Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92 results about "Alkaline peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wayne Chemical Inc. manufactures a unique binary system of patented alkaline, liquid hydrogen peroxide products for enhanced sanitation of all departments including critical ready-to-eat operations. Alkaline hydrogen peroxide products are a less corrosive, safer alternative to existing chlorine cleaners for a variety of applications.

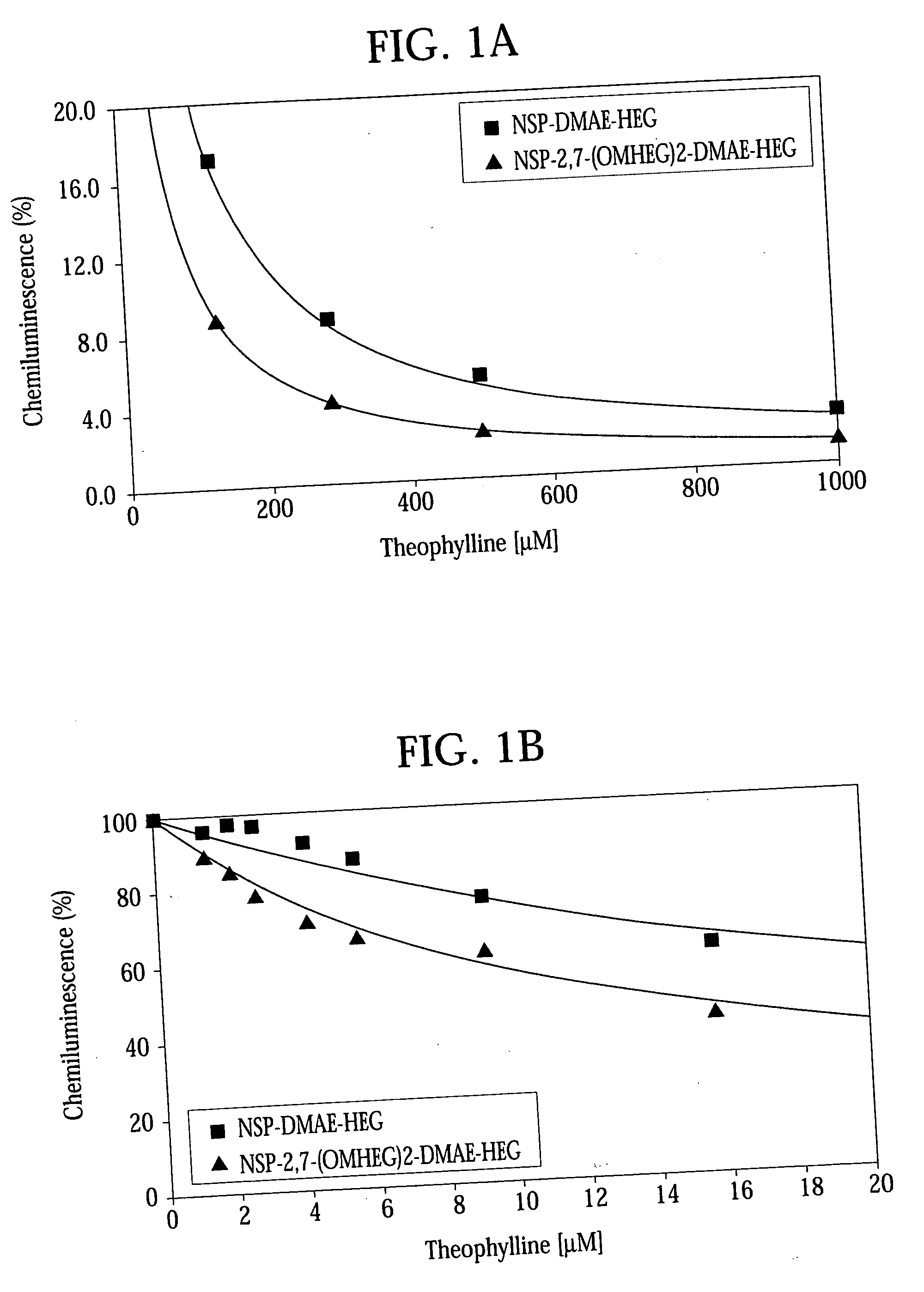

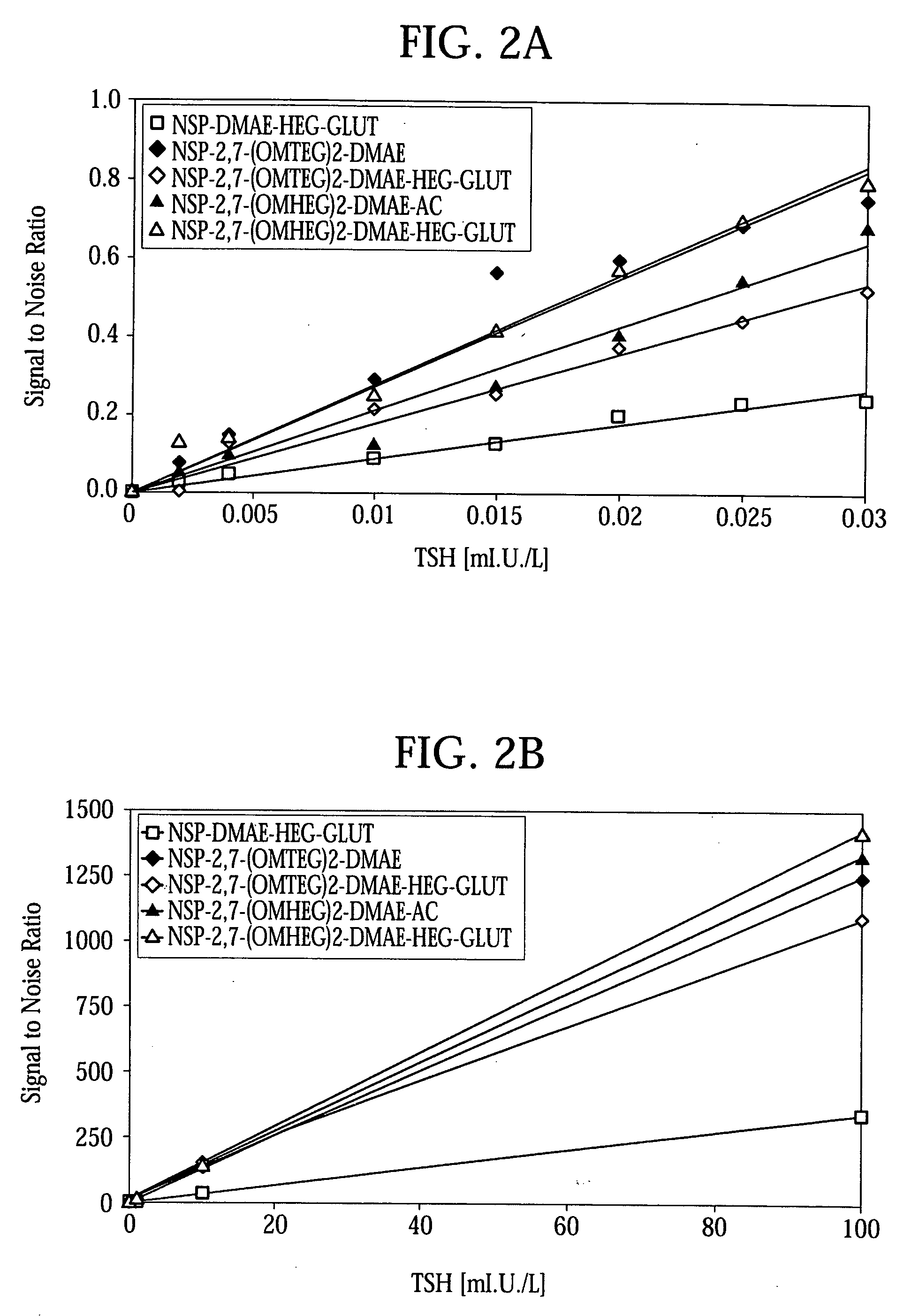

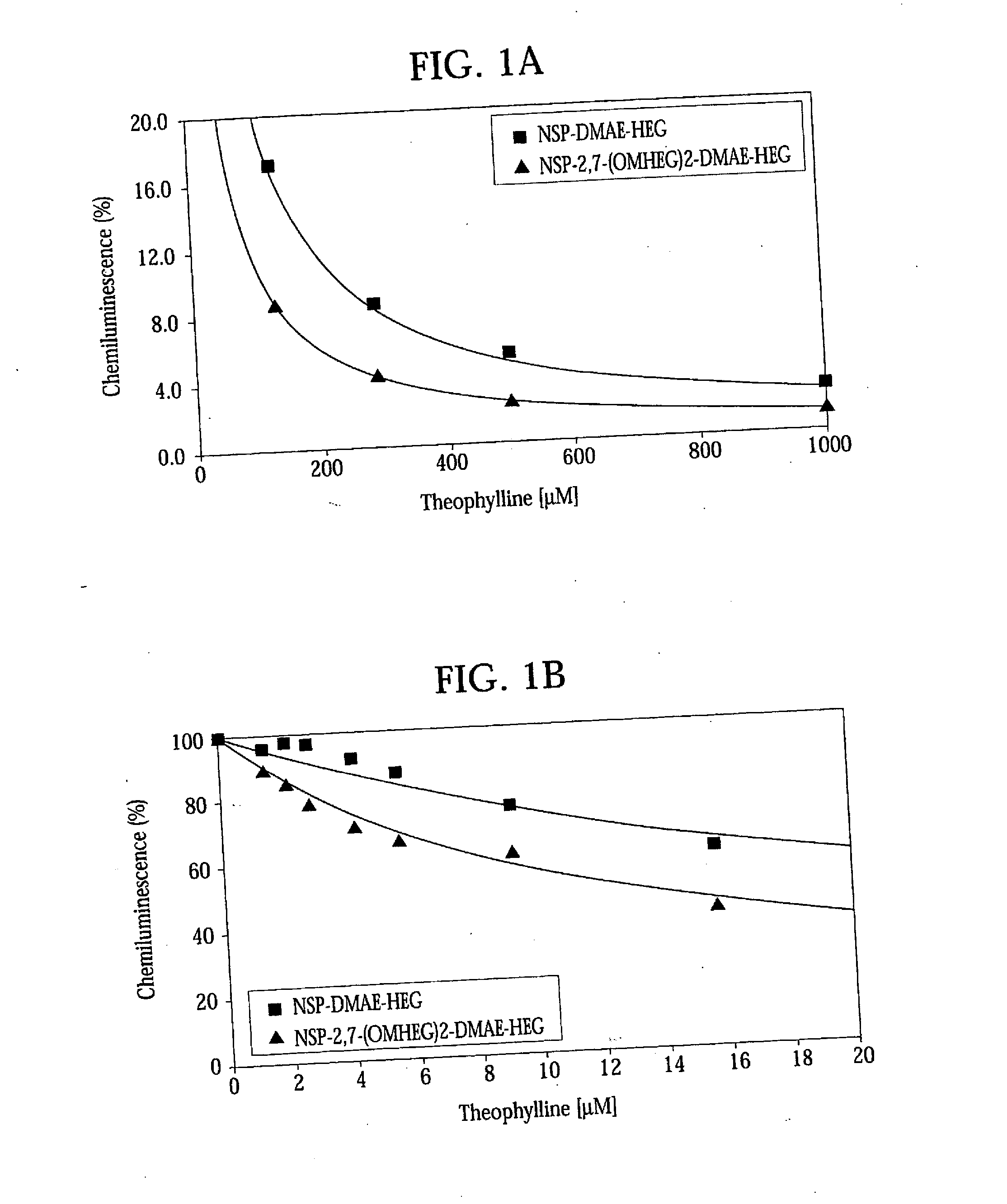

High quantum yield acridinium compounds and their uses in improving assay sensitivity

InactiveUS7309615B2Organic chemistryMaterial analysis by observing effect on chemical indicatorAcridineQuantum yield

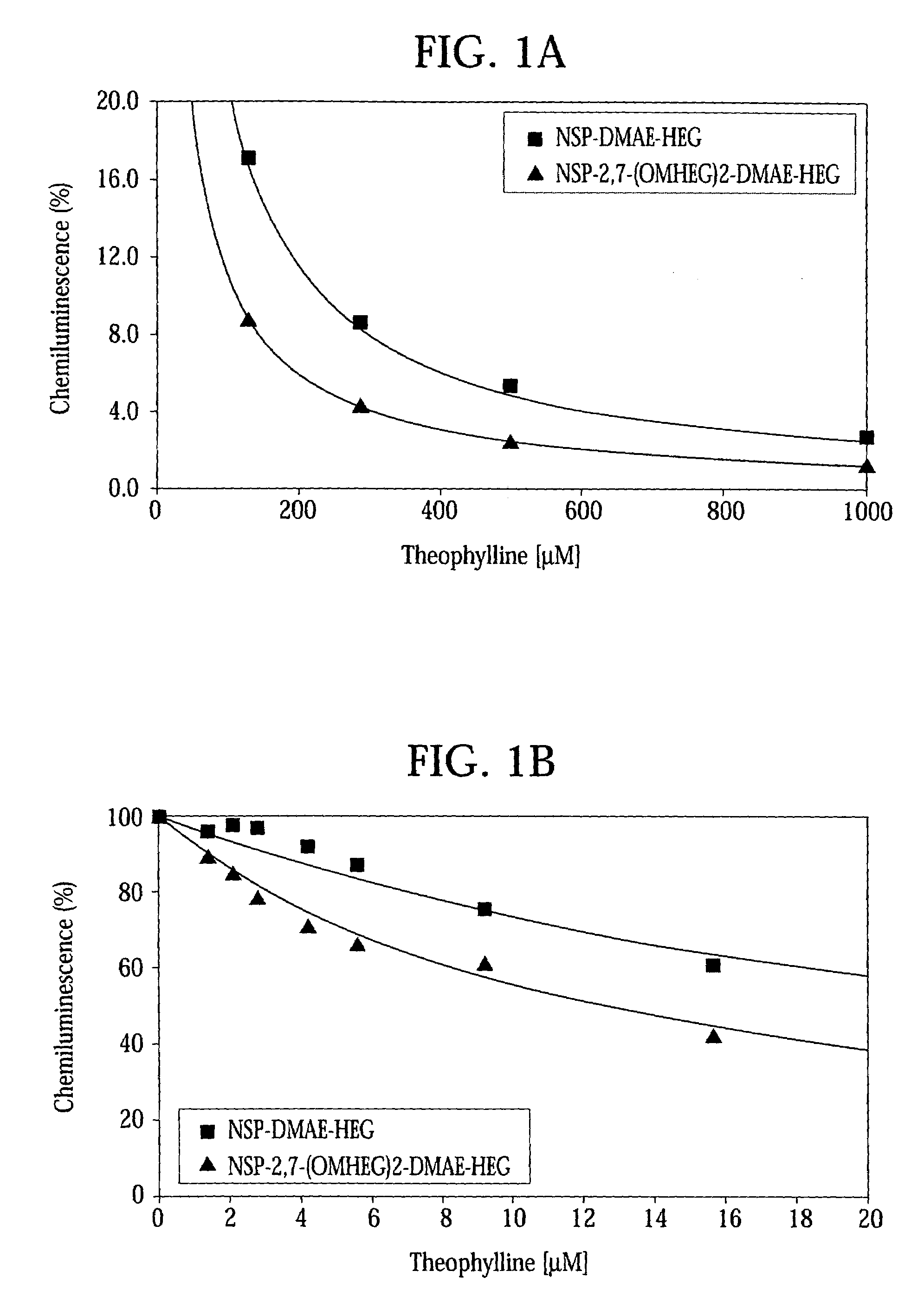

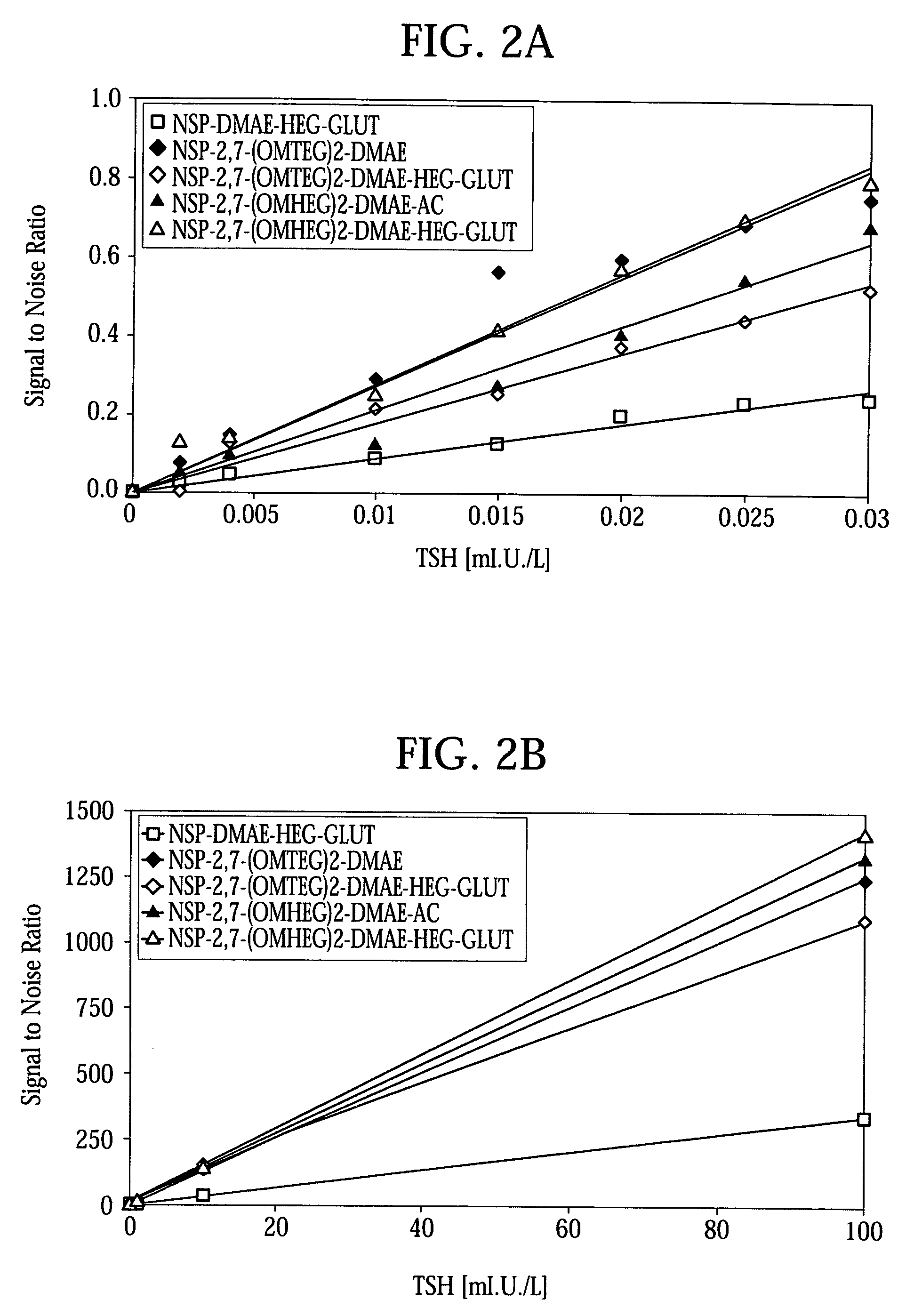

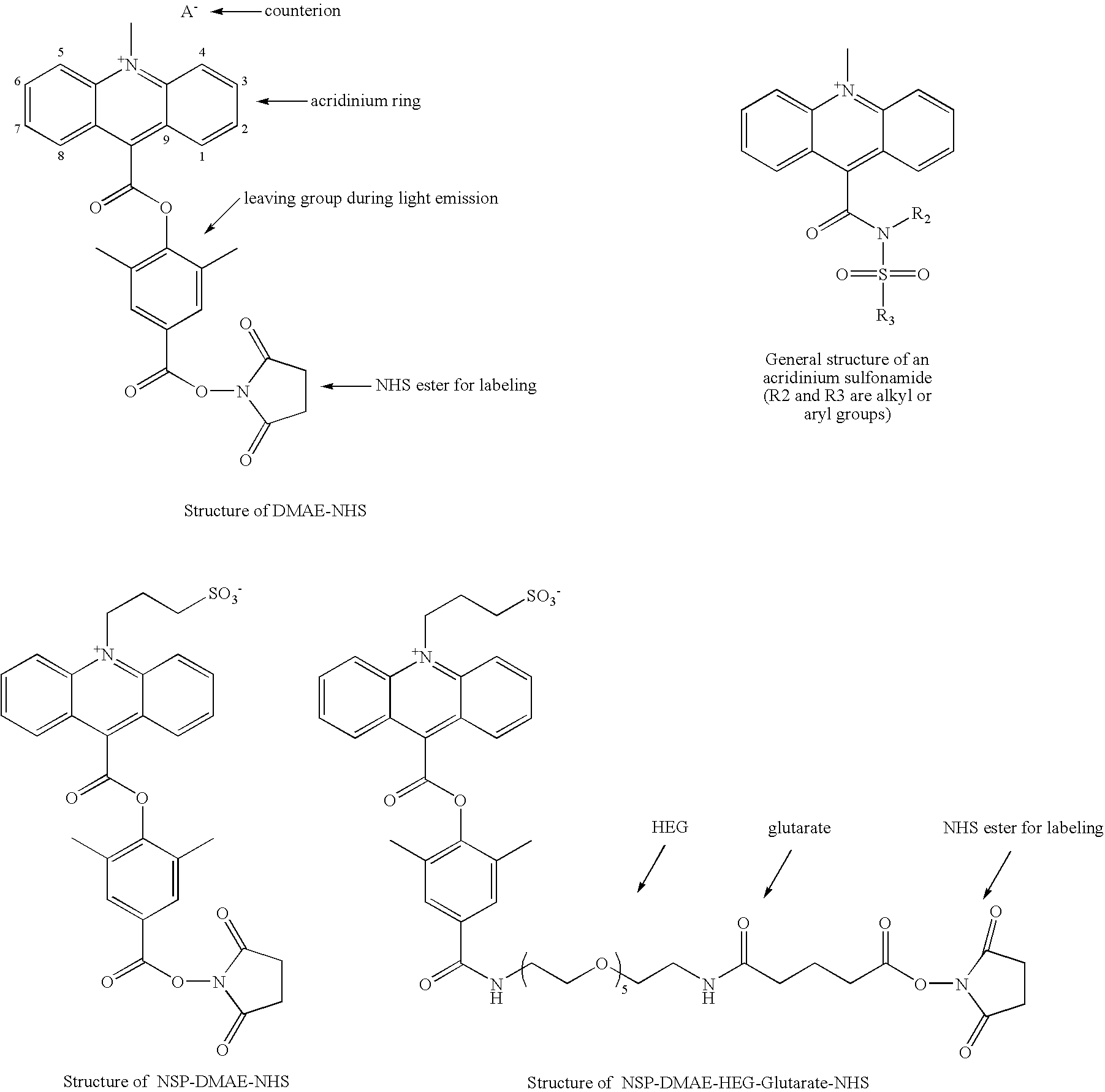

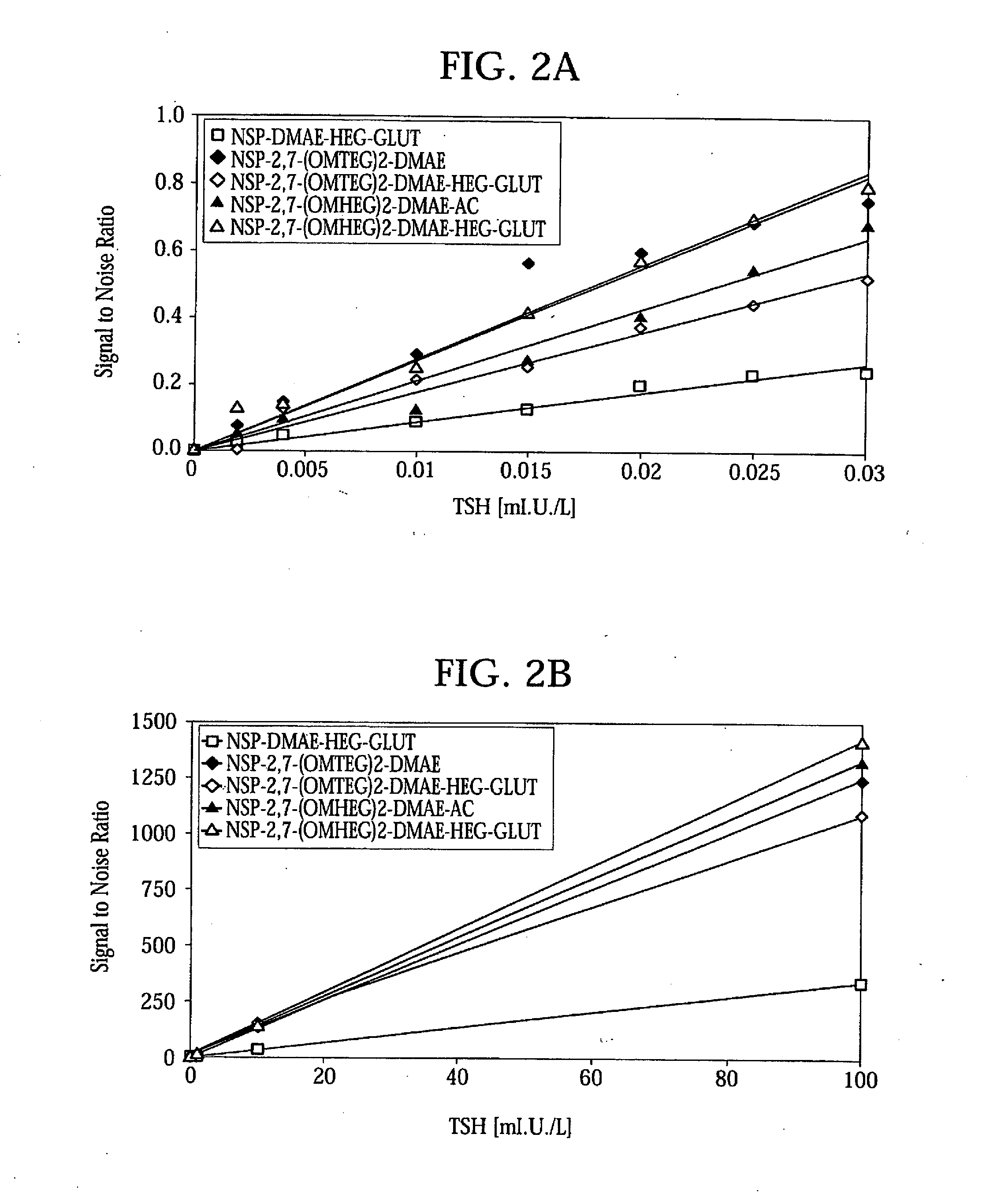

The present invention relates to hydrophilic, high quantum yield acridinium compounds. It has been discovered that the placement of electron-donating groups in the acridinium ring system increases the amount of light that is emitted by the corresponding acridinium compound when its chemiluminescence is triggered by alkaline peroxide. More specifically, it has been found that the placement of one or two hydrophilic, alkoxy groups at the C-2 and / or C-7 position of the acridinium ring system of acridinium compounds increases their quantum yield and enhances the aqueous solubility of these compounds. The present hydrophilic, high quantum yield, acridinium compounds are useful chemiluminescent labels for improving the sensitivity of immunoassays.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

Bamboo chemimechanical pulp bioenzyme pretreatment method

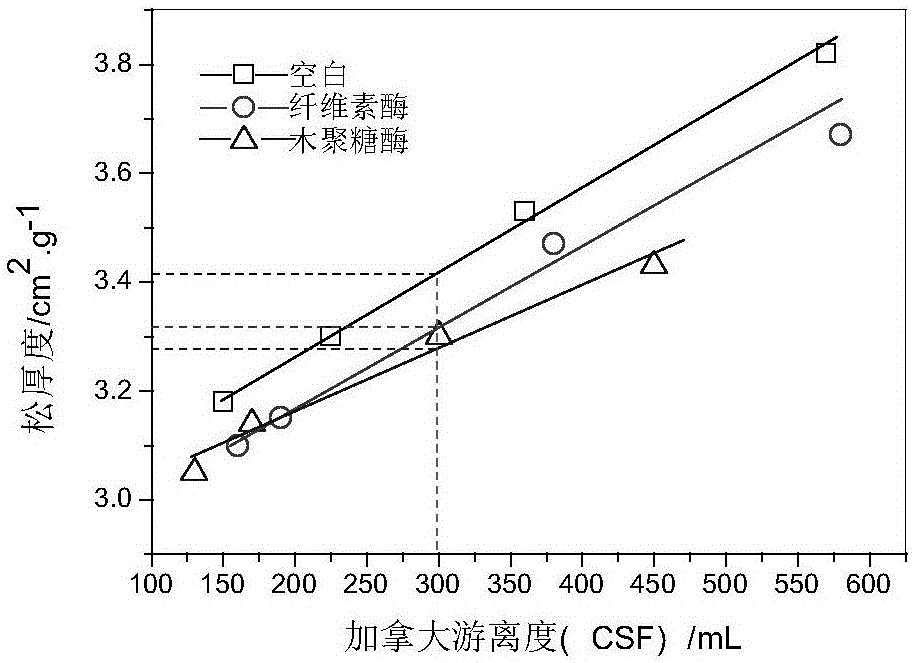

ActiveCN106381741AReduce physical strengthHigh whitenessFibrous raw materialsCellulose treatment using microorganisms/enzymesPretreatment methodPre treatment

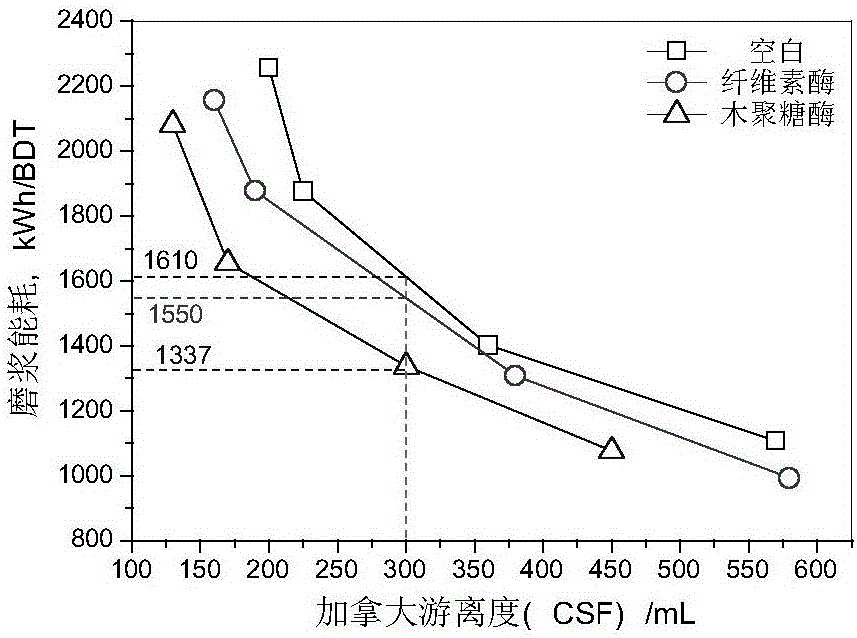

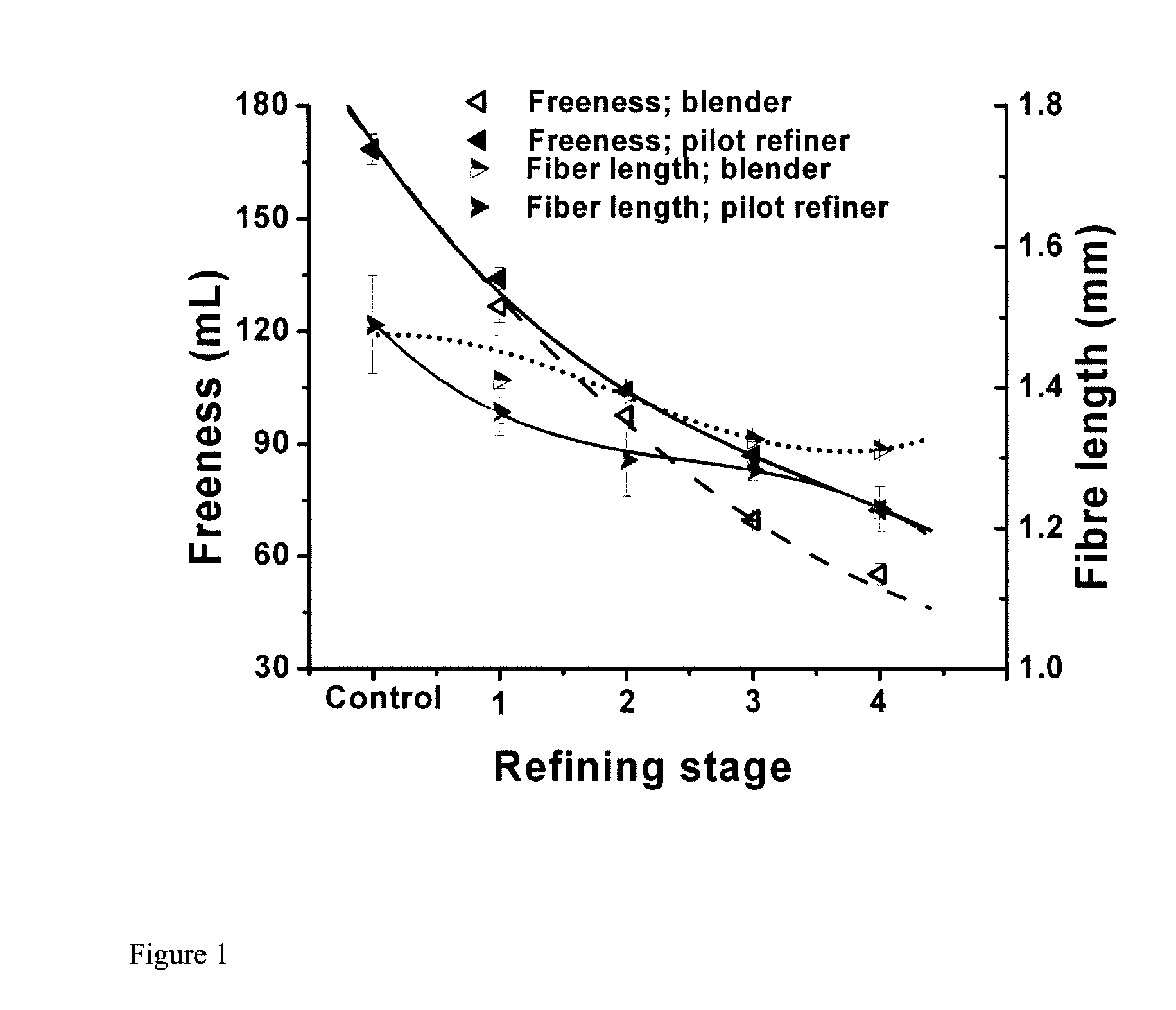

The invention discloses a bamboo chemimechanical pulp bioenzyme pretreatment method. The bamboo chemimechanical pulp bioenzyme pretreatment method comprises the following steps: feeding bamboo pieces into a steaming cabin for normal-pressure pre-steaming after screening the bamboo pieces, and then carrying out first-stage screw extrusion; adding bioenzyme in an extruded material for pretreatment, then carrying out high-temperature deactivation, washing and dewatering, then carrying out first-stage and second-stage chemical pre-impregnating in sequence, then carrying out first-stage high-consistency normal-pressure pulp grinding by using a high-consistency disc refiner of which rho is 300, and completing bleaching reaction by enabling pulp to stay in a high-consistency reaction cabin for about 50 to 60 minutes; then carrying out follow-up pulp grinding by using a disc refiner, preparing pulp samples in different Canadian freeness degrees by controlling and inputting different pulp grinding energy consumptions, respectively recording the pulp grinding energy consumption needed for preparing each pulp sample, and using the different pulp samples for paper pulp performance testing after respectively carrying out latent elimination, acidification, washing, screening and dewatering concentration. According to the bamboo chemimechanical pulp bioenzyme pretreatment method disclosed by the invention, by carrying out pretreatment on bamboo bioenzyme, compared with a traditional PRC (Preconditioning Refiner Chemical)-APMP (Alkaline Peroxide Mechanical Pulping) technology, the difference in respects of pulp grinding energy consumption and pulp performance can be observed, and a reference technology is provided for preparing chemimechanical pulp by using bamboos as raw materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

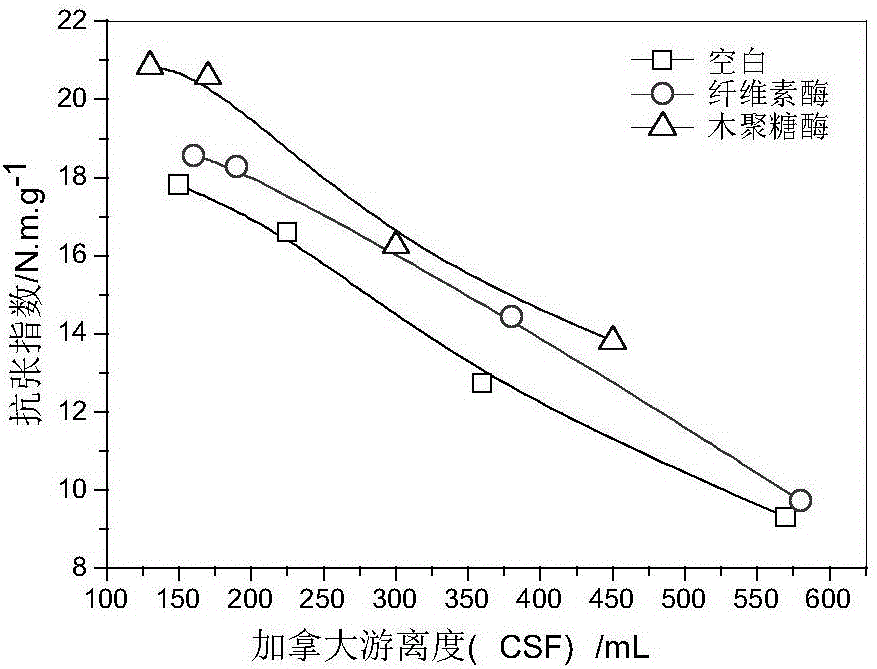

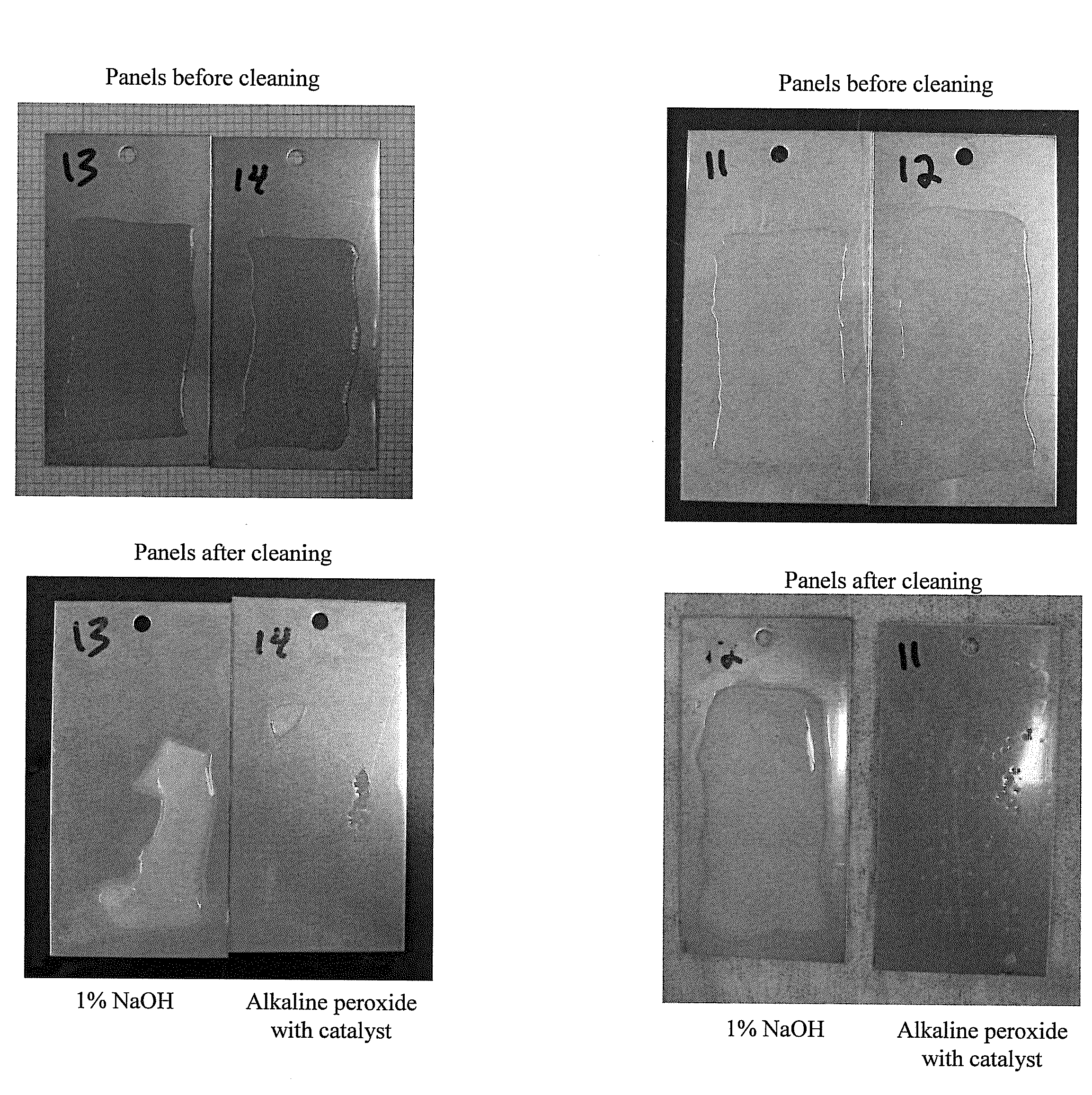

Use of activator complexes to enhance lower temperature cleaning in alkaline peroxide cleaning systems

InactiveUS20090325841A1Anionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsAlkalinityCoordination complex

The present invention provides for the use of activator complexes to enhance lower temperature cleaning in alkaline peroxide cleaning systems. Compositions including at least one of an activator complex, an active oxygen source, and a source of alkalinity are applied to the surface to be cleaned at temperatures between about 5° C. and about 50° C. The methods and compositions of the present invention provide for enhanced soil removal with reduced energy, water, and chemistry consumption.

Owner:ECOLAB USA INC

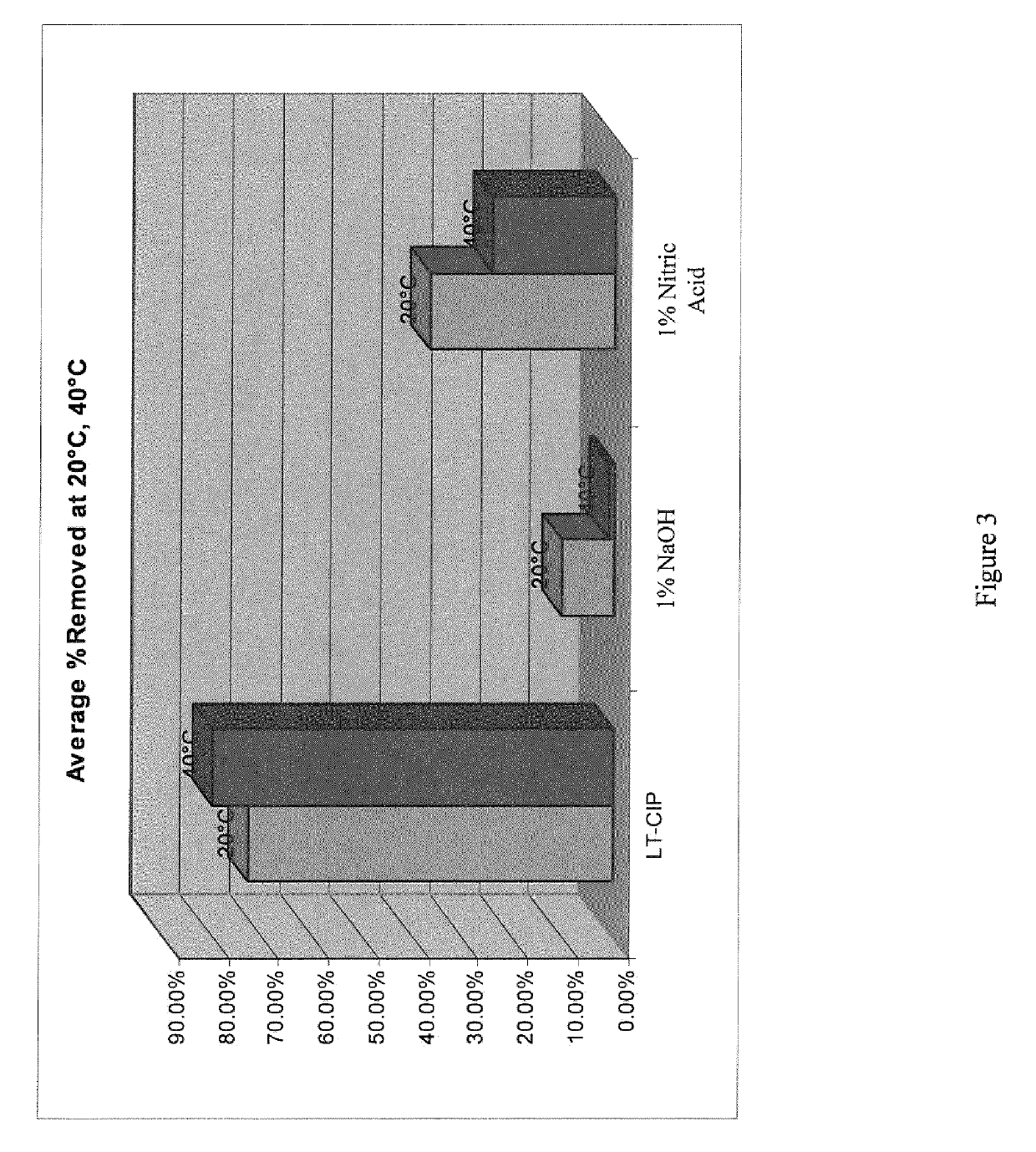

Electrochemistry method for simultaneously producing sodium chlorate and alkaline peroxide

InactiveCN101392386AImprove utilization efficiencyReduce manufacturing costCellsElectrochemistryOxygen

The invention relates to an electrochemical method which produces sodium chloride and alkaline hydrogen peroxide simultaneously. The method can improve the use efficiency of the two poles of the electricity, and lower the production cost. The method adopts an electrolytic tank consisting of an anode, a cation exchange membrane, an anion exchange membrane and a cathode, wherein, the electrodes combine with the membranes in sequence to form an anode chamber, an intermediate chamber and a cathode chamber; sodium chloride solution and sodium chlorate solution are circulated to the anode chamber, sodium hydroxide solution and air is circulated to the cathode chamber and sodium hydroxide solution is circulated to the intermediate chamber; after direct current circulating among the electrodes, chlorine is produced in the anode while the oxygen in the cathode deoxidizes and produces hydrogen peroxide and the concentration of the sodium hydroxide solution in the intermediate chamber is increased; the anolyte flowing out of the anode chamber flows into an external heated reaction tank, and chlorine is transferred into sodium chlorate; the anolyte is circulated back to the anode chamber of the electrolytic tank; a part of the concentrated sodium hydroxide solution which flows out of the intermediate chamber can be used for adjusting the pH value of the anolyte without using extra sodium hydroxide, thereby lowering the running cost.

Owner:SHANGHAI JIAO TONG UNIV

A kind of manufacturing method of micro-coating elegant pure paper

InactiveCN102277776AReduce loadReduce processing costsDefoamers additionWater-repelling agents additionFiberWhite water

The invention discloses a method for making slightly-coated elegant pure paper. The method comprises the following key steps of: making poplar APMP (alkaline peroxide mechanical pulp), CTMP (chemithermomechanical pulp), bleached chemical needlebush pulp and bleached chemical reed pulp; blending; adding auxiliary materials; making wet paper sheets; squeezing for dehydrating; primarily drying; slightly coating; secondarily drying; calendering; and finishing. The method can greatly lower the production cost, improve the looseness and thickness of paper sheets and ensure high strength of elegant pure paper, solves the problems that glues applied to AKD (alkyl ketene dimer) pulp have a low retention rate and are easy to be hydrolyzed, overcomes the defects of low fine fiber retention rate, high filler loss and the like in the highly-proportional chemimechanical pulp blending process, reduces the pulp consumption and lowers the white water load and subsequent waste water treatment cost, solves the problems of low whiteness, high surface roughness, low surface strength and the like due to the highly-proportional chemimechanical pulp, and can greatly increase the ash content and lower theproduction cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

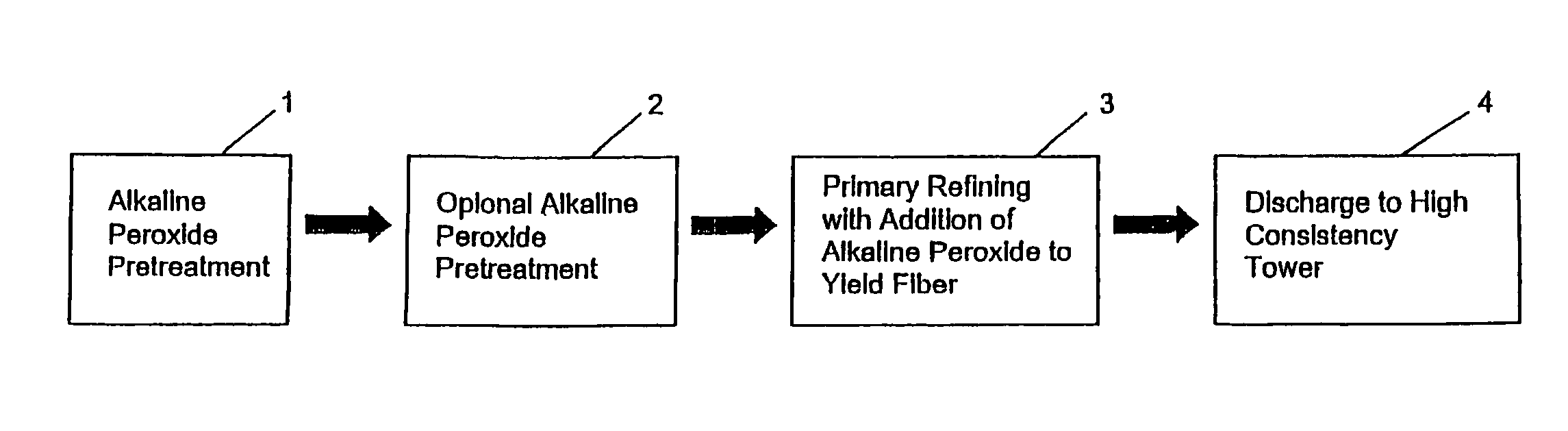

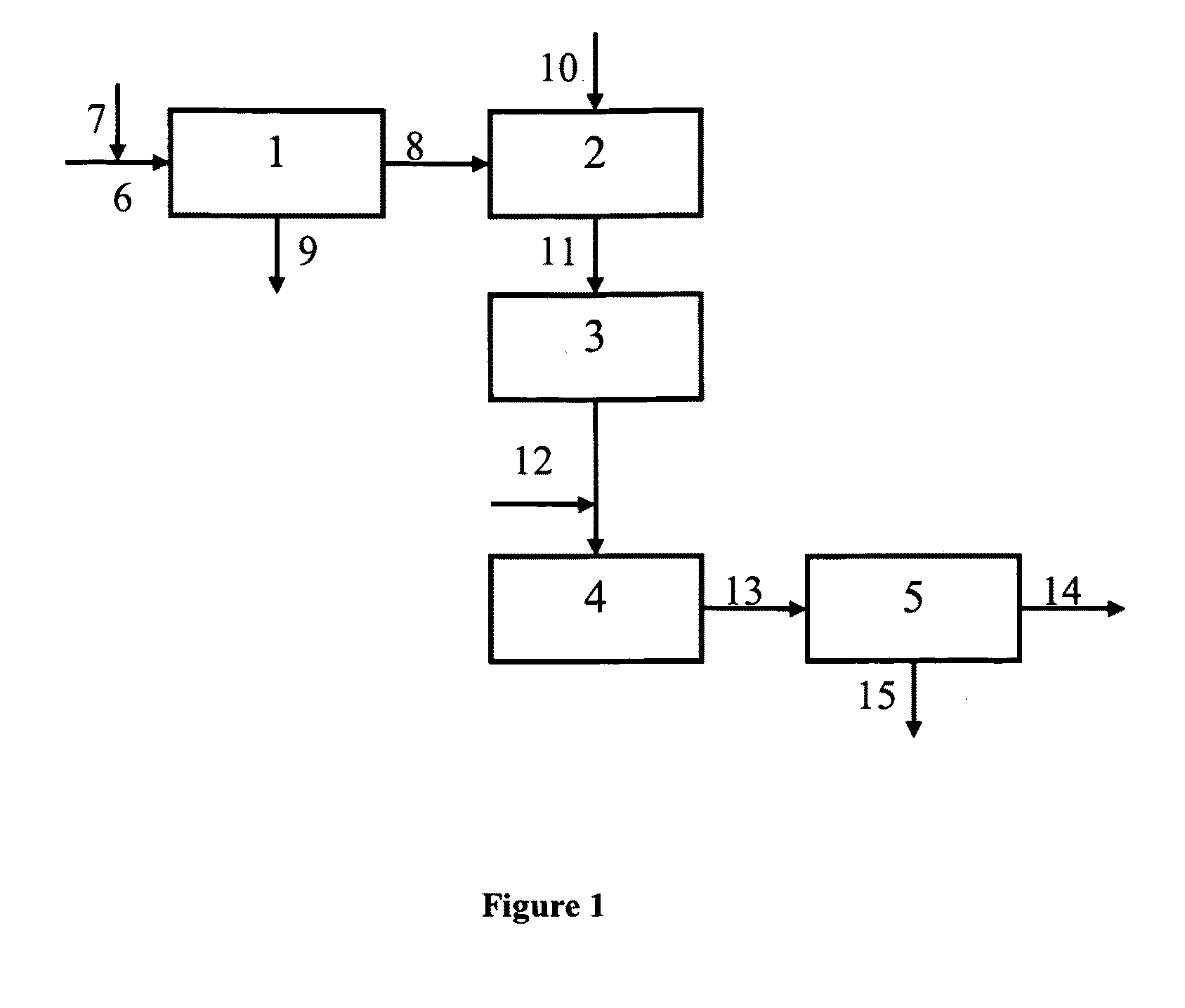

Multi-stage AP mechanical pulping with refiner blow line treatment

InactiveUS20100263815A1More efficient processEffective bleachingDigestersPulp bleachingPulp and paper industryEngineering

The invention combines the step of adding chemicals such as alkaline peroxide to an intermediate line after refining, with the step of applying chemicals such as alkaline peroxide as a pre-treatment before primary refining and / or applying chemicals such as alkaline peroxide at the primary refiner. This is implemented in the preferred embodiment, by pre-treating feed material, refining the materials into a pulp in a superatmospheric refiner, and adding chemicals in the post refining blowline.

Owner:ANDRITZ INC

Multi-stage AP mechanical pulping with refiner blow line treatment

InactiveUS8216423B2Improve efficiencyReduce adverse effectsDigestersPulp bleachingPulp and paper industryPre treatment

The invention combines the step of adding chemicals such as alkaline peroxide to an intermediate line after refining, with the step of applying chemicals such as alkaline peroxide as a pre-treatment before primary refining and / or applying chemicals such as alkaline peroxide at the primary refiner. This is implemented in the preferred embodiment, by pre-treating feed material, refining the materials into a pulp in a superatmospheric refiner, and adding chemicals in the post refining blowline.

Owner:ANDRITZ INC

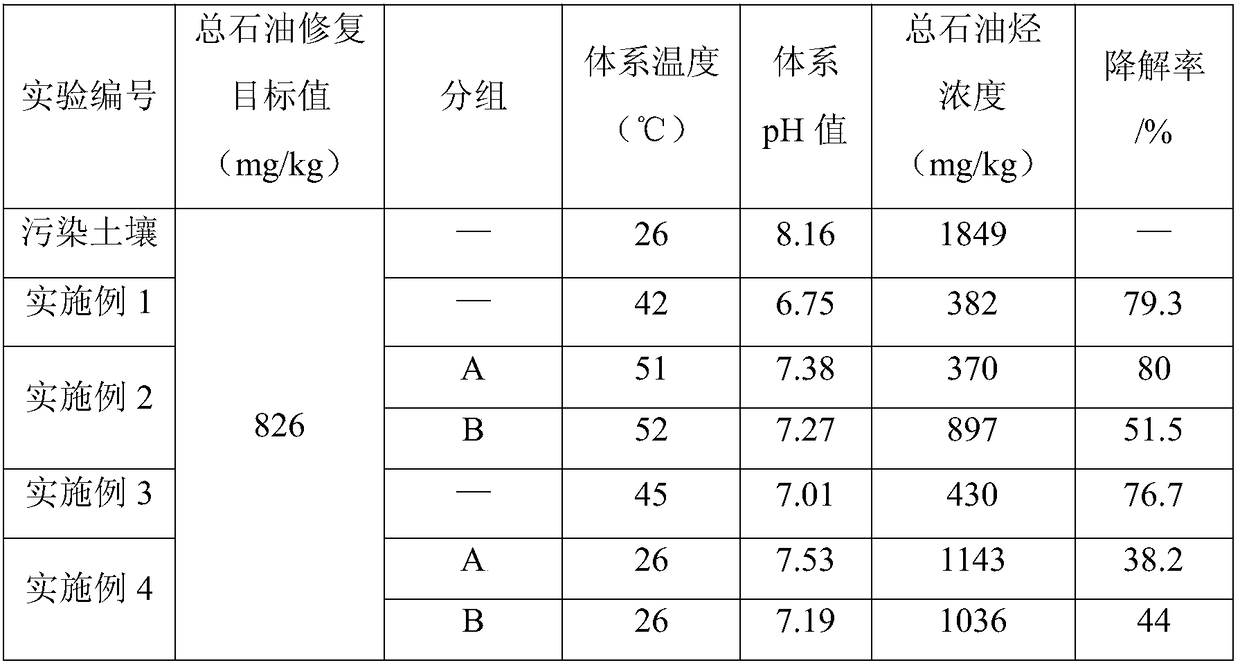

Petroleum hydrocarbon contaminated soil remedying agent and using method thereof

InactiveCN109266359APrevent acidificationImprove repair effectOther chemical processesContaminated soil reclamationStrong bindingSodium sulfate

The invention discloses a petroleum hydrocarbon contaminated soil remedying agent and a using method thereof, and belongs to the field of the soil contamination remediation. Aiming at solving the technical problem, the invention provides the petroleum hydrocarbon contaminated soil remedying agent and a remedying method capable of effectively degrading petroleum hydrocarbon in soil, and avoiding soil acidification. The petroleum hydrocarbon contaminated soil remedying agent is prepared from a surfactant, sodium persulfate, citric acid, ferrite and alkaline peroxide. The method is capable of using the surfactant to release the adsorbed-state petroleum hydrocarbon which has a strong binding force with soil colloid, using the citric acid to complex Fe<2+>, continuously activating the sodium persulfate to generate SO4<->.degraded petroleum hydrocarbon, and using the alkaline peroxide to adjust a soil pH, thereby improving the remediation effect of a petroleum hydrocarbon pollutant in the soil, and avoiding a soil acidification problem caused by the sodium persulfate at the same time.

Owner:四川长虹格润环保科技股份有限公司

Multi-step pulp bleaching

A method for bleaching cellulosic pulp is disclosed, with one embodiment revealing a three-step bleaching method for cellulosic pulp comprising an activating bleach step, an alkaline peroxide step, and a reductive bleach step. The cellulosic pulp treated according to the present invention may possess a greater GE brightness gain than if treated according to conventional methods, while not suffering a significant loss of lignin. The cellulosic pulp may comprise recycled fibers, including those with high groundwood content. The bleaching method may also decrease the pH of the pulp.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

A kind of manufacturing method of micro-coated light-duty paper

ActiveCN102268836AHigh whitenessGood surface smoothnessCoatings with pigmentsWater-repelling agents additionIndustrial engineeringAlkaline peroxide

The invention discloses a method for making slight-coating light paper. The method comprises the following processing steps of: beating by using kraft pulp, Italian poplar alkaline peroxide mechanical pulp, chemi-thermo-mechanical pulp and waste paper deinked pulp, respectively, blending and adding auxiliary materials, making wet paper sheets, pre-drying, slightly coating, post-drying, press-polishing and finishing. According to the method disclosed by the invention, by the treatment way of coating the surface of the light paper slightly, not only are the quality performances, such as, whiteness, surface smoothness, printing suitability and the like, of the light paper increased greatly, but ash content of the light paper after coating is increased greatly also, so that energy consumptionis saved and production cost is reduced; the method disclosed by the invention has the obvious advantages, and has very important meanings to increase of additional values of high-yield chemi-thermo-mechanical pulp and light paper products, to improvement of quality of the products, and to reduction of production cost.

Owner:YUEYANG FOREST & PAPER CO LTD +1

High quantum yield acridinium compounds and their uses in improving assay sensitivity

InactiveUS20050221390A1Organic chemistryMaterial analysis by observing effect on chemical indicatorQuantum yieldAcridine

The present invention relates to hydrophilic, high quantum yield acridinium compounds. It has been discovered that the placement of electron-donating groups in the acridinium ring system increases the amount of light that is emitted by the corresponding acridinium compound when its chemiluminescence is triggered by alkaline peroxide. More specifically, it has been found that the placement of one or two hydrophilic, alkoxy groups at the C-2 and / or C-7 position of the acridinium ring system of acridinium compounds increases their quantum yield and enhances the aqueous solubility of these compounds. The present hydrophilic, high quantum yield, acridinium compounds are useful chemiluminescent labels for improving the sensitivity of immunoassays.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

Use of activator complexes to enhance lower temperature cleaning in alkaline peroxide cleaning systems

InactiveUS20090203567A1Inorganic/elemental detergent compounding agentsSemi-permeable membranesAlkalinityAlkaline peroxide

The present invention provides for the use of activator complexes to enhance lower temperature cleaning in alkaline peroxide cleaning systems. Compositions including an activator complex, an active oxygen source, and a source of alkalinity are applied to the surface to be cleaned at temperatures between about 5° C. and about 50° C. The methods of the present invention provide for enhanced soil removal with reduced energy, water, and chemistry consumption.

Owner:ECOLAB USA INC

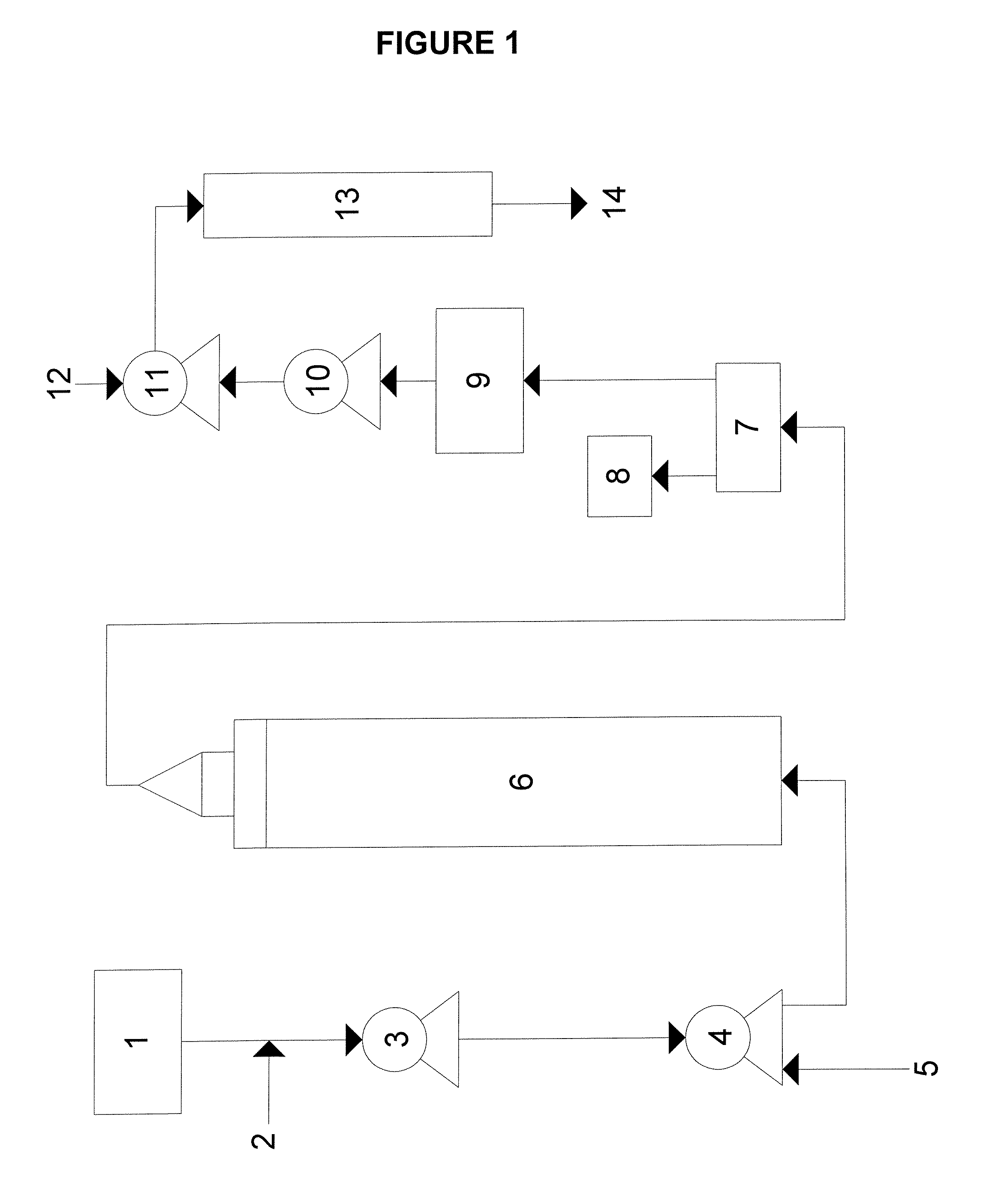

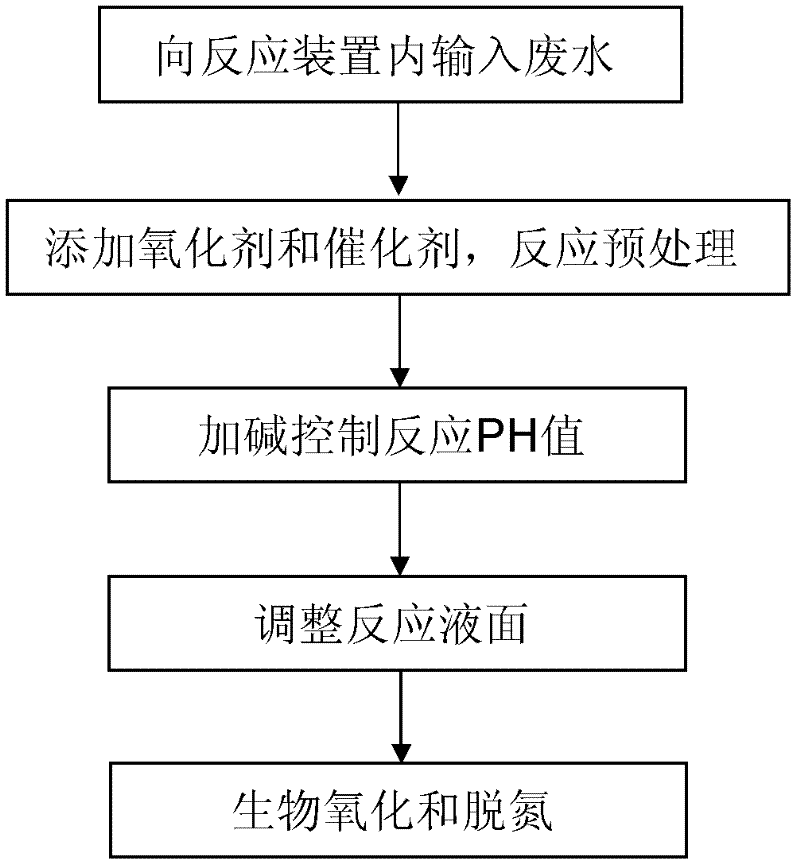

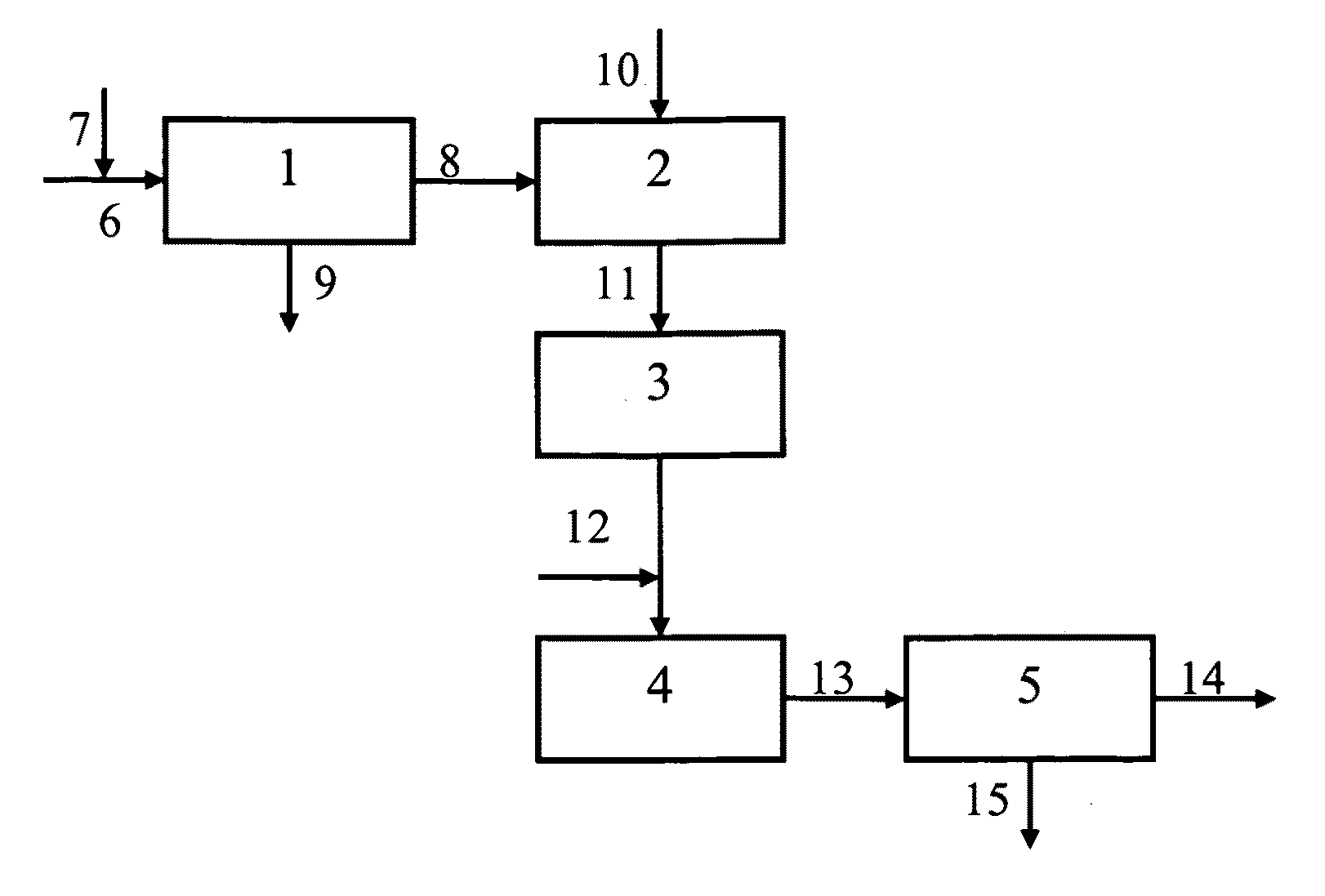

Method and device for treating organic cyanide wastewater

InactiveCN102642986AEasy to handleLow biological toxicityWater contaminantsMultistage water/sewage treatmentNitrogen removalBiological oxidation

The invention discloses a method for treating organic cyanide wastewater. The organic cyanide wastewater is pretreated by reaction using the alkaline peroxide advanced oxidation method, and the pretreated wastewater is subjected to biological oxidation and nitrogen removal by the biological A / O (Anoxic / Oxic) process to obtain effluent water meeting the discharge standards of China and to realize effective treatment of organic cyanide wastewater. The invention further discloses a device for treating the organic cyanide wastewater. As an ideal and clean oxidant, peroxide does not cause secondary pollution, and can reduce biological toxicity of wastewater as well as improve the biodegradability of wastewater, the pH value is controlled in the alkaline range, and highly toxic cyanide gas can be effectively prevented from escaping; and in addition, the operation conditions are simple, and the operation can be carried out at normal temperature and normal pressure.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

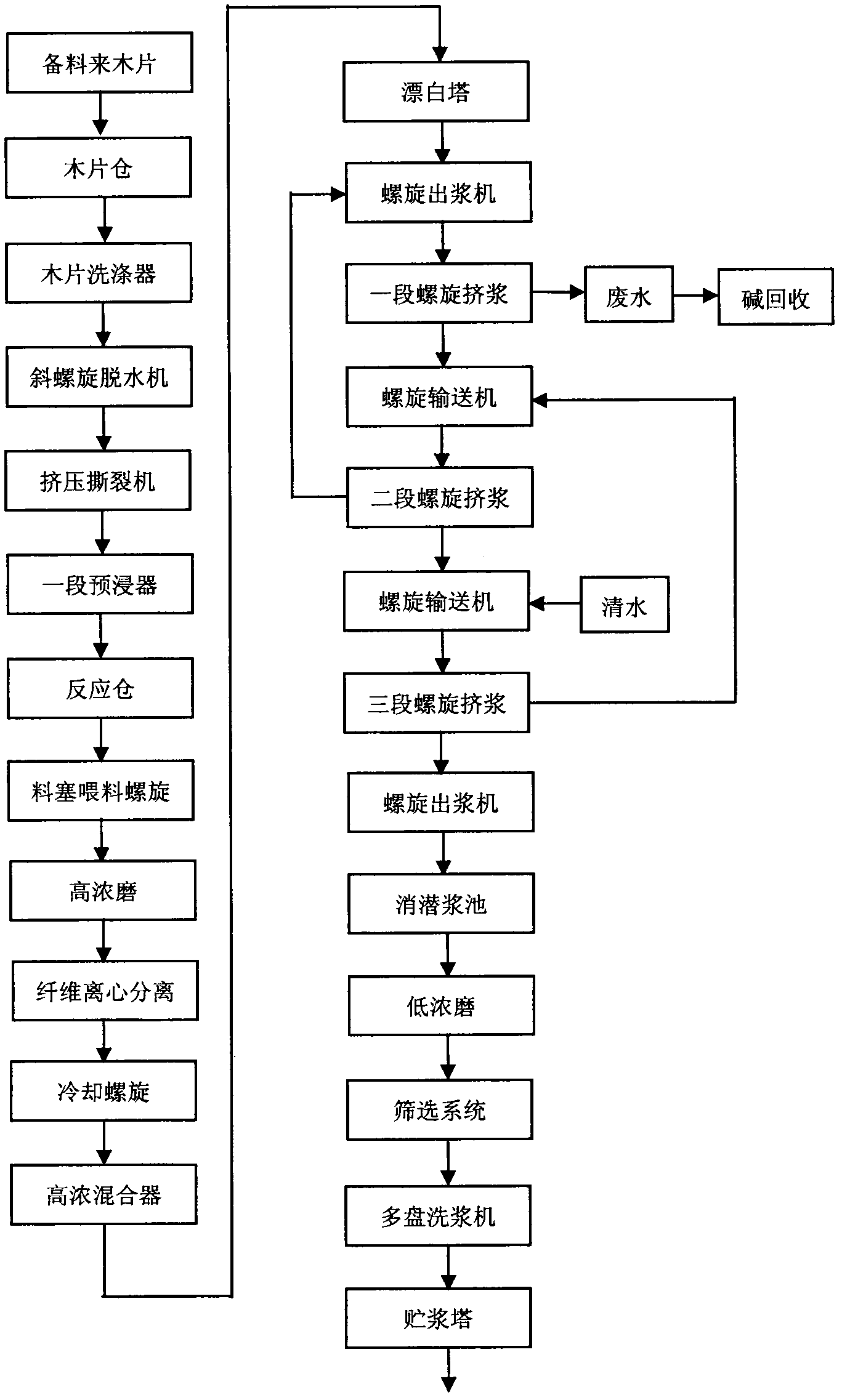

Method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP)

InactiveCN102926253AImprove chemical performancePromote dissolutionPulping with inorganic basesFiberChemical treatment

The invention relates to the technical field of pulping and papermaking, in particular to a method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP), wherein the first period of extrusion processing of needlebush pieces after being steamed is subjected, the first period of chemical processing is subjected after chemical liquid A is added, the chemical liquid A contains sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether (10), the second period of extrusion processing is subjected, the second period of chemical processing is subjected by adding chemical liquid B after the second period of extrusion, the chemical liquid B contains the sodium dodecyl benzene sulfonate and the octyl phenol polyoxyethylene ether (10), the first period of defibrination is subjected after processing and stops, and then the second period of defibrination and eliminate hidden processing are subjected to obtain needlebush P-RC APMP paper pulp. The method for pulping through needlebush P-RC APMP strengthens chemical action of impregnation liquid and dissolution of reactants, softens fiber materials, reduces subsequent pulping energy consumption, improves fiber quality, increases pulp whiteness, reduces pulp resin content, and reduces resin obstacle.

Owner:QILU UNIV OF TECH

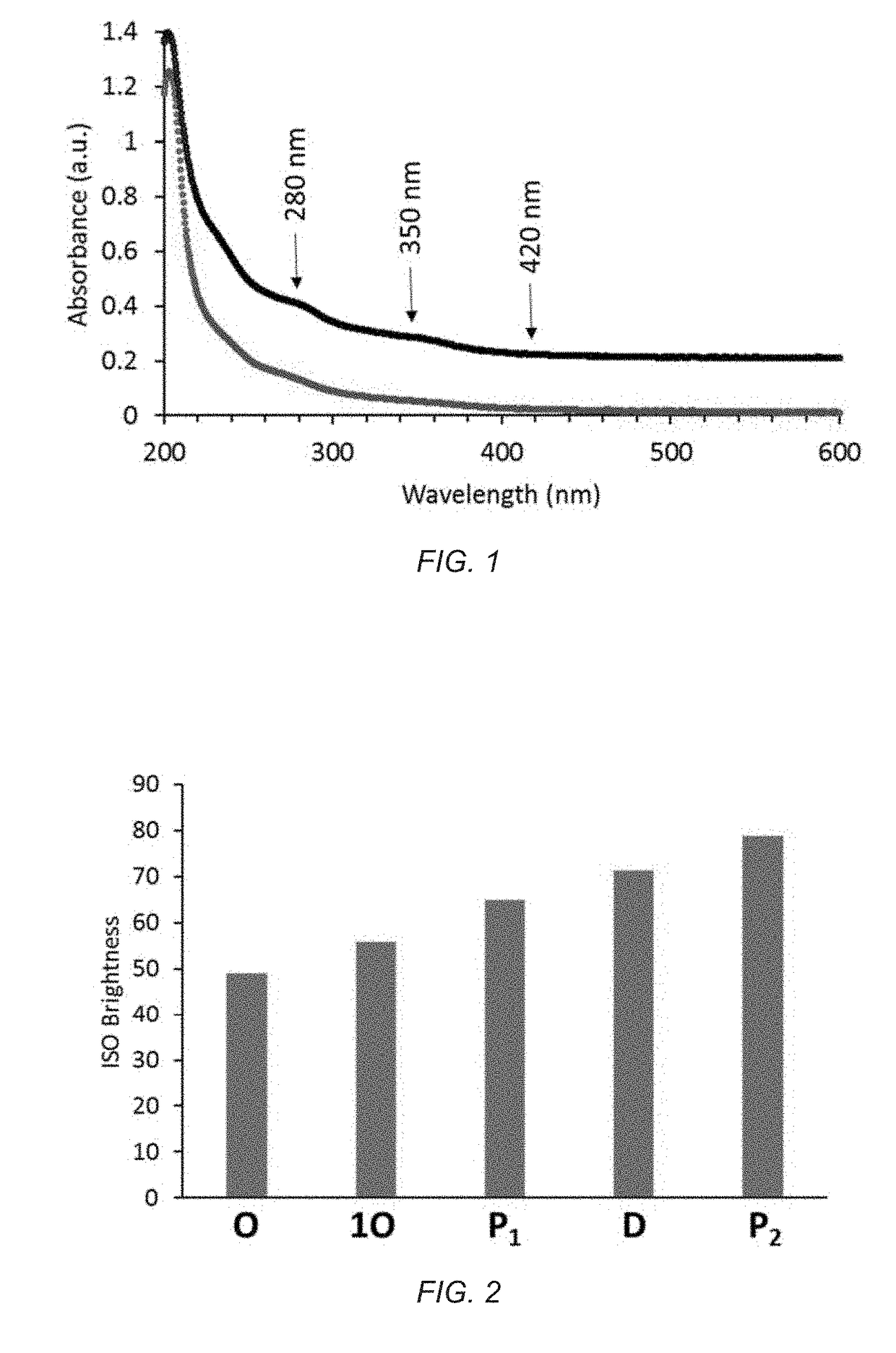

Combined process of peroxide bleaching of wood pulps and addition of optical brightening agents

ActiveUS20090205795A1Improvement in bleaching processPulp bleachingLuminescent/fluorescent substance additionFiberQuenching

A process for improving optical properties of high-yield pulp (HYP) for producing paper products with superior brightness. Optical brightening agents (OBAs) can effectively improve the optical properties of high-yield pulp (HYP). The present process involves incorporating the OBAs into the alkaline peroxide bleaching process. By combining peroxide bleaching with an optical brightening agent, one can decrease the bleaching cost to reach the same brightness target. Some key advantages of adding OBA to HYP at the pulp mill over the conventional wet-end addition of OBA include: i) the quenching effect on OBA by the wet-end cationic polymers such as PEI is decreased by fixing OBA on HYP fibers; ii) the negative impact of metal ions in the white water system on the OBA performance is minimized when OBA is pre-adsorbed and fixed on HYP fibers; iii) the photo-yellowing (color reversion) of HYP and HYP-containing paper sheets is decreased when more OBA is on HYP fibers to protect them from harmful UV radiation.

Owner:UNIVERSITY OF NEW BRUNSWICK

Homogeneous gas-evolving composition

A homogeneous gas-evolving composition is provided that includes an acid, a gas-evolving acid neutralizing agent, and at least one of an inorganic carbonate, inorganic bicarbonate, alkaline peroxide, or alkaline azide. A water-soluble desiccant is homogeneously intermixed with the acid and the gas-evolving acid neutralizing agent. The desiccant is present in an amount able to absorb ambient moisture equivalent to at least 0.01 total weight percent of the composition before gas evolution of more than 50% of the theoretical gas evolution available from the composition. To confer storage stability, the acid, the gas-evolving acid neutralizing agent, and water-soluble desiccant cumulatively have a water content of less than 1 total weight percent water. Through appropriate selection of a desiccant or inclusion of a surfactant foaming agent, the composition foams upon drenching with water. The composition is particularly well suited for consistent usage of glyphosate herbicide. Plant growth inhibition is provided by wetting a plant with water and then applying the composition onto the plant. After allowing sufficient time, the composition absorbs the water and evolves gas, thereby spreading herbicide on the plant preferential to surrounding soil.

Owner:THE ANDERSONS

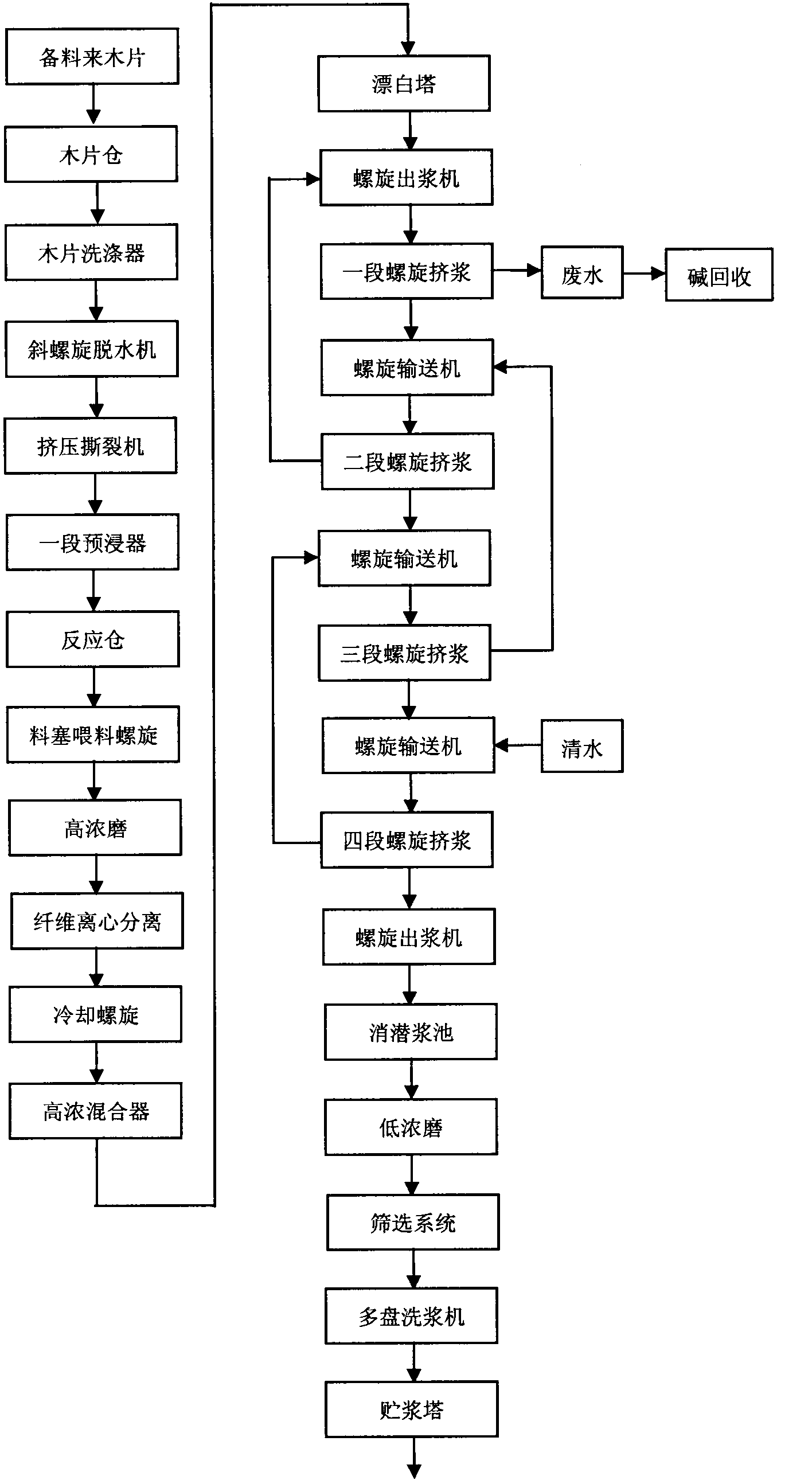

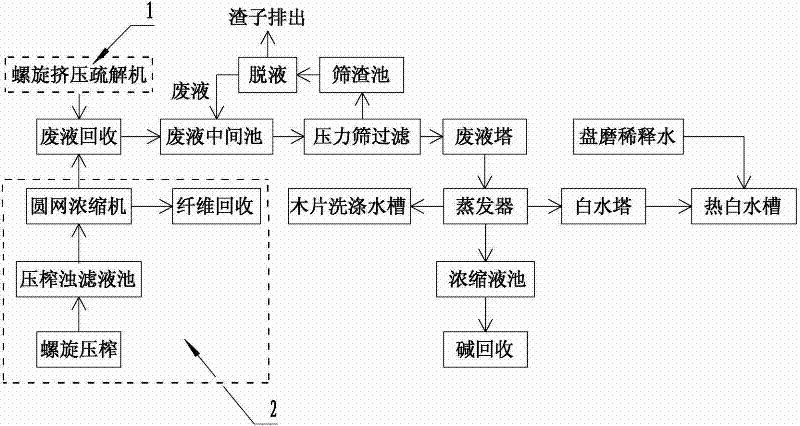

Improved P-RC APMP (preconditioning-refining chemical alkaline peroxide mechanical pulp) new flow path

The invention provides an improved P-RC APMP (preconditioning-refining chemical alkaline peroxide mechanical pulp) pulping new flow path, which is characterized in that three or four in-series double helix press masters are added behind a conventional P-RC APMP flow path bleaching tower to extract a bleaching waste liquid, the gross extraction efficiency of the waste liquid is 80-95%, the improved P-RC APMP pulping new flow path is small in water consumption when the waste liquid is extracted, the extracted waste liquid is high in solid content, within the range of 4.0-8.0%, and the extracted waste liquid is processed by means of alkali recovery, so that the steam use level when the waste liquid is concentrated by means of alkali recovery can be reduced, the washing load of the pulp at a follow-up washing workshop section can be reduced, and the negative influence of anionic trash in the pulp to a wet part of a paper section paper machine can be further reduced simultaneously.

Owner:NANJING FORESTRY UNIV

High Quantum Yield Acridinium Compounds and Their Uses in Improving Assay Sensitivity

InactiveUS20080014660A1Organic chemistryMaterial analysis by observing effect on chemical indicatorQuantum yieldAcridine

The present invention relates to hydrophilic, high quantum yield acridinium compounds. It has been discovered that the placement of electron-donating groups in the acridinium ring system increases the amount of light that is emitted by the corresponding acridinium compound when its chemiluminescence is triggered by alkaline peroxide. More specifically, it has been found that the placement of one or two hydrophilic, alkoxy groups at the C-2 and / or C-7 position of the acridinium ring system of acridinium compounds increases their quantum yield and enhances the aqueous solubility of these compounds. The present hydrophilic, high quantum yield, acridinium compounds are useful chemiluminescent labels for improving the sensitivity of immunoassays.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC

Process for reducing specific energy demand during refining of thermomechanical and chemi-thermomechanical pulp

ActiveUS20110303372A1Reduce consistencyLower energy requirementsCellulosic pulp after-treatmentFibrous raw materialsPulp and paper industryAlkaline peroxide

A method for producing thermomechanical or chemi-thermomechanical pulp is provided. The process is characterized as having a reduced specific energy demand during refining. The process involves processing a pretreated wood material using one or more high consistency refining steps to produce a first pulp, optionally applying a chelating agent to the first pulp during HC refining to produce a stabilized pulp and treating the first or stabilized pulp with an alkaline-peroxide liquor to produce a treated pulp. The treated pulp is then processed by one or more second low consistency refining steps. Alternatively, the first pulp or stabilized pulp may be divided into a primary and secondary stream. The primary stream is treated with alkaline-peroxide liquor to produce a treated pulp. The secondary stream is processed using a secondary HC refining step to produce a partially refined pulp, and removing latency of the partially refined pulp and the treated pulp is removed in a common location. The treated pulp and the partially treated pulp is processed by one or more than one second low consistency refining step to produce a final pulp. The methods utilize less energy when compared with a method for producing pulp that requires both primary and secondary high consistency refining stages.

Owner:THE UNIV OF BRITISH COLUMBIA

Method for preparing high-bulk eucalyptus alkaline peroxide mechanical pulp

ActiveCN102747636AReduce consumptionReduced flexibilityPaper material treatmentPaperboardAlkaline peroxide

The invention discloses a method for preparing high-bulk eucalyptus alkaline peroxide mechanical pulp. The method includes the steps of raw material heating, washing, pre-steaming, extrusion, steeping, reacting, high consistency refining, bleaching, latency removal, low consistency refining, screening, concentrating, and pulp washing for formation of finished pulp. The method uses eucalyptus as raw material, lowers consumption of NaOH and changes refining ways, and accordingly consumption is lowered, and cost is reduced. In addition, bulk of the eucalyptus alkaline peroxide mechanical pulp is increased from lower than 2.8cm<3> / g to more than 3.5cm<3> / g, and paperboard bulkiness is improved greatly.

Owner:GUANGXI JINGUI PULP PAPER

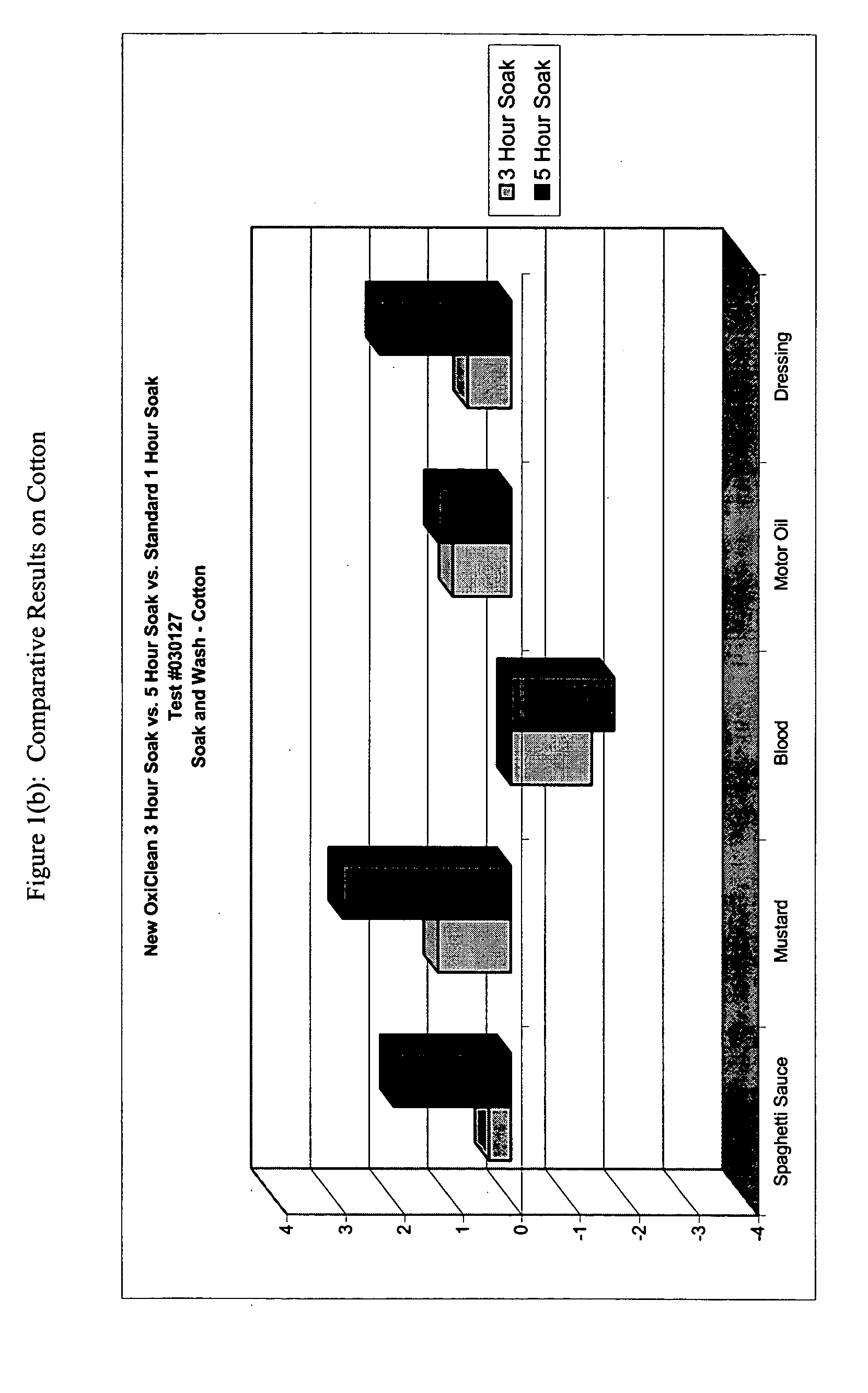

Detergent formulations containing alkaline peroxide salts and organic acids

InactiveUS20050065054A1Good storage stabilityCheap methodNon-surface-active detergent compositionsDry-cleaning apparatus for textilesParticulatesOrganic acid

The invention provides particulate detergent compositions containing alkaline peroxide salts and organic peracid precursors, methods of treating stains with these compositions and methods of making the compositions. The compositions have long term storage stability imparted by a coating to the alkaline peroxide salt. The methods of formulating the compositions to include this coating are relatively easy and inexpensive.

Owner:CHURCH & DWIGHT CO INC

Extraction of hemicellulosic materials

Hemicelluloses may be extracted by alkaline peroxide treatment without removal of ferulate residues. Hemicelluloses prepared in this way retain their ability to gel. Such gelling hemicelluloses may be extracted with a number of different oxidizing species including hydrogen peroxide anion, hydrogen peroxide radical, hydroxyl radical, superoxide radical and oxide radical. A process has thus been developed for producing a hemicellulose gel that may be carried out at cold temperatures, thus facilitating enzymic co-processing, and that is high yielding and produces a gel that is light in color.

Owner:CAMBRIDGE BIOPOLYMERS LTD

Bio enzyme preparation for improvement of paper forming strength of alkaline peroxide mechanical pulp (APMP) and application thereof

The invention discloses a bio enzyme preparation for improvement of paper forming strength of alkaline peroxide mechanical pulp (APMP) and application thereof, and the bio enzyme preparation comprises the following components by weight: 0.1-5 parts of polyethylene glycol, 1-50 parts of liquid cellulase, 1-50 parts of liquid xylanase, 1-10 parts of a surface active agent and the balance of deionized water. When the bio enzyme preparation is used for the treatment of the APMP, the cellulase and xylanase in the bio enzyme preparation selectively and biologically decompose cellulose molecules and lignin molecules in APMP fiber, so that pulp fiber releases more hydroxyl for increasing the binding force bamong the fibers, and the paper forming strength of the APMP is improved.

Owner:ANHUI LEVEKING BIOTECH CO LTD

Coated paper

ActiveCN102733250AElegant paper colorBumpy feelWater-repelling agents additionPaper coatingSulfateSlurry

The invention provides coated paper, which comprises raw paper and coatings formed on two surfaces of the raw paper. Paper pulp for the preparation of the raw paper contains the following slurries of: by weight, 30-80 parts of bleached sulfate hardwood pulp, 0-30 parts of the bleached softwood pulp, 0-30 parts of bleached chemical mechanical pulp and 0-30 parts of alkaline peroxide mechanical pulp. The ash content in the raw paper is 5%-20% by weight. The paint for coating the coating layer contains matt flake china clay. By adjusting the kind and ratio of the raw paper slurries, the ash content of the raw paper to control the roughness and bulkness of the raw paper, the coated paper provided by the invention has an elegant paper color, a concavo-convex feel and a thick loose height. Furthermore, by the addition of matt flake china clay into the paint for coating the coating layer, a high coating seal performance is obtained with fewer coating weight, and the printing effect of the coated paper is good.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Evaporation pretreatment process method for alkaline peroxide mechanical pulp

InactiveCN102230293AHigh purityImprove utilization efficiencySpent liquor concentrationEvaporationPre treatment

The invention provides an evaporation pretreatment process method for alkaline peroxide mechanical pulp, which comprises a waste liquor recovery process and an alkali recovery process, wherein in the waste liquor recovery process, filter water in the production process of the alkaline peroxide mechanical pulp is collected to a waste liquor intermediate pond, and in the alkali recovery process, collected waste liquor in the waste liquor intermediate pond is subjected to alkali recovery treatment. Before the alkali recovery treatment, the method also comprises the following evaporation pretreatment steps of: (a) performing pressure filtering on waste liquor, namely filtering the waste liquor in the waste liquor intermediate pond by a pressure sieve, discharging dregs formed during filtering to a dreg sieving pond, and discharging the filtered waste liquor to a waste liquor tower to enter the step (b); and (b) performing evaporation grading treatment on the filtered waste liquor by an evaporator, wherein heavily-polluted concentrated solution is discharged to a concentrated solution pond for alkali recovery treatment, mildly-polluted concentrated solution is discharged to a wood chip washing water tank to clean wood chips, and after being mixed with disk mill dilution water in a white water tower, white water generated during evaporation is discharged to a hot white water tank and enters a pulping system of the alkaline peroxide mechanical pulp. The evaporation pretreatment process method has the advantages of high alkali recovery efficiency and environment friendliness.

Owner:SHANDONG TAIYANGZHIYE

Methods of pulp fiber treatment

ActiveUS20170335515A1Increase pulp yieldPreserve fiber strengthPulp bleachingPulp by-products recoveryFiberAcetic acid

In some embodiments, a method may include treating pulp. The method may include contacting a wood pulp with a singlet oxygen source. The method may include contacting the wood pulp with an alkaline peroxide source. The singlet oxygen source may include a peracetate oxidant solution and generating a reactive oxygen species. The peracetate oxidant solution may include peracetate anions and a peracid. In some embodiments, the peracetate solution may include a pH from about pH 10 to about pH 12. In some embodiments, the peracetate solution has a molar ratio of peracetate anions to peracid ranging from about 60:1 to about 6000:1. In some embodiments, the peracetate solution has a molar ratio of peracetate to hydrogen peroxide of greater than about 16:1. The peracetate oxidant solution may provide enhanced treatment methods of bleaching, brightening, and delignifying pulp fibers involving the use of peracetate oxidant solutions.

Owner:CLEAN CHEM

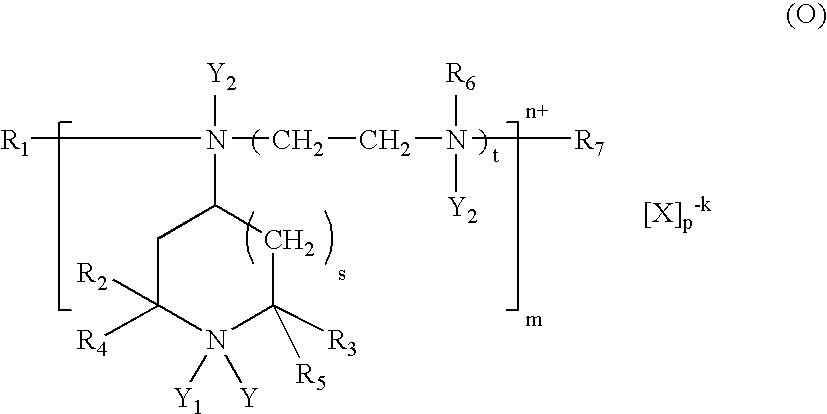

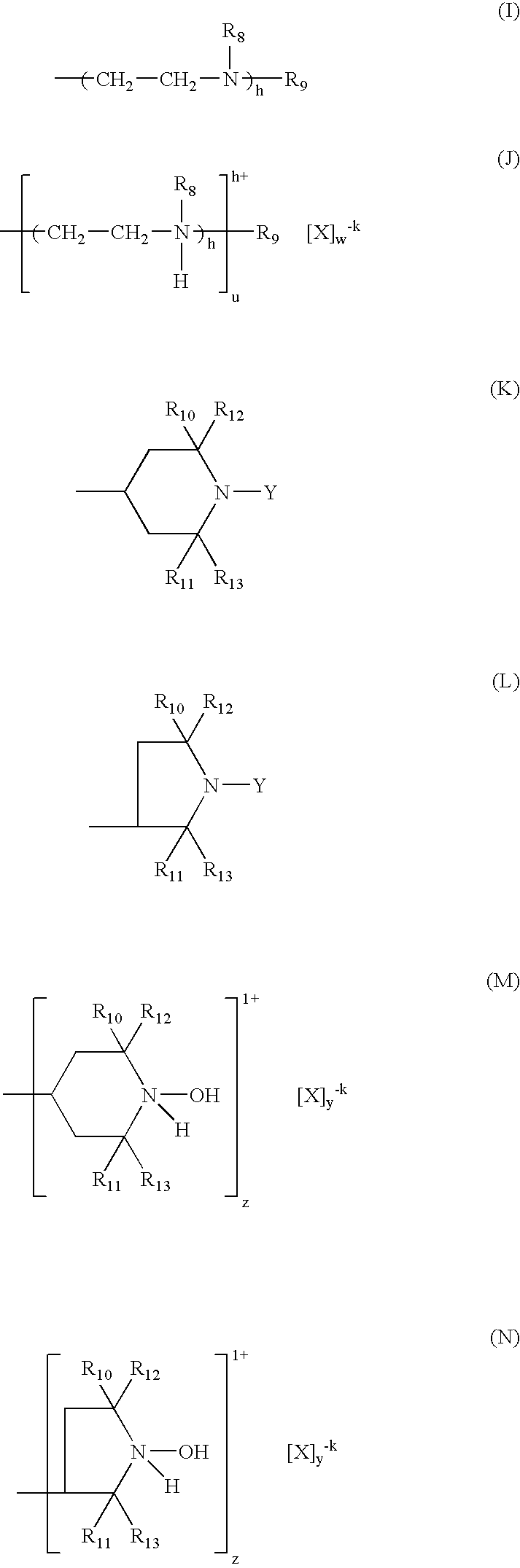

Light-stable and process-stable lignocellulosic materials and their production

InactiveUS20050269049A1Good light stabilityImprove processing stabilityNon-fibrous pulp additionNatural cellulose pulp/paperFiberCellulose

A novel method for the production of light-stable and process-stable lignocellulosic materials, in particular, the production of mechanical wood pulps with much improved light and process stability is described, as well as the resulting pulps of improved light and process stability and papers containing such pulps. The novel method involves the reaction of lignocellulosic materials such as bleached chemithermomechanical pulps (BCTMP) with (a) a water-soluble, fibre-reactive yellowing inhibitor possessing two or more secondary amino or ammonium (—NHR′ or —HN+HR′), tertiary amino or ammonium (—NR′R″ or —HN+R′R″), and / or quaternary ammonium (—N+R′R″R′″) functional groups in an aqueous medium, or (b) a water-soluble, fibre-reactive hindered amine light stabilizer possessing said amino or ammonium functional groups in an alkaline peroxide bleaching medium or in an aqueous medium with a subsequent bleaching of the materials in an alkaline peroxide bleaching medium. Examples of the water-soluble, fibre-reactive yellowing inhibitors are the novel, N-(2,2,6,6-tetramethyl-1-oxyl-piperidin-4-yl)-N′-{2-[2-(2,2,6,6-tetramethyl-1-oxyl-piperidin-4-ylamino)-ethylamino]-ethyl}-ethane-1,2-diamine (abbreviated as TETA-2TEMPO) and its hydroxylamine hydrochloride derivative, N-(2,2,6,6-tetramethyl-1-hydroxyl-piperidin-4-yl)-N′-{2-[2-(2,2,6,6-tetramethyl-1-hydroxyl-piperidin-4-ylamino)-ethylamino]-ethyl}-ethane-1,2-diamine hexahydrochloride (abbreviated as TETA-2TEMPOH-6HCl).

Owner:FPINNOVATIONS INC

Preparation method of coconut-shell cellulose modified acrylate pressure-sensitive adhesive

InactiveCN106118531AEasy to useStrong initial adhesionMacromolecular adhesive additivesEster polymer adhesivesCelluloseCross-link

The invention discloses a preparation method of a coconut-shell cellulose modified acrylate pressure-sensitive adhesive, belonging to the technical field of the preparation of the pressure-sensitive adhesive. The preparation method comprises the following steps: by taking coconut shells as a raw material, extracting coconut-shell cellulose by virtue of alkaline peroxide, utilizing the coconut-shell cellulose as a cross-linking agent to modify acrylate pre-emulsion in a cross-linking manner, thus obtaining modified emulsion, smearing the modified emulsion on a base material, and drying to obtain the pressure-sensitive adhesive. The acrylate emulsion is cross-linked and modified by utilizing the characteristics of the coconut-shell cellulose such as middle holes, longitudinal valleys, transverse branches, good flexibility, good air permeability and good wear resistance to add a cross-linking netted structure of the acrylate pressure-sensitive adhesive, and linear molecules are chemically bonded, so that the stripping strength, primary adhesive force and lasting adhesive force of the pressure-sensitive adhesive are improved, the drying time is shortened, the defects of a traditional single-component acrylate pressure-sensitive adhesive are overcome, and the application prospect is wide.

Owner:仇颖超

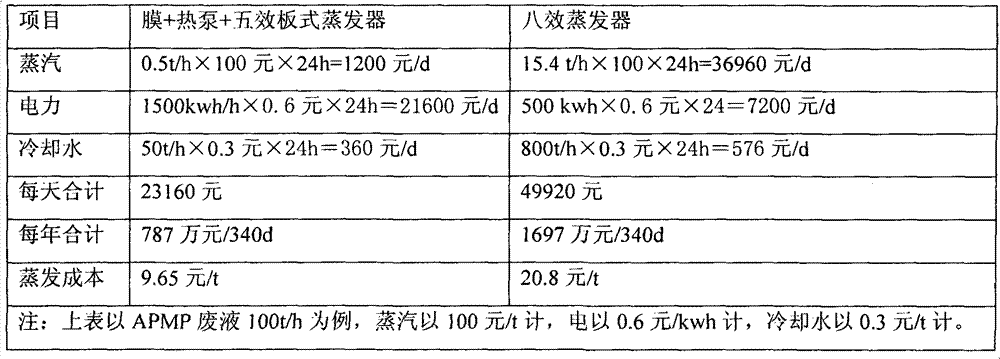

Method for low-energy consumption condensation of waste liquid produced by alkaline peroxide mechanical pulping

InactiveCN102897961AReduce evaporation energy consumptionSave on operating costsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentHigh concentrationLiquid waste

The invention provides a method for low-energy consumption condensation of a waste liquid produced by alkaline peroxide mechanical pulping. The method fully combines characteristics of a ceramic ultrafiltration membrane, a mechanical repeat-compression heat pump and a plate-type falling-film evaporator, and utilizes the devices in concentration of waste liquids which have different properties and are obtained at different discharge points in chemithermomechanical pulping. In the method, the ceramic ultrafiltration membrane replaces an organic membrane, so that a high concentration grinding technology causes a high waste liquid temperature, and can be used for pre-concentration. The mechanical repeat-compression heat pump is used for concentration of a waste liquid from a low concentration to a middle concentration. The plate-type falling-film evaporator is used for concentration of a waste liquid from a middle concentration to a high concentration. The method integrates and optimizes multiple energy-saving technologies, greatly reduces evaporation energy consumption of a waste liquid produced by alkaline peroxide mechanical pulping, realizes waste liquid zero-discharge in the whole alkaline peroxide mechanical pulping process, thoroughly solves the problem that a waste liquid produced by alkaline peroxide mechanical pulping is treated difficultly, and has a simple process flow and a low operation cost.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Bleaching process for broussonetia papyrifera white bast bio-pulp

InactiveCN101161928AHigh whitenessReduce dustNatural cellulose pulp/paperPulp bleachingFiberCOLORED MATERIAL

The invention discloses a bleaching method of broussonetia papyrifera white bast bio-pulp, which is passed through a slot screen of 20-60 mesh, and then processed with centrifugal separation, finally processed with supplementary bleaching with alkaline peroxide. The method can remove most colored material in bio-pulp by physical methods of slot screen and centrifugal separation, thereby effectively reducing dirt count in the bio-pulp, the whiteness of the bio-pulp is increased to 80-85 percent ISO from 38-44 percent ISO, the value of KMnO4 is decreased below 5.81 from 14-16, the yield is 90-95 percent, fiber average length is decreased to 6.92 mm from 6.34 mm, requirements of producing white paper or high grade paper classes can be completely fulfilled. Moreover, the method does not use chlorine-containing bleaching agent, has simple technology, low production cost and no environmental pollution. The invention has a wide application prospect in the pulp and paper field.

Owner:大连中植环境生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com