LED packaging material, its preparation method and application

A technology of LED packaging and ultraviolet light, which is applied in the direction of epoxy resin glue, adhesive type, film/sheet adhesive, etc., can solve the manufacturing and application limitations of LED packaging materials, and the LED packaging film is prone to problems , increase cost and other issues, achieve the effect of improving anti-yellowing property and light transmittance, expanding ultraviolet absorption wavelength and absorption intensity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

[0030]The cross-linking agent (methyl hexahydrophthalic anhydride), cross-linking agent accelerator (tetraethylammonium bromide), antioxidant (tri(2,4-di-tert-butylphenyl) phosphite ), UV stabilizer (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate), UV absorber UV327 (2-(2-hydroxy-3,5- Dibutyl tert-ylphenyl)-5-chlorobenzotriazole) were added into the flask together, heated to 80°C under magnetic stirring, until the mixture was completely dissolved, cooled to room temperature; then added the above weight fraction of bisphenol A type Stir the epoxy resin evenly to obtain an epoxy composition; place it in a vacuum defoamer for 2 hours at room temperature to remove air bubbles, then inject it into a mold with LEDs, and cure it at 130°C for 2 hours. Take it out after natural cooling, and heat it again to 130° C. for 2 hours to remove residual stress and volatile components, and then a packaged light-emitting diode can be obtained. The ultraviolet aging test was carried...

Embodiment 2

[0032]

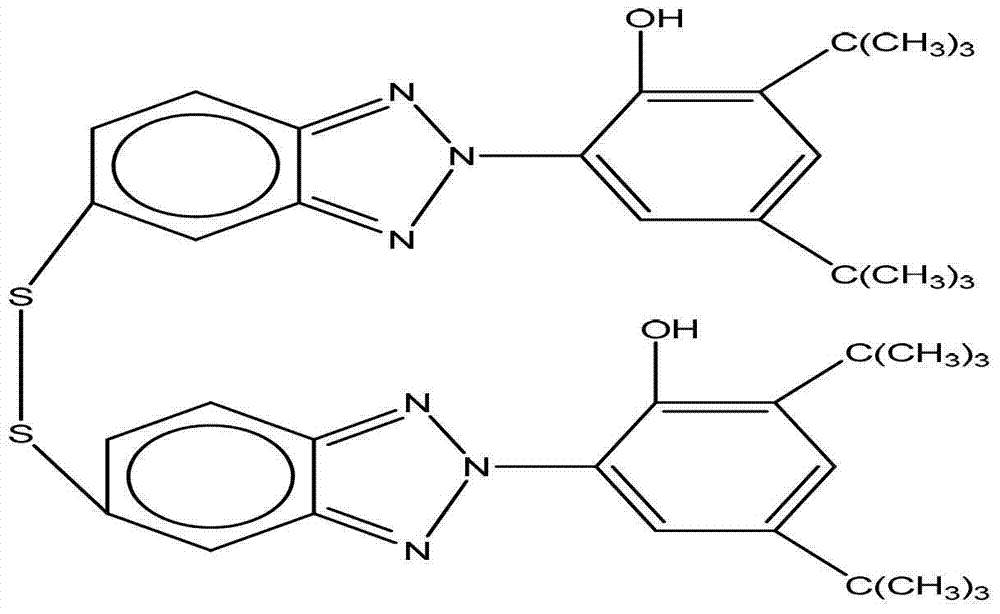

[0033] The cross-linking agent (methyl hexahydrophthalic anhydride), cross-linking agent accelerator (tetraethylammonium bromide), antioxidant (tri(2,4-di-tert-butylphenyl) phosphite ), UV stabilizer (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate), UV absorber (5,5`-dithio-bis-[2 -(2`-Hydroxy-3`,5`-di-tert-butylphenyl)-2H-benzotriazole]) were added into the flask together, heated to 80°C under magnetic stirring, until the mixture was completely dissolved, Cool to room temperature; Add the bisphenol A type epoxy resin of above-mentioned weight fraction again, stir, namely obtain epoxy composition; At room temperature, it is placed in vacuum degassing machine to process 2 hours, to remove the bubble wherein, Then pour into the mold with LED, solidify at 130°C for 2 hours, take it out after natural cooling, and heat it again to 130°C for 2 hours to remove residual stress and volatile components, and you can get a packaged light-emitting diode. The ultraviolet aging...

Embodiment 3

[0035]

[0036] The cross-linking agent (methyl hexahydrophthalic anhydride), cross-linking agent accelerator (tetraethylammonium bromide), antioxidant (tri(2,4-di-tert-butylphenyl) phosphite ), UV stabilizer (bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate), UV absorber (5,5`-dithio-bis-[2 -(2`-Hydroxy-3`,5`-di-tert-butylphenyl)-2H-benzotriazole]) were added into the flask together, heated to 80°C under magnetic stirring, until the mixture was completely dissolved, Cool to room temperature; Add the bisphenol A type epoxy resin of above-mentioned weight fraction again, stir, namely obtain epoxy composition; At room temperature, it is placed in vacuum degassing machine to process 2 hours, to remove the bubble wherein, Then pour into the mold with LED, solidify at 130°C for 2 hours, take it out after natural cooling, and heat it again to 130°C for 2 hours to remove residual stress and volatile components, and you can get a packaged light-emitting diode. The ultraviolet aging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com