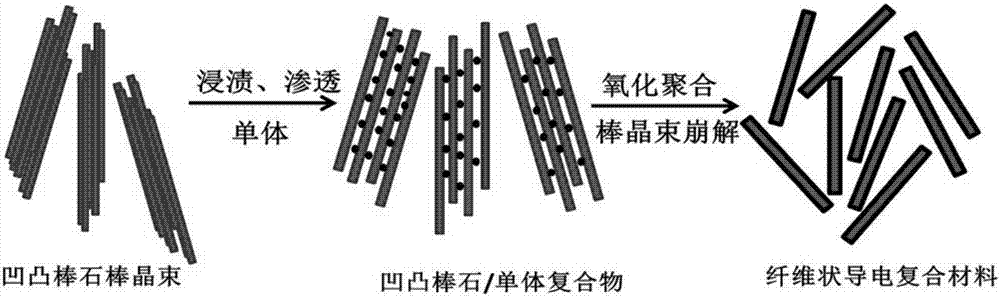

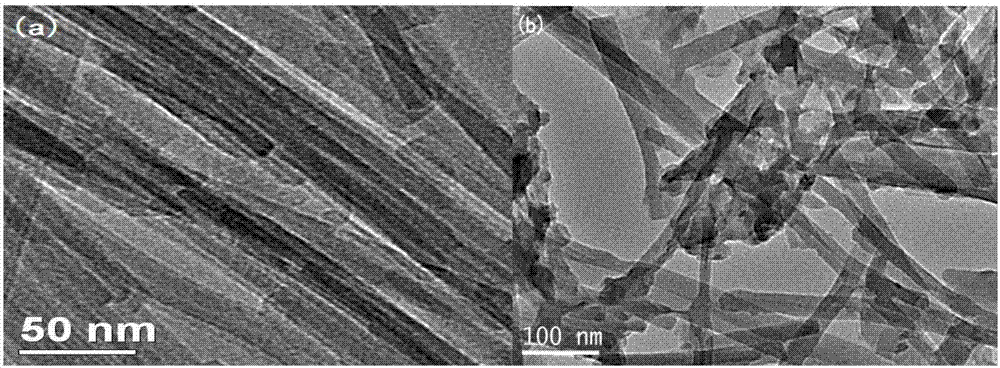

Integrated preparation technology for attapulgite rod-like crystal beam dissociation and conduction composite material

A conductive composite material and a preparation process technology, which are applied in the field of deep processing and high-value utilization of clay minerals, can solve problems such as affecting the application performance of attapulgite nanostructure properties, reducing aspect ratio, and damaging attapulgite crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Fully disperse 1.0 kg of natural attapulgite clay into 6.7 kg of deionized water, then add 0.3 kg of pyrrole monomer to it, and immerse it for 5 days after fully dispersing to obtain a thick composite slurry of attapulgite and pyrrole monomer body;

[0023] (2) adding 1.7 liters of sulfuric acid solution with molar concentration of 12.0 mol / liter to the composite slurry obtained in step (1), after 12 days of immersion reaction, ultrasonic dispersion for 30 minutes, filtering, washing filter cake washing solution pH value is 6 and drying to obtain attapulgite / polypyrrole composite material. Its volume resistivity was measured to be 2.7Ω·cm.

Embodiment 2

[0025] (1) Fully disperse 1.0 kg of natural attapulgite clay into 3.3 kg of deionized water, then add 1.0 kg of aniline monomer to it, fully disperse and soak for 10 days to obtain a thick composite slurry of attapulgite and aniline monomer body;

[0026] (2) adding 5.5 liters of hydrochloric acid solution whose molar concentration is 5.0 mol / liter to the composite slurry obtained in step (1), after immersion reaction for 6 days, ultrasonic dispersion for 60 minutes, filtering, washing filter cake washing solution pH value is 7 and drying to obtain attapulgite / polyaniline composite material. Its volume resistivity was measured to be 0.9Ω·cm.

Embodiment 3

[0028] (1) Fully disperse 1.0 kg of natural attapulgite clay into 4.5 kg of deionized water, then add 0.65 kg of pyrrole monomer to it, and immerse it for 7.5 days after fully dispersing to obtain a thick composite slurry of attapulgite and pyrrole monomer body;

[0029] (2) adding 2.8 liters of nitric acid solution with a molar concentration of 8.5 mol / liter to the composite slurry obtained in step (1), after immersing for 9 days, ultrasonically dispersing for 45 minutes, filtering and washing the filter cake washing solution with a pH of 6.5 and drying to obtain attapulgite / polypyrrole composite material. Its volume resistivity was measured to be 1.5Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com