Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "Moderate molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

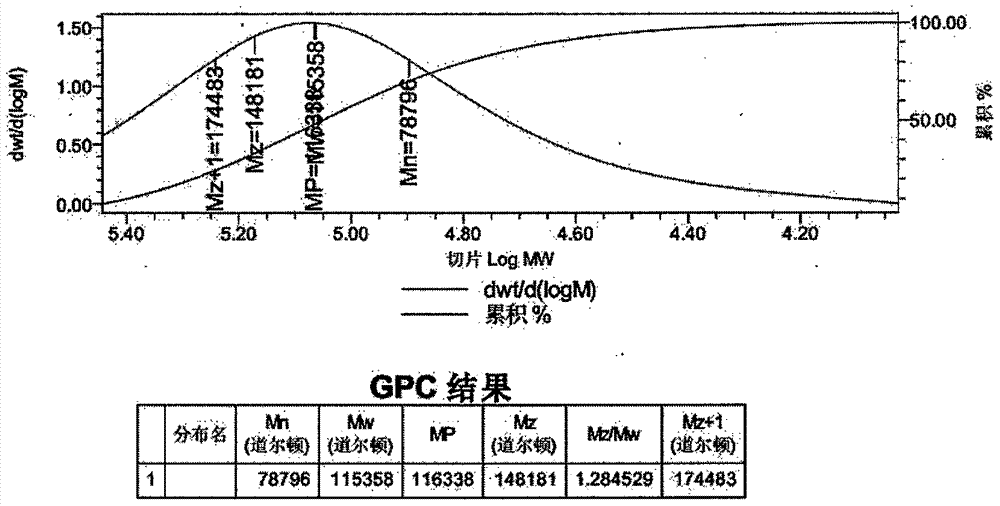

Alcohol soluble polyacrylate resin and preparation method and application thereof

The invention discloses an alcohol soluble polyacrylate resin and a preparation method and an application thereof; the preparation method comprises the following steps: taking 260-800 parts of alcohols solvent, adding the solvent in a reaction kettle with a mixer, a reflux condenser, a heating jacket and a nitrogen covering layer, then heating the system to 70-150 DEG C, mixing the mixture for 10-30min; adding acrylic ester used as hard monomers, acrylic ester used as soft monomers, polar functional group monomers, organosilane monomers and initiator to react for 4-7h and obtain alcohol soluble polyacrylate resin. The alcohol soluble polyacrylate resin prepared by the method of the invention has no excitant odour, the number-average molar mass is 10,000-200,000, the molecular weight distribution is 1.1-4 and the Brookfield viscosity of the resin system is 100-5000cp. The coating which is prepared by mixing the resin with other pigments, fillers and assistants can be applied in glass, aluminium coil and polypropylene plastic for surface decoration and protective function.

Owner:SOUTH CHINA UNIV OF TECH

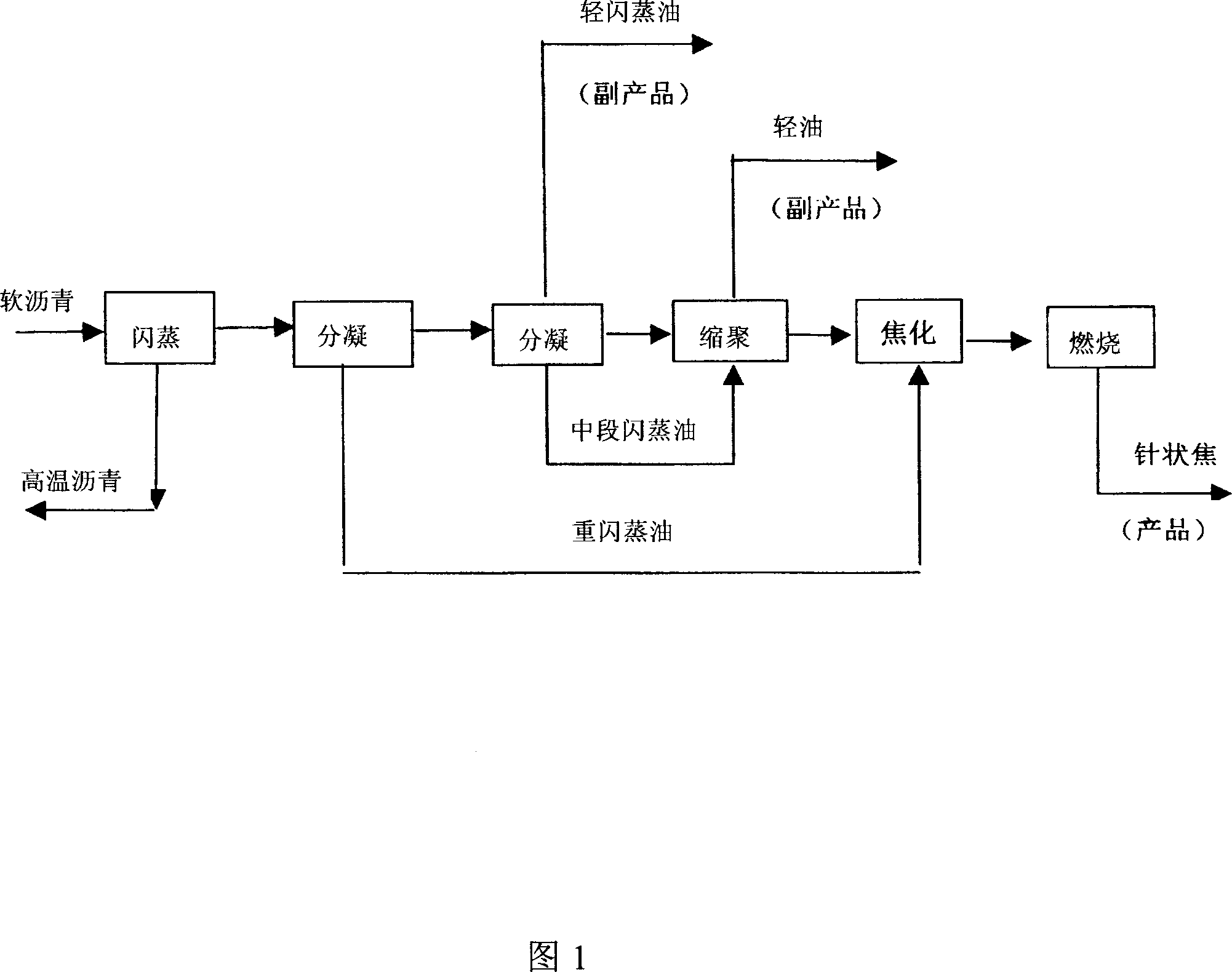

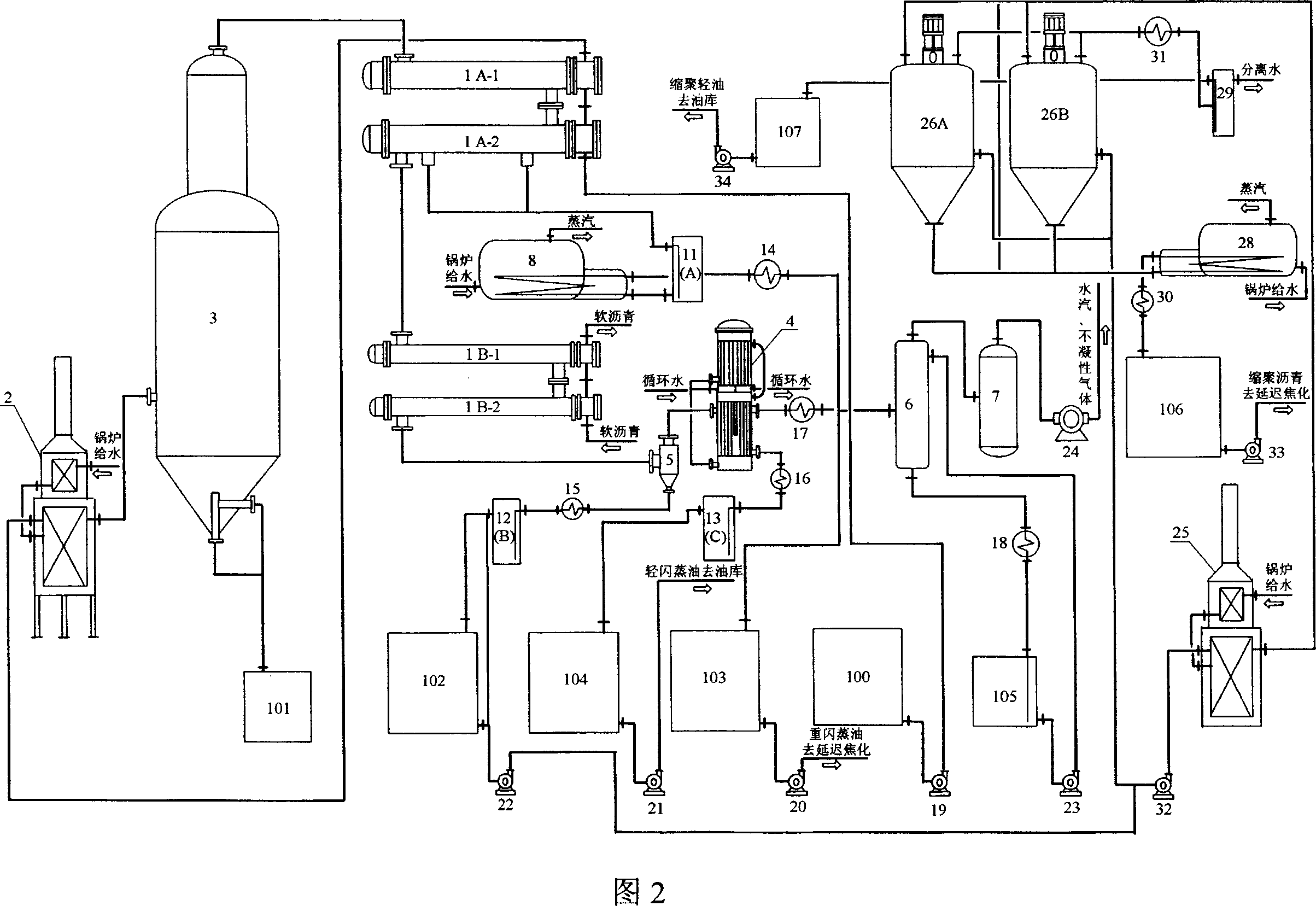

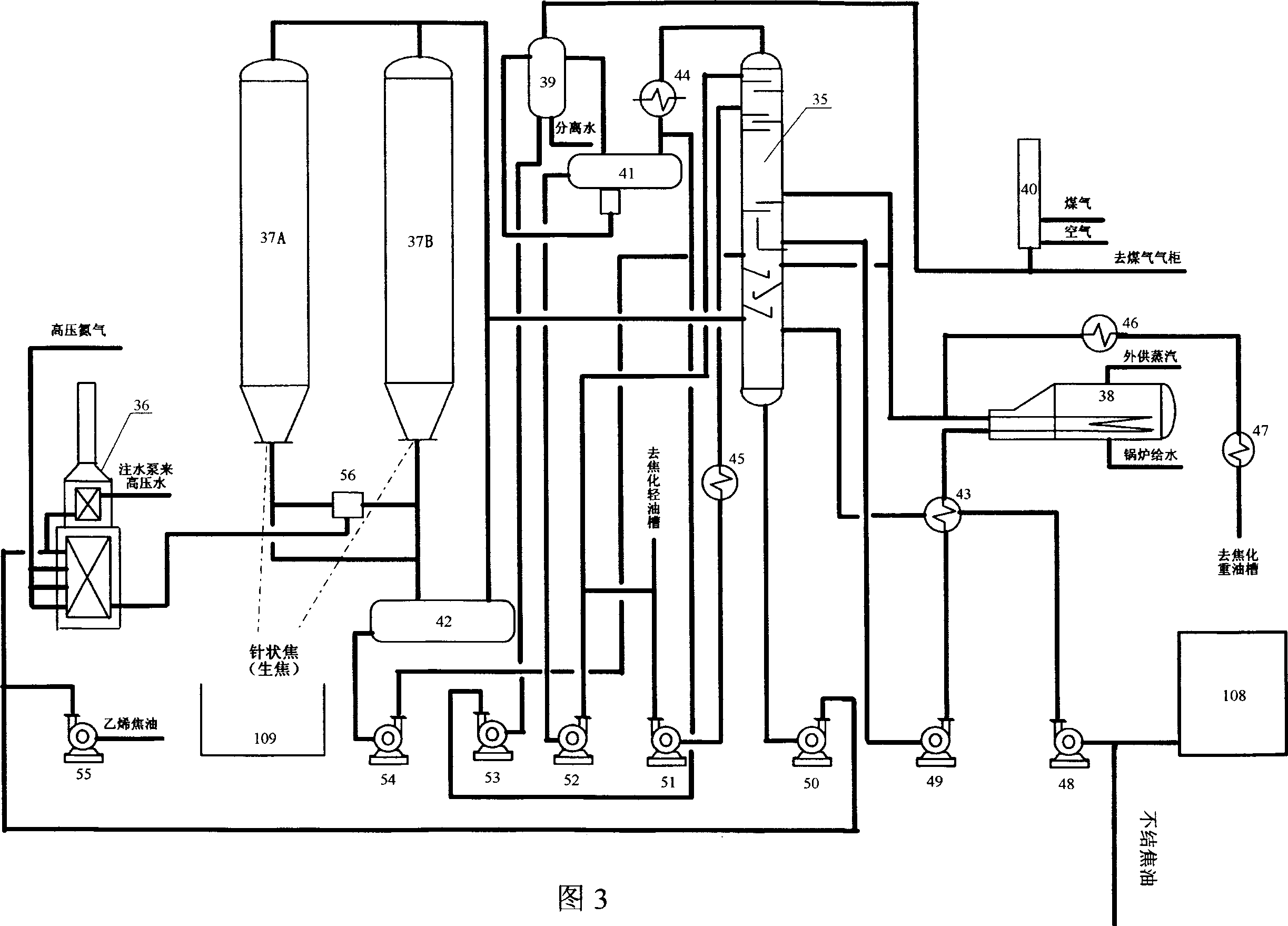

Industrial producing process for coal series needle coke

ActiveCN1944578AHigh molecular weightSmall molecular weightCoking carbonaceous materialsGraphite electrodeGraphite

The industrial producing process of coal series needle coke includes the following steps: stepped condensing the flash oil produced in vacuum flashing of coal tar pitch to obtain three, heavy, medium and light, fractions; polycondensating the medium fraction in an improved pitch circulating process to obtain condensed pitch; delay coking the condensed pitch and the heavy fraction and injecting N2 into the un-coked oil in the later coking stage to perform the final heating and coke drawing of the needle coke forming course; and final high temperature calcining to obtain coal series needle coke. Thus produced coal series needle coke has low thermal expansion coefficient and may be used in producing high power and super high power graphite electrode.

Owner:山西宏特煤化工有限公司

Flame-retardant bismaleimide resin and preparation method thereof

The invention discloses flame-retardant bismaleimide resin and a preparation method thereof. The flame-retardant bismaleimide resin is prepared by uniformly mixing 100 weight parts of bismaleimide resin, 0 to 200 weight parts of allyl compound and 1 to 100 weight parts of amino functional group-containing polysiloxane at the temperature of between 90 and 200 DEG C. The resin has high flame retardance, toughness, heat resistance and dielectric property, can be used as a high-performance resin matrix, an adhesive, an insulating varnish and the like, has great application prospect in the highly technical fields of aerospace, electronic and electrical appliances, transportation and the like; and the preparation method of the resin has the characteristics of high applicability, environmental friendliness, simple operation process and the like.

Owner:苏州亚傲鑫企业管理咨询有限公司

High-solid-content photocuring fluorinated polyurethane-acrylate (PFUA) coating and preparation method thereof

ActiveCN103059706AModerate molecular weightPolyurea/polyurethane coatingsPolymer scienceFunctional monomer

The invention relates to high-solid-content photocuring fluorinated polyurethane-acrylate (PFUA) coating and a preparation method thereof. The preparation method comprises the following steps: performing double bond solution free radical polymerization on an acrylate monomer to prepare hydroxyl fluorinated polyacrylate (PFA) resin; grafting the synthesized PFA resin through a polyisocyanate monomer and controlling the ratio of the hydroxyl to the isocyanate to prepare polyurethane grafted fluorinated polyacrylate (PFUA) resin blocked by isocyanate; and blocking through a hydroxyl acrylic acid functional monomer to prepare the resin with photocuring activity, wherein the resin has high molecular weight and low viscosity. The prepared coating has high solid content, a simple preparation process, high heat resistance, weather resistance and staining resistance and high photocuring rate, is high-performance coating and can be applied to corrosion resistance of automobile cover faces and steel materials.

Owner:GUANGDONG UNIV OF TECH

Preparation method for polyvinylidene fluoride with high molten fluidity

ActiveCN102134292AImprove regulation efficiencyImprove melt fluidityPowdery paintsEnd-groupPolyvinylidene difluoride

The invention relates to a preparation method for polyvinylidene fluoride with high molten fluidity. The initiator used for the polymerization is an organic initiator comprising organic hydrogen peroxide and organic peroxide with a molar ratio of 1-5, and the used conditioning agent is an ester conditioning agent with high dispensing efficiency for the system; the addition way of the initiator and the conditioning agent is a continuous addition way; the polymerization condition is mild; the polymerization product has a stable end group and a moderate molecular weight with a narrow distribution coefficient; and the product has high molten fluidity, good thermochemical stability, and significantly improved mechanical properties and weatherability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

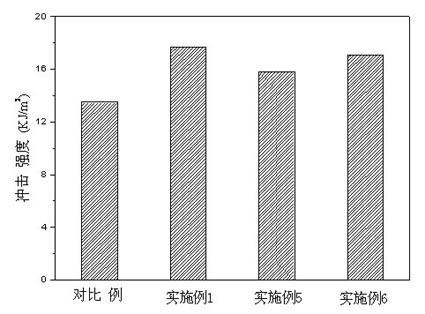

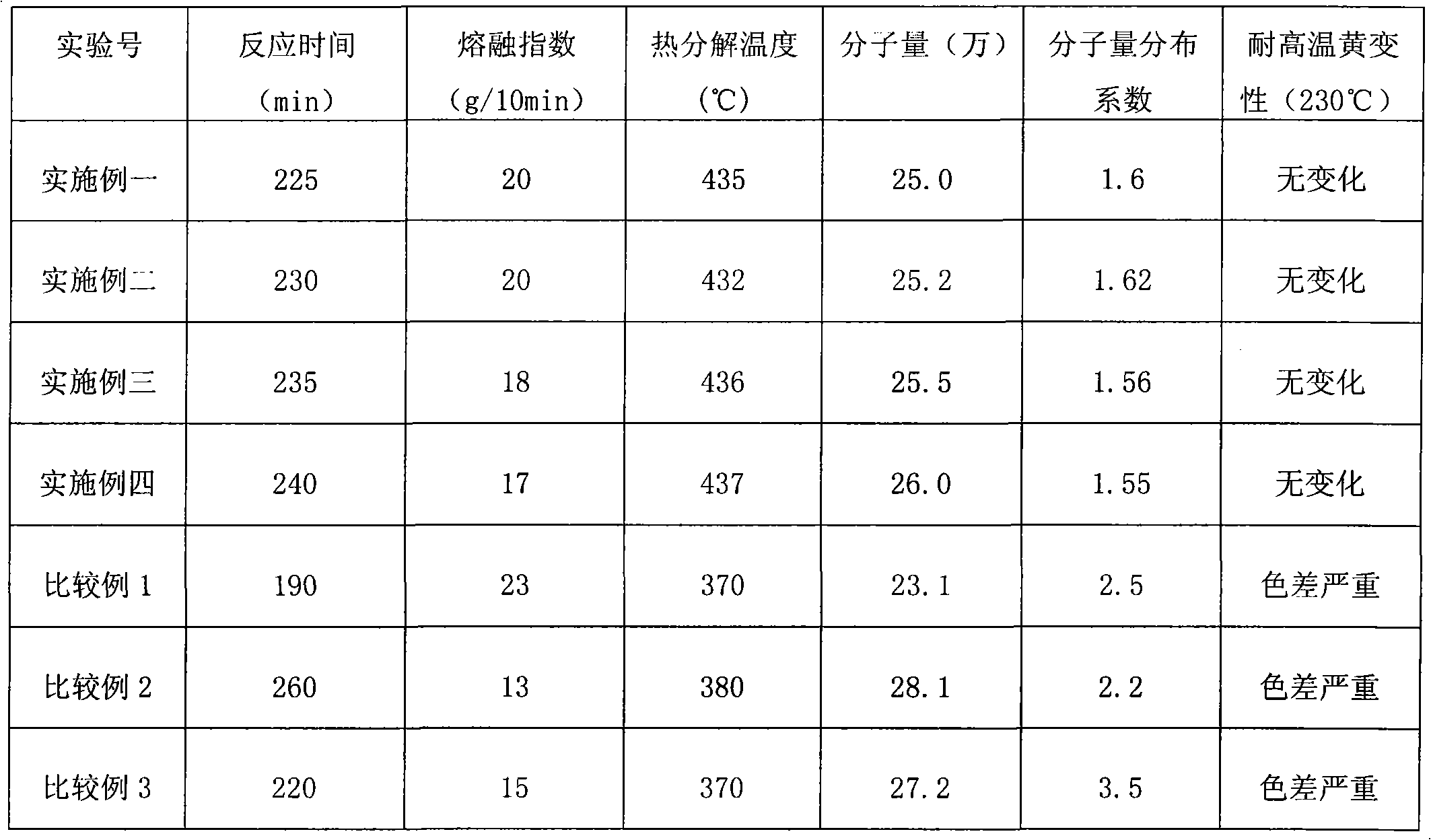

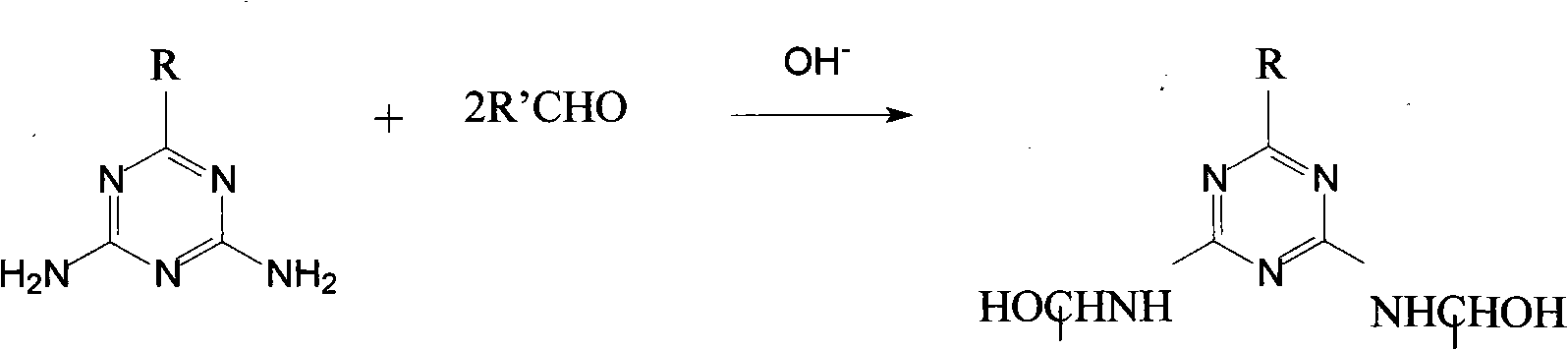

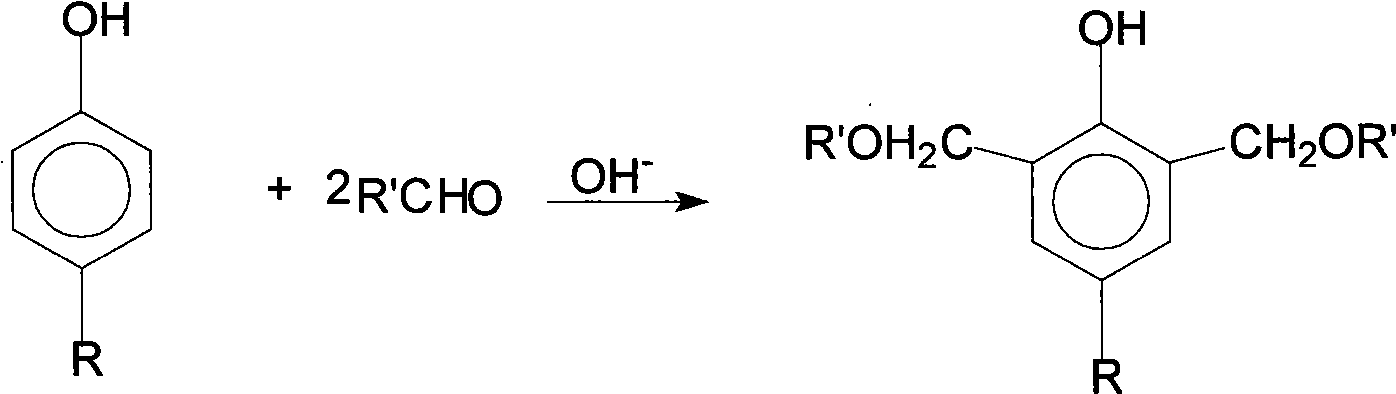

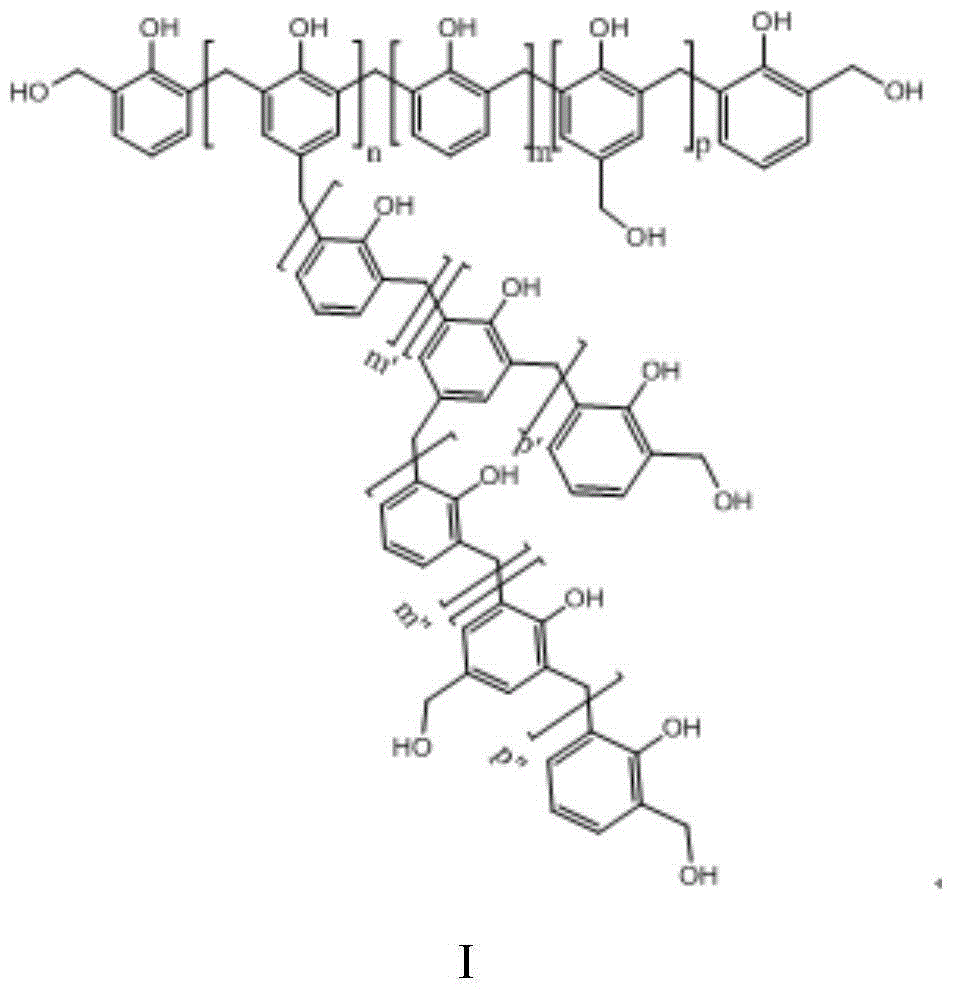

Synthetic method of nitrogen-containing flame-retardant phenolic resin

InactiveCN101323658AModerate molecular weightReasonable molecular weight distributionSolution systemOrganic base

The invention pertains to the technical field of preparing a modified phenolic resin and particularly relates to a synthetic method of a nitrogen-containing and flame-retarding phenolic resin; the synthetic method of the invention comprises the following steps: the monosubstituted melamine monomer and the aldehyde monomer with a mole ratio of 1:2 to 5 are blended and put in to an organic base adjusting solution system with the pH value of 8 to 11 to carry out a hydroxymethylation at a temperature of 65 DEG C to 90 DEG C; the para-orienting organic phenol monomer and the aldehyde monomer with mole ratio of 1:2 to 5 are added into the reaction system; the hydroxymethylation lasts for 0.5 hours to 2 hours at a temperature of 65 DEG C to 90 DEG C; then a condensation polymerization is carried out at the temperature of 75 DEG C to 100 DEG C; an organic solvent is added for the purpose of pressure reduction and azeotropy; the reflow temperature is kept at 60 DEG C to 80 DEG C; after the moisture in the reaction system is removed, an organic solvent is added to dilute, prepare and obtain nitrogen-containing and flame-retarding phenolic resin with a thiotrzinone structure unit, which can be used for producing non-halogen and flame-retarding phenolic resin laminates of grade FV0 and applied as epoxy resin hardeners.

Owner:北京新福润达绝缘材料有限责任公司

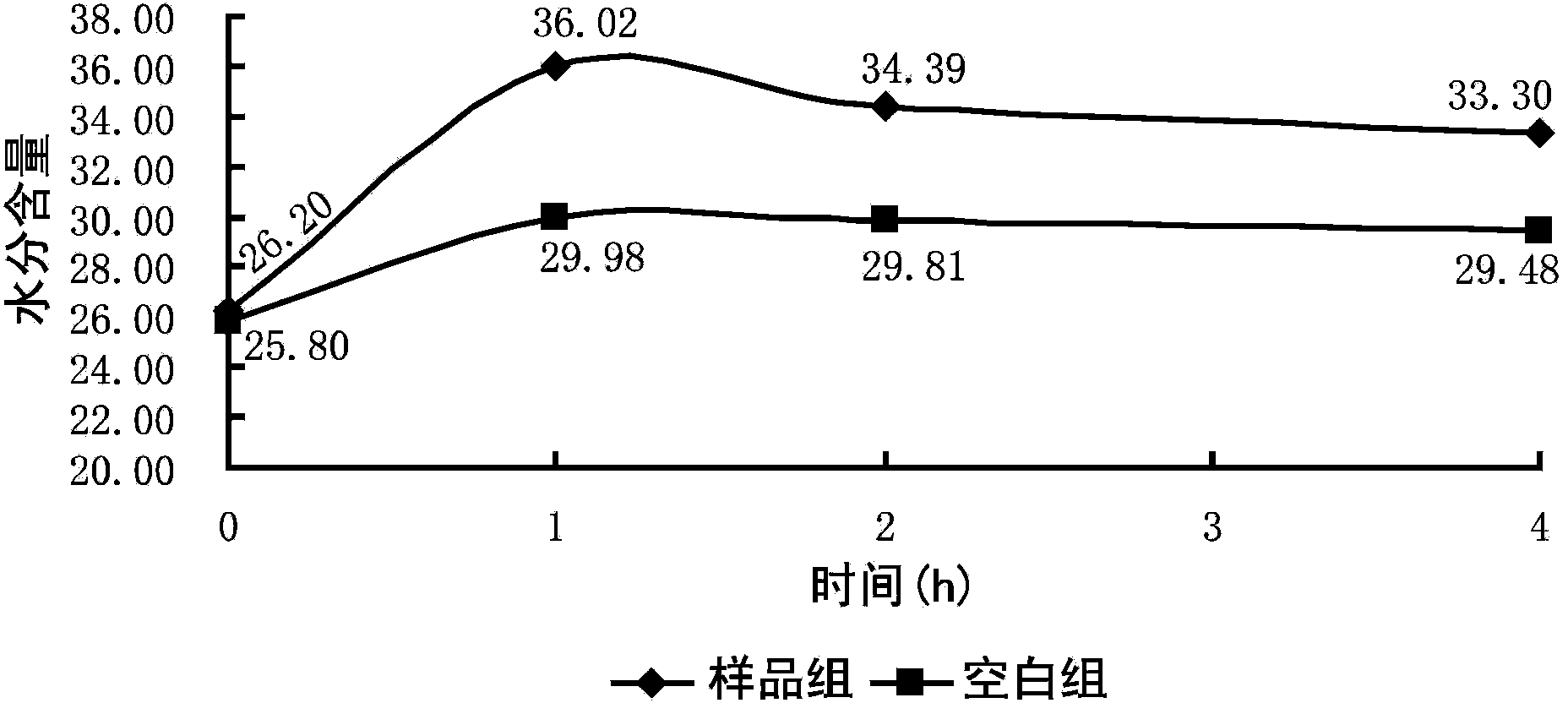

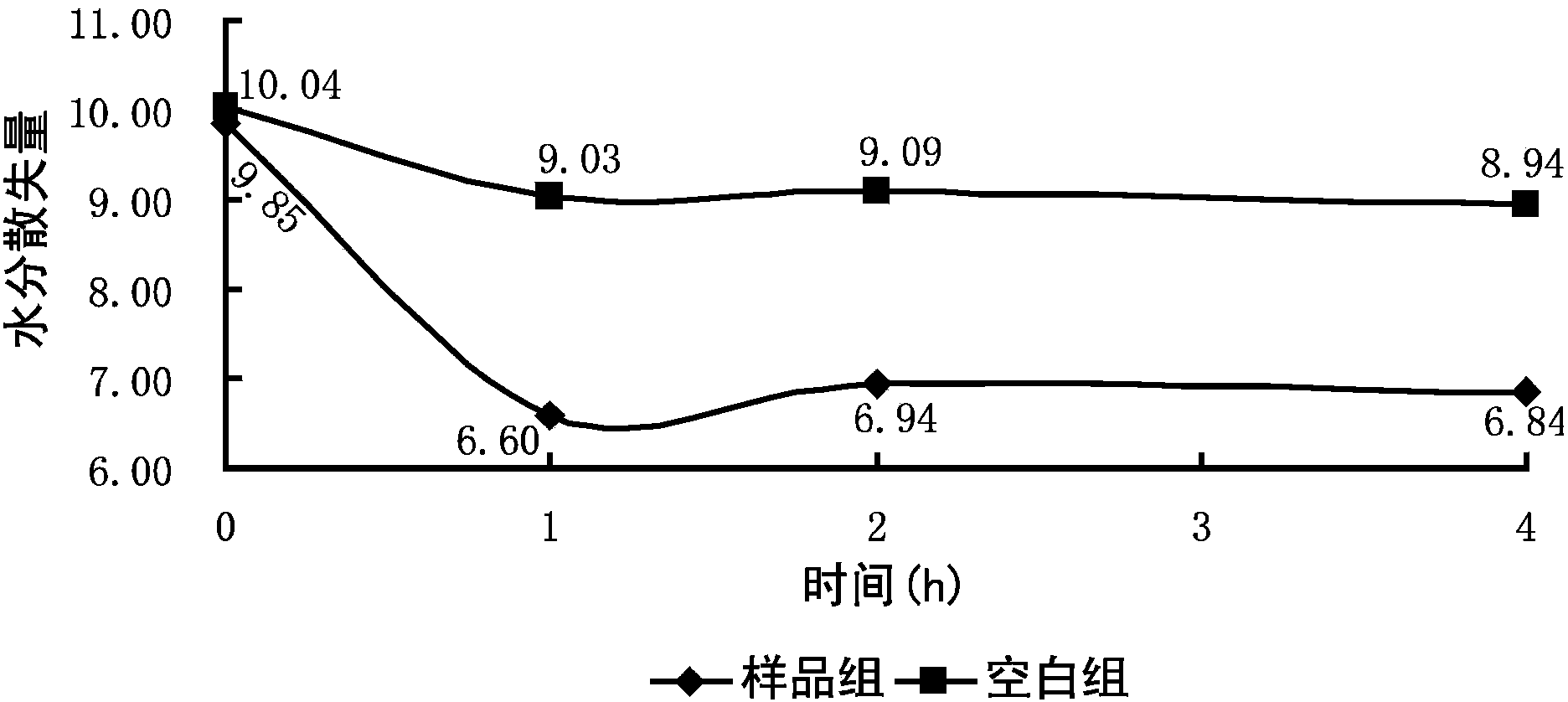

Long-acting combination type wound dressing and preparation method thereof

InactiveCN102078638AProlong the action timeShort onset timeAbsorbent padsBandagesWound dressingGlycerol

The invention relates to long-acting combination type wound dressing and a preparation method thereof. The long-acting combination type wound dressing comprises chitosan, oligo-chitosan, chitosan oligosaccharide, glacial acetic acid, isinglass, glycerol and purified water, wherein 100 milliliters of purified water contains 0.5g-8g of isinglass, 0.5g-10g of oligo-chitosan, 0.5g-10g of chitosan oligosaccharide, 0.3g-6g of isinglass, 0.3 milliliters-6 milliliters of glacial acetic acid and 1 milliliters-10 milliliters of glycerol. The long-acting combination type wound dressing is novel bio-hydrogel dressing which is short in onset time and is long in action time, can promote the healing of burn and scald wounds and acute and chronic wounds, and has three functions of hemostasis, analgesia and healing promotion; three main raw materials with different molecular weight gradients, such as chitosan, oligo-chitosan and chitosan oligosaccharide, are used, so as to achieve the purpose that the main raw materials are gradually absorbed in turn and exerts actions.

Owner:都本立

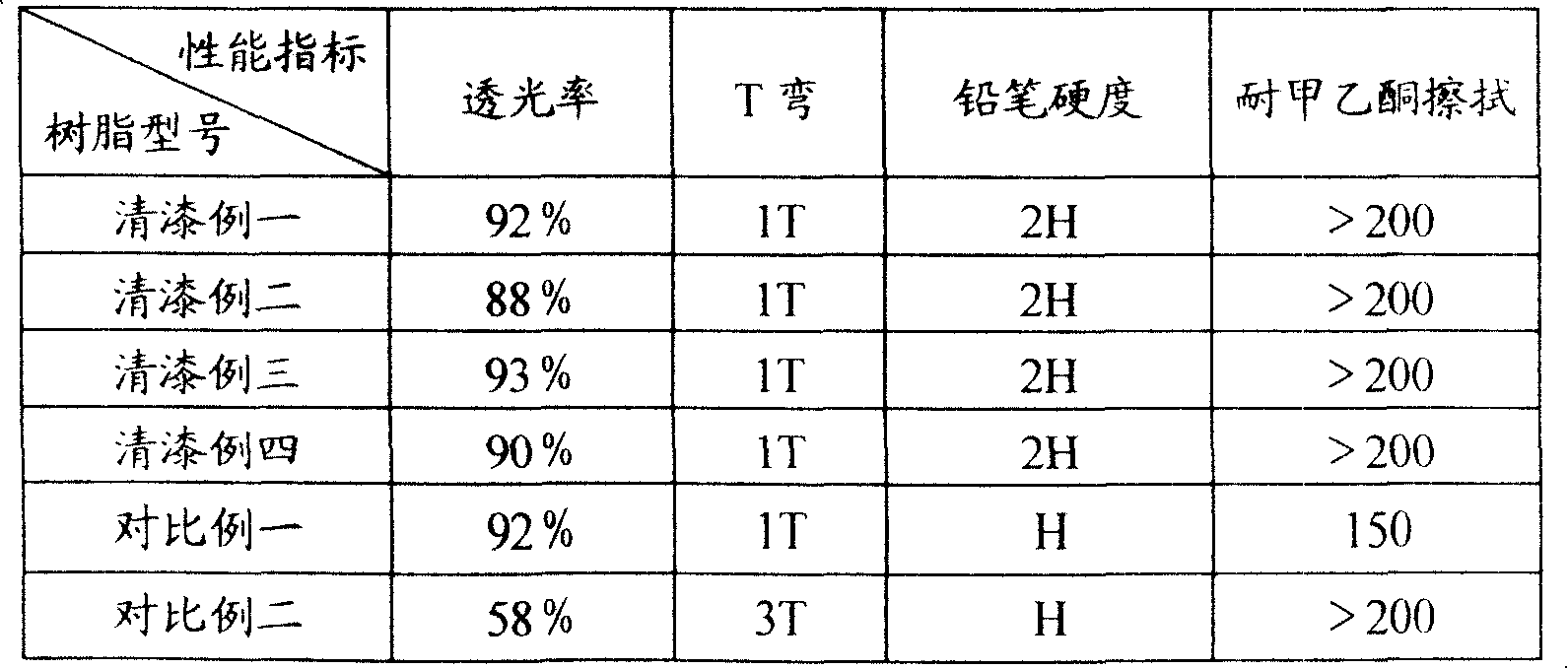

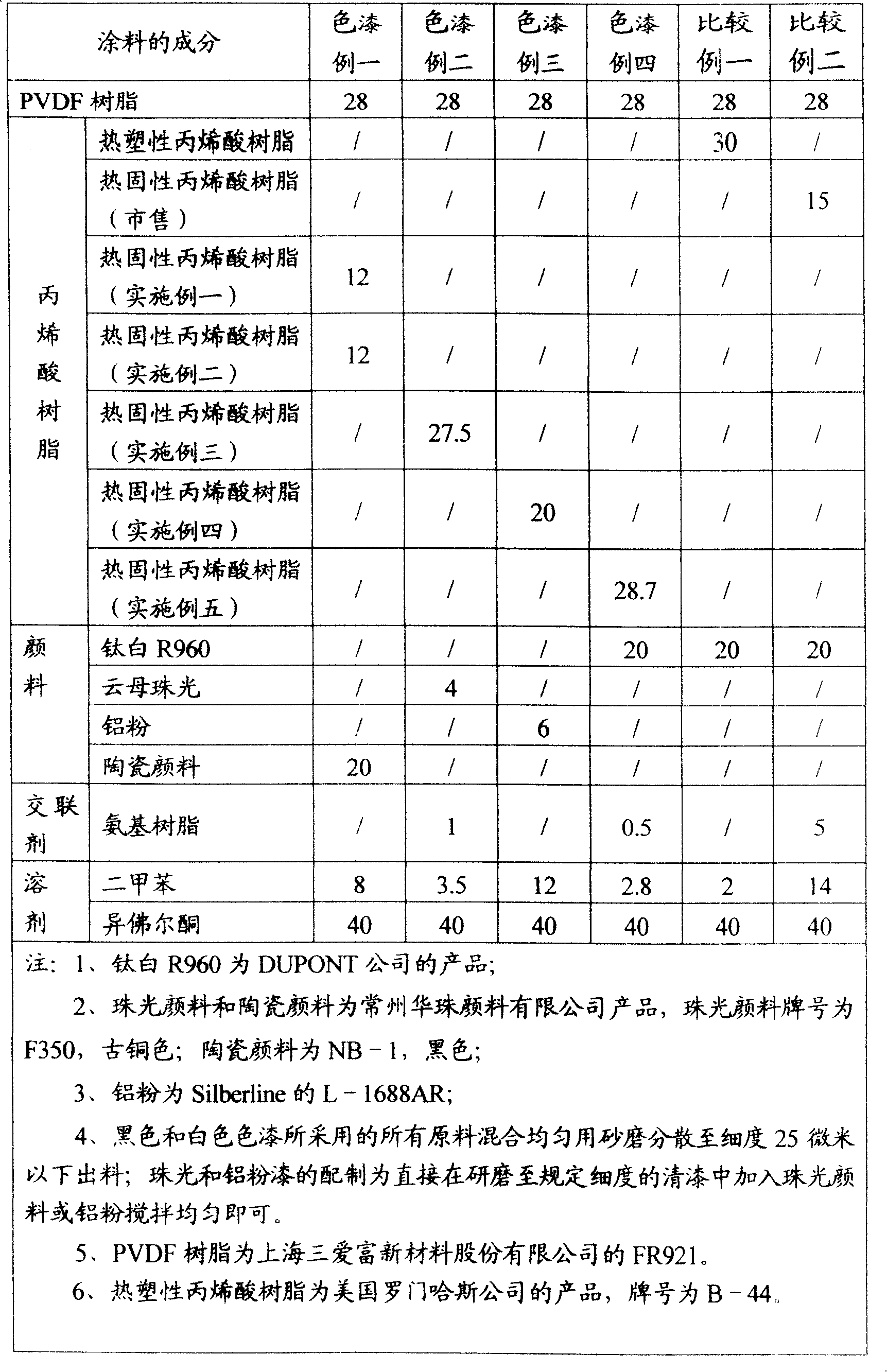

Thermoset acrylic resin for paint and high-temperature firing type polyvinylidene fluoride (PVDF) coiled material paint containing the same

The invention discloses a thermosetting acrylic resin used in paint with the number average molecular weight ranging from 10000 to 50000, as well as the high-temperature firing polyvinylidene fluorine (PVDF) coiled materials with the resin; the copolymer section of the resin comprises the methyl methacrylate ranging from 40.0wt.% to 90.0wt.%, the alkyl acrylate ranging from 10.0wt. % to 60.0wt.% (the atomicity of alkyl carbon is no more than 4) as well as the functional acrylic monomer ranging from 0.1wt.% to 10.0wt.%. With dramatic miscibility with PVDF resin, the invention has the advantages of improving the protective effect and aging resistance of paint film and enhancing the transparency and flexibility of the paint film effectively when used in high-temperature firing polyvinylidene fluorine (PVDF) coiled materials.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

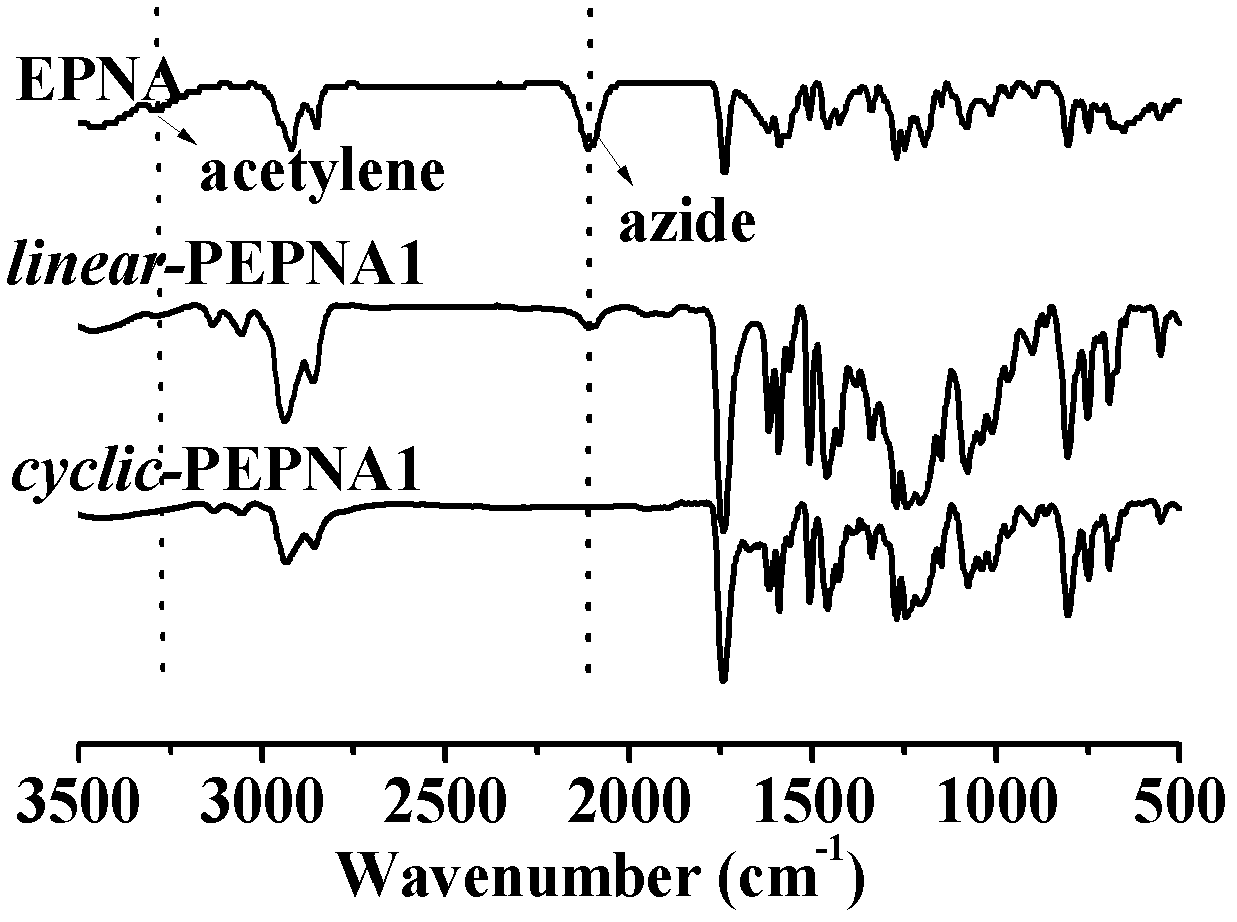

Cyclic polymer and preparation method thereof

InactiveCN102617855AModerate molecular weightLow PDI valueLuminescent compositionsPolymer scienceFluorescence

The invention discloses cyclic polymer and the preparation method thereof. The cyclic polymer is cyclic main chain phenylazo naphthalene polymer. Firstly, monomer EPNA is obtained through preparation, then thermocatalytic solid phase reaction is adopted for click reaction stepwise polymerization to the monomer EPNA, so as to obtain Alpha-azide group and Omega-alkynyl linear-PEPNA; and finally, ring closing reaction to linear-PEPNA is performed in extremely dilute solution through a nitrine / alkynyl CuAAC method, so as to obtain cyclic PEPNA. Compared with the linear polymer with the same molecular weight, the cyclic main chain phenylazo naphthalene polymer synthesized by using the method provided by the invention has the advantages of higher glass transition temperature (Tg), strong fluorescent emission, long fluorescence life time and deep groove depth of SRG (surface relief gratings).

Owner:SUZHOU UNIV

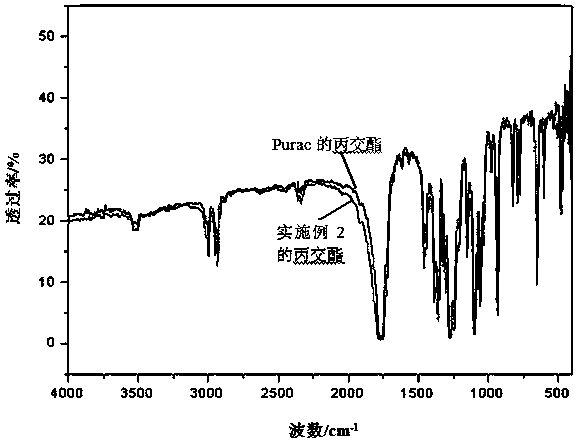

Catalyst for preparing lactides from lactic acid and method for preparing lactides from lactic acid

ActiveCN109894109AIncrease chance of contactBreak dehydration balanceOrganic chemistryCatalyst activation/preparationDepolymerizationLactide

The invention provides a catalyst for preparing lactides from lactic acid and a method for preparing lactides from lactic acid. The catalyst uses butyl titanate and zinc nitrate as raw materials; a sol-gel method is used for preparation to obtain a ZnO-TiO2 composite oxide; then, the ZnO-TiO2 composite oxide is loaded to graphene oxide; hydrothermal sealed treatment is performed to obtain a catalyst. After lactic acid dewatering, the catalyst is used for catalysis; depolymerization is performed at 5.0 to 15.0 kPa and 140 to 150 DEG C; depolymerization is performed at 500 to 100 Pa and 160 to 200 DEG C; coarse lactides are obtained; after purification, lactides are obtained. In the catalyst, the dispersion degree of ZnO and TiO2 particles is increased by graphene; the catalysis capability of active ingredients is improved. Particles with different valence states achieve mutual action in crystal lattices; the speed of the lactic acid polycondensation reaction and the oligomer depolymerization reaction is accelerated; meanwhile, the temperature required in the reaction process is lowered. The prepared lactides have high purity and high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

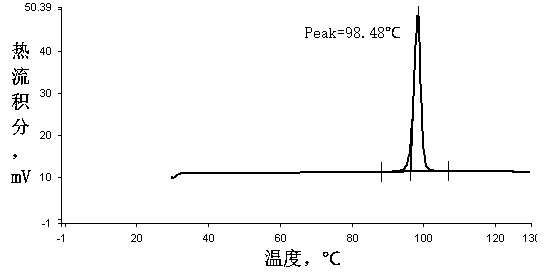

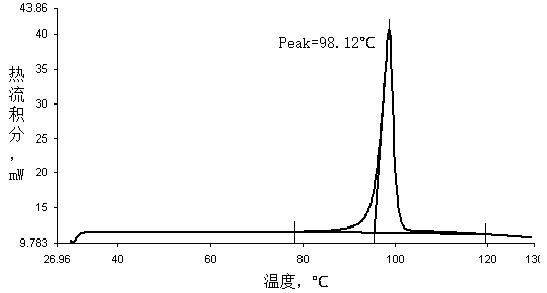

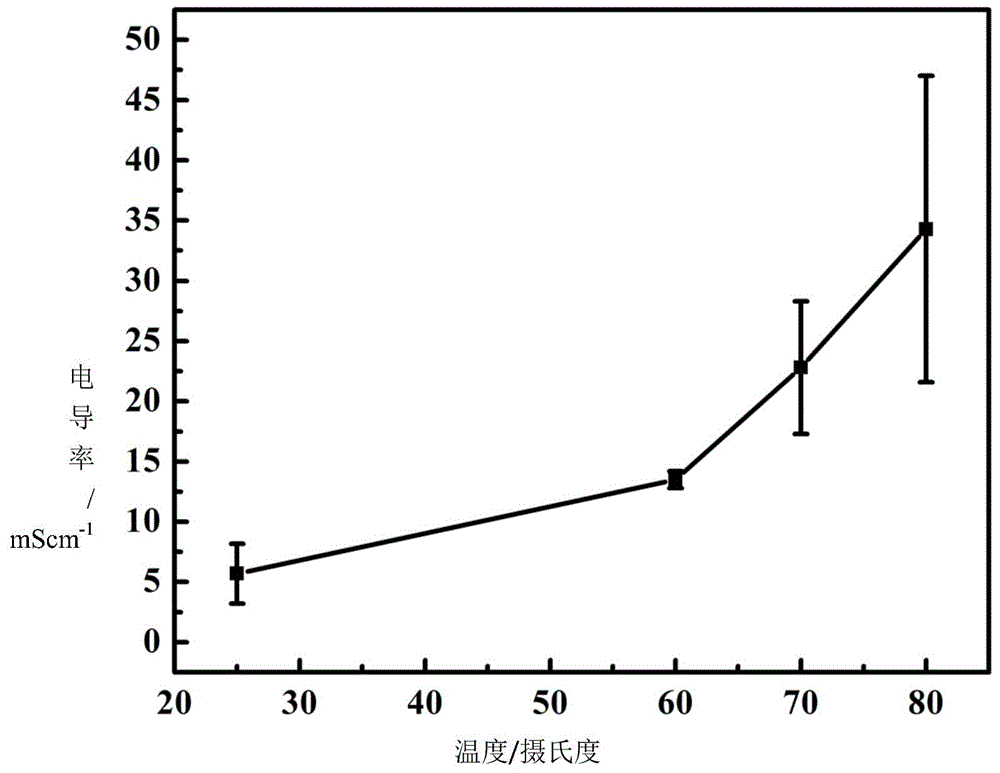

N1 position-substituted imidazole compound and alkaline anion exchange membrane, and preparation methods thereof

InactiveCN105777642ASimple processImprove stabilityOrganic chemistryFinal product manufactureAlkanePhenyl group

In the formula of an N1 position-substituted imidazole compound, R2 is a C1-C10 straight-chain paraffin; and R2 is a C1-C9 chain alkane, or a C3-C6 cycloalkane, or a phenyl group, or a biphenyl group. An alkaline anion exchange membrane comprises a halomethylated high-molecular polymer main chain and an N1 position-substituted imidazole branch chain represented by a molecular formula shown in the description. A preparation method of the alkaline anion exchange membrane comprises the following steps: synthesizing N1 position-substituted imidazole; preparing the halomethylated high-molecular polymer main chain; and preparing the N1 position-substituted imidazole type alkaline anion exchange membrane. The N1 position-substituted imidazole has the advantages of good stability, no toxicity and moderate molecular weight; and the N1 position-substituted imidazole type alkaline anion exchange membrane prepared in the invention has the advantages of uniform and smooth surface, good thermal stability, good mechanical strength, and good application values in alkaline fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation of acrylic polymer retanning agent for highly elastic leather retanning

The invention relates to a preparation method of an acrylic polymer retanning agent for retanning of high elastic leather. Deionized water and isopropanol are added into a three-neck flask which is placed into a water bath for heating and stirring. Mixed acrylic monomers are added into a dropping funnel of constant pressure, ammonium persulphate is dissolved into the deionized water and added into another dropping funnel of constant pressure and after water temperature is raised to 70 DEG C to 80 DEG C, the mixed monomers and an initiator are started dripping simultaneously and controlled to be finished dripping in 60 min to 90 min and the temperature is raised to 80 DEG C to 85 DEG C, which is kept so as to take a reaction. After the reaction, a room temperature is cooled to, systematic pH is adjusted to 4.5 to 6.0, and solvent is distilled off the system completely, and finally discharging is carried out. The acrylic polymer retanning agent of the invention has advantages of easy getting of raw materials, relatively simple experimental operation, the retanning agent prepared with a plurality of different side chain base groups, thus improving elasticity of the leather significantly, increasing value-added content of leather products and reducing dosage of chrome tanning agent and providing with great economic benefit and environmental benefit.

Owner:SHAANXI UNIV OF SCI & TECH

Process for preparing acrylic amide-acrylic sodium polymer nano particle micro emulsion

The preparation process of nanometer microemulsion of acrylamide-sodium acrylate polymer relates to preparation of one kind of new material used in oil production, water treatment, papermaking, textile, printing and dyeing, special paint, adhesive and ink. The process is one reverse microemulsion polymerization process of acrylamide and sodium acrylate as copolymerized monomers, and with composite emulsifier, solvent oil and water as dispersing medium and redox initiation system. The product of the present invention is used widely in oil production, water treatment, papermaking, textile, printing and dyeing, special paint, adhesive, ink and other fields.

Owner:陈尔凡

Preparation method of acrylic acid retanning agents

ActiveCN101851310ANarrow molecular weight distributionModerate molecular weightTanning treatmentChain transferAcrylic acid

The invention provides a preparation method of acrylic acid retanning agents, which comprises the following steps: adding 1500 to 1620 kg of acrylic acid into an overhead tank 1; carrying out polyreaction; adding 150 to 160 kg of chain transfer agents into an overhead tank 2; adding 180 kg of triggering agent solution containing 16 to 20 kg of triggering agents into an overhead tank 3; adding 60 to 80 kg of oxidizing agent solution with the content of 50 percent into an overhead tank 4; adding 20 kg of regulating agent solution containing 1.8 to 1.9 kg of regulating agents into an overhead tank 5; adding 500 to 600 kg of water into a reaction kettle; adding 16 to 20 kg of pH buffer solution; then, heating materials in the reaction kettle to a temperature between 98 and 102 DEG C; simultaneously opening condenser circulation water; at the time, simultaneously beginning to add the acrylic acid, the chain transfer agents and the triggering agents with the material adding time between 4 and 5 hours; controlling the temperature between 98 and 102 DEG C in the period; cooling the materials in the reaction kettle to 80 to 85 DEG C after the material addition is completed; adding the regulating agent solution; continuously carrying out reaction for 1 to 2 hours at 80 to 85 DEG C; then, adding 690 to 700 kg of 30 percent sodium hydroxide solution and simultaneously adding 250 kg of water; regulating the pH value to 4 to 4.5 for continuous reaction for 30 min; raising the temperature in the reaction kettle to 100 DEG C; adding the oxidizing agent solution in 1 to 1.5 hours; preserving the temperature for 2 to 4 hours at 100 DEG C after the addition; lowering down the temperature to 55 to 60 DEG C; adding 1800 to 2000 kg of water to regulate the content to the specified content; and carrying out mixing for 30 min at 55 to 60 DEG C.

Owner:QI HE LI HOU CHEM CO LTD

High abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying

InactiveCN106833295AGuaranteed mechanical strengthModerate molecular weightFireproof paintsEpoxy resin coatingsAcrylic resinPolyamide

The invention relates to a high abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying. The high abrasion-resistant UV white primer is prepared from the following raw materials in parts by weight: 40 to 70 parts of epoxy acrylic resin, 15 to 35 parts of hydroxy acrylic resin, 10 to 20 parts of thermoplastic acrylic resin, 15 to 30 parts of tripropylene glycol diacrylate, 5 to 25 parts of modified graphene, 2 to 6 parts of nanometer silicon dioxide, 1 to 5 parts of nanometer titanium dioxide, 1 to 5 parts of heavy calcium carbonate, 5 to 15 parts of montmorillonite, 10 to 20 parts of white pigment, 2 to 5 parts of zinc stearate, 2 to 6 parts of carboxymethyl cellulose sodium, 1 to 5 parts of polyamide wax, 0.5 to 2 parts of flatting agent, 0.1 to 0.5 part of defoaming agent, 2 to 6 parts of photoinitiator, and 5 to 15 parts of organic solvent. The high abrasion-resistant UV white primer for electrostatic spraying has the advantage that at the premise of ensuring the good electrostatic spraying effect, the anti-sagging property of the primer and the abrasion-resistant property of the primer film are greatly improved.

Owner:TIANCHANG JINLING ELECTRONICS

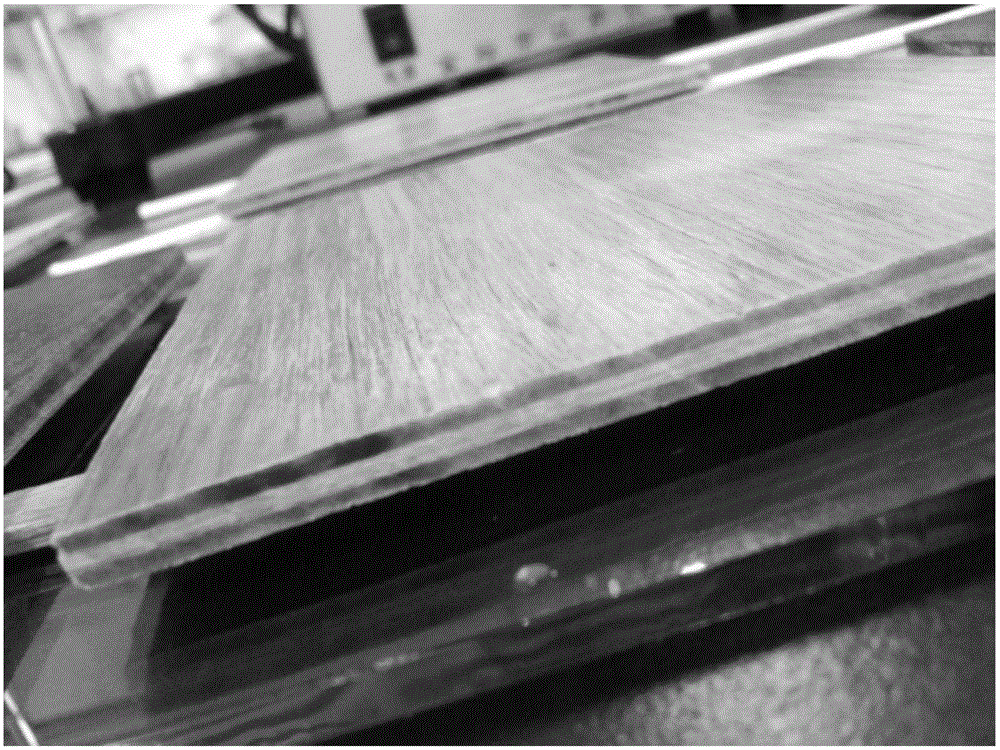

Preparation method for low-cost insulating phenolic resin laminated board resistant to moisture and heat

ActiveCN105773763ATake advantage ofAbsolute price advantagePressure impregnationWood impregnation detailsEpoxyMoisture

The invention provides a preparation method for a low-cost insulating phenolic resin laminated board resistant to moisture and heat, and relates to the preparation method of the phenolic resin laminated board. The preparation method aims at solving the technical problems that at present, electrician laminated wood prepared from birch and epoxy resin raw materials is relatively high in price, high-quality birch resources are wasted, and under the moist and hot environment, the water absorption is high, the water absorption speed is high and insulativity is reduced. The method includes the steps that firstly, phenolic resin is prepared; secondly, poplar veneer is dried and cooled; thirdly, the poplar veneer is soaked in modified resin to be processed; and fourthly, the processed veneer is dried, pre-pressed and hot-pressed. The preparation method is low in production cost, the water absorption of the prepared laminated wood board under the moist and hot environment is effectively reduced, and therefore the moist and hot ageing of laminated wood is slowed down, and the laminated board can have the lasting insulating property. The preparation method is used for preparing the low-cost insulating phenolic resin laminated board resistant to moisture and heat.

Owner:NORTHEAST FORESTRY UNIVERSITY

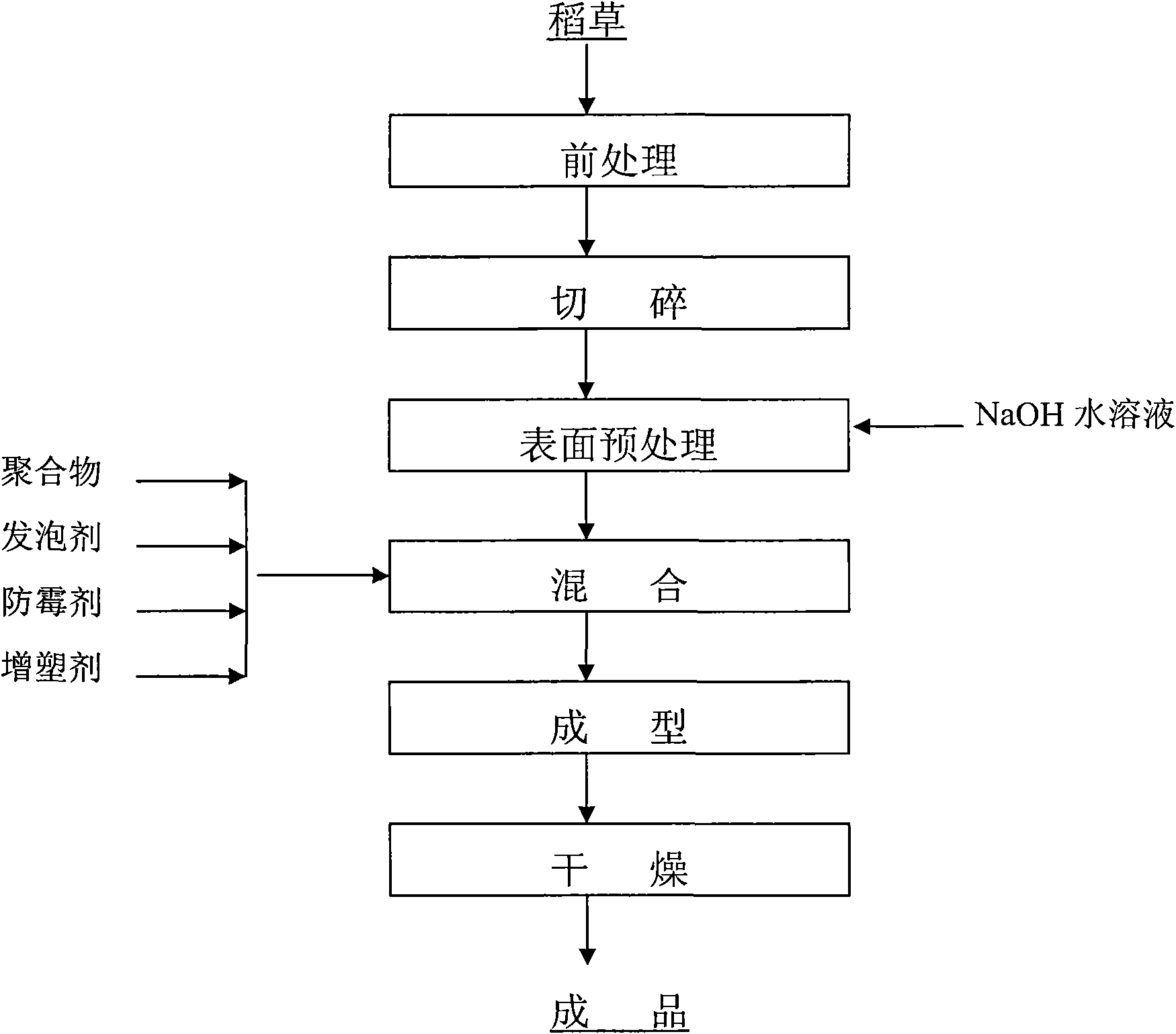

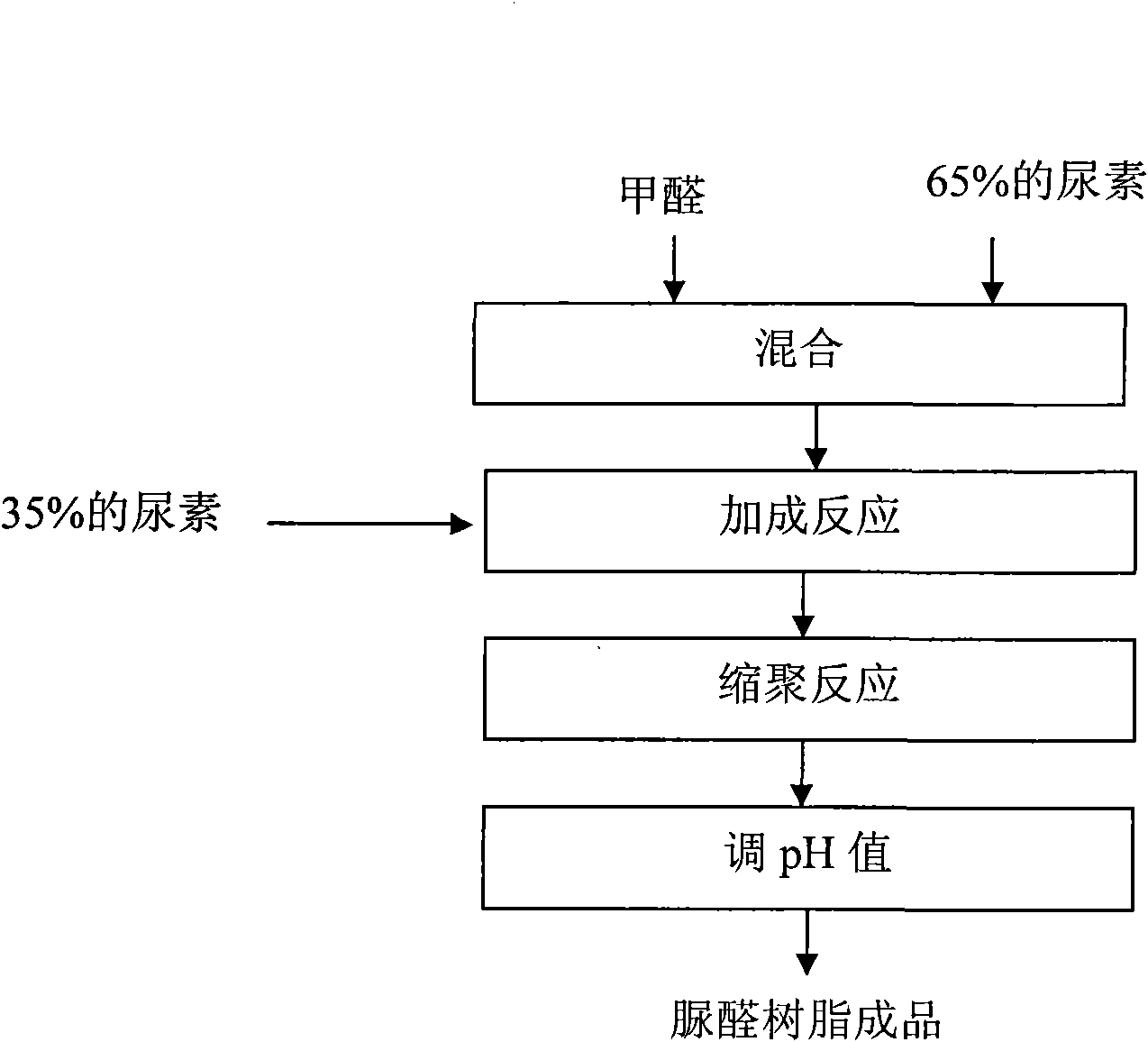

Technology for preparing composite package cushioning material from rice straw fibers

The invention discloses technology for preparing a composite package cushioning material from rice straw fibers. The technology comprises the following technological steps of: (1) pretreating, namely drying and removing impurities; (2) cutting up, namely cutting the rice straw obtained in the step (1) into straw particles with the diameter of 5 to 8mm, and mixing with partial fine rice straw fibers which are cut into the diameter of around 0.1mm and the length of 5mm; (3) performing surface pretreatment, namely soaking for 10 minutes by using aqueous solution of NaOH, filtering and drying for later use; (4) mixing, namely adding polymer into the mixed fibers subjected to surface treatment according to a mass ratio of 2-5:6-9, and adding a proper amount of mildew preventive and foaming agent for uniformly mixing; (5) molding, namely adding the uniformly mixed mixture into a mold, molding and demolding; and (6) drying. The invention also discloses a formula and technology for preparing 35 percent urea resin. The urea resin is a raw material for preparing the polymer in the composite package cushioning material prepared from the rice straw fibers. The technology for preparing the composite package cushioning material has the advantages of simple process flow and no side products. The produced finished product has the advantages of good degradation performance, good elastic resilience, high unit density and compression strength, and low density.

Owner:MYS GRP CO LTD

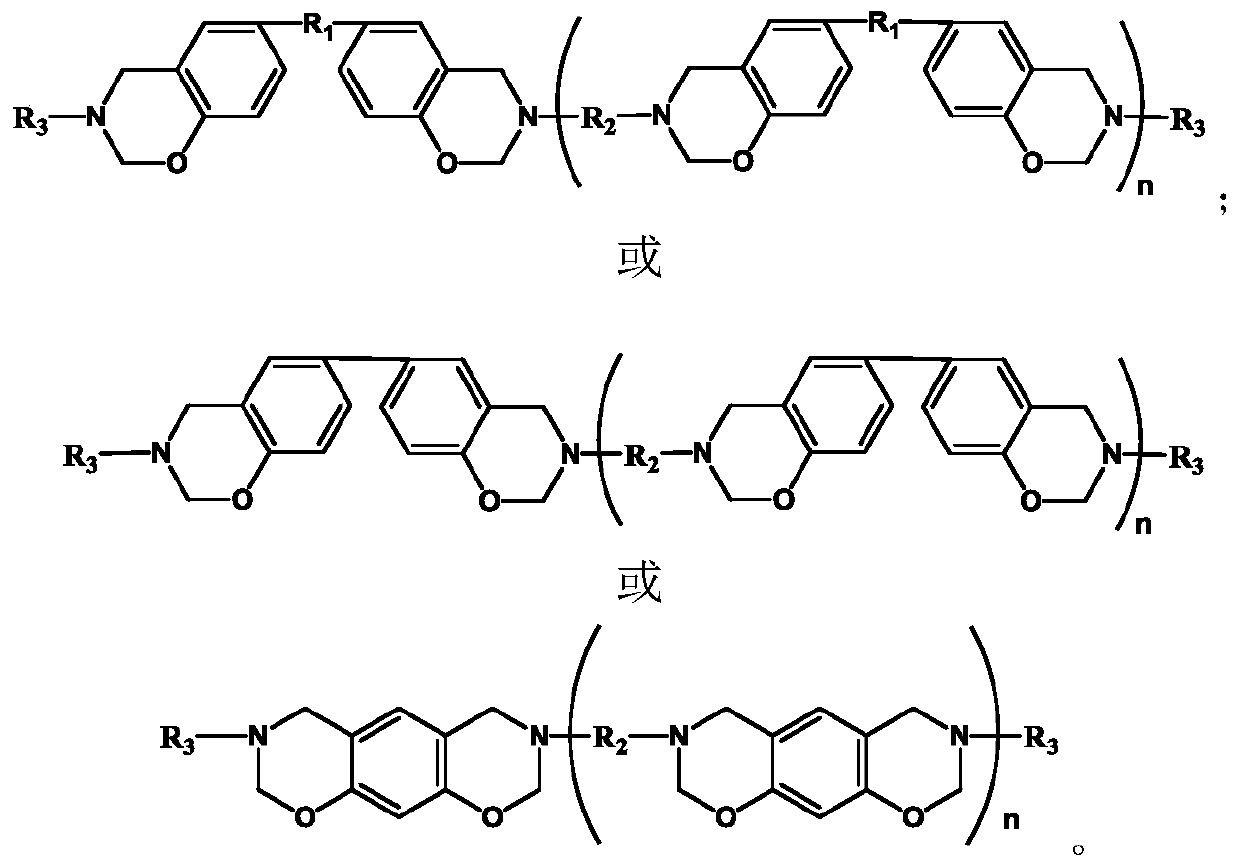

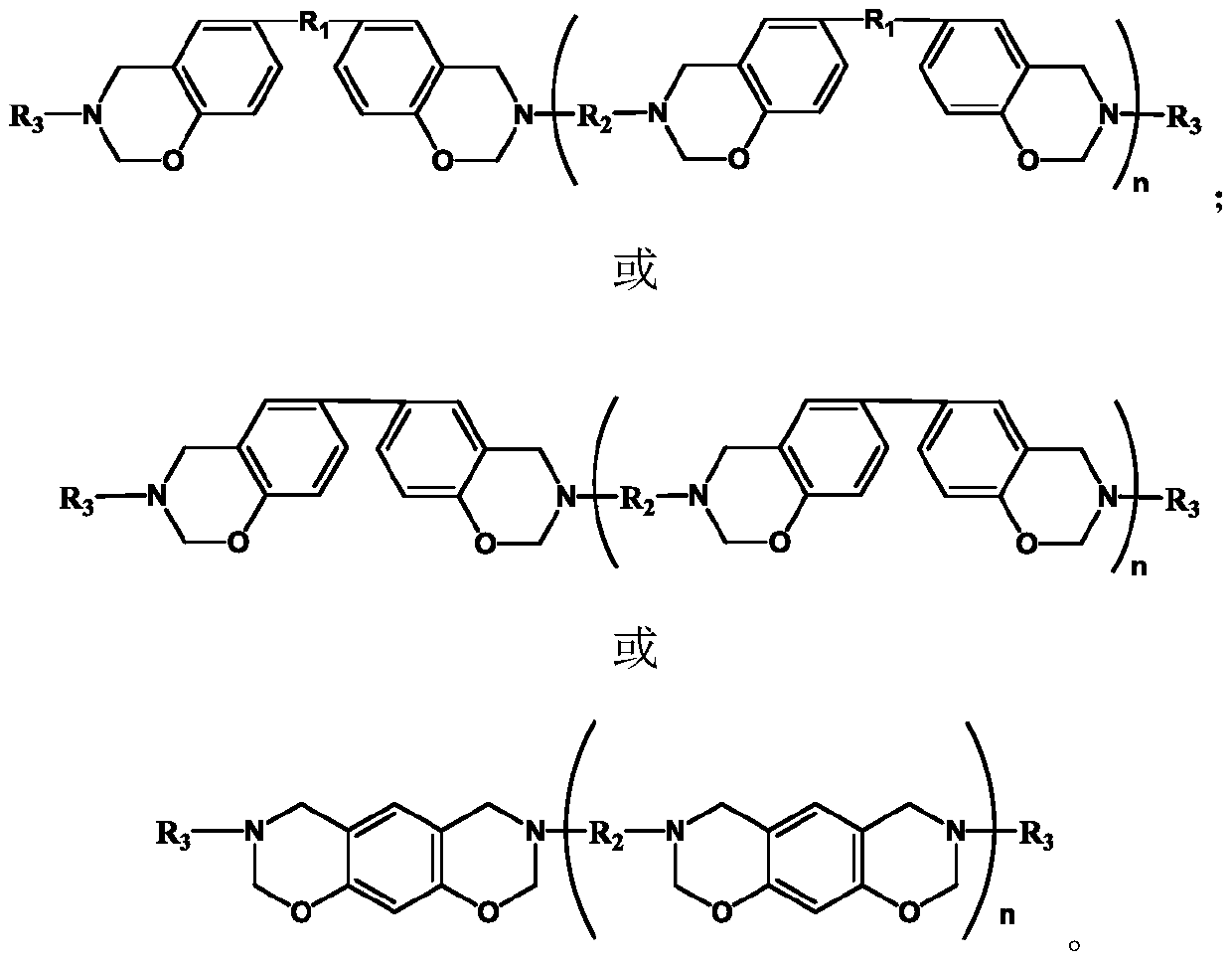

Monoamine-terminated ultrahigh-frequency low-dielectric main chain benzoxazine copolymer oligomer, copolymer resin and preparation method thereof

The invention relates to a monoamine-terminated ultrahigh-frequency low-dielectric main chain benzoxazine copolymer oligomer, copolymer resin and a preparation method thereof. The preparation method of the main chain benzoxazine copolymer oligomer comprises the following steps: adding an aldehyde compound, an amine compound and a dihydric phenol compound into a reaction container in a one-time charging or multi-step and multi-time charging manner, adding an organic solvent to dissolve and react, and carrying out post-treatment to obtain the main chain benzoxazine copolymer oligomer. The copolymer oligomer disclosed by the invention has good processability; the copolymer resin obtained by heating and curing not only retains the high crosslinking density of the pure main chain benzoxazine resin, but also has the advantages of better thermal property, toughness and the like, has low dielectric constant and dielectric loss at ultrahigh frequency, and can be used as a dielectric material tobe applied to multiple fields of ultrahigh frequency and high-speed circuit board substrates and the like. Part of monoamine-terminated oligomers containing cross-linking groups can be further cross-linked, so that more excellent thermal properties and dielectric properties are obtained.

Owner:淮北绿洲新材料有限责任公司

Phenolic-resin-modified urea formaldehyde resin and preparation method thereof

ActiveCN104788633AModerate molecular weightGood water solubilityAldehyde/ketone condensation polymer adhesivesReaction systemResin modified

The invention discloses a phenolic-resin-modified urea formaldehyde resin which is prepared from a phenolic resin, formaldehyde and urea under alkali-acid-alkali technological conditions. The phenolic-resin-modified urea formaldehyde resin has favorable storage stability, and the free formaldehyde content is at most 0.01 wt%. The benzene ring introduced into the urea formaldehyde resin molecular structure enhances the reaction degree between the urea and formaldehyde, and lowers the free formaldehyde content in the reaction system. The phenolic resin used instead of phenol maximally lowers the free phenol residue and enhances the water resistance of the urea formaldehyde resin. The preparation technique is simple and easy to operate, and the prepared urea formaldehyde resin has low formaldehyde content and is suitable for the field of production of plywoods, shaving boards fiberboards and the like.

Owner:湖北合聚高分子材料有限公司

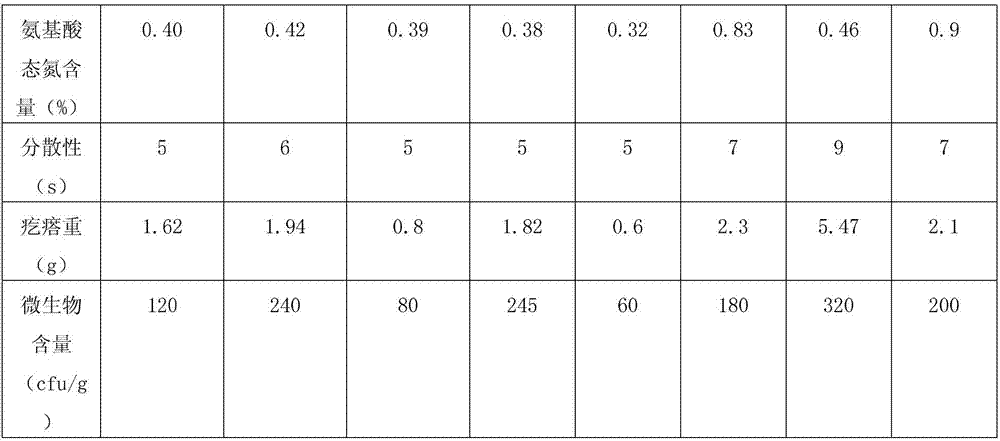

Method for preparing microorganism-dedicated soybean protein isolate

ActiveCN107312813AAppropriate degree of enzymatic hydrolysisAppropriate molecular weightPlant peptidesFermentationAlkaline proteaseNeutral protease

The invention discloses a method for preparing microorganism-dedicated soybean protein isolate. The method comprises the following steps: soaking low-temperature degreased soybean meal in an alkali solution with a pH value of 9.5 to 10.0 at a temperature of 50 to 55 DEG C, adjusting the pH value to 6.8 to 7.4, the sugar content to 8.0 to 9.0, stirring for 40 to 60min, and performing solid-liquid separation to obtain a crude protein extracting solution; adding an acid solution into the crude protein extracting solution at room temperature, stirring for 10 to 50min, and centrifuging to obtain acid-precipitated protein; dissolving the acid-precipitated protein in water at room temperature, adjusting the pH value to 6.00 to 6.30 and the sugar content to 18.0 to 19.5 to obtain an acid-precipitated protein solution; adding neutral protease and alkaline protease, reacting at 50 to 60 DEG C for 0.5 to 3h to obtain enzymatic hydrolysate; performing sterilization, flash treatment and spray drying to obtain the microorganism-dedicated soybean protein isolate. The soybean protein isolate prepared according to the invention has good dispersibility, low viscosity and suitable amino acid nitrogen, and has the advantages of simple process, easy operation, strong protein practicability, wide application in fermentation industry and better popularization value.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

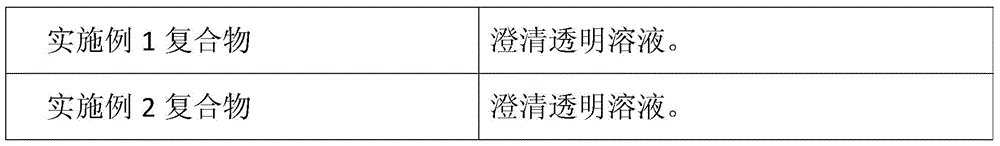

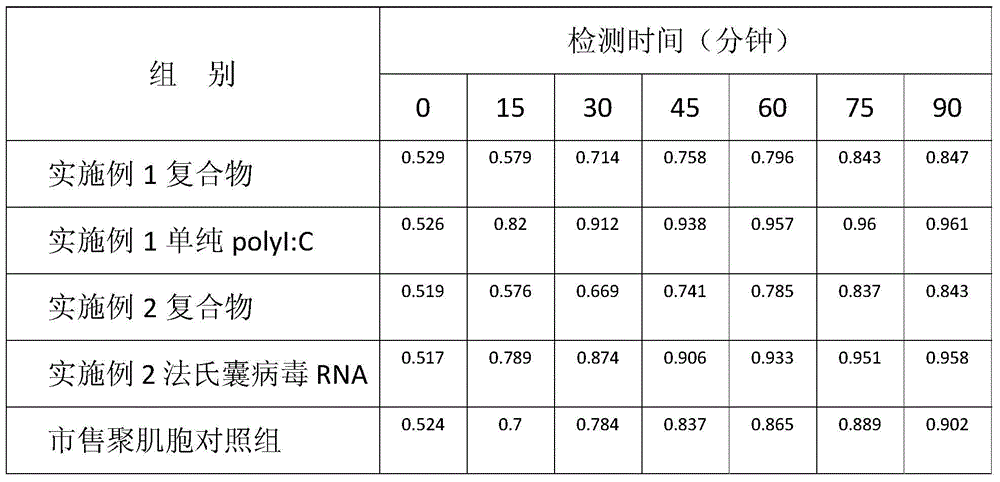

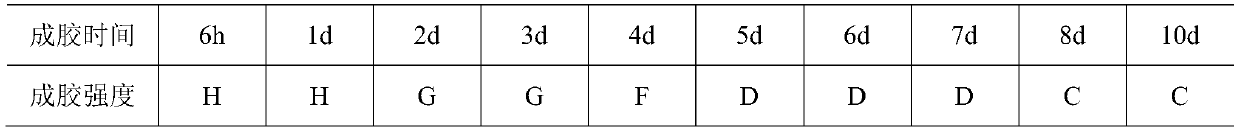

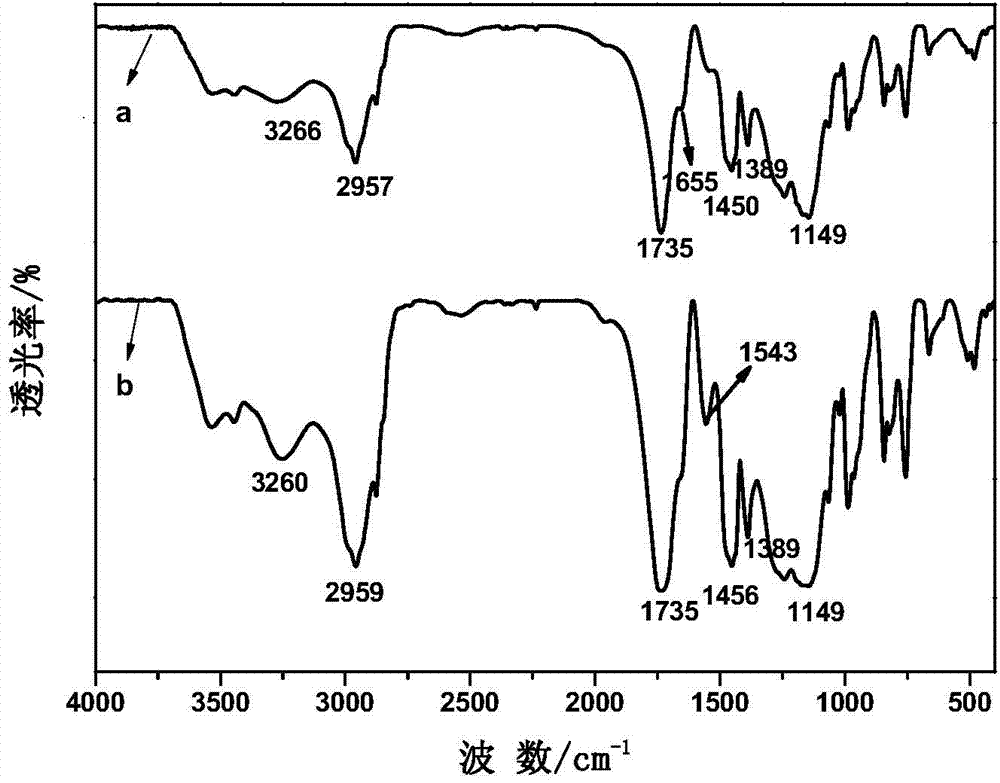

Double-strand oligonucleotide-epsilon-polylysine compound with immune regulation function and preparation and use method of double-strand oligonucleotide-epsilon-polylysine compound

ActiveCN105664152ASimple preparation processStrong resistance to enzymatic degradationSsRNA viruses negative-senseViral antigen ingredientsAntigenChemistry

The invention provides a double-strand oligonucleotide-epsilon-polylysine compound with an immune regulation function and a preparation and use method of the double-strand oligonucleotide-epsilon-polylysine compound and also provides immunogen composition with functions of triggering immunoenhancement reaction and changing the immunoreaction type and a preparation and use method of the immunogen composition. The immunogen composition comprises the double-strand oligonucleotide-epsilon-polylysine compound and an antigen. The compound contains a compound formed through composition of double-stranded polynucleotide, a cation epsilon-polylysine and metal cations. The compound has the pharmacological activity of immunoregulation. The preparation process of the compound is simple. The compound has good water solubility and a bio-enzyme degradation resisting function. The immunogen composition can trigger the immunoenhancement reaction and change the immunoreaction type.

Owner:辽科生物(沈阳)有限公司

Medium-high temperature oil reservoir phenolic gel self-degradation temporary plugging agent and preparation method thereof

The invention relates to a medium-high temperature oil reservoir phenolic gel self-degradation temporary plugging agent and a preparation method thereof. The temporary plugging agent is prepared fromthe following components in percentage by mass: 2 to 2.5 percent of low molecular weight polymer, 0.2 to 0.25 percent of phenolic cross-linking agent, 0.2 to 0.6 percent of aldehyde cross-linking agent, 0.05 percent of stabilizer, 0.1 percent of catalyst, 0.5 to 2 percent of gel breaker and the balance of water, wherein the sum of the mass percent of all the components is 100 percent. The gel temporary plugging agent provided by the invention can meet the requirements that the oil reservoir temperature is 60-100 DEG C, the plugging time is adjustable within 120-168h, and the gel breaking timeis adjustable within 168-240h; the plugging rate of a rock core reaches 98% or above, the permeability damage rate after gel breaking is 10% or below, a high-permeability layer of a target stratum canbe effectively plugged, flowback is easy after automatic gel breaking, damage to the stratum is extremely small, and the plugging agent can be suitable for most conventional oil reservoirs and has good field application value.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks and preparation method thereof

InactiveCN104262526AGuaranteed water solubilityImprove heat resistanceInksHydrophilic monomerWater dispersible

The invention discloses a water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks and a preparation method thereof. The water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks is prepared by copolymerizing the following components in parts by mass: 12-20 parts of hard monomer, 12-20 parts of soft monomer, 4.5-10 parts of first-type hydrophilic monomer, 0.5-2.5 parts of second-type hydrophilic monomer, 0.6-2 parts of crosslinkable monomer, 0.3-0.6 part of initiator and 50-70 parts of solvent. A pH regulator is added to regulate the pH value to 7-8; and 30-60 parts of water is added as a dispersing agent. The ink prepared by using the water-dispersible acrylate resin as the connecting material can implement low-temperature (<50 DEG C) crosslinking curing, and has the advantages of short drying and curing time (the surface drying time is 25-50 seconds), excellent adhesive force (Grade 0) on low-polarity materials (PE (polyethylene) and PP (polypropylene) films), favorable staining power, favorable bonding resistance, favorable water resistance and favorable solvent resistance.

Owner:SOUTH CHINA UNIV OF TECH

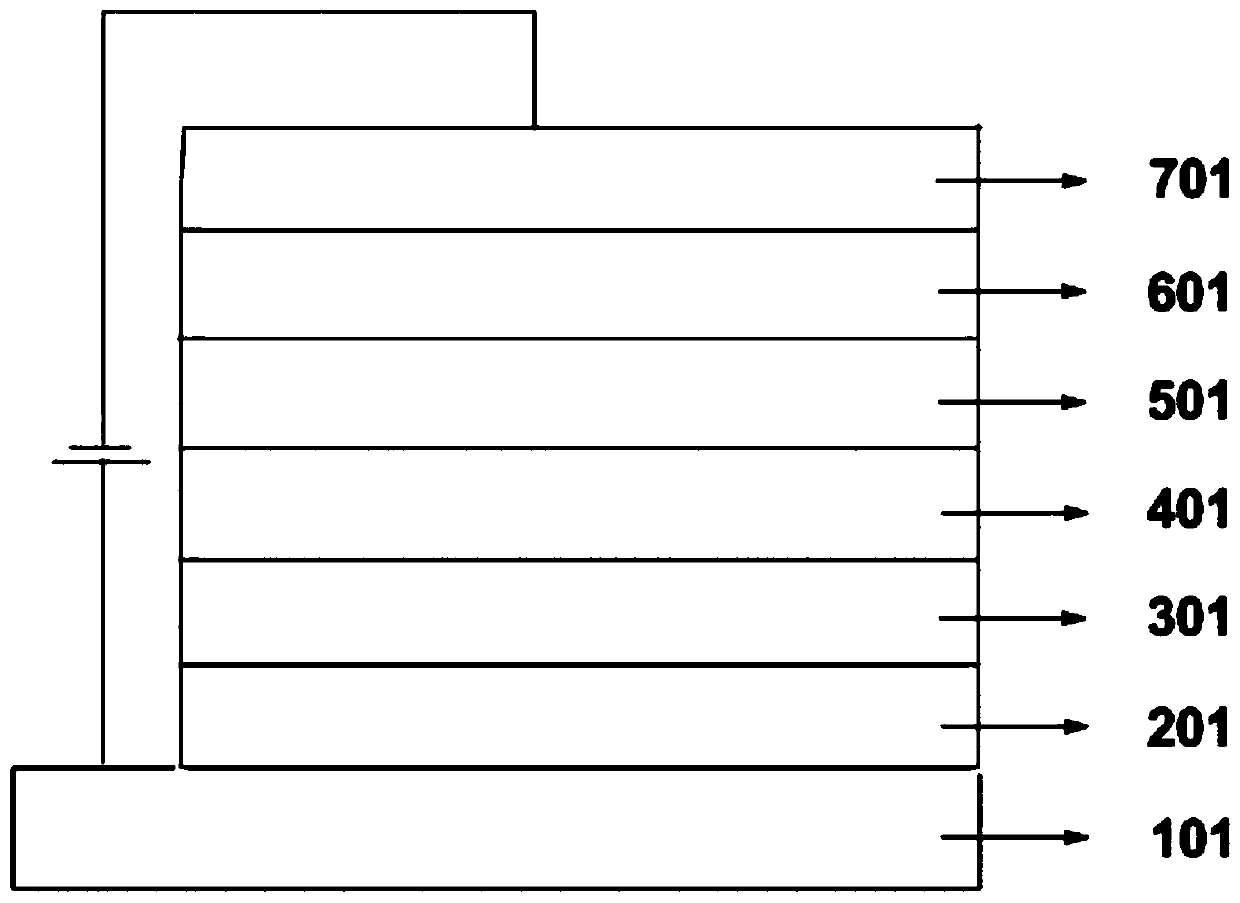

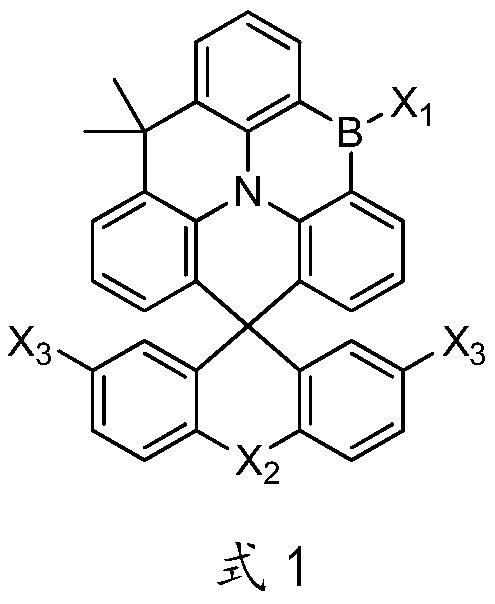

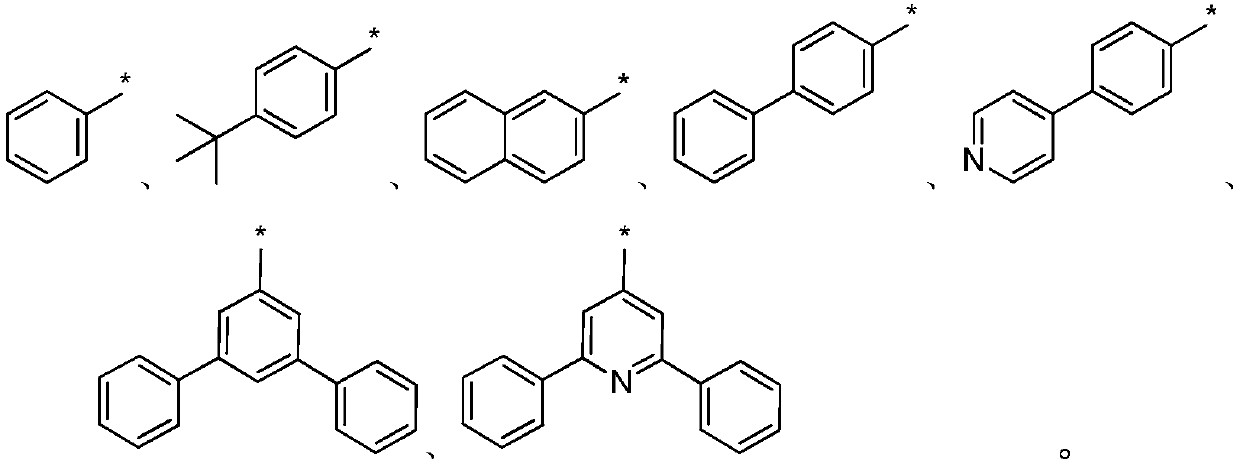

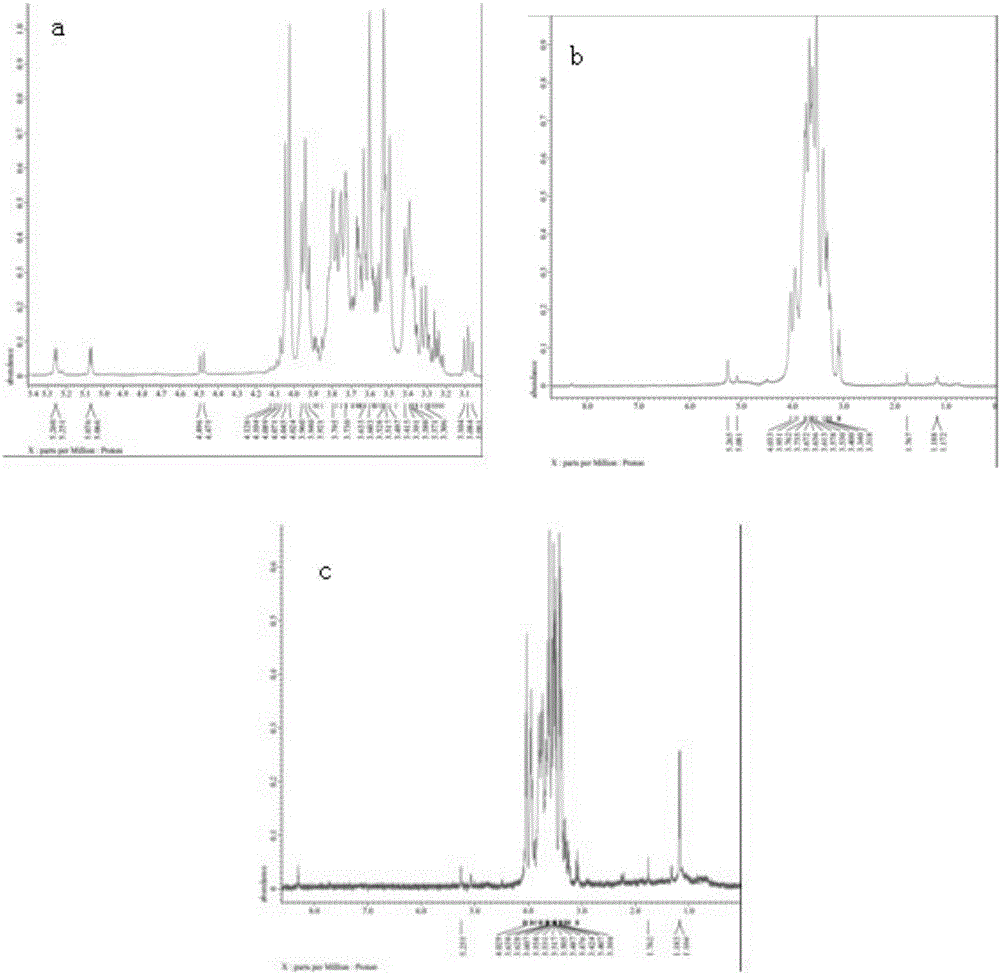

Boron-containing organic electroluminescent material, preparation method and application thereof

InactiveCN109970775AImprove performanceModerate molecular weightSilicon organic compoundsGroup 5/15 element organic compoundsBoron containingOrganic electroluminescence

The invention relates to a boron-containing organic electroluminescent material, a preparation method and application thereof and belongs to the technical field of organic electroluminescence. The novel boron-containing organic electroluminescent material is synthesized through a multi-step buckle reaction, and molecules have a suitable molecular weight (400-1200), a wider energy gap (3.5-4.0eV) and a higher glass transition temperature Tg (120 DEG C or above) and is suitable for use as a light-emitting layer main material. A manufactured organic electroluminescent device has higher current efficiency and longer device life.

Owner:VALIANT CO LTD

Bacillus amyloliquefaciens and preparation method of exopolysaccharides thereof

ActiveCN106520641ANon-irritatingAntigenicBacteriaMicroorganism based processesChromatographic separationBacillus amyloliquefaciens

The invention provides bacillus amyloliquefaciens EZ99. The bacillus amyloliquefaciens is gram positive bacteria, exists in plant rhizosphere soil, has no pathogenicity for people and plants, is collected from an orchard county, in the west of a Qilihe district in the Lanzhou city of the Gansu province, and has been identified, registered and preserved in the China common microorganism strain preservation center, and the preservation number is CGMCC No.13267. Component analysis is performed on bacterial colonies formed by the bacillus amyloliquefaciens on a PMA and MS culture medium, and it is found that the bacillus amyloliquefaciens has the characteristic of synthesizing and secreting exopolysaccharides. Optimal culture medium formulas and fermentation optimal conditions based on fermentation production of the exopolysaccharides of the strains are built, a fermentation solution is subjected to centrifuging, alcohol precipitation, dialysis and chromatographic separation, four purification polysaccharide components are obtained, and four-polysaccharide-component monosaccharide composition and monomer molecular weight are determined. The exopolysaccharides obtained through the strain and the method have the various applications of medicines, cosmetics, food additives, biological film raw materials and the like.

Owner:甘肃尚农生物科技有限公司

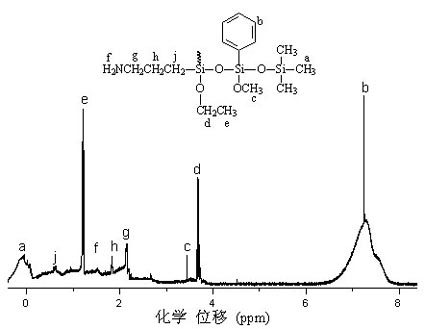

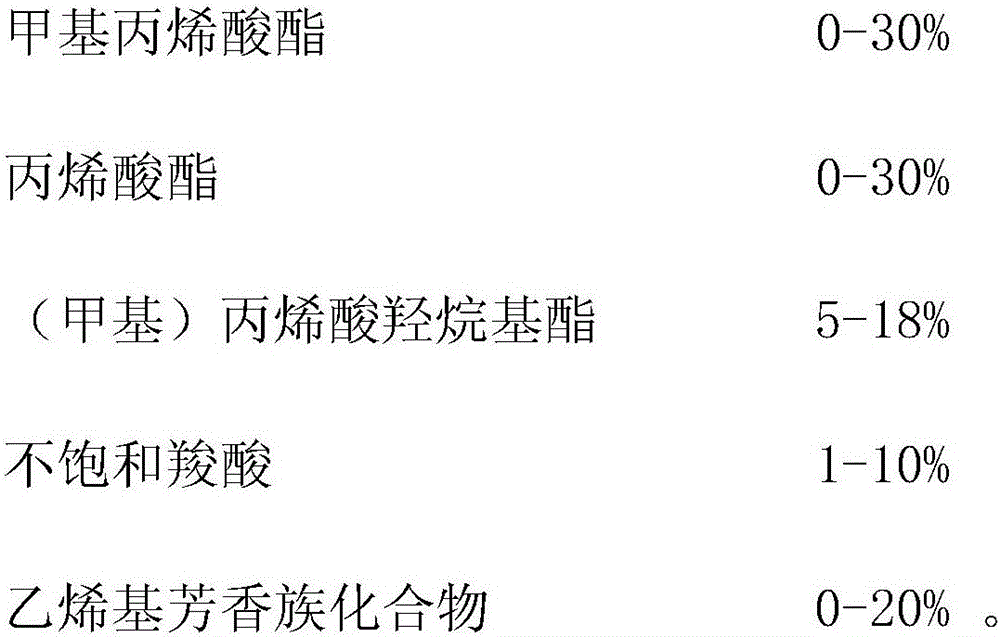

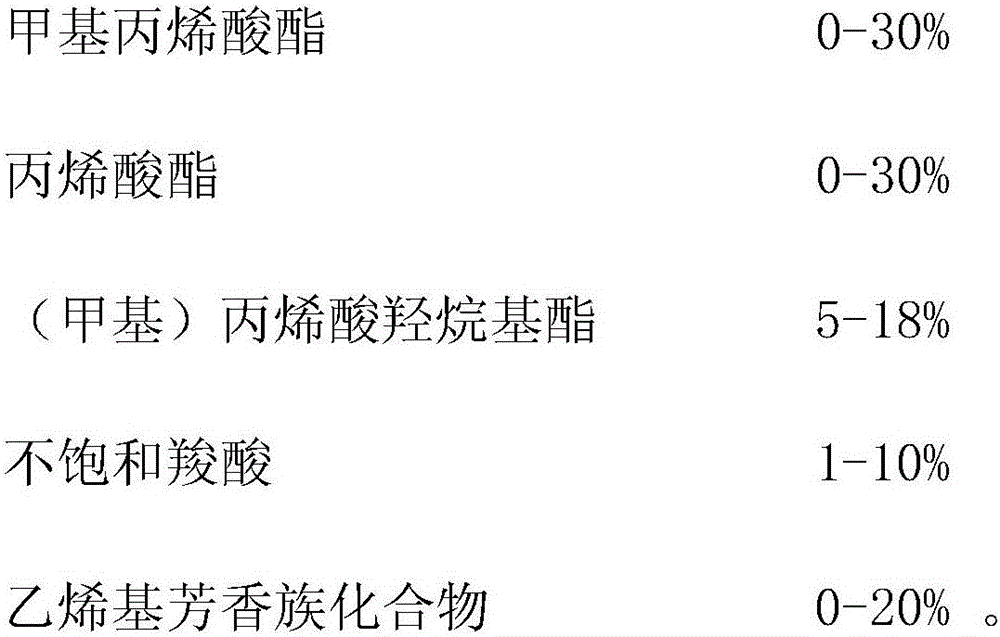

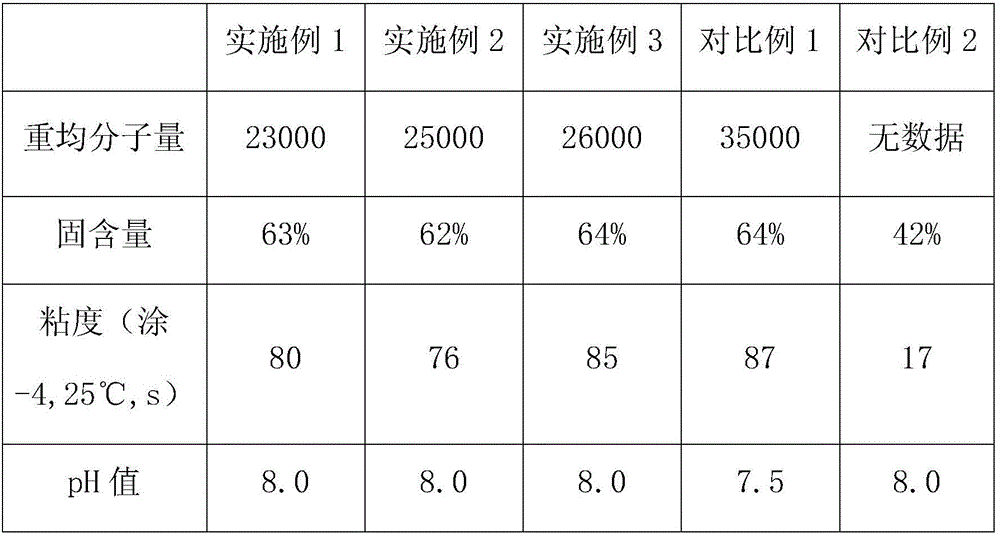

High-adhesion aqueous thermosetting acrylic resin, preparation method and applications thereof

The invention discloses a high-adhesion aqueous thermosetting acrylic resin, a preparation method and applications thereof. According to the present invention, a reaction monomer is modified with a silane coupling agent, a polymerization reaction is performed in an alcohol ether type solvent medium under the effect of an initiator, and neutralization salification is performed with an organic amine to prepare the acrylic resin, wherein the reaction monomer comprises, by mass, 0-30% of methyl propiolate, 0-30% of acrylic acid ester, 5-18% of (methyl) hydroxyalkyl acrylate, 1-10% of unsaturated carboxylic acid, and 0-20% of a vinyl aromatic compound. According to the present invention, the prepared acrylic resin coating material has excellent adhesion to the aluminum material, the paint film has characteristics of high luster, good fullness and high strength, and the excellent protection performance and the excellent decorative effect can be provided for the high-grade aluminum material.

Owner:FOSHAN KINNO METAL TECH

Organopolysiloxane resin and preparation method thereof

InactiveCN107459651AThe preparation process is environmentally friendlyNo generationOrganic solventSilanes

The invention relates to an organopolysiloxane resin and a preparation method thereof. The general formula of the organopolysiloxane resin is (R13SiO0.5)m(R22SiO)n(R3SiO1.5)p(SiO2)q. The preparation method comprises the following steps: placing an end-capping reagent, deionized water, a cosolvent and acid into a reaction vessel and stirring; dropwise adding silane into the reaction vessel, raising the temperature of the reaction system to 60-80 DEG C and reacting for 2-4h; regulating pH value of the reaction solution to 7, stirring, raising the temperature to 80-120 DEG C and distilling till no fraction exists; dissolving the resin into an organic solvent, adding solid alkali, raising temperature to 70-140 DEG C and reacting for 2-4h; centrifuging the reaction solution and removing solid salt; and performing vacuum drying on the reaction solution, thereby acquiring the organopolysiloxane resin. The method has the advantages of high product yield, simple process, no pollution in a production process, less three-waste, energy-saving effect and environmental protection.

Owner:GUANGZHOU TINCI SILICONE TECHNOLOGY CO LTD

Method for preparing ferriccarboxymaltose

The invention discloses a method for preparing ferriccarboxymaltose, the ferriccarboxymaltose is prepared through five steps, selected reagents are green, environmentally friendly, and more suitable for industrial production, a selected oxidant system has strong oxidation capacity, product dispersion coefficient is proper, the molecular weight of the formed ferriccarboxymaltose is proper, and the formed ferriccarboxymaltose is high in Fe content.

Owner:广州仁恒医药科技股份有限公司

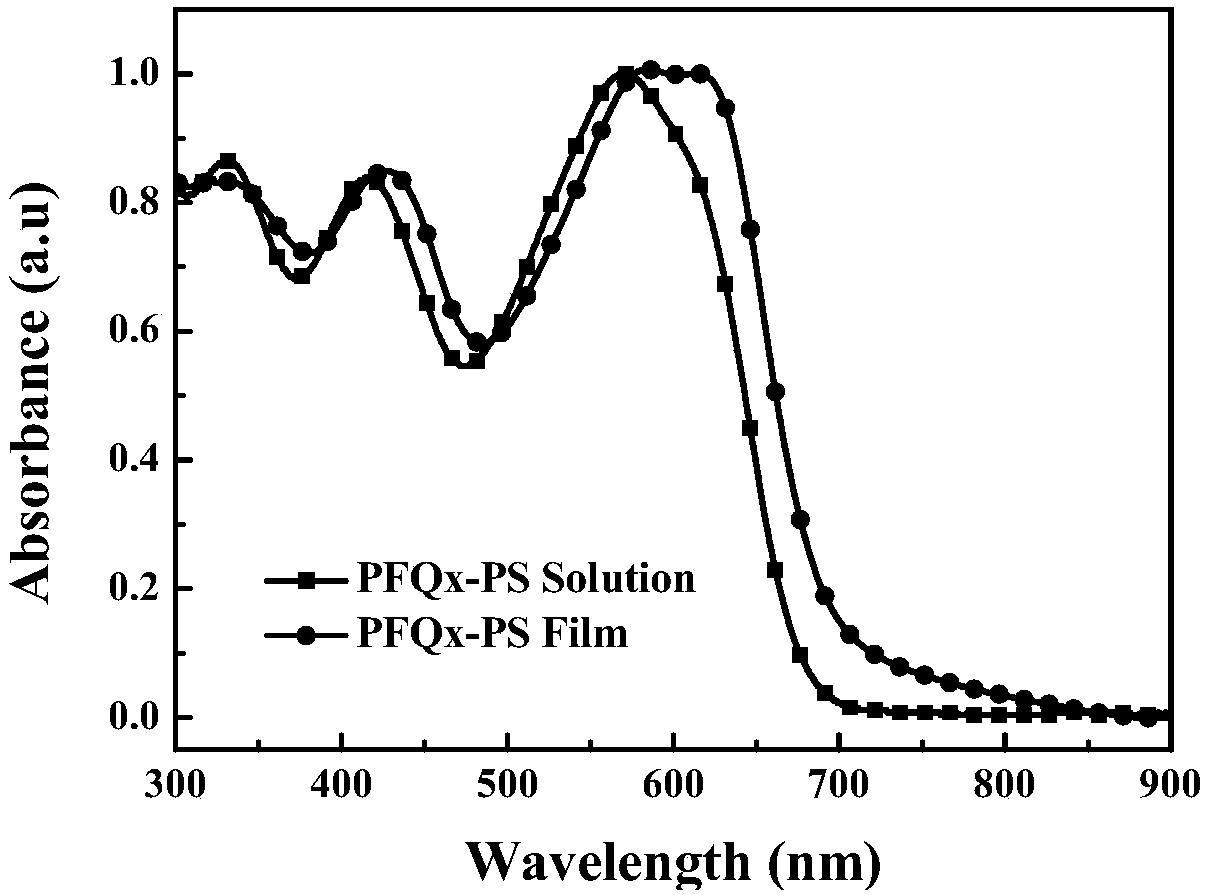

Benzoquinoxaline tetrafluoride compound, benzoquinoxaline tetrafluoride based polymer as well as preparation method and application of enzoquinoxaline tetrafluoride based polymer

InactiveCN105753851AUniversalImprove matchOrganic chemistrySolid-state devicesSolubilityPolymer science

The invention discloses a benzoquinoxaline tetrafluoride compound, a benzoquinoxaline tetrafluoride based polymer as well as a preparation method and an application of the enzoquinoxaline tetrafluoride based polymer. The benzoquinoxaline tetrafluoride based polymer is prepared from a benzoquinoxaline tetrafluoride monomer and a benzodithiophene monomer through a Stille coupling reaction, wherein the side chain of the benzodithiophene monomer is alkylthiophene, alkoxyphenyl, fluoro alkoxyphenyl or phenyl sulfhydryl; the polymer has good solubility in common organic solvents such as dichloromethane, trichloromethane, tetrahydrofuran and the like, is processed into a film easily and has a good photovoltaic conversion function; the photovoltaic conversion efficiency of a prepared solar polymer device is higher than 7%, and the highest photovoltaic conversion efficiency of a single layer device is as high as 8.6%.

Owner:CENT SOUTH UNIV

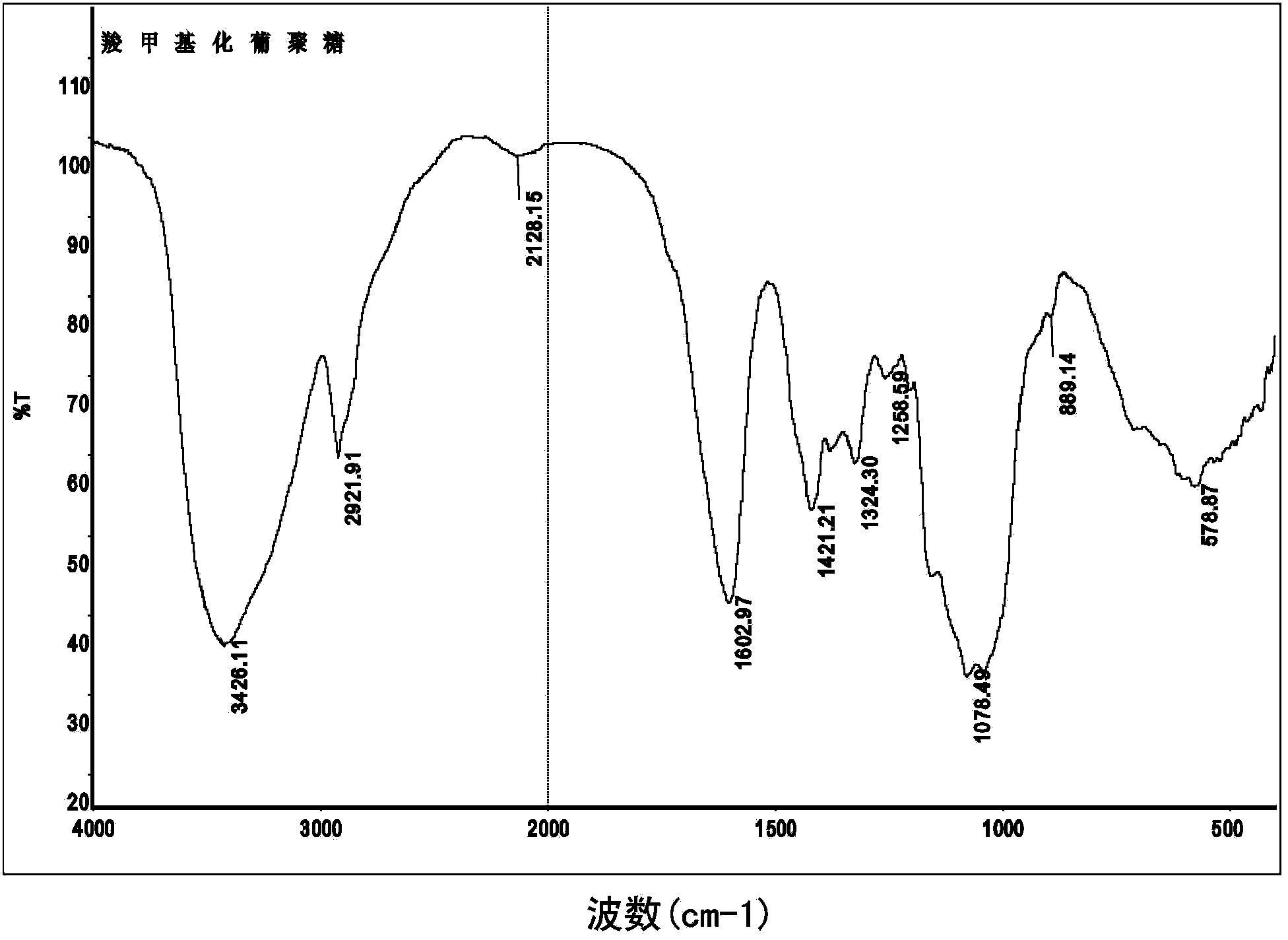

Method for preparing carboxymethyl yeast glucan product and product obtained by using same

ActiveCN103804511AAppropriate degree of substitutionModerate molecular weightCosmetic preparationsToilet preparationsMass ratioChloroacetic acids

The invention relates to a method for preparing a carboxymethyl yeast glucan product and a product obtained by using the same. The preparation method comprises the following steps: adding alkali to yeast glucan according to the ratio that per 1kg of yeast glucan contains 12.5-37.5mol of hydroxyl; simultaneously adding ethanol according to the mass ratio of the yeast glucan to the ethanol being 1:(0.5-2.5), and reacting at 0-30 DEG C; adding a chloroacetic acid to the obtained solution according to the mass ratio of the yeast glucan to the chloroacetic acid being 1:(0.3-1.0), simultaneously adding ethanol according to the mass ratio of the yeast glucan to the ethanol being 1:(0.5-1.5), reacting at 30-80 DEG C and cooling; and adding ethanol in the obtained solution to wash, simultaneously neutralizing by using a hydrochloric acid, washing and centrifugally separating to obtain sediment carboxymethyl yeast glucan. By adopting the carboxymethyl yeast glucan product obtained by the method, the substitution degree is 0.3-1.0, the molecular weight is 100-1,000KD, and the carboxymethyl yeast glucan product is completely dissolved into water, and has the effects of moisturizing, preventing aging and the like when being applied to the field of cosmetics.

Owner:ANGELYEAST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com