Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194 results about "Advanced oxidation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Advanced oxidation processes (abbreviation: AOPs), in a broad sense, are a set of chemical treatment procedures designed to remove organic (and sometimes inorganic) materials in water and wastewater by oxidation through reactions with hydroxyl radicals (·OH). In real-world applications of wastewater treatment, however, this term usually refers more specifically to a subset of such chemical processes that employ ozone (O₃), hydrogen peroxide (H₂O₂) and/or UV light. One such type of process is called in situ chemical oxidation.

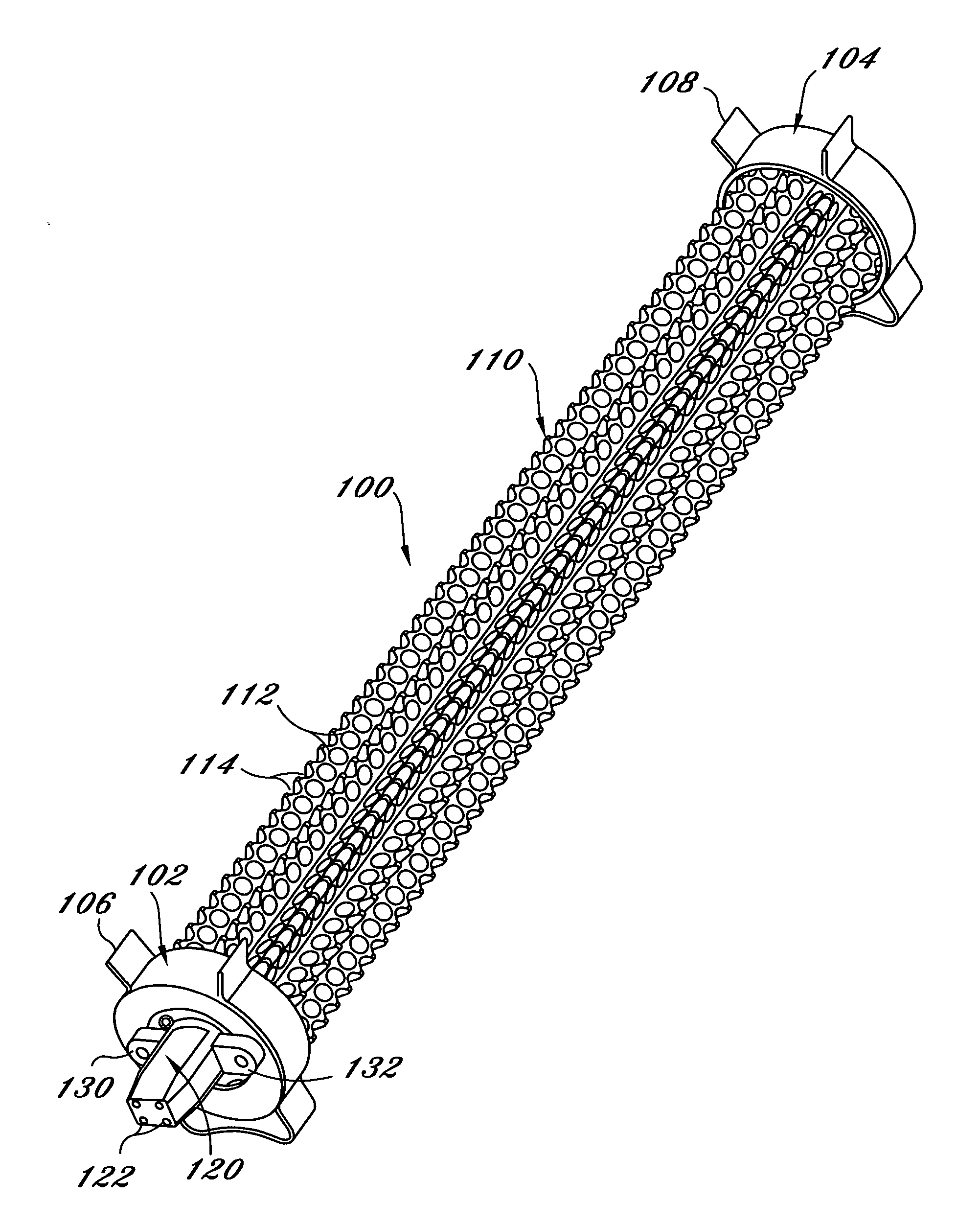

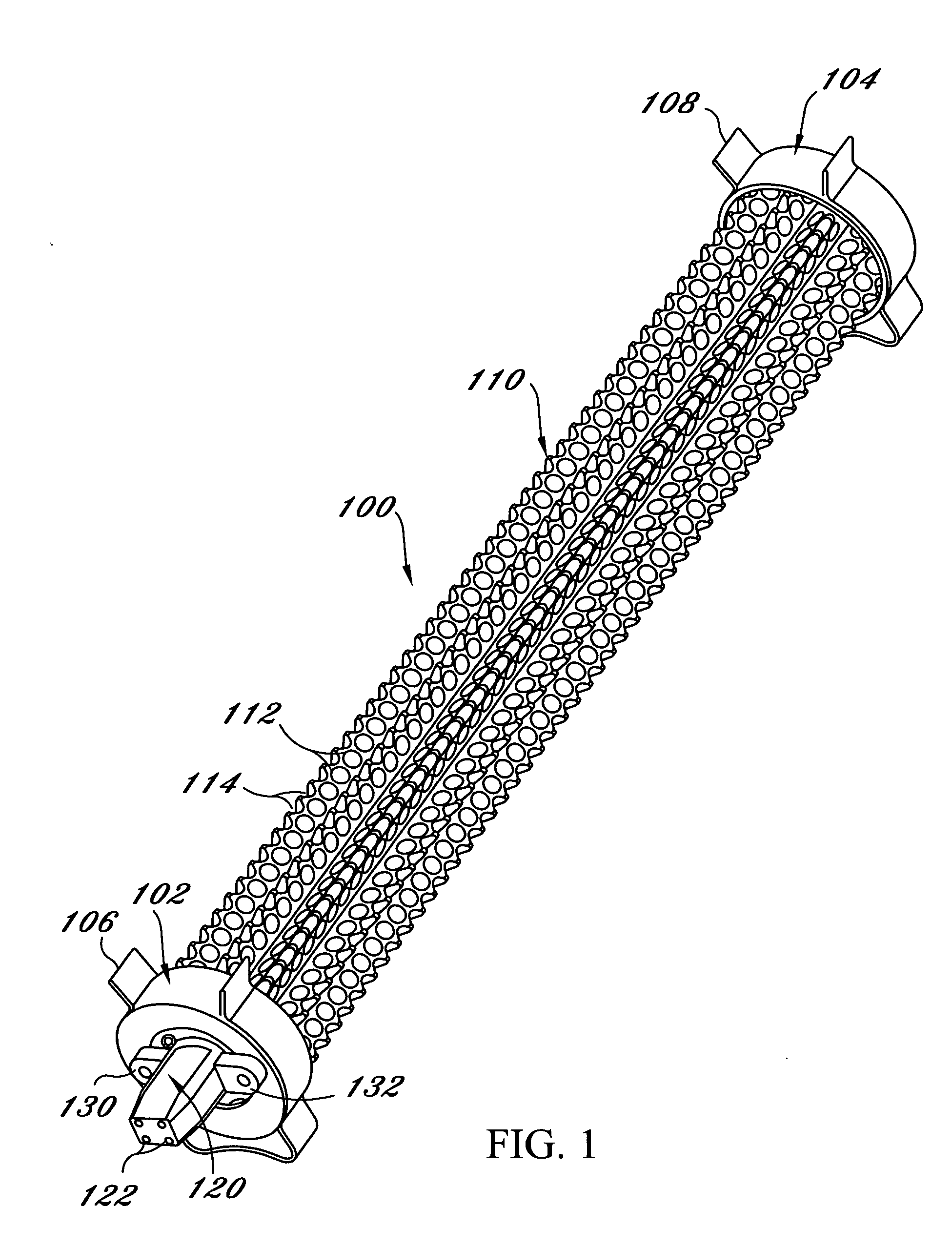

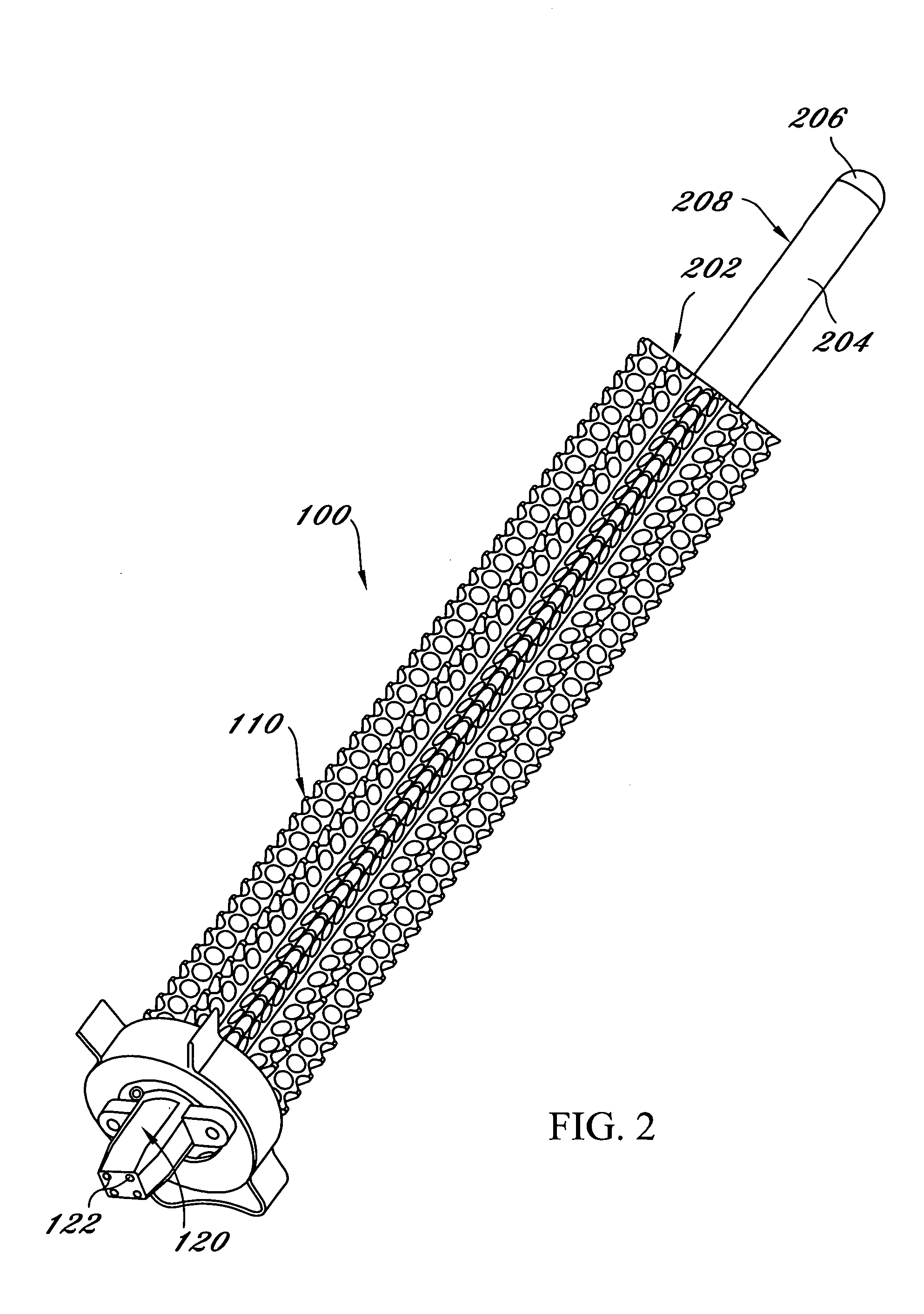

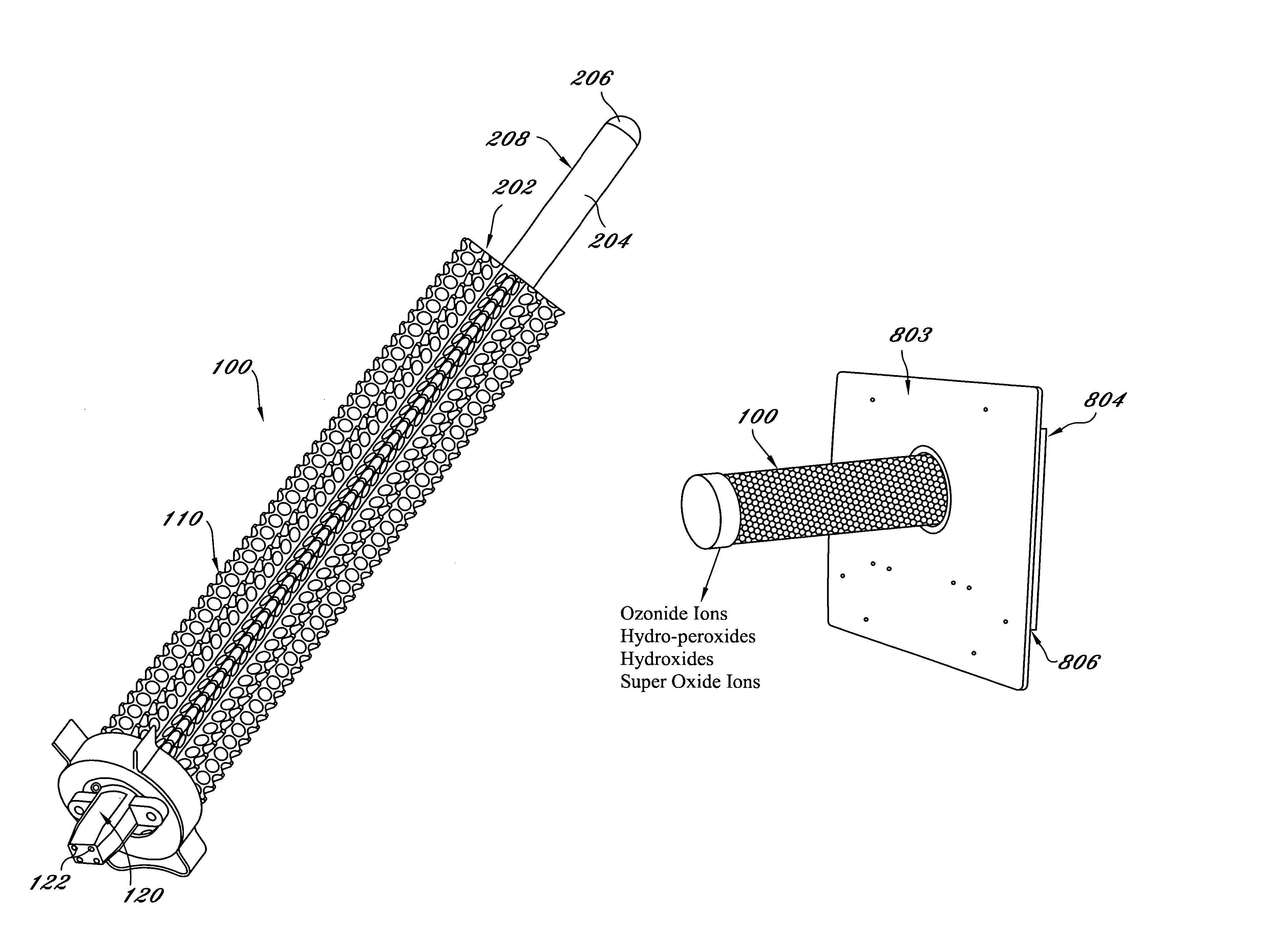

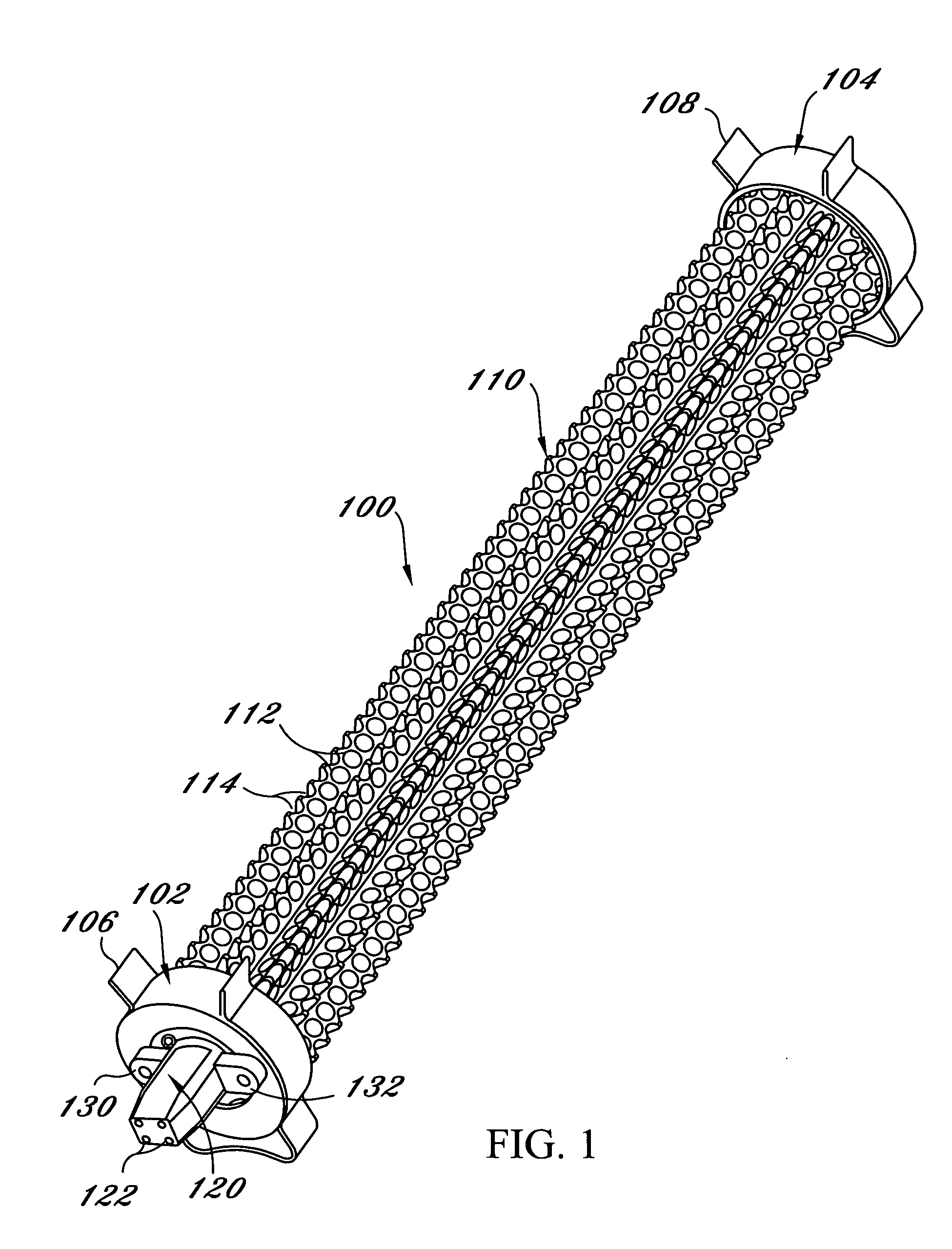

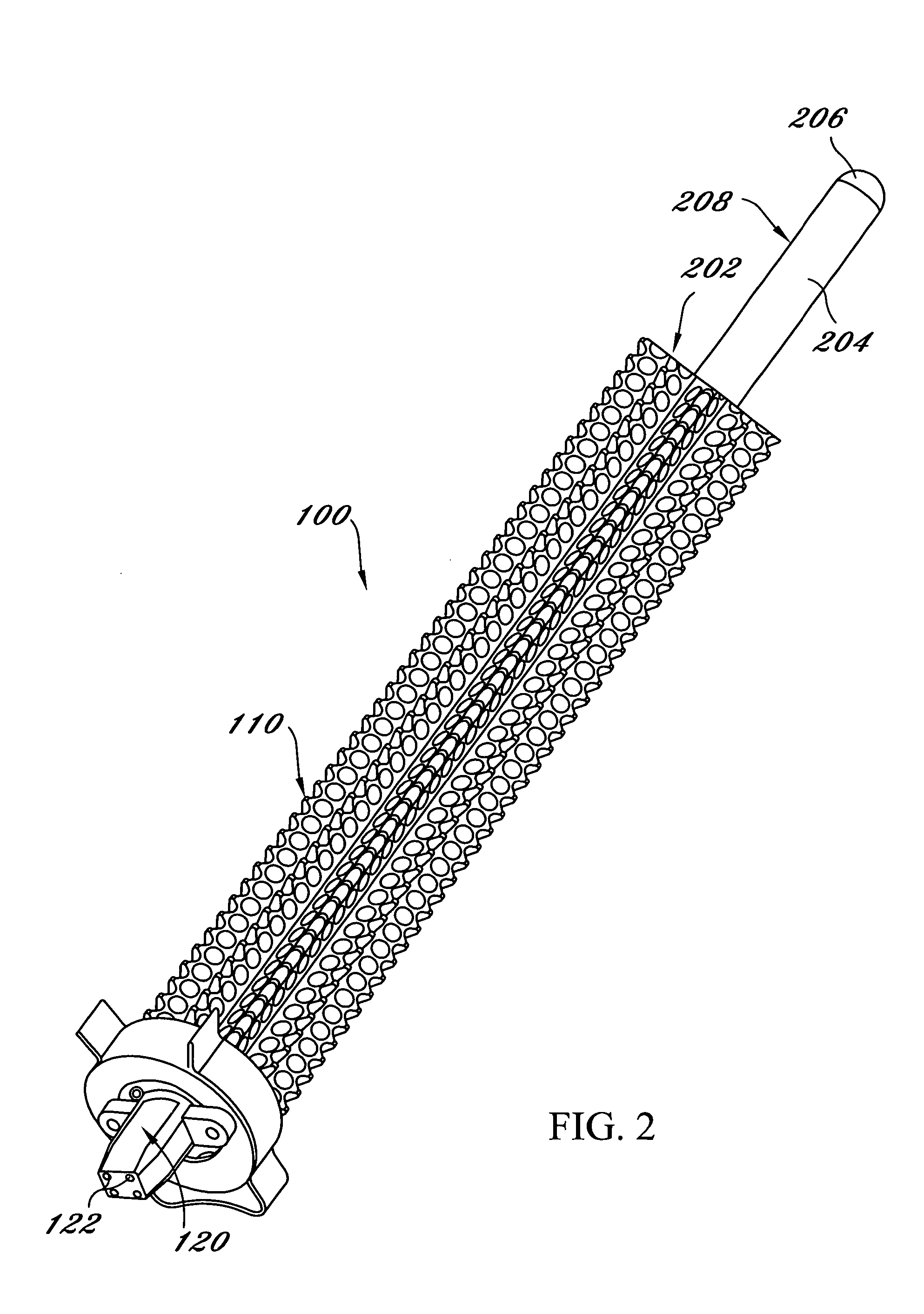

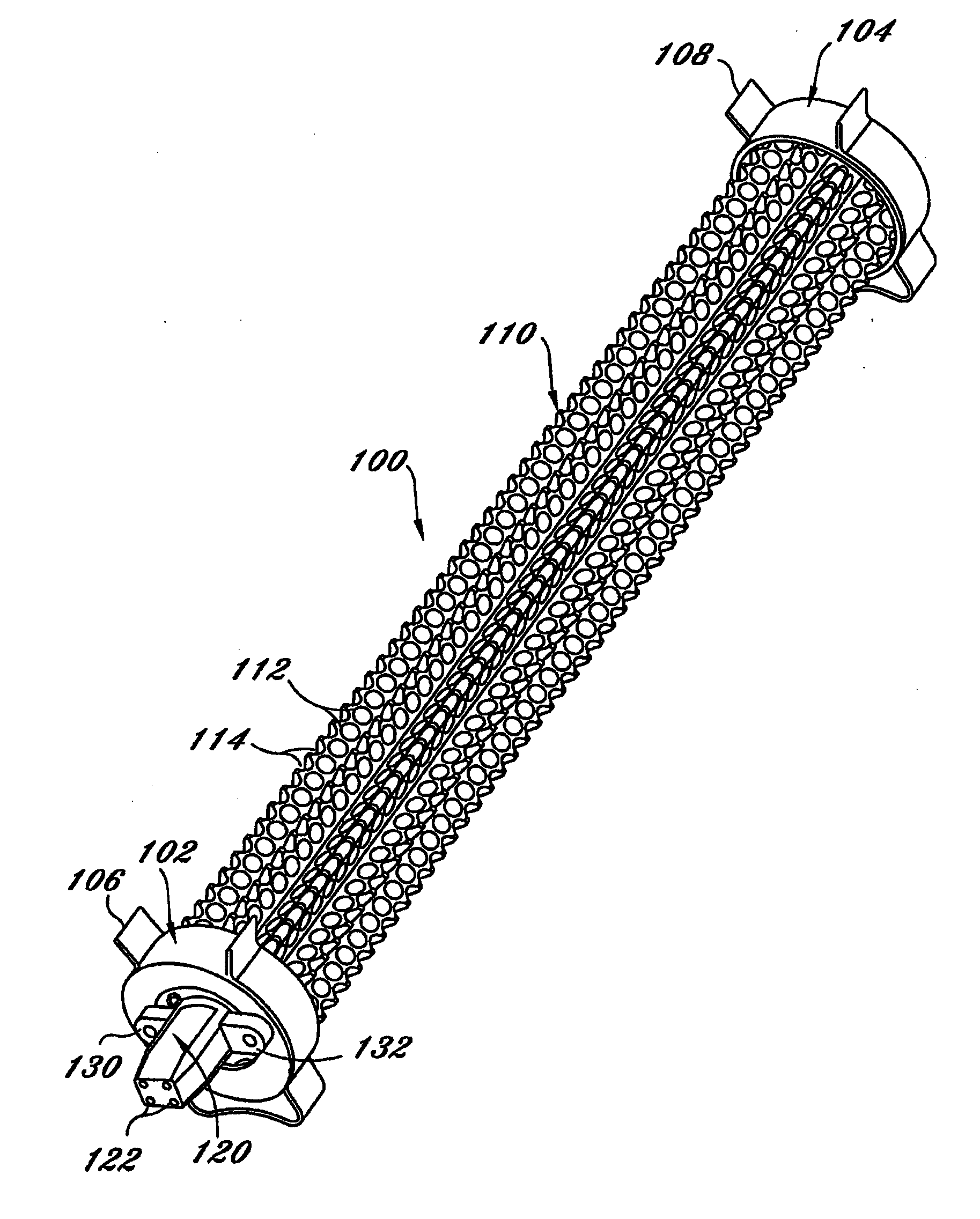

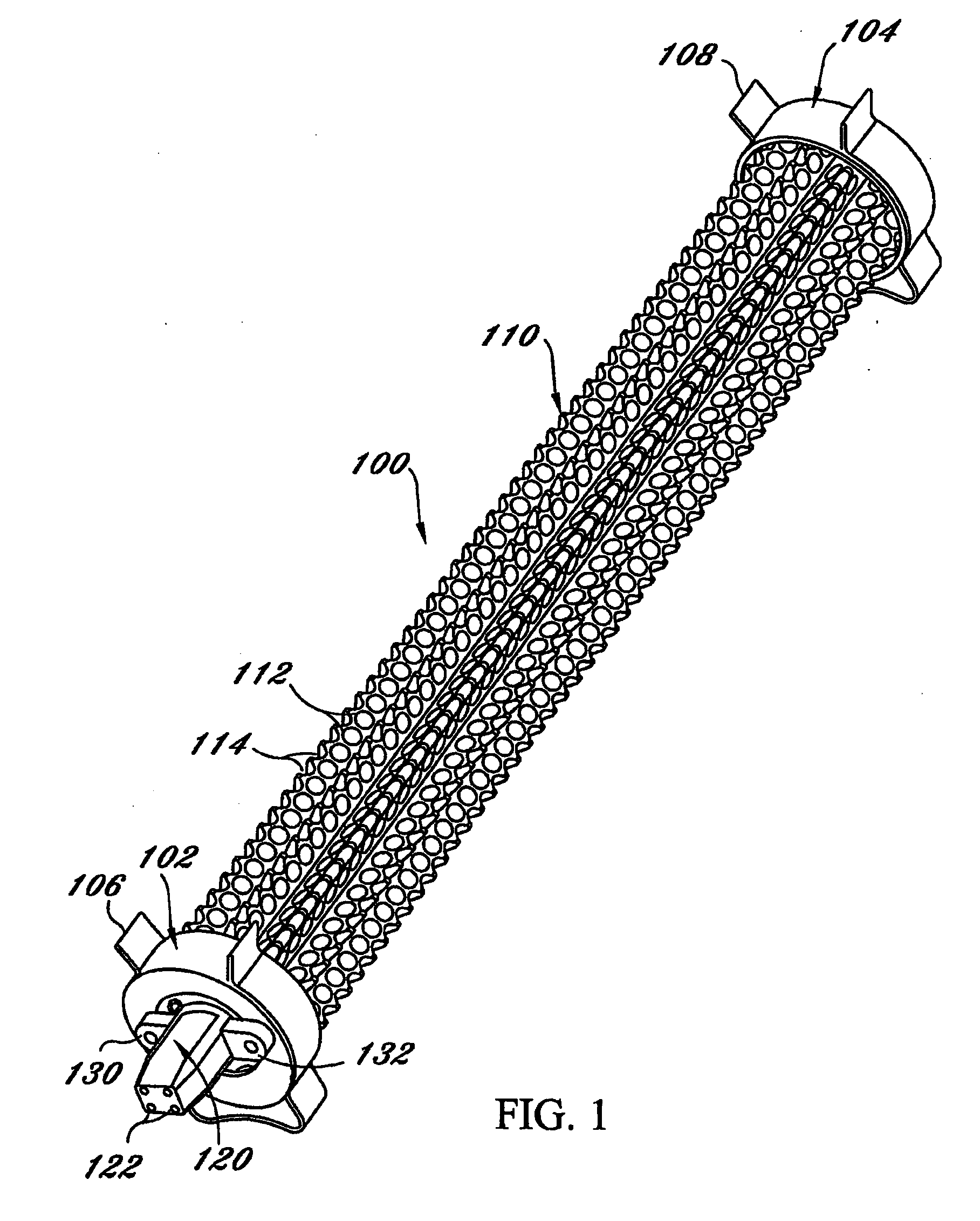

Device, system and method for an advanced oxidation process using photohydroionization

ActiveUS20050186124A1Efficiently formedMechanical apparatusLighting and heating apparatusAdvanced oxidation processUltraviolet lights

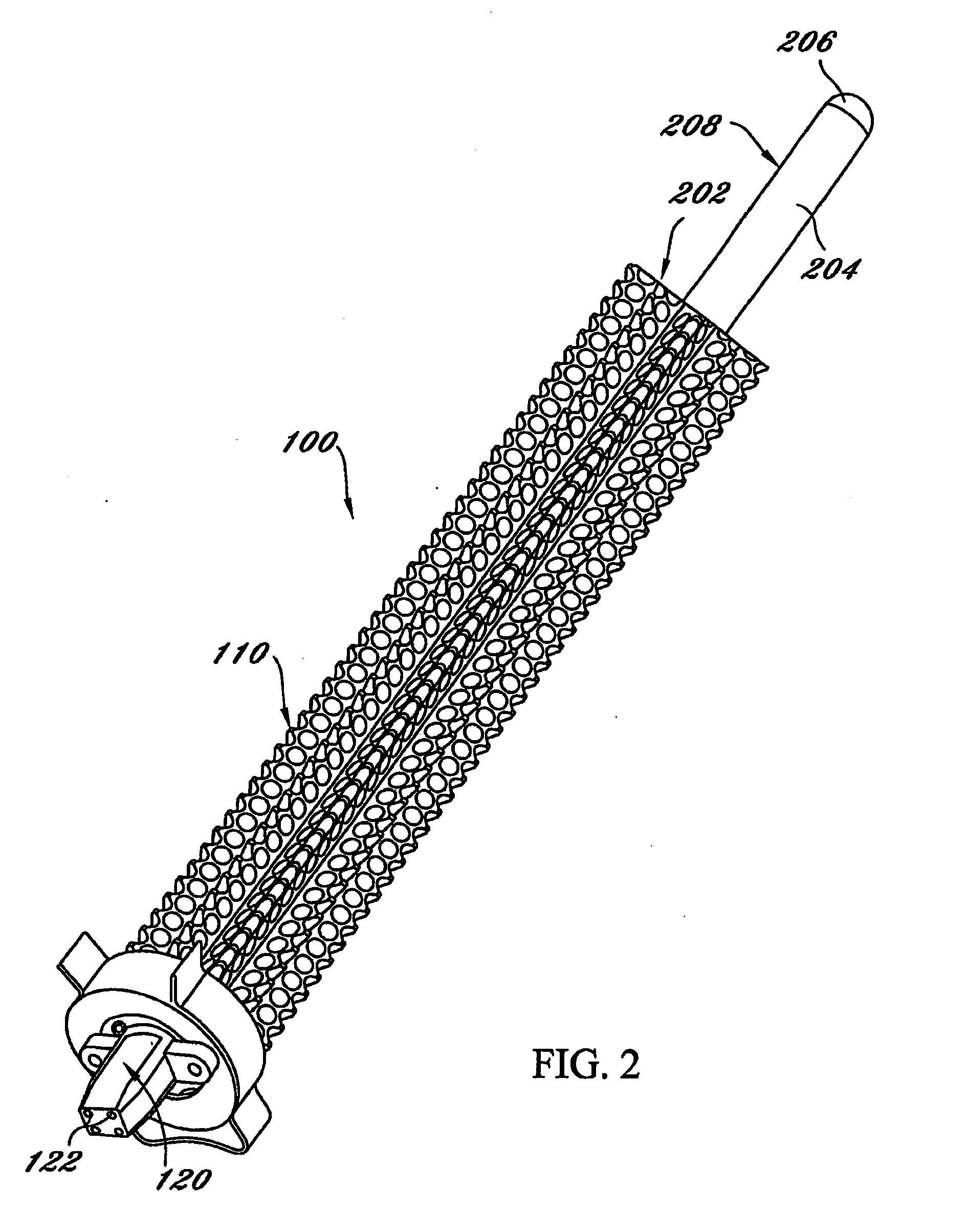

A device, system, and method, for the formation of advanced oxidation products by contacting a hydrated catalytic surface of a catalytic target structure with broad spectrum ultraviolet light in the 100 nm to 300 nm range that preferably includes 185 nm and 254 nm wavelengths. The catalytic surface reacts with the ultraviolet light energy and hydrate at the catalytic surface to form advanced oxidation products. The catalytic surface in one embodiment includes a hydrophilic agent, titanium dioxide, silver, copper, and rhodium. Preferably, the catalytic surface is coated with a coating that includes the hydrophilic agent, titanium dioxide, silver, copper, and rhodium. A photohydroionization cell (100) that includes an ultraviolet light source (204) and a catalytic target structure (110) in an air environment to form advanced oxidation product is also provided. A U.V. light indicator and a monitor and / or control system for the photohydroionization cell (100) are also provided.

Owner:RGF ENVIRONMENTAL GROUP

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

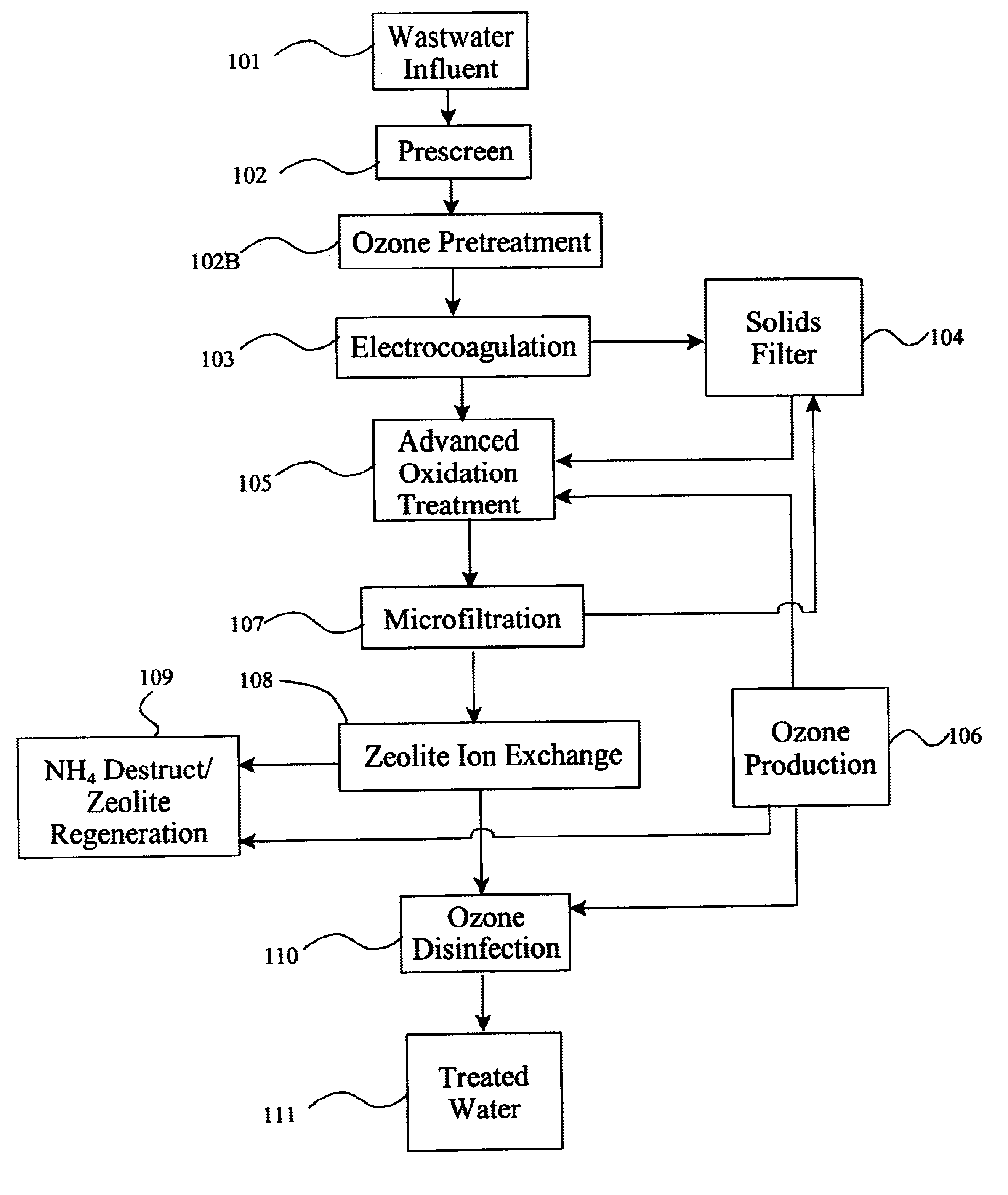

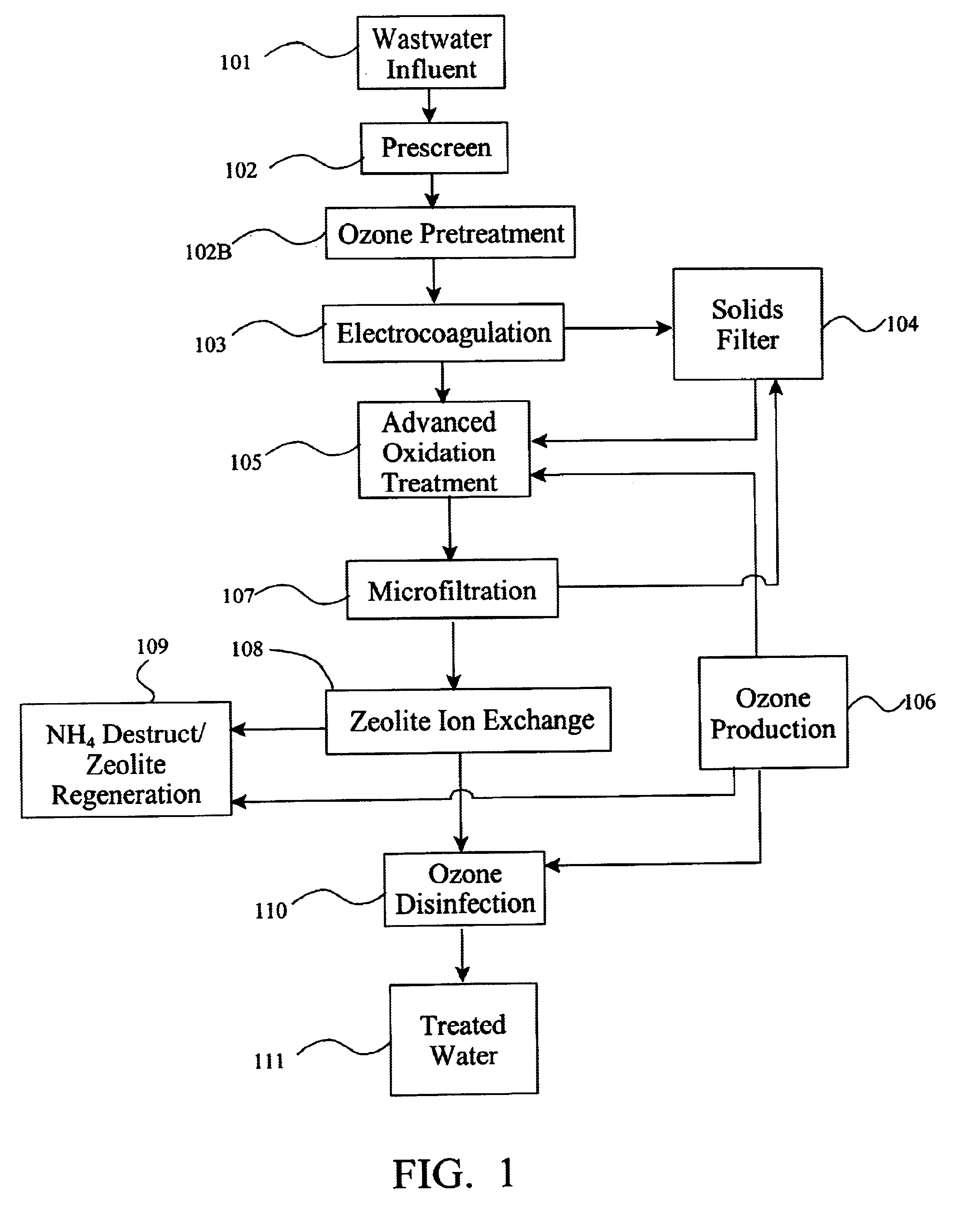

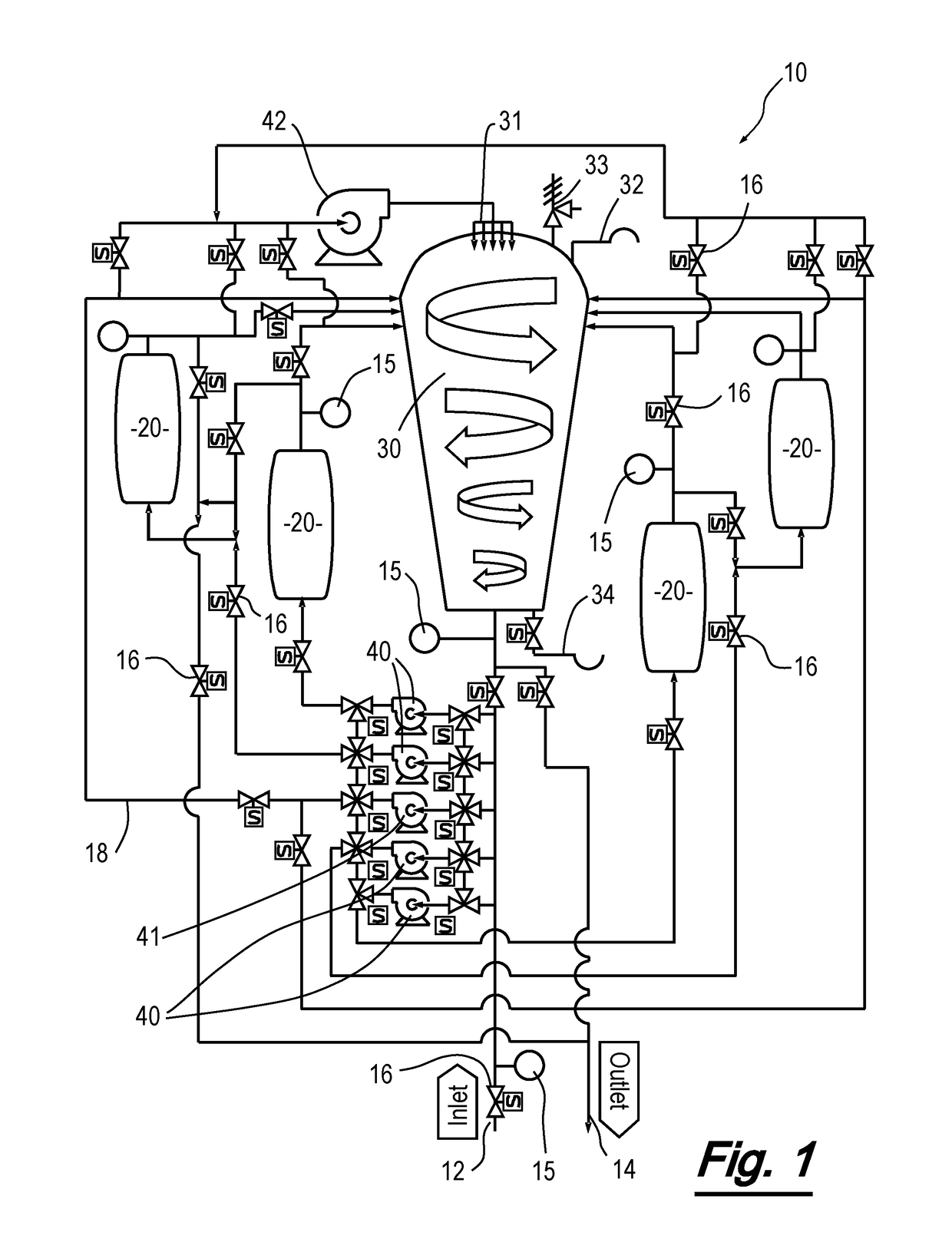

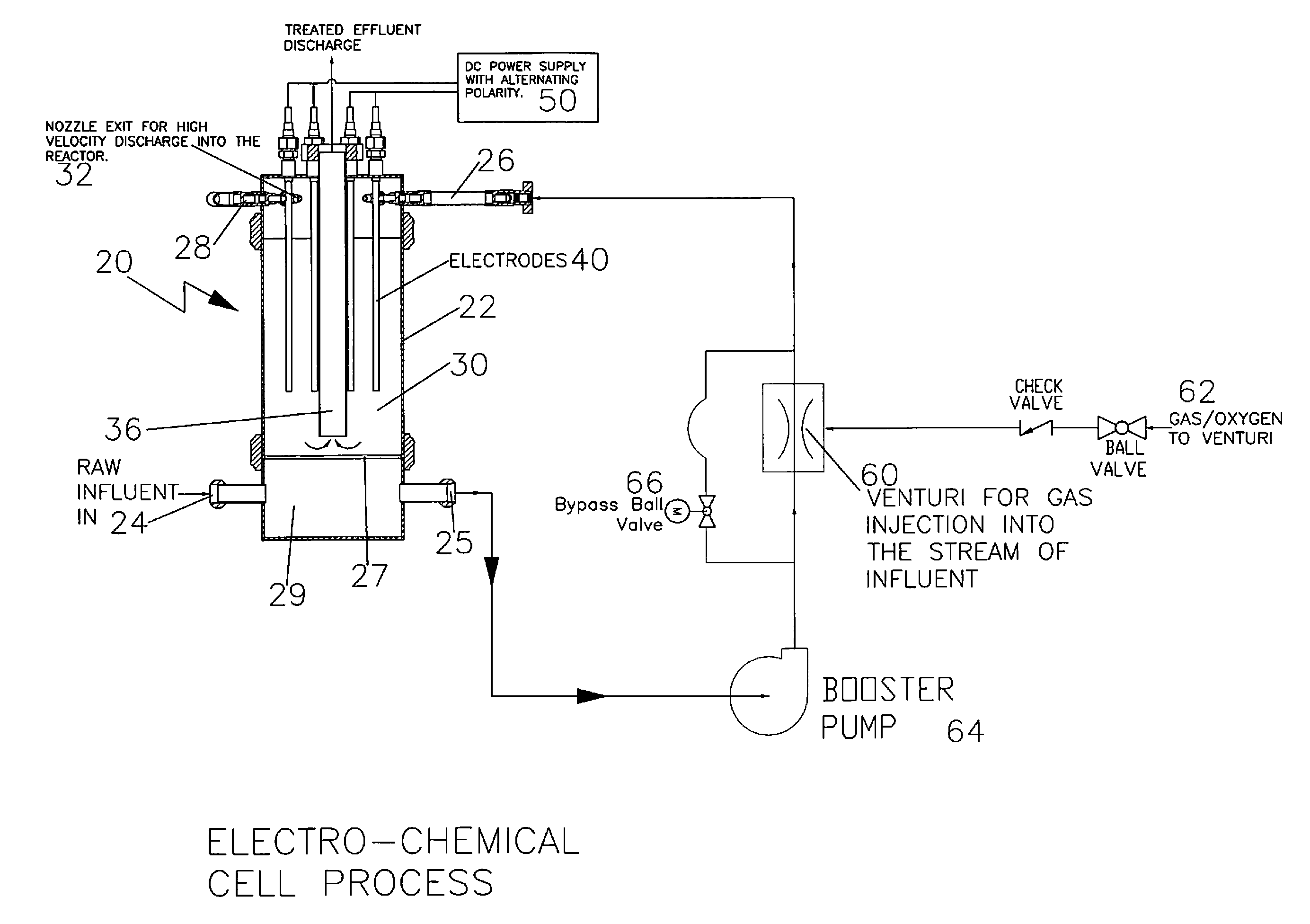

Leachate and wastewater remediation system

InactiveUS6960301B2Effective amount of reactionMany difficultyLiquid separation by electricityFlow mixersAdvanced oxidation processFiltration

A compact portable modular wastewater treatment system which integrates several processing technologies to provide a substantially purified water source. A wastewater stream is sent through an initial filtration step. The filtered wastewater is then subjected to electrocoagulation and then further filtered. The resulting stream containing substantially only organics is then treated in an advanced oxidation process which can include passing an electrical current through the water during the oxidation process. The partially treated water is then passed through ion-exchange columns to polish ammonium and other contaminants. The ion-exchange columns are cycled through regeneration cycles to provide continuous ion-exchange medium. The ammonium rich brine solution used in regeneration is subjected to an ammonium destruct process and then reused in regenerating ion-exchange columns. The water can then be sent through a final disinfection oxidation process to destroy or inactivate pathogens and / or remove any remaining colorants or odor to provide a water source suitable for almost any use.

Owner:NEW EARTH SYST

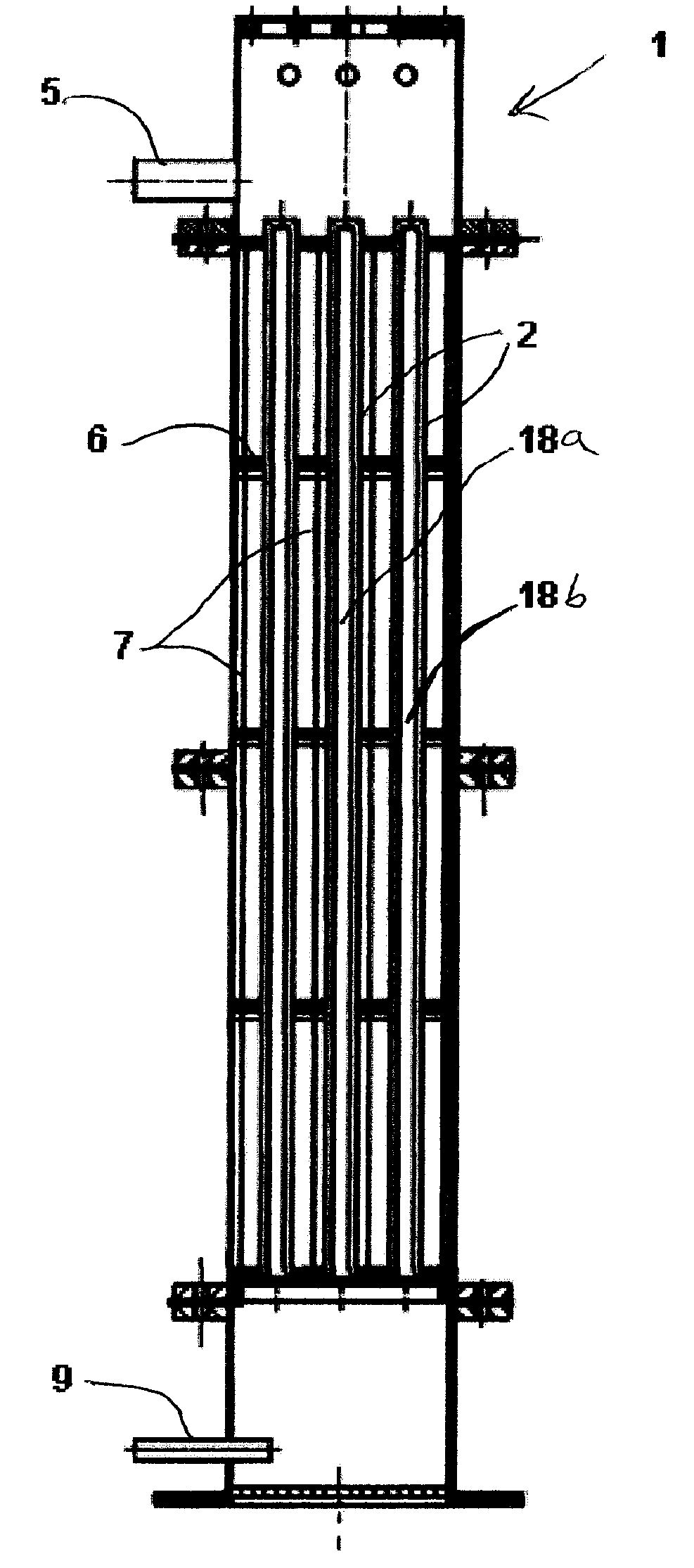

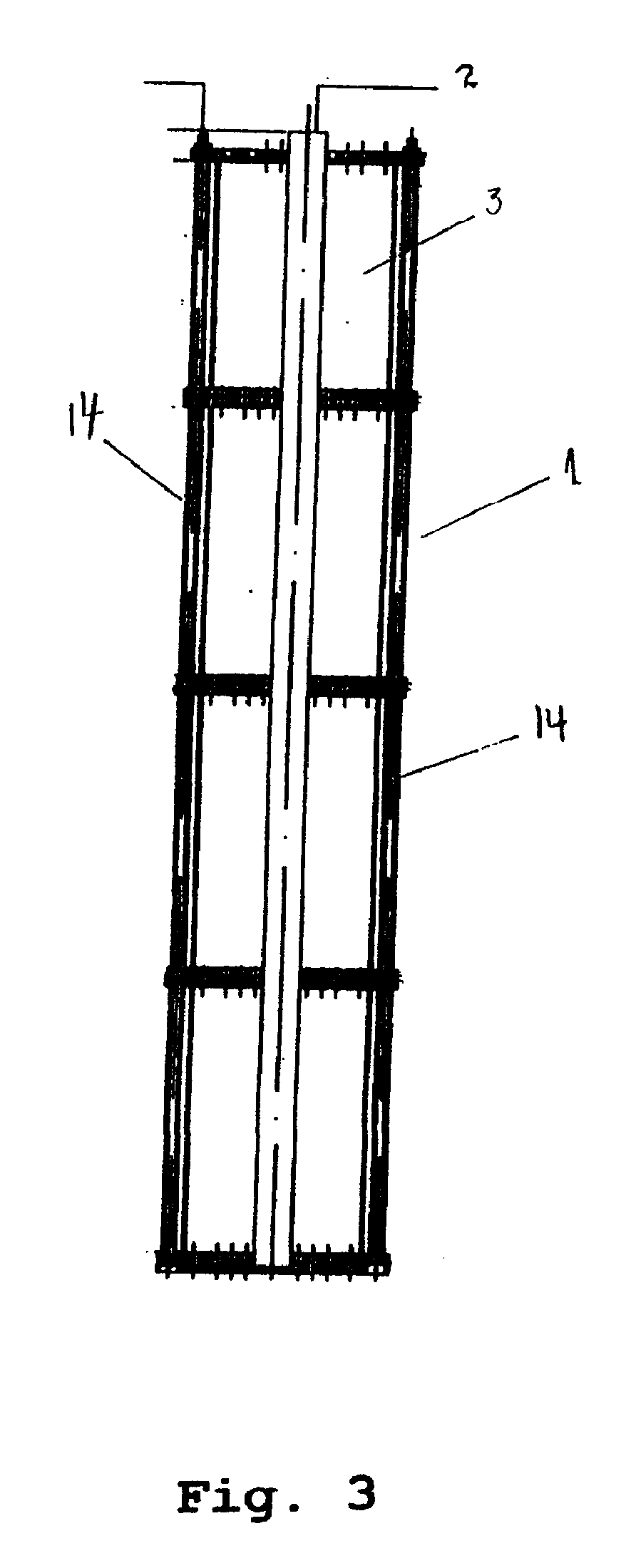

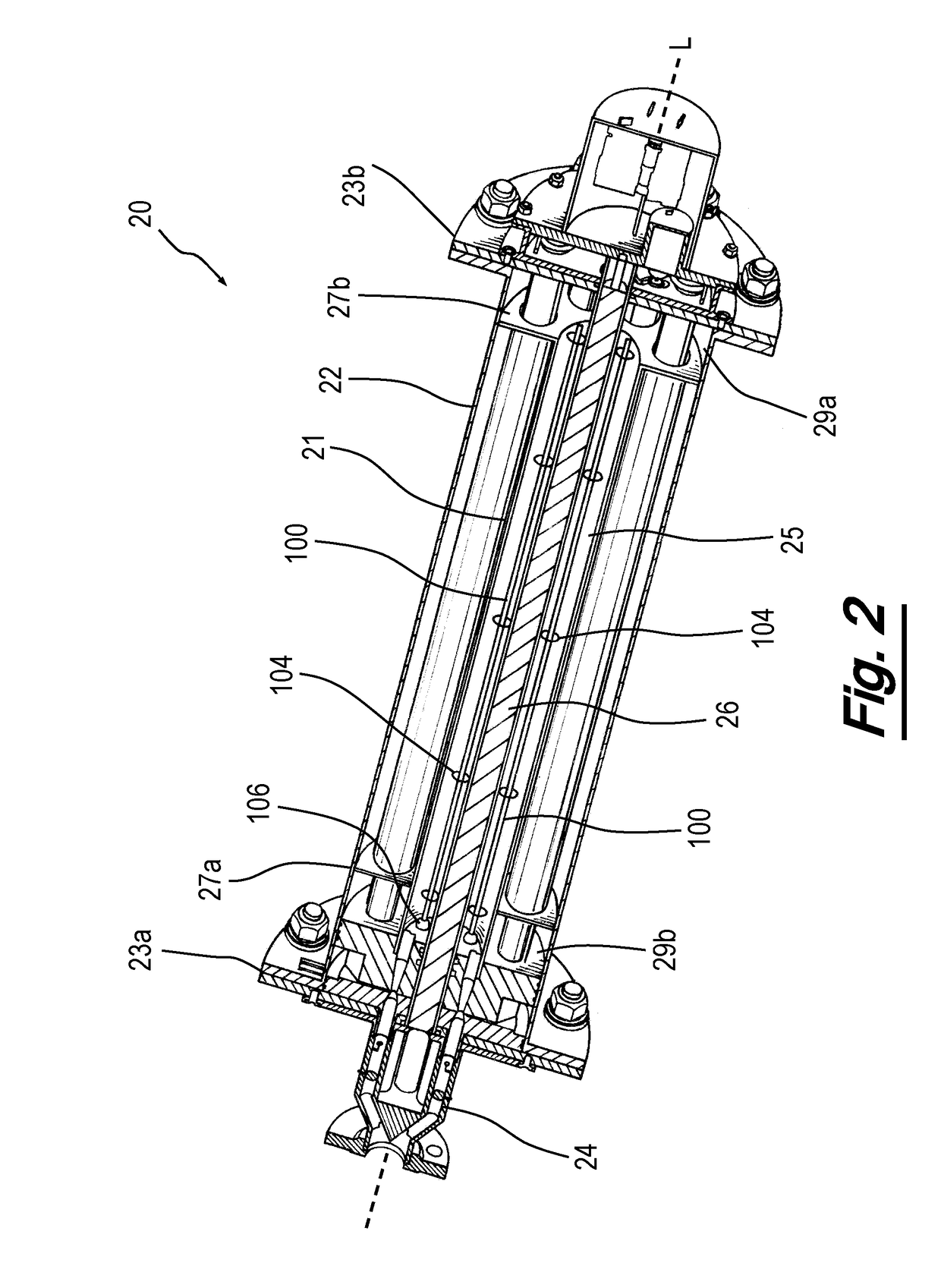

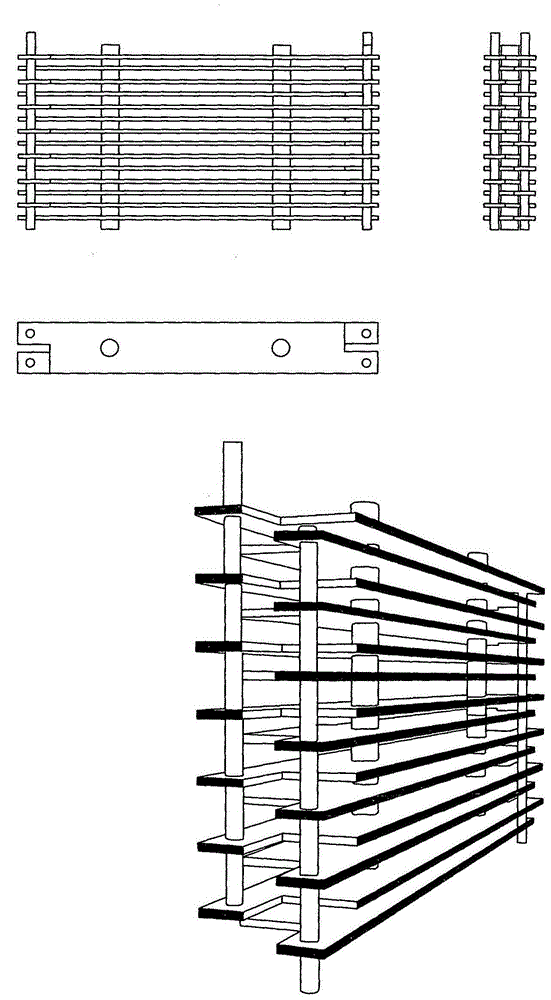

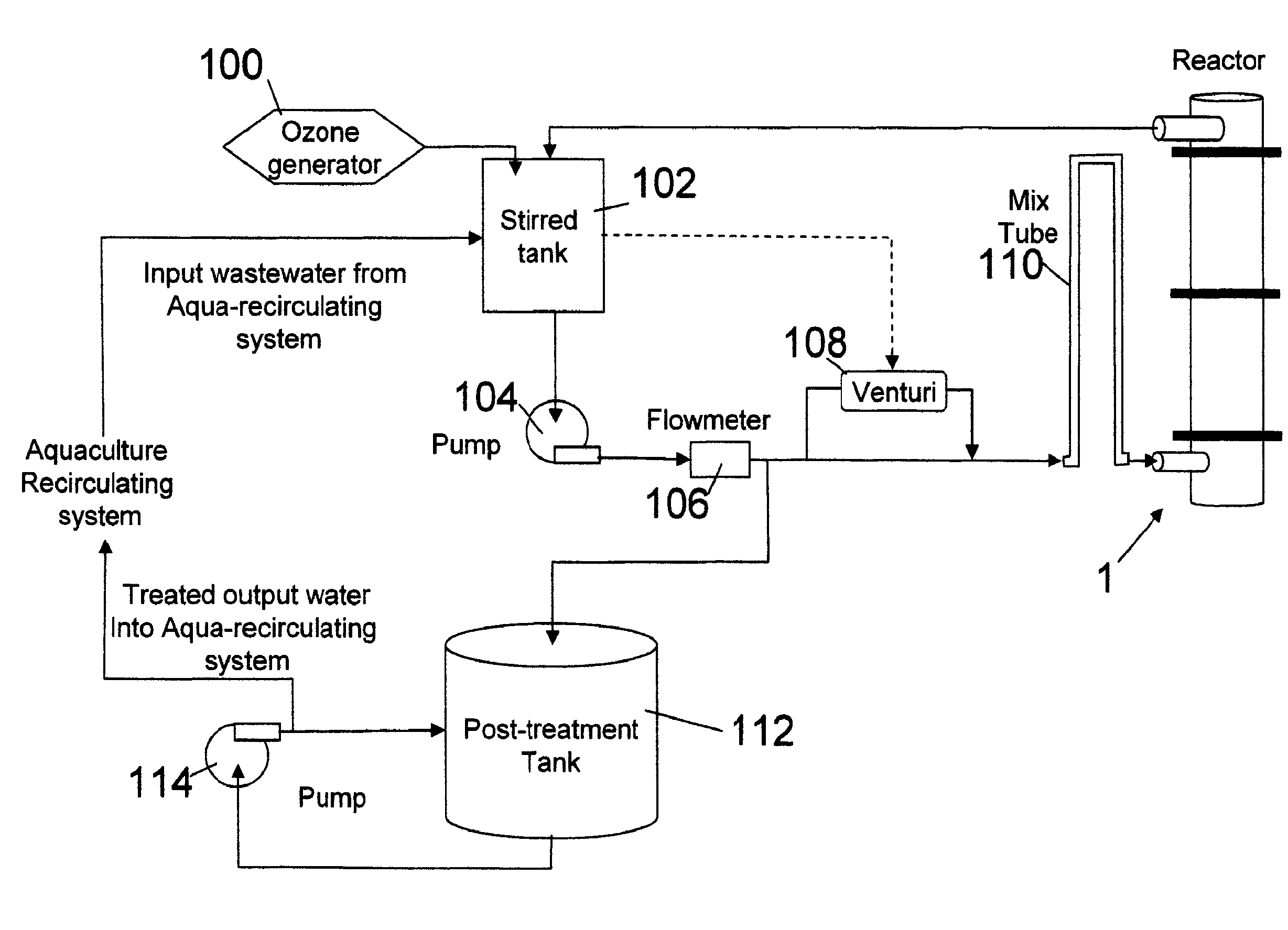

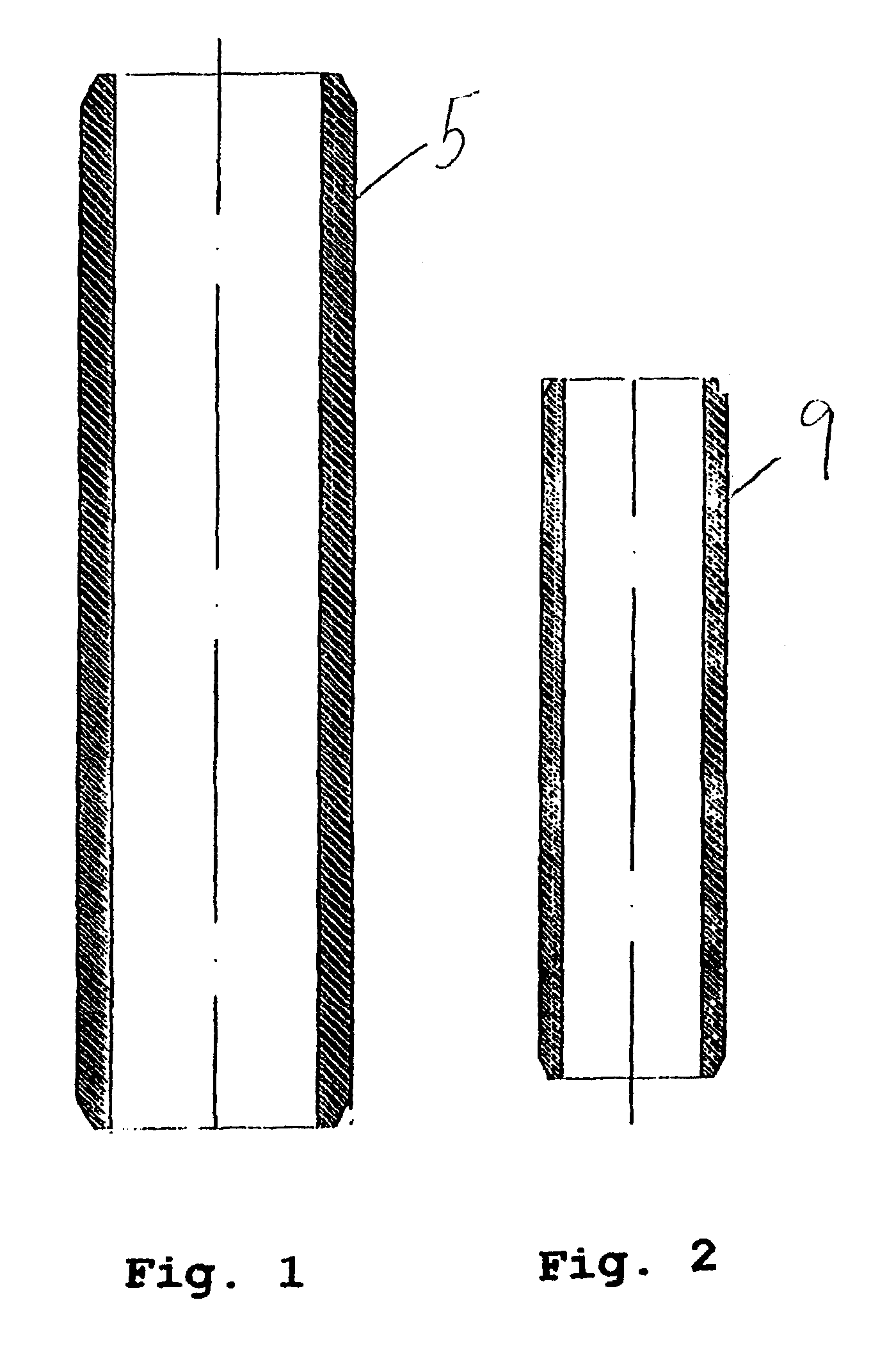

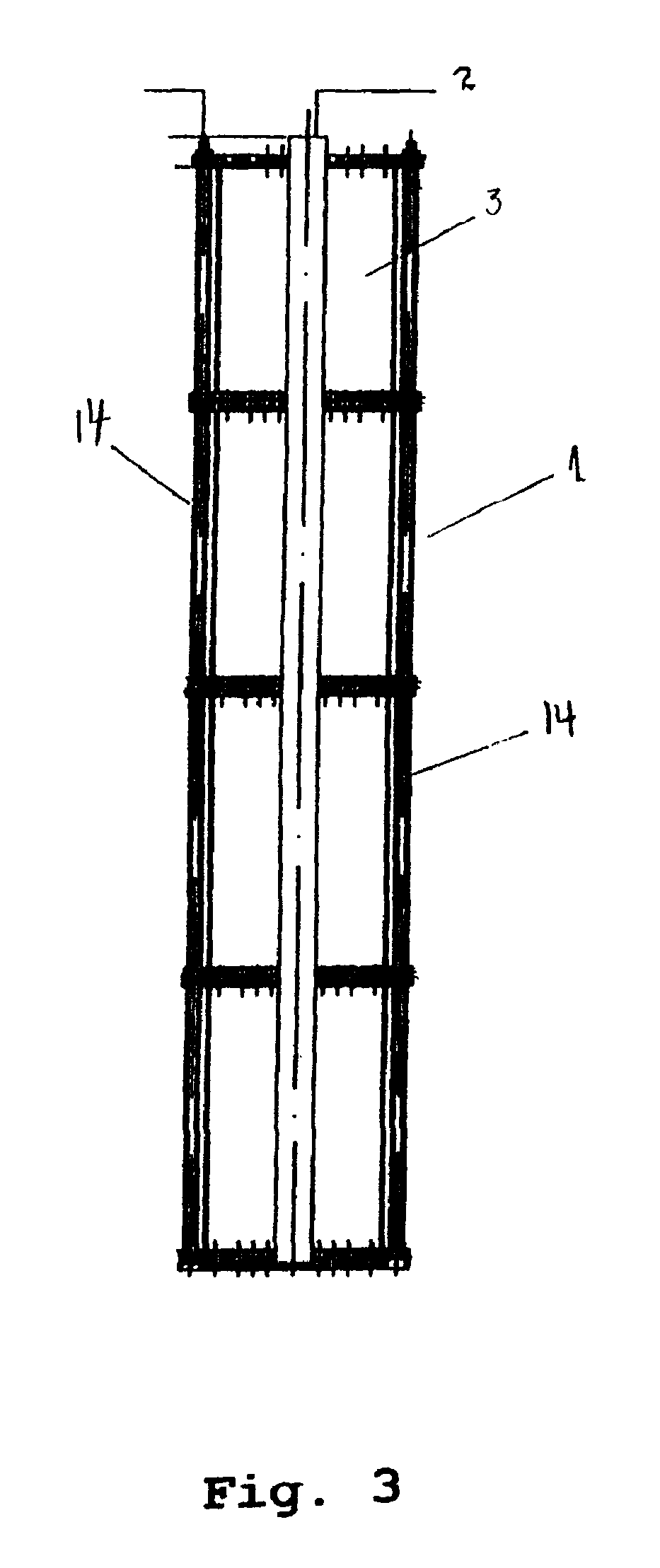

Photocatalytic Reactor and Process for Treating Wastewater

ActiveUS20080179178A1Easy constructionEasy to assembleWater treatment parameter controlWater/sewage treatment by irradiationPhotocatalytic reactionAdvanced oxidation process

A photocatalytic reactor with a modular configuration, based on UV light sources and a catalyst, useful for purifying and disinfecting wastewater from confined aquaculture, using Advanced Oxidation Processes (AOP), wherein the catalyst is supported over glass sheets as fixed strips within the reactor, at an established distance from the UV light source, and wherein the wastewater is treated as “batches” being re-circulated and returned to the circuit. The wastewater is fed through the lower end of the reactor and submitted to a strong turbulence when passing through perforations or holes made on the supports forming the floors that separate the reaction chambers.

Owner:UNIV CATOLICA DE LA SANTISIMA CONCEPCION

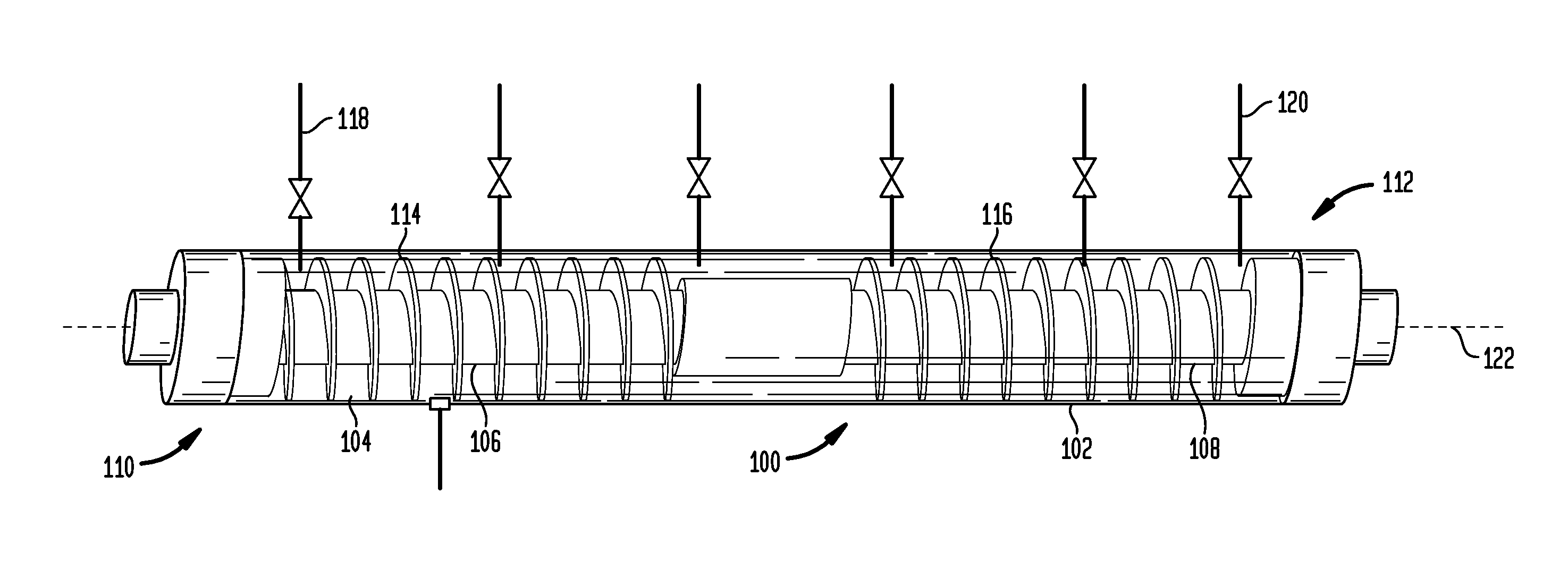

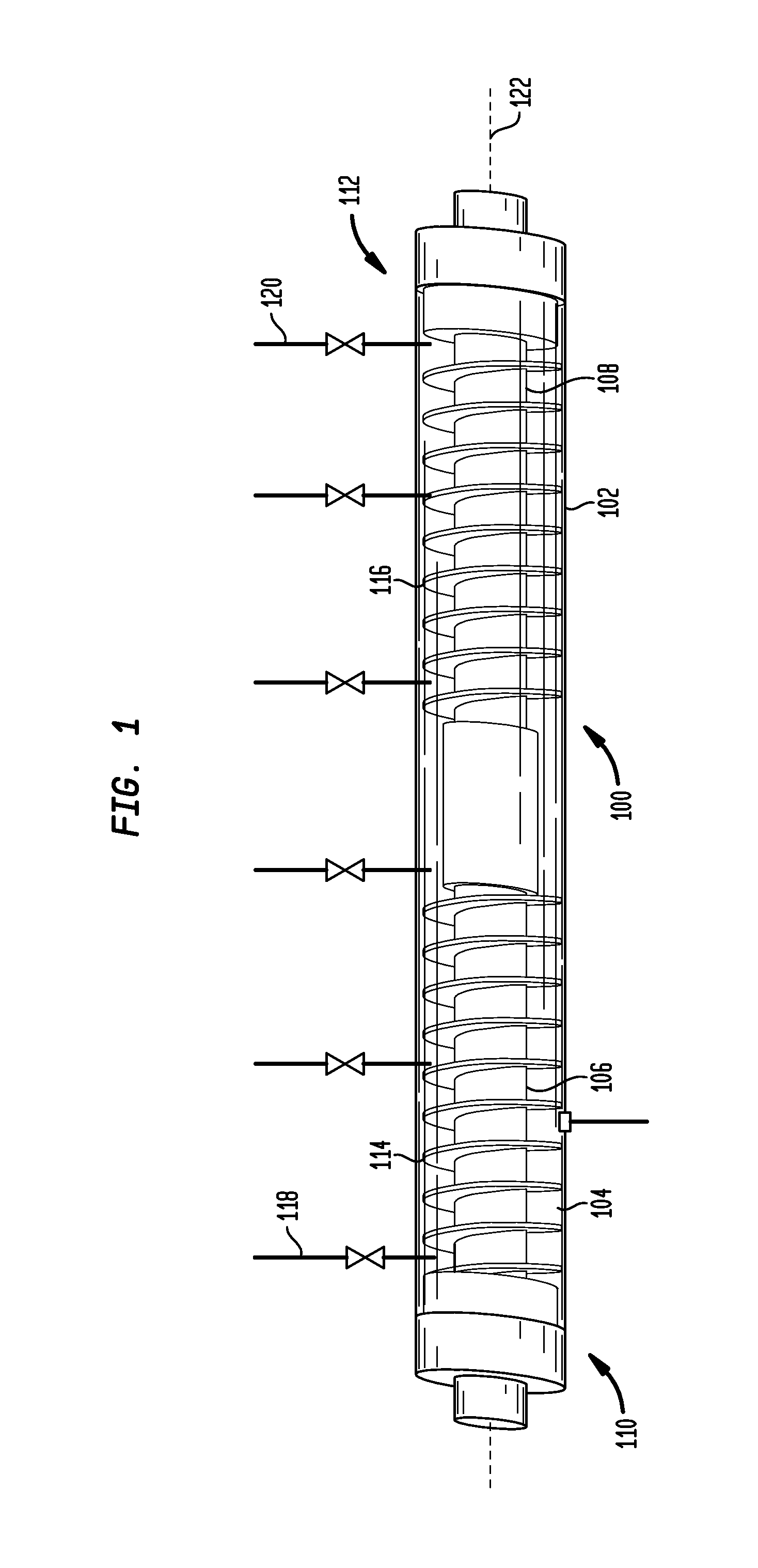

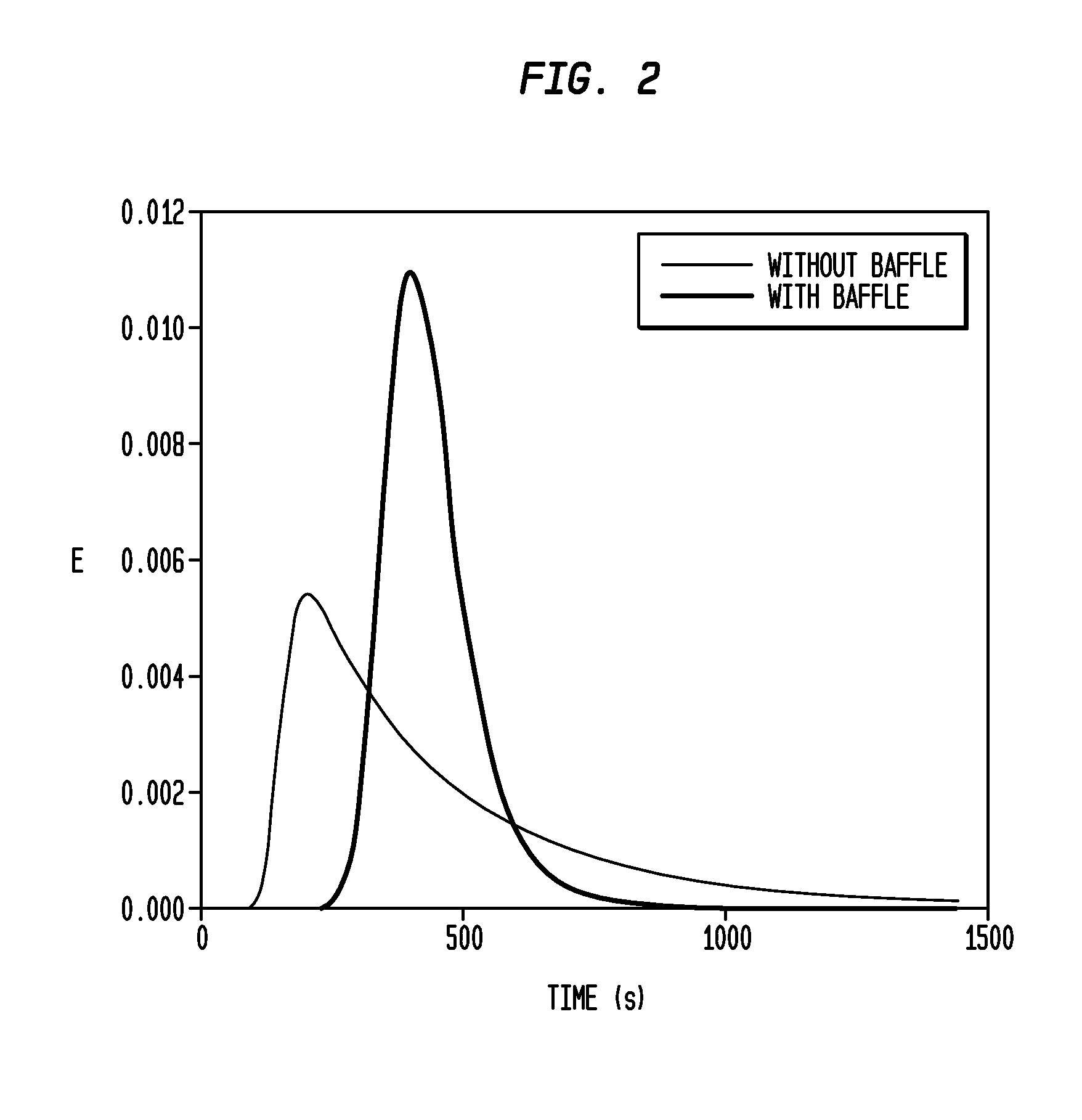

Ultraviolet reactor baffle design for advanced oxidation process and ultraviolet disinfection

InactiveUS20110318237A1Enhanced radial mixingWell mixedWater treatment compoundsChemical/physical/physico-chemical reactor detailsAdvanced oxidation processVertical edge

Ultraviolet reactors having an ultraviolet light source for treating a fluid are disclosed. In one embodiment, a reactor is disclosed which includes a vessel having an inlet for receiving fluid and an outlet for discharging fluid. The vessel further includes a plurality of segmented baffles. The baffles further include a partial circumferential edge section that terminates in a vertical edge section to form right and left segmented baffles. The left and right segmented baffles are arranged in an alternating pattern in the vessel to provide plug flow and enhanced radial mixing.

Owner:EVOQUA WATER TECH PTE LTD

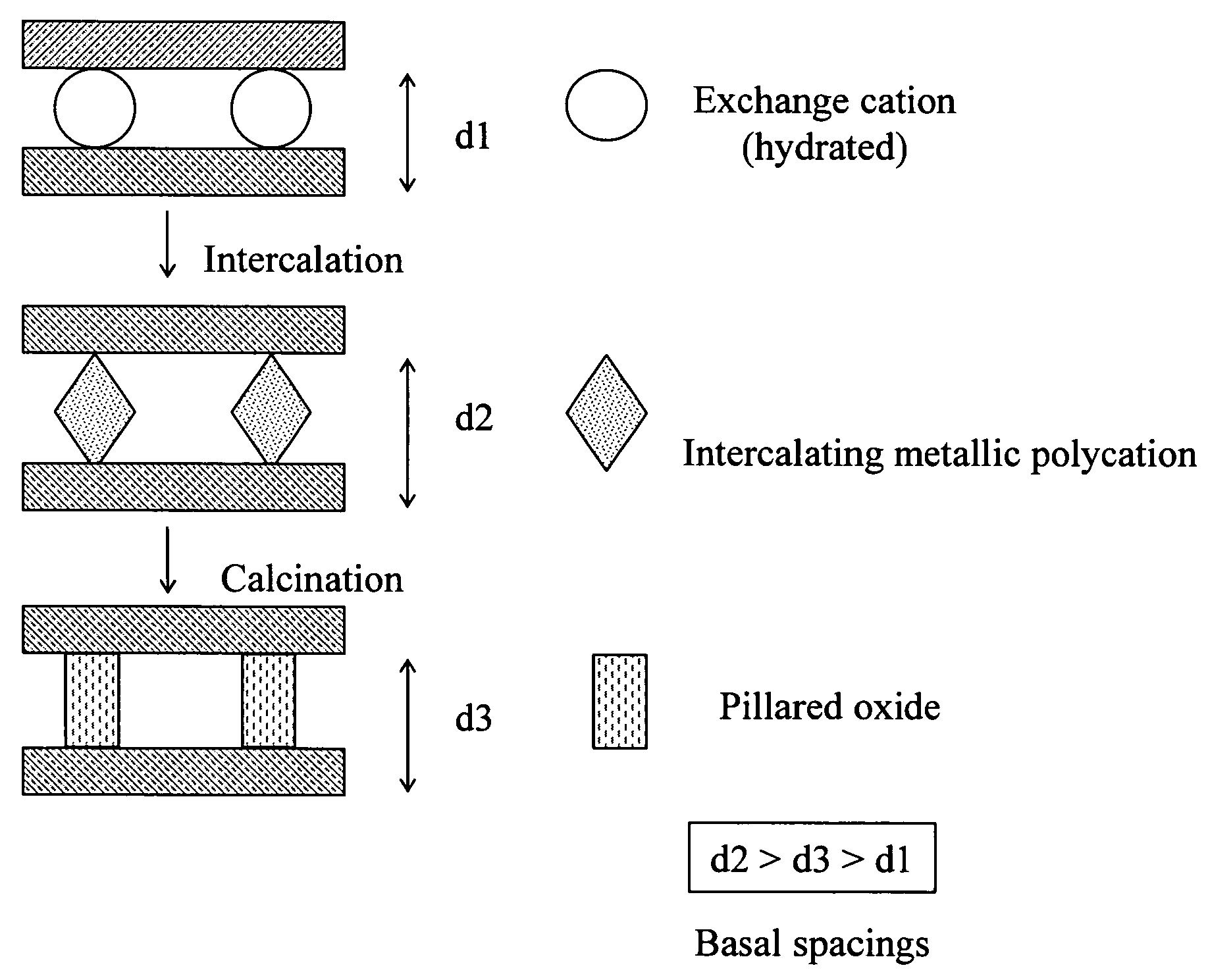

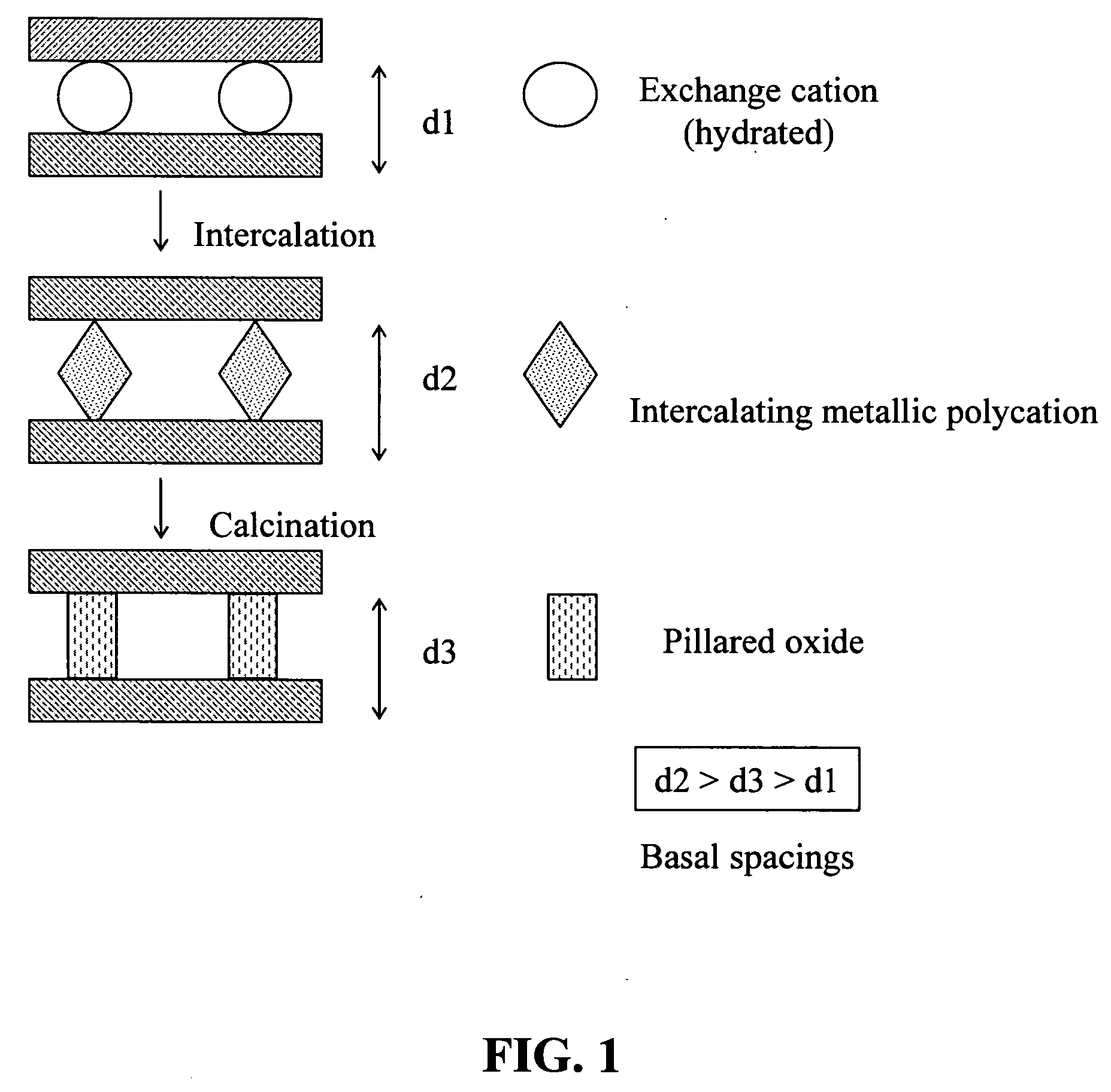

Synthesis of bentonite clay-based iron nanocomposite and its use as a heterogeneous photo fenton catalyst

InactiveUS20060076299A1Material nanotechnologyWater/sewage treatment by irradiationSodium BentoniteAdvanced oxidation process

The present invention provides a method of synthesizing bentonite clay-based Fe nanocomposite, that may be used as a heterogeneous photo Fenton catalyst in advanced oxidation processes (AOP's) for wastewater treatment.

Owner:THE HONG KONG UNIV OF SCI & TECH

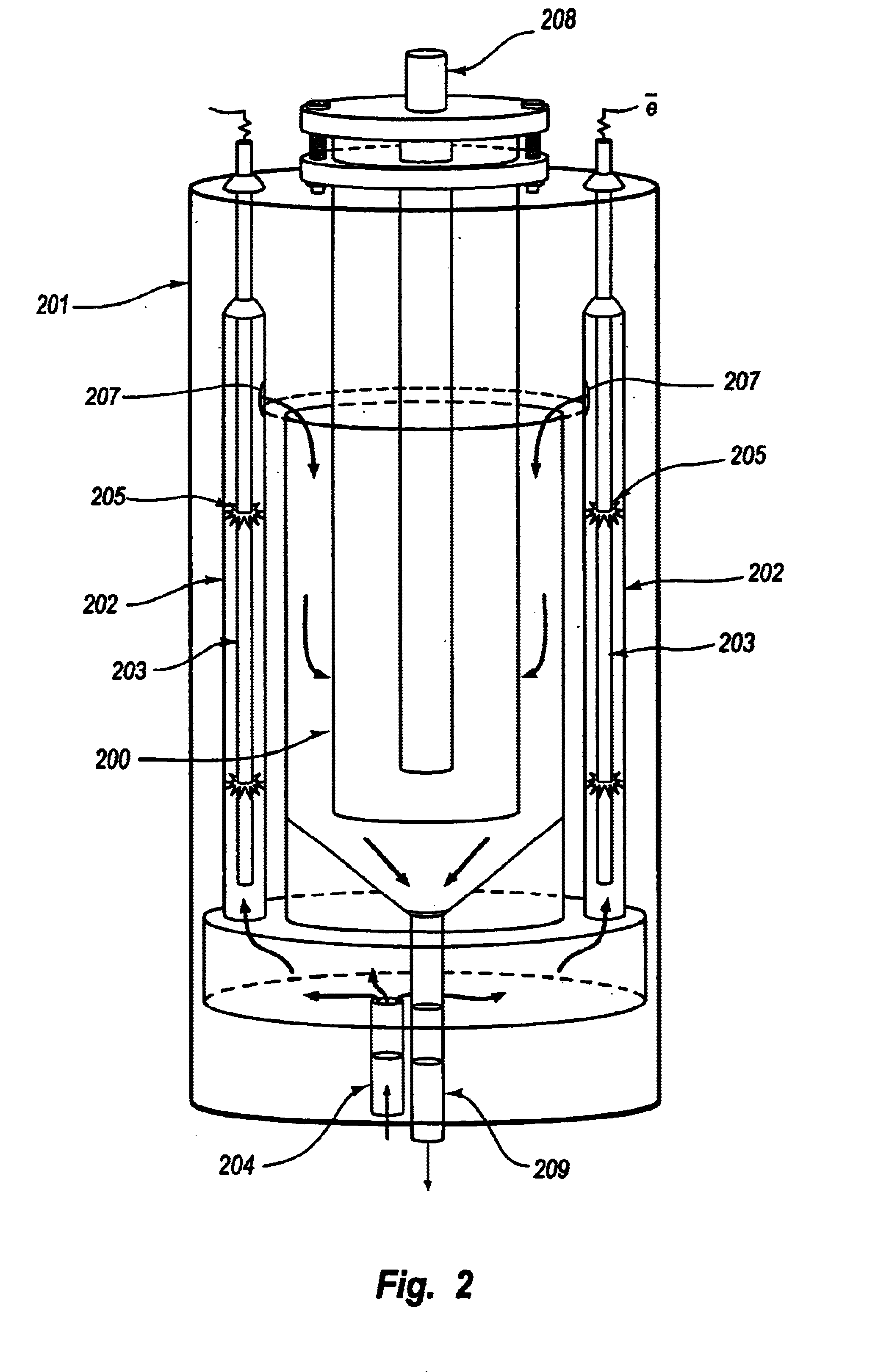

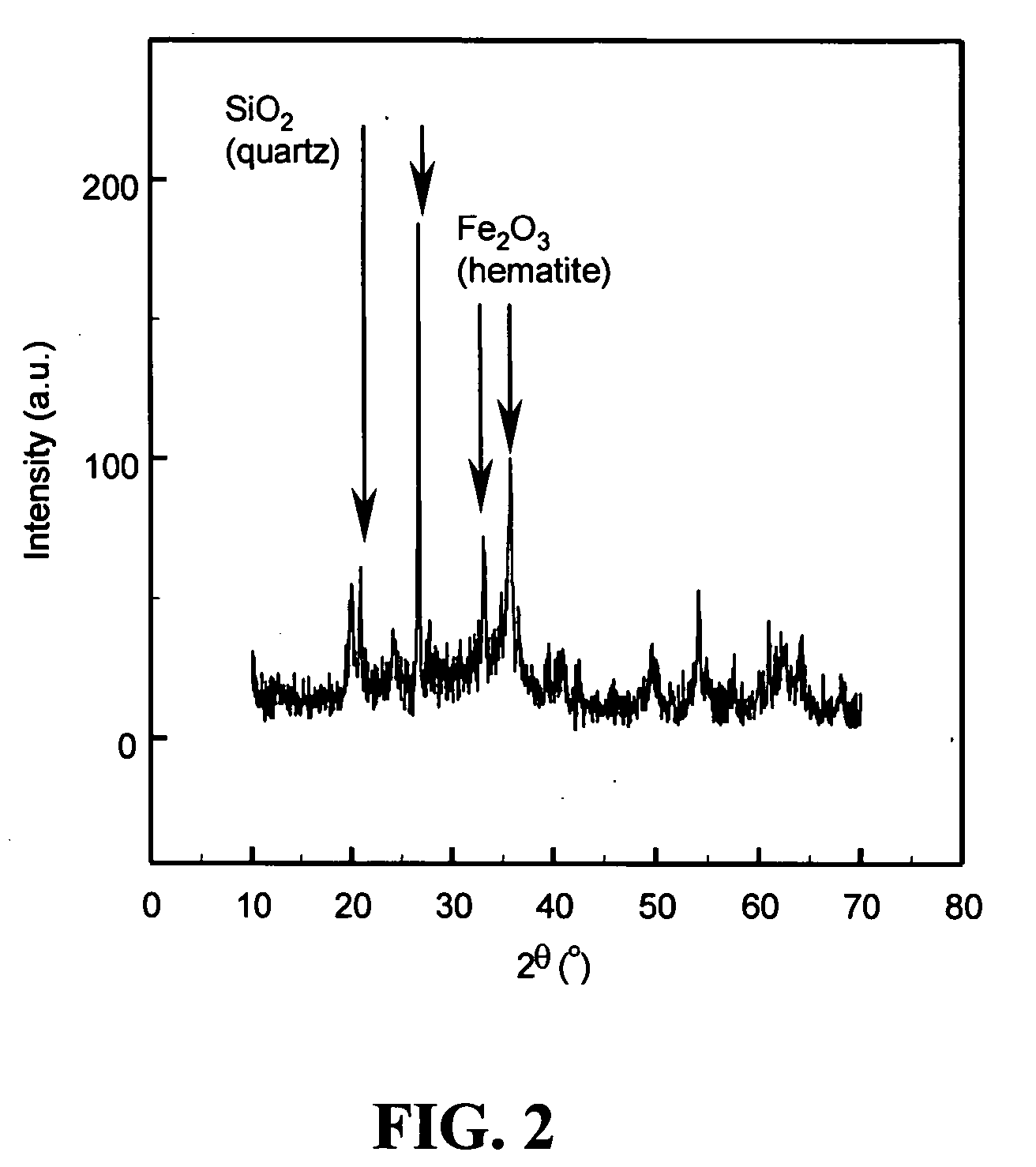

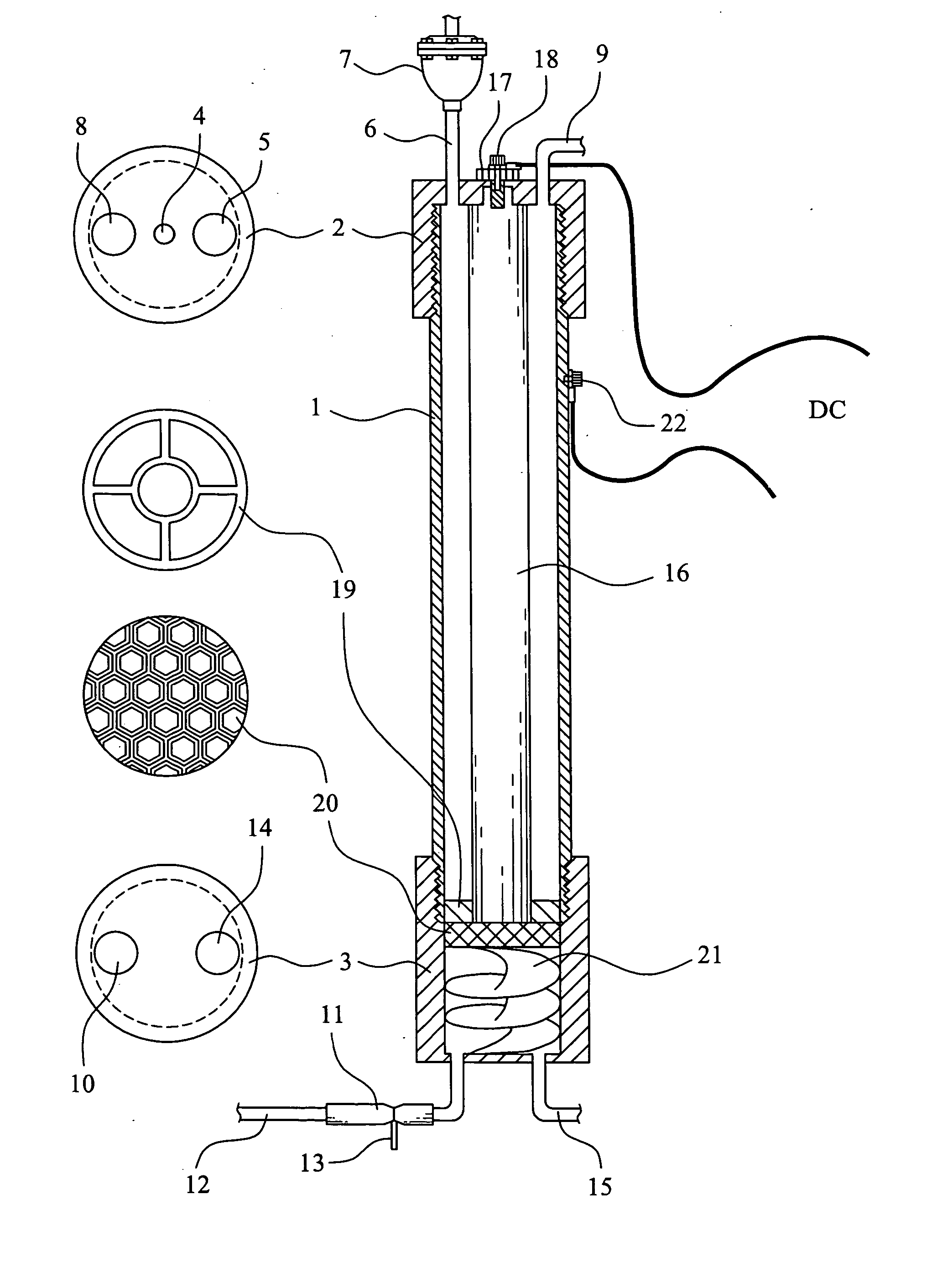

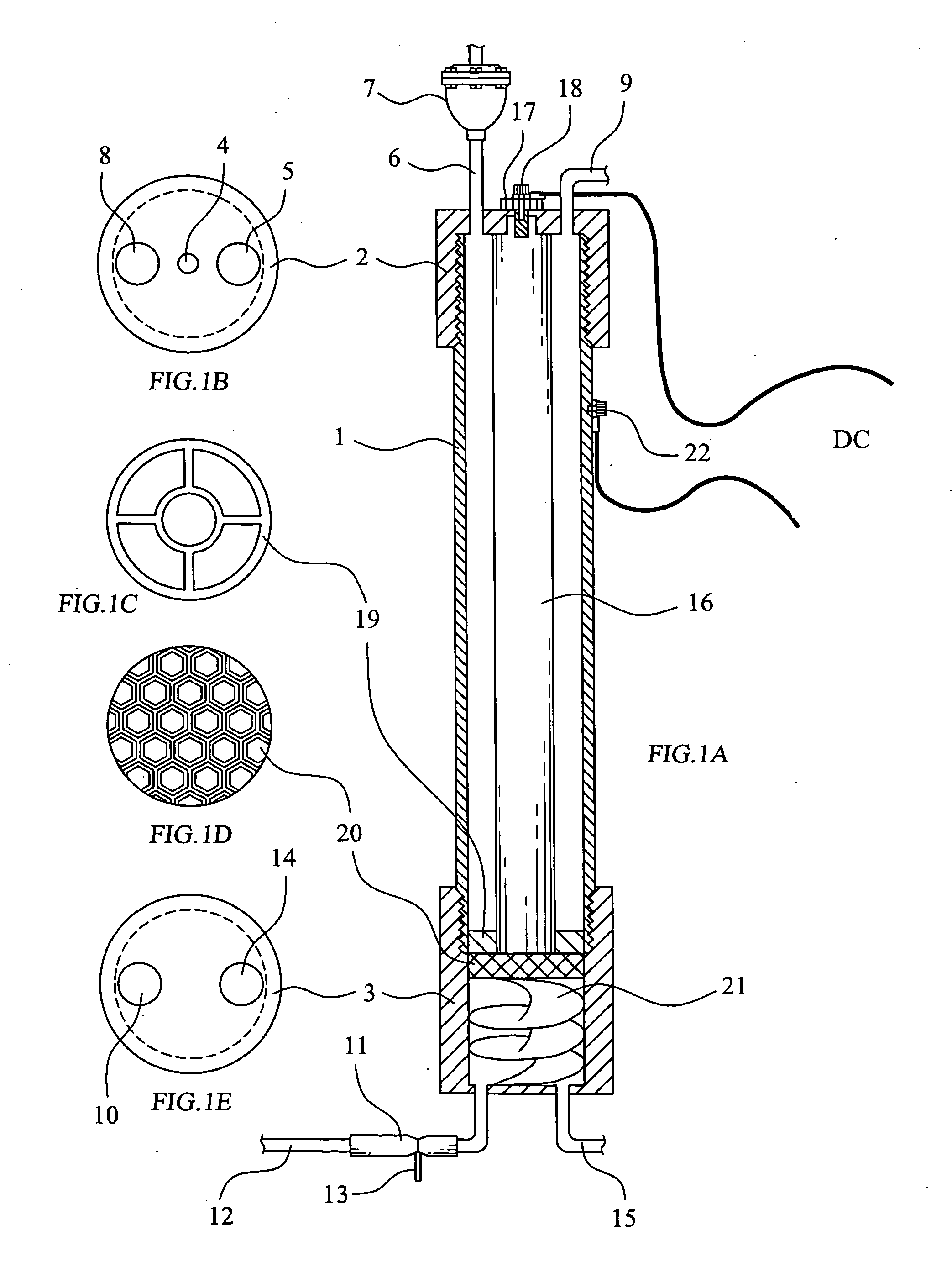

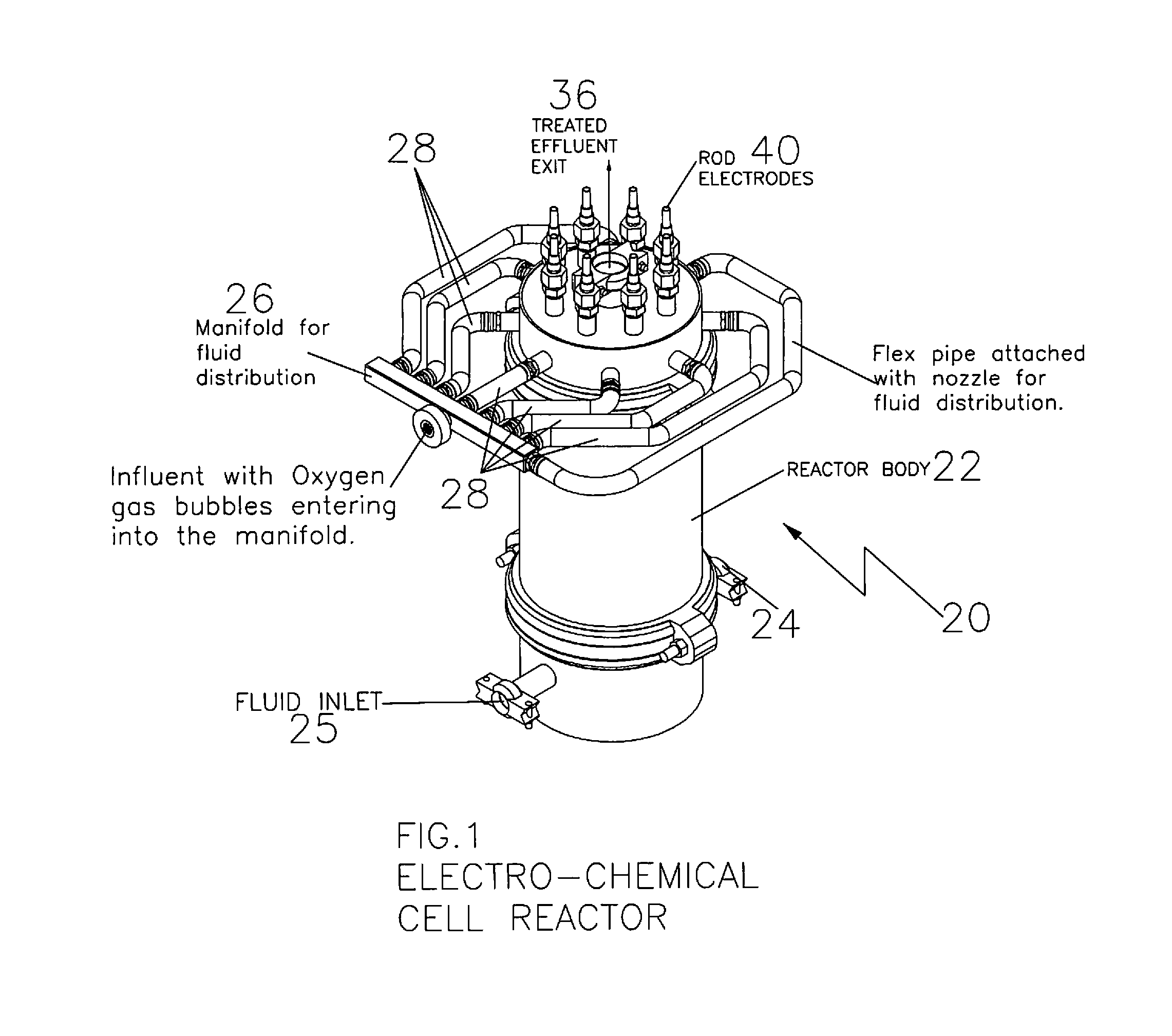

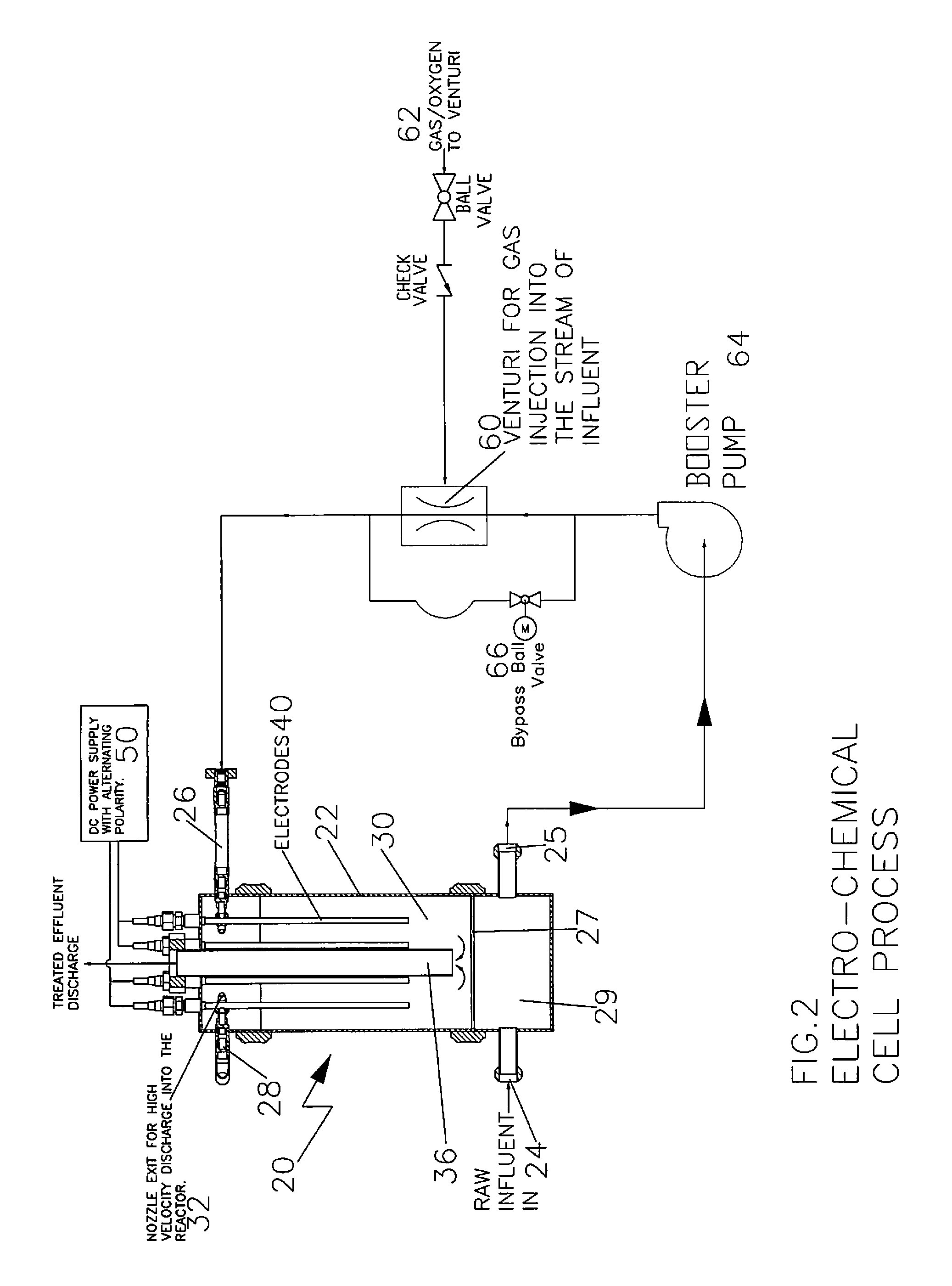

Water treatment reactor for simultaneous electrocoagulation and advanced oxidation processes

InactiveUS20050224338A1Quality improvementCellsWater treatment compoundsElectrocoagulationAdvanced oxidation process

A water treatment reactor adapted to simultaneously carry out electrocoagulation and advanced oxidation processes is disclosed, which includes an upright sealed tank having a metal body, or a metal mounted on an inner wall thereof, used as a cathode; a sacrificial electrode used as an anode, which is disposed in the tank and non-electrically connected to the cathode; a mixing device disposed in the bottom of the tank for enabling mixing of influent water and an air or oxygen-containing gas introduced into the tank; a gas-liquid separator which is in fluid communication with the tank at the top for expelling a gas from the tank without expelling water; and a direct current supply having a positive electrode electrically connected to the anode and a negative electrode electrically connected to the cathode.

Owner:IND TECH RES INST

Wet oxidation process and system

InactiveUS20050171390A1Oxygen-containing compound preparationWater treatment parameter controlAdvanced oxidation processResidual carbon

A process and system for the destruction of compounds having a carbon-hetero atom bond. The process includes wet oxidation at elevated temperature and pressure of an aqueous mixture of at least one compound having a carbon-hetero atom bond to substantially destroy the carbon-hetero atom bond of the at least one compound. The resulting oxidized material may be further treated in an advanced oxidation process to destroy any residual carbon-hetero atom bonds remaining.

Owner:SIEMENS WATER TECH HLDG CORP

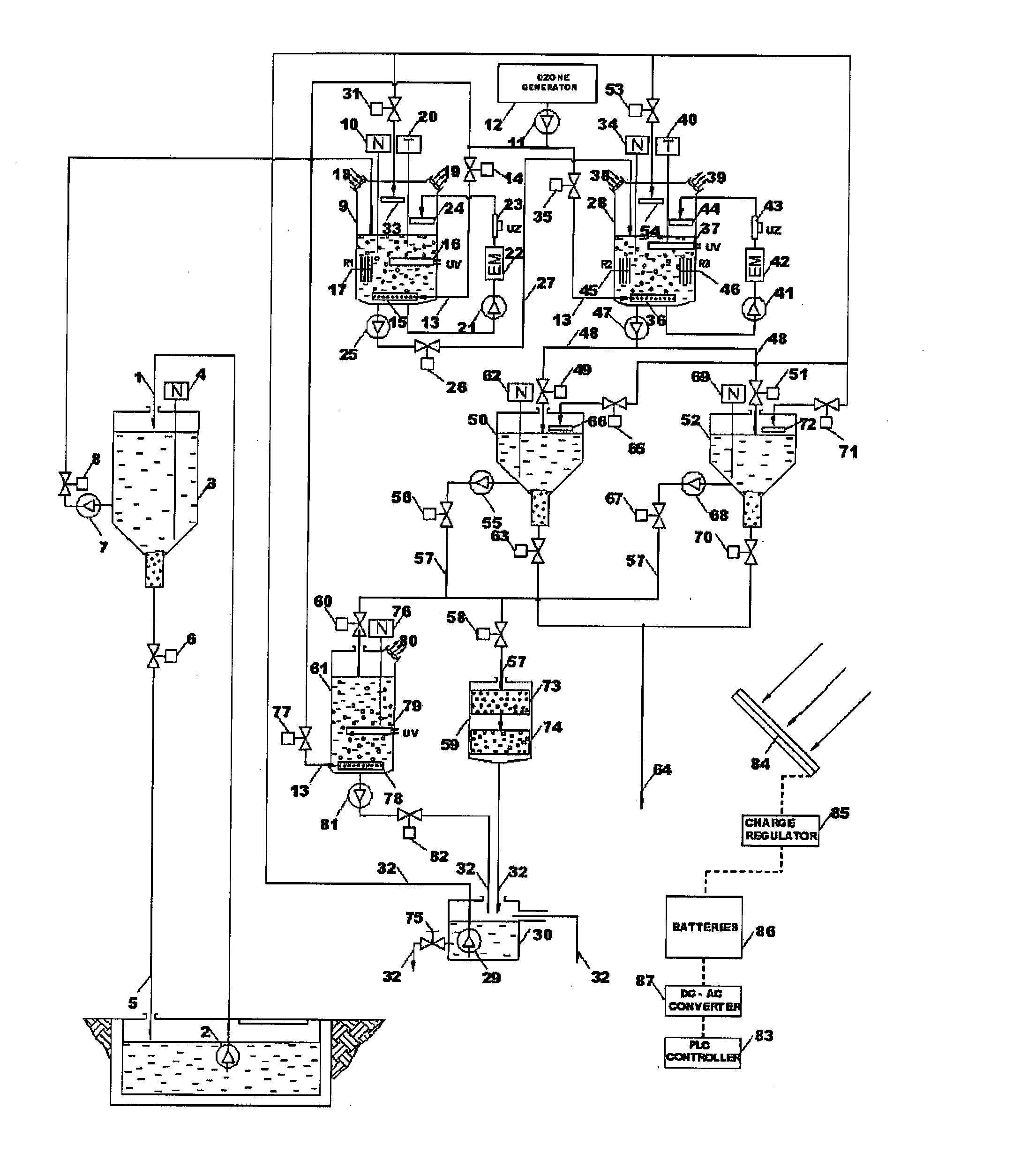

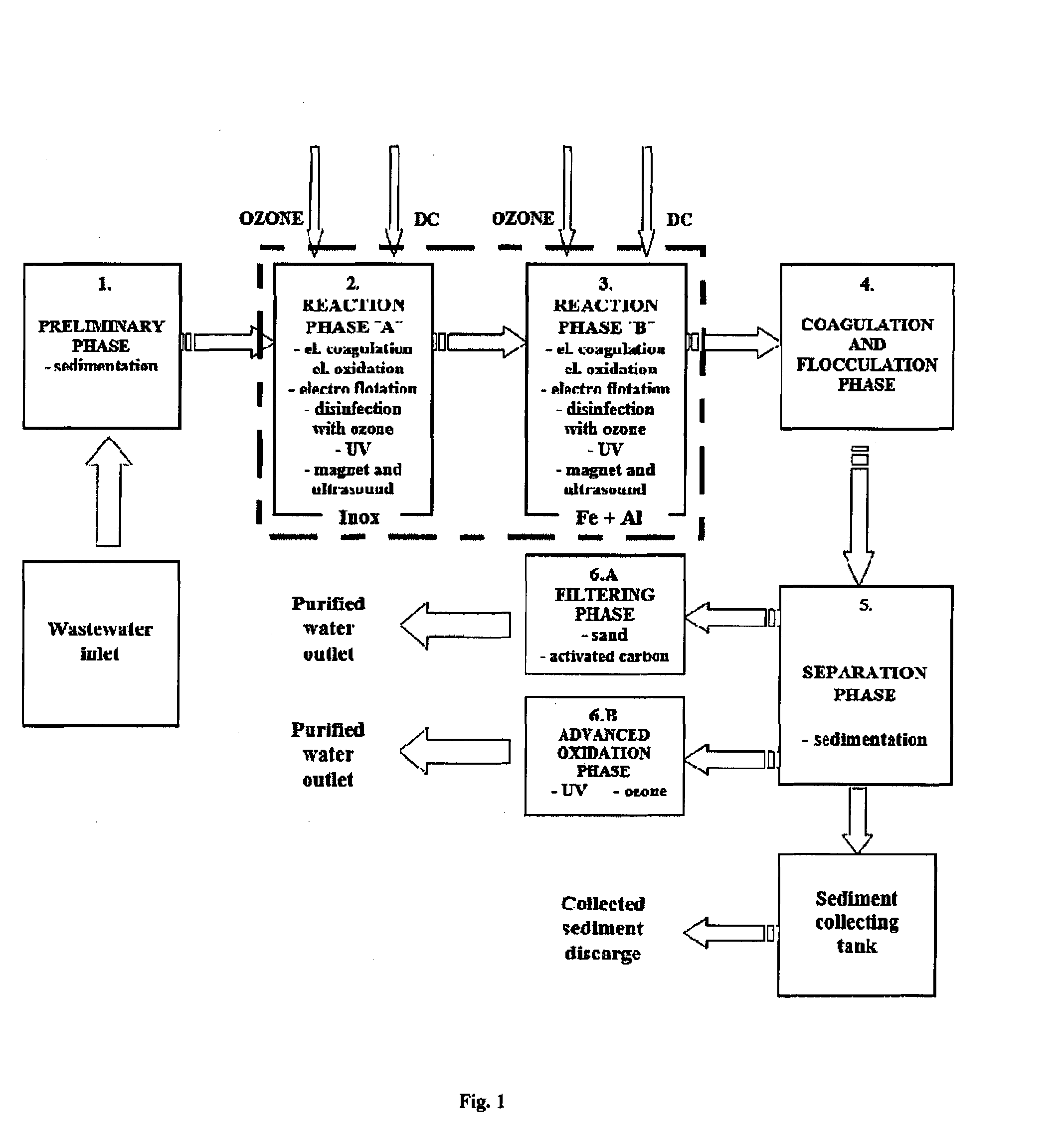

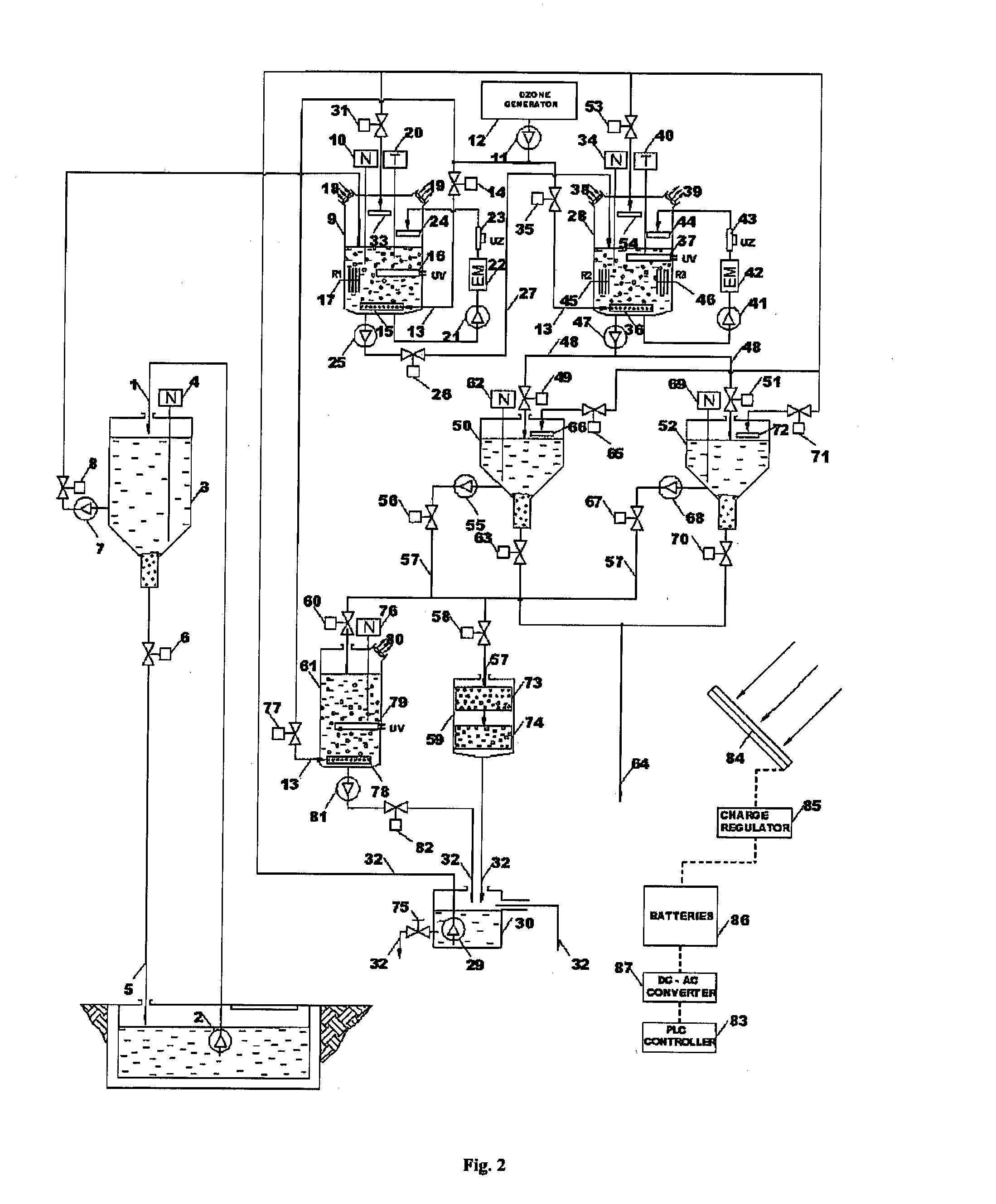

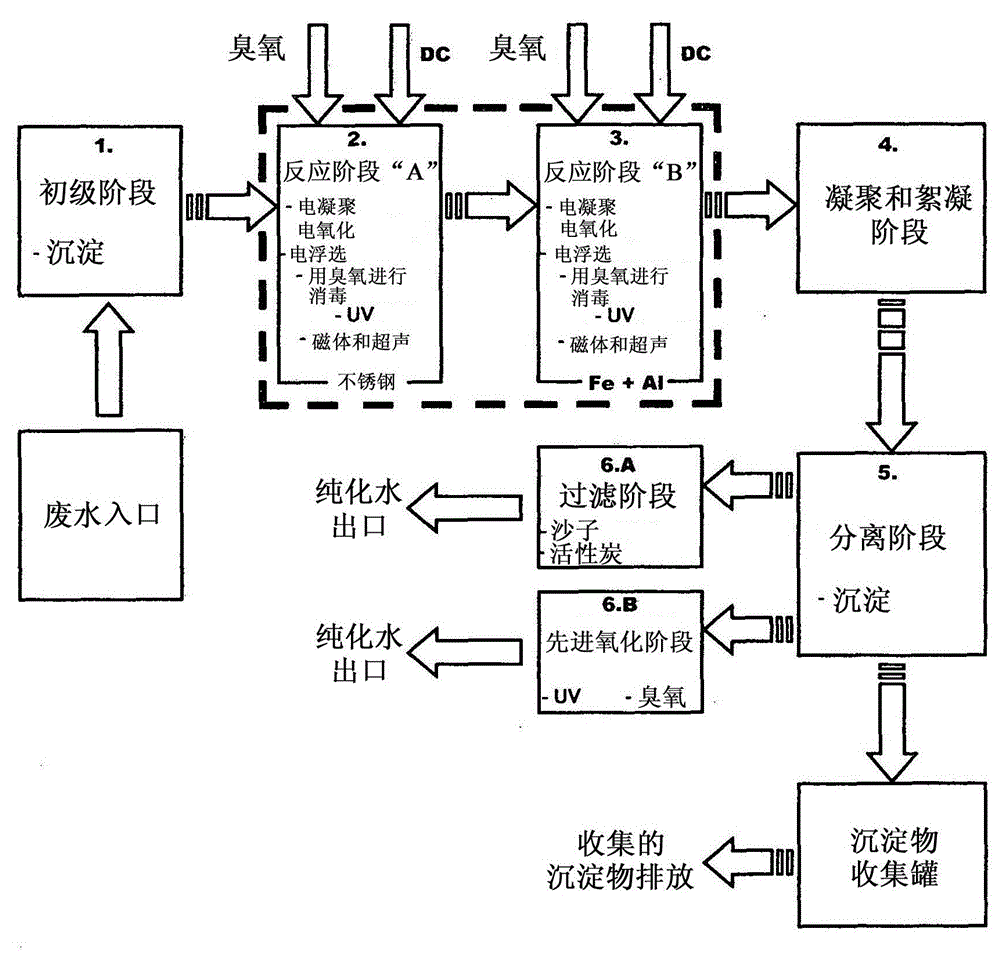

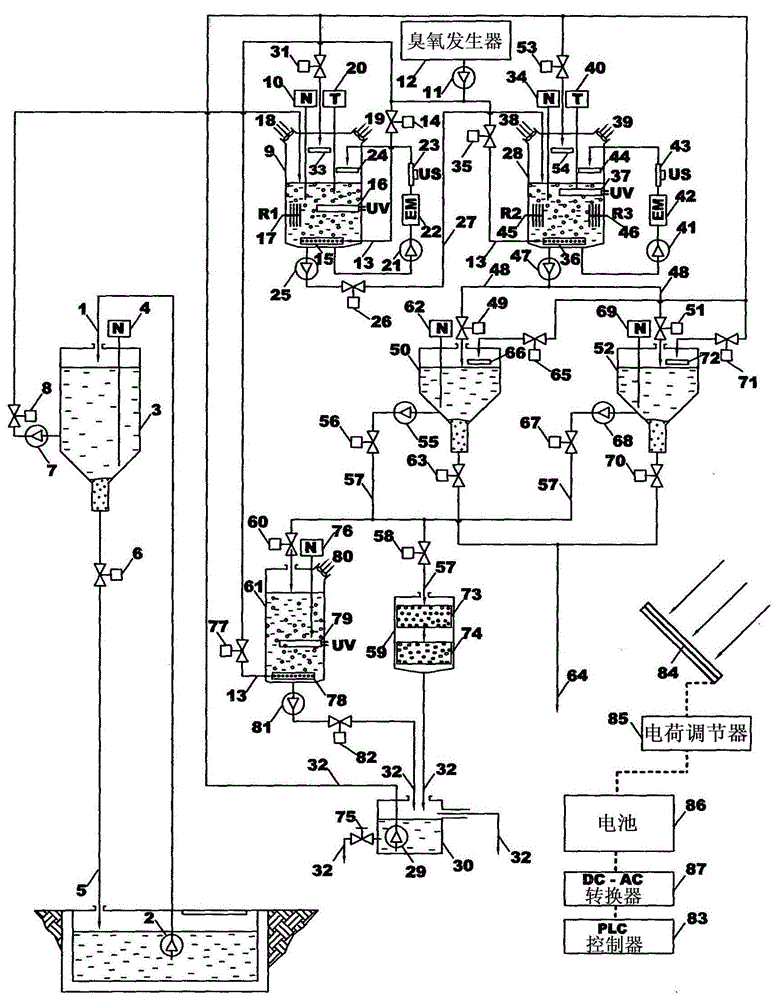

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveUS20150166383A1Lower Level RequirementsTreatment involving filtrationSedimentation separationChemical treatmentIndustrial waste water

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:VISNJA ORESCANIN +2

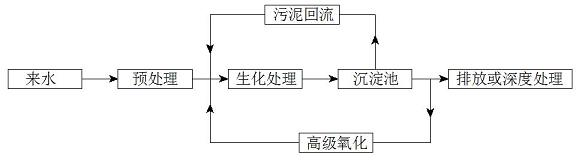

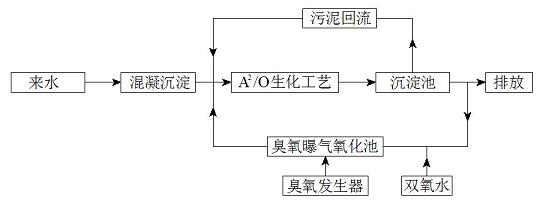

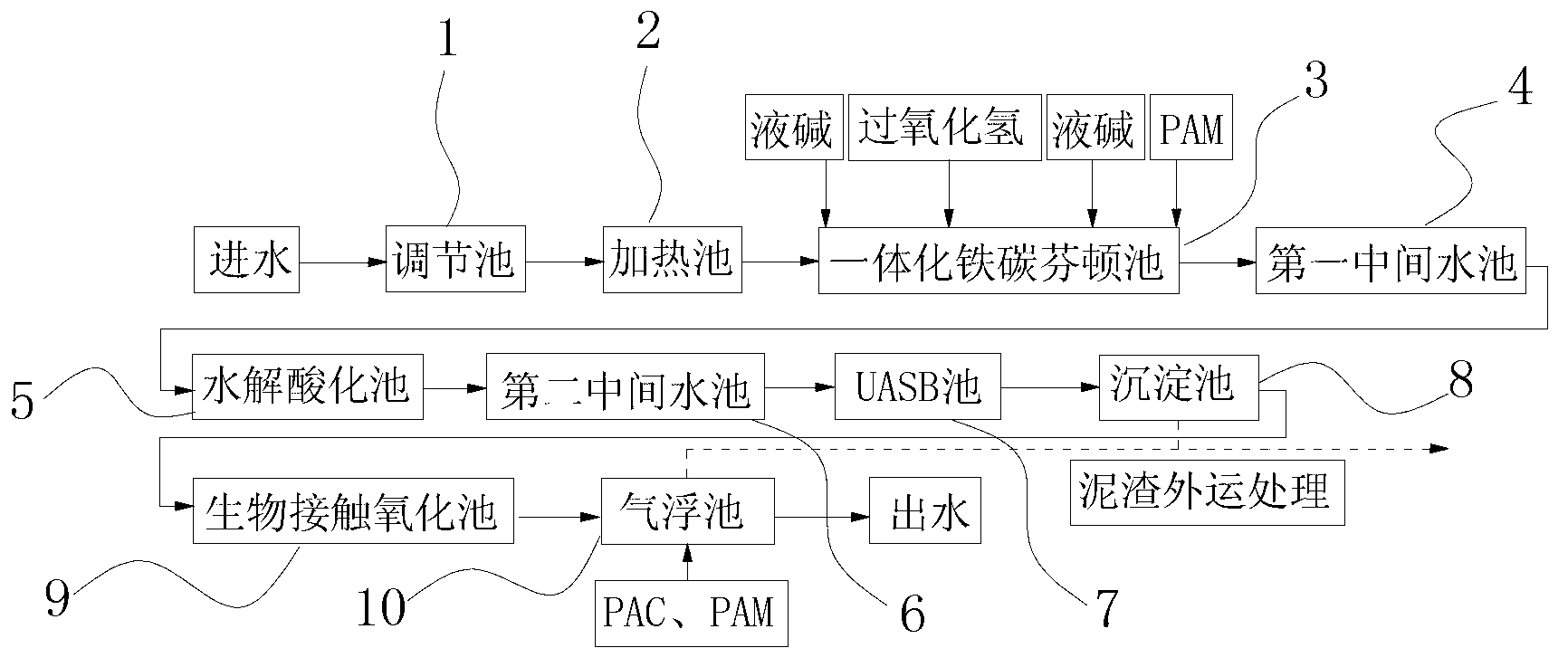

Biochemical treatment/advanced oxidation treatment coupled sewage treatment technique

InactiveCN102452770AIncrease profitReduce concentrationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAdvanced oxidation processSludge

The invention provides a biochemical treatment / advanced oxidation treatment coupled sewage treatment technique which is suitable for treating waste water with high organic pollutant concentration and poor biochemical degradability. The technique comprises steps as follows: sewage is pretreated and enters a biochemical reactor, the silt-water mixture treated by the biochemical reactor enters two sedimentation tanks, the two sedimentation tanks separate the silt-water mixture, most silt flows back to the water inlet end of the biochemical reactor, and the surplus silt goes to a silt concentration tank; most supernatant enters an advanced oxidation treatment unit, and the rest of supernatant is discharged; and the supernatant treated by the advanced oxidation unit flows back to the water inlet end of the biochemical reactor. The invention couples the biochemical treatment and advanced oxidation, fully utilizes the degradation capability of the biochemical technique for micromolecules and the degradation capability of the advanced oxidation technique for macromolecules, organically combines the biochemical technique and the advanced oxidation technique, can efficiently treat nondegradable waste water which can not achieve the standard by biochemical treatment, and is suitable for waste water treatment in chemical engineering, pharmacy, printing and dyeing and other industries.

Owner:MEISHU ENVIRONMENTAL PROTECTION TECH BEIJING +1

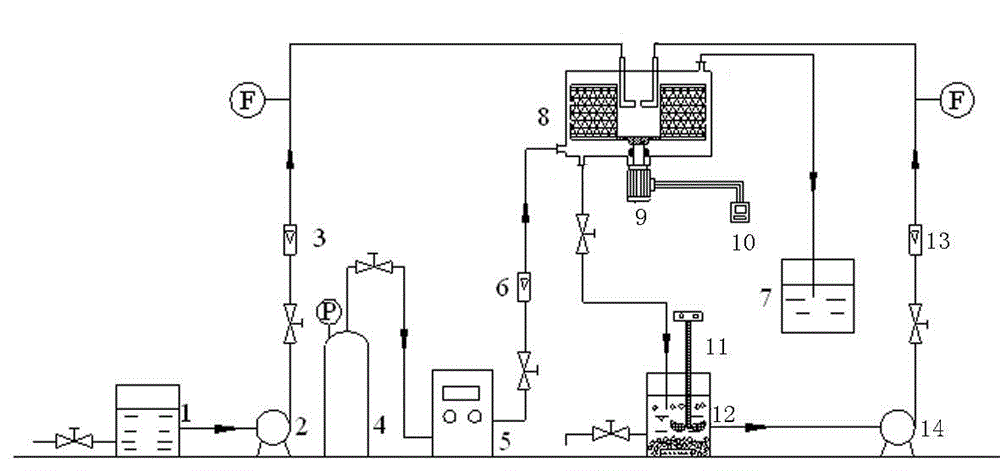

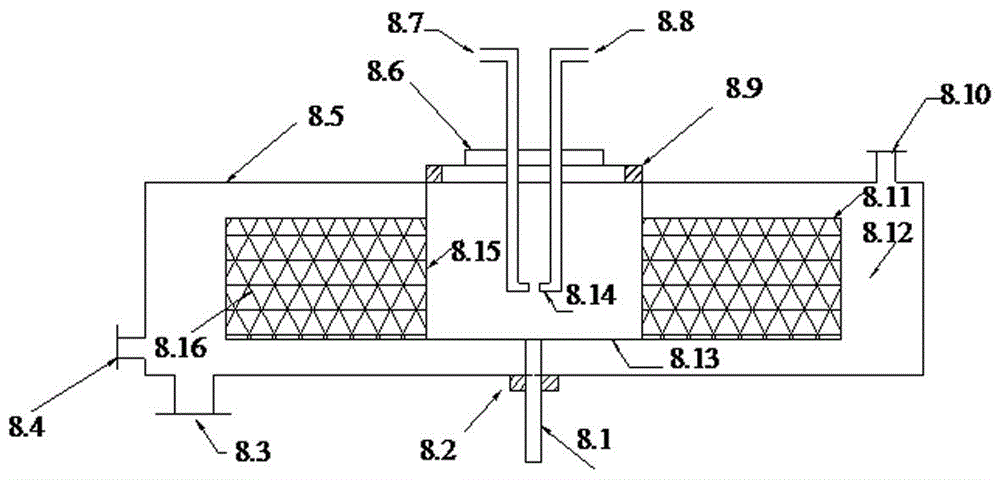

Method and device for treating wastewater by advanced oxidation process

ActiveCN103145274ATo achieve the purpose of biochemicalTo achieve the purpose of treating waste with wasteWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentElectrolysisFenton reagent

The invention belongs to the technical field of treatment for industrial production wastewater, and particularly relates to a method and a device for treating wastewater by an advanced oxidation process, which solve the shortages in the existing methods for treating industrial wastewater. The method comprises the following steps of: performing micro-electrolysis reduction reaction on wastewater; impinging the wastewater with hydrogen peroxide in liquid-liquid reaction equipment; forming Fenton reagent by Fe<2+> and hydrogen peroxide in the wastewater; and performing contact reaction on the wastewater and ozone in the liquid-liquid reaction equipment. The device comprises an impinging stream-rotating packed bed device, wherein nozzles are formed at the outlets of two liquid inlet tubes respectively, the two nozzles are coaxial and the outlets are oppositely arranged, the two liquid inlet tubes are connected with a hydrogen peroxide storage tank and a micro-electrolysis tank respectively, and liquid outlets are connected with the micro-electrolysis tank; and an intake port is connected with an ozone generator, and an exhaust port is connected with a KI adsorption liquid storage tank. The method and the device disclosed by the invention have the beneficial effects that the technical process is simple, the operation is convenient, and wastes are used for treating wastes, thus furthest reducing the treatment cost.

Owner:ZHONGBEI UNIV

Device, system and method for an advanced oxidation process using photohydroionization

ActiveUS7988923B2Efficiently formedMechanical apparatusLighting and heating apparatusAdvanced oxidation processControl system

A device, system, and method, for the formation of advanced oxidation products by contacting a hydrated catalytic surface of a catalytic target structure with broad spectrum ultraviolet light in the 100 nm to 300 nm range that preferably includes 185 nm and 254 nm wavelengths. The catalytic surface reacts with the ultraviolet light energy and hydrate at the catalytic surface to form advanced oxidation products. The catalytic surface in one embodiment includes a hydrophilic agent, titanium dioxide, silver, copper, and rhodium. Preferably, the catalytic surface is coated with a coating that includes the hydrophilic agent, titanium dioxide, silver, copper, and rhodium. A photohydroionization cell (100) that includes an ultraviolet light source (204) and a catalytic target structure (110) in an air environment to form advanced oxidation product is also provided. A U.V. light indicator and a monitor and / or control system for the photohydroionization cell (100) are also provided.

Owner:RGF ENVIRONMENTAL GROUP

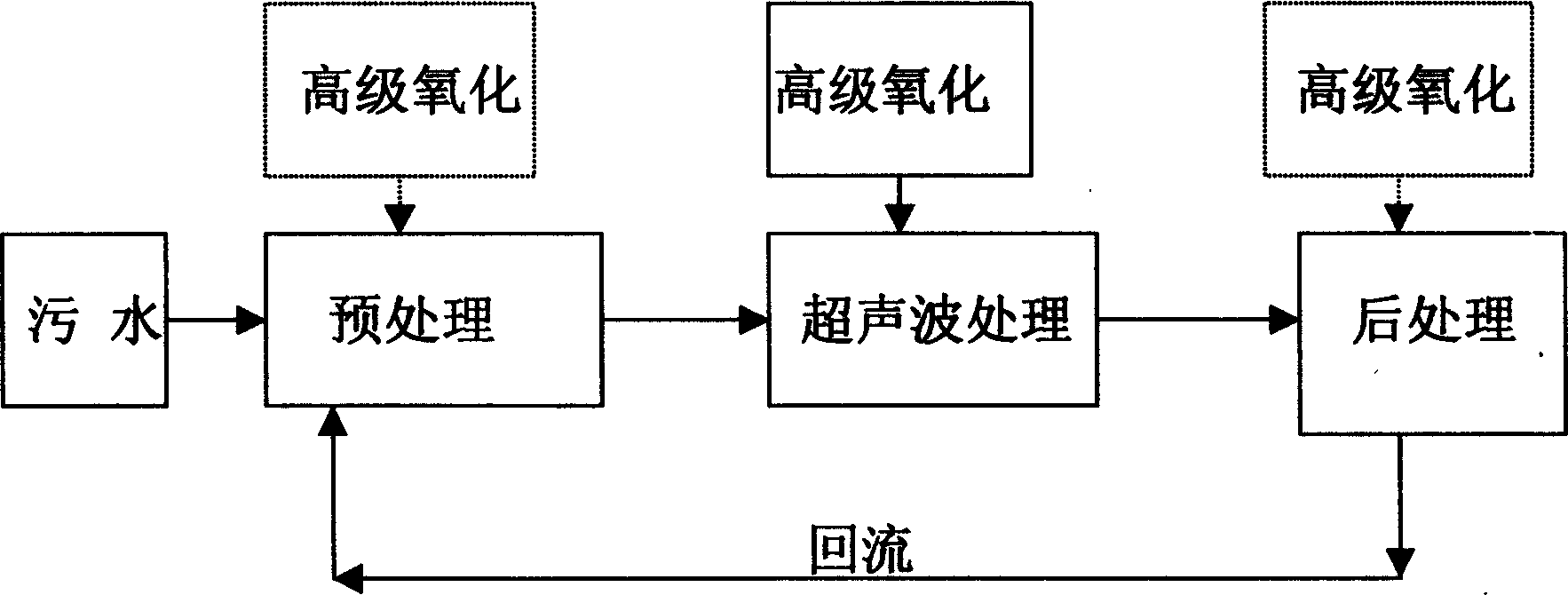

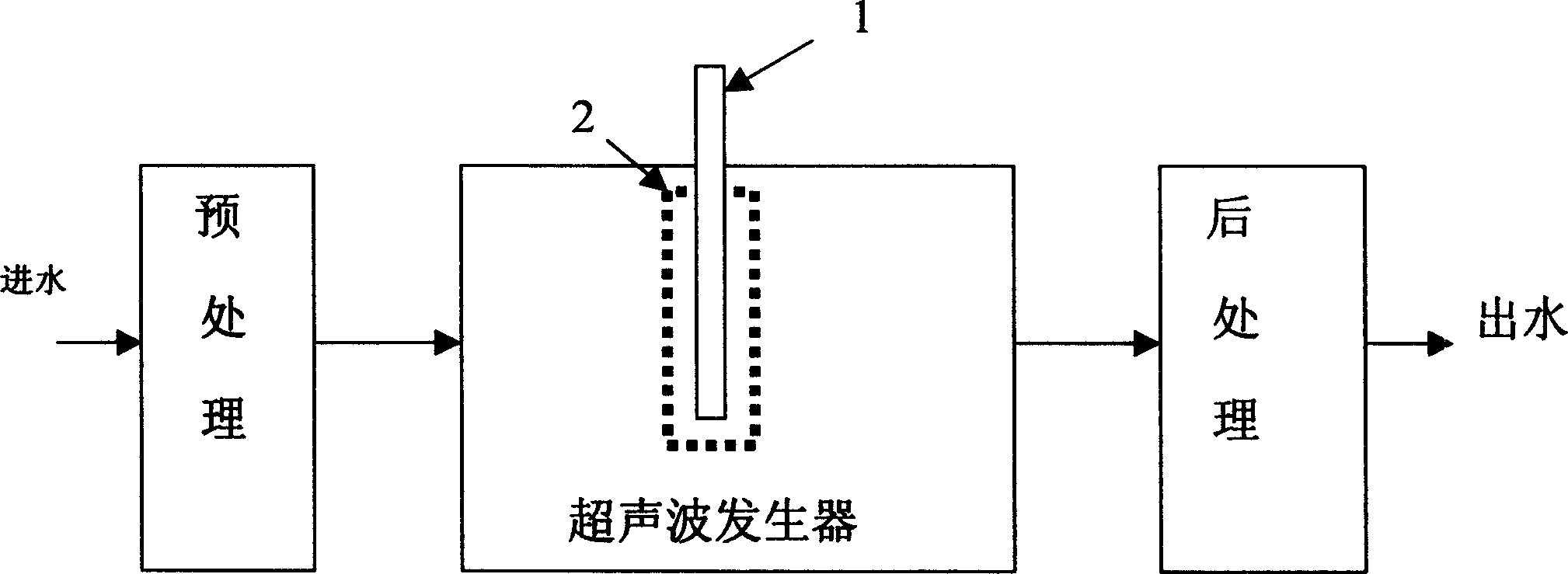

Ultrasonic wave and oxidation sewage treatment method

InactiveCN1544346AHigh yieldIncrease concentrationWater/sewage treatment with mechanical oscillationsWater/sewage treatment by oxidationAdvanced oxidation processTherapeutic effect

The invention relates to a ultrasonic oxidization sewage treatment process which is aimed at solving the problem of unsatisfactory treatment effects to COD, BOD, SS, N, P, chromaticity and various hard-degradable organics in the conventional sewage treatment methods, the process according to the invention comprises the steps of, (1) water pretreatment, (2) subjecting the pretreated water to ultrasonic treatment, (3) subjecting the treated water to post-treatment, high-grade oxidation treatment can be added to each or any one of the steps.

Owner:北京裕京电脑软件有限公司

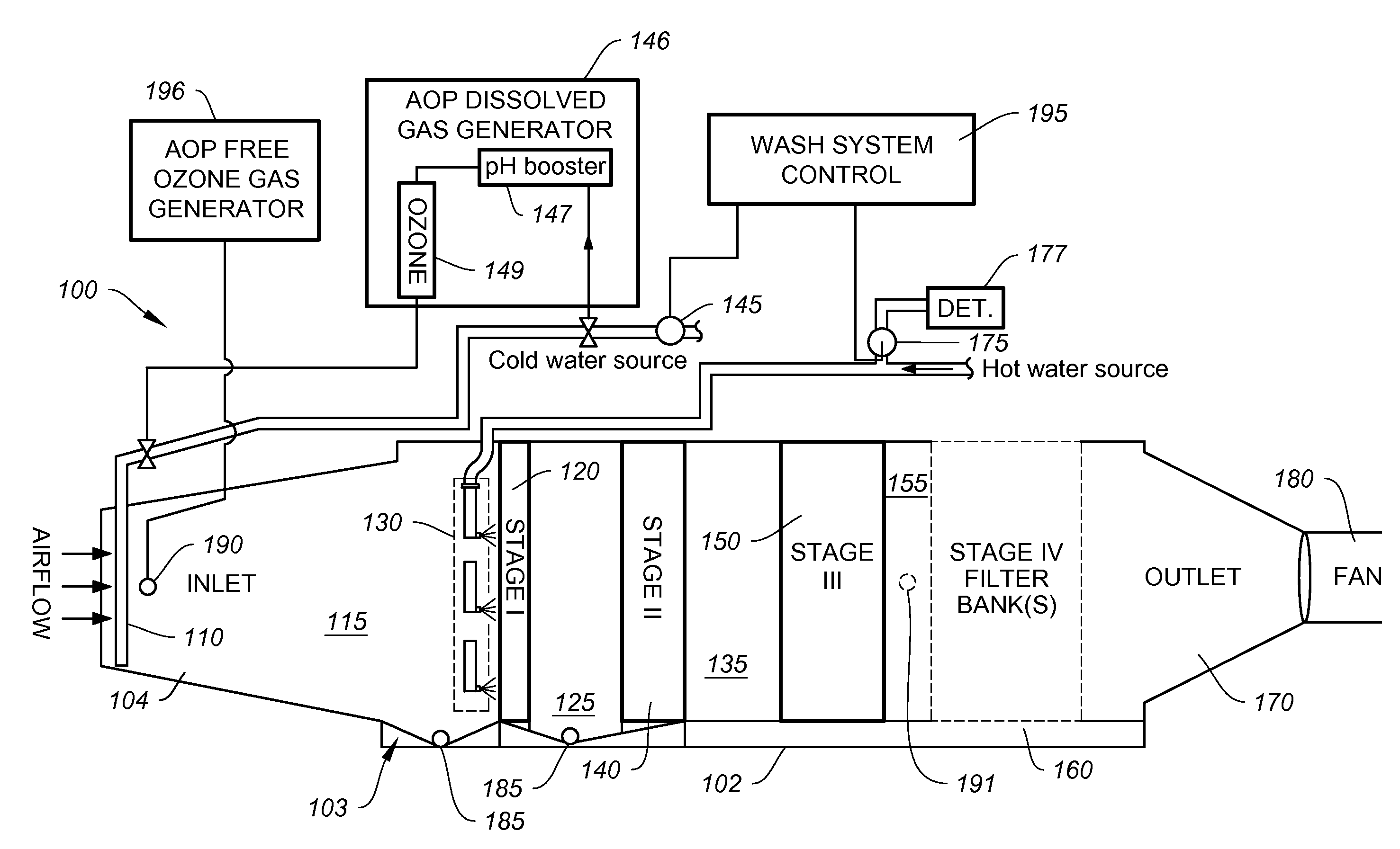

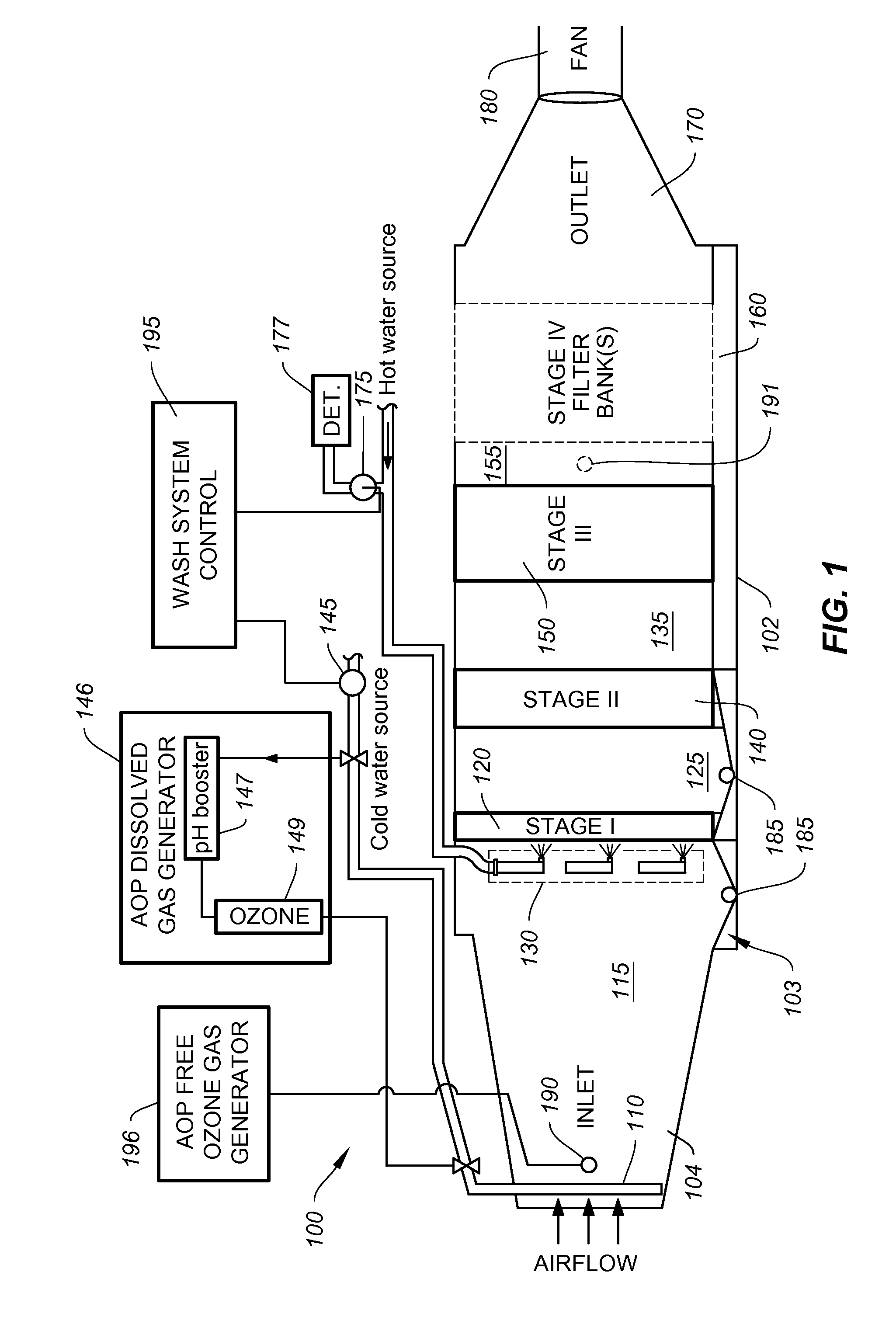

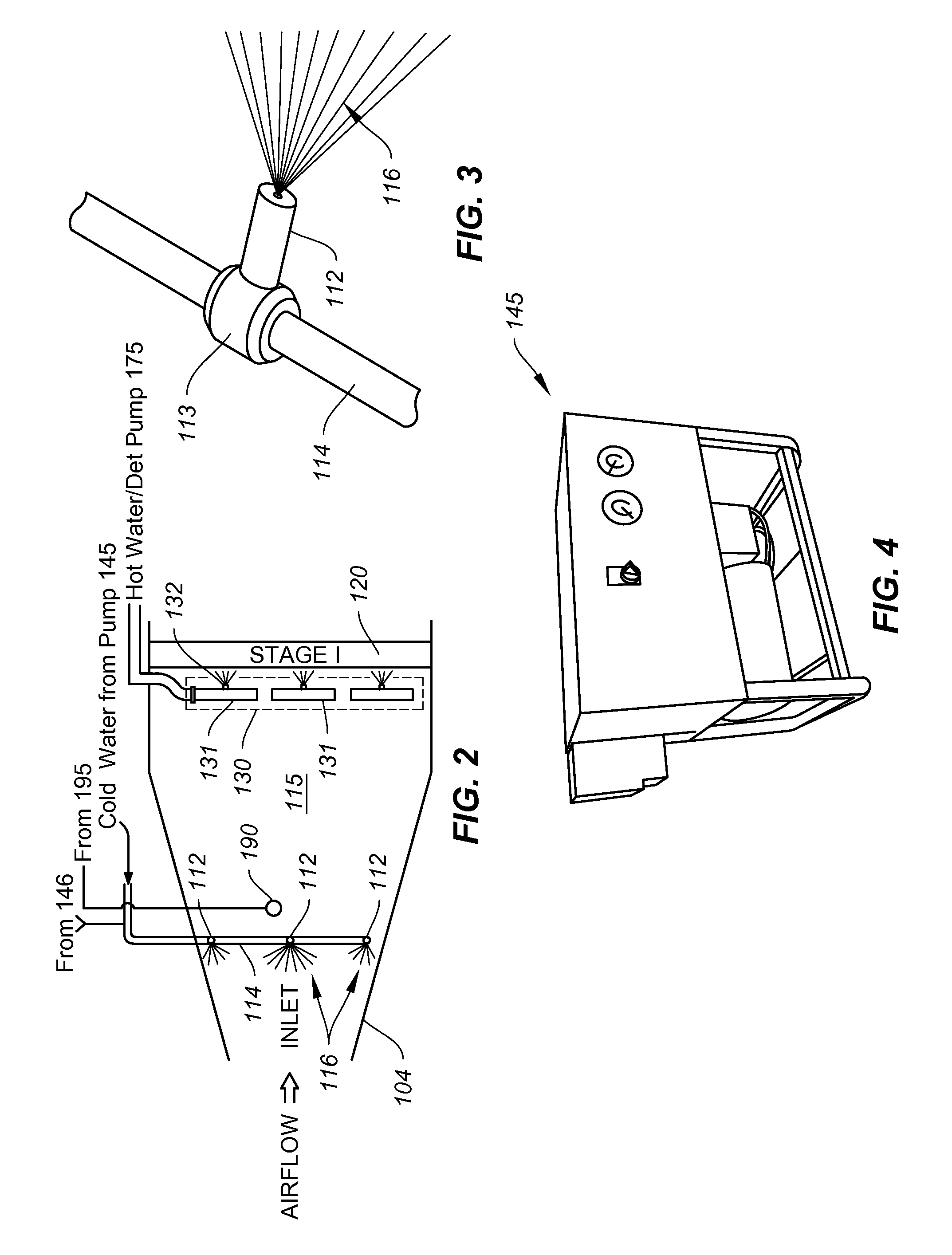

Mechanical filter-based pollution control system to remediate cooking emissions

A mechanical filter-based air pollution control system for removing particle and gas phase pollutants in a waste airstream exhausted from commercial cooking operations is described, which includes a housing enclosing at least three filter stages to remove particle and gas pollutants in the airstream. The example system may include a fogger assembly that sprays fog droplets into the waste airstream to condense a portion of gas phase pollutants into condensed particles, a wash mechanism including spray nozzles to wash surfaces of the first stage filter to remove grease therefrom, and injection means for injecting activated ozone, which comprises ozone with a surplus of hydroxyl radicals, into the housing to initiate advanced oxidation processes (AOPs) to decompose particle and gas phase pollutants within the waste airstream in the filters. Where activated ozone is employed, the system includes a fourth stage filter that adsorbs and retains gas phase pollutants for subsequent oxidation.

Owner:AJEMIAN ROBERT C

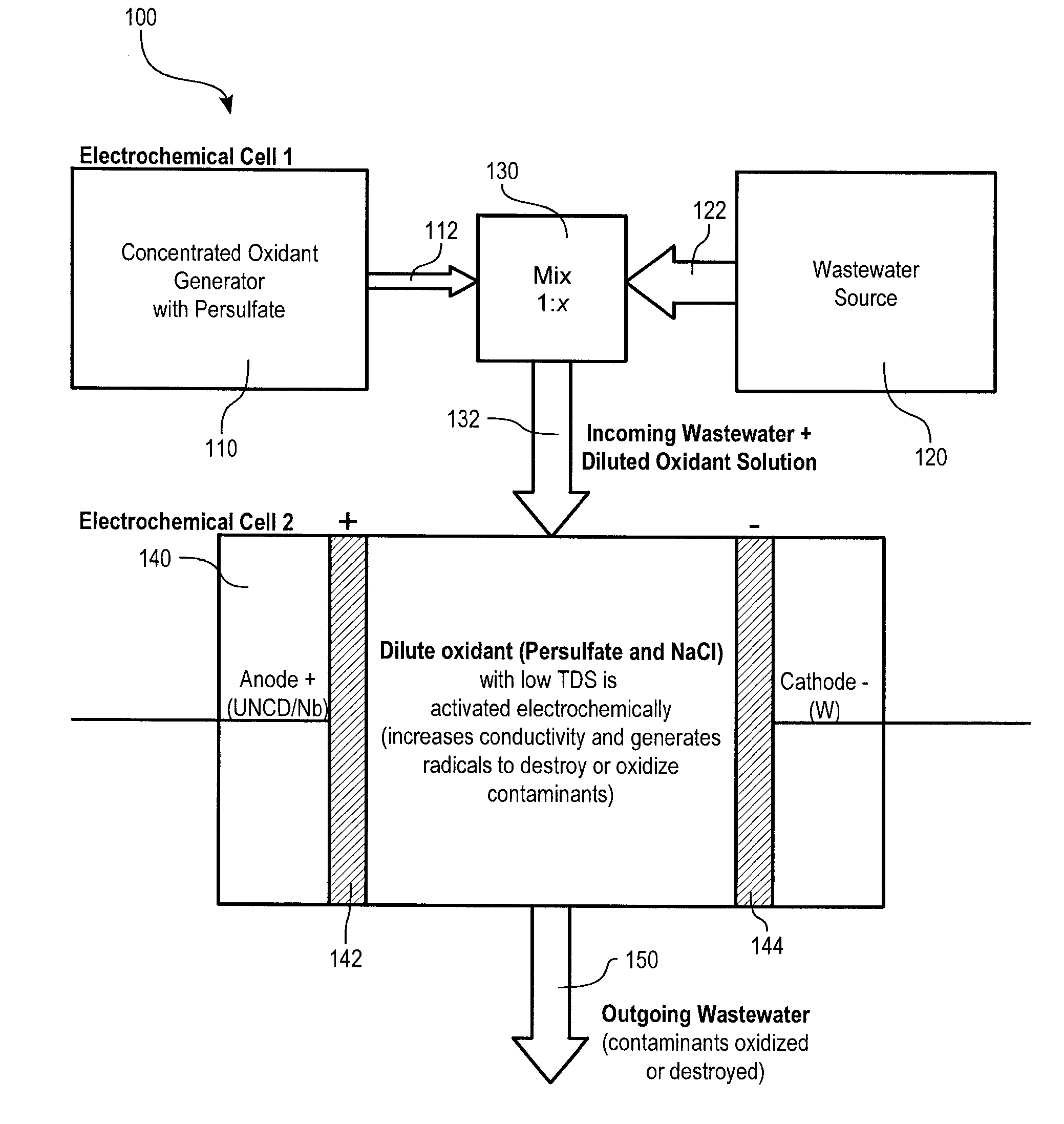

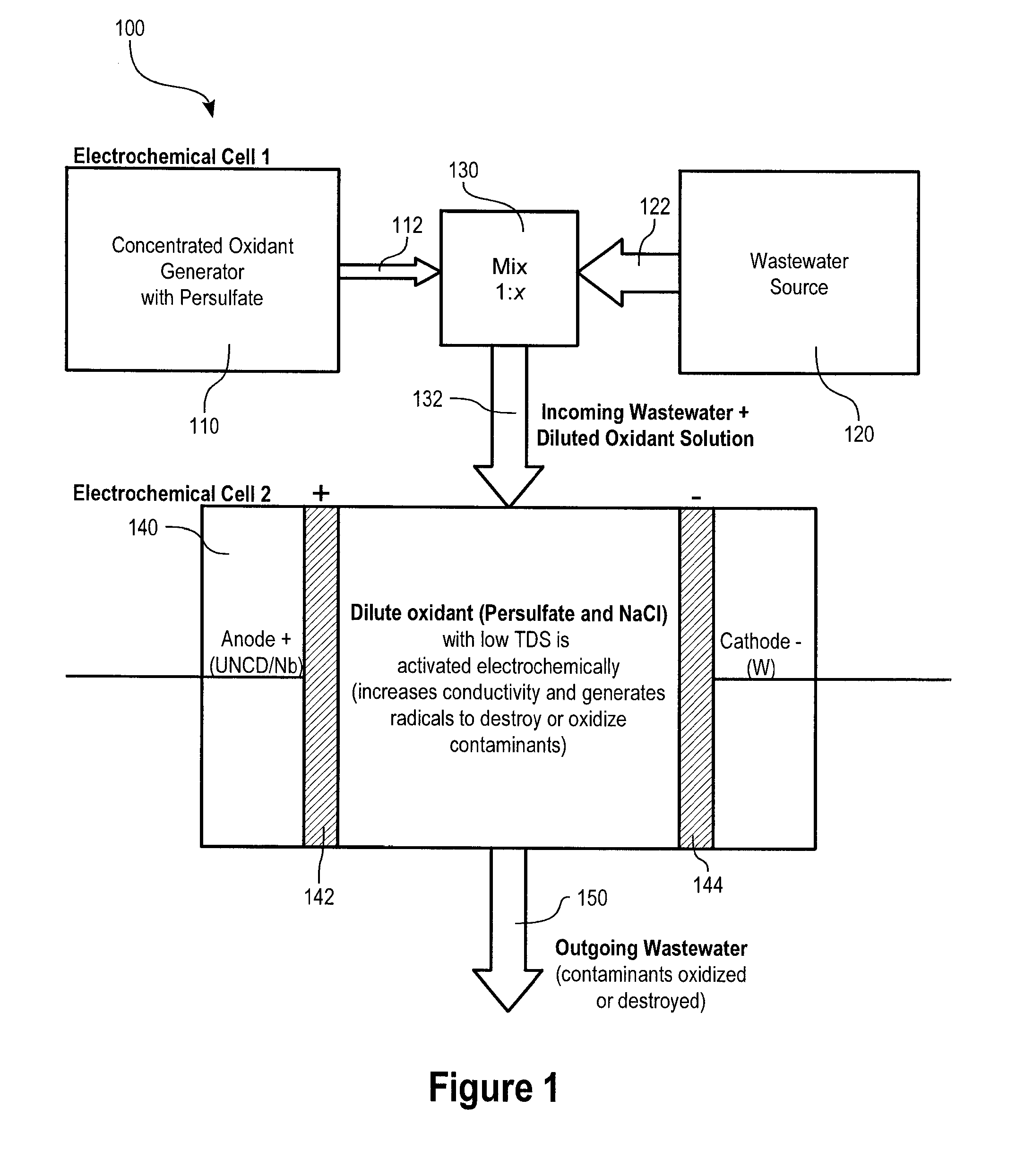

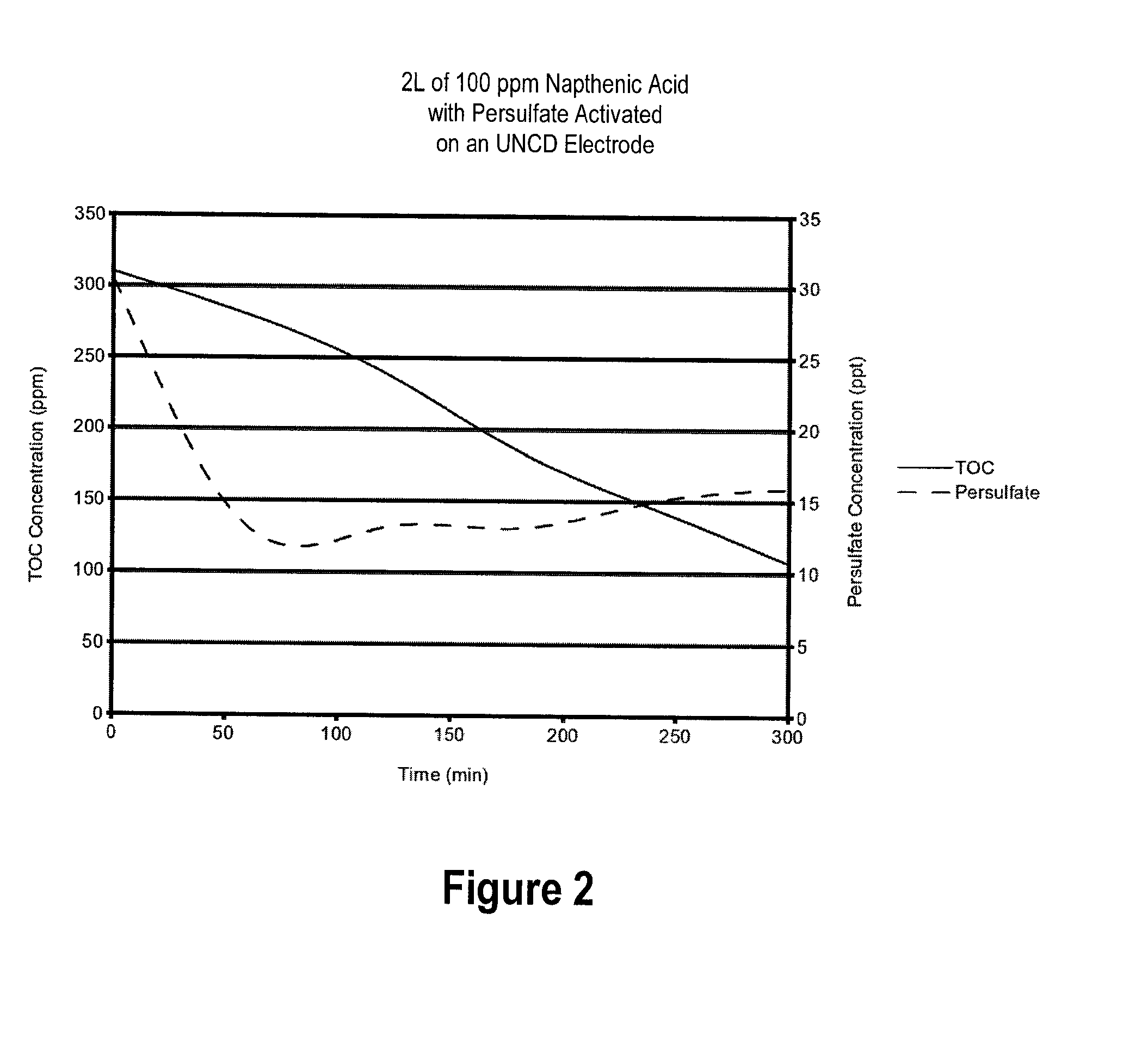

System and Method for Treatment of Wastewater to Destroy Organic Contaminants by a Diamond Activated Electrochemical Advanced Oxidation Process

InactiveUS20130299361A1Improve conductivityIncrease currentCellsWater contaminantsConcentration ratioAdvanced oxidation process

Disclosed is a system and method for treatment of wastewater to destroy organic contaminants using an electrochemical advanced oxidation process. In particular, the method comprises a multistep process, comprising a) generating a concentrated oxidant solution comprising a peroxy oxidant species, such as persulfate or hydrogen peroxide; b) mixing wastewater comprising organic contaminants with the concentrated oxidant solution to provide a mixture comprising wastewater and diluted oxidant, the wastewater and concentrated oxidant solution being mixed in a prescribed ratio to provide a desired concentration ratio of oxidant species to contaminants; and c) in an electrochemical cell comprising a diamond anode, electrolyzing the mixture of wastewater and diluted oxidant, comprising electrochemically activating the peroxy oxidant species for oxidation and destruction of the contaminants. Fast and effective destruction of organic contaminants such as phenol, napthenic acid and other toxic or refractory contaminants is demonstrated at low cost and with reduced usage of added salt.

Owner:ADVANCED DIAMOND TECH

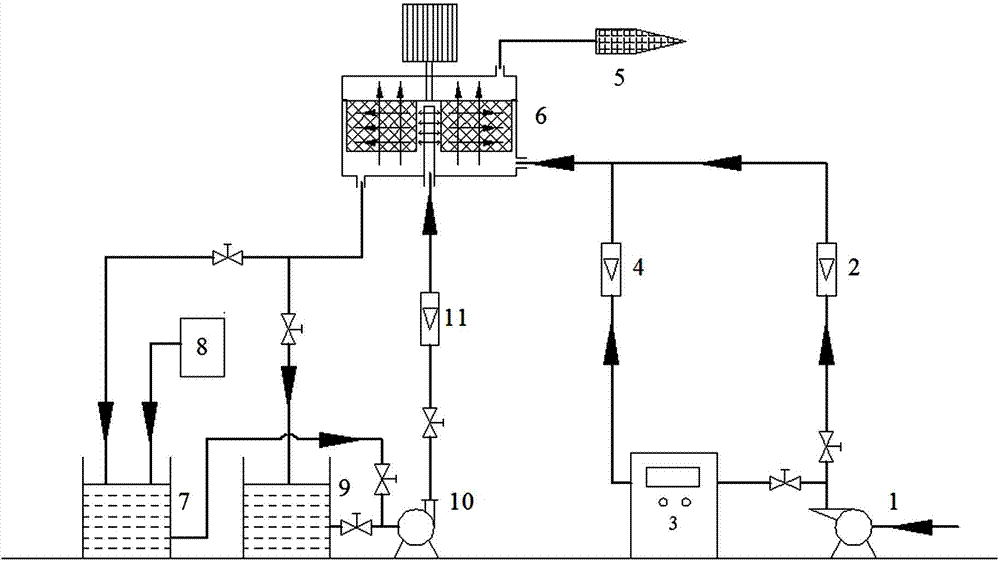

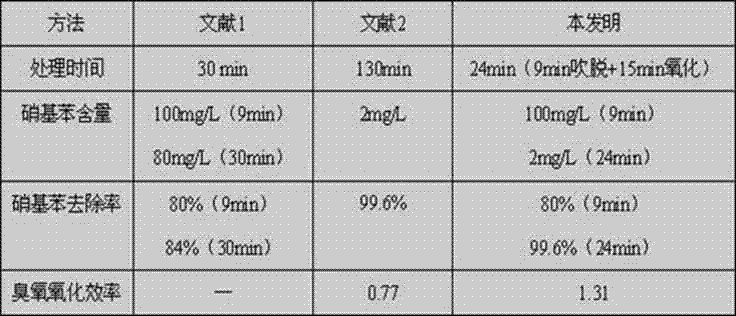

Method and device for stripping, oxidizing and degrading high-concentration nitrobenzene-containing wastewater

ActiveCN104724852AReduce processing timeImprove oxidation efficiencyWater contaminantsMultistage water/sewage treatmentAdvanced oxidation processNitrobenzene

The invention belongs to the technical field of high-concentration nitrobenzene-containing wastewater treatment and provides a method and a device for stripping, oxidizing and degrading a high-concentration nitrobenzene-containing wastewater for solving the high cost problem of the high-concentration nitrobenzene-containing wastewater treatment through the ozone advanced oxidation process. The method comprises the steps of contacting the high-concentration nitrobenzene-containing wastewater with fresh air in a supergravity device to finish a stripping mass transfer process; sending the wastewater into a liquid storage groove after finishing mass transfer process and mixing with hydrogen peroxide, performing contact reaction with an ozone gas in a supergravity device, and degrading the residual organic matter in the wastewater under the synergistic effect of ozone and H2O2. By adopting the method, the ozone oxidation efficiency is increased, the processing time is shortened, the pollutant content in the wastewater is reduced through a blow-off method and the oxidation reaction is performed, the water quality change of the wastewater is furthest reduced, the intermediate product production is reduced, the ozone and the hydroxyl radical depleting substance production is reduced, the ozone oxidation efficiency is increased by 65-75%, the processing time is shortened by 80%, the ozone use amount is reduced by 70% and the processing cost is saved by about 50%.

Owner:ZHONGBEI UNIV

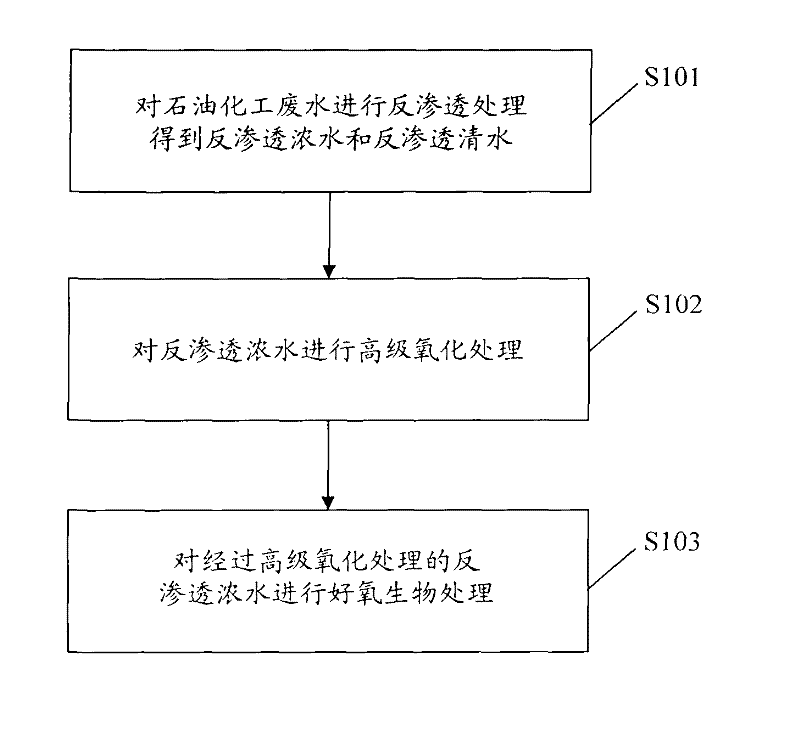

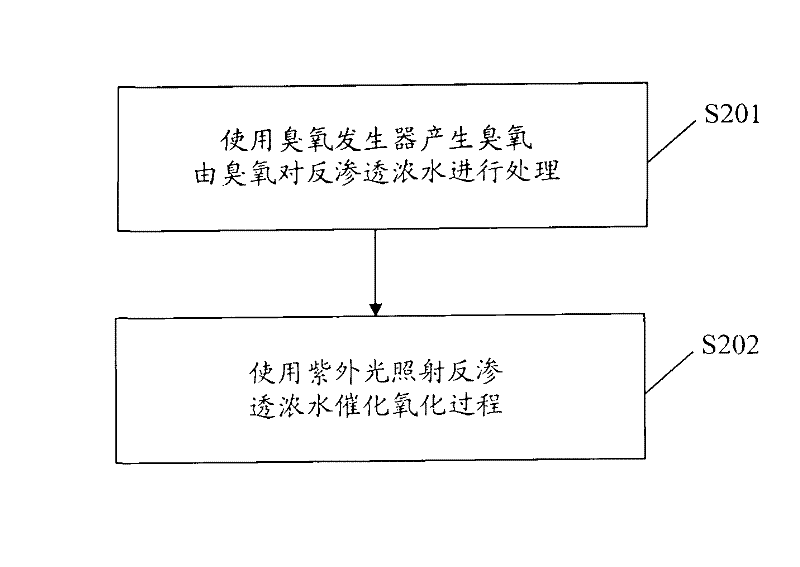

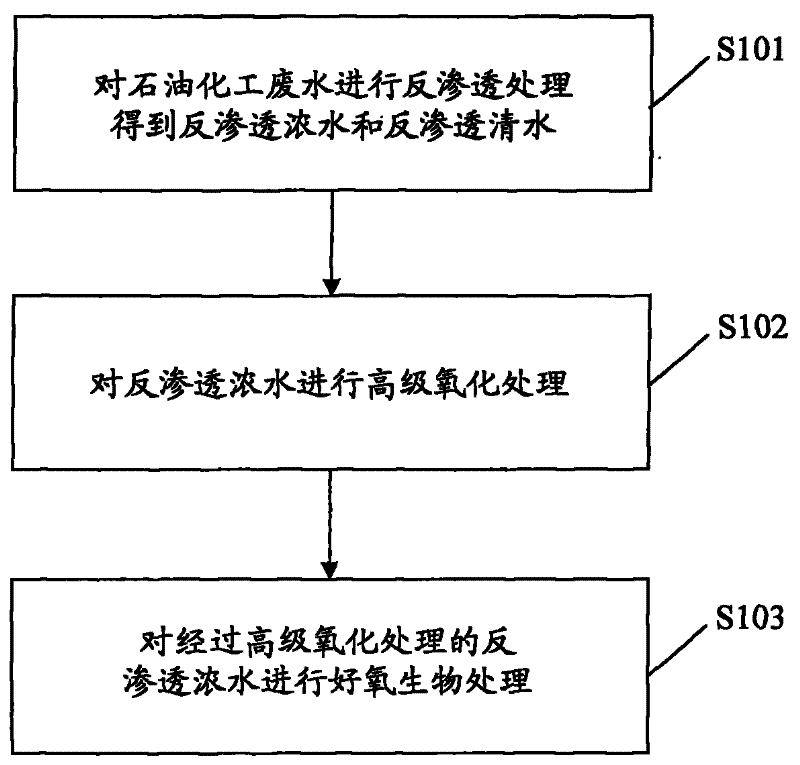

Process for treating petrochemical wastewater

InactiveCN102452766AImprove biodegradabilityImprove water qualityMultistage water/sewage treatmentAdvanced oxidation processEmission standard

The invention discloses a process for treating petrochemical wastewater. The process comprises the following steps of: performing reverse osmosis treatment on the petrochemical wastewater to obtain reverse osmosis concentrated water and reverse osmosis clear water; performing advanced oxidation treatment on the reverse osmosis concentrated water; and performing aerobic biological treatment on the reverse osmosis concentrated water subjected to advanced oxidation treatment. By the process for treating the petrochemical wastewater, a multi-process section series-connected treatment method is adopted, the biochemical degradability of the wastewater is improved by an advanced oxidation process, the effect of improving water quality can be relatively effectively achieved through aerobic biological treatment, and the petrochemical wastewater treated by the scheme meets the emission standard.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

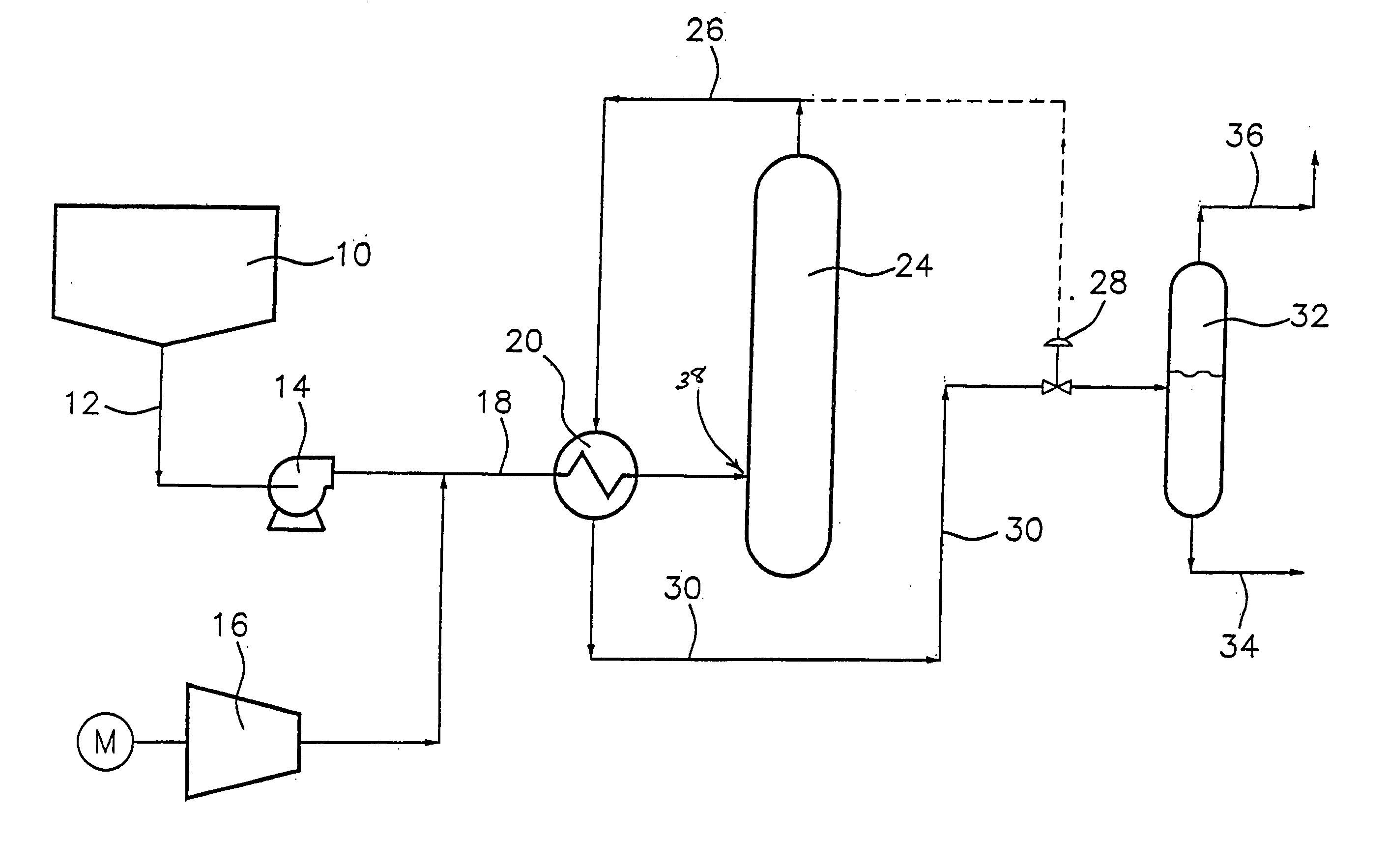

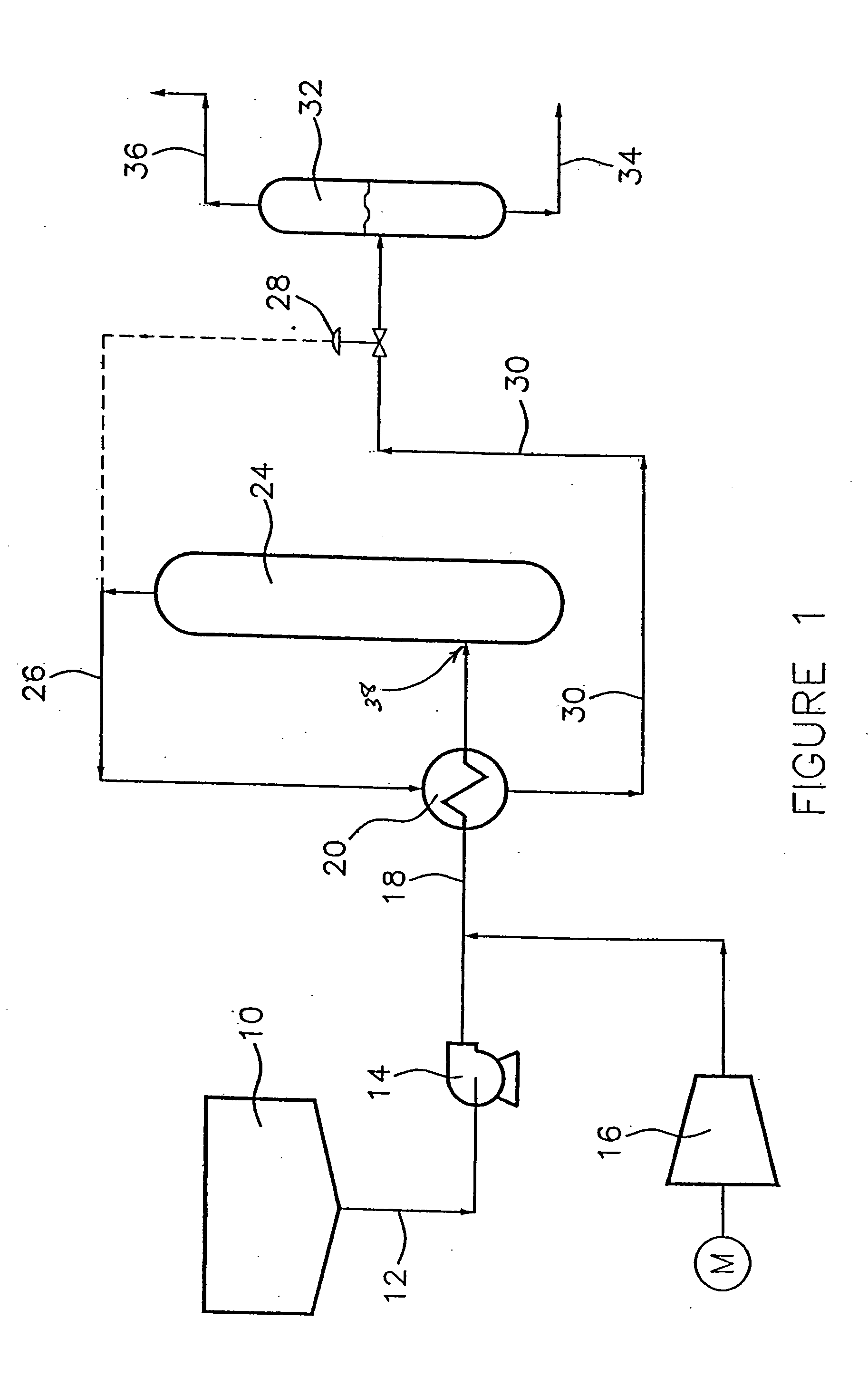

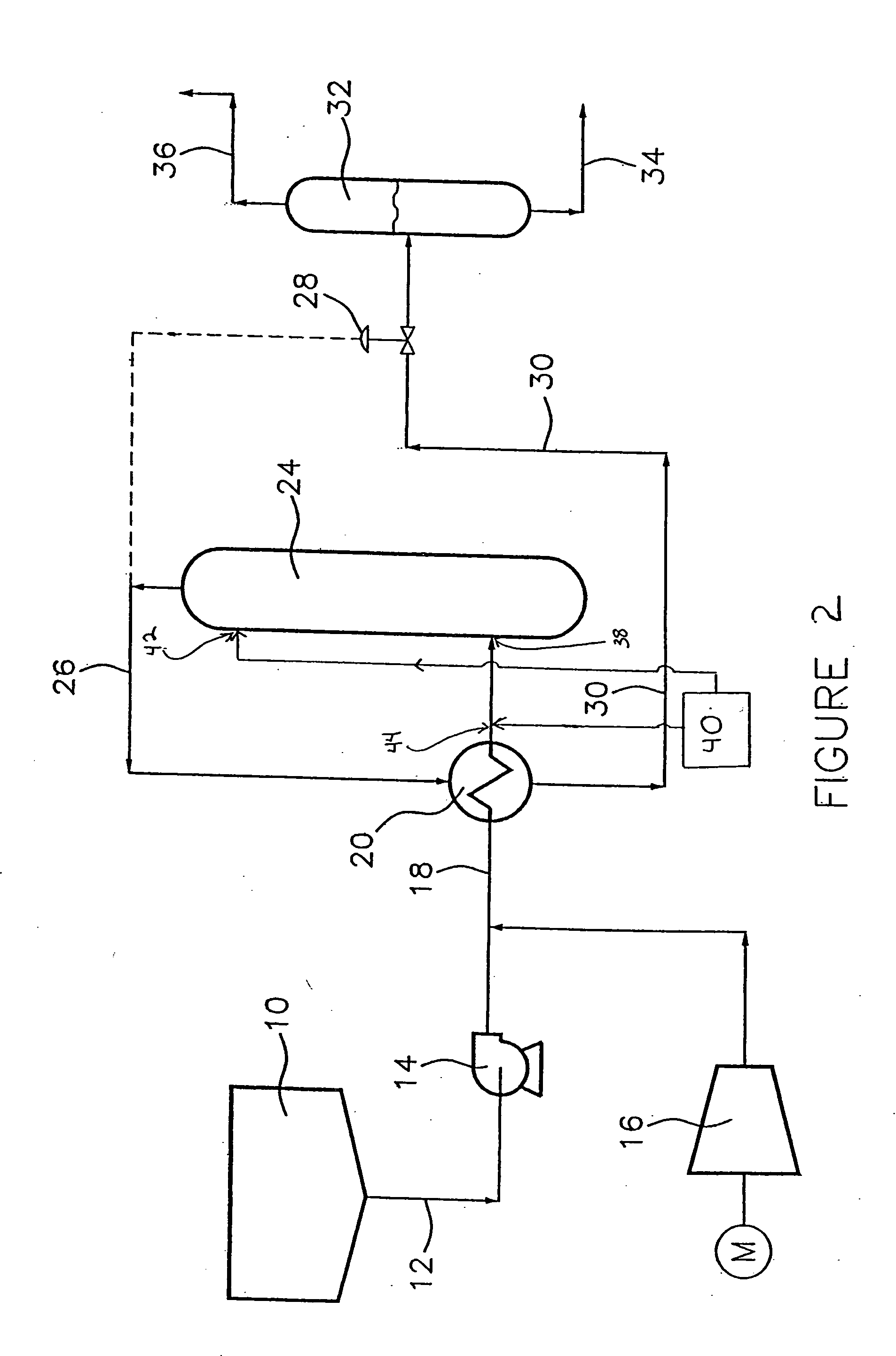

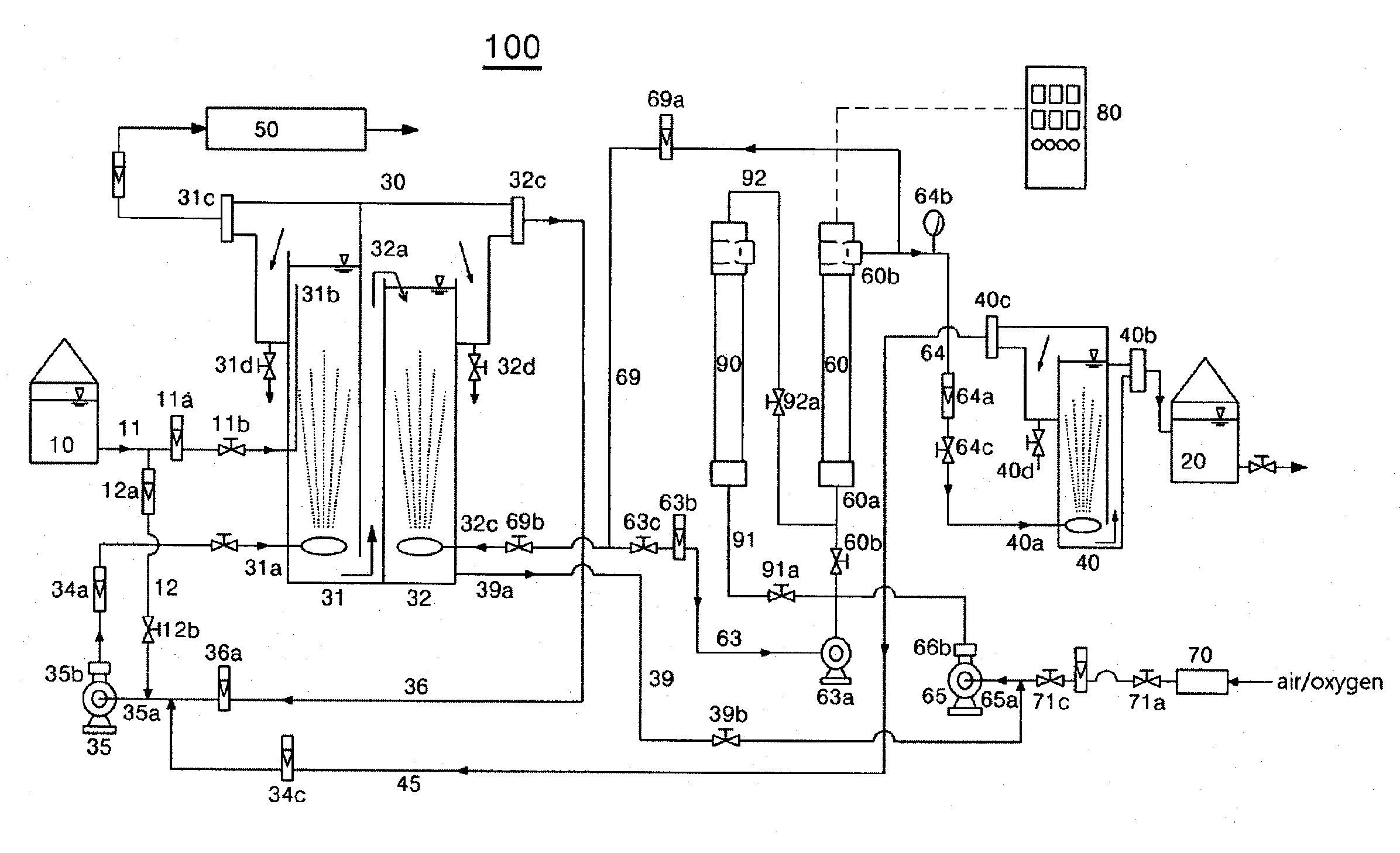

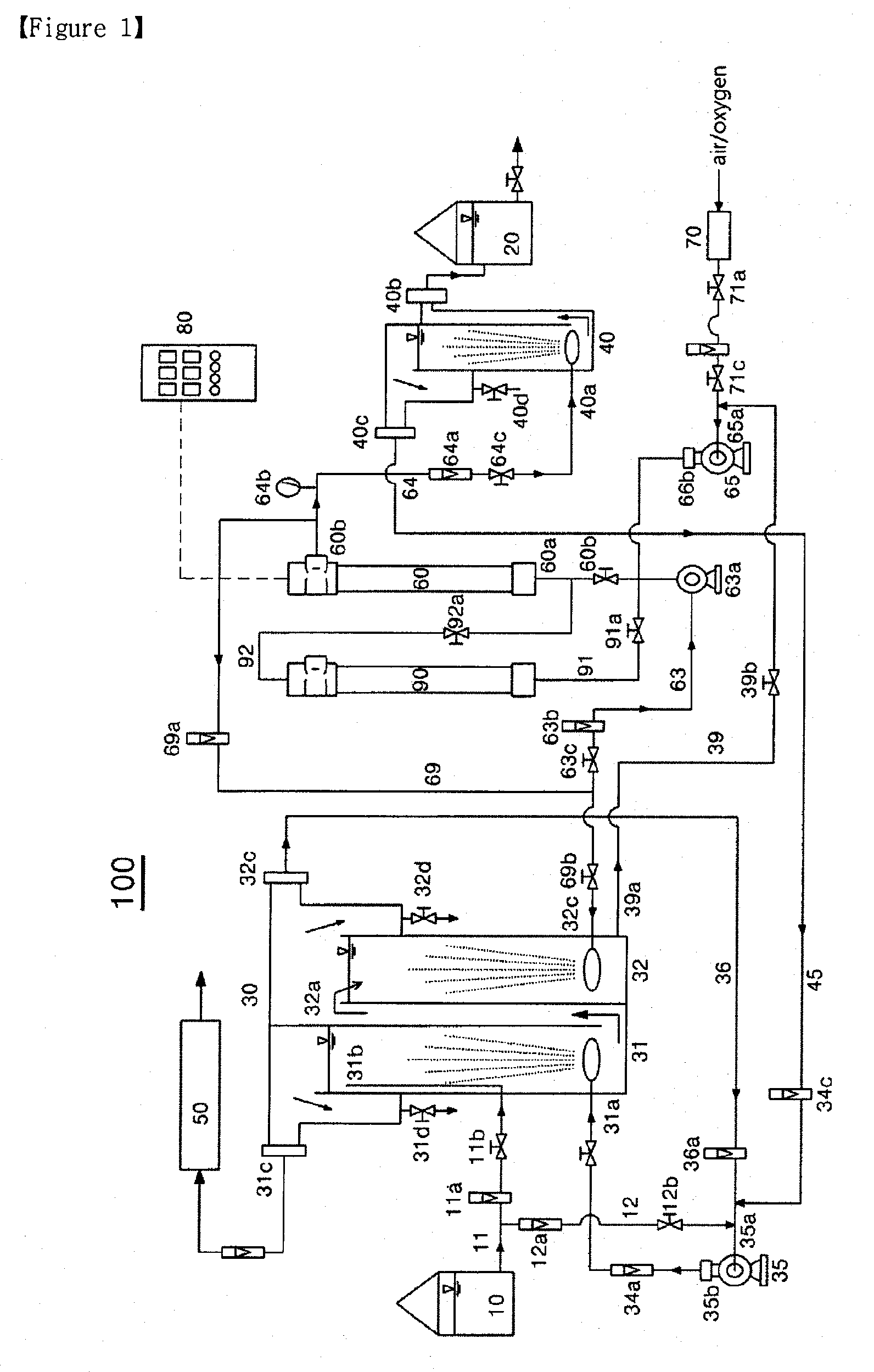

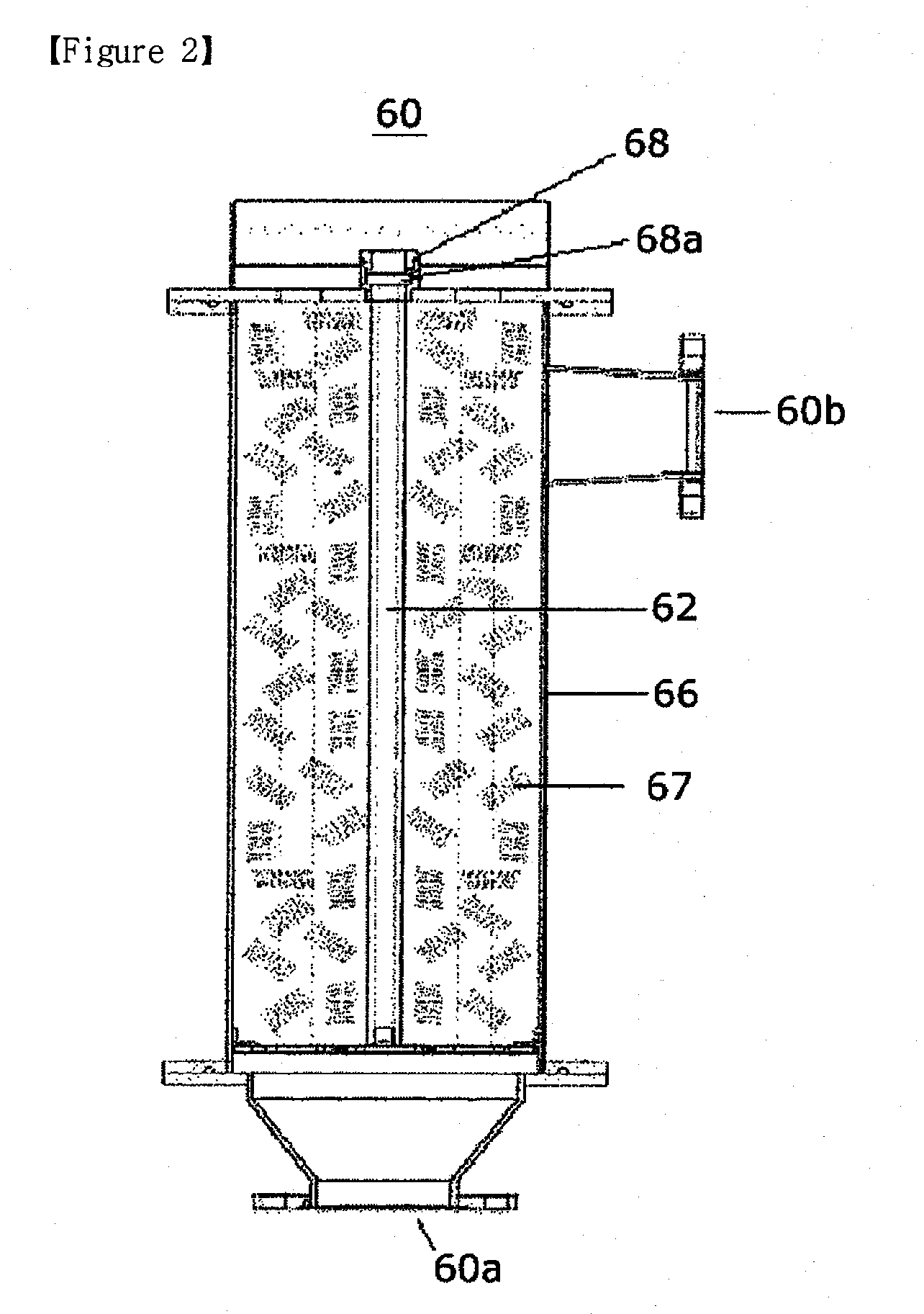

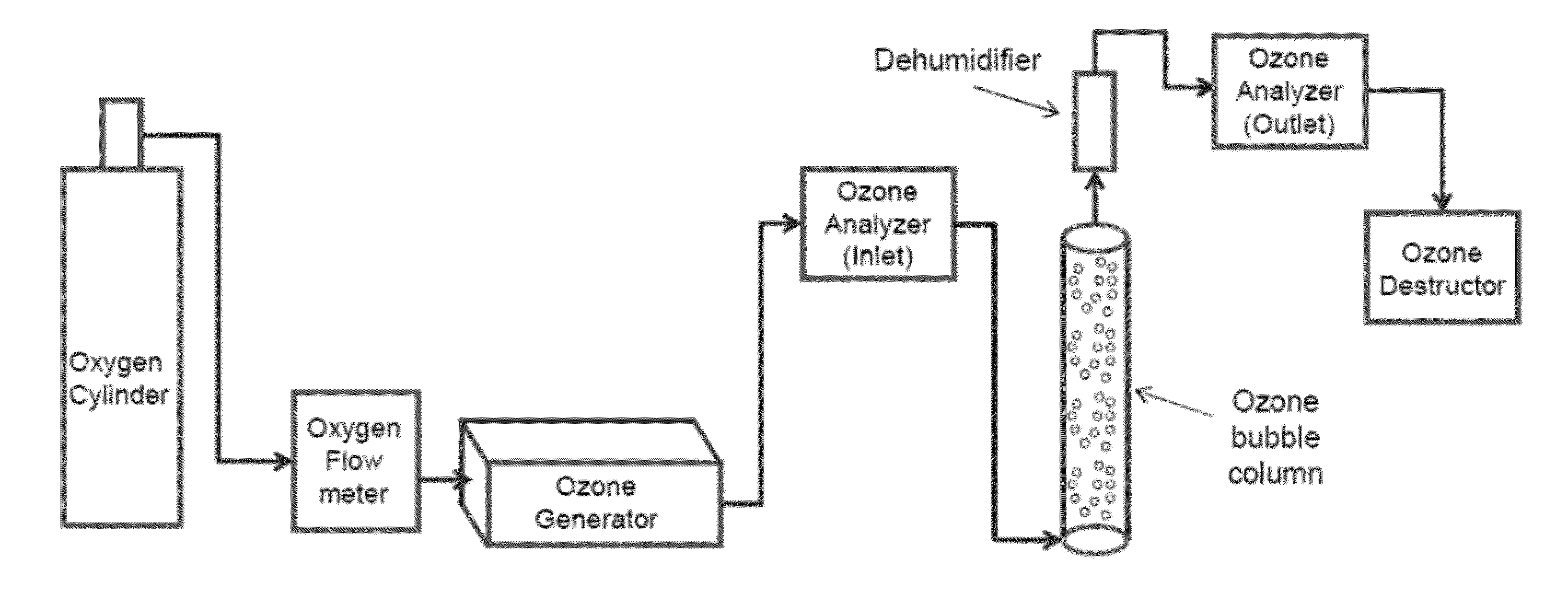

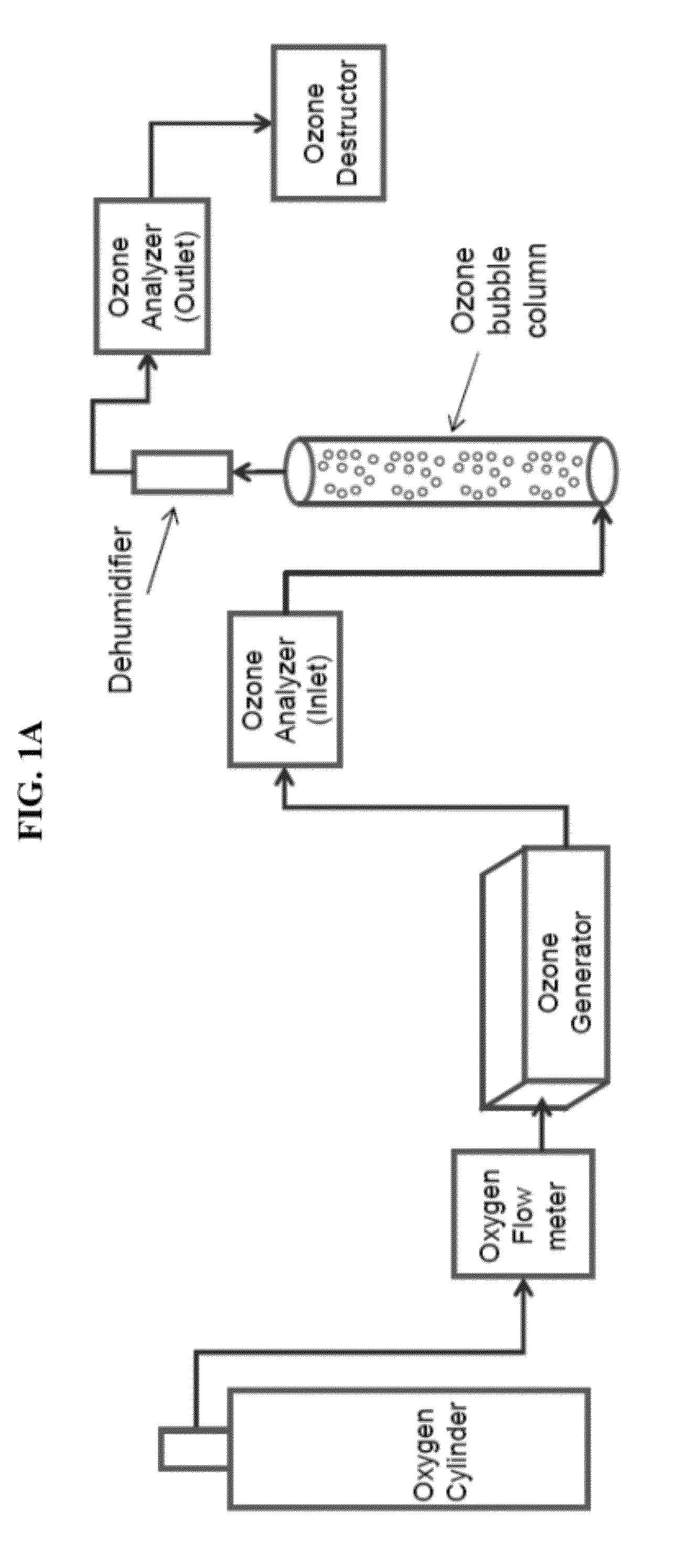

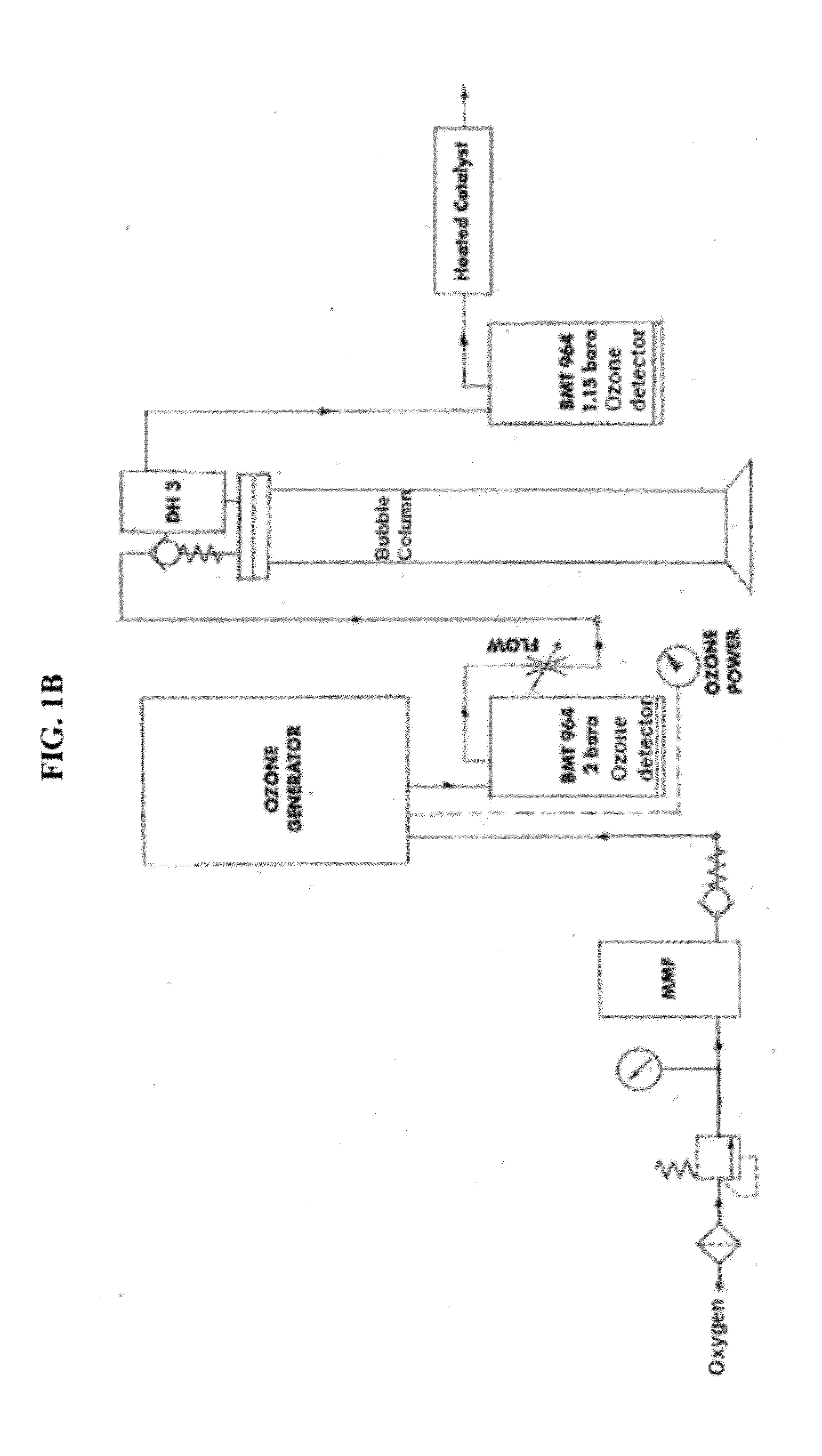

Water treatment system and method using high pressure advanced oxidation process with unreacted ozone reusing

InactiveUS20110031187A1Improve contact efficiencyReduce capacityWater treatment parameter controlWater/sewage treatment by irradiationWater treatment systemDecomposition

A water treatment system using a high pressure advanced oxidation process with unreacted ozone reusing is disclosed, which are able to increase a decomposition speed of a pollutant by reusing a high pressure advanced oxidation process which uses an ozone and photocatalyst and a photo-oxidation reaction of a ultraviolet ray. The capacity of the expensive ozone generator can be reduced as compared to the conventional advanced oxidation process which uses a large capacity ozone generator in which almost ozone is discharged into the air. In addition, it is possible to decrease the load of the off-gas ozone removing apparatus for removing the off-gas ozone which is discharged into the air.

Owner:SHIM JONG SEOB

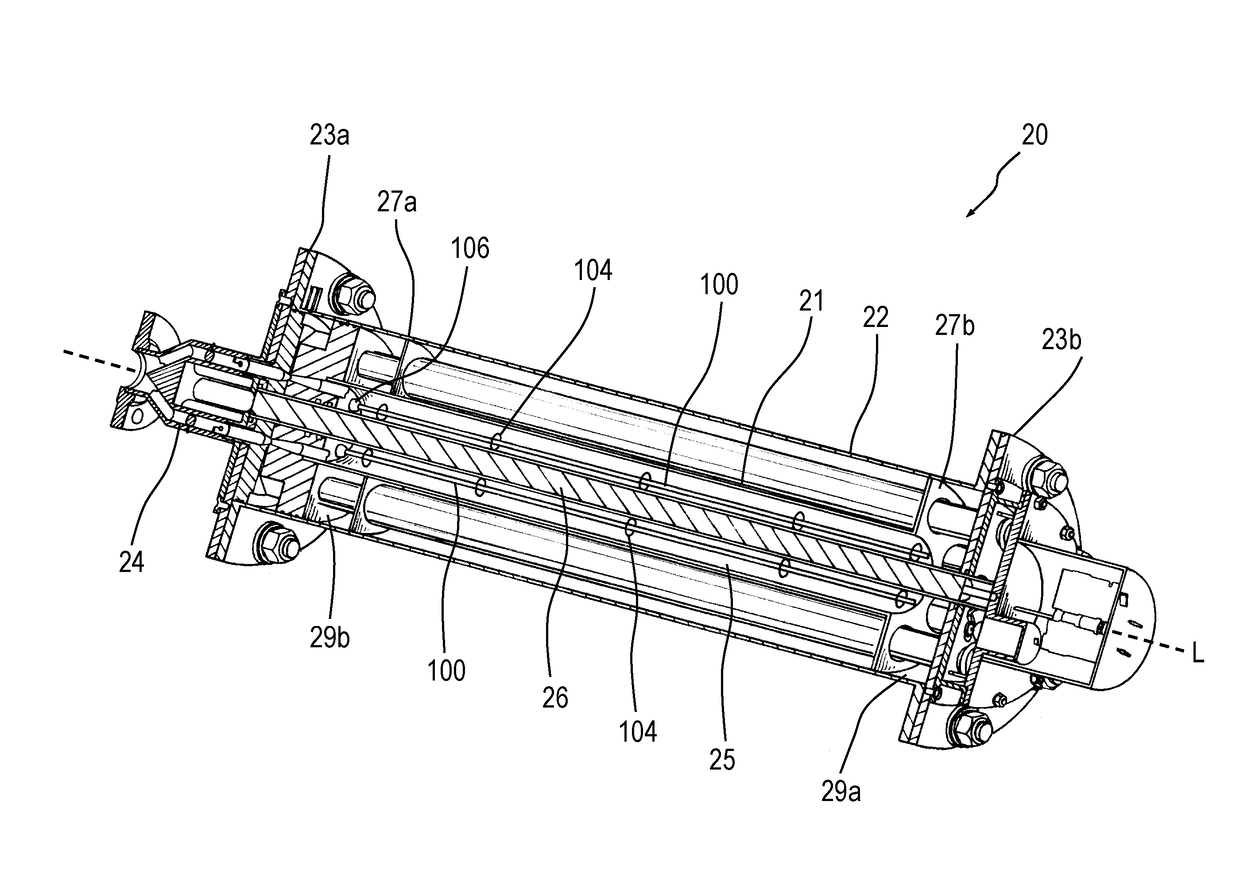

Apparatus and method for water treatment

ActiveUS20170320754A1Improve photocatalytic performanceImprove efficiencyWater/sewage treatment by irradiationWater treatment compoundsCavitationAdvanced oxidation process

An apparatus for use in a liquid treatment process, and a method of use is described. The apparatus comprises an inlet configured to be connected to a source of liquid to be treated and an outlet for discharging liquid from the apparatus. At least one liquid treatment vessel or conduit is disposed between the inlet and the outlet, and is arranged to expose liquid in the vessel to ultraviolet radiation in an advanced oxidation process reaction. A source of ultraviolet radiation extending along the liquid treatment vessel or conduit, such that an annular flow volume is defined in the vessel or conduit around the source of ultraviolet radiation. A rotary device is disposed in the annular flow volume and a drive mechanism drives rotation of the rotary device. The rotary device is operable to induce cavitation in a liquid present in the annular flow volume.

Owner:GREENTHREAD

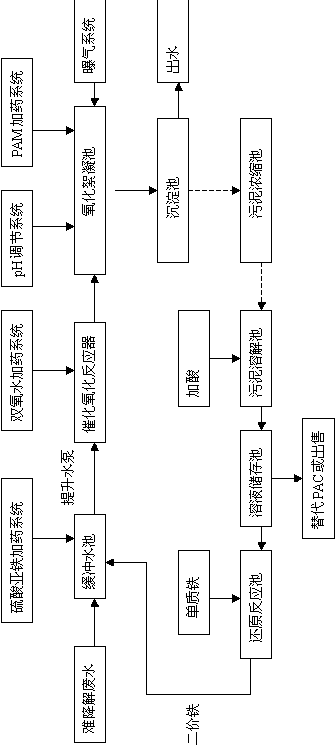

Processing method capable of recycling iron-containing sludge generated in advanced oxidation techniques

A processing method capable of recycling iron-containing sludge generated in advanced oxidation techniques comprises the following steps: a. putting iron-containing sludge, which is in a sedimentation tank, into a sludge concentrating tank for gravity concentration, so that the volume and water content of the sludge are largely reduced; b. moving the concentrated sludge into a sludge dissolving tank, adding acid into the sludge dissolving tank, adjusting the pH to not greater than 1.5, and stirring at the same time to fully dissolve the sludge; c. moving the sludge-dissolved solution, the main component of which is ferric iron, into a storage tank for storage, leaving a portion of the solution as a flocculant which can substitute aluminum salts, and moving the rest of the solution into a reduction reaction tank; and d. adding single substance of Fe into the reduction reaction tank, so that the ferric iron undergoes reduction reactions to generate ferrous iron and the ferrous iron is moved into a buffer pool to decrease ferrous iron usage. The method has the following advantages: the method reduces the cost of sludge disposal; the flocculant can substitute PAC, so that medicament cost is lowered; and the recovered ferrous ion catalyst reenter reaction processes, so that catalyst usage can be reduced.

Owner:山东申龙水务有限公司

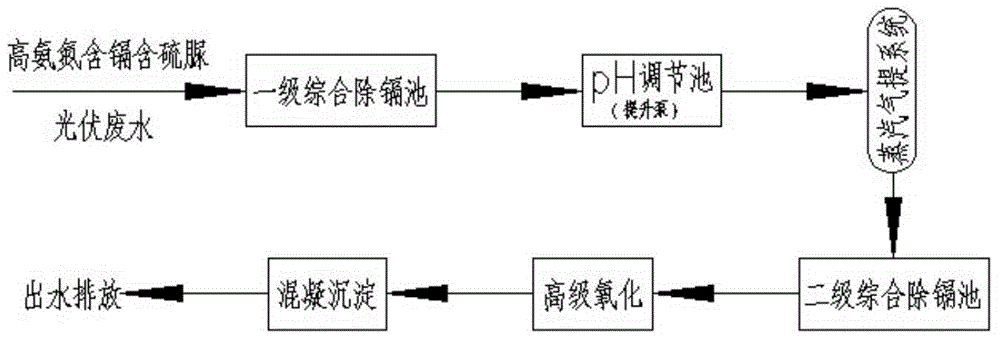

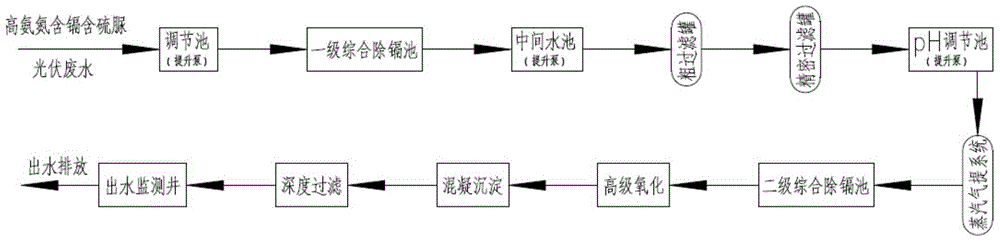

Method and system for treating high-ammonia nitrogen photovoltaic waste water containing cadmium and thiourea

ActiveCN106277513AGuaranteed uptimeImprove environmental benefitsGeneral water supply conservationEnergy based wastewater treatmentAdvanced oxidation processDistillation

The invention discloses a method and system for treating high-ammonia nitrogen photovoltaic waste water containing cadmium and thiourea. The high-ammonia nitrogen photovoltaic waste water containing cadmium and thiourea enters a primary comprehensive cadmium removing pool, NaOH, PAC and PAM are added in order for carrying out a coagulation reaction, cadmium precipitates are added into the waste water, NaOH is added for adjusting a pH value and the waste water enters a distillation stripper, and at the same time ammonia nitrogen in the waste water is recycled and converted into 16-19% ammoniacal liquor; effluent enters a secondary integrated cadmium removing pool, NaOH, TMT, PAC and PAM are added in order for carrying out a coagulation reaction, and a secondary treatment is carried out for residual cadmium substances in water; effluent enters an advanced oxidation pool, agent H2SO4, FeSO4, H2O2, and NaClO are added in order, and oxidation and decomposition are carried out for thiourea substances and residual ammonia nitrogen in the waste water; effluent enters a coagulative precipitation tank, agent NaOH, TMT, PAC and PAM are added in order, residual cadmium in water and oxidation products in the advanced oxidation technology are removed, and water quality of discharged water reaches a B grade standard in 'wastewater quality standards for discharge to municipal sewers' (GJ343-2010).

Owner:何义亮 +1

Process and device for electrochemical treatment of industrial wastewater and drinking water

InactiveCN104797535ATreatment involving filtrationSedimentation separationActivated carbon filtrationAdvanced oxidation process

Subject matter of the invention is the procedure and plant for industrial wastewater and / or drinking water treatment by means of electrochemical methods and advanced oxidation processes. The preparatory phase of gravitational sedimentation is followed by main treatment consisting of electrocoagulation, electrooxidation and electroflotation through action of metal electrode sets made of inox, steel and aluminium respectively, with parallel disinfection / oxidation with ozone, UV irradiation and ultrasonic treatment, as well as recirculation in the electromagnetic field. At the end of the main treatment, the mixture of floccule and water is subject to coagulation / flocculation by electrochemically generated steel and aluminium floccule with slow infusion of ozone. The next phase is separation of sediment from clean water which is discharged through sand and activated charcoal filters for the purpose of removal of light floating floccule in the collection tank. If required, the water is subject to oxidation with simultaneous action of UV irradiation and ozone for the purpose of final destruction of organic matter and ammonia, and potential residues of microbiological contamination.

Owner:奥雷斯卡宁·维斯贾 +2

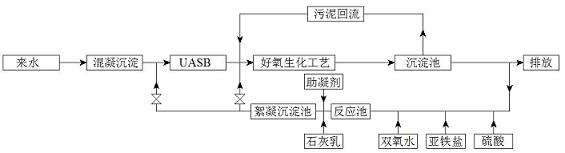

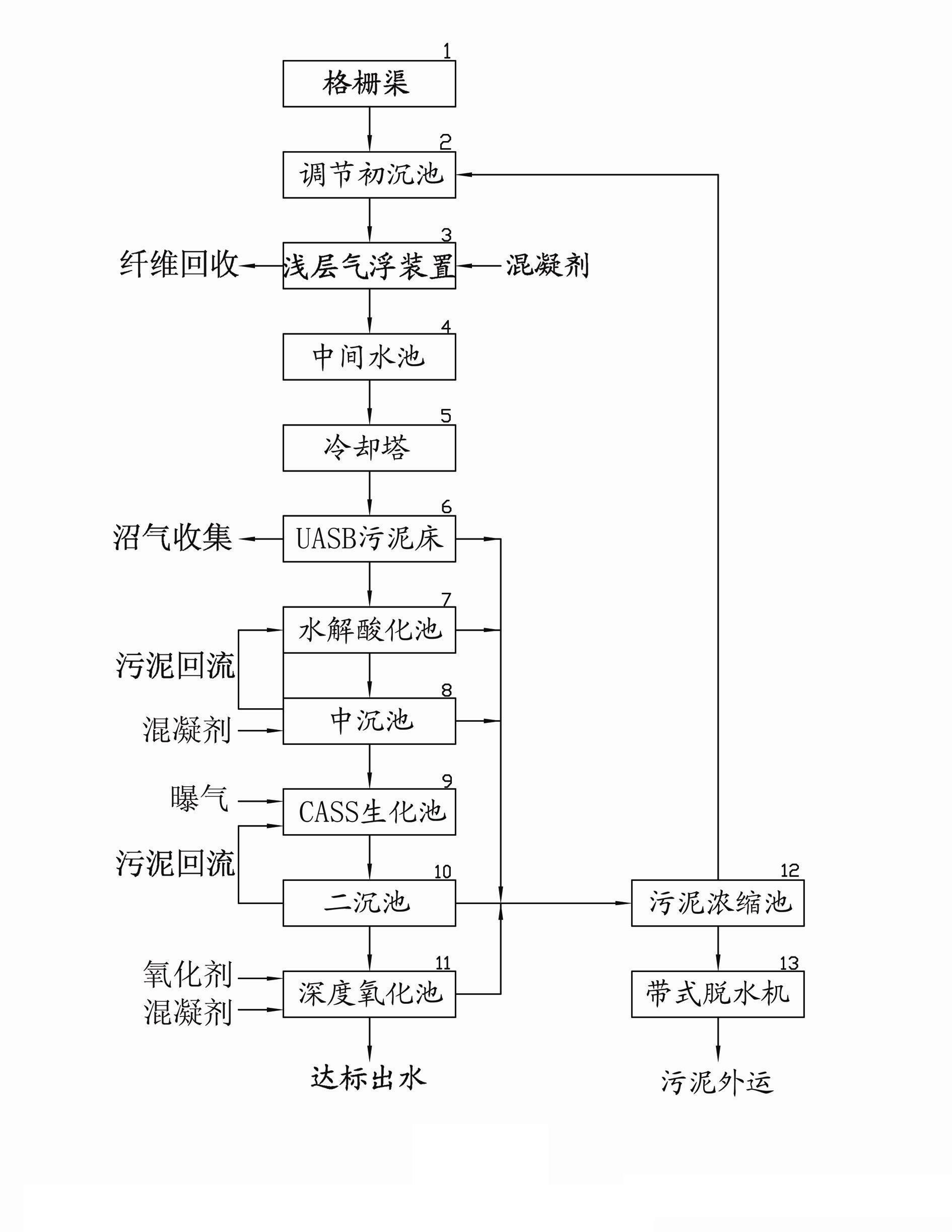

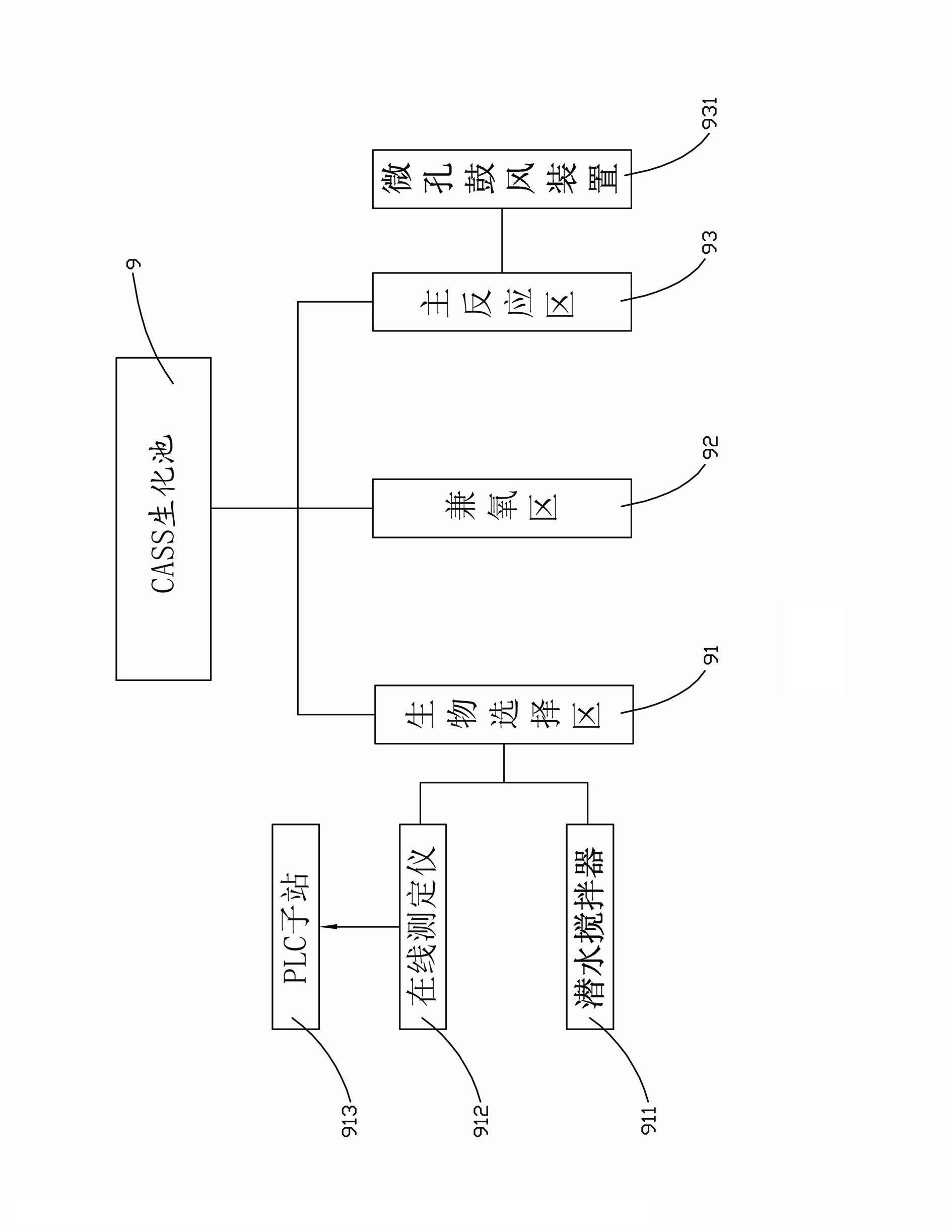

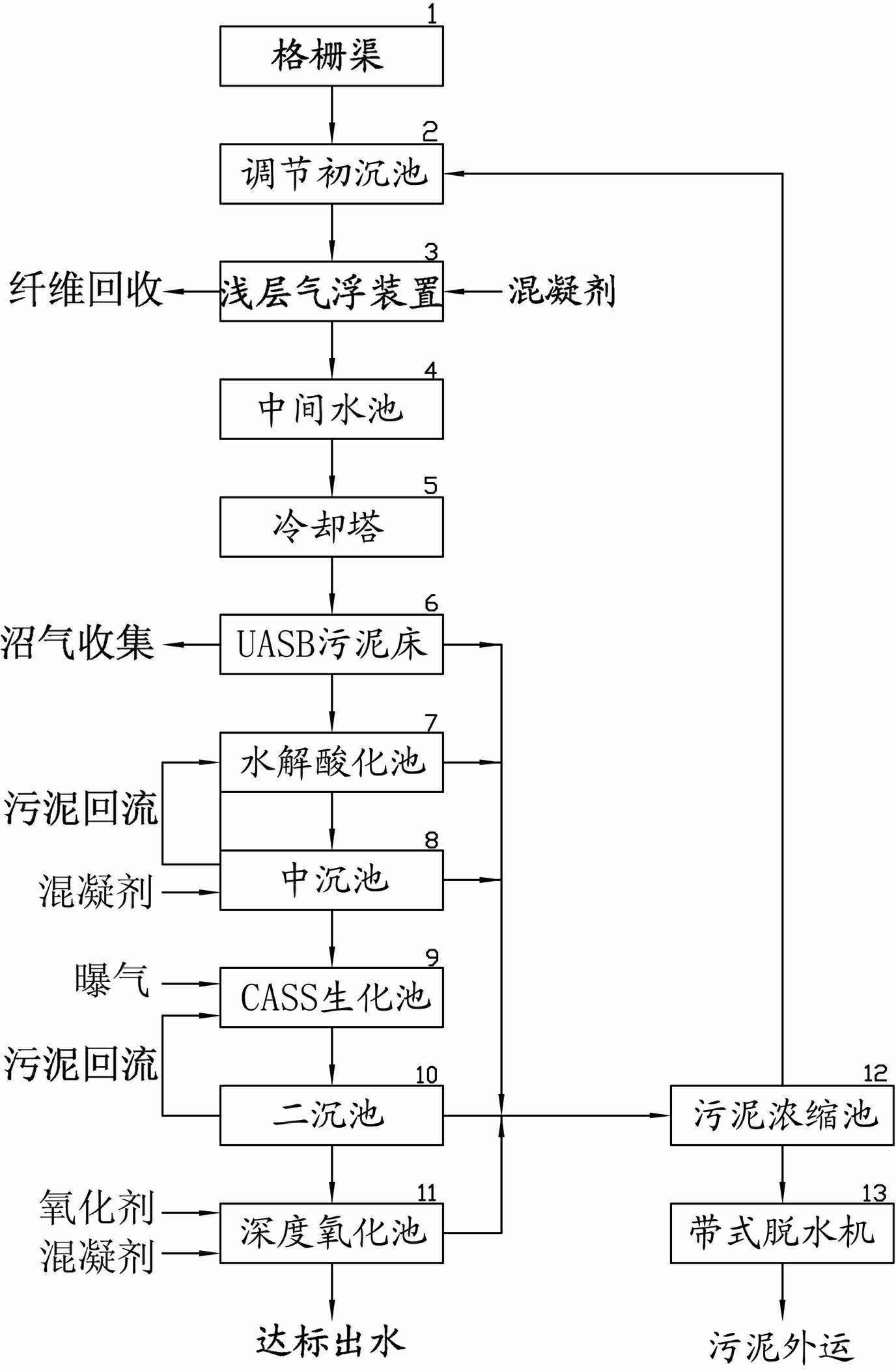

Device for treating wastewater produced in production process of alkaline peroxide mechanical pulp (APMP)

InactiveCN102616998AEasy to handleReduce loadMultistage water/sewage treatmentChemical oxygen demandAdvanced oxidation process

The invention discloses a device for treating wastewater produced in the production process of alkaline peroxide mechanical pulp (APMP). The device consists of a grid trench, an adjustment primary settlement tank, a shallow layer air floatation device, a middle water tank, a cooling tower, an upflow anaerobic sludge blanket (UASB), a hydrolysis and acidification tank, a middle settlement tank, a cyclic activated sludge system (CASS) biochemical tank, a secondary settlement tank and an advanced oxidation tank which are sequentially connected; the secondary settlement tank is connected with a sludge concentration tank; the sludge concentration tank is connected with a belt dehydrator; the CASS biochemical tank comprises an organism selection area adopting an anaerobic environment, a facultative area which has the effect of buffering water quality, and a main reaction area for degrading organic matter; the main reaction area is provided with an oxygen supply system which ensures long sludge age and low sludge load; and an ozone composition is arranged in the advanced oxidation tank to reduce chemical oxygen demand (COD). The UASB, hydrolysis and acidification, CASS and advanced oxidation process combined device is adopted, so that wastewater produced in the production process of APMP can be effectively treated, and the index of effluent reaches the requirement of GB3544-2008.

Owner:中科天龙(厦门)环保股份有限公司

Electrolytic cell with advanced oxidation process and electro catalytic paddle electrode

ActiveUS20150136591A1Increase organic destruction rateImprove mass transfer efficiencyWaste water treatment from animal husbandryWater distributersCavitationAdvanced oxidation process

Electrolytically treating water through influent inlet arrangements for cavitation and one or more pairs of electrodes. The electrodes can provide continuous anodic and cathodic operation for treating water. The pressurized influent premixed with oxidant gas can be pumped into the reactor vessel through the mixing nozzles arranged radially along the circumference. The polarity of the current to the electrode can be periodically reversed at a set interval. An electro-catalytic paddle electrode can be used for the treatment of flowback and produced water. The paddle electrode can consists of alternate pentagonal flat plate electrodes separated by adjustable variable distance Teflon spacers. The paddle electrode is provided with a chemical coating capable of switching / reversing the polarity of anodes and cathodes at ultra high frequencies under very high current flowing conditions thus making it more efficient, stable and durable under demanding field conditions.

Owner:GLOBAL WATER INVESTMENTS LLC

High-concentration degradation-resistant organic wastewater treatment process

InactiveCN103304094ALow process investment costLow running costWater contaminantsMultistage water/sewage treatmentHigh concentrationAdvanced oxidation process

The invention discloses a high-concentration degradation-resistant organic wastewater treatment process. The process comprises the following steps of: (1) carrying out homogeneous average adjustment and heating treatment; (2) treating in an all-in-one iron carbon Fenton tank; (3) treating in a two-phase two-stage anaerobic tank; (4) carrying out sludge sedimentation in a sedimentation tank; (5) carrying out biological degradation in a biological oxidation tank; and (6) further removing contaminants in a floatation tank. According to the treatment process, the respective advantages of an advanced oxidation process and a biochemical process are fully combined, high-concentration degradation-resistant organic wastewater can be purified stably, economically, safely and efficiently; and besides, the process is low in investment cost, floor area and operating cost.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

Advanced oxidation of kinetic hydrate inhibitors

InactiveUS20120241387A1Reduce processing costsReduce amountWaste water treatment from quariesWater treatment compoundsHigh concentrationAdvanced oxidation process

Advanced oxidation process namely ozonation and Fenton's (hydrogen peroxide / Fe:2+) were utilized to degrade kinetic hydrate inhibitor (KHI). The oxidized solution after scavenging oxygen can be successfully disposed to the injection well. This facilitates use of KHI more frequently and in higher concentrations for future projects oil & gas operations. It also offers an alternative that competes efficiently with thermodynamic hydrate inhibitor (THI) or complements THI.

Owner:CONOCOPHILLIPS CO

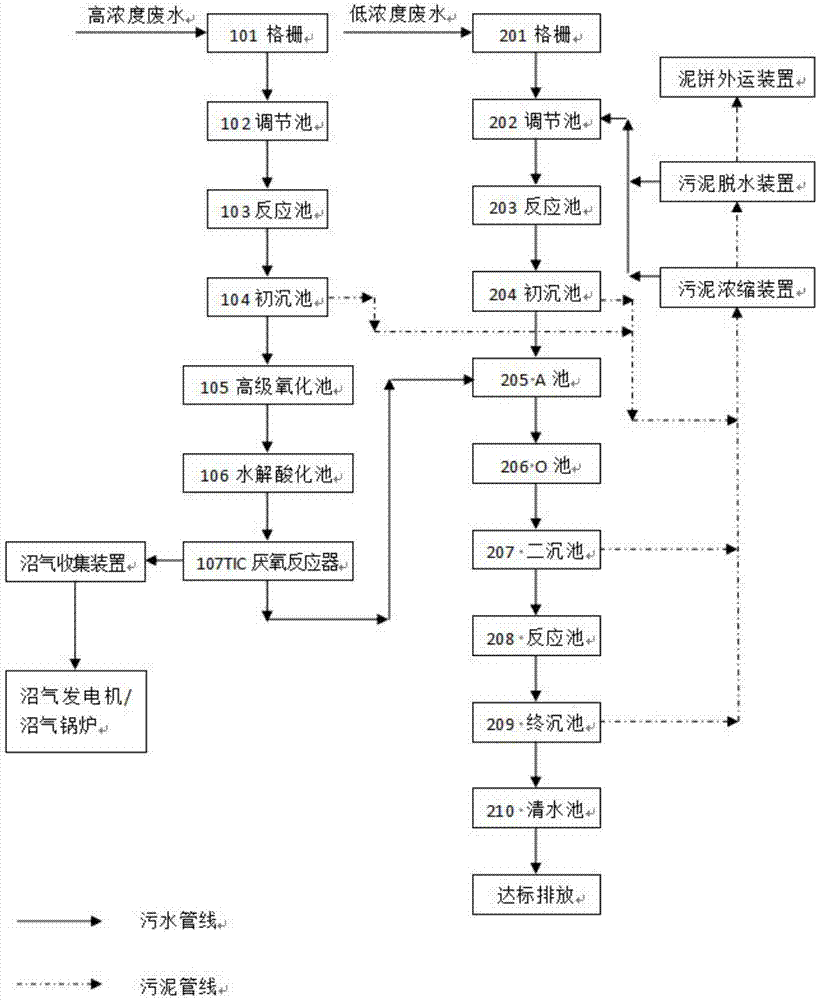

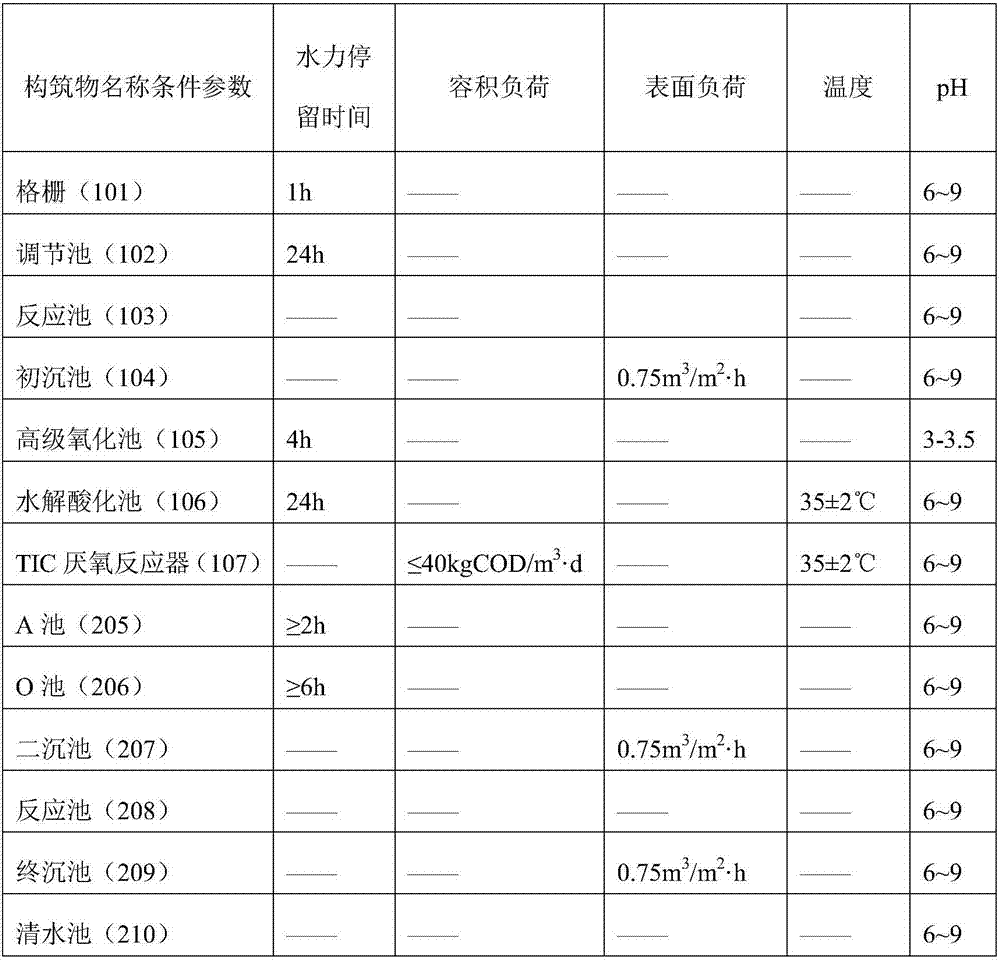

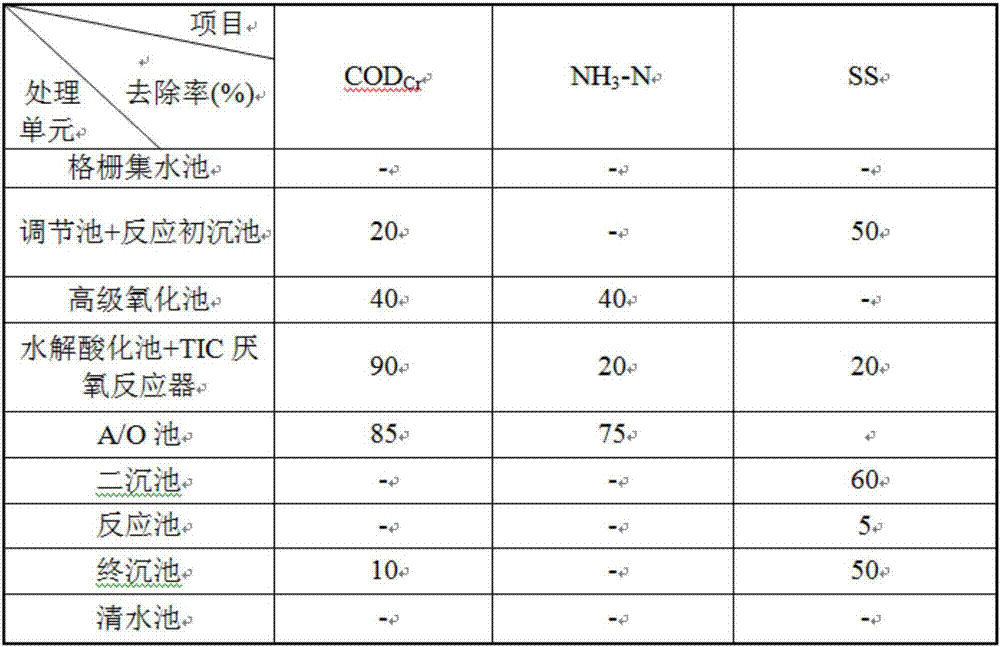

Device and method for treating high-concentration insoluble organic pharmaceutical wastewater

InactiveCN107162318AGuaranteed stabilityImprove biodegradabilityWater contaminantsTreatment involving filtrationHigh concentrationAdvanced oxidation process

The invention belongs to the technical field of pharmaceutical wastewater treatment, and particularly relates to a device and method for treating high-concentration insoluble organic pharmaceutical wastewater. According to the method, high-concentration pharmaceutical wastewater and low-concentration pharmaceutical wastewater are separately treated, the high-concentration pharmaceutical wastewater is treated by adopting a mode combining physicochemical treatment, advanced oxidation process, hydrolysis acidification method and TIC anaerobic reaction tower to remove massive COD, BOD5, SS and the like in water; and the low-concentration organic wastewater is subjected to physicochemical pretreatment to improve the biodegradability of wastewater, and flows into an A / O process, a secondary sedimentation tank, a reaction tank, a final sedimentation tank and a clear water tank to remove ammonia, nitrogen and the like in the water until the water can be discharged at standard. The method has the advantages of stable system operation, remarkable organic matter removing effect, low energy consumption, high load, small floor area and the like, and is applicable to wastewater treatment of large, medium and small sized pharmaceutical factories.

Owner:WUHAN TAICHANGYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Photocatalytic reactor and process for treating wastewater

ActiveUS8038938B2Smooth connectionEasy constructionWater treatment parameter controlWater/sewage treatment by irradiationPhotocatalytic reactionAdvanced oxidation process

A photocatalytic reactor with a modular configuration, based on UV light sources and a catalyst, useful for purifying and disinfecting wastewater from confined aquaculture, using Advanced Oxidation Processes (AOP), wherein the catalyst is supported over glass sheets as fixed strips within the reactor, at an established distance from the UV light source, and wherein the wastewater is treated as “batches” being re-circulated and returned to the circuit. The wastewater is fed through the lower end of the reactor and submitted to a strong turbulence when passing through perforations or holes made on the supports forming the floors that separate the reaction chambers.

Owner:UNIV CATOLICA DE LA SANTISIMA CONCEPCION

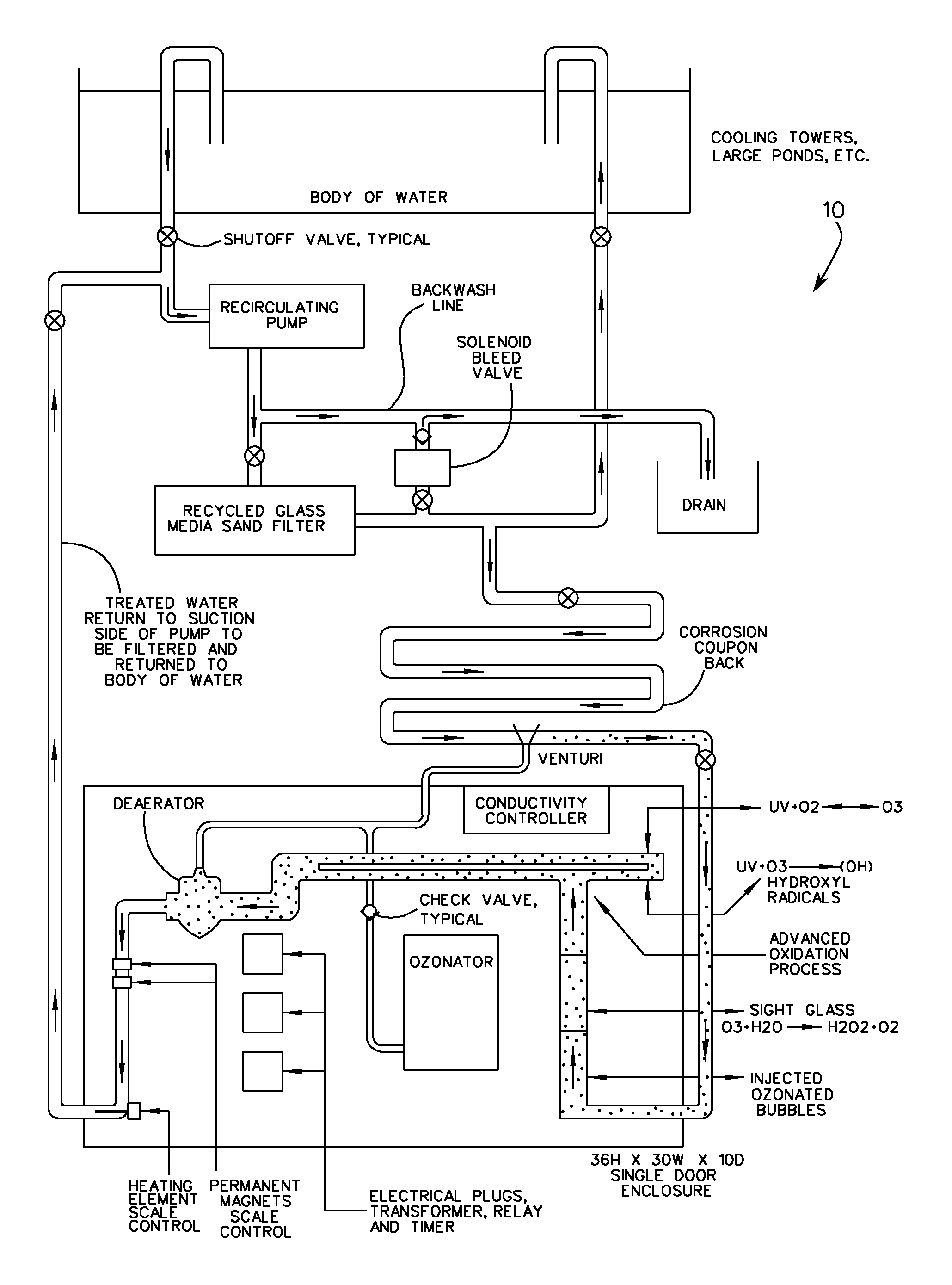

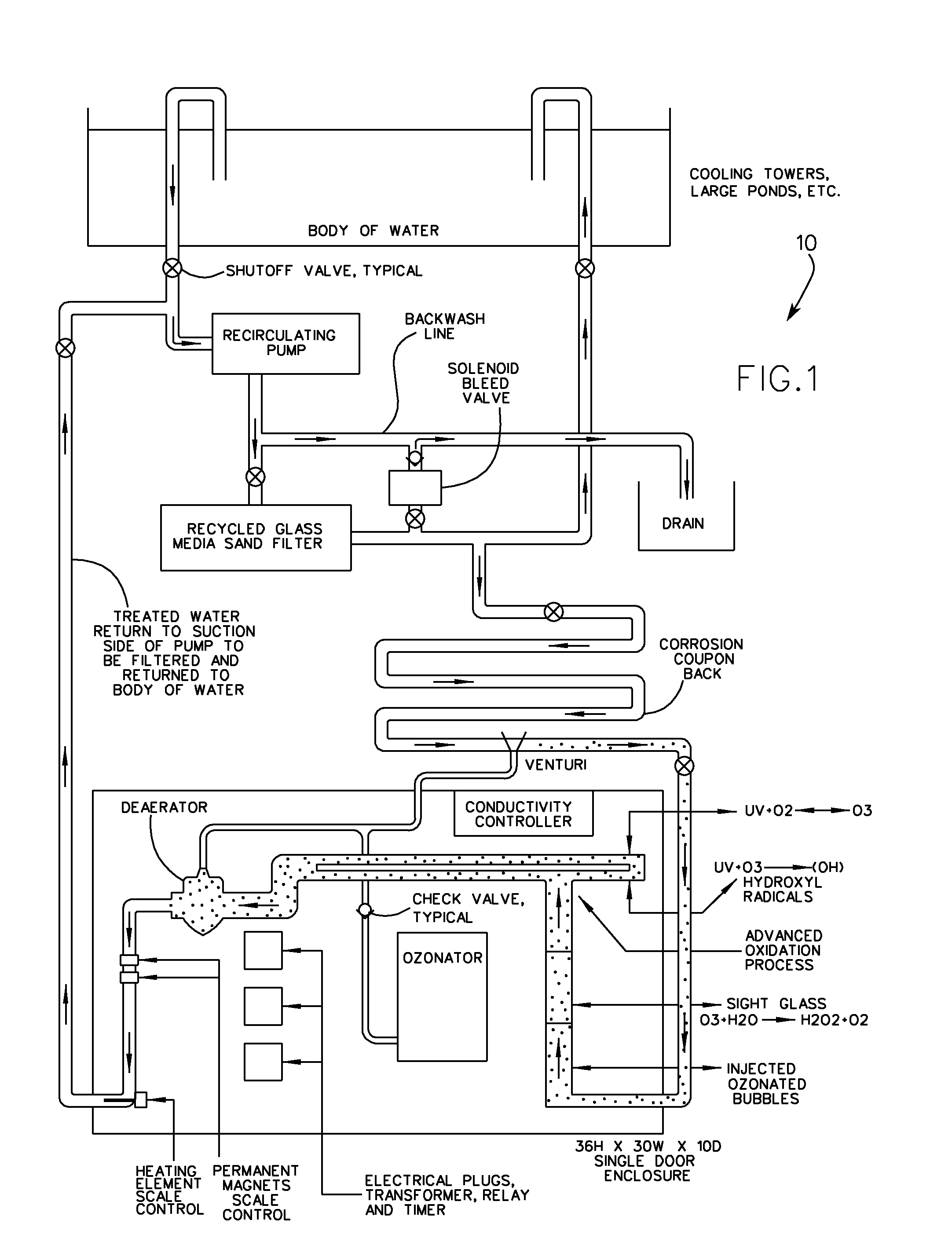

Water treatment for cooling towers and large commercial ponds using a non-chemical residual program

InactiveUS20110147283A1Ion-exchanger regenerationTreatment involving filtrationCooling towerAdvanced oxidation process

A water treatment system can be used to treat bodies of water as found in cooling towers and large commercial ponds to rid the potential of biological contaminants and mineral formations found in heat exchange equipment, on the sides of walls, basins and piping that create corrosive damage and loss of energy through deposits on heat transfer surfaces. The water treatment system may include a recirculating pump for moving water through the system, a filtration system for filtering solids, an ozonator and a UV light for creating an advanced oxidation process, permanent magnets for electrodynamically aligning dissolved minerals in the water, and a heating element for thermodynamically controlling calcium carbonate scaling potential.

Owner:PURE AIR & WATER SYST

Device, system, and method for an advanced oxidation process using photohydroionization

InactiveUS20110250125A1Efficiently formedHydrogen peroxideMechanical apparatusAdvanced oxidation processControl system

A device, system, and method, for the formation of advanced oxidation products by contacting a hydrated catalytic surface of a catalytic target structure with broad spectrum ultraviolet light in the 100 nm to 300 nm range that preferably includes 185 nm and 254 nm wavelengths. The catalytic surface reacts with the ultraviolet light energy and hydrate at the catalytic surface to form advanced oxidation products, The catalytic surface in one embodiment includes a hydrophilic agent, titanium dioxide, silver, copper, and rhodium. Preferably, the catalytic surface is coated with a coating that includes the hydrophilic; agent, titanium dioxide, silver, copper, and rhodium. A photohydroionization cell (100) that includes an ultraviolet light source (204) and a catalytic target structure (110) in an air environment to form advanced oxidation product is also provided. A U.V. light indicator and a monitor and / or control system for the photohydroionization cell (100) are also provided.

Owner:RGF ENVIRONMENTAL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com