Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Septage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Septage is the partially treated sludge stored in a septic tank. The term septage is widely used in USA and in Asia, e.g. India. Septage generally consists of all the household wastewater that is disposed of through a home's plumbing system that neither drain out into the soil nor are converted to gases by the bacteria in the septic tank. Septage is pumped out of a septic tank or onsite sewage facility with a vacuum truck. The septic tanks can be residential or non-residential. Non-residential sources can include wastewater from commercial/industrial development, grease interceptor as well as other sources such as portable toilet, RV, and boat waste.

Process for treating septage

InactiveUS7070693B2Easy to dehydrateQuality improvementSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesSolid fractionPasteurization

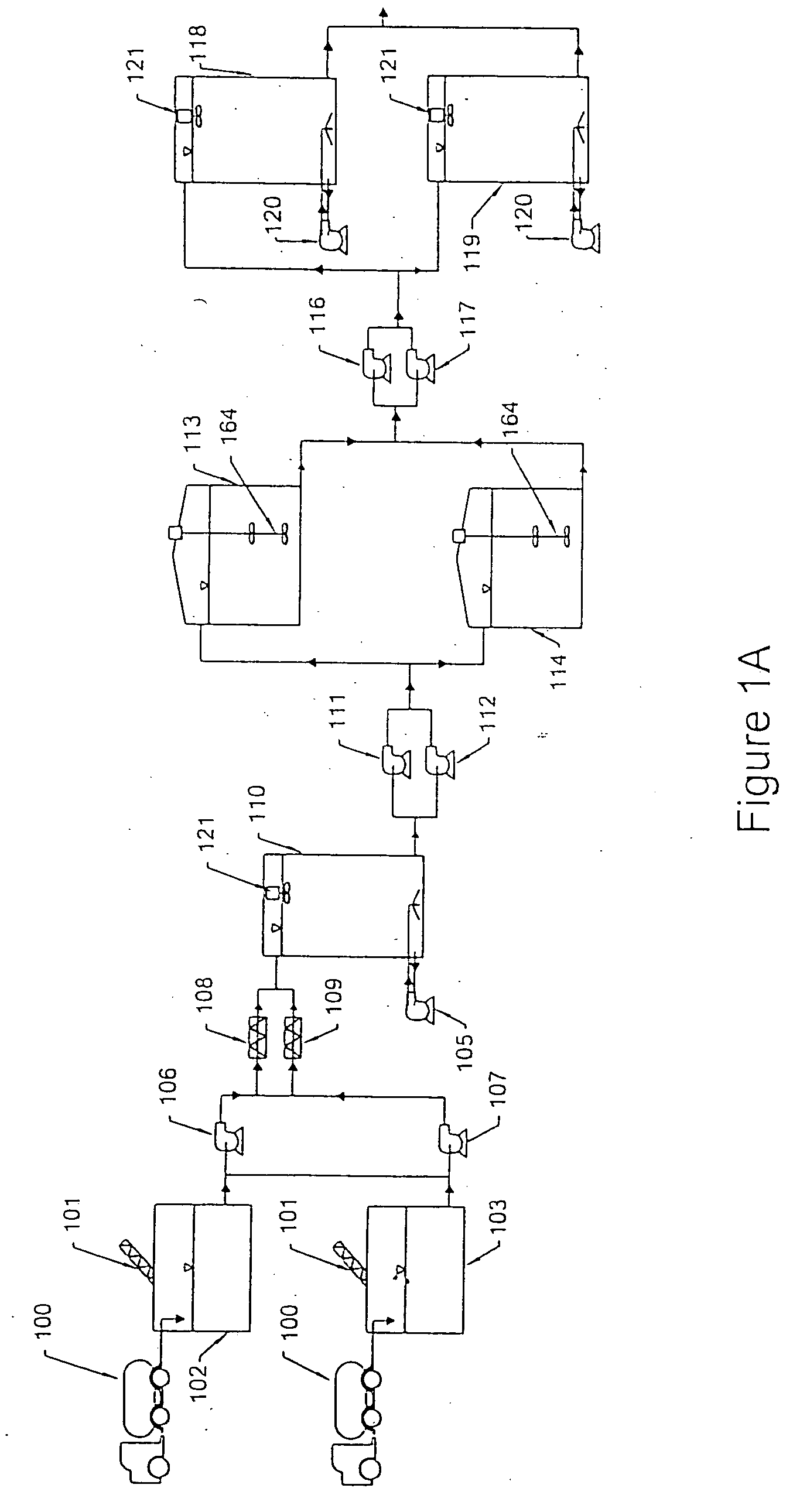

A process and apparatus for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process will convert the septage into Biosolids (sludge) and water dischargeable to the environment. The treated septage achieves pathogen reduction, and reduced vector attraction. Treatment of septage by pasteurization causes the destruction of harmful pathogens. Pasteurization of septage having high water content provides for even temperature elevation and distribution of heat within the thermal mass of the septage allowing for consistent pathogen destruction. An alkaline compound is utilized to form a filter cake from the solids fraction of the pasteurized septage preventing vector attraction, while producing a beneficial bio-solid. The liquid fraction of the septage is treated by biological process allowing for its discharge into the environment.

Owner:KELLY ROBERT J

Process for treating septage to extract a bio-fuel

InactiveUS20070056902A1Uniform and thorough heat treatmentGreat pathogen reductionSludge treatmentOther chemical processesAlternative fuelsBiofuel

A process for the treatment of septage, particularly grease trap waste, is disclosed. The inventive process converts septage into sludge usable as a bio-fuel. The conversion of the septage makes it desirable as an alternative fuel source, as the sludge has a high BTU value due to the large percentage of grease in the septage.

Owner:KELLY ROBERT J

Septage treatment system and process

InactiveUS20120074057A1Eliminate dischargeWater treatment parameter controlSludge treatmentGreenhouseEnvironmental engineering

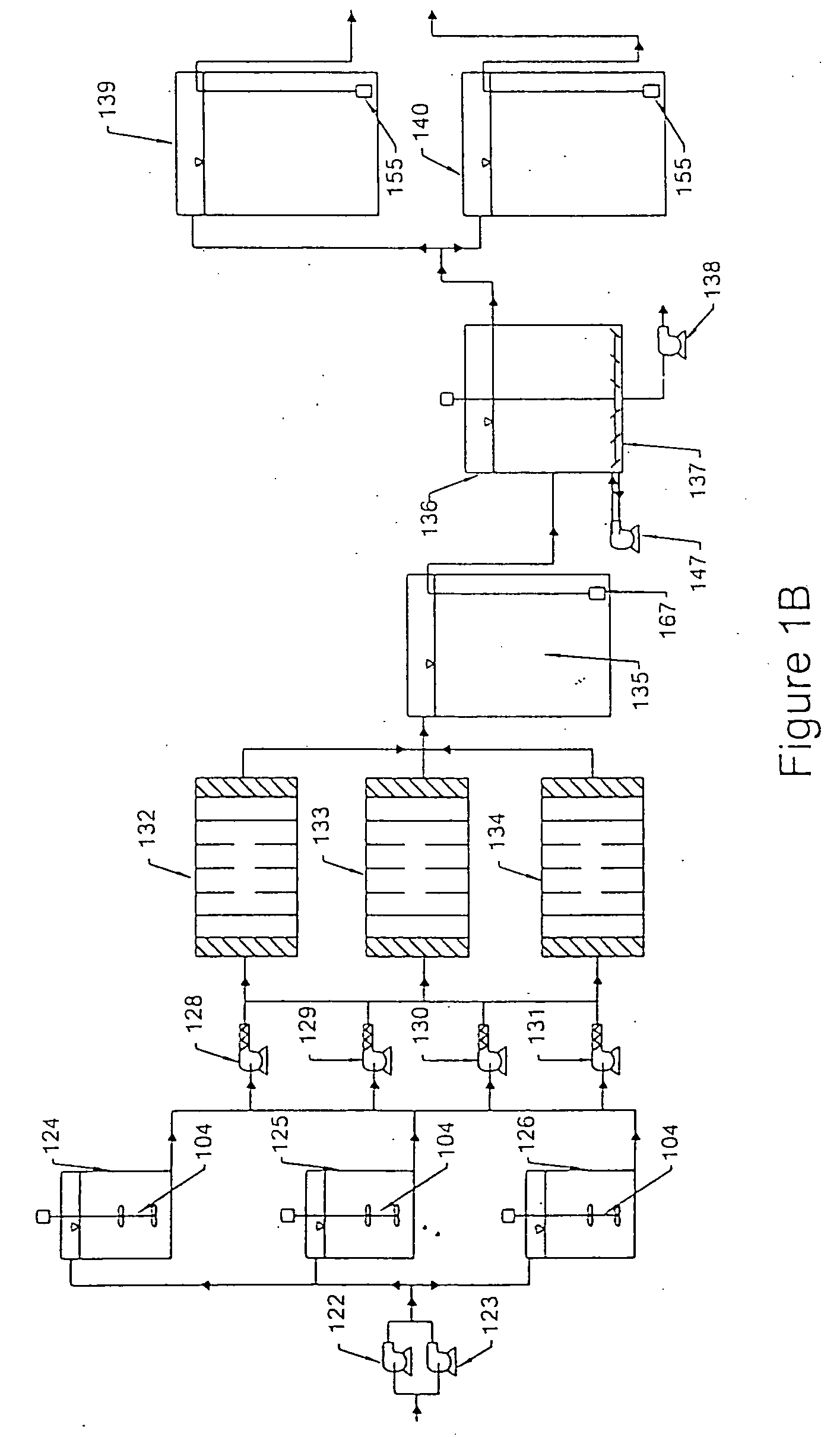

A septage treatment system and process designed to eliminate liquid discharge to groundwater. The system and process use primary treatment, secondary treatment, and tertiary treatment. The tertiary treatment uses a greenhouse system to reclaim septage waste after it has gone through primary and secondary treatment. The greenhouse system fosters ecologically sound usage of septage waste to minimize the environmental impact of septage waste.

Owner:KOVALAK JAMES STEVEN

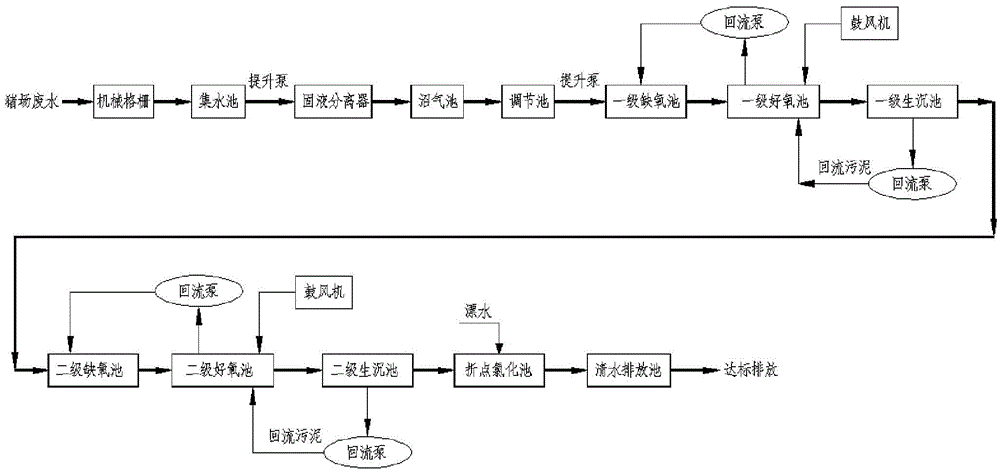

Method for removing high ammonia nitrogen from pig farm dry manure cleaning livestock wastewater

InactiveCN105461174AGuaranteed emission standardsHigh degree of automationWaste water treatment from animal husbandryWater/sewage treatmentPig farmsOxygen

The invention provides a method for removing high ammonia nitrogen from pig farm dry manure cleaning livestock wastewater. The method comprises the following steps: firstly, physically separating ammonia nitrogen from livestock wastewater through a mechanical grid and a solid-liquid separator to obtain residue-isolated wastewater; performing anaerobic fermentation, and performing two-stage hypoxic-aerobic biochemical treatment in order that the nitrogen removal efficiency can be up to 90-95 percent; lastly, arranging a breakpoint chlorination pond at the water outlet of a secondary biological sedimentation pond, and adding a sodium hypochlorite solution once an ammonia nitrogen value exceeds a design value in order to ensure complete removal of the ammonia nitrogen from the wastewater. The method has the advantages of stability, reliability, high automation degree, low running cost, low labor intensity and high impact load resistance, and is worthy of popularization and application. By adopting the method, discharge of the ammonia nitrogen up to standards can be ensured continuously and stably for a long time.

Owner:GUANGDONG SHUIQING ENVIRONMENTAL PROTECTION TECH CO LTD

Septage treatment system

ActiveUS7553410B1Effective treatmentContinuous operationBiological treatment apparatusLiquid displacementActivated sludgeGreenhouse

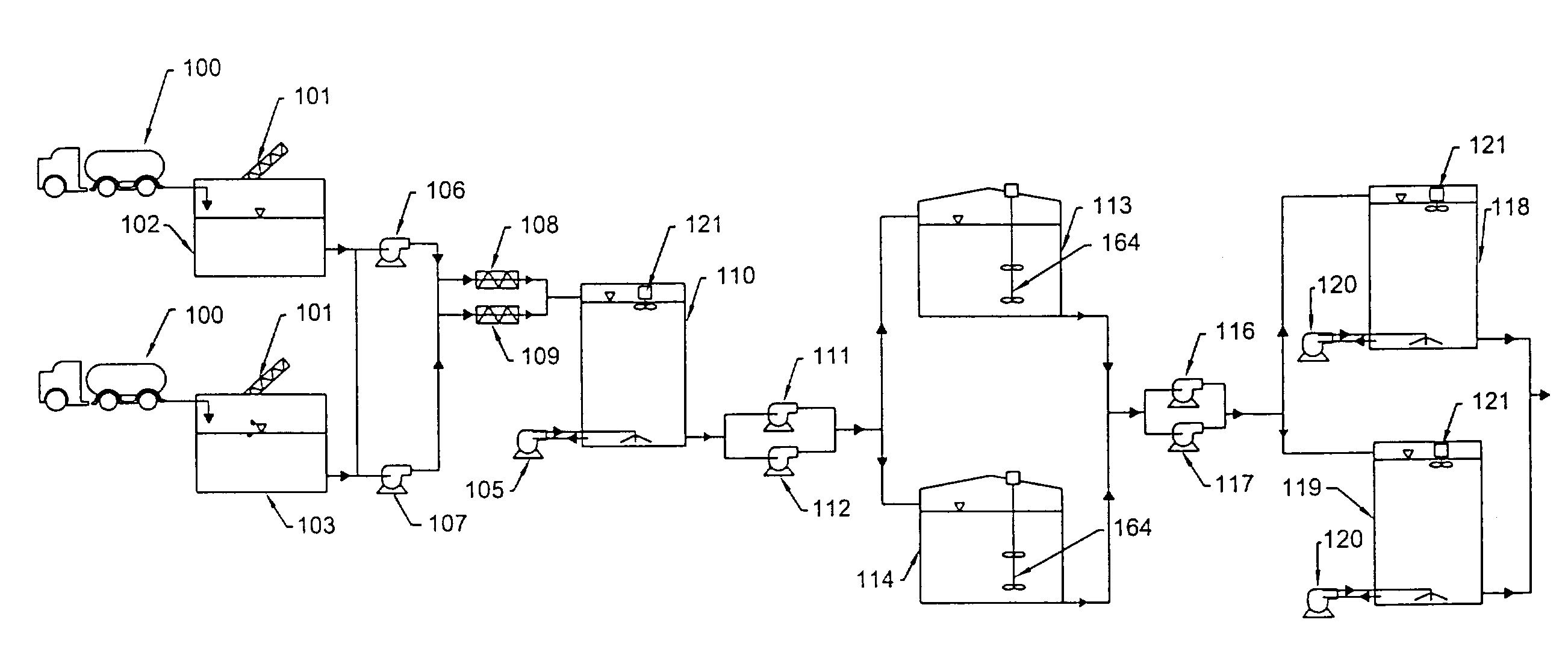

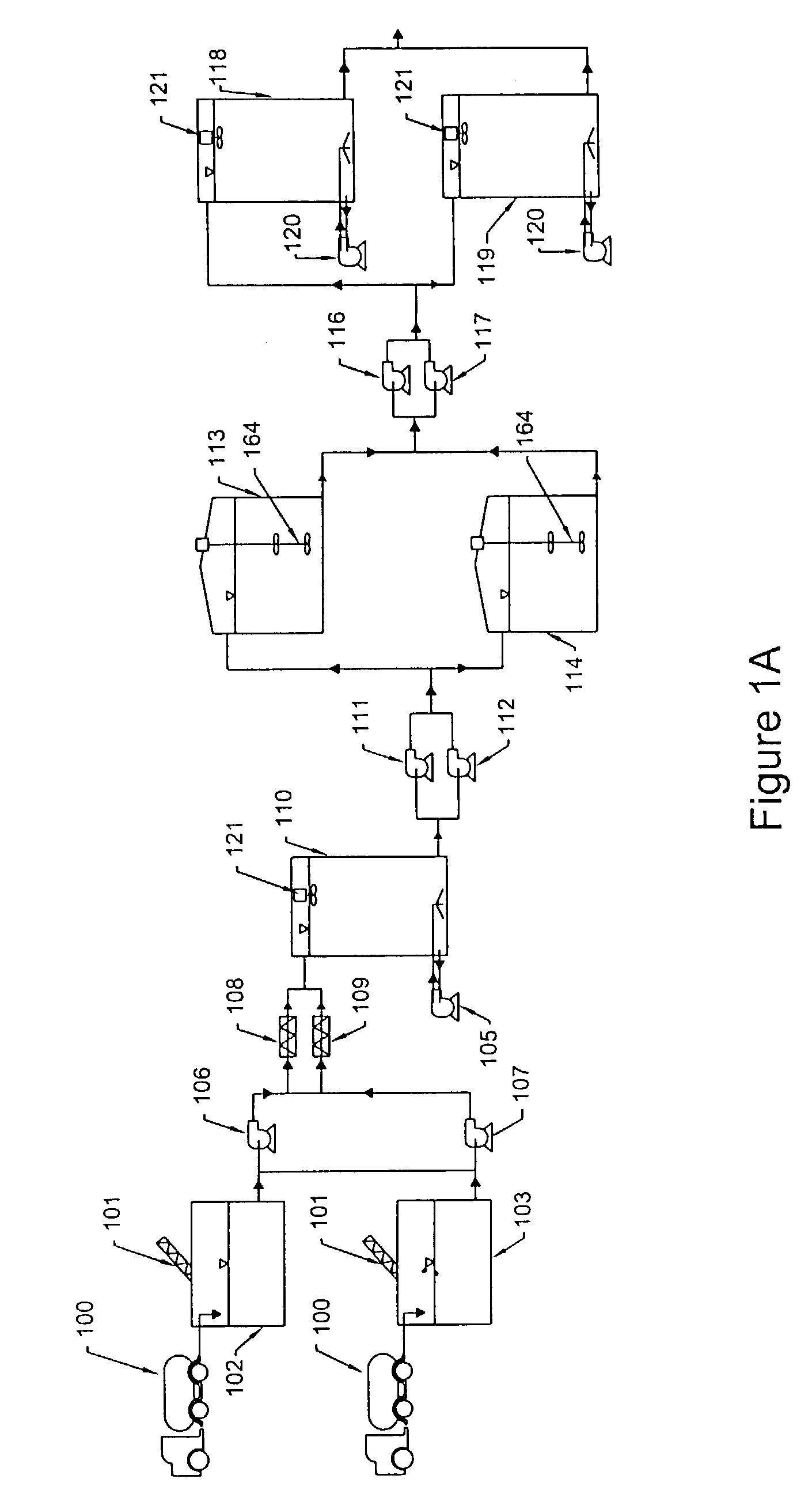

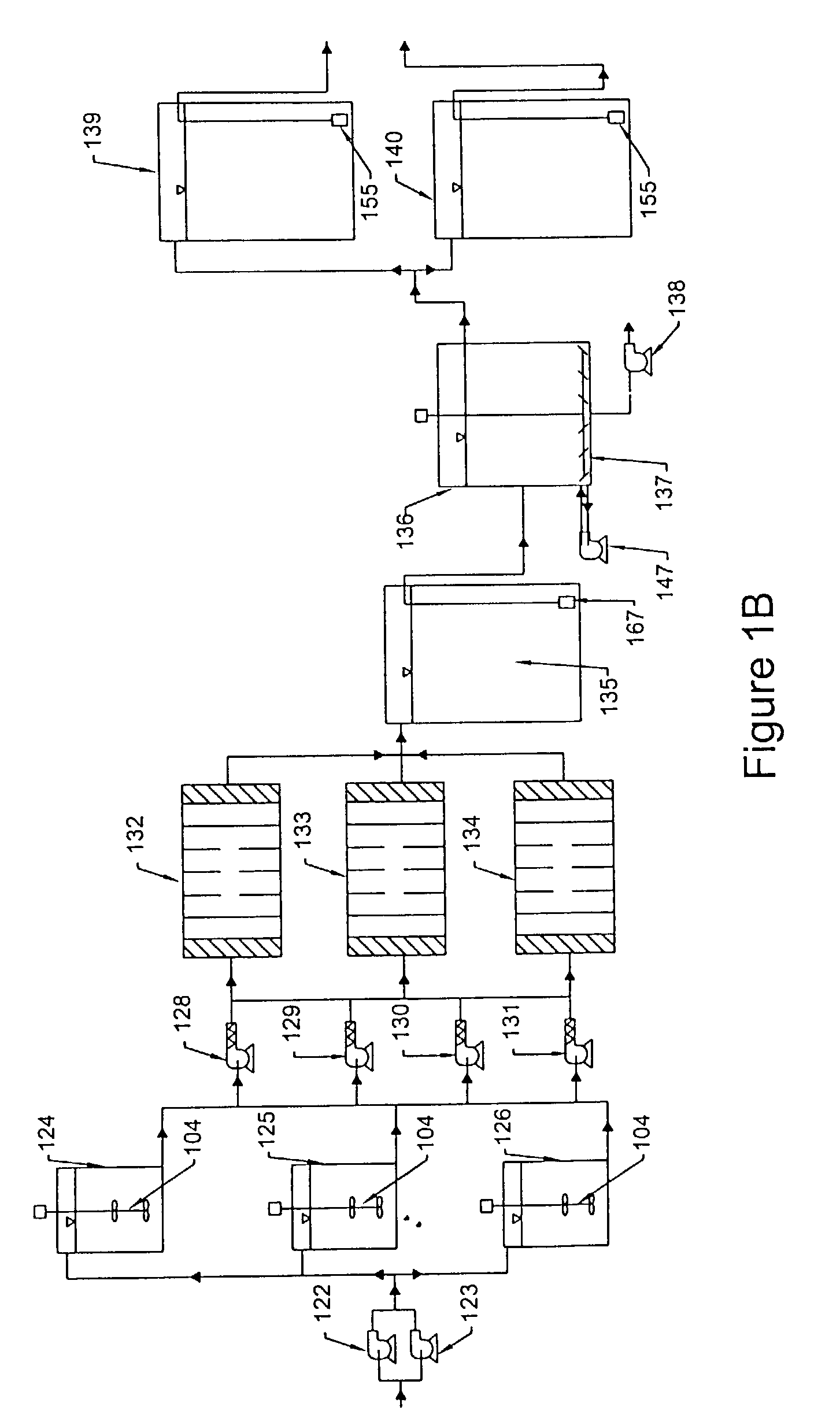

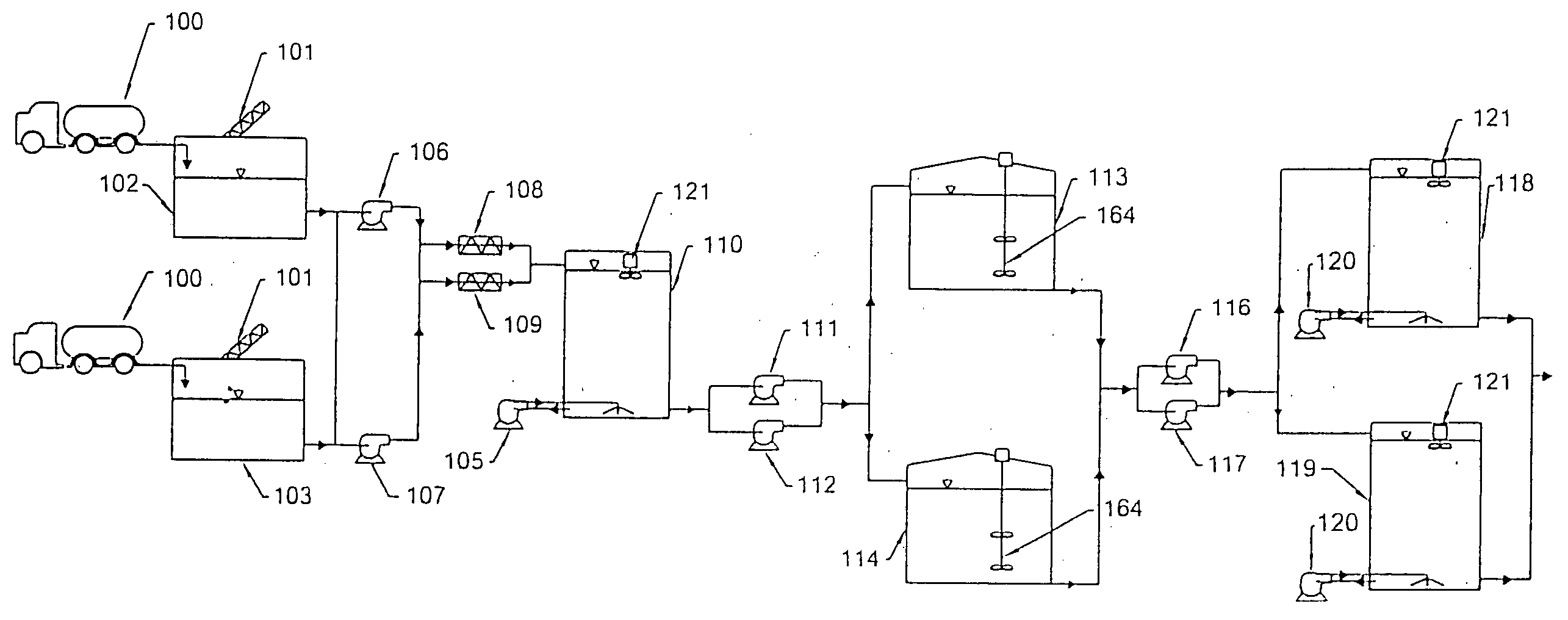

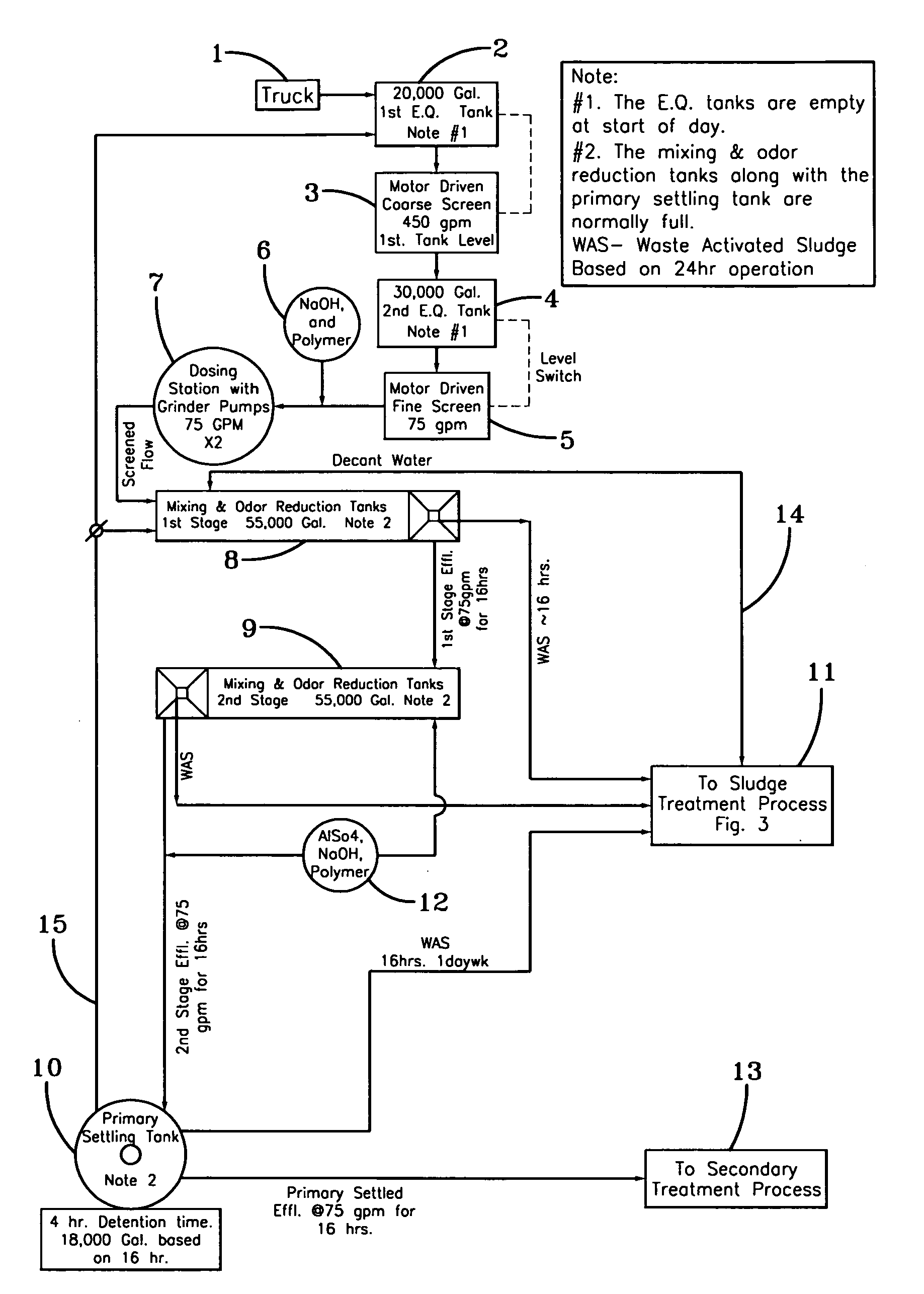

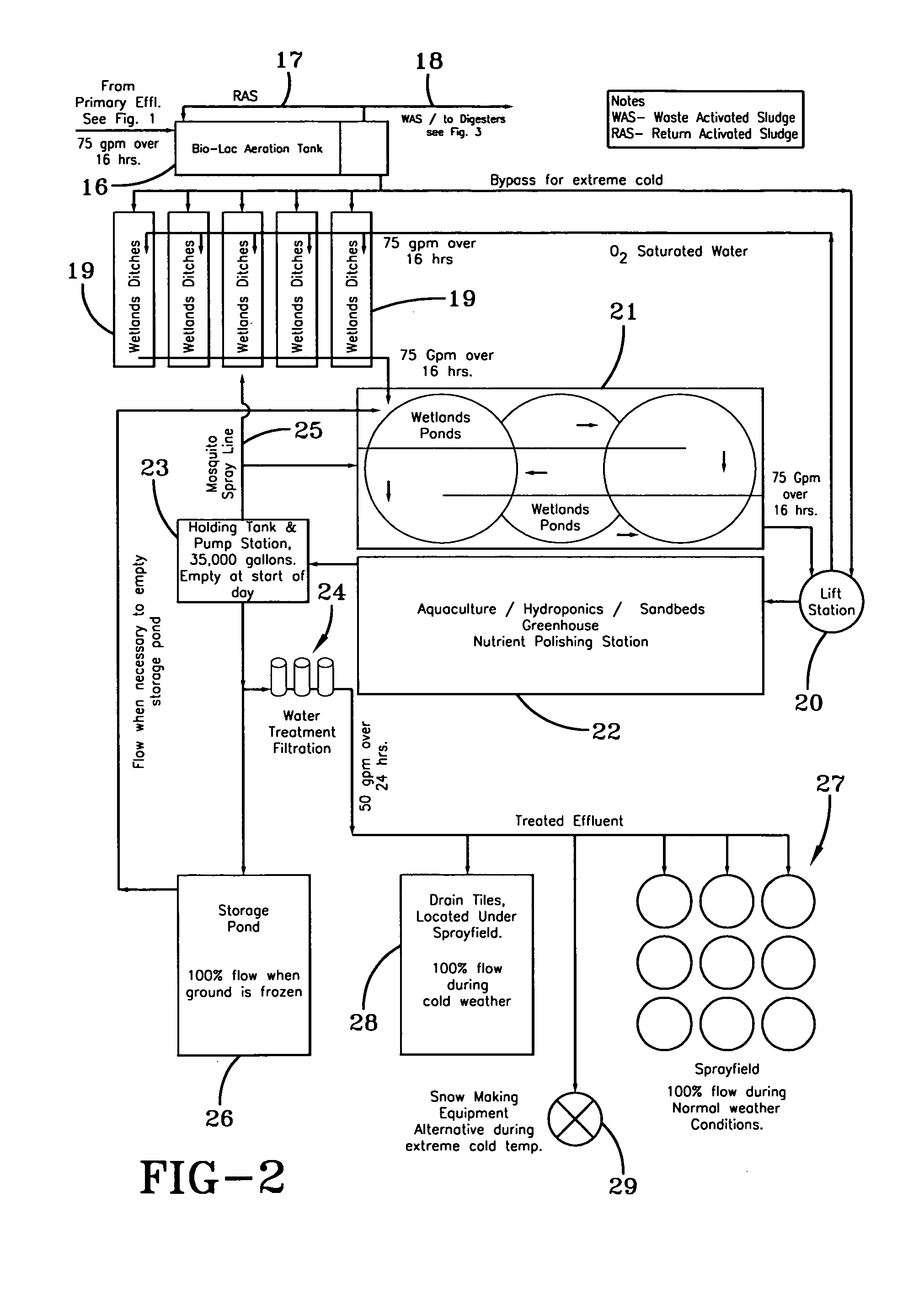

The present invention generally includes a septage treatment system comprising: (a) a primary treatment process system comprising: (1) a receiving station to pump the septage from a vehicle; (2) equalization tank(s) to receive septage from the receiving station; and (3) two or more mixing and odor control tanks to generate waste activated sludge; (b) a primary settling tank to generate waste activated sludge; (c) a secondary treatment process system comprising: (1) aeration tank(s) to receive waste activated sludge from the primary treatment process system and to generate water effluent; and (d) a tertiary treatment process system comprising: (1) wetland ditch(es) to receive water effluent from the aeration tank and to generate filtered water effluent; (2) wetland pond(s) to receive filtered water effluent from the wetland ditch(es) and to generate filtered water effluent; and (3) an aquaculture hydroponics and sand bed greenhouse to generate filtered water effluent.

Owner:EASTWOOD RES

Septage treatment system and method of treating septage

InactiveUS20090277830A1Speed up the processContinuous operationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesActivated sludgeProcess systems

The present invention generally includes a septage treatment system comprising: (a) a primary treatment process system comprising: (1) a receiving station adapted to receive septage from a vehicle and to pump the septage; (2) at least one equalization tanks adapted to receive septage from the receiving station; and (3) at least two mixing and odor control tanks adapted to receive septage from the equalization tanks, and to generate waste activated sludge; (b) a primary settling tank adapted to receive effluent from the mixing and odor control tanks, and to generate waste activated sludge; (c) a secondary treatment process system adapted to receive comprising: (1) at least one aeration tank adapted to receive waste activated sludge from the primary treatment process system and to generate water effluent; and (d) a tertiary treatment process system adapted to receive comprising: (1) at least one wetland ditch adapted to receive water effluent from the aeration tank and to generate filtered water effluent; (2) at least one wetland pond adapted to receive filtered water effluent from the at least one wetland ditch and to generate filtered water effluent; and (3) an aquaculture hydroponics and sand bed greenhouse adapted to receive filtered water effluent from the at least one wetland pond and to generate filtered water effluent.

Owner:EASTWOOD RES

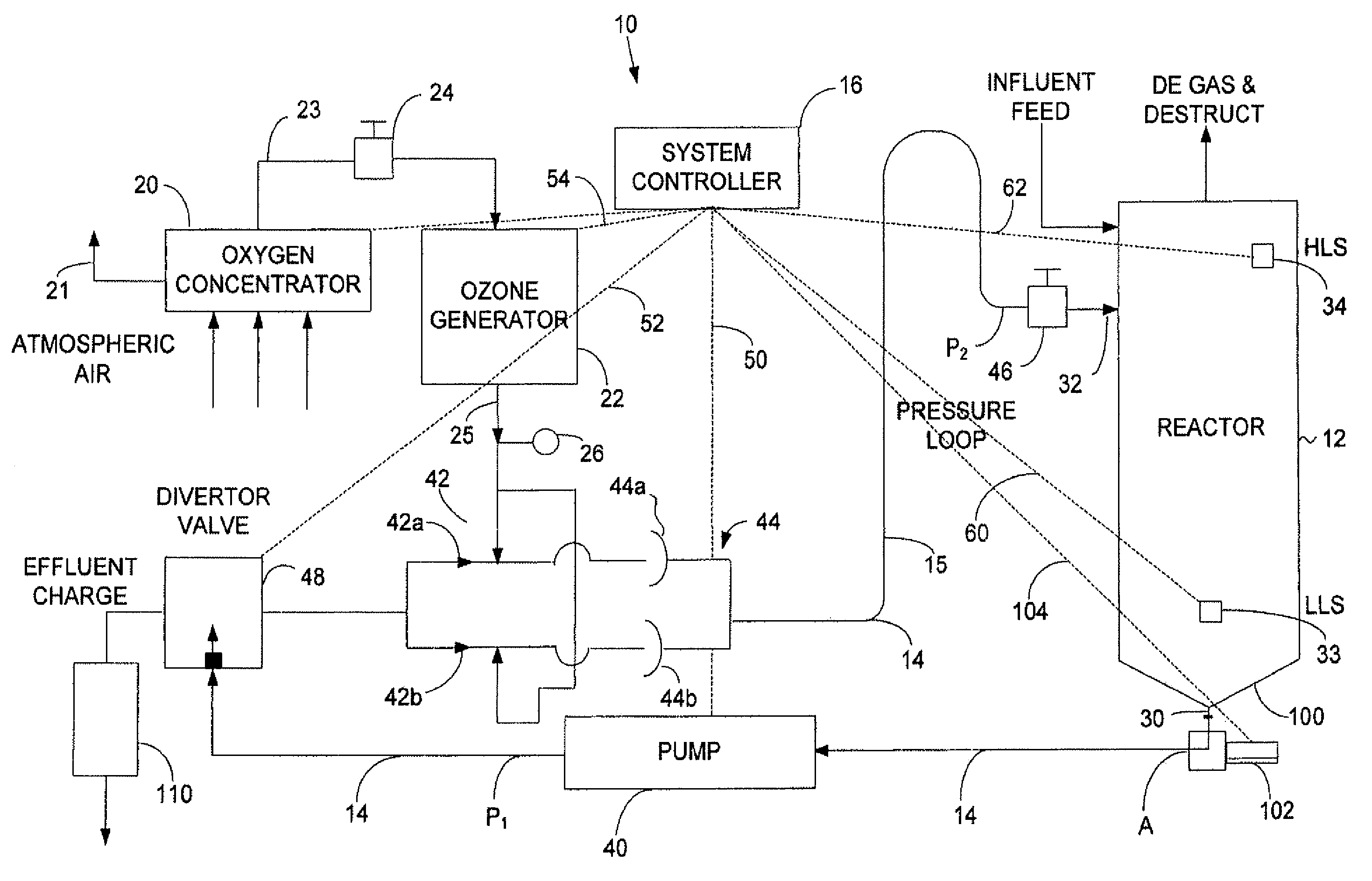

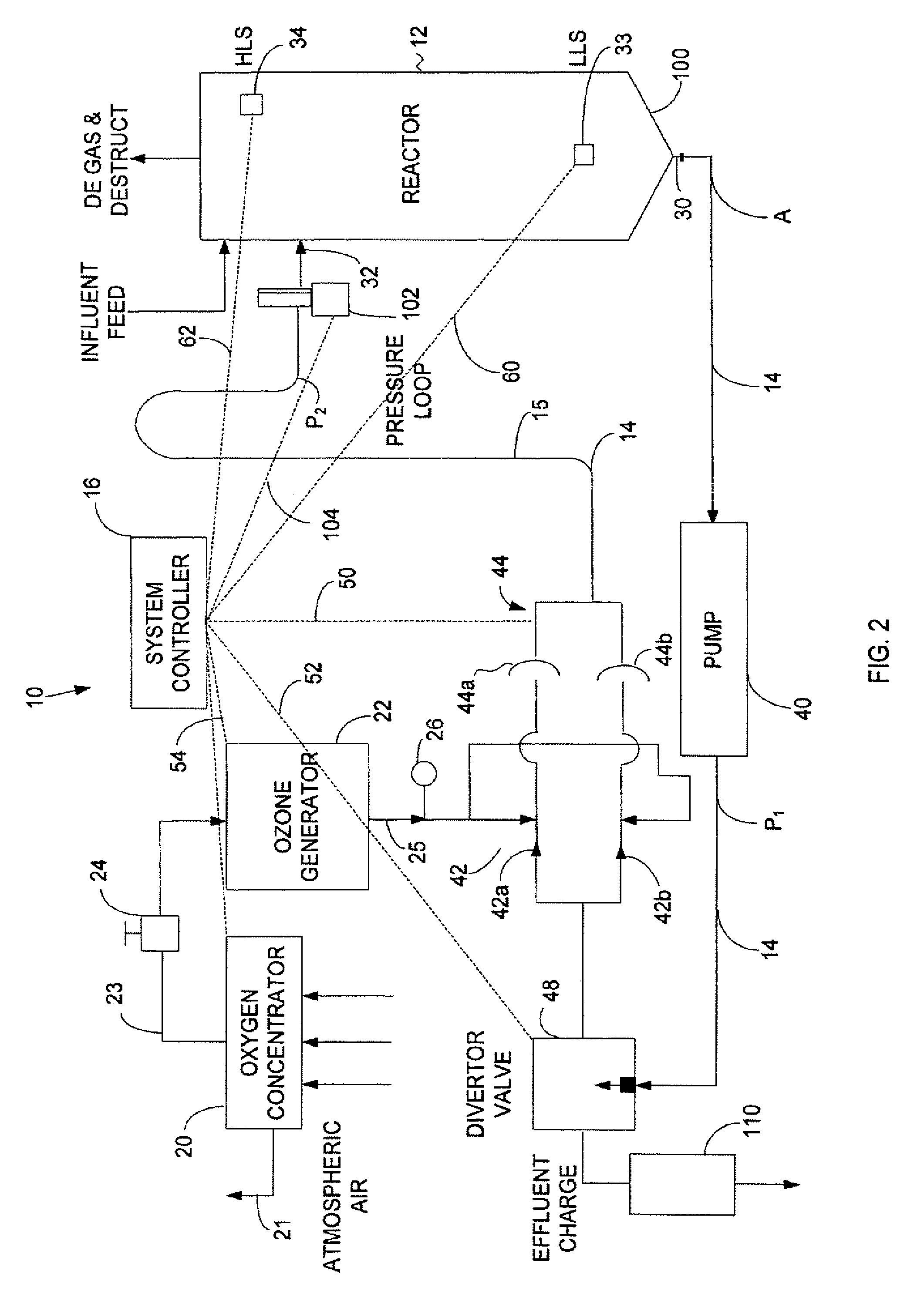

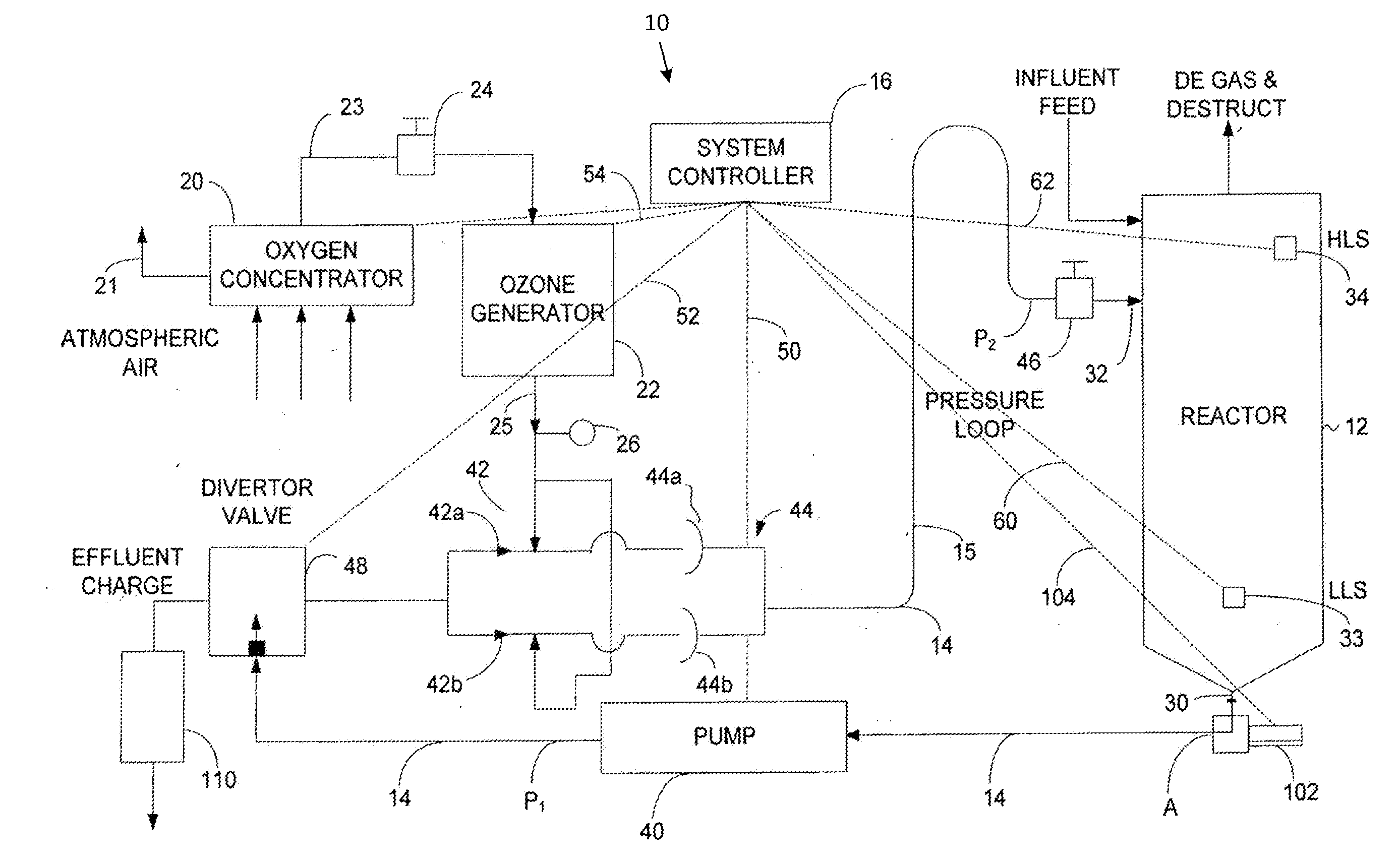

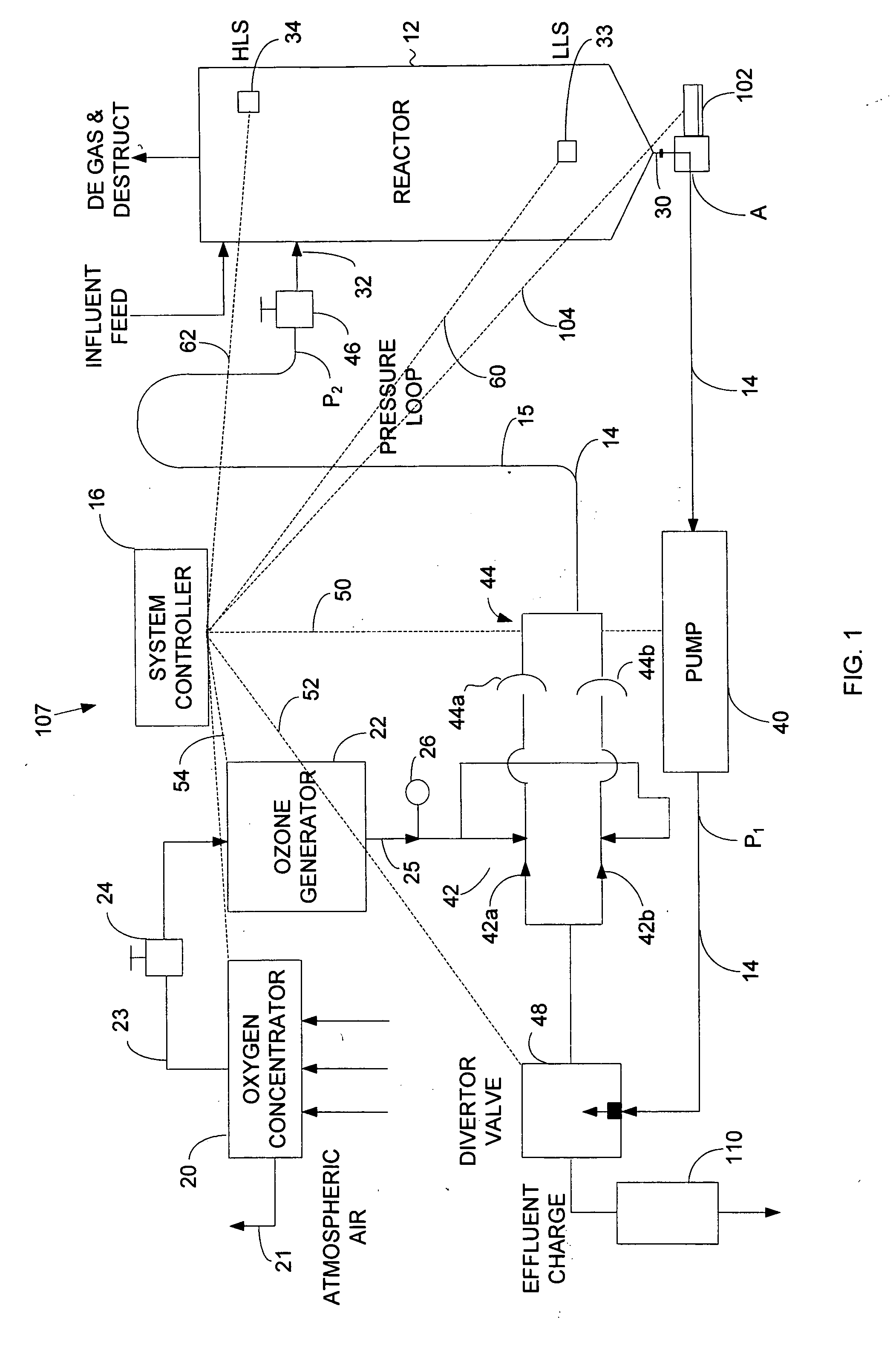

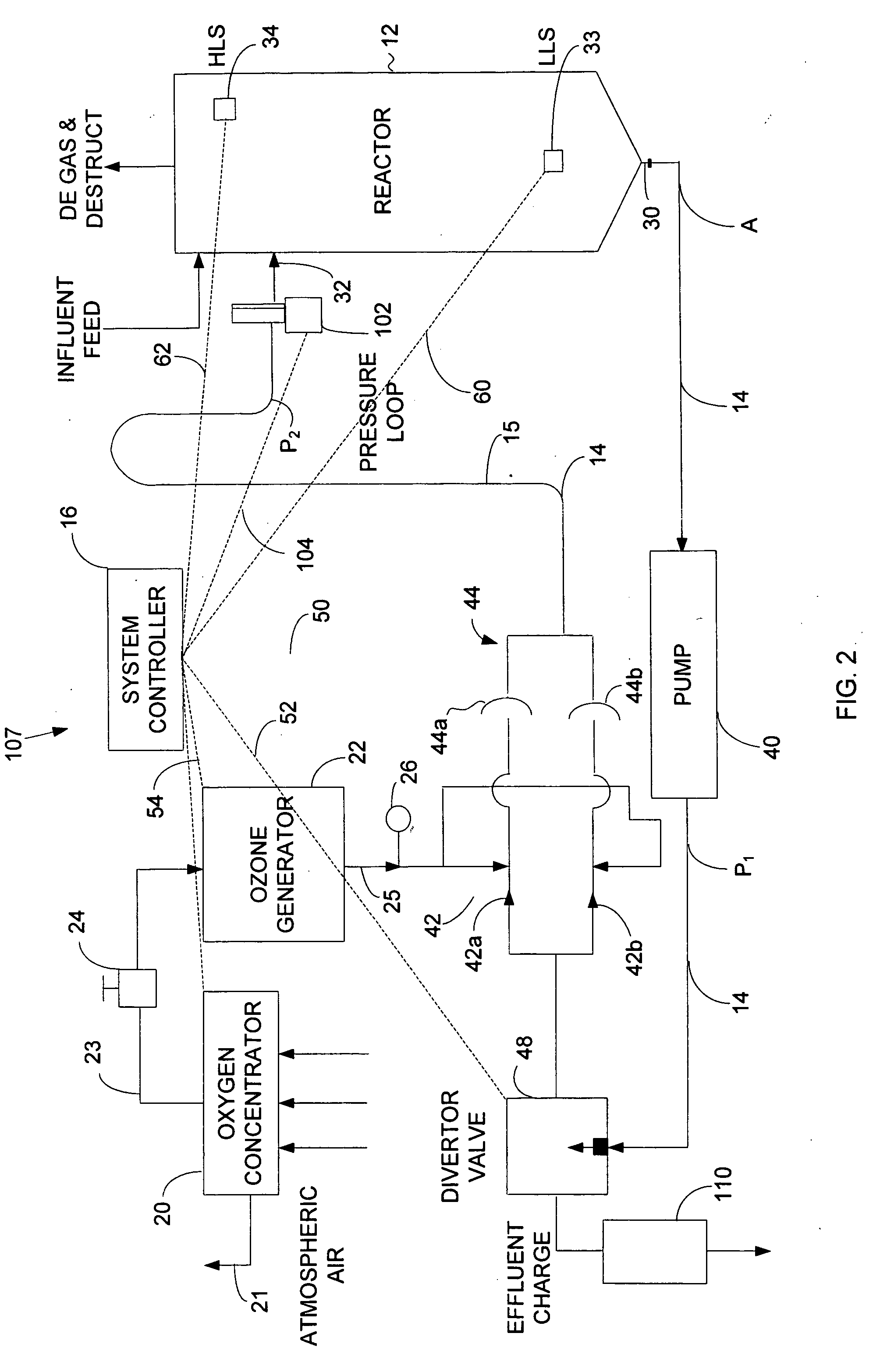

Oxidation process

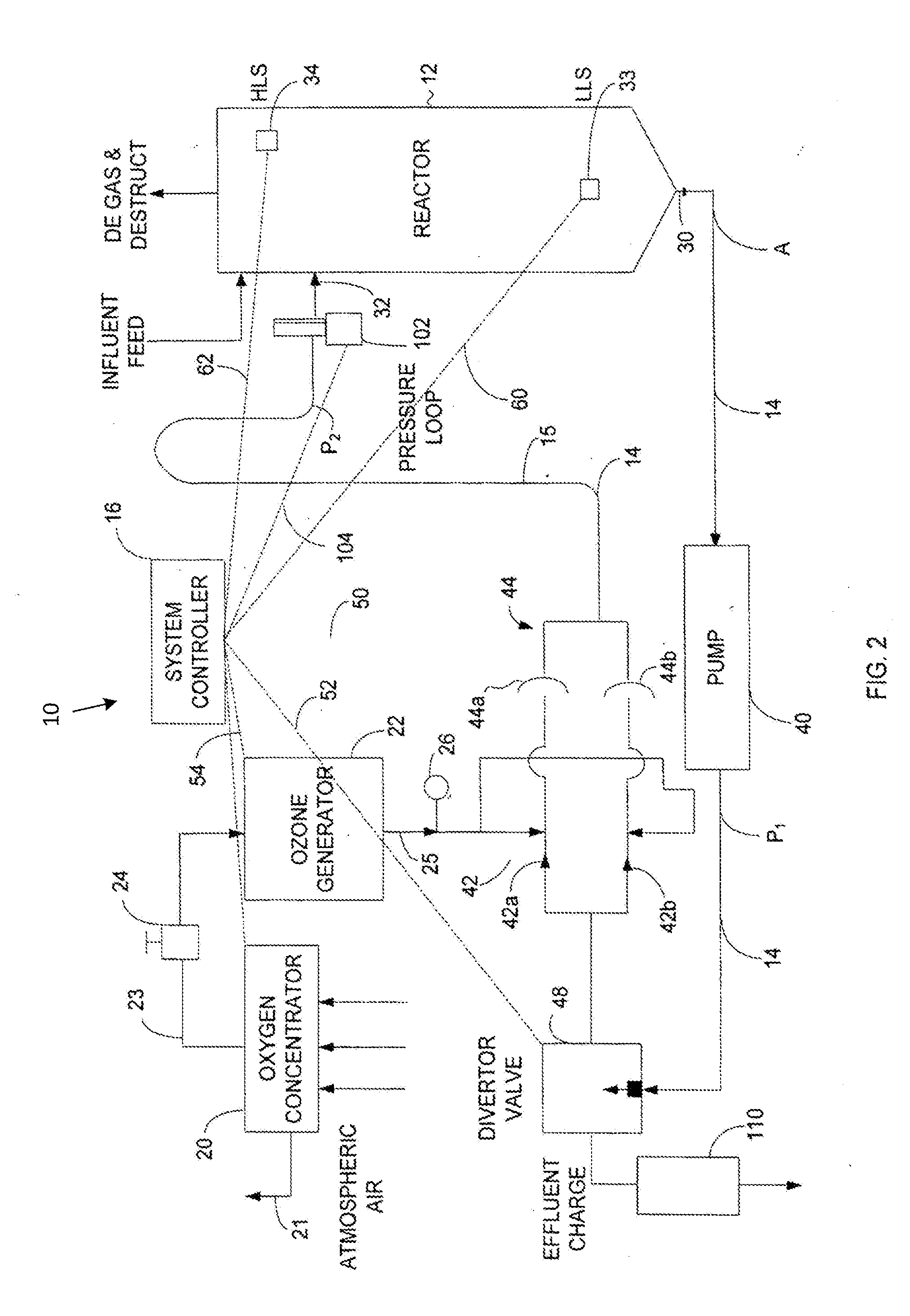

InactiveUS20130068701A1Ion-exchanger regenerationEnergy based wastewater treatmentAdvanced oxidation processHigh pressure

Treatment of an aqueous solution to yield a product is more desirable for disposal by an advanced oxidation process. Ozone is mixed with the solution, and maintaining at an elevated pressure for a time. The process may include recirculation past injector that injects ozone into the solution. Influent may be sewage, septage, leachate, ballast, and so on. The process disinfects and / or denutrifies the effluent. It may include (a) back-to-back processing of batches (b) overlapping processing with a previously treated batch (c) off-gassing (d) repetitive high pressure and low pressure cycles (e) post processing steps, such as retention without addition of ozone for a period of time to permit flocculates longer to form (f) post process filtering to remove flocculates (g) simultaneous post-processing of one batch while another batch is being processed. The process may include the treatment of solutions containing pharmaceuticals.

Owner:GREAT LAKES CLEAN WATER PARTNERSHIP

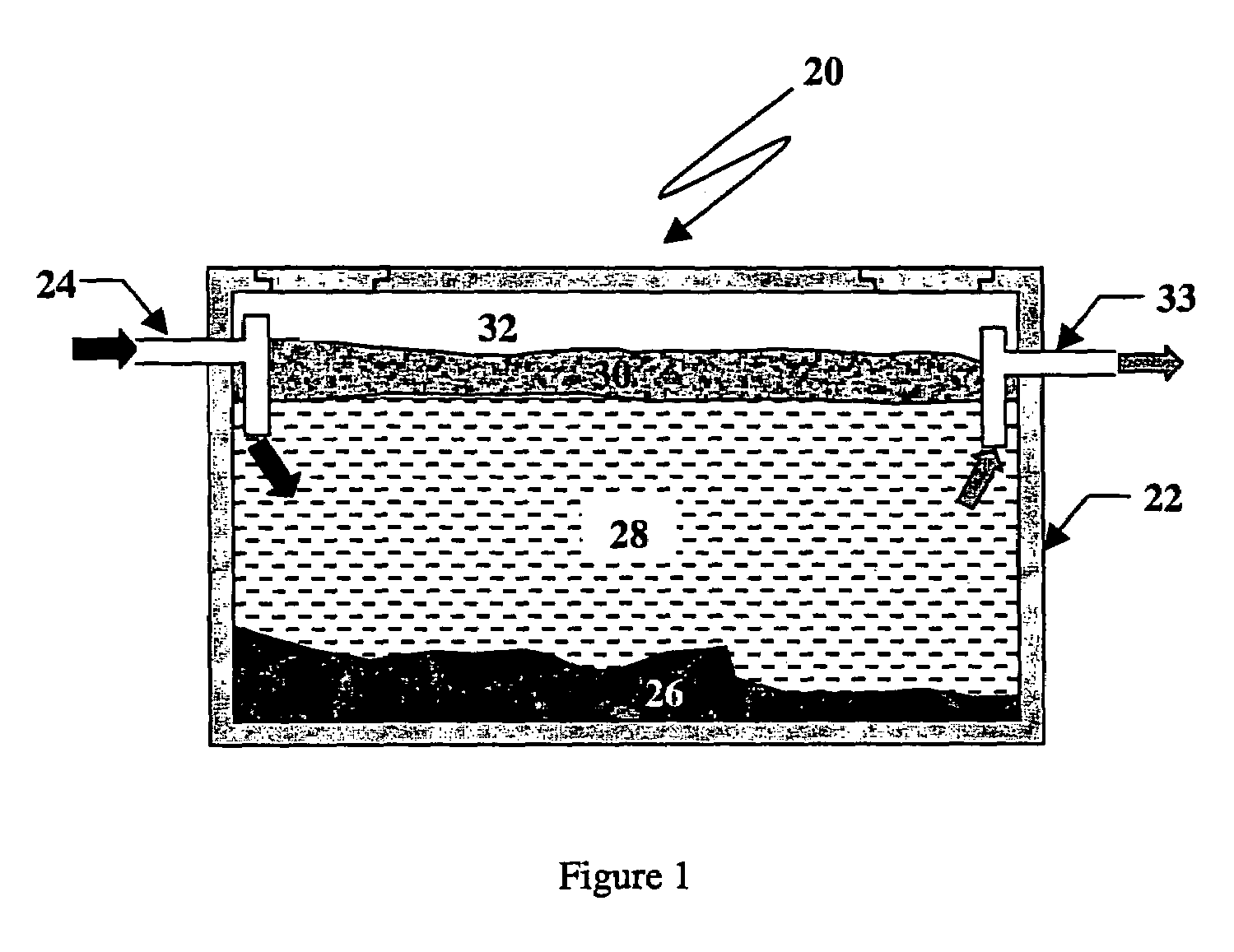

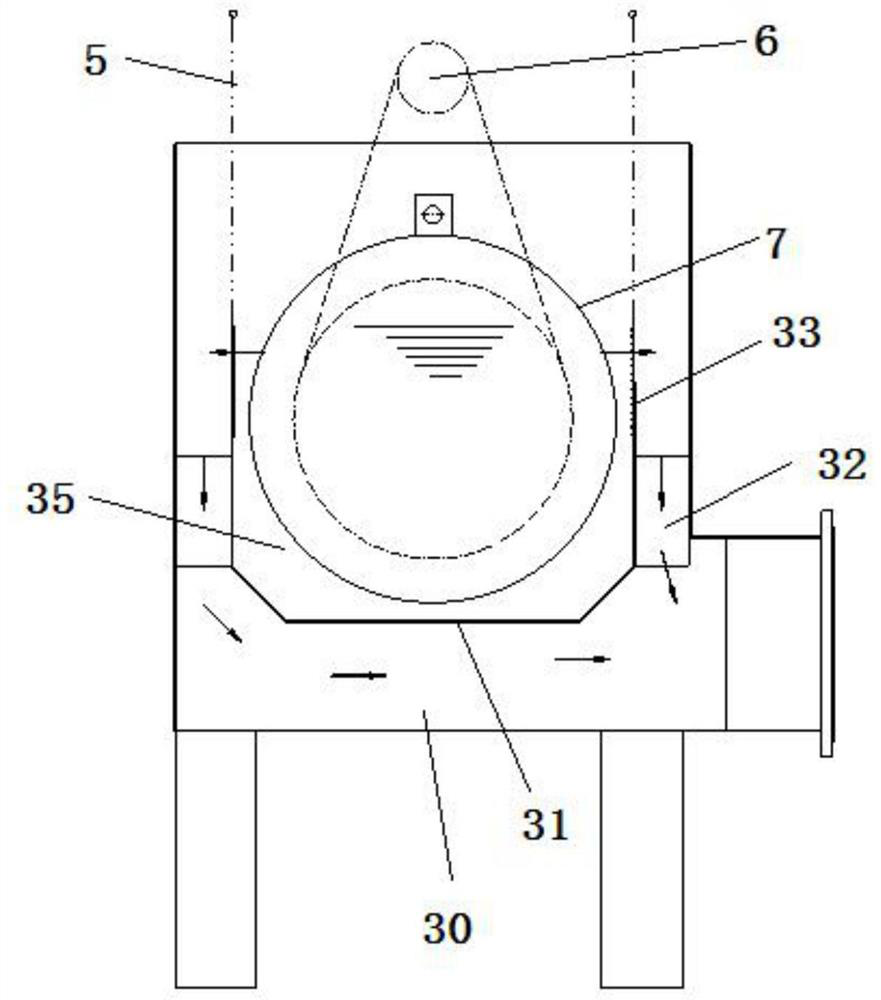

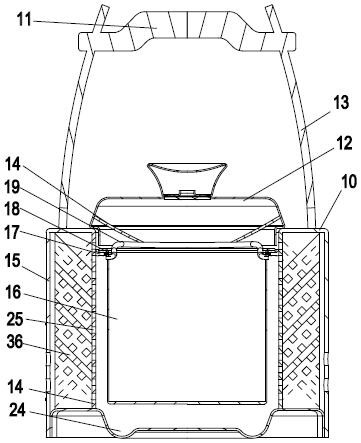

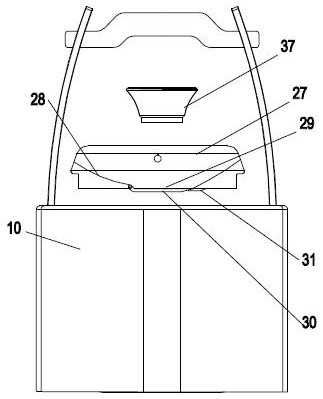

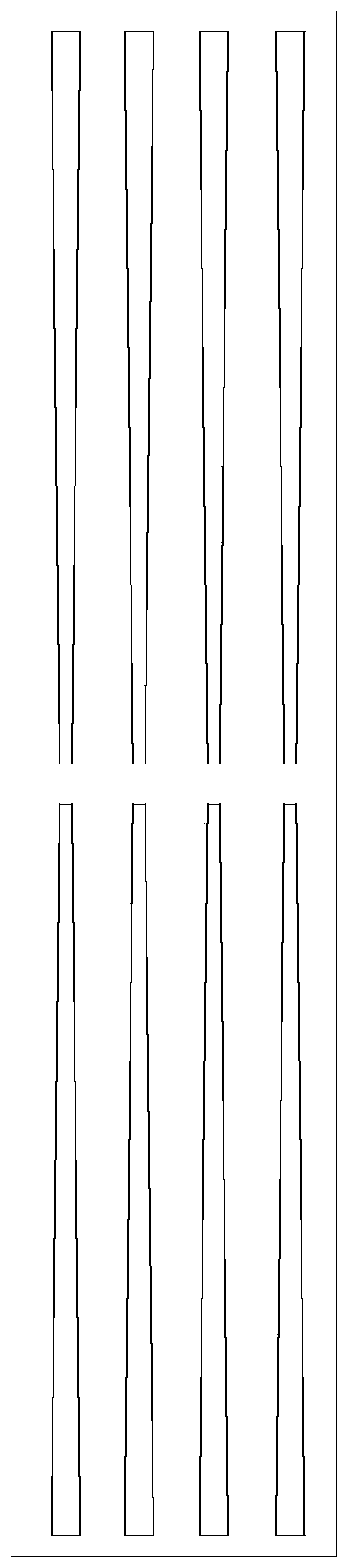

Versatile pre-thickened aerobic digester system

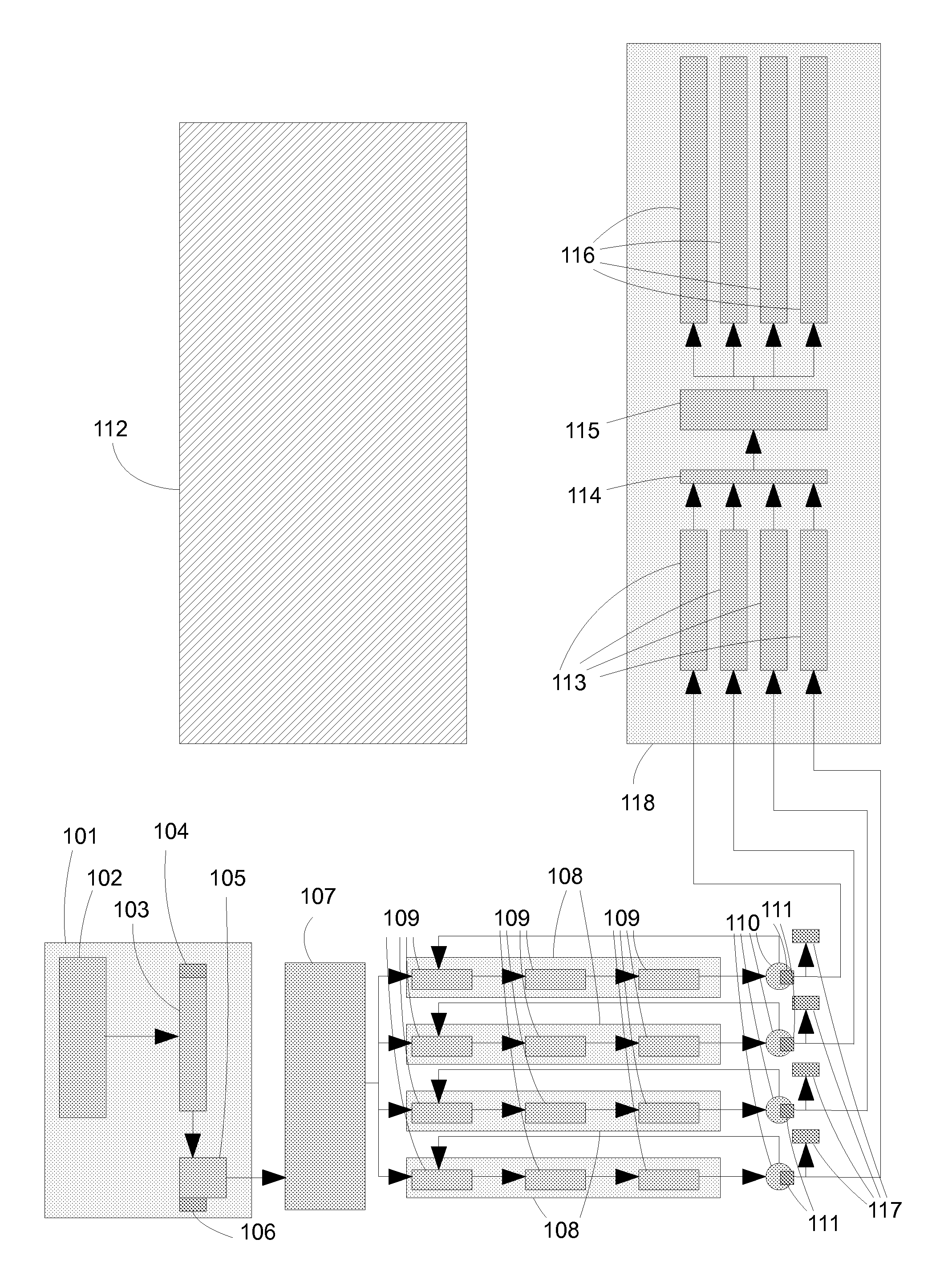

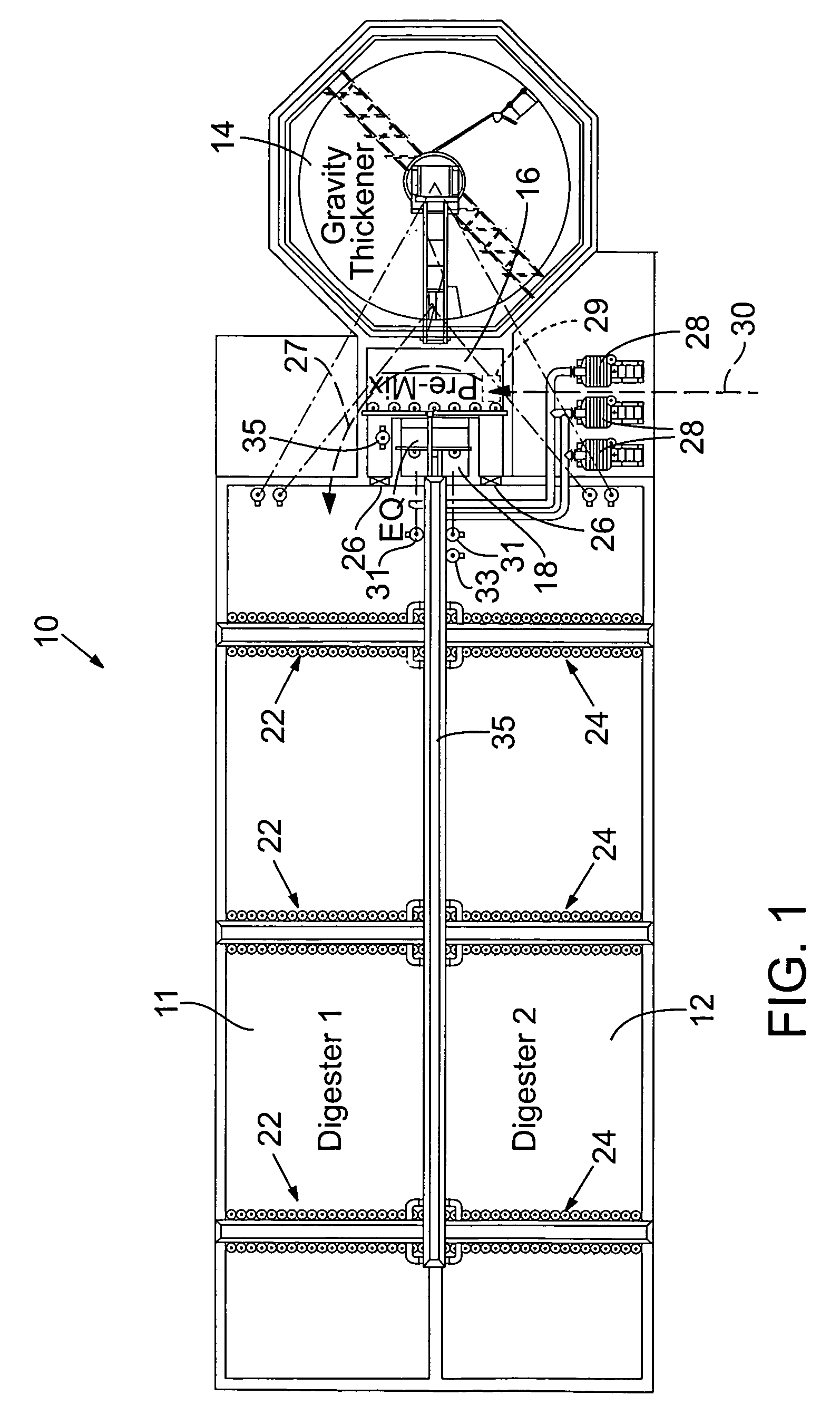

ActiveUS7169306B1Treatment using aerobic processesBiological treatment apparatusEngineeringStreamflow

An aerobic digester system in a wastewater treatment plant is made more versatile for different conditions by addition of an equalizer basin or in some embodiments, a bypass pipe. If infeed is received from a sequential batch reactor or from a concentrated septage, for example, the equalizer basin can contain one batch, and then deliver the batch out incrementally to a gravity thickener basin. The equalizer basin also enables the gravity thickener of the system to be removed from service when needed, providing increased flexibility for the system. Importantly, the equalizer or bypass enables versatile modes of operation so that a plant designed for a larger, later flow can operate at an initially low flow or at several levels of flow before reaching the largest design flow. This applies to other conditions of variable flow as well such as seasonal.

Owner:OVIVO INC

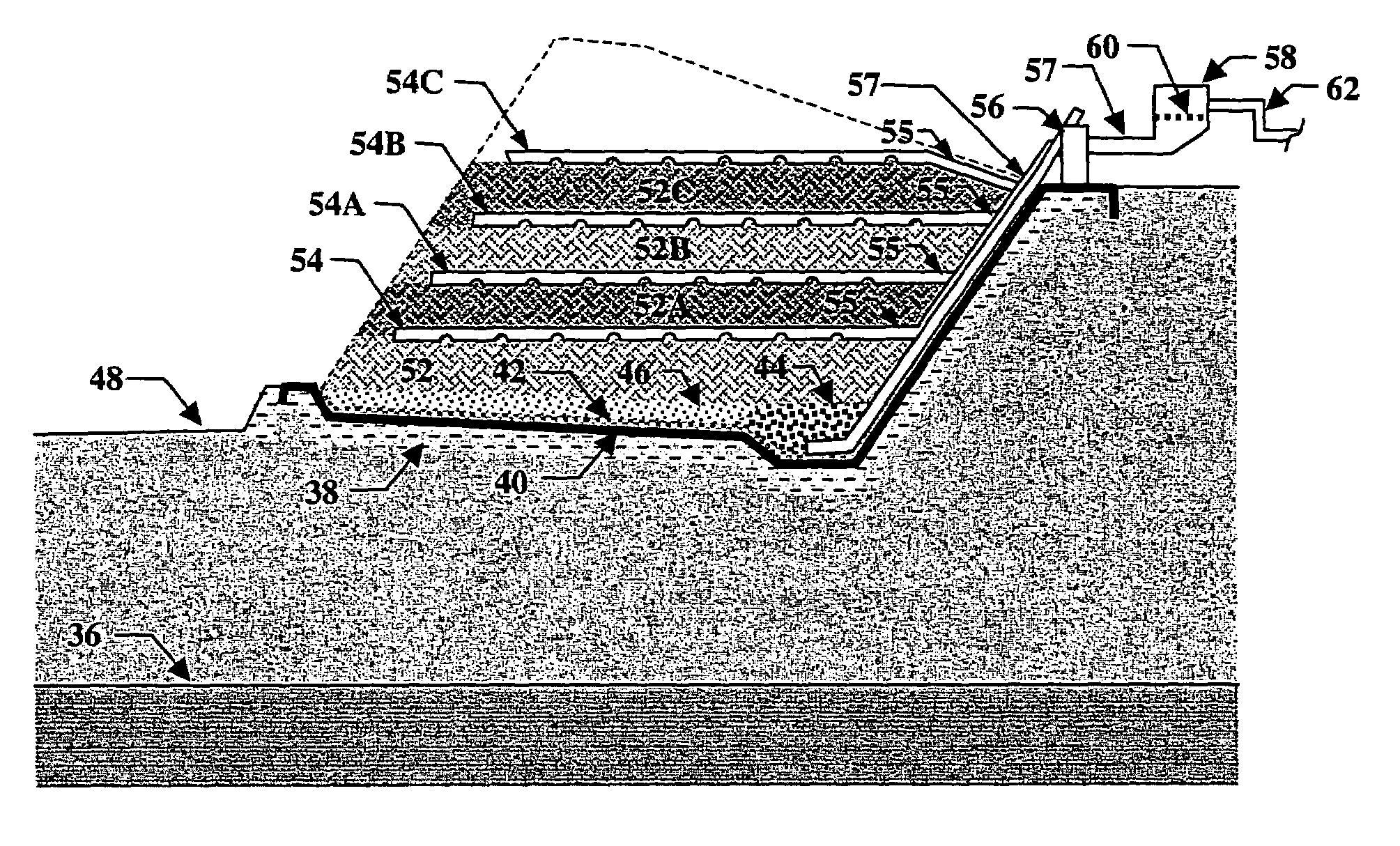

Landfills and methods of operating a landfill

InactiveUS7347648B2Promote decompositionIncrease spacingSolid waste disposalLandfill technologiesSewageLitter decomposition

Owner:ACCELERATED LANDFILL TECH +1

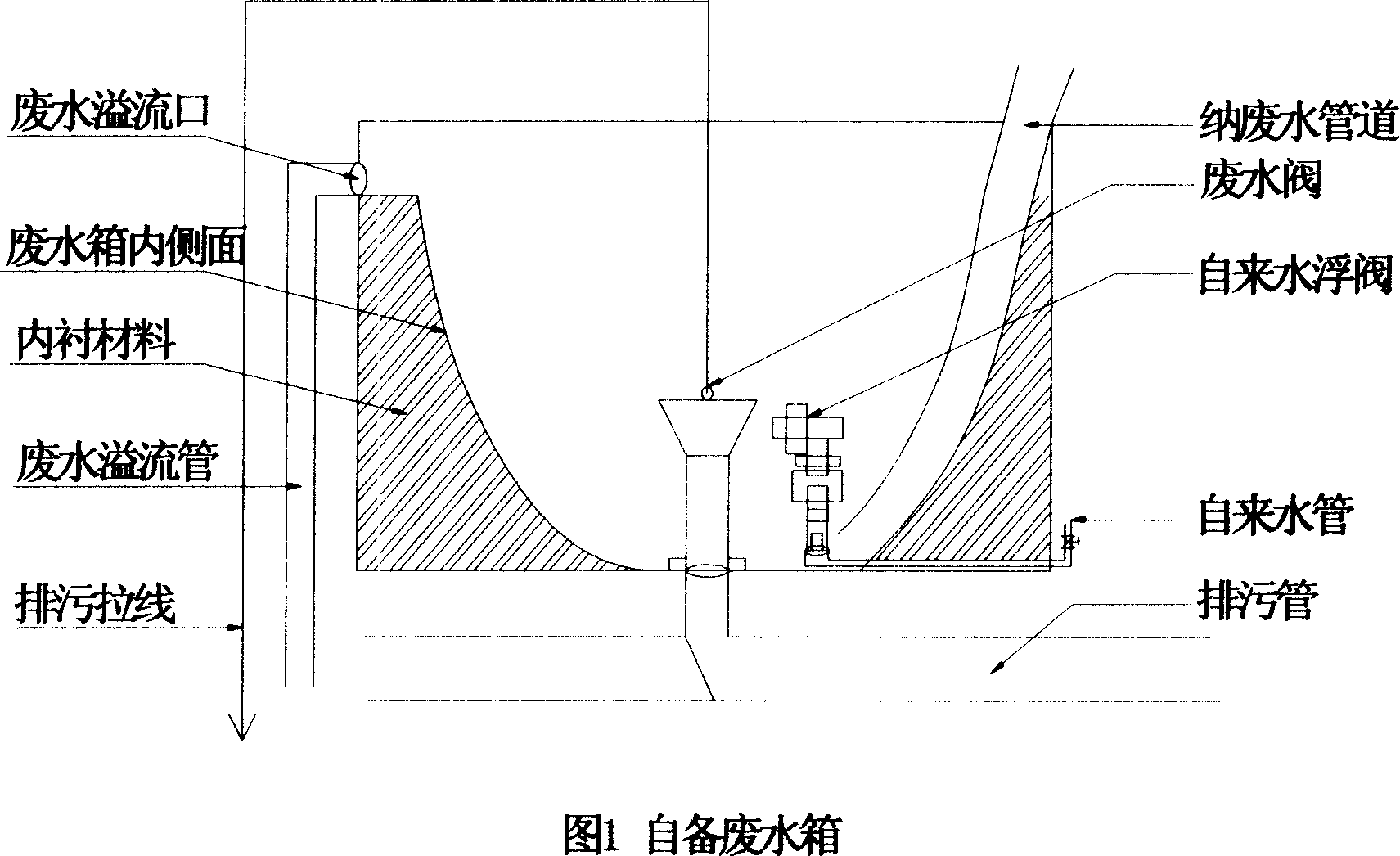

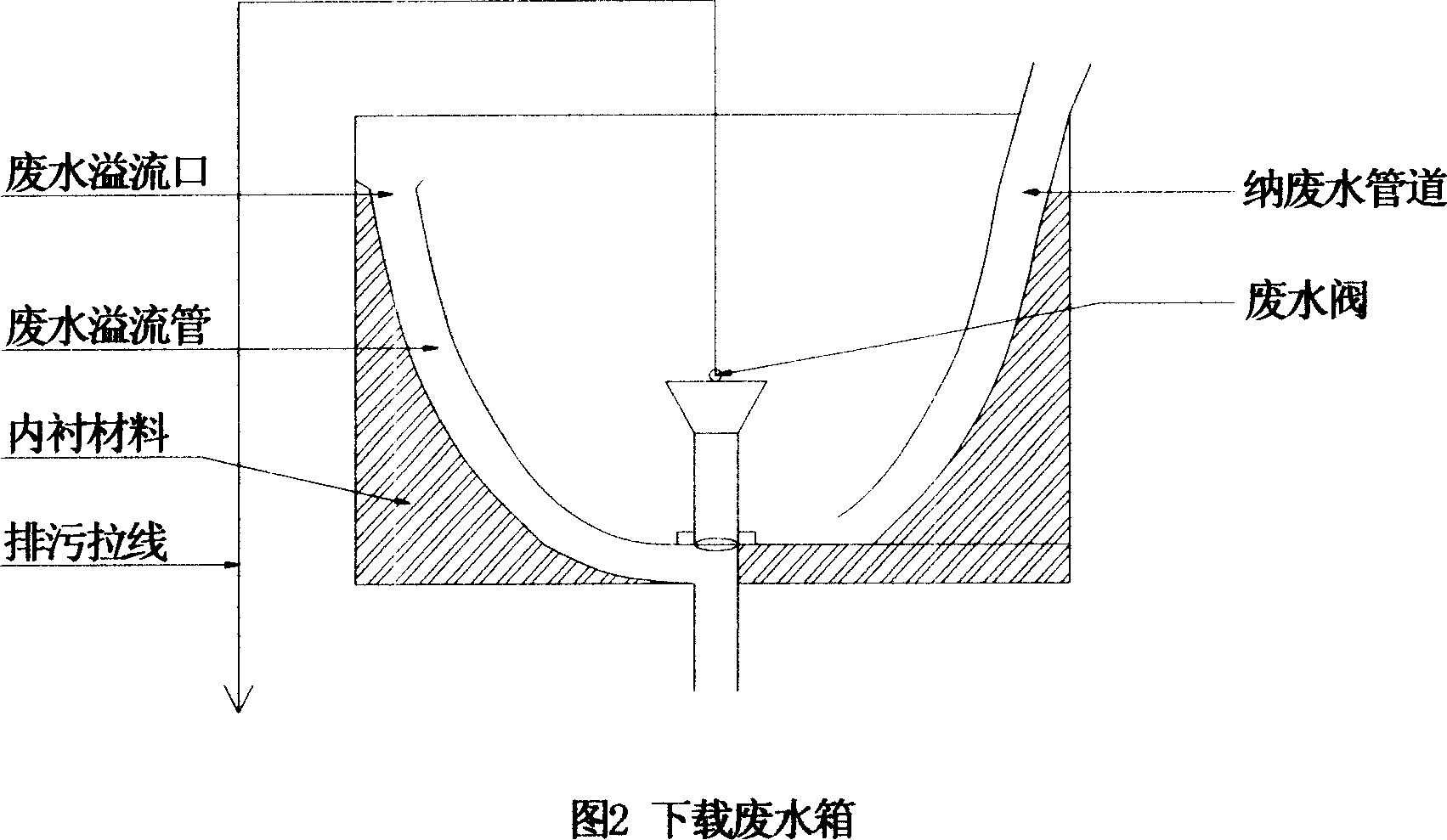

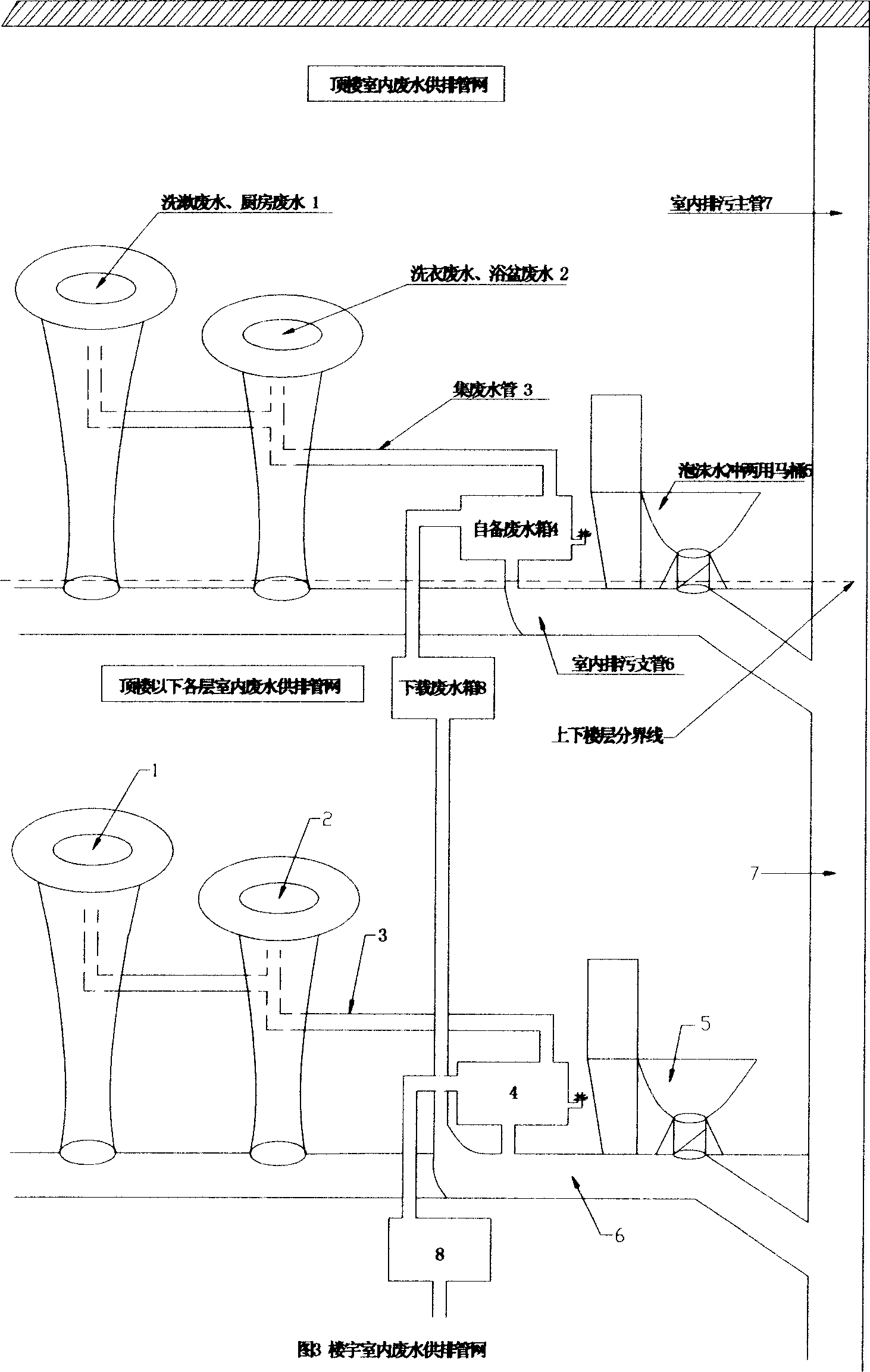

Technique for building water saving, fertilizer production cleaning, reducing domestic sewage discharge and promoting agriculture organification

InactiveCN101063314AProcess design is simple and convenientWorkmanship is feasibleBio-organic fraction processingSludge treatmentOrganificationEngineering

The invention discloses building water saving, fertilizer producing cleaning, domestic sewage and agriculture organic technology. The invention adopts the foam blocking, water flush dual purpose toilet seat, the interior supply discharge net and its sewage box mutually to largely save the tap water, secondly, high quality fertilizer is generated to realize building sewage discharge via the fertilizer producing clearing anaerobic device replacing the traditional septage disposing building sewage, thirdly, the agriculture is drove to develop to the organic technology via collecting organic fertilizer. The invention simultaneous discloses the construct graph of the interior sewage box and the engineering flow sheet of the building water saving, fertilizer producing cleaning and propelling of the organic technology.

Owner:北京市唐杰城市节能环保科技发展有限公司

Oxidation process

ActiveUS8449777B2Water treatment parameter controlIon-exchanger regenerationAdvanced oxidation processSewage

A batch process for the treatment of an aqueous solution so that the treated product is more desirable for disposal includes obtaining an influent batch of aqueous solution for treatment, treating the batch of solution by an advanced oxidation process. The advanced oxidation process including causing ozone to be mixed with the solution, maintaining the mixture of solution and ozone at a pressure above atmospheric for a time of at least two seconds. In a preferred embodiment of the process, the process includes continuously recirculating the fluid to be treated, through a recirculation conduit, the recirculation conduit including an ozone injector and the ozone injector is adapted to inject ozone into the aqueous solution as the aqueous solution circulates through an ozone injector. Influent to be treated may be selected from the group including sewage, septage, leachate, ballast or other aqueous solutions where it is desirable to treat the fluid prior to disposal, further treatment, or reuse. The process is carried out to improve a level of disinfection and / or denutrification of the effluent.

Owner:GREAT LAKES CLEAN WATER PARTNERSHIP

Oxidation process

InactiveUS20160318780A9Ion-exchanger regenerationEnergy based wastewater treatmentAdvanced oxidation processHigh pressure

Treatment of an aqueous solution to yield a product is more desirable for disposal by an advanced oxidation process. Ozone is mixed with the solution, and maintaining at an elevated pressure for a time. The process may include recirculation past injector that injects ozone into the solution. Influent may be sewage, septage, leachate, ballast, and so on. The process disinfects and / or denutrifies the effluent. It may include (a) back-to-back processing of batches (b) overlapping processing with a previously treated batch (c) off-gassing (d) repetitive high pressure and low pressure cycles (e) post processing steps, such as retention without addition of ozone for a period of time to permit flocculates longer to form (f) post process filtering to remove flocculates (g) simultaneous post-processing of one batch while another batch is being processed. The process may include the treatment of solutions containing pharmaceuticals.

Owner:GREAT LAKES CLEAN WATER PARTNERSHIP

Oxidation process

ActiveUS20090026147A1Water treatment parameter controlIon-exchanger regenerationBatch processingAdvanced oxidation process

A batch process for the treatment of an aqueous solution so that the treated product is more desirable for disposal includes obtaining an influent batch of aqueous solution for treatment, treating the batch of solution by an advanced oxidation process. The advanced oxidation process including causing ozone to be mixed with the solution, maintaining the mixture of solution and ozone at a pressure above atmospheric for a time of at least two seconds. In a preferred embodiment of the process, the process includes continuously recirculating the fluid to be treated, through a recirculation conduit, the recirculation conduit including an ozone injector and the ozone injector is adapted to inject ozone into the aqueous solution as the aqueous solution circulates through an ozone injector. Influent to be treated may be selected from the group including sewage, septage, leachate, ballast or other aqueous solutions where it is desirable to treat the fluid prior to disposal, further treatment, or reuse. The process is carried out to improve a level of disinfection and / or denutrification of the effluent.

Owner:GREAT LAKES CLEAN WATER PARTNERSHIP

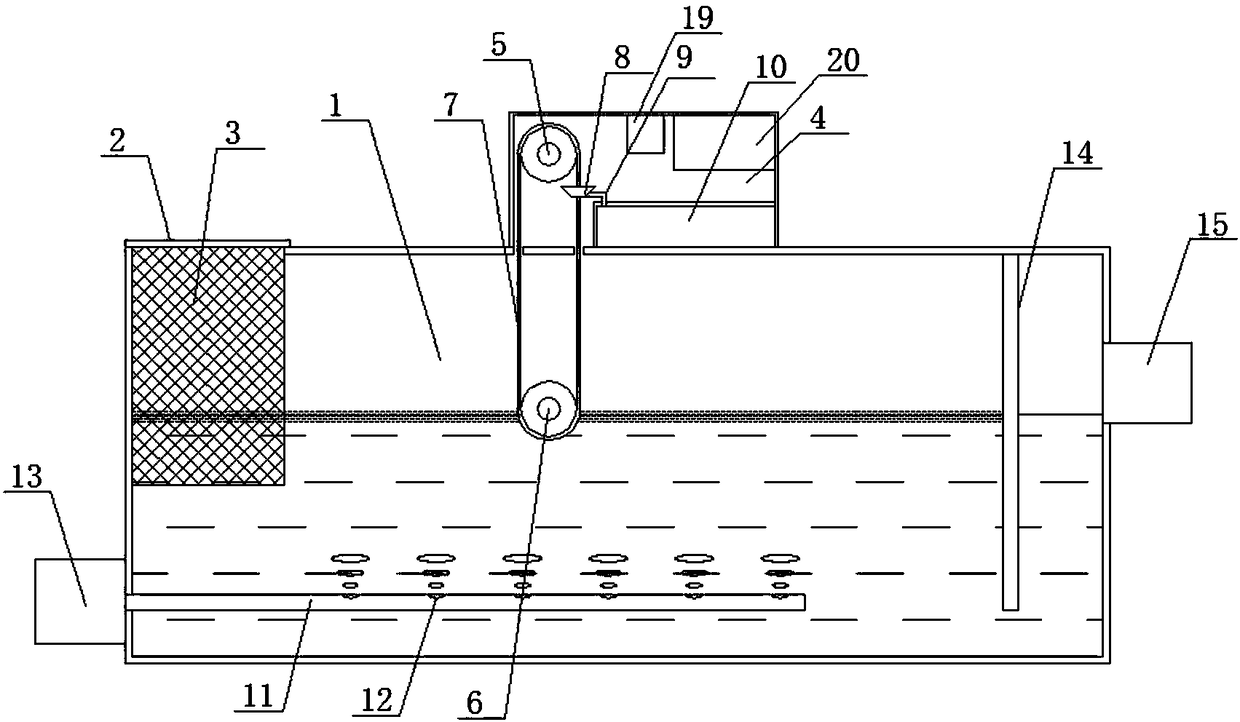

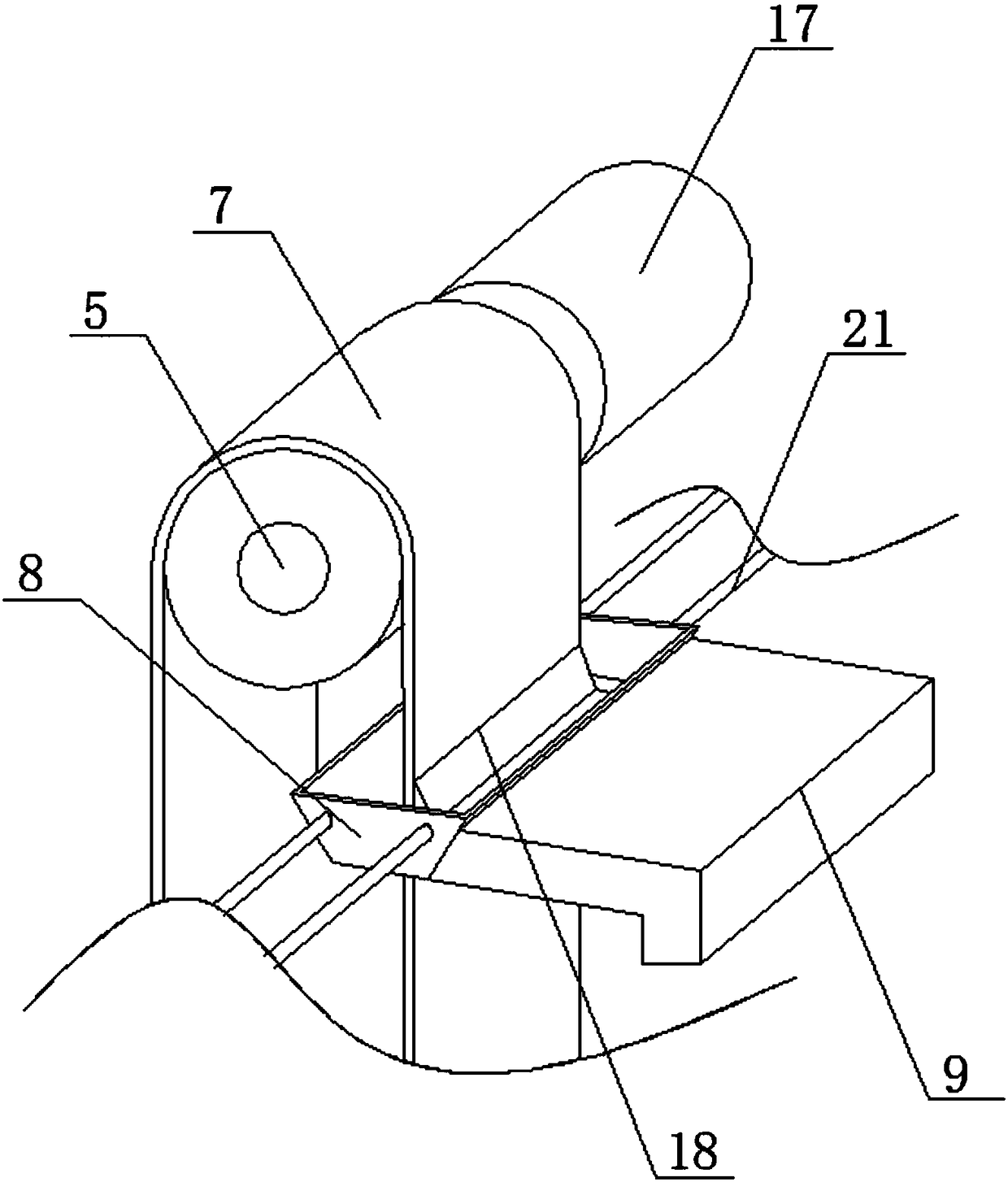

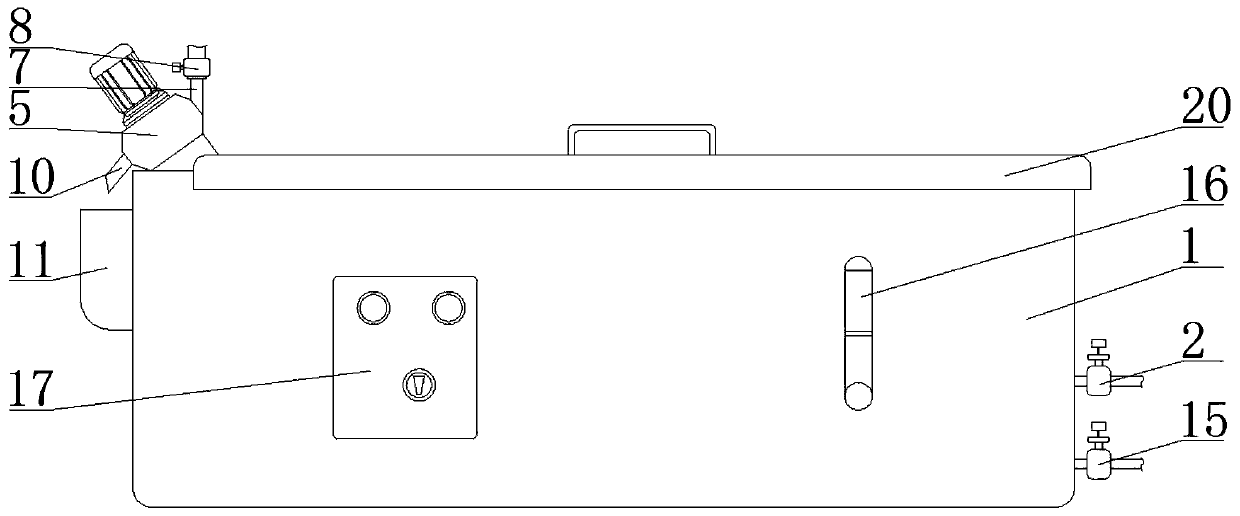

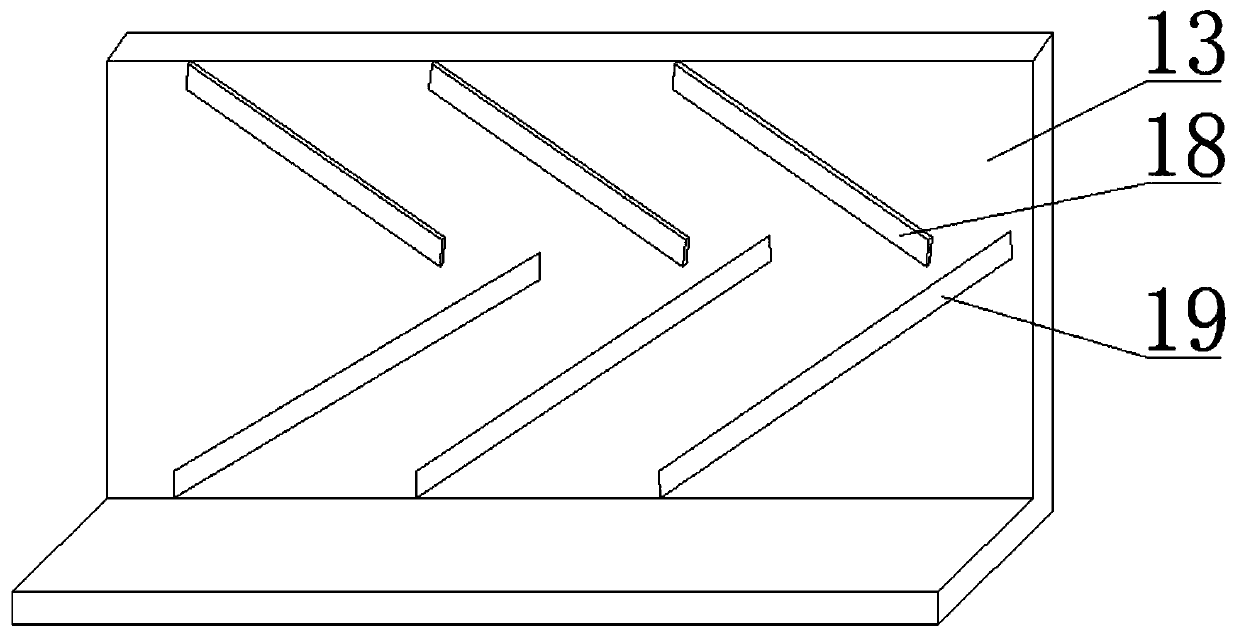

Domestic sewage environment-friendly treatment box

InactiveCN108569796AEasy to cleanEasy to pourSpecific water treatment objectivesTreatment involving filtrationApparent densitySuspended particles

The invention belongs to the technical field of sewage treatment and discloses a domestic sewage environment-friendly treatment box. The domestic sewage environment-friendly treatment box comprises asewage box, a dreg separation basket, an impurity removing box, an impurity sticking tape and an air floating generator, wherein a water inlet is formed in the left side of the top of the sewage box;the dreg separation basket is arranged at a part, located at the lower end of the water inlet, in the sewage box. According to the domestic sewage environment-friendly treatment box, the dreg separation basket is arranged and sewage can be primarily filtered; meanwhile, the dreg separation basket can be lifted out from the top of the sewage box and the dreg separation basket is convenient to topple over and wash and is more convenient to use; the air floating generator is arranged and can generate a lot of highly-dispersed tiny bubbles through air holes on an air pipe; the air bubbles are adhered to suspended particles in sewage to form floc with the apparent density smaller than the apparent density of water, and the floc floats on the water surface and is convenient to clean; the floc onthe water surface is stuck on the impurity sticking tape through the impurity sticking tape and is scraped into a collection box through a scraping plate; the floc in the collection box flows into animpurity storage box through a drainage pipe and suspended matters in the water are cleaned; the cleaned water can be utilized again.

Owner:芜湖杰汇环保科技有限公司

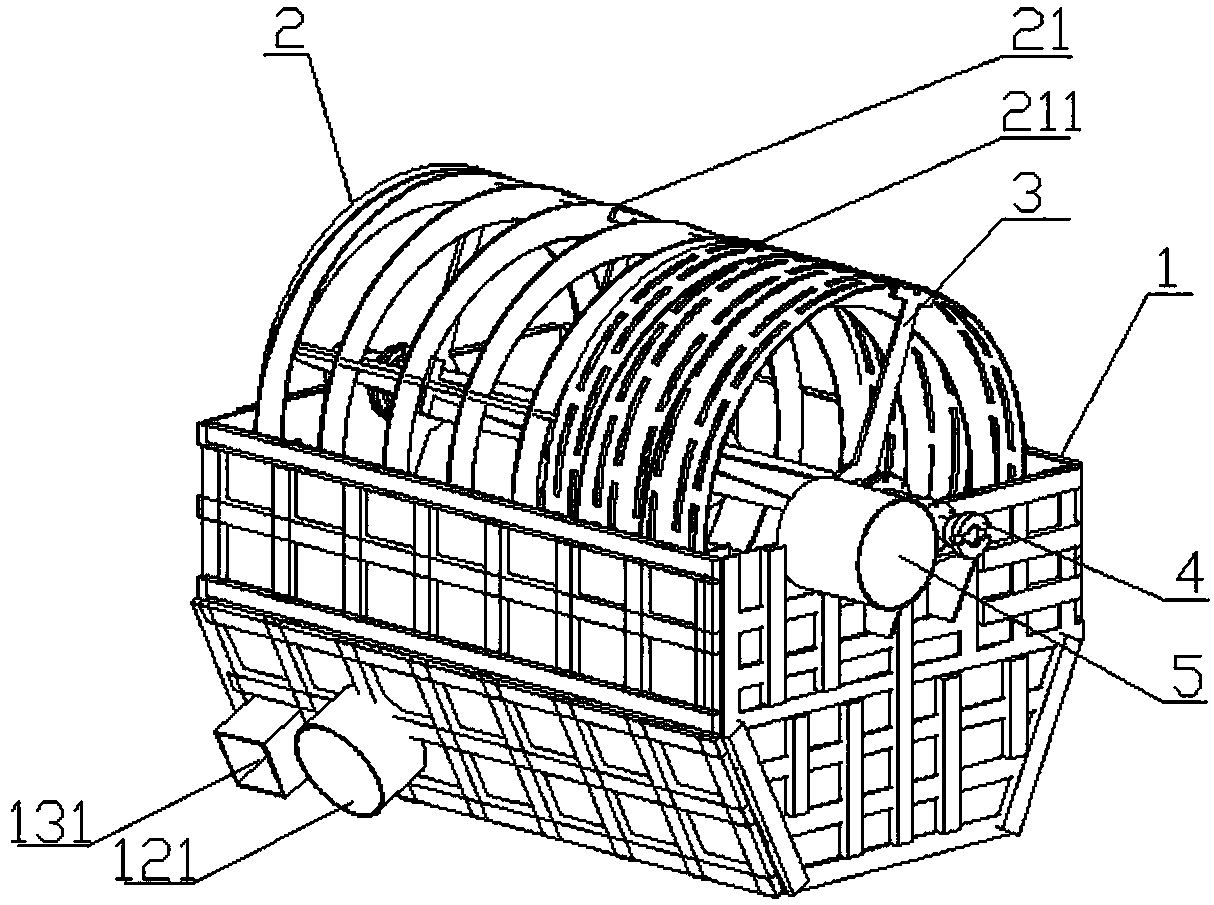

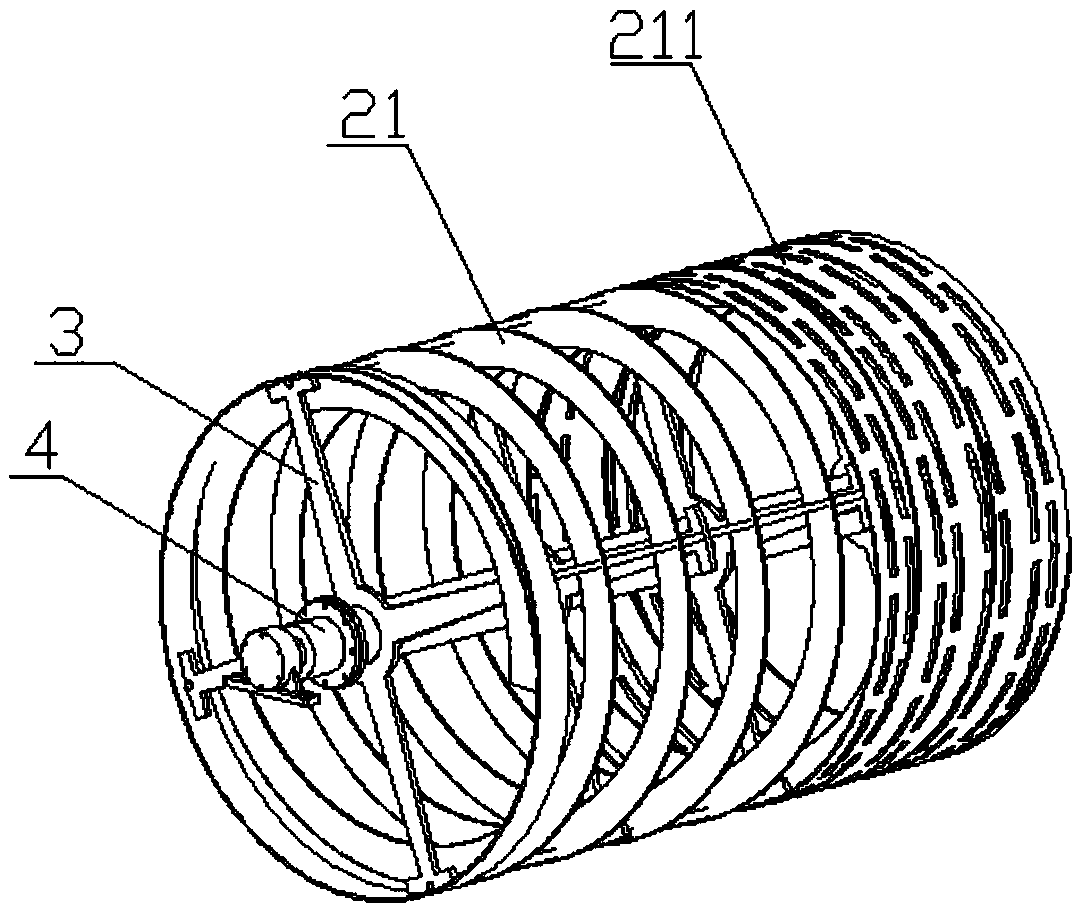

Slag separation and beneficiation device

The invention provides a slag separation and beneficiation device, and belongs to the technical field of mine equipment. The slag separation and beneficiation device comprises a groove body, a rollerand a main shaft; the roller comprises a spiral frame and a screen; the spiral frame is connected with the main shaft through a connecting piece; the screen wraps the spiral frame; the groove body isa hollow shell with an opened upper end; two ends of the main shaft are arranged on the side walls of the groove body; a separation plate is arranged in the groove body for dividing the groove body into a first discharge hopper and a second discharge hopper; a first discharge port is formed in the lower part of the first discharge hopper; a second discharge port is formed in the lower part of thesecond discharge hopper; a feed port is formed in the upper part of a feeding end of the first discharge hopper; and a gap is formed between the end, relative to the feed port, of the spiral frame andthe inner wall of the groove body. The slag separation and beneficiation device is smooth in slag removal, prolongs the service life of the main shaft and the screen, saves the cost, and improves theworking efficiency.

Owner:HEBEI IRON AND STEEL

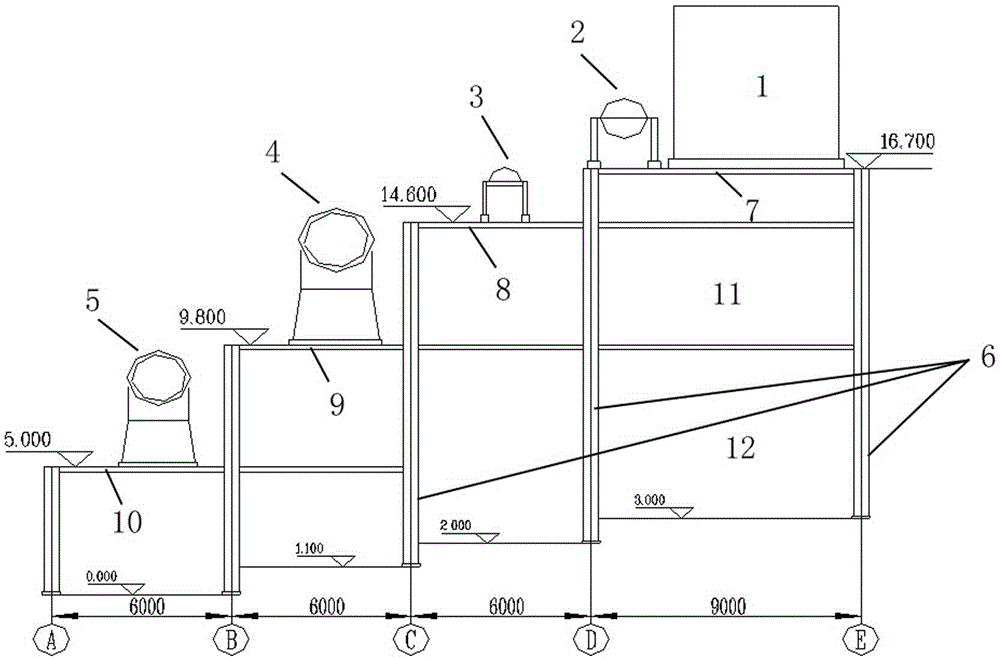

Magnetic separation combination workshop for iron separation from red mud

The invention relates to the field of metallurgical ore dressing and in particular relates to a magnetic separation combination workshop for iron separation from red mud. The magnetic separation combination workshop for iron separation from red mud comprises a stepped platform, a red mud mixing tank, a cylindrical slag isolation screen, a drum magnetic separator, a coarse magnetic separator and a fine magnetic separator; automatic flowing of a red mud slurry is realized, such that energy consumed by slurry conveying can be greatly saved; meanwhile, a power distribution chamber and a power distribution cabinet as well as the magnetic separation equipment are disposed in the same workshop, such that cables needed by power distribution can be saved.

Owner:云南九州再生资源开发有限公司

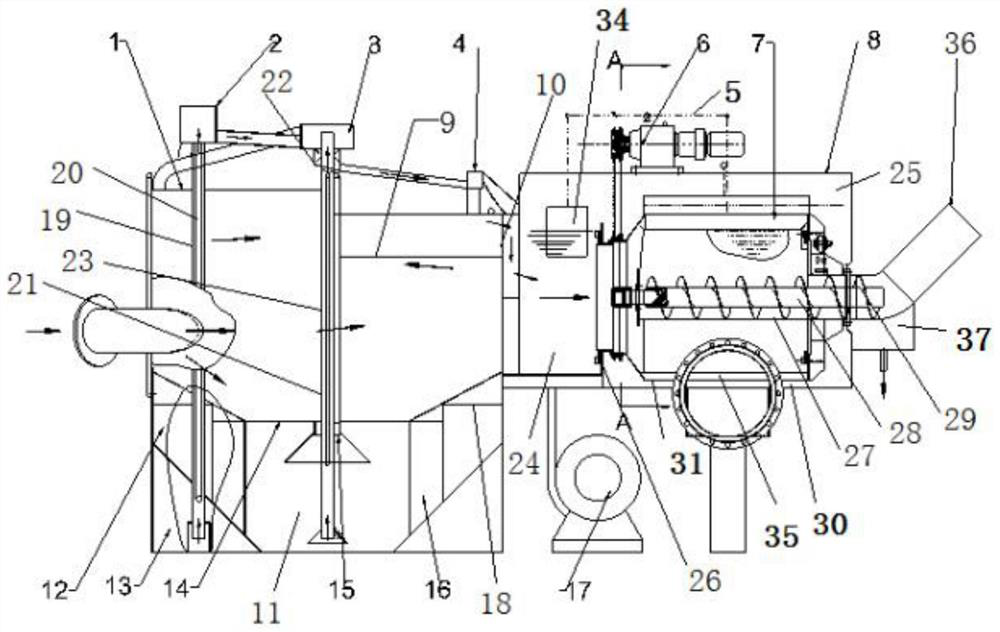

Oil-water separator for catering

InactiveCN111170540AGuaranteed Collision CoalescingTo promote floatingFatty/oily/floating substances removal devicesTreatment involving filtrationHelical bladeCommunicating vessels

An embodiment of the invention discloses an oil-water separator for catering. The oil-water separator comprises a separator box body, wherein a dreg separation chamber is fixedly installed in the separator box body; a servo motor is fixedly installed at the top of the dreg separation chamber; the output end of the servo motor extends into the dreg separation chamber and is fixedly connected with aspiral blade; the top of the dreg separation chamber fixedly communicates with a water inlet; and the top of the water inlet fixedly communicates with a liquid induction communicating vessel. According to the oil-water separator for catering, the dreg separation chamber, the spiral blade and a dreg outlet are cooperated with each other, so dreg in catering wastewater entering from the water inletis lifted and discharged, a filter residue basket can be prevented from being blocked when the filter residue basket is adopted; meanwhile, emulsified oil in water can react with small holes in the dreg separation chamber, and then demulsification operation is conducted, so the emulsified oil attached to dreg is subjected to demulsification and then separated from the dreg, and oil removal treatment does not need to be conducted on the dreg in a later period.

Owner:廊坊嘉杨鸣科技有限公司

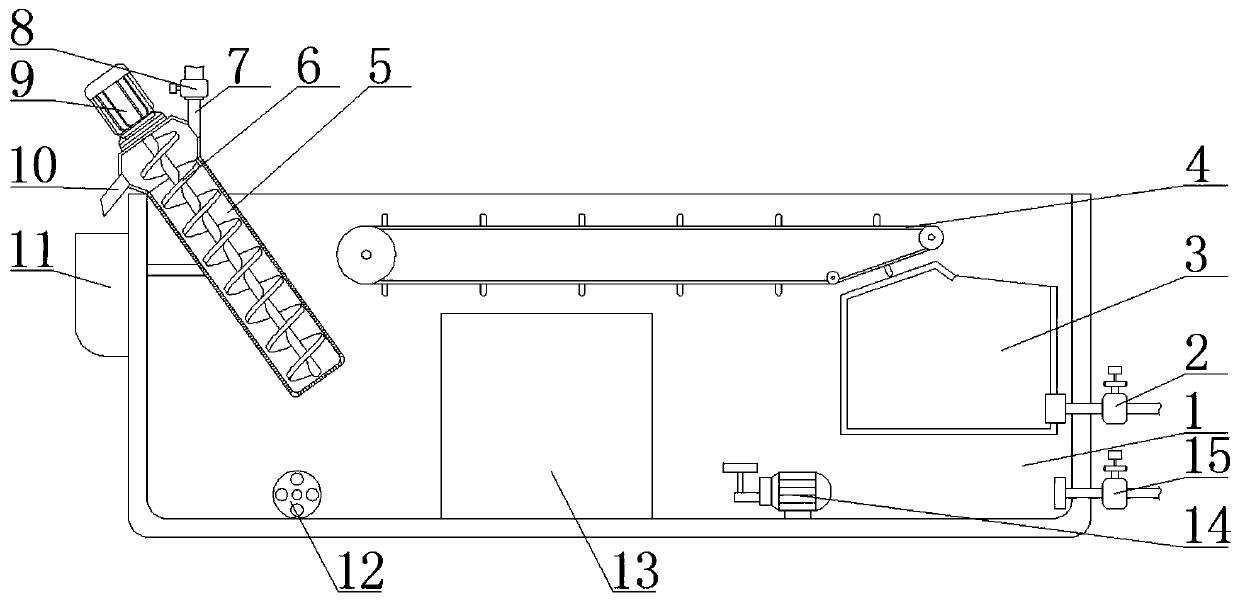

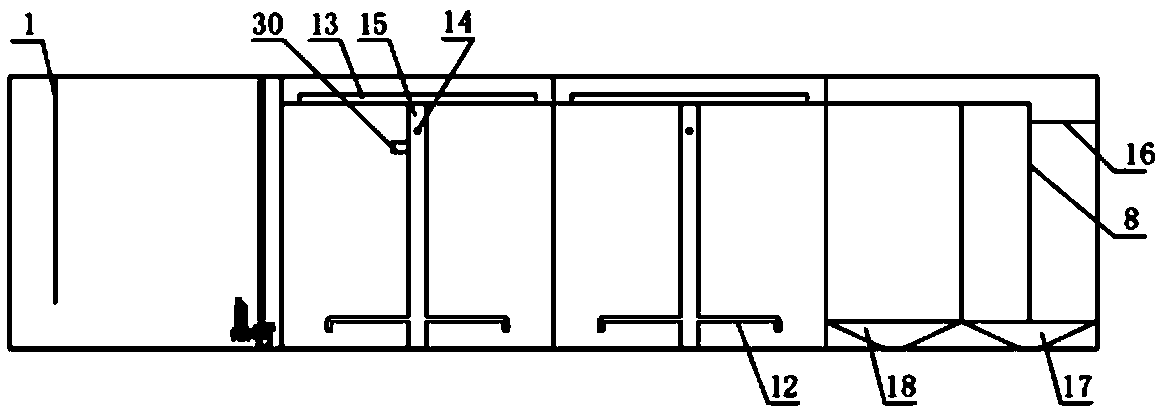

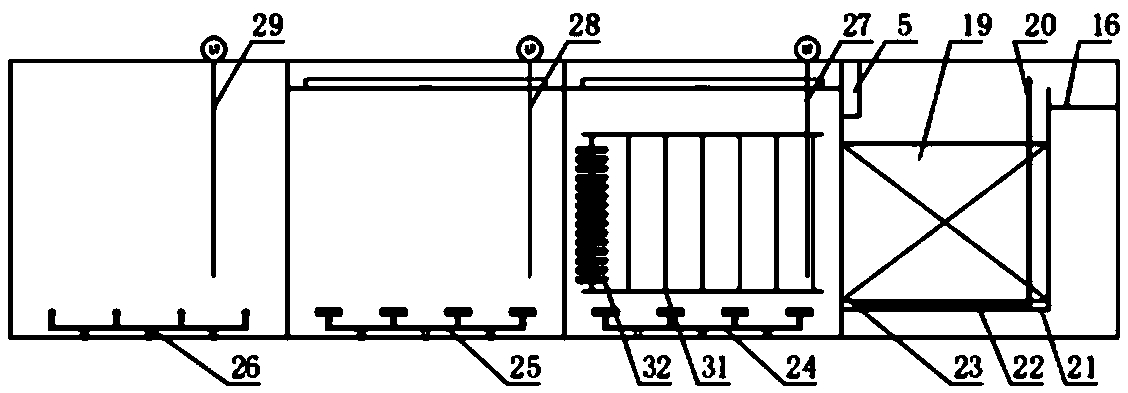

Zero-power-consumption horizontal cylinder type residue isolating equipment

The invention discloses zero-power-consumption horizontal cylinder type residue isolating equipment. The equipment comprises a screen drum device, a feeding device for supplying high-flow-speed ore pulp, a residue discharge tank for receiving slag of a particle size larger than the diameter of screen apertures, an ore receiving tank for receiving materials of a particle size smaller than the diameter of the screen apertures, and a supporting device. The screen drum device can rotate relative to the supporting device; the opening of the residue discharge tank communicates with a discharge opening of the screen drum device; a plurality of the screen apertures are formed in the side of the screen drum device; specially shaped bumper plates are arranged in the inner circumferential wall of theside of the screen drum device in a corresponding mode; a radial structure can be formed between two adjacent specially shaped bumper plates, so the slag falls when the screen drum rotates to a highposition; and the feeding device is provided with a sprayer for spraying the ore pulp and the spraying direction of the sprayer is targeted towards the specially shaped bumper plates, so kinetic energy of the high-speed ore pulp is converted to rotating kinetic energy of the screen drum device. The device can separate slap and materials without extra addition of driving force and manual cleaning is not required; and the device is simple in structure and convenient to use and can be popularized.

Owner:PANGANG GRP MINING

Kitchen waste wastewater treatment process

InactiveCN111003887AEffective purificationImprove practicalityTreatment using aerobic processesTreatment with anaerobic digestion processesCentrifugationWaste oil

The invention relates to the technical field of wastewater treatment, in particular to a kitchen waste wastewater treatment process and the process comprises the following steps: oil and slag separation: separating waste oil and waste slag in a separation tank under the action of centrifugation or gravity to obtain wastewater; pretreatment: allowing the wastewater to flowinto a pretreatment pool to be subjected to coagulation, flocculation and neutralization treatment in sequence; precipitation: enabling the wastewater to flow into a sedimentation tank for precipitation treatment; hydrolytic acidification treatment: enabling the wastewater to flow into a hydrolytic acidification tank for treatment; anaerobic treatment: enabling the wastewater to flow into an anaerobic tank for treatment; aerobic treatment: enabling the wastewater to flow into an aerobic tank for treatment; precipitation: enabling the wastewater to flow into the sedimentation tank for precipitation treatment; MBRfilm treatment: treating the wastewater by utilizing an MBR film; NR film treatment: treating the wastewater by using an NR film; and emission. The process has the advantage of environmental protection.

Owner:广东迈洁尔生物环保科技有限公司

Improved SBR sewage treatment device and method

PendingCN111423059AIncrease biomassLarge biomassWater treatment parameter controlSpecific water treatment objectivesWater treatment systemWater production

The invention discloses an improved SBR sewage treatment device. The device comprises a separated slag regulating tank with a lifting pump, wherein the rear end of the slag separation regulating tankis sequentially connected with two sets of parallel SBR tanks, a coagulating tank, a first-stage sedimentation tank, a second-stage sedimentation tank and a filler filter tank, and the SBR tanks are not provided with a decanter. According to the invention, water production is achieved through a top water mode, triangular weirs are arranged around the tops of the SBR tanks to collect SBR effluent,movable cuboid-shaped fixed filler assemblies are arranged in the tanks, and soft combined fillers are suspended; and the filler filter tank adopts a modular structure capable of being rapidly replaced and can be replaced by treatment units with different depths according to different effluent standards. The improved SBR sewage treatment device is a brand-new intelligent control sewage treatment system with the advantages of simple hydraulic structure, less power equipment, less fault points, low operation energy consumption, low maintenance cost, convenience in use, long service life, modularflexible combination and full automation.

Owner:水艺环保集团股份有限公司

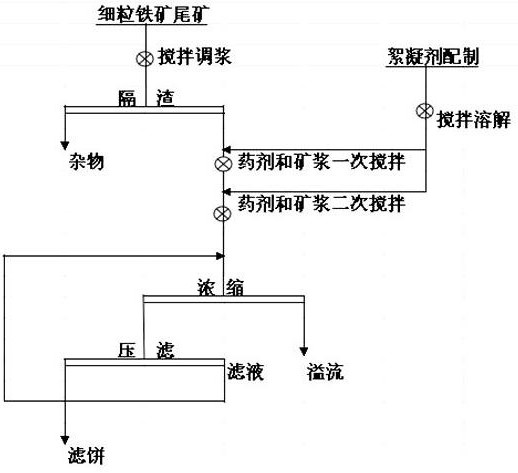

Concentration and dehydration process of ultra-fine tailings

The invention relates to a process for concentrating and dehydrating ultra-fine tailings, which is characterized in that the process comprises the following steps: 1) stirring the tailings slurry to make it into a suspended slurry; Slag separation to remove sundries; 3) Preparation of flocculant, adding to the slurry after separation of slag and stirring twice; 4) Mixing of flocculant and pulp, using a high-efficiency thickener to concentrate the pulp; 5) Concentration underflow It is sent to the filter press for pressure filtration, and the overflow is clarified and used as industrial circulating water. This solution greatly reduces the moisture content of the tailings, the filter cake is loose and does not need to be broken up, the forklift shovel does not stick to the bucket, the car transport unloads the material without sticking to the box, and there is no dripping during transportation. The quality requirements of the calibrator improve the utilization rate of tailings resources.

Owner:NANJING MEISHAN METALLURGY DEV +1

A decontamination and sand removal machine

ActiveCN107042025BLow costReduce shipping costsSettling tanks feed/dischargeTreatment involving filtrationEnvironmental engineeringSand filter

The invention discloses a decontamination and sand removal machine, comprising a cyclone grit chamber and a grid tank; the bottom of the cyclone grit chamber is provided with a central sand hopper, an extended sand tank, a slag separation orifice, an aeration sand washing device, The sand filter tank and the filtered water tank; the sand filter tank is arranged above the filtered water tank, and a filter screen is arranged in it, and the sand filter tank and the filtered water tank are connected; a water lifting device is installed in the filtered water tank, and the water lifting device includes a The outer wall of the water pipe is attached with a water-lifting gas pipe; the top of the water-lifting pipe is provided with a cylindrical water tank; the center of the grit chamber is equipped with a water-elution sand-extracting device, and the water-elution sand-extracting device includes a central sand-lifting pipe, a sand leakage groove, and a large cylinder with an open upper end The large cylinder is connected with the cylindrical water tank; the outer wall of the central sand-lifting pipe is attached with a sand-lifting gas pipe; the sand leakage tank is arranged at the bottom of the large cylinder and communicated with it; The invention provides a cleaning and sand removing machine with more reasonable structure, better cleaning and slag removal effect and lower energy consumption.

Owner:GUANGDONG XINHUAN ELECTROMECHANICAL EQUIP MFG CO LTD

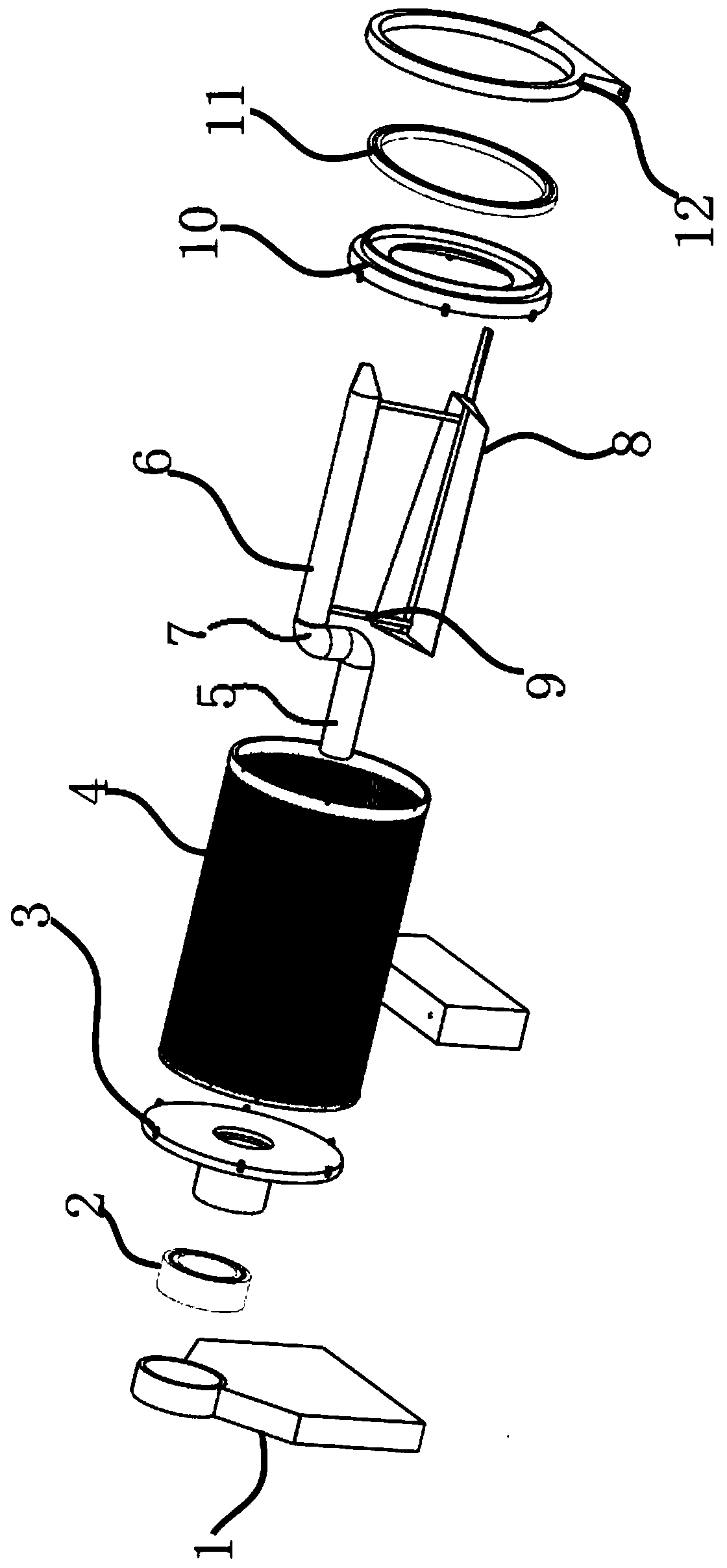

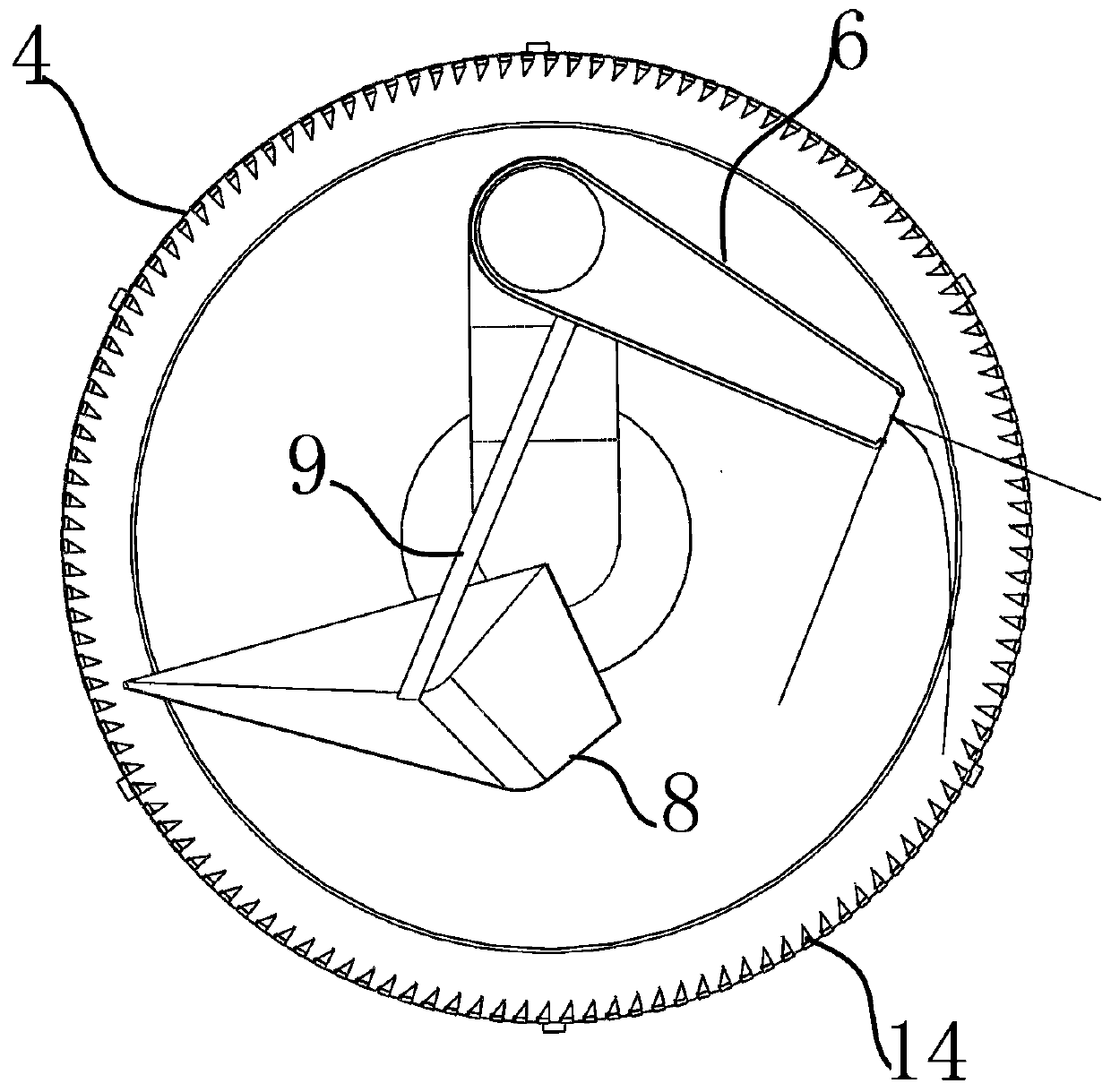

An Antique Stove-Type Medicine Pot Device

ActiveCN108078782BWith physical anti-dry functionScientific and compact structureElectrotherapyPharmaceutical product form changeMedicinal herbsEngineering

The invention discloses an antique heater type medicine pot device. The antique copper square base includes a stainless steel heating plate and a charcoal fire plate provided with heat through hole grooves; The swing spring hook for hanging the ancient barrel-shaped medicine tank; the ancient barrel-shaped medicine tank includes an outer tank and an inner tank with a hole in the slag separation for placing medicinal materials. There is a microporous interlayer filled with Xinjiang single-crystal tourmaline. The outer bottom of the outer tank has a rough surface and is coated with black heat-absorbing material; the side wall of the stainless steel tank cover is also provided with an interlayer filled with Xinjiang single-crystal tourmaline. Its advantages are: scientific and compact structure, separation of salt and medicinal materials; when in use, the prepared medicinal materials can be directly put into the inner tank with holes in the slag separation, which is convenient to use; durable; it is heated by light waves, energy saving and environmental protection, and also has a heater Function, can meet people's daily needs, has a very large promotion value.

Owner:许军华

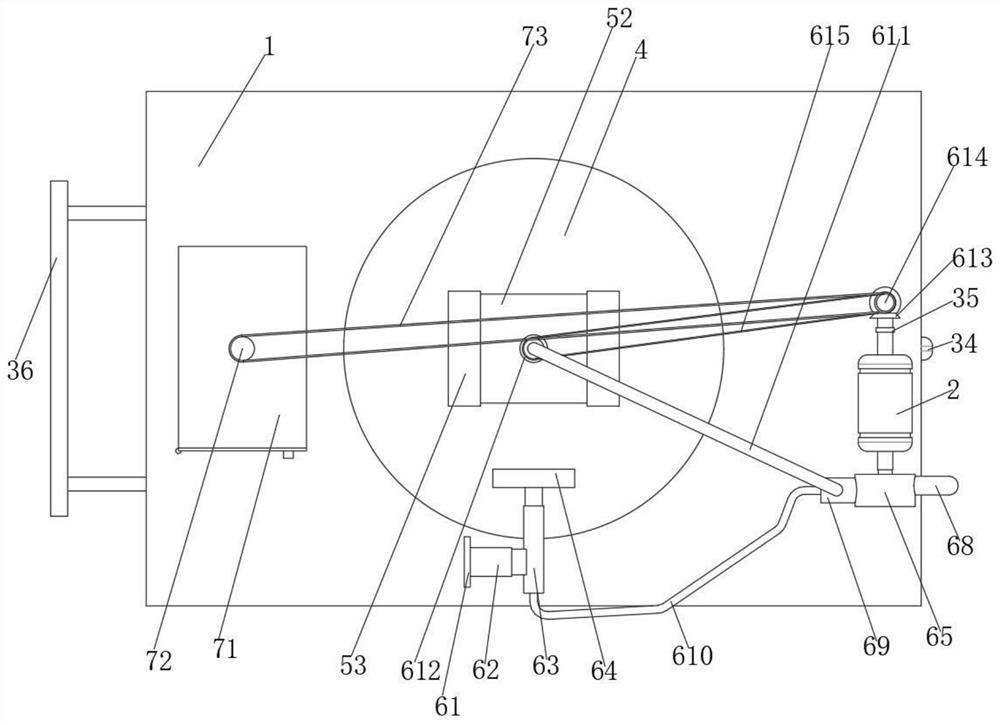

Scraper-adjustable sewage treatment air floatation unit

PendingCN111573910AAvoid disturbanceSimple structureMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSewageSanitary sewer

The invention relates to a scraper-adjustable sewage treatment air floatation unit. The air floatation unit comprises a tank body, the left side of the tank body is a fast-slow mixing tank, and a contact chamber and a separation chamber are arranged in the middle of the tank body. The fast-slow mixing tank is communicated with the two sides of the contact chamber through sewage pipelines. A releaser is arranged in the contact chamber, the releaser is connected with a gas dissolving system, and one side of the contact chamber is communicated with the separation chamber. The bottom of the separation chamber is communicated with a clear water tank through a clear water collecting system. A scum tank is arranged on one side of the separation chamber, and a scum separating plate is arranged between the separation chamber and the scum tank. A scum scraping mechanism is arranged above the scum separating plate and comprises a driving shaft which is rotationally mounted on the tank body through a bearing. The air floatation unit is simple in structure, the separation length is greatly reduced, sufficient dissolved air water exists at the rear end of the separation area, and the effluent quality is improved; the amount of water treated by a single air floatation unit is multiplied; the scum scraping mechanism is arranged on a single side of the separation chamber, scum is gradually taken away, and the separation chamber is prevented from being disturbed.

Owner:WUXI HUDONG MASCOT ENVIRONMENTAL ENG +1

Satellite hole plugging and reinjection multifunctional gas extraction hole sealing device

The invention discloses a satellite hole plugging and reinjection multifunctional gas extraction hole sealing device. The hole sealing device comprises an extraction pipe arranged in the front-back direction in the length direction, the front end of the extraction pipe is coaxially connected with a special-shaped grouting flow guide connector, the special-shaped grouting flow guide connector is coaxially connected with an extraction reducer union, a plurality of cylindrical bags are arranged on the extraction pipe at intervals, the extraction pipe is provided with an inner slurry outlet located in each bag and an outer slurry outlet located between every two adjacent bags, hoops for fixedly connecting the bags and the extraction pipe in a sealed mode are arranged at the positions, at a front end opening and a rear end opening of each bag, of the extraction pipe, and the rear end of the extraction pipe is provided with a slag separating, air guiding and slurry blocking end. The device is used for hole sealing in the early stage, grouting and leaking stoppage in the middle stage for drilling deformation and drilling gas leakage caused by roadway stress concentration, and water injection in the later stage after coal seam drilling construction is completed, the dust falling effect is achieved on coal mining infiltration and stabilization of a coal body, one set of device has multiple purposes, and normal drilling gas extraction in the whole extraction period is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

Residue separation oil remover

PendingCN113264570AAchieve separationEasy to separateFatty/oily/floating substances removal devicesLiquid separationOil and greaseOil intake

The invention discloses a residue separation oil remover which comprises a box body and an oil collecting box. A water inlet and a water outlet are formed in the box body; the oil collecting box is arranged in the box body, the top of the oil collecting box is provided with an oil inlet for grease to flow in, the oil collecting box is provided with an oil outlet, and the water inlet flow of the water inlet is larger than the water outlet flow of the water outlet, so that the liquid level in the box body rises, and grease on the upper layer of the liquid level flows into the oil collecting box. According to the residue separation oil remover, the separation degree of grease and water can be improved, the separated water layer automatically flows out through the water outlet, and the separated grease layer is discharged through the oil drain valve by the cleaner so that the working time of the cleaner in the oil discharge process can be saved, and the working efficiency of the cleaner is improved.

Owner:深圳市康灵盾智能厨具设备有限公司

Internal cleaning device for hydraulic valve block machining and cleaning method thereof

InactiveCN113731912AEasy to moveEasy to cleanDrying gas arrangementsCleaning using liquidsElectric machineryStructural engineering

The invention discloses an internal cleaning device for hydraulic valve block machining and a cleaning method thereof, and relates to the technical field of hydraulic valve block cleaning. The internal cleaning device comprises a circular through groove plate, and a double-shaft motor is fixedly connected with the middle of the right side of the top of the circular through groove plate through a connecting block. According to the internal cleaning device for hydraulic valve block machining and the cleaning method thereof, the double-shaft motor provides power support, a bucket-shaped filter screen body, a stabilizing plate, a telescopic transverse body, a telescopic water pipe, a hollow through net body, a water pump, a water tank box, a slag separation structure, a slag separation net plate, an eccentric wheel rod, a lower conveying belt, a water pumping bent pipe, a water drainage main pipe, a hose, a bent water pipe, a water spraying body, a bevel gear, a bevel gear rod and a conveying connecting belt are used, so that the hydraulic valve block is conveniently and comprehensively cleaned; and meanwhile, residues are removed in time, a telescopic adjusting seat, a bidirectional telescopic plate and a clamping block body are used for conveniently fixing the hydraulic valve block, and a drying box, a fan body, an upper conveying belt, a heating plate and a bearing net plate are used for conveniently drying the cleaned hydraulic valve block.

Owner:湖南兴众科技有限公司

Assembled upwelling medium filtering device

PendingCN111252929AAvoid scourReduce distractionsFatty/oily/floating substances removal devicesWater contaminantsSurface waterMechanical engineering

The invention discloses an assembled upwelling medium filtering device, comprising a box body, wherein a baffle is arranged in an inner cavity of the box body; the baffle divides the inner cavity of the box body into a first-stage treatment chamber and a second-stage treatment chamber; a water inlet pipe is connected to the water inlet side of the box body, and a water outlet pipe is connected tothe water outlet side of the box body; a residue separation assembly and an upwelling medium filter are arranged in the second-stage treatment chamber; the residue separation assembly comprises an outer residue separation frame, an oil absorption rod and a residue separation breast board; the residue separation breast board is vertically suspended and fixed in the box body; the outer residue separation frame is arranged on one side, close to the baffle, of the residue separation breast board; the oil absorption rod is enclosed in the outer residue separation frame; the upwelling medium filteris arranged between the residue separation breast board and the water outlet side of the box body; and the upwelling medium filter is composed of a medium filtering frame and a medium filler. The device can achieve the effects of runoff control, retention and storage of surface water, reduction of flood peak flow, reduction of non-point source pollution, improvement of effluent quality standard, rainwater recycling and the like, and is low in maintenance cost.

Owner:苏州汇义德科技有限公司

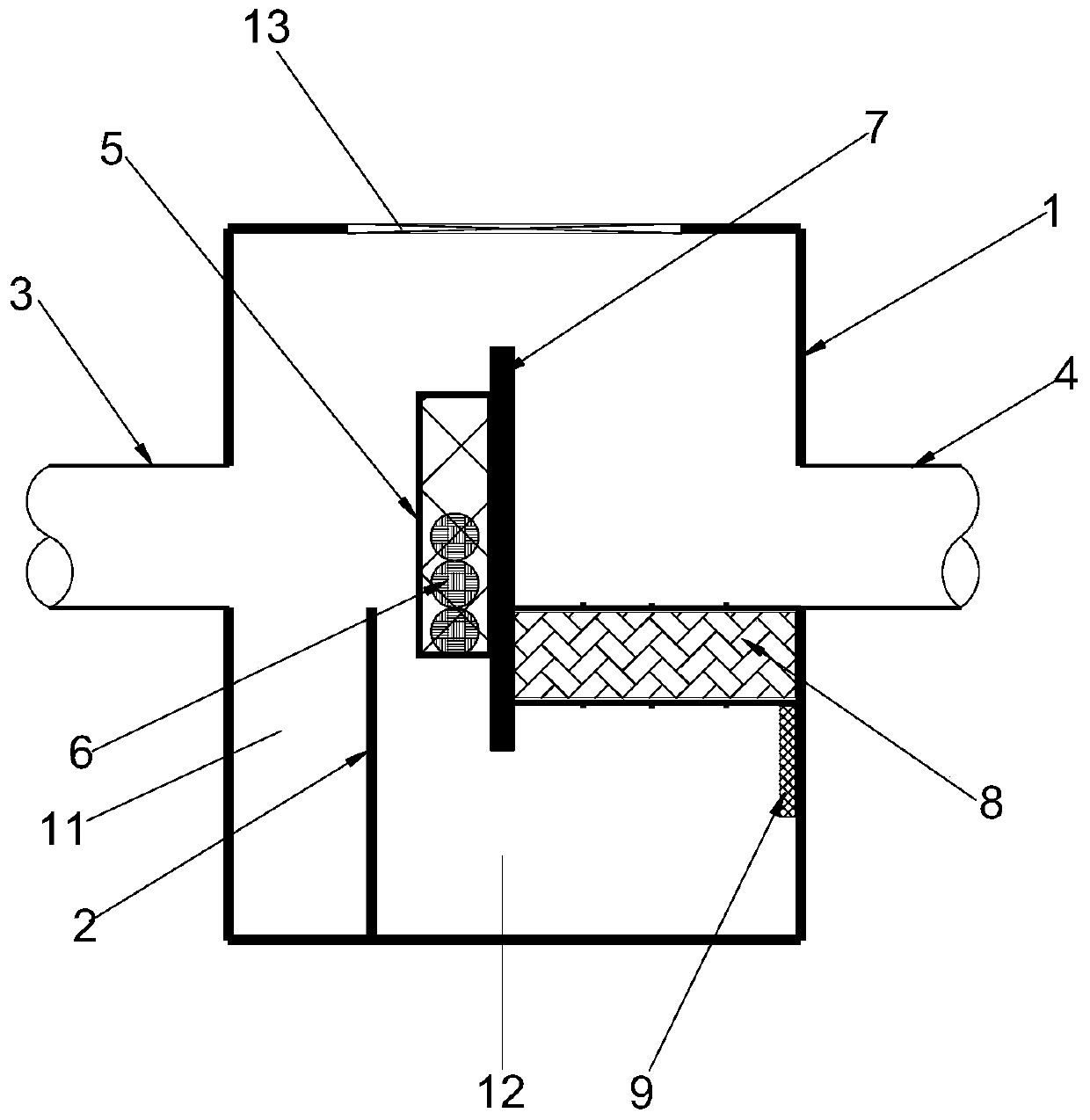

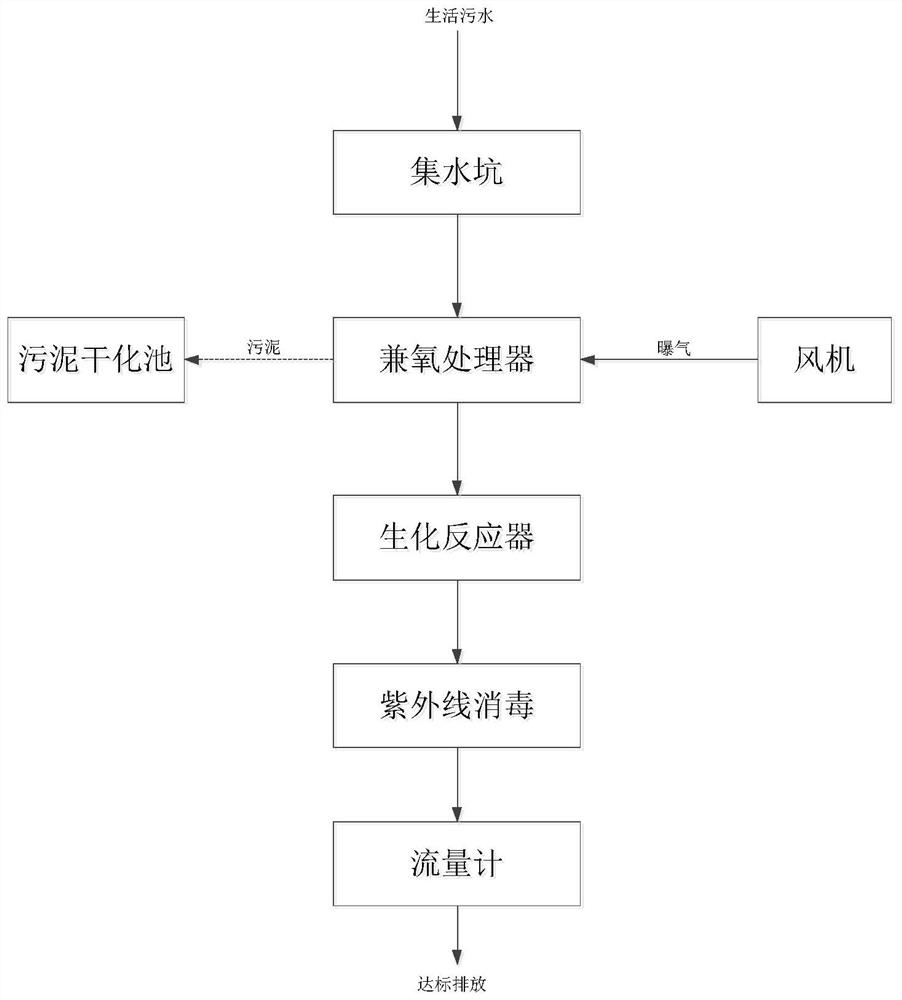

Domestic sewage treatment system and method

PendingCN114230092AEasy to handleAvoid influenceFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationParticulatesOil separation

The invention discloses a domestic sewage treatment system and method. The domestic sewage treatment system comprises a sump, a facultative treatment device, a biochemical reactor and a sludge drying tank, the sump is used for storing domestic sewage; the facultative treatment device is connected with the water collecting pit through a pipeline, the facultative treatment device comprises three layers of water treatment structures, the upper layer is a residue and oil separation layer and is used for removing oil residues and oil stains in domestic sewage, and the middle layer is an aerobic biological filler layer and is used for carrying out aerobic biological treatment; the lower layer is an anaerobic biological filler layer for anaerobic biological treatment; the biochemical reactor is used for intercepting particulate matters and carrying out an aerobic biochemical reaction; and the sludge drying tank is used for collecting sludge in the facultative treatment device. The domestic sewage treatment effect and quality are improved, and the cost is saved.

Owner:融碳科技(成都)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com