Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

306results about How to "Improve anti-yellowing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LOCA (Liquid Optical Clear Adhesive) and preparation method thereof

ActiveCN105524589AGood light curing performancePrevents free radical polymerizationNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryPhotoinitiator

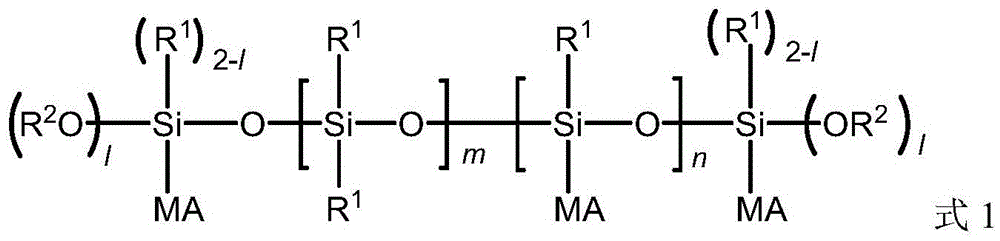

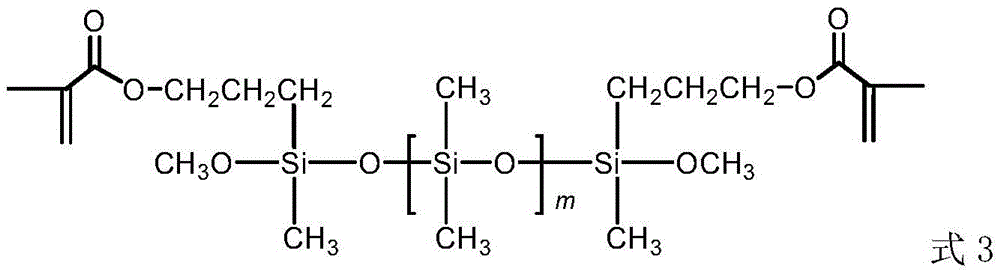

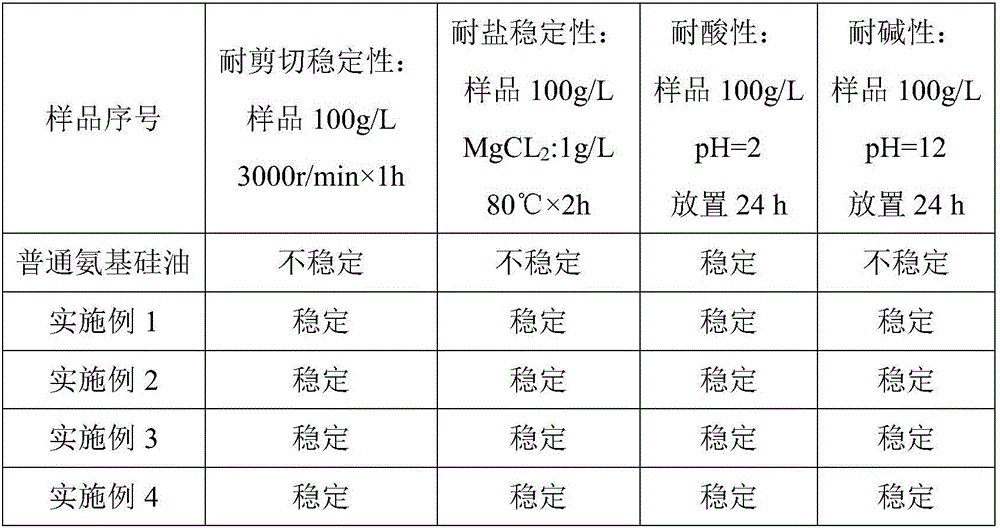

The invention discloses an LOCA (Liquid Optical Clear Adhesive), and a preparation method and application of the LOCA. The LOCA is prepared from (A) 100 parts of (methyl) acryloyloxy alkylate polysiloxane, (B) 0 to 200 parts of hydroxyl or alkoxyl end-capping poly dialkyl siloxane, (C) 0 to 100 parts of organic silicon resin, (D) cross-linking agent which occupies 0 to 10 percent of the total amount of (A), (B) and (C) and connected with silicon and can be used for hydrolyzing groups, (E) 0.01 to 5 parts of photoinitiator, (F) 0.01 to 5 parts of polymerization inhibitor and (G) 0.0001 to 2 parts of condensation catalyst. The LOCA disclosed by the invention not only can be cured through an ultraviolet irradiation mode, but also can be cured through a moisturizing mode, and the LOCA can be widely applied to the adhesion of display screens, touch screens and optical devices.

Owner:矽时代材料科技股份有限公司

Xanthochromia-resistance dacron afterprocessing oil solution and manufacturing method thereof

The invention discloses terylene afterprocessing oil agent for preventing xanthochromia, which is mainly formed by smoothing agent, emulsifying agent, cleaning agent and addition agent, and is characterized in that weight percentage of each component is smoothing agent 85%-90%, emulsifying agent 5%-10%, cleaning agent 2%-4% and addition agent 1%-1.5%. According to the weight percentage of each component, the method for preparation is that firstly packing emulsifying agent and cleaning agent with precise measure into an autoclave to heat from 50 DEG C to 80 DEG C, secondly packing smoothing agent into the autoclave to mix for 40-60 min, thirdly charging addition agent to mix homogeneously, and then cooling, filtering and packaging. The terylene after-processing oil agent for preventing xanthochromia has the advantages that interfacial force is low, permeability and diffusibility are good, the applying oil process is quick and homogeneous, the volume for applying oil is easy to be controlled, after-processing is smooth and has no imperfect effect on weave process and causticity component, and the invention is easy for washing and not influence on coloration and topical finish, and is good in cohesion property and forming of silk can, high in oil film strength, and strong in ability of preventing xanthochromia, thereby being favorable to store silks.

Owner:TONGKUN GRP

Single compound toners for use in polyesters

InactiveUS6875811B2Reduce extractionImprove anti-yellowing effectOrganic dyesMixingPolyesterUltraviolet

Individual compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such an individual compound is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive single bluing agent compound thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

Quaternary ammonium modified block polyether/amino silicone oil and preparation method thereof

InactiveCN106381715AHigh retention rateActive hydrogen reductionGrip property fibresEpoxyOrganic acid

The invention relates to quaternary ammonium modified block polyether / amino silicone oil and a preparation method thereof. The preparation method comprises the following steps: bis(glycidoxy-terminal), DMC and an organic solvent, adding an alkaline catalyst, heating to 80-110 DEG C, and balancing for 6-8 h; heating to about 140 DEG C to decompose the catalyst for 1-2 h, and carrying out underpressure distillation to obtain colorless or flavescent epoxy-terminated silicone oil; uniformly mixing the epoxy-terminated silicone oil, polyetheramine and a solvent, reacting at 60-80 DEG C for 15-20 h to prepare a block polyether / amino silicone oil prepolymer; and respectively adding a tertiary amine compound and equimolar quantity of organic acid into the product obtained in the step b, continuously reacting at 70-80 DEG C for 4-8h so as to obtain the final product. The amino silicon oil prepared by the method has excellent hand feeling, has little influence on whiteness and hydrophilicity of fabrics, can completely replace common amino silicon oil, and has an excellent application prospect.

Owner:ZHEJIANG KEFENG ORGANIC SILICON CO LTD

Novel single compound toners for use in polyesters

InactiveUS20030212172A1Low extractionExcellent resultOrganic dyesMixingPolyesterMethods of production

Individual compounds that provide effective toning (or bluing) to combat yellowing within polyester articles (such as bottles, containers, and the like) are provided. Such a novel toner permits effective neutralization of yellowness while also providing highly desirable low haze and increased brightness due to a sharp absorption peak within the needed range of wavelengths (e.g., from about 565 to 590 nm) and a narrow half-height band width. Furthermore, such an individual compound is preferably liquid in nature and may thus be incorporated within an added ultraviolet absorber solution or shelf-stable dispersion to facilitate addition within target polyesters at various stages of production. The particular UV absorbers desired as additives within target polyesters also tend to exhibit certain yellowing effects that require attention as well. The inventive single bluing agent compound thus also accords effective neutralization of such UV absorber yellowing as well. Methods of production and liquid UV absorber / individual bluing agent formulations are also encompassed within this invention.

Owner:MILLIKEN & CO

Textile fluoride-free waterproofing agent and preparation method thereof and textile

InactiveCN105369621AImprove waterproof performanceImprove anti-yellowing effectLiquid repellent fibresEmulsionFluoride

The invention provides a textile fluoride-free waterproofing agent and a preparation method thereof and textile applying the fluoride-free waterproofing agent. The fluoride-free waterproofing agent is prepared from the components by mass of 5%-30% of fluoride-free polymer, 5%-30% of (modified) polyethylene wax emulsion, 3%-15% of chemically modified chitosan, 0.001%-10% of auxiliary and the balance of water. Acid, acid anhydride or isocyanate materials are taken as modifiers for chemically modifying amino of the chitosan, functional groups such as carboxyl, ester and hydroxyl are introduced while the amino is reduced, the compatibility is good, contents and the matching relationship of all components in the fluoride-free waterproofing agent are adjusted so that the fluoride-free waterproofing agent has excellent waterproofness and yellow degeneration resistance, washing waterproofness can still be maintained to be level 5 after the fluoride-free waterproofing agent is used for washing the textile for 10 times, and the yellow degeneration resistance can also be as high as level 5.

Owner:WUXI CHANGAN SHUGUANG GLOVE FACTORY

Preparation method of rosin ester

ActiveCN103627326ALight colorGood weather resistanceNatural resin chemical modificationWeather resistanceAlcohol

The invention discloses a preparation method of a rosin ester, and comprises the following steps: (1) feeding the rosin ester in a reactor, warming to 170-180 DEG C under the protection of inert gas to melt the rosin; (2) adding unsaturated acid which is 0.5-8% of the rosin weight at 130-200 DEG C, and reacting for 0.5-2 hours; (3) adding a homemade composite reduced-color reagent which is 0.01-1% of the rosin weight and alcohol which is 11-18% of the rosin weight at 180-230 DEG C, reacting for 2-8 hours at 180-285 DEG C, adding saturated acid, and then reacting for 2 hours, removing water produced in reaction in a vacuum mode, cooling to 180-240 DEG C, adding a stabilizer which is 0.1-0.6% of the rosin weight to obtain the rosin ester. The preparation method disclosed by the invention is simple in process and low in cost, and the rosin ester with light color, good weather resistance, good yellowing resistance and good temperature tolerance can be prepared.

Owner:湖南科茂林化有限公司

Transparent dealcoholized single-component RTV silicone rubber sealant and preparation method thereof

InactiveCN103361023AImprove anti-yellowing effectFast curingNon-macromolecular adhesive additivesOther chemical processesScavengerOmega

The invention relates to a transparent dealcoholized single-component RTV silicone rubber sealant and a preparation method thereof. The preparation method comprises the following steps: stirring 100 parts by mass of alpha, omega-dihydroxyl polydimethylsiloxane, 3 to 10 parts by mass of dimethicone, 5 to 10 parts by mass of a reinforcing filling material and 1 to 5 parts by mass of a hydroxyl radical scavenger under vacuum in a power mixer; then adding 0.3 to 2 parts of a coupling agent and carrying out stirring under vacuum; and adding 1 to 10 parts of a cross-linking agent and 0.1 to 3 parts of a catalyst and carrying out stirring under vacuum and packaging so as to obtain a finished product. The sealant provided by the invention has the advantages of yellowing resistance, a fast curing speed, no toxicity, environment friendliness, etc.

Owner:兆舜科技(广东)有限公司

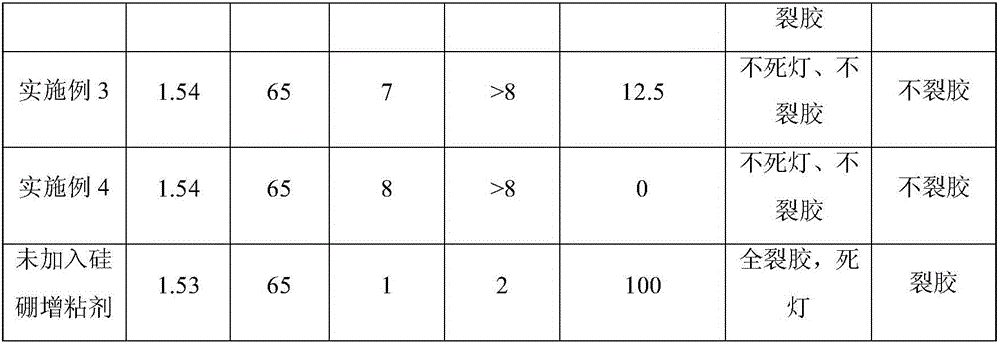

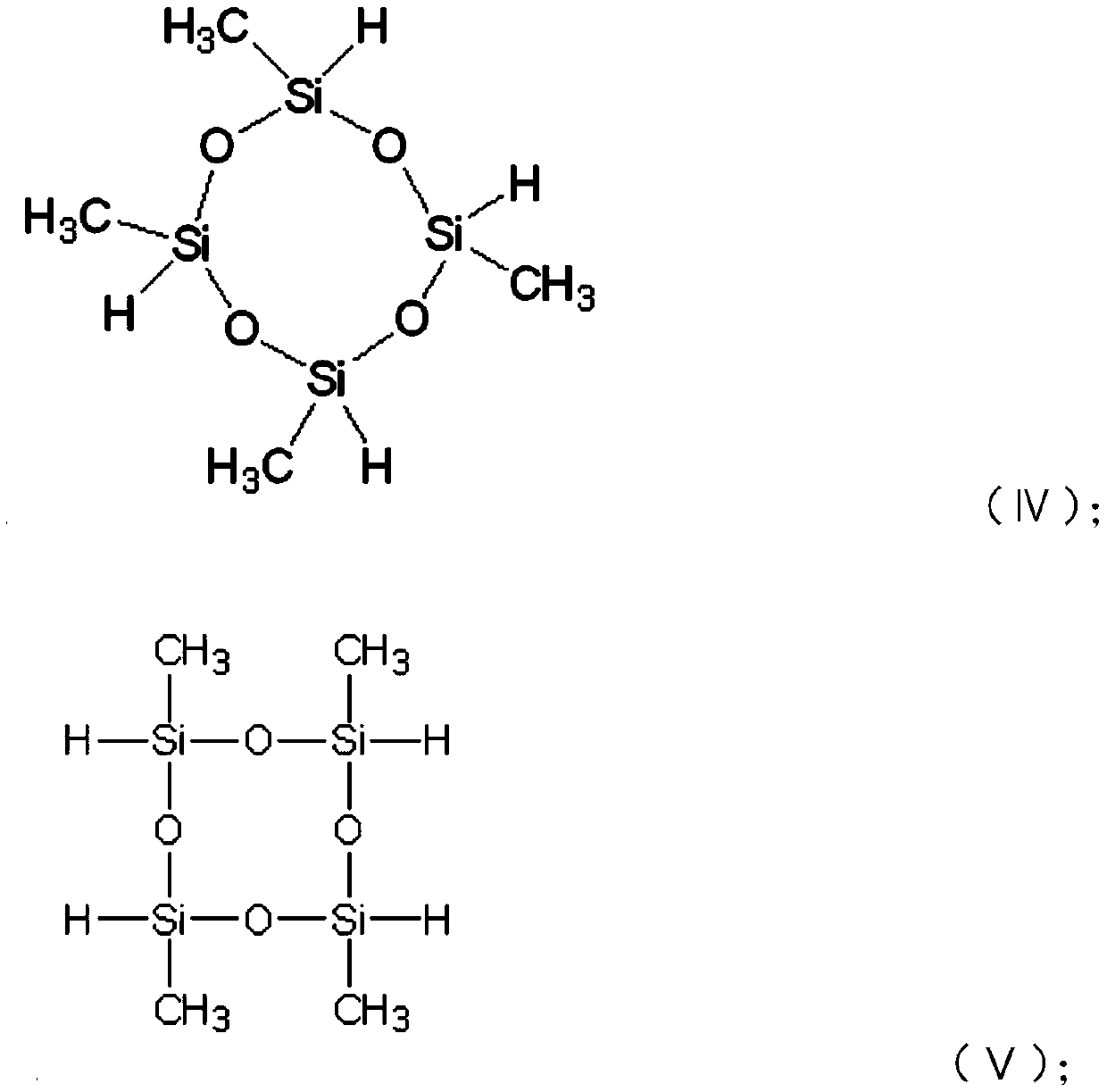

Silicon boron tackifier, preparation method thereof and application thereof in double-component LED packaging gel

ActiveCN105802532AImprove adhesionHigh refractive indexMacromolecular adhesive additivesPrepolymerChemistry

The invention belongs to the field of organosilicon materials and discloses a silicon boron tackifier, a preparation method thereof and application thereof in double-component LED packaging gel. The preparation method includes: subjecting unsaturated monomer with epoxy group and polysiloxane with hydrogen group to hydrosilylation to obtain epoxy modified polysiloxane; subjecting silane monomers R1Me2SiOR, PhR2Si(OR)2, R4Si(OR)3 and Si(OR)4 to hydrolytic condensation under an acidic condition to obtain a phenyl polysiloxane prepolymer; mixing the epoxy modified polysiloxane with the phenyl polysiloxane prepolymer, adding borate, and allowing reaction under action of alkaline catalysis to obtain the silicon boron tackifier. The silicon boron tackifier can be directly added into an LED packaging silica gel system, adhesion between the LED packaging silica gel and lamp beads is improved, requirements on sealing the lamp beads are met, and the silicon boron tackifier has high refractive rate and good yellowing resistance.

Owner:清远市美佳乐环保新材股份有限公司

Special halogen-free flame retardant reinforced PA (polyamide) 56 composite material for casing of low-voltage circuit breaker

InactiveCN104861648AImprove flame retardant performanceImprove flame resistanceGlass fiberLow voltage circuits

The invention discloses a special halogen-free flame retardant reinforced PA (polyamide) 56 composite material for a casing of a low-voltage circuit breaker. The composite material comprises components in parts by mass as follows: 35-70 parts of PA 56, 20-40 parts of alkali-free glass fiber, 0.1-1.2 parts of a glass fiber dispersing agent, 6-20 parts of halogen-free flame retardant, 12-30 parts of modified filler, 0.3-0.9 parts of an antioxidant, 0.2-0.6 parts of a lubricant and 0.5-1.2 parts of a coupling agent. The composite material can have excellent flame retardance and burning resistance, and can meet the low-voltage circuit breaker industry requirement that the material is contacted with a glow wire for 30 s at the temperature of 960 DEG C and a flame is extinguished within 10 s after the material is separated.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Silicone gel and preparation method thereof

The invention provides silicone gel. The silicone gel is prepared from, in parts by weight, a component A and a component B, wherein the component A comprises 0.1-100 parts of vinyl silicone oil, 0.1-100 parts of hydrogen-terminated silicone oil, 0.1-30 parts of hydrogen-containing silicone oil and 0-1 part of an inhibitor, and the component B includes 100 parts of vinyl silicone oil and 0.0001-0.5 part of a platinum catalyst. The invention also provides a preparation method of the silicone gel. The provided silicone gel has good light transmittance and excellent anti-yellowing properties, thesilicone gel can be used in the optical field, and can also be applied to potting protection of multiple electronic products, meanwhile, the production process of the product is simple, and only thecomponent A and the component B are mixed uniformly at a ratio.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

Method for synthesizing modified epoxy acrylate

The invention discloses a method for synthesizing modified epoxy acrylate. The method comprises the steps of: A, adding 18-22 parts by weight of reactive diluent, 20-30 parts by weight of anhydride, 0.1-0.3 part by weight of inhibitor, 0.1-0.2 part by weight of catalyst and 0.2-0.4 part by weight of antioxidant into a synthesizer; B, cooling the mixture obtained in the step A to 100 plus or minus 2 DEG C, adding 30-40 parts by weight of epoxy resin, 0.1-0.3 part by weight of catalyst, 0.1-0.3 part by weight of inhibitor and 0.1-0.2 part by weight of antioxidant, heating the mixture to 105 plus or minus 2 DEG C and carrying out heat insulation for 2 plus or minus 0.5 hours, then heating to 110-115 DEG C and carrying out heat insulation for 2 plus or minus 0.5 hours until AV is not larger than 10; and C, cooling the mixture which is obtained in the step B to below 95 DEG C, then adding 15-25 parts by weight of non-benzene activated monomer, uniformly stirring the mixture and cooling to 80 plus or minus 2 DEG C. The product which is obtained by the method has good performance and high environmental friendliness..

Owner:HUIZHOU CHANGRUNFA PAINT

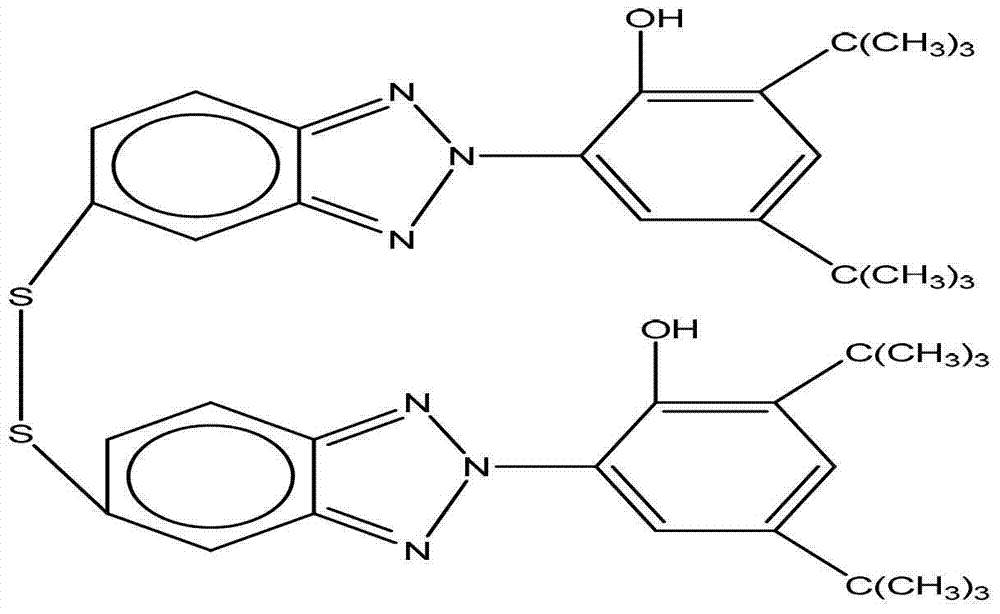

LED packaging material, its preparation method and application

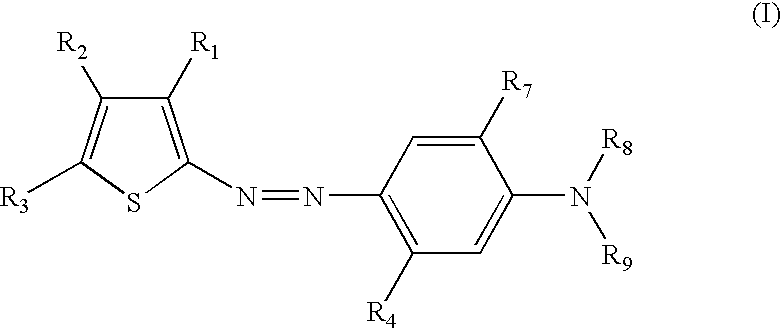

InactiveCN103289317AExpand UV absorption wavelength and absorption intensityReduce dosageNon-macromolecular adhesive additivesFilm/foil adhesivesUltraviolet absorptionLed packaging

Belonging to the field of packaging materials, the invention relates to an LED packaging material, its preparation method and application. The material is composed of the following components by weight: 100 parts of epoxy resin, 60 parts of a crosslinking agent, 2 parts of a crosslinking accelerant, 0.1-5 parts of an antioxidant, 0.05-0.25 part of an ultraviolet stabilizer, and 0.05-0.50 part of an ultraviolet absorber. In the invention, a sulfur-containing benzotriazole compound is adopted as the ultraviolet absorber, which has excellent performance and can reach a good synergistic effect with the antioxidant and the ultraviolet stabilizer, and can be used as the ultraviolet absorber of the LED packaging material. Compared with original ultraviolet absorbers, the ultraviolet absorber effectively enlarges the ultraviolet absorption wavelength and the absorption strength, thereby reducing the dosage of the ultraviolet absorber, lowering the cost, and improving the yellowing resistance of an adhesive film. The prepared LED adhesive film product has good stability, and has wide application prospects in industrial production.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Composite heat-yellow discolouration resistant finishing agent of chinlon, spandex and blended fabric of two

InactiveCN103556459AImprove yellowingImprove the problem of color changeFibre typesAntioxidantMaterials science

The invention relates to a composite heat-yellow discolouration resistant finishing agent of chinlon, spandex and a blended fabric of the two. The composite heat-yellow discolouration resistant finishing agent mainly comprises a potentiating agent, a synergist and a main antioxidant. After the chinlon, the spandex and the blended fabric are treated by a solution of the composite heat-yellow discolouration resistant finishing agent, the yellow discolouration and colour change of the chinlon, the spandex and the blended fabric can be remarkably alleviated. The composite heat-yellow discolouration resistant finishing agent is low in cost, simple in treatment process and high in industrial application value.

Owner:SICHUAN UNIV

Light diffuser board integrated with high transmittance, high haze and high toughness in one body

InactiveCN103645525AGood light diffusion effectImprove uniformityDiffusing elementsPolystyreneStabilizing Agents

The invention discloses a light diffuser board integrated with high transmittance, high haze and high toughness in one body. A fiber-level GPPS such as transparent and blue-background polystyrene is taken as a main material, glass beads are taken as a silicon diffusion agent, and a high haze flexibilizer SCBS is innovatively added. Based on the diffuser board having functions of light collection, light diffusion and light reflection, a product formula is improved and added, auxiliary agents such as a diffusion agent, a light stabilizing agent and a high haze flexibilizer are added to a raw material, and thereby functions of light refraction, light reflection and light diffusion are realized in products, not only can quite high light diffusion and emergent light uniformity be realized, but also a utilization rate of the power source is high, anti-folding performance and shielding performance are good, a penetration rate of products can reach 93%+ / -5%, and the haze can reach 99%+ / -1%.

Owner:HUIZHOU YUETAIXIANG TECH

ABS (acrylonitrile-butadiene-styrene) plastic for automobile inner ornaments and preparation method thereof

ActiveCN103937144AGood formabilityStrong mechanical propertiesEthylene-propylene-diene-monomerAging resistance

The invention discloses an ABS (acrylonitrile-butadiene-styrene) plastic for automobile inner ornaments and a preparation method thereof. The ABS plastic for automobile inner ornaments comprises the following components in parts by weight: 100 parts of ABS resin, 80-120 parts of PC (polycarbonate) resin, 5-15 parts of EPDM (ethylene-propylene-diene monomer) resin and 1-3 parts of anti-yellowing agent. The preparation method comprises the following steps: proportionally weighing the raw materials, uniformly mixing, melting and compounding, and extruding and granulating. The ABS plastic for automobile inner ornaments has the advantages of favorable formability, favorable mechanical properties, high impact strength, high temperature resistance, favorable ultraviolet resistance, favorable light aging resistance and the like, and can be used for preparing automobile inner ornaments by an injection molding technique.

Owner:SHANDONG HANSHI AUTOMOTIVE COMPONENTS

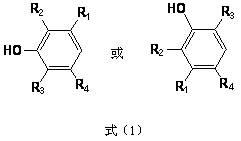

Double-hindered phenol structure-contained hydrazides compound and preparation method thereof

ActiveCN102344389AHigh molecular weightEnhance thermal oxidation resistanceHydrazide preparationPtru catalystOrganosolv

The invention discloses a double-hindered phenol structure-contained hydrazides compound for a light stabilizer and a preparation method thereof. The double-hindered phenol structure-contained hydrazides compound has a double-hindered phenol and double-hydrazide structure, thus, the molecular weight is increased, and the migration resistance and thermal oxidation resistance capacity is strong. The preparation method comprises the following steps: performing addition reaction on hindered phenols and alpha, beta-acrylic ester under the action of a catalyst to obtain an addition product, wherein the molar ratio of the hindered phenols to the alpha, beta-acrylic ester is 1.0:(0.6-1.8), and the catalyst is alkali metal, an alkali metal hydroxide, an alkali metal hydride or an alkali metal alcoholate; then, performing carbonyl nucleophilic substitution reaction on the addition product and a hydrazine hydrate in an organic solvent A to obtain a hydrazides substitution product, wherein the molar ratio of the addition product to the hydrazine hydrate is 1.0:(0.8-5.0); performing the reaction between a diisocyanate compound and the hydrazides substitution product at the temperature of 0-10 DEG C; and carrying out recrystallization to obtain a goal product. By adopting the preparation method disclosed by the invention, the operation is simple, the raw materials are available, and the cost is low.

Owner:YANTAI RUILONG CHEM TECH CO LTD

Single-component oxime-removed silicone sealant for sealing solar cell module and preparation method thereof

ActiveCN103571427AGood weather resistanceImprove anti-yellowing effectNon-macromolecular adhesive additivesOther chemical processesSilicone sealantMethyl silicone

The invention discloses a single-component oxime-removed silicone sealant for sealing a solar cell module. The single-component oxime-removed silicone sealant is composed of the following components in parts by weight: 100 parts of alpha, omega-dihydroxyl polydimethylsiloxane having the viscosity in the range from 20000 to 80000, 1-6 parts of polyisobutene resin, 10-40 parts of active calcium carbonate, 1-15 parts of methylsilicone oil, 10-50 parts of fire retardant, 1-5 parts of titanium dioxide, 1-7 parts of fumed silica, 9-15 parts of cross-linking agent, 2-5 parts of silane coupling agent and 0.5-1.5 parts of catalyst. The invention also discloses a preparation method of the sealant. The sealant provided by the invention has the characteristics of excellent weather fastness, yellowing resistance, flame resistance, low water vapor transmittance, good storage stability and the like.

Owner:SINOCHEM LANTIAN +1

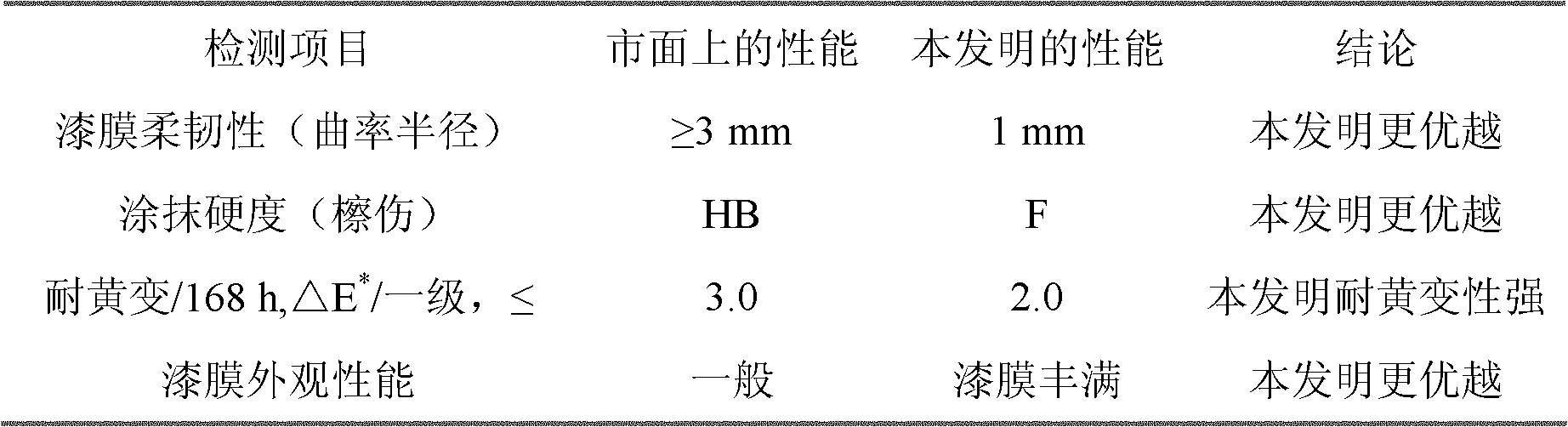

Novel polyurethane semi-matte white finish for woodware protection

InactiveCN101967340AHigh glass transition temperatureSmall steric hindrancePolyurea/polyurethane coatingsWaxDeodorant

The invention discloses novel polyurethane semi-matte white finish for woodware protection. The finish is prepared by mixing the following components: stearic acid modified alkyd resin, polyketone resin solution, an antifoaming agent, an anti-settling agent, a dispersing agent, white slurry, handfeel wax powder, aerosol extinction powder, 20 percent hydroxyl modified vinyl acetate (VAGH) resin, a leveling agent, an anti-yellowing auxiliary agent, a deodorant and butyl ester. A film prepared from the novel polyurethane semi-matte white finish has the advantages of fullness, moderate hardness, high flexibility, high water resistance, yellowing resistance and environmental protection; and the semi-matte white finish has high comprehensive performance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Nano sterilizing anionic double-component aqueous wood paint

InactiveCN101880500ANo pollutionWon't hurtAntifouling/underwater paintsPaints with biocidesAcrylic resinLacquer

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano sterilizing anionic double-component aqueous wood finishing paint and a preparation method thereof. The nano sterilizing anionic double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano sterilizing anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, strong sterilization and mildew prevention, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

High-anti-yellowing silicon rubber compound and preparation method thereof

The invention discloses a high-anti-yellowing silicon rubber compound which is characterized by comprising the following raw materials by weight: 100 parts of raw silicon rubber, 1-20 parts of hydroxy silicone oil, 20-70 parts of white carbon black, 0.1-3 parts of zinc stearate used as an inner release agent, 1-10 parts of hydrogen-containing silicone oil and 0.01-0.5 part of pyrophosphoric acid used as an anti-yellowing assistant. The invention also discloses a preparation method of the high-anti-yellowing silicon rubber compound. The high-anti-yellowing silicon rubber compound and the preparation method have the advantages that on the basis of not reducing the physical and mechanical properties of the silicon rubber compound, the high-anti-yellowing silicon rubber compound is good in anti-yellowing capability, good in processability and good in physical and mechanical properties.

Owner:阳江市小天星实业有限公司 +1

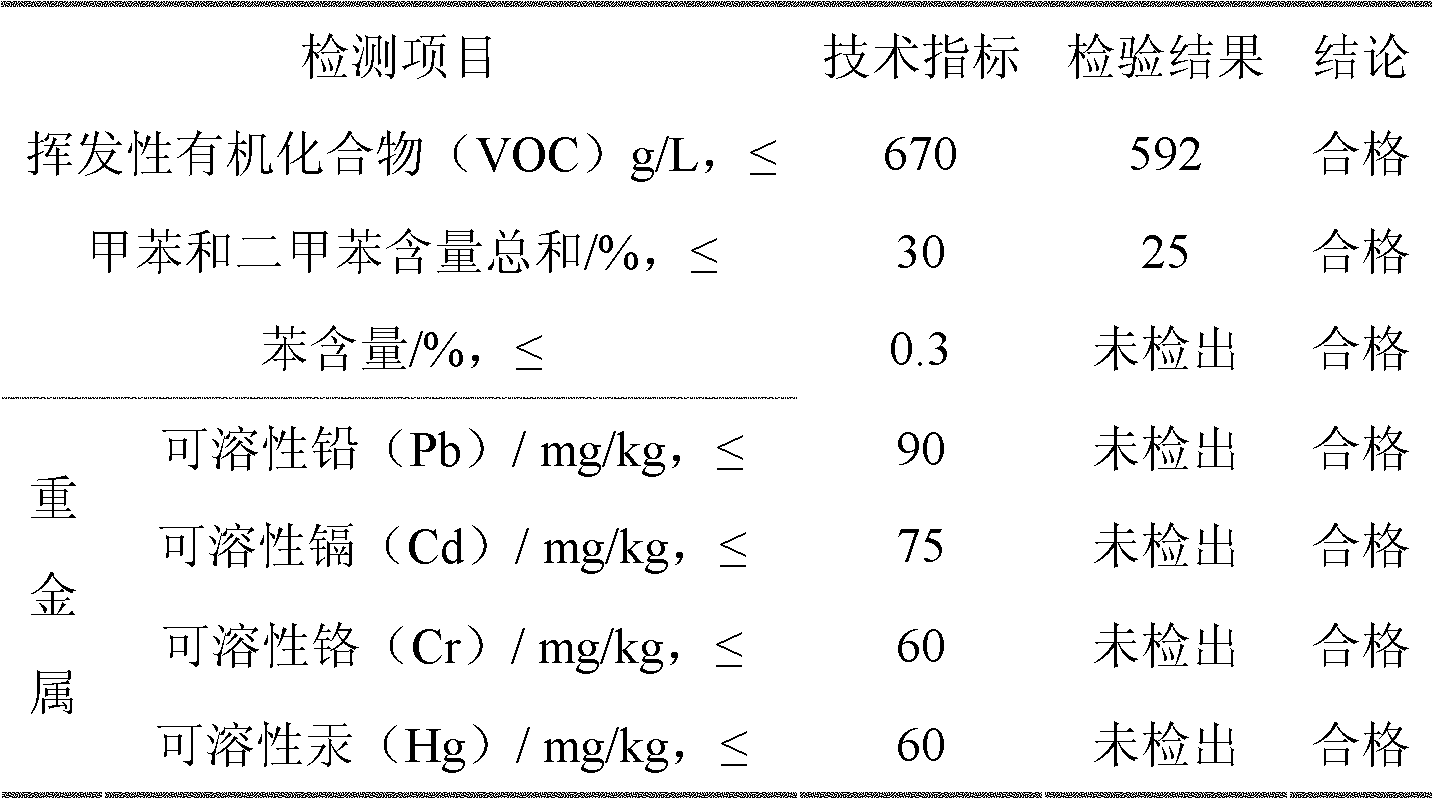

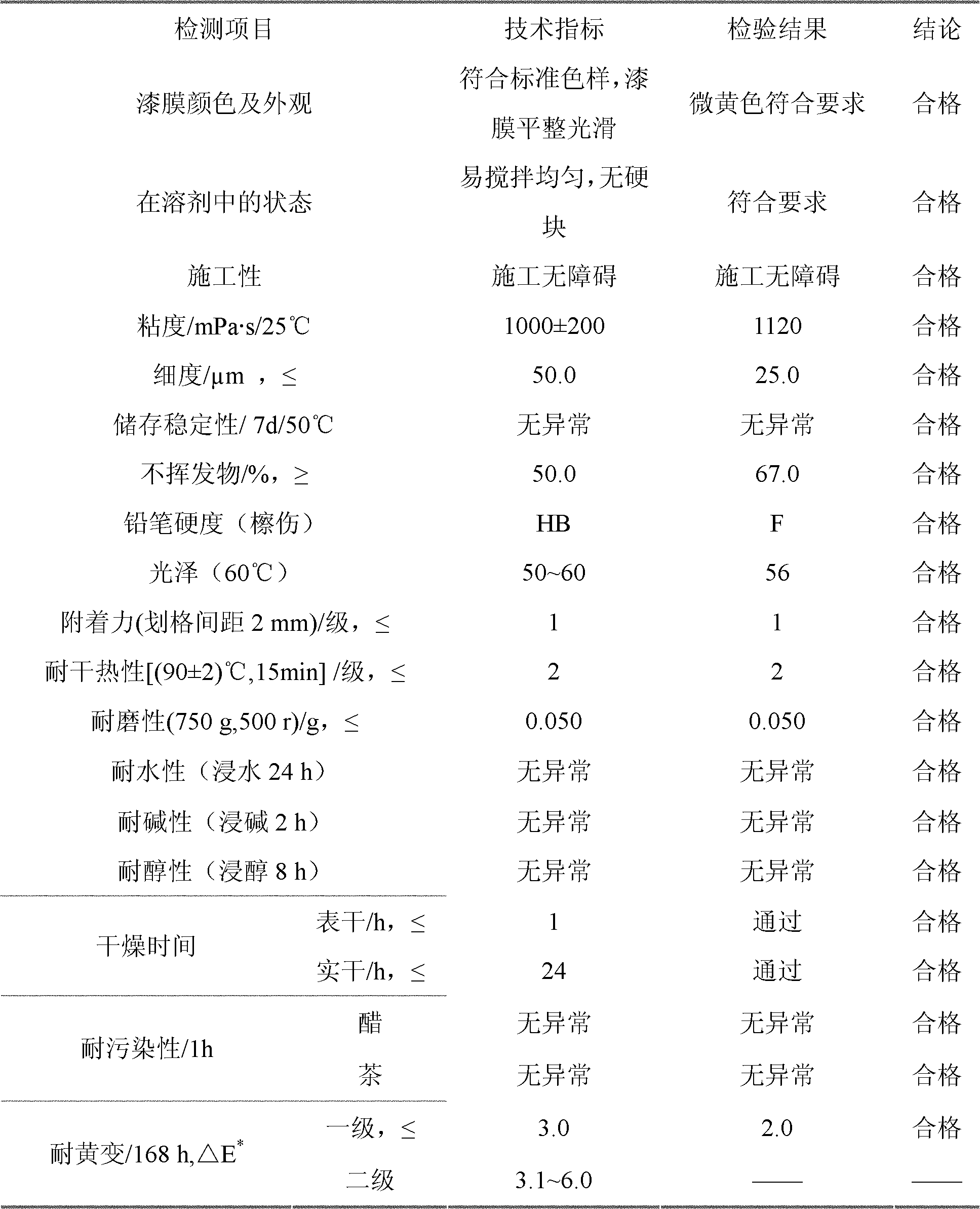

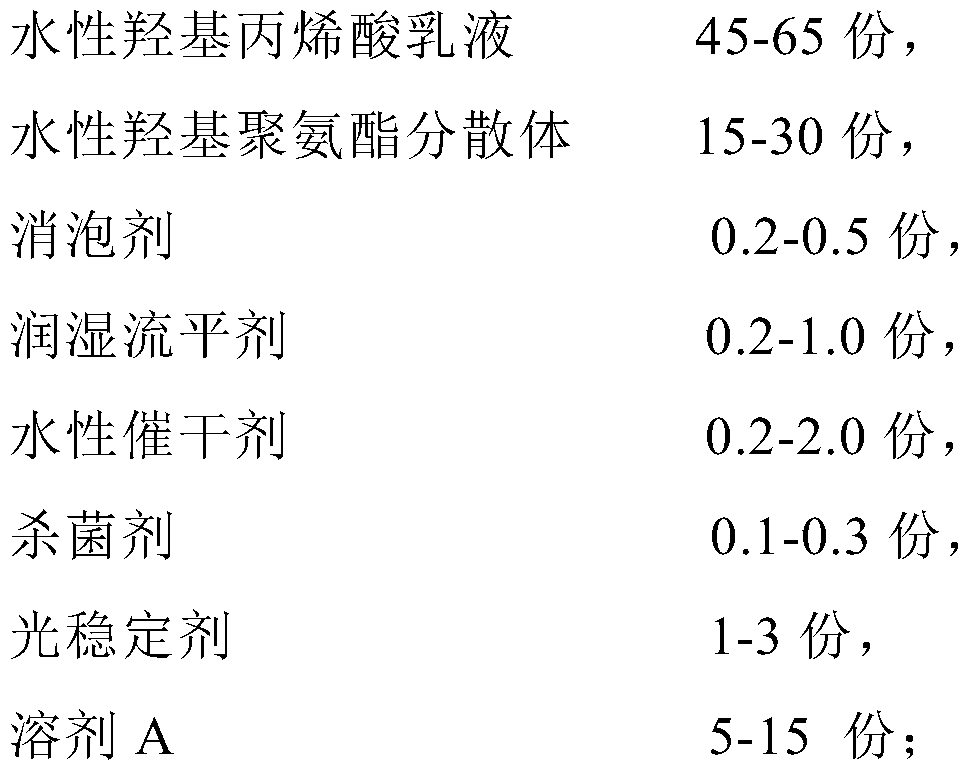

Ultra-gasoline resistant aqueous varnish and preparation method thereof

ActiveCN109749611AHigh hardnessImprove scratch resistancePolyurea/polyurethane coatingsSolventBiological activation

The invention relates to ultra-gasoline resistant aqueous varnish and a preparation method thereof. The aqueous varnish comprises a component A resin paint and a component B curing agent in a weight ratio of 3: 1, wherein the component A resin paint comprises 45-65 parts of aqueous hydroxyl acrylic emulsions, 15-30 parts of aqueous hydroxyl polyurethane dispersions, 0.2-0.5 part of a defoaming agent, 0.2-1.0 part of a wetting leveling agent, 0.2-0.6 part of an aqueous drier, 0.1-0.3 part of a bactericide, 1-3 parts of light stabilizers and 5-15 parts of solvents A; and the component B curing agent comprises 55-75 parts of curing agents and 10-30 parts of solvents B. Compared with the prior art, the preparation method is simple, raw materials are widely selected, and the prepared aqueous varnish has excellent chemical resistance, especially gasoline resistance, effectively improves surface drying speed and activation period, has good interlayer adhesion, and has the advantages of fast hardness establishment, high fullness and the like.

Owner:DONGLAI COATING TECH SHANGHAI

High-transparency polyether type double-mirror TPU (thermoplastic polyurethane) thin film

ActiveCN107141774AIncrease production capacityHigh surface glossAntioxidantThermoplastic polyurethane

The invention belongs to the technical field of materials, and particularly relates to a high-transparency polyether type double-mirror TPU (thermoplastic polyurethane) thin film and a preparation method for the same. The TPU thin film is prepared from the following components in parts by weight: 100 parts of TPU resin, 0.1 to 0.8 part of antioxidant, 0.1 to 1.8 part of light stabilizer and 0.01 to 0.05 part of processing lubricant. The preparation method comprises the following steps: adding each component into a stirring machine for uniform mixing according to the using amounts in the formula, then pumping the components into a dehumidification dryer for drying, and then performing extrusion casting, mirror counter-compression, cooling, shearing and compression winding to obtain a high-transparency polyether thin film product. The process difficulties of poor transparency, plasticization non-uniformity, high fisheye formation rate and high roller sticking rate are overcome, the productivity is improved, and the high-transparency polyether type double-mirror TPU thin film prepared by the invention has the characteristics of uniform thickness, high transparency, high surface glossiness, yellowing resistance and the like.

Owner:FUZHOU UNIV

Acroleic acid mixed powder coating

InactiveCN101225275AImprove outdoor durabilityGood hardnessPowdery paintsEpoxy resin coatingsChemistryHardness

The invention relates to an acrylic acid mixed powder coating, which is characterized in that the formula comprises the following components in pbw (part by weight): 25 to 40 portions of epoxy resin, 25 to 40 portions of acrylic acid resin, 0.5 to 2 portions of leveling agent, 30 to 35 portions of filler, 0.1 to 0.2 portion of system catalyst, and 0.1 to 2 portions of other additive. The acrylic acid mixed powder coating has the advantages of lower costs, simple preparation and production, no need for curing agent, better hardness, excellent chemical and pollution resistance, long outdoor endurance, and broad application prospects.

Owner:宁波派特勒新材料股份有限公司

VAc/St/BA (vinyl acetate-styrene-butyl acrylate) stone paint emulsion and preparation method

The invention particularly relates to a VAc / St / BA (vinyl acetate-styrene-butyl acrylate) stone paint emulsion and a preparation method. The emulsion comprises components as follows: 18-23 parts of styrene, 26-30 parts of vinyl acetate, 28-32 parts of butyl acrylate, 14-21 parts of alkyl methacrylate, 1.8-2.7 parts of alkyl acrylate, 2-6 parts of a functional monomer, 2-6 parts of a cross-linking agent, 0.3-1.5 parts of an initiator, 3-7 parts of a mixed emulsifier and 100-140 parts of deionized water. The VAc / St / BA stone paint emulsion has the benefits as follows: the yellowing-resistant effect of the styrene-acrylic emulsion can be improved effectively by the aid of the excellent yellowing resistance of vinyl acetate, and the emulsion has the characteristics of low cost, good water resistance, good paint film hardness, good yellowing resistance, good water white resistance and stable performance.

Owner:佛山市顺德区巴德富实业有限公司

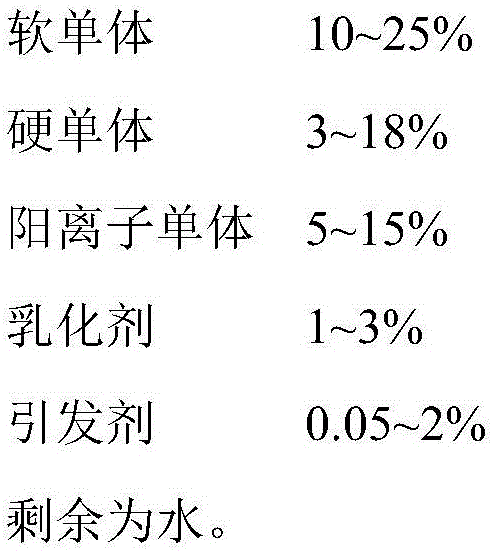

Cationic binder for denim paint dyeing

The invention relates to a cationic binder emulsion for denim paint dyeing. The binder emulsion is generated after a reaction of soft monomers, hard monomers, cationic monomers, crosslinking monomers, a compound emulsifier and an initiator. During preparation, a mixture of all the monomers and an initiator water solution are added into the emulsifier and distilled water for a reaction, cooling and filtering are conducted, and the cationic binder is prepared. The cationic binder is used for the denim yarn / fabric paint dyeing process or the paint overdyeing process, and during use, it is not needed to pretreat yarn / fabric or paint.

Owner:CHANGZHOU UNIV

Epoxy resin composition for luminous characters

The invention discloses an epoxy resin composition for luminous characters, which consists of the following components in percentage by weight: 20-80% of epoxy resin, 10-40% of a curing agent, 5-10% of an accelerant, 4-10% of a diluent and 0-0.5% of an antifoaming agent, and most preferably 60% of epoxy resin, 24% of a curing agent, 8% of an accelerant, 7.8% of a diluent and 0.2% of an antifoaming agent. The epoxy resin composition disclosed by the invention has short normal-temperature curing time that the epoxy resin composition can be cured in 6-8 hours, can improve the working efficiency, and has the advantages of good surface effect, good luminous effect, excellent yellowing resistance and long-term luminous effect.

Owner:DONGGUAN SCI IND

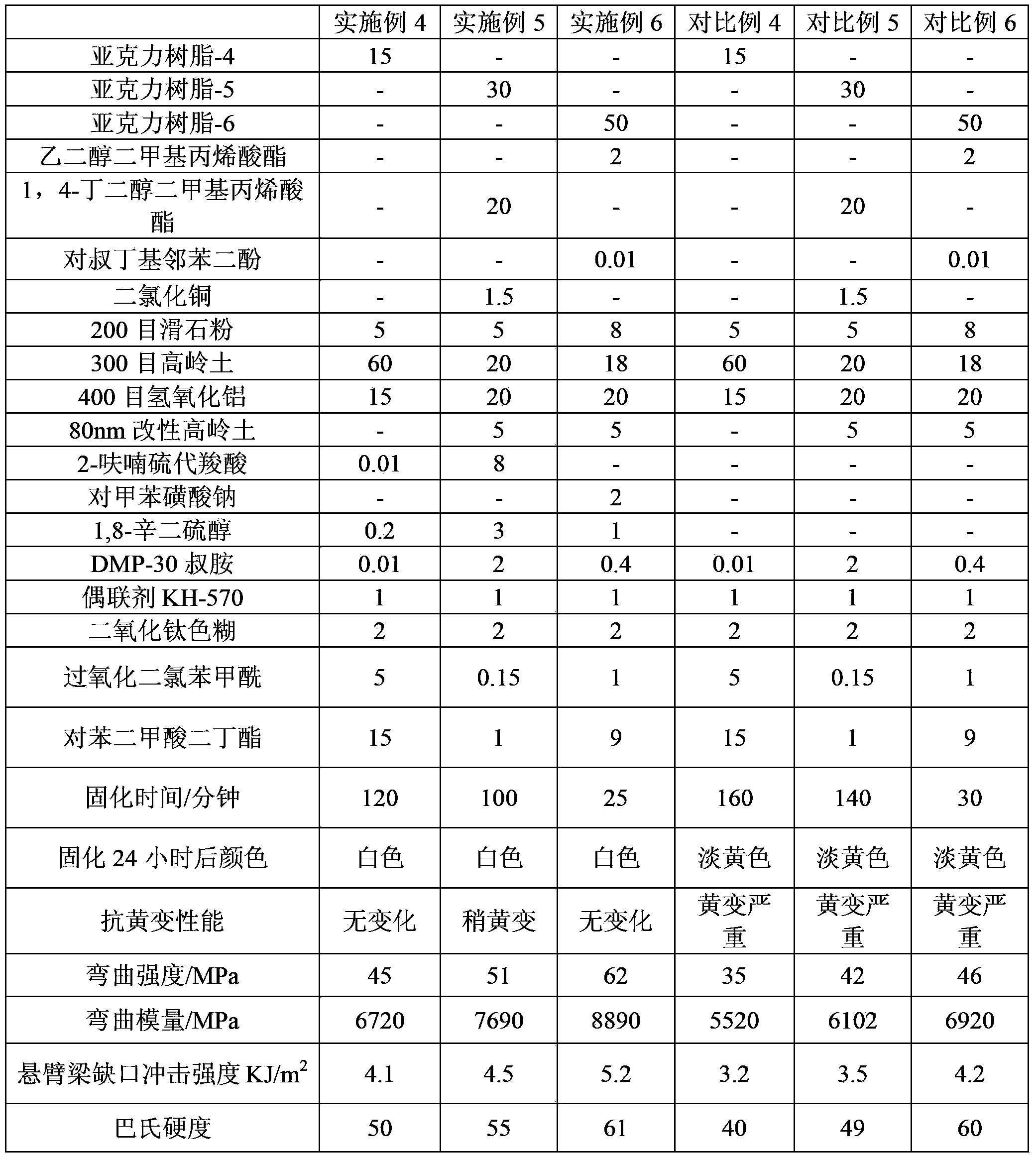

Normal-temperature bi-component or multi-component curing system and application thereof

ActiveCN103360553AImprove anti-yellowing effectFast curing rateNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveOrganic acidAlcohol

The invention discloses a normal-temperature bi-component or multi-component curing system and an application thereof. The normal-temperature bi-component or multi-component curing system comprises the following components in parts by weight: (A) 10-90 parts of acrylic-based resin, (B) 0-30 parts of acrylic ester with the degree of functionality more than or equal to 2, (C) 0-2 parts of polymerization inhibitors, (D) 0-85 parts of fillers, (E) 0.005-10 parts of organic acid and / or organic acid salt, (F) 0-4 parts of sulfur alcohol, (G) 0.05-3 parts of tertiary amine, (H) 0-10 parts of addition agents, (I) 0.1-6 parts of curing agents and (J) 1-15 parts of dispersing agents. The normal-temperature bi-component or multi-component curing system disclosed by the invention is good in yellowing resistance, high in curing velocity and short in curing time and can be conveniently used at the normal temperature or even in winter.

Owner:GUANGDONG FUSHENG INNOVATIVE MATERIAL TECH LTD

High abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying

InactiveCN106833295AGuaranteed mechanical strengthModerate molecular weightFireproof paintsEpoxy resin coatingsAcrylic resinPolyamide

The invention relates to a high abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying. The high abrasion-resistant UV white primer is prepared from the following raw materials in parts by weight: 40 to 70 parts of epoxy acrylic resin, 15 to 35 parts of hydroxy acrylic resin, 10 to 20 parts of thermoplastic acrylic resin, 15 to 30 parts of tripropylene glycol diacrylate, 5 to 25 parts of modified graphene, 2 to 6 parts of nanometer silicon dioxide, 1 to 5 parts of nanometer titanium dioxide, 1 to 5 parts of heavy calcium carbonate, 5 to 15 parts of montmorillonite, 10 to 20 parts of white pigment, 2 to 5 parts of zinc stearate, 2 to 6 parts of carboxymethyl cellulose sodium, 1 to 5 parts of polyamide wax, 0.5 to 2 parts of flatting agent, 0.1 to 0.5 part of defoaming agent, 2 to 6 parts of photoinitiator, and 5 to 15 parts of organic solvent. The high abrasion-resistant UV white primer for electrostatic spraying has the advantage that at the premise of ensuring the good electrostatic spraying effect, the anti-sagging property of the primer and the abrasion-resistant property of the primer film are greatly improved.

Owner:TIANCHANG JINLING ELECTRONICS

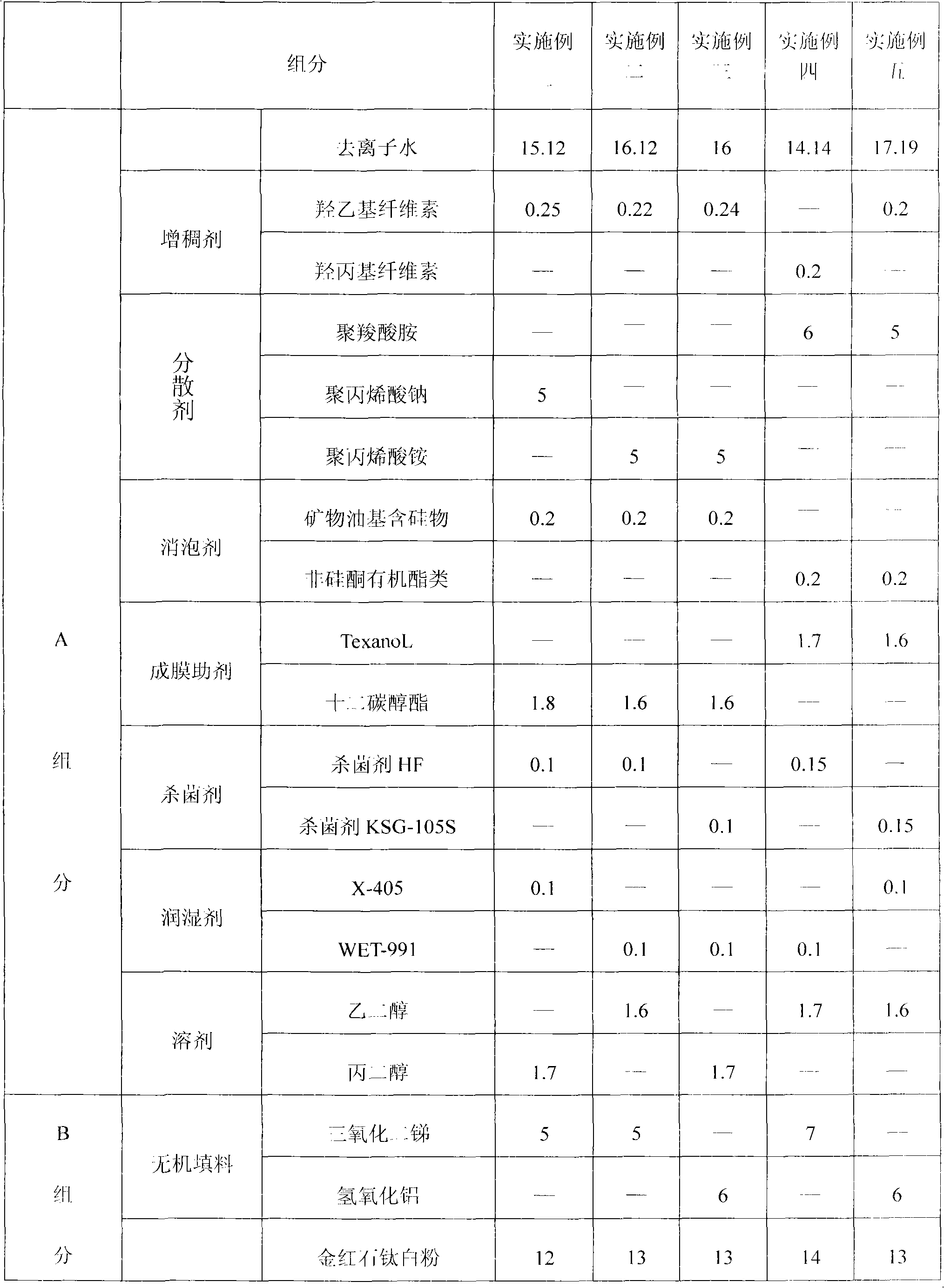

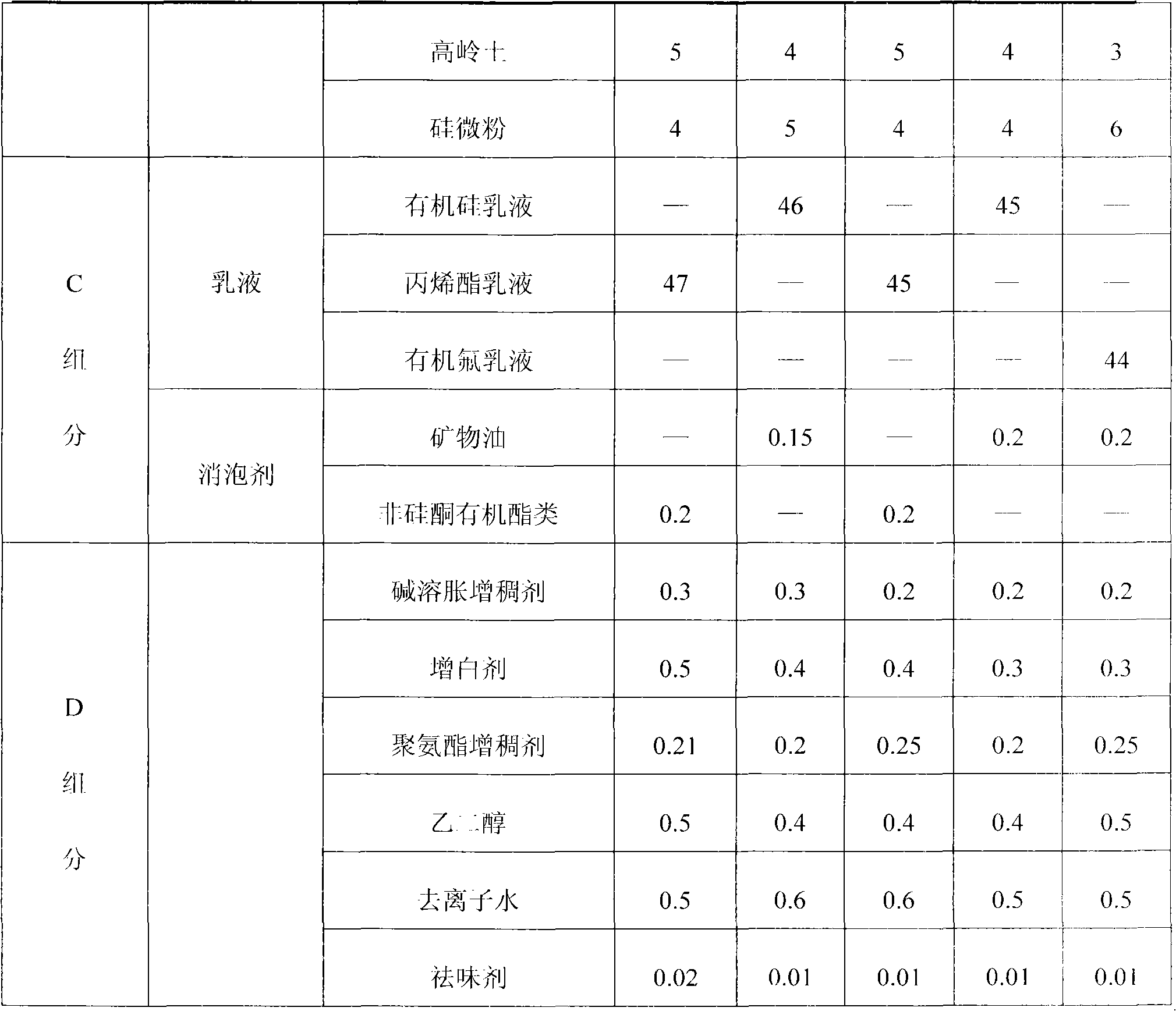

Low carbon wallpaper paint and preparation method thereof

InactiveCN101880987AActive releaseLow VOC contentSpecial visual effect coatingsCoatingsEmulsionOrganic Ester

The invention discloses a low carbon wallpaper paint which comprises the following components in parts by weight: a component A, a component B and a component C, wherein the component A comprises 0.2-0.3 part of thickening agent, 4-7 parts of dispersing agent, 0.1-0.3 part of defoaming agent, 1.5-2.5 parts of film-forming agent, 0.1-0.2 part of sterilizing agent, 0.1-0.2 part of wetting agent, 1-2 parts of solvent and 15-20 parts of water; the component B comprises 4-7 parts of powder, 10-15 parts of titanium white, 2-5 parts of kaoline and 4-7 parts of silica micropowder; the component C comprises 40-60 parts of emulsion, 0.1-0.2 part of deforming agent, 0.2-0.4 part of film-forming agent and 0.1-0.2 part of non-silicone organic ester deforming agent. The low carbon wallpaper paint reaches the international environmental-protection standard, can effectively make up the wall thin cracks, and has excellent scrubbing resisting property, yellowing resisting property and long service life.

Owner:贺佑康

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com