Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136 results about "TEMPERATURE ELEVATION" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

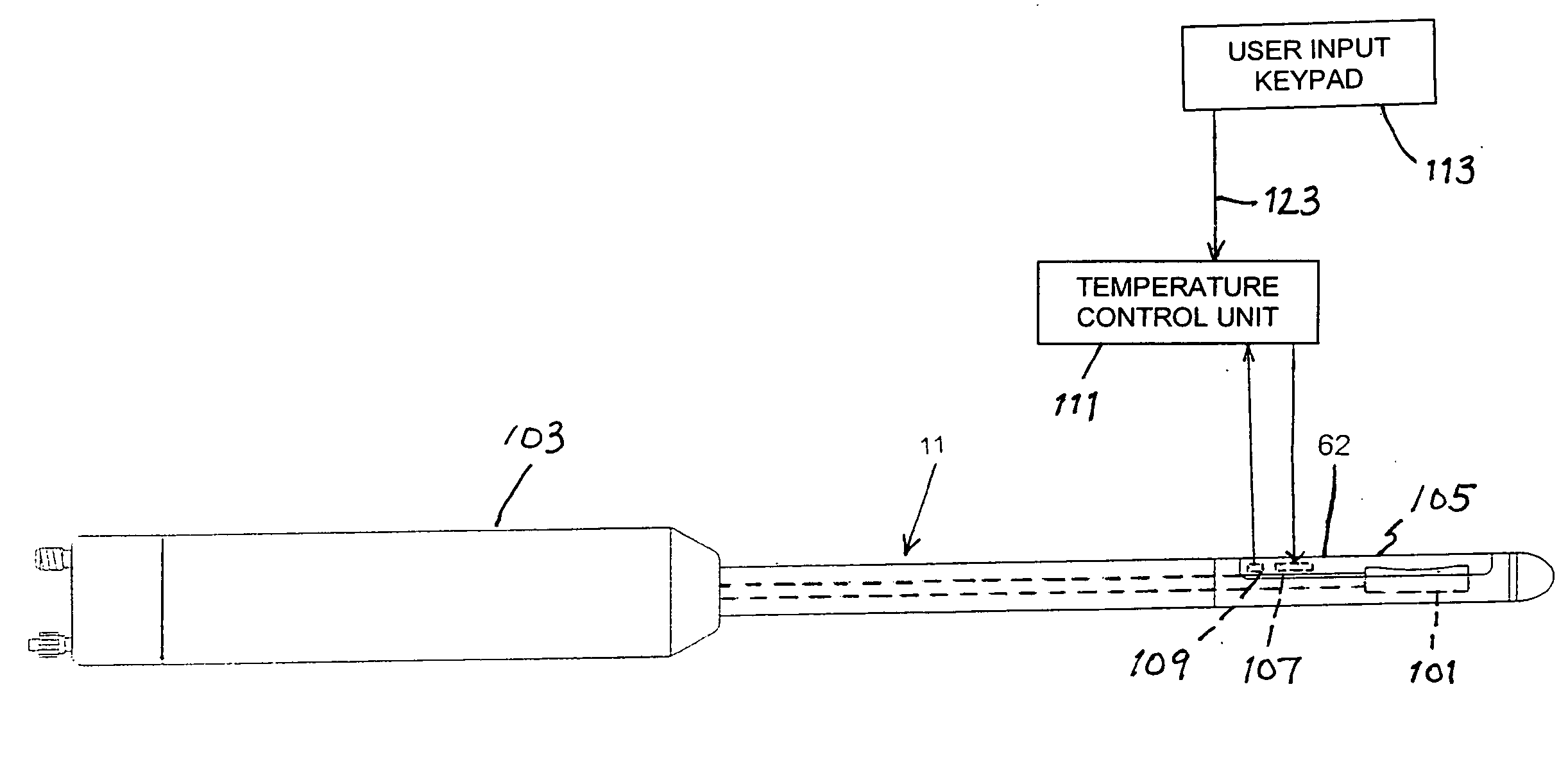

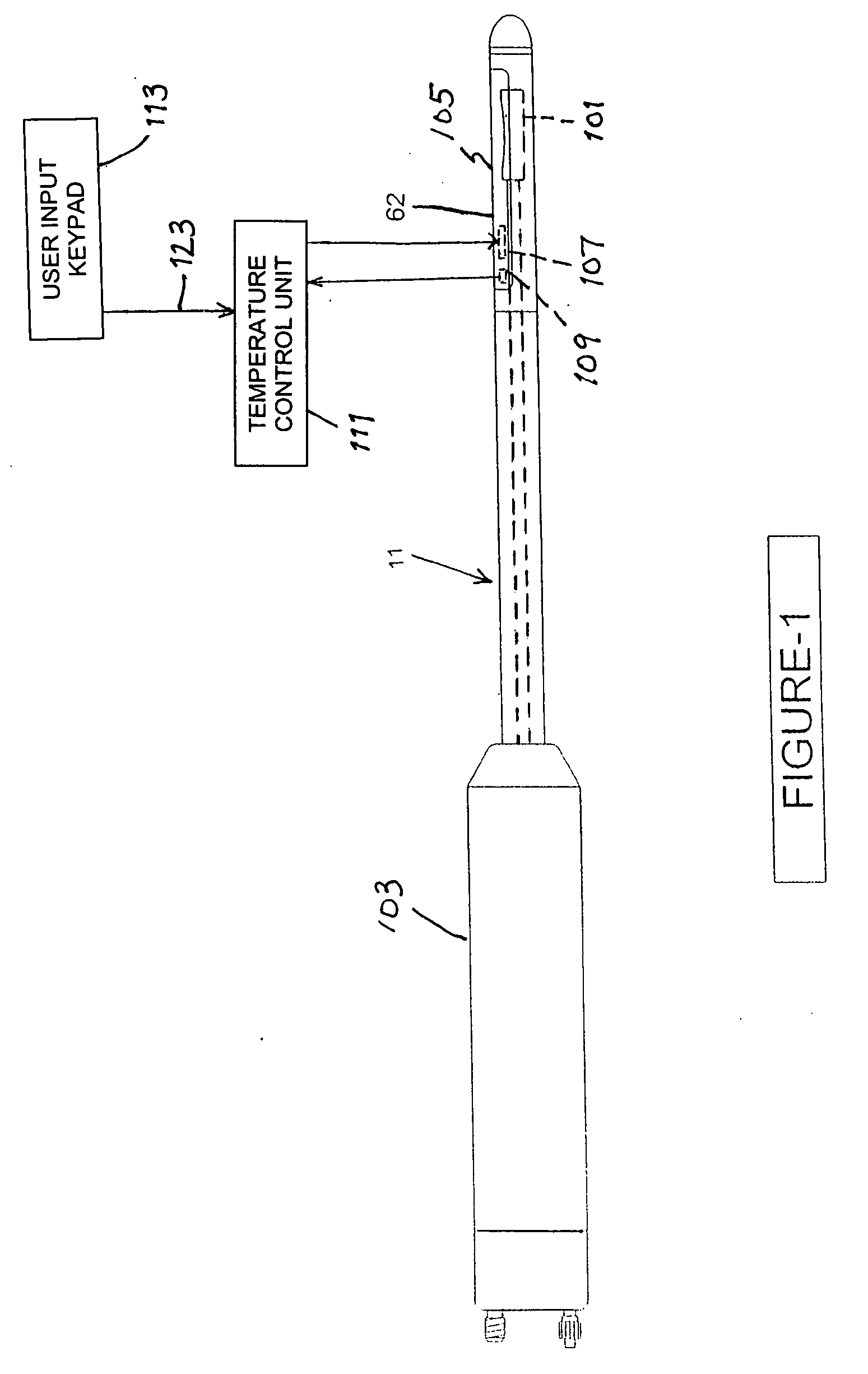

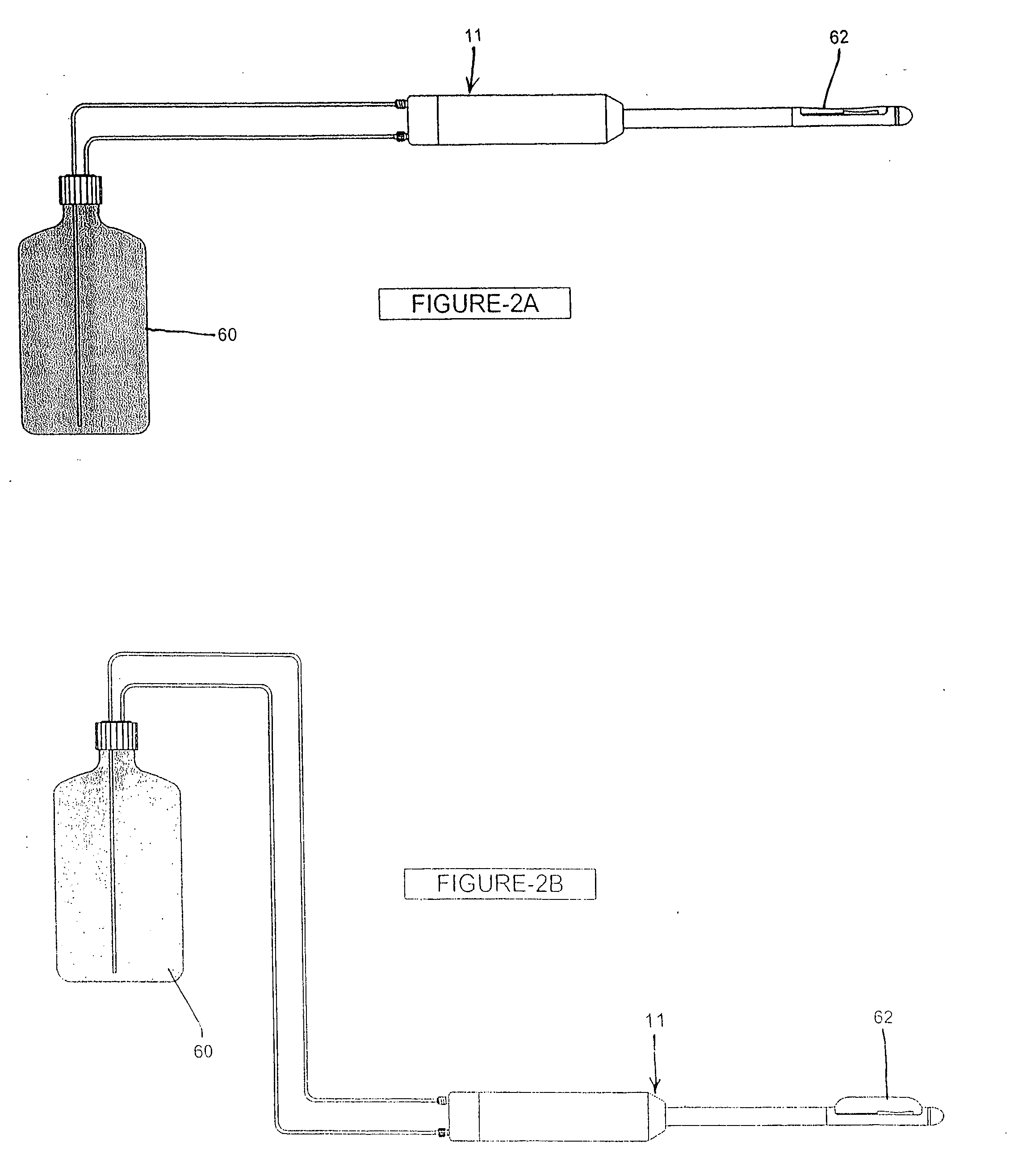

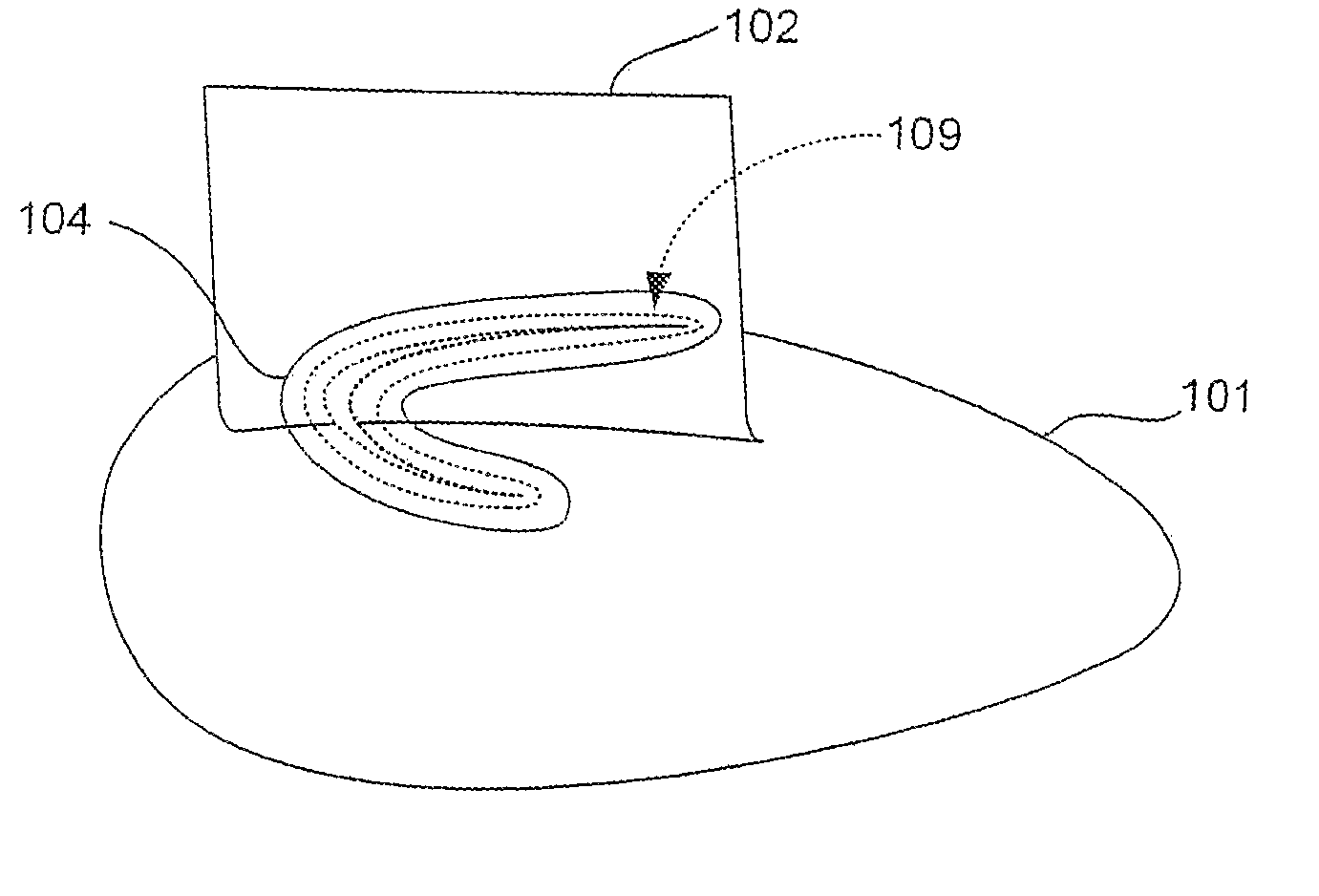

Elevated coupling liquid temperature during HIFU treatment method and hardware

InactiveUS20080281200A1Avoid necrosisEnhanced couplingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyLiquid temperatureUltrasonic vibration

A medical procedure utilizes a high-intensity focused ultrasound instrument having an applicator surface, a liquid-containing bolus or expandable chamber acting as a heat sink, and a source of ultrasonic vibrations, the applicator surface being a surface of a flexible wall of the bolus, the source of ultrasonic vibrations being in operative contact with the bolus. The applicator surface is placed in contact with an organ surface of a patient, the source is energized to produce ultrasonic vibrations focused at a predetermined focal region inside the organ, and a temperature of liquid in the bolus is controlled while the applicator surface is in contact with the organ surface to control temperature elevation in tissues of the organ between the focal region and the organ surface to necrose the tissues to within a desired distance from the organ surface.

Owner:US HIFU

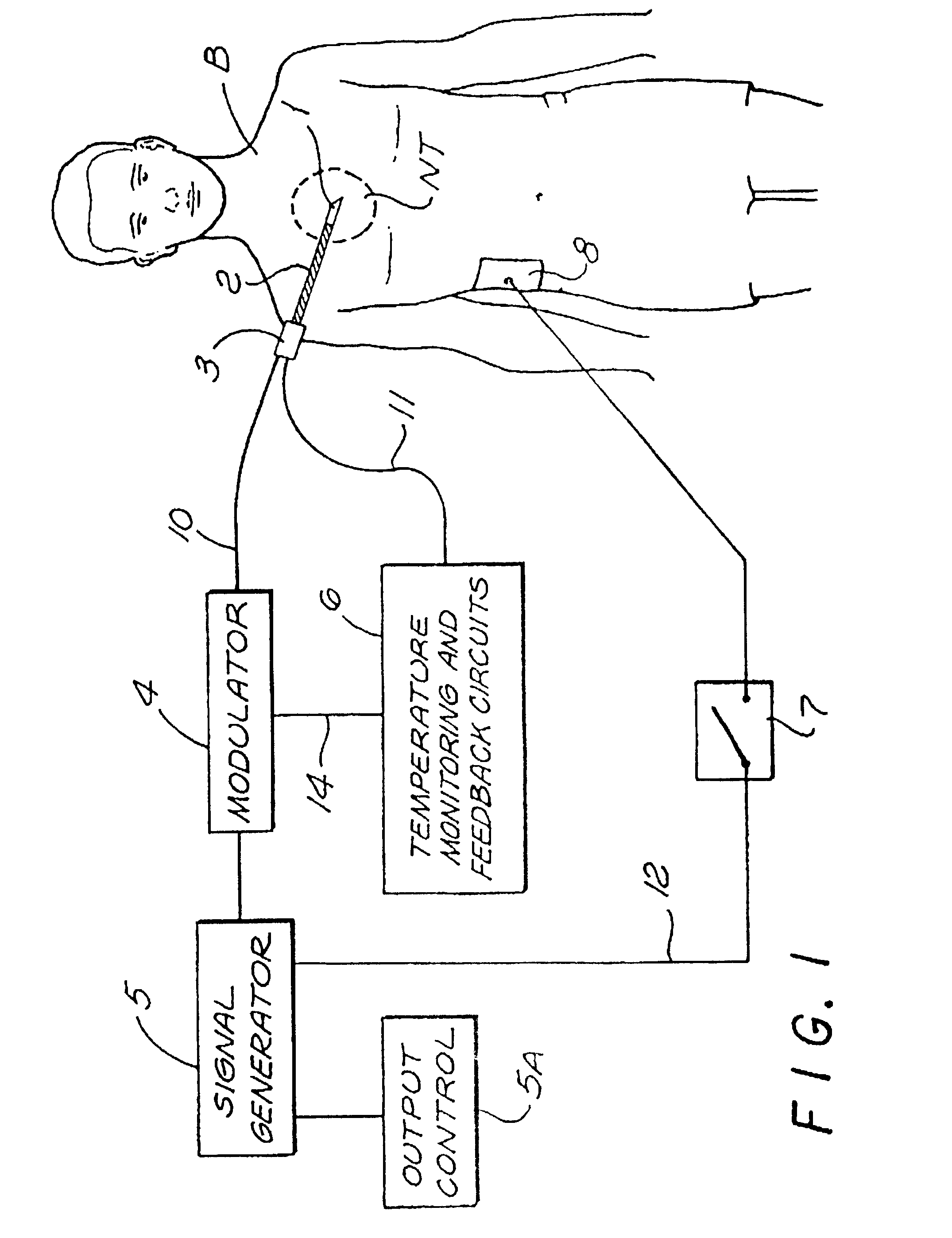

Method and system for neural tissue modification

InactiveUSRE40279E1Relief the painModifiesElectrotherapySurgical instruments for heatingMedicineTEMPERATURE ELEVATION

A method and apparatus for altering a function of neural tissue in a patient. An electromagnetic signal is applied to the neural tissue through an electrode. The electromagnetic signal has a frequency component above the physiological stimulation frequency range and an intensity sufficient to produce an alteration of the neural tissue, the alteration causing the patient to experience a reduction in pain, and a waveform that prevents lethal temperature elevation of the neural tissue during application of the electromagnetic signal to the neural tissue.

Owner:COVIDIEN AG

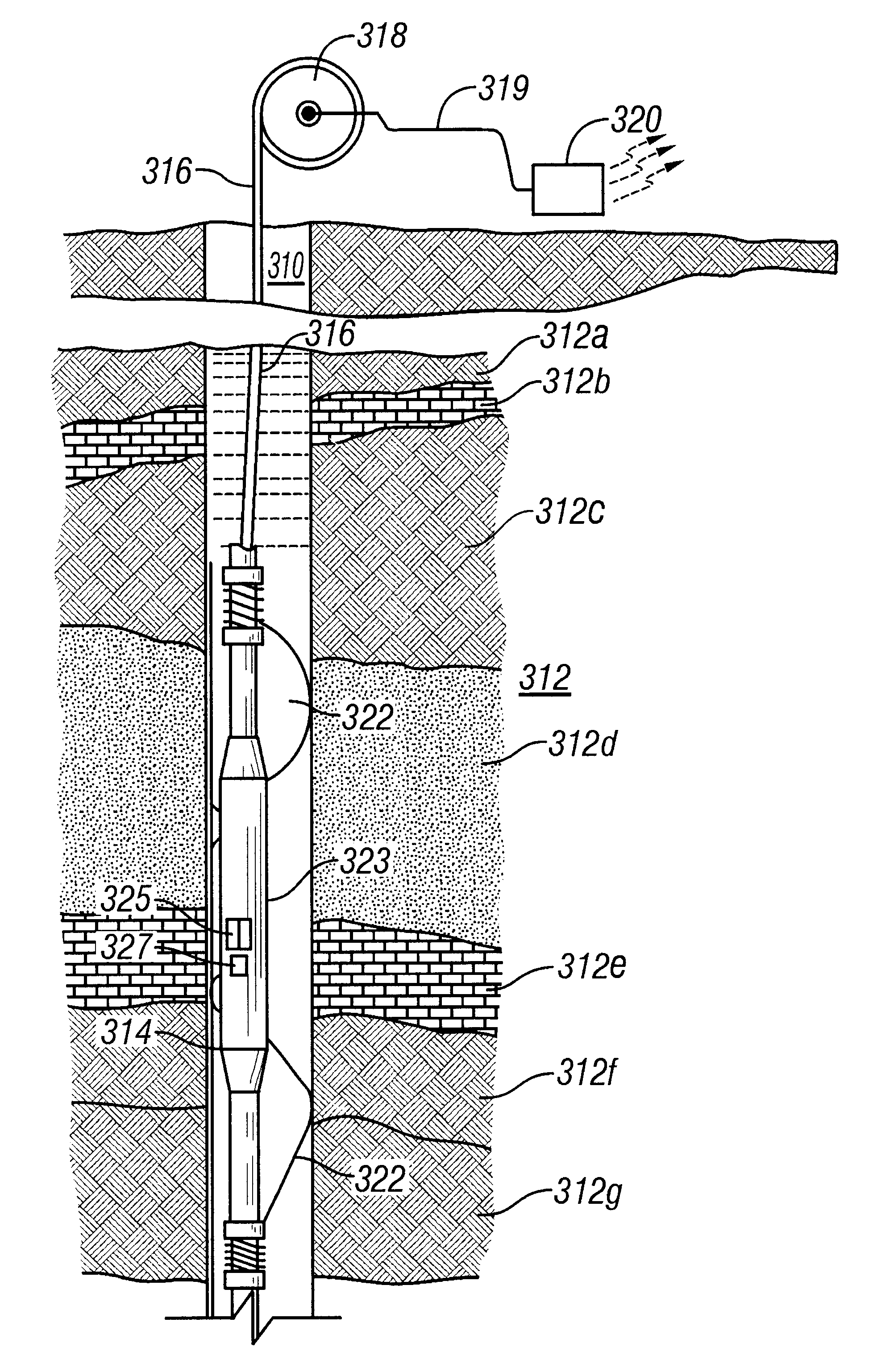

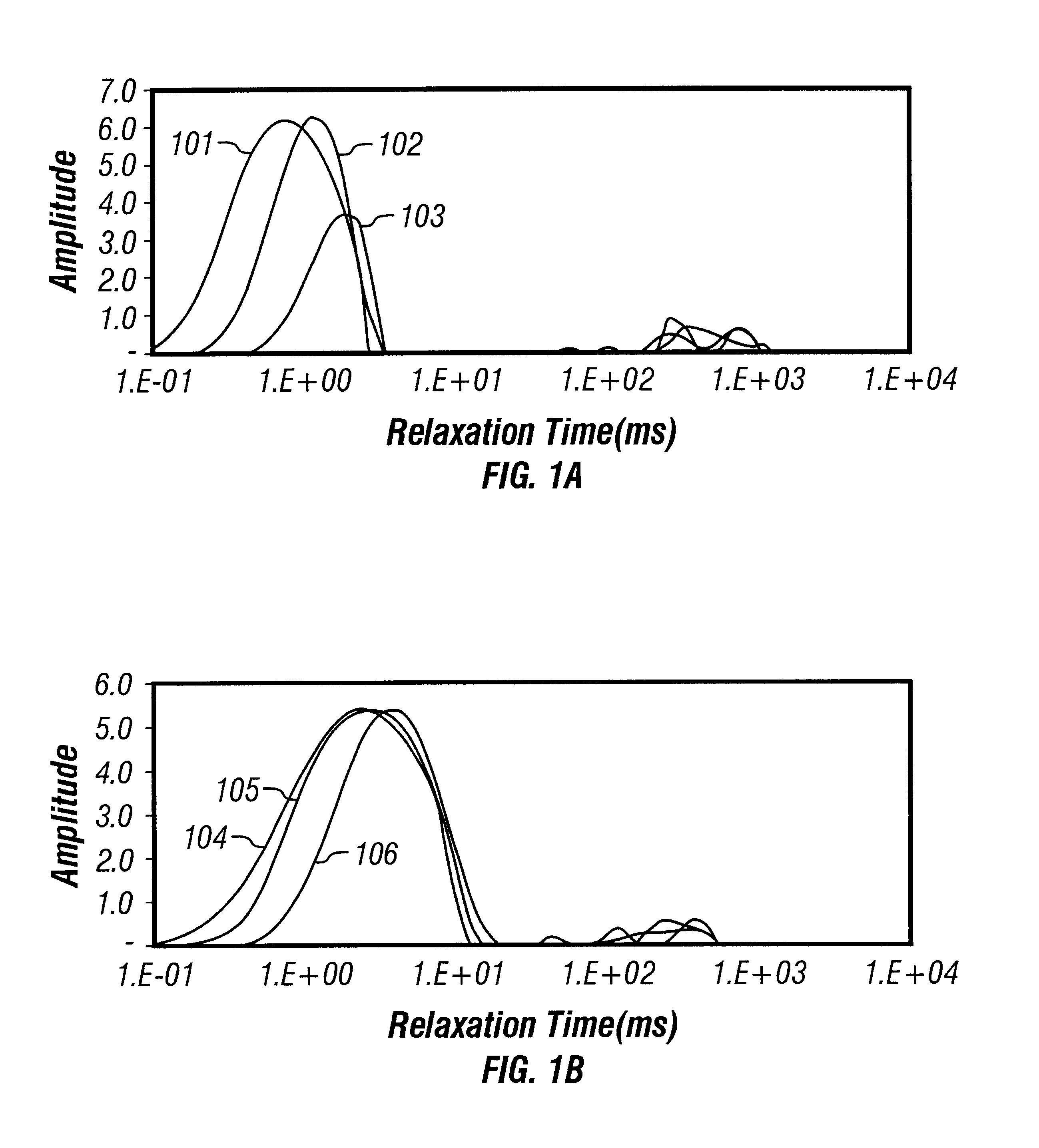

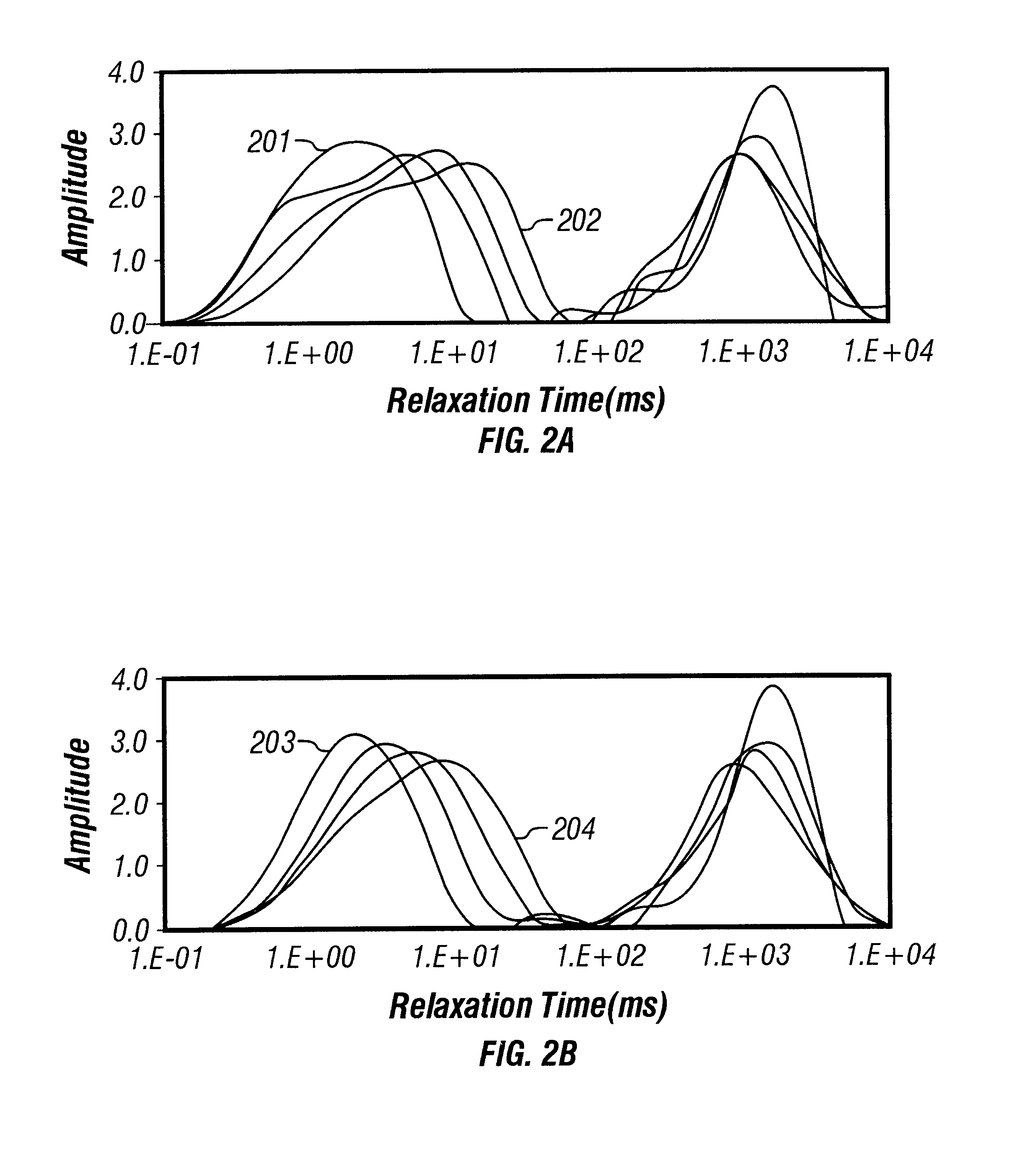

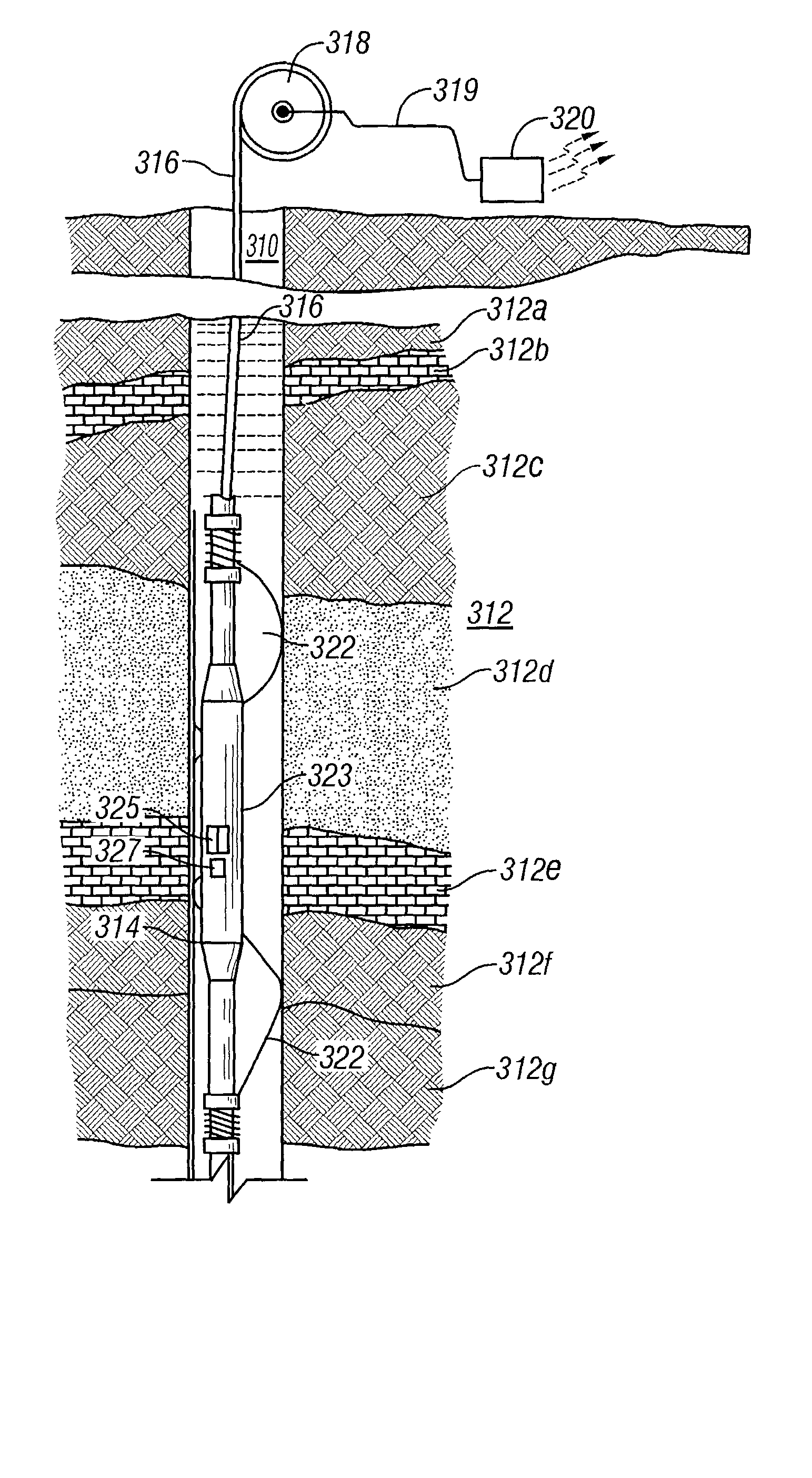

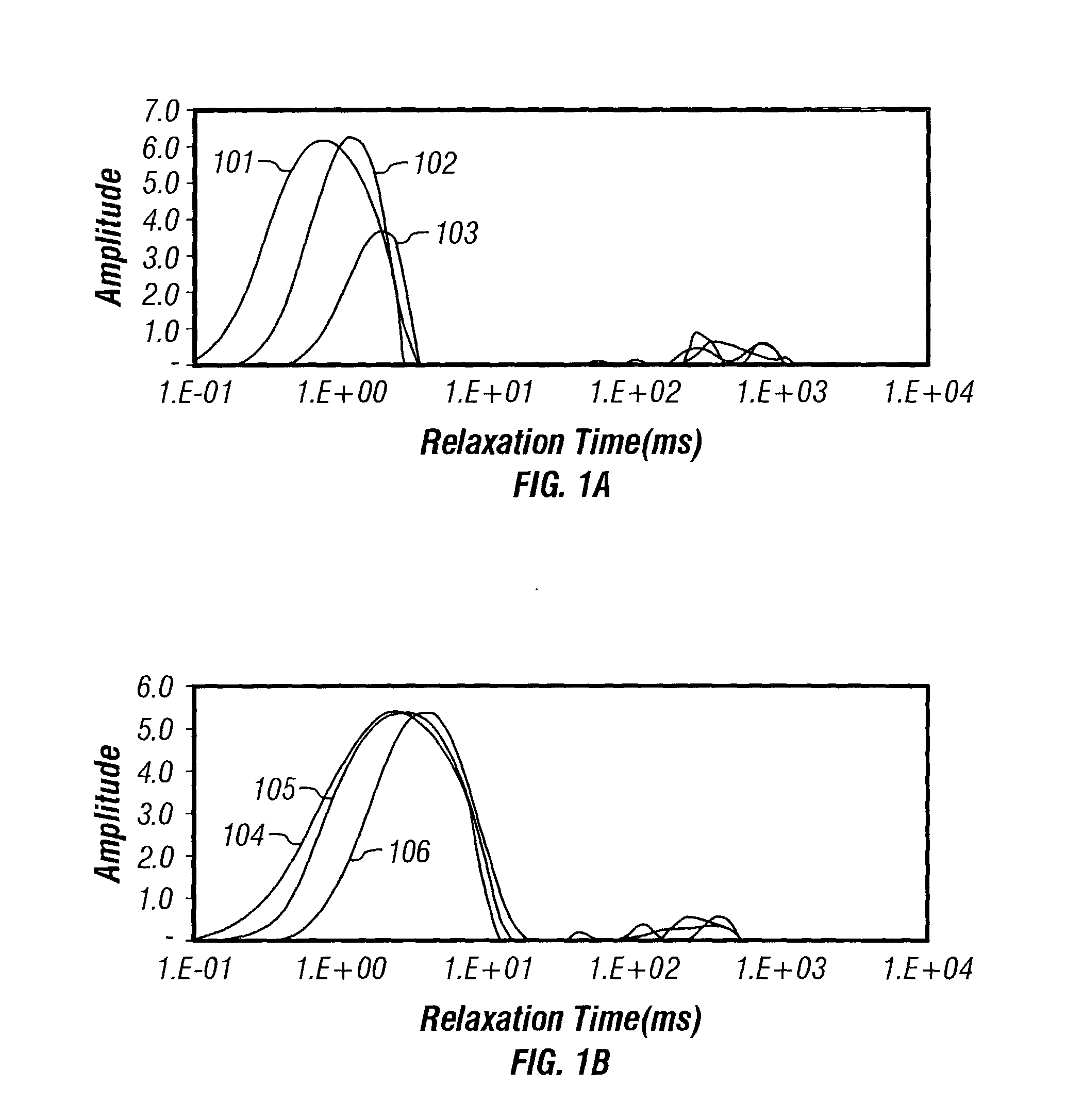

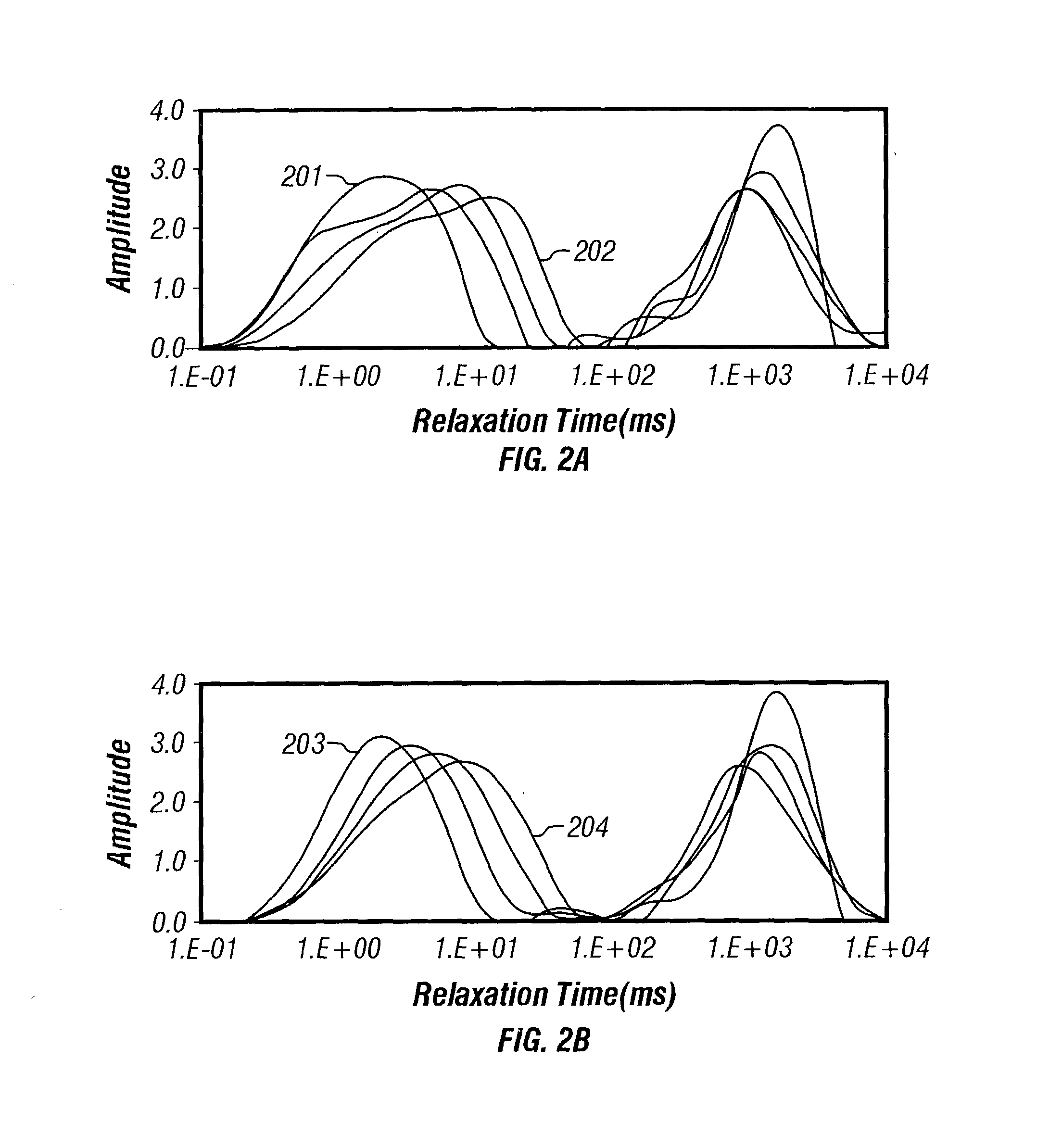

In-situ heavy-oil reservoir evaluation with artificial temperature elevation

Many reservoirs of interest include heavy oil. In such reservoirs, parti at normal temperatures, many instruments commonly used for formation evaluation may not be able to distinguish between heavy oil and bound water in the formation. Passive or active heating is used to elevate the temperature of the fluids in the formation. At elevated temperatures, distinguishing between heavy oil and bound water is easier. Of particular interest is the increase in the resolvability of the transverse relaxation time T2 of NMR spin echo measurements. Additionally, the dielectric constant and the loss tangents of water and heavy oil show different temperature and frequency dependence.

Owner:BAKER HUGHES HLDG LLC

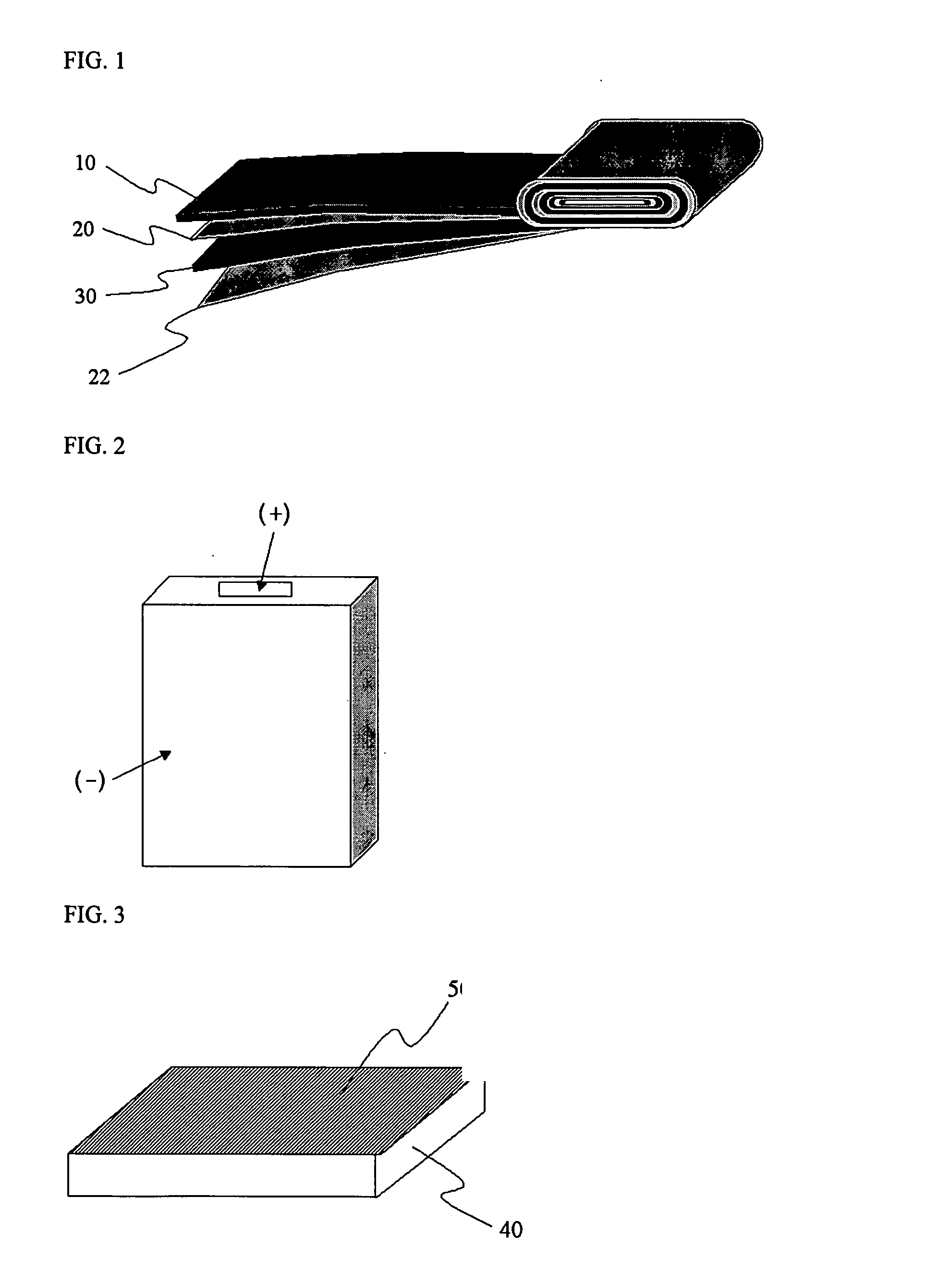

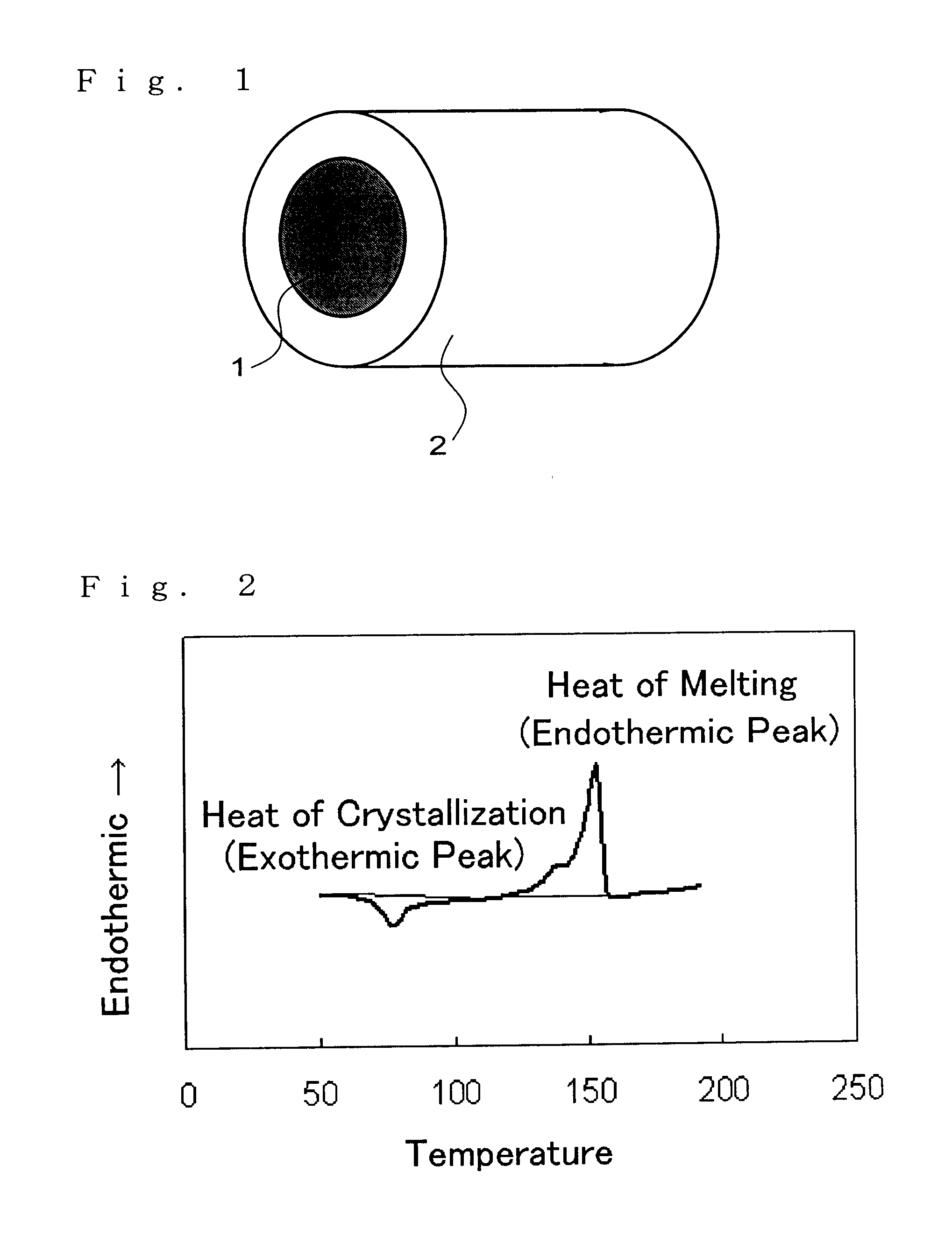

Battery system containing phase change material-containing capsules in interior configuration thereof

ActiveUS20060063066A1Prolong lifeImprove securityFinal product manufactureCell temperature controlEngineeringPhase change

Provided is a battery system in which an interior part of a battery structure includes particles (phase-change particles) containing materials (phase-change materials) having a high latent heat of phase change at a specific temperature, contained in a capsule made of an inert material. The battery system in accordance with the present invention can prolong a service life of the battery by inhibiting temperature elevation inside the battery under normal operating conditions without substantial effects on size, shape and performance of the battery, and further, can inhibit the risk of explosion resulting from a sharp increase in temperature inside the battery under abnormal operating conditions, thereby contributing to battery safety.

Owner:LG ENERGY SOLUTION LTD

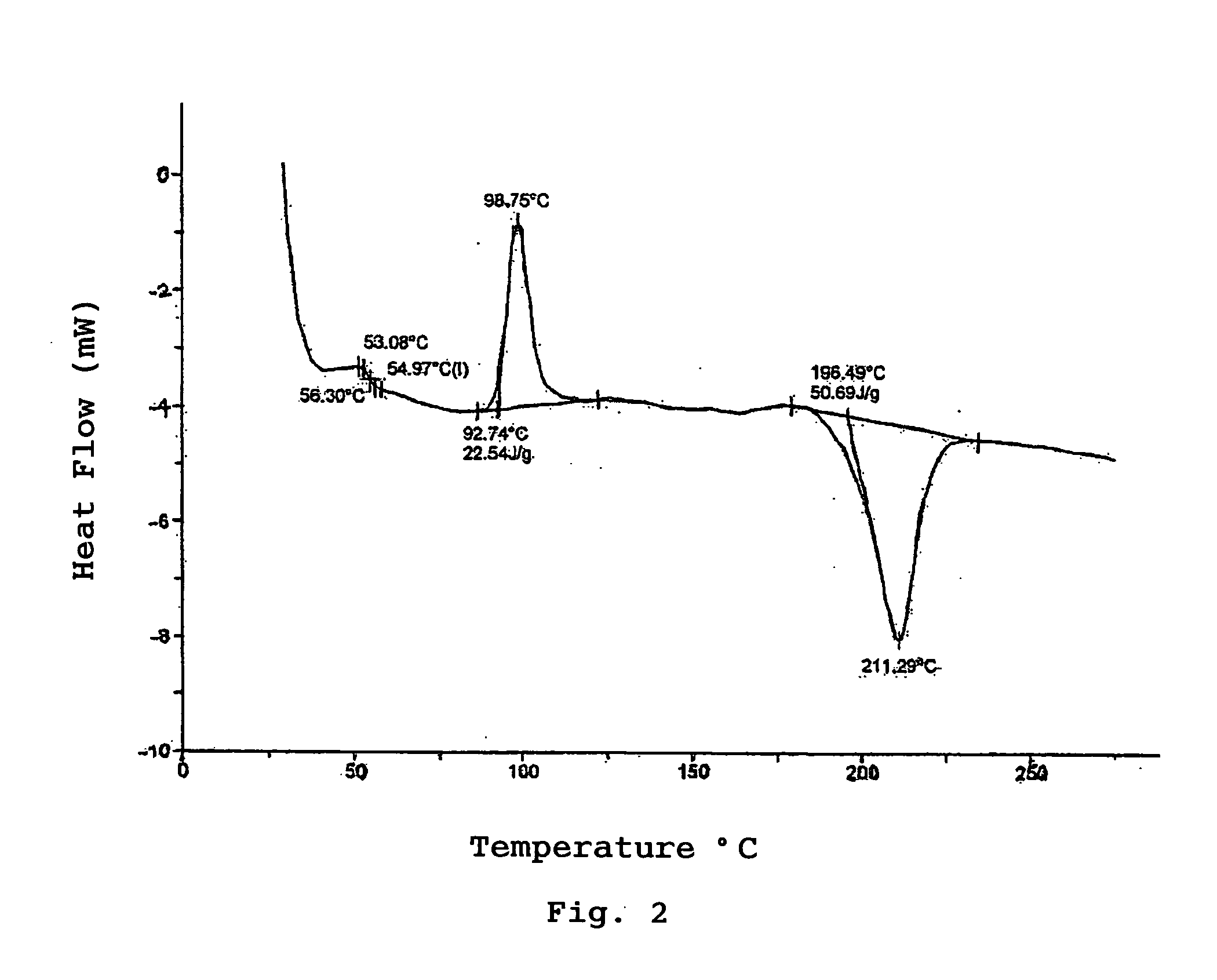

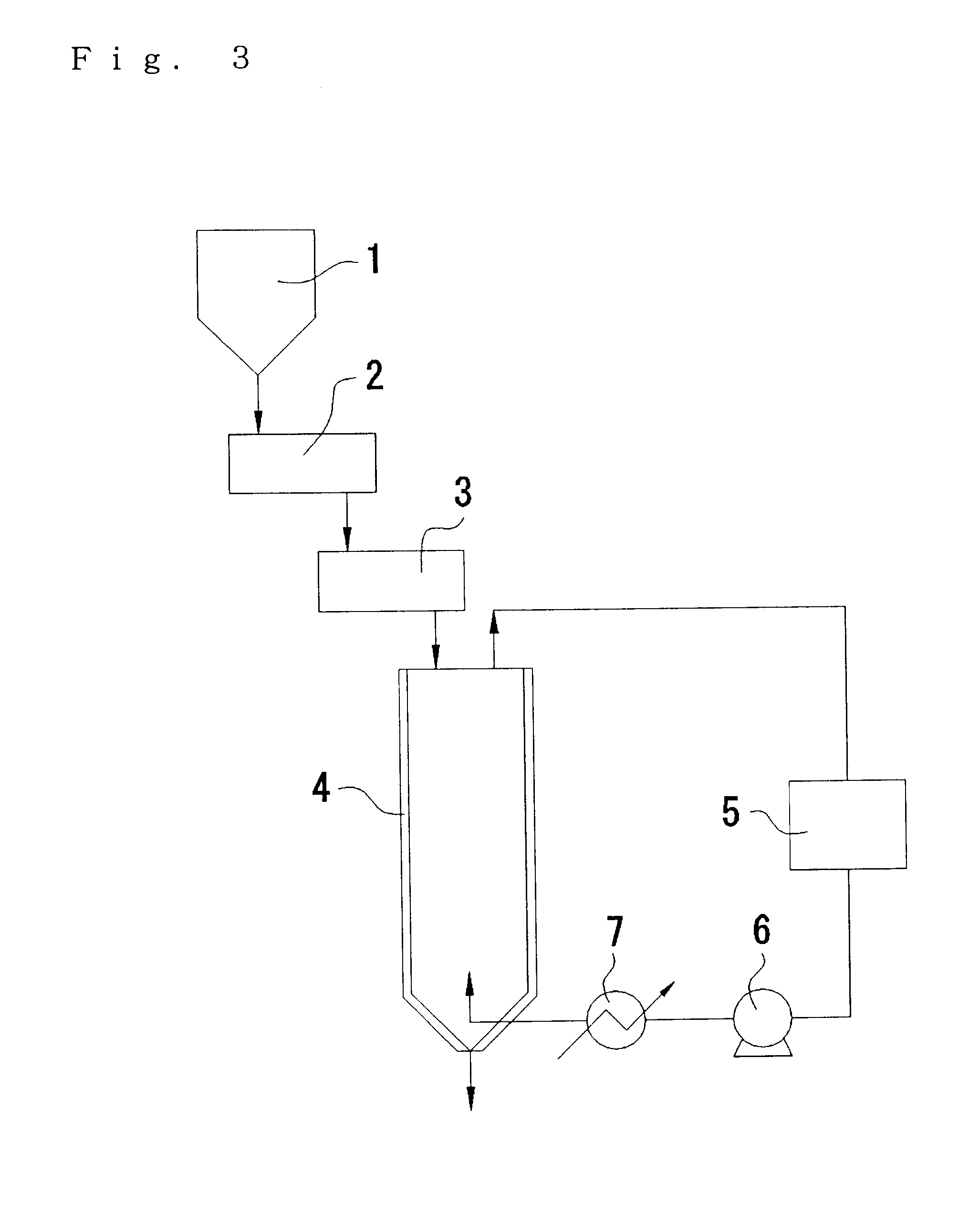

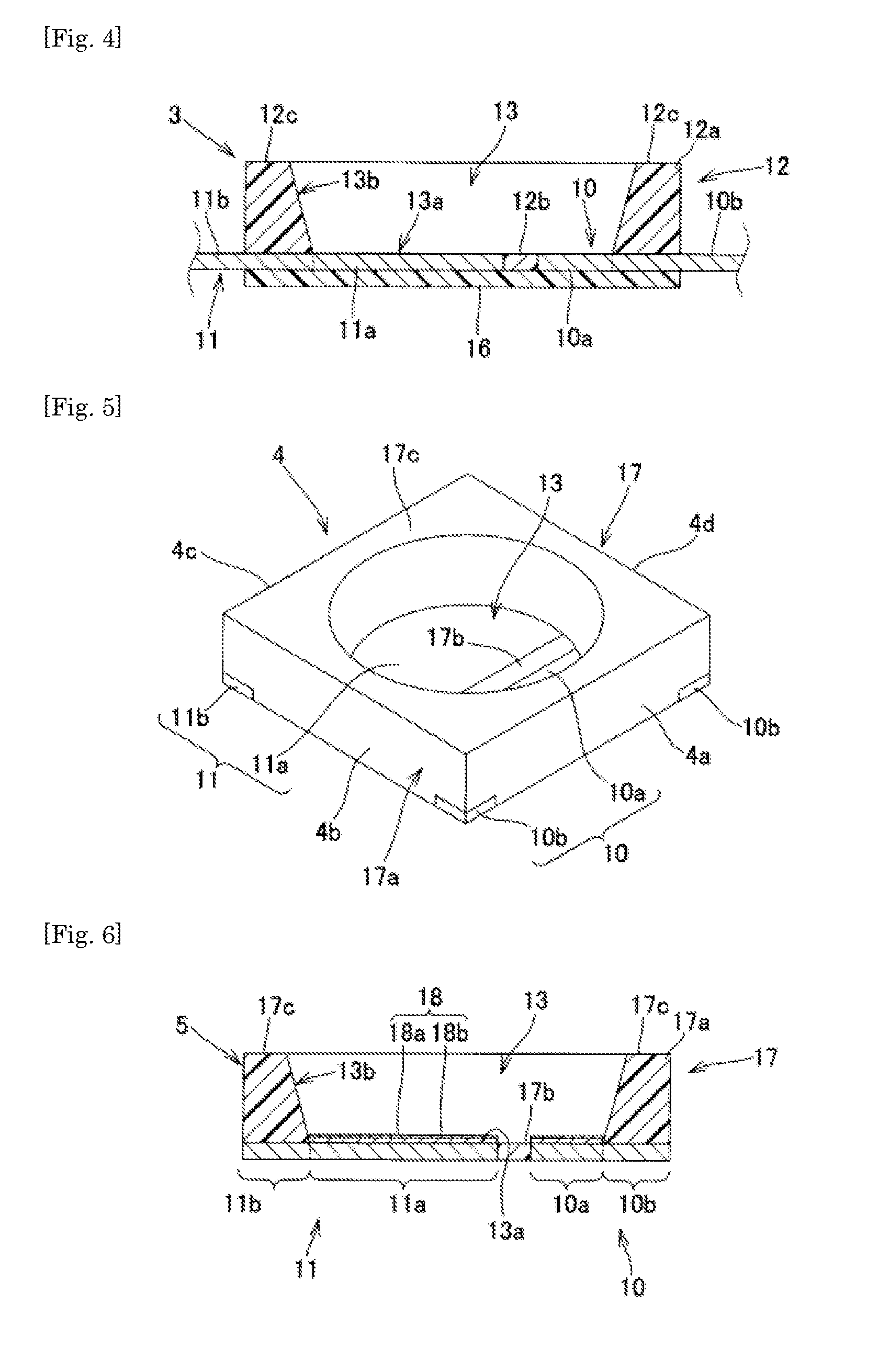

Polyactic Acid and Manufacturing Process Thereof

ActiveUS20080039579A1Improve heat resistanceGood molding effectEmulsion paintsCrystallinityPolylactic acid

It is an object of the present invention to provide polylactic acid containing a stereocomplex crystal and having excellent moldability, a high molecular weight, high crystallinity and a high melting point and a process for manufacturing the same. It is another object of the present invention to provide a composition comprising the polylactic acid and a molded product of the polylactic acid. The present invention is characterized from polylactic acid having a weight average molecular weight of 80,000 to 500,000 and a melting peak at 195° C. or higher which accounts for 80% or more of the total of melting peaks in the temperature elevation step when measured by a differential scanning calorimeter (DSC) and a process for manufacturing the same.

Owner:TEIJIN LTD +3

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

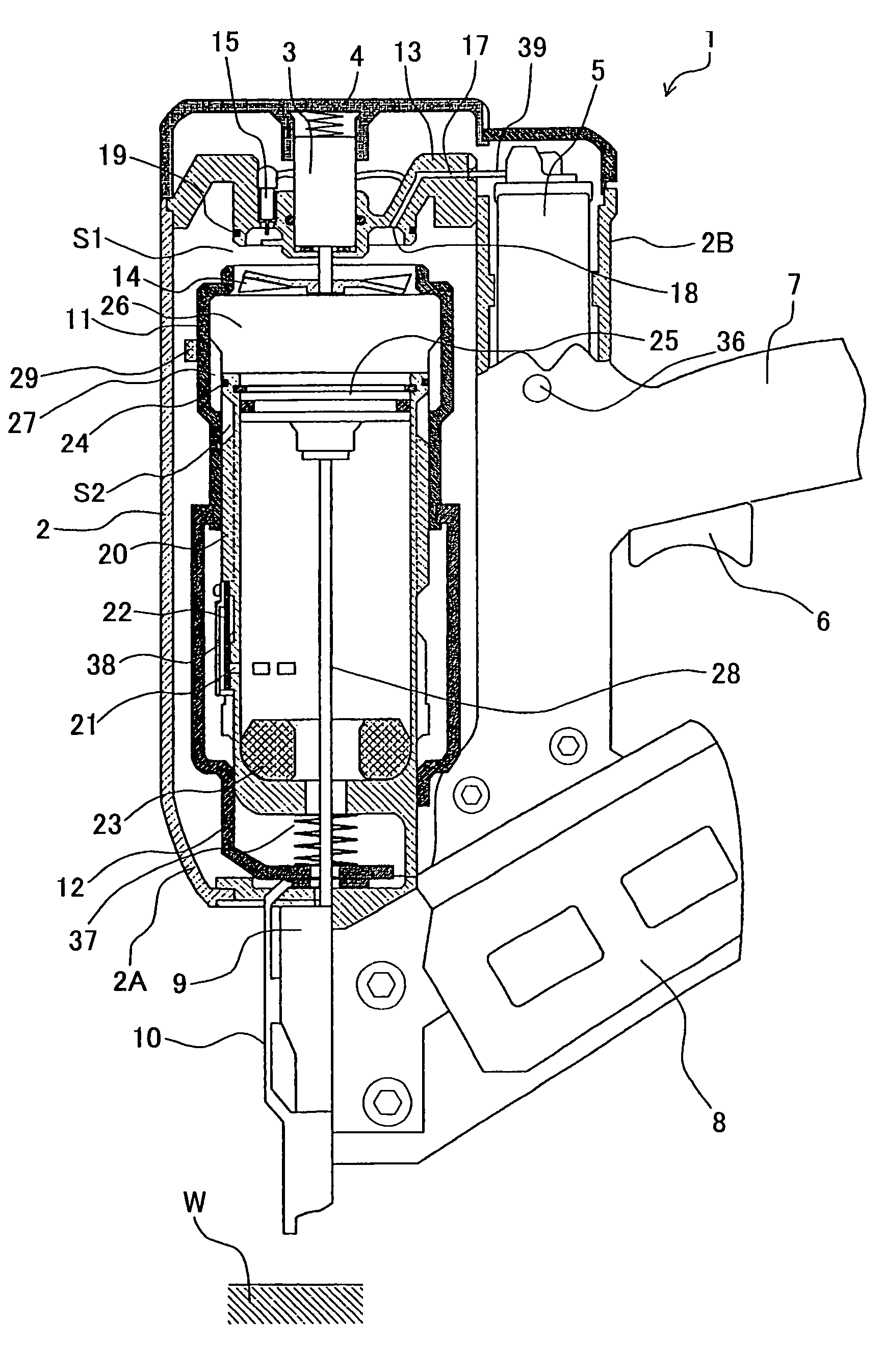

Process for preparing polyhydroxycarboxylic acid

InactiveUS6429280B1High molecular weightEfficient preparationCoatingsVitrificationReaction temperature

A process for preparing a polyhydroxycarboxylic acid having a weight average molecular weight of 50,000 to 1,000,000, which comprises a crystallizing step comprising (A) a step of heating pellets of a polyhydroxycarboxylic acid having a weight average molecular weight of 2,000 to 100,000 under stirring to a temperature from glass transition point or higher to a melting point or lower and heating until a defined result is attained, and (B) a step of heating the polyhydroxycarboxylic acid to a temperature of solid phase polycondensation reaction temperature, and a solid phase polycondensation reaction step of reacting the crystallized polyhydroxycarboxylic acid at an endothermic start temperature or lower of an endothermic peak as recognized upon temperature elevation analysis of the crystallized polyhydroxycarboxylic acid by using a differential scanning calorimeter.

Owner:MITSUI CHEM INC

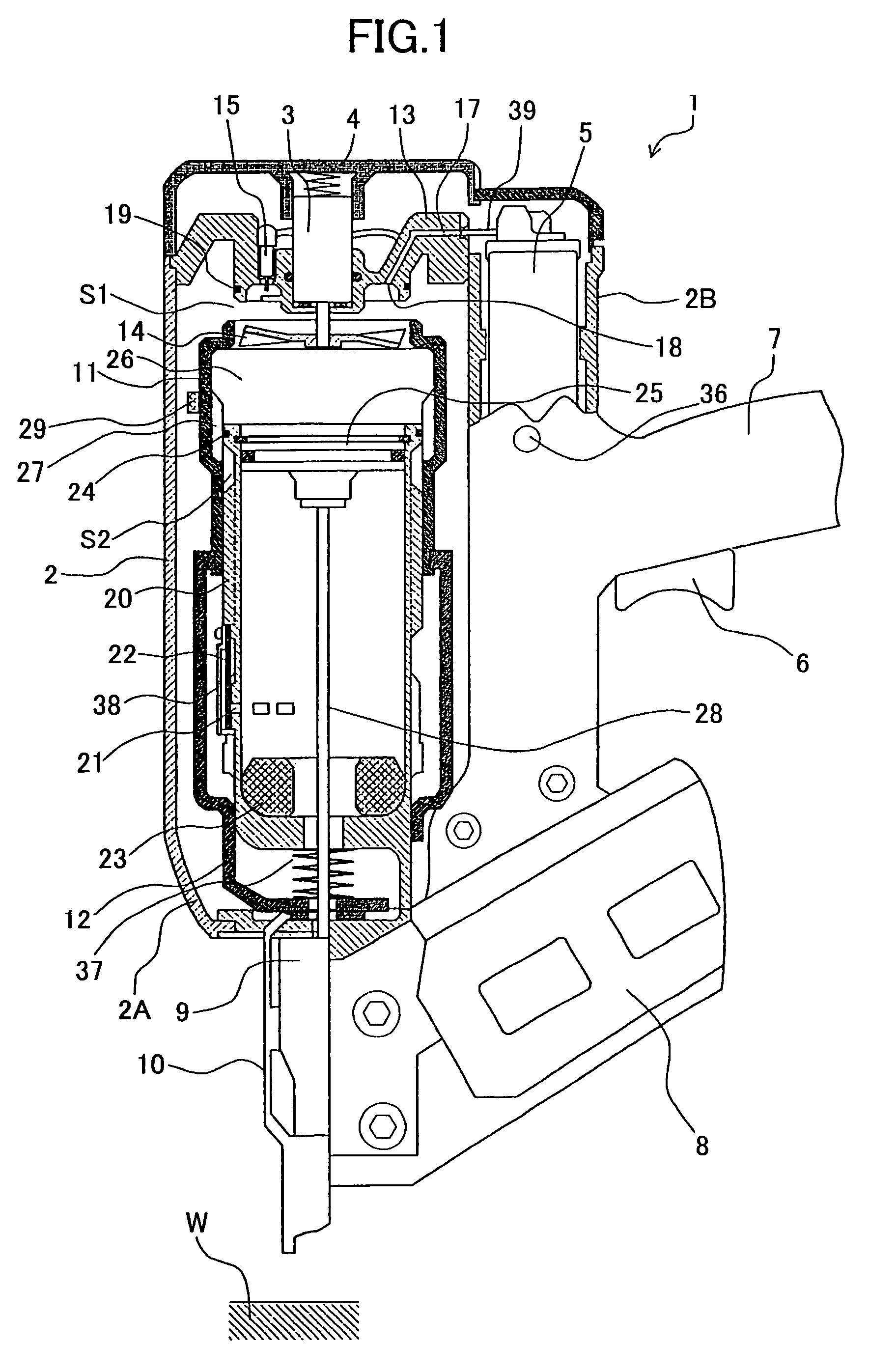

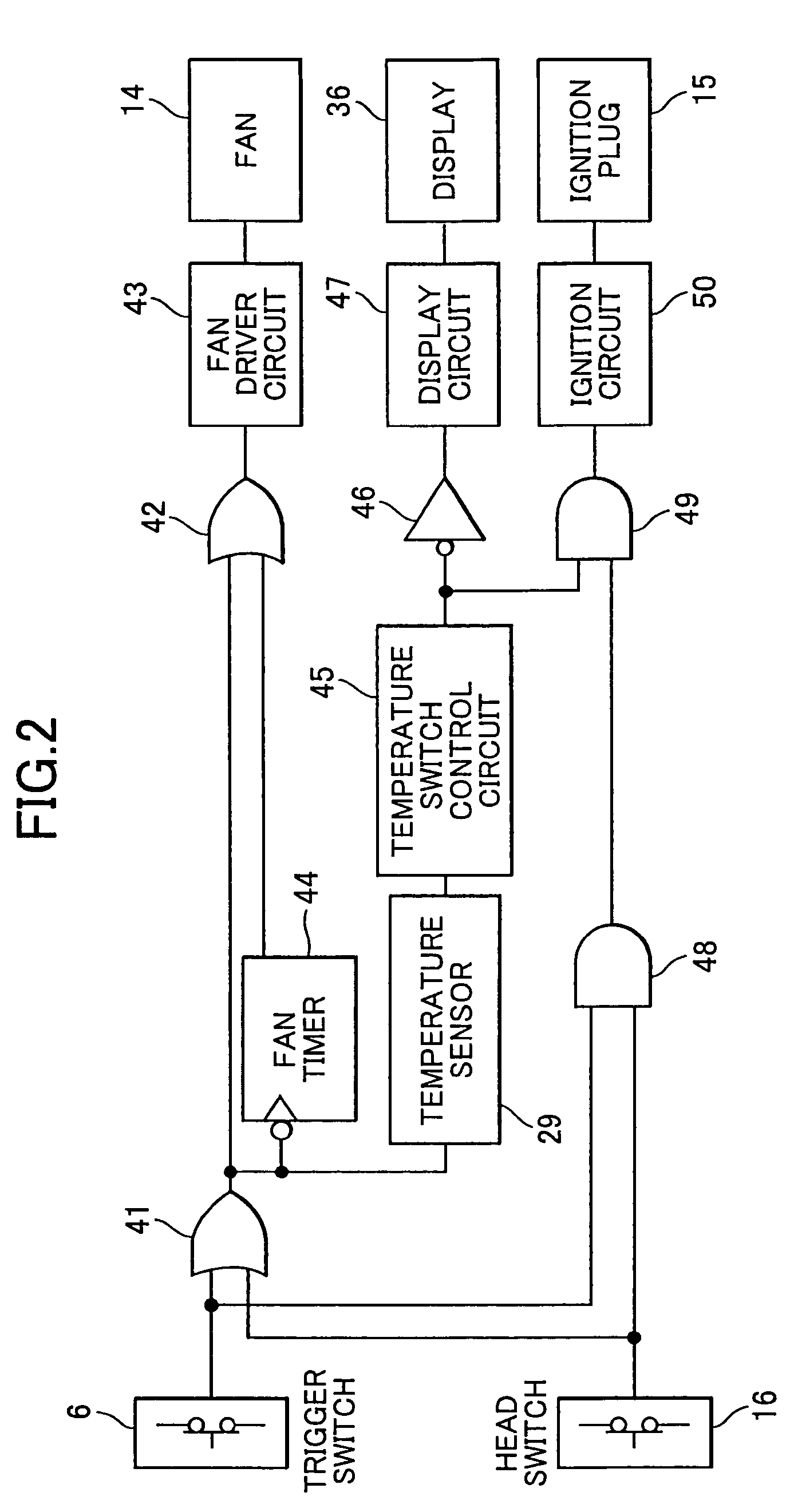

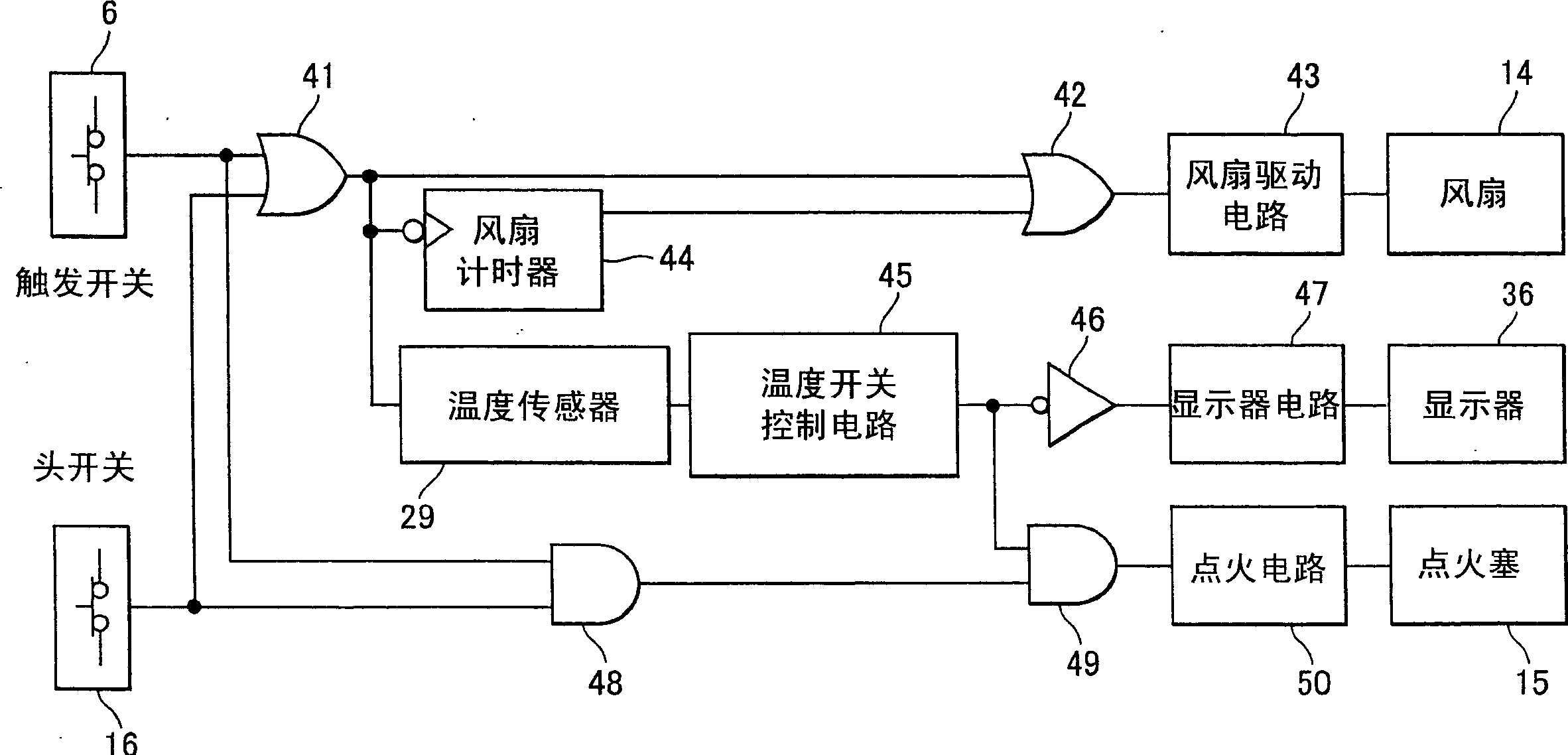

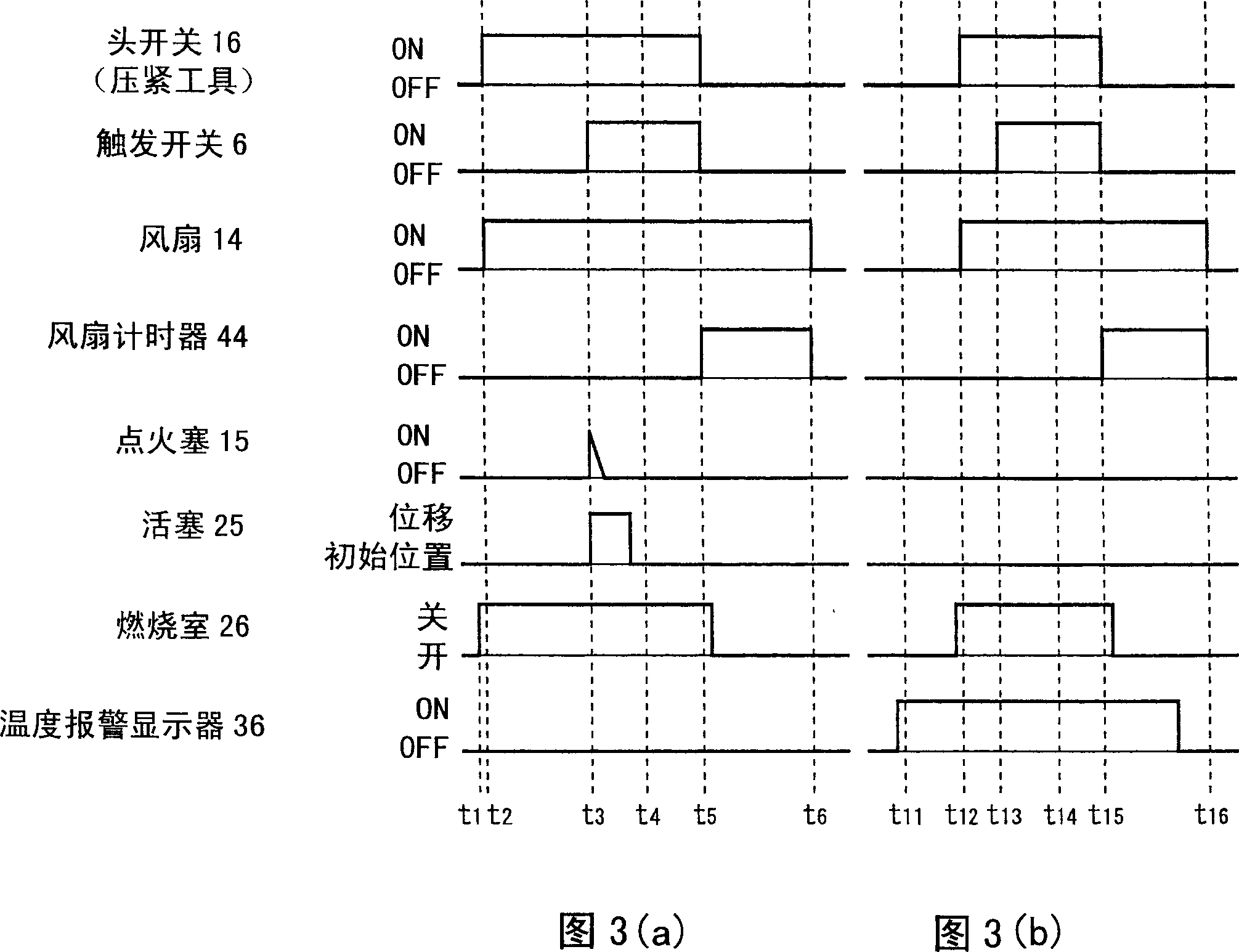

Combustion type power tool having avoiding unit for avoiding overheating to mechanical components in the tool

InactiveUS7021251B2Work lessEliminate thermal deformationFree piston enginesNailing toolsMechanical componentsCombustion chamber

A combustion type power tool capable of avoiding damage to seal members and a housing to prolong a service life, and capable of enhancing operability and workability. Temperature elevation of a combustion chamber frame due to combustion of a mixture of combustible gas and air is detected by a temperature sensor disposed in a housing. If the detected temperature exceeds a preset temperature, ignition of an ignition plug is prohibited by a prohibiting unit in spite of ON operation of a trigger switch. In this state, alarming is performed by a display to notify the user of the inoperable state of the tool. Similar control can be made when the temperature sensor is disposed at a cylinder, an exhaust cover and the housing.

Owner:HITACHI KOKI CO LTD

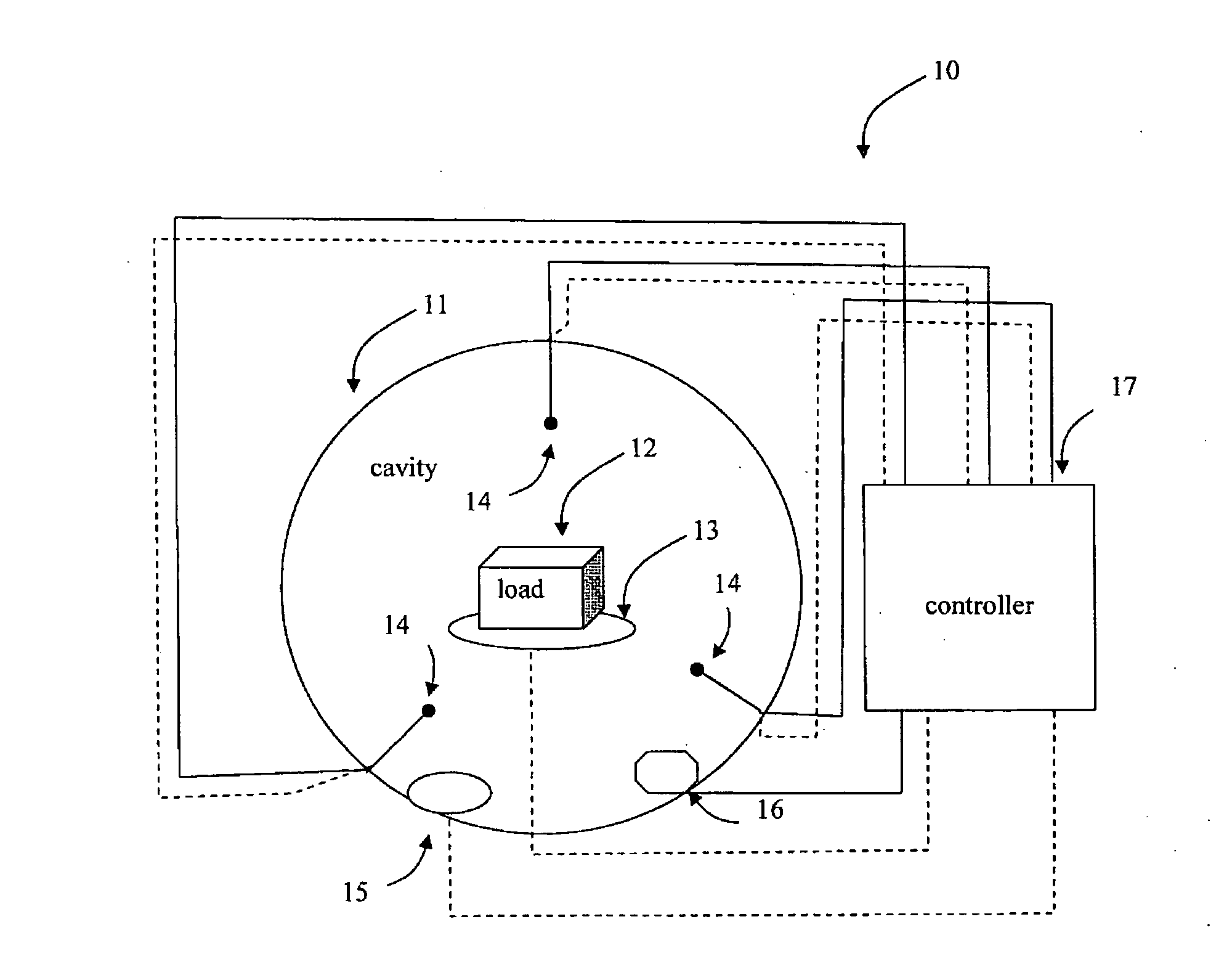

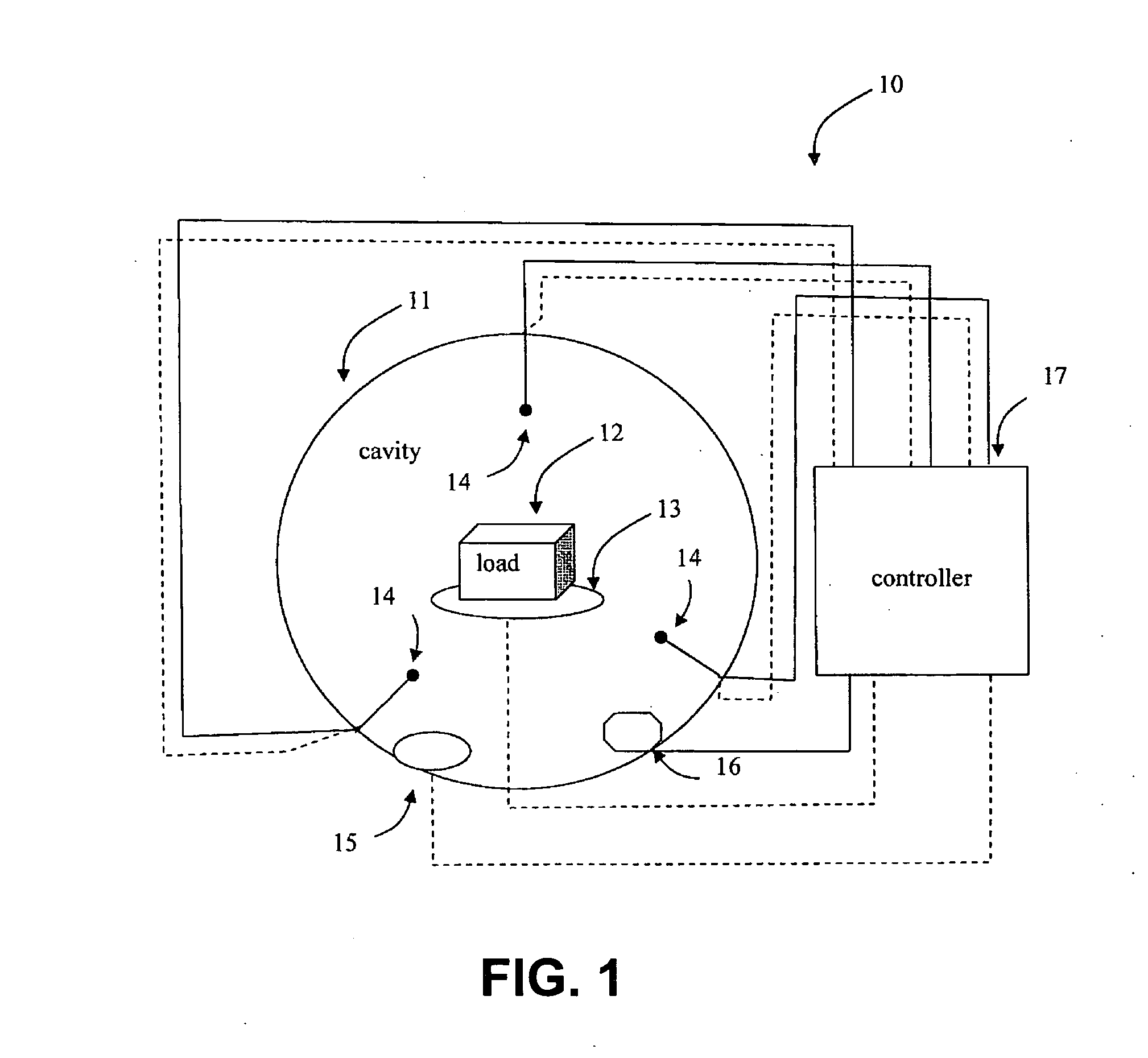

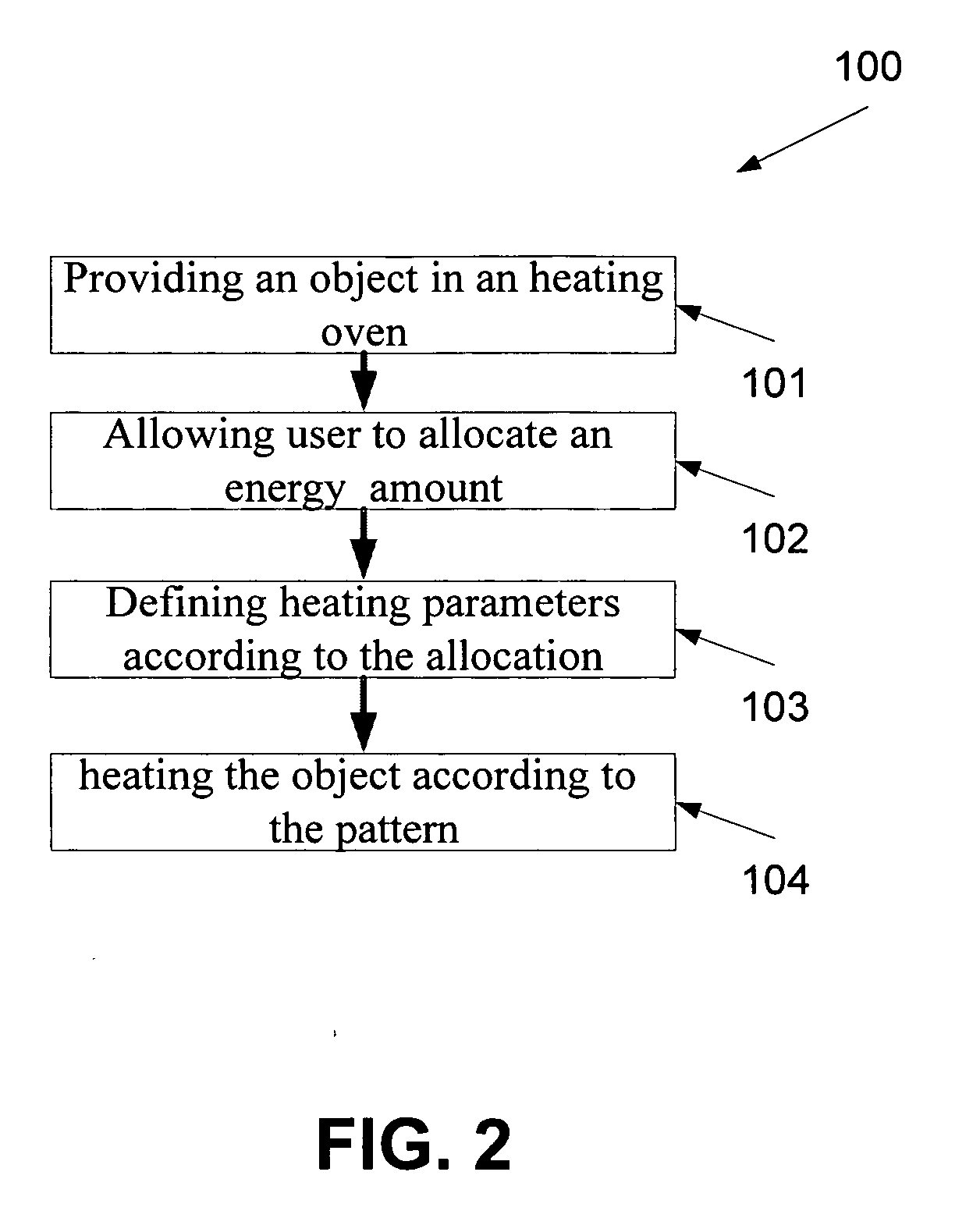

Method and system for dielectric heating and cooking

A method of heating an object using a dielectric heating. The method comprises positioning an object in a cavity of a dielectric heating oven, allowing a user to allocate an amount of energy to dissipate in the object during a temperature elevation of the object, and elevating the temperature of the object by using the dielectric heating oven according to the amount of energy.

Owner:GOJI LTD

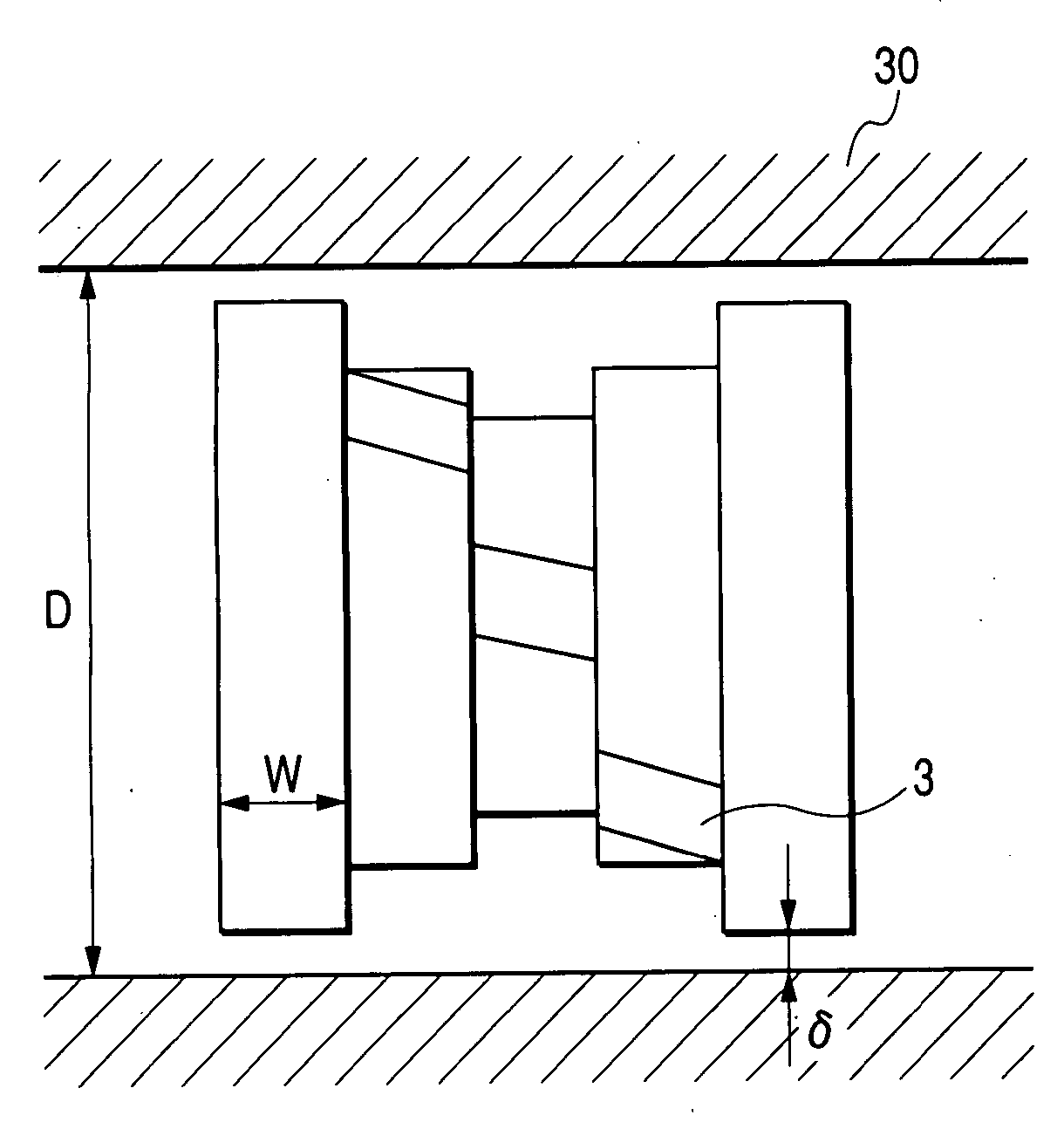

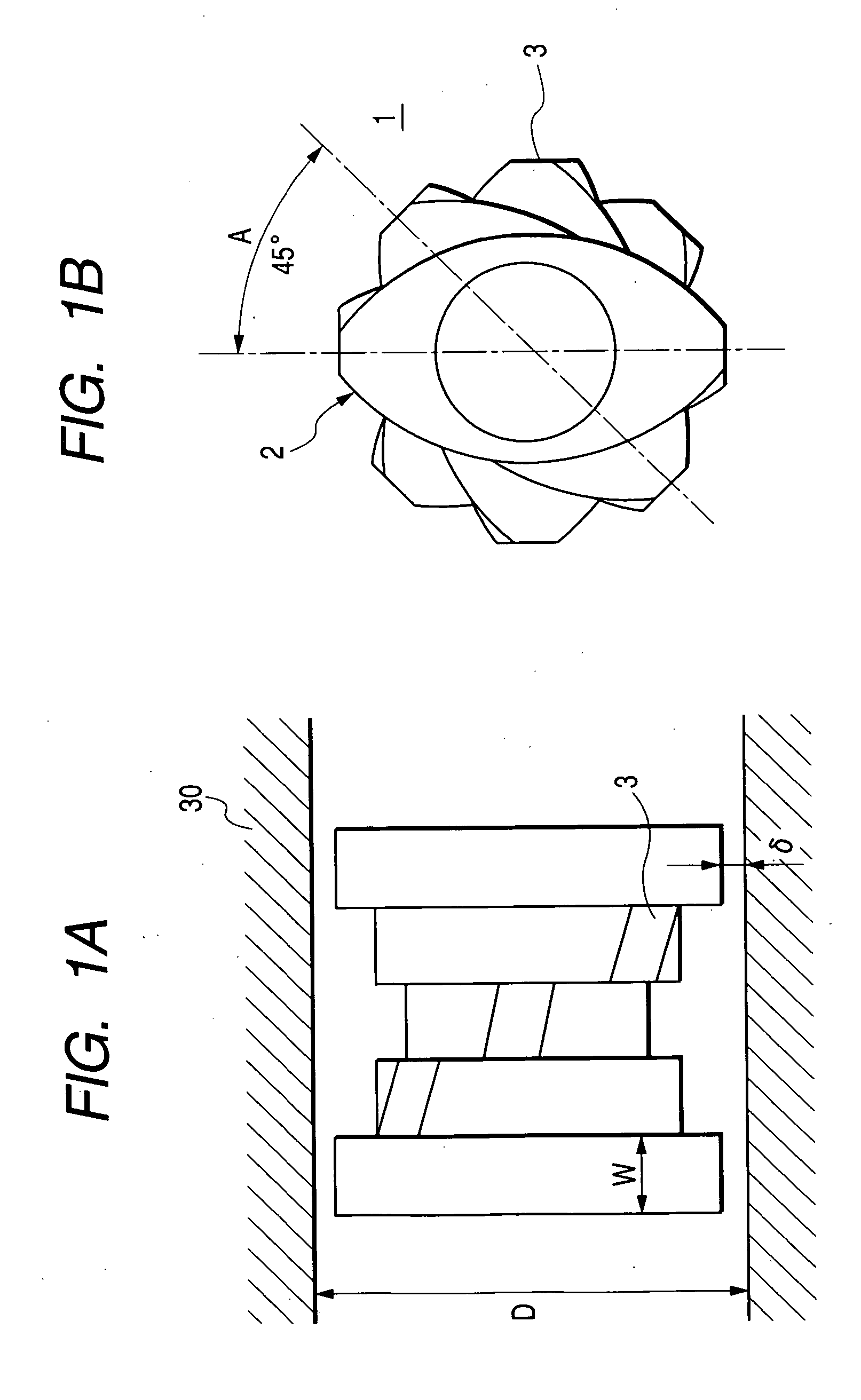

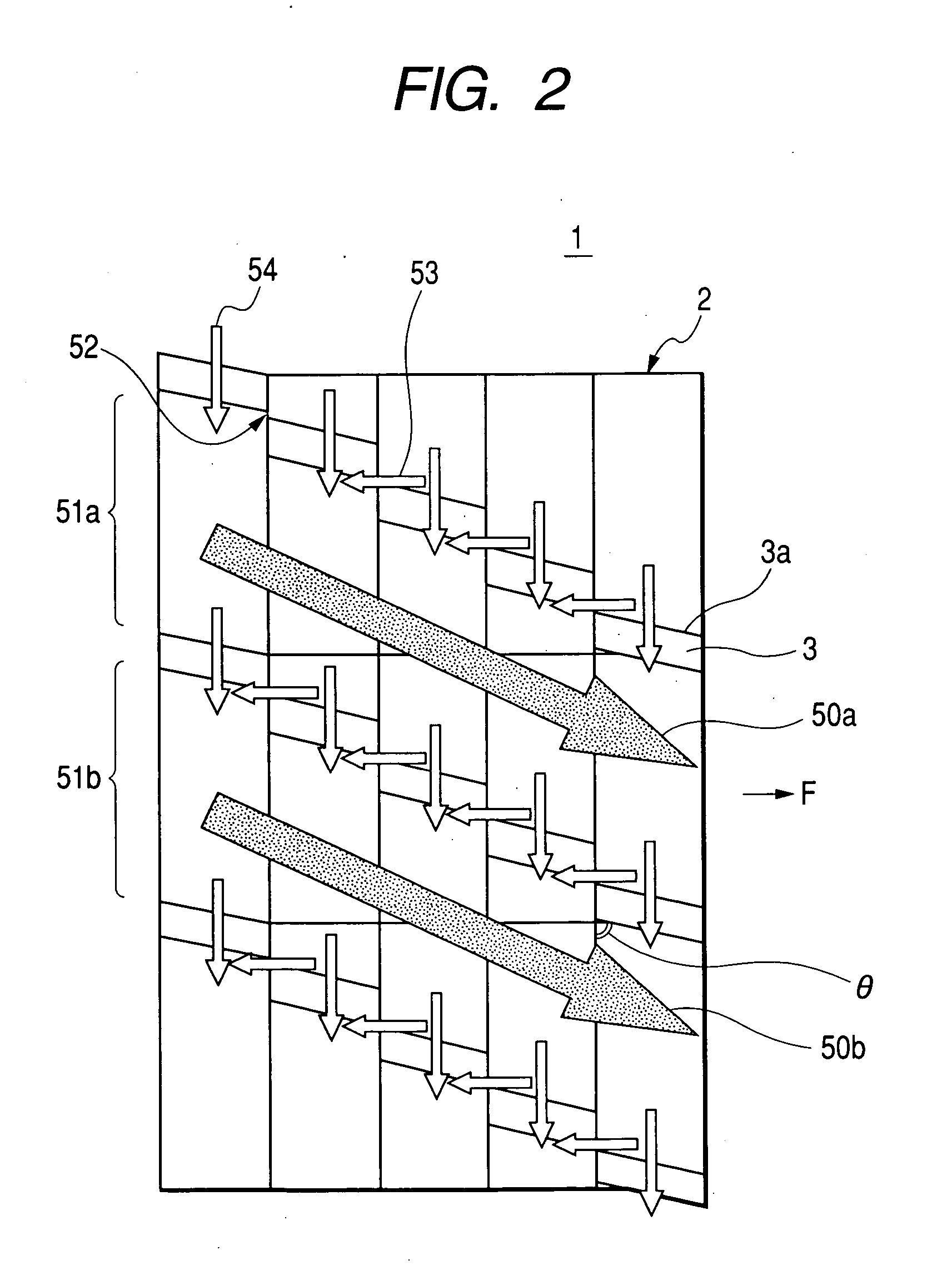

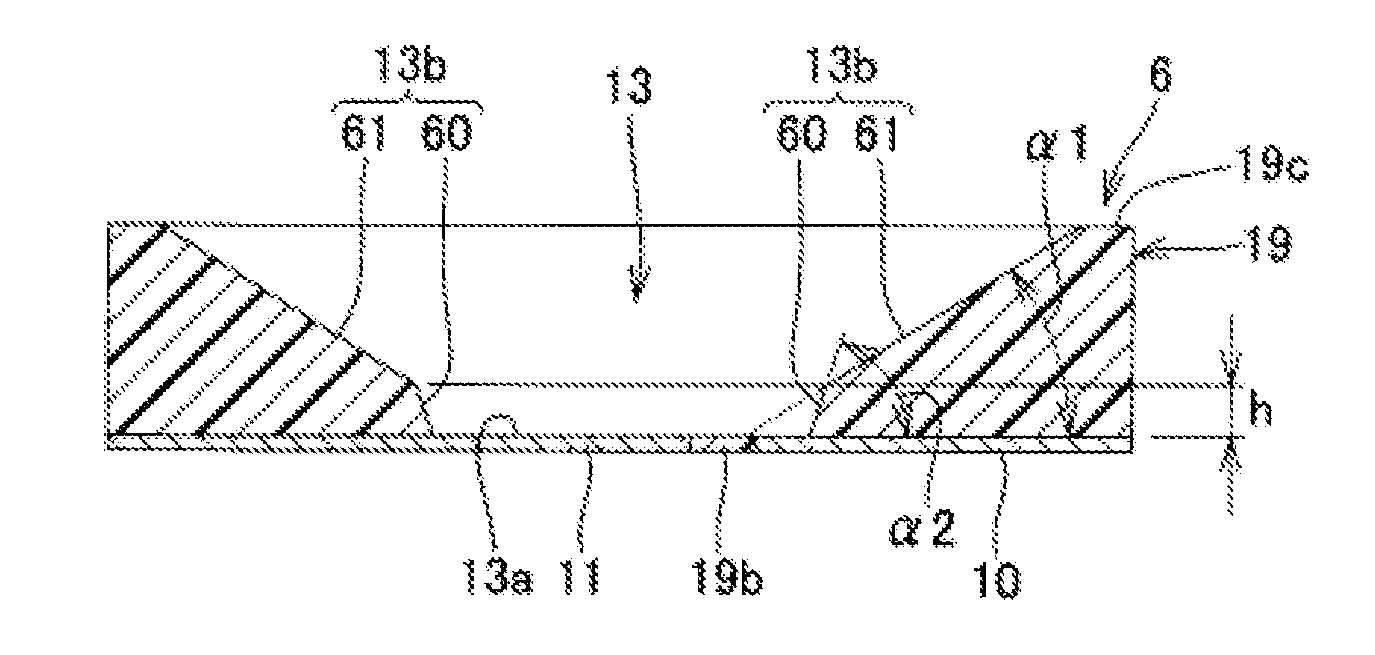

Kneading disk, a disk element and a kneading process

ActiveUS20050013192A1Low resin temperatureReduce the temperatureRotary stirring mixersMixing/kneading with horizontally-mounted toolsCircular discStream flow

A kneading disk has a plurality of disk elements having flight tips arranged at a helix angle E in a direction supporting main streams of a resin. The flight tips of every two adjoining disks have a clearance formed therebetween. The resin is kneaded by undergoing dispersion and distribution without having any excessive temperature elevation in approximately three kinds of streams, i.e. its main streams flowing along the flight tips, its back streams through the clearances and its tip riding streams flowing over the flight tips.

Owner:JAPAN STEEL WORKS LTD

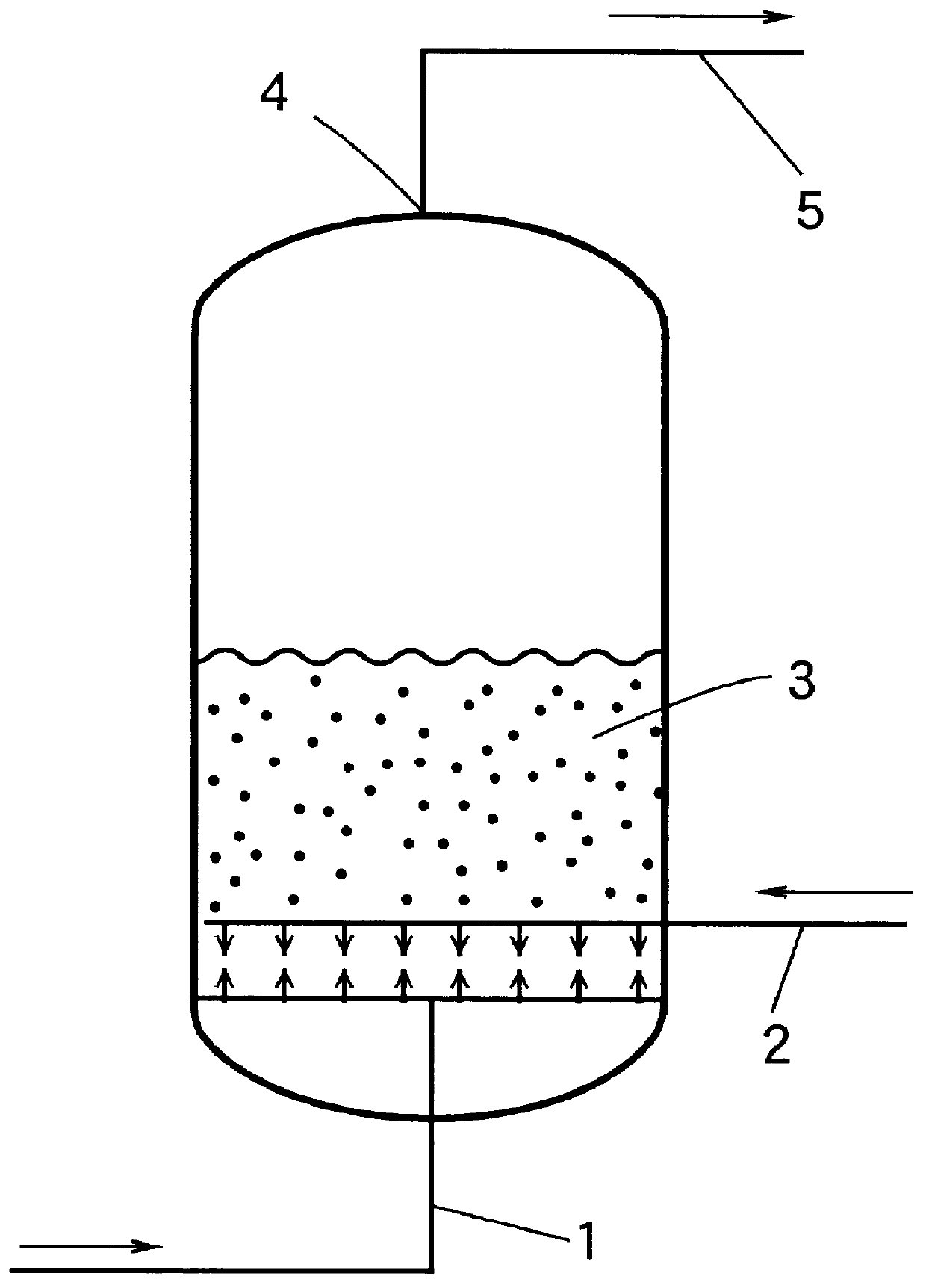

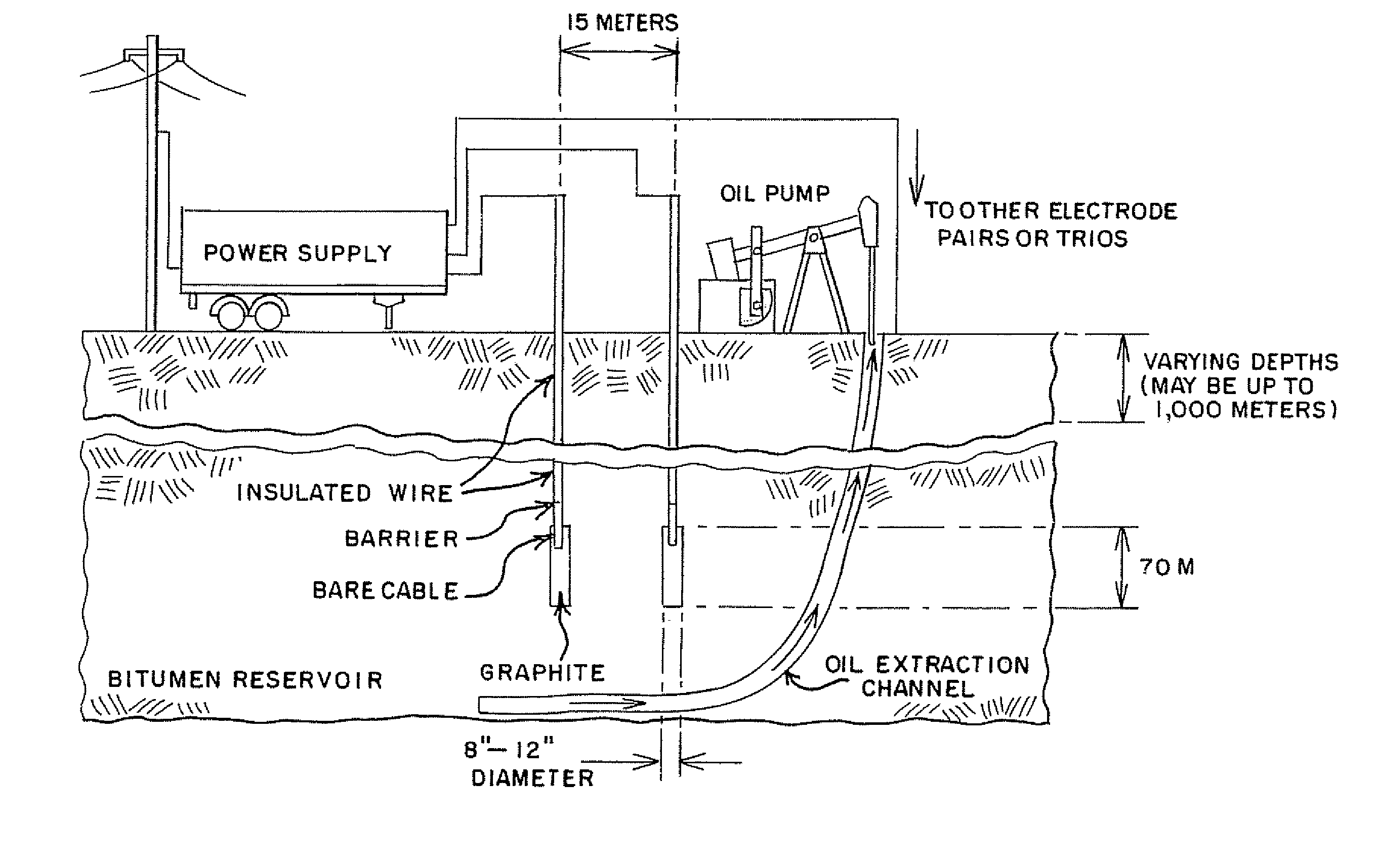

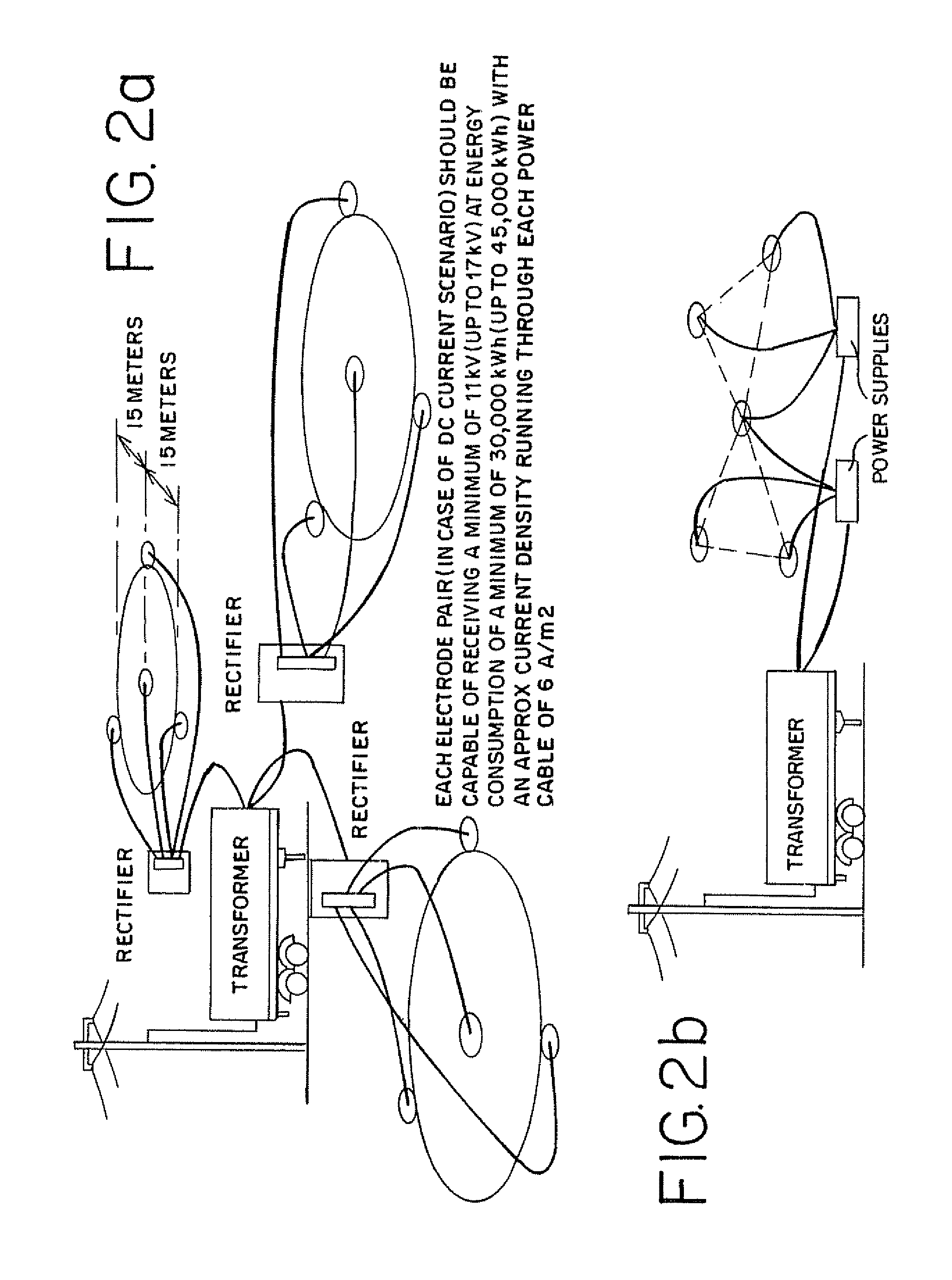

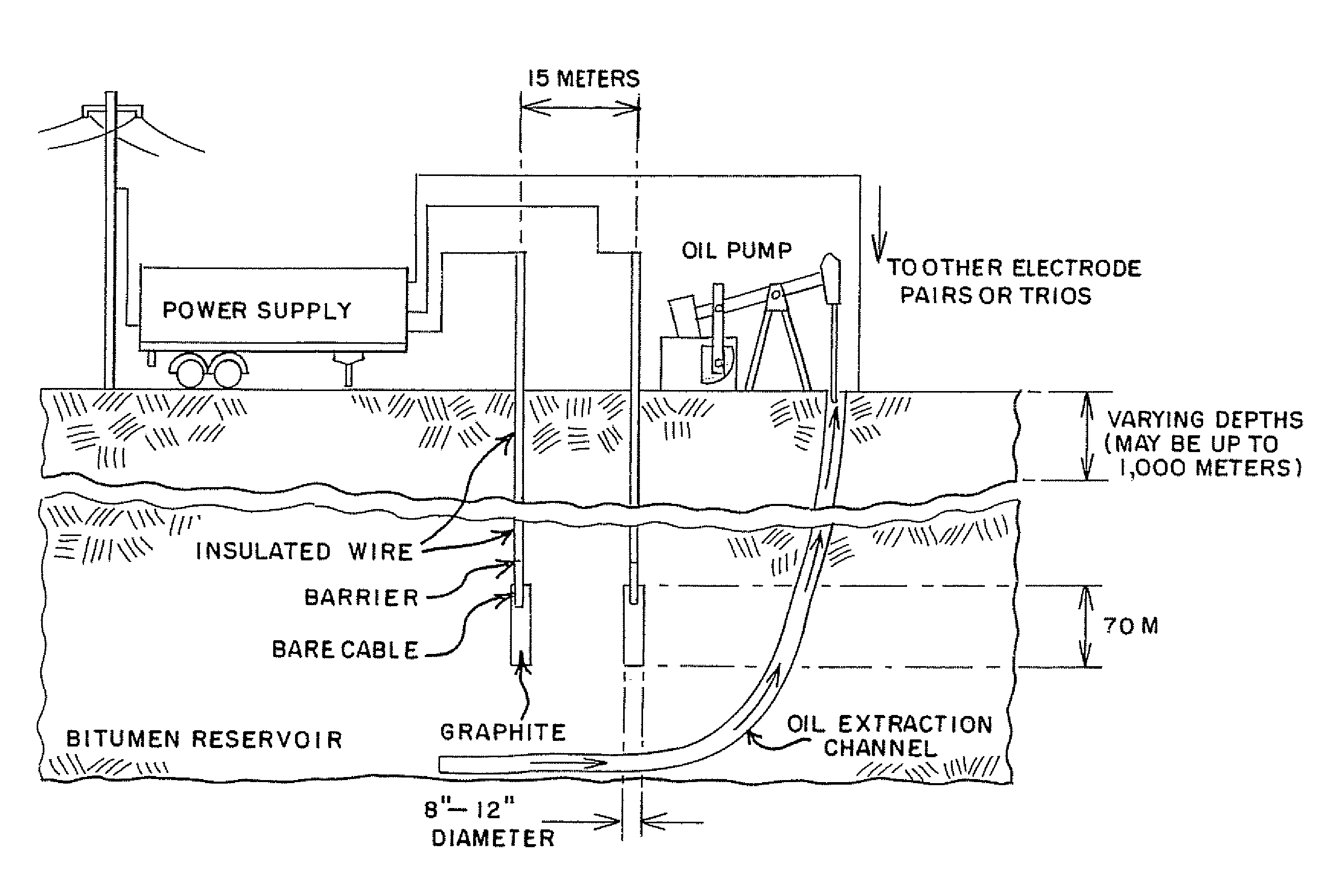

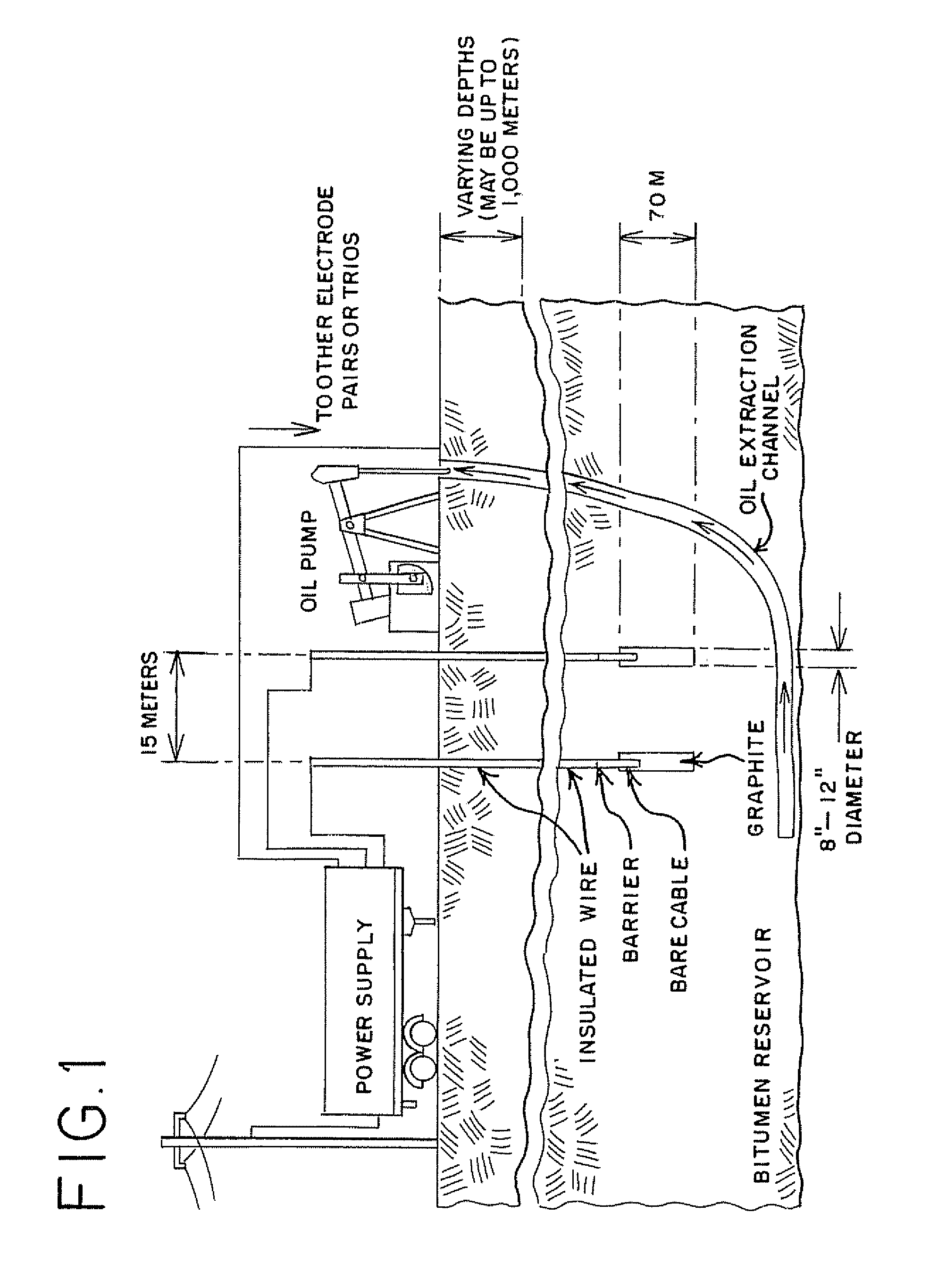

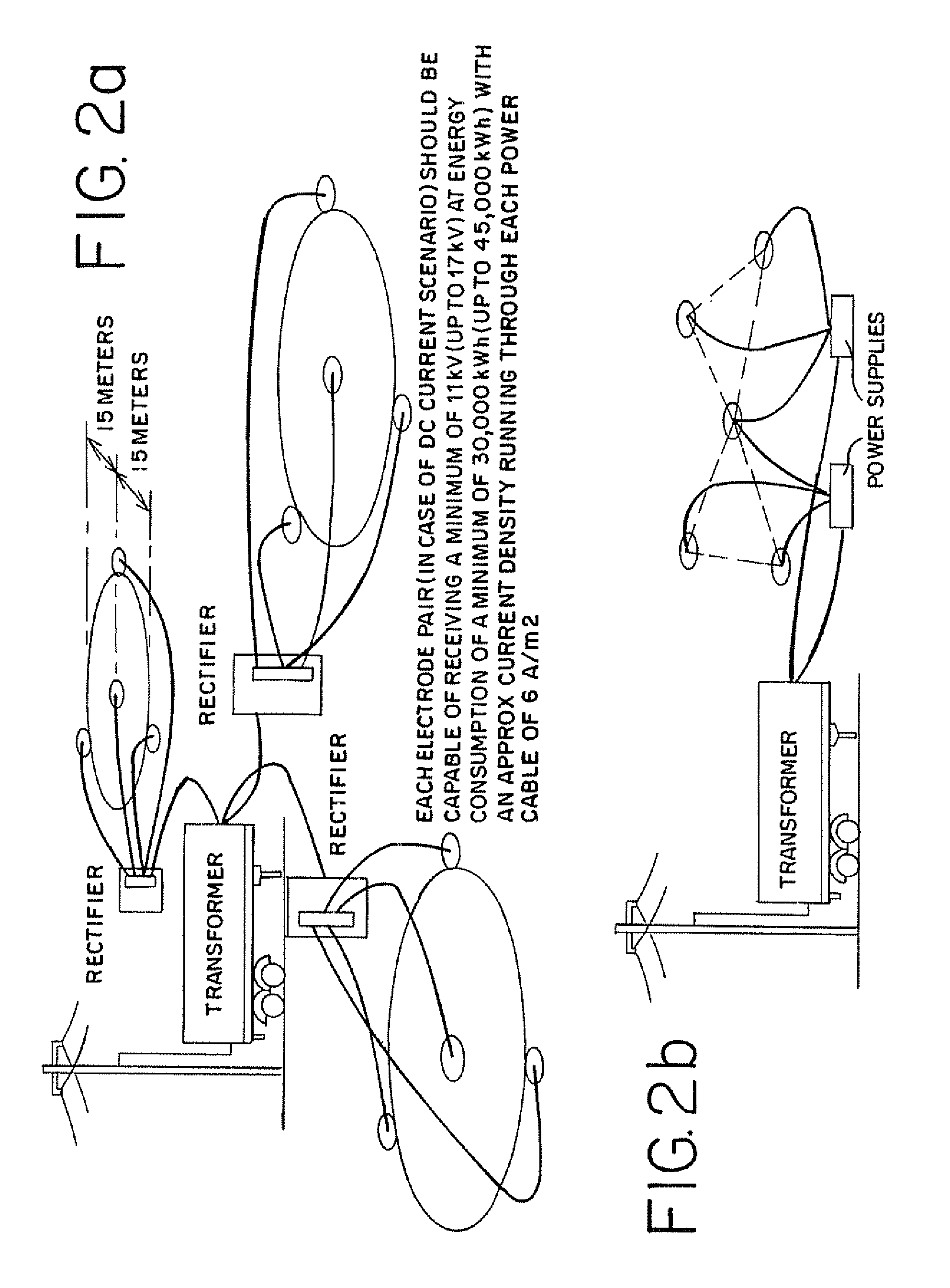

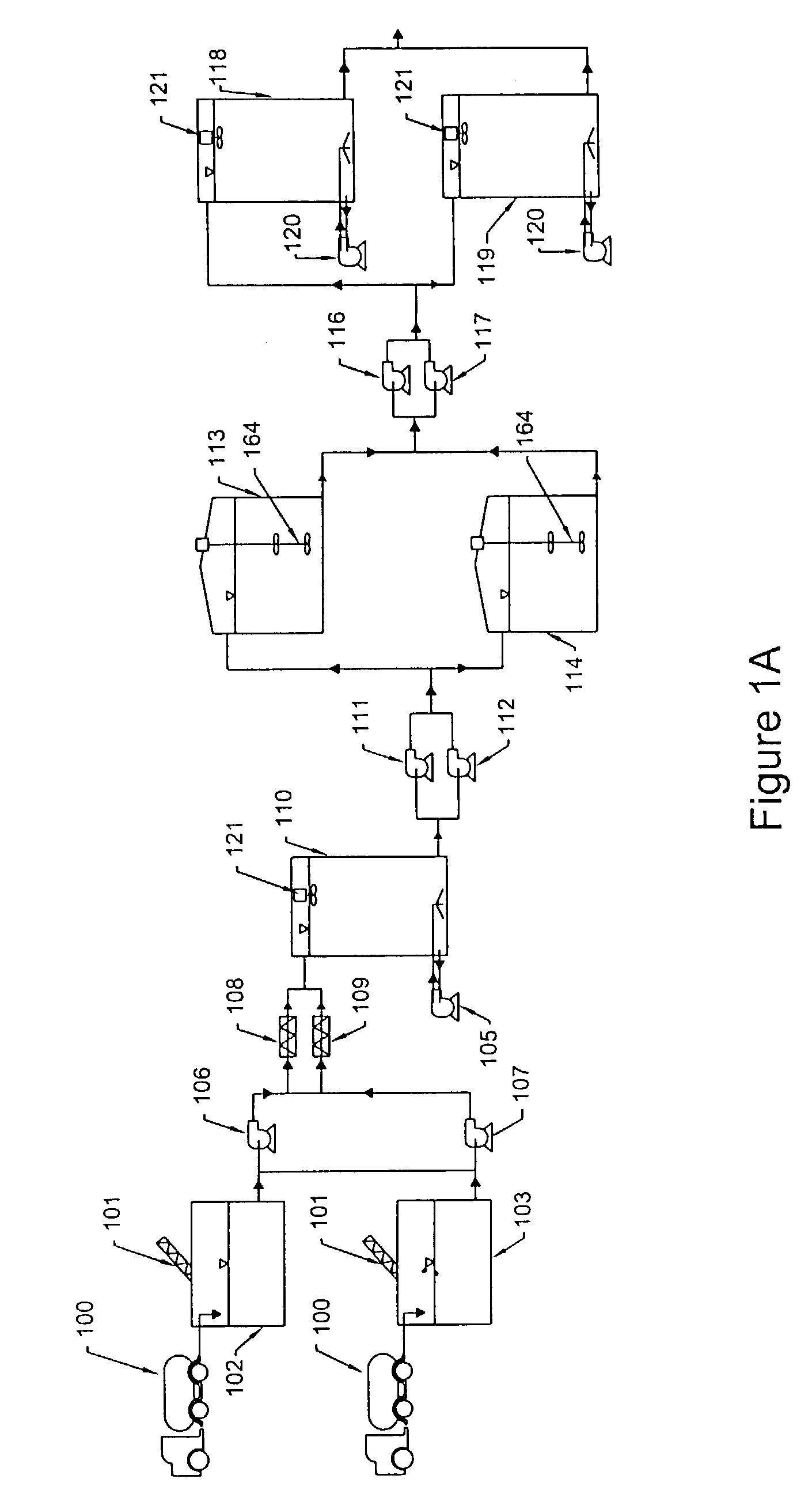

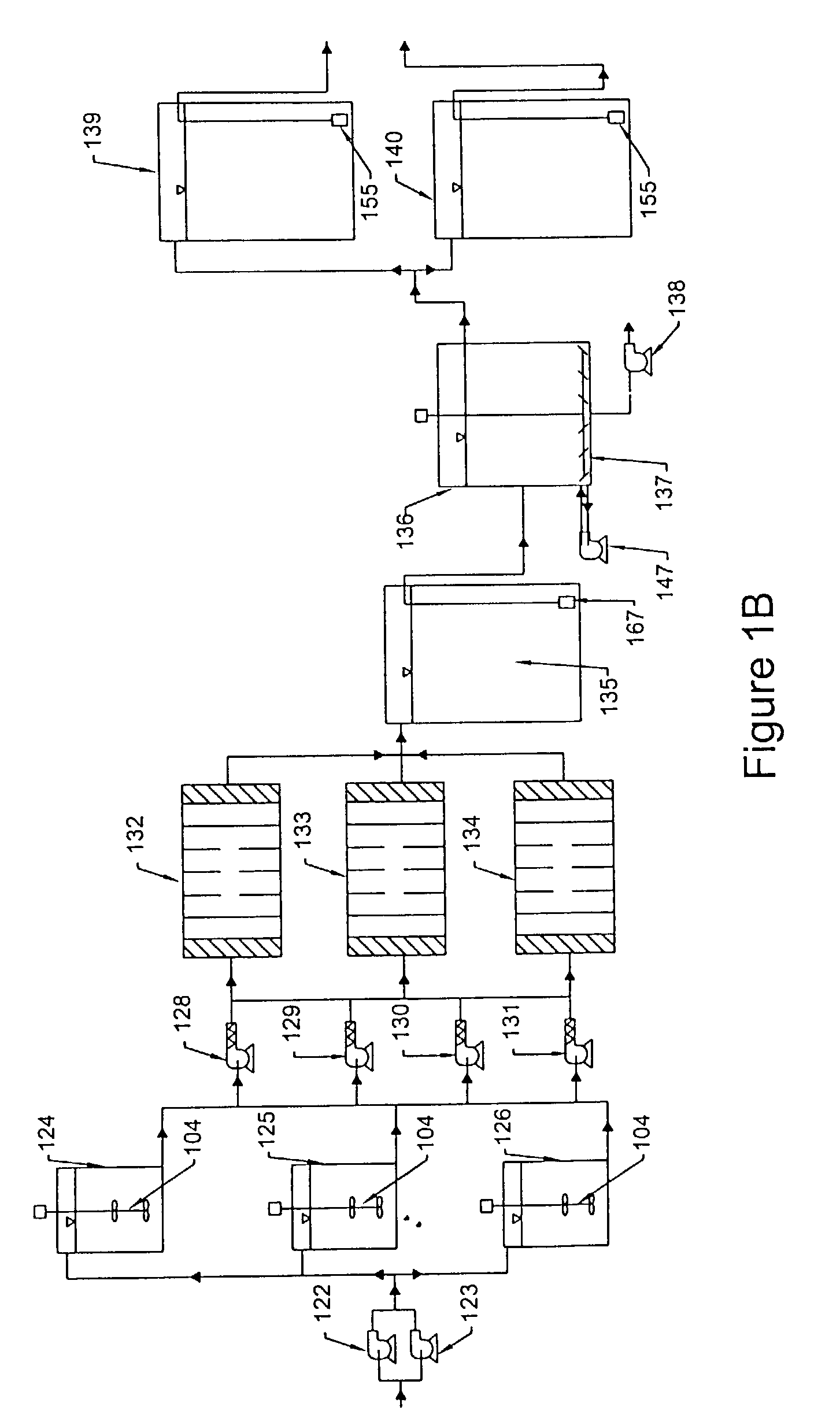

Methods for extracting oil from tar sand

Hydrocarbon containing formations can be processed using an in-situ liquefaction technique. This new technique embodies systematic temperature elevation applied to subsurface formation allowing recoverable hydrocarbons to reach a Newtonian fluid viscosity suitable for extraction.

Owner:SUPERIOR GRAPHITE CORPORATION

In-situ heavy-oil reservoir evaluation with artificial temperature elevation

InactiveUS20030034777A1Electric/magnetic detection for well-loggingSurveyBound waterRoom temperature

Many reservoirs of interest include heavy oil. In such reservoirs, parti at normal temperatures, many instruments commonly used for formation evaluation may not be able to distinguish between heavy oil and bound water in the formation. Passive or active heating is used to elevate the temperature of the fluids in the formation. At elevated temperatures, distinguishing between heavy oil and bound water is easier. Of particular interest is the increase in the resolvability of the transverse relaxation time T2 of NMR spin echo measurements. Additionally, the dielectric constant and the loss tangents of water and heavy oil show different temperature and frequency dependence.

Owner:BAKER HUGHES INC

Methods for extracting oil from tar sand

Hydrocarbon containing formations can be processed using an in-situ liquefaction technique. This new technique embodies systematic temperature elevation applied to subsurface formation allowing recoverable hydrocarbons to reach a Newtonian fluid viscosity suitable for extraction.

Owner:SUPERIOR GRAPHITE CORPORATION

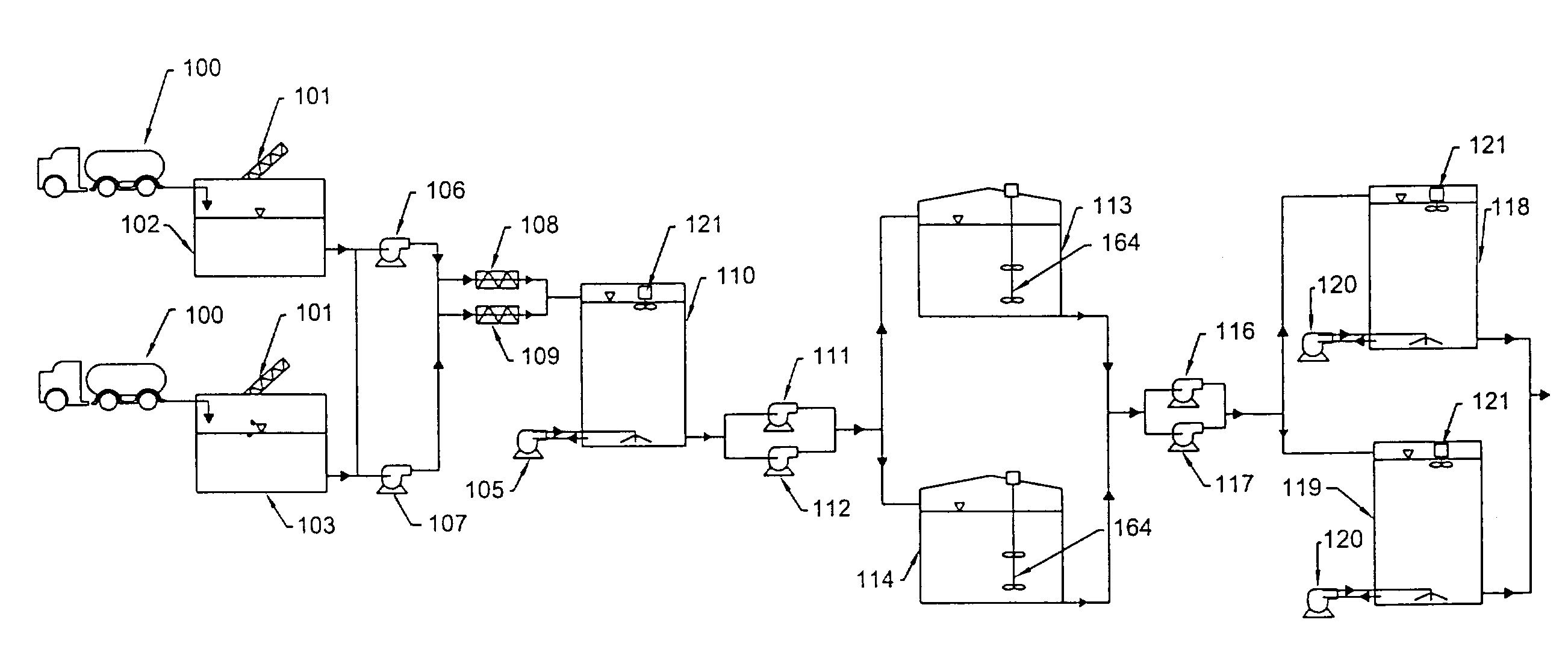

Process for treating septage

InactiveUS7070693B2Easy to dehydrateQuality improvementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid fractionPasteurization

A process and apparatus for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process will convert the septage into Biosolids (sludge) and water dischargeable to the environment. The treated septage achieves pathogen reduction, and reduced vector attraction. Treatment of septage by pasteurization causes the destruction of harmful pathogens. Pasteurization of septage having high water content provides for even temperature elevation and distribution of heat within the thermal mass of the septage allowing for consistent pathogen destruction. An alkaline compound is utilized to form a filter cake from the solids fraction of the pasteurized septage preventing vector attraction, while producing a beneficial bio-solid. The liquid fraction of the septage is treated by biological process allowing for its discharge into the environment.

Owner:KELLY ROBERT J

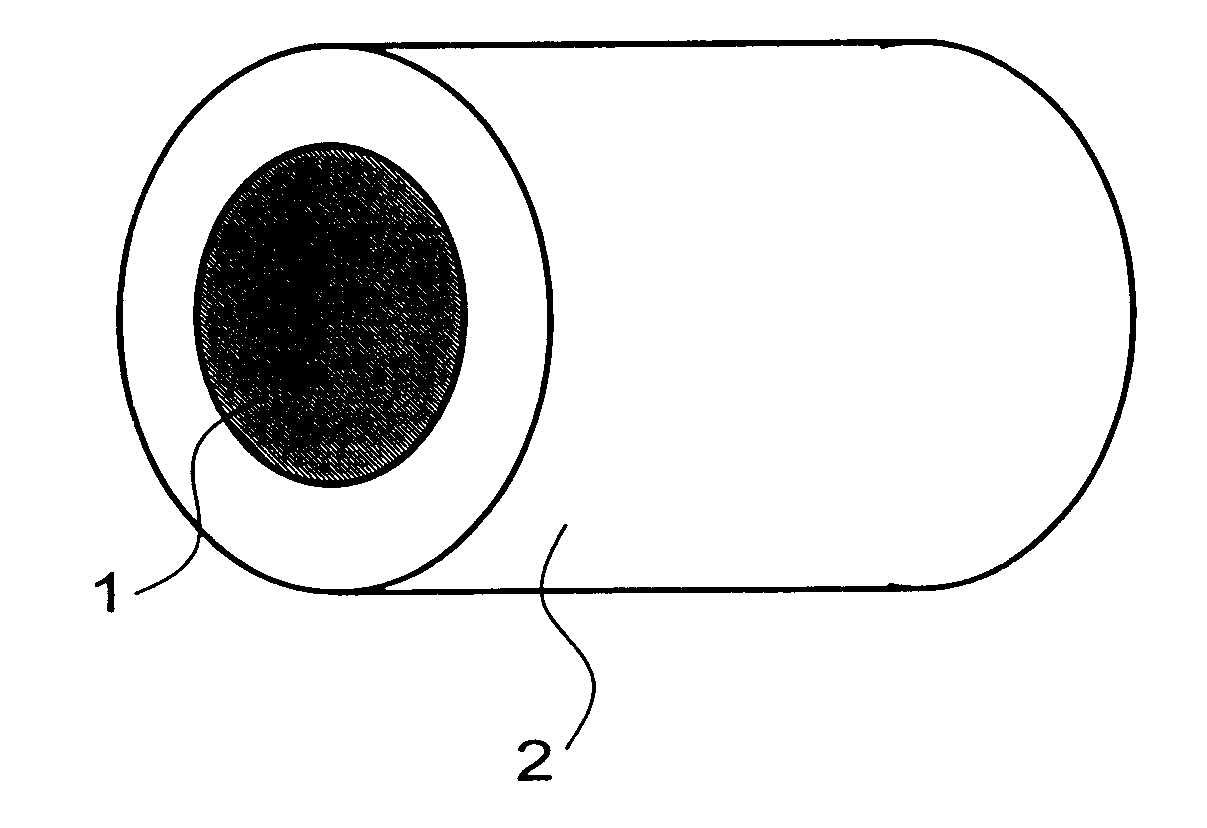

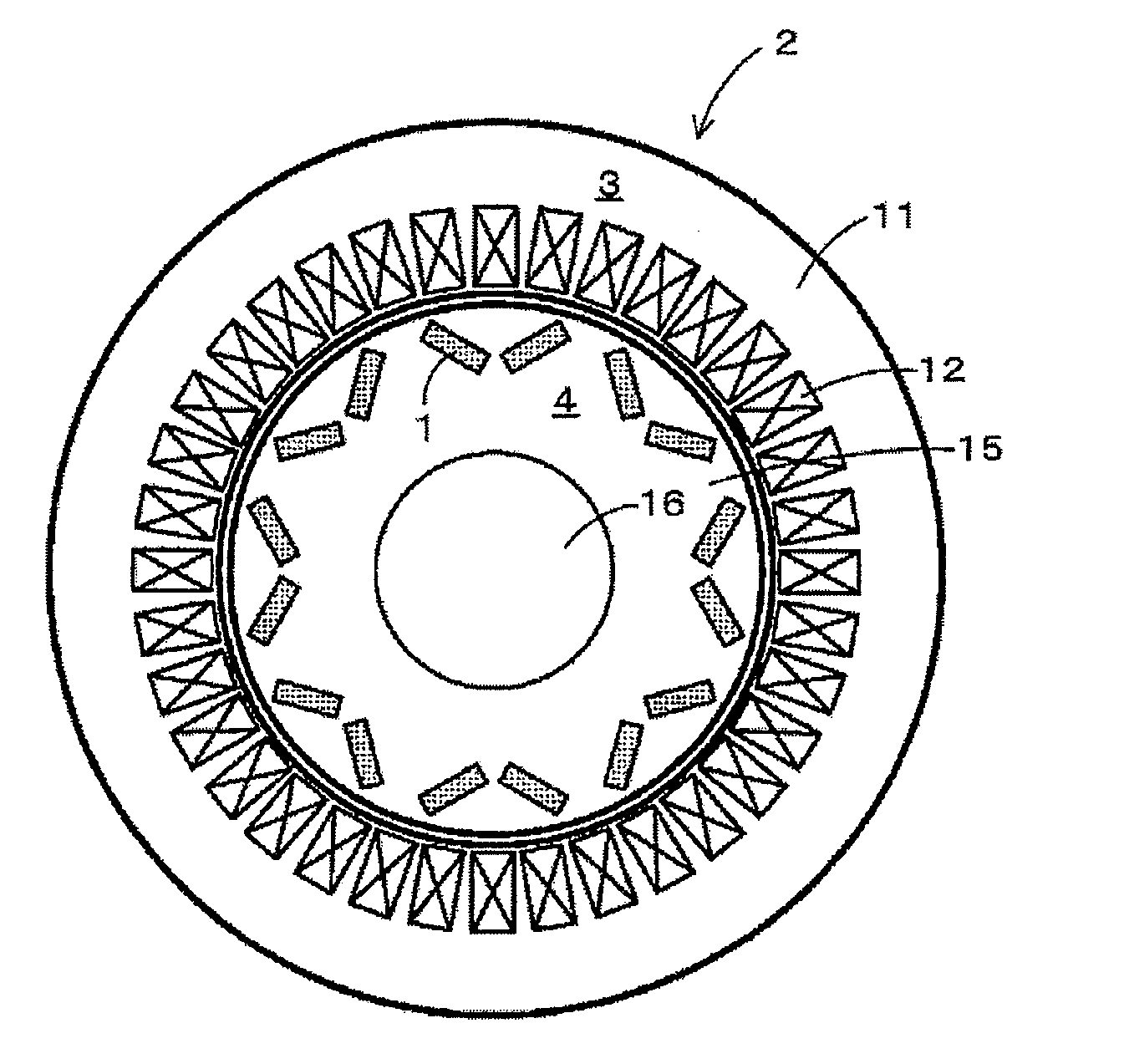

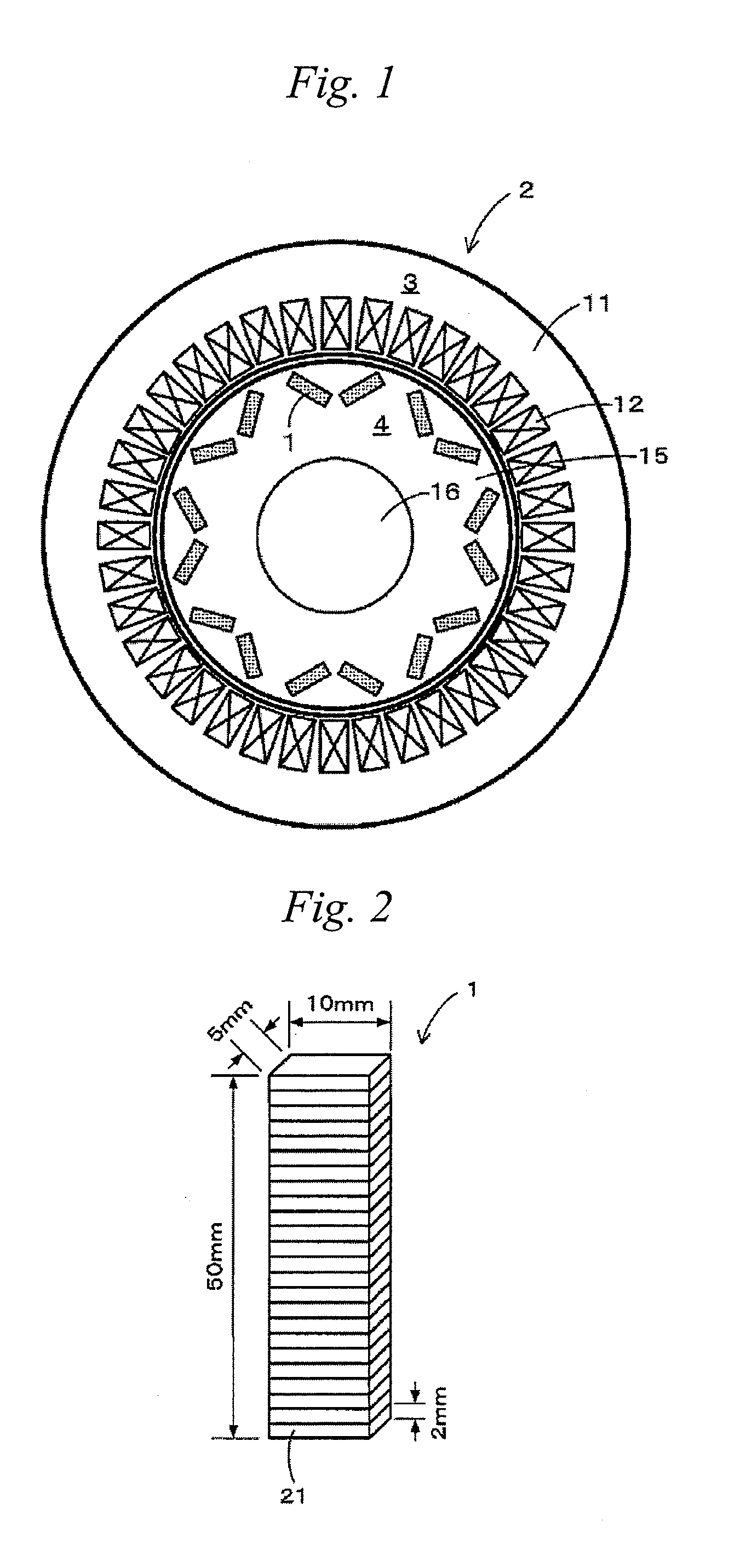

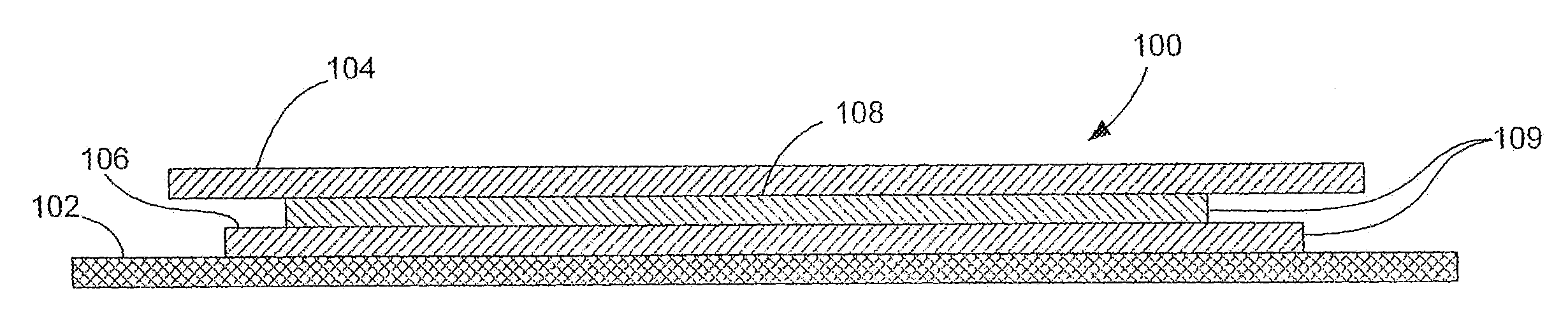

Permanent magnet for motor, and method for manufacturing the permanent magnet for motor

ActiveUS20110012460A1Total current dropDifficulty occurMagnetic circuit rotating partsSynchronous machinesEngineeringPermanent magnet motor

The present invention relates to a permanent magnet for a motor, to be buried in a permanent magnet motor, including: a plurality of sheet magnets for lamination, and an insulating layer arranged between the plurality of sheet magnets for lamination. Since the invention has the above-mentioned constitution, the permanent magnets are free from the problems of temperature elevation and coercive force depression, therefore making it possible to provide a high-power small-sized motor. Furthermore, it is unnecessary to perform the conventional correcting processing after sintering, which can simplify the production steps, and therefore, it becomes possible to mold the permanent magnet with a high degree of dimension accuracy.

Owner:NITTO DENKO CORP +1

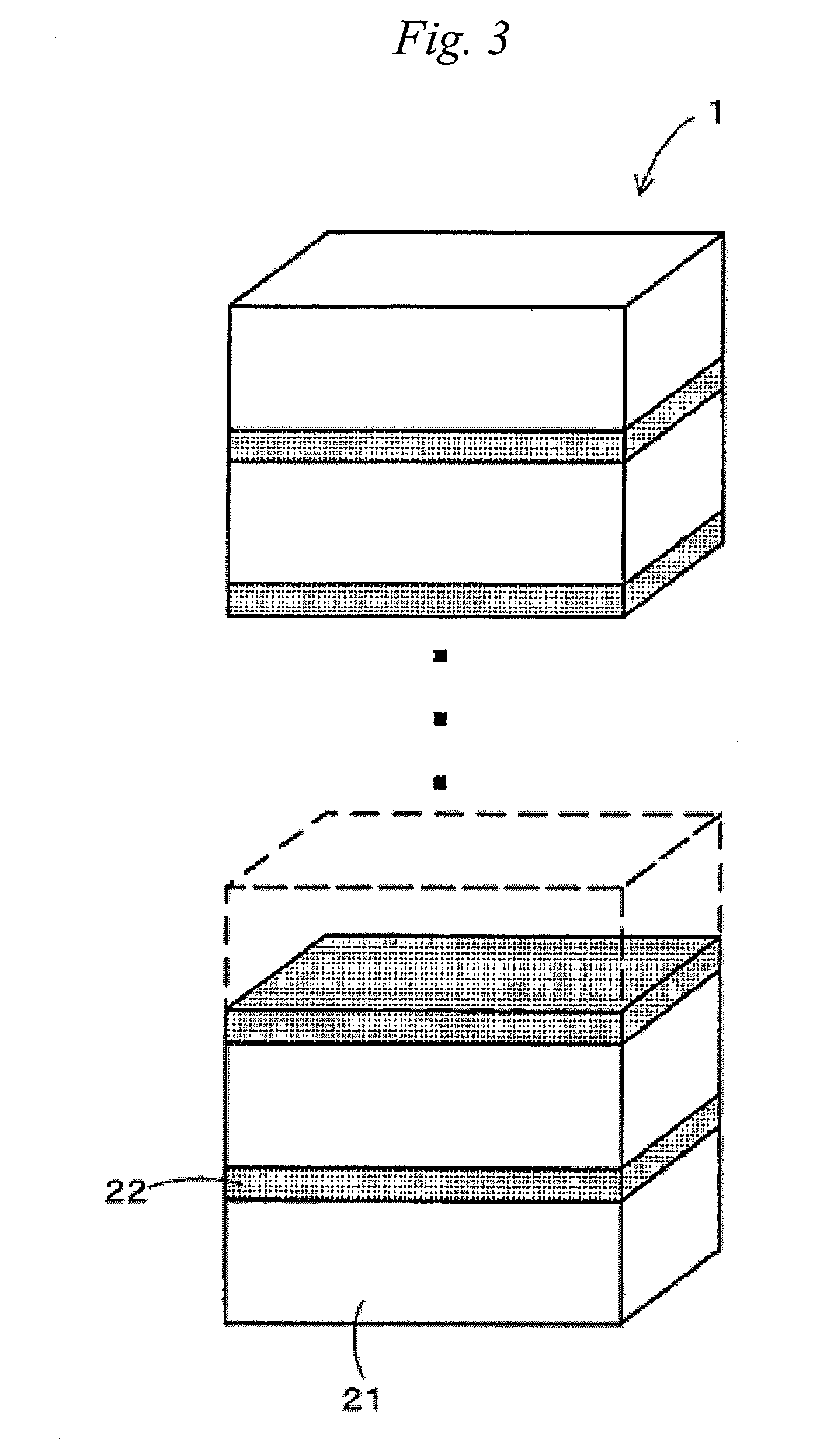

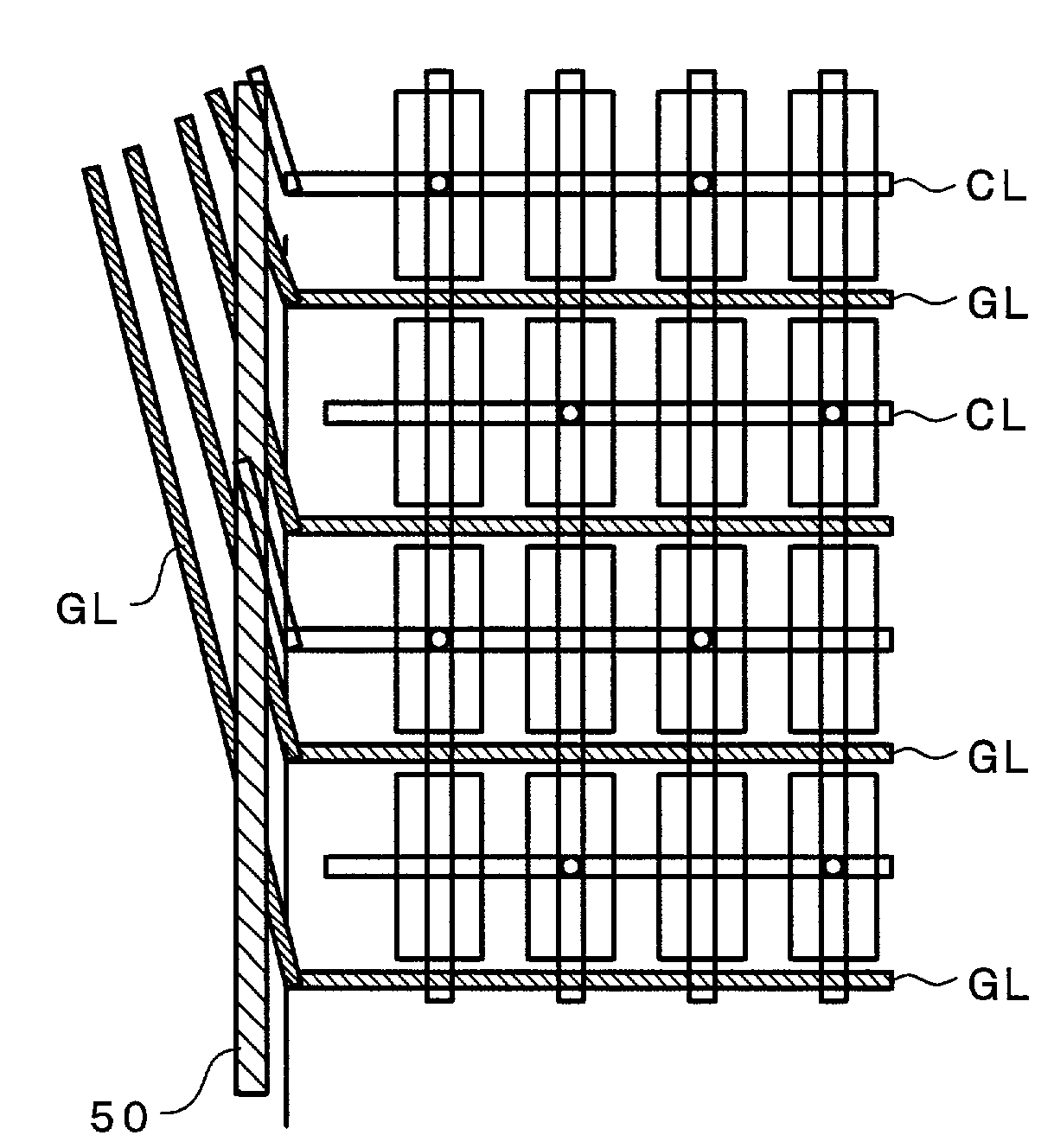

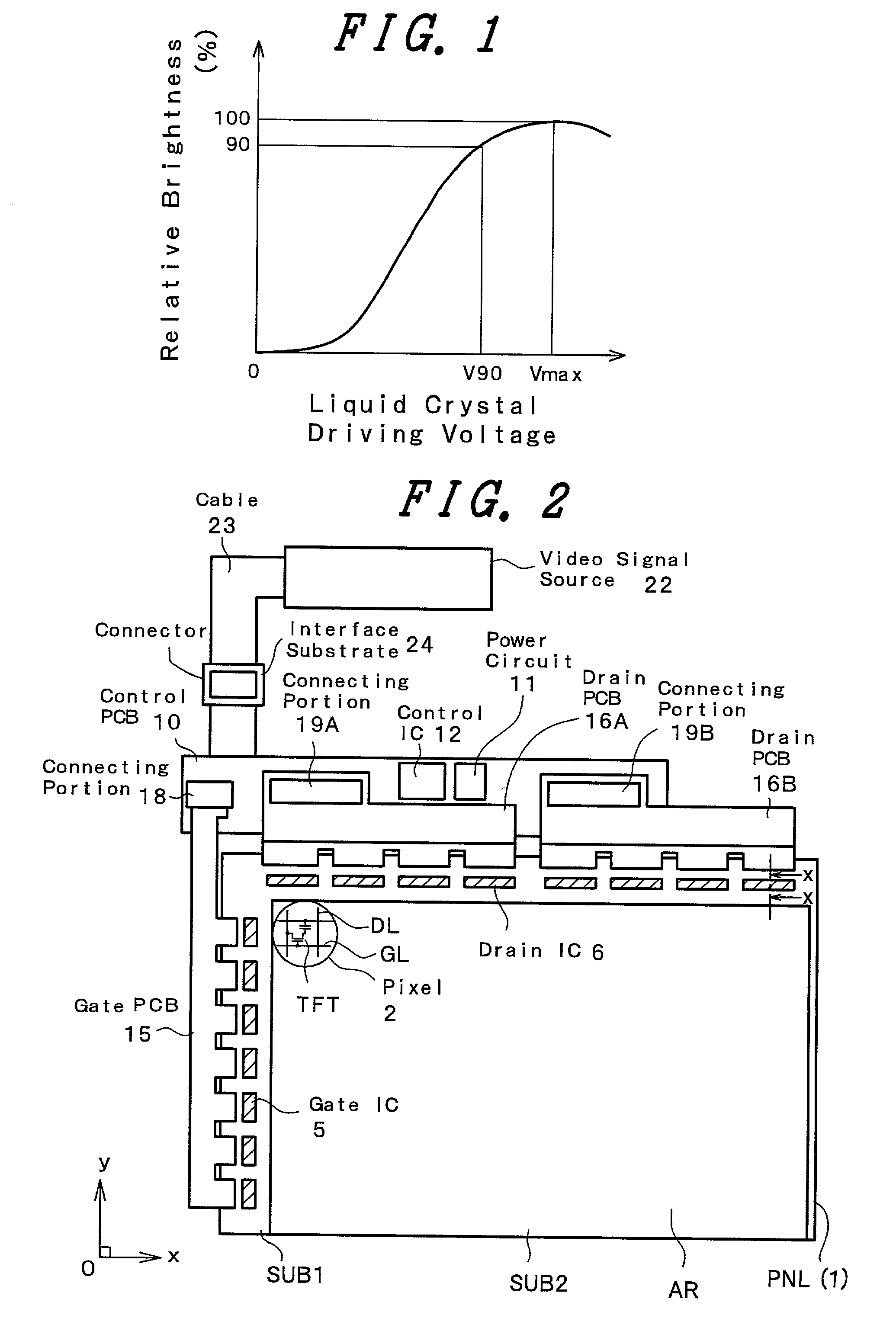

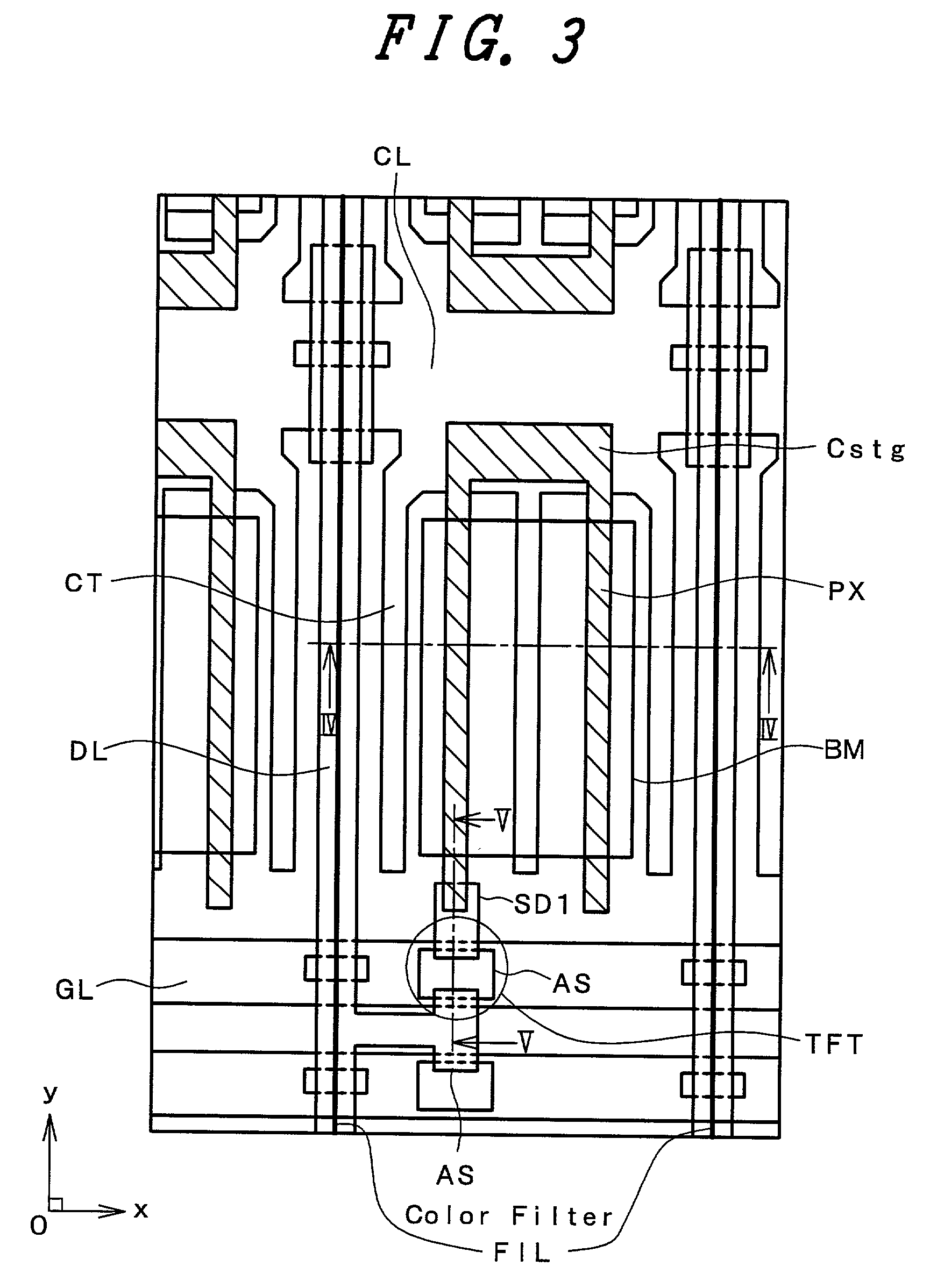

Liquid crystal display device

InactiveUS7164402B2Suppress transmission of stressSuppress alignment displacementStatic indicating devicesNon-linear opticsLiquid-crystal displayTransmittance

A liquid crystal display device can suppress the local temperature elevation of a liquid crystal in the vicinity of drivers. On a liquid-crystal-side surface of one substrate out of substrates which are arranged to face each other in an opposed manner while sandwiching a liquid crystal therebetween, a switching element which is operated in response to scanning signals from a gate signal line, a pixel electrode to which video signals from a drain signal line are supplied via the switching element, and a reference electrode which generates an electric field between the reference electrode and the pixel electrode are mounted on each pixel region of the liquid-crystal-side surface. The video signals from the drain signal line are generated by a driver chip mounted on one substrate. A light transmittivity of the liquid crystal layer is set to take a minimum value when a voltage is not applied between the pixel electrode and the reference electrode. A maximum amplitude of voltage of the video signals is set to a value not more than a voltage necessary for setting a relative transmittivity of the liquid crystal layer to 90%.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Method of baking ceramic honeycomb structure

InactiveUS20050253311A1Shorten ignition timePrevent firing defectsExhaust apparatusSilencing apparatusMetallurgyHoneycomb Pattern

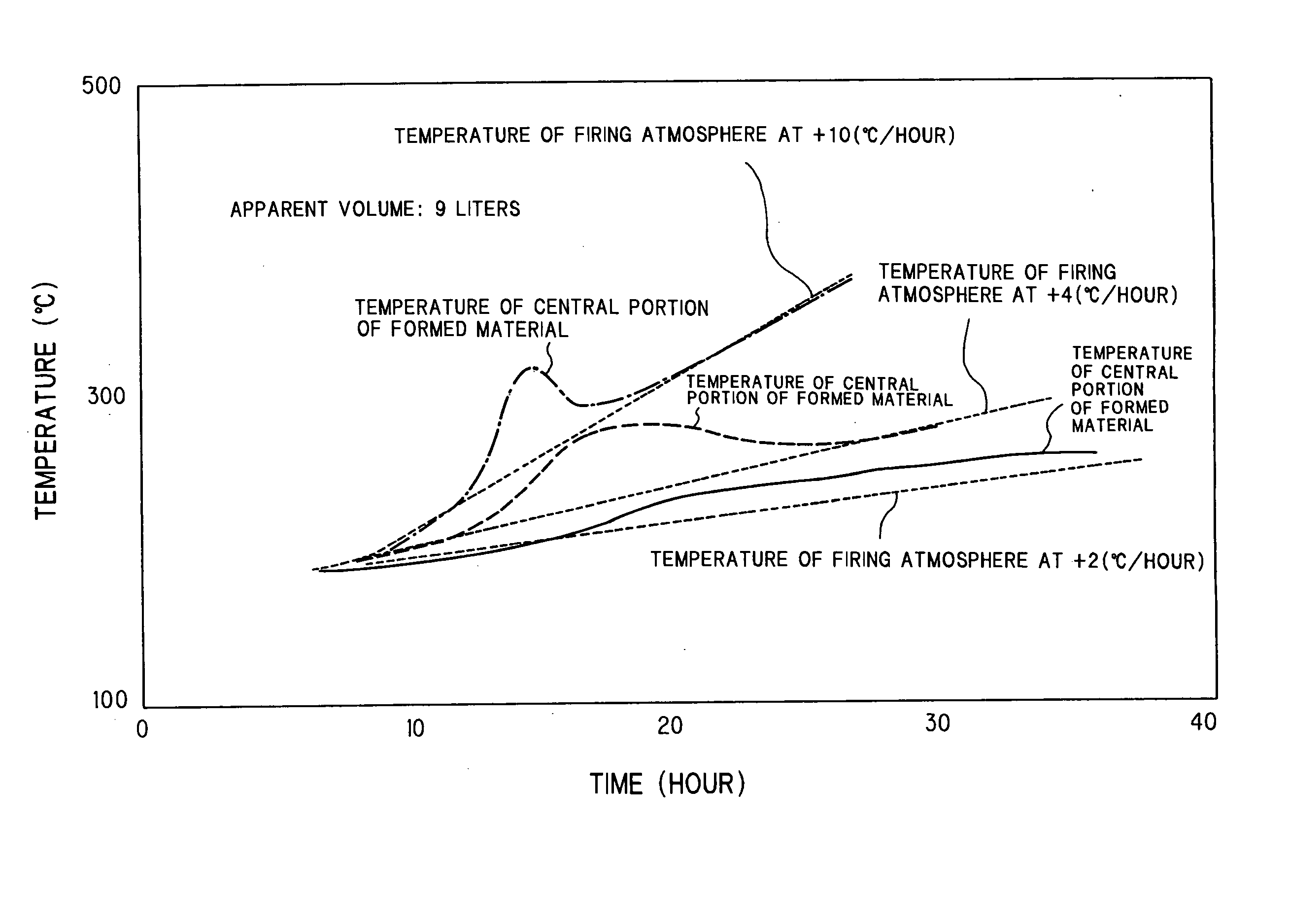

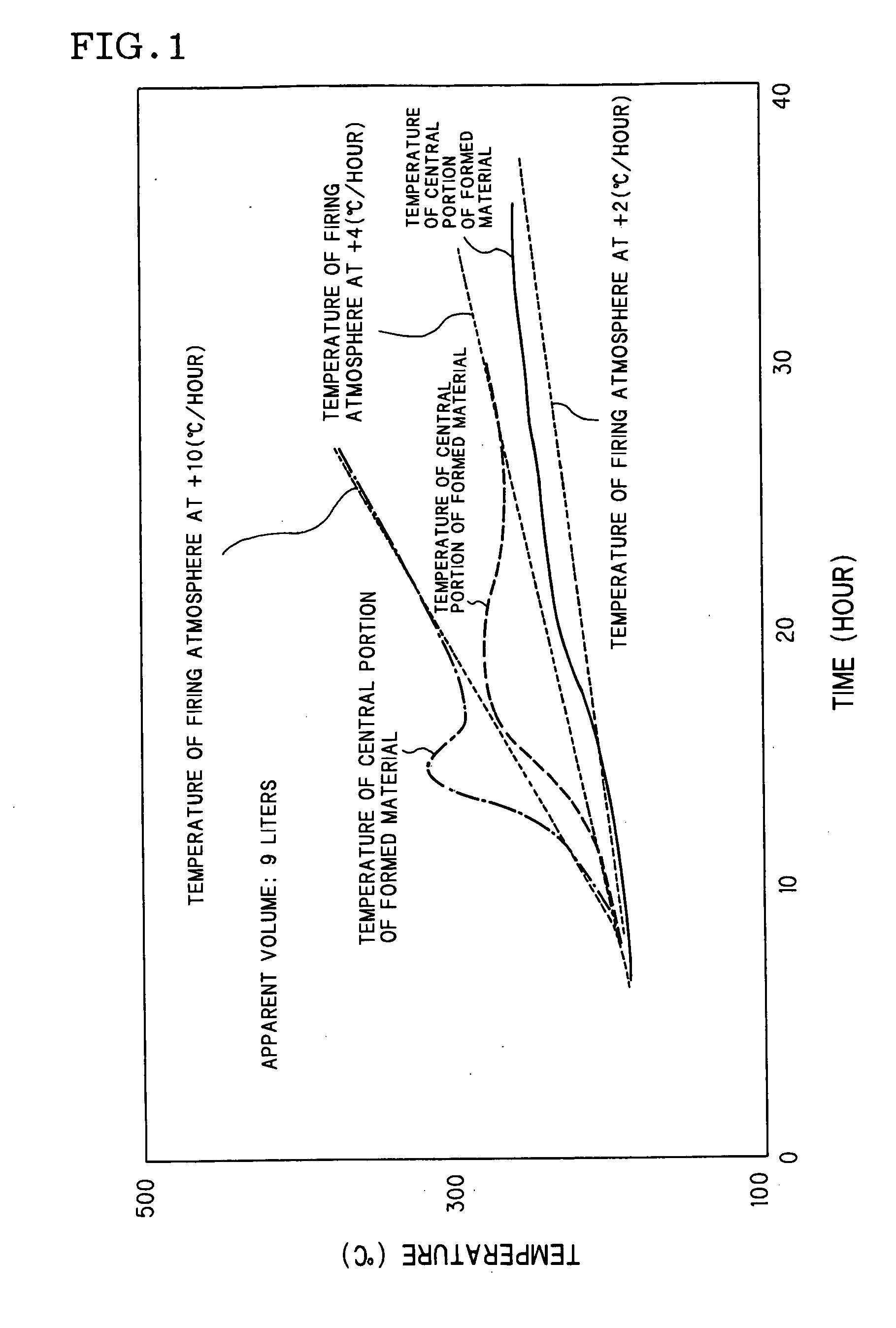

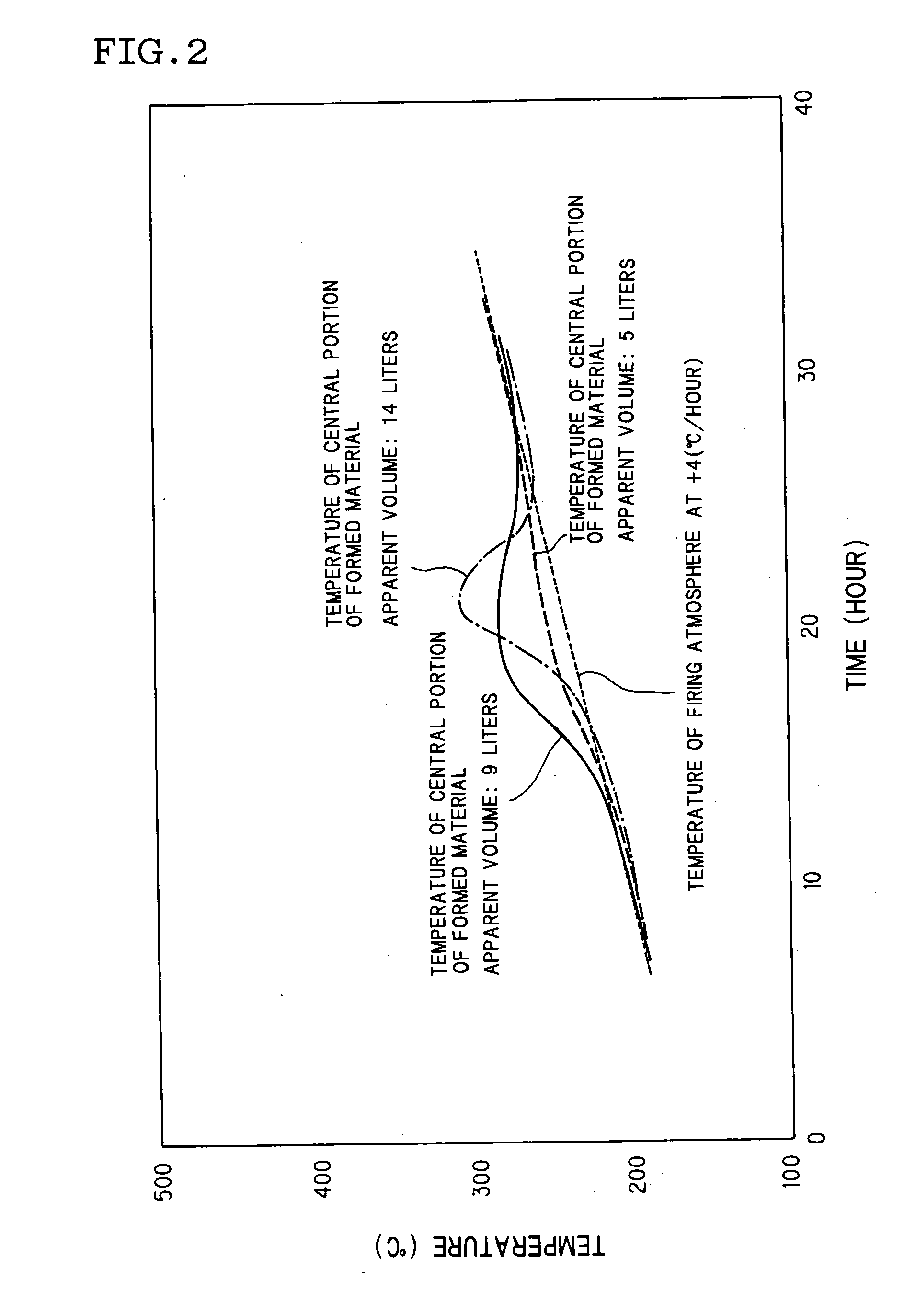

In the method for firing of ceramic honeycomb structure according to the present invention, when a formed honeycomb material having an apparent volume of 5 liters or more is fired in a firing atmosphere, the heating of the firing atmosphere from a temperature (180 to 300° C.) at which the organic binder contained in the formed honeycomb material begins to burn, to 300° C. is conducted at a temperature elevation rate of +25 (° C. / hr) or more and also at such a temperature elevation rate that the difference of the temperature of the central portion of the formed honeycomb material from the temperature of the firing atmosphere is kept in a given temperature range.

Owner:NGK INSULATORS LTD

Barning type power tool with preventer for avoiding mechanical parts overheat in tools

InactiveCN1532027AAvoid damageExtended service lifePortable power-driven toolsNailing toolsCombustion chamberDisplay device

A combustion type power tool capable of avoiding damage to seal members and a housing to prolong a service life, and capable of enhancing operability and workability. Temperature elevation of a combustion chamber frame due to combustion of a mixture of combustible gas and air is detected by a temperature sensor disposed in a housing. If the detected temperature exceeds a preset temperature, ignition of an ignition plug is prohibited by a prohibiting unit in spite of ON operation of a trigger switch. In this state, alarming is performed by a display to notify the user of inoperable sate of the tool. Similar control can be made when the temperature sensor is disposed at a cylinder, an exhaust cover and the housing.

Owner:KOKI HLDG CO LTD

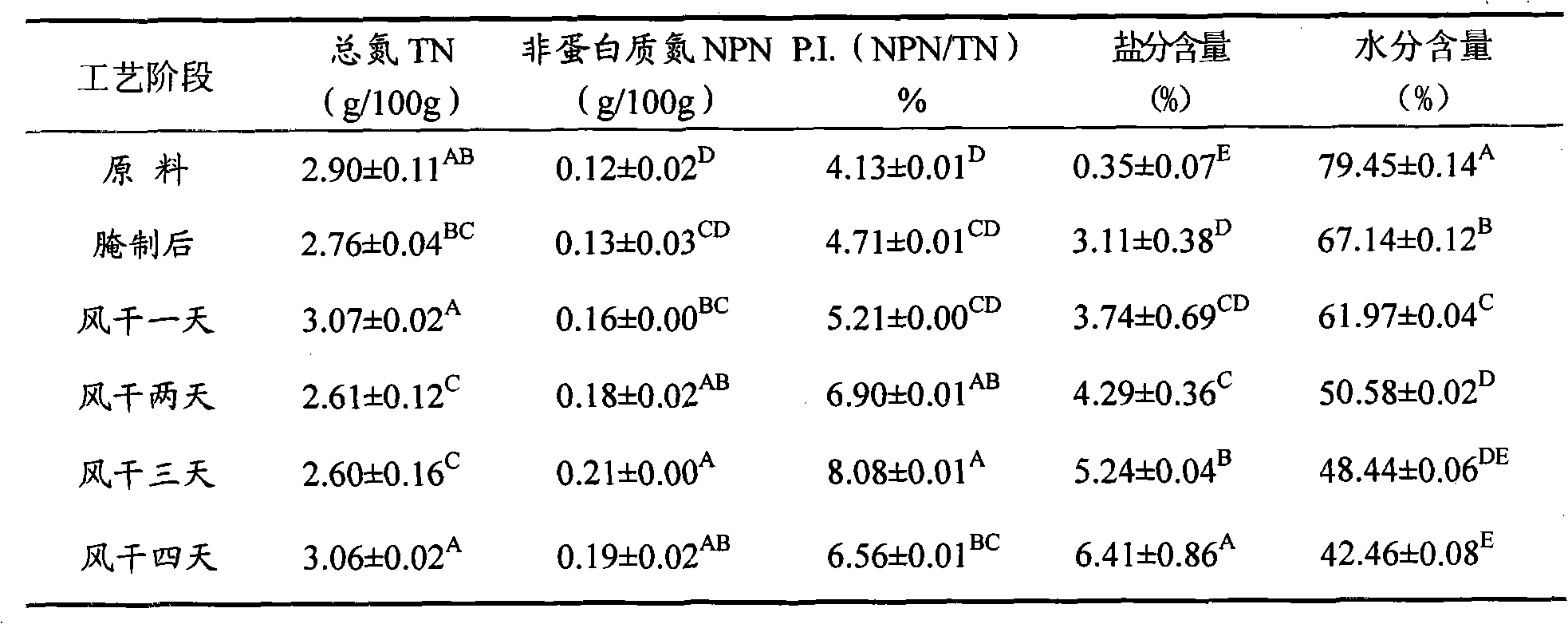

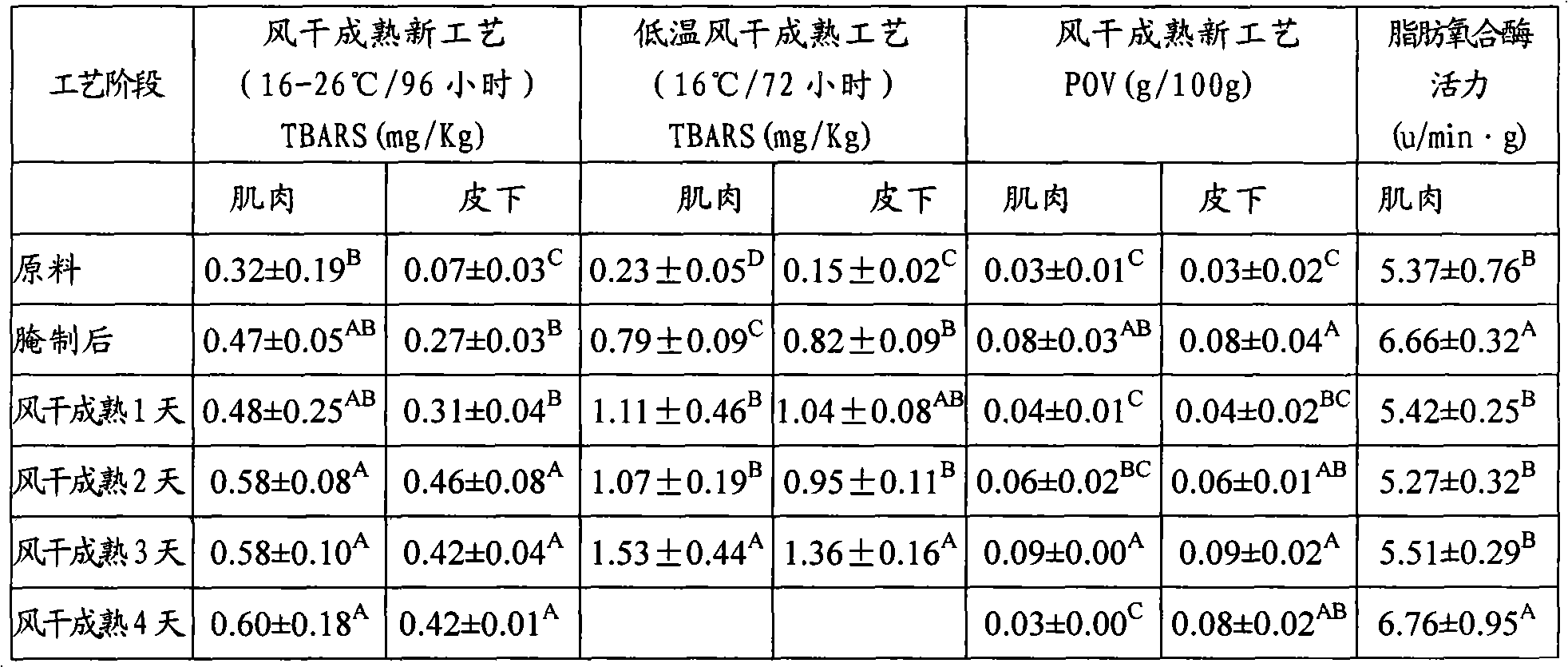

Air drying duck high-temperature maturation process

InactiveCN101254001AHigh activityImprove flavor qualityMeat/fish preservation using acidsFood preparationAdditive ingredientPeroxidase

The invention relates to a novel mature high-temperature air drying process of a dry duck, and belongs to the further processing technology field of animal products. The process includes the steps as follows: a raw ingredient duck is processed with the wet salting (in 3 to 8 DEG C for 18 to 24 hours) in salting liquor (that is NaCl of 10 to 13 percent); then the raw ingredient duck is air-dried to maturity for 3 to 4 days in a gradient temperature elevation way, wherein, the humidity is 55 to 63 percent RH, and the temperature is 13 to 28 DEG C, so that the finished product of the dry duck is obtained. The air drying maturing temperature adopted by the invention is obviously higher than the maturing temperature that is 8 to 10 DEG C in the industrial production of the dry duck at present; the endogenous peroxidase activity and the microbial growth in dry duck muscles can be adjusted through regulating the temperature and the humidity during the air drying maturing process; the decomposition and oxidation of the protein and the lipid in the product and the speed of flavor formation can be accelerated; the fat oxidation index is effectively lowered; based on retaining traditional characteristic flavor of the dry duck, the flavor quality of the dry duck product is effectively increased.

Owner:JIANGSU ZHONGNONG BIOTECH CO LTD

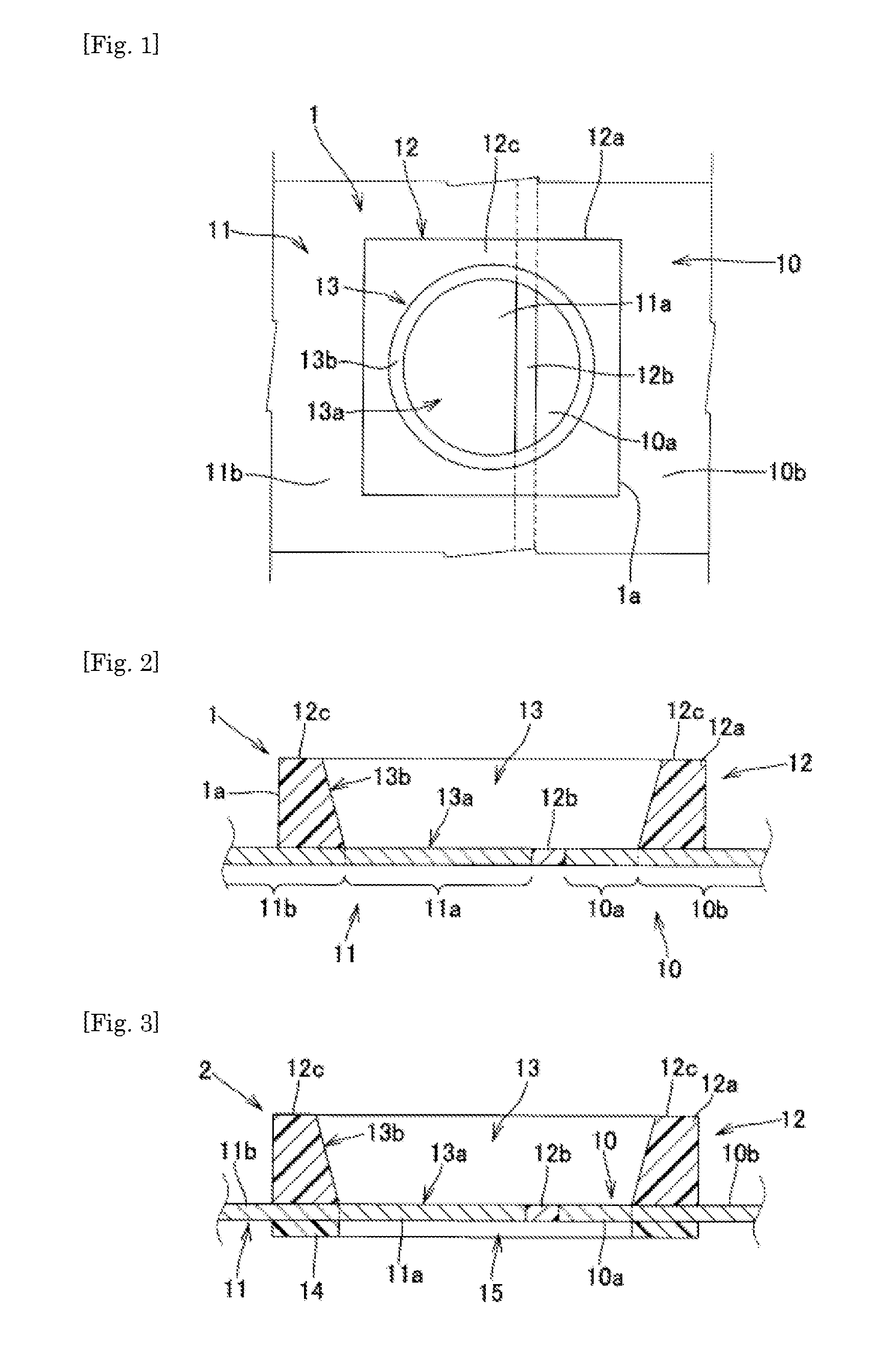

Molded resin body for surface-mounted light-emitting device, manufacturing method thereof, and surface-mounted light-emitting device

InactiveUS20150008455A1High light reflectivitySuitable for mass productionSolid-state devicesCoatingsSurface mountingEngineering

A molded resin body for surface-mounted light-emitting device has cured resin body integrally molded with a plurality of leads and a concave portion to which the plurality of leads are exposed at the bottom portion, in which the ten-point average roughness (Rz) of the opening surface of the concave portion is 1 μm to 10 μm, the glass transition temperature of the cured resin body is 10° C. or higher and the glass transition temperature is a value measured using a thermomechanical analyzer (TMS) under the conditions of a temperature range of −50 to 250° C., a temperature elevation rate of 5° C. / min, and a sample size length of 1 to 5 mm, and the optical reflectance at 460 nm of the opening surface of the concave portion is 80% or more and the optical reflectance retention rate on the opening surface after heating the molded resin body at 180° C. for 72 hours is 90% or more.

Owner:KANEKA CORP

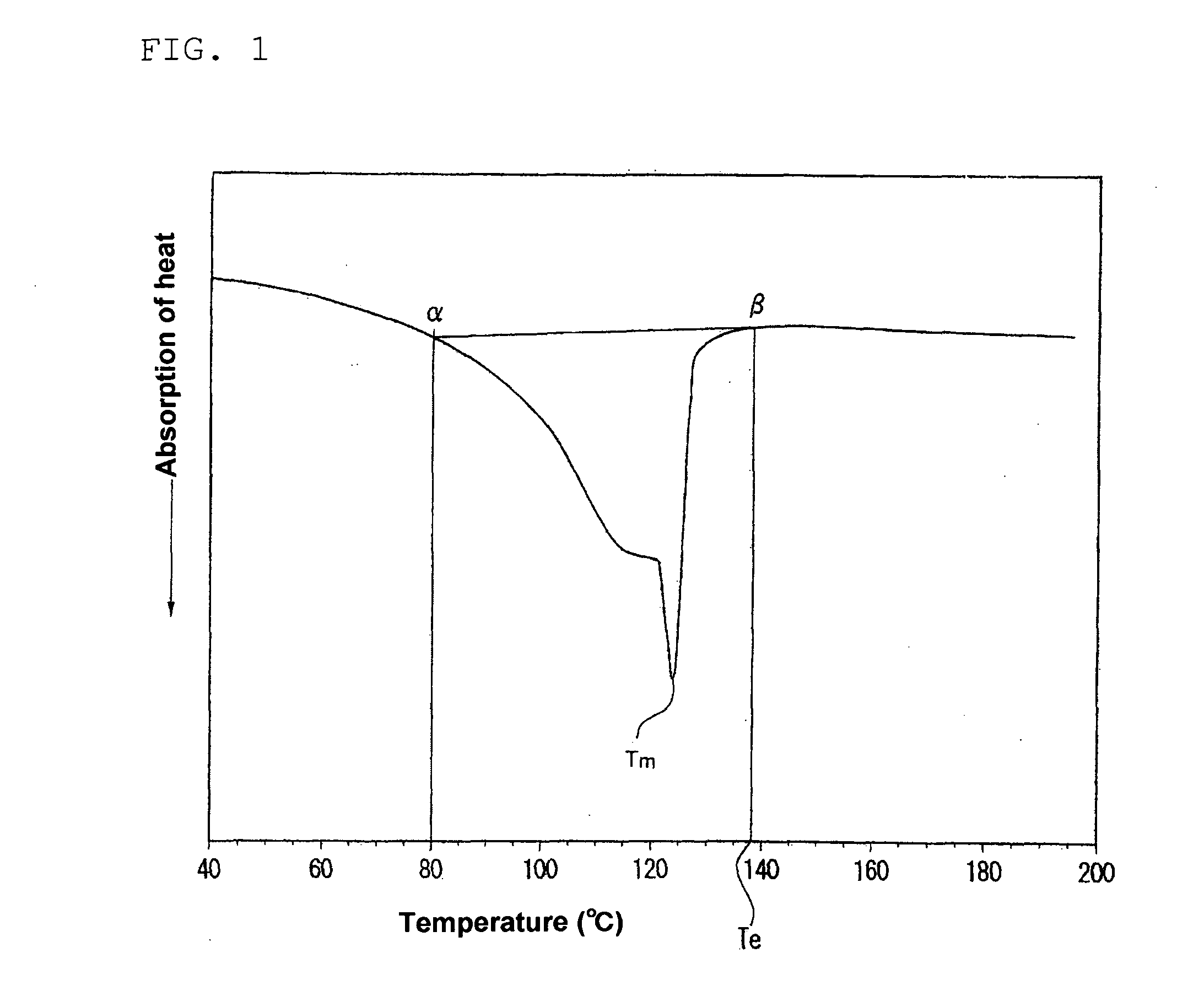

Polypropylene resin foamed bead and molded article thereform

Improved polypropylene resin foamed beads that without detriment to the excellence in properties, such as compression properties and heat resistance, characterizing the polypropylene resin foamed beads, can provide a polypropylene resin foamed bead molded article with equal properties by an molding conducted at low heating temperature. There are disclosed polypropylene resin foamed beads composed of a polypropylene resin of 115 to 135° C. melting point and 500 MPa or higher Olsen flexural modulus. The amount of ash at the surface of the foamed beads is 3000 wt. ppm or less (including 0). With respect to the foamed beads, in the first DSC curve obtained by heating 1 to 3 mg of polypropylene resin foamed beads from room temperature to 200° C. at a temperature elevation rate of 10° C. / min by the use of a differential scanning calorimeter, there appear not only one or more endothermic peak (Pa) having the peak temperature within a temperature zone not higher than the melting point of the resin but also one or more endothermic peak (Pb) having the peak temperature within a temperature zone exceeding the melting point of the resin and not lower than 130° C. The total calorific value of the endothermic peak (Pb) is in the range of 2 to 12 J / g. Further, there is disclosed a foamed bead molded article obtained by molding the above foamed beads.

Owner:JSP CORP

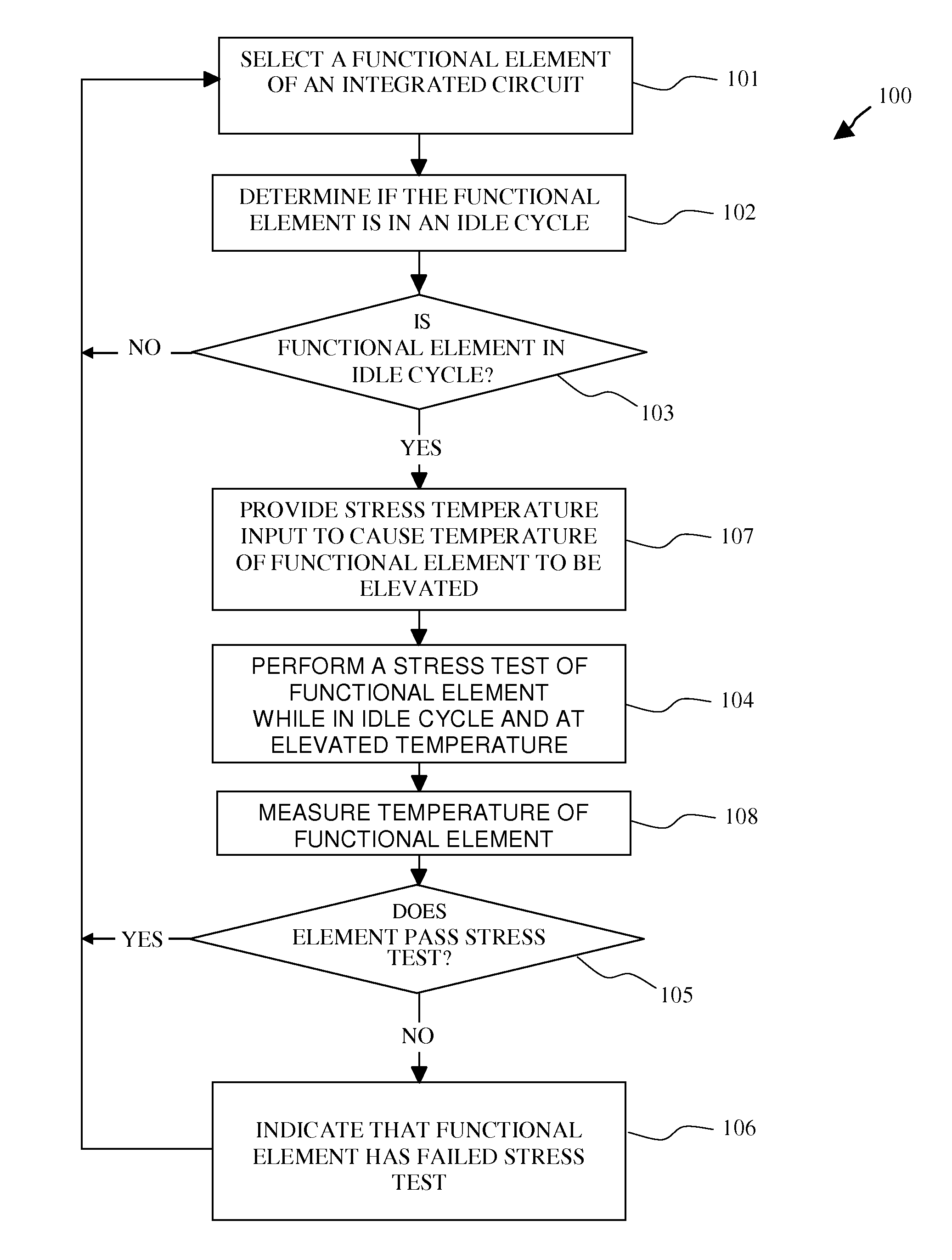

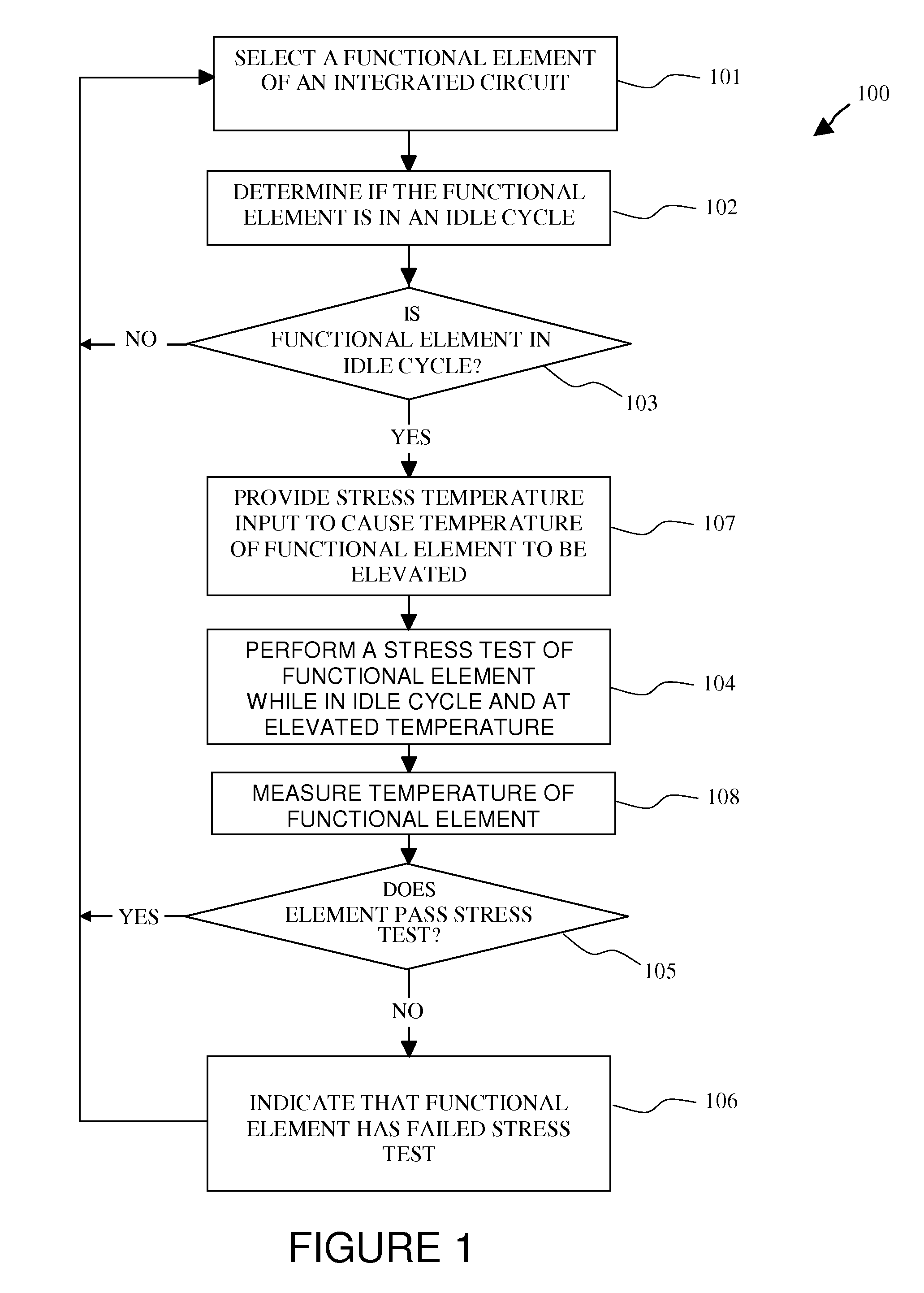

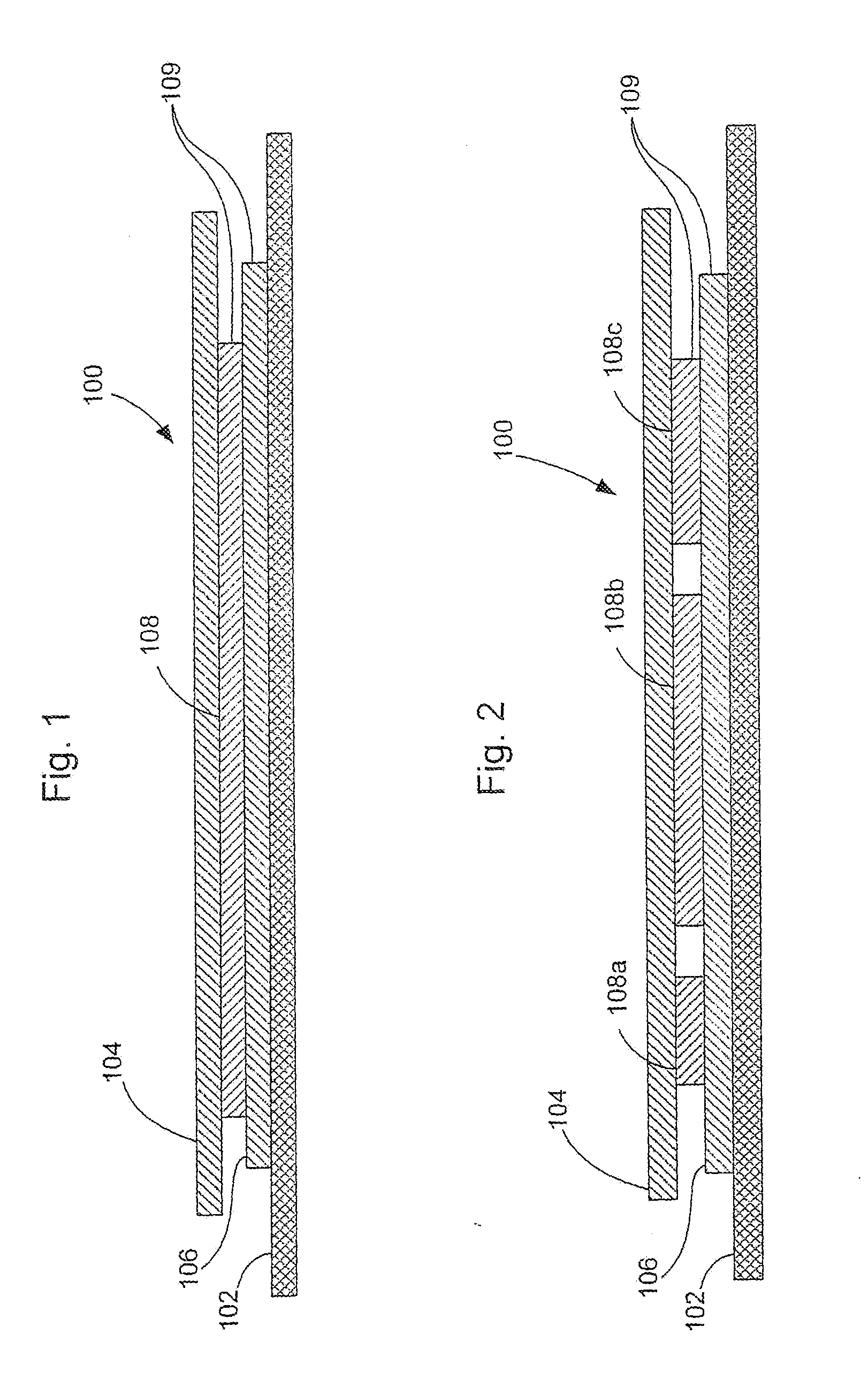

Look-ahead built-in self tests with temperature elevation of functional elements

ActiveUS8028211B1Avoiding system downtimeDoes not impact the performance of the functional element during normal operationElectronic circuit testingPower supply testingDowntimeWorkaround

A method and apparatus are disclosed for predicting the failure of a functional element of an integrated circuit during operation. The method includes determining whether the functional element of the integrated circuit device is in an idle cycle, elevating the temperature of the functional element above a normal operating temperature, performing a stress test of the functional element while the functional element is in the idle cycle, and indicating that the functional element, if it fails the stress test, is a potential future failing element. The stress test can include simultaneously providing a margining test voltage and a stress clock signal to the functional element while the temperature is elevated or at a normal operating temperature. The stress test is performed in the background, during continuous operation of the integrated circuit device, such that normal operation of the integrated circuit device is not interrupted. Thereby, the method and apparatus of the present invention allows for failure prediction in a device before it happens, allowing for planned outages or workarounds and avoiding system downtime for unplanned repairs.

Owner:INTEGRATED DEVICE TECH INC

Aromatic polycarbonate resin composition

InactiveUS20100222486A1Improve heat resistanceImprove mechanical propertiesPhosphoric Acid EstersPolycarbonate

The object of this invention is to provide a resin composition that contains a polymer obtained from biomass resources and constitutes molded articles excellent in heat resistance, mechanical properties and durable stability, this invention including a resin composition comprising(i) a resin component containing 95 to 5% by weight of an aromatic polycarbonate (component A) and 5 to 95% by weight of polylactic acid (component B),(ii) 0.001 to 10 parts by weight, per 100 parts by weight of the resin component, of a phosphoric ester metal salt (component C), and(iii) 0.01 to 5 parts by weight, per 100 parts by weight of the polylactic acid (component B), of a terminal blocker (component F),the stereo-complex crystal content (X) of the following expression (I) being 80% or more,X (%)={ΔHb / (ΔHa+ΔHb)}×100 (I)wherein ΔHa and ΔHb are a melting enthalpy (ΔHa) of a crystal melting point that appears at lower than 190° C. and a melting enthalpy (ΔHb) of a crystal melting point that appears at 190° C. or higher but less than 250° C., respectively, in a temperature-elevation process by a differential scanning calorimeter (DSC), and molded articles thereof.

Owner:TEIJIN KASEK KK

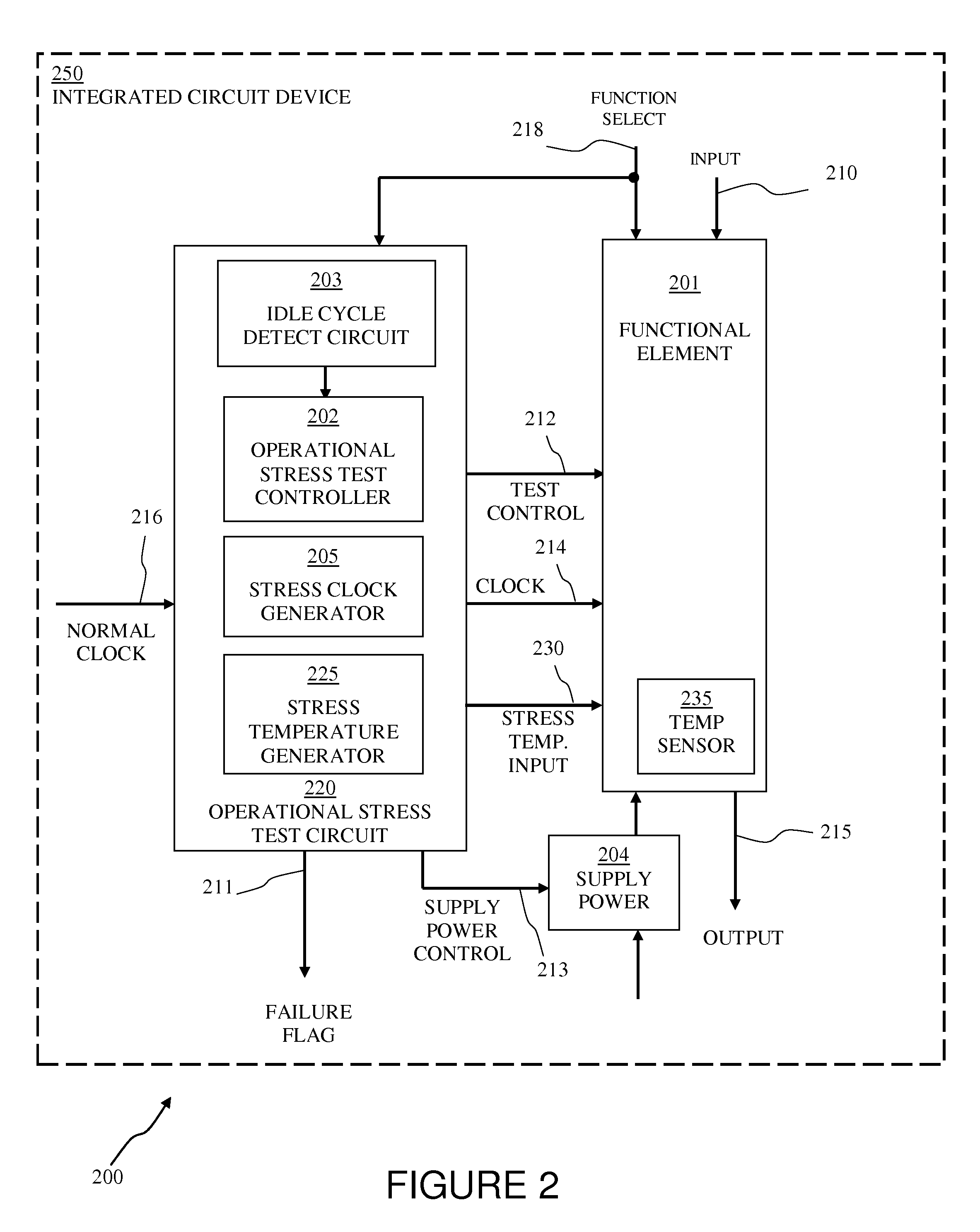

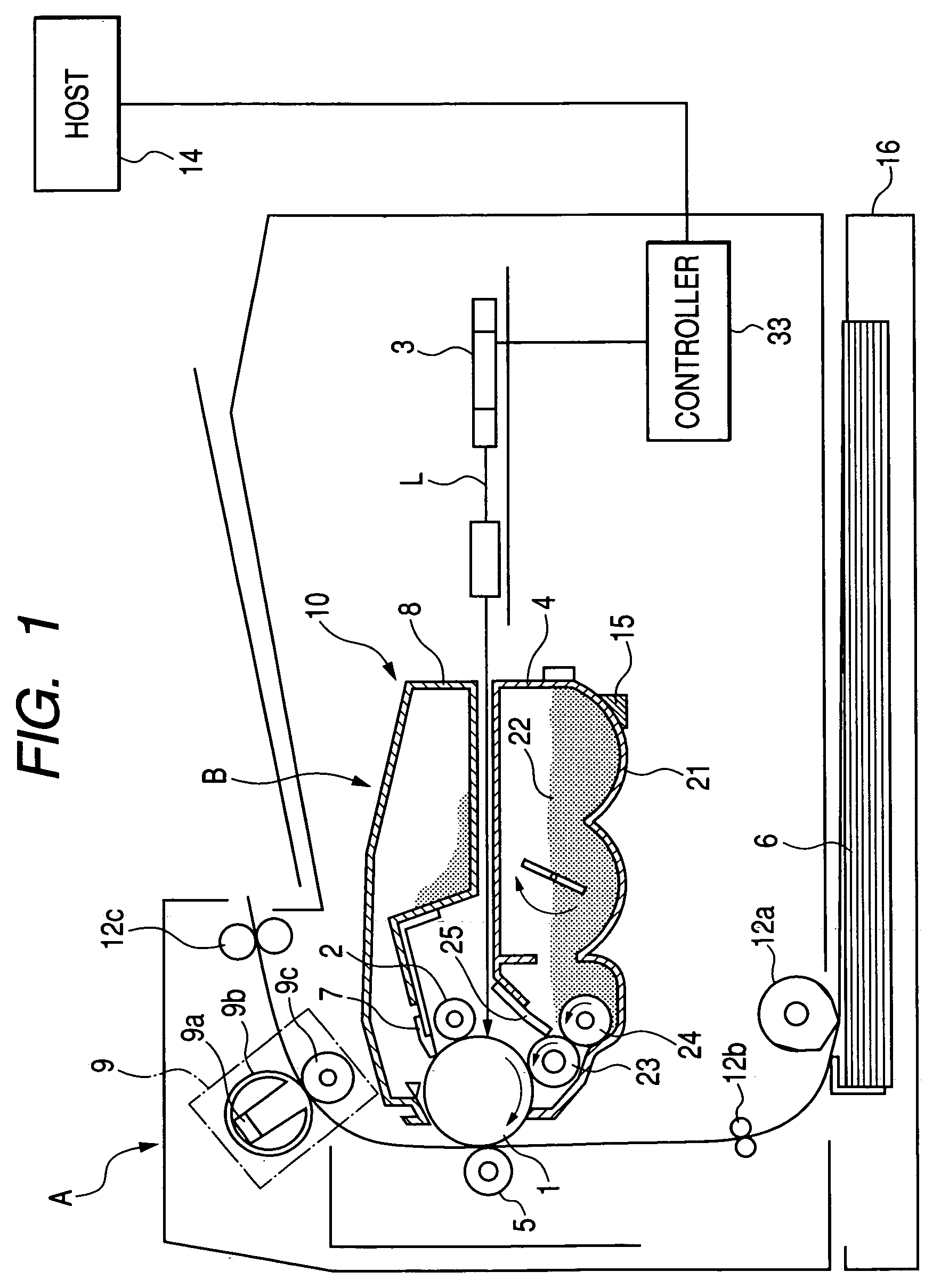

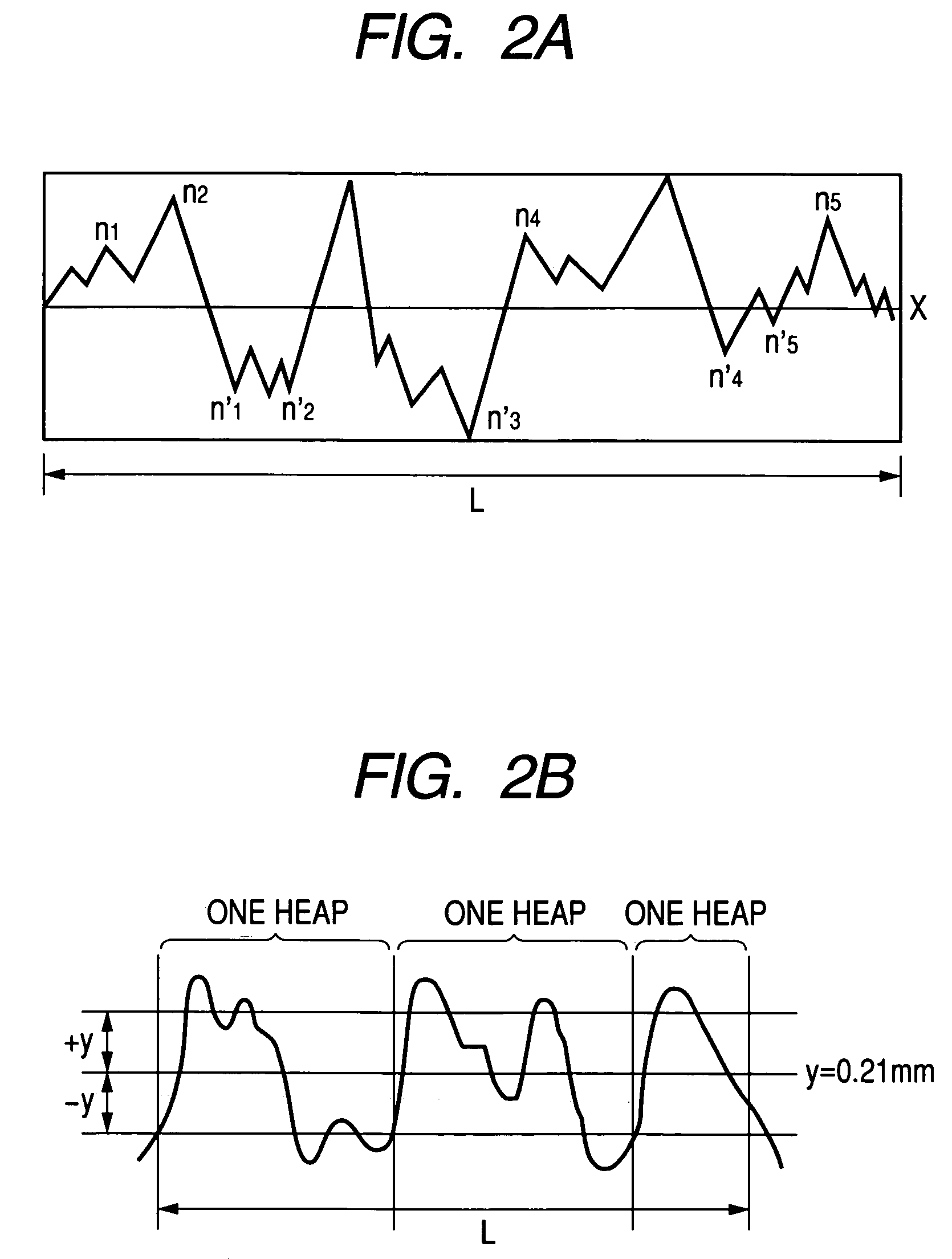

Developing apparatus

ActiveUS7209690B2Suppress failureIncrease speedDevelopersElectrographic process apparatusSurface roughnessEngineering

A developing apparatus including: a developer carrying member for carrying a developer, the developer carrying member being provided with an elastic layer and adapted to develop, with a developer, an electrostatic image formed on an image bearing member; wherein the developer includes a toner, the toner has a shape factor SF-1 of 100 or more but less than 130, the toner has a storage modulus G′ (140° C.) at 140° C. of 2.0×103 dN / m2 or more but less than 2.0×104 dN / m2, the toner has a temperature, when the toner has a viscosity of 1.0×103 Pa·s in a flow tester temperature elevation method, of 115° C. or more but less than 130° C., and, in a surface roughness of the developer carrying member, a center-line mean roughness Ra, a ten-point mean roughness Rz and a mean spacing Sm of irregularities satisfy following relationships (1):0.06≤Rz / Sm≤0.40.8≤Ra≤2.0(μm)}.(1)

Owner:CANON KK

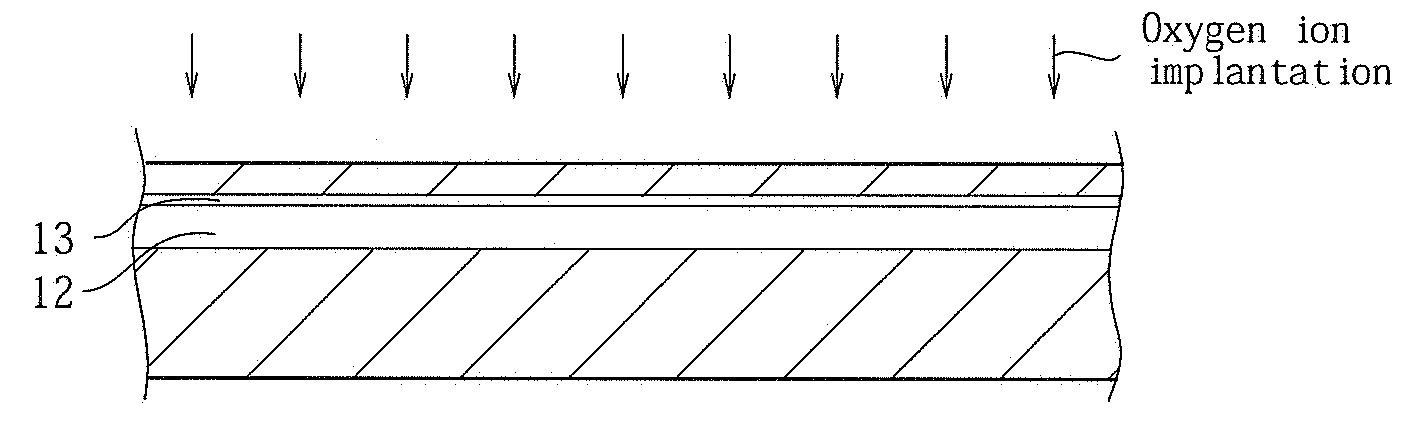

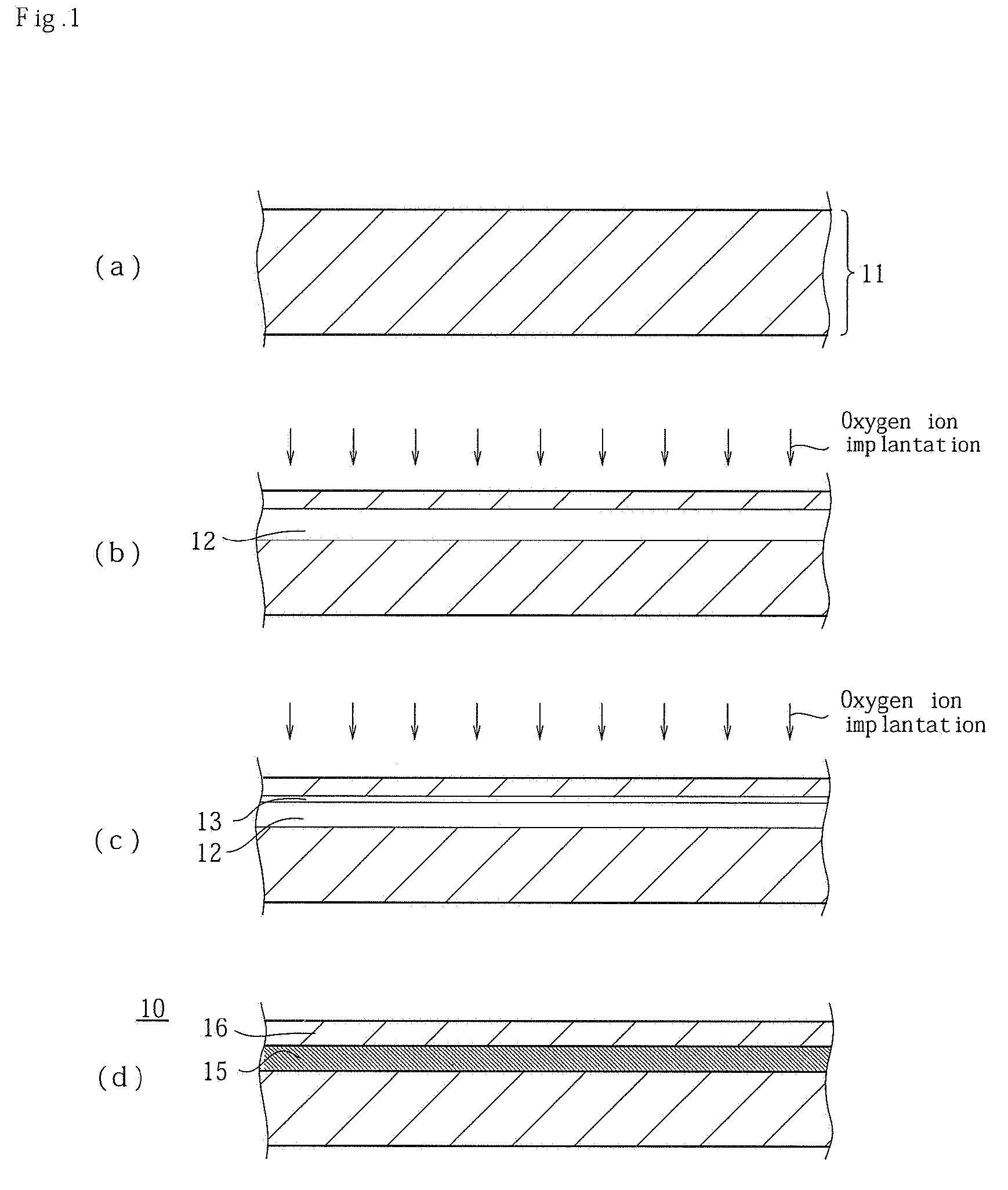

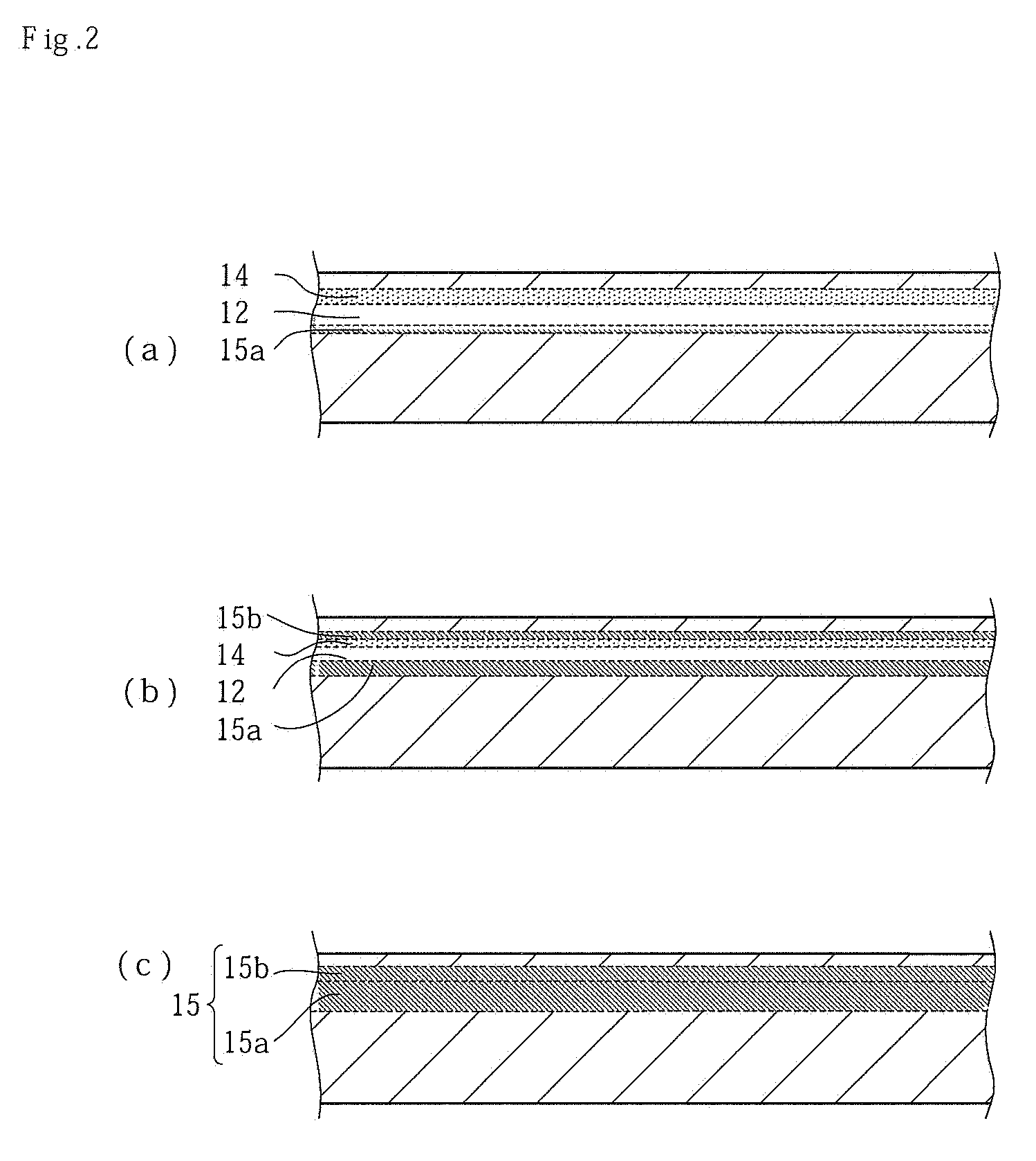

Method for Manufacturing Simox Wafer

InactiveUS20070178680A1Reduction in productivityReduction in in qualitySemiconductor/solid-state device manufacturingProduction rateOxygen

A SIMOX wafer having a BOX layer with a thin film thickness is obtained without a reduction in productivity or deterioration in quality. In a method for manufacturing a SIMOX wafer comprising: a step of forming a first ion-implanted layer in a silicon wafer; a step of forming a second ion-implanted layer that is in an amorphous state; and a high-temperature heat treatment step of maintaining the wafer in an oxygen contained atmosphere at a temperature that is not lower than 1300° C. but less than a silicon melting point for 6 to 36 hours to change the first and the second ion-implanted layers into a BOX layer, a gas containing chlorine that is not less than 0.1 volume % but less than 1.0 volume % is mixed into an atmosphere during temperature elevation in the high-temperature heat treatment.

Owner:SUMCO CORP

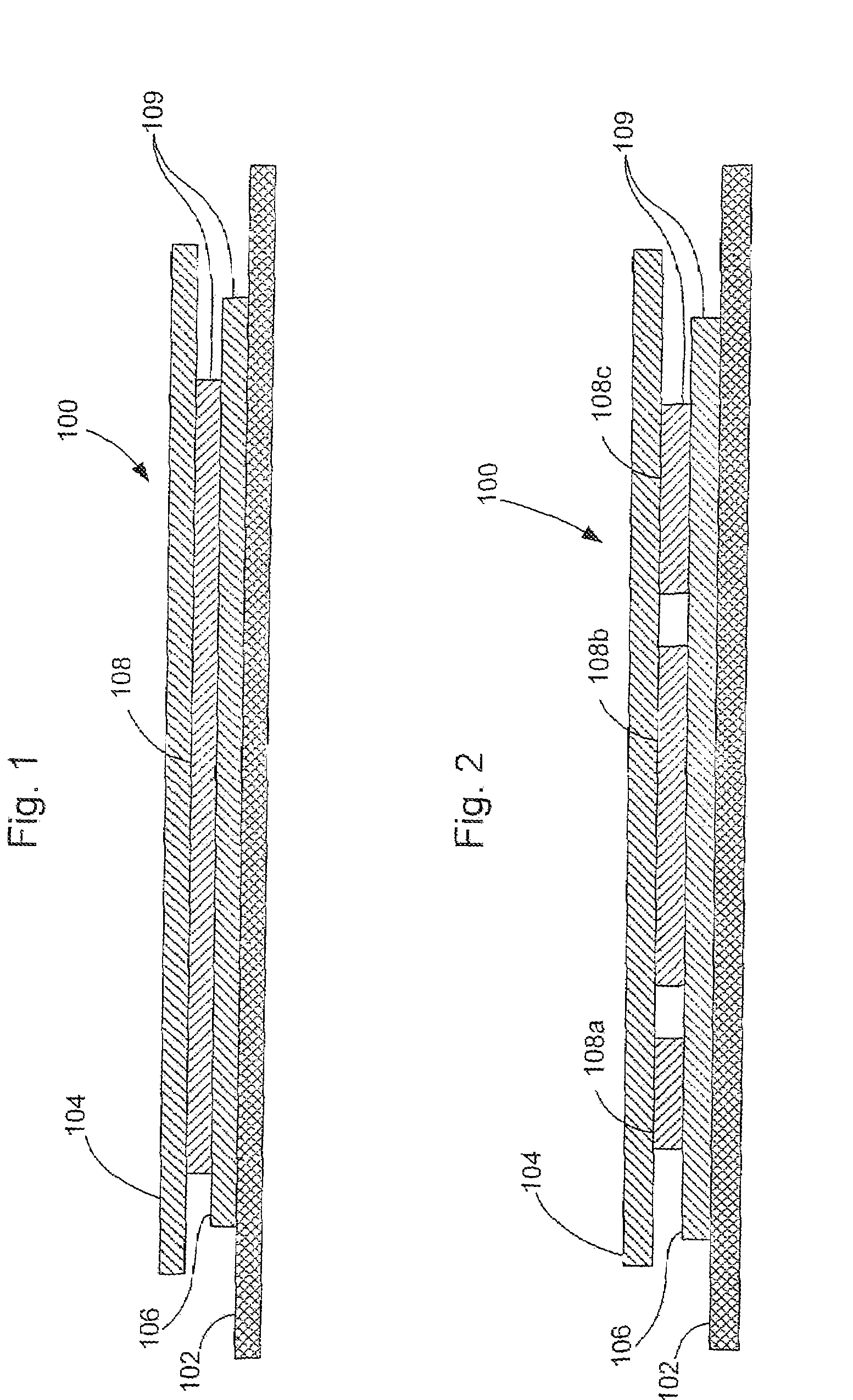

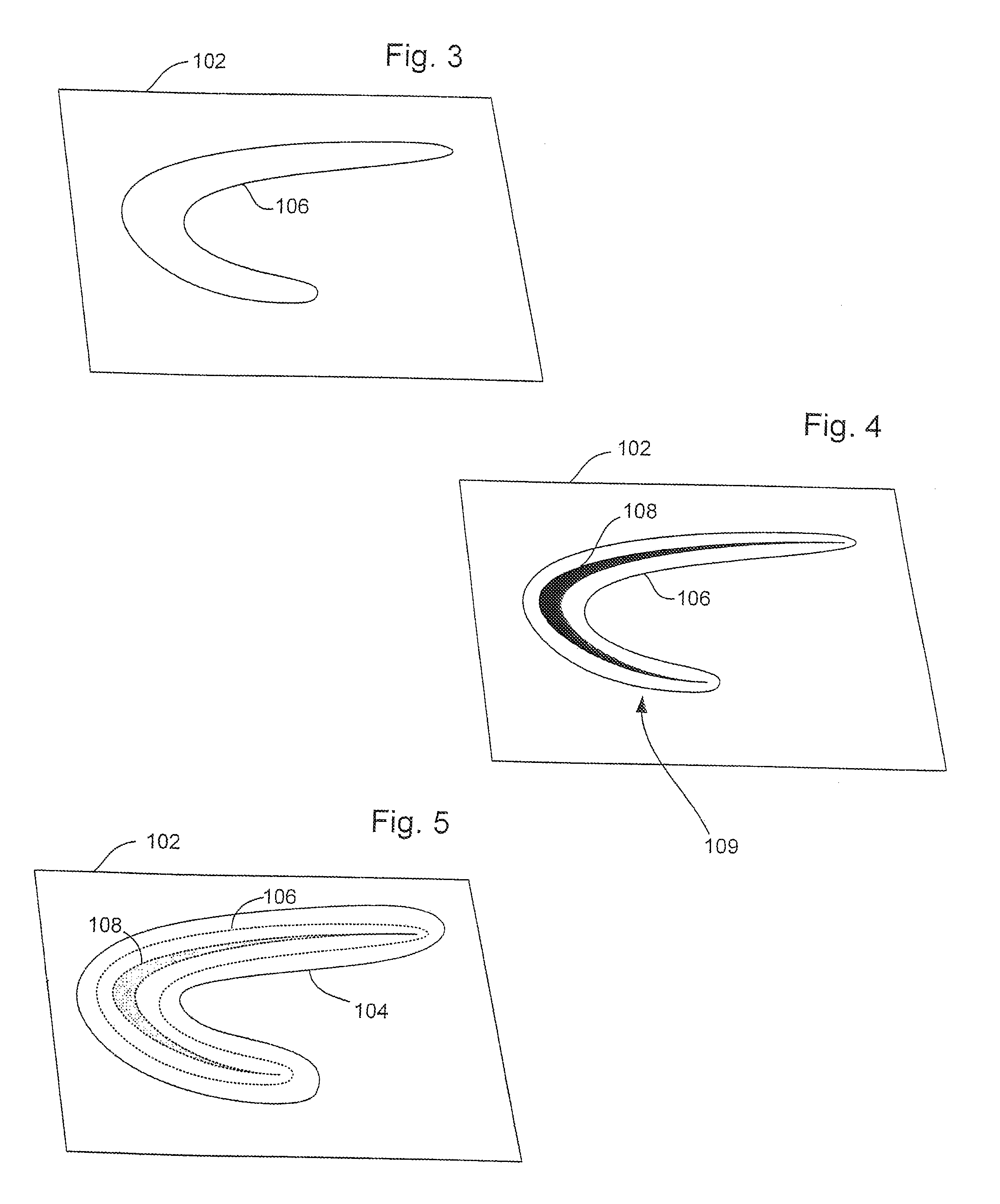

Thermally Reactive Ink Transfer System

InactiveUS20100243140A1Lamination ancillary operationsLayered product treatmentAutomotive paintAdhesive

An ink transfer system including an ink transfer decal that is transferable to a final substrate, such as a bare metal or pre-painted autobody part, without use of a separate adhesive. The transferred ink decal is capable of withstanding temperature elevations common during automotive paint baking without significant thermal degradation, discoloration, shrinkage or pealing.

Owner:DONALD D SLOAN TRUSTEE OF THE DONALD D SLOAN TRUST AND HIS SUCCESSOR & SUCCESSORS UNDER THE FOURTEENTH AMENDMENT TO & COMPLETE RESTATEMENT OF THE DONALD D SLOAN TRUST DATED JUNE 28 2012

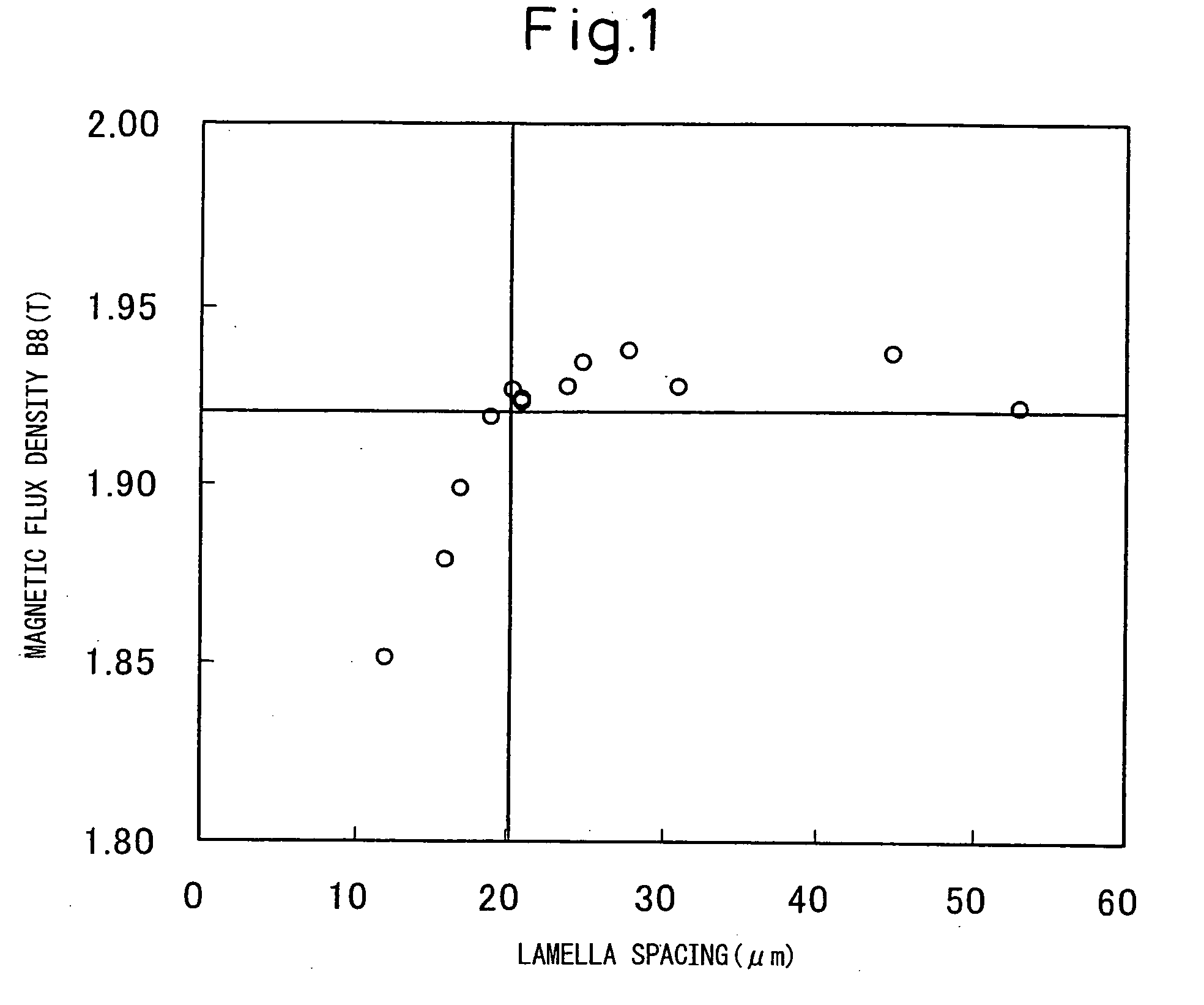

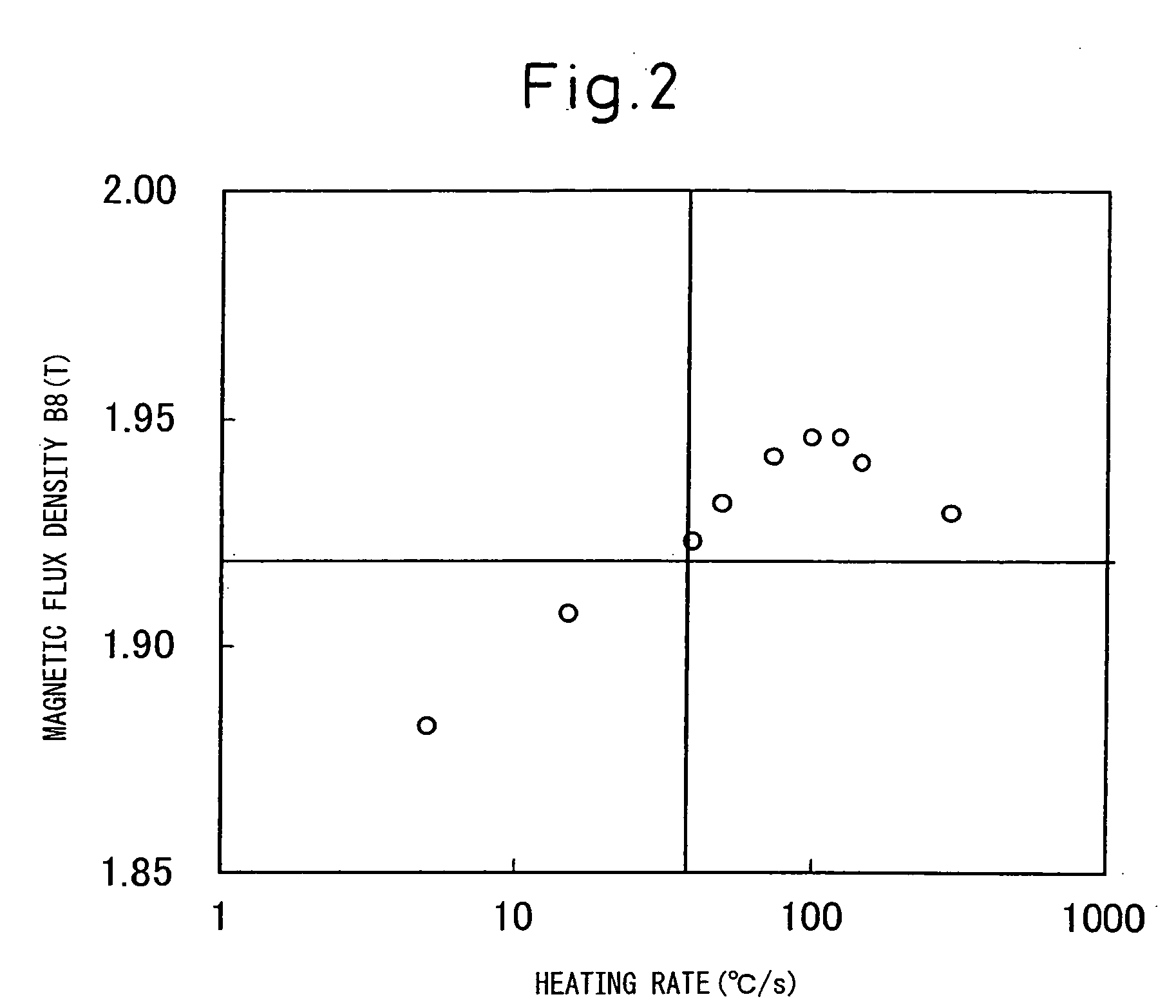

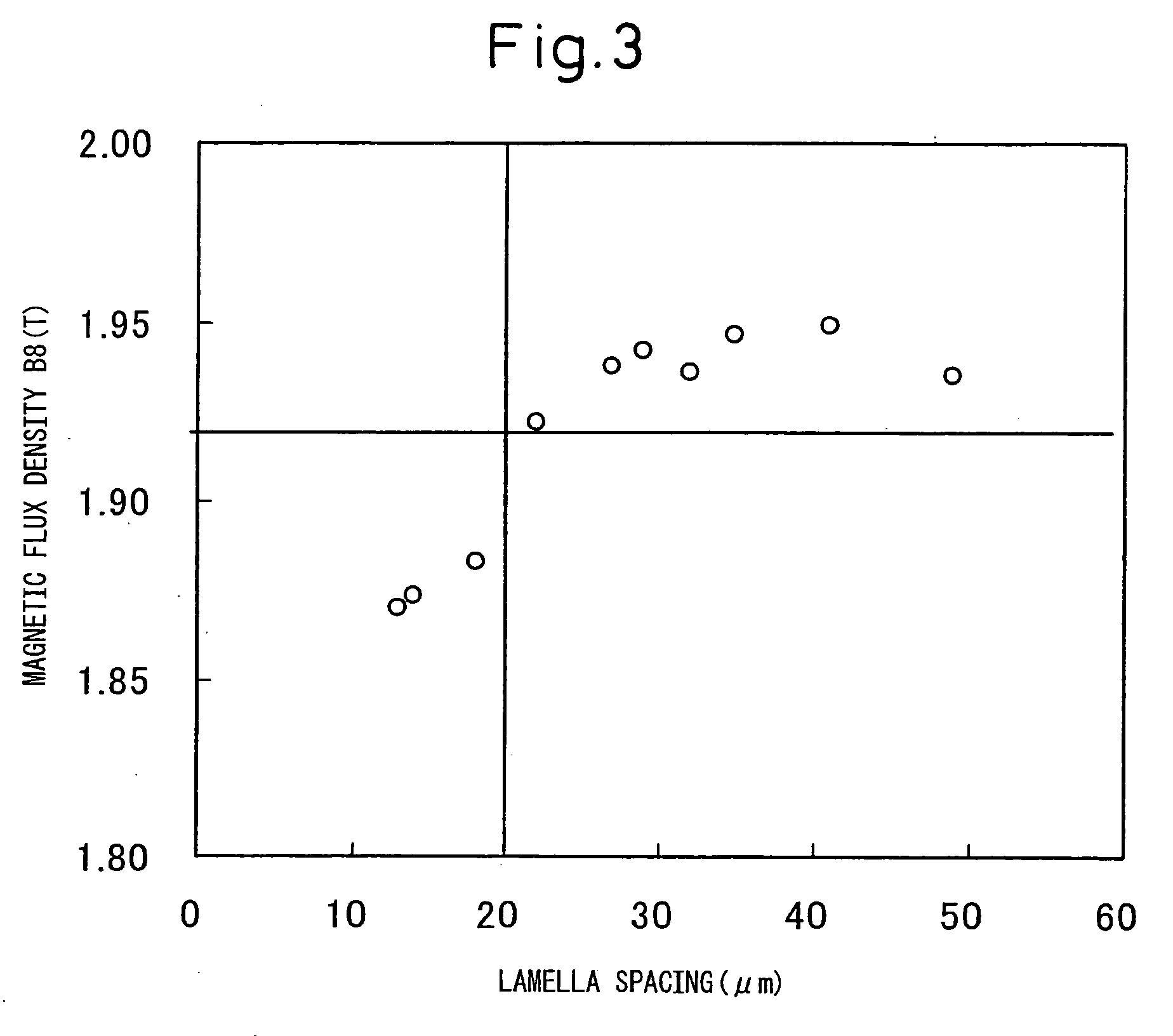

Method of production of grain-oriented electrical steel sheet having a high magnetic flux density

ActiveUS20090126832A1Inorganic material magnetismSolid state diffusion coatingElectrical steelVolumetric Mass Density

In a production of grain-oriented electrical steel sheet that is heated at a temperature of not higher than 1350° C., (a) the hot-rolled sheet is heated to a prescribed temperature of 1000° C. to 1150° C., and after recrystallization is annealed for a required time at a lower temperature of 850° C. to 1100° C., or (b) in the hot-rolled sheet annealing process decarburization is conducted to adjust the difference in the amount of carbon before and after decarburization to 0.002 to 0.02 mass %. In the temperature elevation process used in the decarburization annealing of the steel sheet, heating is conducted in the temperature range of 550° C. to 720° C. at a heating rate of at least 40° C. / s, preferably 75 to 125° C. / s, utilizing induction heating for the rapid heating used in the temperature elevation process in decarburization annealing.

Owner:NIPPON STEEL CORP

Diffusion technology of crystalline silicon solar cell

ActiveCN101707226AAverage non-uniformity dropIncreased average photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesSurface concentrationP–n junction

The invention discloses a new diffusion technology of the crystalline silicon solar cell. The diffusion technology mainly refers to a technology which divides the source step into the following steps based on the original technology: low temperature prediffusion, step-ramp-temperature elevation diffusion and high temperature diffusion. The technology can significantly enhance the uniformity of the diffusion, well control the depth and surface concentration of the PN junction and increase the photoelectric conversion efficiency of the crystalline silicon solar cell. The new diffusion technology can be edited easily which only needs to modify the original technological parameters so as to facilitate the operation. The technology is applicable to industrialized production, does not affect the production progress and can be used in large-scale production lines of the solar cell.

Owner:湖南红太阳新能源科技有限公司

Thermally reactive ink transfer system

An ink transfer system including an ink transfer decal that is transferable to a final substrate, such as a bare metal or pre-painted autobody part, without use of a separate adhesive. The transferred ink decal is capable of withstanding temperature elevations common during automotive paint baking without significant thermal degradation, discoloration, shrinkage or pealing.

Owner:POLYMERIC U S INC

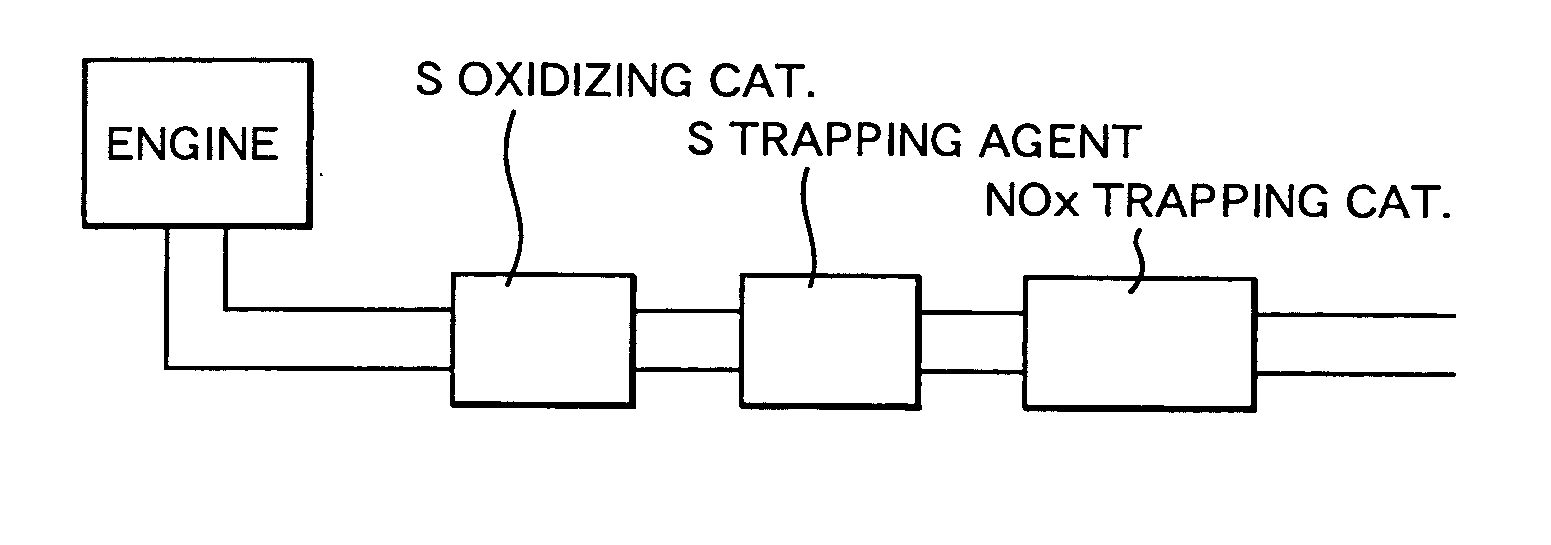

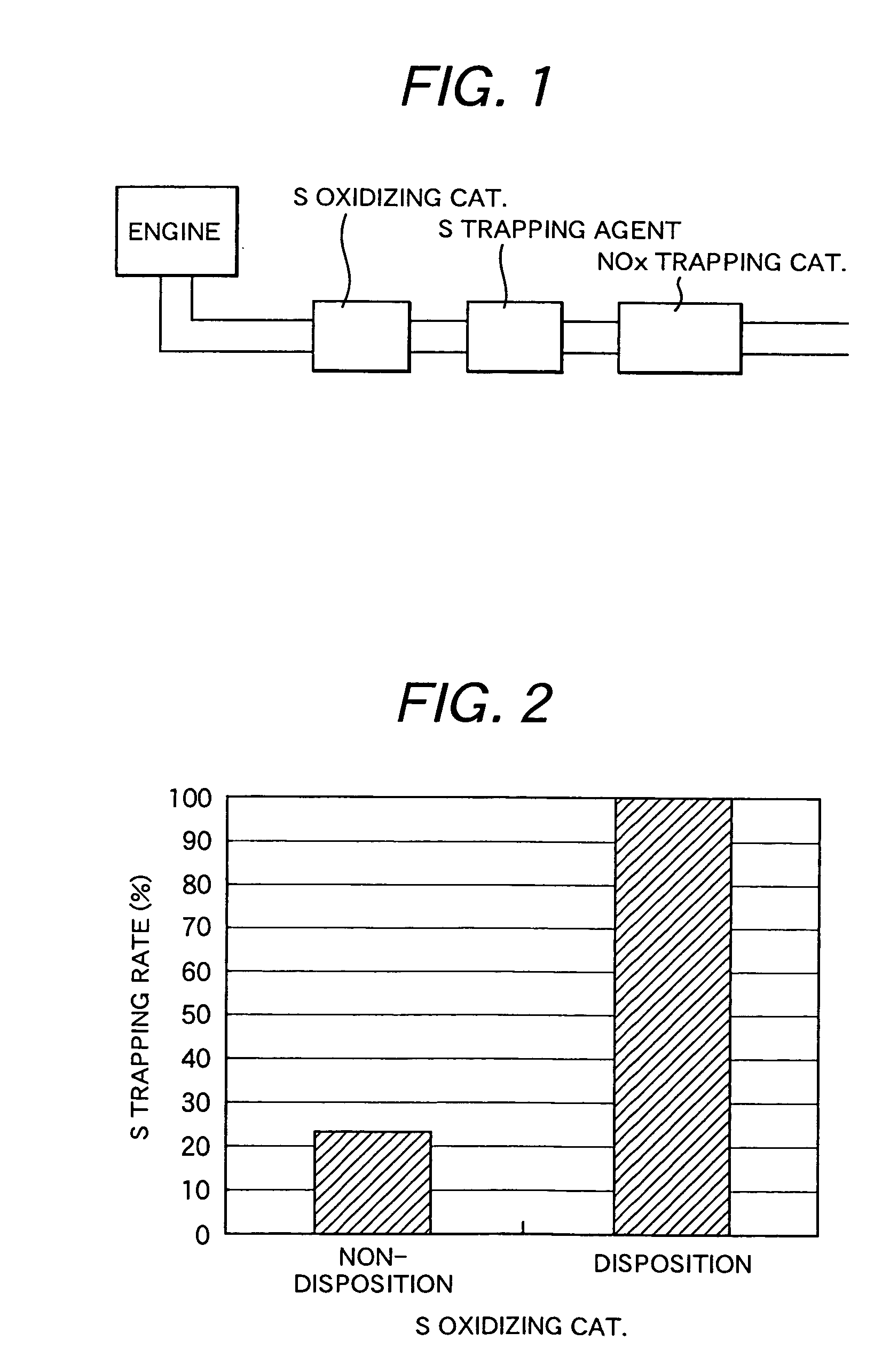

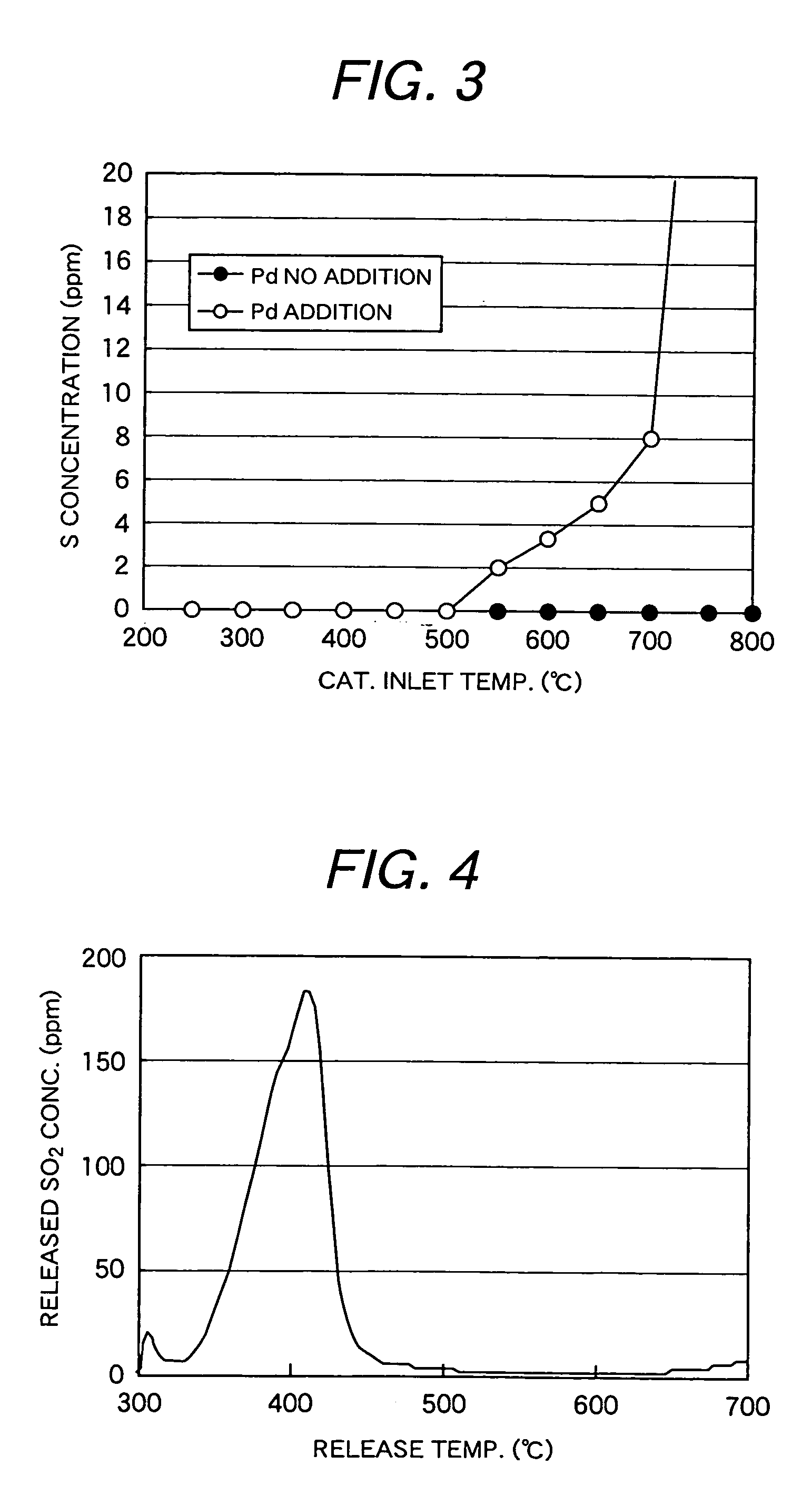

Exhaust gas purification apparatus, exhaust gas purification method, and sulfur component trapping agent for internal combustion engine

InactiveUS20070144143A1Fuel cost becomes worseRich air fuel ratioInternal combustion piston enginesSilencing apparatusPurification methodsTrapping

An object of the present invention is to provide a new exhaust gas purification apparatus for an internal combustion engine operated under a condition of an air fuel ratio leaner than a theoretical air fuel ratio, a method for purification of exhaust gas and an exhaust gas purification catalyst, which is suitable for suppressing degradation of the NOx purification catalyst by sulfur components. An exhaust gas purification apparatus for an internal combustion engine, which comprises an exhaust gas passage for an internal combustion engine into which exhaust gas of lean air fuel ratio and rich or stoichiometric air fuel ratio flows, a NOx trapping catalyst that functions to trap NOx in the exhaust gas when the air fuel ratio is lean, a sulfur component trapping agent for trapping sulfur components in the exhaust gas, which is disposed before the NOx trapping catalyst, and a catalyst for oxidizing the sulfur components, which is disposed before the sulfur component trapping agent, wherein the sulfur component trapping agent has a trapping rate of 85 % or more of an amount of inflow sulfur in a trapping test at a flow rate of 150 ppm SO3-5% O2—balance being N2 gas per 1.5 moles of the sulfur trapping agent at 300° C. and a space velocity of 30,000 / h for 1 hour; and the sulfur component trapping agent has a release rate of sulfur amount of 5 % or less of sulfur trapped in the sulfur component trapping agent in a release test under a flow of a 3000 ppm H2-600 ppm C3H6-3000 ppm O2-3.5 % CO—balance being N2 gas at a temperature elevation rate of 10° C. / min from 250 to 750° C. at an sulfur component trapping agent entrance, after the trapping test.

Owner:BABCOCK HITACHI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com