A kind of preparation method and application of metal Ni-doped hierarchical porous ZSM-5 molecular sieve

A ZSM-5, molecular sieve technology, used in molecular sieve catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as weak catalytic ability, reduction of active sites, and reduction of catalytic reaction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

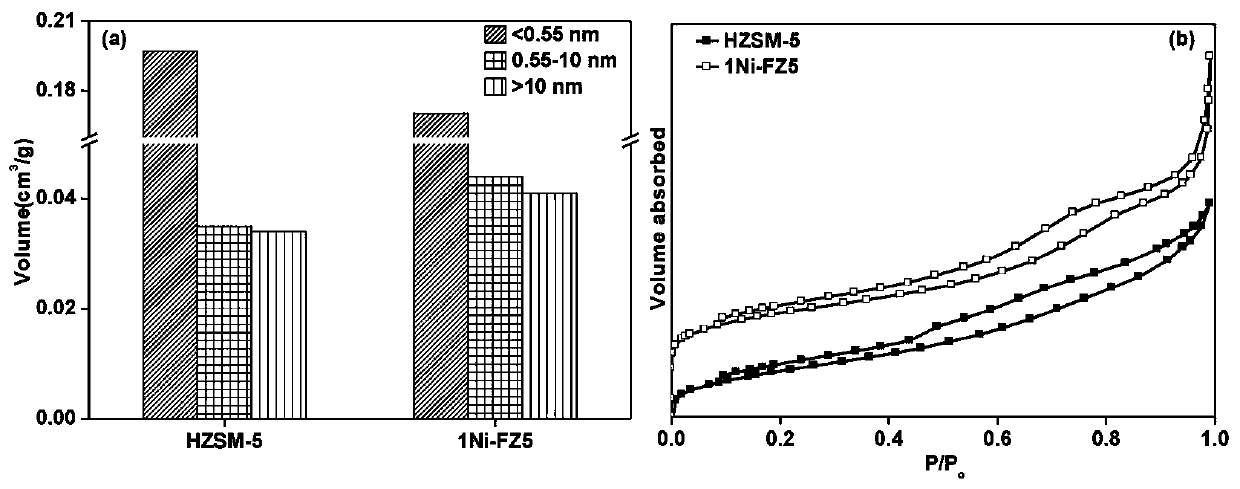

[0023] Step 1. Take 15g of commercial molecular sieve HZSM-5 and grind it into powder (below 200 mesh), put it into a muffle furnace for 10 o C / min heating rate increased to 550 o C roasting, keep 5 h. During the roasting process, the air flow is moderately introduced, and after the end, it is cooled to room temperature and stored in a dry place.

[0024] Step 2. Weigh 3.75 g of HF solution (37wt%) and mix it with deionized water in a polytetrafluoroethylene beaker. The total volume is 150 mL to prepare a 0.5mol / L HF acid etching solution. 15 g of molecular sieves pretreated in step 1 were mixed with hydrofluoric acid solution and stirred for 17 h, then suction filtered and washed until neutral. Then place the blast drying oven at 110 o C drying for 12 h. The dried samples were placed in a muffle furnace at 600 o C by 10 o C / min heating rate roasting 4 h. After finishing, cool down to room temperature to prepare graded zeolite.

[0025] Step 3. Weigh 0.74g of Ni (NO 3...

Embodiment 2

[0027] Example 2. The Ni-FZ5 molecular sieve prepared in Example 1 was used for catalytic reforming of biomass volatiles in a falling bed reactor. The catalyst is placed at the bottom of the quartz tube, and the upper layer is separated by quartz wool, and the dried biomass particles of 16-40 mesh are placed in the feeding bottle at a temperature of 20 o C / min heating rate up to 600 o At C, flow hydrogen at 100mL / min for reduction for 1h, then replace it with Ar, and lower the temperature to 500 o C keeps feeding at a rate of 0.1g / min, and keeps it for 15 minutes after feeding to ensure that the biomass is fully pyrolyzed. The obtained biomass volatiles are reformed in the catalytic bed and then collected with cold hydrazine, which has a good selectivity to light aromatics after testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com