Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

599 results about "Co-processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Co-processing is the use of waste as raw material, or as a source of energy, or both to replace natural mineral resources (material recycling) and fossil fuels such as coal, petroleum and gas (energy recovery) in industrial processes, mainly in energy intensive industries (EII) such as cement, lime, steel, glass, and power generation. Waste materials used for Co-processing are referred to as alternative fuels and raw materials (AFR).

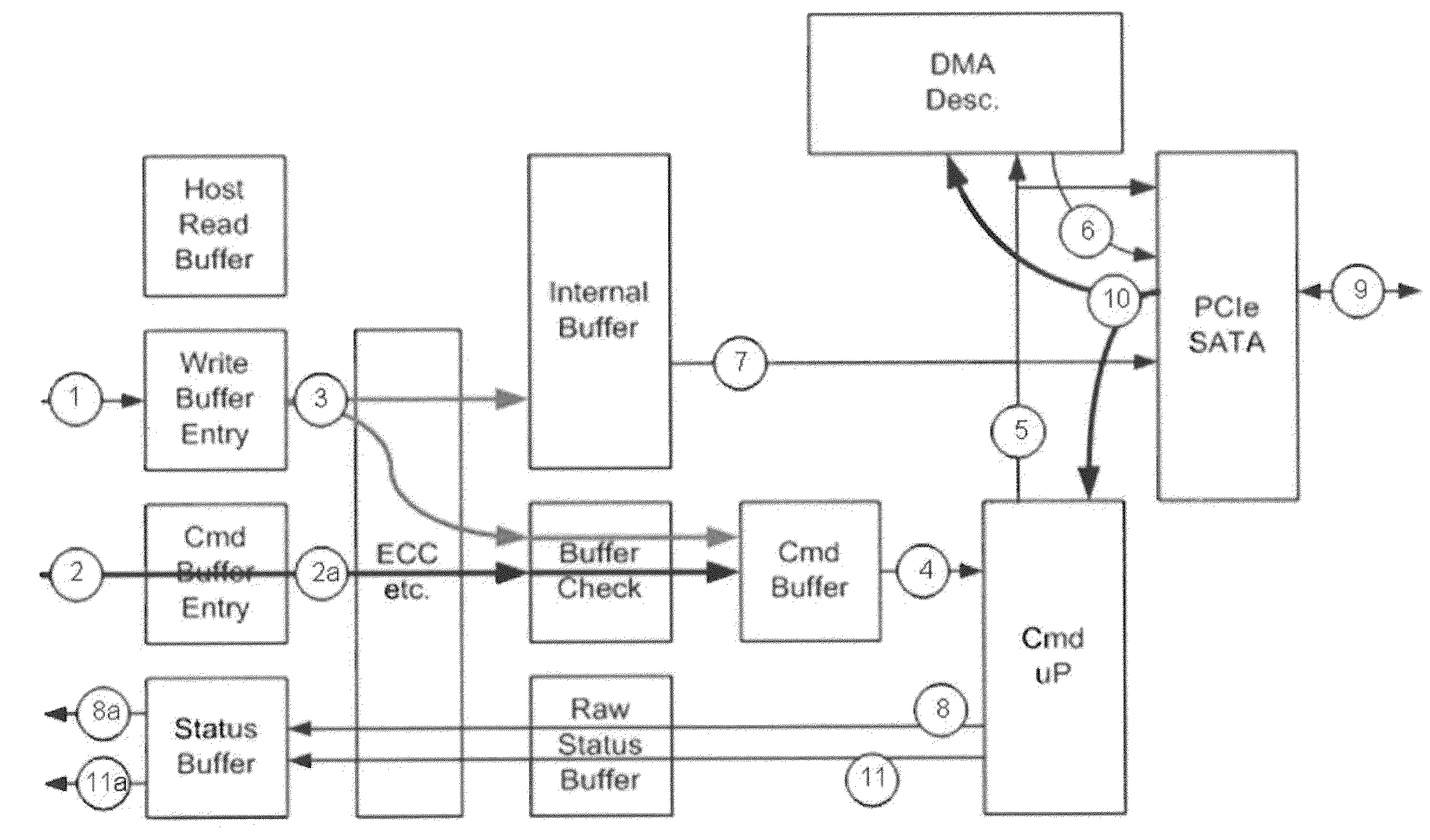

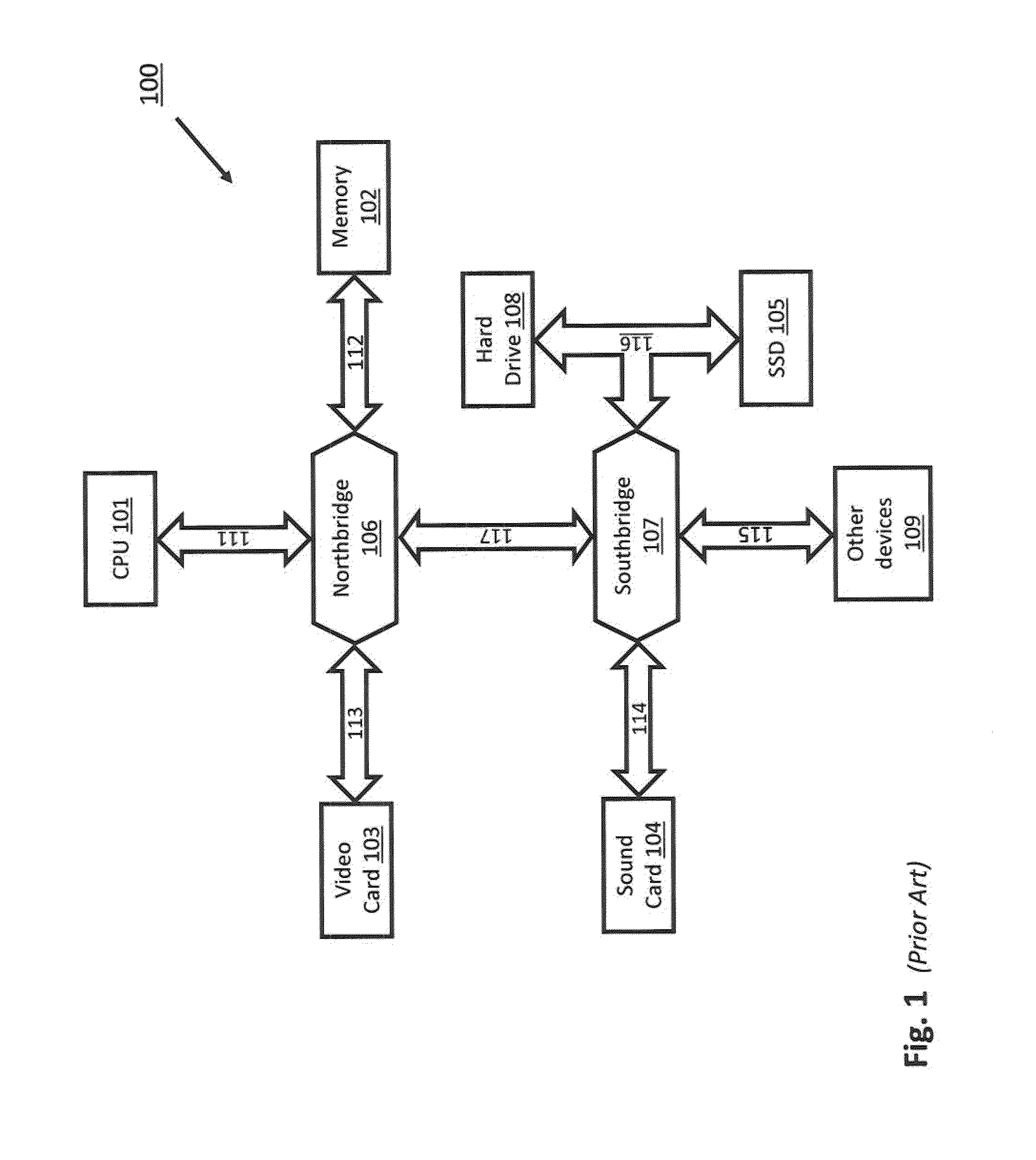

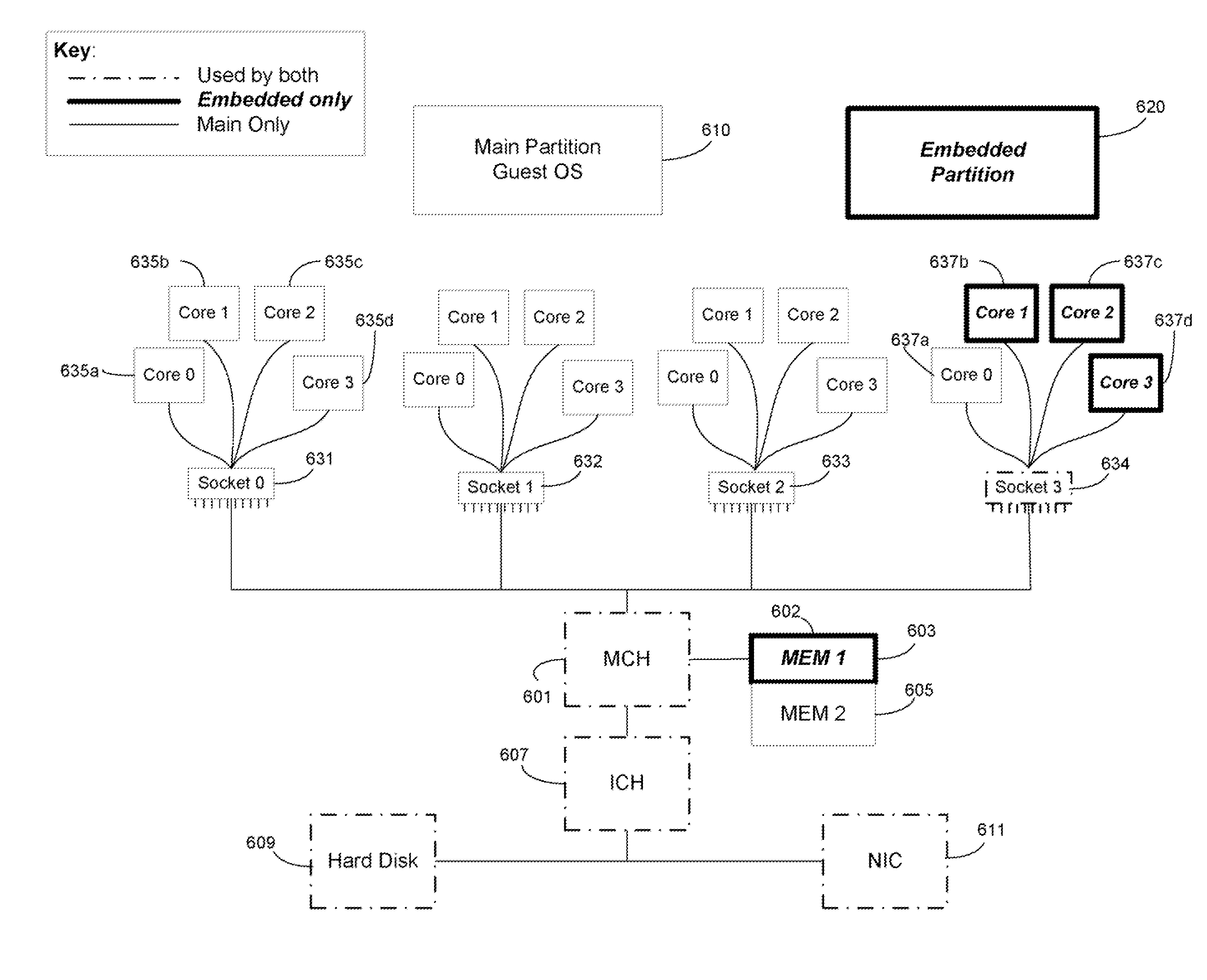

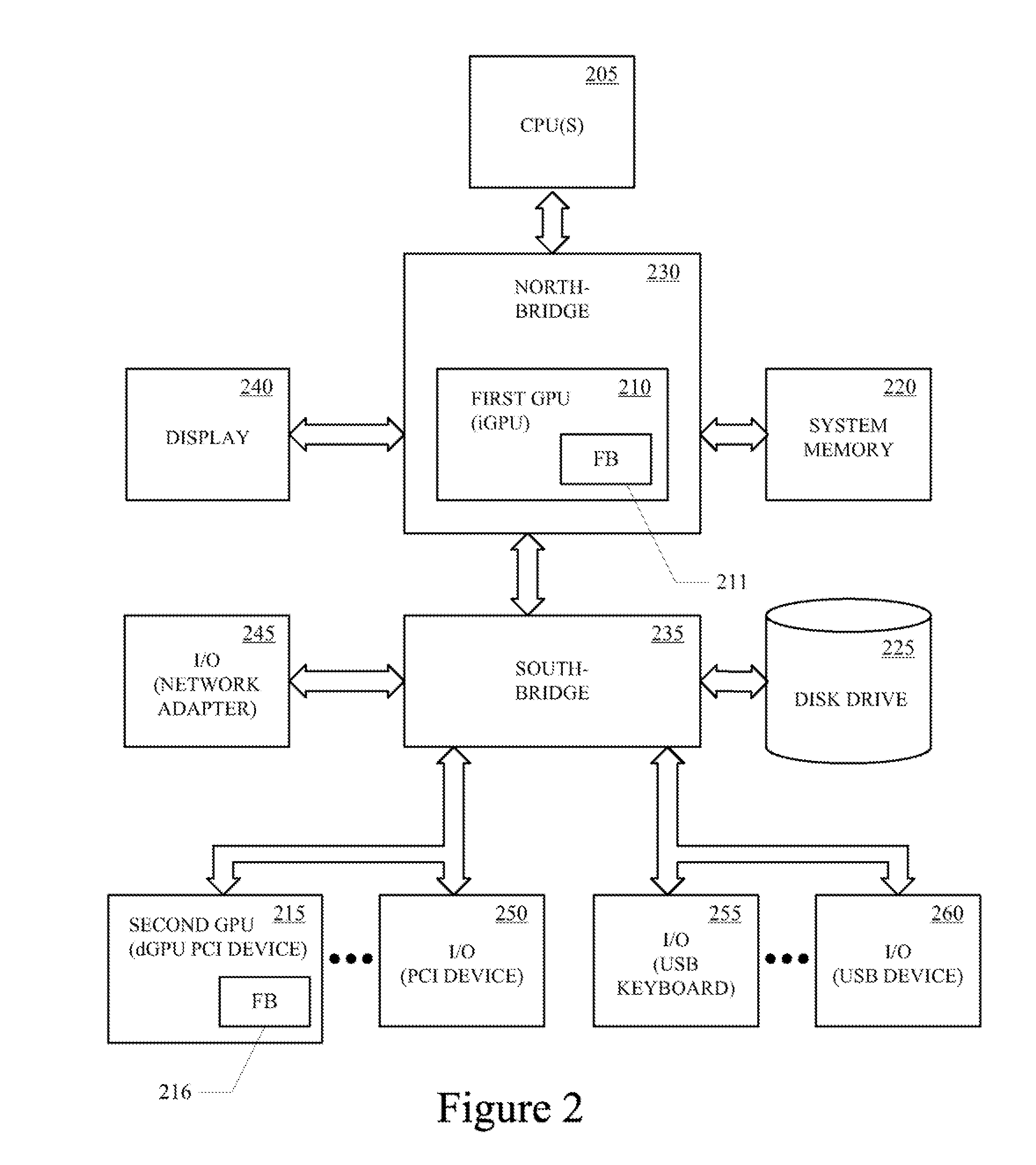

System and method of interfacing co-processors and input/output devices via a main memory system

ActiveUS20120204079A1Memory architecture accessing/allocationError detection/correctionComputer moduleMemory bus

A system for interfacing with a co-processor or input / output device is disclosed. According to one embodiment, the system includes a computer processing unit, a memory module, a memory bus that connects the computer processing unit and the memory module, and a co-processing unit or input / output device, wherein the memory bus also connects the co-processing unit or input / output device to the computer processing unit.

Owner:RAMBUS INC

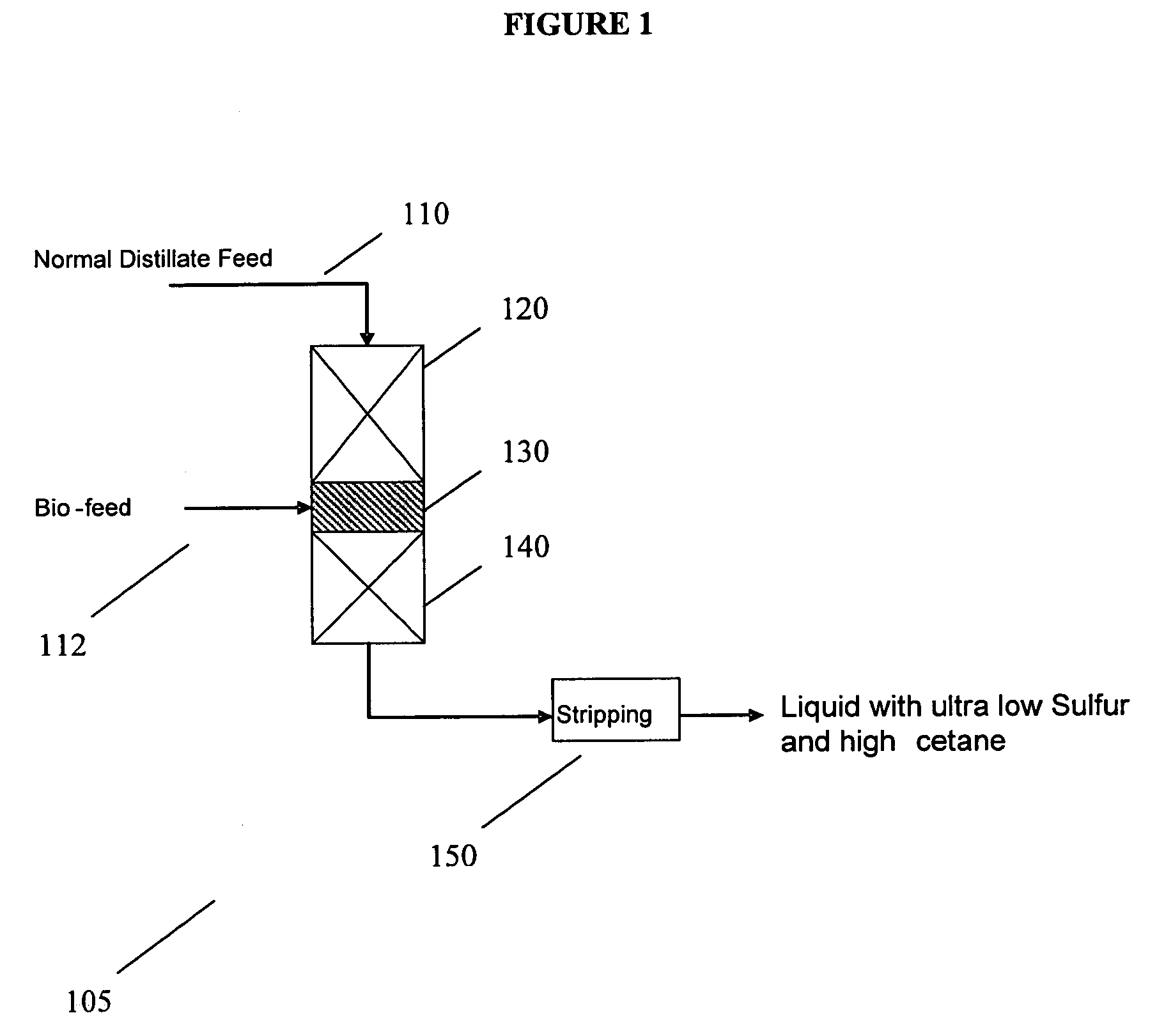

Staged co-processing of biofeeds for manufacture of diesel range hydrocarbons

ActiveUS20090166256A1Liquid hydrocarbon mixture productionTreatment with hydrotreatment processesCo-processingMaceral

Processes are provided for producing a diesel fuel product having a sulfur content of 10 ppm by weight or less from feed sources that include up to 20% by weight of a biocomponent feedstock. The mineral hydrocarbon portions of the feed sources can be distillate or heavier feed sources.

Owner:EXXON RES & ENG CO

Methods for Co-Processing of Biomass and Petroleum Feed

ActiveUS20110154720A1Mitigate equipment cost and energy cost and degradationSpeed up the conversion processCatalytic crackingBiofuelsLiquid hydrocarbonsDelayed coker

A process for producing fuel from biomass is disclosed herein. The process includes torrefying biomass material at a temperature between 80° C. to 400° C. to form particulated biomass having a mean average particle size between 1 μm and 1000 μm. The particulated biomass is mixed with a liquid hydrocarbon to form a suspension, wherein the suspension includes from 1 weight percent to 40 weight percent particulated biomass. The suspension is fed into a unit selected from the group consisting of a pyrolysis reactor, a fluid catalytic cracking unit, a delayed coker, a fluid coker, a hydroprocessing unit, and a hydrocracking unit, and then at least a portion of the particulated biomass of the suspension is converted into fuel.

Owner:MARD INC

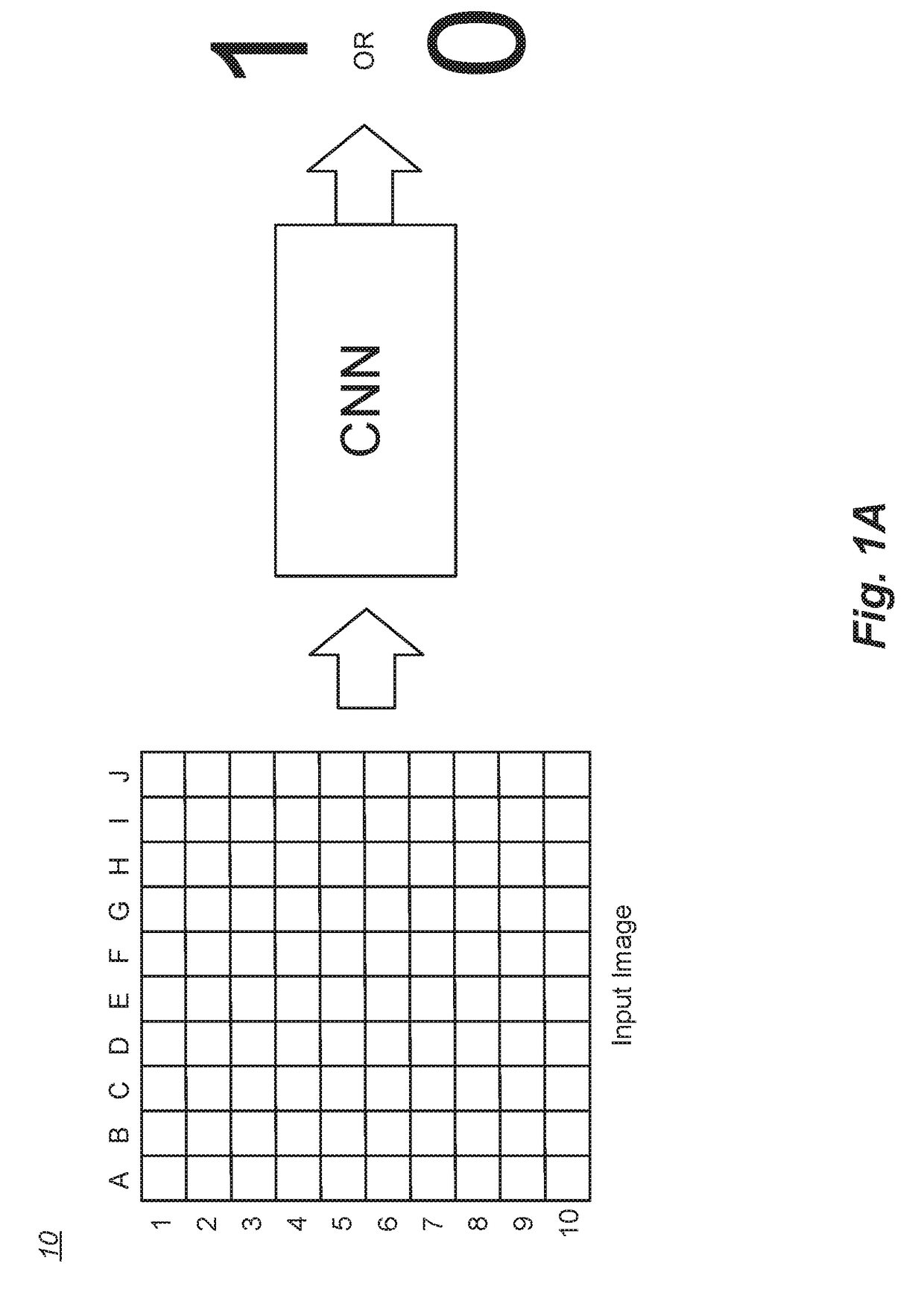

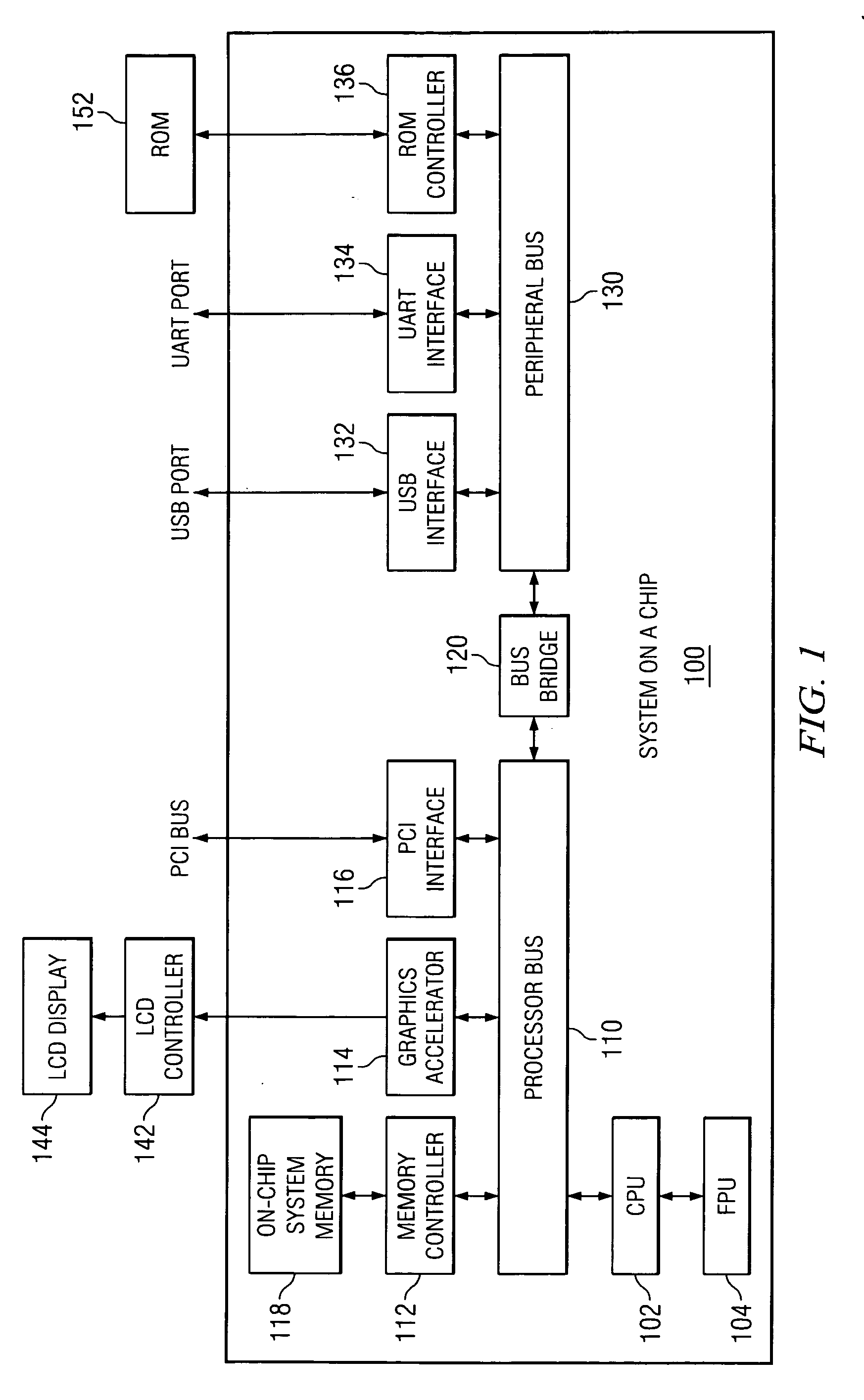

Deep convolutional network heterogeneous architecture

PendingUS20180189229A1Reduce power consumptionImproves data reuseMathematical modelsKernel methodsParallel computingCo-processing

Embodiments are directed towards a system on chip (SoC) that implements a deep convolutional network heterogeneous architecture. The SoC includes a system bus, a plurality of addressable memory arrays coupled to the system bus, at least one applications processor core coupled to the system bus, and a configurable accelerator framework coupled to the system bus. The configurable accelerator framework is an image and deep convolutional neural network (DCNN) co-processing system. The SoC also includes a plurality of digital signal processors (DSPs) coupled to the system bus, wherein the plurality of DSPs coordinate functionality with the configurable accelerator framework to execute the DCNN.

Owner:STMICROELECTRONICS SRL

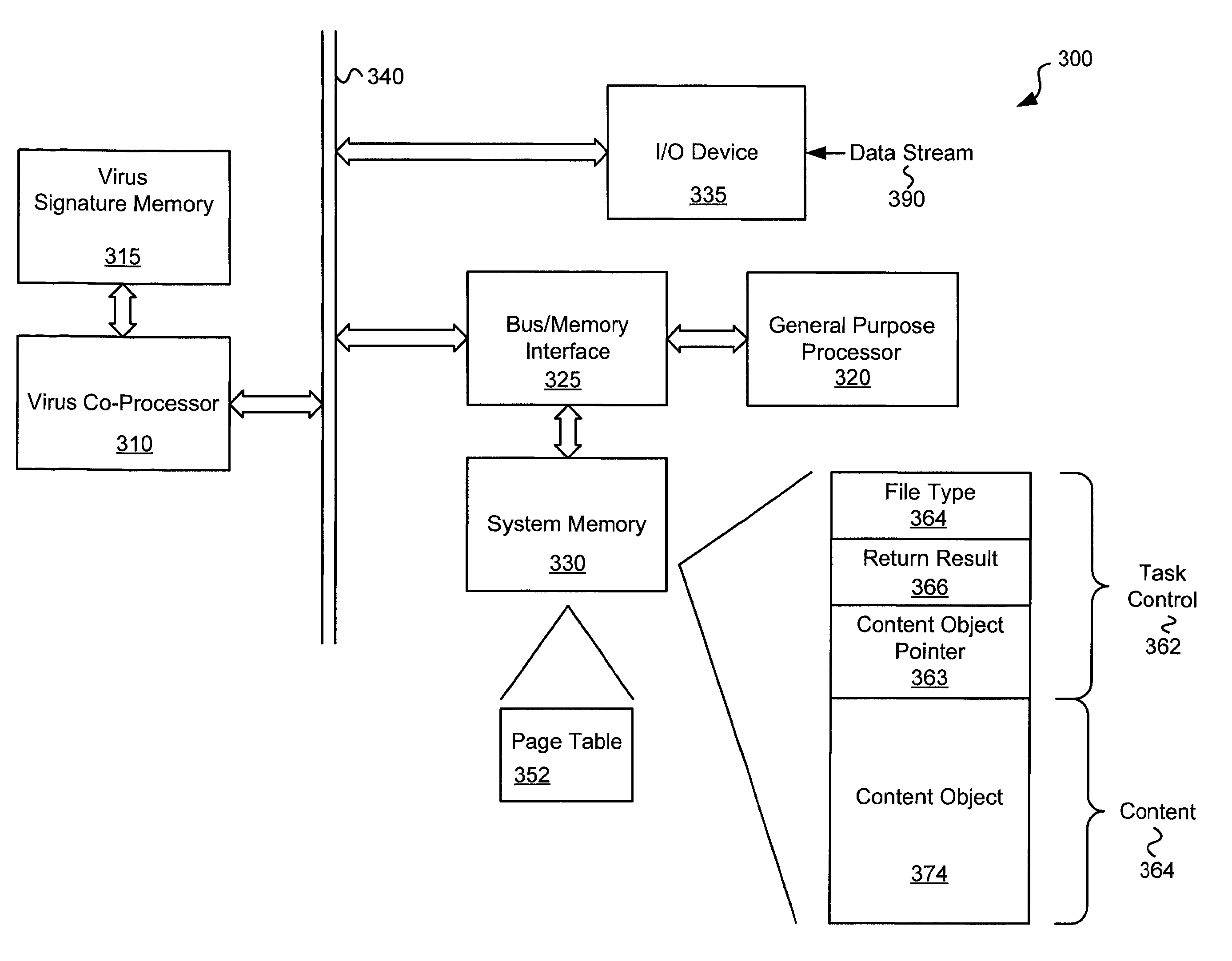

Circuits and methods for efficient data transfer in a virus co-processing system

ActiveUS20090044273A1Memory architecture accessing/allocationMemory loss protectionGeneral purposeData segment

Various embodiments of the present invention circuits and methods for improved virus processing. As one example, such methods may include providing a system memory, a general purpose processor and a virus co processor. The methods further include receiving a data segment at the general purpose processor, and storing the data segment to the system memory using virtual addresses. The date segment is accessed from the system memory by the virus co processor using the virtual addresses. The virus co processor then scans the date segment for viruses and returns results.

Owner:FORTINET

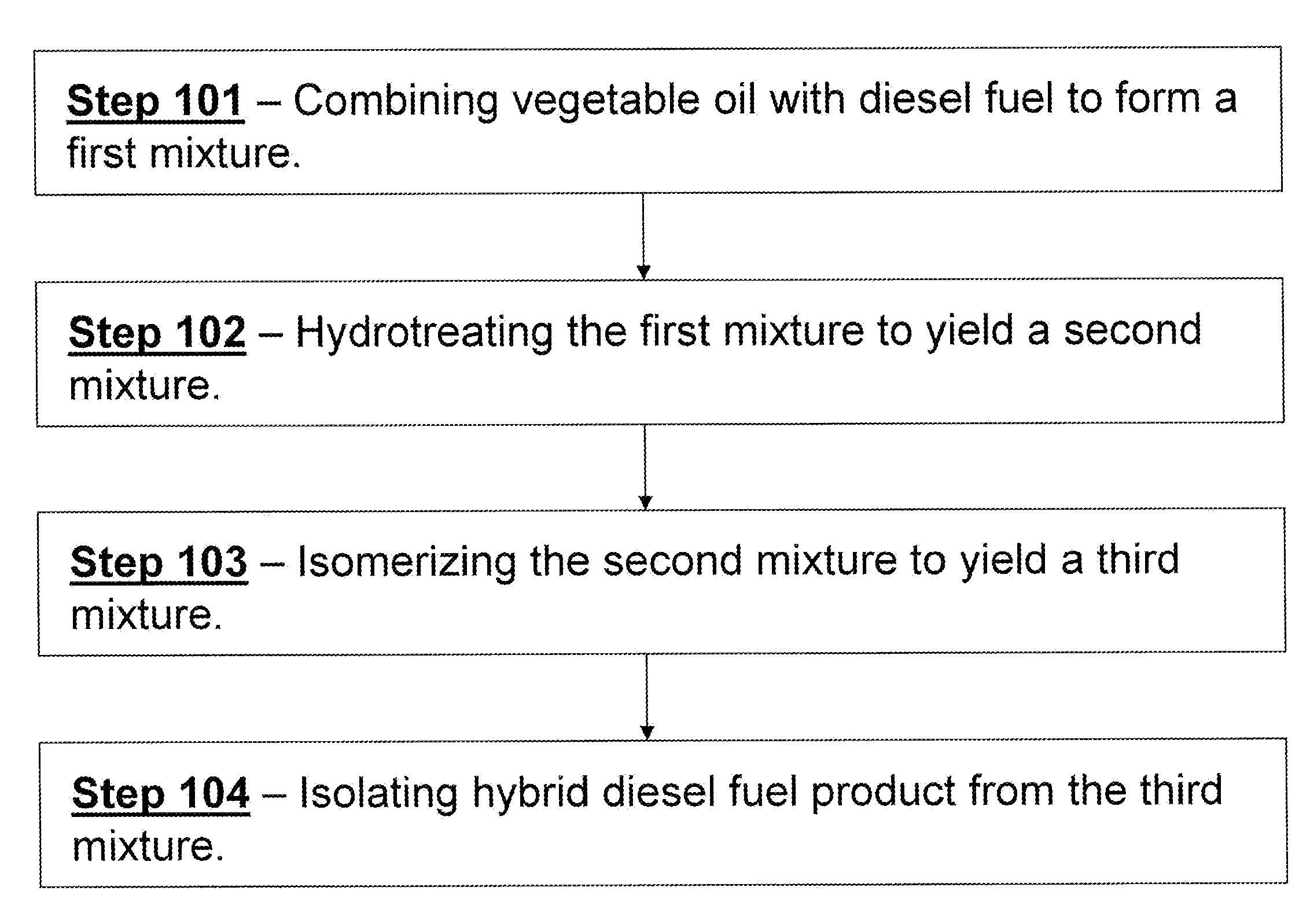

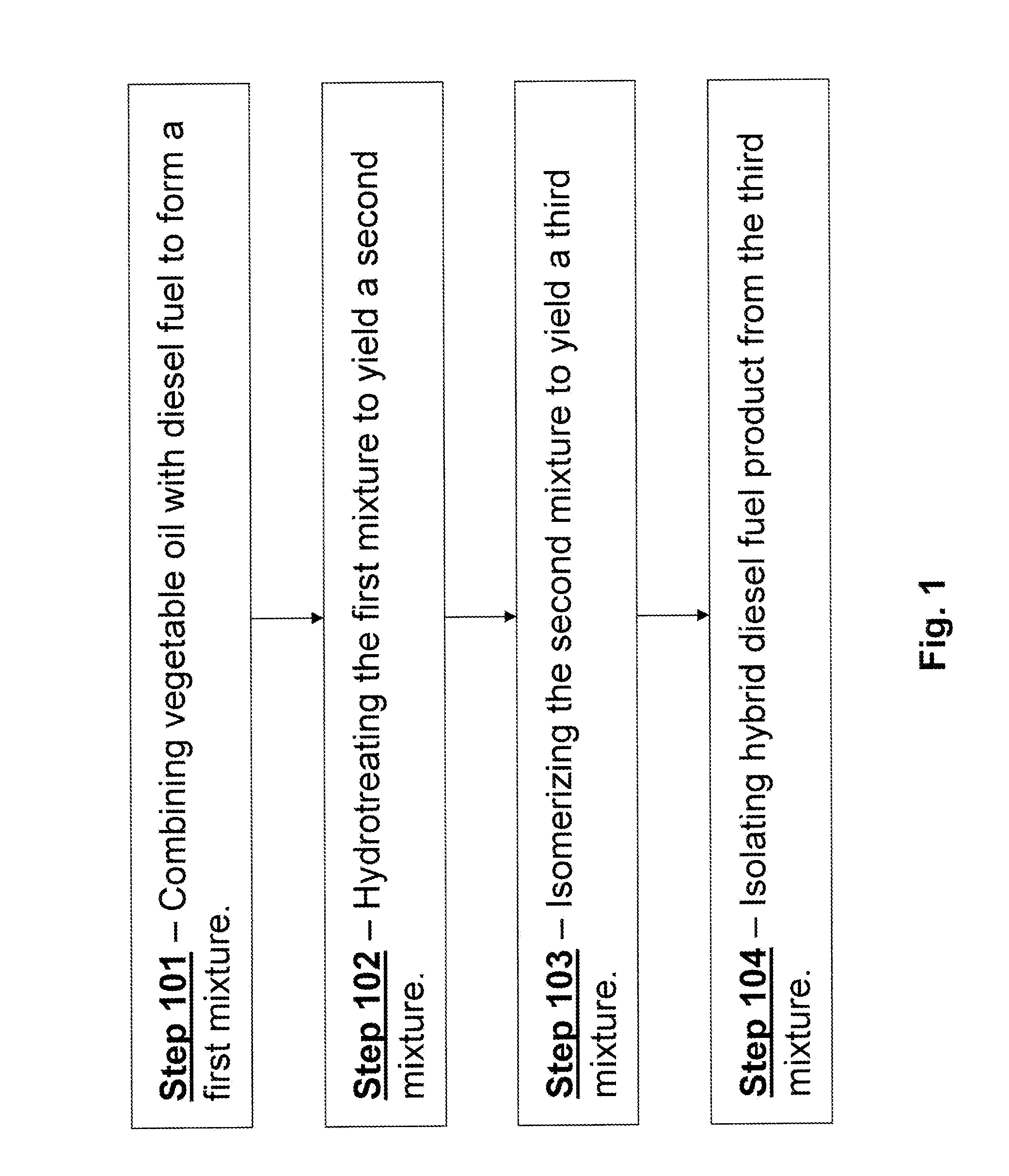

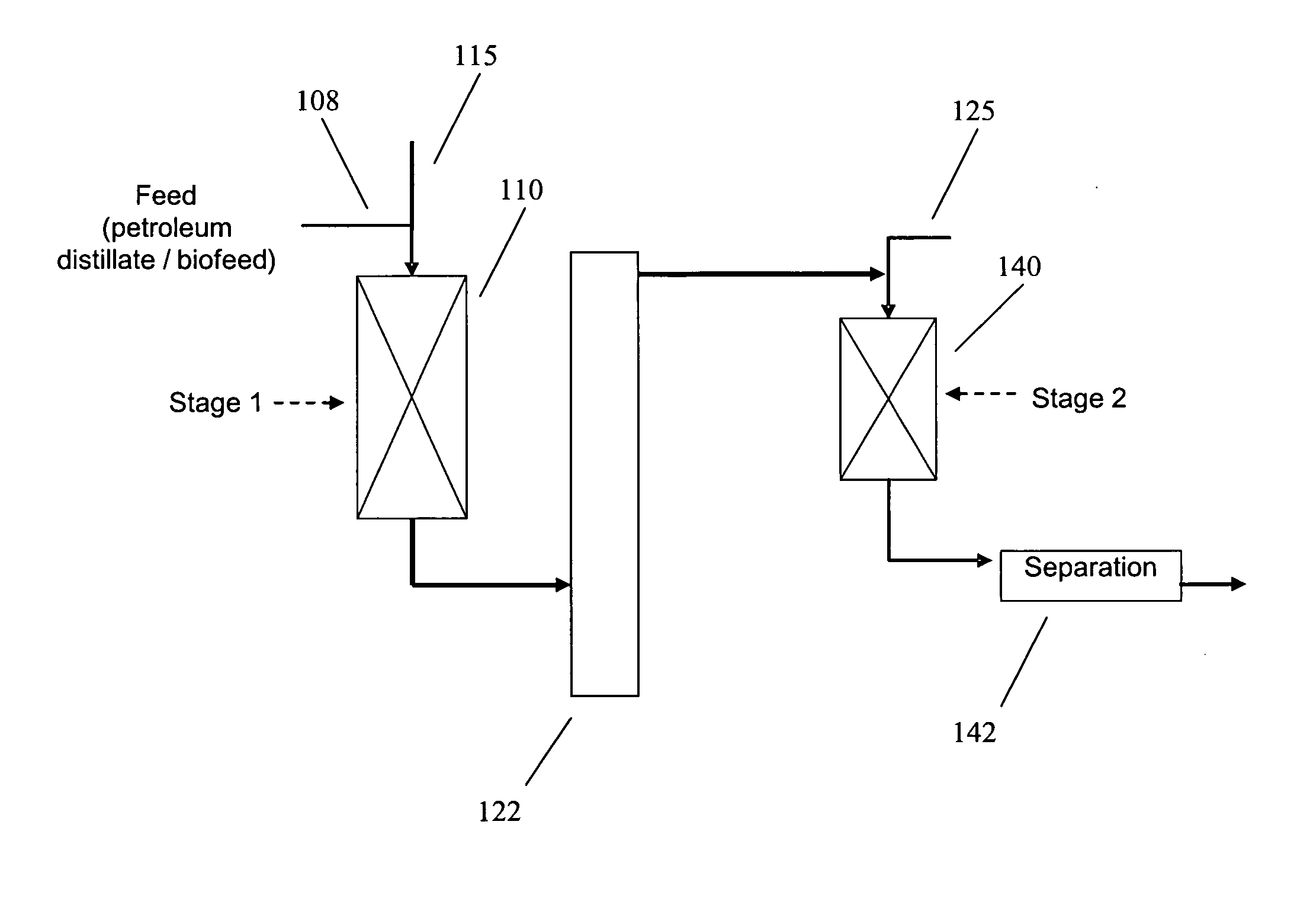

Co-processing diesel fuel with vegetable oil to generate a low cloud point hybrid diesel biofuel

The foregoing describes methods and systems for co-processing vegetable oil and petroleum diesel to yield a hybrid diesel biofuel composition. As previously stated, in some embodiments the present invention is directed to methods / systems by / with which a mixture of vegetable oil and petroleum diesel is co-processed in two stages: the mixture is first hydrotreated to yield a reduced-sulfur hybrid intermediate, and then the hybrid intermediate is processed in an isomerization unit to yield a low cloud point hybrid diesel product that is partially derived from biomass. A notable benefit of at least some such methods / systems is that interstage removal of H2S and NH3 is not required between the stages of hydrotreating and isomerizing, wherein such benefit is afforded by sulfur- and nitrogen-tolerant isomerization catalysts.

Owner:CHEVROU USA INC

Circuits and methods for efficient data transfer in a virus co-processing system

ActiveUS8286246B2Memory architecture accessing/allocationMemory loss protectionGeneral purposeData segment

Various embodiments of the present invention provide circuits and methods for improved virus processing. As one example, such methods may include providing a system memory, a general purpose processor and a virus co-processor. The methods further include receiving a data segment at the general purpose processor, and storing the data segment to the system memory using virtual addresses. The data segment is accessed from the system memory by the virus co-processor using the virtual addresses. The virus co-processor then scans the data segment for viruses and returns a result.

Owner:FORTINET

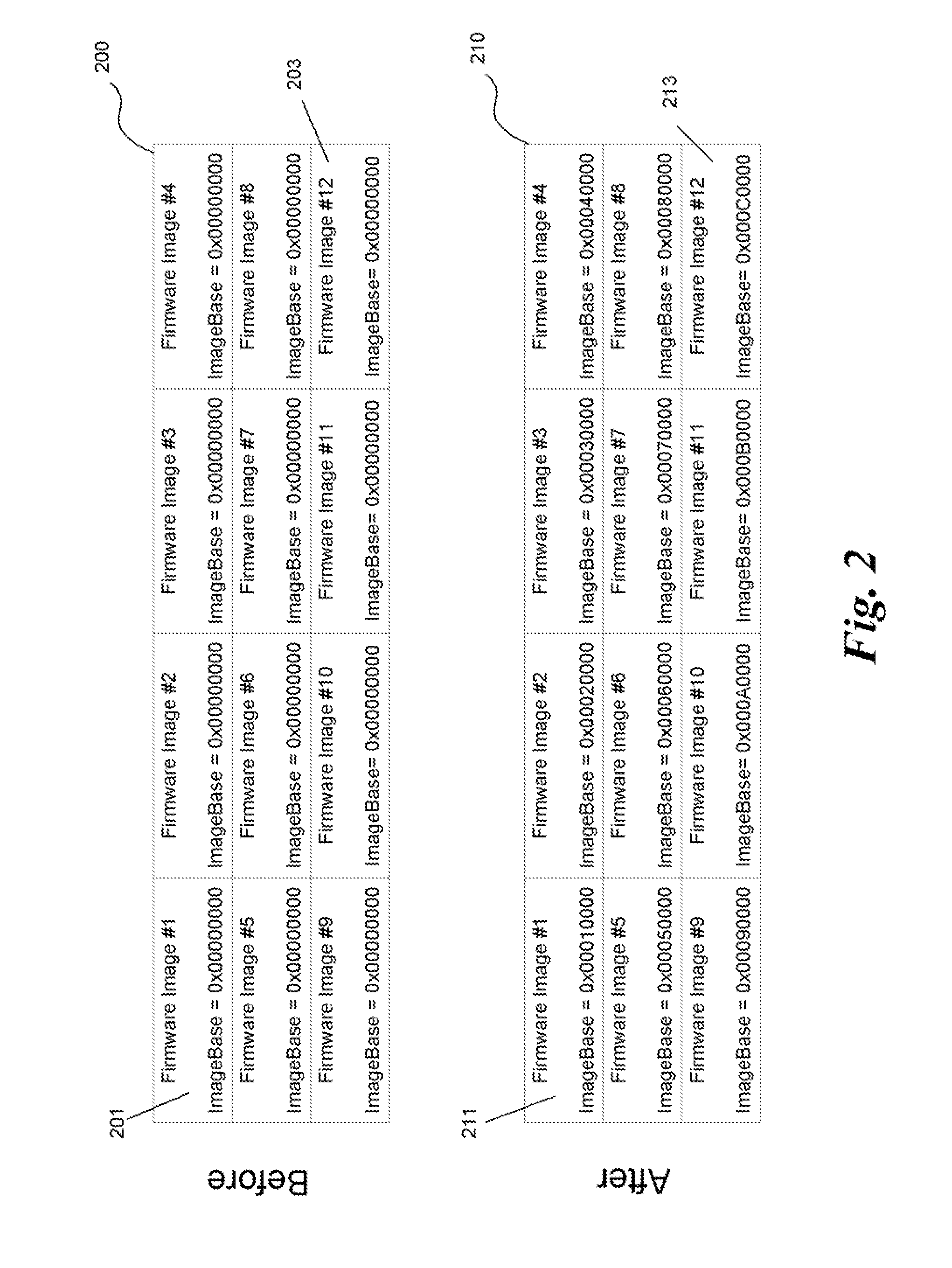

System and method to enable parallelization of early platform initialization

InactiveUS20090172379A1Software engineeringDigital computer detailsOperational systemApplication software

In some embodiments, the invention involves reducing the time required for a platform to boot to its target application / operating-system using parallelization of firmware image content decompression and loading. An embodiment dispatches alternate processing agents as a means to intelligently assist in off-loading some of the initialization tasks so that the main processor may share the burden of boot tasks. In at least one embodiment, it is intended to build firmware images that facilitate parallelization, utilizing co-processing agents that can split these transactions across various processing agents. Other embodiments are described and claimed.

Owner:INTEL CORP

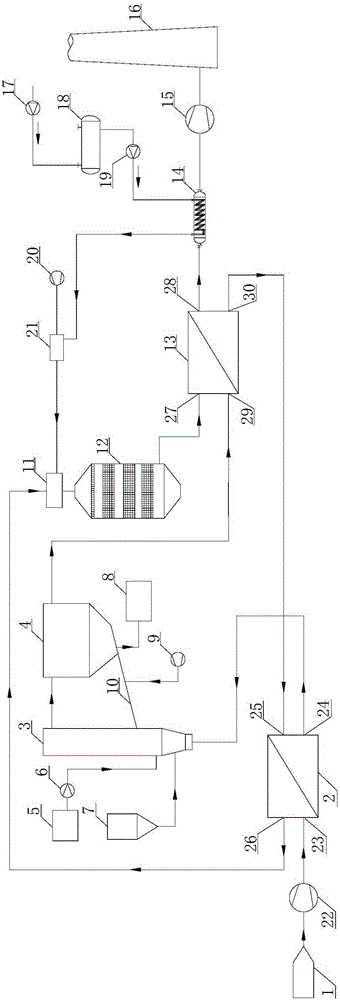

Glass melter flue gas dust removal, desulfurization and denitrification synergetic treatment system, treatment method and application

ActiveCN105169942AAvoid poisoningAvoid cloggingDispersed particle filtrationEngineeringCo-processing

The invention belongs to the technical field of waste gas treatment, and particularly relates to a glass melter flue gas dust removal, desulfurization and denitrification synergetic treatment system, a treatment method and an application. The system comprises an inlet flue, a first flue gas heat exchanger, a desulfurizing tower, a dust remover, an SCR reactor, a second flue gas heat exchanger and an ammonia supply device. The ammonia supply device comprises an ammonium hydroxide storage tank, an ammonia gas evaporator, a mixer and an ammonia spraying grid, all of which are sequentially connected. Compared with an existing glass melter flue gas treatment system, the technical scheme of carrying out desulfuration, dust removal and desulfuration in sequence is adopted, the poisoning effect and blocking of harmful substances in glass melter flue gas on an SCR catalyst are avoided, and the application condition of the SCR low-temperature catalyst can be met. In addition, the SCR low-temperature catalyst is adopted, heat of original flue gas is utilized through two times of heat exchange, the whole system does not need an additional heat source, and operating cost is reduced.

Owner:广州创能电力技术工程有限公司

Biofuel compositions and methods based on co-processing aromatic-rich and aromatic-lean components

InactiveUS20120152801A1Simple processReduce temperature riseEfficient propulsion technologiesWaste based fuelBiofuelOxygenate

Biofuel compositions obtained by the simultaneous hydroprocessing of at least two distinct hydroprocessing feedstocks, either or both of which are derived from biomass, are disclosed. The co-processing of these feedstocks can result in an upgraded product having suitable characteristics, in terms of composition (e.g., quantities of compounds such as aromatic hydrocarbons, present in relatively large amounts) and in terms of quality (e.g., quantities of compounds such as oxygenates, present in relatively small amounts) for use as a hydroprocessed biofuel such as hydroprocessed aviation biofuel.

Owner:UOP LLC

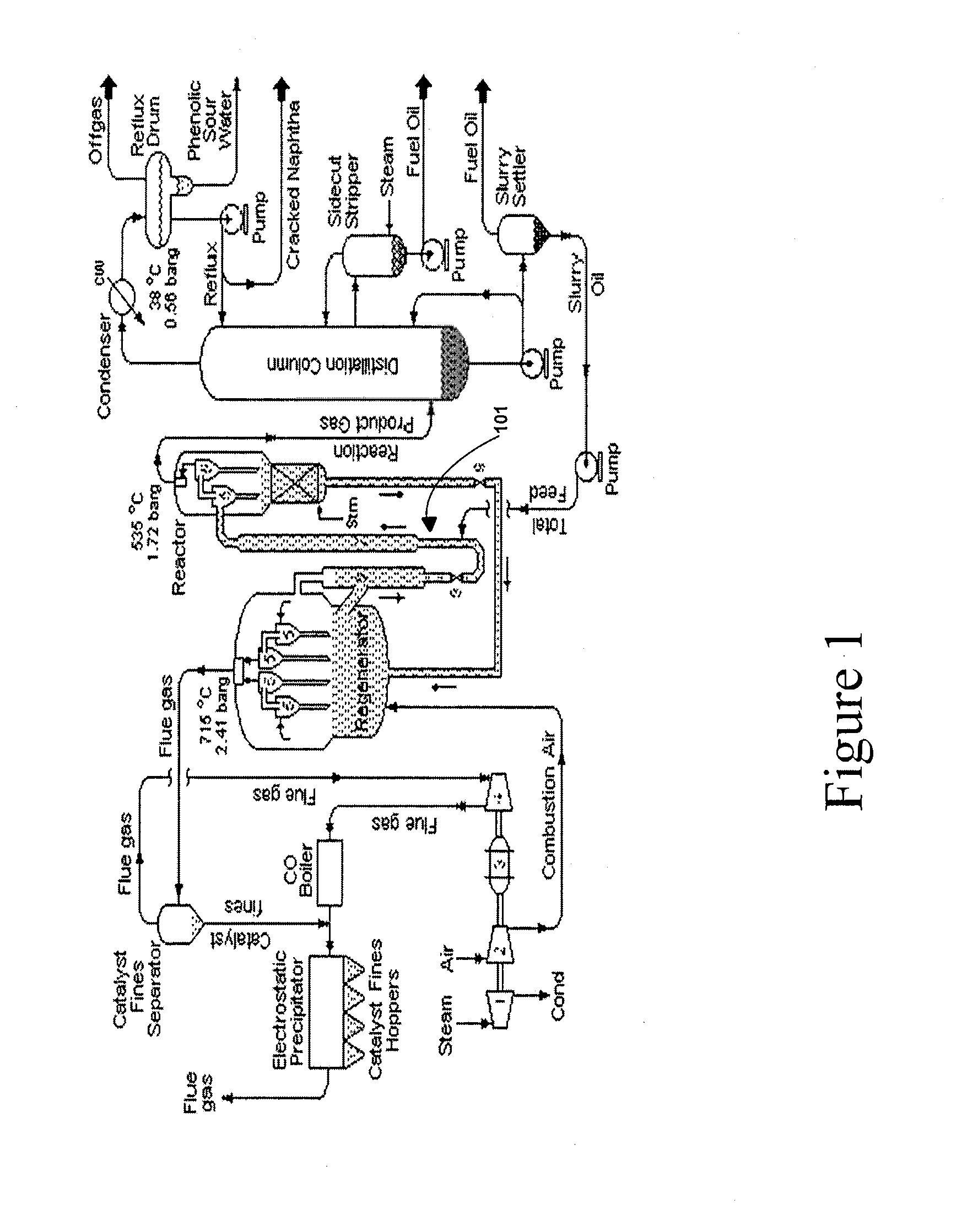

Systems and Methods for Renewable Fuel

The present application generally relates to the introduction of a renewable fuel oil as a feedstock into refinery systems or field upgrading equipment. For example, the present application is directed to methods of introducing a liquid thermally produced from biomass into a petroleum conversion unit; for example, a refinery fluid catalytic cracker (FCC), a coker, a field upgrader system, a hydrocracker, and / or hydrotreating unit; for co-processing with petroleum fractions, petroleum fraction reactants, and / or petroleum fraction feedstocks and the products, e.g., fuels, and uses and value of the products resulting therefrom.

Owner:ENSYN RENEWABLES

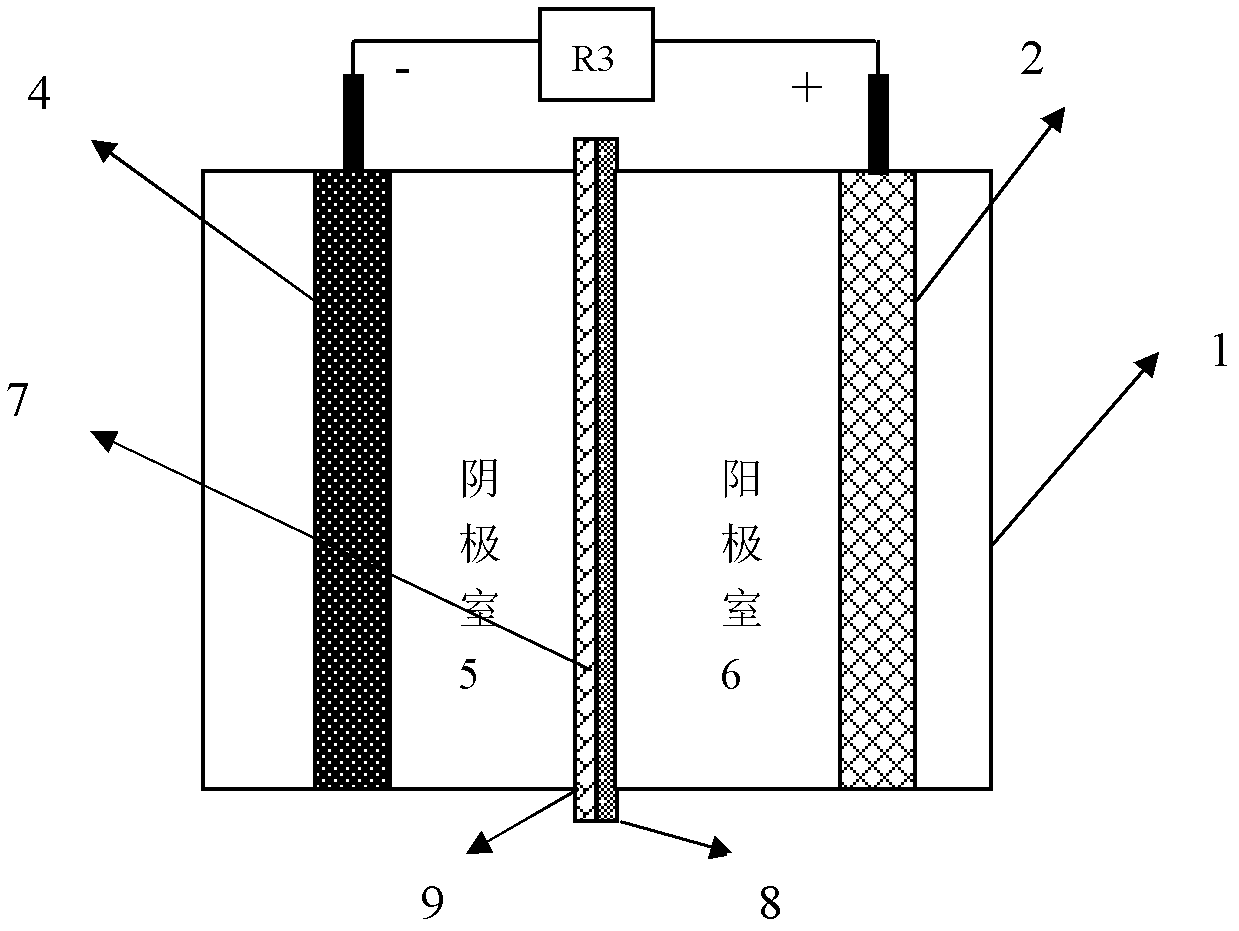

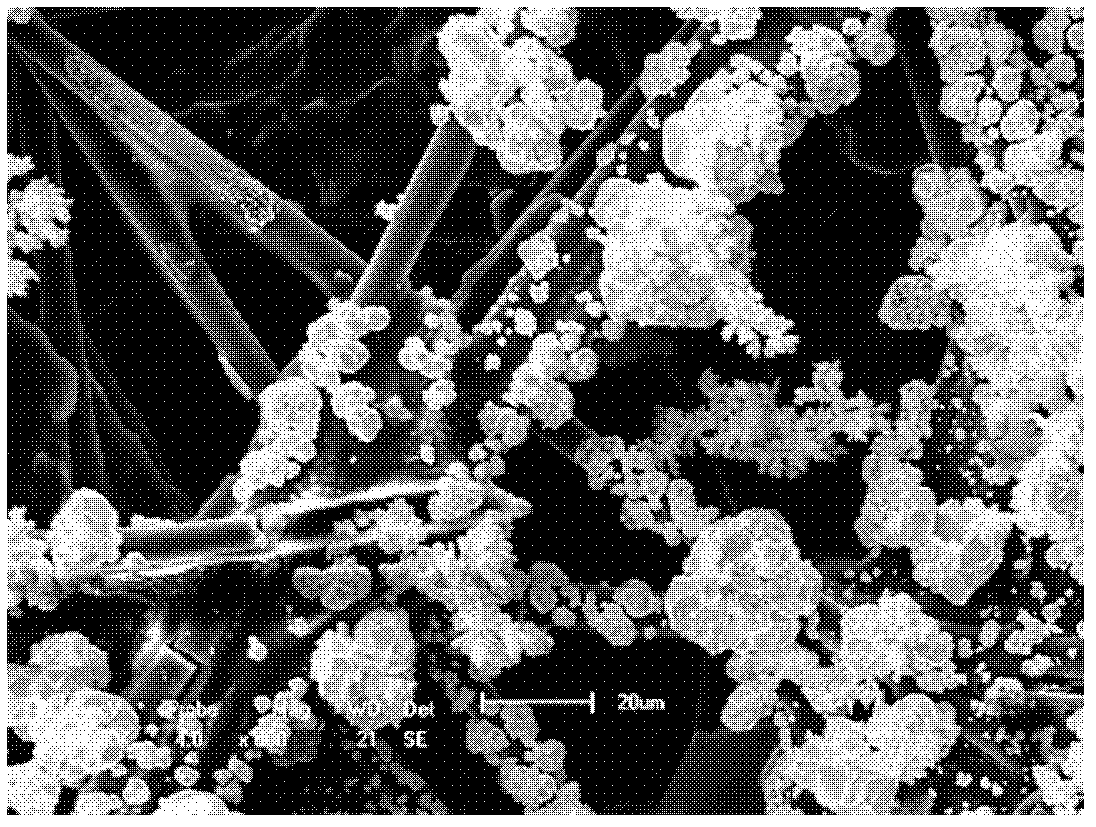

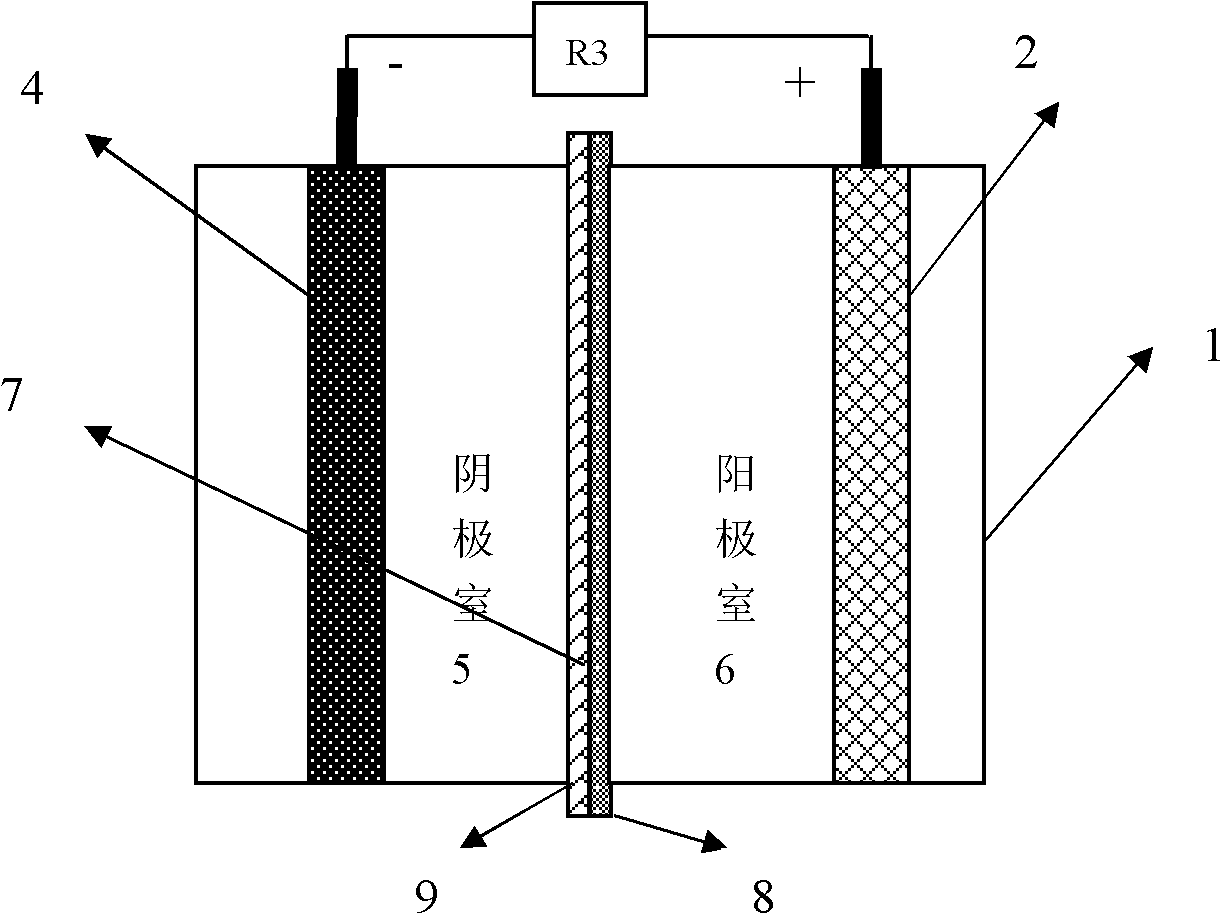

Device for coprocessing heavy metal waste water and organic waste water and generating electric power

InactiveCN102324542AOxidizingBiochemical fuel cellsBiological water/sewage treatmentElectric power systemCo-processing

The invention provides a device for coprocessing heavy metal waste water and organic waste water and generating electric power. The device comprises an electrolytic cell which is separated into an anode chamber and a cathode chamber by a bipolar membrane, wherein an anode and a cathode are respectively arranged in the anode chamber and the cathode chamber, the anode and the cathode are connected with a resistor through a lead, the anode is composed of electric power generating microbes and an anode substrate, the cathode is made from metallic titanium with electrochemical inertia or carbon materials, the anode chamber contains the waste water containing organic pollutants, and the cathode chamber contains the heavy metal waste water. According to the invention, the organic pollutants are oxidized into carbon dioxide by the electric power generating microbes attached to the anode in the same electrochemical cell, and electrons and protons can be simultaneously released, the protons can combine with hydroxyls dissociated from the bipolar membrane to generate water, while the electrons can be transmitted to the cathode by an external circuit, the electrons can reduce the heavy metal in the heavy metal waste water to metal elementary substances and the metal elementary substances deposit on the surface of the cathode, and the protons dissociated from the bipolar membrane can combine with negative ions to generate acid or can be neutralized to water in the cathode chamber.

Owner:XI AN JIAOTONG UNIV

Orally Disintegrating Tablets

InactiveUS20090208576A1High mechanical strengthNervous disorderAntipyreticCalcium silicateOrally disintegrating tablet

The present invention describes a directly compressible composite prepared by co-processing a water-soluble excipient and calcium silicate. The present invention further describes the incorporation of the co-processed composite into a tablet formulation. The orally disintegrating tablets are of optimal mechanical strength and disintegrate within 60 seconds in the oral cavity.

Owner:RUBICON RES PTY LTD

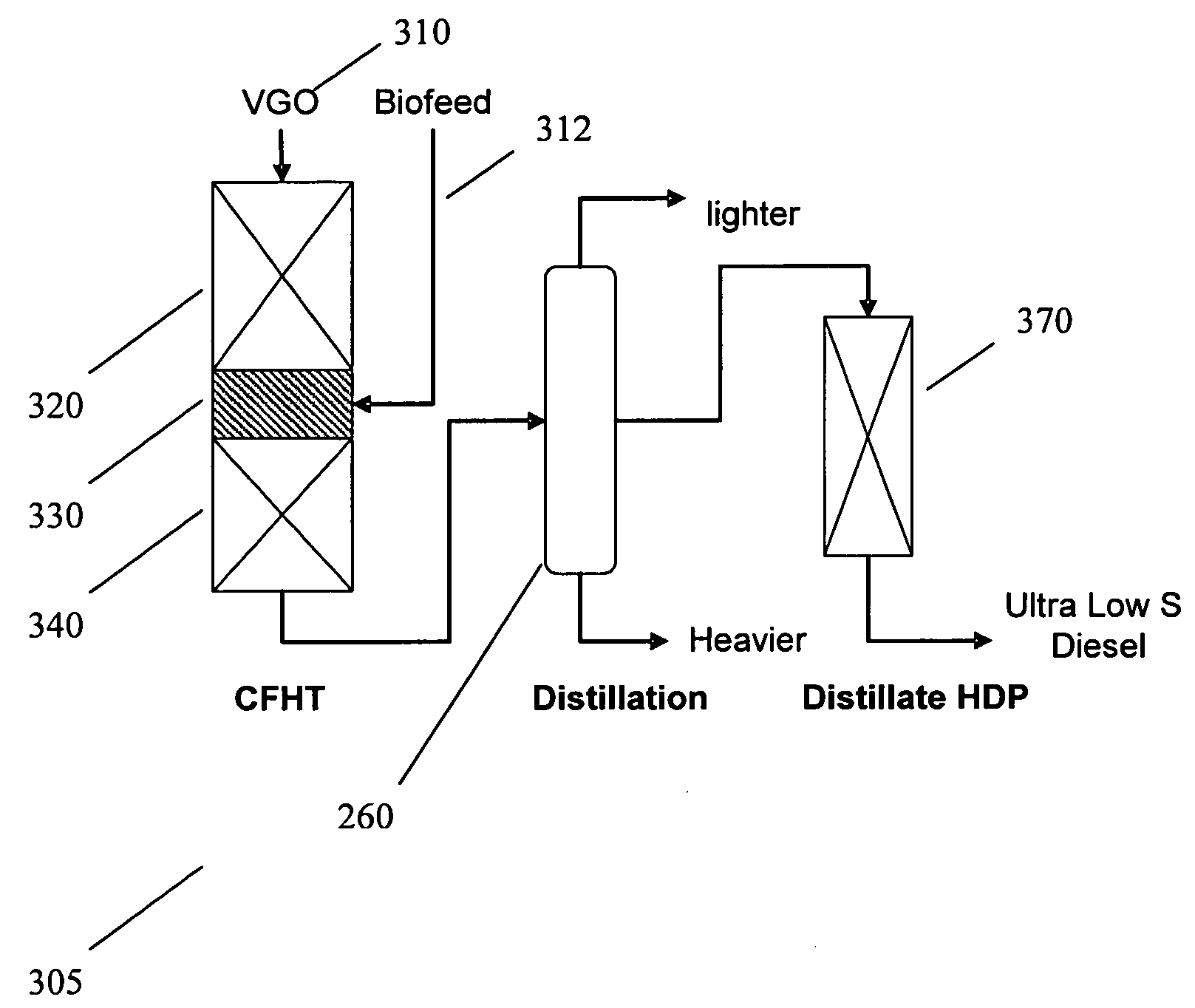

Co-processing of diesel biofeed and heavy oil

ActiveUS20100176026A1Improve cold flowTreatment with plural serial cracking stages onlyCoke ovensFuel oilCo-processing

Processes are provided for producing a diesel fuel product having a sulfur content of 10 ppm by weight or less from feed sources that include up to 50% by weight of a biocomponent feedstock. The biocomponent feedstock is co-processed with a heavy oil feed in a severe hydrotreating stage. The product from the severe hydrotreatment stage is fractionated to separate out a diesel boiling range fraction, which is then separately hydrotreated.

Owner:EXXON RES & ENG CO

Method of converting feeds from renewable sources in co-processing with a petroleum feed using a catalyst based on nickel and molybdenum

InactiveUS20120216450A1Eliminate the effects ofImprove low temperature performanceLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionKeroseneSulfur

The invention relates to a method of hydrotreatment in co-processing of petroleum feeds, in a mixture with at least one feed obtained from renewable sources, for producing fuel bases (kerosene and / or gas oil) having a sulphur content below 10 ppm, said method comprising the following stages:a) a first hydrotreatment stage in which said feed passes through at least one first fixed-bed catalytic zone comprising at least one bulk or supported catalyst comprising an active phase constituted by at least one group VIB element and at least one group VIII element, said elements being in the form of sulphide and the atomic ratio of the group VIII metal (or metals) to group VIB metal (or metals) being strictly greater than 0 and less than 0.095,b) a second hydrotreatment stage into which the effluent from the first hydrotreatment stage is sent directly, and in which said effluent passes through at least one second fixed-bed catalytic zone comprising at least one hydrotreatment catalyst.

Owner:INST FR DU PETROLE

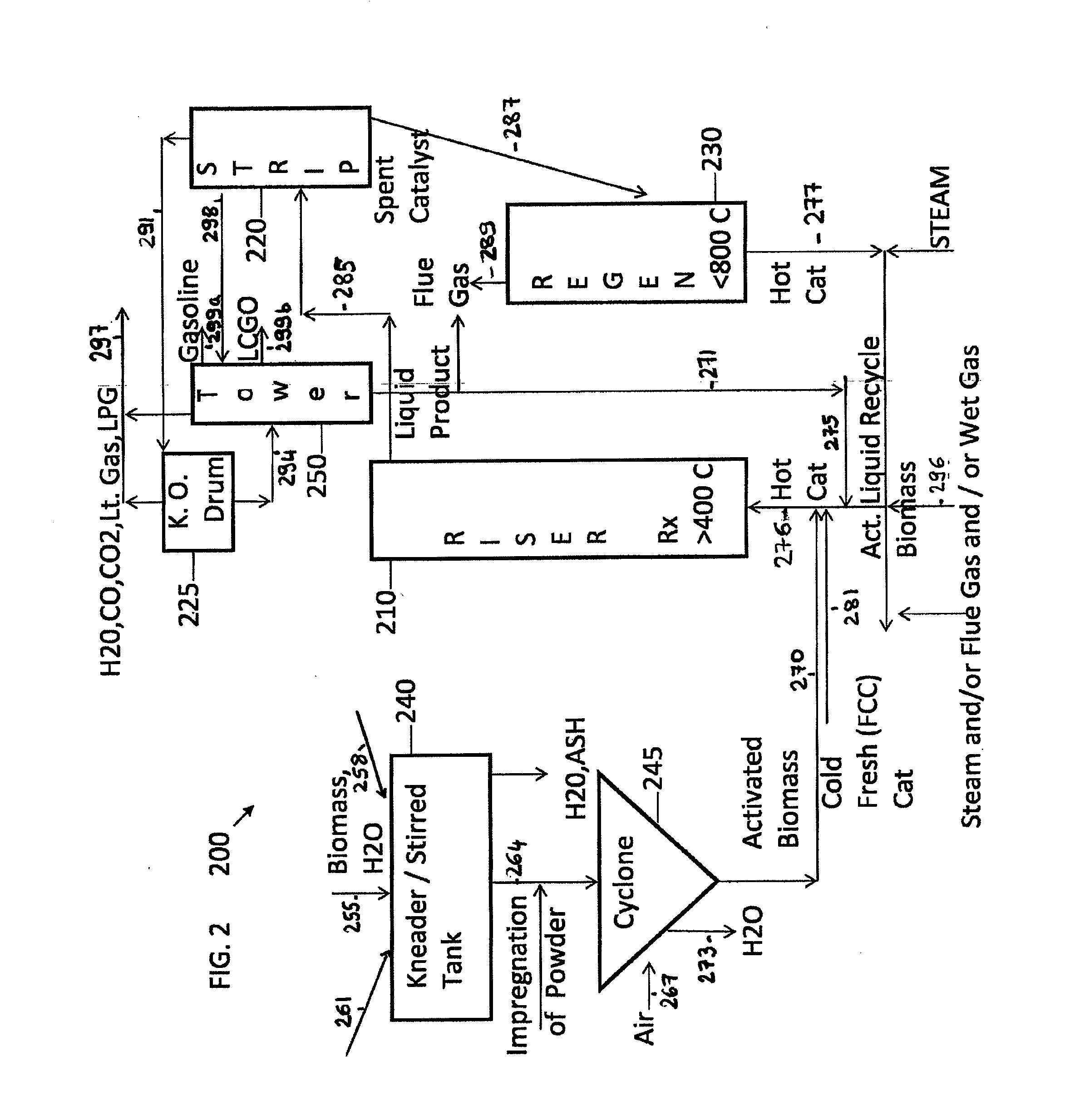

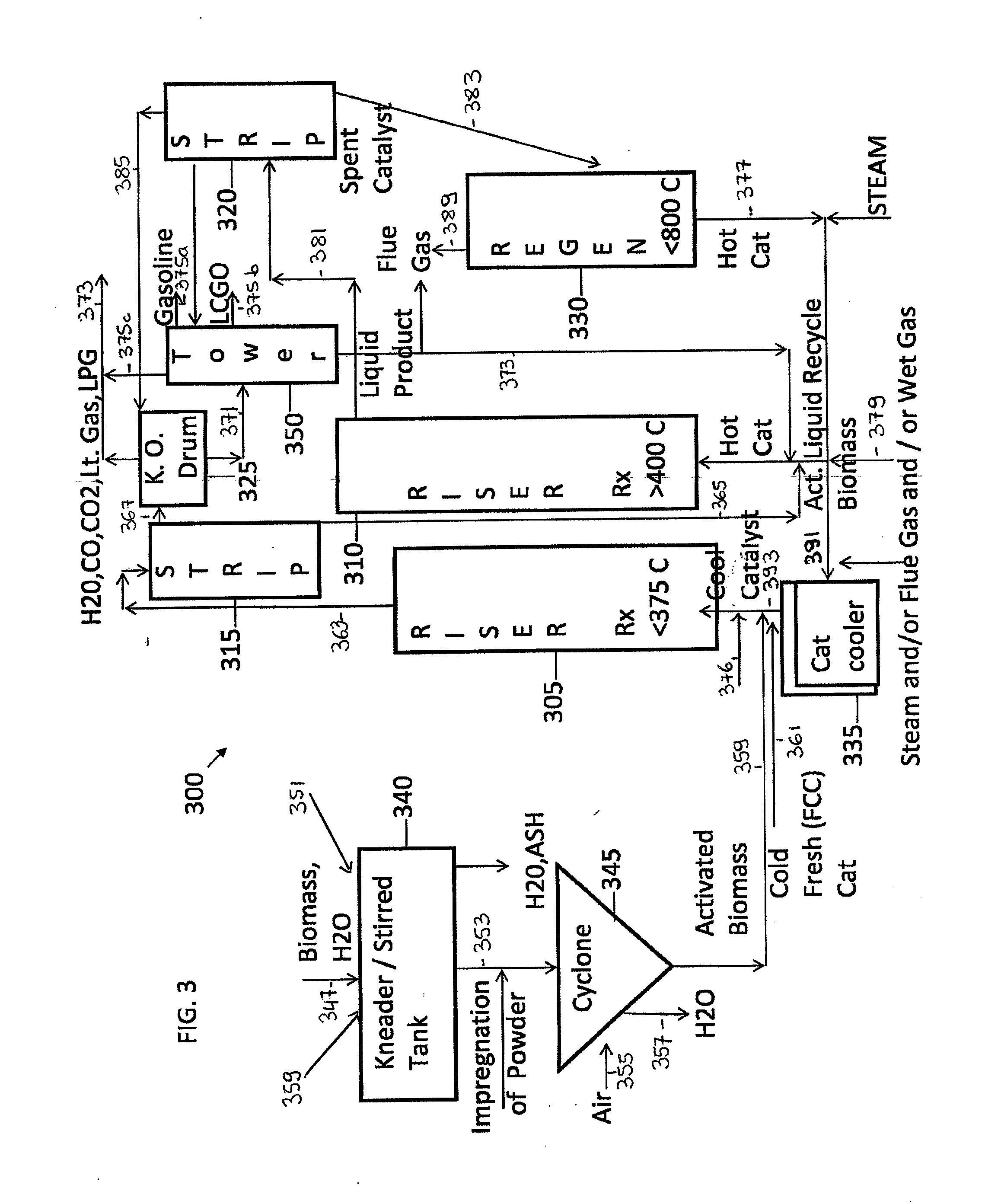

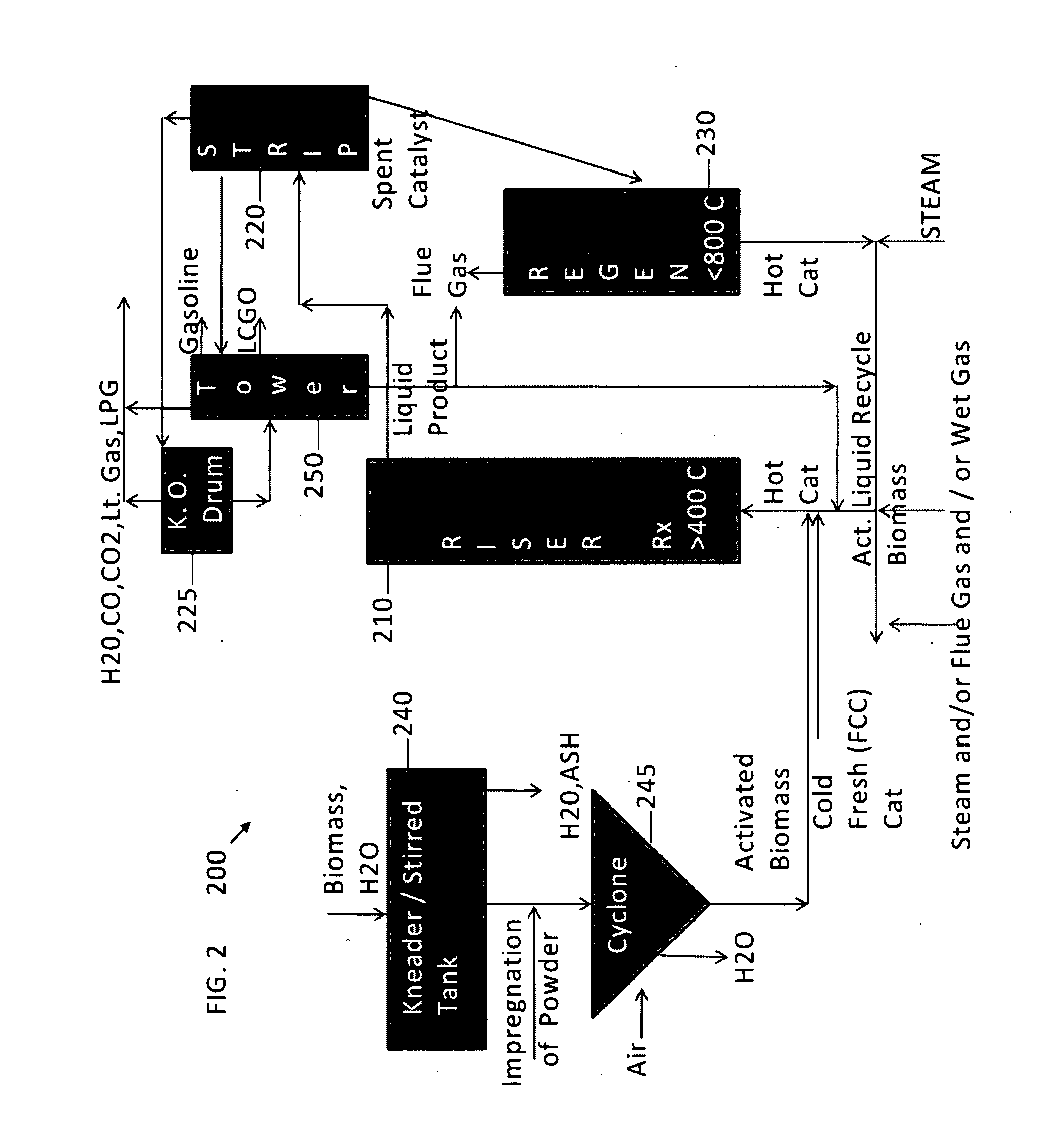

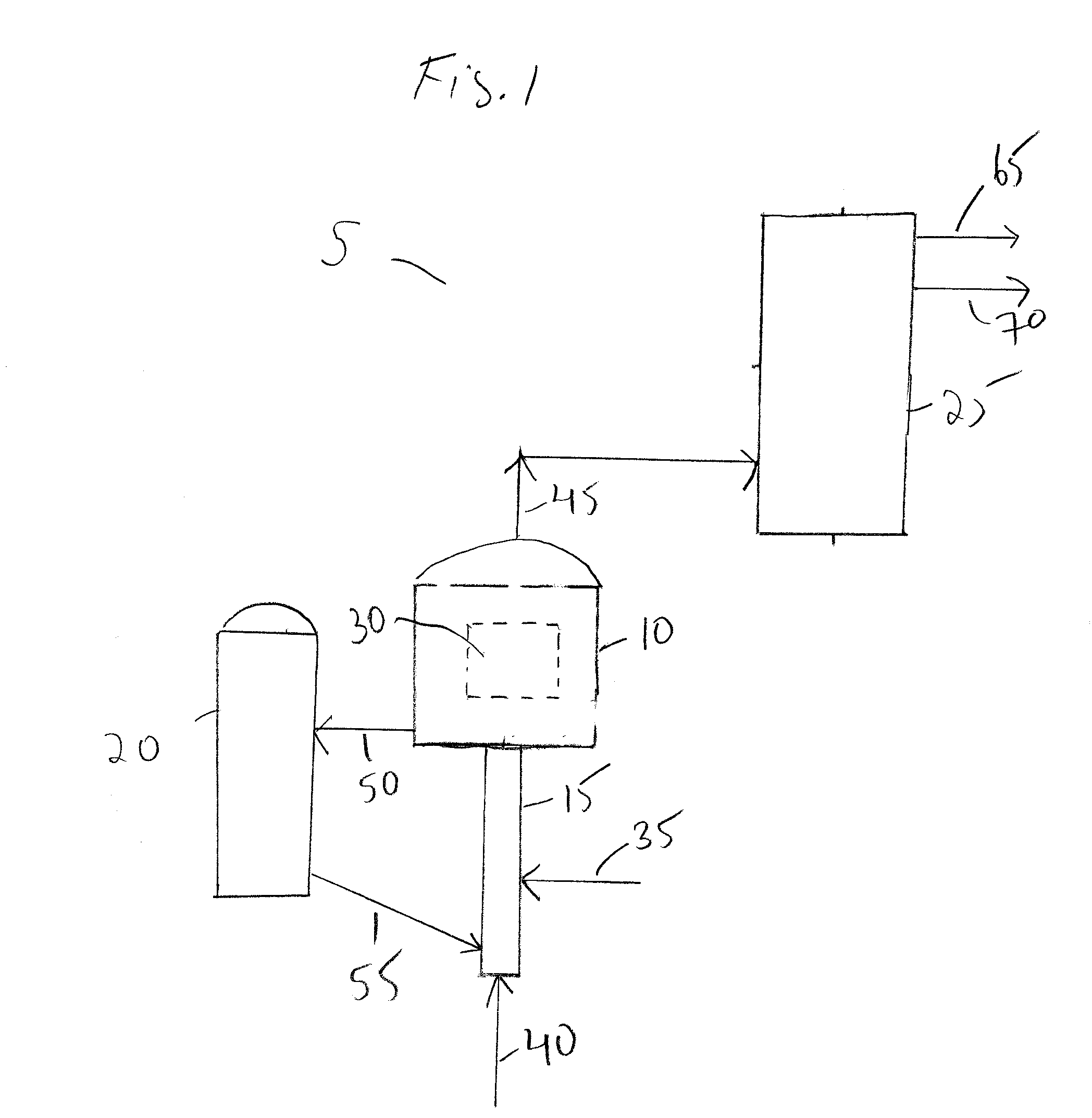

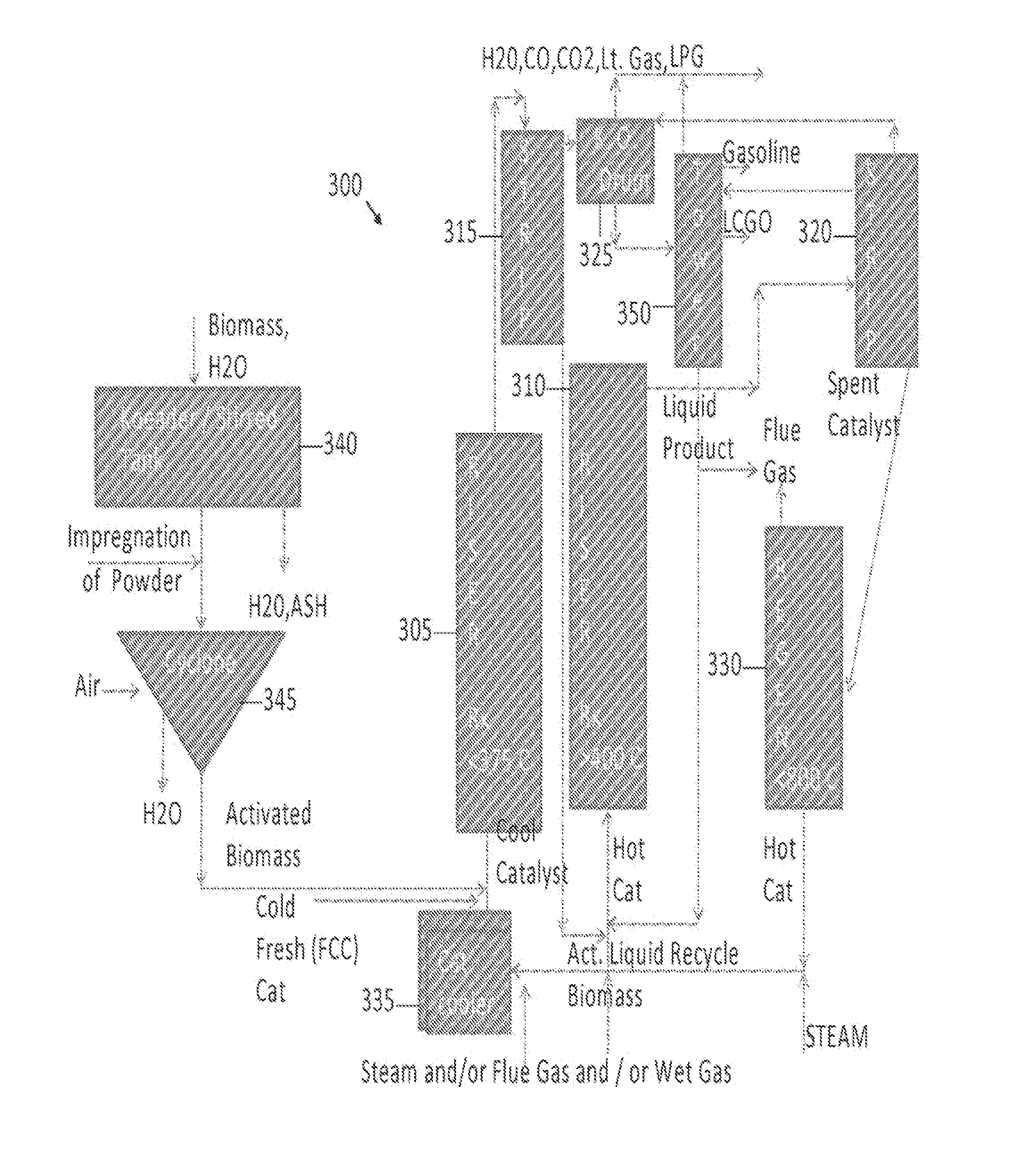

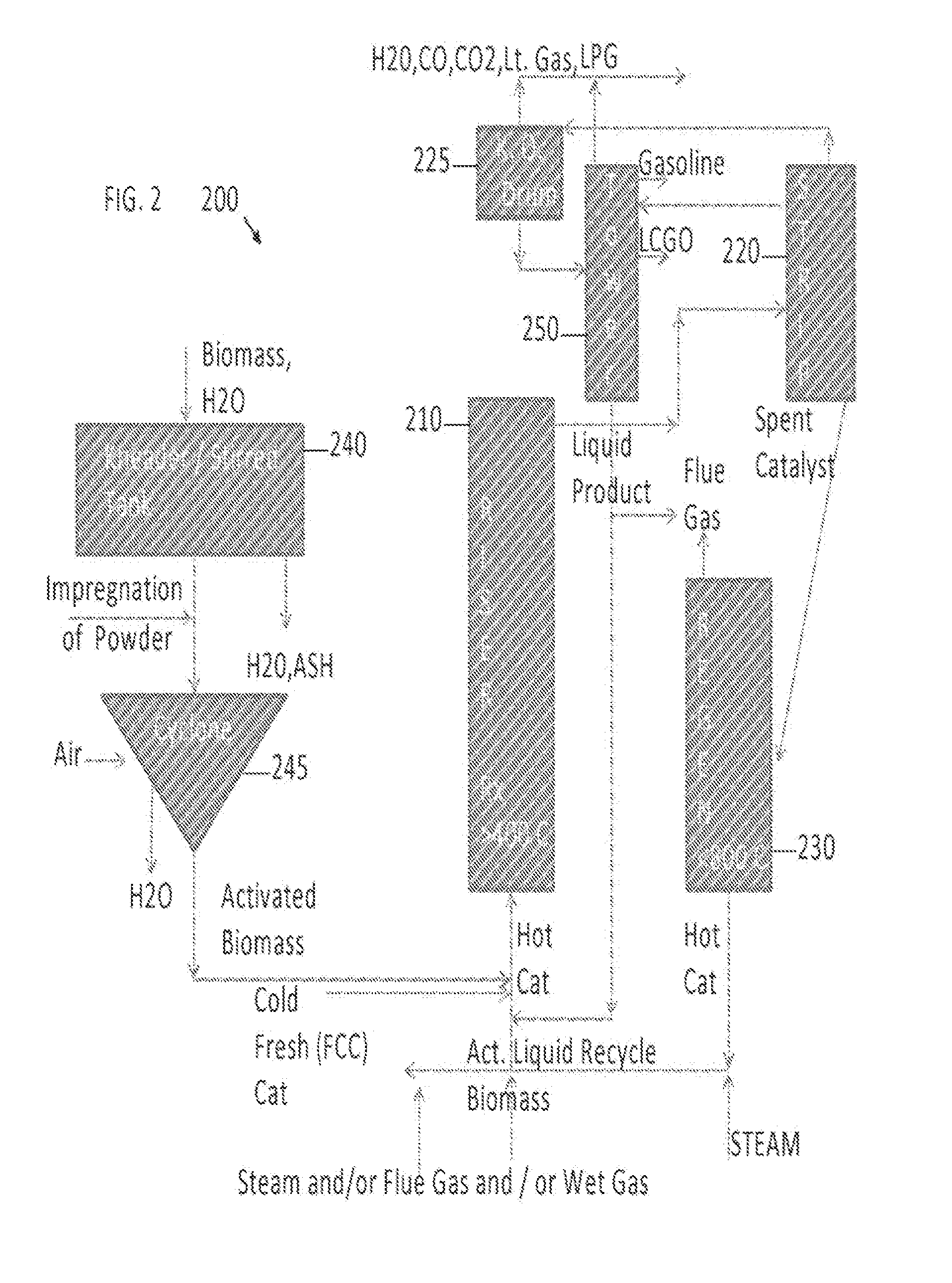

Co-processing solid biomass in a conventional petroleum refining process unit

ActiveUS20120022307A1Reduce degradationReduce energy costsCatalytic crackingOther chemical processesCo-processingPetroleum

Preparing solid biomass particles for catalytic conversion includes agitating solid biomass particles and providing a biomass-catalyst mixture to a conventional petroleum refinery process unit. The biomass-catalyst mixture includes the solid biomass particles and a catalyst. Agitating solid biomass particles includes flowing a gas to provide a velocity to at least a portion of the solid biomass particles sufficient to reduce their sizes. Co-processing a biomass feedstock and a conventional petroleum feedstock includes liquefying at least a portion of a biomass-catalyst mixture and co-processing at least a portion of the liquefied biomass feedstock and a conventional petroleum feedstock in a conventional petroleum refinery process unit. The biomass feedstock includes a plurality of solid biomass particles and a catalyst, which is liquefied to produce a liquefied biomass feedstock.

Owner:MARD INC

Kitchen waste collaborative processing method

ActiveCN102950137AMaximize utilizationAchieve recyclingSolid waste disposalPlant collectionPower station

The invention discloses a kitchen waste collaborative processing method mainly comprising the steps of pretreatment, regulation pulping, anaerobic fermentation, biogas utilization and biogas residue processing. With the kitchen waste collaborative processing method provided by the invention, favorable conditions in a waste incineration power plant are sufficiently utilized. Waste incineration power plant waste hot steam is adopted as a heat source for high-temperature fermentation, such that energy consumption and processing cost are reduced. Sundries produced in the pretreatment step and biogas residue produced in the biogas residue processing step are subjected to an incineration treatment in the waste incineration power plant, such that waste is effectively utilized, and investment cost is reduced. In addition, through purification, biogas is prepared into CNG vehicle fuel which is provided for waste incineration power plant collection and transportation vehicles, such that biogas resource utilization efficiency is improved, circulation links are reduced, and fossil energy utilization is reduced. The kitchen waste collaborative processing method provided by the invention is energy-saving and environment-friendly. The method has high resource utilization rate, low energy consumption, and low processing cost.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +2

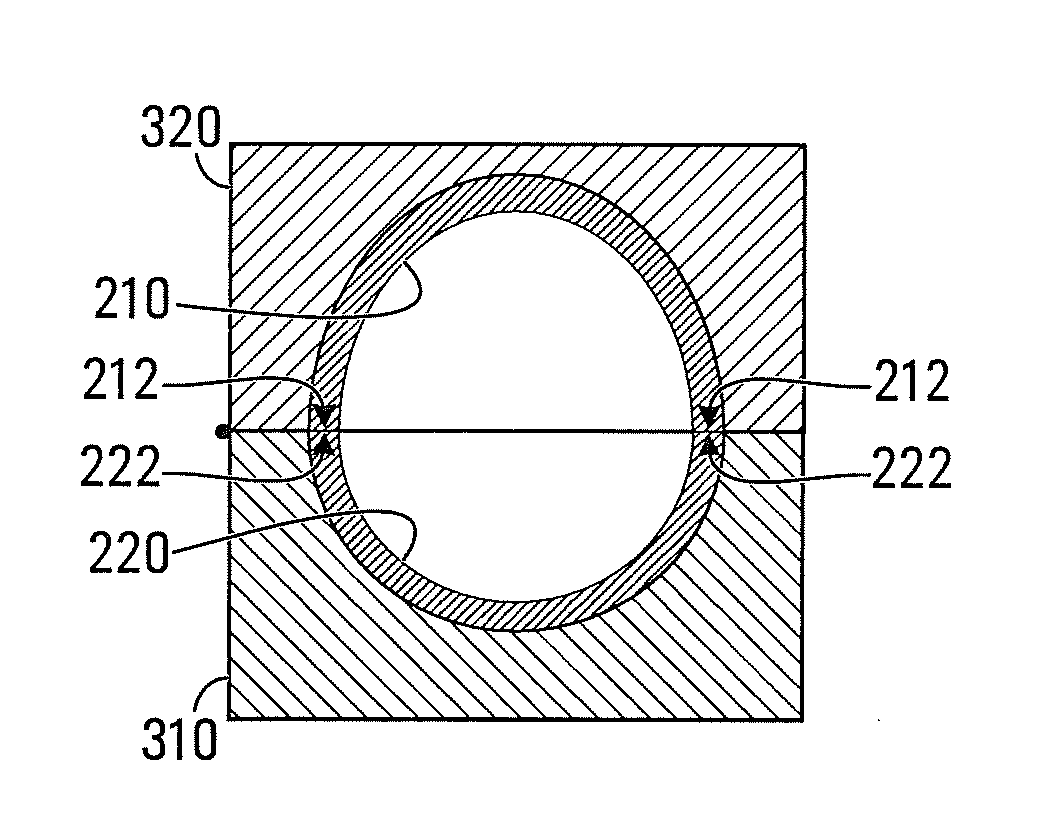

Method for co-processing components in a metal injection molding process, and components made via the same

A method comprising molding a first component from a first feedstock comprising a first material powder and a first binder, molding a second component from a second feedstock comprising a second material powder and a second binder, placing the first component and the second component in physical communication with each other in order to form an assembled component, removing the first binder and the second binder from the assembled component and performing a sintering operation on the assembled component so as to bond the first component and the second component together.

Owner:HOWMEDICA OSTEONICS CORP

Programmable graphics processing engine

InactiveUS20060050077A1Memory adressing/allocation/relocationMultiple digital computer combinationsMemory addressGraphics

A fully programmable graphics processing engine is provided. The graphics processing engine includes three independent, programmable processors that run independent sets of instructions from independent instruction storage facilities. Graphics processing tasks may be distributed among the serially pipelined processors to allow for load balancing and parallel processing. The graphics processing engine may be a graphics co-processing core within a larger, general purpose computing system. Register files and storage units may be addressable by the system host processor. Each processor accepts incoming data for state or context updates. Each processor may execute a specific graphics processing function by executing a set of instructions when a predetermined memory address is accessed.

Owner:GOOGLE LLC

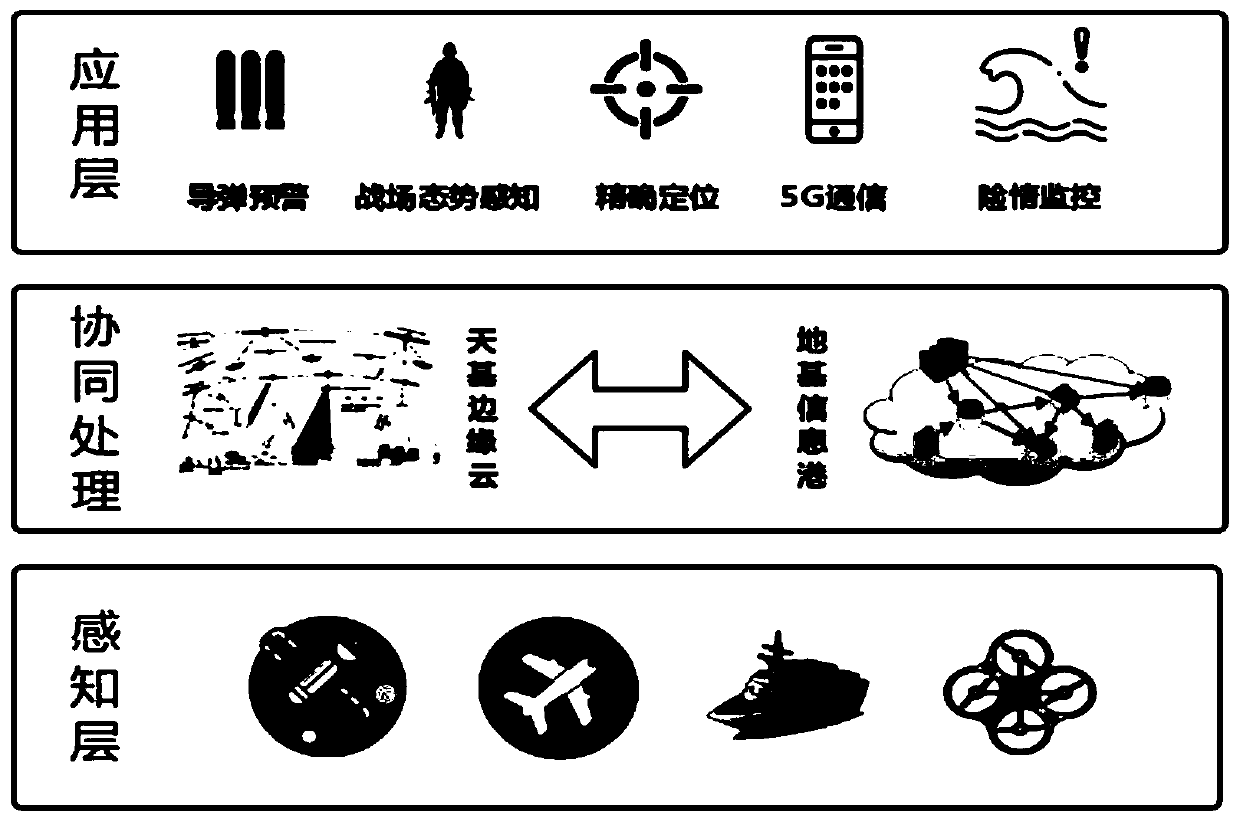

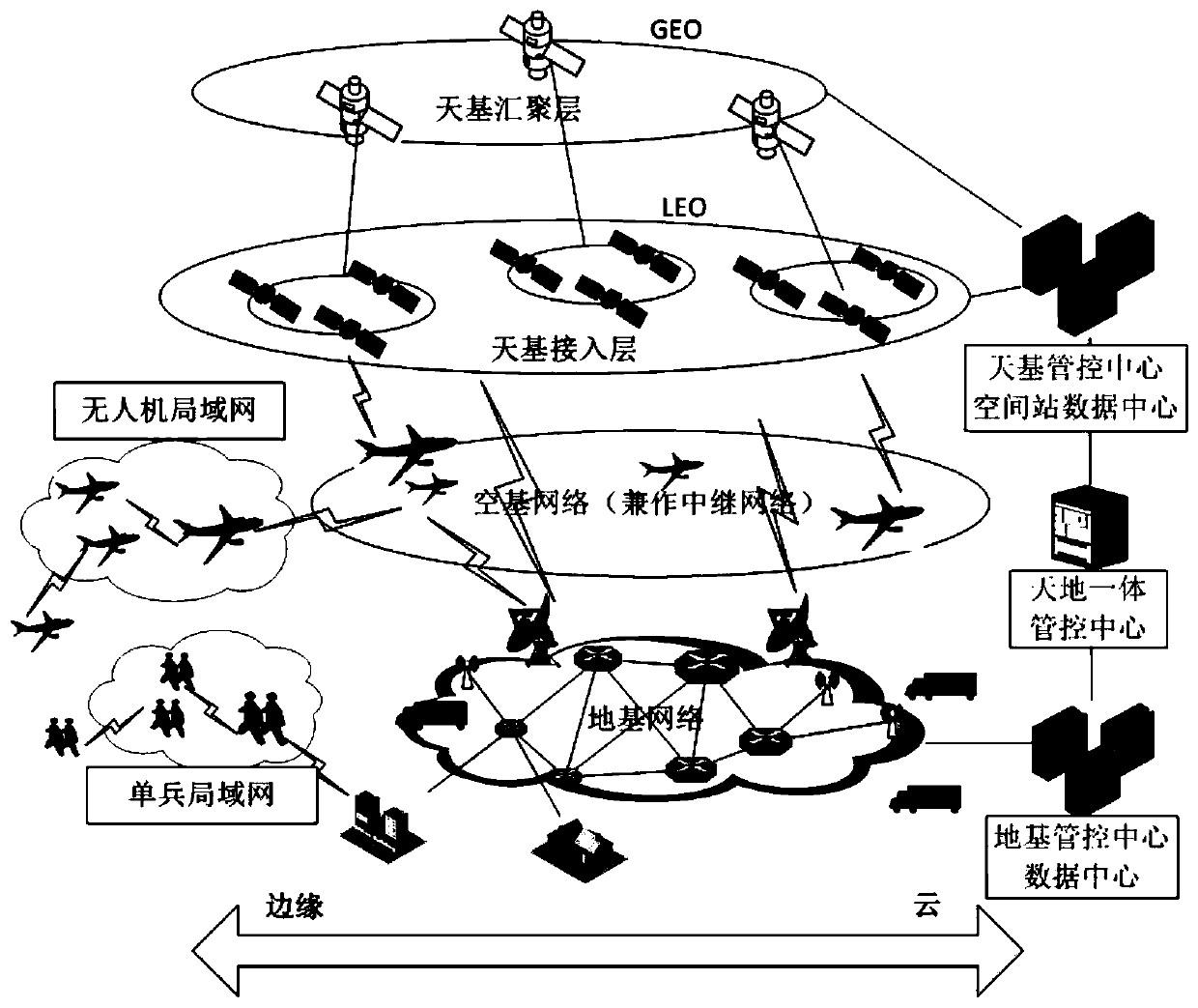

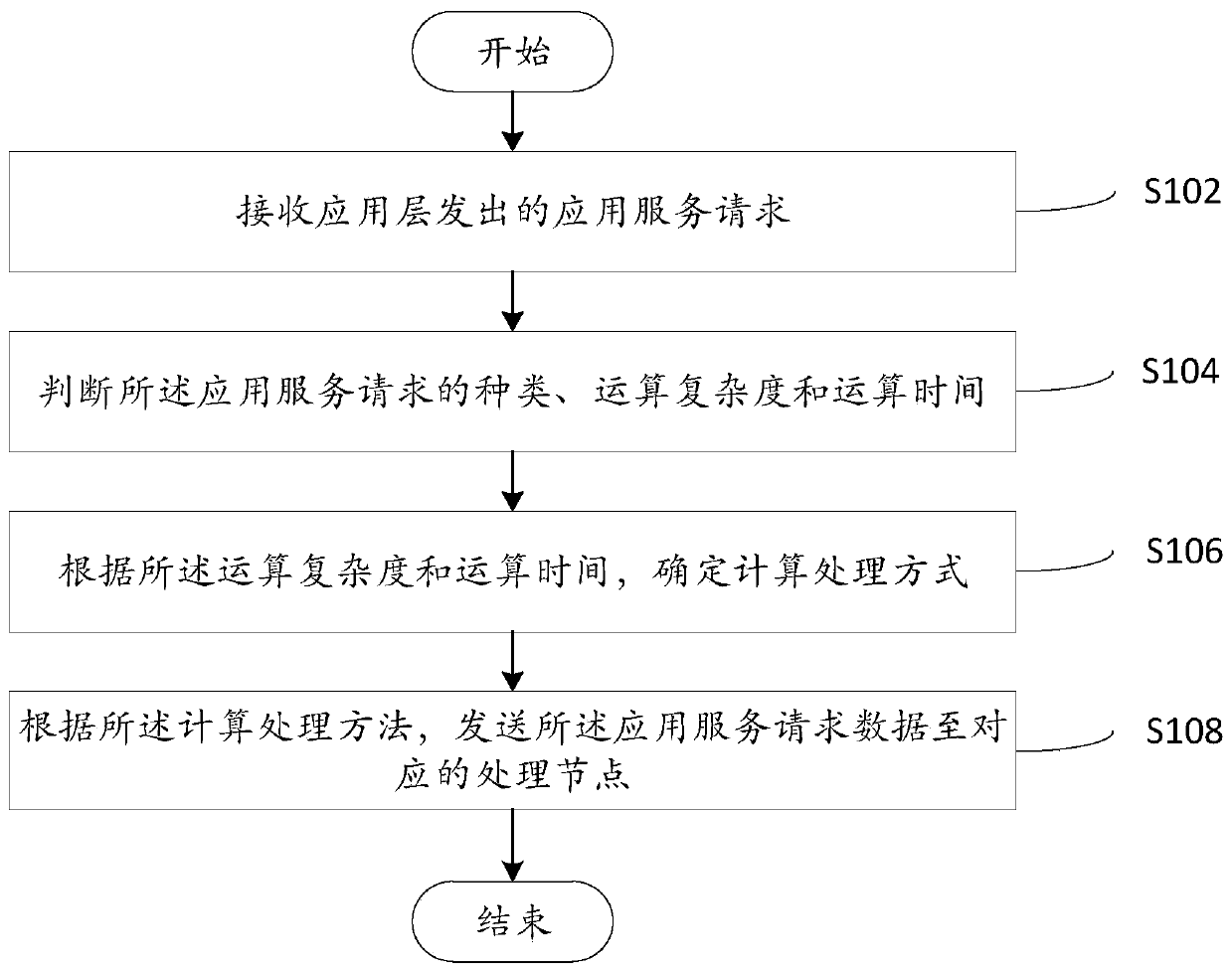

Fog computing-based spatial information network architecture and method, and readable storage medium

The invention discloses a fog computing-based spatial information network architecture, a fog computing-based spatial information network architecture method and a readable storage medium, and the architecture comprises a sensing layer which is used for collecting basic information of one or more applications in remote sensing, weather and positioning and sending the collected information to a cooperative processing layer; the cooperative processing layer used for co-processing the information acquired by the sensing layer; and an application service layer used for receiving the information processed by the sensing layer and the cooperative processing layer and providing comprehensive application services for space-based, space-based, sea-based and land-based users. According to the invention, distributed storage and distributed calculation can be provided, the network bandwidth can be saved, the CDN is optimized, the network bandwidth is saved, and the interaction rate is improved. Inaddition, the computing mode can be selected according to the content of the application service, the application service can be processed more quickly, and computing resources can be utilized to themaximum extent.

Owner:TECH & ENG CENT FOR SPACE UTILIZATION CHINESE ACAD OF SCI

Preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oils and oxygenated chemical

ActiveCN102206502AFacilitate catalytic conversionReduce energy consumptionHydrocarbon purification/separationLiquid hydrocarbon mixture productionOil and greaseReaction temperature

A preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oil and an oxygenated chemical is characterized by: introducing raw materials such as the plant oil and the oxygenated chemical into a catalytic cracking reactor; carrying out a catalytic conversion reaction through contacting with a catalytic cracking catalyst in the reactor with an operating temperature of 500 to 670 DEG C, an operating pressure of 0.1 to 5.0 MPa, a weight hourly space velocity of 0.1 to 100 h<-1> and an agent-oil ratio of 1 to 50; separating a reaction oil gas from the spent catalyst when the reaction is finished; recycling the separated spent catalyst after stripping, burning and regenerating; obtaining fractions such as a liquefied gas, gasoline and the like through fractionating the reaction oil gas and obtaining the low-carbon olefins through a manner that the liquefied gas enters a gas separating system; and obtaining the aromatic hydrocarbon product through carrying out a further aromatic extraction on the gasoline fraction. The method provided by the present invention allows the reaction temperature to be controlled through co-processing the plant oil and the oxygenated chemical, the selectivity of the target product gasoline to be improved, and energy consumption to be reduced. In terms of a reaction apparatus, equipment flow is simplified because heat exchangers which are arranged for removing reaction heat can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

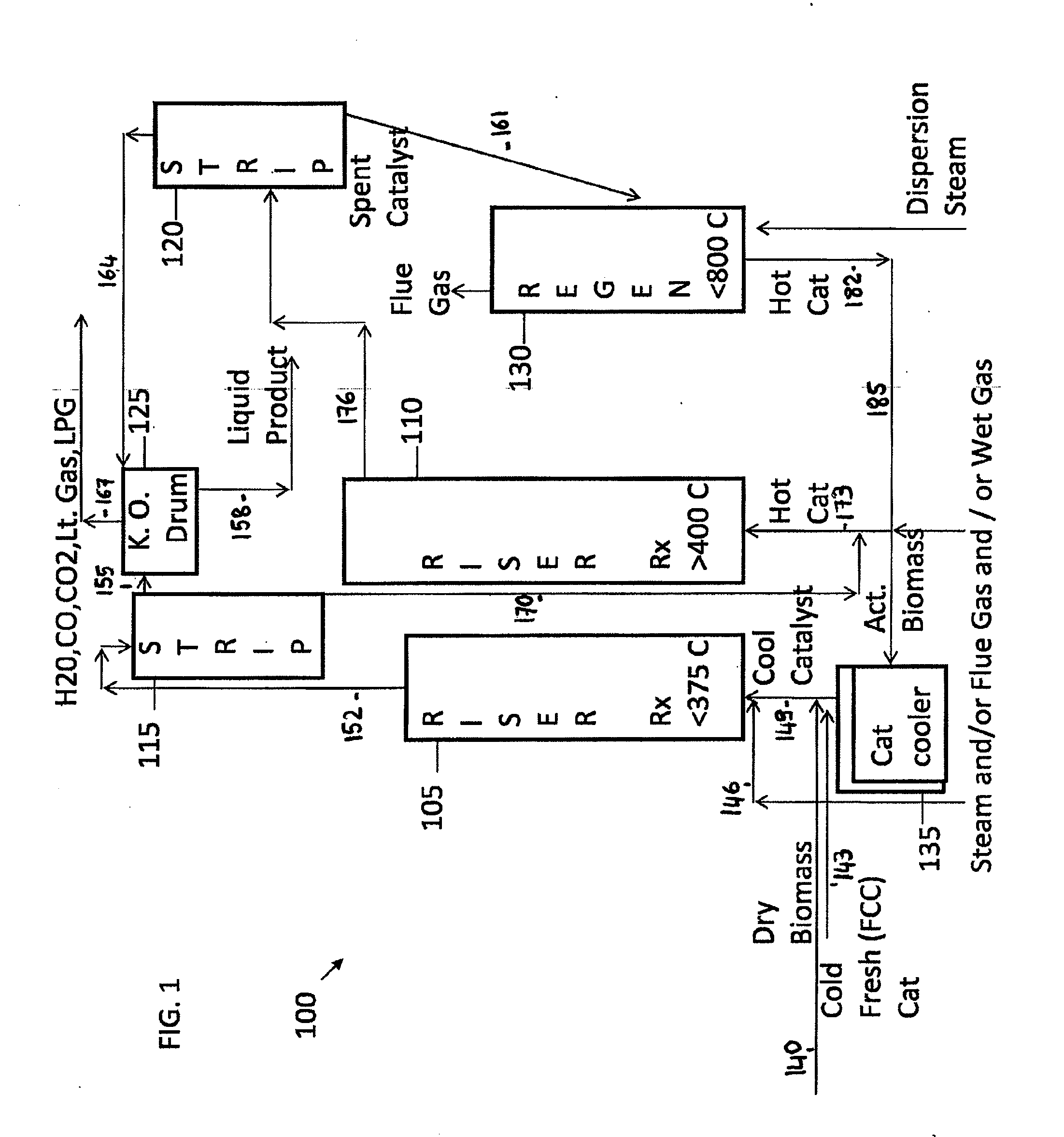

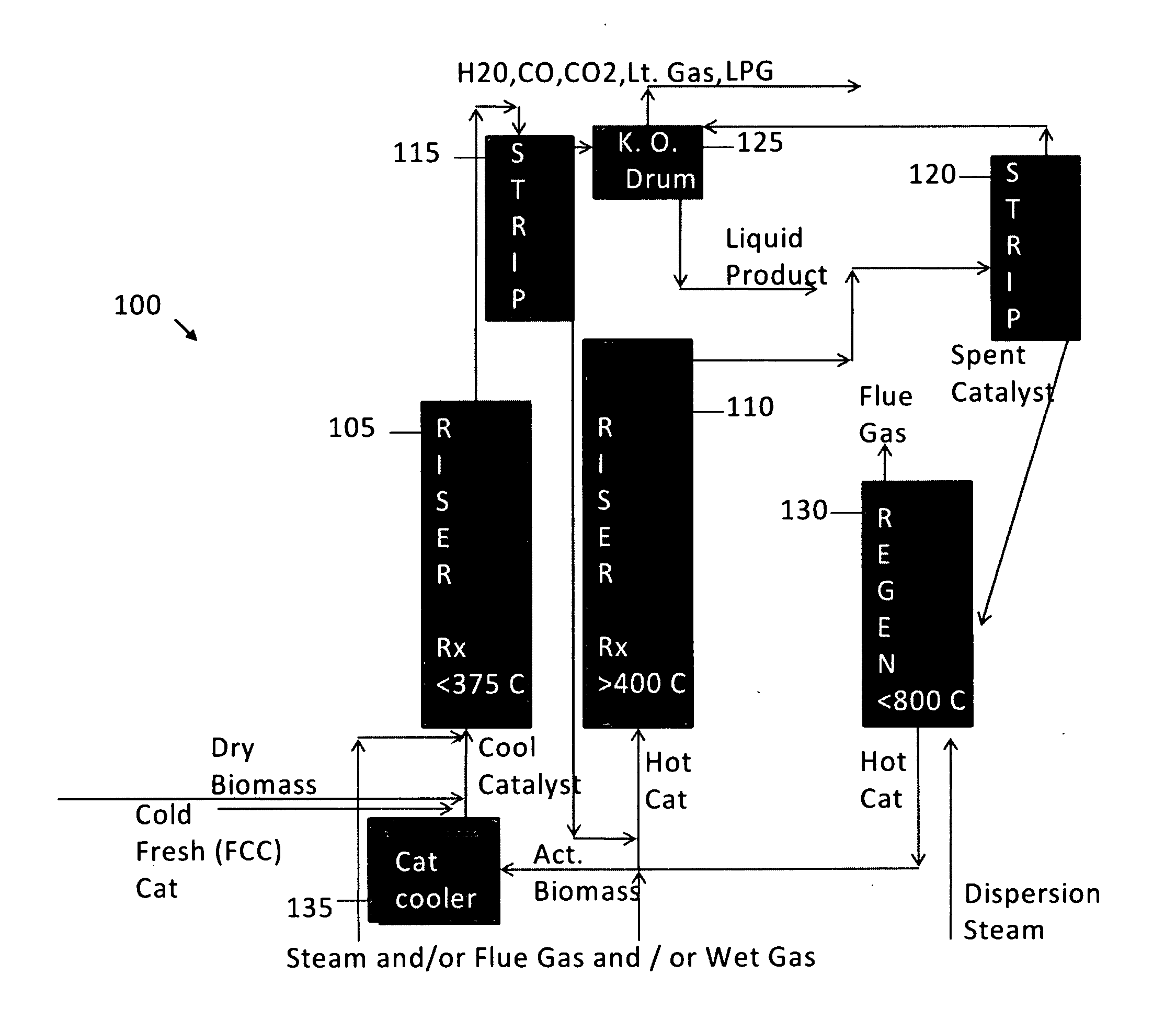

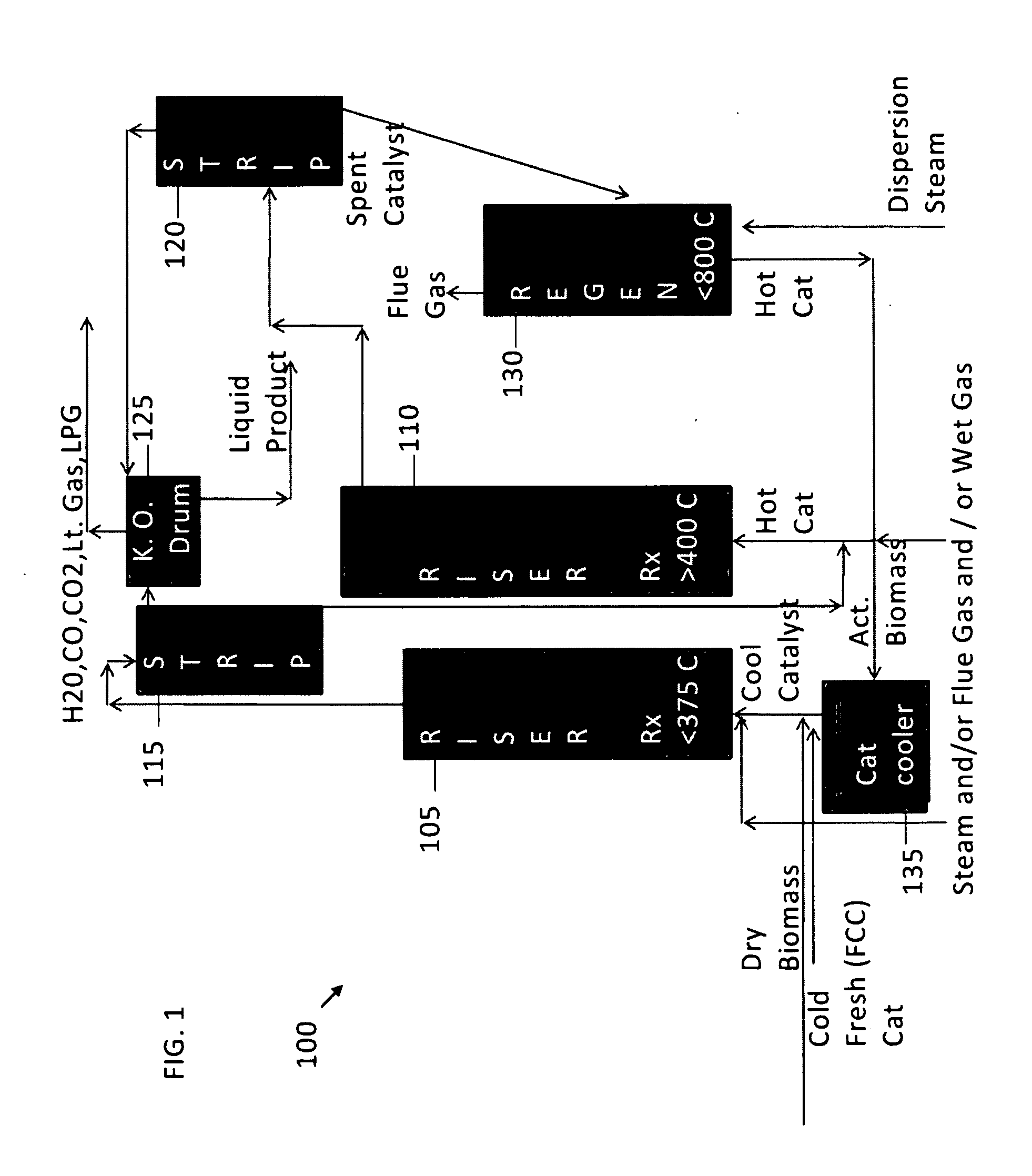

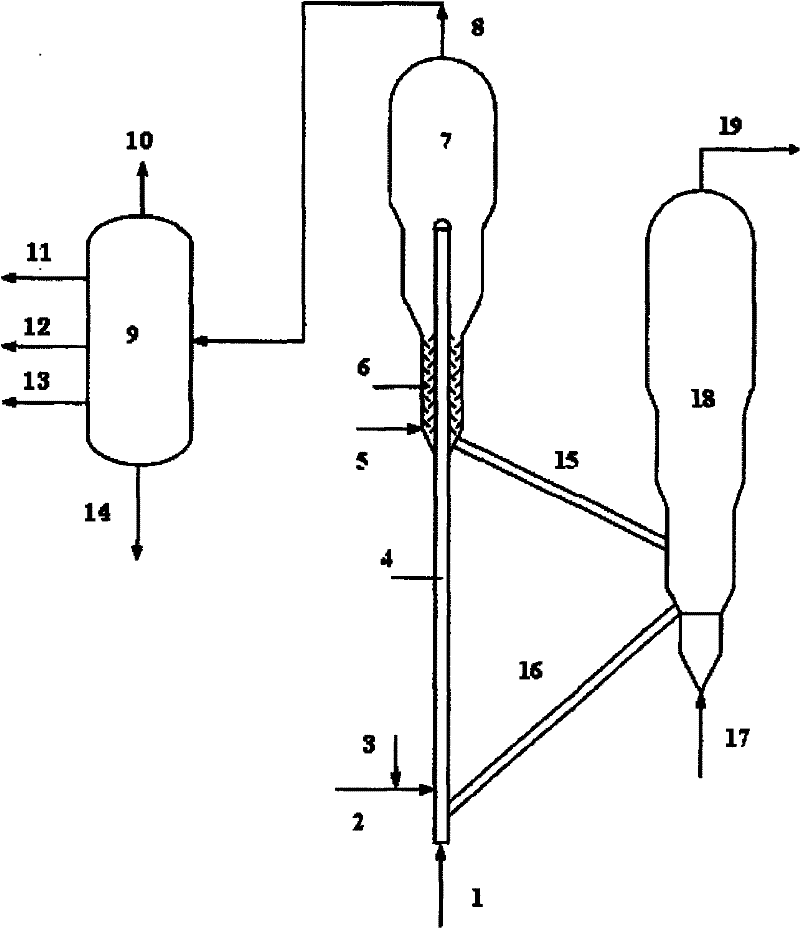

Deep Deoxygenation of Biocrudes Utilizing Fluidized Catalytic Cracking Co-Processing with Hydrocarbon Feedstocks

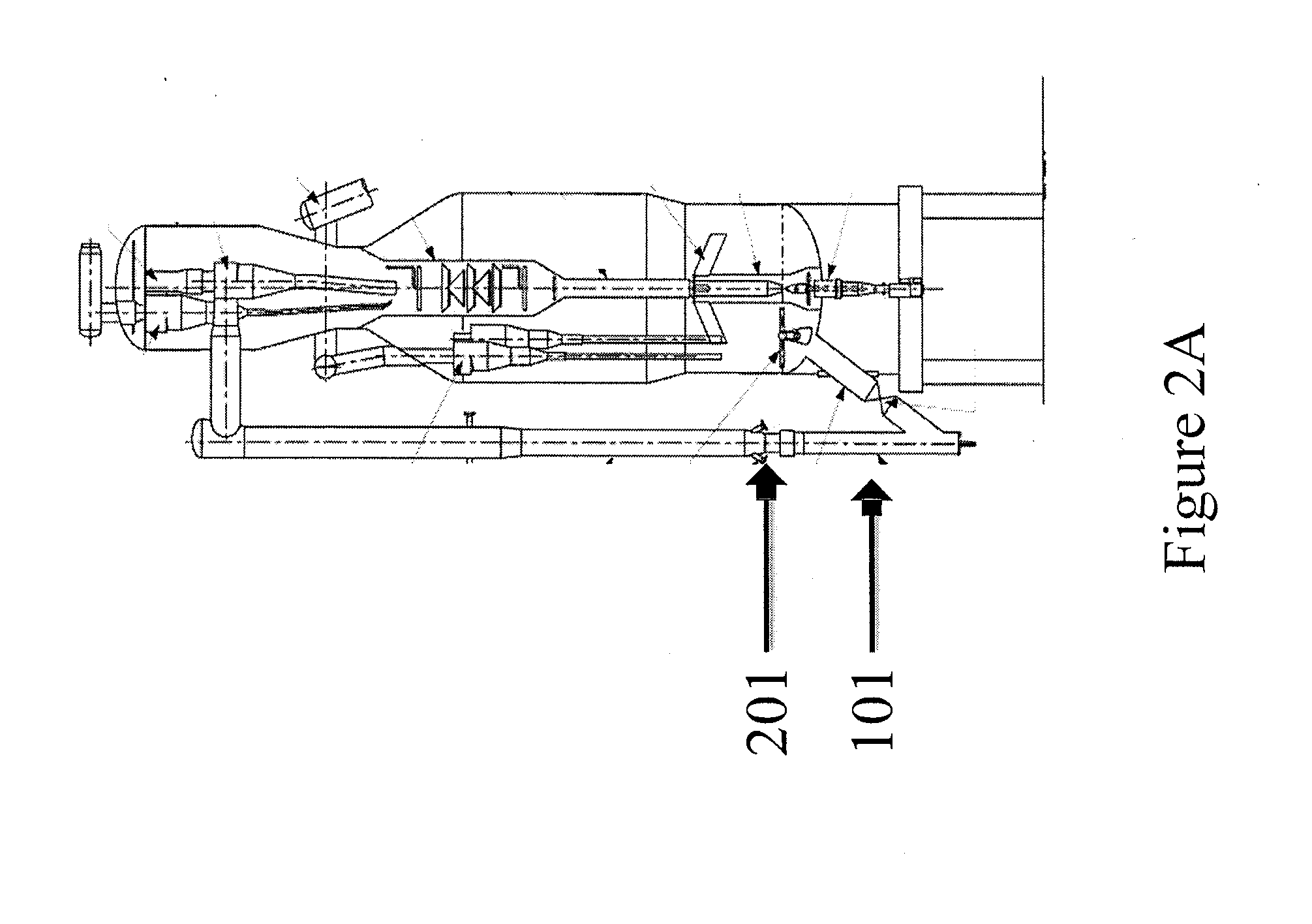

A system and method produce hydrocarbons from biomass by fluid catalytic cracking. In one embodiment, the system is a fluid catalytic cracking system. The system includes a riser. The riser contains a catalyst. The system also includes a biological feed comprising biomass-derived liquid for the riser. In addition, the system includes a hydrocarbon feed comprising hydrocarbons for the riser. The biological feed and the hydrocarbons react in the riser in the presence of the catalyst to convert at least a portion of the biological feed and the hydrocarbons to hydrocarbon products. The hydrocarbon products comprise a concentration of oxygen from about 0.005 wt. % to about 6 wt. %.

Owner:PHILLIPS 66 CO +1

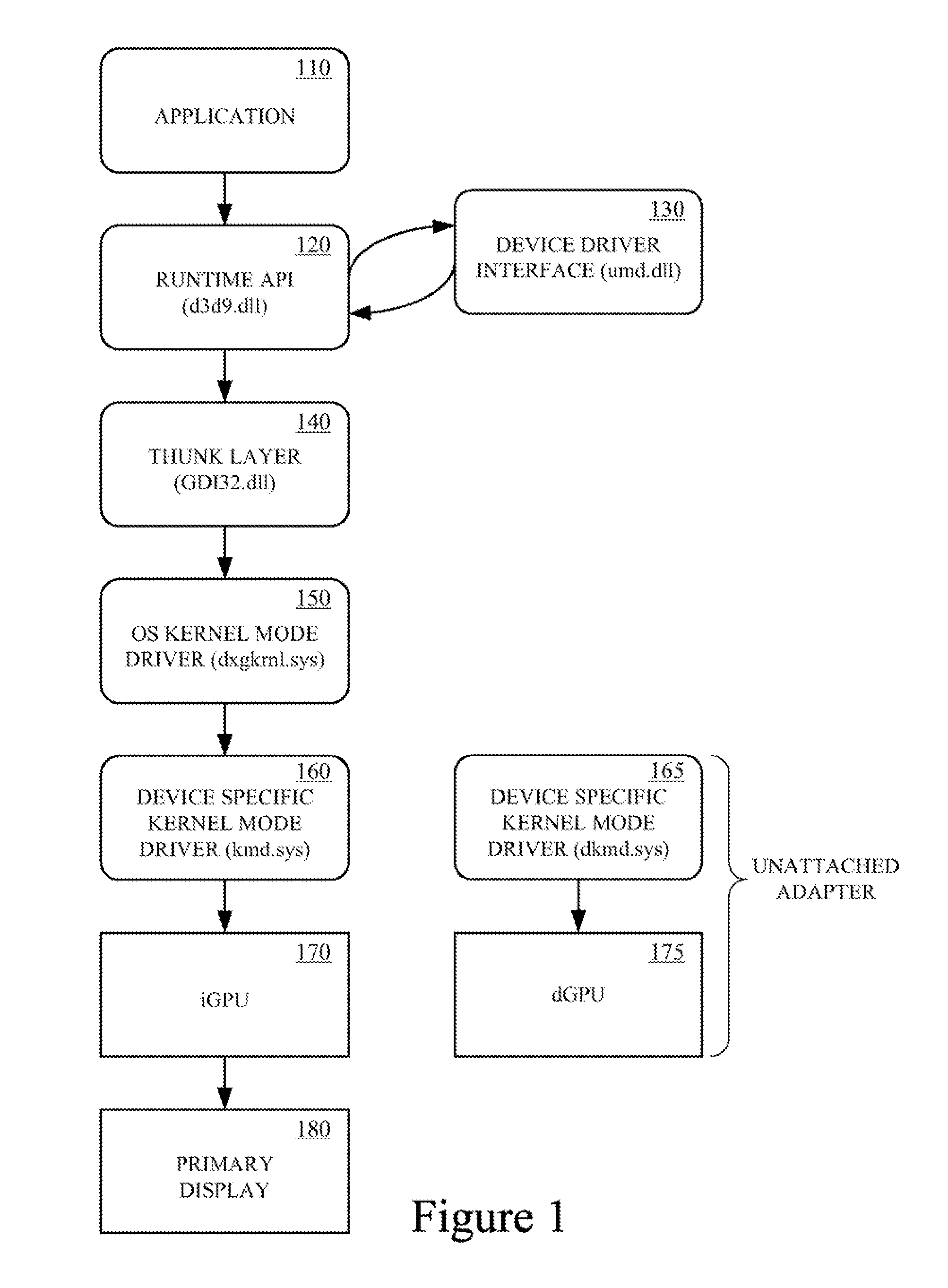

Content Protection Techniques on Heterogeneous Graphics Processing Units

InactiveUS20110169844A1Image data processing detailsExecution for user interfacesDisplay deviceCo-processing

The graphics co-processing technique includes receiving display operation for execution by a graphics processing unit on an unattached adapter. The display operation is split into an encrypt content by the graphics processing unit on the unattached adapter, a copy from a frame buffer of the graphics processing unit on the unattached adapter to a buffer in system memory, a copy from the buffer in system memory to a frame buffer of graphics processing unit on a primary adapter, a decrypt the encrypted content in the frame buffer of the graphics processing unit on the primary adapter, and a present from the frame buffer of the graphics processing unit on the primary adapter to a display. Execution of the copy from the frame buffer of the graphics processing unit on the unattached adapter to the buffer in system memory and the copy from the buffer in system memory to the frame buffer of the graphics processing unit on the primary adapter are synchronized.

Owner:NVIDIA CORP

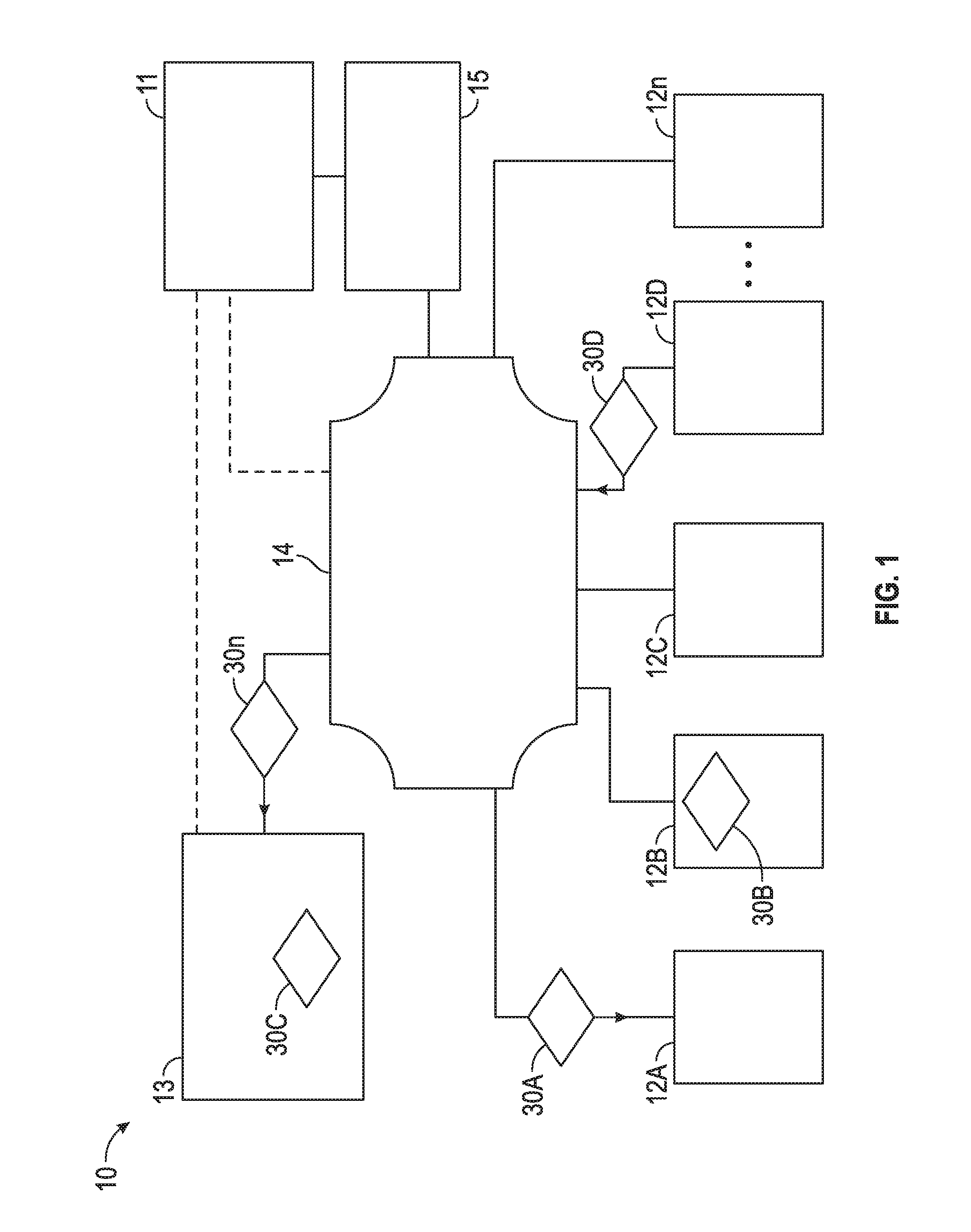

System and method for parallel processing using dynamically configurable proactive co-processing cells

ActiveUS20140337850A1Facilitates communication among system resourcesImprove interoperabilityProgram initiation/switchingInterprogram communicationCoprocessorProcessing element

A parallel processing architecture includes a CPU, a task pool populated by the CPU, and a plurality of autonomous co-processing cells each having an agent configured to proactively interrogate the task pool to retrieve tasks appropriate for a particular so-processor. Each co-processor communicates with the task pool through a switching fabric, which facilitates connections for data transfer and arbitration between all system resources. Each so-processor notifies the task pool when a task or task thread is completed, whereupon the task pool notifies the CPU.

Owner:SWARM TECH

Co-processing solid biomass in a conventional petroleum refining process unit

ActiveUS8288599B2Low costReduce degradationCatalytic crackingOther chemical processesCo-processingPetroleum

Preparing solid biomass particles for catalytic conversion includes agitating solid biomass particles and providing a biomass-catalyst mixture to a conventional petroleum refinery process unit. The biomass-catalyst mixture includes the solid biomass particles and a catalyst. Agitating solid biomass particles includes flowing a gas to provide a velocity to at least a portion of the solid biomass particles sufficient to reduce their sizes. Co-processing a biomass feedstock and a conventional petroleum feedstock includes liquefying at least a portion of a biomass-catalyst mixture and co-processing at least a portion of the liquefied biomass feedstock and a conventional petroleum feedstock in a conventional petroleum refinery process unit. The biomass feedstock includes a plurality of solid biomass particles and a catalyst, which is liquefied to produce a liquefied biomass feedstock.

Owner:MARD INC

Method for extracting aluminum oxides from aluminum-containing waste residues

ActiveCN103420405ALower iron levelsHigh puritySolid waste disposalAluminium oxides/hydroxidesRed mudAluminium hydroxide

The invention discloses a method for extracting aluminum oxides from aluminum-containing waste residues. The method comprises the following steps: mixing coal gangue and / or coal ash with a certain amount of red mud and Na2CO3, sintering to obtain sintered clinker with high reaction activity, performing acid leaching by a hydrochloric acid solution to form an aluminum salt solution, adding concentrated hydrochloric acid with the mass concentration of 30-37% to prepare aluminum chloride crystals, dissolving the aluminum chloride crystals, separating out aluminum hydroxide by ammonia precipitation, calcining at the temperature of 400-1300 DEG C to obtain aluminum oxides with different crystal forms. The method is simple in process, the prepared aluminum oxides are low in iron content and high in purity, and the method is a good method for co-processing the red mud and the coal gangue and / or the coal ash.

Owner:SHANXI UNIV +1

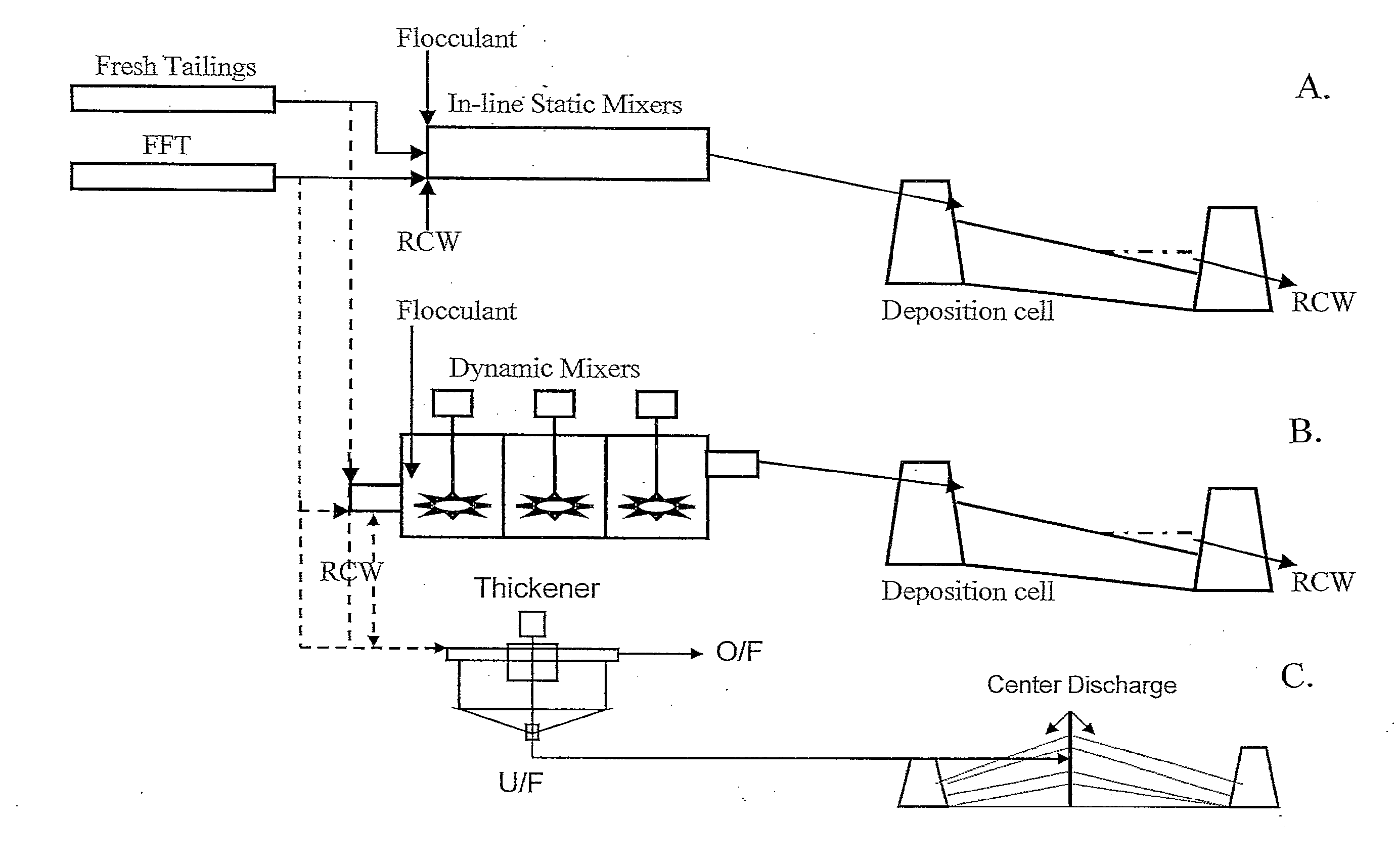

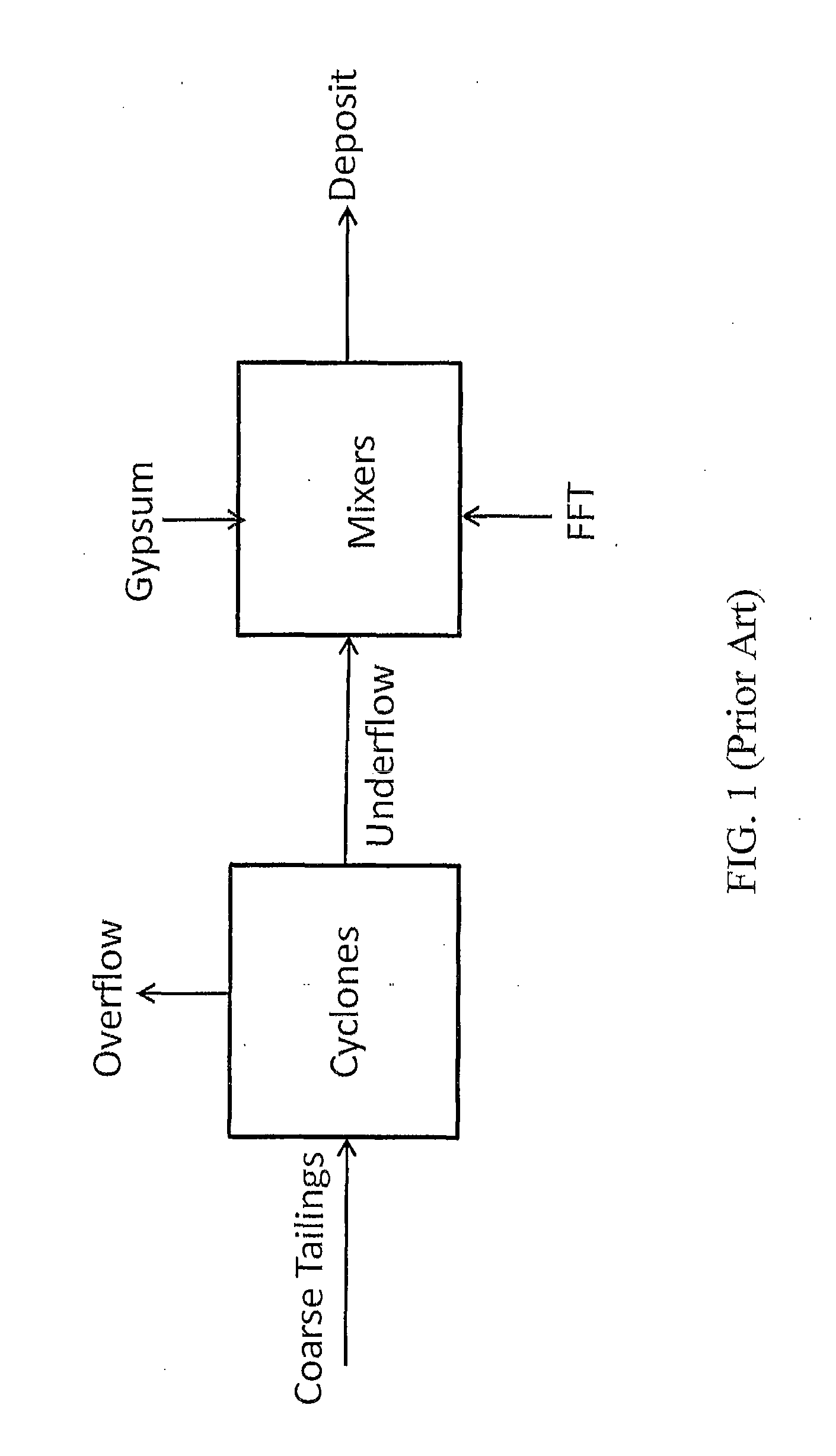

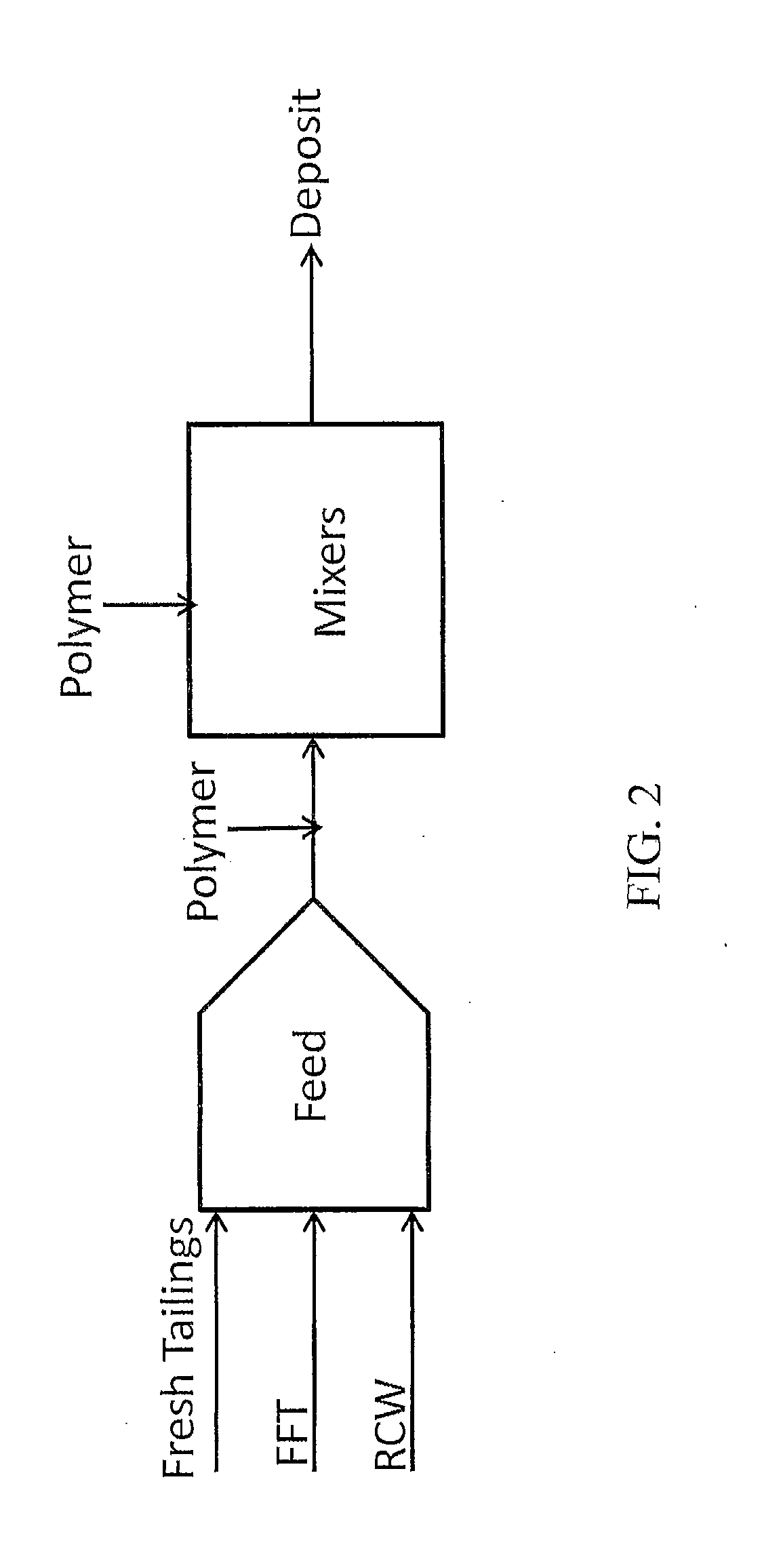

Co-processing of fluid fine tailings and fresh oil sands tailings

InactiveUS20140116956A1Improves permeability and strengthWaste water treatment from quariesWater treatment parameter controlOptimal densityCo-processing

A process is provided for dewatering fluid fine tailings, comprising combining fluid fine tailings with fresh oil sands tailings to create a tailings mixture having a sand to fines ratio of about 1.0 to about 2.0; optionally diluting the tailings mixture with water to an optimal density; adding an aqueous polymeric flocculant to the tailings mixture and mixing the polymeric flocculant and tailings mixture to form a flocculated material; and transferring the flocculated material to a deposition cell for dewatering.

Owner:SYNCRUDE CANADA LTD

Cement kiln co-processing system for waste incineration fly ash

ActiveCN105107820ANo secondary pollutionAvoid pollutionSolid waste disposalCement productionFiltrationReverse osmosis

The invention relates to a cement kiln co-processing system for waste incineration fly ash. Washing water generated by a waste incineration fly ash three-stage washing desalination system enters a coagulating sedimentation heavy-metal removal system through a pipeline; a solution with the salt content of 1-2 percent, obtained by the coagulating sedimentation heavy-metal removal system, enters a sodium filtration and reverse osmosis pre-concentration system; and the sodium filtration and reverse osmosis pre-concentration system removes calcium and magnesium ions in washing water and concentrates the solution with the salt content of 1-2 percent into a concentrated liquor with the salt content of 6-8 percent, which is conveyed into a slight trace carnallite removal system for carnallite removal, and finally, a nearly saturated liquid enters an MVR (Mechanical Vapor Recompression) evaporative crystallization system for evaporative crystallization. The cement kiln co-processing system for waste incineration fly ash is a device for cement kiln co-processing of waste incineration fly ash, can dispose a great amount of fly ash, is high in cement output, realizes innocent treatment, and obtains industrial salt through evaporative crystallization, which is used in paper making process, snow-melting agents and the chlor-alkali industry.

Owner:湖州京兰环保科技有限公司

Kitchen waste and household garbage incineration power generation cooperative treatment technology

InactiveCN105798050AImprove reusabilityReduce processing costsWaste processingSolid waste disposalPower stationOil water

A kitchen waste and household garbage incineration power generation cooperative treatment technology comprises the following specific steps that 1, kitchen waste is collected; 2, the collected kitchen waste is subjected to exotic matter sorting, and sorted combustible materials are conveyed to a household garbage incineration power plant to be combusted for power generation; 3, materials obtained after exotic matter sorting are crushed; 4, the crushed materials are homogenized; 5, the homogenized materials are subjected to water removal treatment, and liquid materials obtained after water removal treatment are stored temporally; and 6, the liquid materials are subjected to oil-water primary separation treatment, water obtained after oil-water primary separation treatment is collected into an anaerobic fermentation tank, and biogas residues, biogas slurry and biogas are generated after anaerobic fermentation and are separated. The technology is advanced, the cooperative treatment advantages of the household garbage incineration power plant and kitchen waste fermentation are fully and reasonably utilized, and harmless, reducing and recycling garbage treatment is achieved.

Owner:张共敏 +2

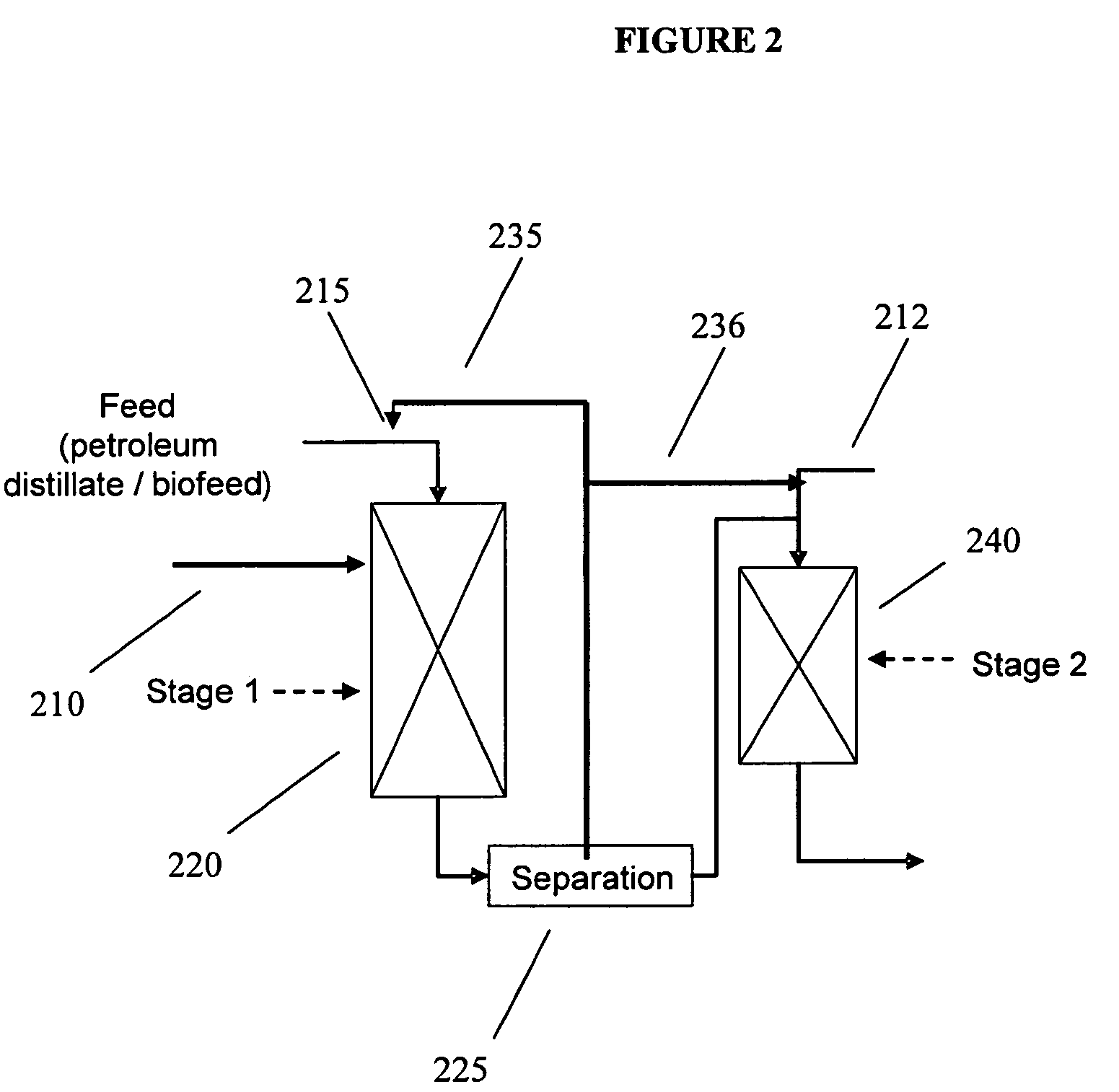

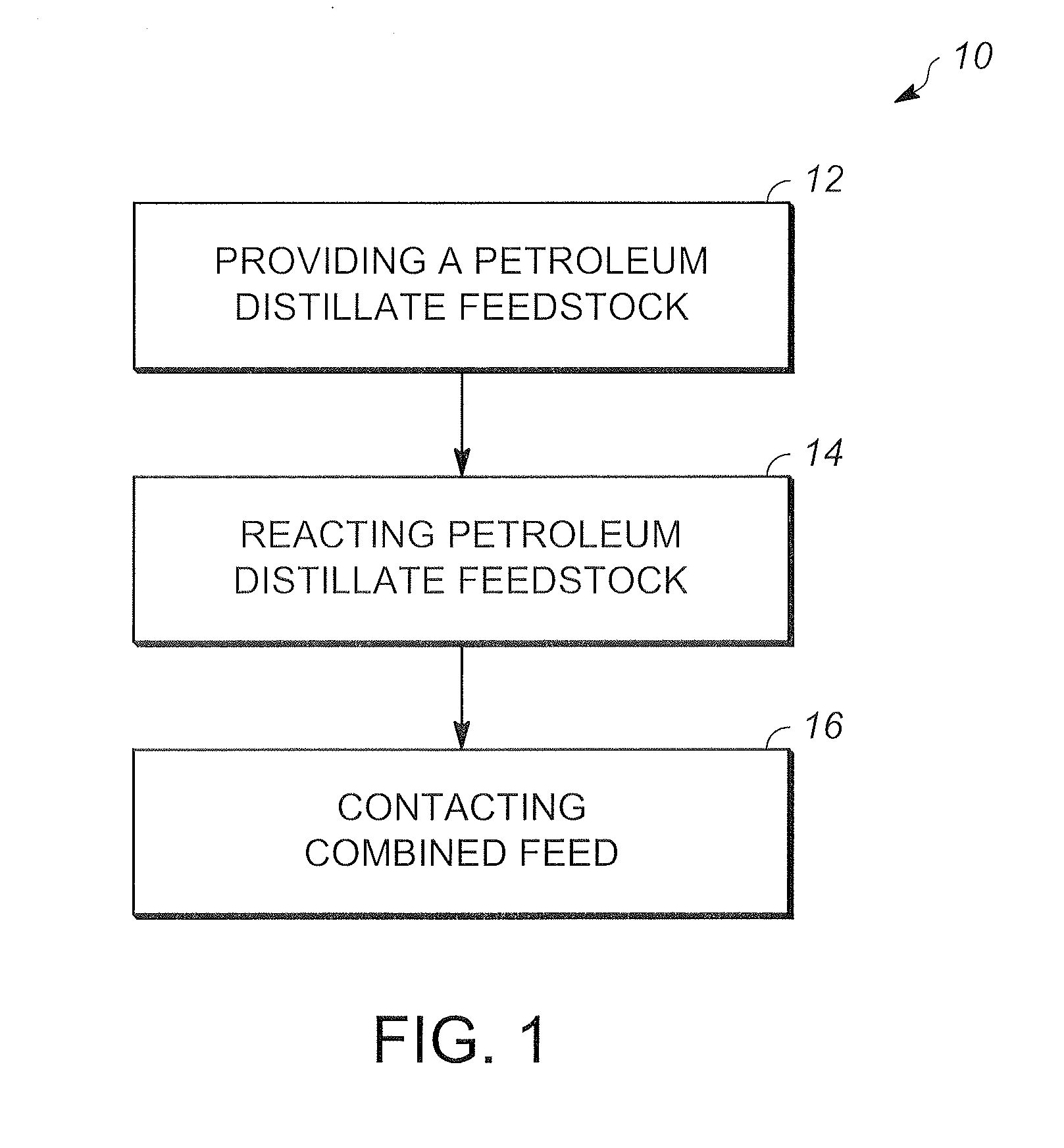

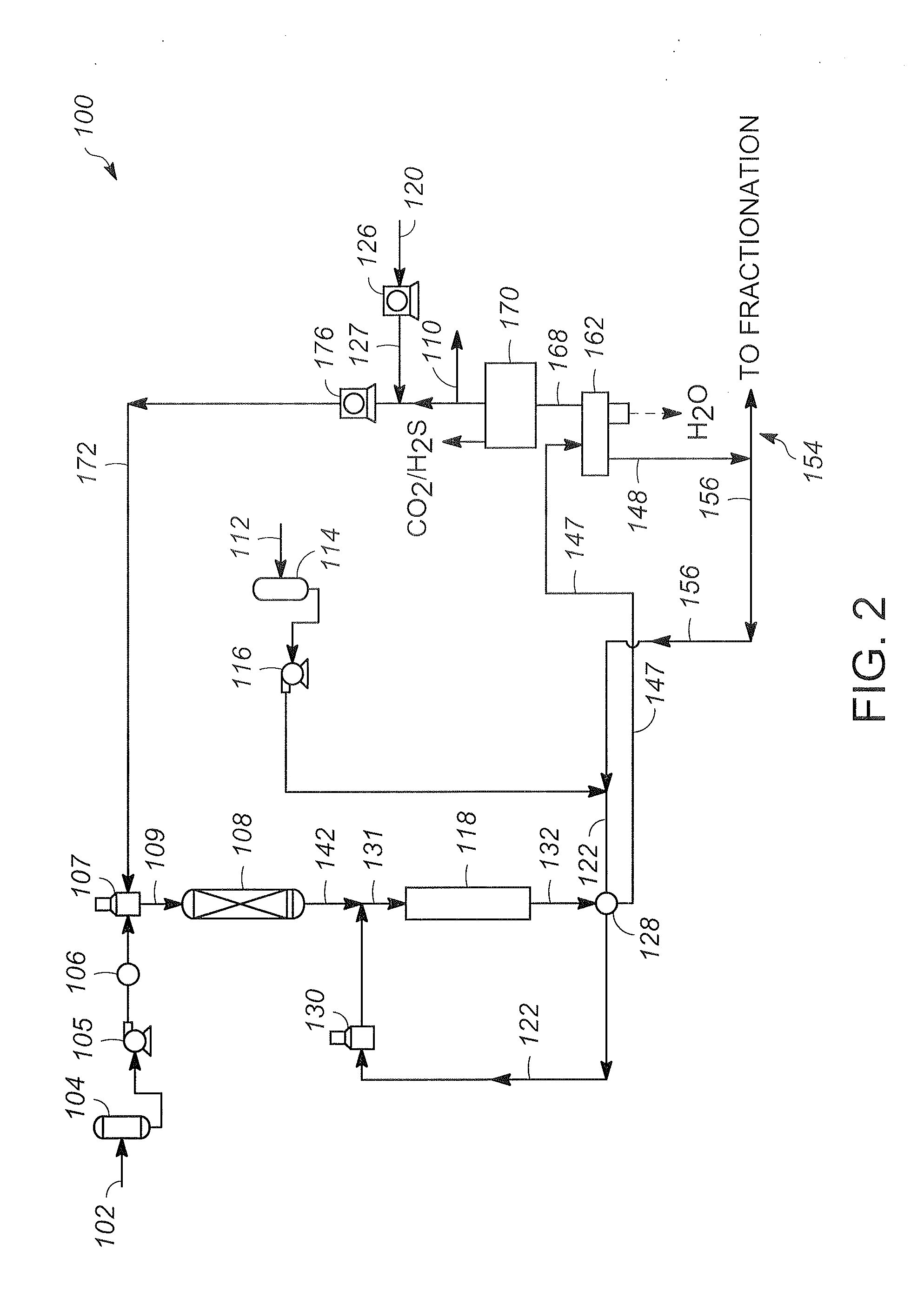

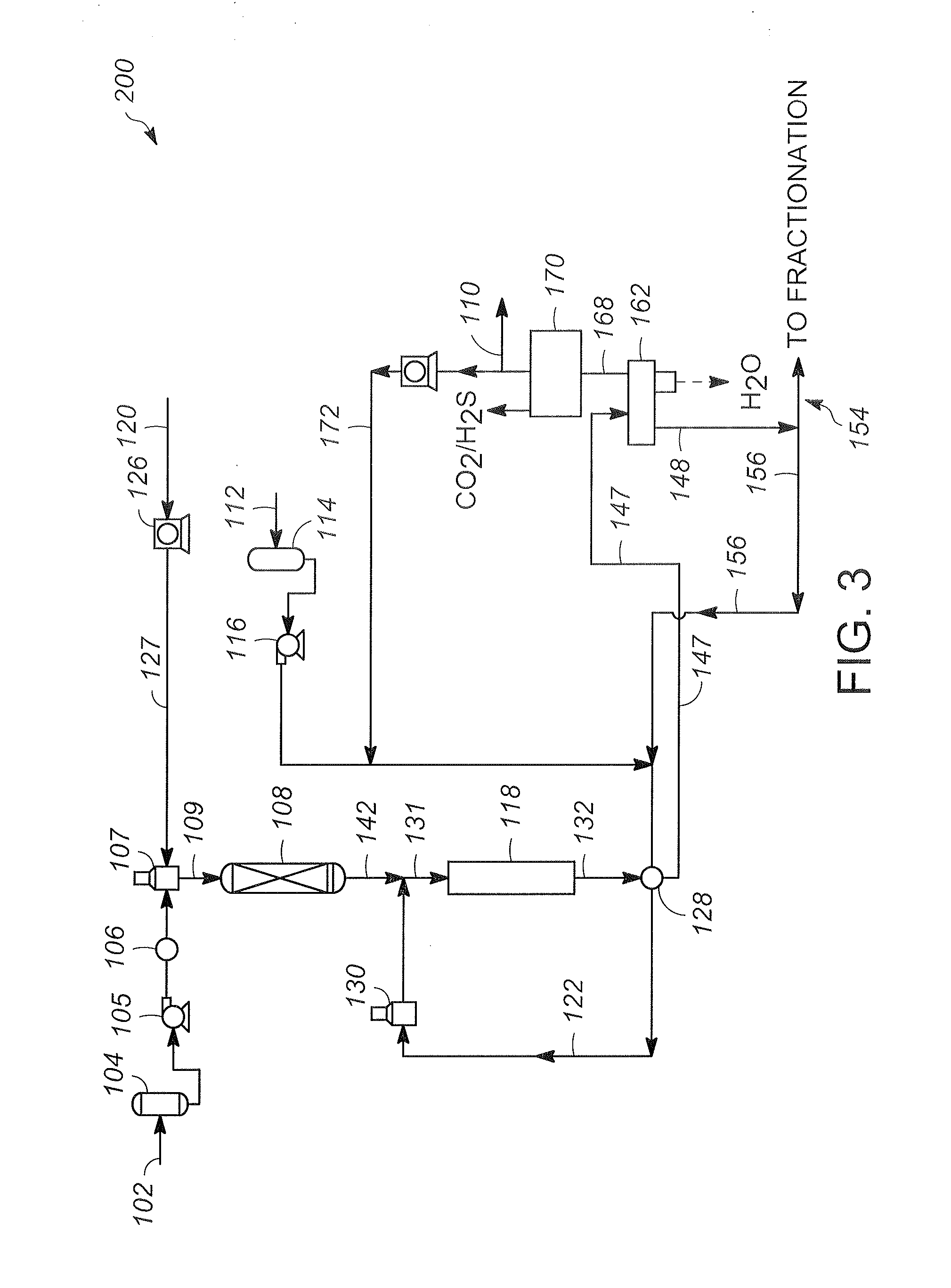

Methods for co-processing biorenewable feedstock and petroleum distillate feedstock

Methods for co-processing a biorenewable feedstock and a petroleum distillate feedstock are provided. The petroleum distillate feedstock containing sulfur is reacted with hydrogen gas in the presence of a hydrotreating catalyst thereby forming an effluent mixture comprising hydrogen sulfide. A combined feed comprising the effluent mixture, optionally a recycle liquid, and the biorenewable feedstock is contacted with hydrogen gas in a reaction zone with a deoxygenation catalyst under reaction conditions to provide a reaction product comprising a hydrocarbon fraction. The combined feed comprises greater than 50 weight percent biorenewable feedstock.

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com