Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1105results about "Clay mixing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistive RAM having at least one varistor and methods of operating the same

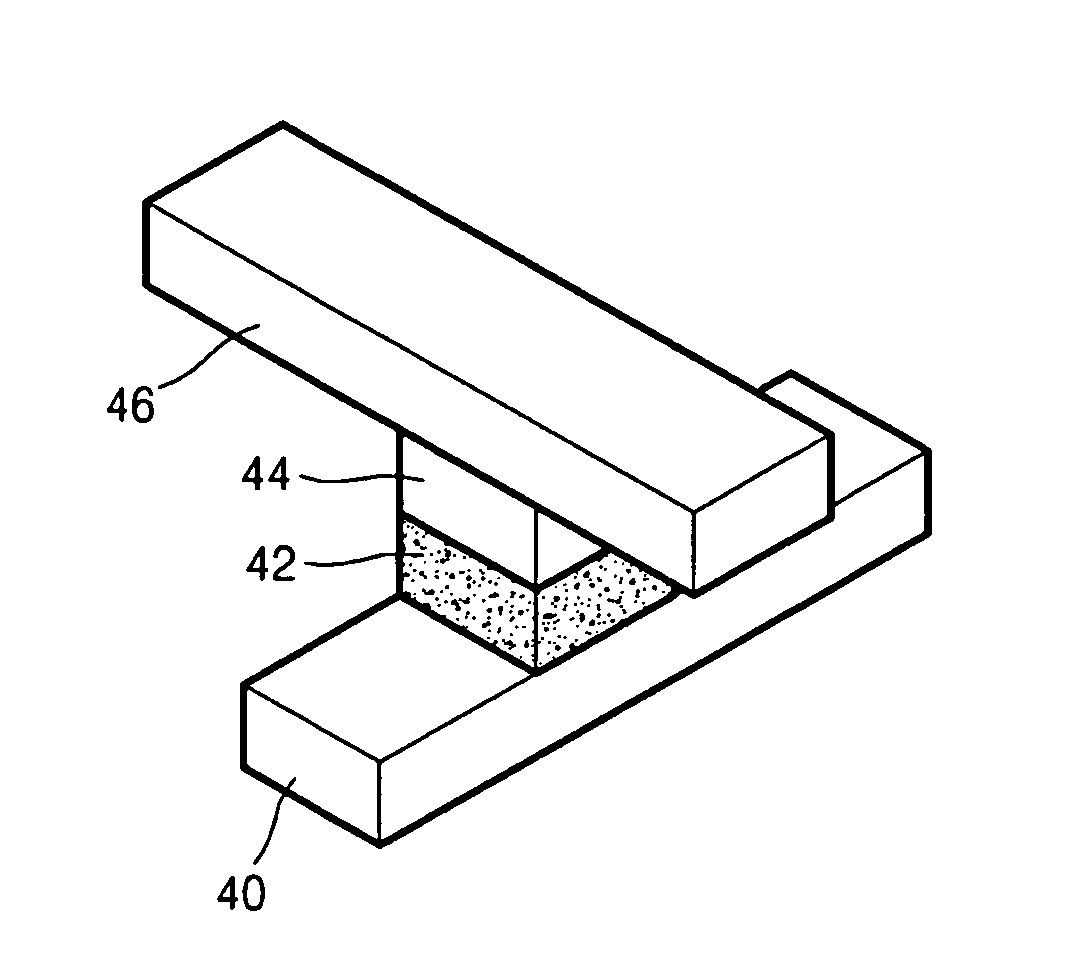

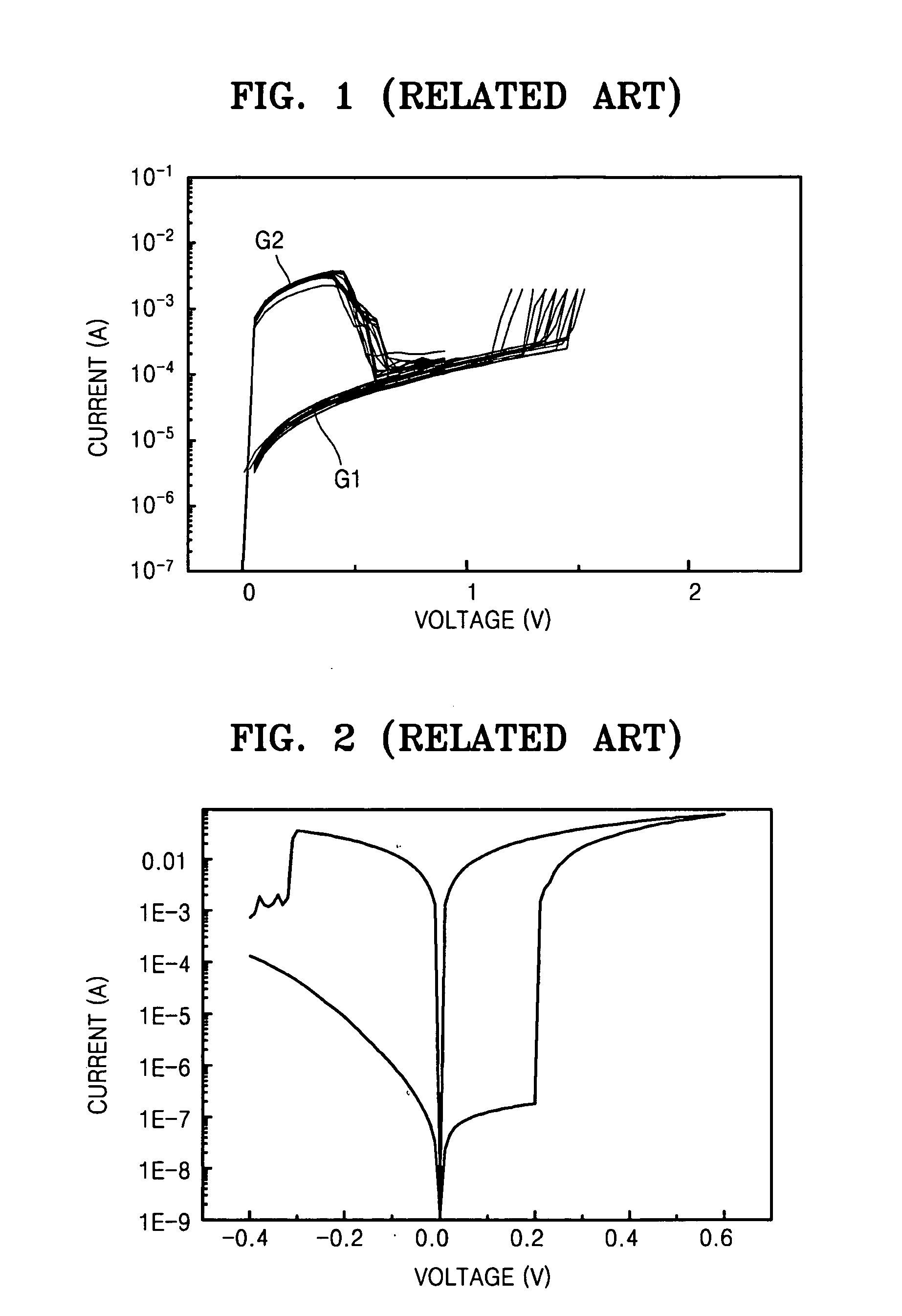

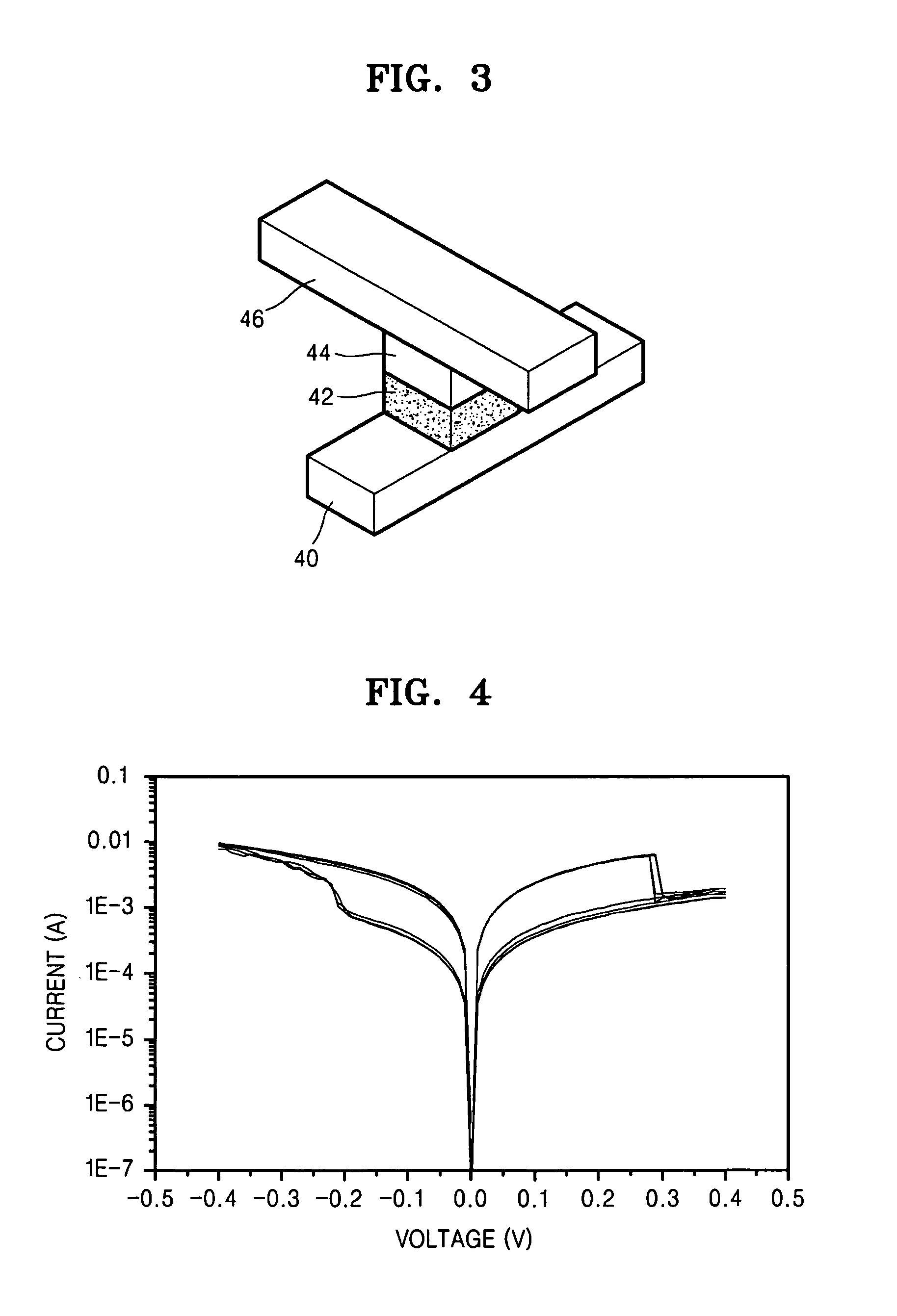

Resistive memory devices having at least one varistor and methods of operating the same are disclosed. The resistive memory device may include at least one bottom electrode line, at least one top electrode line crossing the at least one bottom electrode line, and at least one stack structure disposed at an intersection of the at least one top electrode line and the at least one bottom electrode line including a varistor and a data storage layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Two-step method for dehydrating plastic dispersions

InactiveUS6287470B1Avoid excessive wearQuality improvementLiquid degasificationRotary stirring mixersPolymer scienceOrganic chemistry

The invention relates to a method for dehydrating a two-phase liquid mixture consisting of a thermoplastic synthetic melt phase and an aqueous phase, comprising the following steps: a) coagulation of the two-phase liquid mixture in a first extruder; b) dehydration of the coagulate in a twin screw extruder with a de-watering zone and screws working in an opposite direction; c) separation of constituents by degasifying. The inventive method is characterized in that a single screw extruder or a twin screw extruder with screws working in the same direction is used as a first extruder in step a).

Owner:EVONIK ROEHM GMBH

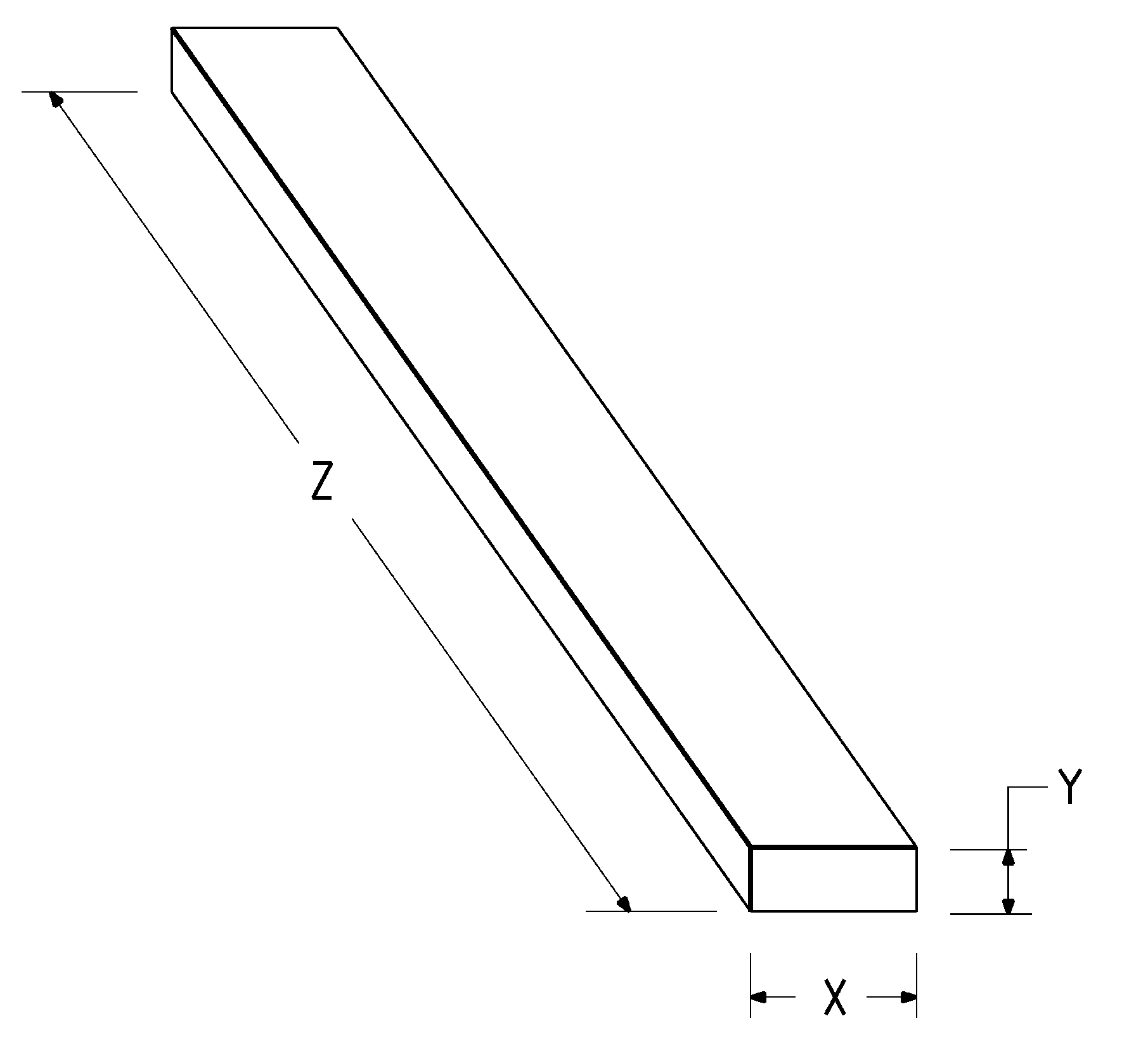

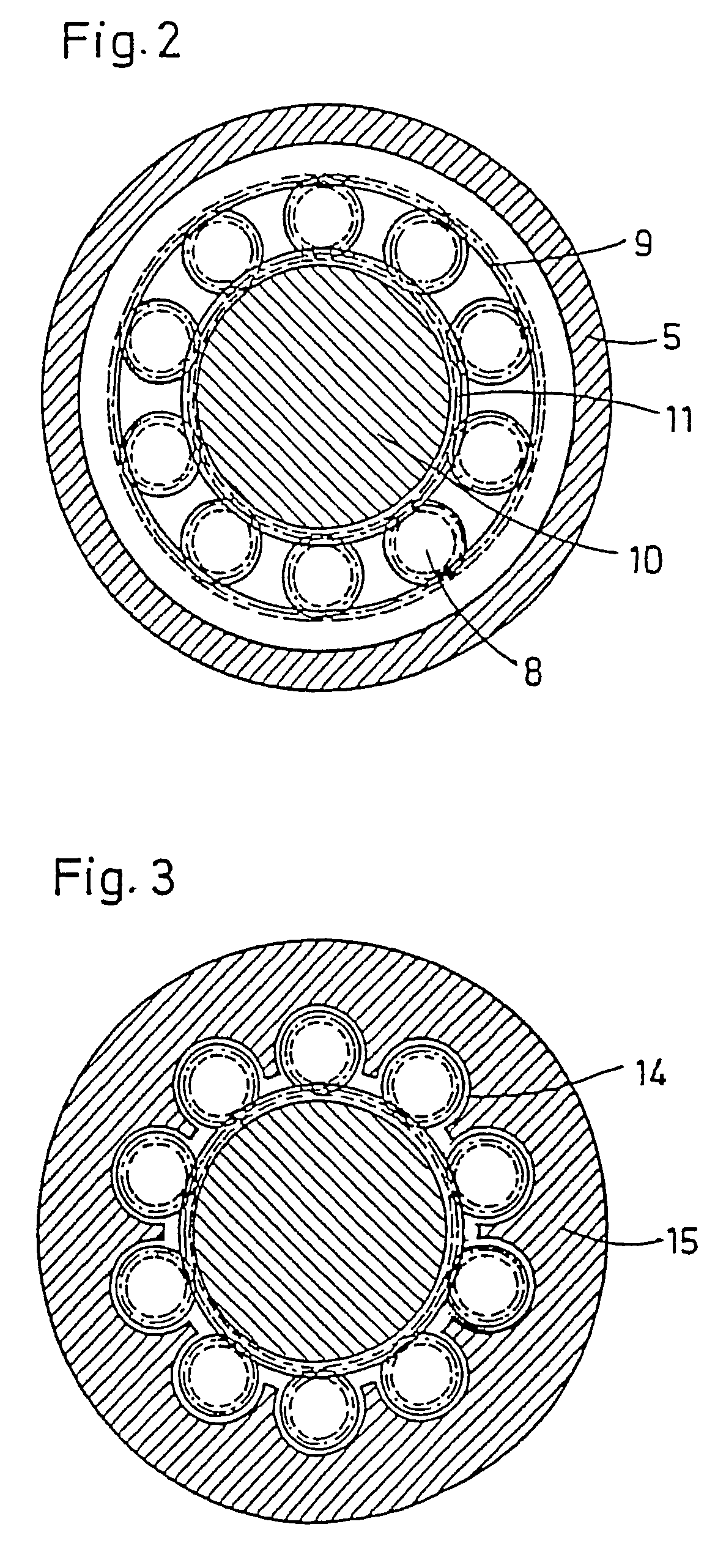

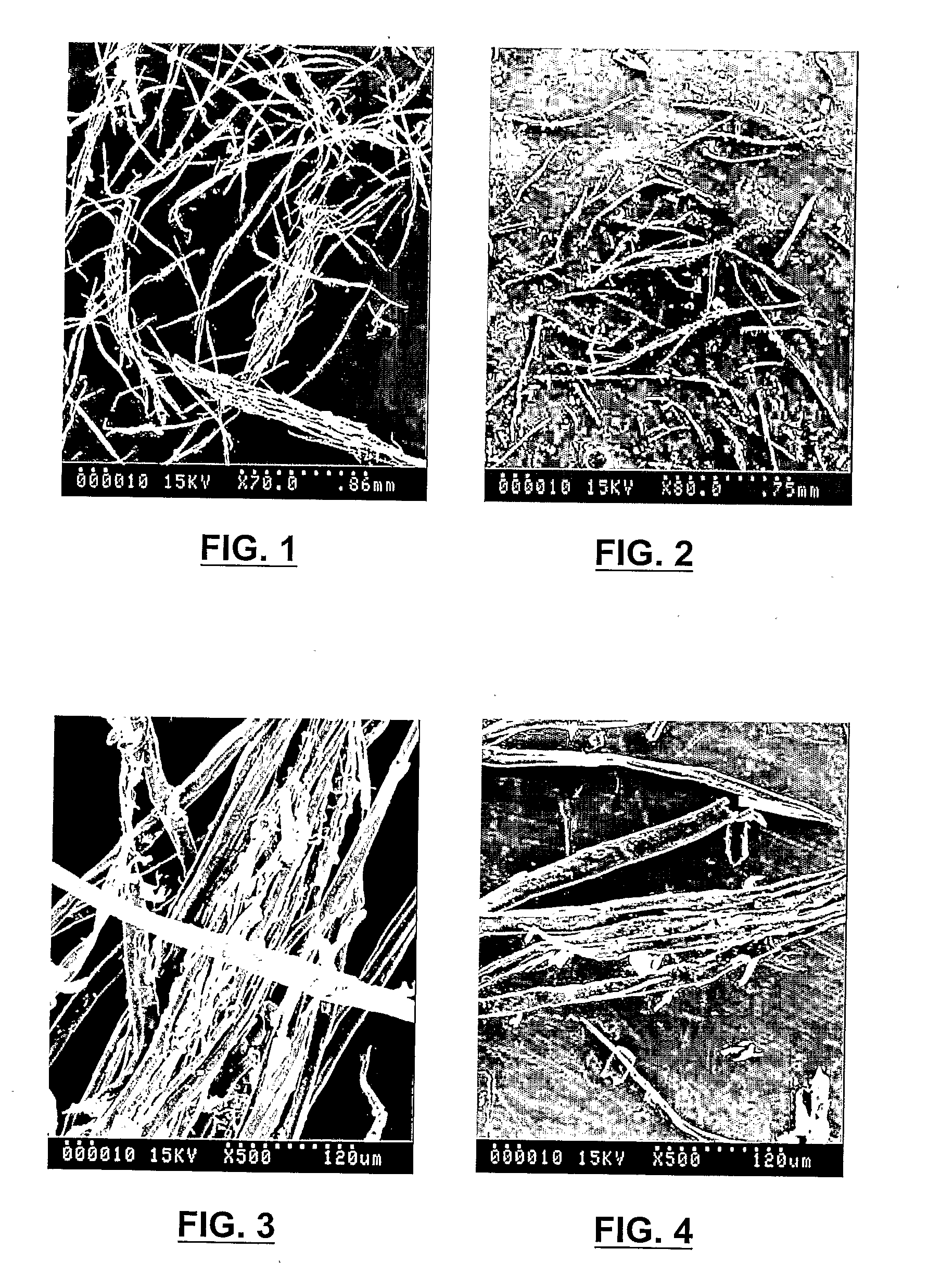

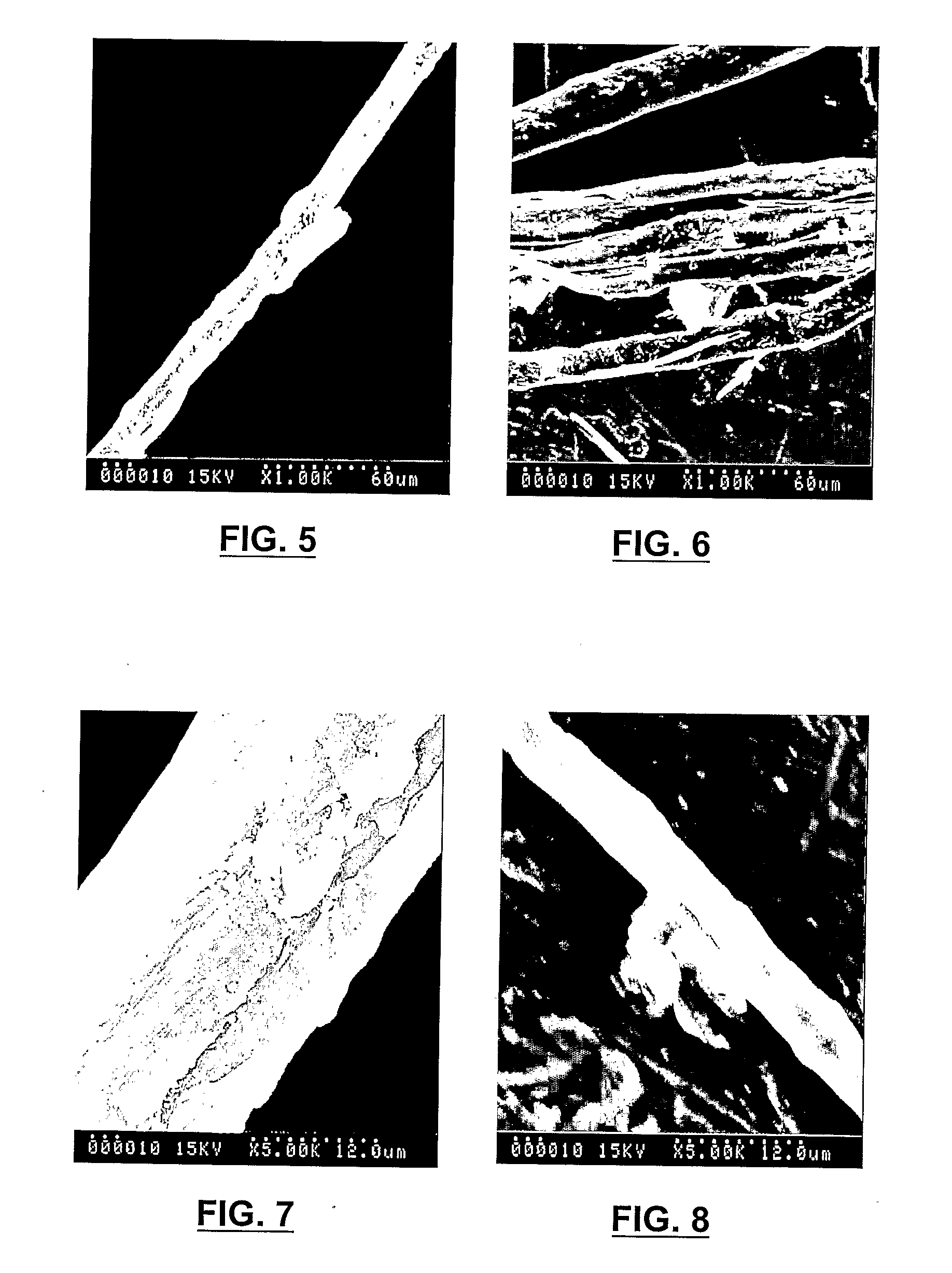

High-temperature polyamide molding compounds reinforced with flat glass fibers

ActiveUS20090062452A1Advantage in mechanical propertyAdvantage in in processingRotary stirring mixersSpecial tyresFlat glassGlass fiber

The present invention relates to reinforced polyamide molding compounds containing high-melting partially aromatic polyamides and flat glass fibers, in particular with a rectangular cross section, i.e., glass fibers with a noncircular cross-sectional area and a dimension ratio of the main cross-sectional axis to the secondary cross-sectional axis of 2 to 6, in particular 3 to 6, most especially preferably from 3.5 to 5.0. The present invention also relates to a method for manufacturing polyamide molding compounds and molded articles manufactured therefrom, i.e., in particular injection-molded parts. The inventive molded parts have a high transverse stiffness and transverse strength.

Owner:EMS PATENT AG

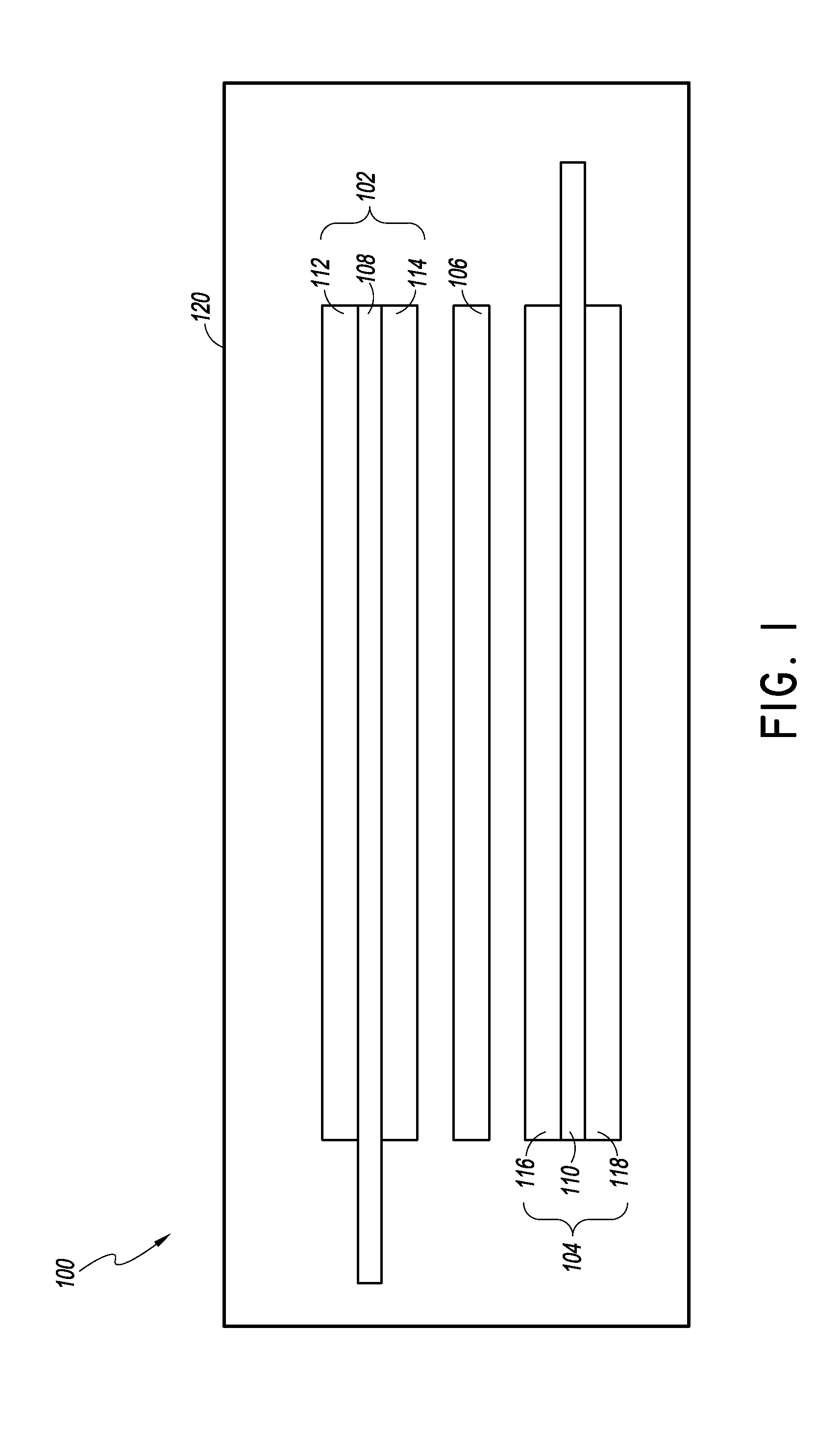

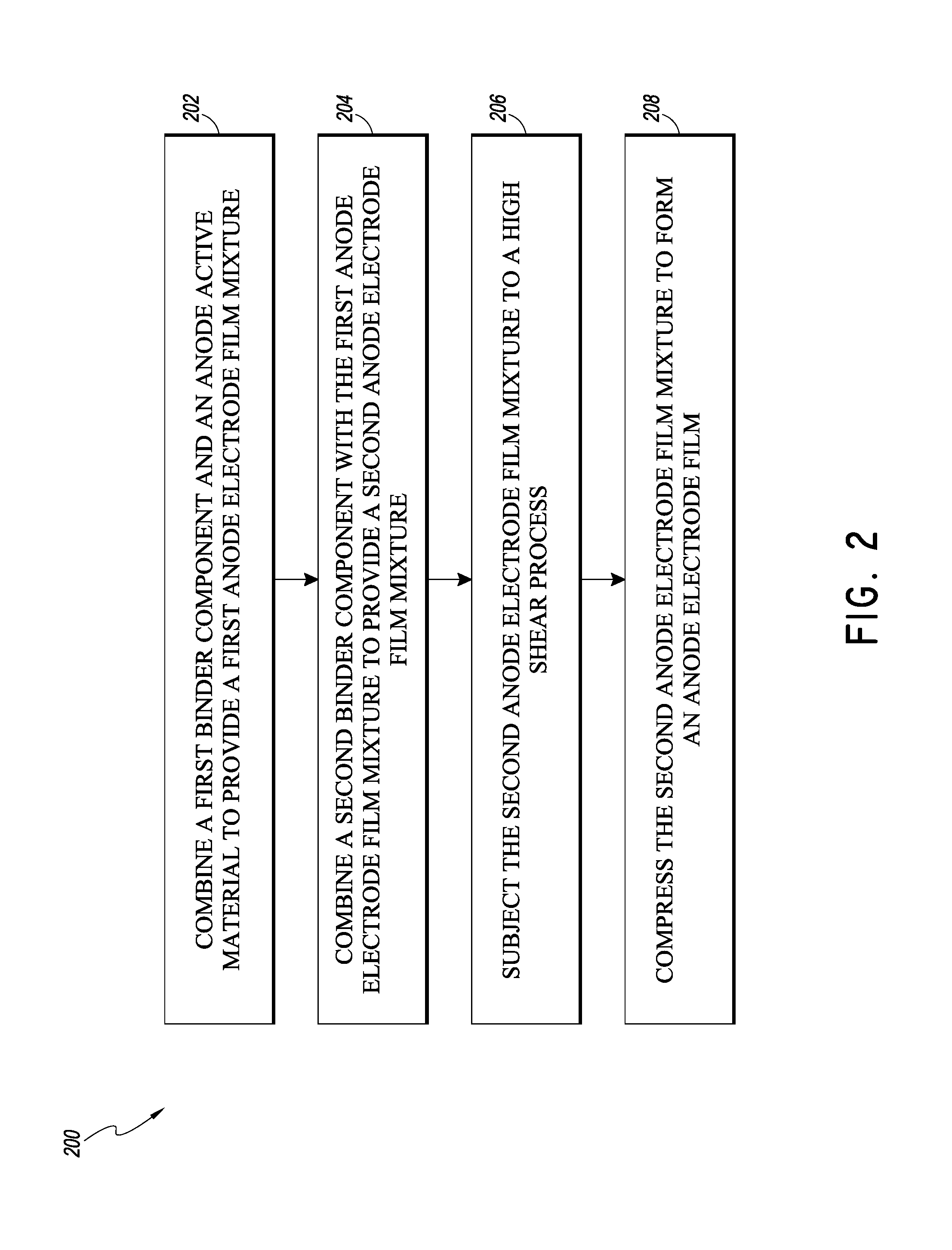

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

Process for the production of polyester nanocomposites

InactiveUS20080315453A1Increase polyester molecular weightHigh molecular weightMaterial nanotechnologyRotary stirring mixersCompound aMasterbatch

A method for dispersing sepiolite-type clay particles in a polyester matrix by melt-compounding a mixture of: sepiolite-type clay, at least one linear polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition; and, optionally, subjecting said nanocomposite composition to solid state polymerization to increase polyester molecular weight. Further described is a method for preparing a polyester nanocomposite composition from a masterbatch, comprising melt-compounding a mixture of: sepiolite-type clay, at least one polyester oligomer, and at least one polyester polymer to produce a nanocomposite composition containing a greater concentration of sepiolite-type clay than is desired in the final resin composition; optionally, subjecting said nanocomposite composition to solid state polymerization to increase the polyester molecular weight; and further melt compounding said nanocomposite composition with polyester polymer and, optionally, additional ingredients.

Owner:EI DU PONT DE NEMOURS & CO

Static mixer and a method of manufacture thereof

ActiveUS7198400B2Evenly distributedConsistent levelFlow mixersTransportation and packagingEngineeringStatic mixer

Owner:HUSKY INJECTION MOLDING SYST LTD

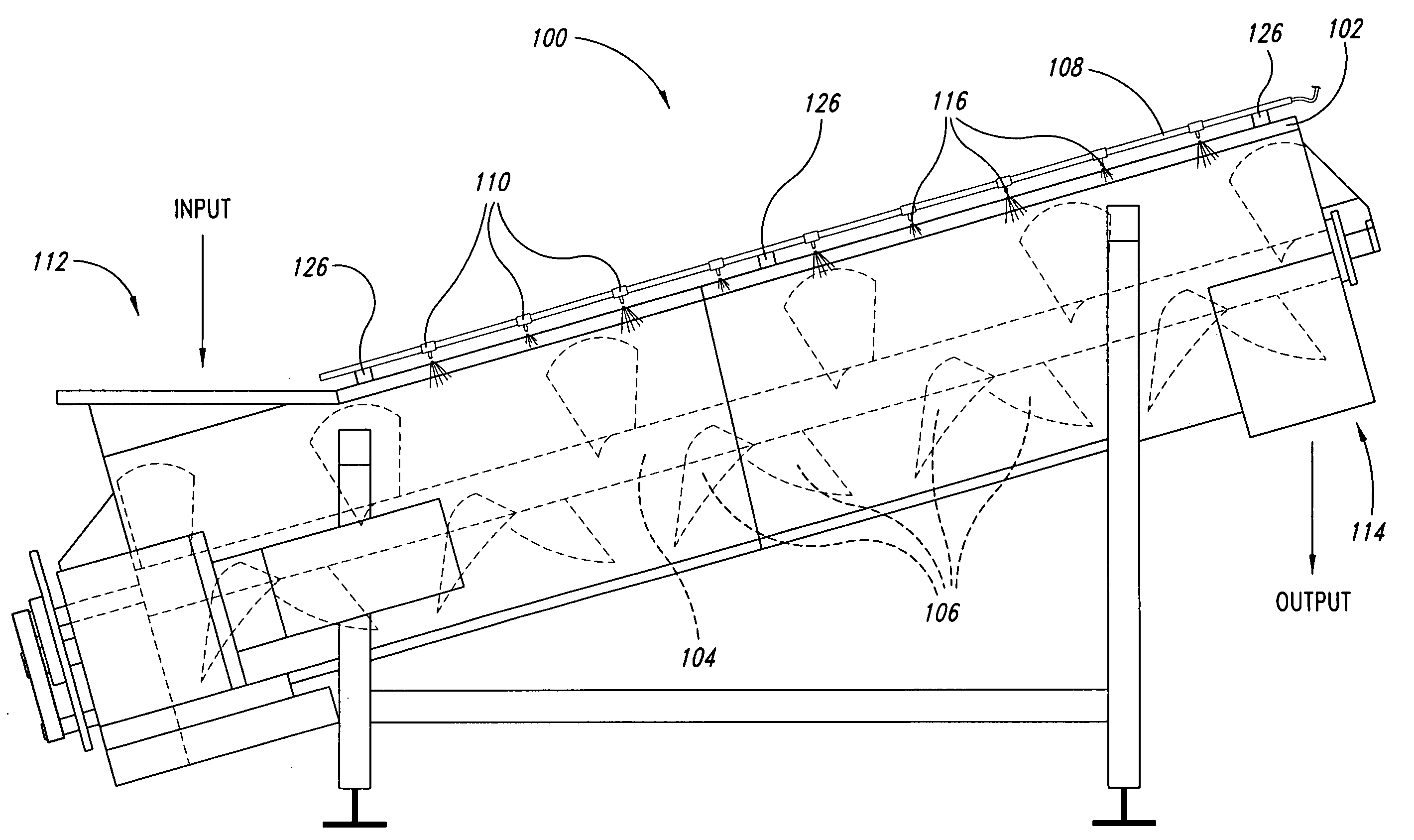

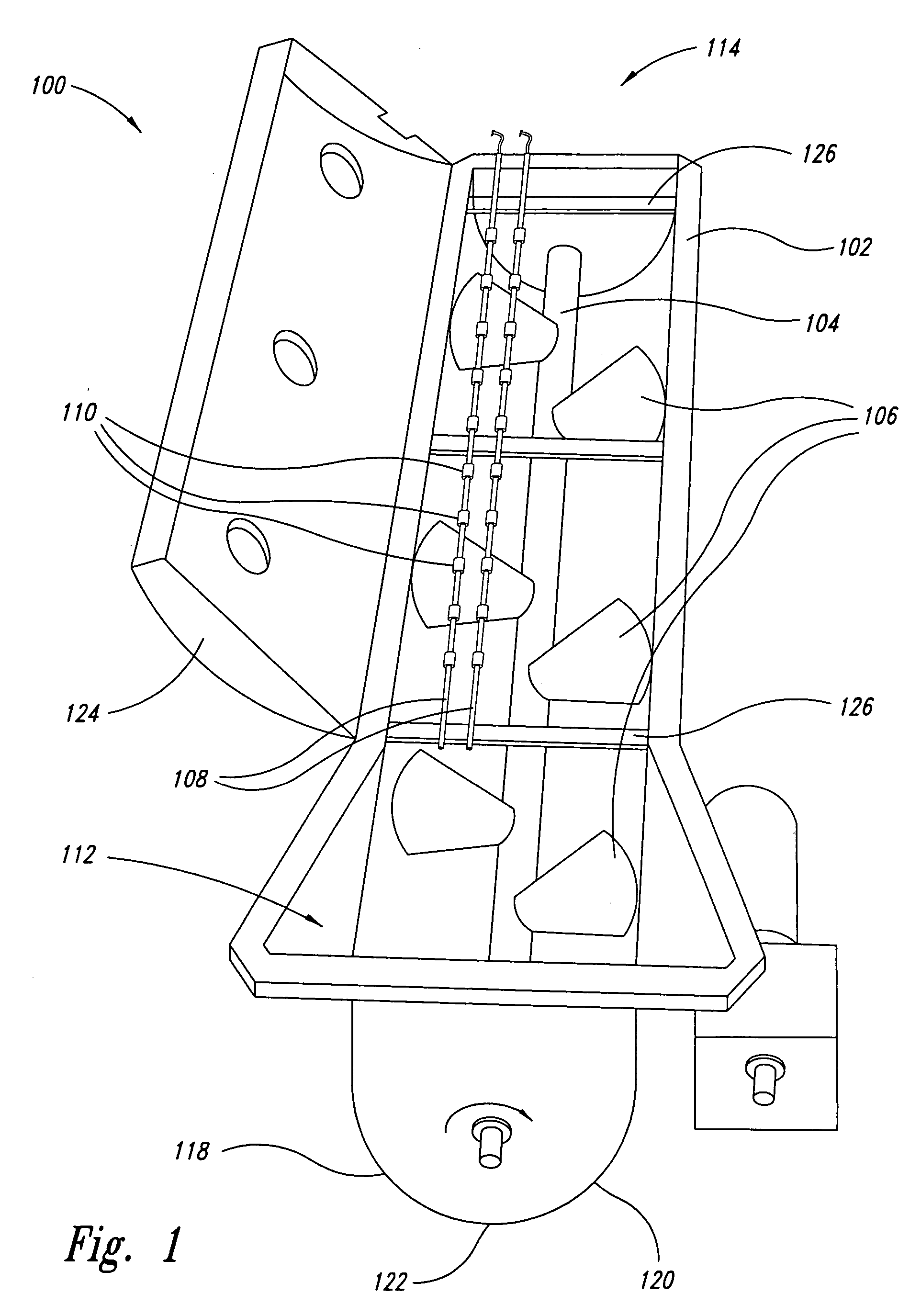

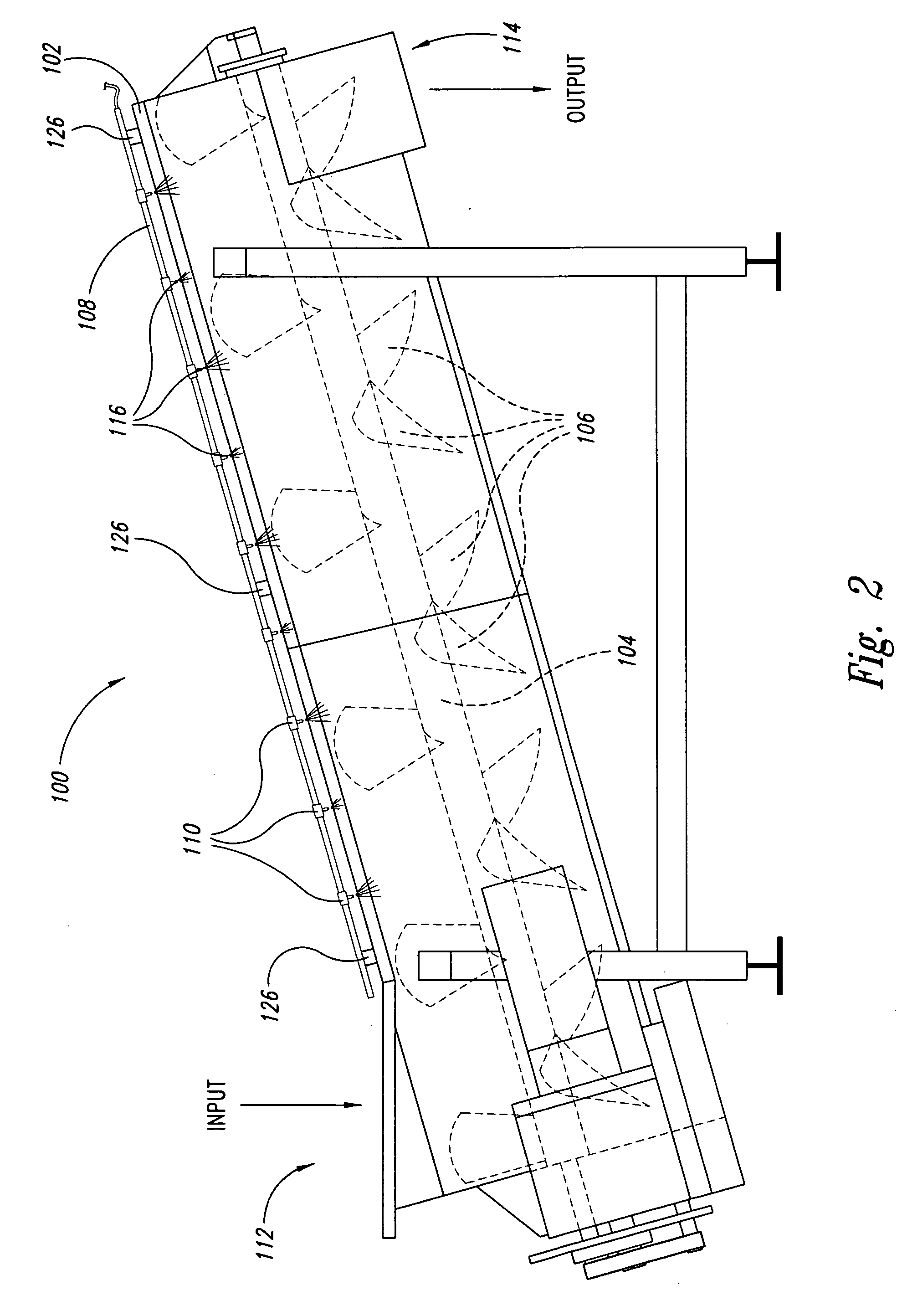

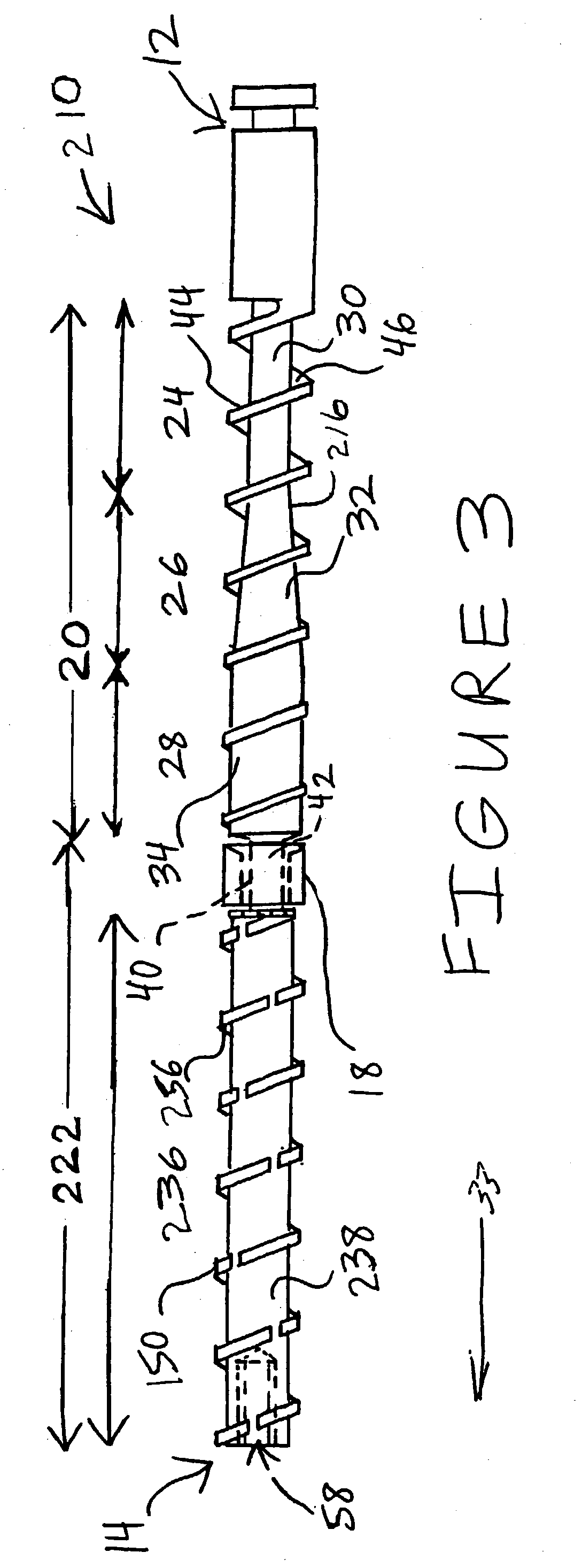

Treatment fluid application apparatus for foodstuffs and methods related thereto

InactiveUS20050058013A1Good lookingImprove EdibilityRotary stirring mixersMeat/fish preservation using liquidsSpiral bladeDisinfectant

Apparatus and methods for applying treatment fluids, such as disinfectants, flavoring agents, and tenderizing agents, to foodstuff surfaces to, for example, reduce populations of microorganisms or fungi, alter taste, or alter texture. In representative embodiments, the apparatus includes a housing, a fluid delivery system, and a shaft with a protruding surface, the latter adapted to rotatably convey, while agitating and tumbling, the foodstuffs from an inlet to an outlet of the housing, as the fluid delivery system applies a treatment fluid to the foodstuffs. In more specific embodiments, the protruding surface may be paddles, or paddles interconnected by a solid web and having angled distal surfaces, or a spiral blade with radial protrusions, or such a spiral blade along a first longitudinal portion of the shaft and paddles along a second longitudinal portion of the shaft.

Owner:ALCIDE CORP

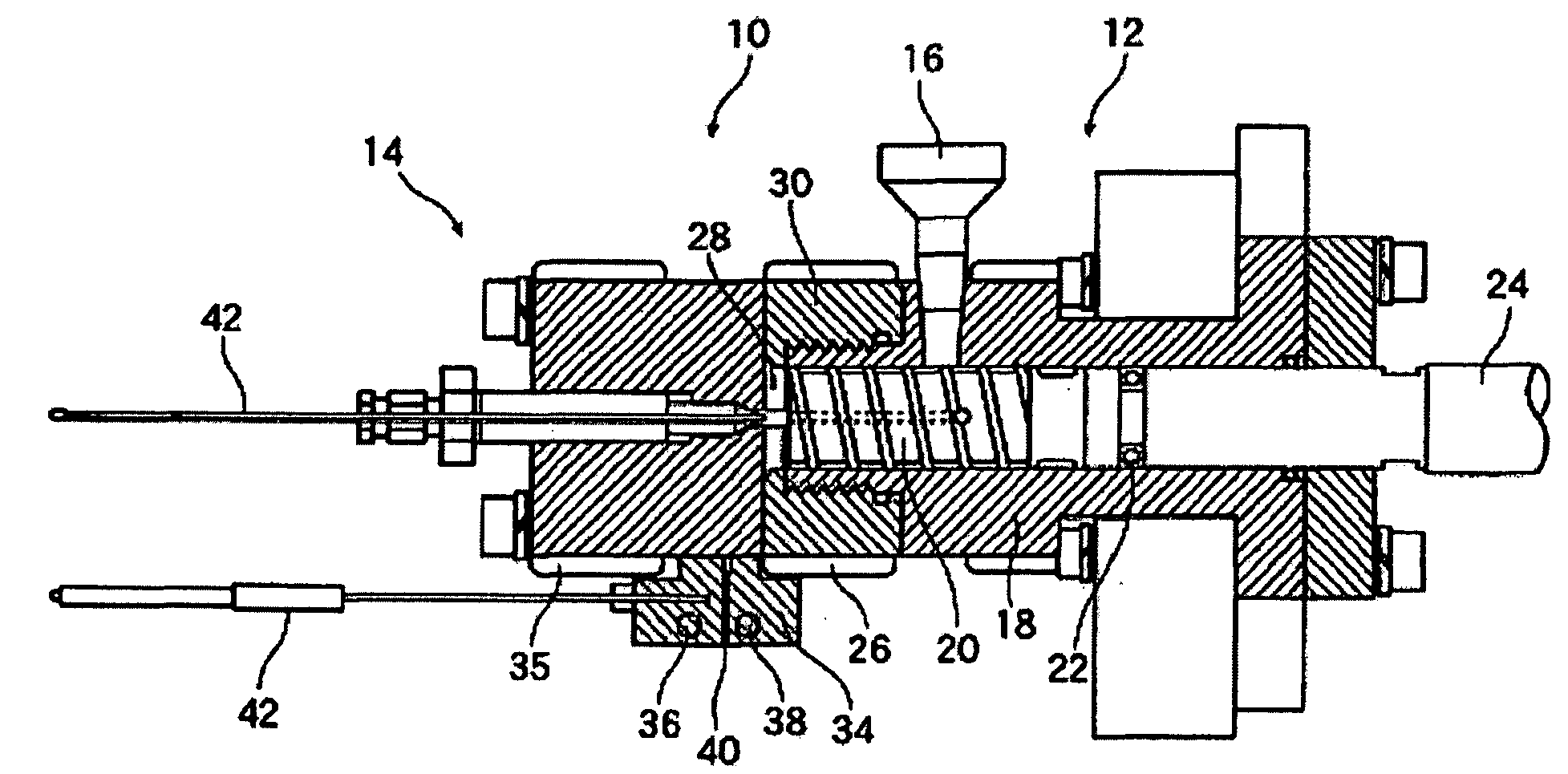

Injection molding screw

InactiveUS7172333B2Minimized pressure lossRotary stirring mixersFrozen sweetsEngineeringInjection molding machine

An injection molding screw for metal injection molding includes a first end, a second end, a longitudinal body with a first stage and a second stage extending axially along a length of the screw between the ends, a pressure retention device, and optionally, a screw tip. The pressure retention element minimizes loss of pressure in the second stage portion.

Owner:SOUTHCO +1

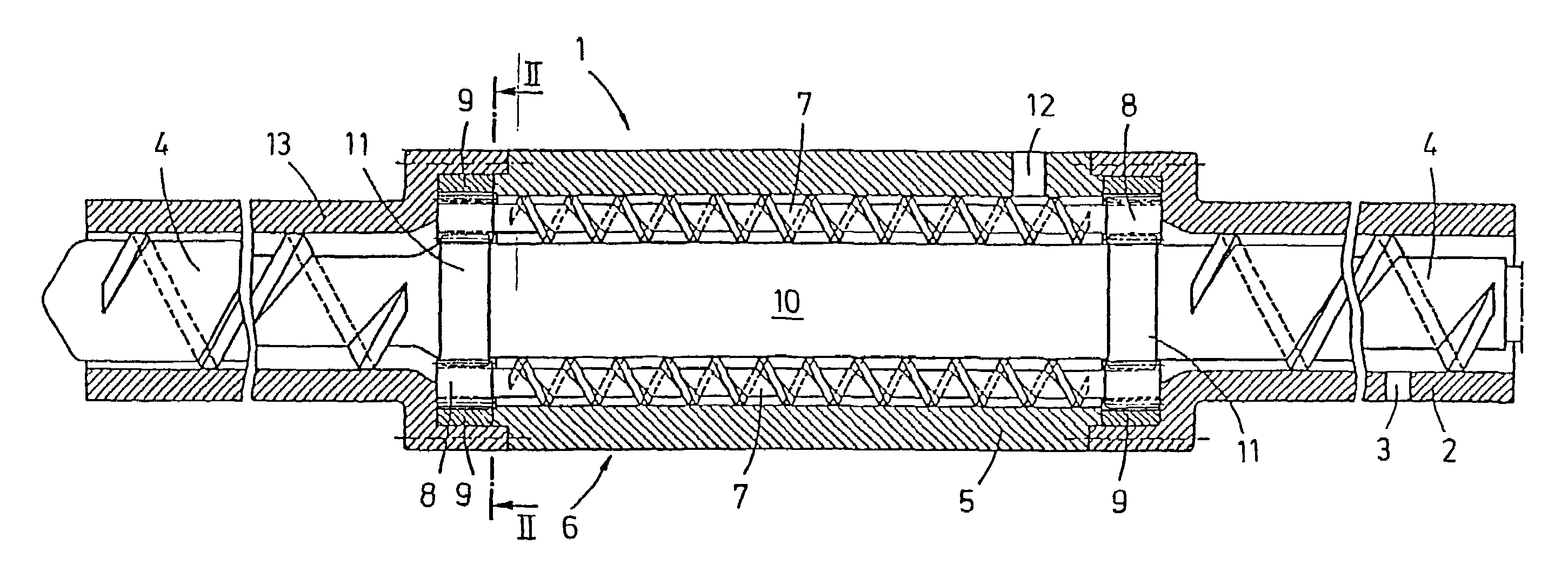

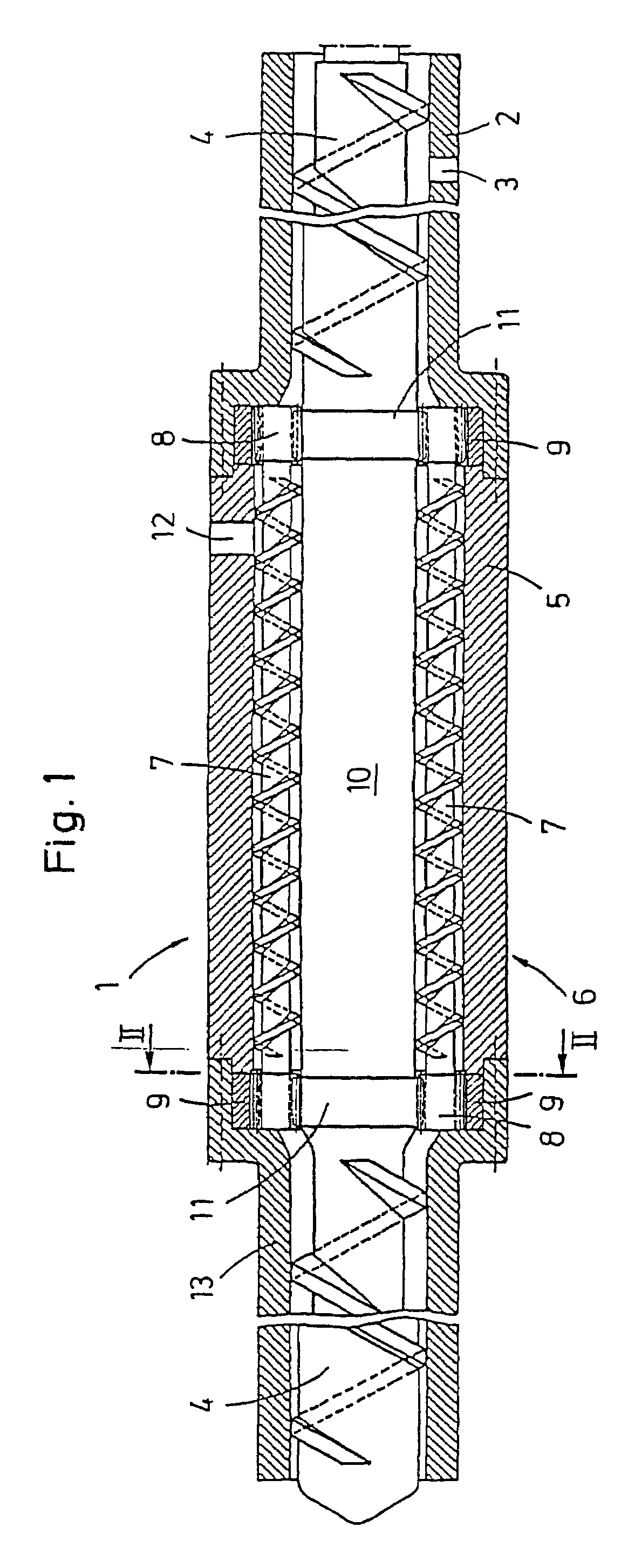

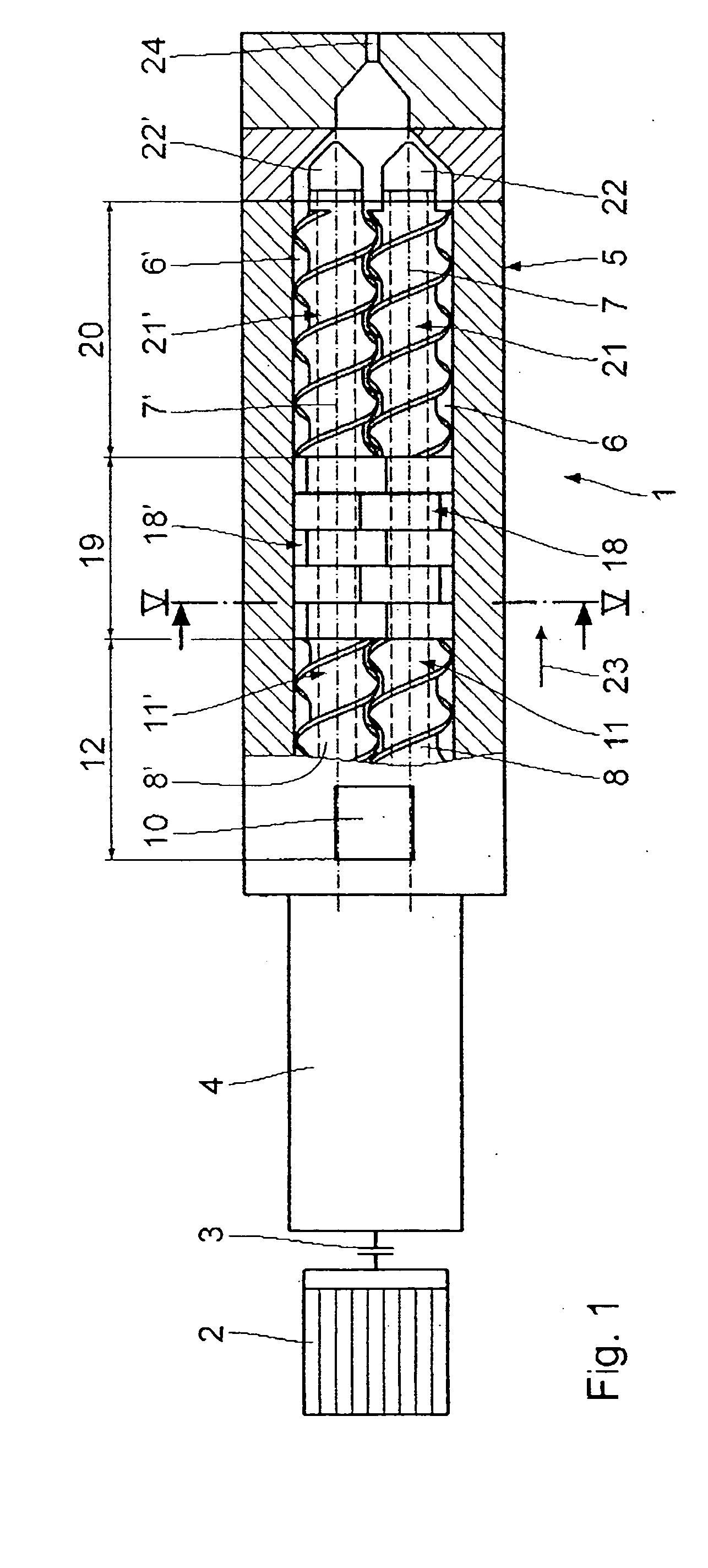

Extruder for producing molten plastic materials

InactiveUS7513677B2Simple designAvoid damageRotary stirring mixersMixing/kneading with horizontally-mounted toolsFoaming agentThin layer

The invention concerns an extruder for producing molted plastic materials from plastic granules available on the market, by heating and mixing granules, with heated single- or double-screw extruders, and for carrying out polycondensation or polymerization using part of a multiple-screw extruder and by means of vacuum chambers for removing the constituents of low molecular weight and / or foaming agents or the like, for obtaining larger molecules and hence a higher viscosity, and for increasing the mechanical strength of plastic materials produced from said molten material. The invention aims at designing said extruder such that the molten material can be processed in thin layers enabling exposure of large surfaces in contact with the vacuum, and hence a molten plastic material ensuring desired levels of degassing and polymerization using simple means. Therefor, the envelopes of the stems of the screws (7) are mutually spaced apart at least in the polycondensation zone of said extruder part with multiple screws (6), relative to the extruder screw (4) or its shaft section (10) and relative to cylindrical zones enclosing them, by a distance not less than zero (≧0).

Owner:GNEUSS KUNST

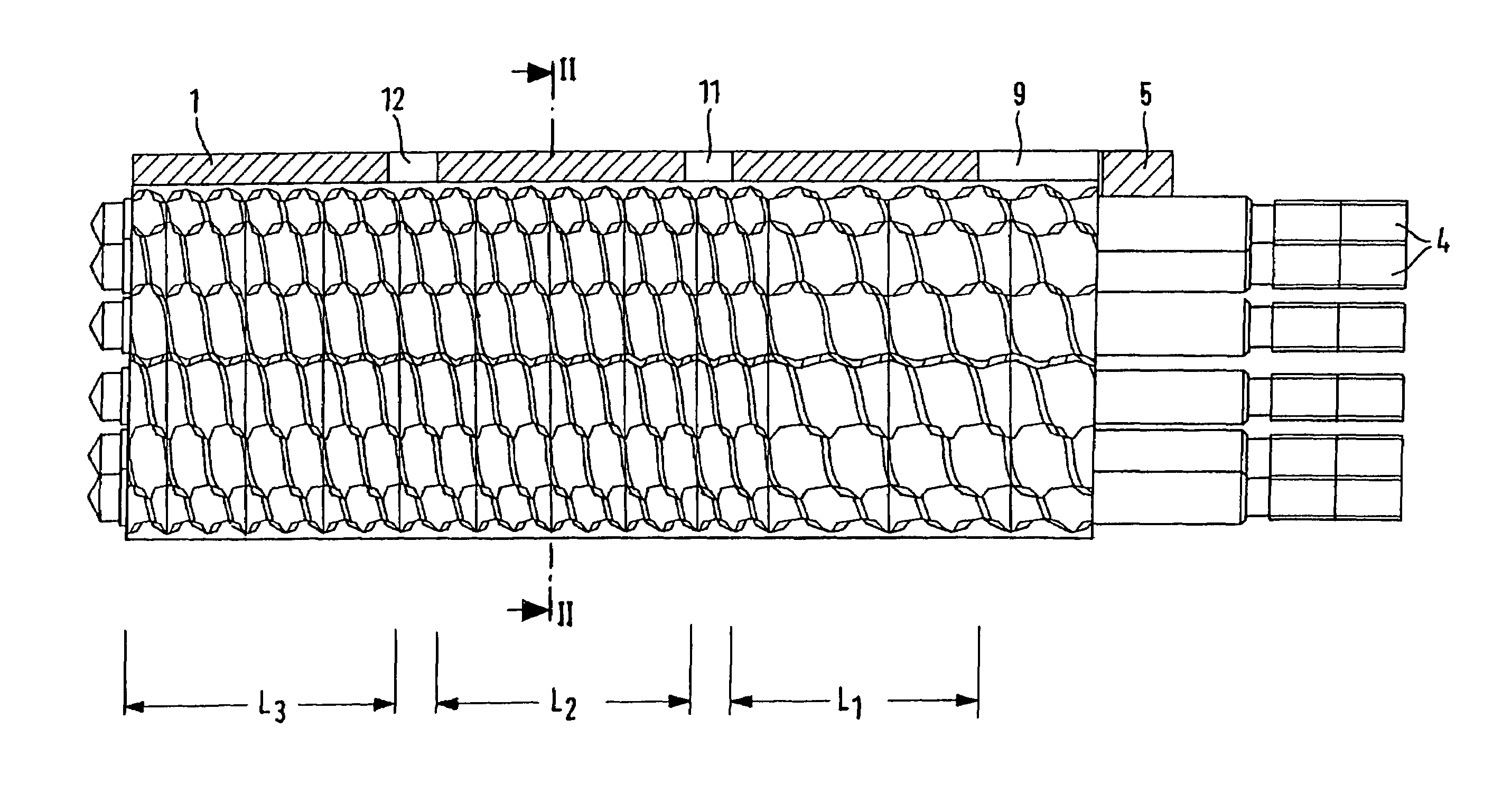

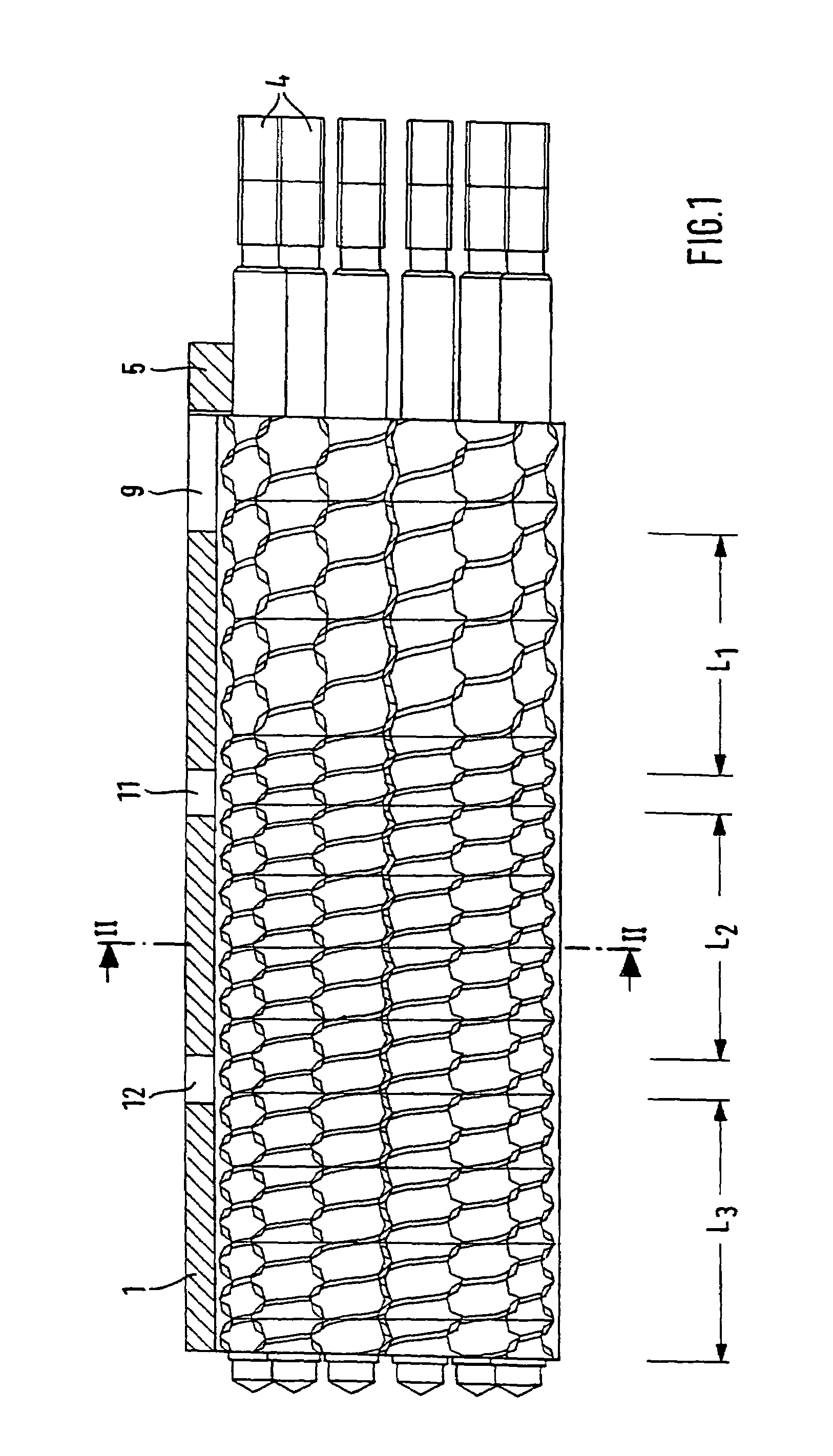

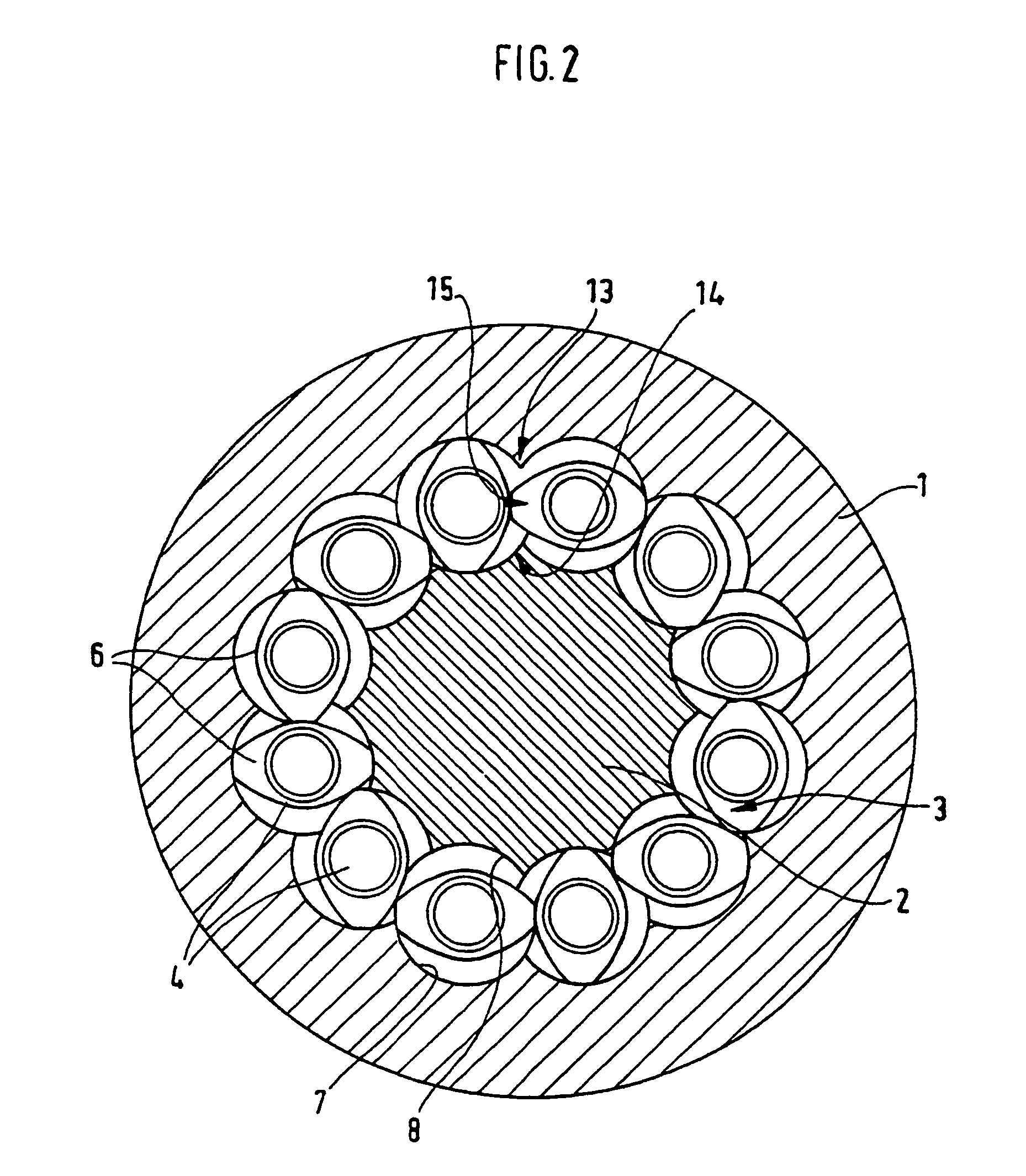

Homogenizing and/or dispersing device comprising endless screws

An apparatus for homogenizing and / or dispersing at least one viscous substance and at least one solid and / or at least one other substance of different viscosity includes in a space in a housing axis-parallel rotatable shafts disposed along a circle with equal central-angle distance and provided with tightly intermeshing screw elements. The shafts in the area outside the openings in the housing are provided with screw elements having a pitch (S) of at most three quarters of the outside screw diameter (D) over a length (L=L1+L2+L3) corresponding to at least ten times the outside diameter (D) of the screw elements.

Owner:BLACH VERWALTUNGS GMBH

Preparation method of superfine ceramic powder injection molding mixture

The invention discloses a preparation method of a superfine ceramic powder injection molding mixture, which belongs to the technical field of ceramic injection molding. The preparation method of the superfine ceramic powder injection molding mixture comprises the steps: carrying out ultrasonic dispersion or high-speed ball grinding dispersion and surface modification of submicron or nanometer level ceramic powder in surface active agent solution; evenly mixing the surface modified powder with a non water-solubility organic binding agent, a water-solubility organic binding agent and other additives in a mixer according to a specific order; injecting and molding obtained injecting and mixing material on an injection molding machine to obtain a blank body; and quickly degreasing the blank body by water in water and ethanol mixing solution with a certain proportion under a certain degreasing temperature system. The obtained water-degreased injection material has even mixture, high strength of a green blank and good fluidity. The degreasing method has high degreasing speed and good blank shape maintaining performance and avoids the defects of cracking, bubbling, and the like.

Owner:TSINGHUA UNIV

Heat insulation non-burning refractory brick and production method thereof

ActiveCN101928152ACorrosion resistantWith thermal insulationCeramic shaping apparatusClay mixing apparatusRefractoryFire brick

The invention relates to a heat insulation non-burning refractory brick, belonging to the technical field of refractory material. The heat insulation non-burning refractory brick comprises the components by weight percent: 60-90% of compact refractory raw material with the particle size of 0-10mm, 5-30% of light refractory raw material with the particle size of 0-5mm and 2-30% of binding agent. The method takes the compact refractory raw material as main material which is added with part of light refractory raw material to be prepared into the non-burning heat insulation refractory material with the performance between the compact refractory raw material and the light refractory raw material, so that the non-burning heat insulation refractory material has the compression strength and the corrosion resistance of the compact refractory raw material as well as heat preservation and heat insulation performances of the light refractory raw material; and an industrial kiln built by the heat insulation non-burning refractory brick reduces the heat loss and the energy consumption.

Owner:鞍山钢铁冶金炉材科技有限公司

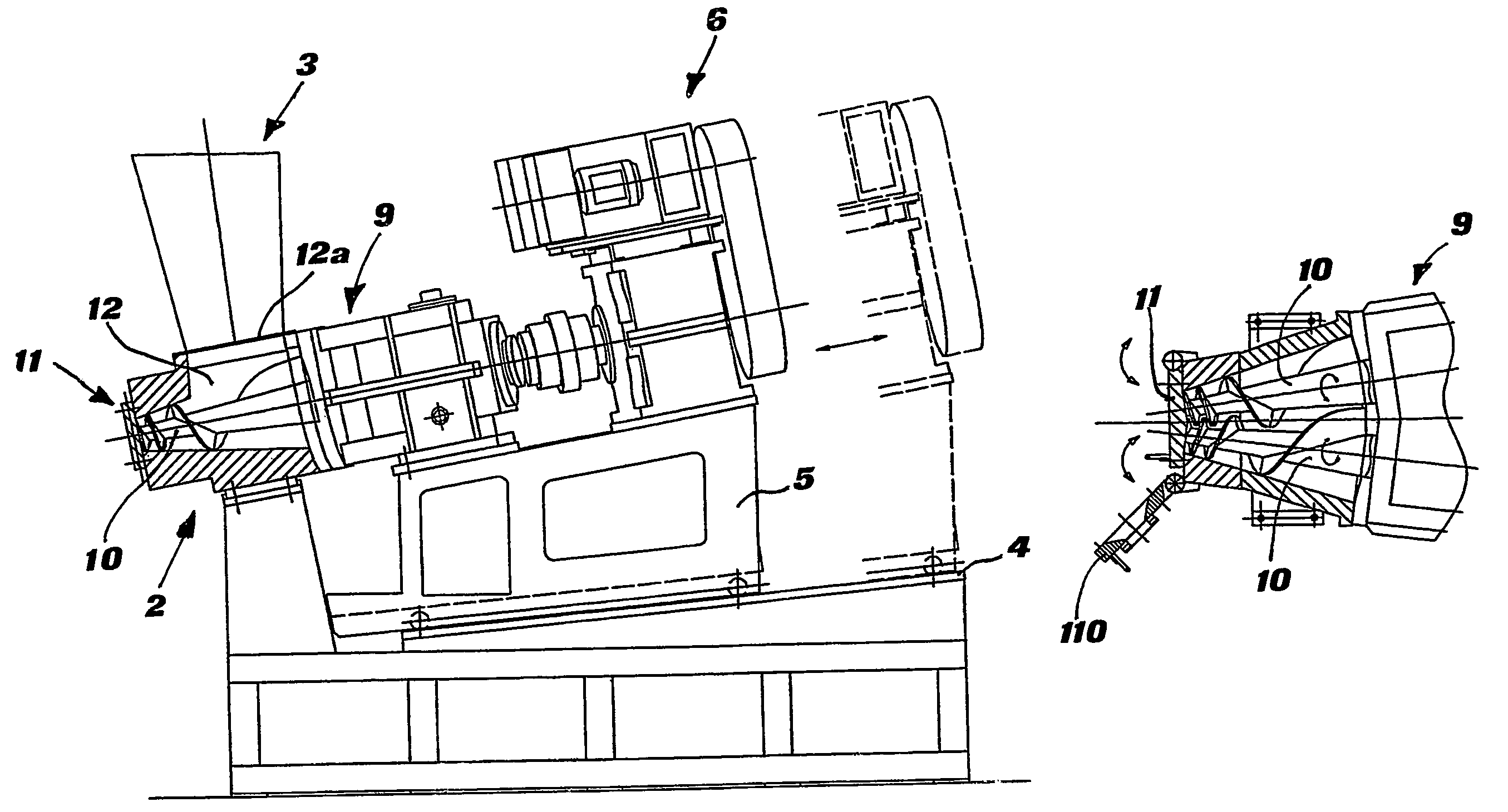

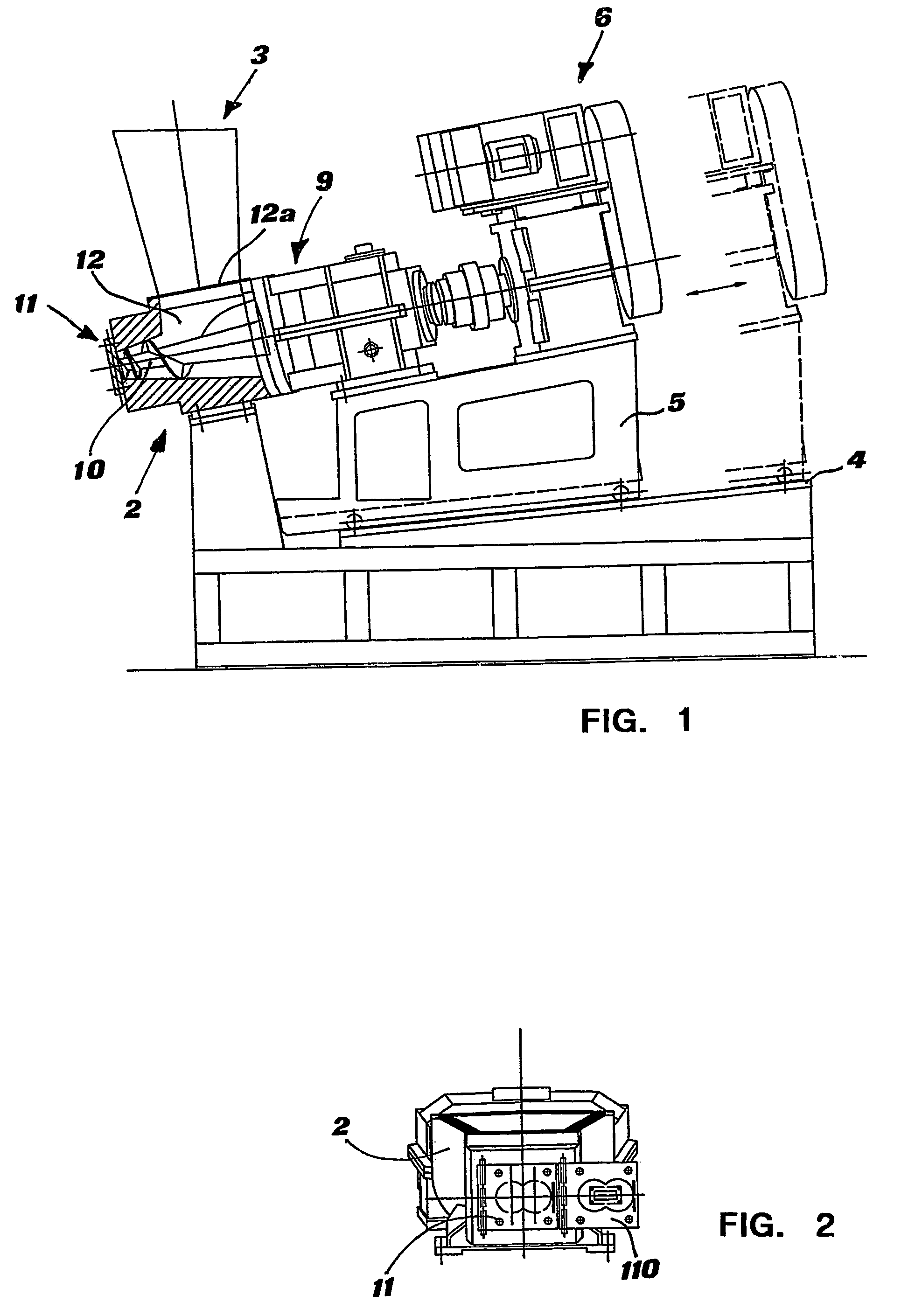

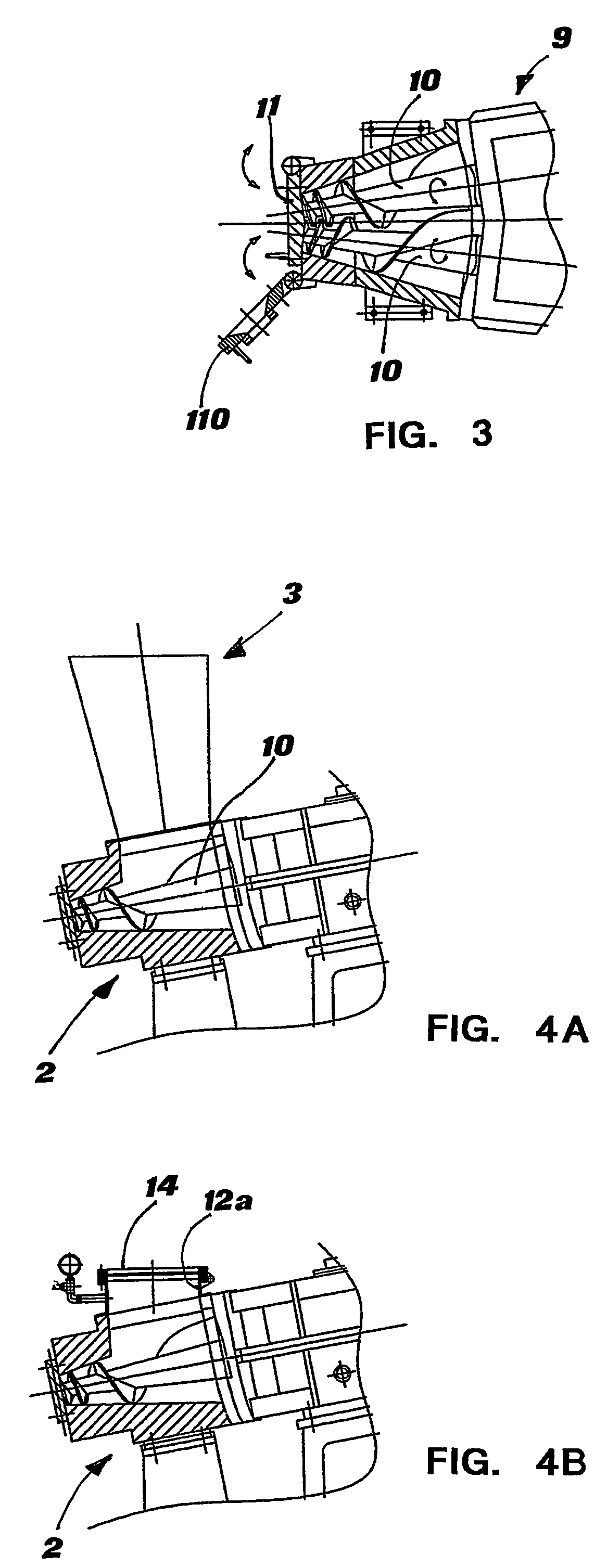

Machine for mixing and extruding rubber-based and silicone-based plastic materials and method therefor

A machine for the mixing and extrusion of rubber-based and silicone-based plastic materials and method thereof is disclosed, comprising a dump extruder with conical converging twin screws (10) arranged in a batching chamber (12) in which the outlet of the dump extruder is temporarily closed by a removable blind flange (11), the batching chamber also acting as a compounding chamber.

Owner:COLMEC

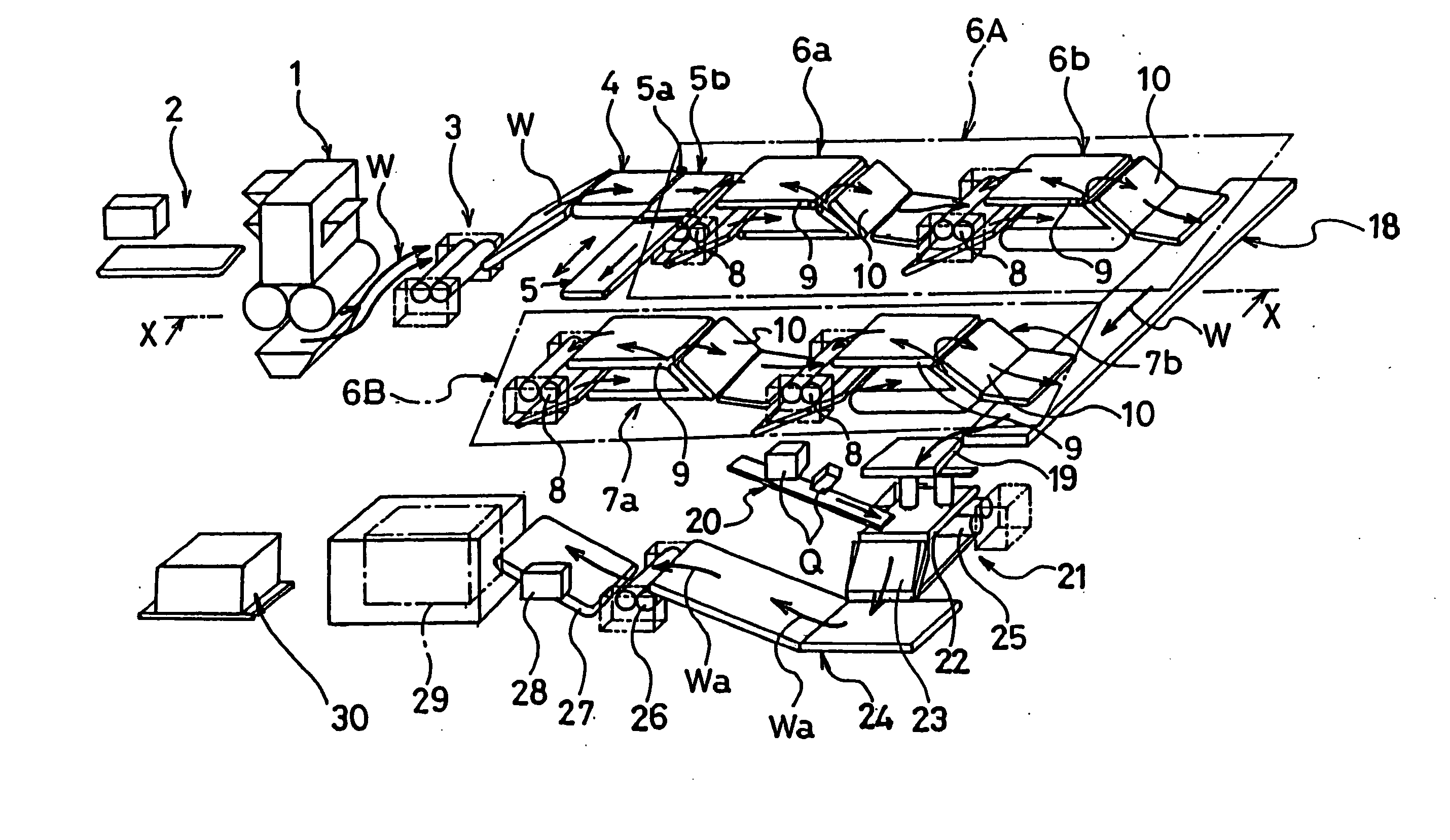

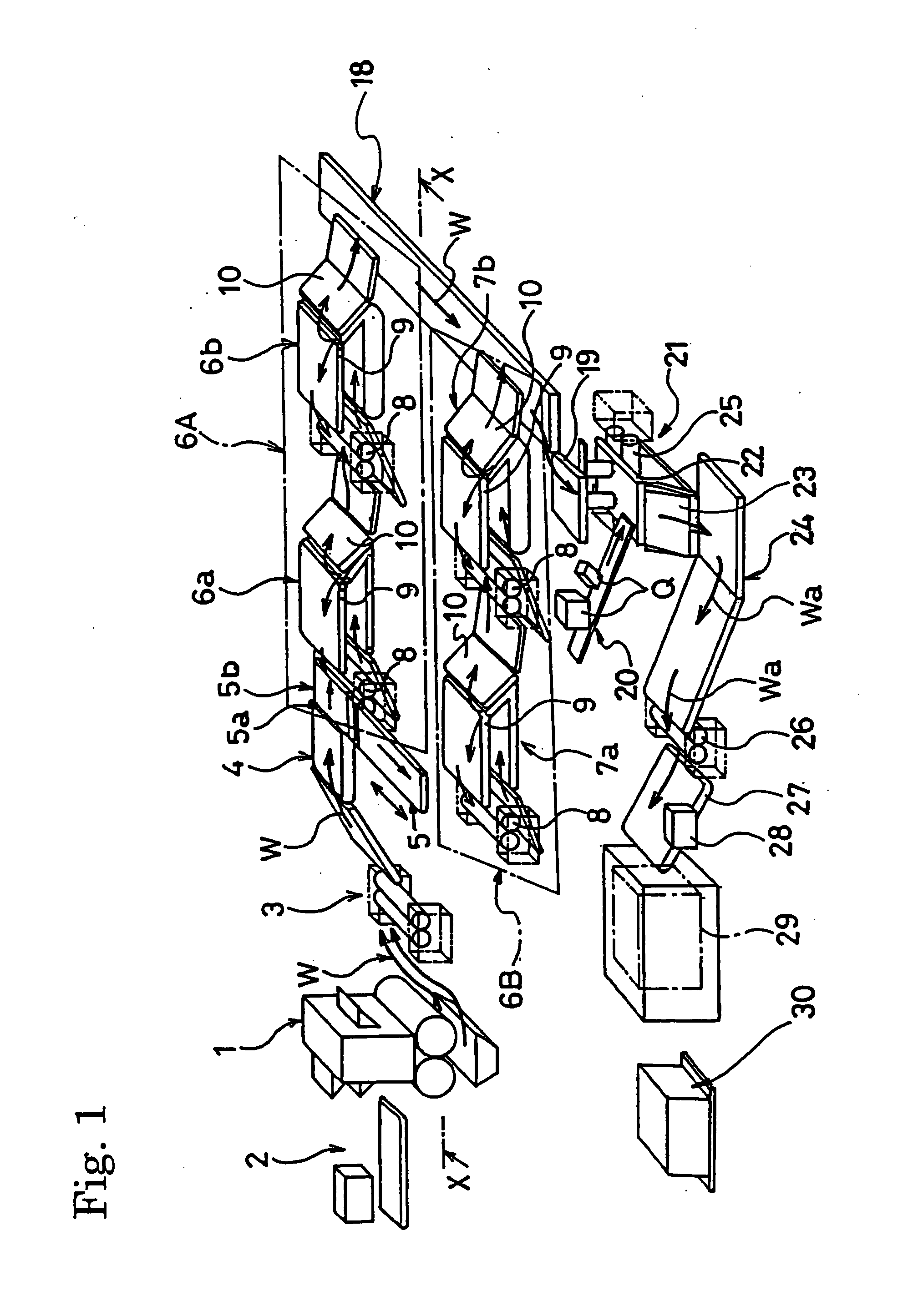

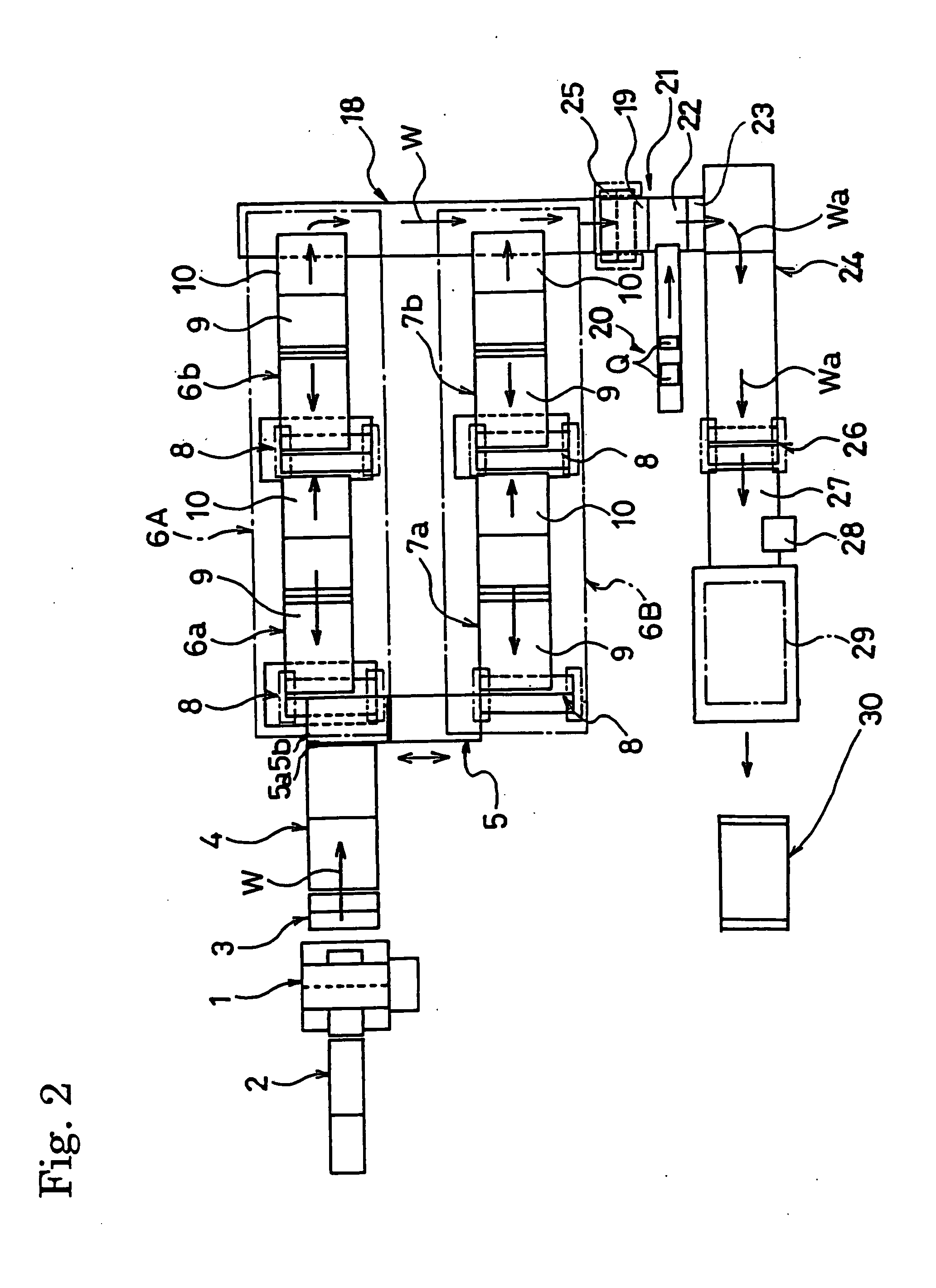

Apparatus for and Method of Kneading Rubber Material

InactiveUS20090238027A1Reduce energy lossLow viscosityDischarging apparatusMixing operation control apparatusRubber materialVulcanization

Disclosed are: an apparatus for kneading a rubber material which continuously performs a series of processes which are kneading a rubber material with a non-vulcanization compounding agent at the beginning, kneading it with a vulcanization compounding agent, and finally obtaining final kneaded rubber; and a kneading method using this kneading apparatus. Preparatory kneaded rubber having been kneaded in one internal mixer is selectively fed, by a distribution conveyor, to a group of kneading lines where at least two kneading lines are provided to be arranged side by side. Each of the kneading line consists of a plurality of open roll mixers serially connected with each other. Intermediate kneaded rubber resulted in having a target viscosity after having been kneaded in the group of kneading lines is kneaded with a vulcanization compounding agent, whereby final kneaded rubber is obtained.

Owner:YOKOHAMA RUBBER CO LTD

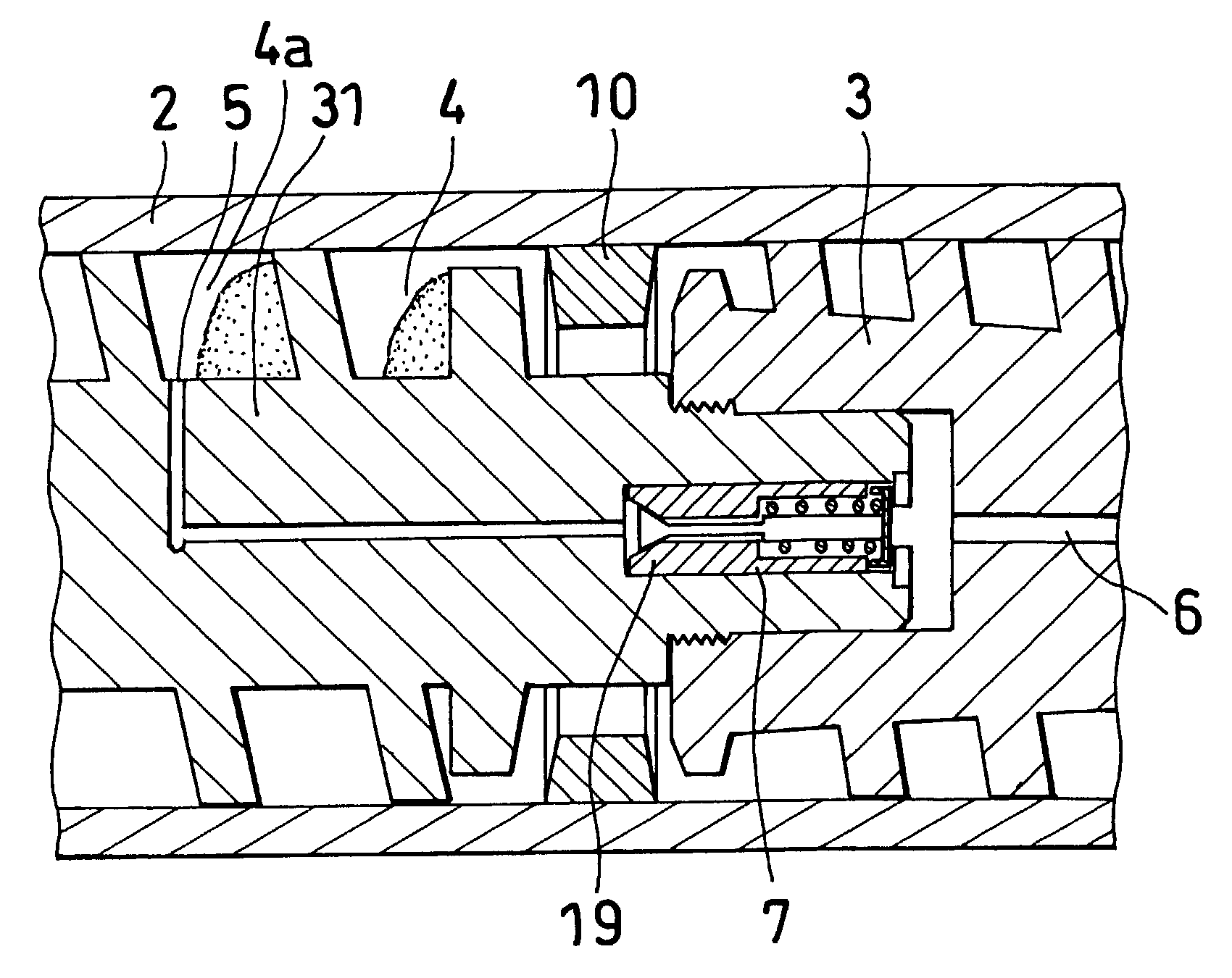

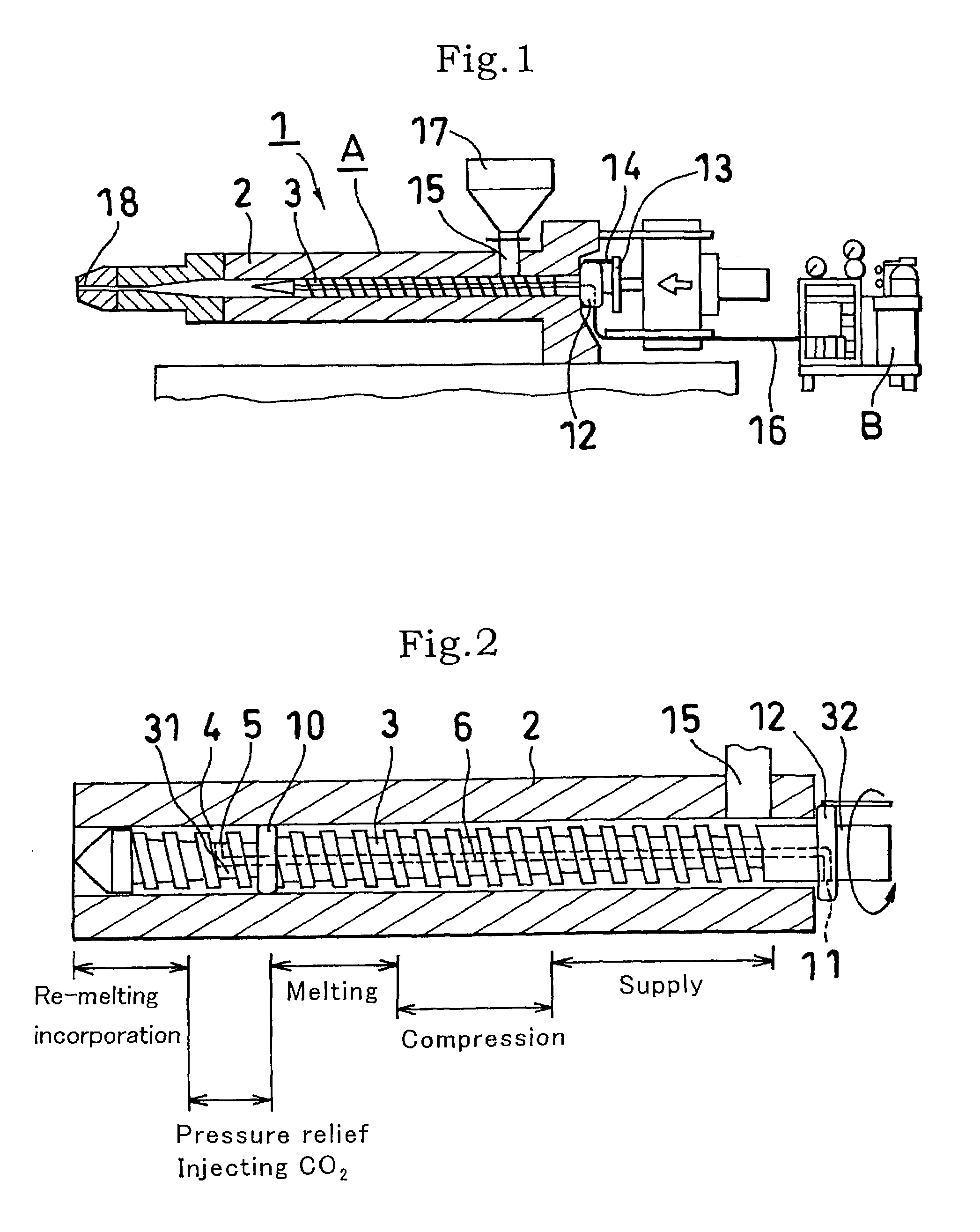

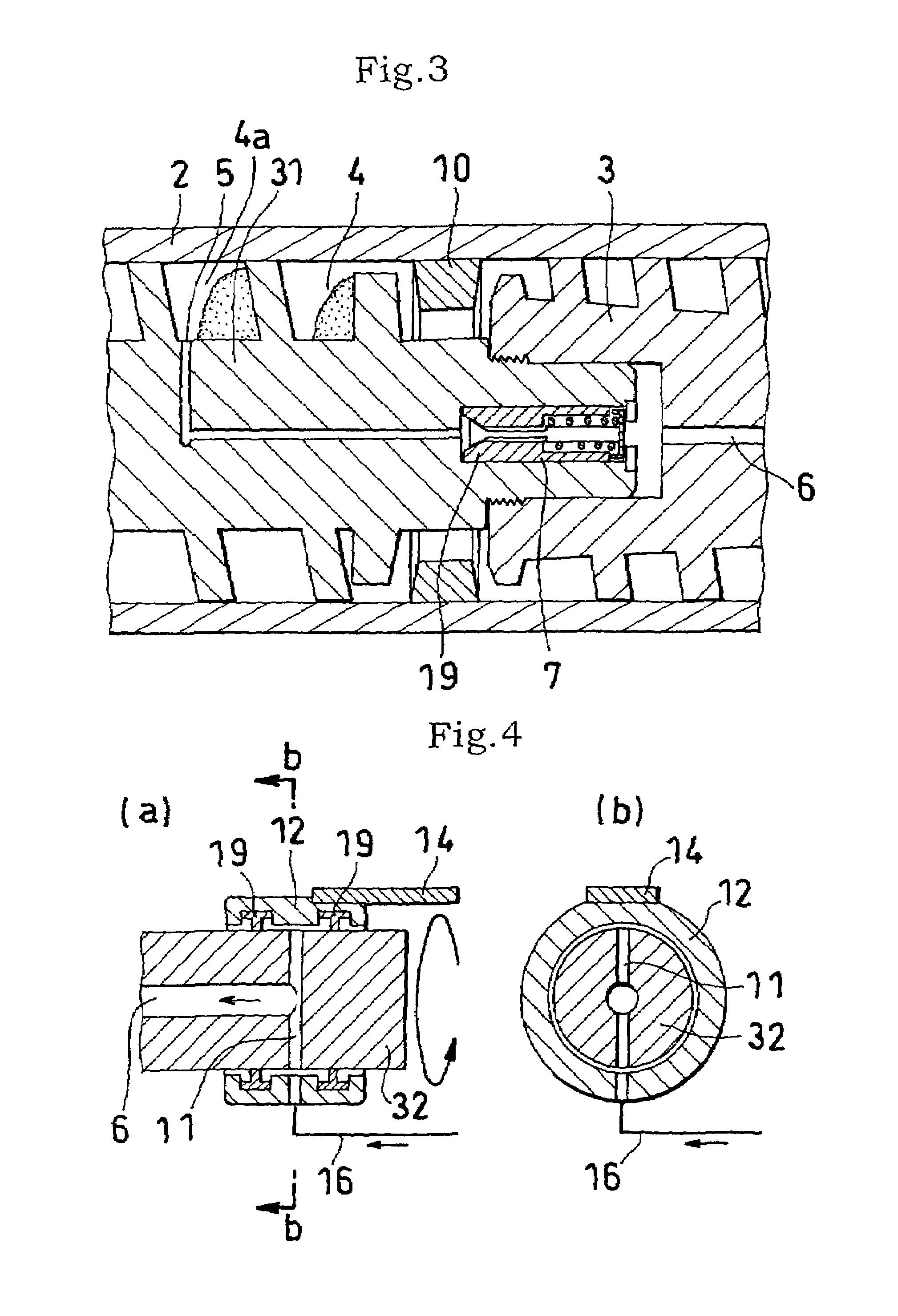

Injection molding process and injection molding apparatus for thermoplastic resin molded articles

InactiveUS6949208B1Efficient meltingIncrease pitchRotary stirring mixersFrozen sweetsFoaming agentReactive gas

Owner:SEKISUI CHEM CO LTD

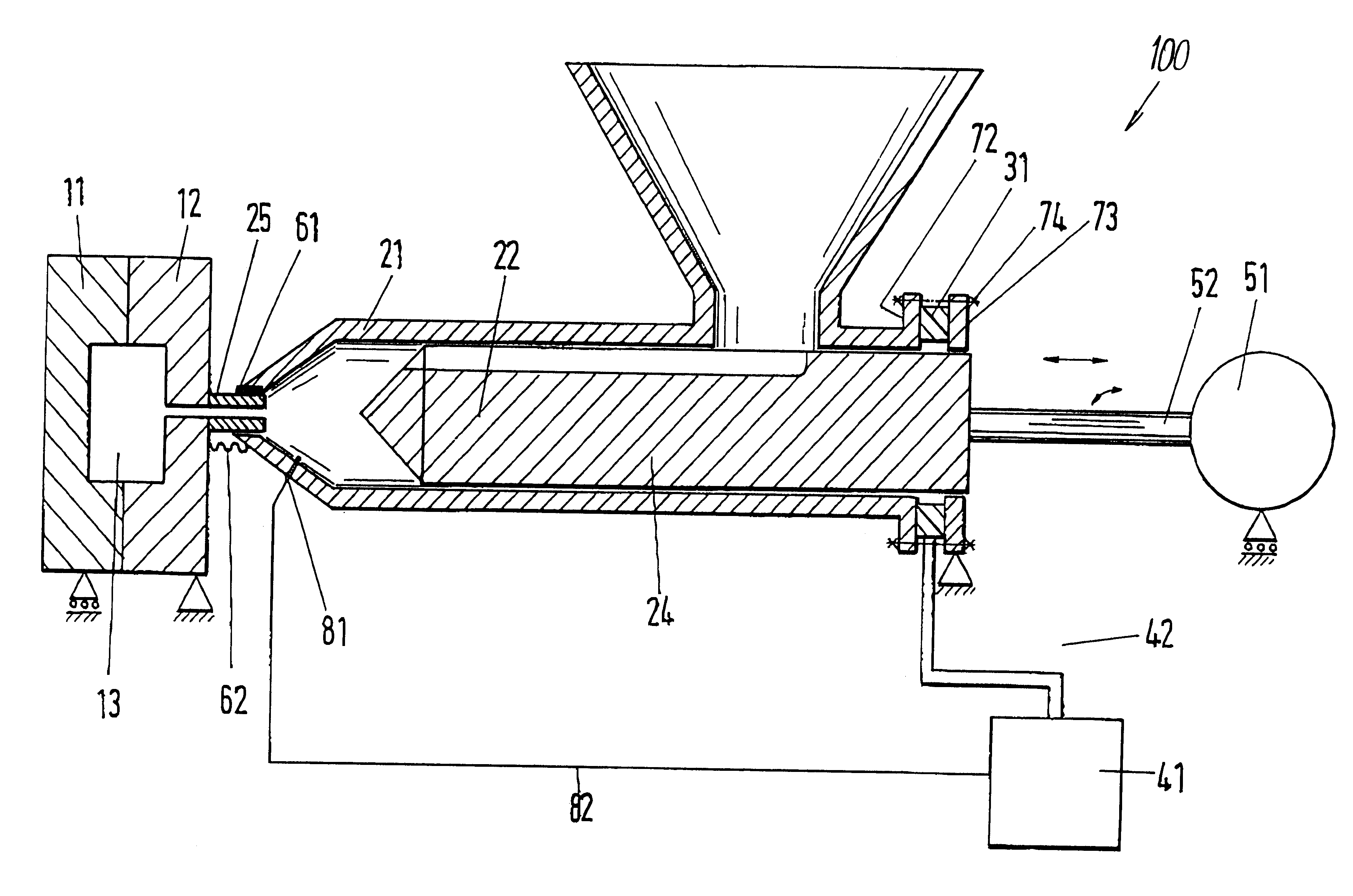

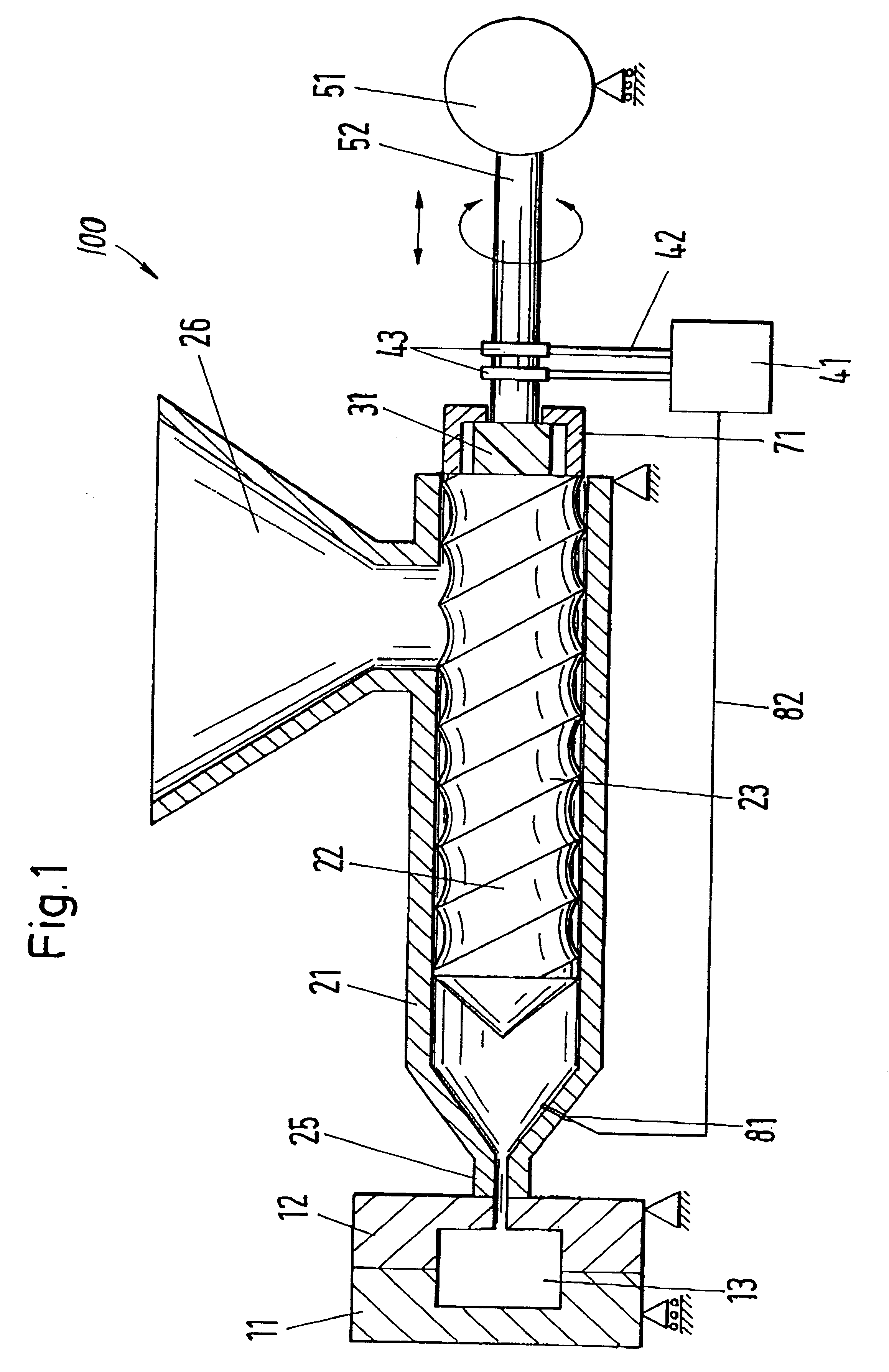

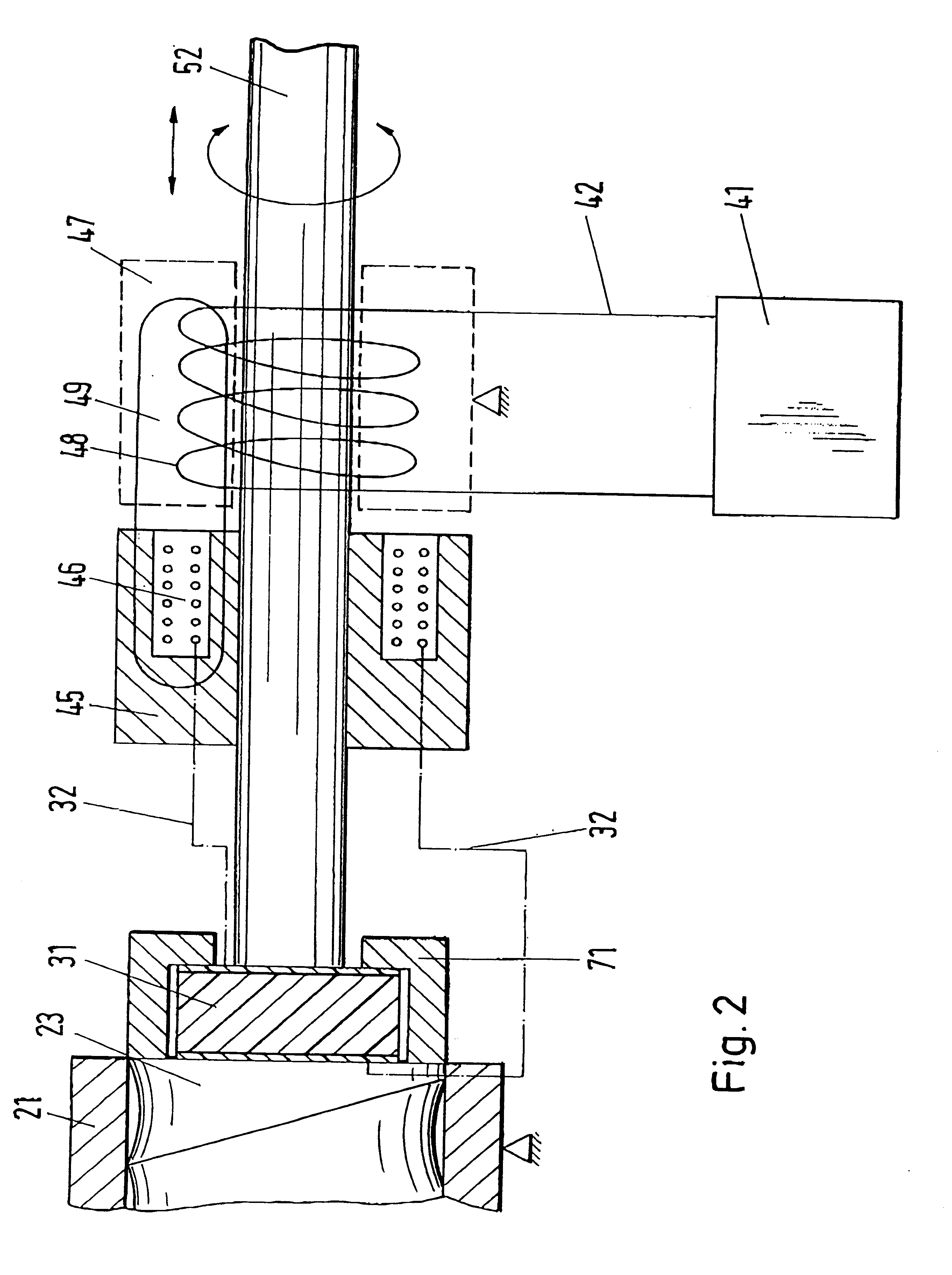

Resonating injection molding machine and process for its operation

InactiveUS6203747B1Reducing internal molecular frictionImprove the mixing effectRotary stirring mixersFrozen sweetsEngineeringInjection moulding

An injection molding machine includes an injection molding cylinder with a material supply at one end and an injection nozzle at the other end and a material conveyance unit attached to a drive and movable in the injection molding cylinder. The injection molding machine also includes a vibration element for inducing a flow of melt within the injection molding cylinder for homogenizing the melt.

Owner:ATECS MANNESMANN GMBH +1

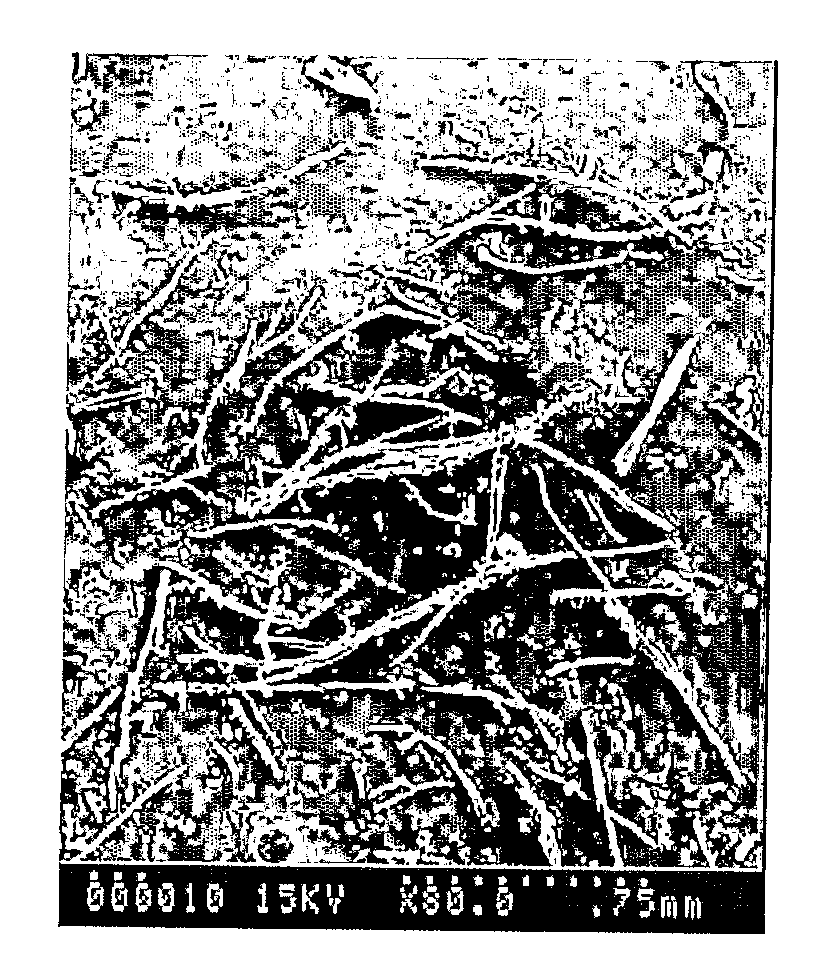

Manufacturing process for high performance lignocellulosic fibre composite materials

InactiveUS20090065975A1Structure moreStrict requirementsRotary stirring mixersLaminationDecompositionFlexural strength

The present invention relates to a process for the manufacture of composite materials having lignocellulosic fibres dispersed in a thermoplastic matrix, while generally maintaining an average fibre length not below 0.2 mm. The process comprises defibrillation of the lignocellulosic fibres using a mixer and at a temperature less than the decomposition temperature of the fibres in order to separate the fibres and generate microfibres, crofÊbres, followed by dispersion of the fibres in the thermoplastic matrix by mechanical mixing to get the moldable thermoplastic composition, followed by injection, compression, extrusion or compression injection molding of said composition. The process produces high performance composite materials having a tensile strength not less than about 55 MPa, a flexural strength not less than about 80 MPa, a stiffness not less than about 2 GPa, notched impact strength not less than about 20 J / m, and un-notched impact strength not less than about 100 J / m. The composite materials of the present invention are well-suited for use in automotive, aerospace, electronic, furniture, sports articles, upholstery and other structural applications.

Owner:SAIN MOHINI M +2

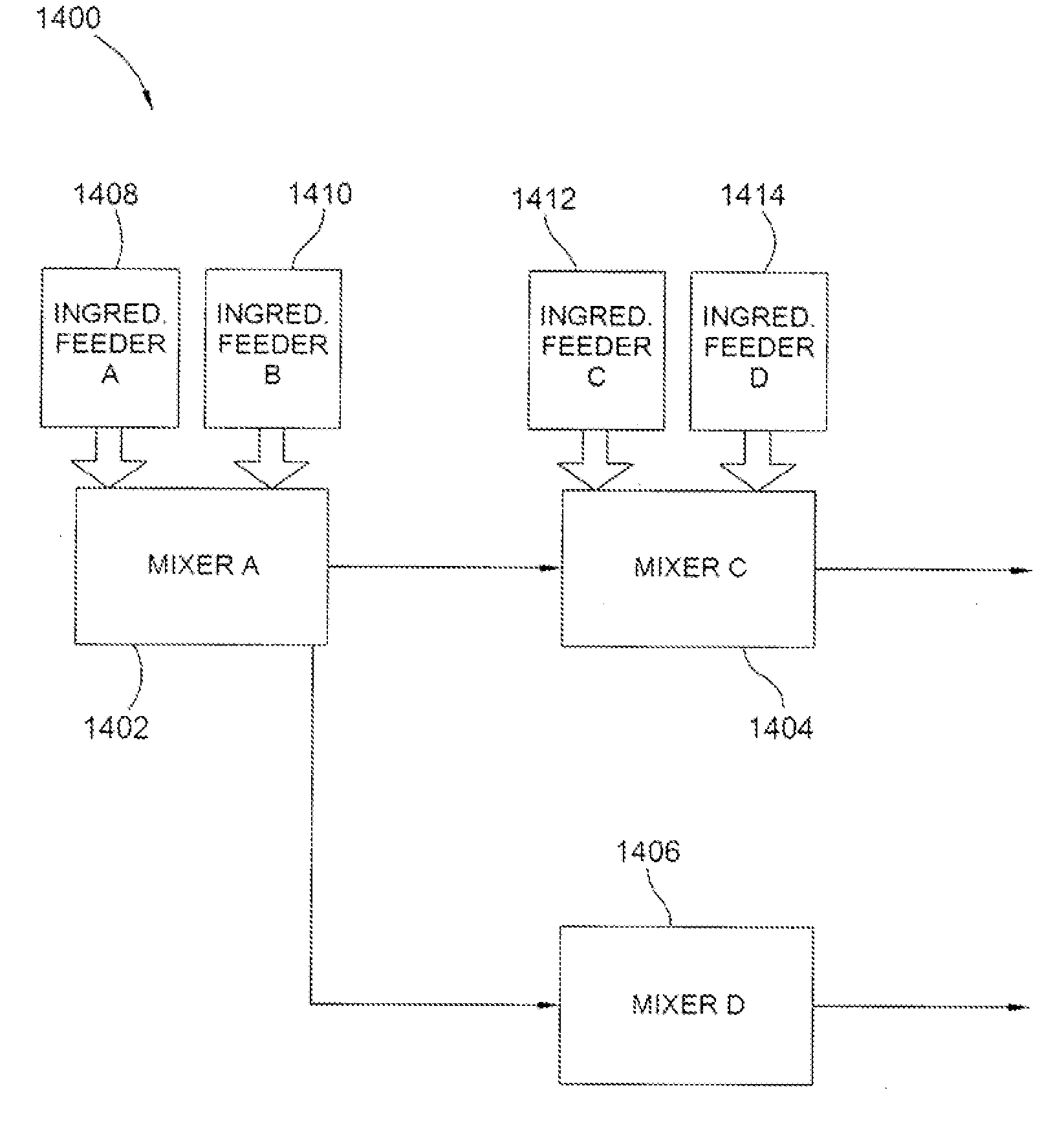

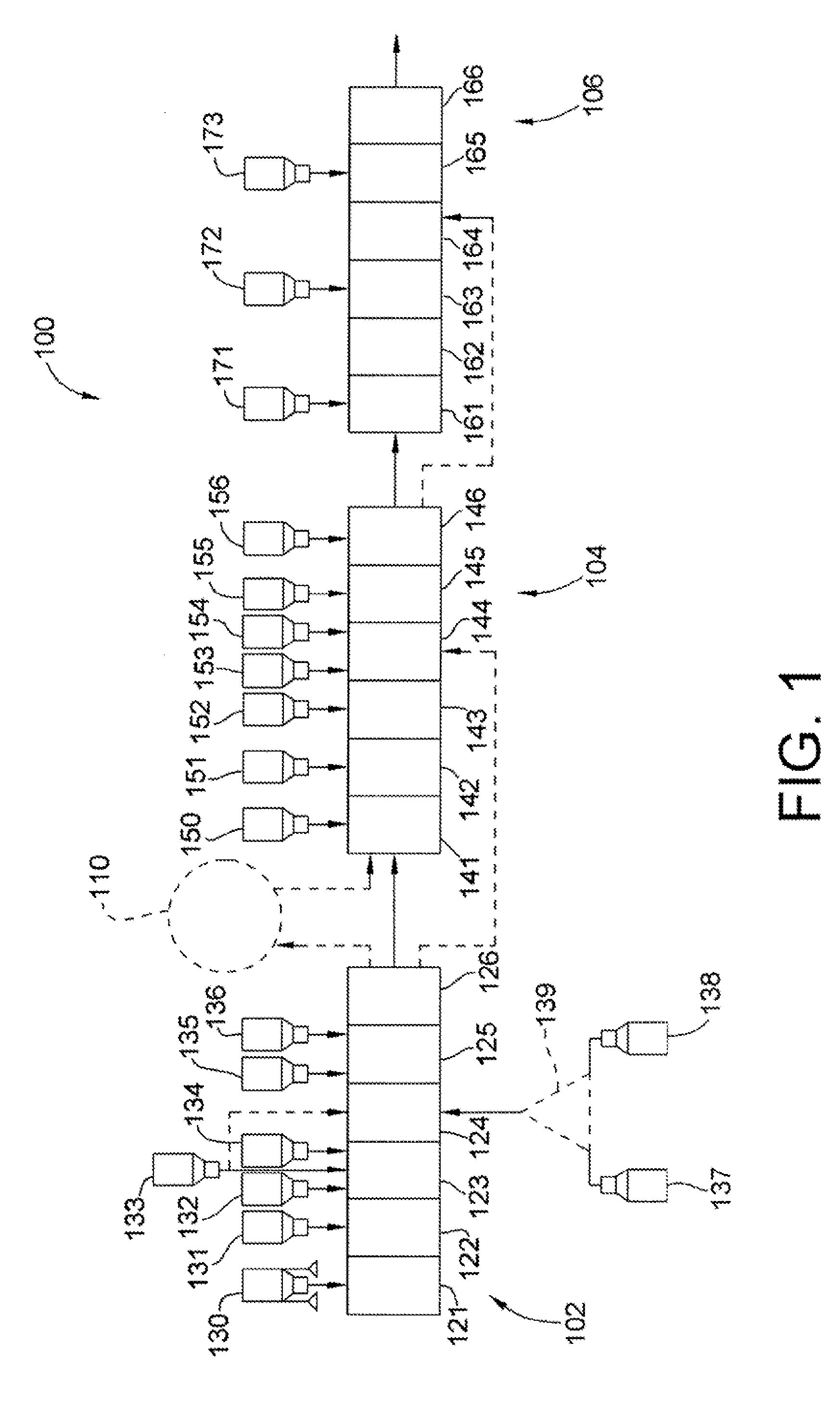

Parallel Gum Component Mixing Systems And Methods

InactiveUS20090162476A1Rotary stirring mixersMixing/kneading with horizontally-mounted toolsHybrid systemAdditive ingredient

A system and method for mixing and forming gum structures is provided. The system may include combinations of continuous and batch mixers arranged generally in parallel and / or series for mixing gum base ingredients with subsequent gum ingredients. In one embodiment, the system and method first forms a gum structure that is not a gum base and then adds a subsequent gum ingredient such that the gum structure is less than a gum base in combination with a subsequent gum ingredient. In other embodiments, the system and method includes forming a gum base in addition to some subsequent gum ingredients that are not quite finished gum. Further, in other embodiments, the system and method may perform some of the mixing of the ingredients at a first location while mixing of further ingredients is performed at a remote location.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

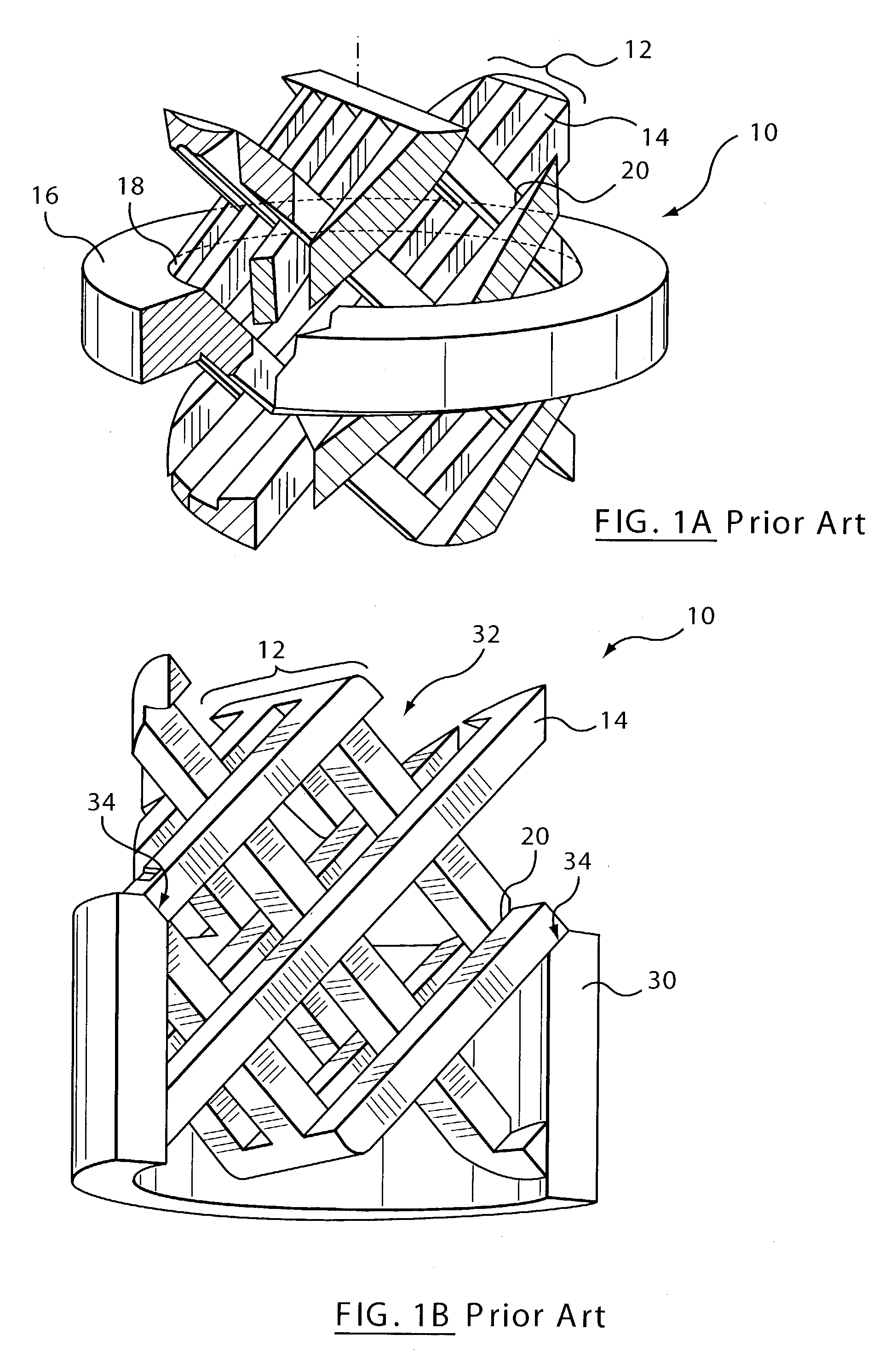

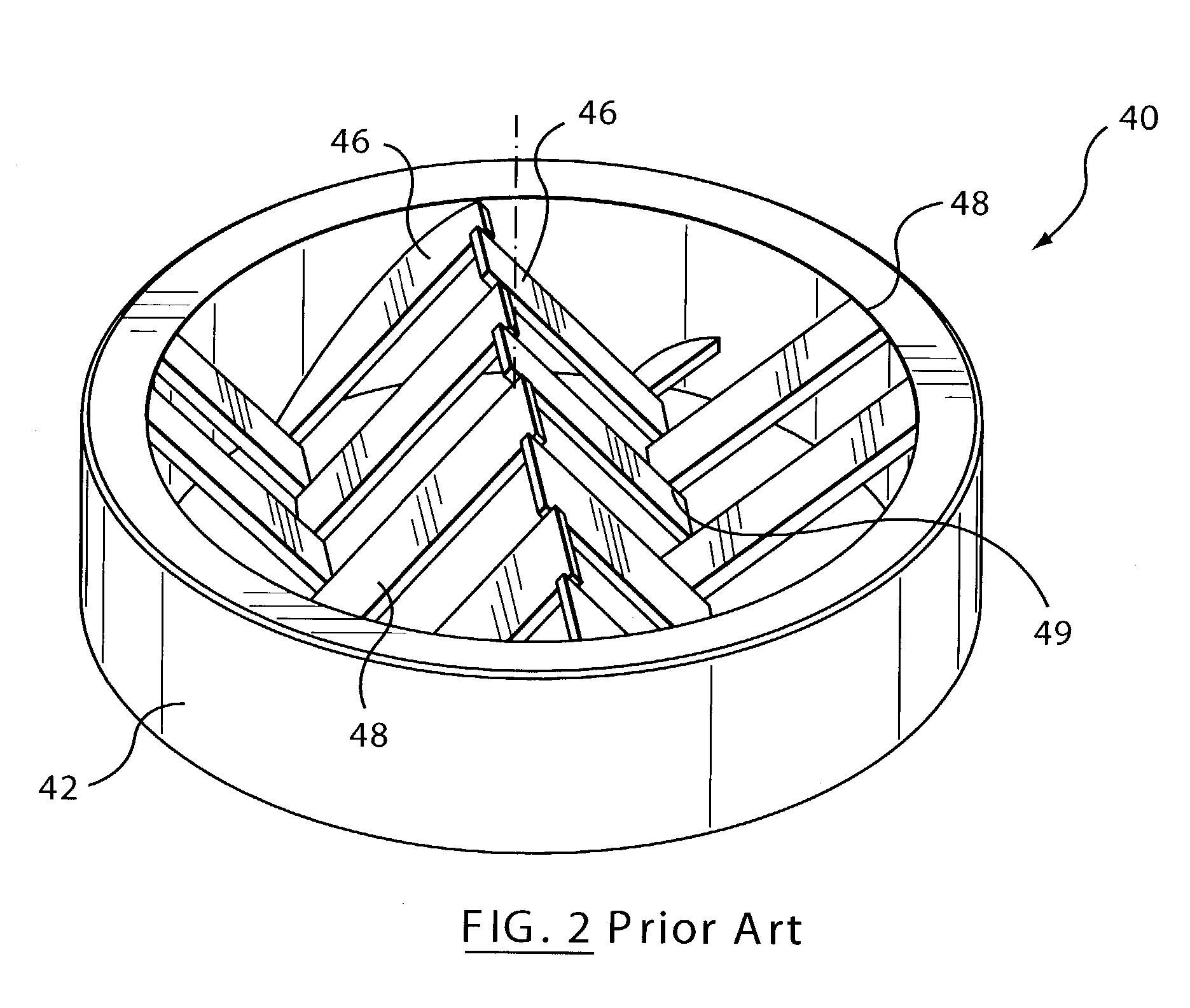

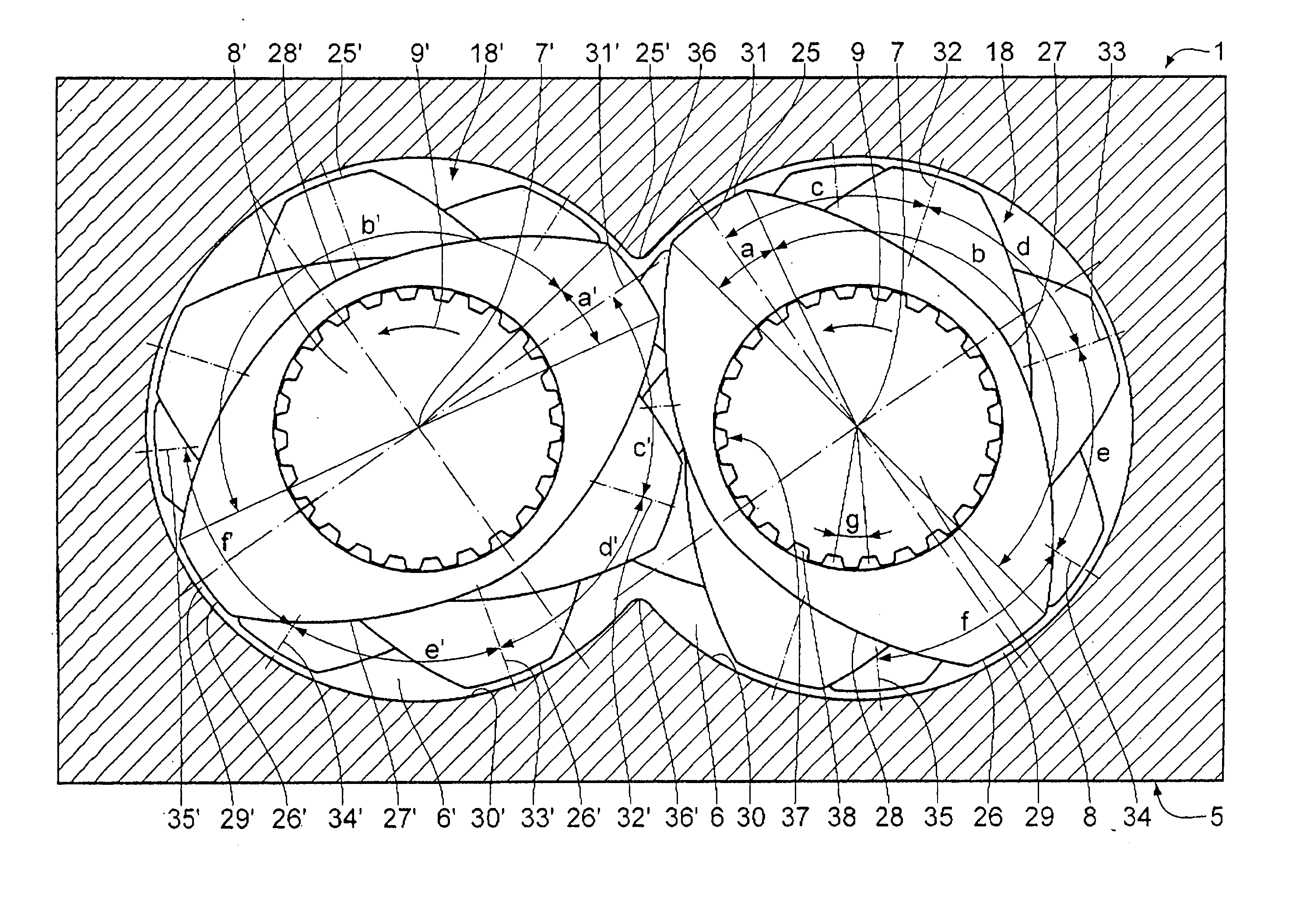

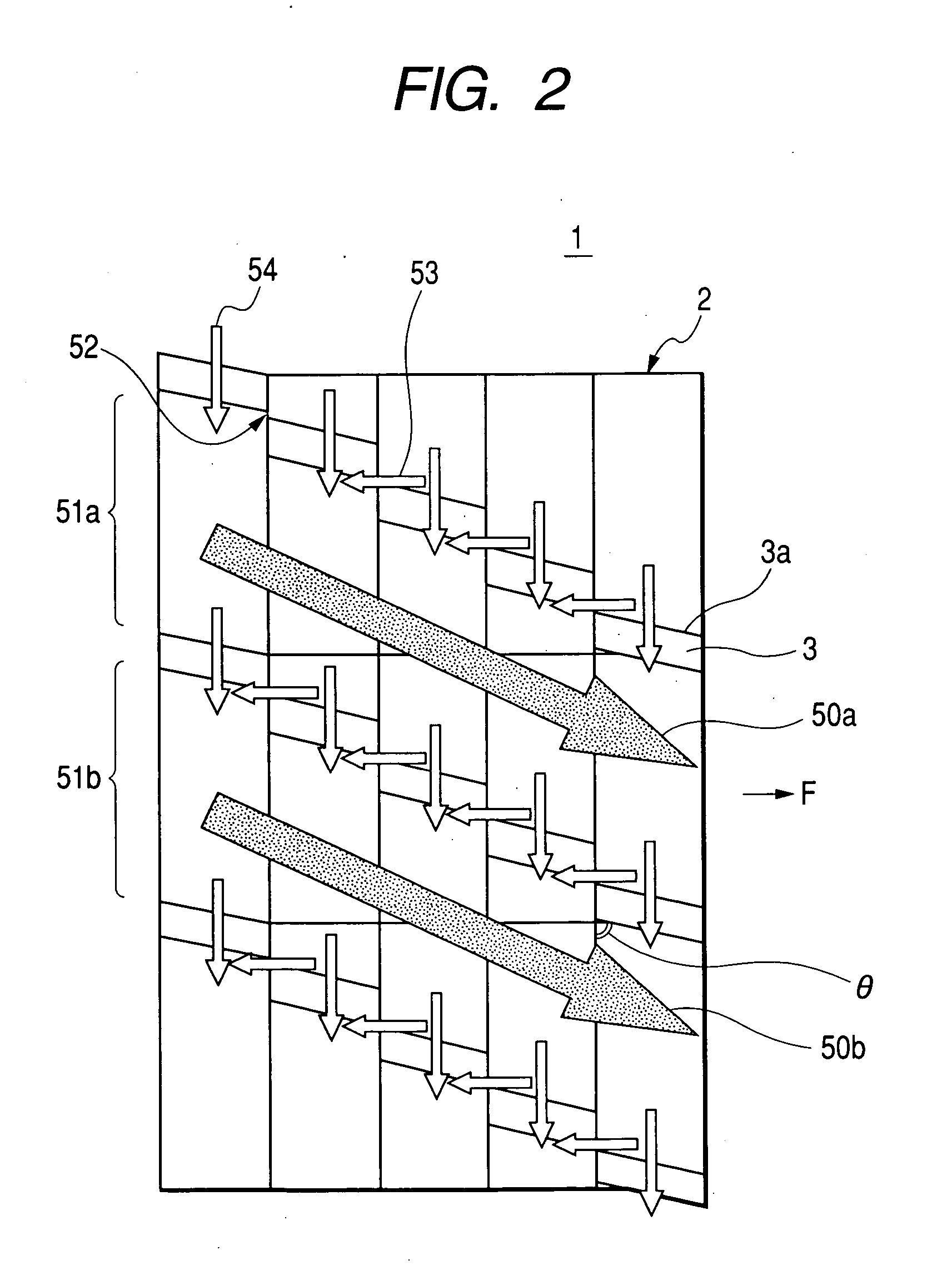

Screw-type extruding machine comprising mixing and kneading disks

InactiveUS20050041521A1Reduce decreaseRotary stirring mixersMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

A screw-type extruding machine comprises at least two casing bores with screw shafts disposed therein, on which several successive mixing and kneading disks are mounted, interengaging in pairs. Successive mixing and kneading disks make an angle of crest misalignment which is not integrally contained in 360°.

Owner:COPERION

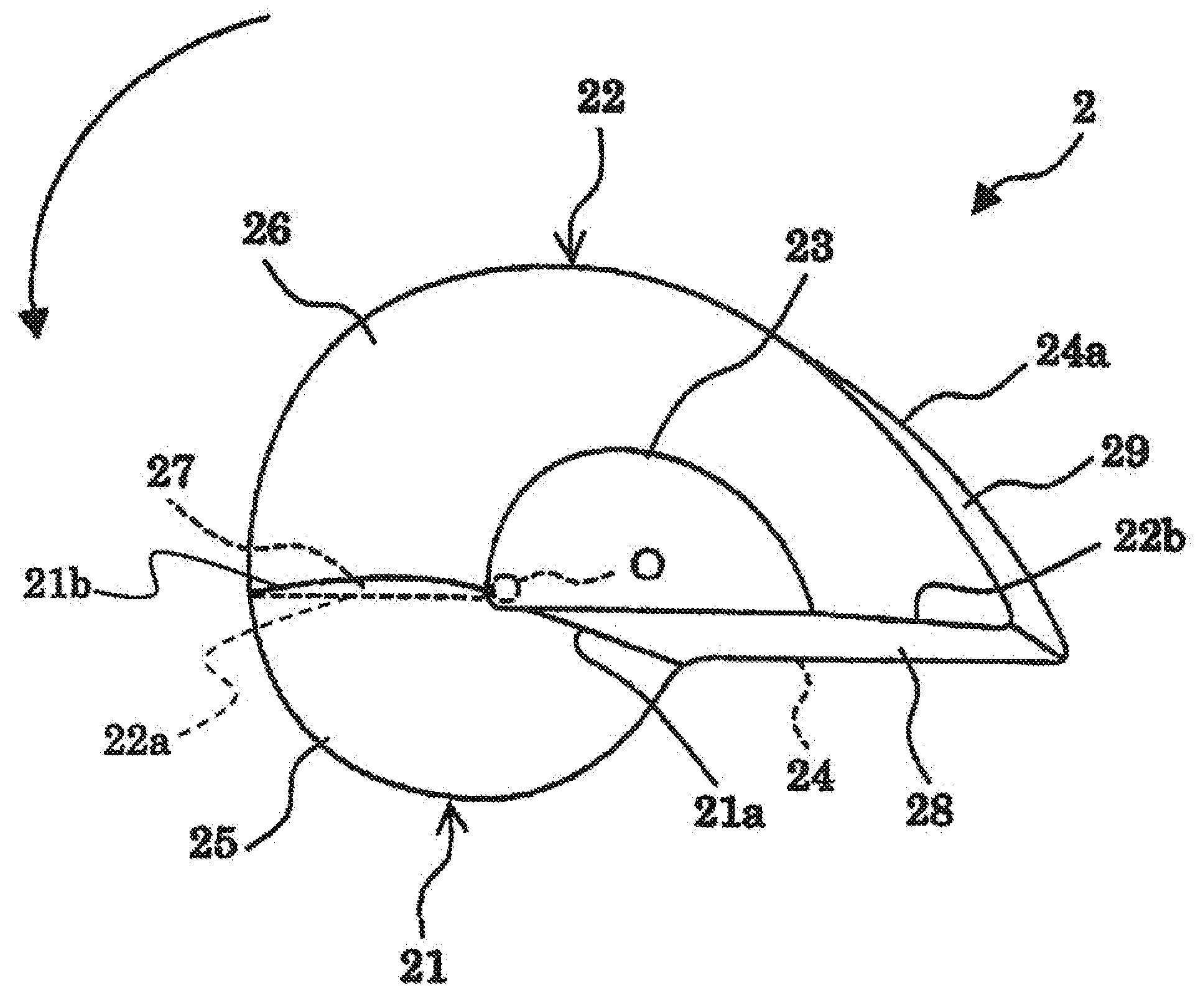

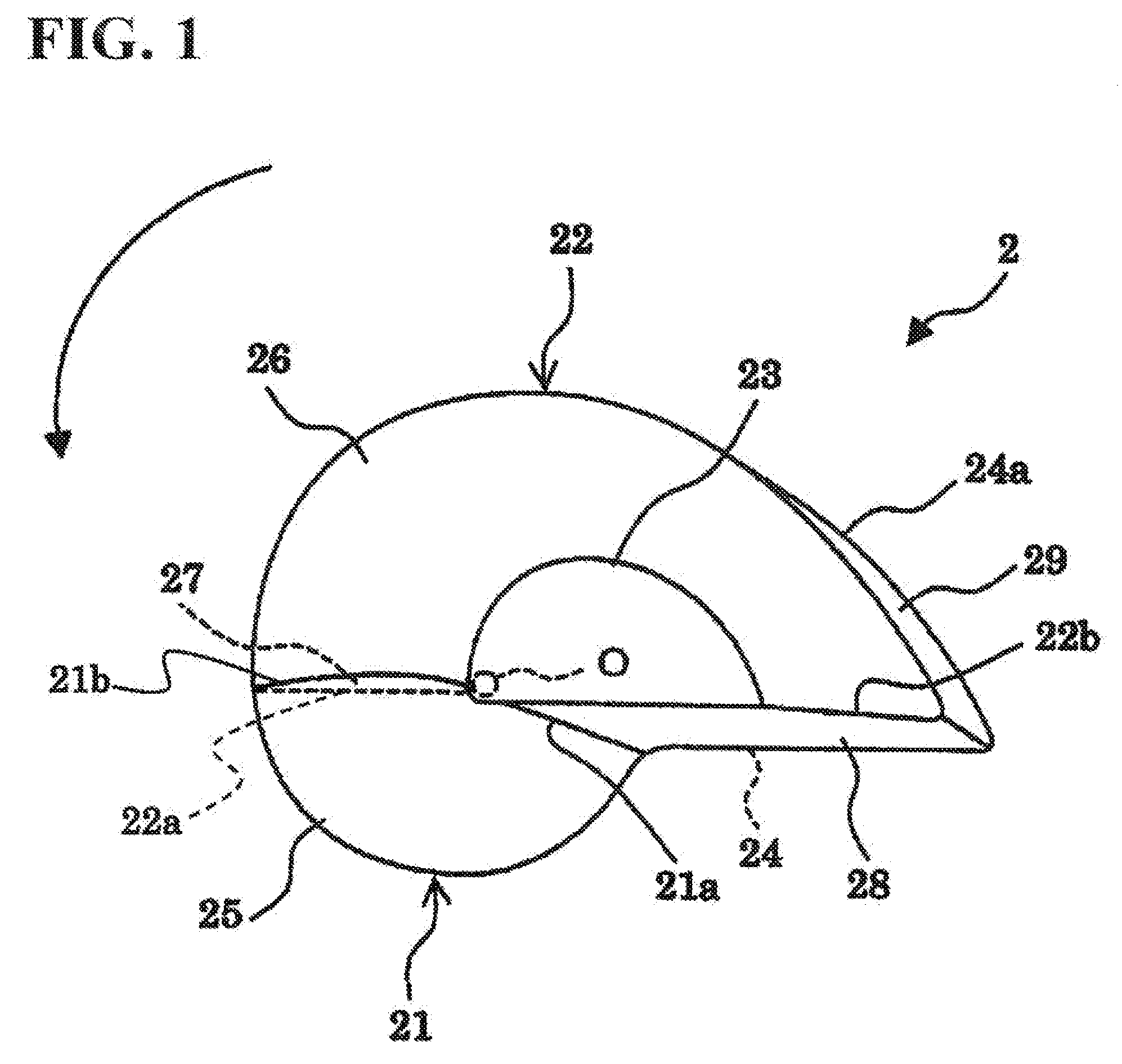

Kneading Element of Kneader, Kneader, and Bread Machine

InactiveUS20100147160A1Efficient kneadingReduce adhesionMixing/kneading structural elementsRotary stirring mixersMechanical engineeringEngineering

Owner:JAPAN KNEADER

High speed and direct driven rotating equipment for polyolefin manufacturing

An apparatus and method for melting polymer is provided. In at least one embodiment, the apparatus includes a housing, two or more rotatable members at least partially contained within the housing, where each rotatable member having a shaft coupled thereto. The apparatus also includes a motor having a drive shaft directly coupled to the shaft of the rotatable members such that the rotatable members rotate at a speed of the motor drive shaft. The rotatable members are preferably non-intermeshing and counter-rotating.

Owner:UNIVATION TECH LLC

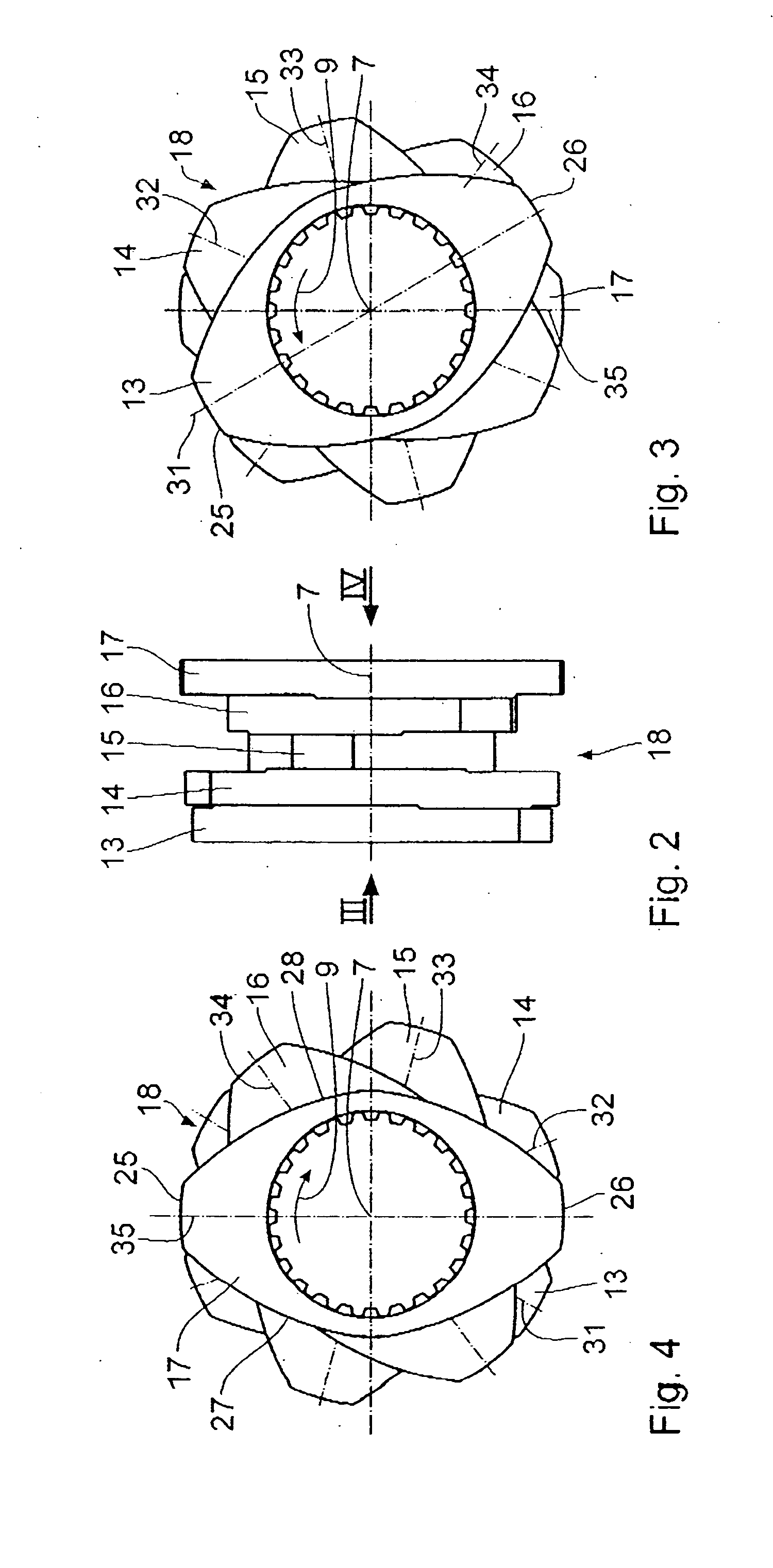

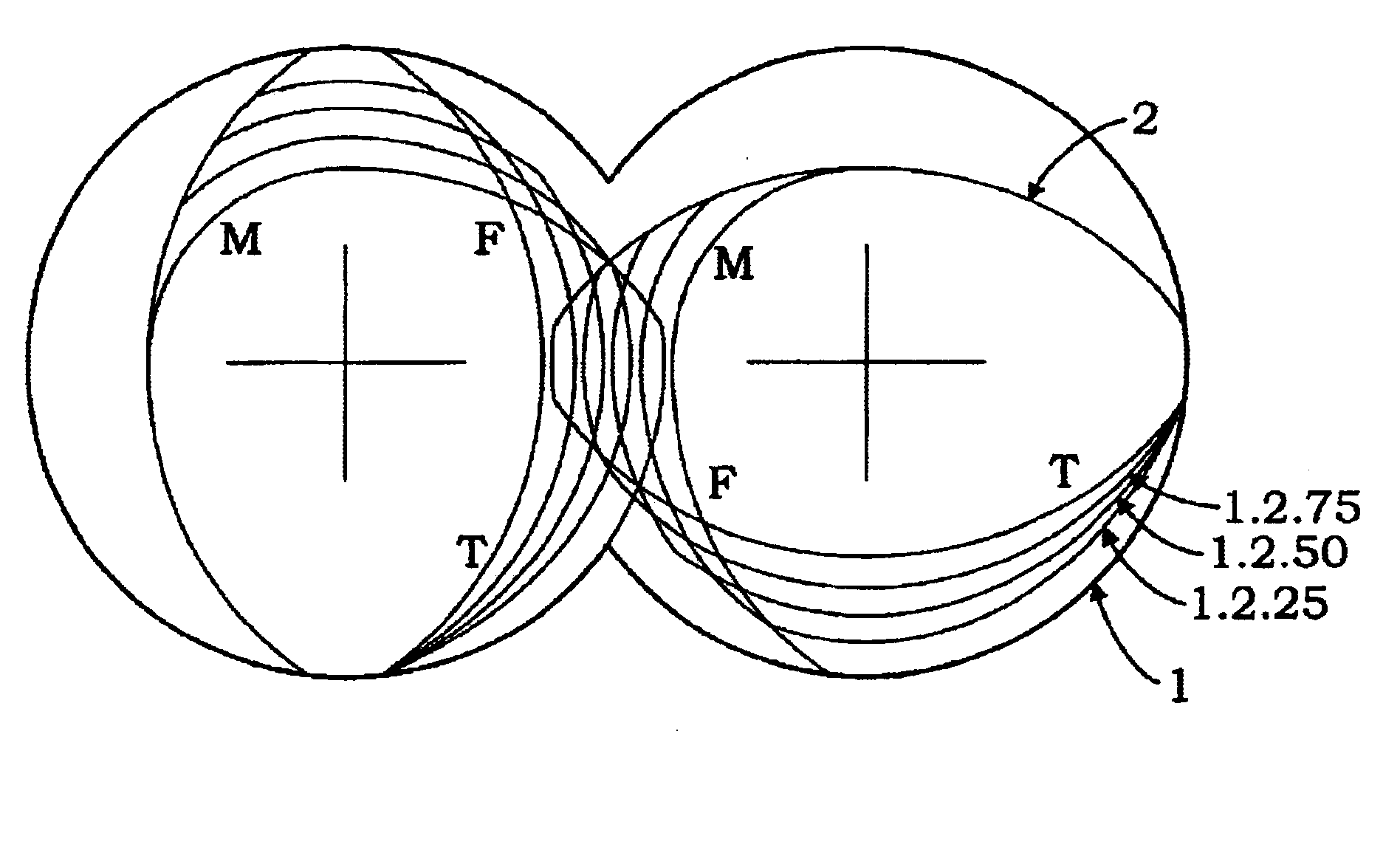

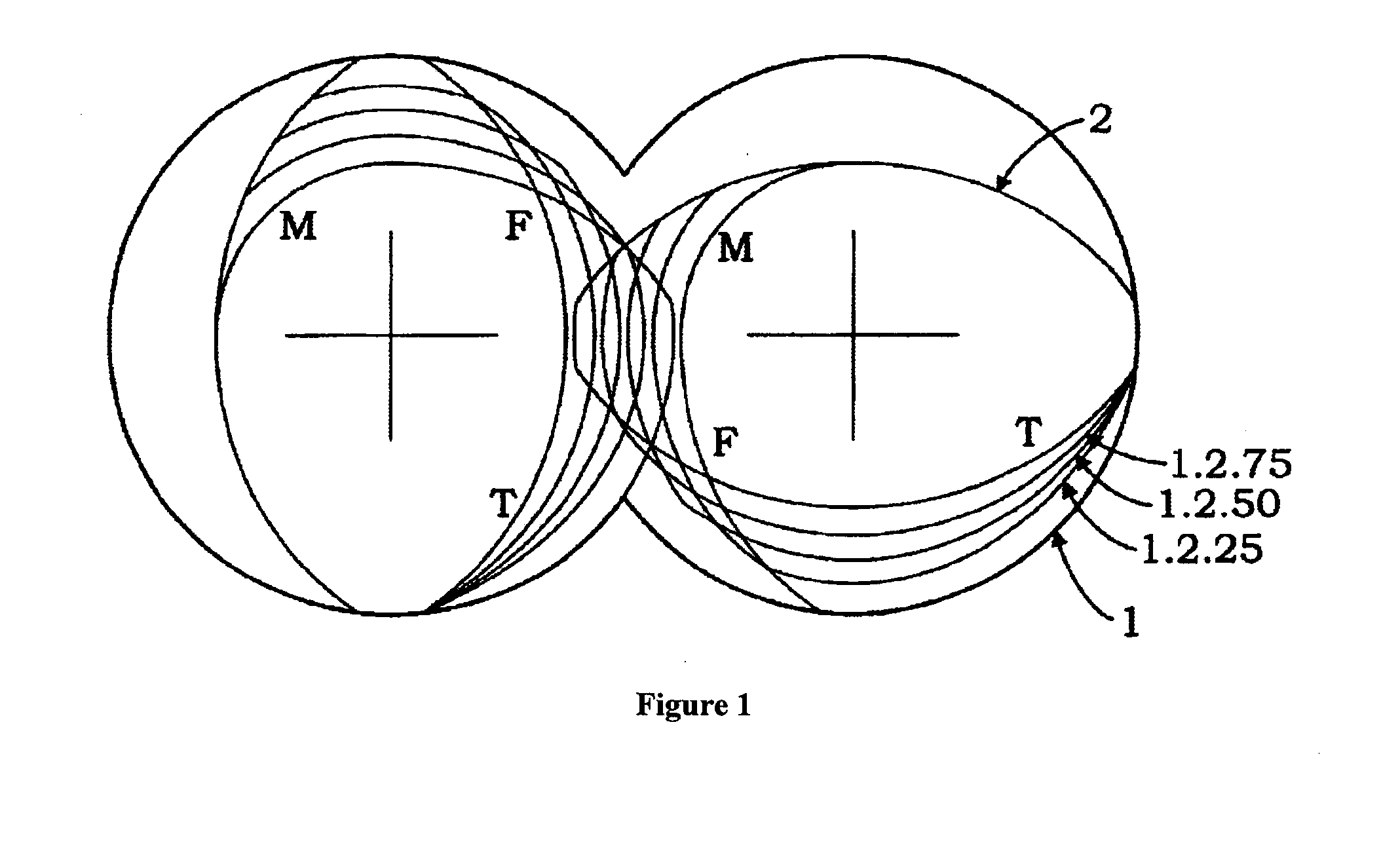

Kneading disk, a disk element and a kneading process

ActiveUS20050013192A1Low resin temperatureReduce the temperatureRotary stirring mixersMixing/kneading with horizontally-mounted toolsCircular discStream flow

A kneading disk has a plurality of disk elements having flight tips arranged at a helix angle E in a direction supporting main streams of a resin. The flight tips of every two adjoining disks have a clearance formed therebetween. The resin is kneaded by undergoing dispersion and distribution without having any excessive temperature elevation in approximately three kinds of streams, i.e. its main streams flowing along the flight tips, its back streams through the clearances and its tip riding streams flowing over the flight tips.

Owner:JAPAN STEEL WORKS LTD

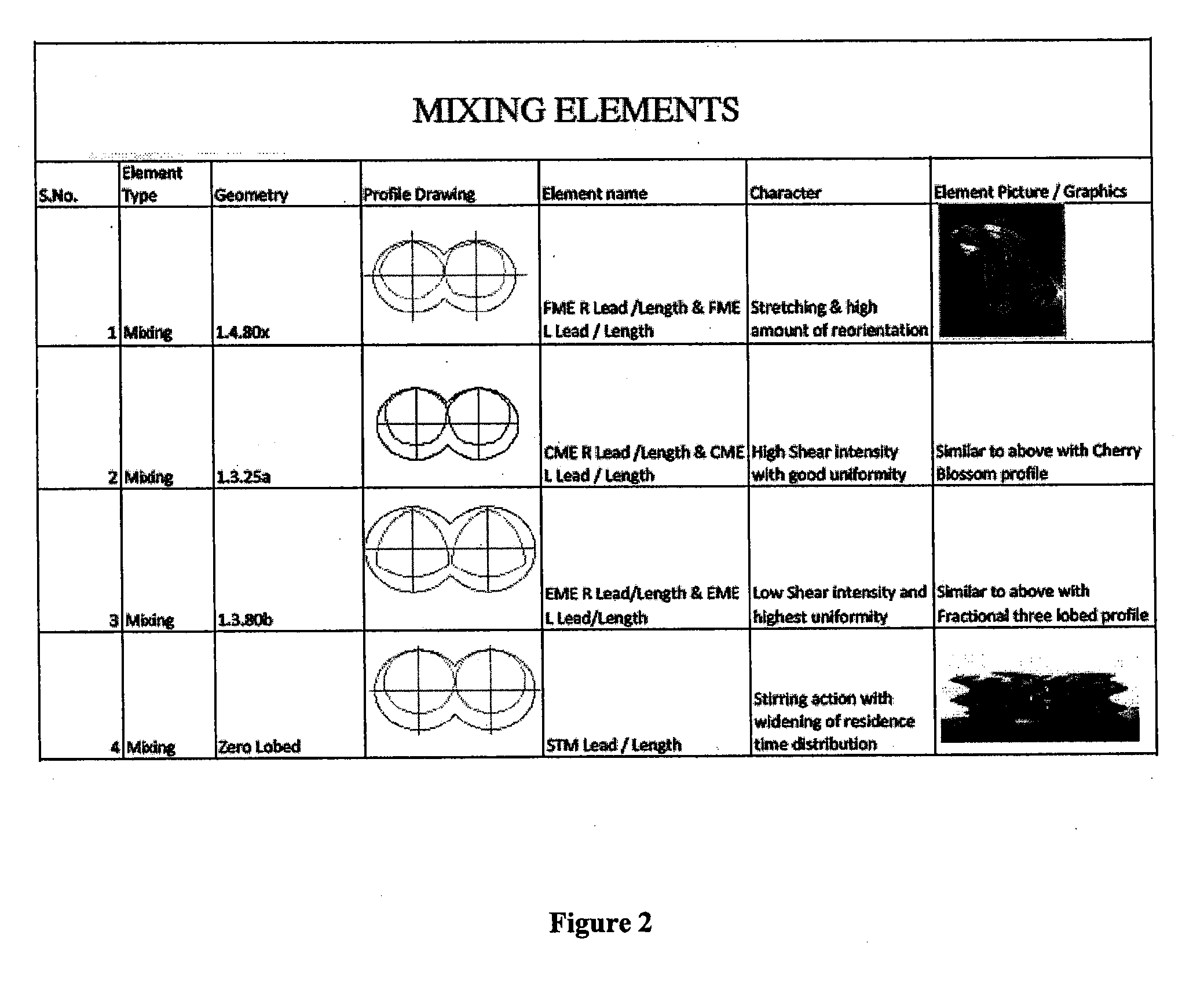

Method of extruder operation

InactiveUS20110063940A1Rotary stirring mixersMixing/kneading with horizontally-mounted toolsMechanical engineeringMixing zone

An extruder capable of improved mixing is disclosed. The extruder comprises of a housing having at least two cylindrical housing bores, each housing bore having an axis disposed parallel to the other axis. The extruder further comprises of at least a first screw shaft and a second screw shaft being disposed in the first and second housing bores. The first and second screw shaft being provided with extruder processing elements that defines a mixing zone. The first and second screw each having extruder D and a screw root diameter d. The first and second screw shaft each having a volumetric ratio of at least 1.4 wherein the volumetric ratio is defined by the extruder diameter D divided by the screw inner diameter d.

Owner:STEER ENG PRIVATE

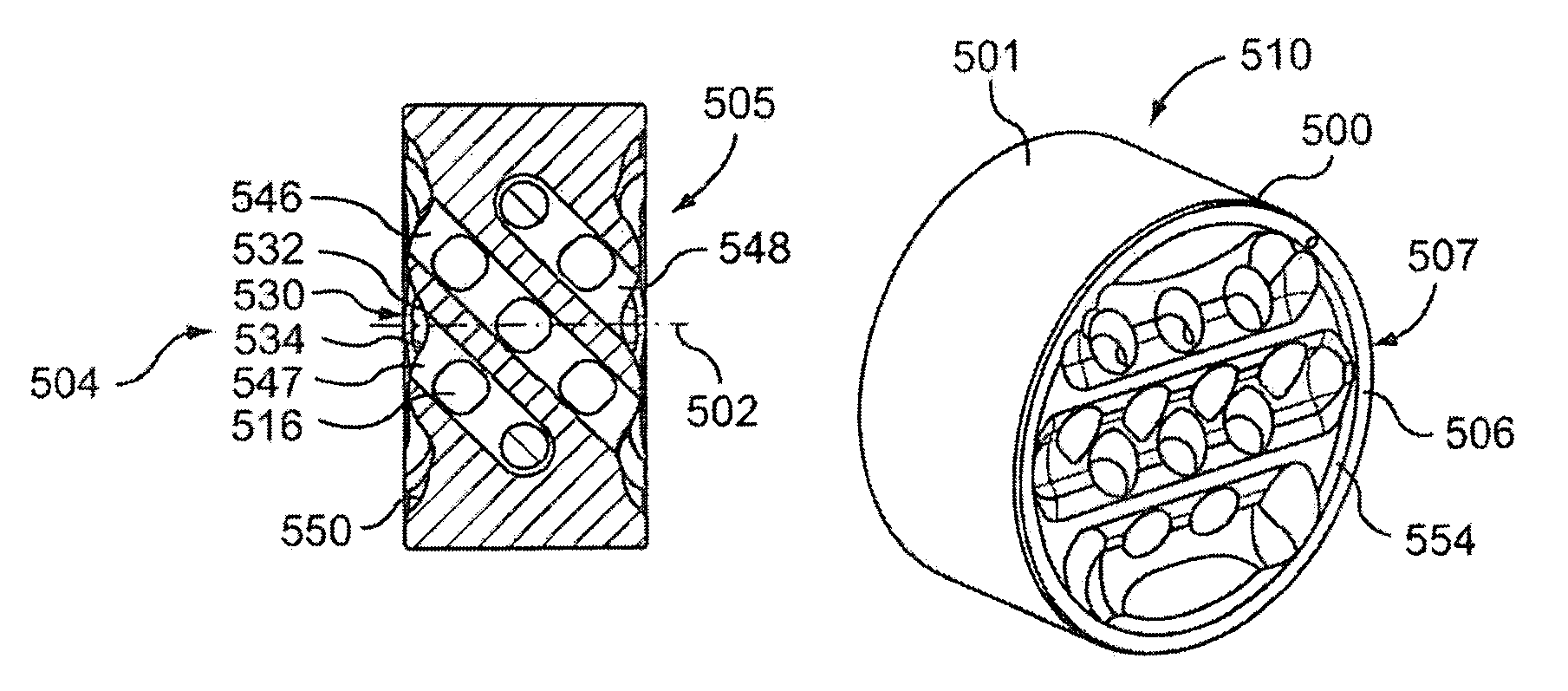

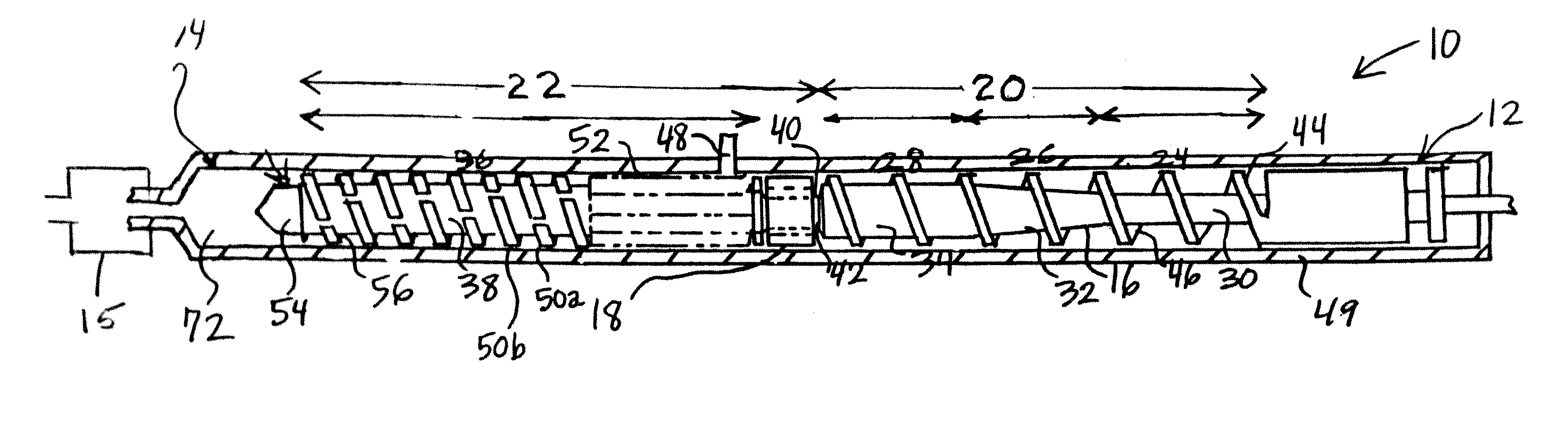

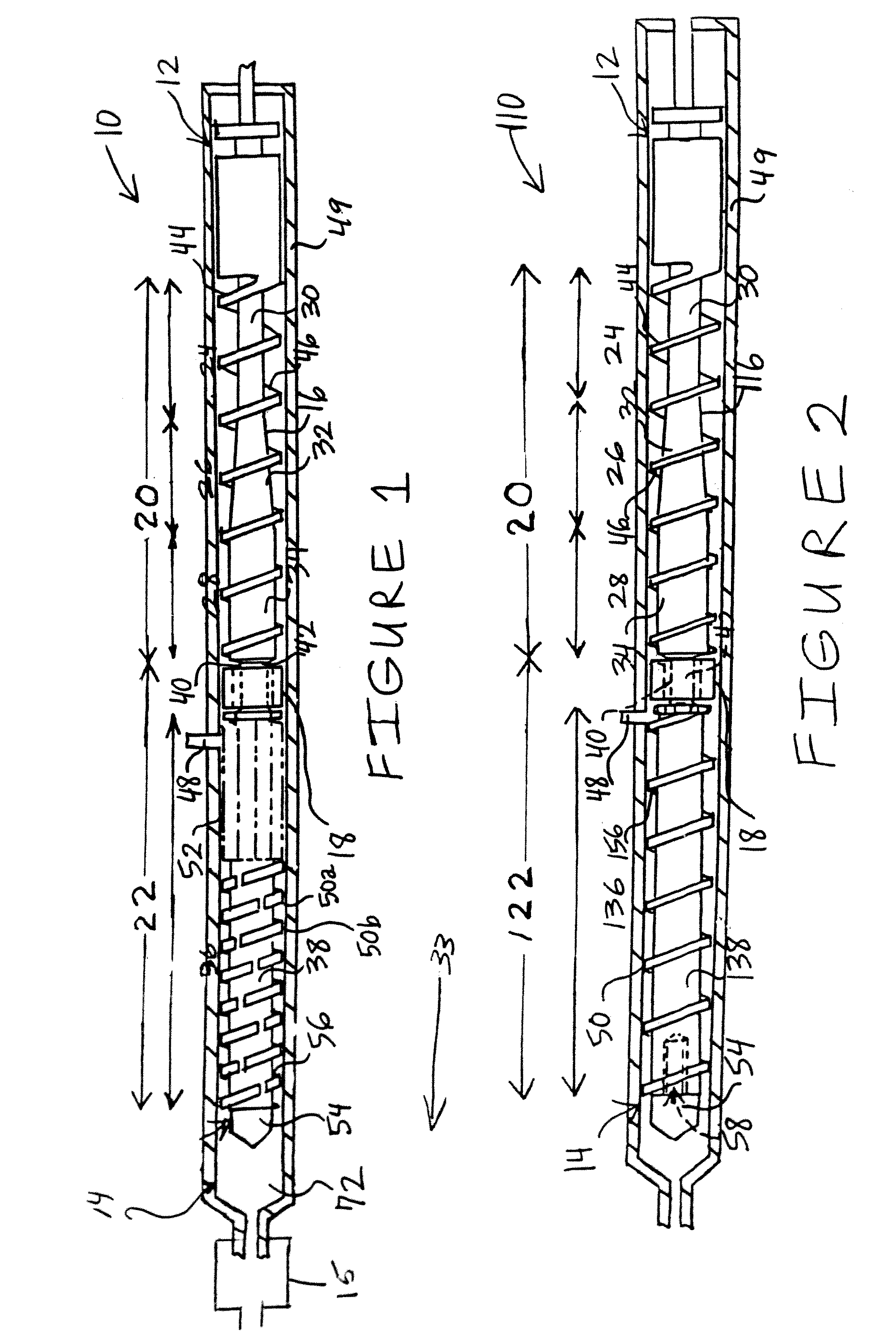

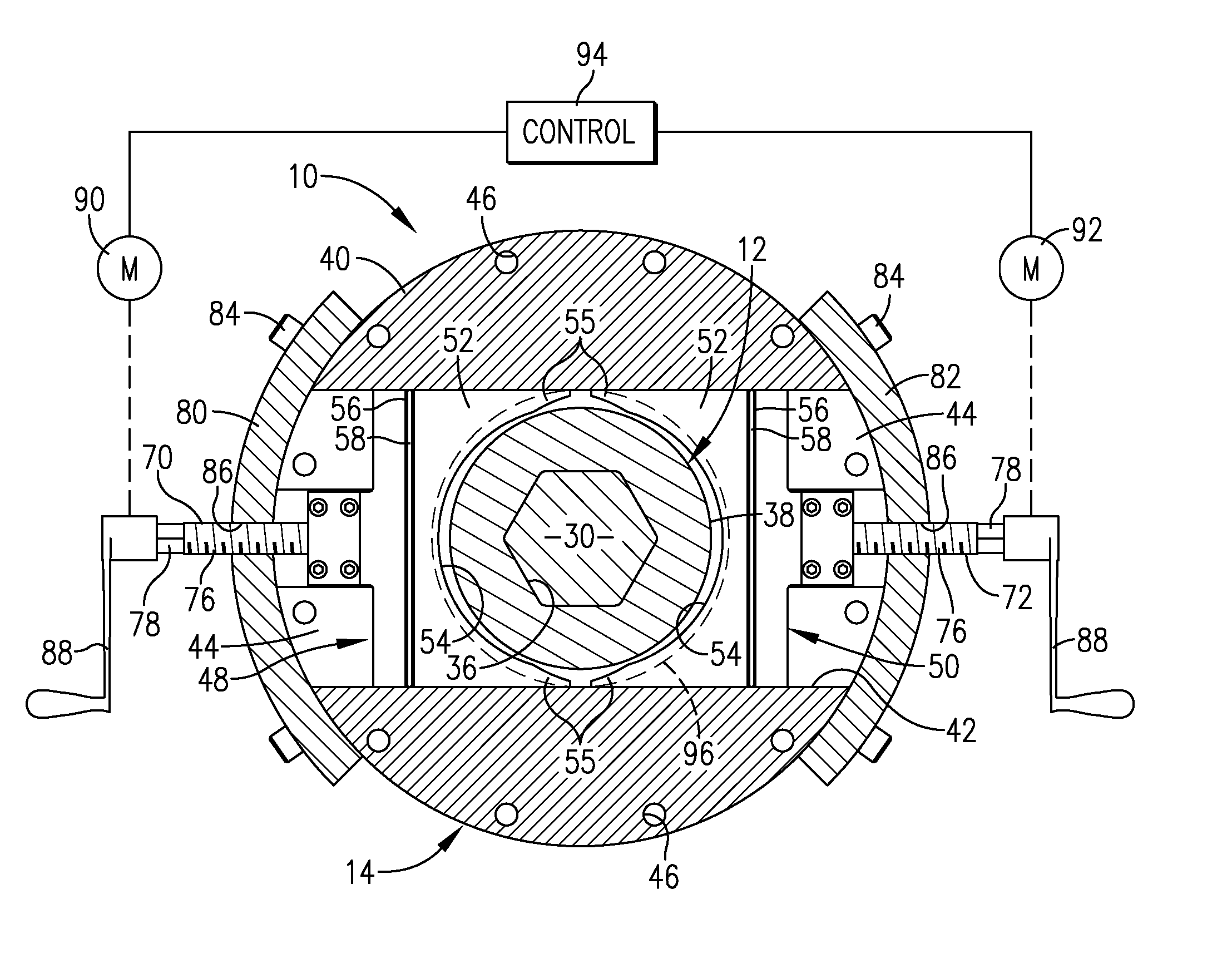

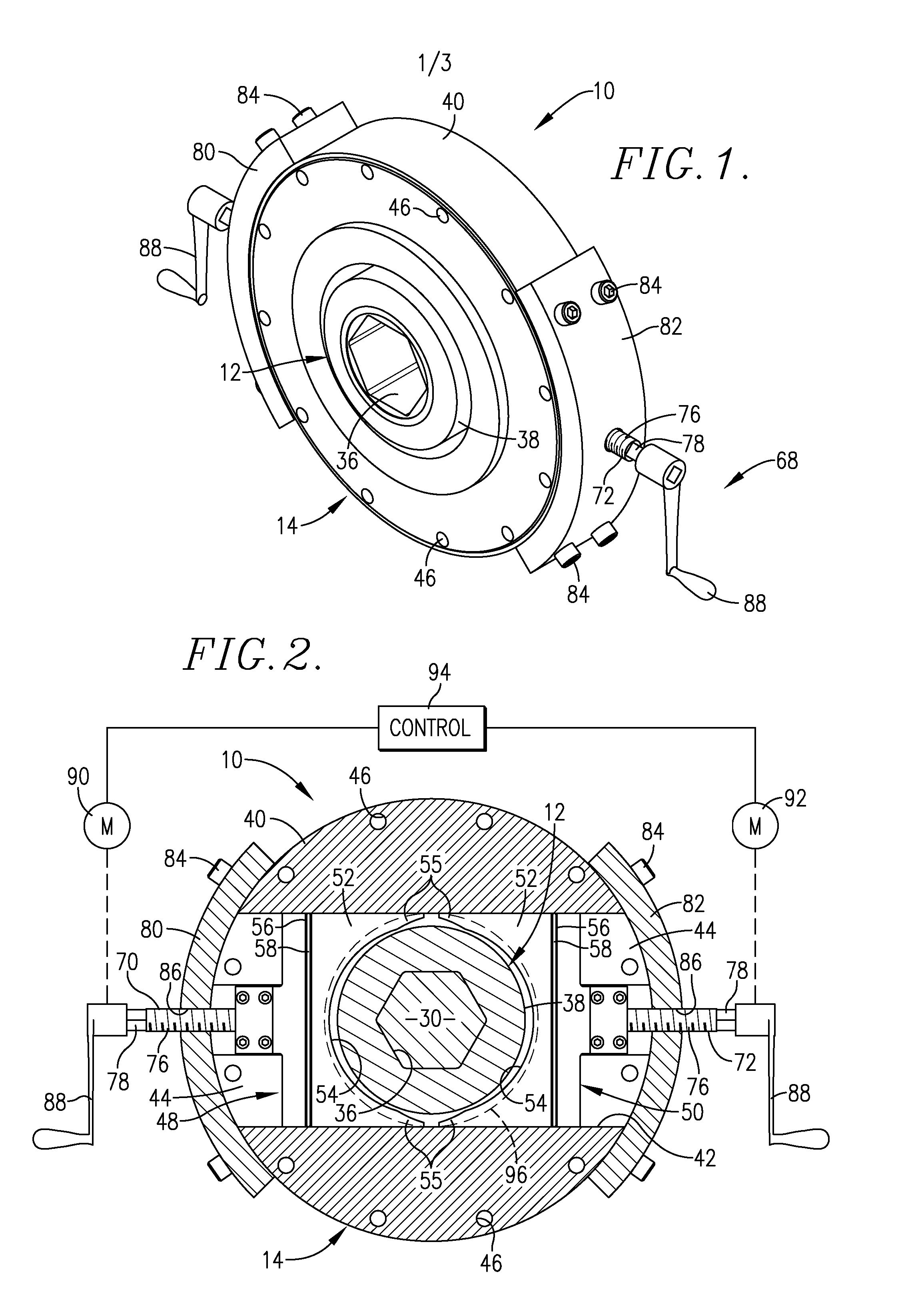

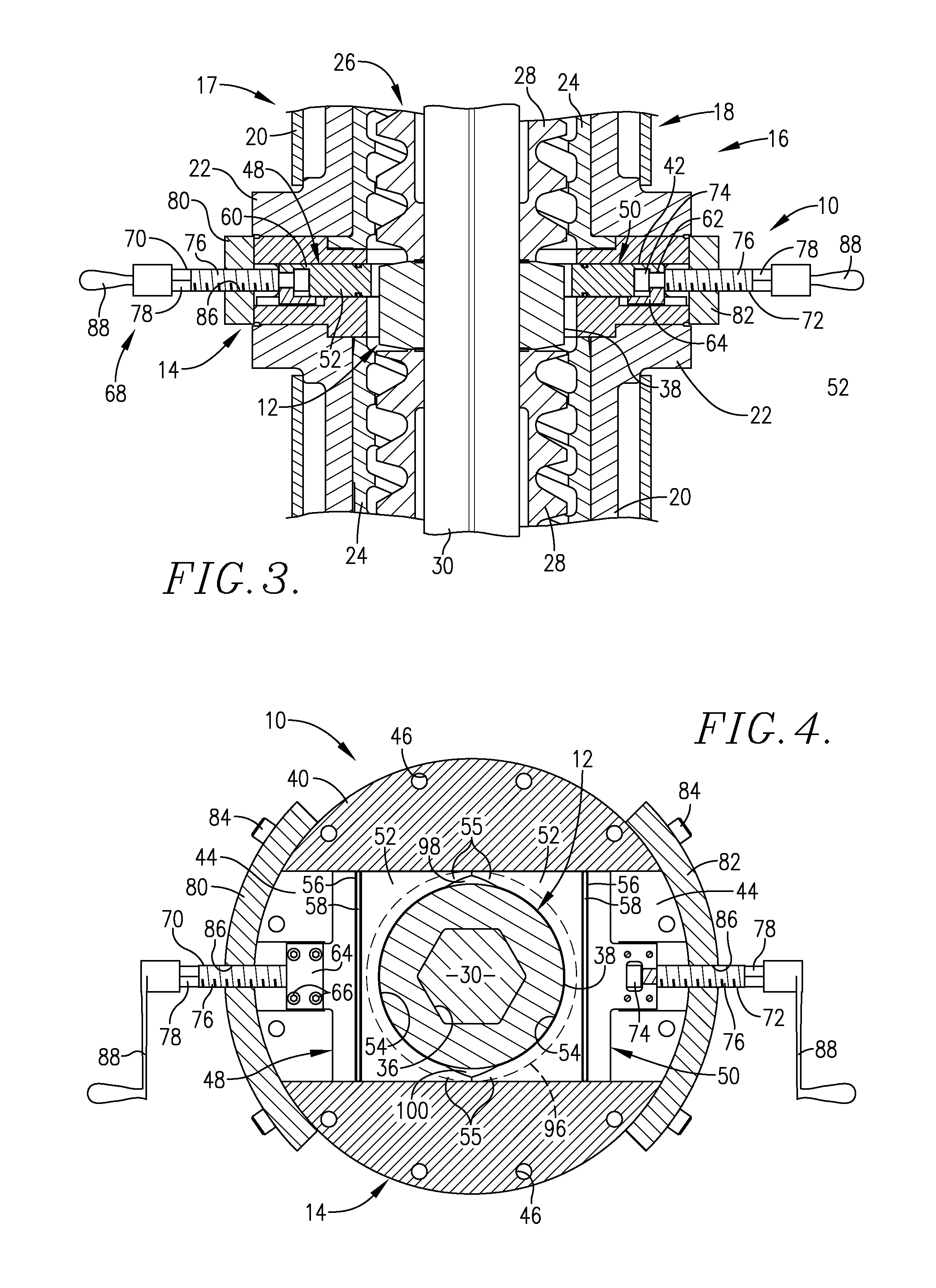

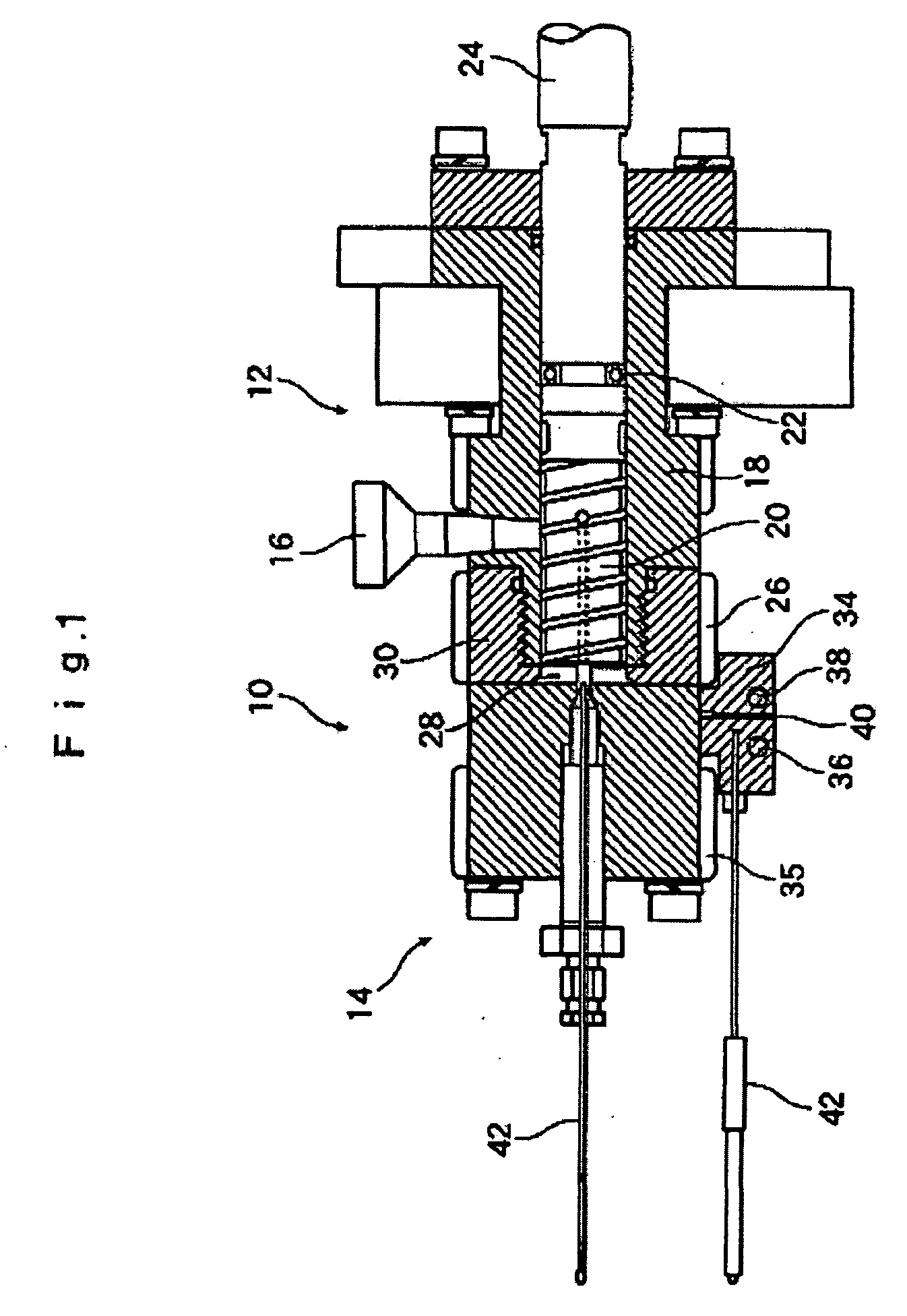

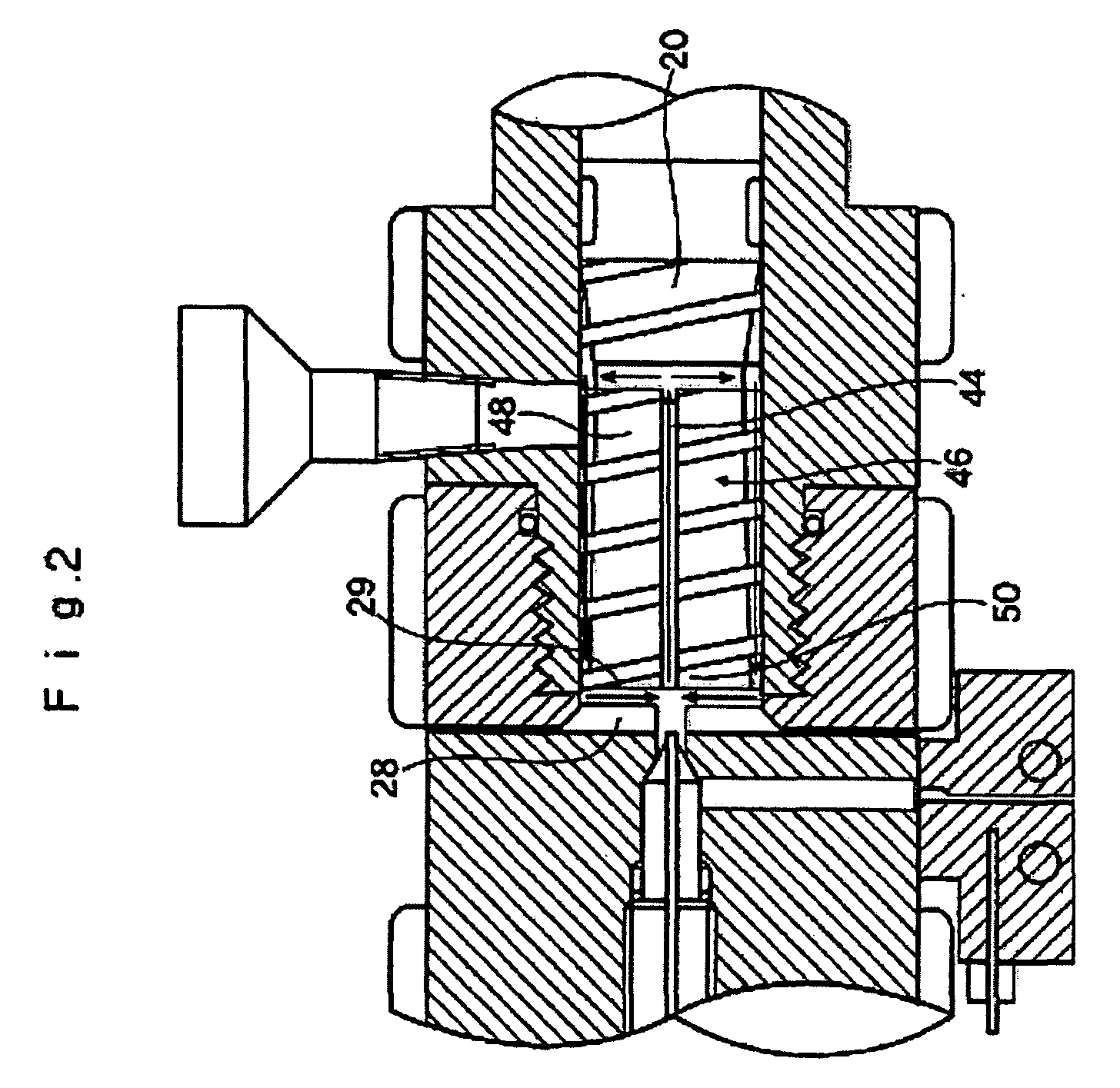

Extruder mid-barrel adjustable valve assembly

InactiveUS20070237022A1Overcome problemsRotary stirring mixersMixing/kneading with horizontally-mounted toolsDrive shaftVALVE PORT

Flow restriction assemblies (10,10a) adapted to be mounted on single or twin screw extruders (17,102) in order to allow selective adjustment of material flow through the extruders (17,102), with consequent alteration in back pressure and shear conditions. The assemblies (10,10a) each have shearlock(s) (12,12a) mounted on the extruder drive shaft(s) (34,34a), together with restriction units (14,14a). The units (14,14a) have opposed flow restriction components (48,50,48a,50a) supported on opposite sides of the shearlock(s) (12,12a) and mounted for a substantially aligned and rectilinear back and forth sliding movement. In this fashion, the clearance between the inner surfaces (54,55,54a,55a) of the components (48,50,48a,50a) can be selectively adjusted. The assemblies (10,10a) are small in size and can be located at various points along the length of extruders (17,102)

Owner:WENGER MANUFACTURING INC

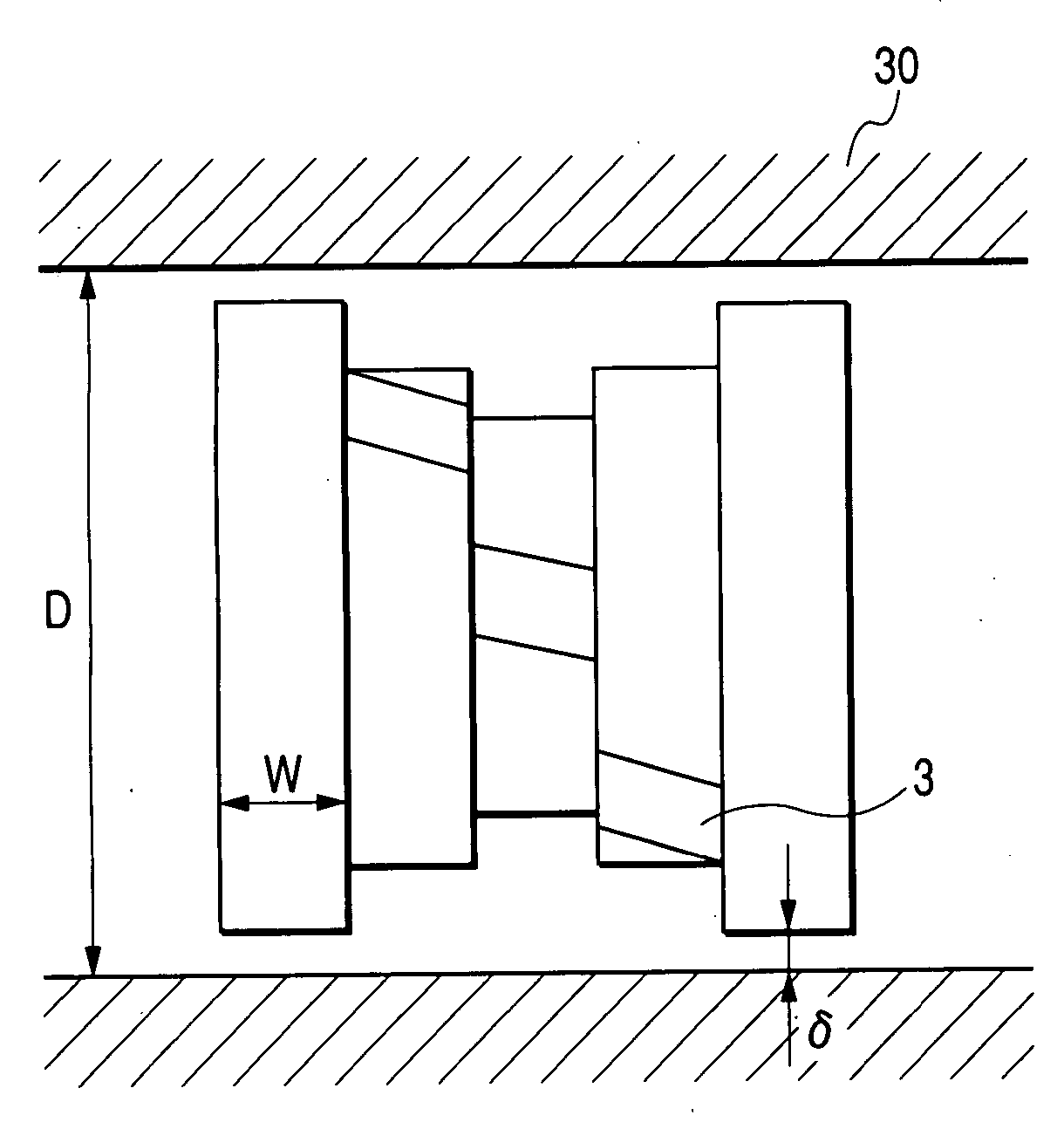

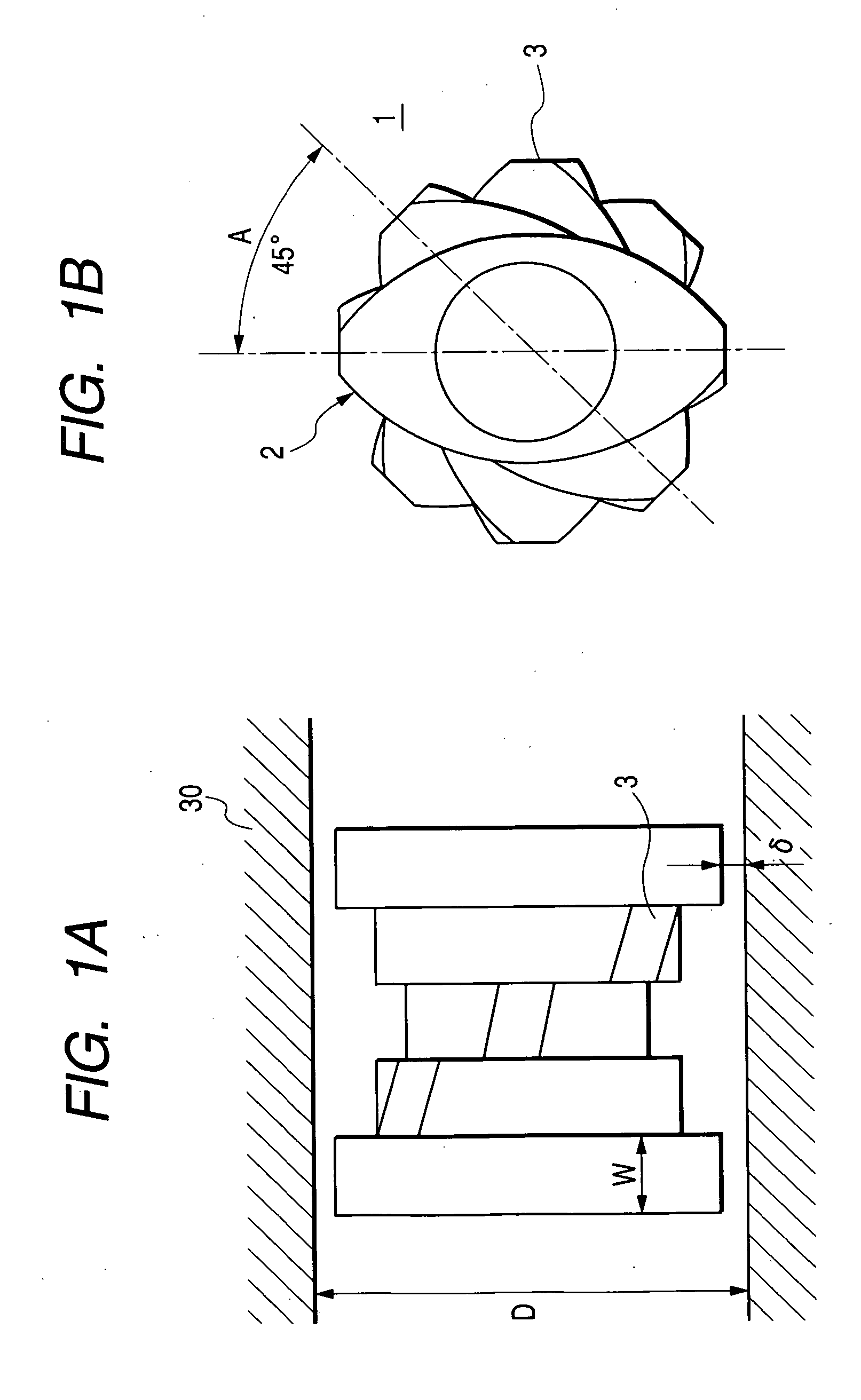

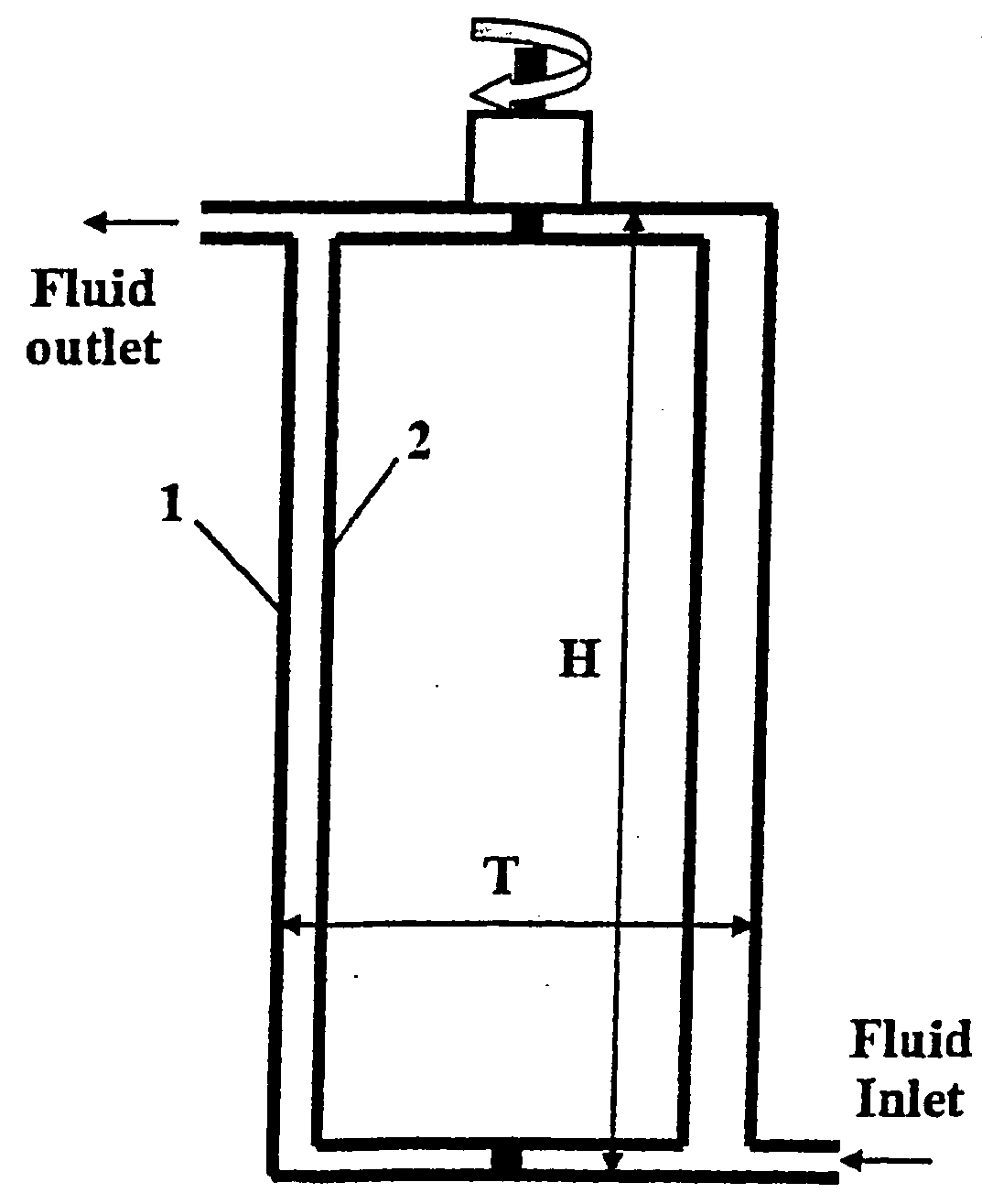

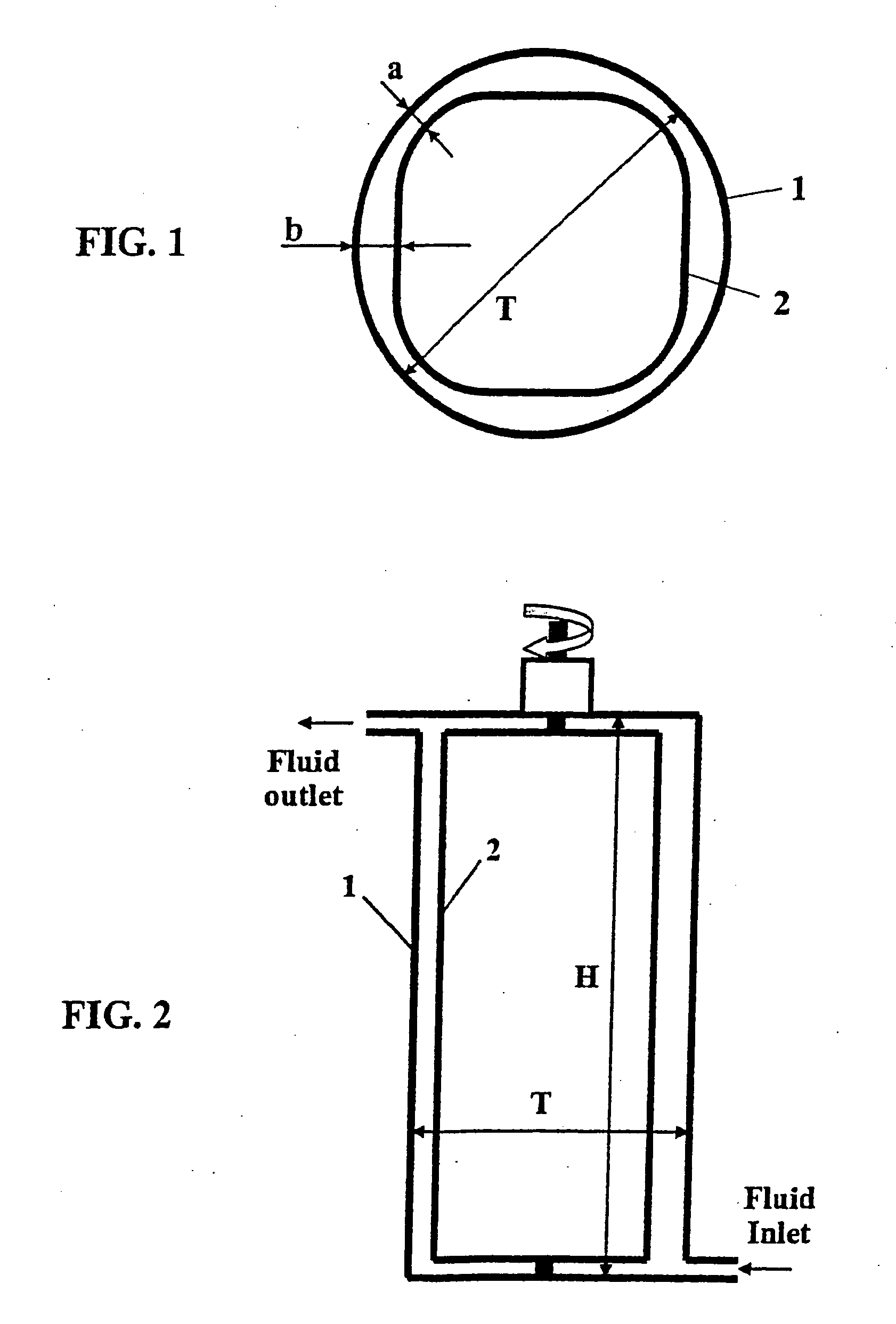

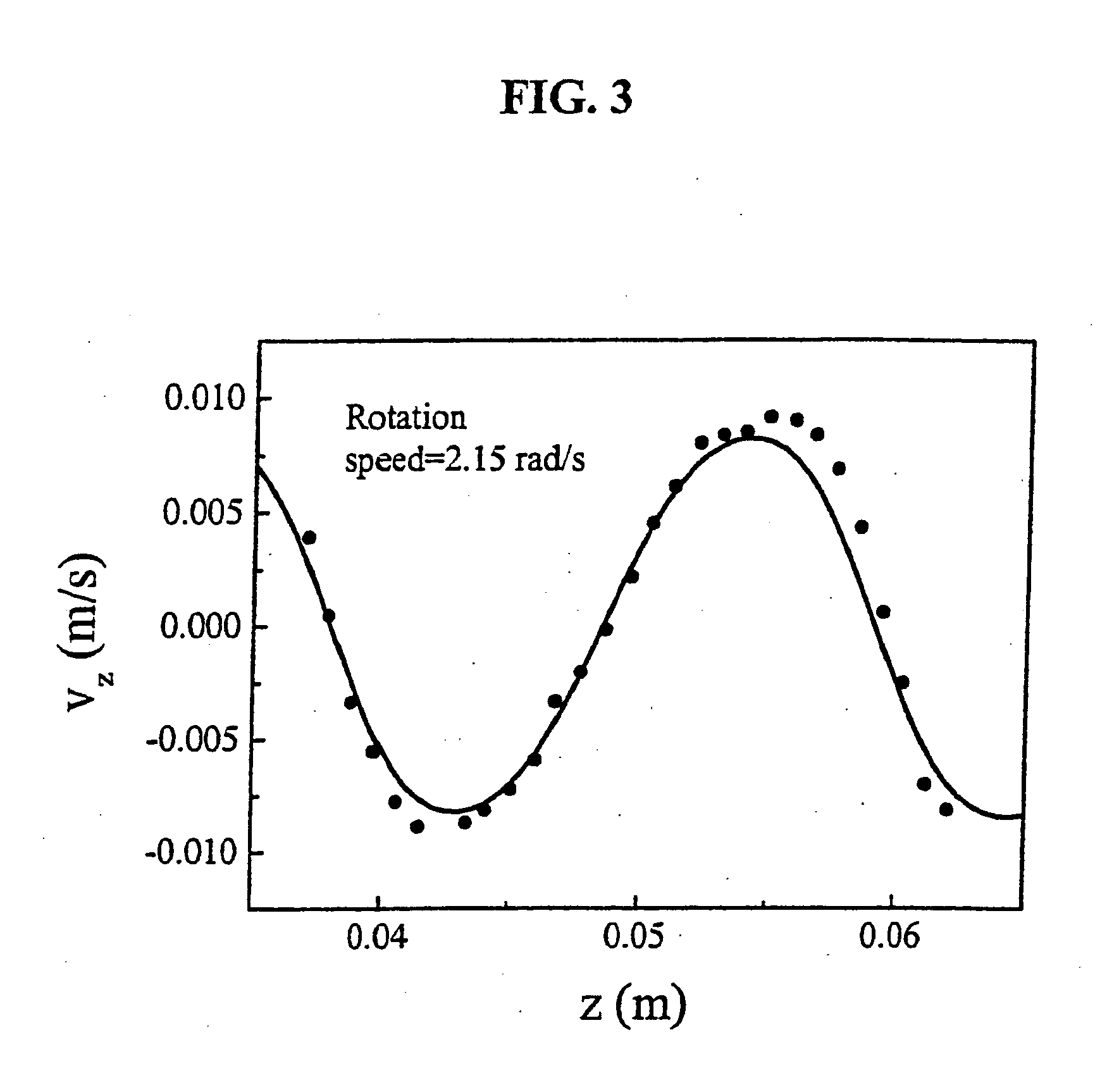

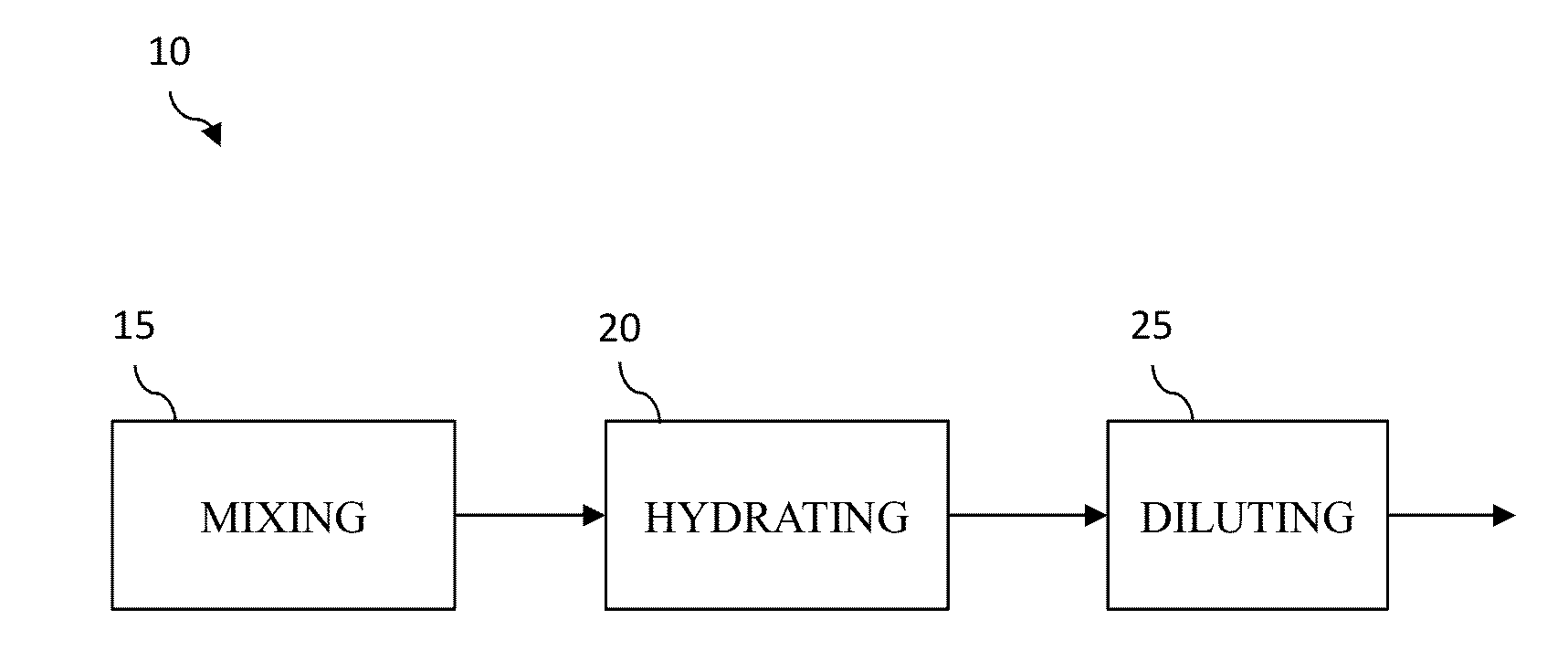

Rotating Stirring Device with Substantially Narrow Distribution of Energy Dissipation Rate

InactiveUS20080226513A1Rotary stirring mixersTransportation and packagingShear rateVolumetric Mass Density

A rotating stirring device for generating substantially narrow distribution of energy dissipation rate and avoiding presence of Taylor vortices is disclosed. The device includes an outer member (1) such as a cylinder with cross-section of circular shape and an inner member (2) with cross-section of equilateral or inequilateral polygon shape with curved cusps. The inner member is preferably concentrically placed within the outer cylinder and rotates. Such device is particularly advantageous as a reactor or mixer for processes where chemical and physical properties are sensitive to the variations in the shear rate and for processes that involve fragile components. The device can be also used to replace Taylor Couette device for the purposes of improving mass transfer and of avoiding separate of components in the gap in the case of presence of differences in density among components.

Owner:ETH ZZURICH

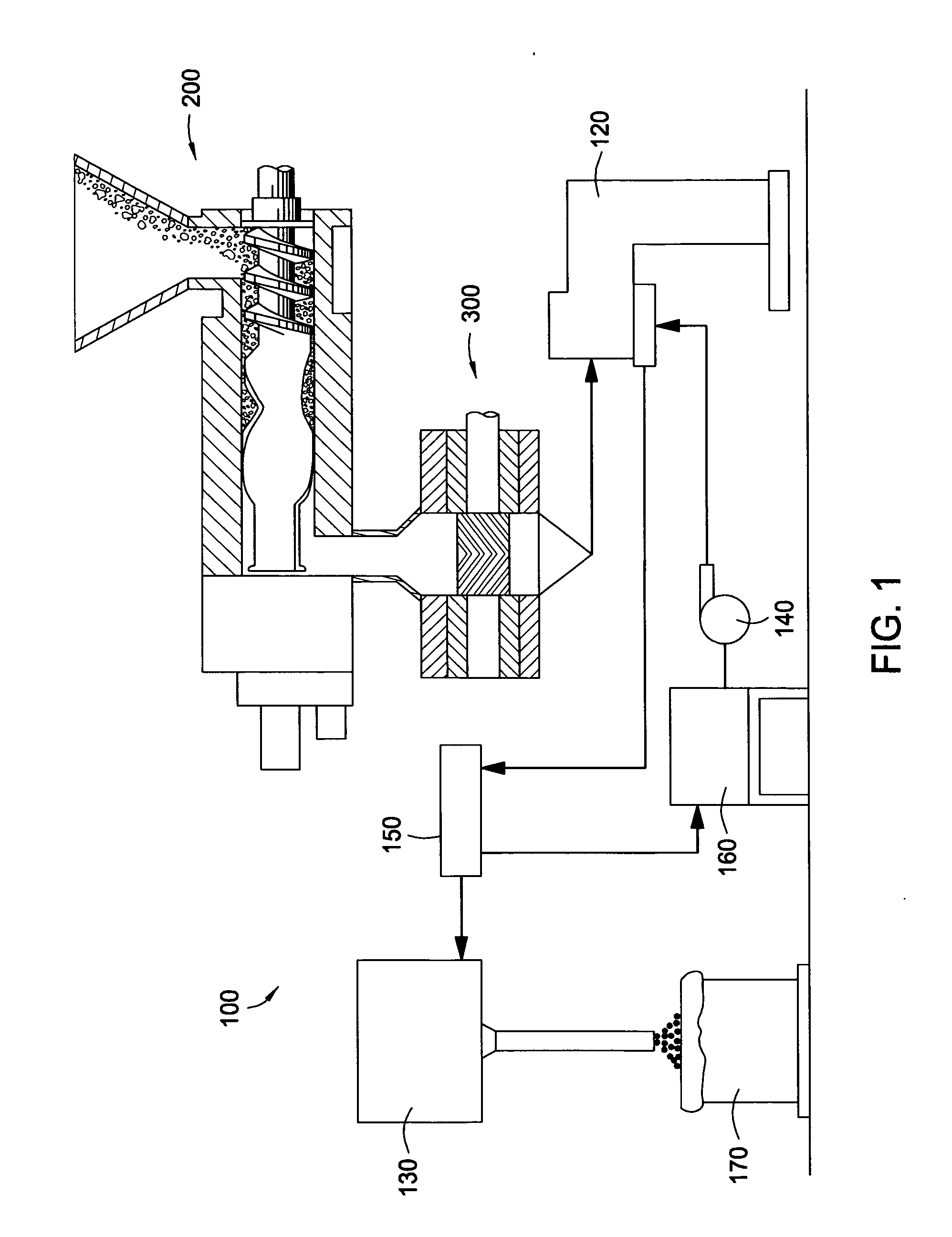

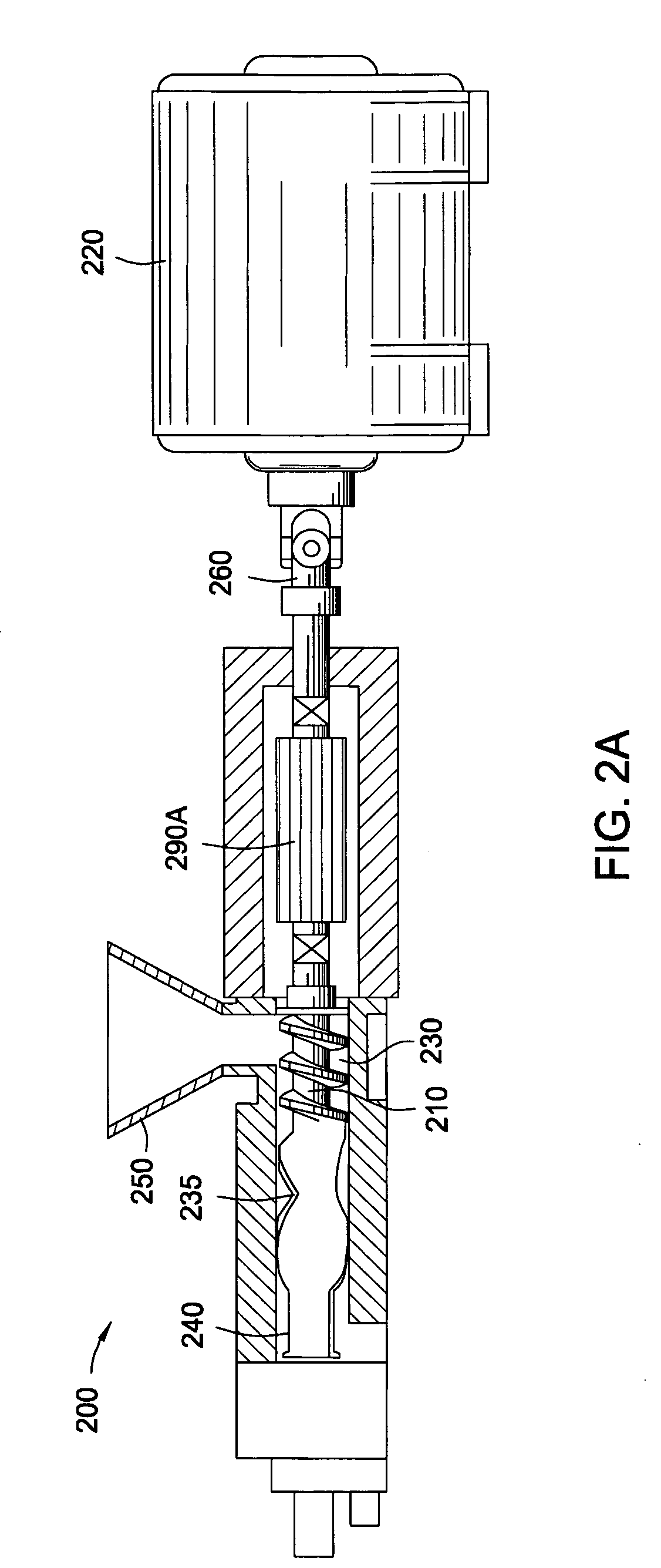

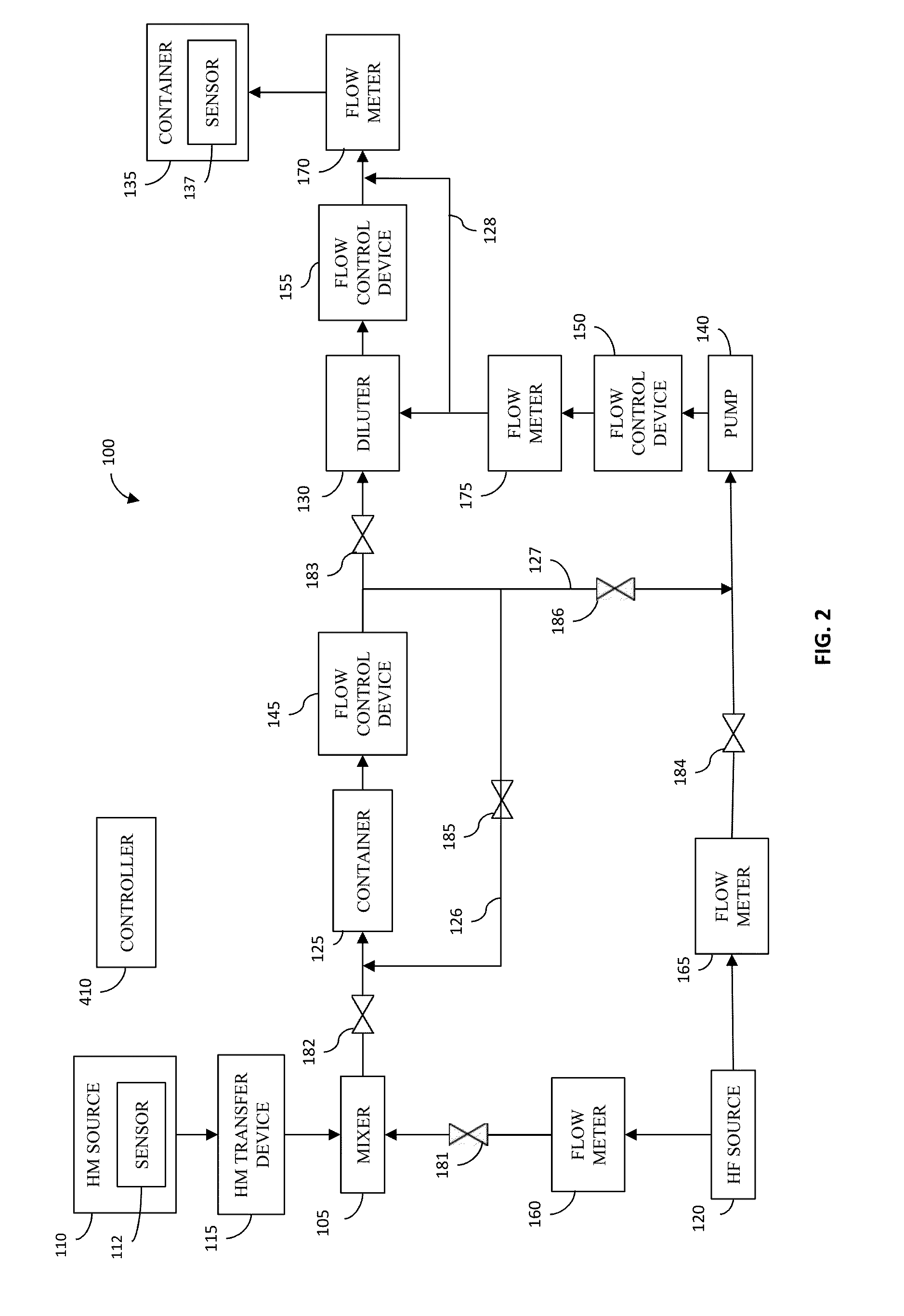

Hydration systems and methods

A substantially continuous stream of aqueous fluid and a substantially continuous stream of gel having a first concentration are combined to form a substantially continuous stream of gel having a second concentration. The second concentration is substantially lower than the first concentration. The gel having the second concentration may thereafter be utilized in conjunction with a well fracturing operation.

Owner:SCHLUMBERGER TECH CORP

Melt-kneaded products, molded resin products, and production method thereof

InactiveUS20090123731A1Evenly dispersedMaintain good propertiesNanotechRotary stirring mixersCyclic processElastomer

A melt-kneading method for filling material and elastomer or resin, characterized in that a filling material constituted by a filler, and an elastomer or resin (thermoplastic resin or thermosetting resin), are introduced from a material introduction part at the end of a melt-kneading part having a cylinder with a screw and a heater, and the molten elastomer or resin and filling material constituted by a filler are kneaded under the conditions of 1000 to 3000 rpm in the rotation speed of the screw and 1500 to 4500 sec−1 in shear speed to feed the mixture from the rear edge to tip of the screw to be trapped in a space provided at the tip of the screw, after which the mixture is moved from the space to the rear edge of the screw through a hole provided at the center of the screw, with the cycle process performed for a specified period based on recirculation using the screw.

Owner:NAT INST OF ADVANCED IND SCI & TECH

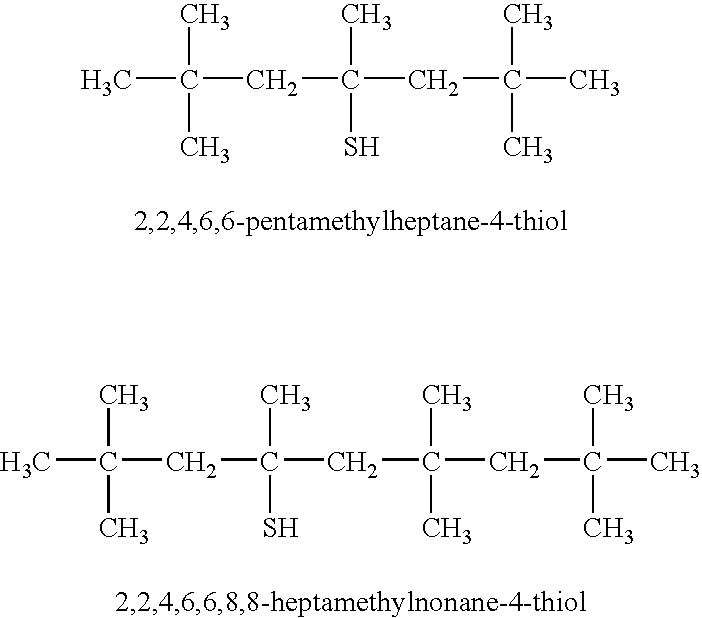

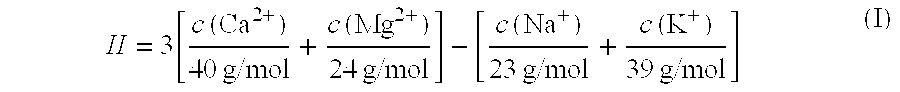

Nitrile rubbers

ActiveUS20080293868A1Fast initialFast full vulcanizationGroup 4/14 element organic compoundsRotary stirring mixersNitrile rubberVulcanization

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a particular ion index and a particular magnesium content which is responsible for an excellent vulcanization rate and leads to vulcanizates having an advantageous property profile.

Owner:ARLANXEO DEUT GMBH

Method for preparing construction material by utilizing electrolytic manganese slag

InactiveCN101570037ARemove hidden dangers of pollutionGood environmental benefitsSolid waste managementMixing operation control apparatusElectrolysisSlag

The invention provides a method for preparing a construction material by utilizing electrolytic manganese slag, including the following steps: (1) pretreatment: additive is blended in the electrolyticmanganese slag, water is added for fully stirring, and the raw material reacts in the open air for 1-7 days, wherein the added additive is mixture of lime, plaster and kaolin; (2) cement, sandstonescoarse aggregate, sandstones fine aggregate and component selection air entraining agent are added into the electrolytic manganese slag after the pretreatment, water is added and blended evenly to form a mixture; (3) the mixture is loaded into a mould and formed on a compression forming machine by vibration and pressurizing, and then demoulding is carried out; (4) adobe is naturally cured for 14-28 days, thus obtaining the electrolytic manganese slag construction material product. The technique is simple with high product quality and low production cost and has good social, economic and environmental benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

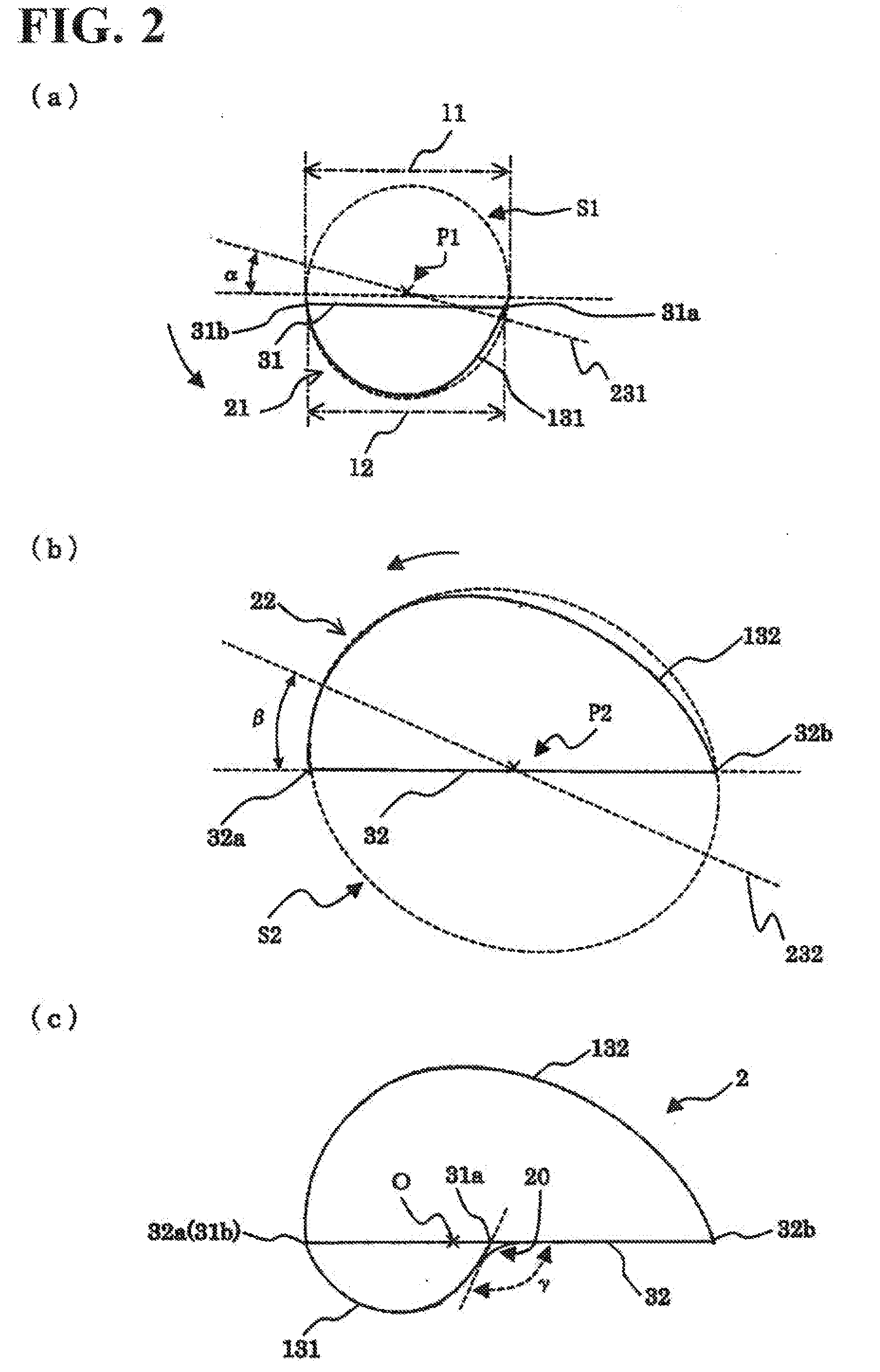

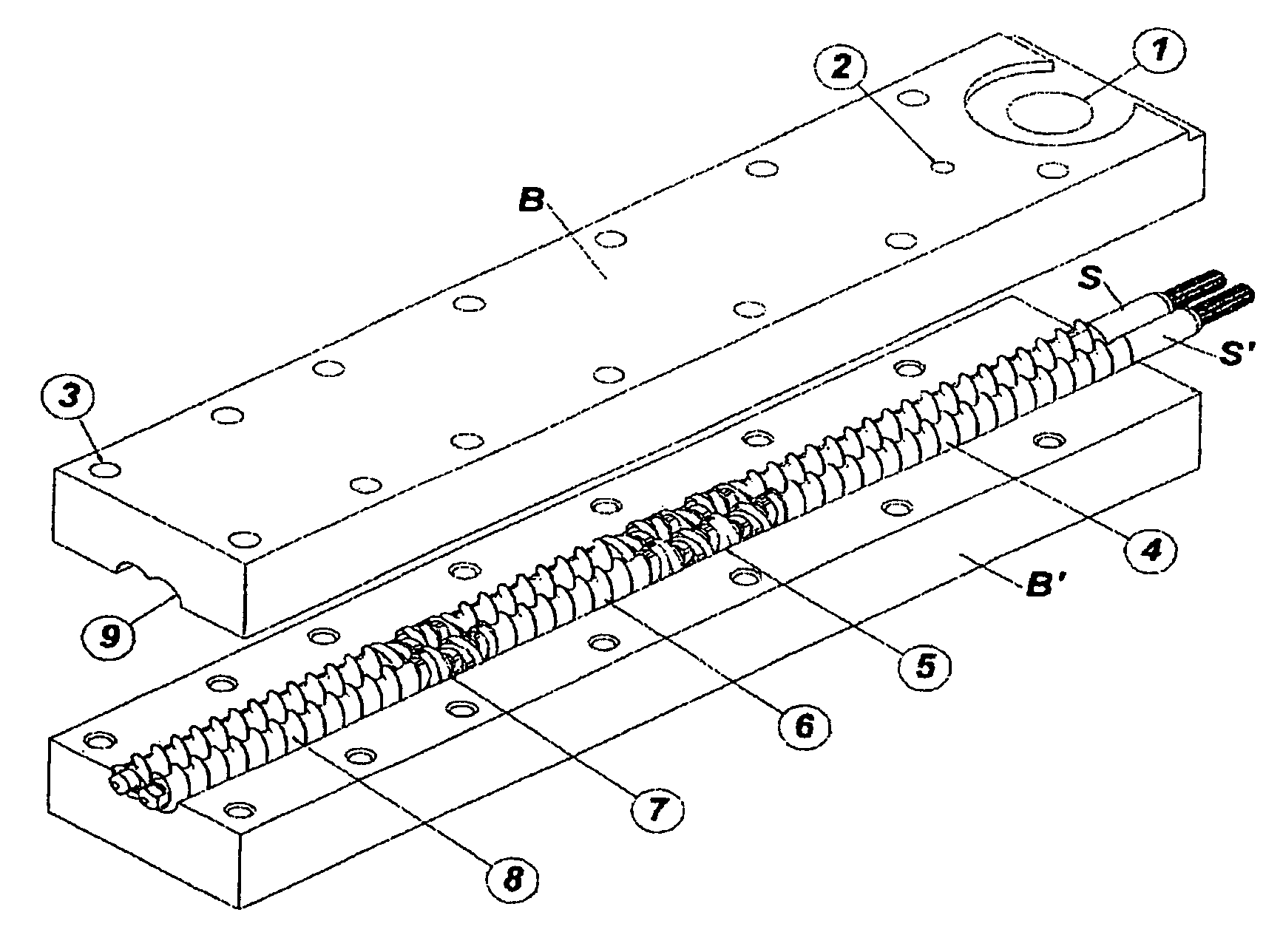

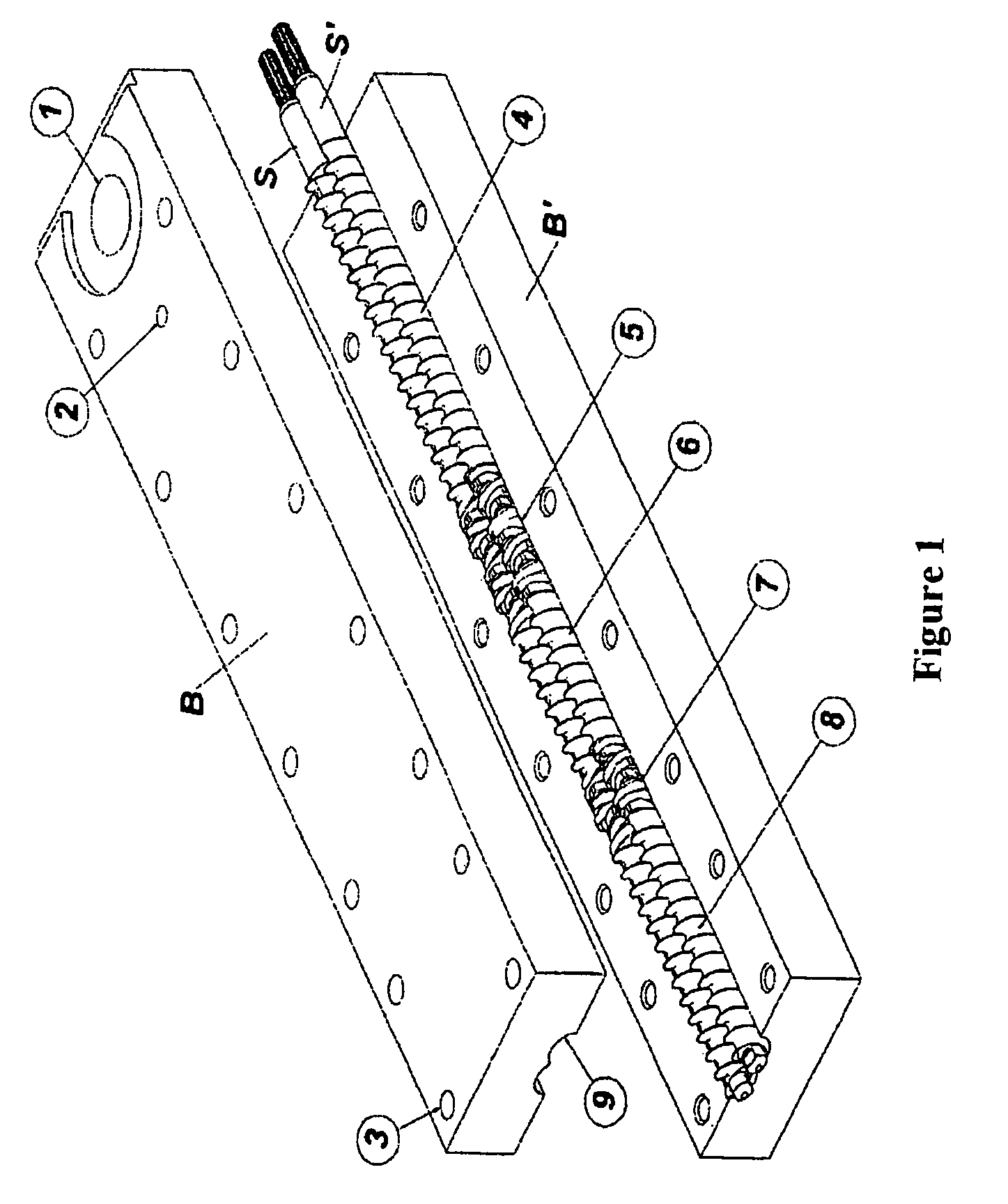

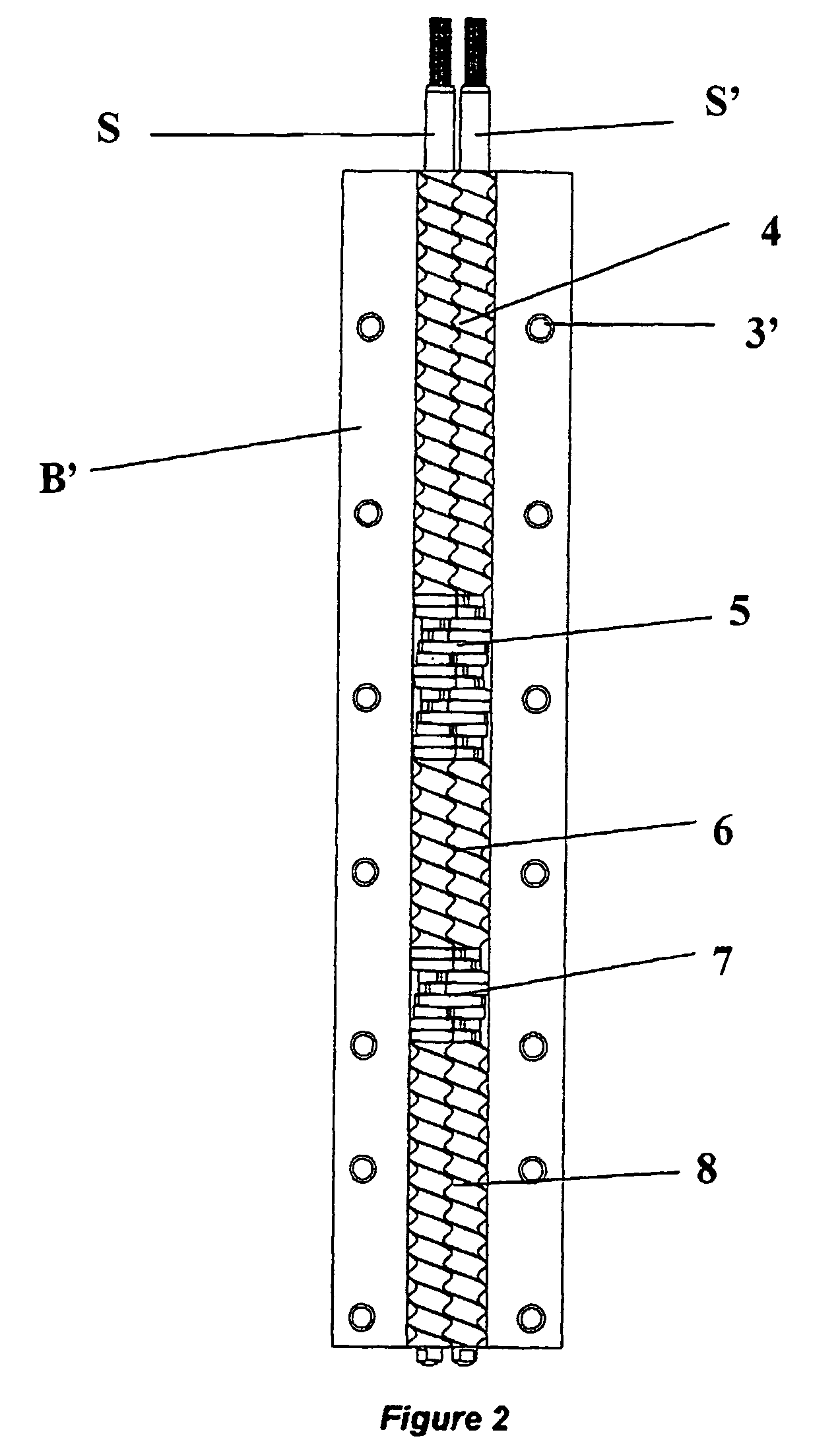

Process and apparatus for continuous wet granulation of powder material

ActiveUS7910030B2Simple processQuantity minimizationRotary stirring mixersFrozen sweetsEngineeringActive ingredient

An apparatus for wet granulating a powder material comprises: —a barrel having a granulation chamber and being provided with a first inlet (1) for receiving said powder material and for supplying it to said granulation chamber and with a second inlet (2) for receiving a granulating liquid and for supplying it to said granulation chamber, said granulation having an aperture (9) for discharge of granules from said barrel, and —a transporting means (S) for advancing said powder material toward the end of said granulation chamber while granulating it with the aid of said granulating liquid, said transporting means (S) comprising a first transport zone (4) at its rear end, an agglomeration zone (5) downstream from the first transport zone (4) and a second transport zone (8) at its front end, said first inlet (1) and said second inlet (2) being positioned above the first transport zone (4), wherein said aperture (9) has a shape tightly fitting the terminal portion of the transporting means (S) for directly discharging said granules from the granulation chamber. The apparatus is useful for continuously wet granulating biologically-active ingredient formulations, chemicals, detergents and foodstuffs.

Owner:UNIV GENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com