High speed and direct driven rotating equipment for polyolefin manufacturing

a technology of rotating equipment and polyolefin, which is applied in the direction of clay mixing apparatus, rotary stirring mixer, mixing/kneading with horizontally mounted tools, etc., can solve the problems of consuming energy, requiring maintenance time and expense, and expensive addition of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

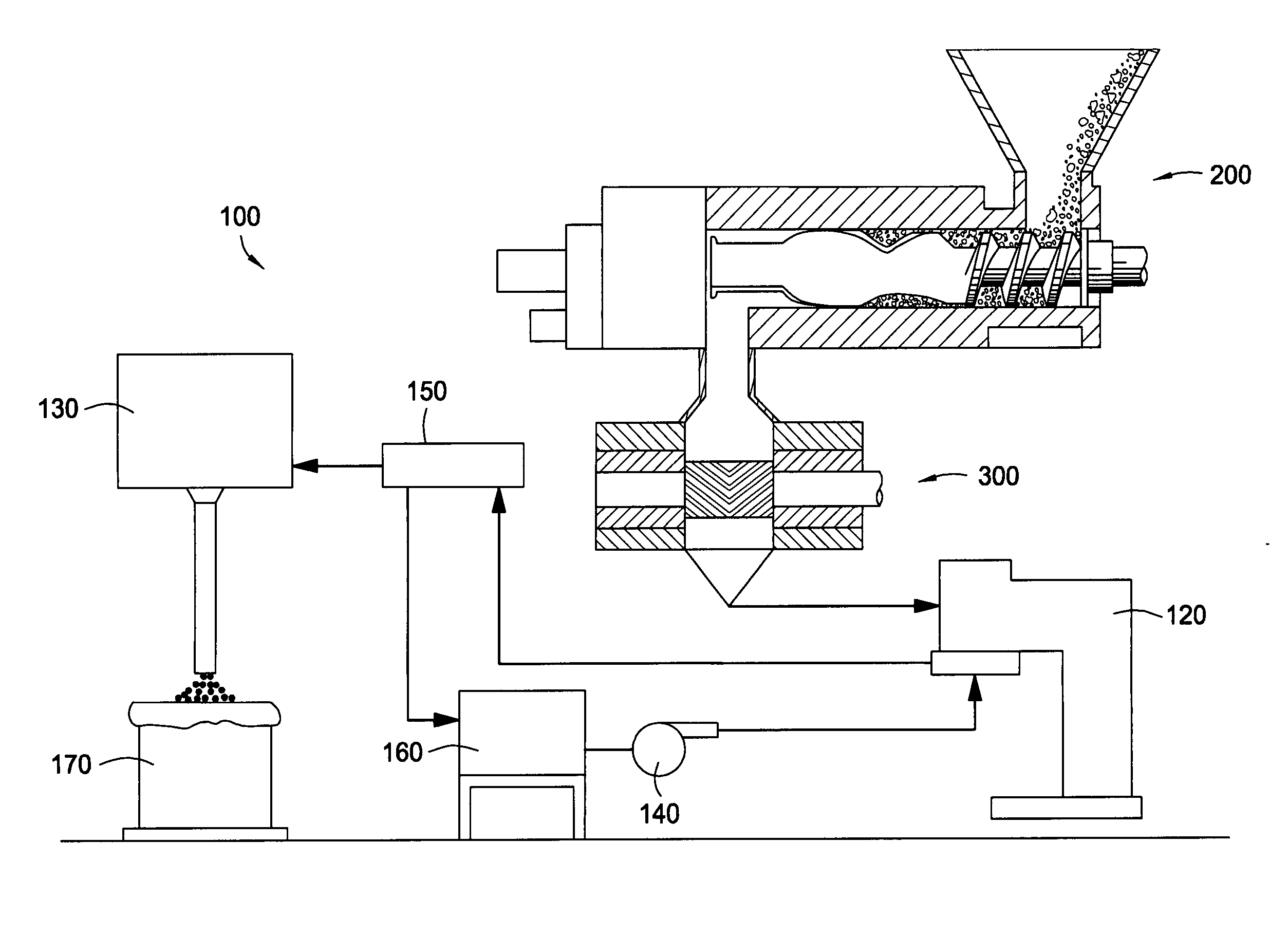

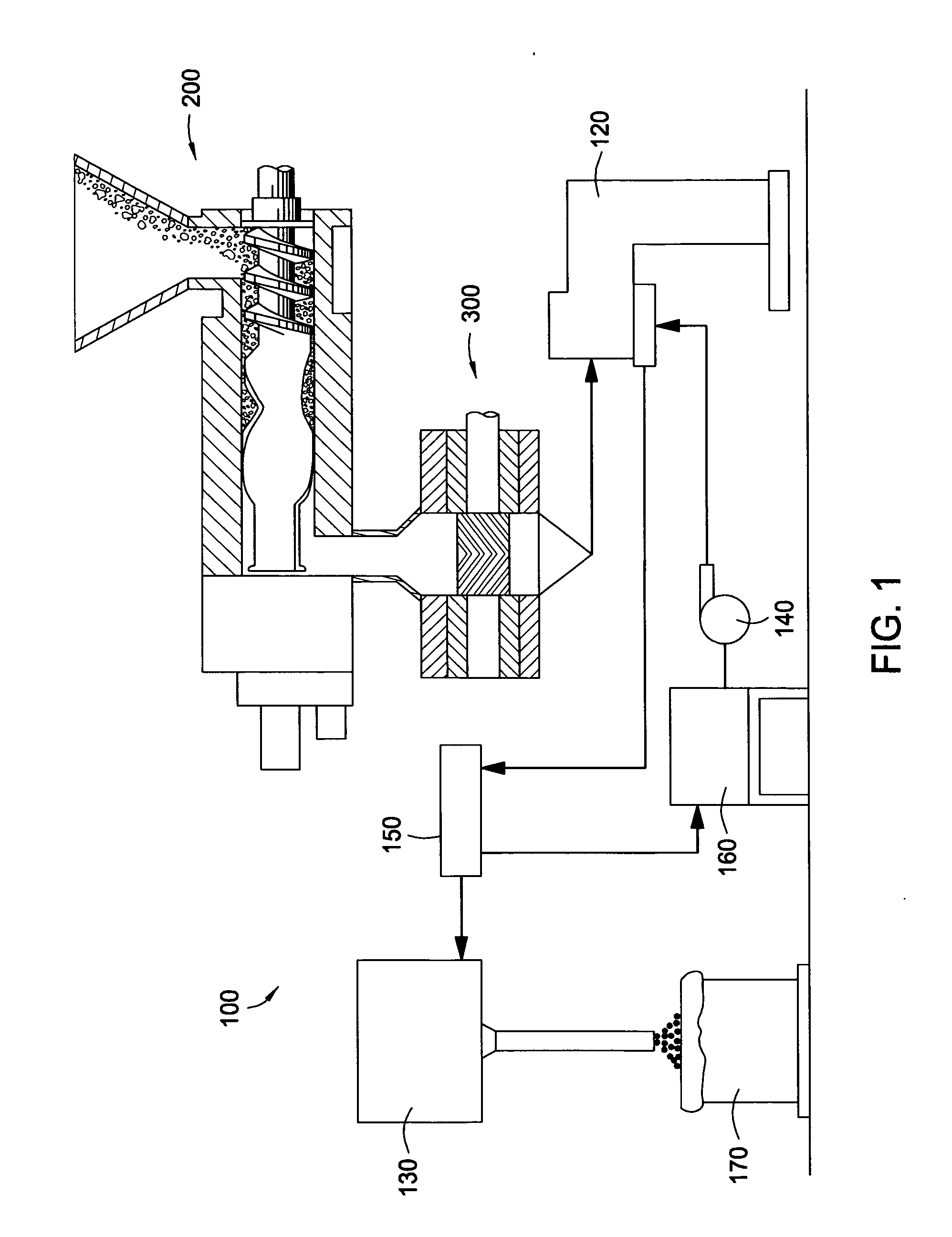

[0018]FIG. 1 is a schematic diagram showing an illustrative polymer pelletizing system 100. The pelletizing system 100 includes one or more pelletizers 120, drier systems 130, pumps 140, screens 150, surge tanks 160, material containers 170, continuous mixers 200, and gear pumps 300. In operation, a polymer is introduced to the mixer 200 where the polymer is melted and mixed. The polymer then passes from the mixer 200 to the gear pump 300. The gear pump 300 passes the molten polymer to the pelletizer 120. Pelletizers are well known, and any pelletizer or pelletizing system can be used. Preferably, an underwater pelletizer commercially available from Berstorff, Coperion W&P, Farrel, Gala, Japan Steel Works, Kobe Steel, and so on. At the discharge end of the pelletizer 120, the polymer is slurried to the drier system 140 through a hydraulic loop containing a pump 140, separator screen 150 and surge tank 160. The screen 150 separates the conveying liquid (water) from the pelletized pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residence time | aaaaa | aaaaa |

| Residence time | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com