Bogie lifting device

A technology of lifting frame and rotating sleeve, which is applied in the direction of transportation and packaging, load hanging components, etc. It can solve the problems of inconvenient maintenance, difficulty in moving and flipping, and narrow application area, and achieves wide application range, accurate positioning, and simple and convenient structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

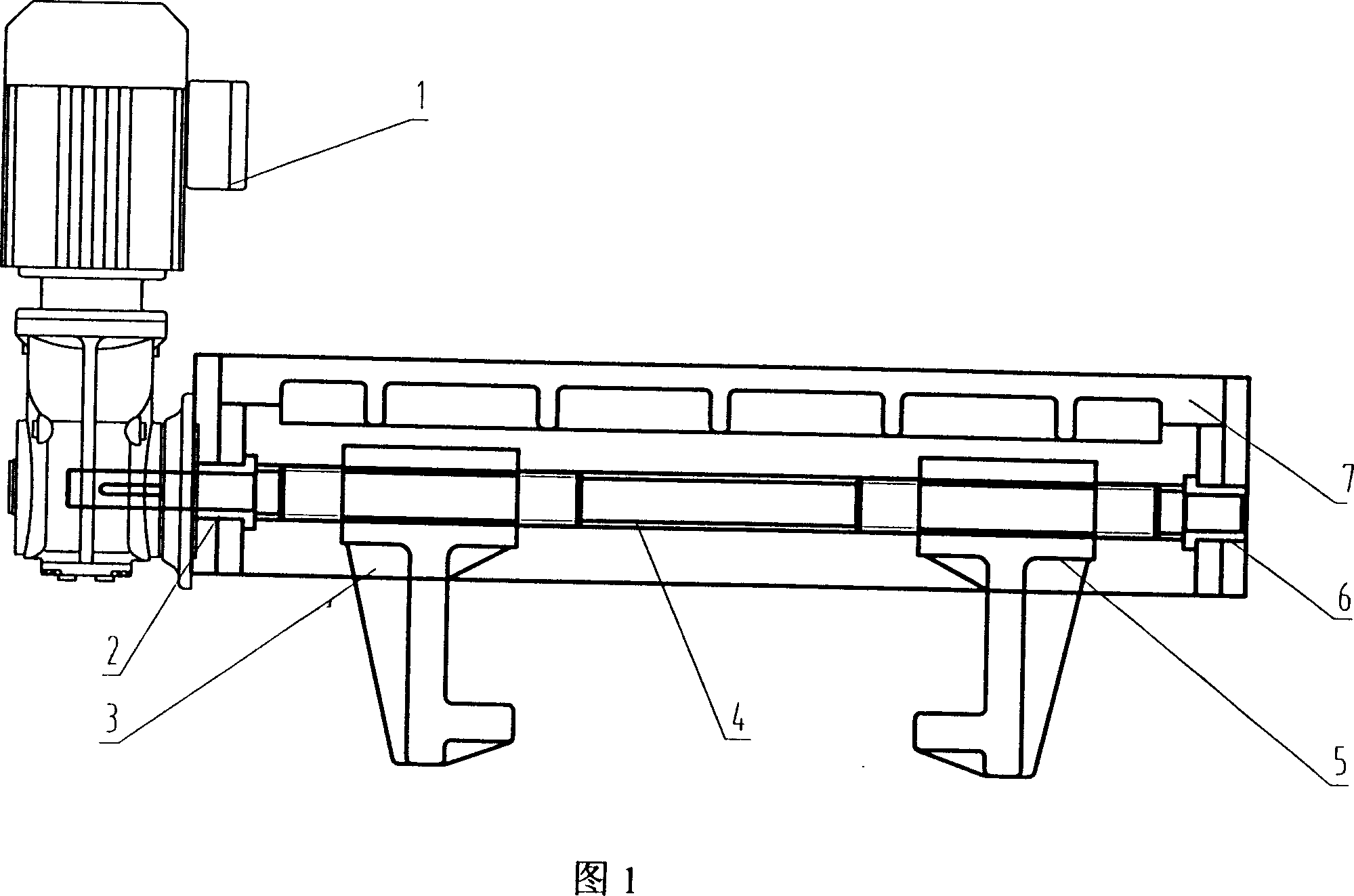

[0009] Referring to accompanying drawing 1, its structure is that rotating motor 1 is connected with drive screw shaft 4 through key, and rotating motor 1 is connected with hoisting frame 7 by bolt and is fixed on the hoisting frame 7, and driving screw shaft 4 is rotated through the left sleeve. 2. The right rotation sleeve 6 is connected with the lifting frame 7. The transmission screw shaft 4 is threaded with the left claw 3 and the right claw 5. Because the transmission screw shaft 4 is connected with the rotary motor 1, and the left claw 3 and the right claw 5 are threadedly connected with the transmission screw shaft 4, the transmission screw shaft 4 is driven by the rotary motor 1 to rotate. Reversing can make the left claw 3 and the right claw 5 threadedly connected with the transmission screw shaft 4, so that the left and right claws 3 and 5 can be relatively closed or opened.

[0010] The left claw 5 and the right claw 6 are in the shape of hooks, which can fix the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com