Water-dispersible quick-drying low-temperature self-crosslinked acrylate resin for inks and preparation method thereof

An acrylate and dispersibility technology, which is applied in the field of ink water-dispersible, quick-drying low-temperature self-crosslinking acrylate resin and its preparation, can solve the problem of poor mechanical properties and water and solvent resistance of the resin coating film, and the impact of the surrounding environment on construction workers , large molecular weight distribution coefficient, etc., to achieve the effect of improving water resistance and solvent resistance, good storage stability, and moderate molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

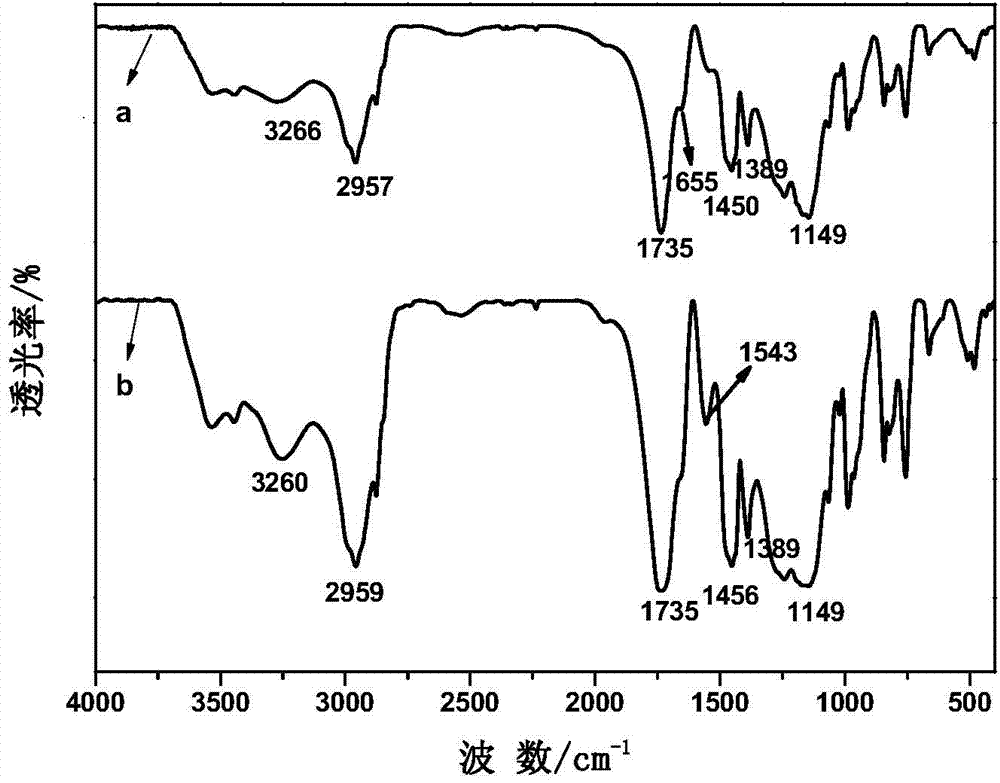

Method used

Image

Examples

Embodiment 1

[0051] Take a mixed solvent of 50g ethanol and 10g ethyl acetate into a 250mL four-neck flask equipped with a stirrer and reflux condenser, heat to 75°C and keep refluxing for 10min; add 16g methyl methacrylate, 16g butyl acrylate, Mix 6g acrylic acid, 2g 2-hydroxypropyl acrylate, 1.2g diacetone acrylamide, 0.4g azobisisobutyronitrile, and pass through 60mL constant pressure drop after dissolving diacetone acrylamide and azobisisobutyronitrile The funnel was added dropwise to the flask, and the addition was completed in 2.5 hours; after the addition, the reaction was carried out at this temperature for 4 hours, and then the temperature was lowered to 40°C. 2-3mL ammonia water was added dropwise to the flask, and the stirring was continued; In the flask, continue to stir for 20 minutes and discharge.

[0052] After testing, the obtained water-dispersible low-temperature self-crosslinking acrylic resin is a colorless translucent viscous liquid, no irritating odor, stable storage, g...

Embodiment 2

[0057] Take the mixed solvent of 40g ethanol and 10g ethyl acetate into a 250mL four-necked flask equipped with a stirrer and reflux condenser, heat to 73°C and keep refluxing for 10 minutes; add 20g ethyl methacrylate, 20g ethyl acrylate, 7.5g of methacrylic acid, 2.5g of 2-hydroxyethyl acrylate, 1g of diacetone acrylamide, 0.5g of azobisisobutyronitrile are mixed uniformly, after the diacetone acrylamide and azobisisobutyronitrile are dissolved, pass through 60mL constant The pressure dropping funnel was added dropwise to the flask, and the addition was completed in 3 hours; after the addition, the reaction was carried out at this temperature for 4 hours, then the temperature was reduced to 40°C, 4-5mL ammonia water was added dropwise to the flask, and the stirring was continued; weigh 50g Water was added to the flask, stirring was continued for 20 minutes, and the material was discharged.

[0058] After testing, the obtained water-dispersible low-temperature self-crosslinking ...

Embodiment 3

[0062] Take a mixed solvent of 40g ethanol and 30g ethyl acetate, add it to a 250mL four-neck flask equipped with a stirrer and reflux condenser, heat to 72℃ and keep refluxing for 15min; add 15g ethyl methacrylate and 9g acrylic acid-2 -Ethylhexyl ester, 4.5g methacrylic acid, 1.5g 2-hydroxypropyl acrylate, 0.6g N-methylolacrylamide, 0.3g azobisisobutyronitrile and mix well, and wait until N-methylol propylene After the amide and azobisisobutyronitrile are dissolved, they are added dropwise to the flask through a 60mL constant-pressure dropping funnel, and the addition is completed in 2.5 hours; after the addition, the reaction is performed at this temperature for 3.5 hours, and then the temperature is reduced to 40°C and transferred to the flask. Add 2-3 mL of triethanolamine dropwise, and continue to stir; weigh 30 g of water into the flask, continue to stir for 20 minutes, and discharge.

[0063] After testing, the obtained water-dispersible low-temperature self-crosslinking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com