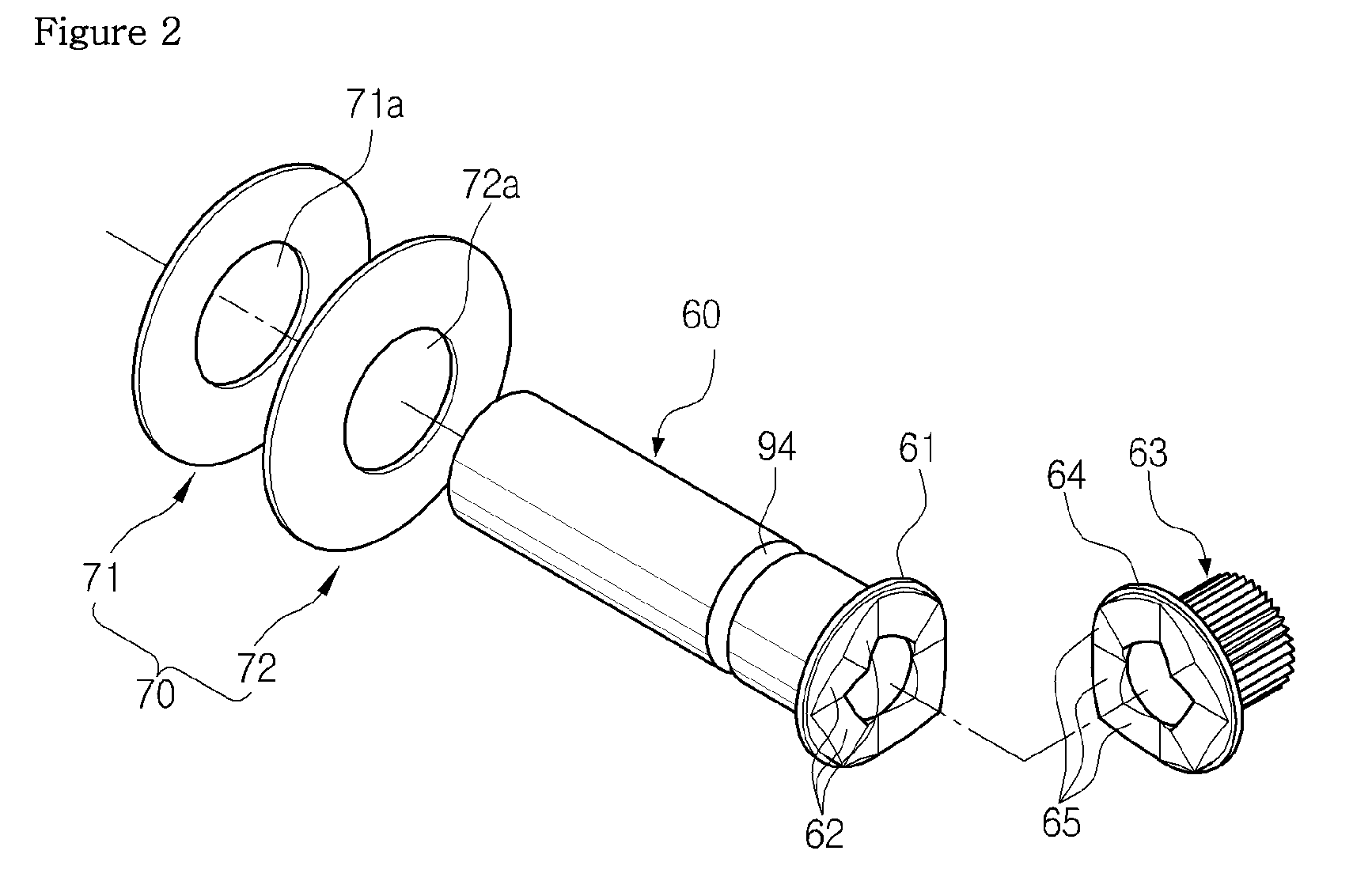

Ball screw device having tunnel raceway, and method for manufacturing the same

ActiveUS20100132494A1Reduce the number of partsSimple methodPortable liftingToothed gearingsBall screwEngineering

A ball screw device of a screw axis with a helical groove on its outer circumference for balls to circulate thereon includes a nut with a helical groove on its inner circumference for balls to circulate thereon, a number of balls to circulate in an orbit along the helical groove of the screw axis and the helical groove of the nut, and a tunnel raceway for the balls to circulate unlimitedly. The device has a through-hole formed within the wall of the nut for the balls to circulate from one end of the helical groove to the other end, the through-hole having a guidepath on either end of the helical groove to feed the balls into the tunnel raceway. Means are provided between the helical groove on one end face of the nut and the helical groove on the screw axis to prevent the balls from exiting either helical groove.

Owner:ABOM

Nut System and Aircraft Engine Mounting Structure Comprising Same

ActiveUS20080232924A1Satisfy securitySatisfactory reliabilityDrilling rodsPower plant constructionEngine mountScrew axis

The invention relates to a nut system (100) comprising a nut (104) provided with a main thread (106) with pitch p1 and arranged along a screwing axis (108) of the nut. According to the invention, it also comprises a threaded device (116) coupled in rotation with the nut, this threaded device comprising a secondary non-screwed thread (122) on the main thread (106) from which it is separated, the secondary thread being arranged along the screwing axis and having a pitch p2 different from p1. Application of the invention with a device for resistance of thrusts generated by an aircraft engine.

Owner:AIRBUS OPERATIONS (SAS)

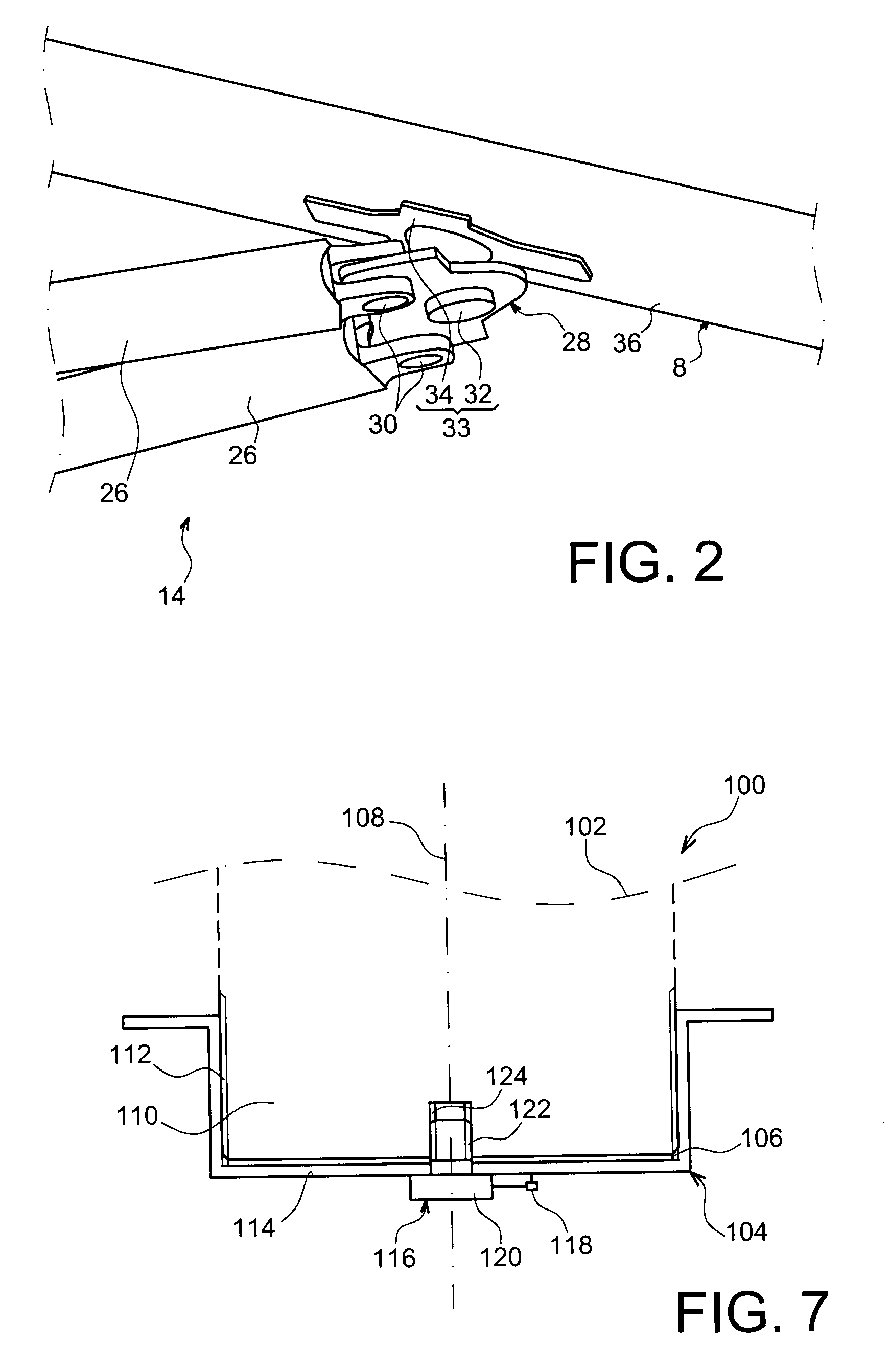

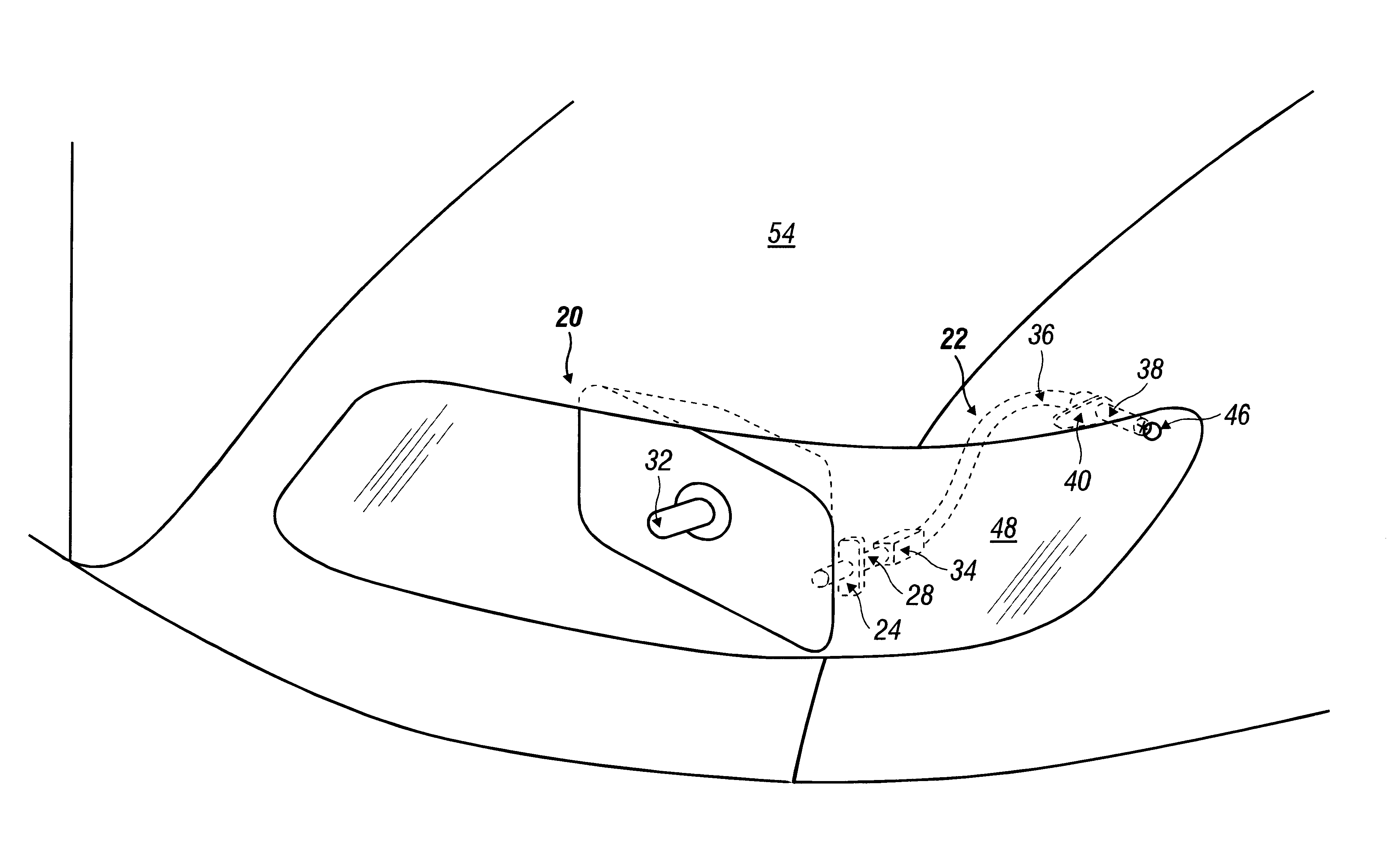

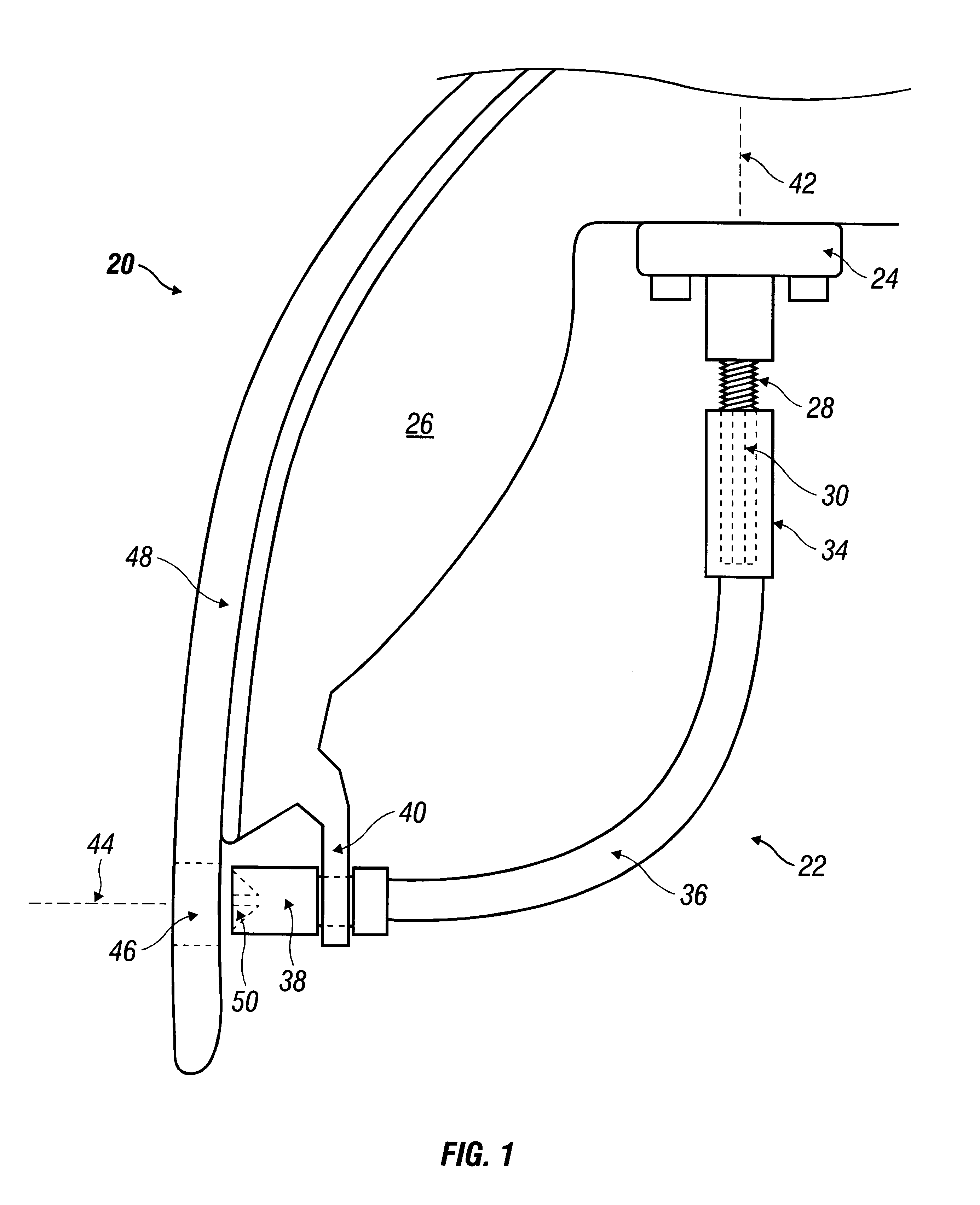

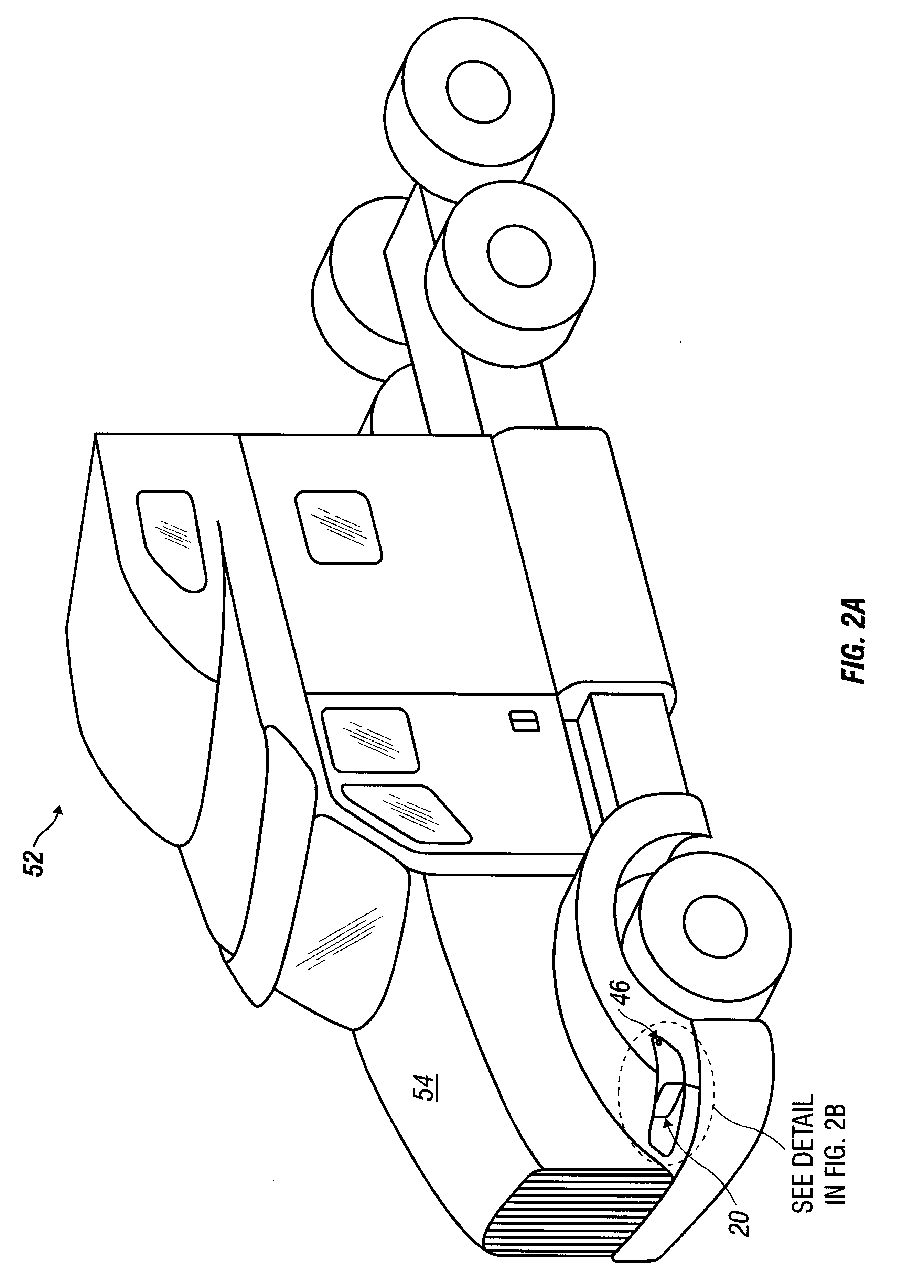

Remote headlamp adjustment system

A remote headlamp adjustment system comprises a headlamp adjustment mechanism attached to a headlamp housing. The headlamp adjustment mechanism is adapted to adjust an aim of a headlamp relative to the headlamp housing. An adjustment screw protrudes from the adjustment mechanism to a terminal screw head. The screw is adapted to control a tilt movement for the aim of the headlamp. The screw has a screw axis along a longitudinal extent of the screw that the screw rotates about when the headlamp aim is being adjusted using the adjustment mechanism. A flexible shaft has first and second shaft ends. The first shaft end is rotatably connected to the screw head such that a rotation of the shaft actuates a rotation of the screw about the screw axis. The shaft has first and second shaft axes that portions of the shaft rotate about when the headlamp aim is being adjusted using the adjustment mechanism. The first shaft axis projects from the first end and substantially aligns with the screw axis. The second shaft axis projects from the second shaft end and the second shaft axis does not axially align with the first shaft axis. A clip protrudes from the headlamp housing. The second shaft end interlocks within the clip such that the clip retains a position of the second shaft end relative to the clip and relative to the adjustment mechanism, but the clip also allows the second shaft end to rotate within the clip about the second shaft axis.

Owner:PACCAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com