Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Improve cold flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

ActiveUS7342070B2Reduce fuel consumptionImprove performanceSpecial tyresRolling resistance optimizationHysteresisPolymer science

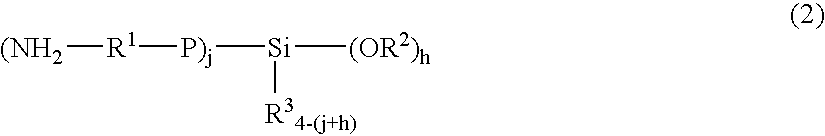

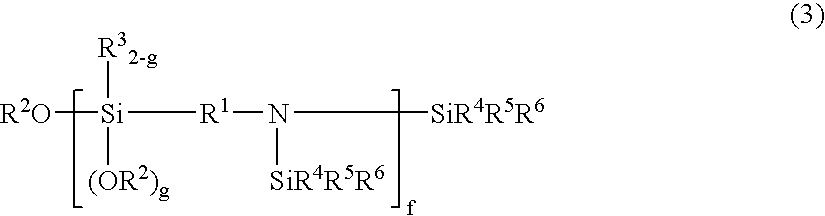

Disclosed are a conjugated diolefin (co) polymer rubber formed from either a conjugated diolefin or a conjugated diolefin and an aromatic vinyl compound, wherein the (co) polymer rubber has a primary amino group and an alkoxysilyl group which are bonded to a (co) polymer chain; a process for producing the same; a rubber composition; a composite; and a tire. The (co) polymer rubber has satisfactory processability, and can give an automotive tire tread having a balance among wear resistance, failure characteristics, low hysteresis loss and wet-skid characteristics.

Owner:ENEOS MATERIALS CORP

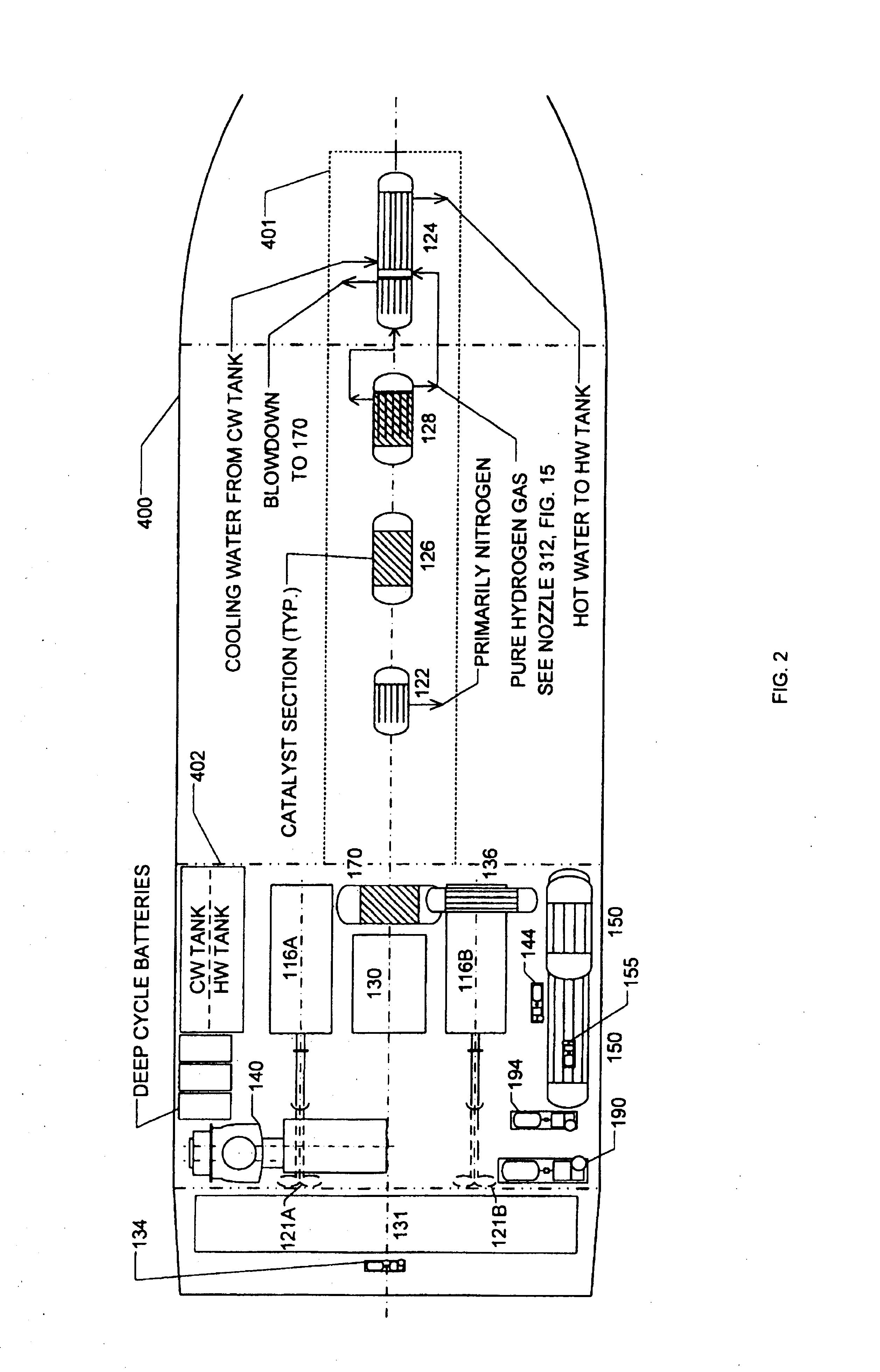

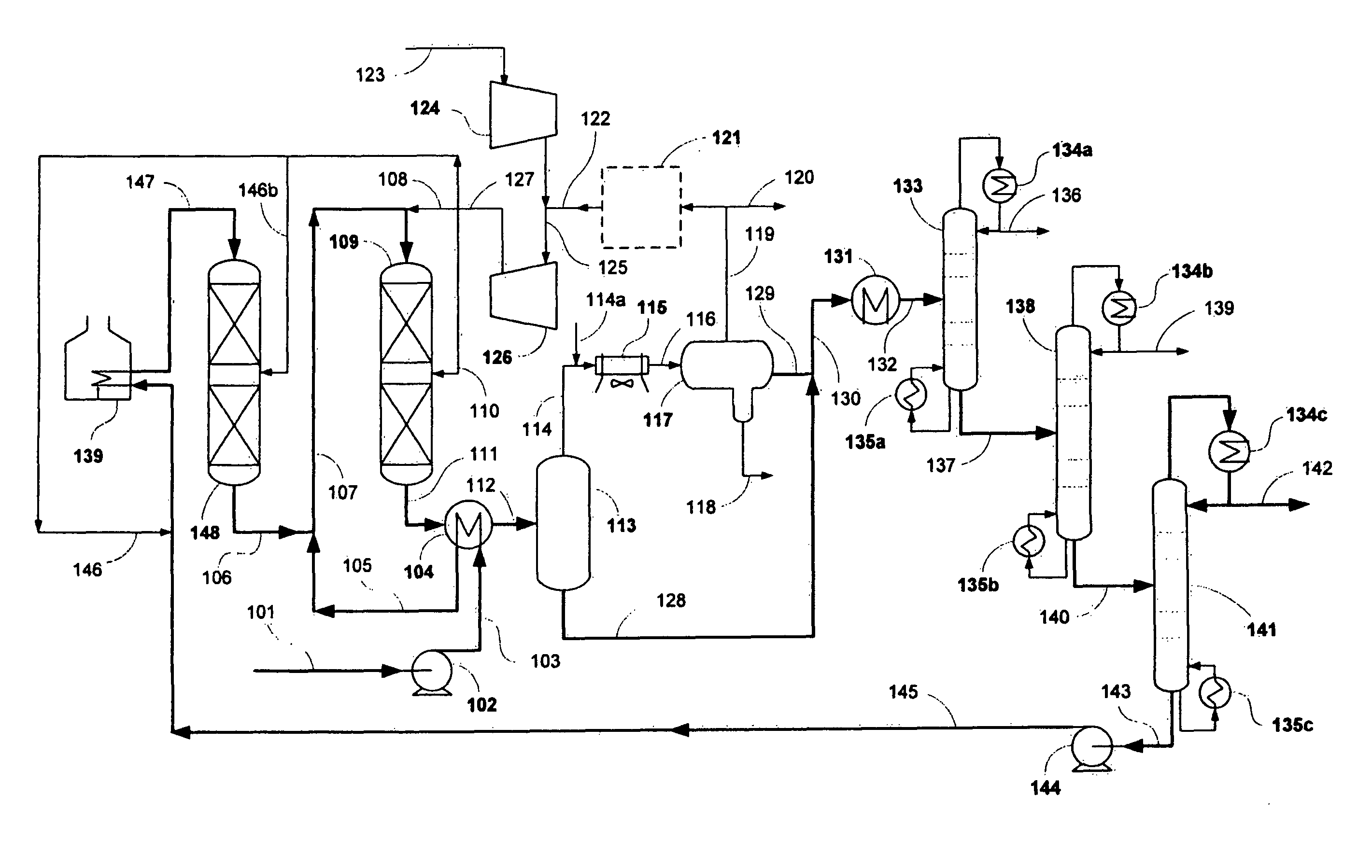

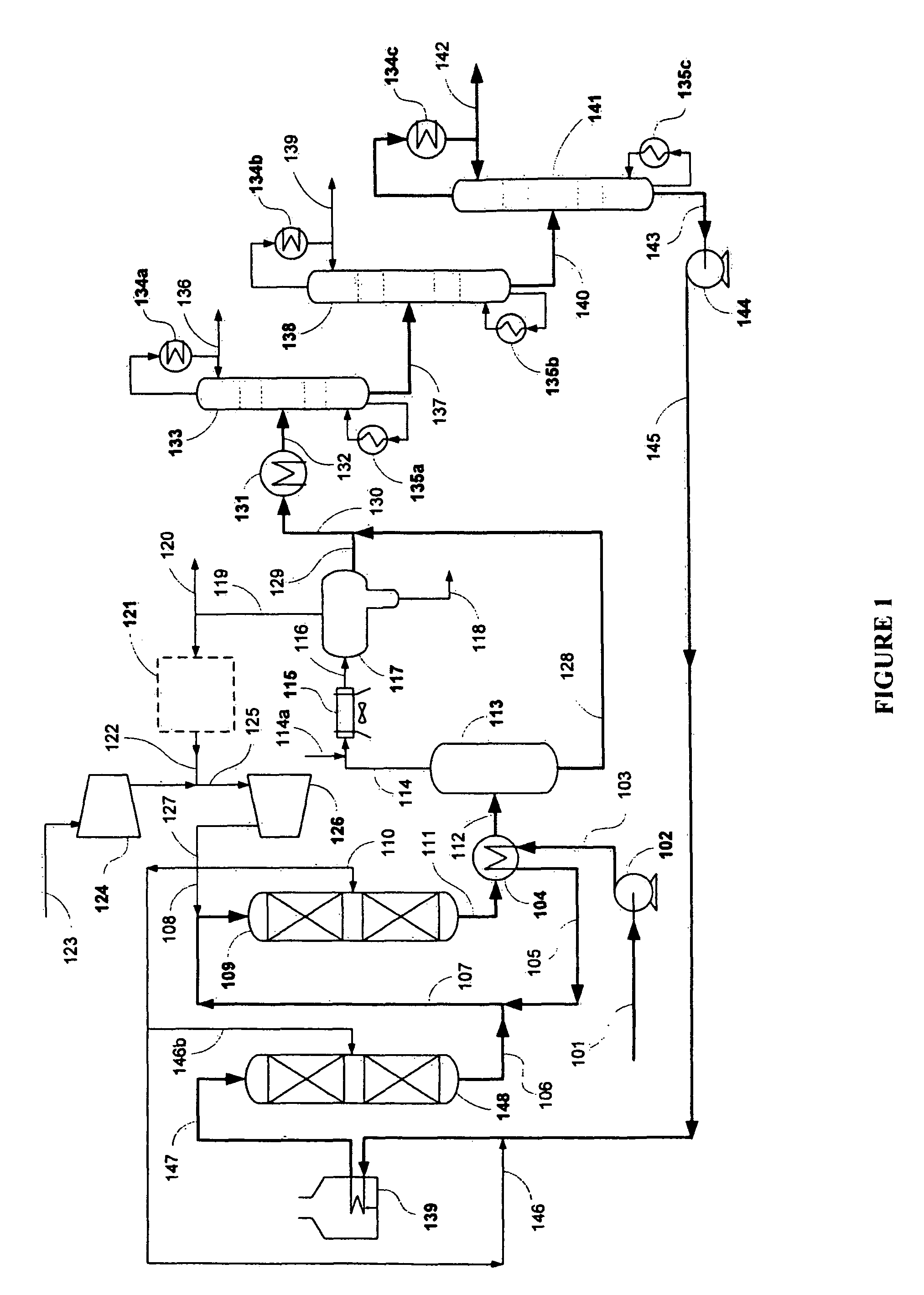

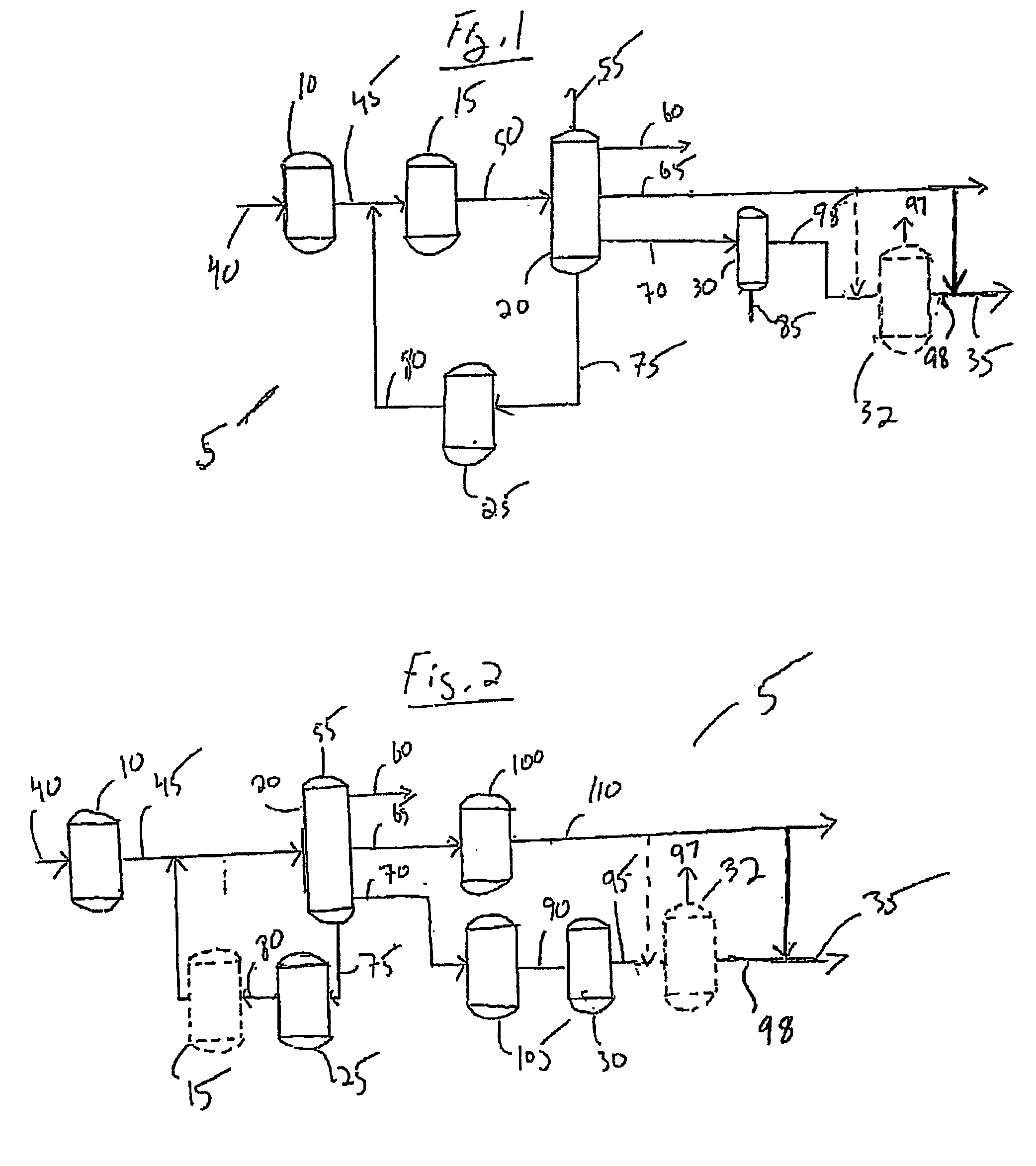

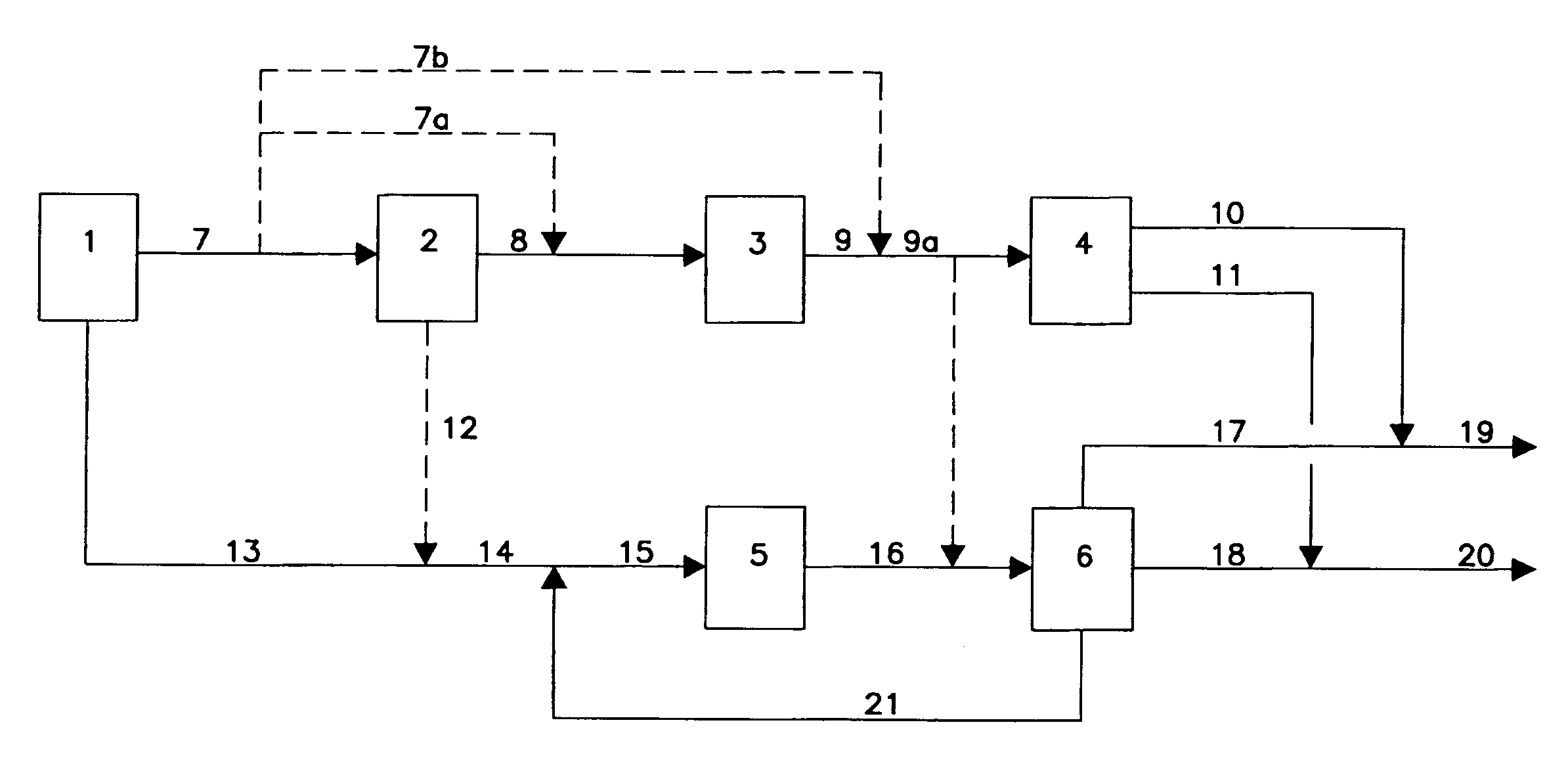

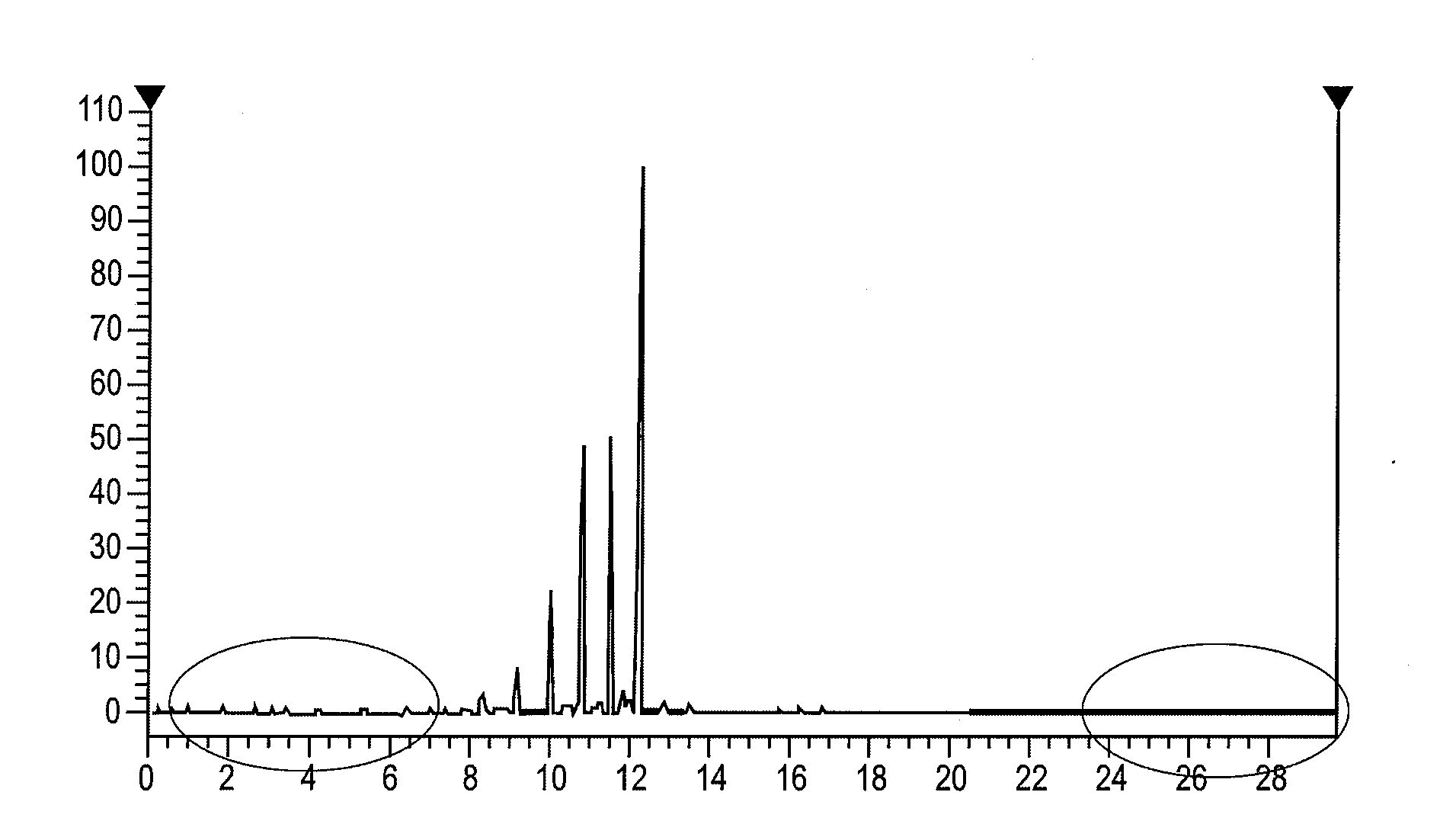

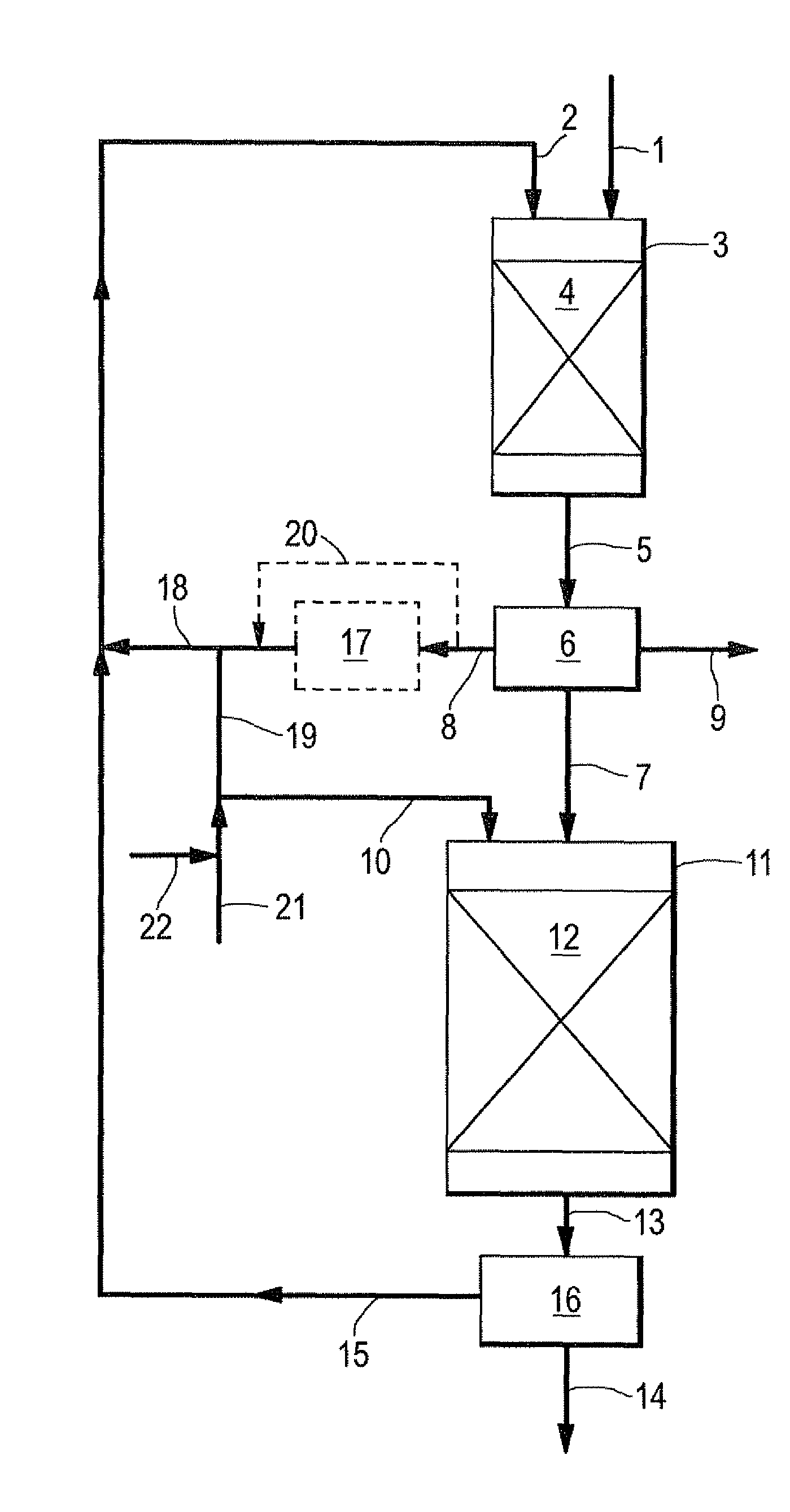

Fuel cell system with integrated fuel processor

InactiveUS20070122667A1MinimizesMaximize heat utilizationHydrogenOxygen/ozone/oxide/hydroxideBiodieselWater balance

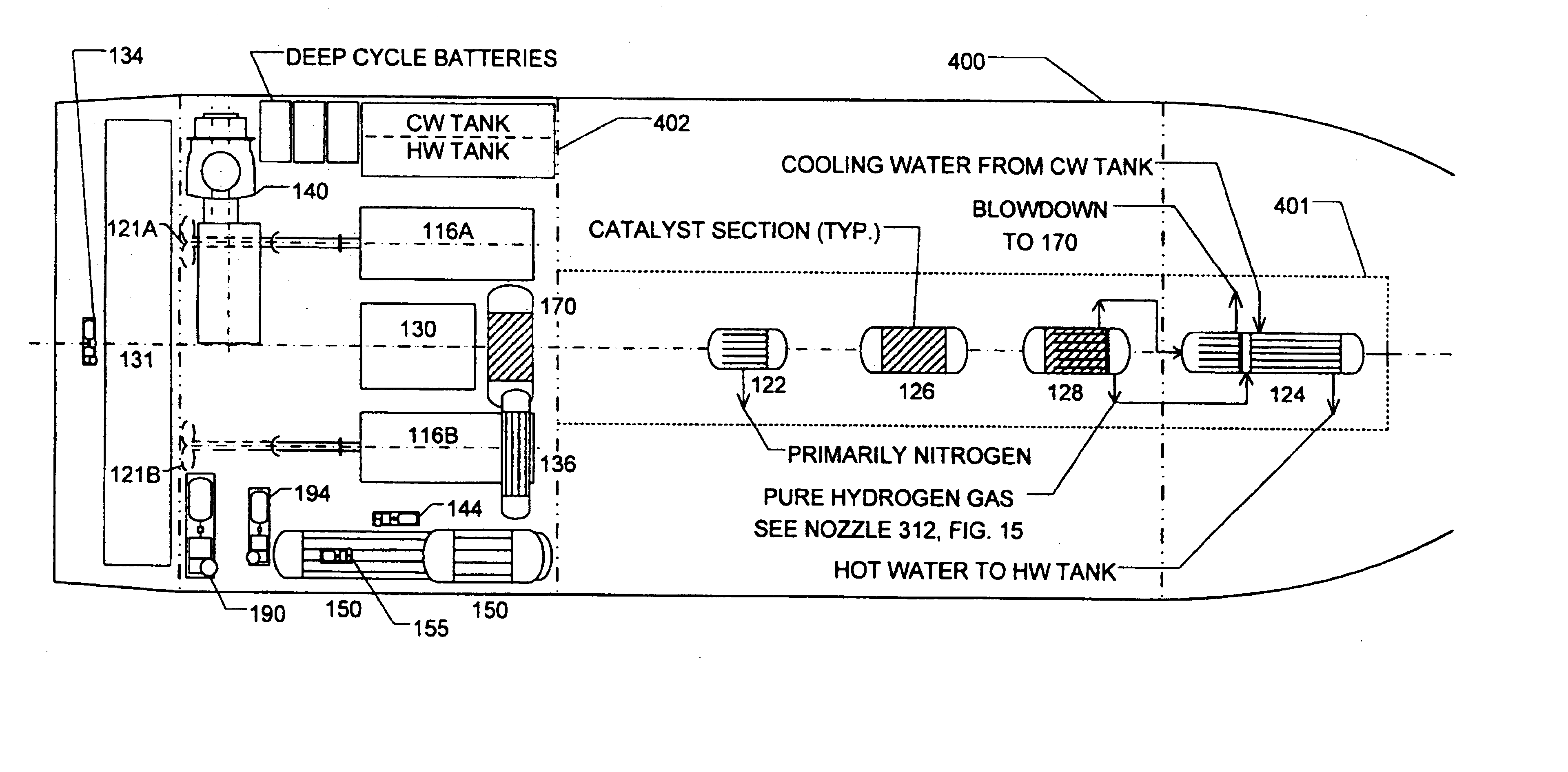

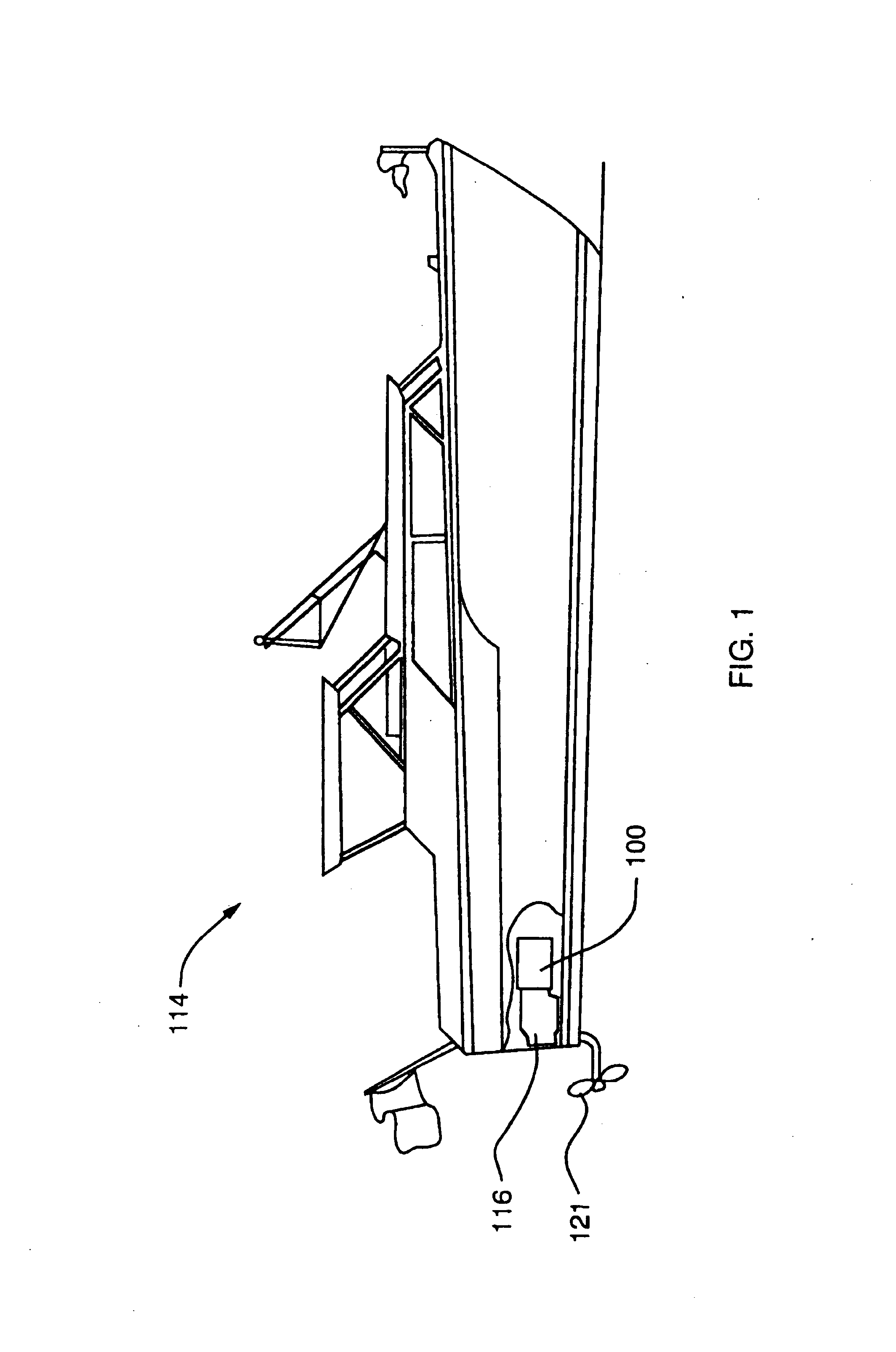

A fuel cell system with fuel processor for integration with a marine vessel propulsion system. The system includes an auto thermal reactor that is the fuel processor for producing hydrogen from a fuel source. The fuel source is preferably ethanol or biodiesel or a mixture thereof, but can also be a sulfur containing fuel like petrodiesel of JP-8. The system further includes a gas-water shift reactor for further production and concentration of the hydrogen from the auto thermal reactor output. The system also includes a hydrogen permeable membrane separator for generating suitable quantities of essentially pure hydrogen to the fuel cell. The system also includes an oxygen permeable membrane separator for concentrating oxygen and reducing nitrogen to improve the partial pressure of hydrogen in subsequent fuel processing steps. The system contemplates the use of a Polymer Electrolyte Membrane (PEM) fuel cell. The system minimizes preheating of catalysts or other components to the extent just needed to initiate the fuel processor. To that end, heat sources and sinks of the system and associated usage systems are matched so as to minimize heat collection, storage and distribution systems. Water is recycled within the system to the extent necessary to maintain a water balance in the fuel processor and the fuel cell stack(s). The system includes cooling of the fuel cell stack(s) and integrated heat recovery with exothermic and endothermic catalysts. The fuel processor / fuel cell system components are configured to conform to and take advantage of the available space and limitations, such as the space constraints and opportunities associated with a marine vessel.

Owner:KELLEY RICHARD H

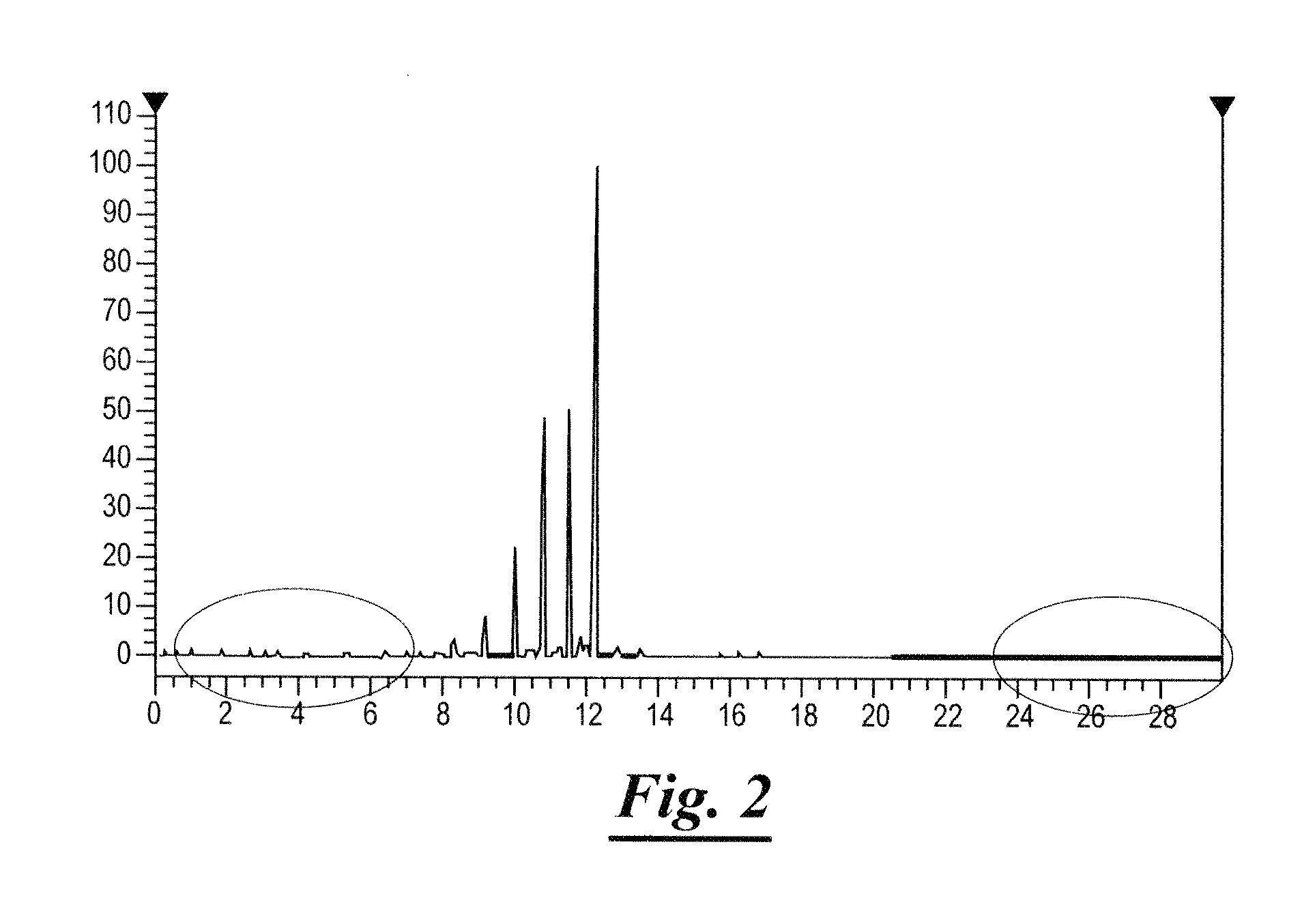

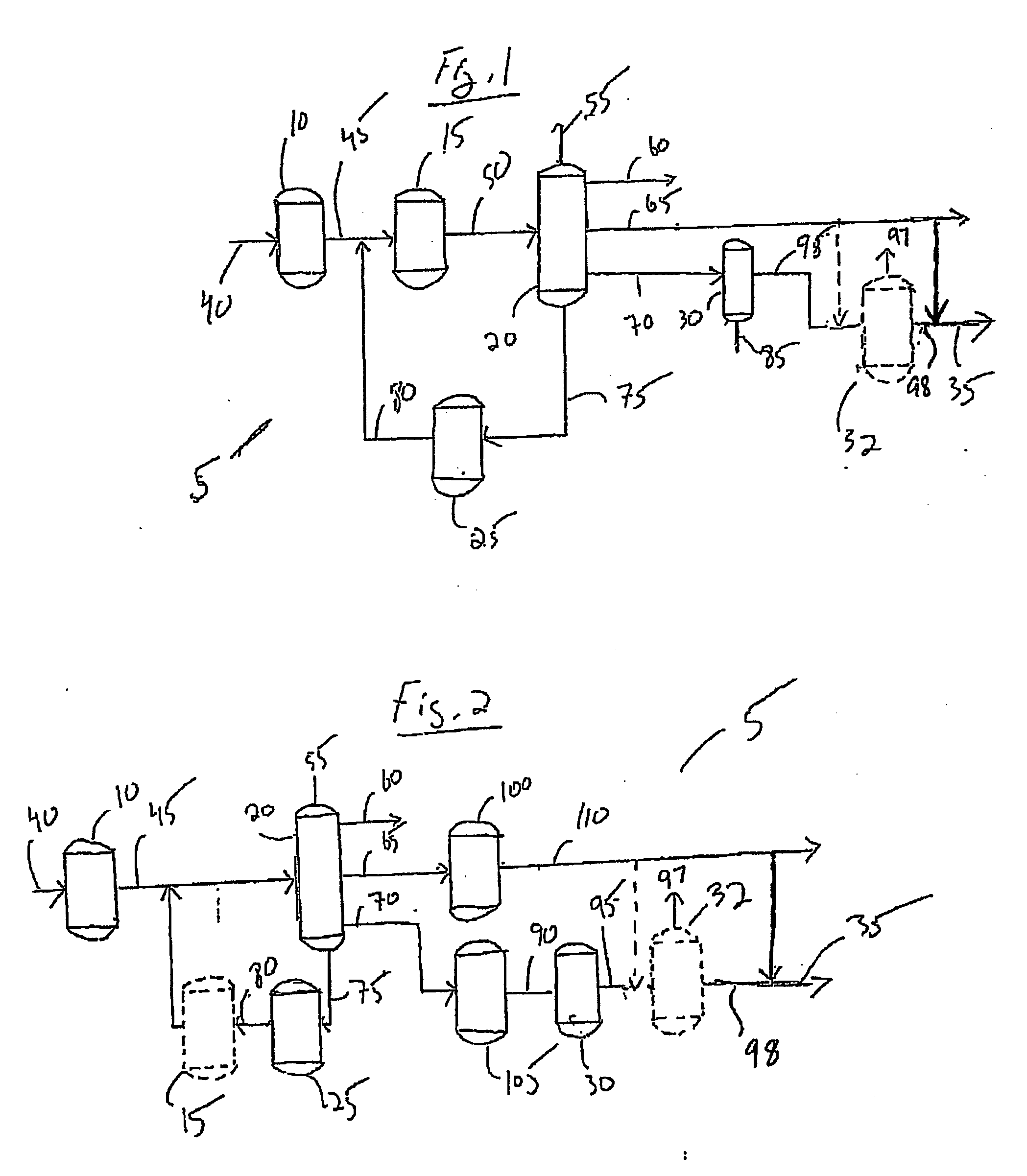

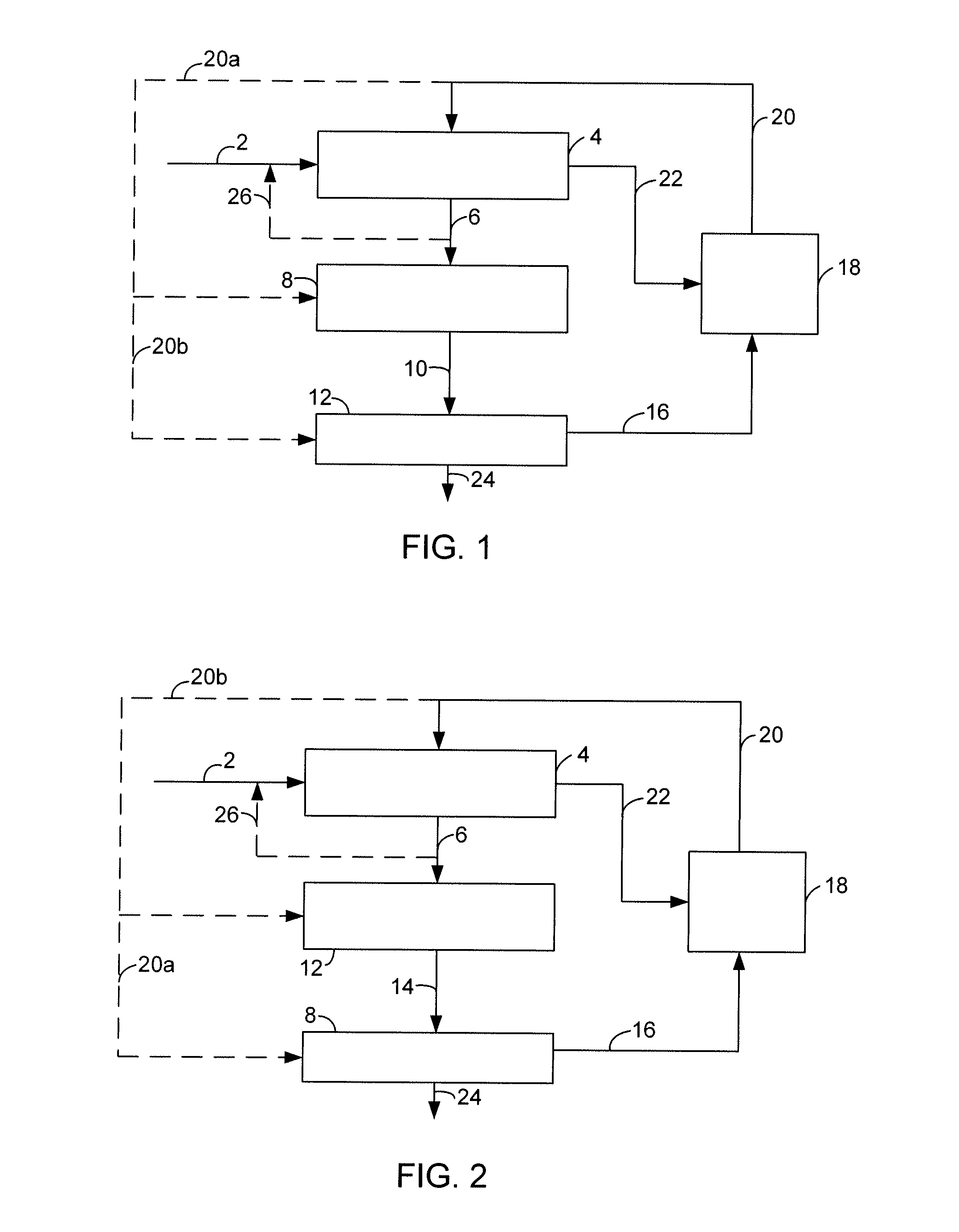

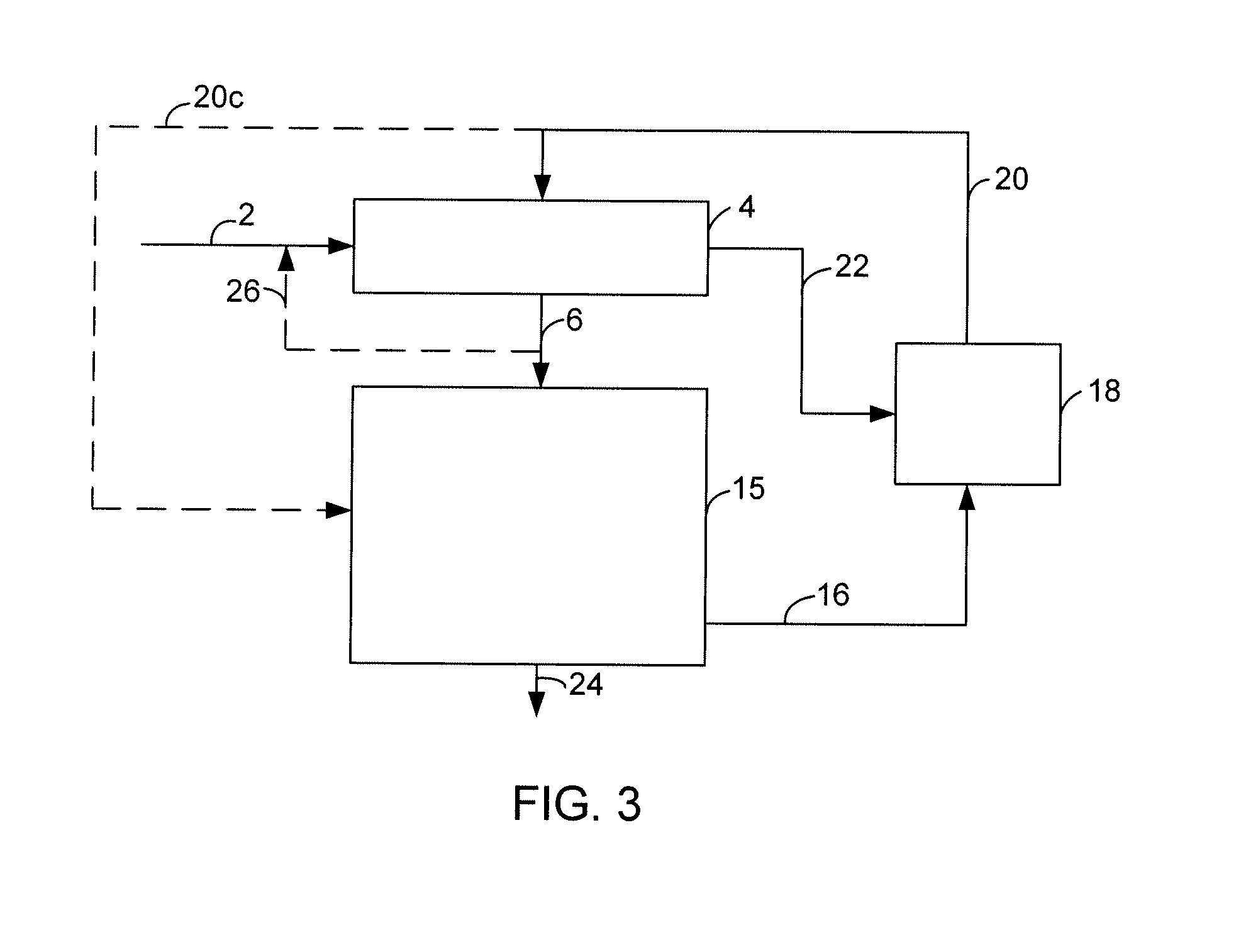

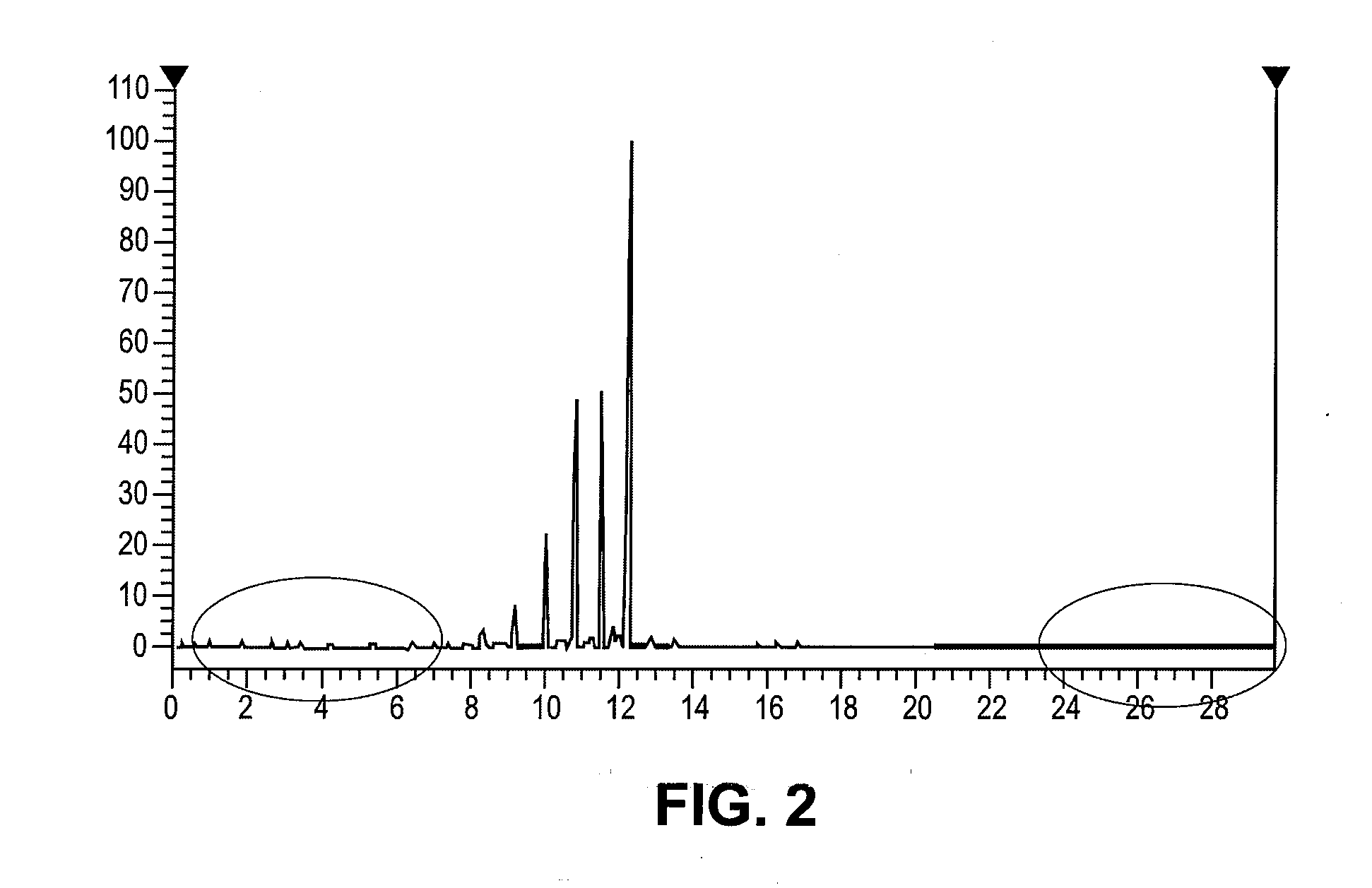

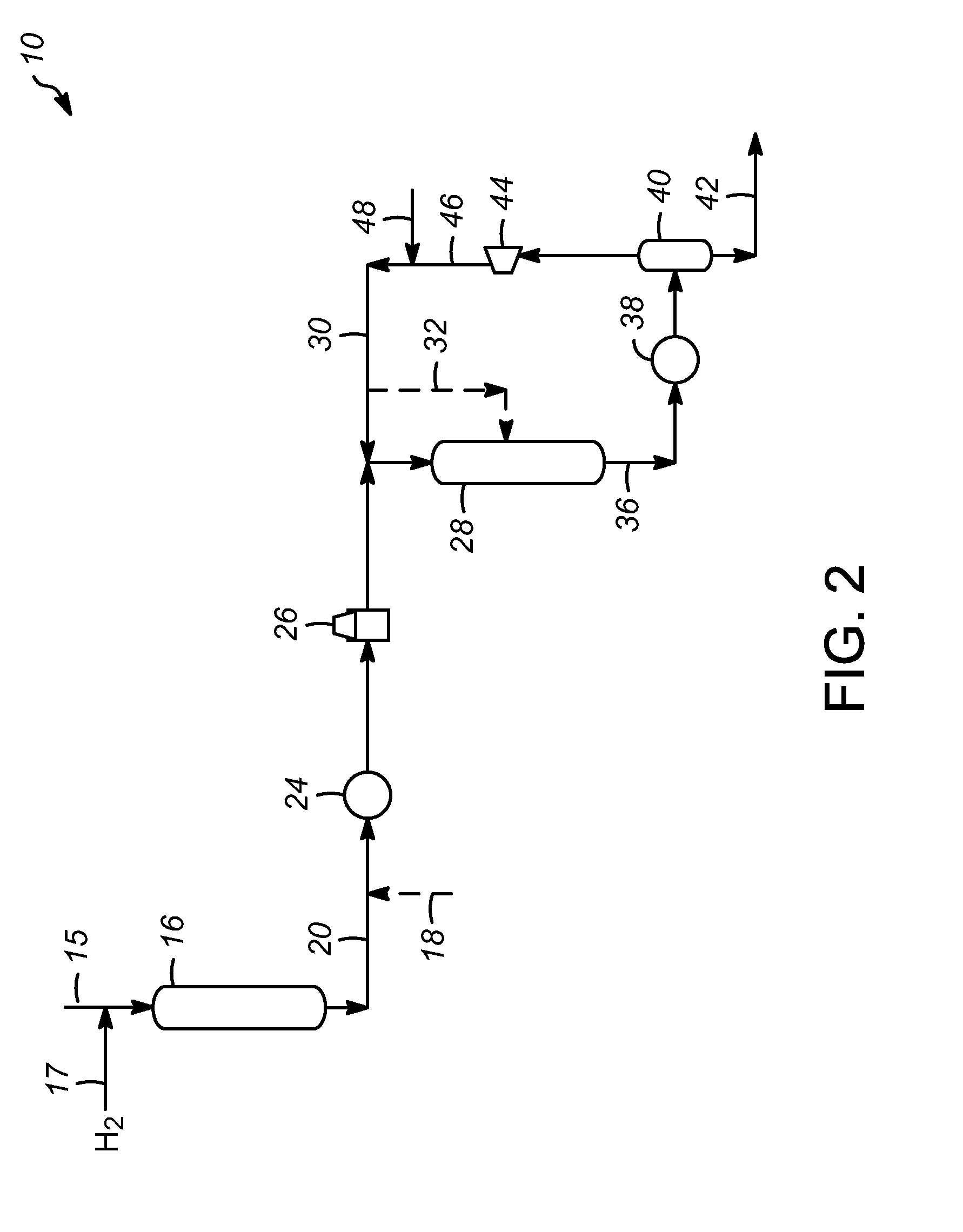

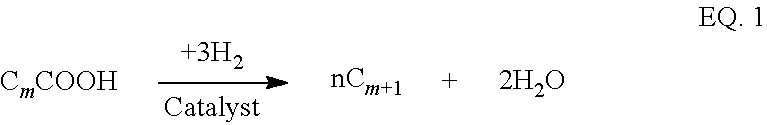

Process for co-producing jet fuel and LPG from renewable sources

ActiveUS7846323B2Improve cold flowHydrocarbon by hydrogenationLiquid hydrocarbon mixture productionEngineeringRenewable resource

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

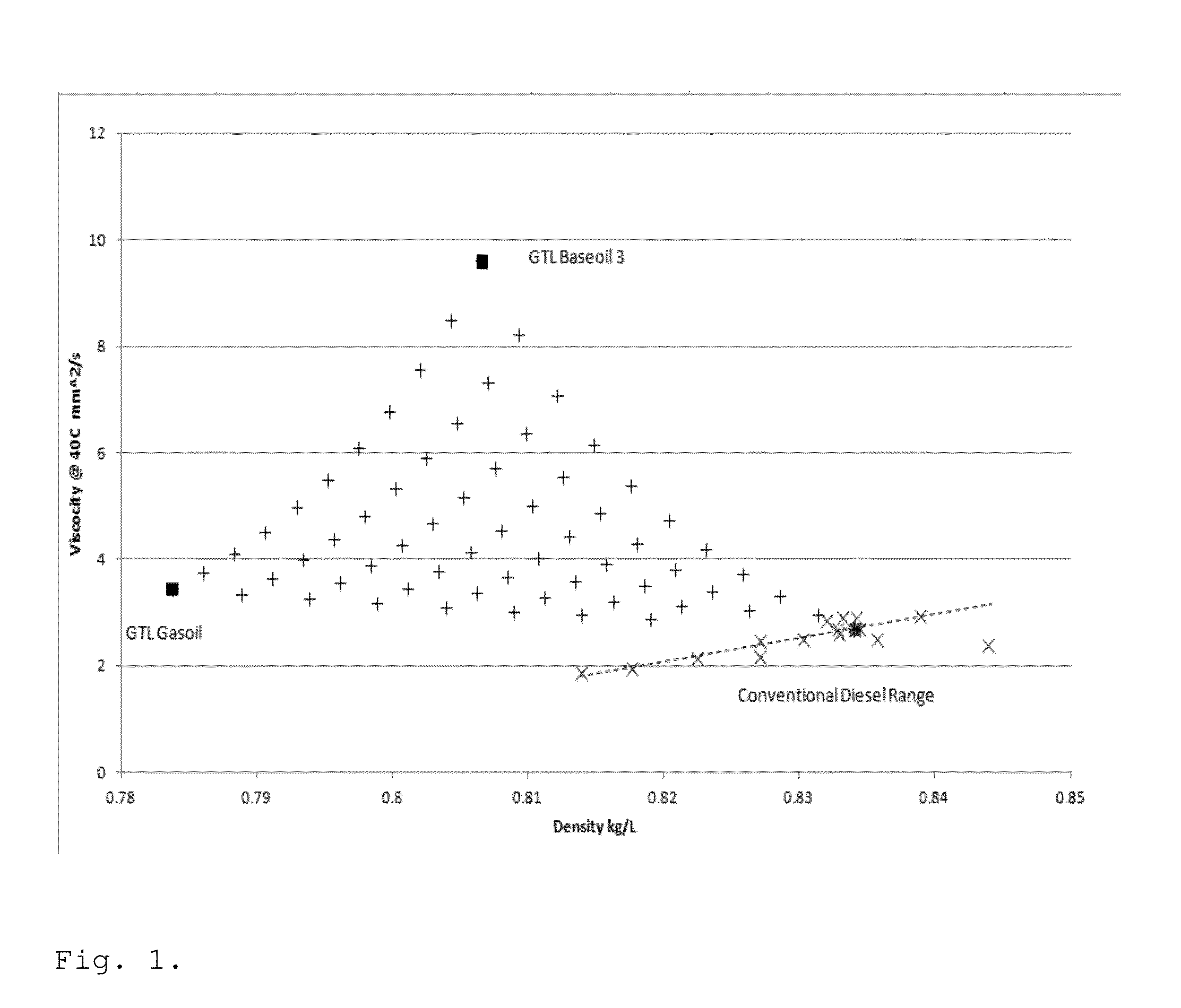

Blending of low viscosity Fischer-Tropsch base oils and Fischer-Tropsch derived bottoms or bright stock

ActiveUS7141157B2High kinematic viscosityLow viscosityHydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionBase oilViscosity

A process for preparing Fischer-Tropsch derived lubricating base oils by blending a Fischer-Tropsch distillate fraction having a viscosity of 2 or greater but less than 3 cSt at 100 degrees C. with a Fischer-Tropsch derived bottoms fraction; lubricating base oil compositions having a viscosity between about 3 and about 10 cSt at 100 degrees C. and a TGA Noack volatility of less than about 45 weight percent; and finished lubricants using the aforesaid lubricating base oils.

Owner:CHEVROU USA INC

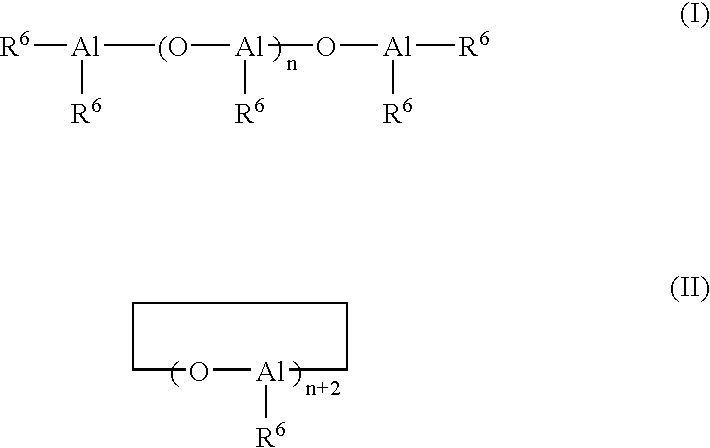

Method for producing modified conjugated diene polymer and rubber composition

ActiveUS20050009979A1Improve quality stabilityImprove abilitiesSpecial tyresPolymer scienceAqueous solution

Disclosed are a method for producing a modified conjugated diene polymer improved in quality stability, more enhanced in low heat buildup and reinforcing ability when used in a rubber composition, excellent in wear resistance, mechanical characteristics and processability, and improved in cold flow; and a rubber composition using the same. The method includes a step of modifying an active end of an active end-containing conjugated diene polymer having a cis-1,4-bond content of 75% or more with an alkoxysilane compound containing at least one functional group selected from the group consisting of (a) an epoxy group, (b) an isocyanate group and (c) a carboxyl group, and a step of adding a condensation accelerator to conduct condensation reaction of the alkoxysilane compound (residue) in an aqueous solution having a pH of 9 to 14 and a temperature of 85 to 180° C.

Owner:ENEOS MATERIALS CORP

Synthetic hydrocarbon products

InactiveUS20060016722A1Overcome deficienciesReadily apparentLiquid organic insulatorsHydrocarbon purification/separationIsomerizationEngineering

The invention includes a process for producing synthetic middle distillates and synthetic middle distillates produced therefrom. In one embodiment, the process comprises fractionating a hydrocarbon synthesis product to at least generate a light middle distillate, a heavy middle distillate, and a waxy fraction; thermally cracking the waxy fraction; and isomerizing the heavy middle distillate. A synthetic diesel or blending component is formed by the combination of at least a portion of the light middle distillate; at least a portion or fraction of the thermally cracked product; and at least a portion or fraction of the isomerized product. In some embodiments, the hydrocarbon synthesis product and / or the thermally cracked product may be hydrotreated. In other embodiments, a synthetic middle distillate comprises at least two fractions: a light fraction with not more than 10% branched hydrocarbons, and a heavy fraction with at least 30% branched hydrocarbons.

Owner:CONOCOPHILLIPS CO

Synthetic hydrocarbon products

InactiveUS20060006098A1Overcome deficienciesReadily apparentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyEngineeringHydrocarbon

The invention includes a process for producing synthetic middle distillates and synthetic middle distillates produced therefrom. In one embodiment, the process comprises fractionating a hydrocarbon synthesis product to at least generate a light middle distillate, a heavy middle distillate, and a waxy fraction; thermally cracking the waxy fraction; and isomerizing the heavy middle distillate. A synthetic diesel or blending component is formed by the combination of at least a portion of the light middle distillate; at least a portion or fraction of the thermally cracked product; and at least a portion or fraction of the isomerized product. In some embodiments, the hydrocarbon synthesis product and / or the thermally cracked product may be hydrotreated. In other embodiments, a synthetic middle distillate comprises at least two fractions: a light fraction with not more than 10% branched hydrocarbons, and a heavy fraction with at least 30% branched hydrocarbons.

Owner:PHILLIPS 66 CO

Process for producing middle distillates

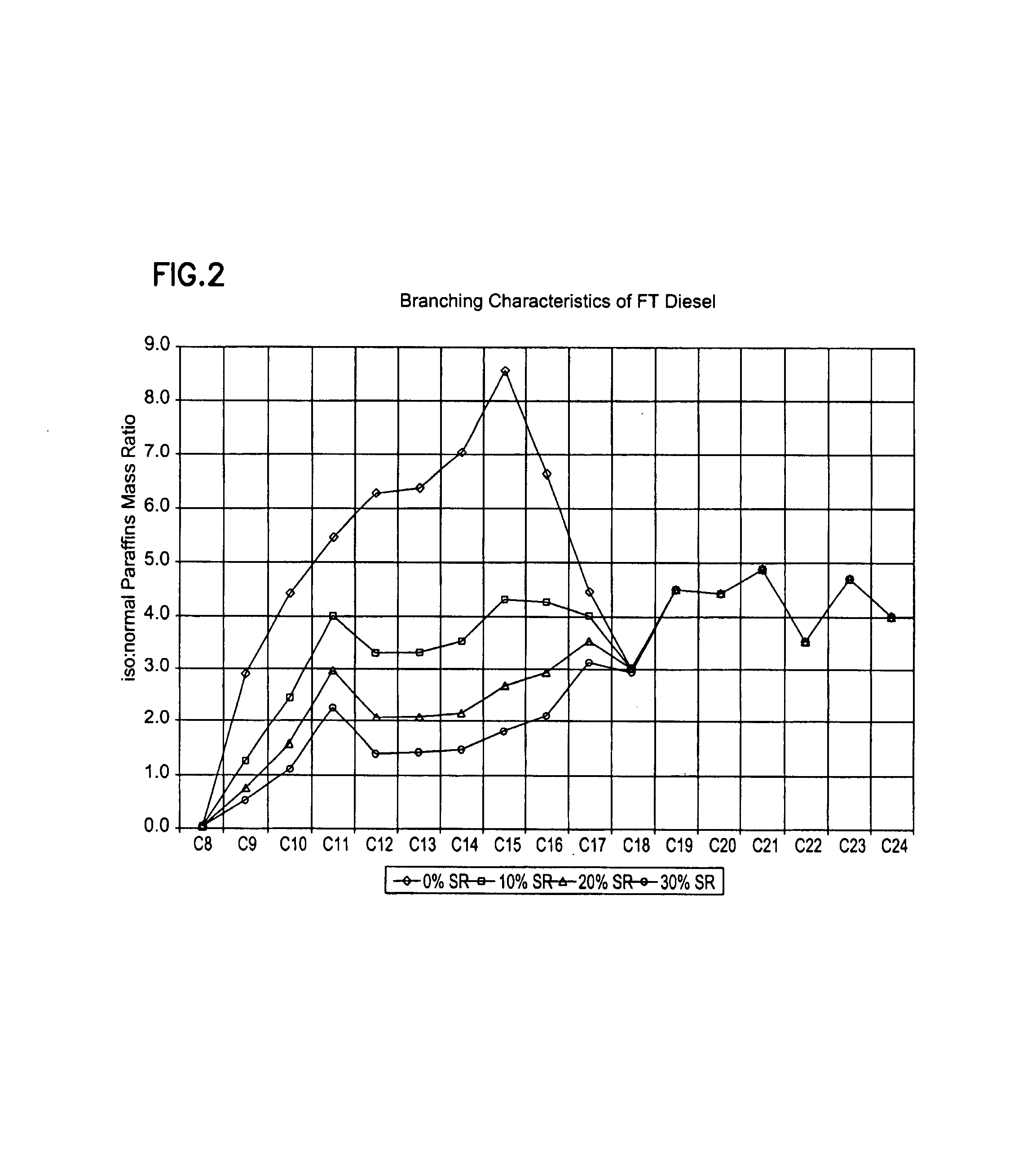

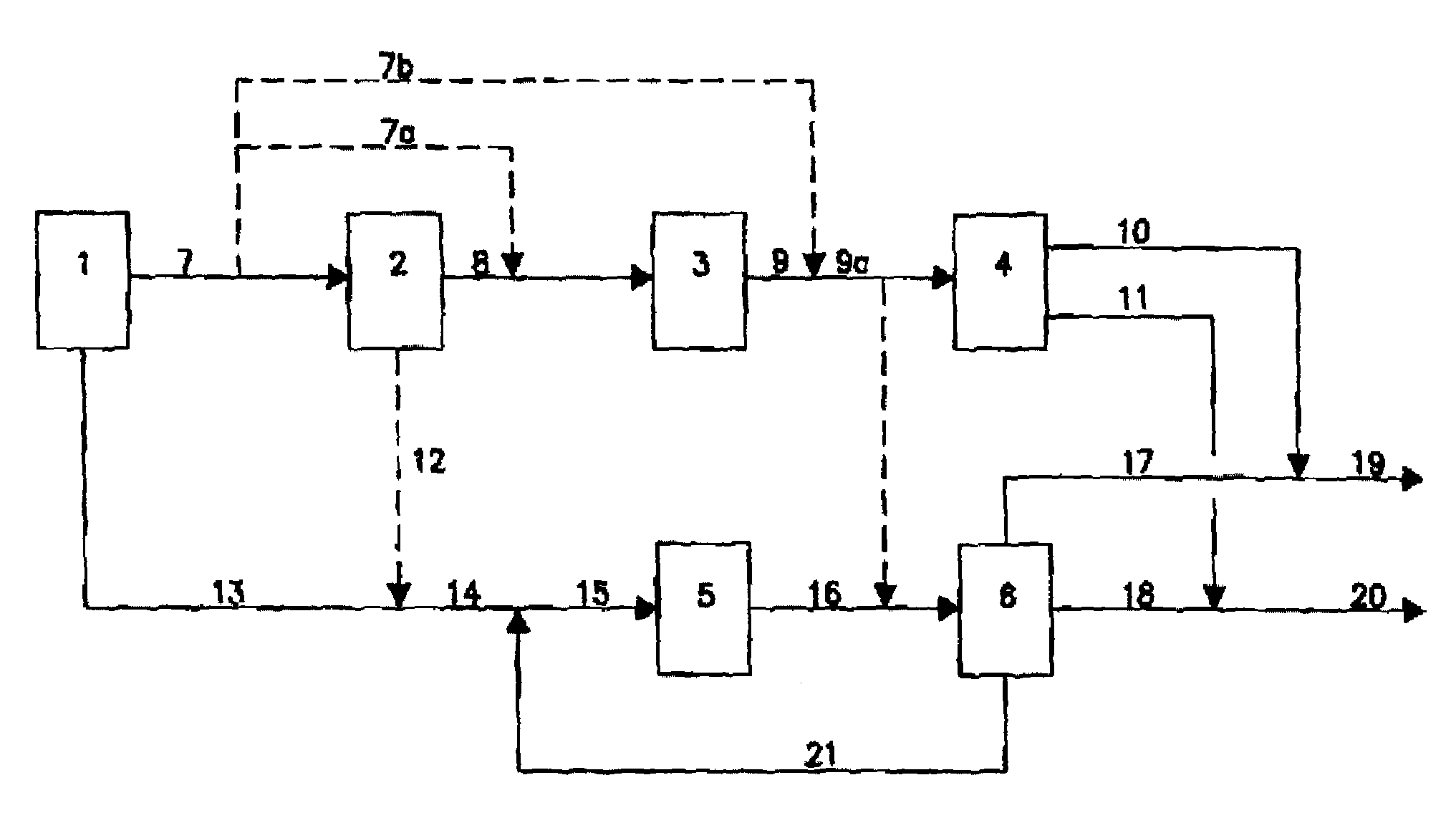

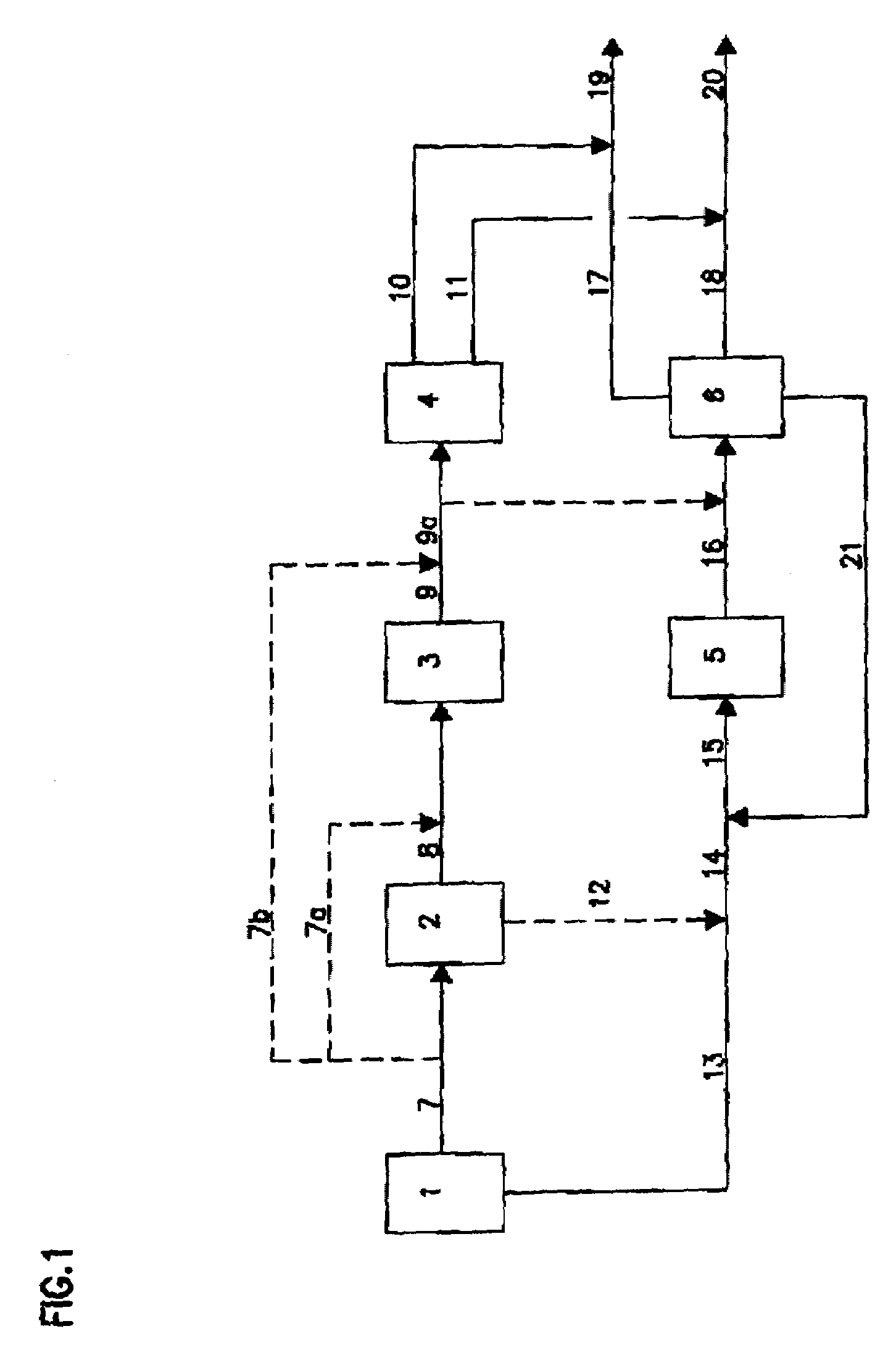

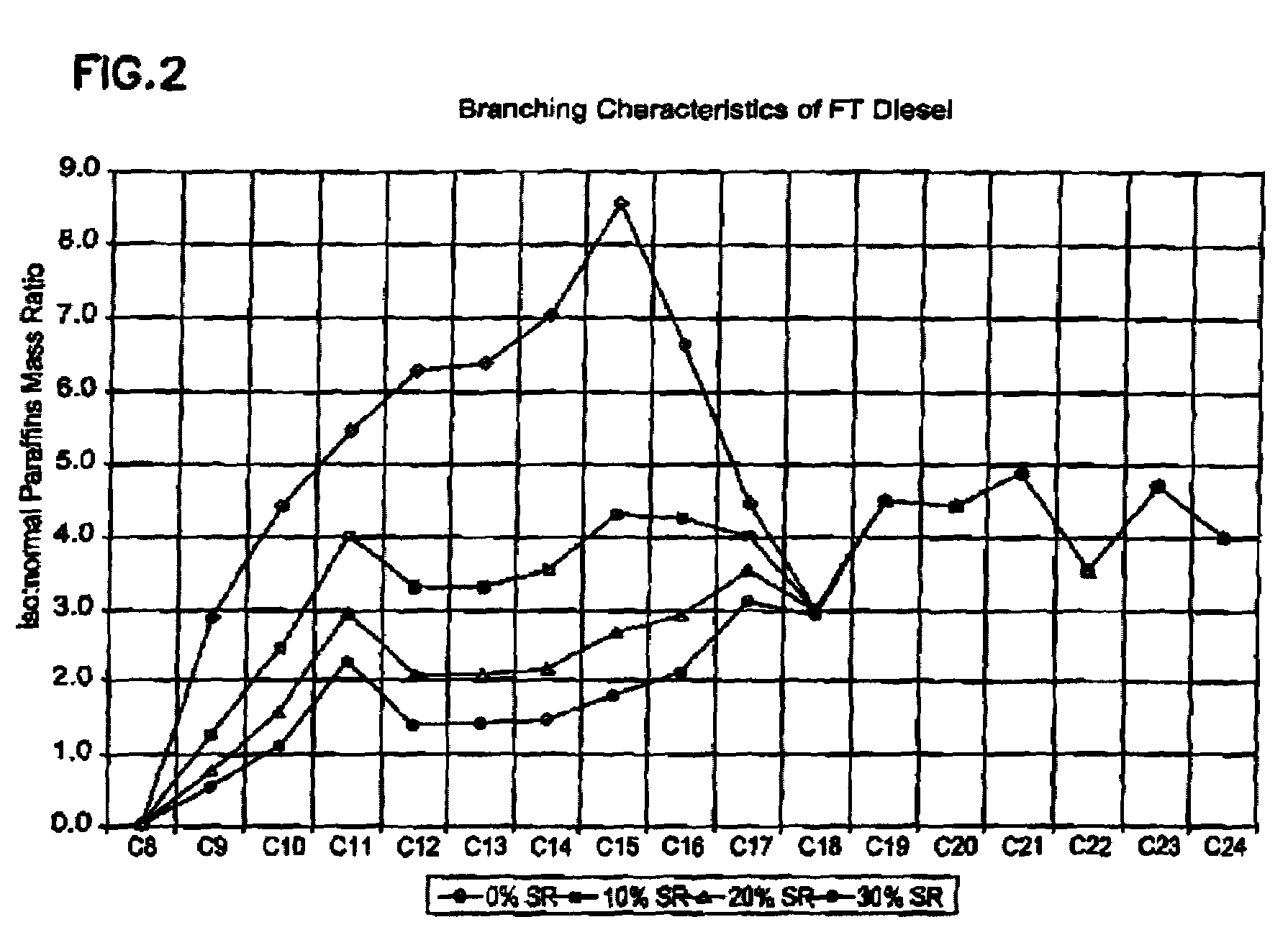

InactiveUS7294253B2Increase cetane numberImprove cold flowOrganic compounds purification/separation/stabilisationOrganic compound preparationAlkanePolymer science

This invention relates to process for producing middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method 309, and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to a process in which middle distillates are produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates produced by the process of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched.

Owner:SASOL TECHNOLOGY (PTY) LTD

Process for producing middle distillates and middle distillates produced by that process

InactiveUS7217852B1Increase cetane numberImprove cold flowHydrocarbon by hydrogenationHydrocarbon distillationAlkaneCold filter plugging point

This invention relates to middle distillates having good cold flow properties, such as the Cold Filter Plugging Point (CFPP) measured in accordance with the IP method (309), and a high Cetane number, as well as to a process for production of such distillates. More particularly, this invention relates to middle distillates produced from a mainly paraffinic synthetic crude which is produced by the reaction of CO and H2, typically by the Fischer-Tropsch (FT) process. The middle distillates of the invention are predominantly isoparaffinic, the isoparaffins being methyl, ethyl and / or propyl branched. The invention also provides a diesel fuel composition including the middle distillates in accordance with the invention. A process for preparing the middle distillates is also included in the invention.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Process for producing hydrocarbons

ActiveUS20160177188A1Improve performanceGuaranteed uptimeRefining to change hydrocarbon structural skeletonLiquid carbonaceous fuelsDiluentFatty acid

The present invention relates to process for producing hydrocarbons, wherein starting material comprising tall oil material and polar co-feed, which polar co-feed comprises fatty acids, is diluted with a non-polar diluent to obtain feedstock, and said feedstock is catalytically hydroprocessed to obtain hydrocarbons, suitable as fuels, fuel blending components and fuel additives.

Owner:UPM-KYMMENE OYJ

Method for producing modified conjugated diene polymer and rubber composition

ActiveUS7202306B2Improve quality stabilityImprove abilitiesSpecial tyresWear resistanceAqueous solution

Disclosed are a method for producing a modified conjugated diene polymer improved in quality stability, more enhanced in low heat buildup and reinforcing ability when used in a rubber composition, excellent in wear resistance, mechanical characteristics and processability, and improved in cold flow; and a rubber composition using the same. The method includes a step of modifying an active end of an active end-containing conjugated diene polymer having a cis-1,4-bond content of 75% or more with an alkoxysilane compound containing at least one functional group selected from the group consisting of (a) an epoxy group, (b) an isocyanate group and (c) a carboxyl group, and a step of adding a condensation accelerator to conduct condensation reaction of the alkoxysilane compound (residue) in an aqueous solution having a pH of 9 to 14 and a temperature of 85 to 180° C.

Owner:ENEOS MATERIALS CORP

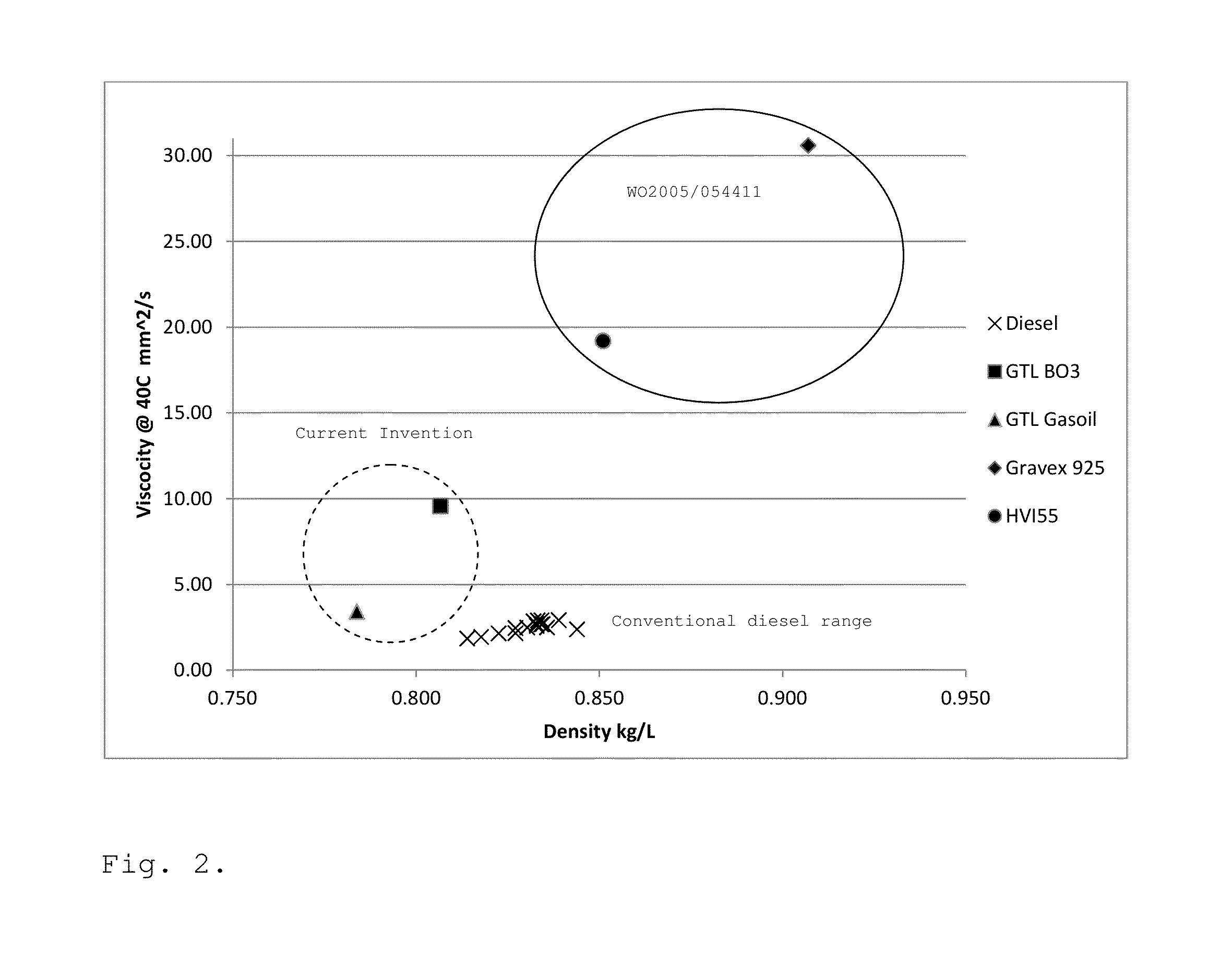

Fuel compositions

Middle distillate fuel composition is provided containing (a) a middle distillate base fuel, in particular a diesel base fuel, and (b) a Fischer-Tropsch derived paraffinic base oil component with a viscosity of at least 8 mm2 / s at 100° C. In component (b), the ratio of the percentage of epsilon methylene carbon atoms to the percentage of isopropyl carbon atoms is suitably 8.2 or below. Its pour point may be −30° C. or lower. Also disclosed is the use of a Fischer-Tropsch derived paraffinic heavy base oil in a middle distillate fuel composition, for the purpose of improving the cold flow properties of the composition and / or for reducing the concentration of a cold flow or flow improver additive in the composition.

Owner:SHELL USA INC

Production of Aviation Fuel from Biorenewable Feedstocks

InactiveUS20090162264A1Improve cold flowHigh selectivityRefining to change hydrocarbon structural skeletonBiofuelsJP-8Alkane

A process has been developed for producing aviation fuel from renewable feedstocks such as plant oils and animals fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide n-paraffins having from about 8 to about 24 carbon atoms. At least some of the n-paraffins are isomerized to improve cold flow properties. At least a portion of the paraffins are selectively cracked to provide paraffins meeting specifications for different fuels such as JP-8.

Owner:UOP LLC

Composition for use in the manufacture of polyurethane systems

InactiveUS20140221518A1Minimal deformationReduce settlementSugar derivativesOther chemical processesOxygenOxygen atom

The invention relates to a composition for producing a polyurethane system, especially a polyurethane foam. The composition comprising one or more compounds comprising at least one 5- or 6-membered ring comprising one or two oxygen atoms and carbon atoms The present invention also relates to a process for producing polyurethane systems by using this composition as well as polyurethane systems obtained from such a process. The present invention also relates to the use of the polyurethane system of the present invention.

Owner:EVONIK DEGUSSA GMBH

Preparation and coating method of anti-corrosive anti-scale coating material

PendingCN105199497AImprove mechanical propertiesLower surface energyPretreated surfacesAnti-corrosive paintsMechanical propertyPolytetrafluoroethylene

The invention discloses a preparation and coating method of an anti-corrosive anti-scale coating material. The method comprises the steps that polytef emulsion is mixed with same amount of absolute ethyl alcohol, and stirred liquid is added into mixed sol obtained by mixing prepared graphene dispersion liquid and titanium dioxide colloid; the coating material is obtained after high-speed stirring is conducted. A metal substrate is coated with the coating material, and a composite nano coating modified metal sheet is obtained after high-temperature sintering, cooling, temperature conservation and drying are sequentially conducted. The preparation and coating method of the anti-corrosive anti-scale coating material has the advantages that the coating material is used for corrosion and scaling prevention of the surface of metal heat exchange equipment, and the defects that a pure polytef coating is prone to creep deformation, poor in heat conductivity and poor in abrasive resistance are significantly improved. By means of introduction of graphene and titanium dioxide composite nano materials, the surface energy of polytef is decreased, the cold flow property and the heat transfer property of the polytef are significantly improved, the anti-fouling performance of the coating is improved, the abrasion resistance of the polytef is significantly improved, the mechanical properties of a composite coating are enhanced, the service life of the coating is prolonged, and the coating material is widely applied to various water-medium heat-exchange equipment.

Owner:DUNAN TIANJIN ENERGY SAVING SYST

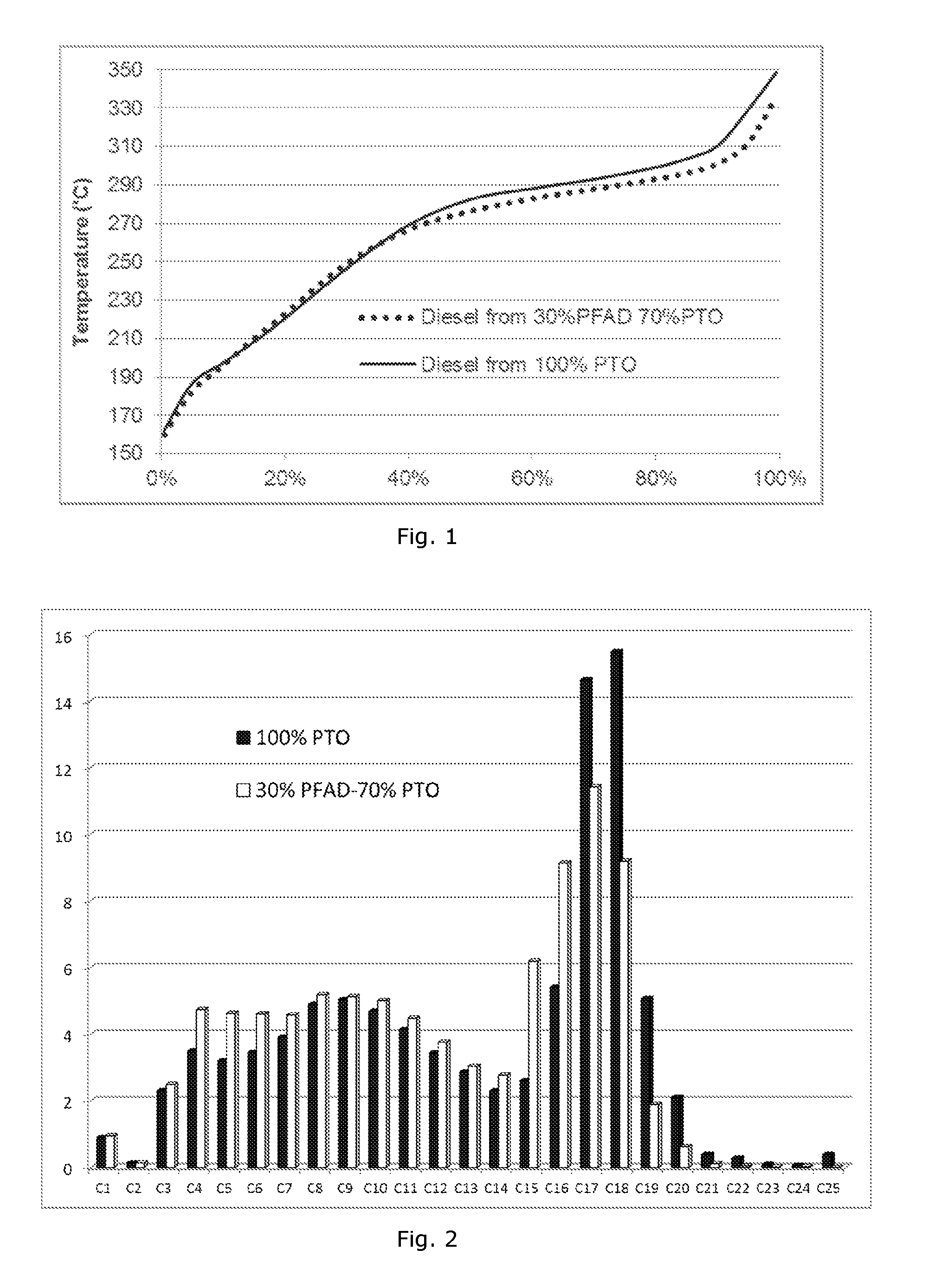

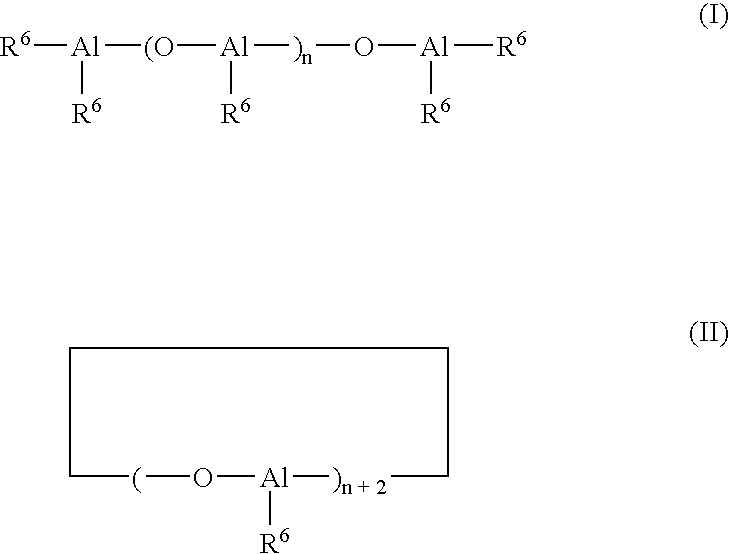

Blended fuel composition having improved cold flow properties

There is provided a fuel composition comprising petroleum based component and a renewable based component, wherein at least 20% of the compounds in said petroleum based component having boiling point range equal or greater than the boiling point of said renewable based component.

Owner:PHILLIPS 66 CO

Process for co-producing jet fuel and LPG from renewable sources

The present invention generally relates to a method for producing an isoparaffinic product useful as jet fuel from a renewable feedstock. The method may also include co-producing a jet fuel and a liquefied petroleum gas (LPG) fraction from a renewable feedstock. The method includes hydrotreating the renewable feedstock to produce a hydrotreating unit heavy fraction that includes n-paraffins and hydroisomerizing the hydrotreating unit heavy fraction to produce a hydroizomerizing unit heavy fraction that includes isoparaffins. The method also includes recycling the hydroisomerizing unit heavy fraction through the hydroisomerization unit to produce an isoparaffinic product that may be fractionated into a jet fuel and an LPG fraction. The present invention also relates to a jet fuel produced from a renewable feedstock having improved cold flow properties.

Owner:REG SYNTHETIC FUELS LLC

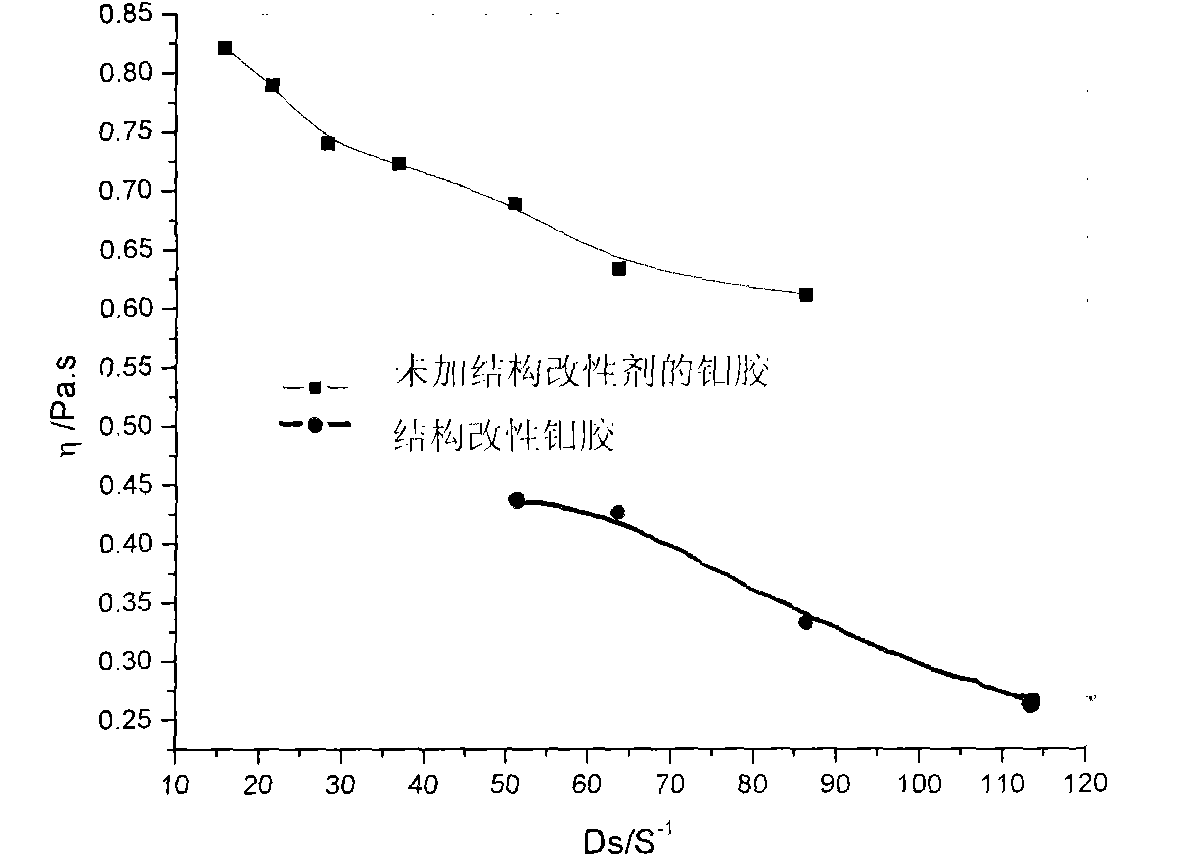

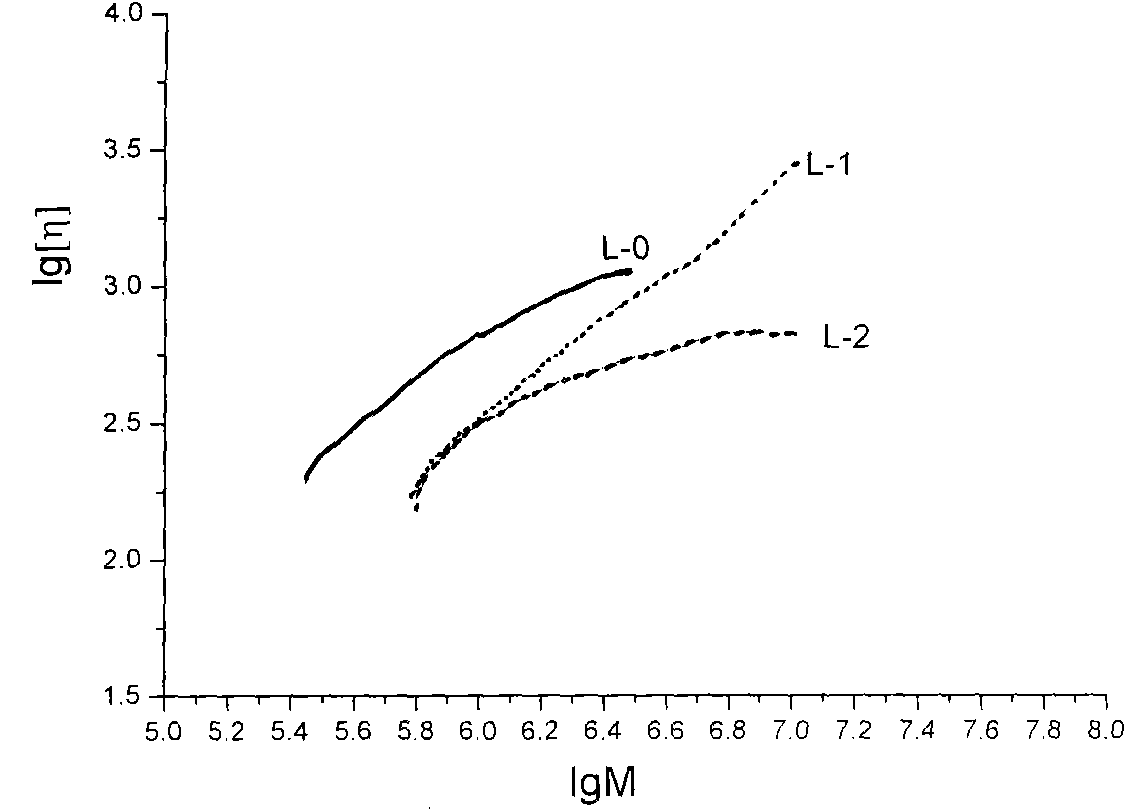

Preparation method of structure-modified 1,2-polybutadiene rubber

The invention relates to a preparation method of structure-modified 1,2-polybutadiene rubber, belongs to a macromolecular compound obtained by carbon-carbon unsaturated bond reaction, relates to a preparation method of butadiene homopolymers, and is characterized by comprising (1) raw materials used; (2) the preparation method of the structure-modified 1,2-polybutadiene rubber; (3) a preparation method of mixed stock of the structure-modified 1,2-polybutadiene rubber. The invention provides a molybdenum catalyst system which can substantially raise the activity of the catalysis system, reduce the molecular weight of a polymerization product, widen molecular weight distribution and decrease the polymerization glue solution viscosity, and simultaneously also provides a structure modifier for improving cold-flow performance and processability of a polymer and wet traction and aging resistance of vulcanized rubber and greatly increasing the service life of the rubber by generating a branched structure of the polymer, so as to realize the industrial preparation method of the structure-modified 1,2-polybutadiene rubber product by molybdenum catalytic synthesis.

Owner:CHINA PETROLEUM & CHEM CORP

Methods for producing diesel range materials having improved cold flow properties

InactiveUS20120090223A1Improve cold flowImprove catalytic selectivityRefining to change hydrocarbon structural skeletonCatalytic naphtha reformingAlkaneProcess conditions

Embodiments of a method for producing a diesel range material having improved cold flow properties are provided. In one embodiment, the method includes the steps of providing a waxy diesel range feedstock, producing an intermediary product stream containing a predetermined amount of oxygenated organocompounds from the waxy diesel range feedstock, and contacting the intermediary product stream with a dewaxing catalyst under process conditions at which the oxygenated organocompounds chemically interact with the dewaxing catalyst to convert a portion of the n-paraffins within the intermediary product stream to iso-paraffins while minimizing cracking of the diesel range material.

Owner:UOP LLC

Method for producing modified conjugated diene polymer and rubber composition

InactiveUS20060264560A1Improve quality stabilityImprove abilitiesSpecial tyresOrganic dyesPolymer sciencePolymer

Owner:JSR CORPORATIOON

Synthetic hydrocarbon products

InactiveUS7345211B2Reduce the numberImprove cold flowThermal non-catalytic crackingTreatment with plural serial cracking stages onlyEngineeringHydrocarbon

The invention includes a process for producing synthetic middle distillates and synthetic middle distillates produced therefrom. In one embodiment, the process comprises fractionating a hydrocarbon synthesis product to at least generate a light middle distillate, a heavy middle distillate, and a waxy fraction; thermally cracking the waxy fraction; and isomerizing the heavy middle distillate. A synthetic diesel or blending component is formed by the combination of at least a portion of the light middle distillate; at least a portion or fraction of the thermally cracked product; and at least a portion or fraction of the isomerized product. In some embodiments, the hydrocarbon synthesis product and / or the thermally cracked product may be hydrotreated. In other embodiments, a synthetic middle distillate comprises at least two fractions: a light fraction with not more than 10% branched hydrocarbons, and a heavy fraction with at least 30% branched hydrocarbons.

Owner:PHILLIPS 66 CO

Process for improving friability and cold-flow of carbon dioxide epoxy propylane copolymer

Owner:迁安市宏奥低碳科技有限公司

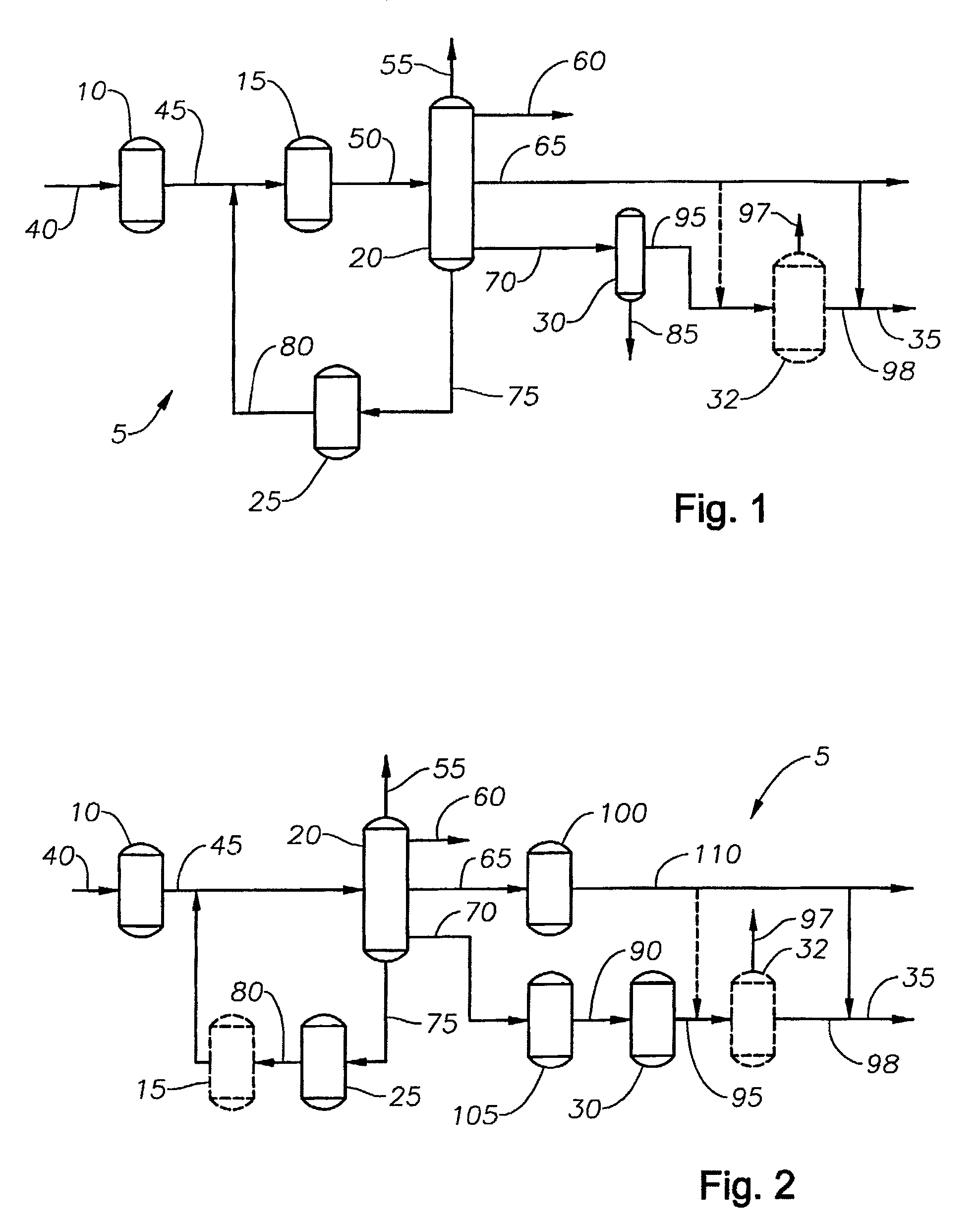

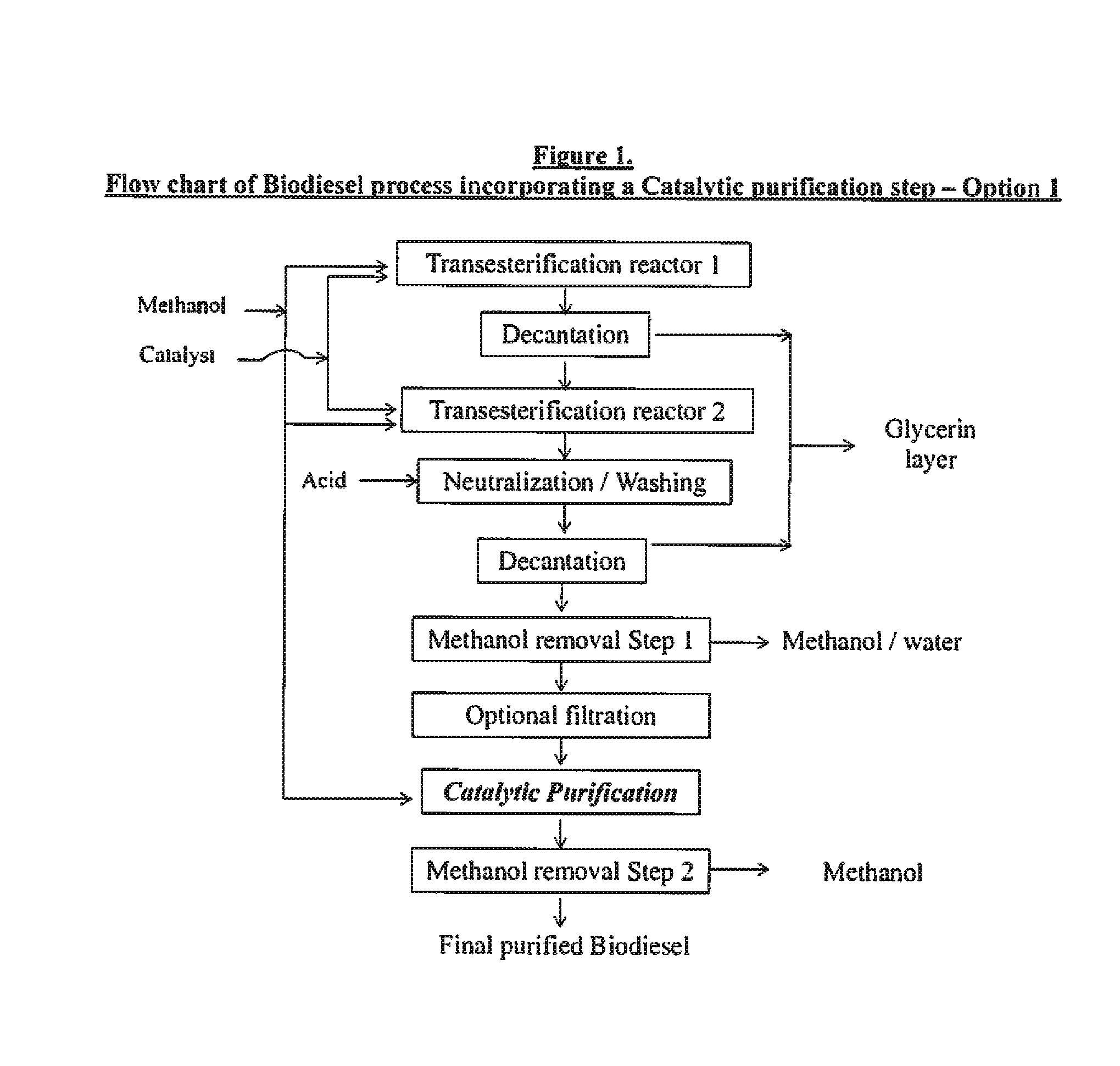

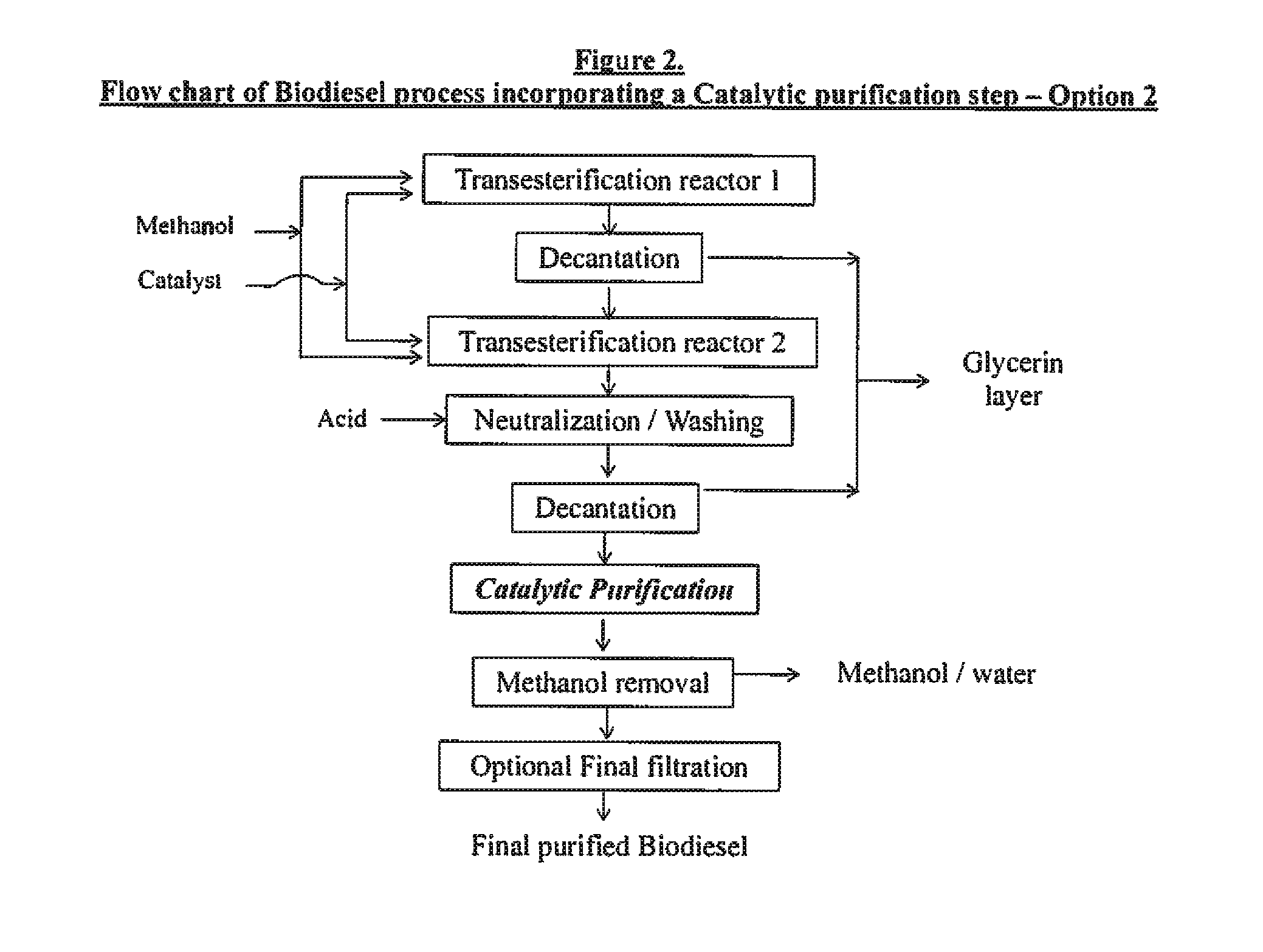

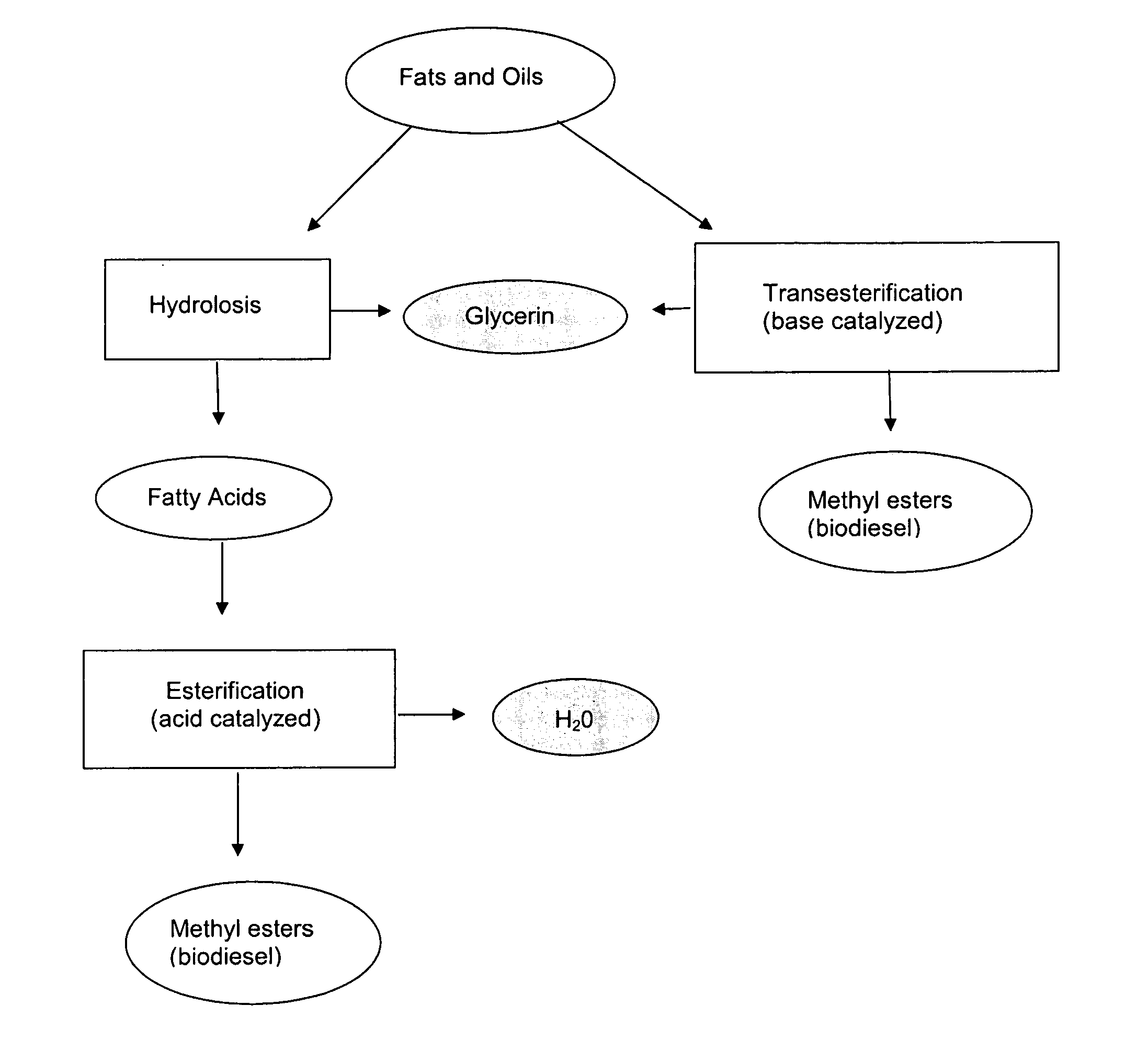

Catalytic purification of fatty acid alkyl esters used in fuels

ActiveUS20140109466A1Reduce the amount requiredImprove cold flowFatty acid esterificationPreparation by ester-hydroxy reactionMonoglycerideFiltration

The process of this invention removes impurities from transesterification products comprising primarily fatty acid alkyl esters (FAAE) that are being processed for final fuel products, such as biodiesel. The inventive process is catalytic, and the resulting ester is suitable for use as biodiesel. Metal oxide and mixed metal oxide catalysts are particularly suitable. The invention is particularly suitable for treating fatty acid alkyl ester compositions comprising impurities such as glycerin, sterol glycosides, and / or triglyceride, diglyceride and / or monoglyceride. The invention is particularly useful in treating FAAE transesterification products made using homogeneous alkali catalysts. The treated ester exhibits improved performance under cold weather conditions, which can be measured by methods such as ASTM 7501 Cold Soak Filtration Test (CSFT).

Owner:WR GRACE & CO CONN

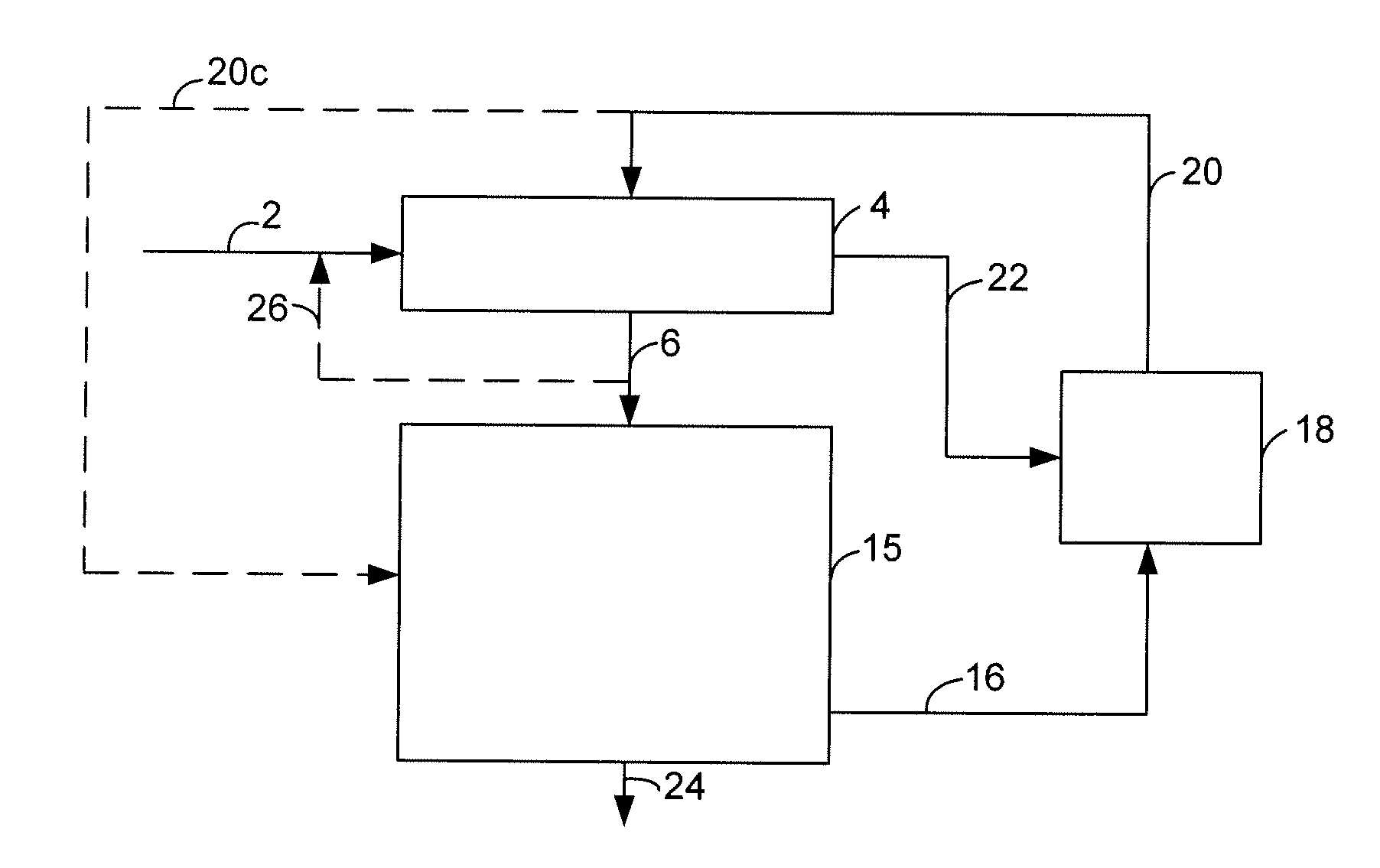

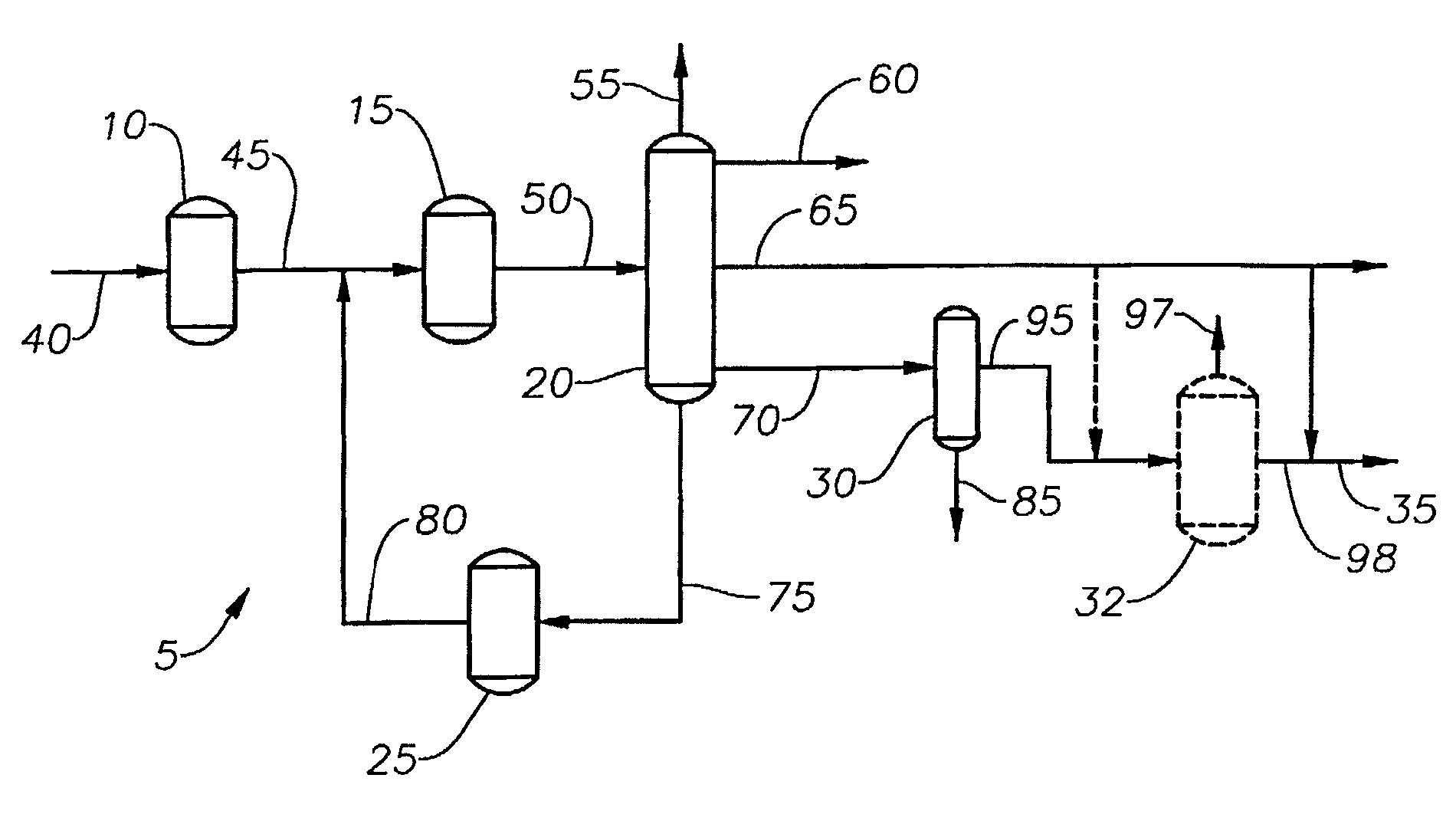

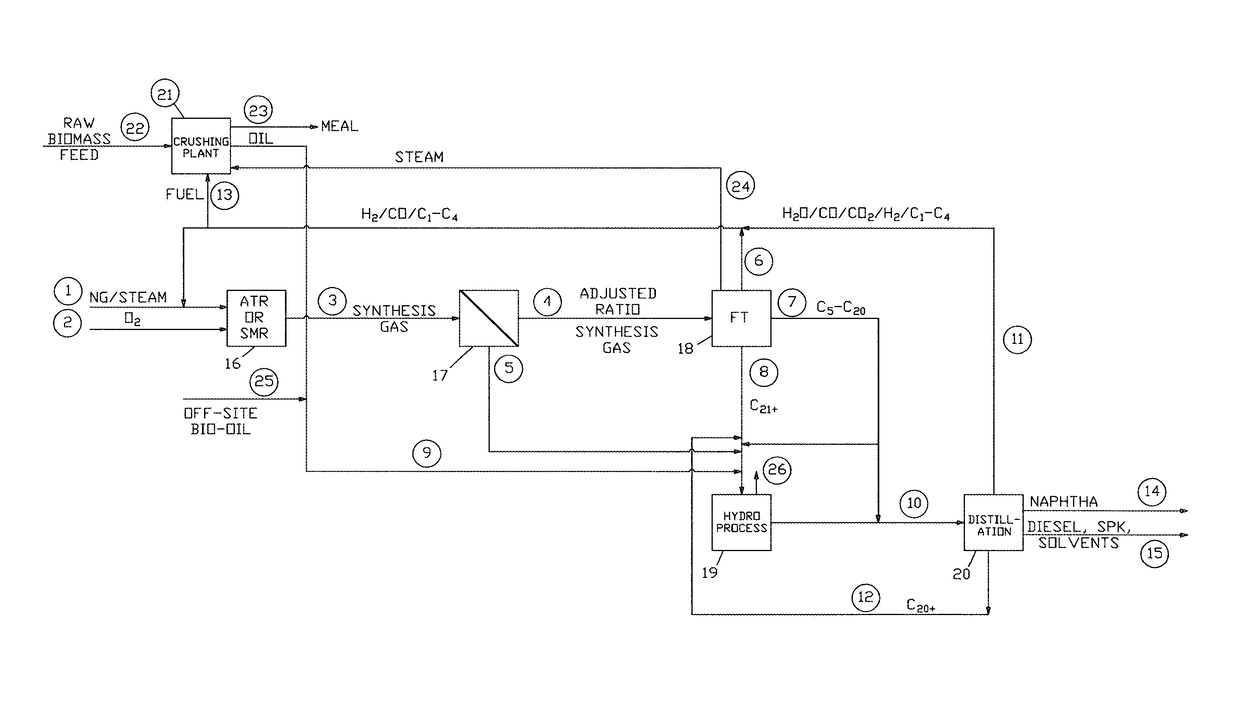

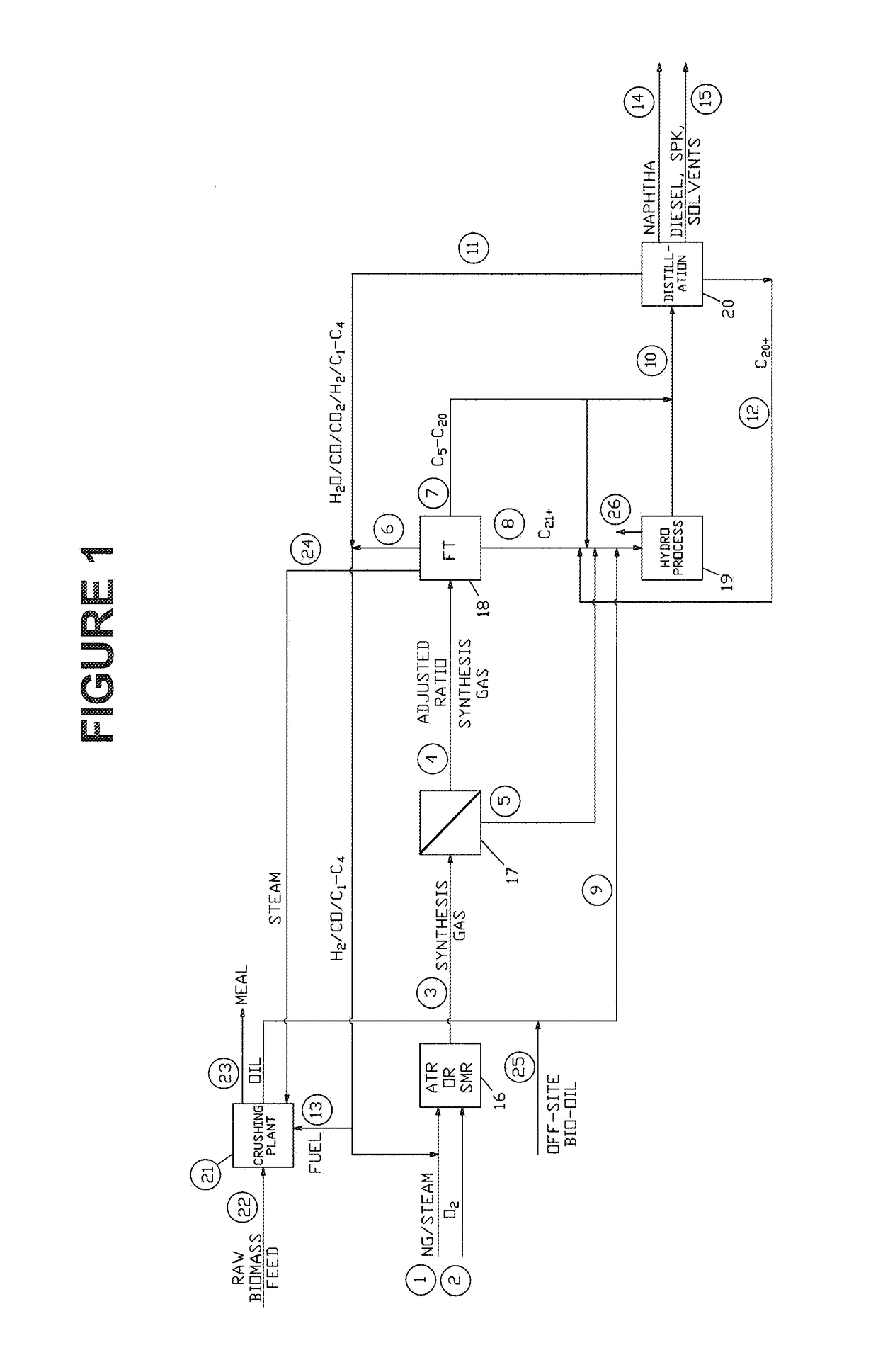

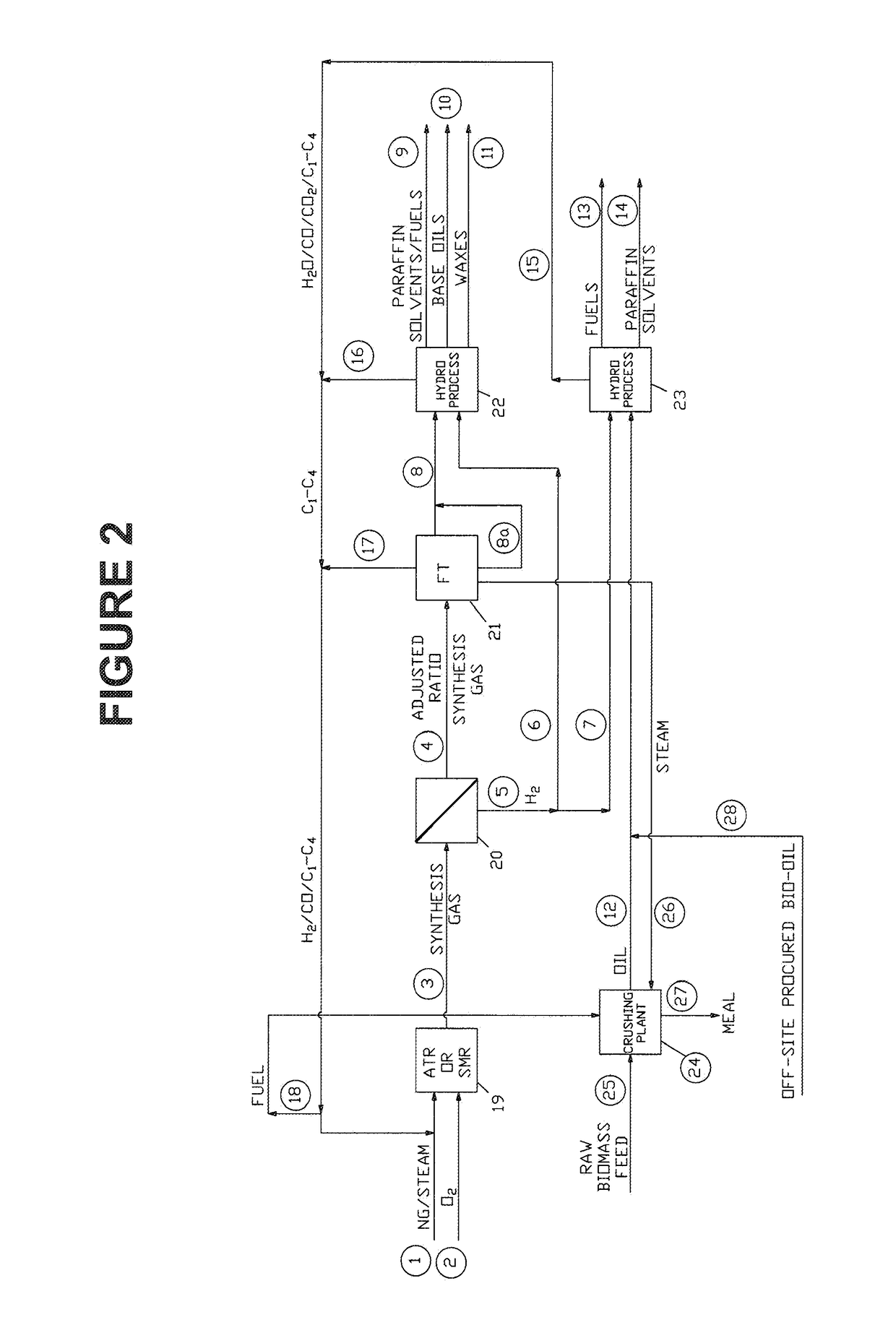

Integrated fuel processing with biomass oil

ActiveUS9677005B1Low cost hydrogenEfficient use ofLiquid hydrocarbon mixture productionHydrocarbon oil crackingSyngasGas to liquids

A gas to liquids process with a reduced CO2 footprint to convert both natural gas and a renewable feedstock material into fuels or chemicals. In one embodiment of the invention, a natural gas feed is converted into synthesis gas containing hydrogen and carbon monoxide. A minor portion of the hydrogen is thereafter extracted from the synthesis gas. The synthesis gas is converted to hydrocarbons in a Fischer Tropsch reaction. The Fischer Tropsch hydrocarbon product and a renewable feedstock are hydroprocessed with the extracted hydrogen in order to produce fuels and / or chemicals. Waste products from the renewable feed are recycled to produce additional synthesis gas for the Fischer Tropsch reaction.

Owner:EMERGING FUELS TECH

Alkylester fatty acid blends and uses therefor

InactiveUS20110023352A1Maintain good propertiesGood effectBiofuelsEfficient propulsion technologiesFatty acid methyl esterMedium chain fatty acid

Provided herein are blends oils or fatty acids comprising more than 50% medium chain fatty acids, or the fatty acid alkyl esters thereof, and having low melting points. Such blends are useful as a fuel or as a starting material for the production of, for example, a biodiesel. Also provided genetically altered or modified plants, modified such that the amount of medium chain fatty acids generated by the plant are increased. Further provided is a method of predicting the melting point of a blend of fatty acid methyl esters and the use of such a method for identifying blends suitable for use as, for example, a biodiesel.

Owner:CIBUS

Composition for blending of transportation fuels

InactiveUS20070033859A1Environmentally friendlyImprove cold flowSolid fuelsTreatment with plural serial refining stagesInternal combustion engineOrganic compound

Disclosed are fuel compositions for internal combustion engines comprising as a predominant component organic distillates which exhibit suitable physical properties, and a low-sulfur fraction of an alkylated petroleum feedstock which, for example, consisted of material boiling between about 600° C. and about 345° C. More particularly, compositions of the invention comprise low-boiling, low-sulfur, blending components, advantageously obtained by a process for converting sulfur-containing organic compounds which are unwanted impurities, to higher boiling products by alkylation and removing the higher boiling products by fractional distillation. Products can be used directly as transportation fuels and / or blending components to provide fuels which are more friendly to the environment.

Owner:INST FR DU PETROLE

Process for producing paraffinic hydrocarbons

ActiveUS8809610B2Improve cold flowImprove stabilityMolecular sieve catalystsHydrocarbon by hydrogenationAlkaneMonoglyceride

A process for producing paraffinic hydrocarbons from a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids, the process comprising the following steps: (a) hydrode oxygenating the triglycerides, diglycerides, monoglycerides and / or fatty acids in the feedstock by contacting hydrogen and the feedstock with a hydrogenation catalyst at a temperature in the range of from 250 to 380° C. and a total pressure in the range of from 20 to 160 bar (absolute), to obtain an effluent comprising paraffinic hydrocarbons and water; (b) separating a liquid stream rich in paraffinic hydrocarbons from the effluent obtained in step (a); and (c) hydroisomerising the paraffinic hydrocarbons in the liquid stream rich in paraffinic hydrocarbons by contacting hydrogen and the liquid stream with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound at a temperature in the range of from 280 to 450° C. and a total pressure in the range of from 20 to 160 bar (absolute).

Owner:SHELL USA INC

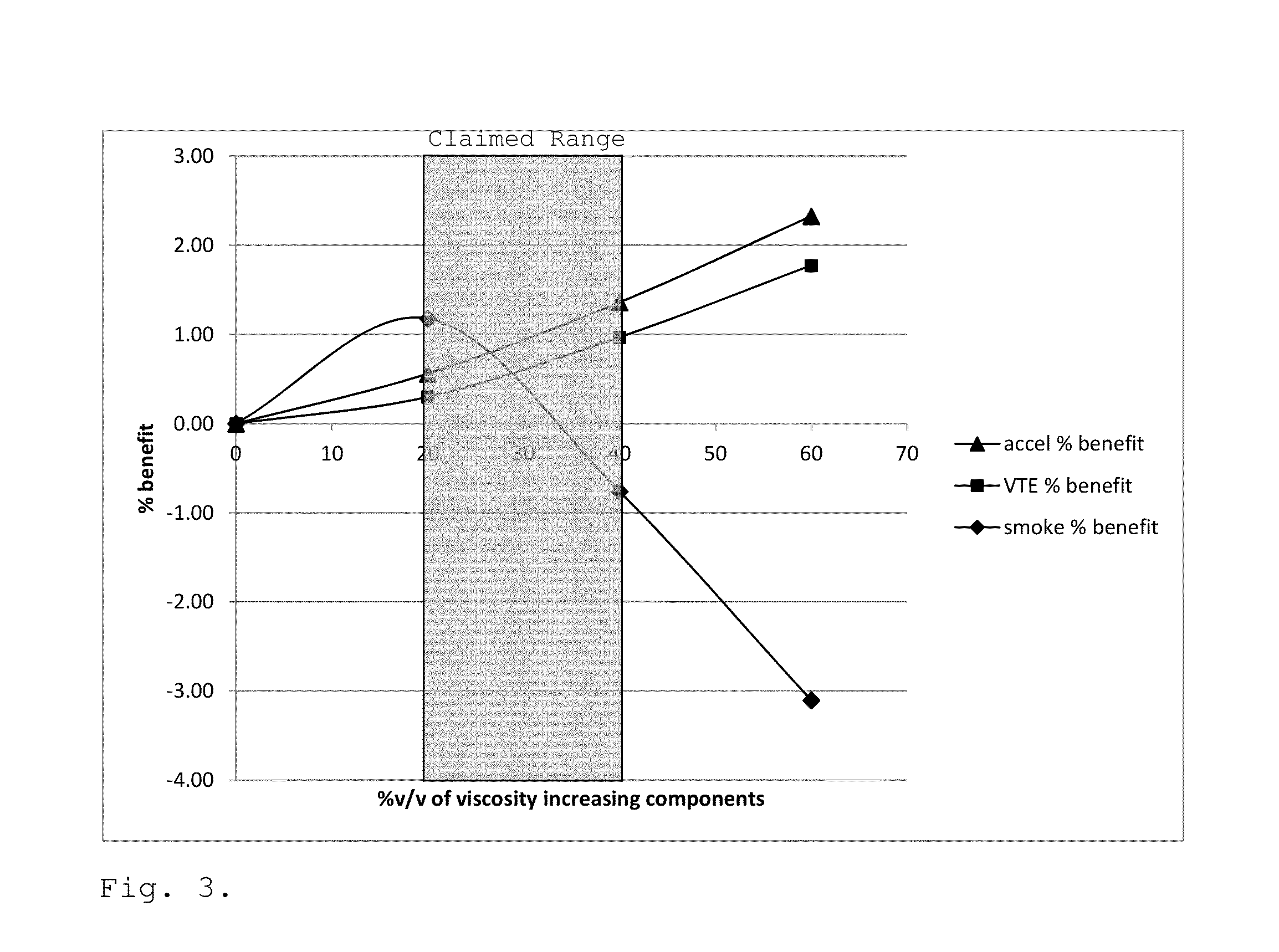

High power fuel compositions

InactiveUS20150021232A1Improve powerHigh viscosityLiquid carbonaceous fuelsFuel additivesGasolineBase oil

A fuel composition is prepared by blending a petroleum derived low sulphur diesel with a Fischer-Tropsch derived gasoil and a Fischer-Tropsch derived base oil wherein the amount of the petroleum derived low sulphur diesel is from 60% up to 80% v / v of the total composition; the amount of Fischer-Tropsch derived gasoil is from 10% up to 30% v / v of the total composition; the amount of Fischer-Tropsch derived base oil is from 10% up to 30% v / v of the total composition; the amounts of the Fischer-Tropsch derived gas oil and Fischer-Tropsch derived base oil together being at least 20% v / v of the total composition.The fuel compositions of the invention have improved properties, in terms that they display increased power when compared to fuel compositions in which the Fischer-Tropsch derived base oil component is not present.

Owner:SHELL OIL CO

Monomethyl paraffin adsorptive separation process

InactiveUS6670519B1Small sizeImprove cold flowHydrocarbonsAdsorption purification/separationWaxAlkane

The amount of the adsorbent needed to recover a set quantity of monomethyl branched C10-C15 paraffins from a mixture comprising normal paraffins and other nonnormal hydrocarbons such as di-isoparaffins, di-isoolefins, naphthenes and aromatics by simulated moving bed adsorptive separation is reduced by adjusting three operating factors: percentage recovery of the paraffin, operating temperature and cycle time. This reduces the capital cost of the process. The recovered monomethyl hydrocarbons may be used to form a monomethyl branched alkylaromatic hydrocarbon useful as a detergent precursor.

Owner:UOP LLC

Process for producing paraffinic hydrocarbons

ActiveUS20110166405A1Improve cold flowImprove stabilityMolecular sieve catalystsCatalyst activation/preparationAlkaneMonoglyceride

A process for producing paraffinic hydrocarbons from a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids, the process comprising the following steps: (a) hydrode oxygenating the triglycerides, diglycerides, monoglycerides and / or fatty acids in the feedstock by contacting hydrogen and the feedstock with a hydrogenation catalyst at a temperature in the range of from 250 to 380° C. and a total pressure in the range of from 20 to 160 bar (absolute), to obtain an effluent comprising paraffinic hydrocarbons and water; (b) separating a liquid stream rich in paraffinic hydrocarbons from the effluent obtained in step (a); and (c) hydroisomerising the paraffinic hydrocarbons in the liquid stream rich in paraffinic hydrocarbons by contacting hydrogen and the liquid stream with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound at a temperature in the range of from 280 to 450° C. and a total pressure in the range of from 20 to 160 bar (absolute).

Owner:SHELL USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com