Gasoline preparing method by refining plant oil and oxygenated chemicals together

A compound and vegetable oil technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, biological raw materials, etc., can solve the problems of interfering with the ability of catalysts to promote reactions, catalyst failure, etc., to facilitate catalytic conversion, improve selectivity, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

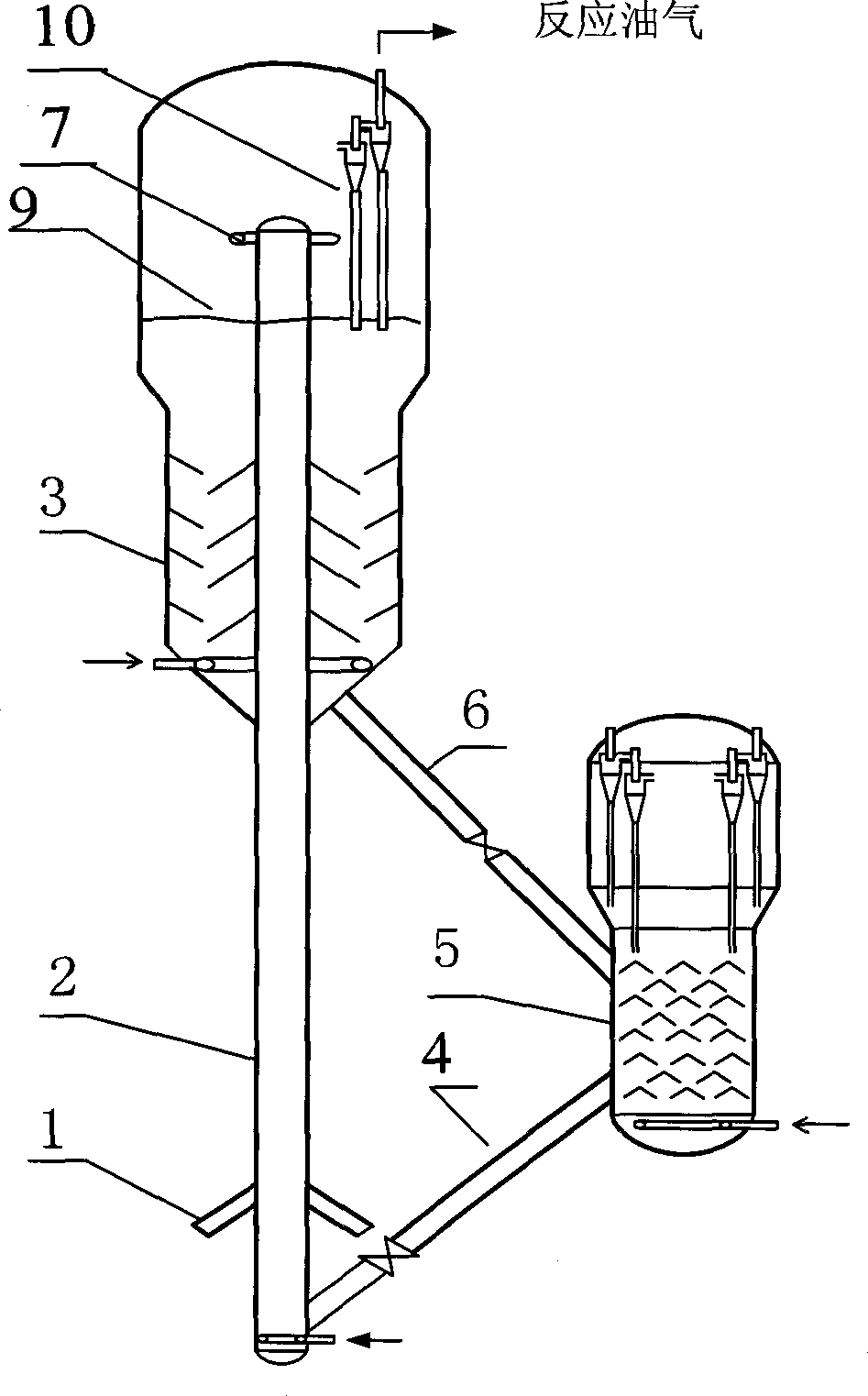

[0042] Embodiment 1 adopts attached figure 1 In the medium-scale test device shown, the outlet temperature of the riser is 490°C, and the temperature of the regenerant entering the riser is 580°C. The pressure of the reactor is 0.3MPa, and the weight hourly space velocity of the raw material is 6h -1 , the raw materials are palm oil and methanol, and the mass ratio of the two is 3:1. The mass ratio of the catalyst flow rate to the raw material flow rate was 5. See Table 3 for product distribution and Table 4 for gasoline hydrocarbon composition.

Embodiment 2

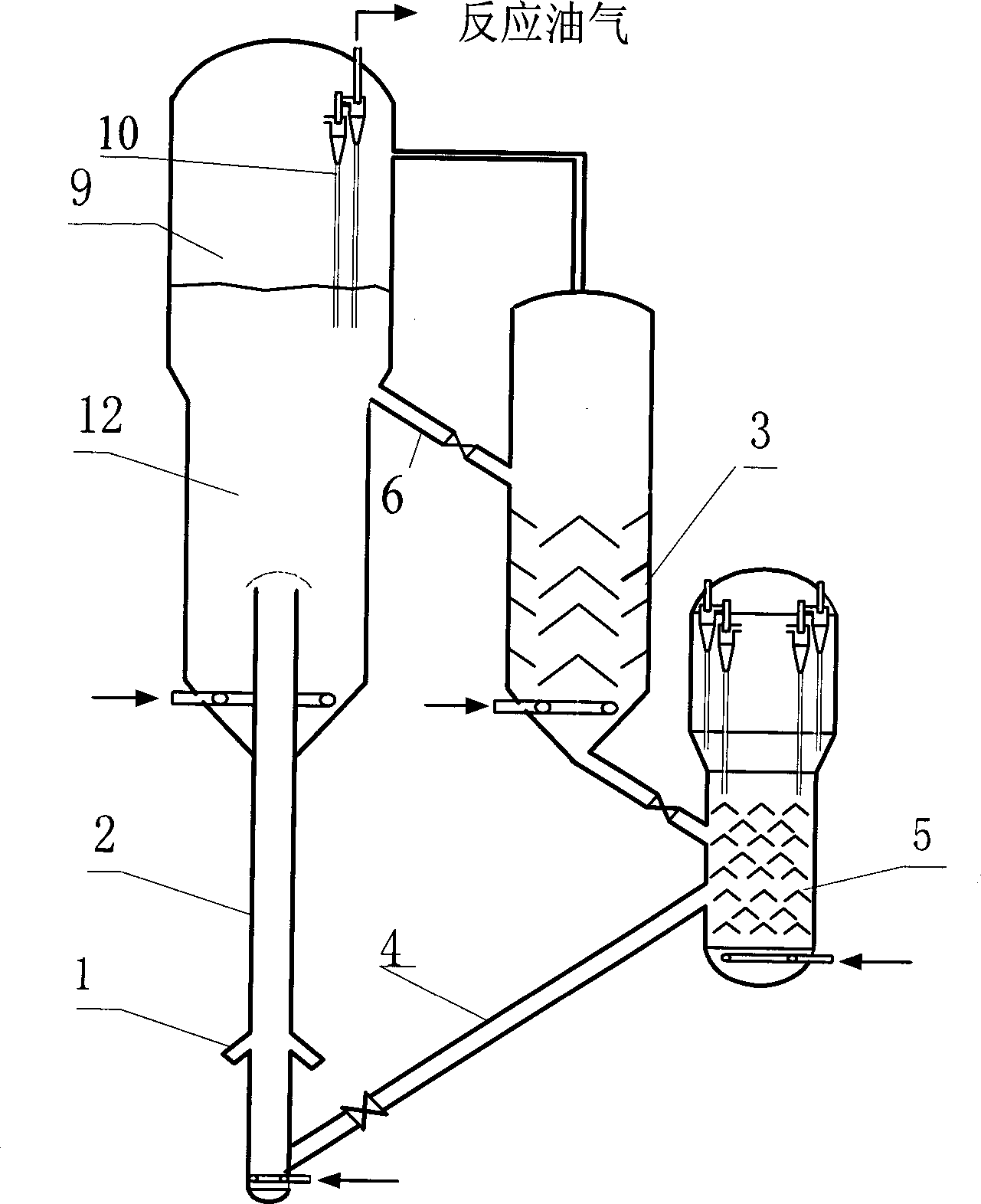

[0044] Example uses image 3 The mesoscale test setup shown. The raw material for the riser is 80wt% palm oil + 20wt% soybean oil. After the vegetable oil is preheated at 200°C, it enters the riser through the nozzle of the riser and reacts with the catalyst coming from the riser. The temperature of the regenerant entering the riser from the regenerator is 500°C. Preheated methanol at 200°C enters the bed from the fluid distribution pipe below the bed to contact and react with the catalyst. The mass ratio of vegetable oil to methanol is 4:1. The bed temperature of the fluidized bed at the outlet of the riser is 380°C, the reactor pressure is 0.3MPa, and the vegetable oil weight hourly space velocity is 6h -1 , methanol weight hourly space velocity is 2h -1 . See Table 3 for product distribution and Table 4 for gasoline hydrocarbon composition.

[0045] Table 1

[0046] Element

Palmitic acid, wt%

35

14

Stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com