Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

685results about "Pulping with organic solvents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

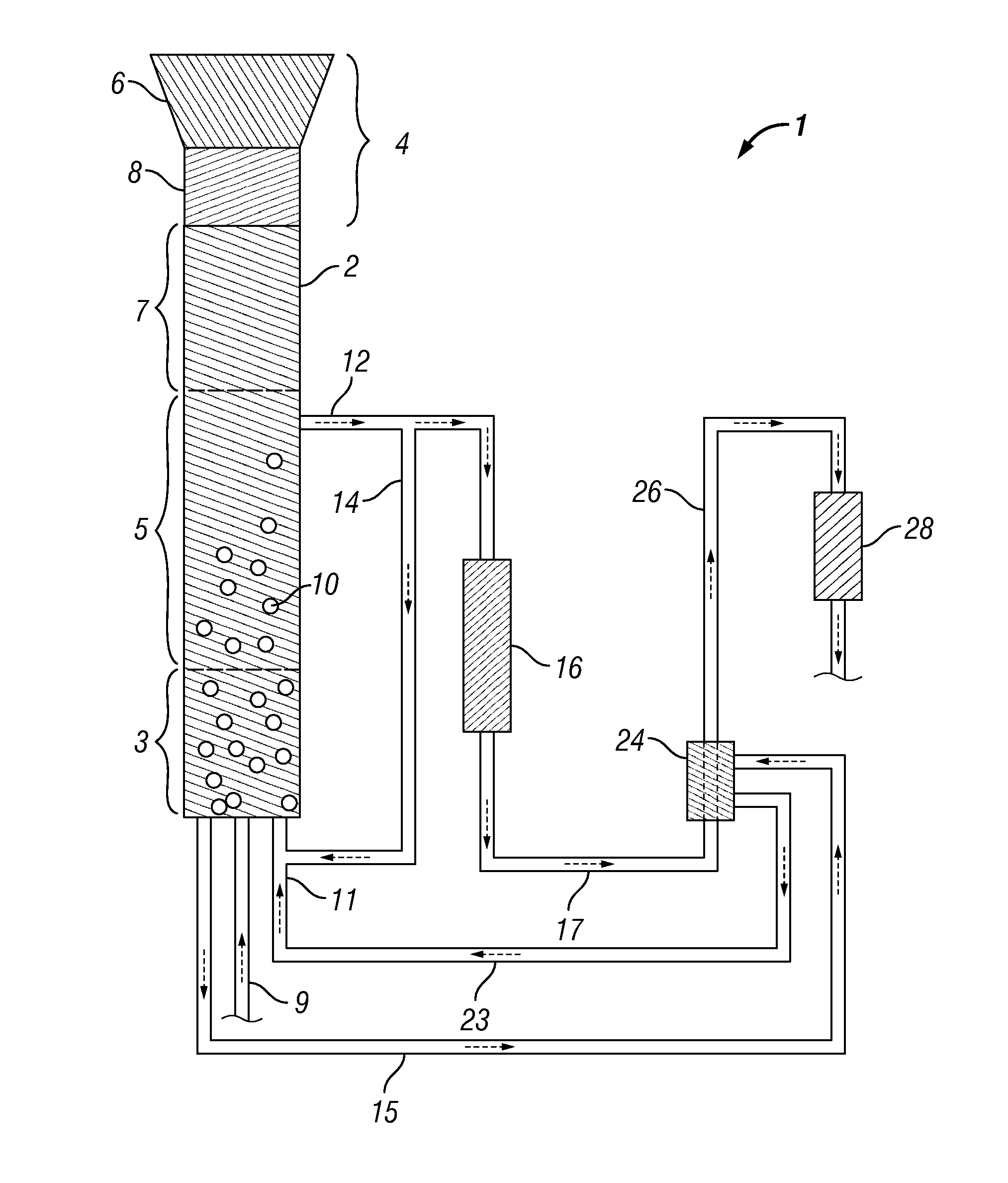

Continuous counter-current organosolv processing of lignocellulosic feedstocks

InactiveUS7465791B1Low viscosityNon-fibrous pulp additionBiological substance pretreatmentsFractionationOrganosolv

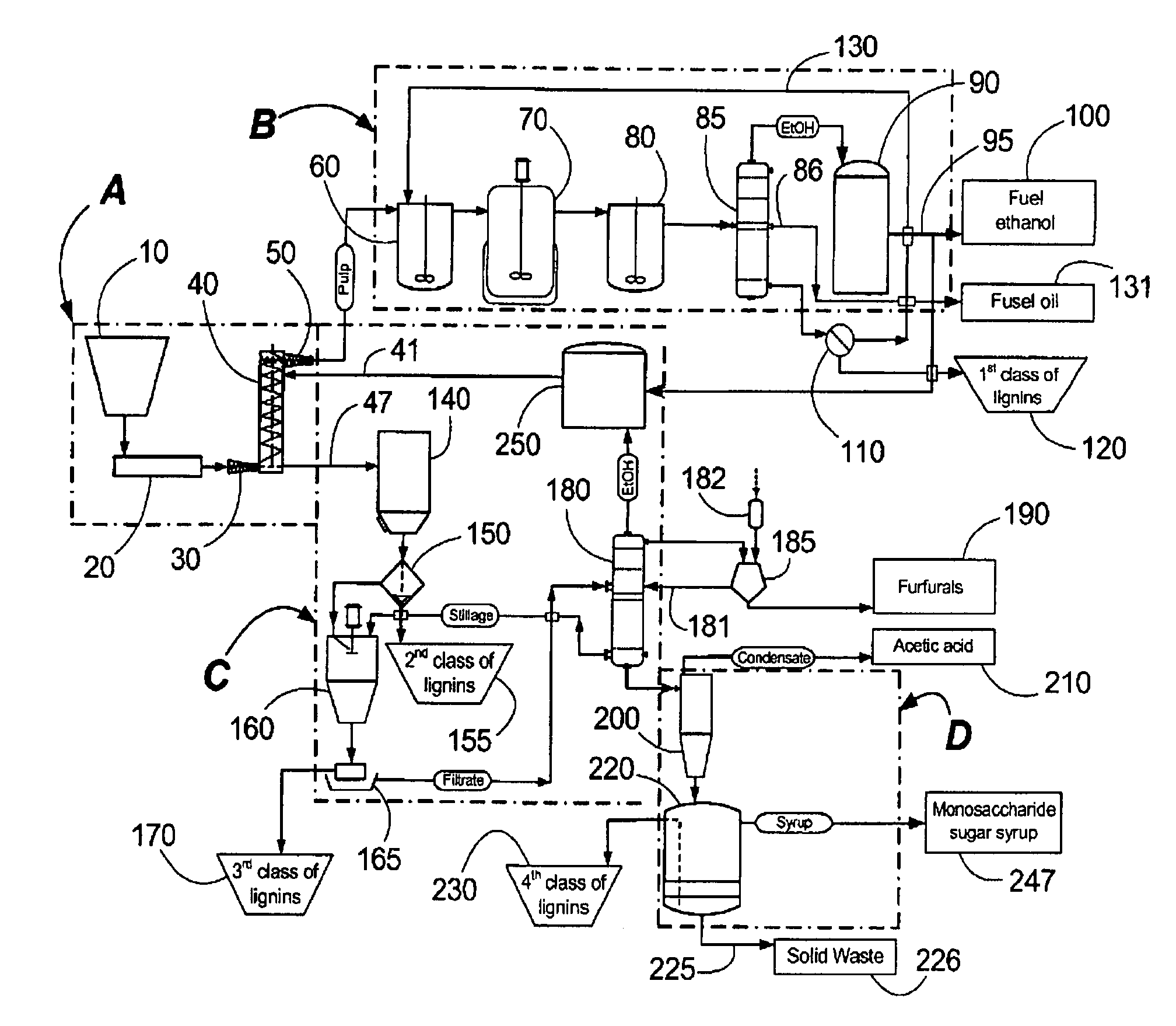

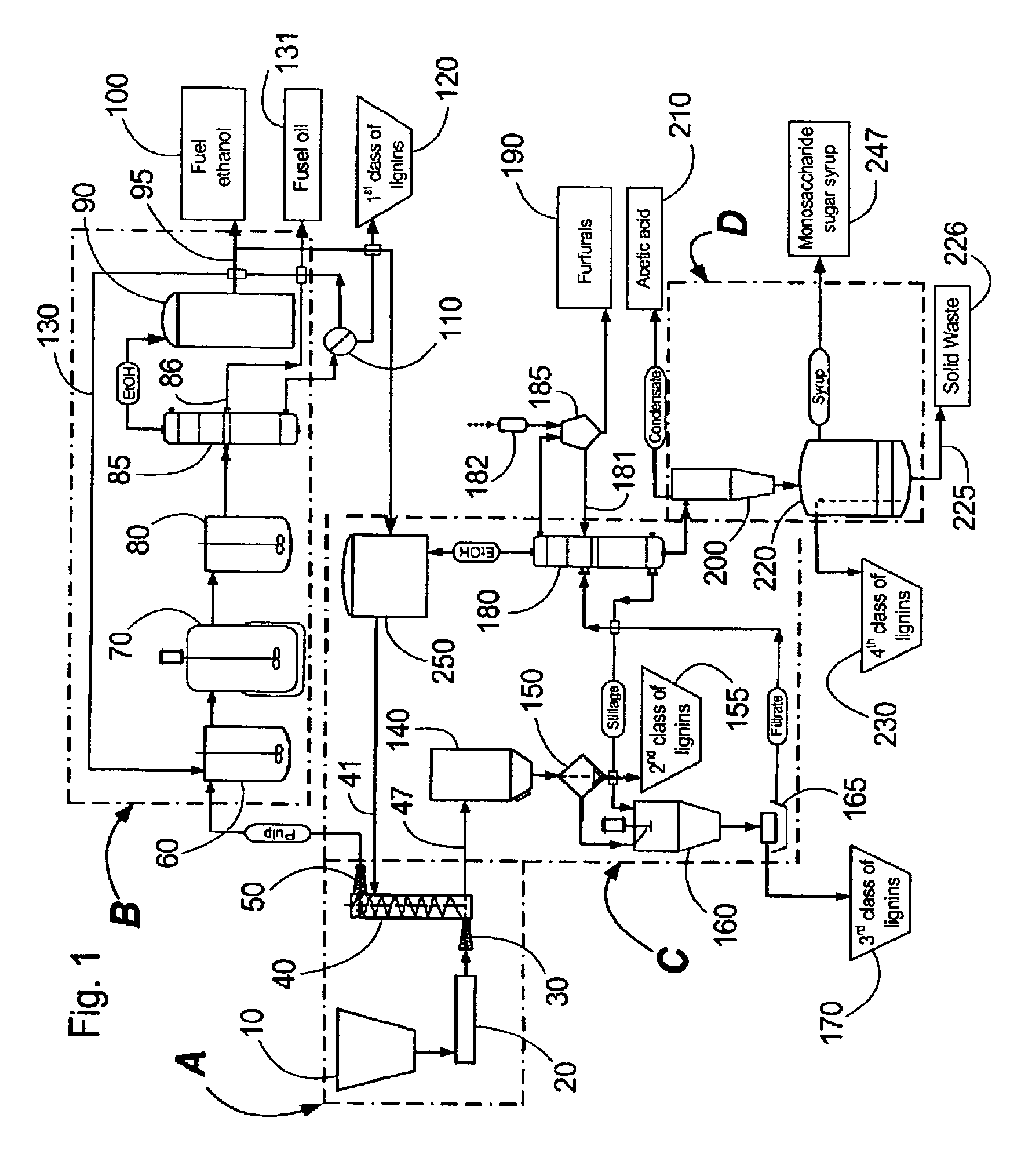

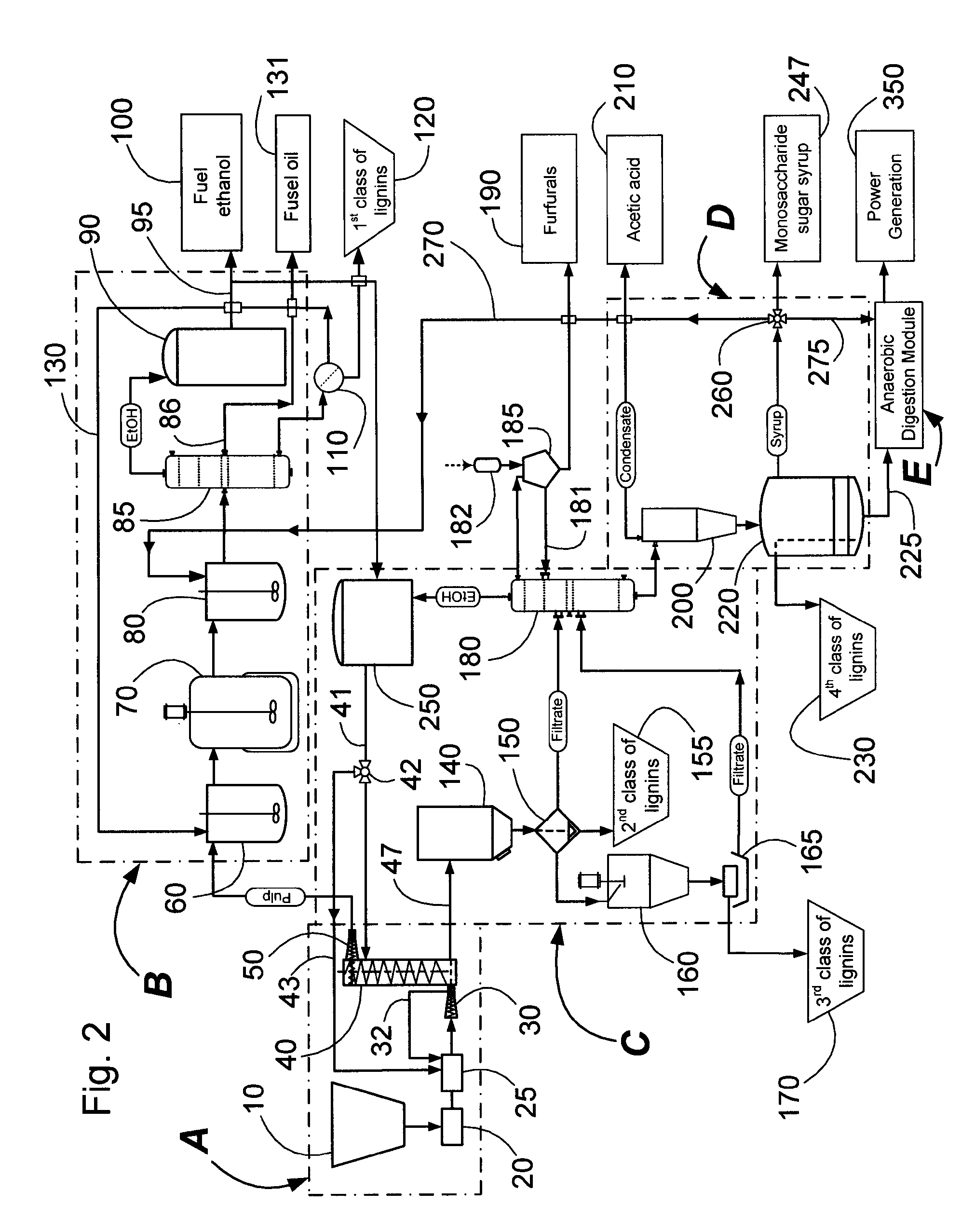

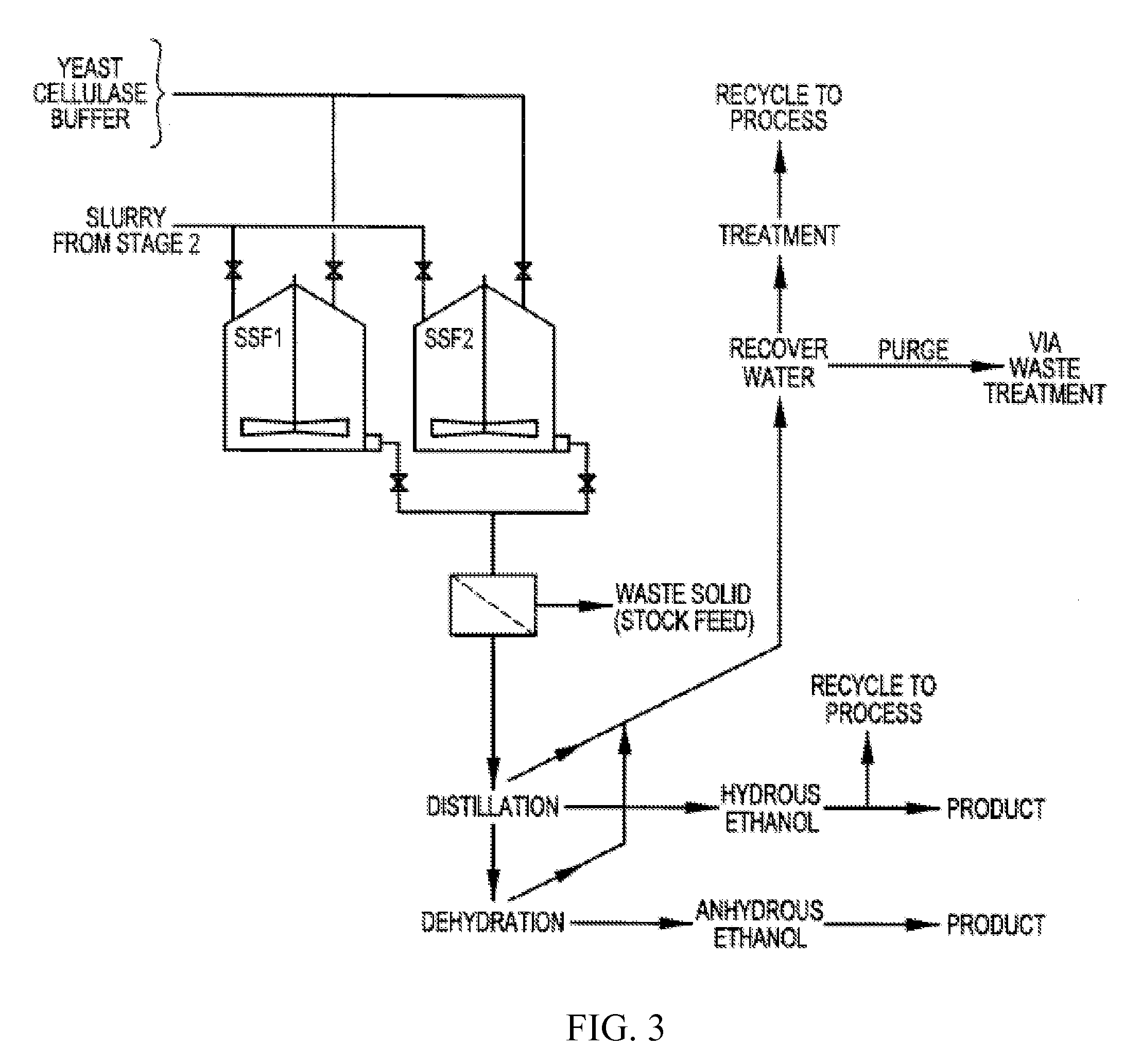

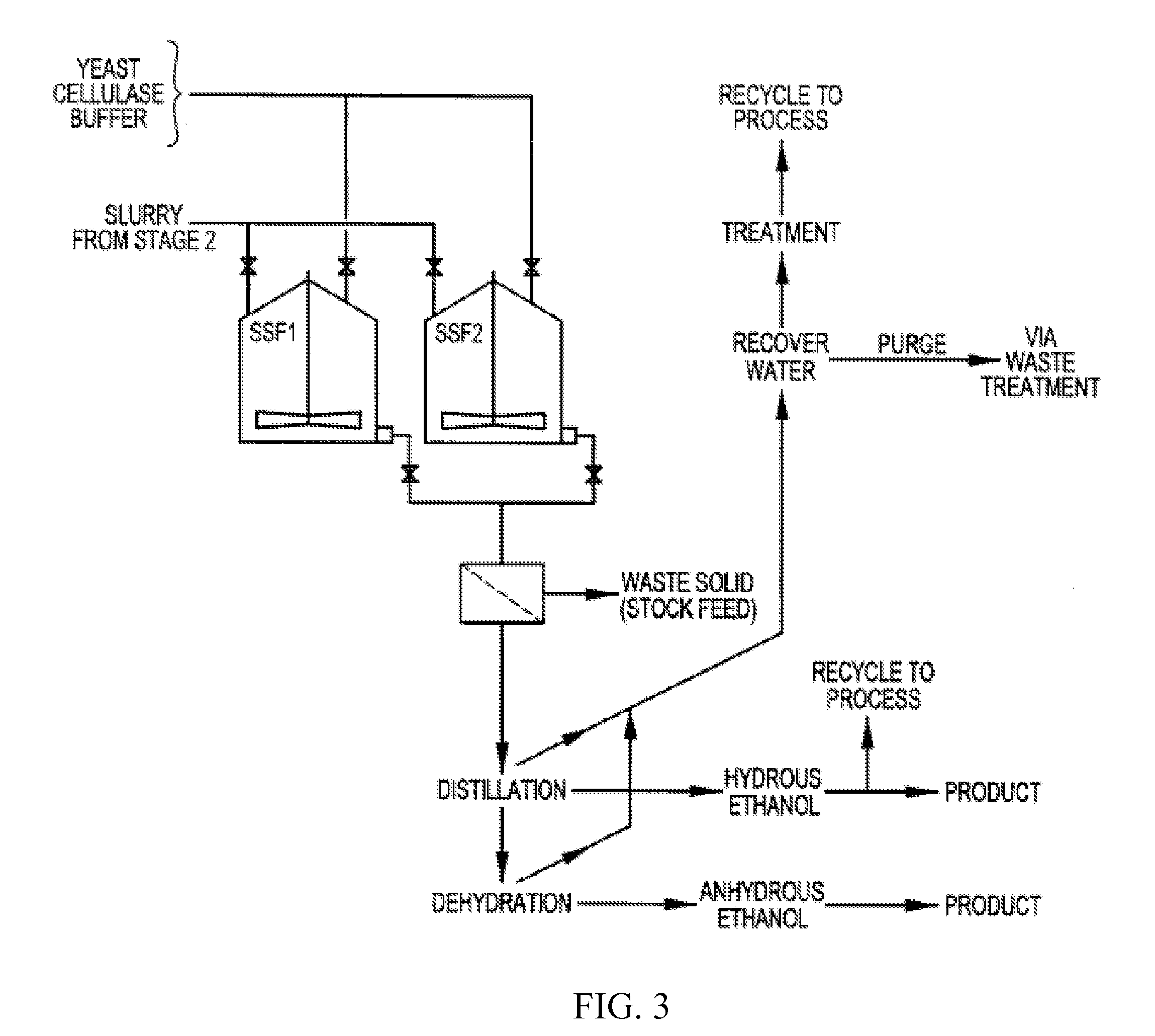

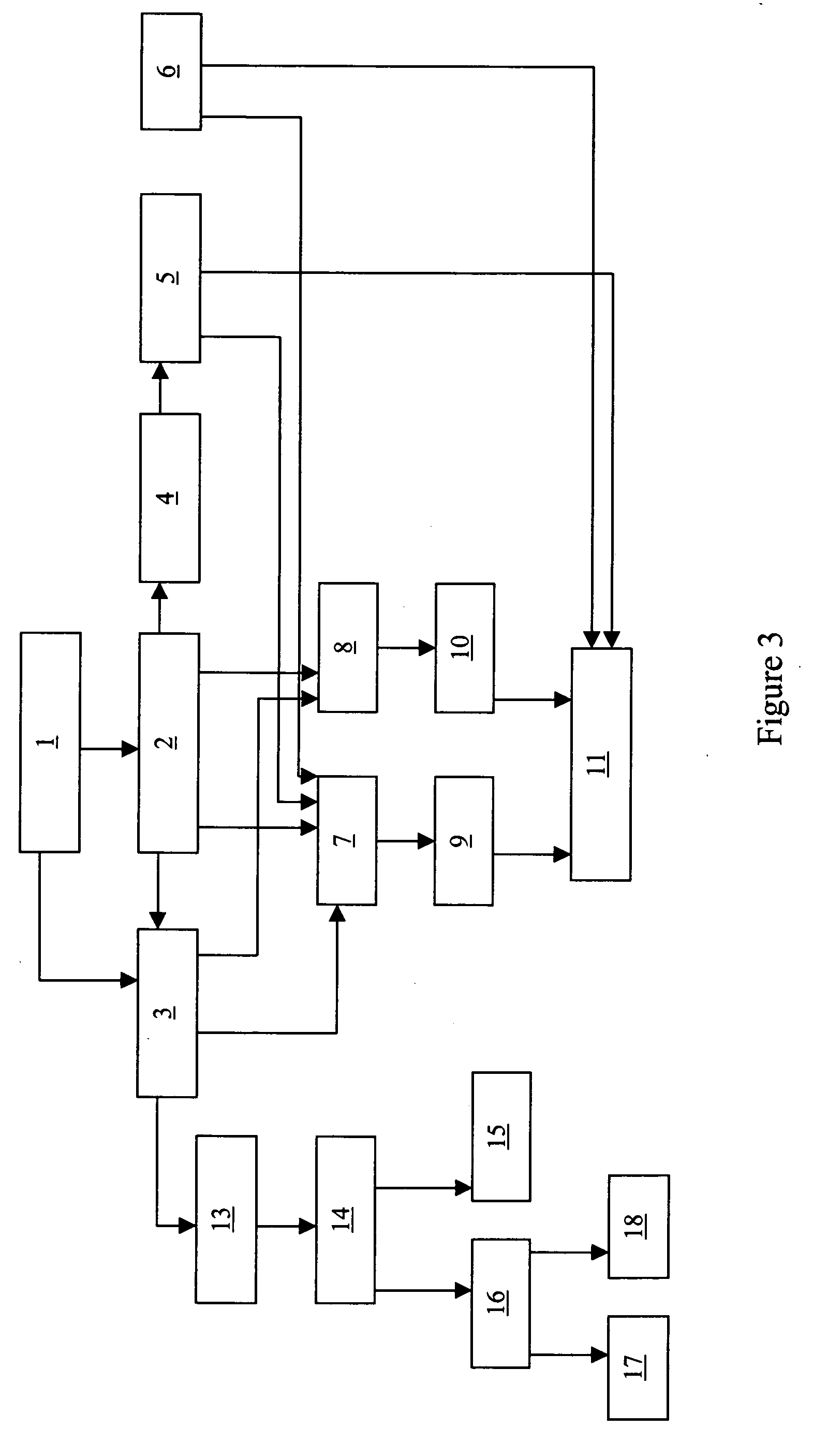

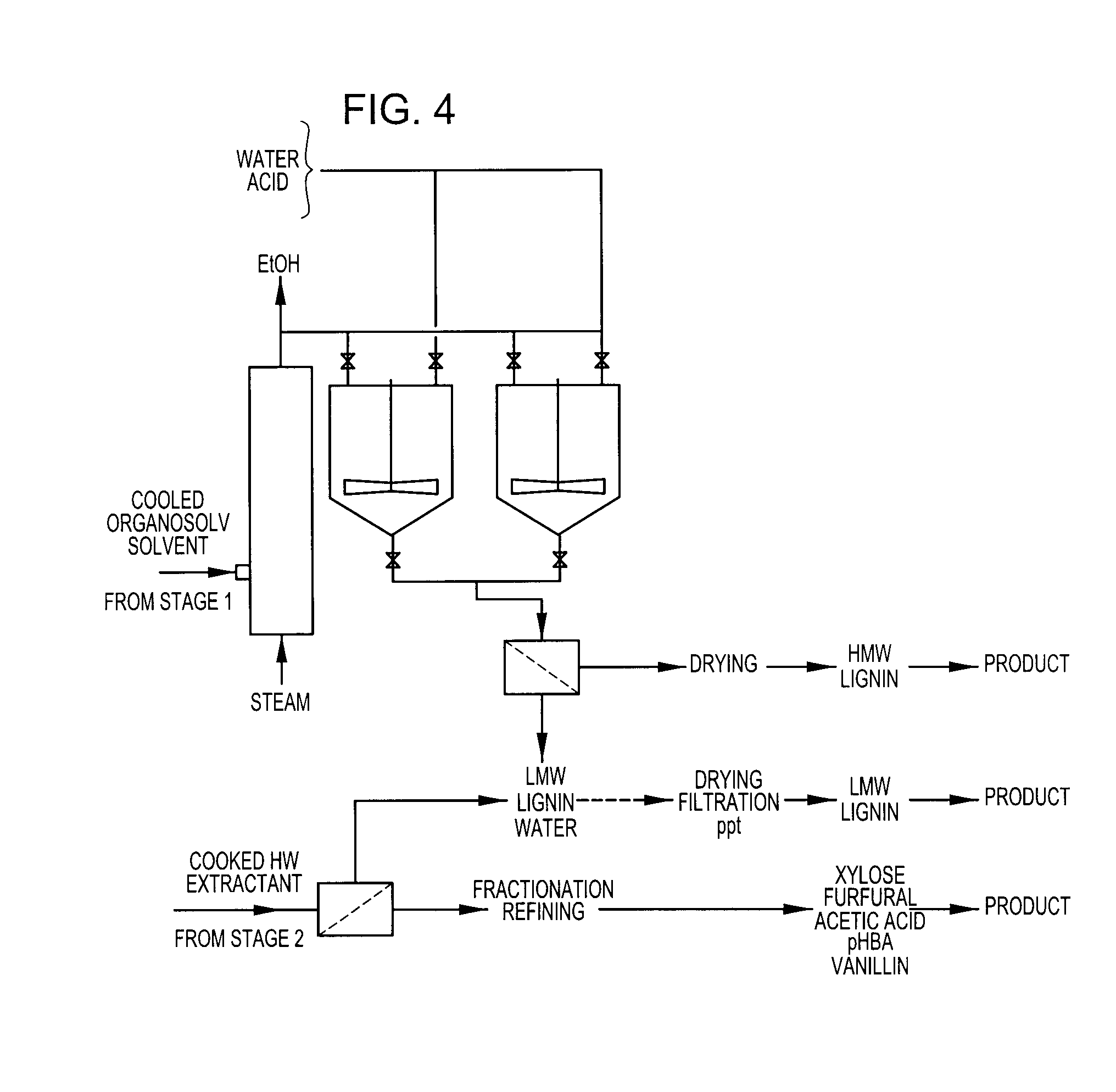

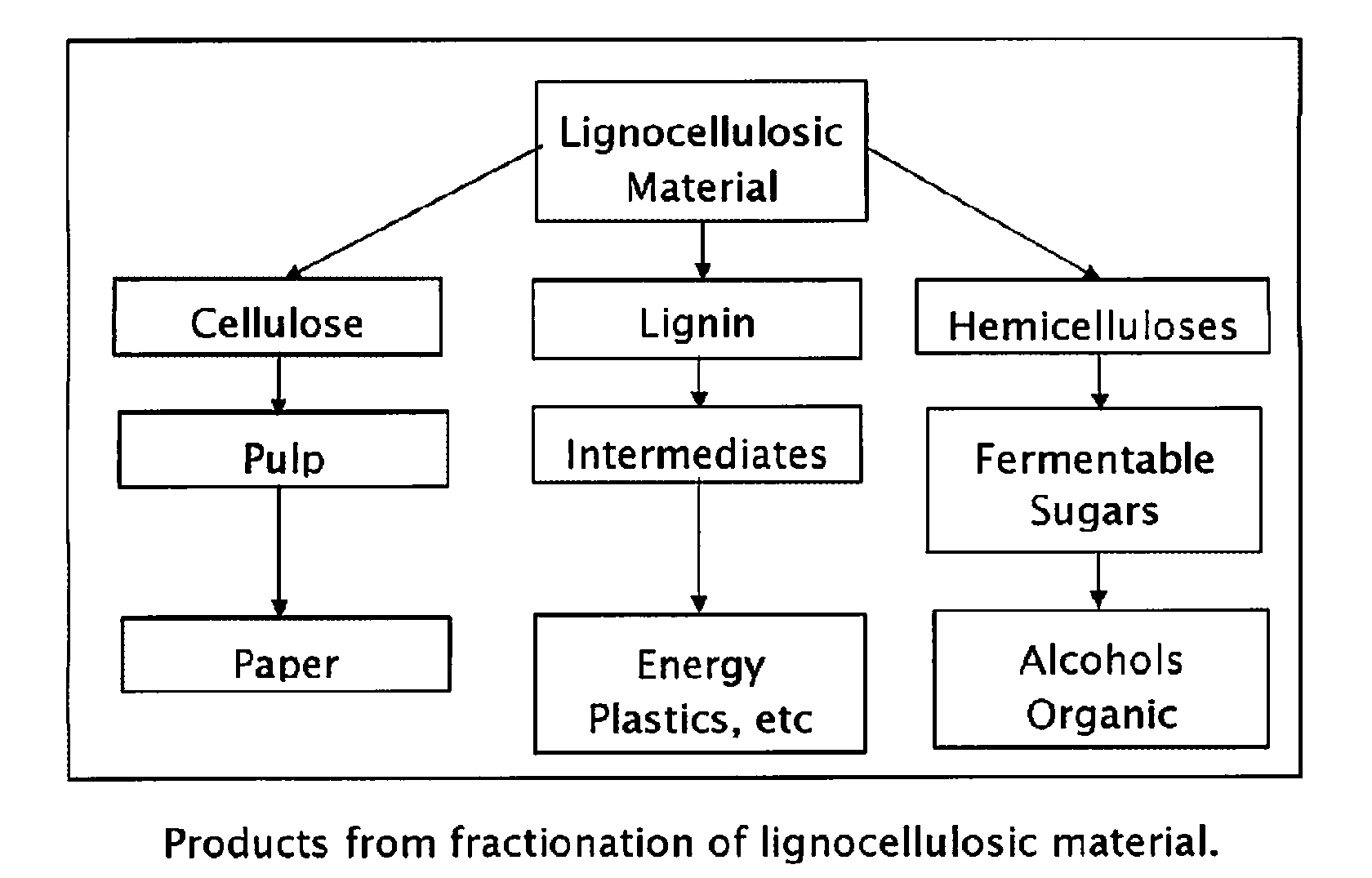

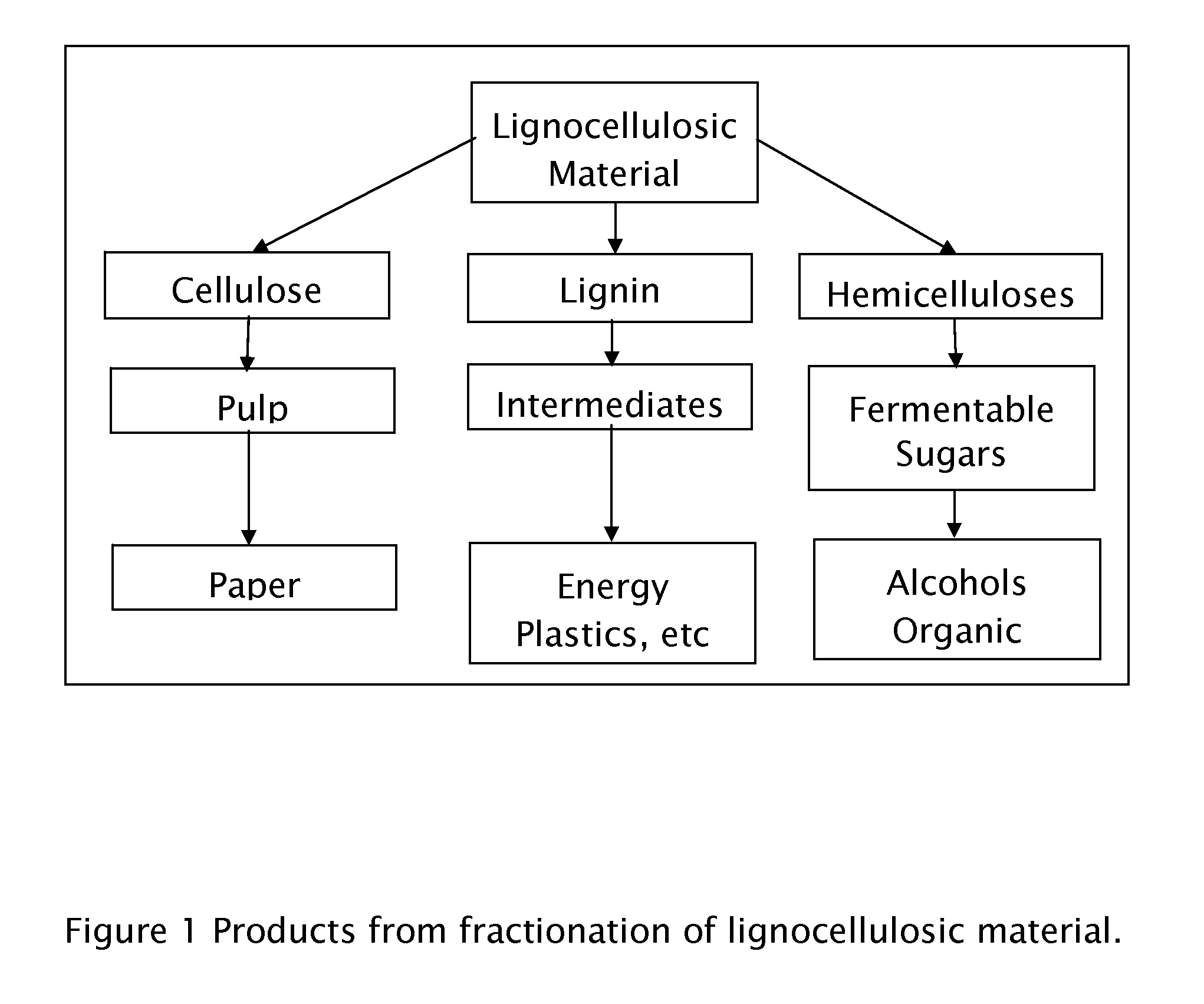

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into at least fuel-grade ethanol and four classes of lignin derivatives. The modular process comprises a first processing module configured for physico-chemically digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for producing at least a fuel-grade ethanol and a first class of novel lignin derivatives from the cellulosic solids fraction, a third processing module configured for separating a second class and a third class of lignin derivatives from the liquid fraction and further processing the liquid fraction to produce a distillate and a stillage, a fourth processing module configured for separating a fourth class of lignin derivatives from the stillage and further processing the stillage to produce a sugar syrup.

Owner:SUZANO CANADA INC

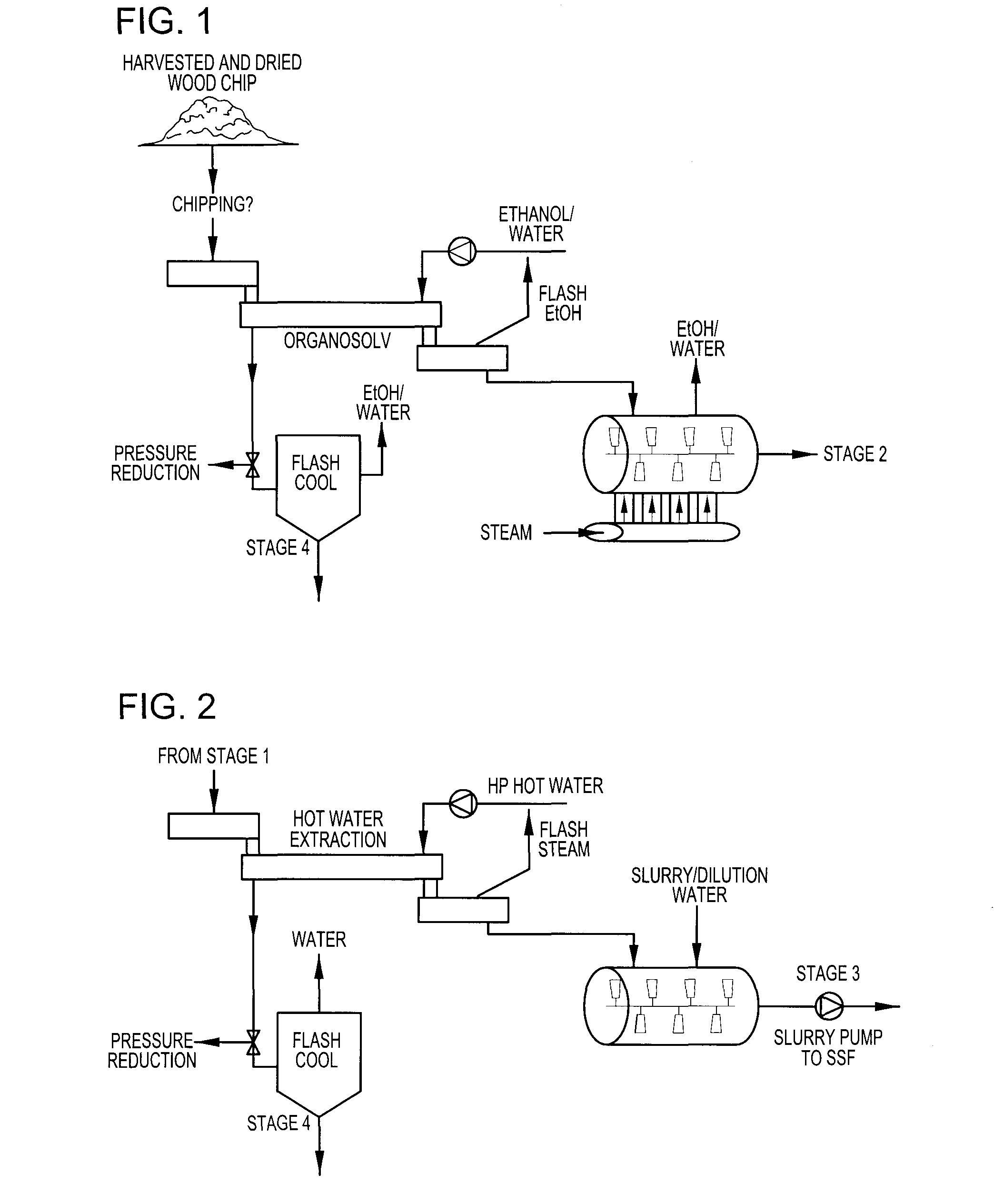

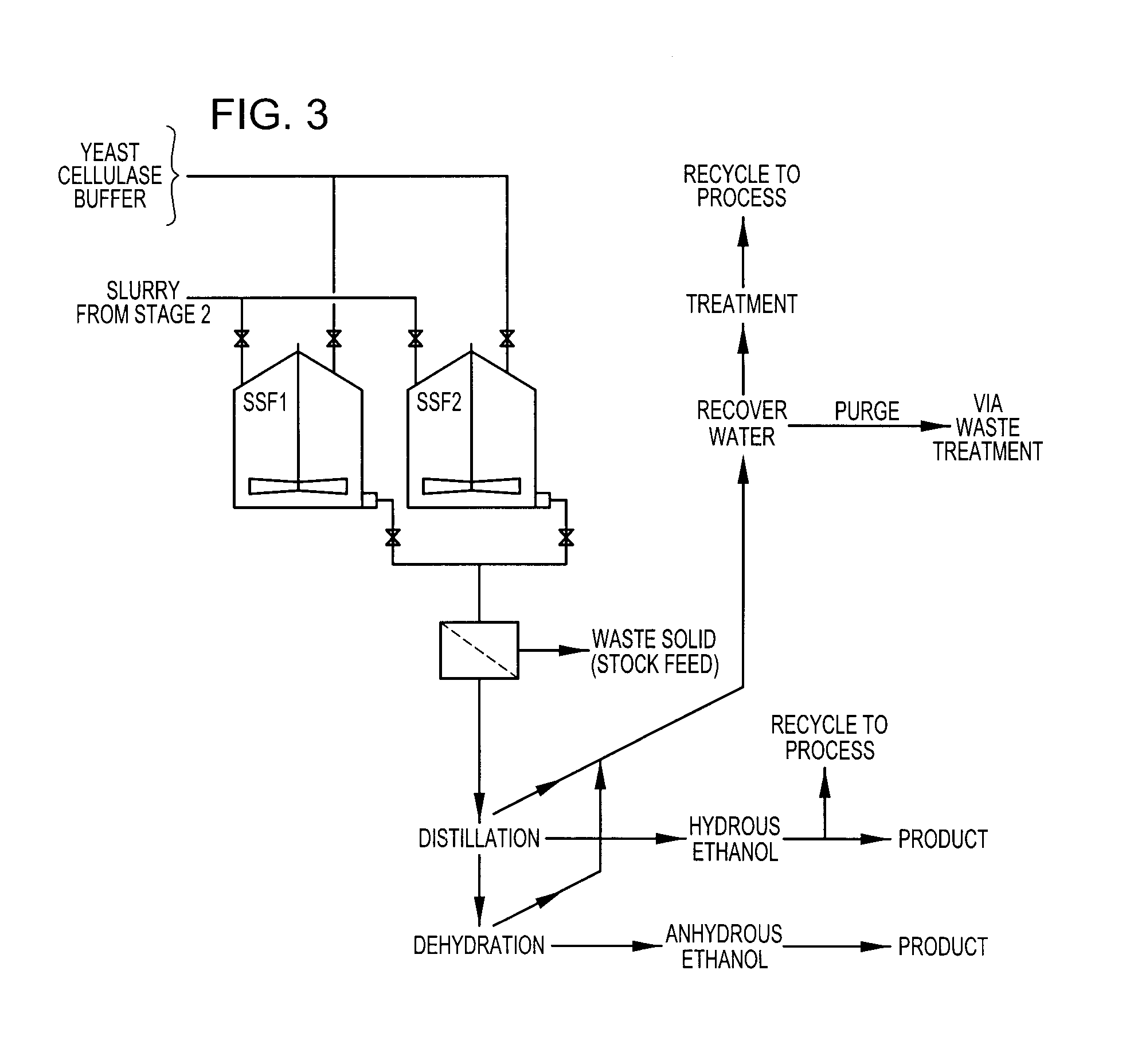

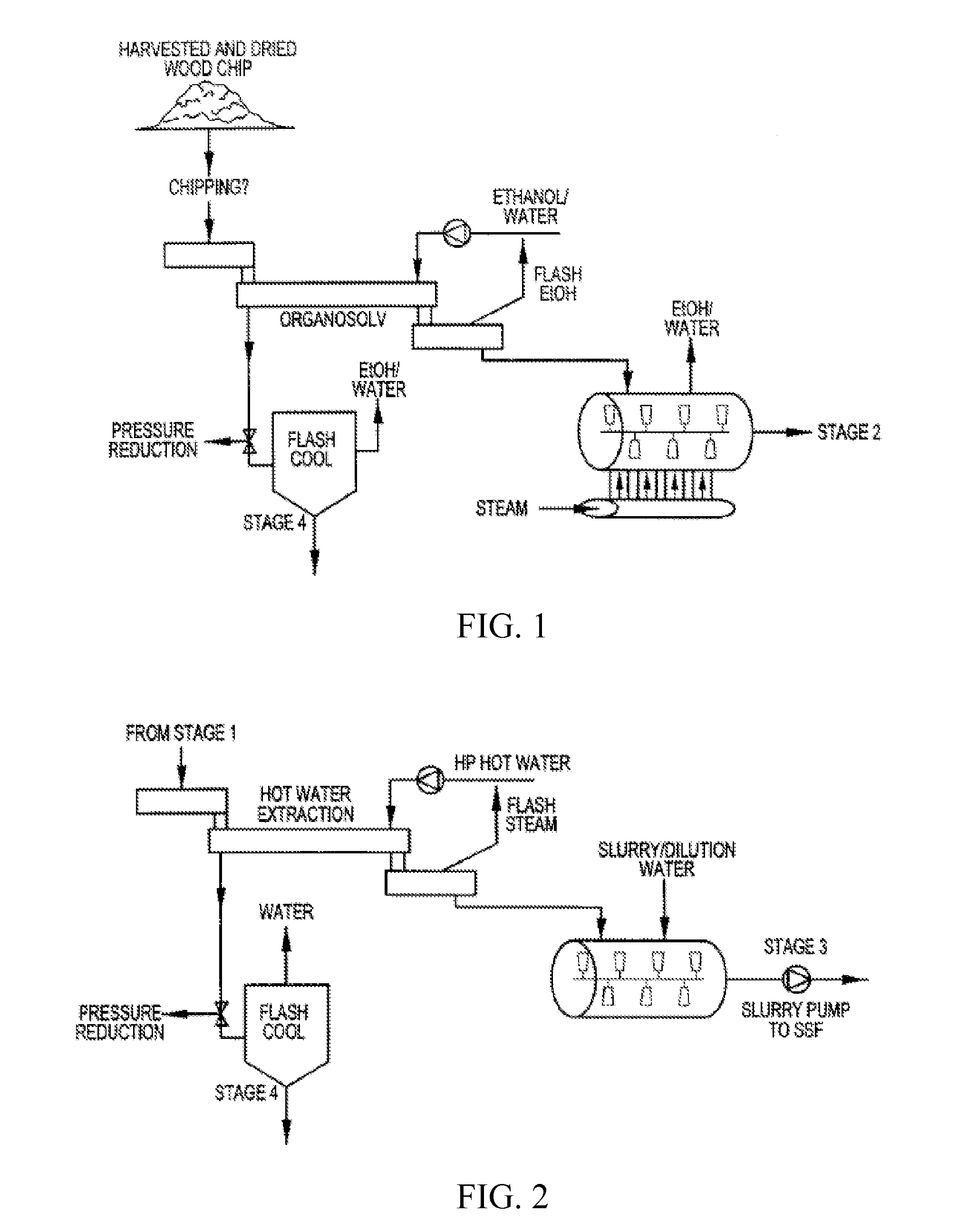

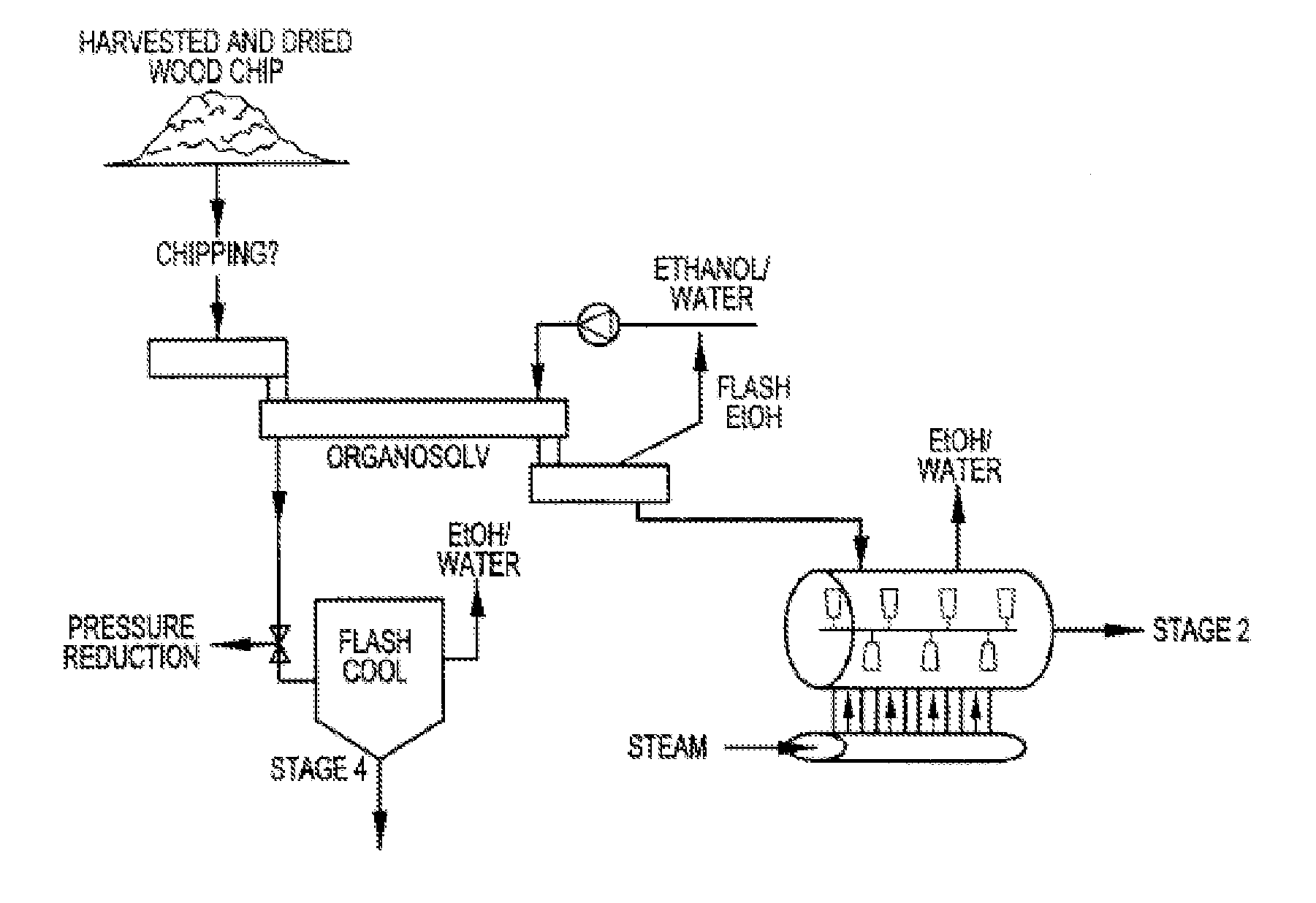

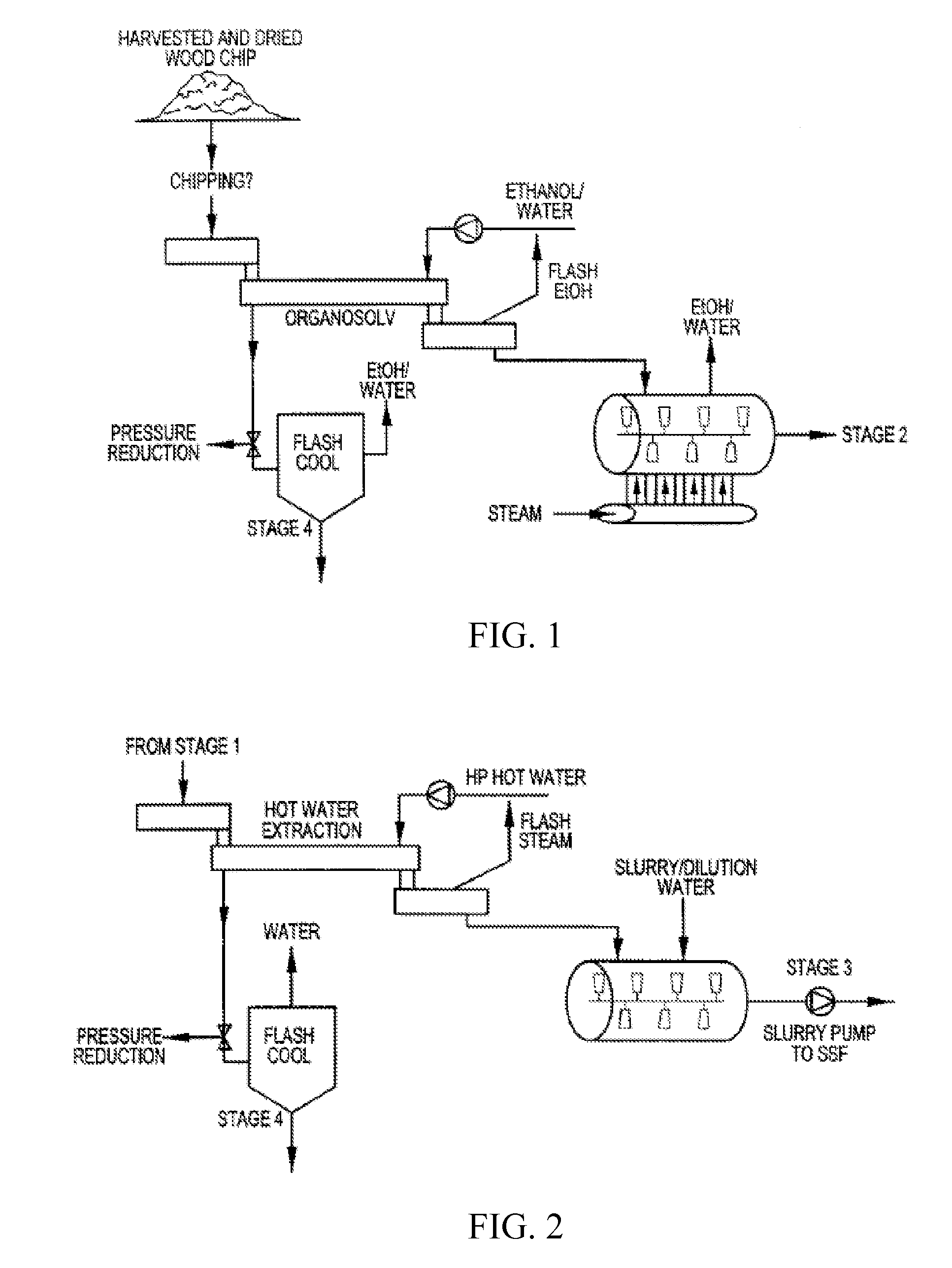

Process for the production of biofuel from plant materials

InactiveUS20070259412A1Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseBiofuel

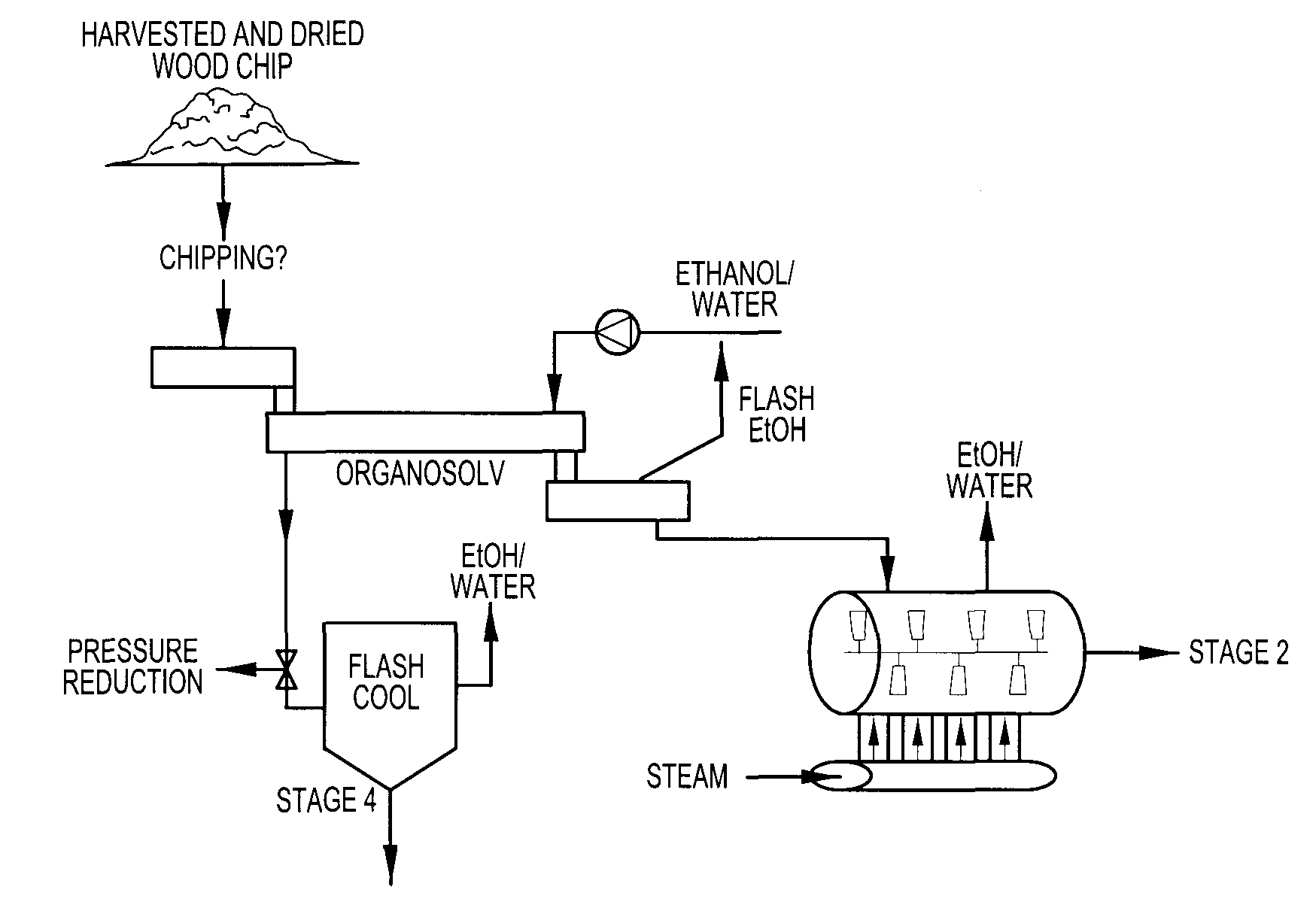

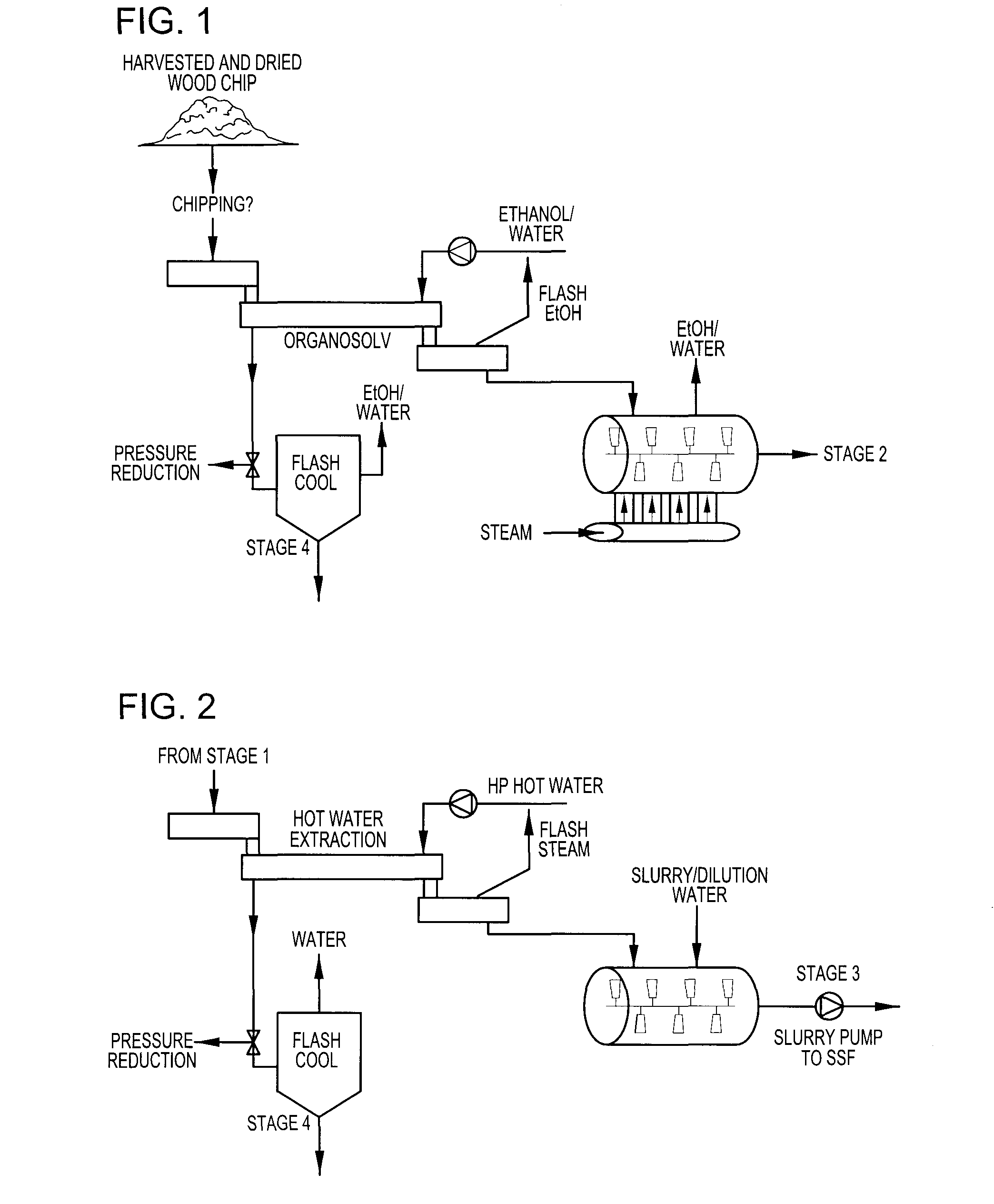

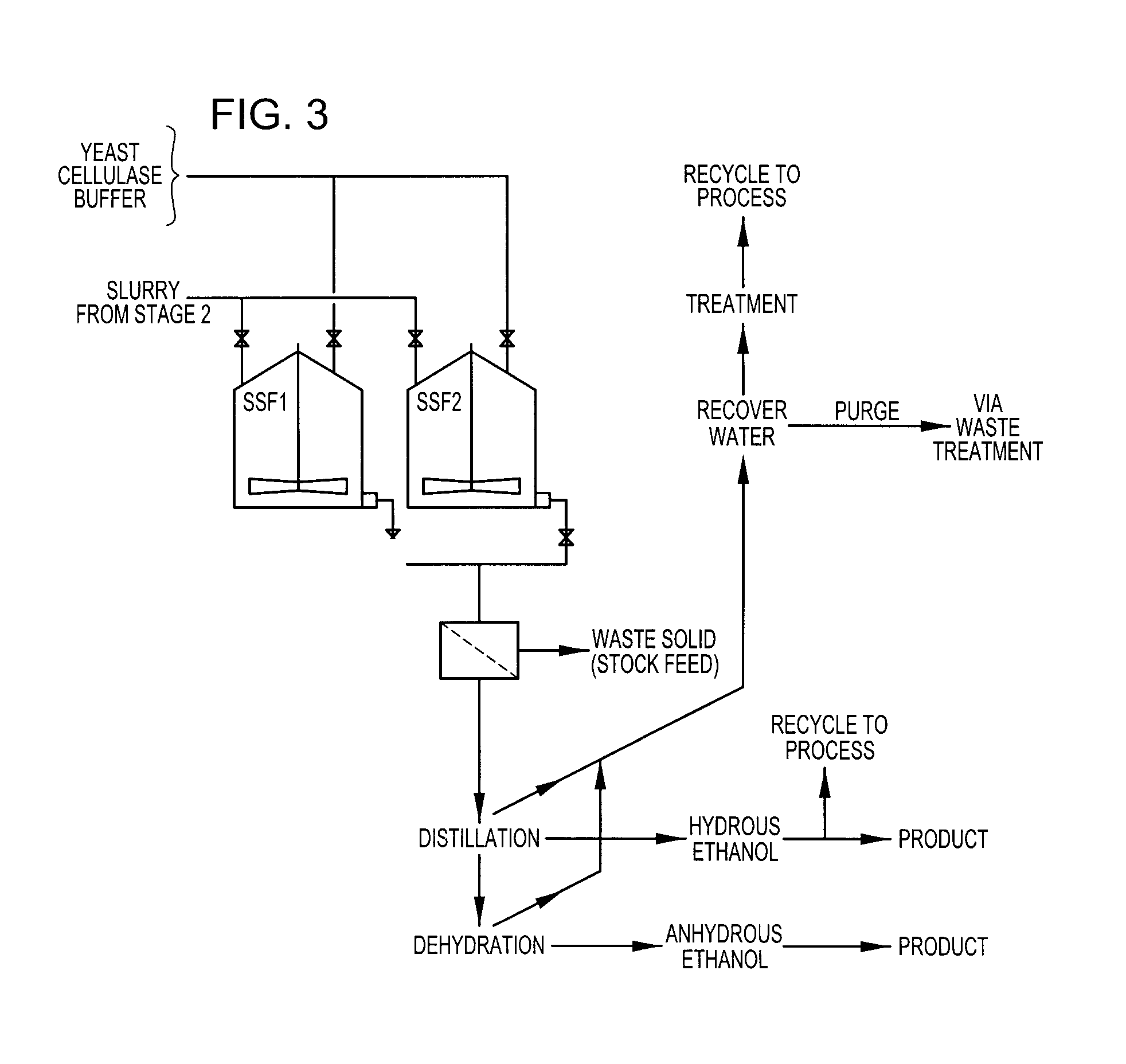

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

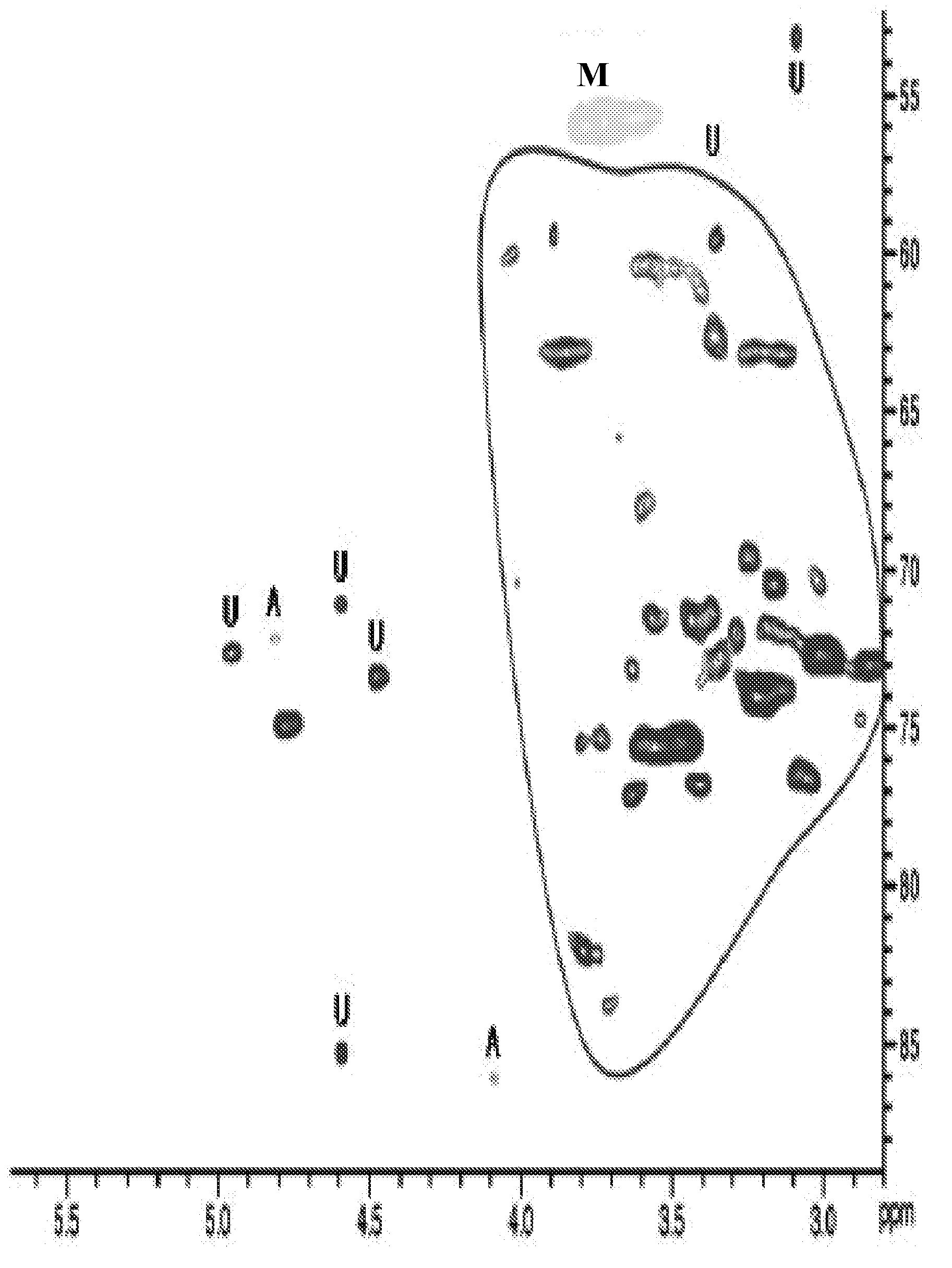

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090062516A1Good for healthImprove responseSugar derivativesOrganic compound preparationFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

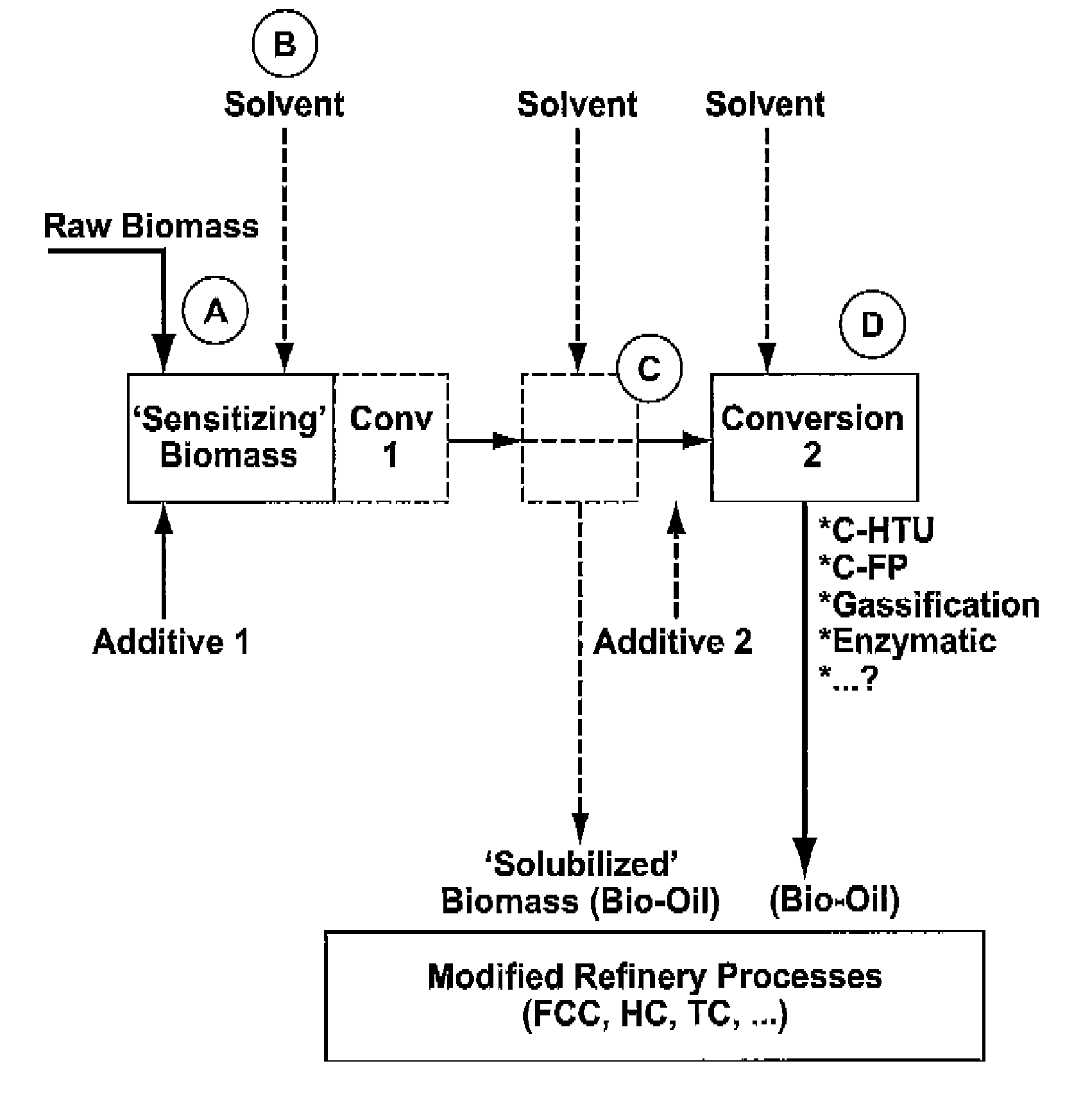

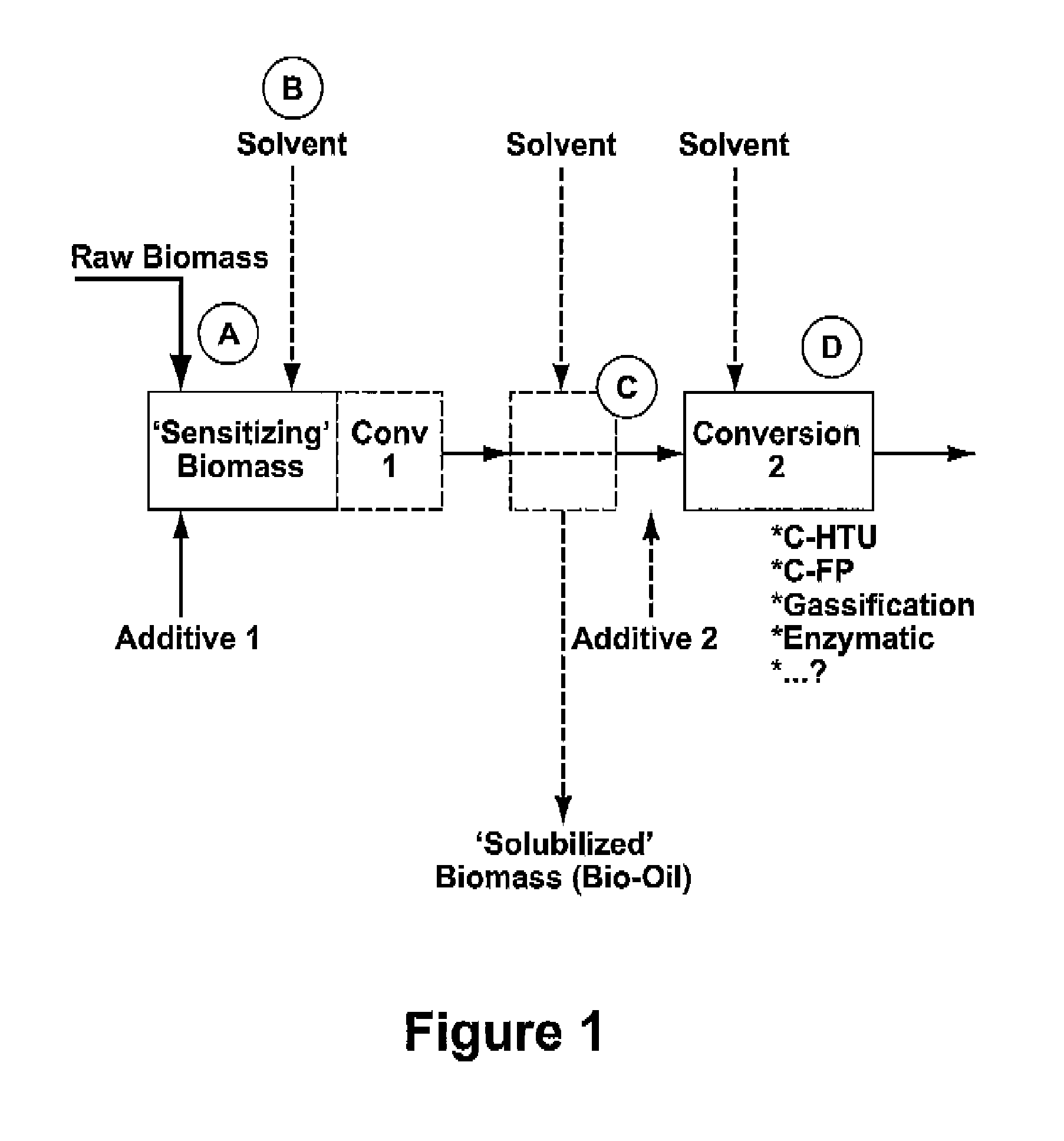

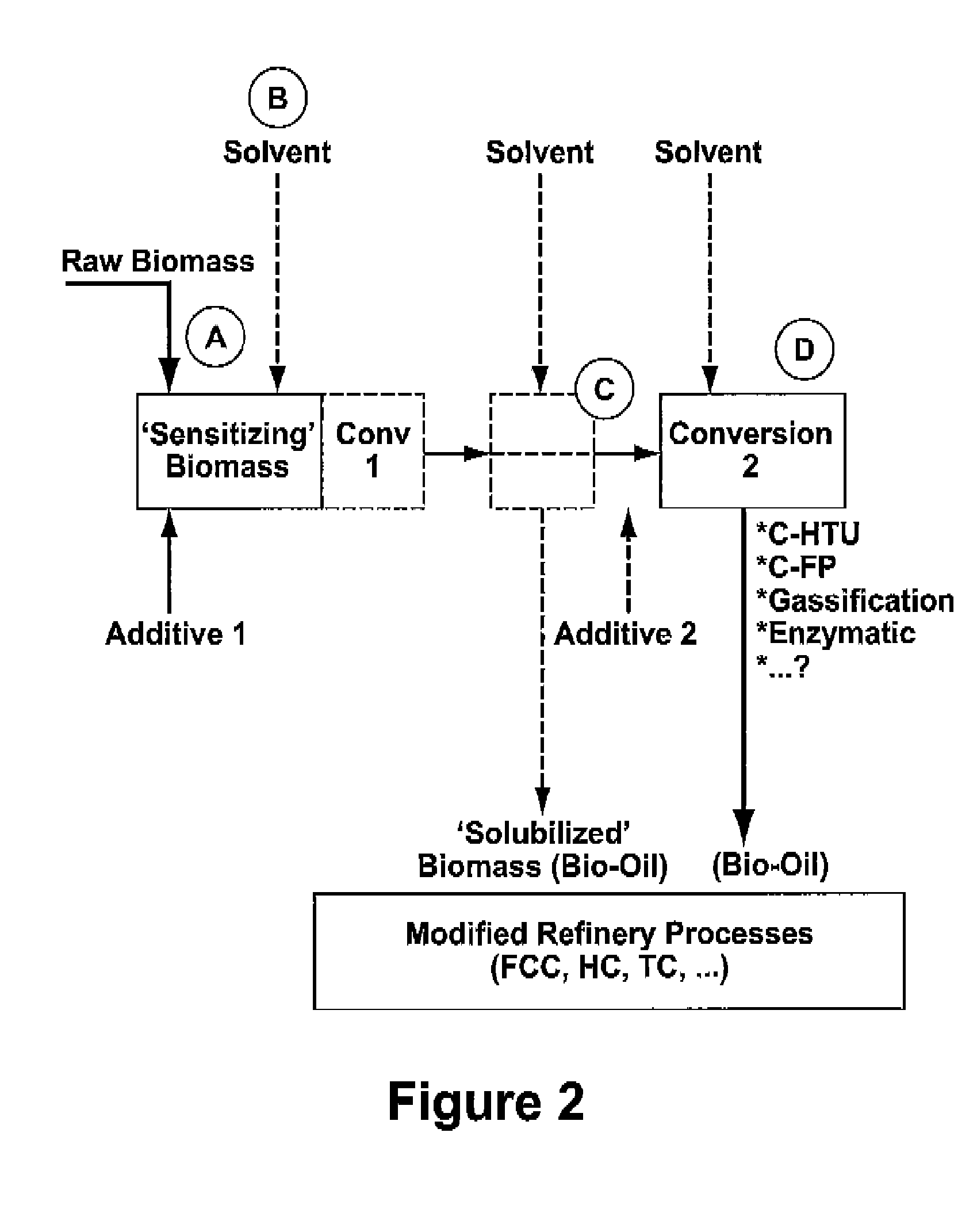

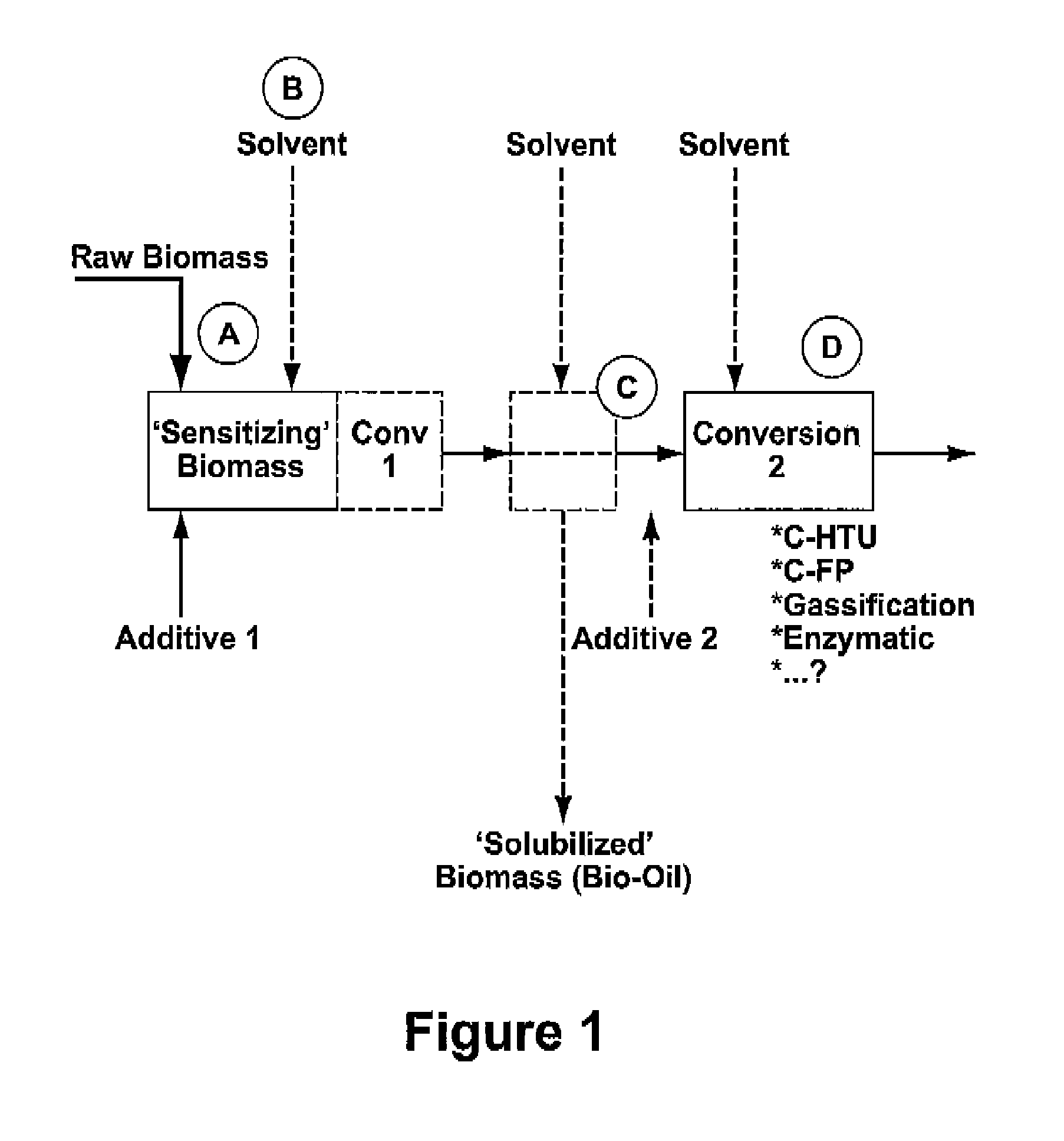

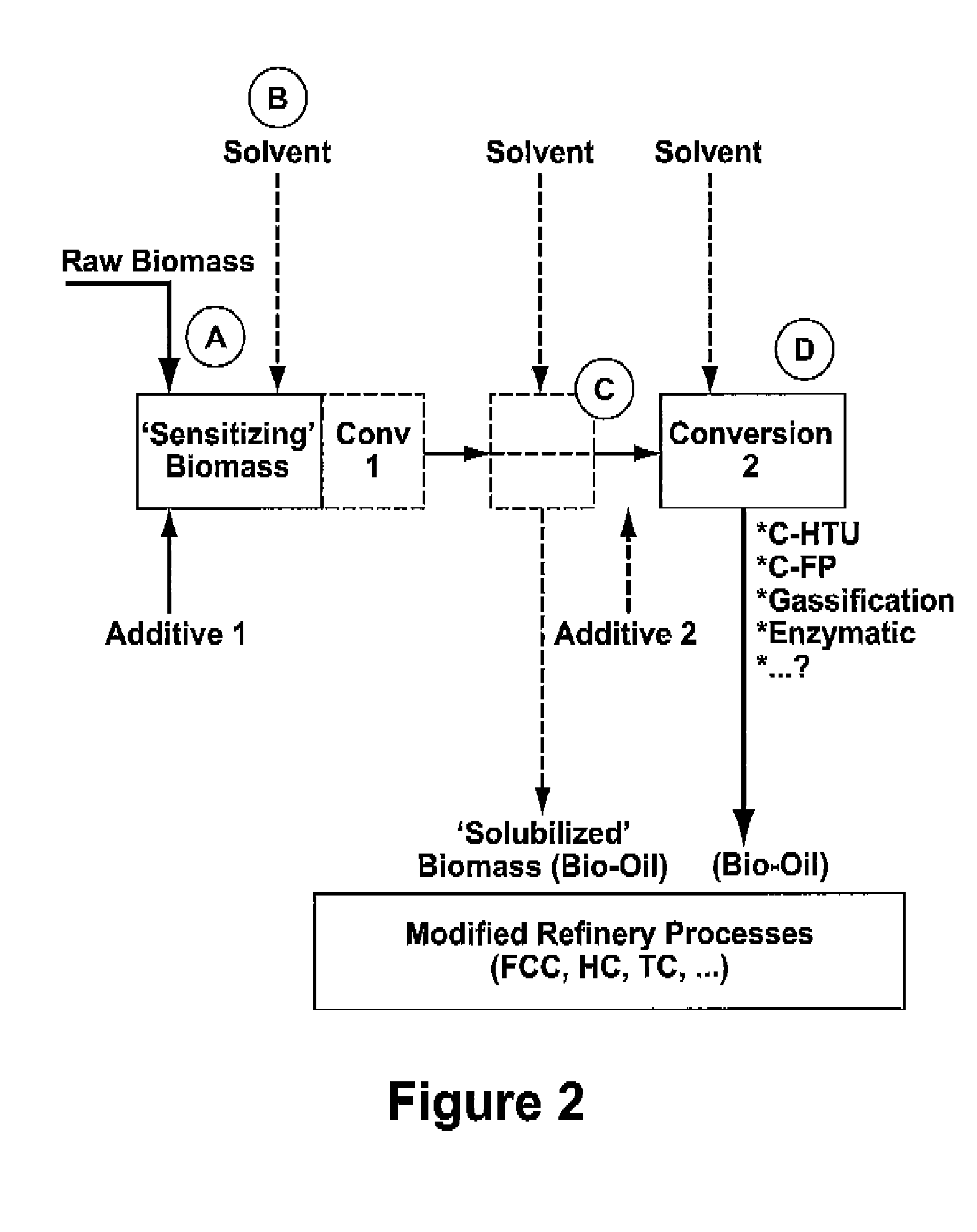

Process for the conversion of biomass to liquid fuels and specialty chemicals

Disclosed is a hydrothermal treatment process for conversion of a carbon-based energy carrier material. The process comprises a step for sensitizing or activating the carbon based energy carrier material to increase its susceptibility to hydrothermal conversion. As a result of the sensitization step, the hydrothermal conversion step itself may be carried out under relatively mild conditions.The process comprises the steps of sensitizing the carbon-based energy carrier material to increase its susceptibility to hydrothermal conversion; and subjecting the sensitized carbon-based energy carrier material to hydrothermal conversion at a temperature of less than 300 degrees centigrade in a hydrothermal treatment reactor.

Owner:MARD INC

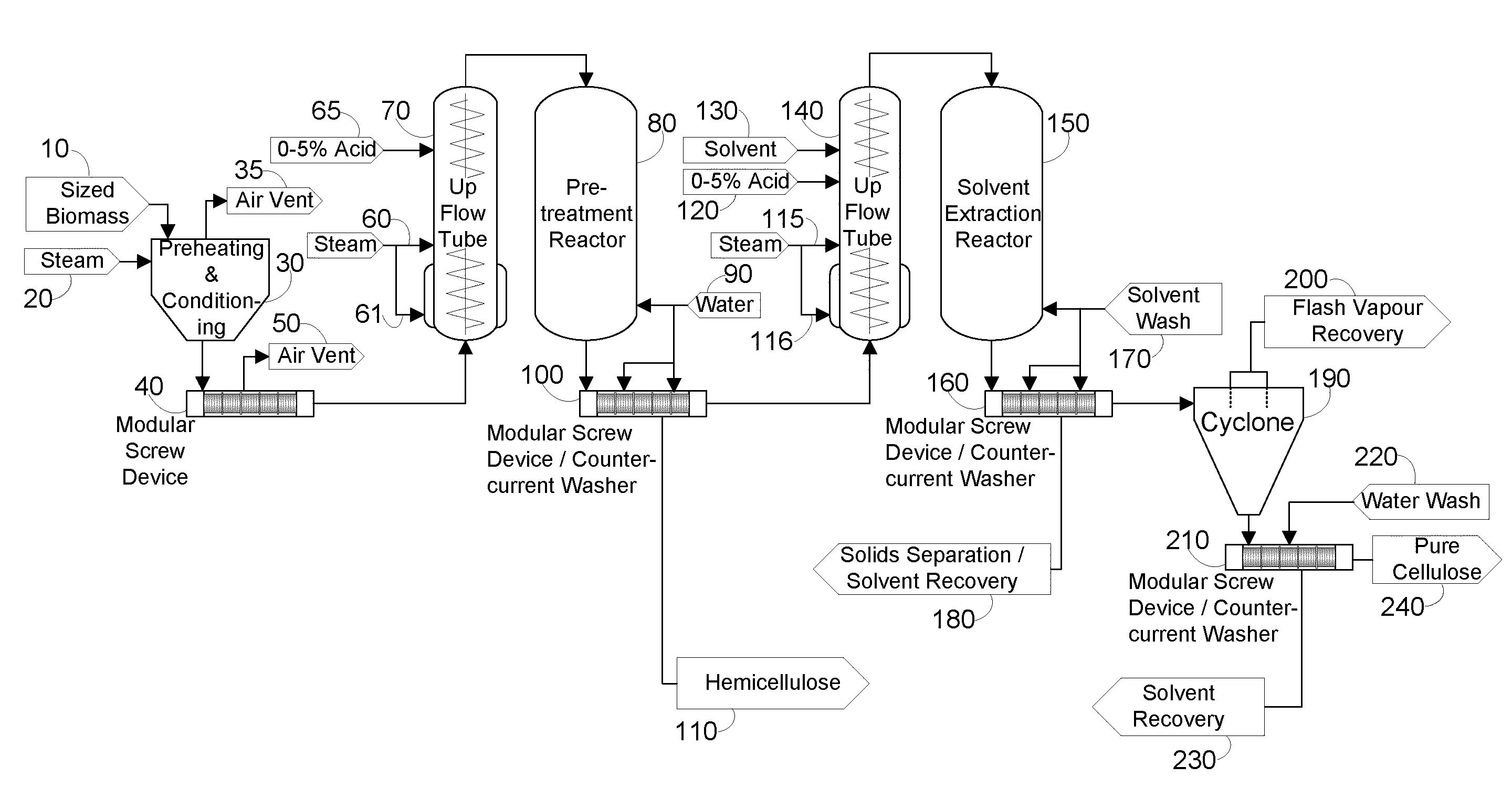

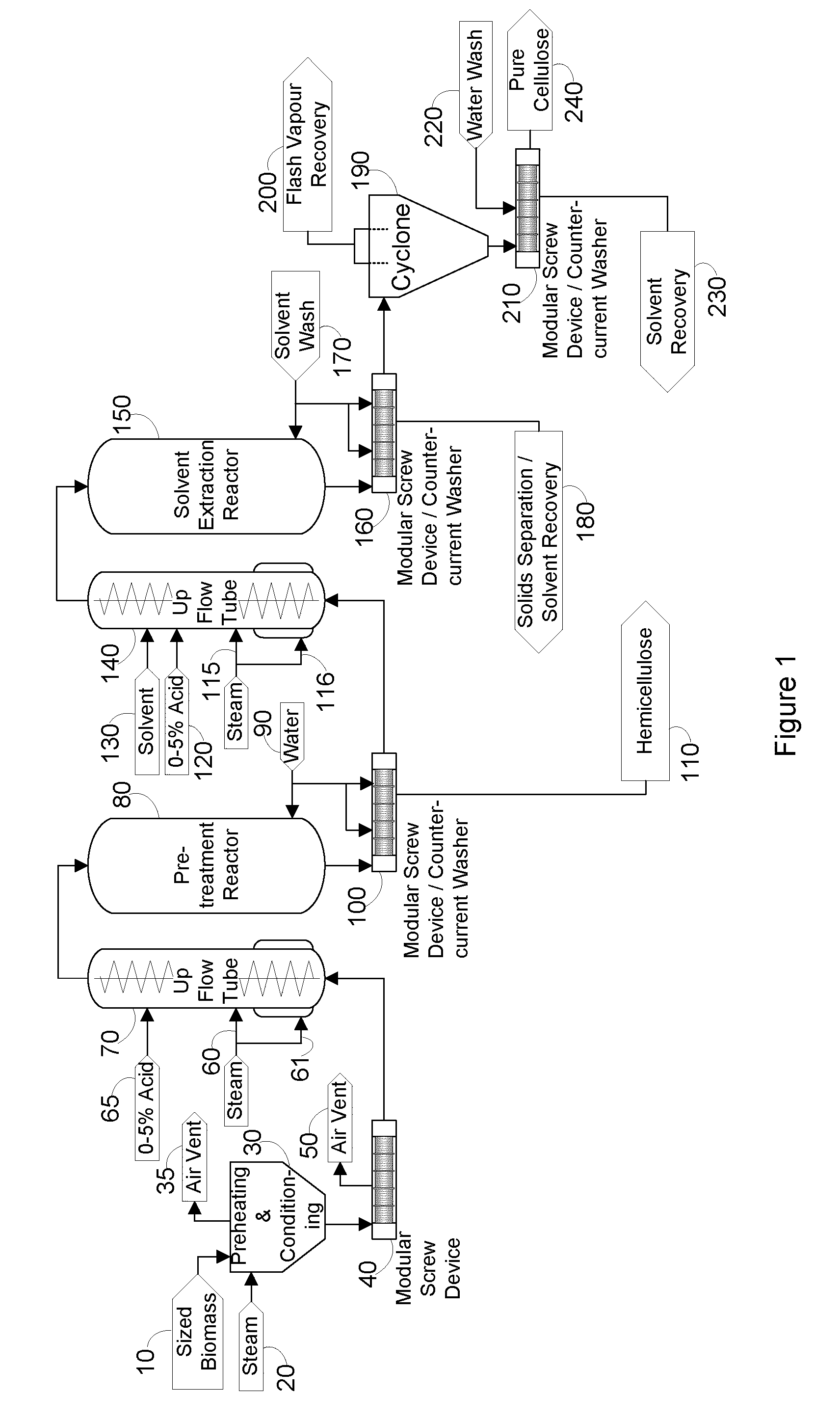

Separation of reactive cellulose from lignocellulosic biomass with high lignin content

InactiveUS20100269990A1Reduce inhibitionReduce extractionCellulosic pulp after-treatmentBiofuelsFiberLignocellulosic biomass

A process for separating the components of lignocellulosic biomass for the purpose of producing a pure reactive cellulose is disclosed. The process has two stages. In the first stage, the lignocellulosic biomass is pretreated with steam, with or without an acid catalyst, and then pressed, with or without the presence of an eluent, to remove hemicellulose and other impurities. In the second stage, the pretreated biomass is extracted with a solvent such as ethanol with or without acid catalysts in order to remove lignin and release a purified cellulose stream. The extracted cellulose is then rapidly decompressed to rupture the fibrous structure. The process provides a purified cellulose stream that is relatively easy to hydrolyze with enzymes and ferment to biofuels and other chemicals such as ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

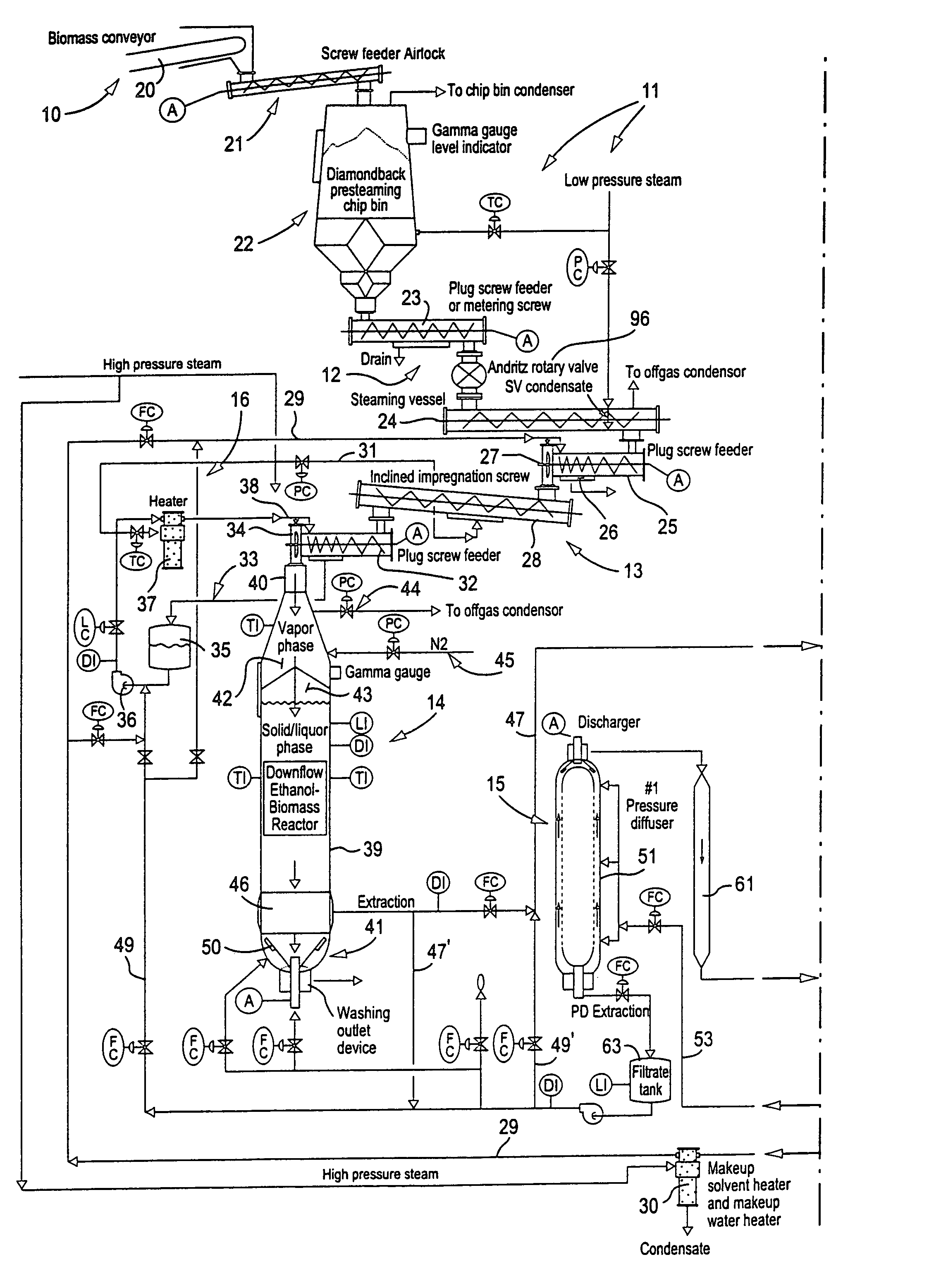

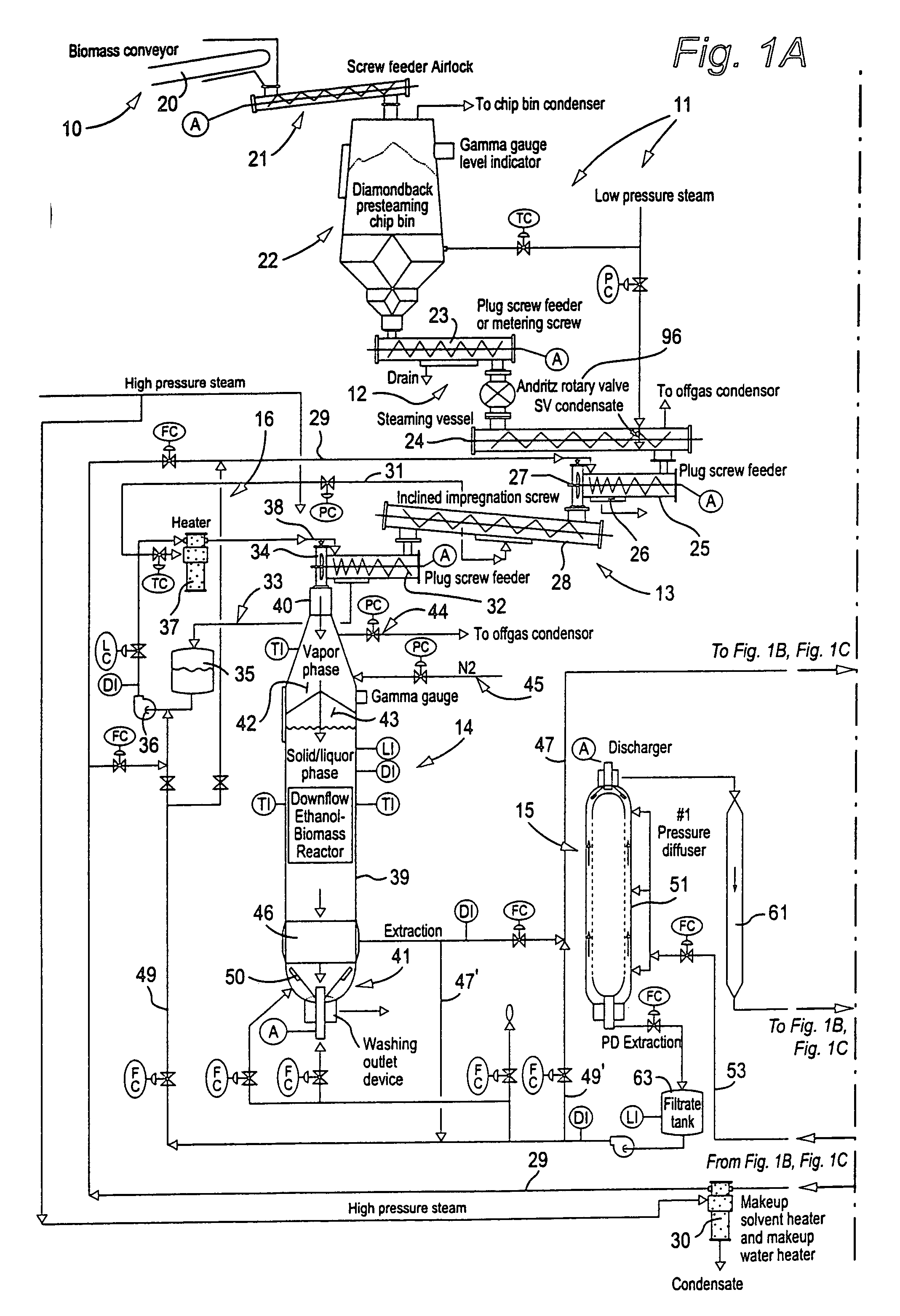

Solvent pulping of biomass

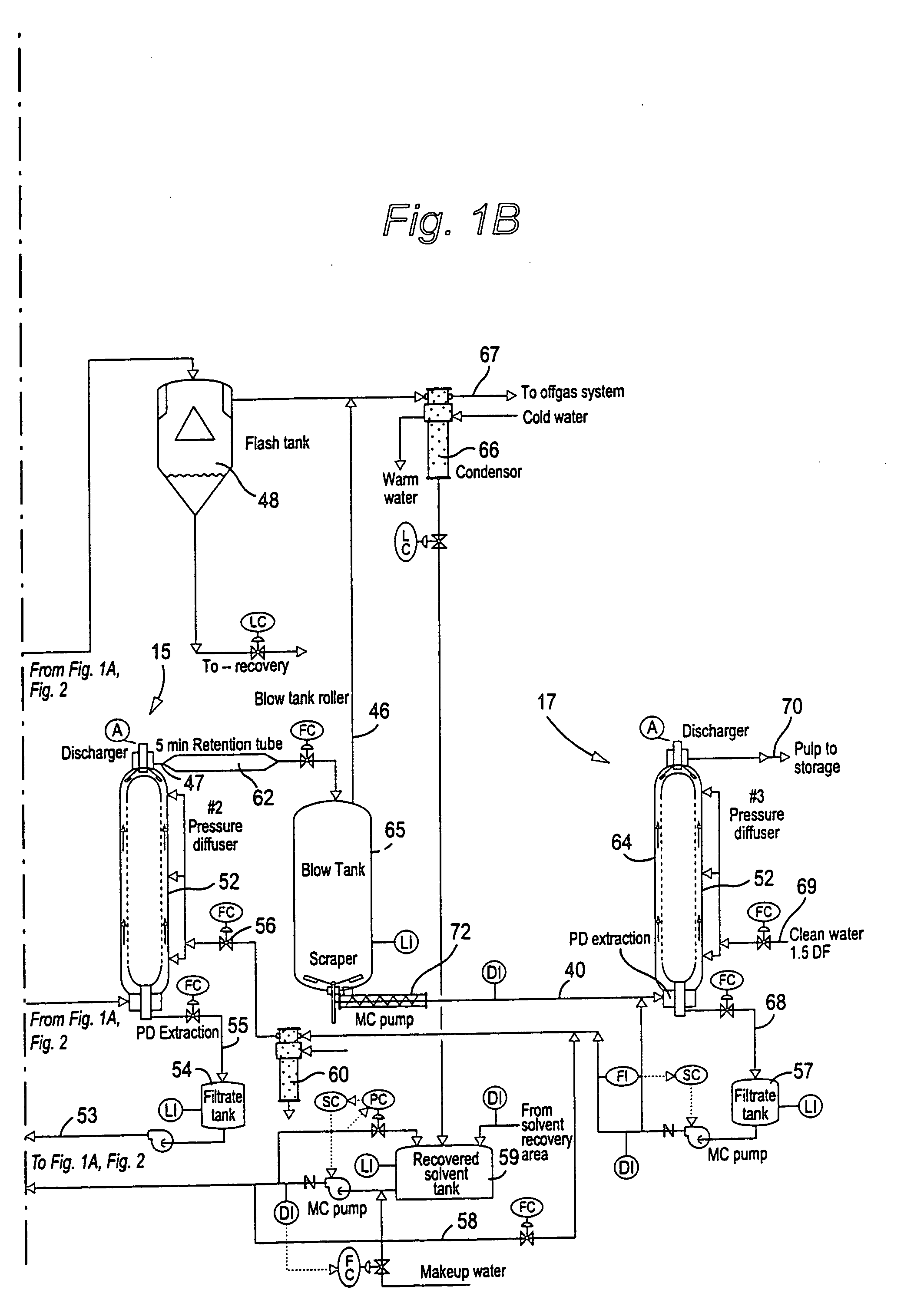

InactiveUS20040060673A1Pretreatment with water/steamWashing/displacing pulp-treating liquorsCellulose fiberChemistry

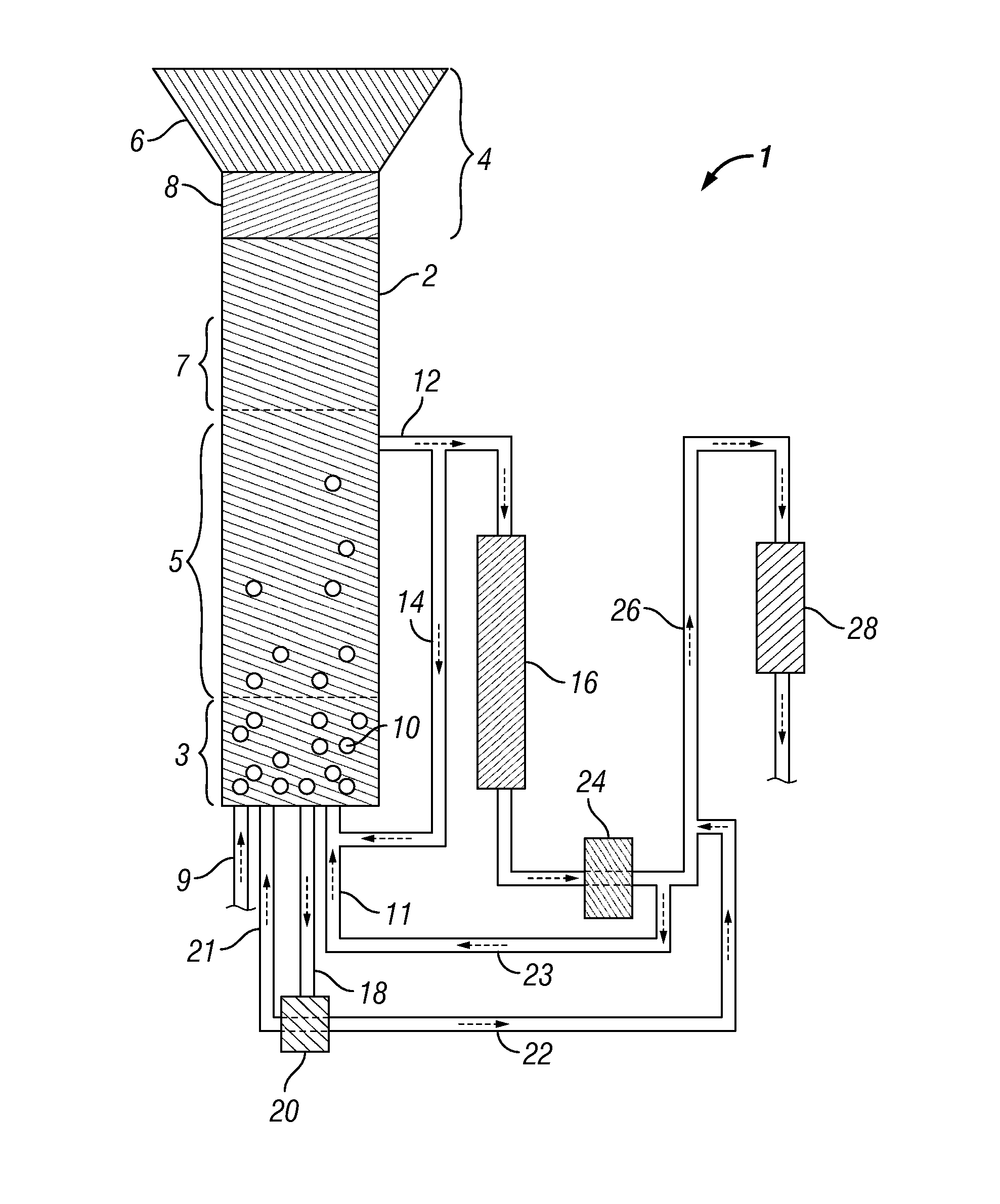

An apparatus and process for solvent pulping of cellulose-containing biomass utilizes at least one steaming vessel, a plug screw feeder or compression screw device, at least one super-atmospheric impregnation vessel, a solvent delignification reactor capable of operating at a pressure of 350 psig or more, and a solvent containing line for introducing solvent-containing liquor at the plug screw feeder outlet or compression screw device outlet. The process and system can also include at least one series connected pressure diffuser and optionally a retention tube downstream of each pressure diffuser to provide sufficient retention time to substantially preclude re-deposition of lignin on the cellulose fibers of the biomass, a blow tank connected to the last of the pressure diffusers and retention tubes, and vessels for multistage alcohol washing. The method steams the biomass and impregnates it with solvent to produce an aqueous slurry of biomass and solvent, delignifies the particulate biomass in the slurry, removes solvent while continuing delignification of the biomass in the slurry and while substantially precluding re-deposition of lignin on the cellulose of the biomass, reduces the pressure of the slurry; and then washes the slurry.

Owner:ANDRITZ INC

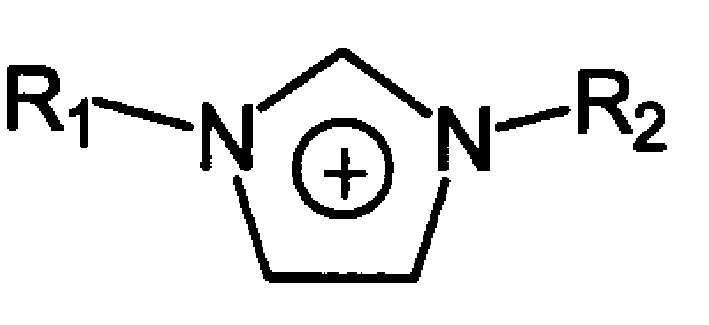

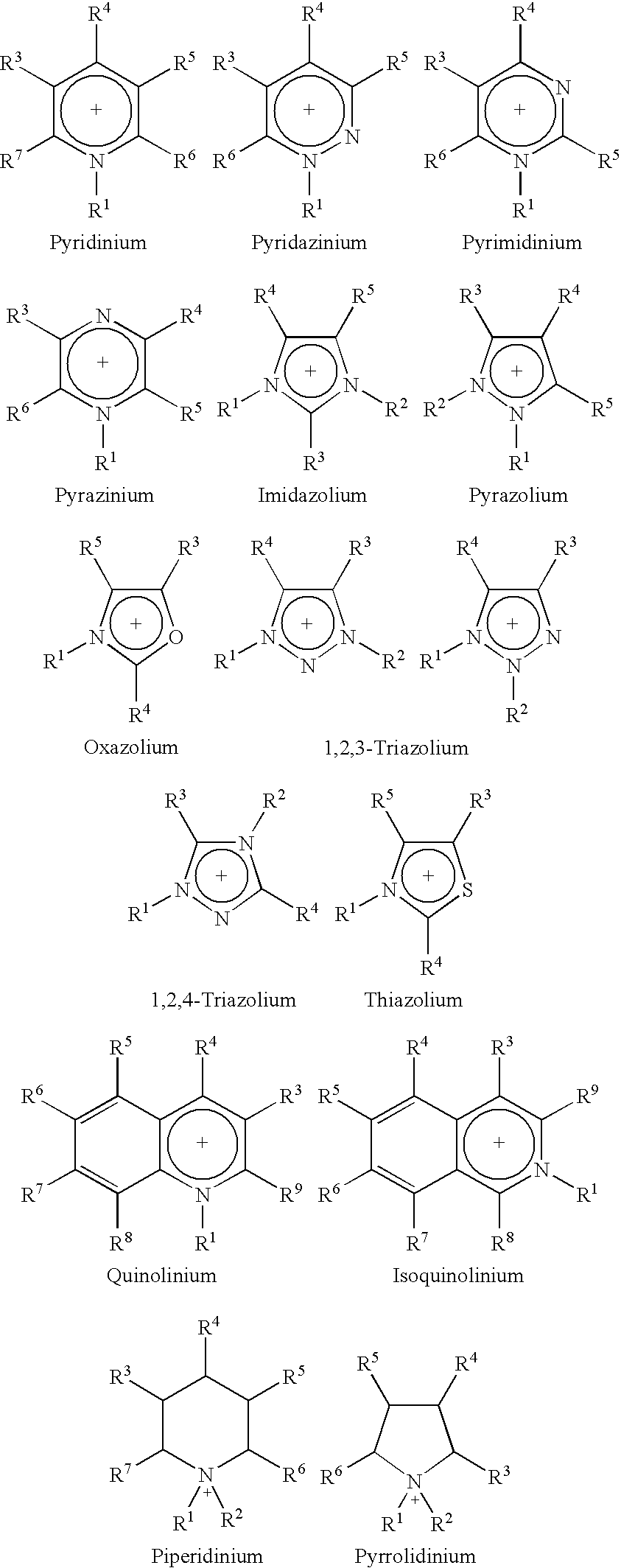

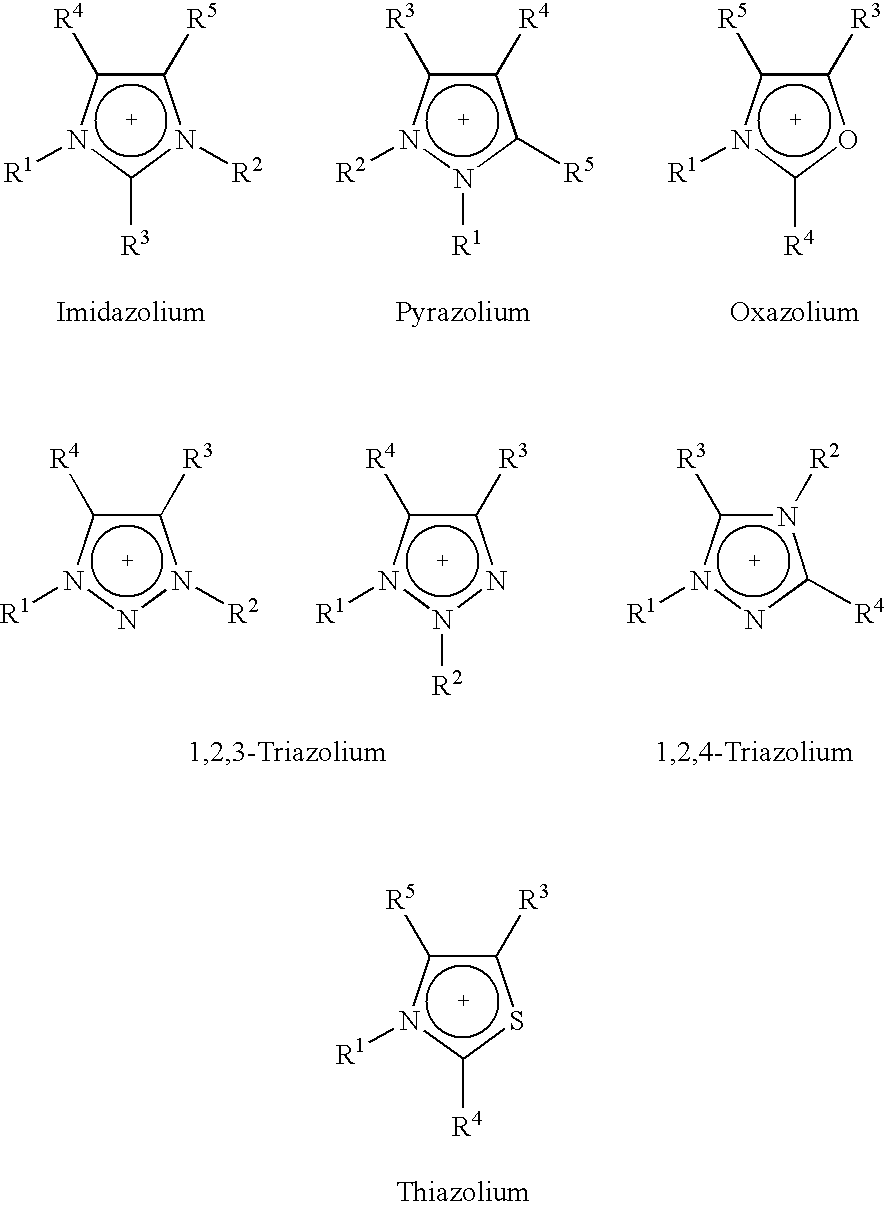

Room temperature ionic liquid containing unsaturated double bond and its prepn and application

InactiveCN1417407AGroup 5/15 element organic compoundsPulping with organic solventsSulfate radicalsTriflic acid

The room temperature ionic liquid containing unsaturated double bond has the general expressino of A+B-, where A+ contains R1 being hydroxyl with 1-4 carbon atoms and R2 containing 2-20 carbon atoms and at least one double bond; and B- is one of anions, including chlorate radical, bromate radical, iodate radical, acetate radical, sulfate radical, nitrate radical, tetrafluorobromate radical, etc. Its preparation is to mixture and react olefin halide R1X and N-alkyl imidazole to obtain ionic liquid dialkyl imidazolium halide. The present invention also relates to the application of the ionic liquid in dissolving cellulose and preparing cellulose derivative.

Owner:山东中科恒联生物基材料有限公司

Lignin and other products isolated from plant material, methods for isolation and use, and compositions containing lignin and other plant-derived products

InactiveUS20090069550A1Great potentialTotal calories lowLignin derivativesPulp by-products recoveryFiberElastomer

Lignin polymers having distinctive properties, including a generally high molecular weight and generally homogeneous size distribution, as well as preservation of native reactive side groups, are isolated by solvent extraction of plant materials. Methods for isolation of lignin polymers, and for use of the isolated lignin polymers are disclosed. Compositions containing lignin isolated from plant materials, such as carbon fiber composites, resins, adhesive binders and coatings, polyurethane-based foams, rubbers and elastomers, plastics, films, paints, nutritional supplements, food and beverage additives are disclosed. Xylose and xylose derivatives, furfural, fermentable sugars, cellulose and hemi-cellulose products may be used directly or further processed. The lignin polymers and other plant-derived products disclosed herein may be produced in abundance at low cost, and may be used as substitutes for feedstocks originating from fossil fuel or petrochemical sources in the manufacture of various products.

Owner:VERTICHEM CORP

Methods and systems for processing lignin during hydrothermal digestion of cellulosic bionass solids

InactiveUS20140117277A1Easy to adaptOther chemical processesLiquid hydrocarbon mixture productionCelluloseAlcohol

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in a digestion solvent; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase; and separating the phenolics liquid phase from the aqueous phase.

Owner:SHELL OIL CO

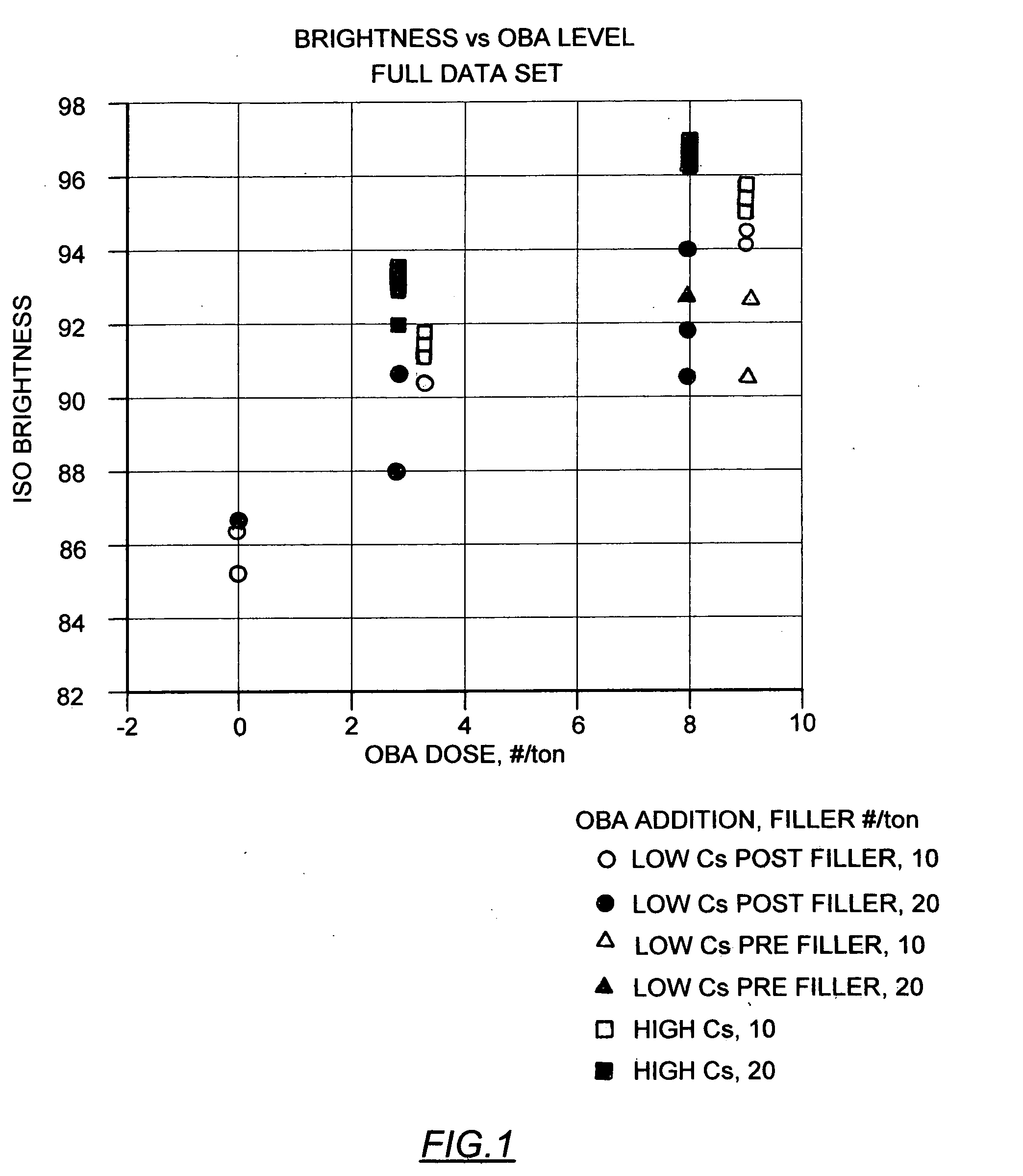

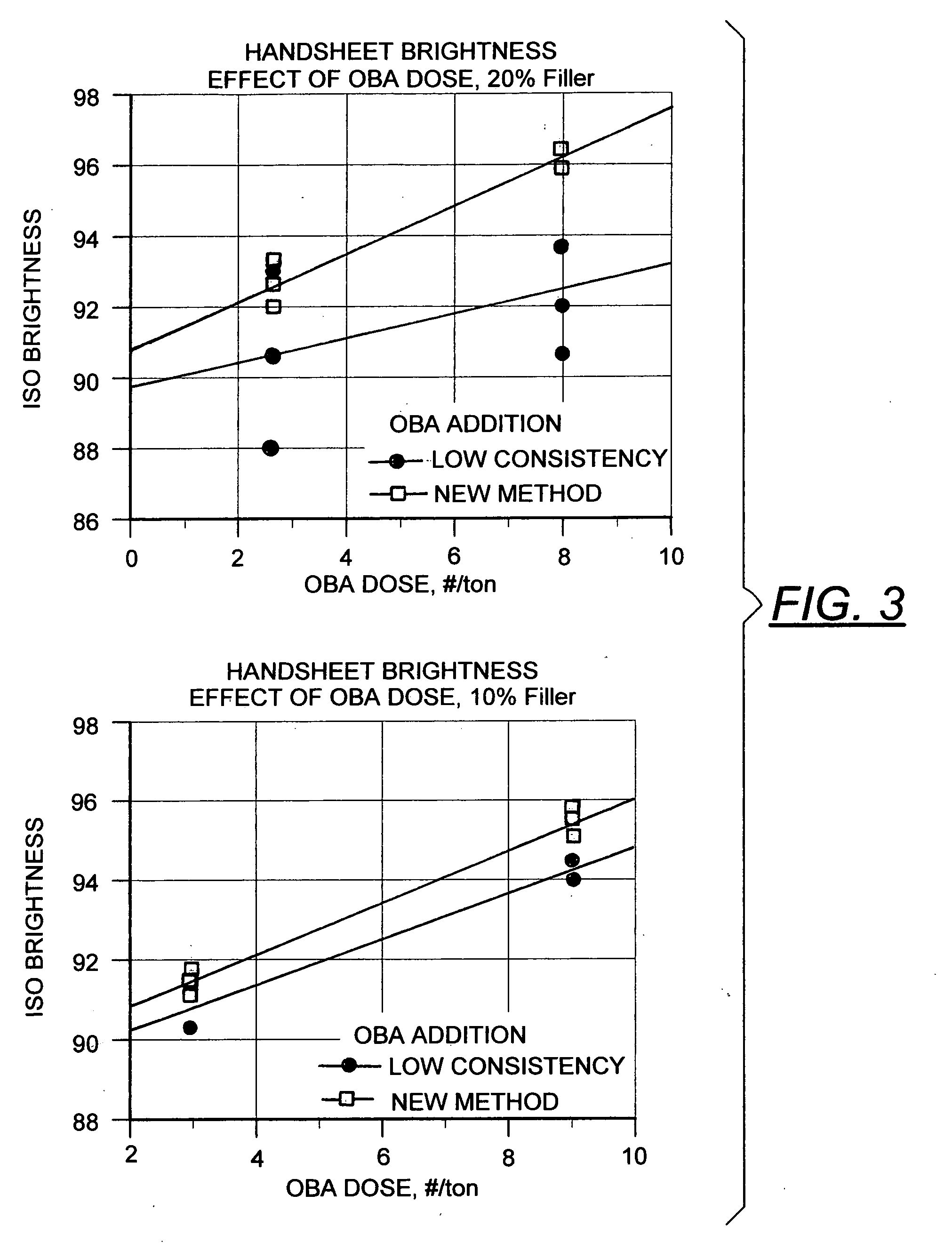

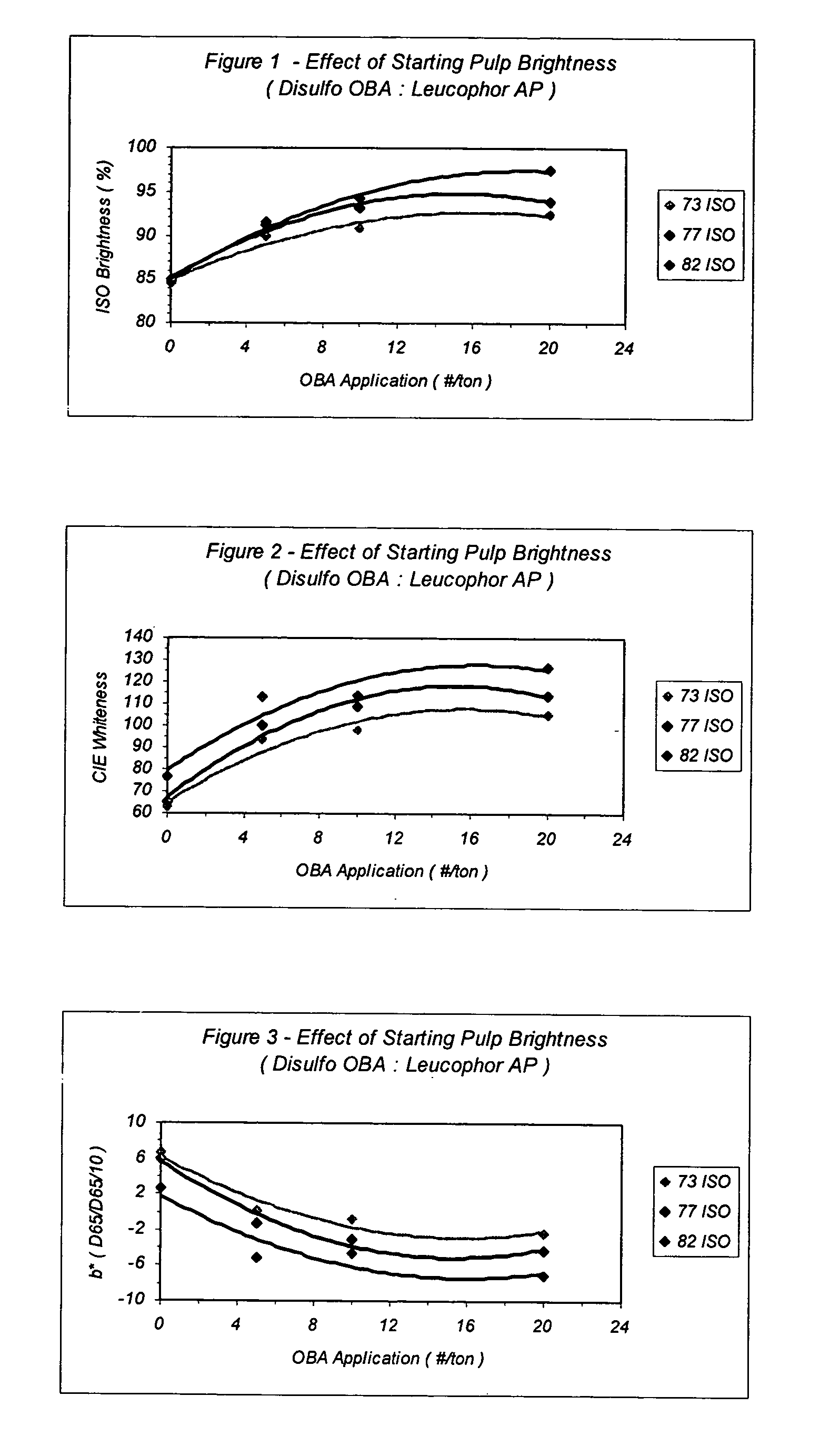

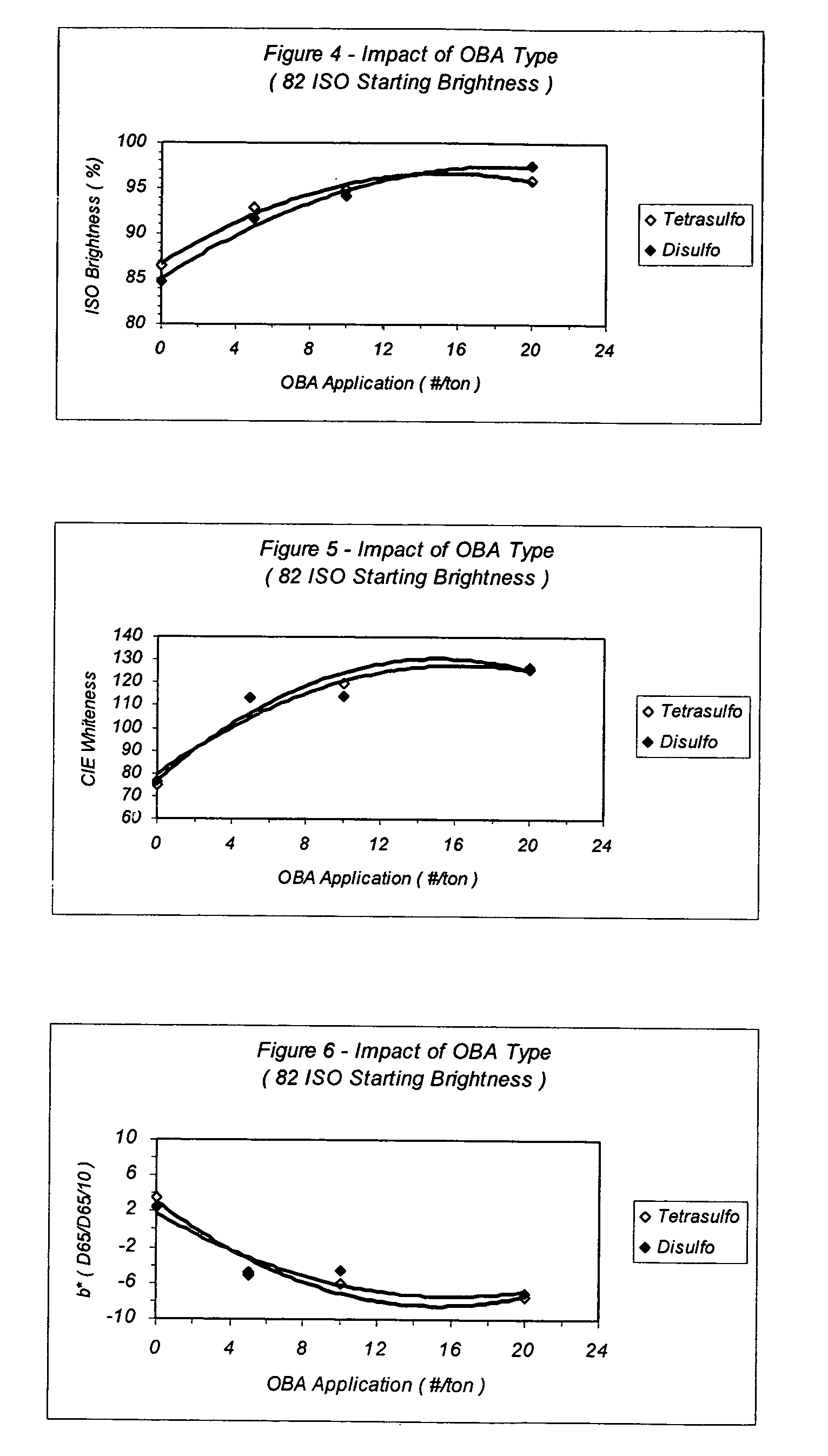

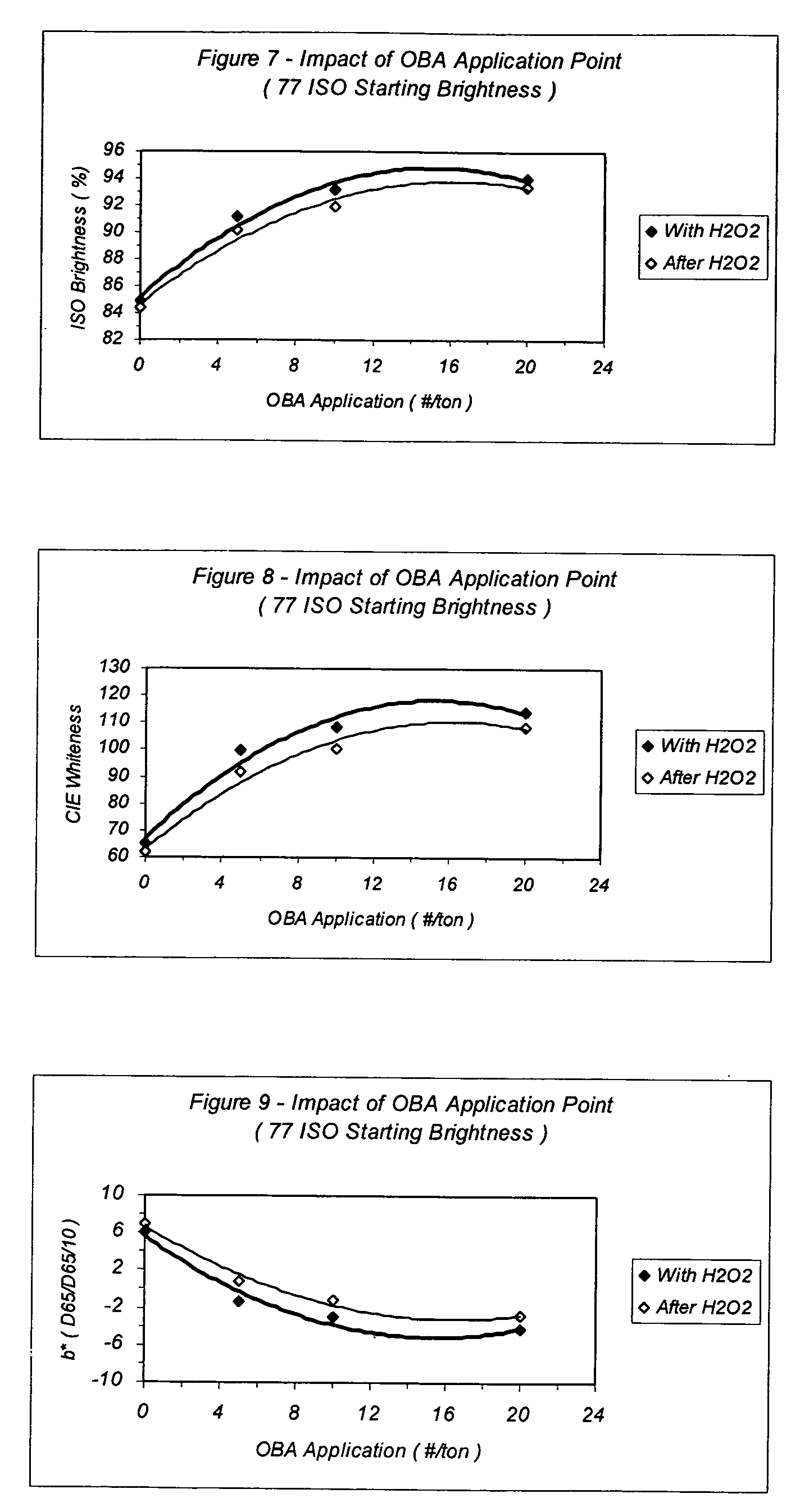

Pulp and paper having increased brightness

InactiveUS20070193707A1Natural cellulose pulp/paperSpecial paperPulp and paper industryBrightness perception

Owner:INT PAPER CO

Process for manufacturing pulp, paper and paperboard products

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

Dissolution Method

The invention relates to a method for dissolving wood, straw and other natural lignocellulosic materials in an ionic liquid solvent under microwave irradiation and / or under pressure. The invention also relates to the resulting solution and to methods for separating cellulose and other organic compounds, such as lignin and extractives, from the solution.

Owner:VESA MYLLYMAKI +1

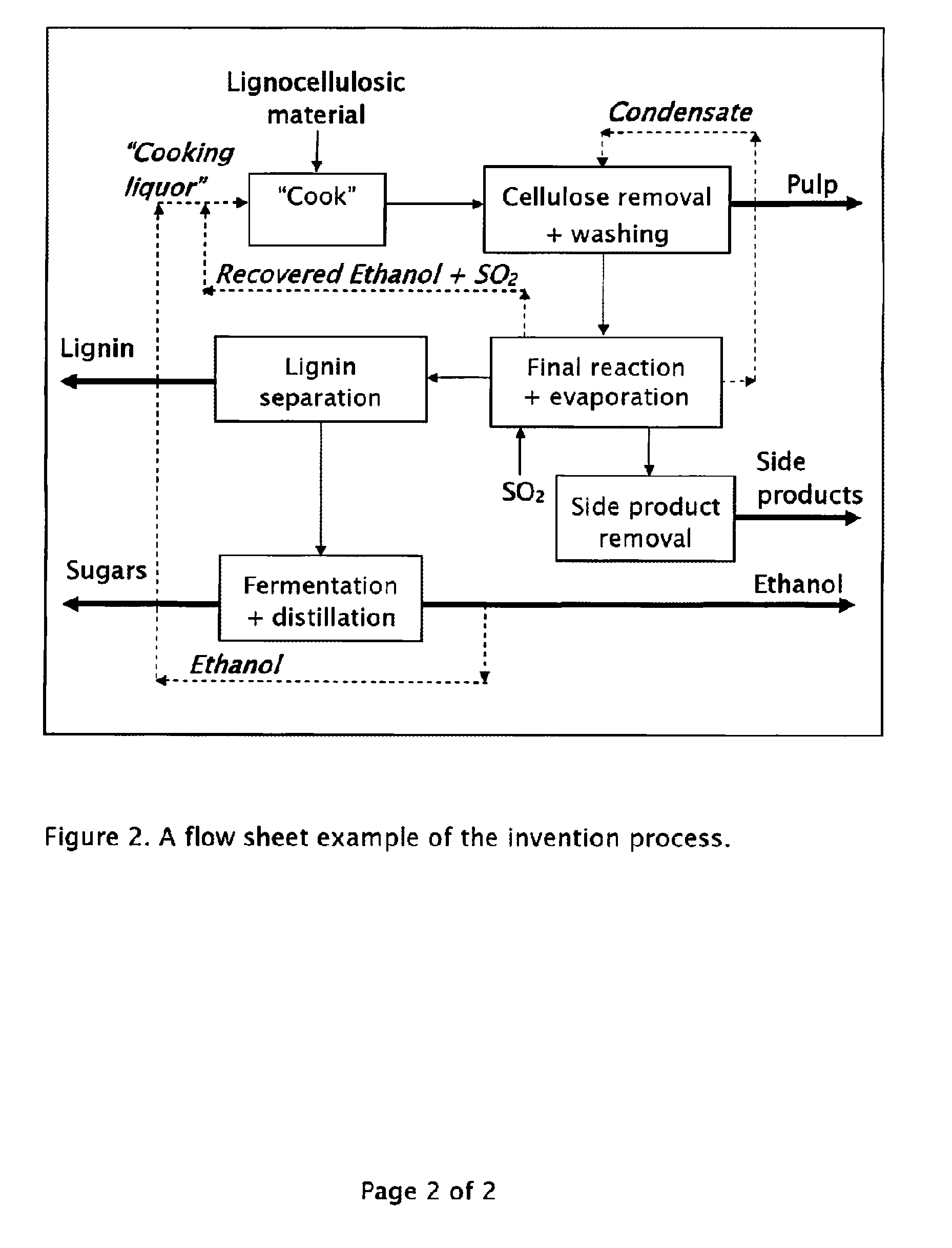

Product and processes from an integrated forest biorefinery

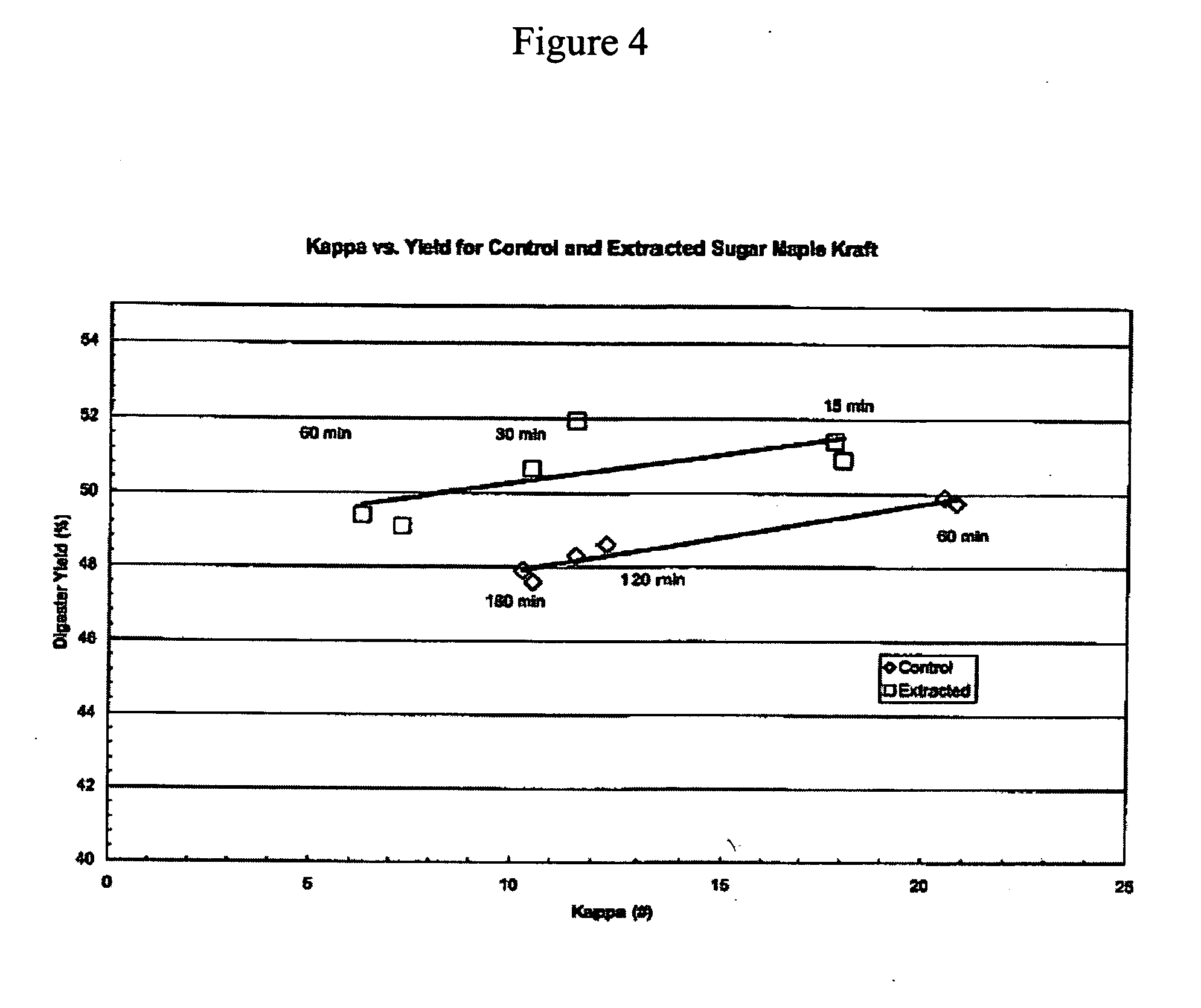

ActiveUS20070079944A1Easy to optimizePretreatment with water/steamPulping with acid salts/anhydridesPulp and paper industrySugar

An omnibus process of pulping and bleaching lignocellulosic materials in which a charge of a lignocellulosic material is biopulped and / or water extracted prior to pulping and bleaching. The lignocellulosic material may be mechanically pulped and bleached in the presence of an enzyme that breaks lignin-carbohydrate complexes. The aqueous extract in embodiments including a water extract step is separated into acetic acid and hemicellulose sugar aqueous solutions.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

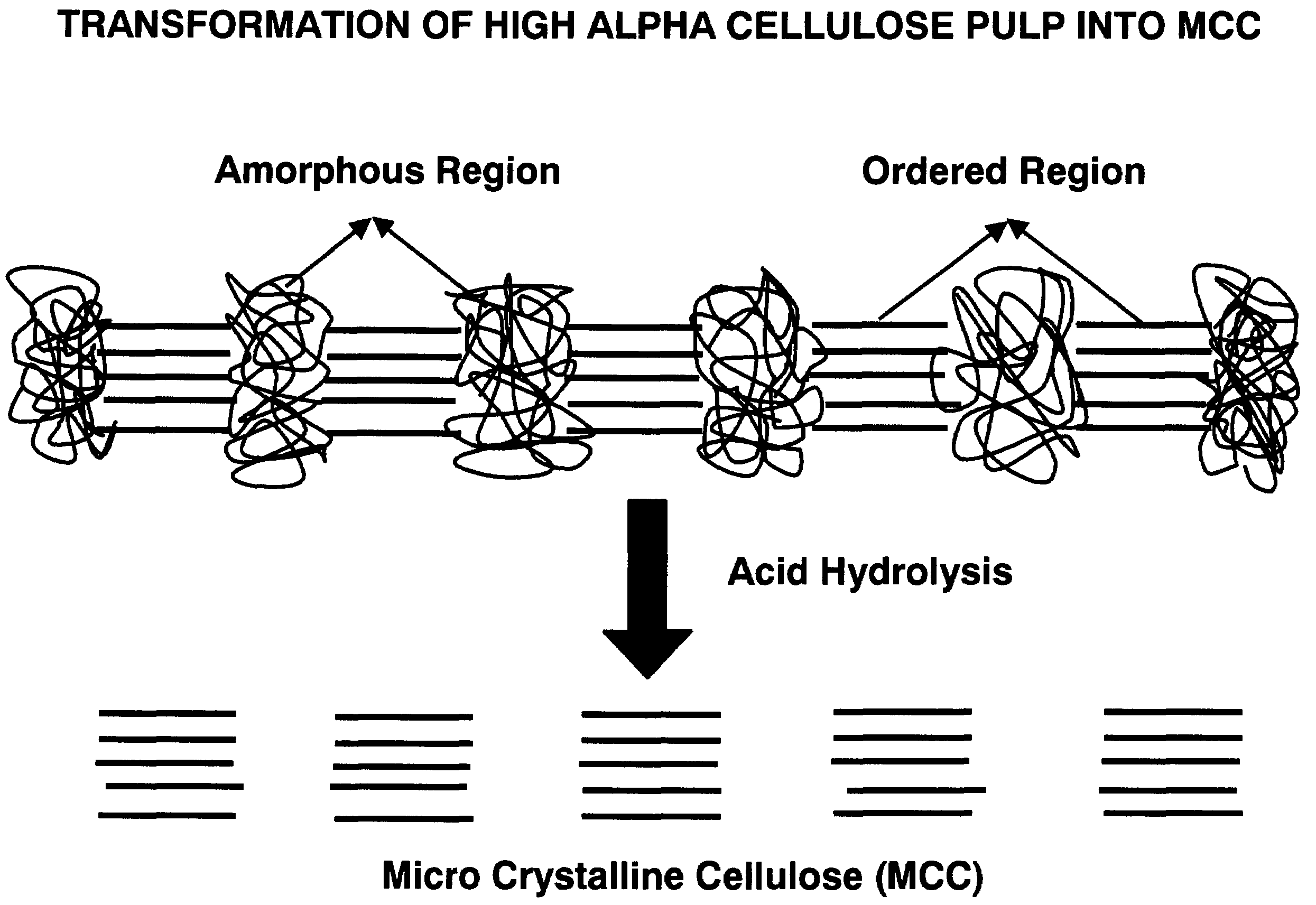

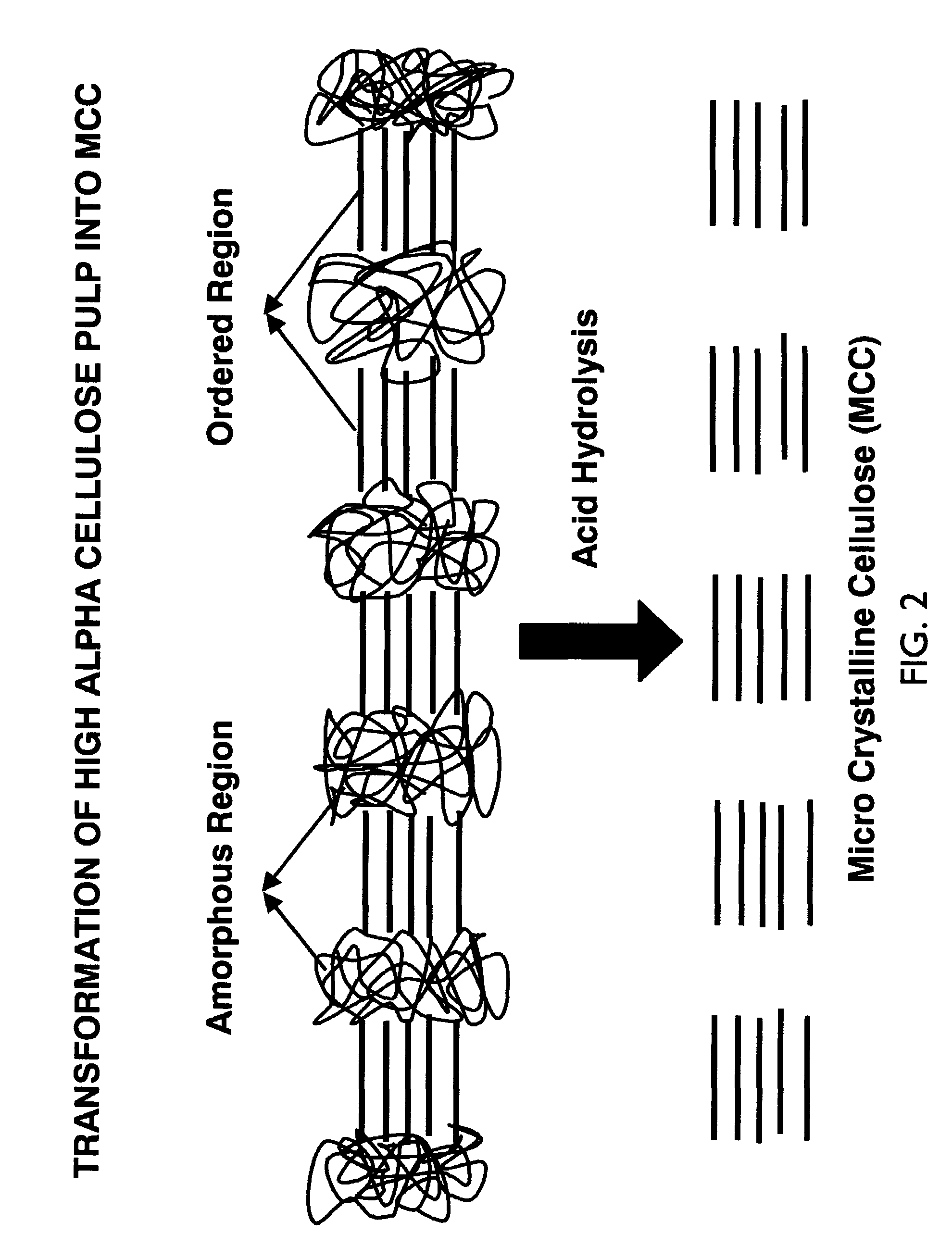

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS7037405B2High binding capacityImprove abilitiesNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

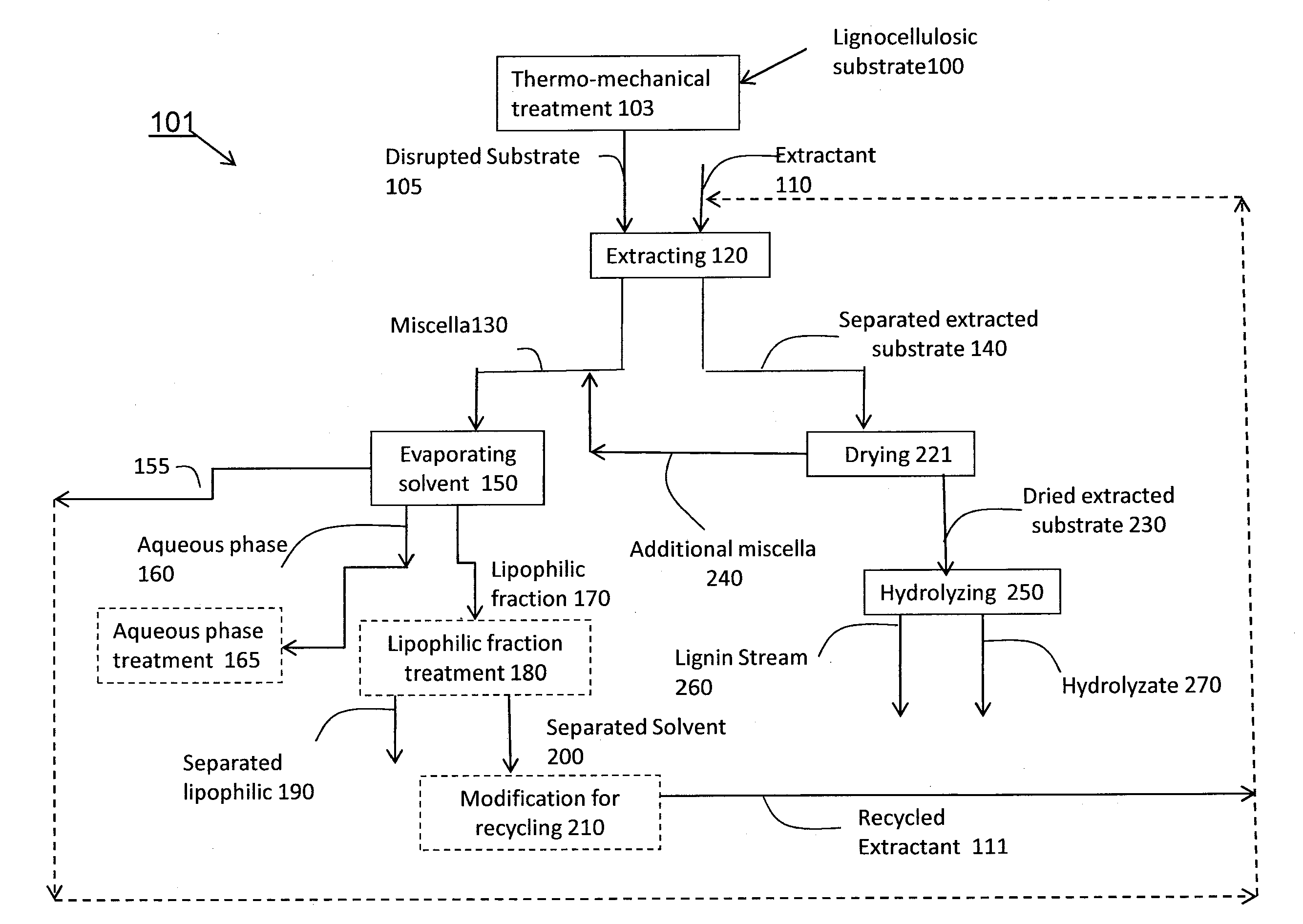

Methods and systems for processing lignocellulosic materials and related compositions

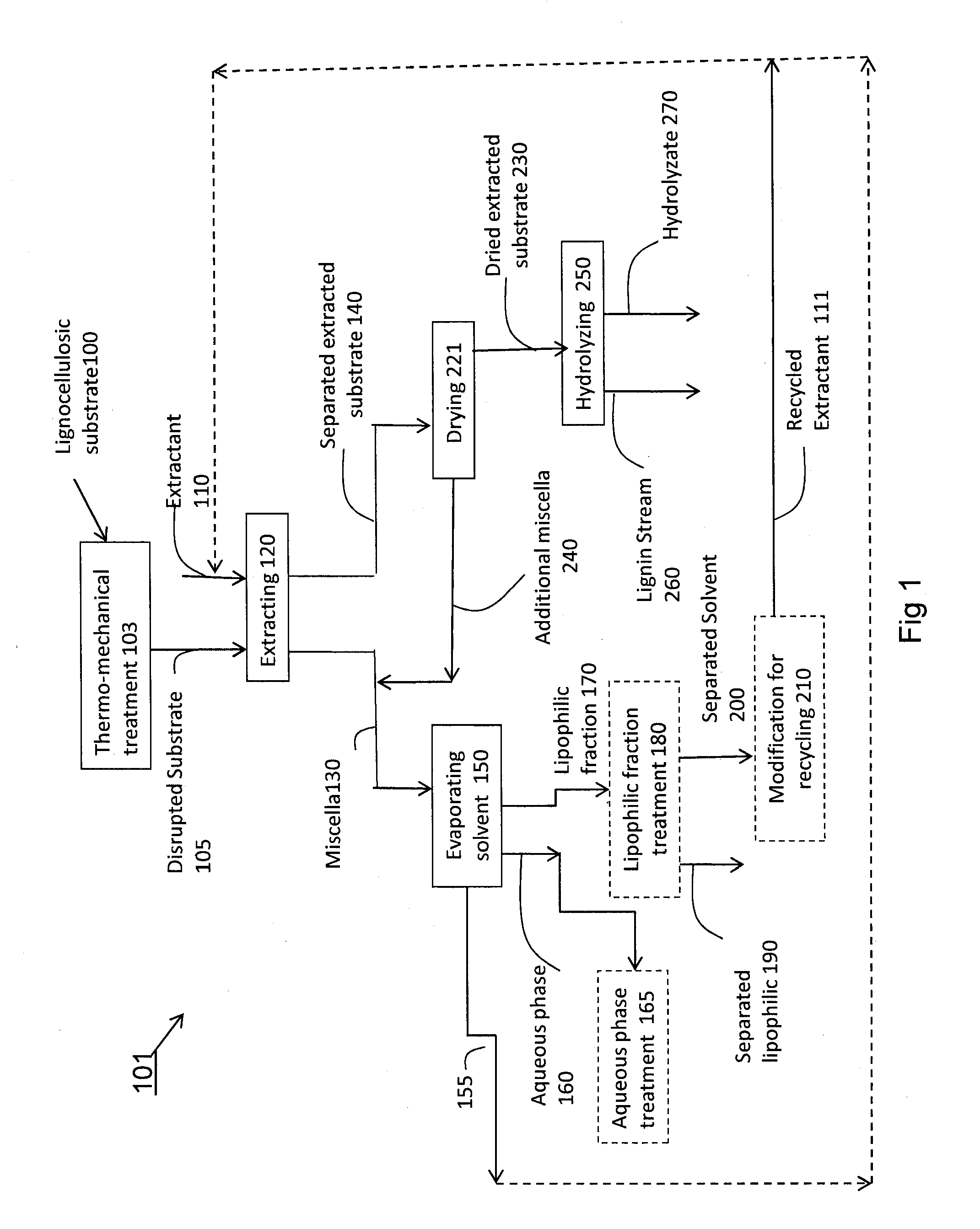

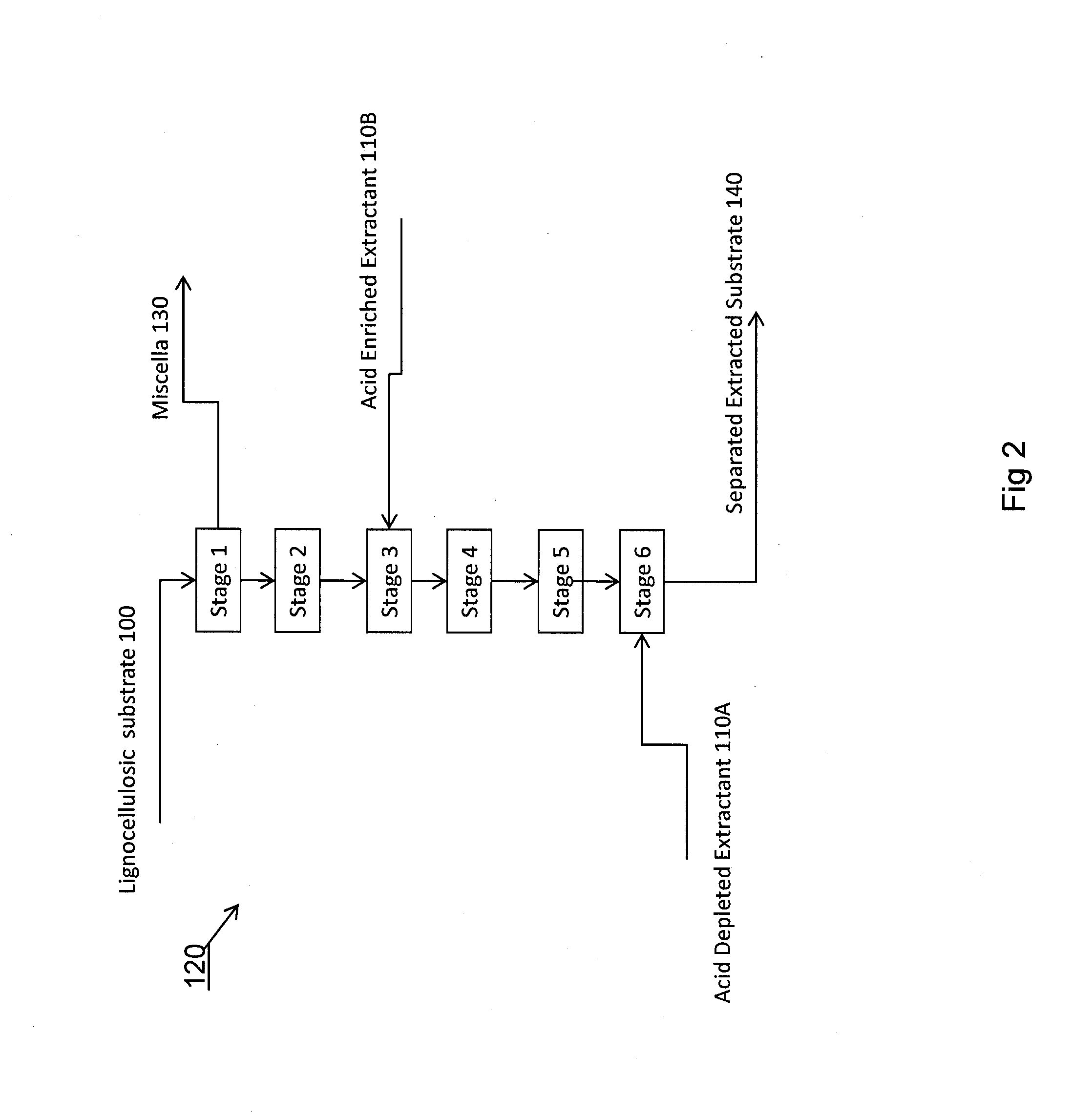

A method comprising: (a) providing a lignocellulosic substrate; (b) contacting said lignocellulosic substrate with an extractant comprising a water-soluble organic solvent to form an extracted substrate and a miscella; (c) removing miscella from said extracted substrate; and (d) hydrolyzing said extracted substrate using a chemically catalyzed process.

Owner:VIRDIA

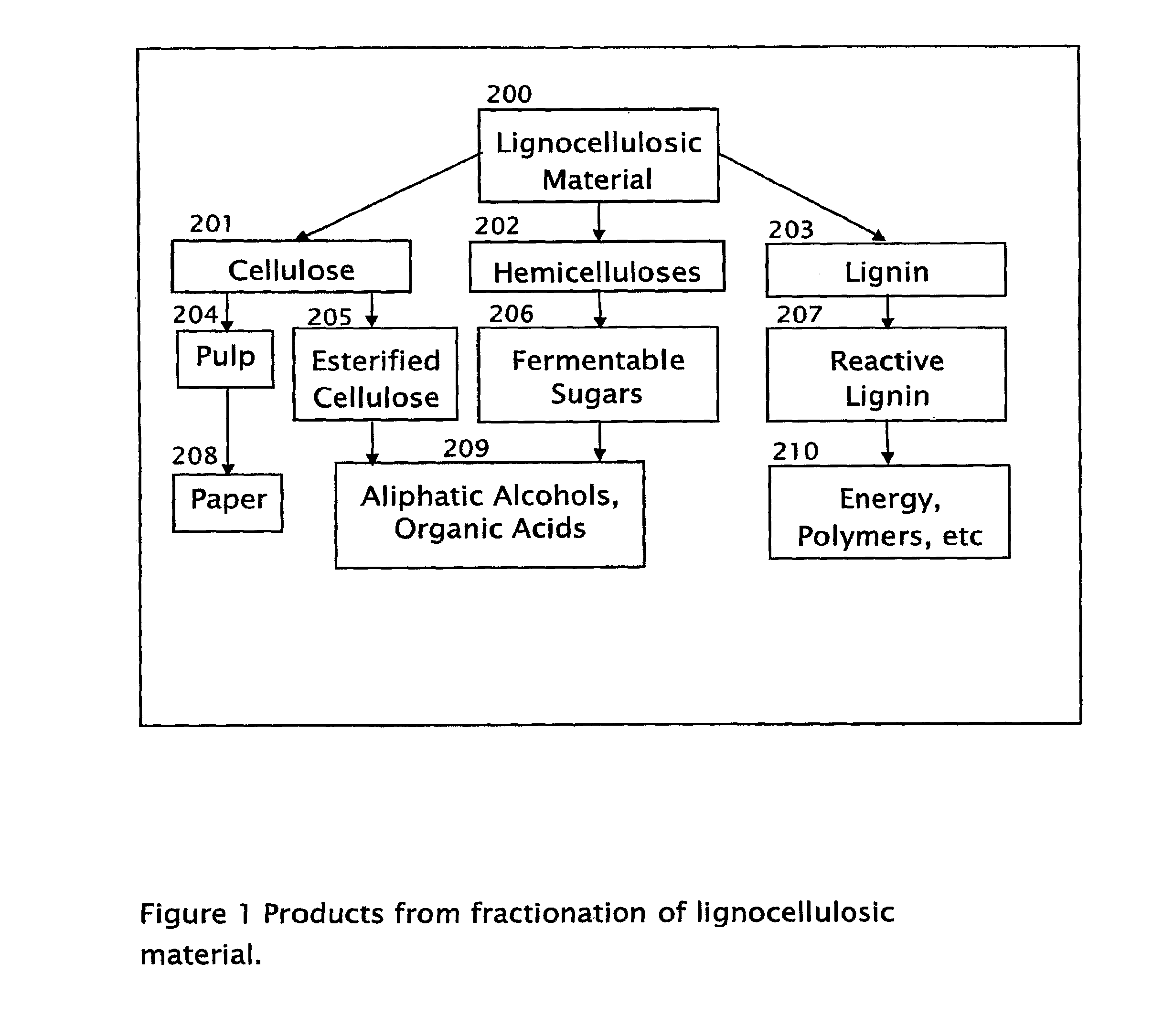

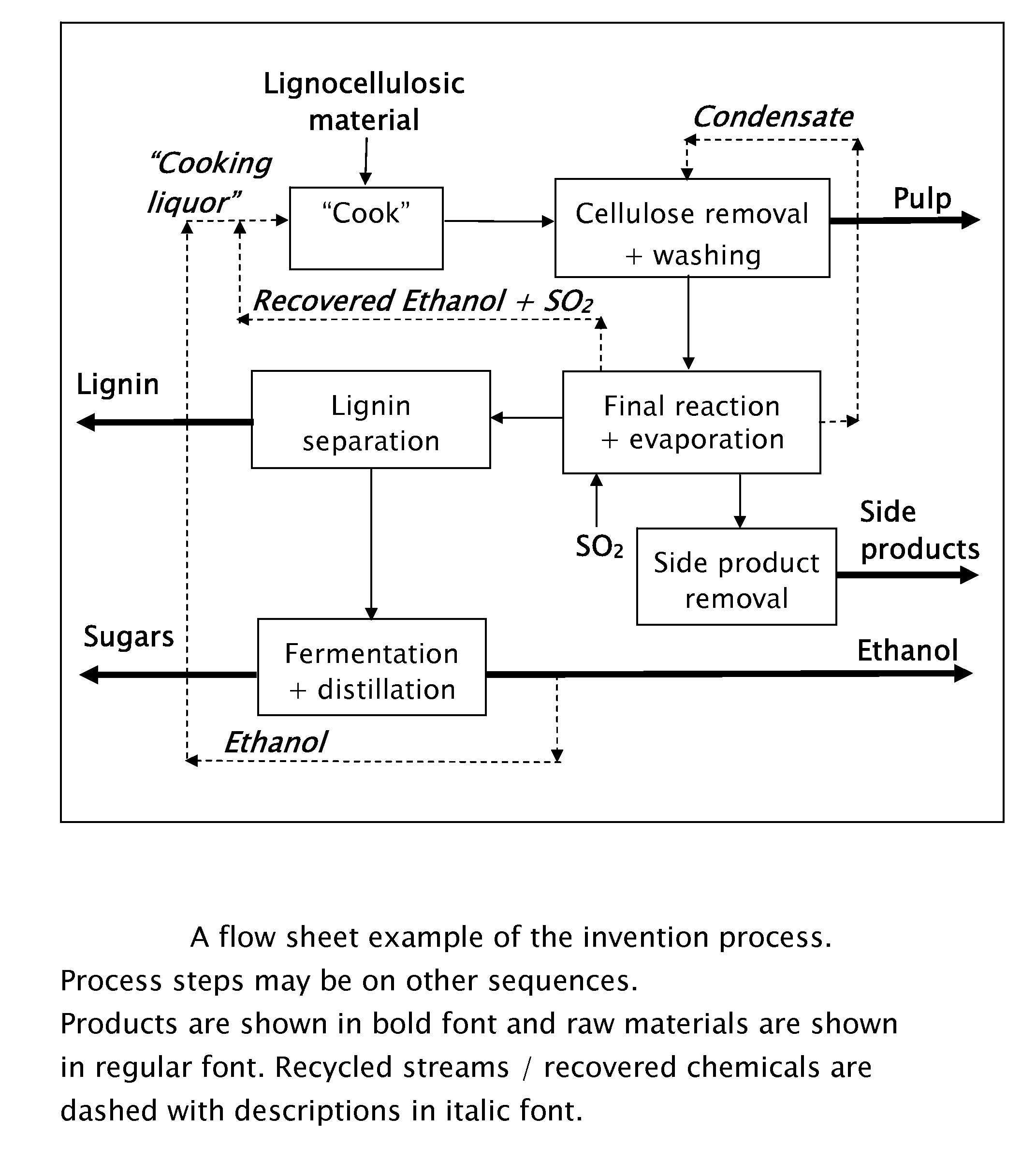

Method for the production of fermentable sugars and cellulose from lignocellulosic material

ActiveUS8030039B1High yieldIncreased ethanol yieldFats/resins/pitch/waxes removal in pulpPulping with organic compoundsOrganic acidAlcohol

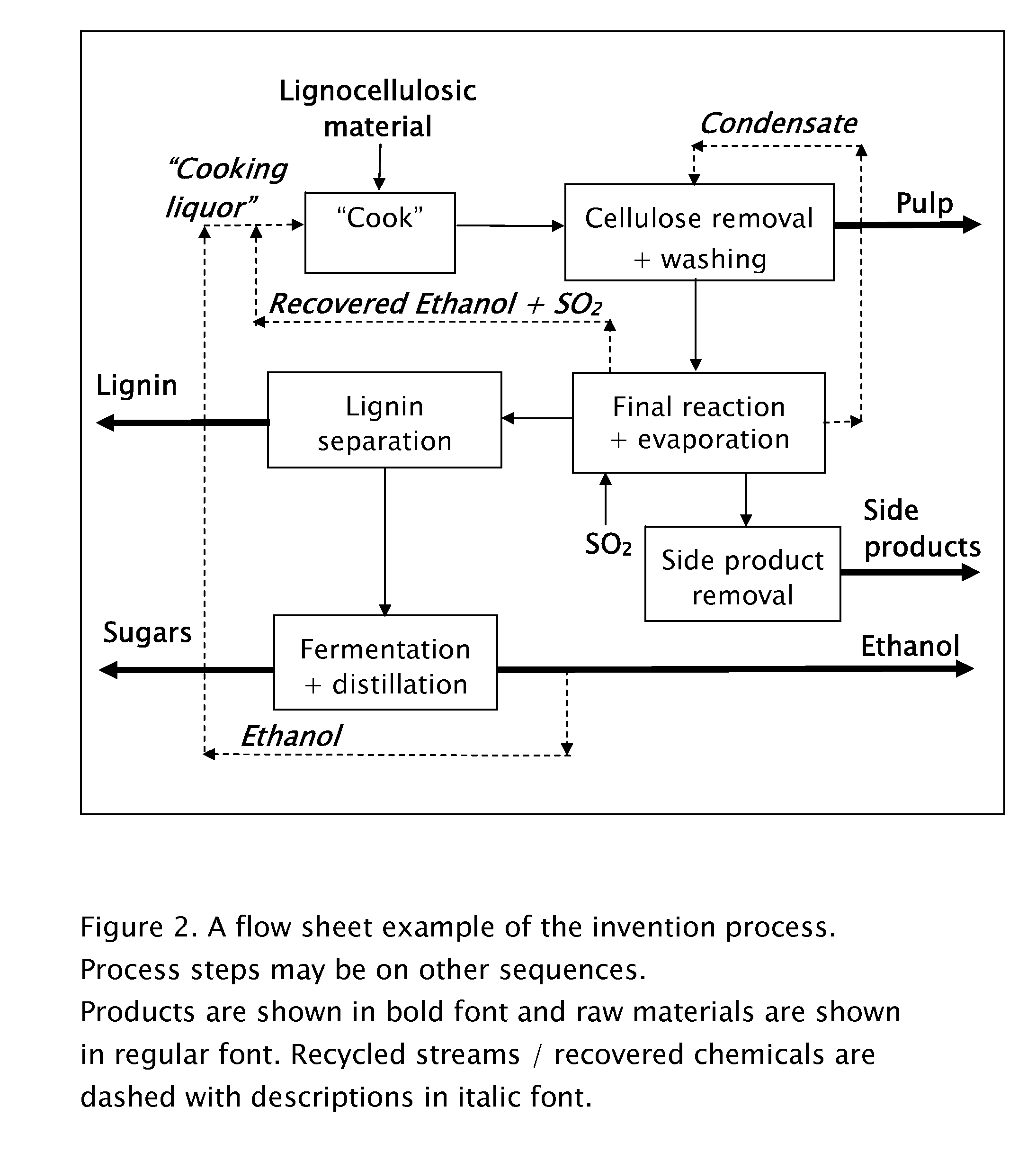

A method for the production of fermentable sugars and high viscosity cellulose from lignocellulosic material in a batch or continuous process is provided. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals can be reused, lignin is separated for the production of process energy, and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

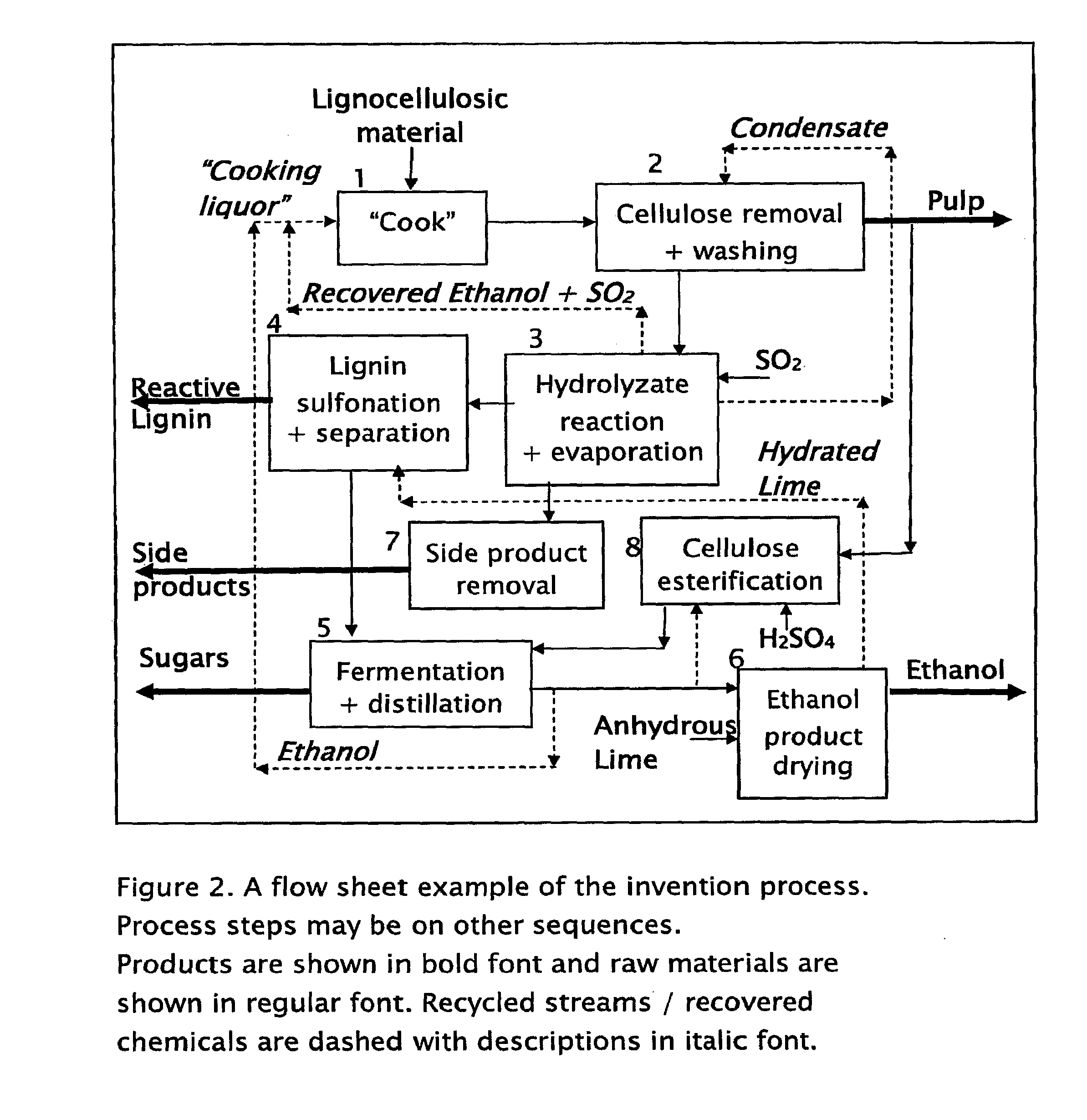

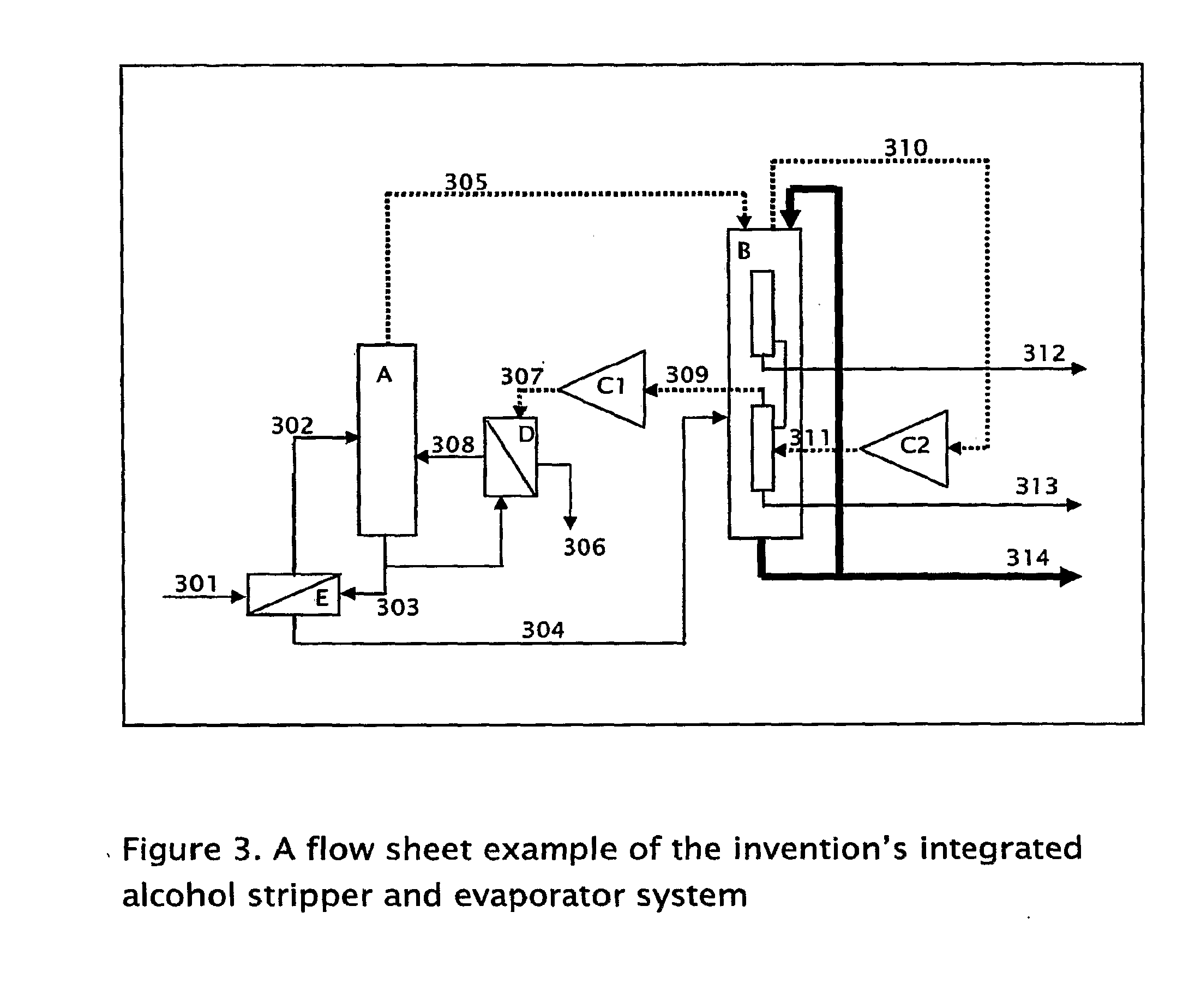

Process for the stepwise treatment of lignocellulosic material to produce reactive chemical feedstocks

InactiveUS20110003352A1Using liquid separation agentCalcium/strontium/barium sulfatesSulfonateLignosulfonates

A method for the fractionation of lignocellulosic materials into reactive chemical feedstock in a batch or semi continuous process by the stepwise treatment with aqueous aliphatic alcohols in the presence of sulfur dioxide or acid. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, or converted to esterified cellulose, cooking chemicals are reused, lignin is separated in the forms of reactive native lignin and reactive lignosulfonates and hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. In an integrated vapor compression stripper and evaporator system, aliphatic alcohol is removed from a liquid stream and the resulting stream is concentrated for further processing.

Owner:API INTELLECTUAL PROPERTY HOLDINGS LLC +1

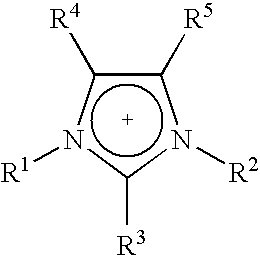

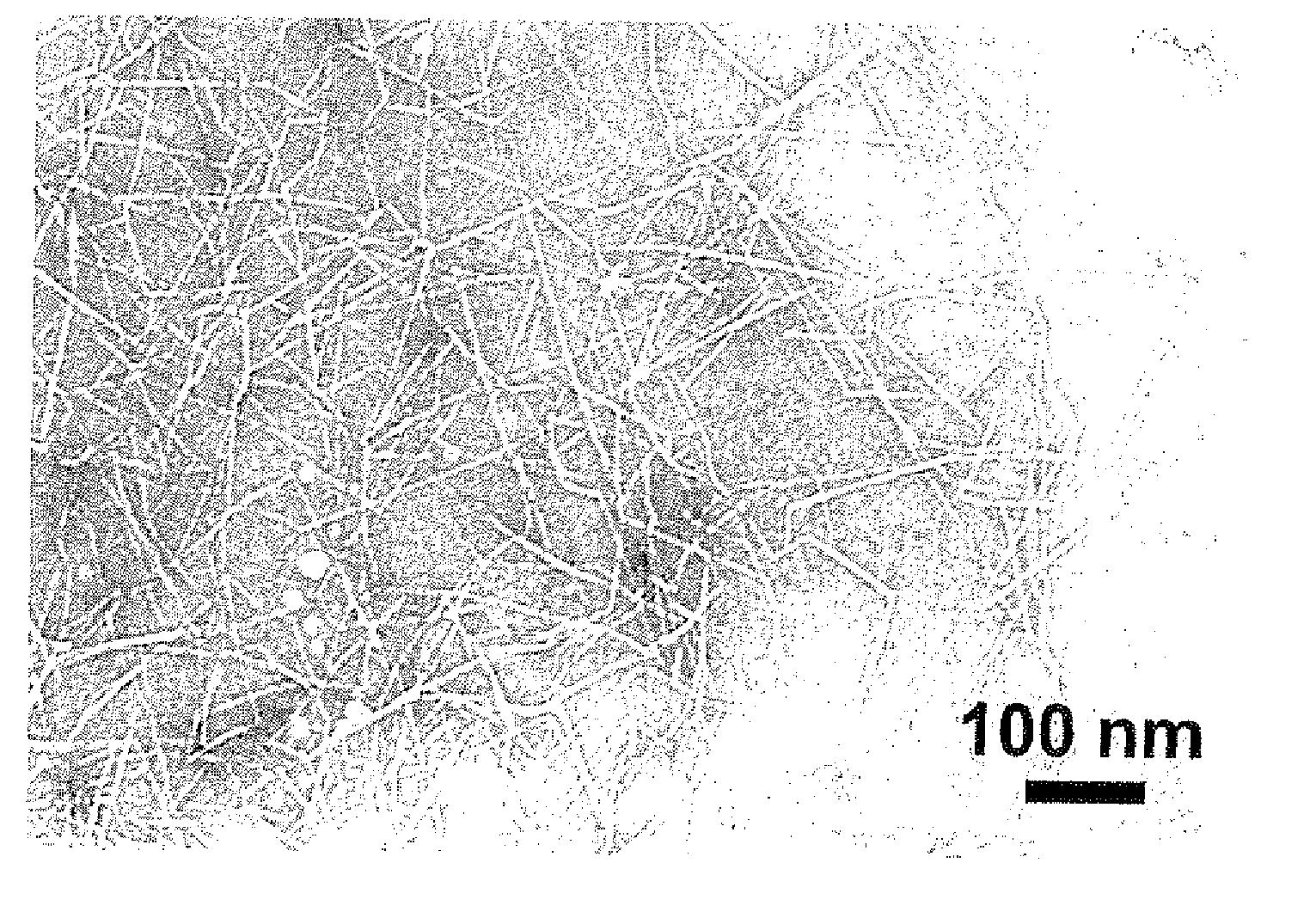

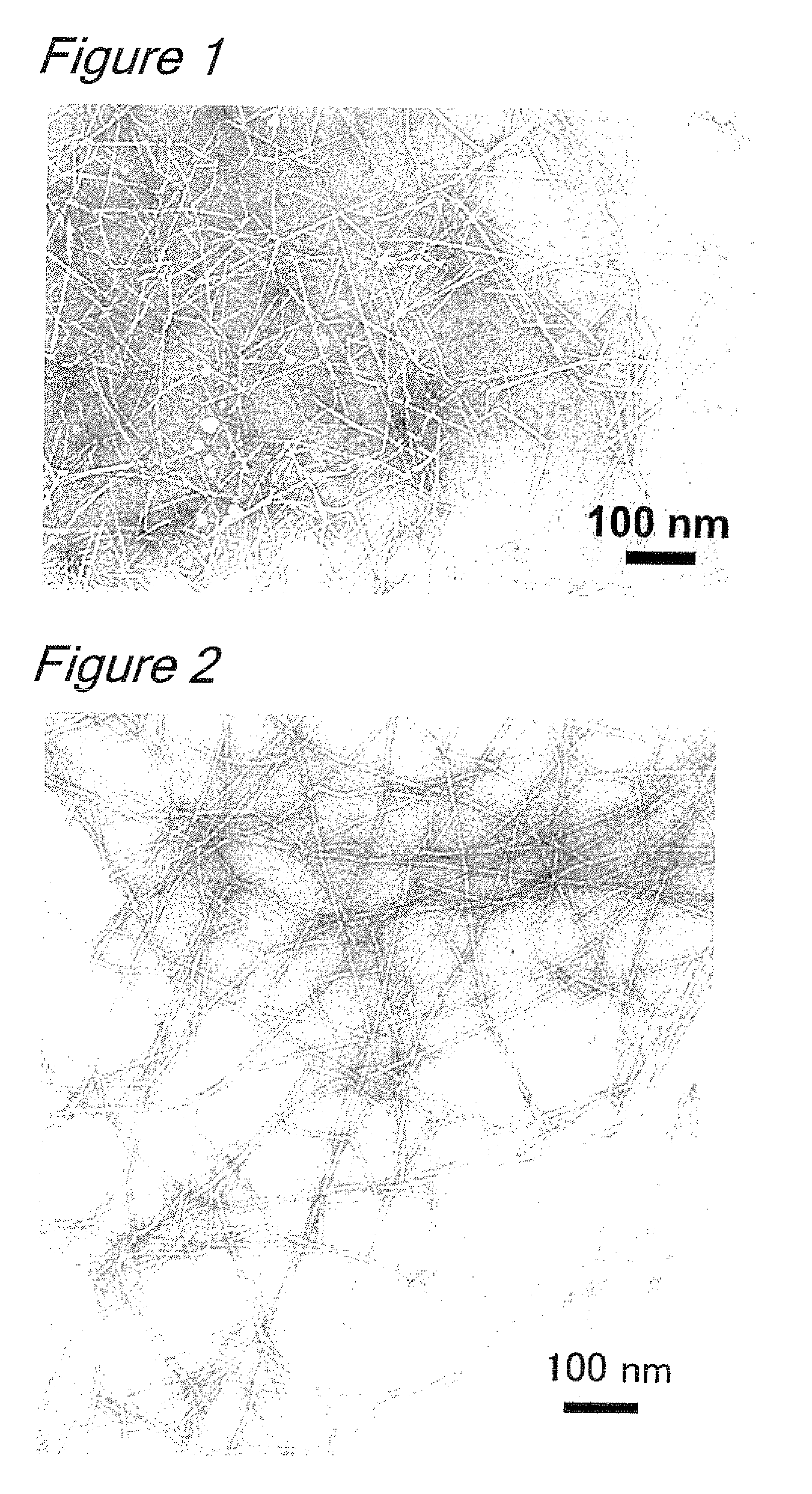

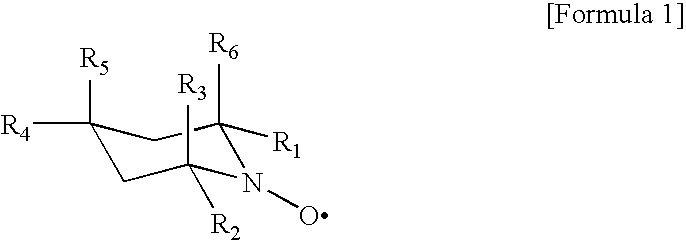

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

Method and Systems for Procesing Lignin During Hydrothermal Digestion of Cellulosic Biomass Solids While Producing a Monohydric Alcohol Feed

InactiveUS20140121418A1Low viscosityOrganic compound preparationOxygen compounds preparation by reductionCelluloseAlcohol

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in the presence of a digestion solvent, molecular hydrogen, and a slurry catalyst capable of activating molecular hydrogen; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising a glycol derived from the cellulosic biomass solids, and an optional light organics phase; wherein at least a portion of the slurry catalyst accumulates in the phenolics liquid phase as it forms; combining the glycol with the phenolics liquid phase, thereby forming a combined phase; and heating the combined phase in the presence of molecular hydrogen; wherein heating the combined phase reduces the viscosity of the phenolics liquid phase and transforms at least a portion of the glycol into a monohydric alcohol.

Owner:SHELL OIL CO

Process for the conversion of biomass to liquid fuels and specialty chemicals

The present invention relates to the conversion of solid biomass to liquid fuels and specialty chemicals. The process utilizes an activating step to make the biomass more susceptible to conversion, that is the biomass is broken down such that the components of the biomass are dissociated. Subsequently, the activated biomass undergoes a reaction to convert it to a bio-oil.

Owner:MARD INC

Method for the production of fermentable sugars and cellulose from lignocellulosic material

InactiveUS20070254348A1Pulping with acid salts/anhydridesPulp by-products recoveryOrganic acidAlcohol

A method for the production of fermentable sugars and cellulose from lignocellulosic material in a batch or continuous process. Lignocellulosic material is fractionated in a fashion that cellulose is removed as pulp, cooking chemicals reused, lignin is separated for the production of process energy, hemicelluloses are converted into fermentable sugars, while fermentation inhibitors are removed. High yield production of alcohols or organic acids can be obtained from this method using the final reaction step.

Owner:RETABINA THEODORA +1

Processes and apparatus for producing nanocellulose, and compositions and products produced therefrom

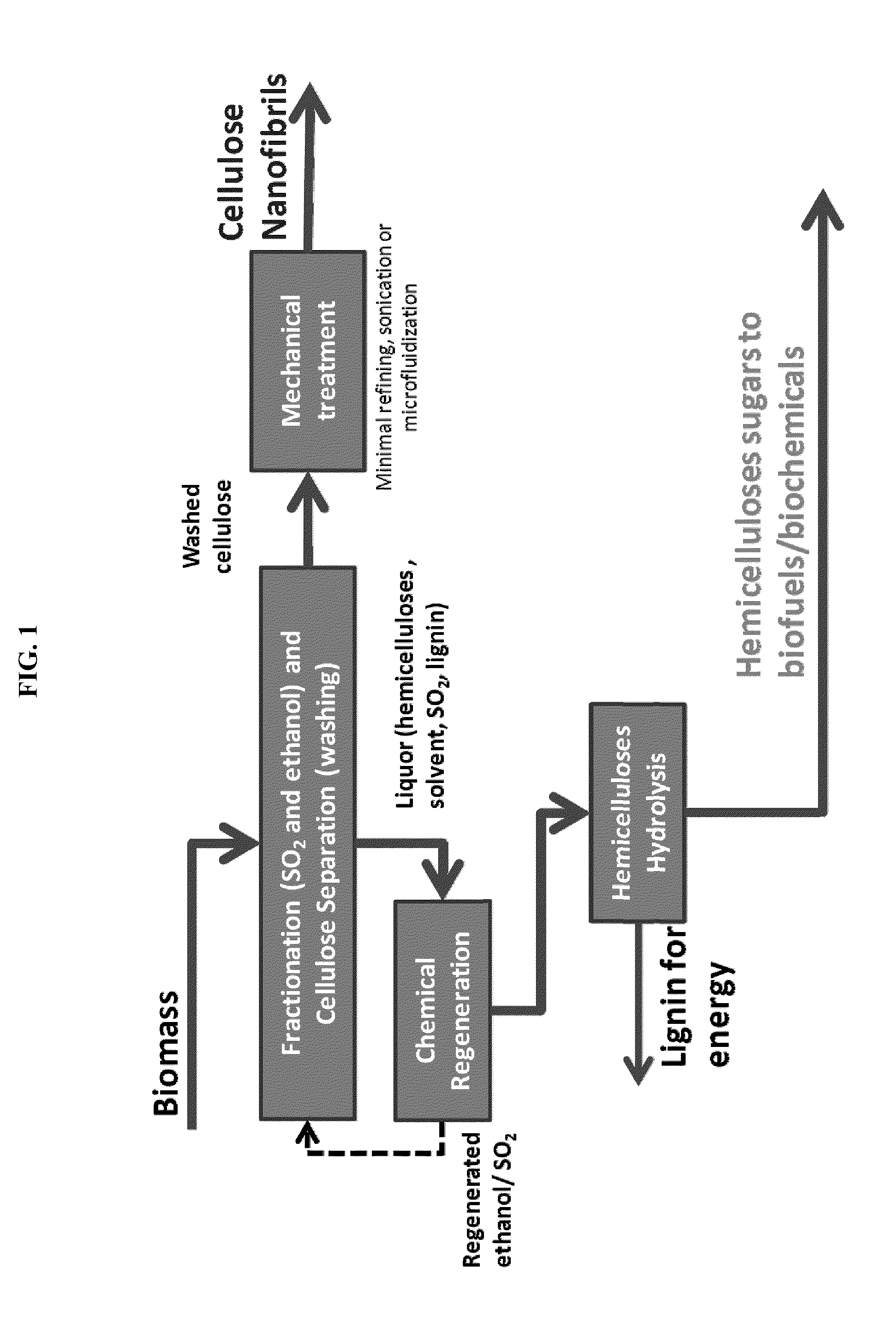

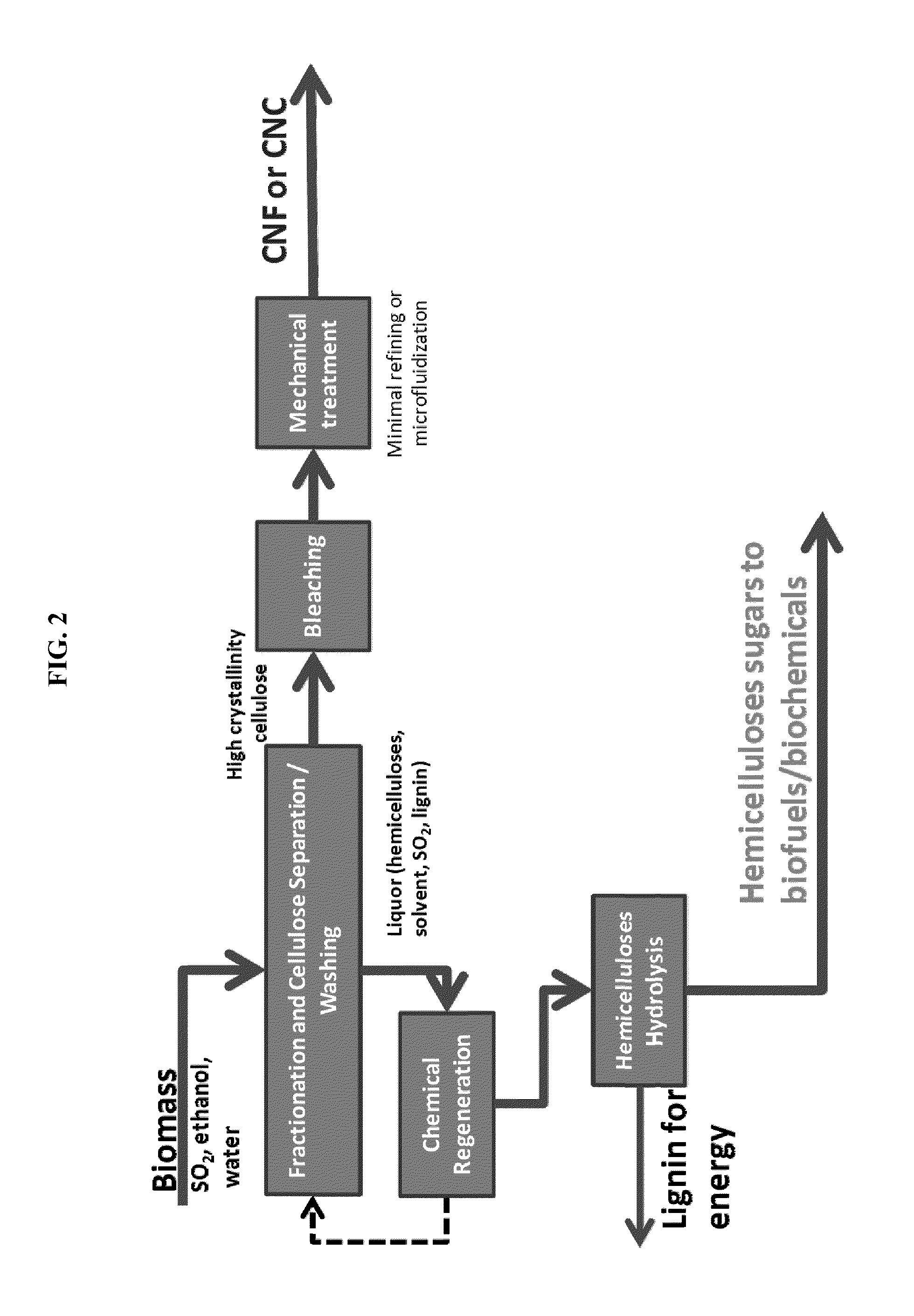

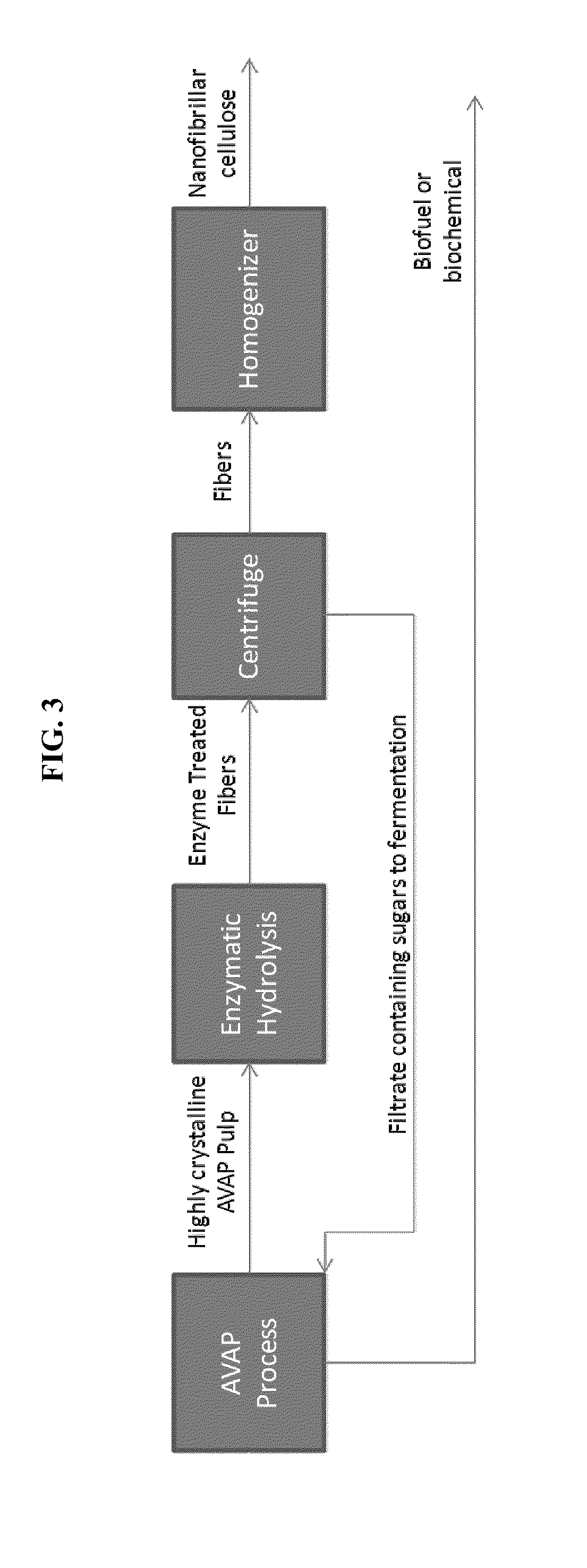

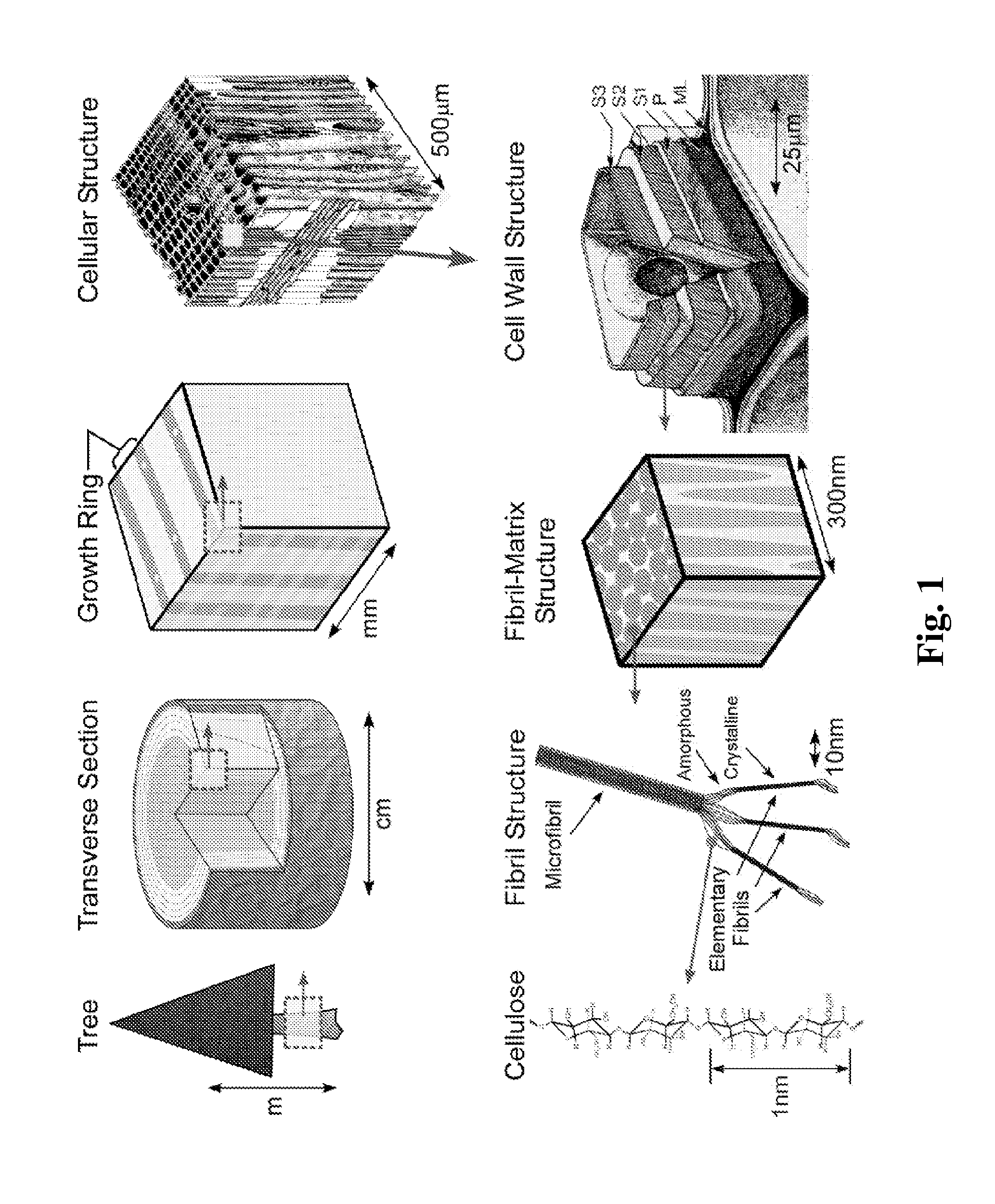

Processes disclosed are capable of converting biomass into high-crystallinity nanocellulose with surprisingly low mechanical energy input. In some variations, the process includes fractionating biomass with an acid (such as sulfur dioxide), a solvent (such as ethanol), and water, to generate cellulose-rich solids and a liquid containing hemicellulose and lignin; and mechanically treating the cellulose-rich solids to form nanofibrils and / or nanocrystals. The total mechanical energy may be less than 500 kilowatt-hours per ton. The crystallinity of the nanocellulose material may be 80% or higher, translating into good reinforcing properties for composites. The nanocellulose material may include nanofibrillated cellulose, nanocrystalline cellulose, or both. In some embodiments, the nanocellulose material is hydrophobic via deposition of some lignin onto the cellulose surface. Optionally, sugars derived from amorphous cellulose and hemicellulose may be separately fermented, such as to monomers for various polymers. These polymers may be combined with the nanocellulose to form completely renewable composites.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

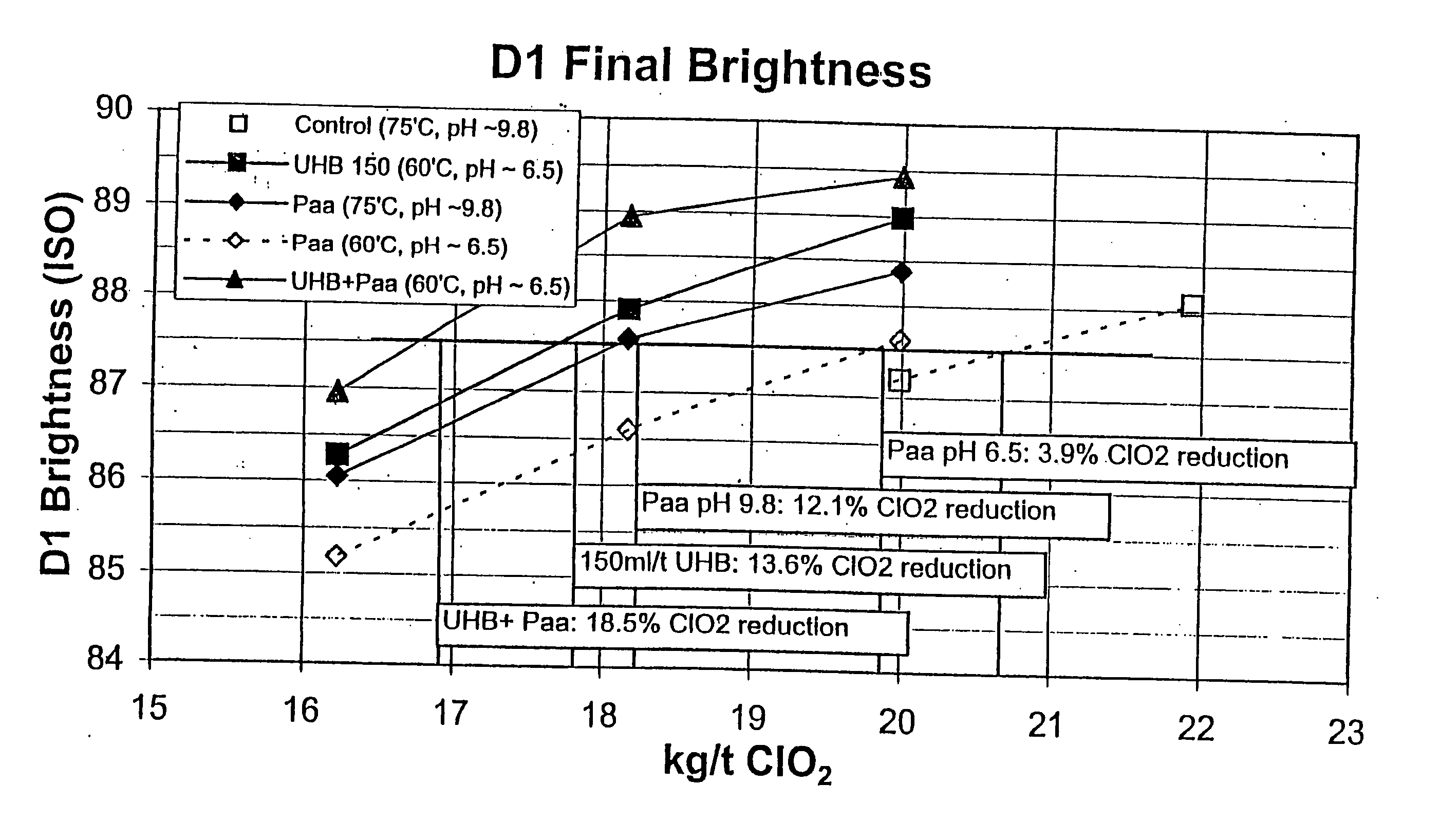

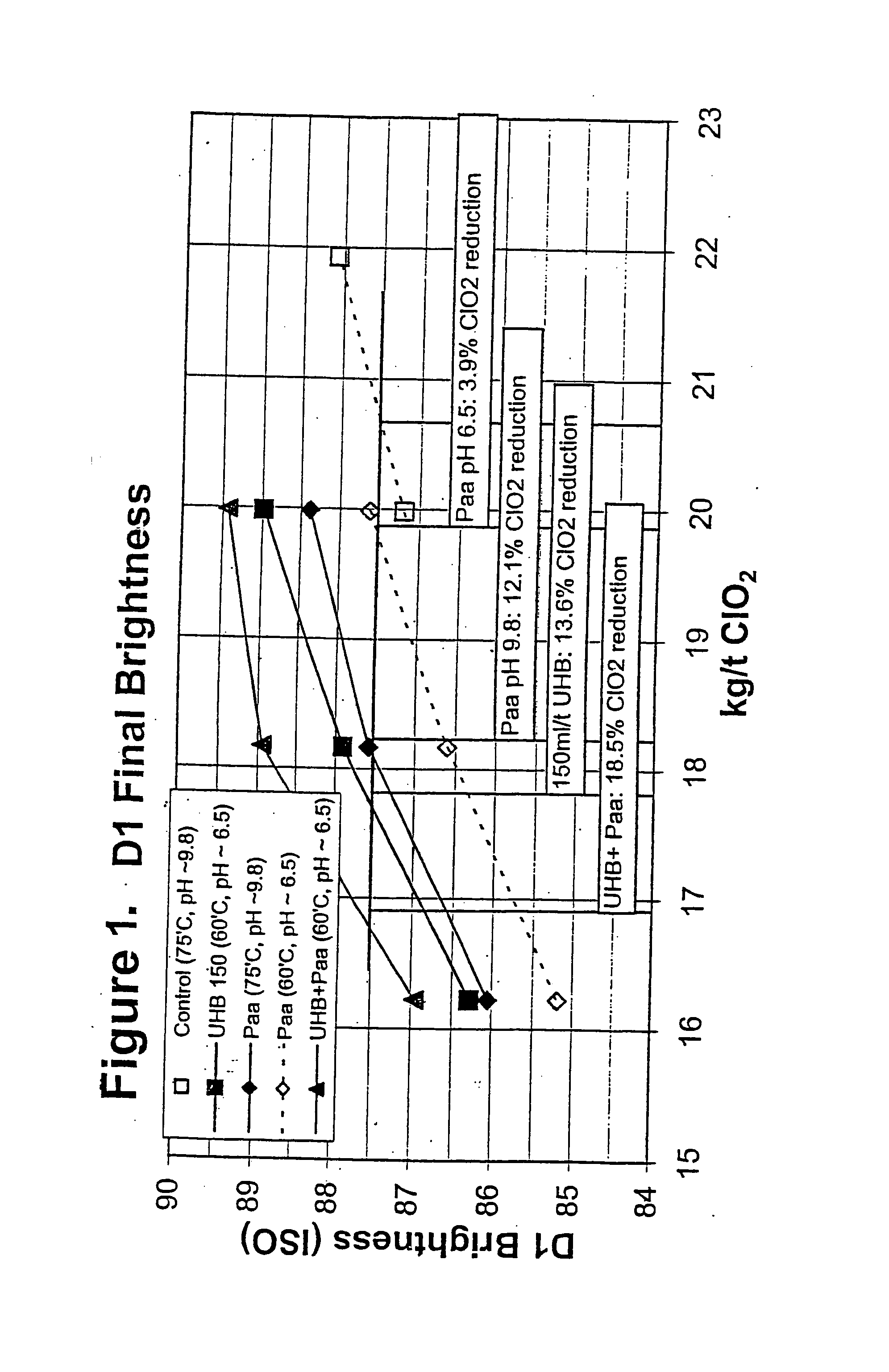

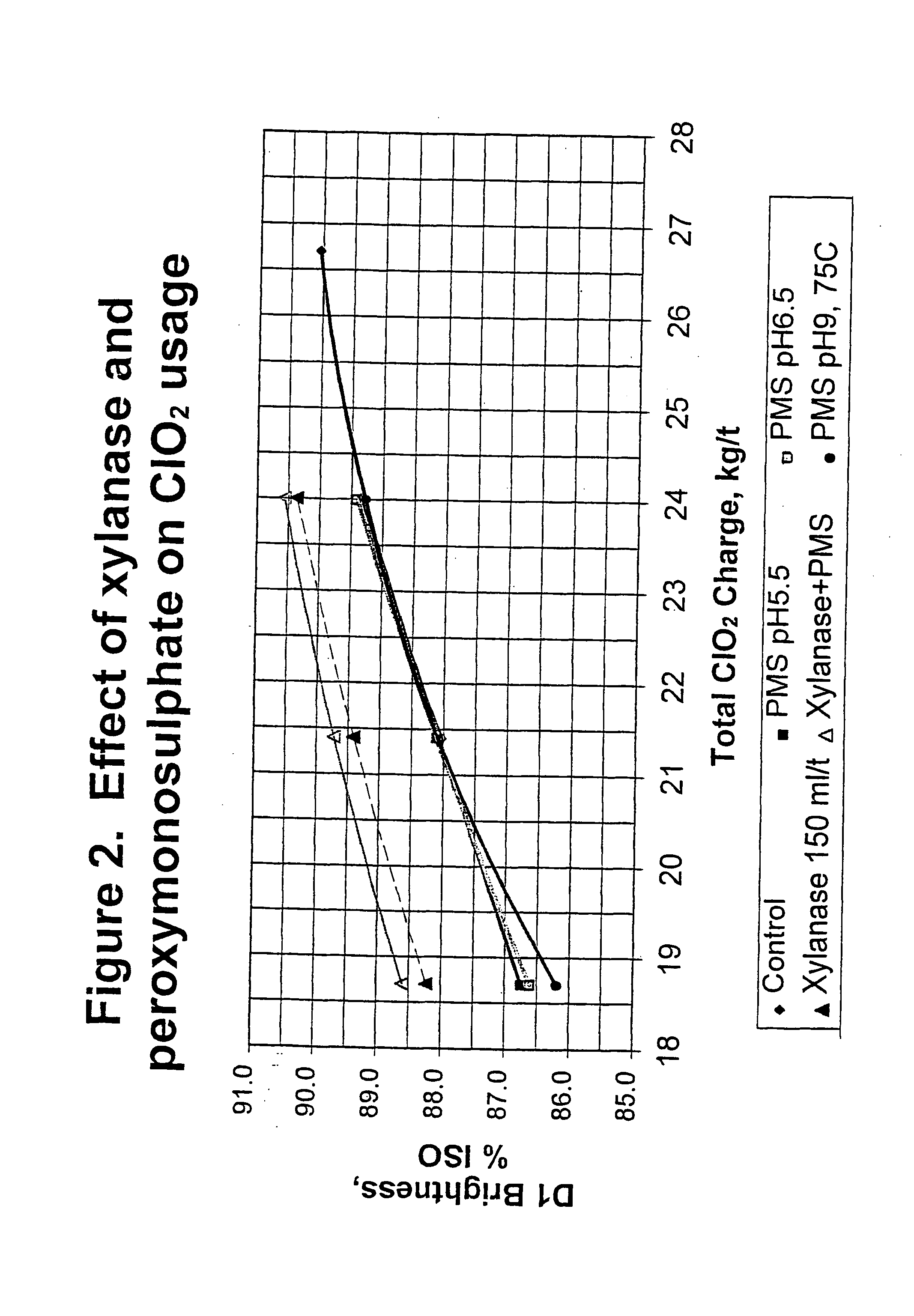

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

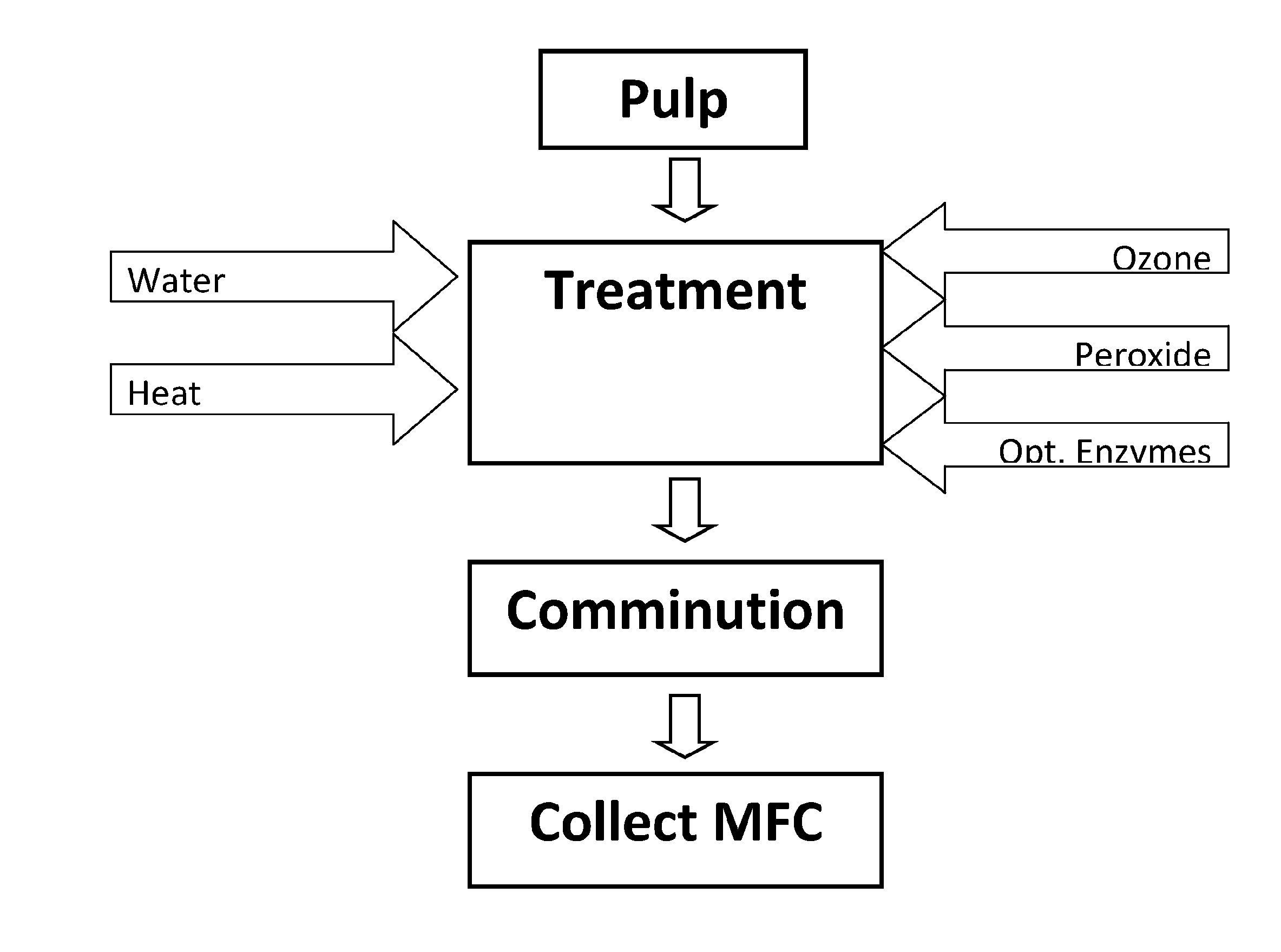

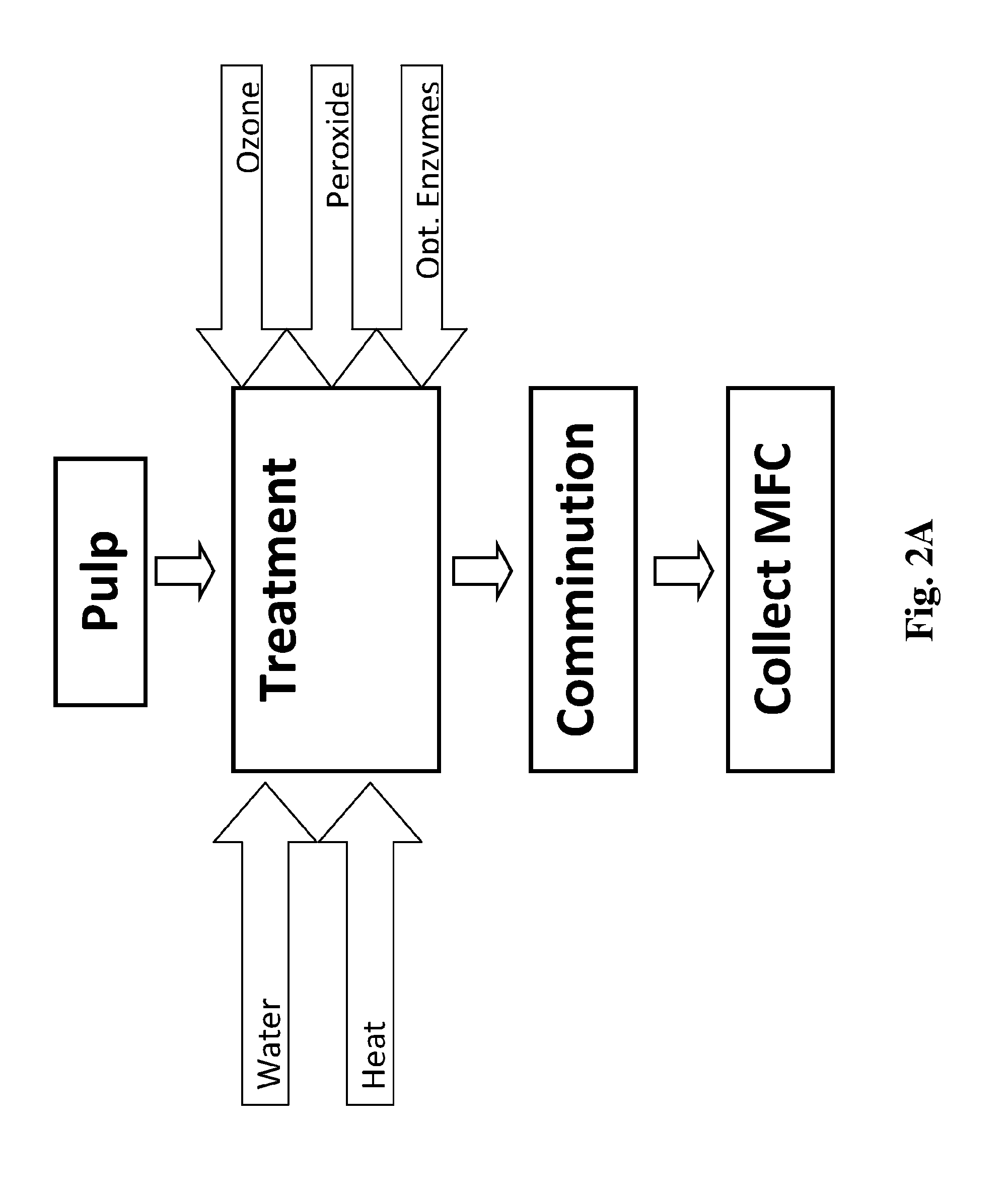

Energy Efficient Process for Preparing Nanocellulose Fibers

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

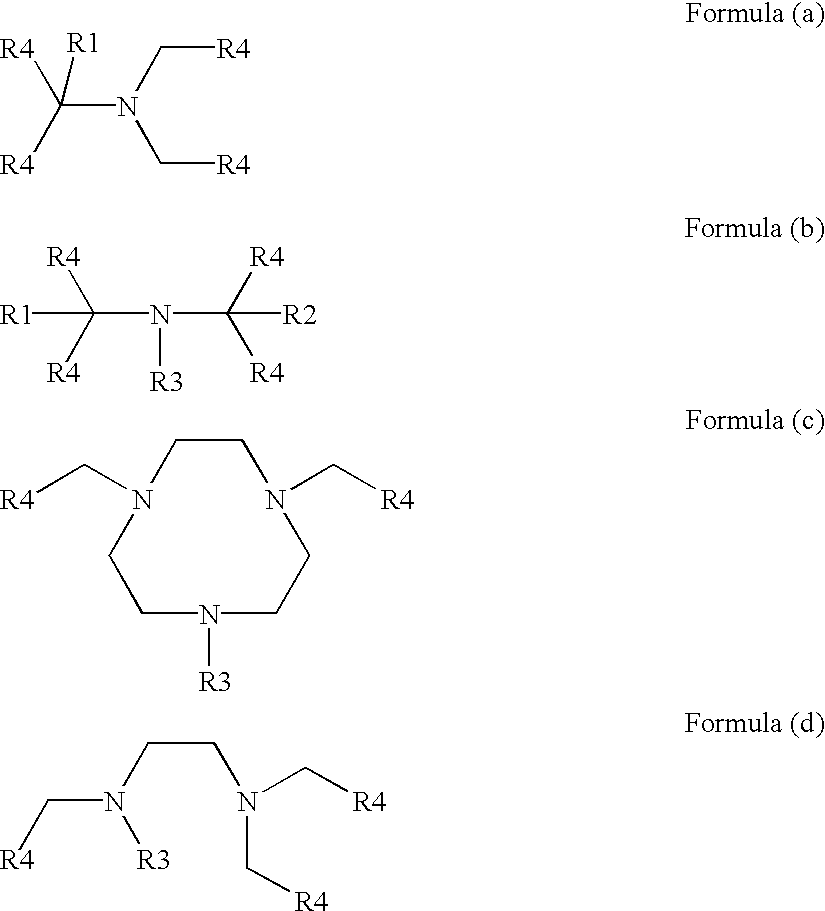

Transition metal complexes with polydentate ligands for enhancing the bleaching and delignifying effect of peroxo compounds

InactiveUS20020066542A1Surpass delignifyingSurpass bleachingPulp bleachingPulping with organic solventsAqueous solutionCobalt

Transition metal complex compounds of polydentate ligands with improved delignifying and bleaching performance. These polydentate ligands are organic ligands which, in aqueous solution and in the presence of atmospheric oxygen, or hydrogen peroxide, form a complex with a transition metal, in particular cobalt. The complexes are mono- or polynuclear and they have, when peroxo compounds are used, better delignifying and bleaching performances than conventional transition metal complex compounds. A delignifying and bleaching method, in which these transition metal complex compounds with polydentate ligands having improved delignifying and bleaching performance are used as catalysts, is also described.

Owner:DEGUSSA AG

Ozone treatment of biomass to enhance enzymatic saccharification

InactiveUS20100159521A1Reduce yieldReduction in yieldSugar derivativesBiofuelsCelluloseFermentable sugar

Methods for treating lignocellulosic biomass to produce readily saccharifiable carbohydrate-enriched biomass are provided. In one method, lignocellulosic biomass comprising lignin is treated with aqueous ammonia, then contacted with a gas comprising ozone at a temperature of about 0° C. to about 50° C. In another method, lignocellulosic biomass comprising lignin is contacted with a gas comprising ozone at a temperature of about 0° C. to about 50° C., then treated with aqueous ammonia. The readily saccharifiable carbohydrate-enriched biomass may be saccharified with an enzyme consortium to produce fermentable sugars.

Owner:EI DU PONT DE NEMOURS & CO

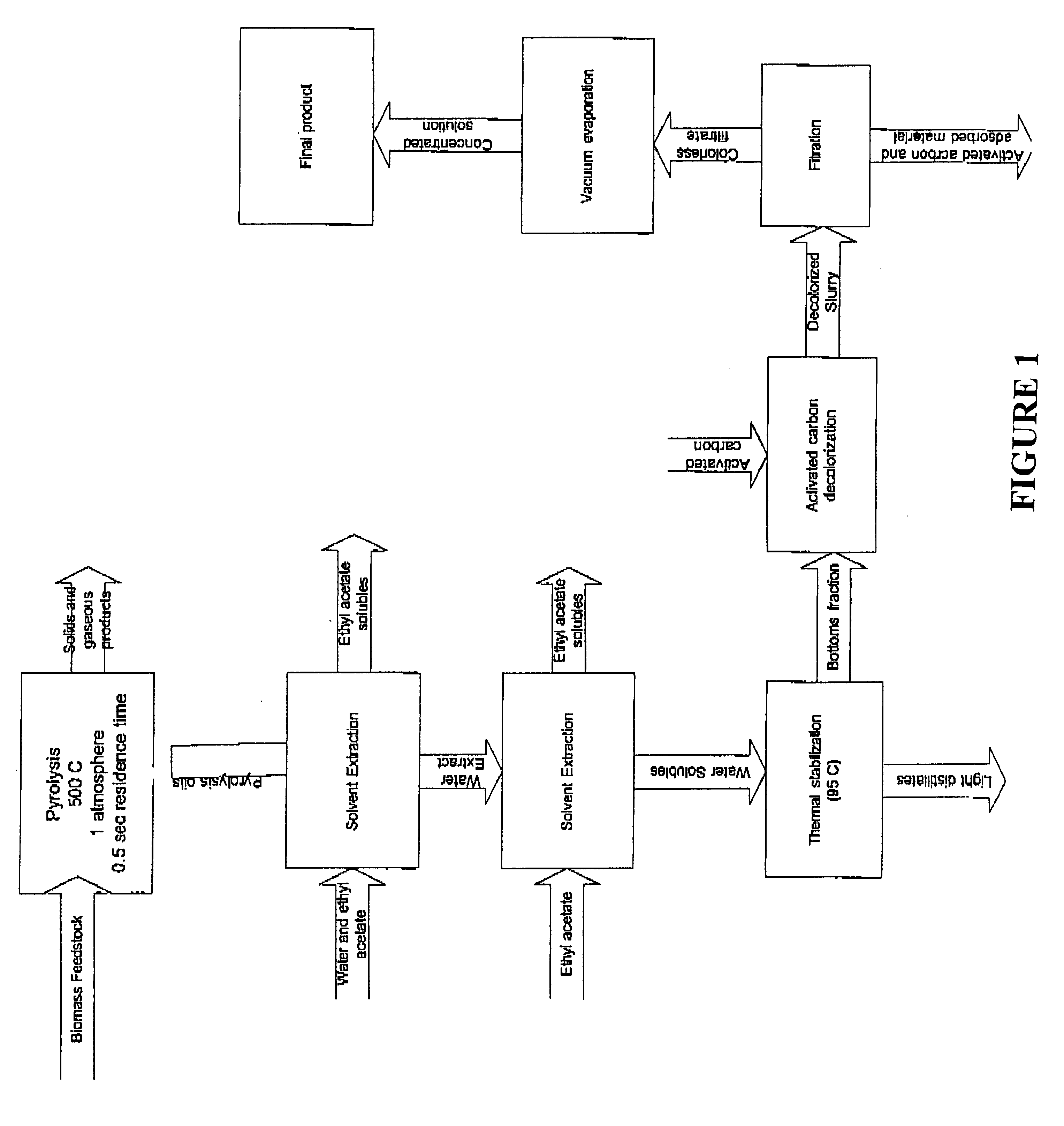

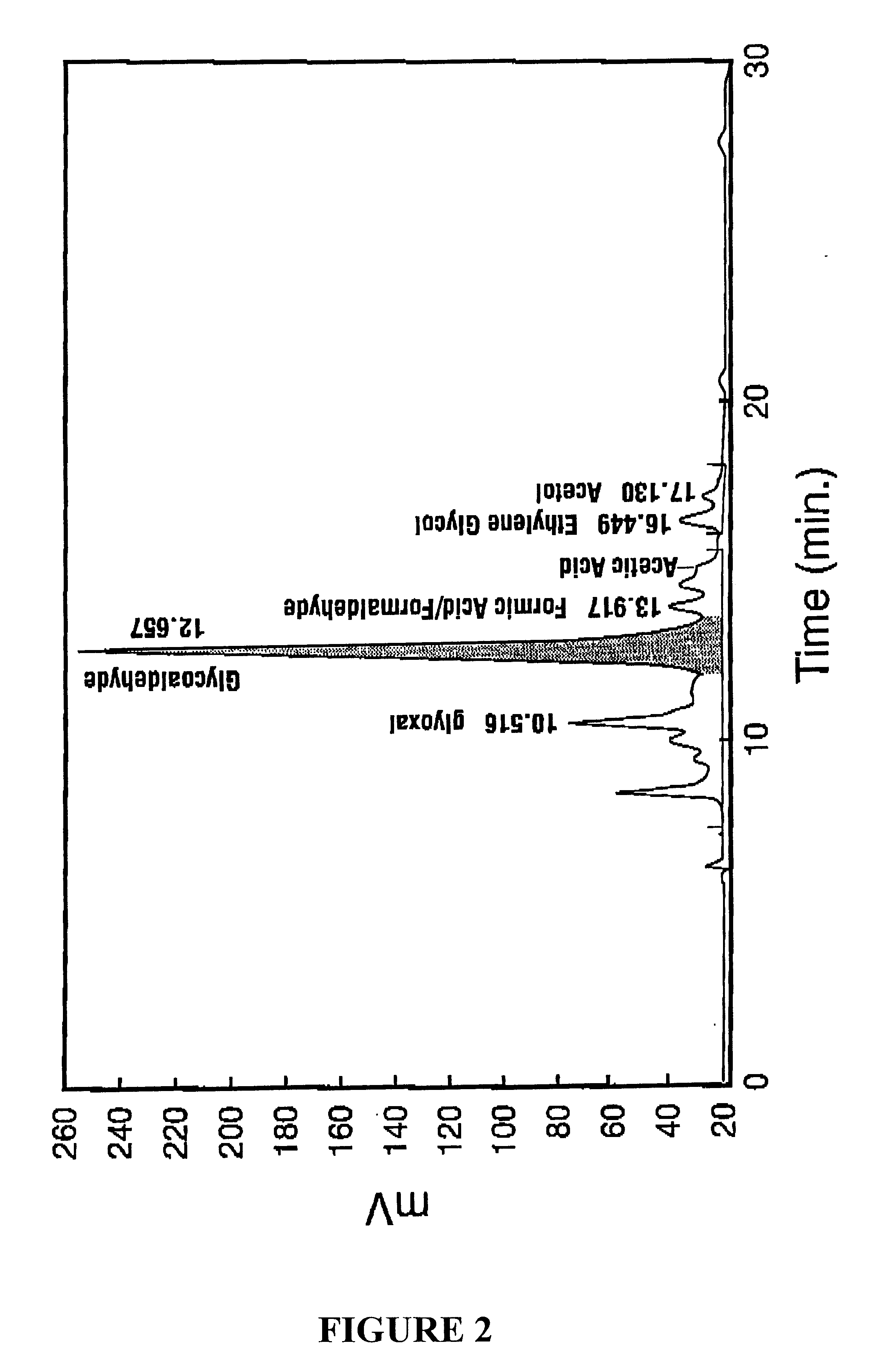

Preparation of brightness stabilization agent for lignin containing pulp from biomass pyrolysis oils

A process for producing a brightness stabilization mixture of water-soluble organic compounds from biomass pyrolysis oils comprising:a) size-reducing biomass material and pyrolyzing the size-reduced biomass material in a fluidized bed reactor;b) separating a char / ash component while maintaining char-pot temperatures to avoid condensation of pyrolysis vapors;c) condensing pyrolysis gases and vapors, and recovering pyrolysis oils by mixing the oils with acetone to obtain an oil-acetone mixture;d) evaporating acetone and recovering pyrolysis oils;e) extracting the pyrolysis oils with water to obtain a water extract;f) slurrying the water extract with carbon while stirring, and filtering the slurry to obtain a colorless filtrate;g) cooling the solution and stabilizing the solution against thermally-induced gelling and solidification by extraction with ethyl acetate to form an aqueous phase lower layer and an organic phase upper layer;h) discarding the upper organic layer and extracting the aqueous layer with ethyl acetate, and discarding the ethyl acetate fraction to obtain a brown-colored solution not susceptible to gelling or solidification upon heating;i) heating the solution to distill off water and other light components and concentrating a bottoms fraction comprising hydroxyacetaldehyde and other non-volatile components having high boiling points; andj) decolorizing the stabilized brown solution with activated carbon to obtain a colorless solution.

Owner:MIDWEST RES INST

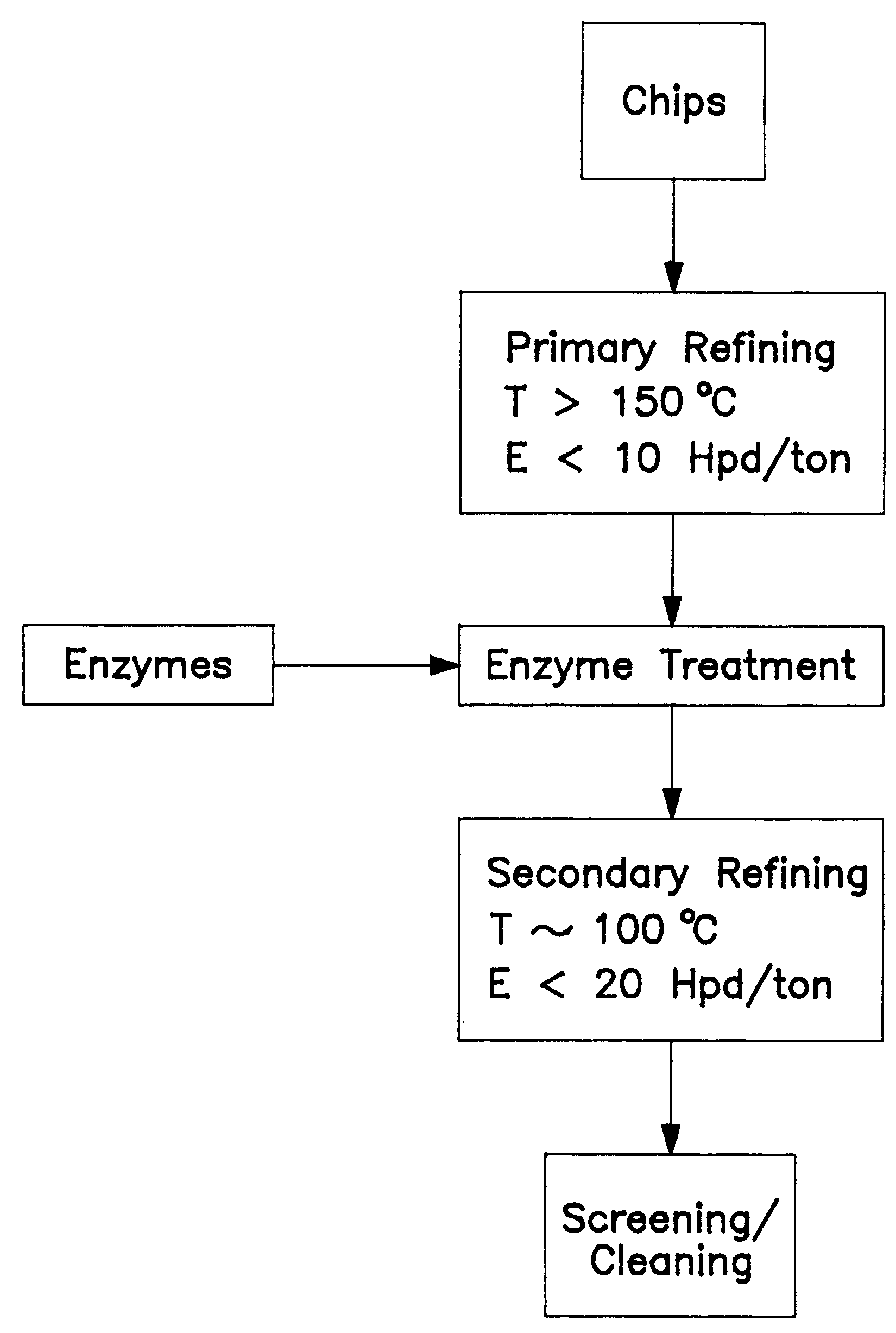

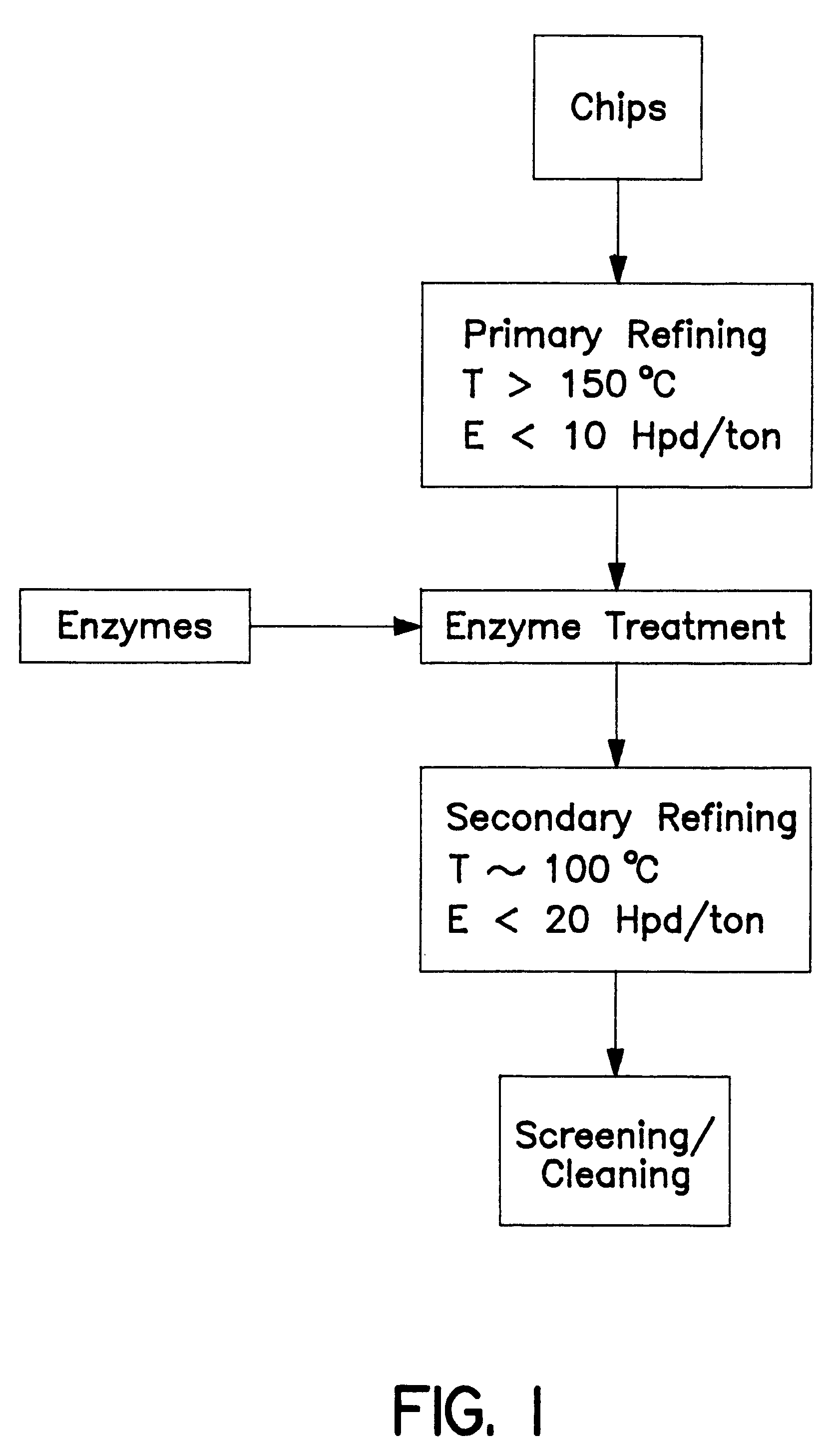

Low energy thermomechanical pulping process using an enzyme treatment between refining zones

InactiveUS6267841B1Pulping with acid salts/anhydridesPulping with inorganic basesPulp and paper industryEnzyme

A low energy thermomechanical pulping process which employs an enzyme treatment stage between two low energy thermomechanical stages.

Owner:INT PAPER CO

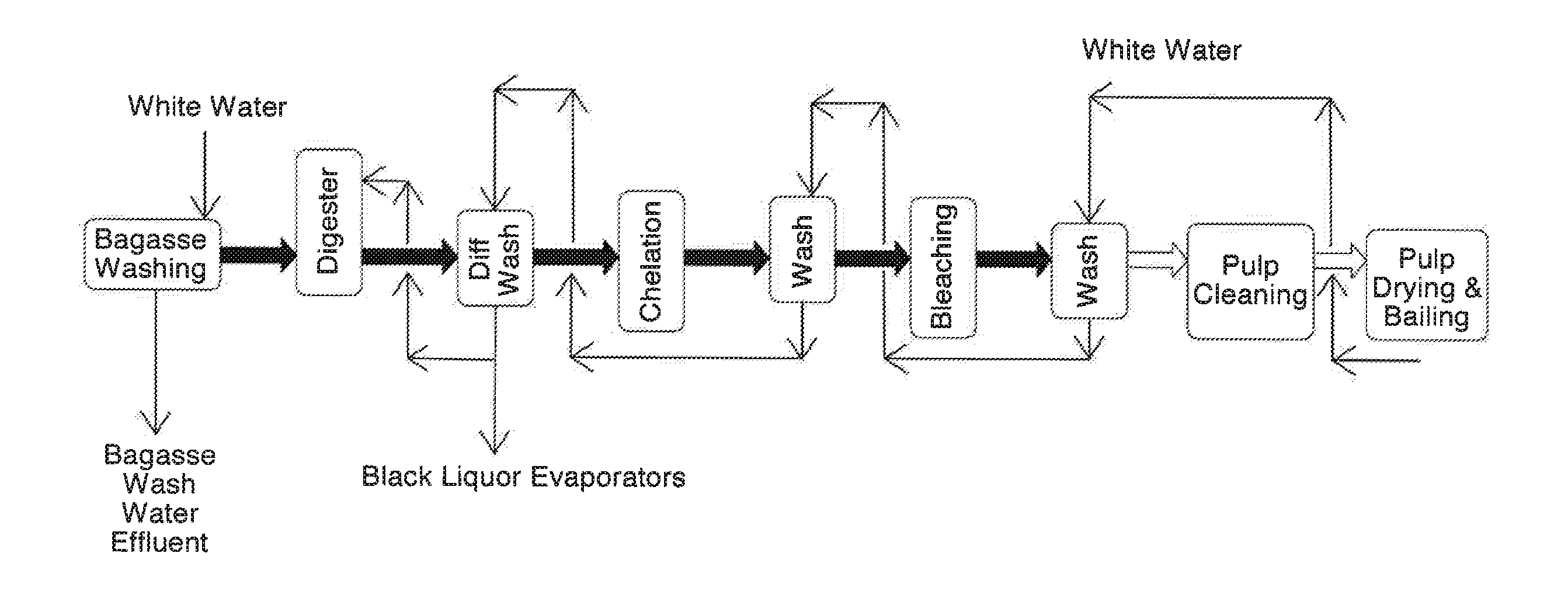

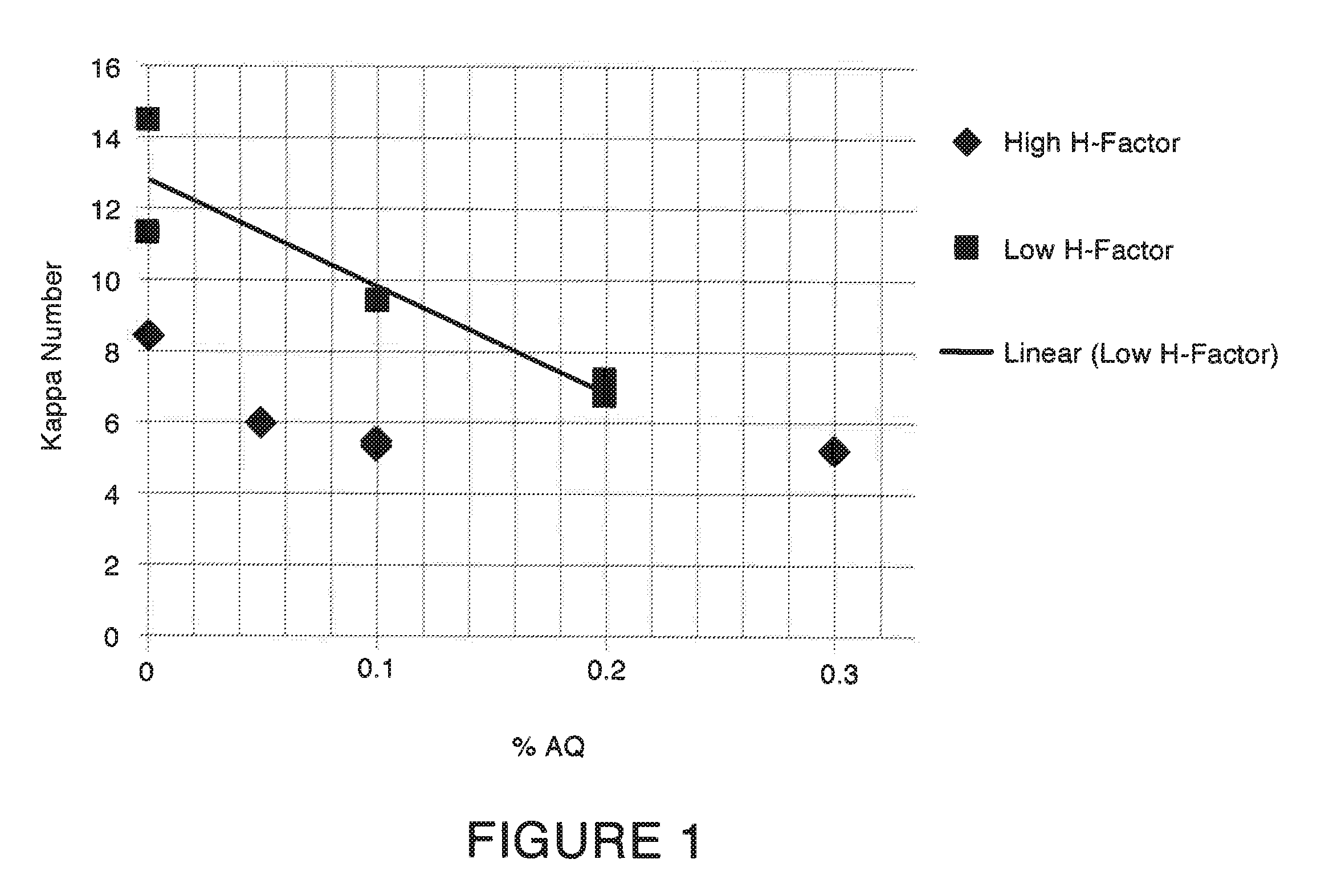

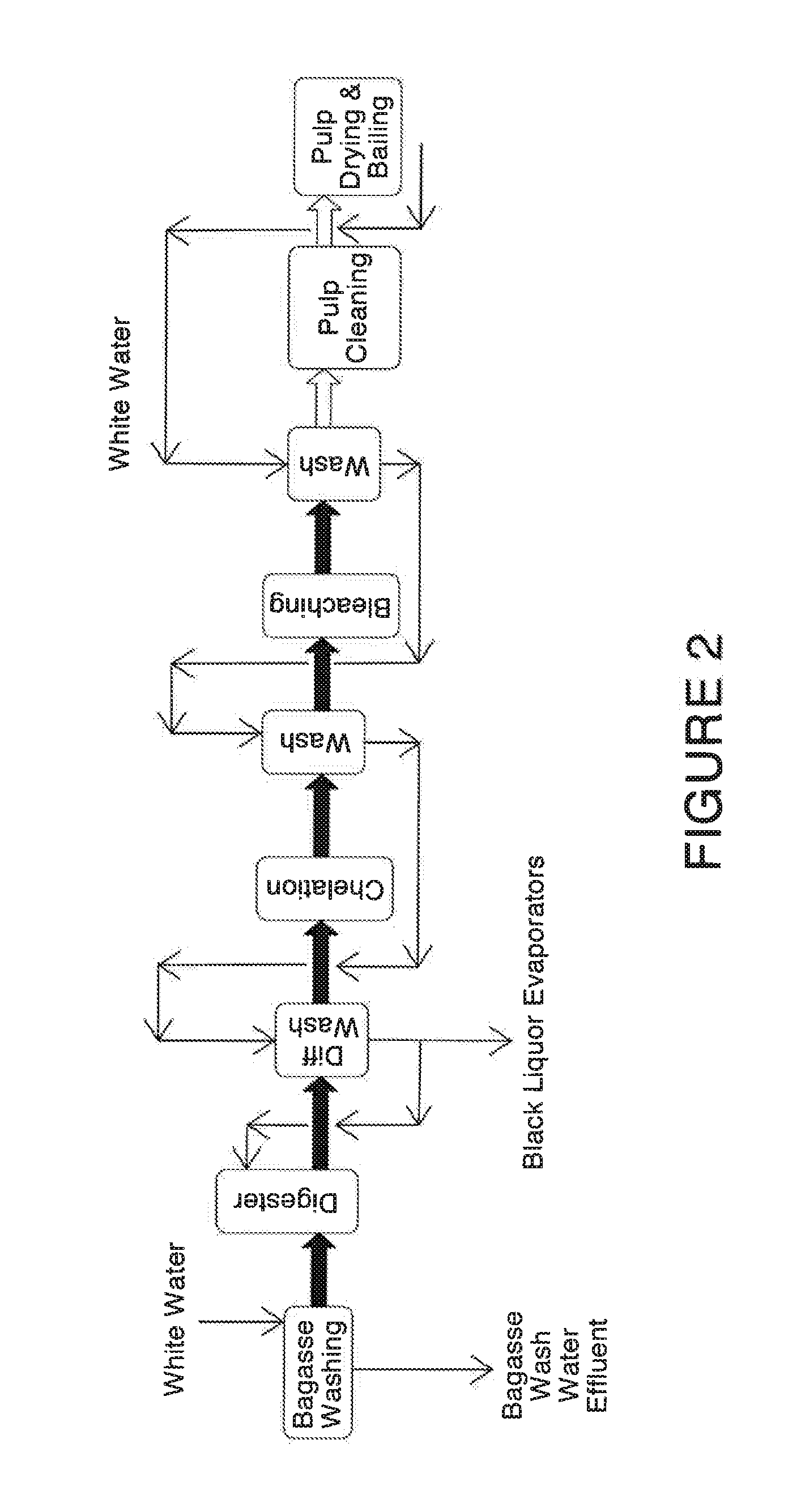

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com