Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2597results about How to "Small smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition of menthol and menthyl lactate, its preparation method and its applications as a cooling agent

InactiveUS6897195B2Small smellReduce volatilityCosmetic preparationsToilet preparationsShaving creamAdditive ingredient

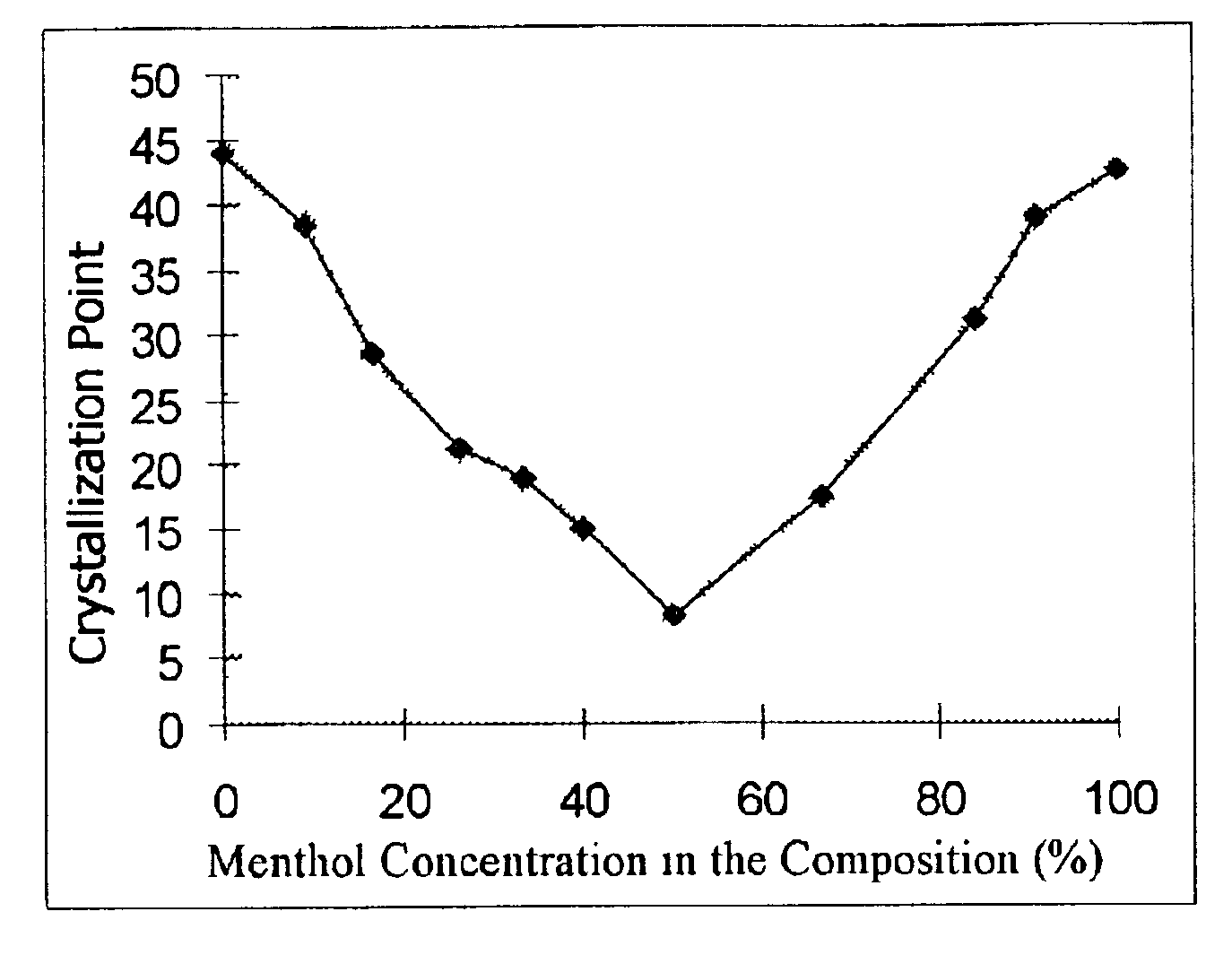

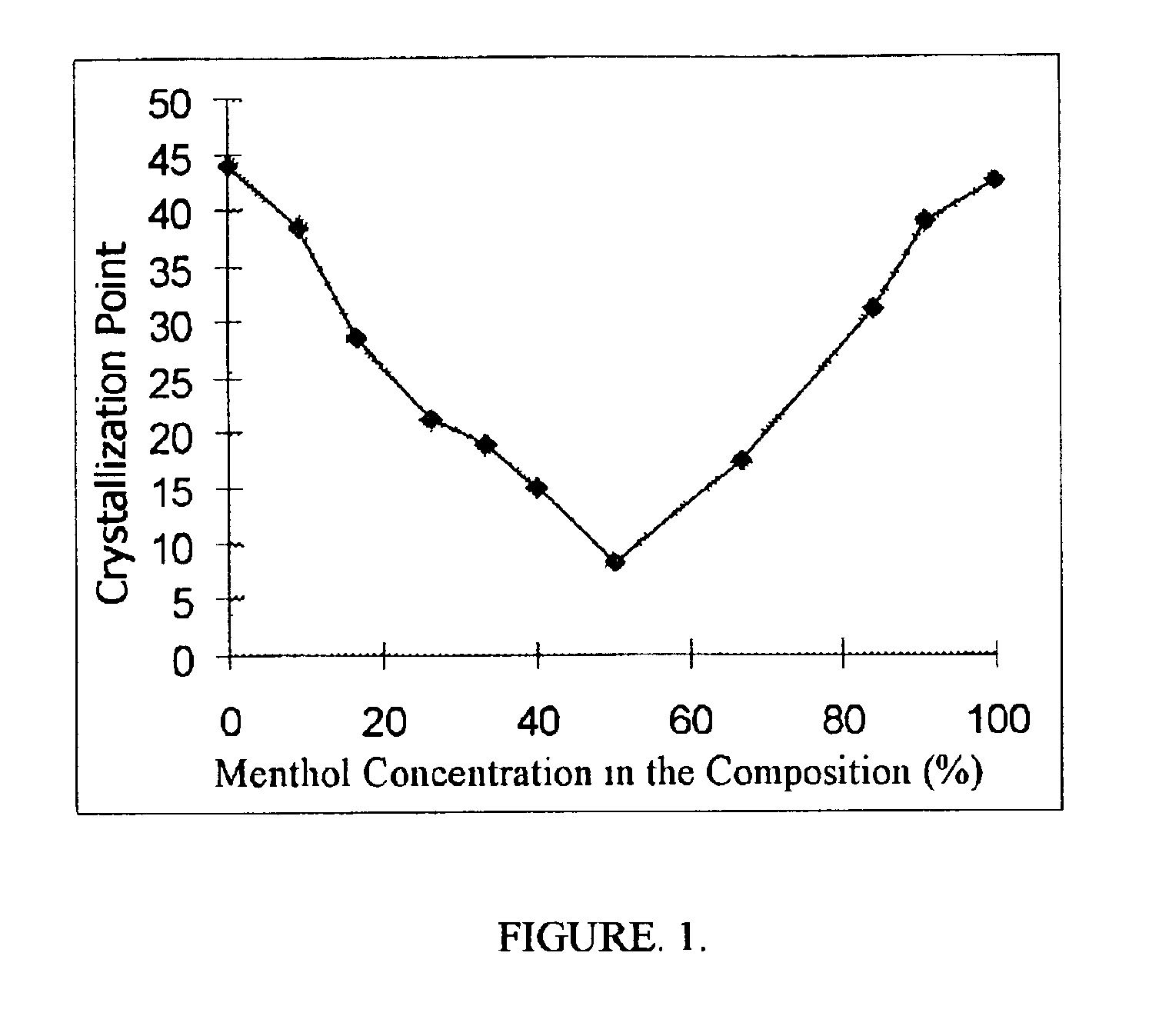

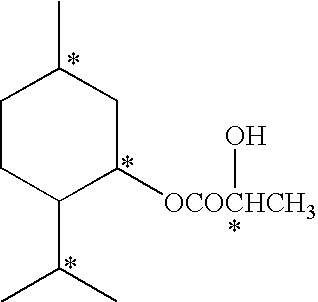

Disclosed here is a composition containing menthol and menthyl lactate, and its preparation method and its applications as a cooling agent and a flavoring agent.The present invention provides a composition characterized in that it comprises menthol and menthyl lactate in a ratio by weight in the range of 1:4˜4:1 and the corresponding crystallization point is below room temperature of 25° C. Such composition has the advantages of being liquid at room temperature; easy to use as a cooling agent or a flavoring agent; no need to use heat to melt menthol and menthyl lactate, which not only saves time, money and heating equipment, but also simplifies manufacturing process and can be used in cold processes at room temperature. The composition can be used as a cooling and / or flavoring agent and / or a fragrance ingredient in toothpaste, mouthwash, fragrance, cleansers, shaving cream, after shave products; shampoo, deodorant, antiperspirant, bath products, drinks, confectionary products, tobacco, pharmaceutical, foods, flavoring and fragrance products.

Owner:NANJING ZHONGSHI CHEM CO LTD

Composite material of polypropylene in low smell and preparation method

InactiveCN1727390AGood physical and mechanical propertiesSimple preparation processMolecular sieveChemistry

A polypropene composition with low odor is proportionally prepared from polypropene, talc powder, molecular sieve (powdered silicoaluminate of alkali-metal), toughening agent poe, and thermal stabilizer.

Owner:SHANGHAI PRET COMPOSITES

Composite material of polypropylene in low smell and volatile matter

A polypropene composition with low odor and low volatile components is proportionally prepared from polypropene, talc powder, fine-porous silica gel, toughening agent poe, thermal stabilizer DSTP, thermal stabilizer 3114 and thermal stabilizer 618 through mixing, dual-screw extruding out and granulating.

Owner:上海天原集团胜德塑料有限公司

Transdermal absorption promoter, and external skin formulation thereof

InactiveUS20130084257A1Small smellImprove securityCosmetic preparationsBiocideIrritationMethyl group

The present invention provides a substance which promotes the transdermal absorption of a pharmacologically active component while little irritating the skin. The present invention relates to a transdermal absorption promoter which comprises, as the active component, at least one member selected from among isopulegol, 2-(menthoxy)ethanol and 2-methyl-3-(menthoxy)propane-1,2-diol; and an external skin formulation which comprises a pharmacologically active component such as a psychotropic component, an anti-inflammatory component, an analgesic component, an antipyretic component, a whitening component or a hair growth-promoting component, together with the aforesaid transdermal absorption promoter.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Low-odour polypropylene composite

The invention relates to a low-odour polypropylene compound, the compound comprises (by weight ratio) polypropylene 55-95, talcum powder 0-40, fatty acid ester compound 0.5-3, nano zinc oxide 0.5-3, nano titanium oxide 0.5-3, heat stabilizer DSTP 0.1-1.0, heat stabilizer 3114 0.1-1.0, heat stabilizer 618 0.1-0.5, wherein the fatty acid ester compound being C25-C45 long-chain fatty acid ester, the heat stabilizer DSTP being octadecyl thiodipropionate, the heat stabilizer 3114 being 3,obtaining 5-ditert-butyl-4-hydroxy benzylphosphonate diethylate, the heat stabilizer being dioctadecyl pentaerythritol diphosphite.

Owner:SHANGHAI PRET COMPOSITES +1

Method of preparing watersoluble polyurethane adhesive

InactiveCN101508879AGood flexibilitySmall smellPolyureas/polyurethane adhesivesPolyurethane adhesiveEmulsion

The invention discloses a preparation method of a waterborne polyurethane adhesive, comprising the following steps: evenly mixing vulcabond and polyglycols, adding in proper amount of catalyst, and reacting so as to obtain polyurethane prepolymer; reacting by adding in hydrophilic chain extender and crosslinking agent, adding 2-hydroxyethyl acrylate into the reaction system so as to obtain polyurethane, terminal group of which is double bond; reducing temperature, neutralizing and emusifying by adding in water under high-speed cutting so as to obtain polyurethane emulsion; and heating up, adding vinyl monomer into the emulsion, and polymerizing initiated by water-soluble initiator so as to obtain the modified waterborne polyurethane emulsion. The invention can completely eliminate the harmful effect to the application and the environment protection of the polyurethane emulsion product caused by small molecular emulsifier and organic solvent. The invention can make full use of combination property through the copolymerization modification between the polyurethane and polyacrylic ester.

Owner:SHAANXI UNIV OF SCI & TECH

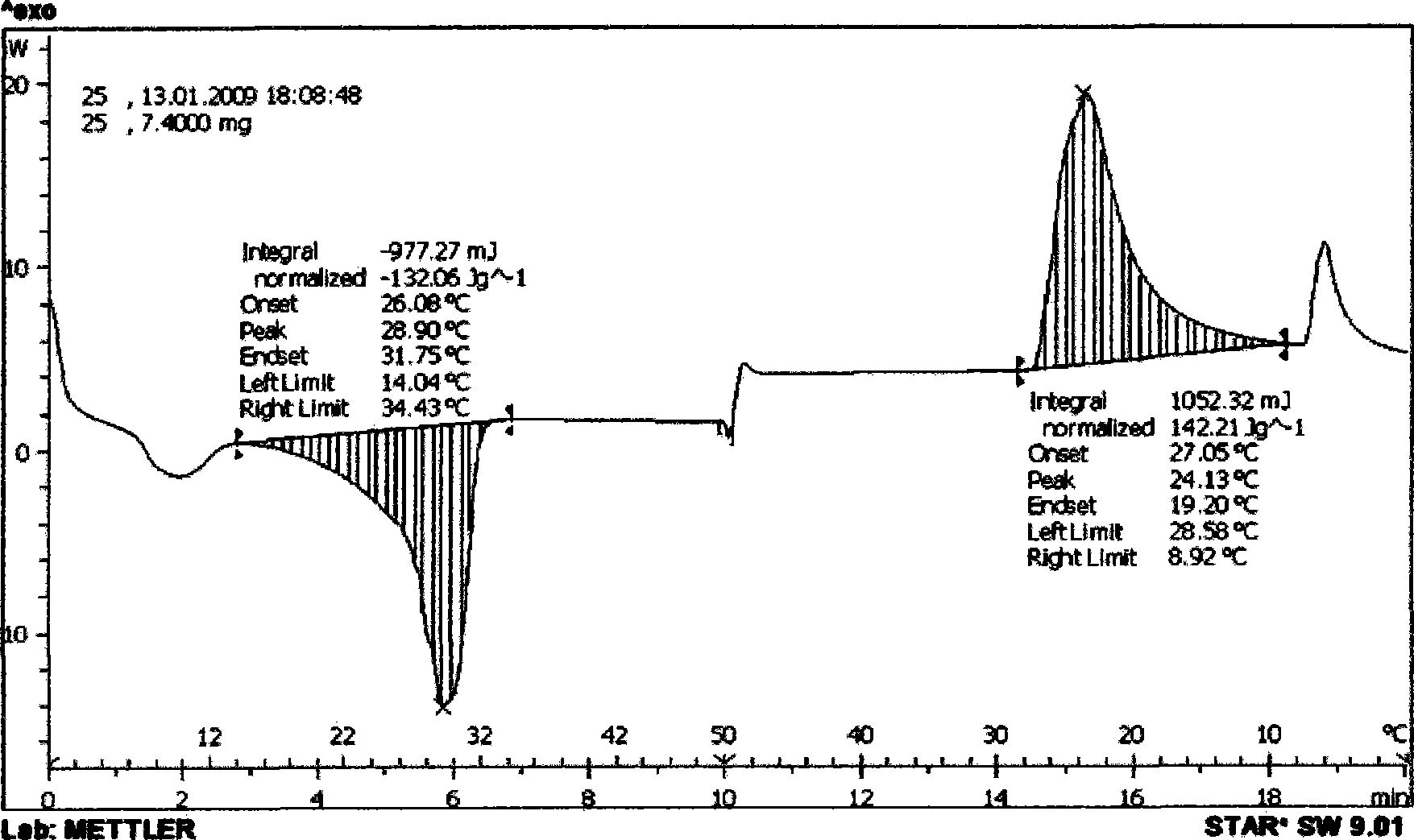

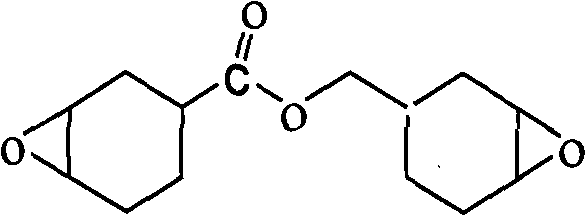

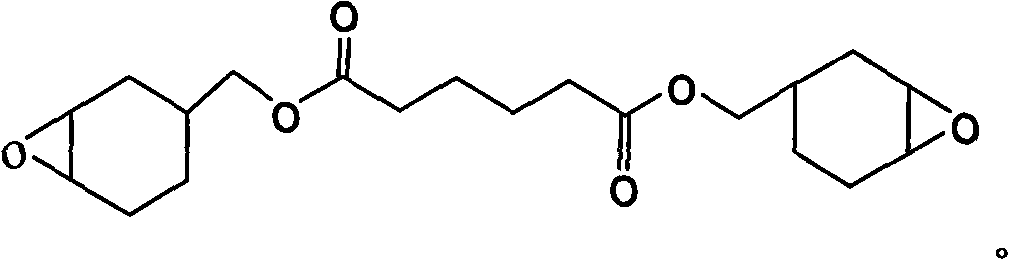

Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

InactiveCN101530772ALess light fastnessSmall smellHeat-exchange elementsMicroballoon preparationPolymer chemistryPhase-change material

A preparing method for phase transited stored energy microcapsule covered with an organic polymer material adopts the following steps: (1) mixing the 10 weight organic phase transited material and 0.5-2.5 weight nonionic surfactant under the condition of heating and blending; (2) picking the organic polymer material monomer A, B 2-3 weight to add to 40-60 weight water, blending and mixing as the water phase; (3) adding the oil phase to the water phase, blending the material as the creaming liquid at 30-50 centigrade, adding the free radical to the initiator for the poly-reaction 1-8h at 35-90 centigrade; then adjusting the low temperature as blending the material and adding the cross linker, filtering, washing and drying to obtain the finished products. The organic polymer material achieves the phase transited capsule envelopment via the creaming polymer reaction of the wall material; the microcapsule is the spherical; the granule is distributed evenly; the polymer wall material has a stable intensity, great tightness and great mechanical performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

High-strength high-toughness low-odor polypropylene composition and preparation method and usage thereof

ActiveCN102757597AMeet the requirements of interior comfortIncrease productivityGlass fiberPolymer science

Owner:滁州格美特科技有限公司

Double-solidification system fast-flowing underfill and preparation method thereof

InactiveCN102010686AGuaranteed reliabilityFast flowOther chemical processesEpoxynovolac adhesivesEpoxyPolyol

The invention discloses a double-solidification system fast-flowing underfill and a preparation method thereof. The underfill comprises the following raw materials in parts by weight: 30-80% of epoxy resin, 10-50% of epoxy acrylate, 5-30% of acrylate, 2-20% of polyol, 1-20% of silane coupling agent, 0.3-4% of cationic initiator, 0.1-3% of radical initiator and 0.1-0.5% of carbon black; and the preparation method comprises the following steps of: weighing the epoxy resin and the cationic initiator in the proportion, putting in a reaction kettle and stirring into a uniform solution; weighing the epoxy acrylate, the acrylate, the polyol, the silane coupling agent, the radical initiator and the carbon black in the proportion, putting in the reaction kettle in sequence, mixing and stirring to obtain the finished product of the double-solidification system fast-flowing underfill.

Owner:YANTAI DARBOND TECH

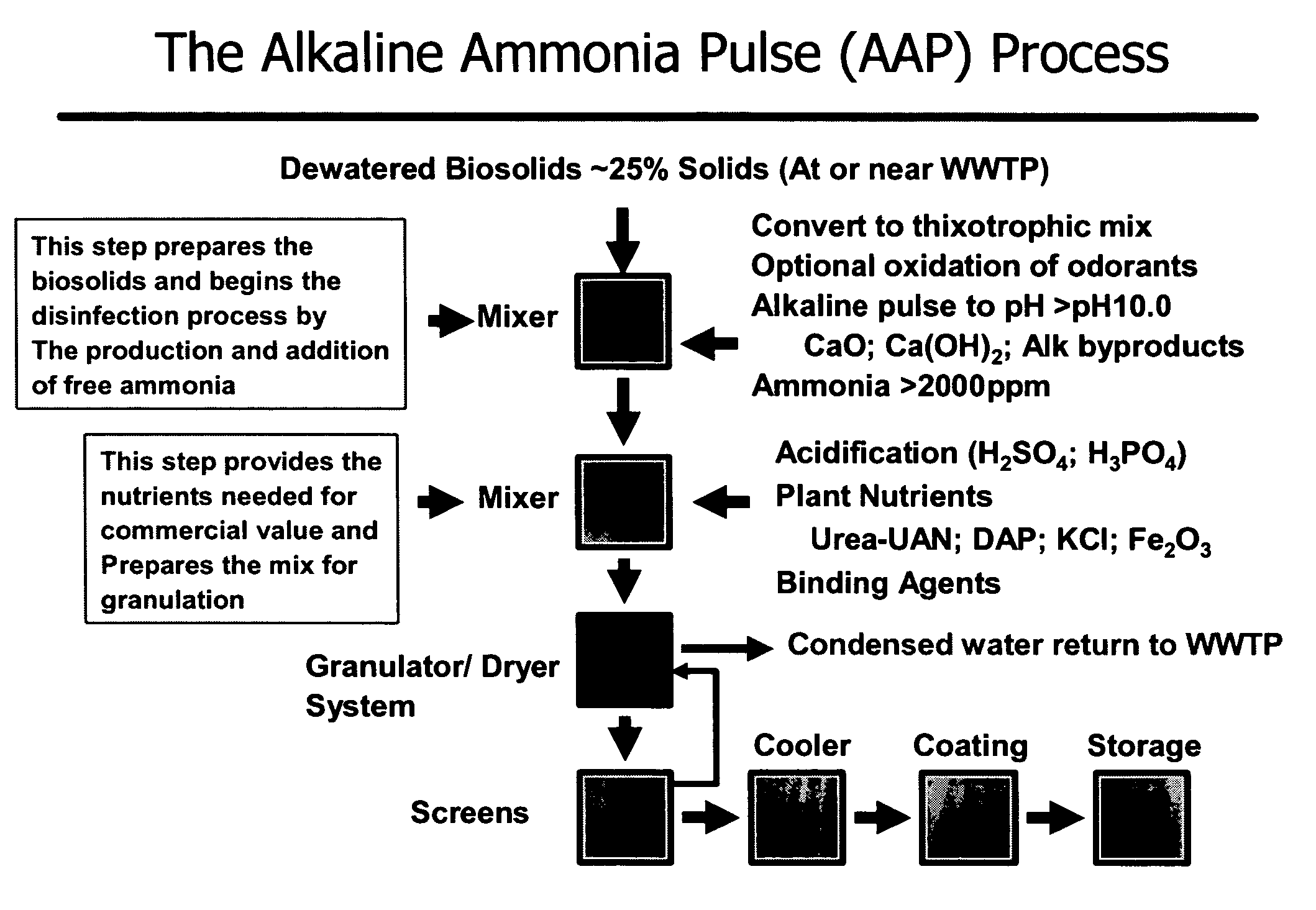

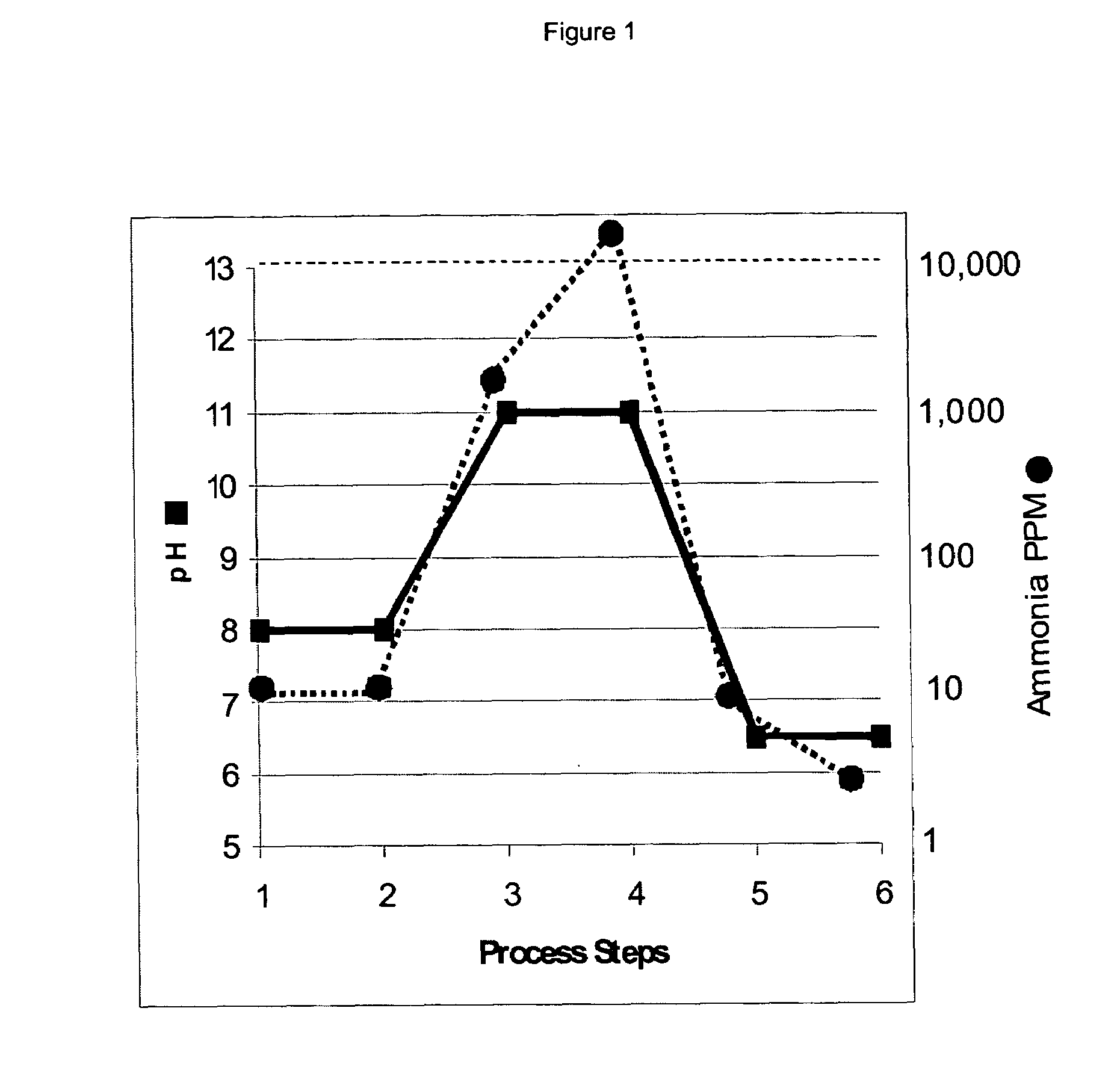

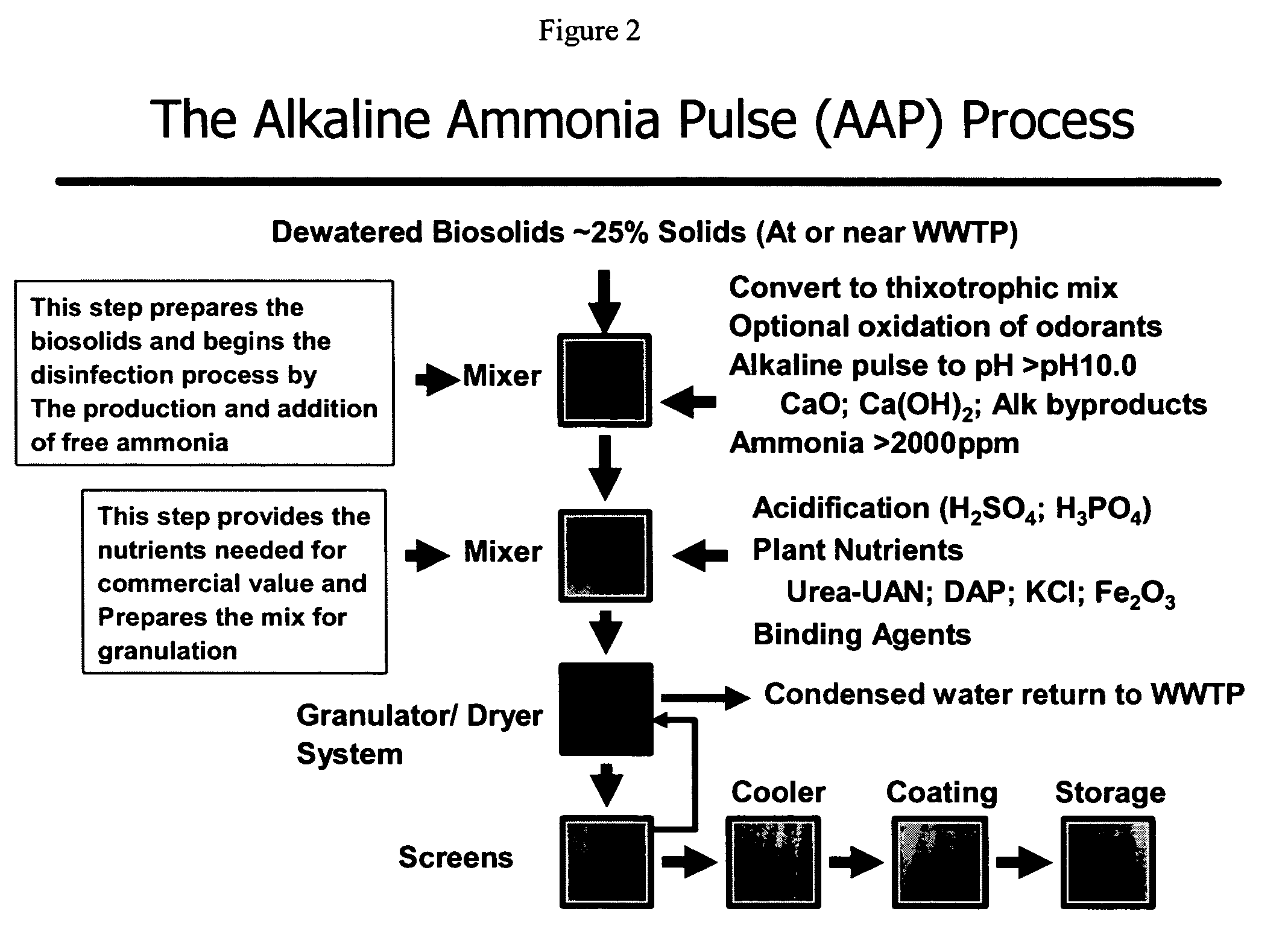

Organic containing sludge to fertilizer alkaline conversion process

InactiveUS7662206B2Reduce odorHigh in nutrientsCalcareous fertilisersBio-organic fraction processingSludgeOrganic manure

This invention is directed to systems, devices and methods for treating organic-containing sludges and converting such sludges to high value fertilizers containing both inorganic and organic fertilizer components, which creates an inorganically-augmented bioorganic fertilizer. The invention describes methods to create a thixotrophic or paste-like material via the application of mixing energy to the organic sludge followed by an alkaline treatment and a subsequent ammoniation. The invention further describes a method to increase the plant nutrient content in the organic containing product to a level which permits the finished granular fertilizer product to compete in the commercial agricultural fertilizer marketplace. Further, the invention reduces odors associated with said organic-containing sludges.

Owner:GENERATE LENDING LLC +1

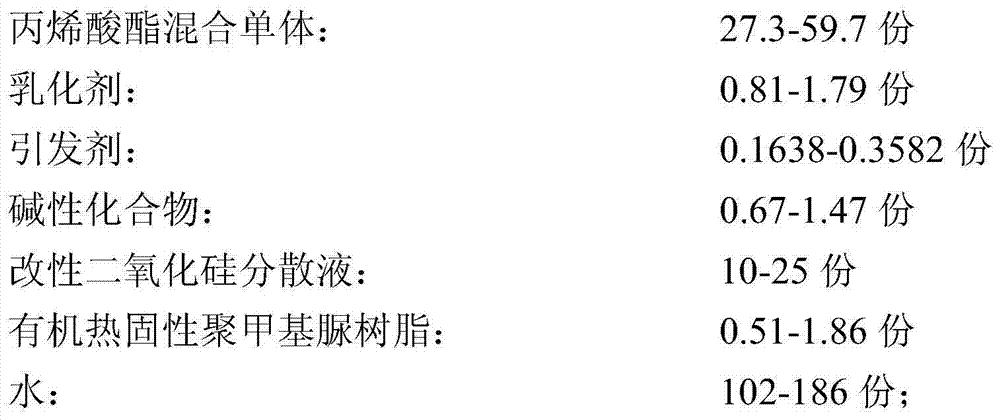

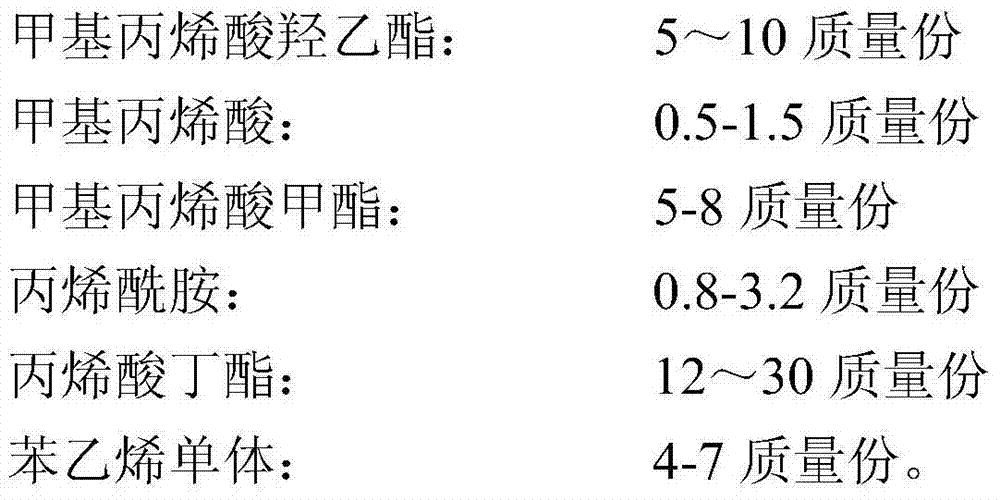

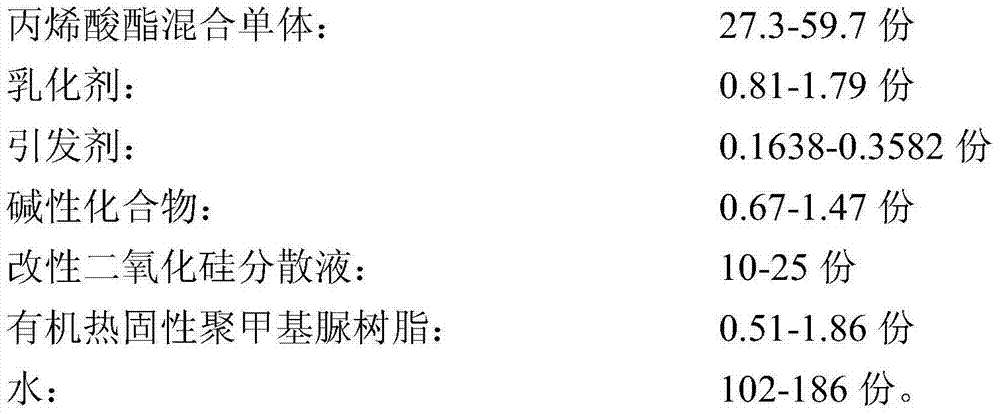

Aqueous multi-functional crylic acid extinction resin and preparation method thereof

The invention discloses an aqueous multi-functional crylic acid extinction resin and a preparation method thereof and belongs to the field of extinction type coatings. The preparation method of the aqueous multi-functional crylic acid extinction resin comprises the following steps: (1) preparing a crylic acid ester mixture monomer; (2) sufficiently mixing water, an emulsifier and a part of the crylic acid ester mixture monomer, heating to 70-90 DEG C, adding an initiator to react for 0.5-1 hour, dropwise adding the rest crylic acid ester mixture monomer within 3-5 hours, adding the rest initiator in different batches, performing heat preservation for 1-3 hours after the dropwise adding, cooling to 45 DEG C, sequentially adding modified silicon dioxide and an organic thermosetting polymethylurea resin with the particle size of 3.5mu m, uniformly stirring, cooling down and discharging so as to obtain the aqueous multi-functional crylic acid extinction resin. The aqueous multi-functional crylic acid extinction resin prepared by the preparation method disclosed by the invention is high in extinction efficiency, excellent in water resistance, acid resistance and alkali resistance, and good in abrasion resistance property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Antibacterial and low-odor decorative polypropylene material used in saloon car and preparation method thereof

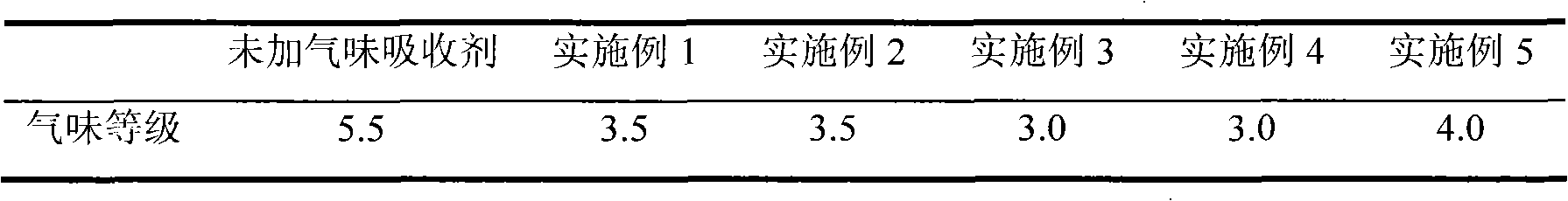

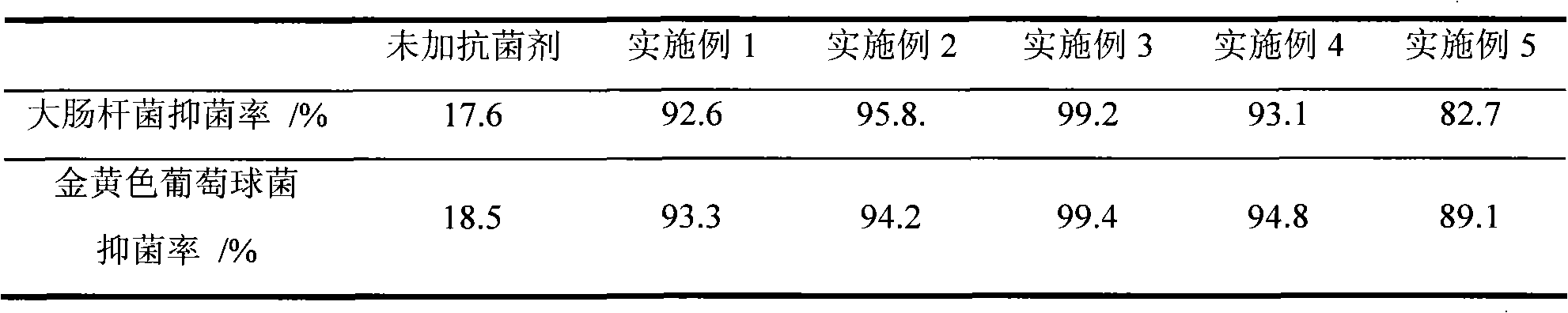

The invention discloses an antibacterial and low-odor decorative polypropylene material used in a saloon car and a preparation method thereof, wherein the material comprises the following components in percentage by weight: 60 to 80 percent of polypropylene, 1 to 20 percent of elastic body, 10 to 30 percent of talcum powder, 1 to 5 percent of photocatalytic micro-powder, 0.5 to 2.0 percent of antibacterial agent, and 0.3 to 1.0 percent of odor absorbent. The polypropylene material can keep low odor enduringly, has antibacterial and mould-proof functions, and has the advantages of strong bactericidal power, quick disinfectant effect, good durability, good stability, no secondary pollution and the like. According to the invention, odorous small molecules such as paraffin, olefins, arenes, amine, phenol, thiol, peroxide, aldehydes, ketones and the like can be effectively removed.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +3

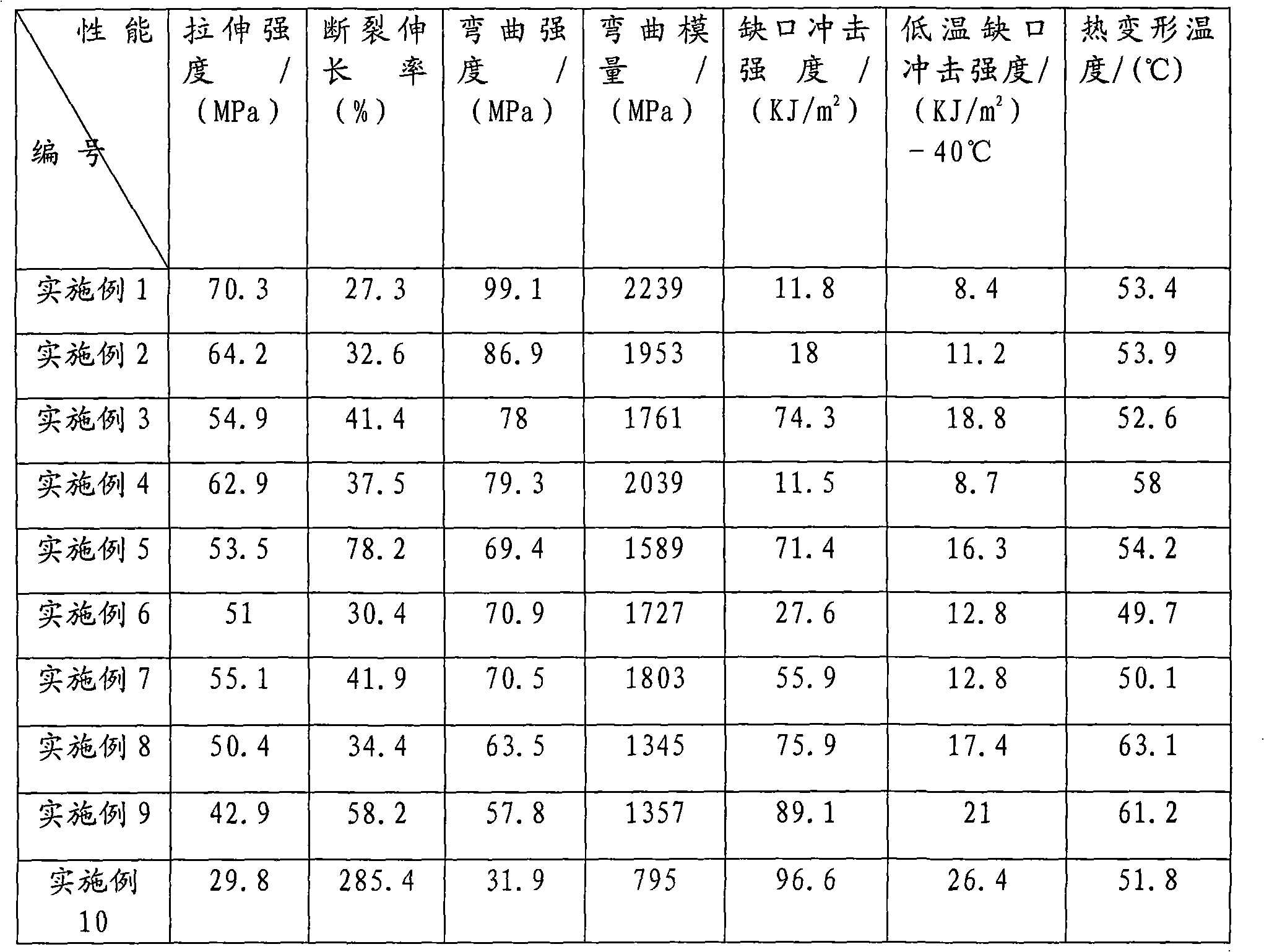

Long glass fibre reinforced nylon material and preparing method thereof

The present invention belongs to high polymer material and forming and processing field thereof, and provides a long glass fibre reinforced nylon material and preparing method thereof, wherein the constituents comprise: 29-67wt% of nylons, 30-60wt% of long glass fibre, 2-10wt% of compatilizer and 0.3-1.0wt% of antioxidants. The preparing method comprises the following steps: first mixing the nylons, compatilizer and antioxidants; adding the mixture into a double-screw extruder, wherein the processing temperature is 235-300 DEG C; extruding resin fondants into a dipping mould connected to the double-screw extruder; enabling the long glass fibre to pass through the dipping mould, wherein the dipping temperature of the dipping mould is 260-300 DEG C, dipping the long glass fibre completely in by the fondants, cooling, dragging and granulating the long glass fibre to obtain the long glass fibre reinforced nylon materials. The method of the present invention can strengthen the dipping effect of glass fibre in nylon fondant, eliminate or decrease harmful substances, reduce environmental pollution, and improve the dipping effect and mechanical property of materials effectively.

Owner:NANJING JULONG SCI&TECH CO LTD

Low-smell toughening polyamide (PA) 6 material and preparation method thereof

The invention discloses a low-smell toughening polyamide (PA)6 material. The low-smell tougheningPA6 material comprises the following raw materials in part by weight: 60 to 95 parts of nylon 6 resin, 5 to 40 parts of polyolefin, 0.5 to 5 parts of maleic anhydride, 0.1 to 0.5 part of peroxide and 0.2 to 5 parts of other additive. By the preparation method, the processing step of preparing toughening polyamide (PA)6 material is simplified, namely the primary two steps are combined into one step, and the preparation of the toughening polyamide (PA)6 material is realized by controlling a processing temperature. The production cost is reduced by the method; the prepared toughening polyamide (PA)6 material is excellent in performance and low in smell, has a certain practicability and commercial value and can be applied in fields, such as vehicles, electronics / electrical appliances and the like.

Owner:SHANGHAI PRET COMPOSITES

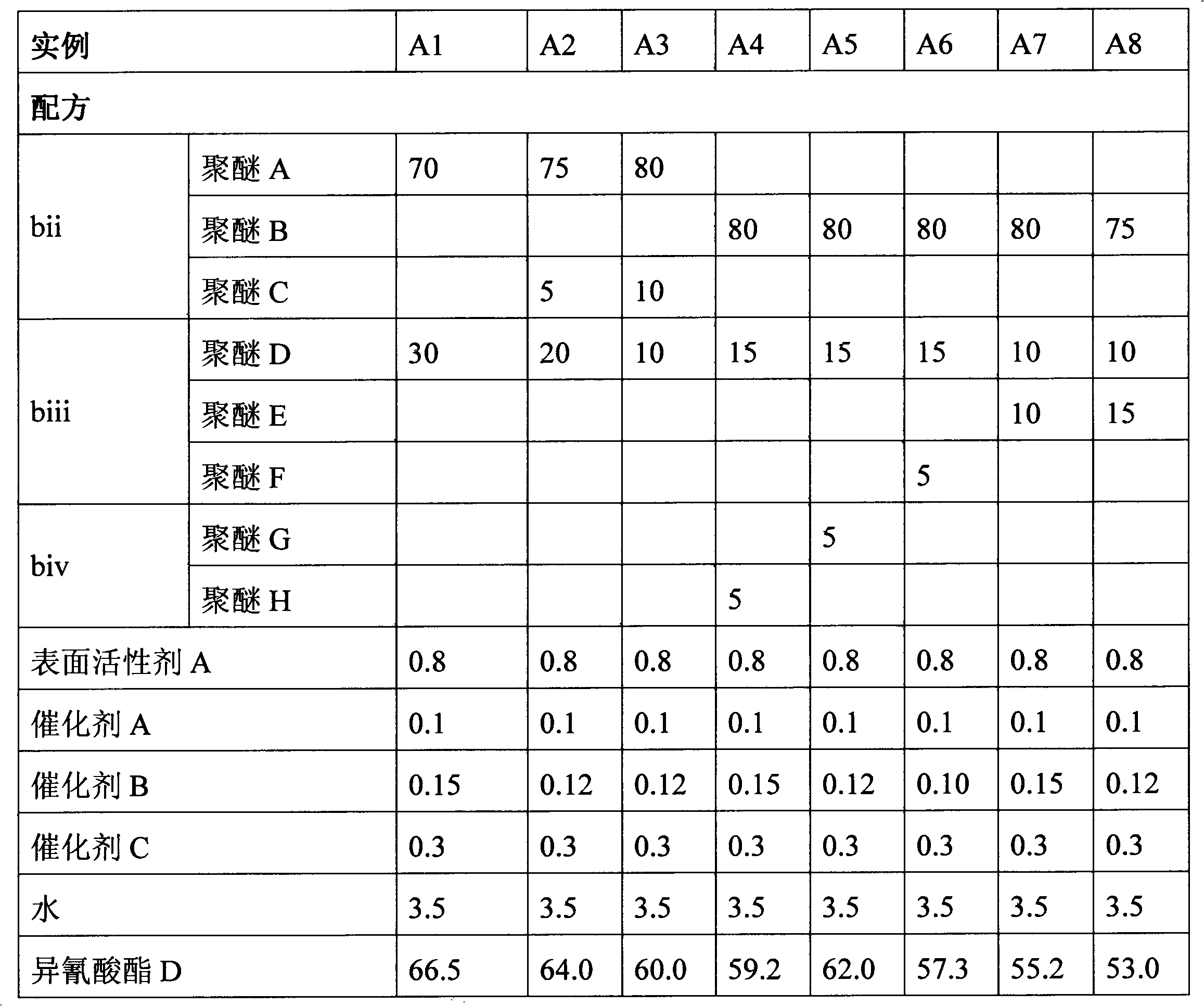

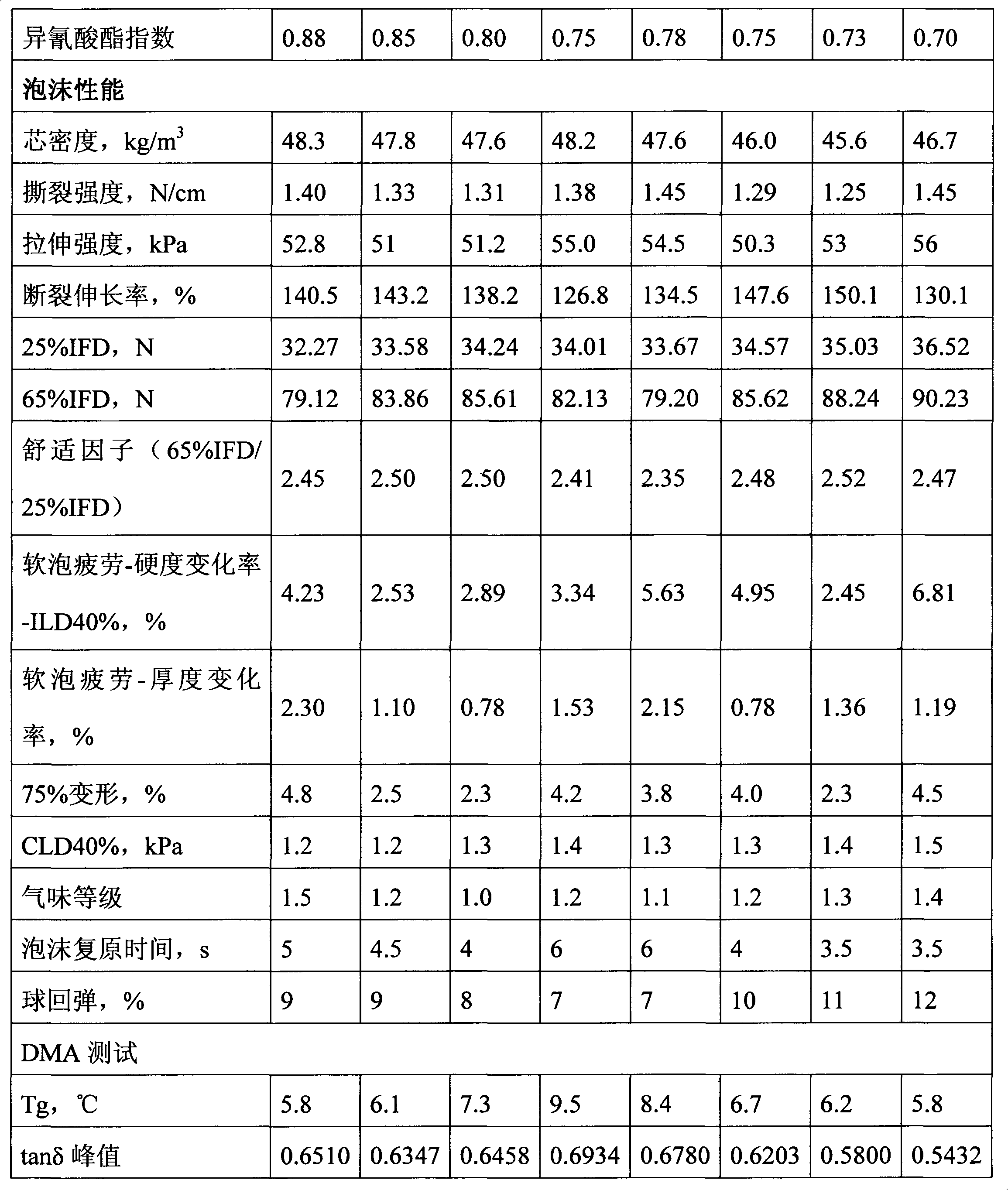

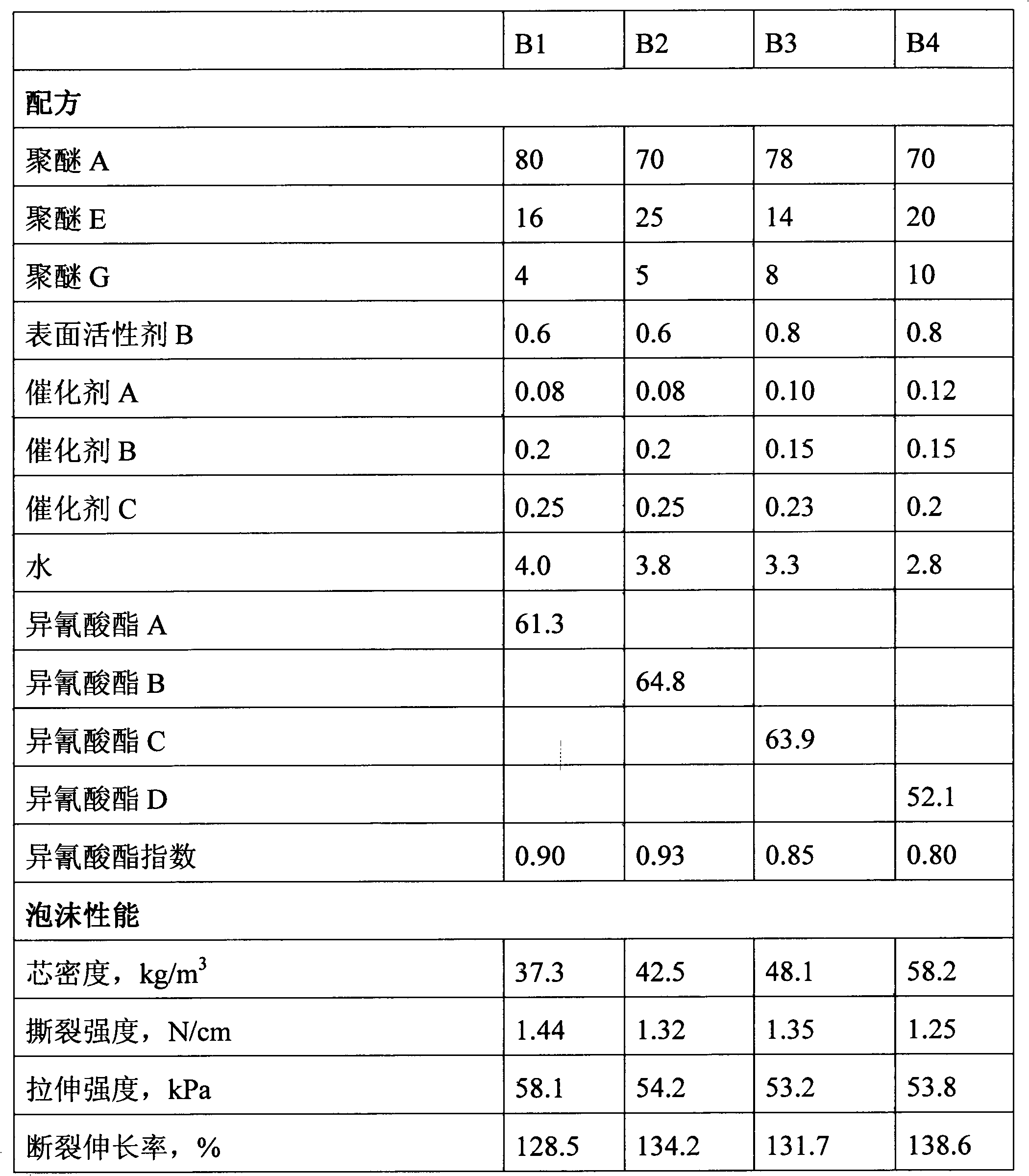

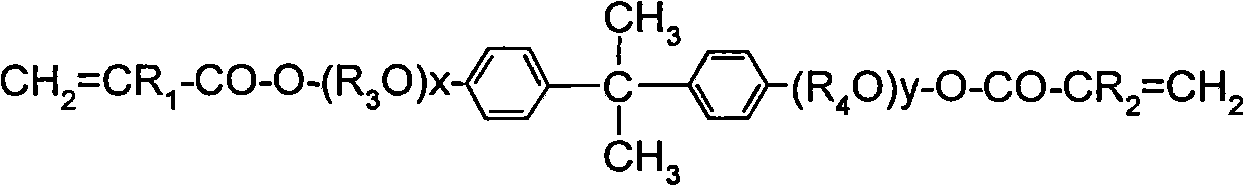

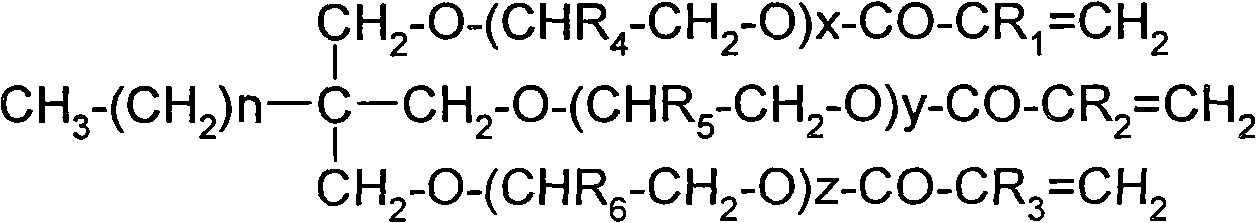

Preparation method for low-density viscoelastic polyurethane foam

The invention relates to a preparation method for low-density viscoelastic polyurethane foam. Based on 100 parts by weight of mixed polyether, Isocyanate reaction active ingredients include (biii) 70-95 percent of propylene epoxide, ethylene oxide copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is not less than 70 percent by weight, (biii) 5-30 percent of propylene epoxide, epoxy ethane copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is 20 percent by weight at most, and (biv) 0-15 percent of propylene epoxide, propylene epoxide copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is 20 percent by weight at most; a reaction system does not contain any toluene diisocynate component or foaming agents except water; at least two polyether polyols are taken as major polyethers; and low-density viscoelastic polyurethane foam with low odor and excellent fatigue resistance is prepared.

Owner:WANHUA CHEM BEIJING +1

Associative acrylate thickening agent as well as preparation method and application thereof

InactiveCN101974134AGood thickening effectHigh transparencyCosmetic preparationsToilet preparationsEmulsionChemistry

The invention discloses an associative acrylate thickening agent as well as a preparation method and application thereof. The thickening agent in dry weight comprises the following component in percentage by mass: 20-40% of hydrophilic monomer, 50-70% of hydrophobic monomer, 1-10% of reactive surfactant and 0.2-2.0% of cross-linking agent. The preparation method comprises the following steps of: mixing the reactive surfactant, the hydrophilic monomer, the hydrophobic monomer, the cross-linking agent and water to prepare a monomer emulsion; reacting a part of monomer emulsion with a part of initiating agent solution to prepare a seed emulsion; adding the reset monomer emulsion and a part of the initiating agent solution into the seed emulsion; and finally adding the rest initiating agent solution to prepare the associative acrylate thickening agent. The thickening agent has the advantages of strong electrolyte resistance, good compatibility with surfactants, wide pH value application range and excellent thickening capability and suspension capability, and is applicable to the thickening of aqueous systems and system mainly containing water.

Owner:GUANGZHOU SHINE POLYMER TECH

Hand-care disposable disinfection gel and preparation method thereof

ActiveCN104873432ASimple preparation processHigh sterilization rateCosmetic preparationsToilet preparationsSolventChemistry

The invention relates to a hand-care disposable disinfection gel and a preparation method thereof. The hand-care disposable disinfection gel comprises ethanol, a bactericide, a cosolvent, a thickener, an emollient, essence and a PH regulator, wherein the essence is used as a carrier to cover pungent odor of ethanol. The hand-care disposable disinfection gel has the advantages of being bactericidal, washing-free, not sticky and greasy, and comfortable in smell, and caring hands. The preparation method comprises the following steps: the thickener swells in purified water fully to prepare a liquid A; meanwhile, the bactericide and the cosolvent are added in ethanol to be mixed uniformly to prepare a liquid B; then, the liquid B is poured into the liquid A; the emollient and the essence are poured in the liquid A, after purified water is supplemented to be sufficient, the PH regulator is added to regulate the PH value to 6.0-8.0, and the uniform mixing is performed.

Owner:HENAN HUIBO MEDICAL CO LTD

Polypropylene combination with low smell and diffusion and preparation method thereof

The invention discloses a polypropylene combination with low smell and diffusion and a preparation method thereof. The polypropylene combination with the low smell and diffusion comprises the compositions as follows: 37-88 percent of polypropylene resin, 5-30 percent of a toughener, 0-40 percent of mineral filler, 0.5-5 percent of medusa particle and 0.1-3 percent of an assistant. The preparation method comprises the steps as follows: the polypropylene resin, the toughener, the mineral filler and the assistant are uniformly mixed in a high mixing machine for 1-3 minutes, places in a main feeding hole of an dual-screw extruder, added with the medusa particles from a side feeding hole, molten, extruded, pelletized and dried at a temperature controlled within 200-215 DEG C and under the rotation speed condition of 450 round / minute, so that the polypropylene combination with the low smell and diffusion is obtained. According to the invention, the medusa particles adopting high-melts foamed PP as a carrier is used as a stripping agent, various kinds of volatile small molecules and organic compounds which are generated during processing can be effectively removed, the prepared polypropylene combination has the characteristics of low smell and diffusion, and can satisfies the demand of automobile for inner decoration.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Novel environmental-friendly double-component acrylate adhesive and preparation method thereof

InactiveCN103074000ASmall smellCreate pollutionPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveAdhesivePollution

The invention relates to a novel environmental-friendly double-component acrylate adhesive, which is composed of a component A and a component B in mass part ratio of 1 to 1, wherein the component A is composed of the following raw materials in mass part: 45-75 parts of acrylic monomer, 15-45 parts of toughened resin, 0.5-10 parts of initiating agent, 0.01-1 part of stabilizing agent, 0.1-5 parts of coupling agent and 0.5-10 parts of thixotropic agent; and moreover, the component B is composed of the following raw materials in mass part: 45-75 parts of acrylic monomer, 15-45 parts of toughened resin, 0.5-10 parts of accelerating agent, 0.01-1 part of stabilizing agent, 0.1-5 parts of coupling agent and 0.5-10 parts of thixotropic agent. The novel environmental-friendly double-component acrylate adhesive provided by the invention has very little smell, does not produce substances harmful to the body, and cannot cause pollution to the environment; and meanwhile, the adhesive with the structure has favorable adhesive property and storage stability.

Owner:BEIJING HYSTIC NEW MATERIALS

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

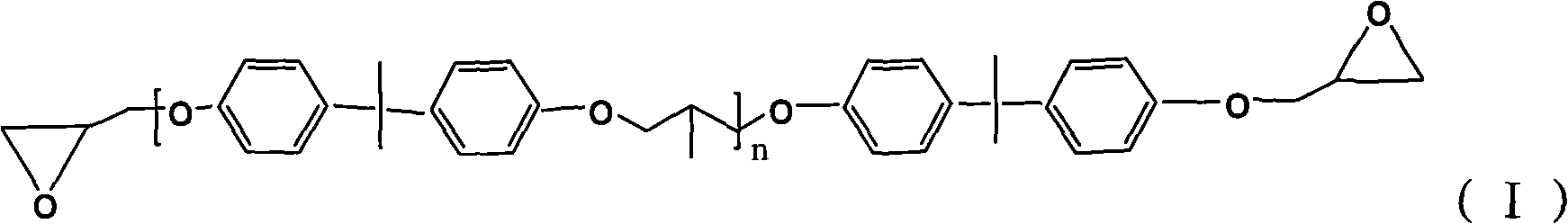

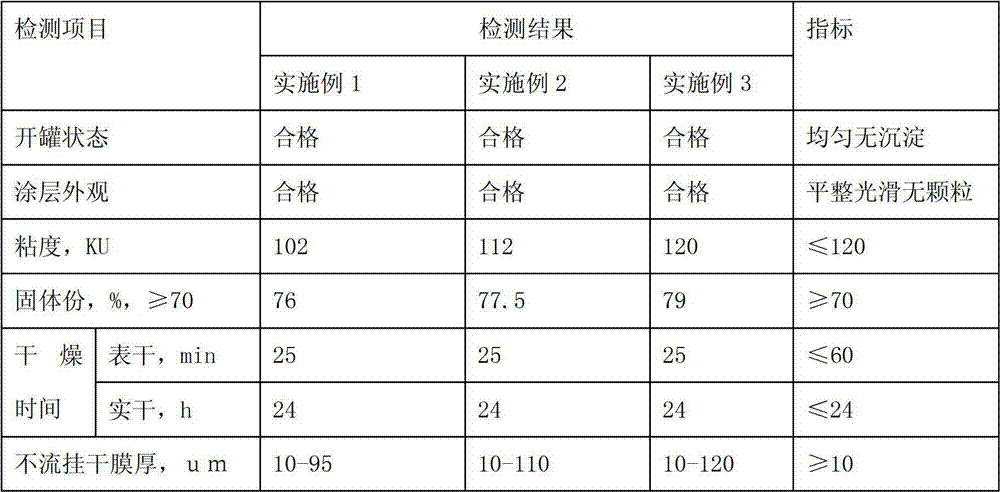

Ultraviolet curing liquid optical clear adhesive and preparation method thereof

InactiveCN103031105ASmall smellModerate viscosityPolyureas/polyurethane adhesivesAdhesiveToluene diisocyanate

The invention relates to an ultraviolet curing liquid optical clear adhesive and a preparation method thereof, and belongs to the field of bonding adhesives. The method comprises the steps that toluene diisocyanate, polyethylene glycol and hydroxyethyl acrylate are taken as raw materials; a urethane acrylate prepolymer is synthesized through polystep reaction by a bulk method; the prepolymer is taken as a main body; a photoinitiator, a composite reactive diluent and other assistants are added; and then the ultraviolet curing liquid optical clear adhesive is prepared. The ultraviolet curing liquid optical clear adhesive prepared by the preparation method has the characteristics that the ultraviolet curing liquid optical clear adhesive is low in smell, moderate in viscosity, good in flexibility, high in light transmittance and refractive index, high in bonding strength, waterproof, and good in cold and heat shock resistance, weather resistance and ageing resistance. The ultraviolet curing liquid optical clear adhesive is completely transparent after being cured, and can keep stable high transparency and is free from yellowing, whitening and degumming for a long term in high-temperature and high-humidity environments.

Owner:SHENZHEN JINLIAN TECH

High-gloss, low-smell, reinforced nylon composite material and preparation method thereof

The invention relates to a high-gloss and low-odor reinforced nylon composite material and the preparation method thereof. The composite material is characterized in that the composite material contains, by weight percentage, PA66 resin, PA6 resin, glass fiber, inorganic minerals, micro-beads, compatibilizer, antioxidant, lubricant, etc. The preparation method comprises the following steps: mixing the above materials in a high-speed mixer; discharging, and extruding and granulating the mixed material in a screw extruder. Compared with common fiber glass reinforced PA and mineral reinforced PA, the PA composite material prepared by the method has the advantages of high gloss, high strength, low odor, etc., and can be widely used for exterior trimming parts such as electric tool housing and motor housing and for interior parts.

Owner:SHANGHAI SUNNY

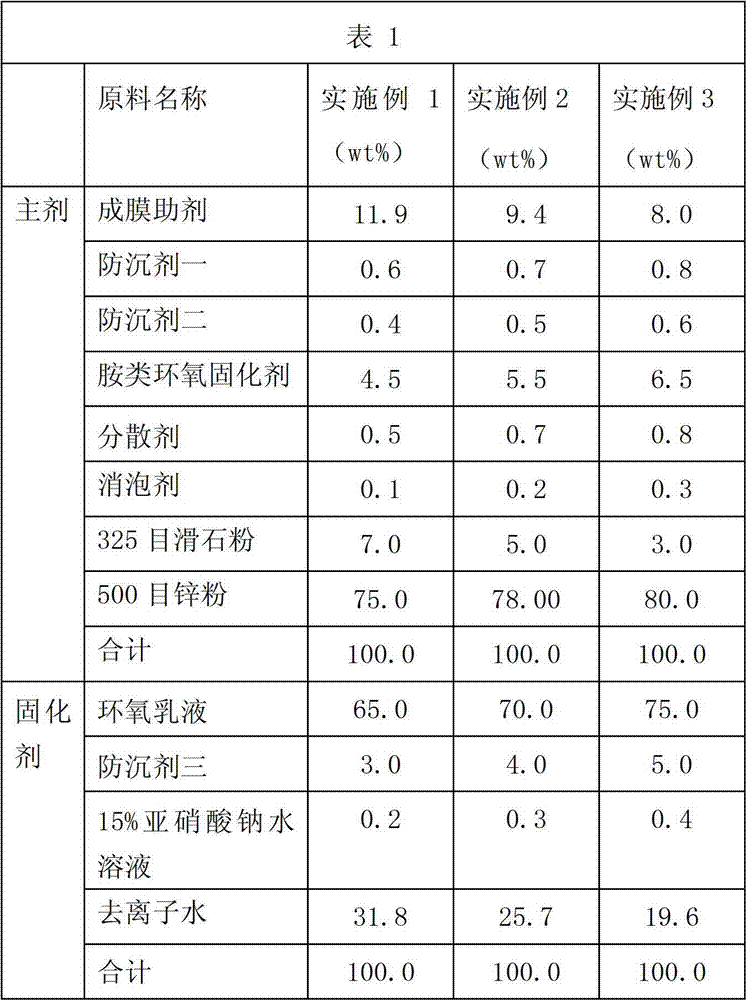

Water-base epoxy zinc-rich priming paint and preparation method thereof

ActiveCN102863874ALow VOC contentSmall smellAnti-corrosive paintsEpoxy resin coatingsSolventEmulsion

The invention discloses a water-base epoxy zinc-rich priming paint and a preparation method thereof. The water-base epoxy zinc-rich priming paint comprises a host and a curing agent according to the weight proportion of 4:1. The host comprises filming auxiliary, a first anti-settling agent, a second anti-settling agent, an amine epoxy curing agent, dispersant, a defoaming agent, filler and zinc powder, and the curing agent comprises epoxy emulsion, a third anti-settling agent, an anti-flash anti-rust agent and deionized water. The preparation method includes steps of preparing the host and the curing agent and proportioning paint by the host and the curing agent according to the weight proportion of 4:1. By taking water as a main dispersion medium, the water-base epoxy zinc-rich priming paint has quite low volatilizable organic content, light smell, low harms on humans, non-combustible property and unique safety in storage, transport and use, safety potential hazards caused by accumulation of a great quantity of harmful solvents are eliminated, harms on physical and psychological health of constructors are reduced to the greatest extent, and further, the requirements of production efficiency of fast paces of a container production line can be met.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

Liquid disinfectant

InactiveCN1476761AReduced stabilityImprove stabilityBiocideAnimal repellantsDialkyl dimethyl ammonium chlorideDisinfectant

The present invention discloses a liquid high-effective disinfectant. It is formed from (wt%) 1-2% of hyamine which is the mixture of alkyl dimethyl benzyl ammonium chloride and dialkyl dimethyl ammonium chloride, 0.1-0.5% of biguanide which is one of chlorhexidine and polyhexamethylene biguanide salt or their mixture, 3-8% of aldehyde which is one of glutaraldehyde, citrial, jasminal and myristic aldehyde or mixture of more than two kinds of them, 5-10% of surfactant, 1-5% of urea, 40-50% of hydrophilic solvent, 0.1% of EDTA sodium salt, 2.5-35% of water and 0-3% of selectable components, such as aromatic compound, colouring matter and viscosity-regulating agent.

Owner:刘瑞源

Flat varnish for waterborne wood

The invention discloses a flat varnish for waterborne wood, comprising the following components in parts by weight: 30-70 percent of waterborne acrylic emulsion, 0-30 percent of waterborne aliphatic polyurethane and mixture emulsion, 3-10 percent of film forming aid, 0.01-2 percent of antifoaming agent, 0.01-2 percent of dispersing agent, 0.1-5 percent of extinction powder, 0-2 percent of wettingagent, 0.01-2 percent of rheological additive, 0.01-2 percent of wax additive, 0.01-2 percent of hand-feeling addictive, 0.01-2 percent of thickening agent, 0.01-2 percent of ammonia water, 0.01-2 percent of coupling agent and 5-30 percent of water. The flat varnish for waterborne wood has the advantage of ensuring that a varnish film has better fullness, hardness, high chemical resistance, super-strong hand feeling and strong adhesive force on an oil primer. In addition, the flat varnish for waterborne wood can solve the compatibility between the aquosity and the oilness, ensure the varnish film cannot fall off after being dried and can meet the requirement for consumers on high environmental protection, low odor and less pollution.

Owner:HUIZHOU CHANGRUNFA PAINT

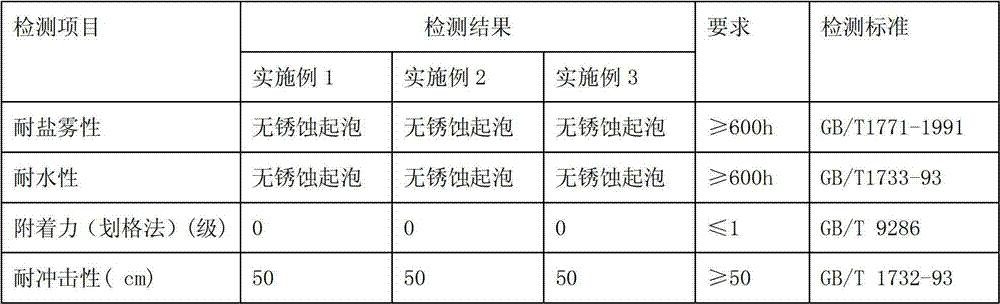

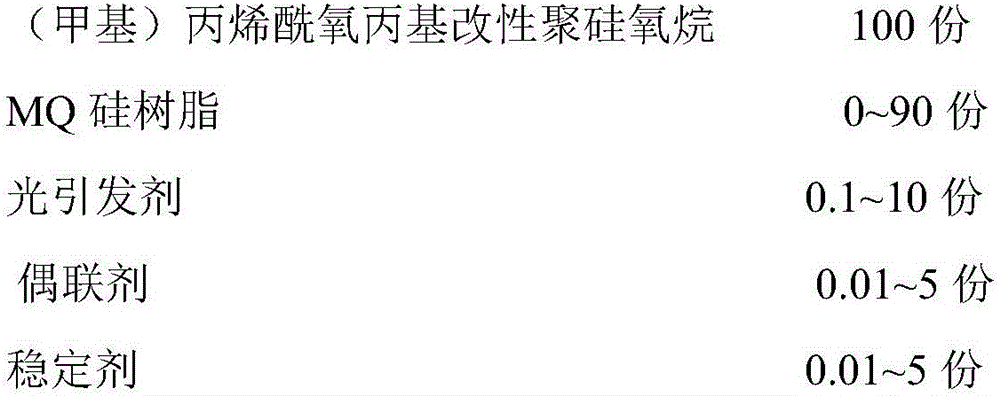

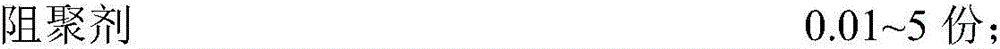

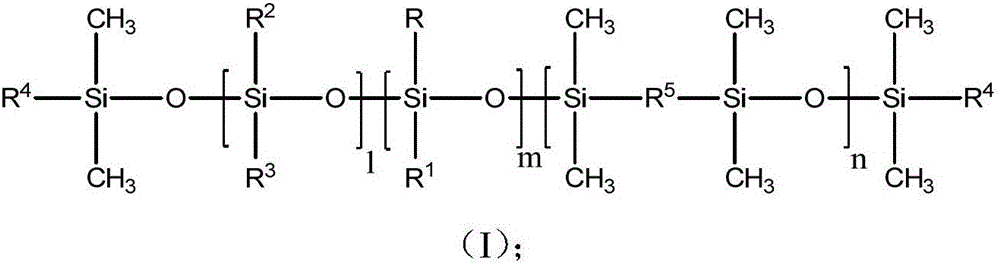

Ultraviolet-curing liquid optical silica gel used for reworkable gluing as well as preparation method and application thereof

InactiveCN106497505AReduce scrap rateAnti-yellowing and agingNon-macromolecular adhesive additivesAdhesiveOptical transmittance

The invention belongs to the technical field of preparation of adhesives and specifically discloses an ultraviolet-curing liquid optical silica gel used for reworkable gluing. The ultraviolet-curing liquid optical silica gel used for reworkable gluing comprises the following ingredients in parts by weight: 100 parts of methacryloyloxyethyl modified polysiloxane; 0-90 parts of MQ silicon resin, 0.1-10 parts of a photoinitiator, 0.01-5 parts of a coupling agent, 0.01-5 parts of a stabilizer and 0.01-5 parts of a polymerization inhibitor. The liquid optical silica gel provided by the invention has high light transmittance, small shrinking percentage, small yellowing index and good reworkable performance; the liquid optical silica gel can be repeatedly used for gluing an optical element and a screen; meanwhile, the rejection rate of materials can be effectively controlled, the production cost of enterprises is greatly reduced, and the application prospect is wide.

Owner:矽时代材料科技股份有限公司

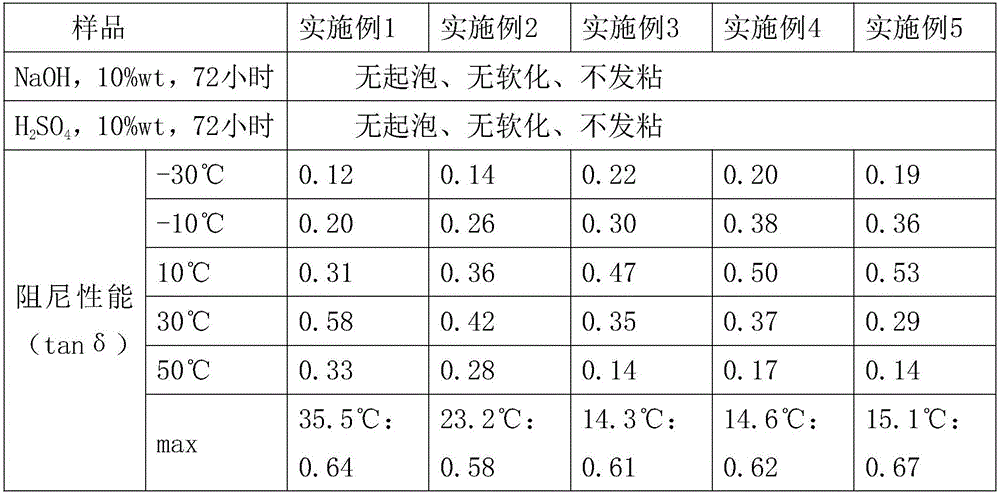

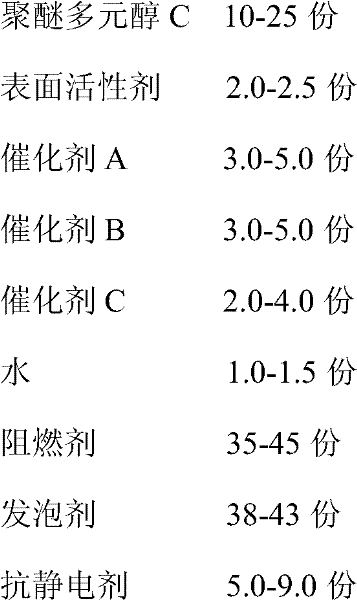

Acid-resistant and alkali-resistant waterborne damping coating with wide temperature range and high damping capacity and method for preparing same

InactiveCN106009961AWide damping temperature rangeHigh dampingAnti-corrosive paintsEmulsionDefoaming Agents

The invention discloses an acid-resistant and alkali-resistant waterborne damping coating with a wide temperature range and high damping capacity, comprising, by weight, 30-65 parts of a waterborne emulsion, 15-45 parts of a filler, 10-35 parts of a flame retardant, 0.1-2 parts of fibers, 0-5 parts of a film-forming agent, 0.1-1.5 parts of a dispersing agent, 0.1-1.5 parts of a defoaming agent, 0-4 parts of an antifreeze agent, 0.2-3 parts of a thickening agent and 1-8 parts of a multifunctional aid. The acid-resistant and alkali-resistant waterborne damping coating with wide temperature region and high damping capacity has the advantages that the acid-resistant and alkali-resistant waterborne damping coating is high in damping performance, wide in damping temperature range and excellent in acid resistance and alkali resistance; loss factors of materials in the temperature range ranges from -30 DEG C to 50 DEG C reach 72 hours as shown by acid-resistant and alkali-resistant tests on the materials by the aid of 10% NaOH solution and 10% H2SO4 solution, and the acid-resistant and alkali-resistant waterborne damping coating is free of foaming, softening and sticking and excellent in acid resistance and alkali resistance.

Owner:安徽贝卫新材料科技有限公司

Low-odor antistatic and high tenacity polycarbonate composite

The invention discloses a low-odor antistatic and high tenacity polycarbonate composite, comprising 30-75 parts of polycarbonate by weight parts, and the polymerized ingredients are as follows by weight parts: 10-65 parts of acrylonitrile-butadiene-styrene grafting copolymer ABS, 5-15 parts of macromolecule antistatic agents and 2-10 parts of styrene-N-benzyl maleimide-maleic anhydride copolymer; the olycarbonate composite prepared by the technical proposal is manufactured into automobile plastic interior decorating products, has the advantages of low odor and high shock resistance and being hard to stick and adsorb the dust, and is used for manufacturing various automobile interior decorating products, such as automobile instrument panel, door panel and the like.

Owner:SHANGHAI PRET COMPOSITES

Antistatic and ultraviolet resistant PC/ASA material composition

InactiveCN101759982AImprove antistatic performanceReduce volatilityAntistatic agentWeather resistance

The invention discloses an antistatic and ultraviolet resistant PC / ASA material composition and belongs to the field of macromolecular composition materials. The composition is characterized by consisting of the following components in part by weight: 30 to 85 parts of polycarbonate, 5 to 30 parts of acrylonitrile-styrene-acrylic ester graft copolymer, 0 to 30 parts of acrylonitrile-styrene copolymer, 5 to 15 parts of macromolecular antistatic agent, 2 to 10 parts of compatilizer, 0.2 to 2 parts of light stabilizer and 0.2 to 1 part of antioxidant. The interior plastic parts of an automobile, which are made of the PC / ASA composition of the invention, have the advantages of high weather resistance, ultraviolet resistance and heat resistance, difficult adsorption of dust and the like, and can be used for manufacturing interior-exterior parts, such as automotive door plates and shells of inner-outer view mirrors, of various automobiles.

Owner:SHANGHAI PRET COMPOSITES

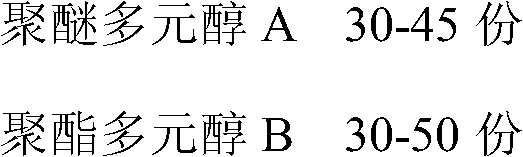

Spraying and wind leaking stoppage polyurethane combined polyether for coal mine as well as preparation and use methods thereof

InactiveCN102585139AReduce dosageFine cellsUnderground chambersTunnel liningHigh resistanceChemical synthesis

The invention belongs to the field of chemical synthesis and in particular relates to a spraying and wind leaking stoppage polyurethane combined polyether for a coal mine as well as preparation and use methods thereof. According to the invention, the polyether is prepared through formulation regulation by using HCFC (hydrochlorofluorocarbon)-365mfa and / or HCFC-245fa as foaming agents, is free of fluorine and is environment-friendly; because the boiling point of HCFC-245fa is low, prepared foam is good in size stability; a reaction type amine catalyst with low VOC (volatile organic compound) and low smell is applied, thus the problem of irritative smell is solved; and the foam prepared by using a fire retardant is good in fire retardant property, and an antistatic agent is added so as to improve the problem of high resistance on the surface of polyurethane foam.

Owner:SHANGHAI DONGDA POLYURETHANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com