Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2656results about "Discharging apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

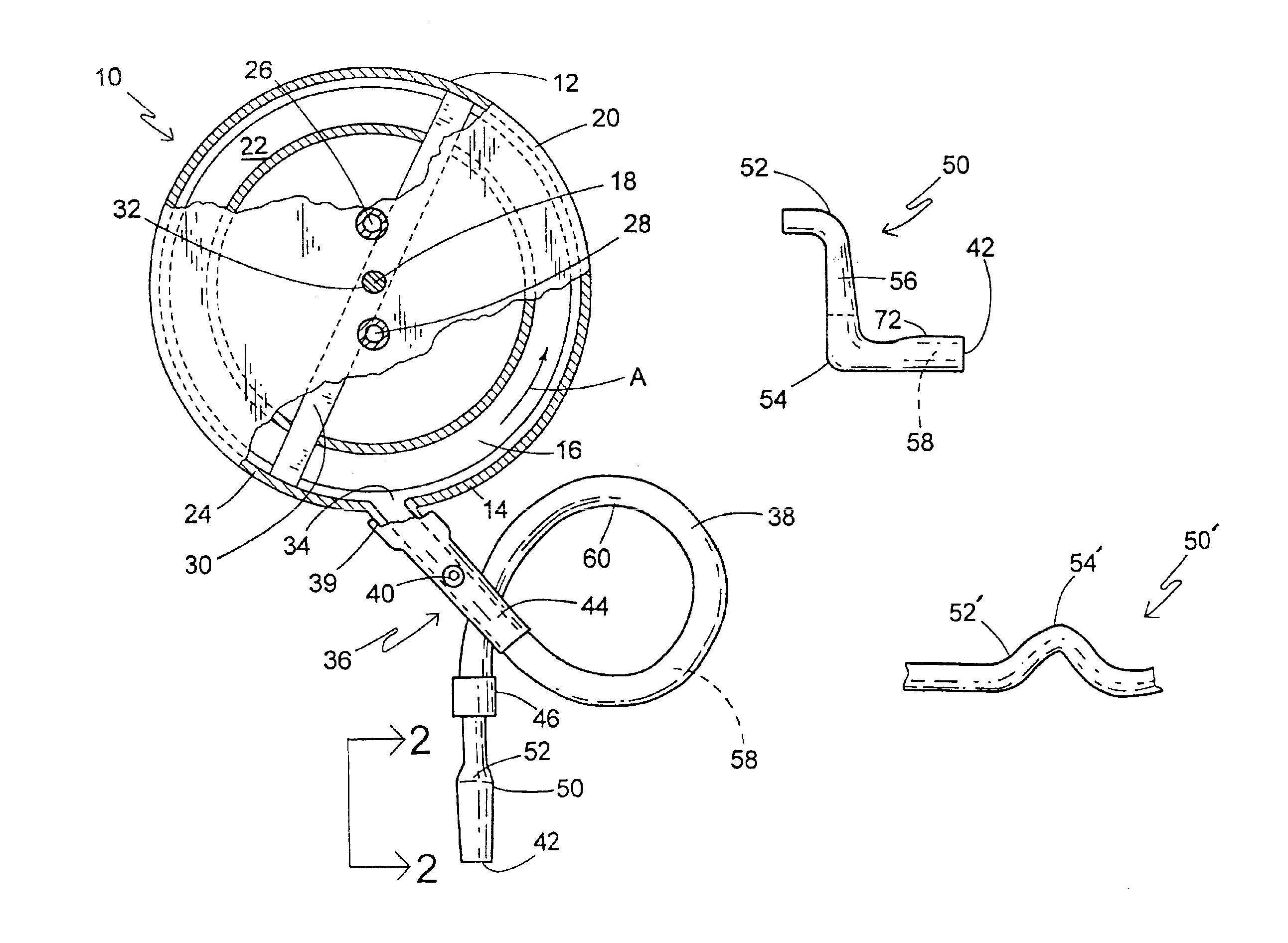

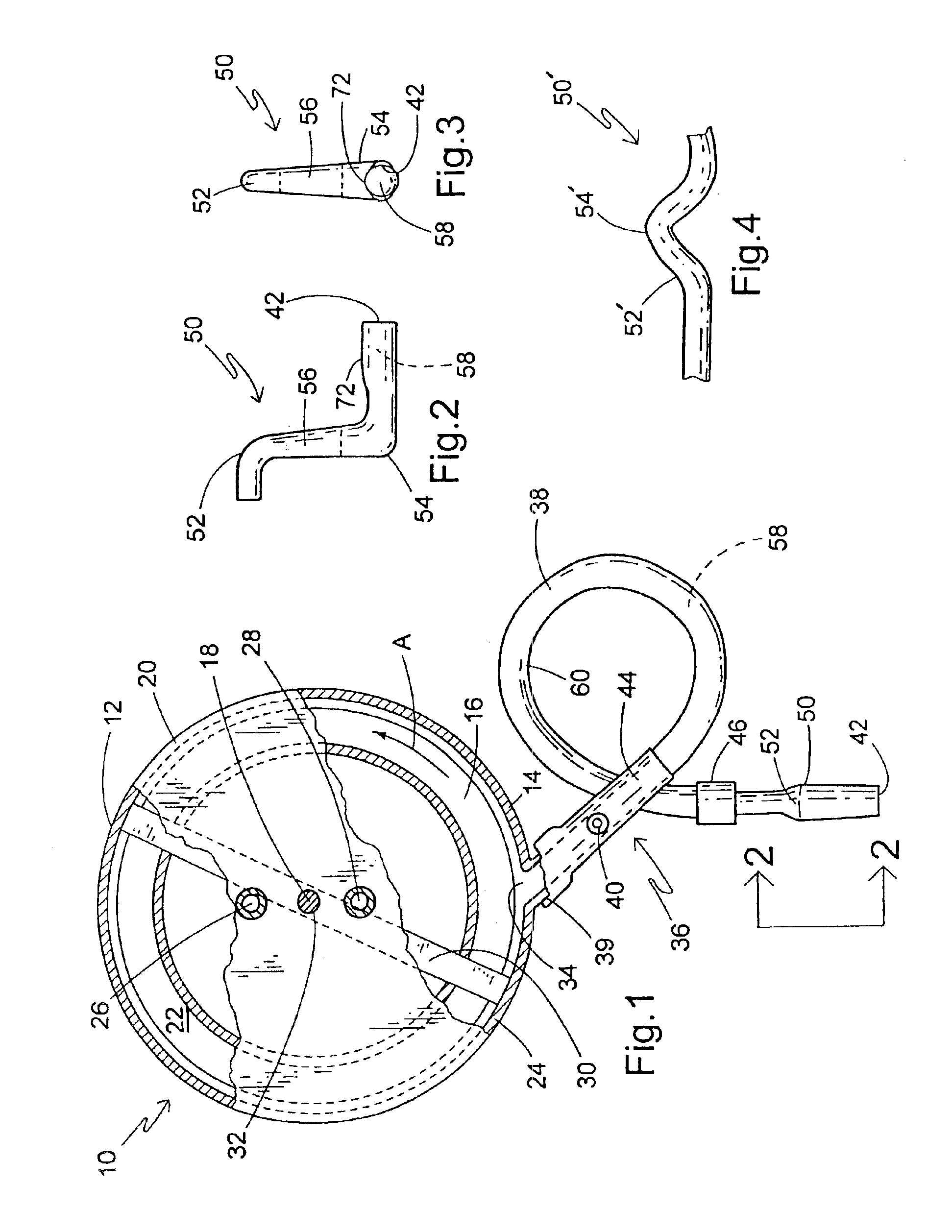

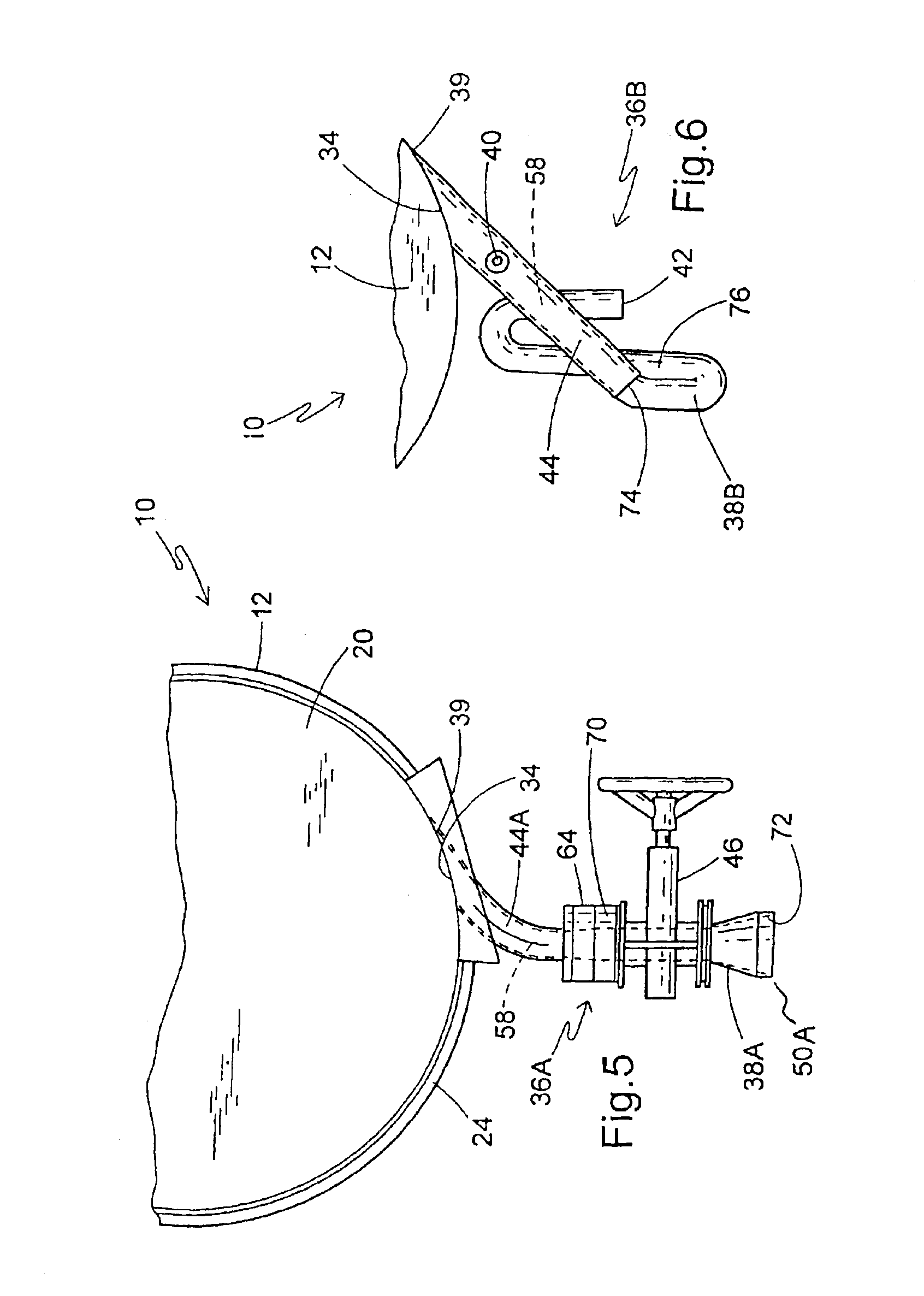

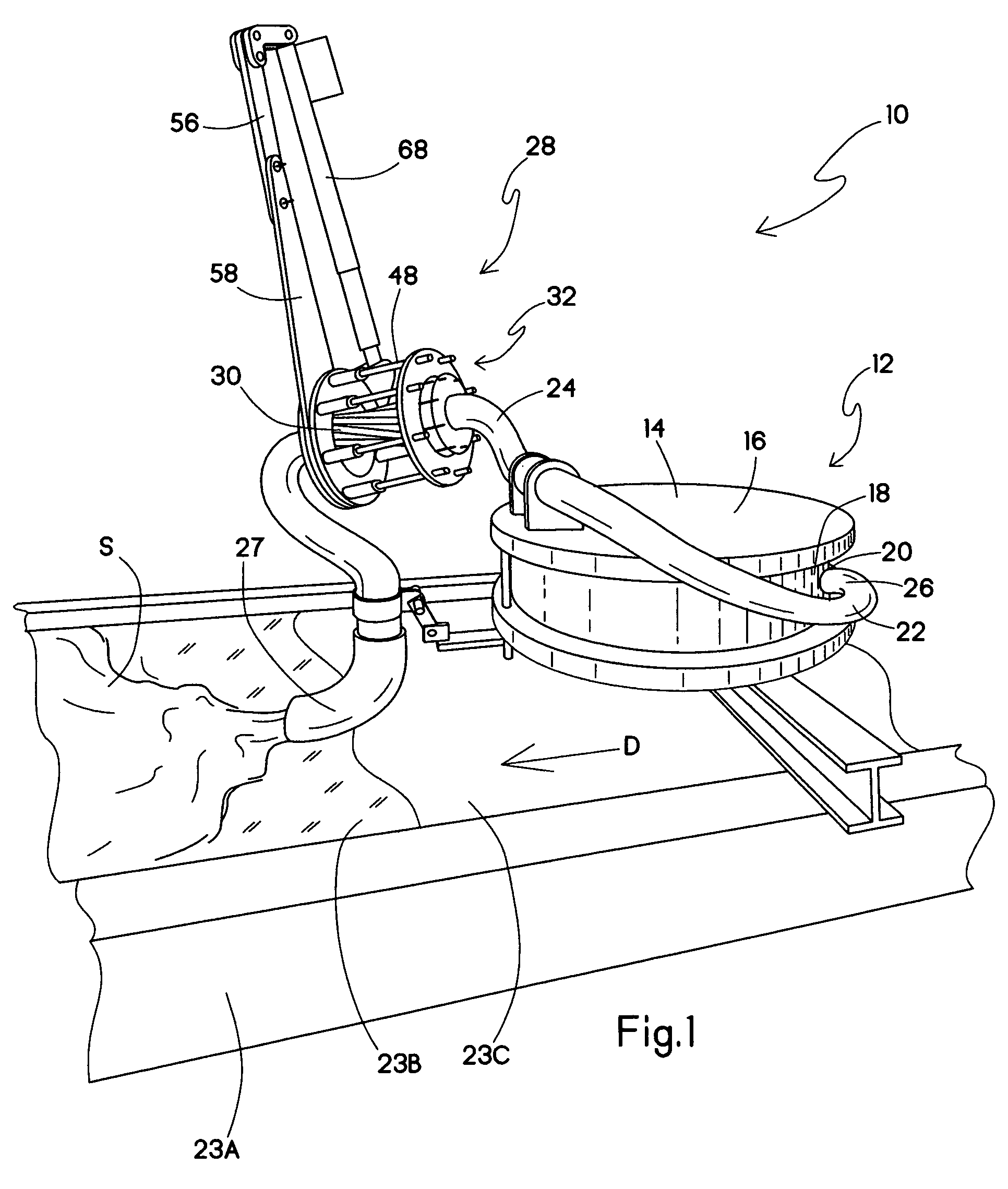

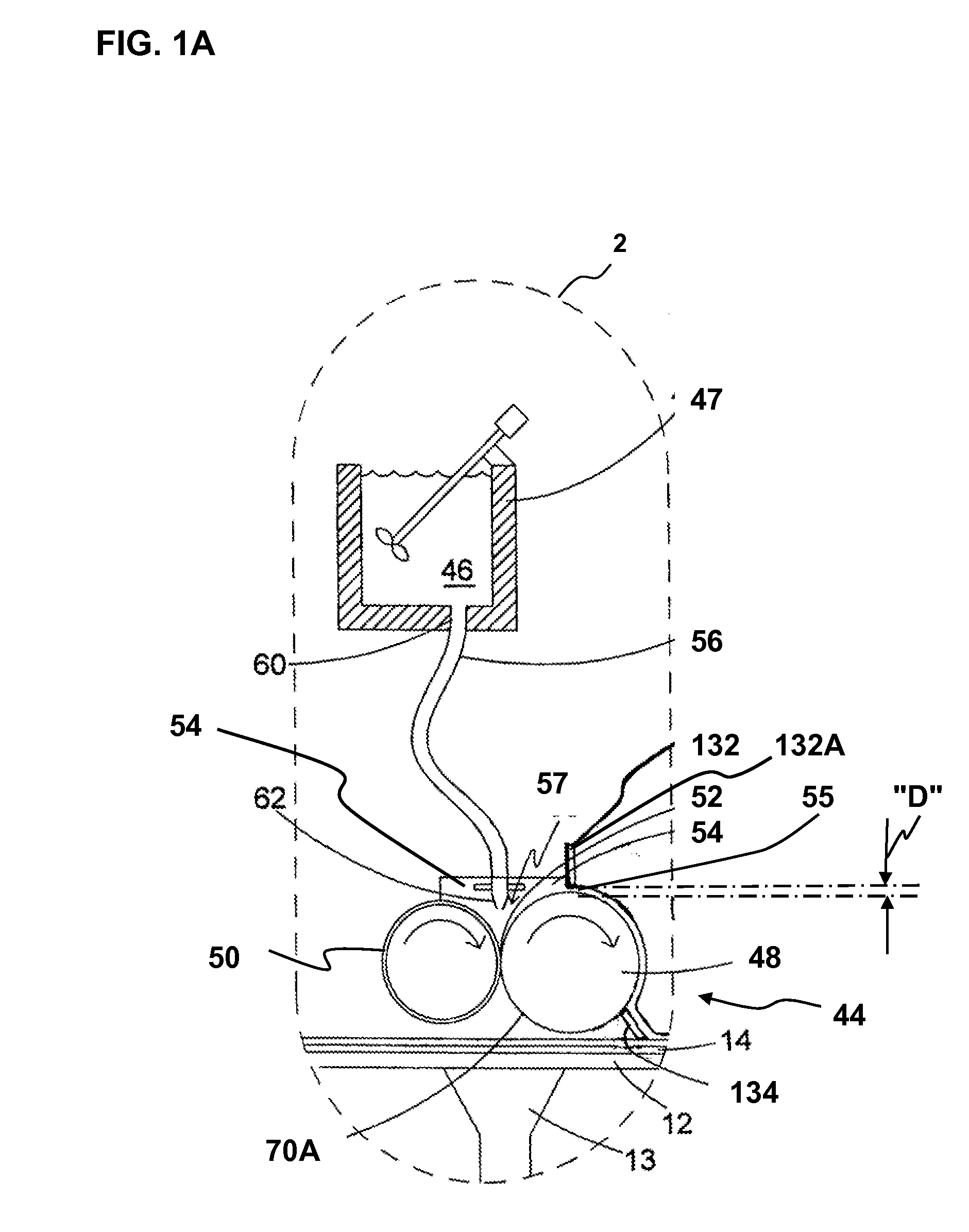

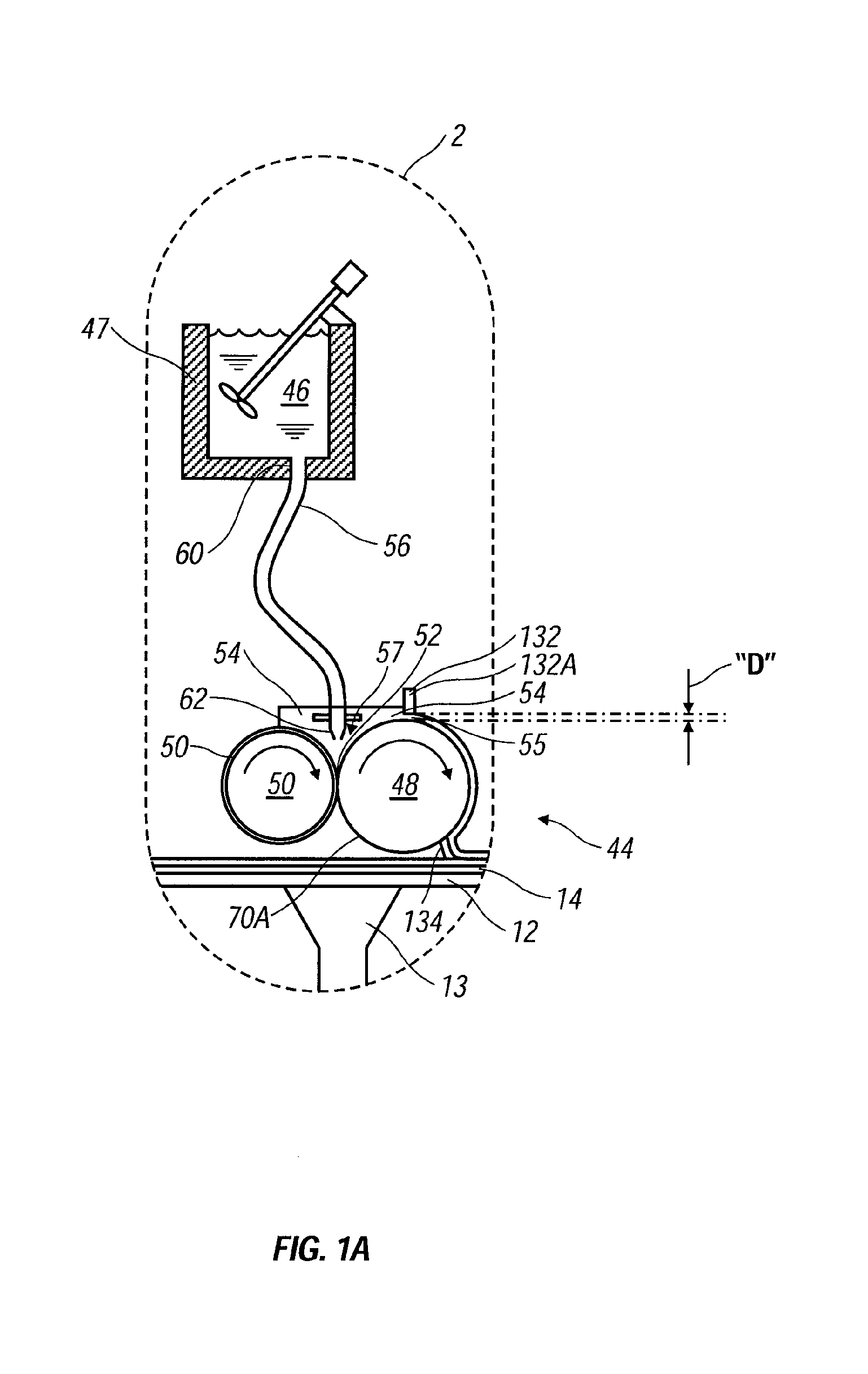

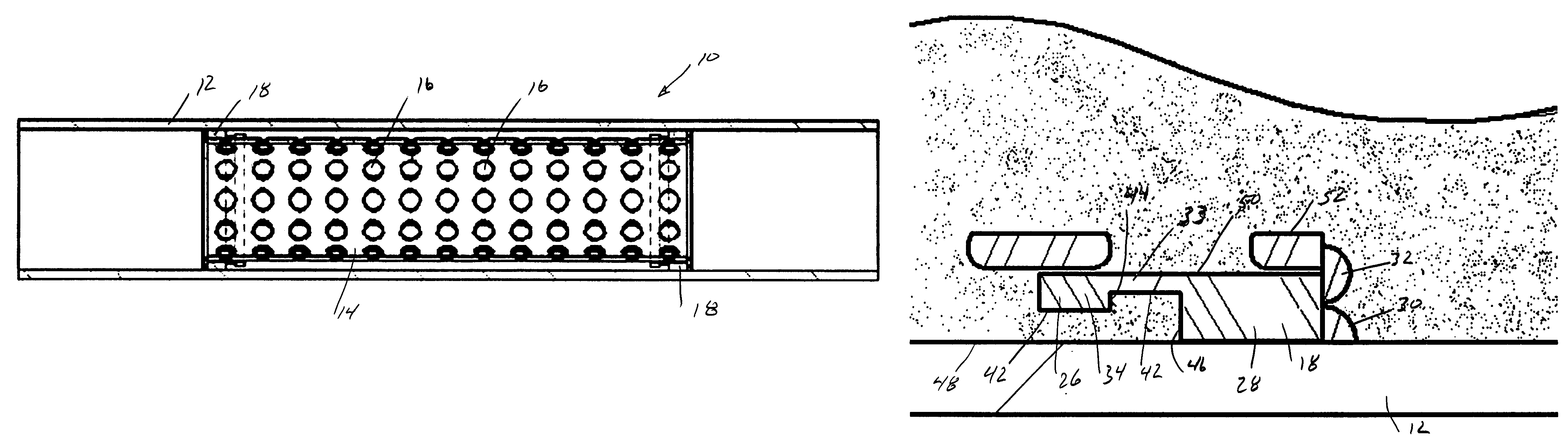

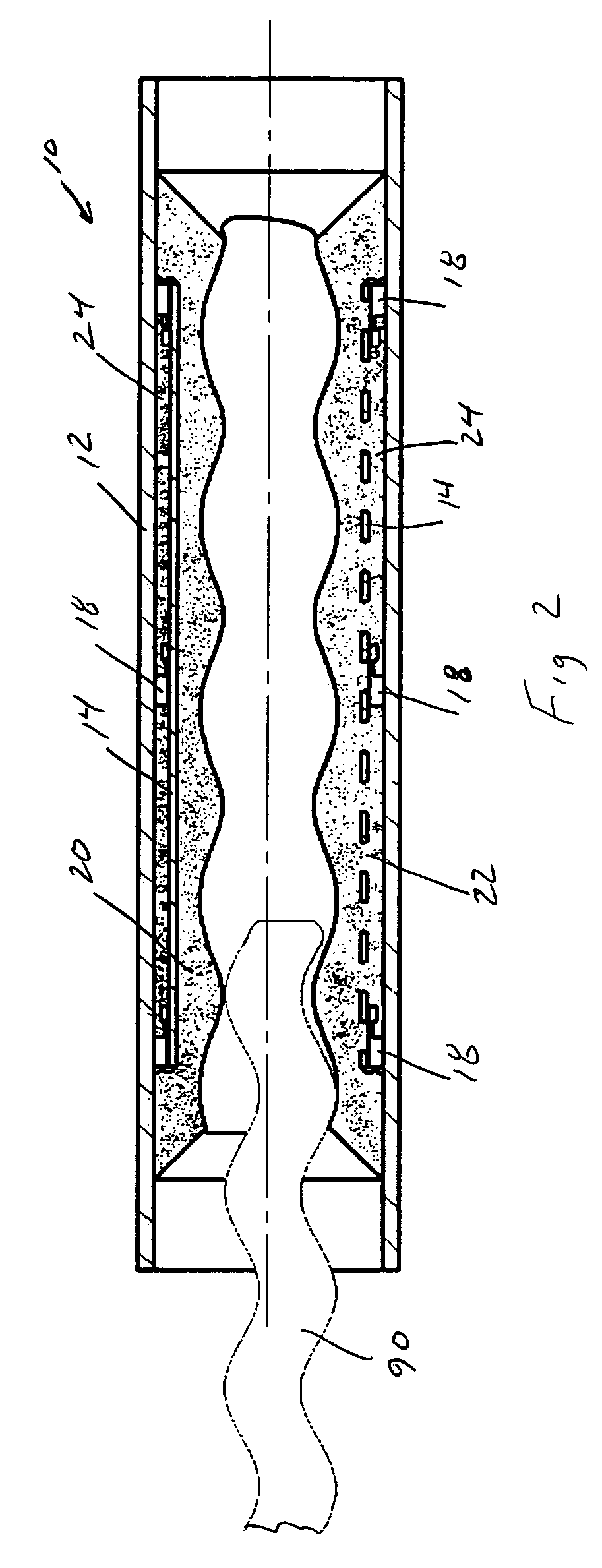

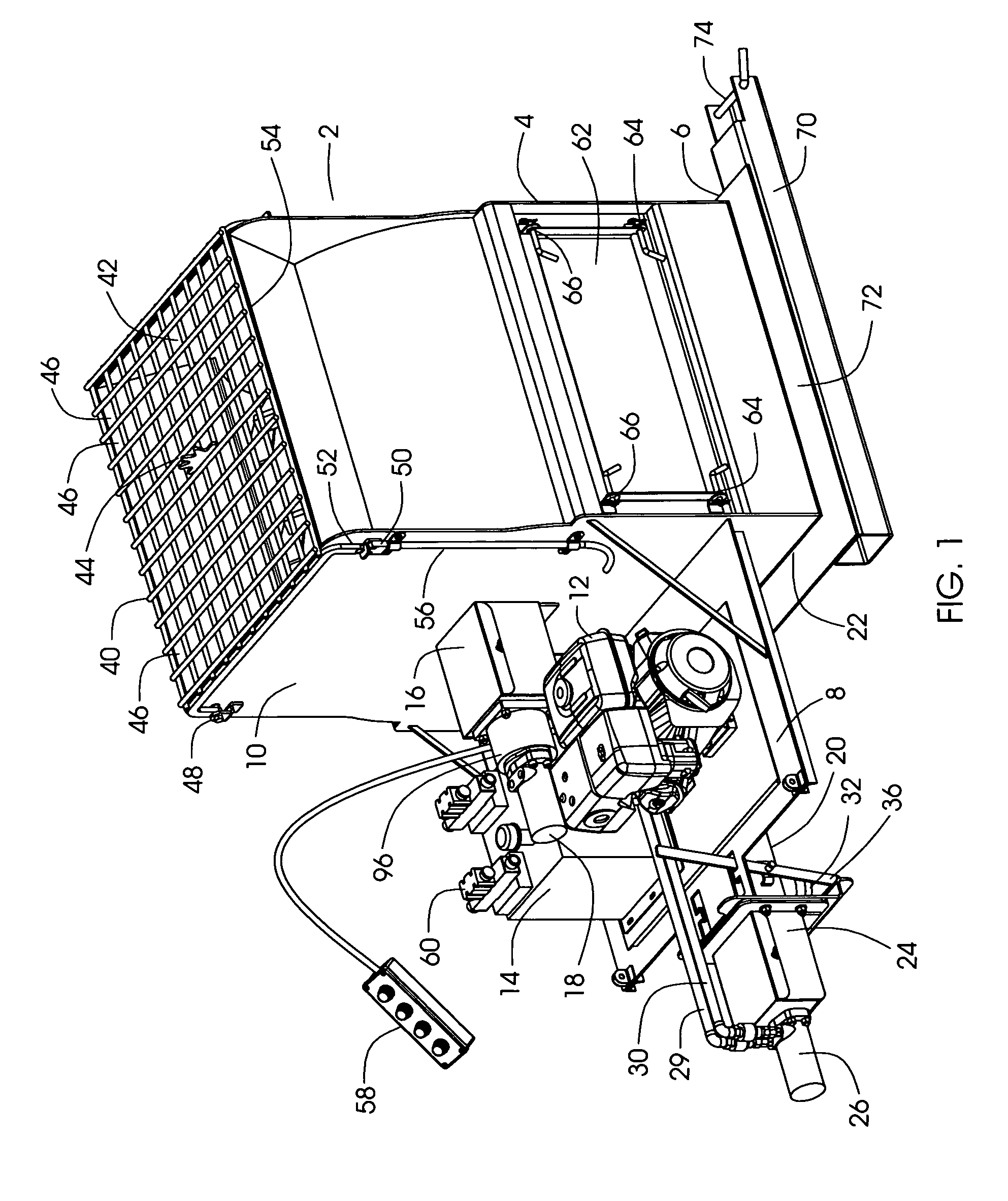

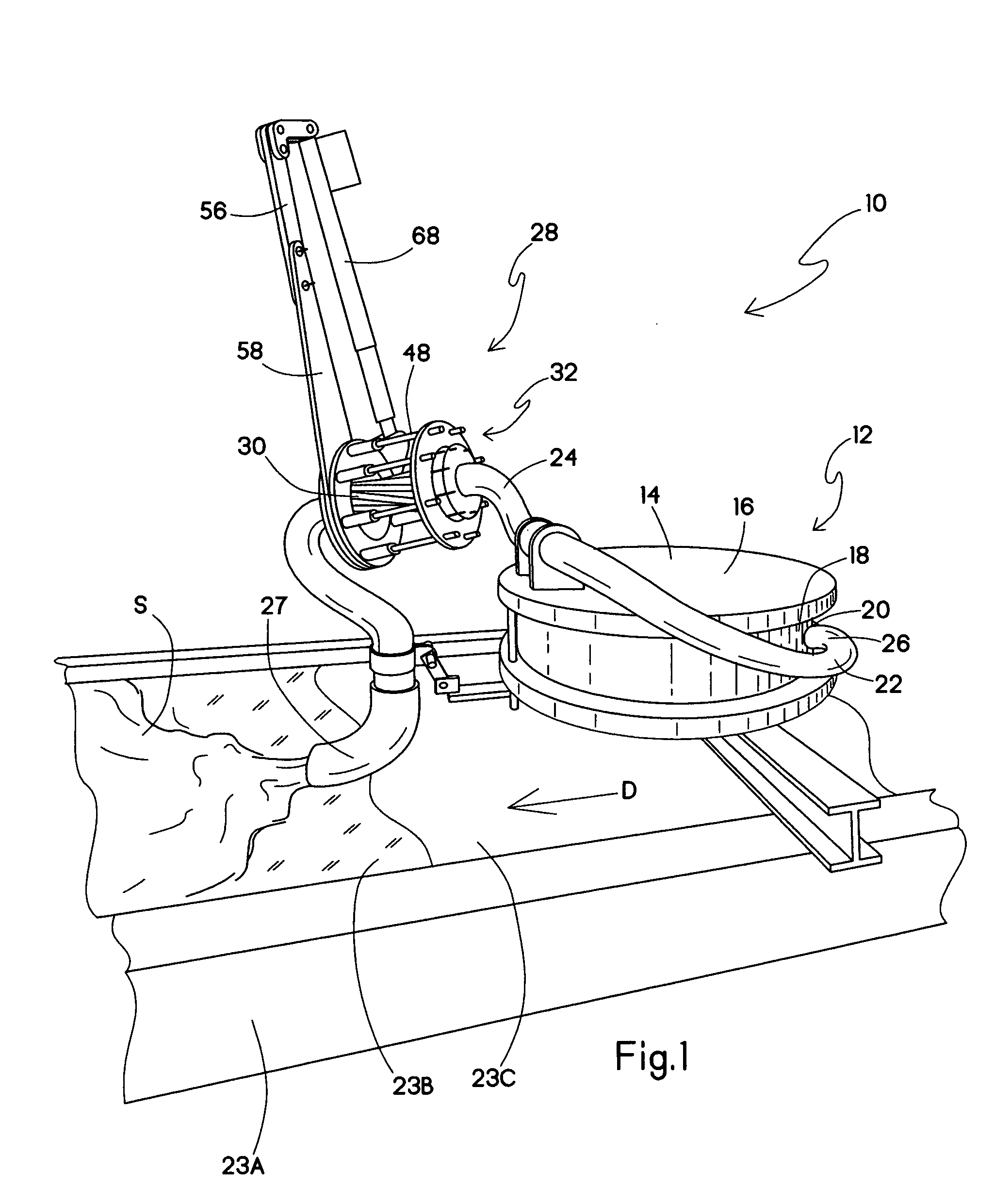

Slurry mixer outlet

InactiveUS6874930B2Unwanted premature setting is preventedReduce generationFlow mixersDischarging apparatusSlurryReducer

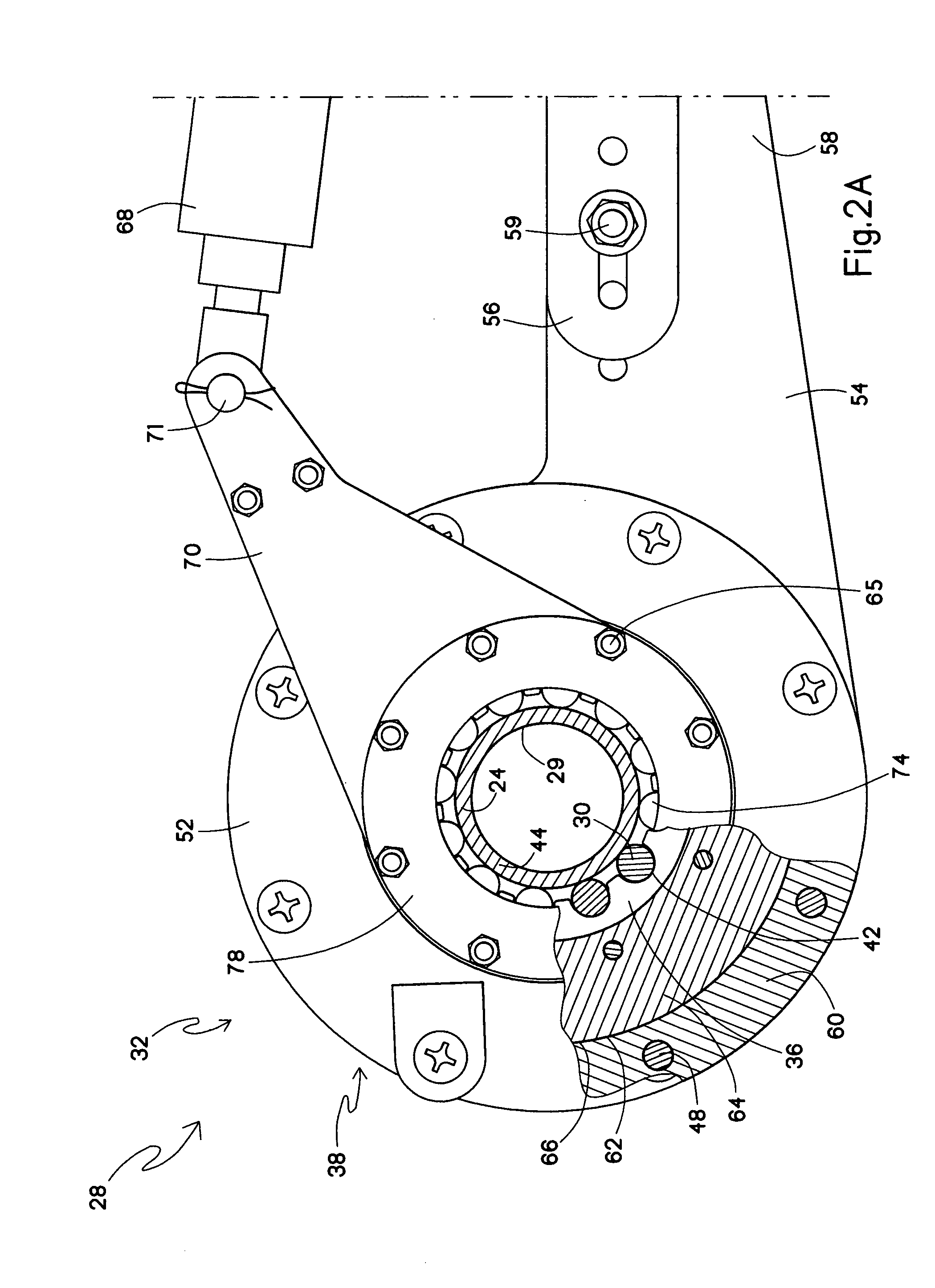

An apparatus configured for connection to a mixer for receiving a slurry and altering the flow characteristics of the slurry includes a conduit having a main inlet in slurry receiving communication with the mixer outlet and extending to a spout for discharging the slurry, at least one conduit restrictor associated with the conduit for creating back-pressure between the conduit restrictor and the mixer outlet for keeping the mixer full, and at least one pressure reducer associated with the discharge spout and configured for reducing the pressure of the slurry dispensed from the discharge spout. The apparatus is configured for maintaining a generally laminar flow from the mixer outlet to the discharge spout.

Owner:UNITED STATES GYPSUM CO

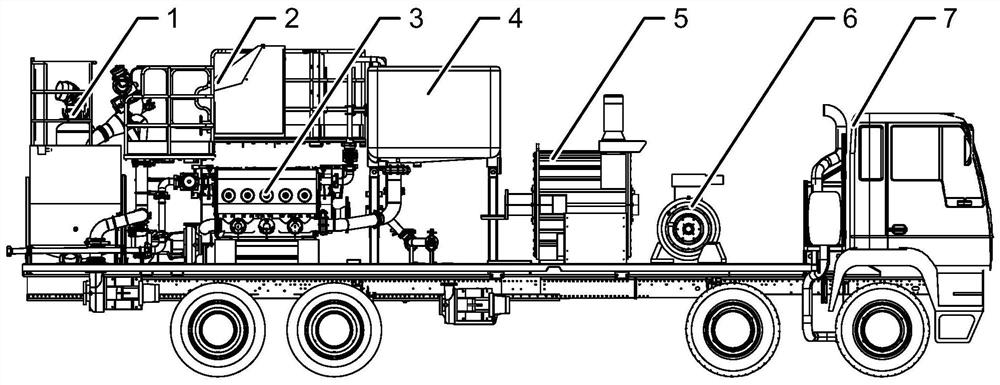

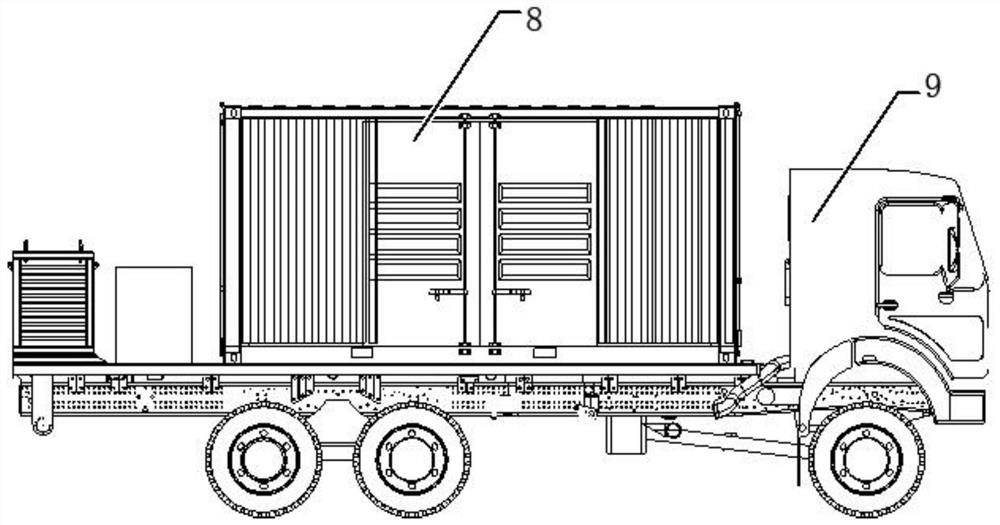

Electrically-driven ultra-large-displacement well cementation equipment

PendingCN111677476AIncrease layout spaceReduce dependenceDischarging apparatusPumpsConvertersFrequency changer

The invention discloses electrically-driven ultra-large-displacement well cementation equipment. The electrically-driven ultra-large-displacement well cementation equipment comprises a first loading body and a second loading body; an auxiliary motor, a main motor, a clear water module, a pumping module, a control module, a hydraulic module and a mixing module are fixedly loaded on the first loading body; and a frequency converter module is fixedly loaded on the second loading body. The electrically-driven ultra-large-displacement well cementation equipment has the beneficial effects that the main motor is adopted to drive a plunger pump, torque converters are reduced, the layout space of the whole vehicle is increased, the auxiliary motor is adopted to drive a whole vehicle hydraulic system, and the number of driving motors is reduced; the frequency converter module and the well cementation equipment are loaded separately, the loading requirement is lowered, the structure is simpler, the occupied space is reduced, one frequency converter module can supply power to all the modules on the multiple first loading bodies at the same time, and use is flexible; and the main motor, the auxiliary motor and the hydraulic heat dissipation device are intensively distributed on the front portion of the first loading body, wiring is simple, connection is convenient, heat dissipation of equipment is intensively achieved, scalding accidents of workers in the operation process are avoided, and operation safety is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Slurry mixer constrictor valve

ActiveUS7007914B2Increase volumePrevent premature solidificationDiaphragm valvesEngine diaphragmsSlurryEngineering

Owner:UNITED STATES GYPSUM CO

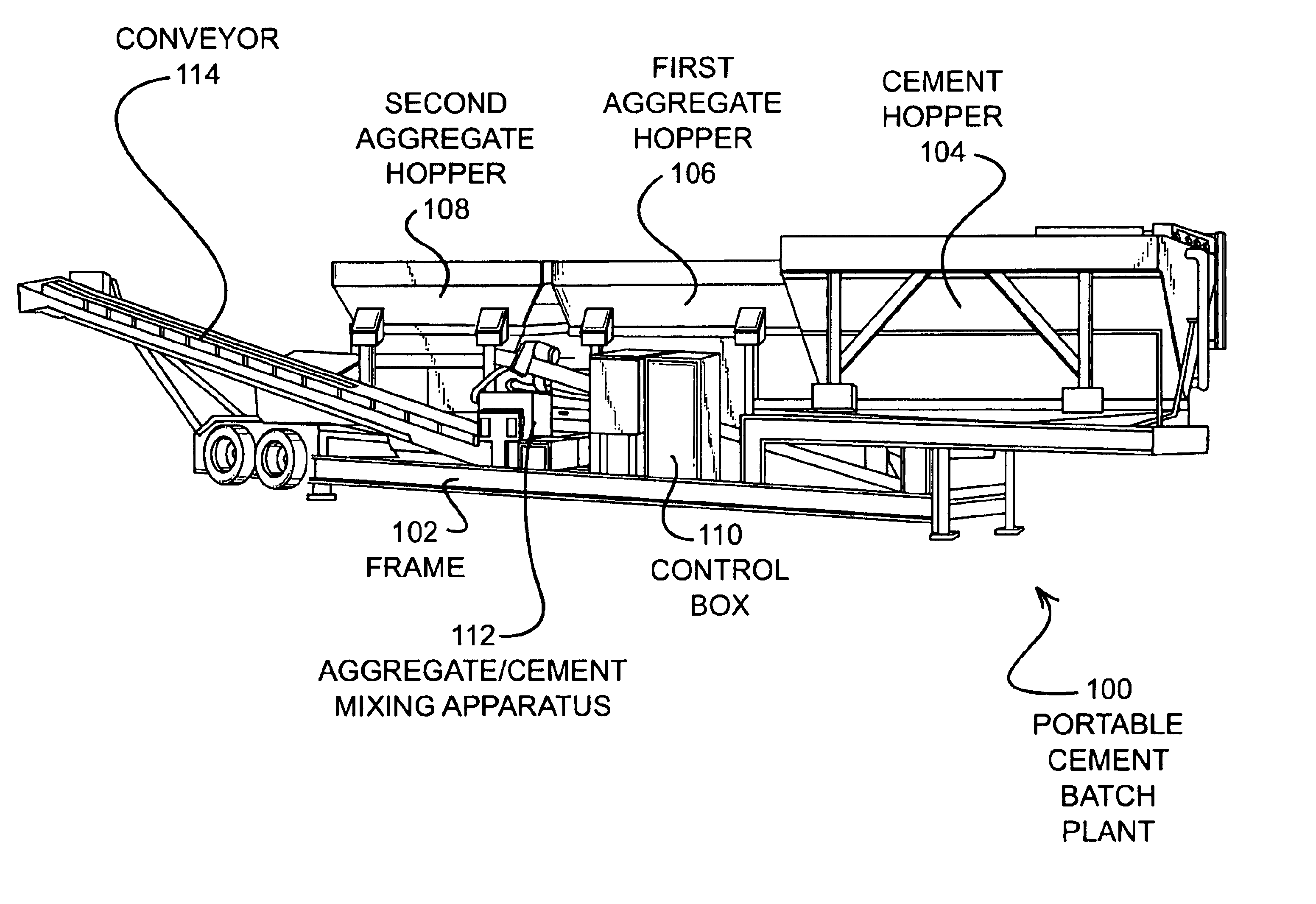

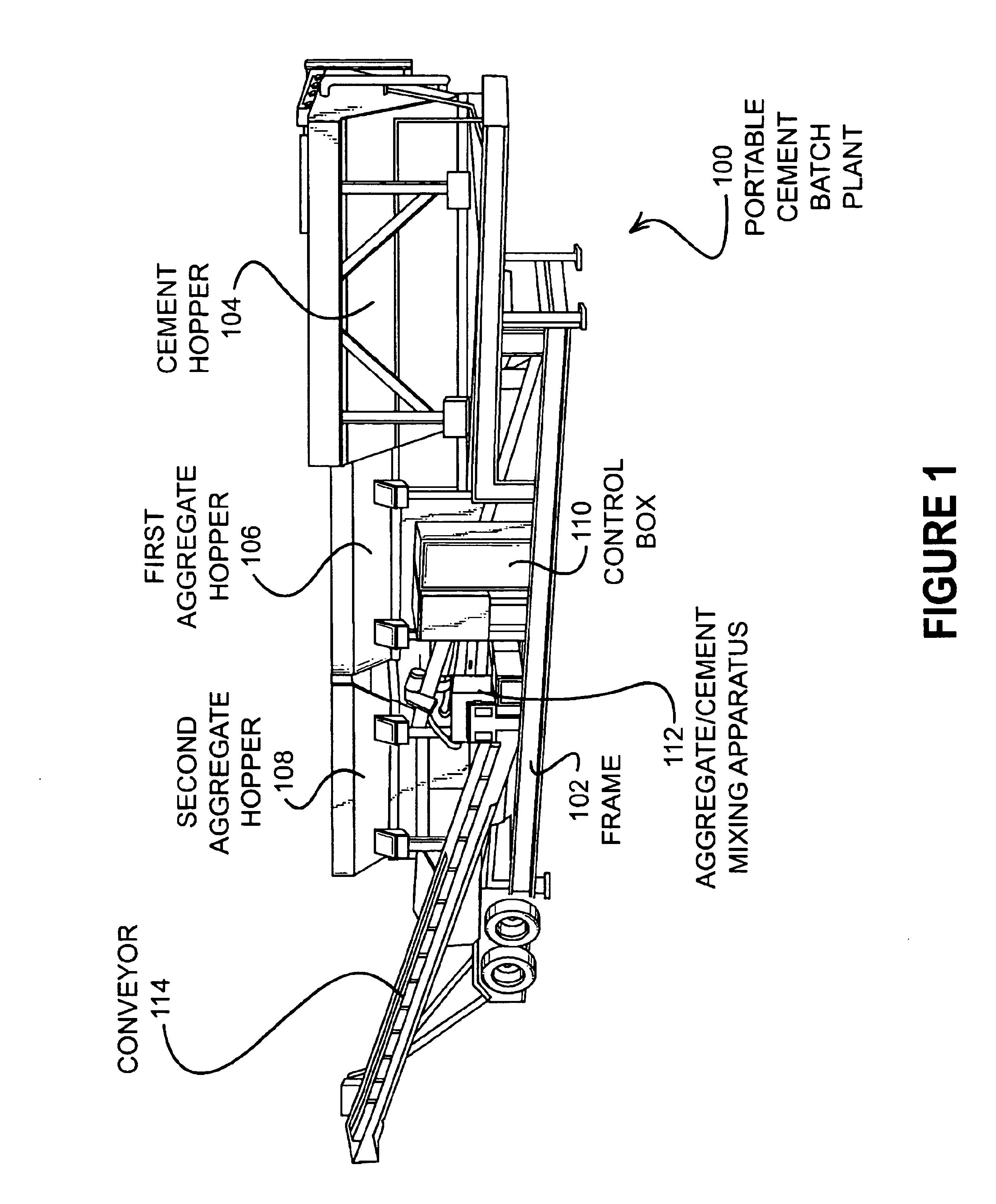

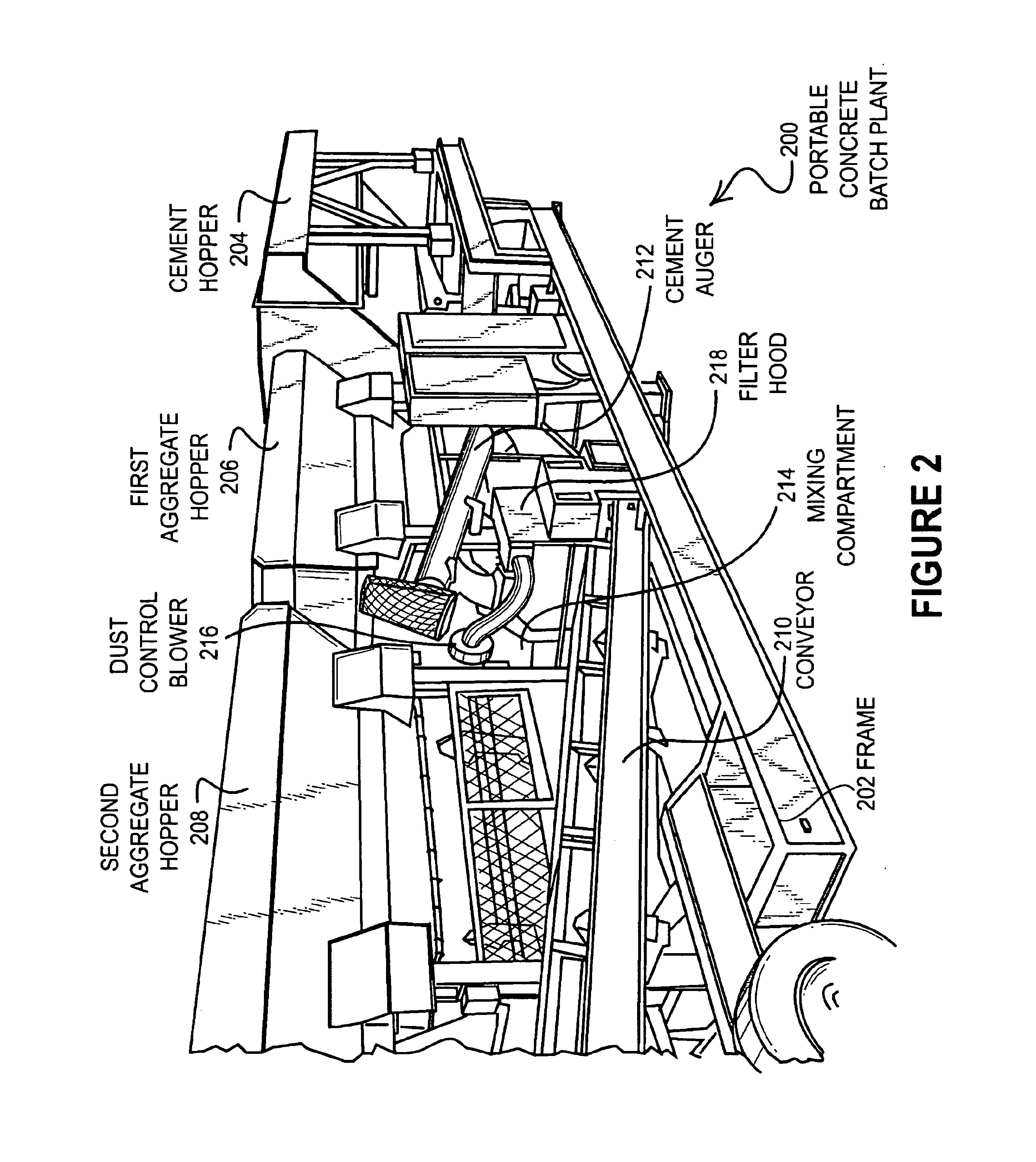

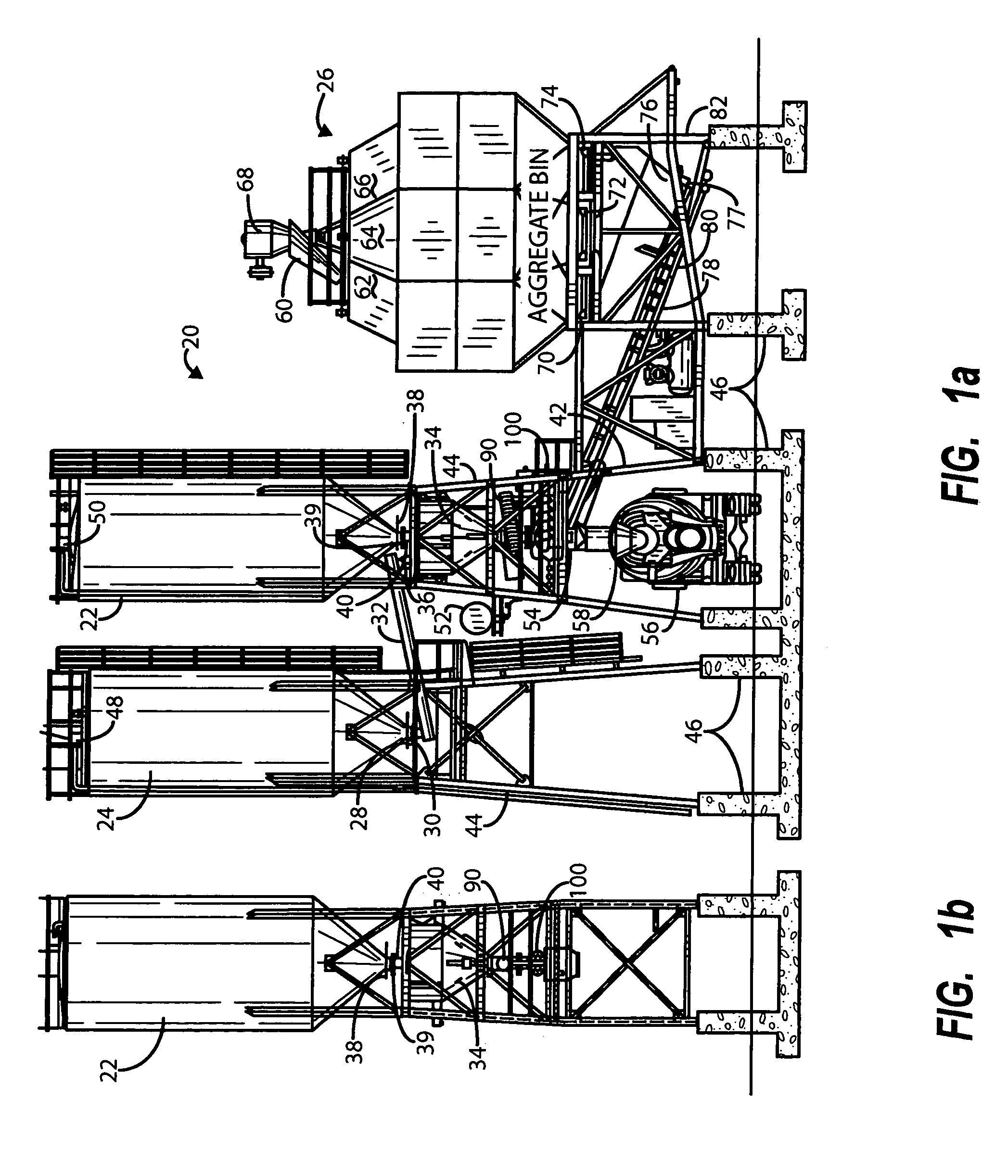

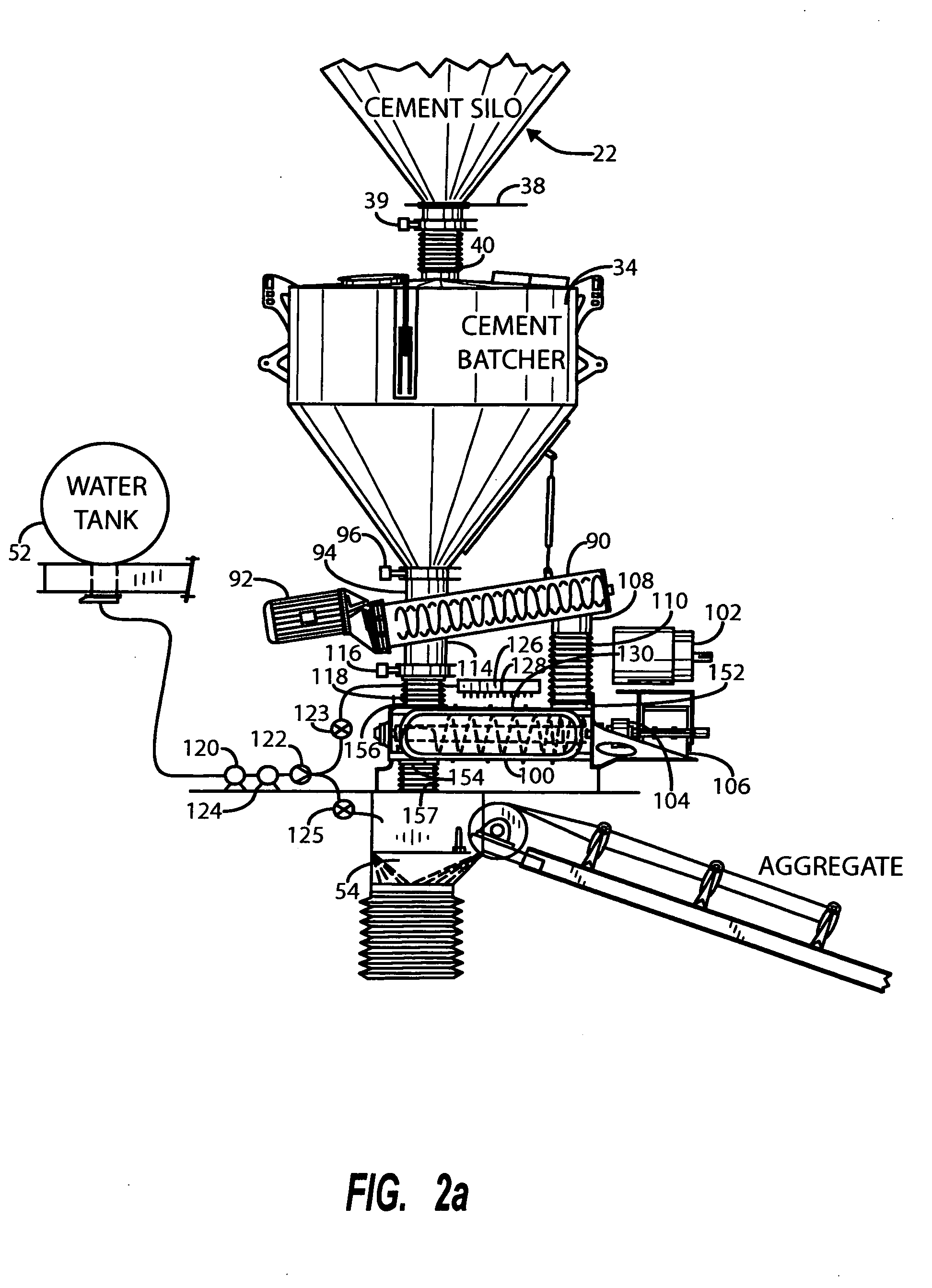

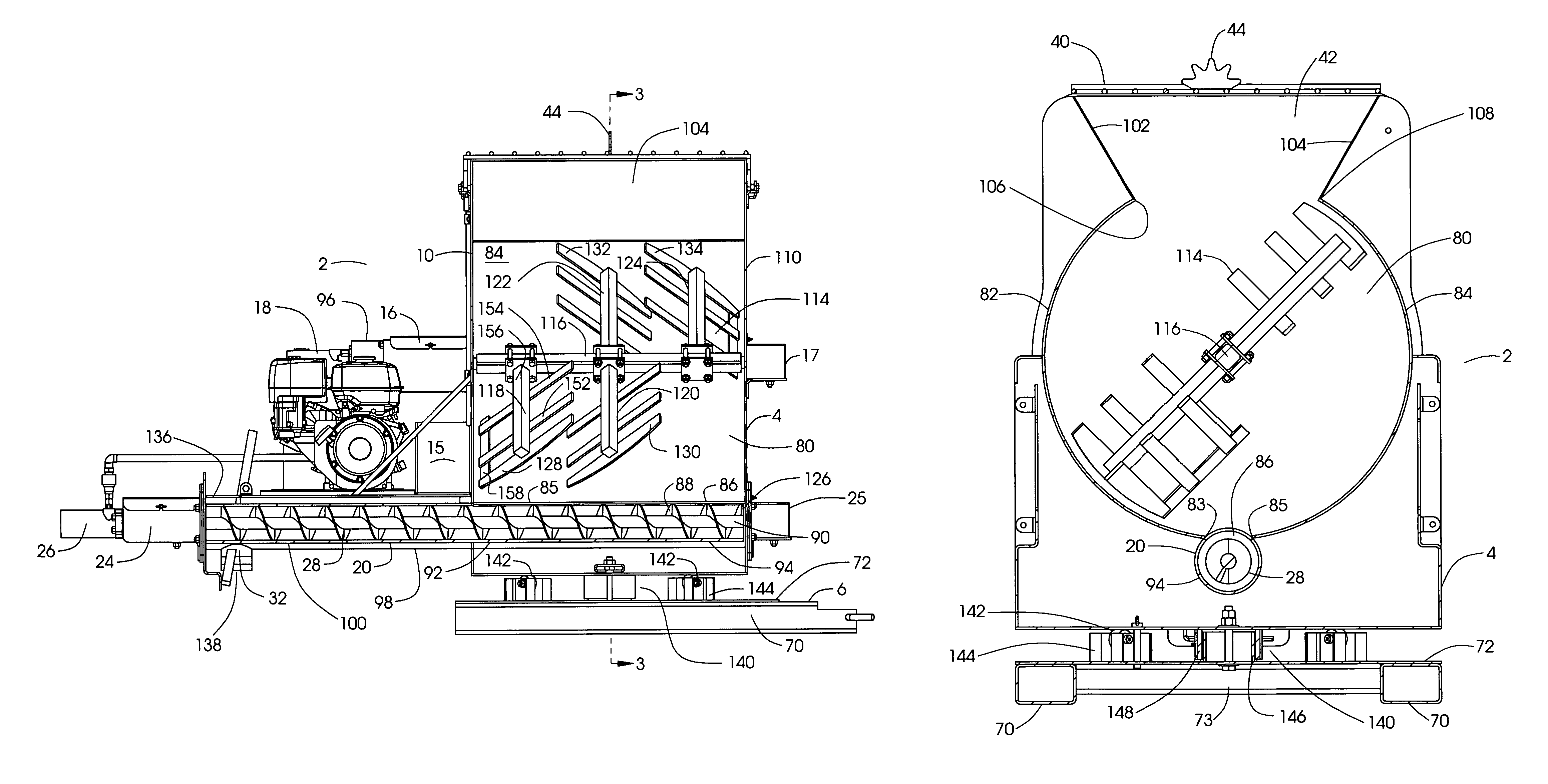

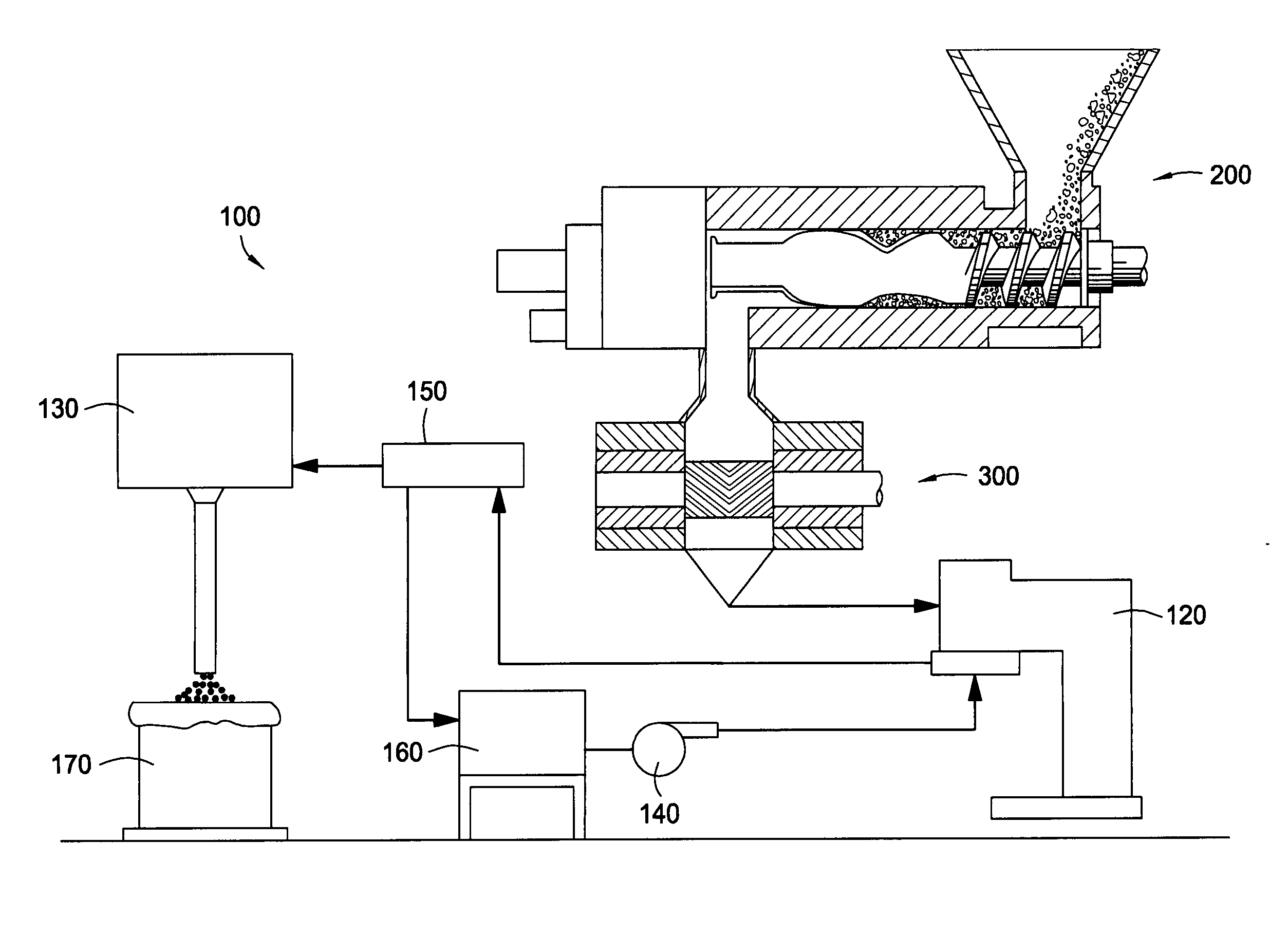

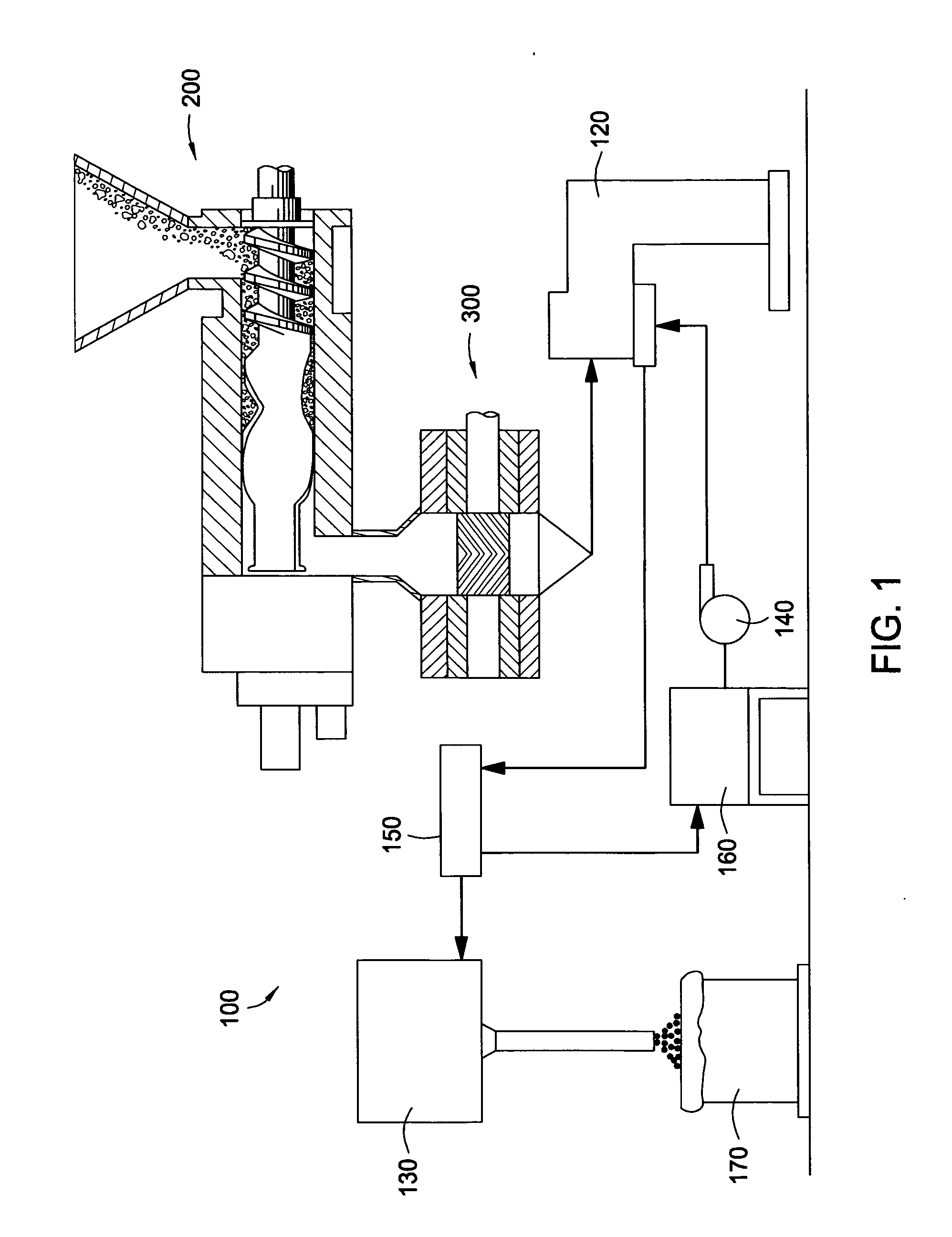

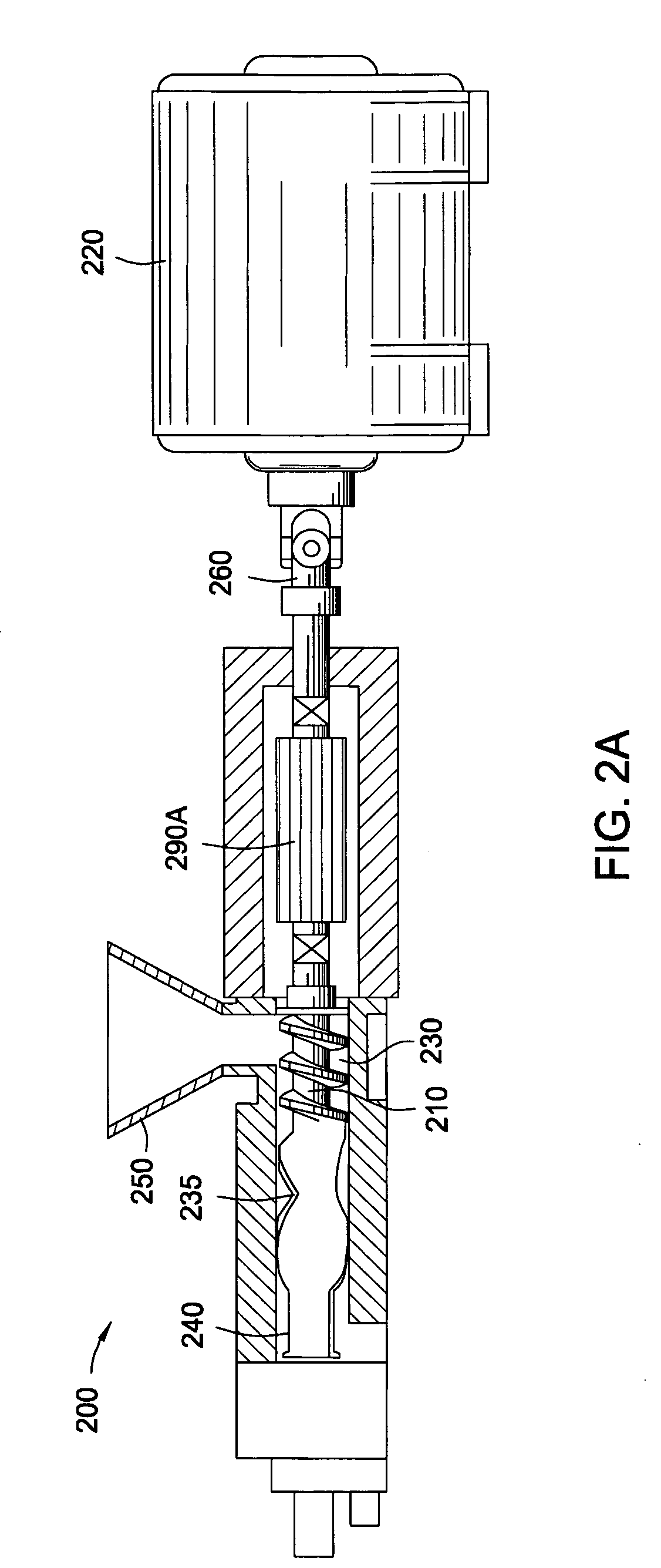

Portable concrete plant dispensing system

ActiveUS6876904B2Dispensed more accuratelyGood repeatabilitySampled-variable control systemsDischarging apparatusDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

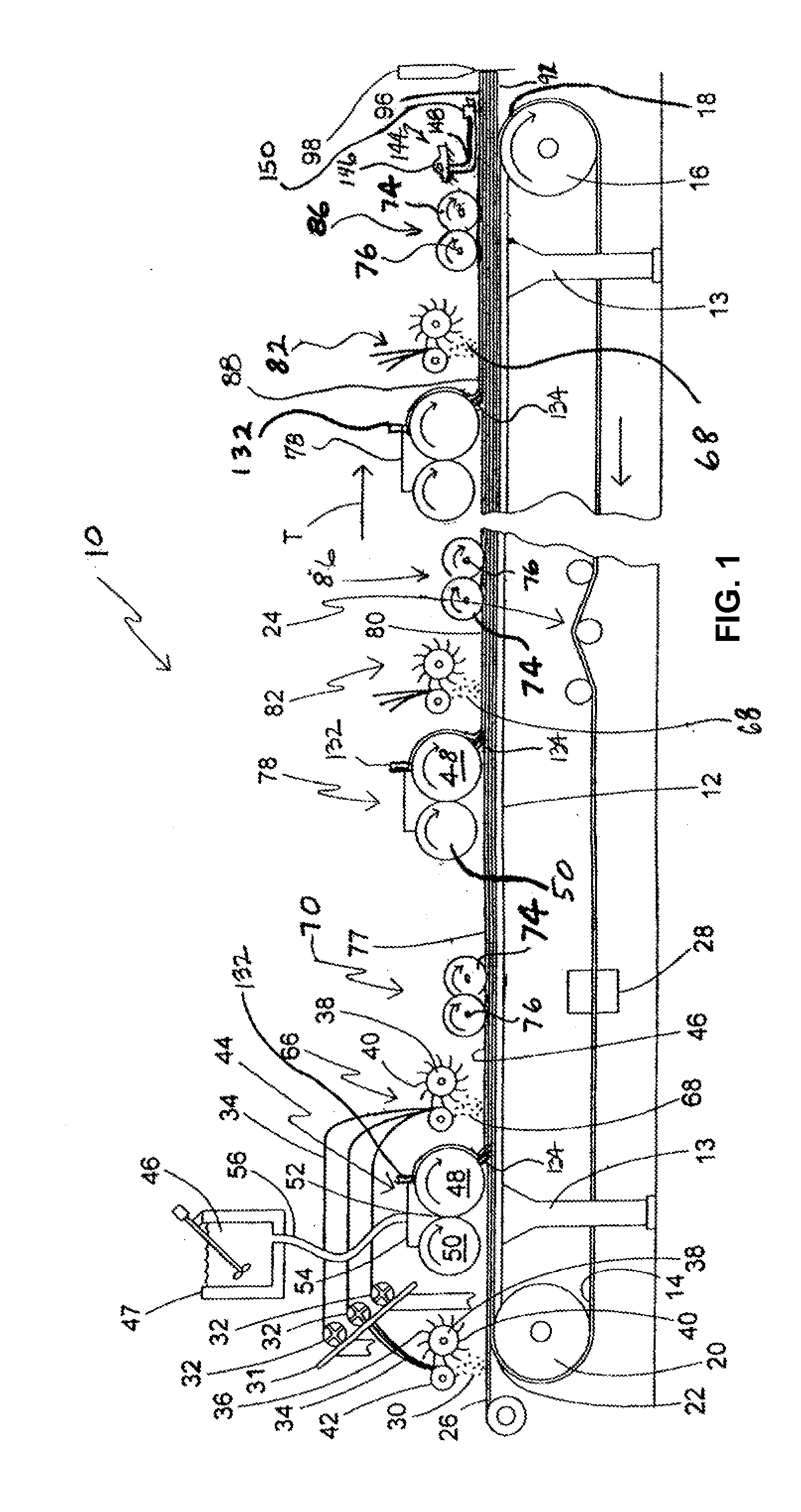

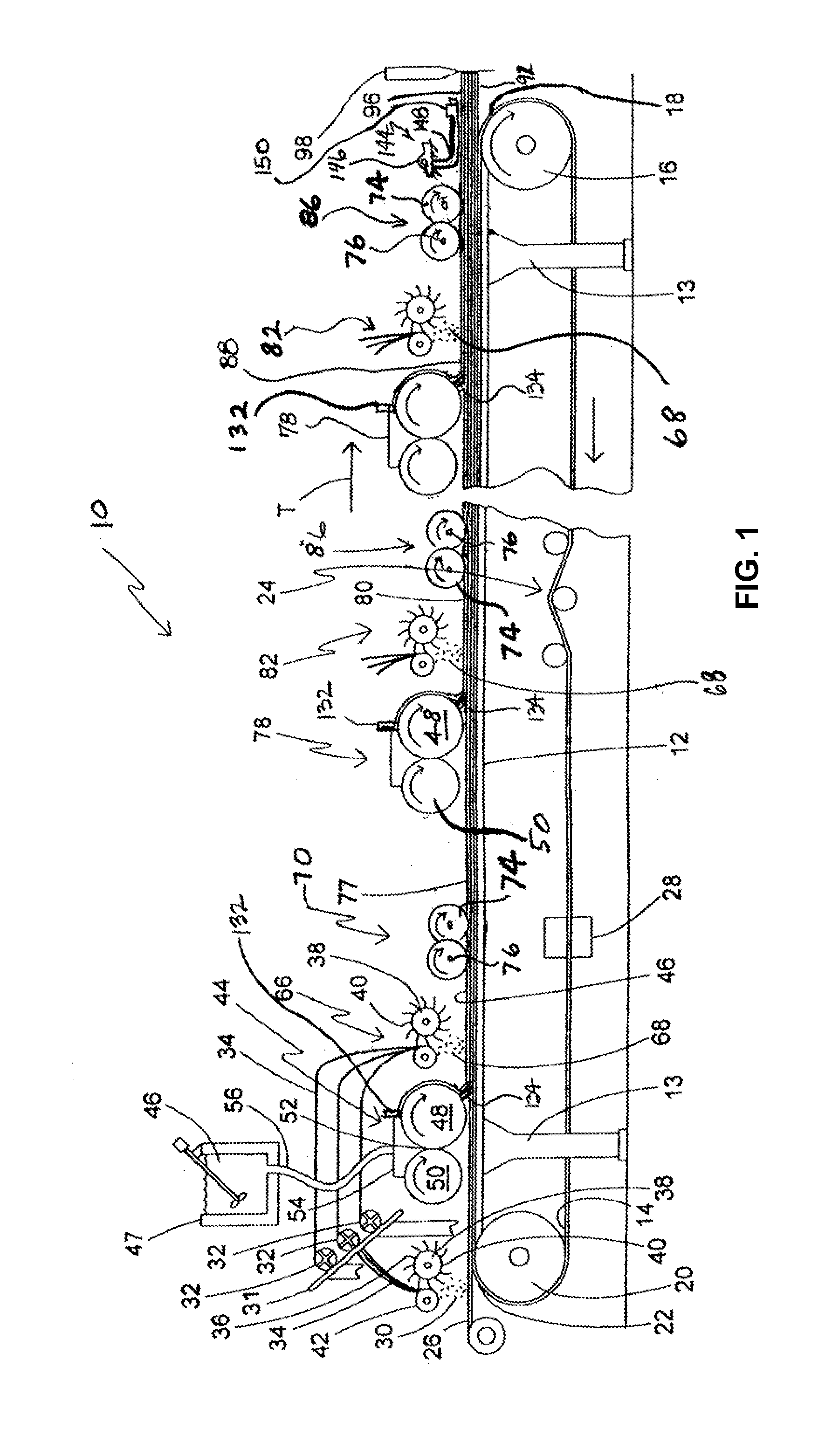

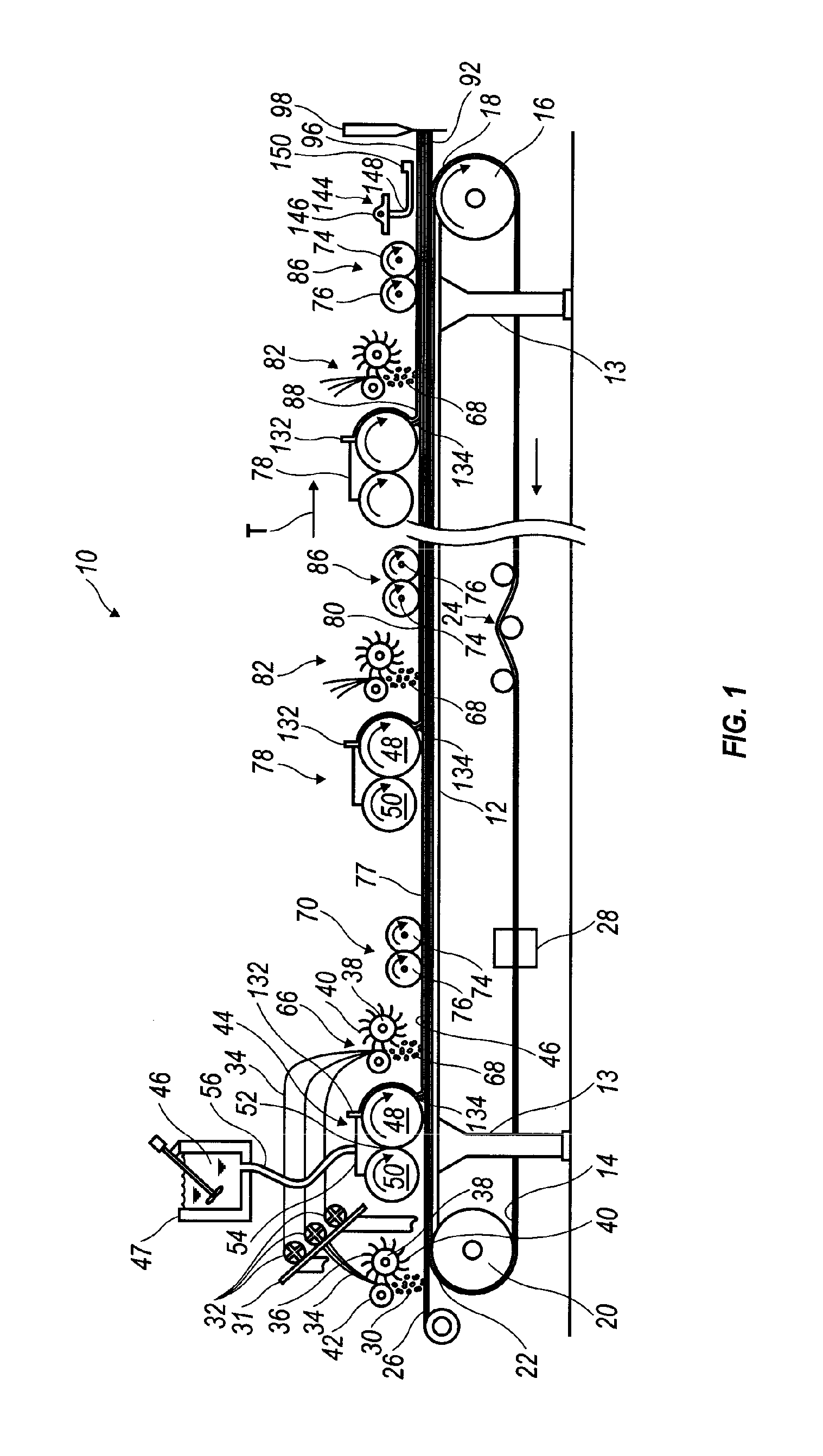

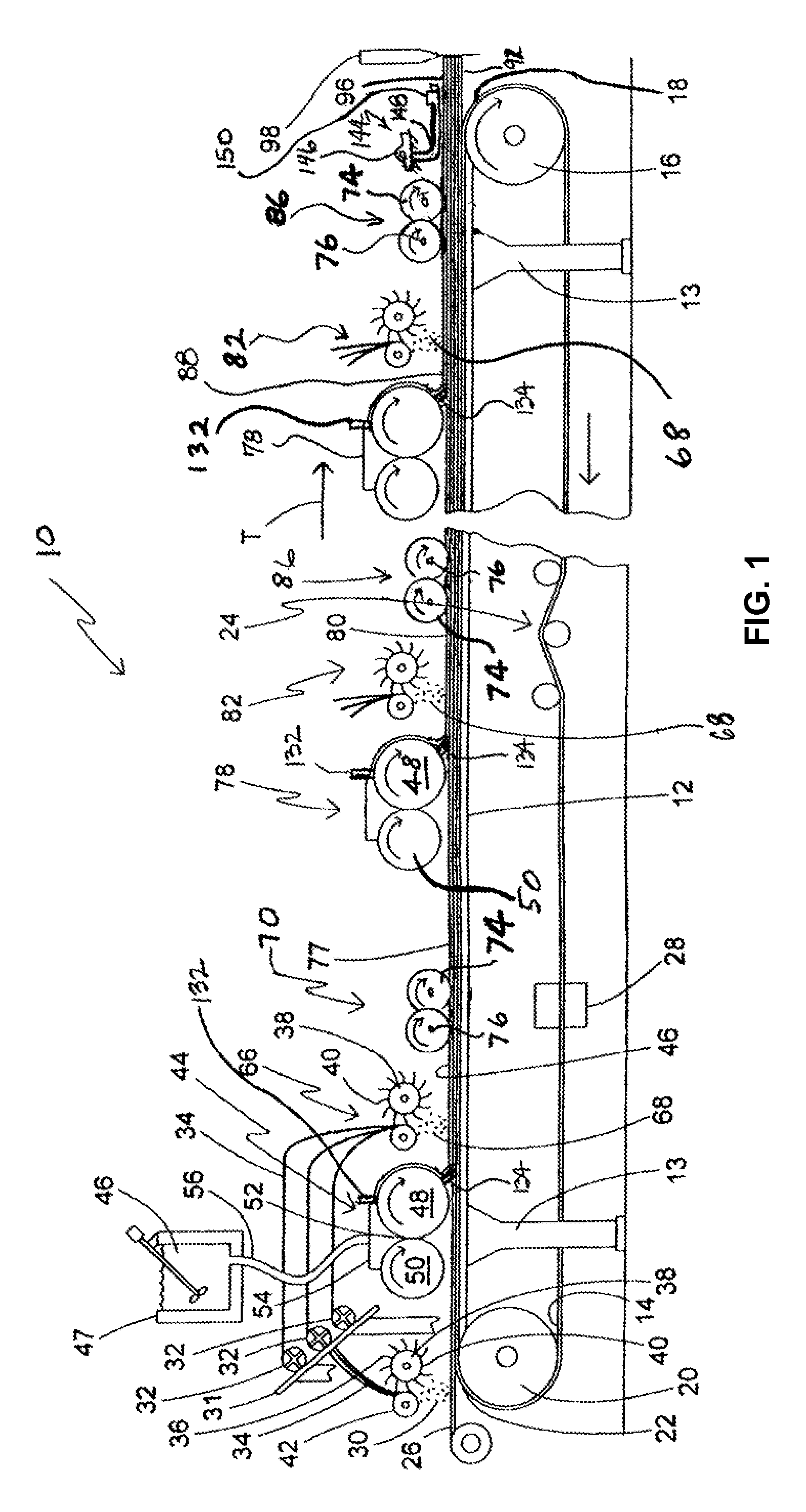

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS20080101150A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed means for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

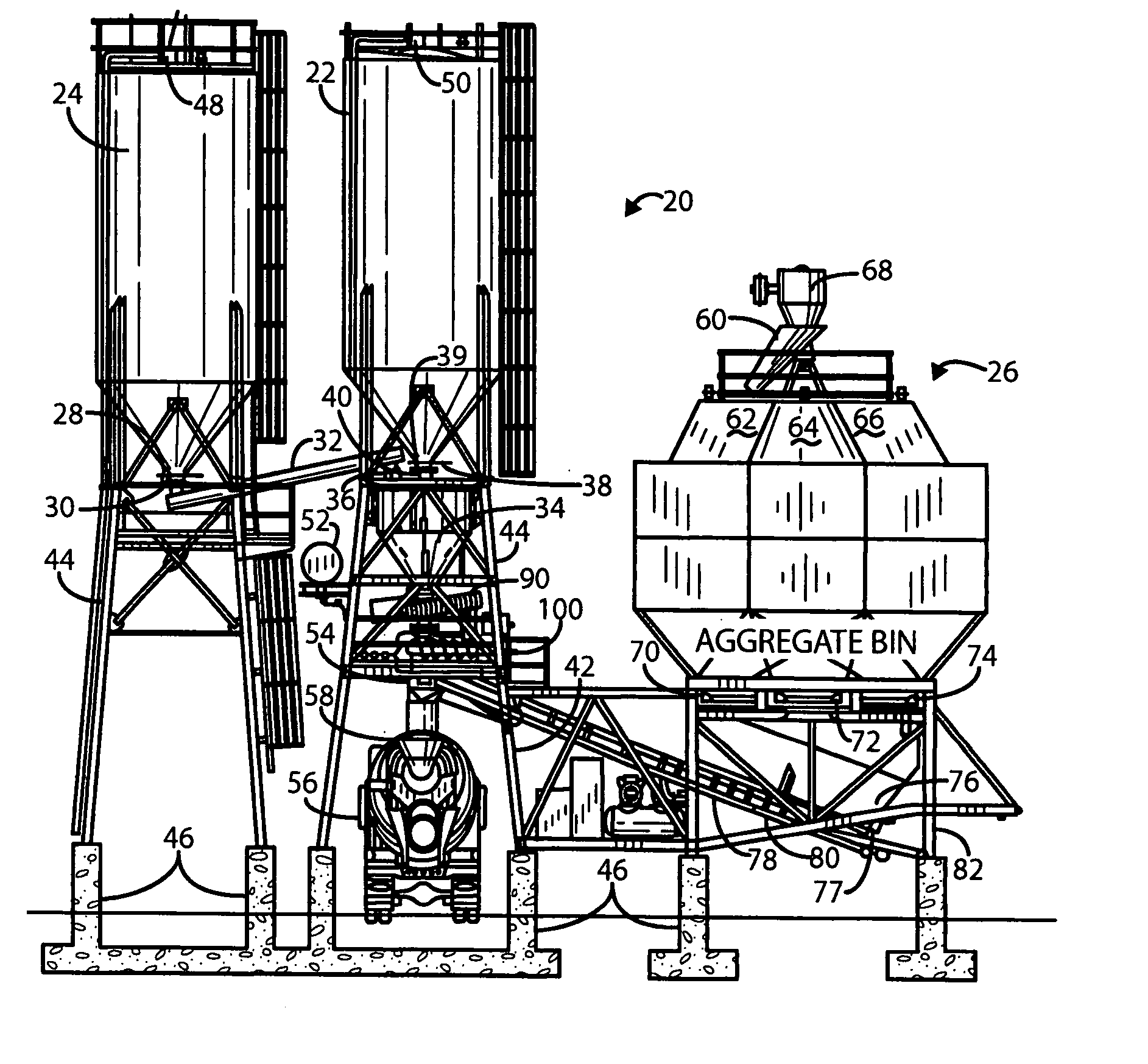

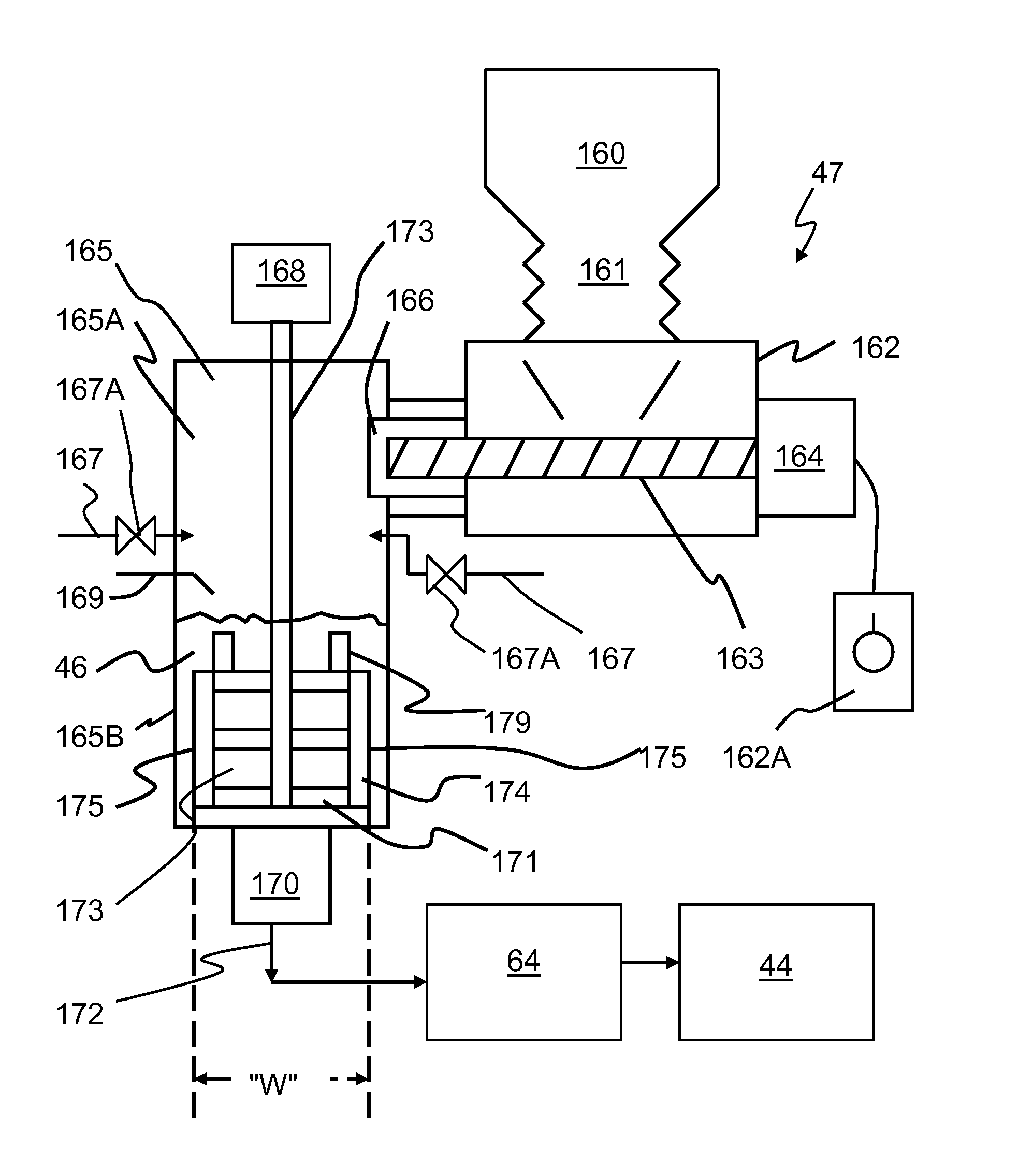

Concrete batching facility and method

ActiveUS20050219941A1Promote productionStrength optimizationDischarging apparatusRotary stirring mixersHybrid systemAdditive ingredient

A concrete batch mixing system and method are disclosed that enable the batch master to measure and control both the water and cementitious ingredient feeds in relation to each other so as to be able to blend the two ingredients in a known, selected, adjustable and repeatable manner, and to agglomerate these ingredients in a counter-rotating twin screw mixing apparatus for use in the preparation of batches of mixed concrete in a concrete batching process.

Owner:MCNEILUS TRUCK & MFG INC

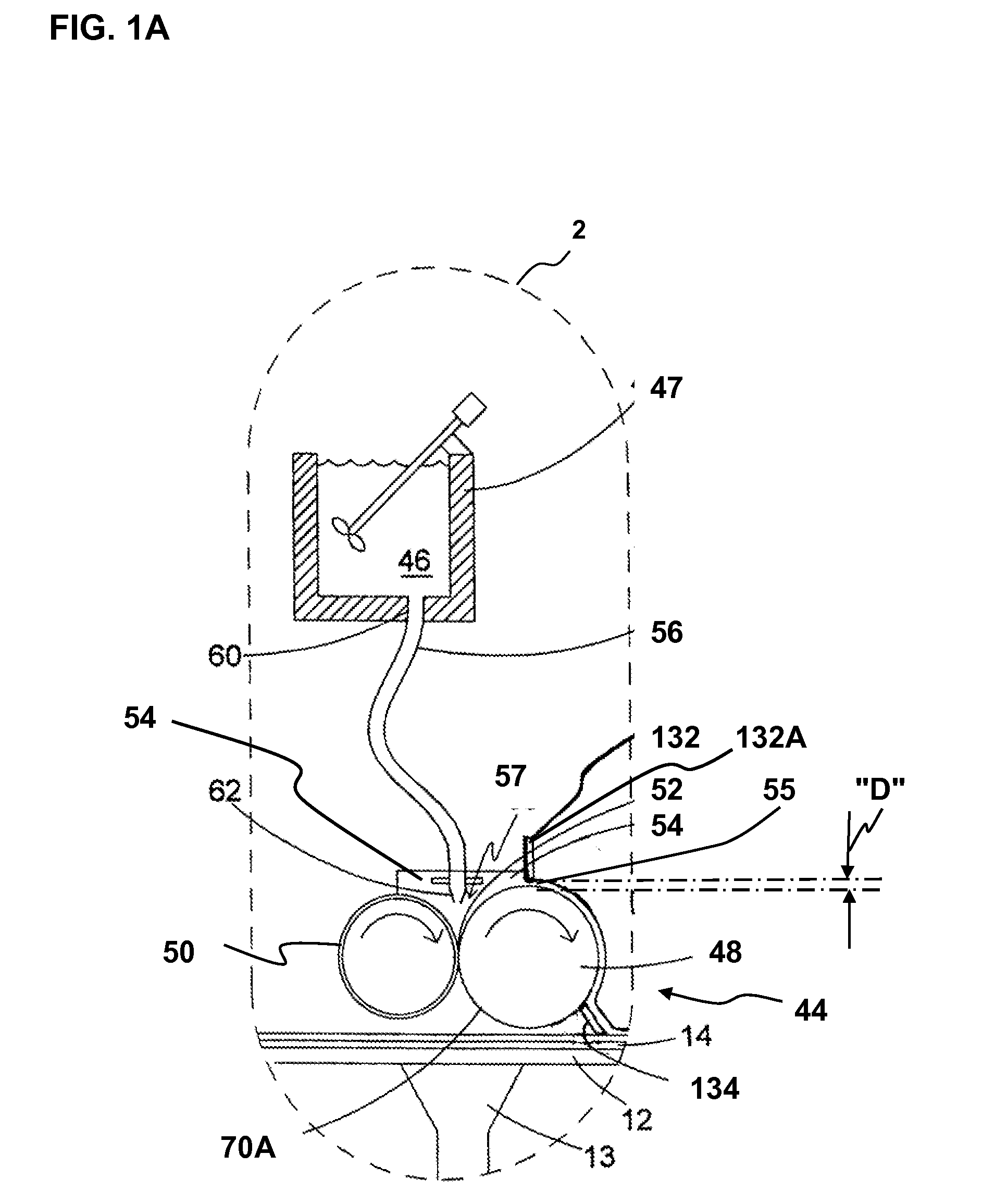

Apparatus and method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080101151A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

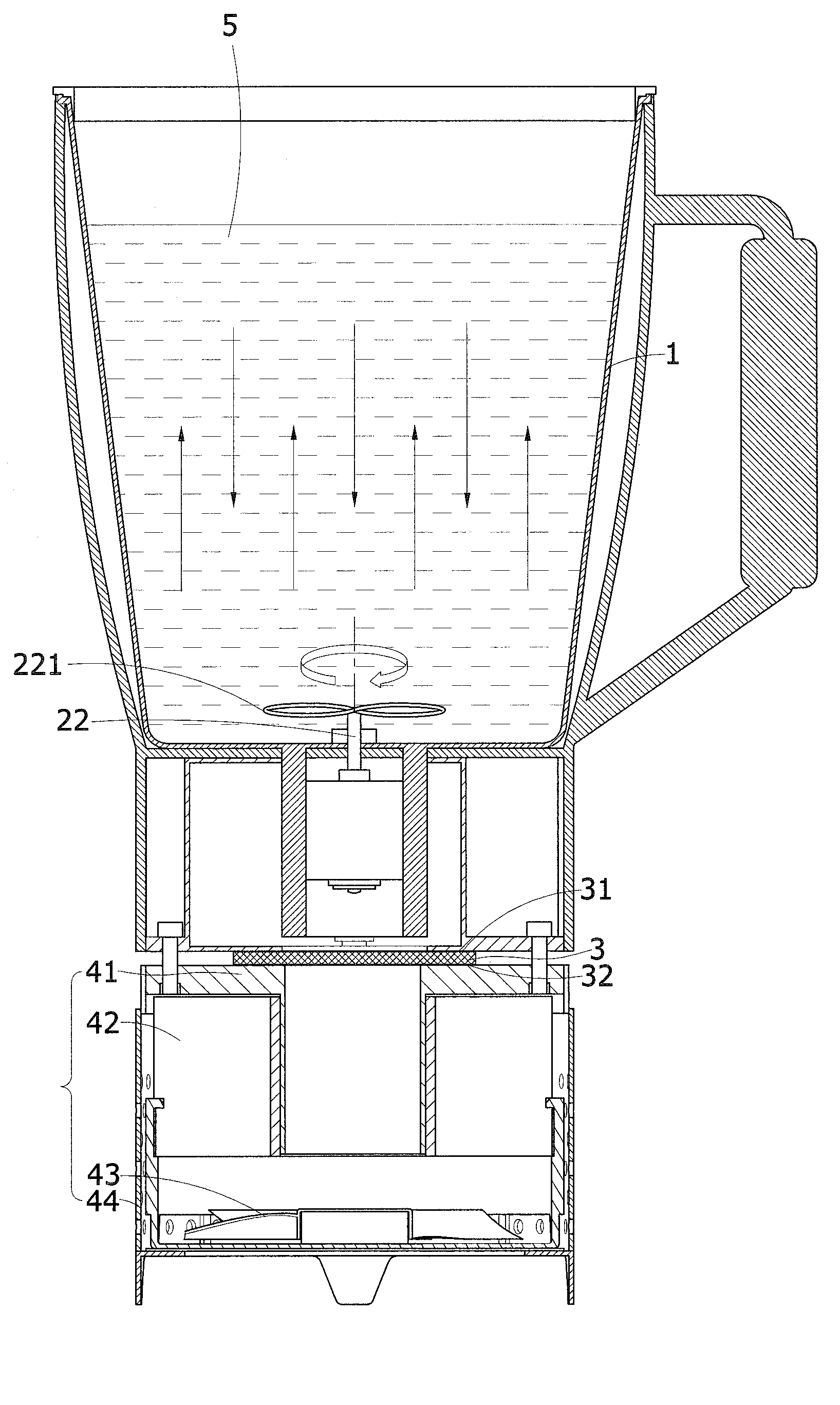

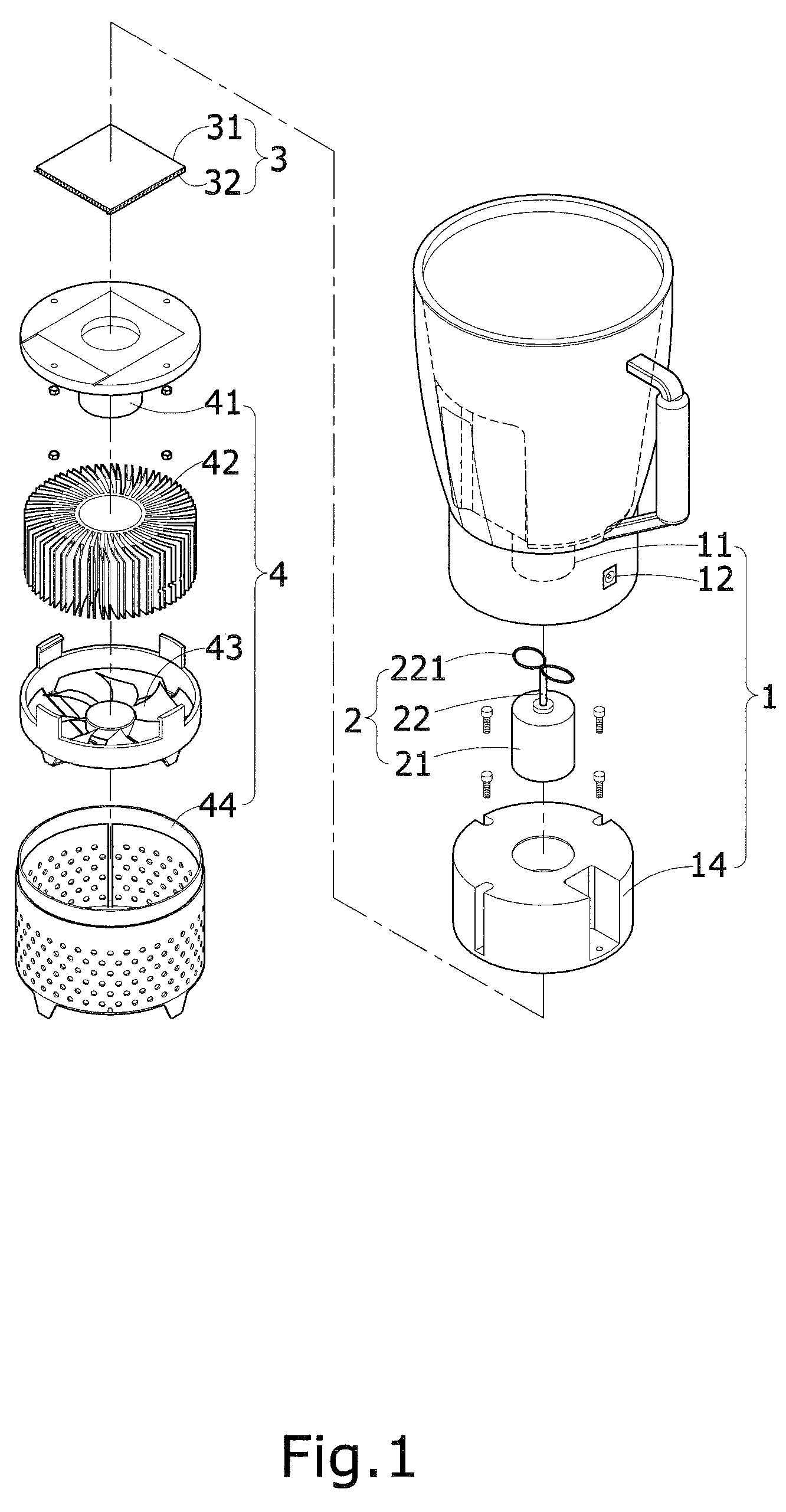

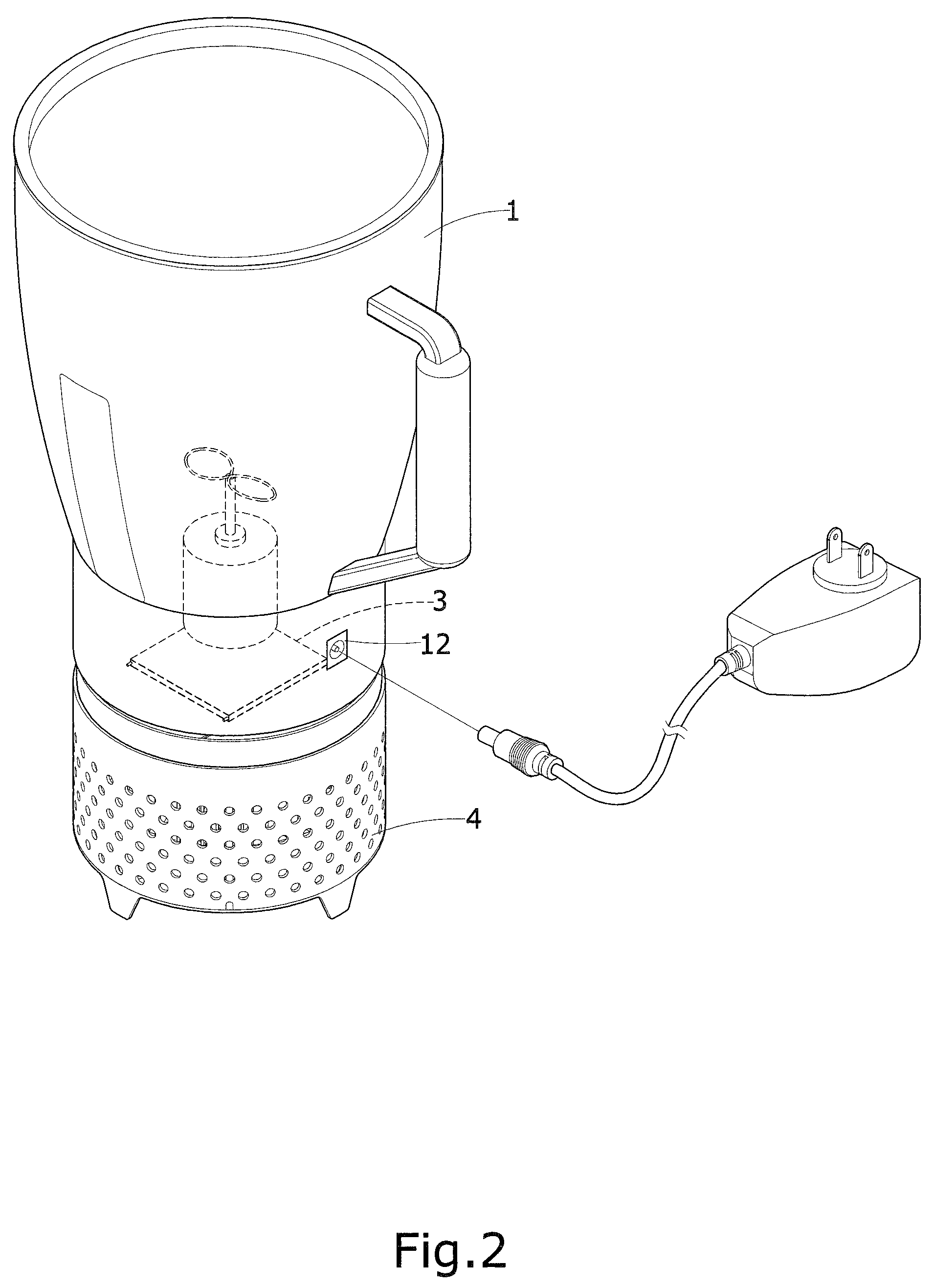

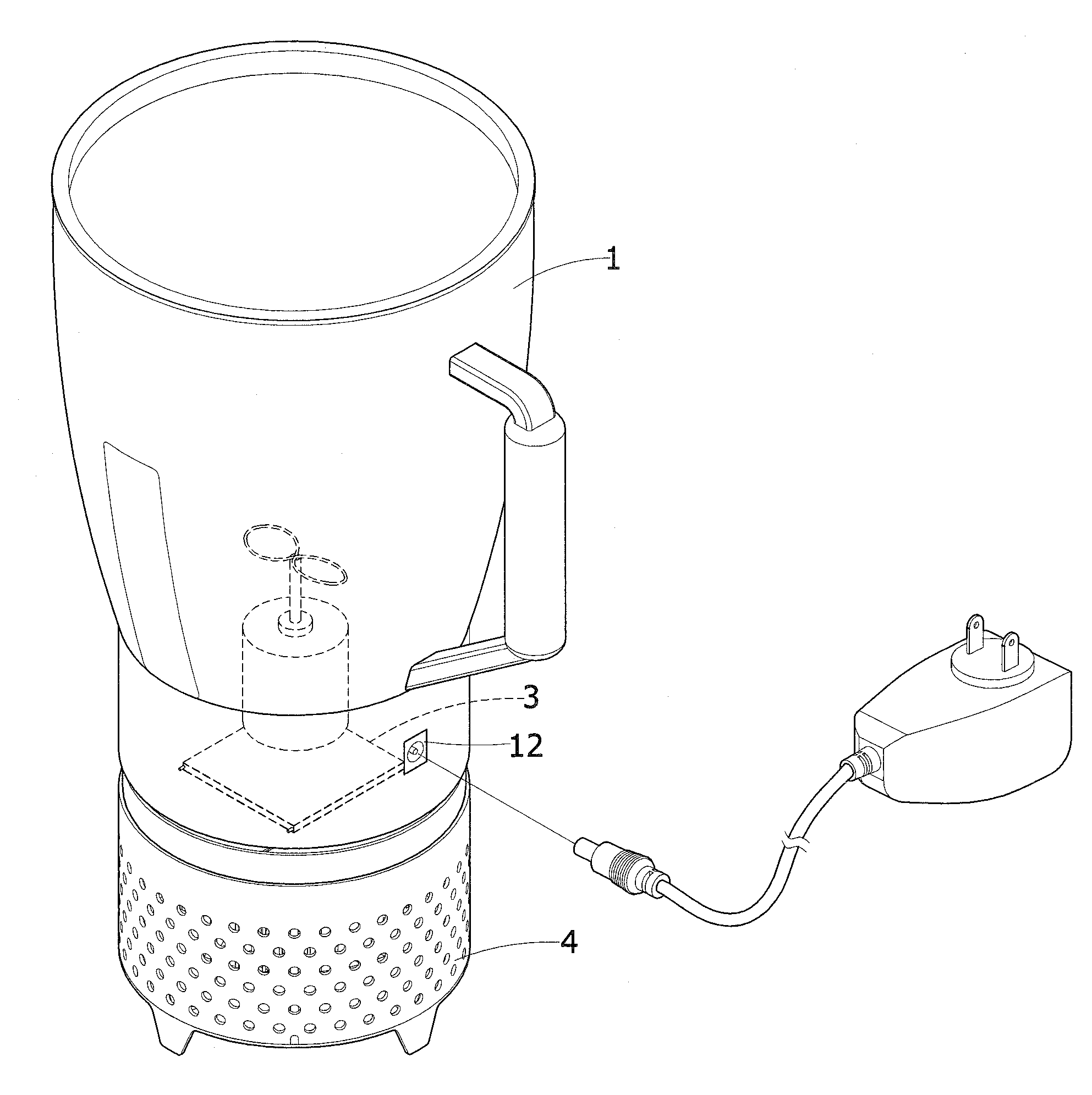

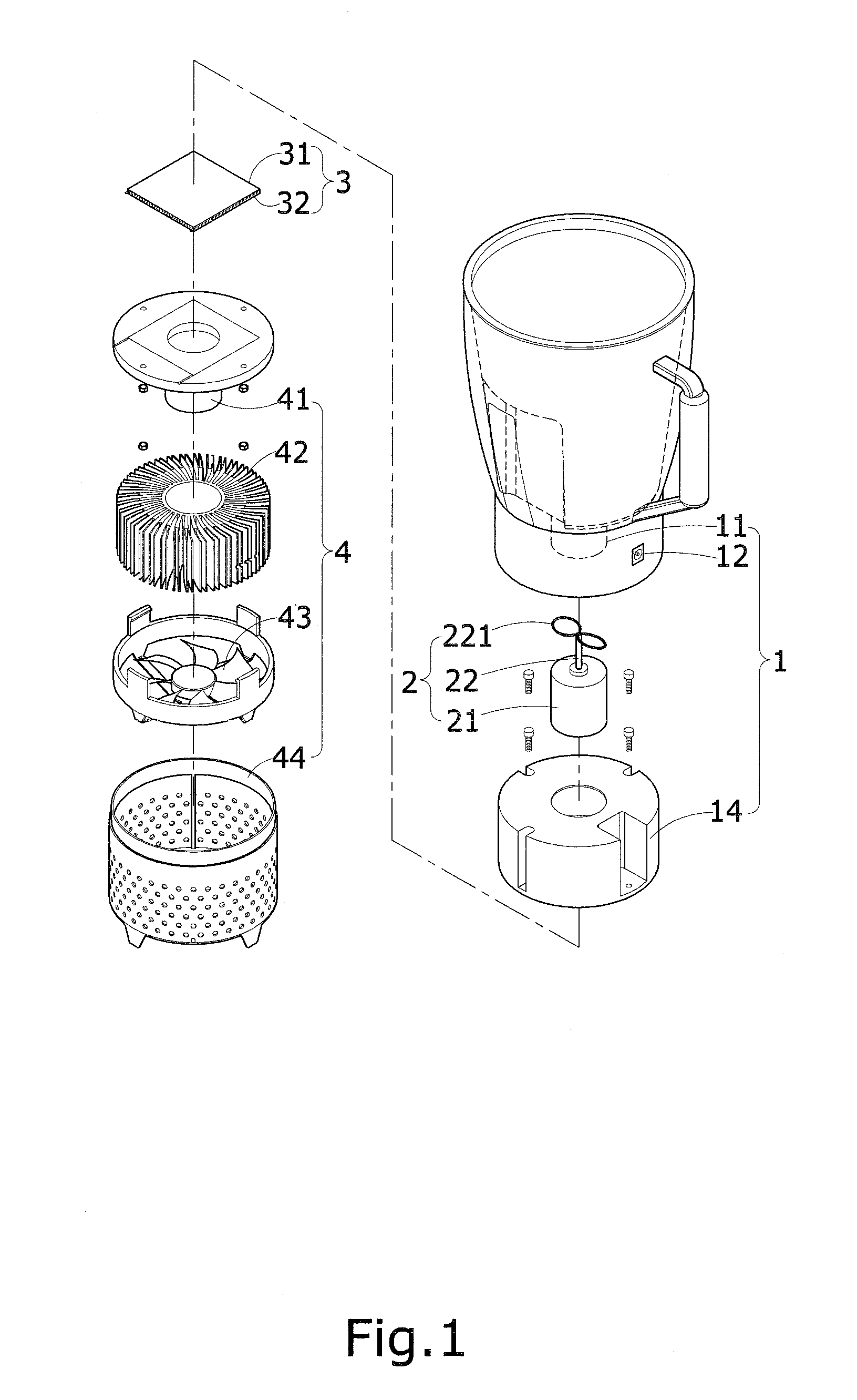

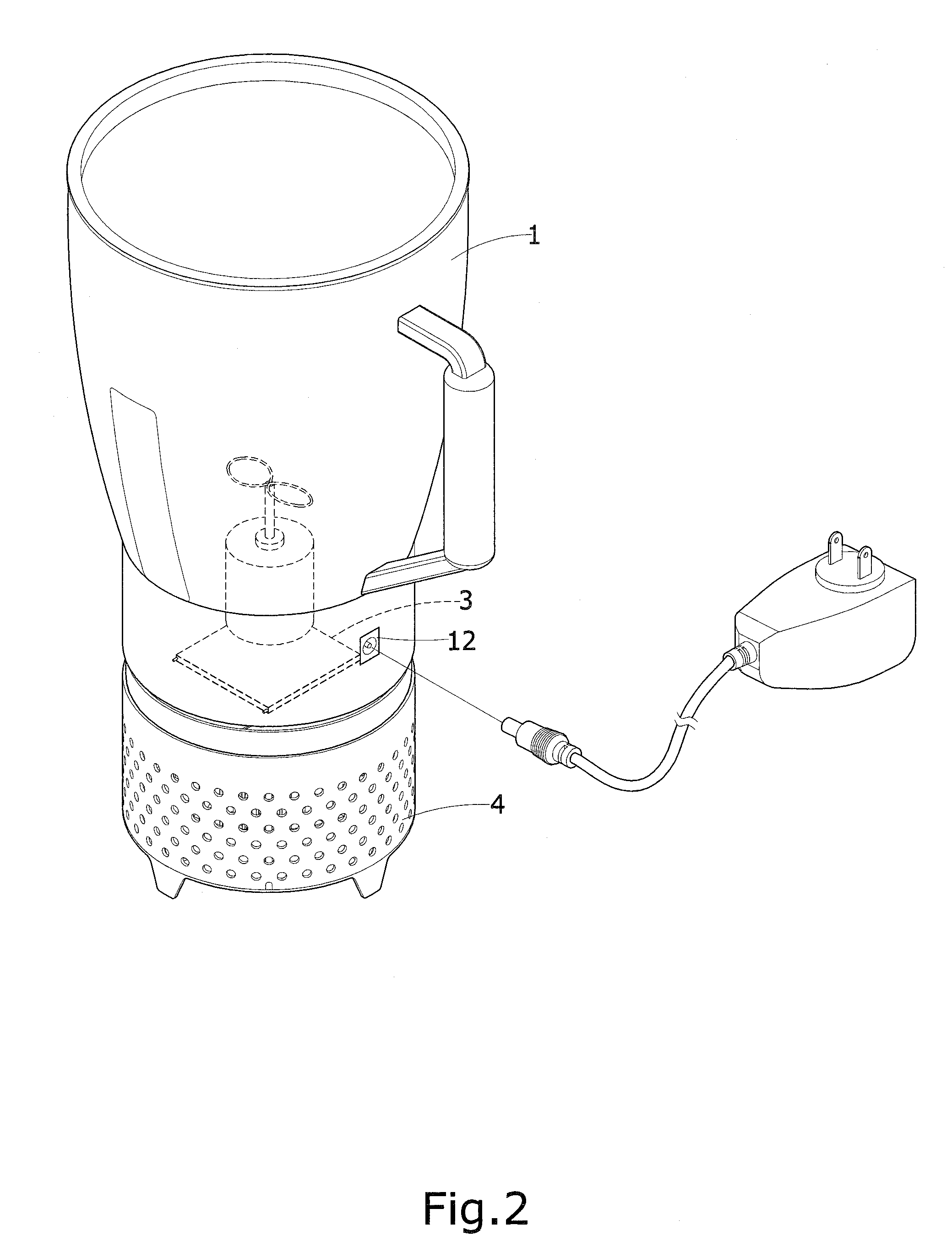

Heating and cooling cup

A heating and cooling cup includes a cup body, a stirring device, a heating and cooling chip, and a heat sink module. A heat conductive block is disposed under the cup body, the heat conductive block abuts against the heating and cooling chip, the stirring device has a stirring rod disposed in the cup body, and a bottom surface of the heating and cooling chip abuts against a heat conductive block of the heat sink module. A temperature of the cup body is changed through the heating and cooling chip, for cooling or heating liquid food in the cup body, and the liquid food is forced to generate convection through the stirring rod for accelerating a temperature variation process.

Owner:LIU PEI CHUAN +1

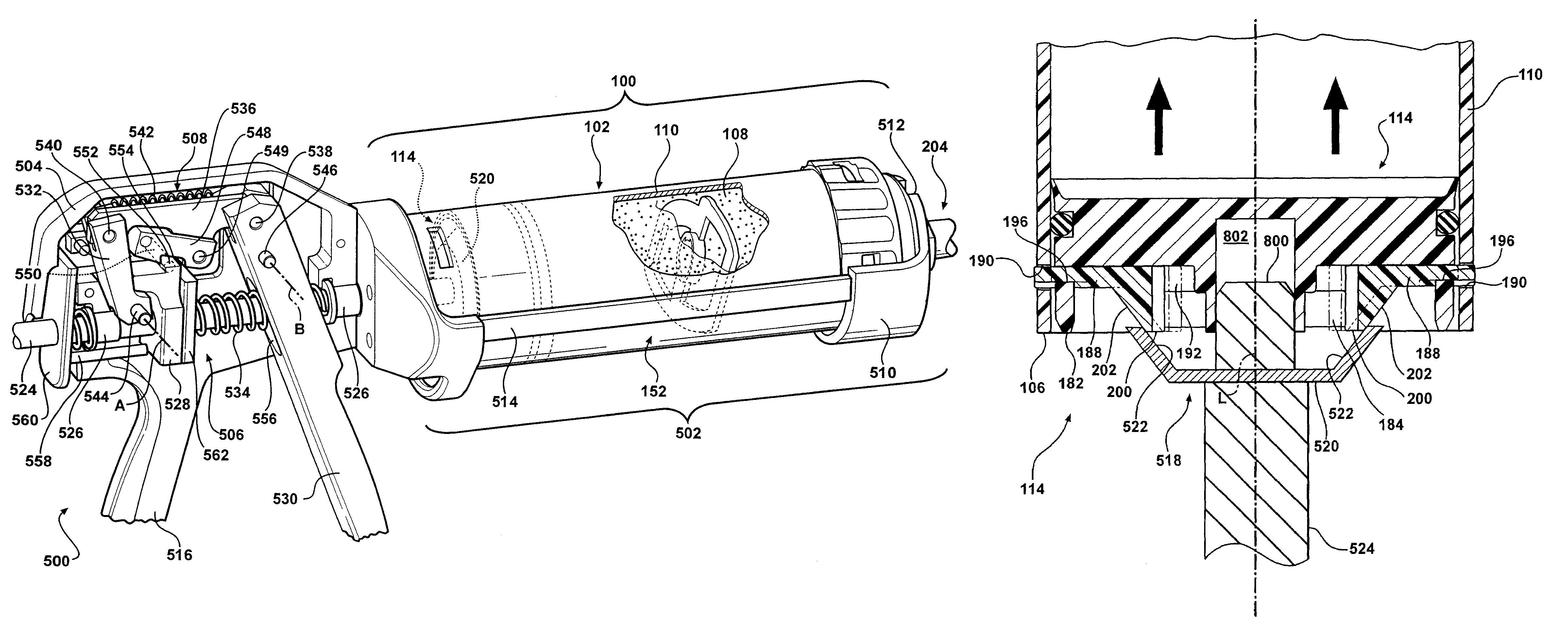

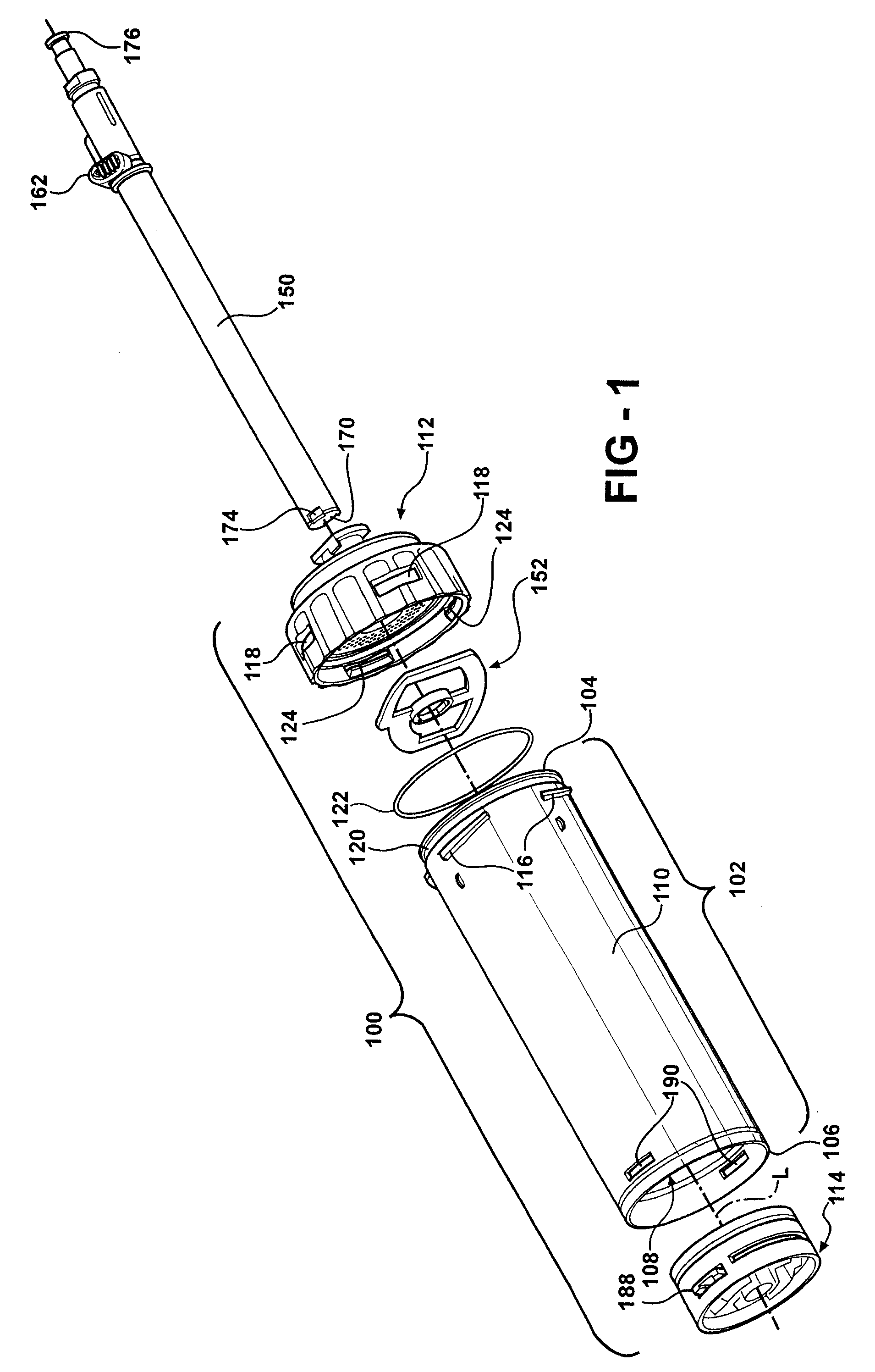

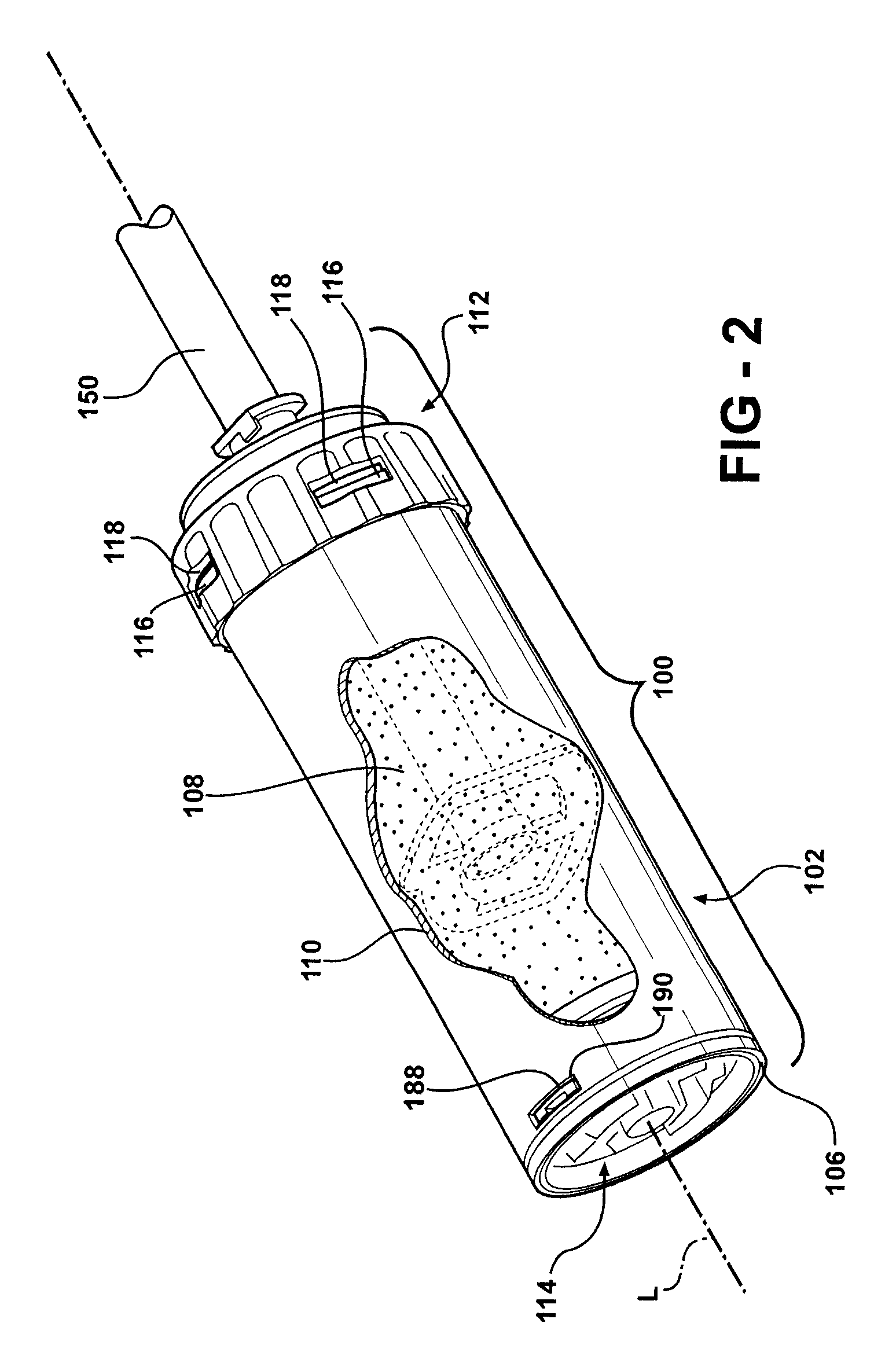

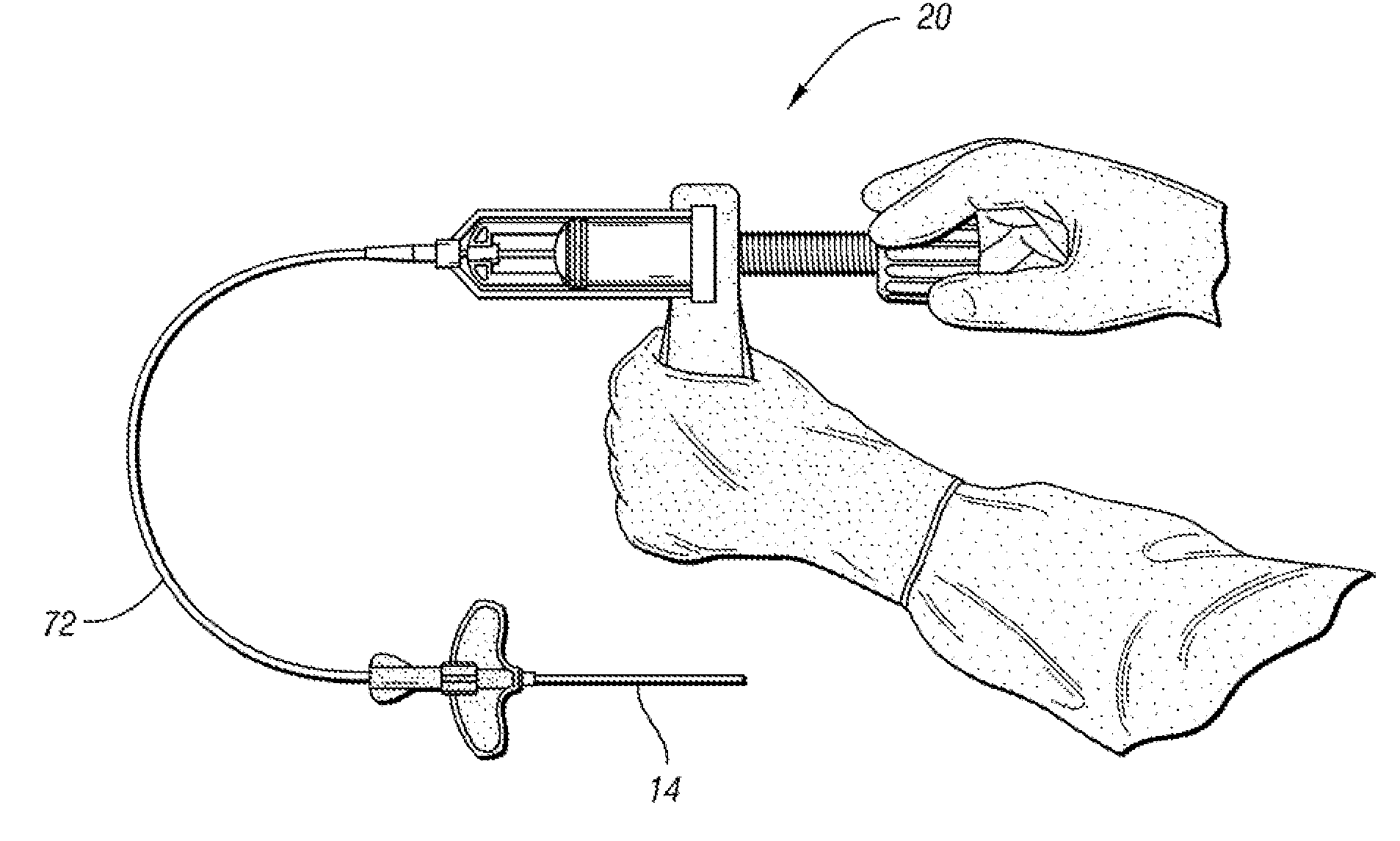

Bone cement mixing and delivery system including a delivery gun and a cartridge having a piston, the delivery gun configured to release the piston

ActiveUS7393342B2Precise positioningFacilitated releaseShaking/oscillating/vibrating mixersDischarging apparatusEngineeringBone cement

A bone cement mixing and delivery system is provided. The system includes a mixing cartridge for receiving liquid and powder components of bone cement, a mixing device for mixing the components, and a delivery gun for discharging the bone cement from the mixing cartridge. The mixing cartridge comprises a cylinder having proximal and distal ends with a cylinder wall extending between the ends. A piston is locked at the distal end by a locking member that includes a pair of locking tabs protruding into slots in the cylinder wall. With the piston in the locked position, the mixing device, e.g., a mixing shaft and blade, mixes the components. After mixing, the cartridge is placed in the delivery gun and release buttons on the locking member are engaged by a release mechanism on the delivery gun to release the piston from the locked position.

Owner:STRYKER CORP

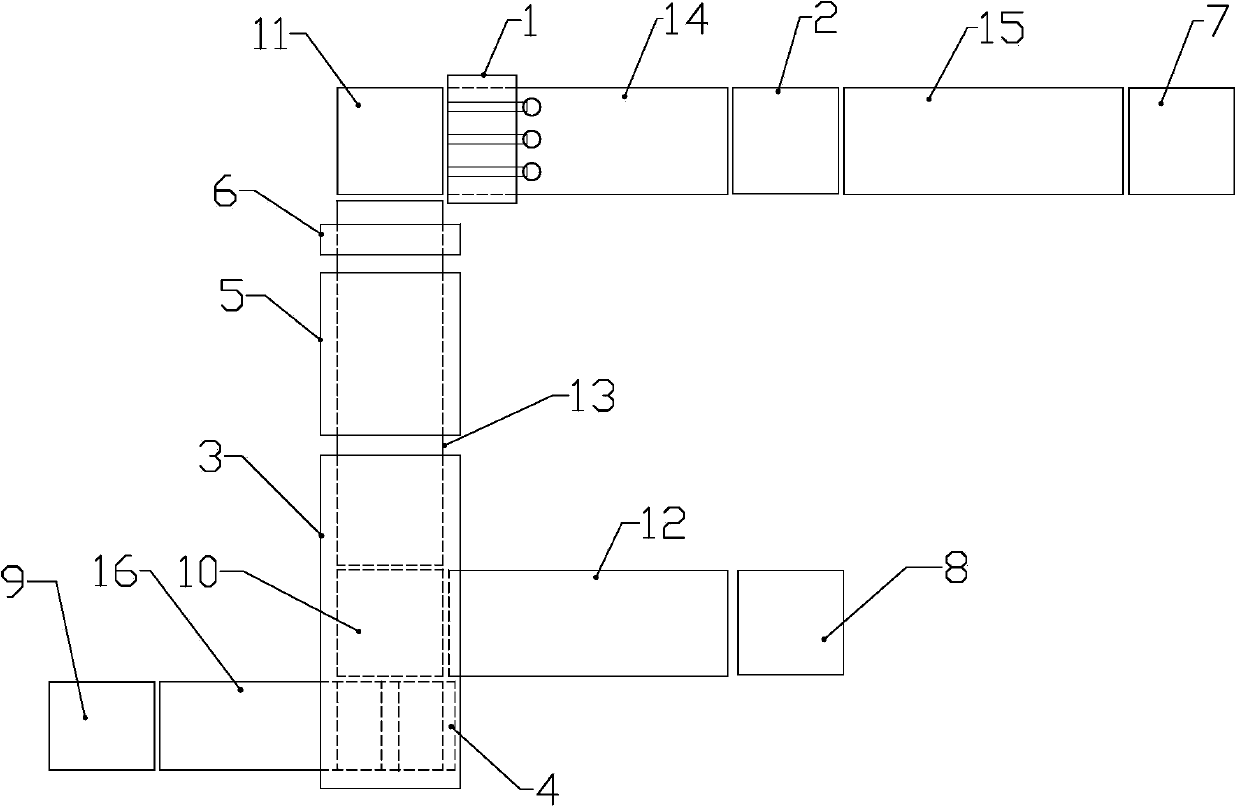

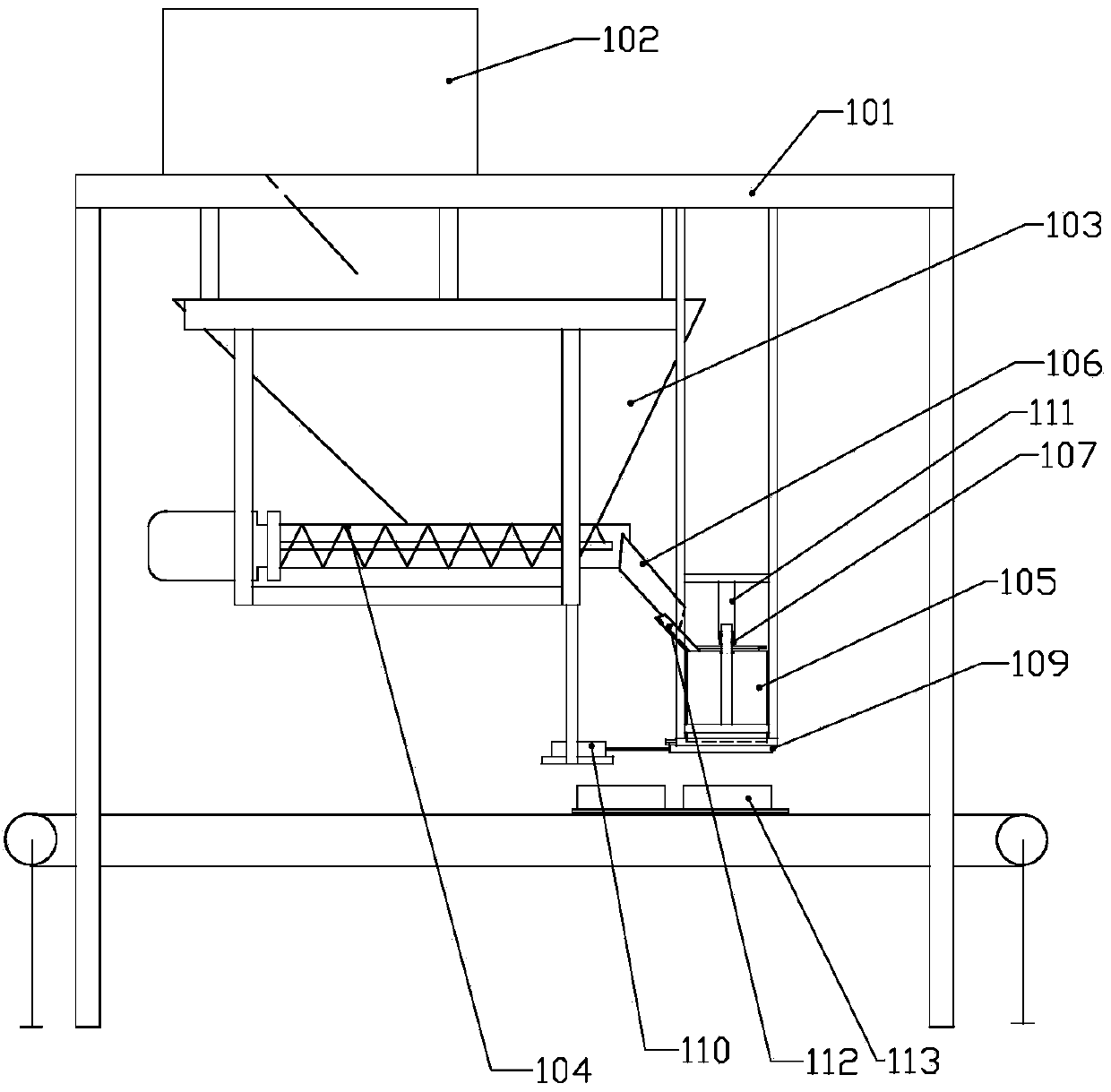

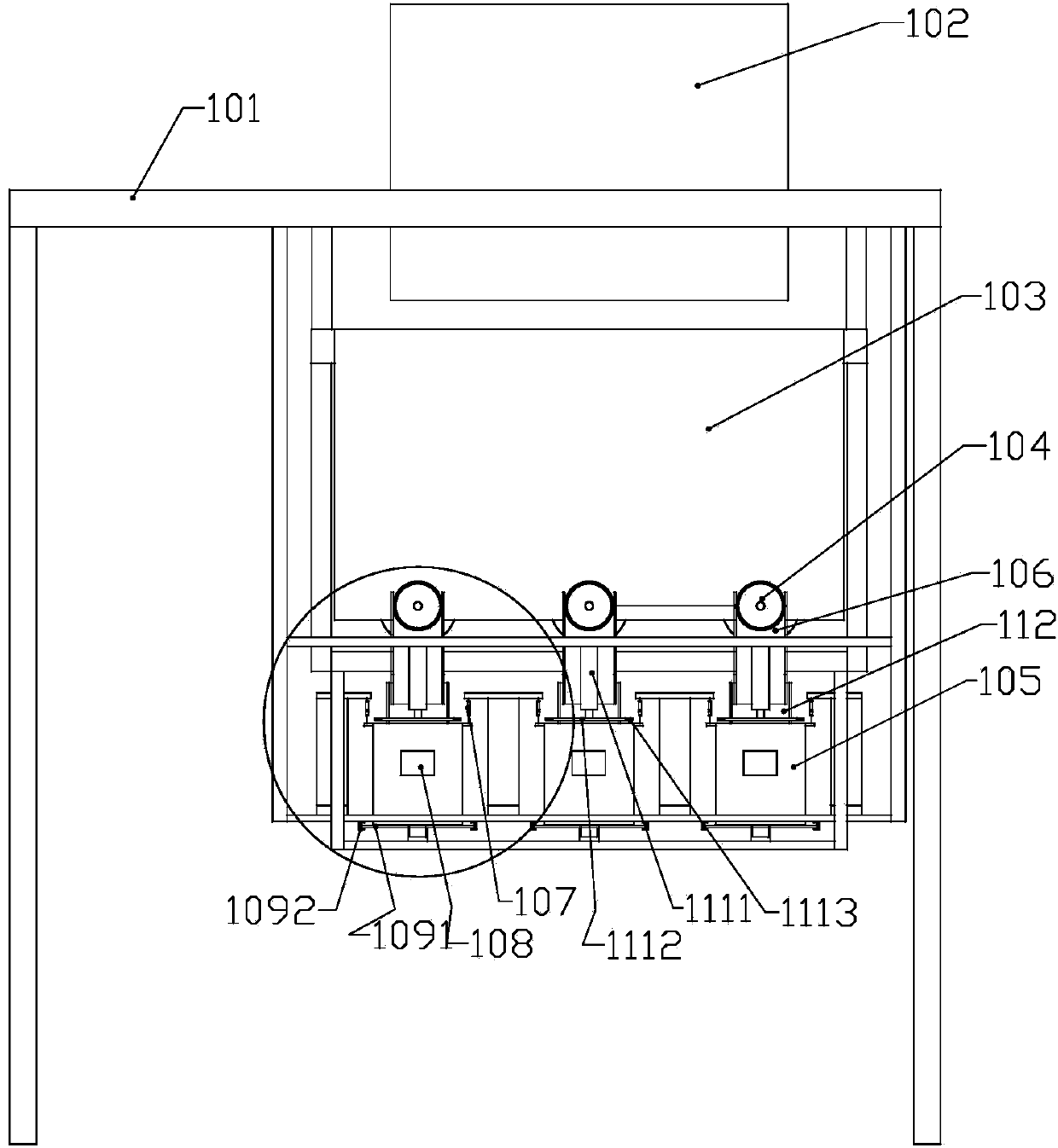

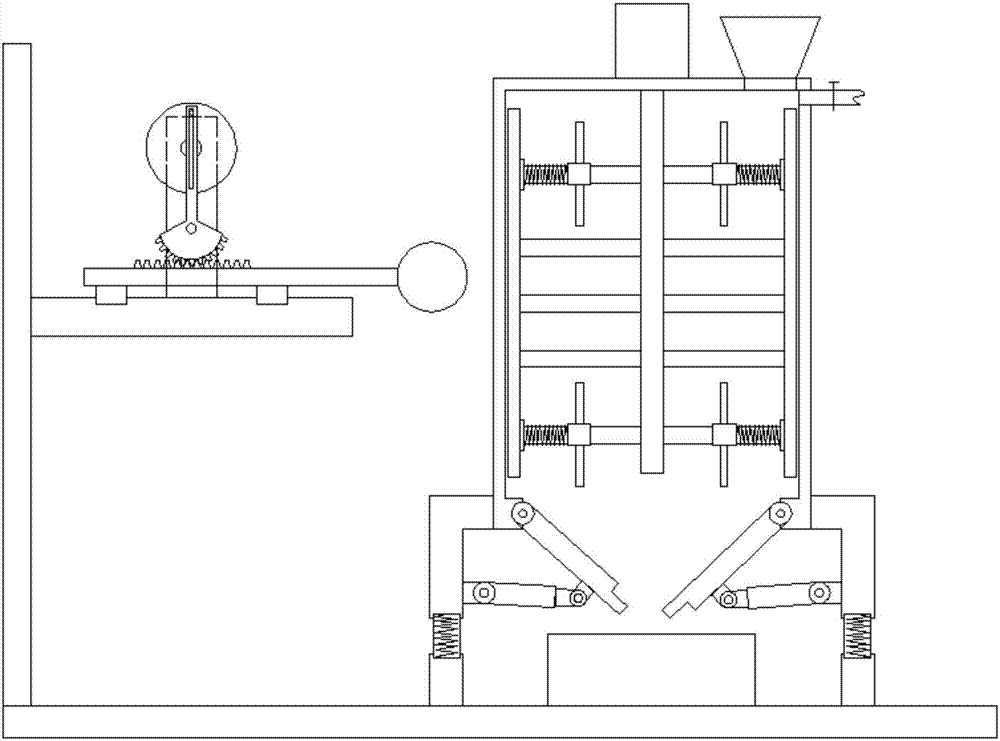

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

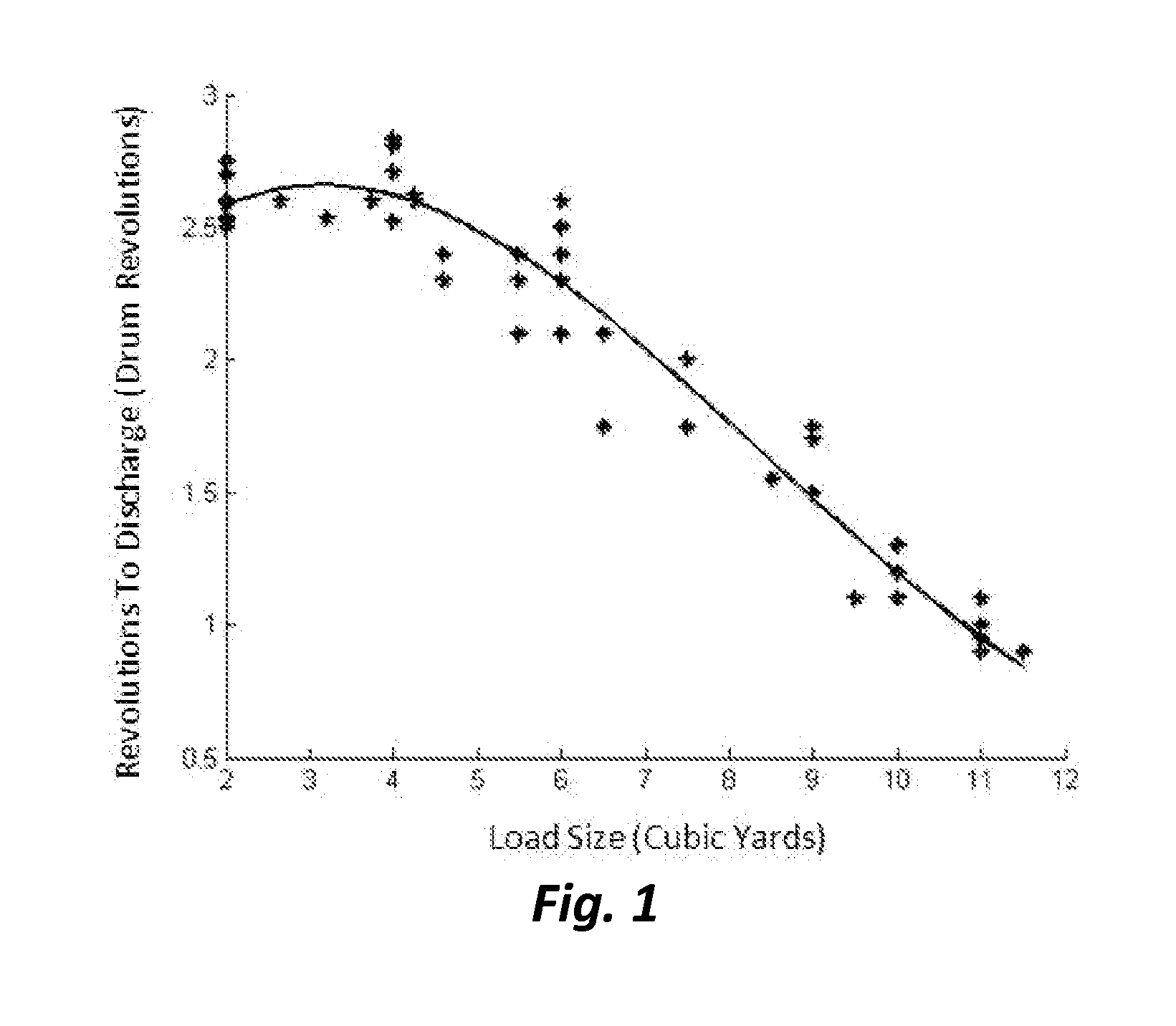

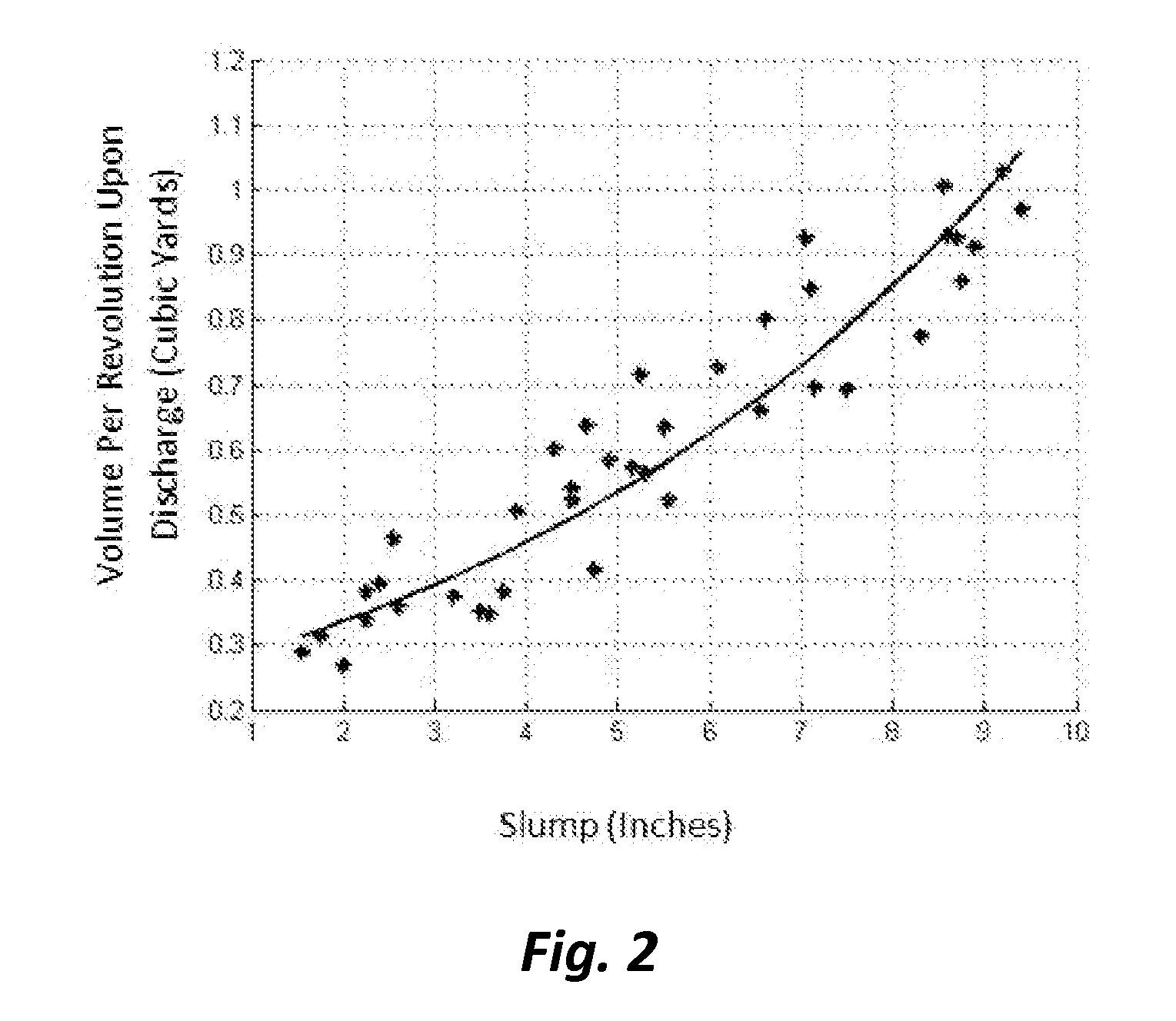

Treating and reporting volume of concrete in delivery vehicle mixing drum

ActiveUS20140104972A1Novel convenient highly accurate methodAccurate and convenient methodSampled-variable control systemsDischarging apparatusDelivery vehicleMonitoring system

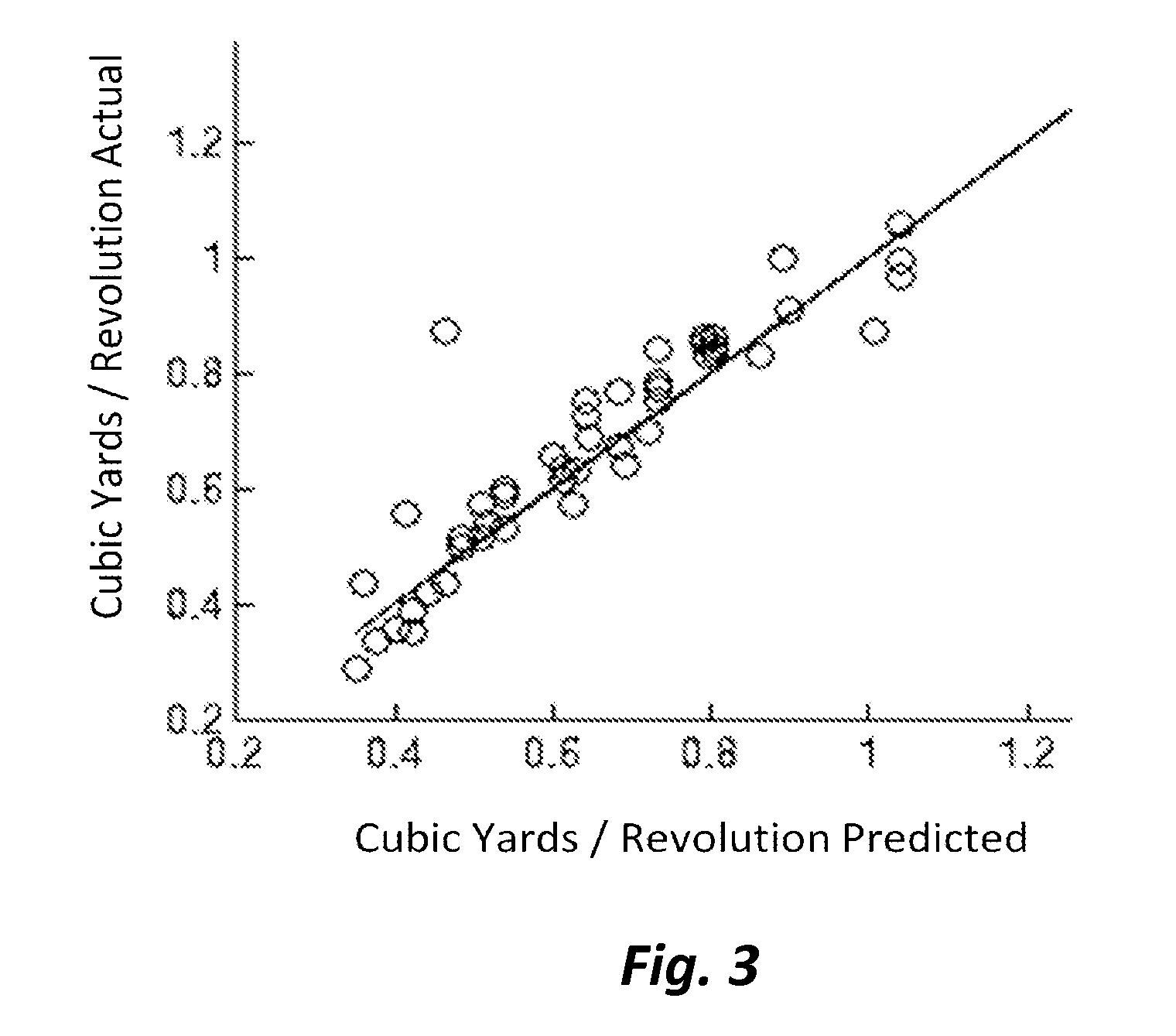

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI

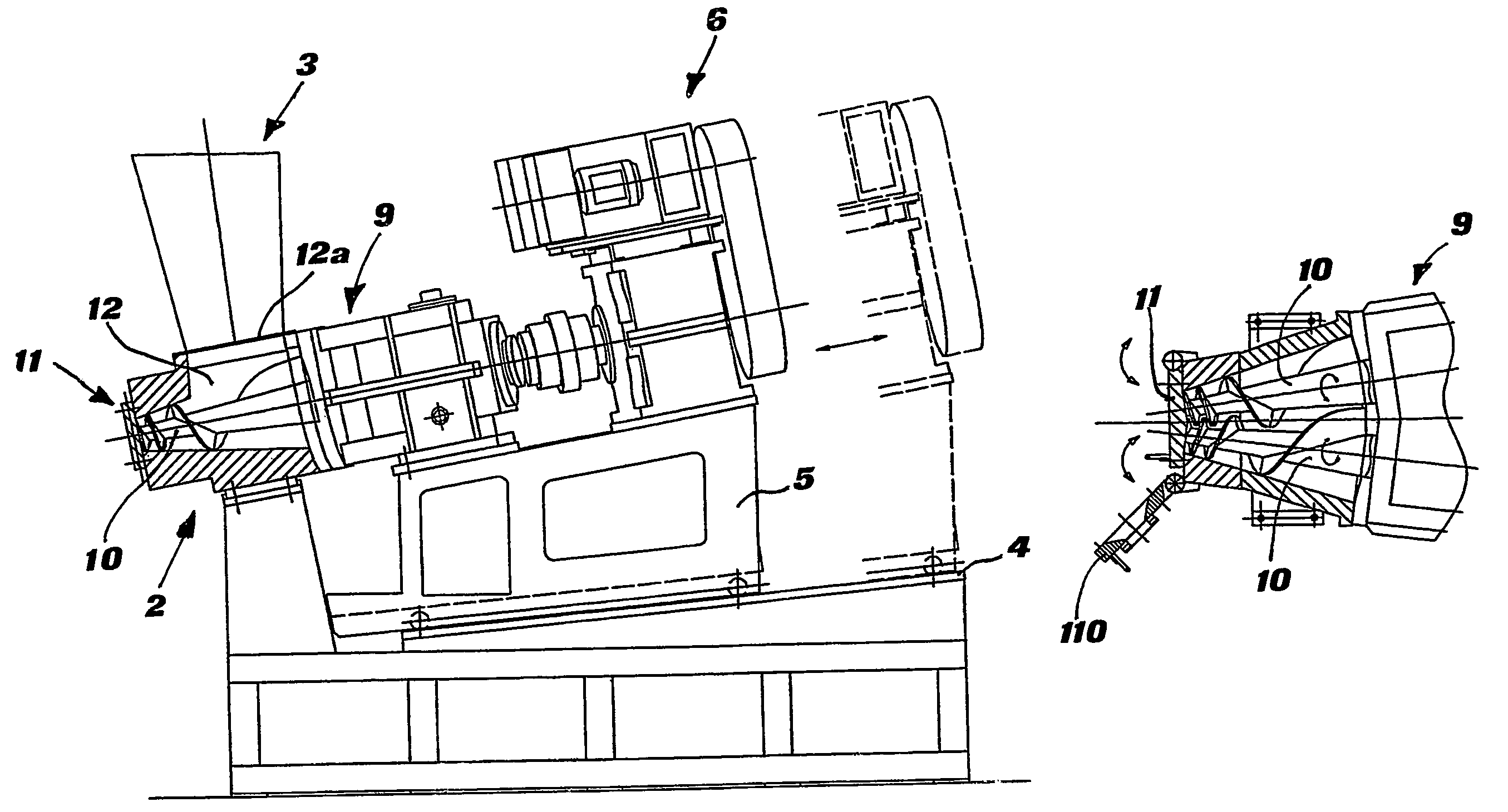

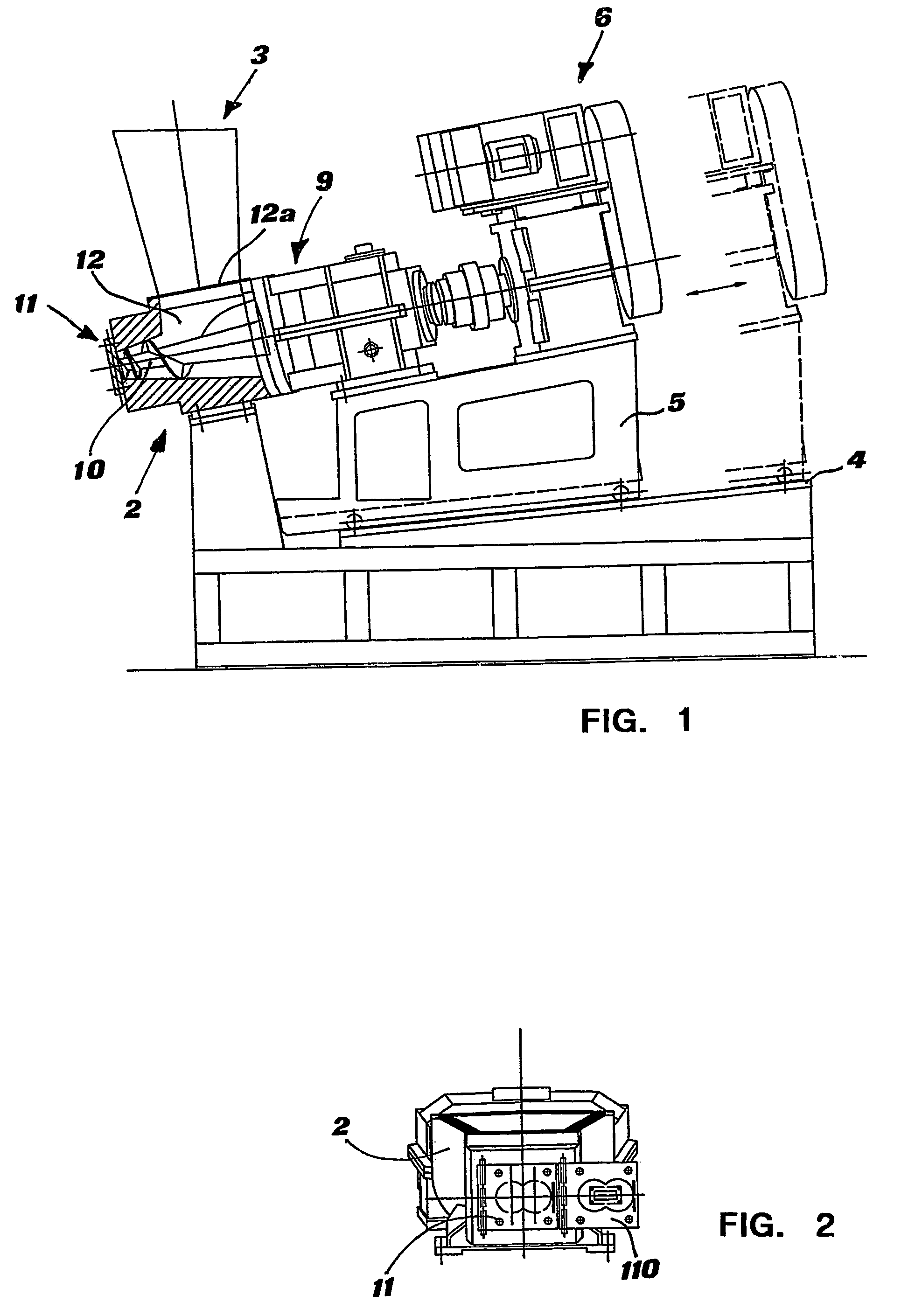

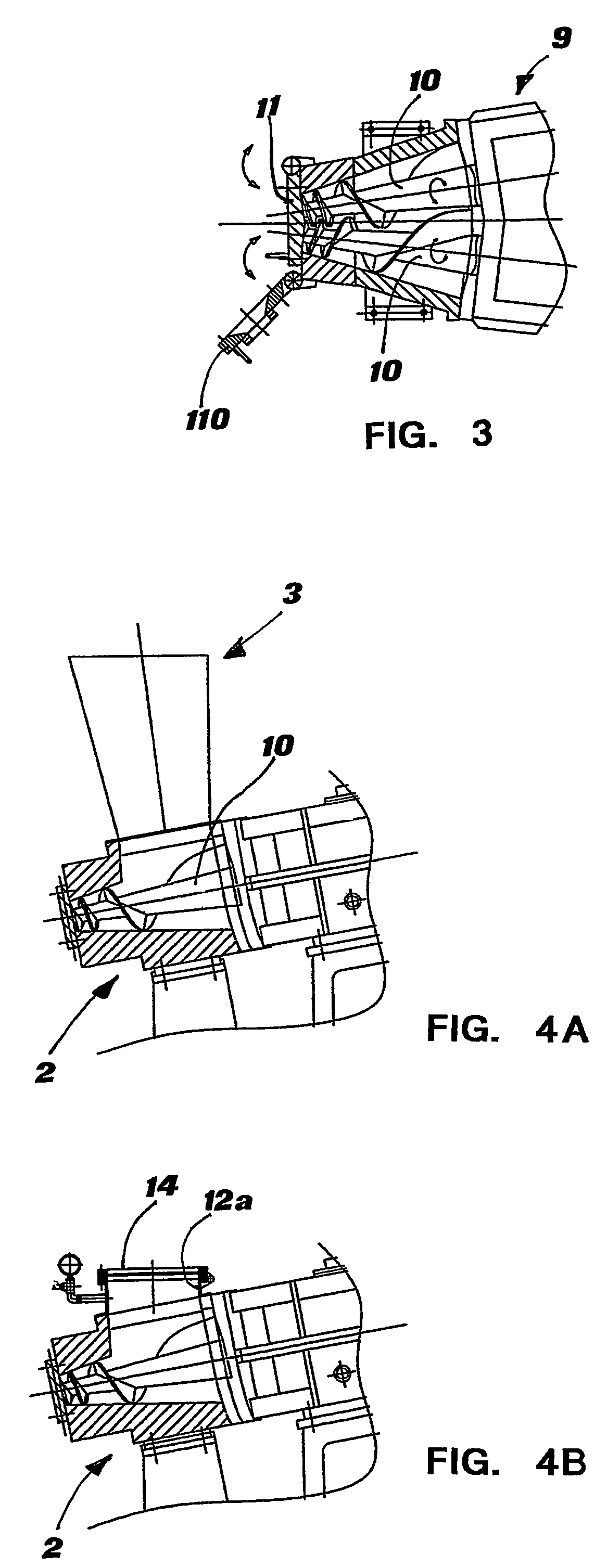

Machine for mixing and extruding rubber-based and silicone-based plastic materials and method therefor

A machine for the mixing and extrusion of rubber-based and silicone-based plastic materials and method thereof is disclosed, comprising a dump extruder with conical converging twin screws (10) arranged in a batching chamber (12) in which the outlet of the dump extruder is temporarily closed by a removable blind flange (11), the batching chamber also acting as a compounding chamber.

Owner:COLMEC

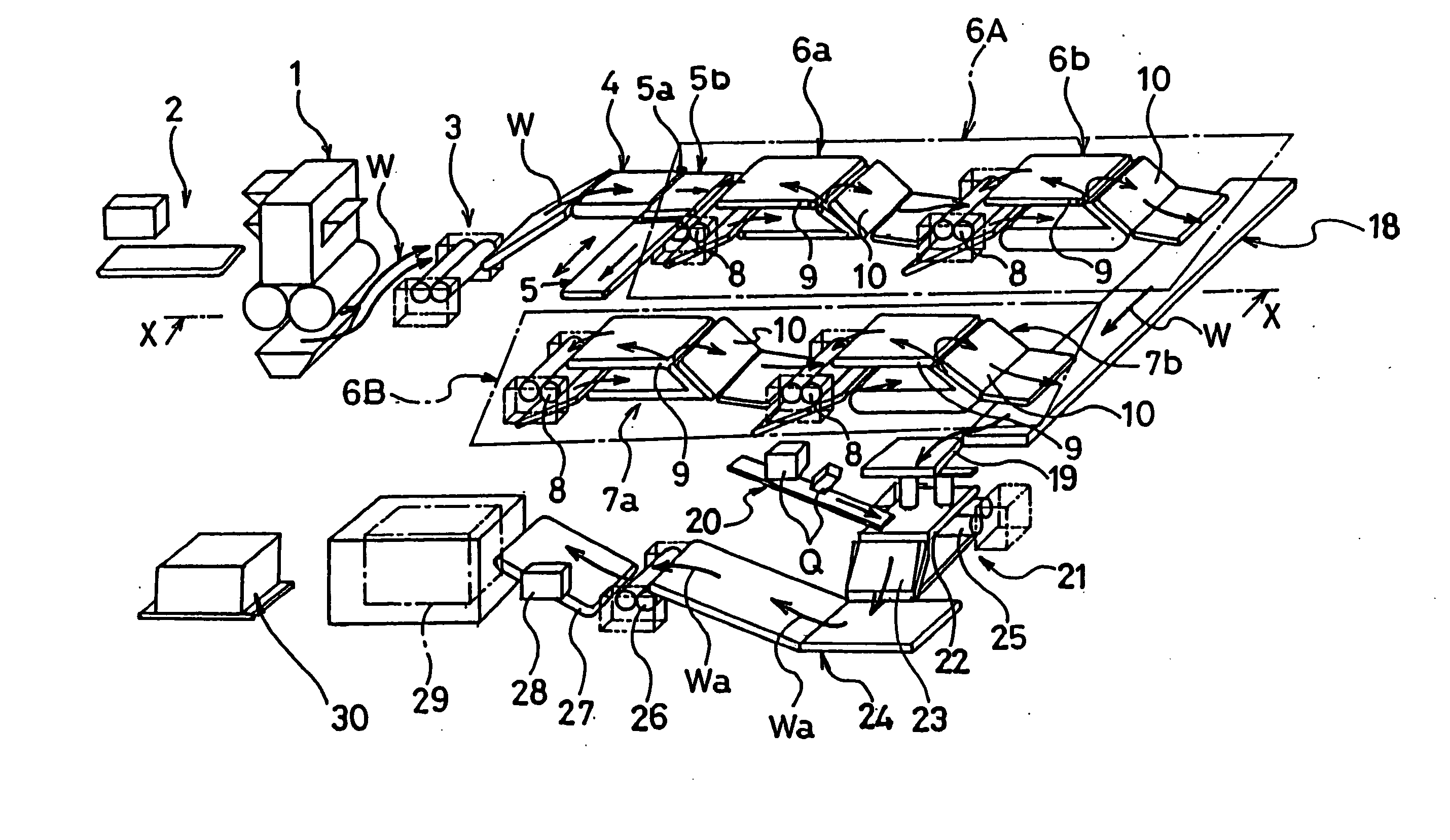

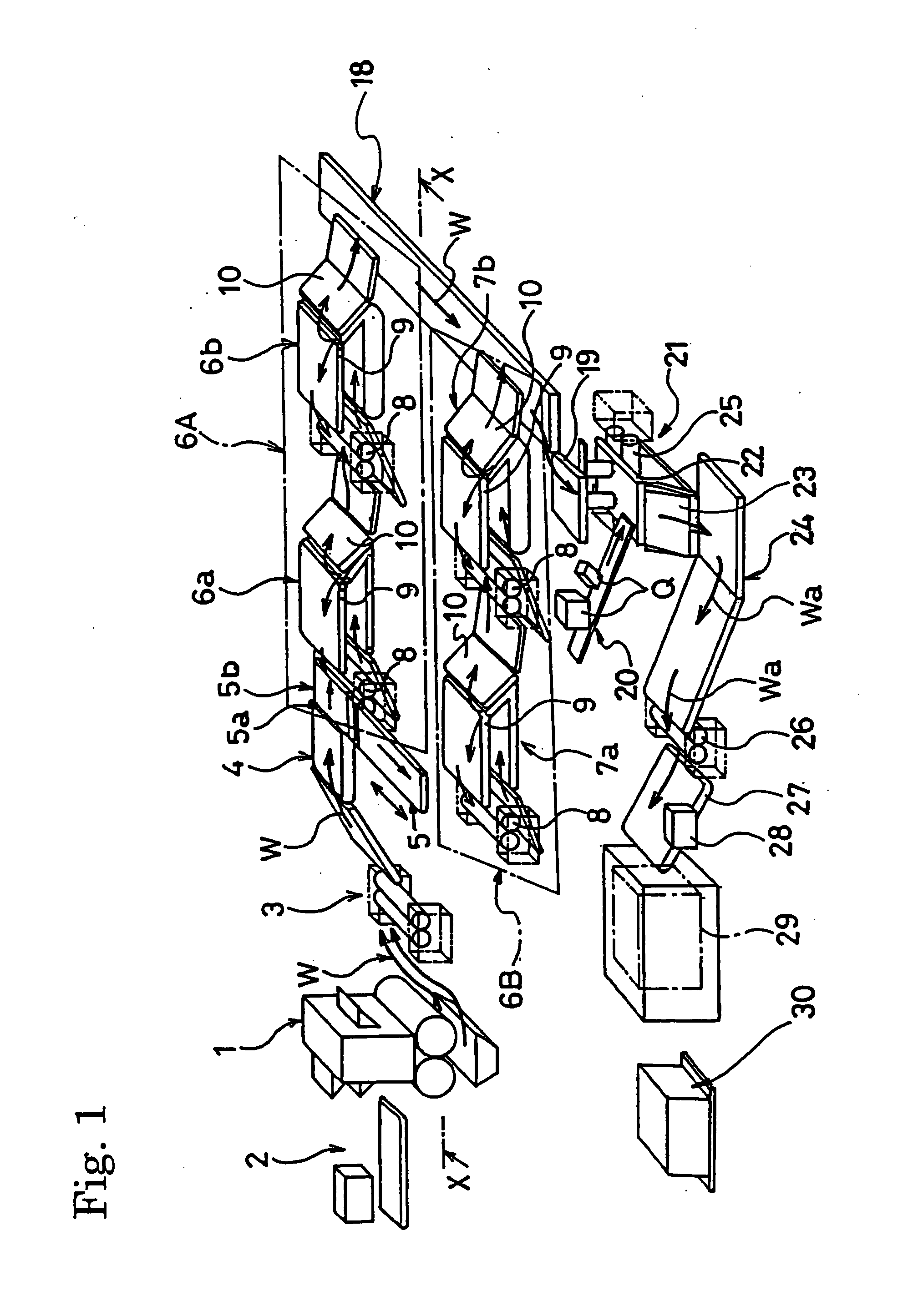

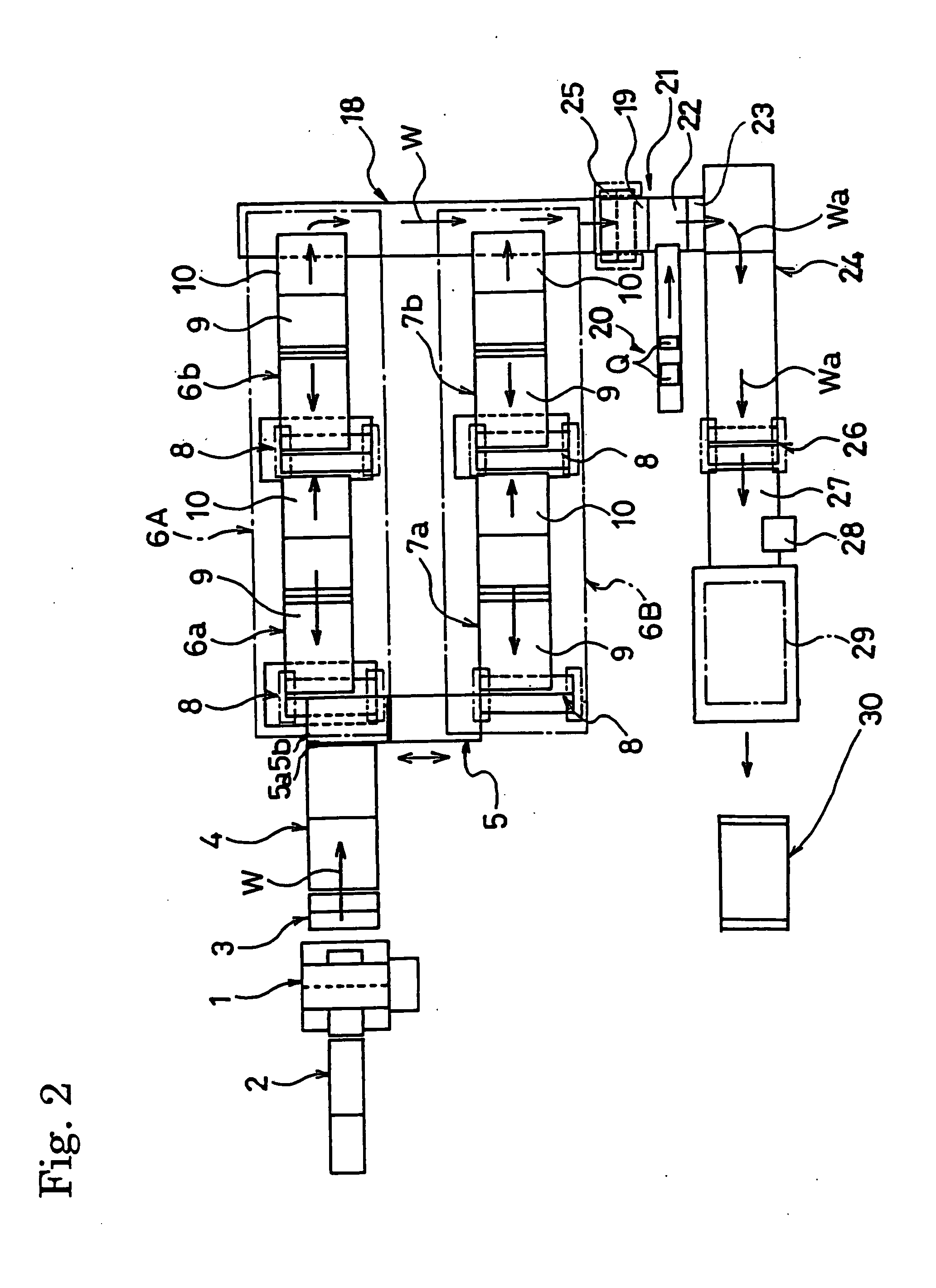

Apparatus for and Method of Kneading Rubber Material

InactiveUS20090238027A1Reduce energy lossLow viscosityDischarging apparatusMixing operation control apparatusRubber materialVulcanization

Disclosed are: an apparatus for kneading a rubber material which continuously performs a series of processes which are kneading a rubber material with a non-vulcanization compounding agent at the beginning, kneading it with a vulcanization compounding agent, and finally obtaining final kneaded rubber; and a kneading method using this kneading apparatus. Preparatory kneaded rubber having been kneaded in one internal mixer is selectively fed, by a distribution conveyor, to a group of kneading lines where at least two kneading lines are provided to be arranged side by side. Each of the kneading line consists of a plurality of open roll mixers serially connected with each other. Intermediate kneaded rubber resulted in having a target viscosity after having been kneaded in the group of kneading lines is kneaded with a vulcanization compounding agent, whereby final kneaded rubber is obtained.

Owner:YOKOHAMA RUBBER CO LTD

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

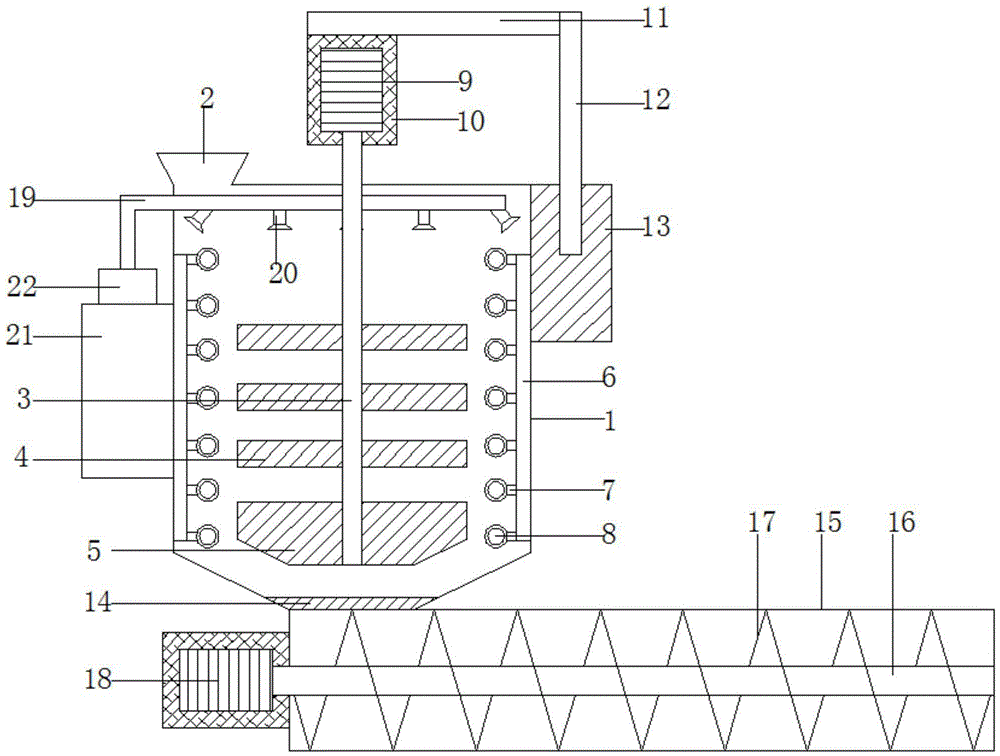

Efficient concrete mixer with water capable of being added automatically

InactiveCN104924462AQuality assuranceReduce noiseDischarging apparatusCement mixing apparatusHydraulic cylinderEngineering

The invention discloses an efficient concrete mixer with water capable of being added automatically. The efficient concrete mixer comprises a mixing drum, a screw conveying drum and spray heads. A feeding funnel is arranged at the left end of the upper side of the mixing drum, a stirring rotating shaft is vertically arranged at the axis of the inside of the mixing drum, stirring blades are arranged on the outer wall of the middle section of the stirring rotating shaft in a left-right symmetrical mode, and the bottom of the stirring rotating shaft is connected with a stirring plate. According to the concrete mixer with water capable of being added automatically, the stirring blades, the stirring plate and stirring wheels are used for stirring concrete in the horizontal direction and the vertical direction at the same time, a hydraulic cylinder is used for driving a mixing mechanism to move up and down for stirring, hence, the stirring effect and working efficiency of the mixer are greatly improved, and the concrete quality is guaranteed; moreover, automatic discharging is achieved through a screw conveying mechanism, the concrete can be stirred continuously in the discharging process, and the working efficiency of the mixer is improved; in addition, noise of the mixer in the working process is small, and automatic water adding and cleaning can be achieved.

Owner:苏晓玲

Heating and cooling cup

A heating and cooling cup includes a cup body, a stirring device, a heating and cooling chip, and a heat sink module. A heat conductive block is disposed under the cup body, the heat conductive block abuts against the heating and cooling chip, the stirring device has a stirring rod disposed in the cup body, and a bottom surface of the heating and cooling chip abuts against a heat conductive block of the heat sink module. A temperature of the cup body is changed through the heating and cooling chip, for cooling or heating liquid food in the cup body, and the liquid food is forced to generate convection through the stirring rod for accelerating a temperature variation process.

Owner:LIU PEI CHUAN +1

Construction cement and yellow sand mixing device with high efficiency

InactiveCN107097345AEliminate agglomerationEasy to useDischarging apparatusMixing operation control apparatusBall screwArchitectural engineering

The invention discloses a construction cement and yellow sand mixing device with high efficiency. The mixing device comprises a shell of which the upper end is provided with an upper cover; the upper cover is provided with a feed pipe, a stirring shaft, a threaded rod, a stop baffle and a thread ring sheath; the right wall of the shell is provided with a first motor; and an electric telescopic rod and a ball screw are arranged above the upper cover; the shell is internally provided with fixed blades; the periphery of the stirring shaft is provided with stirring blades; the side wall of the shell is provided with a fixed sleeve, a sliding rod and a crushing lug; the periphery of the threaded rod is provided with a lifting sleeve, a connecting rod, a material lifting ring, a material lifting shaft and material lifting blades; the lower end of the shell is provided with a discharge pipe, a discharge hole, a discharge valve, a guide plate and a support frame; and the discharge pipe is provided with a second motor, a discharge rotating rod and discharge blades. According to the mixing device disclosed by the invention, materials are mixed through the fixed blades and the stirring blades , and the evenly mixed materials are lifted through the material lifting ring, the material lifting shaft and the material lifting blades; and agglomeration is removed through the fixed sleeve, the sliding rod and the crushing lug, so that the machining efficiency is improved effectively.

Owner:六安市我罗生工业设计有限公司

Blanking adjustable discharging hopper device and concrete batch plant applying same

InactiveCN101890761AControl the degree of opening and closingIncrease unloading speedDischarging apparatusLarge containersEngineeringMechanical engineering

Owner:SANY HEAVY IND CO LTD (CN)

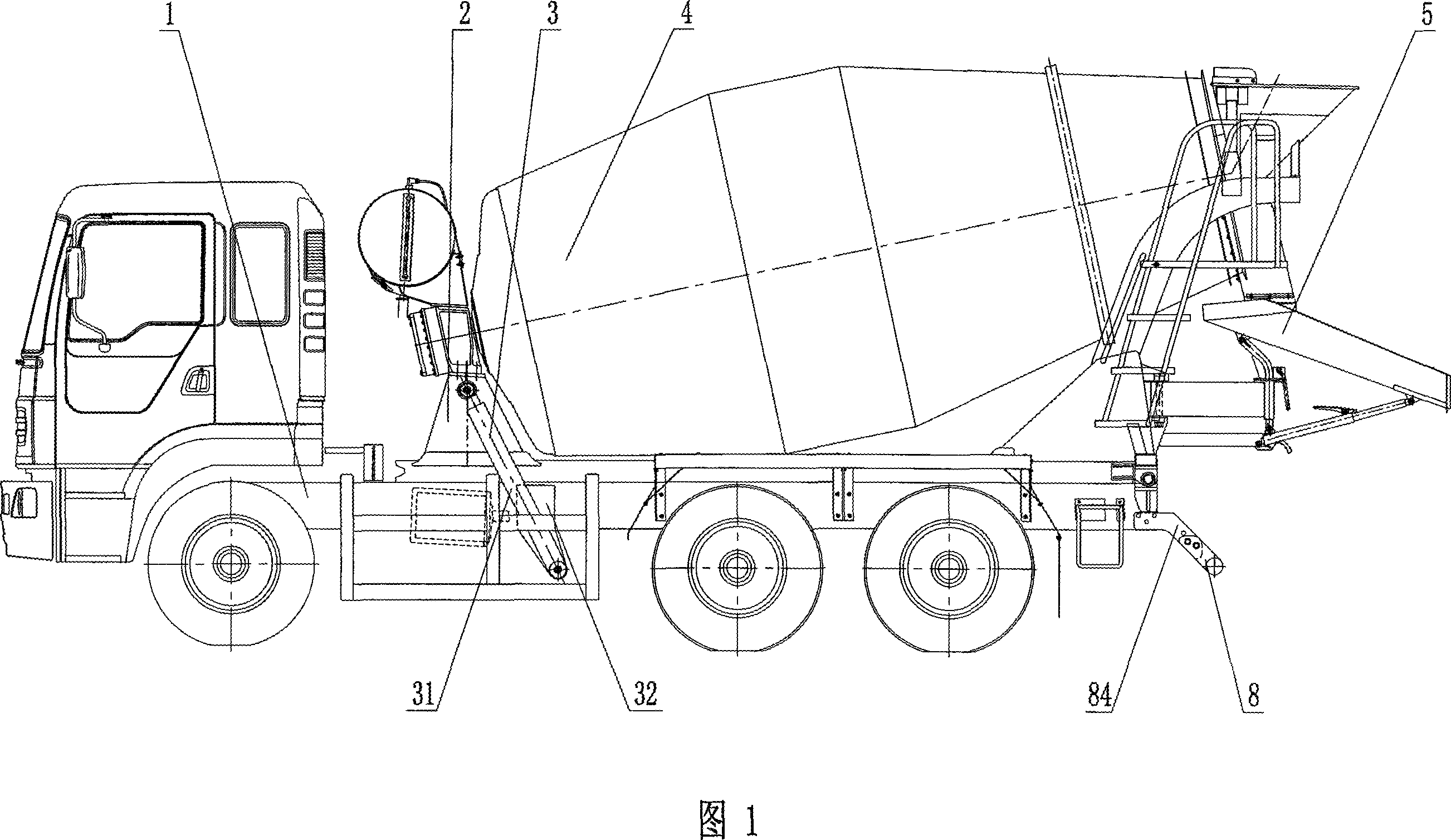

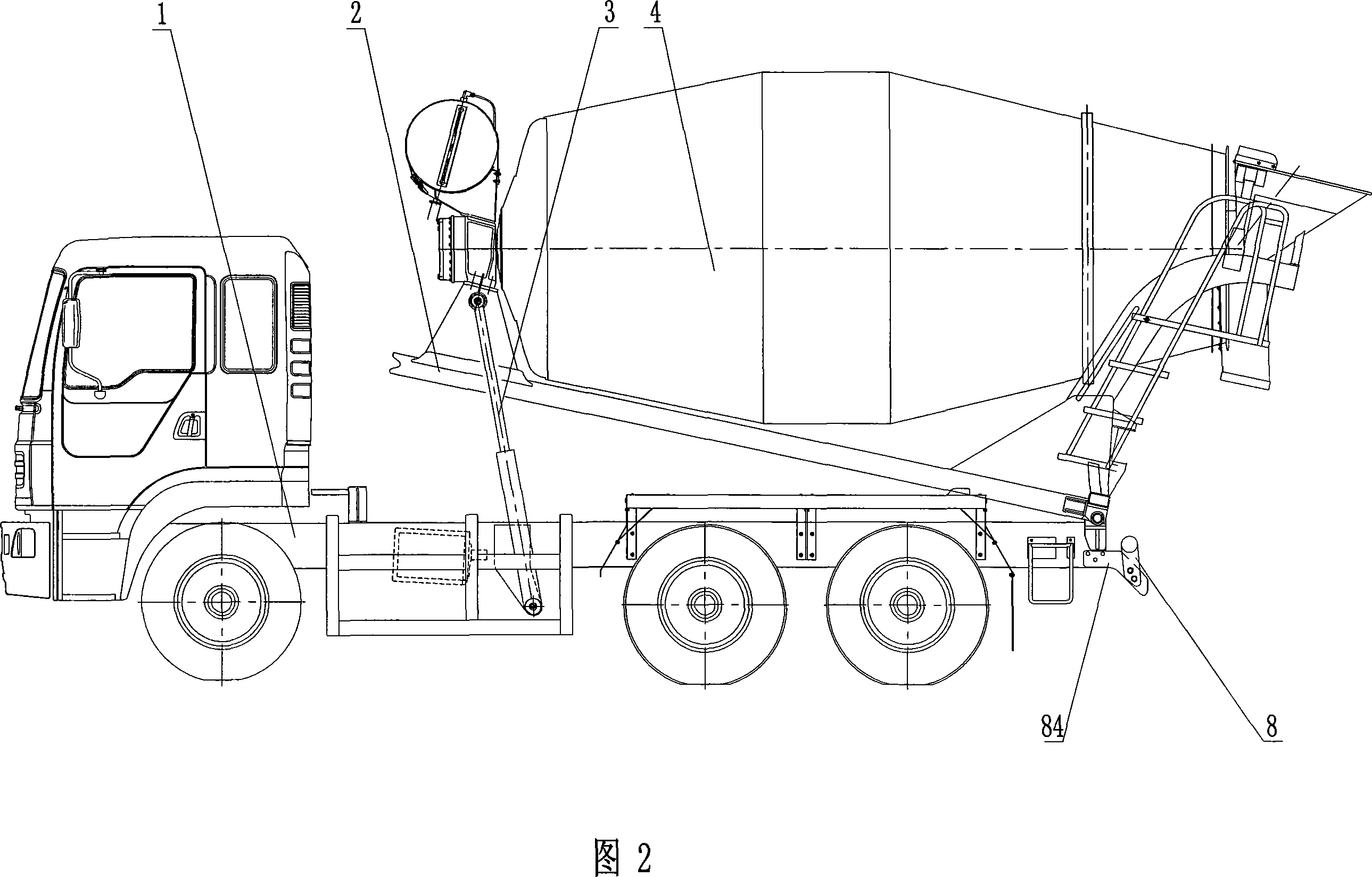

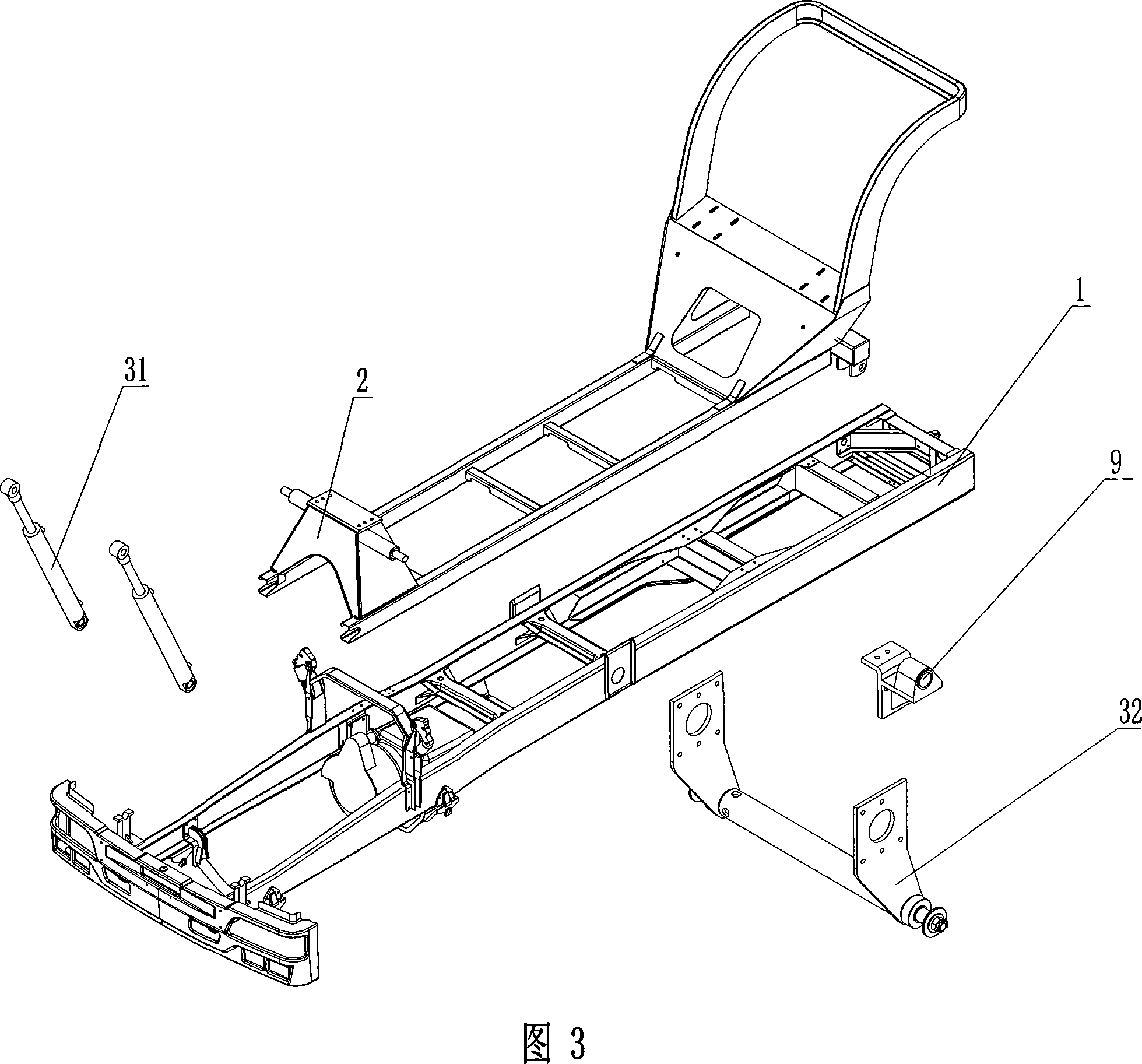

Concrete mixing truck with lifting device

ActiveCN101053980AIncrease the output speedHigh degree of mechanizationConcrete transportationDischarging apparatusVehicle frameSlope angle

The present invention relates to a concrete agitator truck with a lift system and a long life, which is capable of realizing unloading at different slope angles, preventing the agitator drum and subframe from jumping during the running process of the vehicle, and being used for a plurality of operating conditions. The concrete agitator truck with a lift system comprises a chassis, a subframe and a agitator drum supported on the subframe, wherein the tail part of the subframe is hinged with the tail part of the chassis, the front end of the subframe is provided with the lift system which comprises a lift oil cylinder and an oil cylinder support which is arranged on the chassis, the lift oil cylinder is hinged with the oil cylinder support at one end and is hinged with the subframe at the other end.

Owner:SANY HEAVY IND CO LTD (CN)

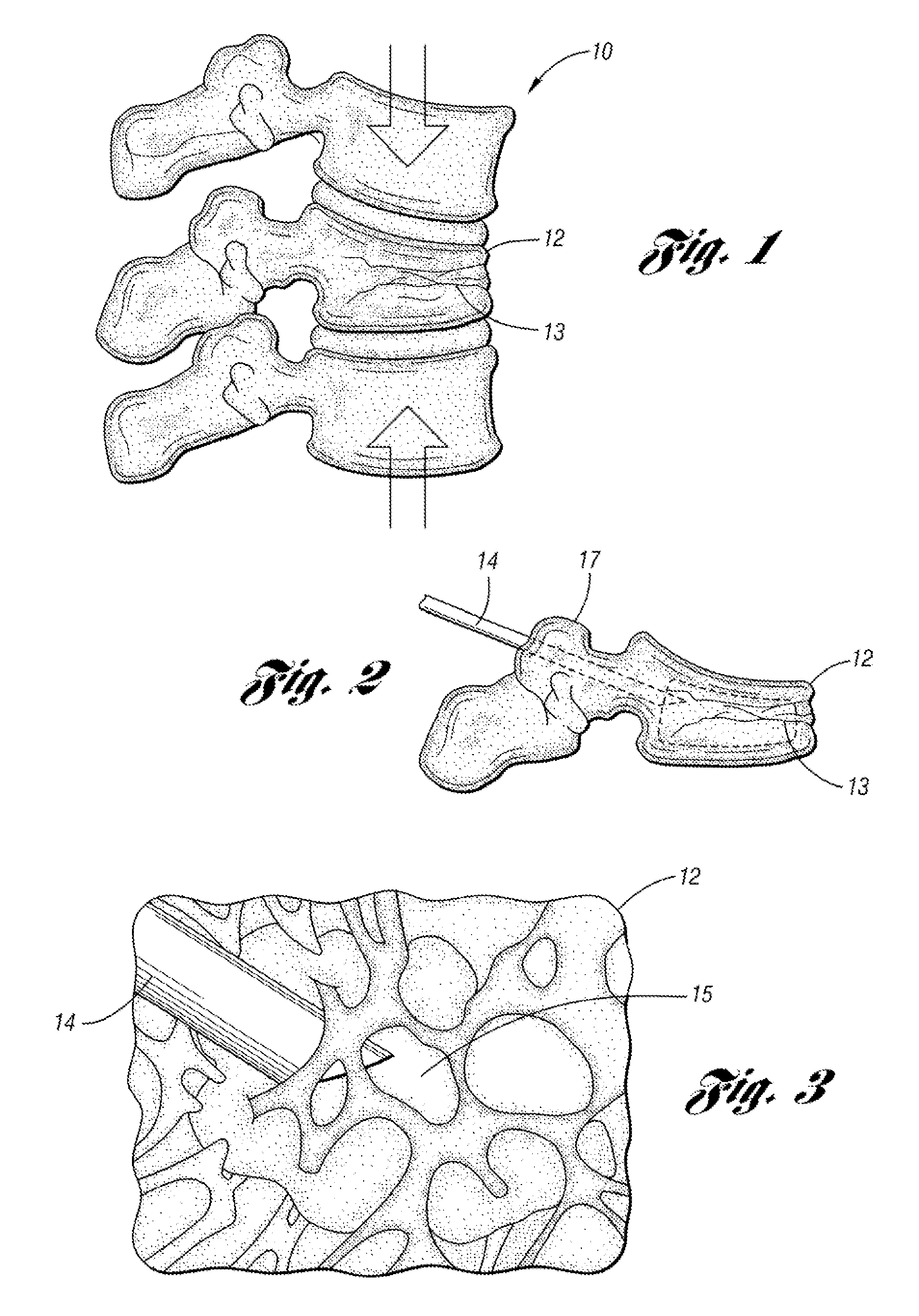

Bone cement mixing and delivery device and method of use

InactiveUS20090281549A1Well mixedEasy dispensingDischarging apparatusRotary stirring mixersBone cementBiomedical engineering

Owner:COOK INC

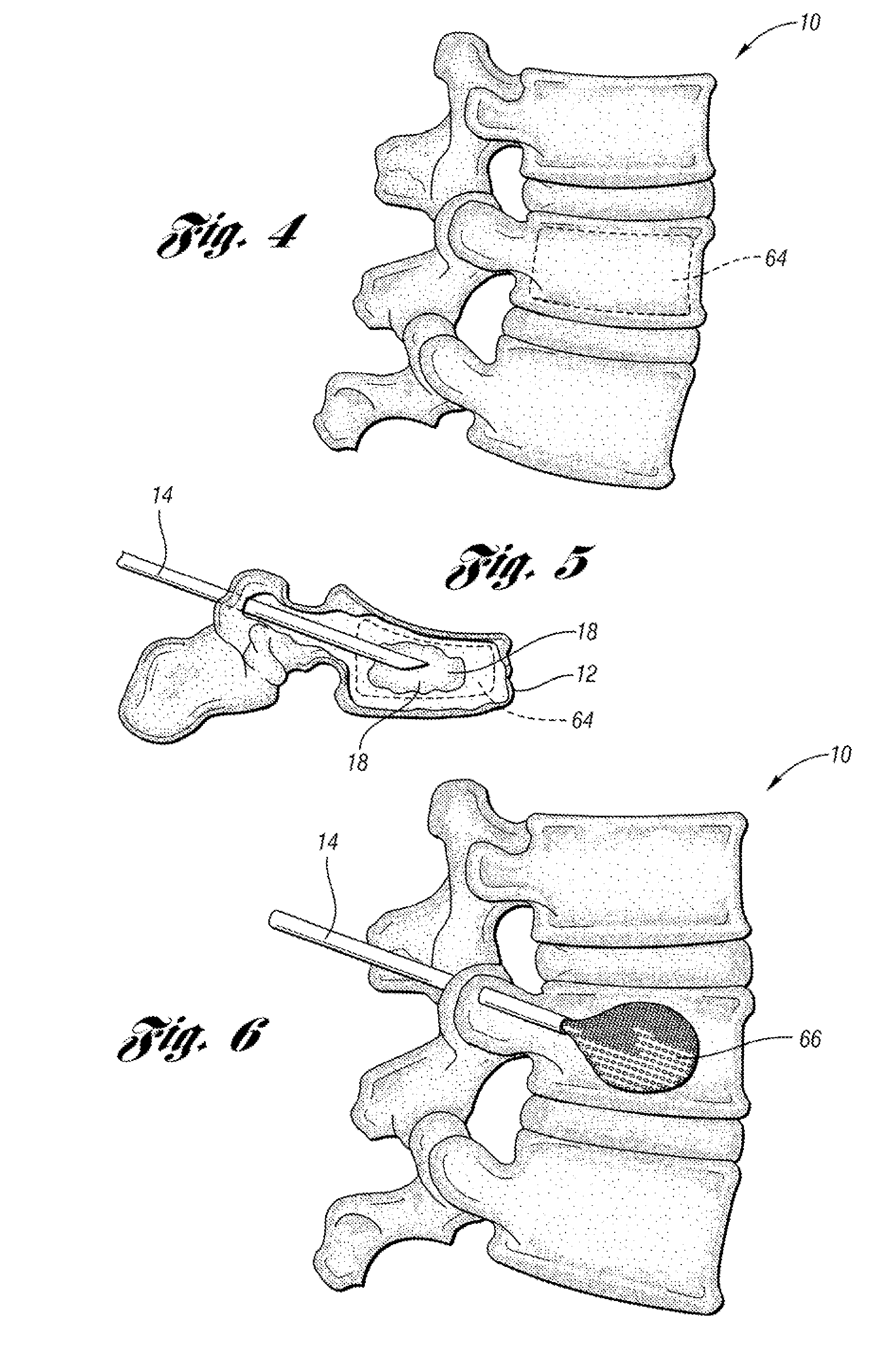

Progressing cavity pump or motor

ActiveUS7407372B2Enlarged cavityEliminate needReaction enginesRadial flow pumpsEngineeringMechanical engineering

A progressing cavity pump or a motor includes, in one embodiment, an outer tube 12, an inner tube 14, and a plurality of apertures 16. A pair of annular seal glands 18 seal the stator material to the outer tube. The stator material is injection molded into the inner tube and passes through the plurality of apertures and into an annular gap between the inner tube and the outer tube. In other embodiments, the outer housing for a progressing cavity pump or motor is provided with one or more grooves, with each groove having an outer surface radius less than the outer housing surface radius. A plurality of apertures are provided in fluid communication with the grooves. According to the method of the invention, the stator material is injected into the apertures and fills a space radially outward of the apertures to bond the stator materiaal to the outer housing.

Owner:ROBBINS & MYERS ENERGY SYST

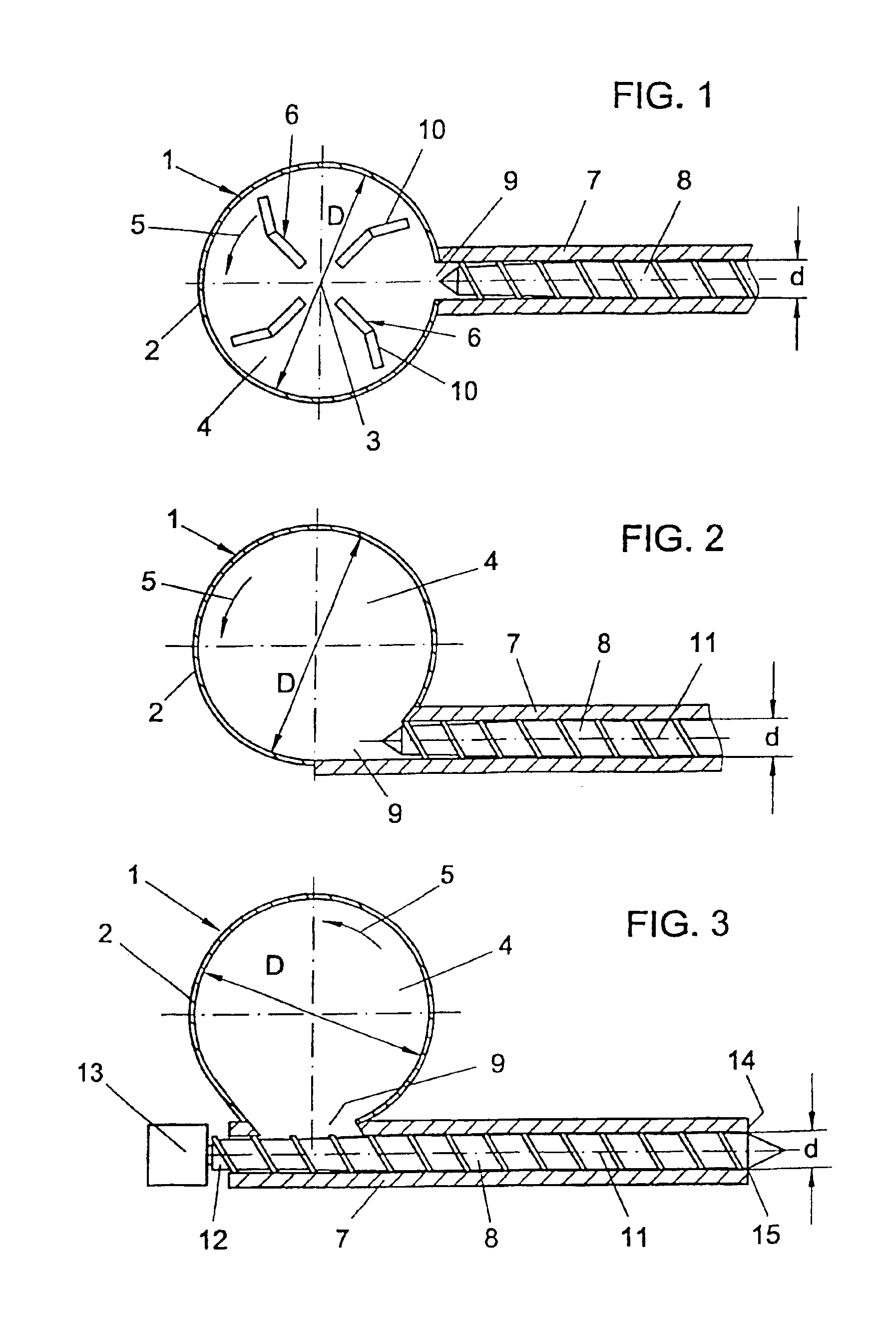

Apparatus for pre-treatment and subsequent plastification or agglomeration of synthetic plastic materials

InactiveUS6883953B1Quality improvementIncrease productionDischarging apparatusMixing operation control apparatusPlastic materialsPre treatment

An apparatus for pre-processing and subsequent plastification or agglomeration of synthetic plastic materials, in particular thermoplastic waste plastics for recycling purposes, has a receptacle (1) in which at least one comminuting tool (6) circulates. The housing (7) of a screw (8) is connected to the receptacle (1). The diameter (D) of the receptacle (1) has the following relationship to the screw diameter (d):D=10.{square root over (K.d2)}, wherein D is the inner diameter of the receptacle in mm,d is the screw diameter in mm andK is a dimension-less constant which amounts to at least 190.Thereby the dwell times of the synthetic plastic material within the receptacle (1) are kept at optimal values.

Owner:BACHER HELMUT +2

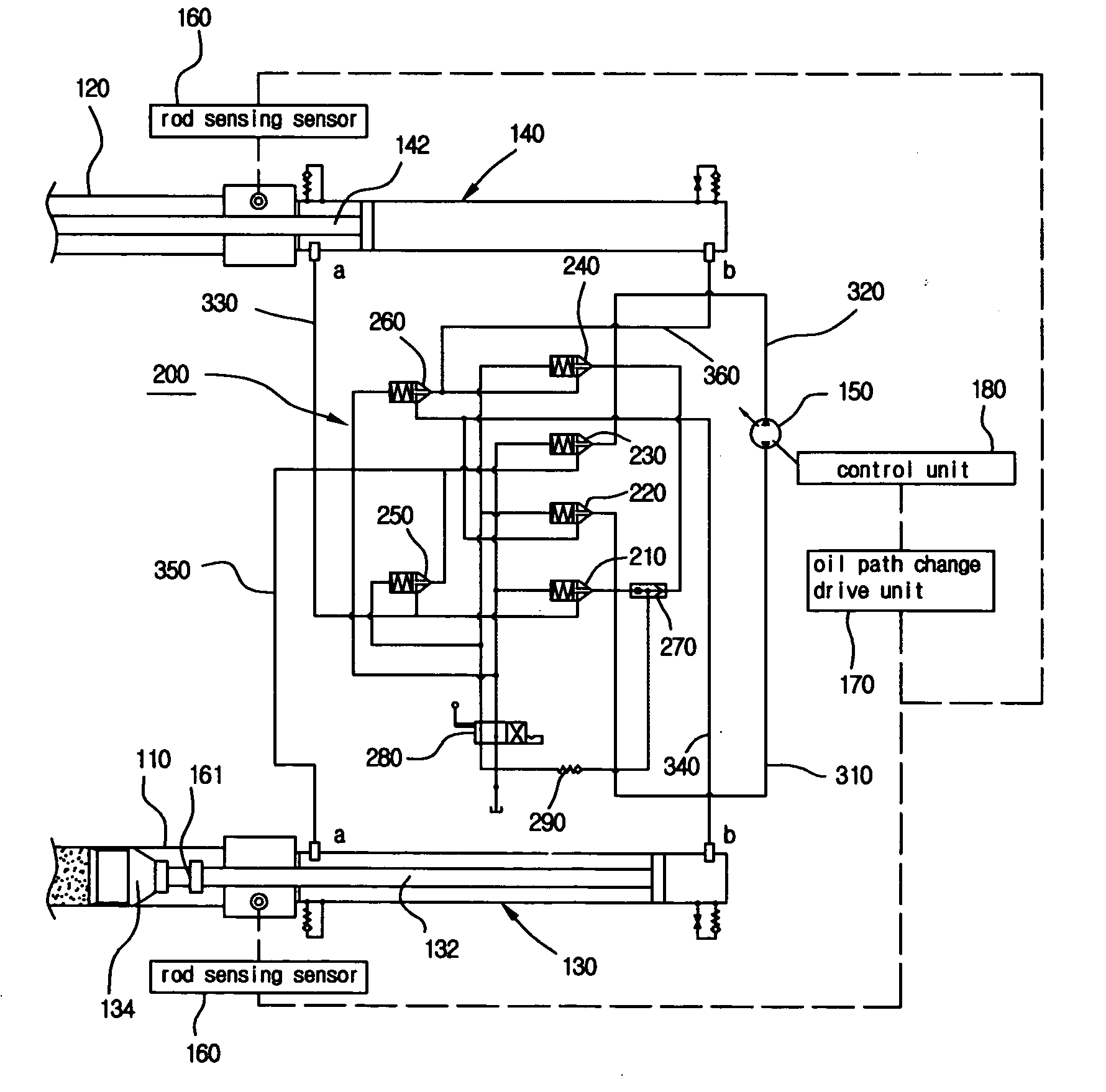

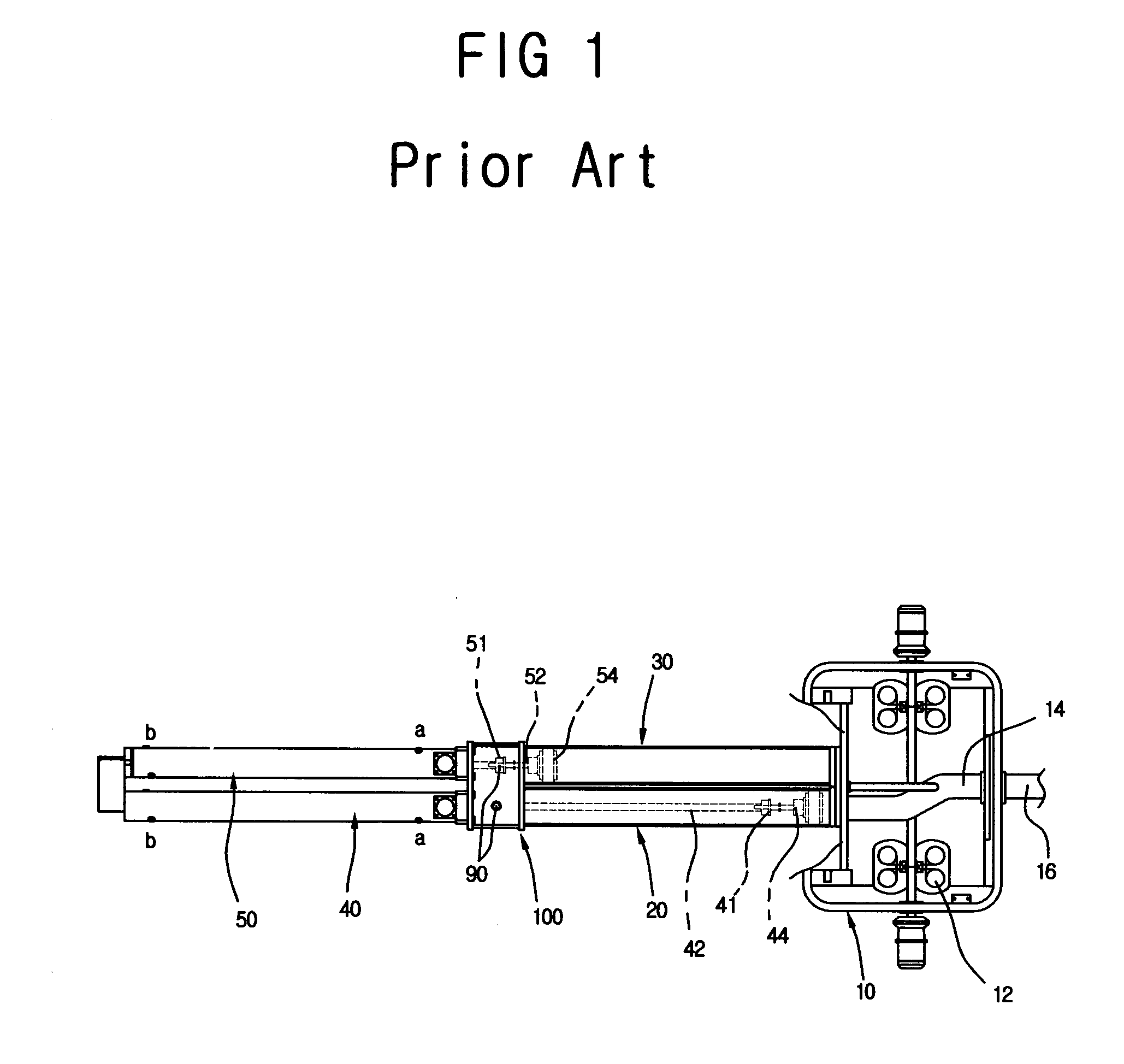

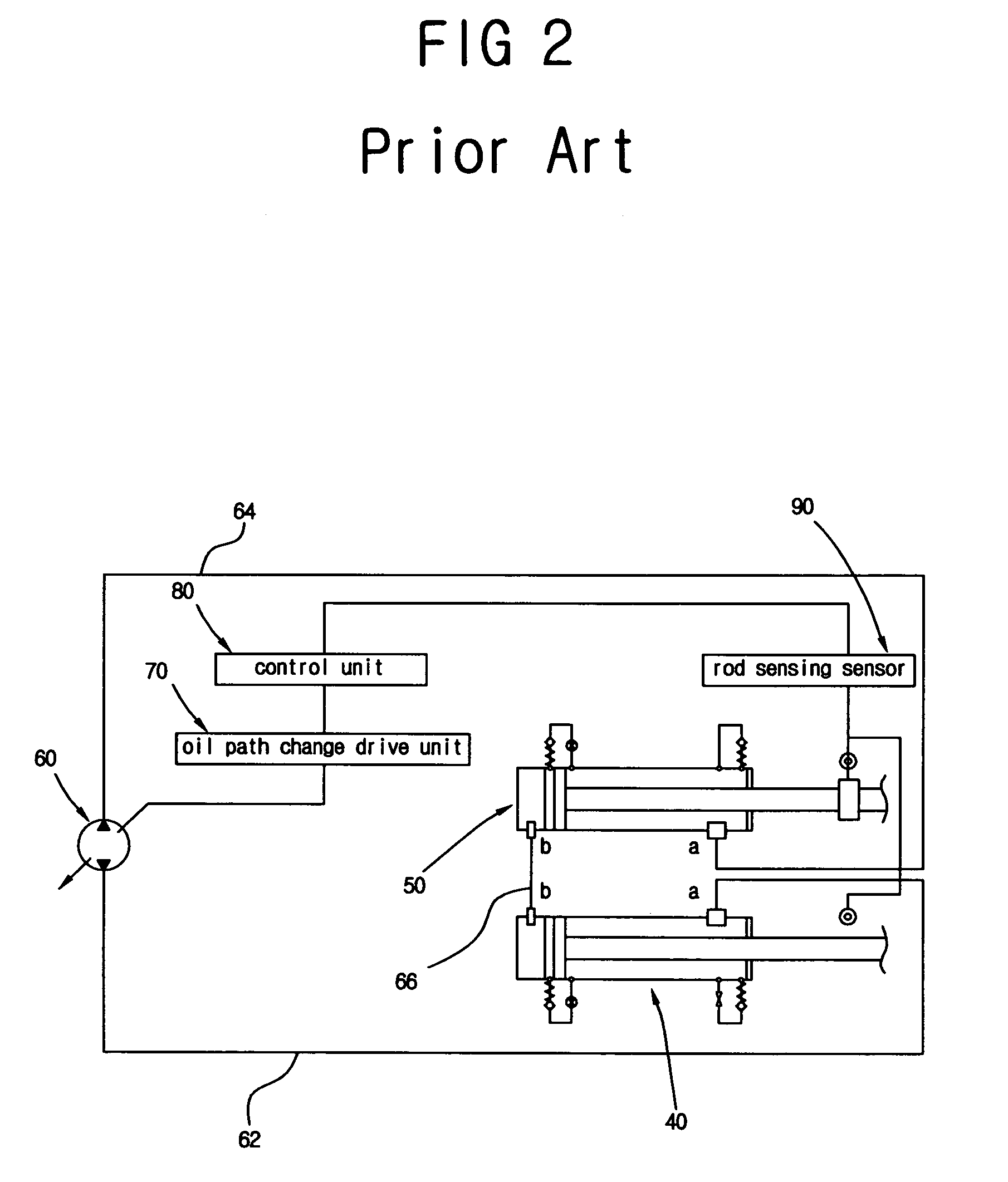

Concrete-mortar transfer system of concrete pump car

InactiveUS20050232069A1Low costEasy to operateServomotor componentsServomotorsReverse currentTransfer system

The present invention relates to a concrete transfer system of a concrete pump car which comprises a pair of concrete input tubes mounted in union to a pair of communication holes punched to the inside surface of a hopper, first and second drive cylinders mounted on the same lines of the concrete input tubes for sucking and transferring the concrete by forward and backward movements of pressure pistons mounted to rod ends, an oil pressure pump for supplying the fluid to the first and second drive cylinders, a rod sensing sensor for sensing the movement of the rods of the first and second drive cylinders, a control unit for performing a predetermined control operation by receiving the sensing signal of the rod sensing sensor, an oil path change drive unit for supplying selectively the fluid with the first and second drive cylinders according to the control signal of the control unit, the concrete transfer system of the concrete pump car comprising: a first logic valve to sixth logic valves, a reverse current preventive device, and a high / low pressure selection valve.

Owner:DNS

Mortar mixing apparatus

A mortar mixing apparatus includes a screw conveyor disposed below the bottom of a mixing container in which a selectively operable agitator is located. An elongate opening in the bottom of the mixing container is open into the housing of the screw conveyor so that mixed mortar may flow into the screw conveyor. The screw conveyor may be rotated in a reverse direction to force materials upward into the mixing container, or it may be operated in a forward direction to convey mortar away from the mixing container. The agitator and the screw conveyor are independently driven by hydraulic motors.

Owner:CUMMER THOMAS J

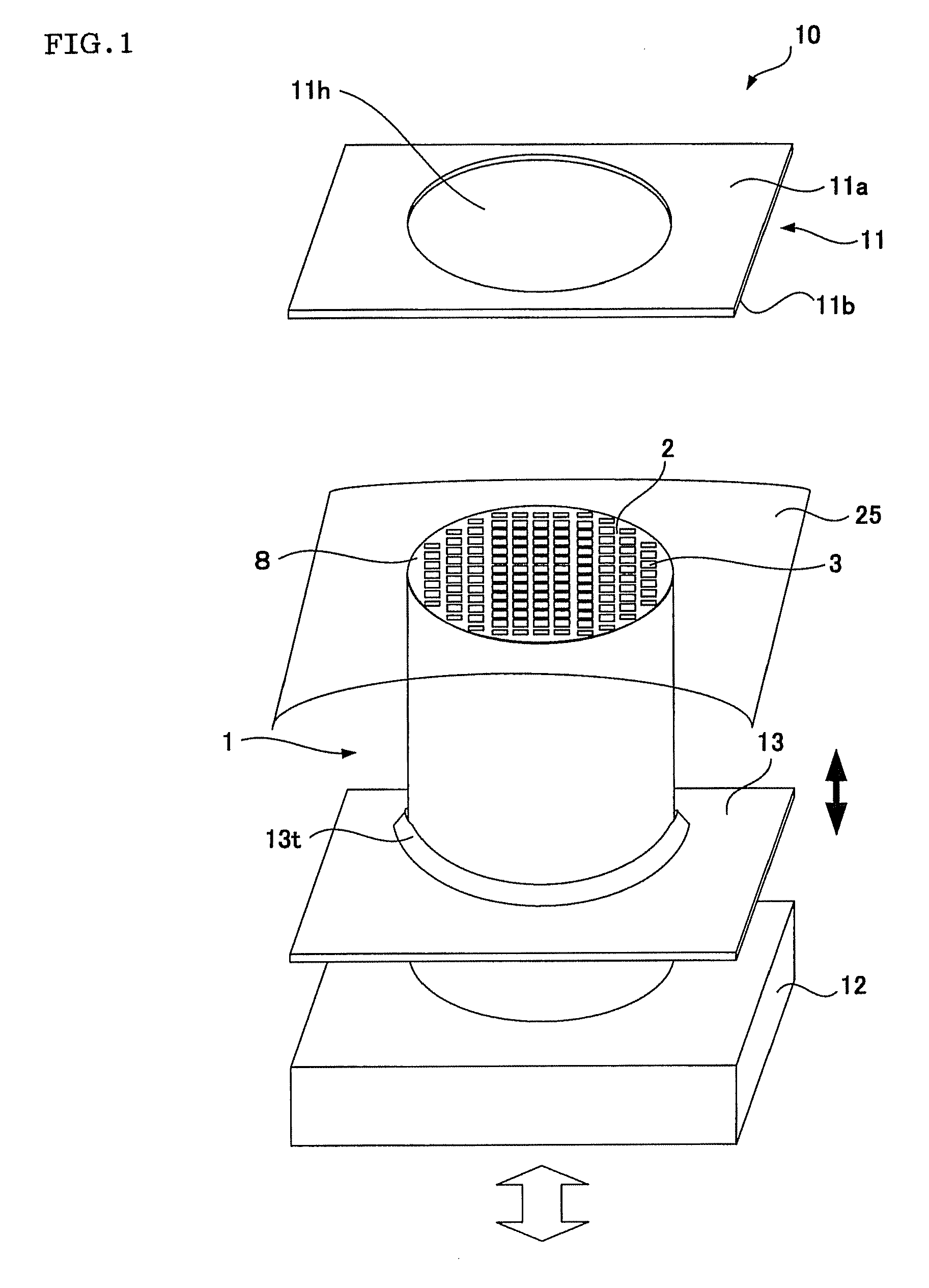

Manufacturing apparatus of plugged honeycomb structure and manufacturing method of the same

ActiveUS7807085B2Shorten production timeReduce manufacturing costButtonsDispersed particle filtrationManufactured apparatusEngineering

A manufacturing apparatus of a plugged honeycomb structure includes a table portion having a through hole into which the end of a honeycomb structure is inserted, positioning means for positioning and holding the honeycomb structure in the through hole of the table portion in such a manner that its end face appears on the side of a first face of the table portion, and a film holding portion fixing the remaining portion of a film on the side of a second face of the table portion. After or before fixing the film, holes corresponding to openings of cells of the honeycomb structure are formed in the film, and a plugging material is filled into the holes, to manufacture the plugged honeycomb structure using the apparatus.

Owner:NGK INSULATORS LTD

High speed and direct driven rotating equipment for polyolefin manufacturing

An apparatus and method for melting polymer is provided. In at least one embodiment, the apparatus includes a housing, two or more rotatable members at least partially contained within the housing, where each rotatable member having a shaft coupled thereto. The apparatus also includes a motor having a drive shaft directly coupled to the shaft of the rotatable members such that the rotatable members rotate at a speed of the motor drive shaft. The rotatable members are preferably non-intermeshing and counter-rotating.

Owner:UNIVATION TECH LLC

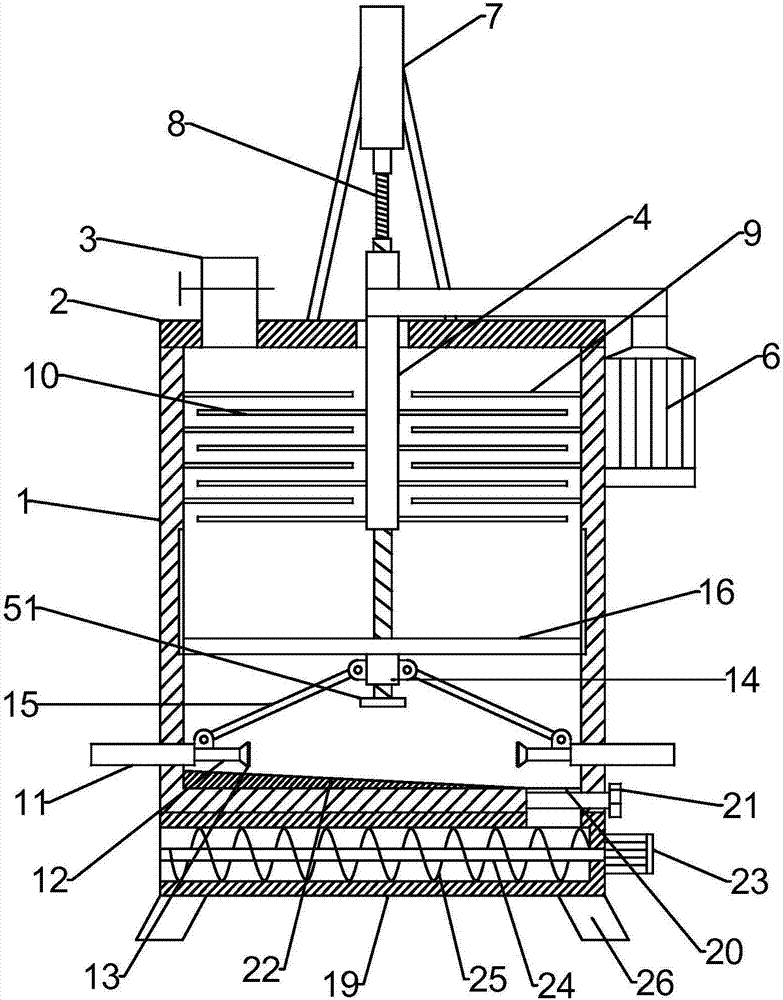

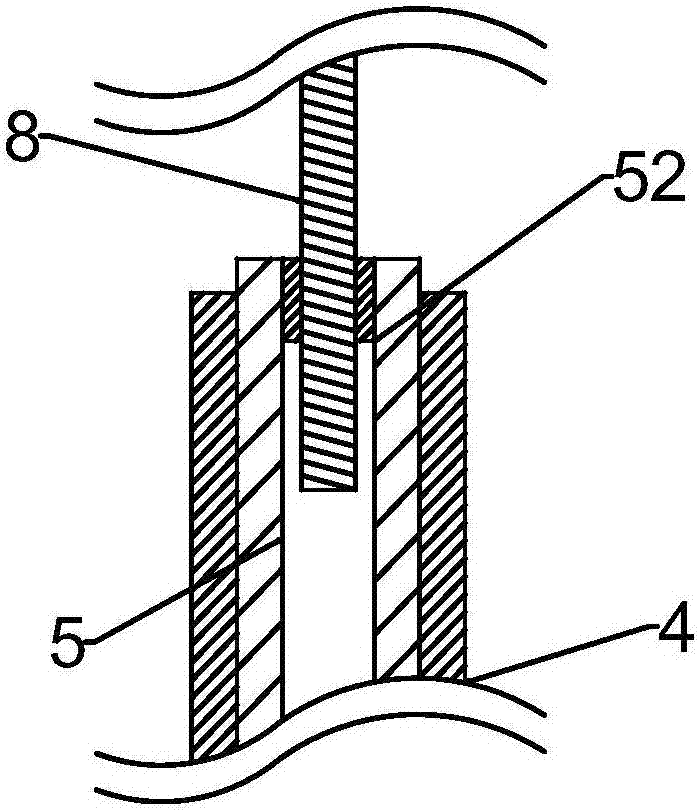

Efficient mixing and stirring device of mortar slurry for building construction

InactiveCN107297827AAvoid wastingAvoid affecting useDischarging apparatusCement mixing apparatusMalletArchitectural engineering

The invention discloses a high-efficiency mixing and stirring device for mortar slurry for building construction, which includes a bottom plate, a left side plate, a mixing bucket, a supporting leg, a shock absorbing device, a semicircular material retaining plate, an electric push rod, a collecting frame, and a frequency conversion motor , stirring shaft, stirring rod, scraper, sliding sleeve, return spring and knocking device, the knocking device includes motor, disc, connecting rod, sector gear, rack and rubber hammer, the present invention is provided with scraper , can scrape off the mortar slurry on the inner wall of the mixing tank, avoid wasting raw materials and affect the next use. It is equipped with a frequency conversion motor, a stirring shaft, a stirring rod, a sliding sleeve, a return spring and a stirring rod, which are adjusted through the above components. The mixing range improves the mixing efficiency. It is equipped with a shock absorbing device and a knocking device. Through the cooperation of the above components, the mixing barrel is continuously shaken, which further improves the mixing efficiency. material.

Owner:安庆海维环保设备有限公司

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7513963B2Increase volumeSmall sizeSolid waste managementTransportation and packagingProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

Slurry mixer constrictor valve

An apparatus and method for controlling the flow of a slurry is provided which includes using a constrictor valve on a mixing and dispensing apparatus. The constrictor valve includes a first guide plate and a second guide plate that are spaced a distance apart along the length of the conduit. Extending between the two guide plates, a plurality of elongate members have first and second ends engaged on the first and second guide plates. Upon rotation of at least one of the first and second guide plates, the elongate members are configured to impart pressure on, and constrict the conduit.

Owner:UNITED STATES GYPSUM CO

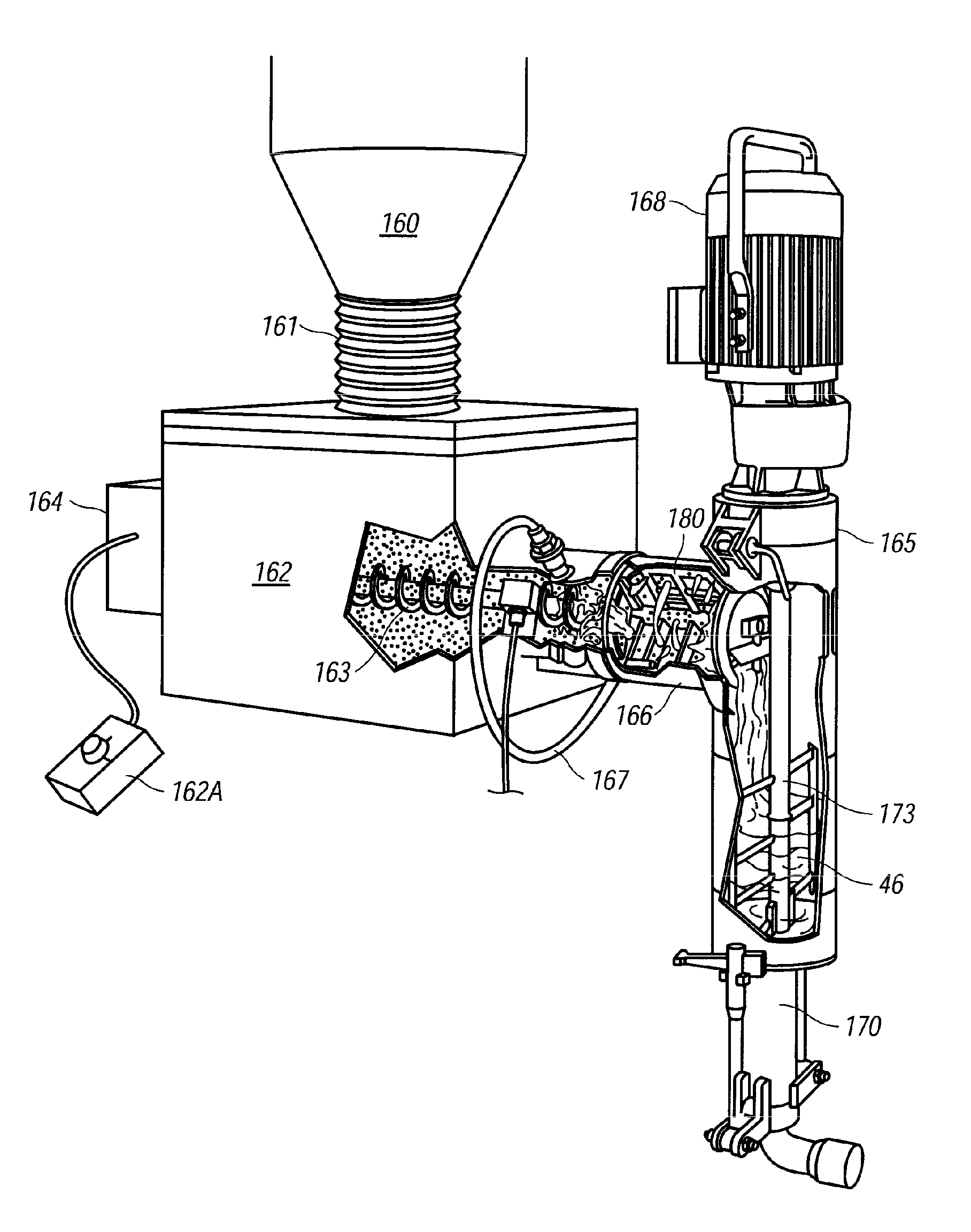

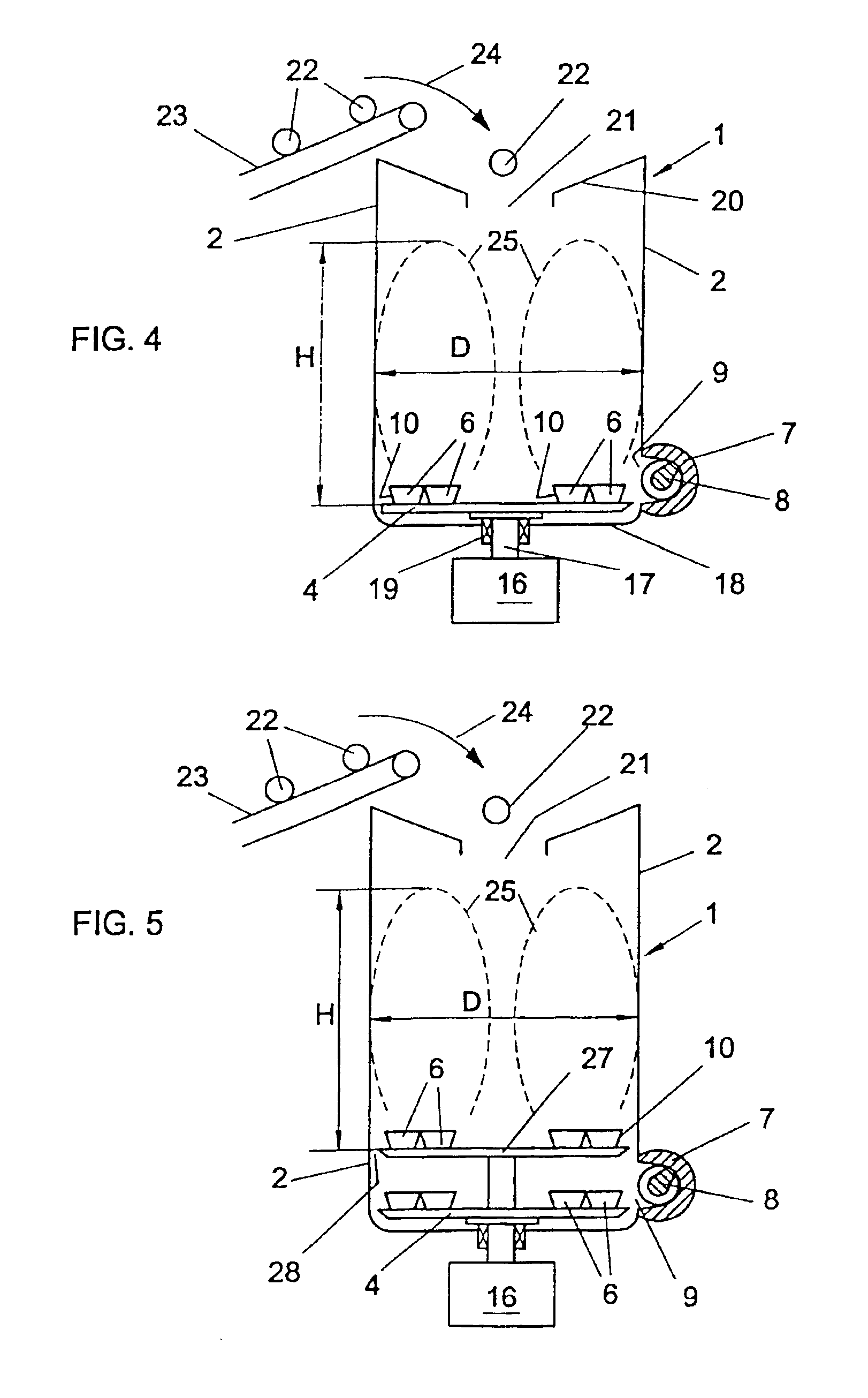

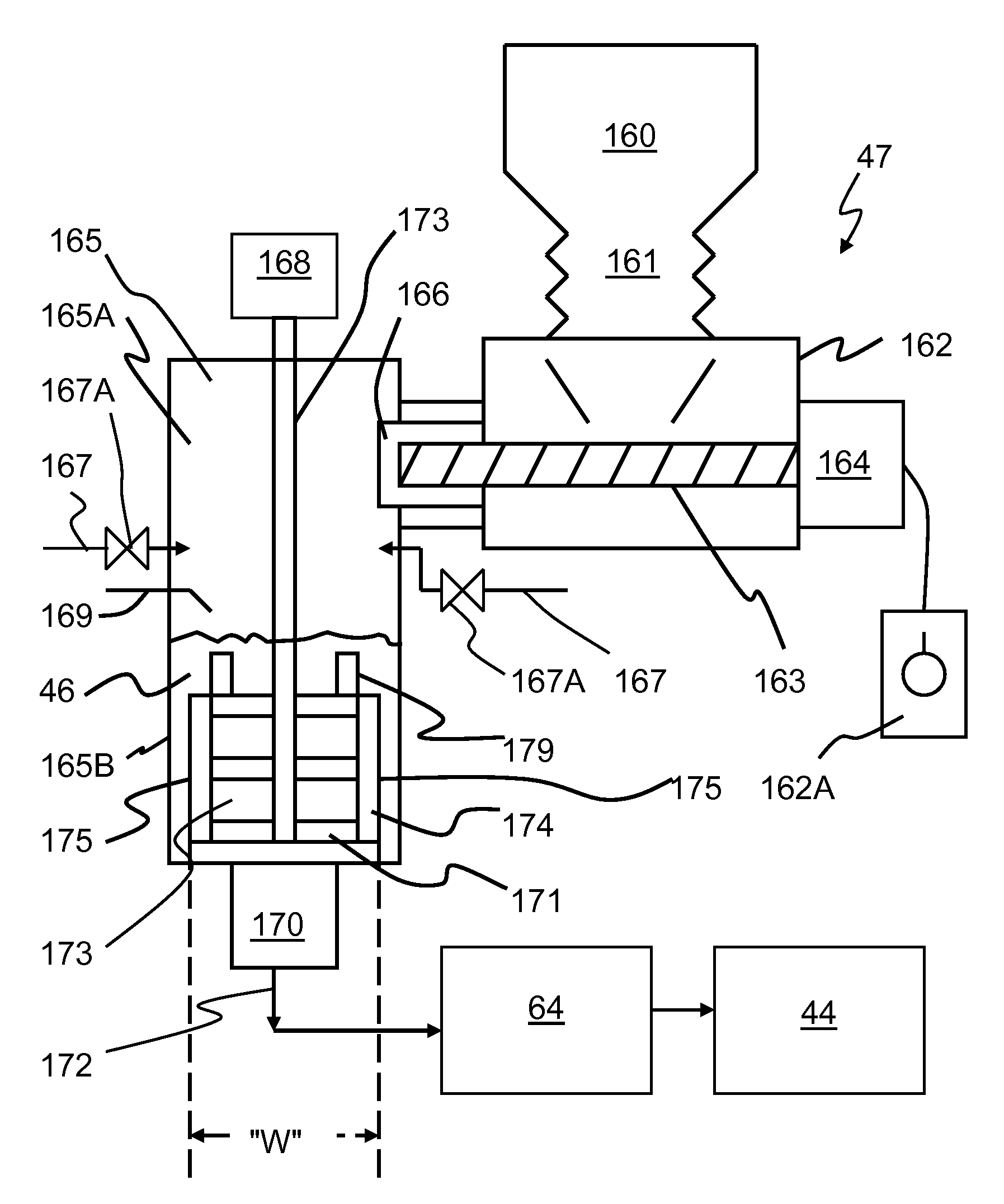

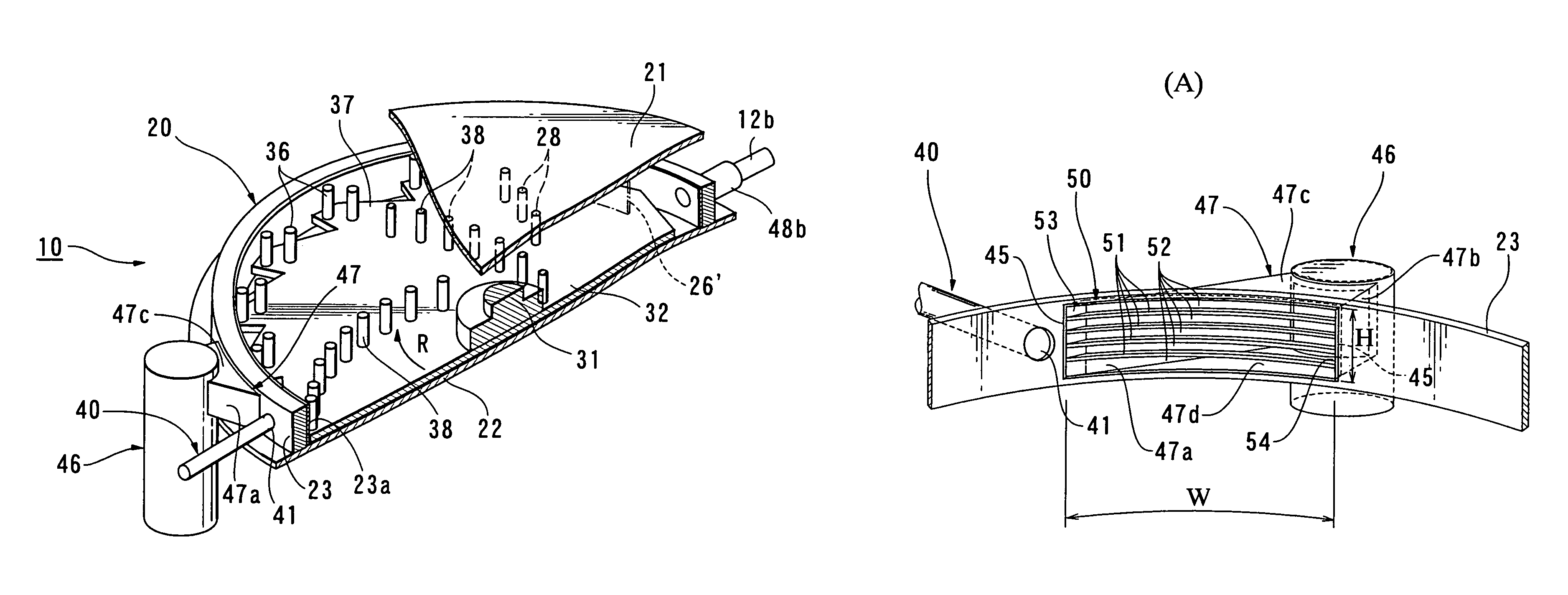

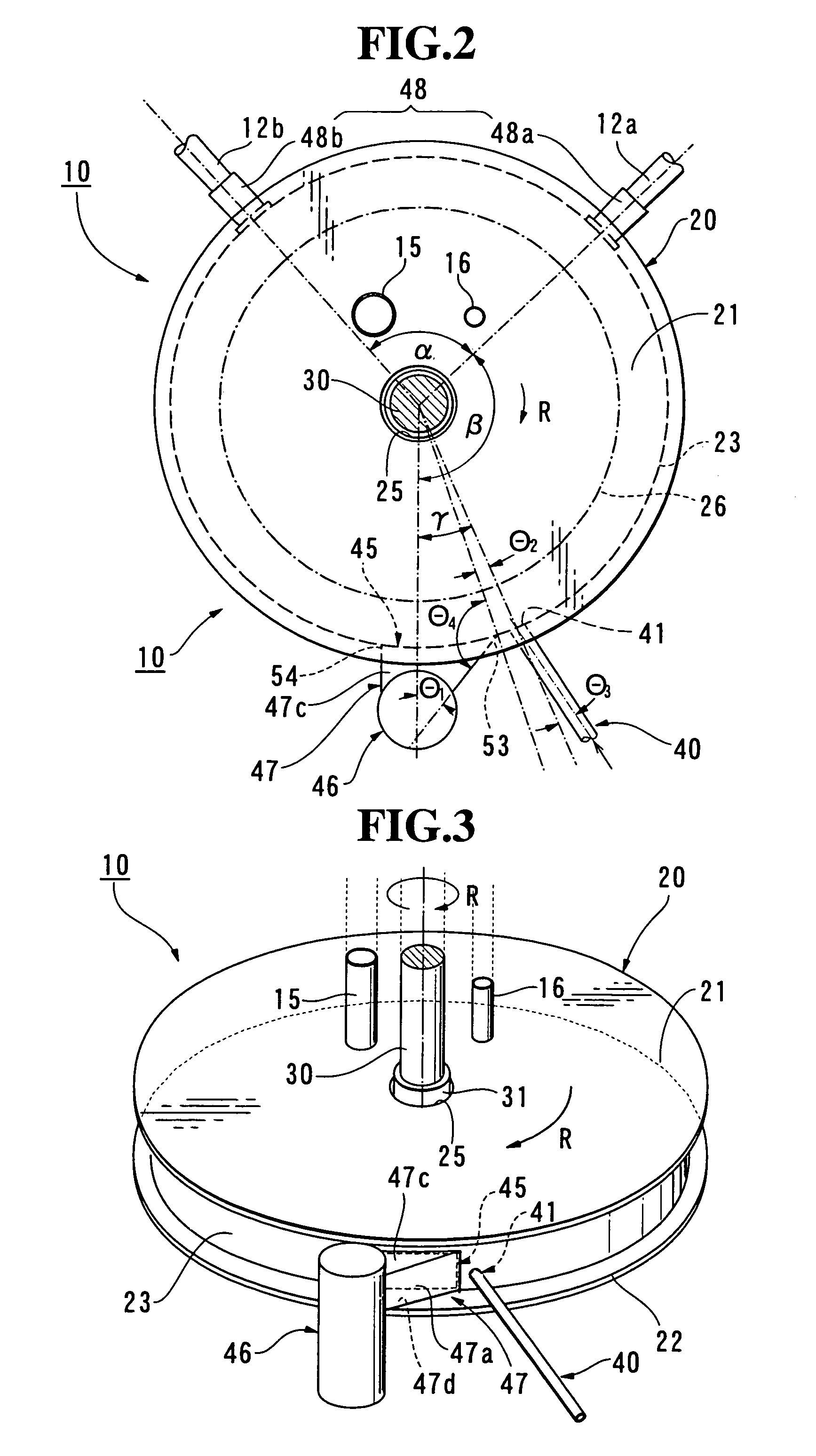

Mixer and mixing method for producing gypsum slurry

ActiveUS7690834B2Increase flow rateReduce in quantityMixing methodsTransportation and packagingProduction rateSlurry

The present invention provides a mixer and a mixing method which enable stable supply of slurry at a high flow rate with foam being uniformly mixed therein, and which enable reduction in consumption of foam to be fed to the slurry. The mixer (10) has a housing (20), a rotary disc (32), a slurry outlet port (45), a slurry delivery conduit (46) and a hollow connector section (47). A foam feeding port (41) is disposed in a predetermined position of an annular wall or the hollow connector section. The foam feeding port feeds the foam to the slurry, immediately before the slurry enters the slurry outlet port, or feeds the foam to the slurry in the hollow connector section. The slurry and the foam mix with each other at the slurry outlet port or on its downstream side. The foam is not substantially subjected to agitation impact of the mixer and a quantity of loss of the foam is reduced. The foam is uniformly mixed with the slurry even when the flow rate of slurry is increased, and therefore, the production rate of gypsum boards can be increased.

Owner:YOSHINO GYPSUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com