Device for coprocessing heavy metal waste water and organic waste water and generating electric power

A technology for co-processing and organic wastewater, applied in biological water/sewage treatment, water/sludge/sewage treatment, biochemical fuel cells, etc., can solve problems such as single composition of heavy metal wastewater, inability of the system to run stably for a long time, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

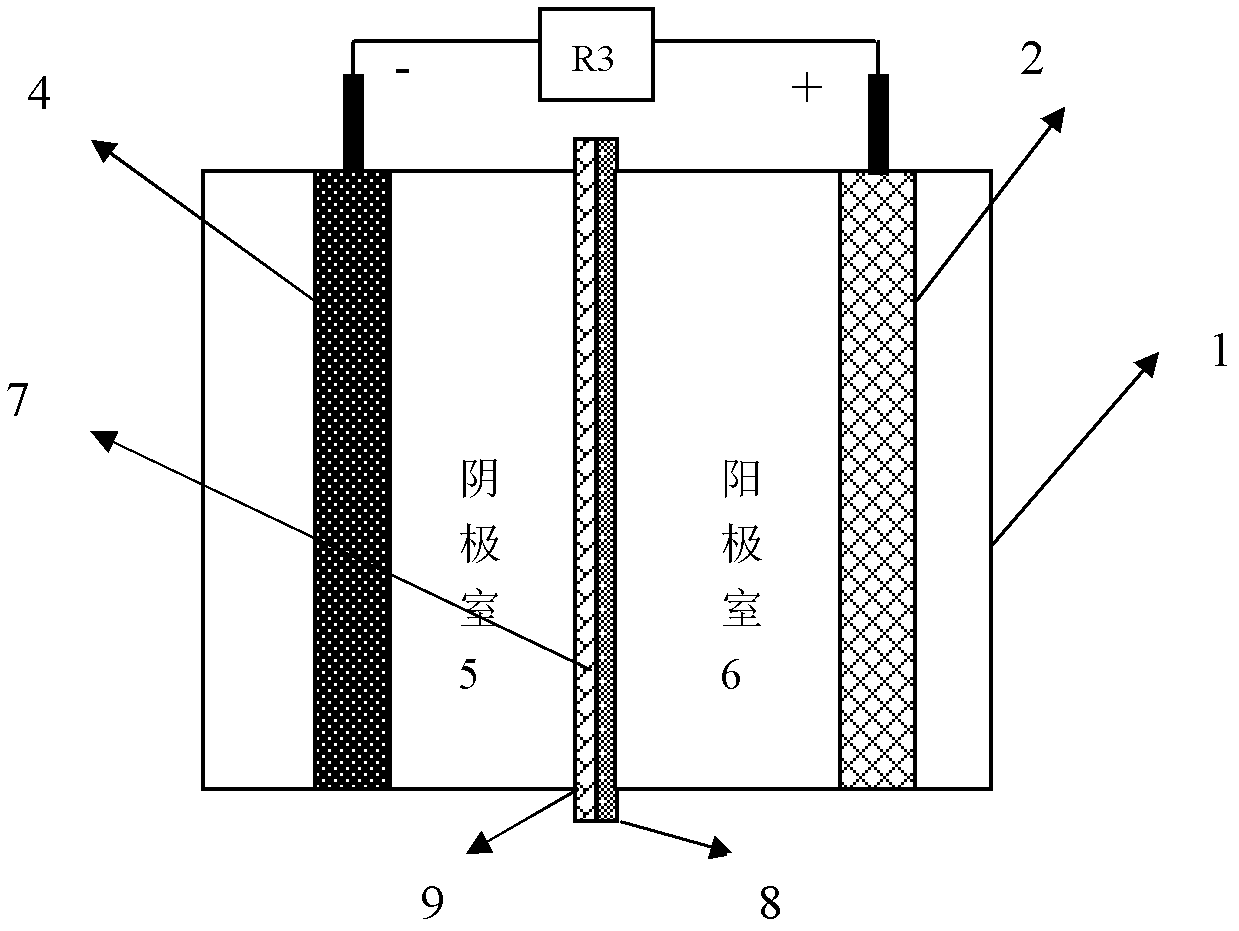

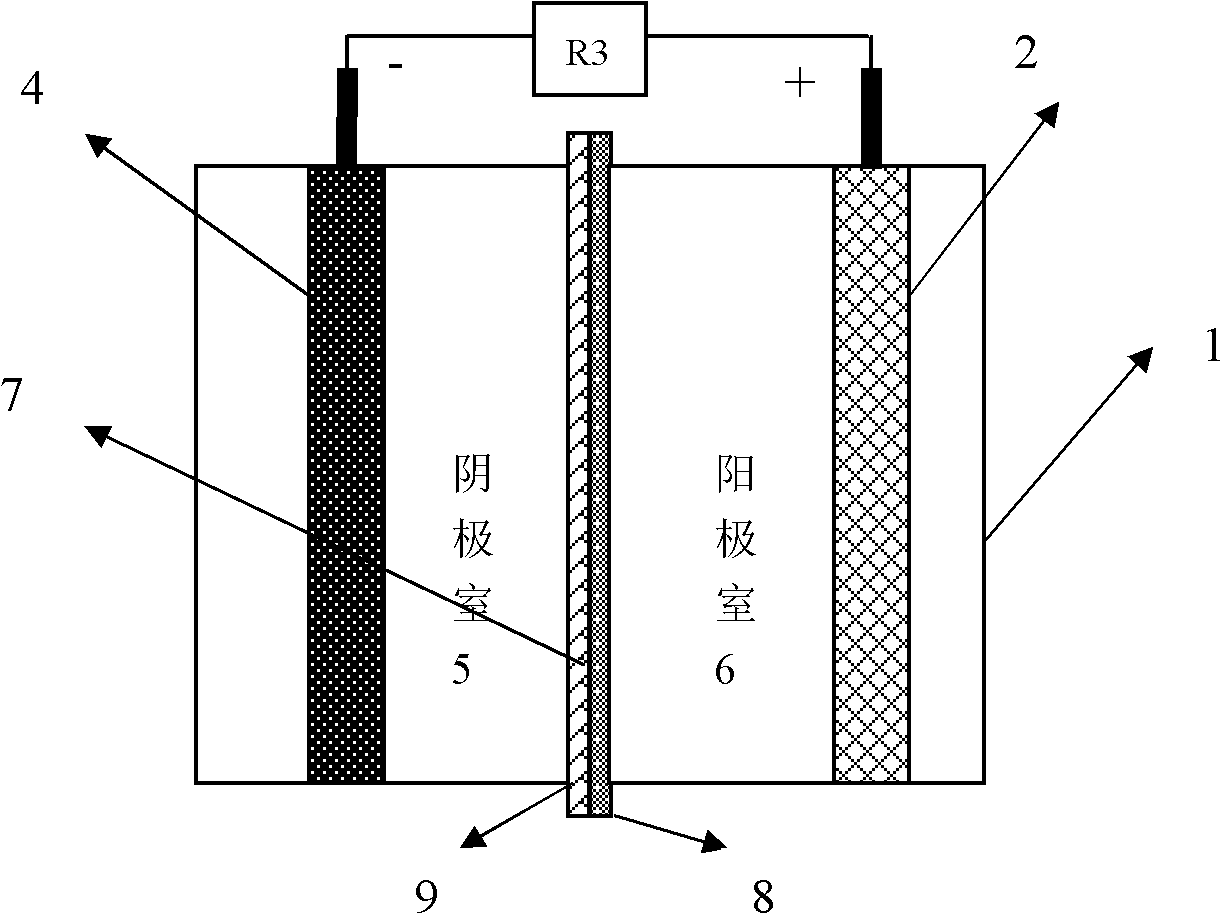

[0013] see figure 1 , the present invention comprises an electrolytic cell 1 and a bipolar membrane 7 arranged in the electrolytic cell 1 to divide the electrolytic cell into an anode chamber 6 and a cathode chamber 5, the bipolar membrane 7 is composed of an anion exchange membrane 8 and a cation exchange membrane 9, Wherein the cation exchange membrane 9 is located in the cathode chamber 5, and the anion exchange membrane 8 is located in the anode chamber 6. The bipolar membrane can dissociate water into protons and hydroxide ions, and diffuse to the cathode chamber and the cathode chamber through the positive membrane side and the negative membrane side respectively. anode chamber. An anode 2 and a cathode 4 are respectively arranged in the anode chamber 6 and the cathode chamber 5. The anode 2 and the cathode 4 are connected to the resistor 3 through wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com