Cement kiln co-processing system for waste incineration fly ash

A waste fly ash and co-processing technology, applied in cement production, solid waste removal, etc., can solve problems such as inadequate supervision, environmental hazards, and high cost of fly ash treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

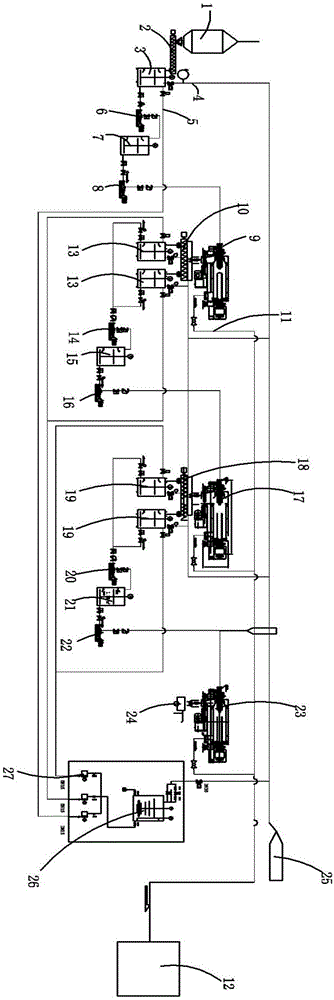

[0030] Examples, see attached Figure 1~6 , a waste fly ash cement kiln co-processing system, which includes a three-stage water washing and desalination system for waste incineration fly ash, coagulation and sedimentation removal system II, sodium filtration III and reverse osmosis pre-concentration system IV, depolarization trace Miscellaneous salt system Ⅴ, MVR evaporation and crystallization system Ⅵ; the washing water produced by the three-stage water elution and desalination system for waste incineration fly ash enters the coagulation sedimentation removal system through the pipeline; the salt content rate obtained by the coagulation sedimentation removal heavy metal system is 1 The -2% solution enters the sodium filtration and reverse osmosis pre-concentration system; the sodium filtration and reverse osmosis pre-concentration system removes calcium and magnesium ions in the washing water, and concentrates the solution with a salt content of 1-2% to 6%-8 % concentrated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com