Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

409results about How to "Reduce extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

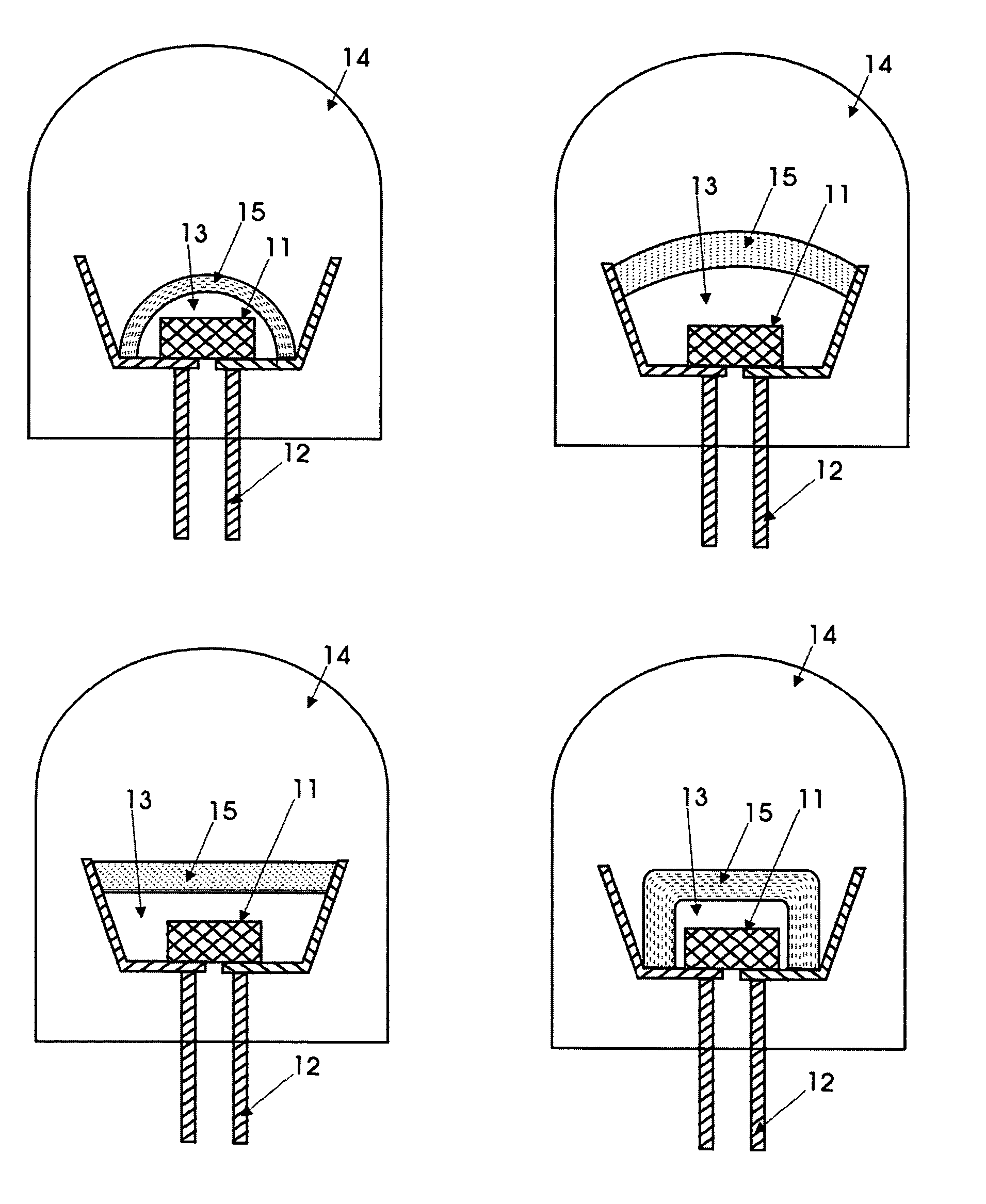

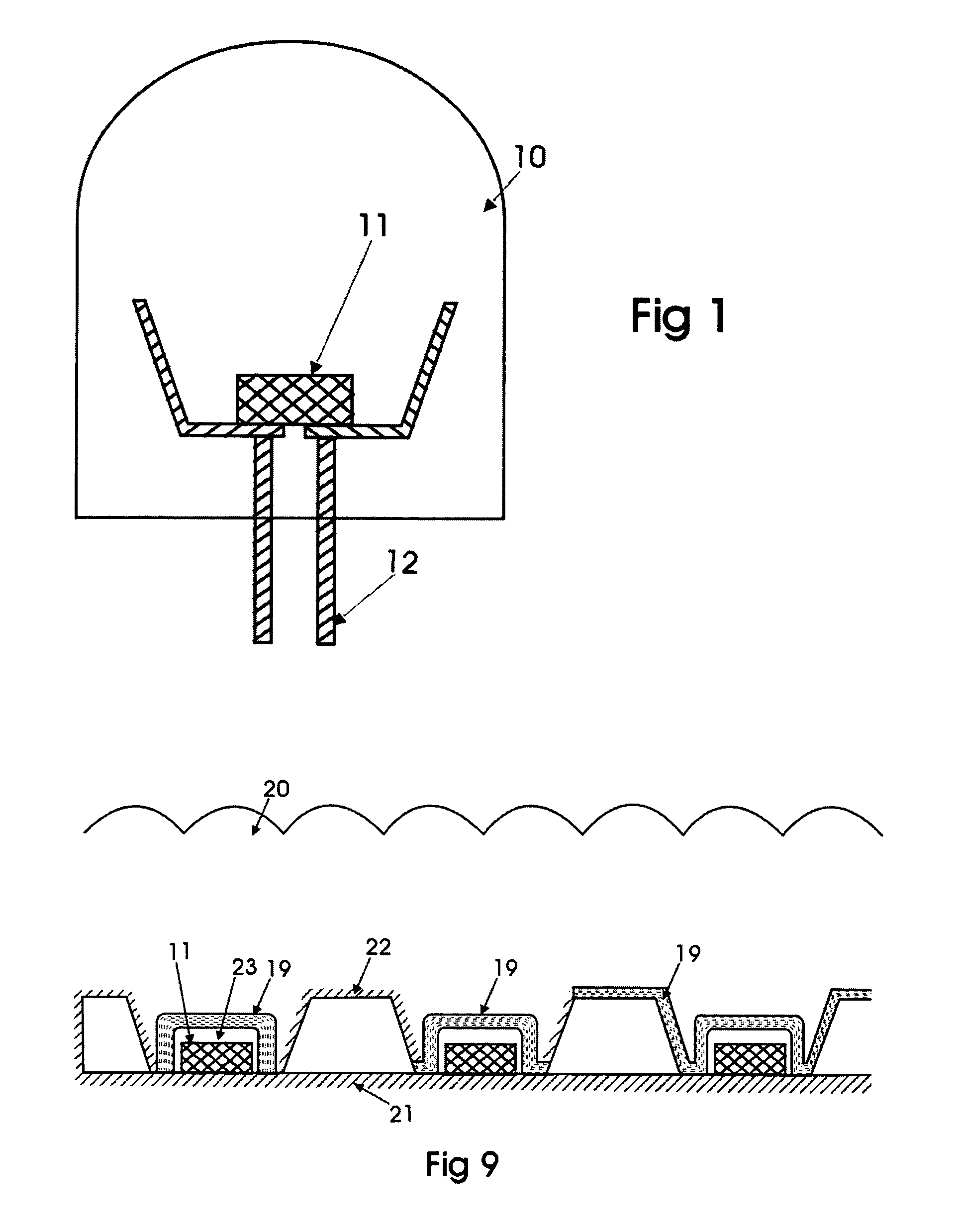

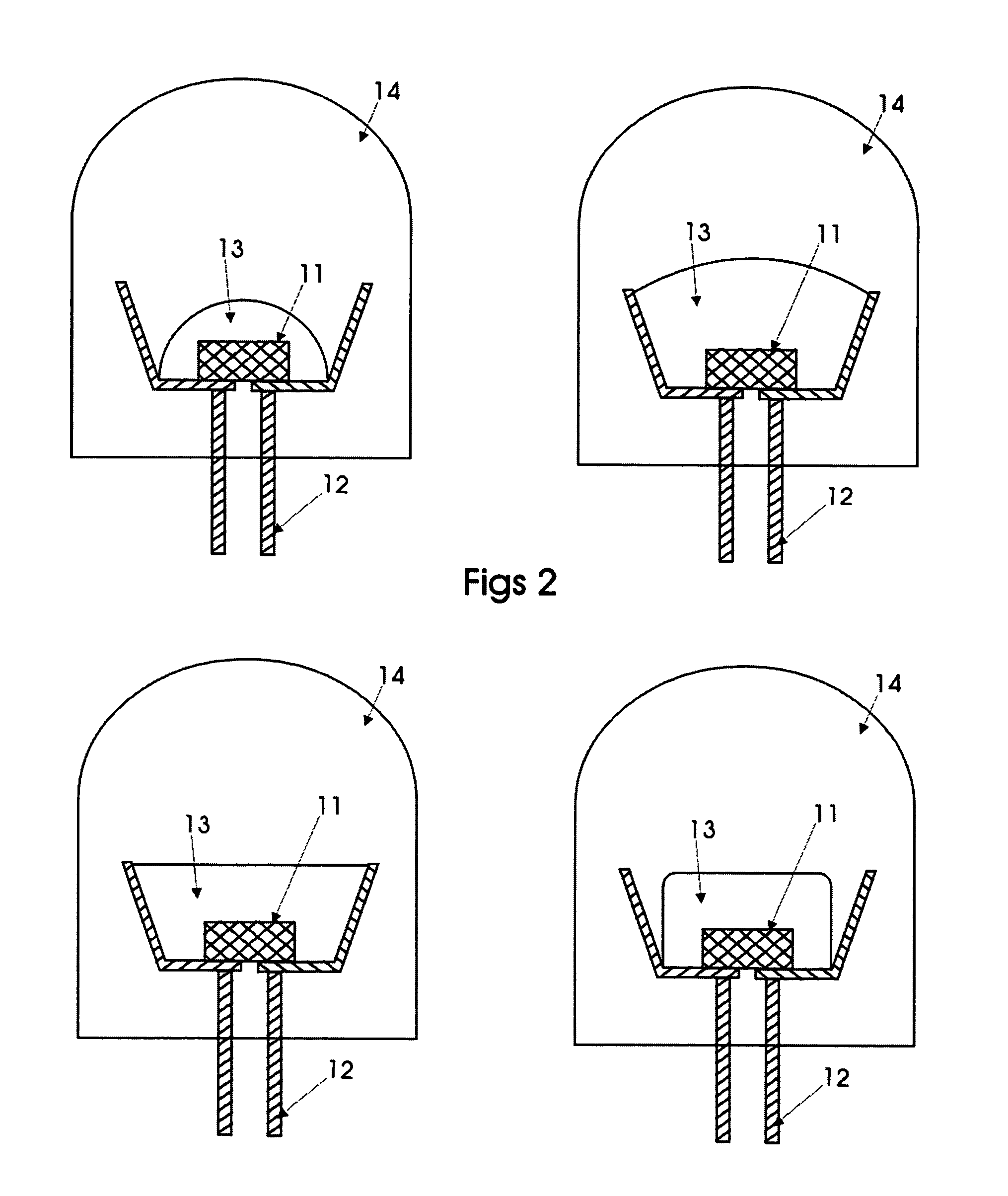

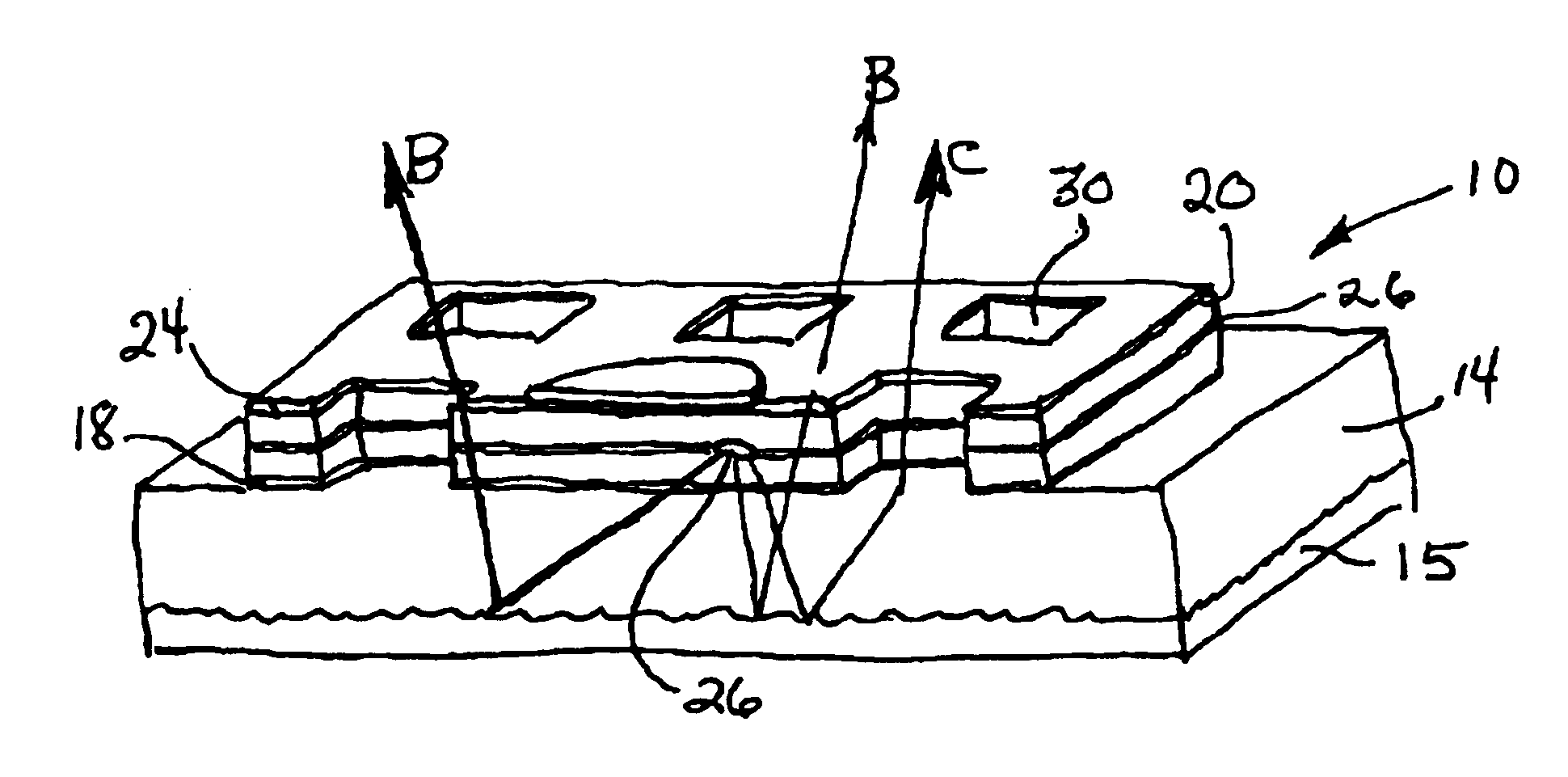

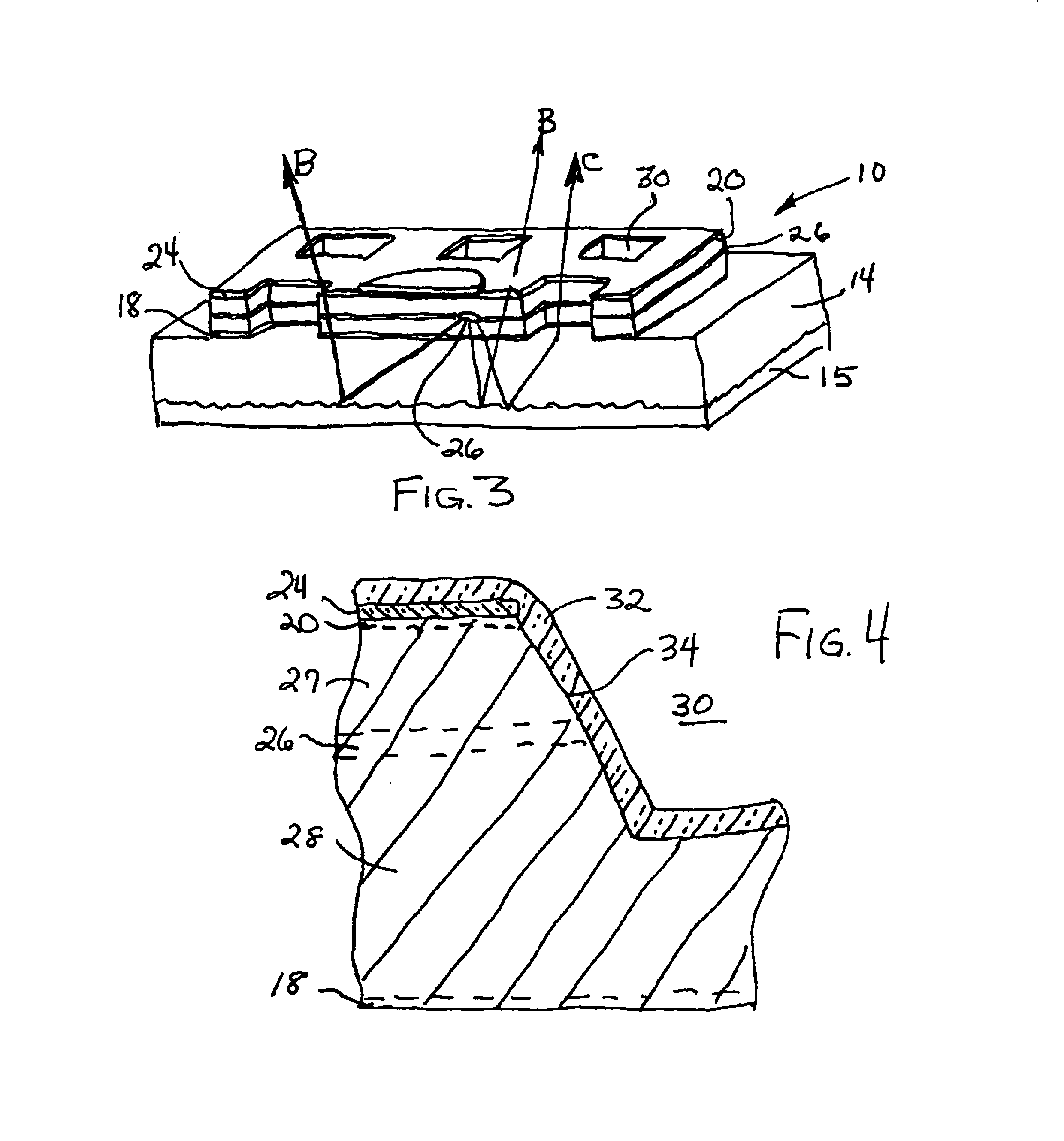

Nanocomposite photonic structures for solid state lighting

InactiveUS7259400B1Quality improvementHigh color rendering indexDischarge tube luminescnet screensCathode ray tubes/electron beam tubesPhosphorNanoparticle

A photonic structure for “white” light generation by phosphors under the excitation of a LED. The photonic structure mounts the LED and an optically transparent nanocomposite matrix having dispersed therein phosphors which will emit light under the excitation of the radiation of the LED. The phosphors dispersed in the matrix may be nanocrystalline, or larger sized with the addition of non light emitting, non light scattering nanoparticles dispersed within the matrix material so as to match the index of refraction of the matrix material to that of the phosphors. The nanocomposite matrix material may be readily formed by molding and formed into a variety of shapes including lenses for focusing the emitted light. A large number of the photonic structures may be arranged on a substrate to provide even illumination or other purposes.

Owner:NANOCRYSTAL LIGHTING

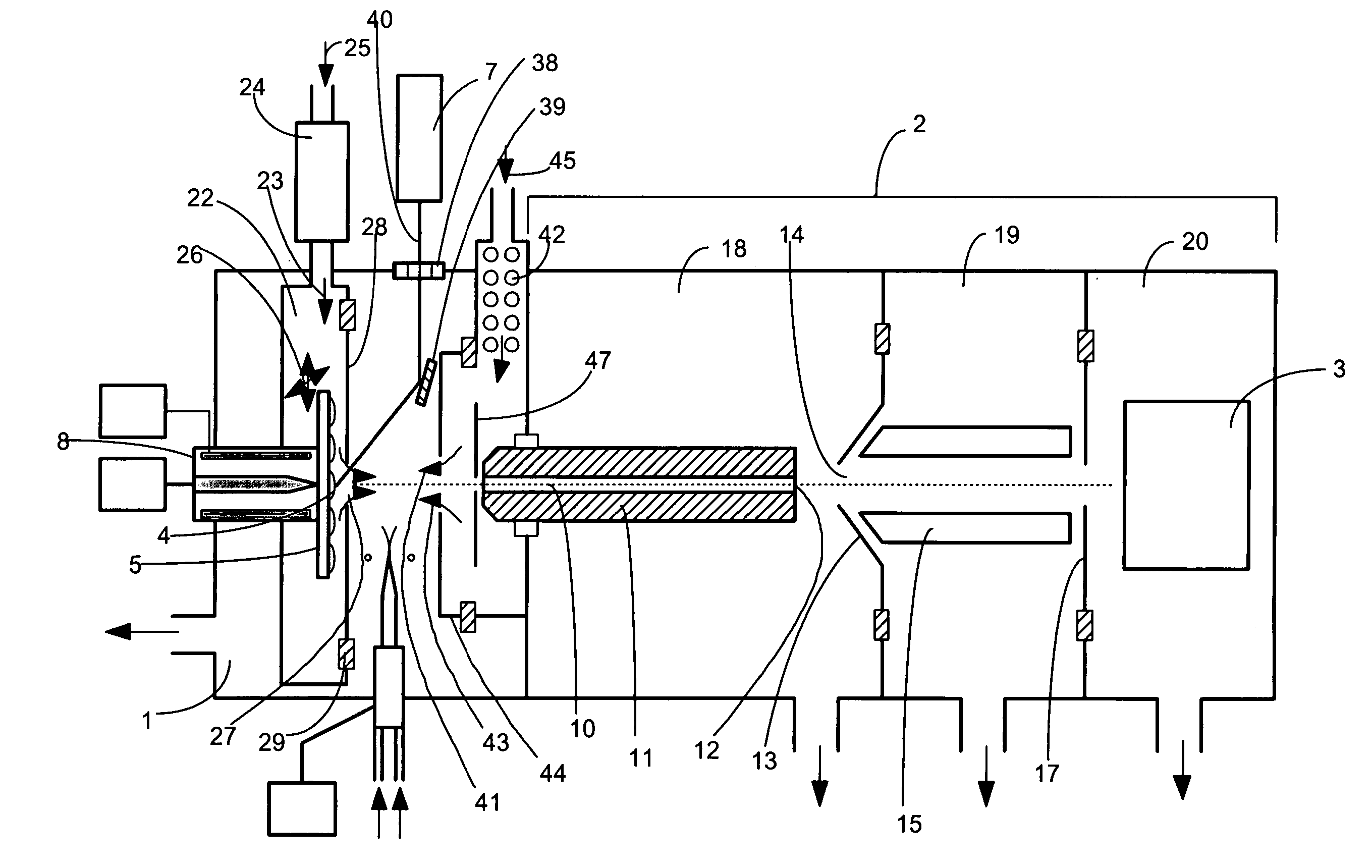

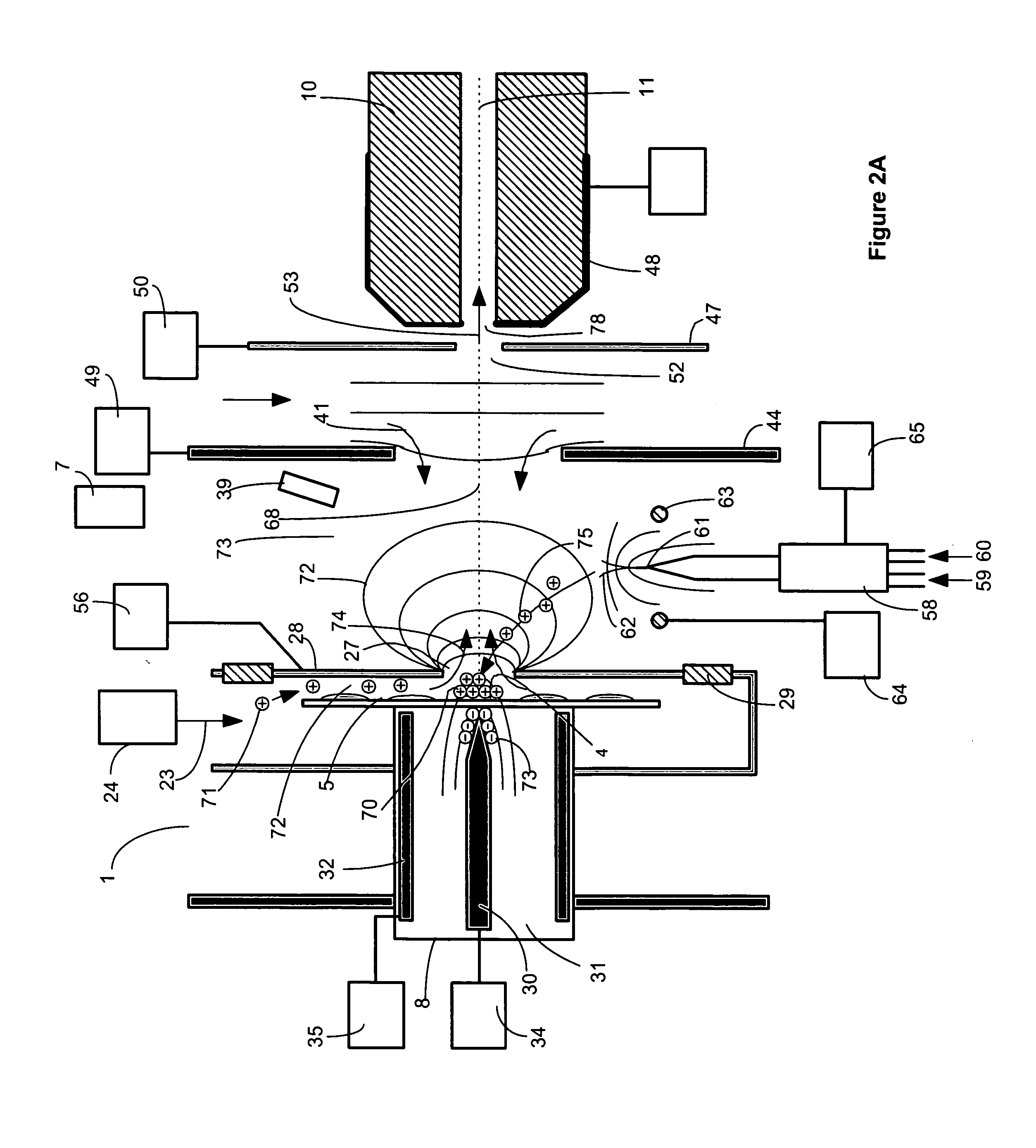

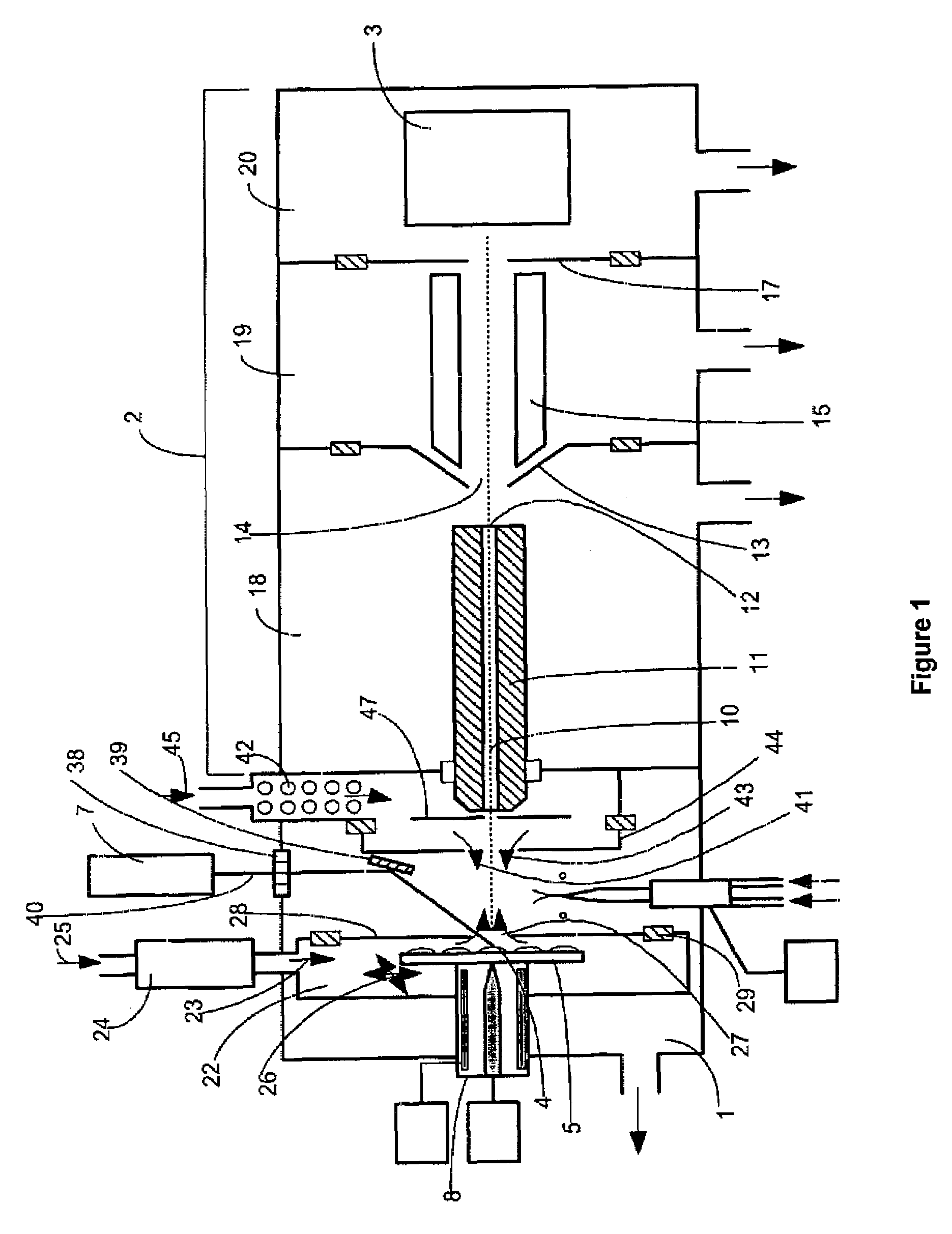

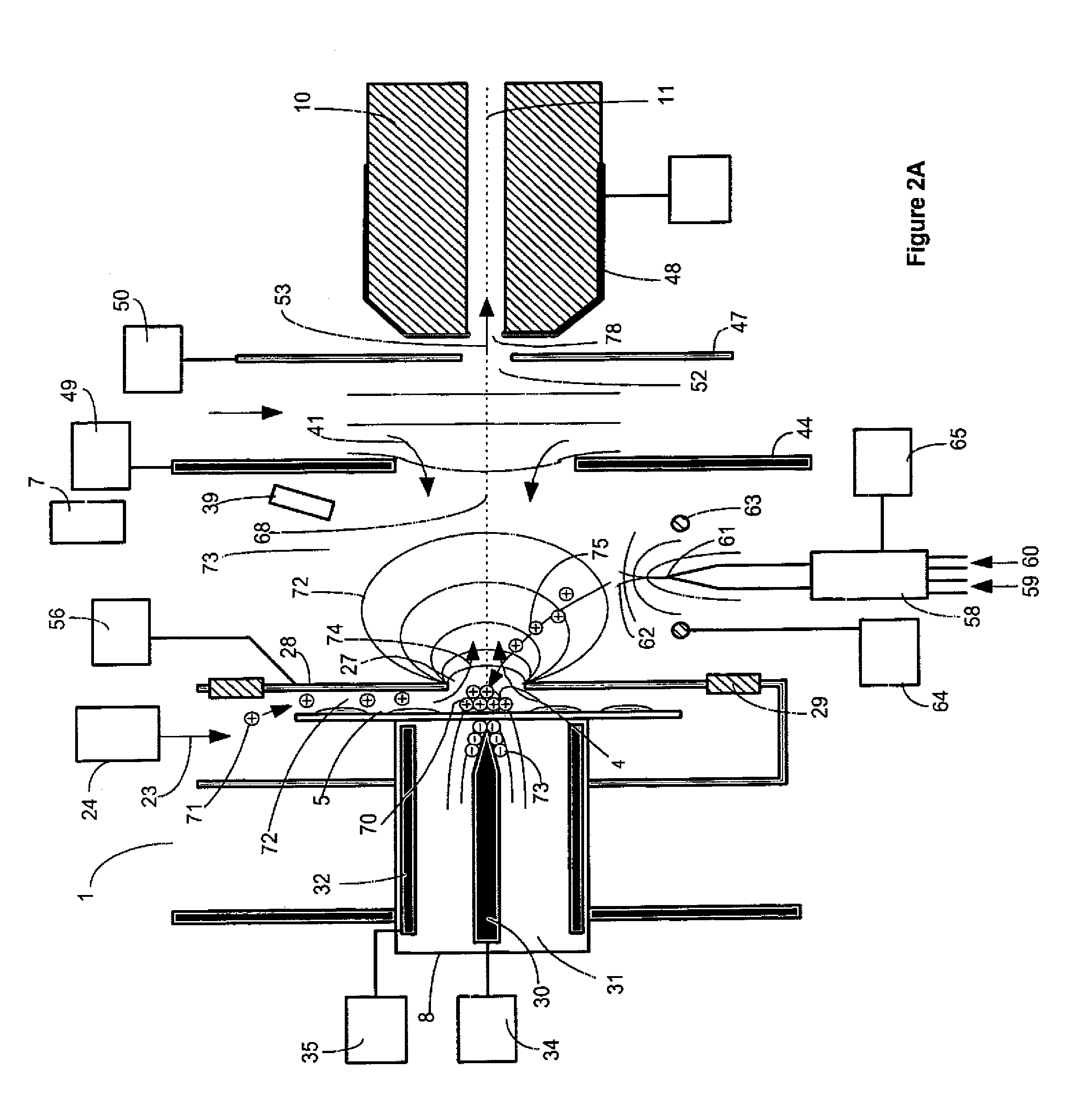

Laser desorption ion source

ActiveUS20050056776A1Efficient extractionImprove ionization efficiencyElectron/ion optical arrangementsIsotope separationPhysicsIonization

Atmospheric pressure, intermediate pressure and vacuum laser desorption ionization methods and ion sources are configured to increase ionization efficiency and the efficiency of transmitting ions to a mass to charge analyzer or ion mobility analyzer. An electric field is applied in the region of a sample target to accumulate ions generated from a local ion source on a solid or liquid phase sample prior to applying a laser desorption pulse. The electric field is changed just prior to or during the desorption laser pulse to promote the desorption of charged species and improve the ionization efficiency of desorbed sample species. After a delay, the electric field may be further changed to optimize focusing and transmission of ions into a mass spectrometer or ion mobility analyzer. Charged species may also be added to the region of the laser desorbed sample plume to promote ion-molecule reactions between the added ions and desorbed neutral sample species, increasing desorbed sample ionization efficiency and / or creating desired product ion species. The cycling of electric field changes is repeated in a timed sequence with one or more desorption laser pulse occurring per electric field change cycle. Embodiments of the invention comprise atmospheric pressure, intermediate pressure and vacuum pressure laser desorption ionization source methods and devices for increasing the analytical flexibility and improving the sensitivity of mass spectrometric analysis.

Owner:PERKINELMER HEALTH SCIENCES INC +1

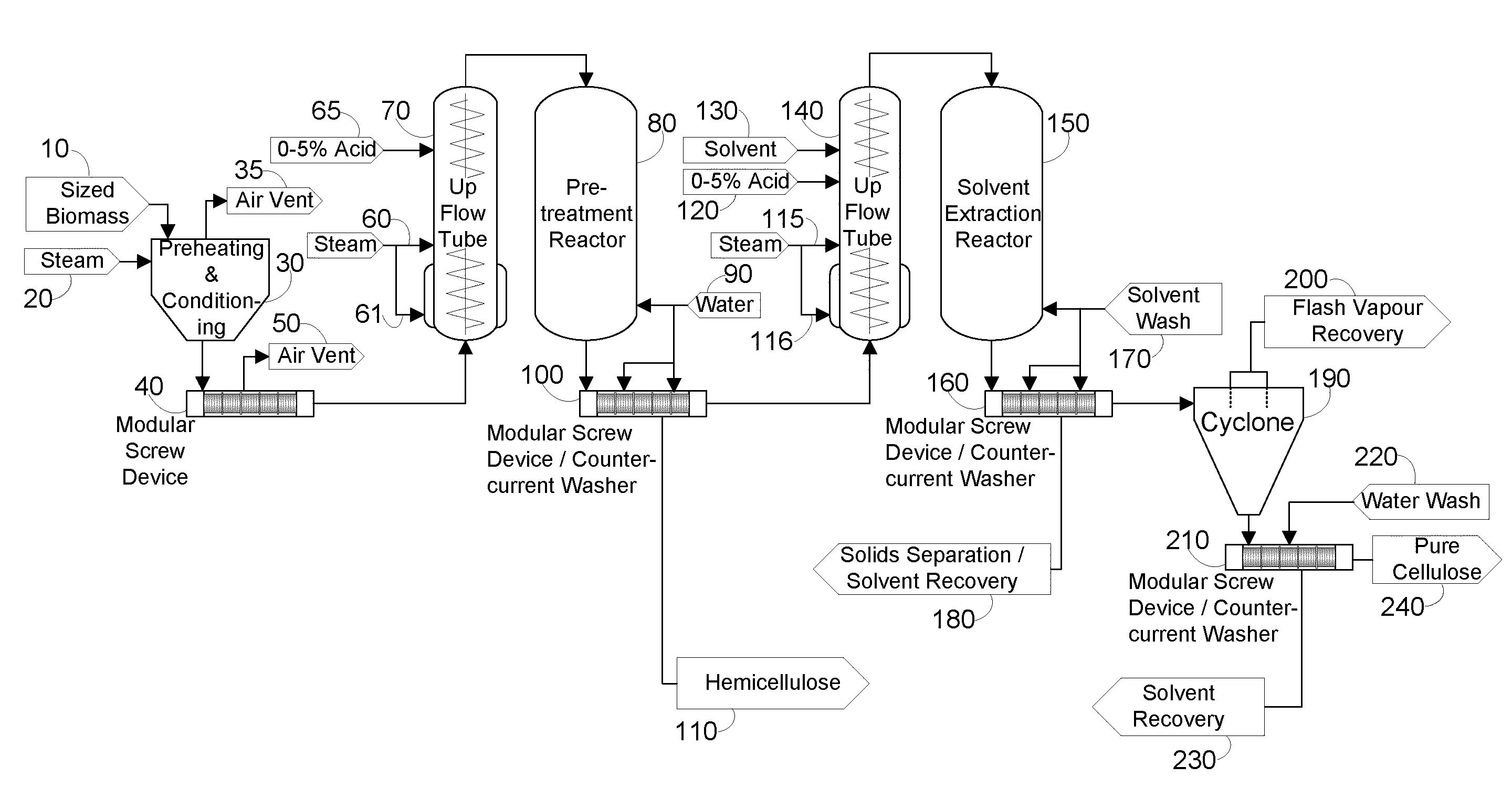

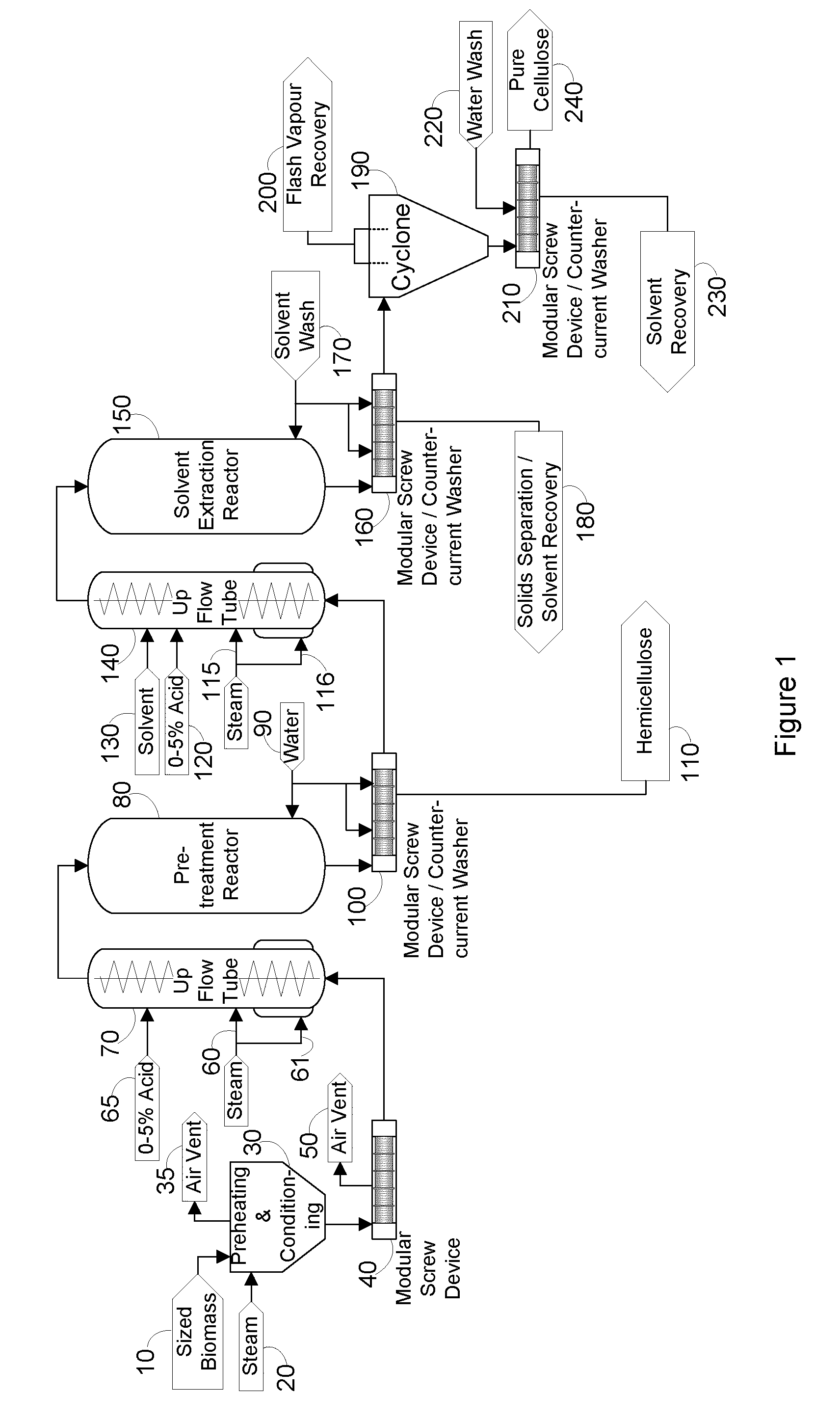

Separation of reactive cellulose from lignocellulosic biomass with high lignin content

InactiveUS20100269990A1Reduce inhibitionReduce extractionCellulosic pulp after-treatmentBiofuelsFiberLignocellulosic biomass

A process for separating the components of lignocellulosic biomass for the purpose of producing a pure reactive cellulose is disclosed. The process has two stages. In the first stage, the lignocellulosic biomass is pretreated with steam, with or without an acid catalyst, and then pressed, with or without the presence of an eluent, to remove hemicellulose and other impurities. In the second stage, the pretreated biomass is extracted with a solvent such as ethanol with or without acid catalysts in order to remove lignin and release a purified cellulose stream. The extracted cellulose is then rapidly decompressed to rupture the fibrous structure. The process provides a purified cellulose stream that is relatively easy to hydrolyze with enzymes and ferment to biofuels and other chemicals such as ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

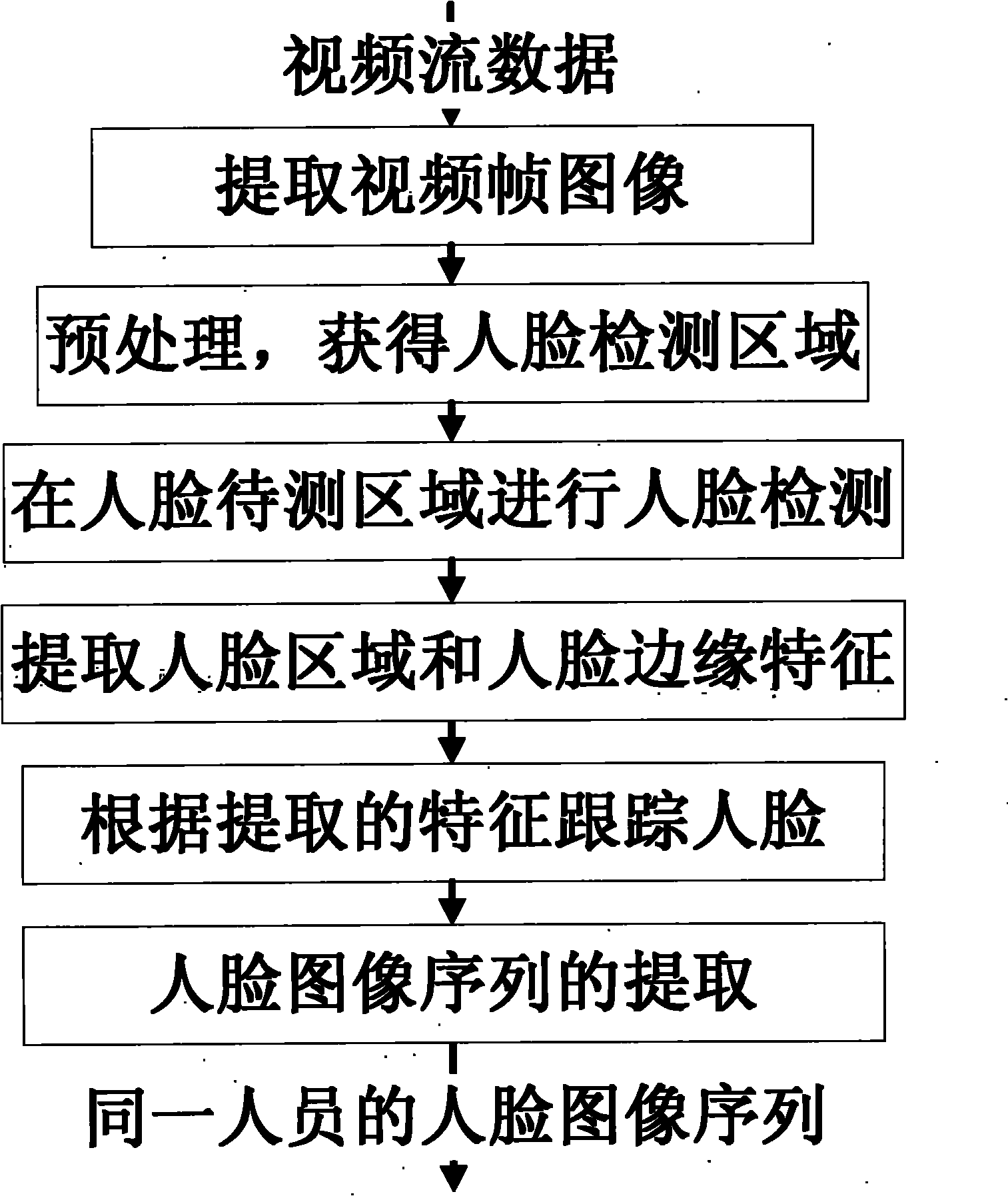

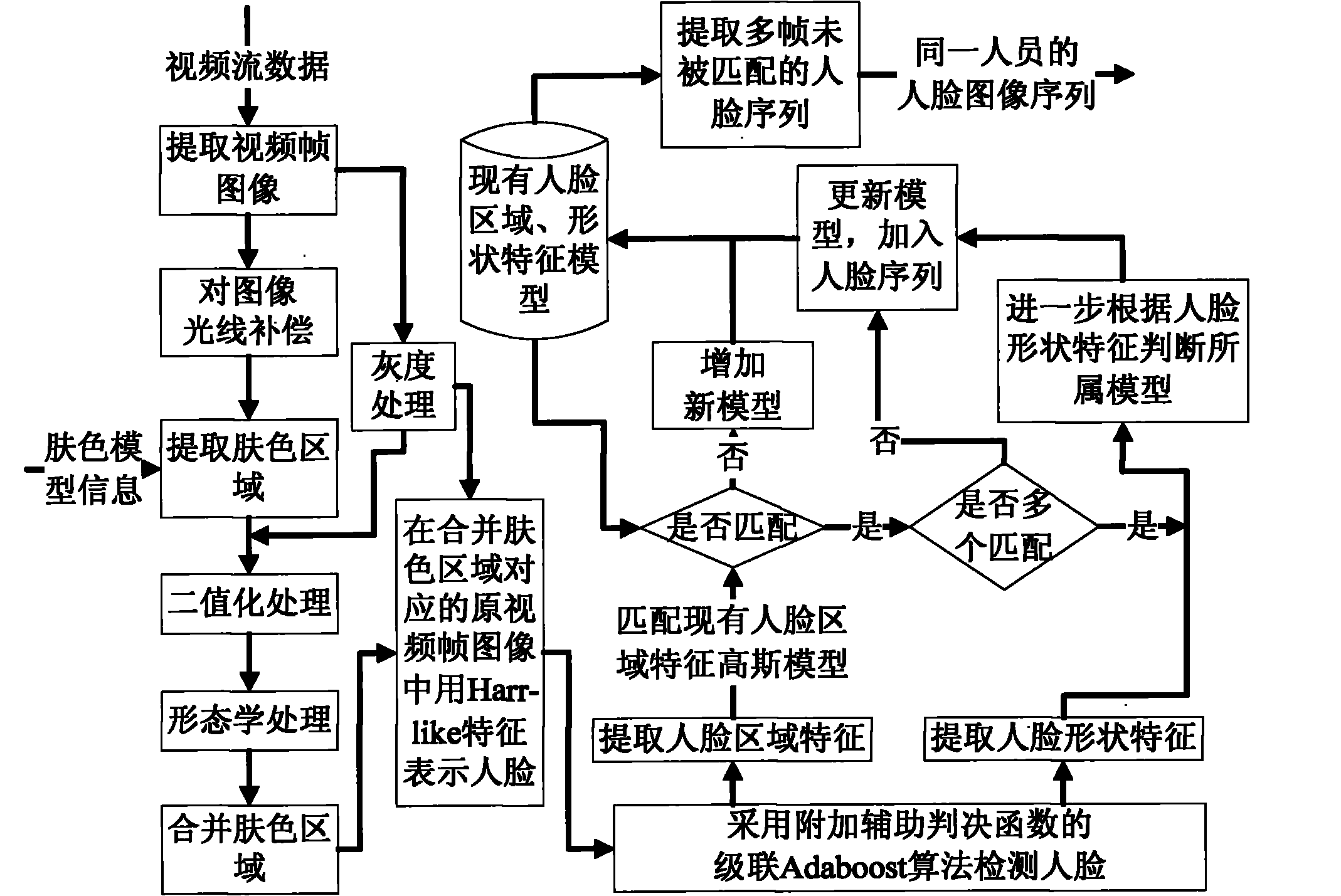

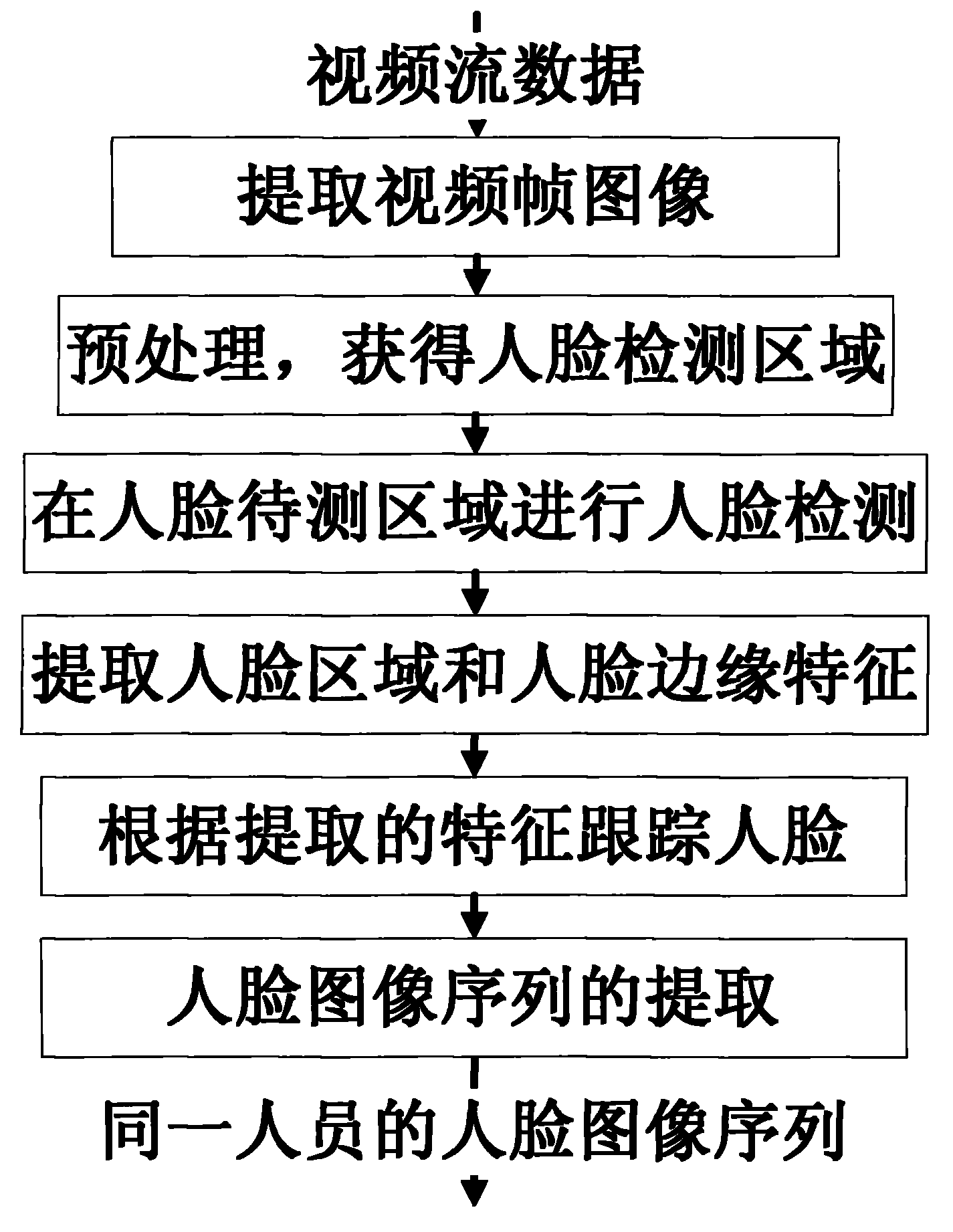

Method for quickly and accurately detecting and tracking human face based on video sequence

InactiveCN102214291AQuick calculationDetection speedCharacter and pattern recognitionPattern recognitionFace detection

The invention discloses a method for quickly and accurately detecting and tracking a human face based on a video sequence, which relates to the technical field of mode identification. The method comprises the following steps of: 1, extracting a video frame image from a video stream; 2, preprocessing the video frame image, namely compensating light rays, extracting skin color areas, performing morphological processing and combining the areas; 3, detecting the human face, namely representing the human face by using Harr-like characteristics and detecting the human face by using a cascaded Adaboost algorithm with an assistant decision function; 4, establishing the characteristics of the human face, namely detecting the area characteristics of the detected human face and the shape characteristics of the edge profile of the human face; 5, tracking the human face, particularly tracking the human face by using a human face area characteristic model when an intersection does not occur in a human face area, and further matching when the intersection occurs according to the shape characteristics of the edge profile of the human face; and 6, extracting the sequence of a human face image. By the technical method, the human face can be detected and tracked quickly and accurately on the basis of the video sequence.

Owner:云南清眸科技有限公司

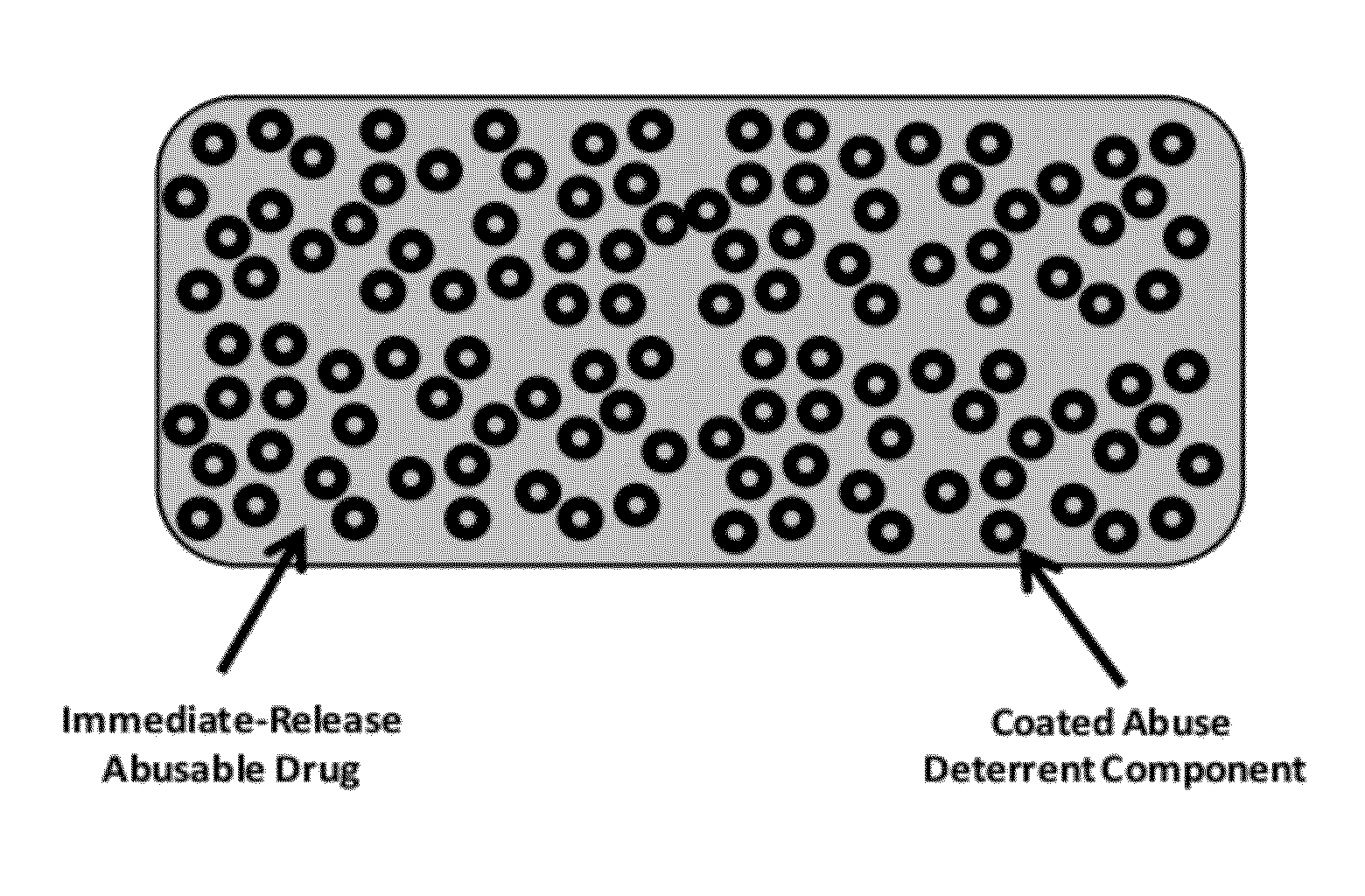

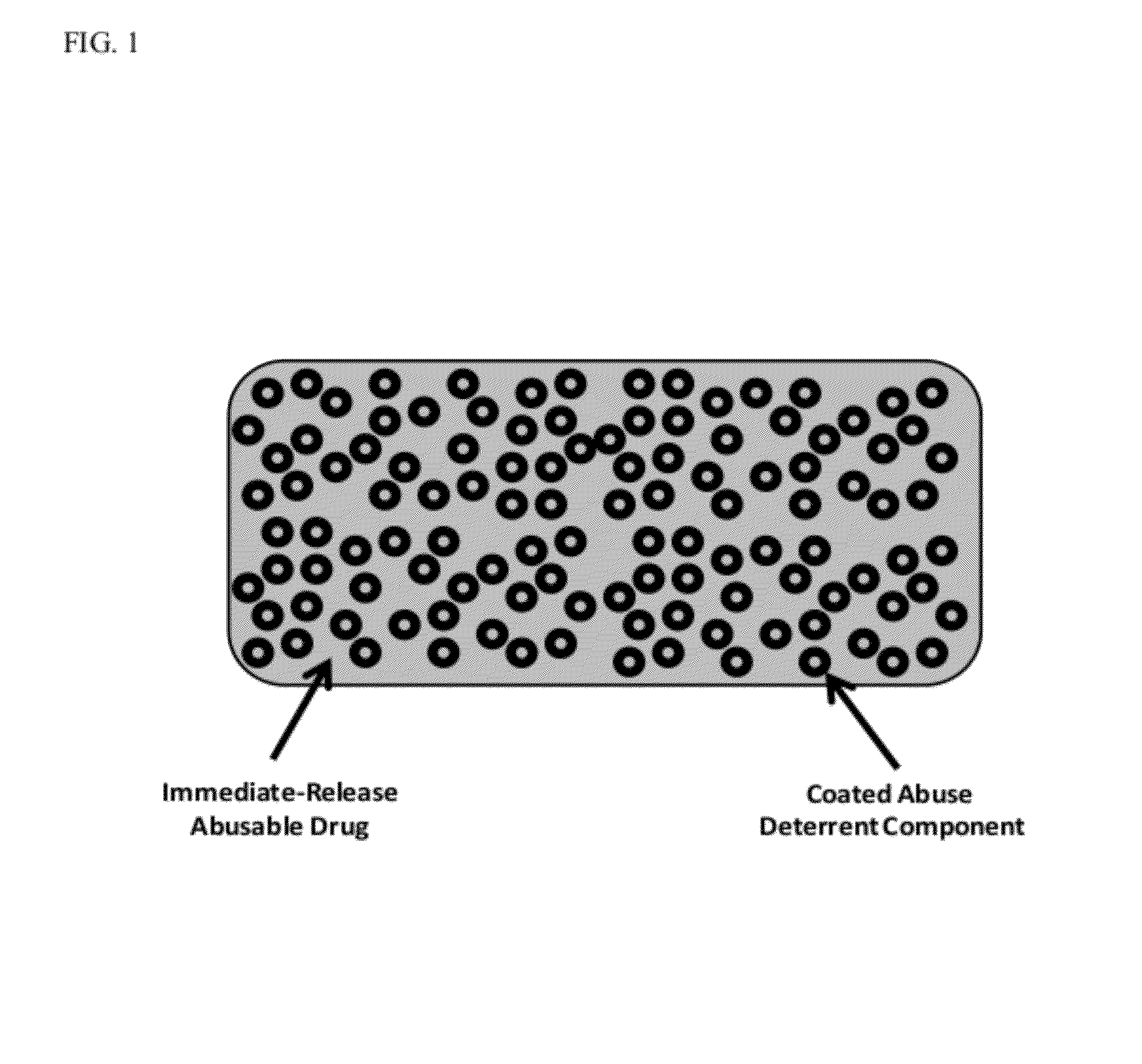

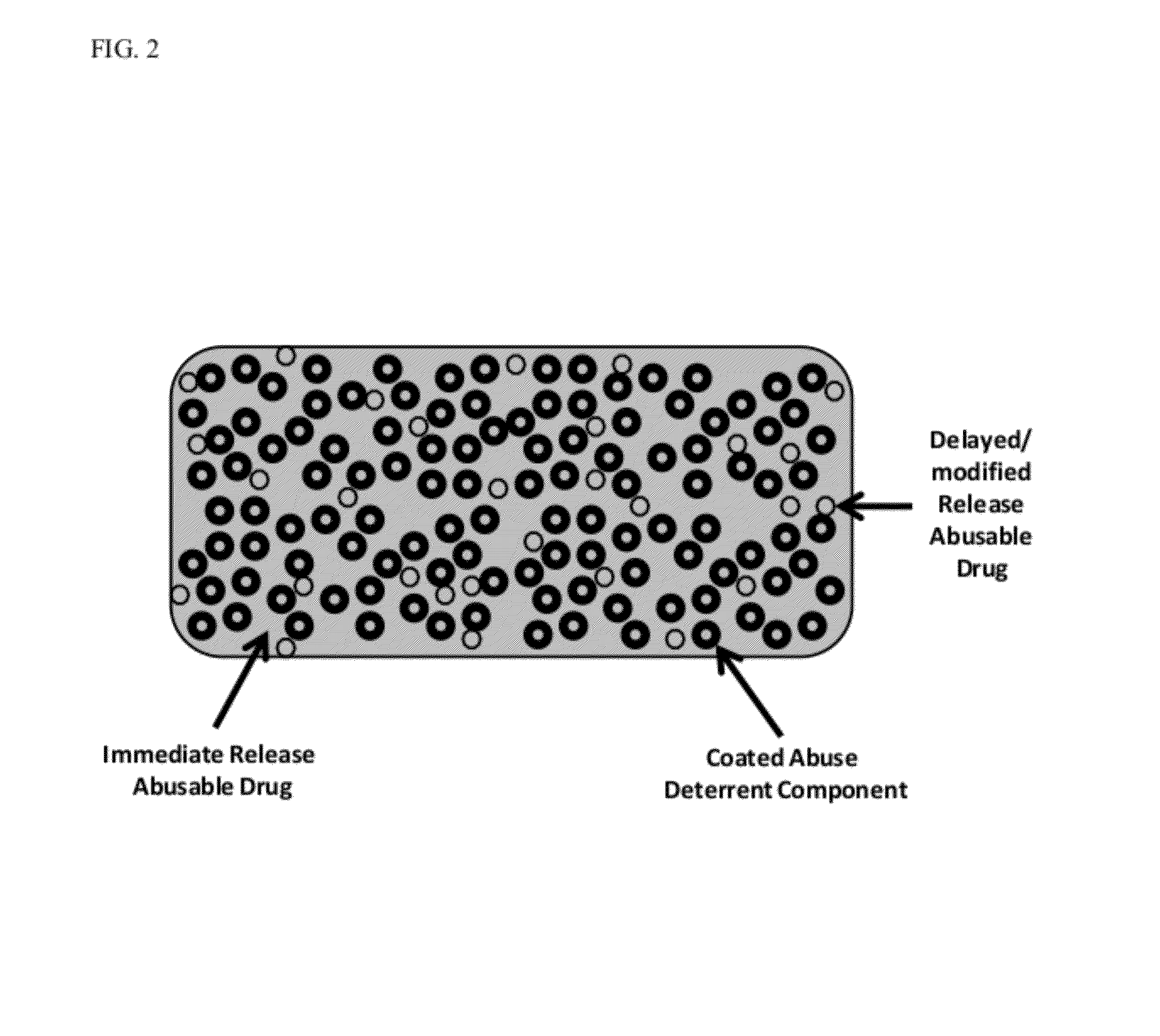

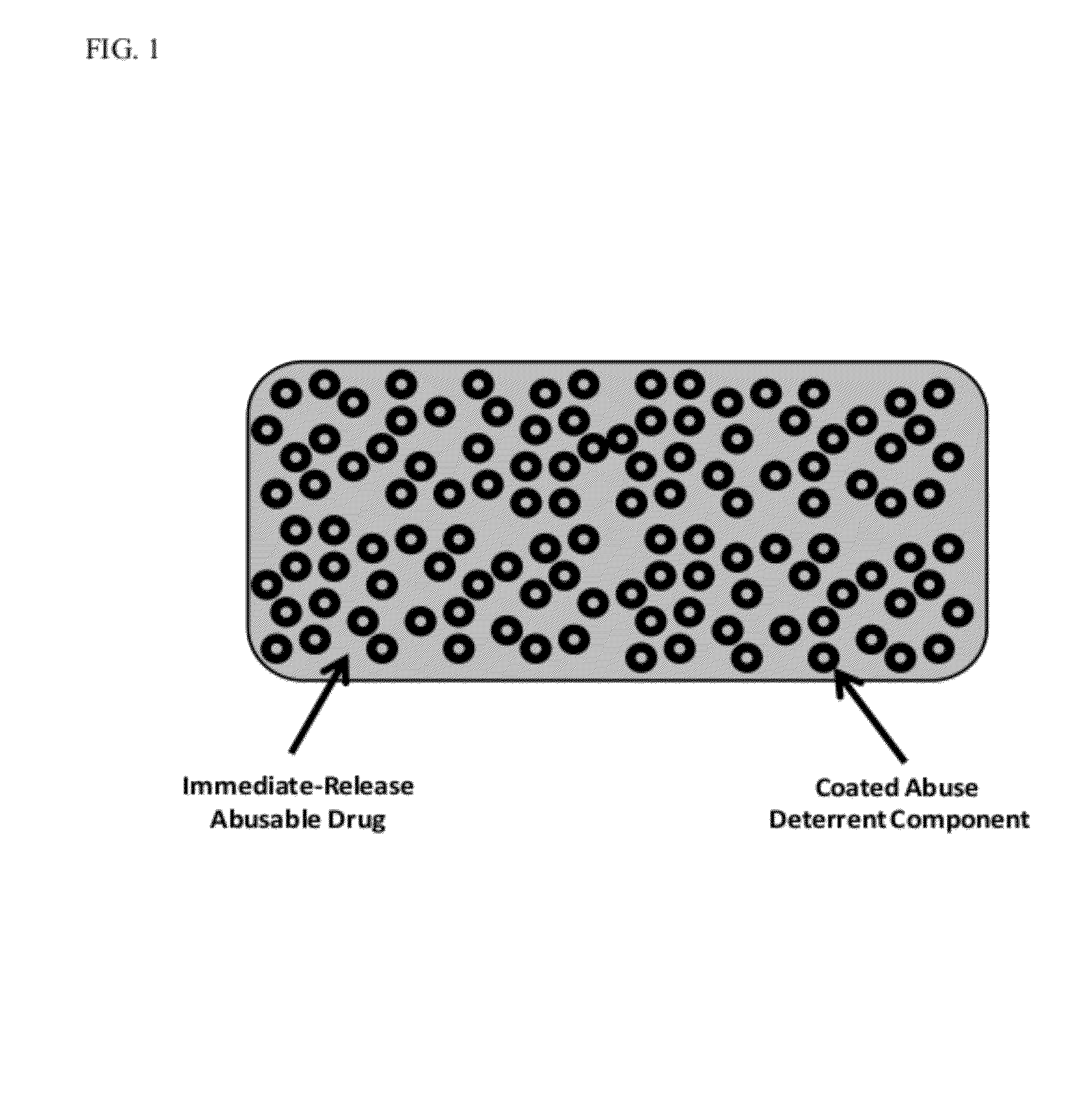

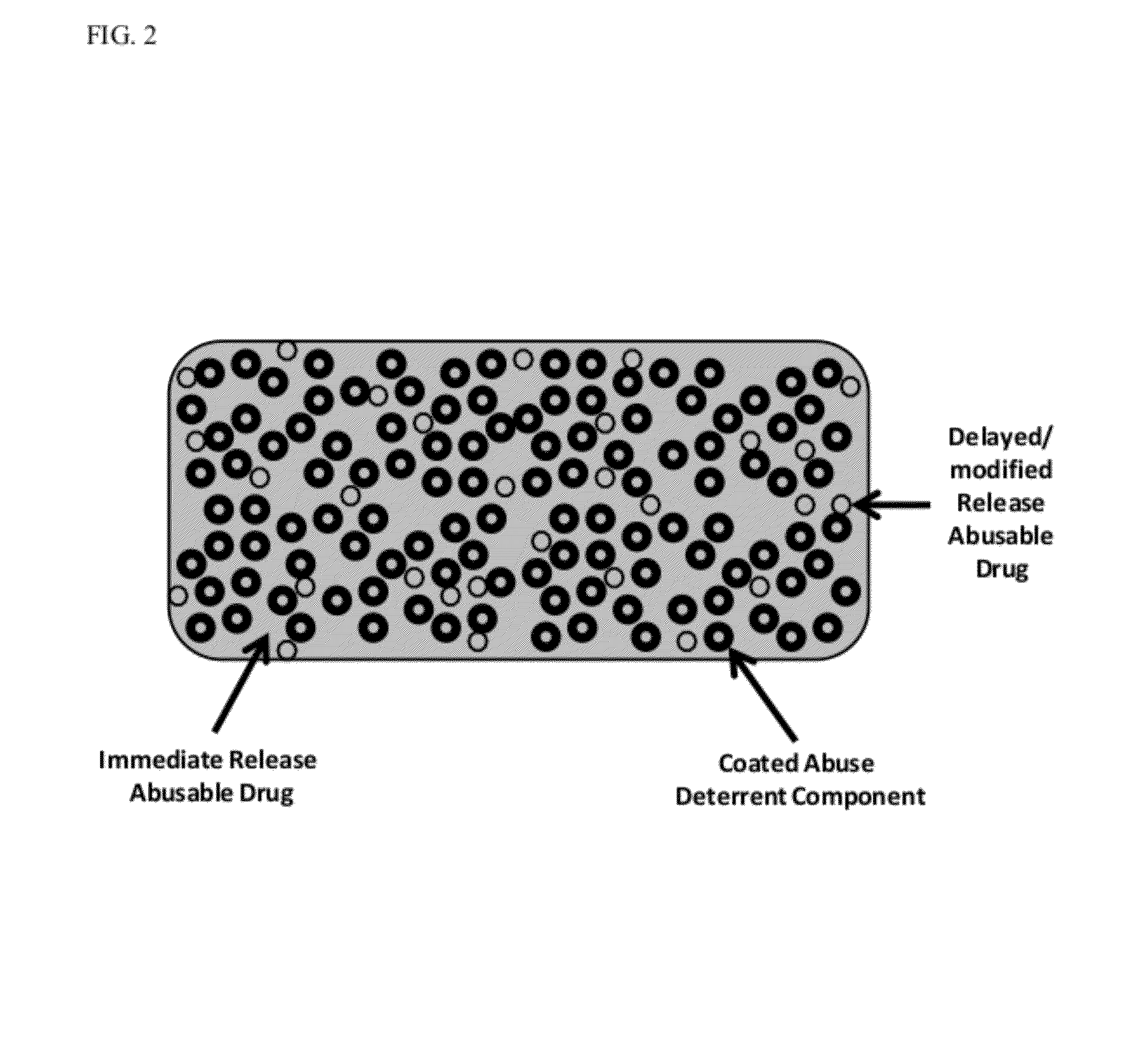

Technology for preventing abuse of solid dosage forms

InactiveUS20120321716A1Excessive amountReduce probabilityBiocidePowder deliveryAbuse deterrentPharmaceutical formulation

Abuse resistant pharmaceutical formulations are provided that contain one or more abusable drugs and one or more abuse deterrent components. The abuse deterrent component(s) prevent the abusable drug(s) from being removed / extracted to an appreciable extent and / or rate. The abuse deterrent component(s) may be in the form of pellets, beads, beadlets, granules, powders, or the like, and may comprise a core that contains a material that is both hydrophilic and hydrophobic, and optionally a pH-dependent coating.

Owner:VACHON MICHAEL +1

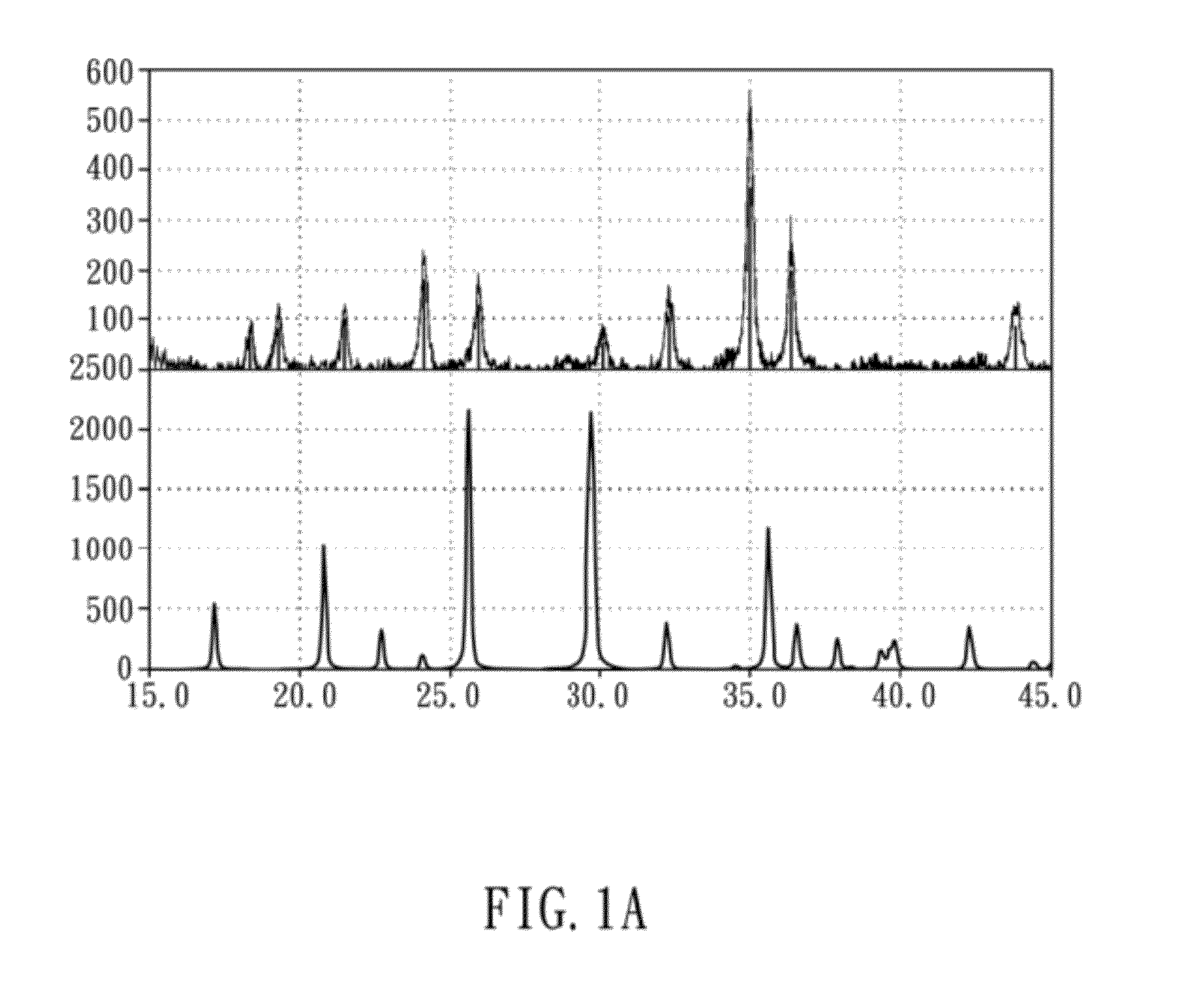

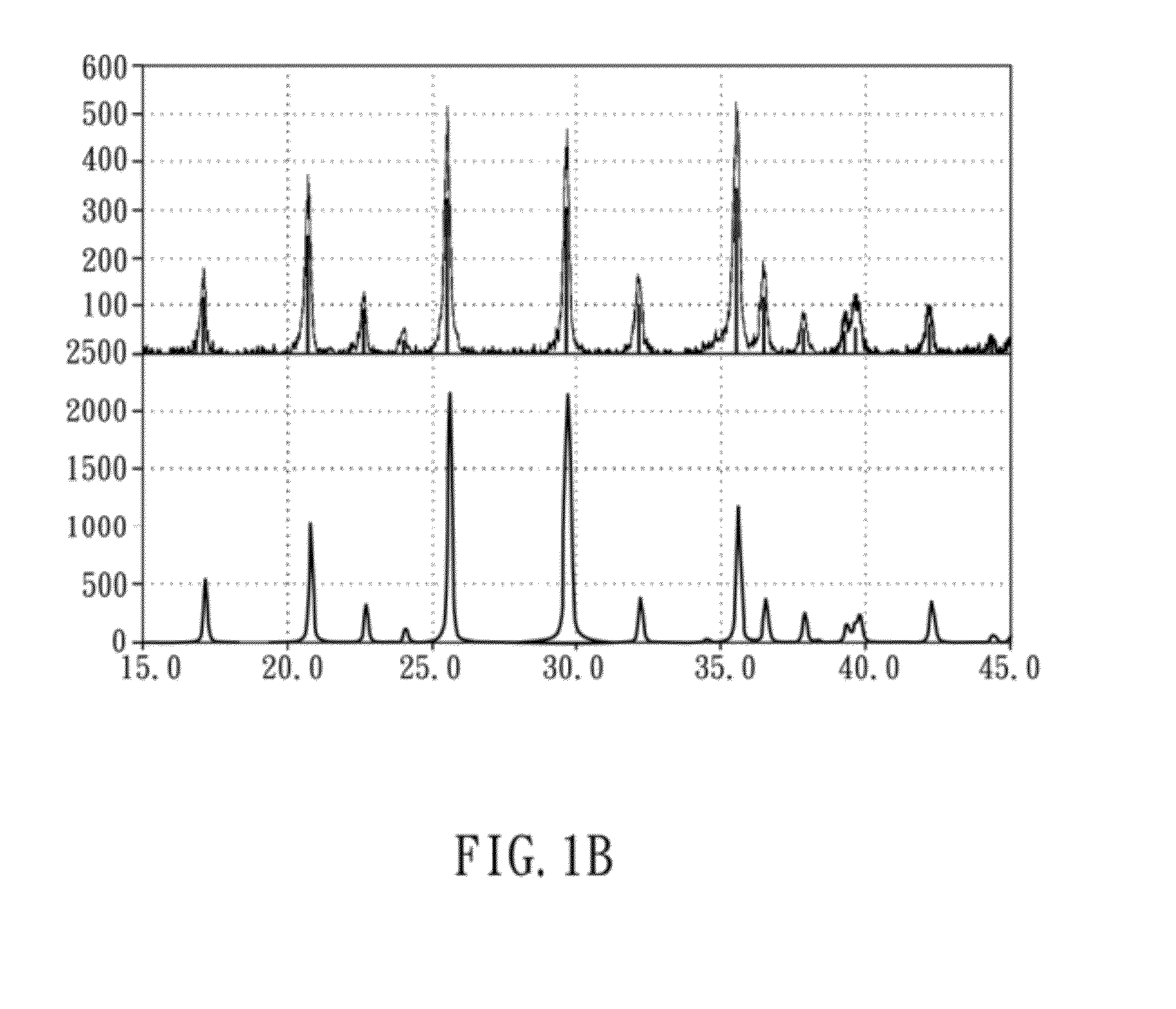

LiFePO4 FLAKES FOR Li-ION BATTERY AND METHOD FOR MANUFACTURING THE SAME

ActiveUS20120328947A1Charge-discharge efficiency can be improvedShort diffusion pathMaterial nanotechnologyPhosphatesCharge dischargeEngineering

LiFePO4 flakes for a Li-ion battery and a method for manufacturing the same are disclosed. The LiFePO4 flakes of the present invention have a thickness of 5 nm-200 nm, and the angle between the flat surface normal of the flake and the Li-ion diffusion channel is 0°-80°. In addition, according to the present invention, the LiFePO4 flakes with short Li ion diffusion path can be prepared through a simple process. Hence, not only the charge-discharge efficiency of the Li-ion battery can be improved by use of the LiFePO4 flakes of the present invention, but also the cost of the Li-ion battery can be further reduced.

Owner:NATIONAL TSING HUA UNIVERSITY

Production of soluble keratin derivaties

InactiveUS7148327B2Low costReduce impactPeptide/protein ingredientsPeptide preparation methodsSulfurIntermediate Filament Protein

A process for the preparation of soluble proteins of high molecular weight with little or no damage to the structural integrity of the proteins. The process is economically and environmentally acceptable by virtue of the cost of reagents that are used, and the recycling of some of those reagents, and is suitable for the production of soluble proteins on a large scale. The process includes a first stage using oxidative sulfitolysis followed by a second stage using mild conditions to extract the soluble protein. In the case of wool as the protein source the process leads to the production of soluble keratin proteins fractionated into the classes S-sulfonated keratin intermediate filament proteins and S-sulfonated keratin high sulfur proteins.

Owner:KERATEC LTD

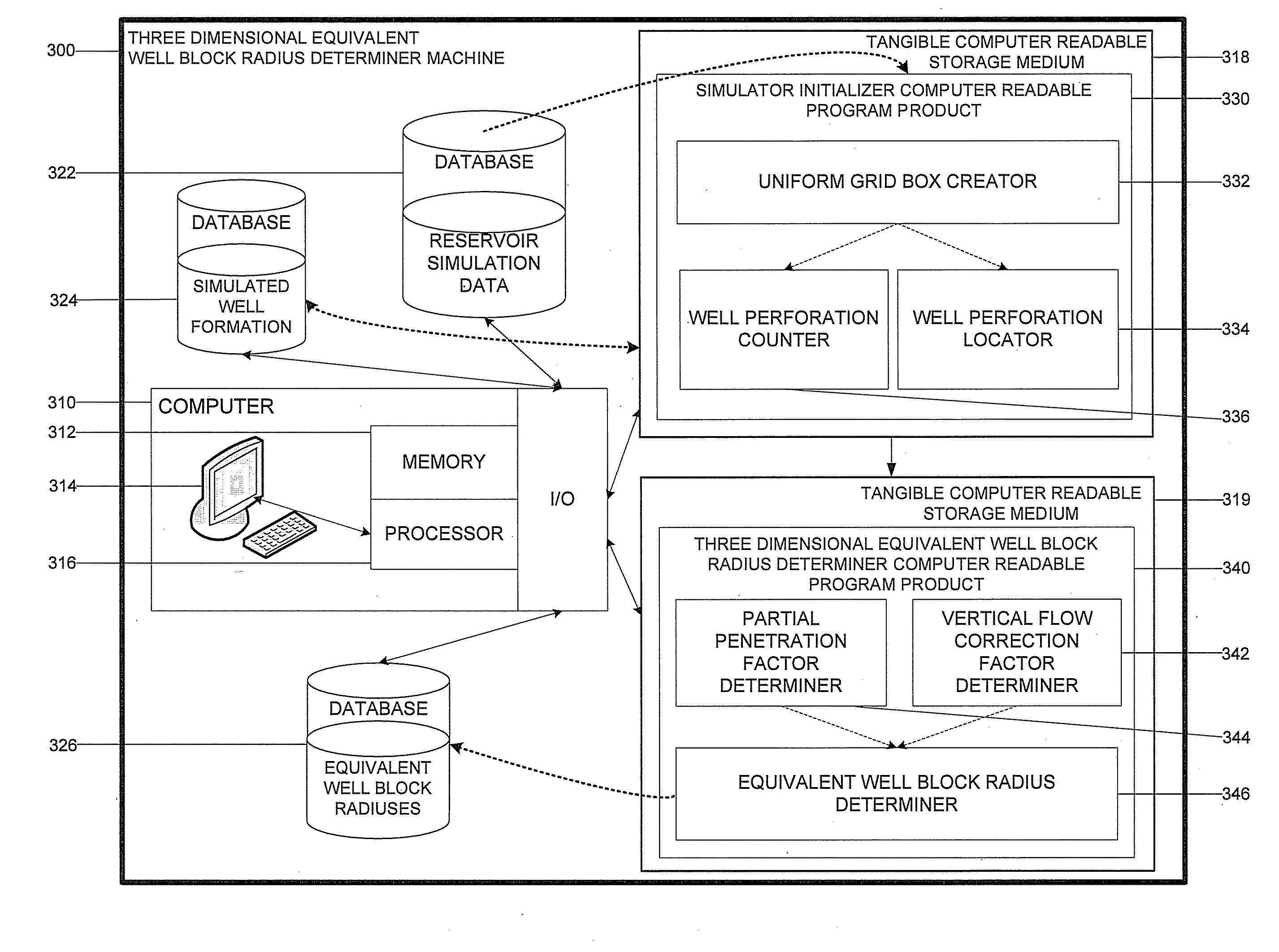

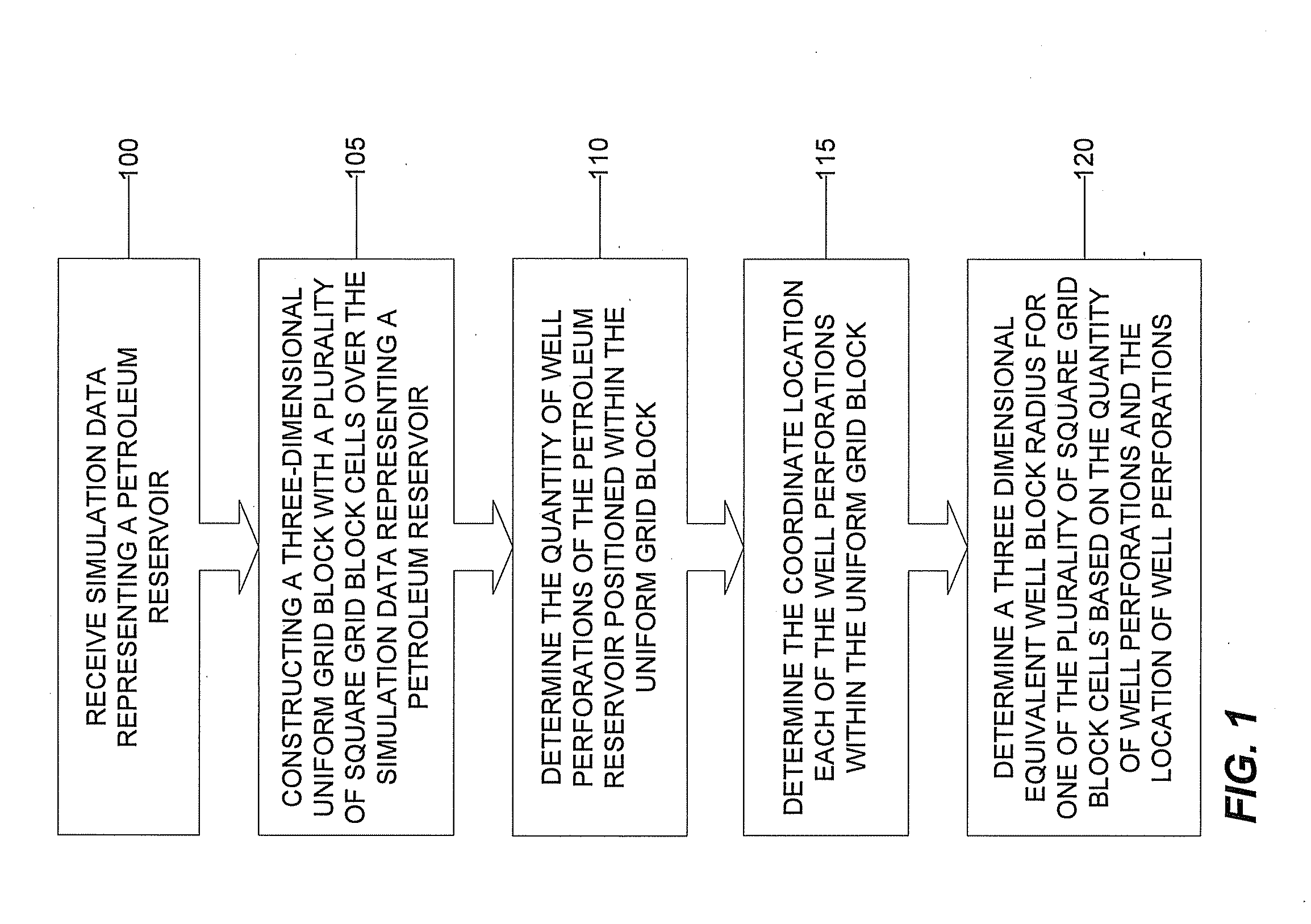

Three Dimensional Well Block Radius Determiner Machine And Related Computer Implemented Methods And Program Products

ActiveUS20100114544A1Improve accuracyLow costAnalogue computers for fluid flowGeological measurementsParallel computingPetroleum reservoir

Three dimensional well block radius determiner machines, systems, program products, and computer implemented methods are provided to determine a three dimensional equivalent well block radius of a perforated grid block cell, with three dimensional flow, of a three dimensional coordinate grid block constructed over a three dimensional simulated well formation in a finite difference petroleum reservoir simulator. Various embodiments of the invention, for example, can beneficially account for both horizontal and vertical flow of oil through a well perforation without the need for complicated, expensive, and time-consuming numerical or iterative solutions. Embodiments of the present invention, for example, can be used as a part of legacy simulators thereby providing more accurate well block radius calculations, by accounting for both horizontal and vertical perforation flow, without introducing significant implementation hurdles, development costs, or simulation runtime delays.

Owner:SAUDI ARABIAN OIL CO

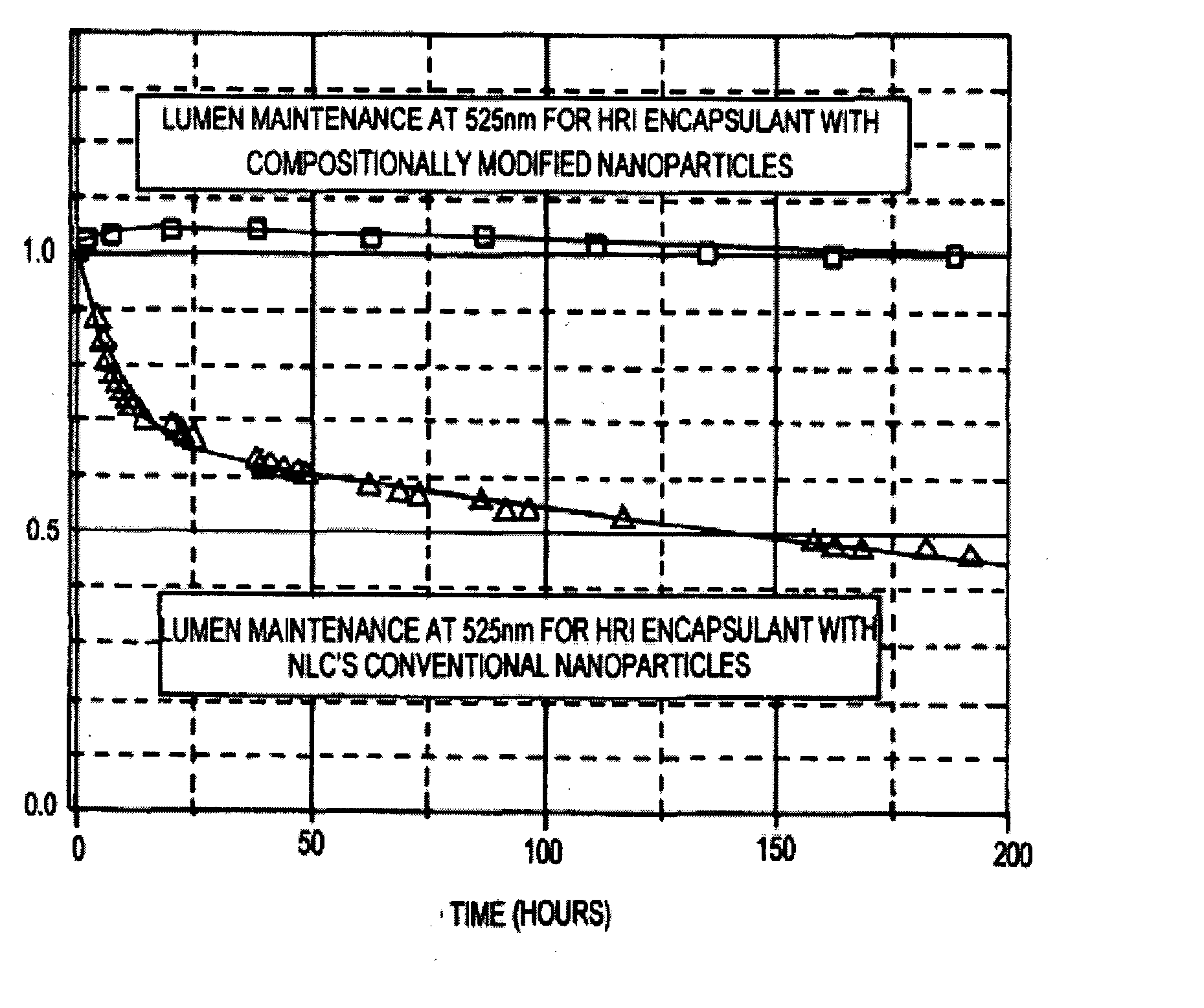

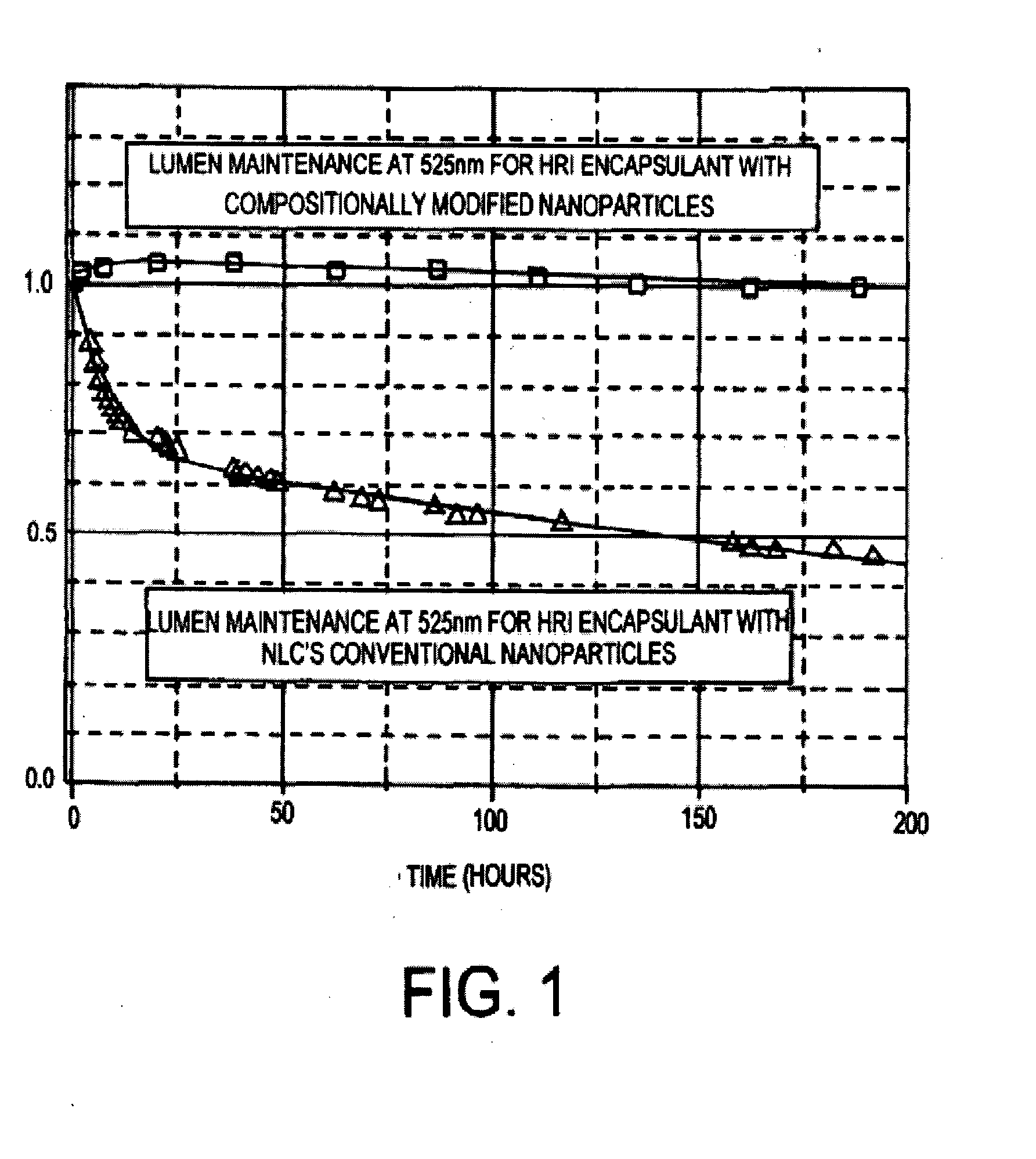

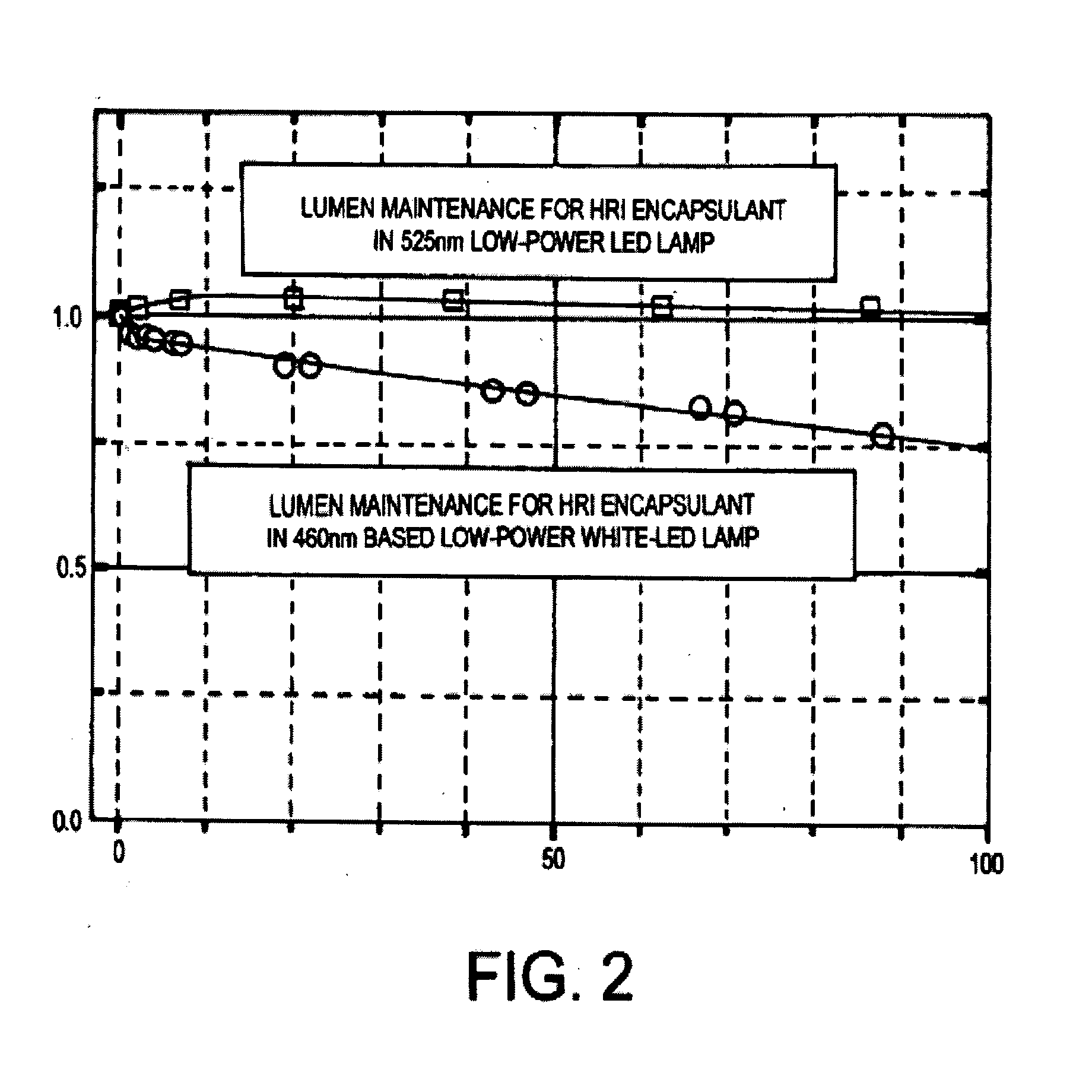

Optically reliable nanoparticle based nanocomposite HRI encapsulant, photonic waveguiding material and high electric breakdown field strength insulator/encapsulant

InactiveUS20070221939A1Good physical propertiesImprove photodegradation resistanceMaterial nanotechnologySemiconductor devicesEpoxyLight equipment

An optically reliable high refractive index (HRI) encapsulant for use with Light Emitting Diodes (LED's) and lighting devices based thereon. This material may be used for optically reliable HRI lightguiding core material for polymer-based photonic waveguides for use in photonic-communication and optical-interconnect applications. The encapsulant includes treated nanoparticles coated with an organic functional group that are dispersed in an Epoxy resin or Silicone polymer, exhibiting RI˜1.7 or greater with a low value of optical absorption coefficient α<0.5 cm−1 at 525 nm. The encapsulant makes use of compositionally modified TiO2 nanoparticles which impart a greater photodegradation resistance to the HRI encapsulant.

Owner:NANOCRYSTALS TECH

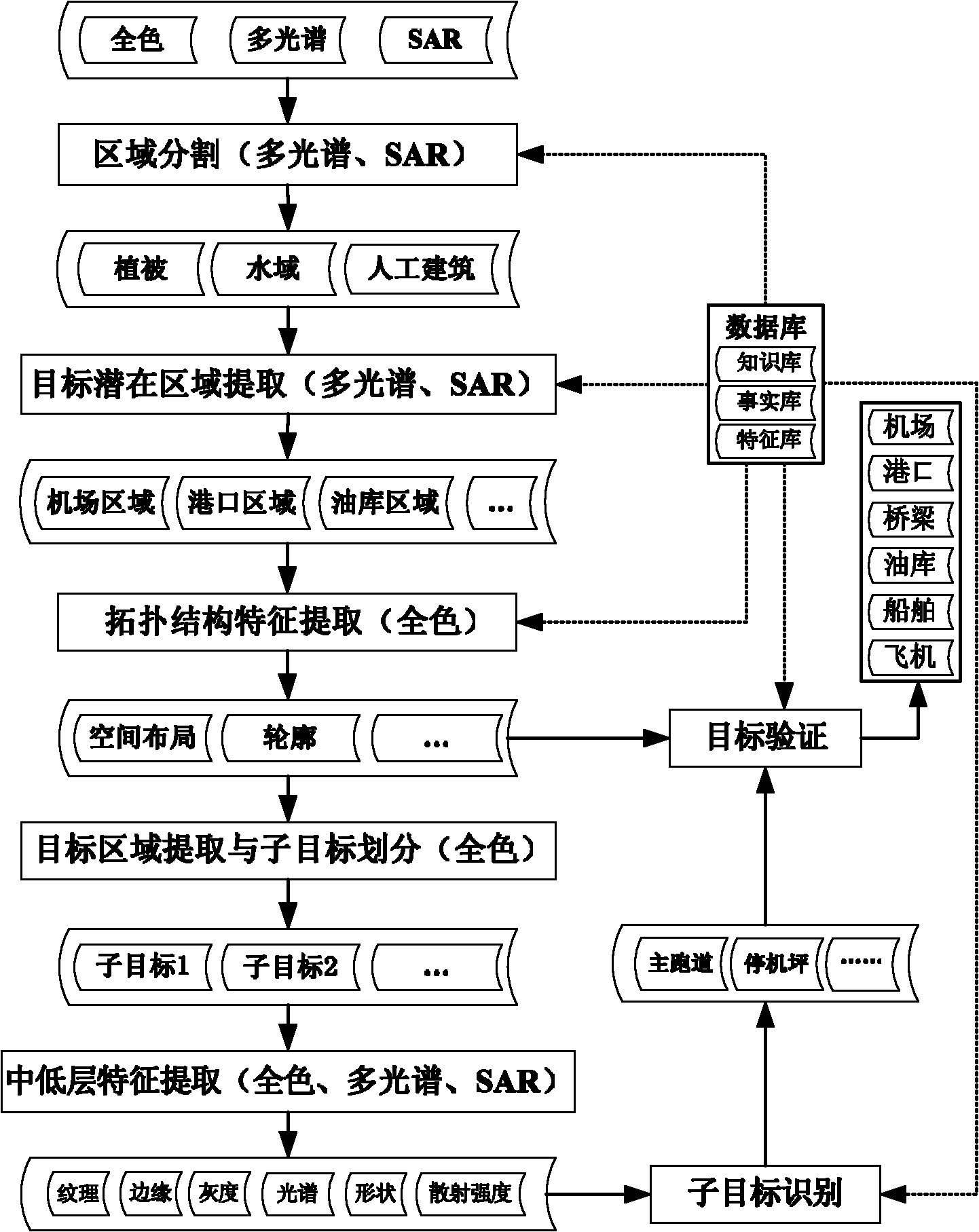

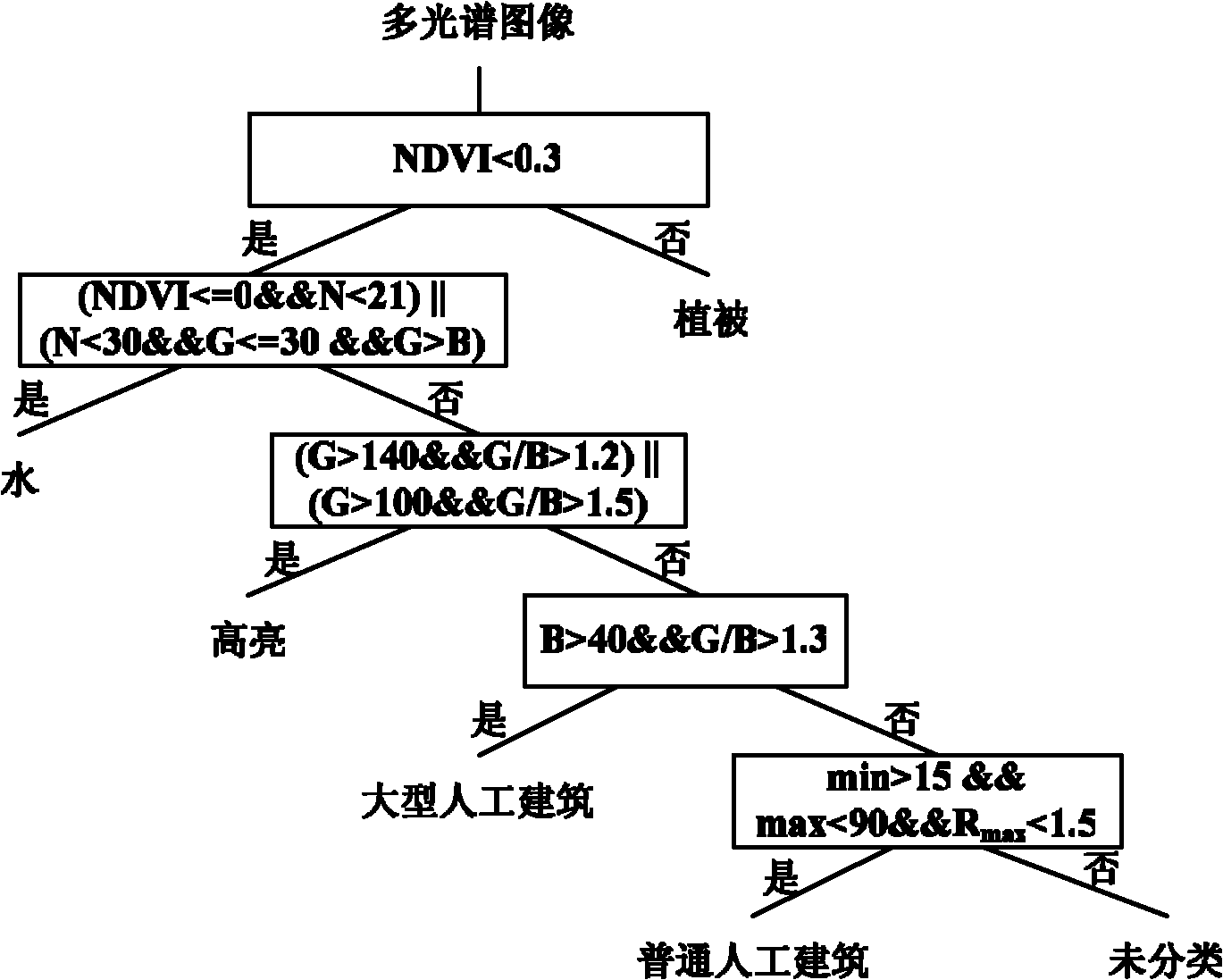

Method of identifying large and medium-sized objects based on multi-source remote sensing image fusion

ActiveCN102663394AImprove efficiencyImprove accuracyImage analysisCharacter and pattern recognitionRemote sensing image fusionObject based

The invention provides a method of identifying large and medium-sized objects based on multi-source remote sensing image fusion. The method comprises that multispectral and SAR images are segmented into image areas according to spectrum distribution between different objects and differences of electromagnetic radiation, and a potential area of an object is extracted according to experience and knowledge of object distribution, so that characteristic extraction and object identification are more targeted while identification efficiency and identification accuracy of the system are improved; that based on the above, object areas are determined by extracting object contour, spatial layout and the like, and sub-object areas are divided according to spatial layout relation of the object contour and sub-object spatial layout; and that sub-object characteristics are extracted, and with the guidance of object characteristic set and object prior knowledge, sub-object identification and object verification are finally realizedby execution of identification rules and matching of characteristics.

Owner:BEIHANG UNIV

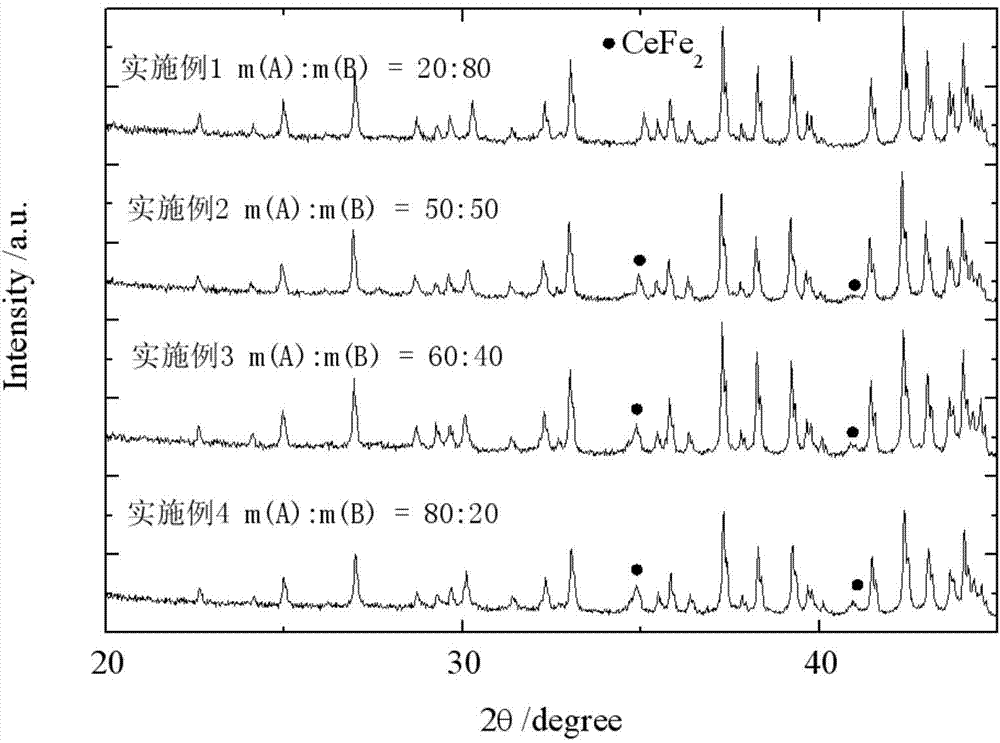

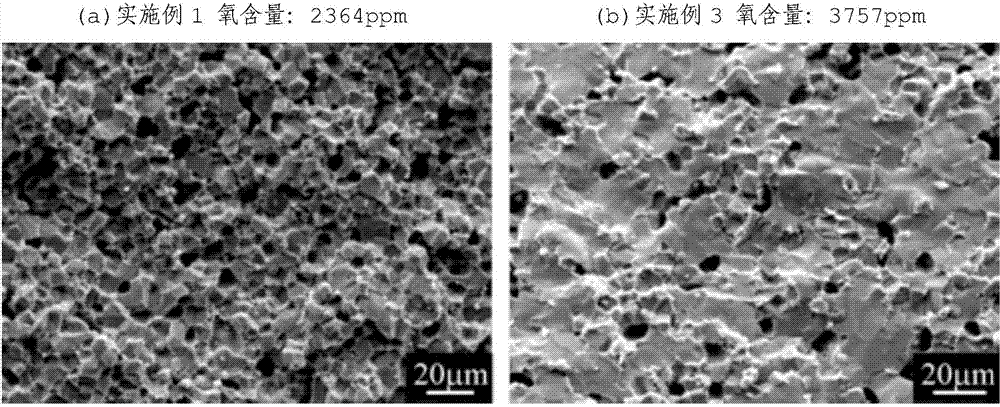

Mixed rare earth sintering permanent magnet and preparation method thereof

ActiveCN104715876AImprove coercive forceReduce extractionPermanent magnetsInductances/transformers/magnets manufactureSintered magnetsRare earth

The present invention provides a mixed rare earth sintered permanent magnet and preparation method thereof. The preparation method of the mixed rare earth sintered permanent magnet prepares the sintered permanent magnet by more than two kinds of alloys. The preparation method of the mixed rare earth sintered permanent magnet of the present invention may produce a sintered magnet with a magnetic energy product such as 2-45 MGOe and optional performance by adjusting proportions of each alloy according to need. A stable main phase of R2Fe14B can be formed by multi-alloy process. Because the permanent magnet is prepared directly by the mixed rare earth, steps of extraction, separation and purification for preparing a single rare earth can be partly saved on one hand, the cost is greatly saved and the environment is protected; the comprehensive utilization of the rare earth resource can be maximized on the other hand.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

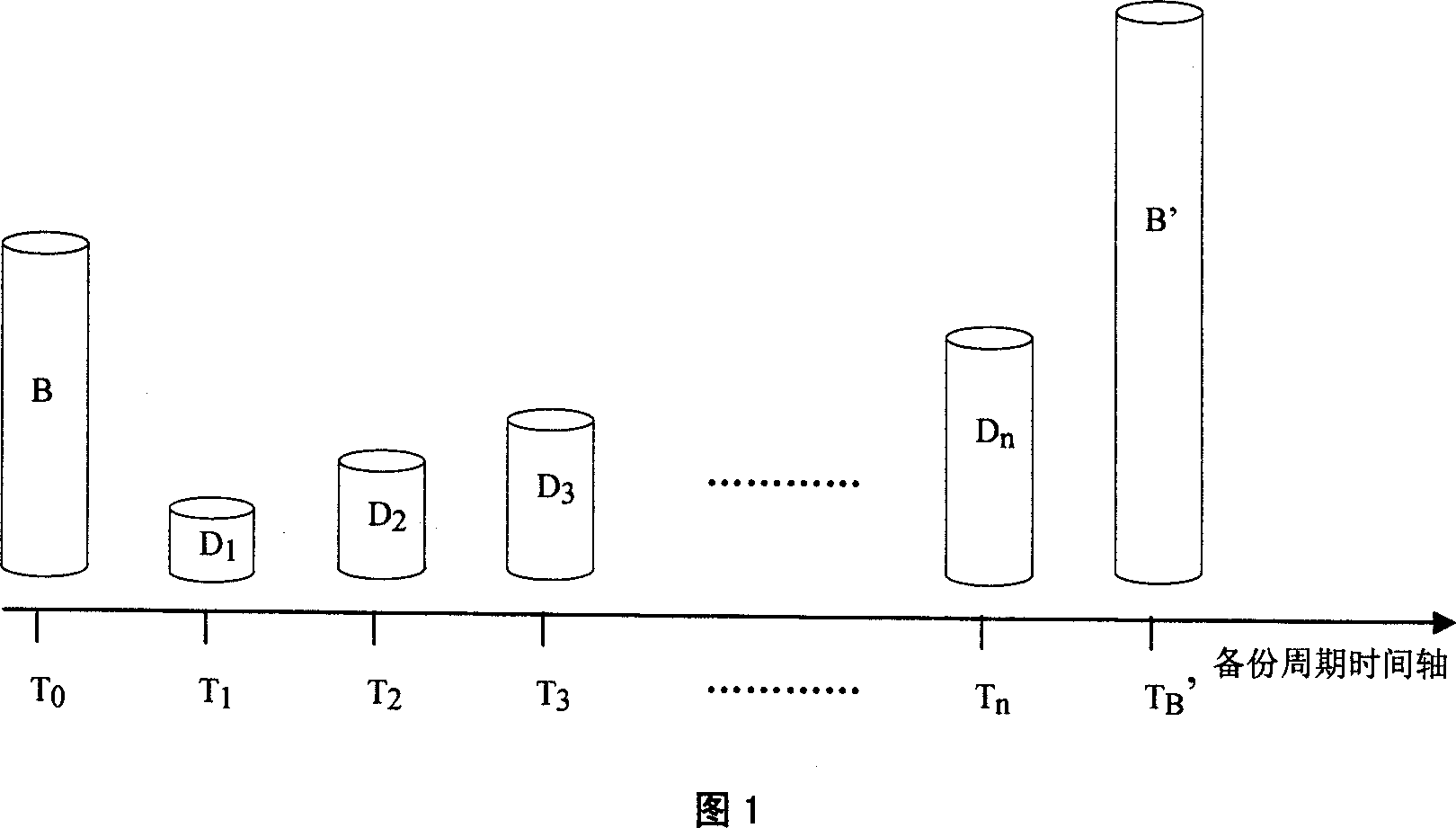

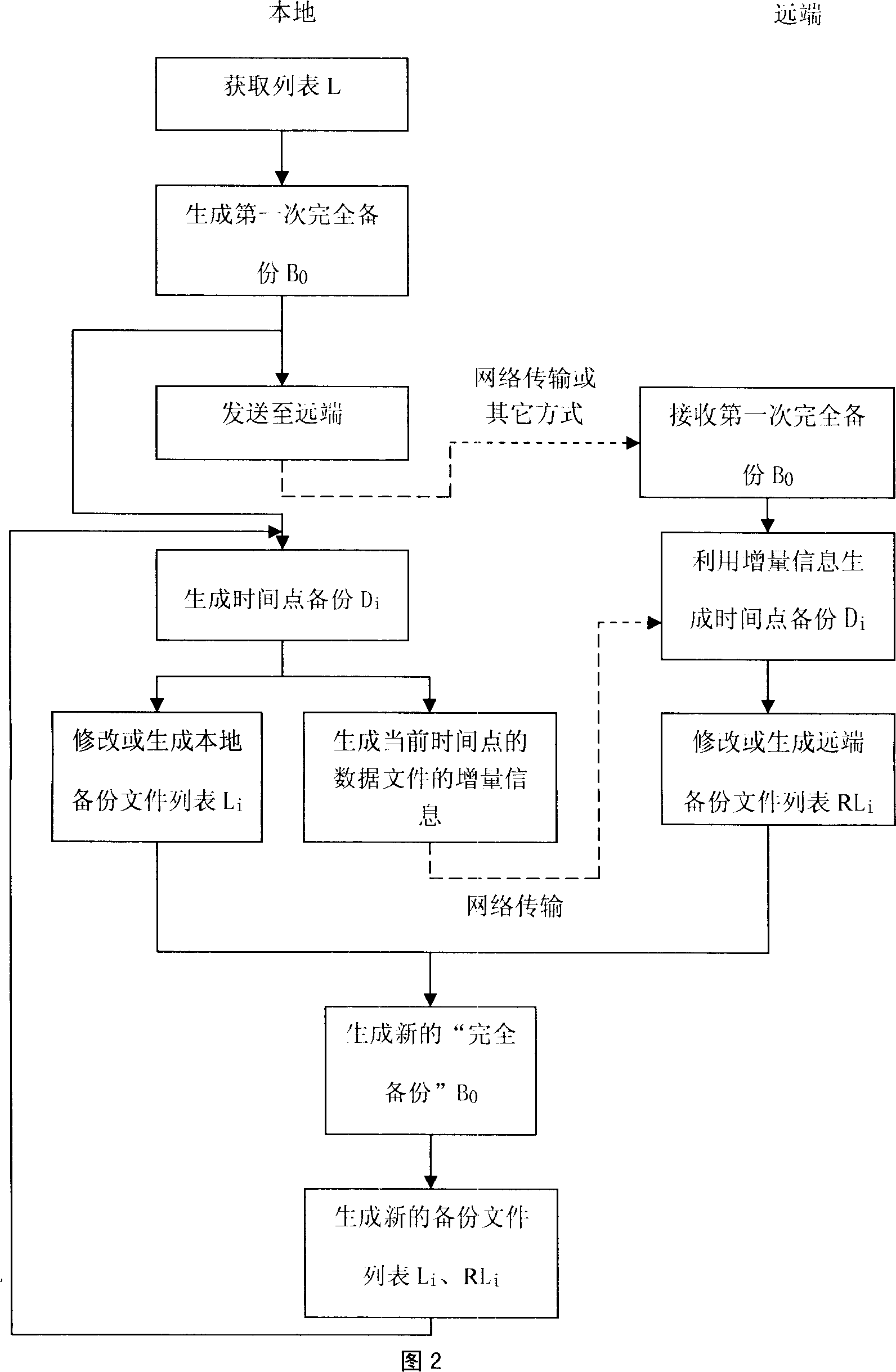

Local and remote backup method for computer network data file

InactiveCN101064730AMeet the needs of full backupBackup guaranteeTransmissionSpecial data processing applicationsData fileNetwork data

The invention relates to a backup method for the local and remote data files in network information technology field. The invention backups the data using the backup data to form new backup to satisfy the customer's requirement, it can ensure the backup for all data and provide a fast 'entire backup' method; when remote backup, it just need to transmit the increased data block which is needed to form a new backup file to the remote terminal. The increase extraction method which adopts the increased backup method generates the data which is used to generate the different backup, and then uses the previous backup different data to form the new different backup. The invention overcomes the disadvantages of low velocity and large remote backup web transport those exist in the present increase backup and different backup.

Owner:SHANGHAI JIAO TONG UNIV

Technology for Preventing Abuse of Solid Dosage Forms

InactiveUS20120321674A1Excessive amountReduce rateBiocideAnimal repellantsDrugPharmaceutical formulation

Abuse resistant pharmaceutical formulations are provided that contain one or more abusable drugs and one or more abuse deterrent components. The abuse deterrent component(s) prevent the abusable drug(s) from being removed / extracted to an appreciable extent and / or rate. The abuse deterrent component(s) may be in the form of pellets, beads, beadlets, granules, powders, or the like, and may comprise a core that contains a material that is both hydrophilic and hydrophobic, and optionally a pH-dependent coating.

Owner:VACHON MICHAEL +1

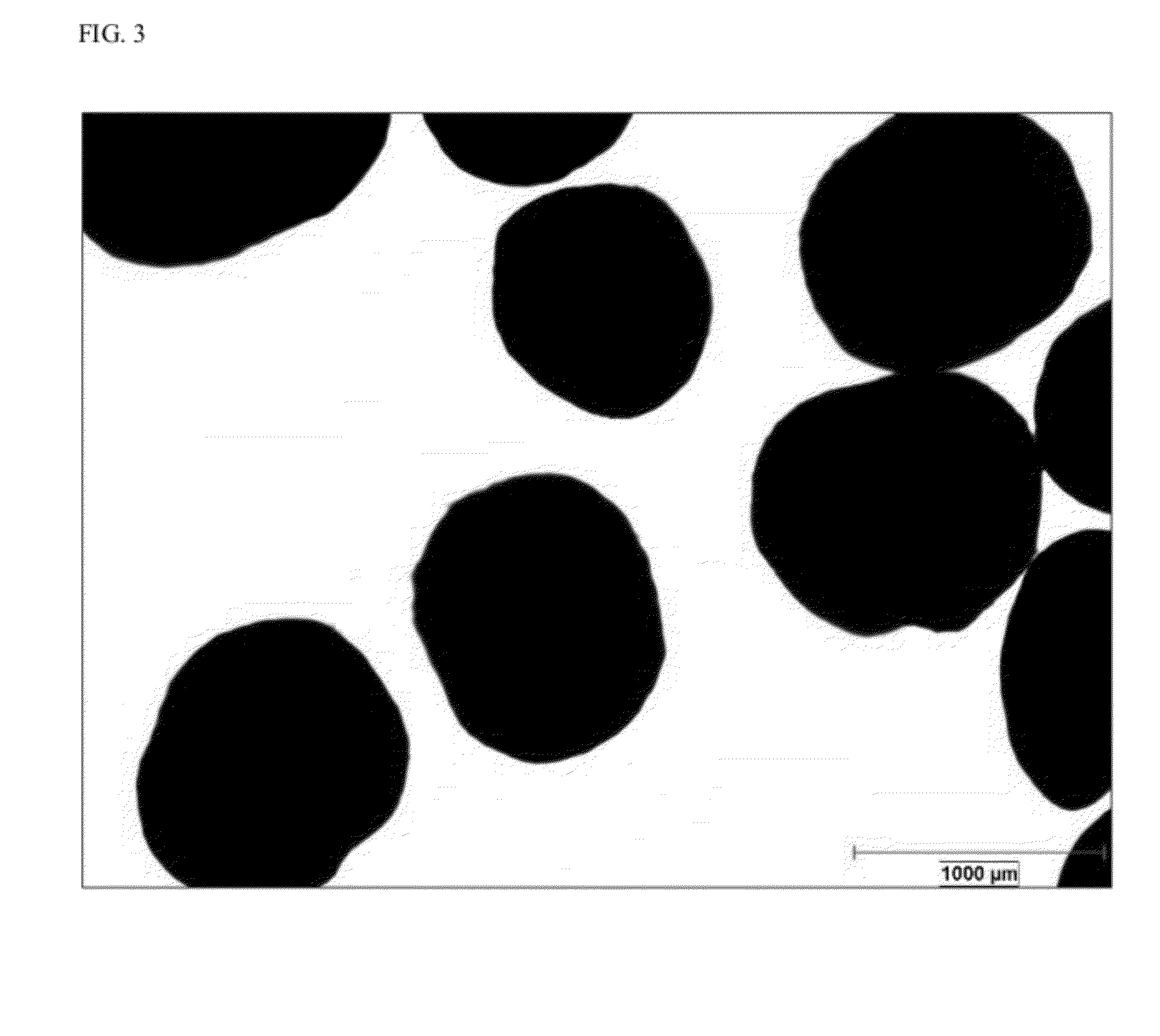

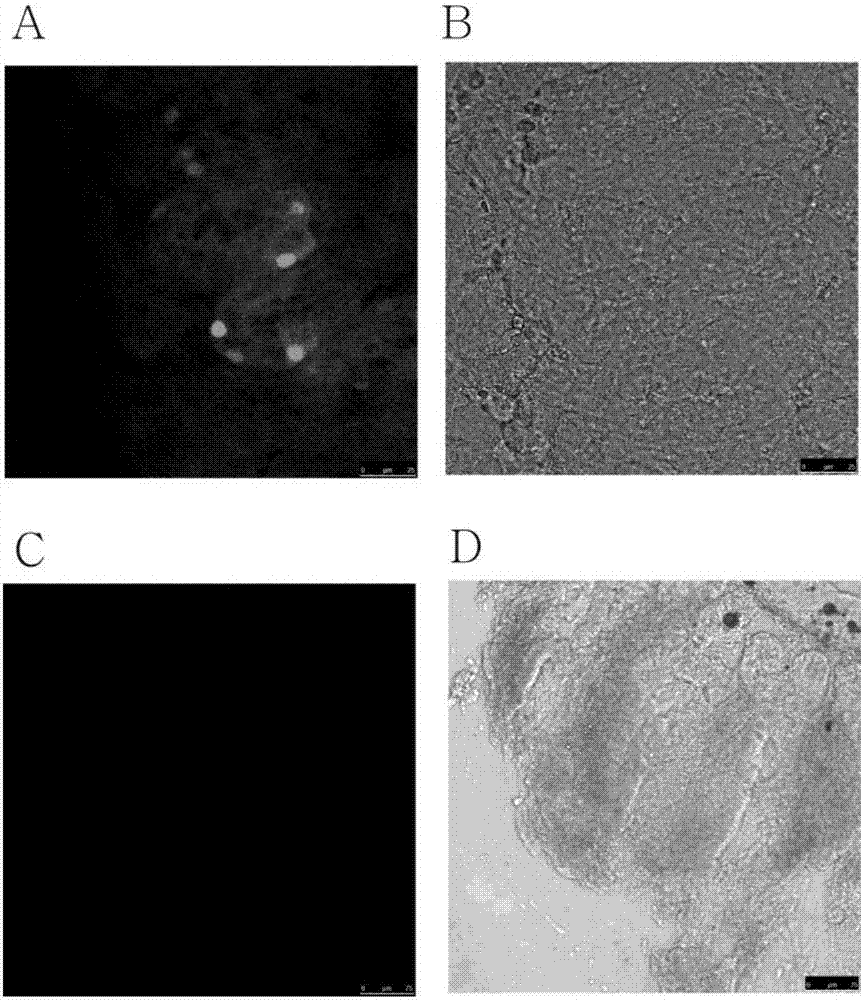

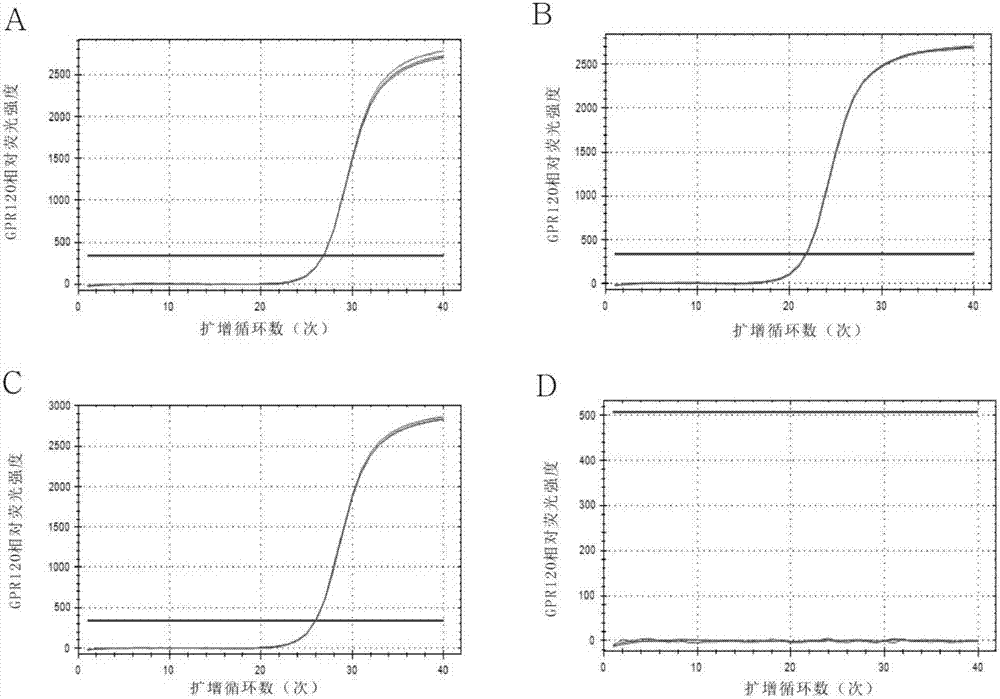

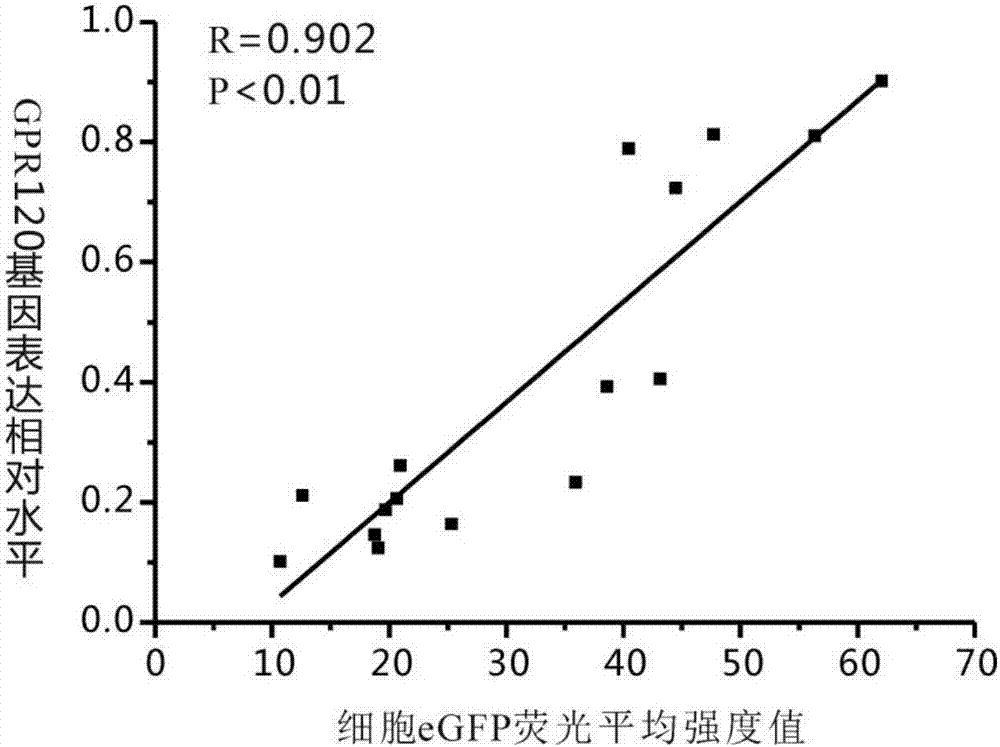

Detection method for expression of GPR120 gene based on eGFP, and application of eGFP to detection of expression of GPR120 gene

InactiveCN107227352AControl errorReduce the error between groupsMicrobiological testing/measurementVector-based foreign material introductionRNA extractionGPR120

The invention discloses a detection method for the expression of a GPR120 gene based on eGFP. The detection method comprises the following steps: inserting an eGFP fragment to the specific site TAA of the termination codon of the GPR120 gene by using CRISPR / Cas 9 technology so as to obtain a transgenic model mouse with eGFP-labeled GPR120 positive cells; and carrying out excitation by using a fluorescence analyzer and determining the fluorescence intensity of the positive cells of the mouse. The method carries out real-time monitoring on the expression of the GPR120 gene so as to control and reduce errors among groups, guarantee the reliability of results and compensate for and overcome the problems of variability caused by comparison of different groups of histocytes and incapability of monitoring the changes of gene expression at a living cell level in the prior art. According to the invention, the expression level of the GPR120 gene can be immediately determined after collection of cells, and operations and reactions like RNA extraction, inverse transcription and PCR are omitted, so detection of the expression of the GPR120 gene is simpler.

Owner:XIAN MEDICAL UNIV

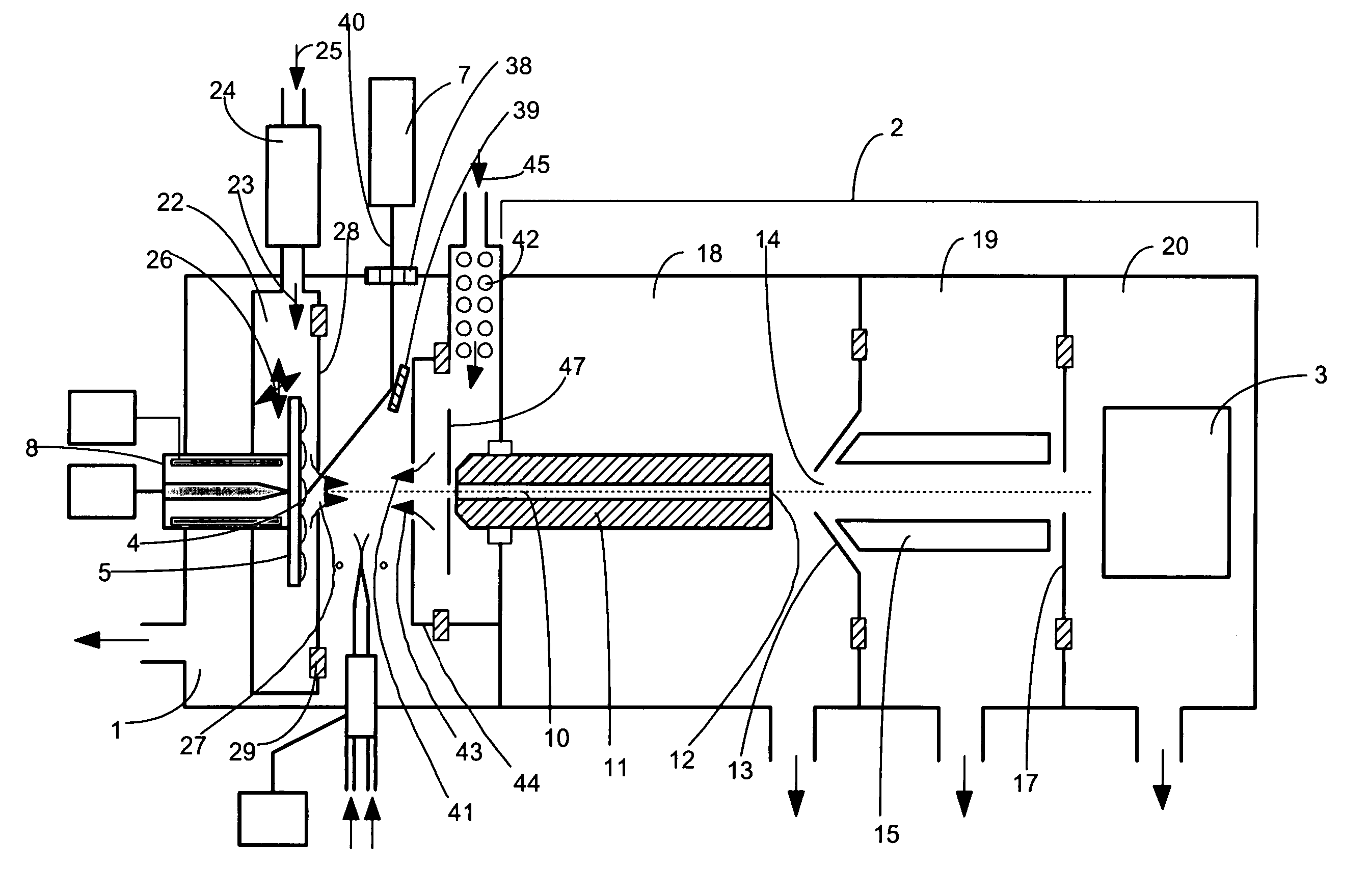

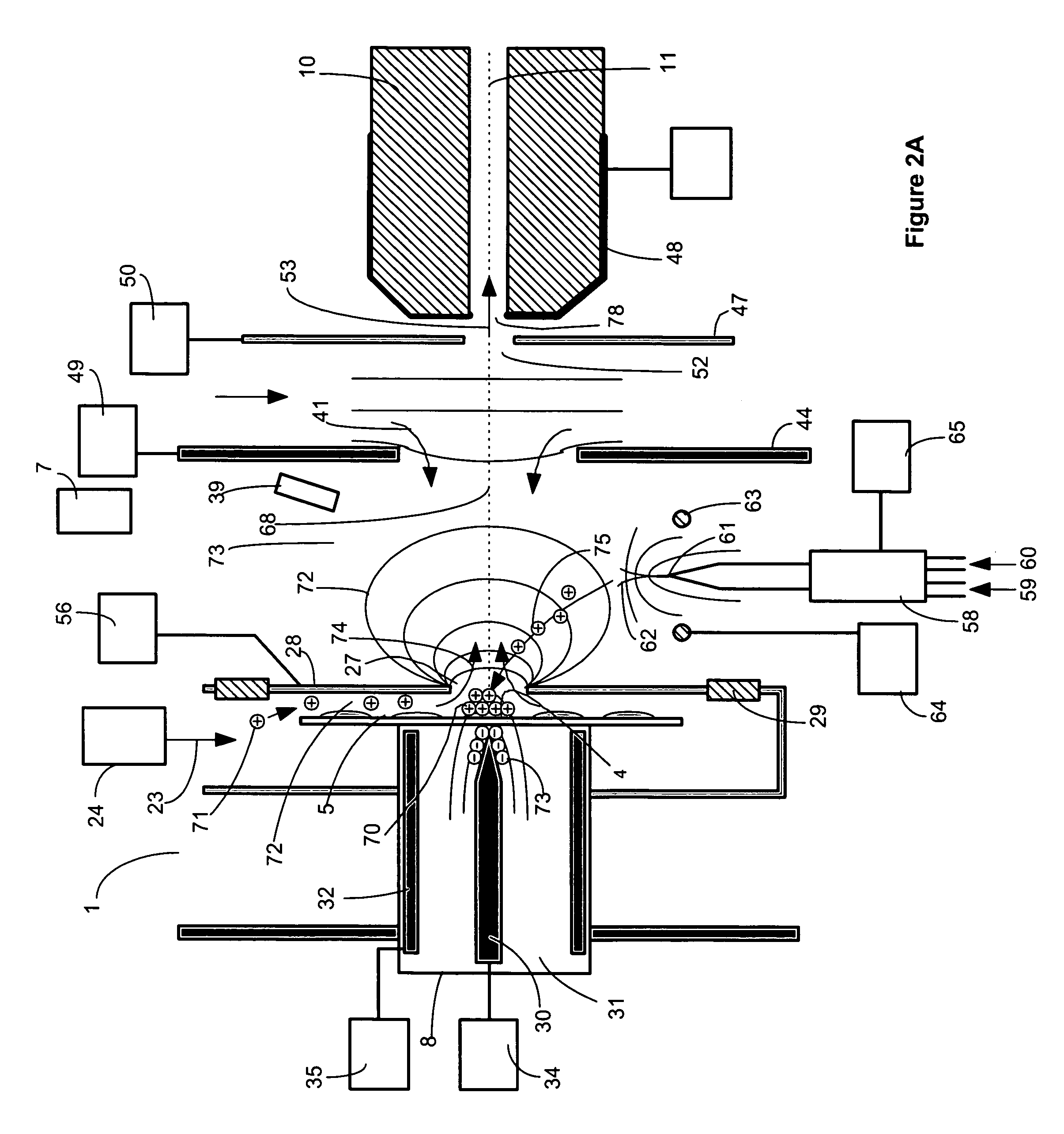

Laser desorption ion source

ActiveUS7087898B2Improve efficiencyImprove ionizationTime-of-flight spectrometersSamples introduction/extractionDesorptionMass analyzer

Atmospheric pressure, intermediate pressure and vacuum laser desorption ionization methods and ion sources are configured to increase ionization efficiency and the efficiency of transmitting ions to a mass to charge analyzer or ion mobility analyzer. An electric field is applied in the region of a sample target to accumulate ions generated from a local ion source on a solid or liquid phase sample prior to applying a laser desorption pulse. The electric field is changed just prior to or during the desorption laser pulse to promote the desorption of charged species and improve the ionization efficiency of desorbed sample species. After a delay, the electric field may be further changed to optimize focusing and transmission of ions into a mass spectrometer or ion mobility analyzer. Charged species may also be added to the region of the laser desorbed sample plume to promote ion-molecule reactions between the added ions and desorbed neutral sample species, increasing desorbed sample ionization efficiency and / or creating desired product ion species. The cycling of electric field changes is repeated in a timed sequence with one or more desorption laser pulse occurring per electric field change cycle. Embodiments of the invention comprise atmospheric pressure, intermediate pressure and vacuum pressure laser desorption ionization source methods and devices for increasing the analytical flexibility and improving the sensitivity of mass spectrometric analysis.

Owner:PERKINELMER HEALTH SCIENCES INC +1

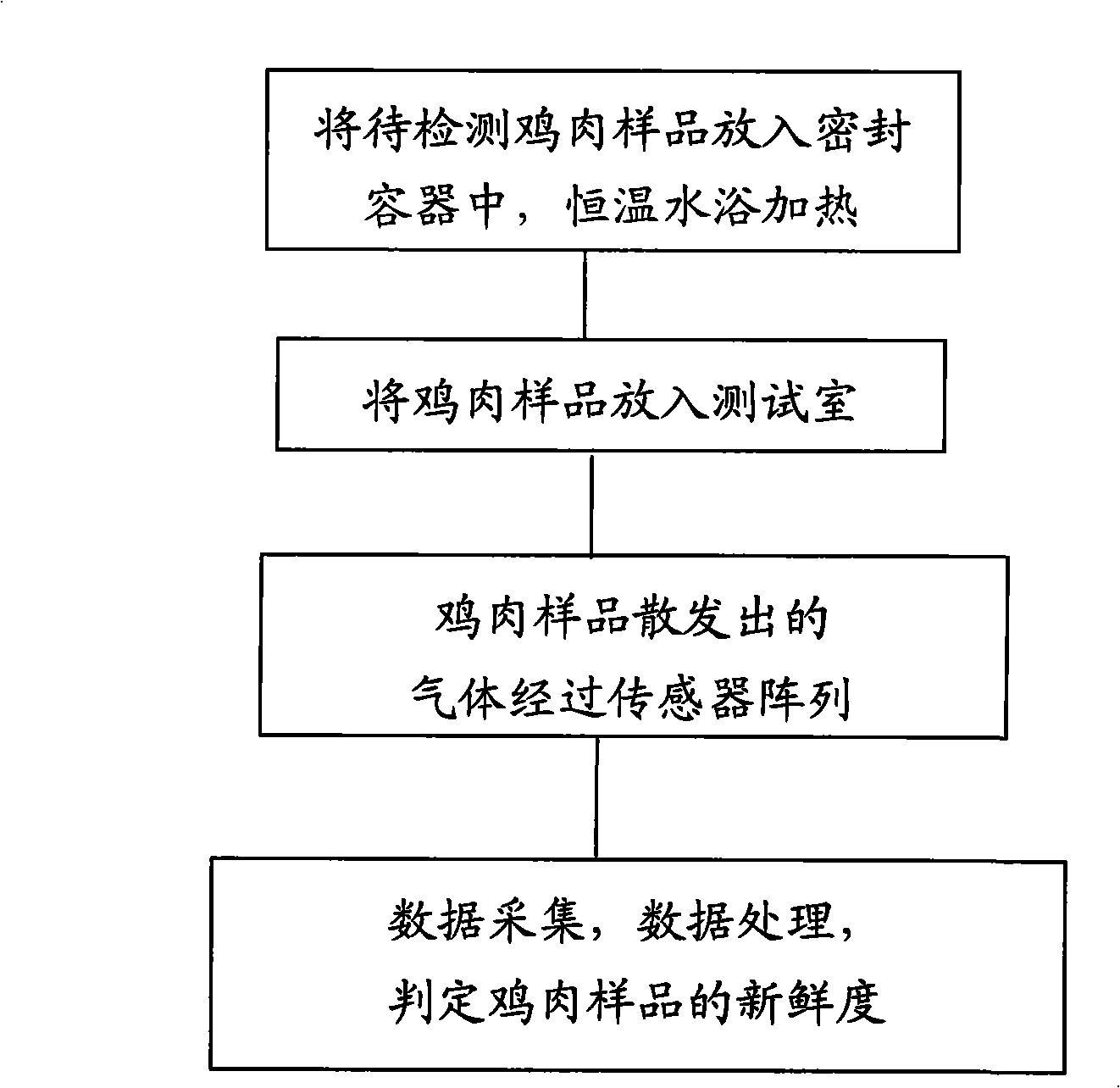

Method for detecting fresh degree of chicken meat by electronic nose

The invention discloses a method for using an electronic nose to detect the freshness of chicken. The invention aims at providing a method which uses the electronic nose to detect the freshness of chicken, has the advantages of rapidity and simpleness, easy use and objective and reliable detection result, and can reduce the impact of storing conditions to the detection result. The method comprises the following steps: a chicken sample to be detected is put into a sealed container and then heated in water bath with thermostatic control; the heated chicken sample is put into a test room, and then smell sent by the sample is detected by a gas sensor array which consists of four gas sensors of different types; the data which is aquired by the gas sensor array is collected and processed; and then the freshness of chicken is judged according to the processing result of the data. The detection method uses an electronic nose which consists of four gas sensors of different types to detect the chicken sample, and has the advantages of objective, accurate, and fast detection result, good repeatability, simple analysis process and small using amount of sensors, and reduces the extraction of eigenvalues.

Owner:TIANJIN UNIV OF COMMERCE

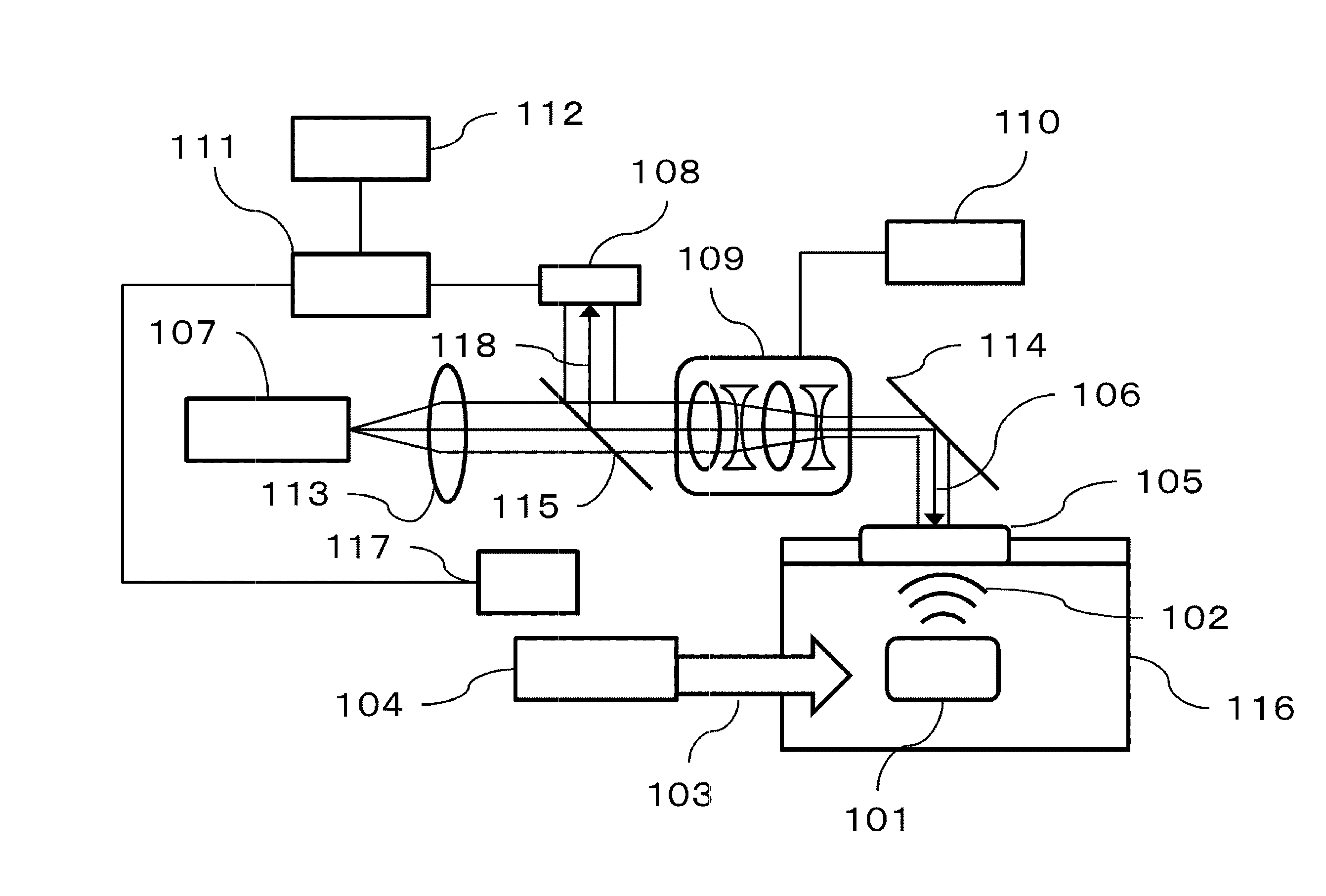

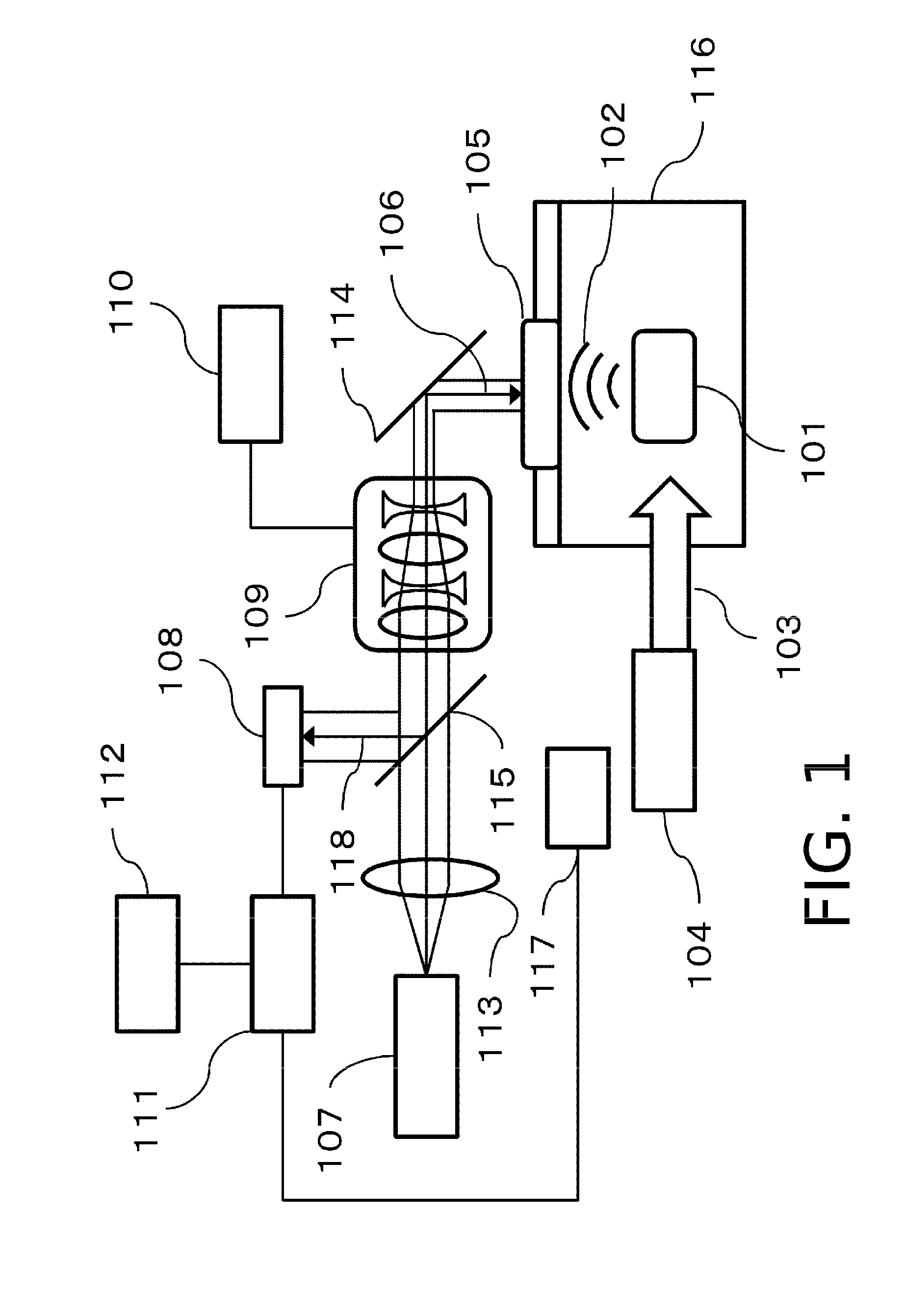

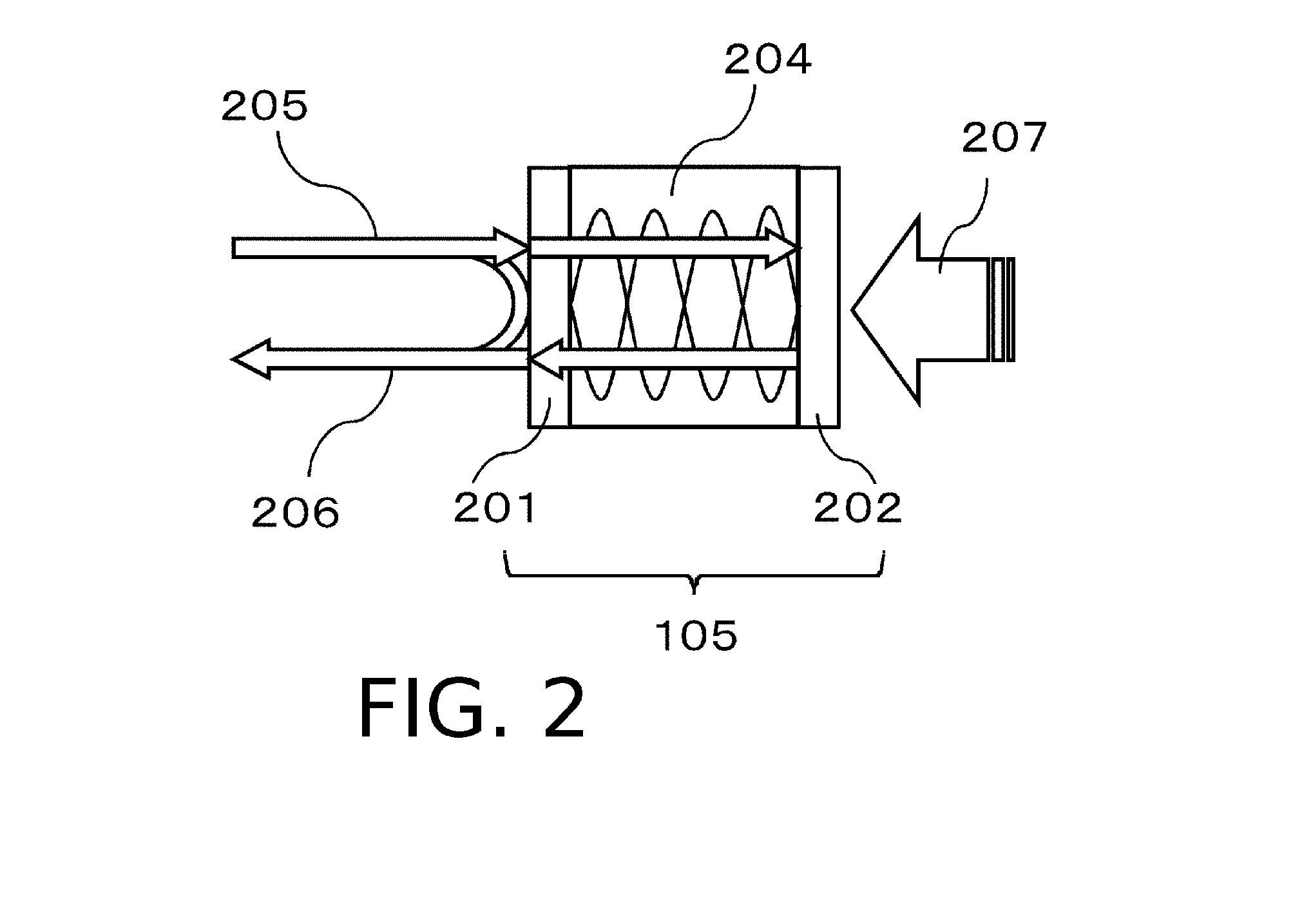

Acoustic wave acquiring apparatus

InactiveUS20130160557A1Resolve changeResolution imaging areaVibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsImage resolutionBeam diameter

Provided is a technique capable of changing resolution or an imaging area during imaging, in an acoustic wave acquiring apparatus using a Fabry-Perot probe. An acoustic wave acquiring apparatus includes a measurement light source emitting measurement light, a probe having a Fabry-Perot interferometer including a first mirror, upon the side of which the measurement light is incident, and a second mirror, upon the side of which an elastic wave from an object is incident, an optical system changing a beam diameter of the measurement light, a controller controlling change in the beam diameter performed by the optical system, a photosensor measuring a light intensity of the measurement light reflected on the Fabry-Perot interferometer, and a processor acquiring intensity of the elastic wave on the basis of change in the light intensity measured by the photosensor due to incidence of the elastic wave.

Owner:CANON KK

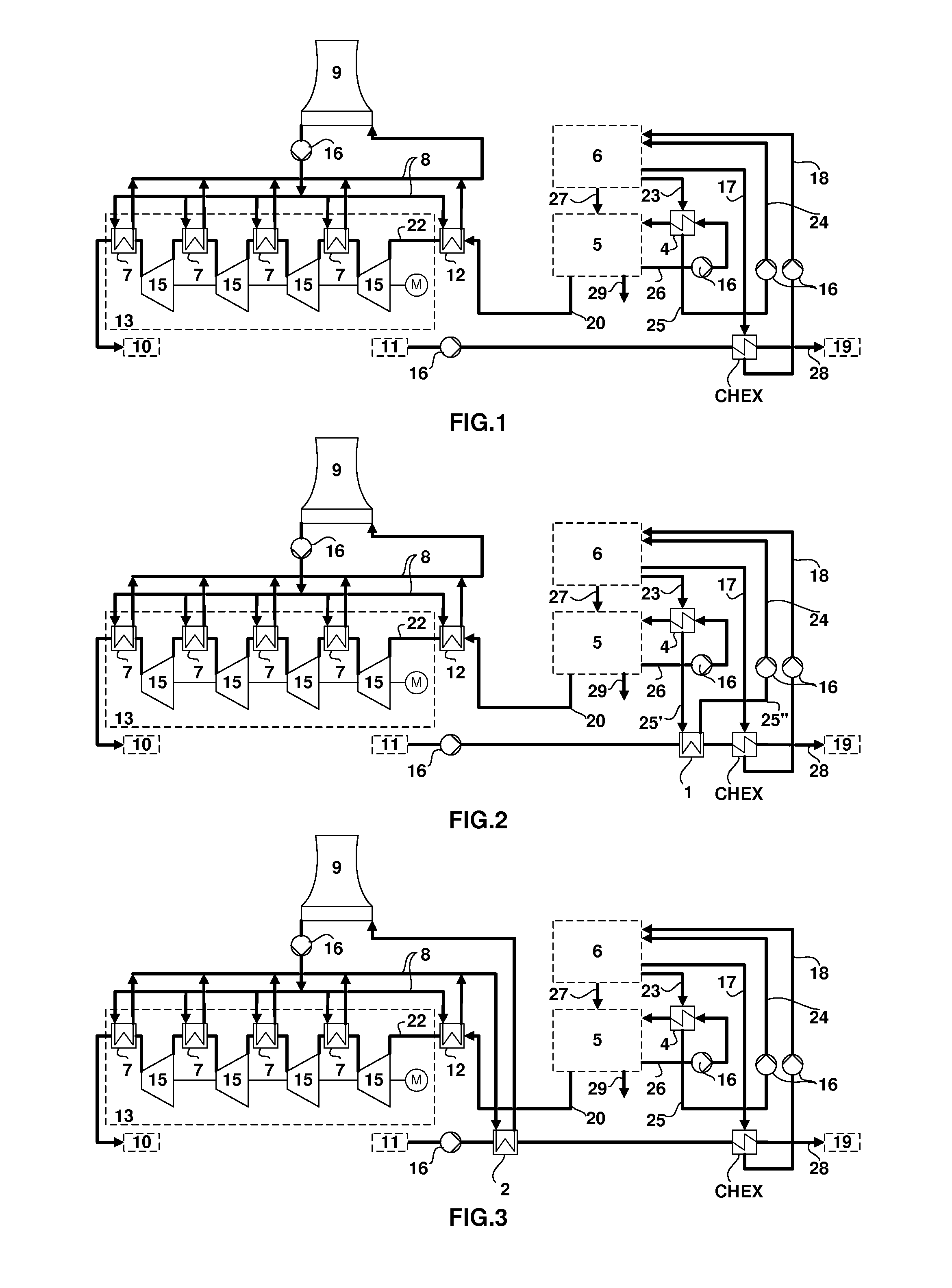

Thermal integration of a carbon dioxide capture and compression unit with a steam or combined cycle plant

ActiveUS20110265477A1Improve power efficiencyReduce extractionGas treatmentCarbon compoundsElectricityHeat flow

A power plant system including a fossil fuel fired power plant (6) for the generation of electricity, a carbon dioxide capture and compression system (5, 13), and an external heat cycle system has at least one heat exchanger (1,2,3) for the heating of the flow medium of the external heat cycle system. The heat exchanger (1,2,3) is connected to a heat flow from the CO2 capture plant (5) or a CO2 compression unit (13). A return flow from the heat exchanger (1,2,3) is led to the CO2 capture and compression system (5,13) or to the power plant (6). The power plant system allows an increase in overall efficiency of the system.

Owner:GENERAL ELECTRIC TECH GMBH

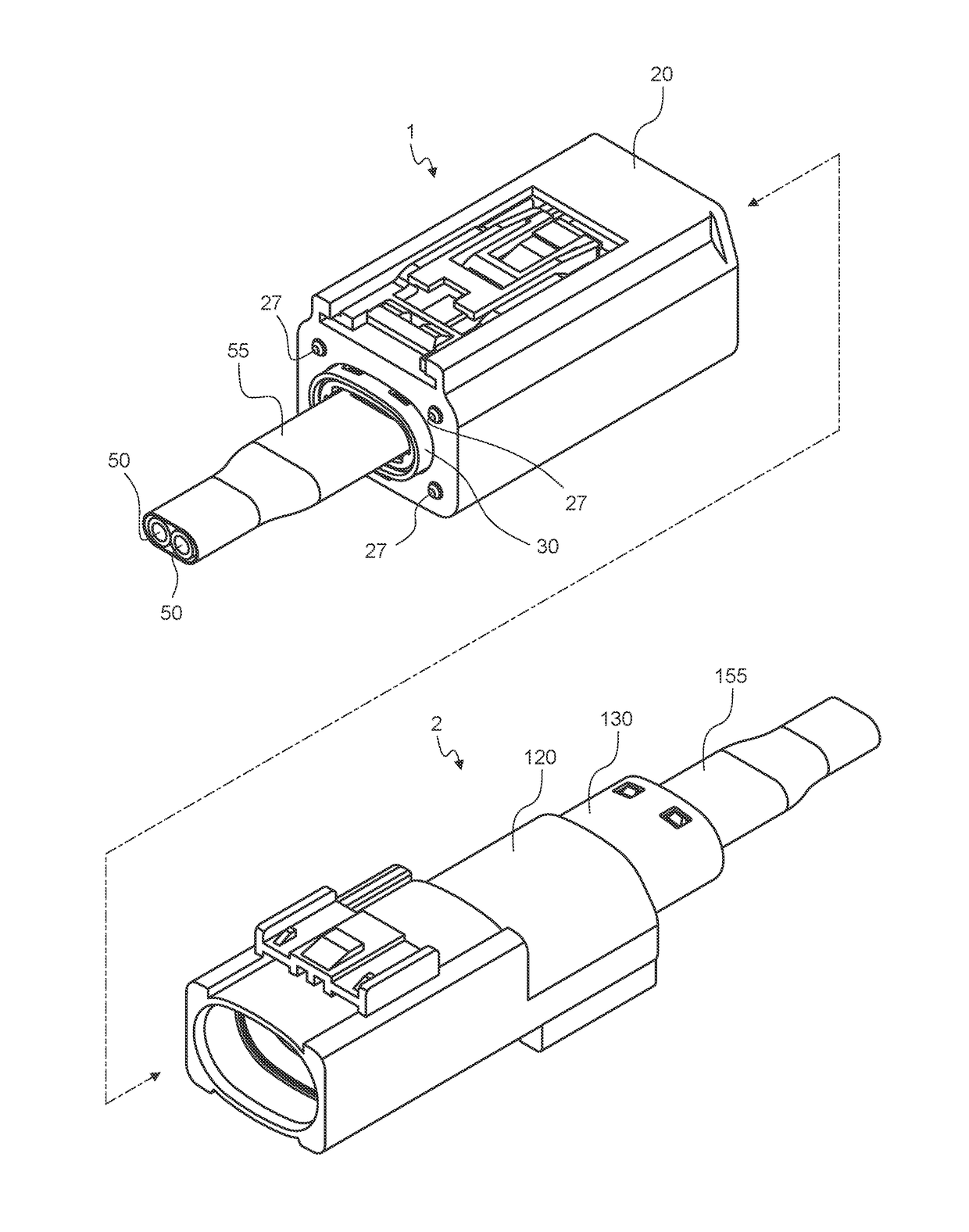

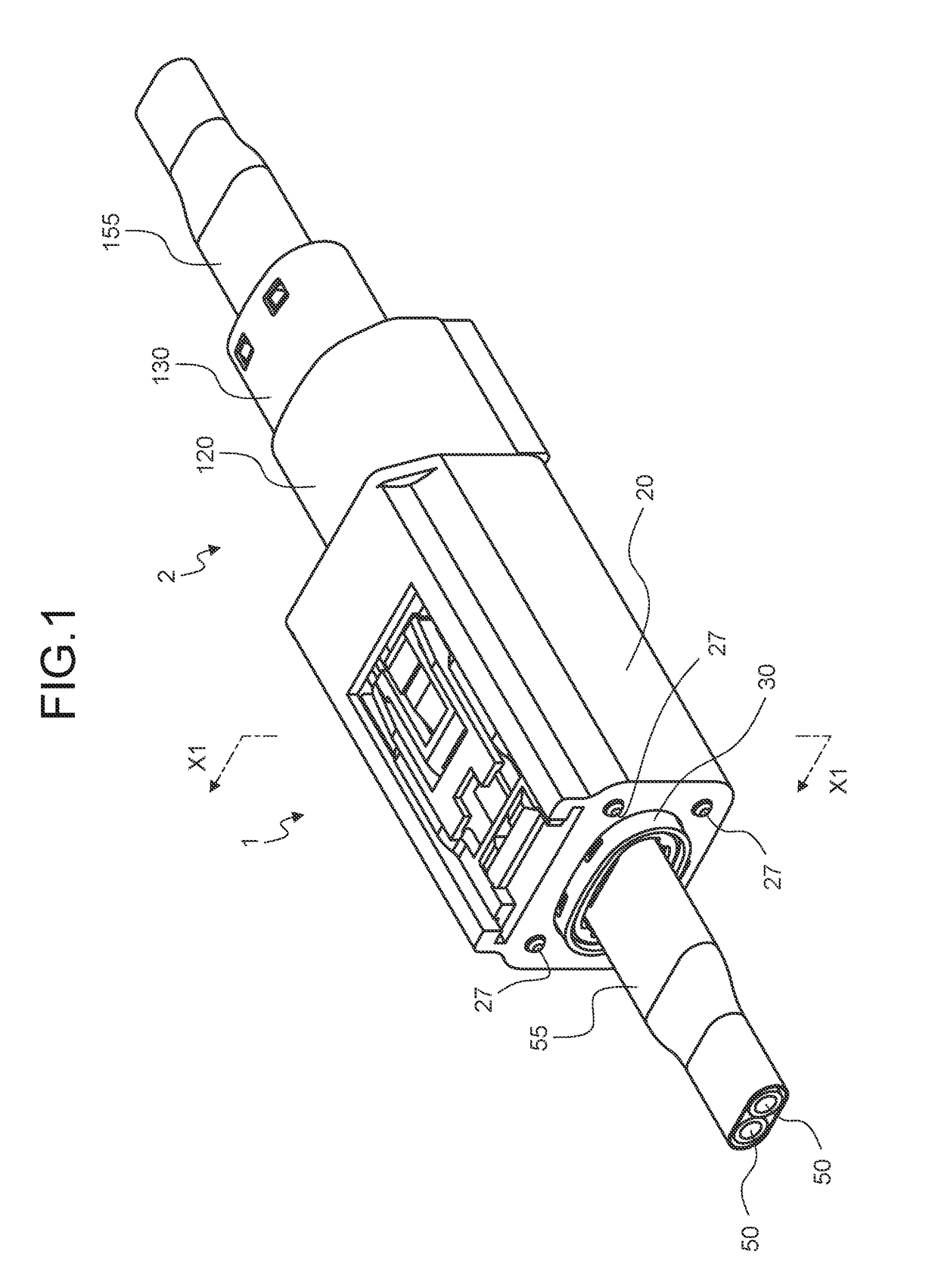

Female and male connectors

ActiveUS20170338600A1Reducing extraction forceReduce insertionCoupling contact membersTwo-part coupling devicesEngineering

A female connector includes a female terminal, an inner housing which holds the female terminal, an outer housing relatively movable to the inner housing, tubular first shield shell integrated with the inner housing, and an elastic member which generates a resilient force. The male connector includes a male terminal, a housing which holds the male terminal, and the tubular second shield shell integrated with the housing. First shield shell abuts against the second shield shell on the connector insertion direction side with insertion of the connectors and is pressed against the second shield shell by the resilient force of the elastic member.

Owner:YAZAKI CORP

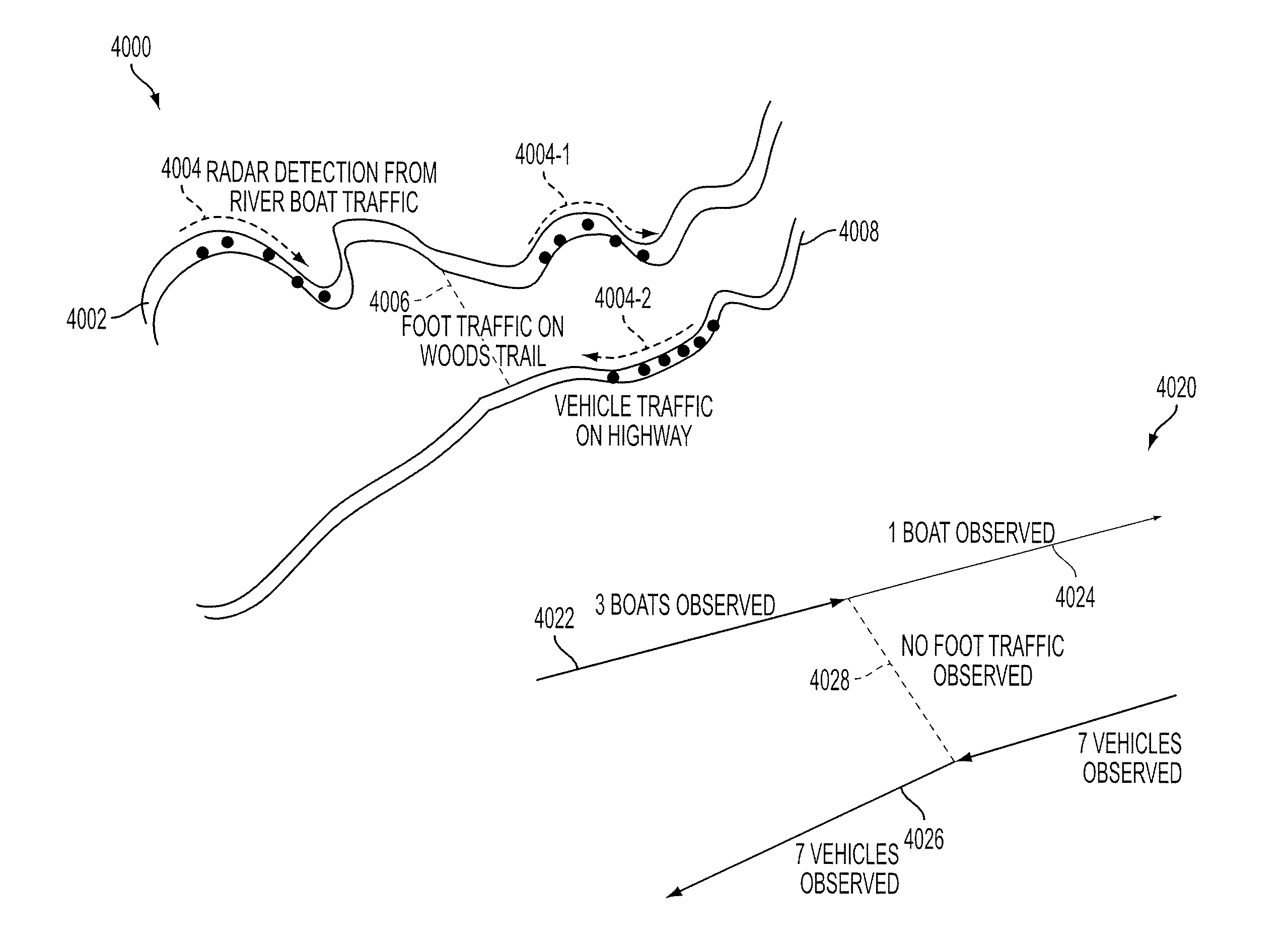

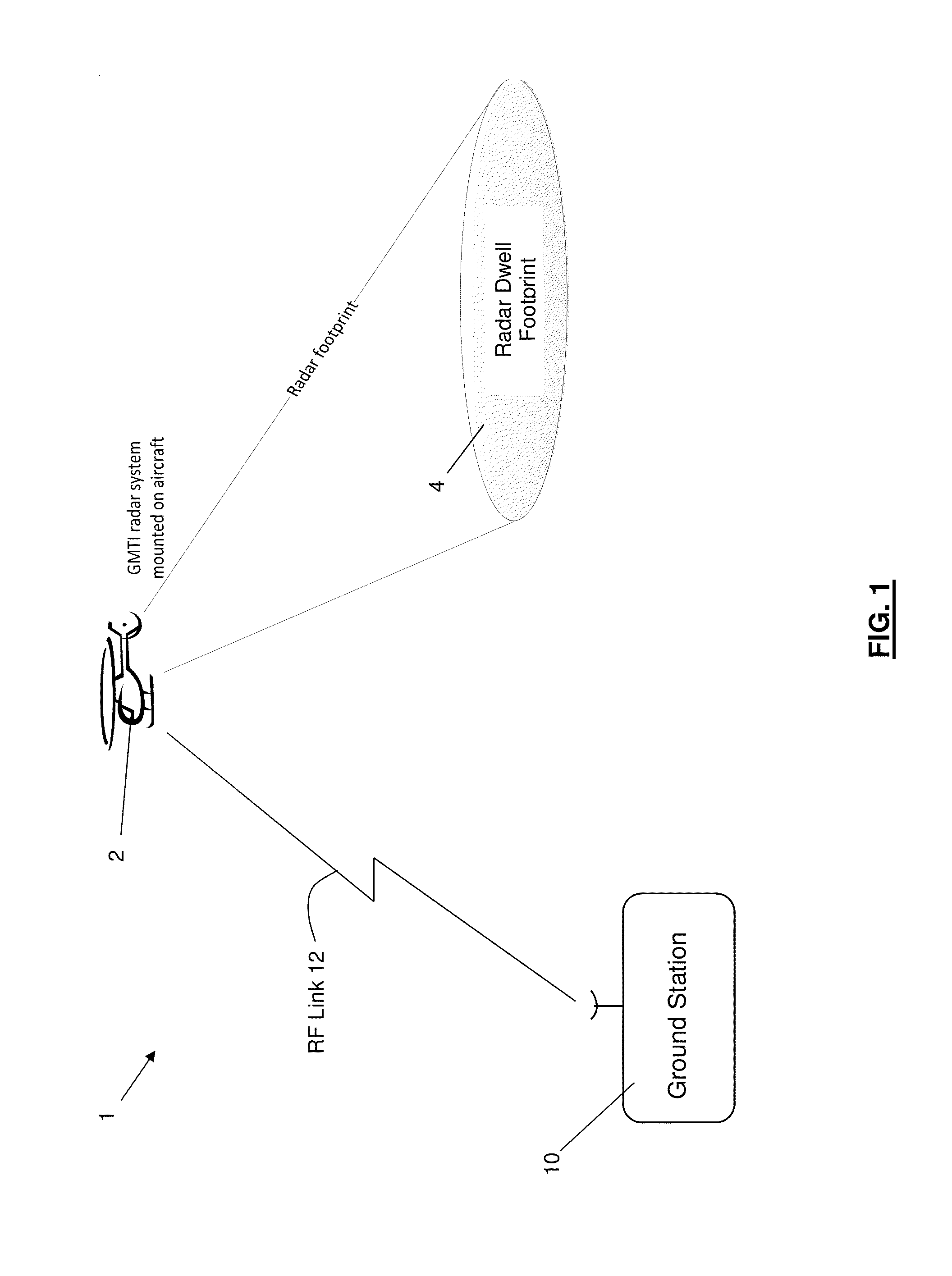

GMTI Ground Activity Sematic Reasoning Engine

ActiveUS20140279820A1Enhanced Situational AwarenessLifts the fog of warChaos modelsNon-linear system modelsAlarm messageRadar systems

The present invention is directed to a system that includes a semantic reasoning engine that is configured to convert radar track data into a directed graph representation (DGR) of the predetermined surveillance region and iteratively combine the DGRs to create a weighted directed graph (WDG) aligned and superimposed with the digital map data. The WDG includes first WDG elements corresponding to moving objects detected by a radar system. The WDG is compared to historical data to obtain a surveillance detection parameter. An alarm message is generated if the surveillance detection parameter deviates from the historical data by a predetermined amount. An output device is coupled to the semantic reasoning engine and is configured to provide a representation of the digital map data, the WDG and the at least one alarm message.

Owner:SRC INC

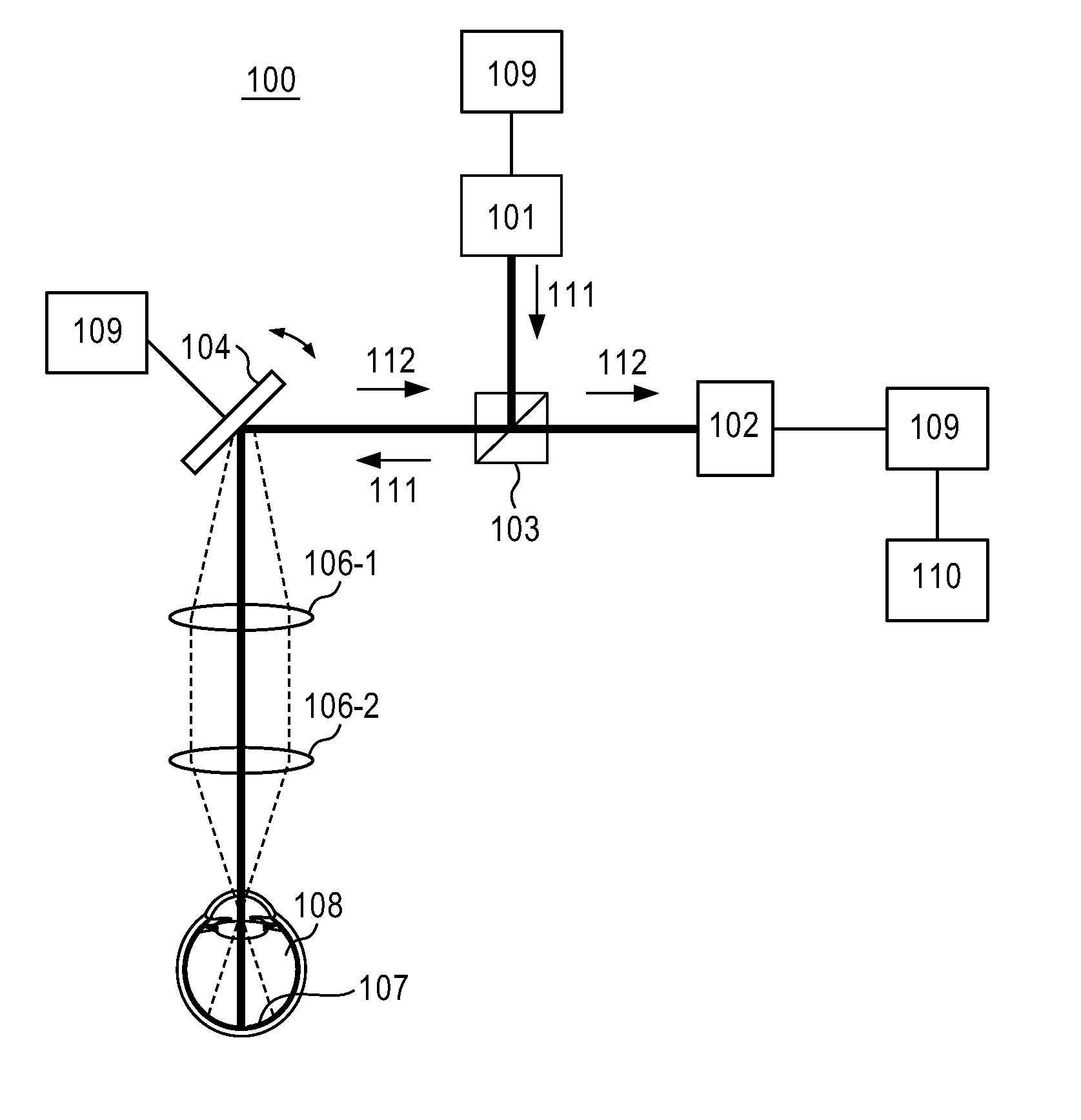

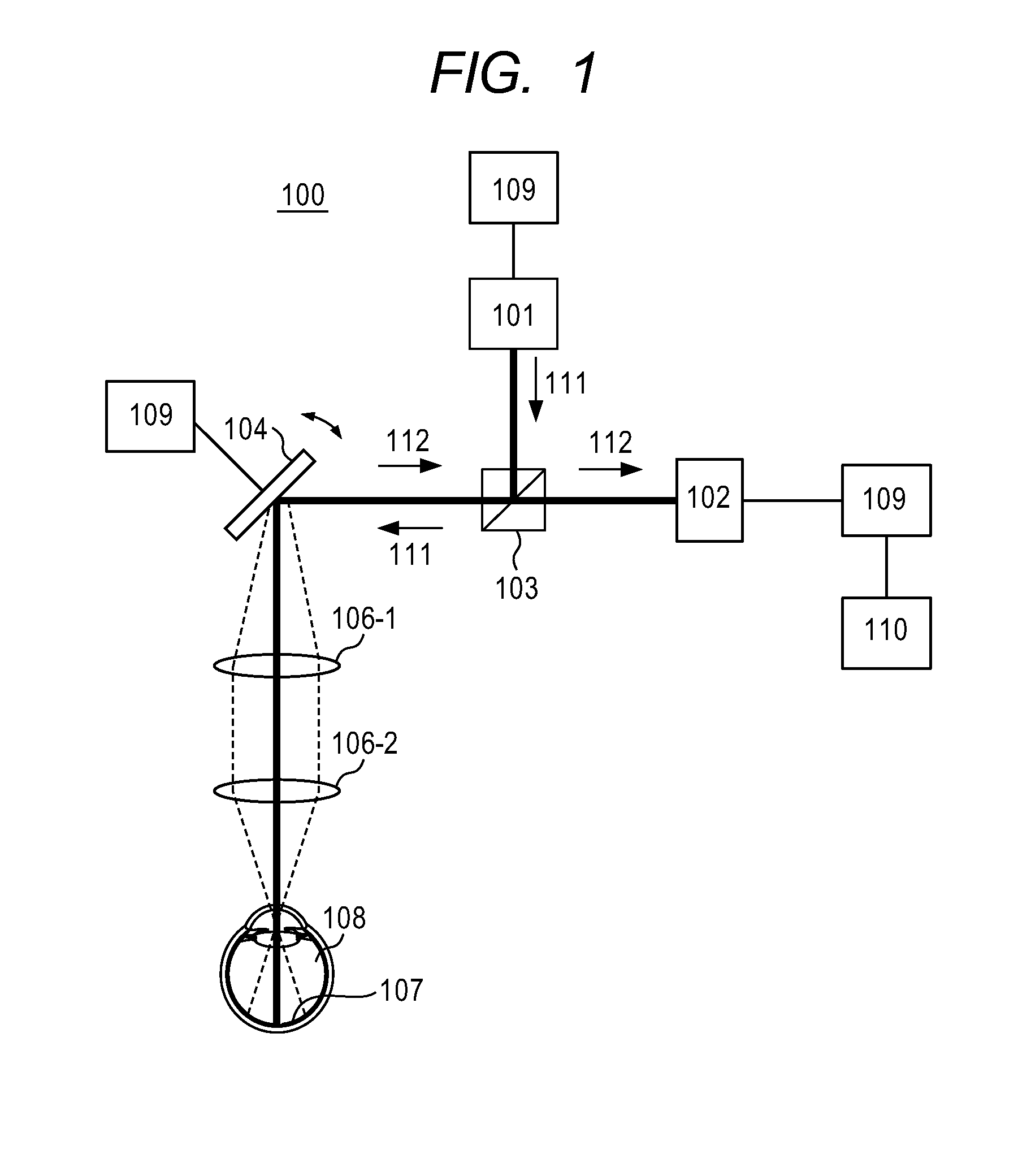

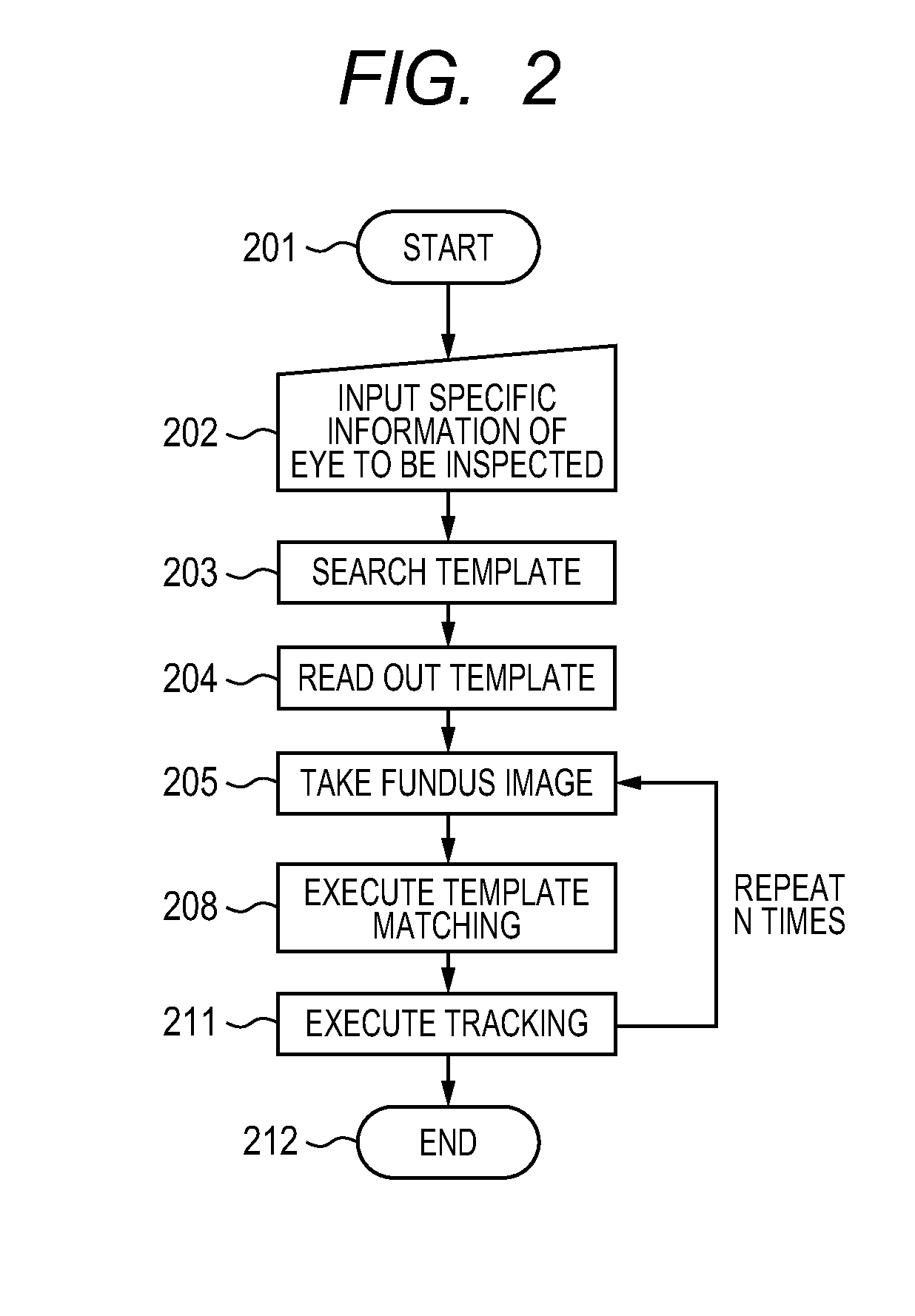

Ophthalmologic apparatus and ophthalmologic system

InactiveUS20120002166A1Reduce the burden onReduce extractionOthalmoscopesTemplate matchingOphthalmology

Provided are a fundus imaging apparatus and a fundus imaging method capable of alleviating loads on an operator and a patient in fundus imaging and of acquiring a high-resolution fundus image. The fundus imaging apparatus having a tracking function is configured to: determine whether or not a template is recorded based on specific information of an eye to be inspected (203); when the template is recorded, read out the template (204); execute template matching on an acquired fundus image (208); and execute tracking at the time of fundus imaging according to a result of the template matching (211).

Owner:CANON KK

Laser desorption ion source

InactiveUS7816646B1Improve efficiencyImprove ionizationSamples introduction/extractionIsotope separationMass analyzerMass spectrography

Owner:PERKINELMER HEALTH SCIENCES INC +1

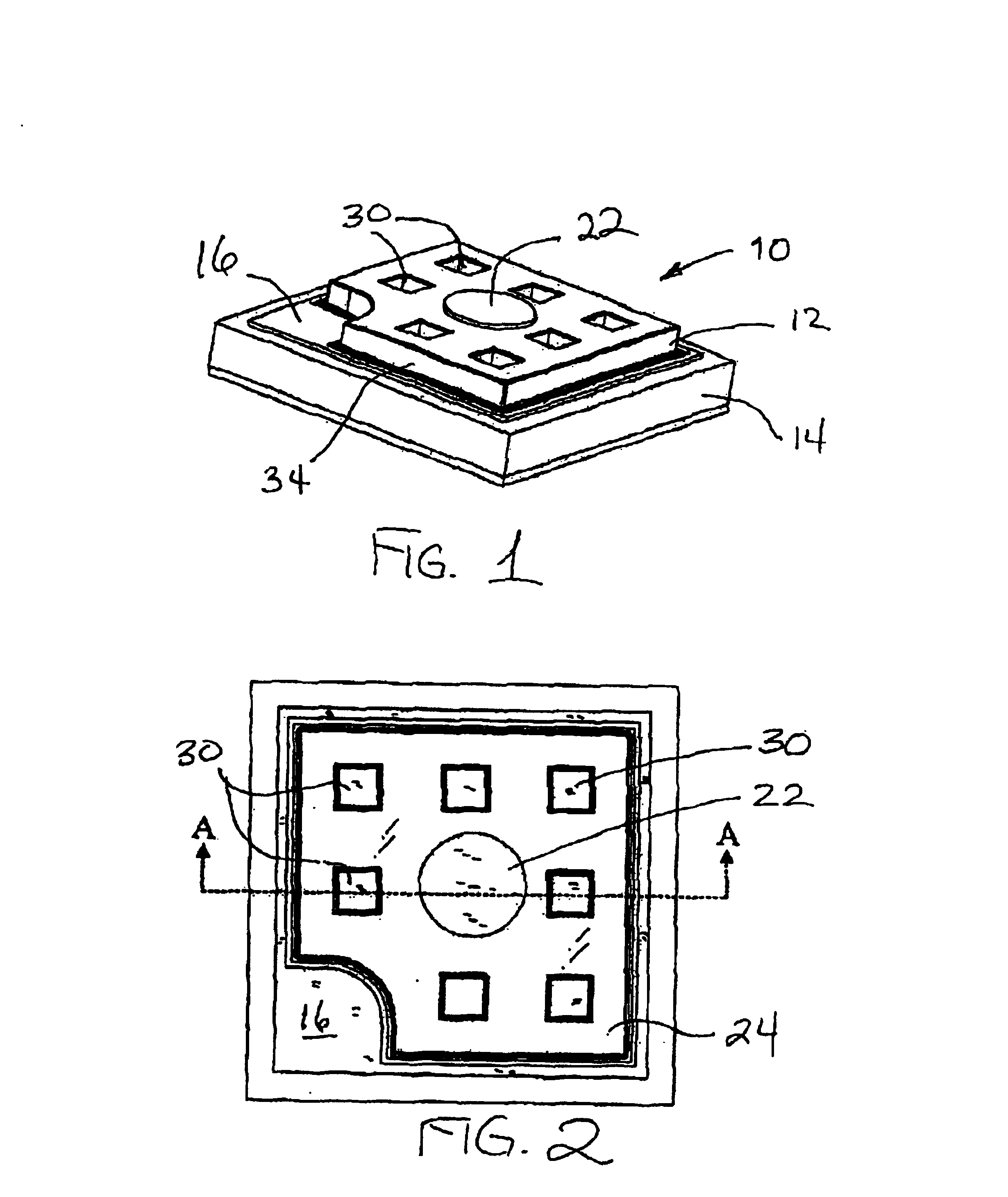

Light emitting diode having multiple pits

InactiveUS6885034B1Improve extraction efficiencyReduce distanceSolid-state devicesSemiconductor/solid-state device manufacturingRefractive indexOperational stability

The light extraction efficiency of a Light Emitting Diode (LED) is improved by providing pits etched into a top, emitting, surface of the LED. The presence of the pits reduces the mean distance to a sidewall in active regions, and creates regions of higher transmission at which a semi-transparent contact is not present. The walls of the pits are preferably coated with a passivating layer, such as silicon dioxide, to reduce surface leakage currents and to improve the operational stability of the device at the expense of a reduction in optical extraction efficiency commonly obtained with encapsulants having a higher index of refraction.

Owner:SCHOENFELD WINSTON VAUGHAN

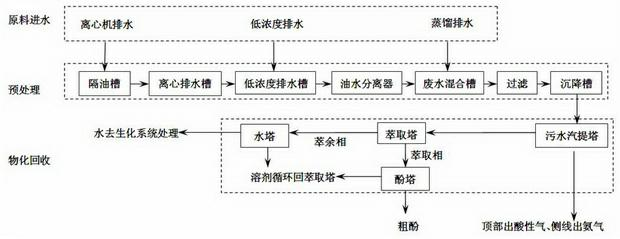

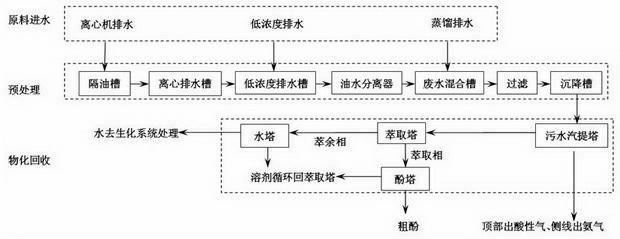

Separation treatment method for waste water in coal tar machining process

InactiveCN102674609AEasy to handleEmission complianceMultistage water/sewage treatmentWater/sewage treatment by heatingWastewaterProcess engineering

The invention discloses a separation treatment method for waste water in a coal tar machining process. The separation treatment method mainly comprises the following steps of: at first, pre-treating the waste water in the coal tar machining process to remove free oil and emulsified oil, and then entering a waste mixing groove; secondly, further removing oil matter by filtering and entering a subside for removing depositions through settling, so as to obtain oil-removed waste water; removing hydrogen sulfide and amine after the oil-removed waste water enters a sewage steam stripping tower, and extracting after acid-removed and amine-removed waste water enters an extraction tower; recovering crude carbolic acid and an extracting agent after an extract phase enters a phenol tower; separating the extracting agent from water after a residual extract phase enters a water tower; and processing after the water enters a follow-up biochemical system. The separation treatment method provided by the invention firstly removes acid and anime of the waste water, provides a good acid-alkali condition for follow-up solvent extraction and dephenolization, and has no need of adding a great amount of the acid and alkali in a treatment process. Meanwhile, byproducts, such as the crude carbolic acid, the anime, the hydrogen sulfide and the like, can be recovered. The water quality of the treated waste water can meet the water inlet requirements of the normal biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH

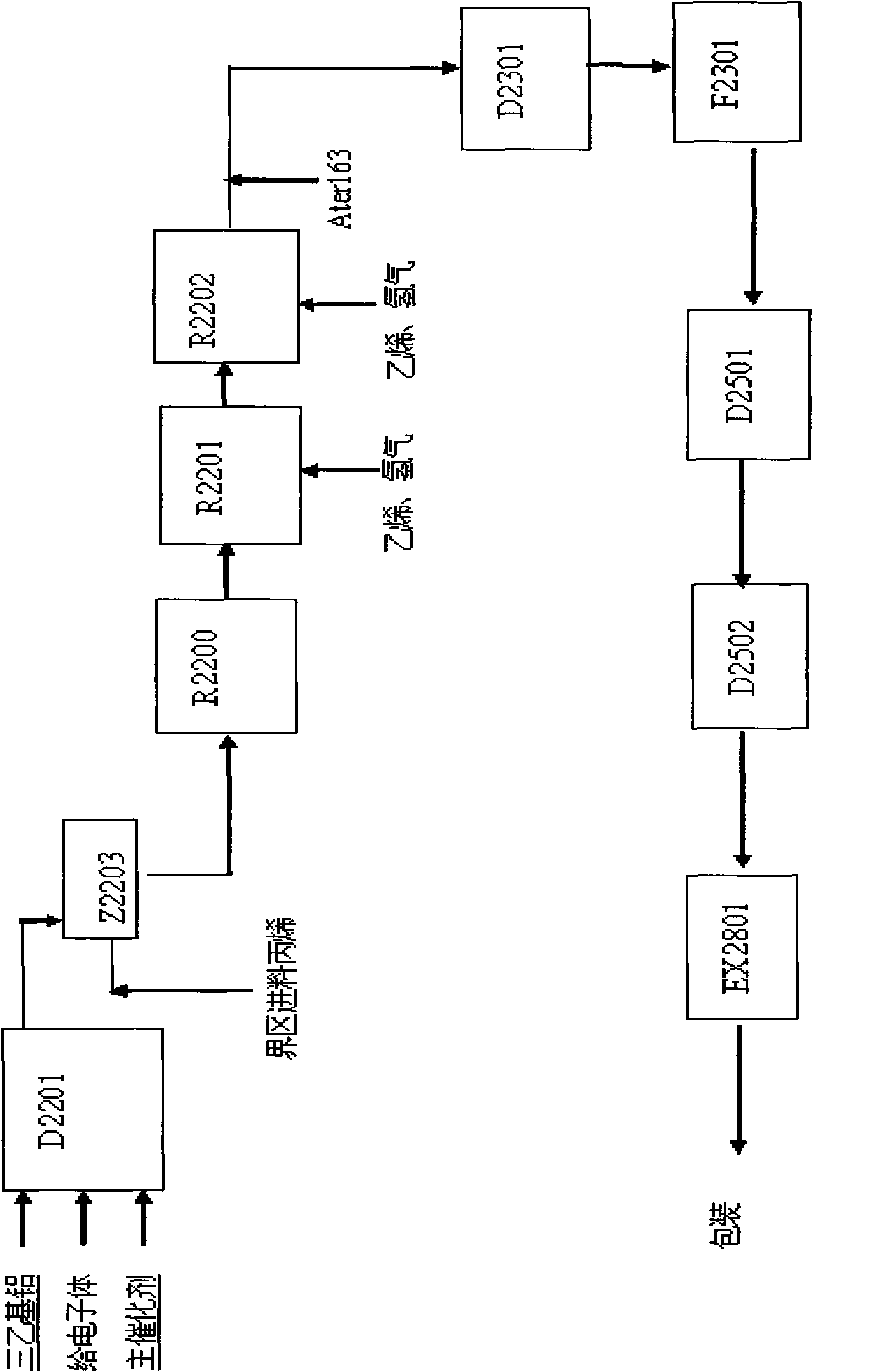

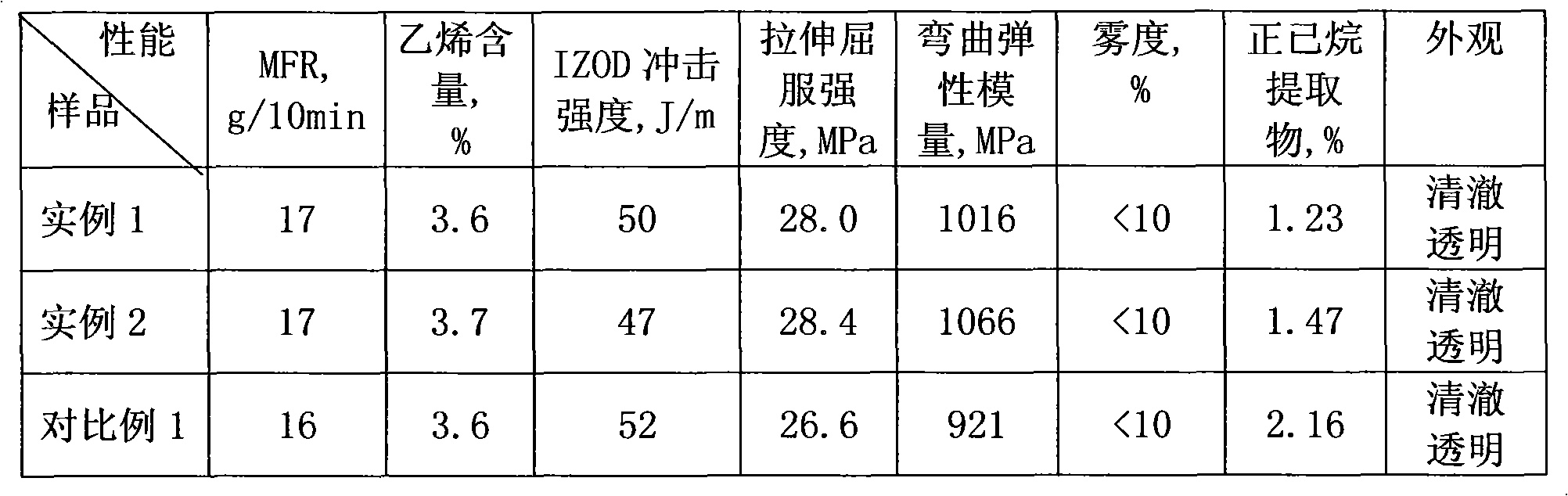

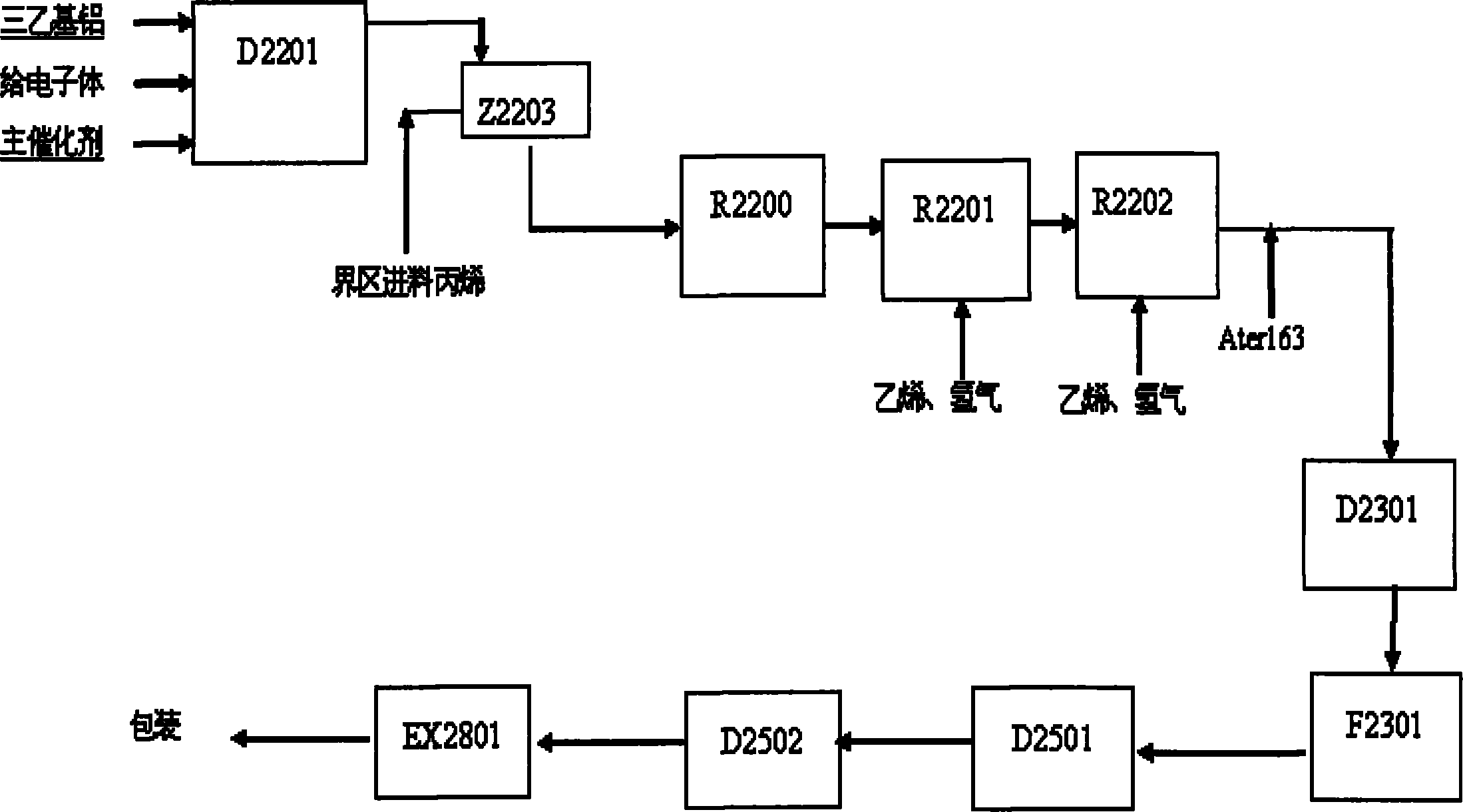

Preparation method of high-flowing high ethylene content polypropylene randon transparent copolymer resin

The invention relates to a preparation method of a high-flowing high ethylene content polypropylene randon transparent copolymer resin, characterized in that: a 4th Z-N catalyst is used, the ratio of triethyl aluminum flow to propylene flow is 0.1-0.30, the ratio of external electron donor flow to propylene flow is 0.04-0.2, the addition of ethylene in a single-loop polymerization reactor accounts for 30-50 % of the total amount of ethylene, the addition of ethylene in a dual-loop polymerization reactor accounts for 70-50 % of the total amount of ethylene, hydrogen concentrations of the two loop polymerization reactors are both 0.12-0.15 %, the melt flow rate of polymeric powder is controlled within 11-14 g / 10 min, the ethylene content is controlled within 3.6-4.0 %, a premix consisting of anti-oxidant, neutralizer and nucleating agent and rheological masterbatch are added and then extrusion granulation is carried out, and a final product has the melt flow rate of 16-18 g / 10 min, the ethylene content of 3.6-4.0 %, the hexane extract content of less than 1.6 %, and the haze of less than 10%.

Owner:PETROCHINA CO LTD

Method For Sterilizing Blood Purifier And Blood Purifier Package

ActiveUS20080087599A1Safe and reliableReduce extractionDialysisLavatory sanitoryNuclear medicineMoisture

The present invention provides a method for sterilizing a blood purifier, which method is effective to decrease the amounts of extracts from the blood purifier attributed to the deterioration of the selectively permeable separation membranes with time during and after exposure to a radioactive ray or an electron ray, and which method is highly reliable in safety when employed for hemocatharsis therapy. The present invention also provides a blood purifier package.The present invention relates to a method for sterilizing a blood purifier which comprises substantially dried selectively permeable separation membranes as a main component, by way of the exposure of the same blood purifier to a radioactive ray and / or an electron ray, and this method is characterized in that the blood purifier is sealed in a packaging bag, together with an oxygen scavenger and a humectant or together with an oxygen scavenger capable of releasing a moisture, and is then sterilized in such a sealed state by the above exposure.

Owner:NIPRO CORP

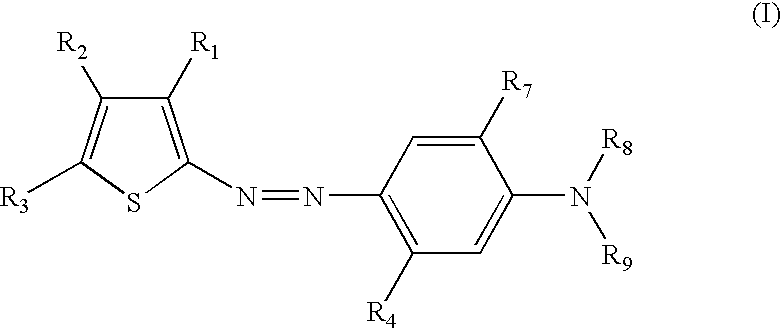

Single compound toners for use in polyesters

InactiveUS6875811B2Reduce extractionImprove anti-yellowing effectOrganic dyesMixingPolyesterUltraviolet

Individual compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such an individual compound is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive single bluing agent compound thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

Processes for recovering metals from ores using organic solvent extraction and aqueous stripping at selected temperature differentials

InactiveUS20060117908A1Reduce temperature differenceIncrease temperatureProcess efficiency improvementPregnant leach solutionOrganic solvent

The disclosed invention concerns a process comprising: (a) providing a pregnant leach solution comprising copper values; (b) contacting the pregnant leach solution with an organic phase comprising a copper extractant at an extraction temperature, Text, to form a loaded organic phase comprising the metal values; (c) contacting the loaded organic phase with an aqueous stripping solution at a stripping temperature, Tstrip, to form a copper-enriched stripping solution; wherein the difference in temperature (ΔT) between the stripping temperature and the extraction temperature according to equation (I): ΔT=Tstrip−Text is less than or equal to about 10° C. In other increasingly more preferred embodiments of the invention, the difference in temperature (ΔT) is less than or equal to about 5° C., less than or equal to about 2.5° C., less than or equal to about 0° C., less than or equal to about −5° C., and less than or equal to about −10° C. Also disclosed are economic means to manipulate the extraction, strip, and electrowinning temperatures to achieve these temperature differentials.

Owner:COGNIS IP MANAGEMENT GMBH

Novel single compound toners for use in polyesters

InactiveUS20030212172A1Low extractionExcellent resultOrganic dyesMixingPolyesterMethods of production

Individual compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such an individual compound is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive single bluing agent compound thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

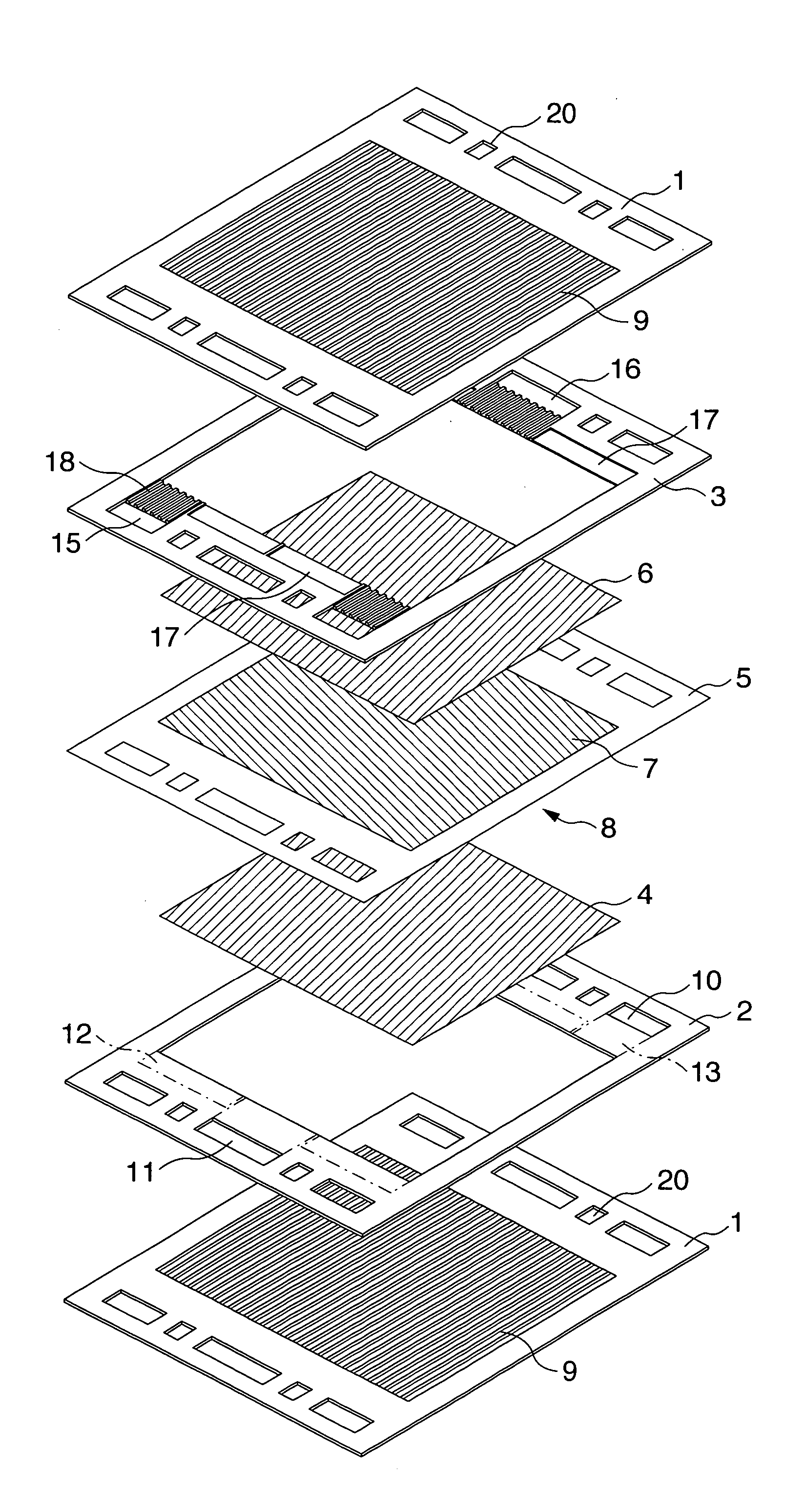

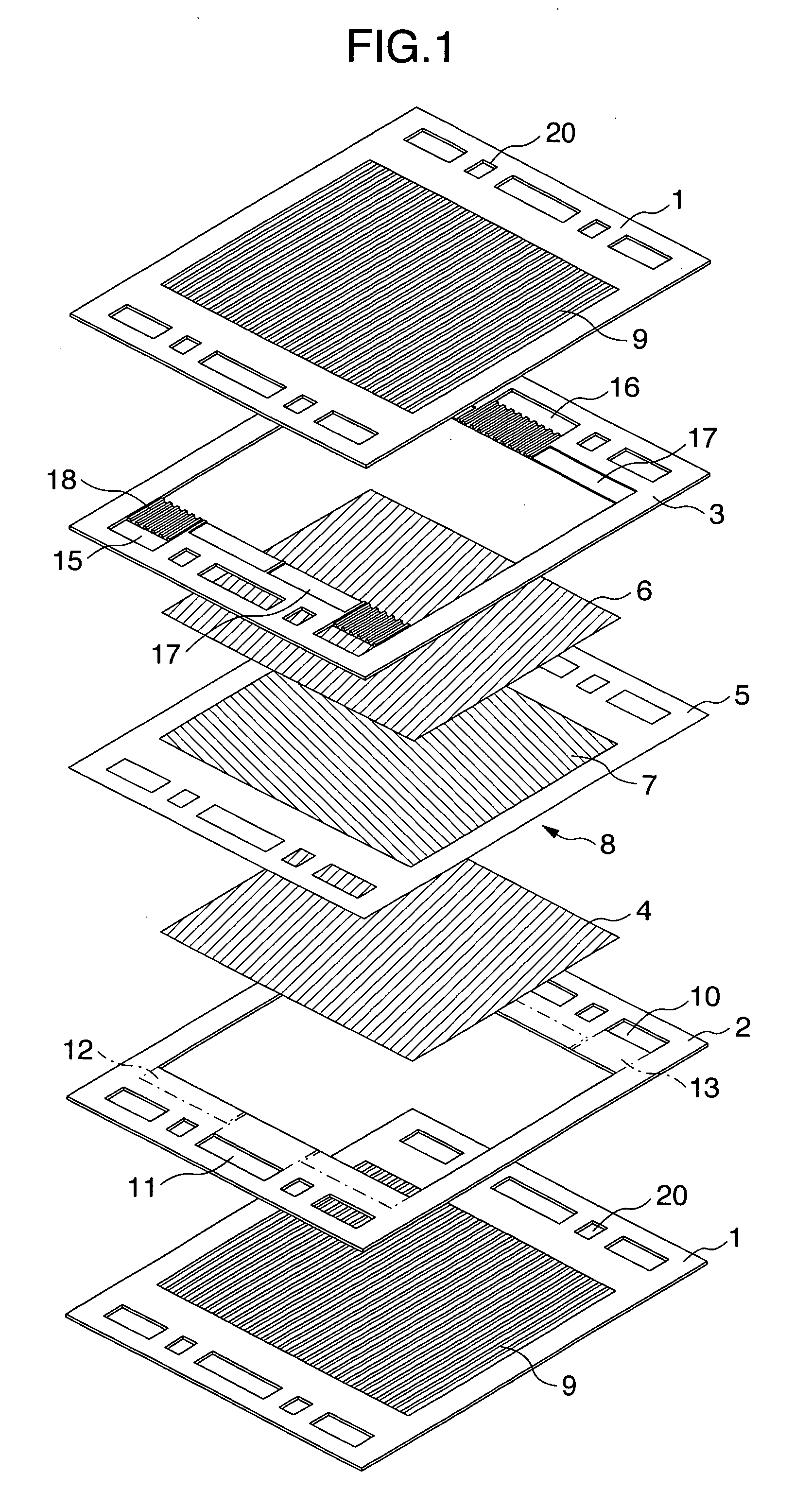

Solid polymer type fuel cell, metal separator for fuel cell, and kit for fuel cell

InactiveUS20050277013A1Reduce total pressure lossGas velocity can be suppressedFuel cells groupingCell electrodesFuel cellsHydrogen

The present invention provides a fuel cell employing a metal separator in which low gas pressure loss, high hydrogen utilization factor operation and long term power generation are possible. The fuel cell according to the present invention is constituted by laminating a plurality of units, the units combining a metal gas channel plate having on both faces a frame portion and a plurality of gas channel sets formed inside the frame portion, a frame having a supply manifold for supplying reaction gas to an end turn-around portion of the gas channels closely attached to the frame portion of the above described metal gas channel plate and a discharge manifold for discharging reaction gas, a reaction gas diffusion layer in contact with the above described frame, an electrolyte membrane which is in contact with the above described diffusion layer and in which one side is in contact with an anode and another side in contact with a cathode, a reaction gas diffusion layer in contact with the above described anode or the above described cathode, the above described metal gas channel plate and the above described frame, wherein a plurality of supply manifolds and / or discharge manifolds are provided per each frame.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com