Preparation method of aromatic hydrocarbons and low-carbon olefins through co-processing animal and plant oils and oxygenated chemical

A technology of animal and vegetable oils and low-carbon olefins, which is applied in the direction of hydrocarbons, chemical instruments and methods, and the preparation of liquid hydrocarbon mixtures. It can solve problems such as high viscosity, strong corrosion, and large waste liquid discharge, and achieve simplified The effect of equipment flow, less water intake and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 illustrates the situation of using a fixed fluidized bed reactor to co-refine tallow and ethanol to produce light olefins and aromatics.

[0039] The fluidized bed reactor is operated intermittently. The raw material of tallow, ethanol and atomized steam is heated to about 200°C by the preheating furnace, and then enters the bottom of the fluidized bed reactor through the feed nozzle, and contacts with the hot catalyst for catalytic conversion reaction. . After the generated reaction oil gas is separated from the catalyst, the reaction oil gas is subjected to fractional distillation to obtain gas products and liquid products. The separated spent catalyst is stripped to remove hydrocarbon products adsorbed on the spent catalyst. After the stripping, the raw catalyst is introduced into the catalyst regenerator and fed with oxygen-containing gas for coke regeneration, and the next reaction can be carried out after the catalyst is regenerated. The main operat...

Embodiment 2

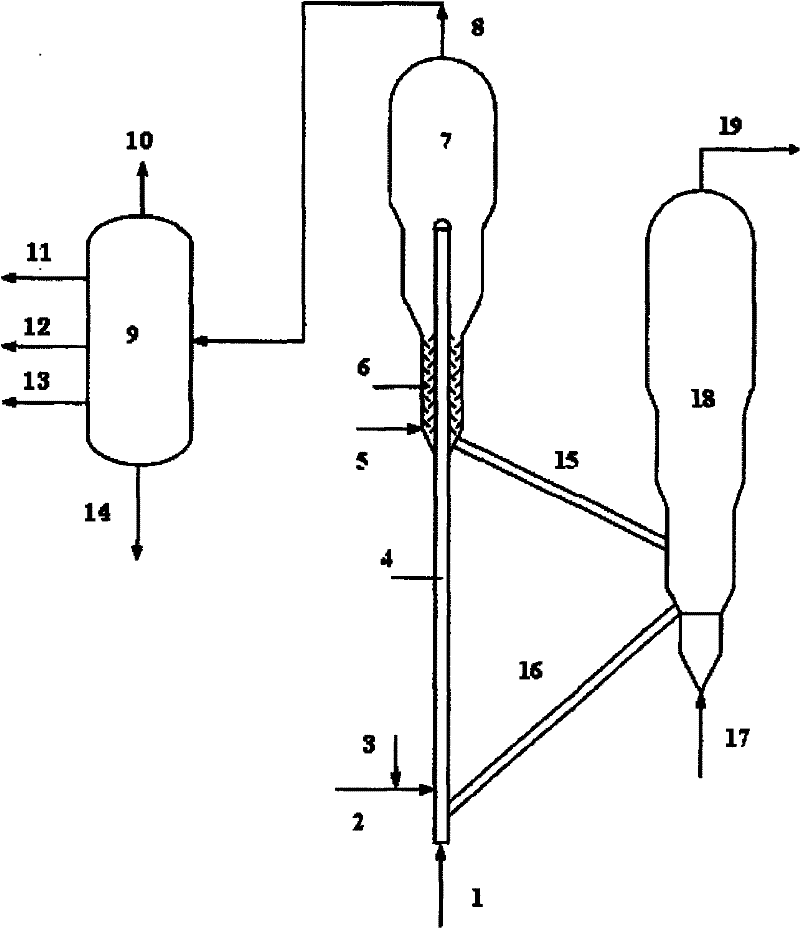

[0041] Example 2 illustrates the use of a riser reactor to co-catalyze the conversion of vegetable oil and oxygenated compounds to produce light olefins and aromatics.

[0042] The medium-sized riser device that adopts continuous reaction-regeneration operation is tested, and the inner diameter of described riser reactor is 16 millimeters, and height is 6 meters, and there is one section of fluidized bed reaction section above the outlet of riser reactor, and the inner diameter of this reaction section It is 64mm and the height is 0.3m.

[0043] The operation mode of one-way pass is adopted, the oxygenated compound methanol and dimethyl ether, and the regenerated catalyst with a temperature of about 700 ° C enter the bottom of the riser reactor through the regenerated inclined tube, and flow upward under the action of the pre-lift steam. Soybean oil and castor oil raw materials are heated to about 250°C in a preheating furnace, mixed with atomized steam, and then enter the ris...

Embodiment 3

[0046] Example 3 illustrates the situation in which light olefins and aromatics are produced by co-catalytic conversion of animal and vegetable oils and oxygenates at different positions using the riser + bed reactor mode.

[0047] The oxygen-containing compound is methanol, and the reactor adopts the riser + bed reaction mode. The inner diameter of the riser reactor is 16 mm and the height is 4 meters. The bed reactor is a single-stage fluidized bed reactor, the inner diameter of the single-stage fluidized bed reactor is 64mm, and the height is 2.5m, and the diameter of the catalyst cooler is 70mm, and the height is 3m. The outlet of the riser reactor is located at the bottom of the dense-phase bed of the single-stage fluidized bed reactor, the catalyst inlet of the cooler is located at the upper part of the single-stage fluidized bed reactor, and the cooled catalyst returns to the lower part of the dense-phase fluidized bed. The palm oil raw material is heated to about 250°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com